Patents

Literature

51results about How to "Different sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

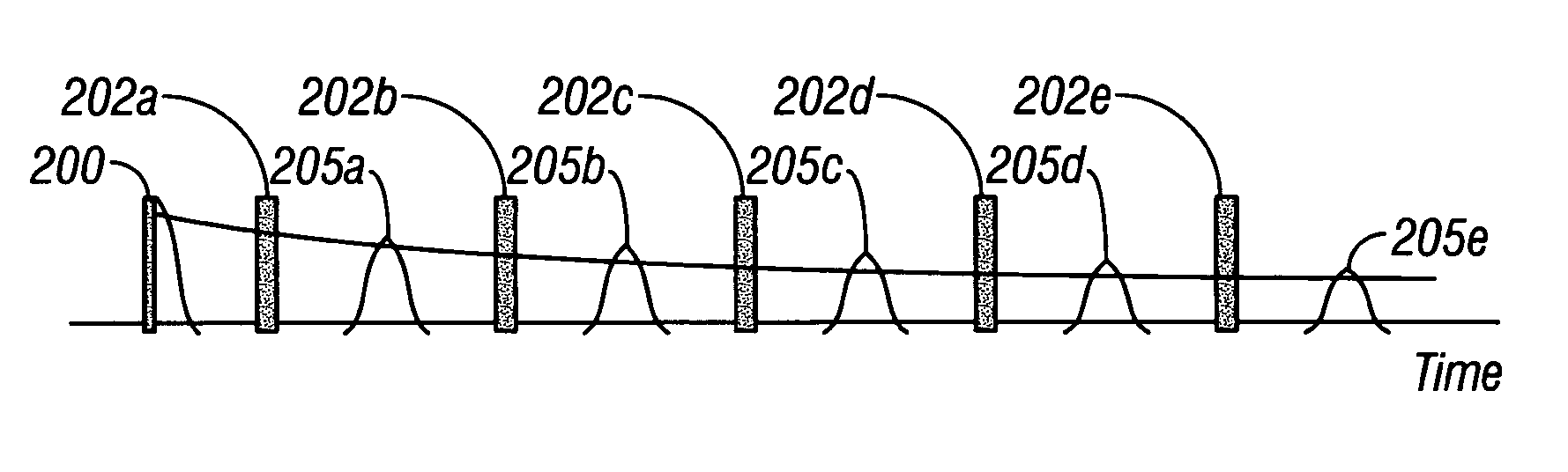

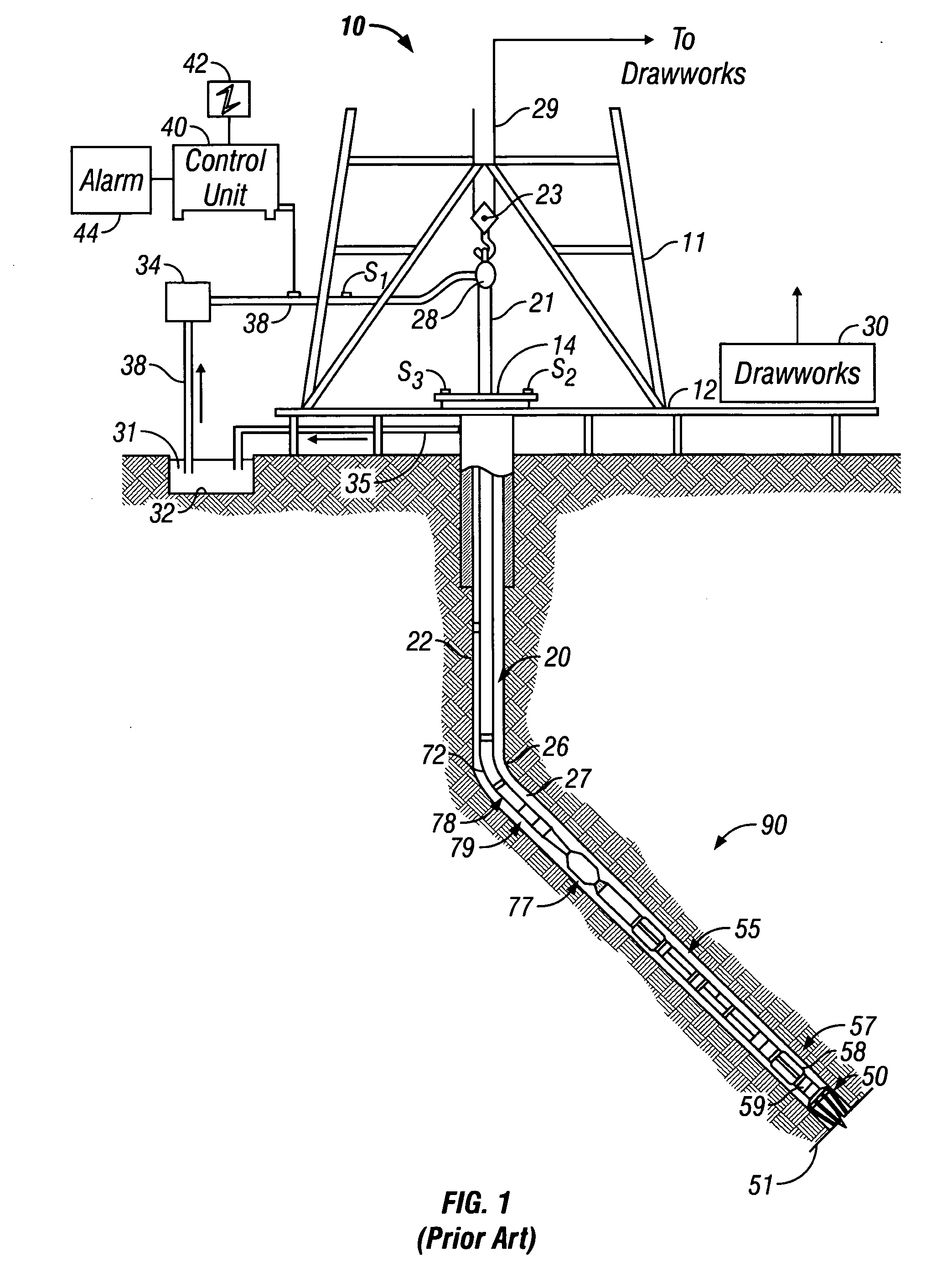

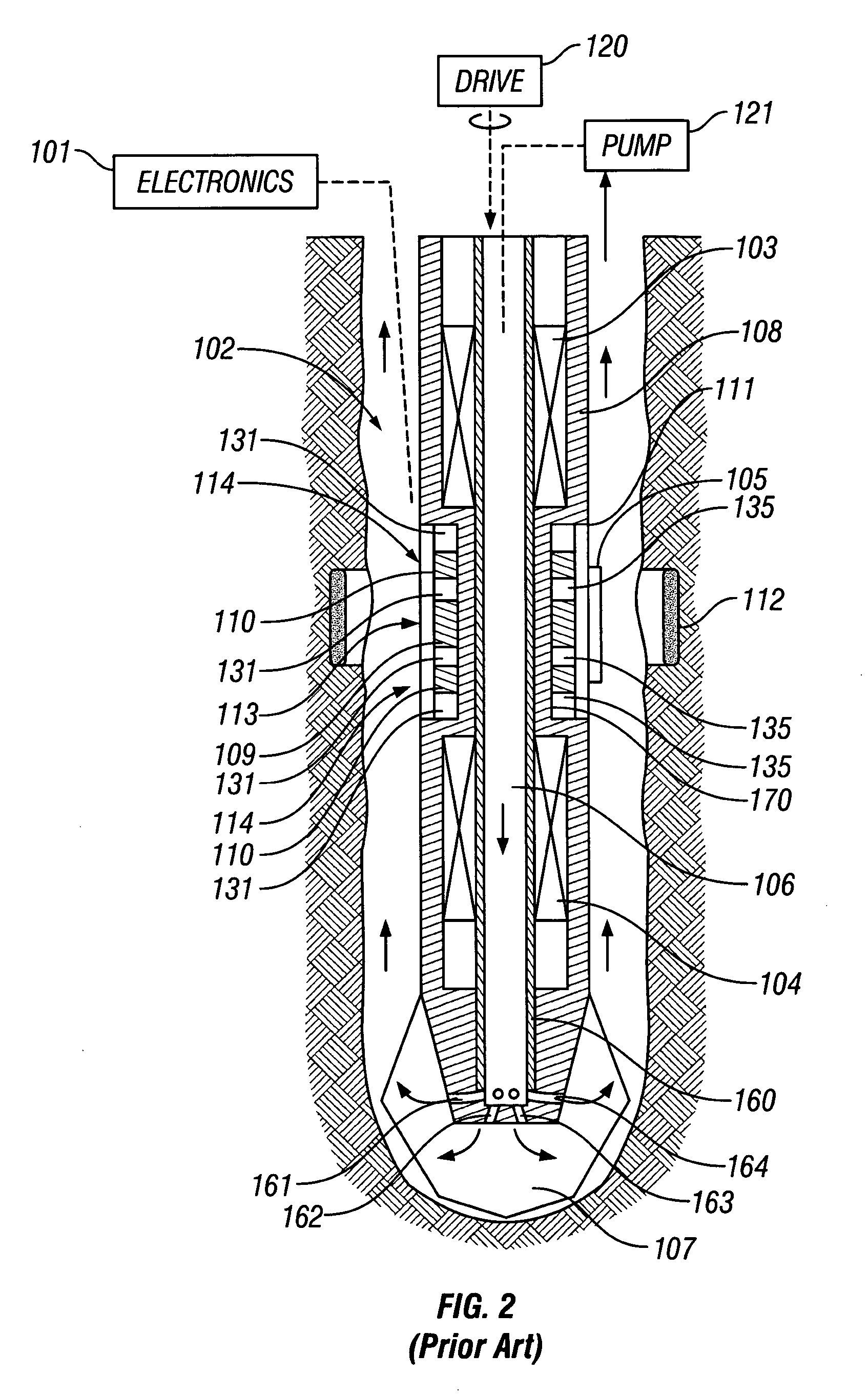

Reduction of motion artifacts in NMR

ActiveUS20050248342A1Different sensitivityElectric/magnetic detection for well-loggingDetection using electron/nuclear magnetic resonanceMagnetic fluxMotion artifacts

NMR spin echo signals, acquired on a MWD logging tool, are susceptible to errors magnetic flux density has a gradient and the magnet on the logging tool is moving relative to the earth. The errors can be corrected by having the excitation pulse cover a smaller or a larger volume than the refocusing pulses. Correction may also be made by selective saturation, or by echo averaging.

Owner:BAKER HUGHES INC

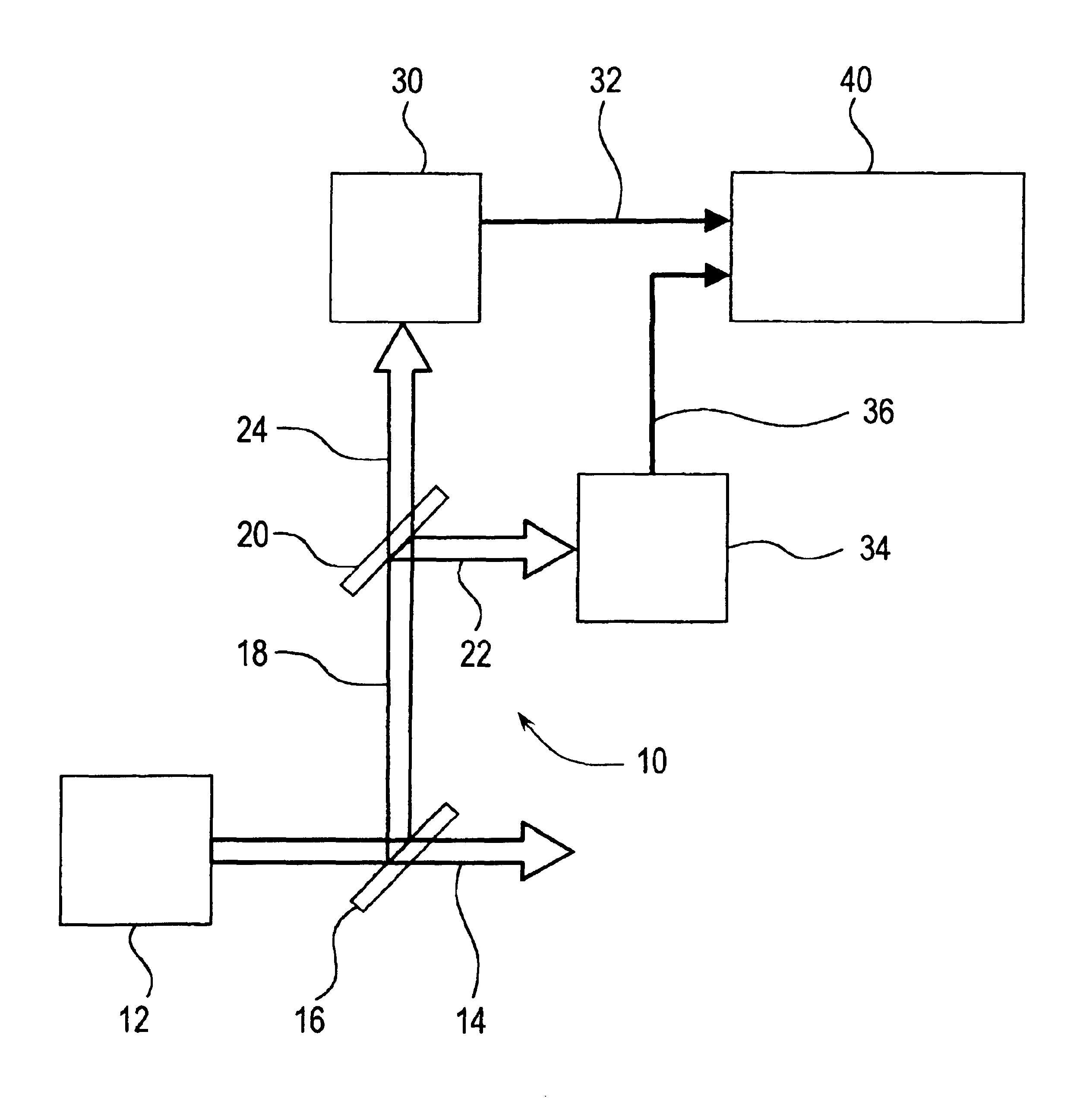

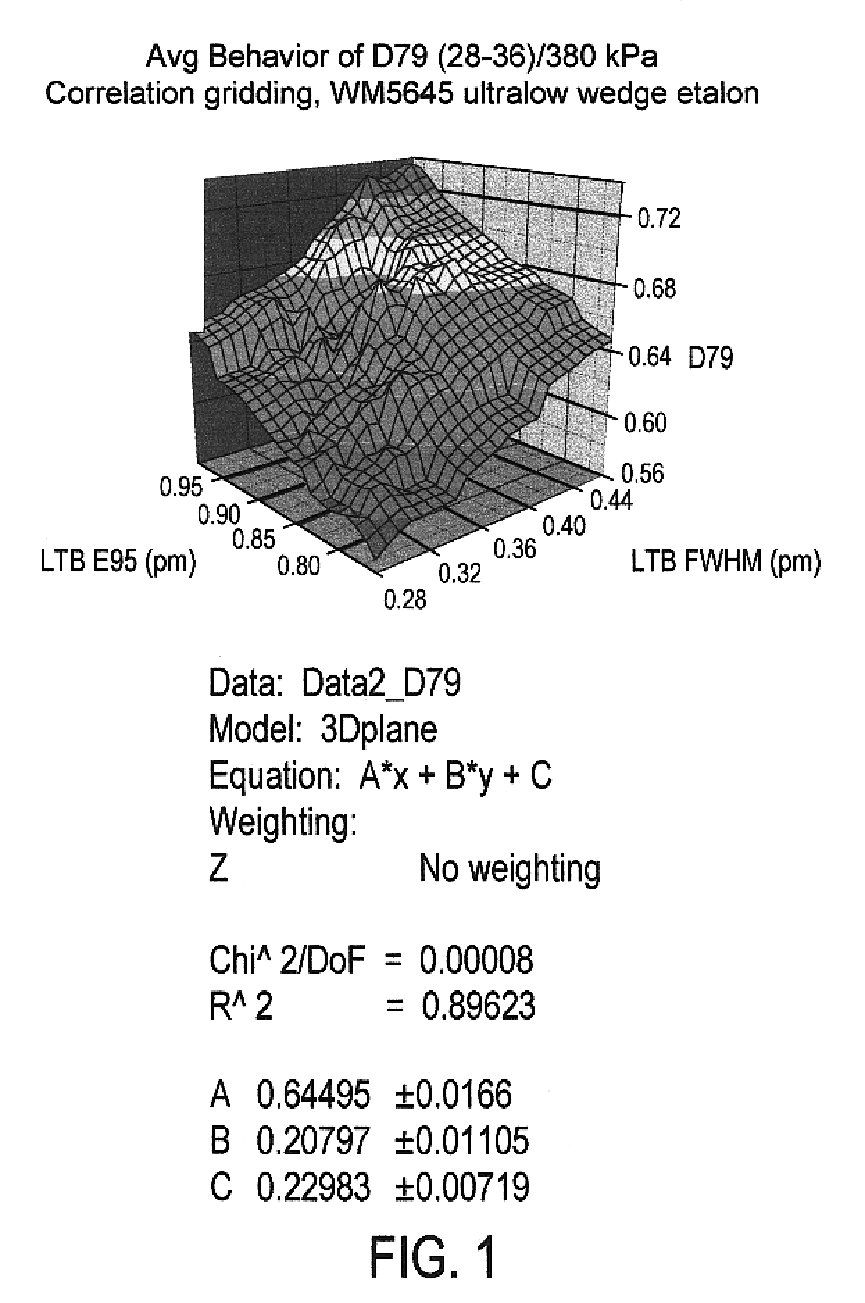

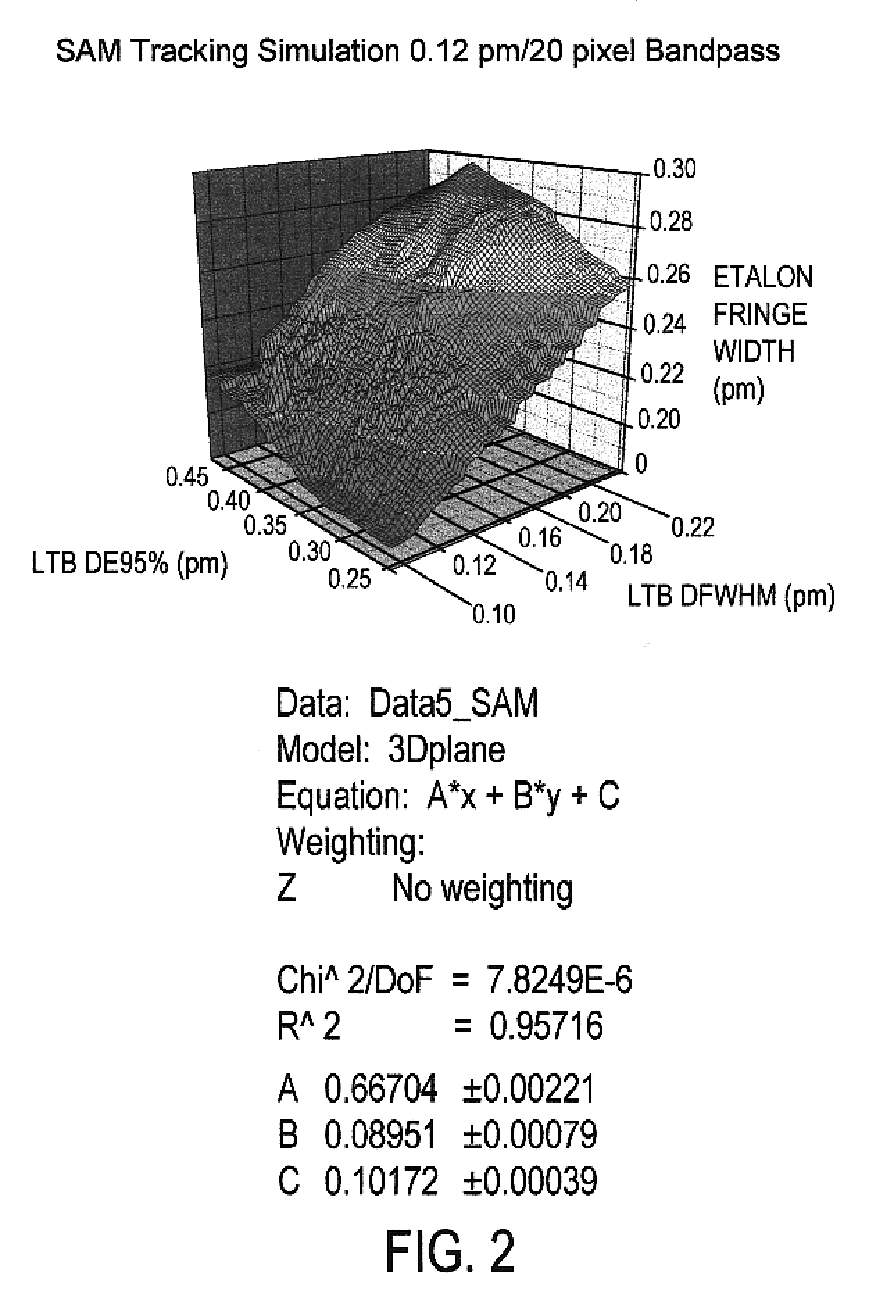

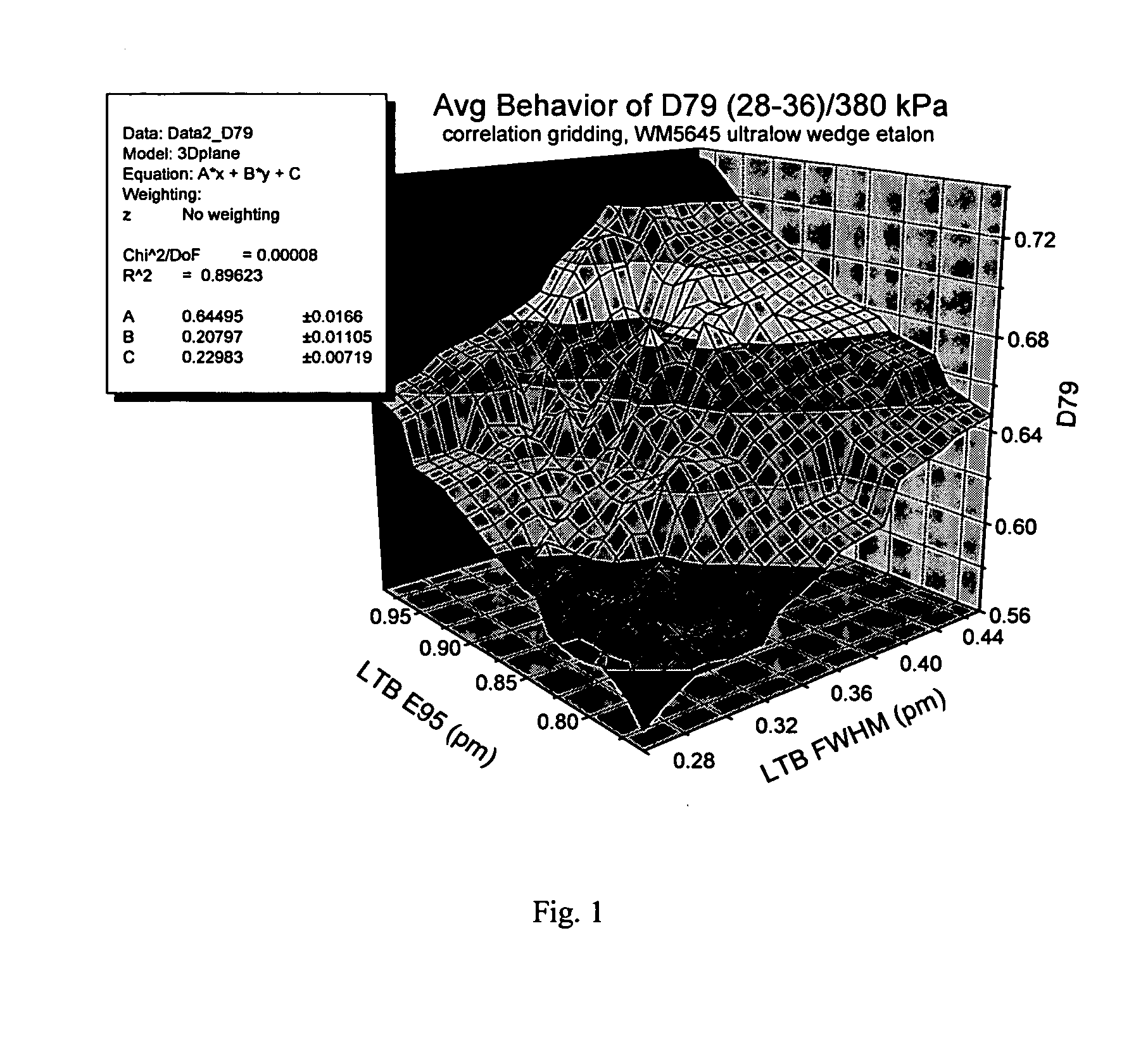

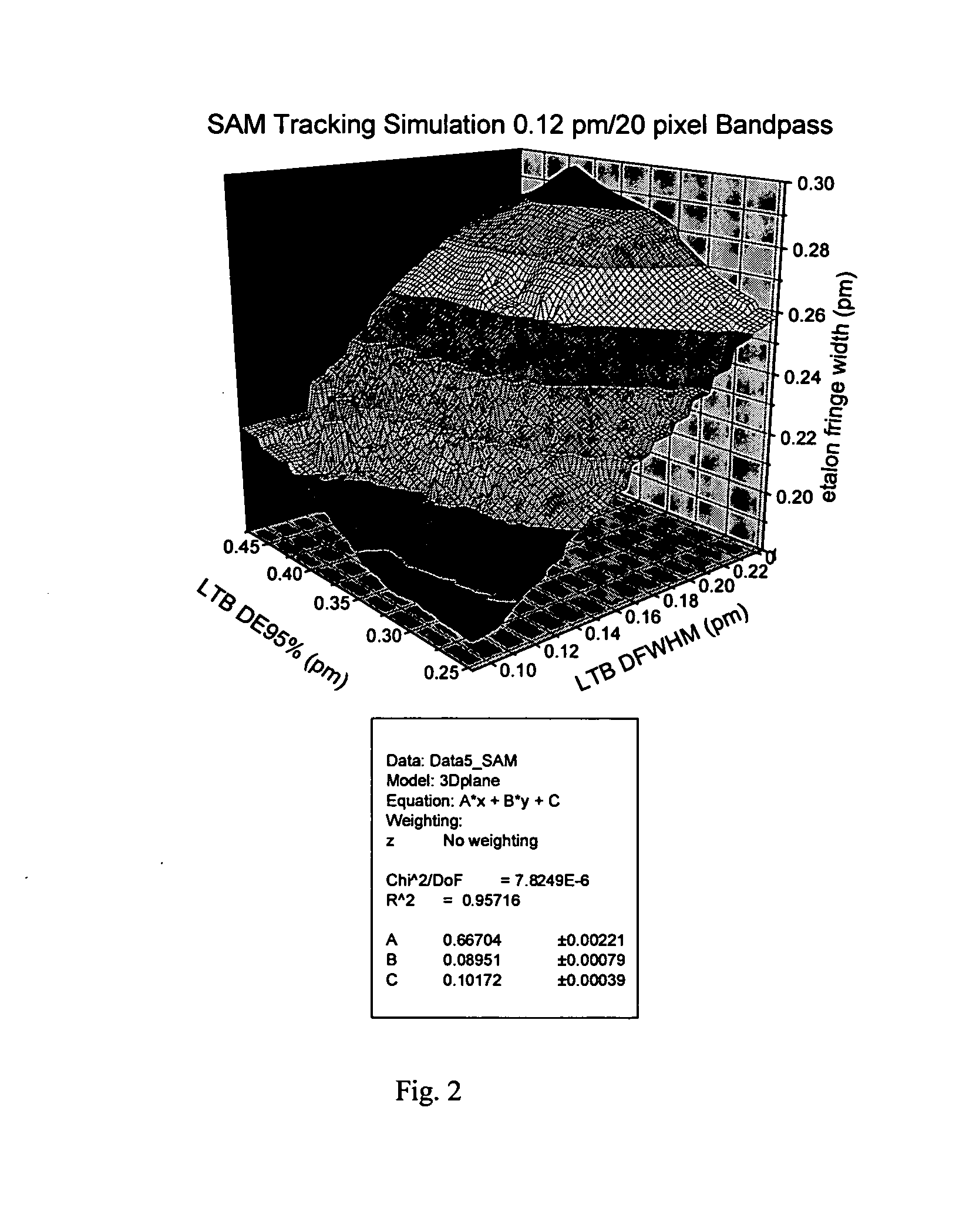

Method and apparatus for measuring bandwidth of a laser output

InactiveUS6952267B2Mitigate and similar errorDifferent bandwidthRadiation pyrometryInterferometric spectrometryFrequency spectrumLength wave

A method and apparatus for measuring bandwidth of light emitted from a laser which may comprise: first and second wavelength sensitive optical bandwidth detectors providing, respectively, an output representative of a first parameter indicative of the bandwidth of the emitted light as measured respectively by the first and second bandwidth detectors, and an actual bandwidth calculation apparatus adapted to utilize these two outputs as part of a multivariable linear equation employing predetermined calibration variables specific to either the first or the second bandwidth detector, to calculate a first actual bandwidth parameter or a second actual bandwidth parameter. The first actual bandwidth parameter may be a spectrum full width at some percent of the maximum (“FWXM”), and the second actual bandwidth parameter may be a portion containing some percentage of the energy (“EX”). The first and second bandwidth detectors may an etalon and the outputs may be representative of a fringe width of a fringe of an optical output of the respective etalon at FWXM. The precomputed calibration variables may be derived from respective three dimensional plots representing, respectively, detector outputs in relation to a calibrating input light with known values of the first and second actual bandwidth parameters.

Owner:CYMER INC

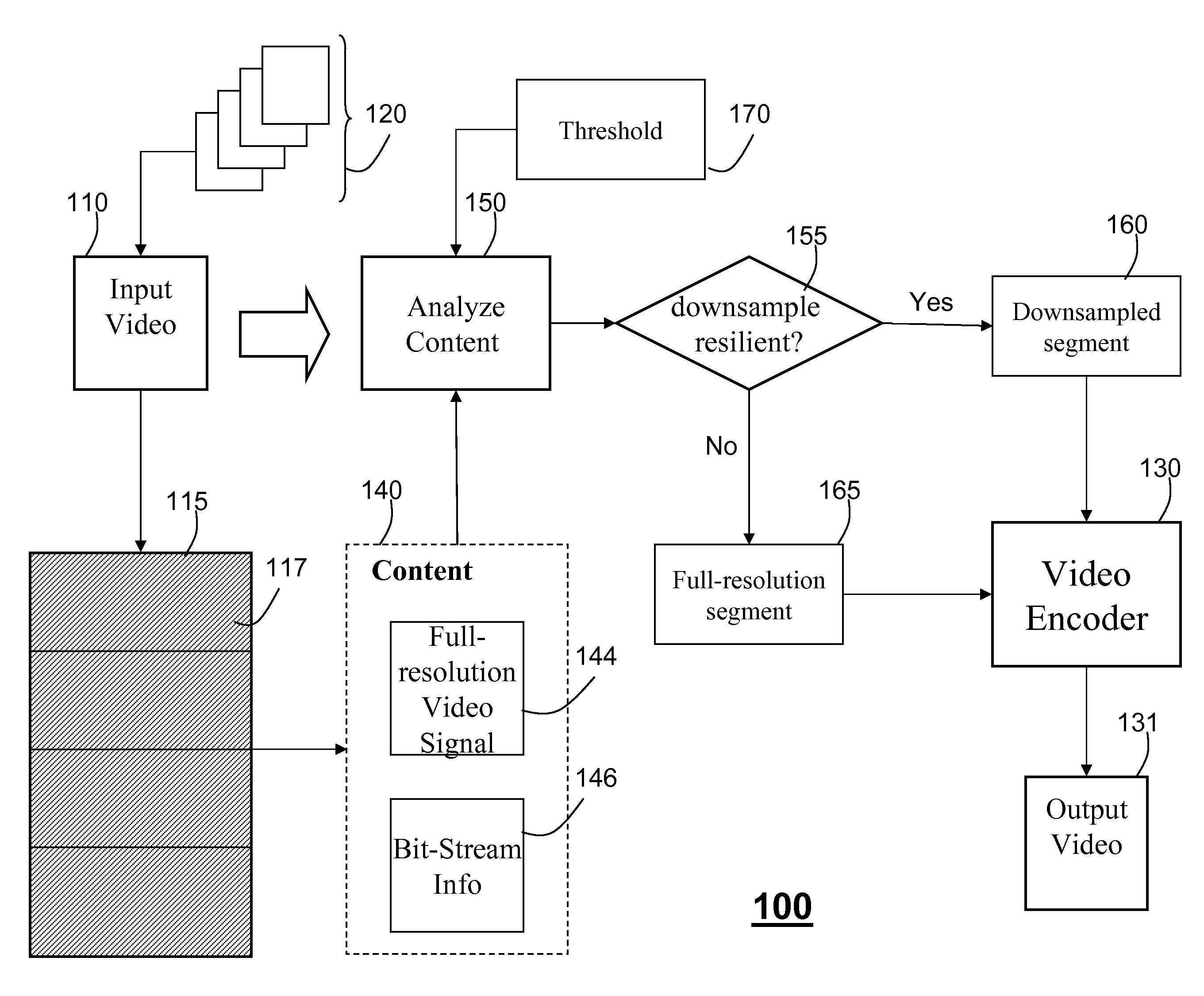

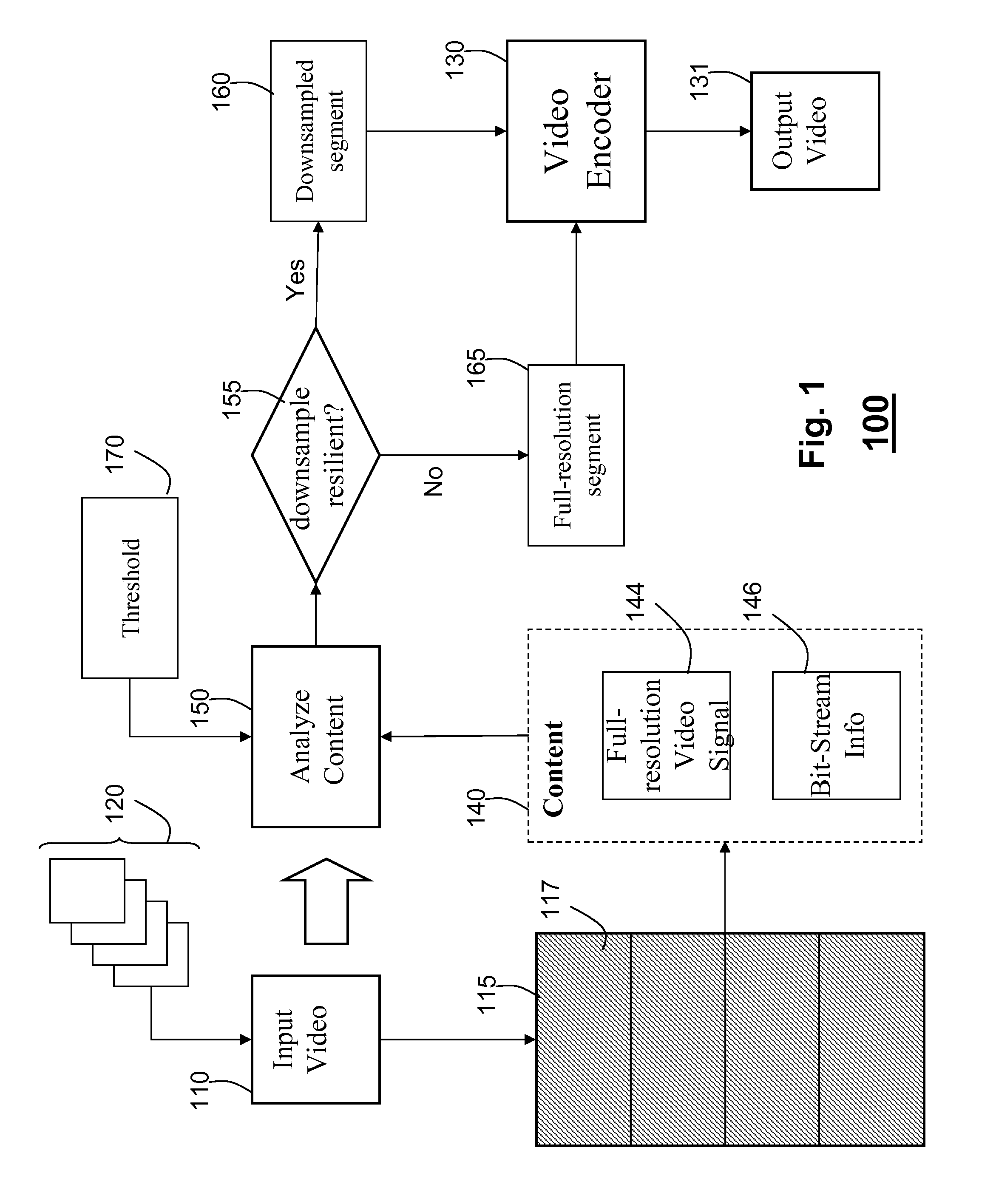

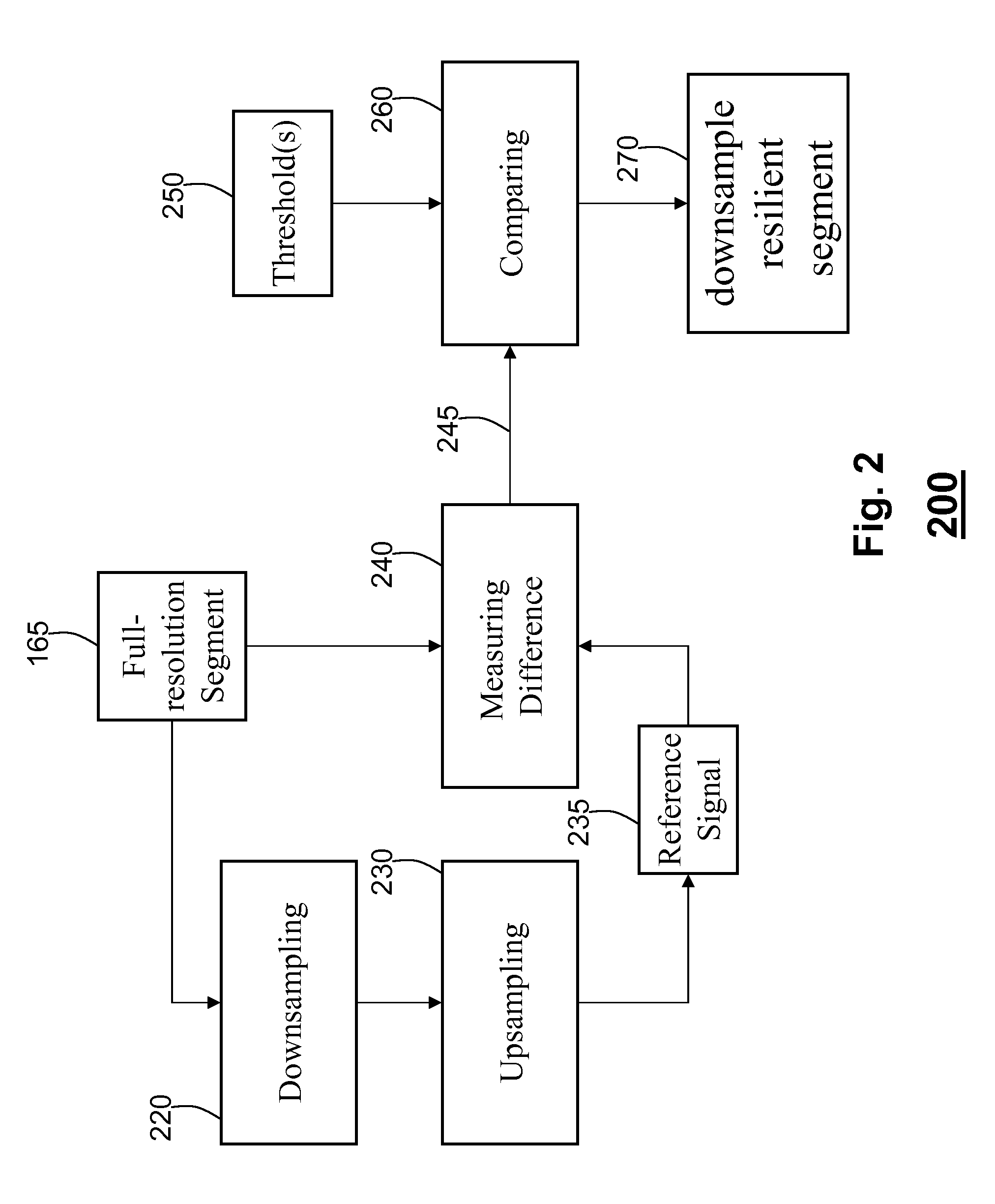

Adaptive Video Transcoding

InactiveUS20110013692A1Reduce complexityQuality improvementColor television with pulse code modulationColor television with bandwidth reductionComputer visionTranscoding

Embodiments of the invention describe a method for transcoding an input video in a first encoded format to an output video in a second encoded format, wherein the videos include a set of segments and each segment includes frames. First, the method is determining a set of downsample resilient segments in the input video and a set of full-resolution segments in the input video. Next, the method is downsampling the set of downsample resilient segments to produce a set of downsampled segments and transcoding the input video using the set of full-resolution segments and the set of downsampled segments to produce the output video including at least two segments with different resolutions.

Owner:MITSUBISHI ELECTRIC RES LAB INC

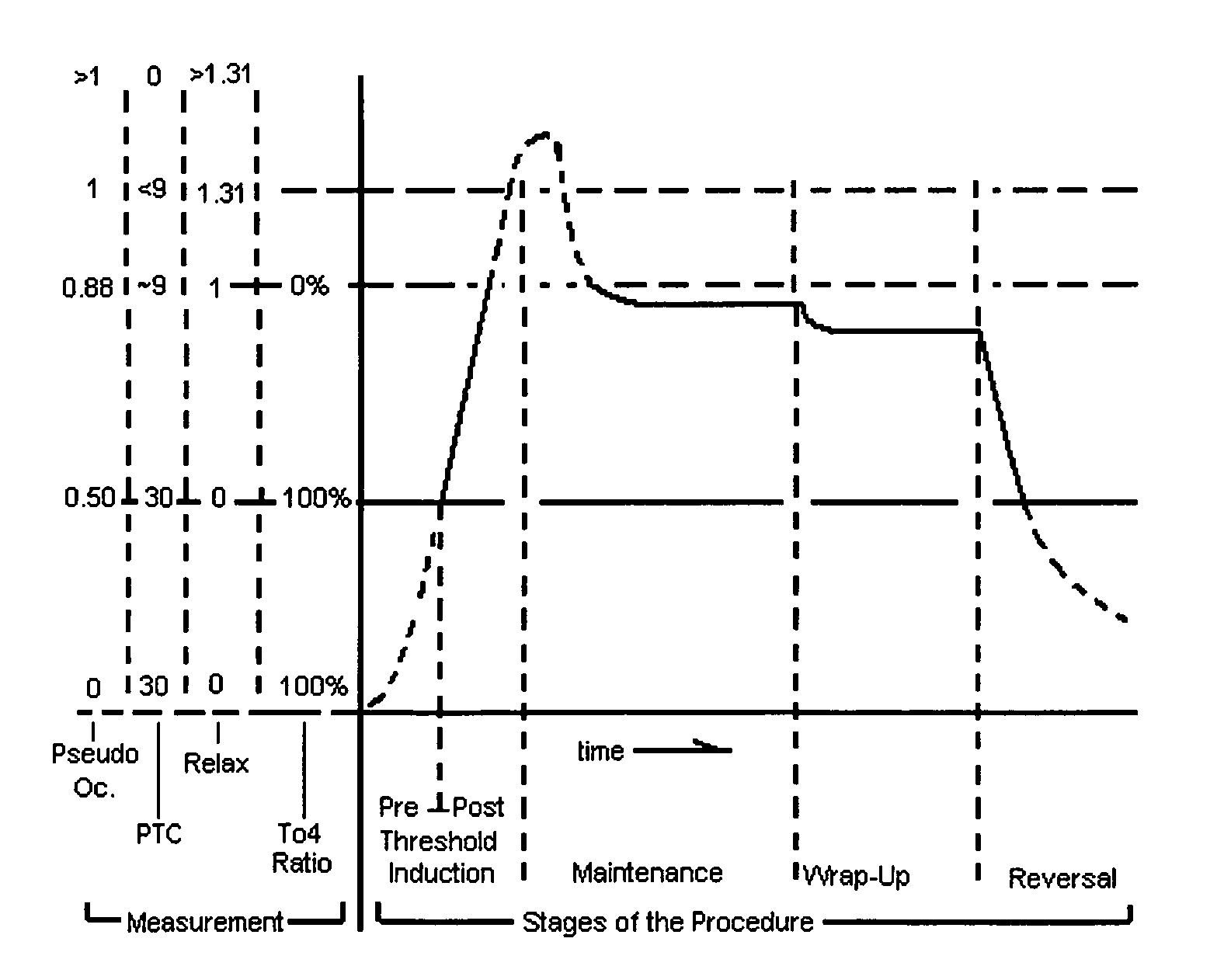

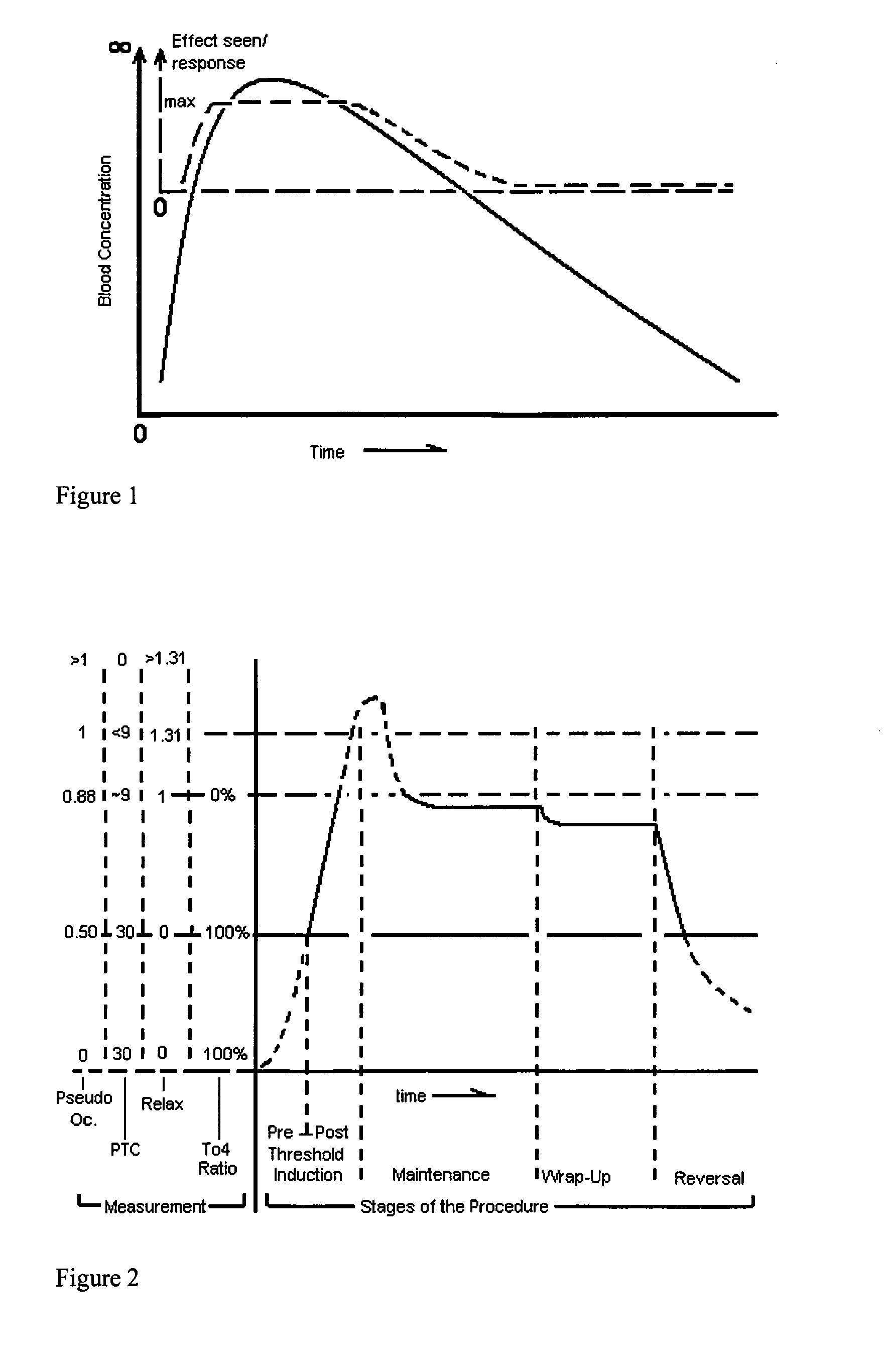

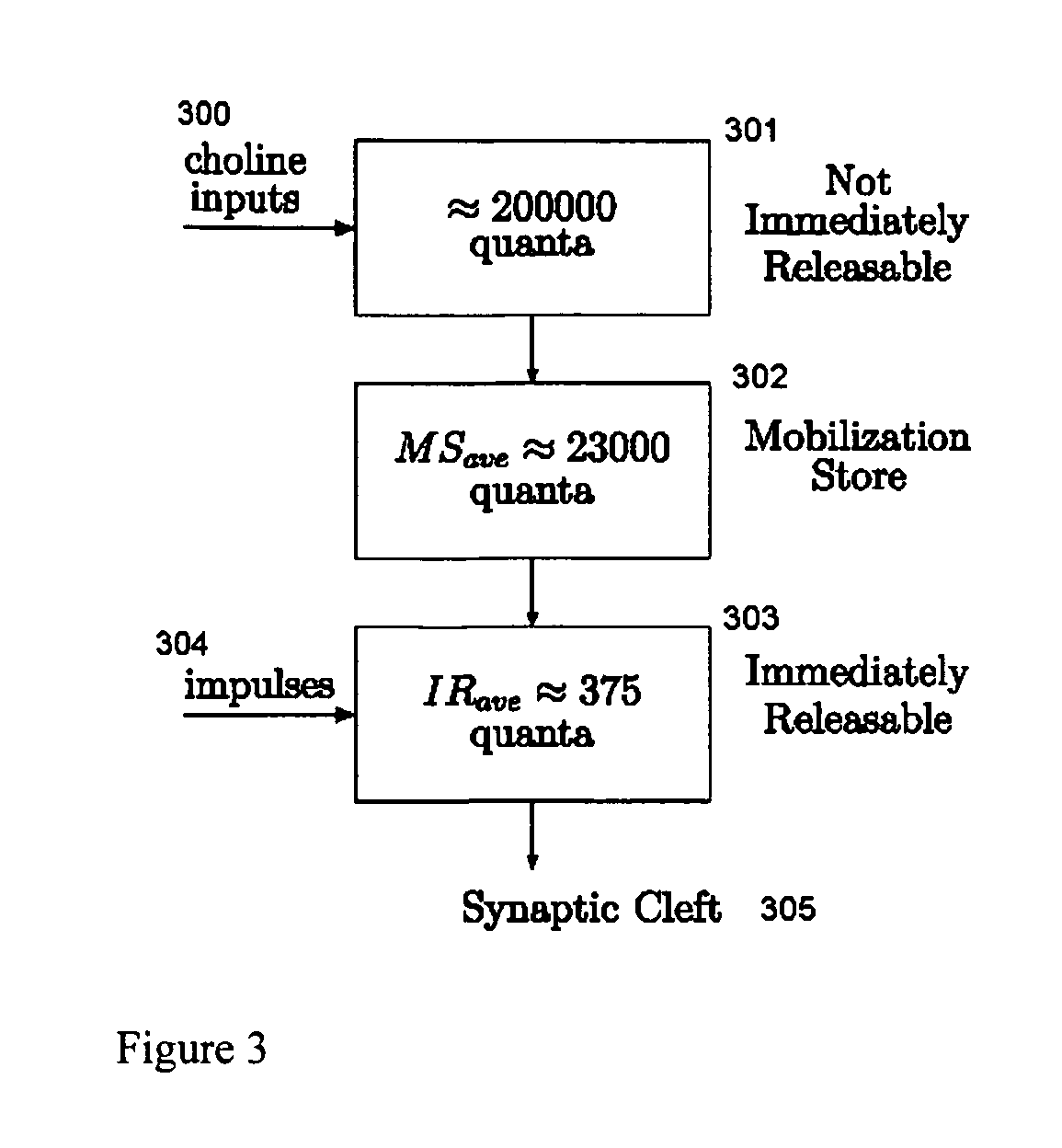

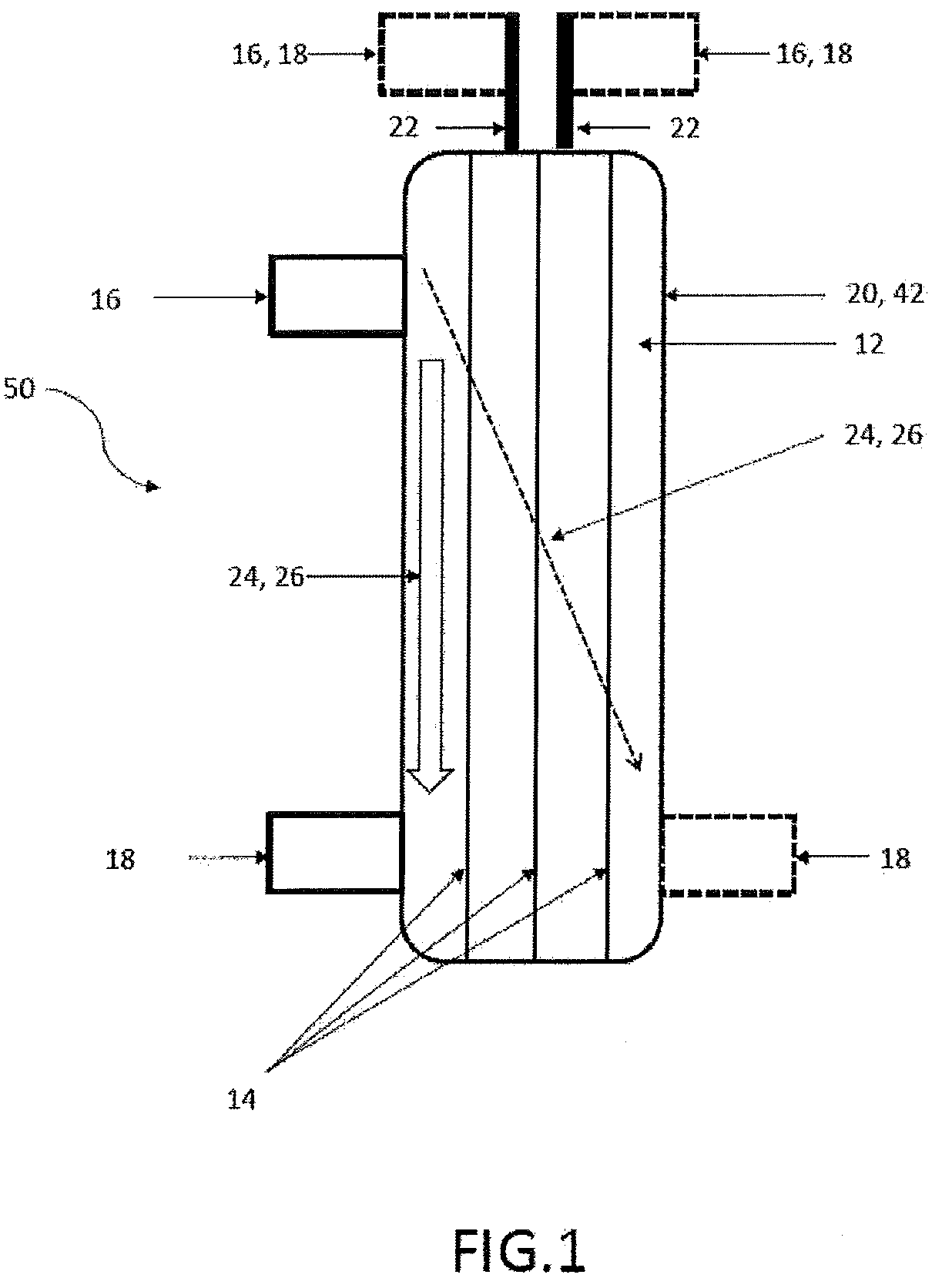

Improved sensors and sensing for monitoring neuromuscular blockade

InactiveUS20100081963A1Optimize dataIncrease the amount of dataMedical simulationDiagnostic signal processingMedicineNeurotransmitter storage

Improved sensors and sensing methods for detection of Neuromuscular Blockade (NMB), for example to improve monitoring generally, as well as facilitate automated NMB drug administration. The methods, systems, devices, etc., herein can increase the quantity and quality of data available. The methods, etc., include translation between commonly available sensing types, use of partially saturated sensor measurements, use of a model of neurotransmitter storage and release and sophisticated use of more than one sensor simultaneously. These methods are aided by new sensors and methods of decreasing electrical noise. An implementation of the methods, systems, devices, etc., herein is automated drug delivery for NMB, whether through an advisor system or through with full computer control.

Owner:GILHULY TERENCE

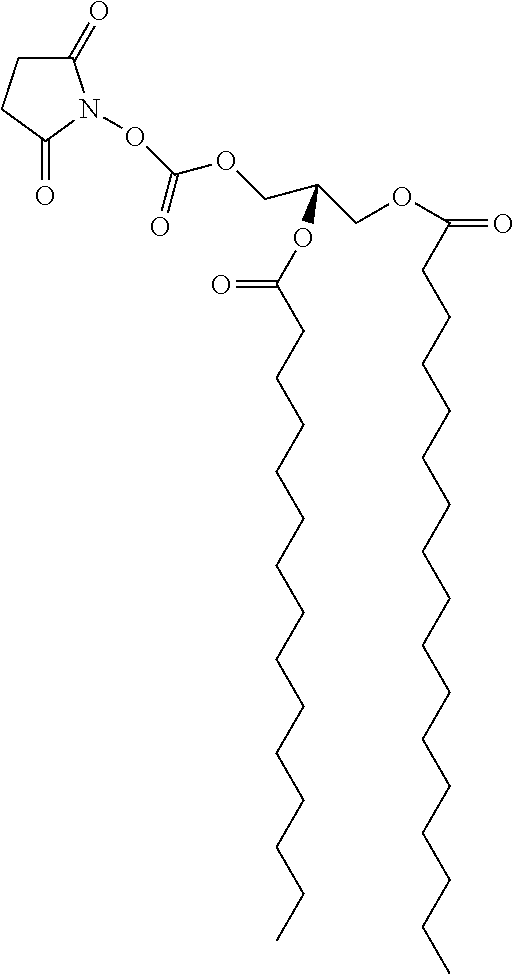

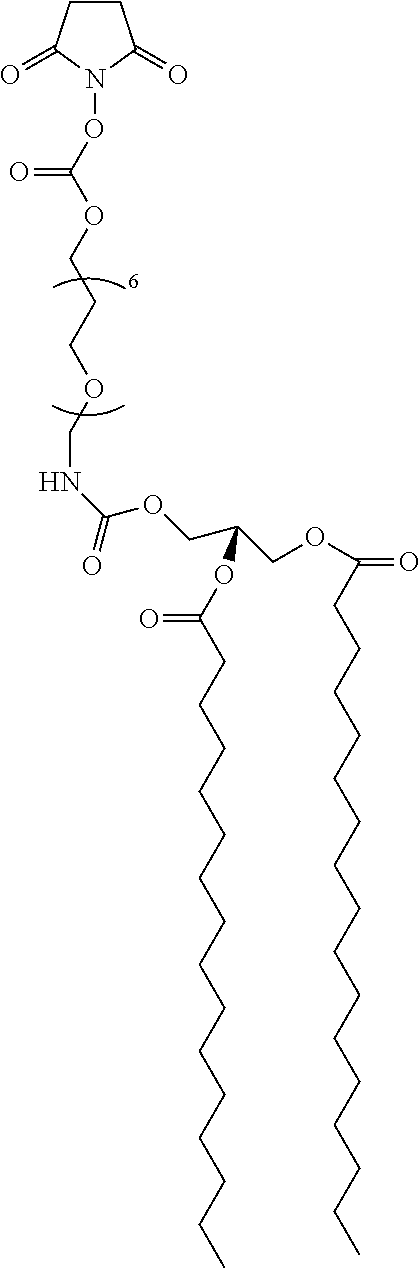

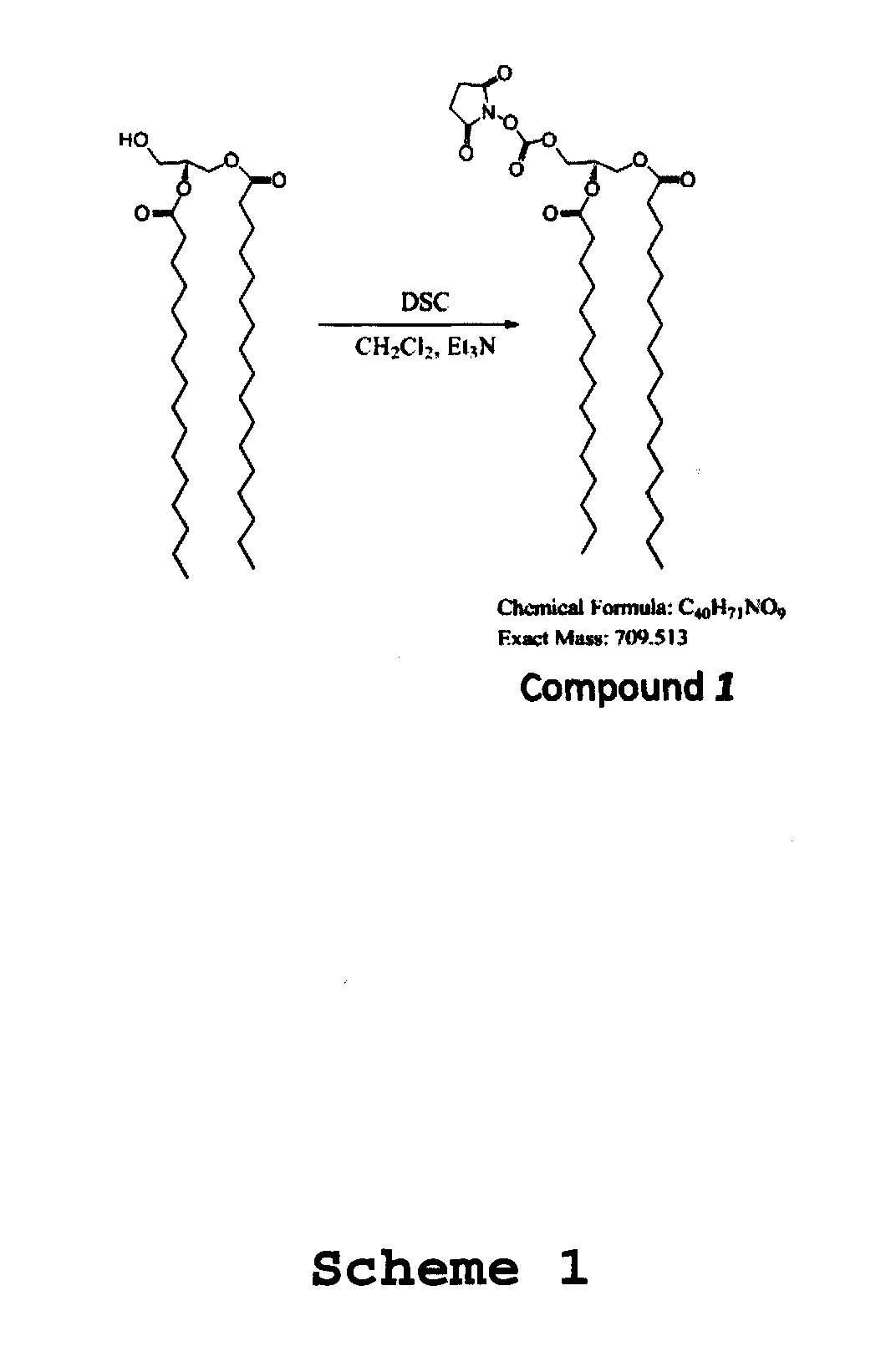

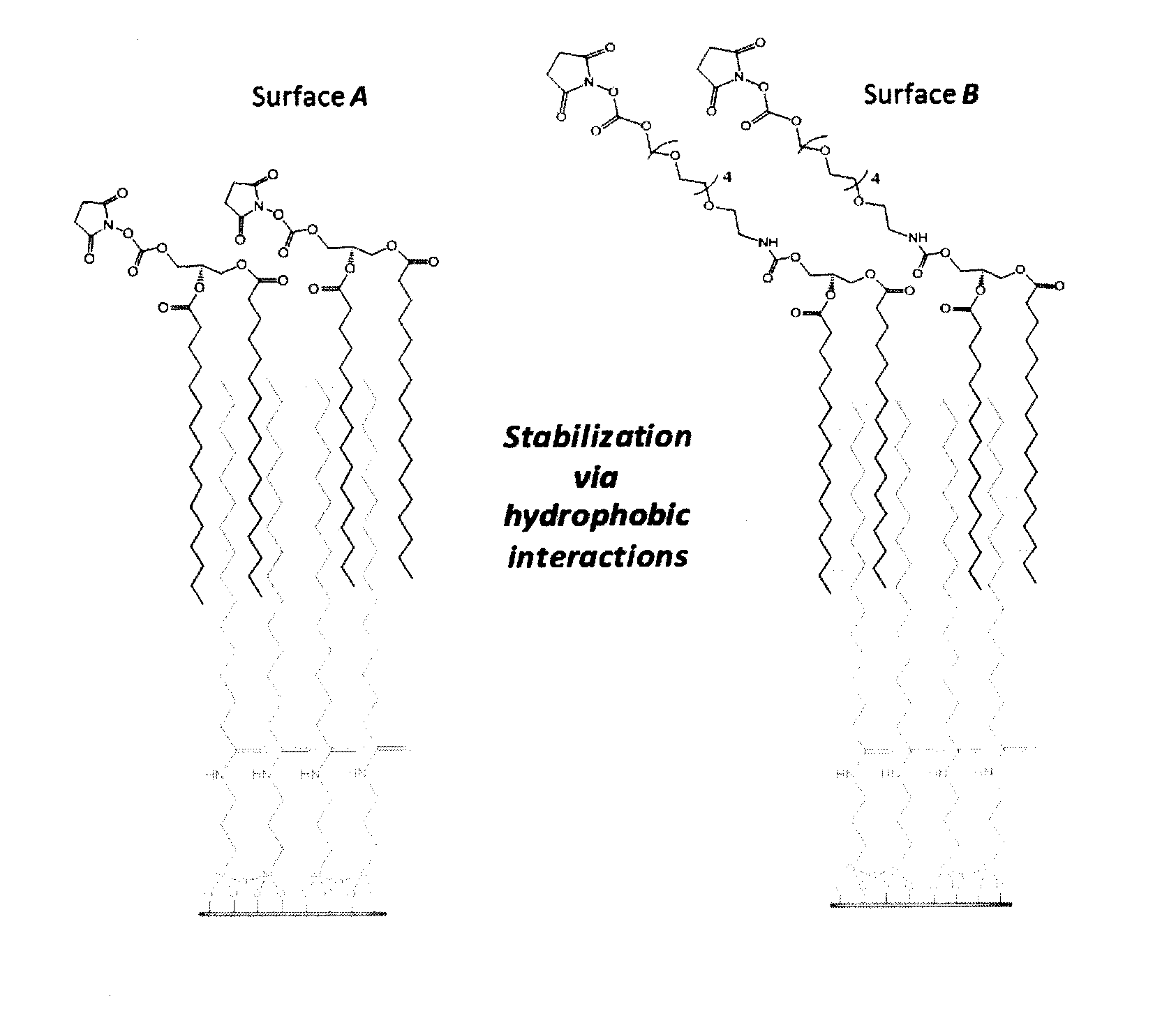

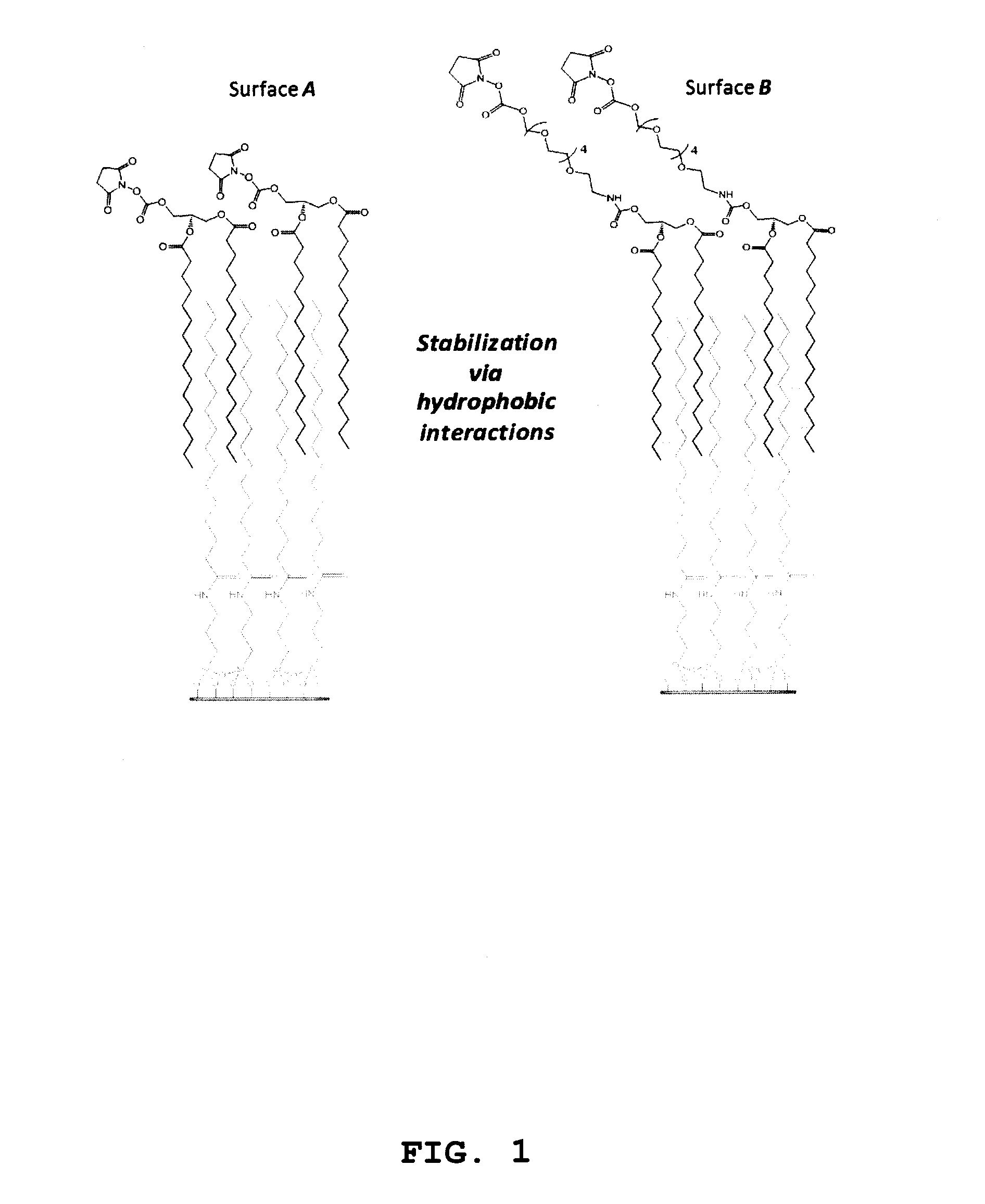

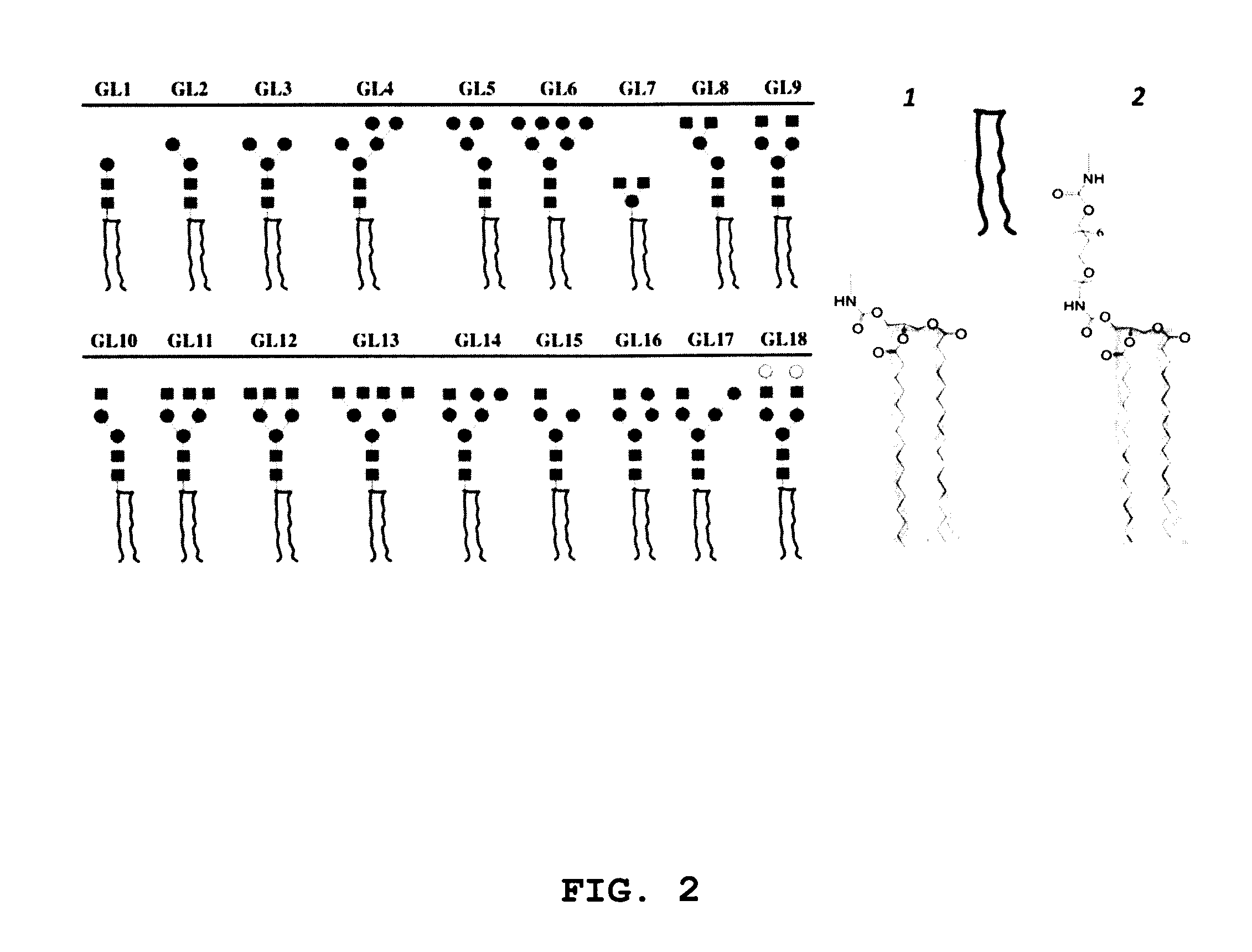

Methods for making microarrays and their uses

ActiveUS20140274771A1Limiting scale and degreeAvoid wastingPeptide librariesLibrary screeningFluorescenceSurface binding

The present invention provides microarrays that can be analysed by more than one technique using a non-covalent ligand attachment strategy to solid supports such as indium tin oxide (ITO) covered transparent glass slides. This provides, inter alia, glycan arrays on a micrometer scale which allow multimodal readout by MALDI-Tof-MS, fluorescence and optical microscopy. Glycans functionalized with a C5-aminolinker were attached in situ on a picomolar scale to a hydrophobic tag bound to this surface, thus avoiding the wasteful off-chip ligand tagging of other approaches. Glycan arrays prepared using this methodology were analysed both with a fluorescence scanner and by on-chip MALDI-mass spectrometry in a series of glycomics experiments specifically requiring a multimodal readout.

Owner:ASOCIACION CENT DE INVESTIGACION COOP & BIOMATERIALES - CIC BIOMAGUNE

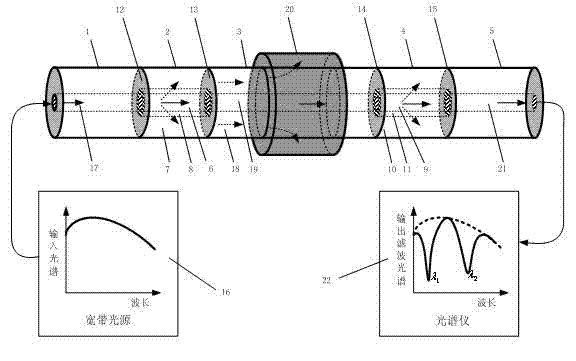

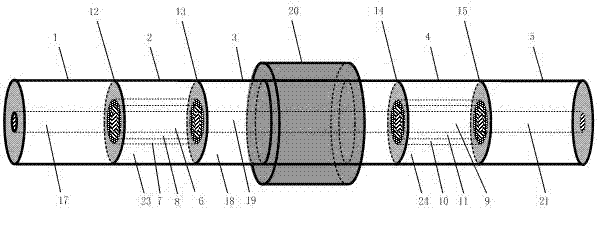

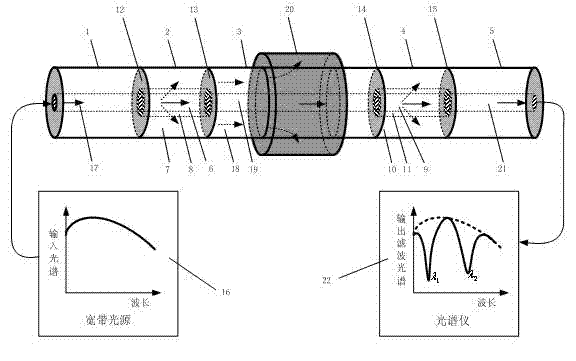

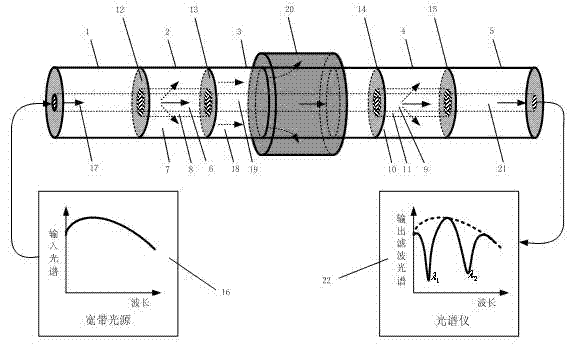

Dual-parameter optical fiber sensor for temperature and stress based on coaxial optical fiber

InactiveCN102261967ADifferent SensitivitySimple preparation processForce measurement by measuring optical property variationThermometers using physical/chemical changesResonanceLength wave

The invention relates to a coaxial optical fiber-based temperature and stress dual-parameter optical fiber sensor which is formed by sequentially connecting a single mode input optical fiber, a first coaxial optical fiber, an intermediate single mode optical fiber, a second coaxial optical fiber and a single mode output optical fiber, wherein the single mode input optical fiber, the first coaxialoptical fiber and the intermediate single mode optical fiber are sequentially welded to form a first sensing unit; and the intermediate single mode optical fiber, the second coaxial optical fiber andthe single mode output optical fiber are sequentially welded to form a second sensing unit. The first coaxial optical fiber and the second coaxial optical fiber have different structural parameters, the first sensing unit and the second sensing unit have resonance filtering spectrums with different wavelengths; and the two resonance filtering spectrums have different sensitivities for two parameters, namely the temperature and the stress, thereby the dual-parameter optical fiber sensor can be realized. The coaxial optical fiber-based temperature and stress dual-parameter optical fiber sensor disclosed by the invention has the advantages of simple preparation process, low cost, compact structure, stable performance, easiness for integration with a standard single mode optical fiber system,and the like.

Owner:SHANGHAI UNIV

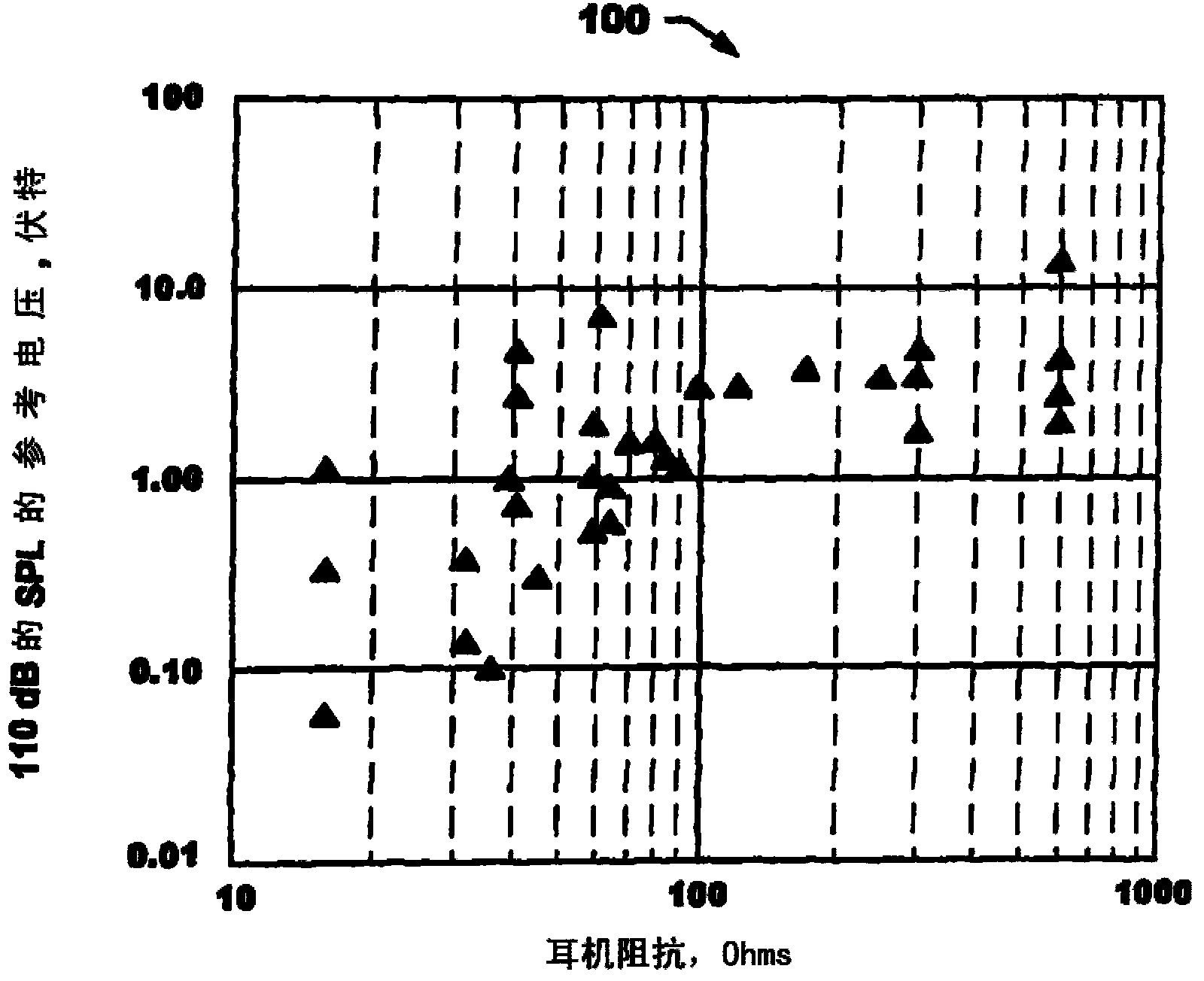

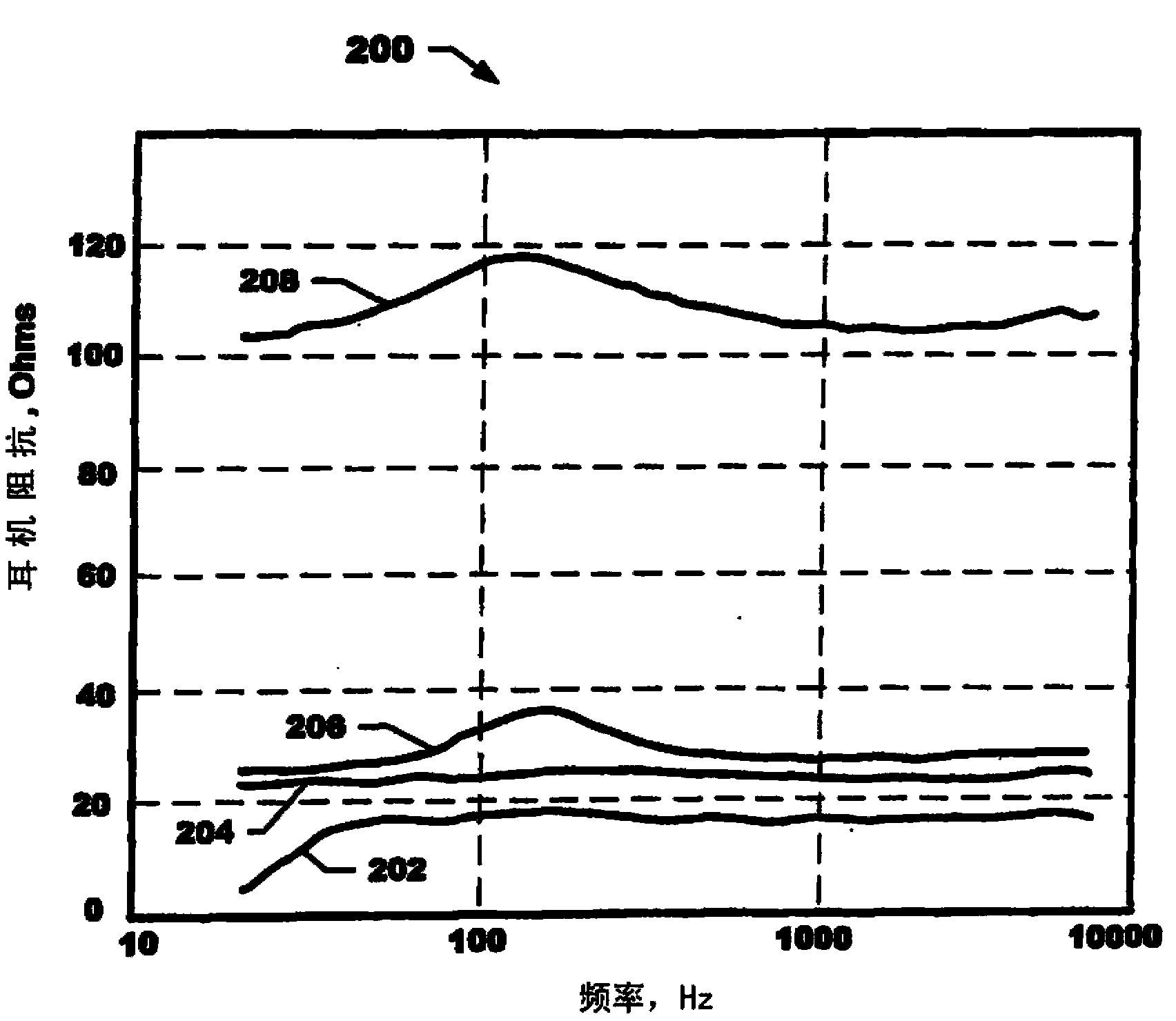

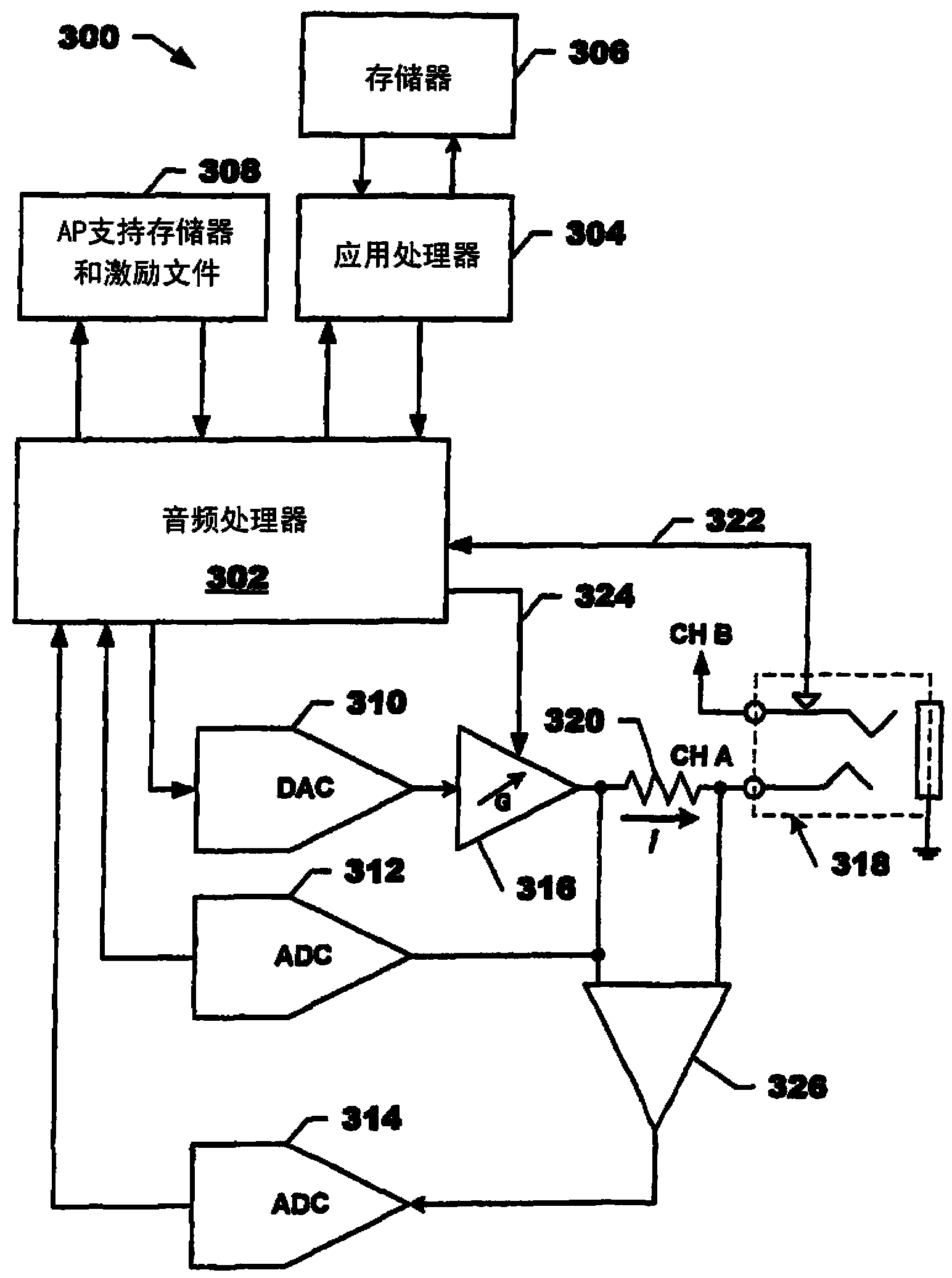

System and method for optimized playback of audio signals through headphones

ActiveCN103546852ADifferent sensitivityDifferent impedance characteristicsEarpiece/earphone mechanical/electrical switchesAudio power amplifierHeadphones

The application discloses a system and method for playback of audio signals though a large variety of headphone devices. To optimize playback, the specific headphone device is identified so the proper amplifier gain and equalization settings can be applied. Such identification is determined by measuring the headphone impedance as a function of frequency, and comparing the impedance data with data of know devices in a database. Once a match is found, the appropriate audio gain and equalization settings can be applied.

Owner:MAXIM INTEGRATED PROD INC

Optical bandwidth meter for laser light

ActiveUS20050007600A1Little computational overheadSimple equationRadiation pyrometryInterferometric spectrometryFrequency spectrumLaser light

A method and apparatus for measuring bandwidth of light emitted from a laser is disclosed which may comprise: a first and second wavelength sensitive optical bandwidth detectors providing, respectively, an output representative of a first parameter indicative of the bandwidth of the emitted light as measured respectively by the first and second bandwidth detectors, and an actual bandwidth calculation apparatus adapted to utilize these two outputs as part of a multivariable linear equation employing predetermined calibration variables specific to either the first or the second bandwidth detector, to calculate a first actual bandwidth parameter or a second actual bandwidth parameter. The first actual bandwidth parameter may be a spectrum full width at some percent of the maximum (“FWXM”), and the second actual bandwidth parameter may be a portion containing some percentage of the energy (“EX”). The first and second bandwidth detectors may an etalon and the outputs may be representative of a fringe width of a fringe of an optical output of the respective etalon at FWXM. The precomputed calibration variables may be derived from respective three dimensional plots representing, respectively, detector outputs in relation to a calibrating input light with known values of the first and second actual bandwidth parameters, which may be FWXM and EX. The first / second three dimensional plot may provide a solution: (first / second output)=(a / d*(calibrating input light known value of FWXM))+(b / e*(calibrating input light known value of EX)+c / f; and the actual bandwidth calculation apparatus may use the derived equation: (first actual bandwidth parameter)=((b*(second output))−(e*(first output))+ce−bf) / (bd−ae), or the equation: (second actual bandwidth parameter)=((a*(second output))−(d*(first output))+cd−af) / (ae−bd). FWXM may be FWHM and EX may be E95. The transfer function of the first optical bandwidth detector may be selected to be much more sensitive to FWXM than to EX and the transfer function of the second optical bandwidth detector may be selected to be much more sensitive to EX than to FWXM.

Owner:CYMER INC

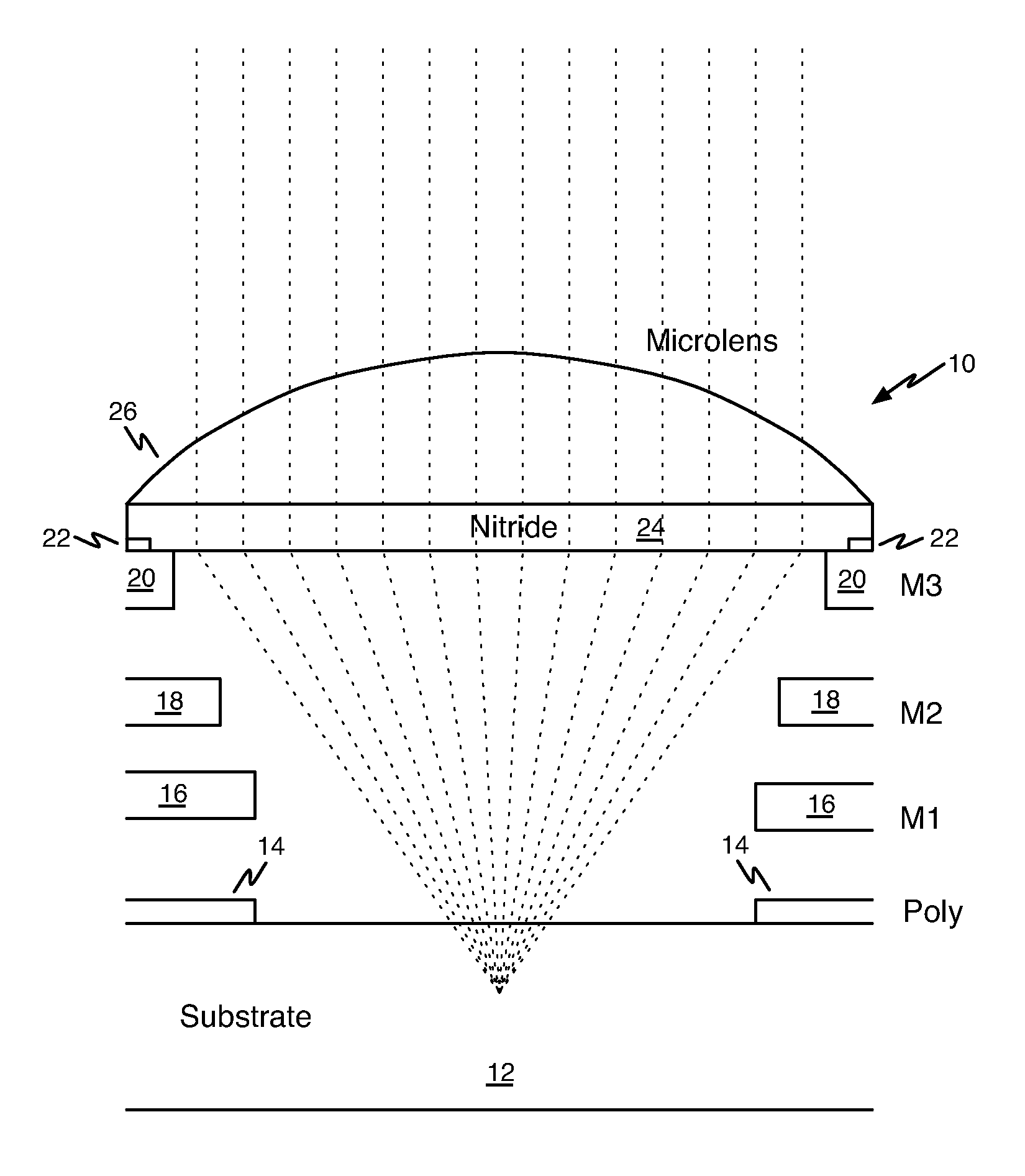

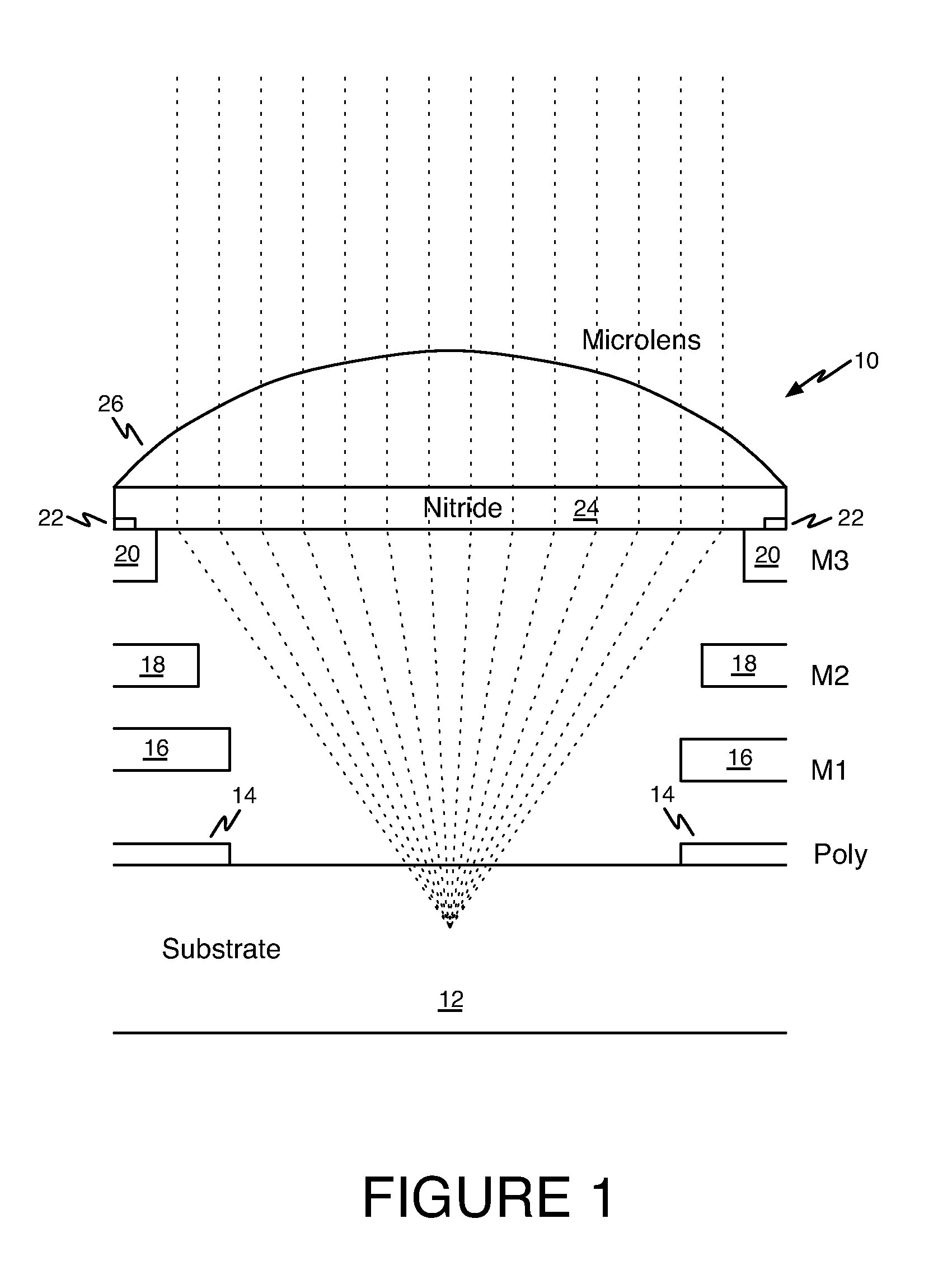

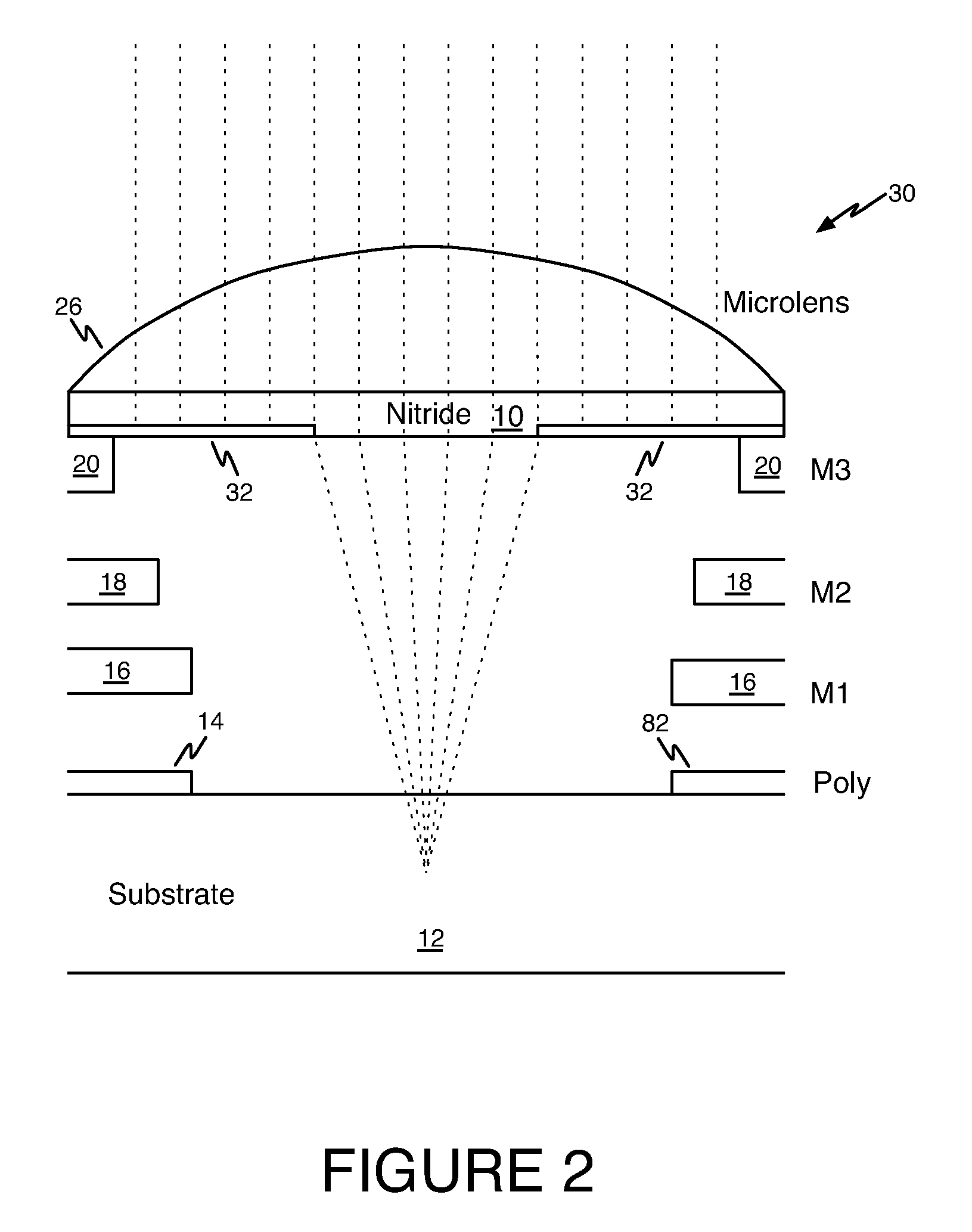

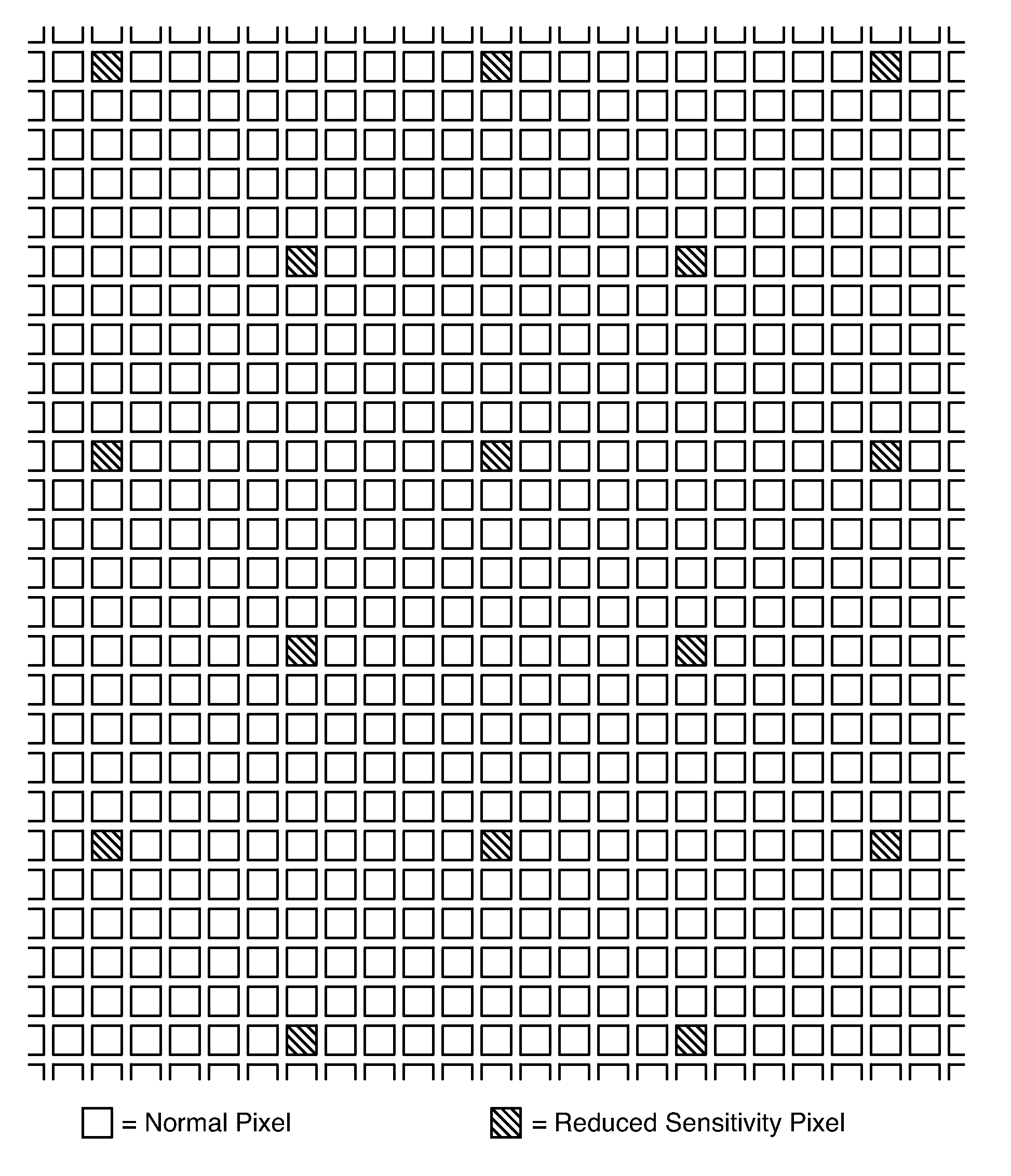

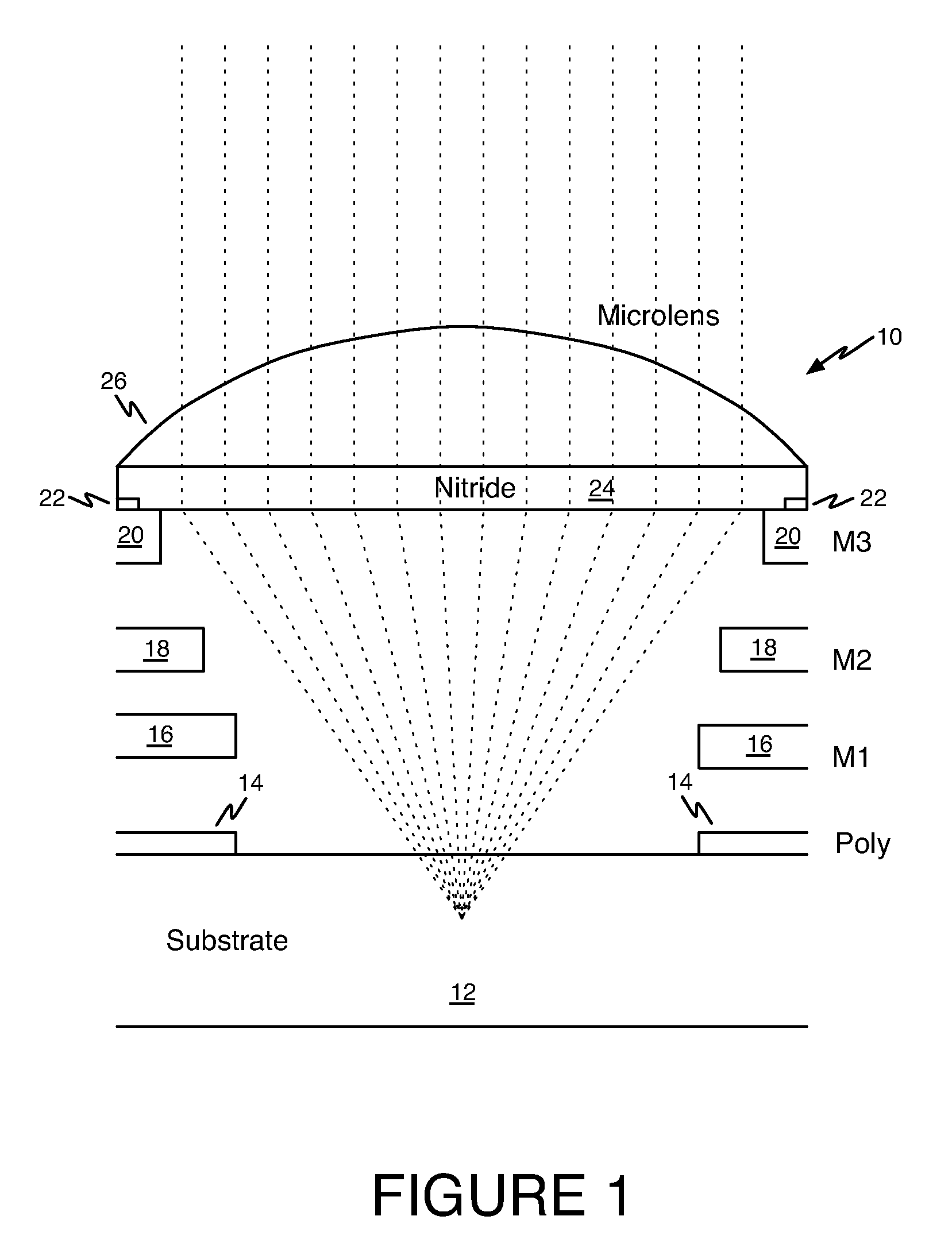

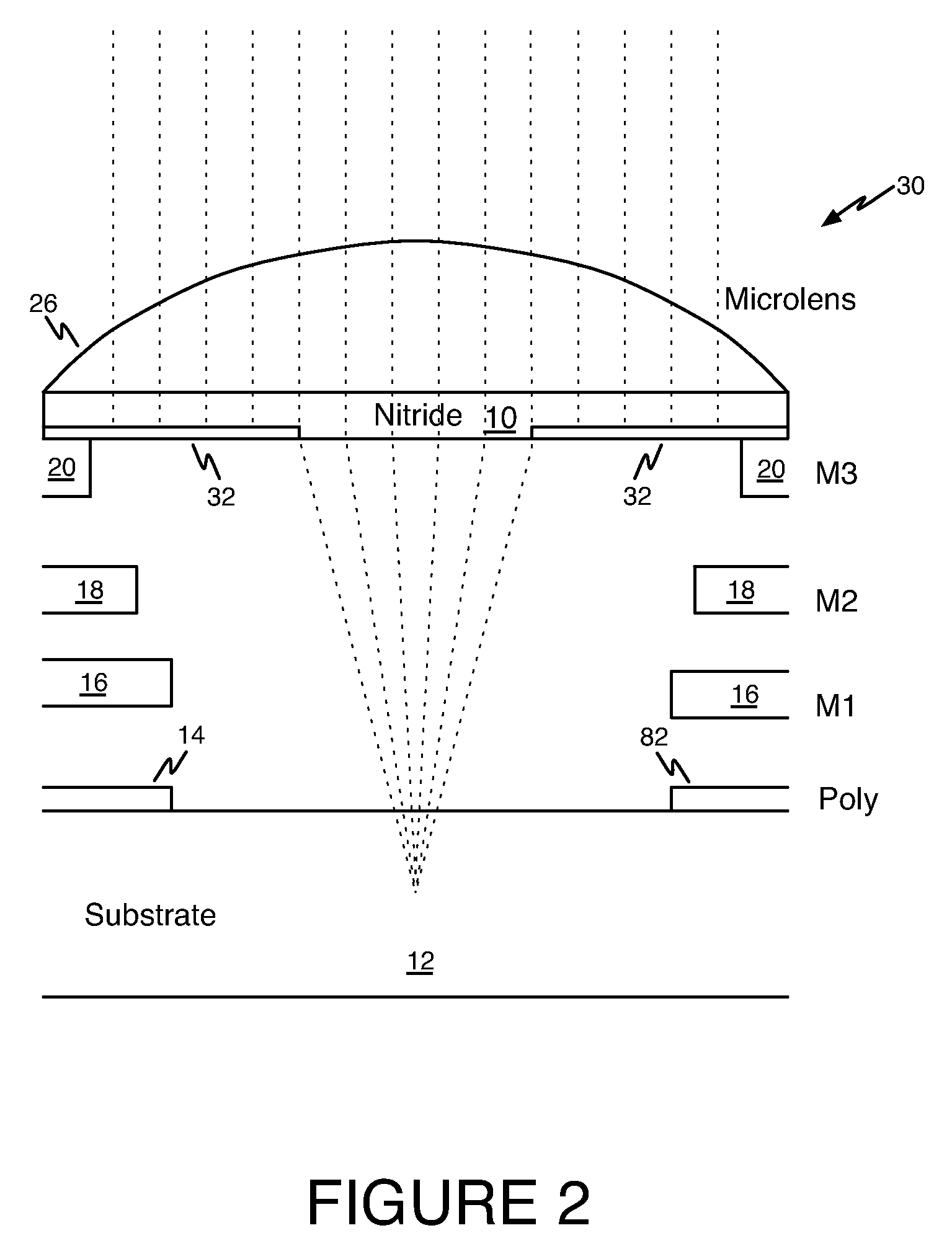

Imaging array having photodiodes with different light sensitivities and associated image restoration methods

ActiveUS20130027591A1Improve dynamic rangeEnhances quality rangeTelevision system detailsColor signal processing circuitsSensor arrayImage restoration

A pixel sensor array includes a plurality of pixel sensors having a first gain and a plurality of pixel sensors having a second gain less than the first gain.

Owner:FOVEON

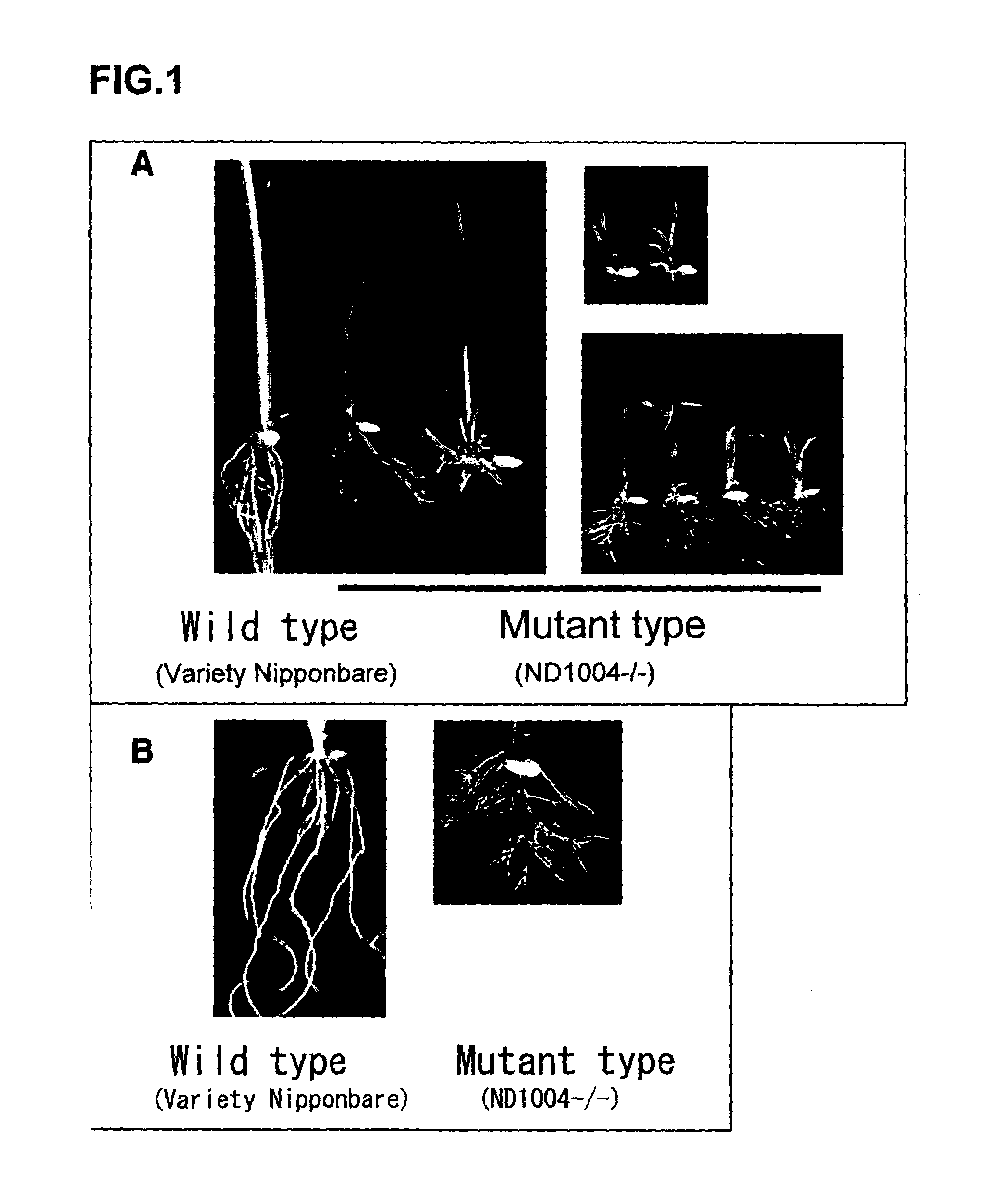

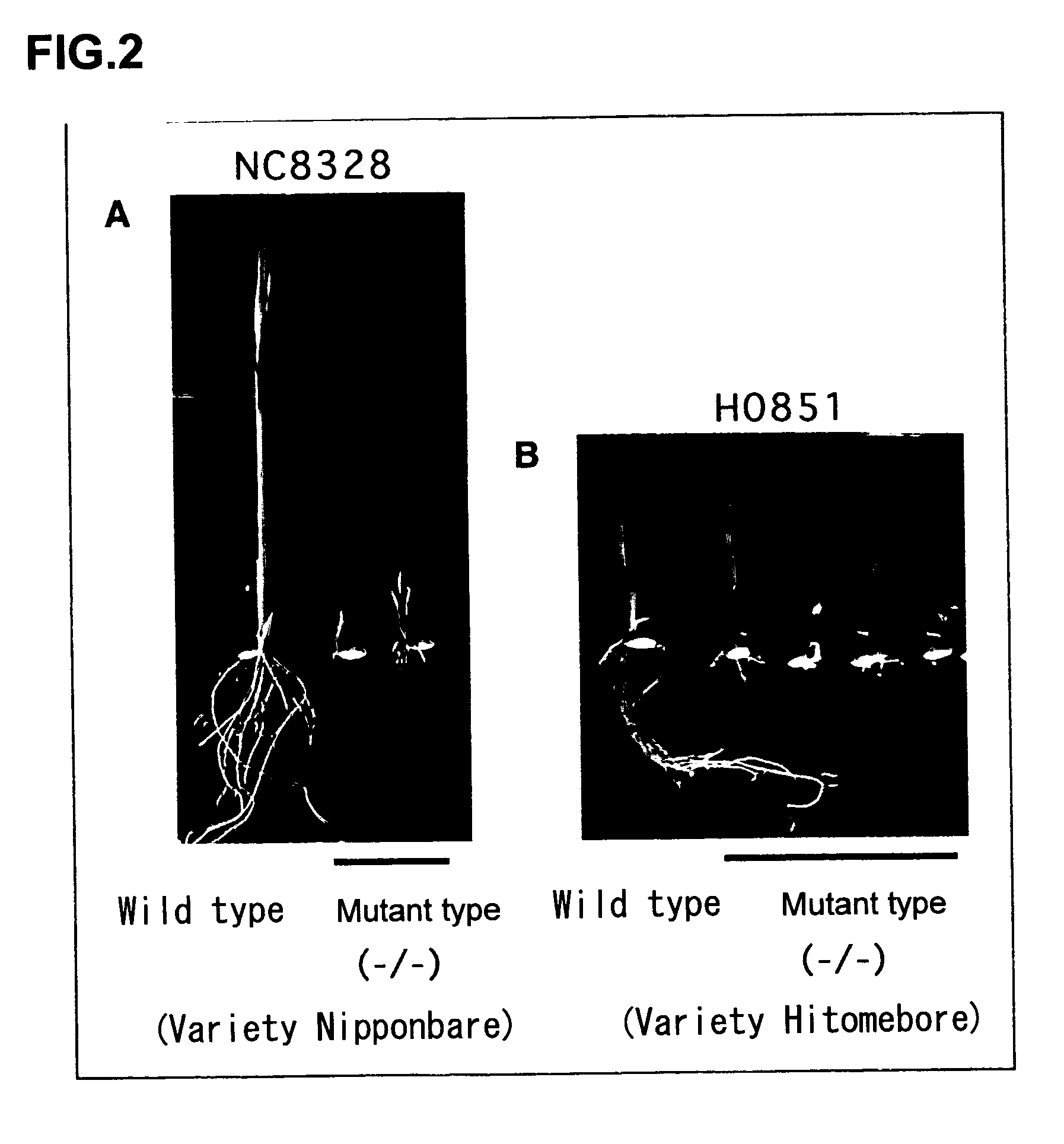

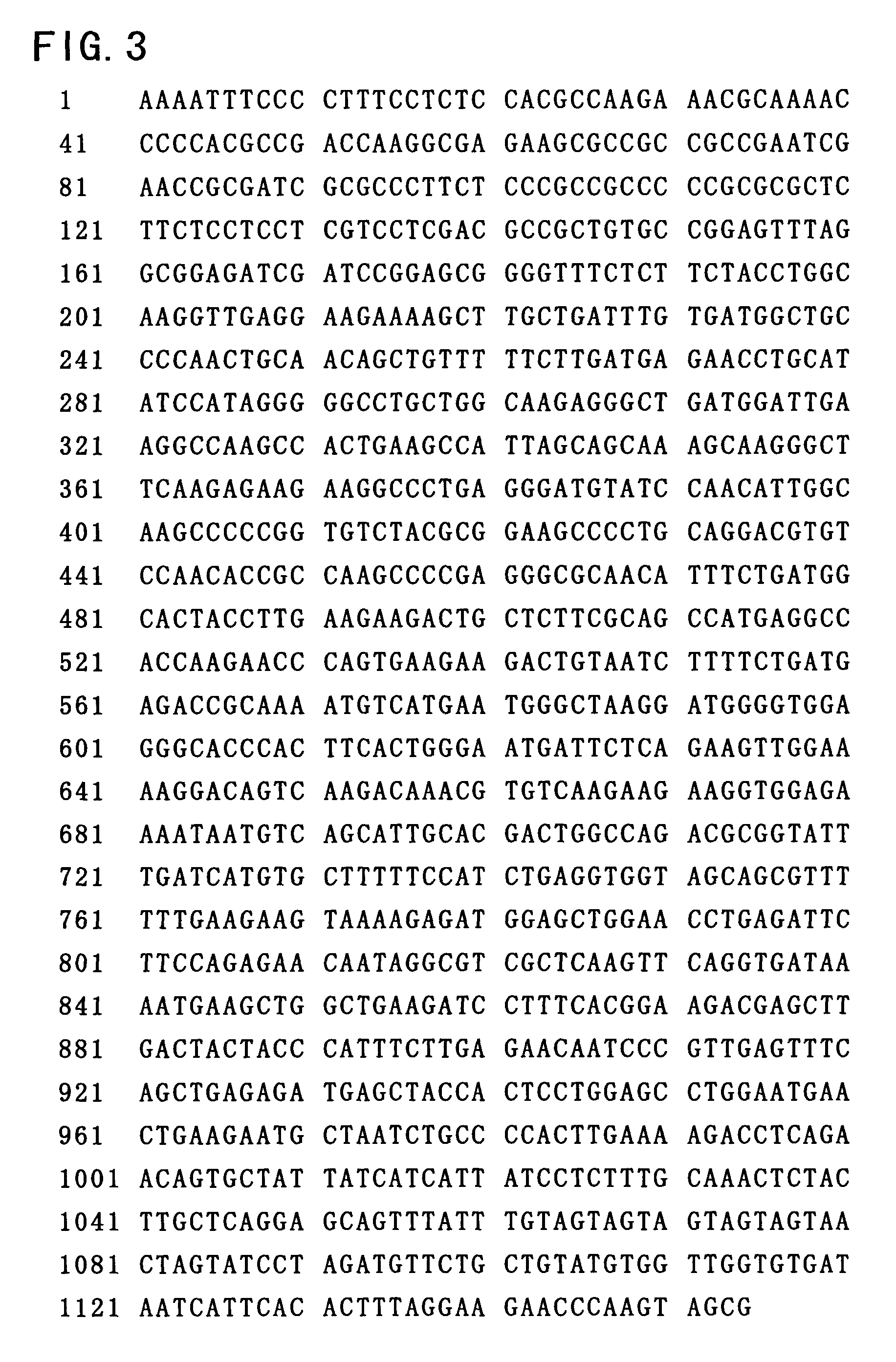

Rice gene for controlling tolerance to salt stress

InactiveUS7034139B2Controlling osmotic stress toleranceImprove toleranceImmunoglobulinsFermentationNucleotideMethionine biosynthesis

A gene encoding a protein capable of controlling salt stress tolerance is provided. A polynucleotide encoding a plant gene capable of controlling salt stress tolerance is provided. The polynucleotide includes a polynucleotide which has a nucleotide sequence encoding an amino acid sequence from methionine at position 1 to asparagine at position 243 of SEQ ID NO: 2 in the sequence listing, or which has a nucleotide sequence encoding the amino acid sequence having one or several amino acid deletions, substitutions and / or additions and is capable of controlling salt stress tolerance.

Owner:INC ADMINISTRATIVE AGENCY NAT AGRI & BIO ORIENTED RES ORG

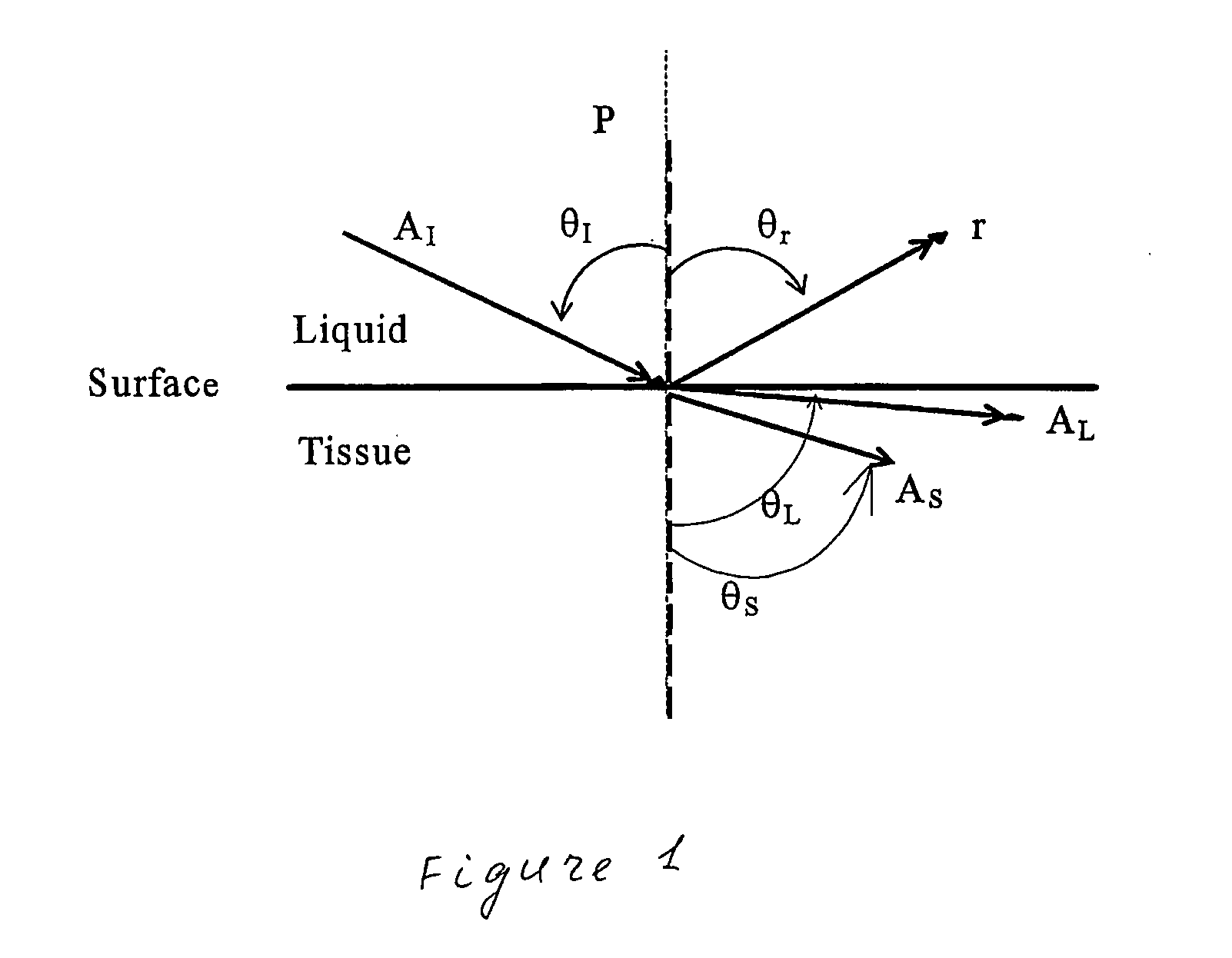

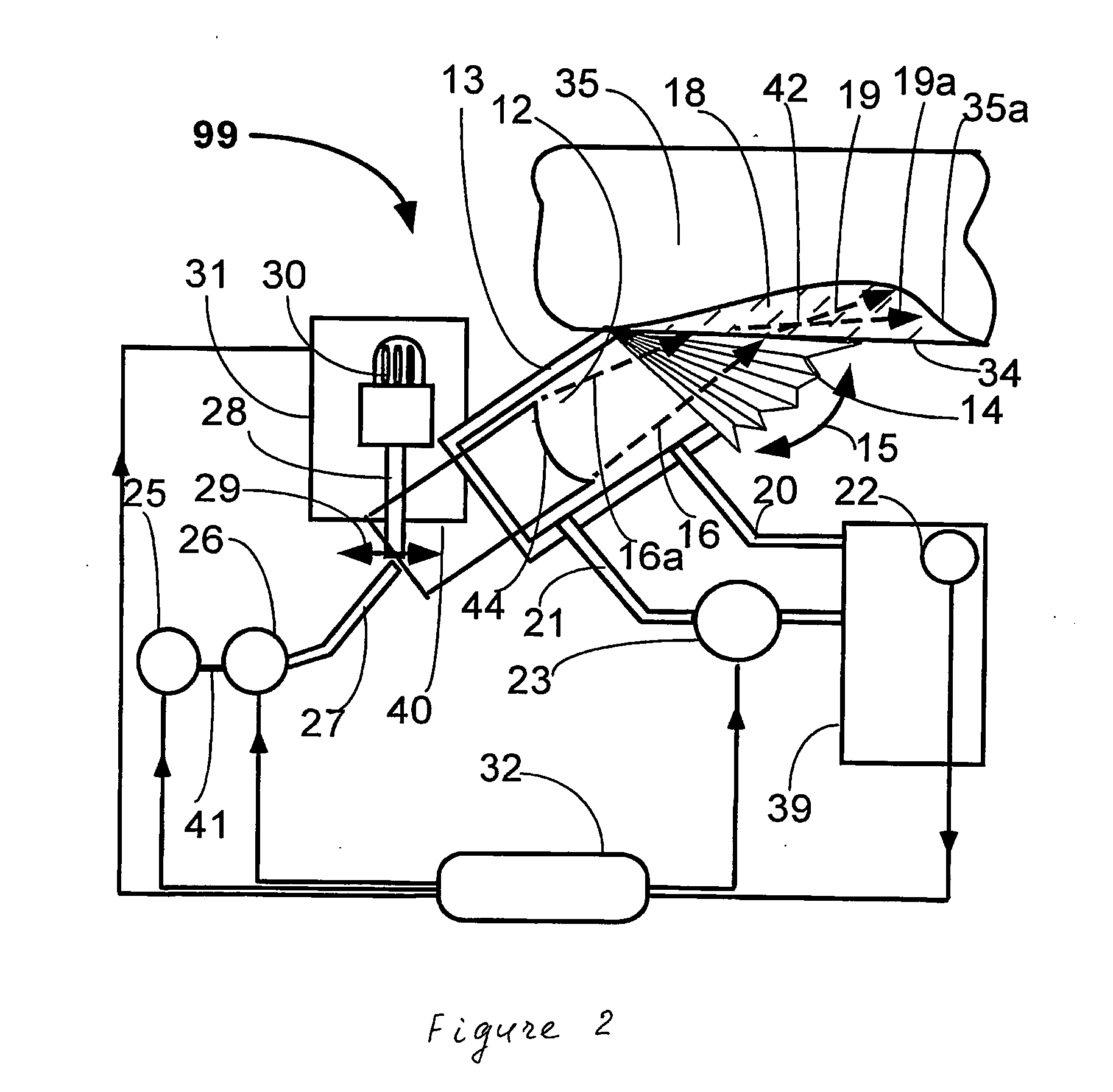

Method and apparatus for altering activity of tissue layers

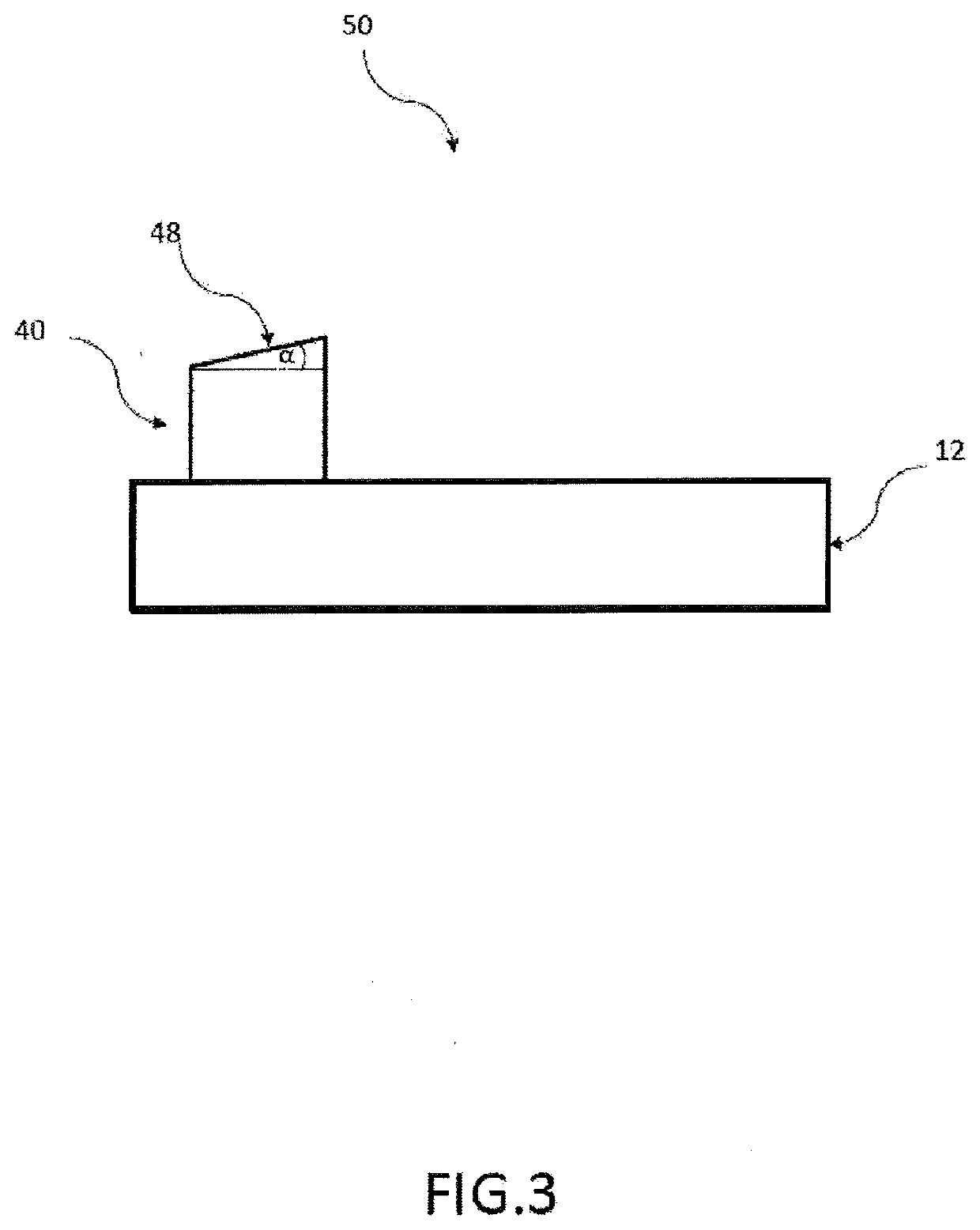

InactiveUS20050228318A1Speed up the descentDifferent sensitivityUltrasound therapyChiropractic devicesInvasive treatmentsIrradiation

The present invention concerns ultrasonic methods and devices for altering activity of layers of natural—or of artificial tissues and organs, and for altering activity of particular components within said layers, while minimizing alterations in neighboring layers located deeper to—or outer to—treated layer. It is carried out by focused or non focused irradiation at certain angles and preferably via cooling medium, so to at least partially create surface waves propagating in the appropriate layers, and altering their activity, while leaving the other layers essentially intact. System can allow also monitoring of beam location and of effect. The device can be constructed for either superficial treatment, or minimal invasive treatment, or layered tissues and organs. It can be used as stand alone or add on device in cosmetic and clinical applications.

Owner:IGER YONI

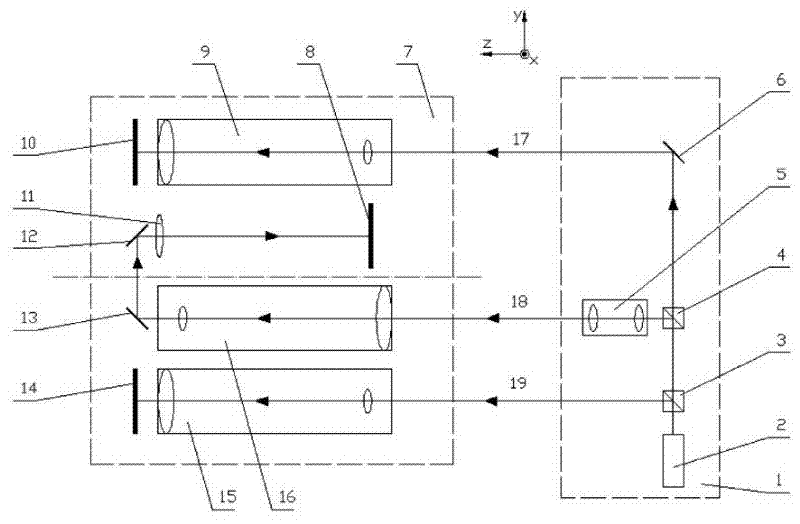

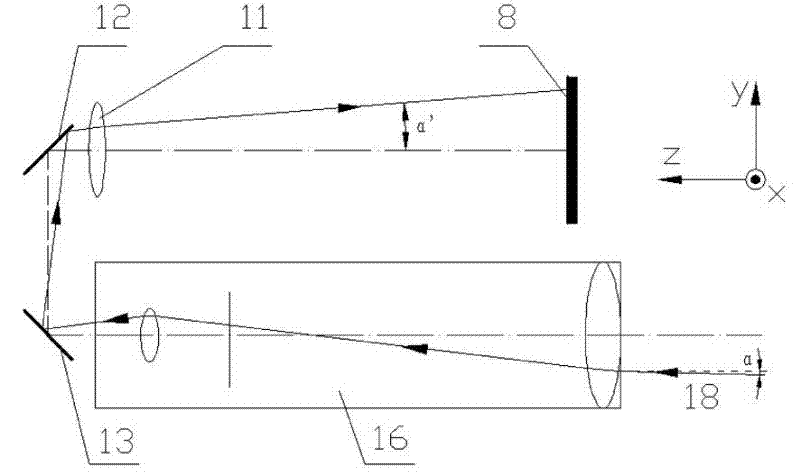

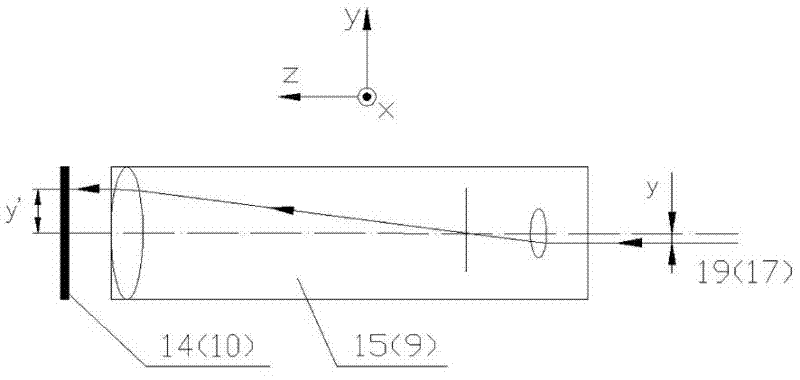

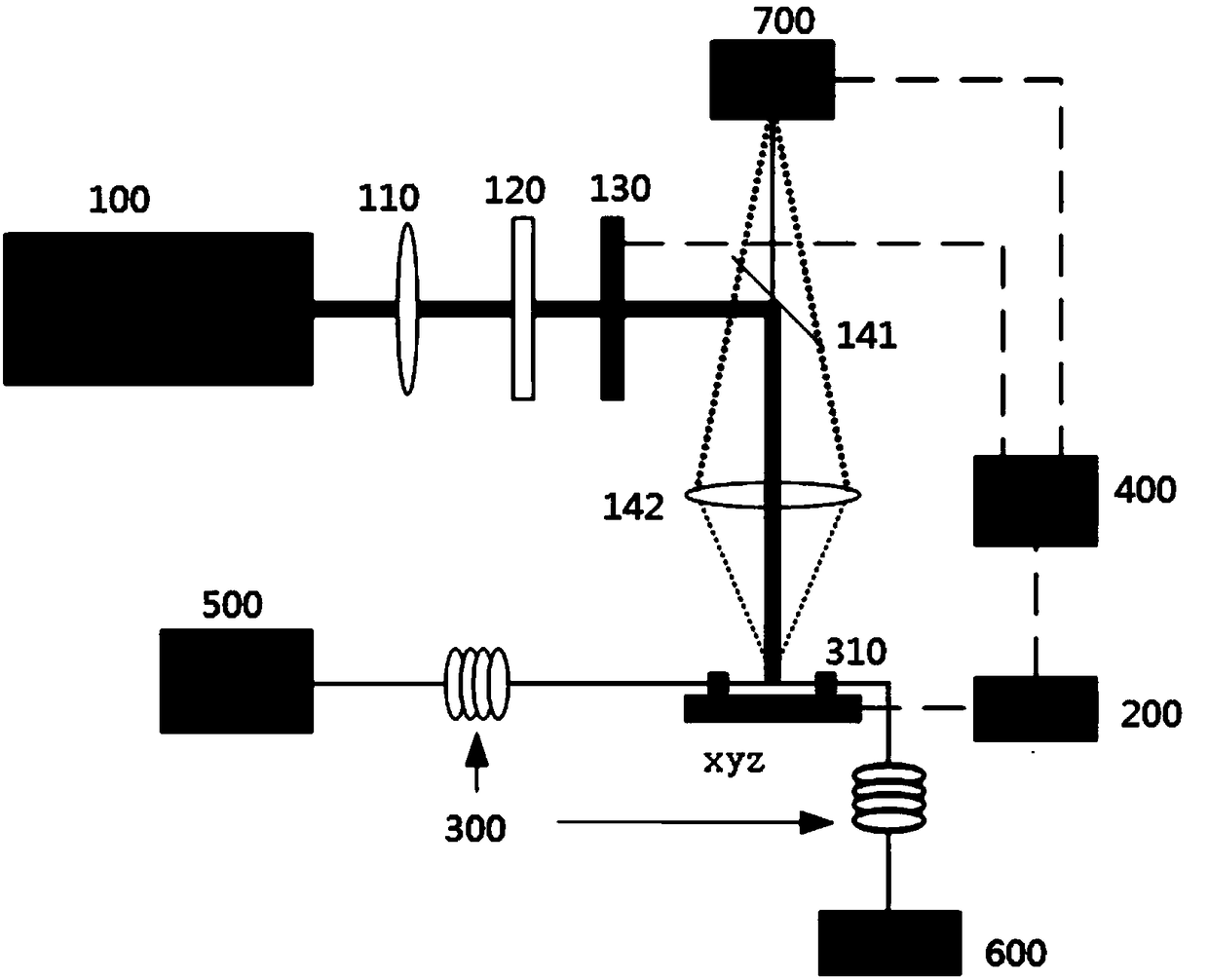

Laser multiple degrees of freedom precision measurement system based on telescope system

InactiveCN102252634AEasy to adjustDifferent sensitivityUsing optical meansEngineeringMechanical engineering

The invention relates to a laser multiple degrees of freedom precision measurement system based on a telescope system. The system comprises a moving mechanism and a fixed mechanism, and the moving mechanism generates three beams of parallel light; the fixed mechanism comprises a first measurement telescope mechanism, a second measurement telescope mechanism and a third measurement telescope mechanism which are arrayed in parallel; entrance ports of the three measurement telescope mechanisms respectively correspond to the three beams of parallel light which are emitted by the moving mechanism; exit ports are correspondingly provided with photoelectric receivers; and two reflectors and a lens are sequentially arranged between the exit port and the photoelectric receiver of the second measurement telescope mechanism. The system provided by the invention is used for measuring two straightness errors and three angle errors which are vertical to the proceed direction, and the light path adjustment is simple; less optical devices are used in the system, the system has the advantages of simple structures and small size is convenient for installation and adjustment, and the rapid measurement with high accuracy can be obtained; and the system can also finish six-degree-of-freedom full posture measurement together with length measuring technology such as a laser interferometer.

Owner:UNIV OF SCI & TECH OF CHINA

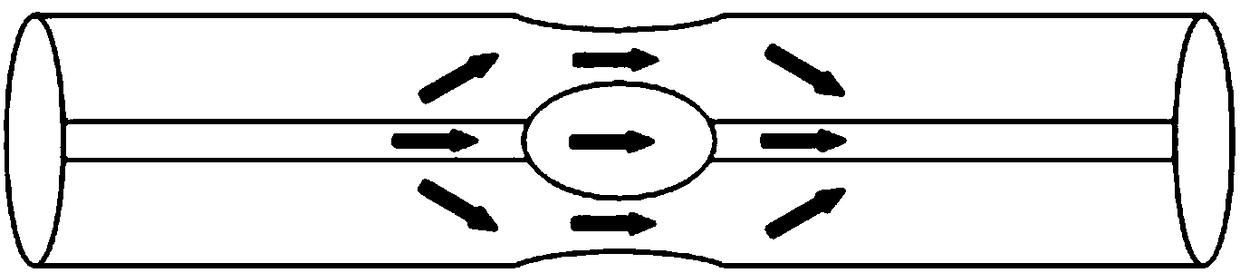

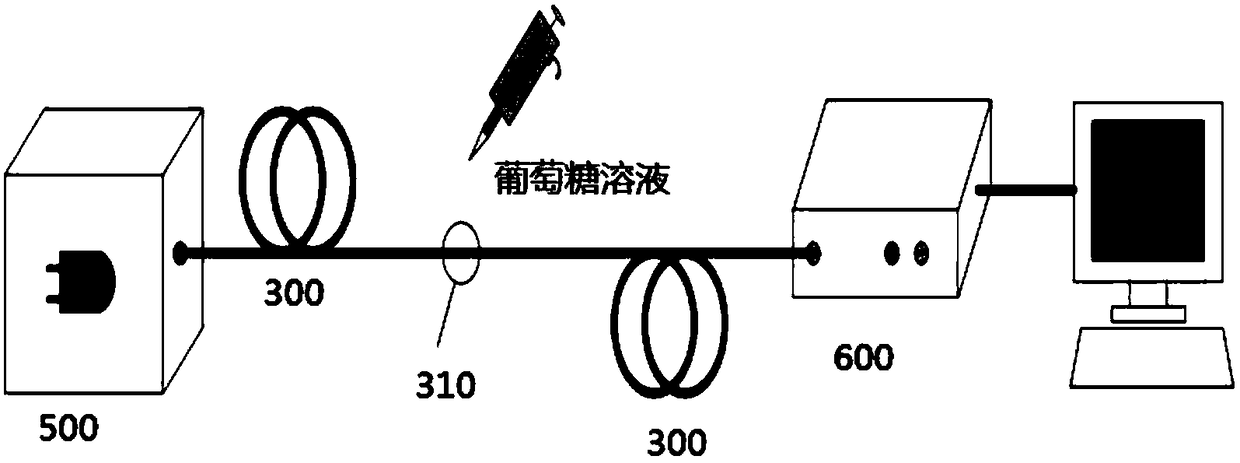

Method for measuring glucose concentration on basis of long period fiber grating temperature and glucose concentration two-parameter sensor

ActiveCN108107021AHigh measurement accuracyReliable measurementPhase-affecting property measurementsThermometers using physical/chemical changesPhysicsLight source

The invention provides a long period fiber grating temperature and glucose concentration two-parameter sensor. According to the characteristic that a long period fiber grating is extremely sensitive for external environment refractive index, the femtosecond write-through long period fiber grating is adopted, the sensor is of a grating structure with different sensitivity for glucose concentrationand a cavity structure by strictly controlling the grating parameter of the sensor, when a broadband light source enters into the long period fiber grating, two obvious attenuation peaks exist in a transmission spectrum, when the concentration or temperature changes, two characteristic wavelengths are of different offsets, and the relationships between the resonant wavelength of the long period fiber grating and the temperature as well as between the resonant wavelength of the cavity structure and the concentration of a solution to be measured are calculated respectively, so that an equation set is formed, namely, the glucose concentration and temperature can be measured simultaneously.

Owner:BEIJING INFORMATION SCI & TECH UNIV

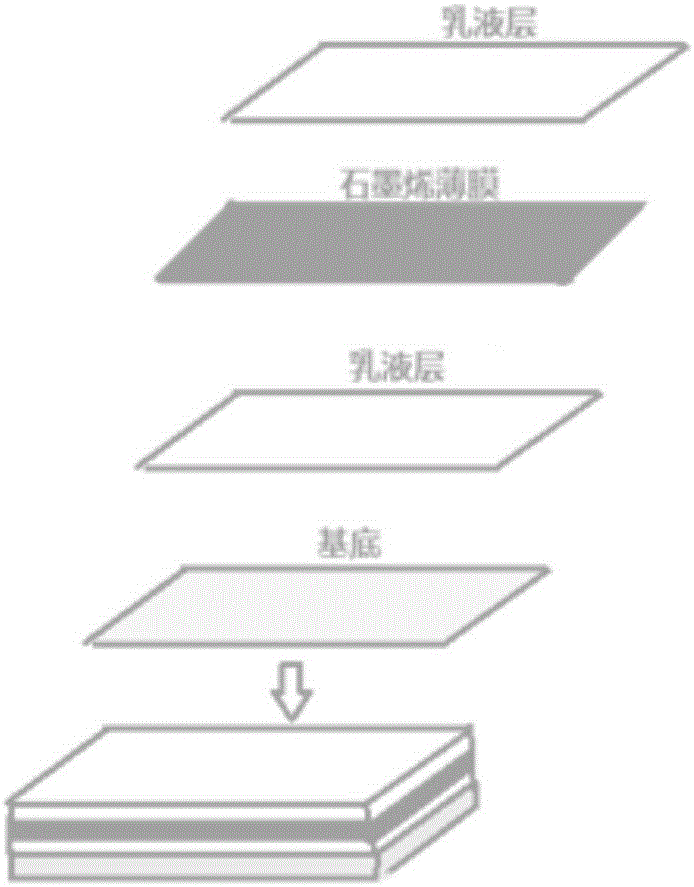

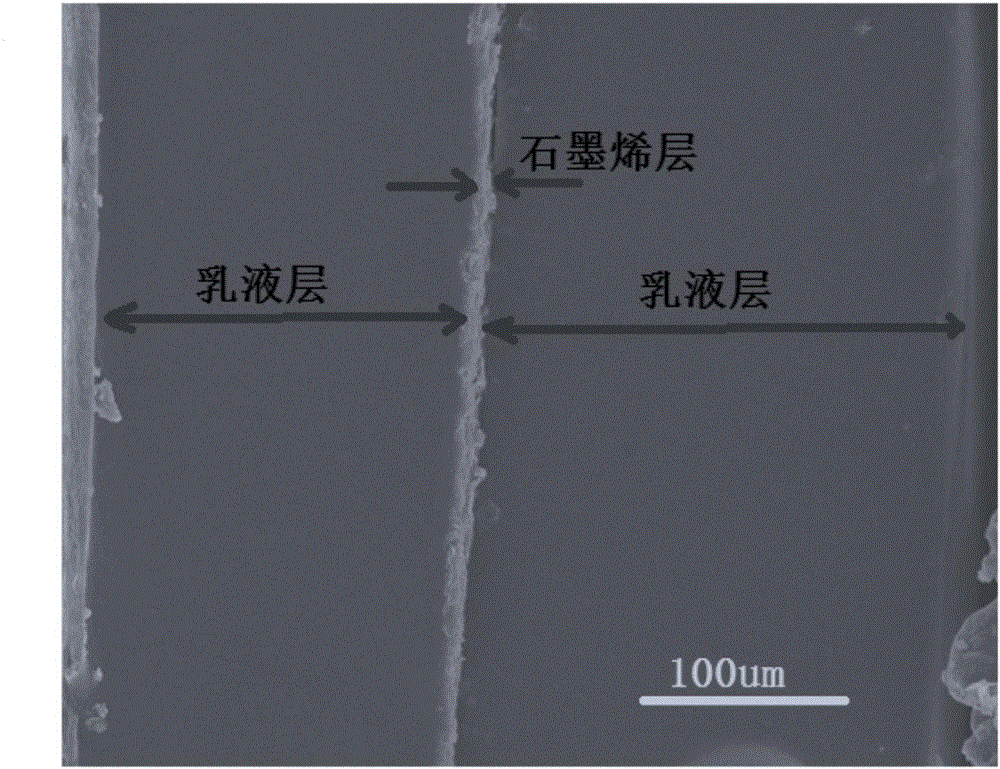

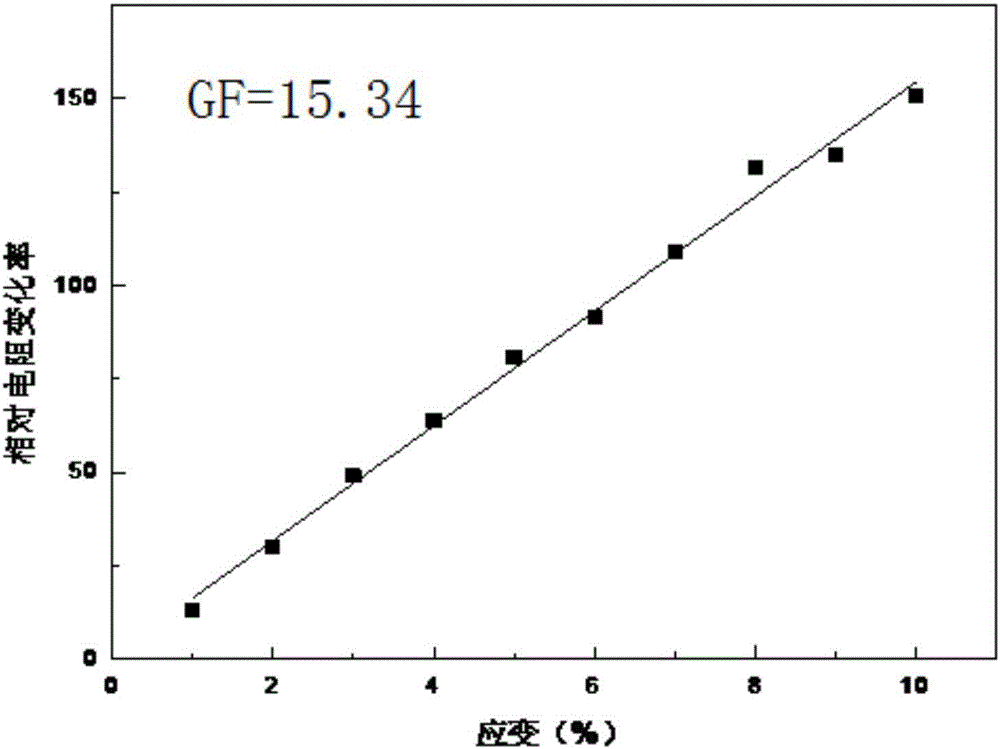

Graphene-based strain sensing film and preparation method and application thereof

ActiveCN106643460ADurableIncreased durabilityElectrical/magnetic solid deformation measurementPolymer scienceWeather resistance

The invention relates to a graphene-based strain sensing film and a preparation method and an application thereof. The strain sensing film is a composite coating film formed by an upper emulsion coating, a lower emulsion coating and an intermediate graphene coating, wherein both ends of the film are connected to a wire, the upper emulsion coating and the lower emulsion coating are prepared from an acrylate emulsion polymer, and the graphene coating is prepared from a graphene dispersion liquid. Compared with the prior art, the graphene-based strain sensing film can operate on any shapes of substrates, the method is simple and the cost is low; the graphene dispersion liquid is used to act as a raw material, electrical and mechanical properties of graphene are directly utilized, and the technological process is simplified; the emulsion coating is sprayed, so that the graphene coating is effectively protected from being damaged, the service life of the strain sensing film is prolonged, the reusability and the weather resistance of the strain sensing film are improved, and no adverse effects are imposed on the appearance of the strain sensing film at the same time because the applied polymer emulsion has high transparency after film formation; and the sensitivity of the strain sending film can be set at will according to requirements.

Owner:TONGJI UNIV

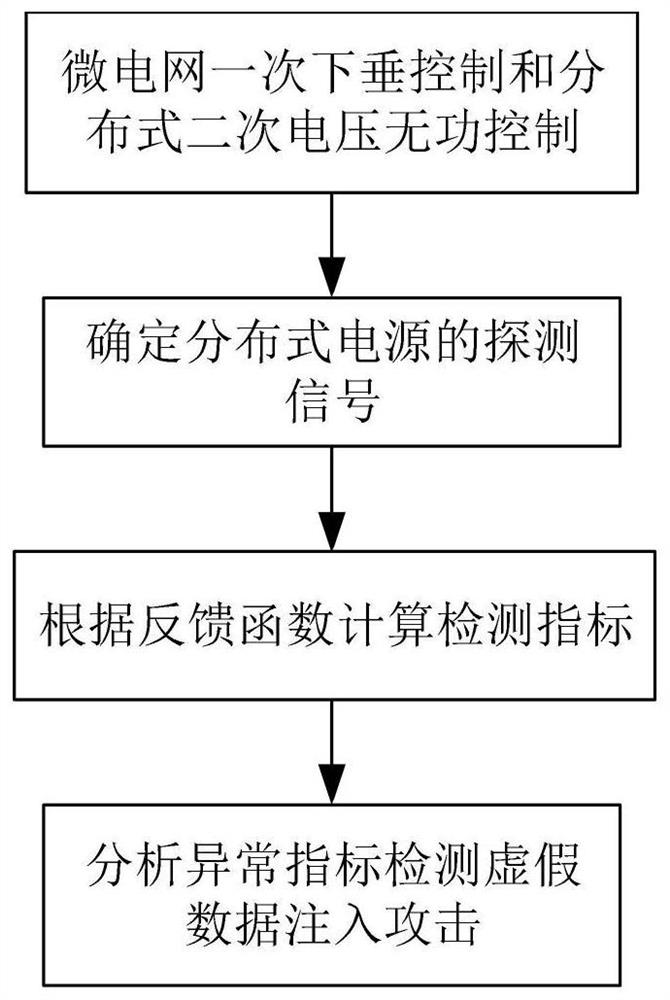

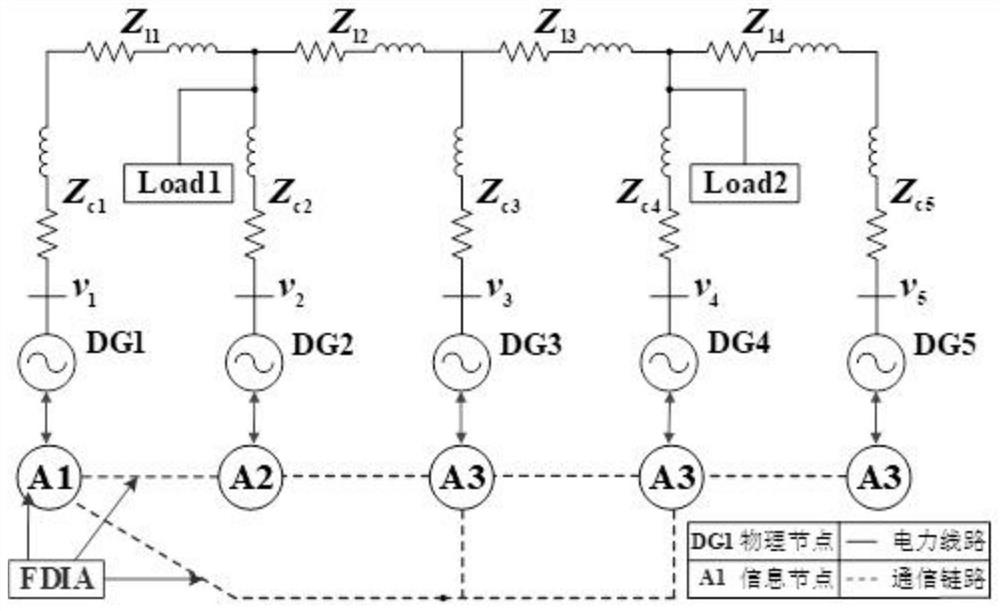

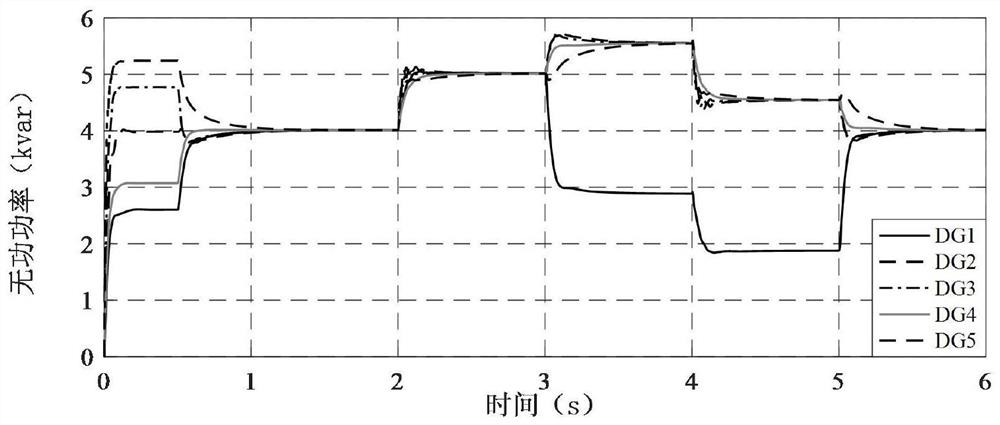

Micro-grid distributed synchronous detection method for false injection attack

ActiveCN113285495ADifferent sensitivitySingle network parallel feeding arrangementsPower oscillations reduction/preventionPacket lossEngineering

The invention relates to a micro-grid distributed synchronous detection method for a false injection attack, and belongs to the technical field of micro-grid operation control. The detection method comprises the specific steps of performing primary droop control and distributed secondary voltage reactive power control on the micro-grid, determining a detection signal of a distributed power supply, calculating a detection index according to a feedback function, and analyzing an abnormal index to detect a false data injection attack. The detection method is based on consistency control of a multi-agent system, is a distributed method, can adapt to delay and packet loss in a communication network, and has different sensitivities to attack signals.

Owner:SOUTHEAST UNIV

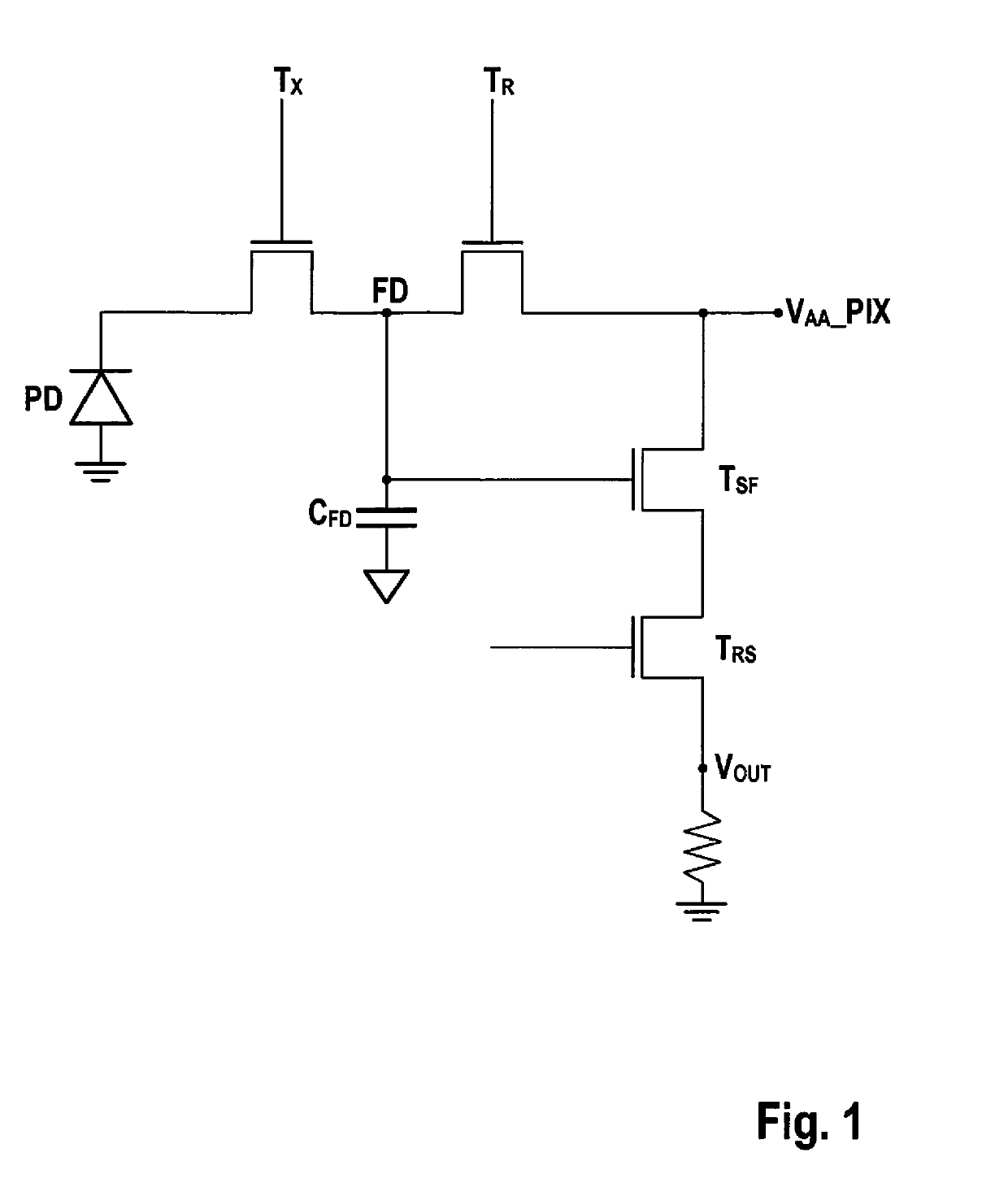

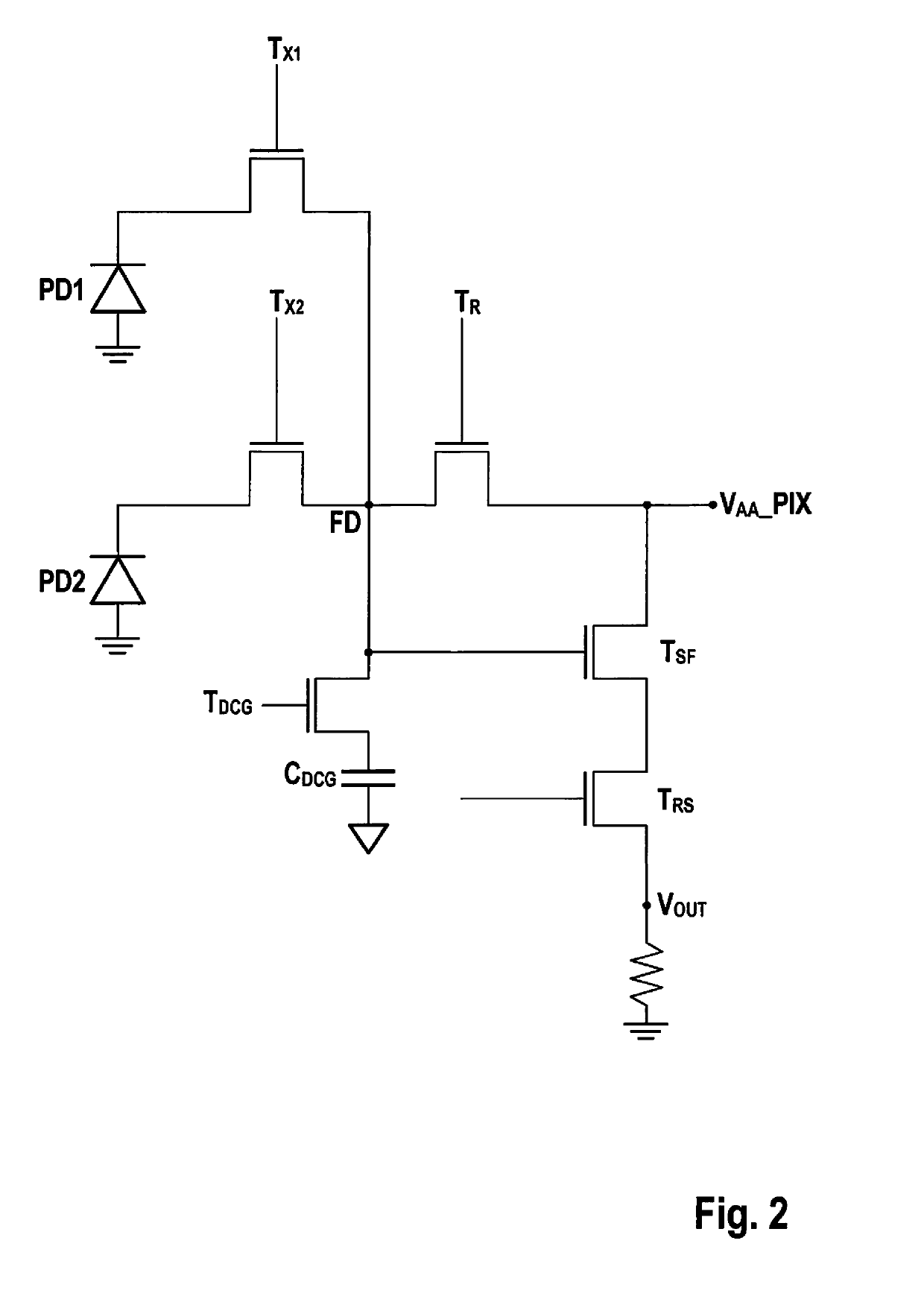

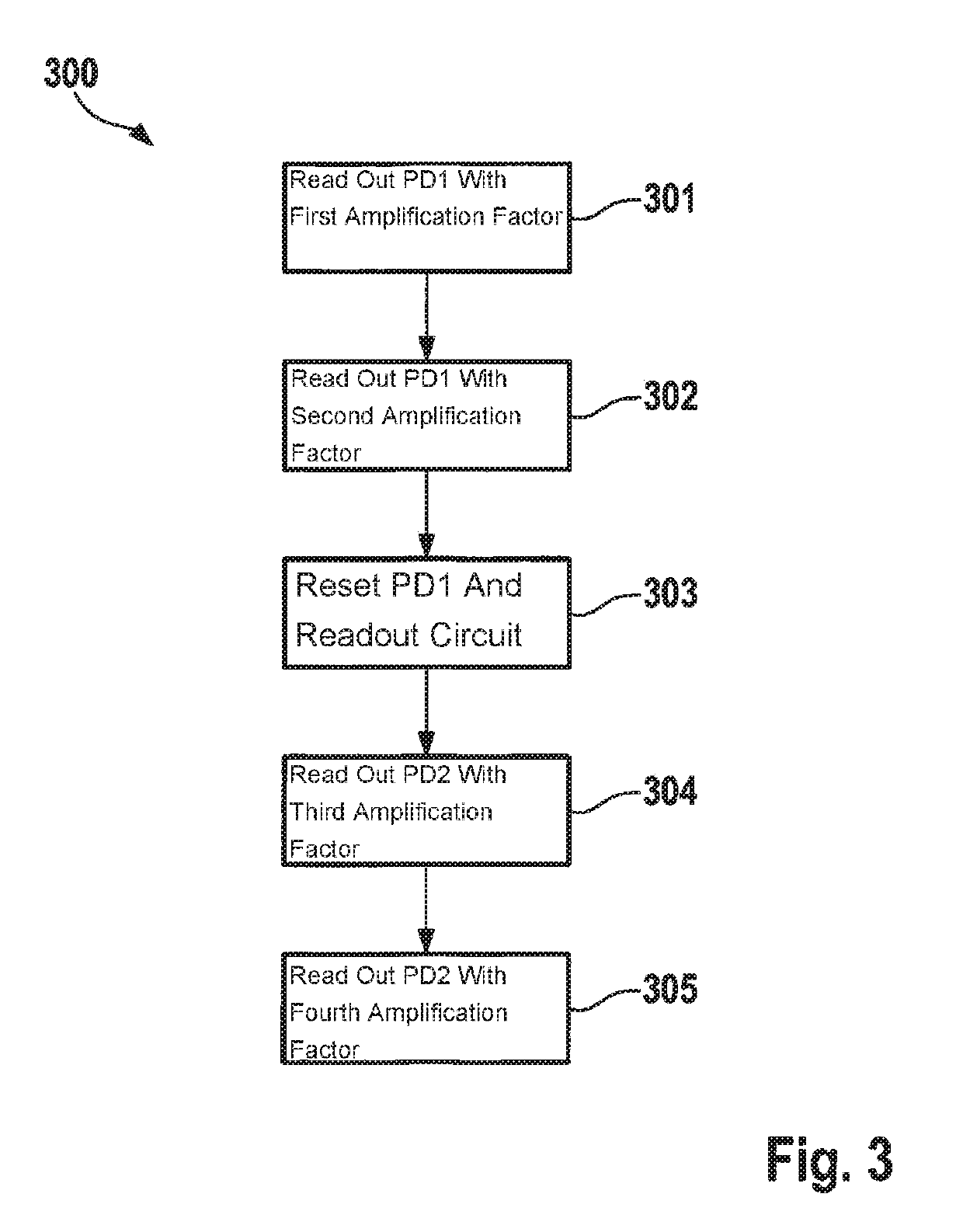

CMOS pixel, image sensor, and camera and method for reading out a CMOS pixel

ActiveUS20190296059A1Strong amplification factorImprove dynamic rangeTelevision system detailsDiffusing elementsCapacitanceCmos pixels

CMOS pixel having a dual conversion gain readout circuit, including at least one first photodiode (PD1), a diffusion region (FD) having a first capacitance (CFD) for accommodating a charge of the at least one first photodiode (PD1), the dual conversion gain readout circuit being designed to read out the charge of the diffusion region (FD) with the aid of a first amplification factor and with the aid of a second amplification factor, the CMOS pixel including at least one second photodiode (PD2), the diffusion region (FD) furthermore being designed to accommodate a charge of the at least one second photodiode (PD2), and the dual conversion gain readout circuit being designed to read out the charge of the diffusion region (FD) with the aid of at least one third amplification factor and at least one fourth amplification factor.

Owner:ROBERT BOSCH GMBH

Imaging array having photodiodes with different light sensitivities and associated image restoration methods

ActiveUS9191556B2Quality improvementIncrease rangeTelevision system detailsSolid-state devicesSensor arrayImage restoration

A pixel sensor array includes a plurality of pixel sensors having a first gain and a plurality of pixel sensors having a second gain less than the first gain.

Owner:FOVEON

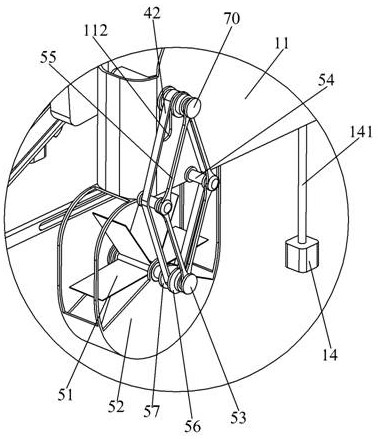

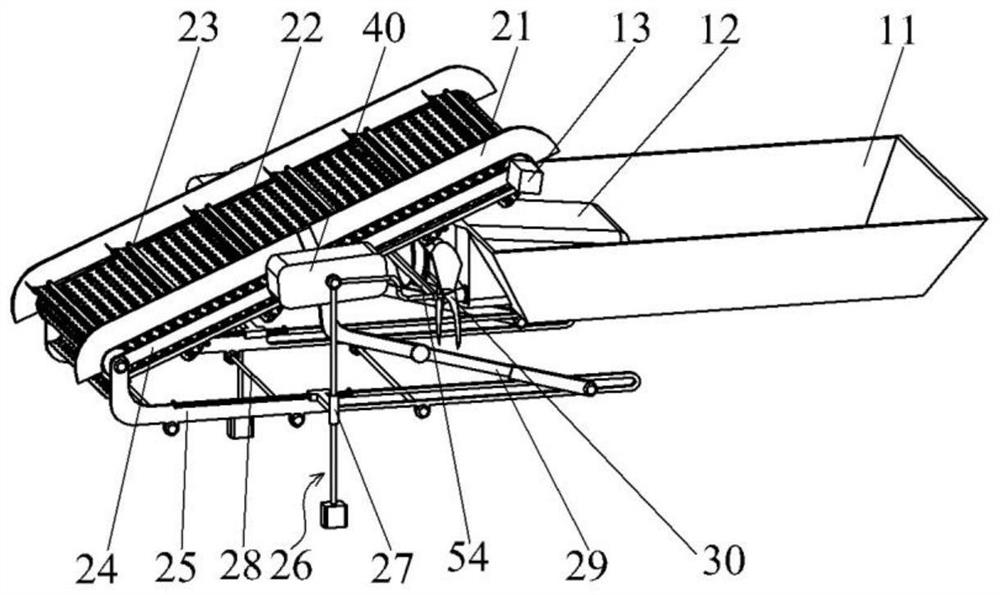

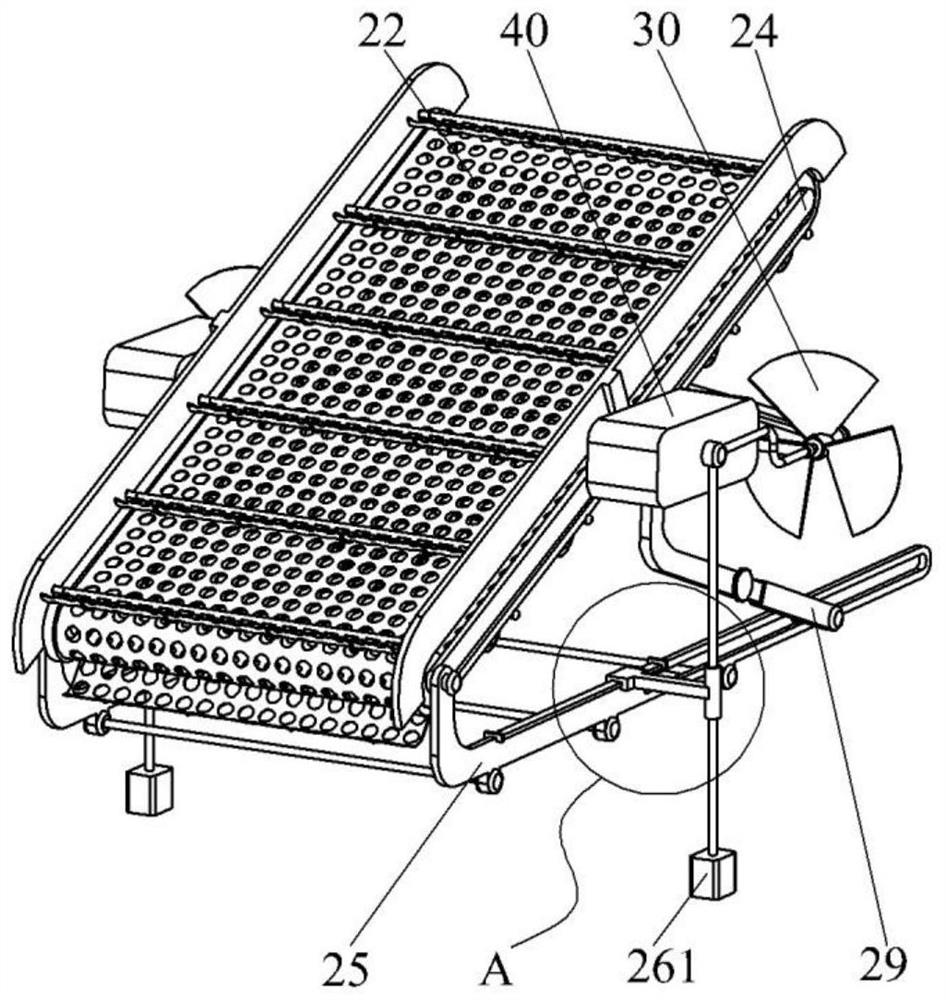

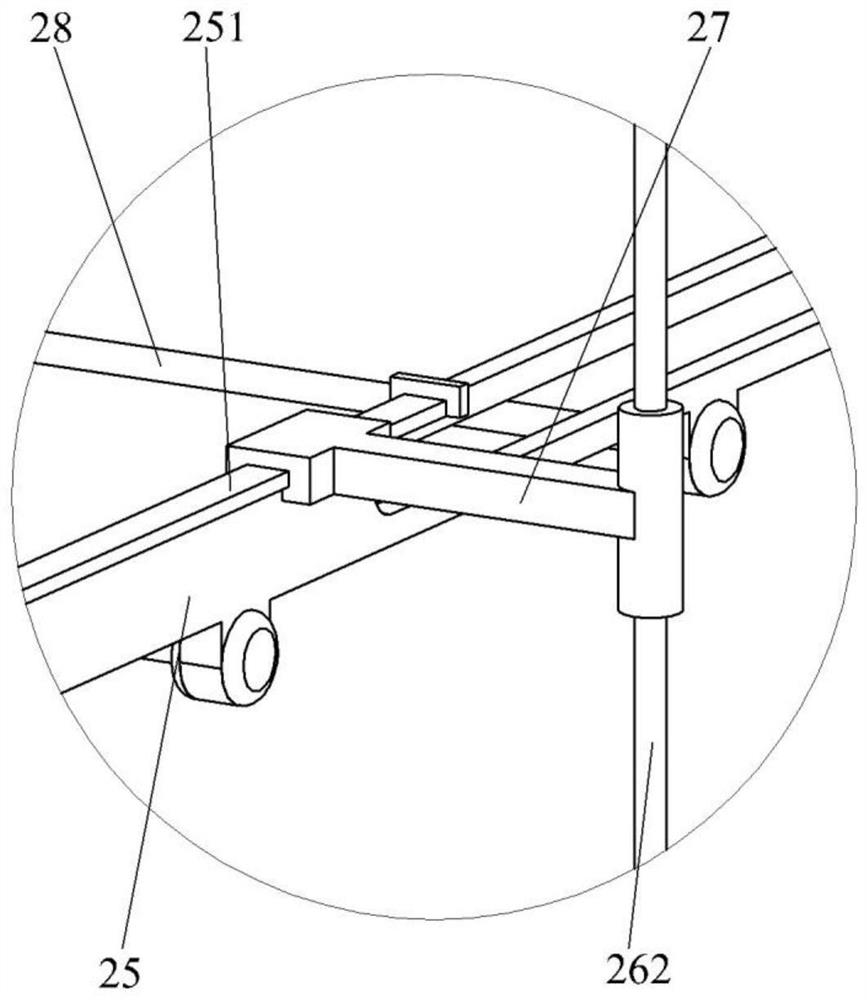

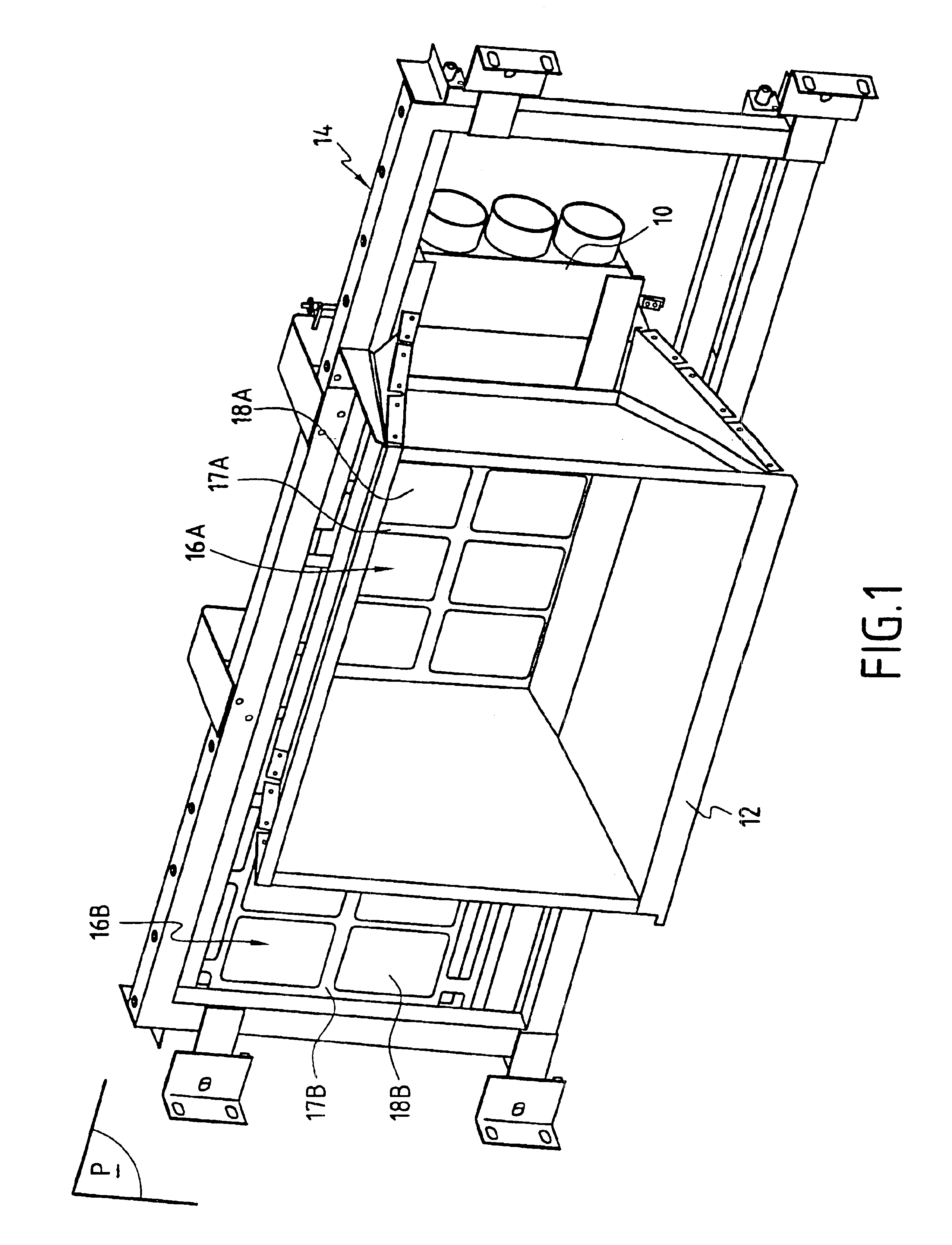

Intelligent sewage treatment device

The invention relates to the technical field of sewage treatment, and particularly relates to an intelligent sewage treatment device. The intelligent sewage treatment device comprises a cleaning module, two input shafts and a sewage collecting bin, wherein the cleaning module comprises a frame and a conveying belt; the sewage collecting bin is mounted on the frame through the input shafts; a power module and an impeller assembly are arranged on the sewage collecting bin; the power module is connected with the input shafts; the input shafts are connected with the conveying belt; and the input shafts are connected with the impeller assembly through a speed change mechanism. When the cleaning module rotates and drives a rotating column to rotate, the rotating column drives a main movable wheel of a driving wheel to move inwards so as to be away from a main fixed wheel, the transmission ratio is increased to reduce the rotating speed of the impeller assembly, thus, the intelligent sewage treatment device can dynamically match advancing and cleaning power of a garbage truck according to resistance generated by floating garbage in front, when the garbage in front is much, the power distributed to advancing by the power module is reduced, the power distributed to cleaning is increased, the cleaning effect is ensured, and the cleaning efficiency is improved.

Owner:启东市新港阀门仪表成套有限公司

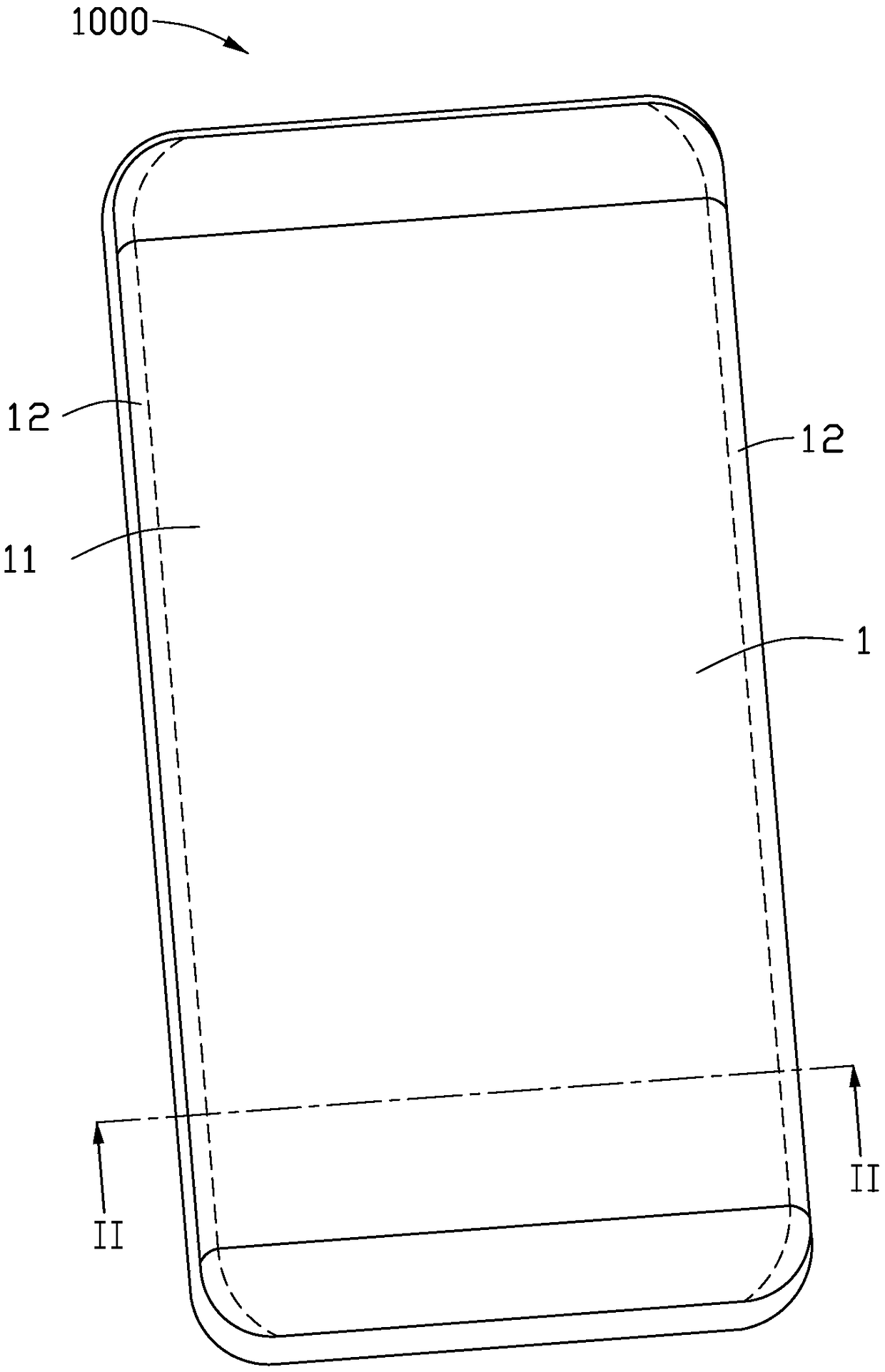

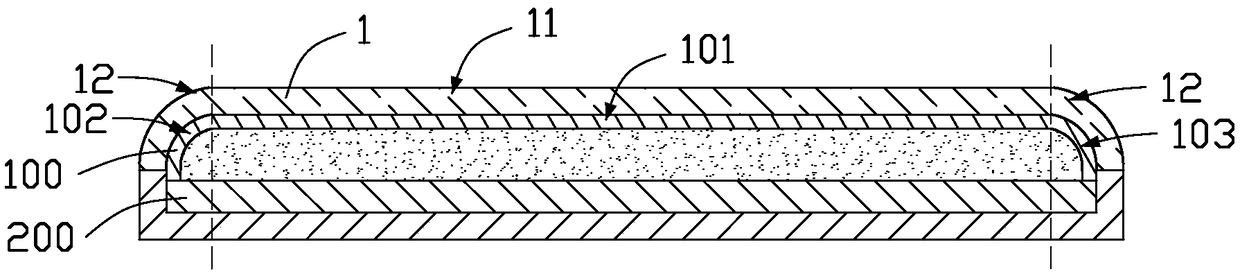

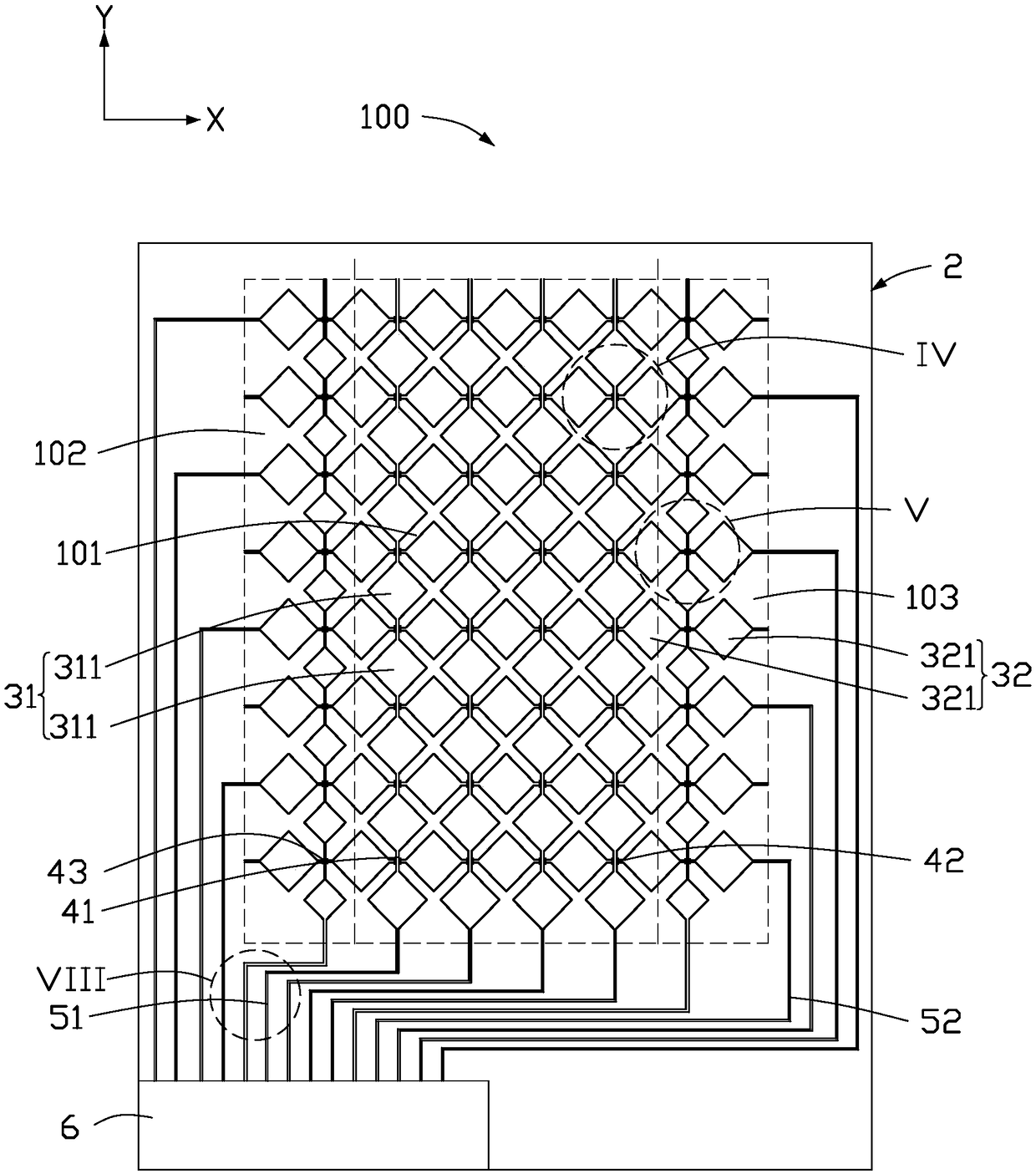

Touch control panel and touch control display device using touch control panel

ActiveCN108710452ADifferent sensitivityInput/output processes for data processingDisplay deviceEngineering

The invention provides a touch control panel. The touch control panel comprises a substrate, and a plurality of first sensing electrodes and a plurality of second sensing electrodes, wherein the plurality of first sensing electrodes and the plurality of second sensing electrodes are formed on the substrate; the two adjacent first sensing circuits are connected with each other through a first bridging part; the two adjacent second sensing circuits are connected with each other through a second bridging part; a distance between the corresponding first sensing electrode and the corresponding second sensing circuit adjacent to each other is defined as a space; the size of at least one space is different from the size of the other spaces or the superposition area between the first bridging partand the second bridging part is different or a distance between the first bridging part and the second bridging part corresponding to the first bridging part is different. The sensing electrodes of the touch control panel disclosed by the invention have different spaces or the bridging parts have different superposition areas or the bridging parts have different distances, so that different sensing sensitivity is formed in the touch control panel.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Coaxial optical fiber-based temperature and stress dual-parameter optical fiber sensor

InactiveCN102261967BDifferent SensitivitySimple preparation processForce measurement by measuring optical property variationThermometers using physical/chemical changesResonanceLength wave

The invention relates to a coaxial optical fiber-based temperature and stress dual-parameter optical fiber sensor which is formed by sequentially connecting a single mode input optical fiber, a first coaxial optical fiber, an intermediate single mode optical fiber, a second coaxial optical fiber and a single mode output optical fiber, wherein the single mode input optical fiber, the first coaxialoptical fiber and the intermediate single mode optical fiber are sequentially welded to form a first sensing unit; and the intermediate single mode optical fiber, the second coaxial optical fiber andthe single mode output optical fiber are sequentially welded to form a second sensing unit. The first coaxial optical fiber and the second coaxial optical fiber have different structural parameters, the first sensing unit and the second sensing unit have resonance filtering spectrums with different wavelengths; and the two resonance filtering spectrums have different sensitivities for two parameters, namely the temperature and the stress, thereby the dual-parameter optical fiber sensor can be realized. The coaxial optical fiber-based temperature and stress dual-parameter optical fiber sensor disclosed by the invention has the advantages of simple preparation process, low cost, compact structure, stable performance, easiness for integration with a standard single mode optical fiber system,and the like.

Owner:SHANGHAI UNIV

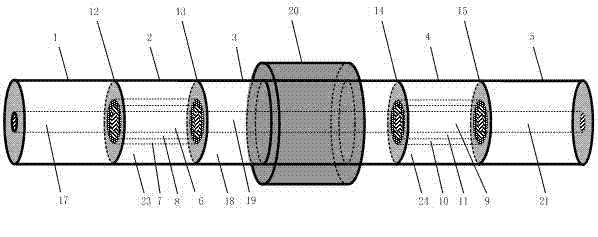

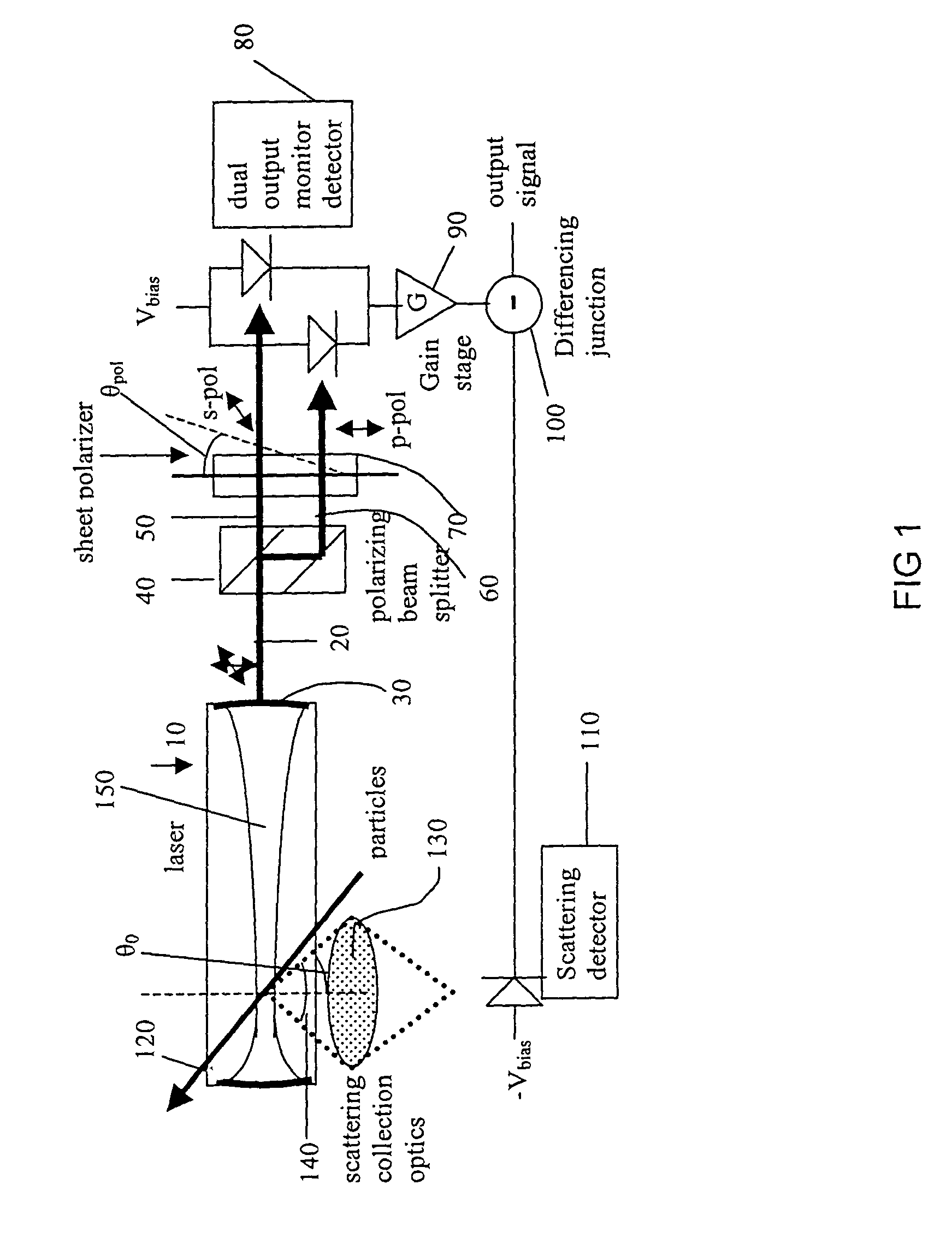

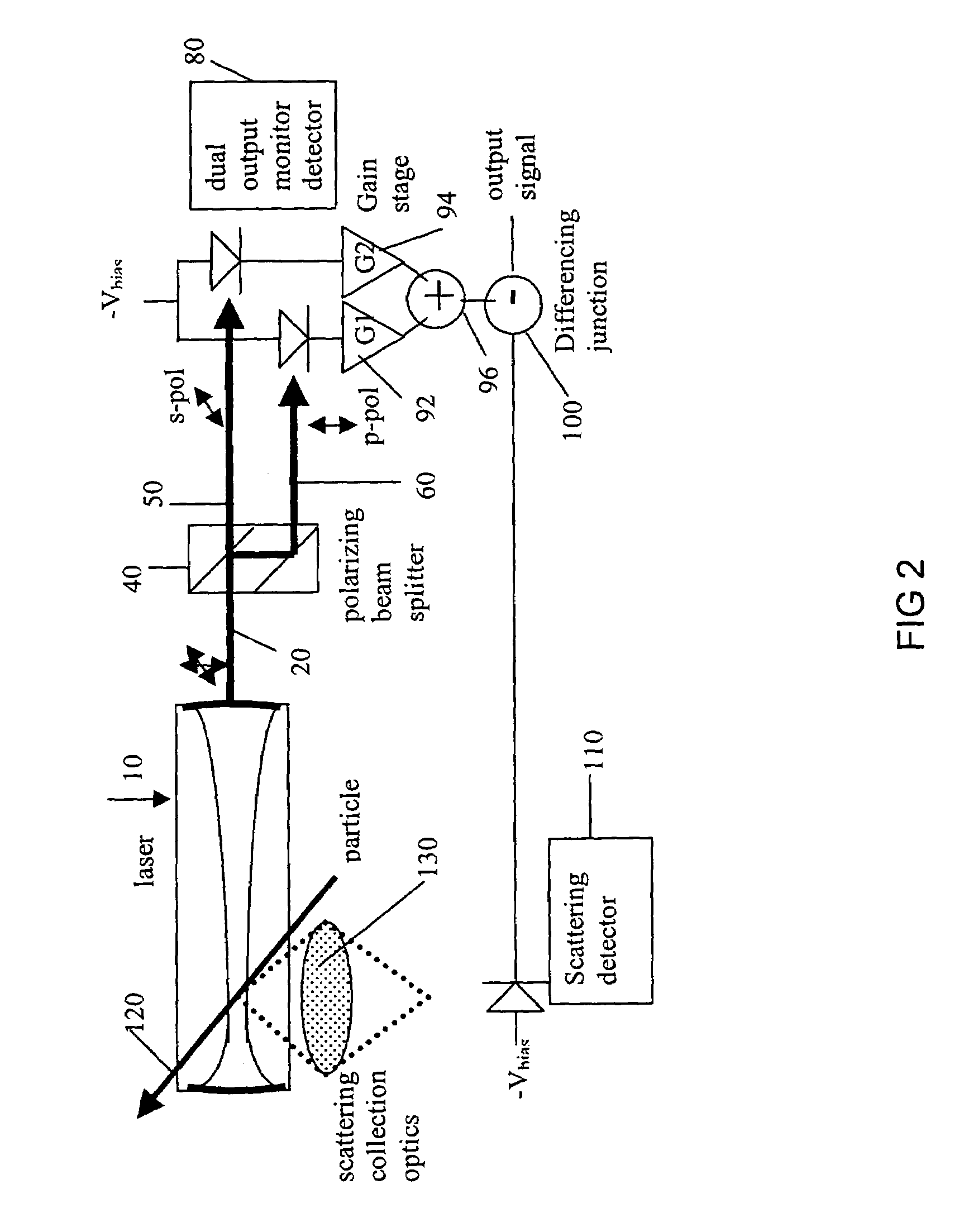

Method of noise cancellation in an unpolarized-laser instrument

ActiveUS7079243B2Improve signal-to-noise ratioImprove Noise CancellationMaterial analysis by optical meansParticle size analysisRelative intensityOptoelectronics

A method of noise reduction in a system where polarization mode fluctuations contribute to the noise in a signal is provided. Specifically, a corrected signal is formed by adjusting the relative and overall intensity of the orthogonal polarization components of an unpolarized laser source at a first detector positioned at a first angle with respect to the laser beam axis so that the first detector has the same sensitivity to polarization as a second detector positioned at a second angle with respect to the laser beam axis. This corrected signal is then subtracted from the signal at the second detector which detects a desired signal.

Owner:EXCELITAS TECH

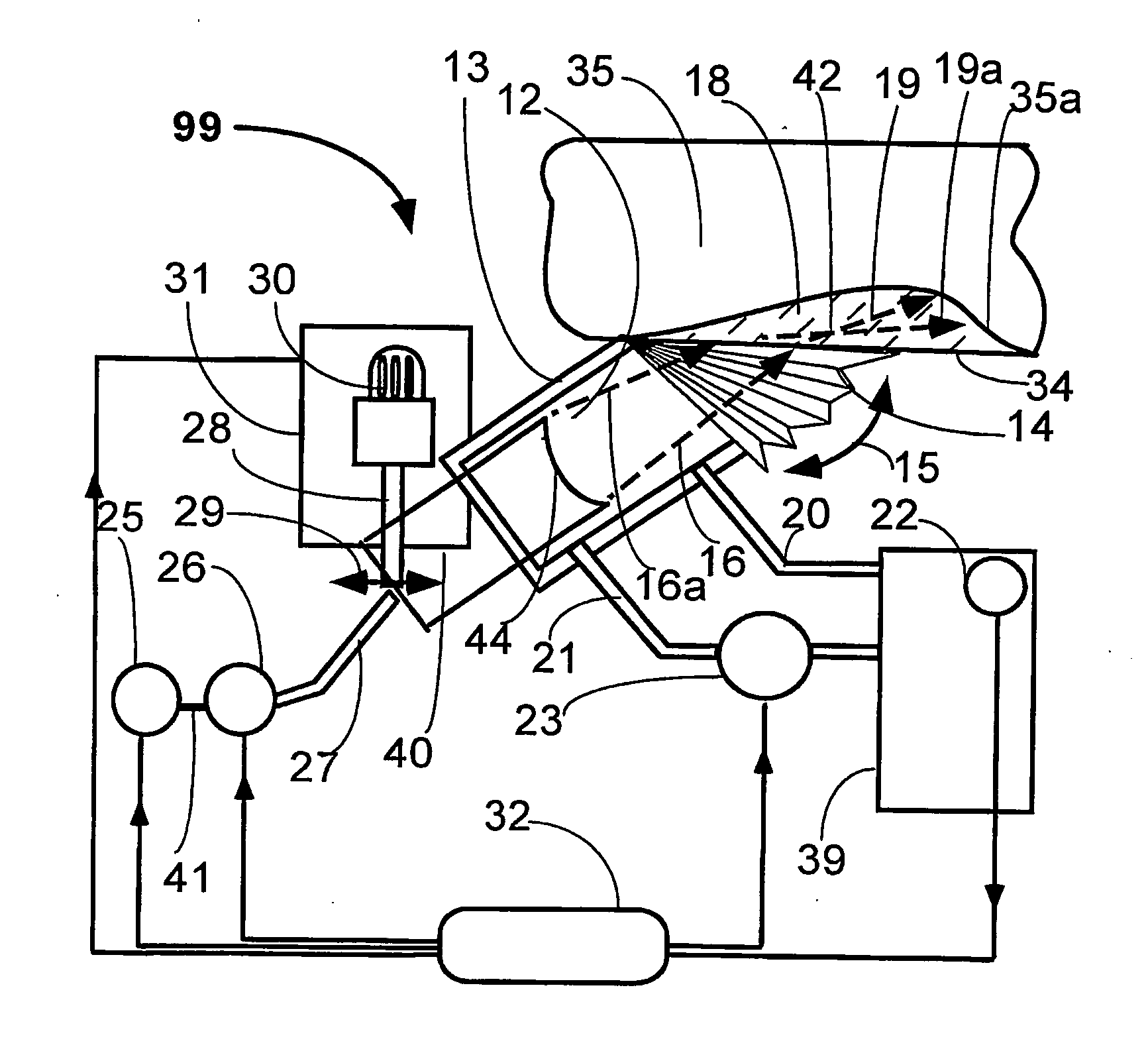

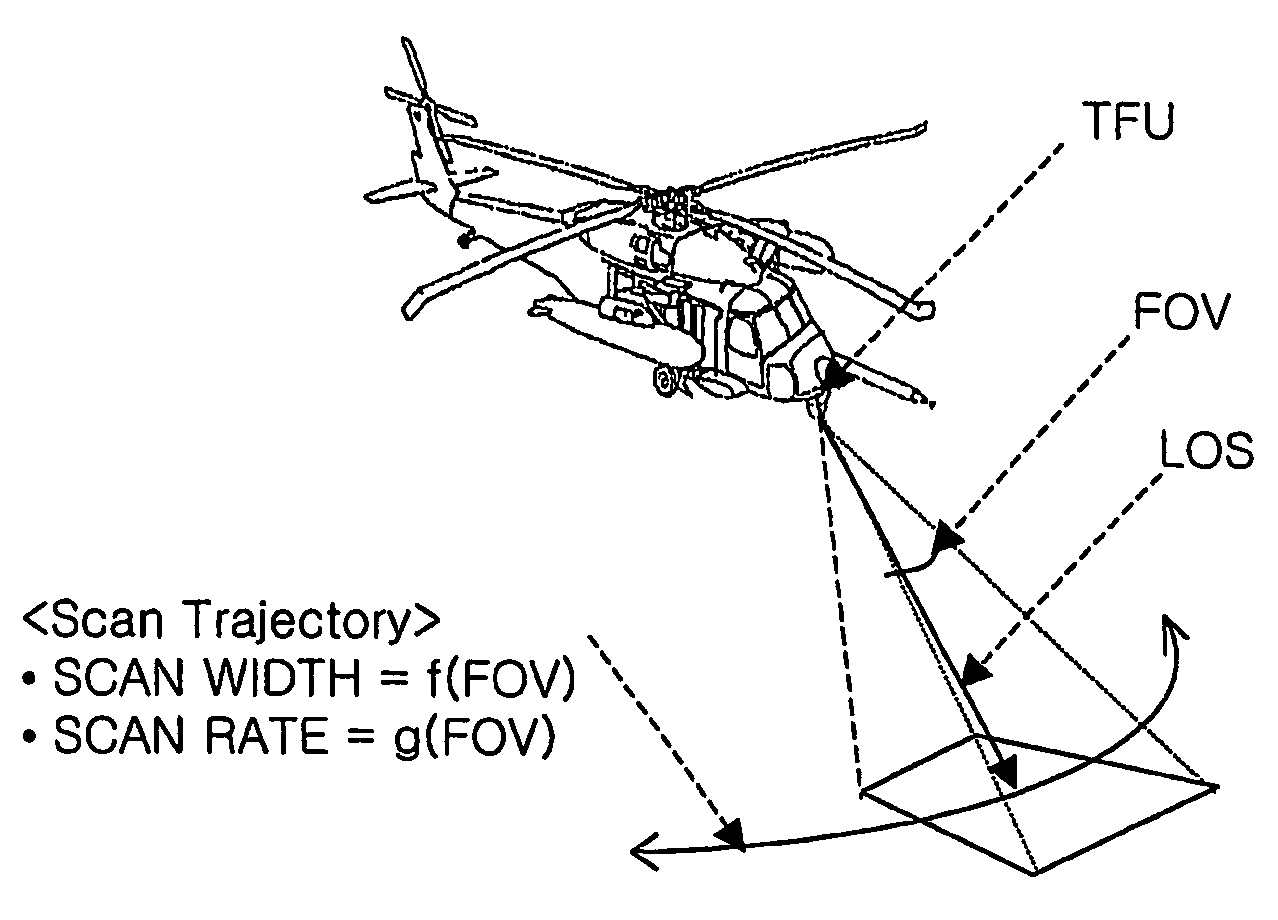

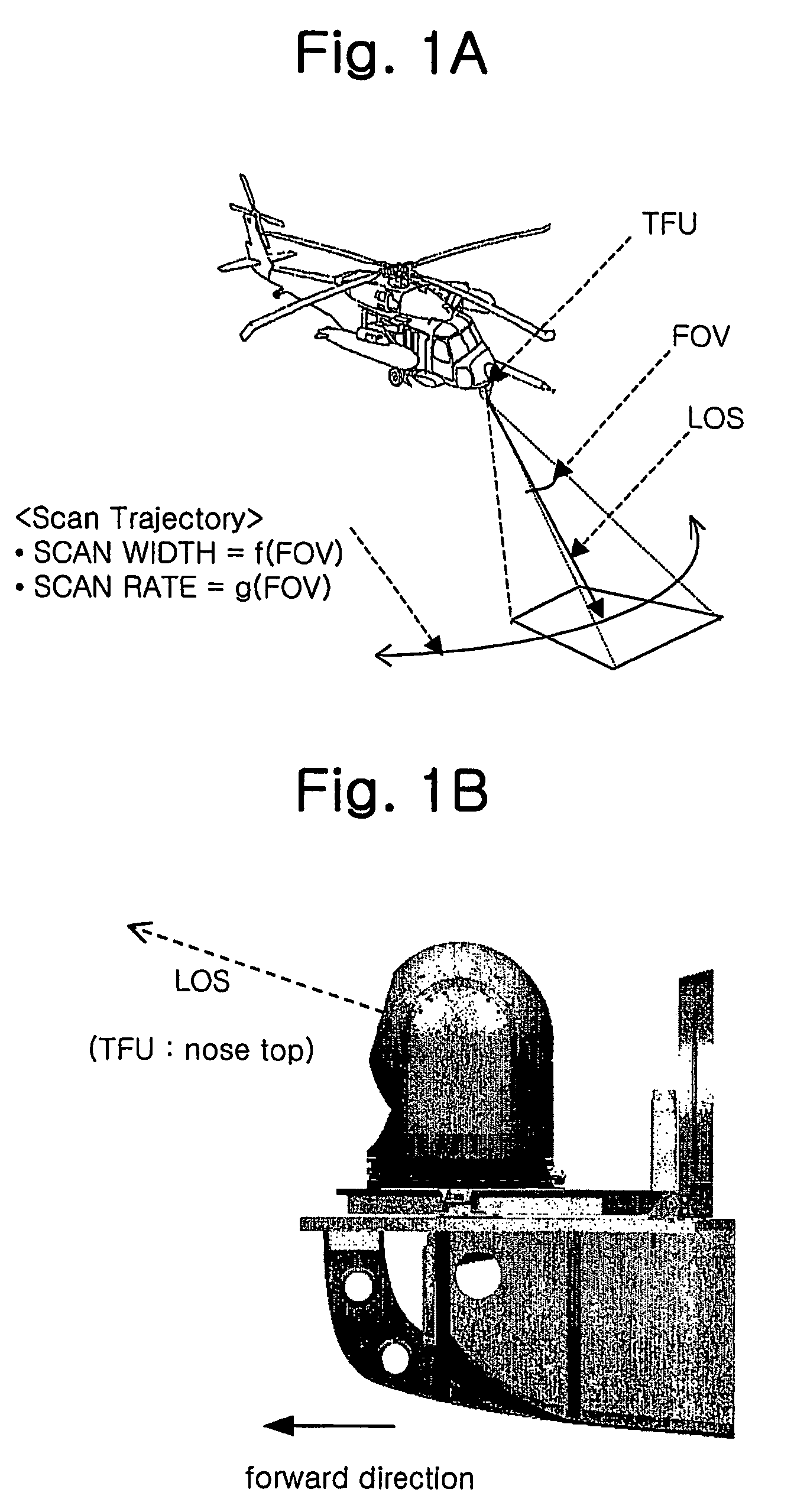

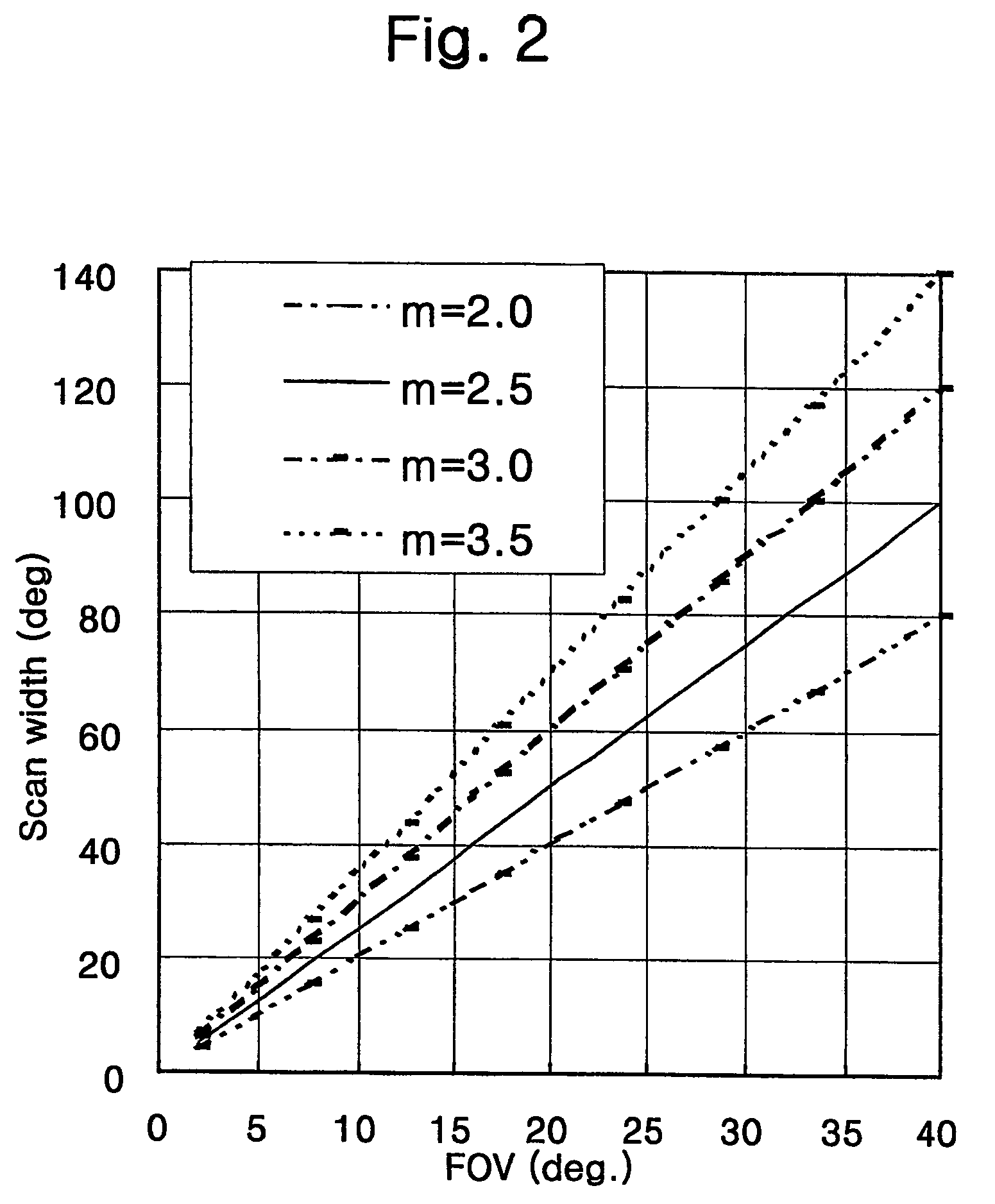

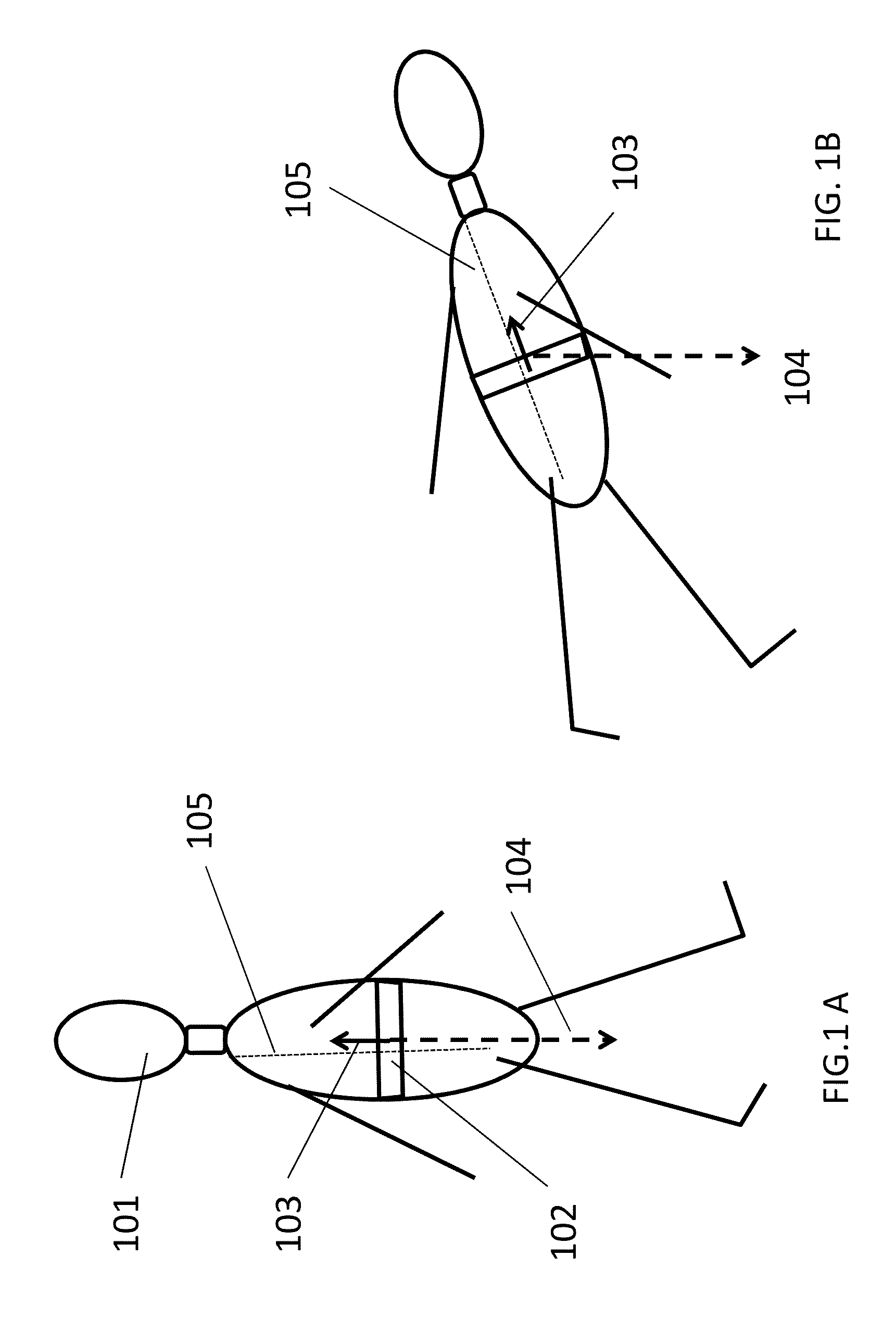

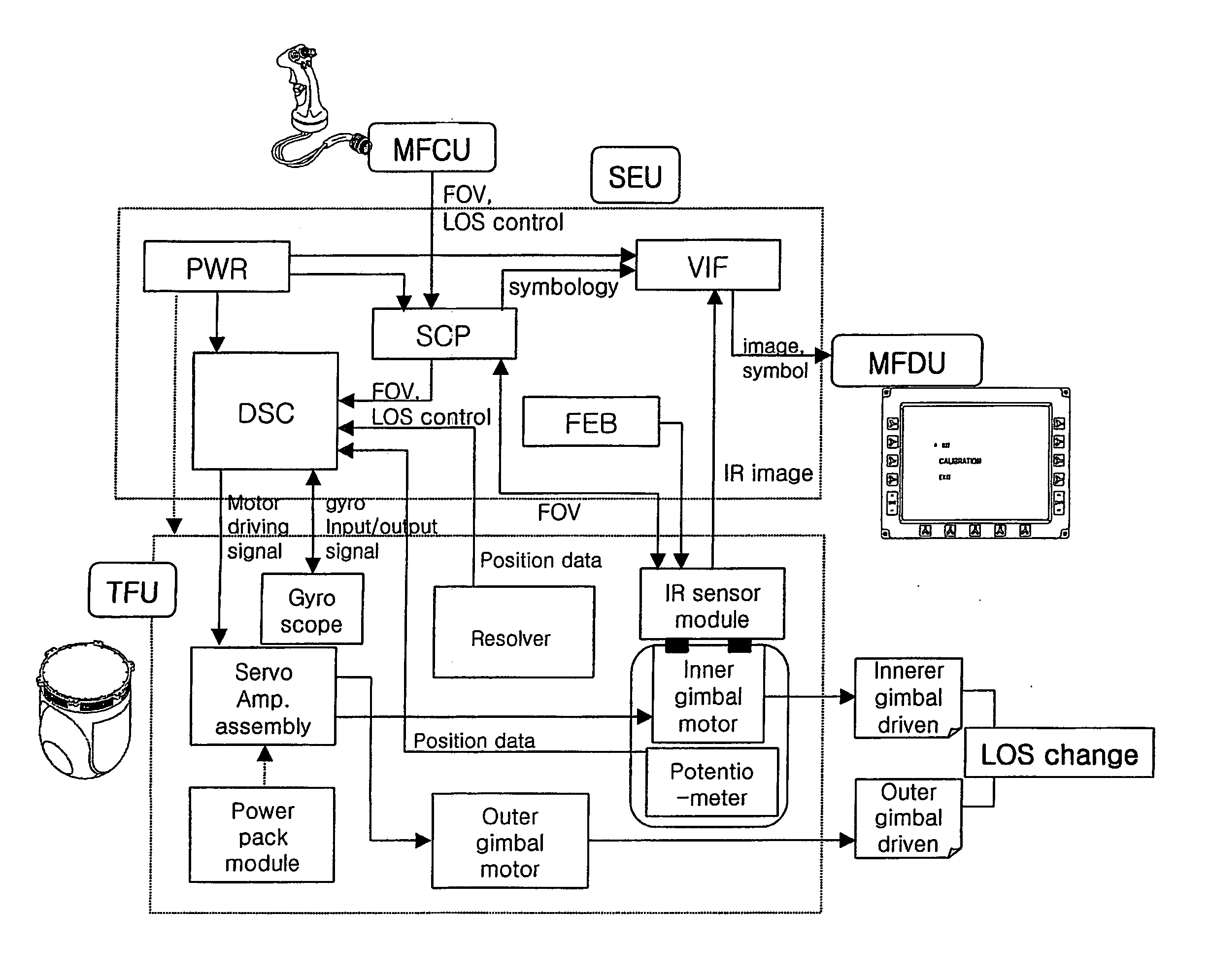

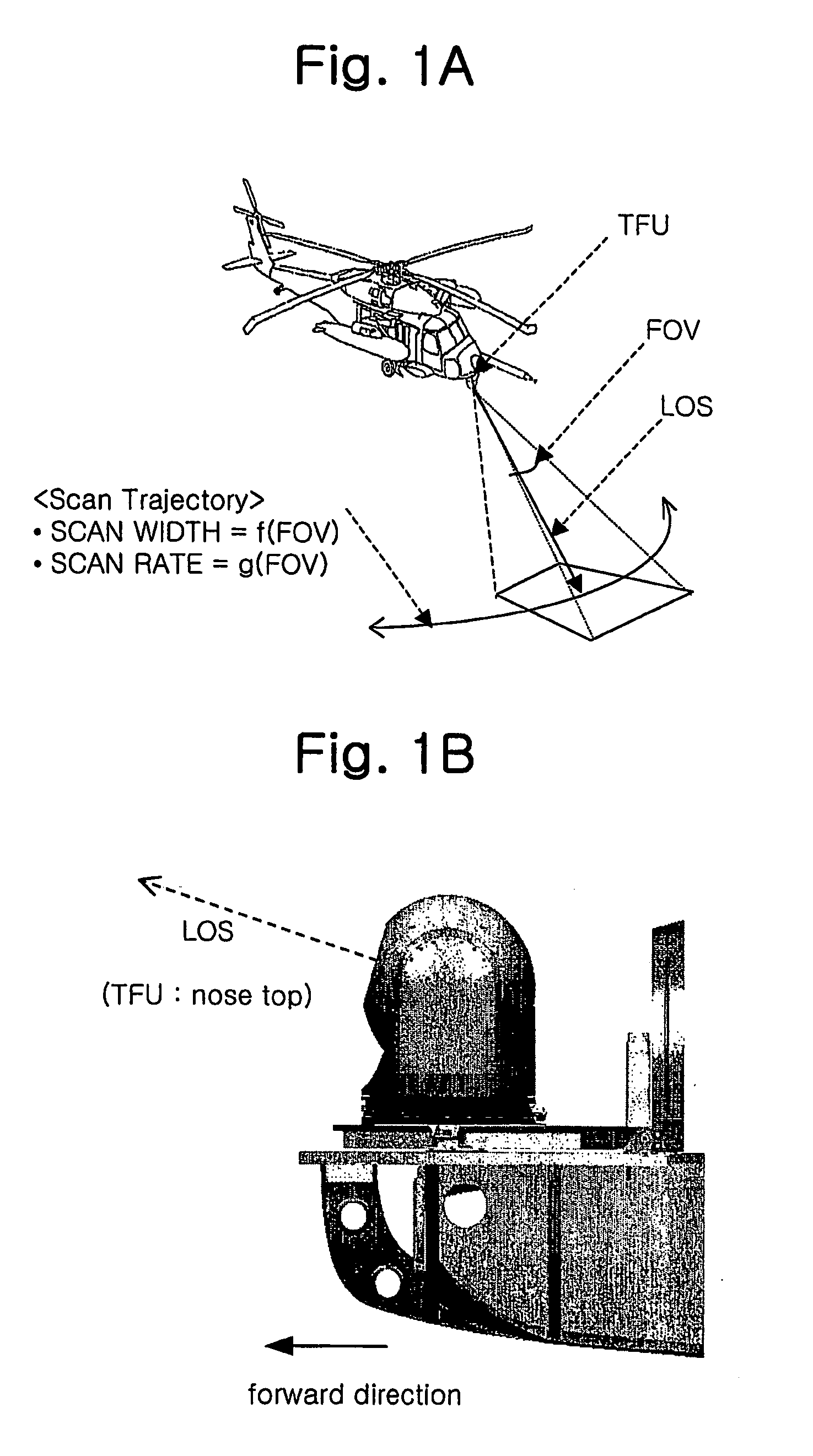

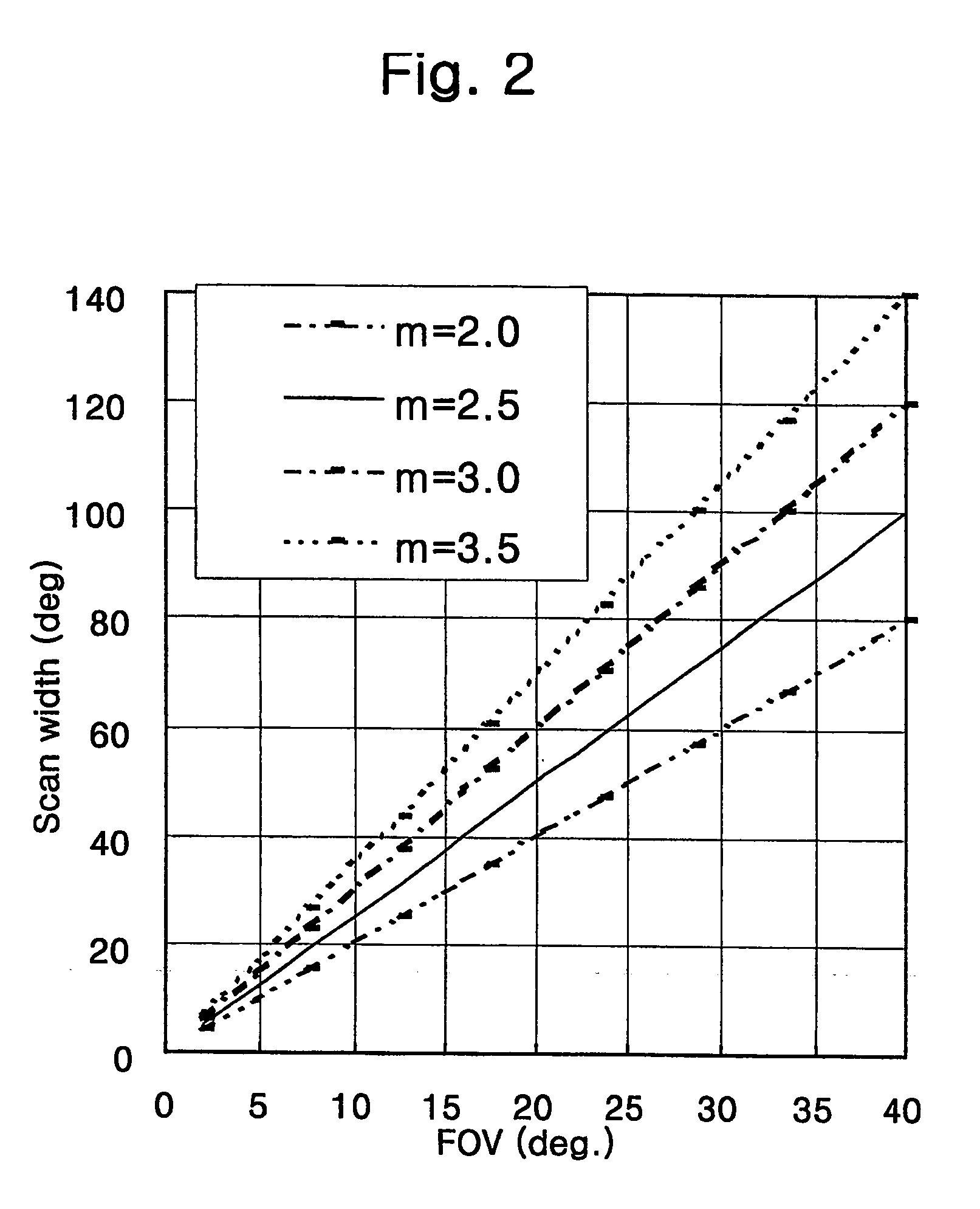

Method and apparatus for scanning the camera LOS in a continuous zoom camera system

InactiveUS7468740B2Different sensitivityTelevision system detailsPicture taking arrangementsField of viewTurret

A FOV(field of view) dependent LOS(line of sight) scan method and apparatus for a turret aided camera system with continuous zoom optics is disclosed. According to this invention, the scan width and rate of the LOS are automatically determined as a function of the FOV selected by the user: scan width=f1(FOV, m) and scan rate=f2(FOV, te) where m is the observation range constant and te is the eye integration time. Moreover, the sensitivity to the FOV can be controlled by adjusting the relevant parameter sets (said m and te), allowing the user to select the scan condition proper to himself. This invention is quite useful for all kinds of turret aided camera system (the IR or day light TV cameras) for reconnoitering application.

Owner:AGENCY FOR DEFENSE DEV

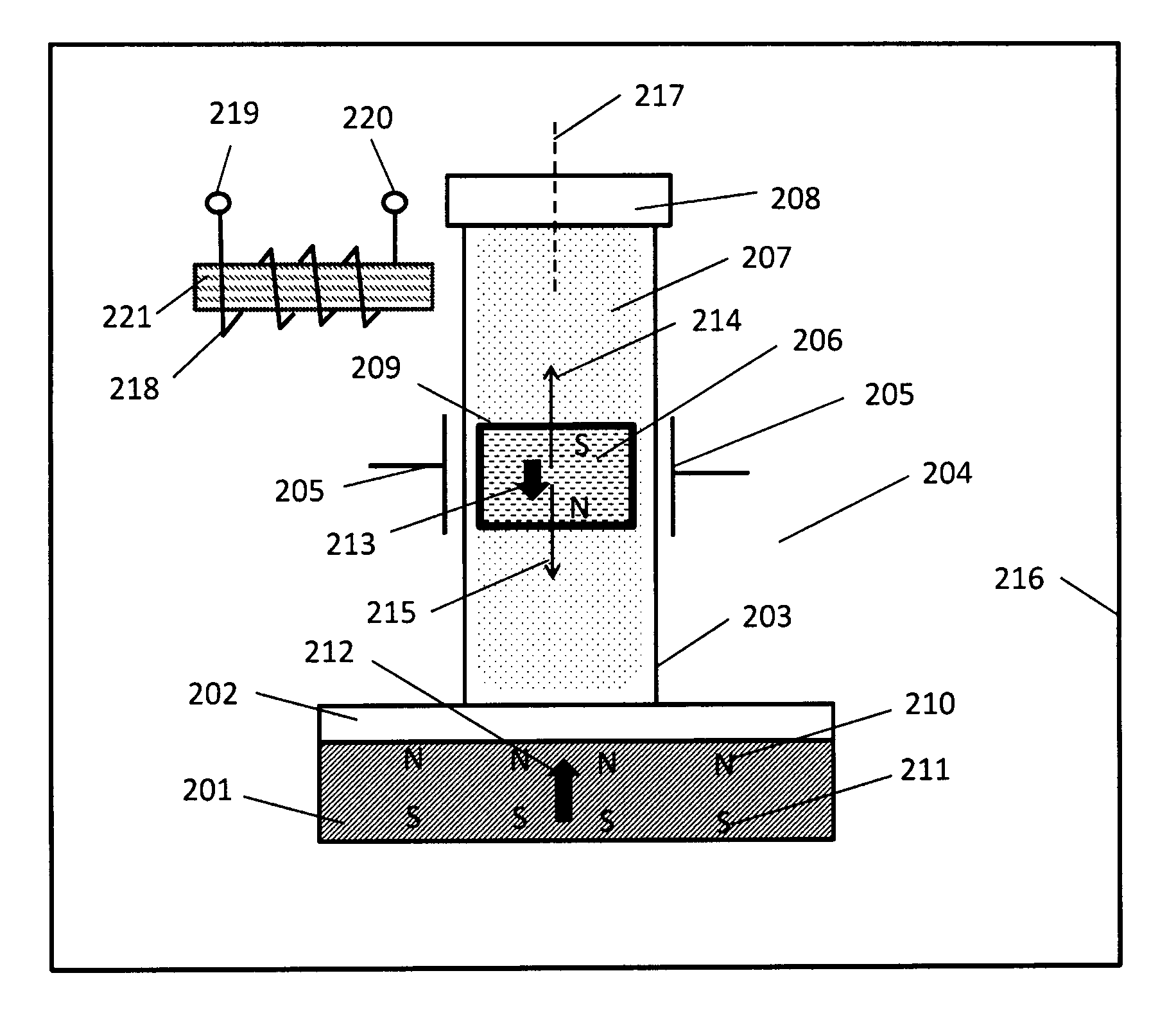

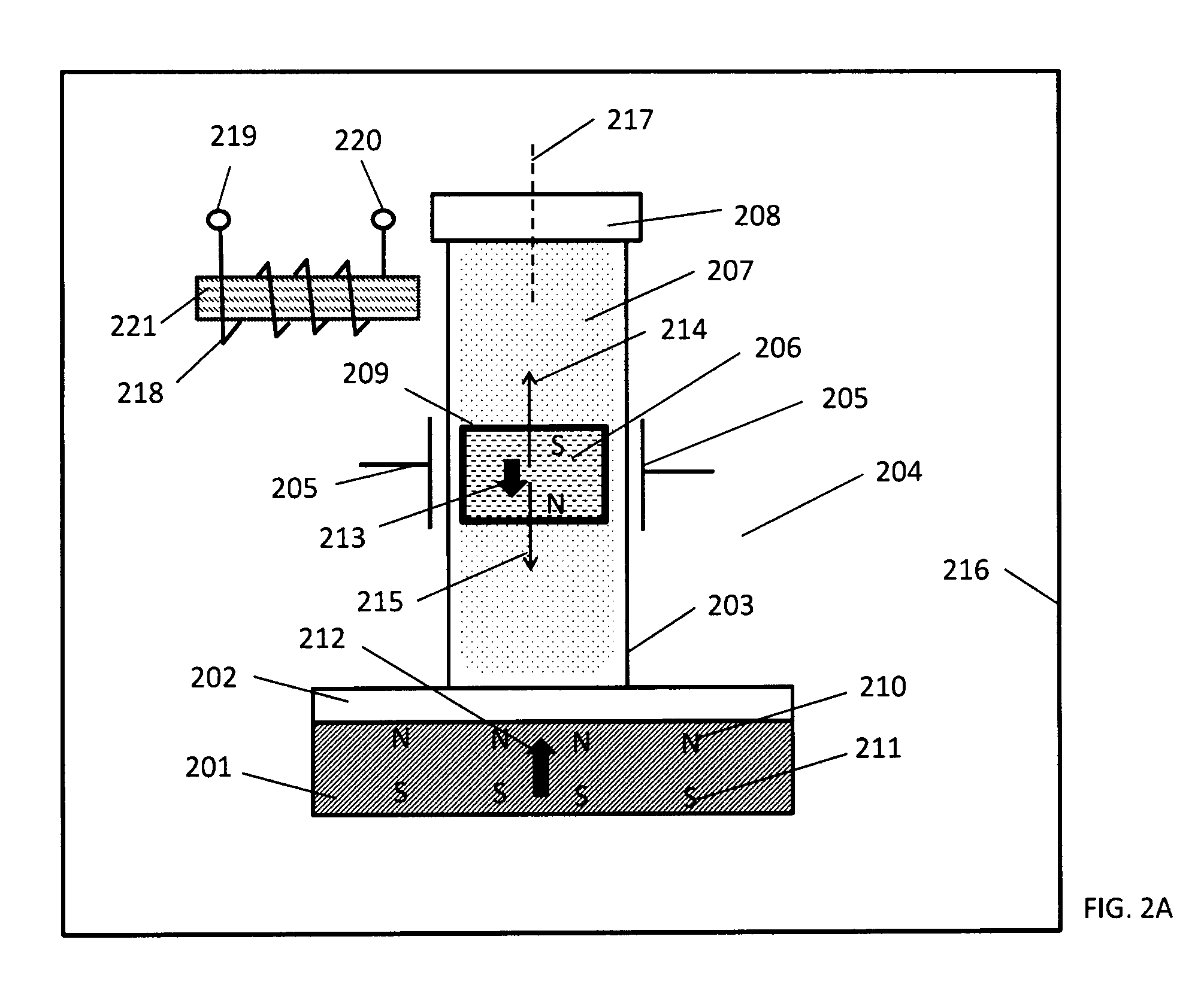

Multi-purpose sensor

ActiveUS9299925B2Low-cost large scale manufactureDifferent sensitivityAcceleration measurement using interia forcesMagnetic measurementsEngineeringSensor system

A three-dimensional sensor system made from an assembly of three either semi- or fully independently oriented sensors, each of which has a working principle based on detecting the movement of a floating magnet supported by magnetic levitation. The sensor system can be used for fall detecting, tilting monitoring and vibration tracking. The volume fabrication method of making individual sensor for such as system is also given.

Owner:GE YI +1

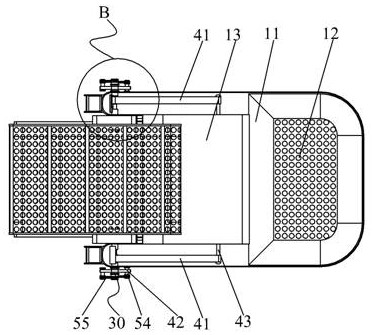

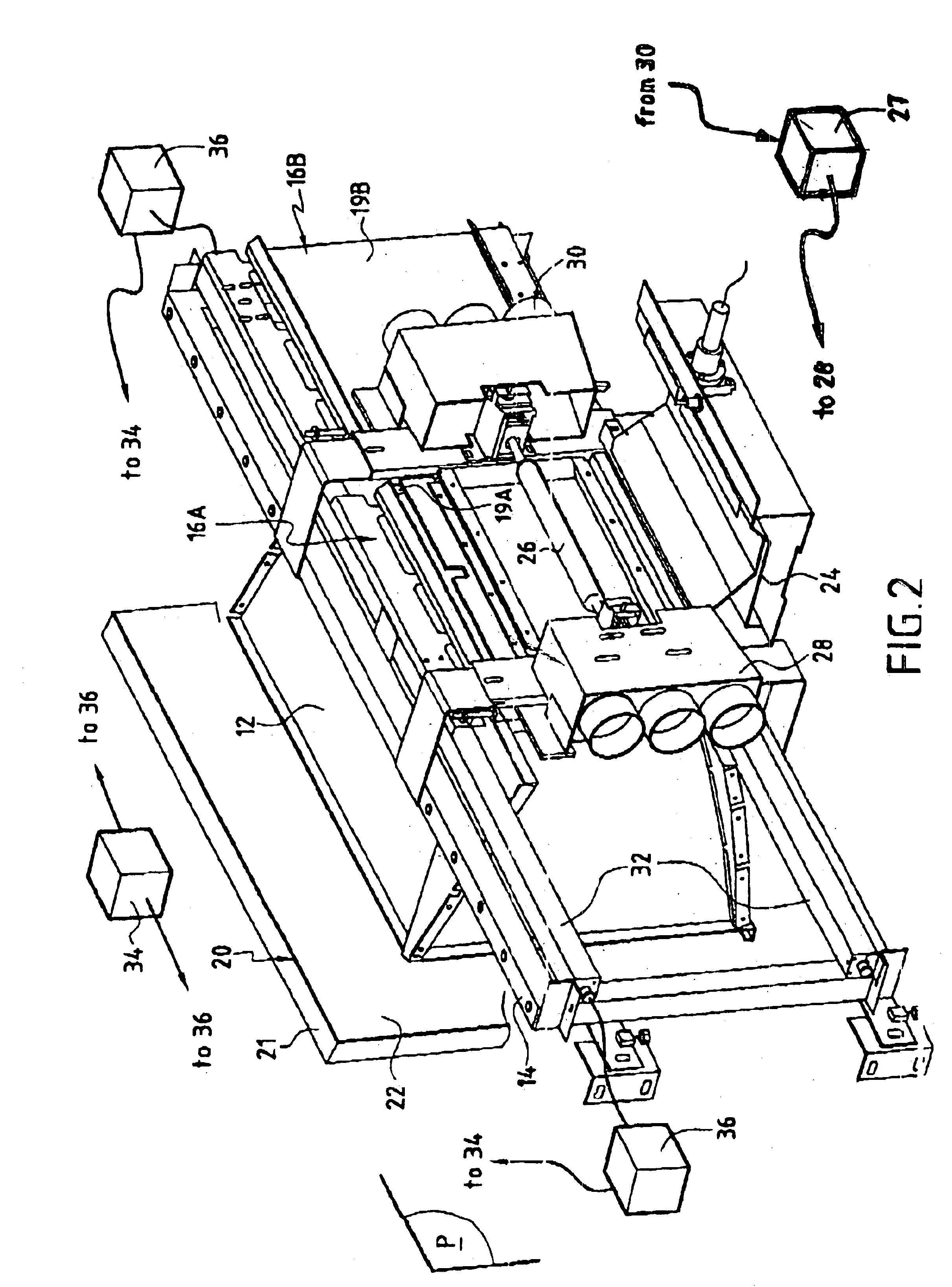

Garbage recovering device for green hydraulic engineering

ActiveCN112942274AImprove collection effectImprove collection efficiencyWater cleaningRefuse collectionStructural engineering

The invention relates to the technical field of hydraulic engineering garbage recovering, in particular to a garbage recovering device for green hydraulic engineering. The garbage recovering comprises leveling bottom plates, a power module, a collecting assembly, two supporting rods and two buoyancy bubbles; the collecting assembly comprises a mounting frame and an annular filter screen wound on the mounting frame and used for collecting garbage; the lower end of the mounting frame is hinged to the front ends of the two leveling bottom plates; one ends of the two supporting rods are hinged to the middle of the mounting frame; the other ends of the two supporting rods are rotationally connected with the leveling bottom plates and are arranged on the leveling bottom plates in a front-back sliding mode; and the middles of the two buoyancy bubbles are fixedly connected with the upper ends of the supporting rods. The included angle between the collecting assembly and a base can be changed according to the magnitude of forward resistance, then the immersion depth is changed, floating garbage is prevented from crossing the bottom of the device, and the garbage collecting effect and collecting efficiency are improved.

Owner:高占彩

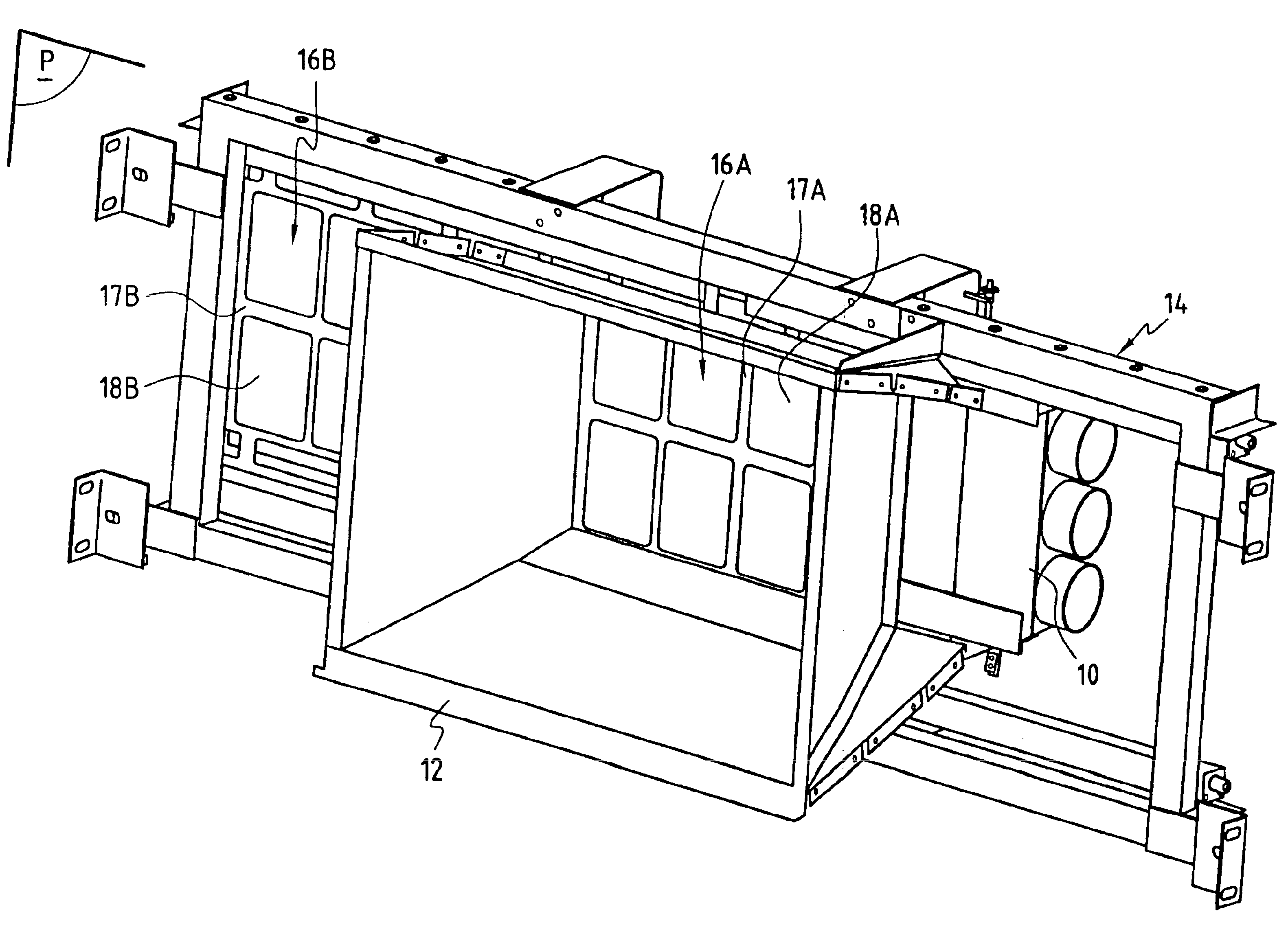

Device for exposing a face of a panel

InactiveUS6798496B2Increase exposureDifferent sensitivityPhotomechanical exposure apparatusPrinted circuit manufactureWindow shutterOptoelectronics

The invention provides apparatus for exposing a face of a panel, in particular a printed circuit panel, the device including a light source. The device further comprising:two moving shutters suitable for masking said light source, each of said shutters presenting a respective edge, said edges together defining a window through which a light zone is generated on said face of the panel to be exposed;means for displacing said shutters in a plane lying between said light source and said panel; andcontrol means for controlling the displacement of said shutters in such a manner that both shutters move past said face of the panel at substantially the same speed and in the same direction.

Owner:AUTOMA TECH

Diagnosis of batteries

InactiveUS20210194070A1High sensitivityDifferent sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesElectronic circuit testingEngineeringAcoustics

A diagnostic device for critical changes in batteries having multi-layered structures, a battery system including the diagnostic device, and a method of use thereof. The device determines critical changes relative to a target state in battery cells having a plurality of layers frictionally connected to each other, at least one receiver and, optionally, a transmitter. The receiver receives acoustic plate waves and / or acoustic torsion waves and transmits a corresponding signal to an evaluating unit that evaluates parameters characteristic for an actual state of the battery cell, and compares them to at least one previously defined threshold. Exceeding or falling short of the threshold is evaluated as identification of battery cells having a critical change to the physical properties thereof. A transmitter of the diagnostic device is suitable for exciting the acoustic plate waves or torsion waves in the battery cell having a propagation direction along the layers.

Owner:RWTH AACHEN UNIVERSITY

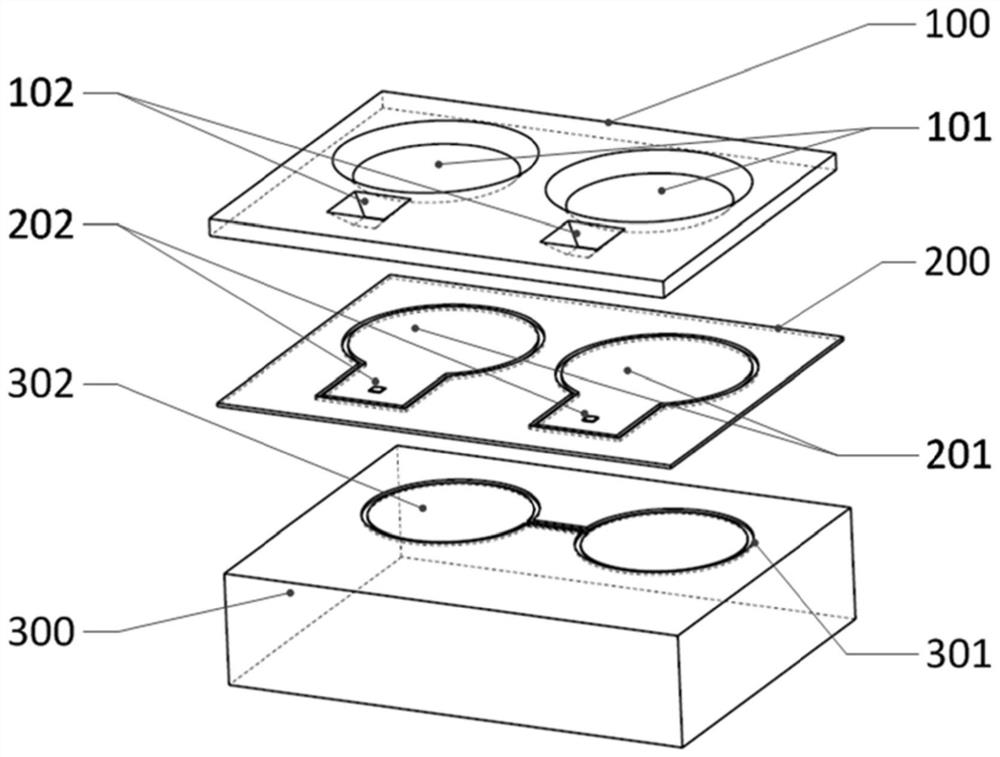

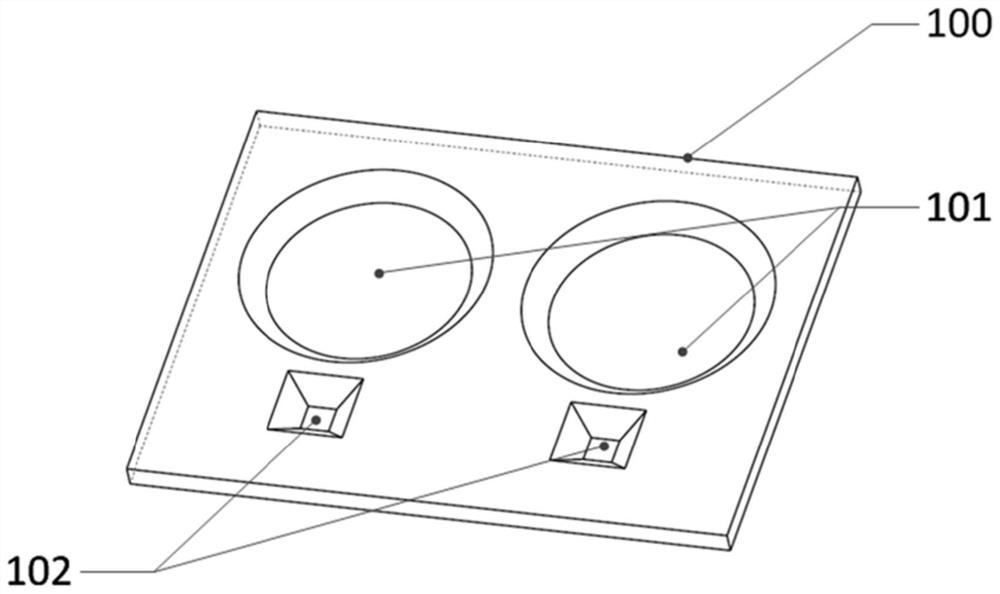

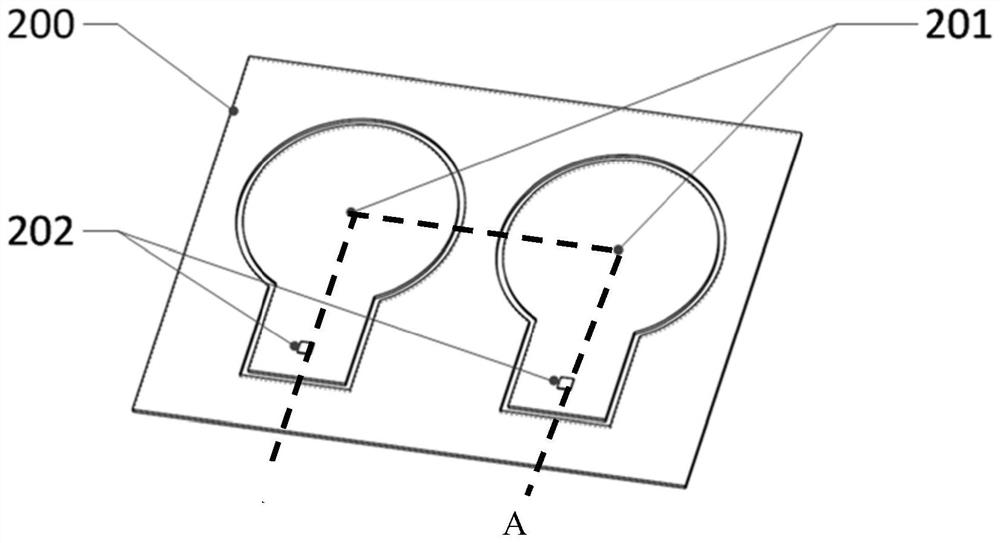

MEMS absolute pressure sensor and processing method thereof

ActiveCN112897450ALow equipment requirementsSimple processTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsAnodic bonding

The invention provides an MEMS absolute pressure sensor and a processing method thereof. The sensor comprises a glass cover plate, a silicon pressure sensing film and a glass substrate. One side of the silicon pressure sensing film is in anodic bonding with the glass substrate to form two communicated vacuum reference cavities, the other side of the silicon pressure sensing film is in anodic bonding with the glass cover plate to form two independent open type gas pressure sensing structures, and the two communicated vacuum reference cavities correspond to the two independent open type gas pressure sensing structures up and down, and form a series mutual inductance double-capacitor structure with a silicon pressure sensing film, and a lead electrode is processed on the silicon pressure sensing film and used for leading out an air pressure detection signal. External air pressure is applied to the silicon pressure sensing film through the open type gas pressure sensing structure, pressure difference is formed between the external air pressure and the vacuum reference cavity to enable the silicon pressure sensing film to deform, then the distance between the silicon pressure sensing film and the capacitance plate of the glass substrate is changed, and the capacitance value is changed to reflect the external air pressure. The processing technology based on the sensor is few in steps, extremely high in qualified rate, good in long-term stability of products and convenient for large-scale batch production.

Owner:BEIJING RES INST OF TELEMETRY +1

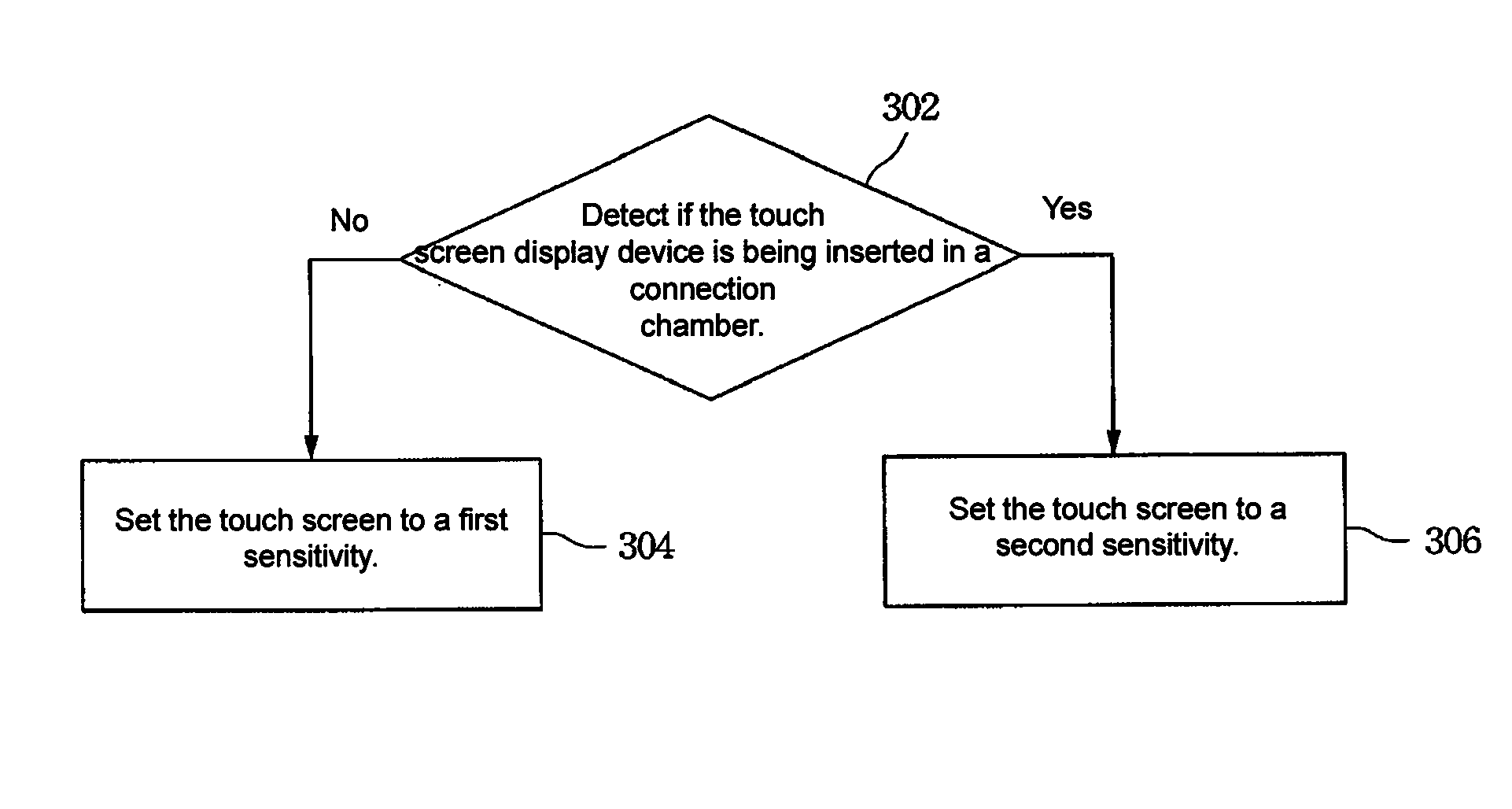

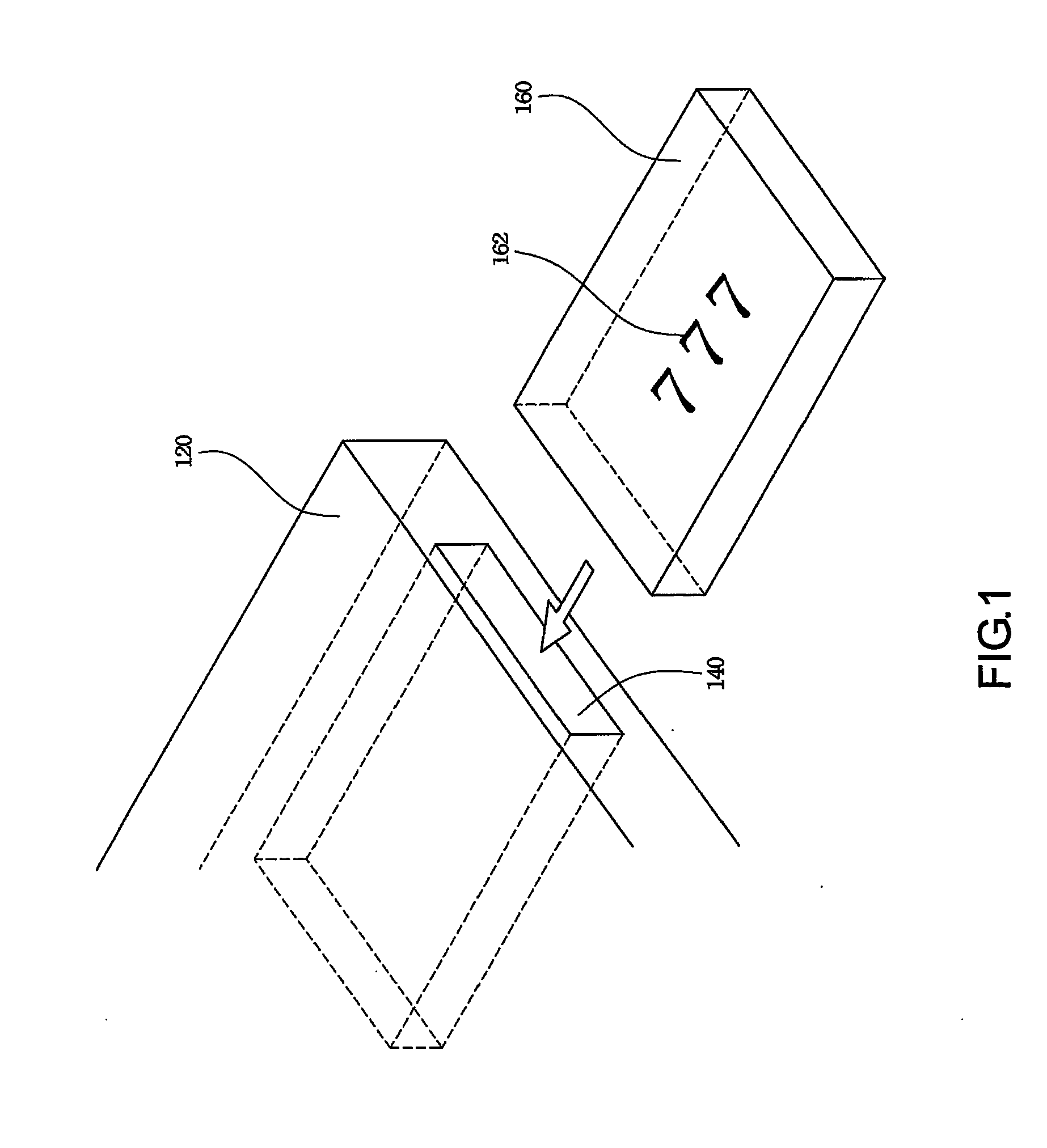

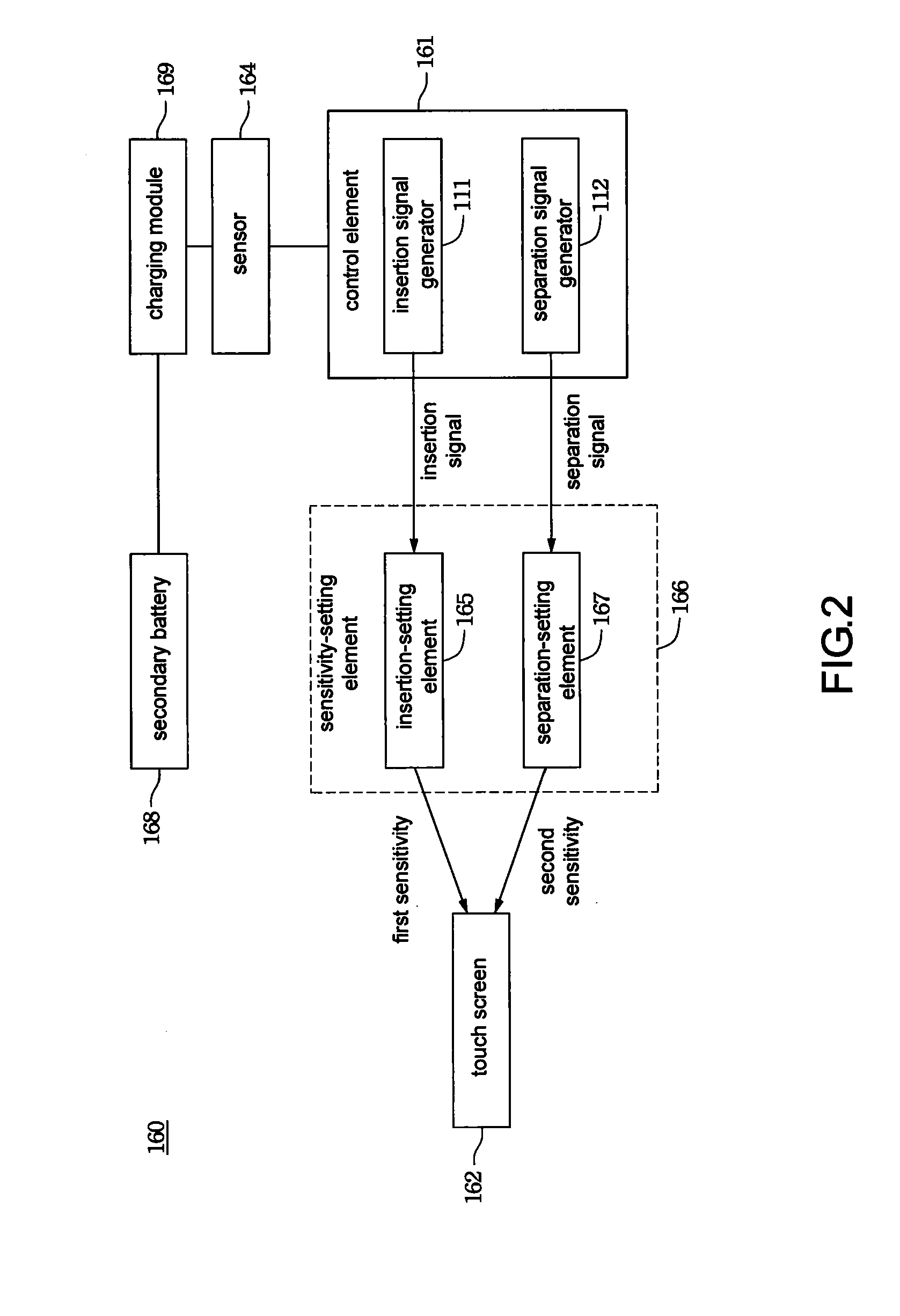

Touch screen display device and application thereof

ActiveUS20100007614A1Easy to operateDifferent sensitivityDetails for portable computersInput/output processes for data processingControl signalDisplay device

A touch screen display device is provided. The touch screen display device includes a touch screen, a sensor, a control element and a sensitivity-setting element. The sensor is configured to detect if the touch screen display device is being inserted in a connection chamber. The control element is electrically connected with the sensor and is configured to generate a control signal according to an insertion status of the touch screen display device. The sensitivity-setting element is configured to set the touch screen to a first sensitivity or a second sensitivity according to the control signal. The touch screen with the first sensitivity is more sensitive than with the second sensitivity. A method for setting sensitivity of a touch screen is also provided.

Owner:WISTRON CORP

Method and apparatus for scanning the camera los in a continuous zoom camera system

InactiveUS20050231614A1Different sensitivityTelevision system detailsPicture taking arrangementsSight lineVideo camera

A FOV(field of view) dependent LOS(line of sight) scan method and apparatus for a turret aided camera system with continuous zoom optics is disclosed. According to this invention, the scan width and rate of the LOS are automatically determined as a function of the FOV selected by the user: scan width=f1(FOV, m) and scan rate=f2(FOV, te) where m is the observation range constant and te is the eye integration time. Moreover, the sensitivity to the FOV can be controlled by adjusting the relevant parameter sets (said m and te), allowing the user to select the scan condition proper to himself. This invention is quite useful for all kinds of turret aided camera system (the IR or day light TV cameras) for reconnoitering application.

Owner:AGENCY FOR DEFENSE DEV

Methods for making microarrays and their uses

ActiveUS9453838B2Limiting scale and degreeAvoid wastingBiological material analysisLibrary creationFluorescenceMicrometer scale

The present invention provides microarrays that can be analysed by more than one technique using a non-covalent ligand attachment strategy to solid supports such as indium tin oxide (ITO) covered transparent glass slides. This provides, inter alia, glycan arrays on a micrometer scale which allow multimodal readout by MALDI-Tof-MS, fluorescence and optical microscopy. Glycans functionalized with a C5-aminolinker were attached in situ on a picomolar scale to a hydrophobic tag bound to this surface, thus avoiding the wasteful off-chip ligand tagging of other approaches. Glycan arrays prepared using this methodology were analysed both with a fluorescence scanner and by on-chip MALDI-mass spectrometry in a series of glycomics experiments specifically requiring a multimodal readout.

Owner:ASOCIACION CENT DE INVESTIGACION COOP & BIOMATERIALES - CIC BIOMAGUNE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com