Patents

Literature

50 results about "Silicon microstructures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

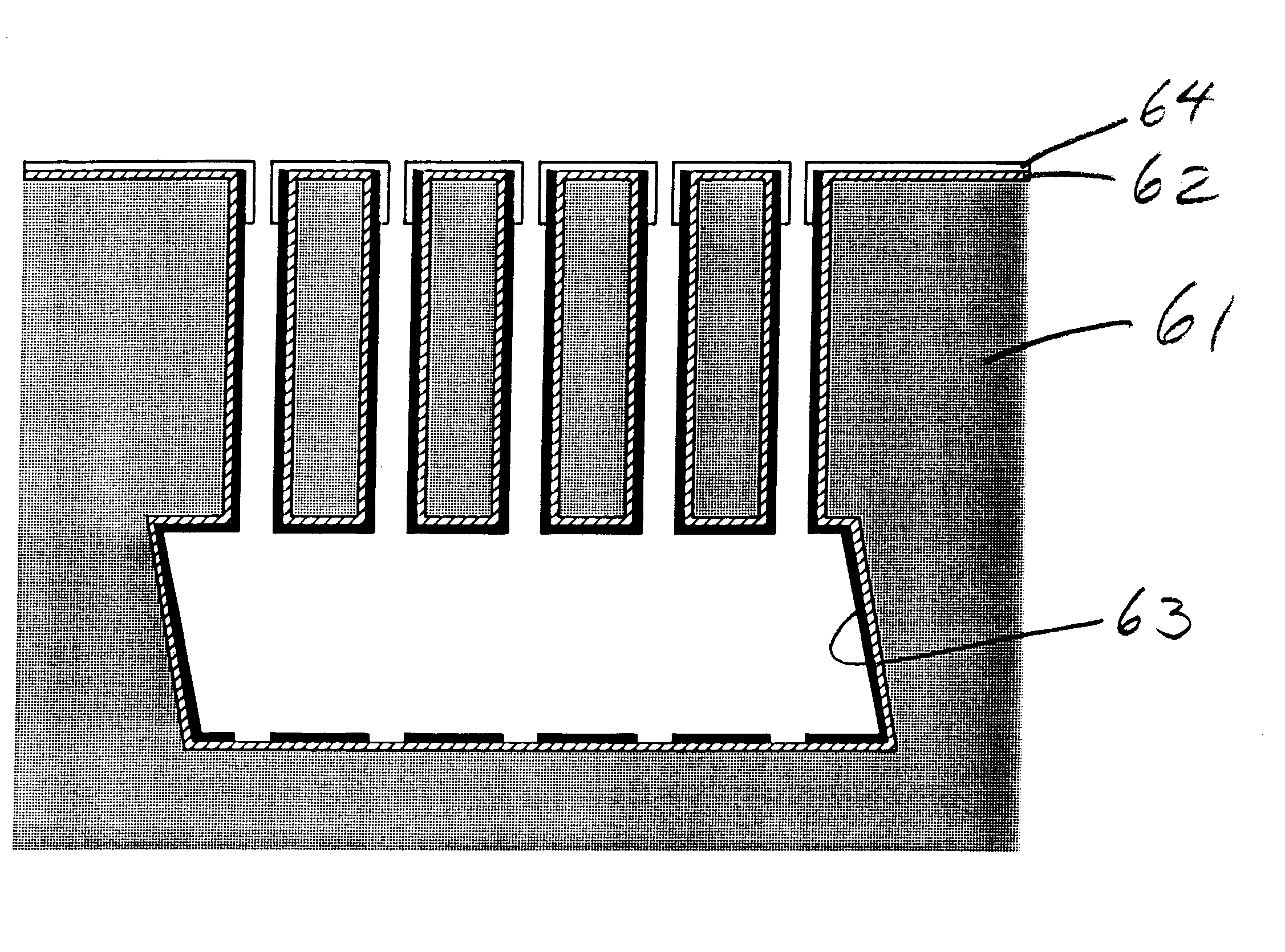

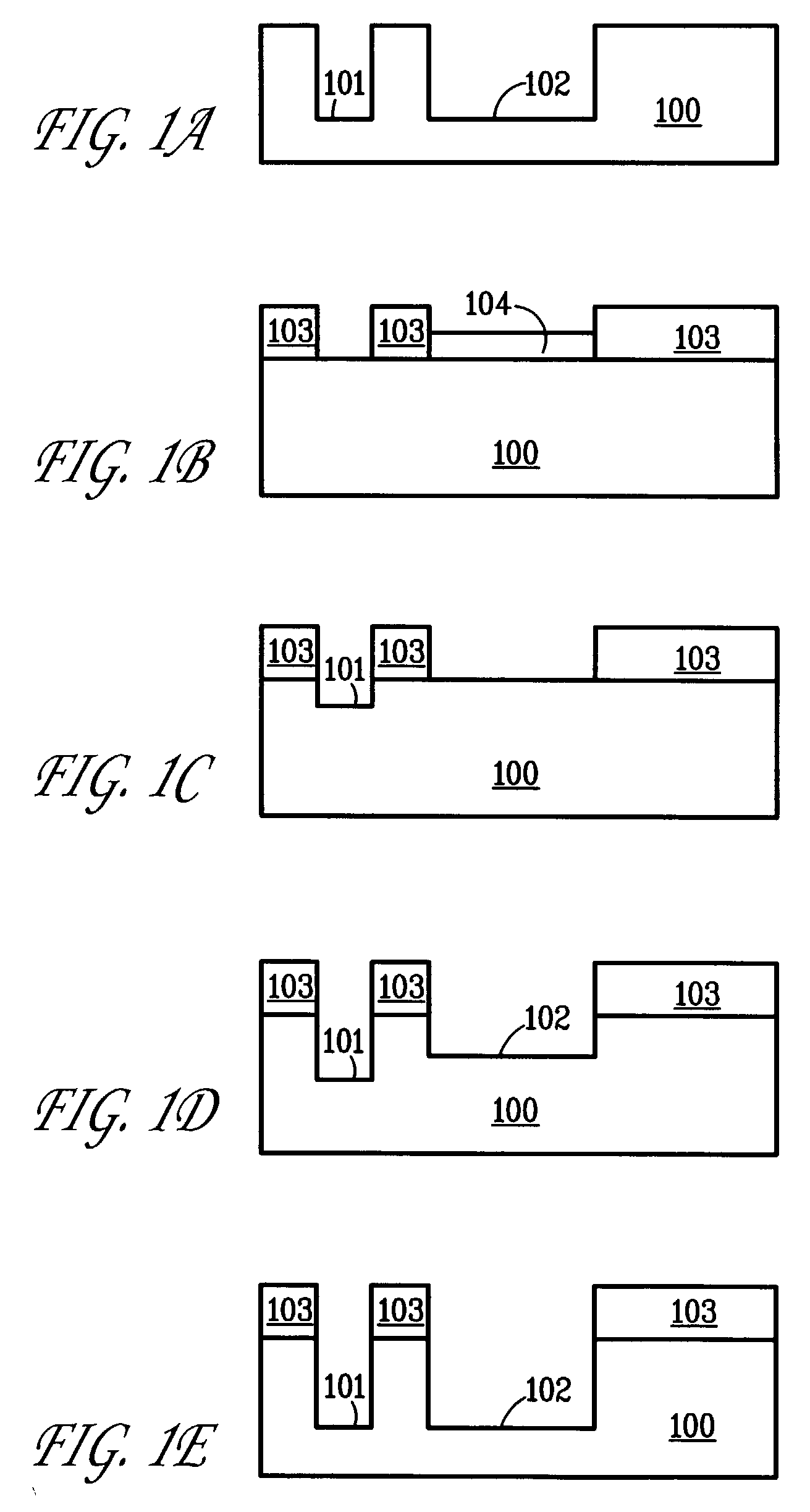

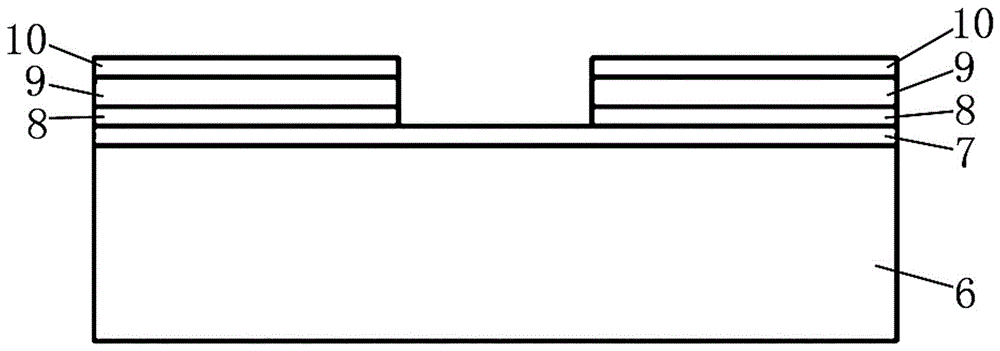

Triple layer isolation for silicon microstructure and structures formed using the same

InactiveUS6569702B2Decorative surface effectsSemiconductor/solid-state device manufacturingInsulation layerTriple layer

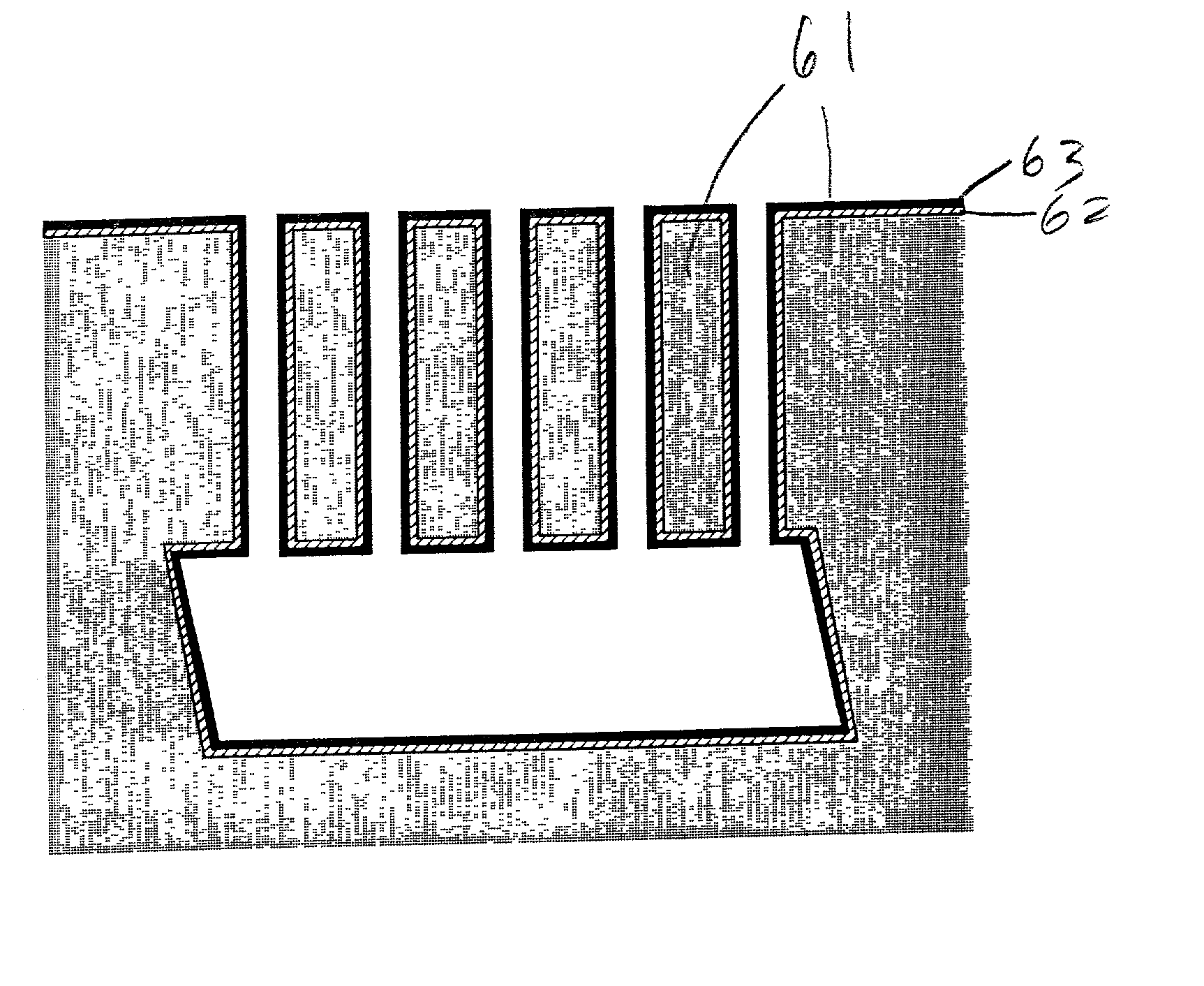

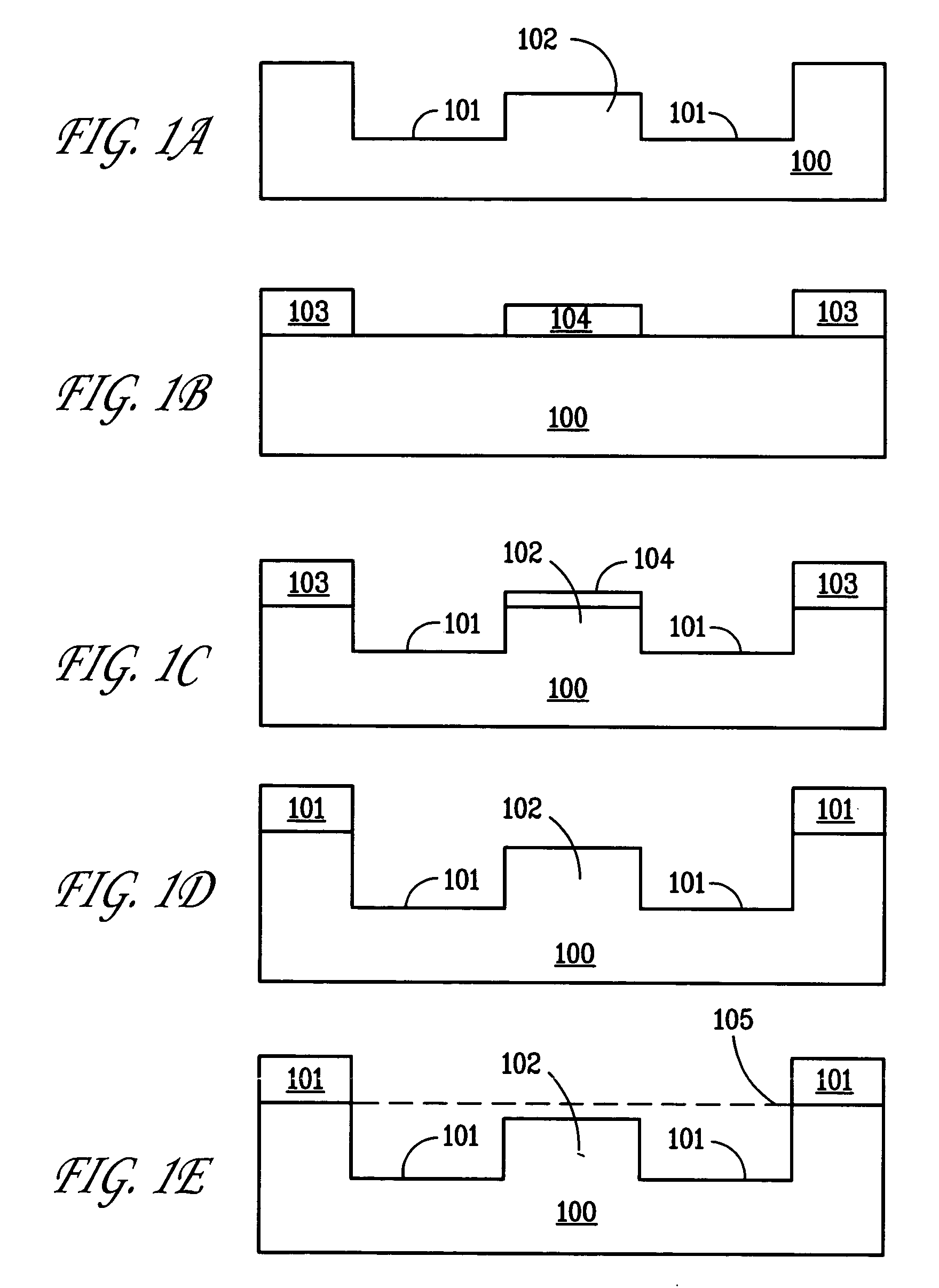

An isolation method for a single crystalline silicon microstructure using a triple layer structure is disclosed. The method includes forming the triple layer composed of an insulation layer formed over an exposed surface of the silicon microstructure, a conductive layer formed over the entire insulation layer, and a metal layer formed over a top portion of the microstructure; and partially etching the conductive layer to form electrical isolation between parts of the microstructure. The method does not require a separate photolithography process for isolation, and can be effectively applied to microstructures having high aspect ratios and narrow trenches. Also disclosed are single crystalline silicon microstructures having a triple layer isolation structure formed using the disclosed method.

Owner:BARUN ELECTRONICS CO LTD

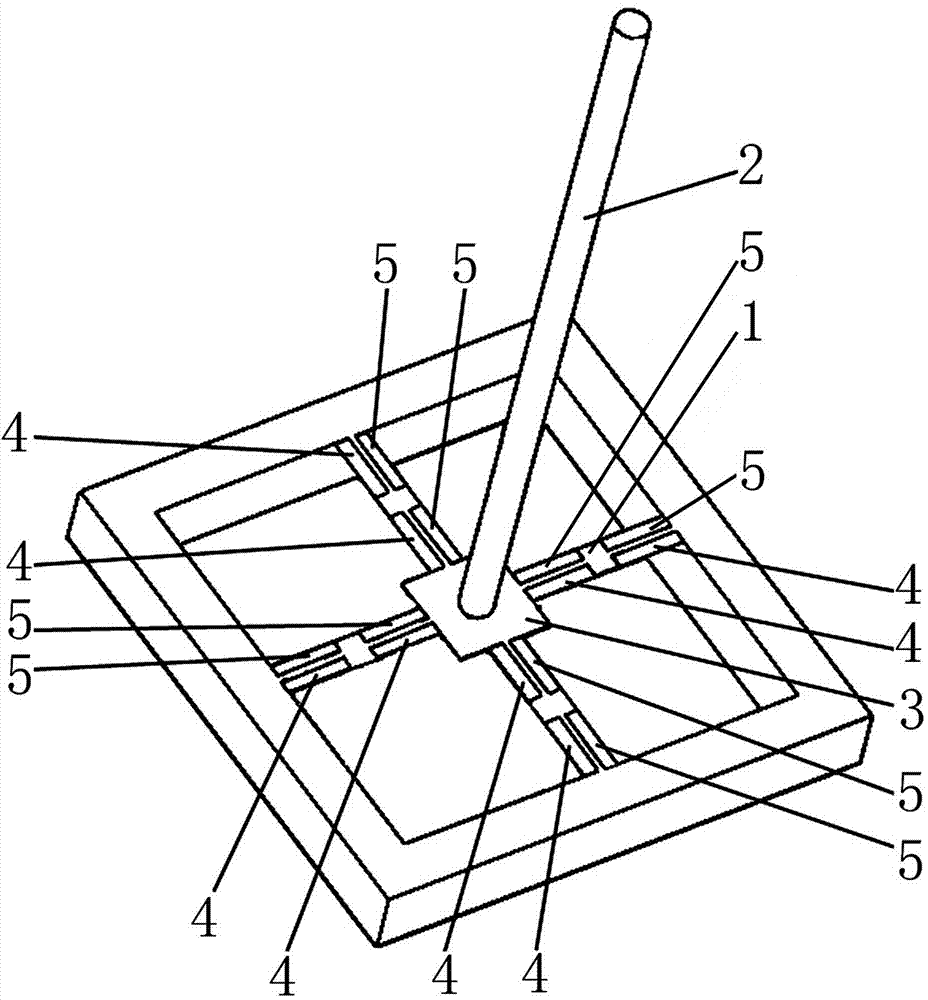

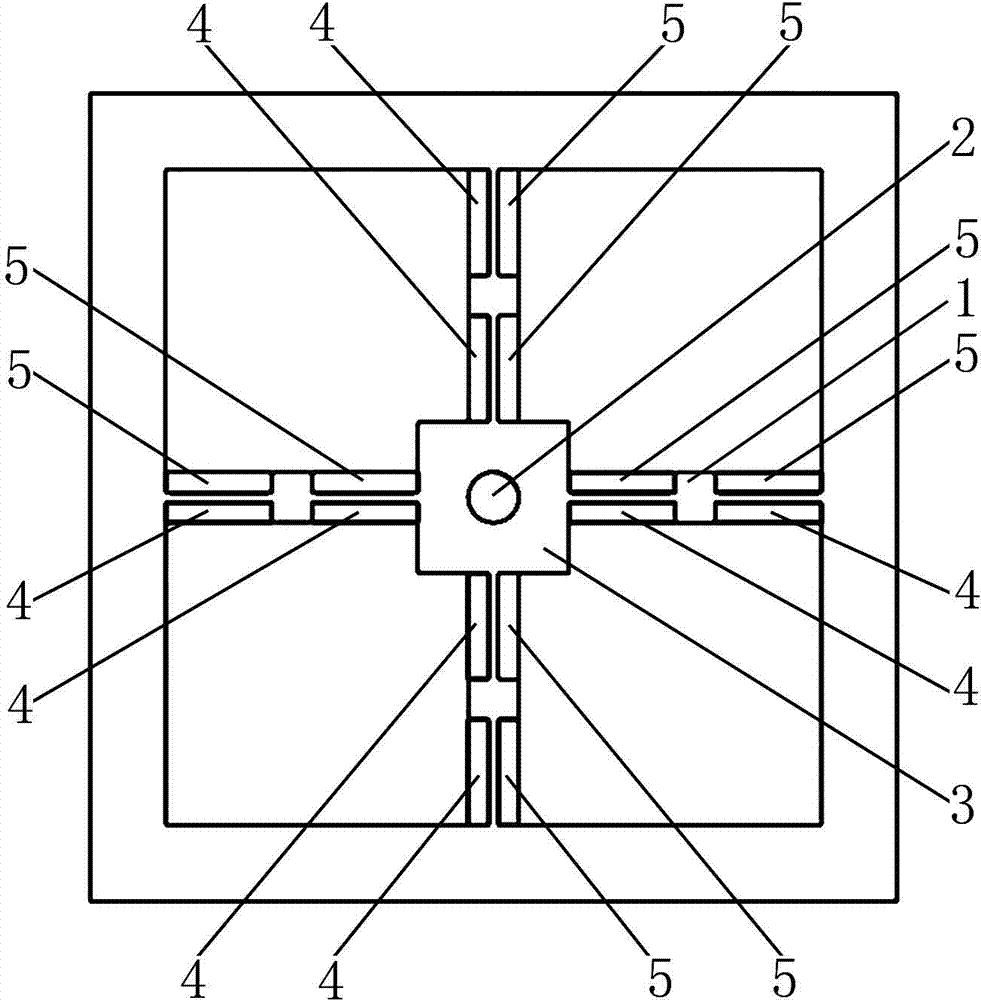

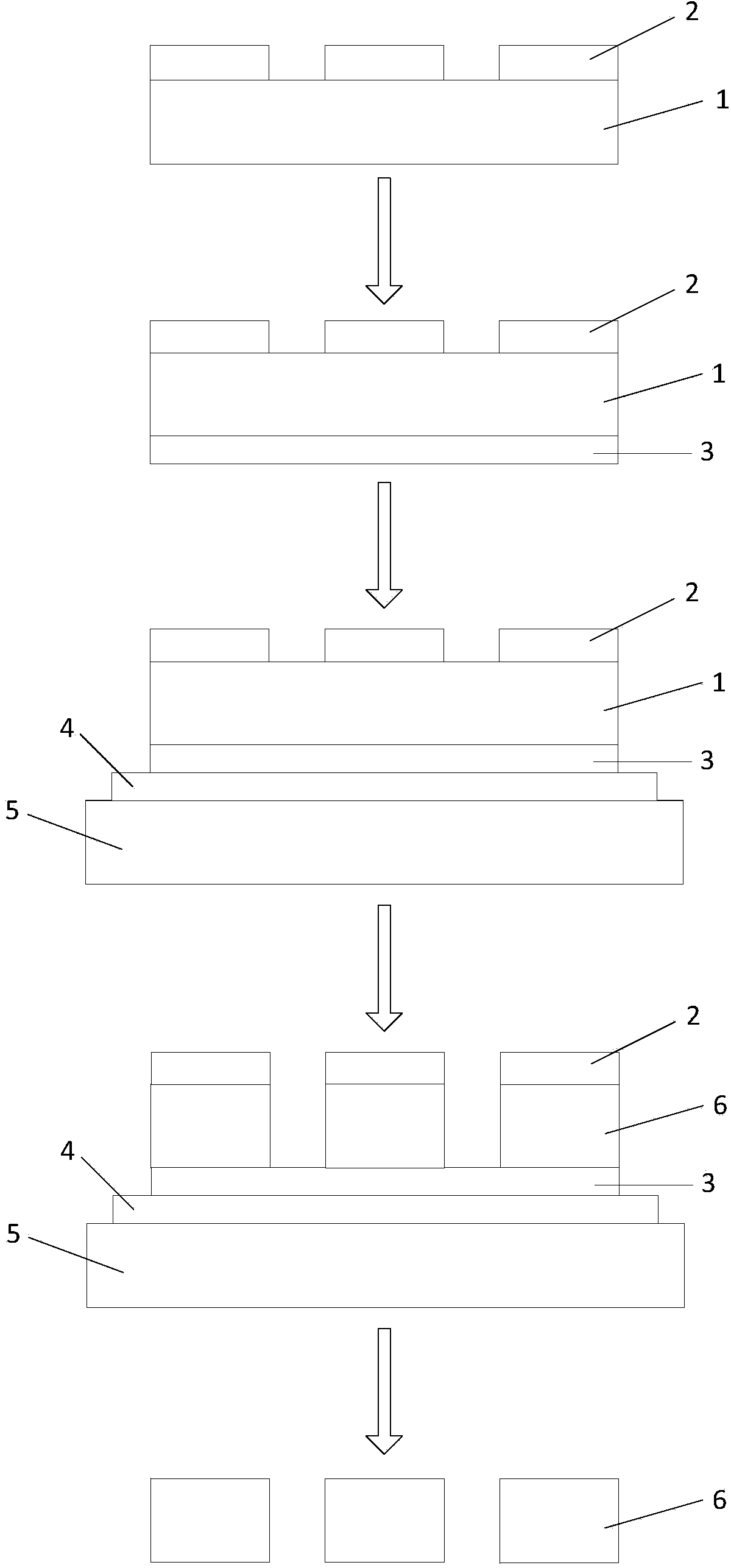

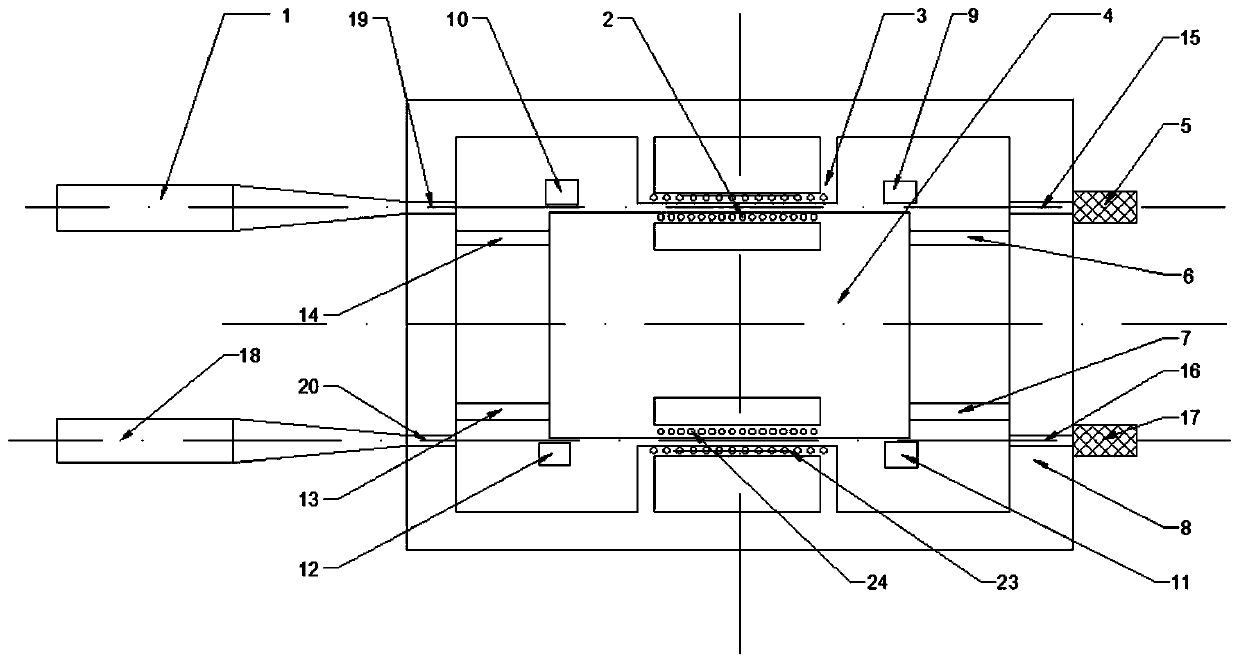

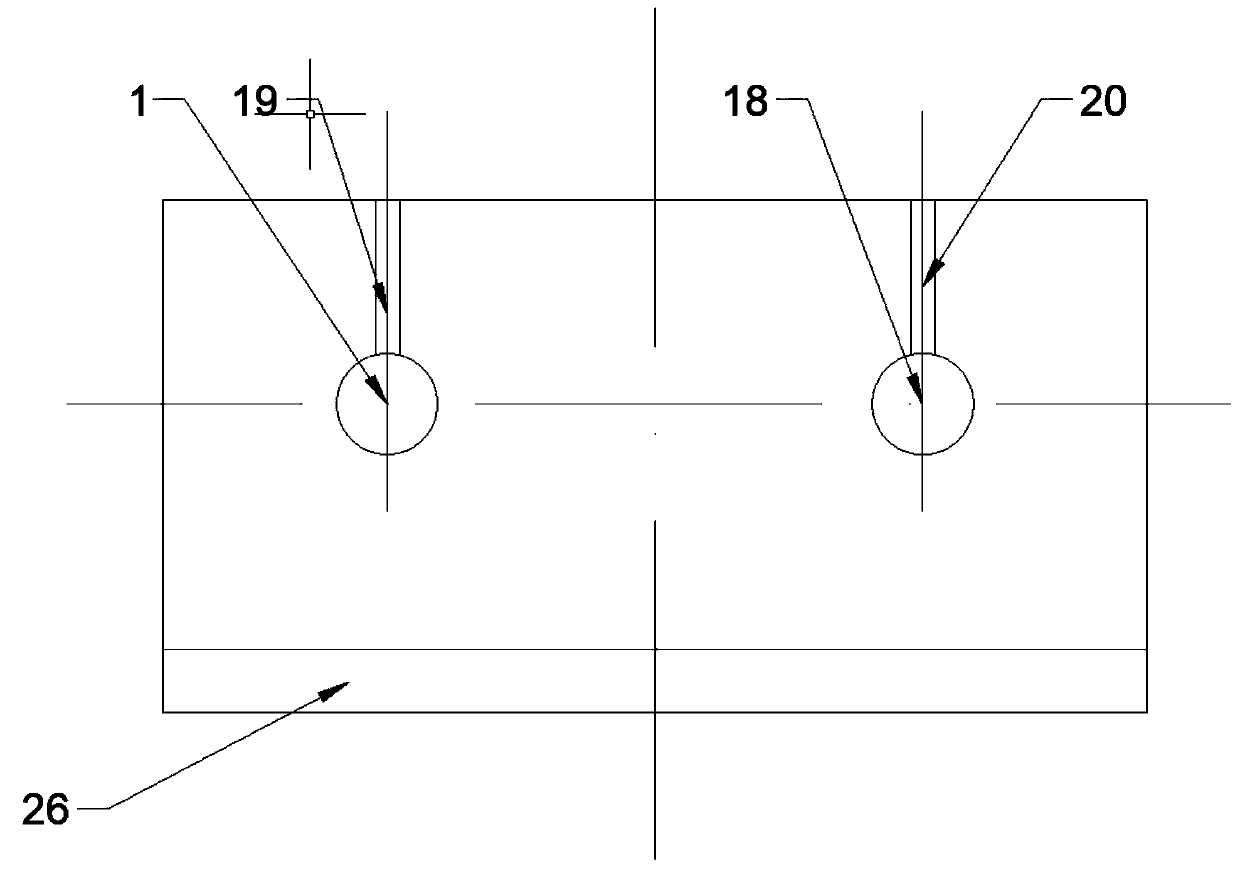

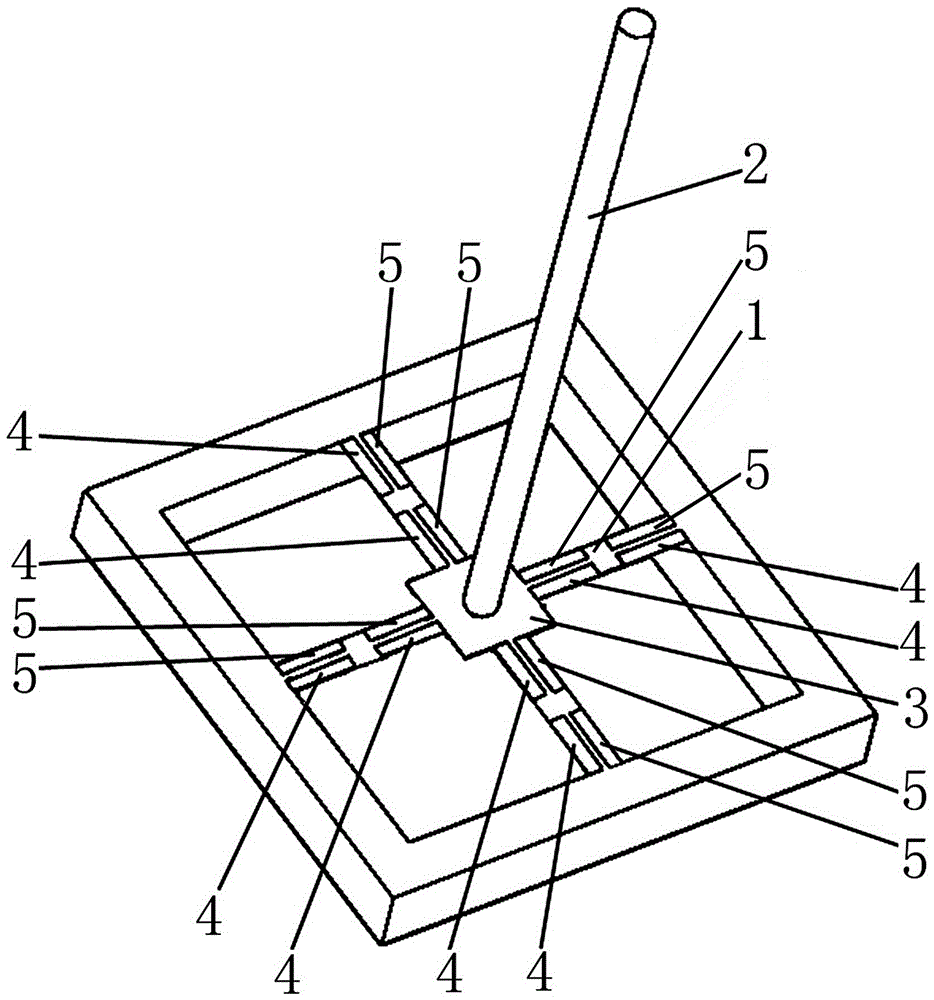

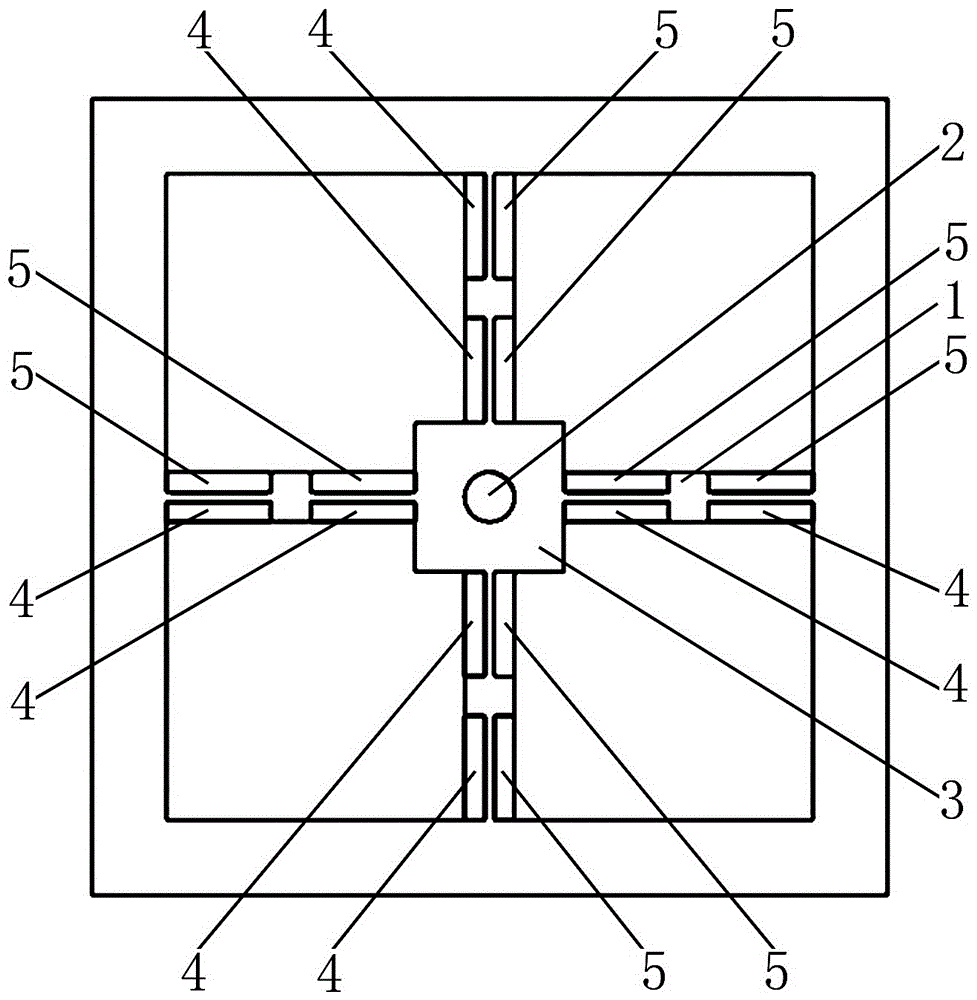

High-sensitivity resonant MEMS vector hydrophone structure

ActiveCN104121984AHigh sensitivityImprove anti-interference abilitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansHydrophoneSilicon microstructures

The invention relates to a vector hydrophone and specifically relates to a high-sensitivity resonant MEMS (Micro Electro Mechanical System) vector hydrophone structure. The high-sensitivity resonant MEMS vector hydrophone structure is used for solving the problems of poor antijamming capability and low sensitivity of the existing vector hydrophone. The high-sensitivity resonant MEMS vector hydrophone structure comprises a four-beam arm silicon microstructure, a micro cylindrical body, a central connector, driving electrodes and detection electrodes, wherein the four-beam arm silicon microstructure and the central connector are located in the same plane; the lower end of the micro cylindrical body is vertically fixed in the center of the upper surface of the central connector; eight driving electrodes and eight detection electrodes are arranged; the first driving electrode is paved on the left front part of the upper surface of the front beam arm of the four-beam arm silicon microstructure, while the second driving electrode is paved on the left rear part of the upper surface of the front beam arm of the four-beam arm silicon microstructure. The high-sensitivity resonant MEMS vector hydrophone structure is applicable to accurate positioning and measurement of underwater acoustic pressure signals.

Owner:ZHONGBEI UNIV

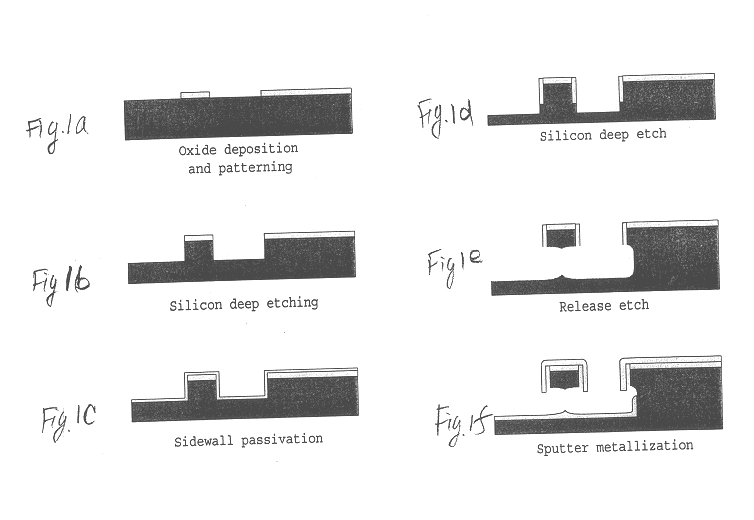

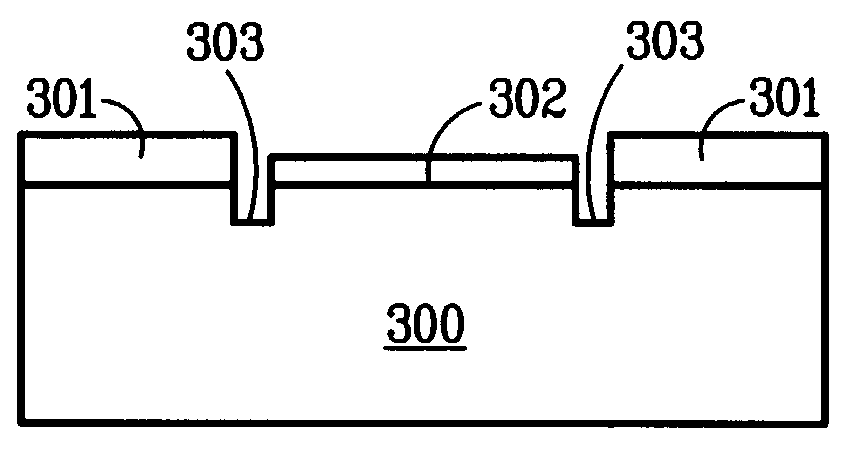

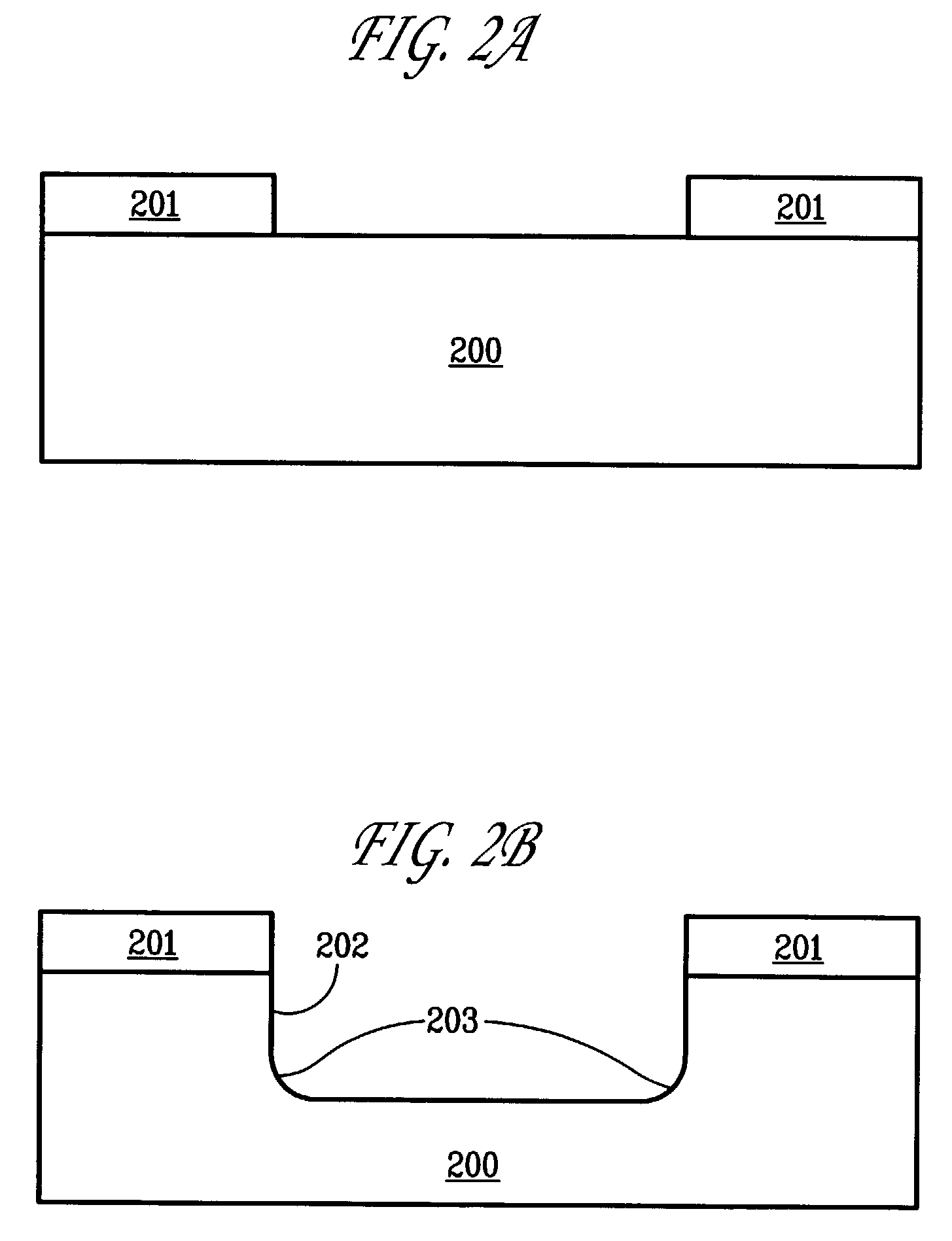

Method to control artifacts of microstructural fabrication

ActiveUS7105098B1Vacuum gauge using ionisation effectsDecorative surface effectsOptoelectronicsSilicon microstructures

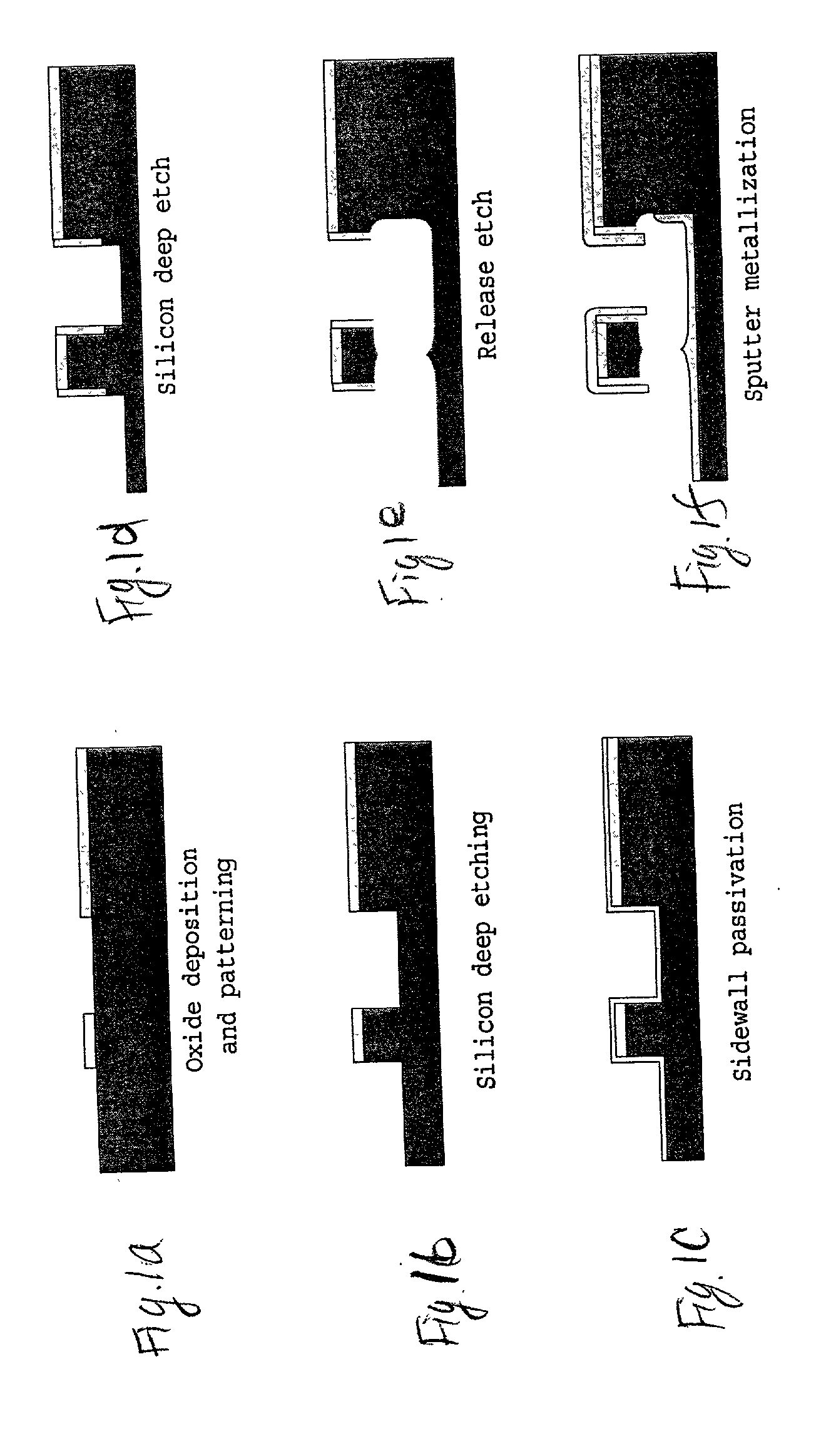

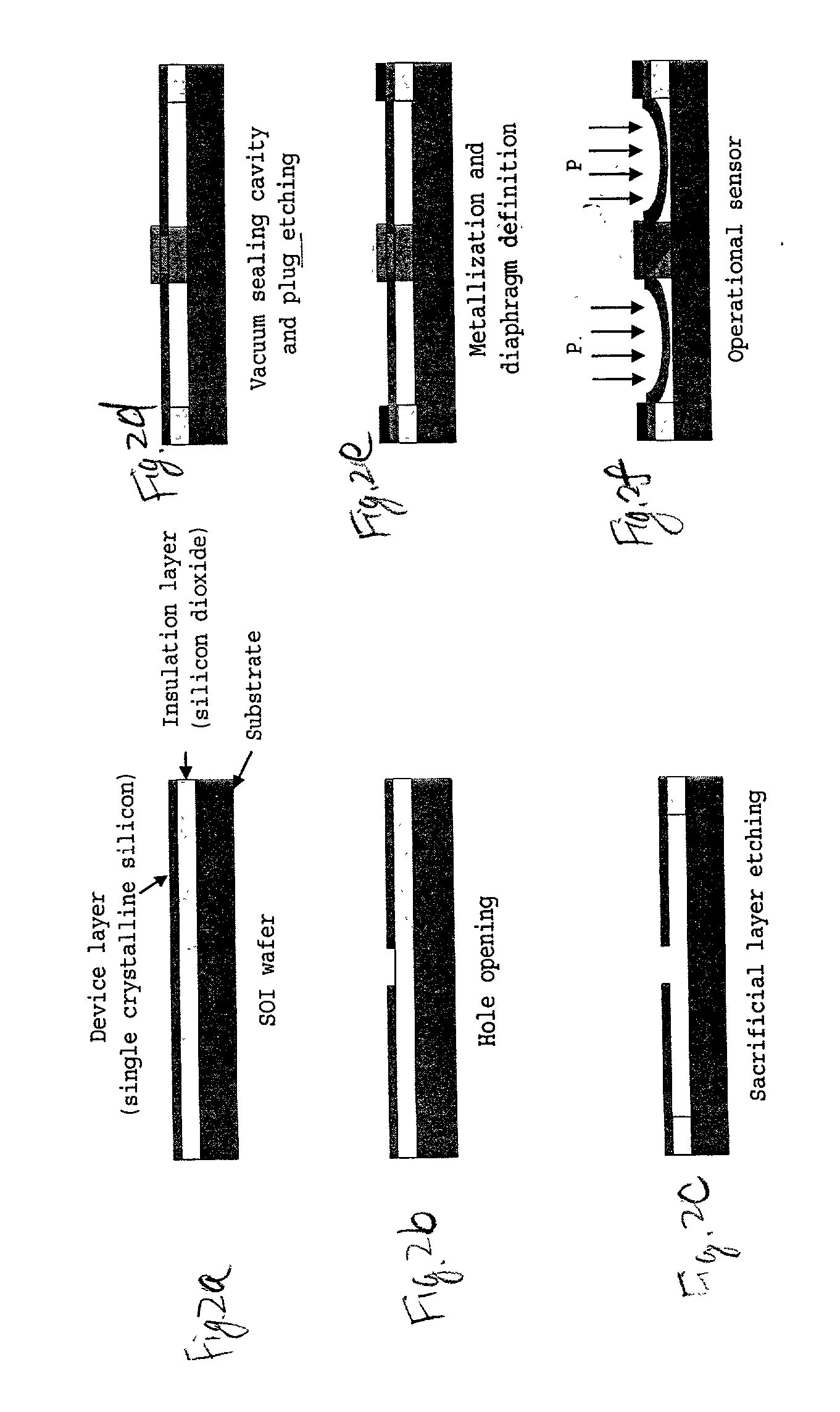

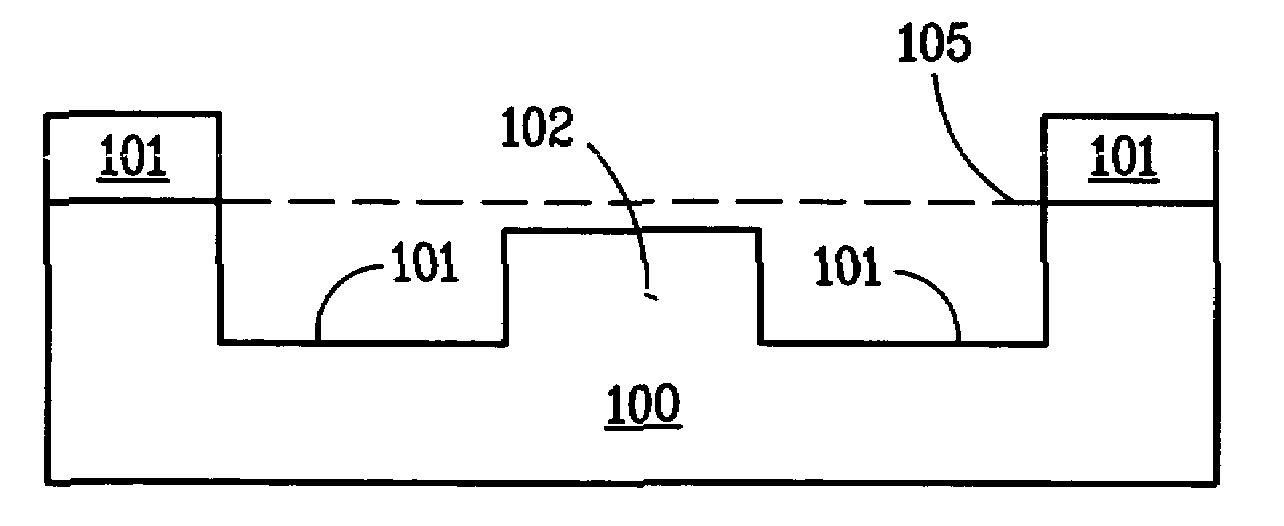

New methods for fabrication of silicon microstructures have been developed. In these methods, an etching delay layer is deposited and patterned so as to provide differential control on the depth of features being etched into a substrate material. Compensation for etching-related structural artifacts can be accomplished by proper use of such an etching delay layer.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

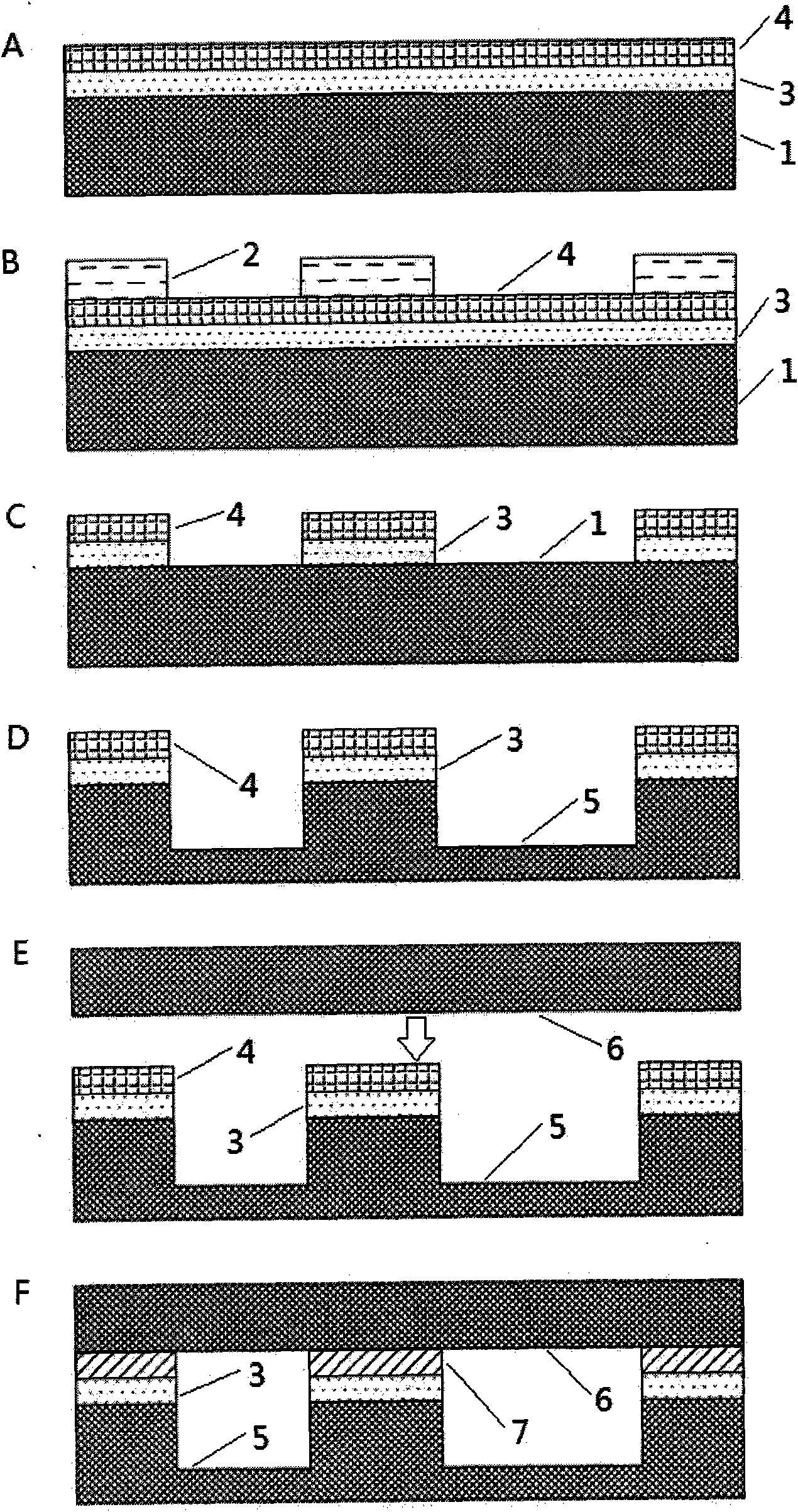

Bulk silicon etching and gold silicon bonding combined process method

ActiveCN101913553AThe process steps are simpleImprove efficiencyDecorative surface effectsChemical vapor deposition coatingGold filmSilicon etching

The invention discloses a bulk silicon etching and gold silicon bonding combined process method, which comprises the following steps of: firstly, forming a gold mask pattern on a first silicon wafer; secondly, dryly etching or wetly corroding the first silicon wafer by using a gold mask to form a bulk silicon microstructure; and finally, positioning a second silicon wafer on the first silicon wafer with a pattern structure to perform the gold silicon bonding. In the process method, a gold film layer is ingenuously used as a masking layer for forming the silicon microstructure in the etching process and also used as a bonding layer in a subsequent eutectic bonding process. In the traditional process, the etching of silicon and the bonding of the silicon wafer are two independent steps; while in the process method of the invention, the etching and the bonding are organically combined together, so that a process flow is simplified and production efficiency is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Triple layer isolation for silicon microstructure and structures formed using the same

InactiveUS20020001871A1Decorative surface effectsSemiconductor/solid-state device manufacturingInsulation layerTriple layer

An isolation method for a single crystalline silicon microstructure using a triple layer structure is disclosed. The method includes forming the triple layer composed of an insulation layer formed over an exposed surface of the silicon microstructure, a conductive layer formed over the entire insulation layer, and a metal layer formed over a top portion of the microstructure; and partially etching the conductive layer to form electrical isolation between parts of the microstructure. The method does not require a separate photolithography process for isolation, and can be effectively applied to microstructures having high aspect ratios and narrow trenches. Also disclosed are single crystalline silicon microstructures having a triple layer isolation structure formed using the disclosed method.

Owner:BARUN ELECTRONICS CO LTD

Method to fabricate multi-level silicon-based microstructures via use of an etching delay layer

ActiveUS6930051B1Easy to controlDecorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsSilicon microstructures

New methods for fabrication of silicon microstructures have been developed. In these methods, an etching delay layer is deposited and patterned so as to provide differential control on the depth of features being etched into a substrate material. Structures having features with different depth can be formed thereby in a single etching step.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

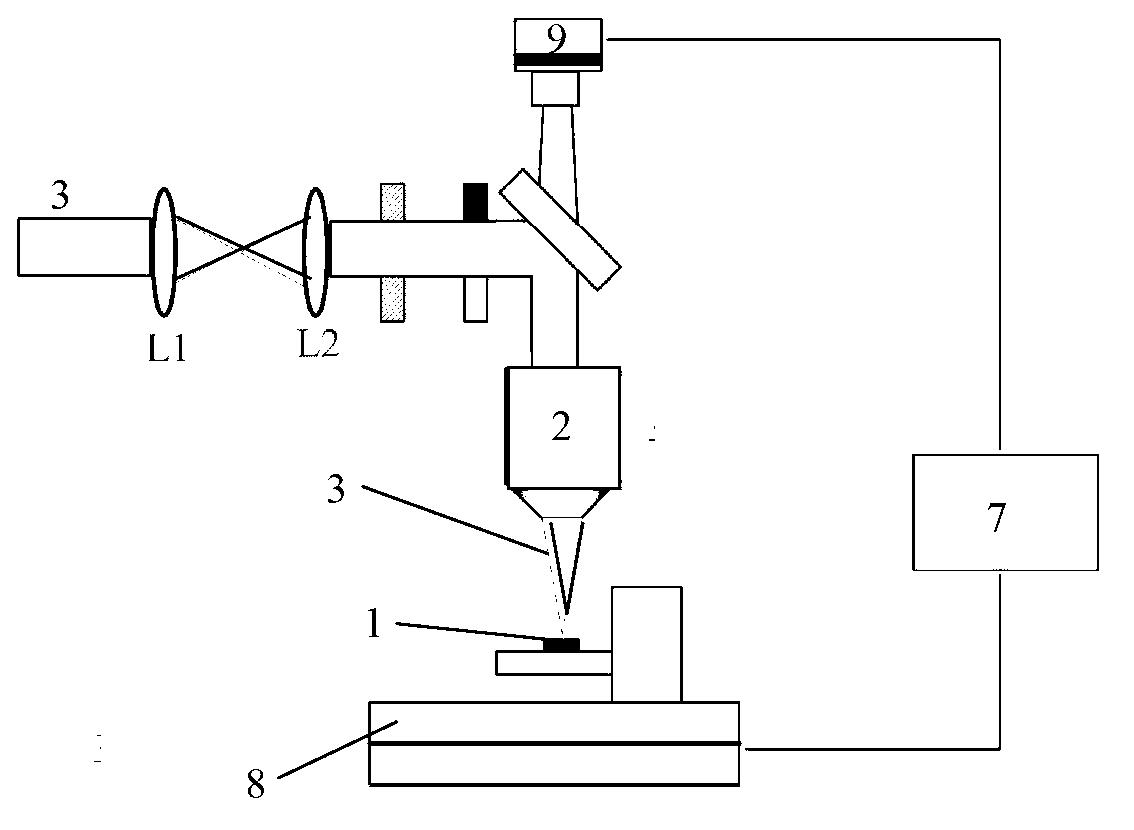

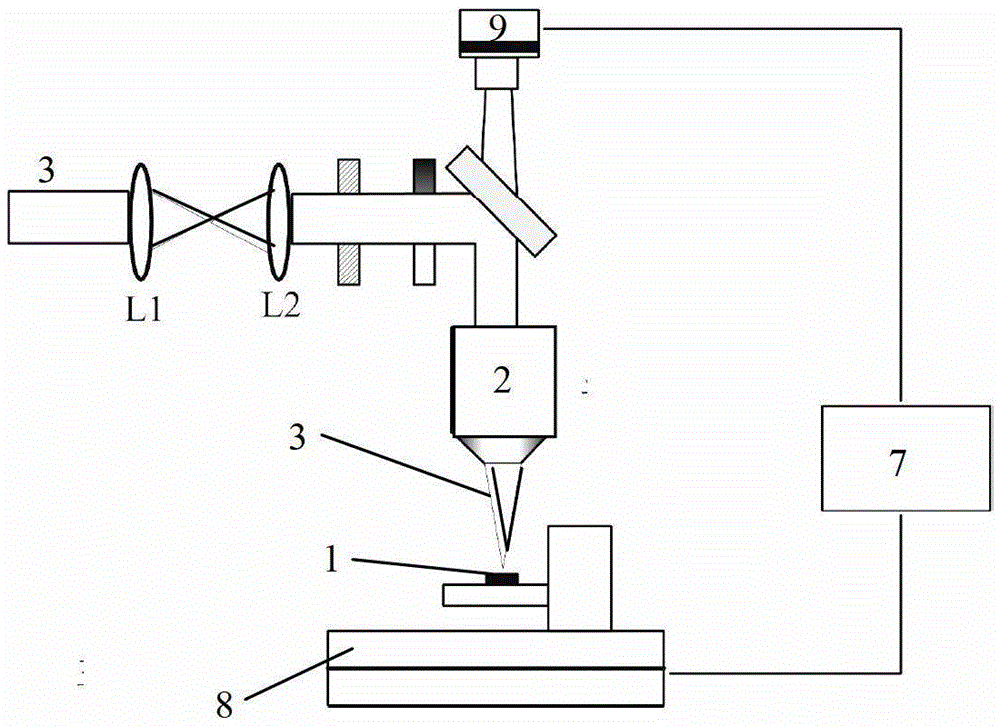

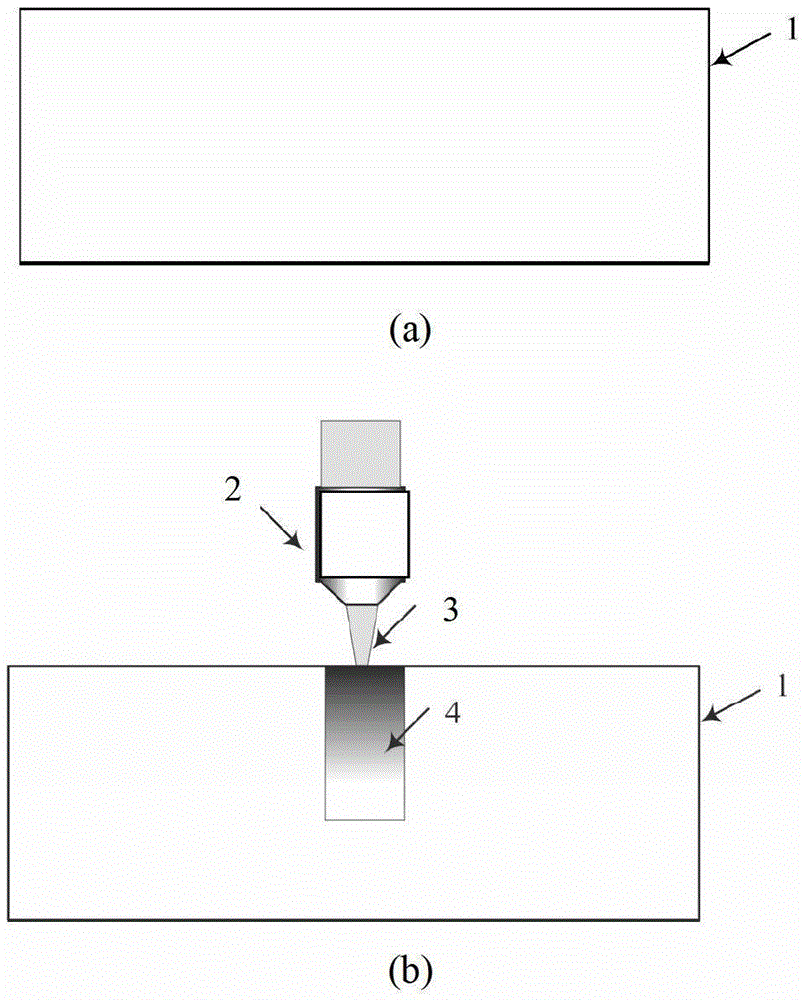

Silicon microstructure processing method based on femtosecond laser treatment and wet etching

ActiveCN103232023ASimple processHigh aspect ratioDecorative surface effectsSemiconductor/solid-state device manufacturingRefractive indexOxygen

The invention discloses a silicon microstructure processing method based on femtosecond laser treatment and wet etching. The method comprises the steps of scanning a monocrystal silicon substrate by using a femtosecond laser at an oxygen-containing gas atmosphere; inducing silicon to generate refractive index change in a scanning region; and then, etching by using a hydrofluoric acid wet process to remove a refractive index change region to form a silicon microstructure. The method disclosed by the invention is simple in process; compared with the prior art, the method has the advantage that a distribution drawing of the microstructure does not need to be defined by using a mask plate; compared with the ordinary wet etching and dry etching, the method has the advantages that the corrosion selectivity is good, the etching region is completely determined by a femtosecond laser processing region, and no sidewise underetching exists; and a silicon slot with high depth-to-width ratio and large depth can be obtained during deep silicon slot processing. The method disclosed by the invention can be applied to a micro-electro-mechanical system.

Owner:XI AN JIAOTONG UNIV

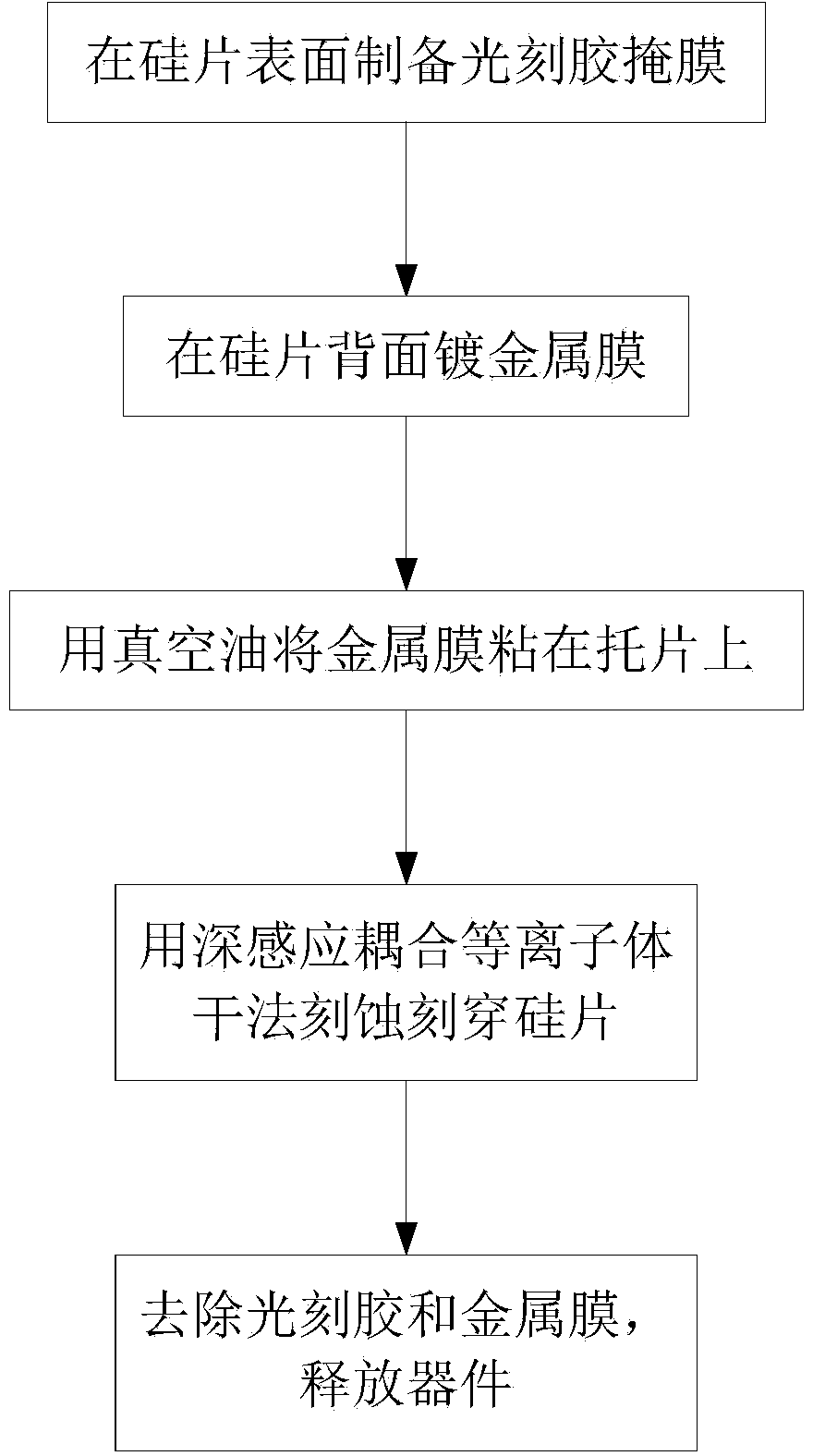

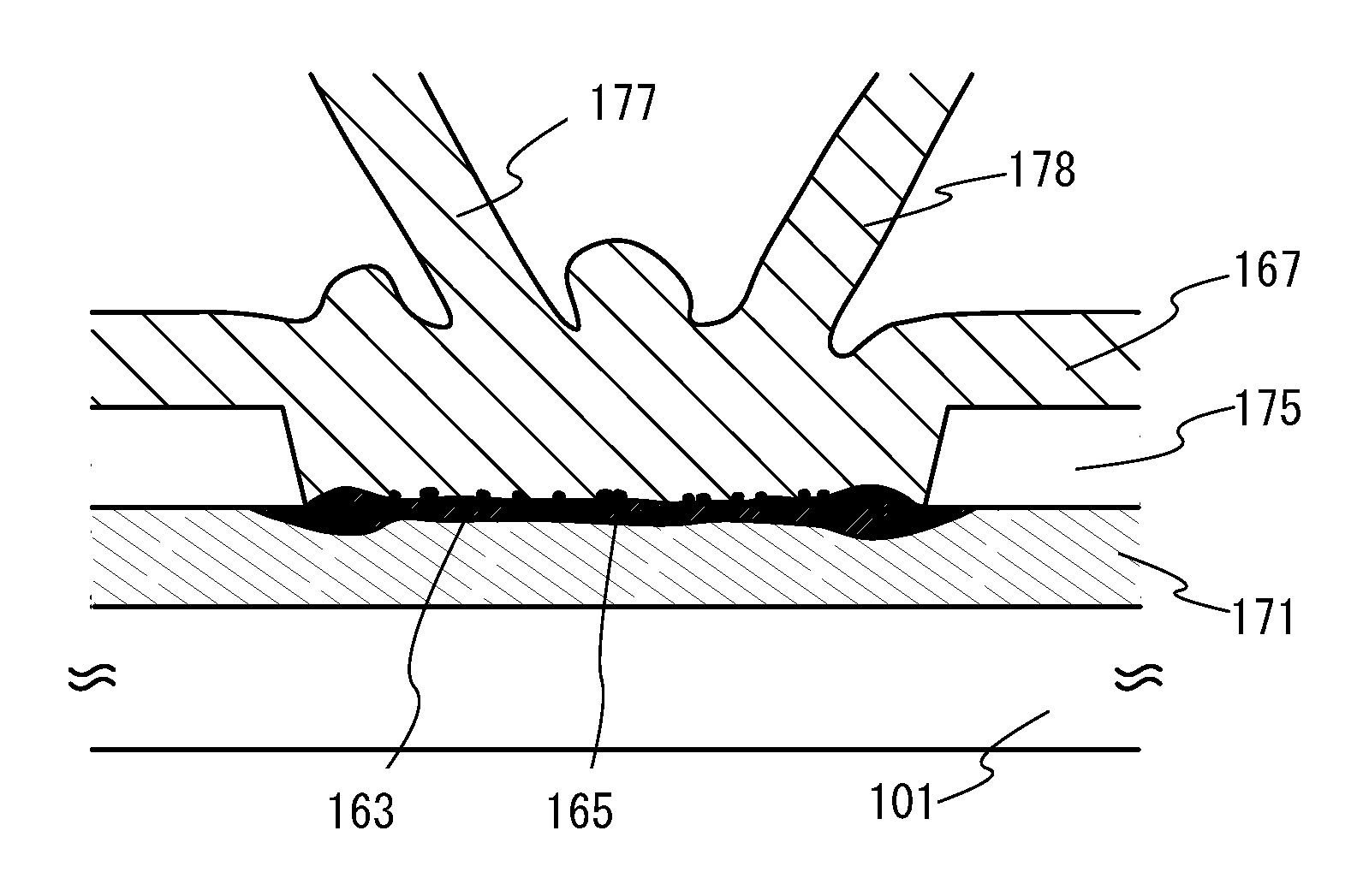

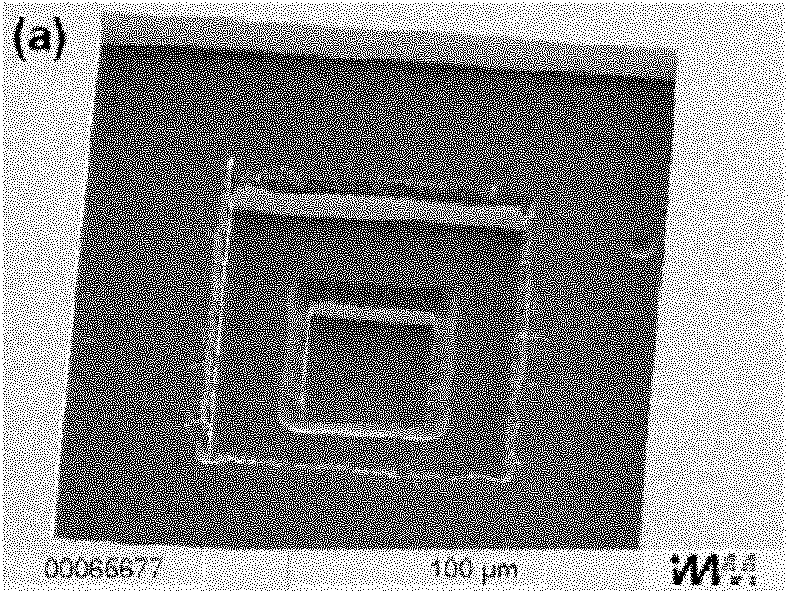

Bulk silicon machining process based on silicon chip etching and puncturing

ActiveCN103896206AAchieve physical bombardmentReduce physical bombardmentDecorative surface effectsChemical vapor deposition coatingInductively coupled plasmaMachining process

The invention discloses a bulk silicon machining process based on silicon chip etching and puncturing, which comprises the following steps of preparing a patterned photoresist mask on the surface of a silicon chip; putting a metal film on the back surface of the silicon chip; adhering the metal film to a supporting chip by using vacuum oil, wherein the supporting chip is a silicon chip with an oxide layer on the surface; etching and puncturing the silicon chip to obtain a bulk silicon microstructure by using an inductively coupled plasma dry-etching system, wherein a staged etching method is adopted for inductive coupled plasma dry-etching, and comprises a plurality of etching stages each of which is alternately and cyclically implemented by three steps of passivation, bombardment and etching in an inductive coupled plasma machine, and along with the increasing of the etching depth, the bombardment intensity of the bombardment step in each etching stage is gradually enhanced; removing the photoresist mask and the metal film, and releasing the bulk silicon microstructure. According to the process, the selection ratio of photoresist, the etching depth and the perpendicularity of the sidewall of an etching groove can be effectively increased.

Owner:HUAZHONG UNIV OF SCI & TECH

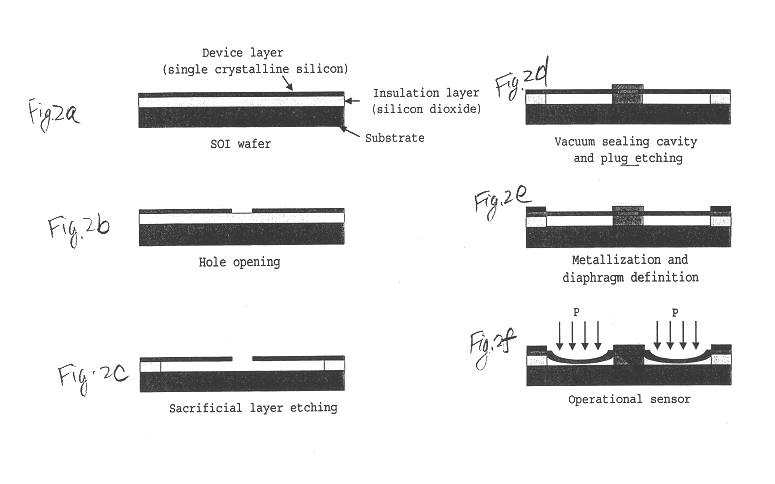

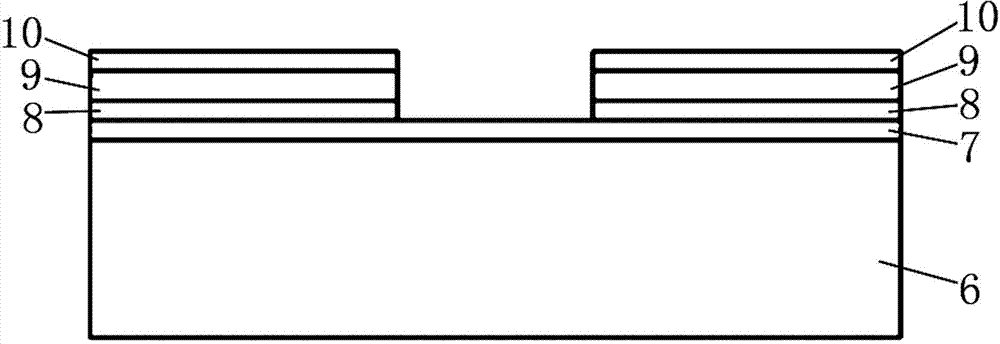

FBAR (Film Bulk Acoustic Resonator) and preparation method thereof

InactiveCN106130498ASimple structureSimple preparation processImpedence networksAtmospheric pressureMechanical property

The invention discloses a FBAR (Film Bulk Acoustic Resonator) and a preparation method thereof, and in particular relates to a FBAR based on an MEMS micromachining technology. An epitaxial mono-crystal silicon process is mature; a formed silicon microstructure is good in mechanical property; particularly, the sealing property of a cavity structure formed by using epitaxial mono-crystal silicon is very excellent; therefore, the resonant frequency of the formed FBAR is mainly determined by the thickness of a film bulk, and influenced by environment temperature; the resonant frequency of the FBAR is reduced with the increase of the temperature; furthermore, the obvious monotony is displayed; the property can be used for data detection, such as temperature and pressure; and, in combination with the MEMS micromachining technology, the FBAR is small in size, low in cost and short in response time.

Owner:HOHAI UNIV CHANGZHOU

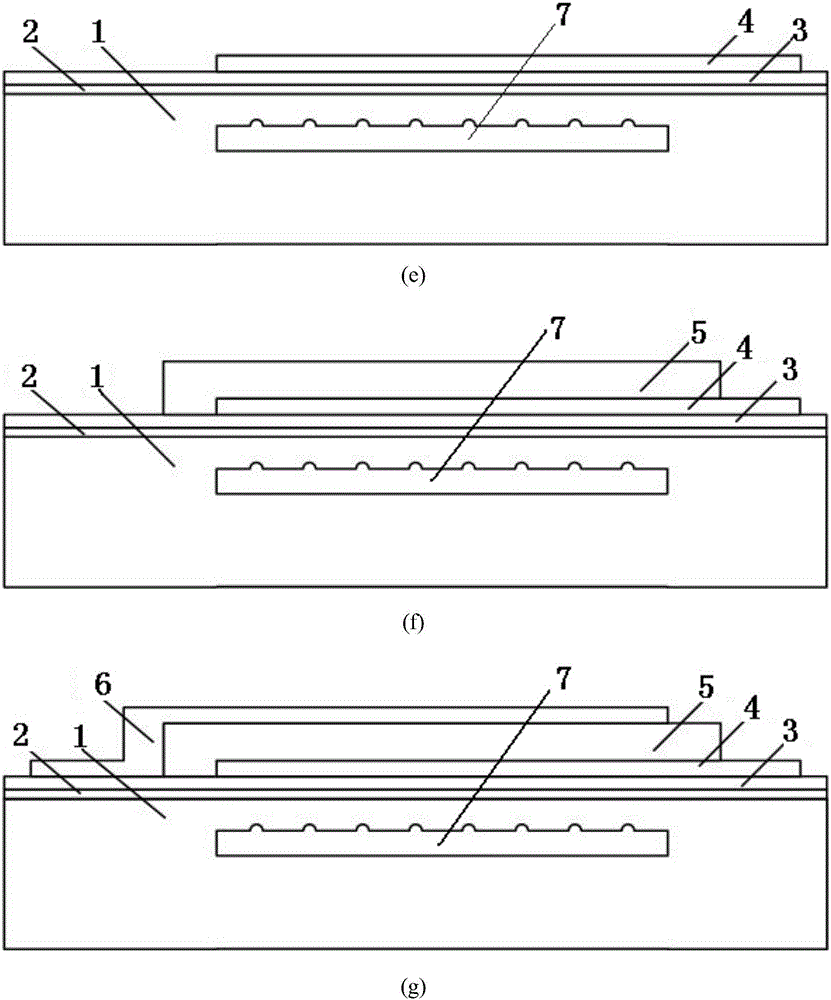

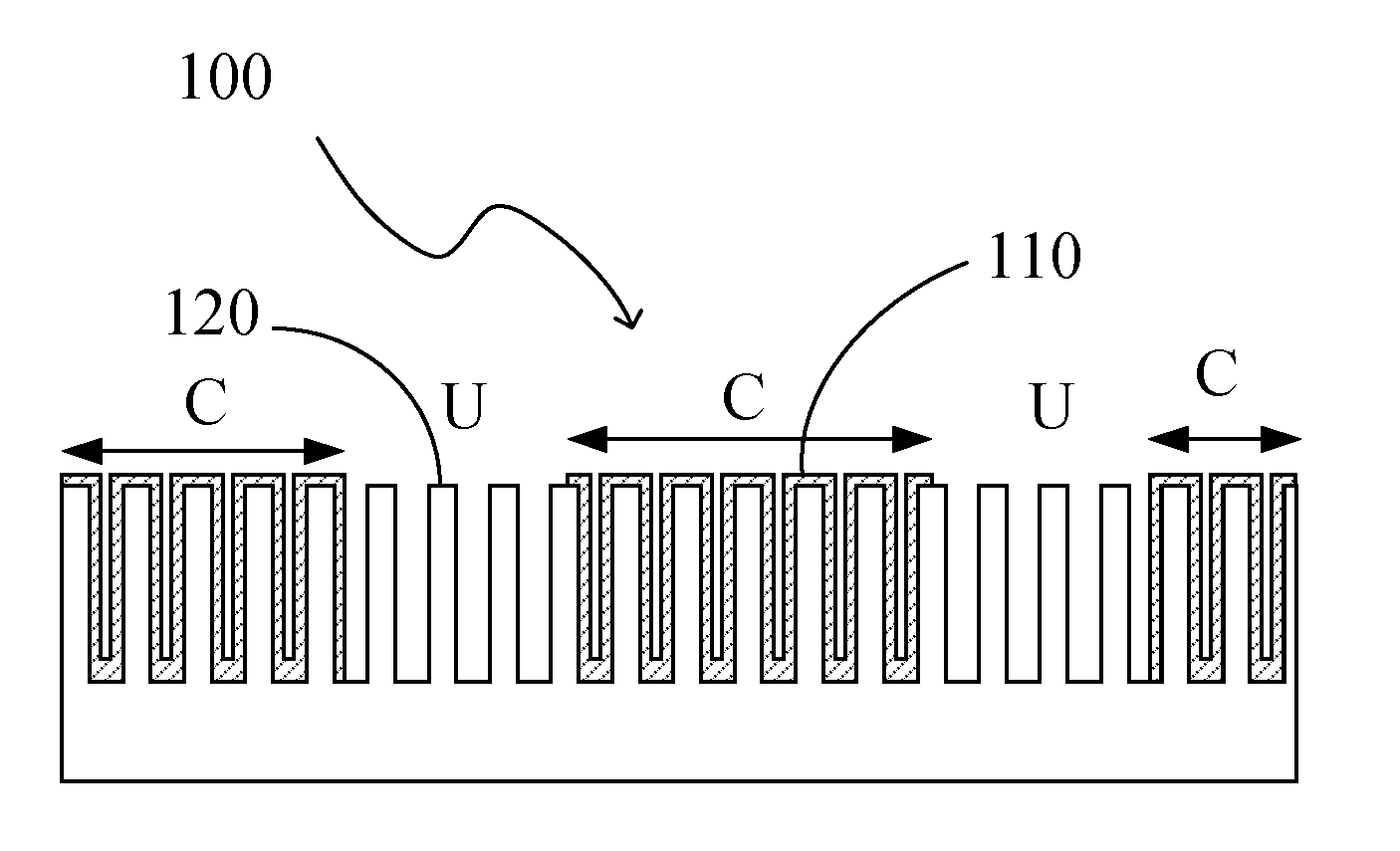

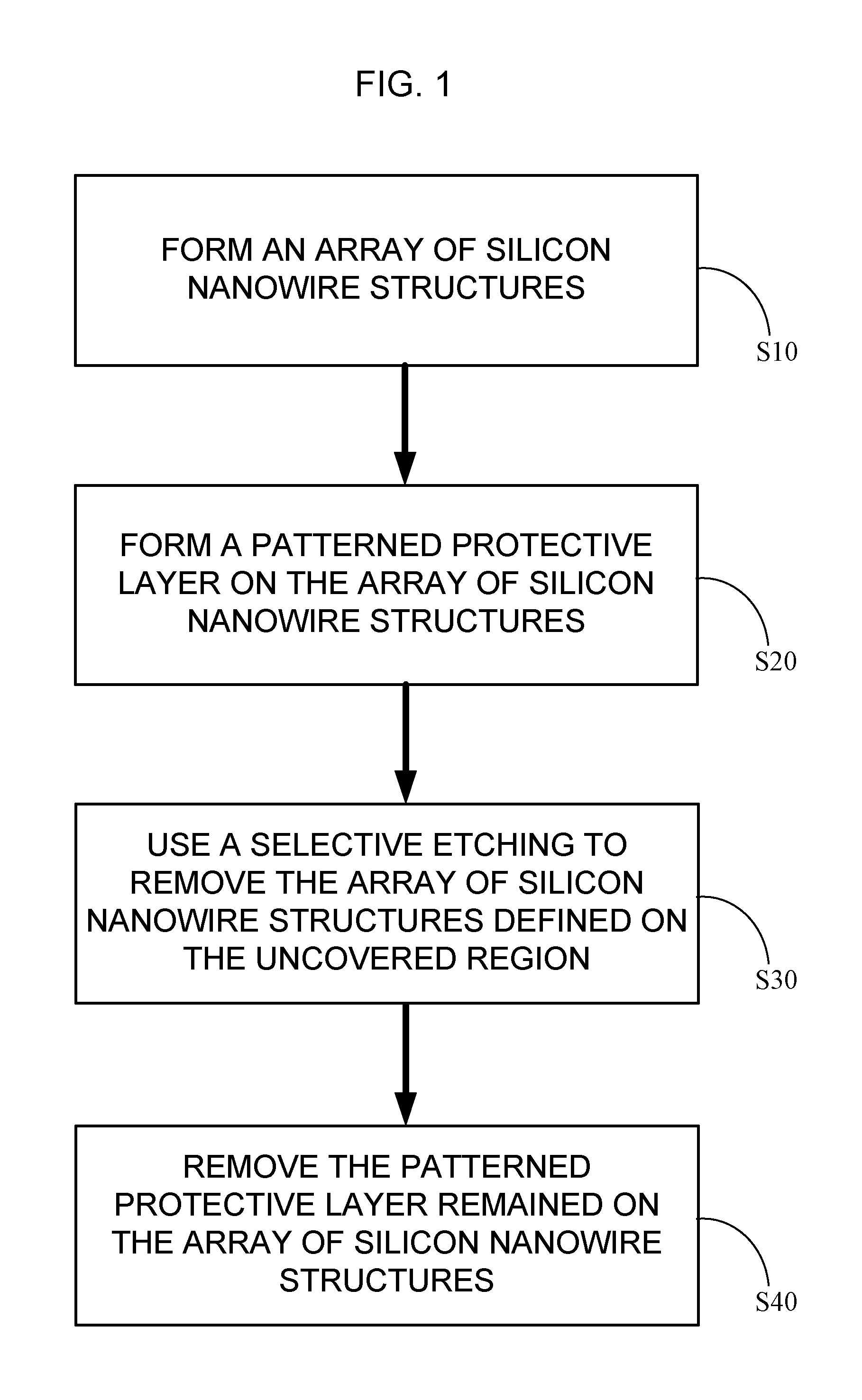

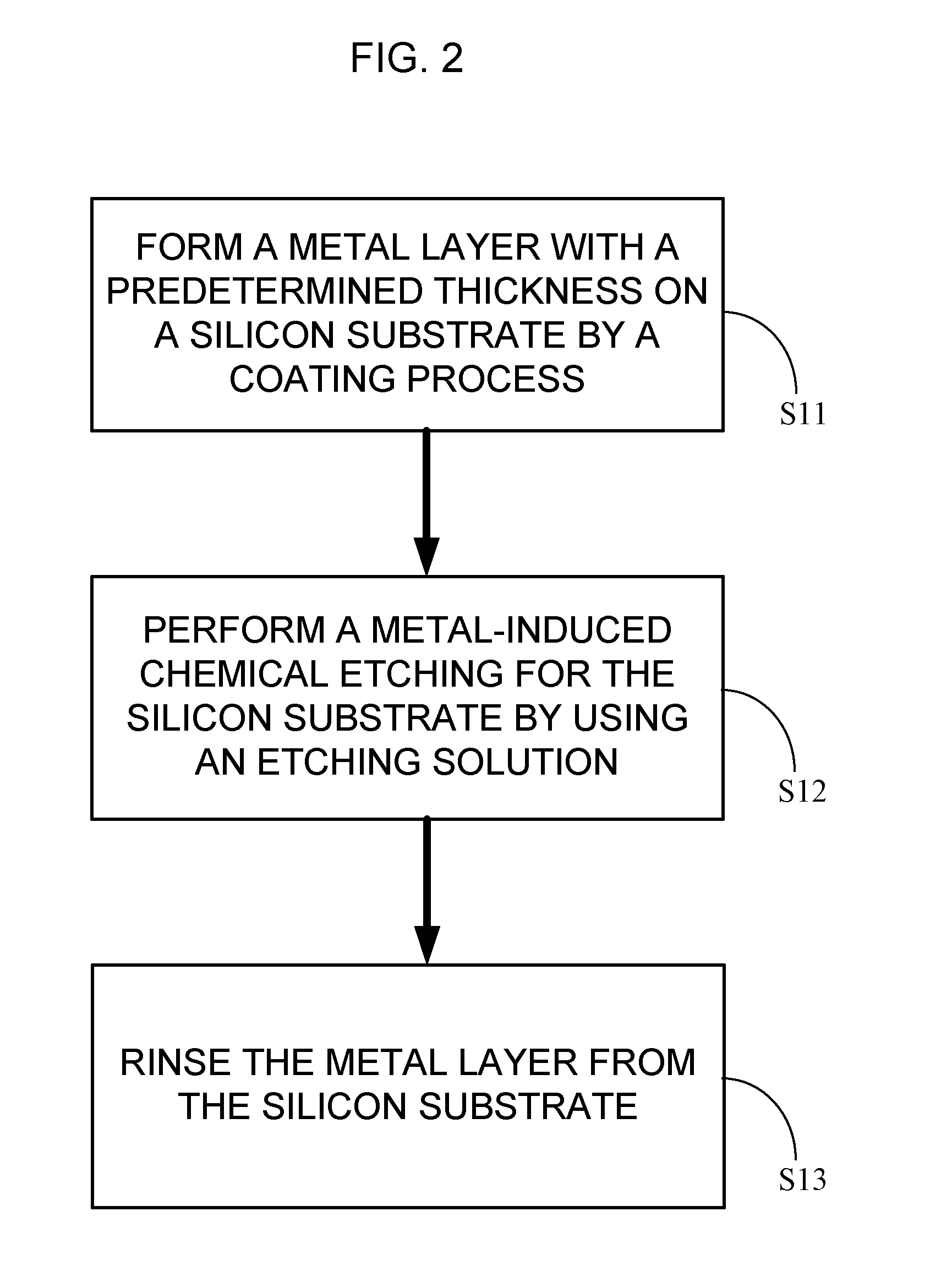

Method for fabricating patterned silicon nanowire array and silicon microstructure

InactiveUS20140030873A1Easily and low-costly manufacturingElectric discharge tubesNanoinformaticsEtchingSilicon nanowires

A method for fabricating a patterned silicon nanowire array is disclosed. The method includes: forming a patterned protective layer on silicon nanowire array structures, forming a patterned protective layer on the array of silicon nanowire structures, the patterned protective layer defining a covered region and a uncovered region on the array of silicon nanowire structures; using a selective etching to remove the array of silicon nanowire structures defined on the uncovered region; and removing the patterned protective layer remained on the array of silicon nanowire structures. A method for fabricating a silicon microstructure is also disclosed.

Owner:NAT TAIWAN UNIV OF SCI & TECH

Microelectronic air pressure sensor and preparation method therefor

InactiveCN106586942AReduce volumeReduce power consumptionDecorative surface effectsChemical vapor deposition coatingCapacitanceElectricity

The invention discloses a microelectronic air pressure sensor based on the technology of monocrystalline silicon epitaxial cavity sealing and a preparation method for the microelectronic air pressure sensor, specifically a capacitive-type air pressure sensor based on the MEMS micromachining technique. Because the epitaxial monocrystalline silicon technology is mature, a formed silicon microstructure is good in mechanical performances, and especially the cavity structure formed through the epitaxial monocrystalline silicon technology is excellent in sealing performance. Therefore, the capacitance of the capacitive-type air pressure sensor is mainly determined by the thickness of a film, and is affected by the environment temperature and pressure. Based on the theory of the dielectric flexible effect, the dielectric constant of a capacitor dielectric material changes with the withstood pressure, and is monotonous apparently. The above characteristic can achieve the data detection of pressure or air pressure. Combining with the MEMS micromachining technique, the sensor is small in size, is low in power consumption, and is short in response time.

Owner:HOHAI UNIV CHANGZHOU

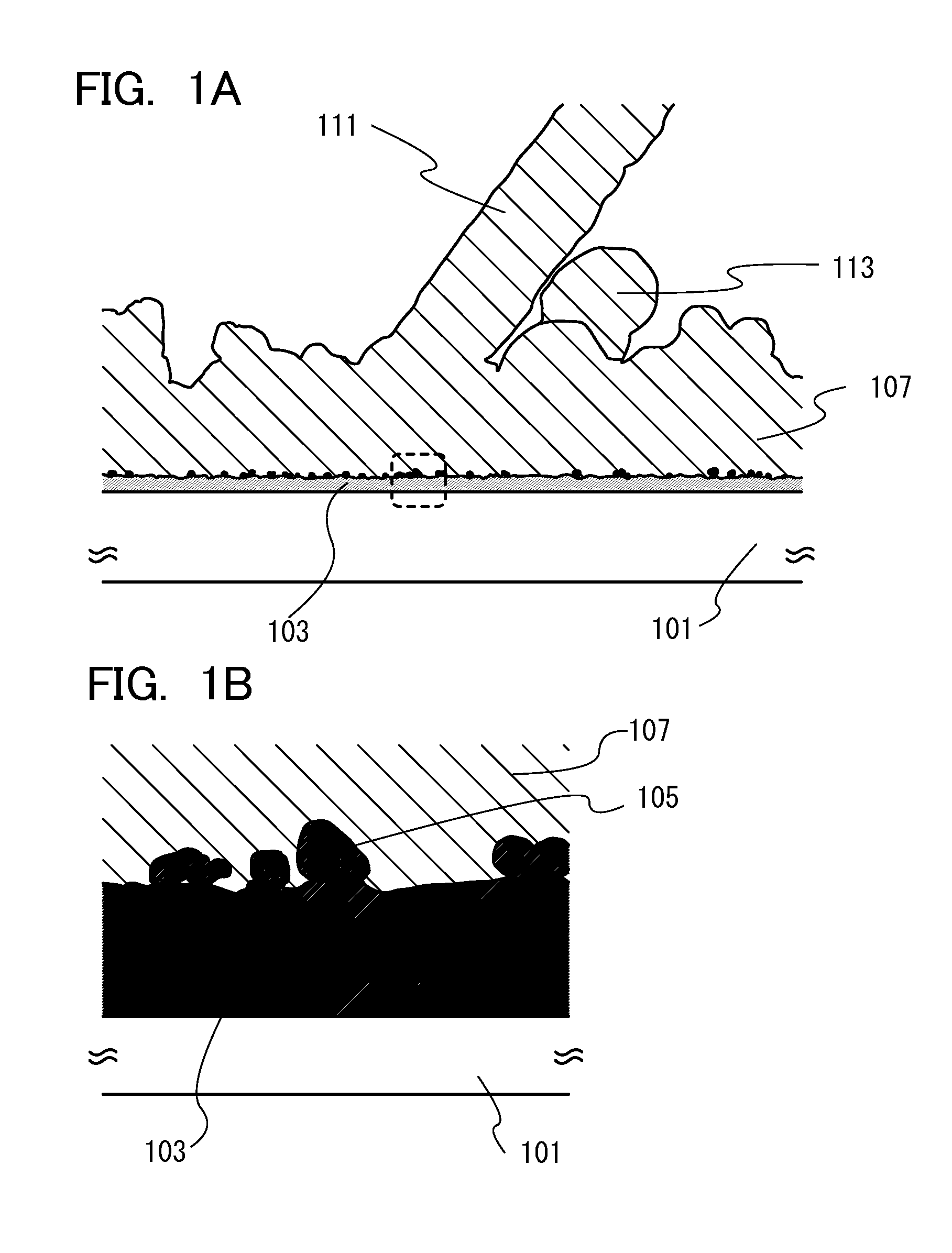

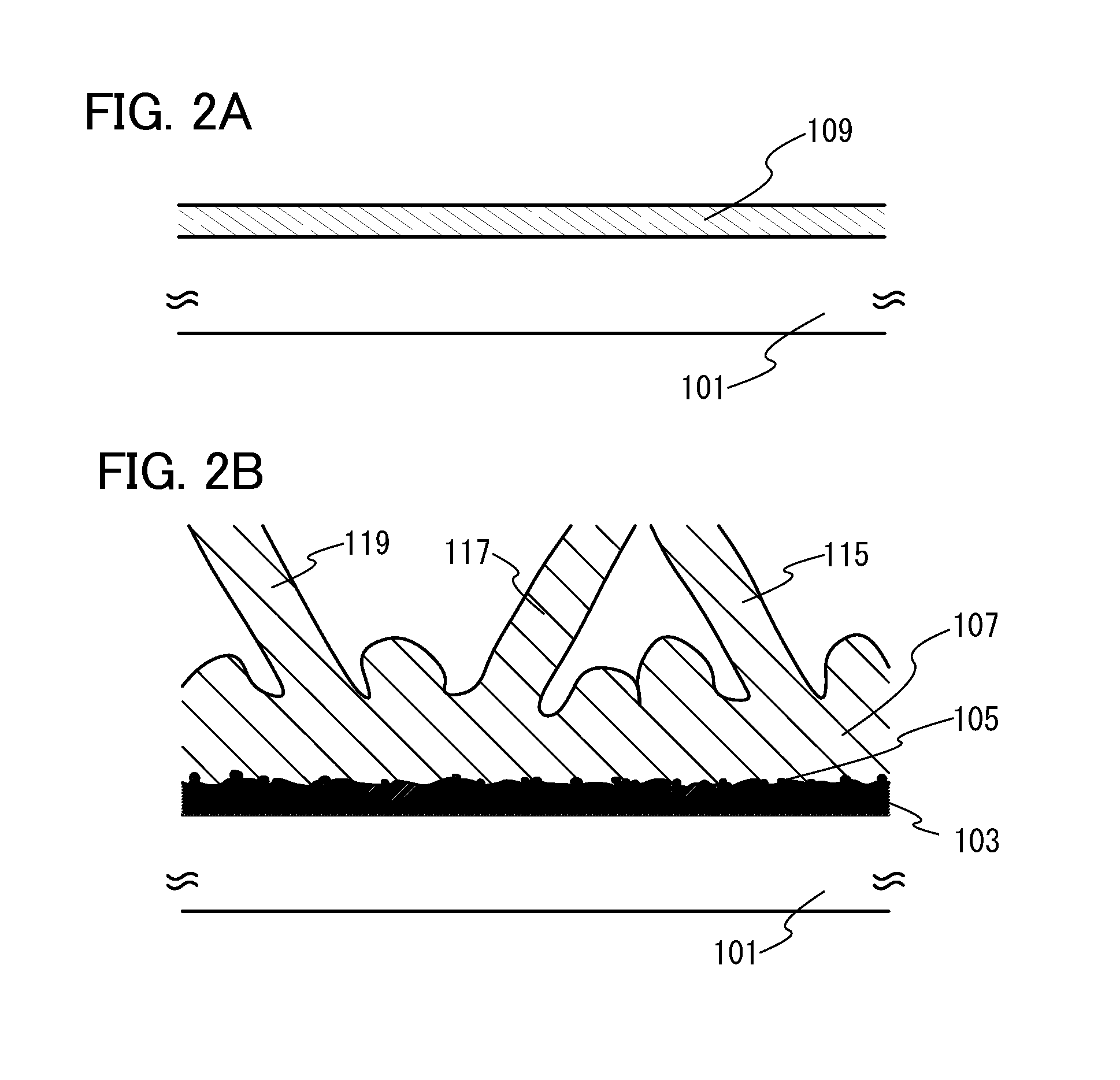

Semiconductor film, method for manufacturing the same, and power storage device

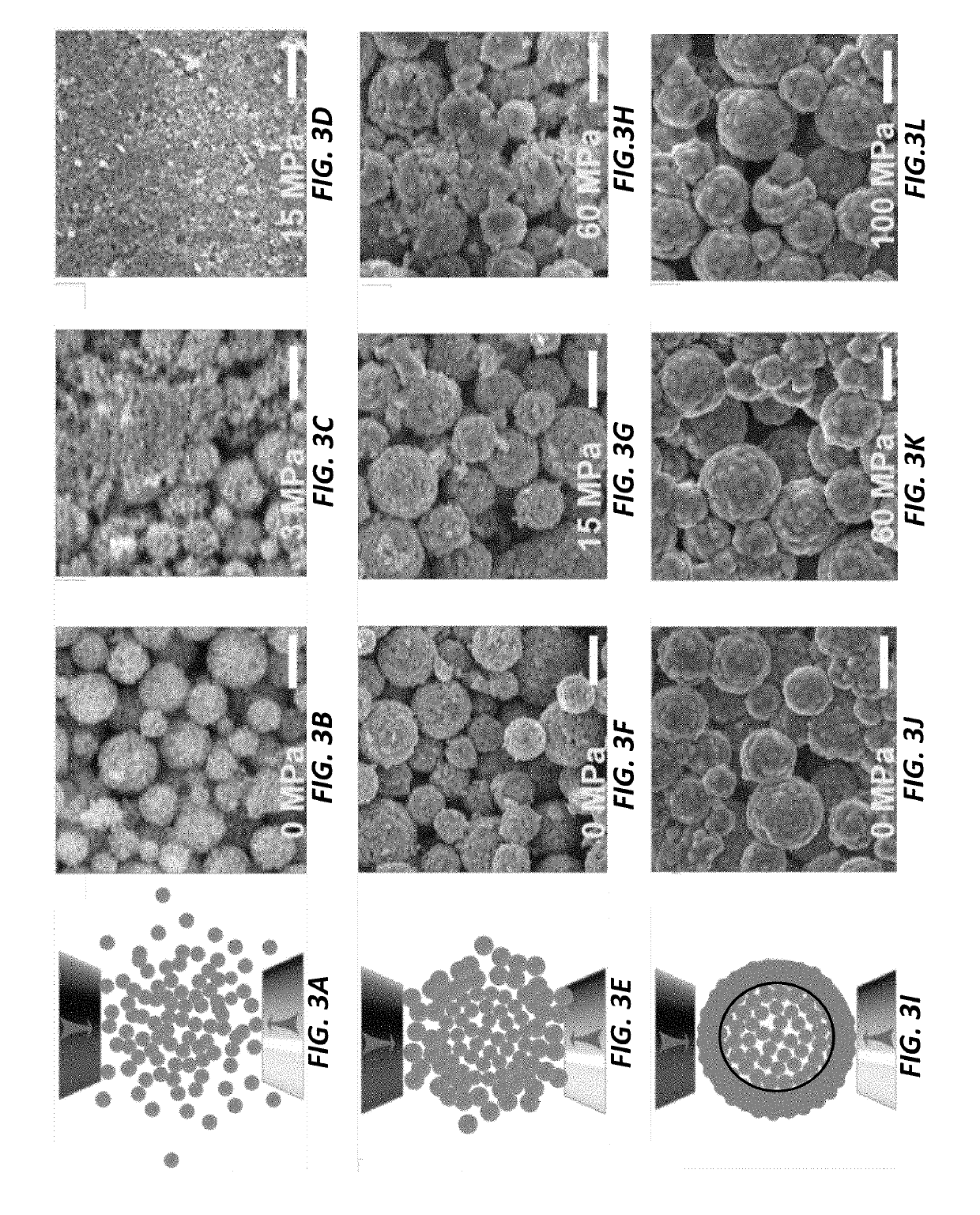

ActiveUS20120135302A1High charge and discharge capacityEnhanced vapor depositionHybrid capacitor electrodesSemiconductor/solid-state device detailsHigh densityCharge discharge

Provided are a semiconductor film including silicon microstructures formed at high density, and a manufacturing method thereof. Further, provided are a semiconductor film including silicon microstructures whose density is controlled, and a manufacturing method thereof Furthermore, a power storage device with improved charge-discharge capacity is provided. A manufacturing method in which a semiconductor film with a silicon layer including silicon structures is formed over a substrate with a metal surface is used. The thickness of a silicide layer formed by reaction between the metal and the silicon is controlled, so that the grain sizes of silicide grains formed at an interface between the silicide layer and the silicon layer are controlled and the shapes of the silicon structures are controlled. Such a semiconductor film can be applied to an electrode of a power storage device.

Owner:SEMICON ENERGY LAB CO LTD

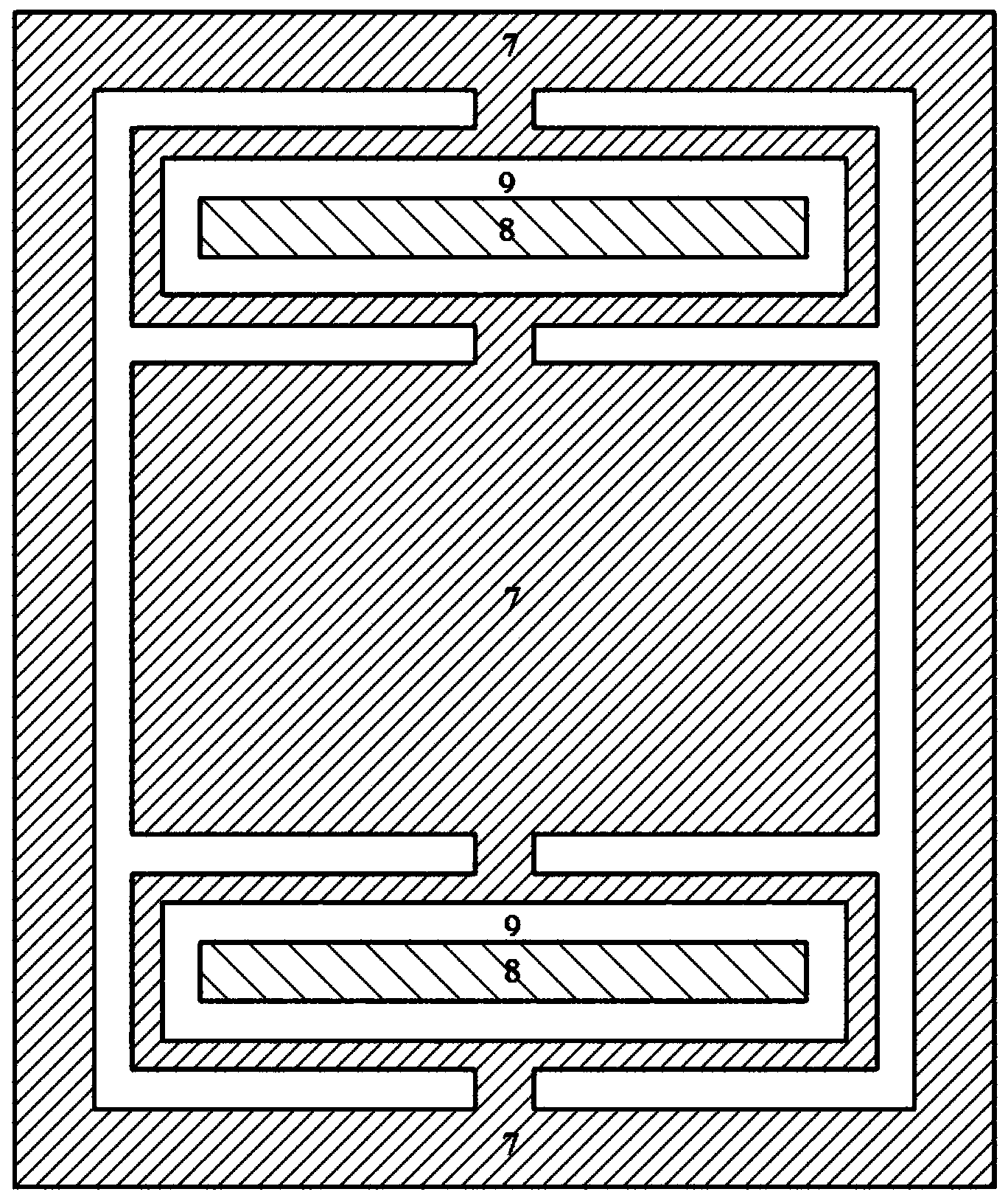

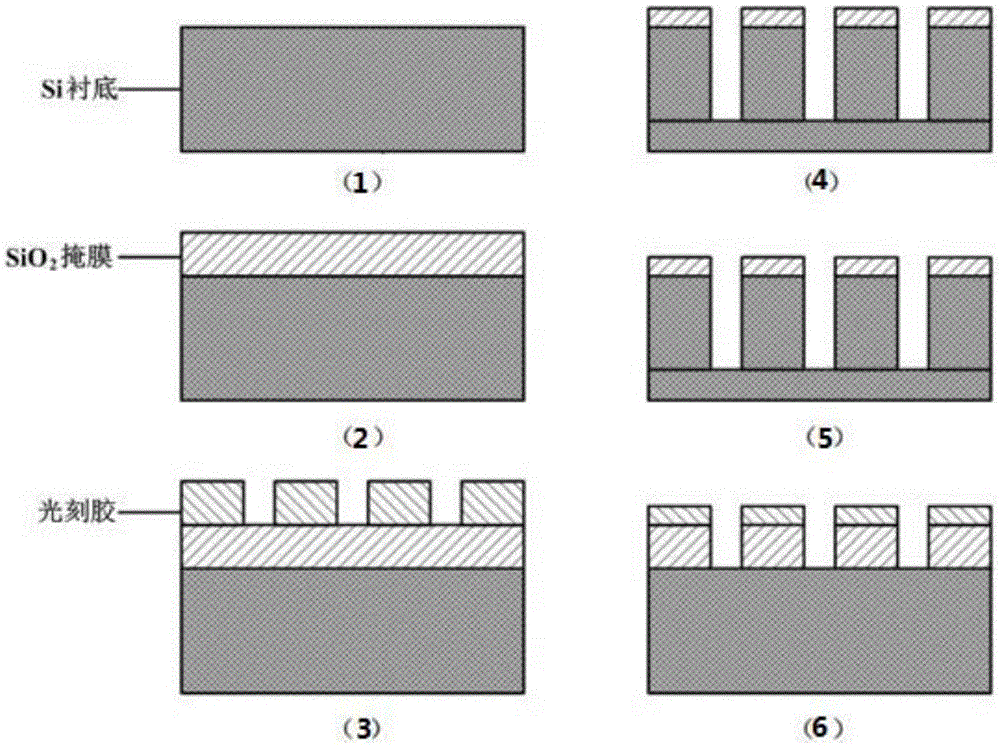

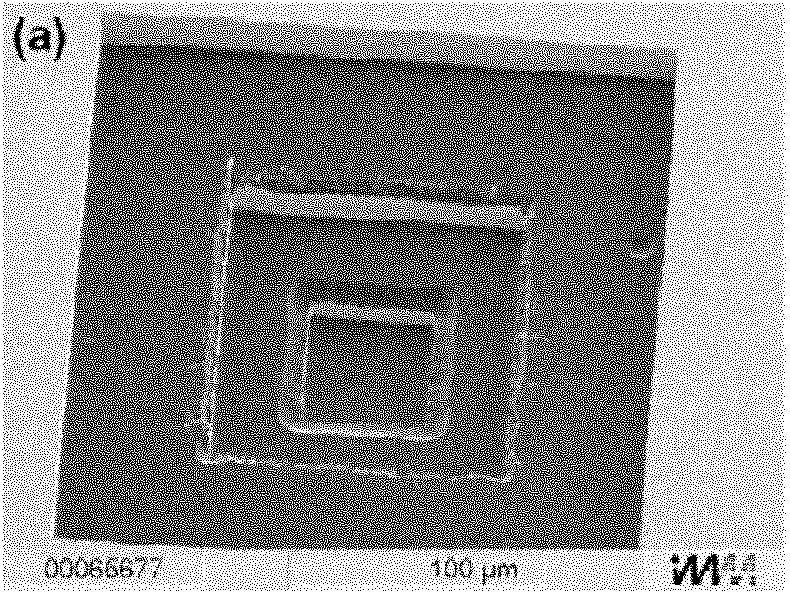

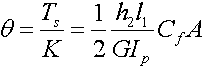

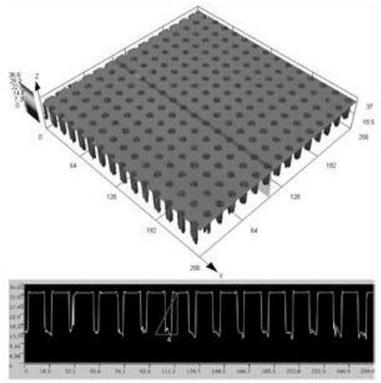

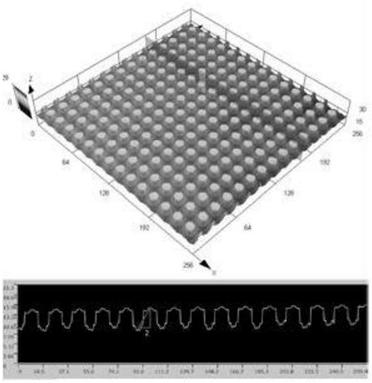

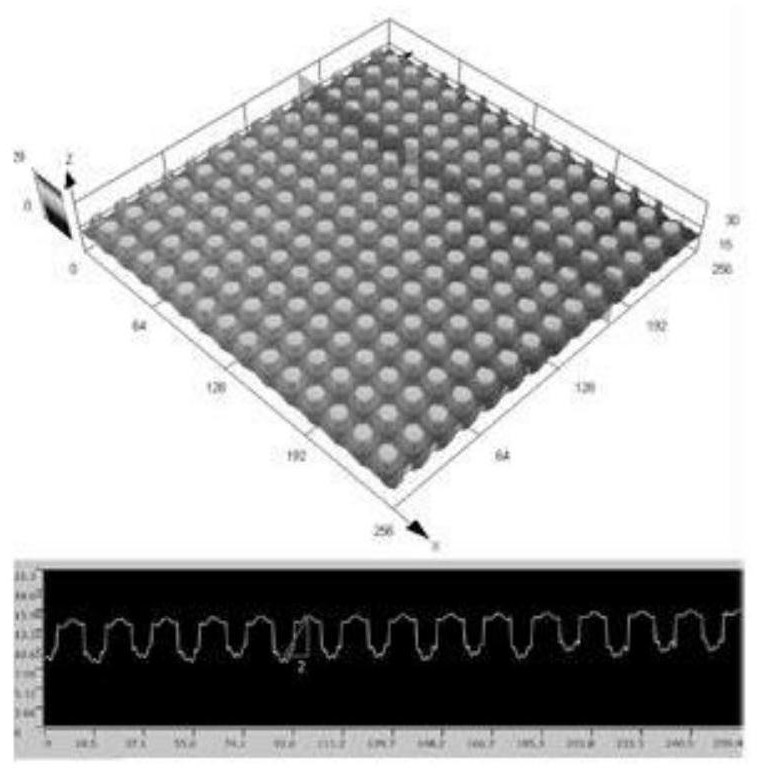

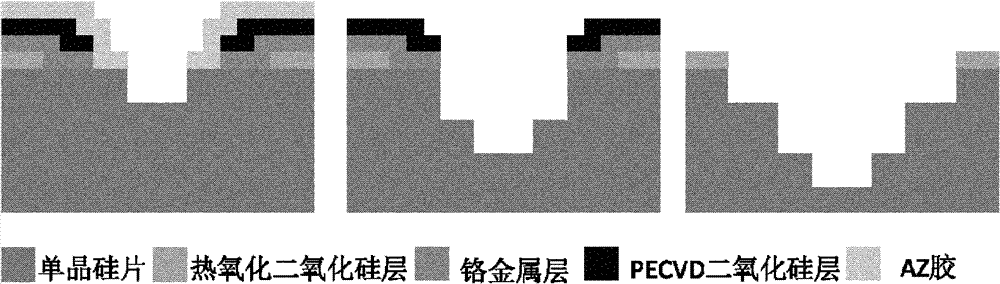

Method for preparing high aspect ratio silicon microstructure on basis of deep reactive ion etching technology

InactiveCN105600740AFacilitate transitionEtch fastDecorative surface effectsChemical vapor deposition coatingTime ratioHigh surface

The invention discloses a method for preparing a high aspect ratio silicon microstructure on the basis of a deep reactive ion etching technology. The method adopts a photoresist / SiO2 composite mask to achieve high perpendicularity, low roughness etching and accurate pattern transfer of the high aspect ratio structure, and a high aspect ratio of the high aspect ratio silicon microstructure prepared by the method can reach over 100:1. By controlling etching parameters of gas flow, an etching and passivation time ratio, etching power and the like, processing on the high aspect ratio three-dimensional silicon microstructure is achieved. The method solves the technical difficult problems of small surface area, poor side wall perpendicularity, serious drill etching phenomenon, high surface roughness and the like. The three-dimensional silicon microstructure has the characteristics of large capacity-volume ratio, high reliability and the like, is very suitable for MEMS (Micro Electro Mechanical System) energy storage devices, and meets the development requirements for microminiaturization, intelligence and integration of an energy system.

Owner:苏州工业园区纳米产业技术研究院有限公司

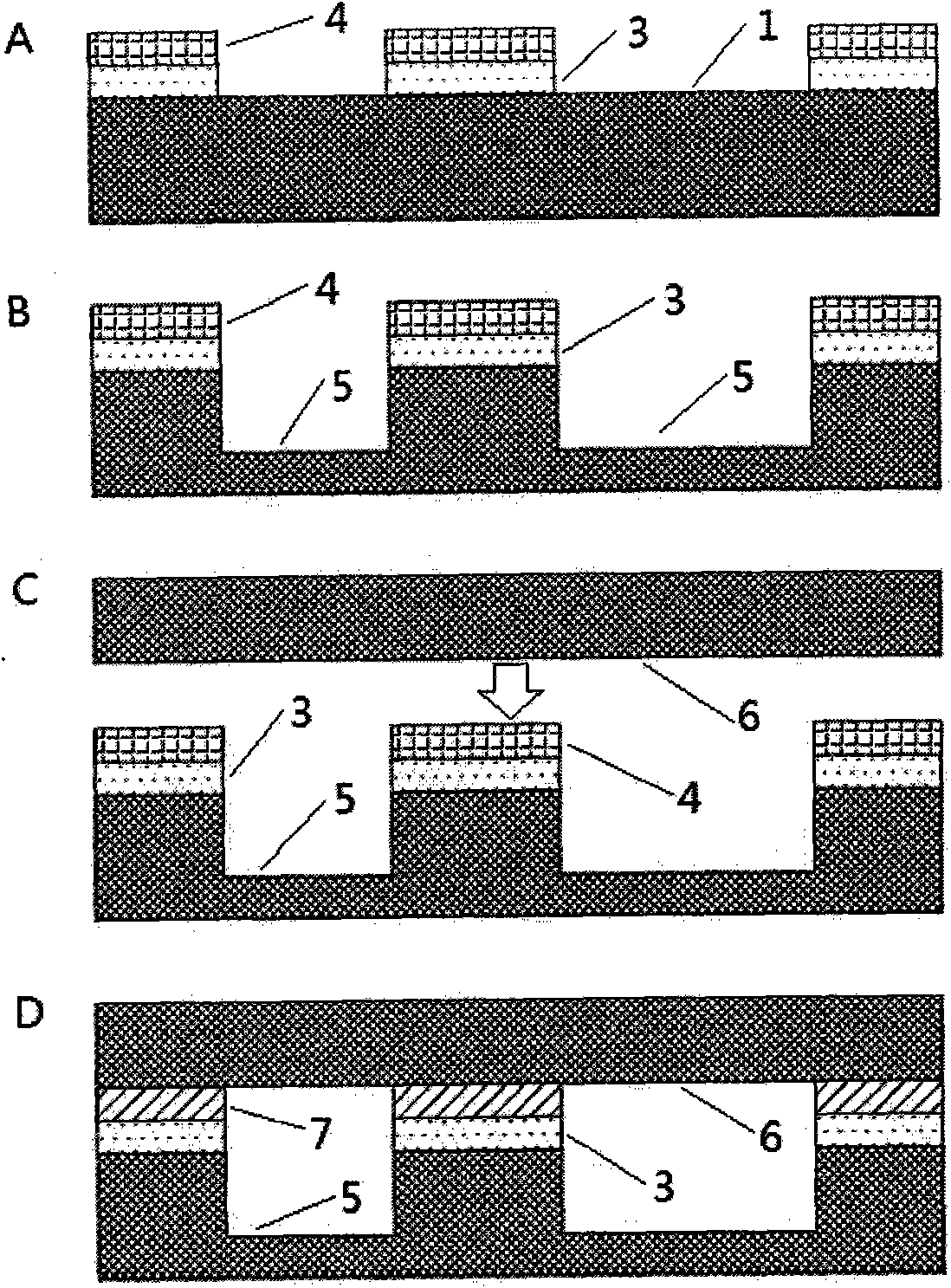

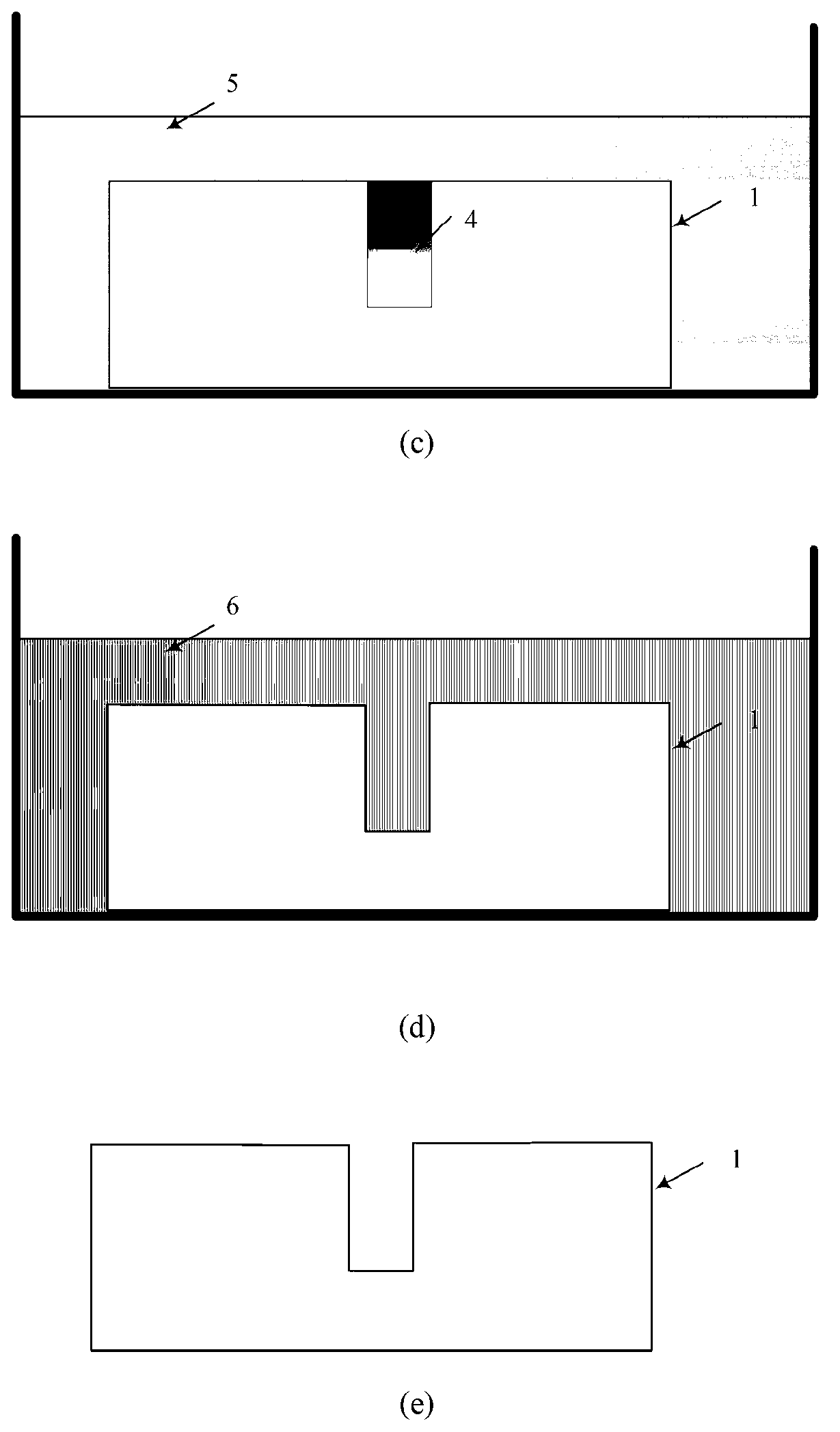

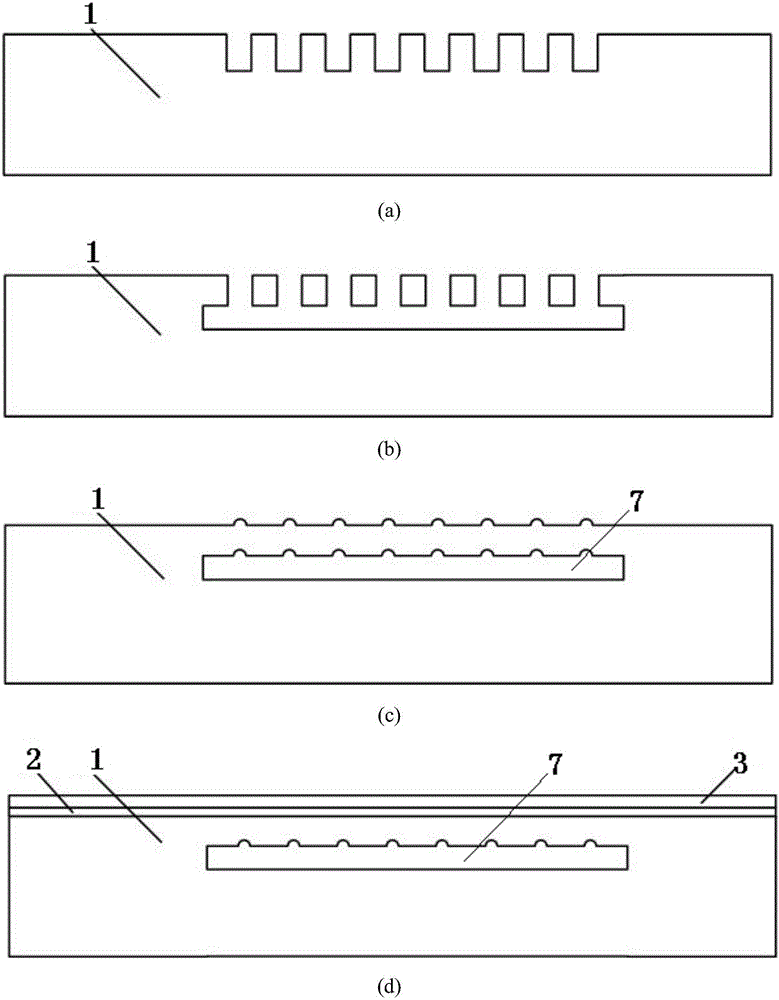

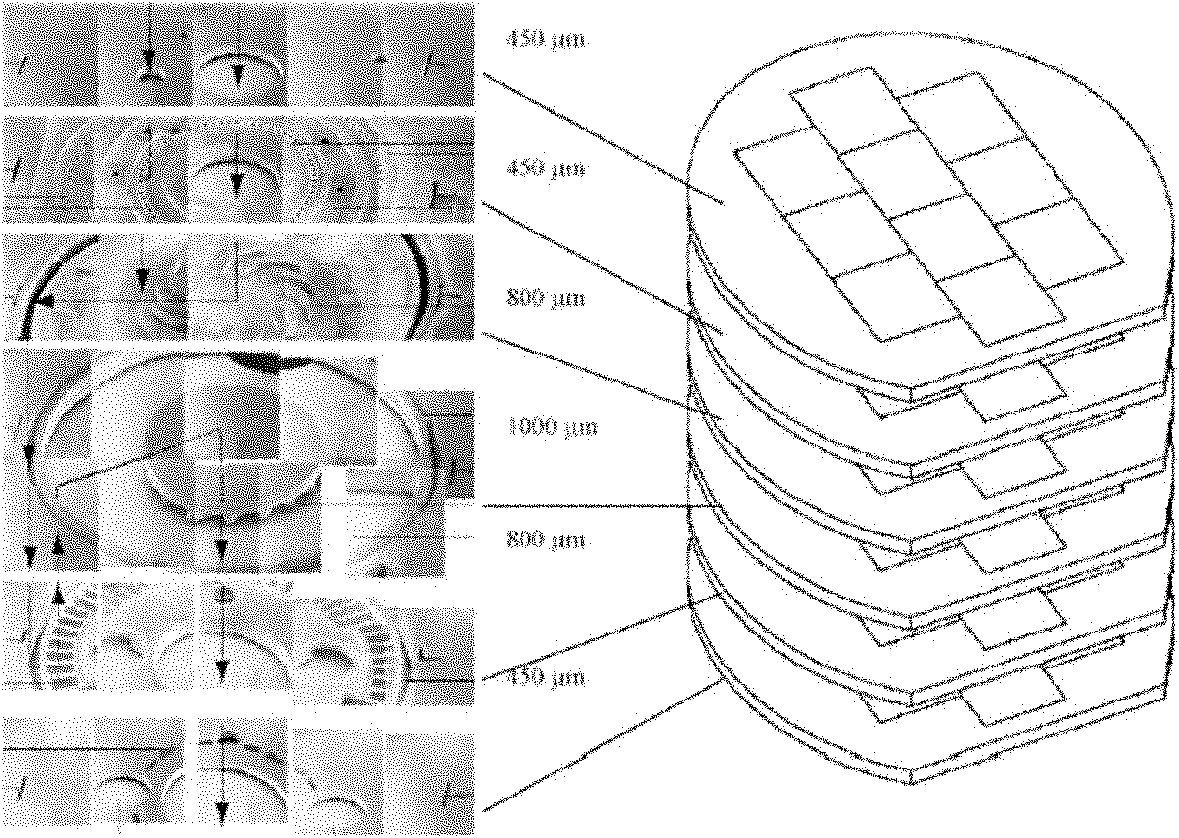

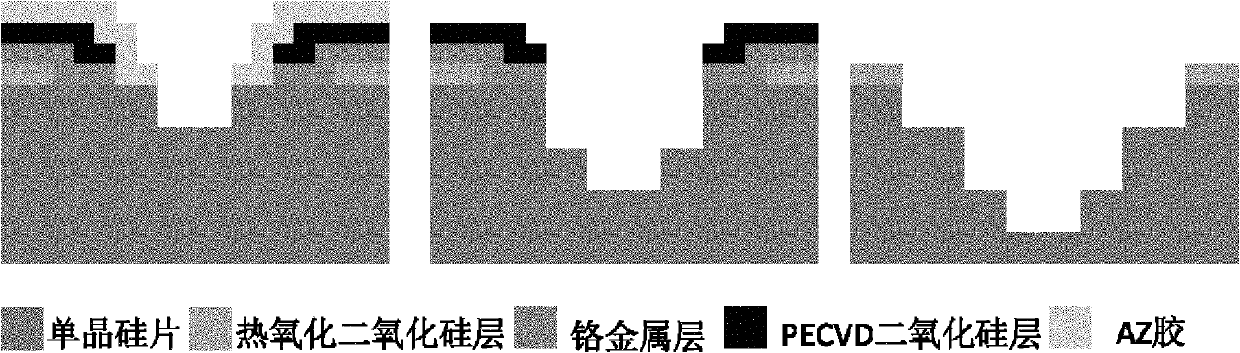

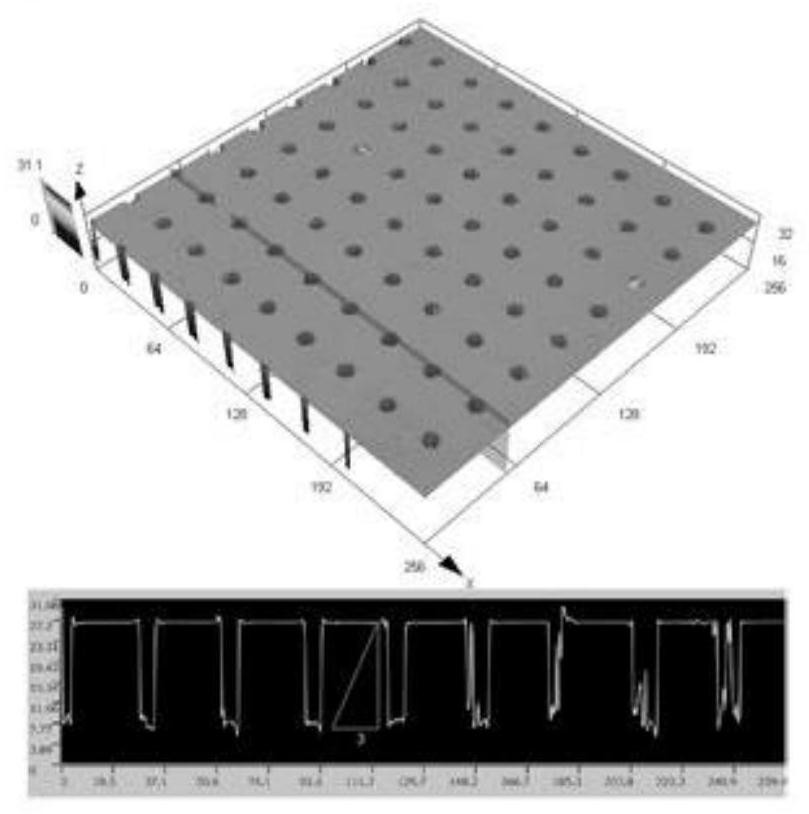

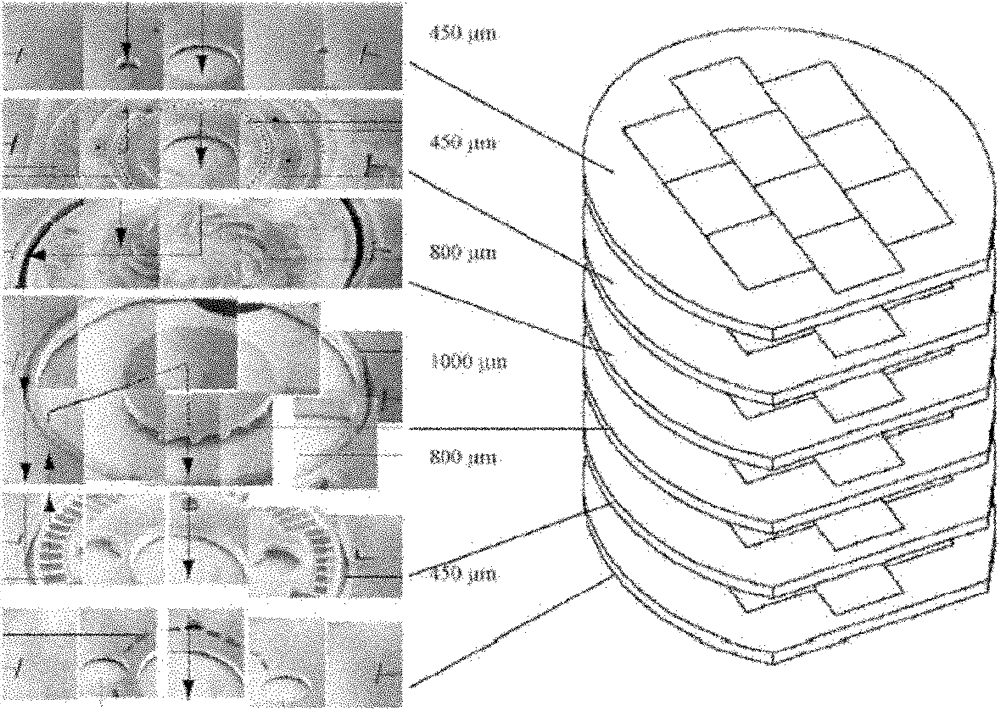

Masking method for deep-etching multi-layer silicon structure by dry method

InactiveCN102001618AHigh dimensional accuracyPerfect edge structureDecorative surface effectsPhotomechanical apparatusEtchingPhysical chemistry

The invention discloses a masking method for deep-etching a multi-layer silicon structure by a dry method. The masking method comprises the following steps of: A, photoetching an Az positive photoresist pattern; B, performing the deep-etching on a silicon structure by taking the obtained Az positive photoresist pattern as a mask; C, cleaning the Az mask and the silicon structure, and coating a first layer of Su8 negative photoresist; D, photoetching the Su8 photoresist to obtain a mask pattern of a lower structure by an alignment mark; and E, deep-etching a lower silicon structure by taking the pattern obtained from the step D as the mask; and repeating the steps to obtain the multi-layer silicon microstructure with greater structure depth. The method has the advantages that: because the Su8 photoresist is selected as the mask for deep reactive ion etching of the inductively coupled plasmas, an effect of protecting an etched structure is achieved and the direct physical bombardment of ions caused by exposing a previous etching structure in the plasmas is effectively avoided; and the method has high process repeatability, can be used in the same component repeatedly and realizes three or more layers of monocrystalline silicon microstructures with a high aspect ratio.

Owner:TIANJIN SEAGULL WATCH CO LTD +1

Method for fabricating MEMS friction sensor based on visual alignment

ActiveCN108467007AImprove assembly accuracyHigh precisionDecorative surface effectsForce measurement using piezo-resistive materialsVision basedHemt circuits

The invention discloses a method for fabricating a MEMS friction sensor based on visual alignment. The MEMS friction sensor is decomposed into five parts of a floating component, a silicon microstructure, an electrode substrate, an interface circuit and a package tube. The silicon microstructure and the electrode substrate are fabricated by a MEMS process, the floating component and the package tube are fabricated by precision machining processing technology, and the interface circuit is fabricated by ceramic-based precision micro-strip circuit technology. The MEMS friction sensor uses specialmicro-assembly equipment and micro-assembly process, the micro-assembly equipment consists of a precision vision positioning system, a three-degree-of-freedom micro-operation alignment platform, a vacuum nozzle and an image recognition system, and the assembly of the MEMS friction sensor is completed by using the visual precision positioning and micro-operation alignment technology. The method for fabricating the MEMS friction sensor based on visual alignment provided by the invention improves the processing and assembly precision of the MEMS friction sensor, thereby improving the accuracy ofmeasuring the frictional resistance of the surface in the hypersonic wind tunnel.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

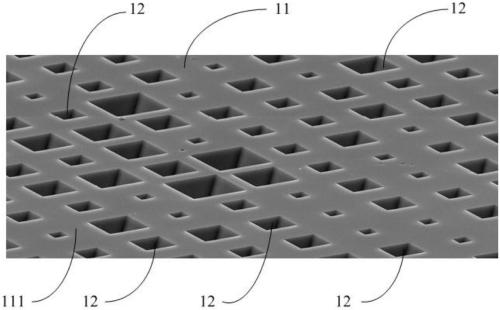

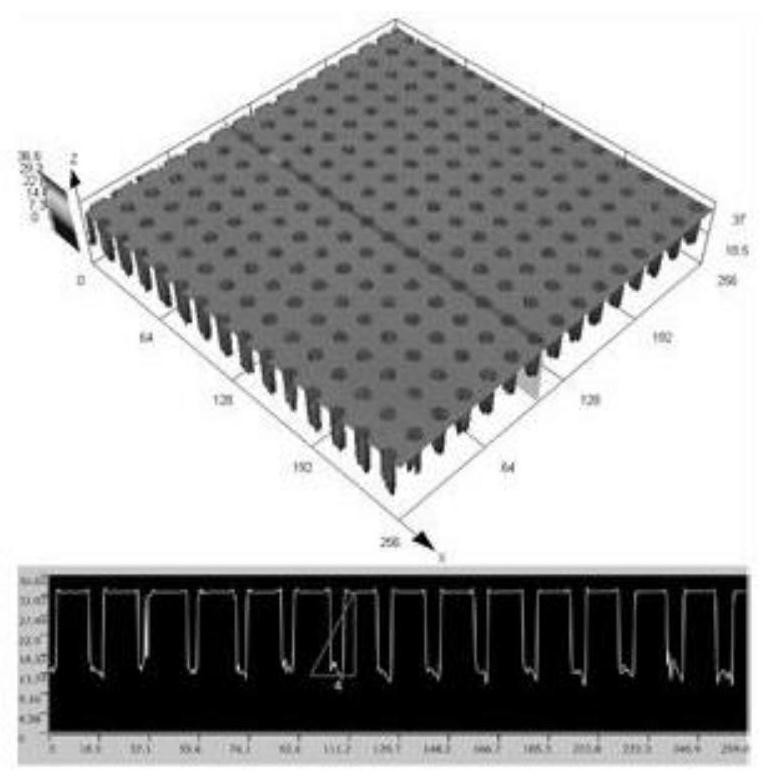

Preparation method of microstructure surface with alternate hydrophilic-hydrophobic distribution

ActiveCN109337105AAdjustment areaEnhanced Broad Spectrum Antifouling PerformanceCoatingsRolloverEtching

The invention belongs to the technical field of marine antifouling material preparation, and particularly relates to a preparation method of a microstructure surface with alternate hydrophilic-hydrophobic distribution. The method is characterized in that a monocrystalline silicon surface is covered by a photomask with a set pattern obtained through electron beam etching, and the set pattern with aset depth is obtained through etching; the etched monocrystalline silicon surface is used as a female die, and a hydrophobic organic silicon microstructure surface with a set structure is obtained through etching rollover; and through processes including plasma processing, hydrogen peroxide activation, hydrophobic liquid hole sealing, washing and hydrogel filling, an organic silicon microstructure is filled with hydrogel in an orderly manner, so that the regularly-structured microarray surface with the alternate hydrophilic-hydrophobic distribution is obtained. The method has the advantages that the height of the hydrogel in a microarray can be controlled to adjust projection area proportions and space area proportions of hydrophilic areas and hydrophobic areas in the microstructure surface with the alternate hydrophilic-hydrophobic distribution, so that a hydrophilic-hydrophobic microstructure is achieved, the broad-spectrum antifouling performance of a microstructure material is improved, and the method can be used for preventing and removing biofouling on the surfaces of ships and marine structures.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

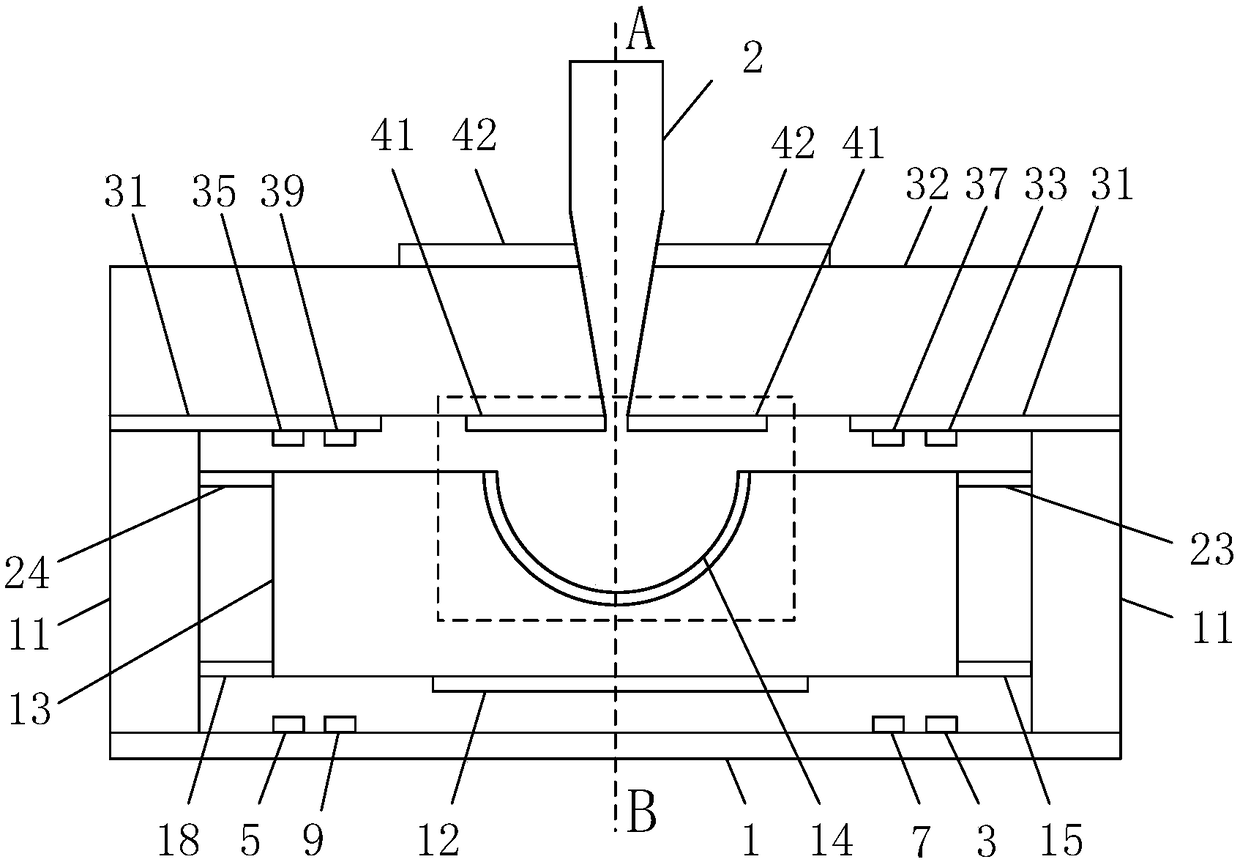

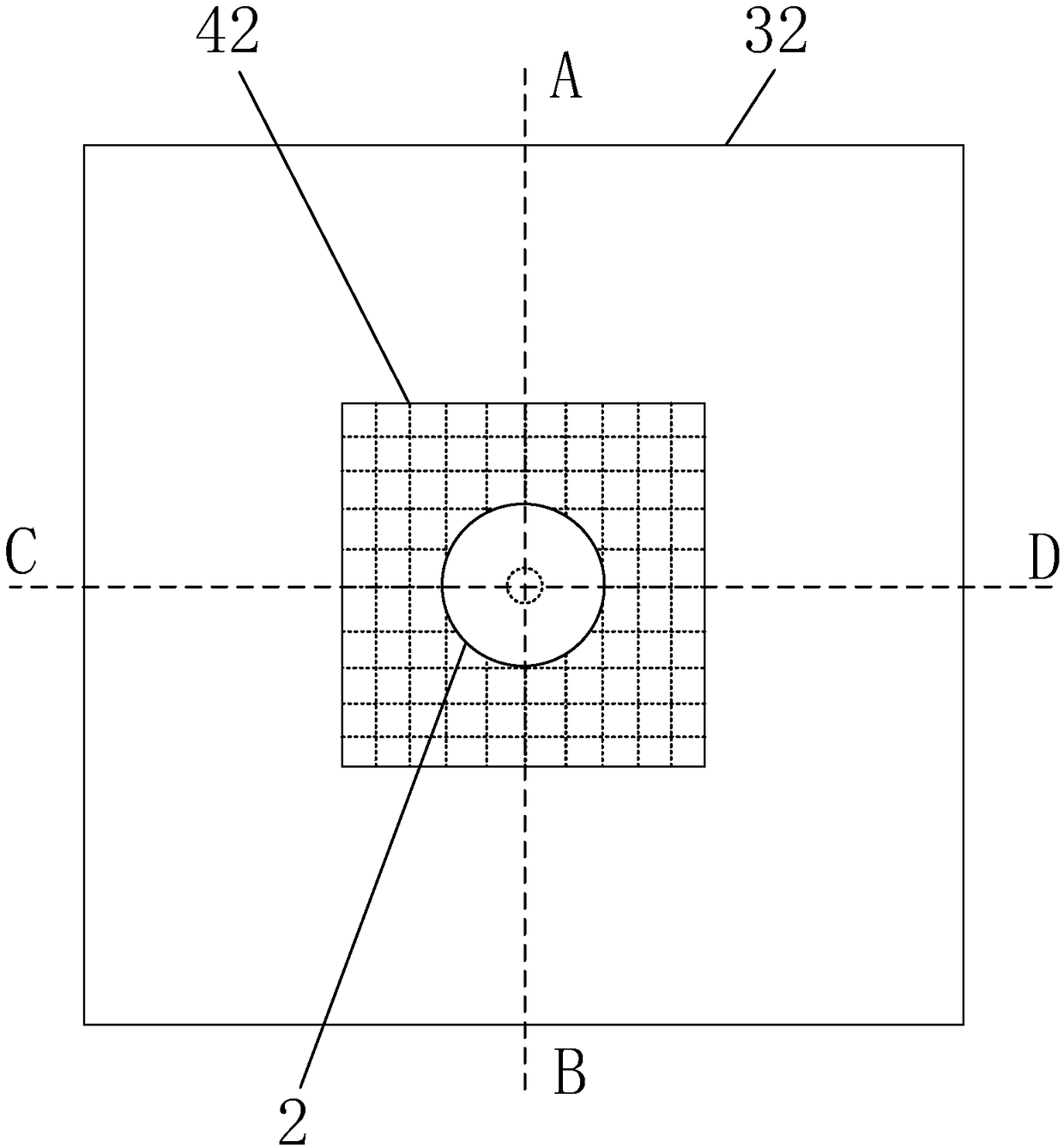

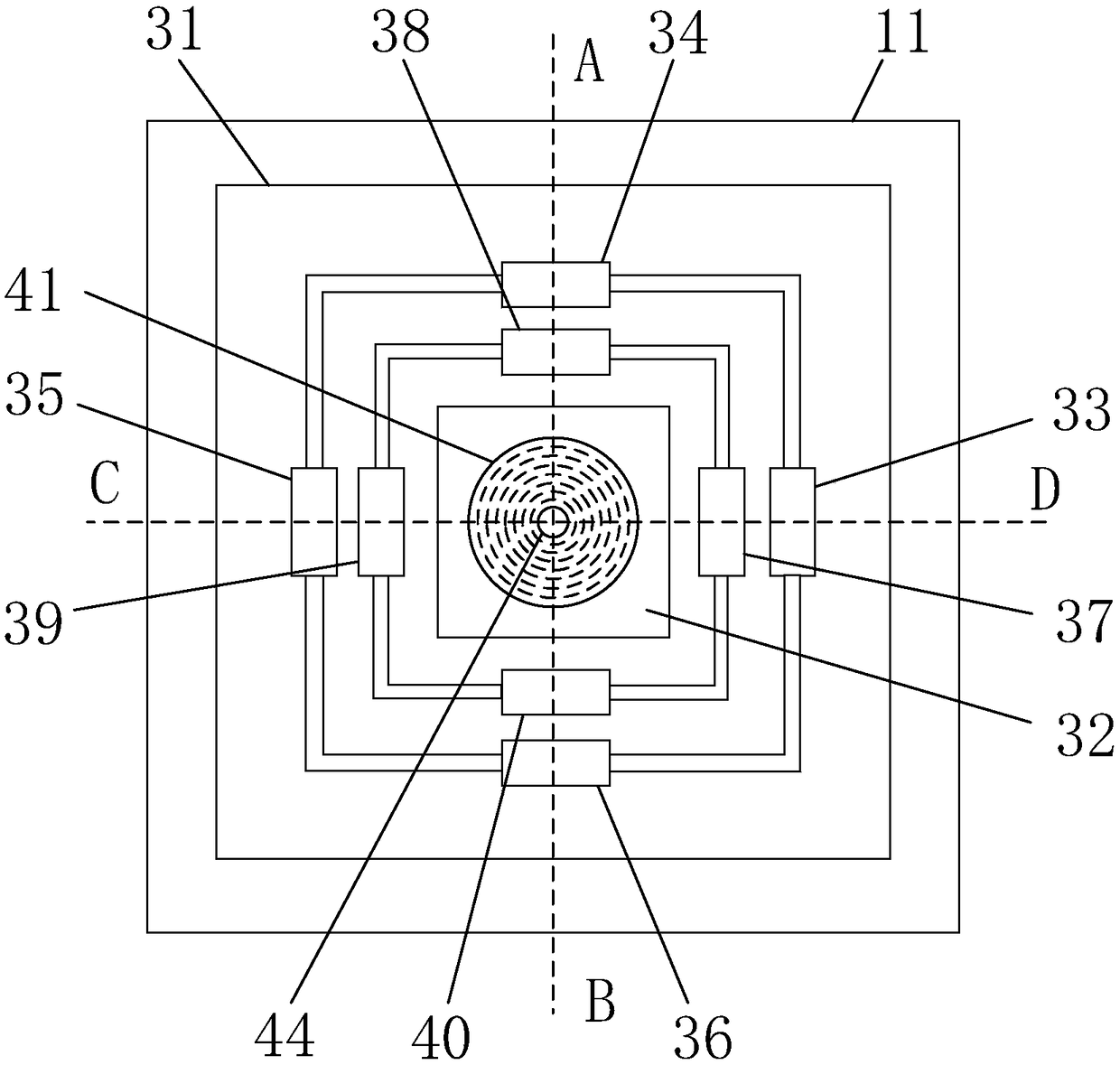

High-precision optical-mechanical accelerometer based on hemispherical micro-nano cavity mechanical-optical coupling

InactiveCN109142788AIncrease detection limit capabilityHigh sensitivityAcceleration measurement using interia forcesMicro nanoAccelerometer

The invention discloses a high-precision optical-mechanical accelerometer based on hemispherical micro-nano cavity mechanical-optical coupling. The high-precision optical-mechanical accelerometer comprises an upper planar cavity silicon microstructure, a middle hemispherical cavity silicon microstructure and a lower glass substrate with electrode leads. The upper structure is bonded on the middlestructure through the upper end of the annular fixed anchor points, and the middle structure is bonded on the lower structure through the lower end of the annular fixed anchor points. The upper structure comprises micro-nano optical fibers, a planar cavity, an upper antireflection coating layer, an upper mirror coating layer, an insulating layer, a feedback electrode and a spacing adjusting electrode. The middle structure comprises a hemispherical cavity mass, a lower antireflection coating layer, a lower hemispherical mirror coating layer, the annular fixed anchor points and multiple elasticcantilever beams. The lower structure comprises a feedback electrode, a spacing adjusting electrode, a signal lead and the glass substrate. The optical signal is used as the measuring signal of the micro accelerometer and the hemispherical optical micro-nano cavity is used so that the sensitivity is high and the dynamic range is large.

Owner:SOUTHEAST UNIV

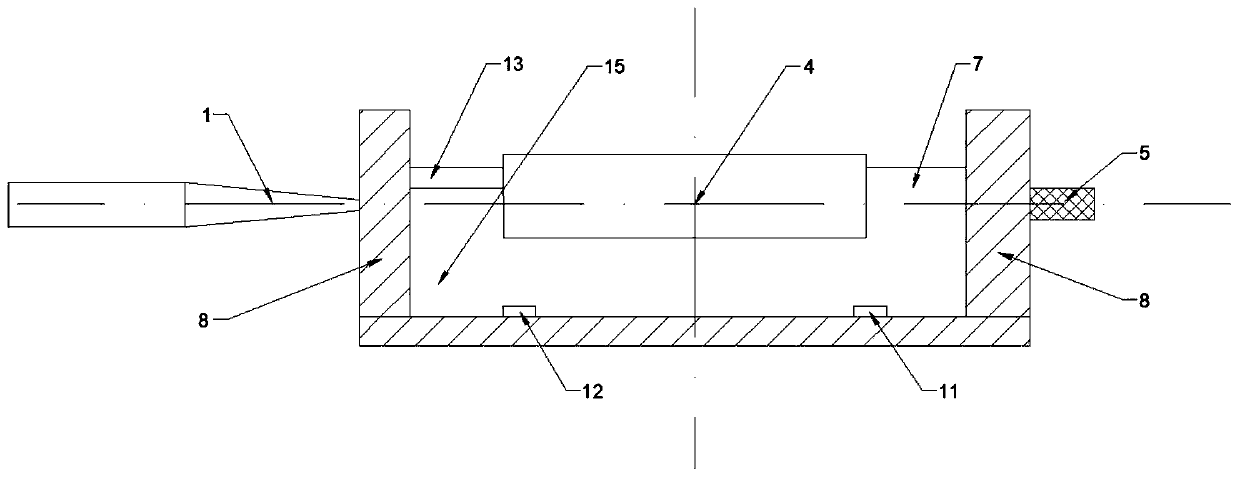

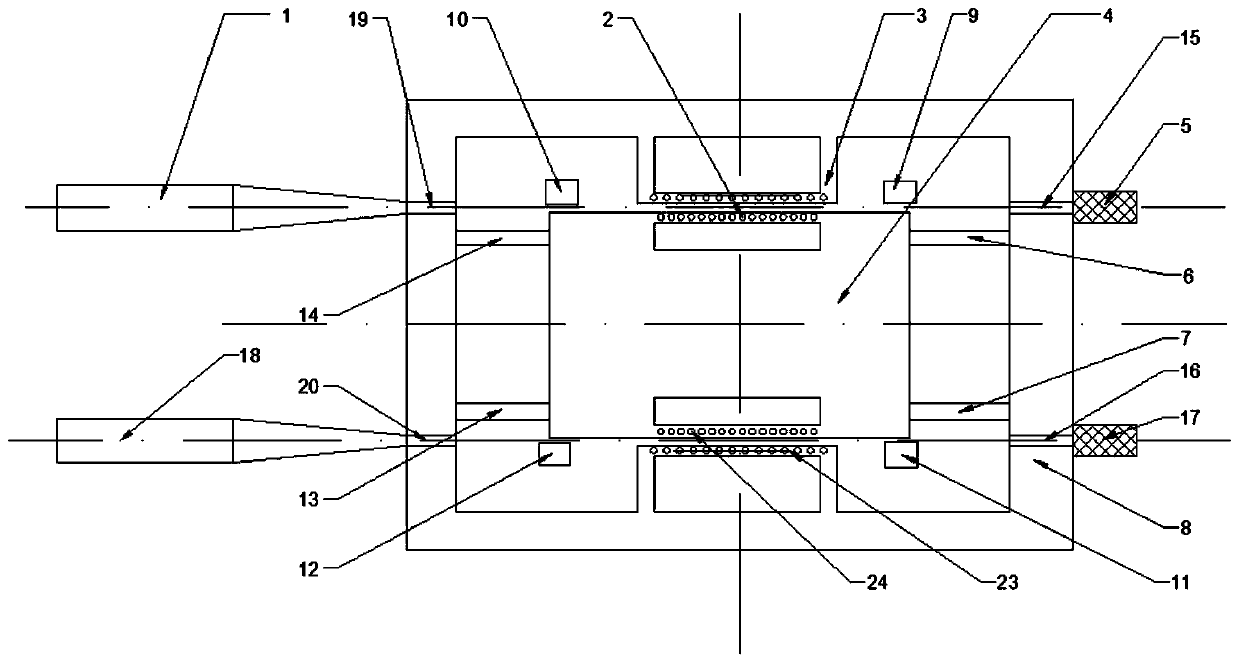

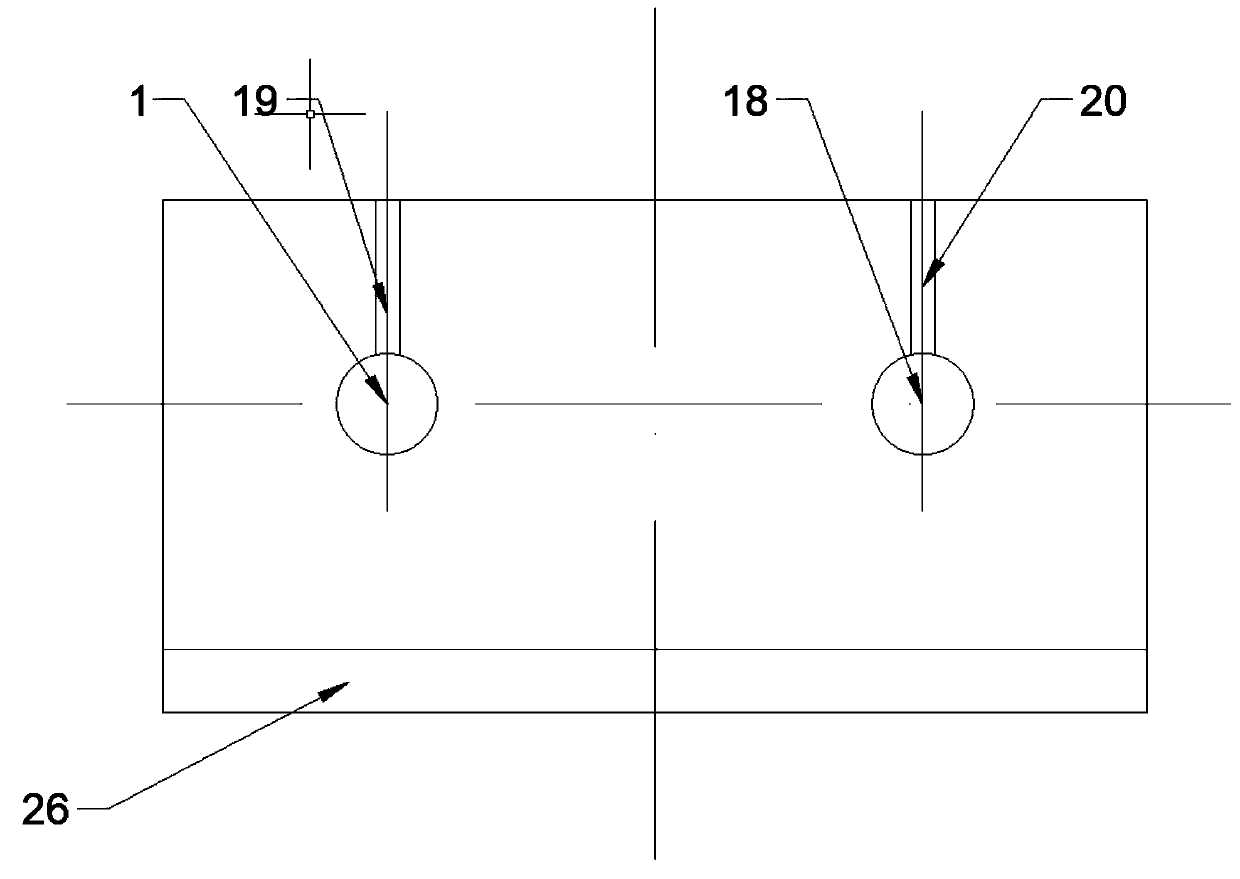

High-precision photodynamic accelerometer based on zipper type photonic crystal micro-nano cavity

ActiveCN109946480AIncrease detection limit capabilityHigh sensitivityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMicro nanoAccelerometer

The invention discloses a high-precision photodynamic accelerometer based on a zipper type photonic crystal micro-nano cavity. The accelerometer comprises a laser input and reception structure arranged in the left and right sides of the accelerometer structure, a silicon micro mechanical structure arranged in the middle portion of the accelerometer, and a glass substrate structure positioned in the bottom of the silicon micro mechanical structure and provided with electrodes. A laser incident structure is arranged in an input groove in the left side of a main silicon microstructure, a reception structure is arranged in an output groove in the right side of the main silicon microstructure. An optical signal serves as a measurement signal of the micro accelerometer, the sensitivity is high,the uncertainty is low, the detection limit of the micro accelerometer is improved, and the detection sensitivity is improved greatly. The zipper type photonic crystal micro-nano cavity is used, the performance is more stable and the optical precision is higher compared with a common planar parallel resonance micro-nano cavity at present, and higher acceleration sensitivity is achieved.

Owner:SOUTHEAST UNIV

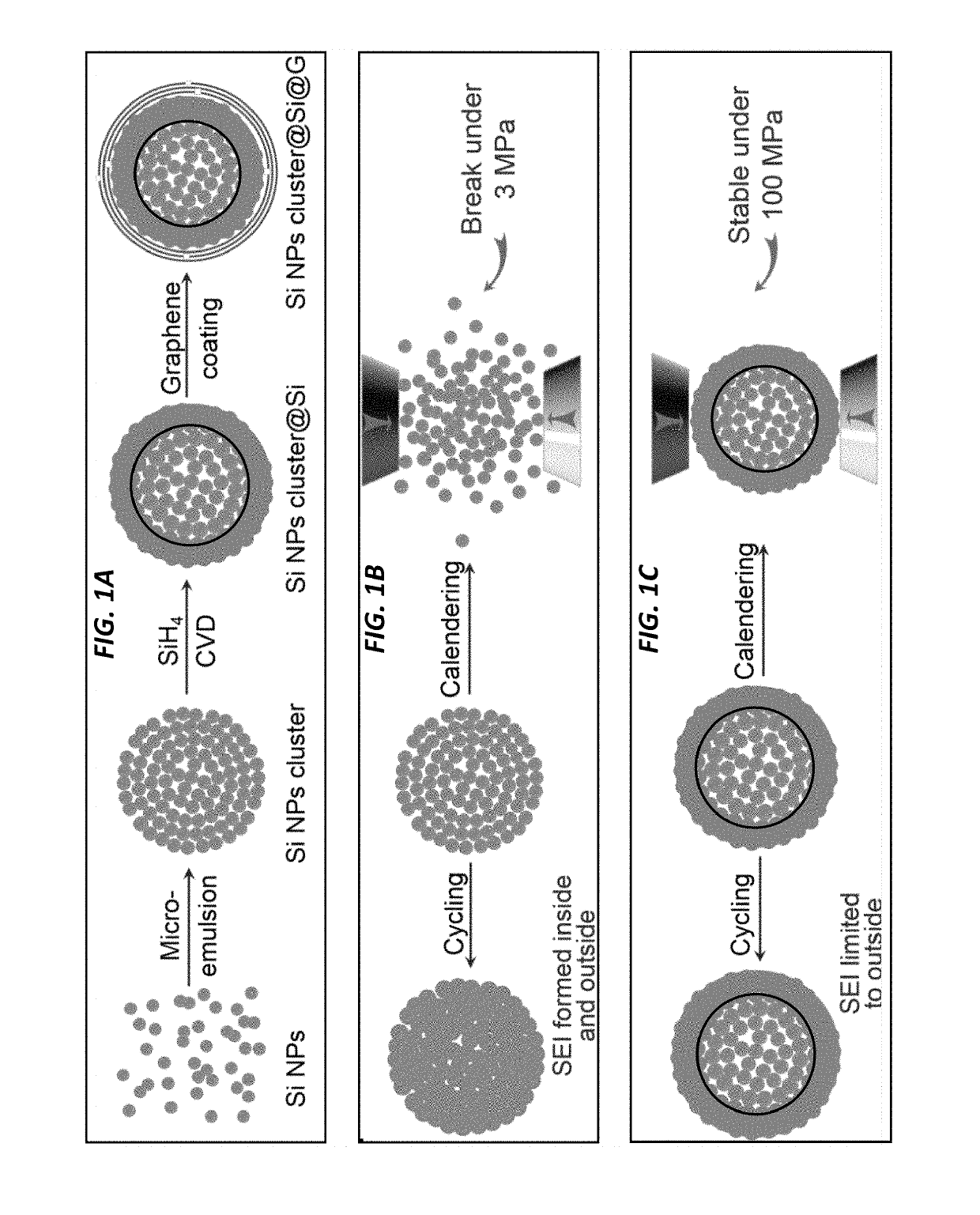

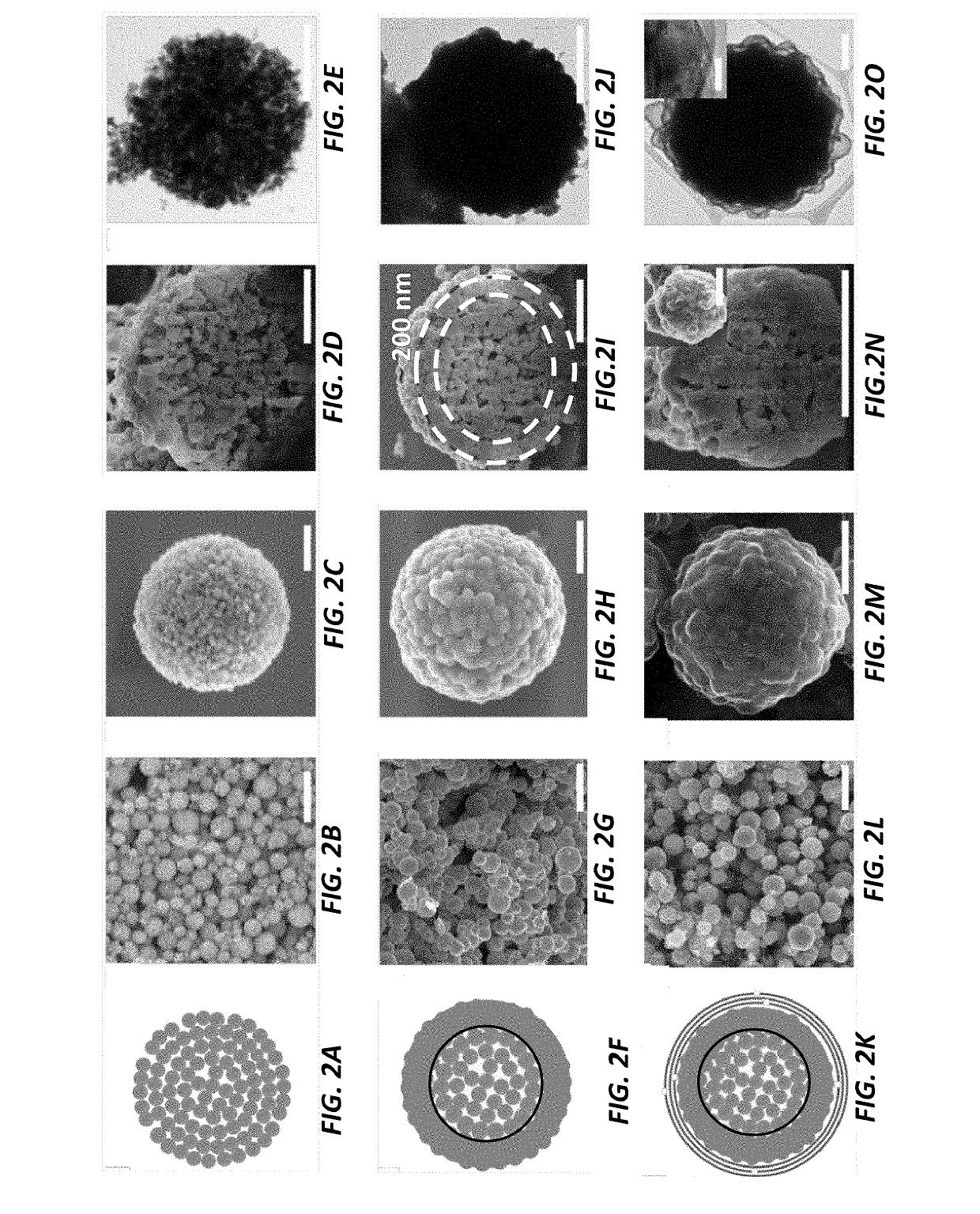

Silicon sealing for high performance battery anode materials

ActiveUS20190305295A1High densityInhibited DiffusionElectrode thermal treatmentNegative electrodesGraphene coatingSilicon microstructures

A battery electrode is provided that includes a porous silicon microstructure precursor, a silicon shell coating deposited on the silicon microstructure precursor, and a graphene coating deposited on the silicon shell coating, where the graphene coating encapsulates the silicon shell coating forming a graphene-encapsulated silicon-shell-protected porous silicon microstructure precursor battery electrode.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Silicon structure with patterned surface and preparation method thereof and solar cell

ActiveCN111192932AFinal product manufacturePhotovoltaic energy generationPhysical chemistryEngineering

The invention provides a silicon structure with a patterned surface and a preparation method thereof and a solar cell. The silicon structure comprises: a silicon substrate having a first surface and asecond surface opposite to the first surface; a plurality of silicon microstructures which have different reflectivity, wherein each silicon microstructure comprises a plurality of silicon microunitswith the same reflectivity, and each silicon microunit is constructed on the silicon substrate and etched for a preset depth from the first surface of the silicon substrate to the direction close tothe second surface of the silicon substrate, the number of each silicon microstructure and the arrangement mode of all the silicon micro-units on the silicon substrate are determined according to a preset pattern, so that the pattern formed by all the silicon micro-units is visually consistent with the preset pattern. According to the scheme provided by the invention, any grayscale image can be drawn on the silicon solar cell panel on the premise of not losing obvious optical-electric conversion performance.

Owner:苏州纳捷森光电技术有限公司

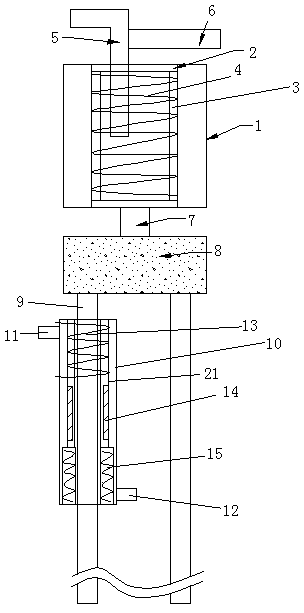

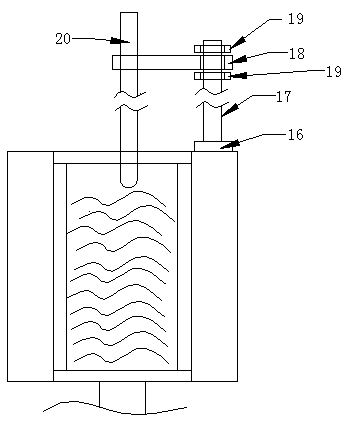

Continuous casting device for hypereutectic aluminum-silicon alloy and manufacturing method thereof

The invention belongs to the metal material preparation and application technology field, and especially discloses a continuous casting device for hypereutectic aluminum-silicon alloy. The device is composed of a molten pool component and an electromagnetic stirring component used in cooperation with the molten pool component. The device has advantages that a large number of ''heterogeneous'' nucleation particles generated by a powdery or granular alterant serve as a ''core'' of crystallization of primary silicon, an effective nucleation rate of the primary silicon is increased, the primary silicon is refined, morphology of the primary silicon is changed, a primary silicon microstructure is refined, a use amount of the alterant is reduced, and cost is decreased; an electromagnetic stirrerand an airflow stir an alloy melt so that rapid dispersion strengthening of the alterant is promoted, and meanwhile, a temperature field and a component field of the alloy melt can be promoted to be more uniform; through arrangement of a powder spraying pipe connected with a powder spraying device, an influence of a skin effect of an electromagnetic field is avoided, distribution of the electromagnetic field is more uniform, and the temperature field and the component field of the alloy melt are more uniform too; and the hypereutectic aluminum-silicon alloy melt is treated, and a high-qualityhypereutectic aluminum-silicon alloy blank material can be obtained.

Owner:泰州市金鹰精密铸造有限公司

A method for preparing a hydrophilic-hydrophobic interactive distribution microstructure surface

The invention belongs to the technical field of marine antifouling material preparation, and particularly relates to a preparation method of a microstructure surface with alternate hydrophilic-hydrophobic distribution. The method is characterized in that a monocrystalline silicon surface is covered by a photomask with a set pattern obtained through electron beam etching, and the set pattern with aset depth is obtained through etching; the etched monocrystalline silicon surface is used as a female die, and a hydrophobic organic silicon microstructure surface with a set structure is obtained through etching rollover; and through processes including plasma processing, hydrogen peroxide activation, hydrophobic liquid hole sealing, washing and hydrogel filling, an organic silicon microstructure is filled with hydrogel in an orderly manner, so that the regularly-structured microarray surface with the alternate hydrophilic-hydrophobic distribution is obtained. The method has the advantages that the height of the hydrogel in a microarray can be controlled to adjust projection area proportions and space area proportions of hydrophilic areas and hydrophobic areas in the microstructure surface with the alternate hydrophilic-hydrophobic distribution, so that a hydrophilic-hydrophobic microstructure is achieved, the broad-spectrum antifouling performance of a microstructure material is improved, and the method can be used for preventing and removing biofouling on the surfaces of ships and marine structures.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

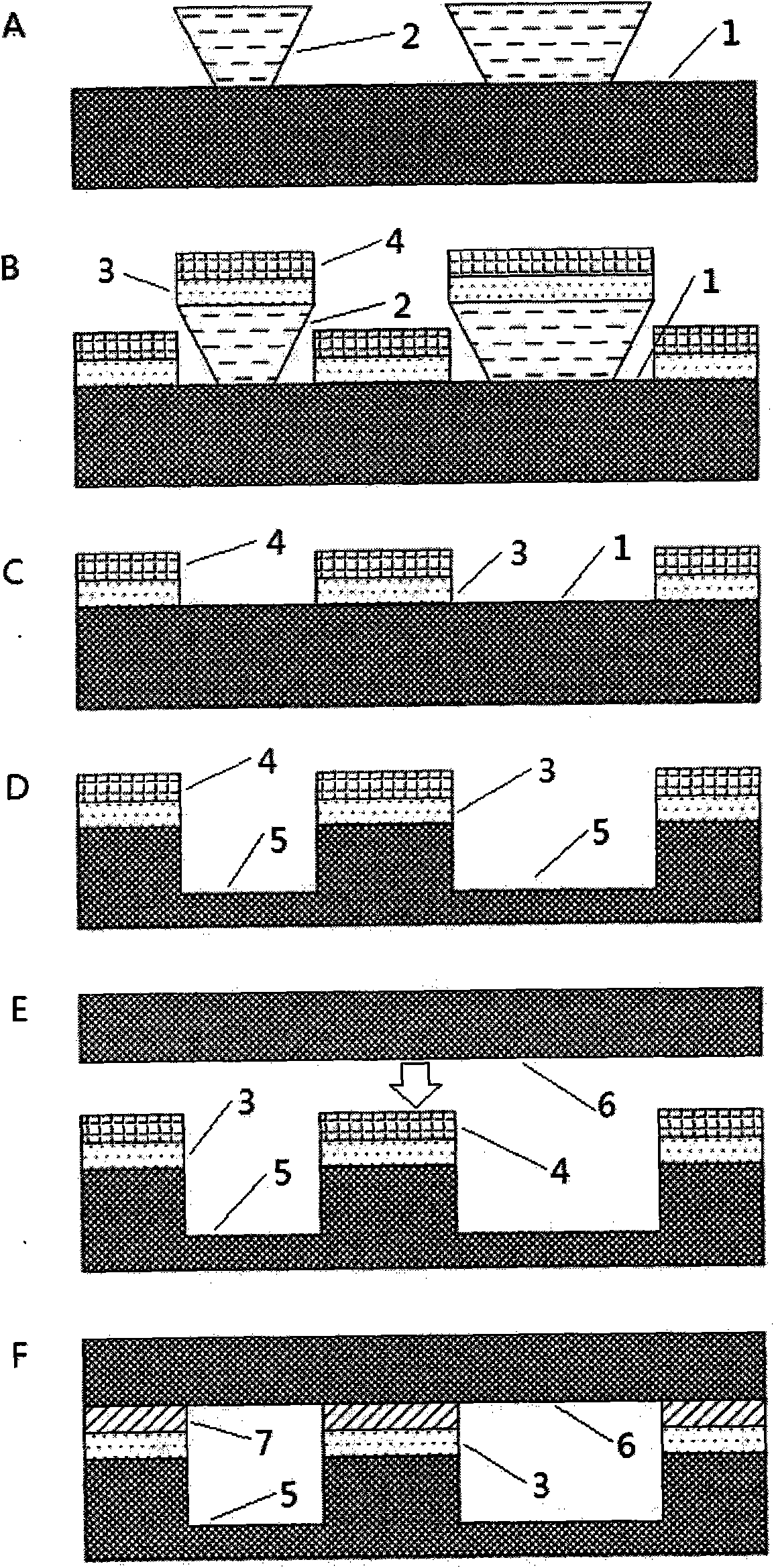

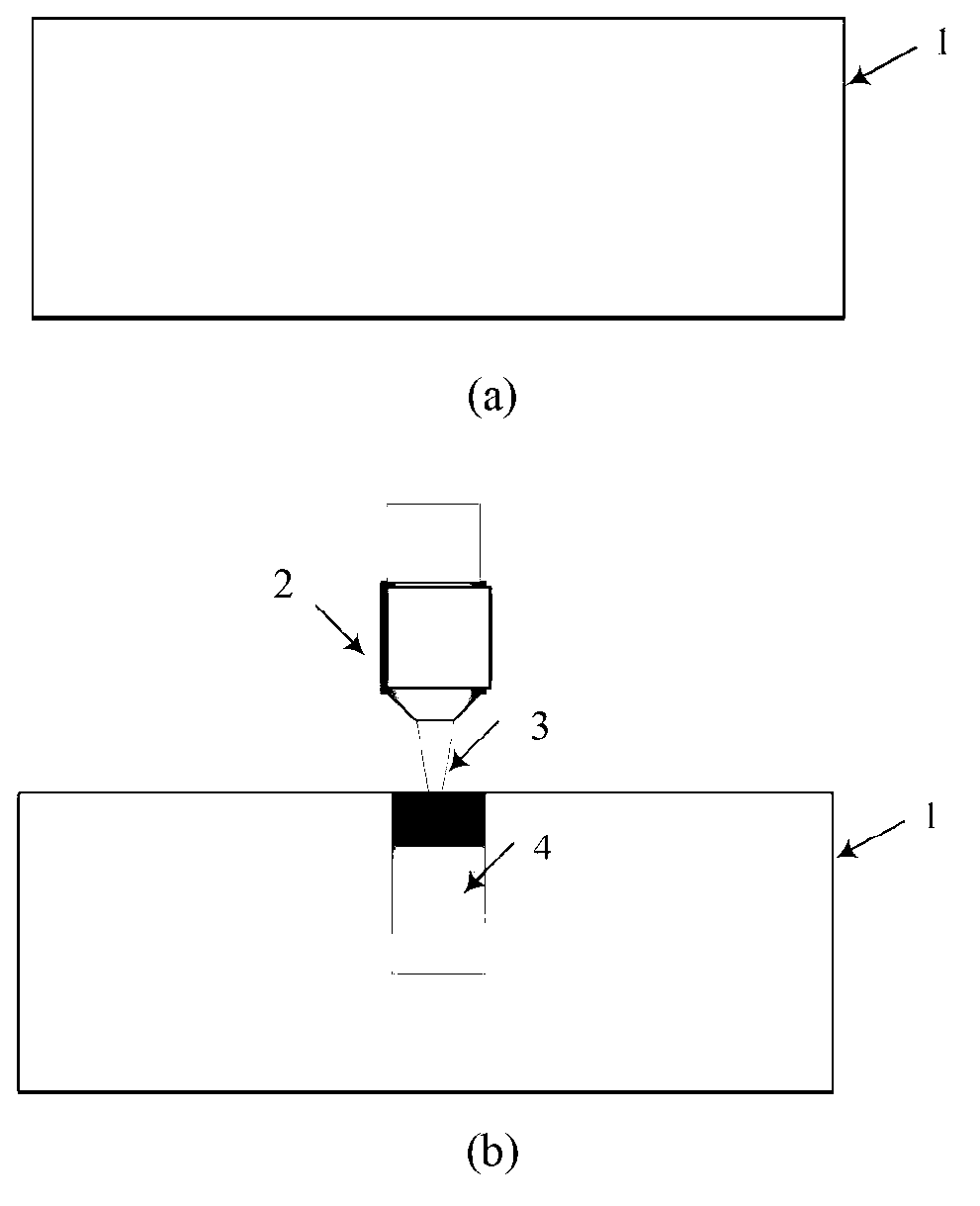

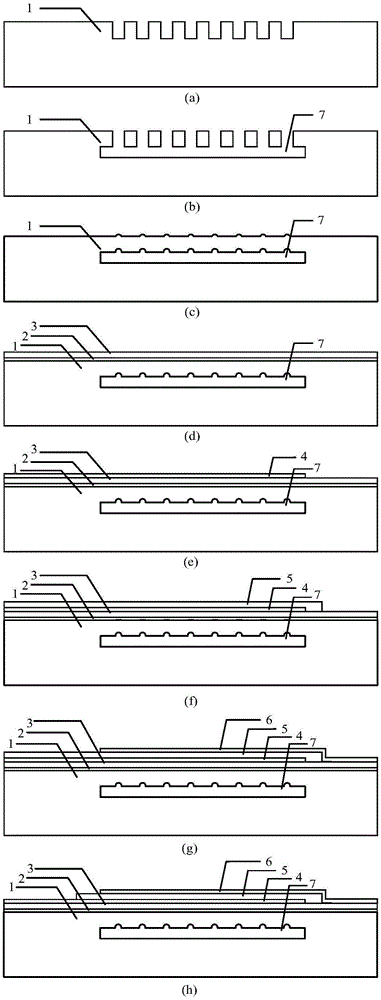

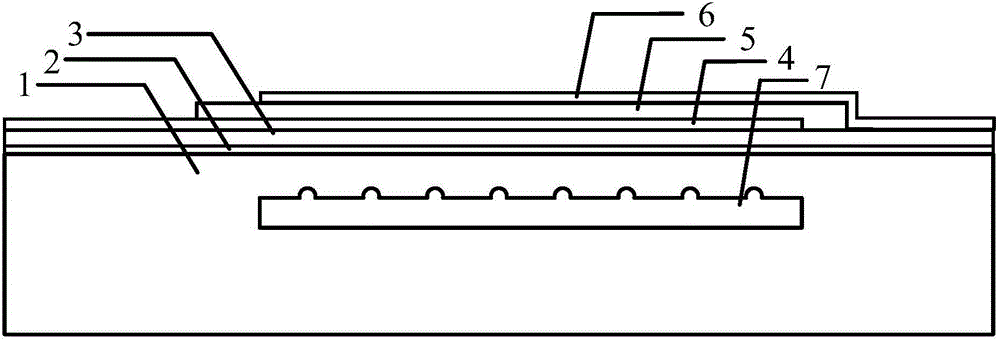

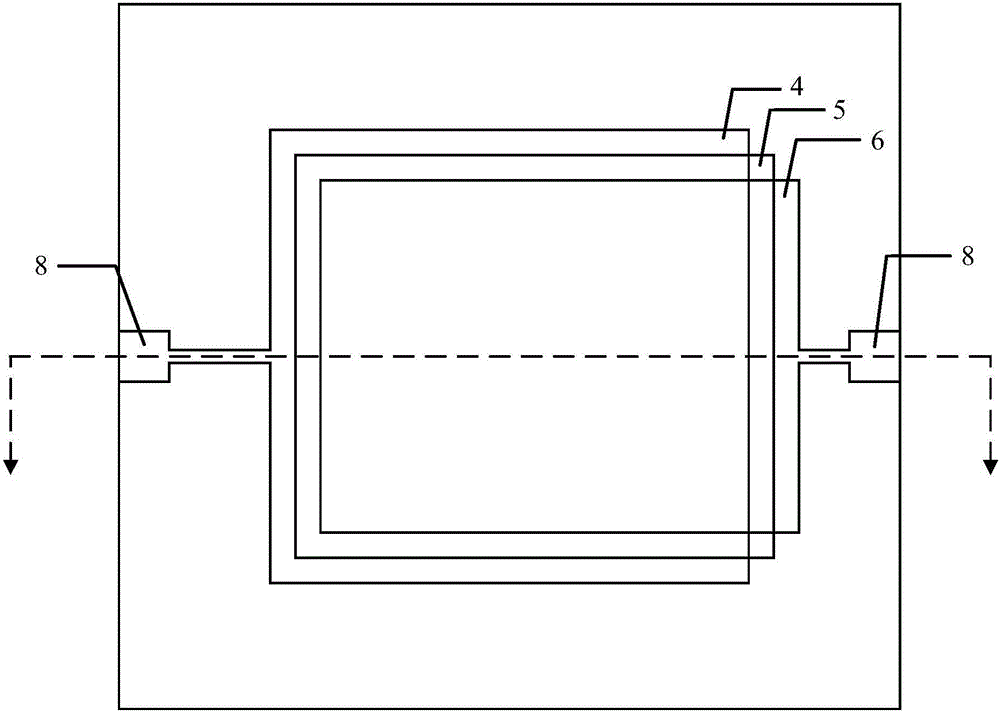

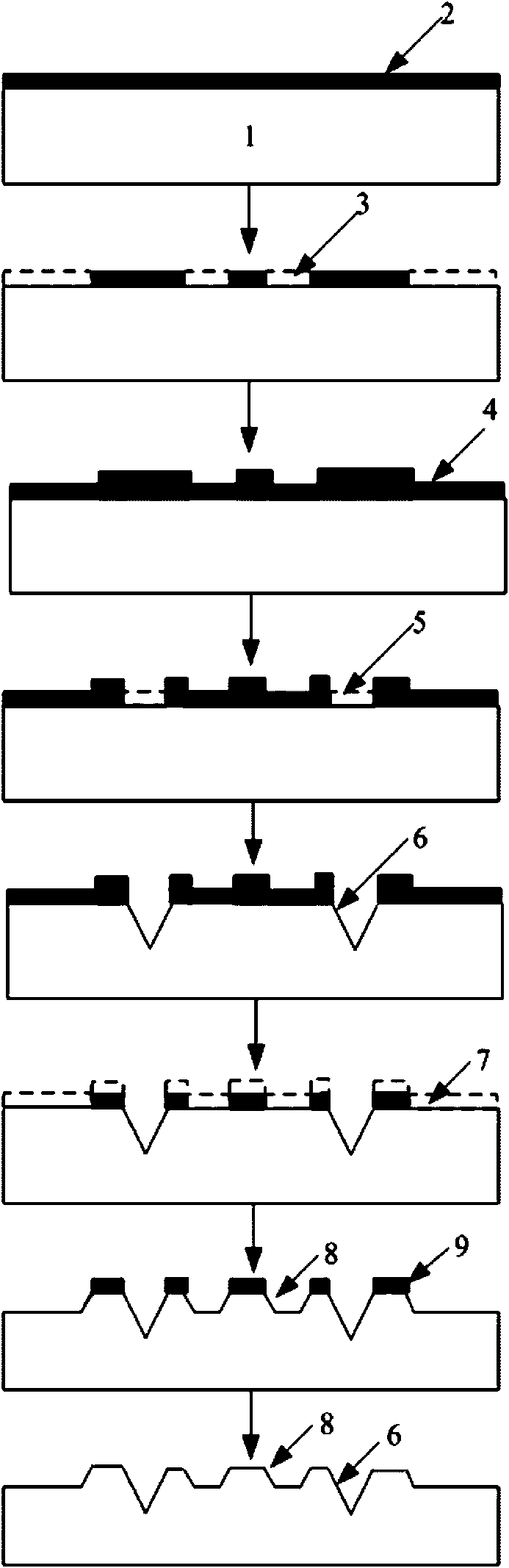

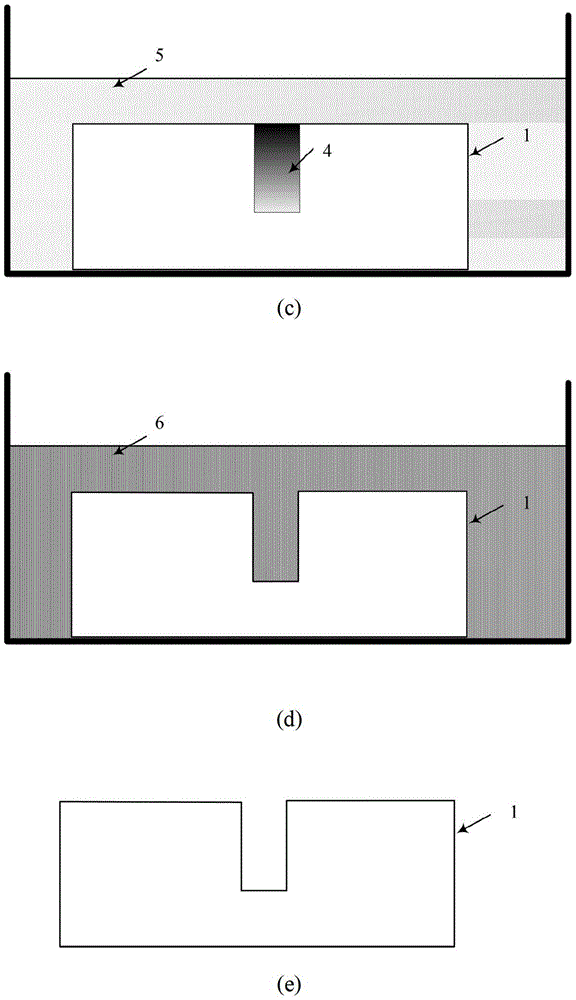

Bulk-silicon processing method for manufacturing microstructure on basis of multiple masking layers

InactiveCN101613077ASolving difficult-to-prepare problemsImprove compatibilityDecorative surface effectsChemical vapor deposition coatingProcess manufacturingSilicon chip

A complex microstructure manufactured by the conventional silicon process is susceptible to glue heap and stripping problems during secondary spin coating and photoetching, so that the manufacturing of the microstructure on a silicon substrate cannot be performed. The invention discloses a bulk-silicon processing method for manufacturing a microstructure on basis of multiple masking layers, belongs to the field of silicon process manufacturing, and is used for realizing the manufacturing of a complex microstructure on a silicon chip. The method uses masking layer growing and nesting technology to transfer patterns on a plurality of masks onto the silicon chip layer by layer and complete all photoetching steps related to the whole process, thereby solving the glue heap and stripping problems caused by the existence of the silicon microstructure and realizing the manufacturing of a micro complex structure on the silicon chip. The method has the advantages of solving the problem of difficult manufacturing of the micro complex structure in the conventional silicon process, along with excellent compatibility with the conventional silicon process as well as flexible operation and simplicity.

Owner:DALIAN UNIV OF TECH

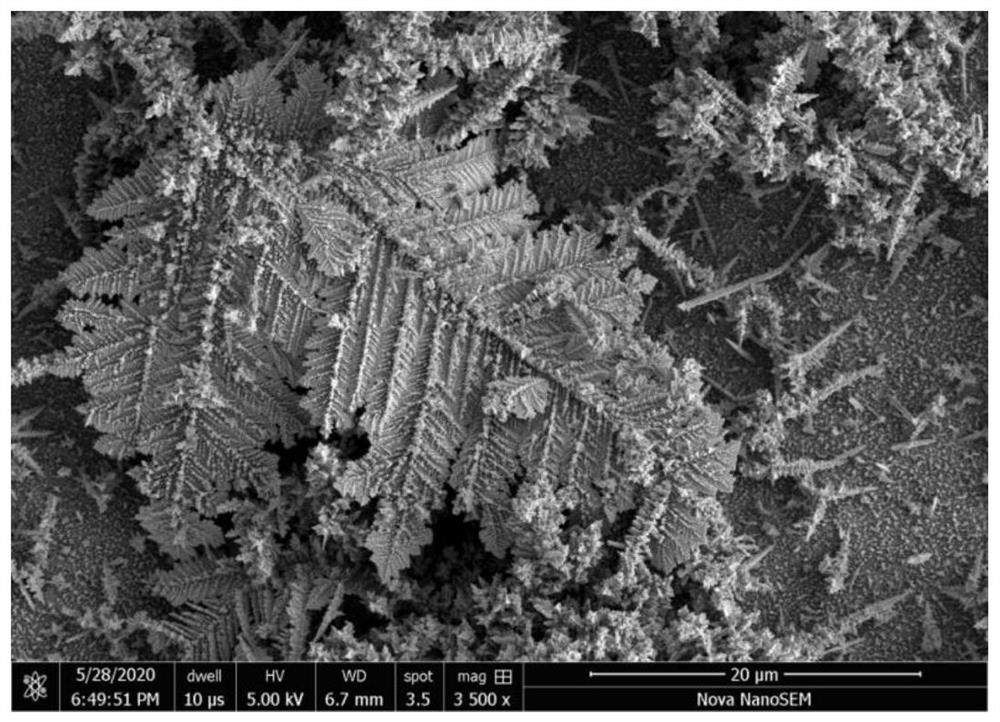

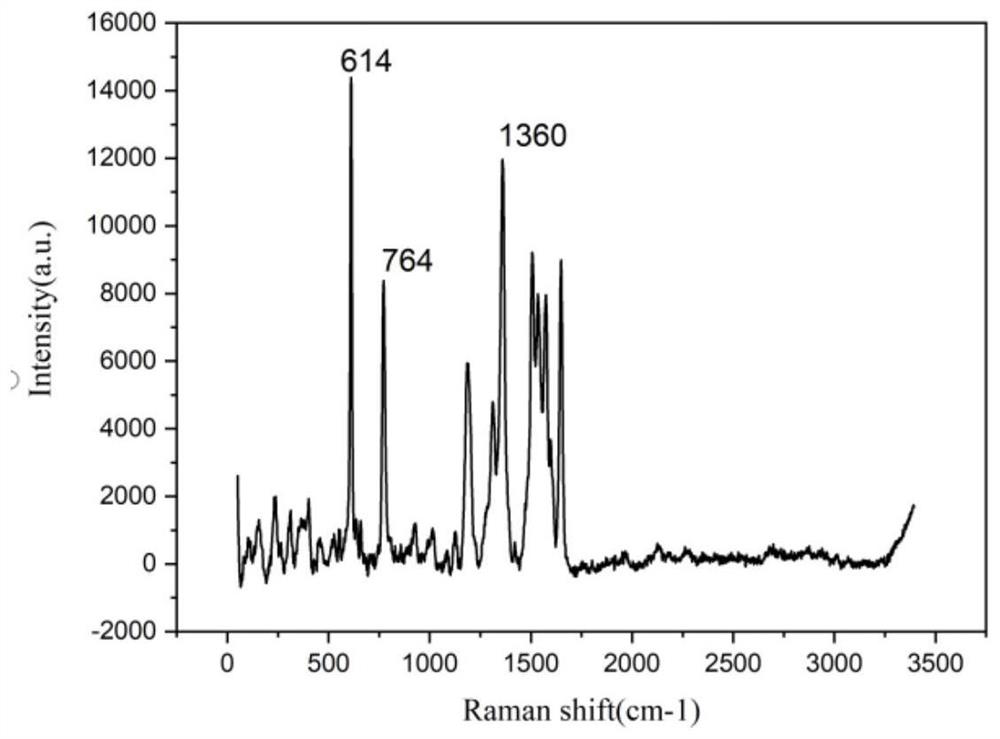

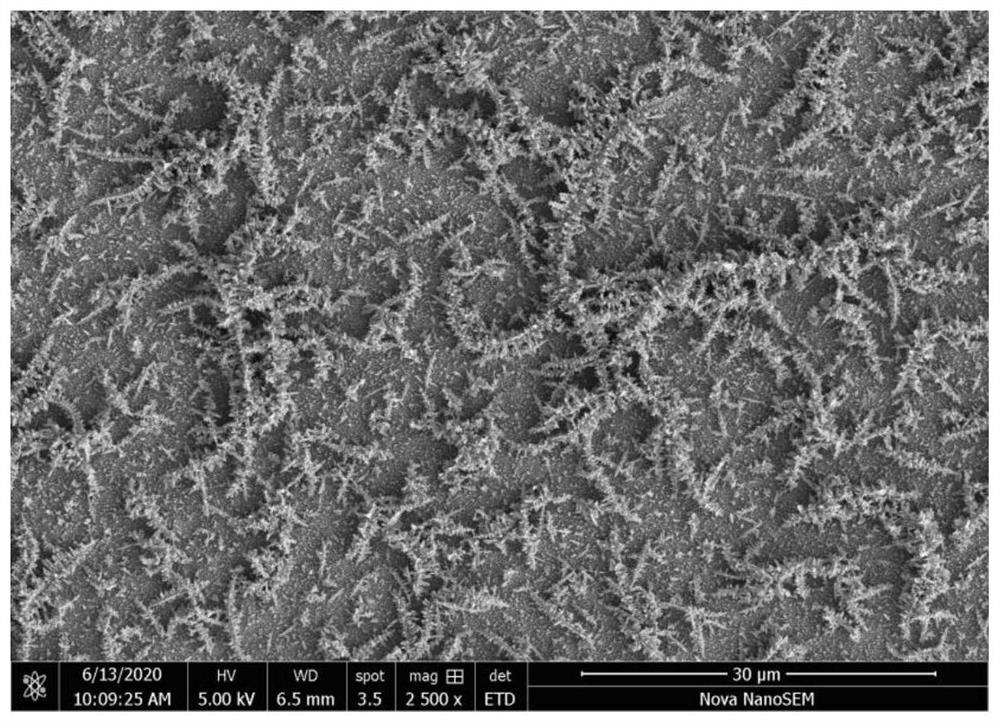

Single-step rapid preparation method of porous silicon-gold dendritic crystal composite structure

PendingCN111965158AOne-step rapid preparationFast preparationRaman scatteringNanosensorsHydrofluoric acidPhysical chemistry

The invention belongs to the technical field of electrochemical corrosion and silicon microstructure preparation, which relates to a rapid preparation method of a porous silicon-gold dendritic crystalcomposite structure. The method comprises the following specific steps of firstly, selecting a silicon wafer, and cutting and cleaning the silicon wafer to obtain a pretreated silicon wafer, then mixing hydrofluoric acid, dimethylformamide and a tetrachloroauric acid solution to obtain an electrochemical corrosive liquid, immersing the pretreated silicon wafer, applying a constant current, and performing electrochemical corrosion to obtain a porous silicon-gold dendritic crystal composite structure through one-step treatment, and finally, cleaning the prepared porous silicon-gold dendritic crystal composite structure to obtain a final composite structure. According to the preparation method disclosed by the invention, the single-step rapid preparation of the porous silicon-gold nano composite structure is realized by preparing the electrochemical corrosive liquid and immersing the silicon wafer, and the SERS performance of the composite structure is regulated and controlled by changing the concentration of the tetrachloroauric acid solution; the method is simple in step, convenient to operate and short in consumed time, and the porous silicon-gold dendritic crystal composite structure can be rapidly and efficiently prepared.

Owner:JIANGSU UNIV

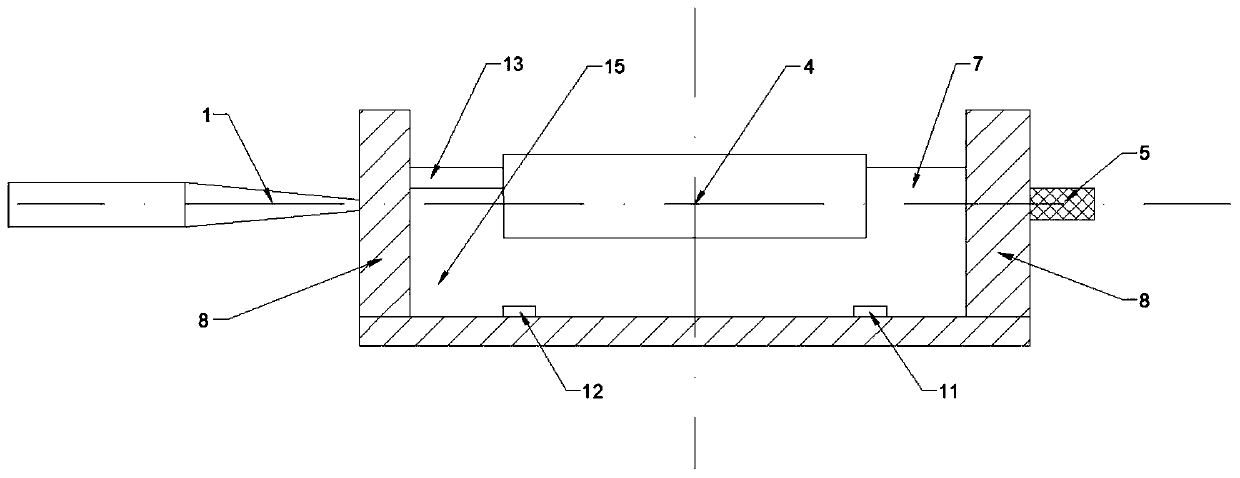

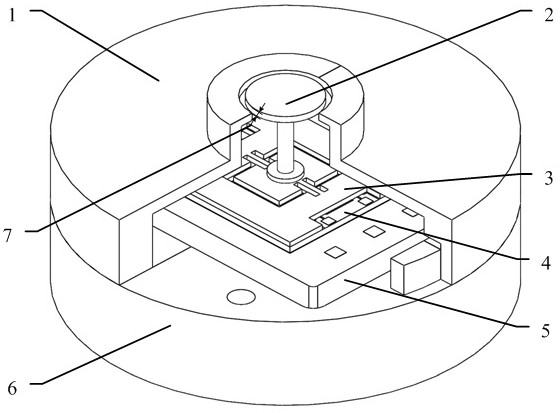

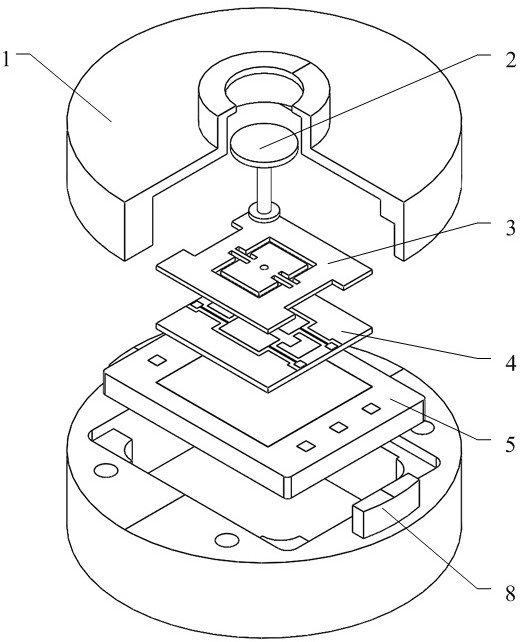

High-frequency-response wide-range MEMS friction resistance sensor

ActiveCN114216648AReduce Capacitive GapHigh response frequencyAerodynamic testingUsing mechanical meansCapacitanceFlight vehicle

The invention belongs to the field of MEMS (Micro Electro Mechanical System) sensors in a micro electro mechanical system, and discloses a high-frequency-response wide-range MEMS friction resistance sensor. The MEMS friction resistance sensor is composed of a packaging cover plate, a meter head structure, an interface circuit and a packaging tube socket. The packaging cover plate and the packaging tube seat are cylinders which are stacked up and down, and the meter head structure and the interface circuit are mounted in central cavities of the packaging cover plate and the packaging tube seat; the header structure is a main component of the MEMS friction sensor, is composed of a floating element, a silicon microstructure and an electrode substrate, and is used for sensing the friction on the surface of an aircraft model and converting the friction into a differential capacitance signal. According to the MEMS friction resistance sensor, a three-dimensional MEMS meter head structure in which a floating element is flush with a wall surface to be measured and a signal output microstructure is isolated from a wind tunnel flow field is adopted, and a plate capacitance differential detection and measurement method is adopted.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

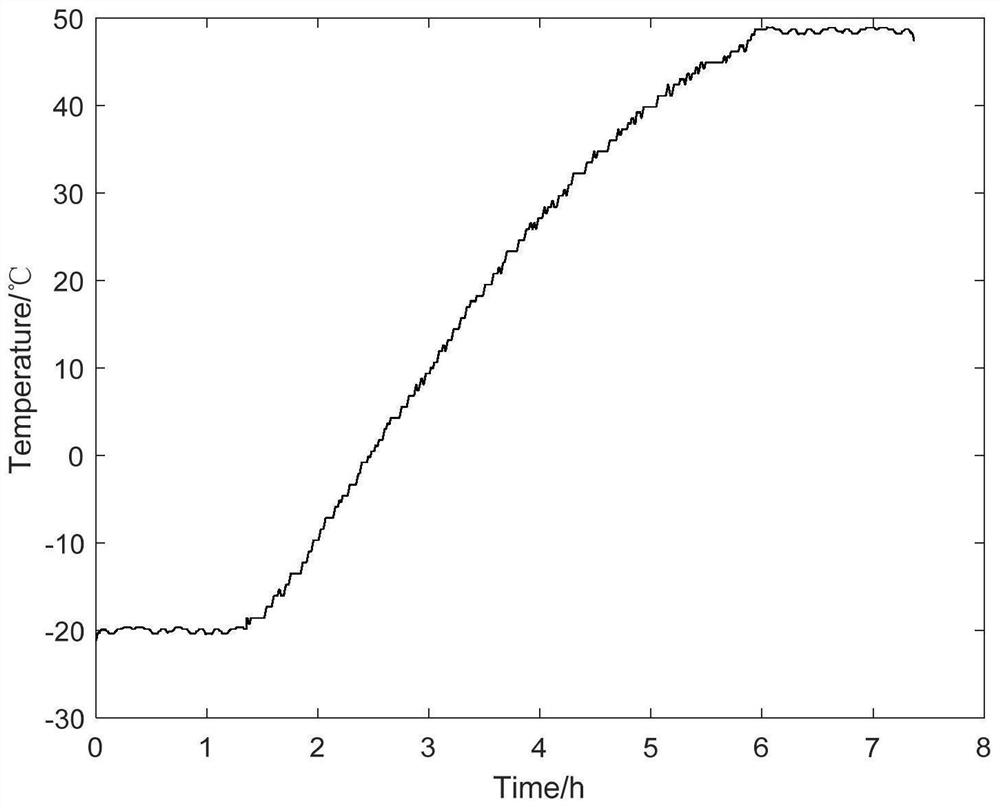

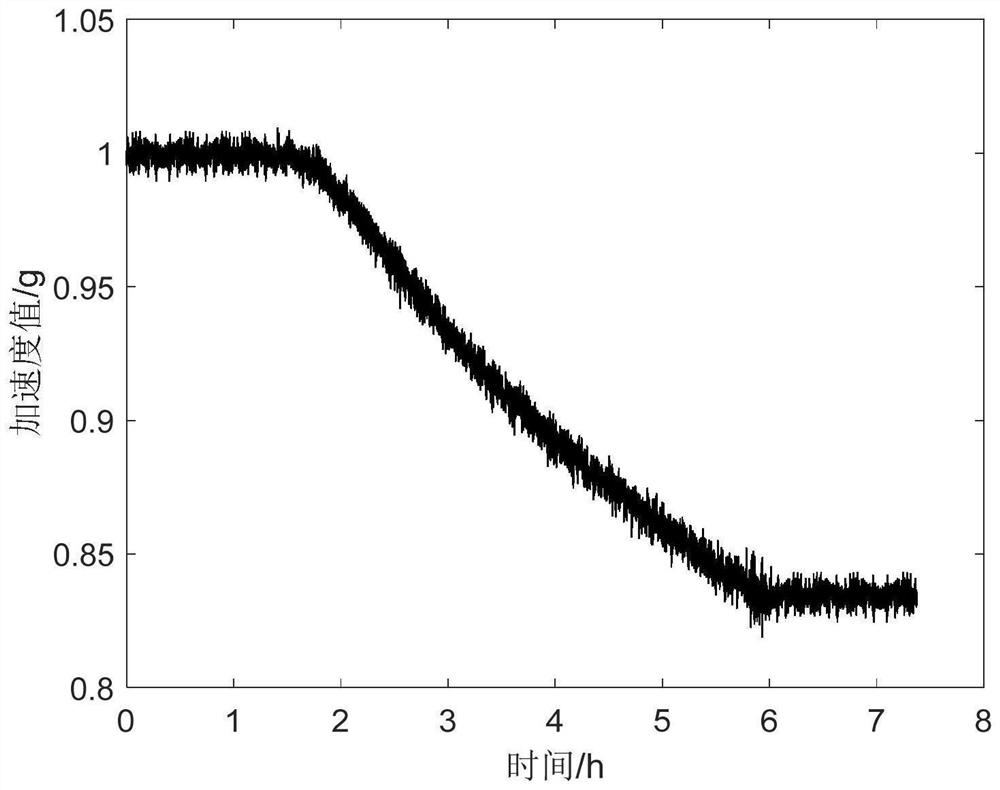

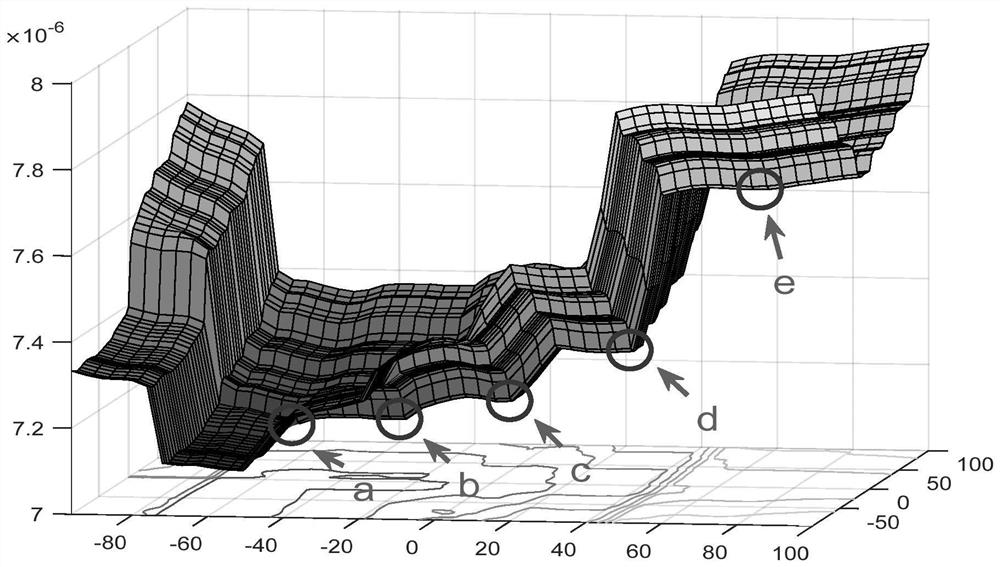

MEMS accelerometer temperature drift error estimation method based on silicon microstructure analysis

ActiveCN113392591ATemperature dependent decouplingReal-time precision outputArtificial lifeDesign optimisation/simulationAccelerometerEngineering

The invention discloses an MEMS accelerometer temperature drift error estimation method based on silicon microstructure analysis, and belongs to the field of novel micro inertial devices. According to the method, the problem that the temperature correlation quantity of the MEMS accelerometer temperature drift error is not completely explored by a traditional method, so that the temperature drift error estimation of the MEMS accelerometer is not accurate due to non-precise modeling of the estimated temperature drift error is solved. According to the method, the temperature dependence of the silicon-based material is comprehensively analyzed in detail from the perspective of the microstructure effect, the temperature dependence of the silicon-based material is well decoupled, and under the condition that the environment temperature is complex and changeable, the environmental adaptability of the MEMS accelerometer can be completely improved by compensating the temperature drift error, and the MEMS accelerometer accurately, stably and reliably outputs carrier acceleration information in real time. The method can be applied to carrier acceleration detection.

Owner:HARBIN ENG UNIV

A high-sensitivity resonant mems vector hydrophone structure

ActiveCN104121984BHigh sensitivityImprove anti-interference abilitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansHydrophoneSilicon microstructures

The invention relates to a vector hydrophone and specifically relates to a high-sensitivity resonant MEMS (Micro Electro Mechanical System) vector hydrophone structure. The high-sensitivity resonant MEMS vector hydrophone structure is used for solving the problems of poor antijamming capability and low sensitivity of the existing vector hydrophone. The high-sensitivity resonant MEMS vector hydrophone structure comprises a four-beam arm silicon microstructure, a micro cylindrical body, a central connector, driving electrodes and detection electrodes, wherein the four-beam arm silicon microstructure and the central connector are located in the same plane; the lower end of the micro cylindrical body is vertically fixed in the center of the upper surface of the central connector; eight driving electrodes and eight detection electrodes are arranged; the first driving electrode is paved on the left front part of the upper surface of the front beam arm of the four-beam arm silicon microstructure, while the second driving electrode is paved on the left rear part of the upper surface of the front beam arm of the four-beam arm silicon microstructure. The high-sensitivity resonant MEMS vector hydrophone structure is applicable to accurate positioning and measurement of underwater acoustic pressure signals.

Owner:ZHONGBEI UNIV

A high-precision optical accelerometer based on zipper-type photonic crystal micro-nano cavity

ActiveCN109946480BIncrease detection limit capabilityHigh sensitivityTelevision system detailsImpedence networksAccelerometerEngineering

The invention discloses a high-precision photodynamic accelerometer based on a zipper type photonic crystal micro-nano cavity. The accelerometer comprises a laser input and reception structure arranged in the left and right sides of the accelerometer structure, a silicon micro mechanical structure arranged in the middle portion of the accelerometer, and a glass substrate structure positioned in the bottom of the silicon micro mechanical structure and provided with electrodes. A laser incident structure is arranged in an input groove in the left side of a main silicon microstructure, a reception structure is arranged in an output groove in the right side of the main silicon microstructure. An optical signal serves as a measurement signal of the micro accelerometer, the sensitivity is high,the uncertainty is low, the detection limit of the micro accelerometer is improved, and the detection sensitivity is improved greatly. The zipper type photonic crystal micro-nano cavity is used, the performance is more stable and the optical precision is higher compared with a common planar parallel resonance micro-nano cavity at present, and higher acceleration sensitivity is achieved.

Owner:SOUTHEAST UNIV

A silicon microstructure processing method based on femtosecond laser processing and wet etching

ActiveCN103232023BSimple processHigh aspect ratioDecorative surface effectsSemiconductor/solid-state device manufacturingFemto second laserRefractive index

The invention discloses a silicon microstructure processing method based on femtosecond laser treatment and wet etching. The method comprises the steps of scanning a monocrystal silicon substrate by using a femtosecond laser at an oxygen-containing gas atmosphere; inducing silicon to generate refractive index change in a scanning region; and then, etching by using a hydrofluoric acid wet process to remove a refractive index change region to form a silicon microstructure. The method disclosed by the invention is simple in process; compared with the prior art, the method has the advantage that a distribution drawing of the microstructure does not need to be defined by using a mask plate; compared with the ordinary wet etching and dry etching, the method has the advantages that the corrosion selectivity is good, the etching region is completely determined by a femtosecond laser processing region, and no sidewise underetching exists; and a silicon slot with high depth-to-width ratio and large depth can be obtained during deep silicon slot processing. The method disclosed by the invention can be applied to a micro-electro-mechanical system.

Owner:XI AN JIAOTONG UNIV

Masking method for deep-etching multi-layer silicon structure by dry method

InactiveCN102001618BHigh dimensional accuracyPerfect edge structureDecorative surface effectsPhotomechanical apparatusEtchingRepeatability

The invention discloses a masking method for deep-etching a multi-layer silicon structure by a dry method. The masking method comprises the following steps of: A, photoetching an Az positive photoresist pattern; B, performing the deep-etching on a silicon structure by taking the obtained Az positive photoresist pattern as a mask; C, cleaning the Az mask and the silicon structure, and coating a first layer of Su8 negative photoresist; D, photoetching the Su8 photoresist to obtain a mask pattern of a lower structure by an alignment mark; and E, deep-etching a lower silicon structure by taking the pattern obtained from the step D as the mask; and repeating the steps to obtain the multi-layer silicon microstructure with greater structure depth. The method has the advantages that: because the Su8 photoresist is selected as the mask for deep reactive ion etching of the inductively coupled plasmas, an effect of protecting an etched structure is achieved and the direct physical bombardment ofions caused by exposing a previous etching structure in the plasmas is effectively avoided; and the method has high process repeatability, can be used in the same component repeatedly and realizes three or more layers of monocrystalline silicon microstructures with a high aspect ratio.

Owner:TIANJIN SEAGULL WATCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com