Patents

Literature

69results about How to "Improve sequence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

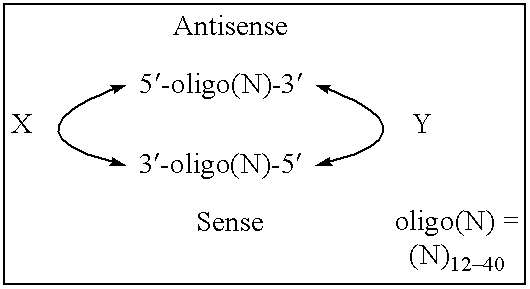

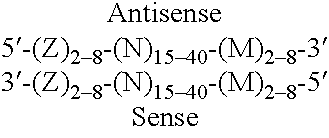

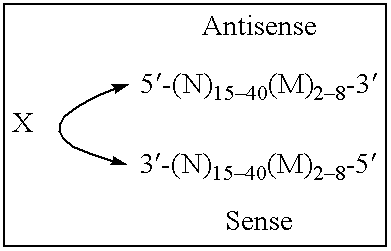

Double-stranded oligonucleotides

InactiveUS20060009409A1Inhibit gene functionImprove sequenceOrganic active ingredientsSenses disorderOligonucleotideDouble stranded

Antisense sequences, including duplex RNAi compositions, which possess improved properties over those taught in the prior art are disclosed. The invention provides optimized antisense oligomer compositions and method for making and using the both in in vitro systems and therapeutically. The invention also provides methods of making and using the improved antisense oligomer compositions.

Owner:LIFE TECH CORP

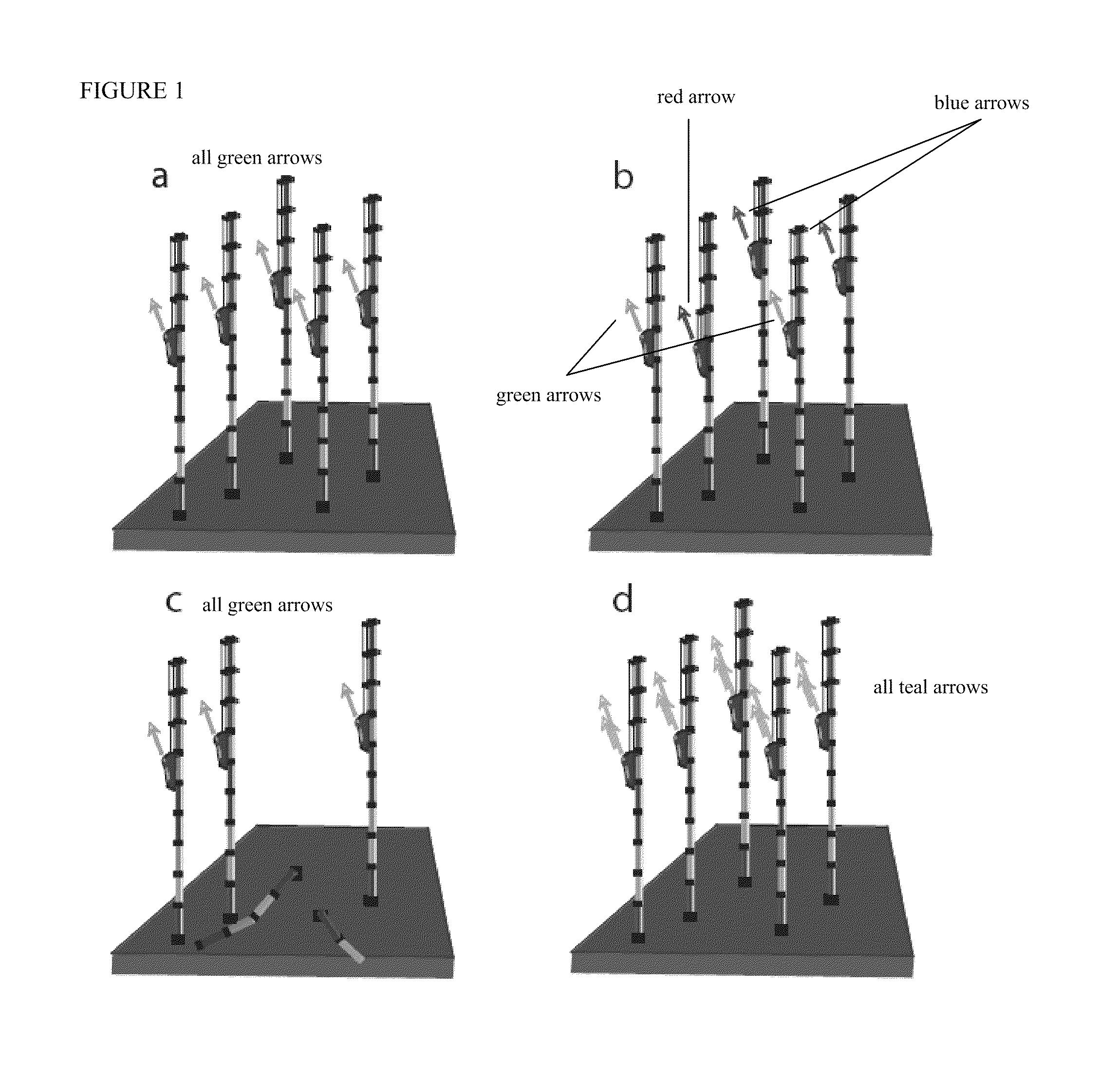

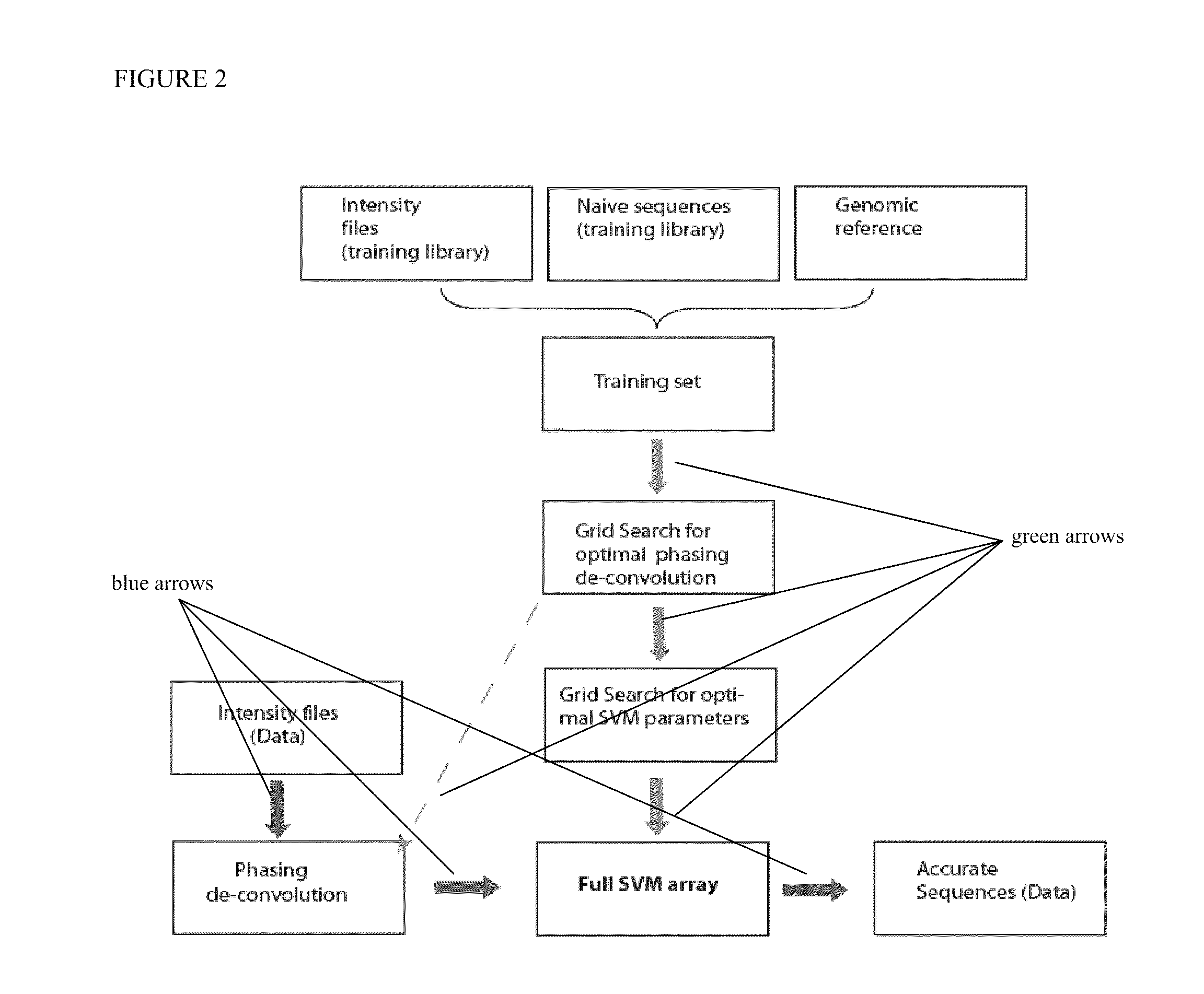

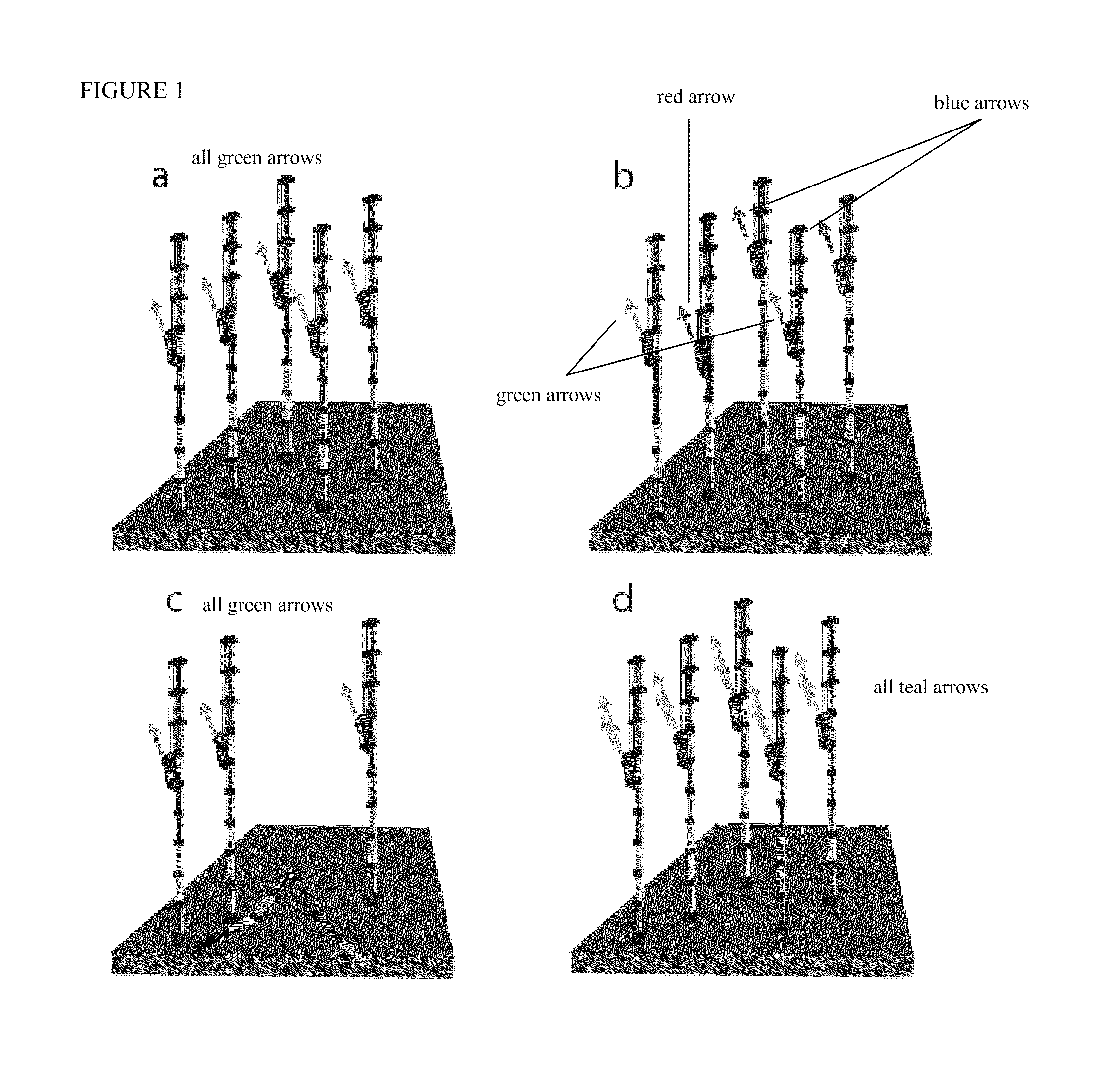

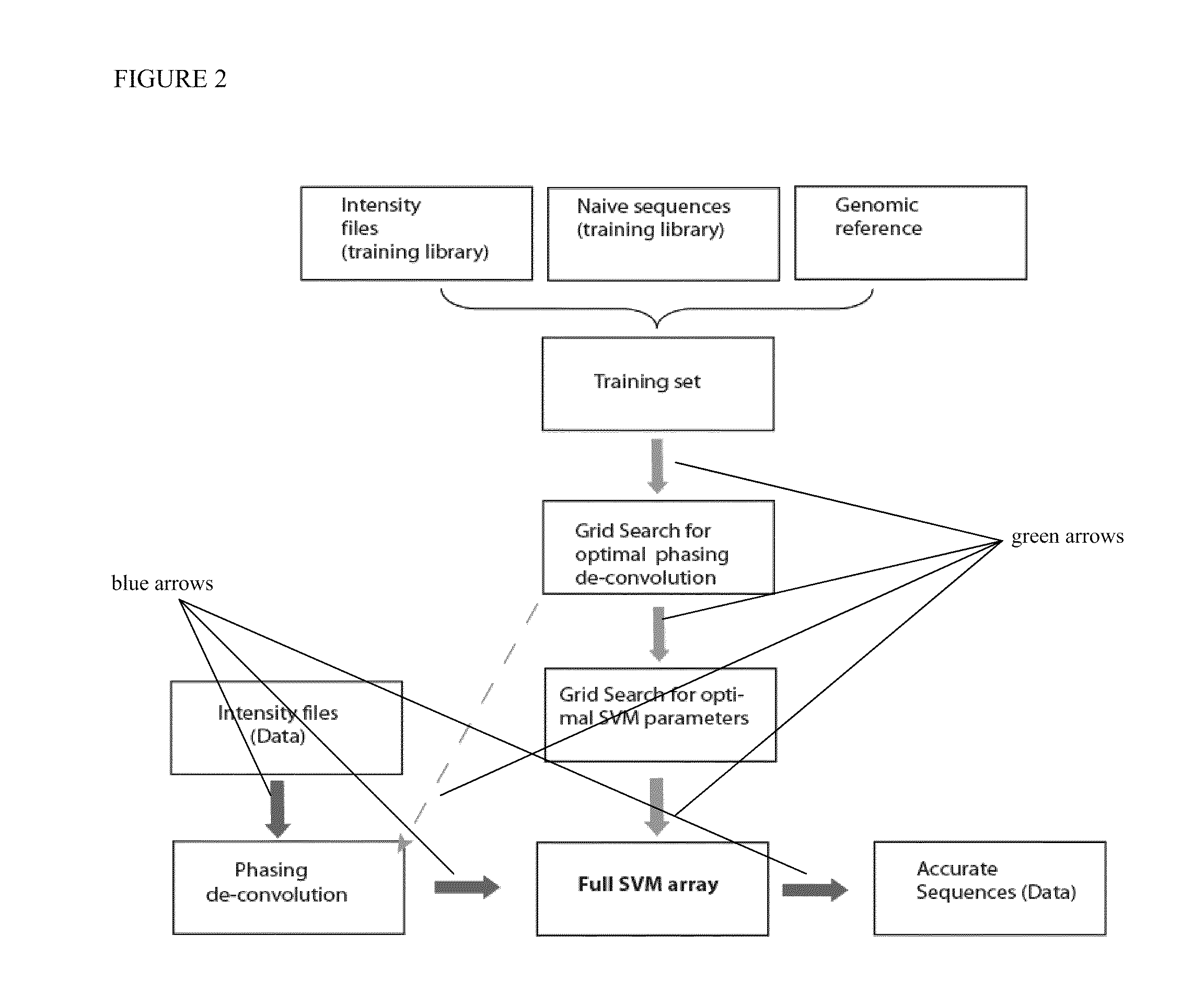

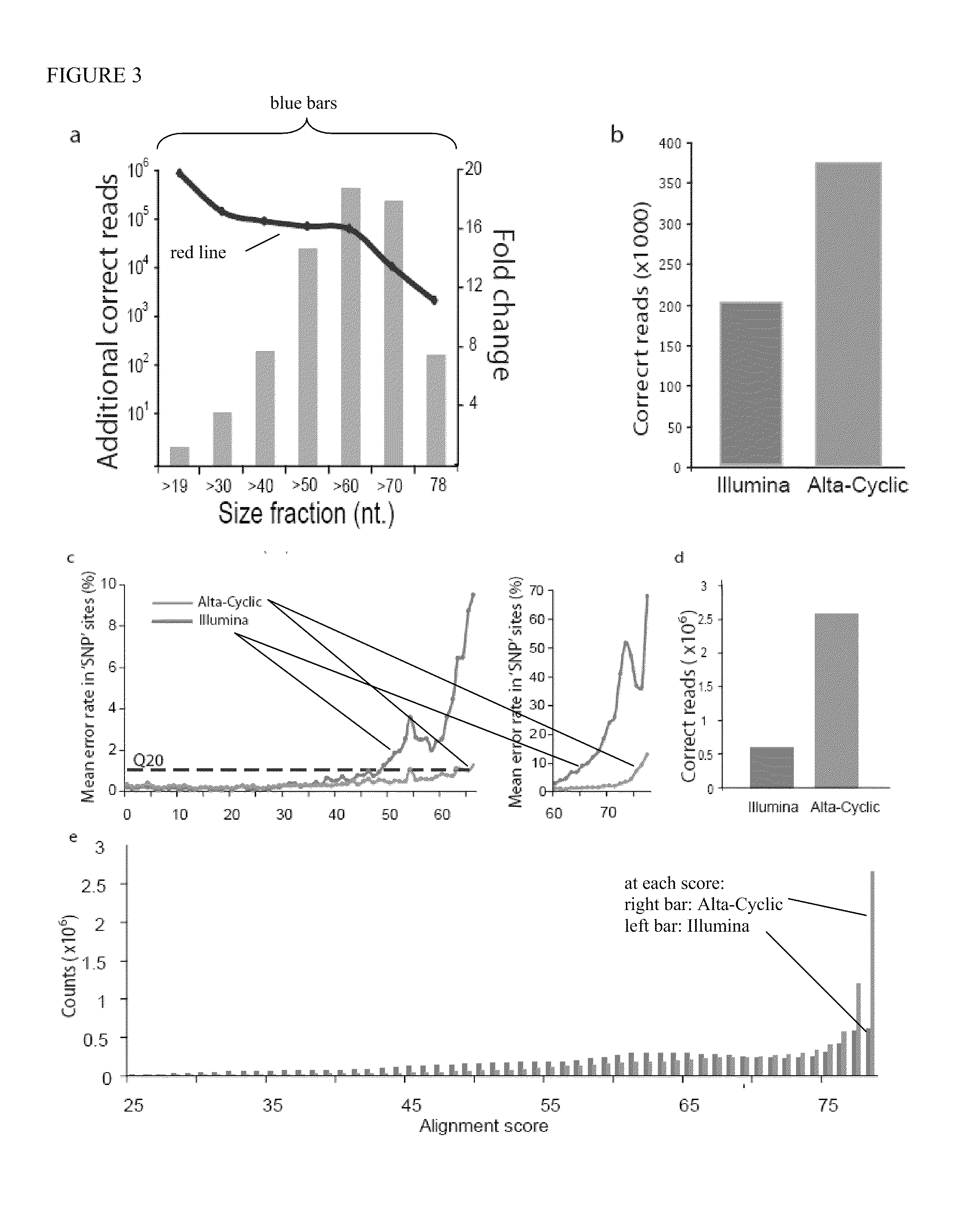

Methods and systems of DNA sequencing

ActiveUS20100160172A1Quick sortingImprovement in sequence determinationNucleotide librariesLibrary screeningDNA sequencerComputational biology

Owner:COLD SPRING HARBOR LAB INC

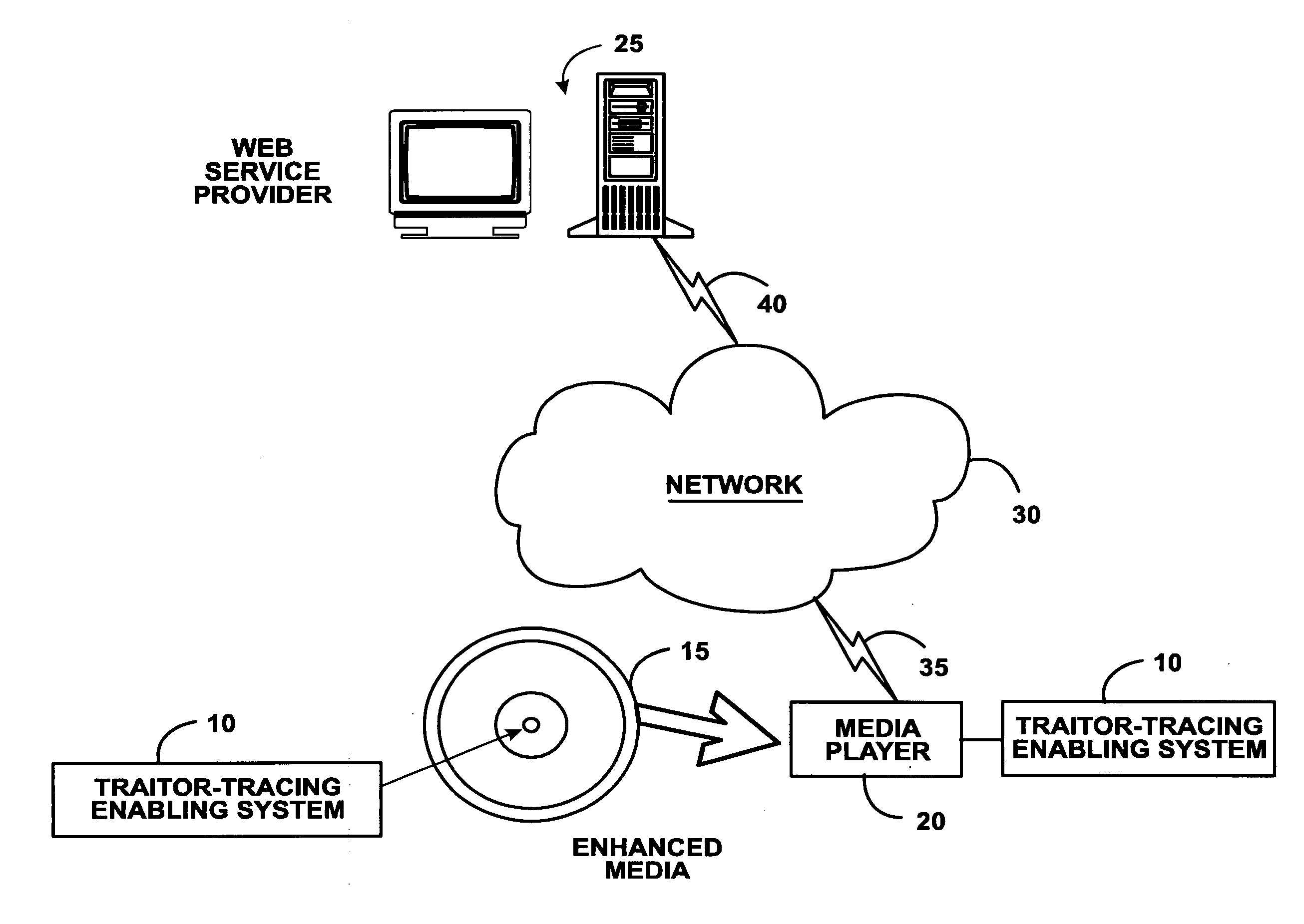

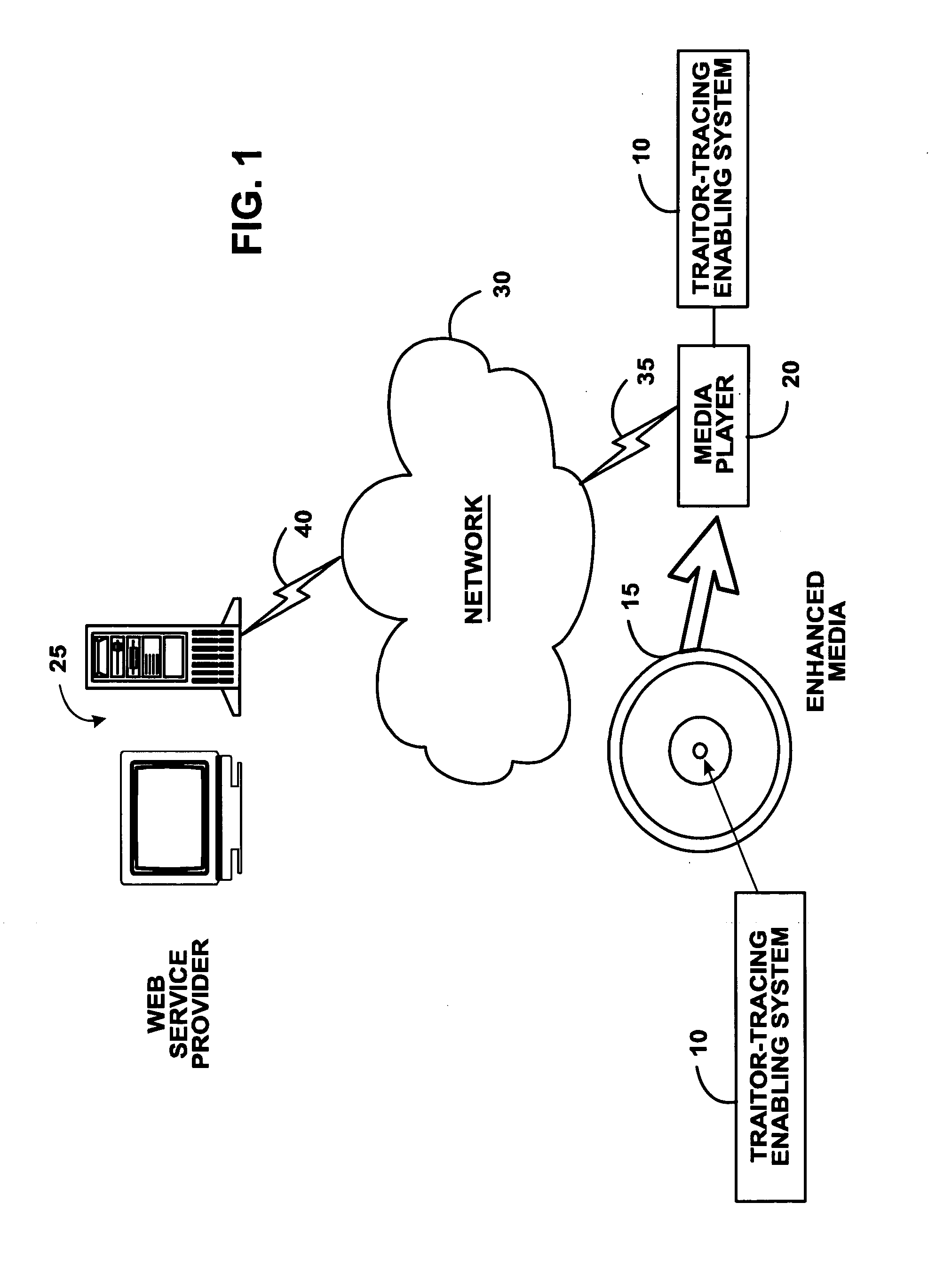

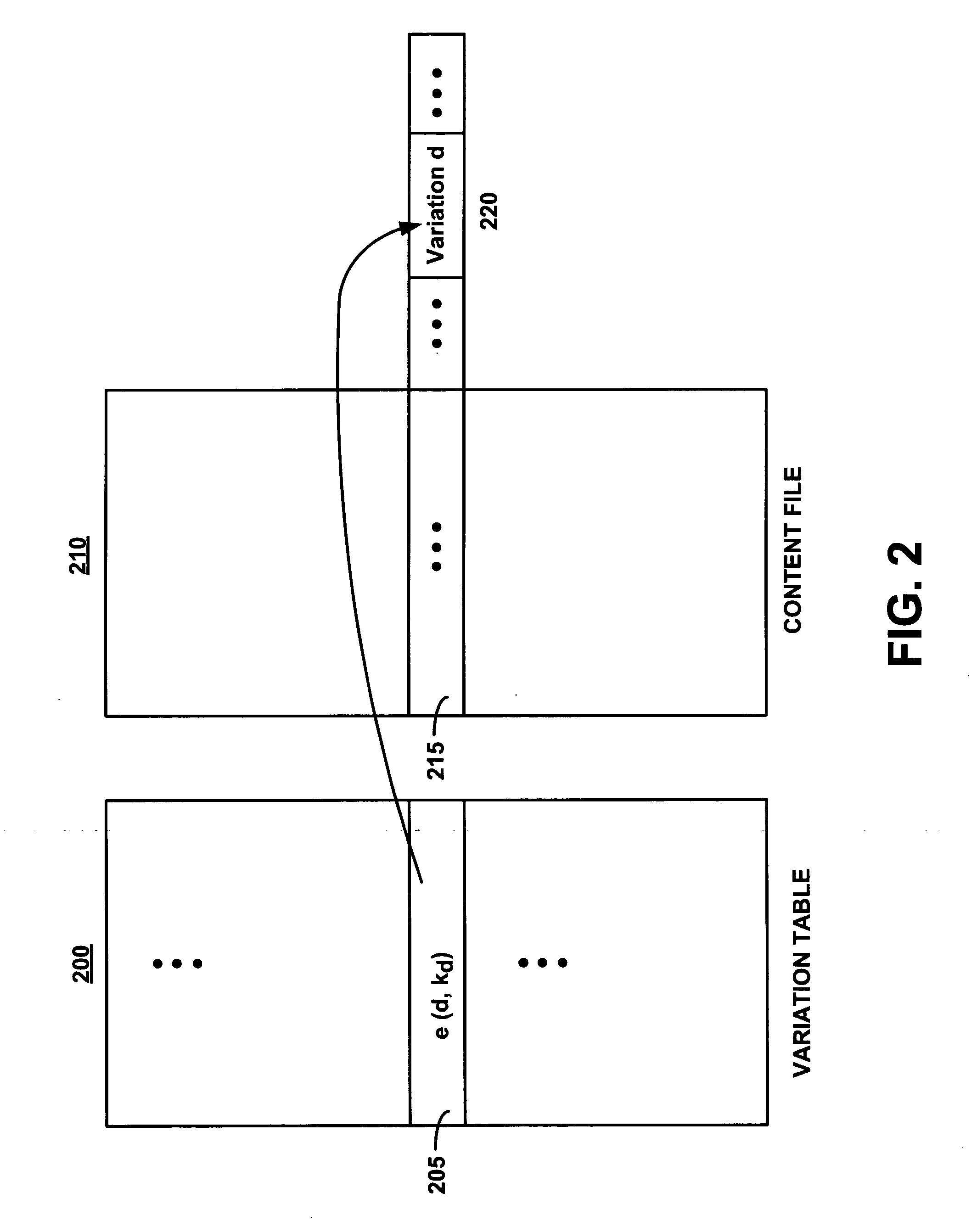

System and method for assigning sequence keys to a media player to enable flexible traitor tracing

ActiveUS20070174637A1Improve the immunityIncrease the number ofDigital data processing detailsUnauthorized memory use protectionComputer hardwareGranularity

A traitor tracing enabling system assigns sequence keys to a media player to enable better tracability with fewer actual variations in the content. The system comprises a technique for increasing a number of sequence keys, allowing a finer granularity in a traitor tracing process with little increase in sequence key storage or in bandwidth required to transmit sequence keys to a media player. The present system comprises a variation table which maps the sequence keys to the individual variations in the file, such that multiple sequence keys can be mapped to a single variation.

Owner:HULU

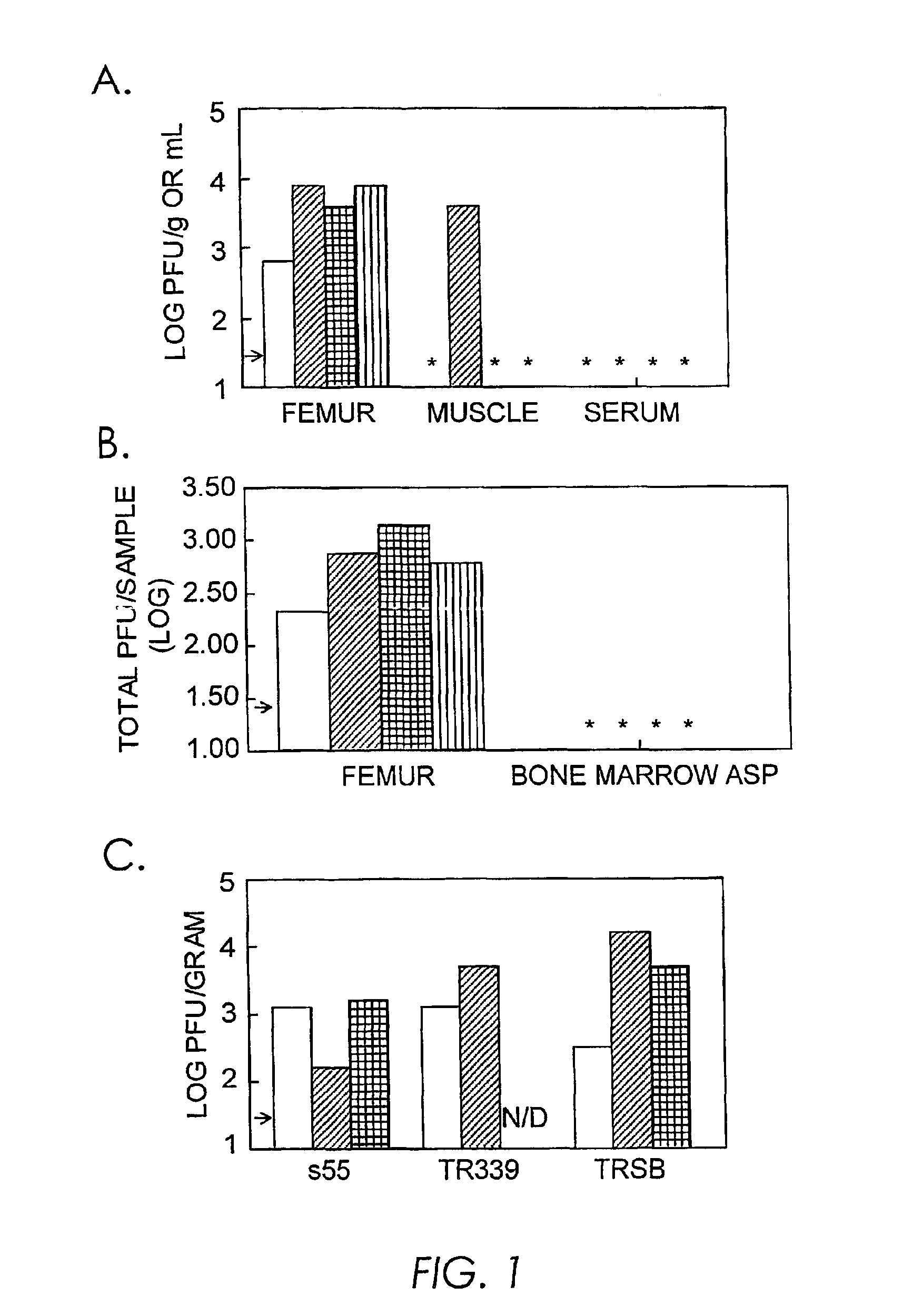

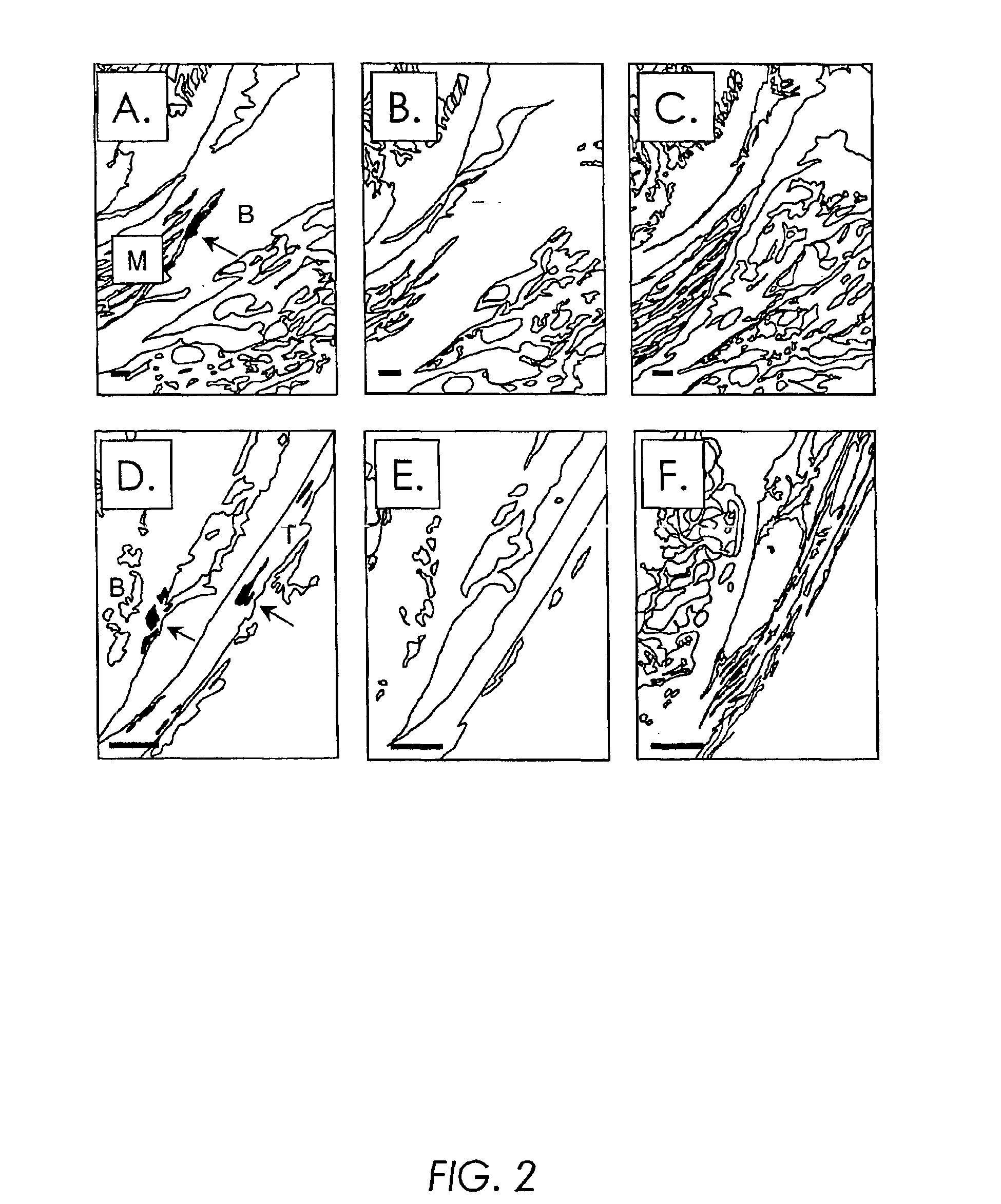

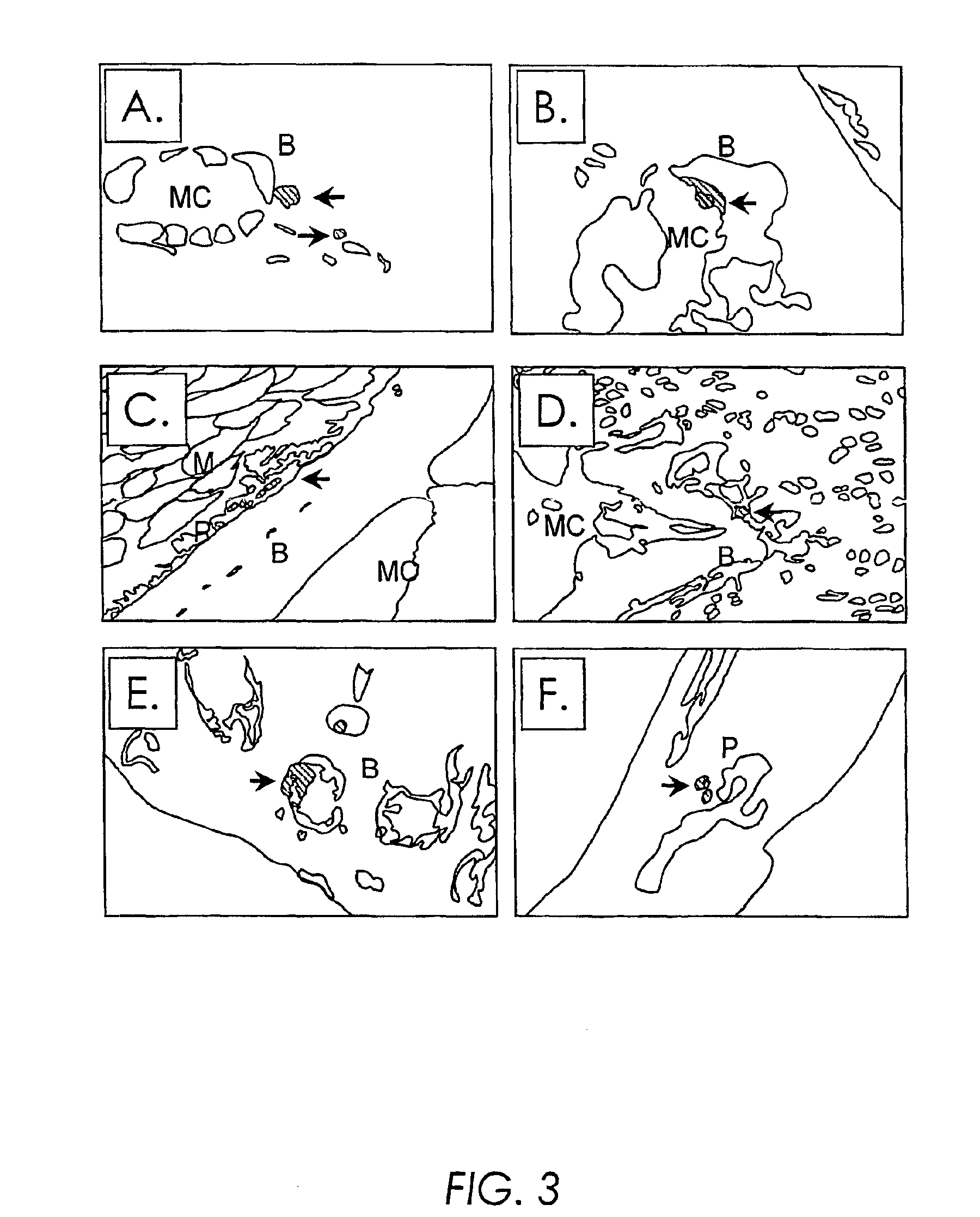

Vectors derived from South African Arbovirus No. 86

InactiveUS6982087B2High expressionImprove sequenceBiocideSsRNA viruses positive-senseConnective tissueNucleotide sequencing

Provided herein are alphavirus vectors derived from South African Arbovirus No. 86 (S.A.AR86) comprising attenuating mutations and methods of making the same. Also provided are improved viral vectors and helper constructs comprising a S.A.AR86 capsid enhancer sequence. The present invention also provides S.A.AR86 replicon and helper constructs comprising an alphavirus capsid enhancer sequence. Further provided are methods of administering an alphavirus vector comprising a heterologous nucleotide sequence (preferably encoding an immunogen or a therapeutic polypeptide) according to the invention to a cell or subject. In preferred embodiments, the alphavirus vector delivers the heterologous nucleotide sequence to the cells of the bone, bone marrow, and / or bone-associated connective tissue.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Methods and systems of DNA sequencing

ActiveUS8407012B2Improve base calling procedureShorten the lengthGeneral purpose stored program computerBiological testingDNA sequencerComputational biology

Owner:COLD SPRING HARBOR LAB INC

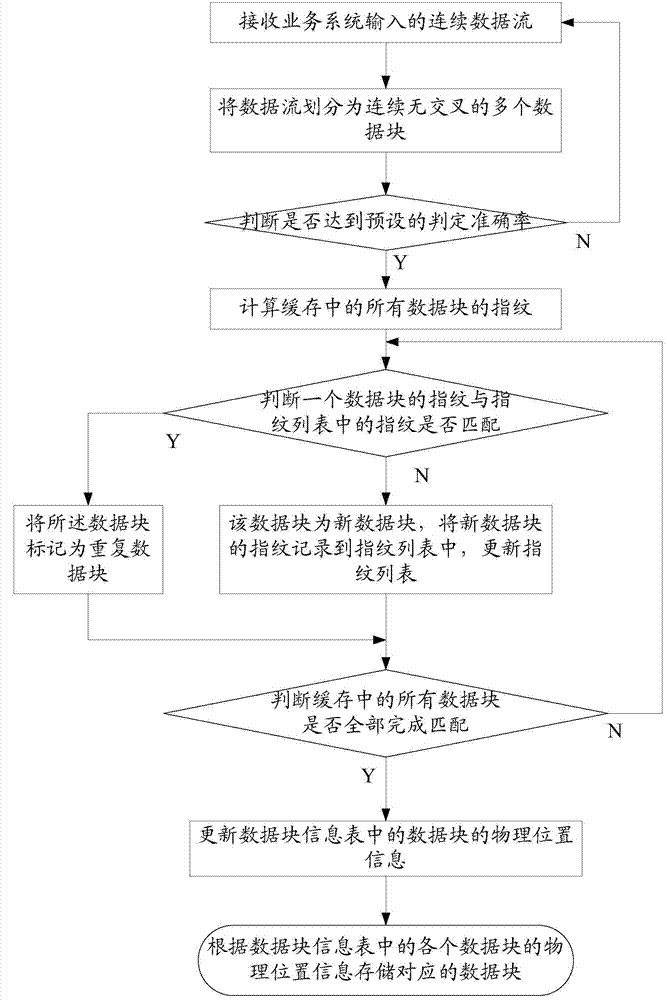

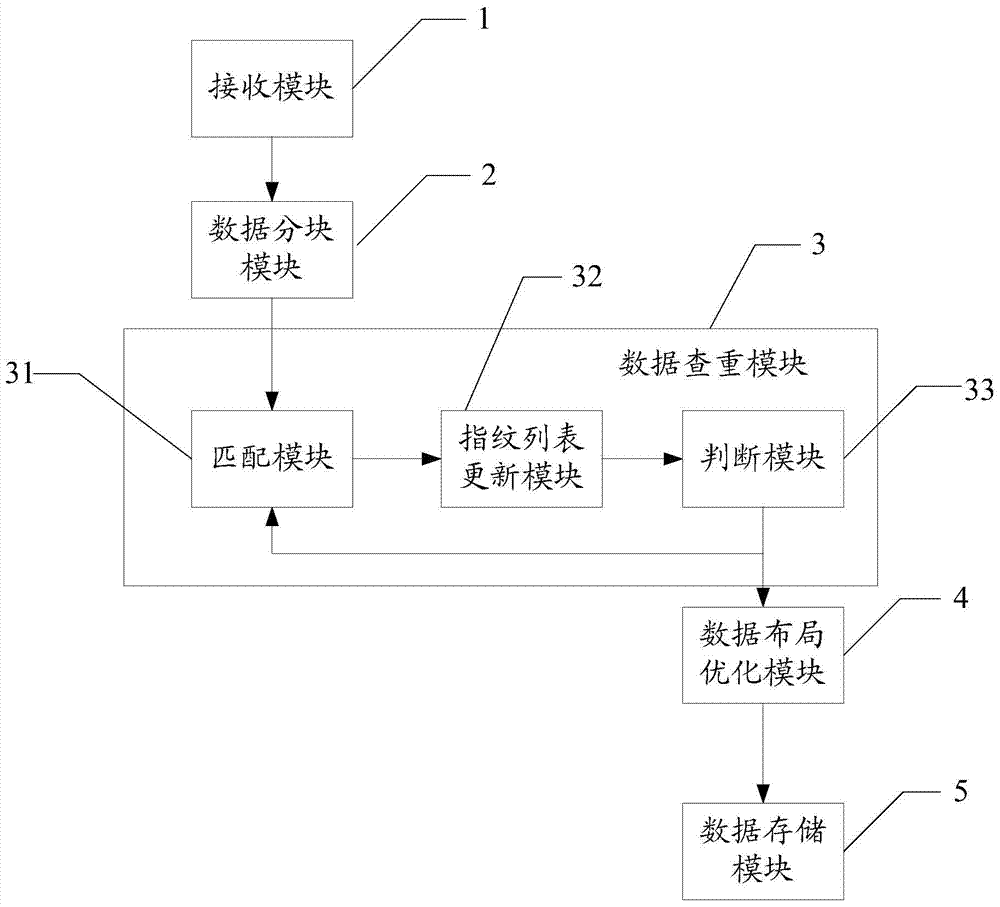

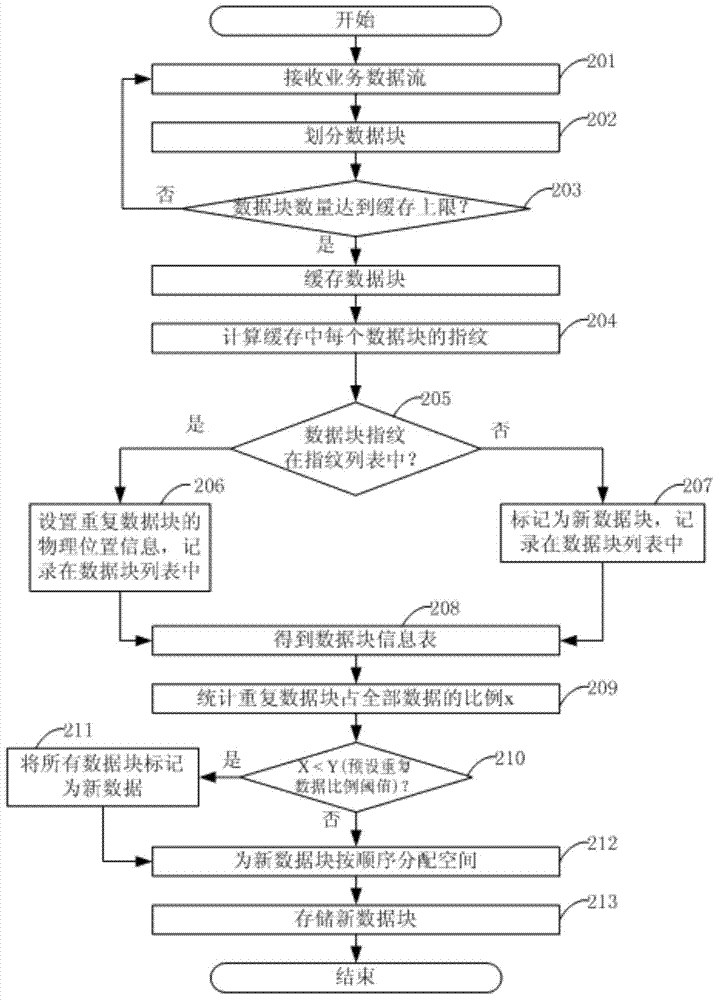

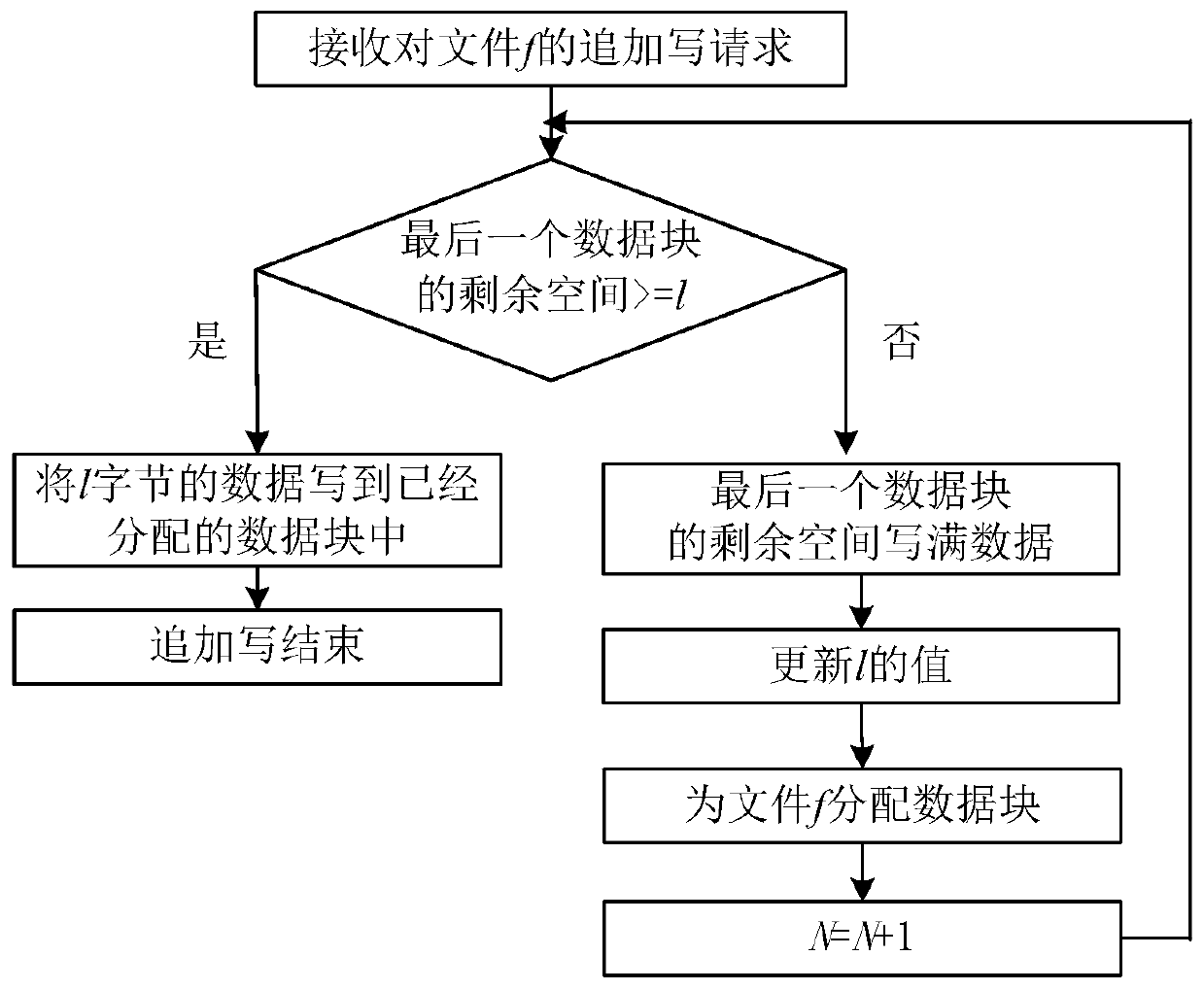

Optimization method and system for data layout

ActiveCN103678158AImprove sequenceReduce discretizationInput/output to record carriersMemory adressing/allocation/relocationService systemFingerprint

The invention relates to an optimization method for data layout. The optimization method comprises the following steps: 1, receiving continuous data flow input by a service system; 2, dividing the data flow into a plurality of continuous data blocks without intersection; 3, judging whether the data blocks to be processed reach the upper limit of caching, if yes, carrying out the next step, and if not, skipping to the step 1; 4, obtaining fingerprints of all the data blocks in caching through calculation; 5, matching the fingerprints of the data blocks in caching and fingerprints in a fingerprint list, marking the matched data blocks as repeated data blocks, and storing the fingerprints which are not matched into the fingerprint list; 6, upgrading the physical location information of the data blocks in a data block information table; and 7, storing the corresponding data blocks according to the physical location information of the data blocks in the data block information table. According to the optimization method, the sequence of data is improved, discretization of data layout is lowered, and the sequential reading and writing performance of a repeated data deleting system is improved.

Owner:INST OF INFORMATION ENG CAS

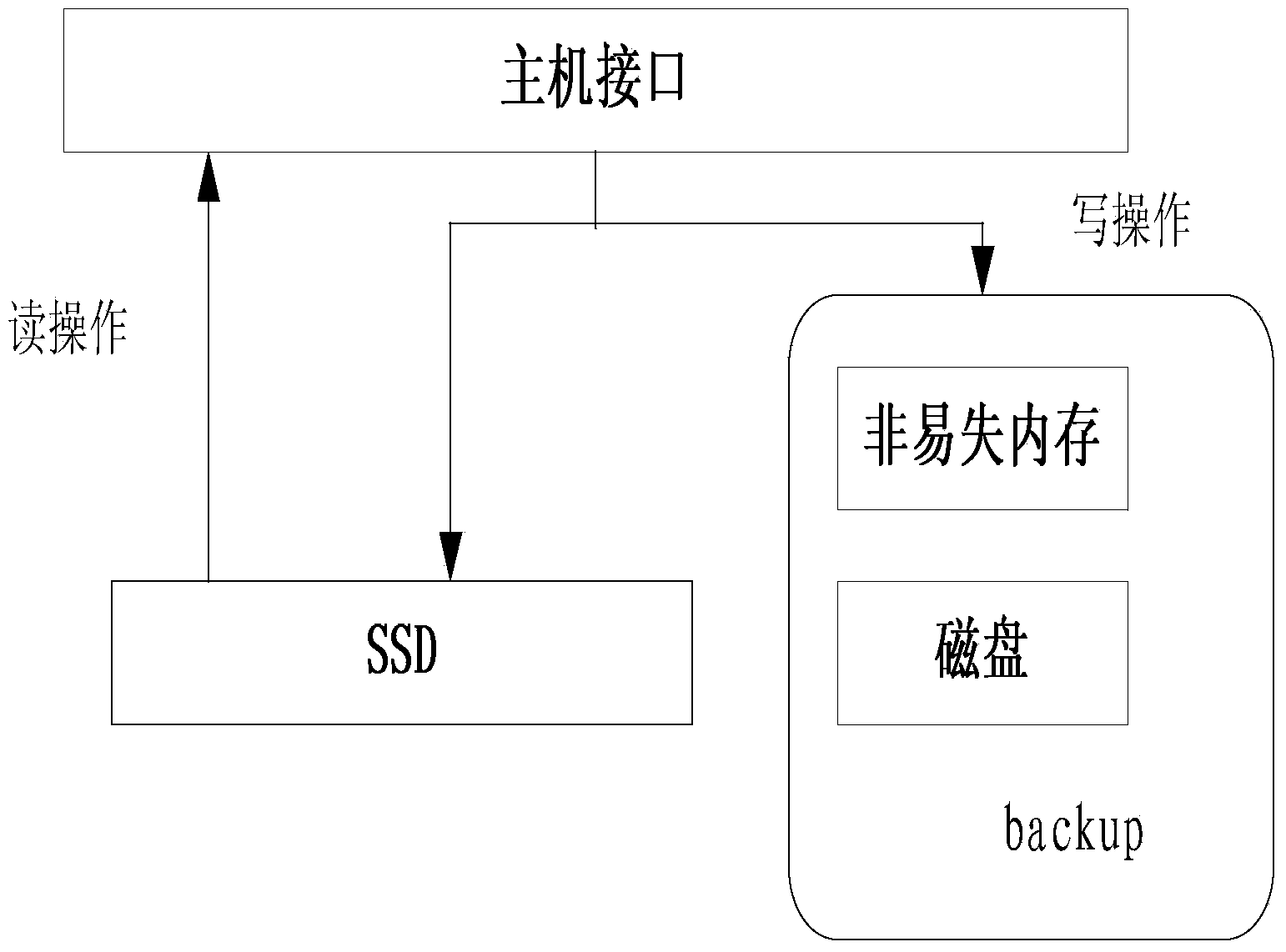

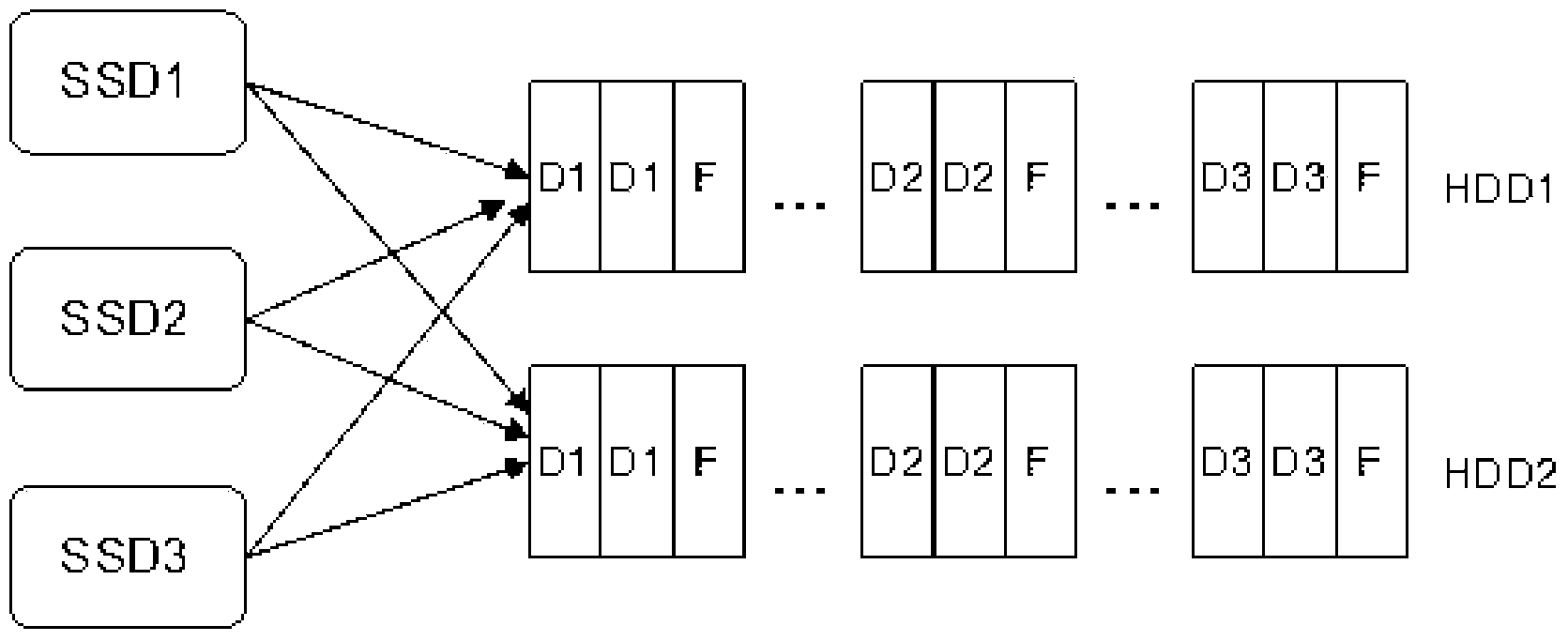

Mixed storage backup method and system based on HDD and SSD

ActiveCN103713973AIncreased responsiveness and performance requirementsEnhanced sequenceInput/output to record carriersRedundant operation error correctionAddress spaceBackup

The invention provides a mixed storage backup method and system based on an HDD and an SSD, and relates to the technical field of computer application. The method includes the following steps that linear address space of the single HDD or multiple HDDs is divided into a plurality of parts, each part comprises a data section and an idle section, and if a writing request reaches, data are written into the corresponding data section according to a preset strategy through the HDD. According to the mixed storage backup method and system, the data on the SSD can be backed up in time through the HDD, and the mixture structure achieves reliable storage system data backup which is low in price and high in performance.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

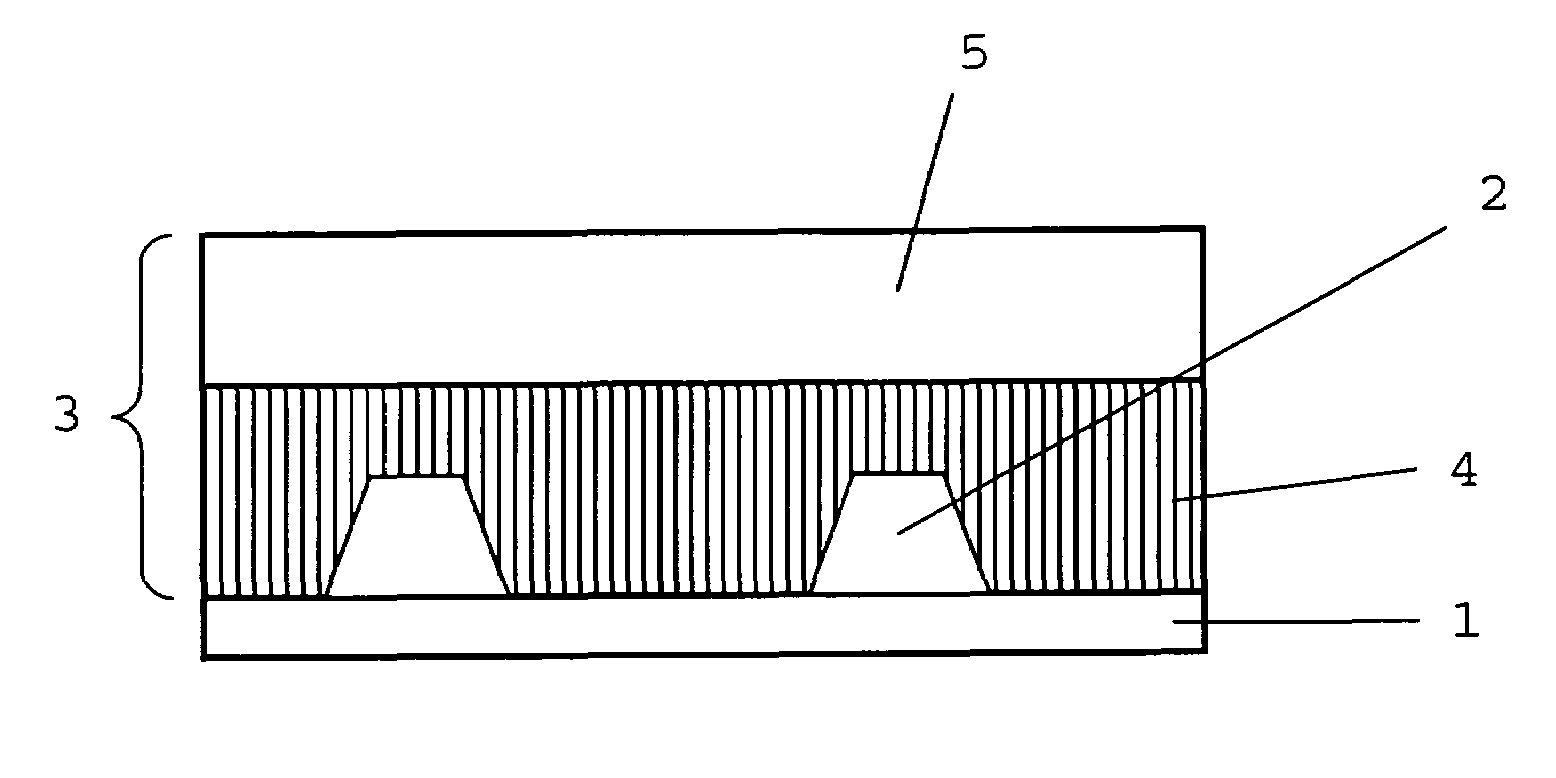

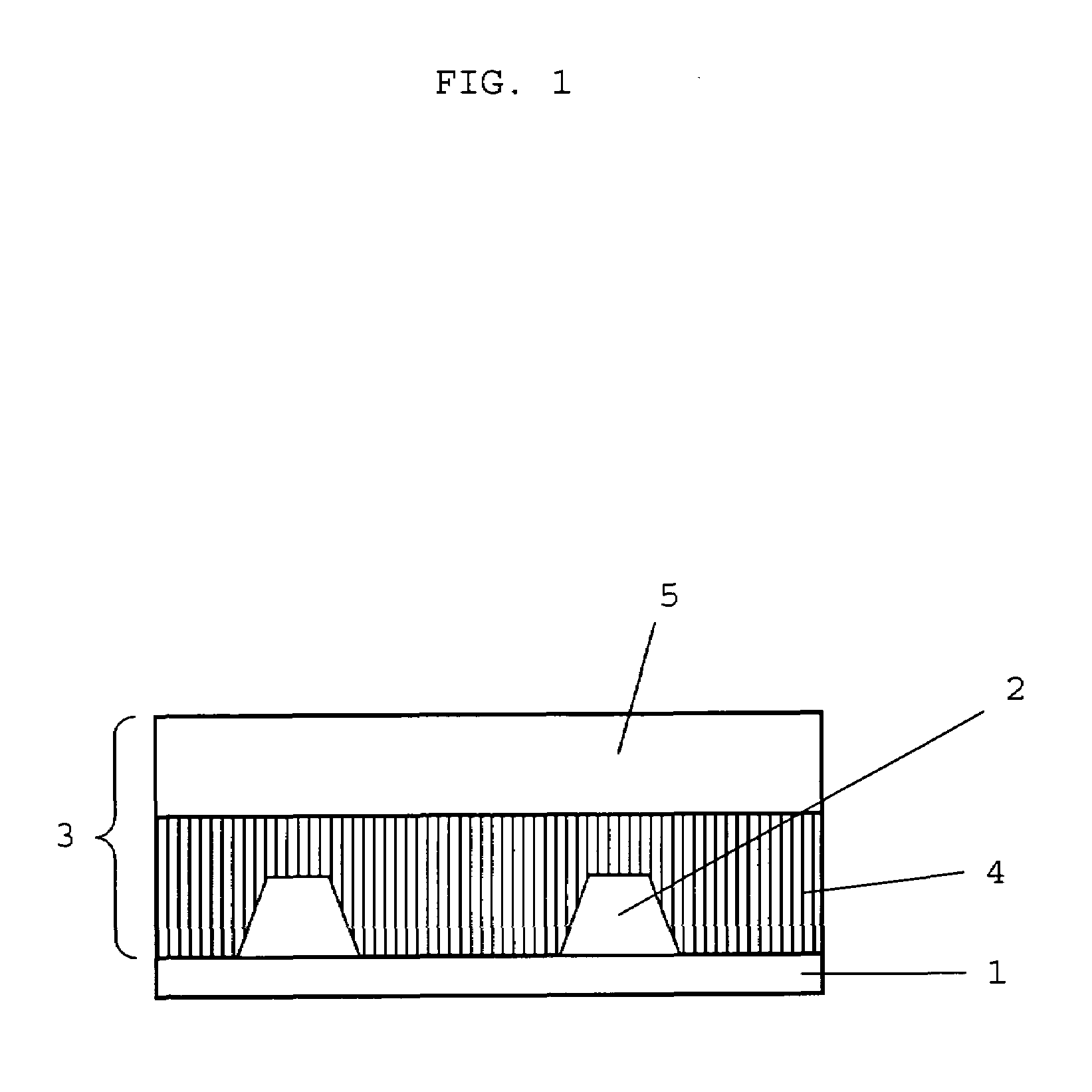

Process for the back-surface grinding of wafers

InactiveUS6958256B2AdhesionIncrease dampingNon-macromolecular adhesive additivesFilm/foil adhesivesWafer backgrindingSurface grinding

The present invention relates to a process for the back-surface grinding of wafers using films which have a support layer, which is known per se, and an adhesion layer which can be polymerized in steps, and to films which include such an adhesion layer which can be polymerized in steps, and to the use thereof.

Owner:POLARIS INNOVATIONS LTD

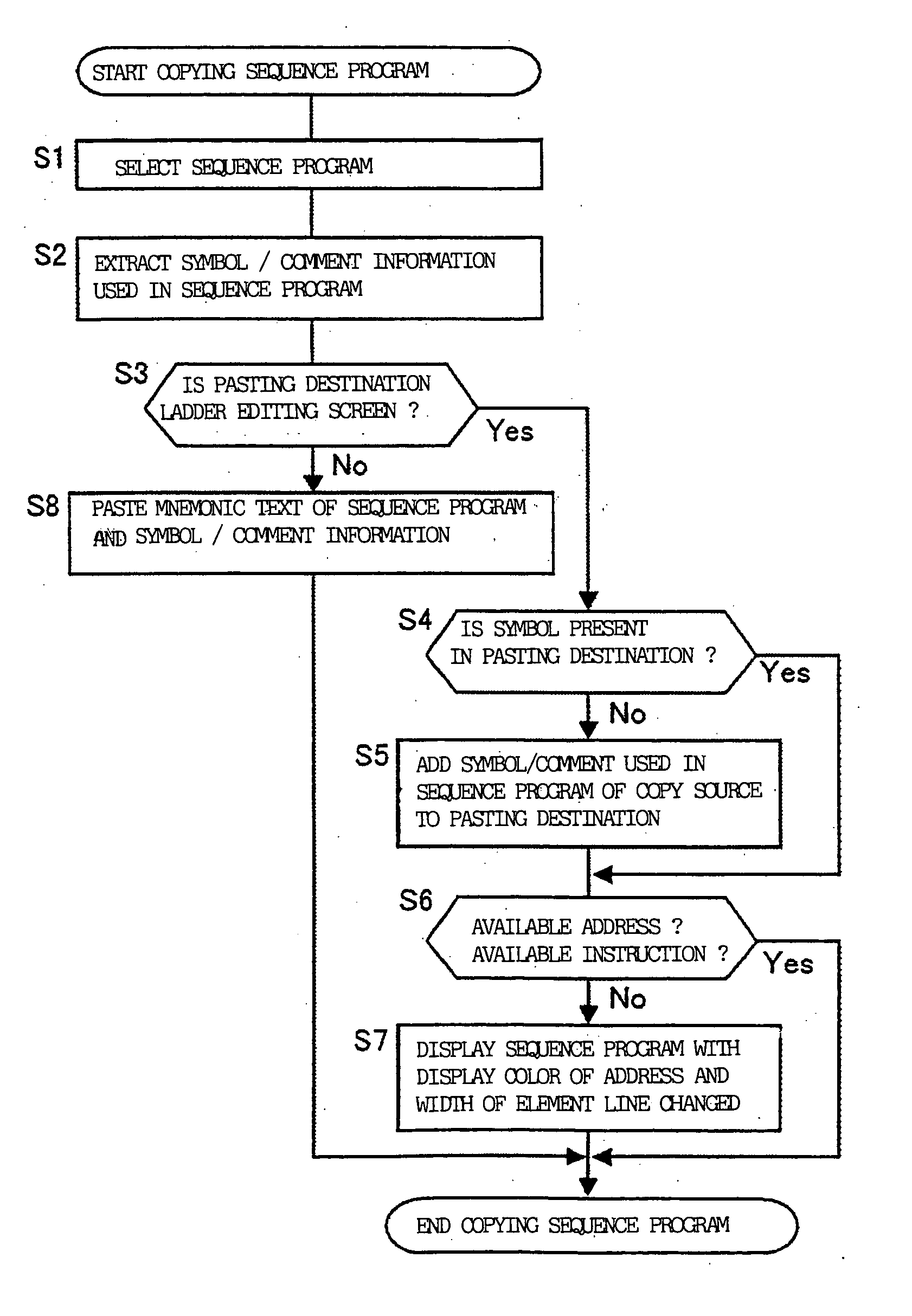

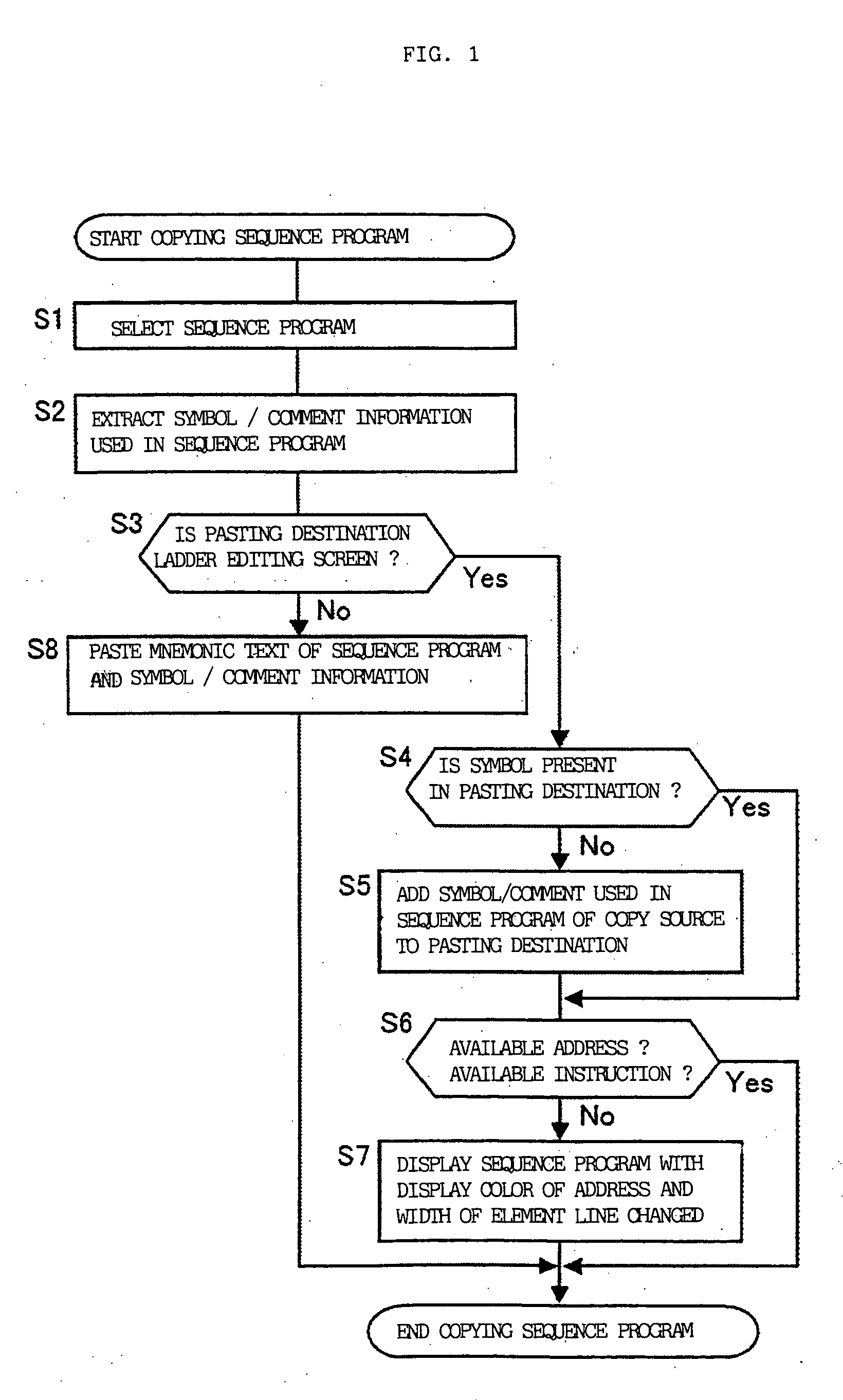

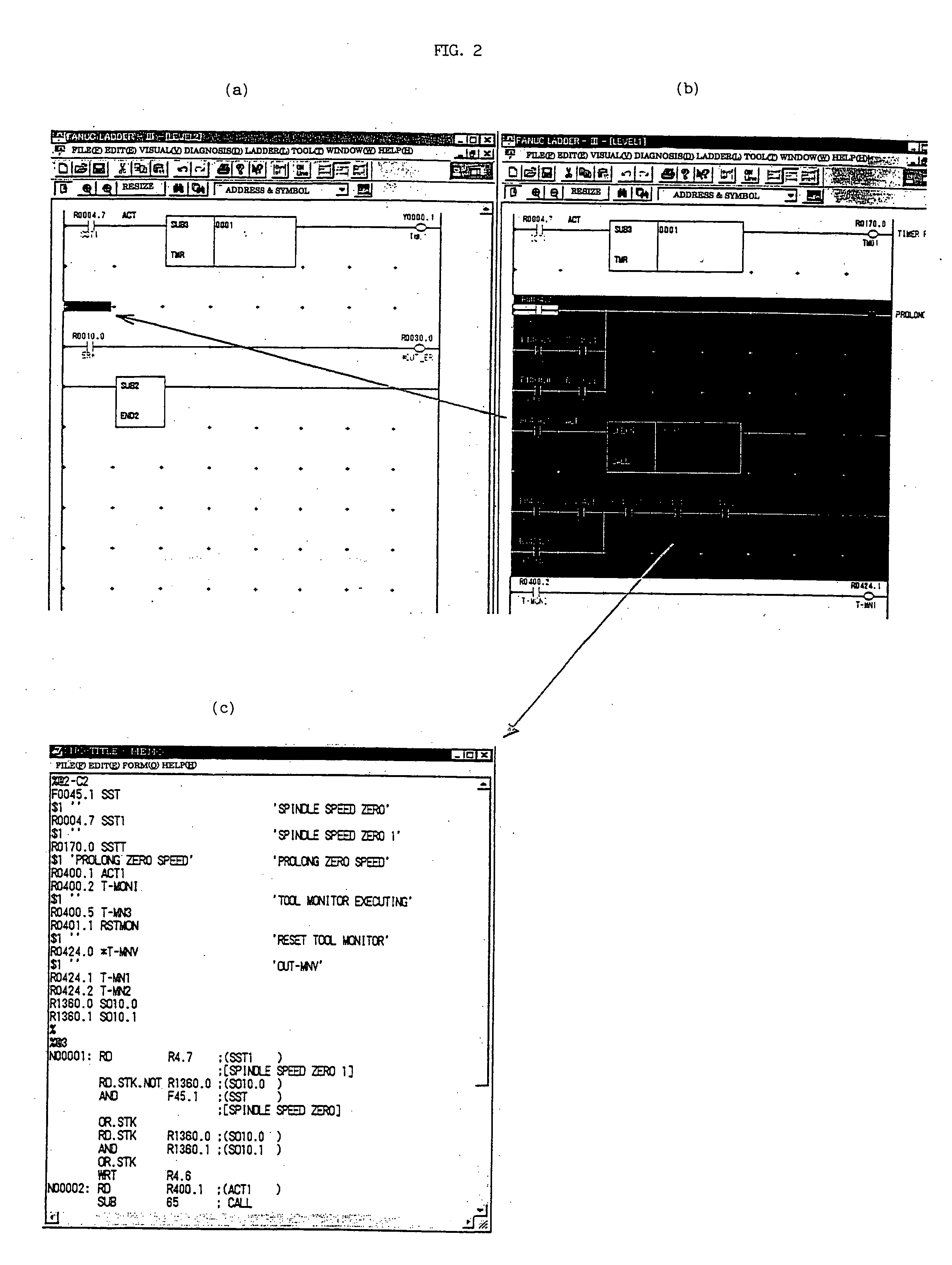

Sequence program editing apparatus

ActiveUS20060089728A1Improve maintainabilityEasy to operateComputer controlSimulator controlStorage cellComputer engineering

A sequence program editing apparatus includes a program storing unit for storing an application program including a sequence program, an information storing unit for storing symbol / comment information used in the sequence program, a selecting unit for selecting a part or a whole of a sequence program displayed on an application screen run by the first application program, an extracting unit for extracting the symbol / comment information included in the selected sequence program from the information storing unit, and a copy unit for copying the selected sequence program on the application screen run by the second application program and copying the extracted symbol / comment information on the information storing unit of the second application.

Owner:FANUC LTD

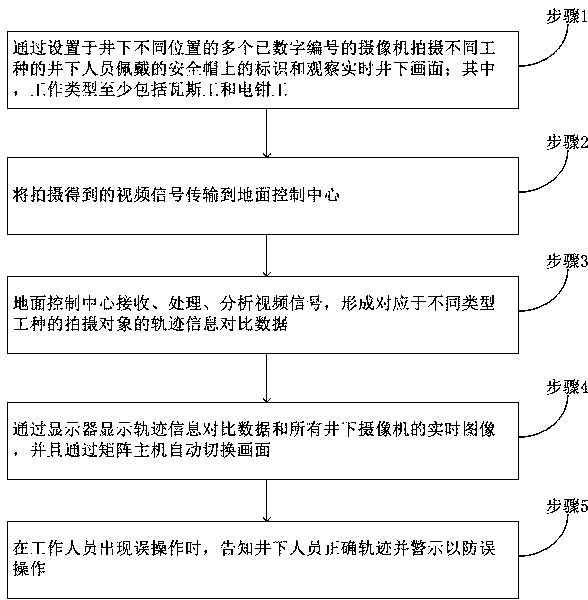

Underground coal mine personnel abnormal trajectory detection system and method based on machine vision

InactiveCN107770491ASolving recognition problemsGuaranteed timelinessClosed circuit television systemsTransmissionMachine visionVideo transmission

The invention discloses an underground coal mine personnel abnormal trajectory detection system based on machine vision. The system comprises a shooting module, a video transmission module, a ground control module, a display module and an early warning module. The shooting module captures an identifier on a safety helmet of underground personnel and an underground real-time video image; the videotransmission module transmits a video signal to a ground control center via the Ethernet; the ground control module quickly processes the image, determines the type of work and a corresponding presettrajectory, and generates a comparison image signal of a real-time action trajectory and the preset trajectory; the display module displays a trajectory comparison map and the real-time images of allunderground cameras; and the early warning module prompts the underground personnel about the correct trajectory when detecting the abnormal trajectory and notify the ground scheduling personnel of the abnormal condition. The detection method considers both scientificity and practicality, supplements the blank of underground personnel trajectory detection, improves the normalization, succession and integrity of the underground operations and effectively avoids the accidents caused by unfamiliar business and personal experience.

Owner:TAIYUAN UNIV OF TECH

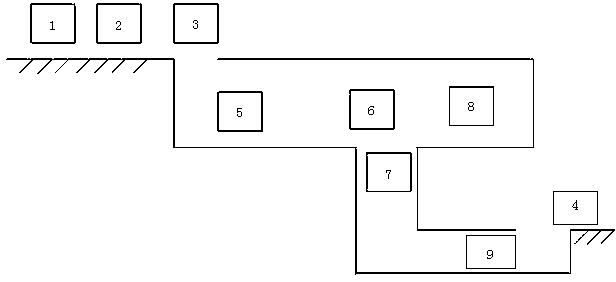

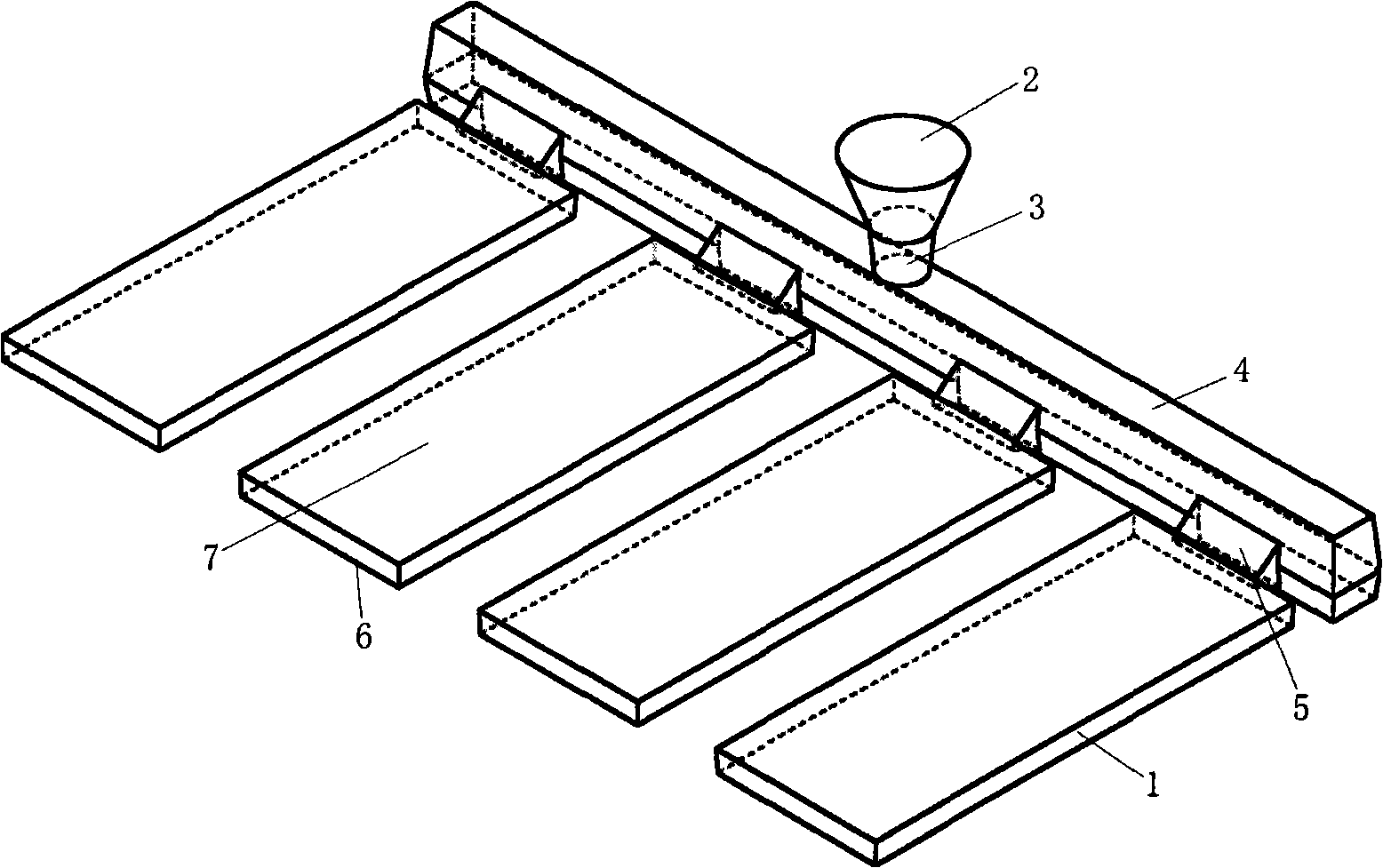

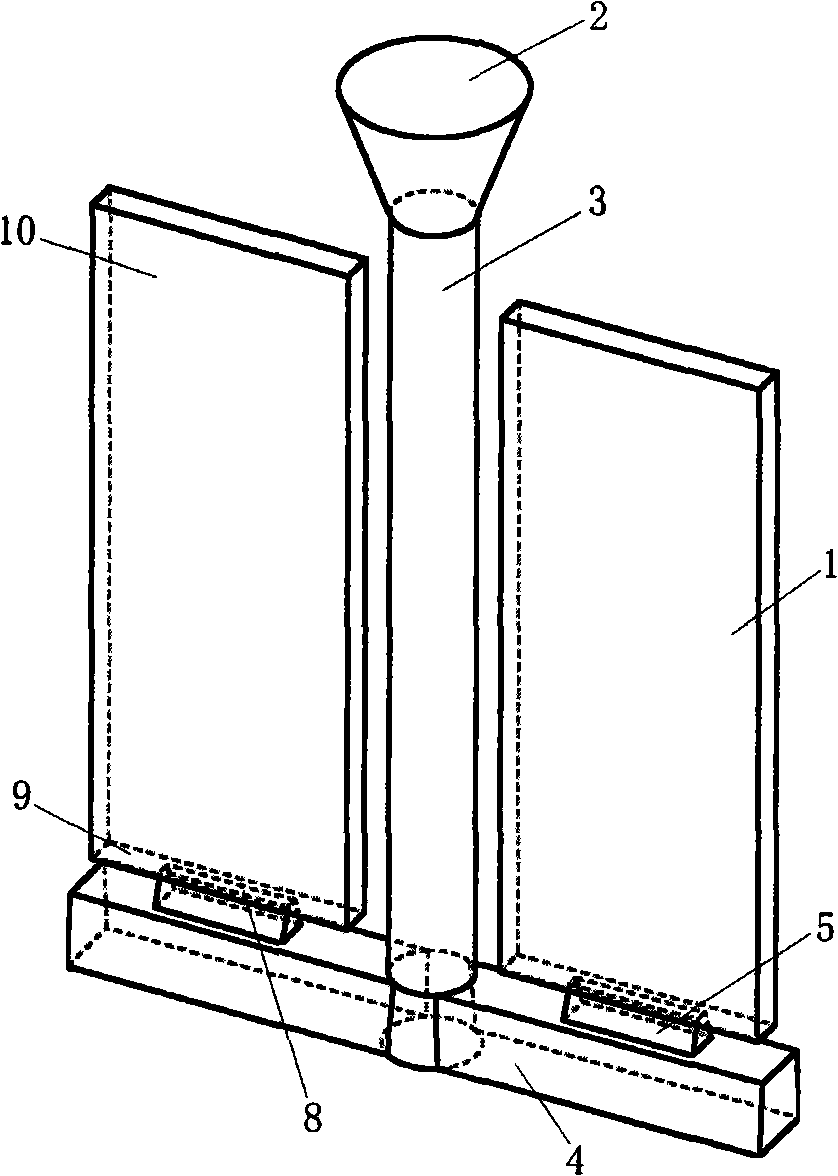

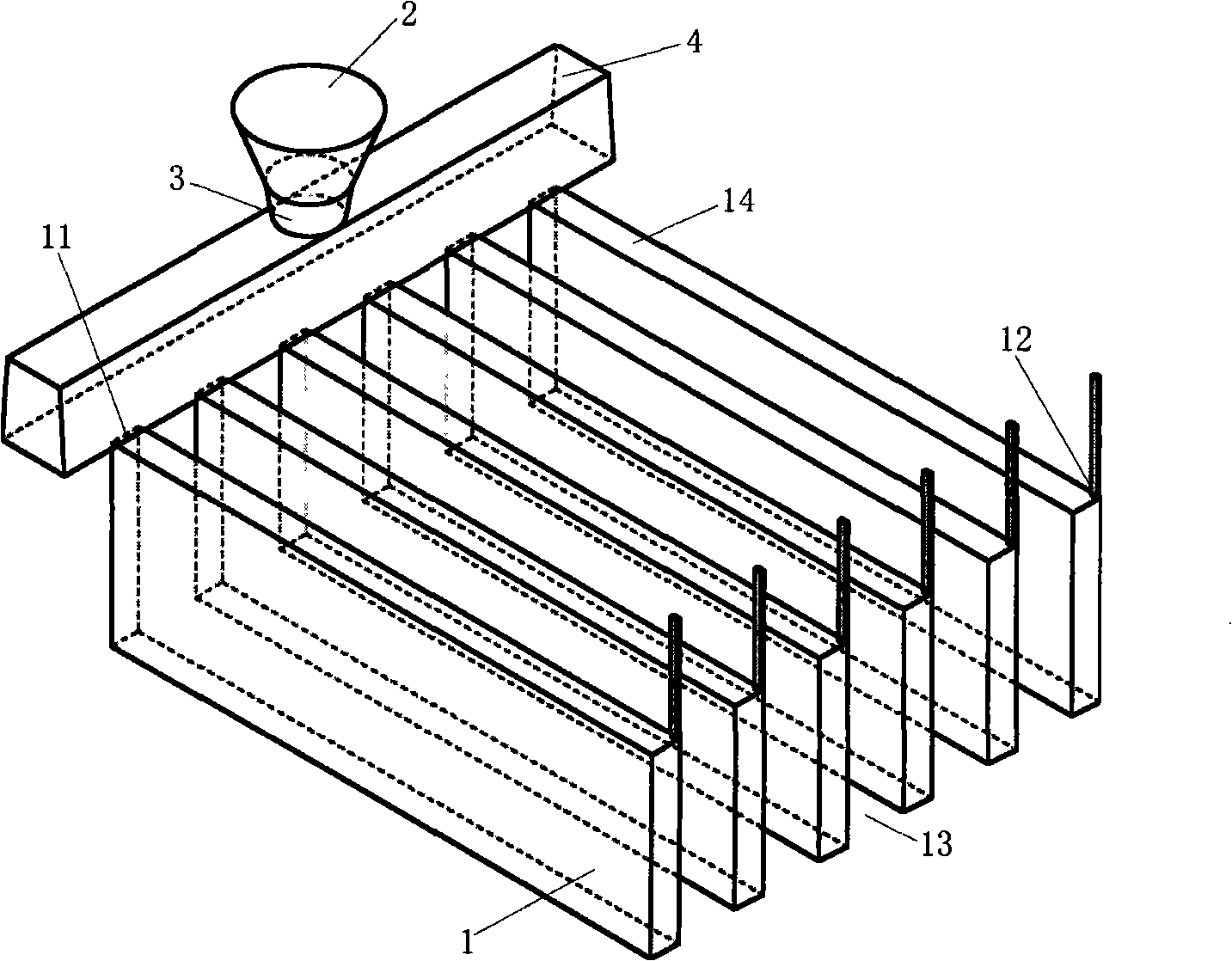

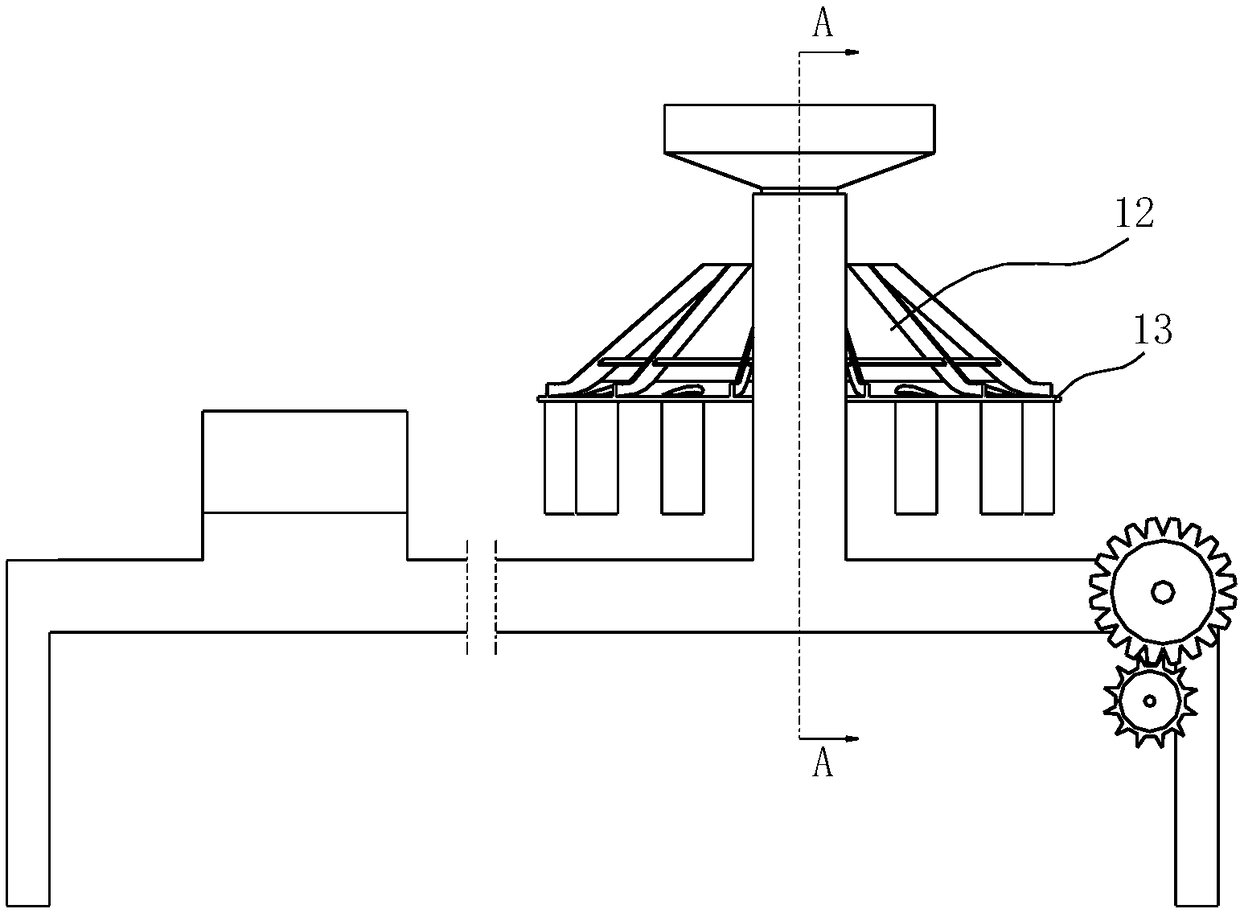

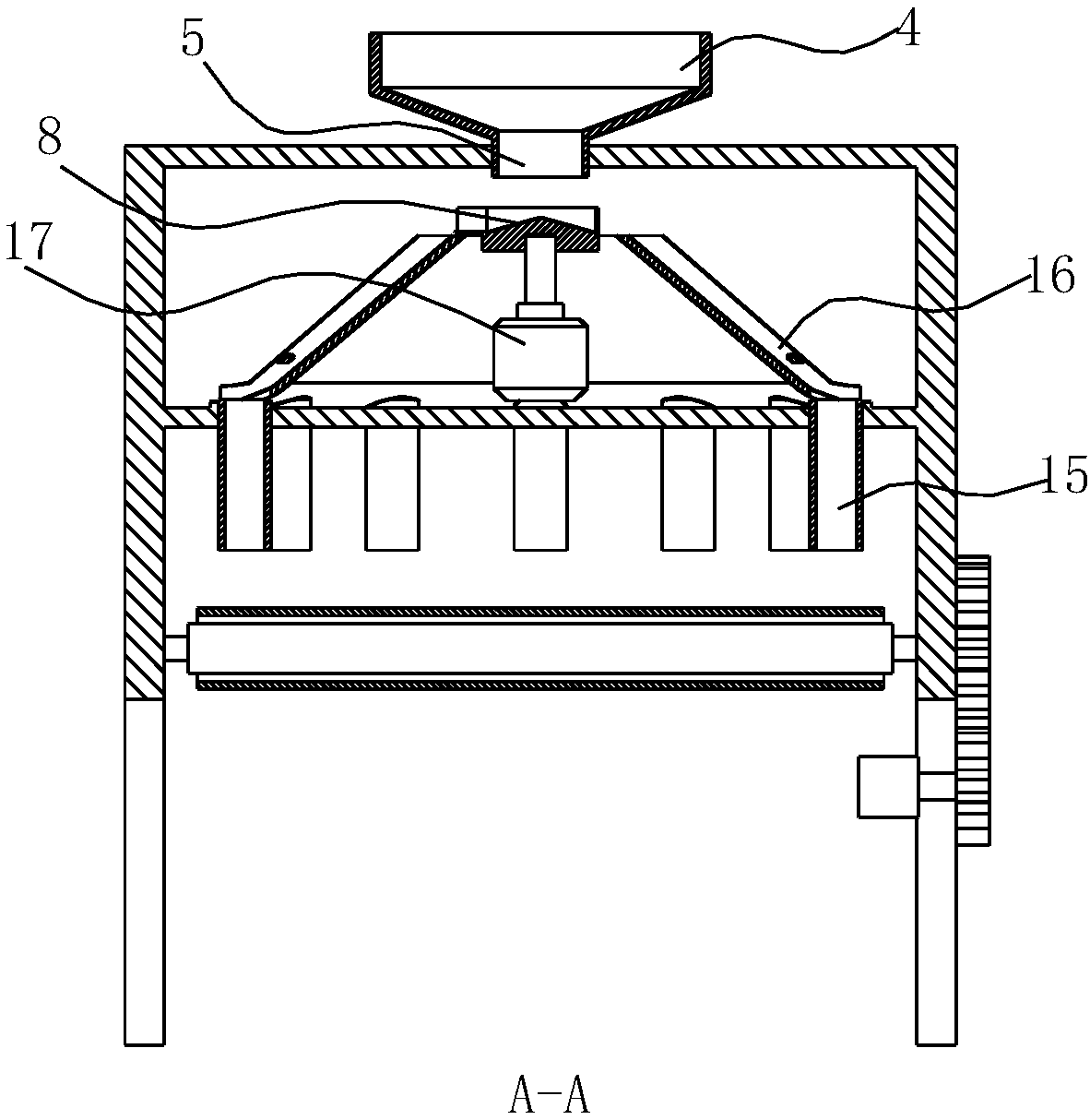

Casting method of tabular spheroidal iron piece and casting system thereof

InactiveCN101301681AReasonable structureSimple structureMolten metal conveying equipmentsCompensation effectSlag

The invention discloses a pouring method and a pouring system used for a plate-shaped ball iron casting. The method adopts a sand casting technique; the pouring system comprises a sprue cup, a sprue, a horizontal runner and a plurality of plate-shaped castings; the method adopts a type that the large plane of the plate-shaped casting is vertically arranged in parallel; the horizontal runner and the plate-shaped casting form a narrow seam edge gate so as to lead the molten steel to flow in along the wall and be stably filled from bottom to top during the pouring process. When the method and the pouring system of the invention are adopted, the molten steel is filled along the wall during the pouring process and the metal is sequentially solidified from bottom to top, thus ensuring the uniformity and consistency of the metallographic structure of the plate-shaped ball iron casting; furthermore, by the narrow seam edge gate, the pouring time is prolonged, the shrinkage compensation effect is provided during the pouring process, furthermore, the slag retaining effect is good and the defects such as slag inclusion, sand inclusion, etc. are avoided; the plate-shaped ball iron casting pouring system of the invention has reasonable and simple structure, saves the metal and has high process yield; furthermore, the pouring system is convenient to be removed; the casting adopts serial pouring, thus having small land occupying and high production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

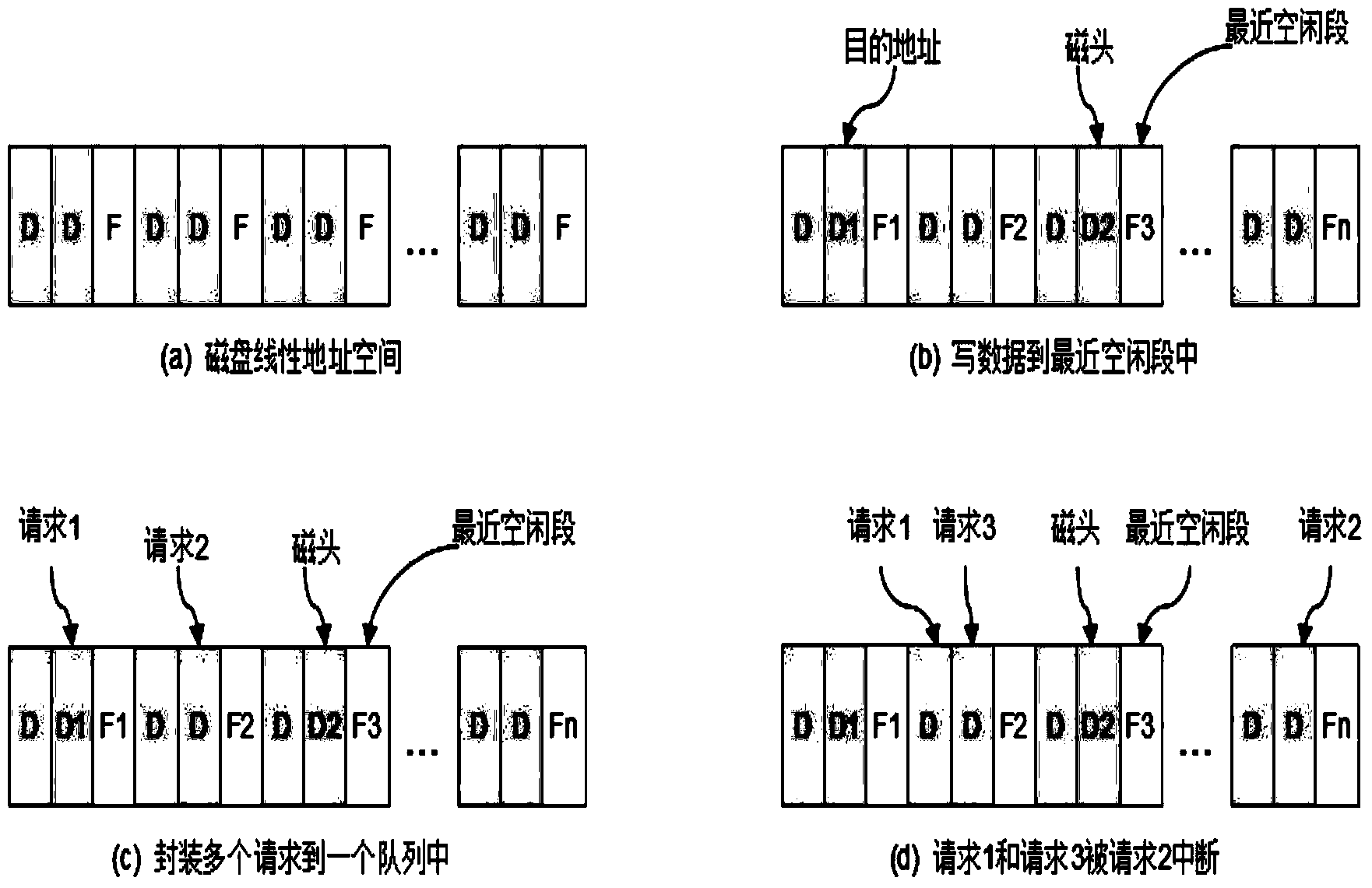

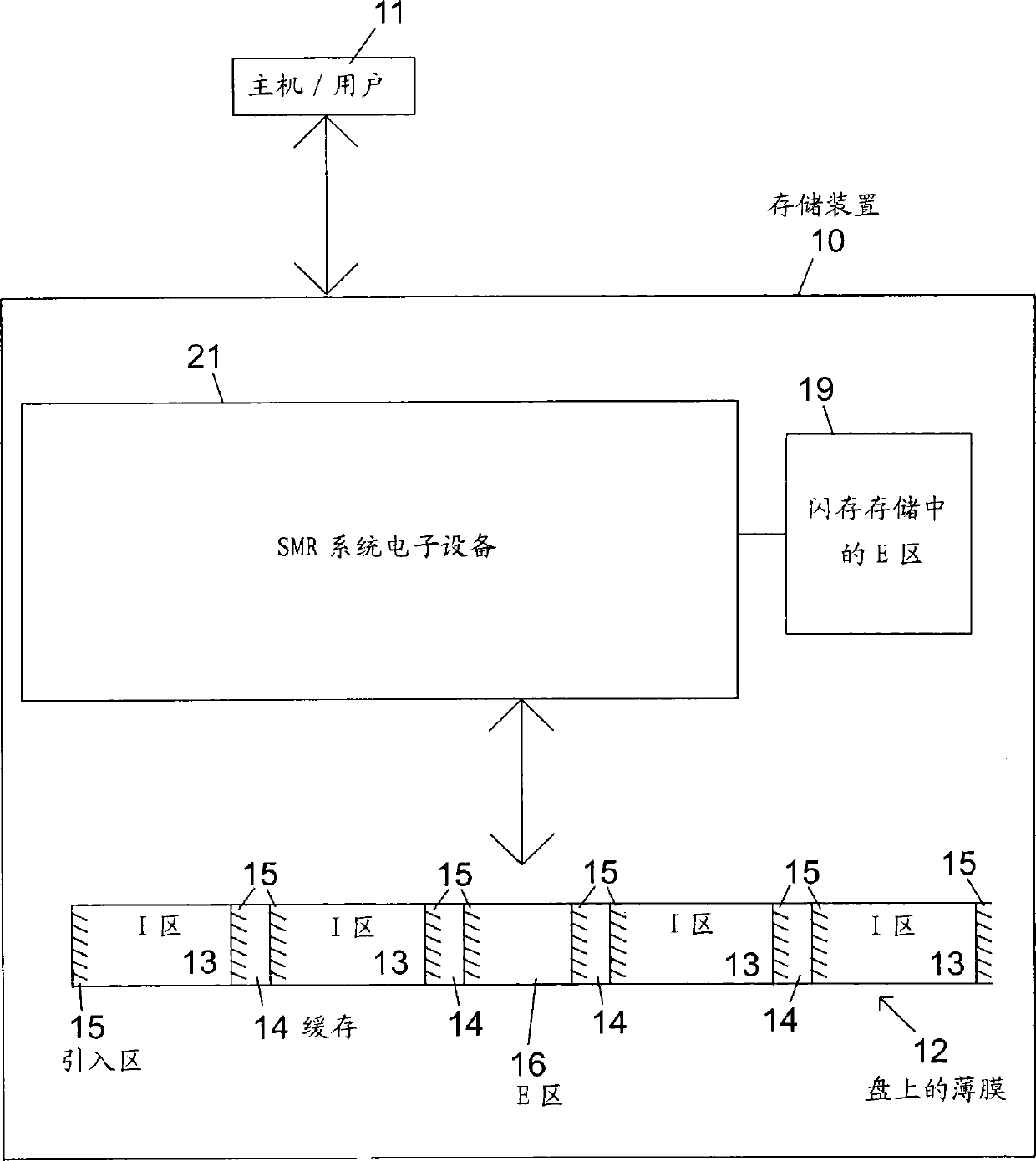

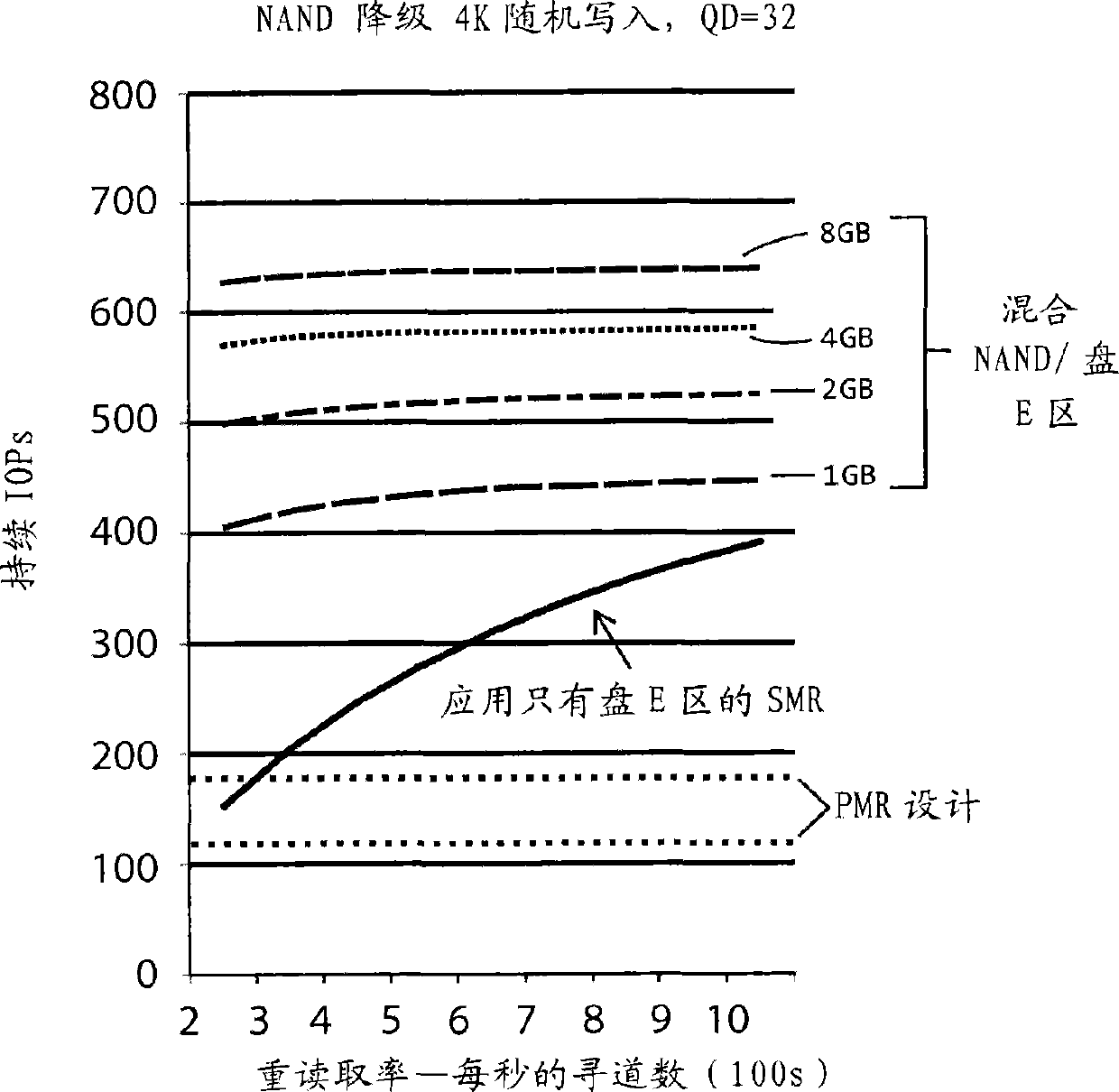

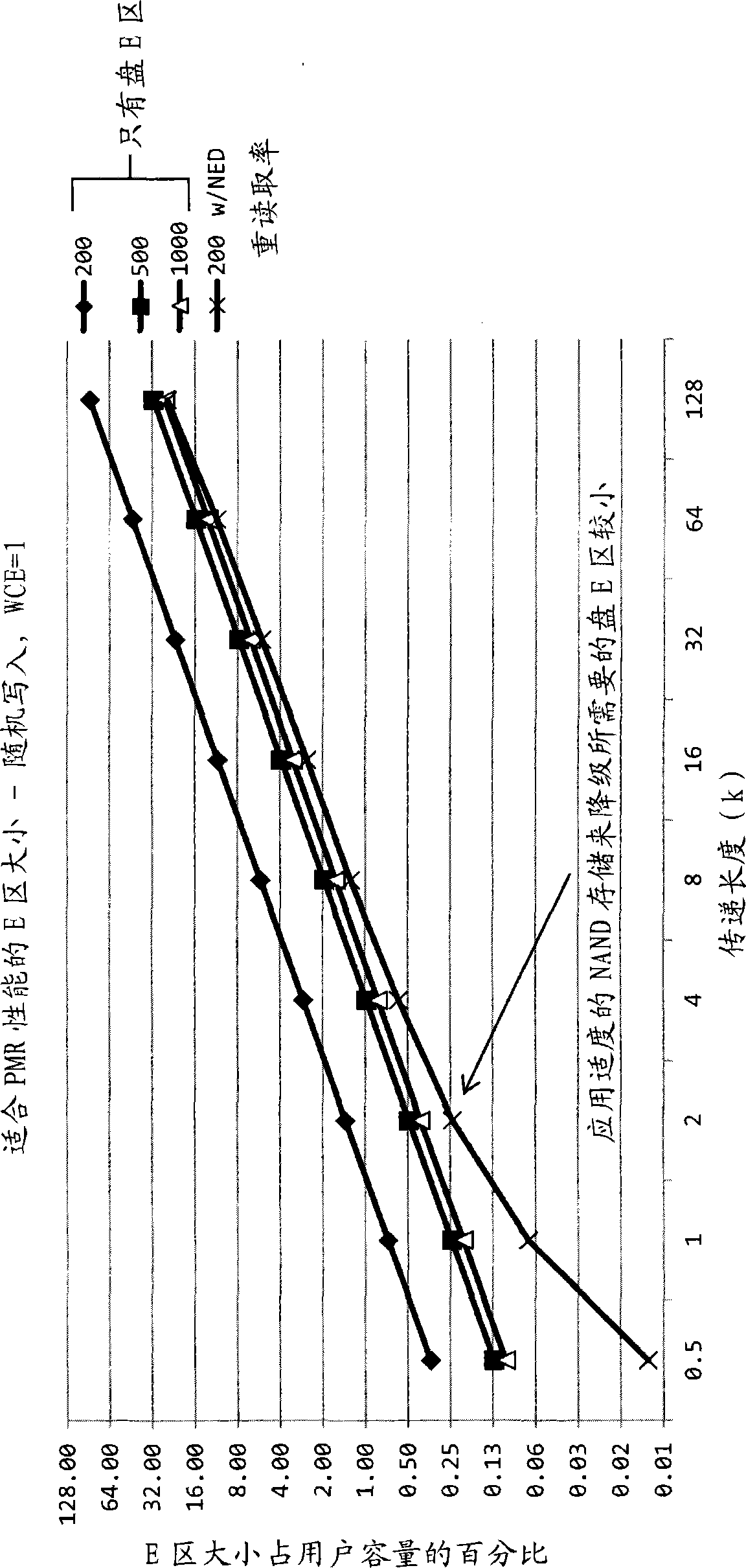

Shingle-written magnetic recording device with hybrid E-regions

InactiveCN103345925AReduce seekImprove sequenceHeads using thin filmsRecording on magnetic disksSolid-state storagePerformance enhancement

The invention relates to an SMR disk drive with hybrid E-regions, including a nonvolatile solid state memory E-region in addition to magnetic media E-regions on the disk. The memory E-region can be used in operations that can be referred as destaging and / or restaging to sequentialize sets of exception records to reduce the time and energy spent in executing seeks in the disk E-region. The ratio of the size of the solid state memory E-region to the total E-region capacity on the disks can be optimized for selected applications according to the invention using tradeoffs between performance and cost. For example, an embodiment with a memory E-region size that is 10% of the total disk E-region capacity achieves substantial performance enhancement over a disk-only E-region implementation and also results in smaller costs than can be required in a NAND-only memory E-region.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

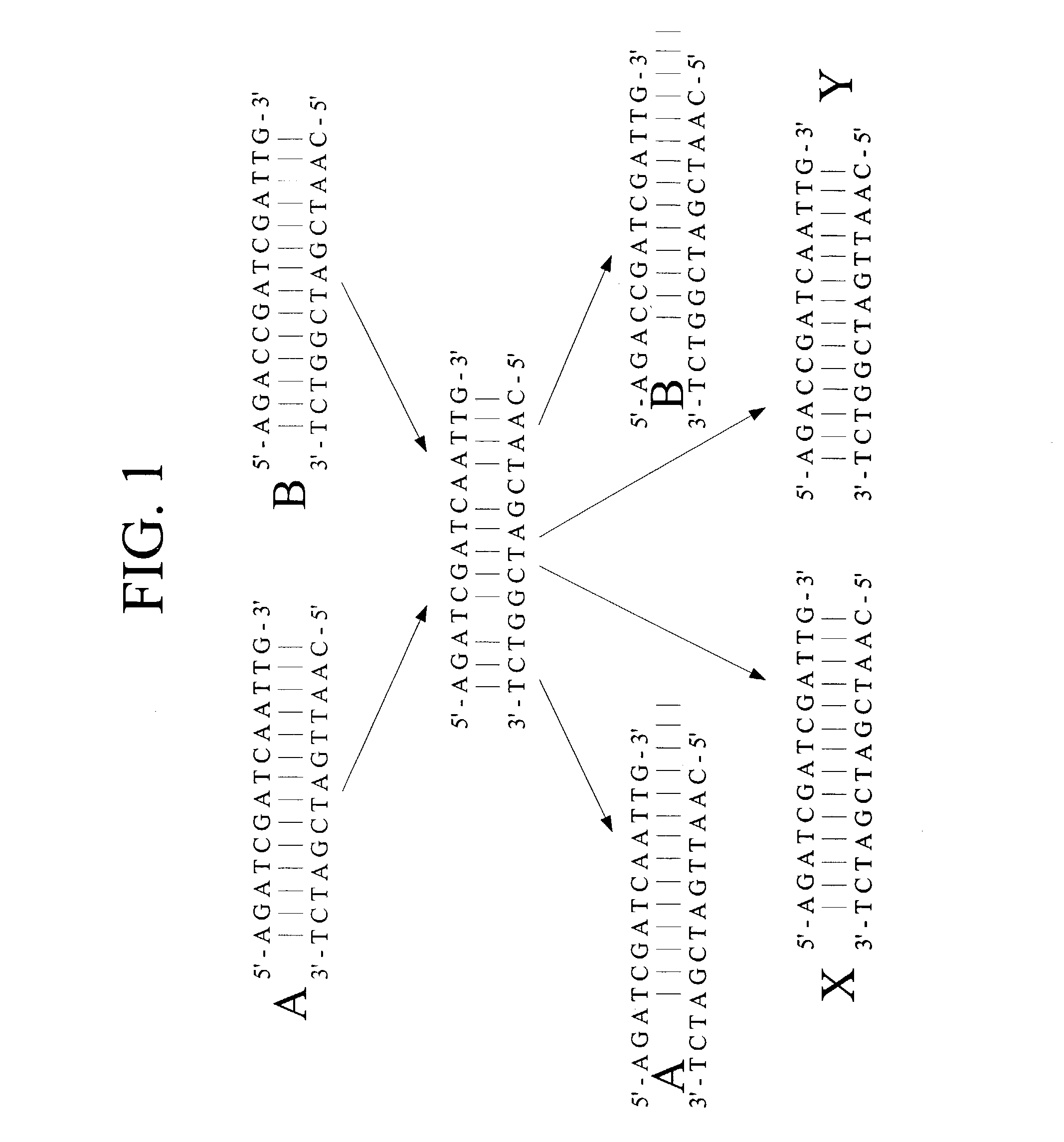

Mismatch endonucleases and methods of use

InactiveUS20030157682A1HomogeneityIncrease the number ofSsRNA viruses positive-senseSugar derivativesHomopolynucleotideNucleotide

We describe here restriction endonucleases and their uses. Restriction endonucleases are useful in finding single nucleotide polymorphisms. They are also useful in an in vitro method of redistributing sequence variations between non-identical polynucleotide sequences.

Owner:NOVICI BIOTECH +1

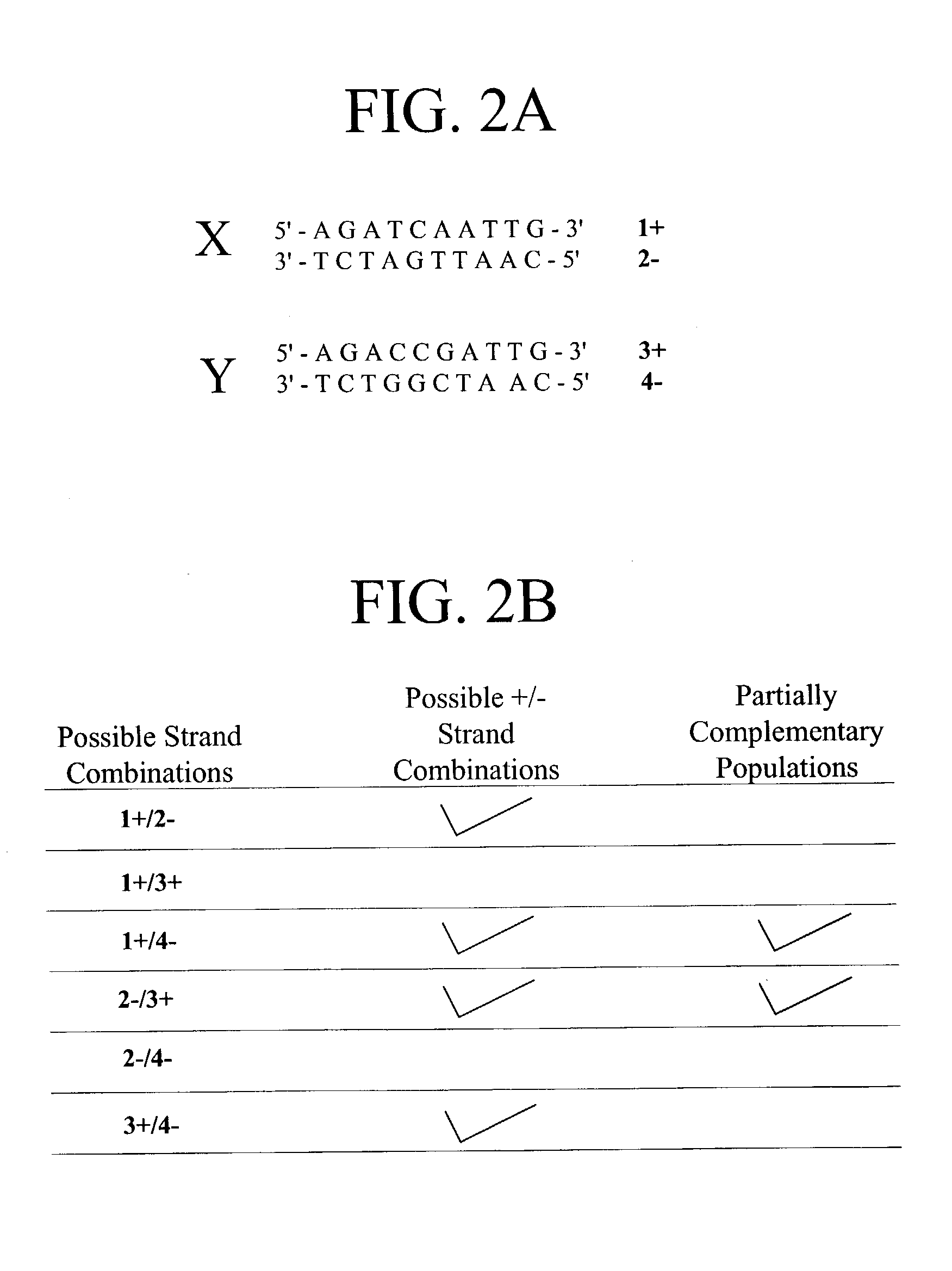

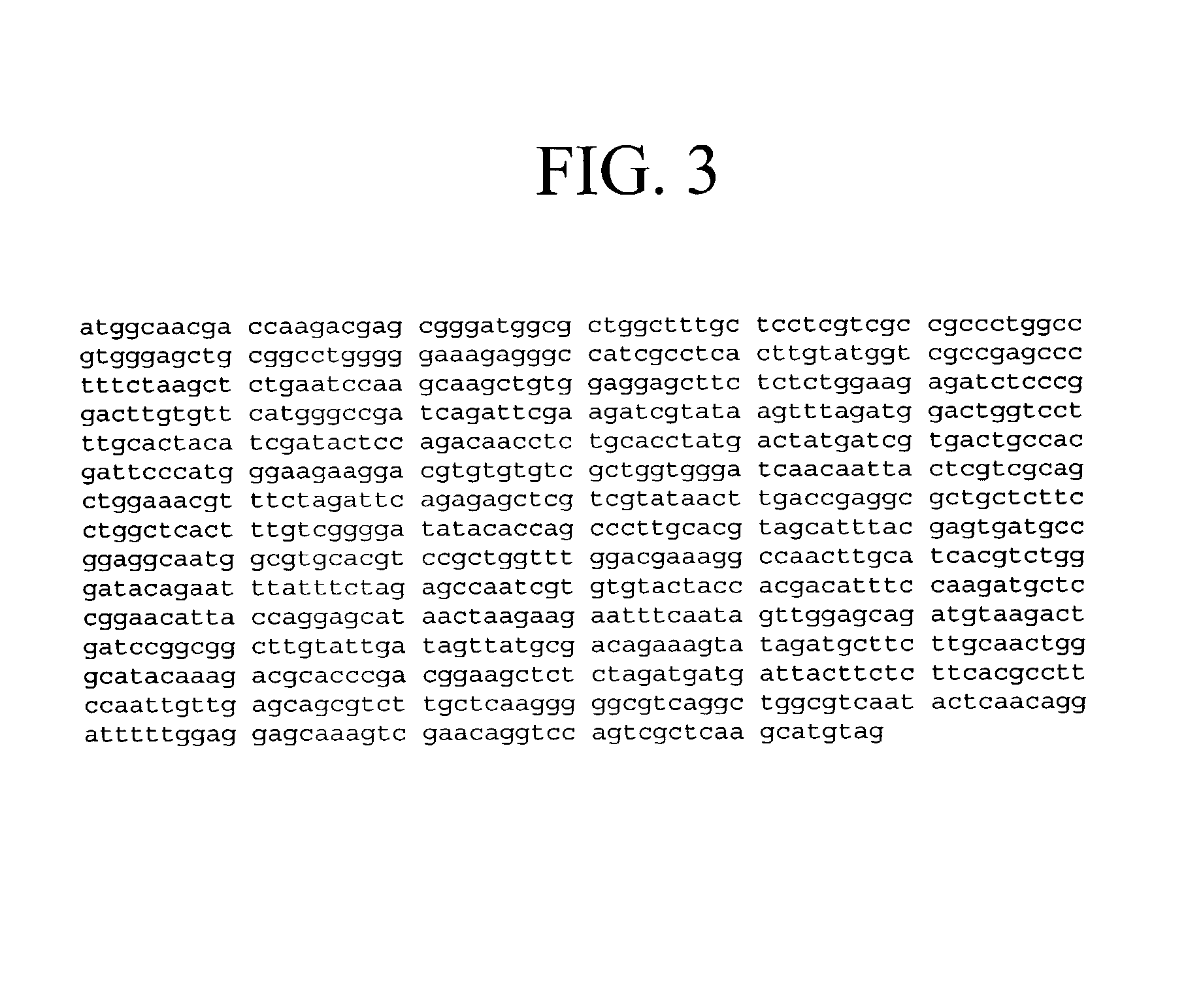

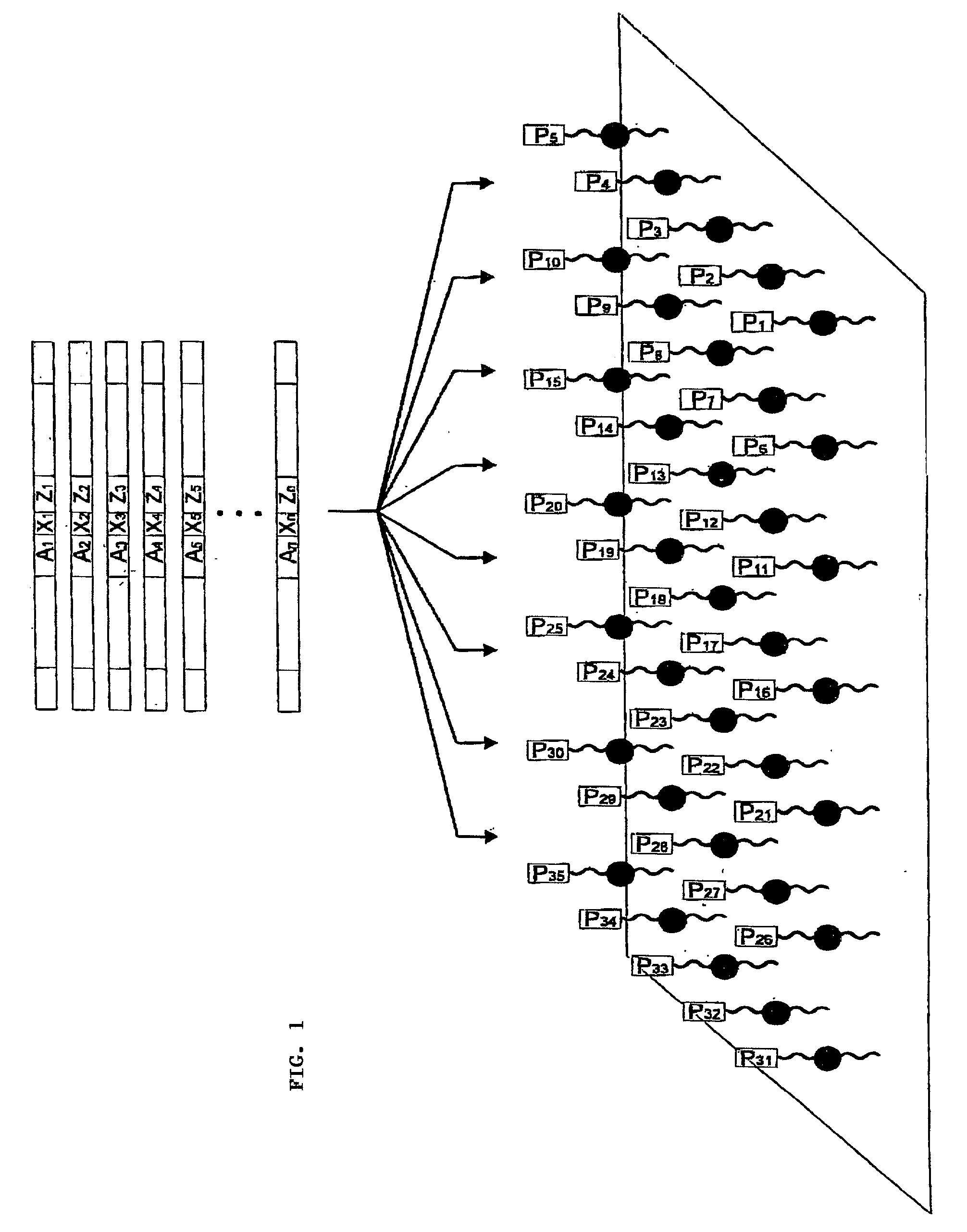

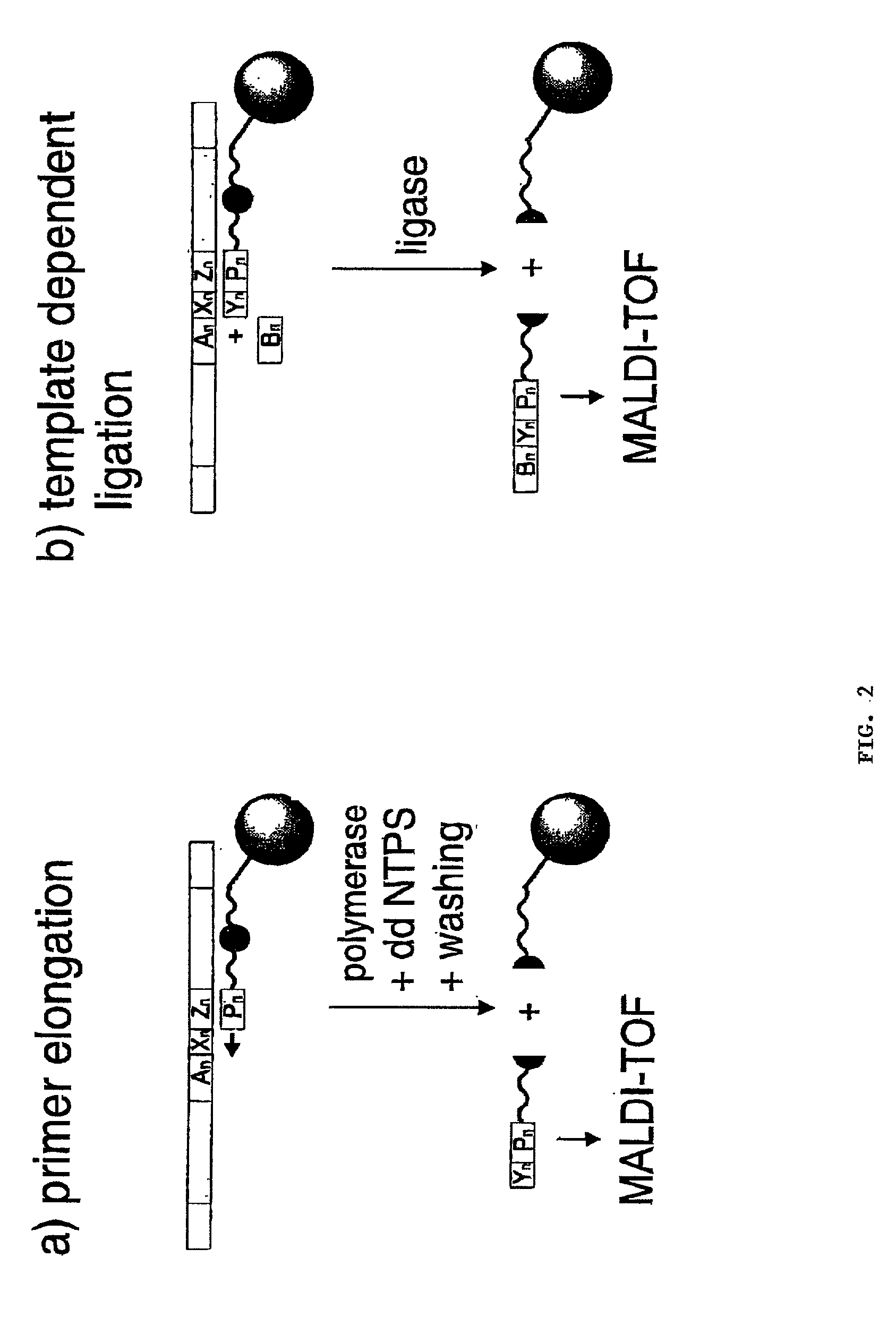

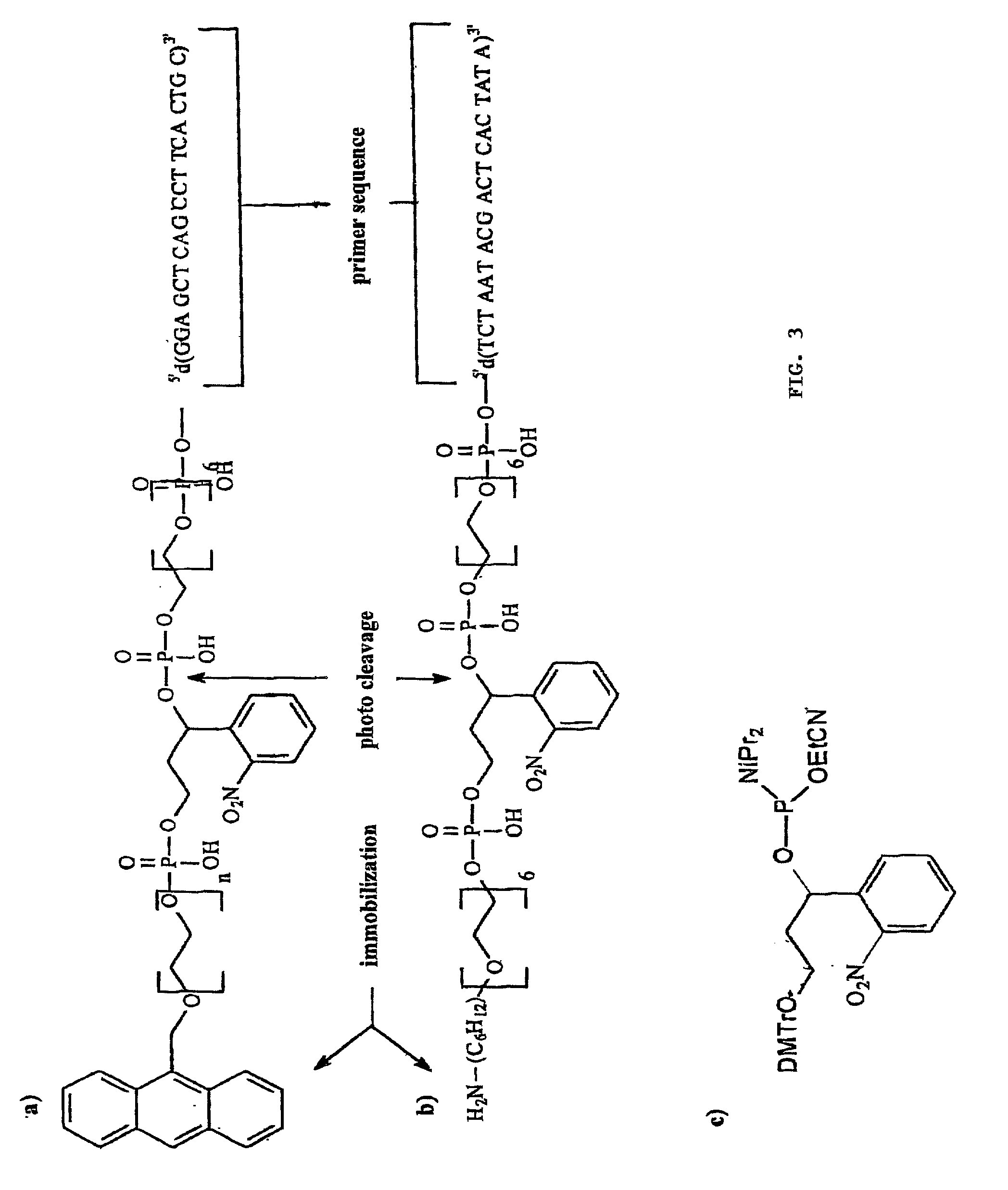

Multiplex sequence variation analysis of DNA samples by mass spectrometry

InactiveUS20010038070A1Strong specificityEfficient washingParticle separator tubesMicrobiological testing/measurementNucleic acid sequencingNucleic acid sequence

The invention relates to the simultaneous analysis of variations in distinct nucleic acid sequences within a complex nucleic acid mixture. The invention consists in the use of chips with spatially separated fields of photocleavable oligonucleotide probes which are commonly processed together with the target sequences and thereby modified in a sequence-dependent way. The probes are cleaved and analyzed by laser desorption mass spectrometry. This allows highly parallel and nevertheless sequence-specific reactions within a single reaction mixture. Since the photocleavable oligonucleotide probes are placed on a substrate in a spatially defined manner, e.g. in the form of an array, a specific target sequence can be assigned a unique position on the oligonucleotide chip. Since the photocleavable probes are covalently immobilized on the solid surface, the detection reaction can be performed directly on the chip while preserving the probe position pattern. Due to the presence of a photosensitive residue within the probes, these can be controlled photolytically after the detection reaction so that a mass spectroscopic analysis can then be carried out.

Owner:BRUKER SAXONIA ANALYTIK

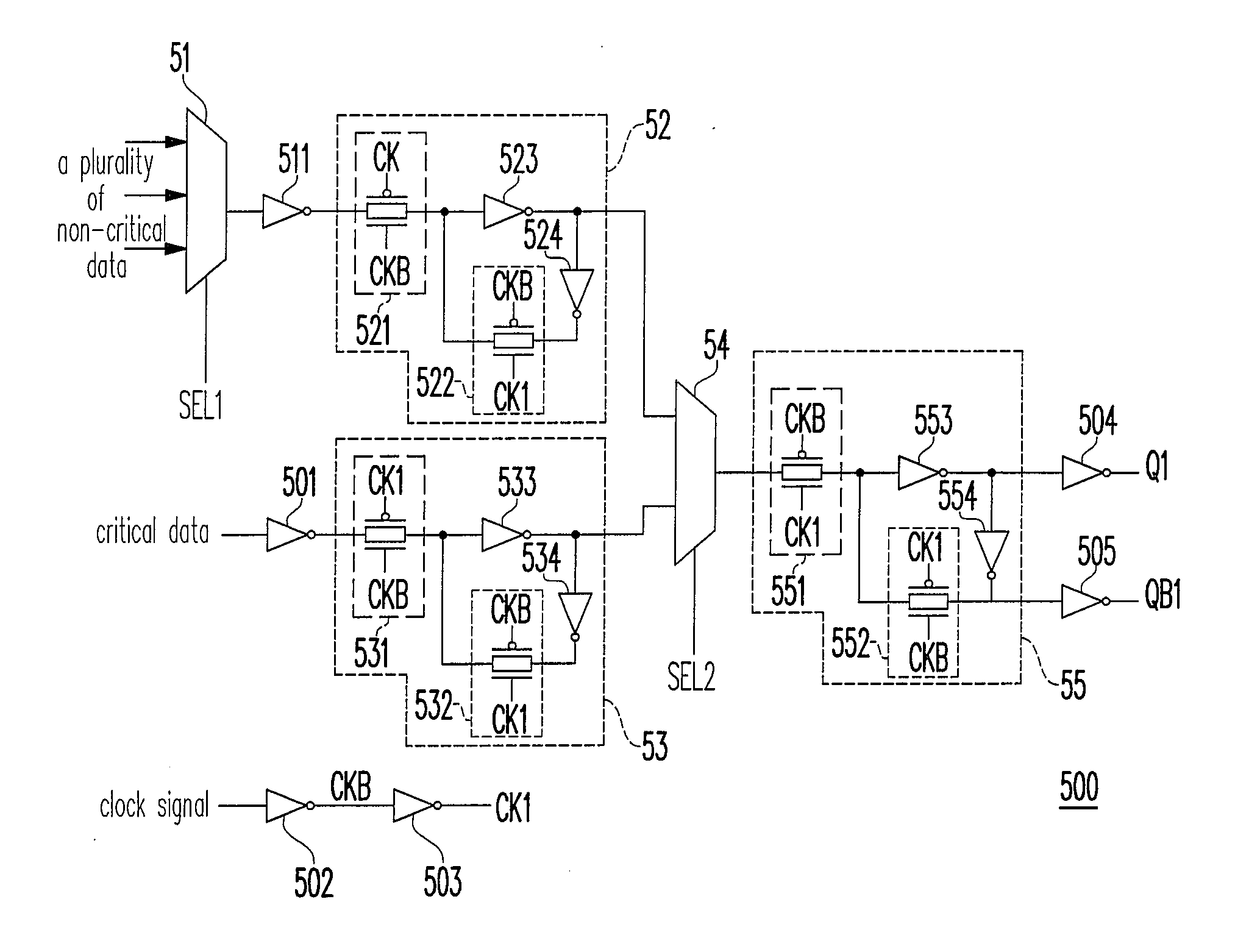

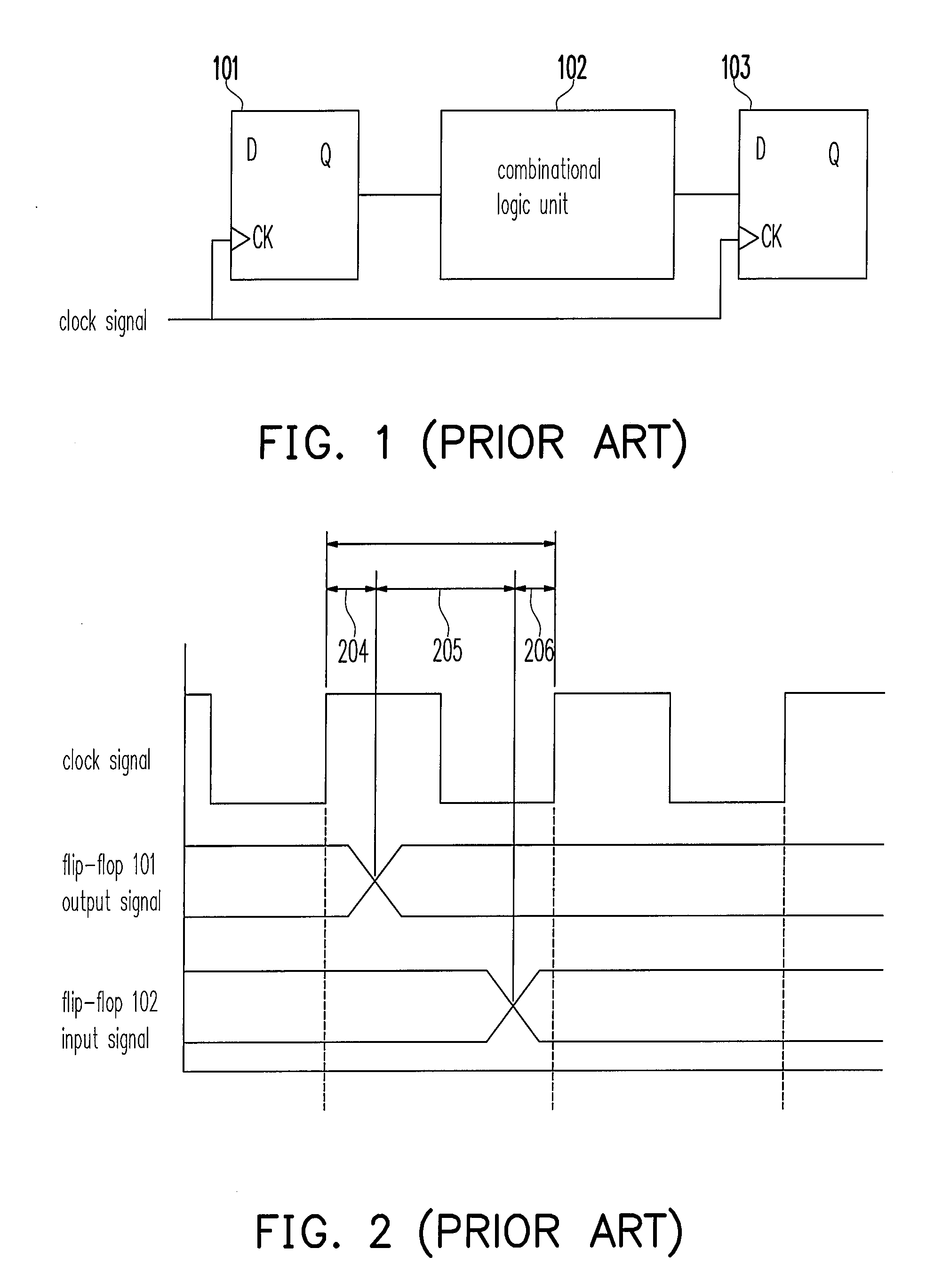

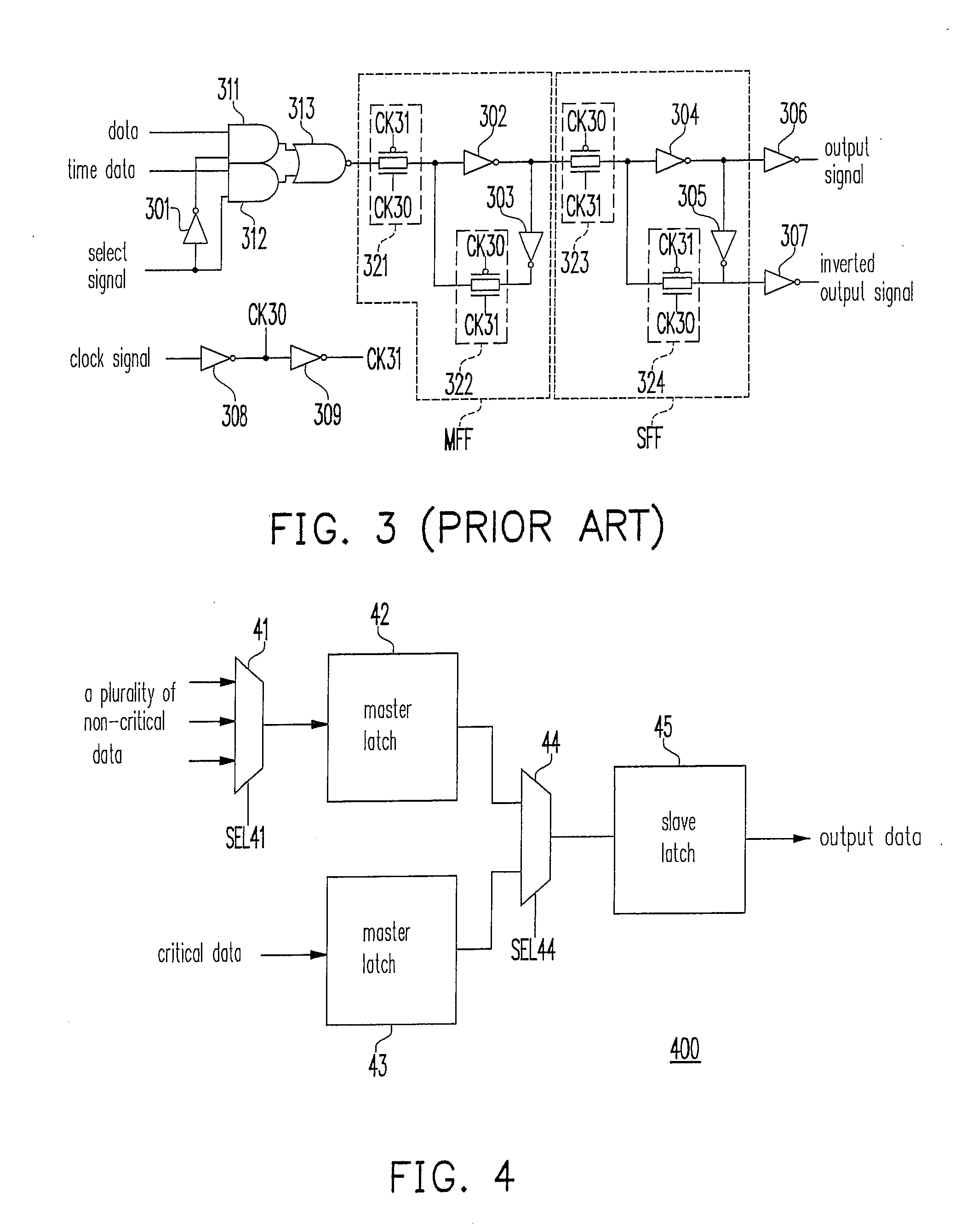

Flip-flop having improved set-up time and method used with

InactiveUS20080024184A1Reduce setup timeImprove sequenceElectric pulse generatorComputer scienceNon critical

Owner:FARADAY TECH CORP

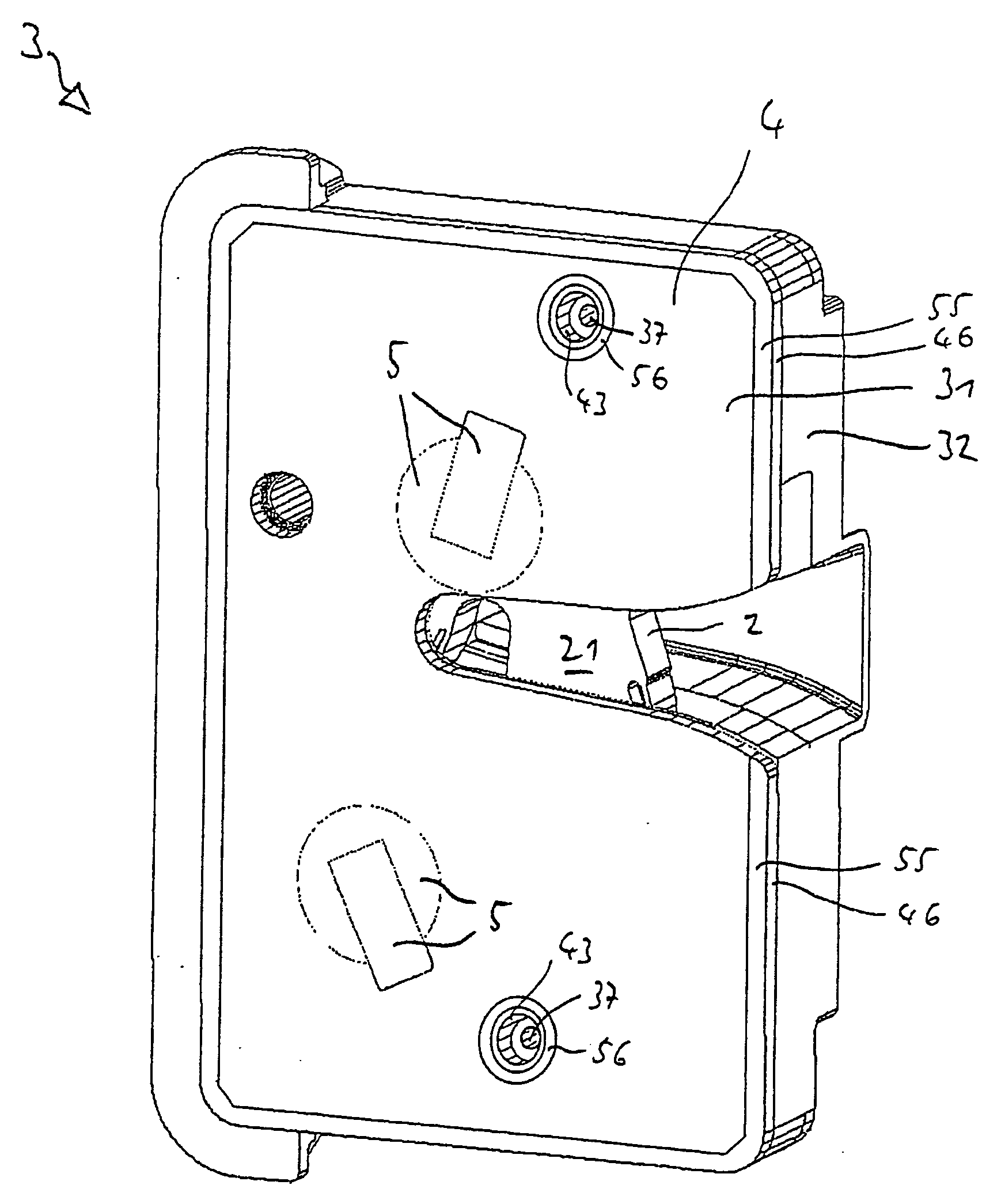

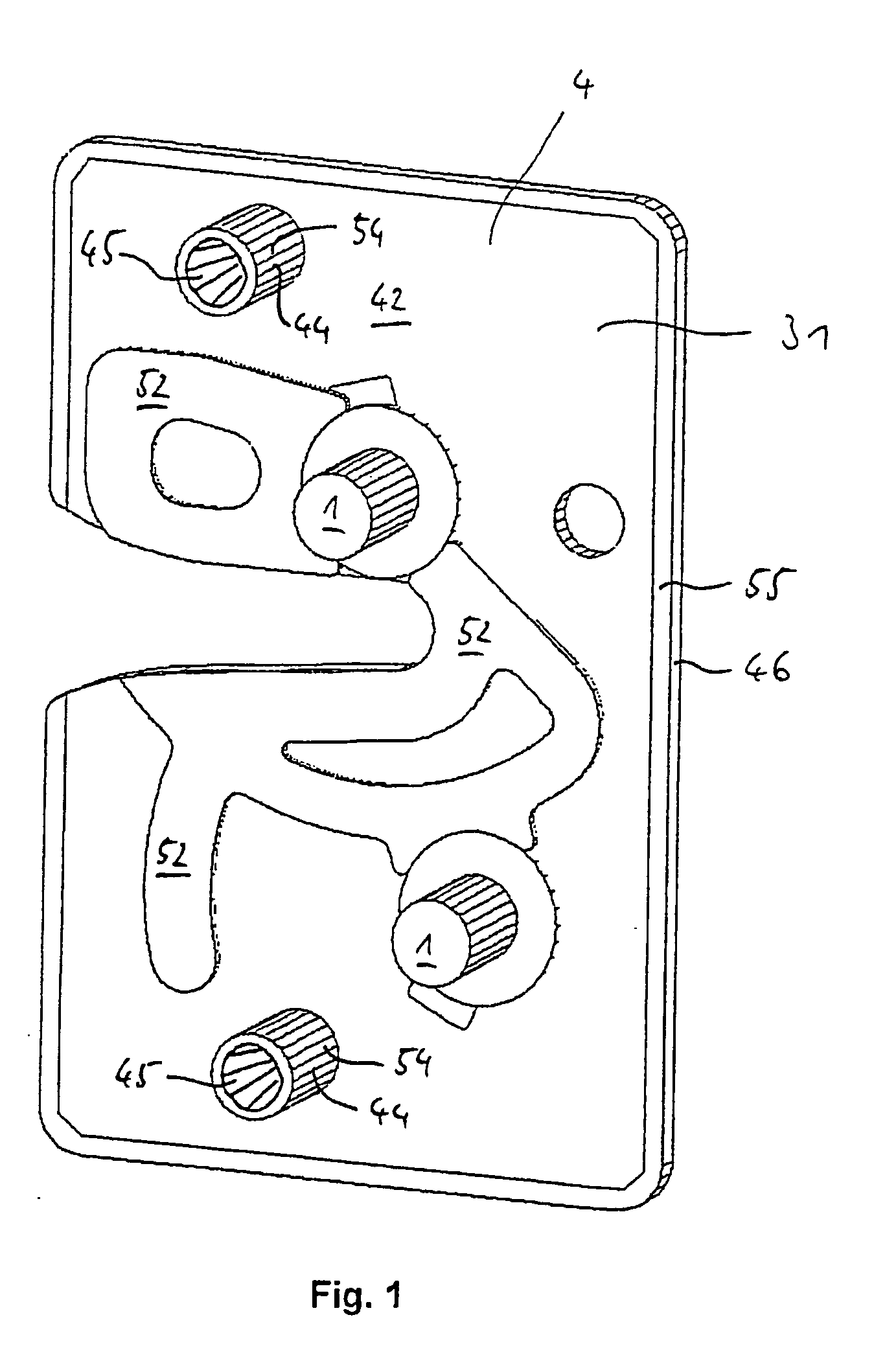

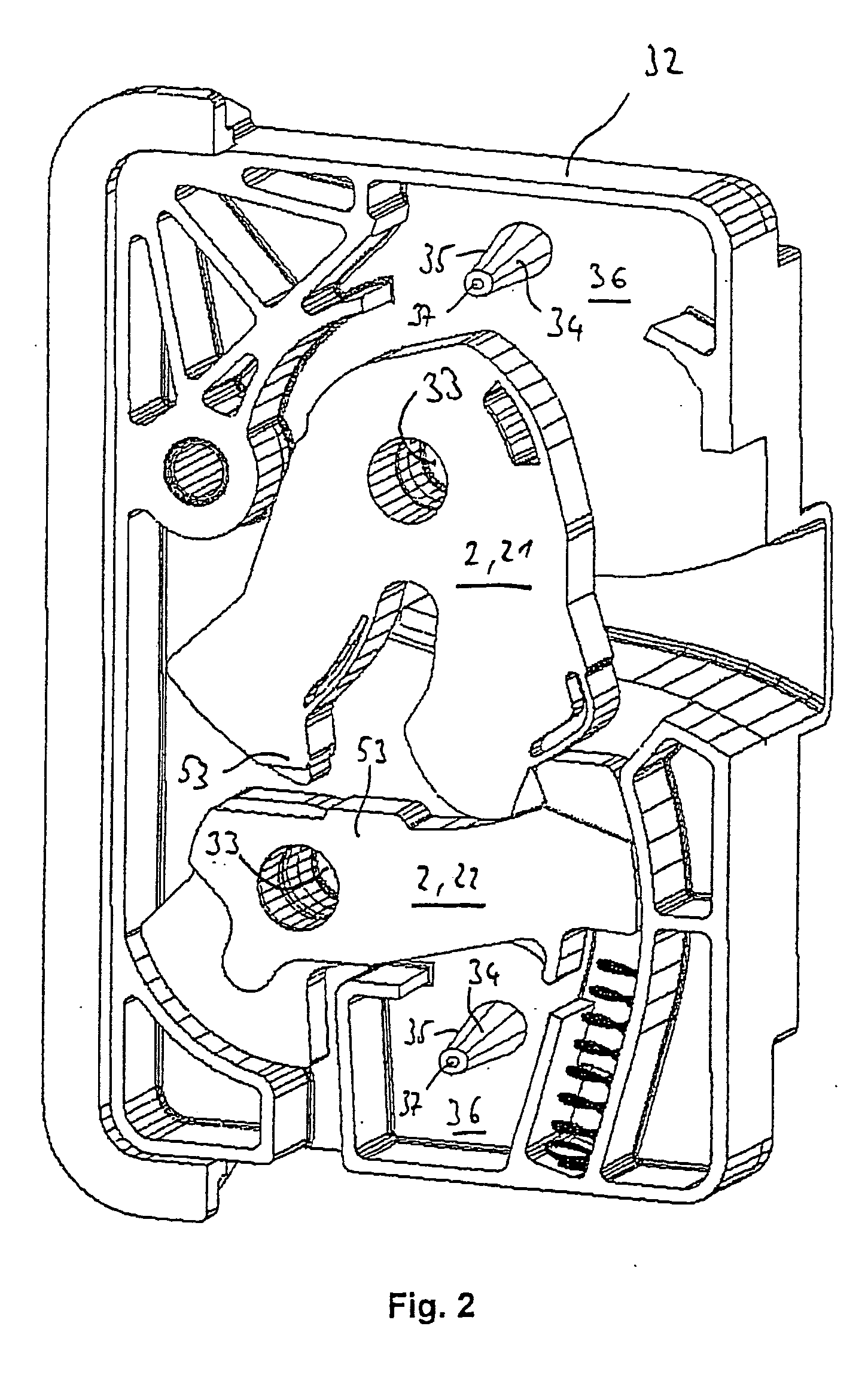

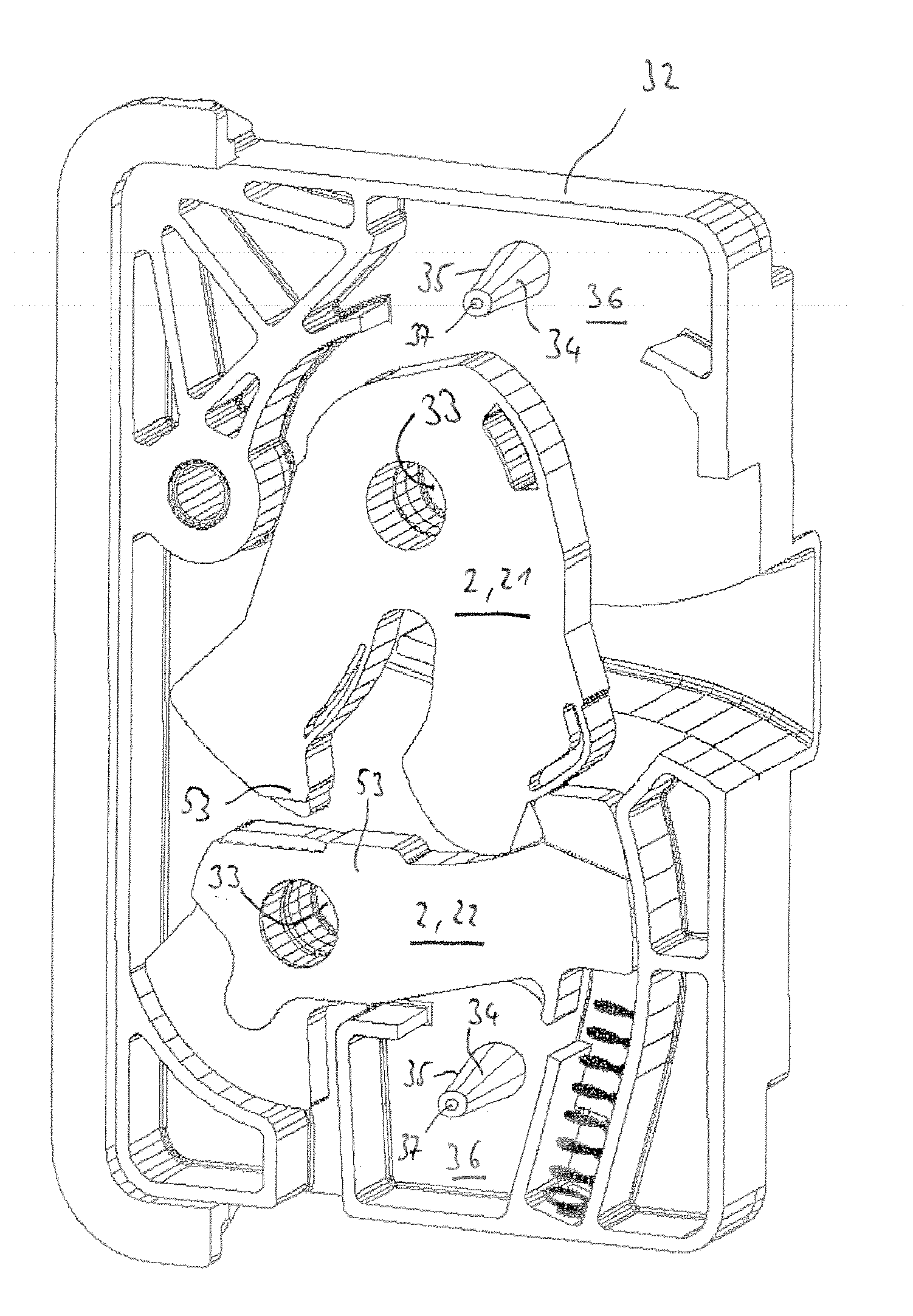

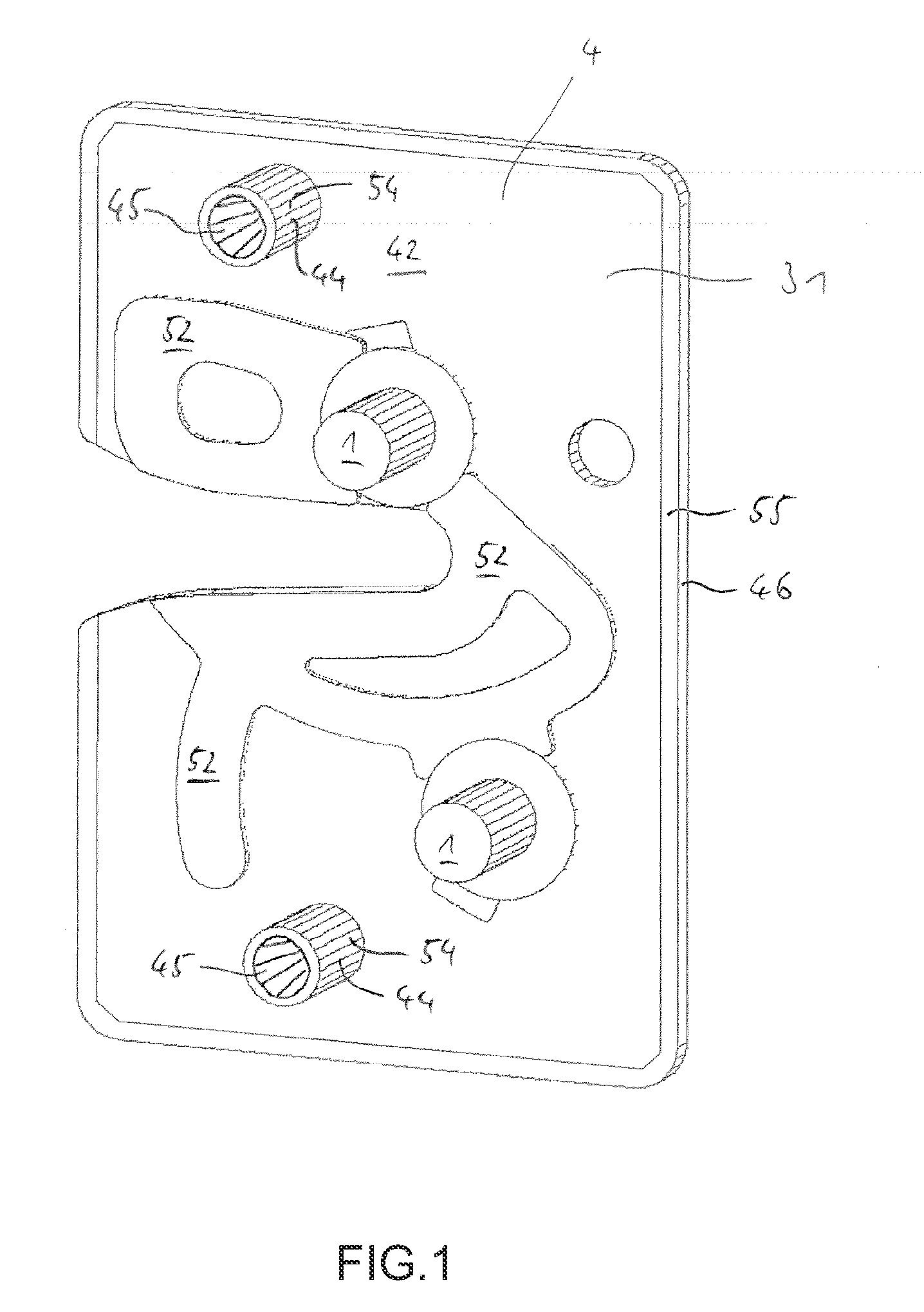

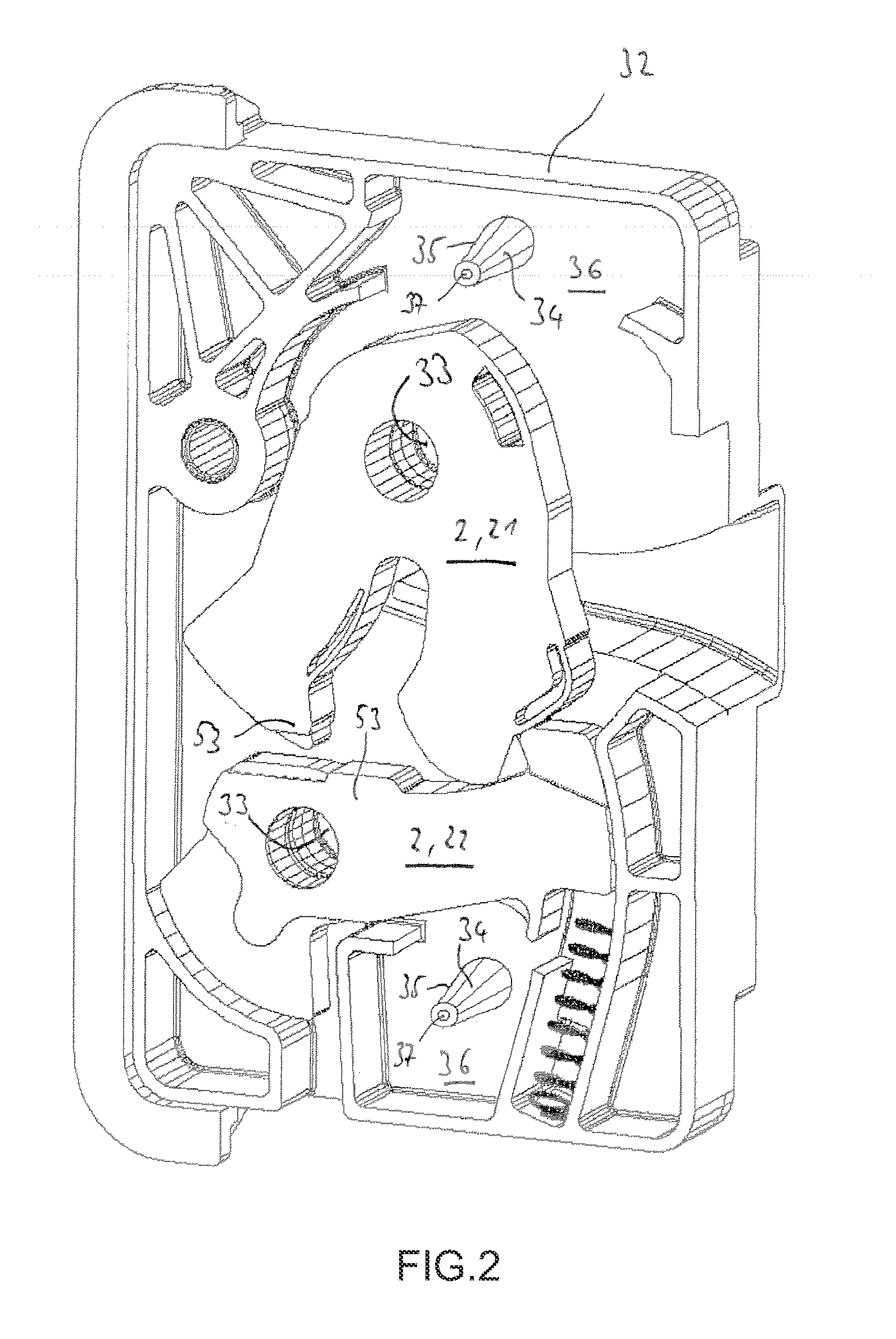

Motor Vehicle Door Lock

InactiveUS20080060395A1Reduce disadvantagesBroaden process sequenceVehicle locksAnti-theft devicesElectrical and Electronics engineeringCar door

Owner:KIEKERT AG

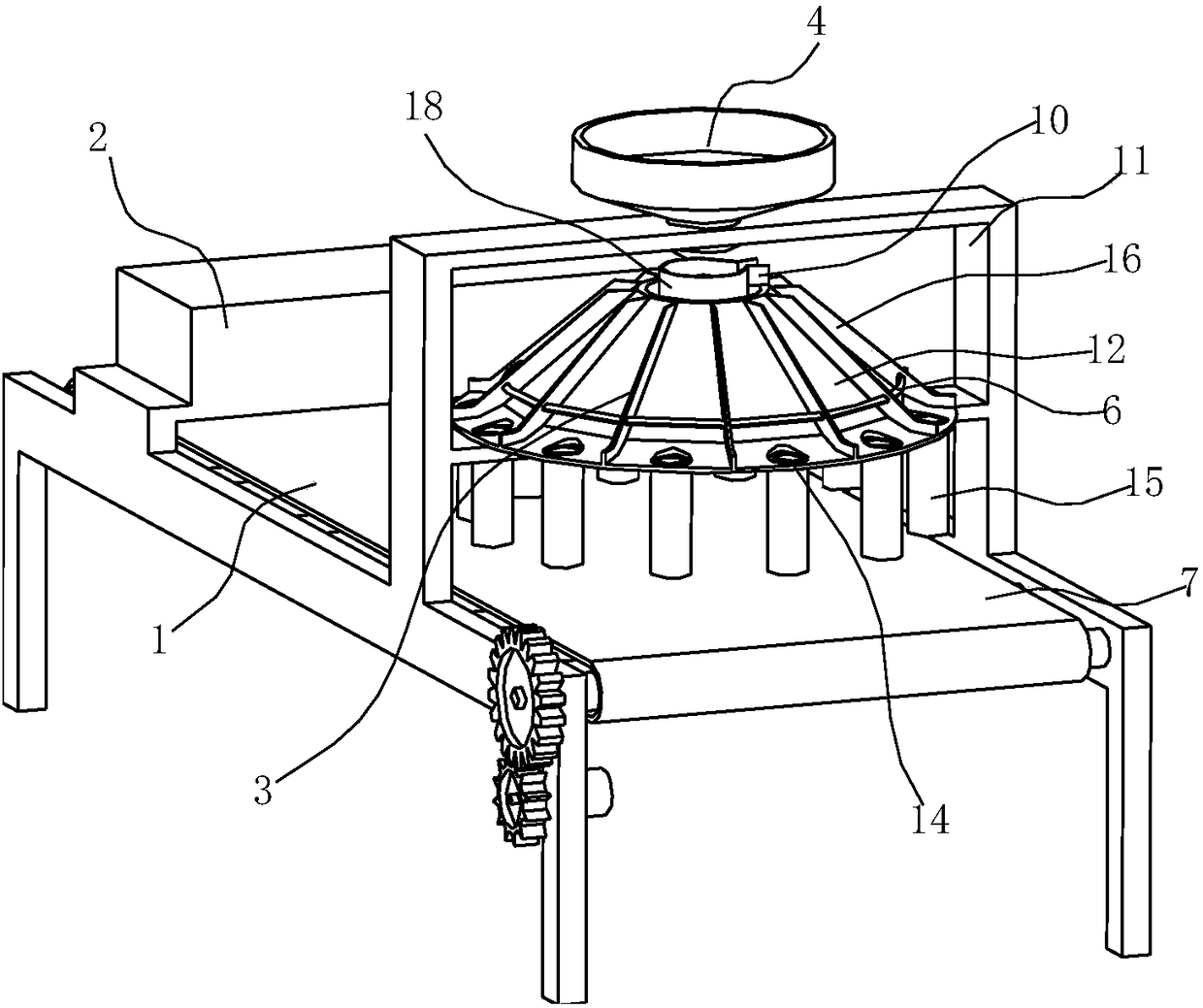

Traditional Chinese medicine decoction piece uniformly spreading and drying equipment and using method thereof

ActiveCN108195181ASpread evenlySpread quicklyDrying machines with progressive movementsDrying safety systemsBiochemical engineeringChinese drug

The invention relates to traditional Chinese medicine decoction piece uniformly spreading and drying equipment and a using method thereof, and belongs to the technical field of traditional Chinese medicine processing equipment. The equipment comprises conveying equipment, wherein a drying box is arranged on the rear side of the conveying equipment, and a spreading mechanism is arranged above the front side of the conveying equipment; and a discharging hopper is arranged above the spreading mechanism, and a 2mm-4mm distance is formed between the discharging hopper and the spreading mechanism. The using method comprises the following three steps of initially adjusting, starting a drying box, and starting a motor I and a motor and the like. According to the using method, the distance betweena baffle ring and the surface of a shell body is determined according to the thickness of the traditional Chinese medicine decoction piece, and the situation that only one traditional Chinese medicinedecoction piece can pass through the space between the baffle ring and the shell body one time prevails; adjustment of the distance between the discharging hopper and the spreading mechanism is subjected to the situation that the traditional Chinese medicine decoction pieces are not stacked and blocked on the spreading mechanism; and the lengths of cylinders are adjusted, so that distance betweenthe lower ends of the cylinders and a conveying belt does not exceed the thickness of the two traditional Chinese medicine decoction pieces, and the influence of the cylinders on conveying of the traditional Chinese medicine decoction pieces is avoided.

Owner:宁夏明德中药饮片有限公司

Additional post-glass-removal processes for enhanced cell efficiency in the production of solar cells

ActiveUSH2207H1Improve sequenceFinal product manufactureSemiconductor/solid-state device manufacturingLattice defectsSilicon oxide

A method is provided for the production of solar cells from raw crystalline p-type silicon wafer material. The surface condition prior to SiNx deposition is improved by providing additional process steps following the phosphorous glass removal and prior to the SiNx anti-reflection coating deposition. In one embodiment, the wafer is submitted to a thermal anneal under oxygen atmosphere followed by a wet-chemical oxide removal. The anneal reduces the surface phosphorous concentration by diffusion, reduces lattice defects in the emitter and oxidizes the silicon surface. In another embodiment, both a surface oxide is obtained and subsequently removed with wet chemistry. This sequence allows for an integration of the phosphorous glass removal, the wet-chemical oxidation, and the SiOx removal into a single machine.

Owner:BIJKER MARTIN D

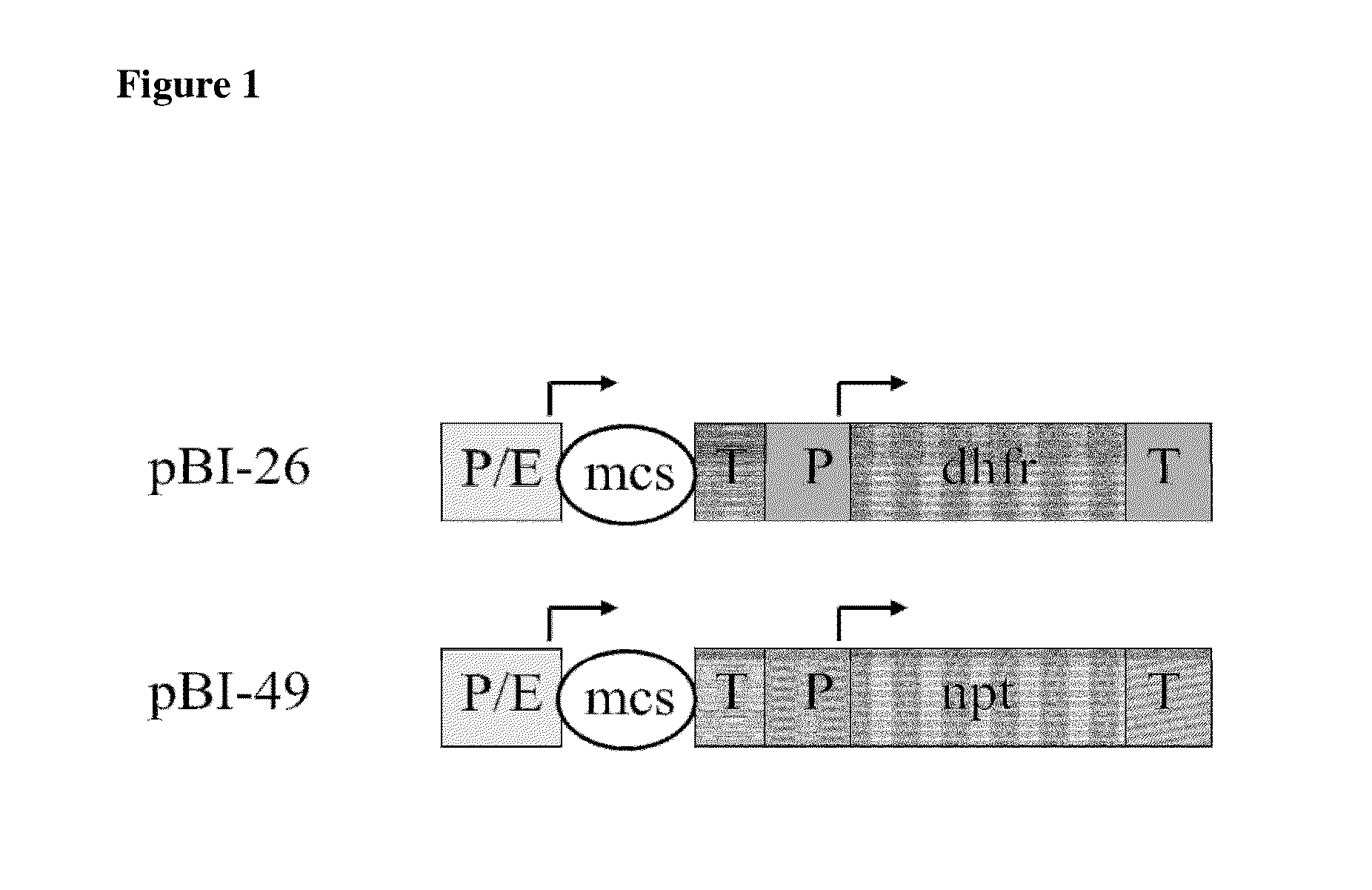

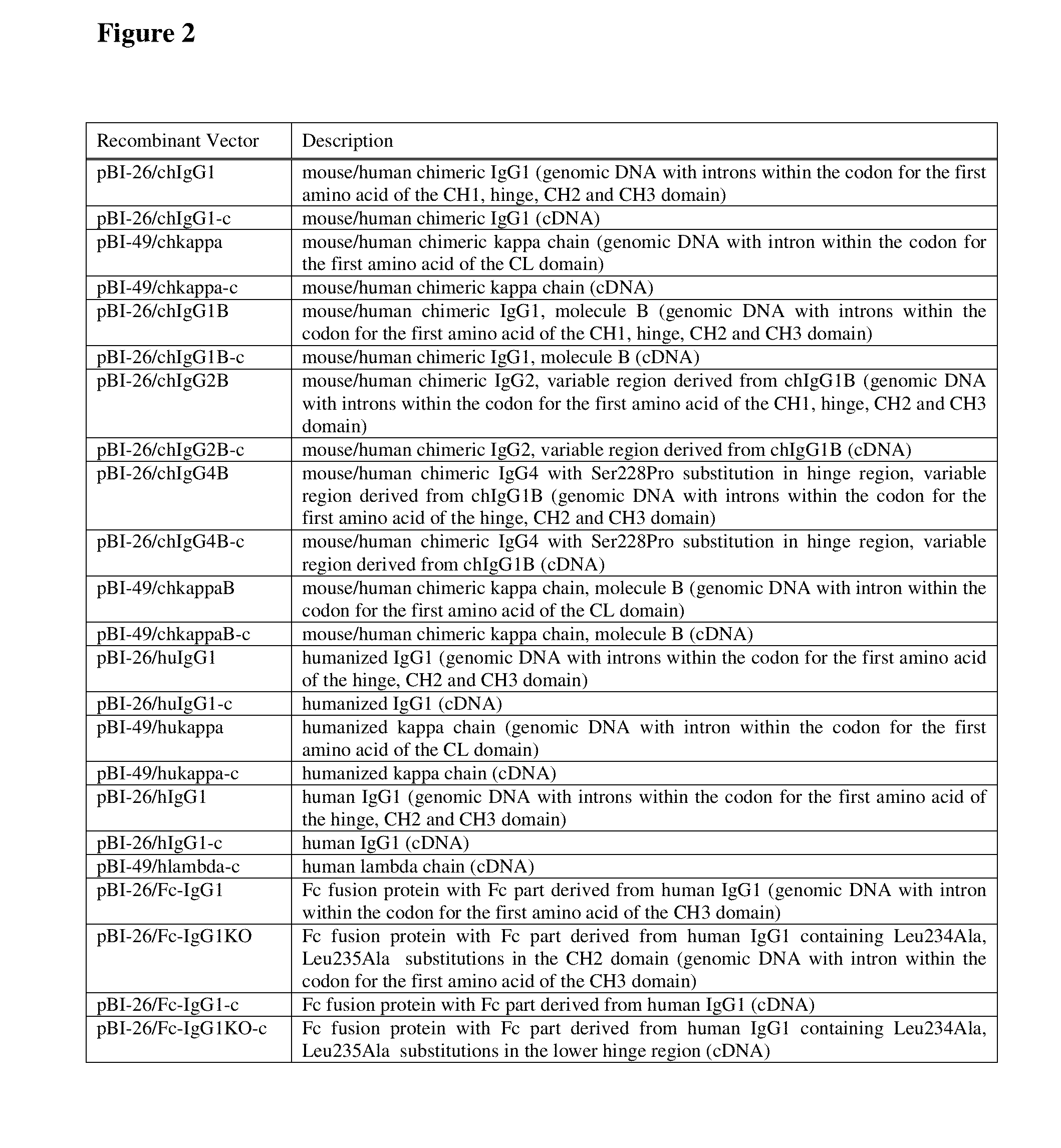

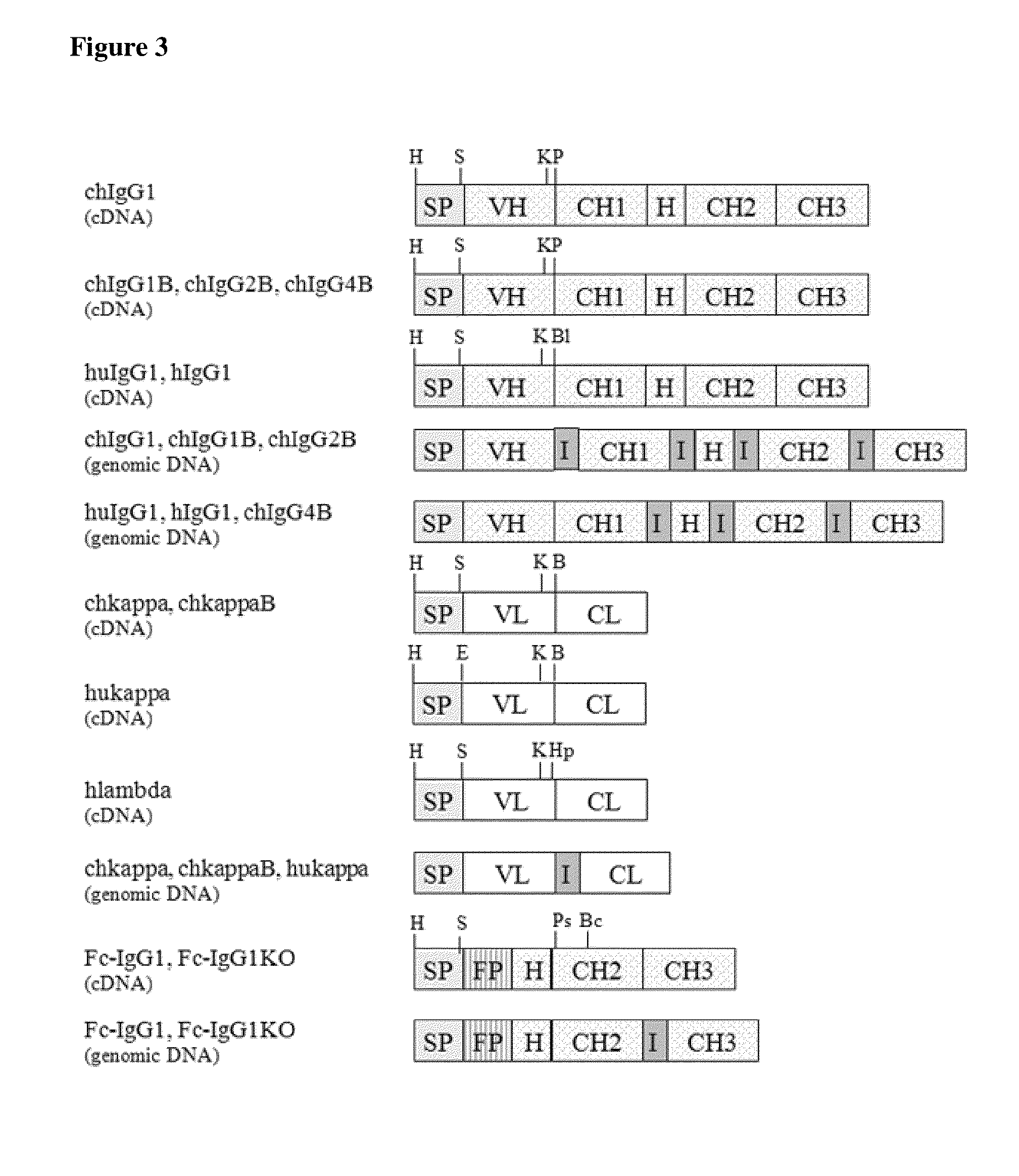

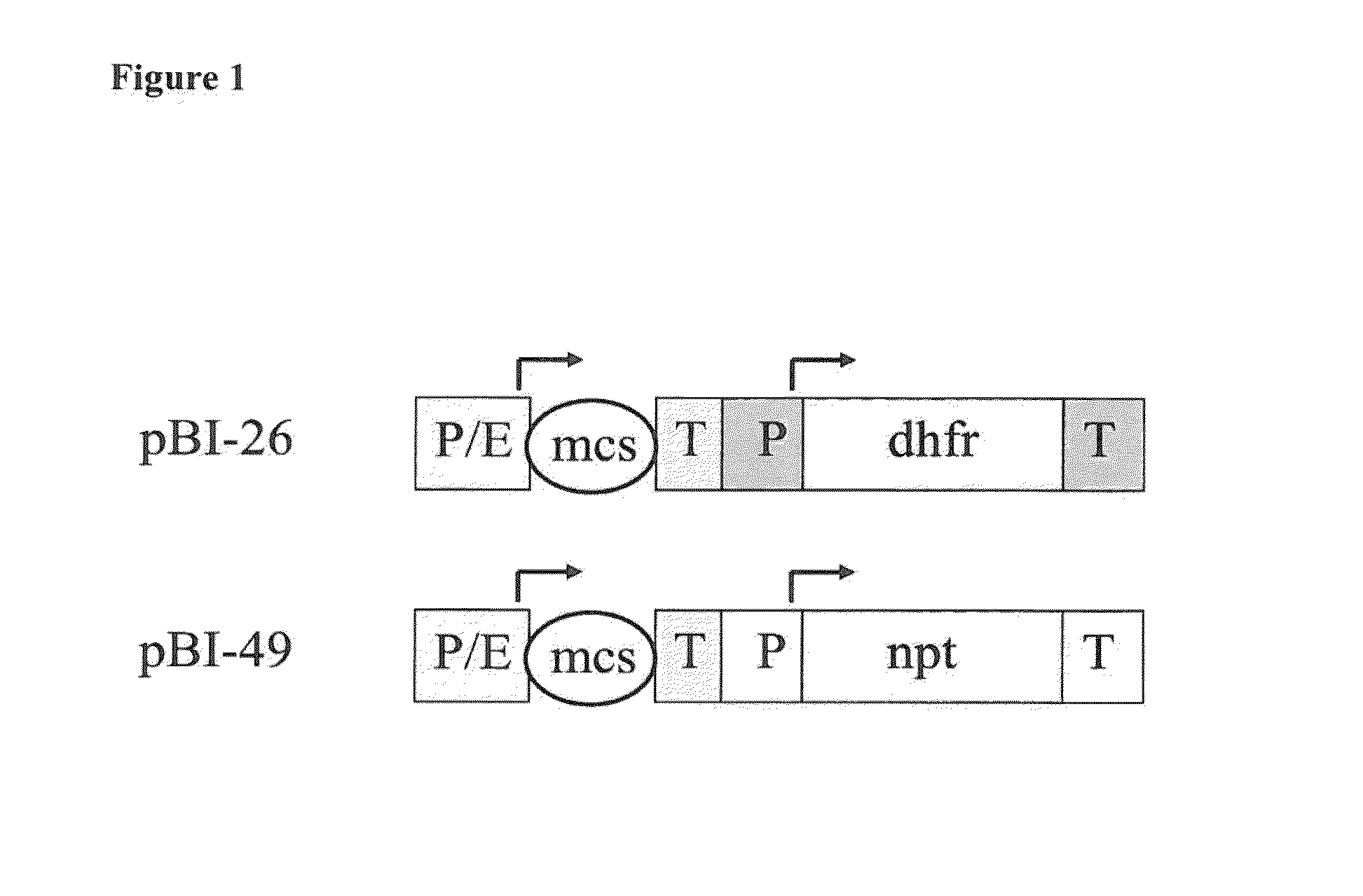

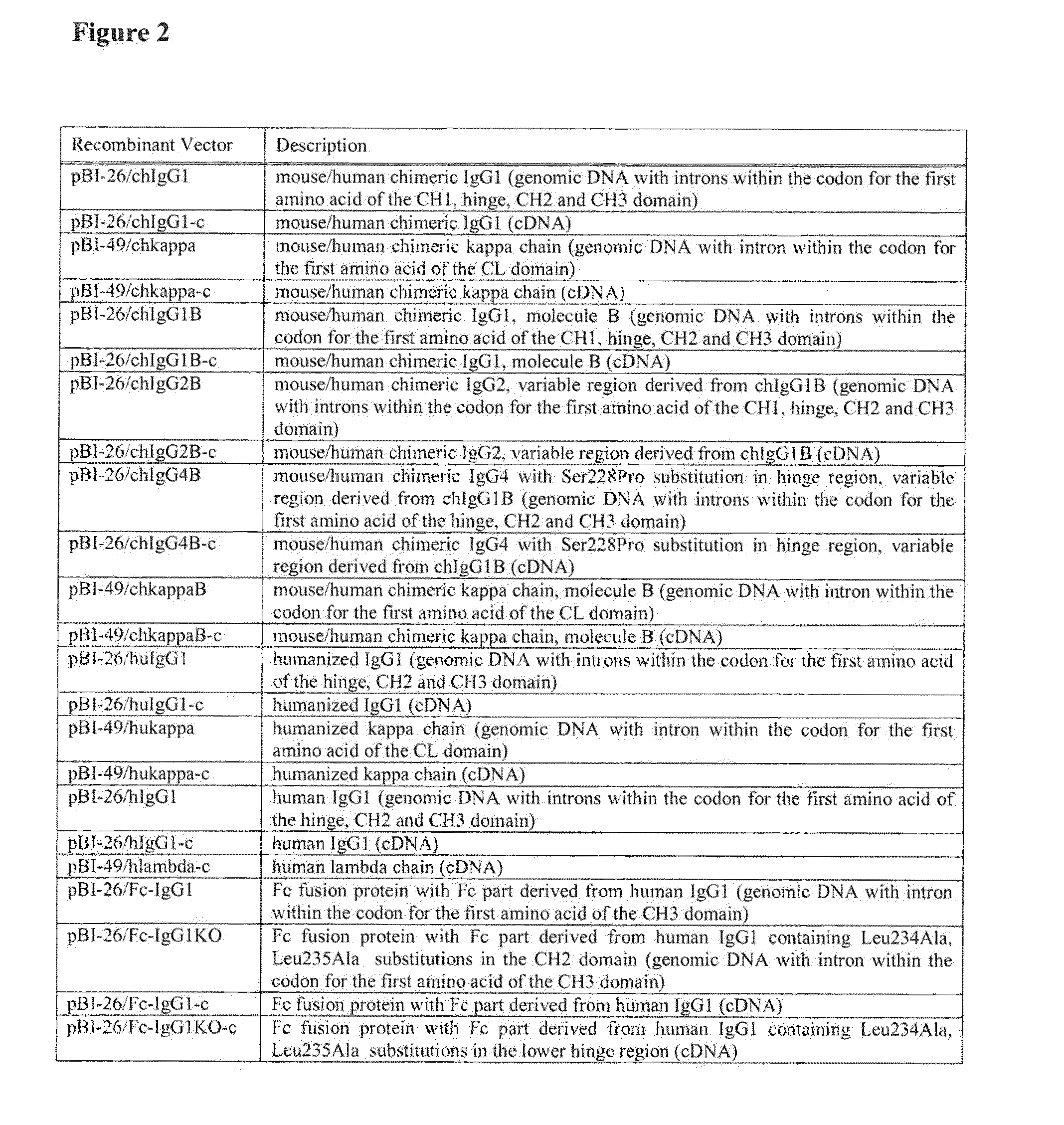

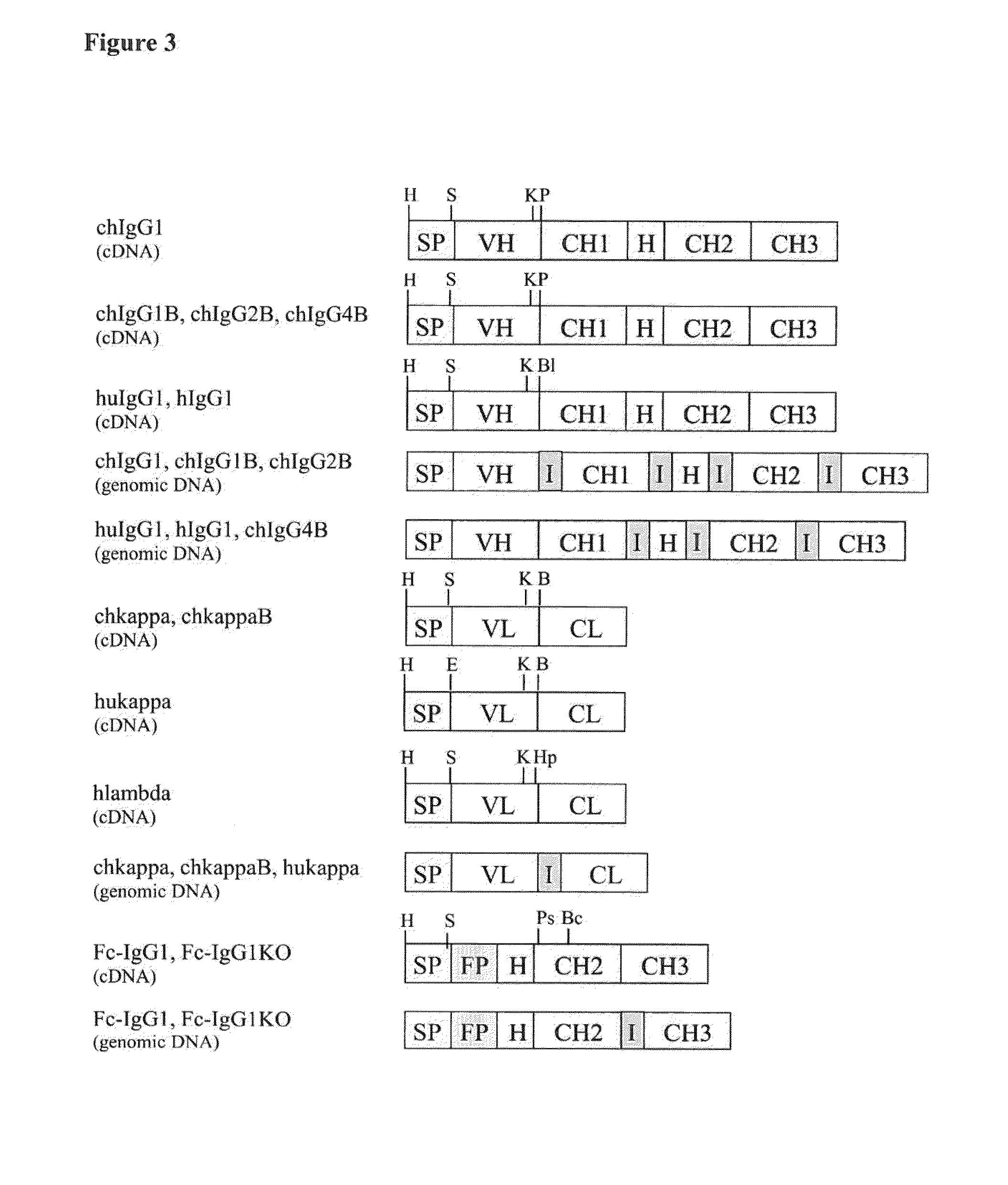

Heterologous intron within an immunoglobulin domain

ActiveUS20140234893A1Driving strong and stable gene expressionHigh expressionAnimal cellsVectorsHeterologousCloned genes

The invention concerns the field of recombinant gene engineering. It concerns novel introns and compositions comprising such introns as well as a method to improve expression of polypeptides from nucleic acids such as cloned genes with heterologous introns, especially genes encoding antibodies and antibody derived fragments, and the production of various polypeptides in eukaryotic host cells using said novel intron sequences as heterologous introns.

Owner:BOEHRINGER INGELHEIM INT GMBH

Motor Vehicle Door Lock

InactiveUS20100024193A1Improve sequenceVehicle locksAnti-theft devicesElectrical and Electronics engineering

Owner:KIEKERT AG

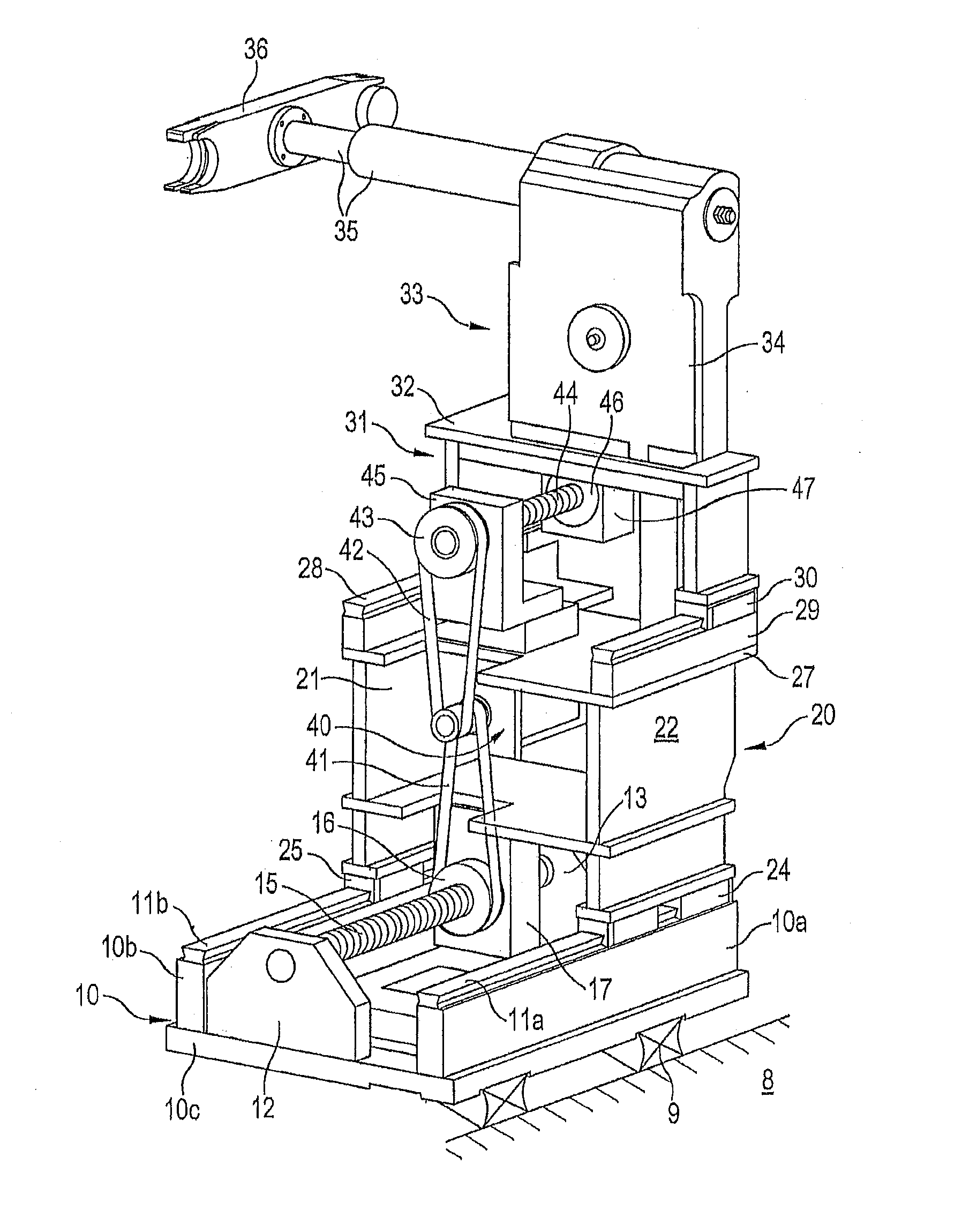

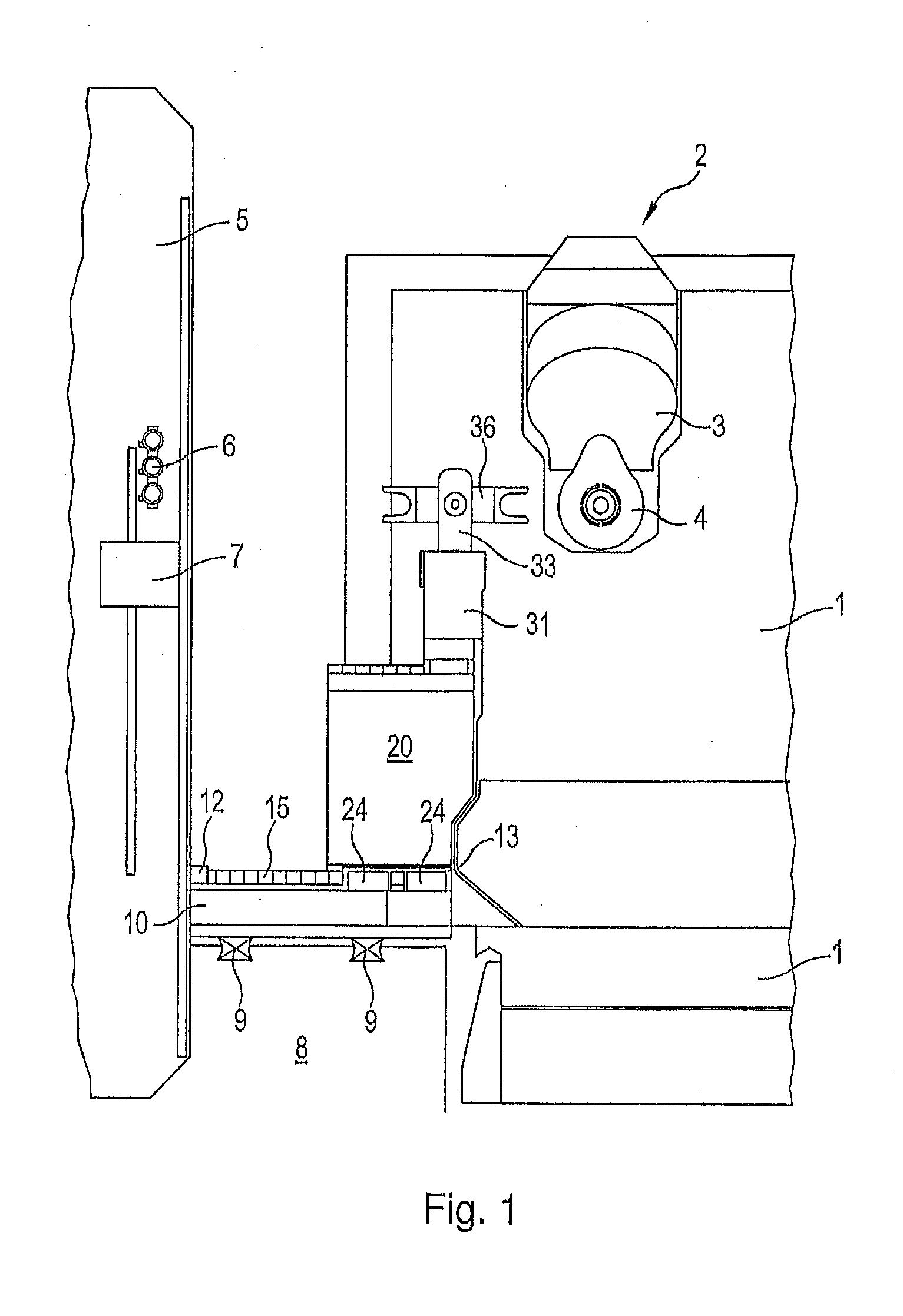

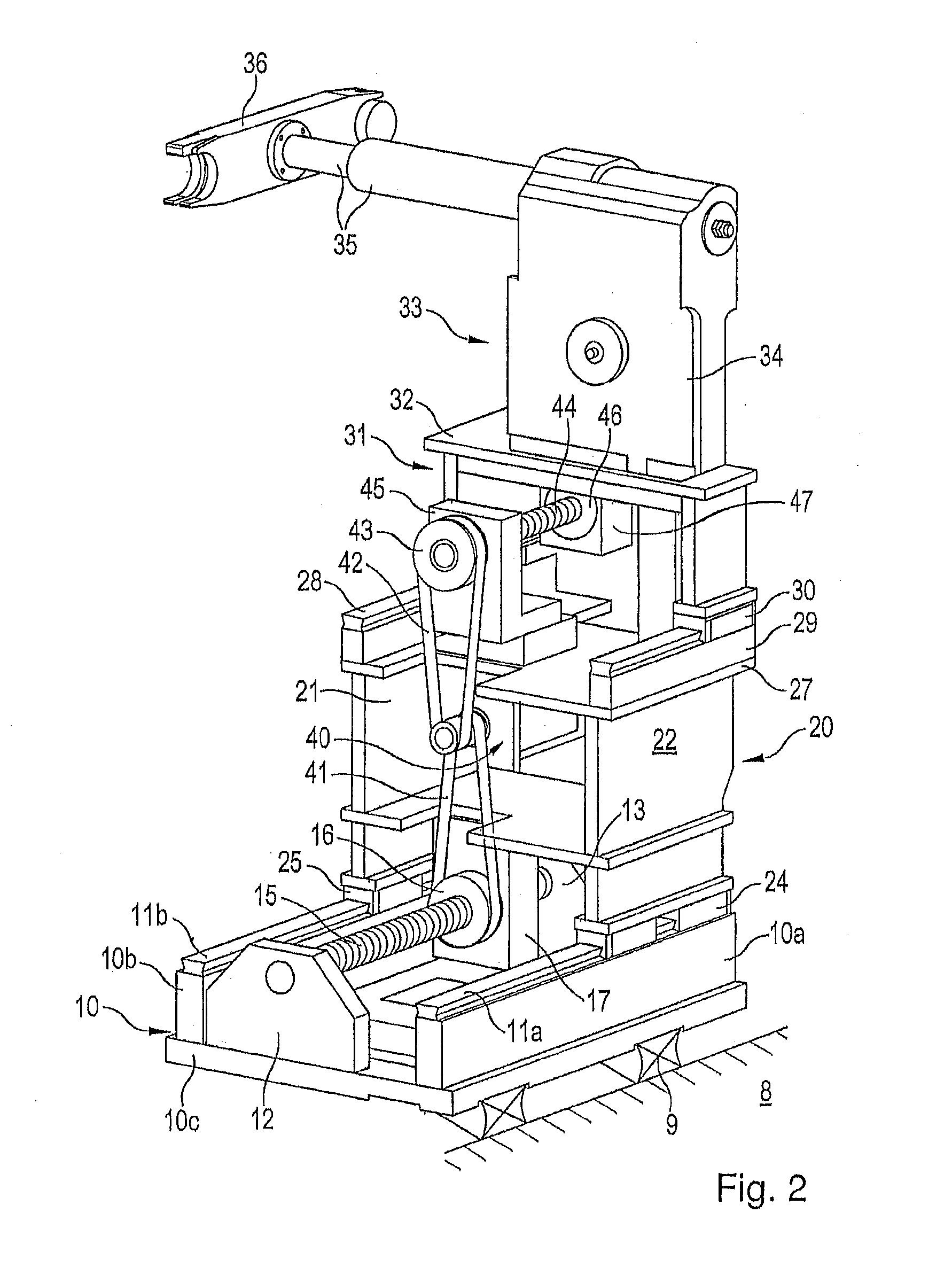

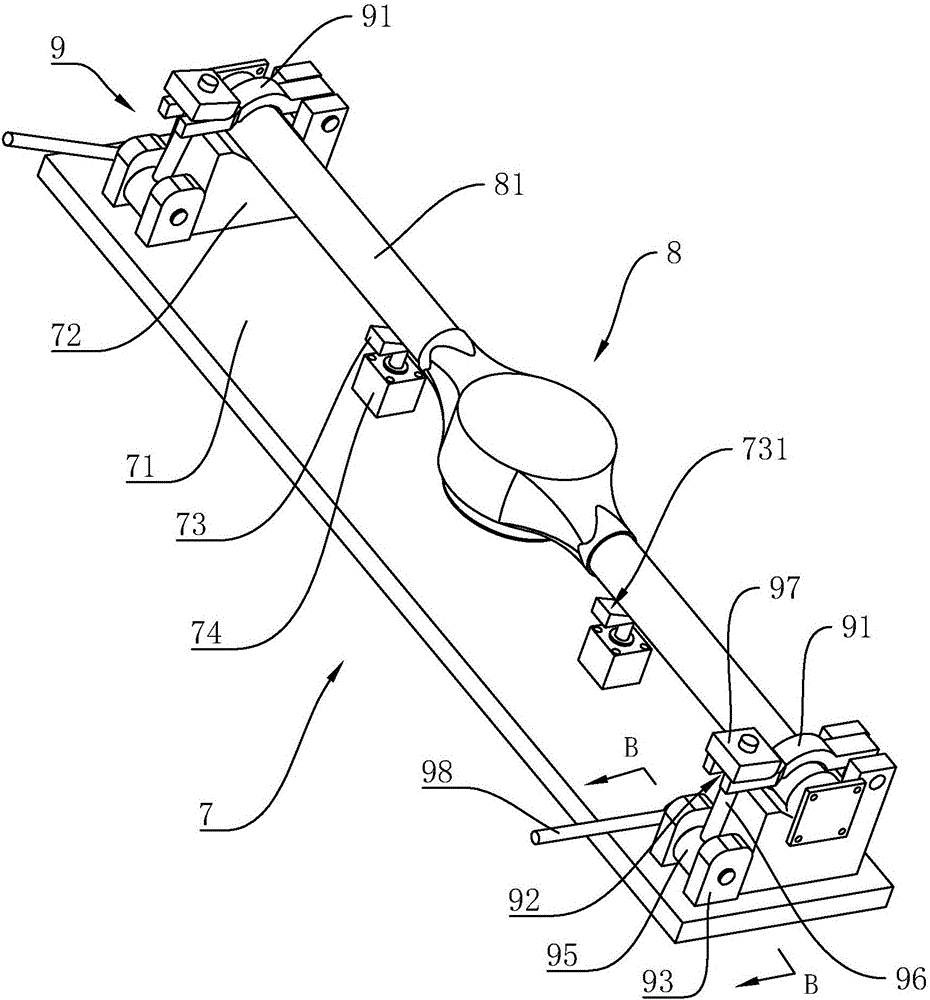

Tool handling device for machine tools

InactiveUS20130095988A1Small required spaceLong travel distanceTool changing apparatusFeeding apparatusEngineeringDrive motor

A tool handling device for machine tools, comprising a tool magazine having a transfer position for the transfer of the tools, including a tool changer movable between the transfer position and an exchange position, which has a rotatable double gripper, and a supporting structure movable on a foundation, on which the tool changer is mounted. In order to achieve fast tool changes in tight spaces on the machine, the supporting structure has an upper slide and a lower slide which can both be displaced by means of spindle drives in the same direction on a foundation, wherein a single drive motor is provided for driving the two spindle drives.

Owner:DECKEL MAHO PFRONTEN GMBH

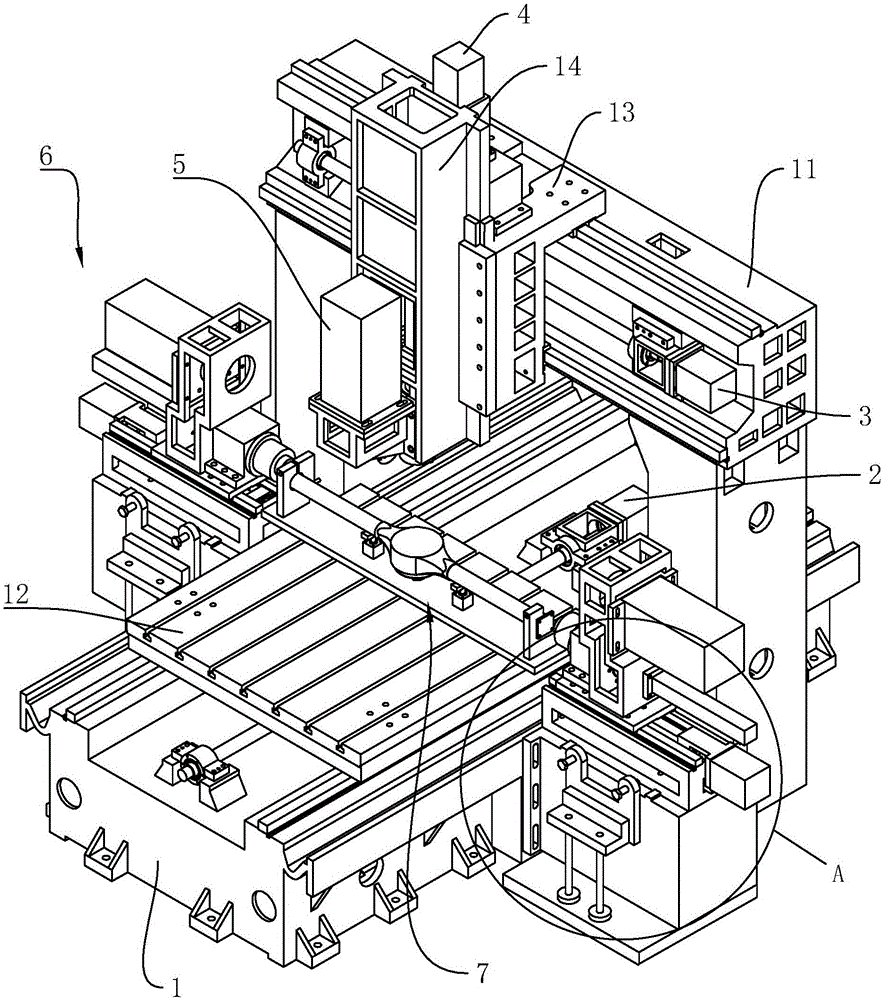

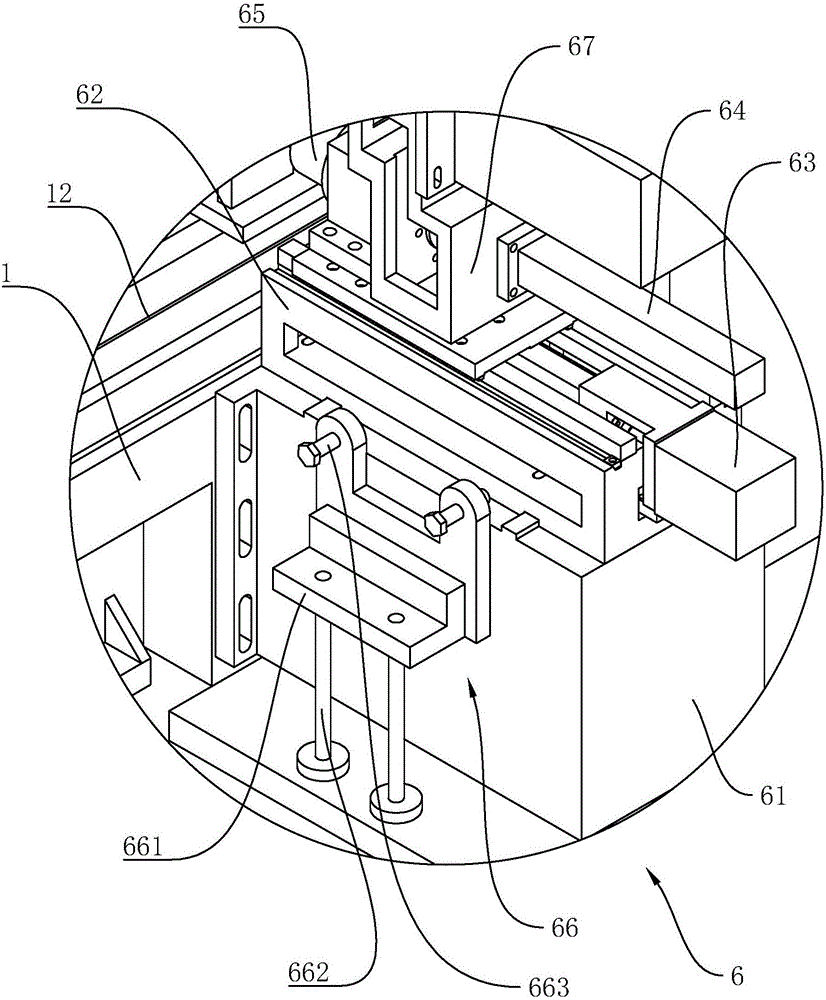

Rear axle processing machine tool

ActiveCN106181438ASimple structureEasy to adjustFeeding apparatusLarge fixed membersEngineeringPower apparatus

The invention discloses a rear axle processing machine tool, which comprises a machine tool body. A portal frame is arranged on the machine tool body; a workbench driven by a first power device and sliding along an X axle is also arranged on the machine tool body; a saddle driven by a second power device is slidably arranged along a Y axle and located on the portal frame above the workbench; a slide seat driven by a third power device is slidably arranged on the saddle along a Z axle; a first spindle driven by a fourth power device is arranged on the slide seat; and end face processing mechanisms arranged in a mirroring way are arranged on two sides of the machine tool body, and are located on one side, provided with the first spindle, on the portal frame. The simultaneous processing of two upper ends and three middle holes on a rear axle can be completed through the one machine tool, so that compared with a traditional rear axle processing machine tool, the problem of requiring the matching of multiple machine tools and multiple clamping is solved, a lot of rear axle transfer time is saved, and the working efficiency is greatly improved; and meanwhile, the rear axle only needs to be clamped and positioned at a time, so that the location degree of the rear axle during processing is ensured, and further the processing accuracy is effectively improved.

Owner:潍坊圣世源电子设备有限公司

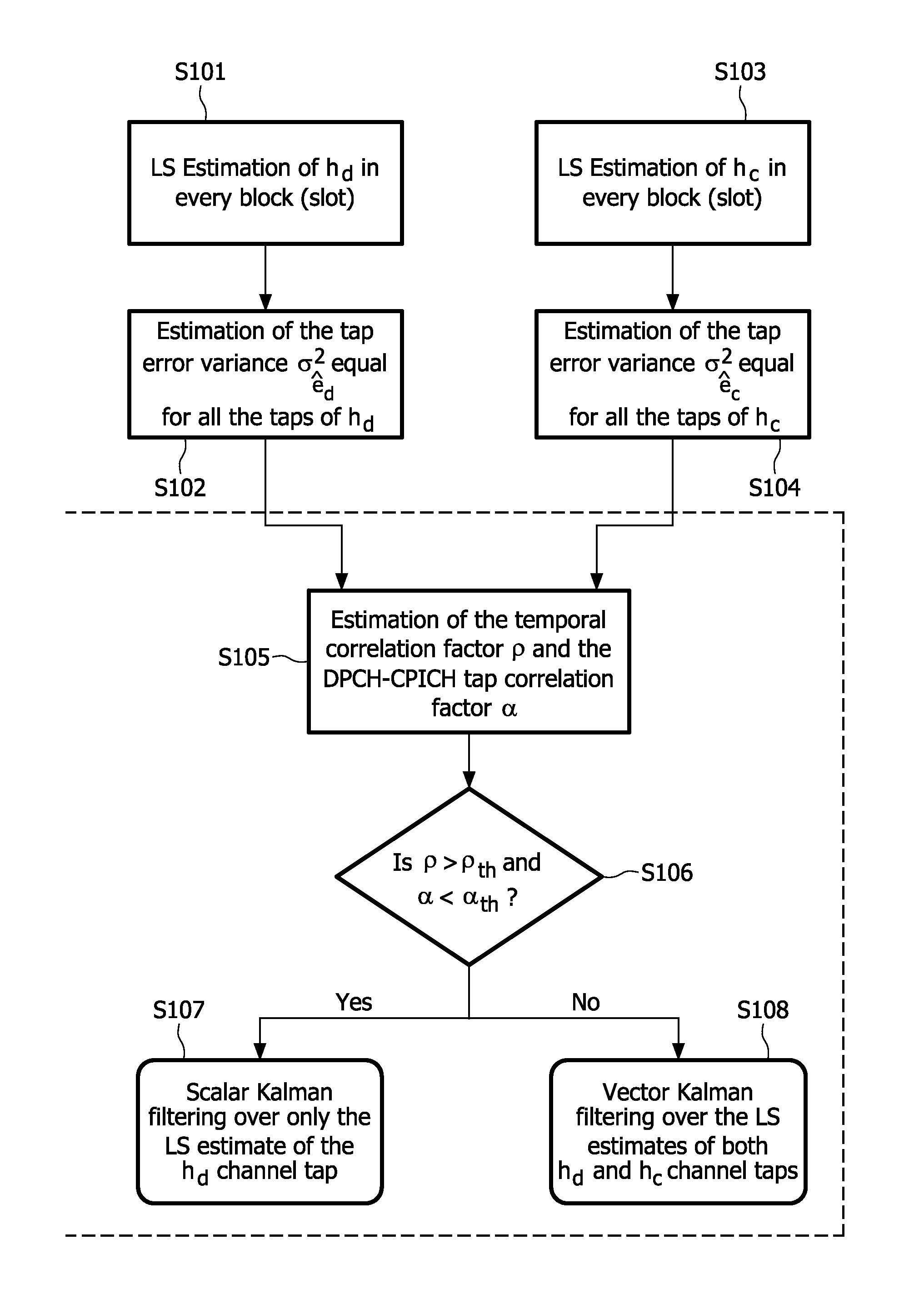

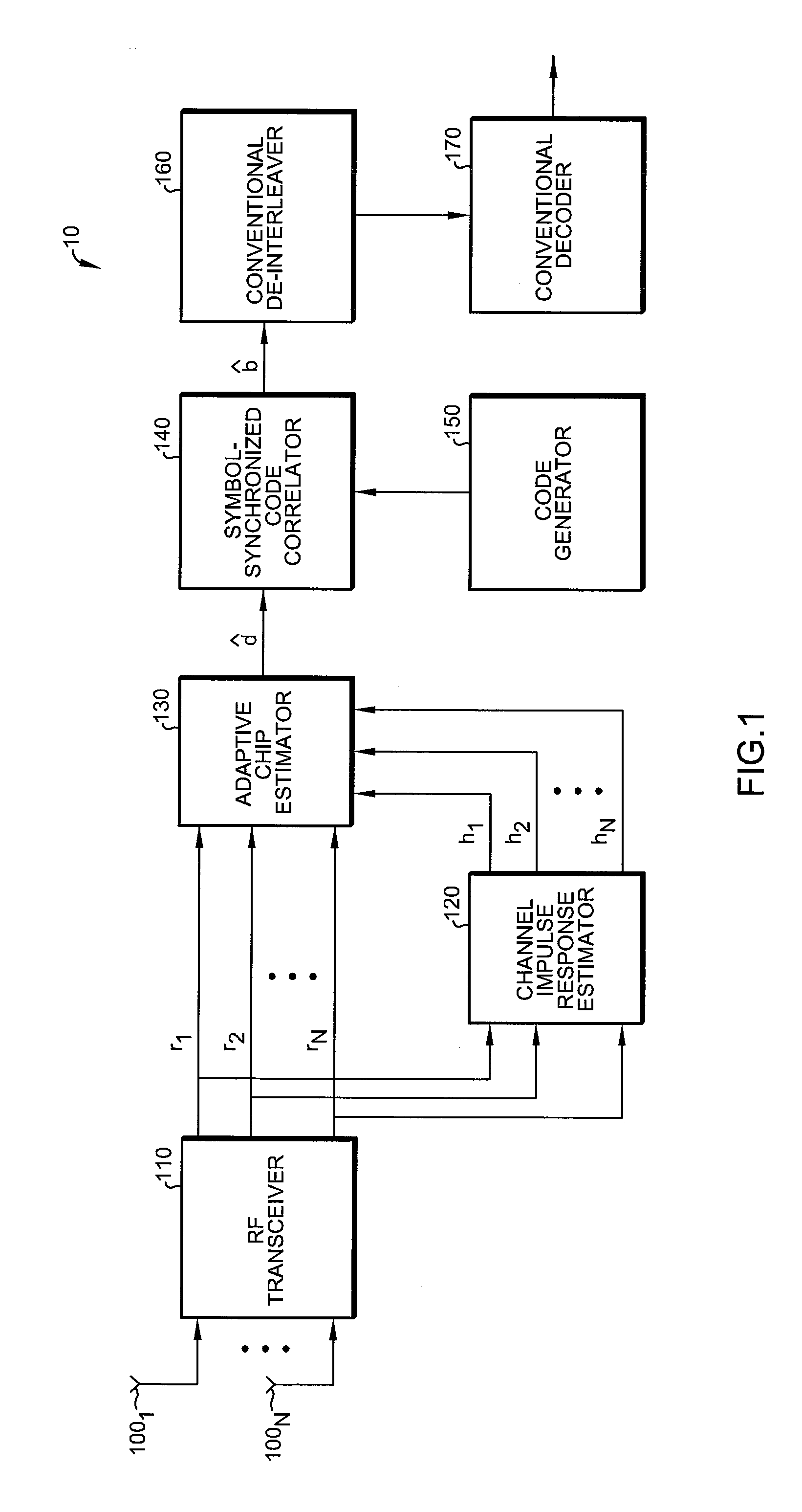

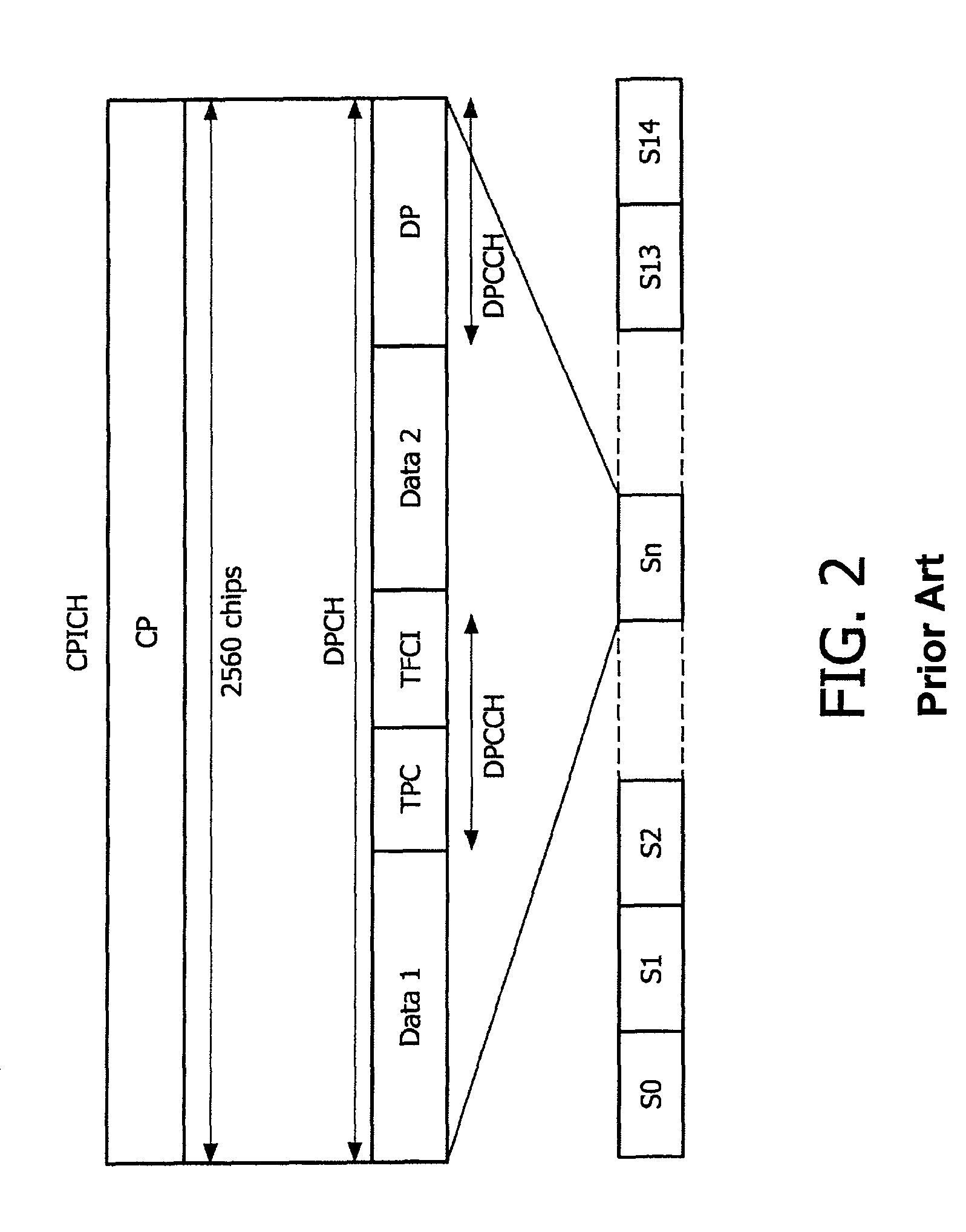

Channel estimation using common and dedicated pilots

InactiveUS8259854B2Increase heightImprove performanceMultiple-port networksTransmission control/equlisationEngineeringTemporal correlation

The present invention relates to a receiver apparatus and method of channel estimation in a telecommunication system which provides at least two pilot sequences, and to a computer program product. Channel estimation is achieved by estimating channel taps separately for each of the at least two pilot sequences in every transmission block, and for applying estimated channel taps obtained from the estimation to at least one of a temporal and spatial filtering or combining operation to refine the channel estimate. Accordingly, temporal correlations and cross-correlations of the at least two pilot sequences are exploited without requiring knowledge of path delays and beamforming parameters.

Owner:ST ERICSSON SA

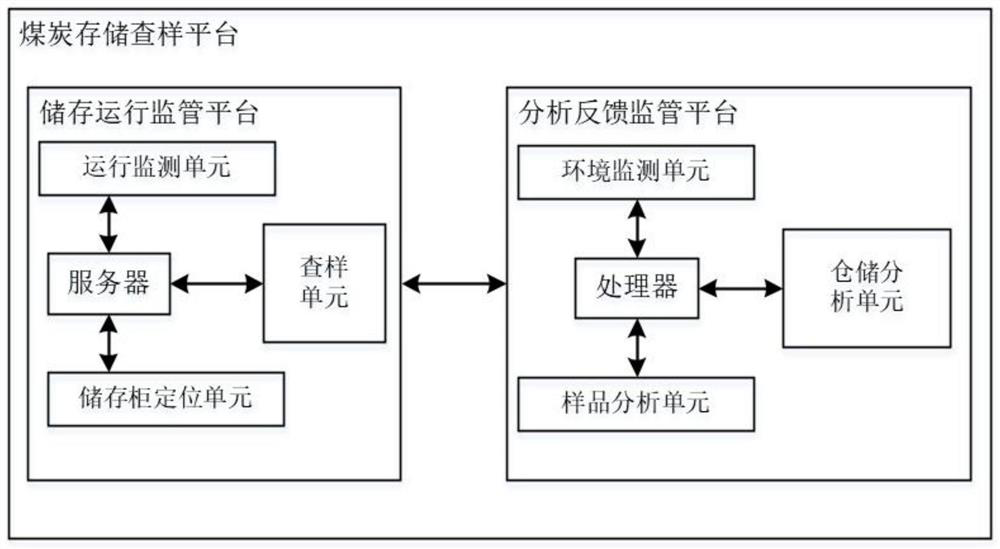

Intelligent coal sample storage, sample checking, feedback and supervision system

ActiveCN113934967AReduce the quality of useImprove operational efficiencyInformation technology support systemComplex mathematical operationsProcess engineeringCoal

The invention discloses an intelligent coal sample storage, sample checking, feedback and supervision system, relates to the technical field of coal sample storage, sample checking, feedback and supervision, and solves the technical problem that multiple data analysis cannot be performed corresponding to coal sample checking in the prior art. The location of storage cabinets for coal samples is determined, coal sample storage abnormity caused by position abnormity of the storage cabinets is prevented, and abrasion of the storage cabinets in the operation process is reduced, so that the operation life of the storage cabinets is prolonged; operation monitoring is performed on the storage cabinets in a selected area, so that the operation sequence of the storage cabinets is improved, and the situation that the storage efficiency is reduced due to disordered operation of the storage cabinets is prevented; environment analysis monitoring is performed on the storage cabinets for sample checking, and the influence of the storage cabinet environment on coal samples is judged; whether the coal samples are abnormally stored in the corresponding sample checking storage cabinets or not is judged; therefore, the state of the coal samples stored in the sample checking storage cabinets in real time is judged, and the qualification of the coal samples is improved.

Owner:INFINITY INTELLIGENCE & INFORMATION (SUZHOU) TECH CO LTD +1

Casting method of aluminum alloy castings

The invention relates to a casting method of aluminum alloy castings. The casting method of aluminum alloy castings comprises the following steps of firstly, making a cope flask and a drag flask according to the shape of one casting, and carrying out coating treatment on the cope flask and the drag flask; secondly, carrying out mold assembly on the cope flask and the drag flask to form a cavity, and carrying out fastening treatment; thirdly, carrying out vacuum pumping treatment on the cavity; fourthly, filling the cavity with aluminum alloy molten metal with the injection speed ranging from 2m / s to 6m / s; fifthly, increasing the pressure of the cavity to 5 Mpa to 10 Mpa, and carrying out pressure maintaining treatment; sixthly, relieving the pressure of the cavity to the normal pressure after the casting formed in the cavity completely solidifies, separating the cope flask from the drag flask, and taking out the casting, namely, the aluminum alloy casting. The aluminum alloy castings prepared with the preparation method is good in surface quality and low in preparation cost.

Owner:益阳仪纬科技有限公司

Heterologous intron within a signal peptide

ActiveUS20140248660A1Driving strong and stable gene expressionHigh expressionAnimal cellsVectorsPeptideSignal peptide

The invention concerns the field of recombinant gene engineering. It concerns novel introns and compositions comprising such introns as well as a method to improve expression of polypeptides from nucleic acids such as cloned genes with heterologous introns, especially genes encoding antibodies and antibody derived fragments, and the production of various polypeptides in eukaryotic host cells using said novel intron sequences as heterologous introns.

Owner:BOEHRINGER INGELHEIM INT GMBH

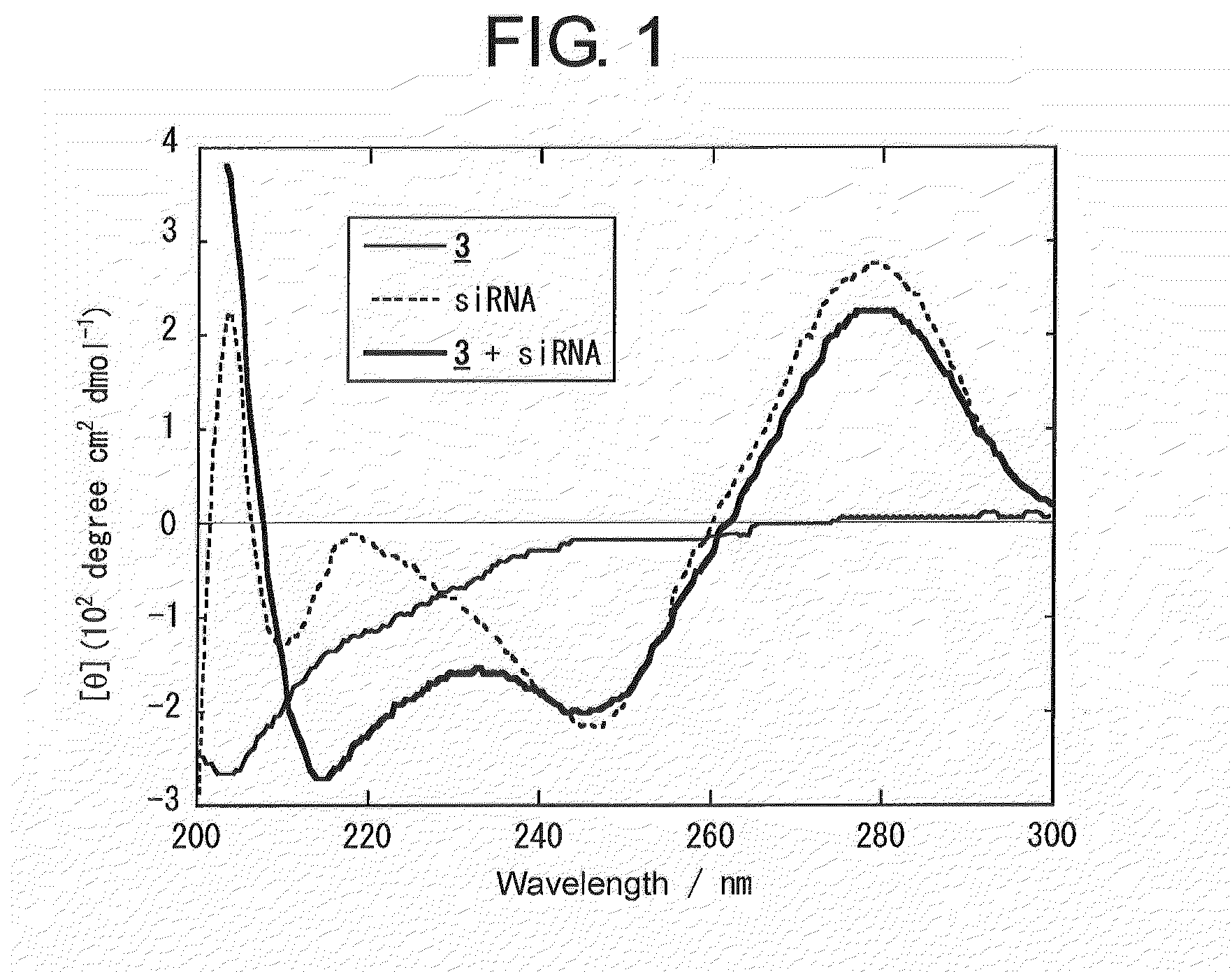

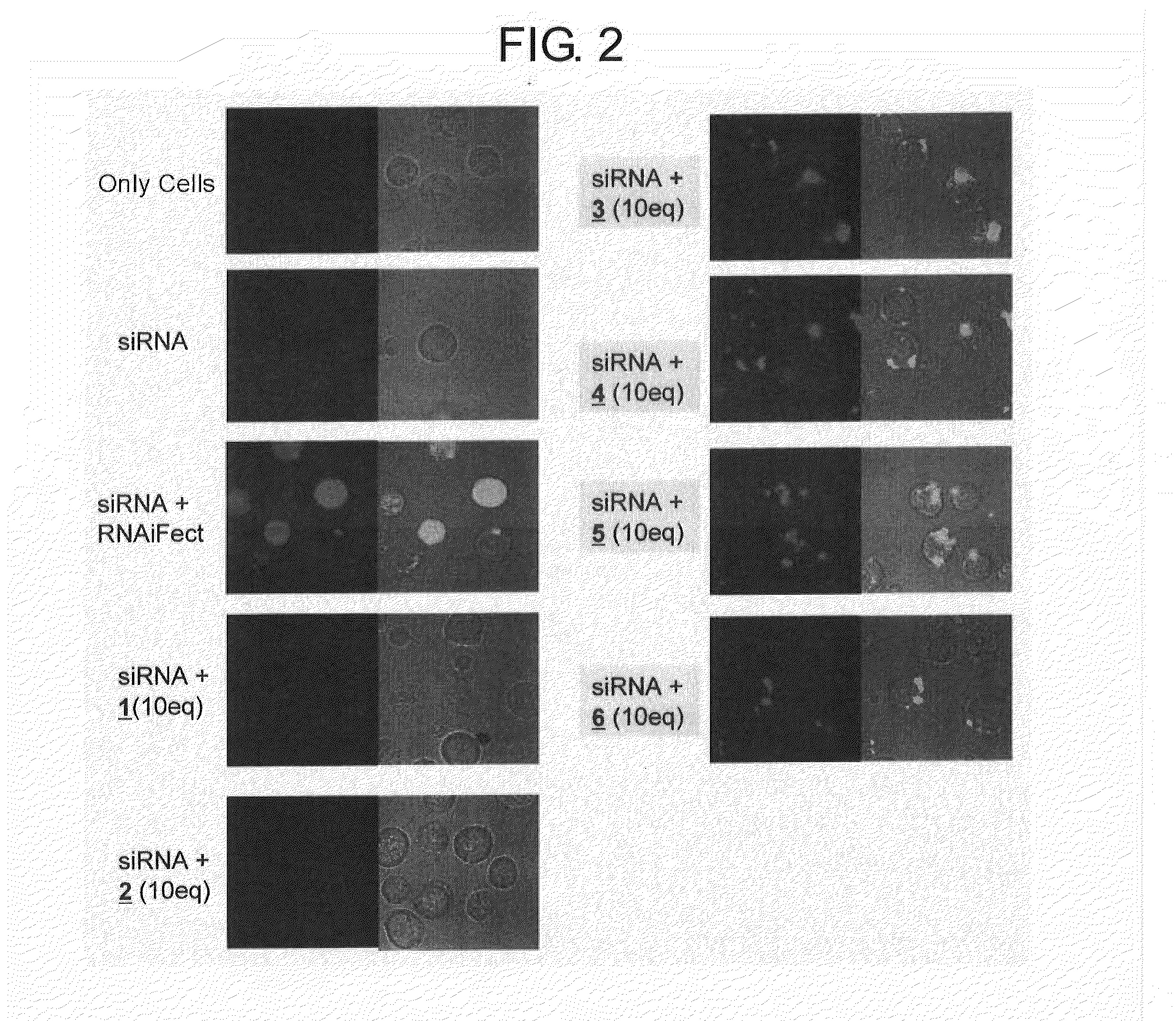

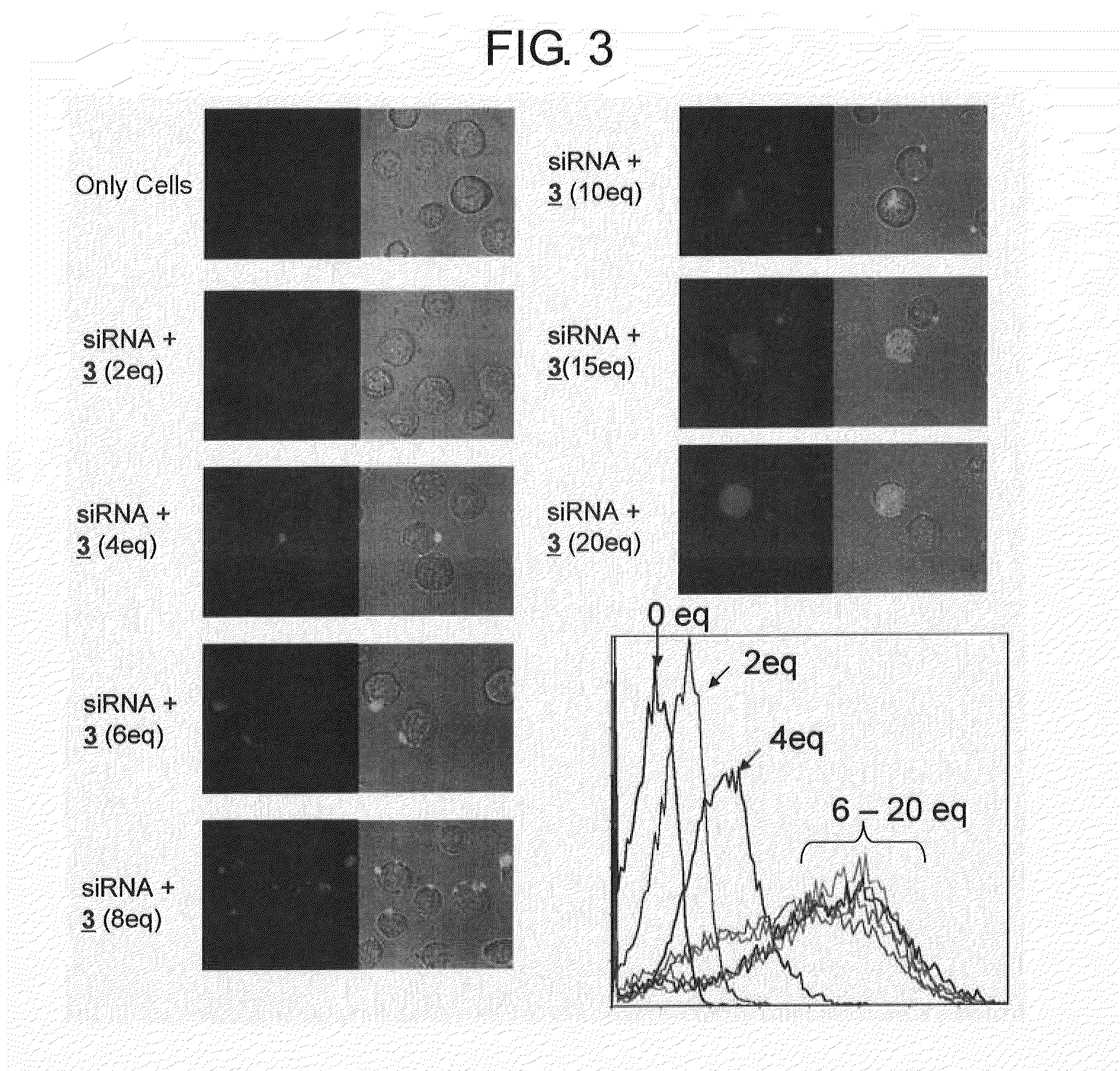

Method for transfecting nucleic acid to cell and nucleic acid complex

ActiveUS20130115700A1Low cytotoxicityImprovement of cell specificitySpecial deliveryTransferasesSide chainDouble strand

A method for transacting nucleic acid to cell comprising a step for forming a nucleic acid complex by bringing a double-stranded nucleic acid molecule into contact with a nucleic acid carrier having an amino acid sequence of alternating a basic amino acid and a hydrophobic amino acid, which has a peptide chain that forms a β-sheet structure in which a side chain of a positively charged basic amino acid is disposed on one surface side and a side chain of a hydrophobic amino acid is disposed on the opposite surface side in the presence of the double-stranded nucleic acid molecule having a double helix structure, and by binding the double-stranded nucleic acid molecule and the peptide chain through either one or both of the electrostatic interaction between the side chains of the basic amino acid and phosphate groups and hydrogen bonds between the double stranded-nucleic acid molecule and the peptide chain and a nucleic acid complex used for the same are disclosed.

Owner:KINKI UNIVERSITY

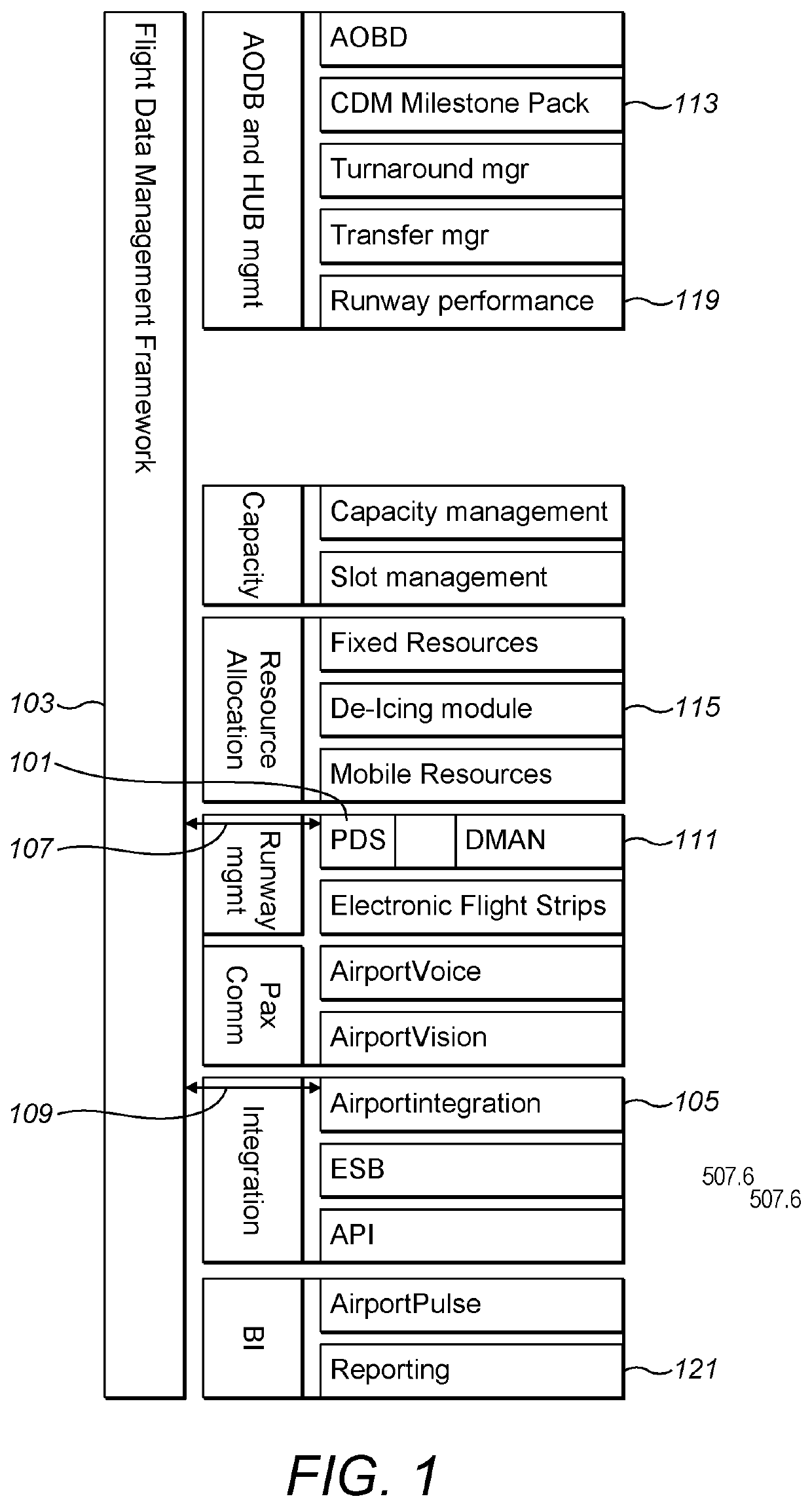

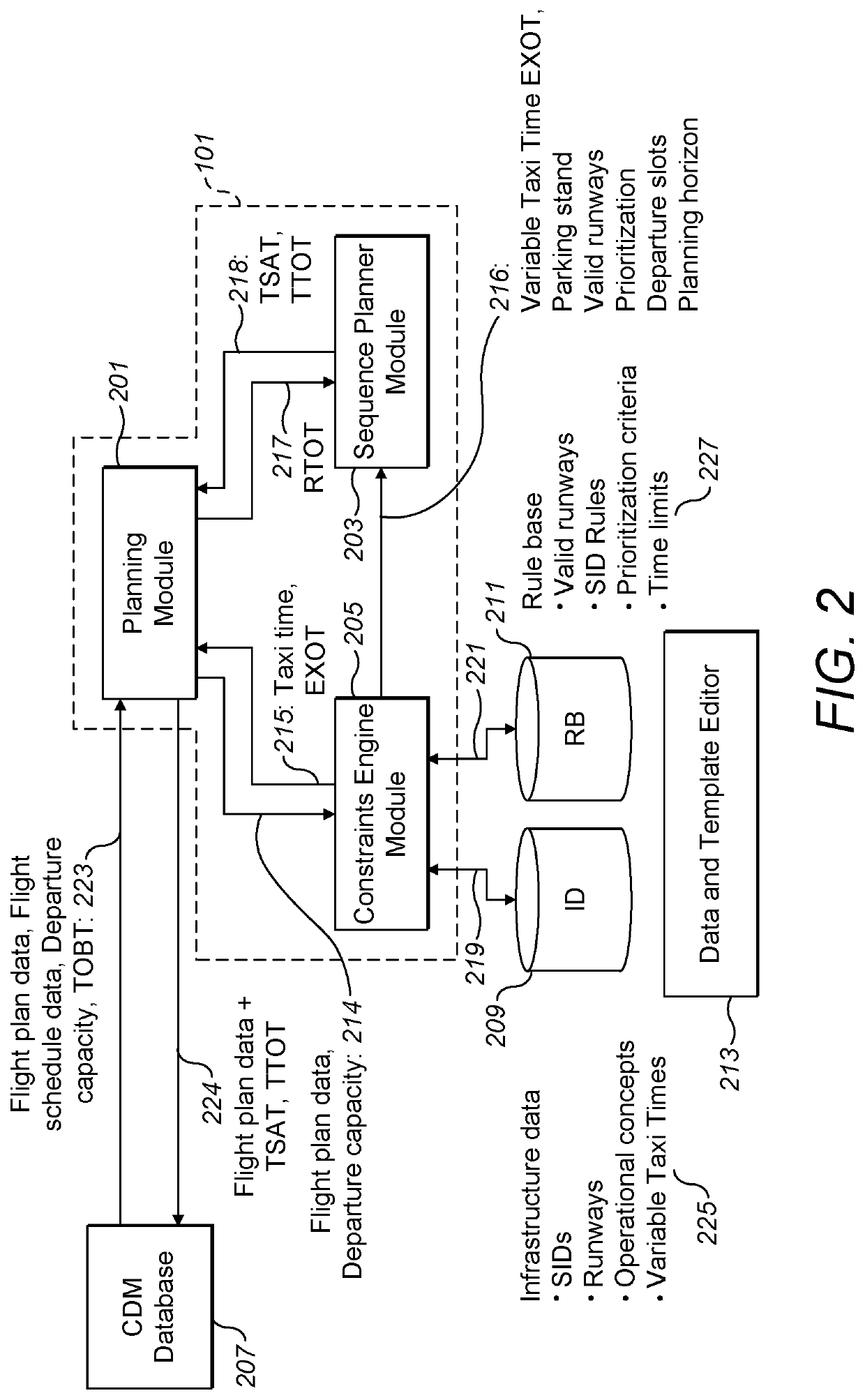

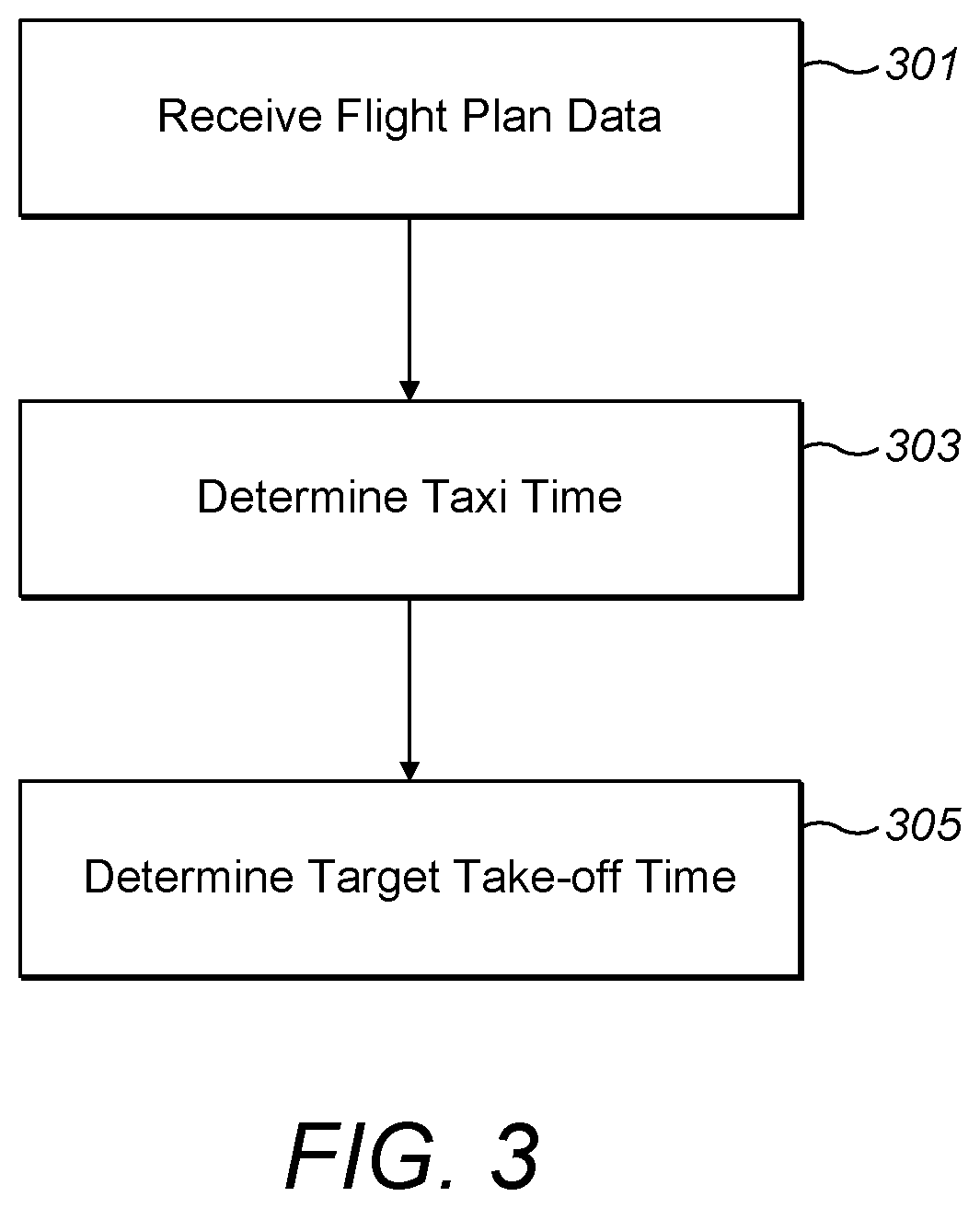

Improved system, device and method for sequencing modes of transportation or items and the like

PendingUS20220020281A1Shorten the timeImprove adhesionFlight plan managementMultiple aircraft traffic managementMode of transportFlight vehicle

A computer processing system for optimising a sequence of aircraft at an airport is disclosed. The system comprises a module (201) configured to receive flight plan data associated with a plurality of journeys between an origin and destination wherein each journey is associated with a different aircraft and wherein the flight plan data comprises flight schedule data associated with the plurality of different journeys; a second module (205) coupled to the first module wherein the second module is configured to determine an aircraft taxi time, EXOT, based on the flight plan data; a third module (203) coupled to the first module (201) and the second module (205) wherein the third module (203) is configured to determine a target take-off time, TTOT, associated with each of the plurality of different journeys wherein the target take-off time is determined based on the taxi time, EXOT, and the flight plan data.

Owner:SITA INFORMATION NETWORKING COMPUTING

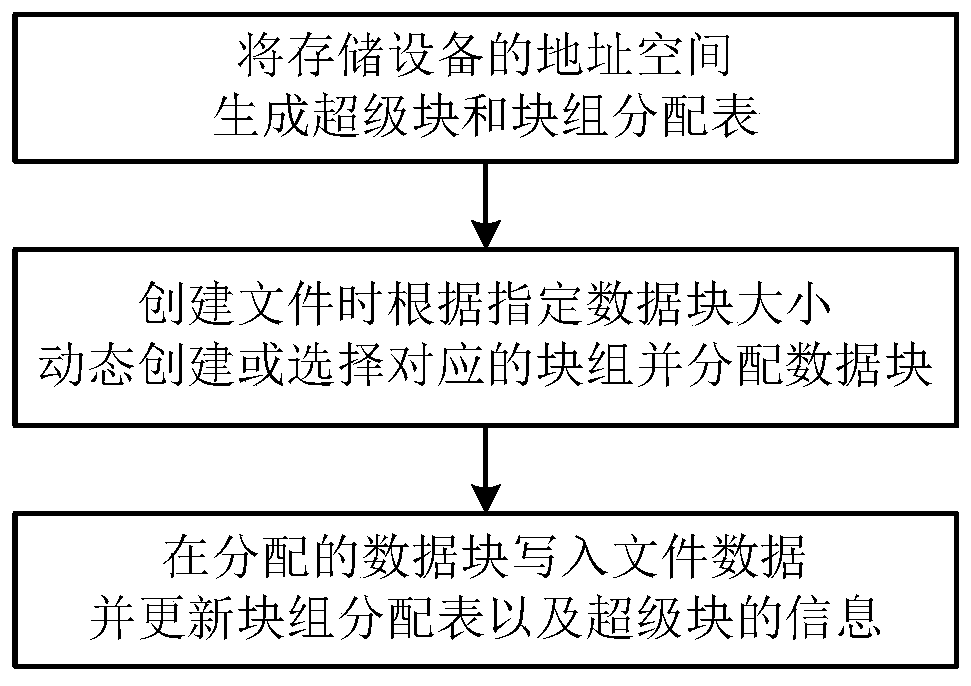

Low-latency file system address space management method and system and medium

ActiveCN111522507AReduce addressing overheadImprove sequenceInput/output to record carriersFile access structuresAddress spaceFile system

The invention discloses a low-latency file system address space management method and system and a medium. The method comprises the steps that a super block and a block group distribution table are generated from an address space of storage equipment, file system information and the distribution situation of a block group on a linear address space of the storage equipment are stored in the super block, and the block group distribution table is used for marking the distribution situation of data blocks in the corresponding block group; when the file is created, dynamically creating or selectinga corresponding block group according to the size of a specified data block, allocating the data block, writing file data into the allocated data block, and updating the information of a block groupallocation table and a super block. It can be guaranteed that which data blocks are occupied by one file on the storage device can be known only through one IO operation, the read-write delay of the file can be remarkably reduced, the addressing expenditure of file read-write can be remarkably reduced, the file read-write sequence can be remarkably improved, and therefore the read-write performance is improved.

Owner:SUN YAT SEN UNIV

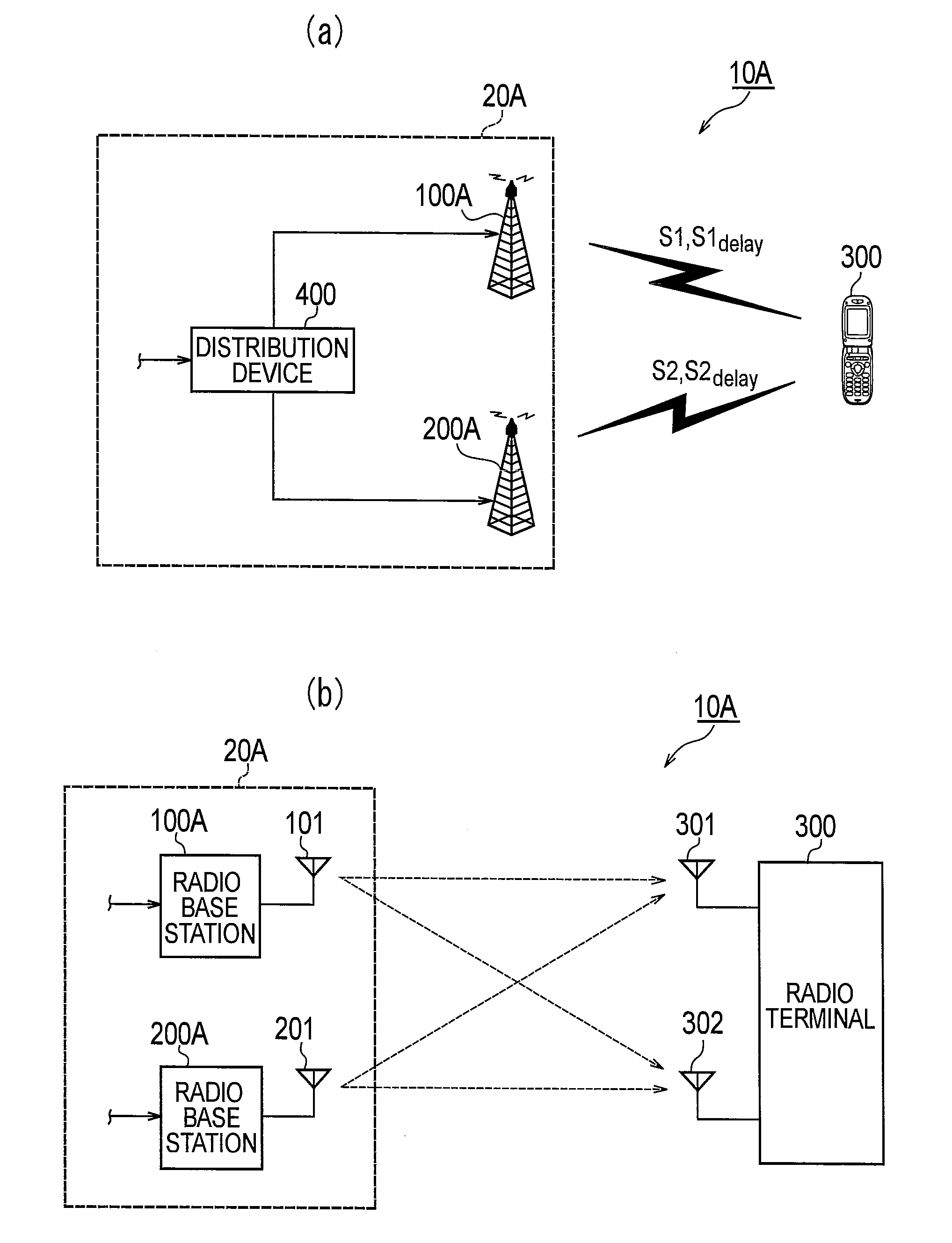

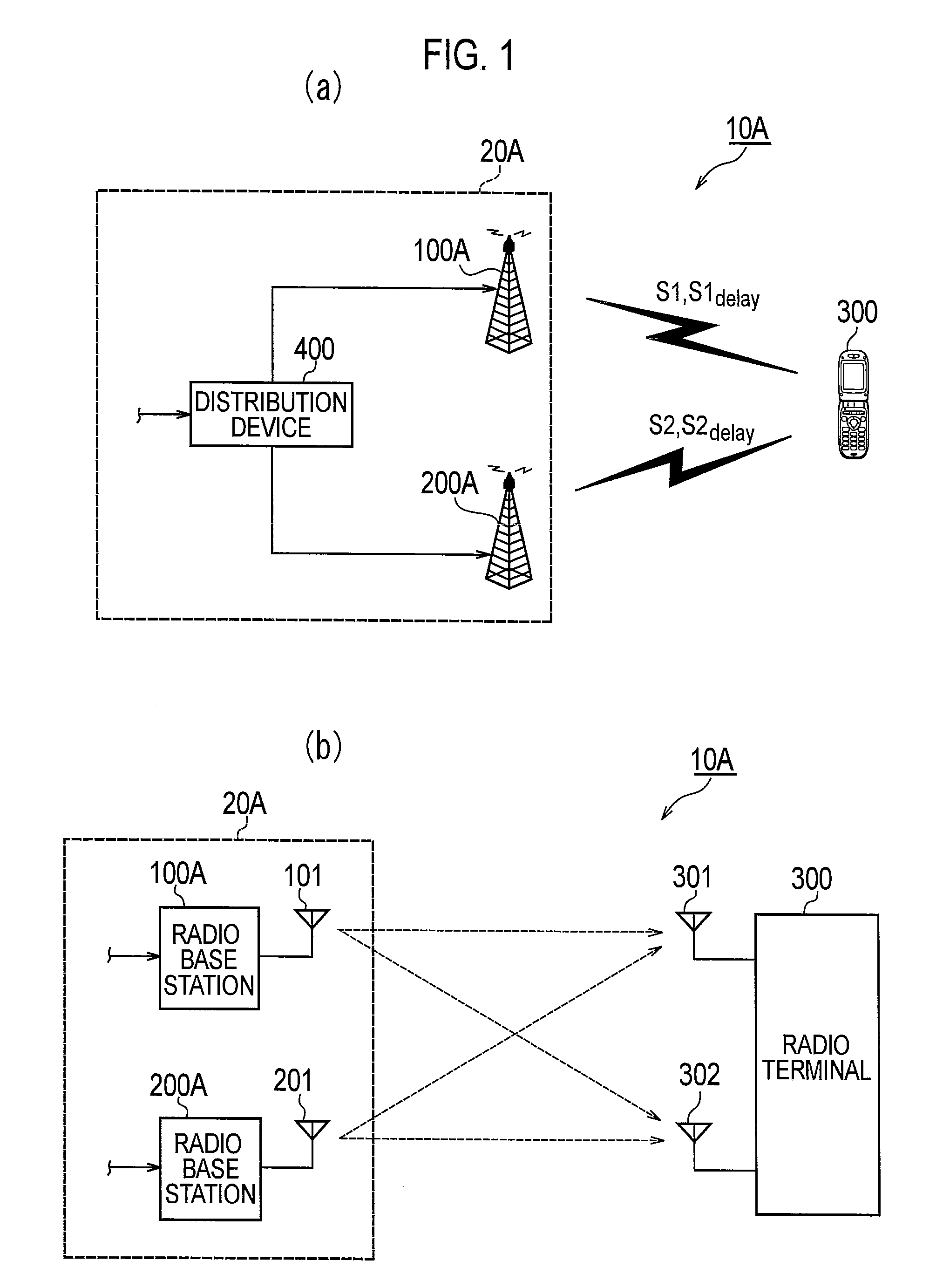

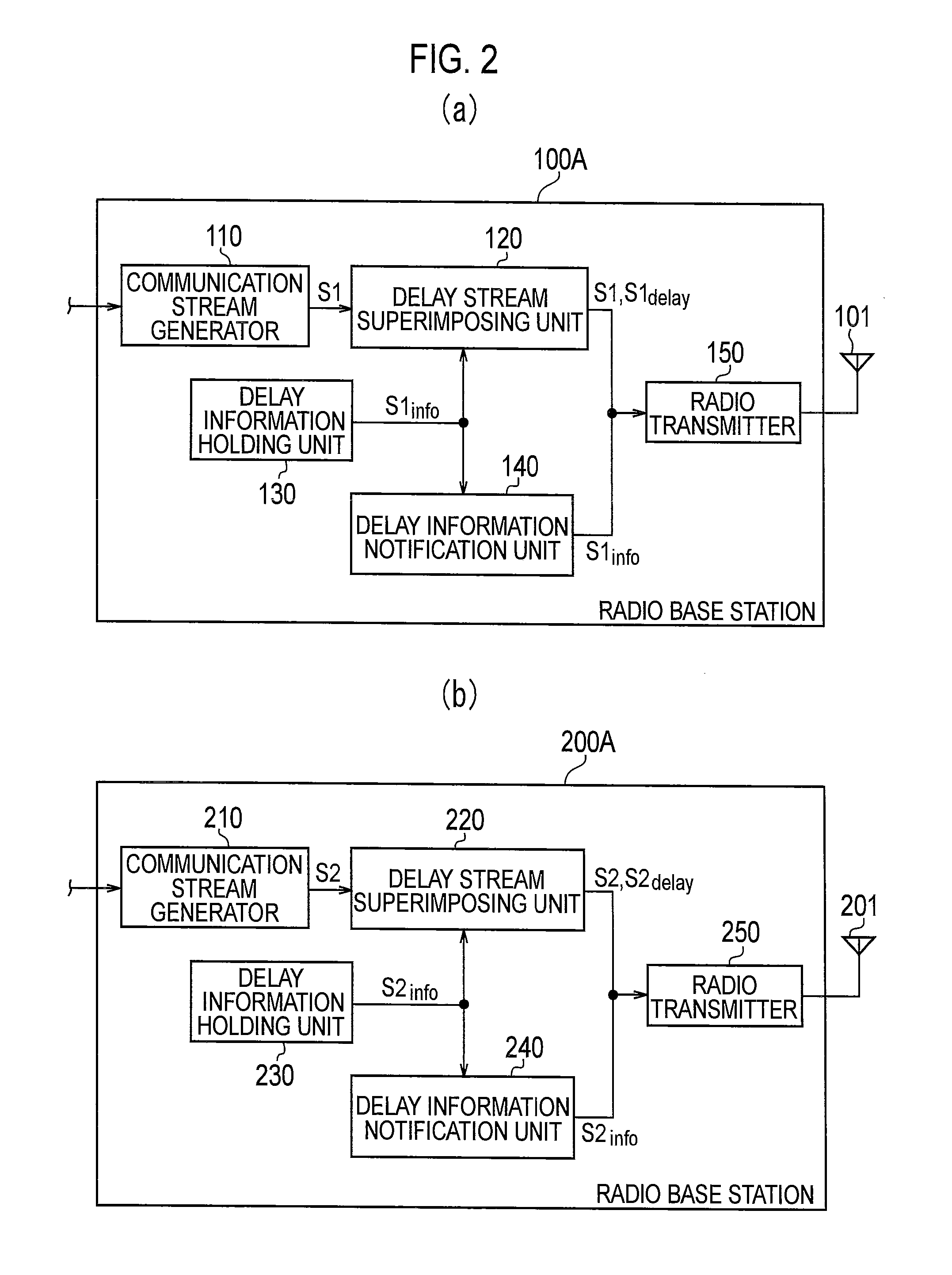

Radio communication system, transmission system, radio terminal and radio communication method

InactiveUS20110223948A1Improving signal separation performanceEasy to separateSubstation equipmentRadio transmissionCommunications systemTransfer system

A radio communication system (10A) has a transmission system (20A) and a radio terminal (300). The transmission system (20A) superimposes and transmits a delay stream (S1delay) and a communication stream (S1), and superimposes and transmits a delay stream (S2delay) having a different delay than the delay stream (S1delay) and a communication stream (S2). A transmission system (20A) notifies delay information (S1info) about the delay stream (S1delay) and delay information (S2info) about the delay stream (S2delay). The radio terminal (300) combines the communication stream (S1) and the delay stream (S1delay) in accordance with the notified delay information (S1info), and combines the communication stream (S2) and the delay stream (S2delay) in accordance with the notified delay information (S2info).

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com