Patents

Literature

33results about How to "Realize breaking up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

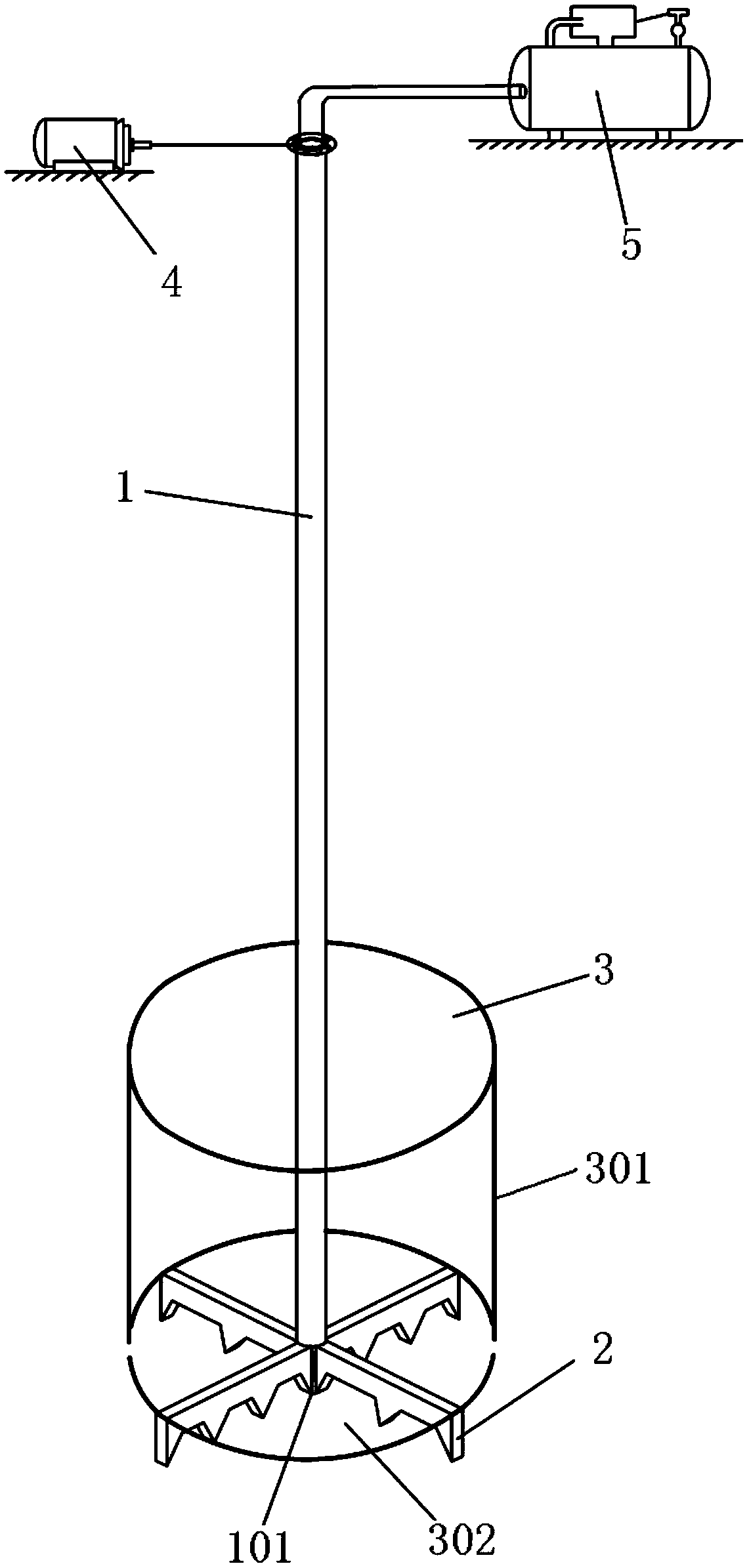

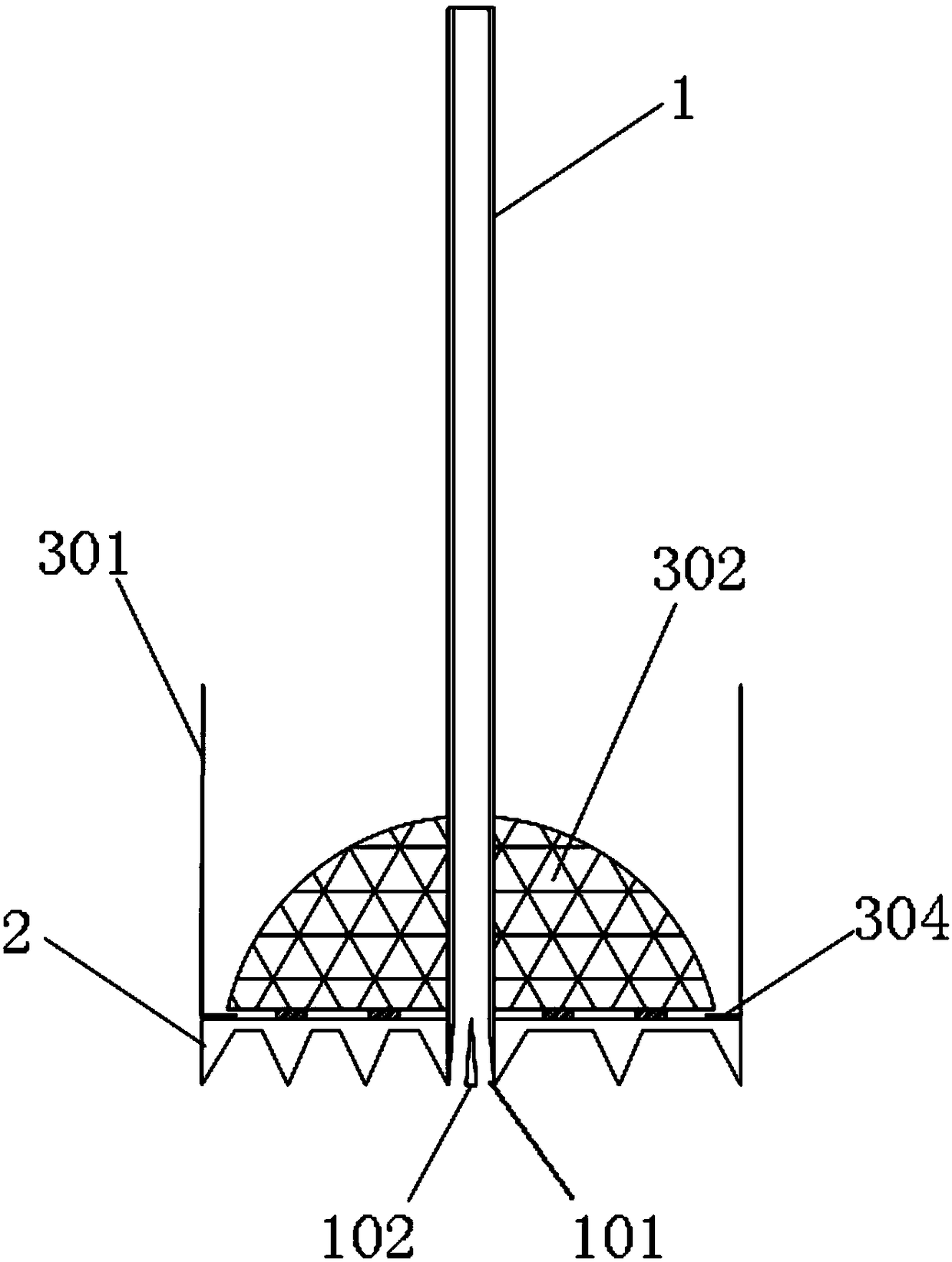

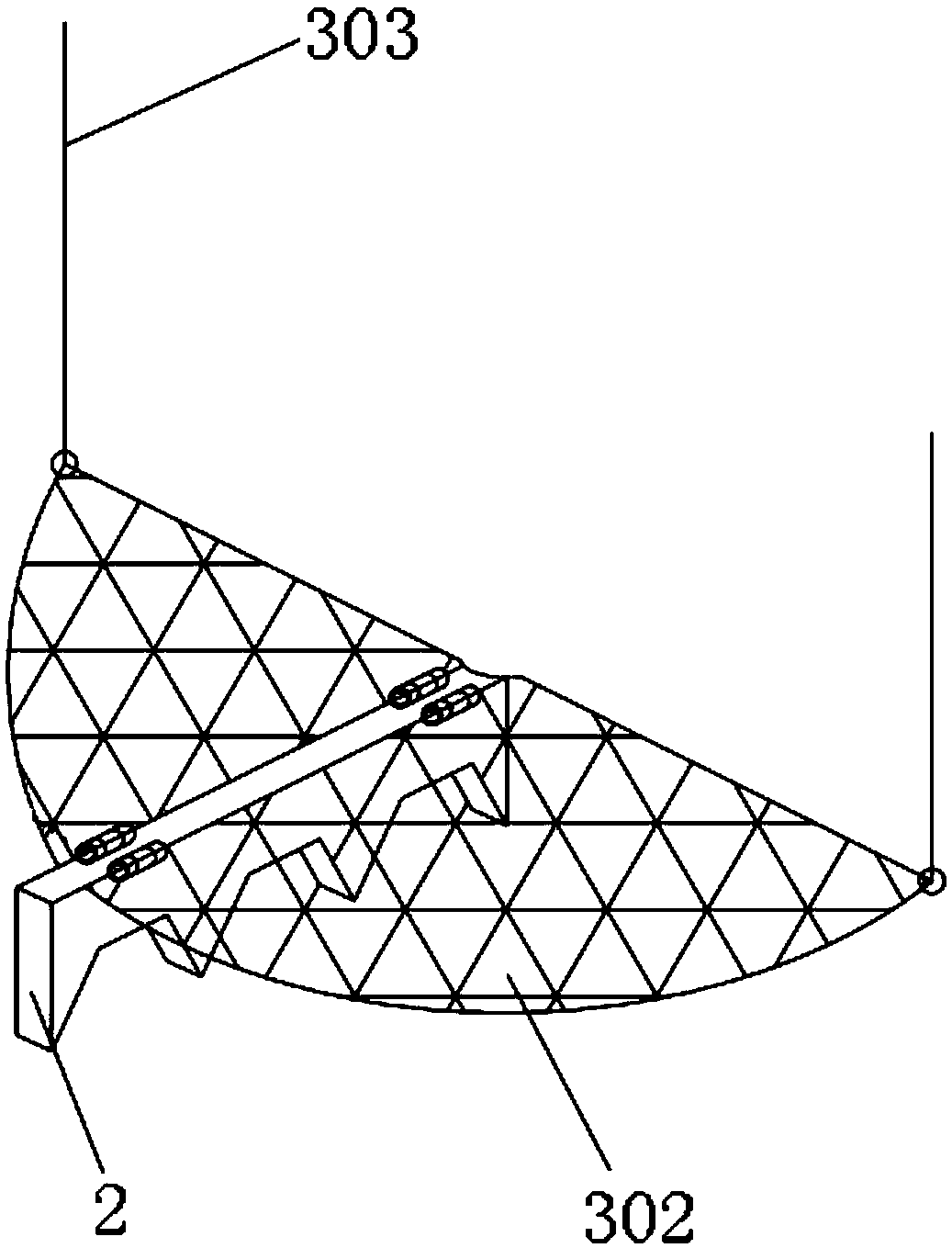

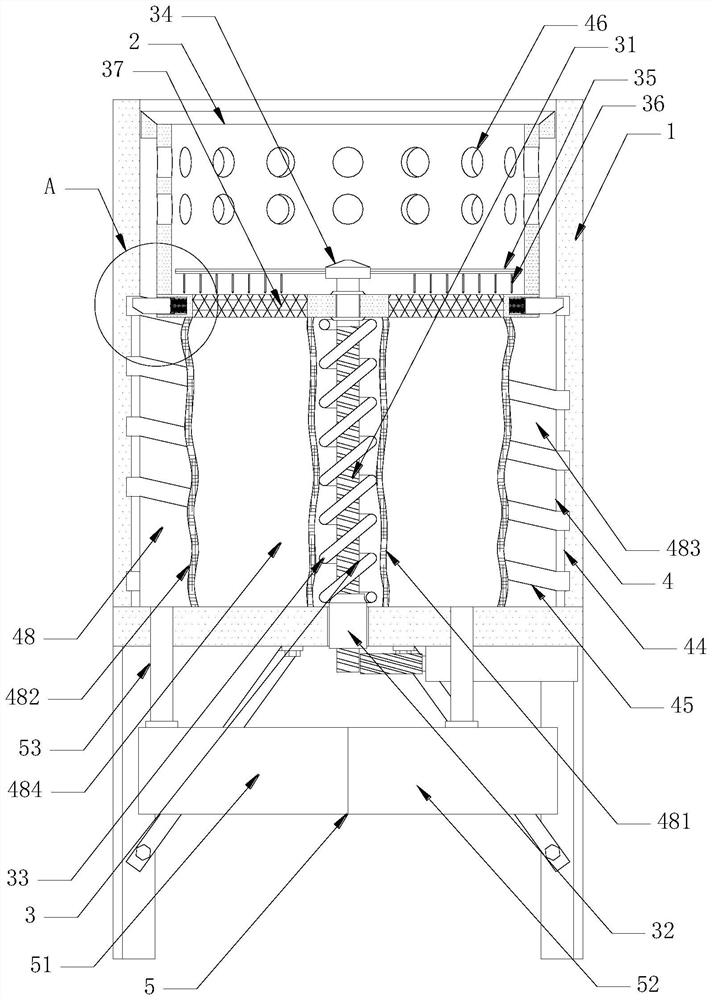

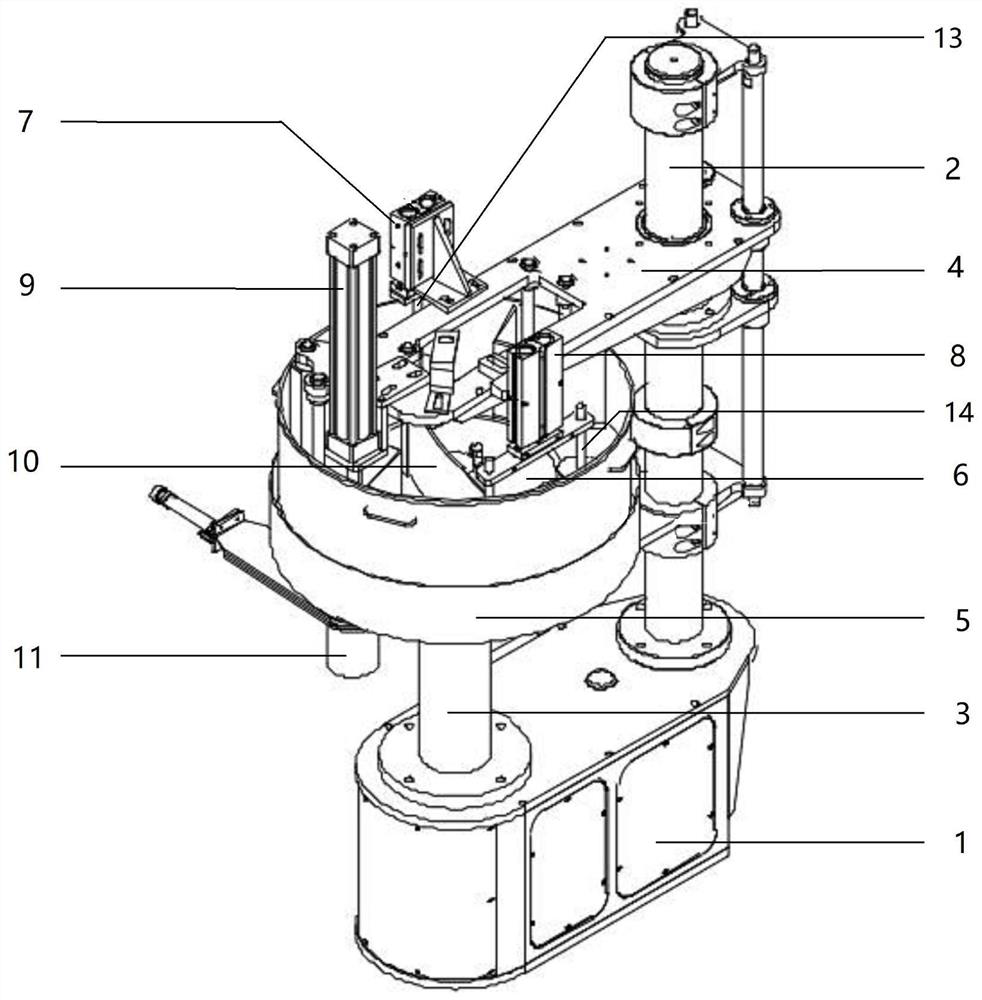

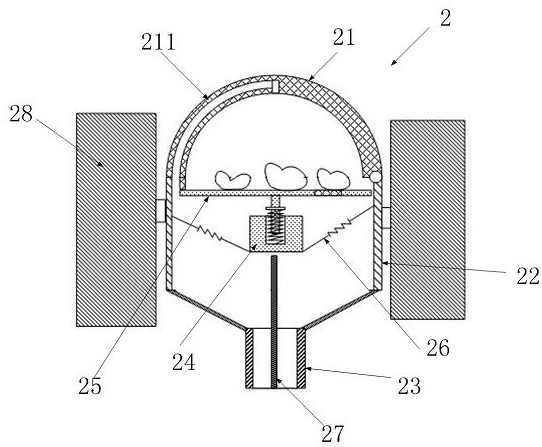

Hole cleaning device and method for cleaning boring-cast-in-situ-pile hole bottom sediments

ActiveCN108868678AAchieve separationRealize breaking upCement mixing apparatusBorehole/well accessoriesEngineeringSlurry

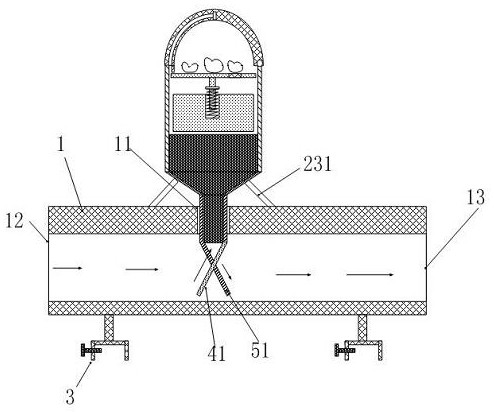

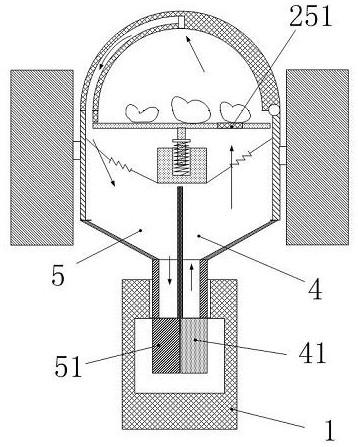

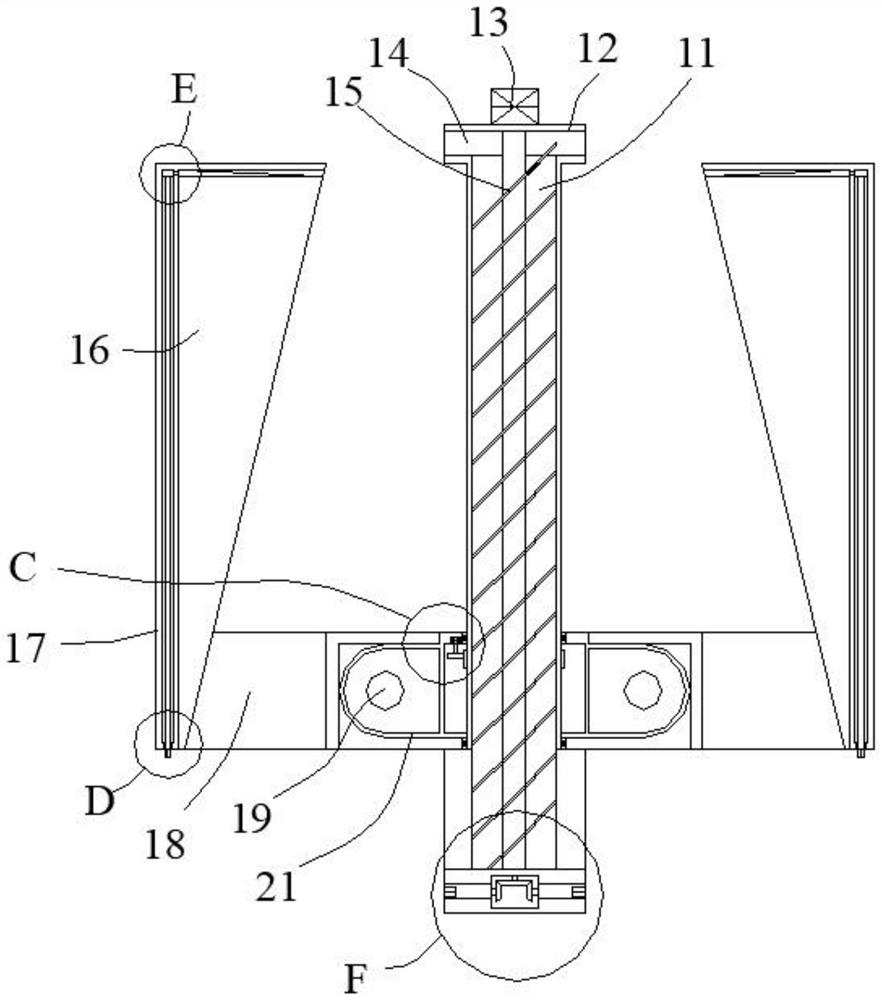

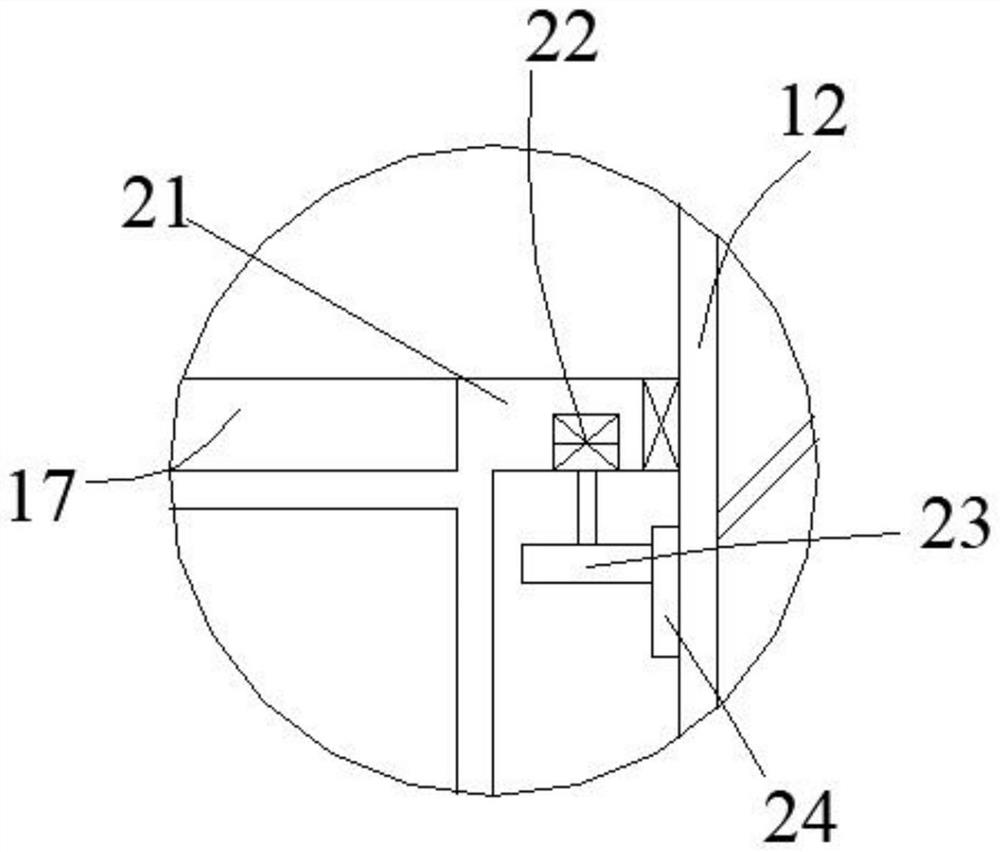

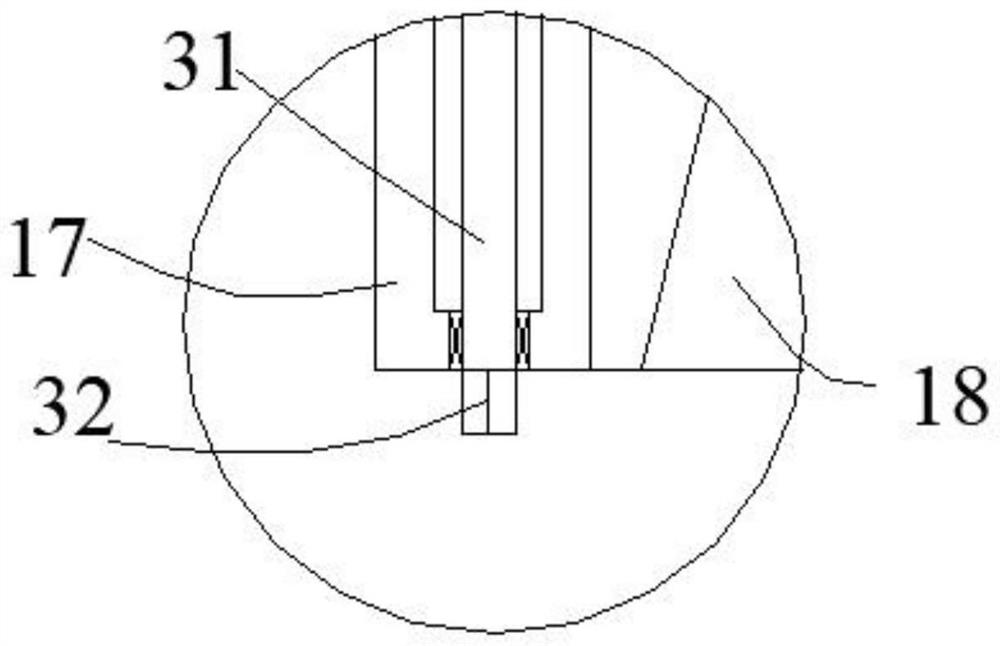

The invention discloses a hole cleaning device and method for cleaning boring-cast-in-situ-pile hole bottom sediments. The hole cleaning device for cleaning the boring-cast-in-situ-pile hole bottom sediments comprises a main rod body, stirring blades, a filtering net structure, a driving mechanism and a high-pressure-air generation device, wherein the main rod body is a hollow transmission shaft,and is used for transferring the torque and extending to the boring-cast-in-situ-pile hole bottom to output high pressure air to the boring-cast-in-situ-pile hole bottom, the high pressure air disturbs slurry to form turbulent flow at the hole bottom, and therefore the hole bottom sediments are turned up and suspended in slurry; the stirring blades are located at the lower portion of the main rodbody and arranged on the main rod body in the radial direction, are used for extending into the sediments of the boring-cast-in-situ-pile hole bottom, and rotate along with the main rod body to stir the sediments, and the sediments are loosed through shear force generated through stirring and suspended; the filtering net structure is located at the upper portions of the stirring blades and installed on the stirring blades and / or the main rod body, and is used for collecting the sediments suspended in the slurry; the driving mechanism is used for driving the main rod body to rotate; the high-pressure-air generation device is used for introducing the high pressure air into the main rod body.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

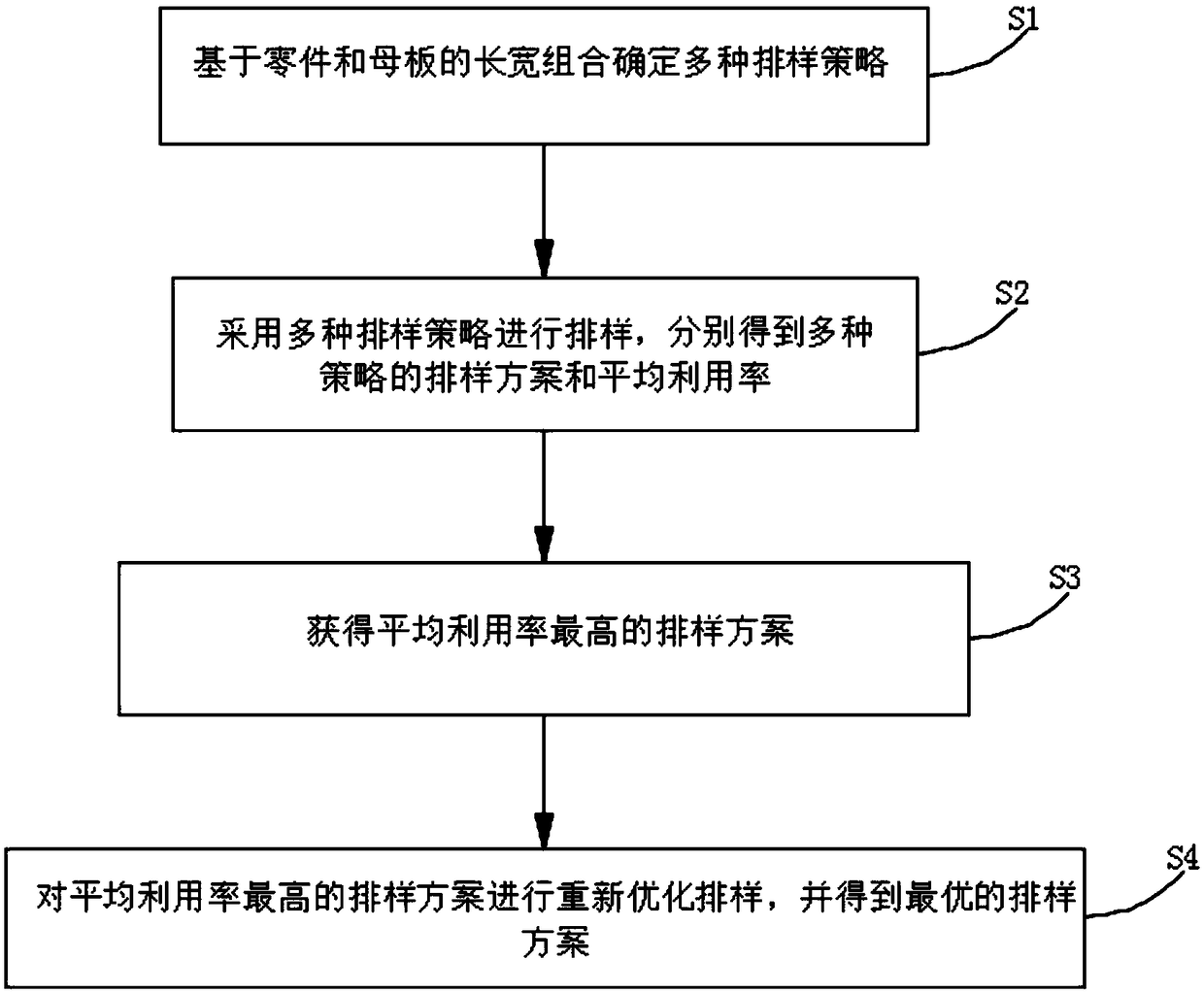

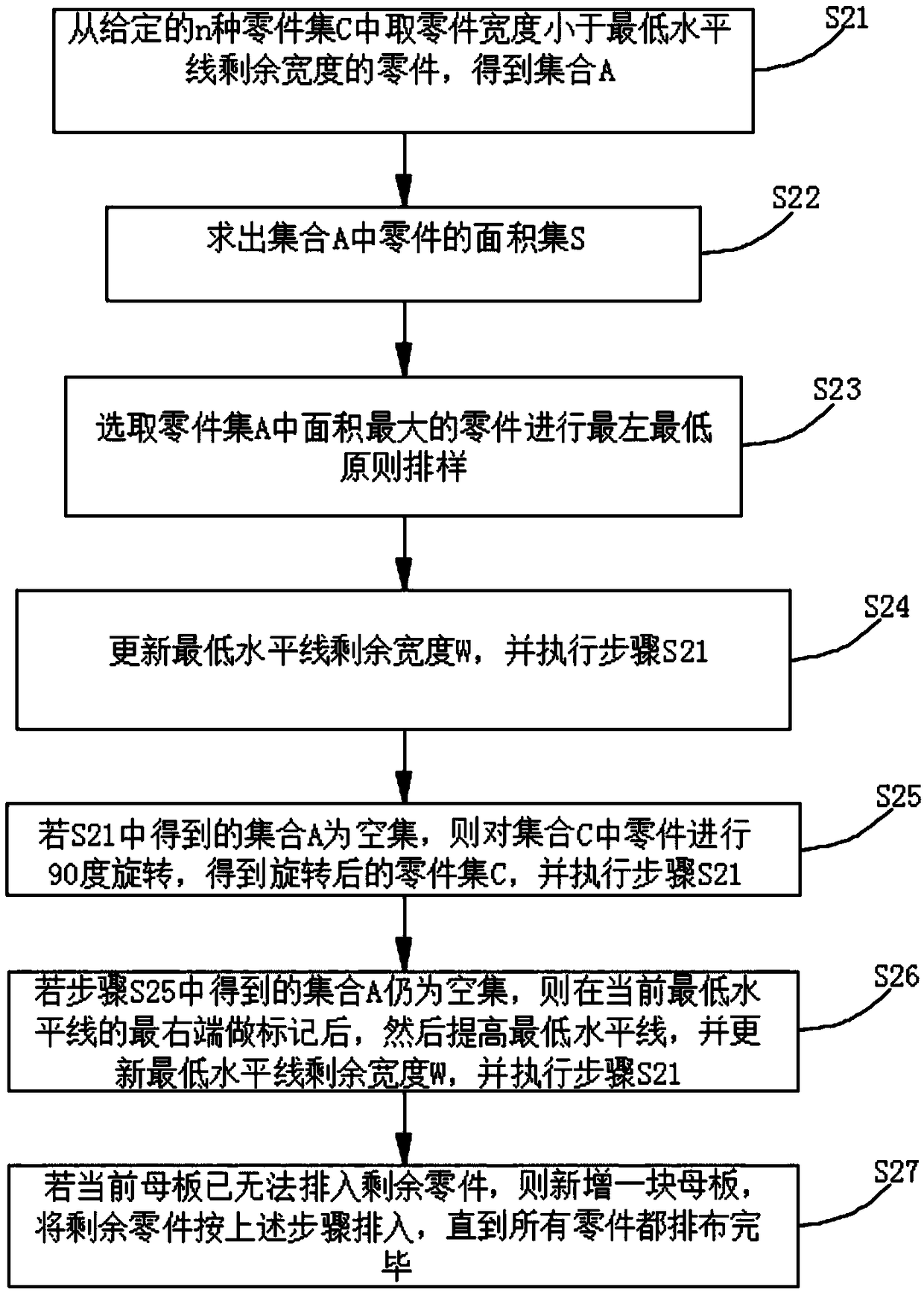

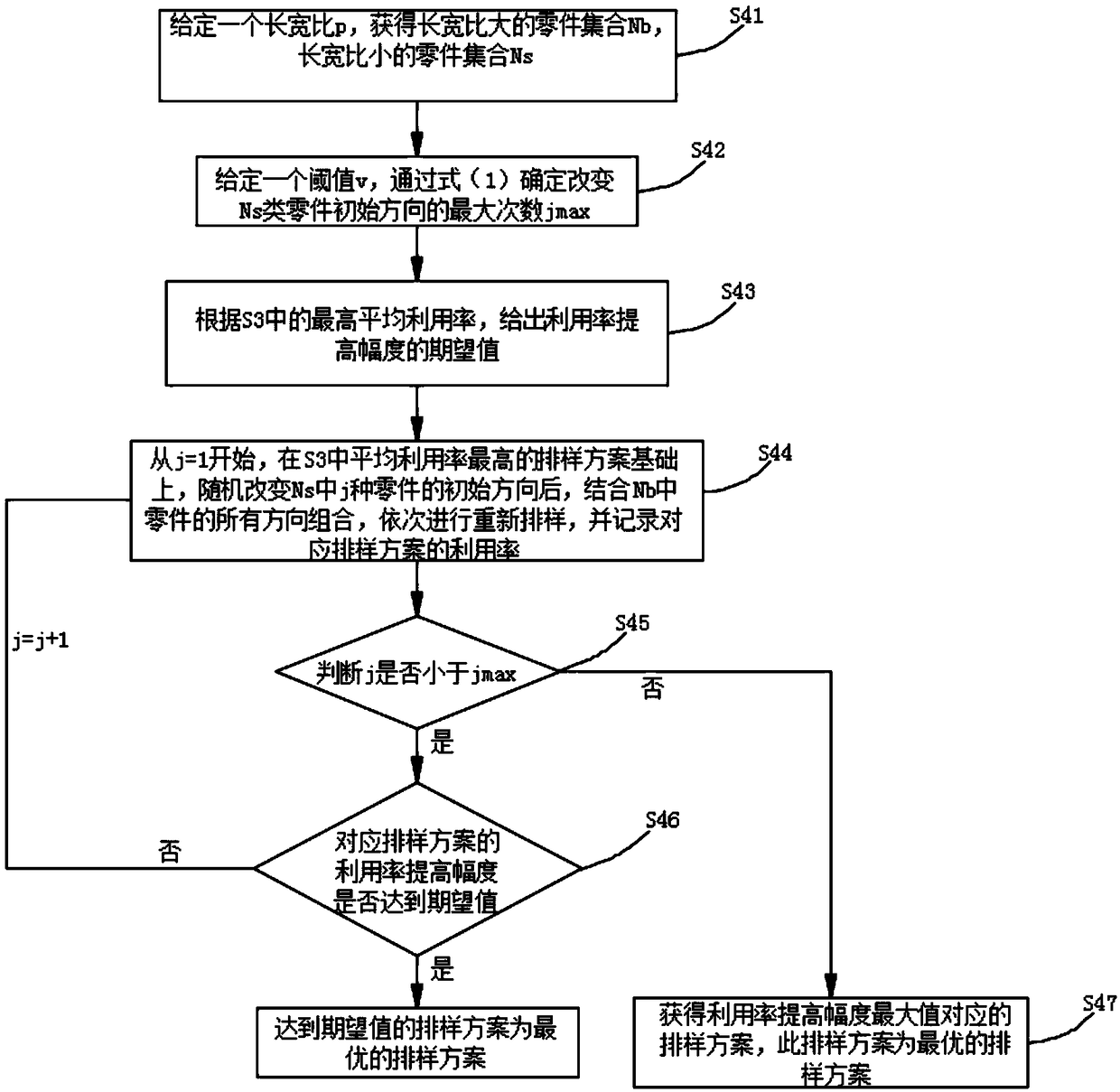

Rectangular optimal layout mixing method based on two stages

InactiveCN108764513ARealize breaking upRealize functionForecastingManufacturing computing systemsHybrid approachComputer science

The invention discloses a rectangular optimal layout mixing method based on two stages. The method comprises the following steps that S1. multiple layout strategies are determined based on the lengthand width combination of the components and the motherboard; S2. layout is performed by using multiple layout strategies so as to obtain the layout schemes and the average utilization rate of multiplestrategies; S3. the layout scheme of the highest average utilization rate is acquired; and S4. optimal layout of the layout scheme of the highest average utilization rate is performed again and the optimal layout scheme is obtained. According to the method, rectangular optimal layout is performed under the condition of considering multiple strategies so that the function of dispersing and recombining the original plates of poor layout can be realized, the optimal layout can be obtained, optimal processing of the rectangular workpiece in actual industrial production and processing can be expanded and the range of application is wider.

Owner:GUANGDONG UNIV OF TECH

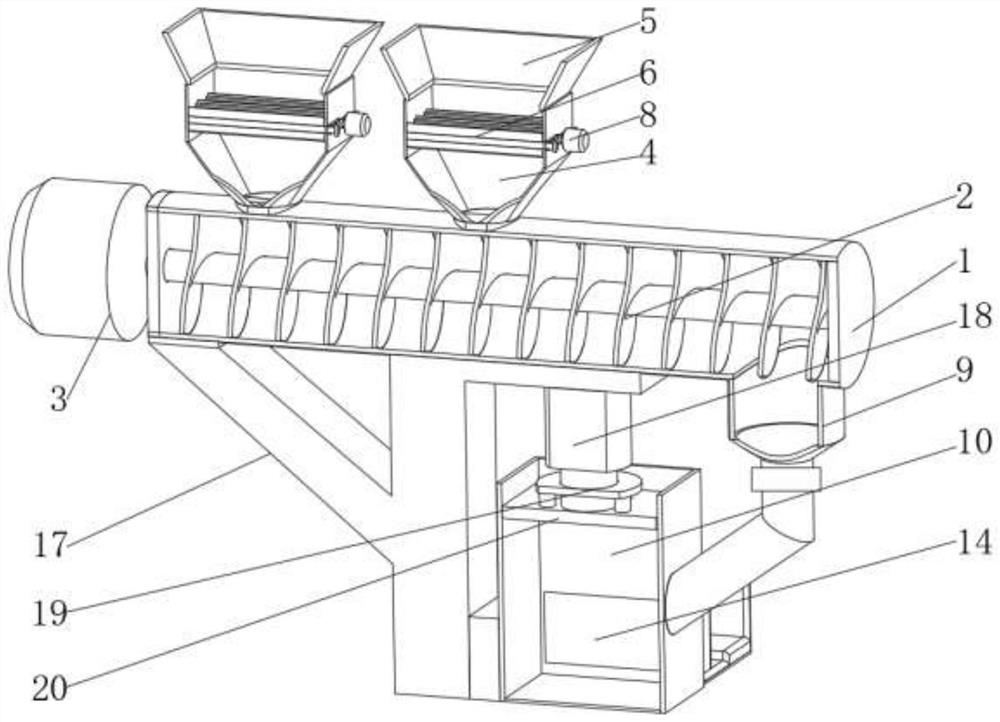

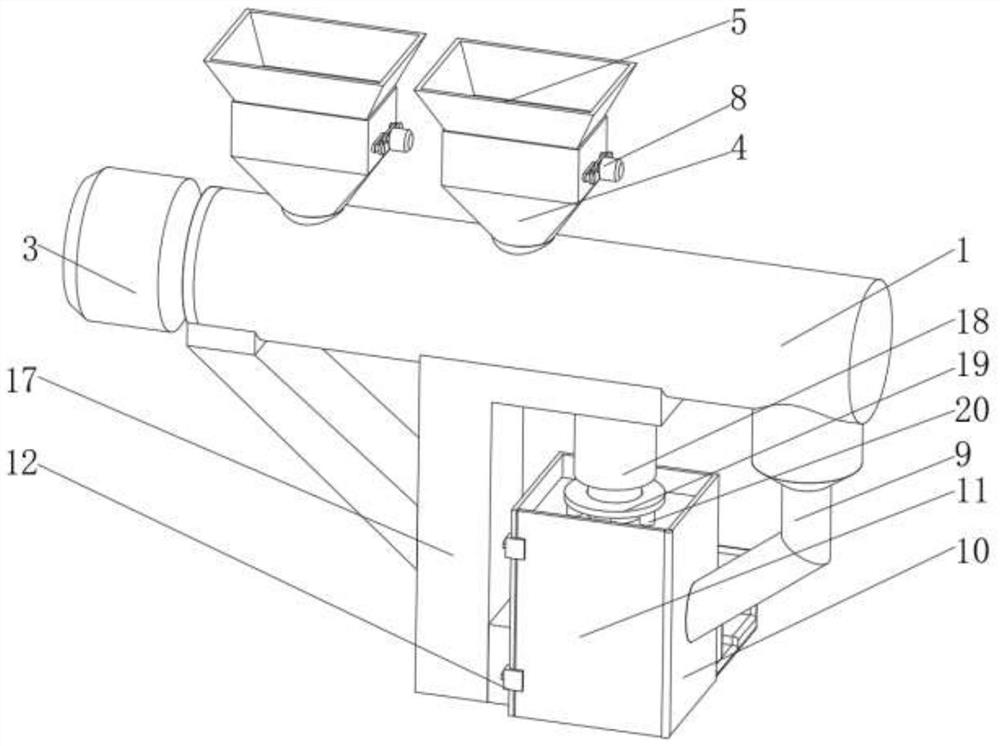

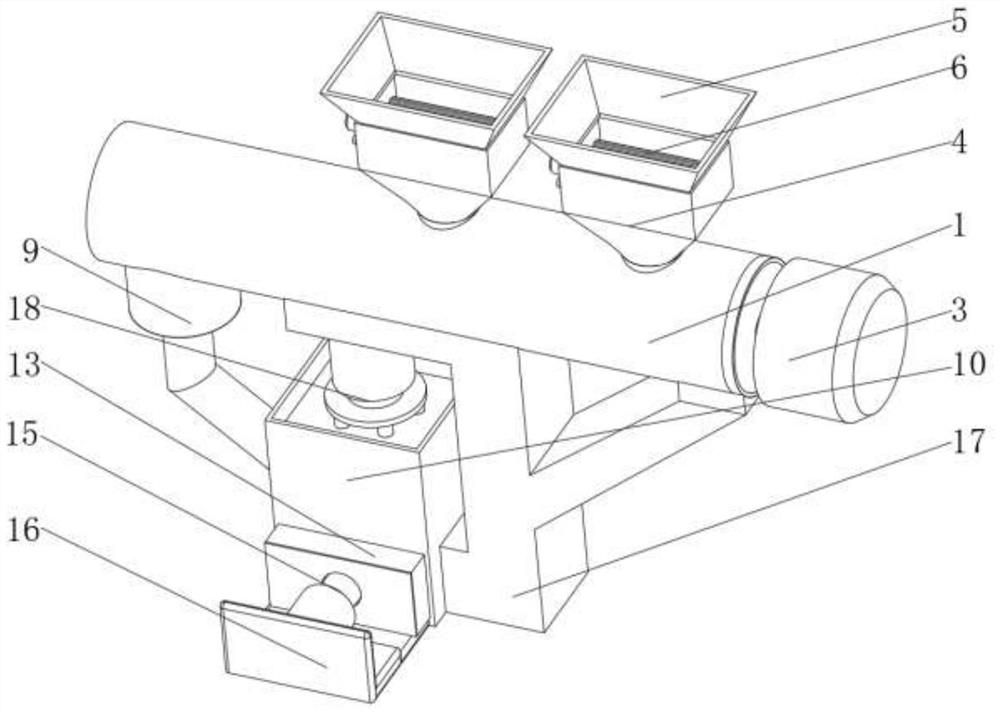

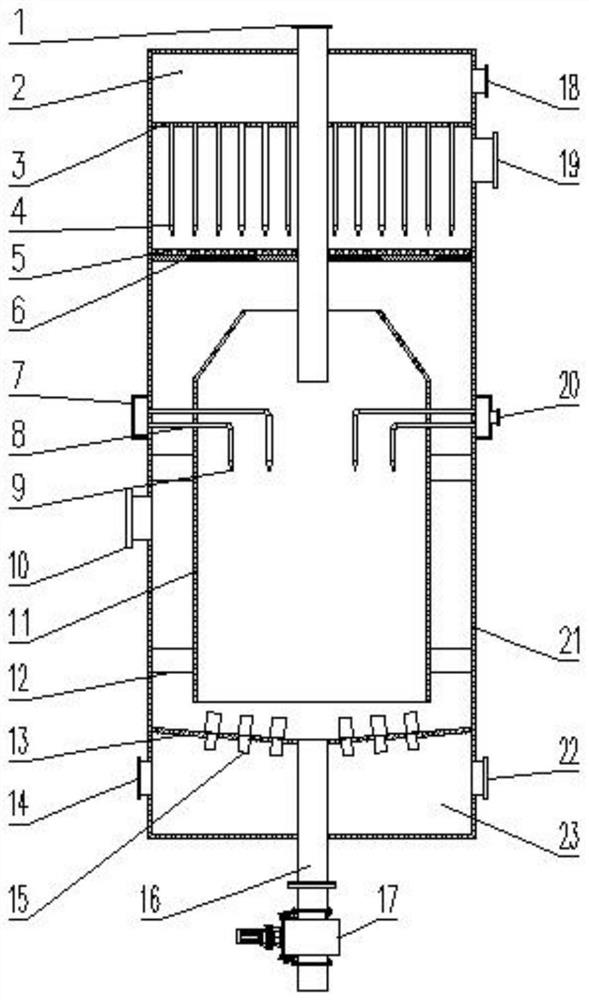

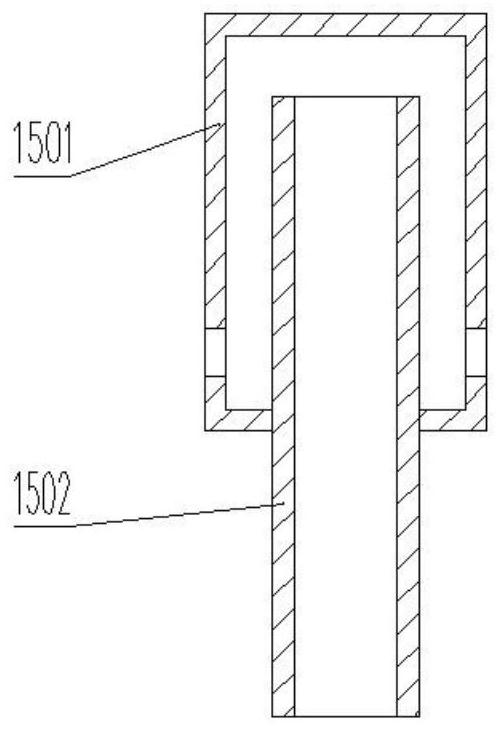

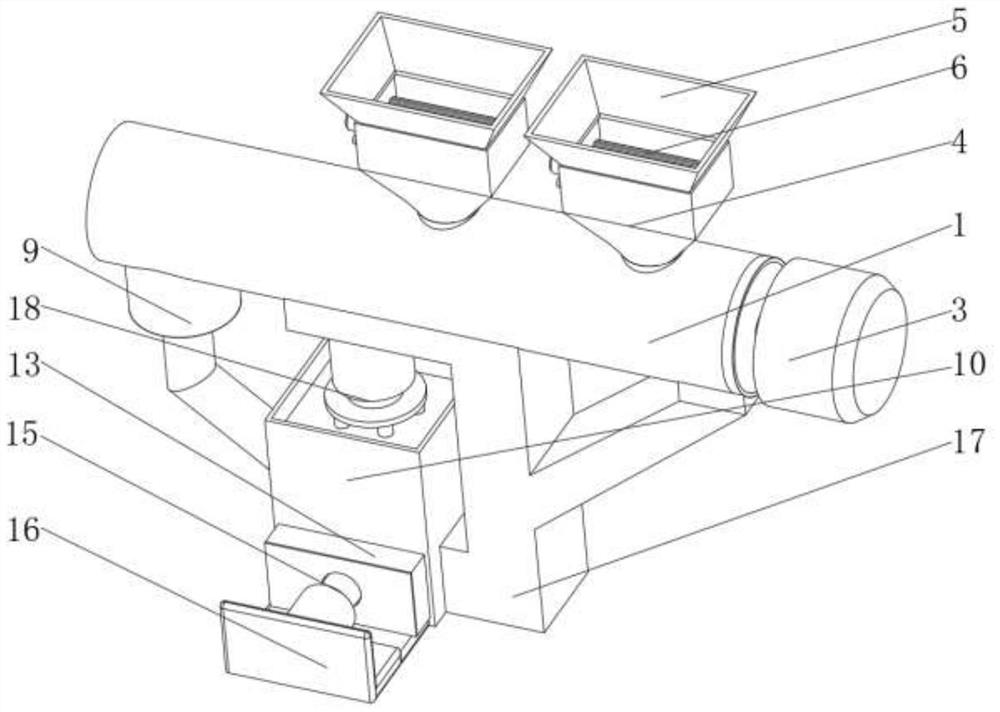

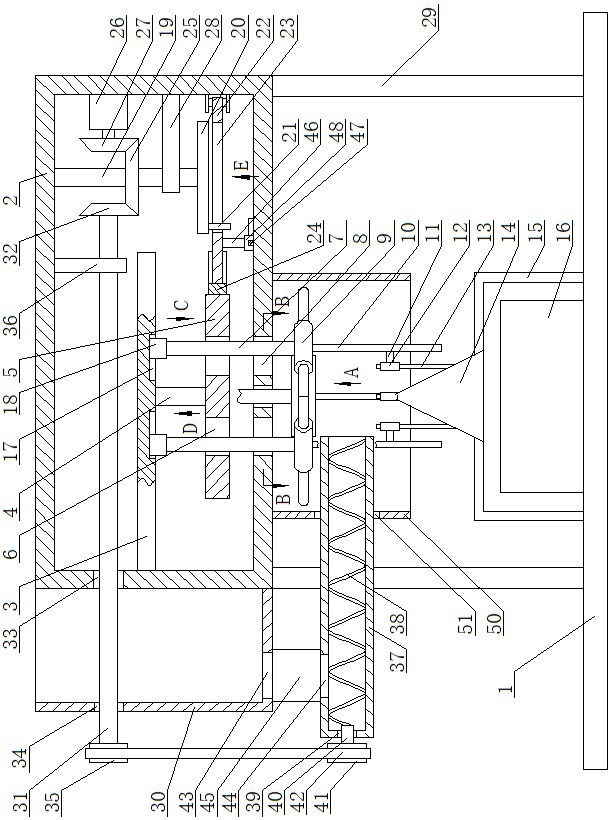

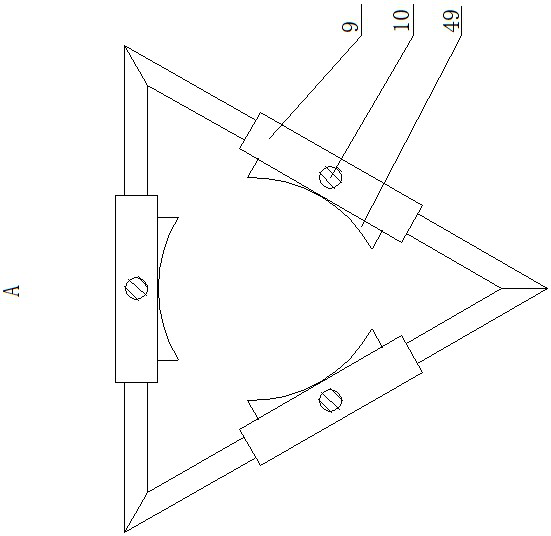

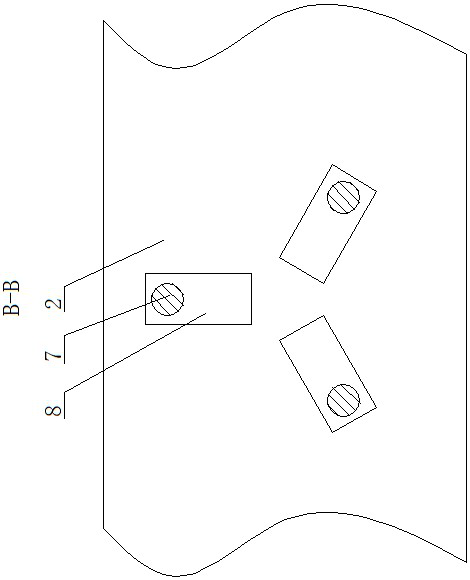

Solid waste solidification device

ActiveCN112157110ASmash Simple Cure EffectGood effectTransportation and packagingSolid waste disposalElectric machineryScrew conveyor

The invention relates to the technical field of waste treatment, and discloses a solid waste solidification device which comprises a conveying cylinder, wherein a screw conveyor is fixedly mounted inside the conveying cylinder; a first motor is fixedly mounted at the left side of the screw conveyor; two material discharging bins are fixedly mounted at the left end of the top of the conveying cylinder; and material feeding bins are fixedly mounted on the tops of the two material discharging bins. According to the solid waste solidification device, the purposes of simple crushing and good solidification effect are achieved through the arrangement of the conveying cylinder, a solidification chamber, crushing rollers and the like. Waste which needs to be solidified is crushed through the crushing rollers in advance, so that internal structures are broken up. Materials are broken up through the screw conveyor so as to ensure good crushing and dispersion effects of the materials. The materials are then put into the solidification chamber, and are solidified and compressed by a hydraulic cylinder, so that effective compression and solidification of the crushed materials can be achieved. Therefore, the solidification effect is good; pores inside the materials are very small; and the solidification degree is high.

Owner:铜仁筱启环保科技有限公司

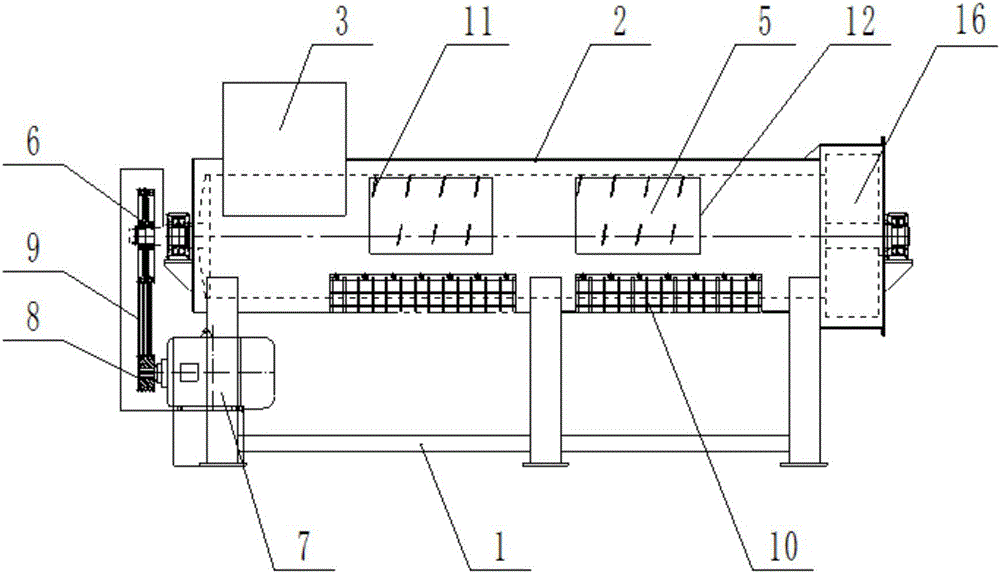

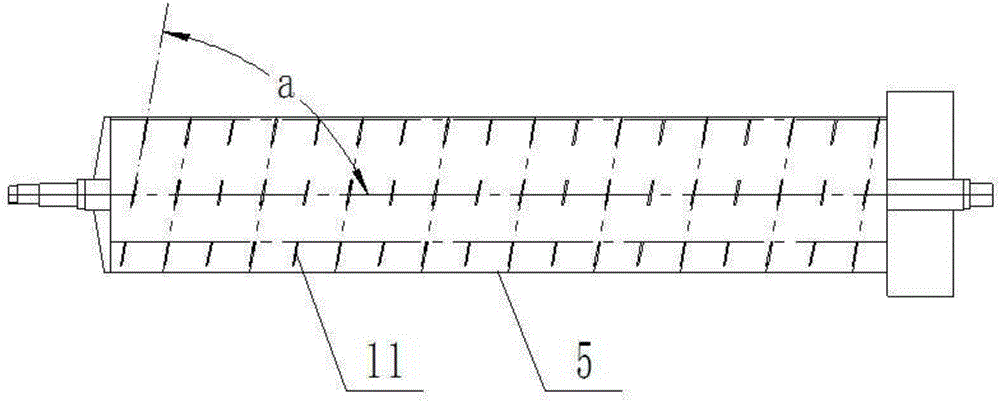

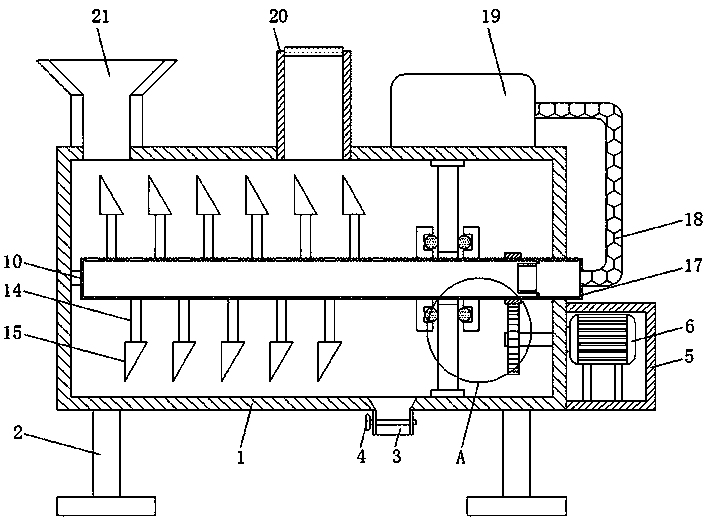

Waste thin film dry cleaning machine

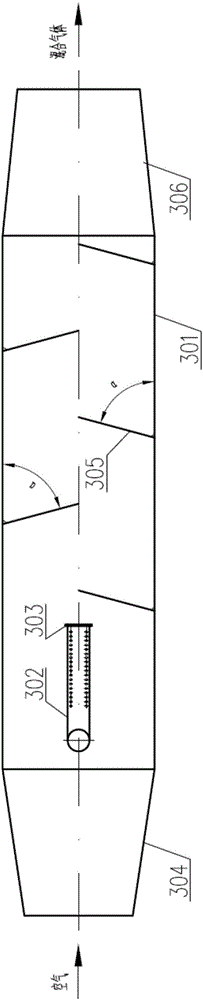

InactiveCN106424025AReduce moisture contentRealize breaking upCleaning processes and apparatusEngineeringHeat energy

The invention relates to a waste thin film dry cleaning machine. The waste thin film dry cleaning machine comprises a rack. A drum body is arranged on the rack, a feeding port is form in one end of the drum body, and a discharge port is formed in the other end of the drum body. A main shaft is arranged in the drum body, and the two ends of the main shaft are provided with bearing seats and connected with the rack. A driving device used for driving the main shaft is arranged on the rack. A screen mesh is arranged at the bottom of the drum body. A plurality of blades are arrayed on the main shaft, and the blades are arranged on the surface of the main shaft in a multi-spiral-shaped mode. Each blade is vertical to the surface of the main shaft, included angles are formed between the blades and the center axis of the main shaft, and the included angles lie between 75 degrees and 85 degrees. According to the waste thin film dry cleaning machine, continuous forward conveying of waste thin films can be achieved, and scattering of the thin films can also be achieved; and automatic separation between the thin films and impurities is achieved, water consumption is reduced, and cost is greatly lowered. Recycled thin films do not contain water, and heat energy is not needed for drying the thin films in later production, so that production cost is lowered, and operating procedures are reduced.

Owner:张家港联冠环保科技有限公司

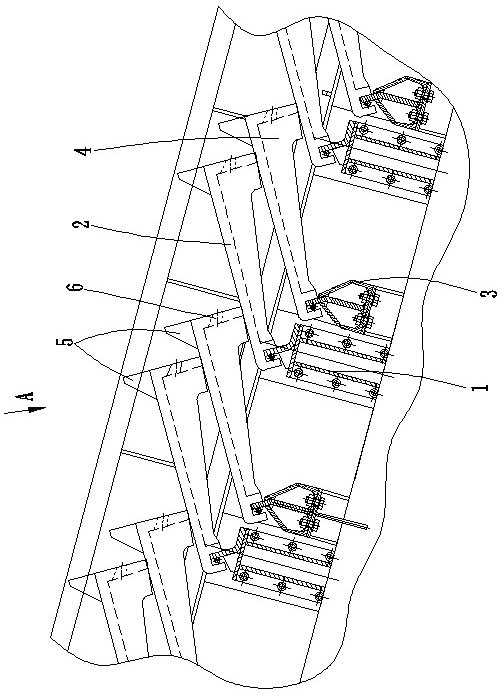

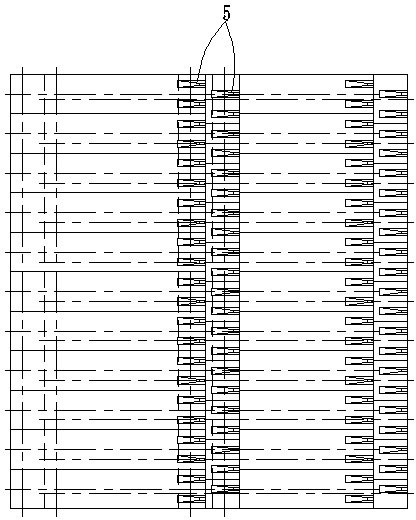

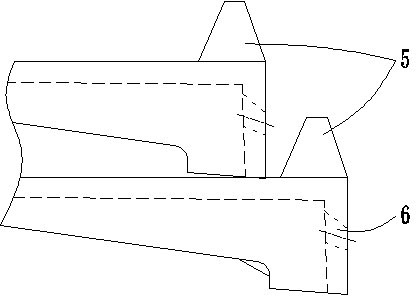

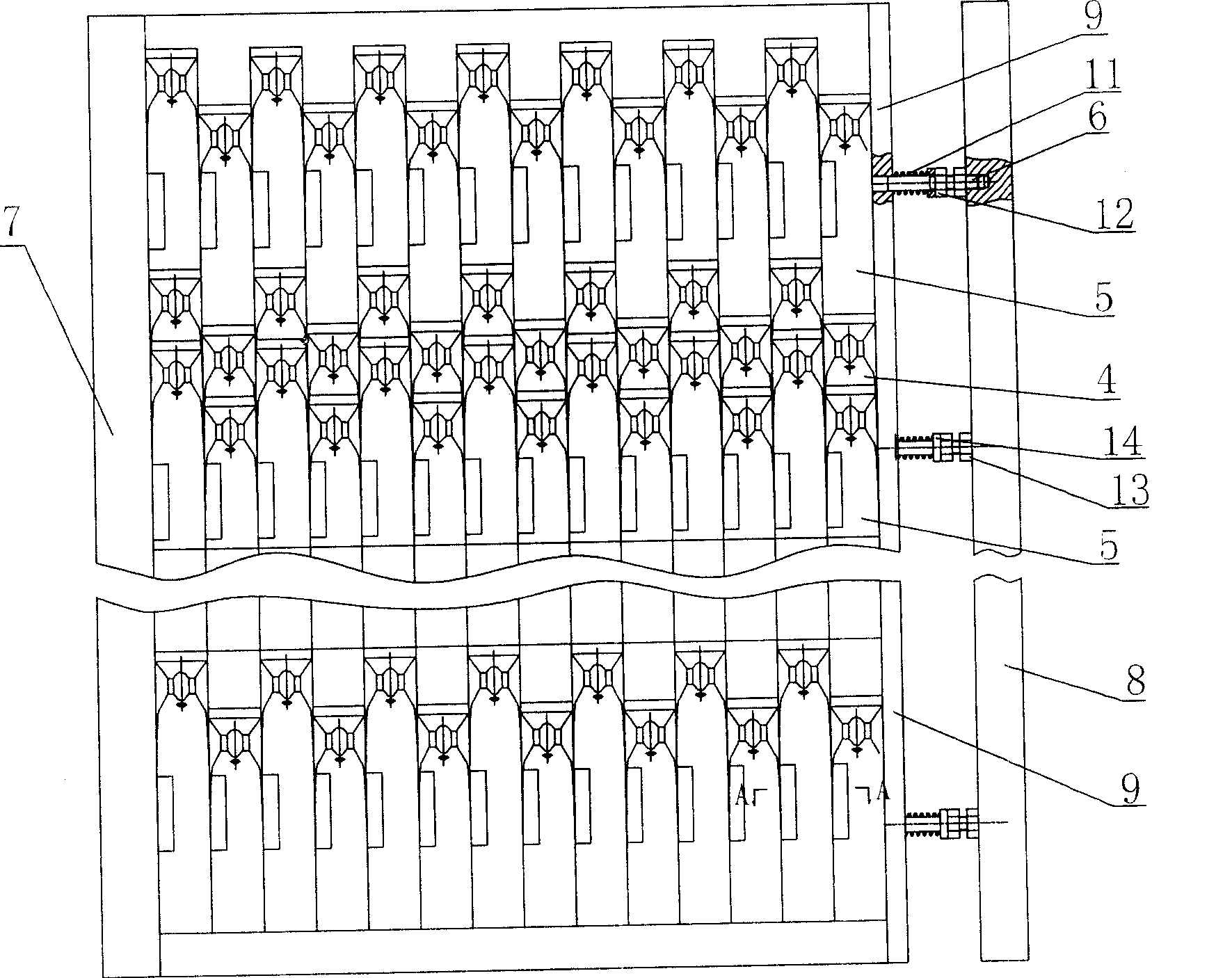

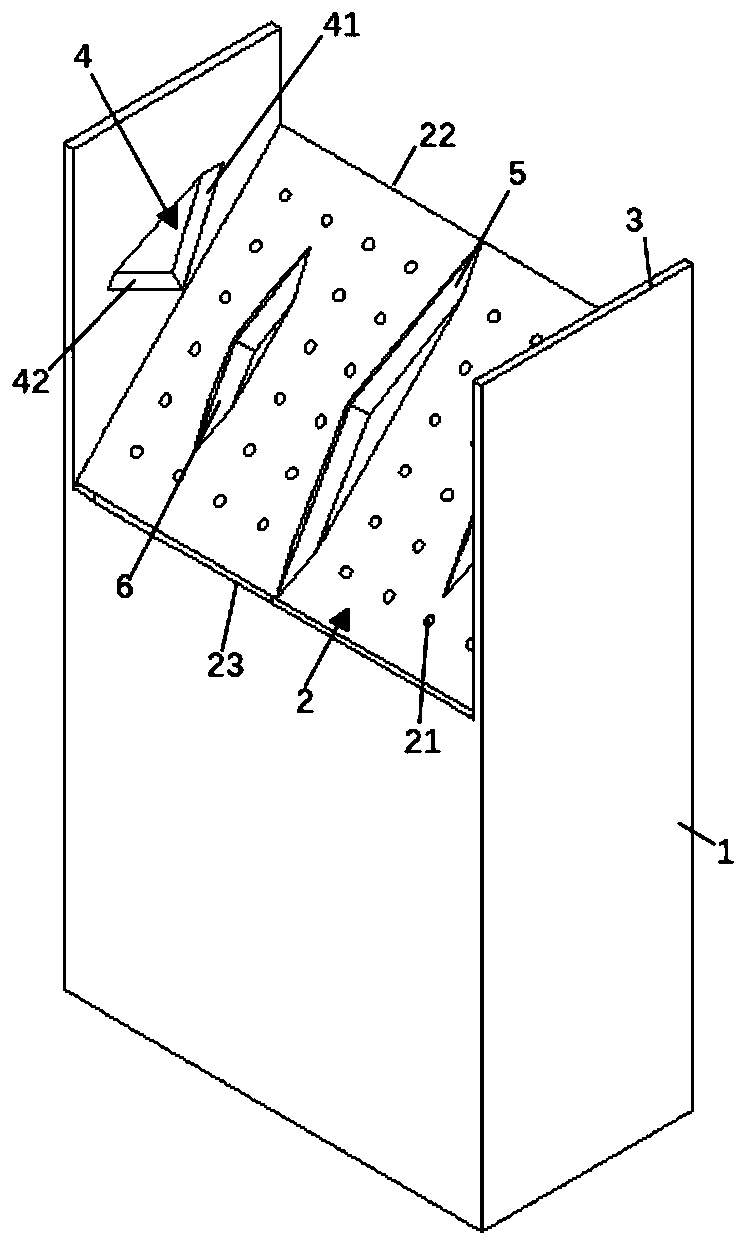

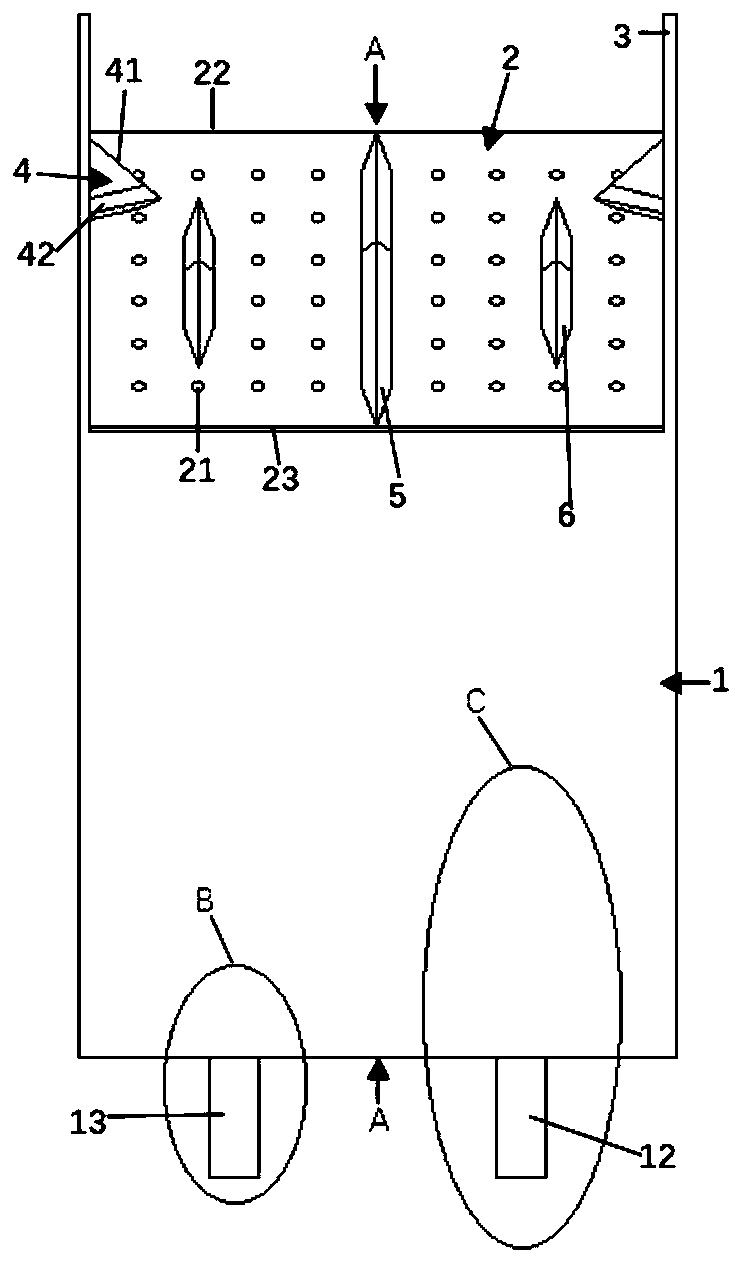

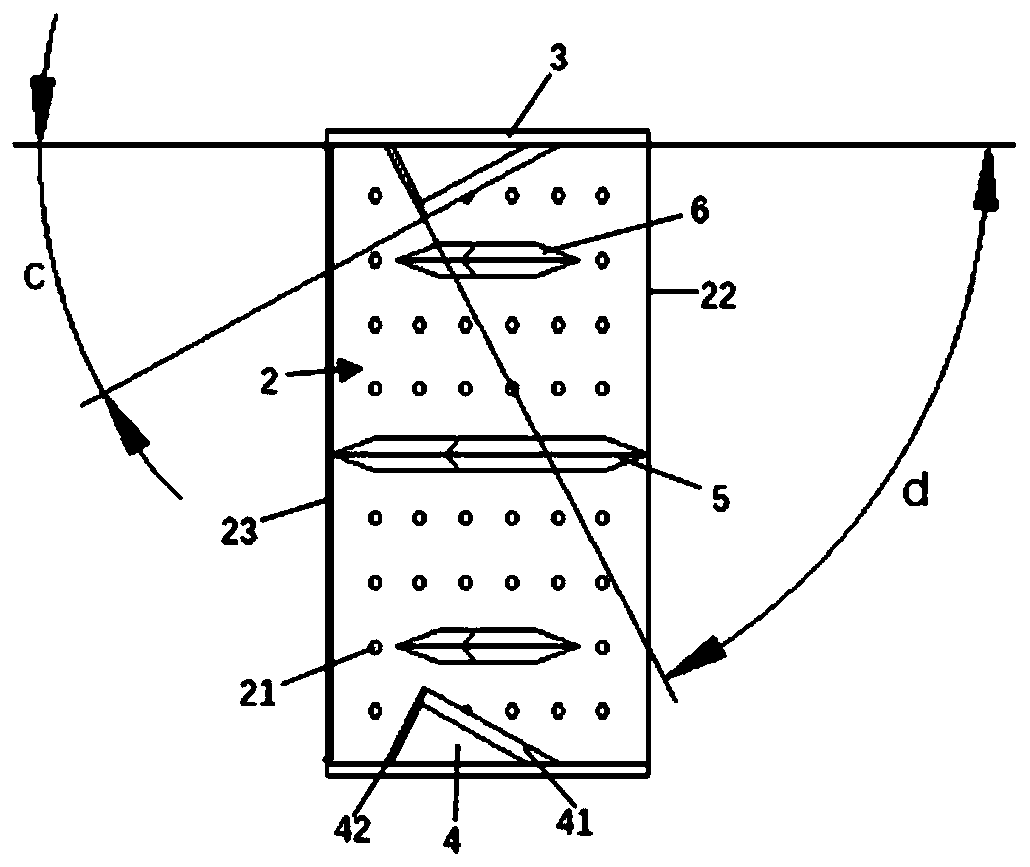

Fire grate of incinerator with laterally arrayed fins

The invention relates to a fire grate of an incinerator with laterally arrayed fins. The fire grate is characterized in that a fixed cross beam mounted on a boundary beam penetrates through a row of slots for fixing the tail part of fire grate segments so as to form a fixed fire grate board, and a moveable cross beam mounted on a pull rod penetrates through a row of slots for moving the tail part of the fire grate segments so as to form a movable fire grate board, wherein the movable fire grate board is forward superposed with the fixed fire grate board and are arrayed at interval to form the fire grate; each fire grate segment is provided with a primary air hole; the front end of the upper surface of each fire grate segment is provided with fins; the fins on the same row of fire grate segments are laterally arranged so as to form a toothed structure; and the fins on two adjacent fire grate segments are staggered longitudinally. The fire grate can scatter, loosen, stir and mix the rubbishes in the incinerator in all directions, avoid the caking and blocking of the rubbishes on the fire grate segments, promote the drying and burning efficiency of the rubbishes and shorten the drying time. The fire grate is in favor of rapidly burning rubbish and can be used as both forwards and backwards fire grates.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lateral alternate arranged grate of incinerator and compensation device

The present invention relates to a transverse alternative arrangement of incinerator fire grate and its compensation device. It is characterized by that it includes movable fire grate segments and fixed fire grate segments, the front portions of movable fire grate segments are overlapped on the fixed fire grate segments, and their front and rear alternatively arranged, and combined together so as to form the invented fire grate. Said invention also provides the concrete combination mode of said movable fire grate segments and fixed fire grate segments, and the invented fire grate can make the garbage obtain full combustion, and can raise garbage incineration efficiency greatly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

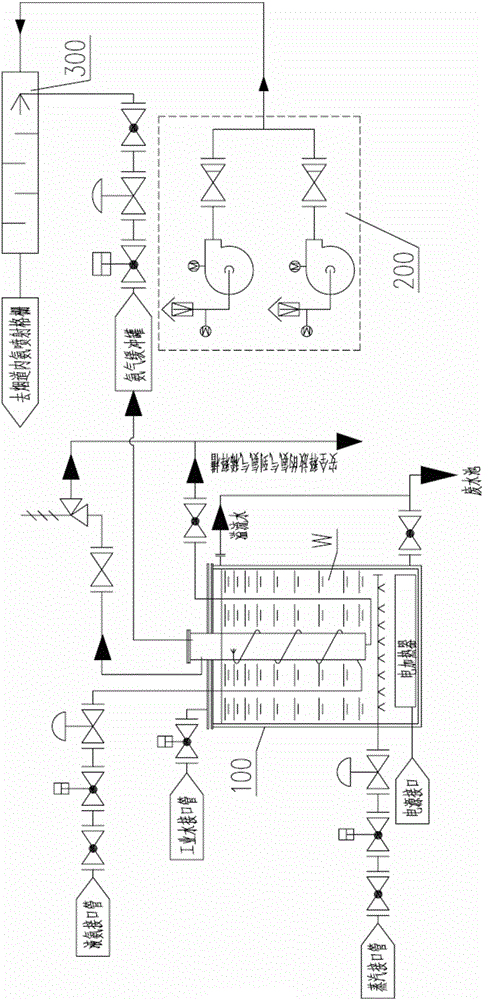

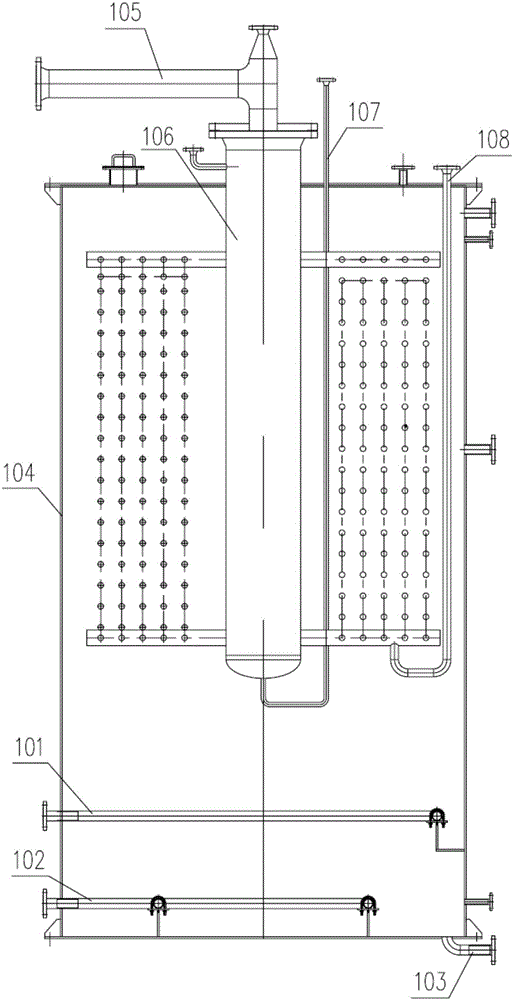

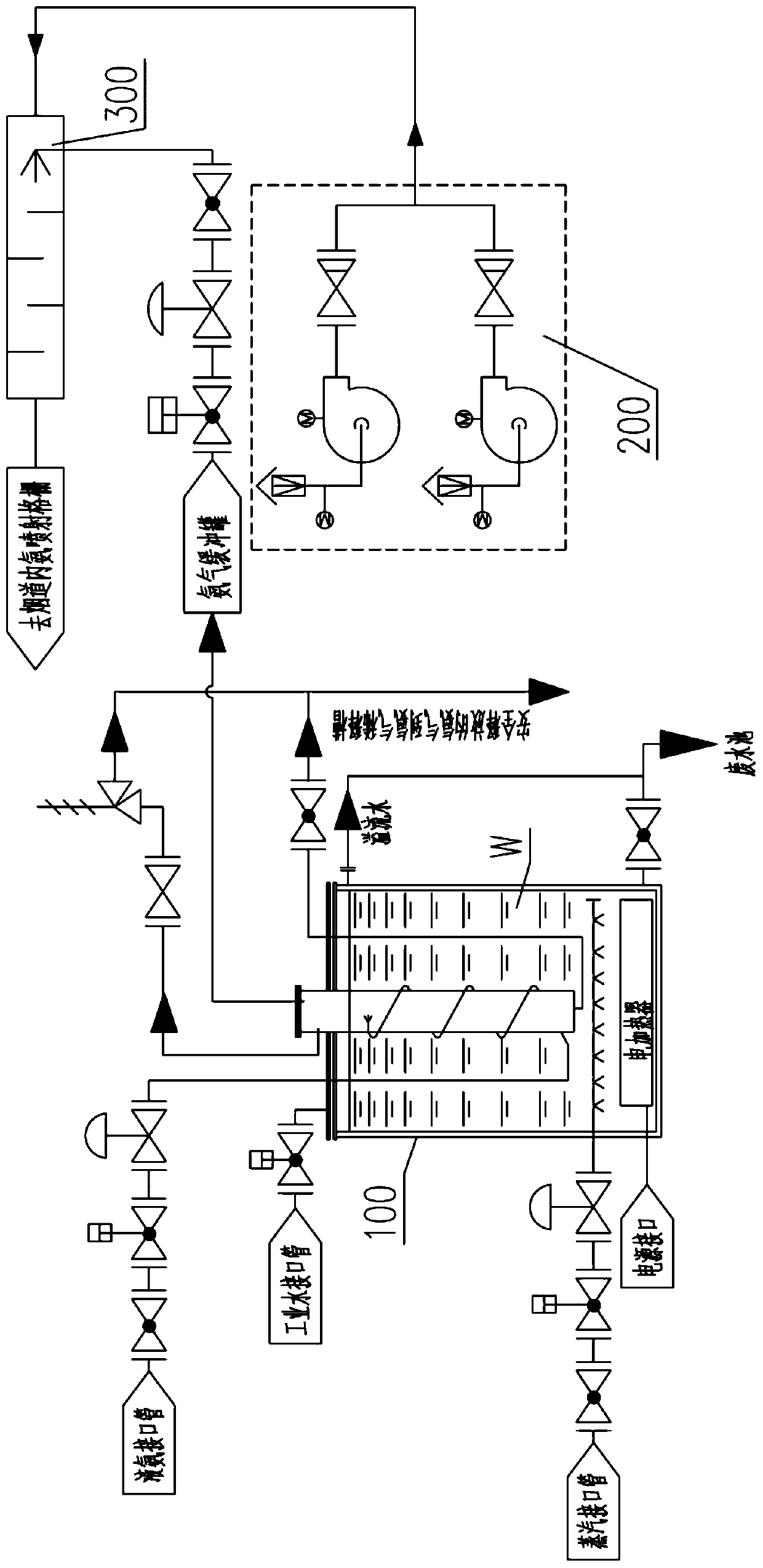

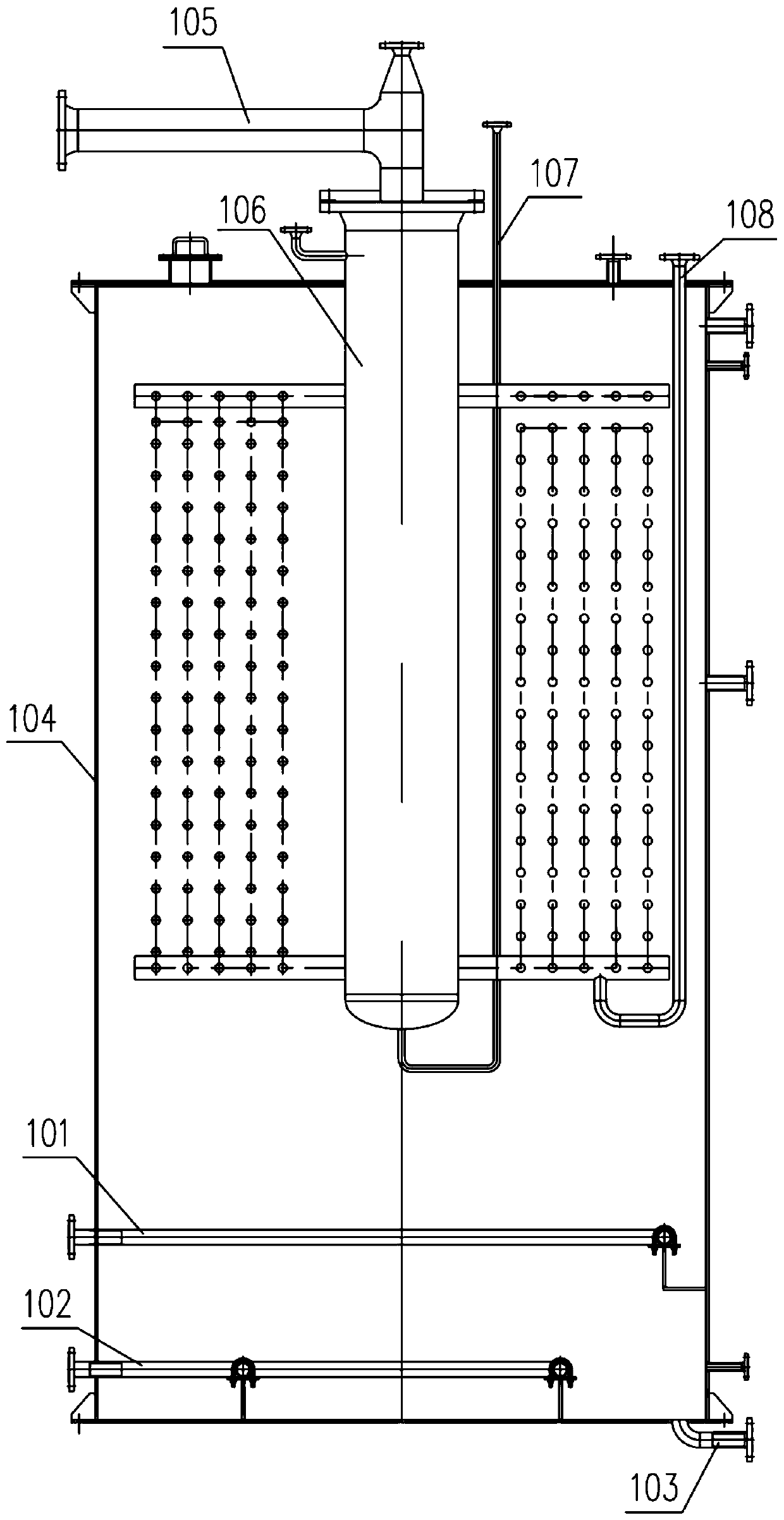

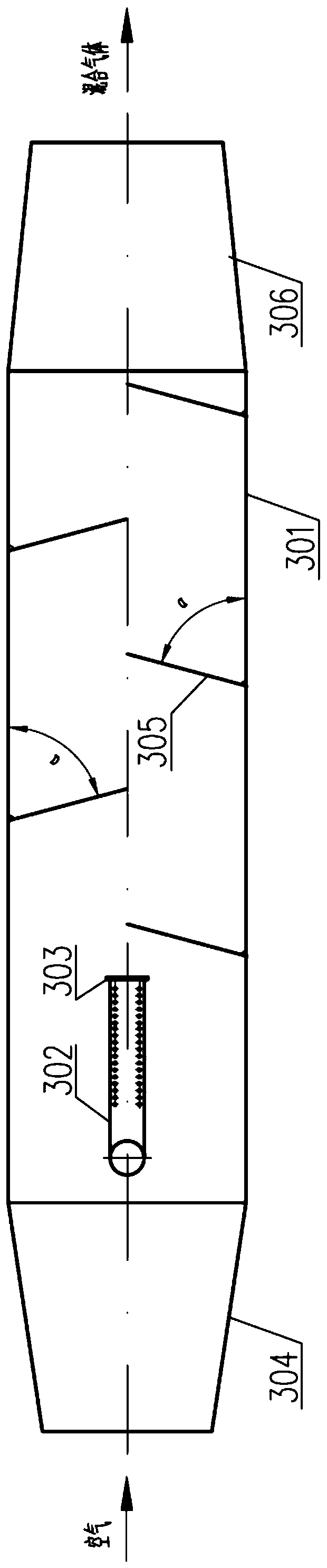

A denitration ammonia gas pretreatment system

A denitration ammonia gas pretreatment system is provided. The system includes a liquid ammonia evaporation device and an ammonia gas-air mixing device. The system allows industrial ammonia to be gasified and diluted rapidly, safely and stably into an ammonia gas-air mixture having a stable temperature and a uniform concentration, ensures stable running of denitration systems and host systems of main factories, and ensures that nitrogen oxides discharged from a denitration outlet reach the standards.

Owner:DATANG ENVIRONMENT IND GRP

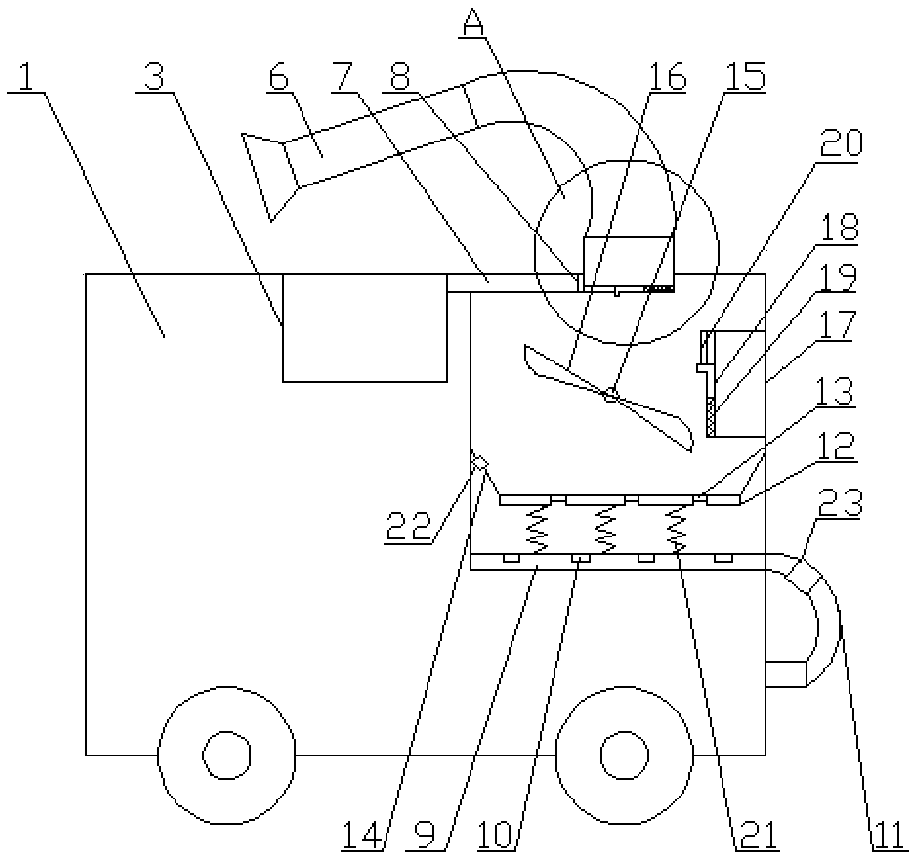

Leaf clearing equipment

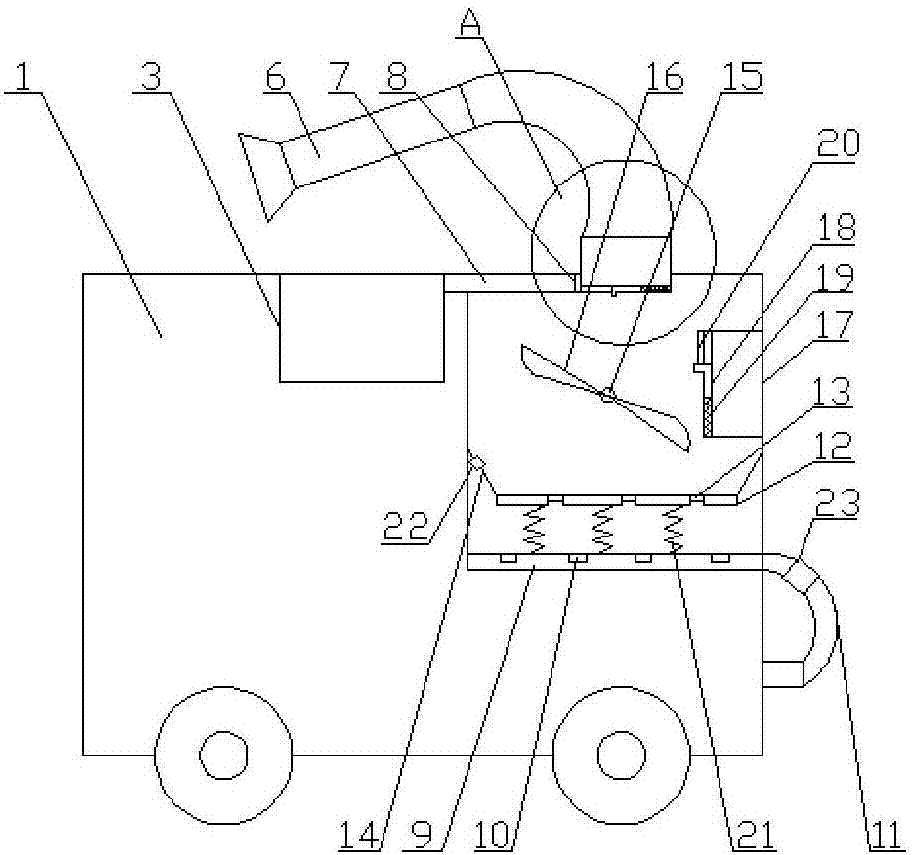

ActiveCN107974989ARealize comprehensive utilizationAvoid it happening againRoad cleaningLandscapingUltimate tensile strength

The invention discloses leaf clearing equipment, and especially relates to the technical field of municipal landscaping. The leaf clearing equipment comprises an operation vehicle. A feed chute is provided with a chute and a first slider. A first spring is connected between the chute and the first slider. A suction tube is connected to the feed tube. A suction pipe is connected between the feed tube and a vacuum pump. An air duct is arranged in a drying chamber. Air ports are arranged in the air duct. A vibration plate is arranged on the air duct. Support springs are arranged between the vibration plate and the air duct. A barrier plate is arranged between the vibration plate and the inner wall of the drying chamber. A motor is arranged between the vibration plate and the feed tube. Bladesare arranged on the motor. A dedusting box is arranged in the drying box. The dedusting box is provided with an opening. A sliding rail and a second slider are arranged at the opening. The second slider can be pushed by the blades. A second spring is connected between the slider and the second slider. By adopting the leaf clearing equipment, the problems of great labor intensity, great difficultyand easiness in breeding of bacteria among leaves in the leaf collection process are overcome, and the leaf clearing equipment can be used for sweeping operations in municipal cleaning.

Owner:遵义湘江园林工程有限责任公司

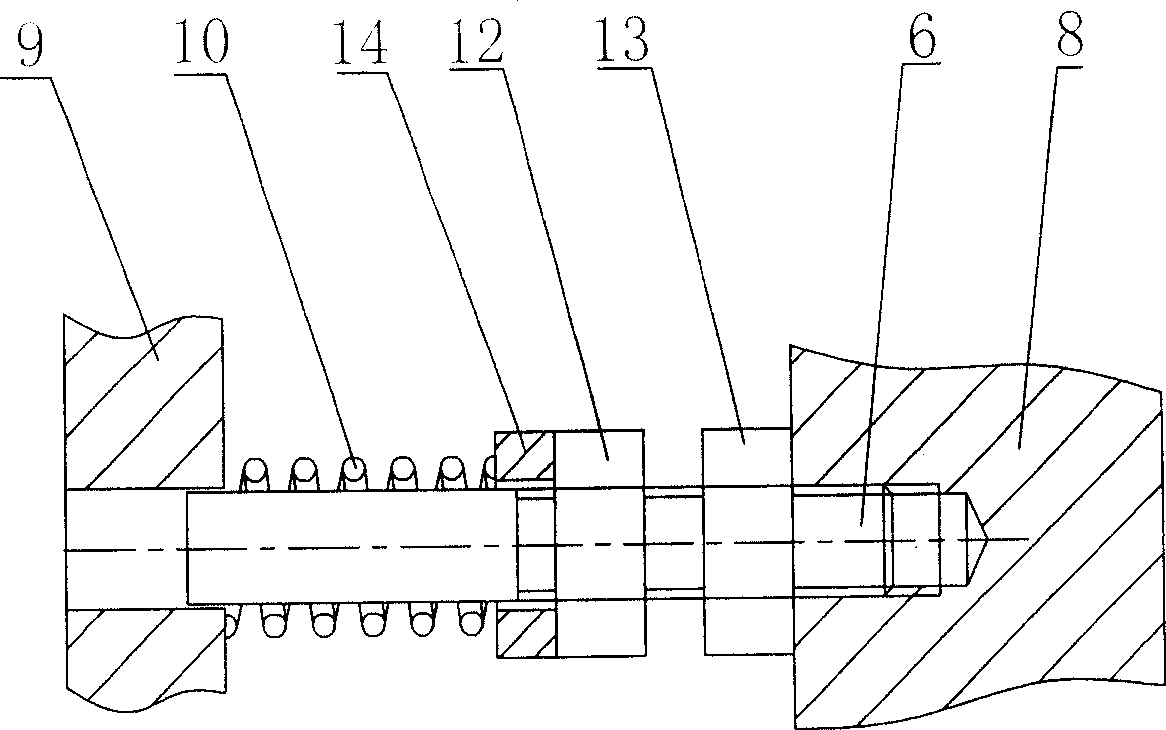

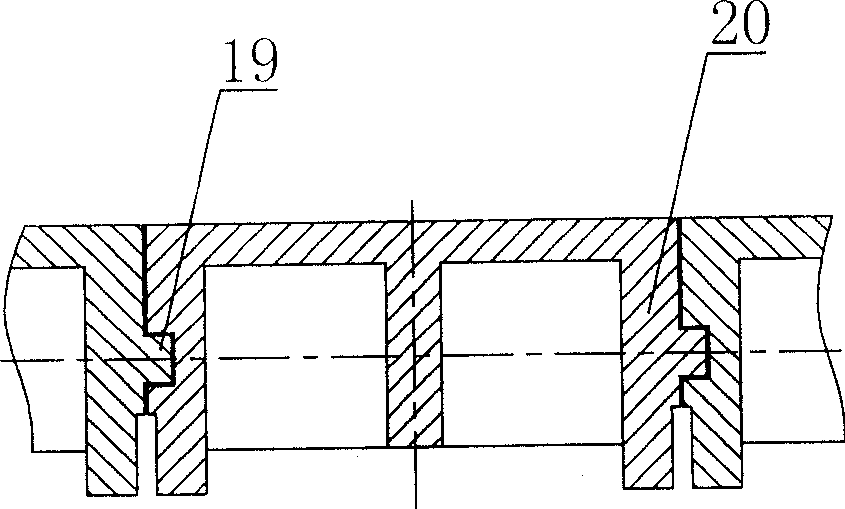

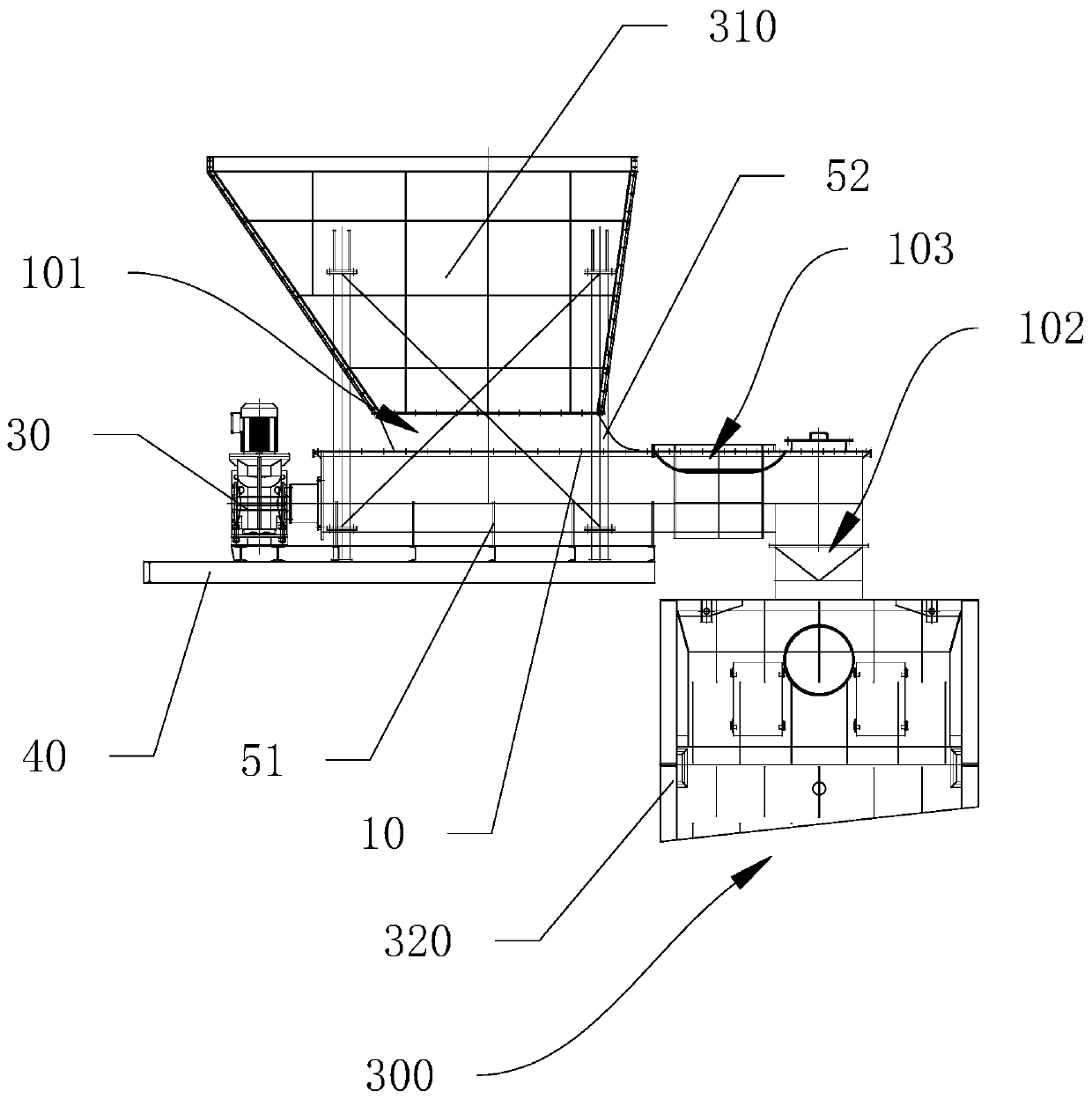

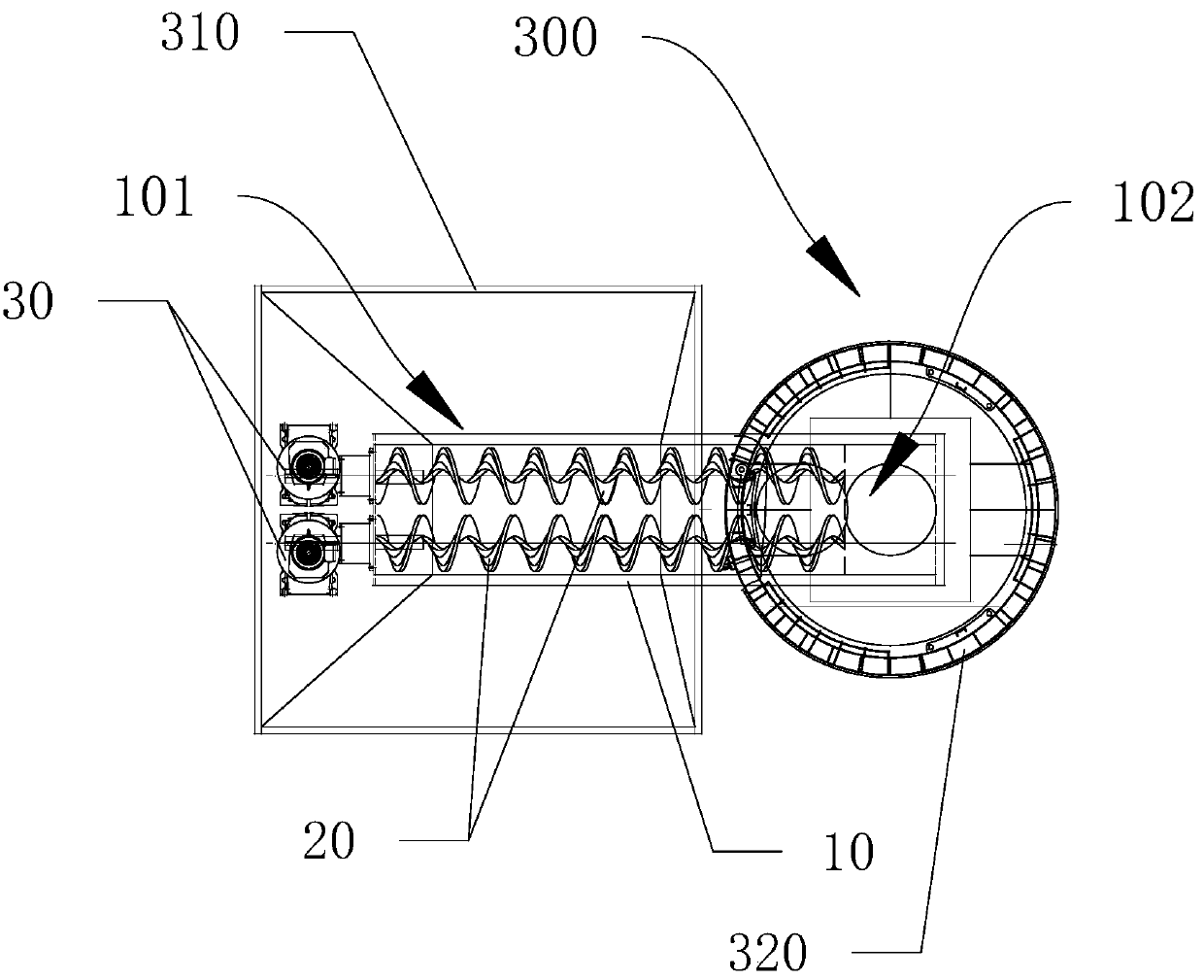

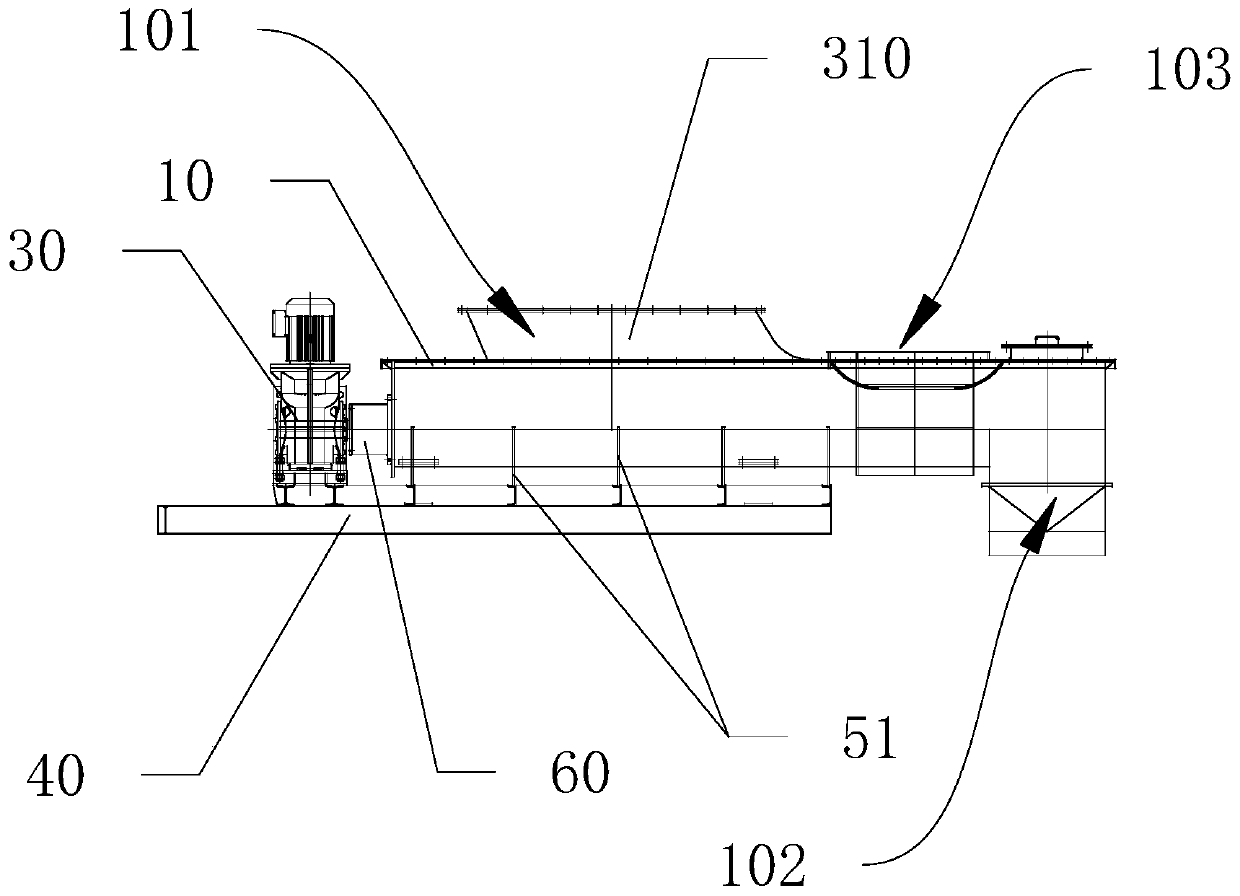

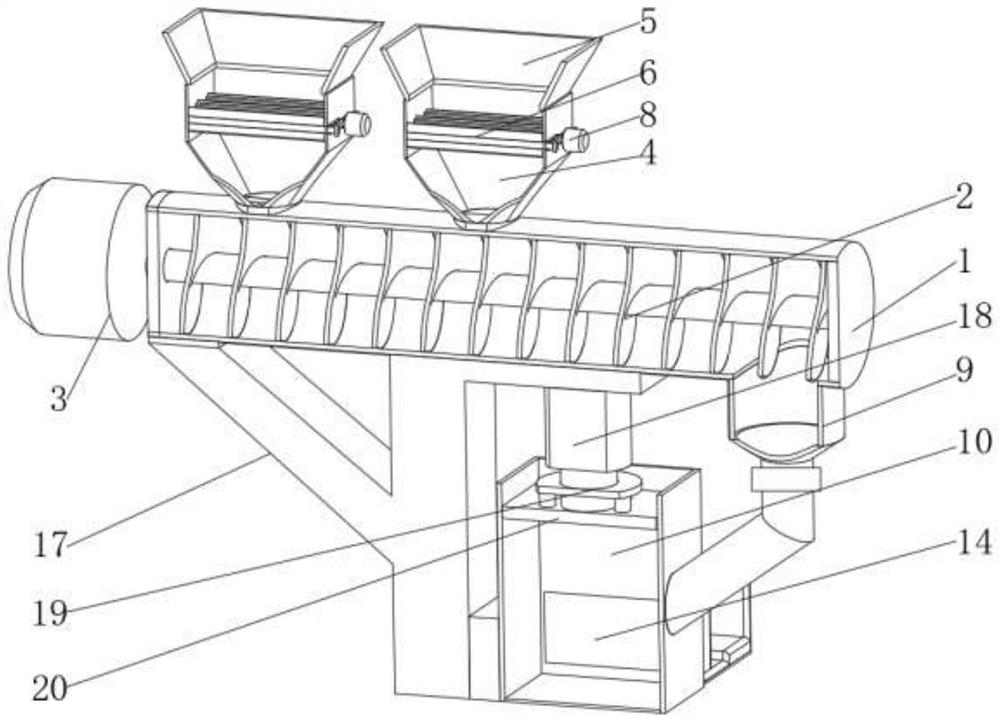

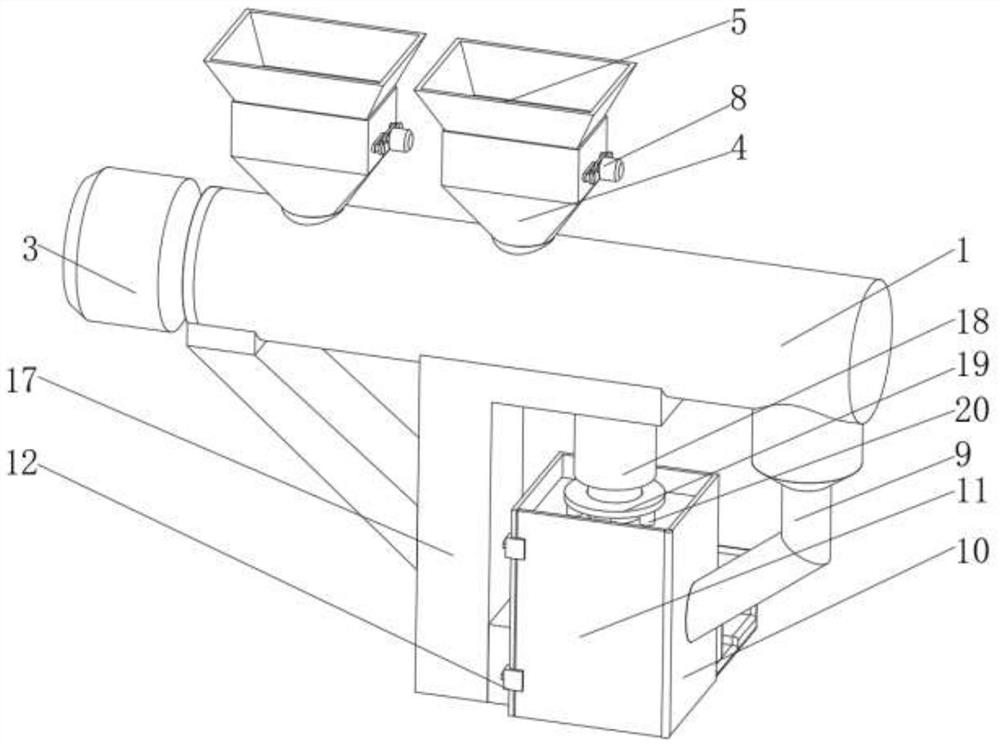

Splitting decomposition gasification furnace shaftless spiral wind-locking feeding device and feeding method thereof

PendingCN110562763AEvenly distributedUniform responsePackagingLoading/unloadingProcess engineeringIndustrial engineering

The invention provides a splitting decomposition gasification furnace shaftless spiral wind-locking feeding device and a feeding method thereof. The splitting decomposition gasification furnace shaftless spiral wind-locking feeding device comprises a machine shell, a driving mechanism and two or more shaftless spiral bodies. The machine shell is provided with a feeding port and a discharging port.All the shaftless spiral bodies are arranged in parallel and side by side in a cavity of the machine shell. The driving mechanism and the shaftless spiral bodies are connected so that the shaftless spiral bodies can be driven. Rotating directions of any two adjacent shaftless spiral bodies are opposite. In the running process, materials entering from the feeding port enter a splitting decomposition gasification furnace gradually from the discharging port under the propelling action of the shaftless spiral bodies; continuous feeding as required can be effectively achieved; uniform distributionand the reaction process of the materials in the splitting decomposition gasification furnace are benefited; and material blocking and winding are avoided so that feeding is smoother. The feeding port of the splitting decomposition gasification furnace can be effectively segregated from outside air by the materials and the shaftless spiral bodies, the wind-locking effect is achieved, and it is avoided that the furnace body is frequently opened for feeding and thus the oxygen-free or anaerobic environment in the furnace is destroyed.

Owner:中城绿建科技有限公司

Acid and alkali resistant rapid liquid mixing application sample separation device and method

PendingCN110926917AReasonable structural designImprove liquidityPreparing sample for investigationPhysical chemistryStrong acids

The invention belongs to the technical field of oil production engineering. An acid and alkali resistant rapid mixing liquid application sample separation device, which comprises a feeding part, a mixing part and a liquid storage sample separation part; the feeding part is used for containing a solution to be mixed; the mixing part is arranged at the bottom of the feeding part and is used for uniformly mixing a to-be-mixed solution; the liquid storage and sample separation part is arranged at the bottom of the mixing part and is used for storing the mixed solution and sampling in groups. The invention further discloses an acid and alkali resistant rapid mixing liquid application sample separation method. The problems of acid-base solution mixing and sample separation can be solved, and static liquid mixing and sample separation are achieved through fluid mechanics. The static liquid mixing and sample separating device is reasonable in overall structural design, can be applied to strongacid or strong base or other liquid with the viscosity smaller than 200 mPa.s, is internally provided with no electronic driving assembly, and achieves static liquid mixing and sample separating by means of the hydromechanics principle.

Owner:DAQING OILFIELD CO LTD +1

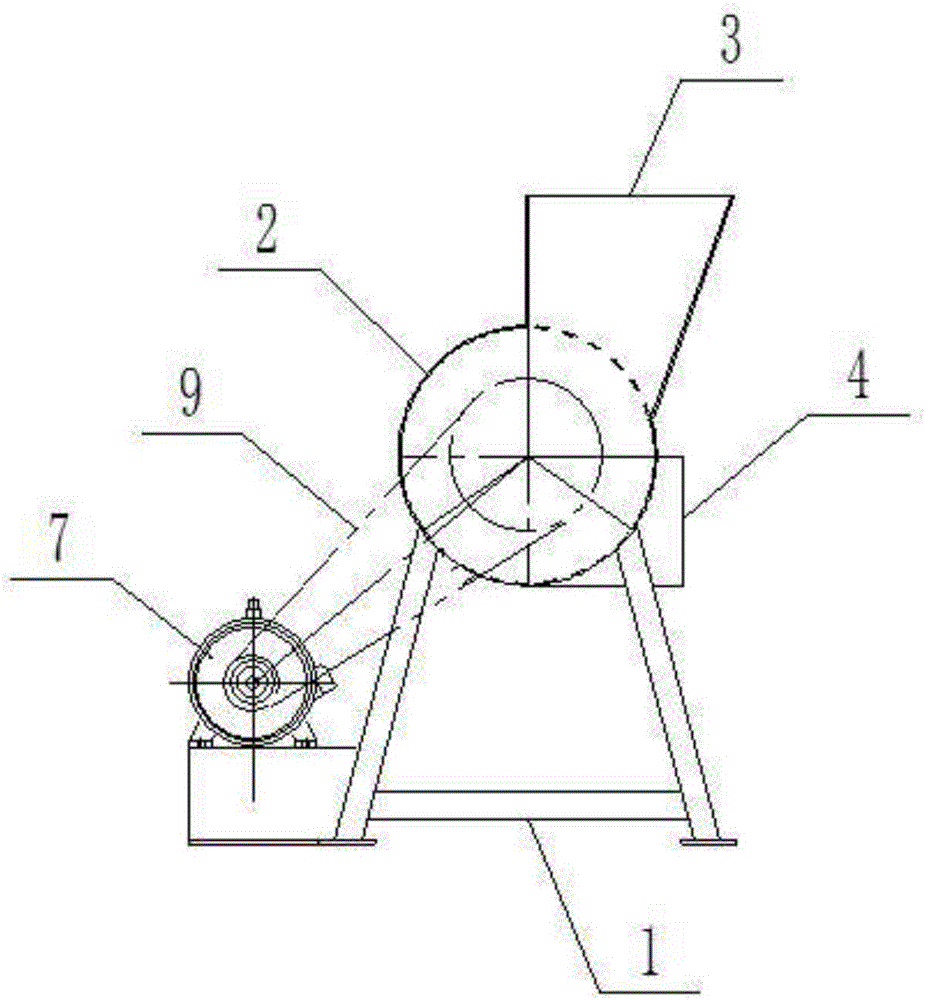

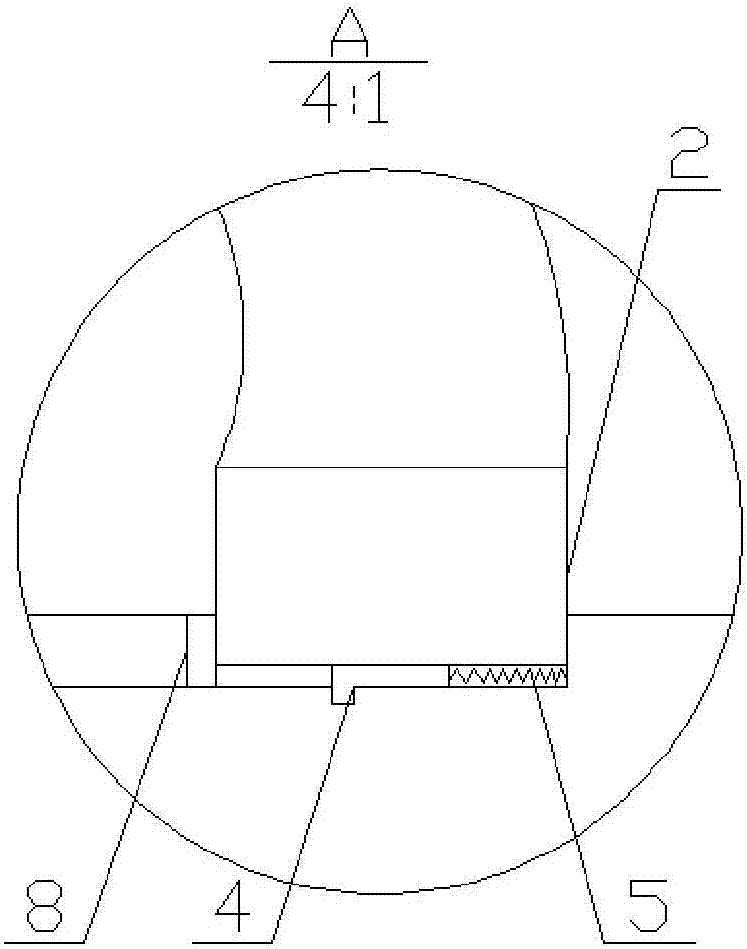

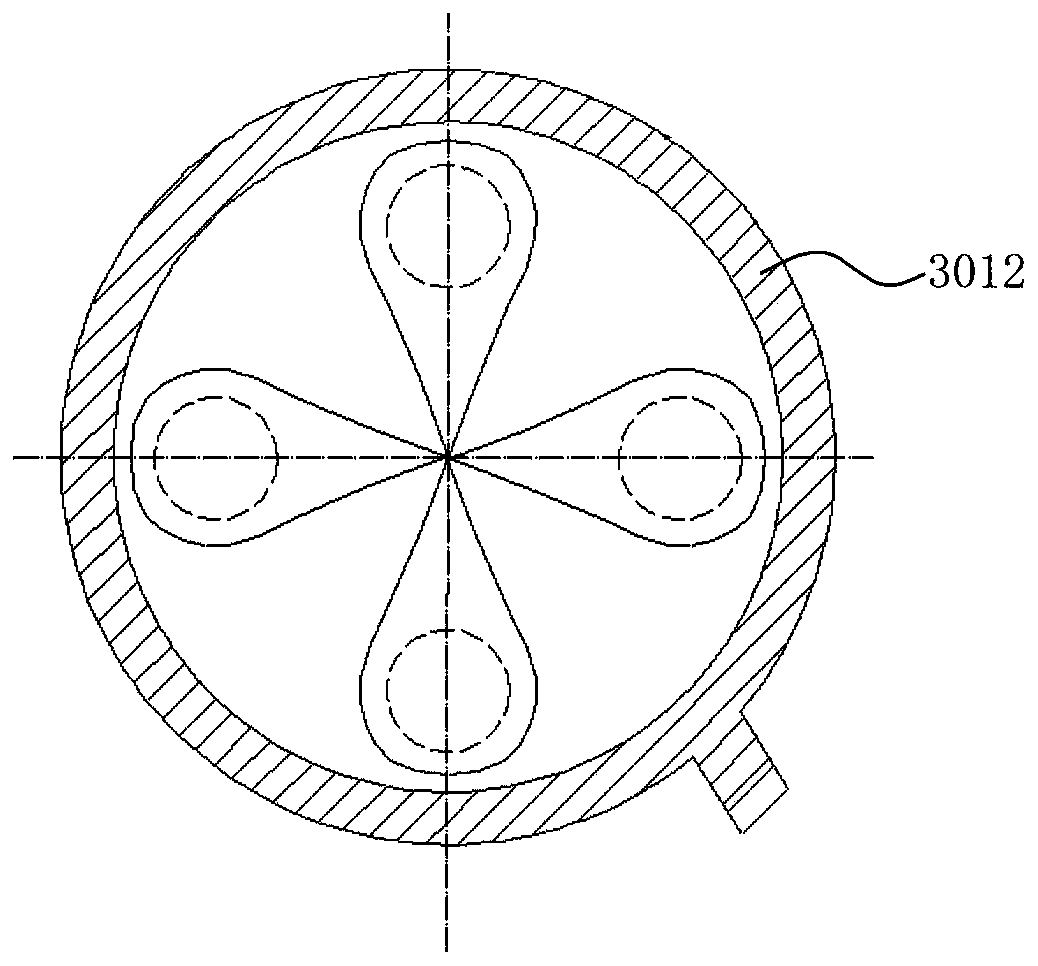

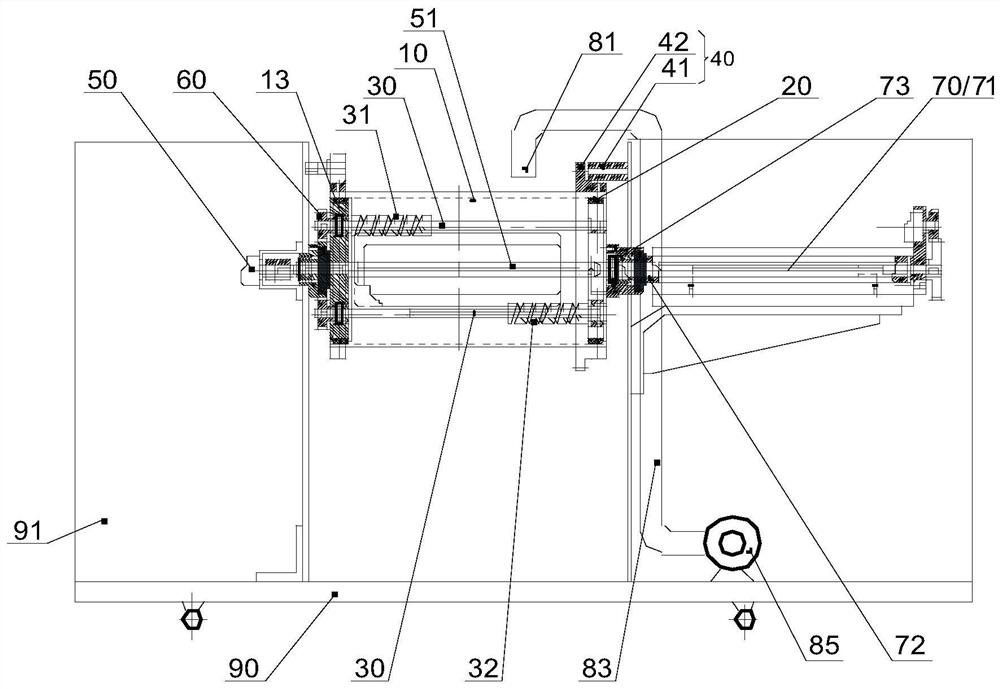

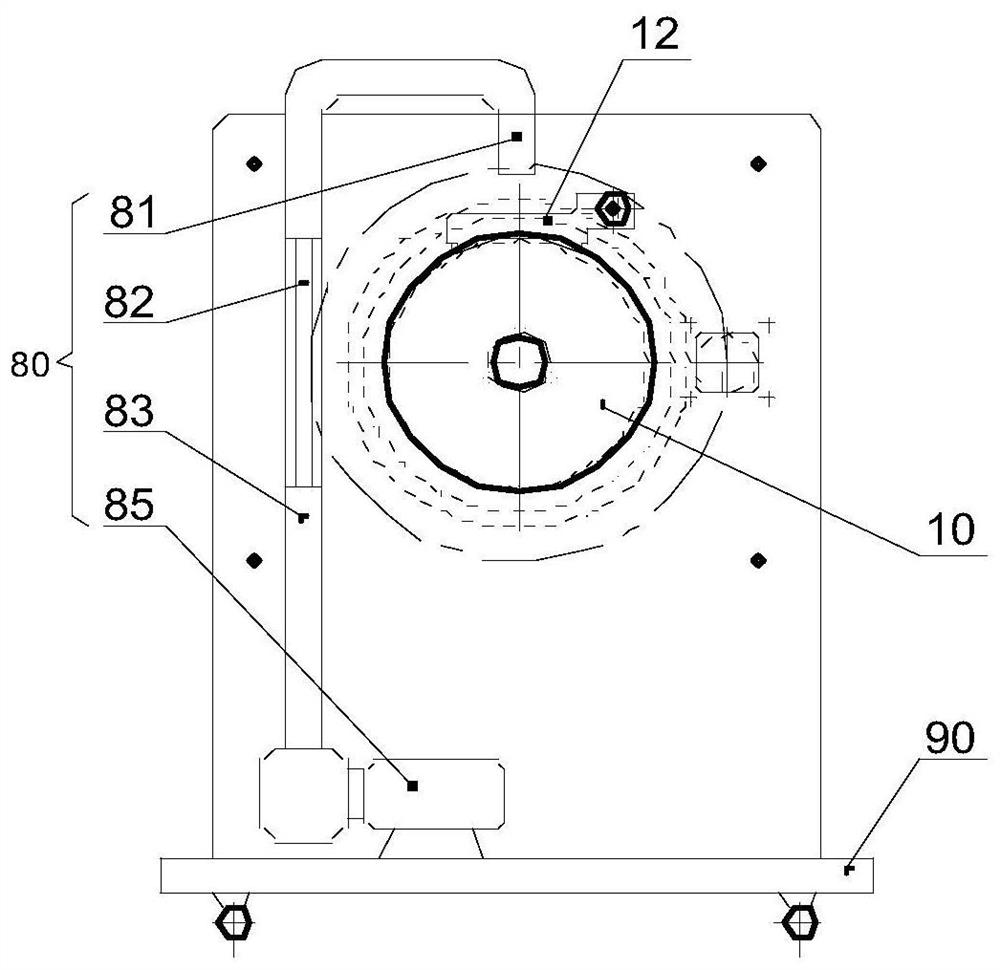

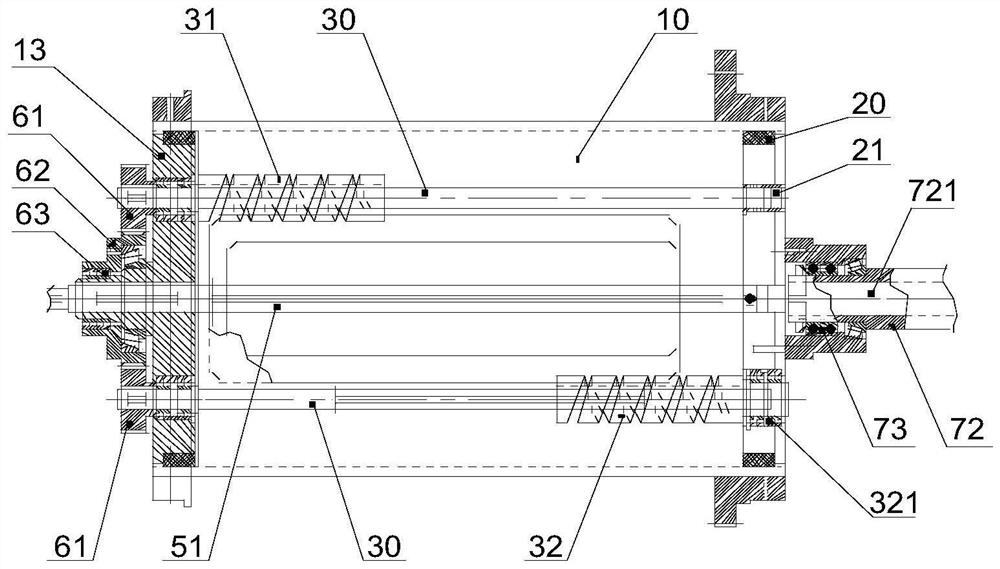

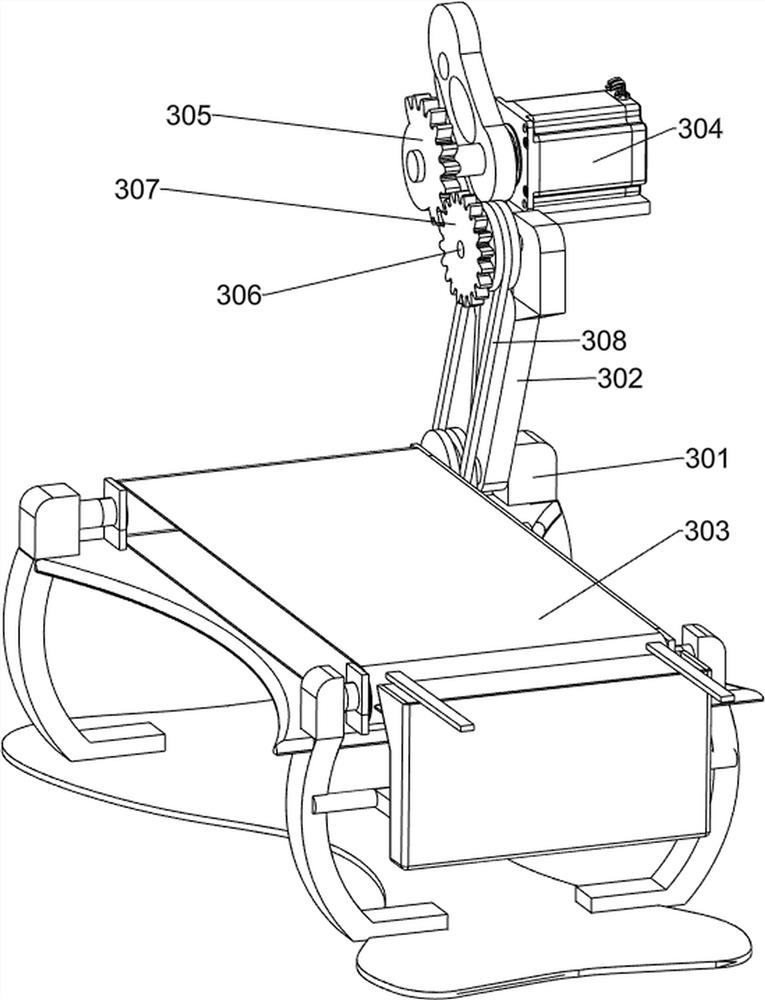

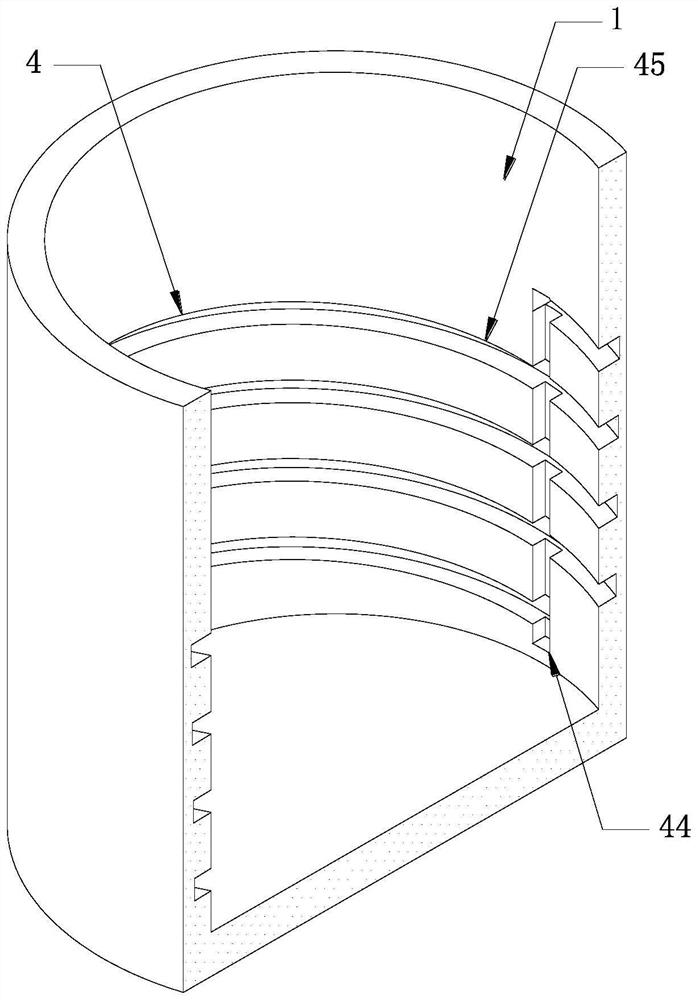

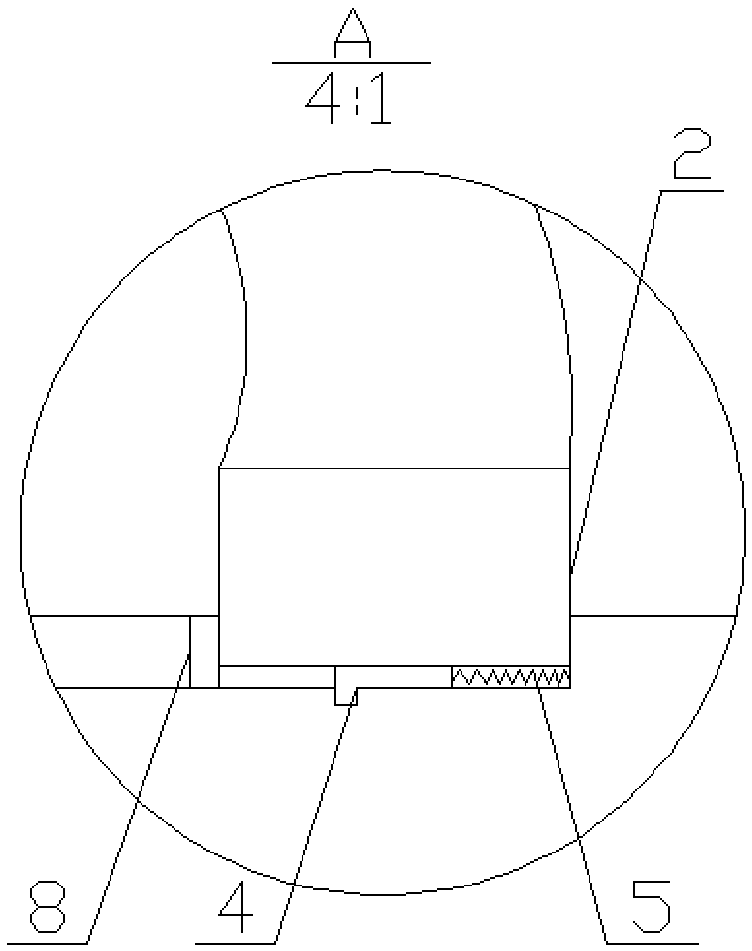

Tea leaf wrapping-kneading machine and tea leaf wrapping-kneading method

PendingCN113080273APackage realizationRealize breaking upPre-extraction tea treatmentStructural engineeringMechanical engineering

The invention provides a tea leaf wrapping-kneading machine and a tea leaf wrapping-kneading method. The tea leaf wrapping-kneading machine comprises a horizontally arranged charging barrel, a side kneading disc, and at least one stirring rod; the charging barrelis connected with a first driving mechanism, and the first driving mechanism is used for driving the charging barrel to rotate; the side kneading disc is movably arranged in the charging barrel and is connected with a translation driving mechanism, and the translation driving mechanism is used for driving the side kneading disc to translate in the charging barrel; and the at least one stirring rod is arranged in the charging barrel in a penetrating manner and is connected with a second driving mechanism, and the second driving mechanism is used for driving the stirring rod to rotate around the axis of the charging barrel in the charging barrel. According to the tea leaf wrapping-kneading machine and the tea leaf wrapping-kneading method of the invention, the technical problems of low cleanliness, low working efficiency and difficulty in guaranteeing the stability of the product quality of a currently used tea leaf wrapping-kneading process are solved.

Owner:黄山小罐茶业有限公司

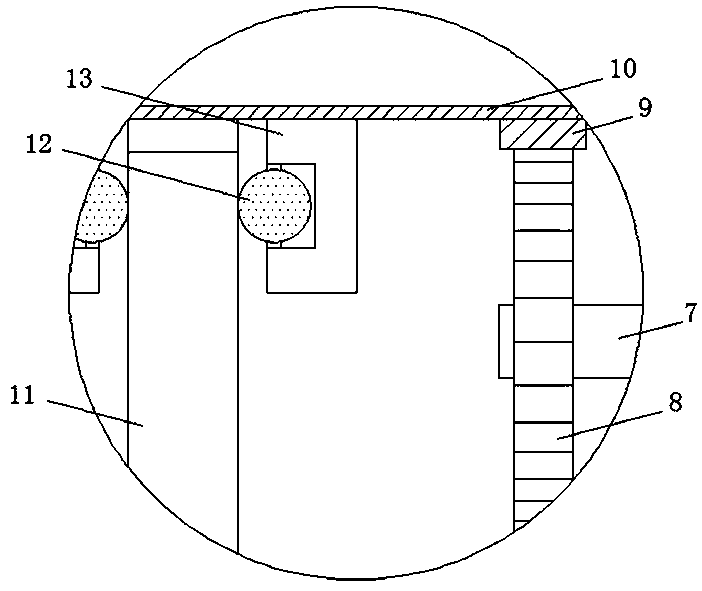

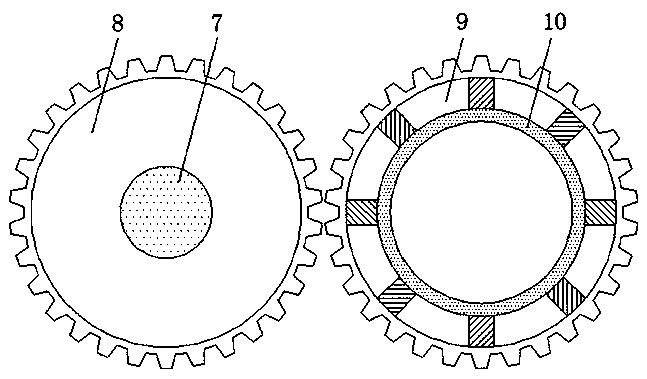

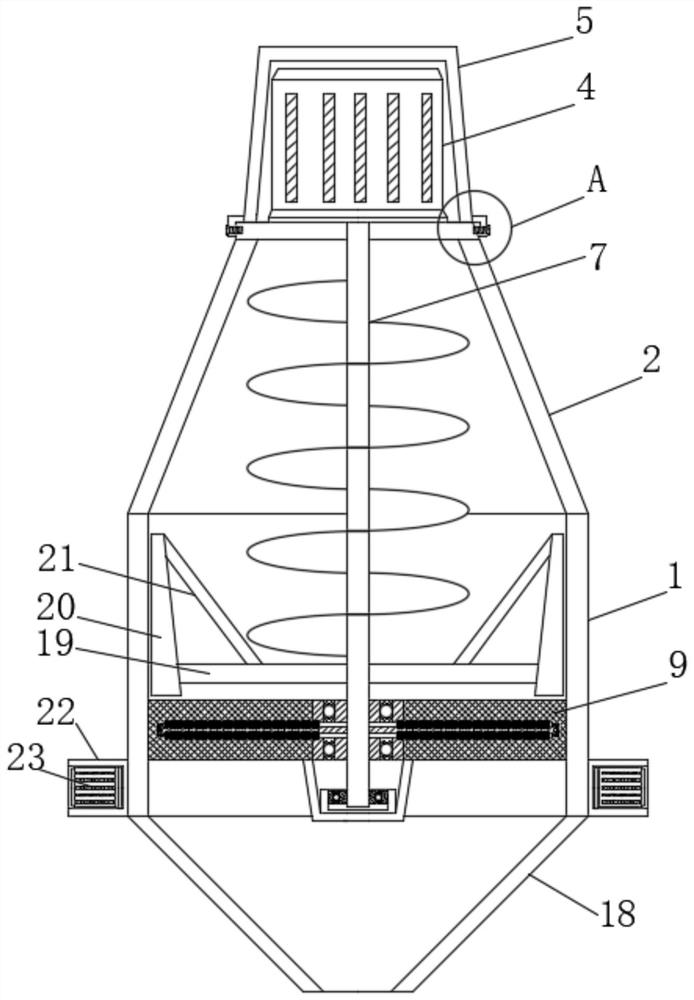

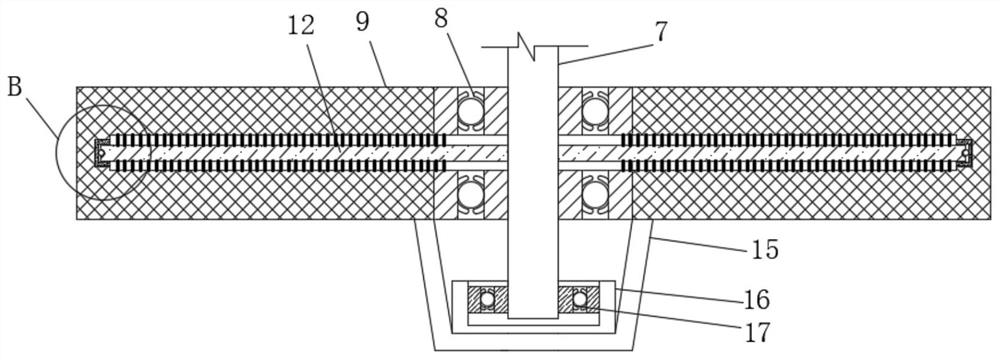

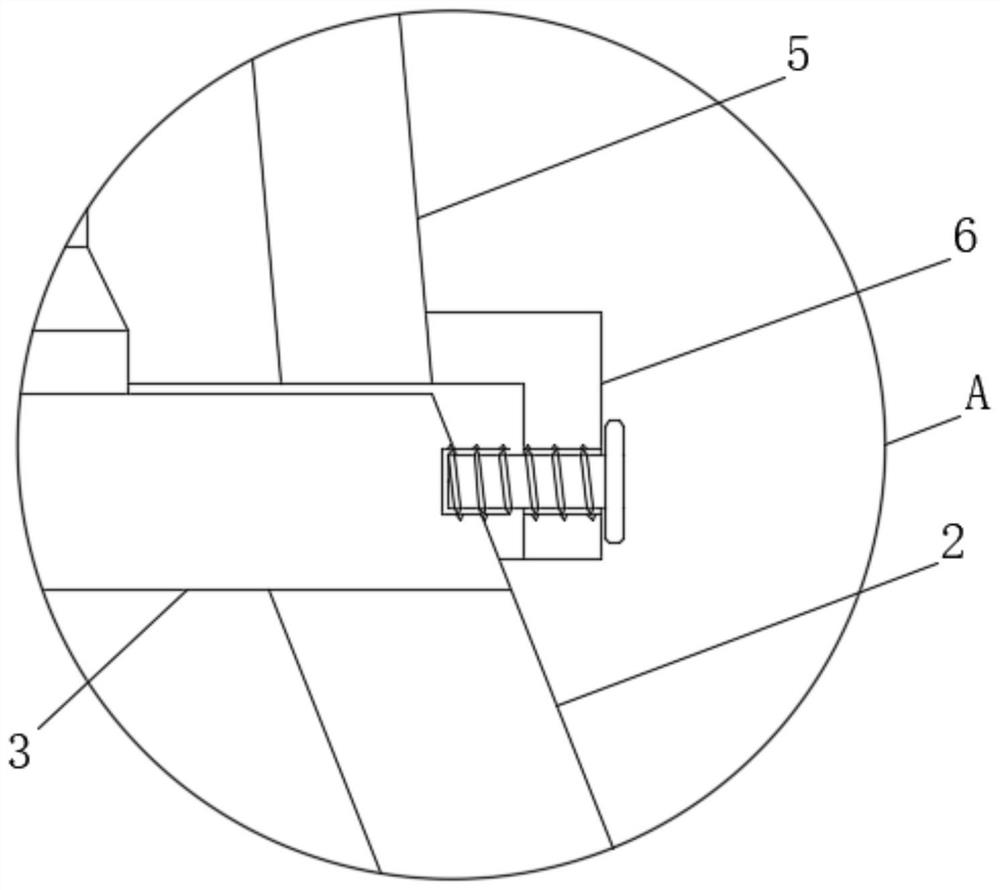

Metal steel tailing drying treatment device based on rotation scattering principle

InactiveCN110940168AAchieve rotationRealize breaking upDrying gas arrangementsDrying chambers/containersThermodynamicsElectric machine

The invention relates to the technical field of metal smelting and discloses a metal steel tailing drying treatment device based on the rotation scattering principle. The metal steel tailing drying treatment device based on the rotation scattering principle comprises a shell. The left side and the right side of the bottom end of the shell are both movably connected with leg racks. The lower end ofthe middle of the shell is movably connected with a discharging opening. The left end of the discharging opening is movably connected with a baffle. The lower end of the right side of the shell is movably connected with a fixing frame. A motor is movably connected into the fixing frame. The left end of the motor is movably connected with a rotating shaft. According to the metal steel tailing drying treatment device based on the rotation scattering principle, by means of cooperative use of a cylinder, partition plates, balls, limiting blocks and other structures, the sufficient drying effect is achieved; by means of cooperative use of the discharging opening, the baffle, an air discharge channel, a funnel and other structures, the effect of easy operation is achieved; and by means of cooperative use of the shell, the leg racks, the fixing frame, the motor and other structures, the effect of a small occupied floor area is achieved.

Owner:HUNAN CHEM VOCATIONAL TECH COLLEGE

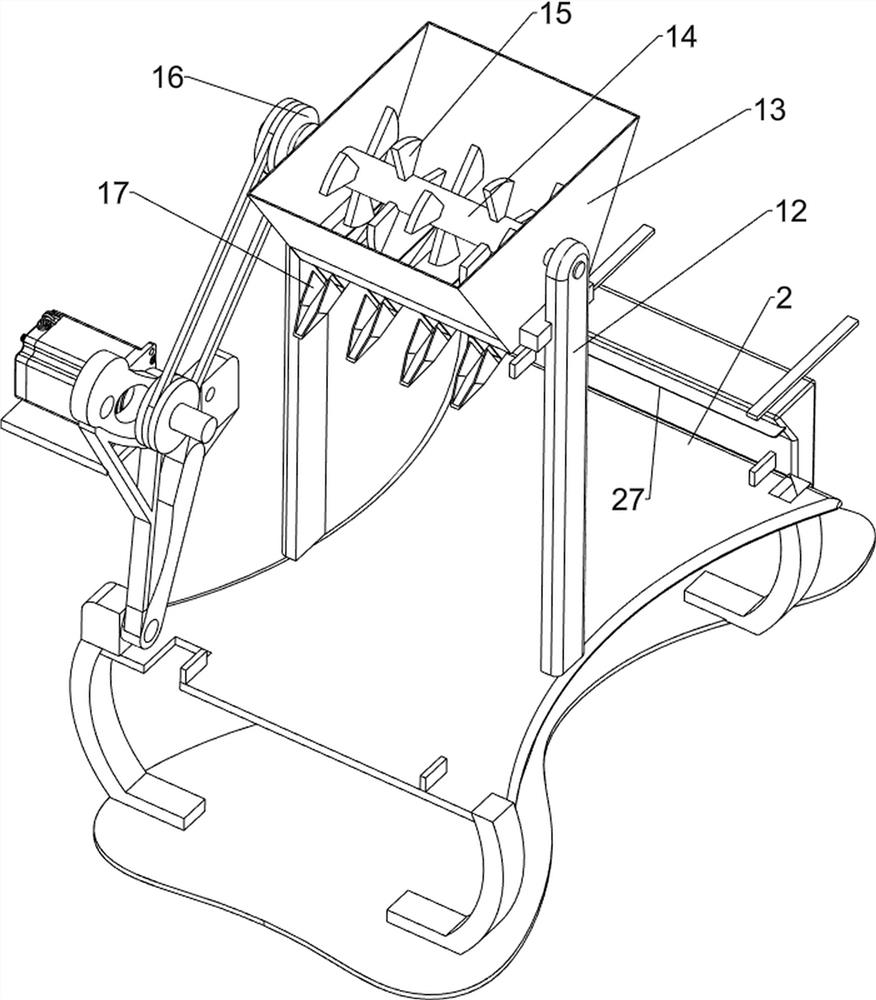

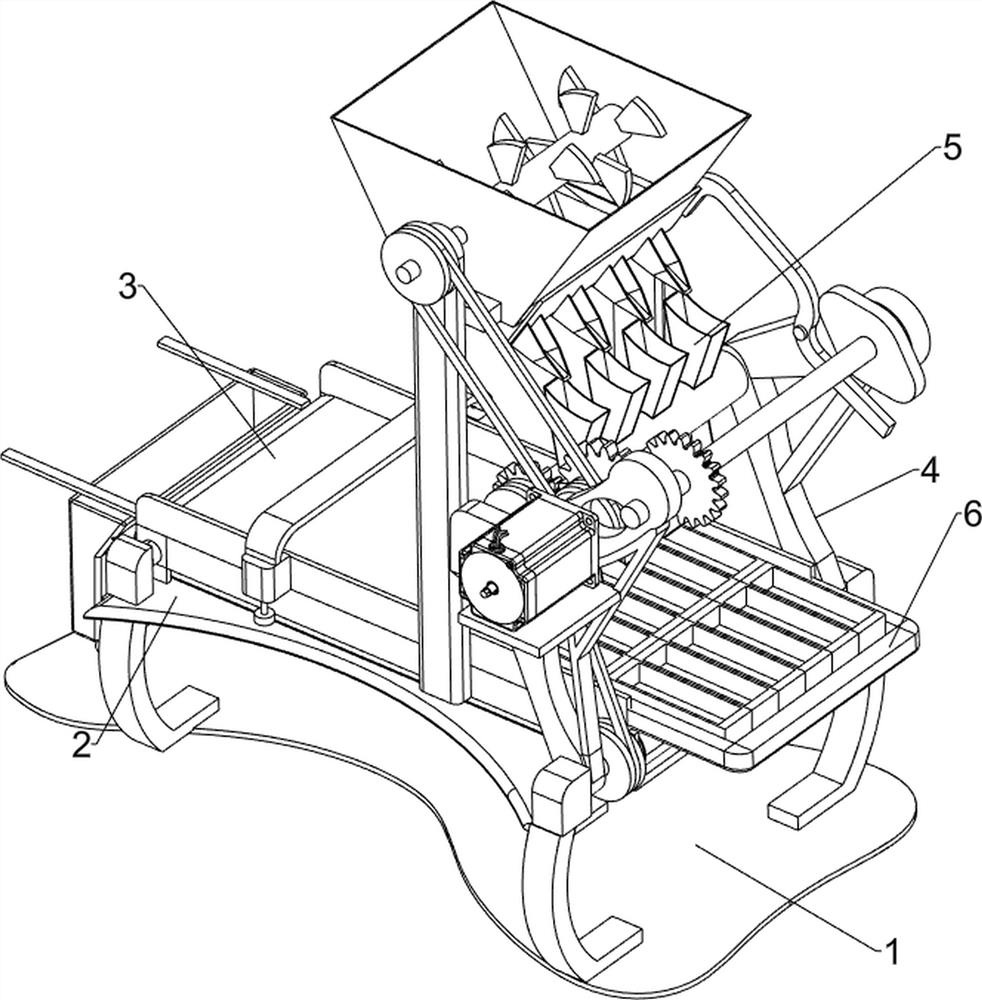

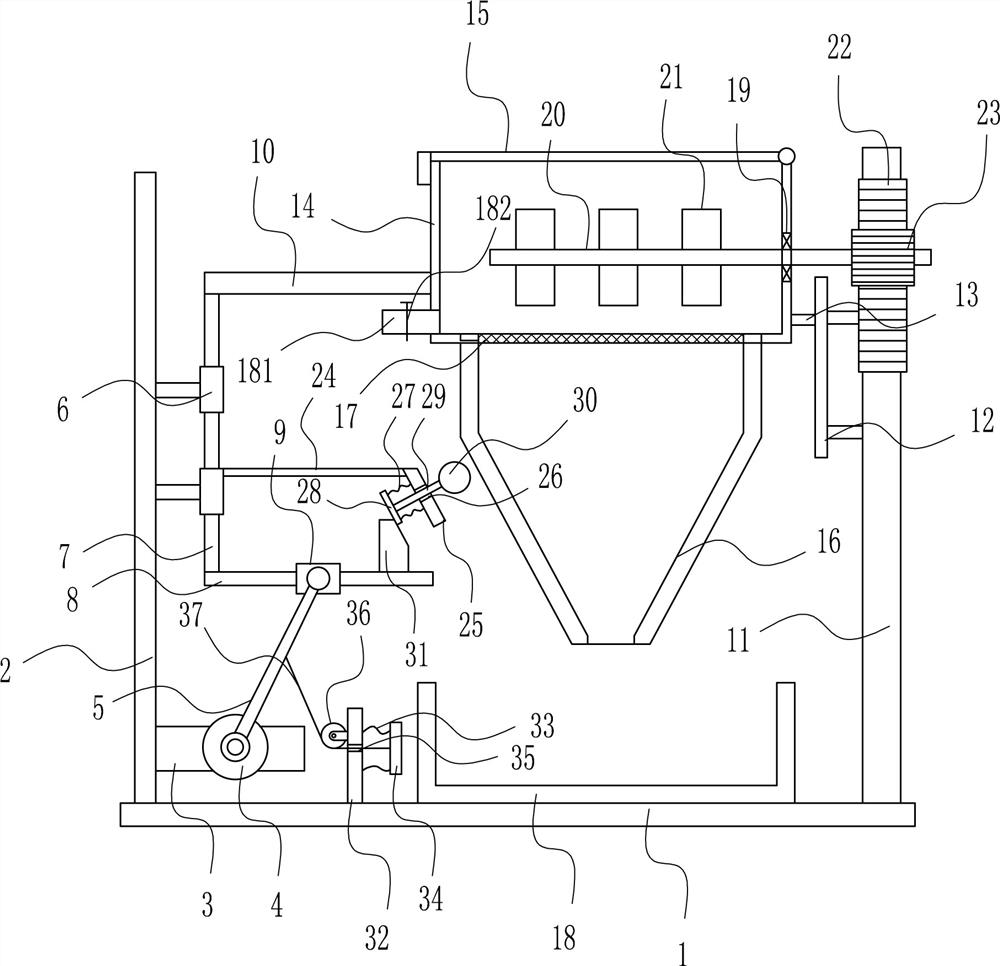

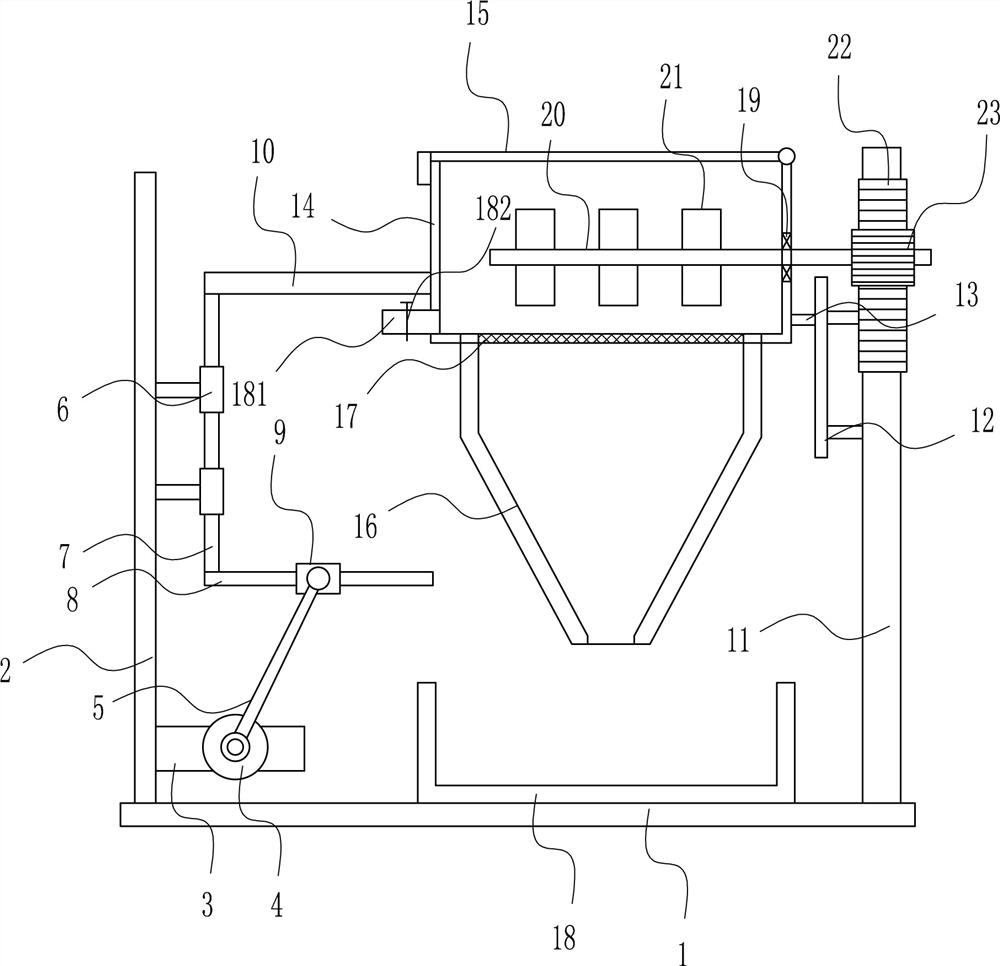

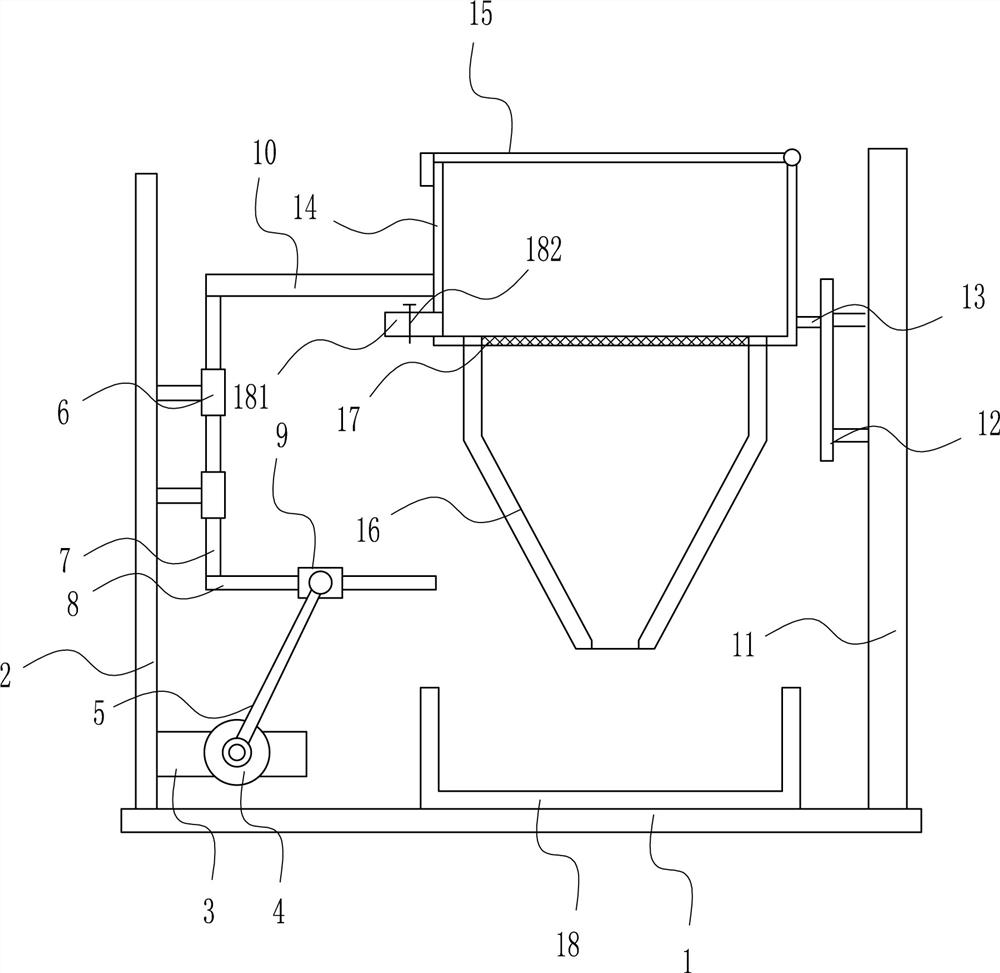

Nutrition bowl batch adding equipment for biological cultivation foundation soil

InactiveCN112840902ARealize breaking upAutomatic feedingCultivating equipmentsGrain treatmentsAgricultural scienceNutrition

The invention relates to the technical field of biological cultivation equipment, in particular to nutrition bowl batch adding equipment for biological cultivation foundation soil. The nutrition bowl batch adding equipment for biological cultivation base soil can automatically load soil and is convenient to operate. The nutrition bowl batch adding equipment for the biological cultivation foundation soil comprises a bottom plate, a conveying mechanism, a mounting plate, a discharging mechanism and a placing frame, wherein a workbench is arranged at the top of the bottom plate; the conveying mechanism is arranged at the top of the workbench; the mounting plate is arranged on a fixed seat on the same side as a mounting bracket; the discharging mechanism is arranged on the mounting plate, and the discharging mechanism is matched with the conveying mechanism; and the placing frame is placed on the conveying mechanism. Intermittent conveying of the placing frames and the nutrition bowls is conducted through the conveying mechanism, and batch adding of the foundation soil can be achieved through the discharging mechanism.

Owner:王丽

A denitrification ammonia gas pretreatment system

ActiveCN106166455BStable supplyWell mixedGas treatmentFlow mixersNitrogen oxidesEnvironmental engineering

The invention provides a denitrification ammonia gas pretreatment system, comprising: a liquid ammonia evaporation device and an ammonia air mixing device. It can quickly, safely and stably gasify and dilute industrial ammonia into ammonia-air mixed gas with stable temperature and uniform concentration, ensure the stable operation of the denitrification system and the host system of the main plant, and effectively ensure that the discharge of nitrogen oxides at the denitrification outlet meets the standard emission.

Owner:DATANG ENVIRONMENT IND GRP

A high-efficiency screening device for pasture seeds for animal husbandry

ActiveCN108515017BEasy to sieveRealize moving up and downSievingScreeningAnimal scienceElectric machinery

Owner:湖州达立智能设备制造有限公司

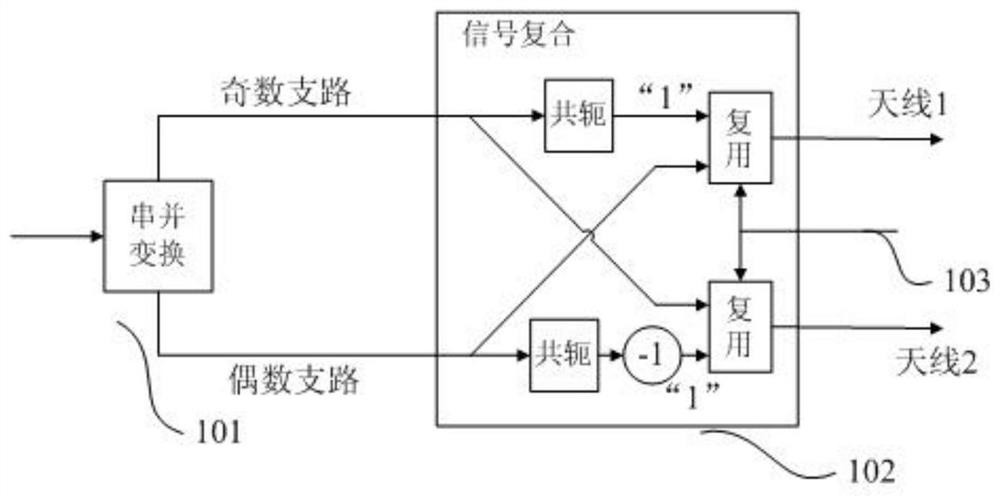

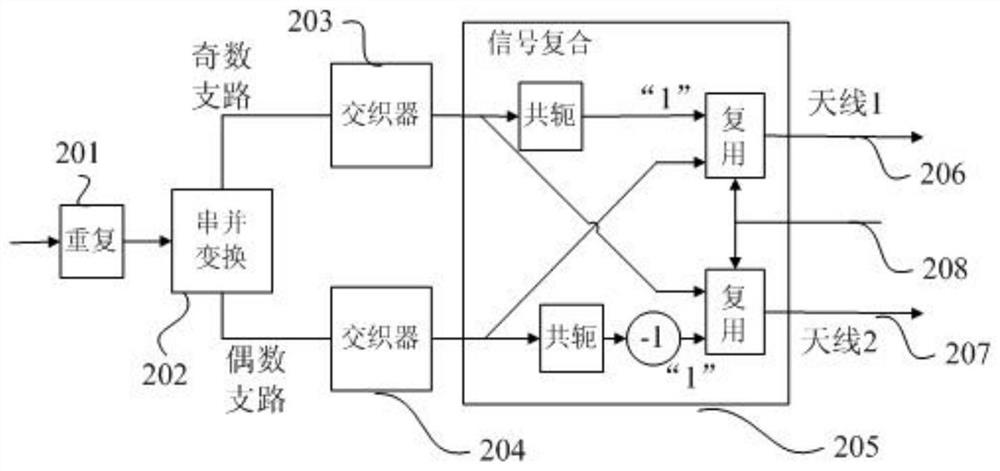

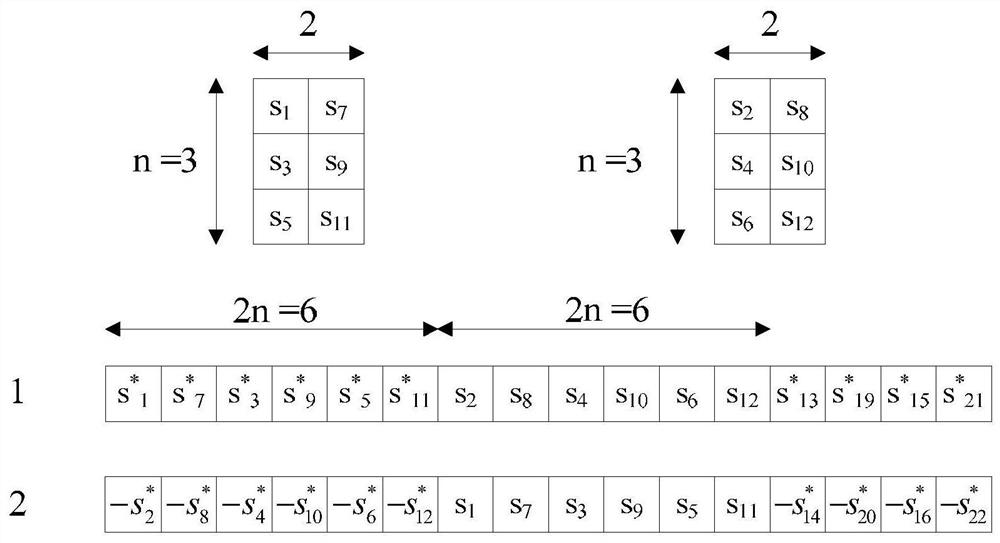

A Impulse Noise Suppression Method in OFDM Communication System

ActiveCN109525532BRealize breaking upImproved immunity to impulse noiseMulti-frequency code systemsForward error control useTime domainInterference (communication)

The present invention provides a method for suppressing impulse noise in an OFDM communication system, comprising: S1: performing embedded interleaved space-time block coding on transmitted data symbols to obtain two transmission symbols; S2: performing IFFT transformation on the two transmission symbols respectively to the time domain, and insert the guard interval signal; S3: respectively up-convert the two time domain signals obtained in S2, and transmit them; S4: receive the signal transmitted in S3, obtain the received signal, and Down-converting the received signal; S5: limiting the down-converted signal; S6: stripping the guard interval from the limited signal, and performing FFT transformation to the frequency domain to obtain a frequency-domain signal. The symbol interleaving method embedded in space-time block coding (STBC) realizes the breaking up of impulse noise interference with a small interleaving depth; combined with the impulse noise suppression of time-domain clipping and the diversity reception function of STBC decoding, it aims at the scattered Impulse noise interference is effectively suppressed and the anti-impulse noise performance is improved.

Owner:深圳市力合微电子股份有限公司

Soil detecting and drying device for water and soil conservation and desertification prevention and control and using method of soil detecting and drying device

PendingCN114838583AAchieve sievingRealize breaking upDrying chambers/containersAgriculture gas emission reductionEnvironmental engineeringResidual soils

The invention relates to the technical field of water and soil conservation and desertification control, in particular to a soil detecting and drying device for water and soil conservation and desertification control and a using method thereof.The soil detecting and drying device comprises a treatment tank, and the top of the treatment tank is of an open structure. According to the soil detecting and drying device for water and soil conservation and desertification control and the using method of the soil detecting and drying device, smashed soil particles meeting the drying requirement penetrate through a screening net to fall into a good material area, and a bowl-shaped inner container moves upwards and rotates along a spiral groove through a matching pile; the rotating bowl-shaped inner container can throw residual soil hard lumps, stones and other substances which cannot be smashed in the bowl-shaped inner container to the outer side, waste materials can penetrate through throwing holes to fall into a waste material area, so that screening and self-emptying of the soil in the equipment are achieved, the waste materials can be directly injected into the soil to be treated again subsequently, and a screw shaft which is pushed by the bowl-shaped inner container to synchronously move downwards rotates along a screw sleeve. The self-weight of soil and dumping potential energy are utilized for energy recovery, soil scattering is achieved, the use and maintenance cost is low, and reliability is good.

Owner:SHANDONG AGRI & ENG UNIV

Method for coating asphalt coating on the surface of outdoor mining machinery and equipment

ActiveCN105921391BIncrease elasticityImprove plasticityPretreated surfacesAnti-corrosive paintsMetallurgyGreenhouse

The invention provides a method of spraying a bituminous coating on the surface of outdoor mine mechanical equipment. The method comprises the following steps: (1) firstly, heating bituminous paint to 80-85 DEG C, stirring for 10-15 minutes, cooling to 75 DEG C, and continuously stirring under constant temperature; (2), then, pumping the bituminous paint into a high-pressure steam spray gun, dispersing the bituminous paint in the high-pressure steam spray gun, spraying the bituminous paint out along with airflow, and directly acting on the surface of the mine mechanical equipment by the high-pressure airflow to form the bituminous coating with the thickness of 1.2-3.5 mm; and (3) finally, carrying out destressing treatment: placing the mine mechanical equipment in a greenhouse of 65 DEG C, carrying out ultrasonic treatment for 25 minutes, spraying atomized water on the surface of the bituminous coating for humidification, raising the temperature of the greenhouse to 72 DEG C, treating for 20 minutes, and moving the mine mechanical equipment out of the greenhouse. According to the invention, high-pressure steam is used as a carrier for dispersing, uniformly heating and humidifying the coating to enhance the stickiness; under the function of high-pressure airflow, the bituminous coating can be uniformly sprayed on the surface of the equipment.

Owner:安徽明威科技发展有限公司

Automatic rice grain filling device and working method thereof

PendingCN111846297ARealize breaking upAvoid stickingSolid materialPackaging machinesAgricultural engineeringControl theory

The invention discloses an automatic rice grain filling device and a working method thereof. The automatic rice grain filling device is characterized by comprising a base, a first fixing shaft, a motor, a rotating shaft, a pushing rod, a first air cylinder, a third air cylinder and a rice hopper, during work, a worker pours rice grains onto a rotating hopper plate through an opening in the upper portion of the rice hopper manually or through a filling device body, a rotating shaft is driven by a motor to rotate, the rotating hopper plate fixedly connected with the rotating shaft rotates together, when the rotating hopper plate rotates at a constant speed, the first air cylinder and a second air cylinder operate at the same time, the rice grains on the rotating hopper plate are flattened and compacted, and therefore the rice grains enter a hopper groove, under the action of the rotating shaft, the hopper groove containing the rice grains can be moved to the position below the third aircylinder, under pushing of the third air cylinder, a push-out rod presses down the rice grains in the hopper groove, a bottom cover at the lower end of the hopper groove is opened, the rice grains areconveyed out and enter a preset containing device, and conveying of the rice grains is completed.

Owner:北京金田麦国际食品有限公司 +3

leaf removal equipment

ActiveCN107974989BRealization of drying and dust removalTo achieve the purpose of dust removalRoad cleaningLandscapingUltimate tensile strength

The invention discloses leaf clearing equipment, and especially relates to the technical field of municipal landscaping. The leaf clearing equipment comprises an operation vehicle. A feed chute is provided with a chute and a first slider. A first spring is connected between the chute and the first slider. A suction tube is connected to the feed tube. A suction pipe is connected between the feed tube and a vacuum pump. An air duct is arranged in a drying chamber. Air ports are arranged in the air duct. A vibration plate is arranged on the air duct. Support springs are arranged between the vibration plate and the air duct. A barrier plate is arranged between the vibration plate and the inner wall of the drying chamber. A motor is arranged between the vibration plate and the feed tube. Bladesare arranged on the motor. A dedusting box is arranged in the drying box. The dedusting box is provided with an opening. A sliding rail and a second slider are arranged at the opening. The second slider can be pushed by the blades. A second spring is connected between the slider and the second slider. By adopting the leaf clearing equipment, the problems of great labor intensity, great difficultyand easiness in breeding of bacteria among leaves in the leaf collection process are overcome, and the leaf clearing equipment can be used for sweeping operations in municipal cleaning.

Owner:遵义湘江园林工程有限责任公司

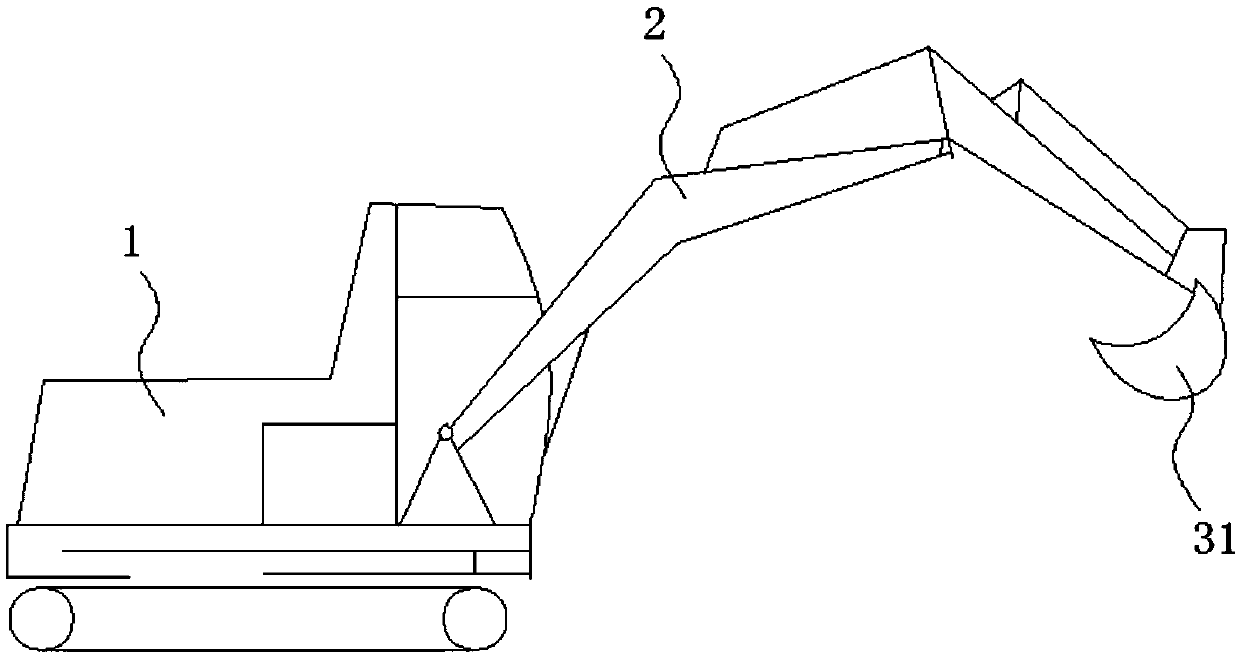

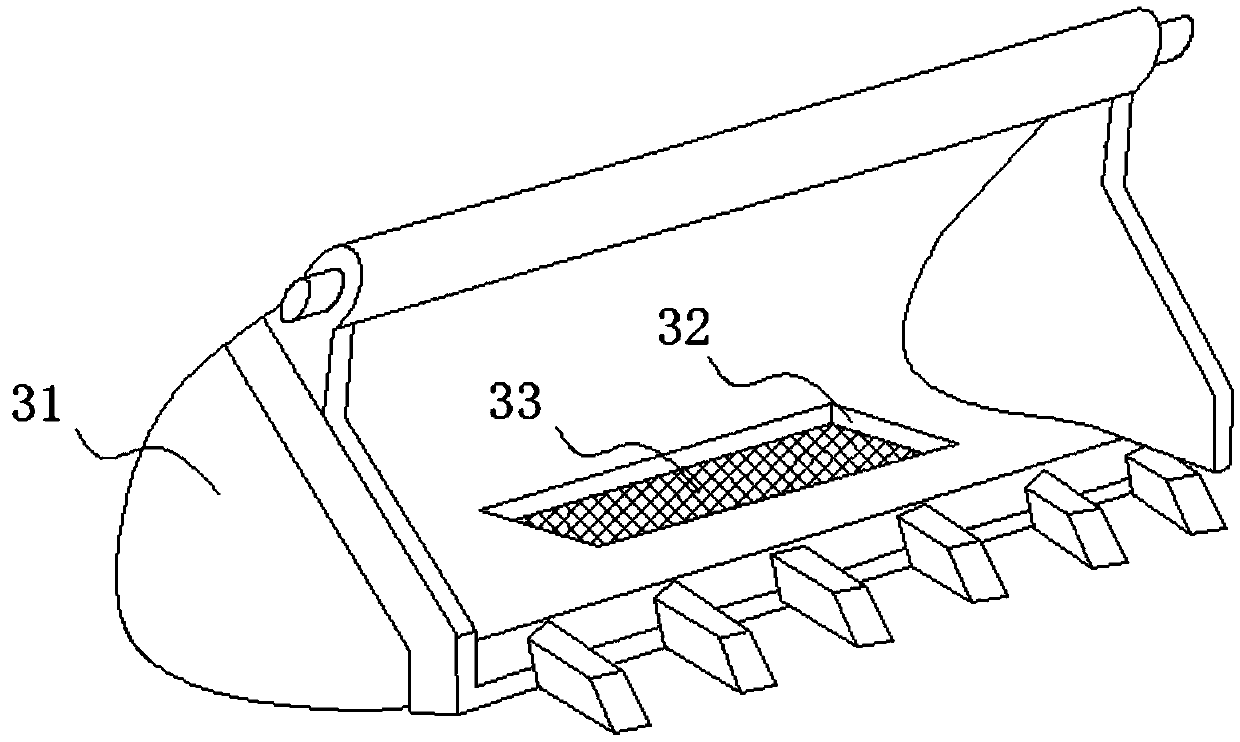

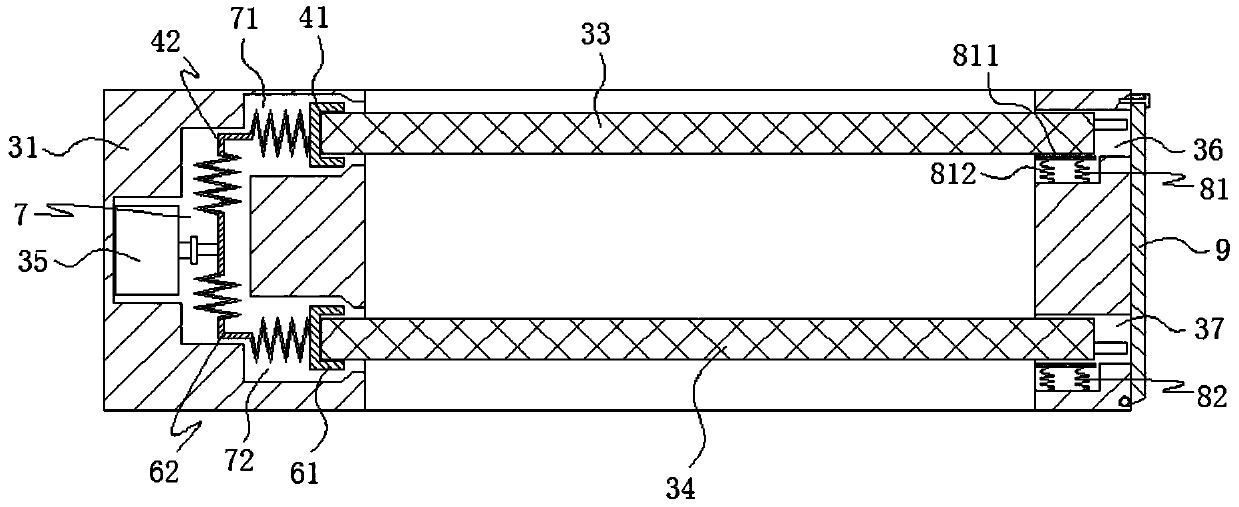

Methods for Soil Remediation

ActiveCN107855356BAdjust the ecological environmentRestoring the balance of the ecological environmentContaminated soil reclamationSoil scienceLowering plants

The invention discloses a method for soil remediation. The method for soil remediation comprises the following step of (1) soil filtering, specifically, soil containing garbage is excavated and loosened through an excavator and then is subjected to primary filtering through a filtering net, and after being filtered, the soil is flattened again through the excavator. By carrying out primary filtering on the to-be-remediated soil, most solid substances, particularly metal and plastic products incapable of being naturally decomposed, can be filtered out, and thus the soil keeps clean; remediationis conducted by planting poplars, the effect that plants absorb part of elements in the soil can be effectively promoted, and thus overhigh sulfur and phosphorus elements in the plants are reduced; and meanwhile, grass has strong vitality, grow rapidly and can also be converted into nutrient substances after death.

Owner:广州穗土环保工程有限公司

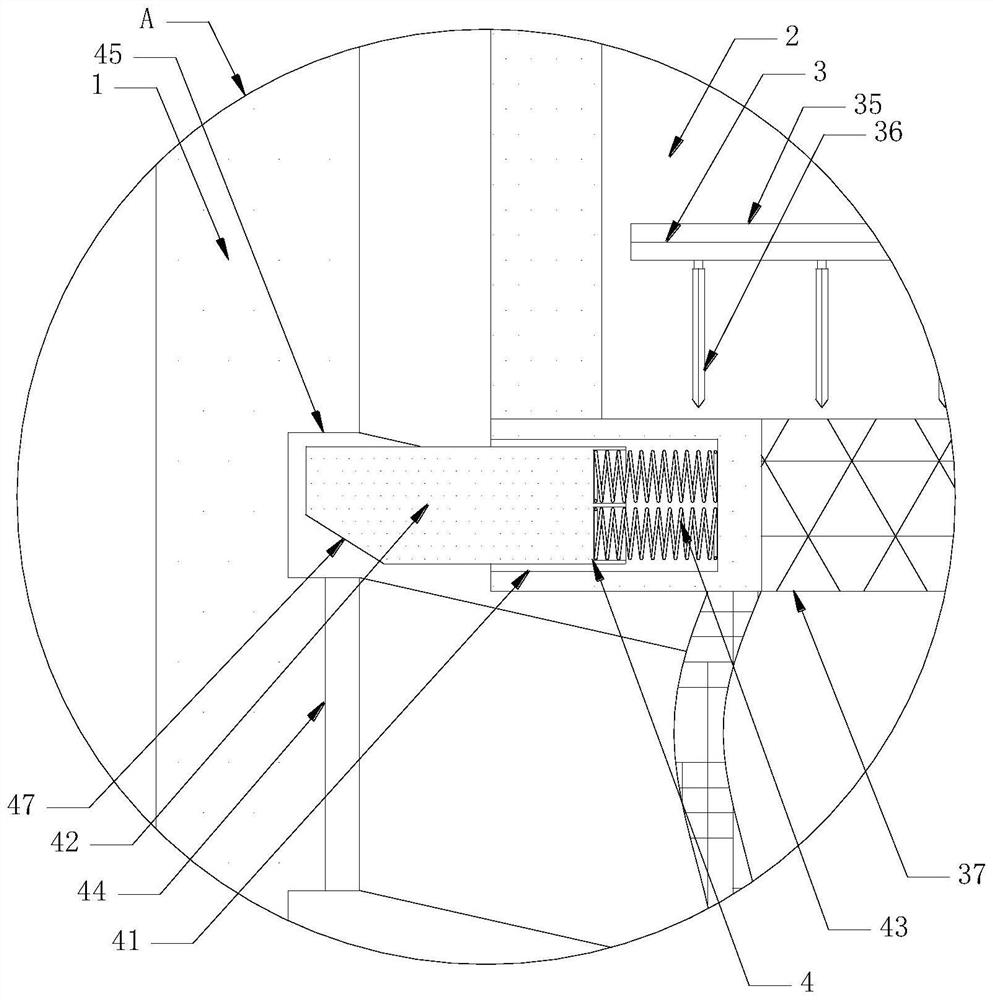

Multi-blade composite fixed grate piece

PendingCN110925766ARealize breaking upAchieve agitationIncinerator apparatusSlide plateRefuse Disposals

The invention belongs to the technical field of garbage treatment equipment, and provides a multi-blade composite fixed grate piece. The grate piece comprises a box body, a feeding sliding plate, sidebaffles, a lateral shifting blade, main crushing blades and secondary crushing blades, wherein one end of the box body is open, the feeding sliding plate is obliquely arranged at an opening of the box body, the side baffles are located on the two sides of the feeding sliding plate, one ends of the side baffles are connected with the feeding sliding plate and / or the box body, the lateral shiftingblade is arranged on the sides, facing the feeding sliding plate, of the side baffles, the main crushing blades and the auxiliary crushing blades are sequentially and alternately arranged on the feeding sliding plate, and the auxiliary crushing blades are close to the lateral shifting blade. According to the multi-blade composite fixed grate plate, garbage can be cut, so that when the garbage is applied to an up-down reciprocating type grate system, the garbage can be scattered, stirred and cut, and the garbage treatment efficiency of an incinerator is higher.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A device for releasing solid bird repellent for high-voltage transmission lines

ActiveCN113317308BAchieve vibrationAchieve releaseAnimal repellantsEngineeringStructural engineering

The invention discloses a solid bird repellent release device for high-voltage power transmission lines, which comprises a ventilation pipeline, a swing device located above the ventilation pipeline and a fixed base. Compared with the prior art, the invention has a simple structure and adopts multi-stage The vibration of the solid bird repellent is realized by shaking, so as to realize the more effective release of the bird repellent, wherein the present invention utilizes the right air inlet channel to realize the wind entering the inside of the device, and the wind can lift the object board to realize the up and down movement of the object board , the elastic rope can drive the bearing end to move up and down, thereby realizing the effective vibration of the bird repellent above the support plate. The front and rear swing of the shock-absorbing spring and the triple vibration mode can better realize the operation of dispersing and crushing the solid bird repellent, and the device structure is reasonable.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

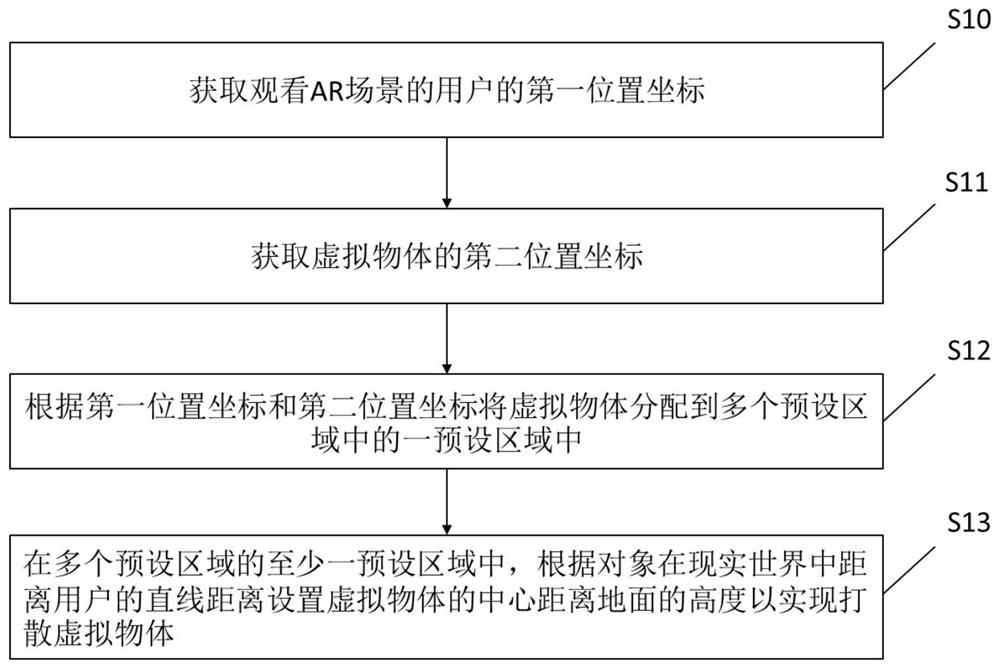

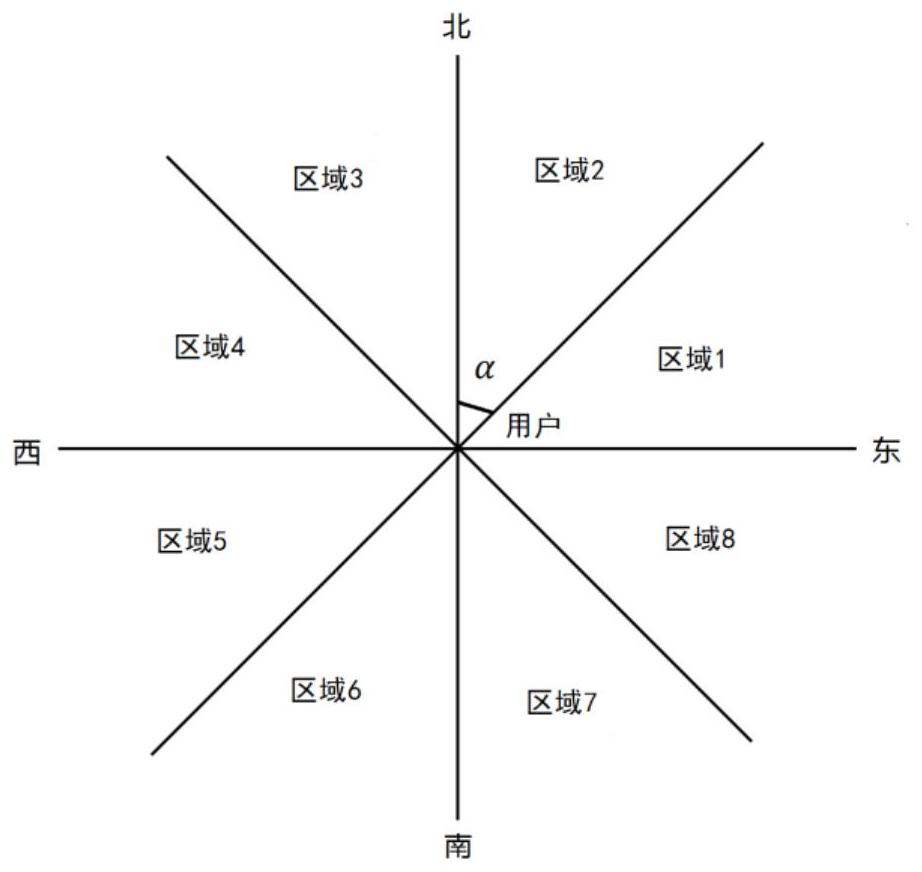

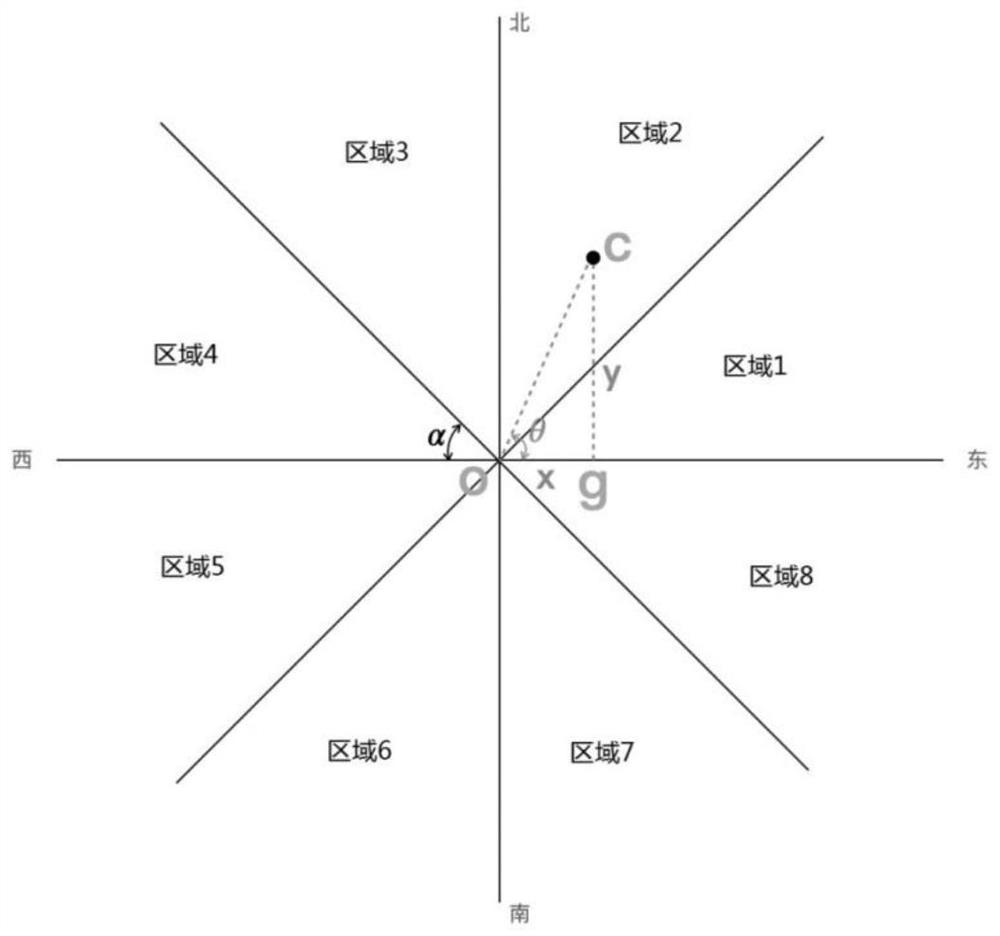

Method and device for scattering virtual objects in AR scene

ActiveCN113393516AReduce mutual occlusionRealize breaking upImage enhancementImage analysisMedicineComputer graphics (images)

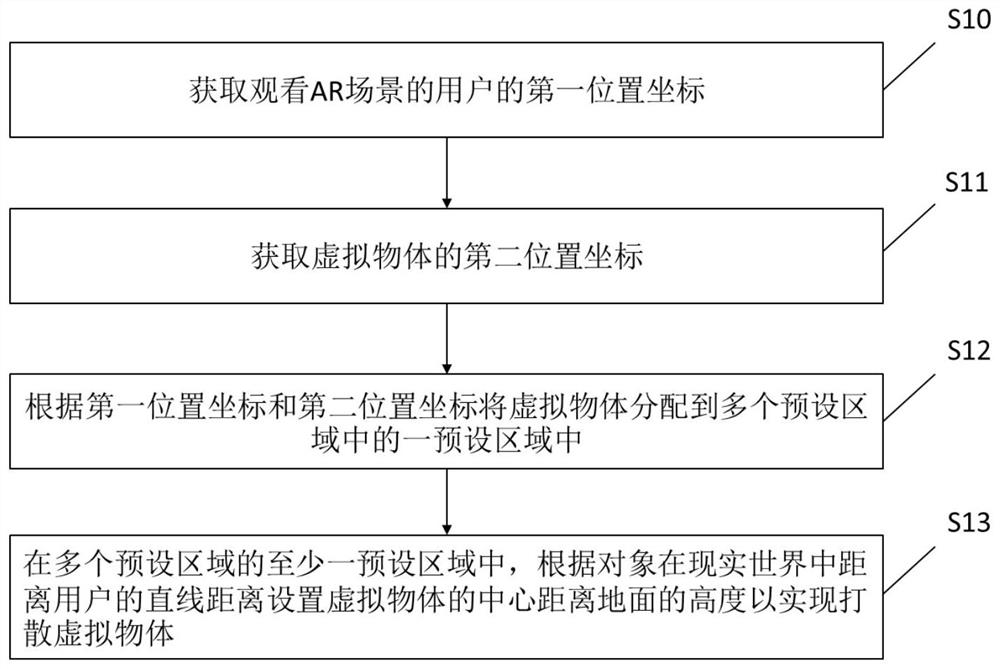

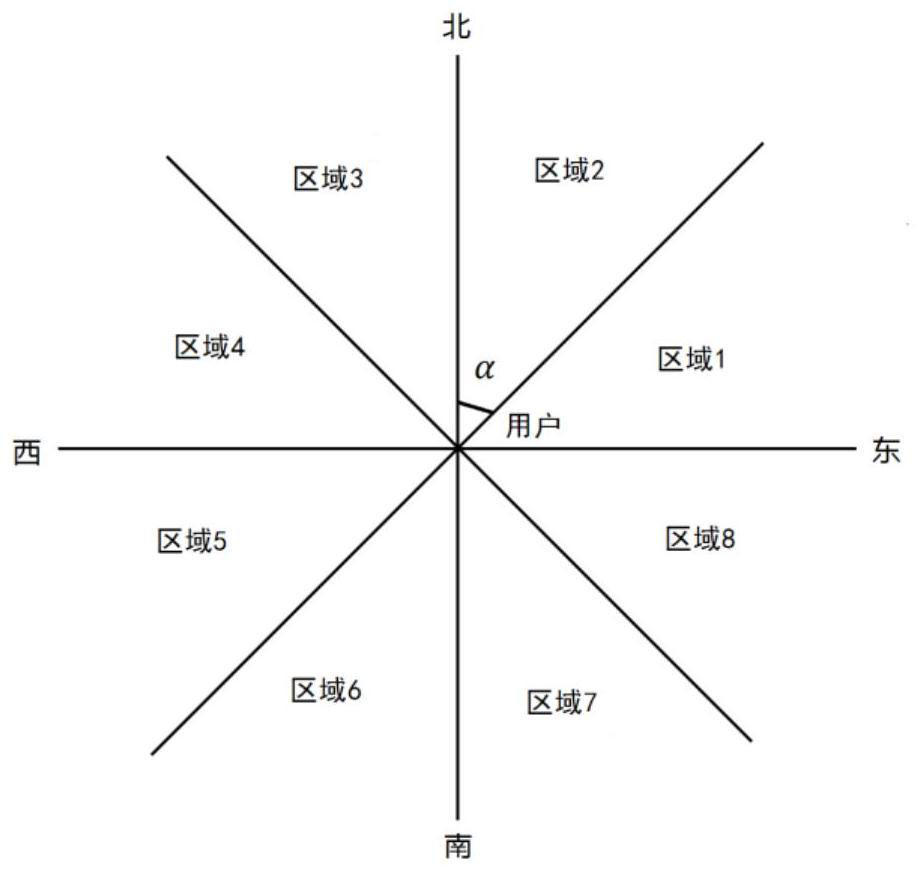

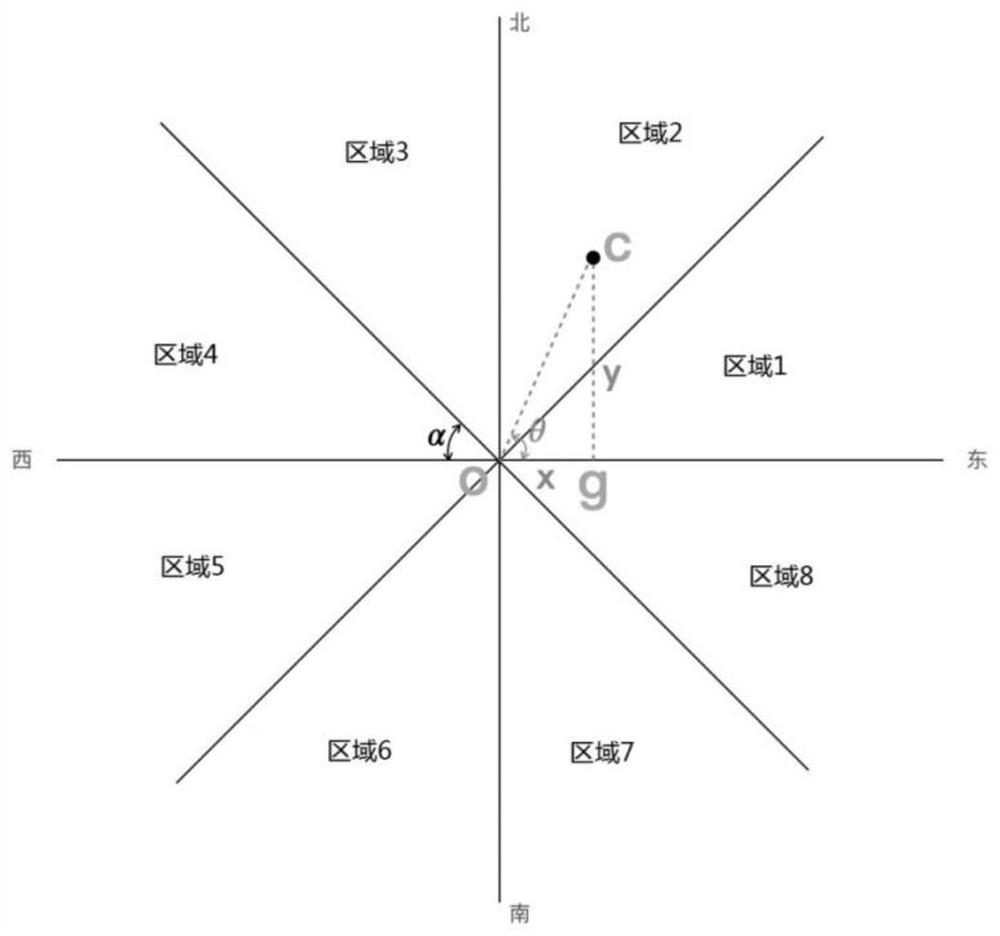

The embodiment of the invention provides a method and device for scattering a virtual object in an AR scene, and belongs to the field of augmented reality. The method comprises the following steps: acquiring a first position coordinate of a user watching an AR scene; obtaining second position coordinates of the virtual object, wherein the second position coordinates are position coordinates of an object in the real world corresponding to the AR scene represented by the virtual object, and the virtual object is used for presenting information about the object; according to the first position coordinate and the second position coordinate, distributing the virtual object to one of a plurality of preset areas, and obtaining the plurality of preset areas by taking the user as a center and dividing an azimuth plane where the user is located into a preset number of areas; and in at least one of the plurality of preset areas, setting the height from the center of the virtual object to the ground according to the linear distance from the object to the user in the real world so as to scatter the virtual object. Therefore, the virtual object is scattered.

Owner:KE COM (BEIJING) TECHNOLOGY CO LTD

Fertilizer block scattering equipment

ActiveCN114177995AAchieve agglomeration crushingBreak up fullyTransportation and packagingMixersAgricultural engineeringStructural engineering

The fertilizer block scattering equipment structurally comprises a matching box body, an inner cavity is formed in the matching box body, symmetrical open inner cavities are formed in the top of the inner cavity in a communicating mode, a driving motor is arranged on one side of the matching box body, and a conveying stirring blade is arranged on one side of the driving motor in a power connection mode; the conveying stirring blades are rotationally connected with the inner cavity in a matched mode, symmetrical transition cavities are formed in the two sides of the bottom of the inner cavity in a communicating mode, a rotating shell is rotationally arranged on the outer side of the matched box body, and a rotating device enabling the rotating shell to rotate relative to the matched box body is arranged in the rotating shell. And an internal rotating motor is arranged in the rotating shell, and a swinging box body is arranged on one side of the internal rotating motor.

Owner:山东新朝阳作物营养有限公司

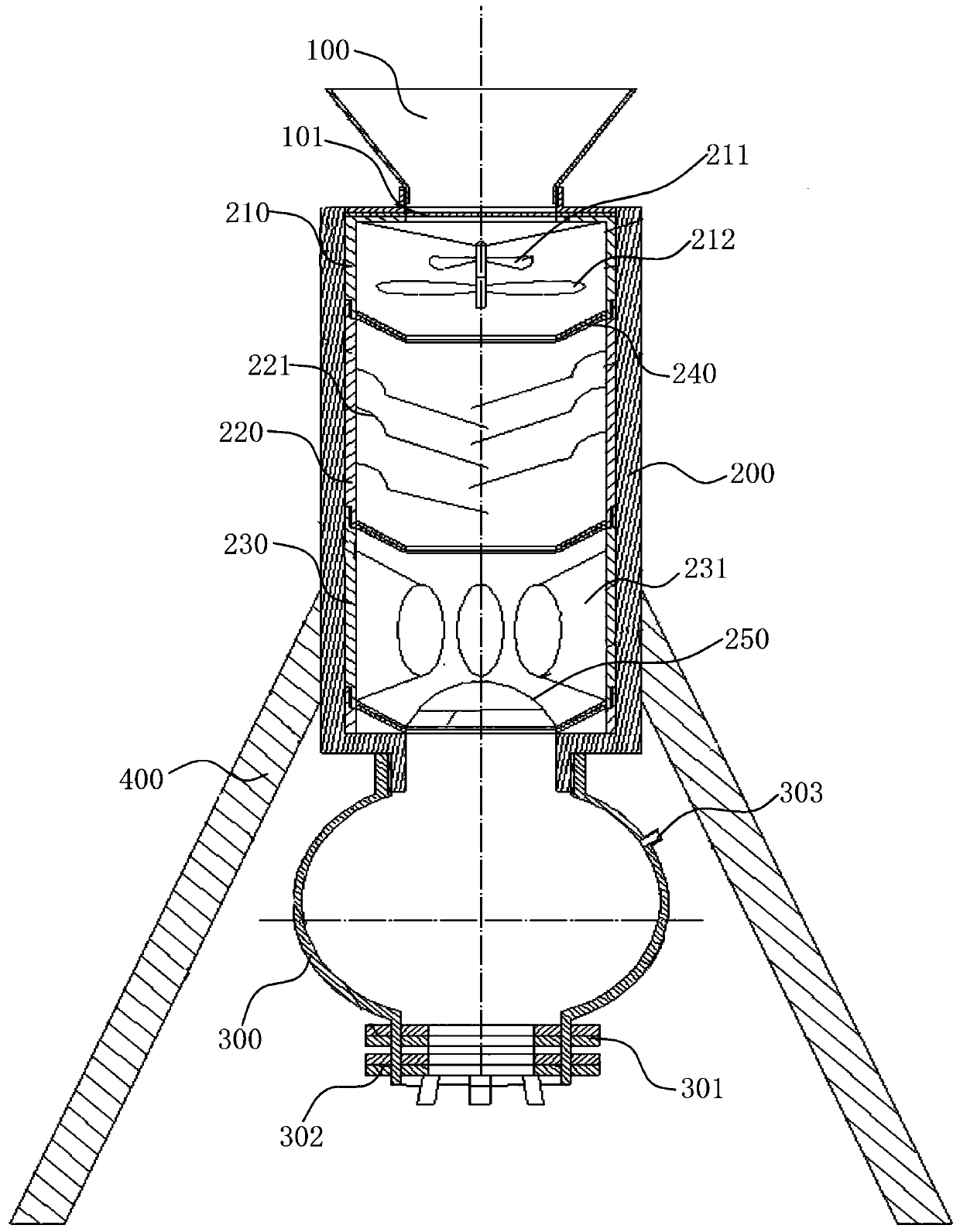

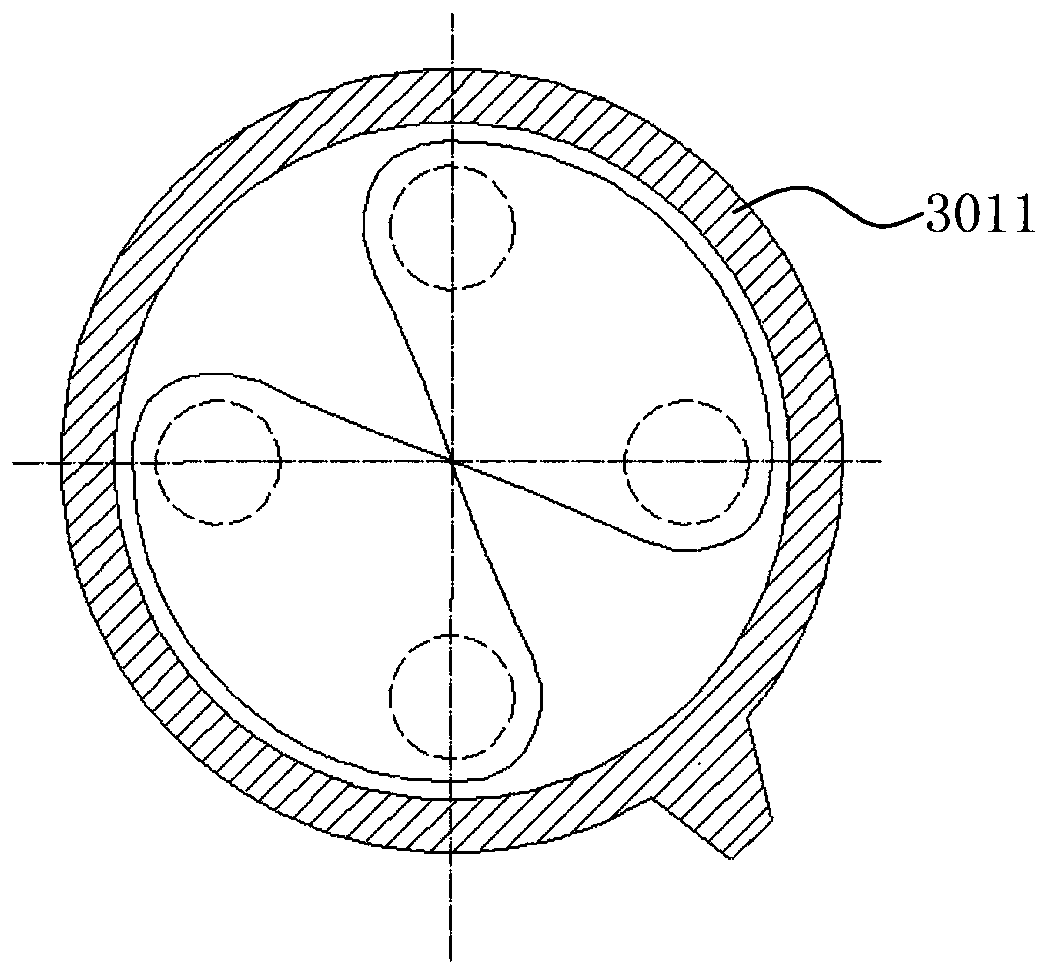

Damp-heat modification device for kudzuvine root crystal vermicelli

PendingCN112715923AGood stabilityGood uniformityFood thermal treatmentFood ingredientsPhysicsCentral cylinder

The invention discloses a damp-heat modification device for kudzuvine root crystal vermicelli. The device is characterized in that a central cylinder is concentrically arranged on the inner side of a modification box, the upper end of the central cylinder is of a conical structure, an air chamber is fixed to the bottom of the modification box, an air distribution plate is fixed between the air chamber and the modification box, the air distribution plate is of a conical structure, and multiple sets of air caps are fixed to the air distribution plate; a plurality of groups of air caps are arranged in an area at the lower part of the central cylinder, atomizing nozzles are uniformly distributed in an inner cavity at the upper part of the central cylinder and are fixed at the outlet end of a spray pipe, an annular water inlet ring cavity is fixed at the outer side of the middle part of the modification box, and the inlet end of the spray pipe is communicated with the water inlet ring cavity; a blowback nozzle fixing pipe is arranged at the upper part of the fixed plate, the blowback nozzle fixing pipe is connected with the inner wall of the modification box, a plurality of groups of blowback nozzles are fixed at the lower part of the blowback nozzle fixing pipe, and the lower end of the feeding pipe is inserted into an inner cavity of the central cylinder. The preparation method has the advantages of good stability and good uniformity.

Owner:安徽省公众检验研究院有限公司

A solid waste solidification device

ActiveCN112157110BGood effect of crushing and dispersingRealize breaking upSolid waste disposalTransportation and packagingHydraulic cylinderThermodynamics

The invention relates to the technical field of garbage treatment, and discloses a solid waste solidification device, which includes a conveying cylinder, an auger is fixedly installed inside the conveying cylinder, and a first motor is fixedly installed on the left side of the auger. The left end of the conveying cylinder top is fixedly equipped with two lower feed bins, and the tops of the two lower feed bins are fixedly equipped with injection bins. The solid waste solidification device is equipped with a conveying cylinder, a solidification chamber, and crushing rollers to achieve the purpose of simple crushing and good solidification effect. The waste that needs to be solidified is crushed by the crushing rollers in advance, and the internal structure can be broken up. , and then use the auger to convey the material to break up, so as to ensure that the material is crushed and dispersed well, and then the material is put into the curing chamber, and at this time, the hydraulic cylinder is used to solidify and squeeze it, which can realize the effective extrusion of the crushed material Curing, at this time the curing effect is good, the pores inside the material are very small, and the degree of curing is high.

Owner:铜仁筱启环保科技有限公司

A New Extrusion Type Walnut Shell Breaking Equipment

Owner:TARIM UNIV

Uniform extruder for chloroprene rubber (CR) production

InactiveCN112374190AReasonable structureFunctionalCleaning using toolsLoading/unloadingPolymer scienceElectric machinery

The invention relates to the technical field of chloroprene rubber (CR) production, in particular to a uniform extruder for chloroprene rubber (CR) production. The uniform extruder comprises an extruder discharge port, wherein an inclined strut is arranged on the top surface of the extruder discharge port;the top end of the inclined strut is connected to the bottom surface of a mounting plate; a driving motor is arranged at the upper part of the mounting plate; the outer side of the driving motor is sleeved with an enclosure cover; the outer side of the enclosure cover is sleeved with a buckleplate; the power output end of the driving motor is in transmission connection with a spiral conveying shaft; and the outer side of the spiral conveying shaft is sleeved with a sealed bearing. The uniform extruder for chloroprene rubber (CR) production has the beneficial effects that the inclined strut is additionally arranged at the top of the discharge port, the top of the inclined strut supports the mounting plate, the driving motor on the surface of the mounting plate drives the spiral conveying shaft to rotate to convey materials downwards, and after the conveyed materials are extruded to pass through a uniform net rack, the materials are scattered, and material caking is avoided.

Owner:刘士洲

Method and device for breaking up virtual objects in AR scene

ActiveCN113393516BReduce mutual occlusionRealize breaking upImage enhancementImage analysisMedicineComputer graphics (images)

Embodiments of the present invention provide a method and device for breaking up virtual objects in an AR scene, belonging to the field of augmented reality. The method includes: obtaining the first position coordinates of the user watching the AR scene; obtaining the second position coordinates of the virtual object, wherein the second position coordinates are the position coordinates of the object in the real world corresponding to the AR scene represented by the virtual object, and the virtual The object is used to present information about the object; according to the first position coordinates and the second position coordinates, the virtual object is assigned to a preset area in a plurality of preset areas, wherein the plurality of preset areas are user-centered, It is obtained by dividing the azimuth plane where the user is located into preset areas; and in at least one of the multiple preset areas, setting the center distance of the virtual object according to the straight-line distance of the object from the user in the real world The height of the ground is used to disperse virtual objects. In this way, virtual objects are broken up.

Owner:KE COM (BEIJING) TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com