Patents

Literature

69results about How to "Excellent in retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition

InactiveUS20050107497A1Improve barrier propertiesImprove moisture resistanceSpecial tyresRecord information storagePolymer scienceAdhesive belt

A resin composition, substrate material, sheet, laminated board, resin-bearing copper foil, copper-clad laminate, TAB tape, printed board, prepreg and adhesive sheet are provided which exhibit improved mechanical properties, dimensional stability, heat resistance and flame retardance, particularly high-temperature physical properties. A resin composition containing 100 parts by weight of a thermosetting resin and 0.1-65 parts by weight of an inorganic compound, the resin composition having a mean linear expansion coefficient (α2) of up to 17×10−3 [° C.−1] over the temperature range from a temperature 10° C. higher than a glass transition temperature of the resin composition to a temperature 50° C. higher than the glass transition temperature of the resin composition.

Owner:SEKISUI CHEM CO LTD

Graft copolymers and impact-resistant flame-retardant resin compositions containing the same

InactiveUS7615594B2Avoid serious impactExcellent in retardancySpecial tyresThermoplasticPolymer science

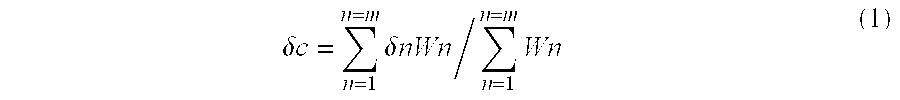

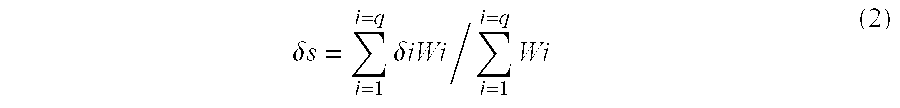

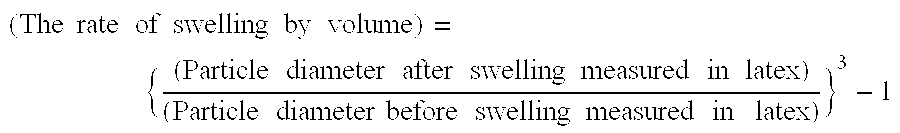

The present invention provides a polyorganosiloxane-containing graft copolymerwhich is obtainable by polymerizing 0.5 to 10 parts by weight of a vinyl monomer (B) comprising 100 to 50% by weight of a polyfunctional monomer (b-1) containing two or more polymerizable unsaturated bonds in the presence of 40 to 90 parts of polyorganosiloxane particles,followed by further polymerizing 5 to 50 parts by weight of a vinyl monomer (C);A polyorganosiloxane-containing graft copolymerwhich is obtainable by polymerizing 0 to 10 parts by weight of a vinyl monomer (B) comprising 100 to 50% by weight of a polyfunctional monomer containing two or more polymerizable unsaturated bonds in the presence of 30 to 95 parts of a polyorganosiloxane in a latex form as obtained by seed polymerization using, as a seed polymer, a hydrophilic polymer capable of swelling in the corresponding organosiloxane,followed by further polymerizing 5 to 70 parts by weight of a vinyl monomer (C);a flame retardant which comprises said copolymer; anda resin composition which comprises said retardant and a thermoplastic resin.

Owner:KANEKA CORP

Electrolytic solution

InactiveUS20110008681A1Improve flame retardant performanceExcellent in noncombustibilityHybrid capacitor electrolytesNon-aqueous electrolyte accumulatorsSolubilityLithium

There is provided an electrolytic solution causing no phase separation even at low temperatures, being excellent in flame retardancy and noncombustibility, assuring high solubility of an electrolyte salt, having a high discharge capacity, being excellent in charge-discharge cycle characteristics and being suitable for electrochemical devices such as lithium ion secondary batteries. The electrolytic solution comprises a solvent (I) for dissolving an electrolyte salt comprising a fluorine-containing ether (A) represented by the formula: Rf1—O—Rf2 (Rf1 and Rf2 are the same or different, Rf1 is a fluorine-containing alkyl group having 3 to 6 carbon atoms, Rf2 is a fluorine-containing alkyl group having 2 to 6 carbon atoms), at least one fluorine-containing solvent (B) selected from the group consisting of a fluorine-containing cyclic carbonate (B1) and a fluorine-containing lactone (B2), and at least one non-fluorine-containing carbonate (C) selected from the group consisting of (C1) a non-fluorine-containing cyclic carbonate and (C2) a non-fluorine-containing chain carbonate, and an electrolyte salt (II), and the solvent (I) for dissolving an electrolyte salt comprises 20 to 60% by volume of the fluorine-containing ether (A), 0.5 to 30% by volume of the fluorine-containing solvent (B), and 5 to 40% by volume of the non-fluorine-containing cyclic carbonate (C1) and / or 10 to 74.5% by volume of the non-fluorine-containing chain carbonate (C2) based on the whole solvent (I).

Owner:DAIKIN IND LTD

Graft copolymers and impact-resistant flame-retardant resin compositions containing the same

InactiveUS20050038149A1Improve flame retardant performanceAvoid serious impactSpecial tyresFire retardantPolymer chemistry

The present invention provides a polyorganosiloxane-containing graft copolymer which is obtainable by polymerizing 0.5 to 10 parts by weight of a vinyl monomer (B) comprising 100 to 50% by weight of a polyfunctional monomer (b-1) containing two or more polymerizable unsaturated bonds in the presence of 40 to 90 parts of polyorganosiloxane particles, followed by further polymerizing 5 to 50 parts by weight of a vinyl monomer (C); A polyorganosiloxane-containing graft copolymer which is obtainable by polymerizing 0 to 10 parts by weight of a vinyl monomer (B) comprising 100 to 50% by weight of a polyfunctional monomer containing two or more polymerizable unsaturated bonds in the presence of 30 to 95 parts of a polyorganosiloxane in a latex form as obtained by seed polymerization using, as a seed polymer, a hydrophilic polymer capable of swelling in the corresponding organosiloxane, followed by further polymerizing 5 to 70 parts by weight of a vinyl monomer (C); a flame retardant which comprises said copolymer; and a resin composition which comprises said retardant and a thermoplastic resin.

Owner:KANEKA CORP

Thermoplastic polymer composition, production method thereof, and shaped article and electric cable obtained therefrom

ActiveUS20080023215A1Raise the ratioReducing brittle temperatureInsulatorsPolymer scienceHeat resistance

Propylene-based resin compositions contain an inorganic filler in a high ratio and are excellent in flexibility, mechanical strength, elongation at break, heat resistance, scratch resistance, whitening resistance and flame retardancy. Shaped articles comprise the compositions. A first propylene-based resin composition of the present invention contains 5 to 64.9% by weight of a propylene-based polymer (A) having a melting point, as measured by differential scanning calorimetry (DSC), in the range of 120° C. to 170° C.; 0 to 59.9% by weight of a propylene-based polymer (B) having a melting point, as measured by differential scanning calorimetry (DSC), of less than 120° C. or having no observed melting point; 0.1 to 30% by weight of a graft-modified propylene-based polymer (C) obtained by graft modifying a propylene-based polymer having a melting point, as measured by differential scanning calorimetry (DSC), of less than 120° C. or having no observed melting point; and 35 to 75% by weight of an inorganic filler (D) (here, the total amount of (A), (B), (C) and (D) is 100% by weight).

Owner:MITSUI CHEM INC

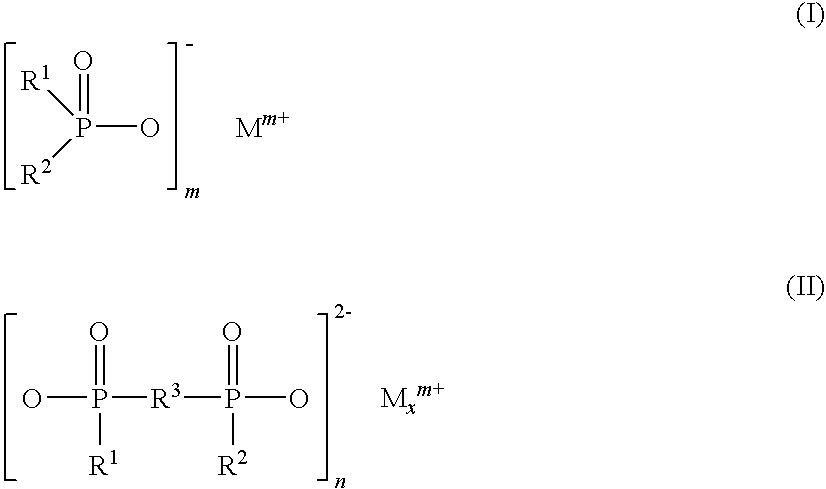

Resin Composition Excellent in Flame Retardance

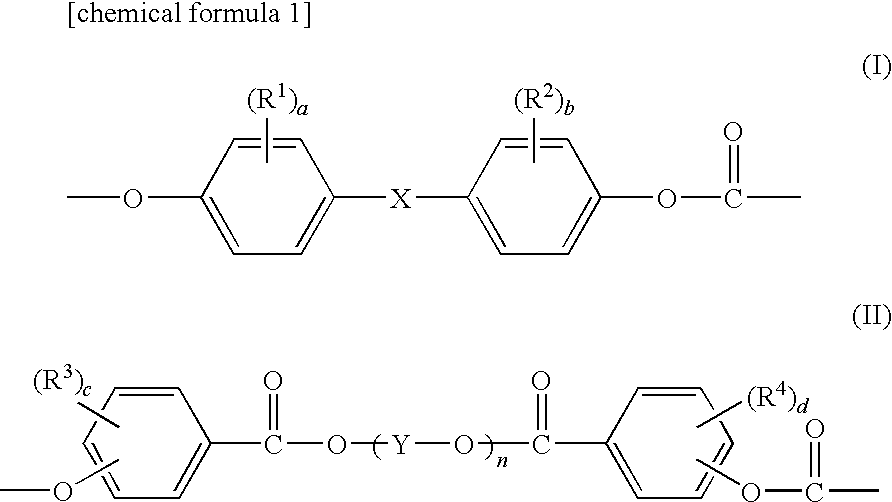

InactiveUS20090275682A1Improve flame retardant performanceImprove impact resistanceGroup 5/15 element organic compoundsEtherPolyamide

The present invention relates to a resin composition containing (A) a polyamide having a viscosity number (as measured in the 96% sulfuric acid according to ISO 307 (1997)) of from 50 ml / g to 250 ml / g; (B) a polyphenylene ether; and (C) a phosphinate represented by a particular formula. The resin composition according to the present invention is excellent in flame retardancy, impact resistance and thin-wall moldability and can significantly suppress gas generation during the molding process and substantially inhibit the generation of deposits on a mold during injection molding. As a result, a molded product thereof excellent in surface appearance can be provided.

Owner:ASAHI KASEI CHEM CORP

Resin composition

InactiveUS20050165151A1Improve flame retardant performanceImprove heat resistancePigmenting treatmentOther chemical processesPolymer scienceAdhesive belt

A resin composition, substrate material, sheet, laminated board, resin-bearing copper foil, copper-clad laminate, TAB tape, printed circuit board, prepreg and adhesive sheet are provided which exhibit improved physical properties, dimensional stability, heat resistance and flame retardance, particularly high-temperature physical properties. A resin composition containing 100 parts by weight of a thermoplastic resin and 0.1-65 parts by weight of an inorganic compound, the resin composition having a mean linear expansion coefficient (α2) of 1.0×10−3 [° C.−1] or below over the temperature range from a temperature 10° C. higher than a glass transition temperature of the resin composition to a temperature 50° C. higher than the glass transition temperature of the resin composition.

Owner:SEKISUI CHEM CO LTD

Sheet for solar cell, and solar cell module

InactiveUS20120097220A1Increased durabilityExcellent in retardancyPV power plantsSynthetic resin layered productsElectrical batteryEther

Provided are a sheet for a solar cell of a monolayer construction or a multilayer construction based on a polyphenylene ether-based resin layer formed of a resin composition using a polyphenylene ether as a main component, which has excellent durability, excellent flame retardancy, excellent dimensional stability and high adhesiveness with a encapsulating resin layer or the like, and a solar cell module obtained by providing the sheet for a solar cell.

Owner:MITSUBISHI PLASTICS INC

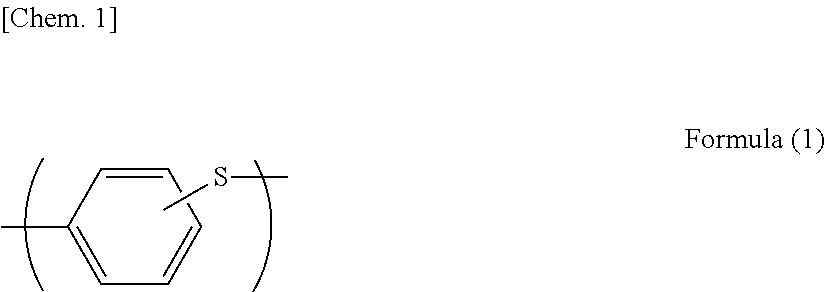

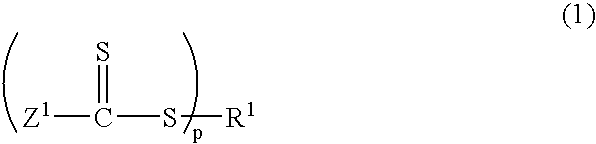

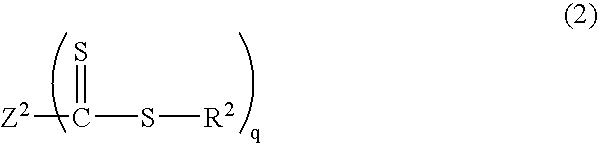

Block copolymer

InactiveUS20040236020A1Improve flame retardant performanceImprove heat resistanceElastomerPolymer science

Provided are a block copolymer including a polymer block containing acrylonitrile or methacrylonitrile as a principal constituent, which is excellent in heat resistance, weatherability, oil resistance, flame retardancy, and low-temperature resistance and which can be economically produced; and a thermoplastic resin composition and an elastomer composition each containing the block copolymer. The block copolymer is produced by reversible addition-fragmentation chain transfer polymerization in the presence of a thiocarbonylthio group-containing compound.

Owner:KANEKA CORP

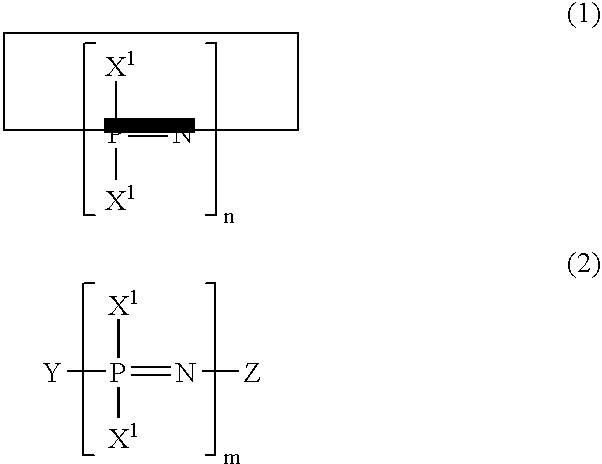

Phosphazene composition

ActiveUS20040039134A1Increase resistanceExcellent in retardancyGroup 5/15 element organic compoundsHydrolysisPolymer chemistry

A phosphazene composition which has a content of volatile components of not less than 0.02% by weight and not more than 1.0% by weight when it is heated at 200° C. for 2 hours; is excellent in resistance to hydrolysis, and when the phosphazene composition is added to a resin, there is provided a resin composition which highly maintains the balance of resistance to hydrolysis, flame retardancy and stability of electric characteristics in a high-frequency field of not less than 1 GHz.

Owner:ASAHI KASEI KK

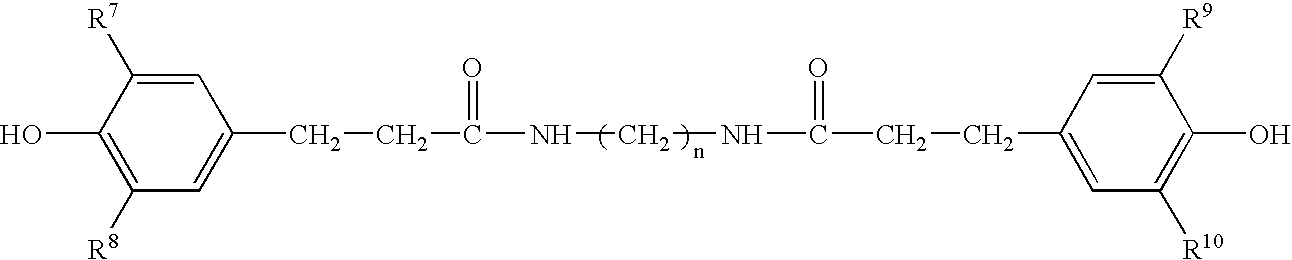

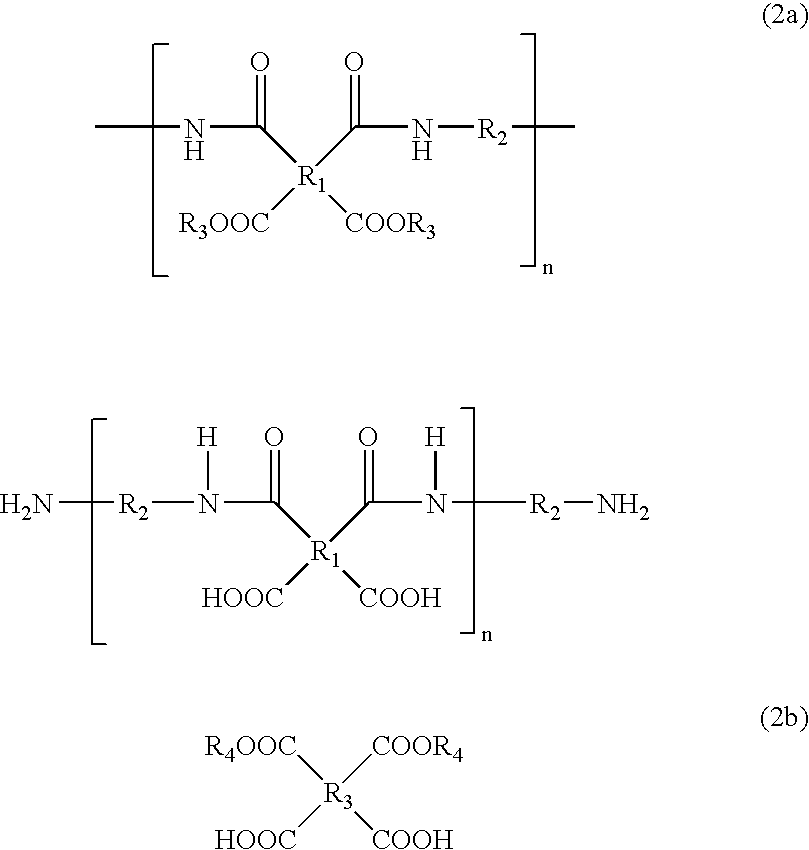

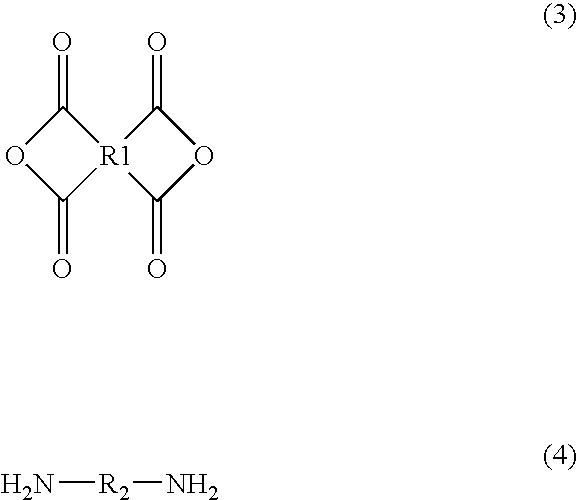

Thermosetting Resin Composition and Use thereof

ActiveUS20090286087A1Improve flame retardant performanceIncrease flexibilitySynthetic resin layered productsThin material handlingEpoxyPolymer science

Disclosed is related to a thermosetting resin composition which comprises a polyimide resin (A) having a phenolic hydroxyl group, preferably a polyimide resin (A) produced from an aminophenol (a), a diamino compound (b) and a tetrabasic acid dianhydride (c), and an epoxy resin (B); and a cured product thereof. The resin composition is excellent in storage stability, and gives a cured product excellent in flame retardancy and heat resistance. Furthermore, when the cured product is in a film form, the product has sufficient flexibility and excellent folding endurance.

Owner:NIPPON KAYAKU CO LTD

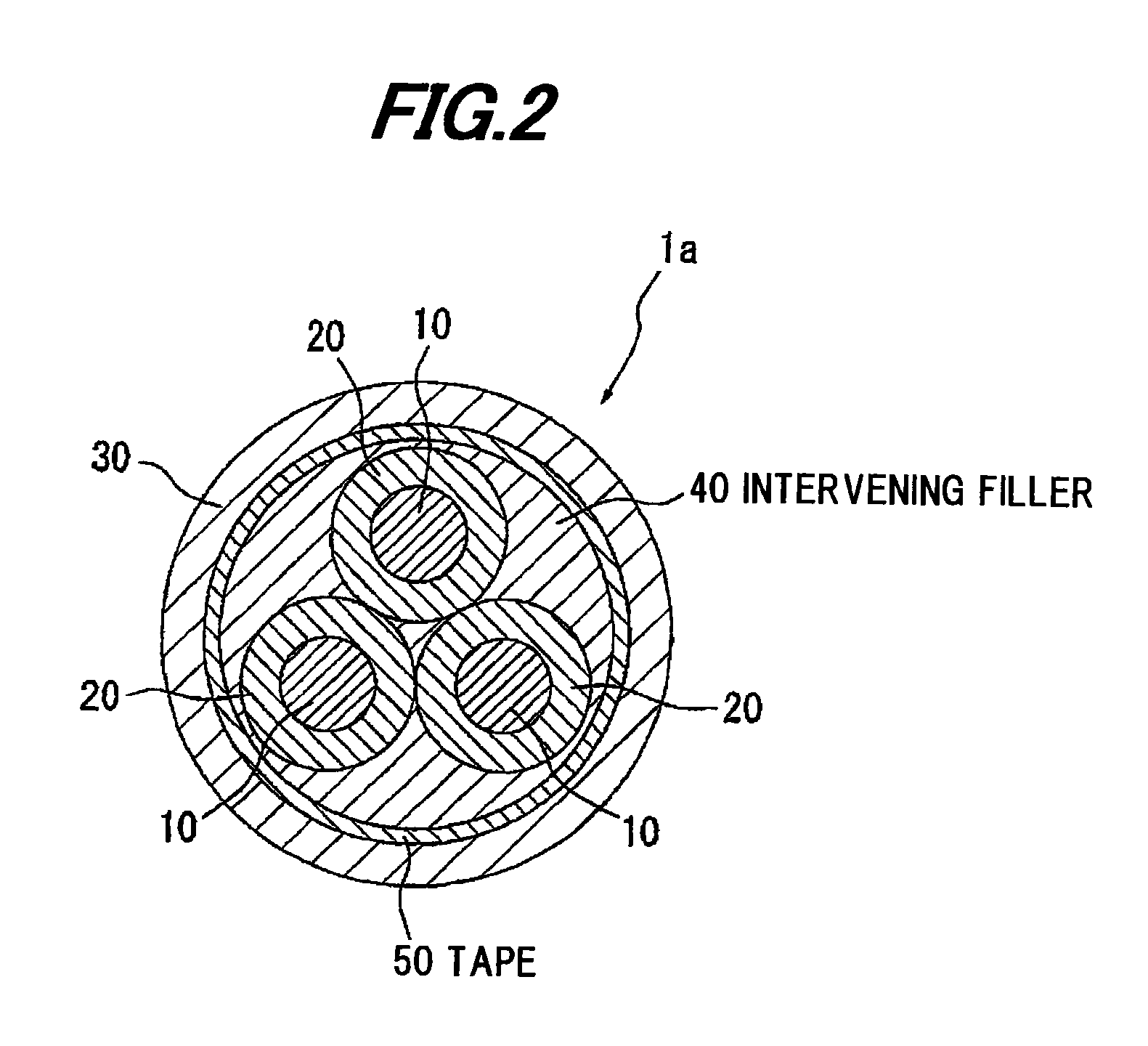

Flame retardant and flame retardant composition using same, molded article thereof, and electric wire with coating

ActiveUS20100212930A1Excellent abrasion resistanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesWear resistanceFire retardant

The flame retardant of the present invention has a flame retardant (a) component, comprising 50 to 97% by mass of a metal hydrate (a-1) component and 3 to 50% by mass of a filler (a-2) component, wherein the filler (a-2) component contains SiO2, Al2O3 and M2 / nO. Here, the total of the metal hydrate (a-1) component and the filler (a-2) component is 100% mass, M represents one or more metal elements selected from a group consisting of K, Na, Mg, Ca, Fe and Zn, and n represents a valence of the metal element. According to the present invention, it is possible to provide a flame retardant capable of providing a molded article and an electric wire with a coating, which are excellent in flame retardancy, abrasion resistance and flexibility, and also have sufficient mechanical strength at low cost.

Owner:EQUSR CHEM LP

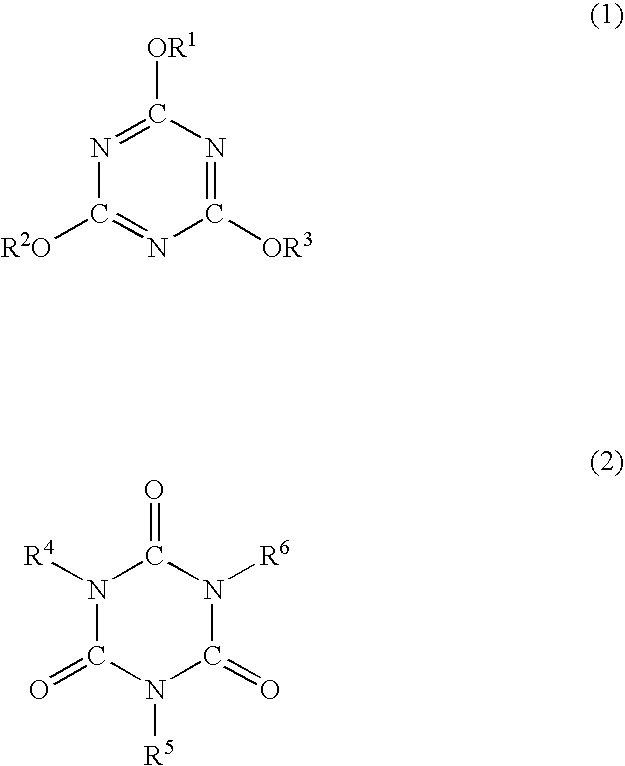

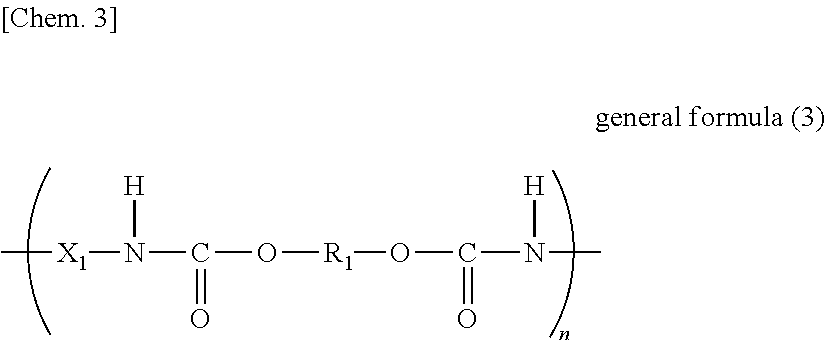

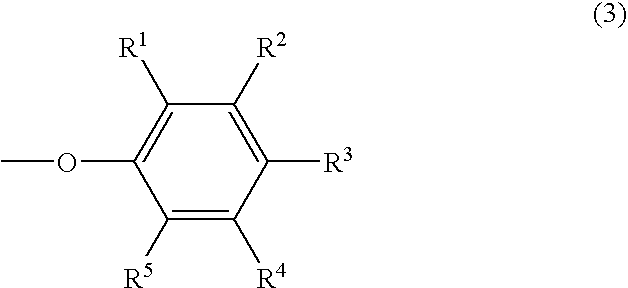

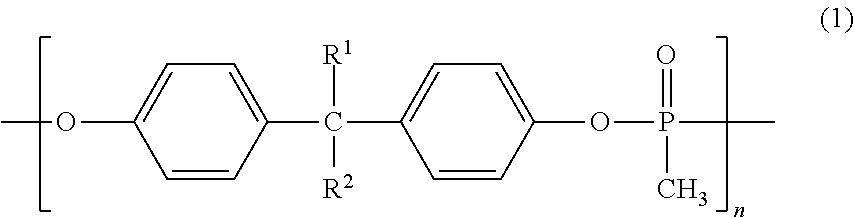

Flame-retardant thermoplastic resin composition

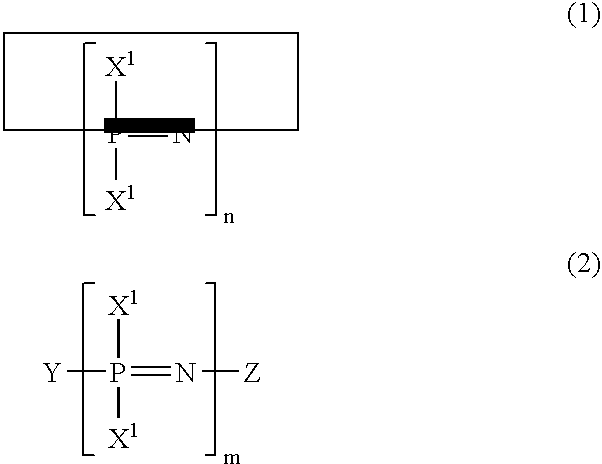

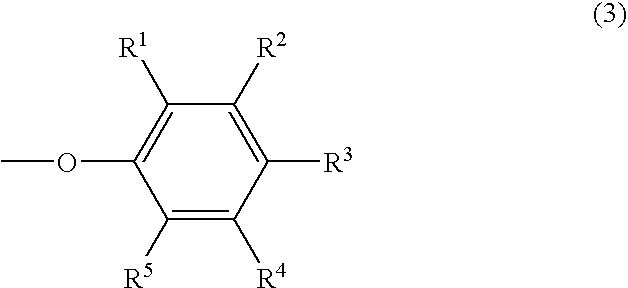

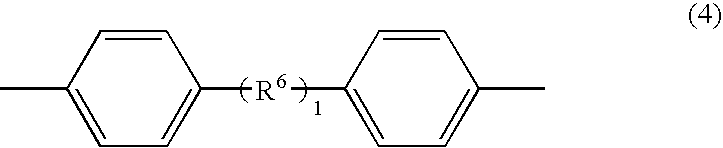

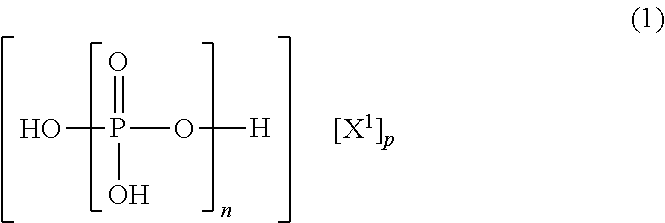

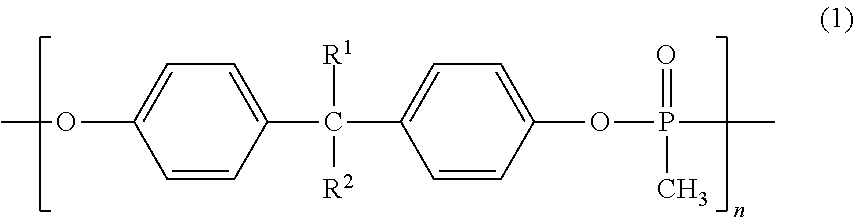

ActiveUS20110130491A1Good compatibilityGood dispersibilityInsulated cablesInsulatorsPhosphoric Acid EstersHydrogen atom

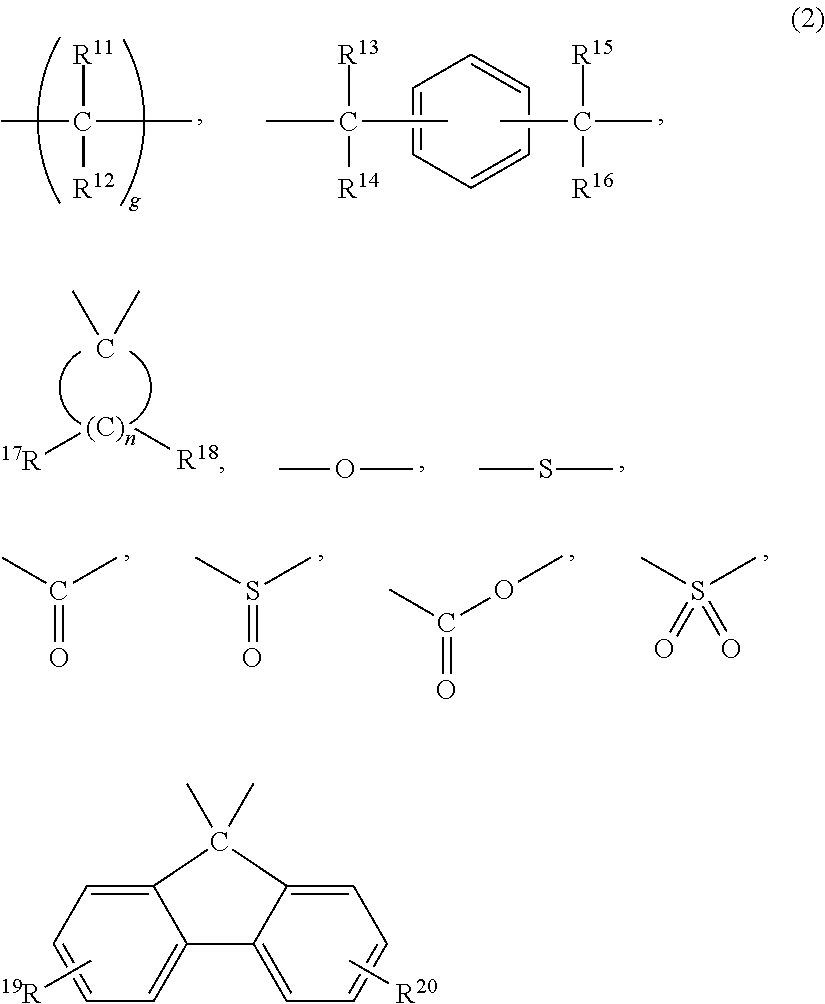

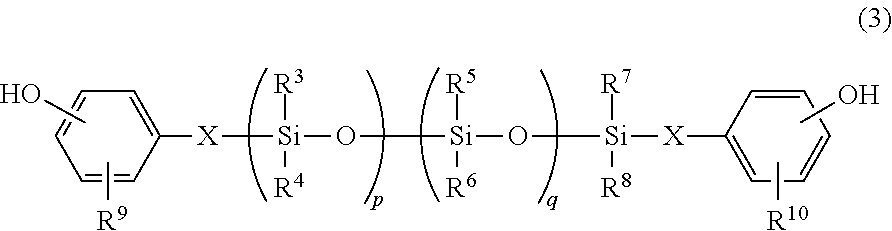

The flame-retardant thermoplastic resin, composition comprised of the following Components (C), (D) and (E) with the thermoplastic resin composition having a thermoplastic polyurethane elastomer of the Component (A) and an ethylene polymer and / or an ethylene copolymer of the Component (B) as the main components;Component (C): a (poly) phosphate compound represented by the following general formula (1).n in the formula (1) represents a number of 1-100; X1 is an ammonia; or a triazine derivative, represented by the following general formula (2); p is a number satisfying a relation of 0<p≦n+2;Component (D): a (poly) phosphate compound represented by the following general formula (3).r in the formula (3) represents a number of 1˜100; Y1 is a diamine containing [R1R2N (CH2)mNR3R4], piperazine or a diamine containing a piperazine ring; R1, R2, R3 and R4 are each a hydrogen atom, or a straight chain or branched alkyl group having 1˜5. carbon atoms; m is an integer of 1˜10; q is a number satisfying a relation of 0<q≦r+2;Component (E): phosphoric acid ester compound represented by the following general formula (4).R7, R8, R10 and R11 in the formula (4) represent an alkyl group having 1˜10 carbon atoms, or an aromatic group represented by the following general, formula (5); R9 represents a bivalent aromatic group represented by the following general formula (6) or (7); s is a number of 0˜30;

Owner:ADEKA CORP

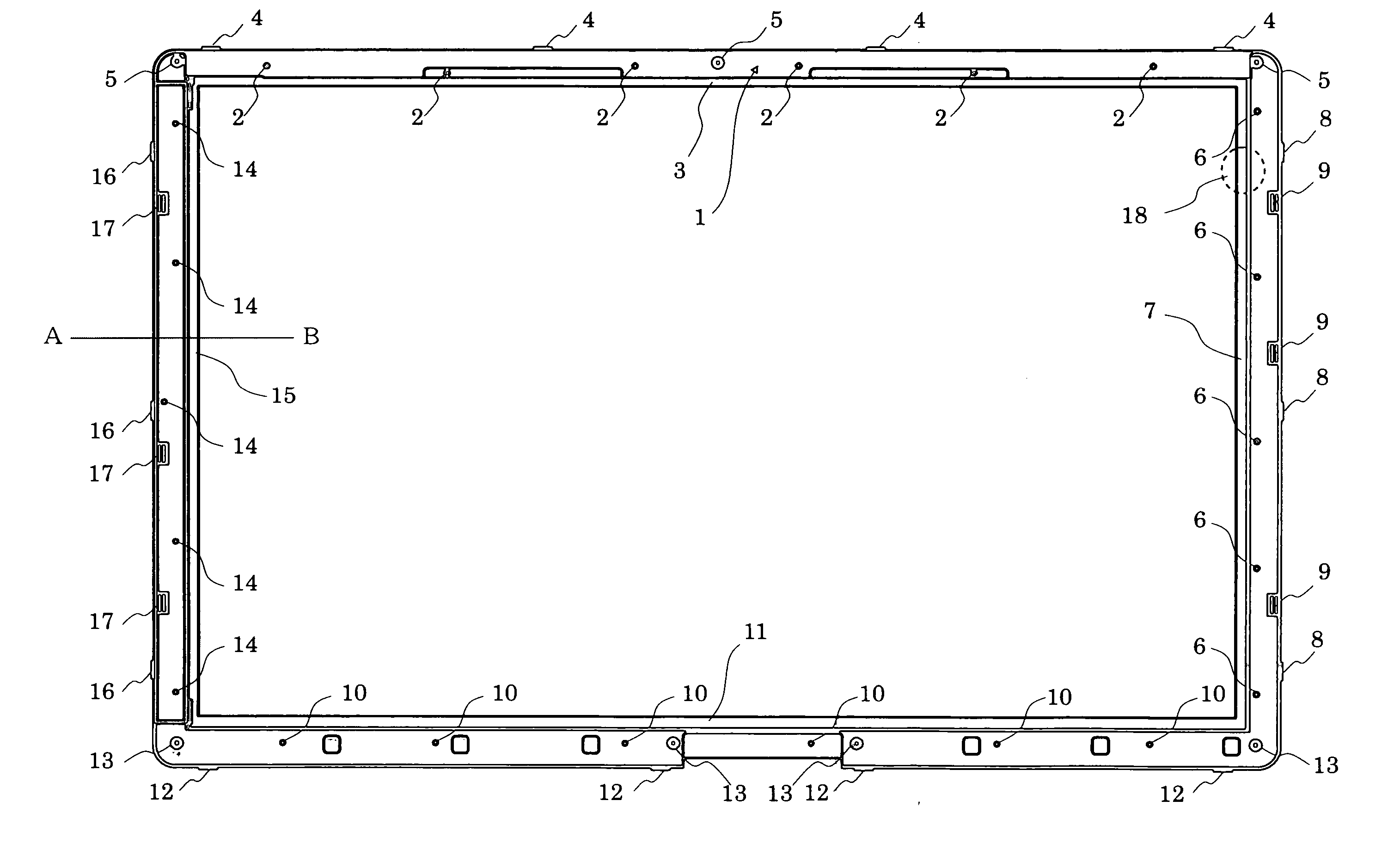

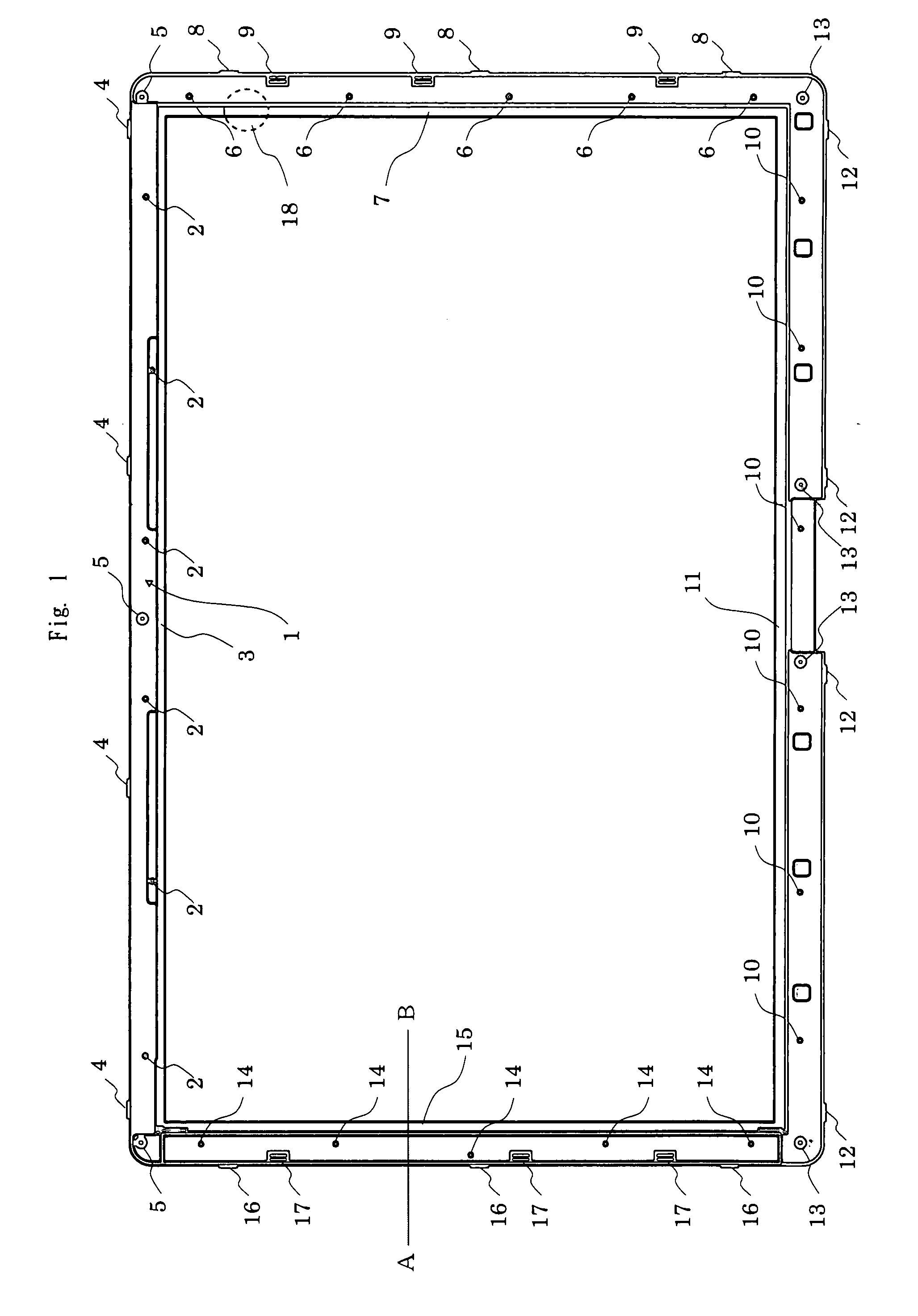

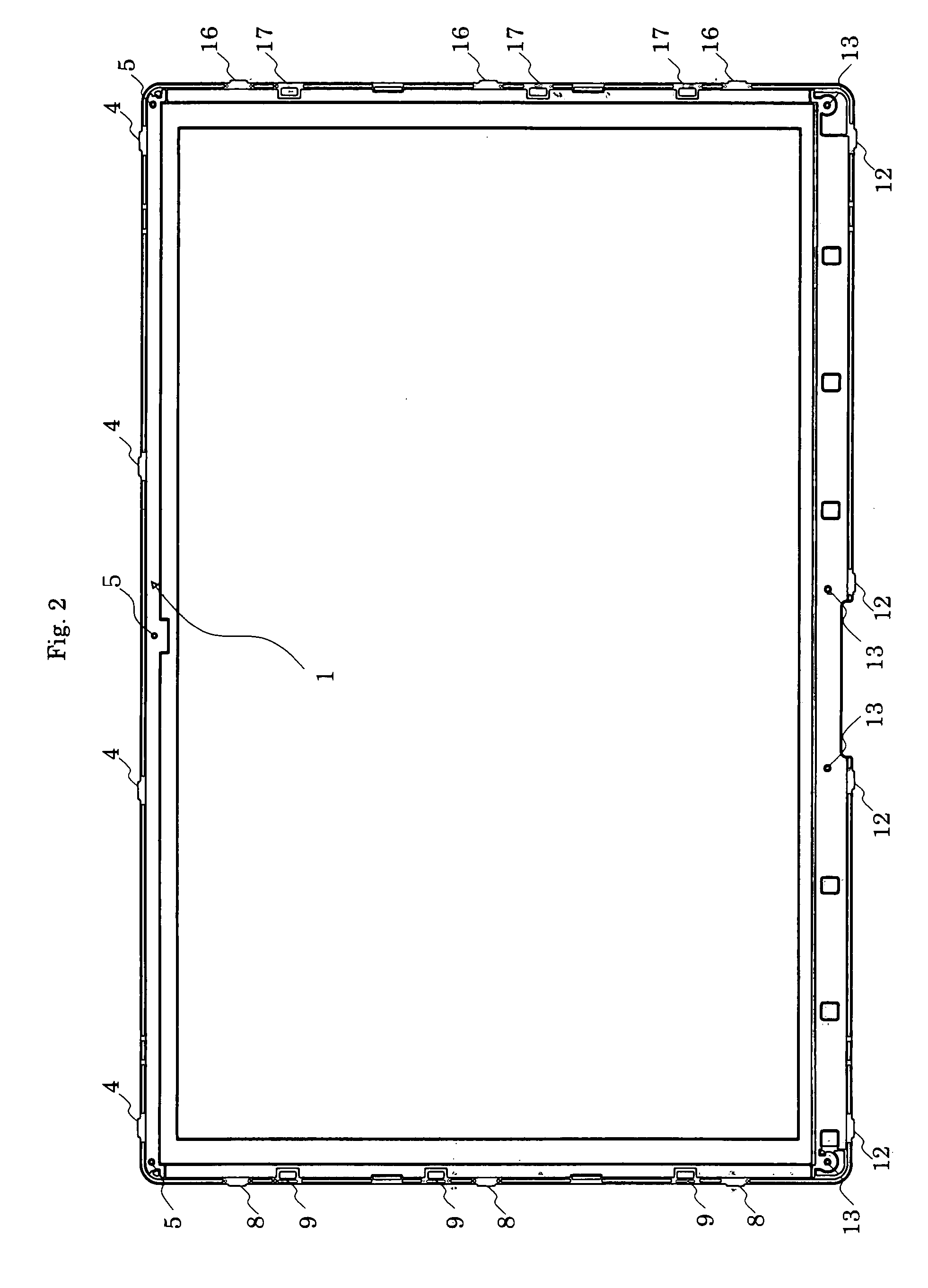

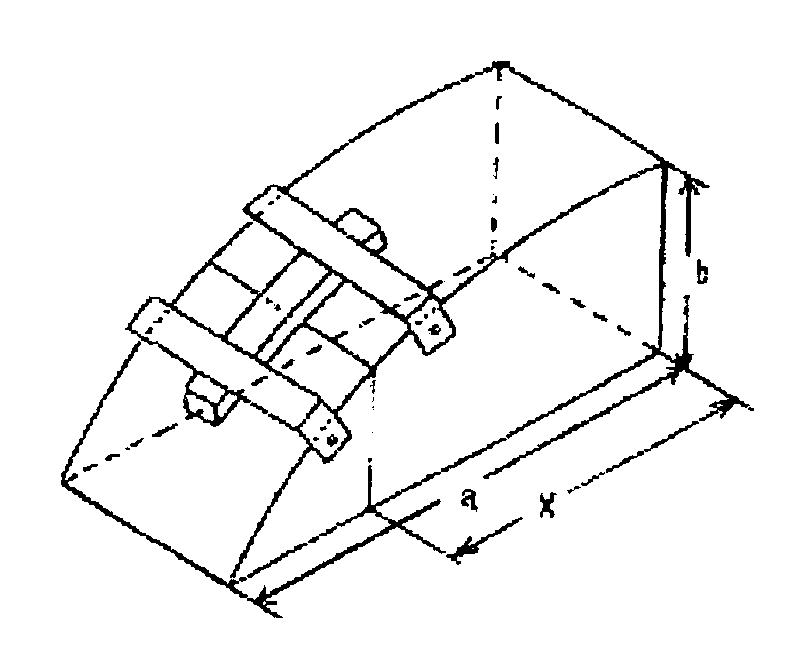

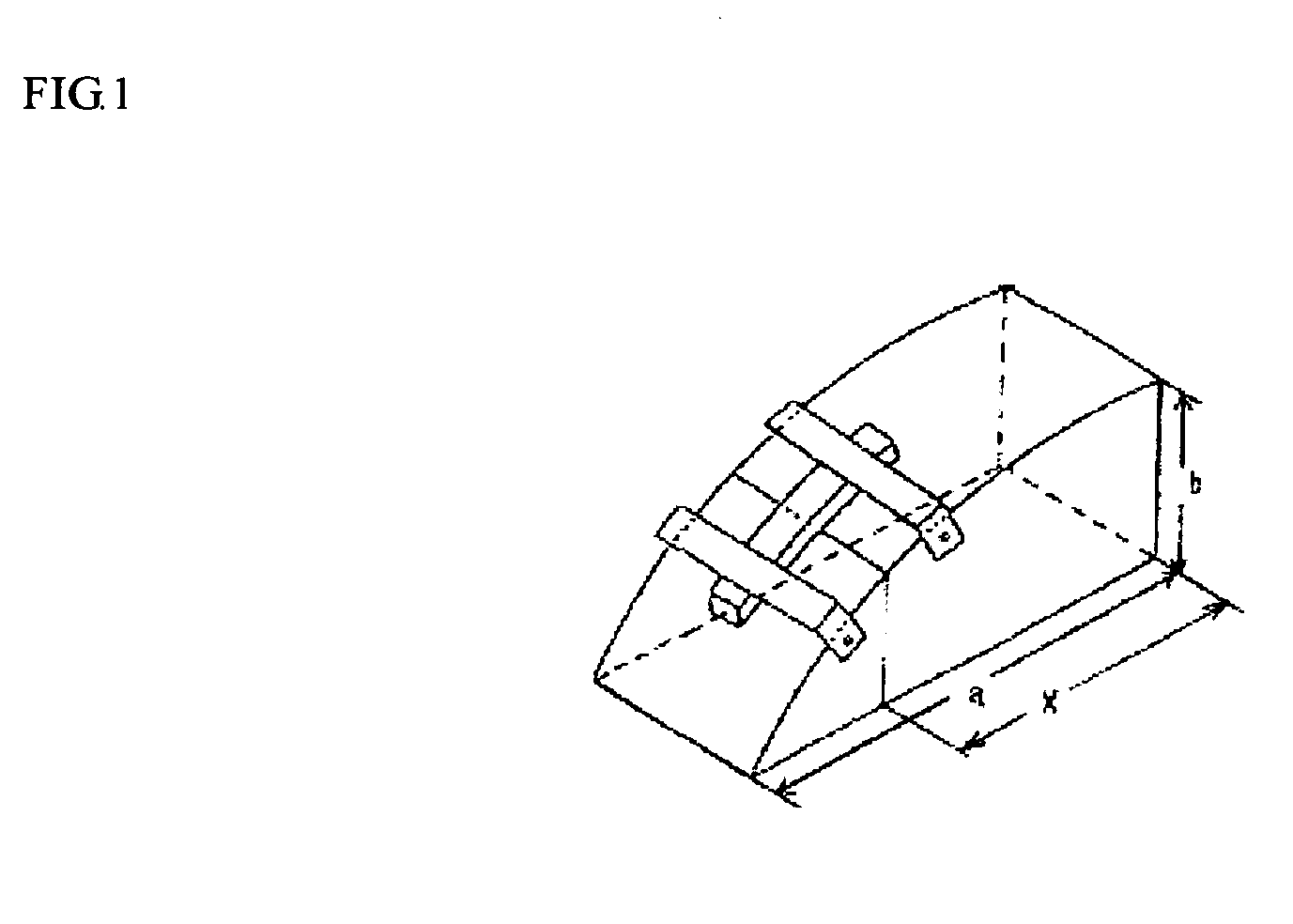

Resin Composition and Flat Panel Display Fixing Frame

InactiveUS20070257401A1Increase fraction defectiveIncrease probabilitySpecial tyresWater/sewage treatment by flocculation/precipitationFlat panel displayMuscovite

The object of the present invention are to provide a resin composition suitable for use in a flat panel display fixing frame having a snap fit structure, which comprises a filler and has stiffness and flame retardancy and a flat panel display fixing frame. There are provided the resin composition comprising (i) an aromatic polycarbonate resin (component A), (ii) at least one lamellar silicate mineral (component B) selected from the group consisting of talc having an average particle diameter of 0.5 to 9 μm (component B-1) and muscovite mica having an average particle diameter of 0.5 to 50 μm (component B-2), (iii) a fluorine-containing dripping preventing agent (component C), and (iv) an organic sulfonic acid alkali (earth) metal salt (component D) in a specific ratio, and is used in a flat panel display fixing frame having at least one snap-fit projection, hole or groove, and a flat panel display fixing frame comprising the composition in the present invention.

Owner:TEIJIN CHEM LTD

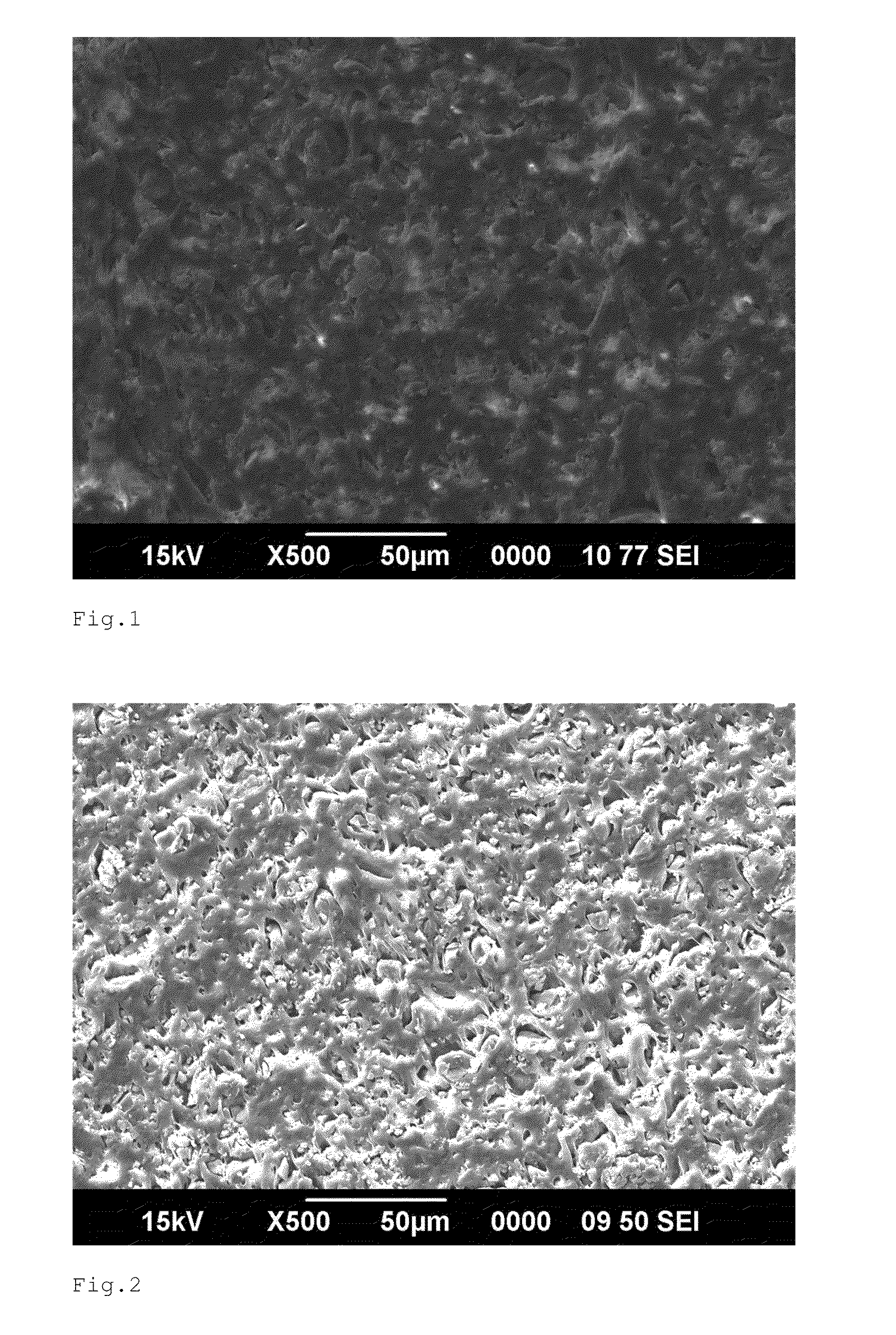

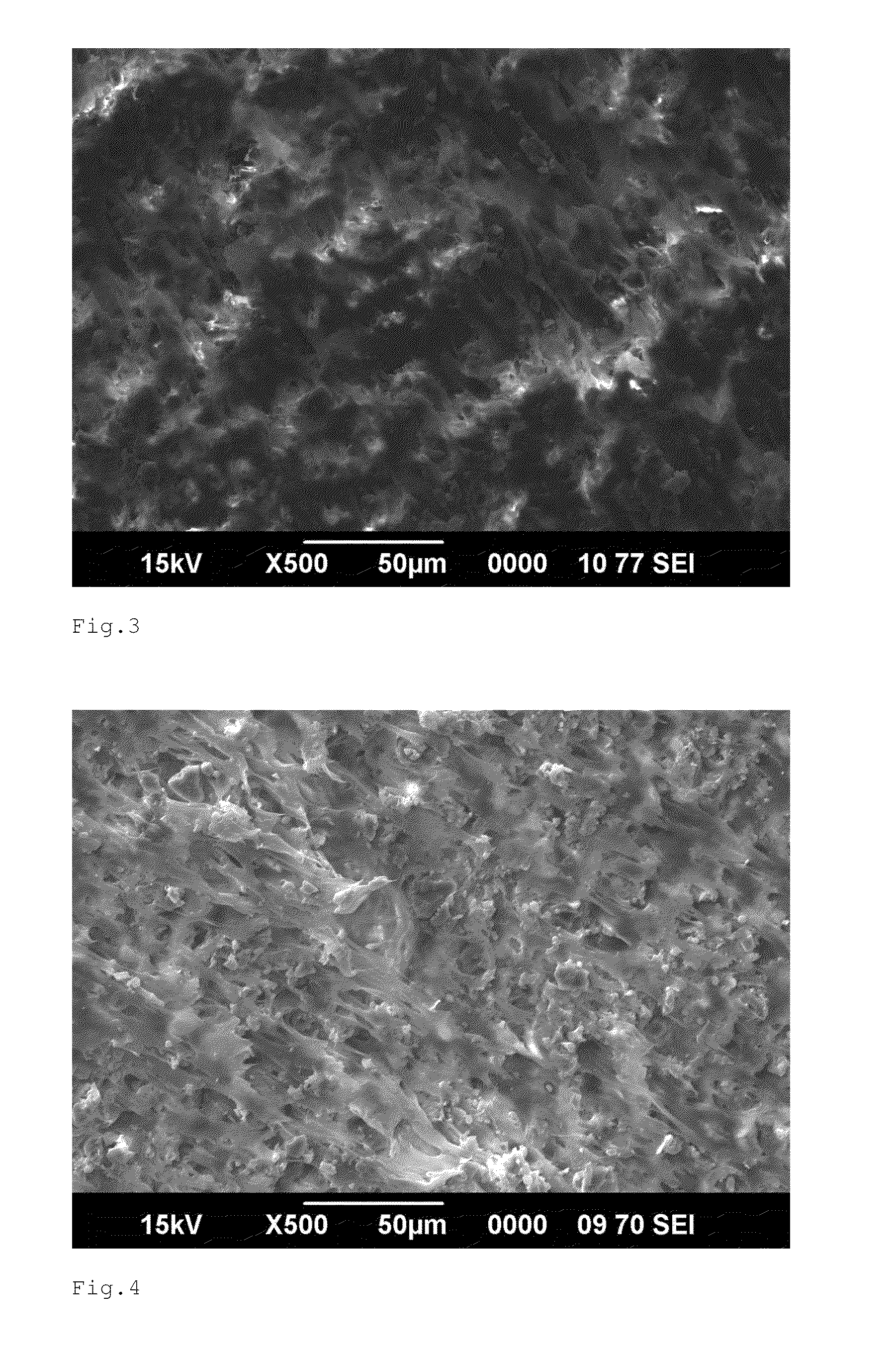

Flame-retardant spun-dyed polysete fiber, flame- retardant material comprising the same, and process for producing flame-retardant spun-dyed polyester fiber

InactiveUS20110086225A1Improve colorabilityIncreased durabilityFlame-proof filament manufactureOrganic dyesMelamine phosphatePolyphosphate

[Problem]A method by which a flame proofing property can easily be provided to polyester fiber having long-term stable color and excellent mechanical properties, particularly, a resin composition and a flame proofing method needed for flame retardant spun-dyed polyester fiber which is excellent in light resistance and durability, and is capable of coloring any of various colors, and also, is environment-friendly, are strongly desired.□Solution□There is provided a flame retardant spun-dyed polyester fiber obtained by melt-spinning a flame retardant polyester resin composition comprising a flame retardant comprising at least one inorganic phosphorus-nitrogen based compound selected from the group consisting of ammonium polyphosphate, melamine polyphosphate and phosphazenes; colorant; and thermoplastic polyester resin, characterized in that content of said inorganic phosphorus-nitrogen based compound is 0.1 to 12% by mass, content of said colorant is 0.01 to 5% by mass, and content of said thermoplastic polyester resin is 83 to 99.89% by mass, based on the total weight of said polyester resin composition. Particularly, when disposed polyester is used as the thermoplastic polyester resin, it contributes to material recycle as well.

Owner:TAKAGI CHEM

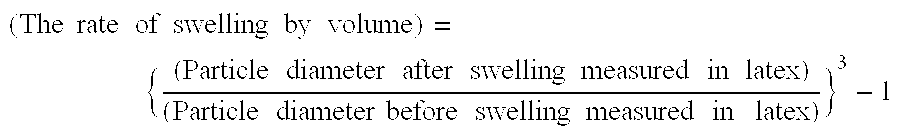

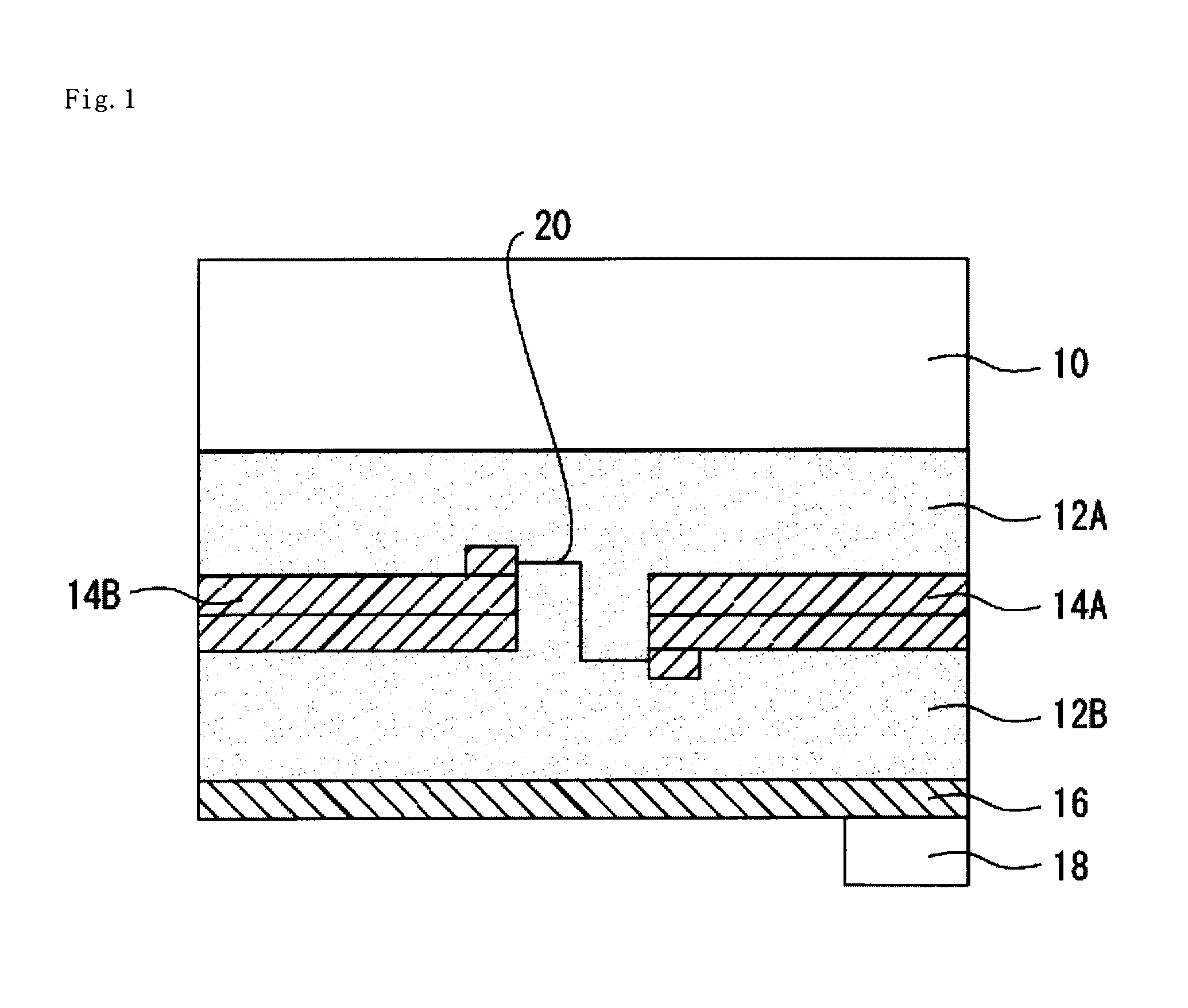

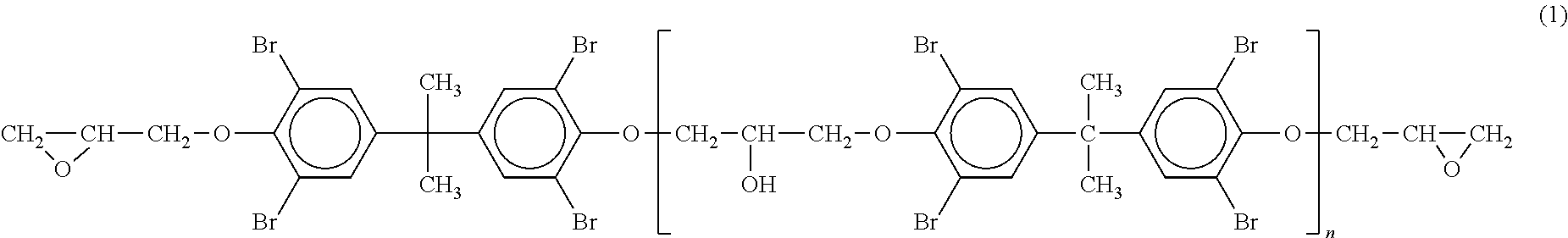

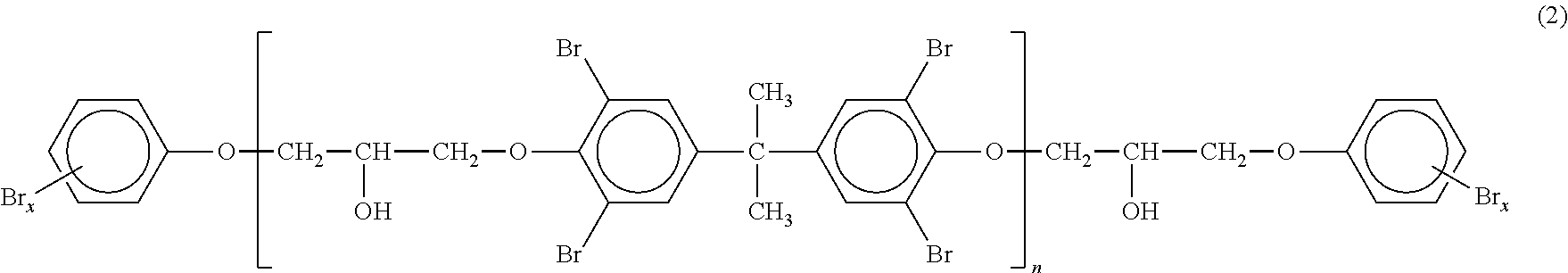

Insert molded article

InactiveUS20140058015A1Improve flame retardant performanceGood heat shock resistanceSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxyPolytetramethylene terephthalate

Provided is an insert molded article provided with a resin member, which has superior heat shock resistance, flame resistance, and hydrolysis resistance, and an insert member. The insert molded article is provided with the insert member and resin member, and a polybutylene terephthalate resin composition in which a halogenated epoxy compound (B) having a specific molecular weight, an antimony oxide compound (C), and a carbodiimide compound (D) are mixed into a polybutylene terephthalate resin (A) is used for the starting material for the resin member. The specific molecular weight of component (B) is a number average molecular weight of 2,000-20,000.

Owner:WIN TECH POLYMER LTD

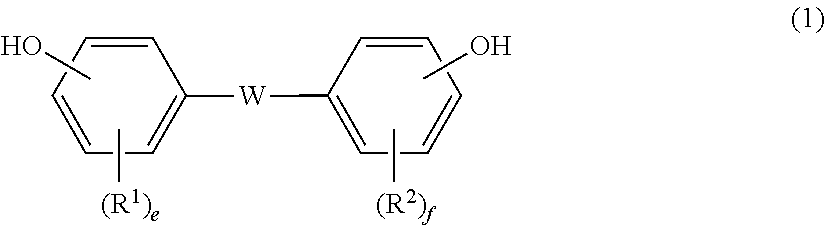

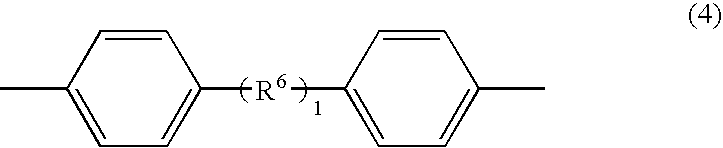

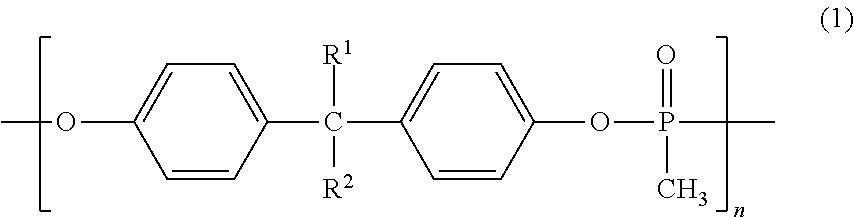

Flame-retardant synthetic resin composition

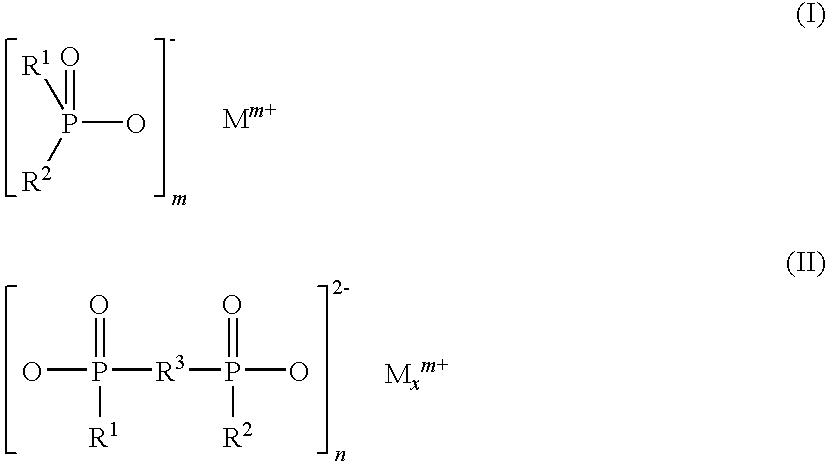

InactiveUS20160068663A1Improve flame retardant performanceImprove heat resistancePhosphorus organic compoundsHeat deflection temperatureHydrogen atom

Provided is a flame retardant resin composition excellent in flame retardancy, heat resistance in terms of heat deflection temperature, and processability and handling properties in terms of melt viscosity. The flame retardant resin composition includes 100 parts by mass of a synthetic resin and 0.5 to 20 parts by mass of a mixture of phosphoric esters represented by general formula (1):wherein R1 and R2 each represent a hydrogen atom or a methyl group; and n represents an integer of 1 to 5. The mixture contains 70% to 75% by mass of the phosphoric ester of formula (1) wherein n=1, with the total of the phosphoric esters of formula (1) wherein n is 1 to 5 being taken as 100% by mass.

Owner:ADEKA CORP

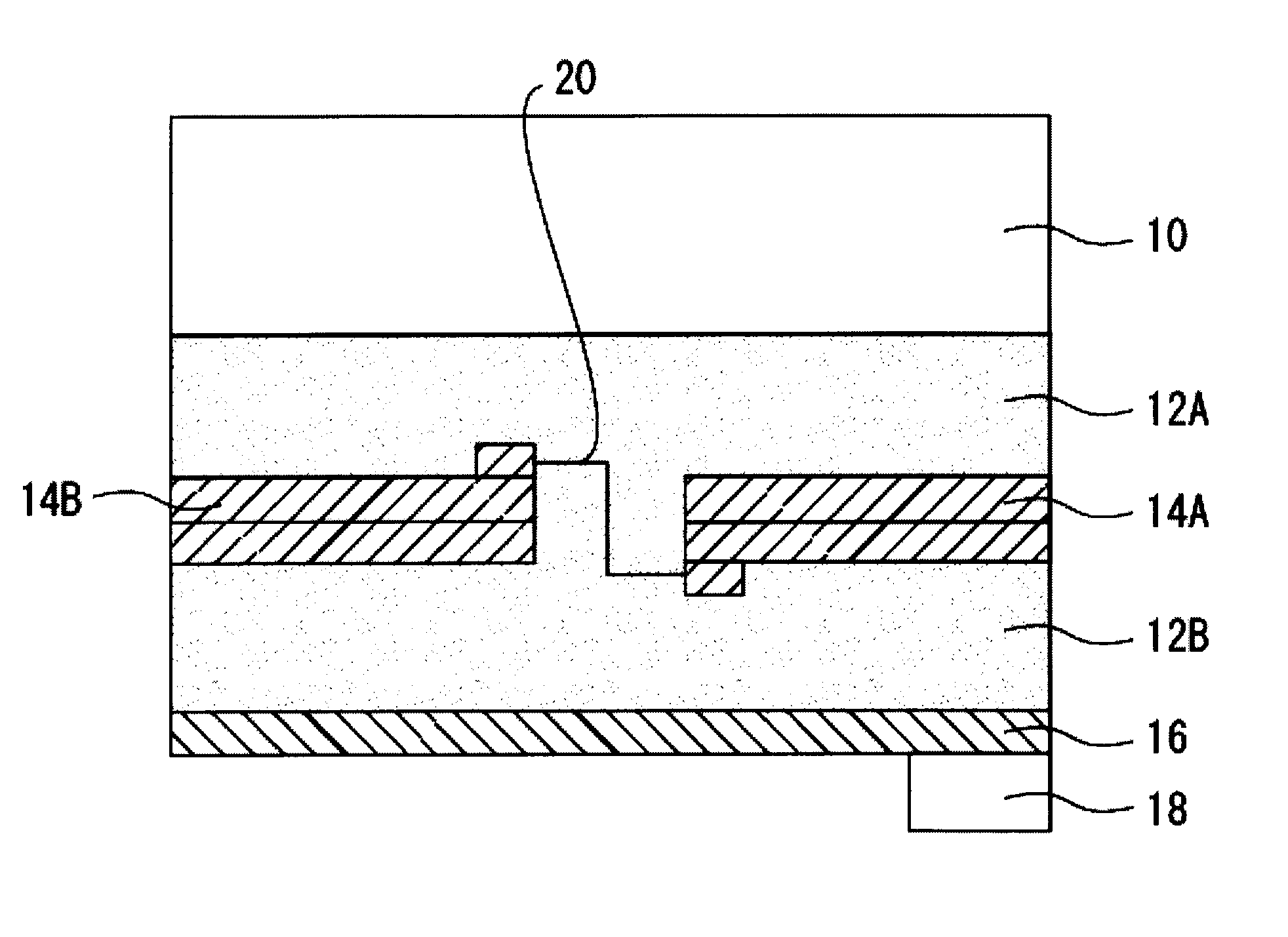

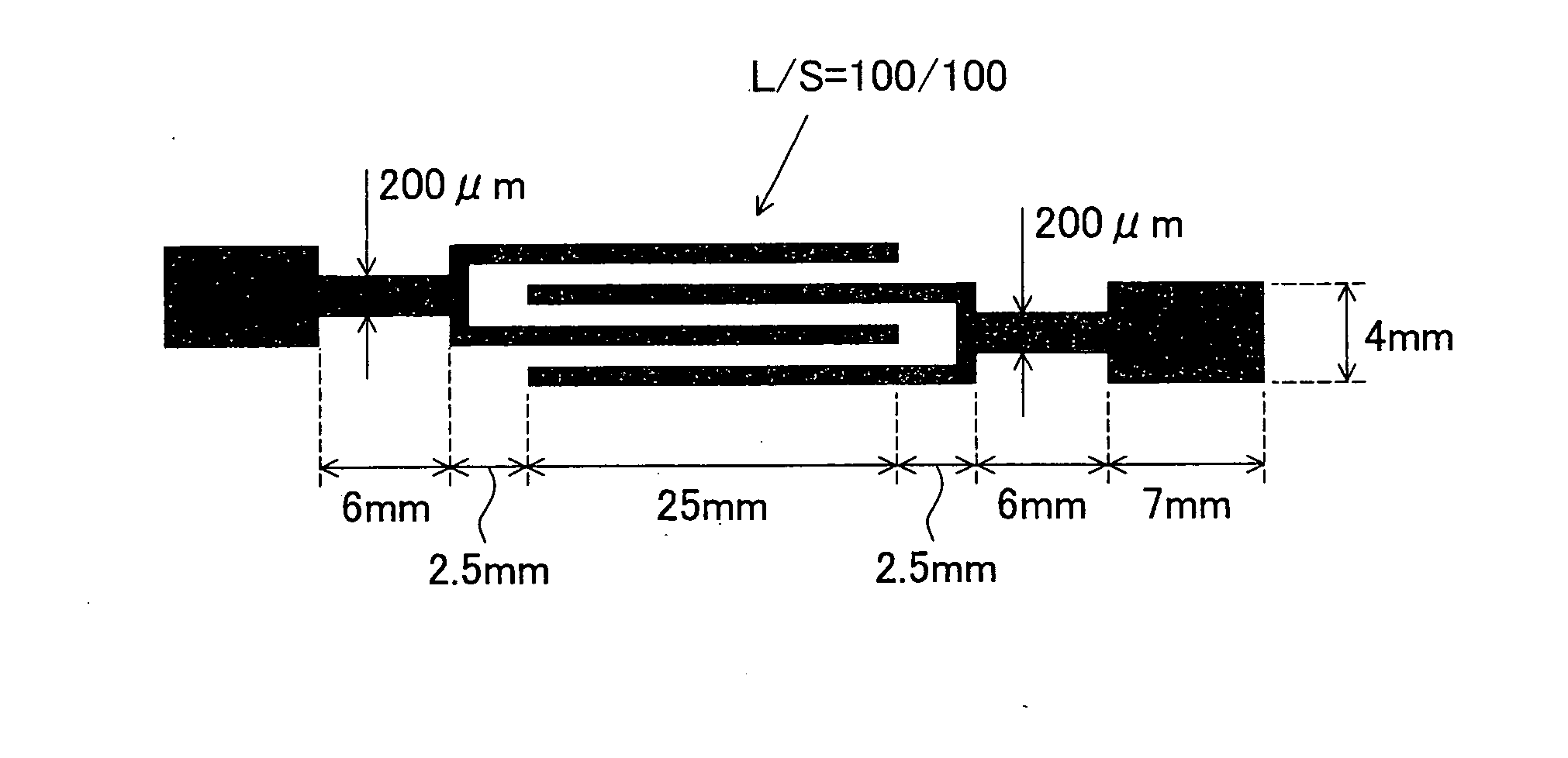

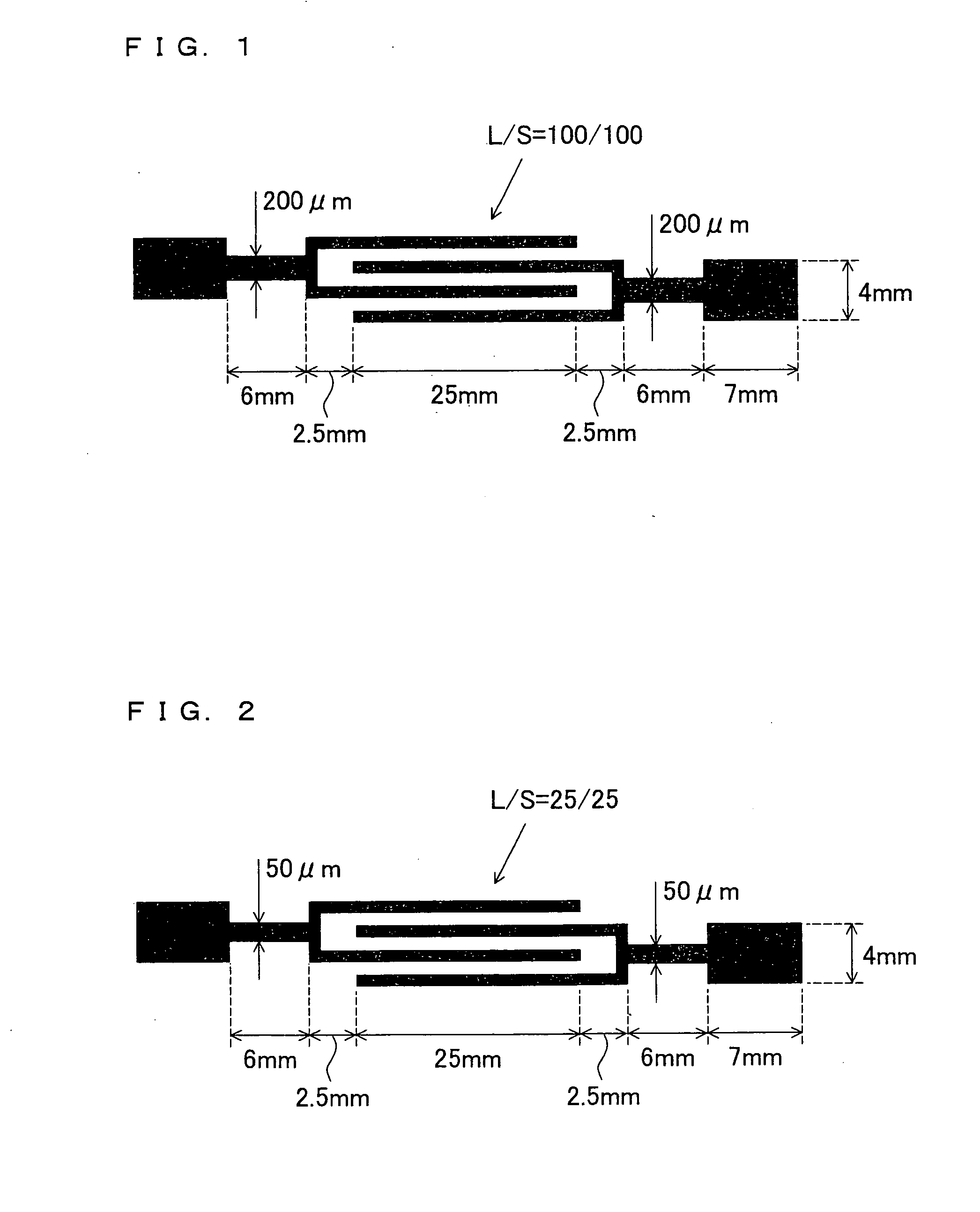

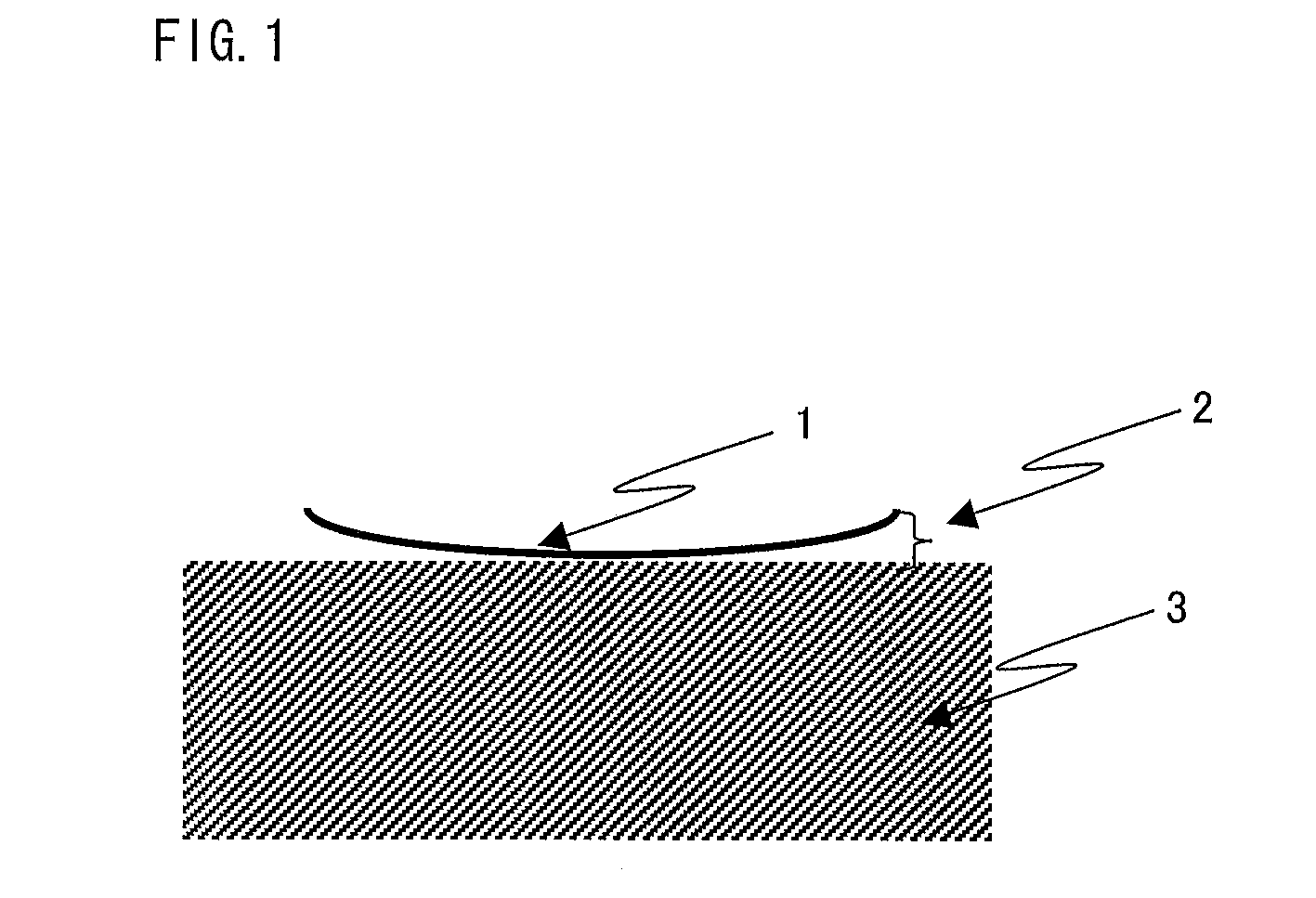

Photosensitive dry film resist, printed wiring board making use of the same, and process for producing printed wiring board

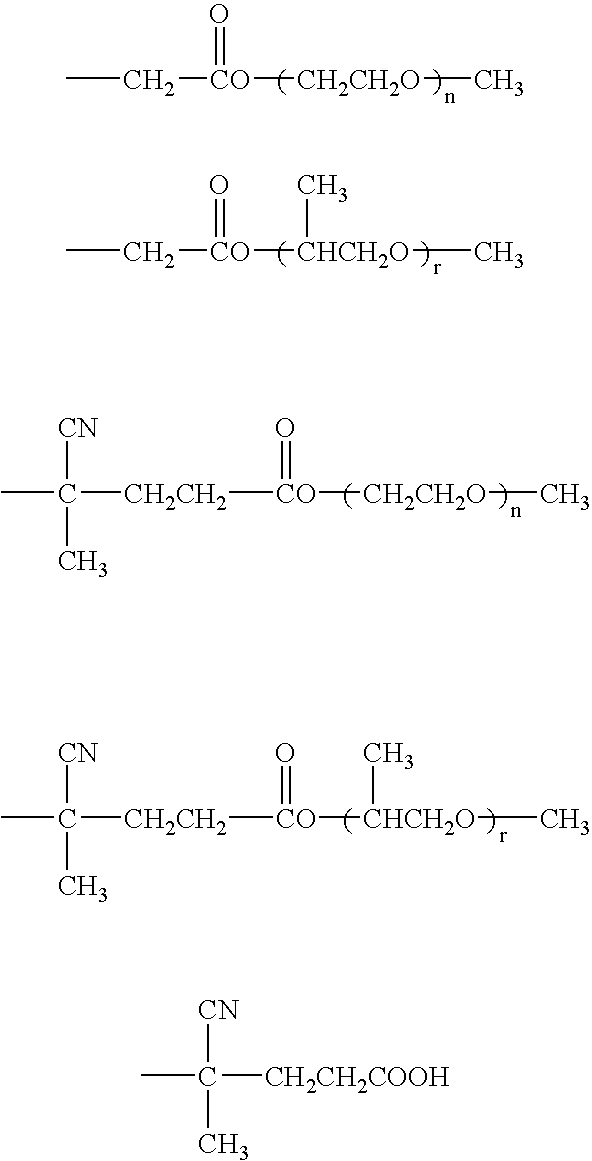

InactiveUS20100218984A1Favorable water system developmentGood adhesivenessPhotosensitive materialsPrinted circuit aspectsResistMeth-

The present invention is to provide (i) a photosensitive dry film resist which allows water system development and which is excellent in resolution, flame retardancy, adhesiveness, moisture resistance, electric reliability, and preservation stability, (ii) a method for producing the photosensitive dry film resist, and (iii) usage thereof.The foregoing object can be achieved by using a multi-layer photosensitive dry film resist comprising at least: a first photosensitive layer which essentially includes a binder polymer (A1), a (meth)acrylic compound (B1), a photoreaction initiator (C1), and a flame retardant (D1), and a second photosensitive layer which essentially includes a binder polymer (A2), a (meth)acrylic compound (B2), a photoreaction initiator (C2) and which substantially does not include a flame retardant (D2), wherein: when a weight ratio of the flame retardant (D1) to an entire weight of the first photosensitive layer is defined as a first photosensitive layer flame retardant content and a weight ratio of the flame retardant (D2) to an entire weight of the second photosensitive layer is defined as a second photosensitive layer flame retardant content, the second photosensitive layer flame retardant content is 0 wt % or more and 10 wt % or less, and in case where the first photosensitive layer flame retardant content is 100, the second photosensitive layer flame retardant content is 0 wt % or more and 50 wt % or less.

Owner:KANEKA CORP

Flame-retardant polyamide resin composition and extrusion-molded product

InactiveUS20050203223A1Excellent in combustibilityImprove flame retardant performanceCarbon numberHexamethyldiamine

The present invention relates to a polyamide resin composition comprising 99 to 80 parts by weight of a polyamide base resin comprising at least one polyamide resin and 1 to 20 parts by weight of a triazine-based flame retardant, the total amount of polyamide base resin and triazine-based flame retardant being 100 parts by weight, said polyamide base resin having constituting units comprising (a) polyamide 6 constituting units comprising a polycondensate of ε-caprolactam and (b) two or more kinds of polyamide constituting units comprising a polycondensate of hexamethylenediamine and a dicarboxylic acid having a carbon number of 6 to 11.

Owner:MITSUBISHI ENG PLASTICS CORP

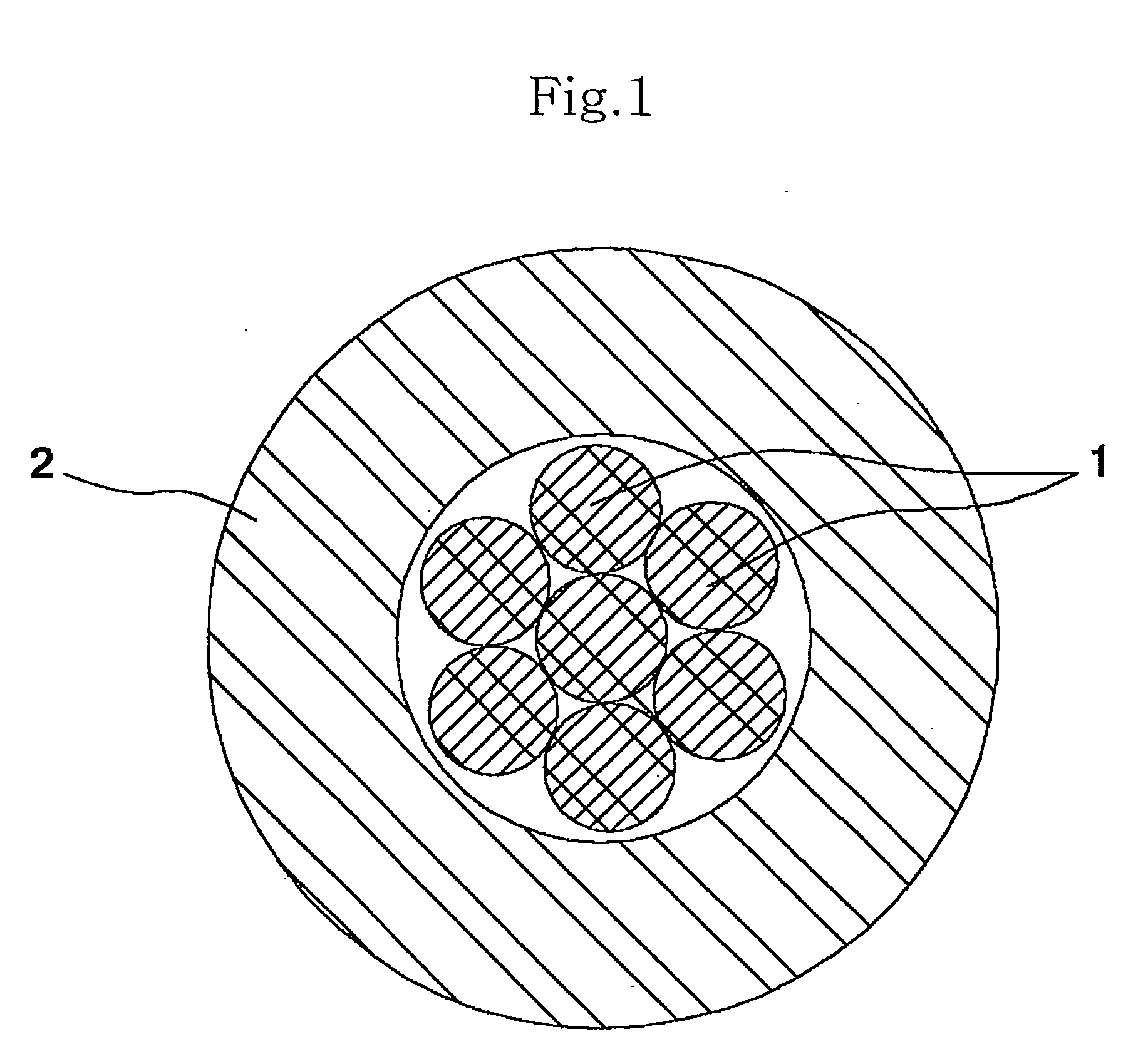

Halogen free polymer and automotive wire using thereof

InactiveUS20070149680A1Reduce generationExcellent abrasion resistancePlastic/resin/waxes insulatorsInsulated cablesAntioxidantHeat resistance

The present invention discloses an insulation composition for halogen-free automotive cables, which comprises a matrix resin, 50-200 parts by weight, based on 100 parts by weight of the matrix resin, of a metal hydroxide flame retardant, and 0.5-20 parts by weight of an antioxidant, in which the matrix resin consists of 1-80 parts by weight of a polyethylene resin, 1-80 parts by weight of an ethylene copolymer resin, and 1-20 parts of a terpolymer of polyethylene, acrylic ester and maleic anhydride. The inventive composition and automotive cables including the same show a reduction generation of poisonous gas and smoke and are eco-friendly. In addition, they are excellent in physical properties, such as flame retardancy, abrasion resistance, scratch resistance, harness, and thermal resistance, and can be extruded at high speed.

Owner:LG CABLE LTD (KR)

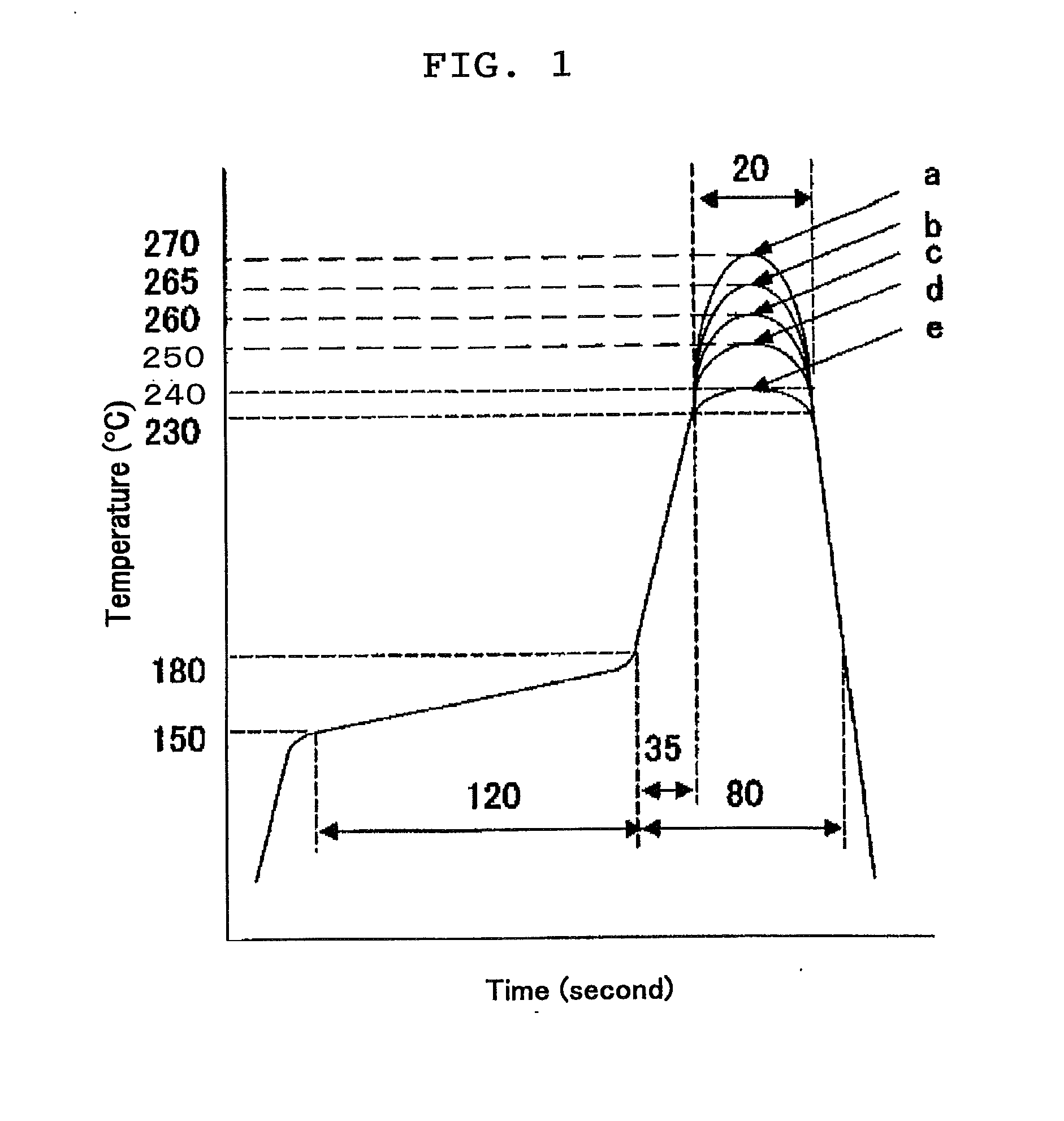

Flame-retardant polyamide composition

Disclosed is a flame-retardant polyamide composition which is excellent in mechanical properties such as toughness, and heat resistance, flame retardancy and flow ability during a reflow soldering process. In addition, this polyamide composition exhibits high thermal stability during molding. Specifically disclosed is a flame-retardant polyamide composition containing (A) 20-80% by weight of a specific polyamide resin, (B) 10-20% by weight of a metal phosphinate, (C) 0.05-1% by weight of a lithium salt, a calcium salt, a barium salt, a zinc salt or an aluminum salt of montanic acid, behenic acid or stearic acid. It is preferable that this flame-retardant polyamide composition contains no halogen flame retardant.

Owner:MITSUI CHEM INC

Glass-fiber-reinforced polycarbonate resin composition

ActiveUS20160024301A1Improve flame retardant performanceIncrease stiffnessPlastic/resin/waxes insulatorsPhosphorus organic compoundsGlass fiberPolymer science

A glass-fiber-reinforced polycarbonate resin composition having a flat cross section and excellent weld strength, stiffness and flame retardancy. The resin comprises:(A) 100 parts by weight of a resin component (component A) consisting of a polycarbonate-polydiorganosiloxane copolymer resin (component A-1) and an aromatic polycarbonate resin (component A-2);(B) 10 to 300 parts by weight of glass fibers having a flat cross section (component B) which have an average value of the long diameter of the fiber cross section of 10 to 50 μm and an average value of the ratio of the long diameter to the short diameter (long diameter / short diameter) of 1.5 to 8;(C) 5 to 25 parts by weight of an adhesion improving agent (component C);(D) 5 to 45 parts by weight of a phosphorus-based flame retardant (component D); and(E) 0.01 to 3 parts by weight of a fluorine-containing dripping inhibitor (component E),the content of the polydiorganosiloxane derived from the component A-1 in the resin composition being 0.05 to 4.00 wt %.

Owner:TEIJIN LTD

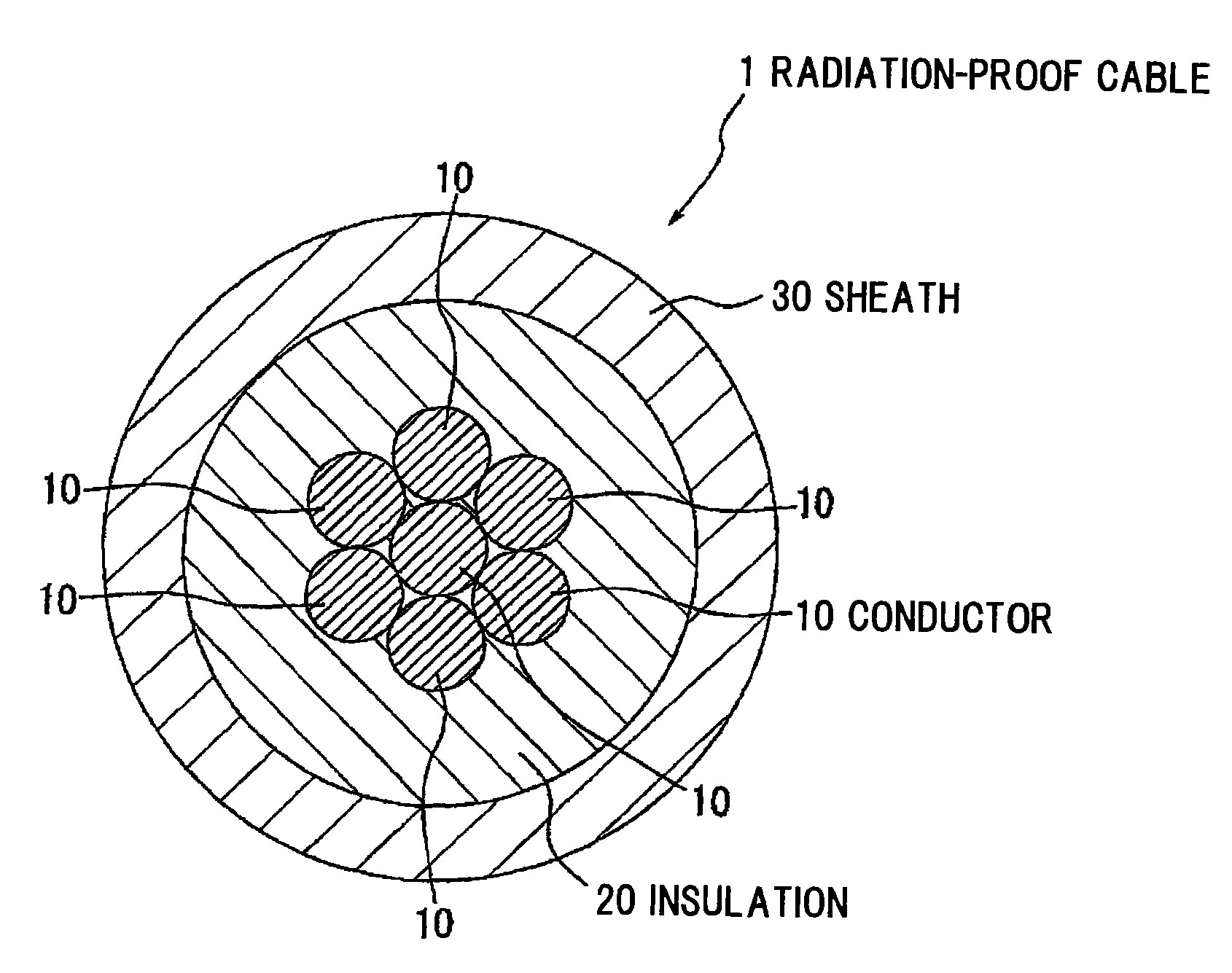

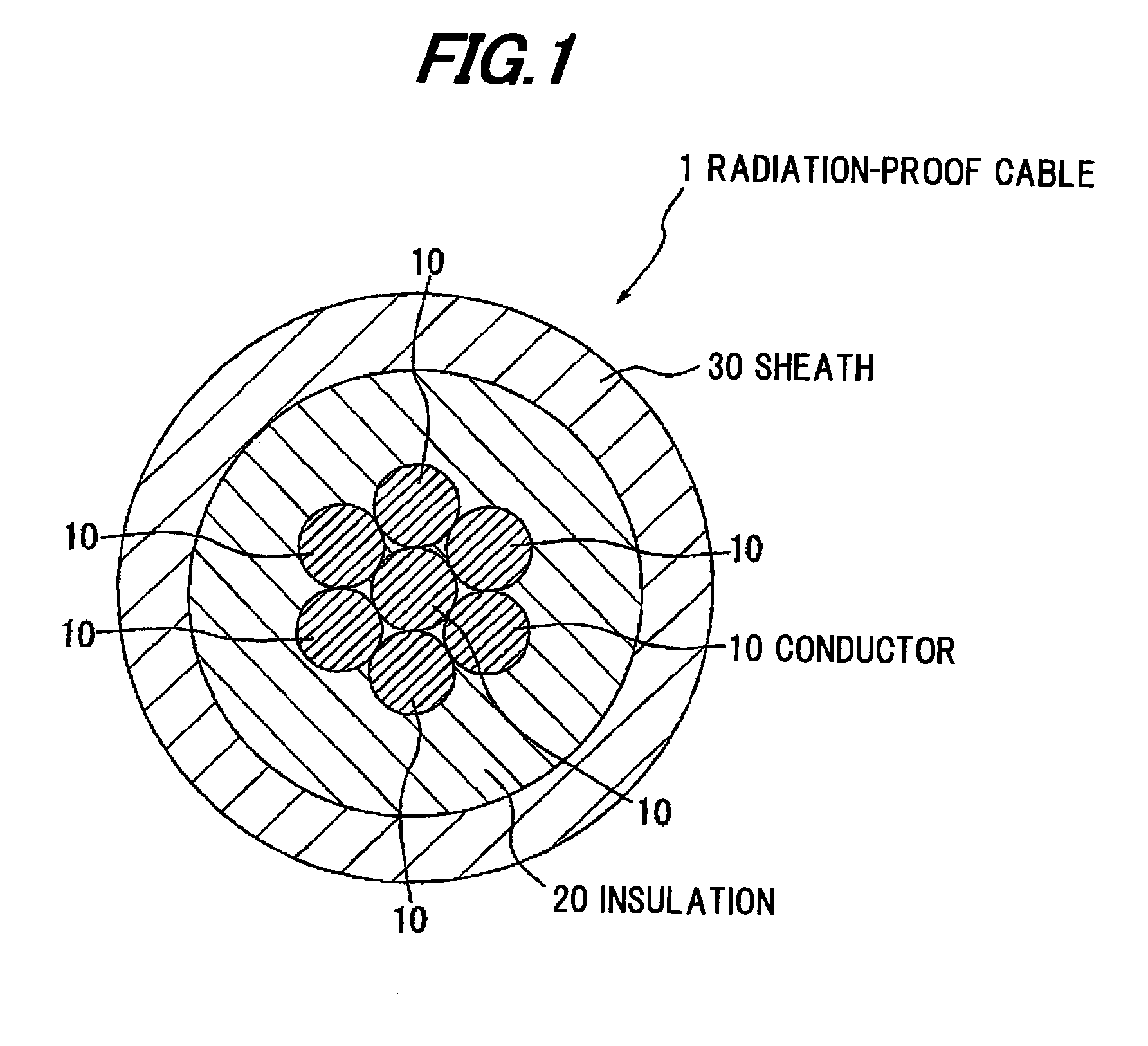

Radiation-proof resin composition and radiation-proof cable

ActiveUS20100051316A1Efficiently captureMaintain good propertiesPlastic/resin/waxes insulatorsIonPolymer chemistry

A radiation-proof resin composition includes a polymer containing chlorine, a radiation resistance providing agent for providing the polymer with a radiation resistance, an amorphous inorganic material for capturing an ionic component generated in the polymer by radiation application, and a reinforcing material for reinforcing a mechanical strength of the polymer. An amount of the reinforcing material is not more than that of the amorphous inorganic material.

Owner:HITACHI METALS LTD

Black photosensitive resin composition and use of same

ActiveUS20150044451A1Good flexibilityImprove flame retardant performancePlastic/resin/waxes insulatorsFlexible printed circuitsElectricityOrganic solvent

Provided is a black photosensitive resin composition being microfabricatable due to its photosensitivity, allowing a cured film obtainable therefrom to be excellent in flexibility, being small in post-curing warpage of a substrate, being excellent in flame retardancy and electric insulation reliability, allowing a reduction in process contamination due to less outgassing during a reflow process, and avoiding a reduction in film thickness. The black photosensitive resin composition contains at least (A) a binder polymer, (B) a thermosetting resin, (C) a flame retardant substantially insoluble in an organic solvent, (D) a photopolymerization initiator, (E) a black colorant reflecting light having a wavelength falling within an infrared range, and (F) an organic solvent, or contains at least (A) a binder polymer, (B) a thermosetting resin, (G) spherical organic beads, (D) a photopolymerization initiator, (E) a black colorant reflecting light having a wavelength falling within an infrared range, and (F) an organic solvent.

Owner:KANEKA CORP

Phosphazene composition

ActiveUS7060744B2Increase resistanceExcellent in retardancyGroup 5/15 element organic compoundsHydrolysisPhosphazene

A phosphazene composition which has a content of volatile components of not less than 0.02% by weight and not more than 1.0% by weight when it is heated at 200° C. for 2 hours; is excellent in resistance to hydrolysis, and when the phosphazene composition is added to a resin, there is provided a resin composition which highly maintains the balance of resistance to hydrolysis, flame retardancy and stability of electric characteristics in a high-frequency field of not less than 1 GHz.

Owner:ASAHI KASEI KK

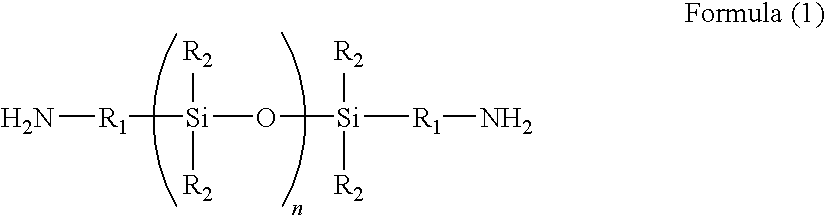

Substrate for flexible printed wiring board and method for manufacturing the same

InactiveUS7384683B2Maintain good propertiesIncrease resistanceSynthetic resin layered productsStacked and attached PCBsEpoxyElectrical conductor

Owner:UNITIKA LTD +1

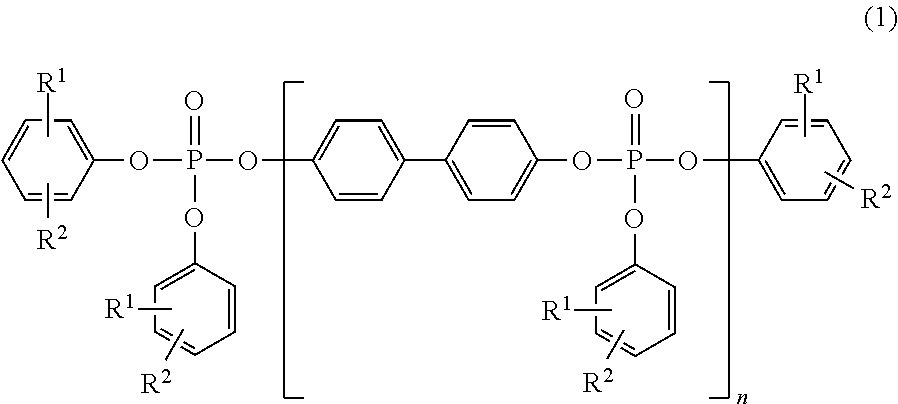

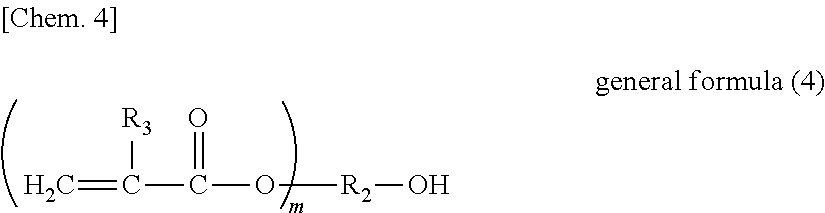

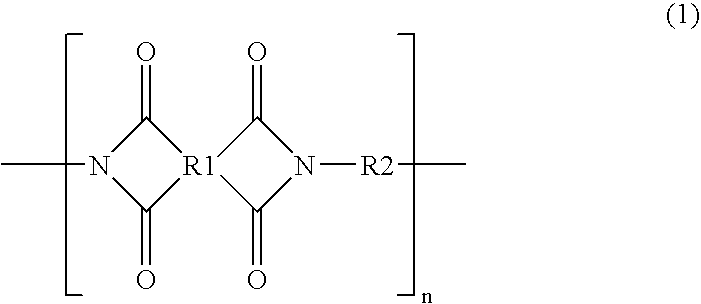

Flame-retardant adhesive composition, coverlay film using same, and flexible copper-clad laminate

ActiveUS20160222192A1Increase stickinessImprove flame retardant performancePrinted circuit detailsFilm/foil adhesivesEpoxyElastomer

The flame-retardant adhesive composition contains a styrene-based elastomer containing a carboxyl group, an epoxy resin, and a phosphorus-containing oligomer including a structural unit represented by general formula (1), and the epoxy resin content is 1-20 parts by mass and the phosphorus-containing oligomer content is 10-50 parts by mass with respect to 100 parts by mass of the styrene-based elastomer containing carboxyl groups.(wherein, R1 and R2 are each independently a hydrogen atom or a methyl group, n is an integer of 1-20.)

Owner:TOAGOSEI CO LTD

Resin composition of layered silicate

InactiveUS7682691B2Maintain good propertiesIncrease resistanceSynthetic resin layered productsSpecial tyresPolymer scienceAdhesive belt

Owner:SEKISUI CHEM CO LTD

Thermosetting resin composition and use thereof

ActiveUS8080319B2Increase flexibilityMaintain good propertiesSynthetic resin layered productsThin material handlingEpoxyFolding endurance

Disclosed is related to a thermosetting resin composition which comprises a polyimide resin (A) having a phenolic hydroxyl group, preferably a polyimide resin (A) produced from an aminophenol (a), a diamino compound (b) and a tetrabasic acid dianhydride (c), and an epoxy resin (B); and a cured product thereof. The resin composition is excellent in storage stability, and gives a cured product excellent in flame retardancy and heat resistance. Furthermore, when the cured product is in a film form, the product has sufficient flexibility and excellent folding endurance.

Owner:NIPPON KAYAKU CO LTD

Thermoplastic resin composition and molded body obtained from the same

InactiveUS20100204390A1Good chemical resistanceImprove flame retardant performancePolyester resinViscosity index

Disclosed is a thermoplastic resin composition characterized by containing a combination of 95 to 5% by mass of a polycarbonate copolymer having a specific repeating unit in a specific amount and having a viscosity index of 30 to 71 (component A) and 5 to 95% by mass of a polyester resin (component B). Also disclosed is a molded body obtained from such a thermoplastic resin composition, which is improved in fluidity, chemical resistance, impact resistance and flame retardancy.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com