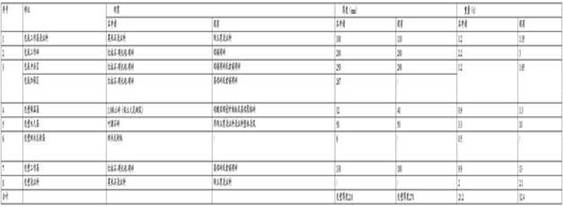

Patents

Literature

49results about How to "Large temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

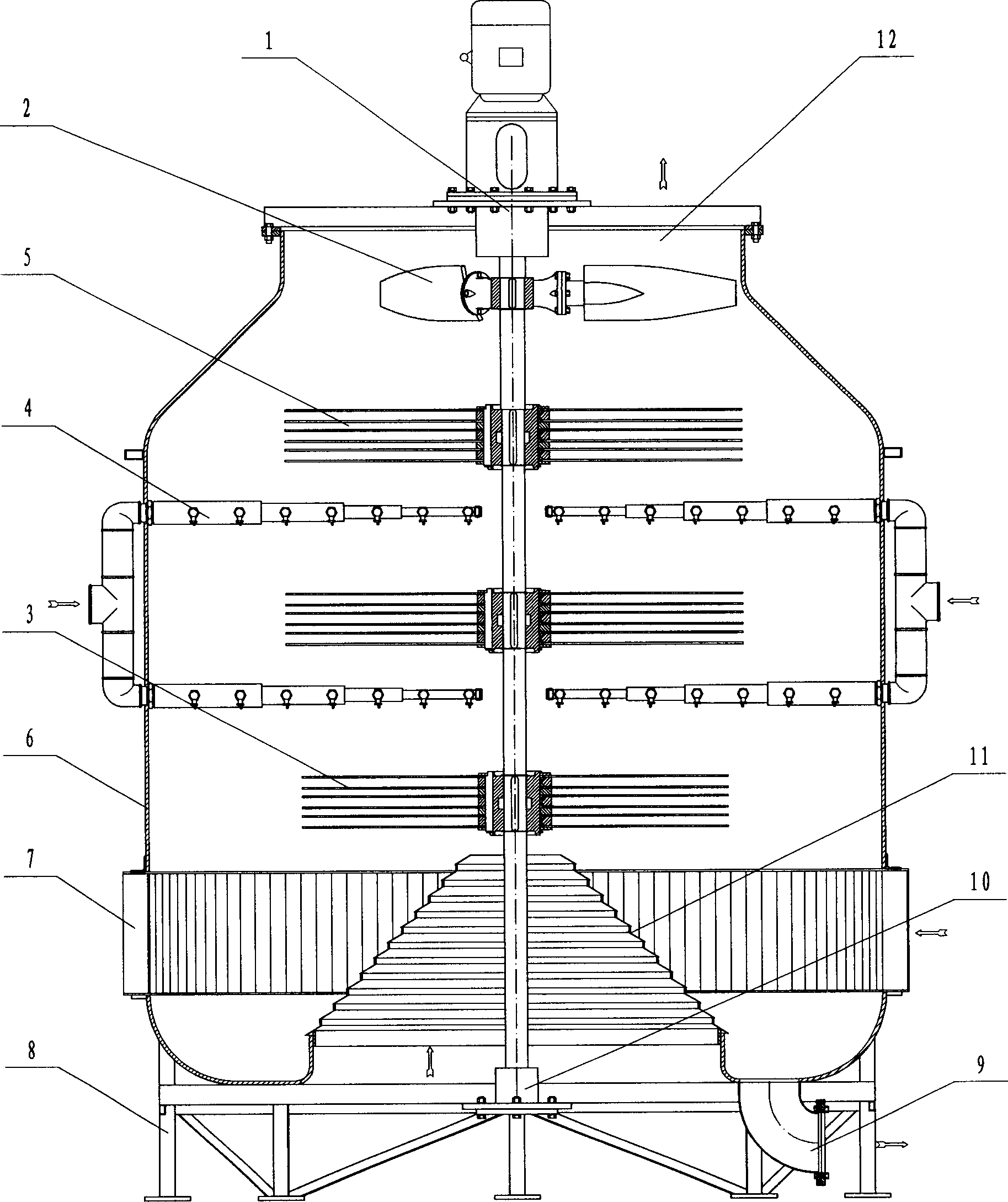

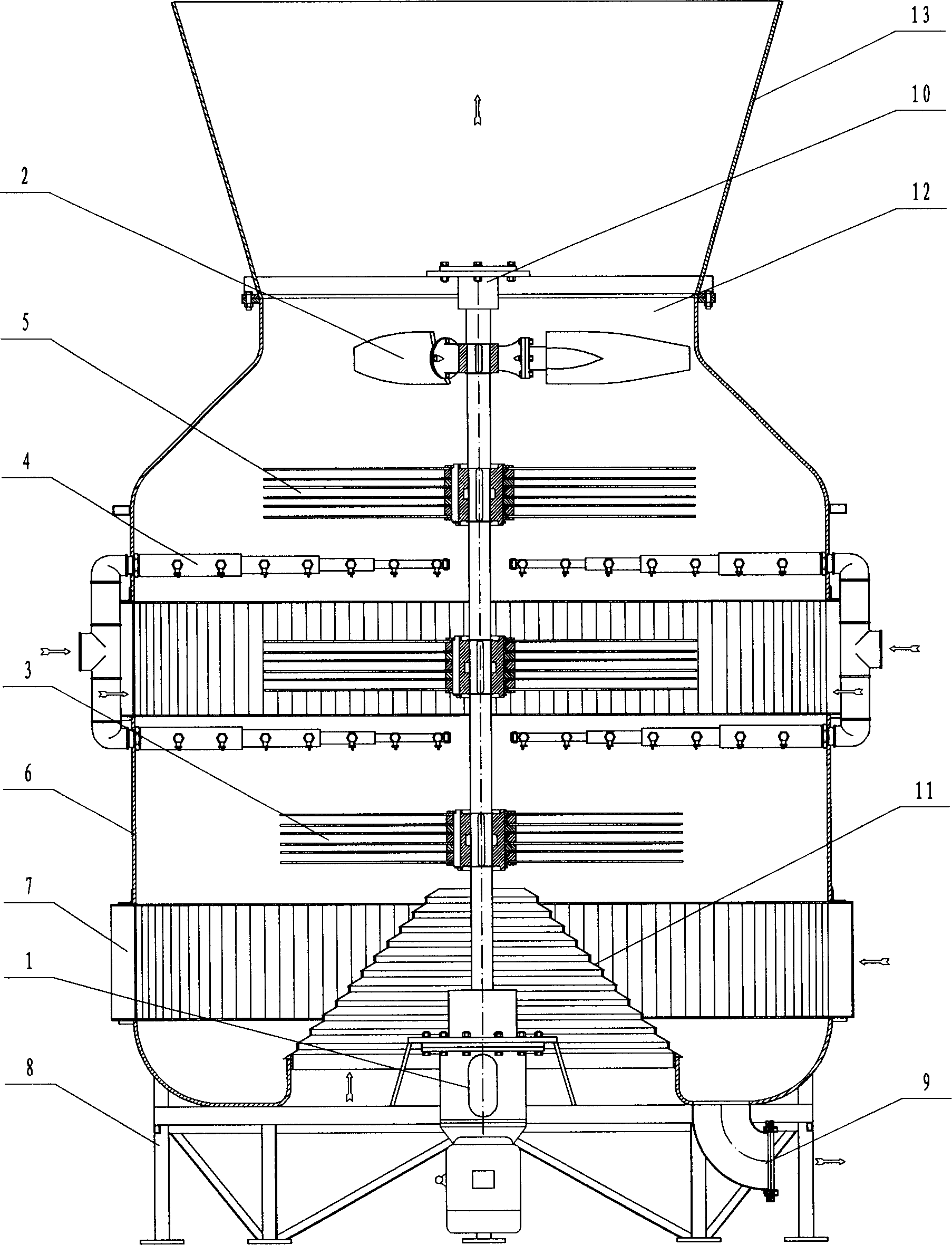

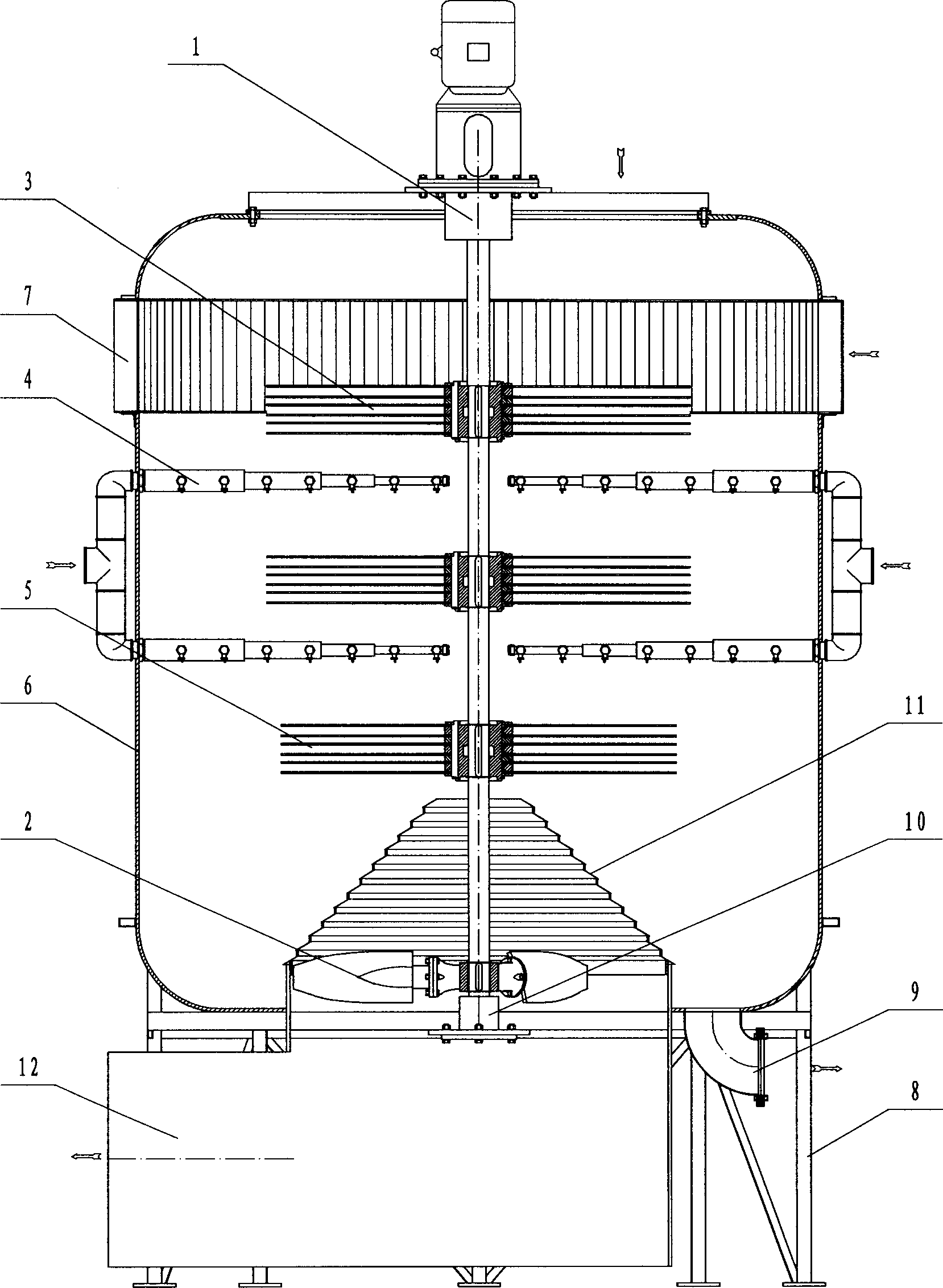

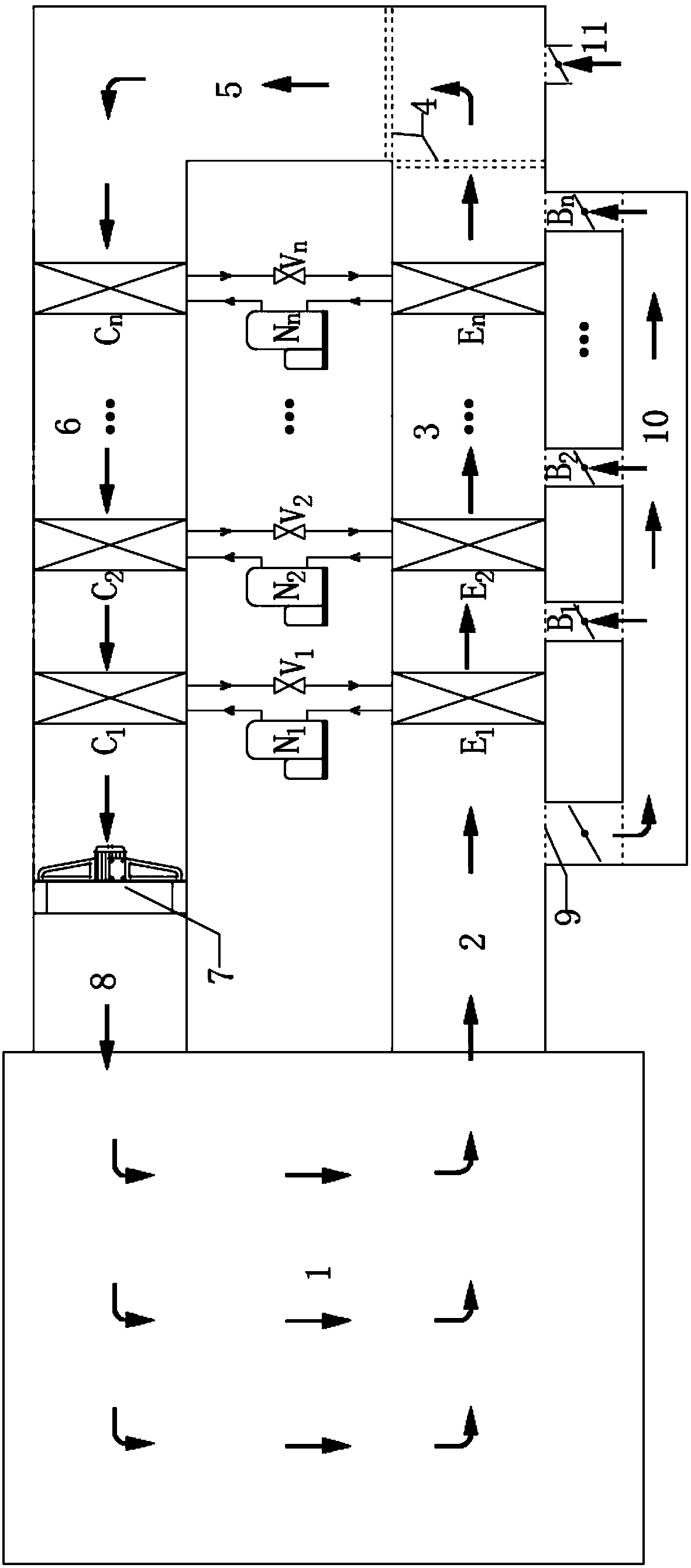

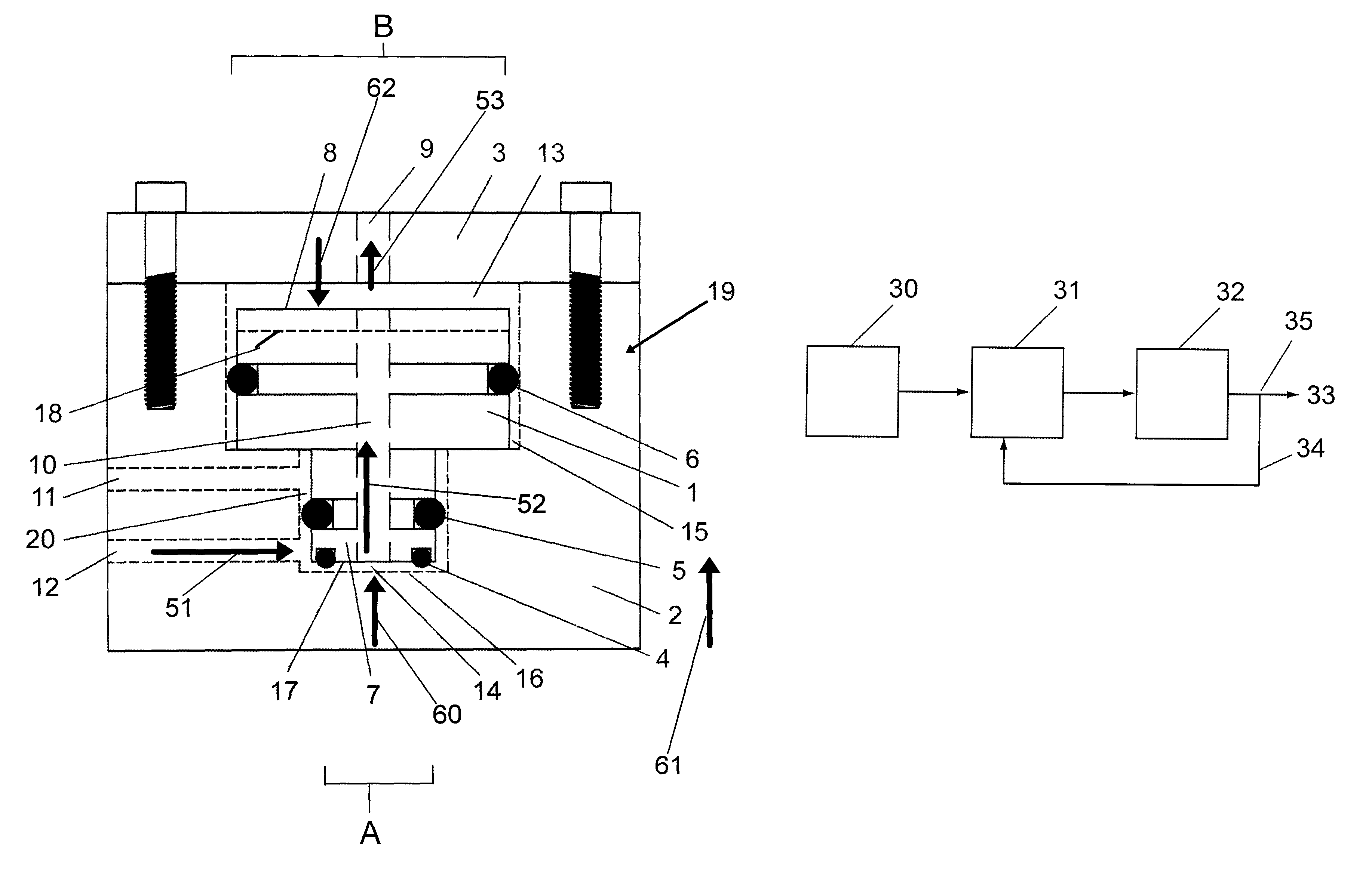

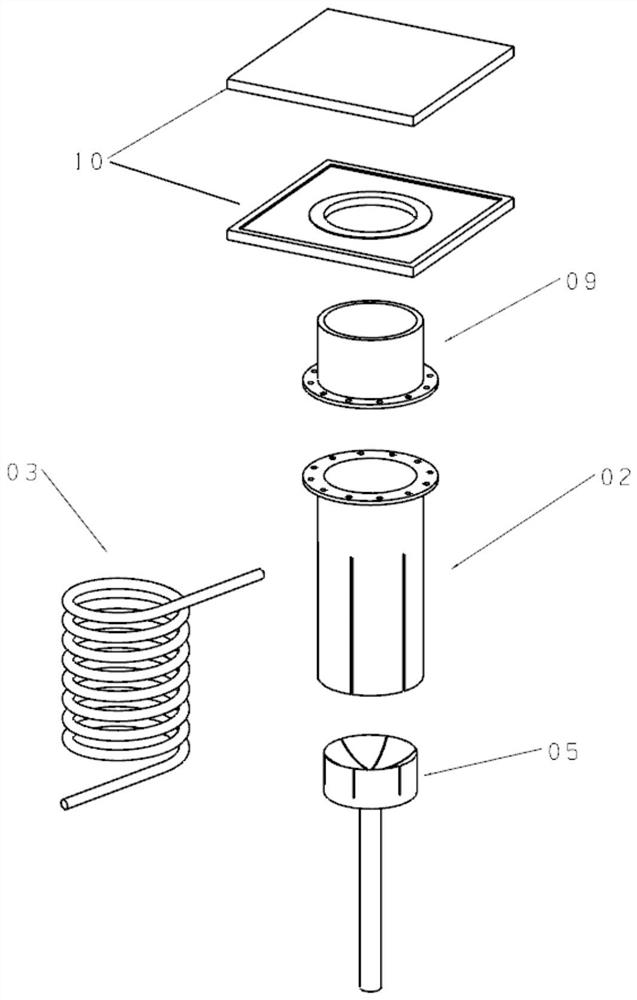

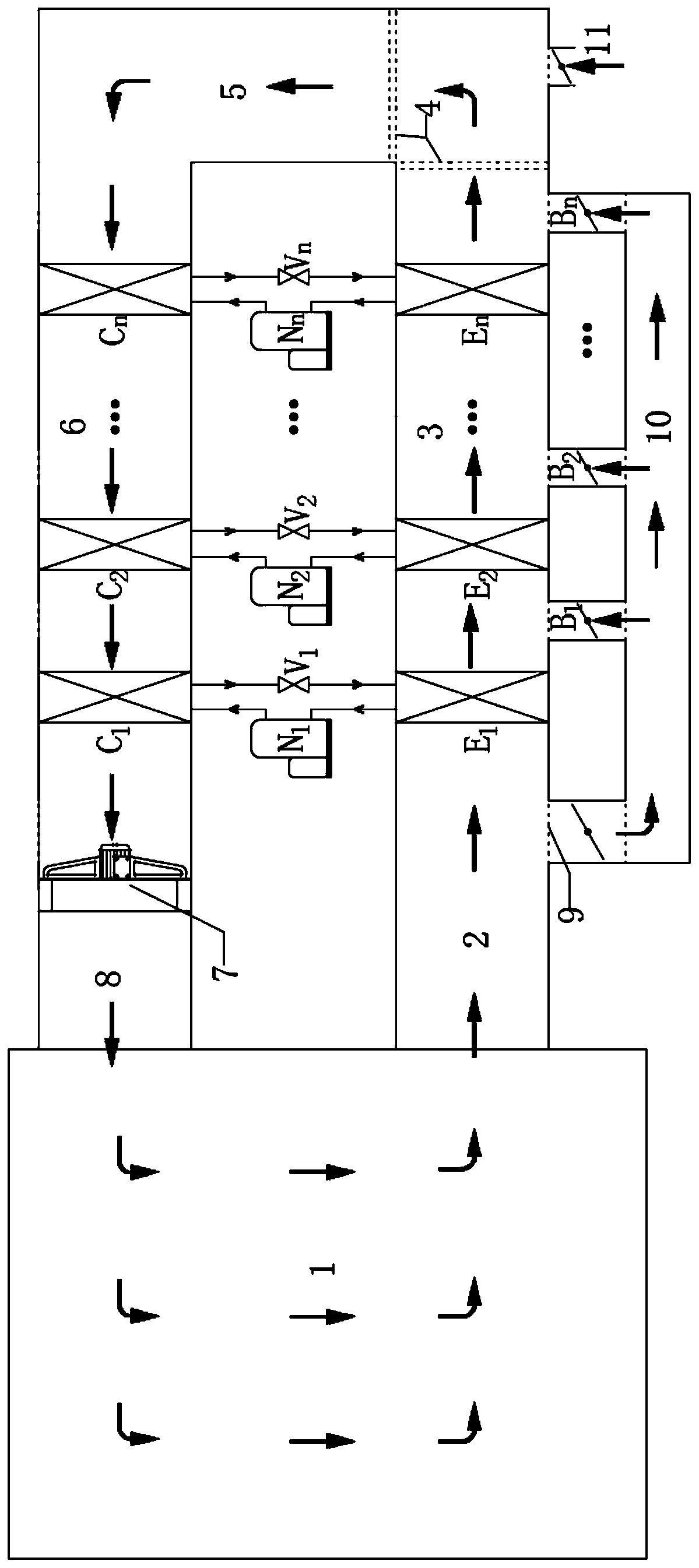

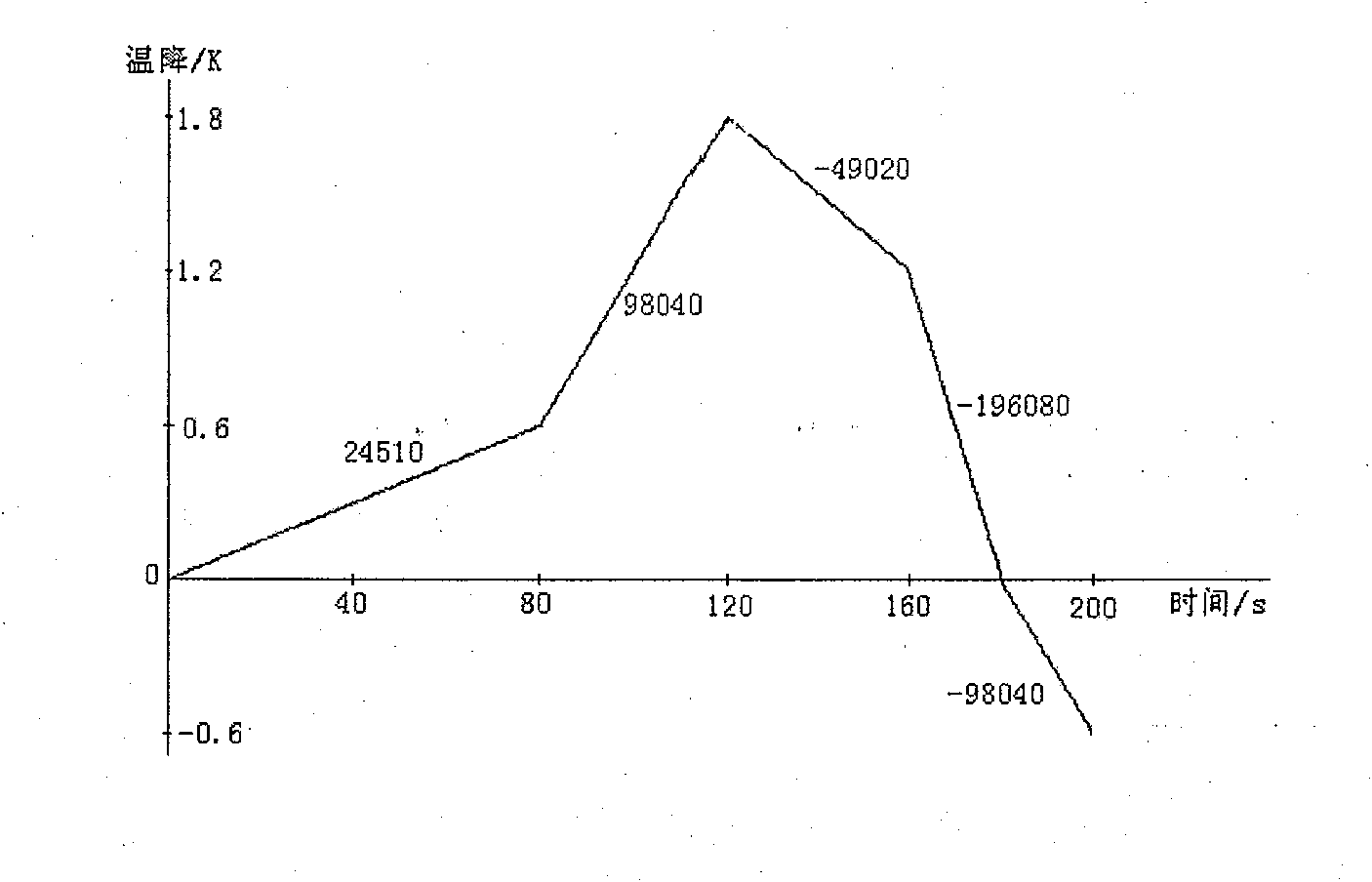

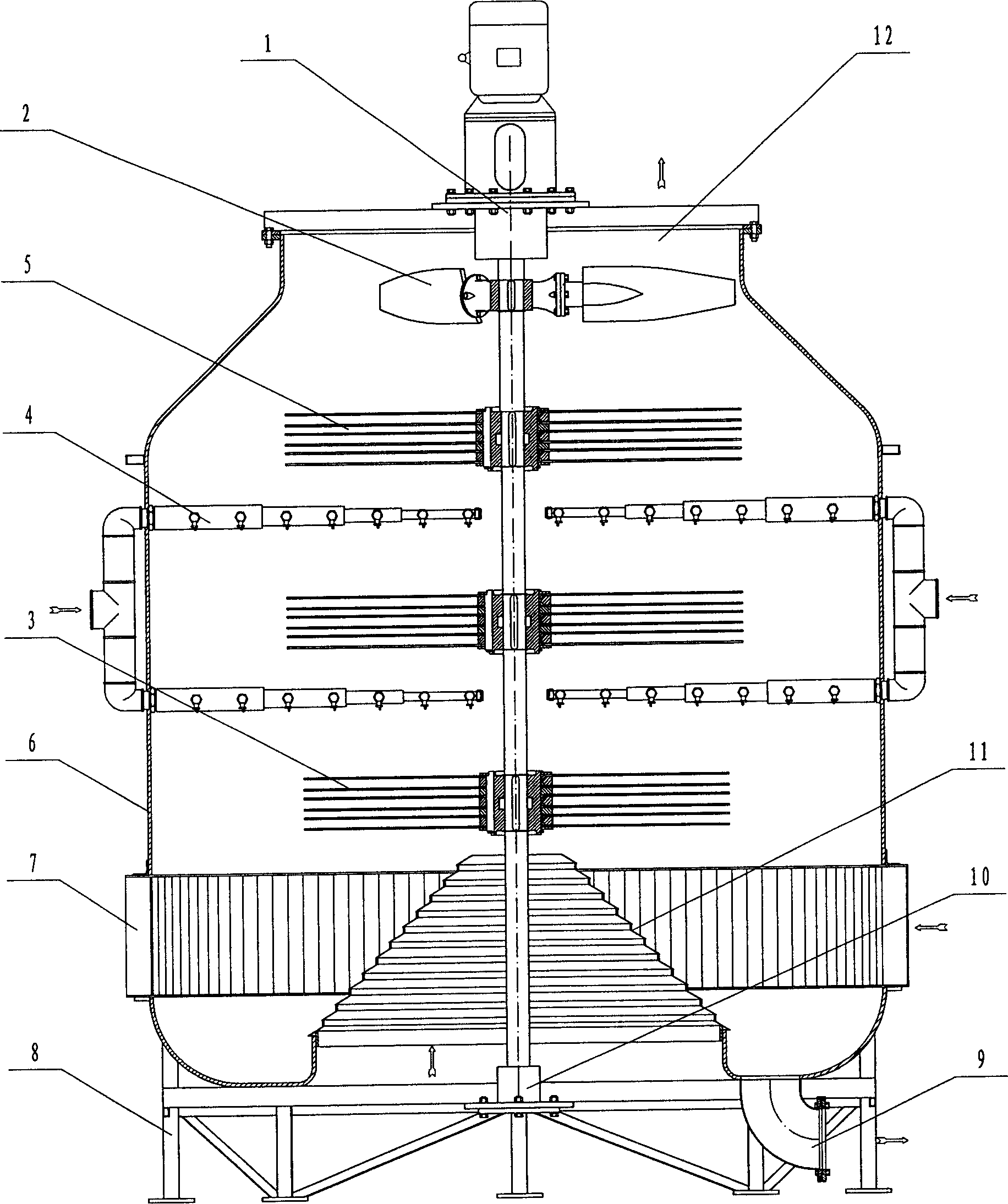

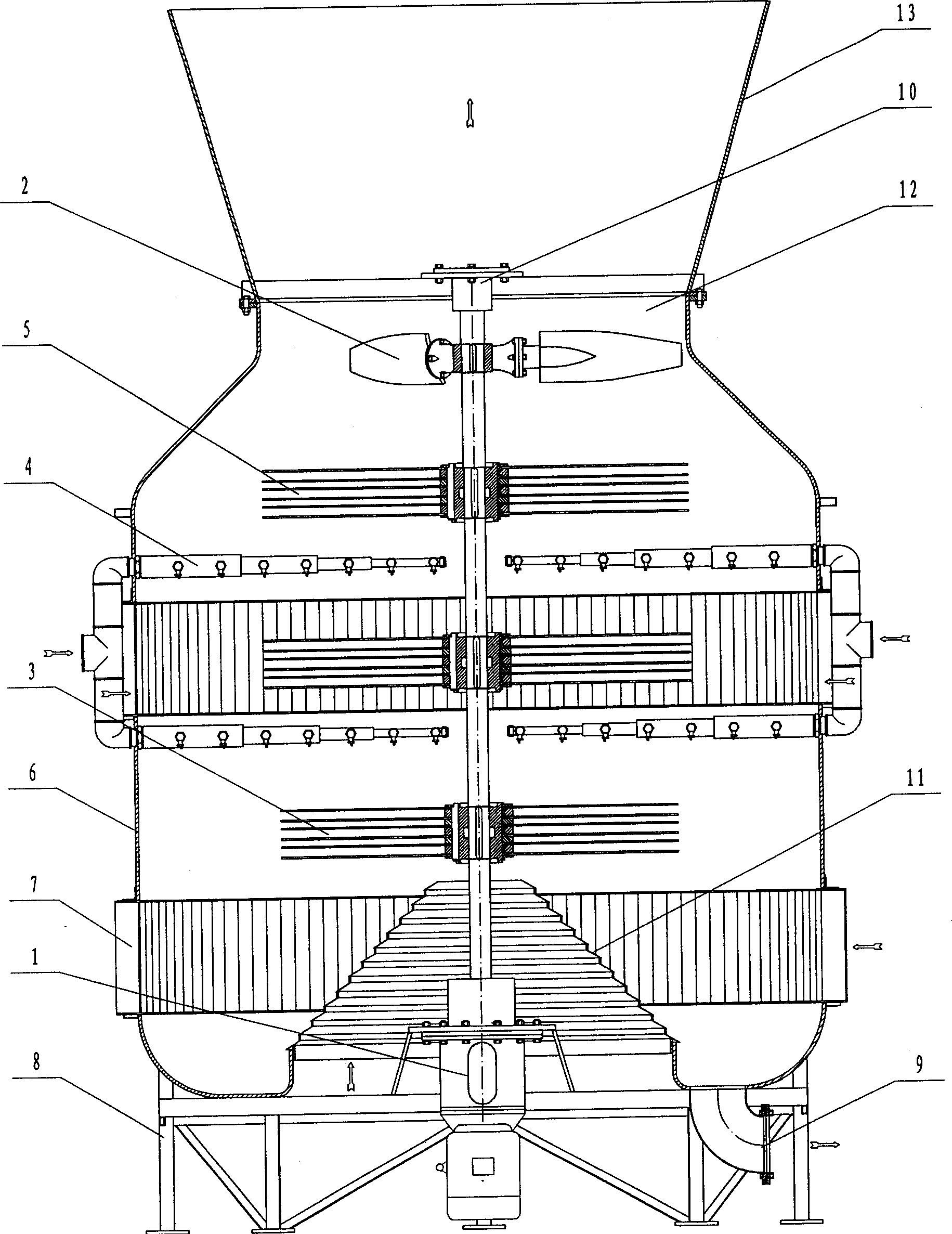

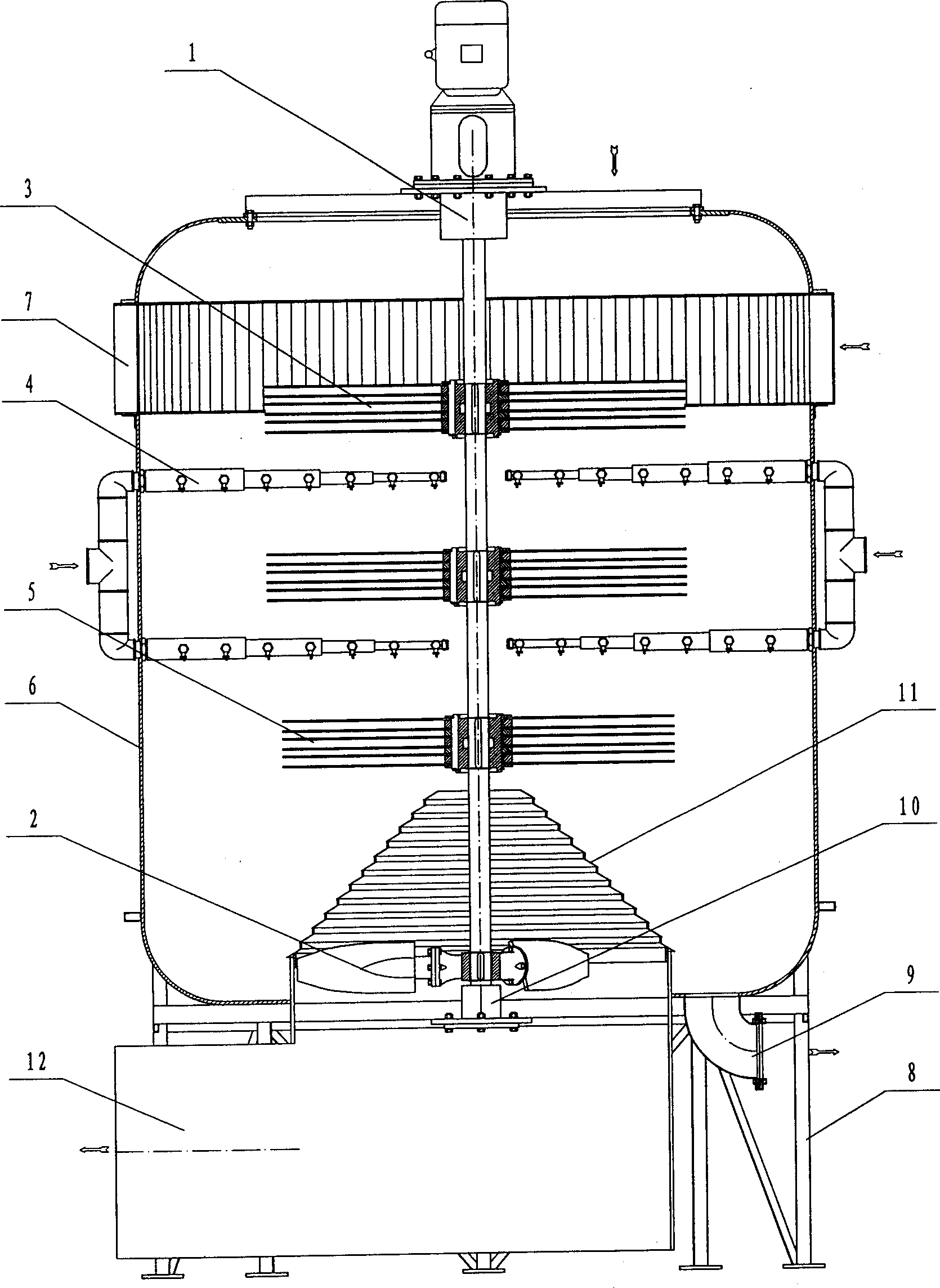

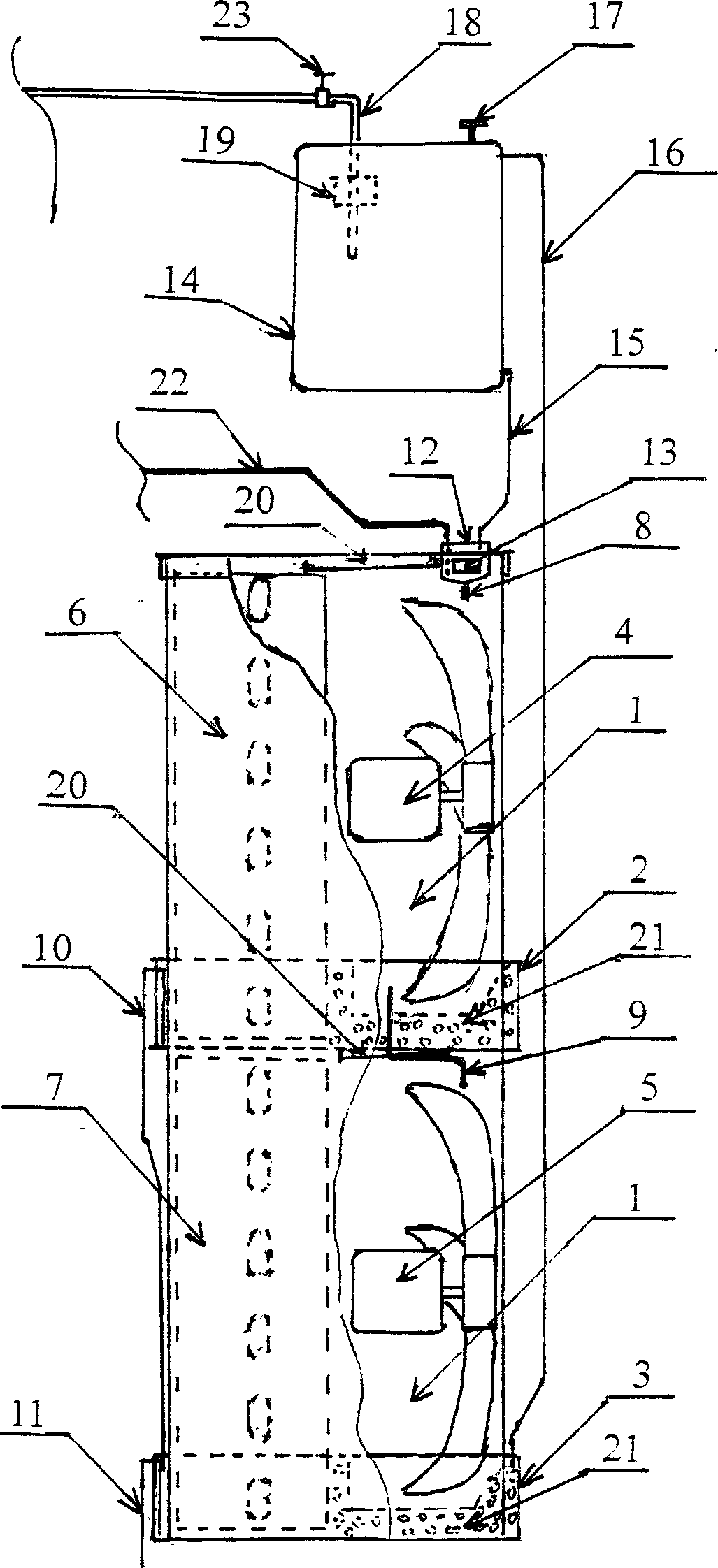

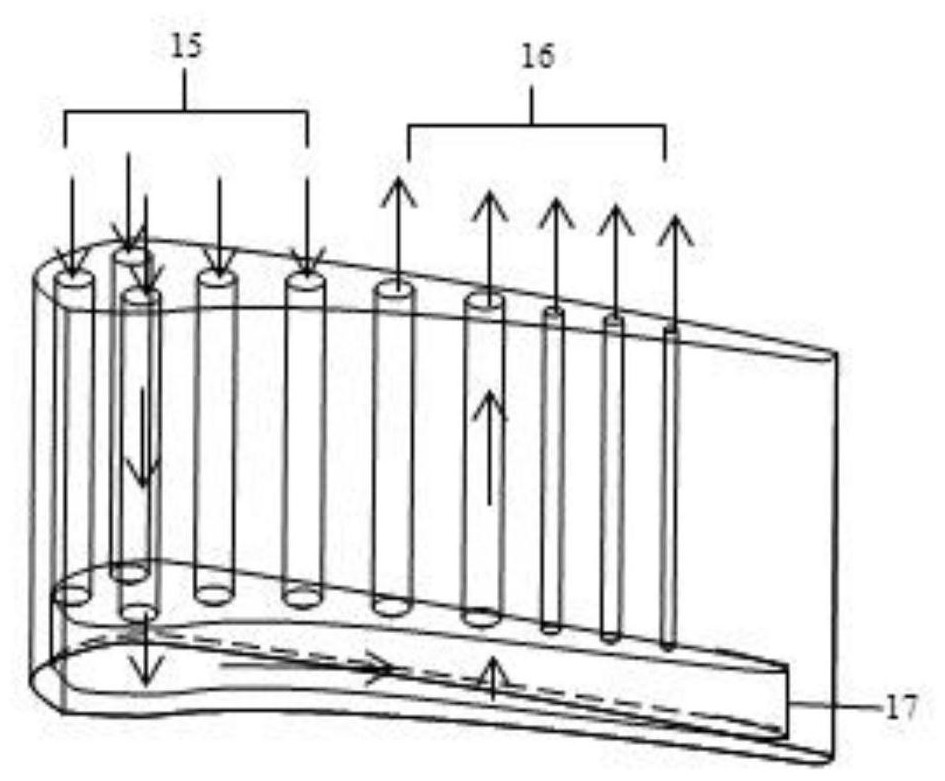

Cyclone cooling method and cooling tower

The cooling tower contains the dispersed pinwheels (3) being piled in layers or the defogging pin wheels (5), the liquid blasting unit sandwiched in-between and without any fillers (4). The pinwheel contains radiating layered thin needle pin (15). The rotary thin needle pins form the rotational flow with consistent argular speed. The specific surface area of the fluid beads and the degree of evendistribution are increased through the decentralization of the nozzles, the rotational flow and the collision between the fluid beads and the thin needle pins. The rotational flow further increases the speed of centripetal heat transfer to increase heat dissipation effect and intensity so as to make the heat dissipation course be flattened and radial. The layered pinwheels and sprinkles and the crossing current cooling of the tower body increase

Owner:高根树

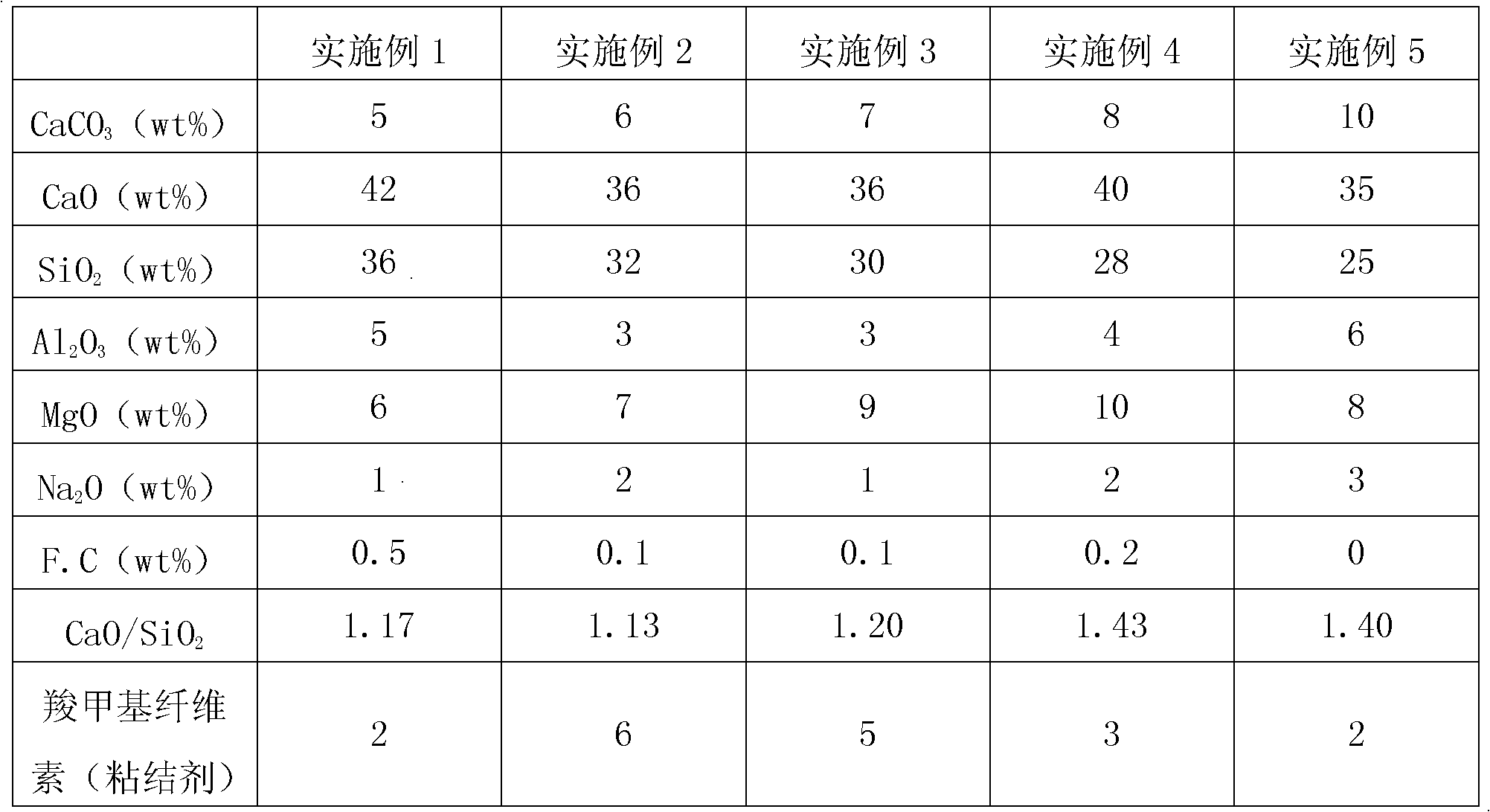

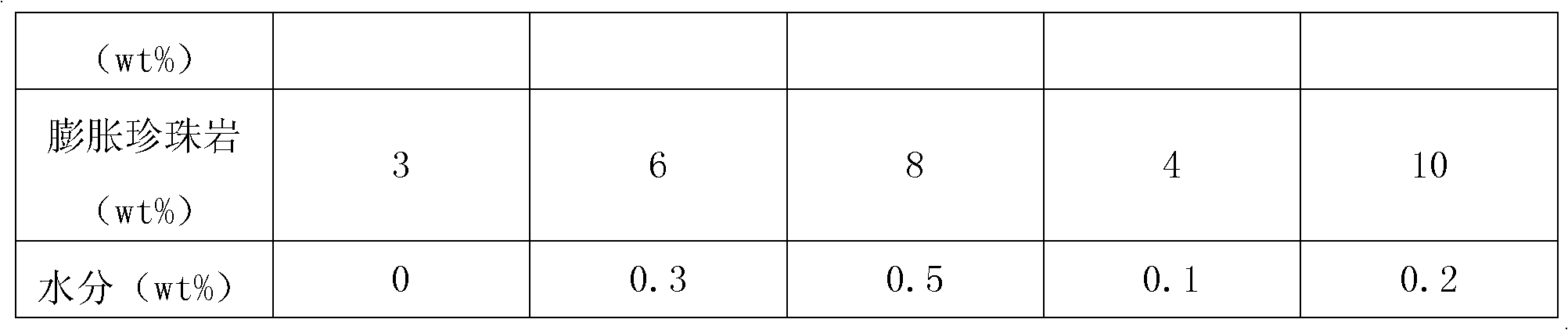

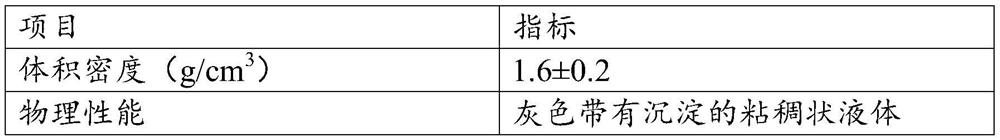

Tundish covering flux

The invention discloses a tundish covering flux, which comprises the following components by mass: 5-10% of CaCO3, 60-80% of CaO+SiO2, 3.0-6.0% of Al2O3, 6.0-10.0% of MgO, 1.0-3.0% of Na2O, 0-0.5% of fixed carbon, 0-10.0% of lightweight bulk material, 2-6.0% of binder, 0-0.5% of water and the balance of inevitable impurities, wherein the ratio of CaO to SiO2 is 1.1-1.5. The tundish covering flux is added into molten steel, and then a three-layer structure comprising a slag formation layer, a sintering layer and a melting layer is formed on the molten steel. The tundish covering flux does not incrust in a using process, and has a proper melting point, spreadability and high heat-preservation performance; and the excessive temperature drop of the molten steel in a tundish can be prevented, and a slag crust is prevented from being formed on the surface of the molten steel.

Owner:BAOSHAN IRON & STEEL CO LTD +1

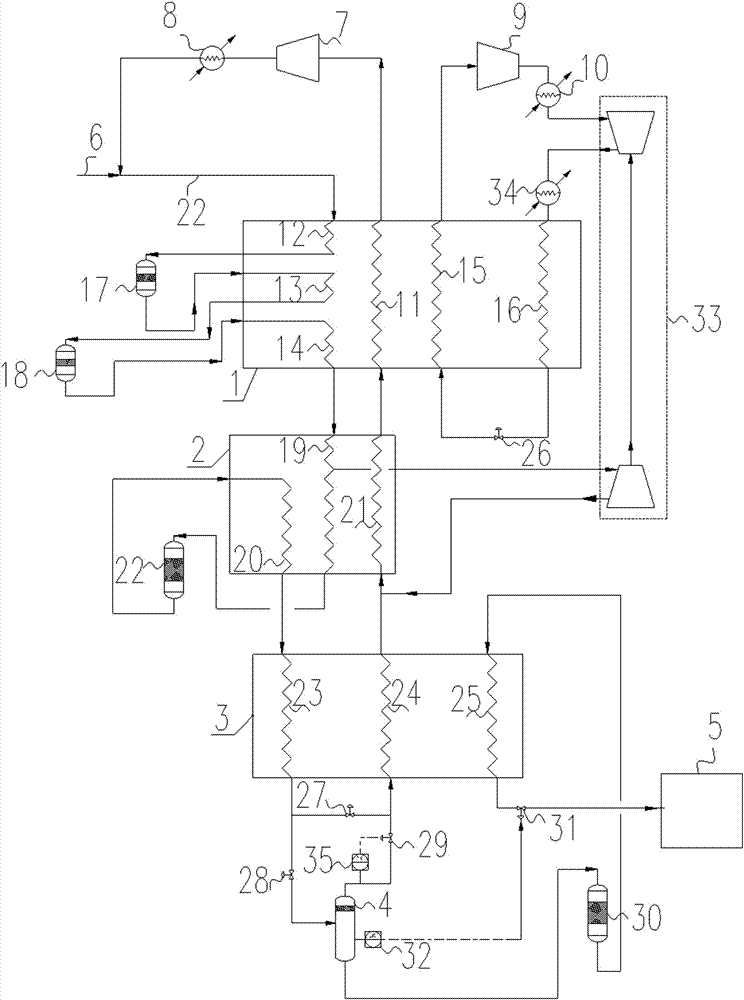

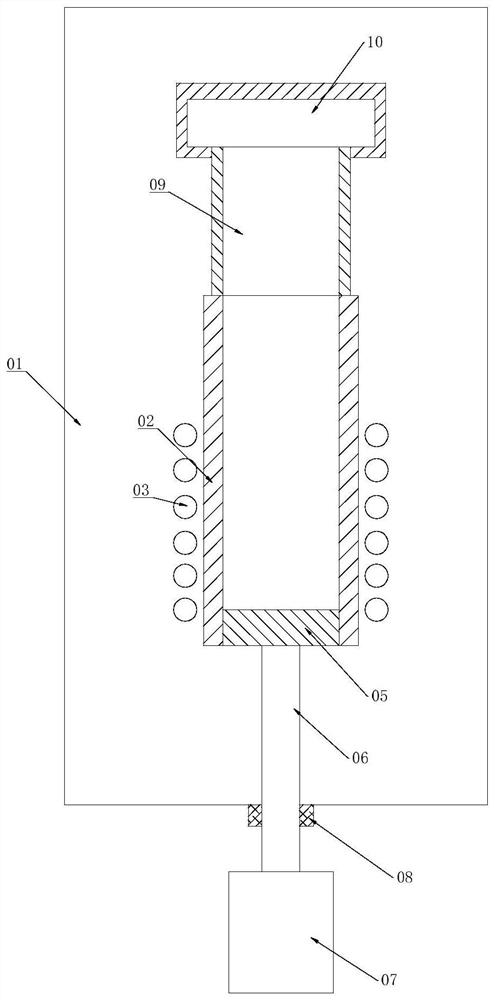

Hydrogen liquefying device and method

ActiveCN107014151AReduce energy consumptionSimple processSolidificationLiquefactionLiquid hydrogenChemistry

The invention discloses a hydrogen liquefying device. The hydrogen liquefying device comprises a hydrogen intake pipe, a heat exchanger A, a heat exchanger B, a heat exchanger C, a flash tank and a liquid hydrogen storage tank for communicating in sequence. The invention further discloses a hydrogen liquefying method, comprising the following steps: (S1) hydrogen is precooled; (S2) orthohydrogen and parahydrogen are converted and liquefied; (S3) one part of liquid hydrogen serves as supercooled gas to input back into the heat exchanger C; (S4) hydrogen steam and the liquid hydrogen are separated by the flash tank; and the liquid hydrogen is prepared and stored; and (S5) unliquefied hydrogen is recovered. The hydrogen liquefying method is simple in flow, flexible in adjustment, reliable in work, convenient to maintain and low in energy consumption.

Owner:四川蜀道装备科技股份有限公司

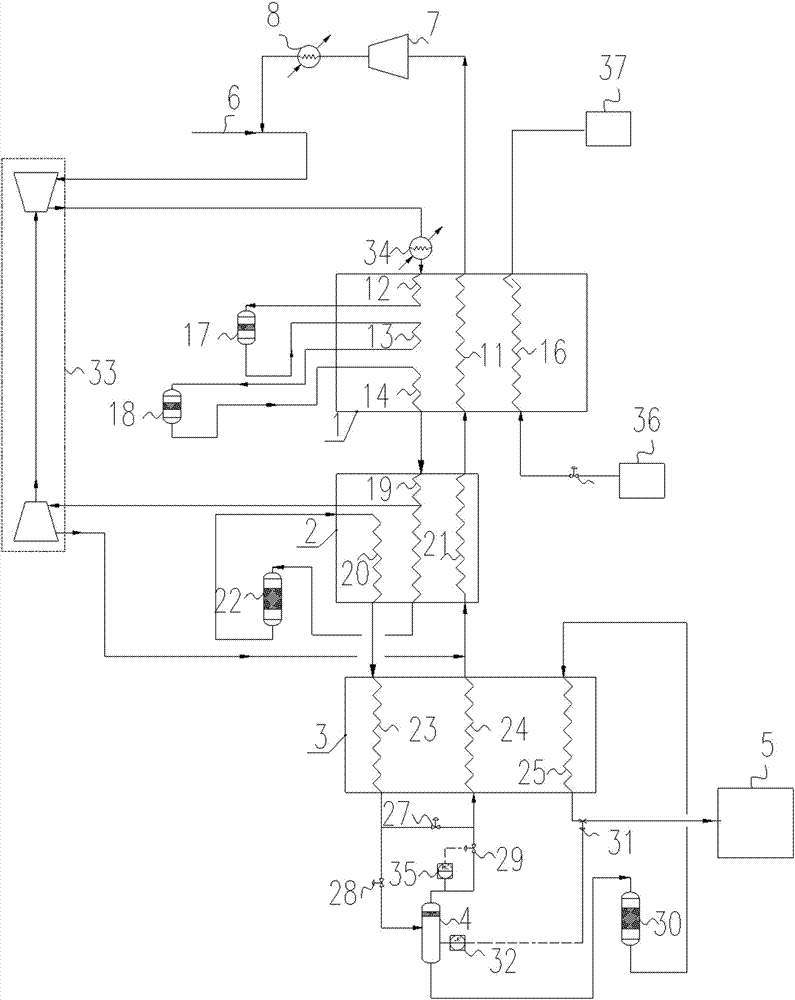

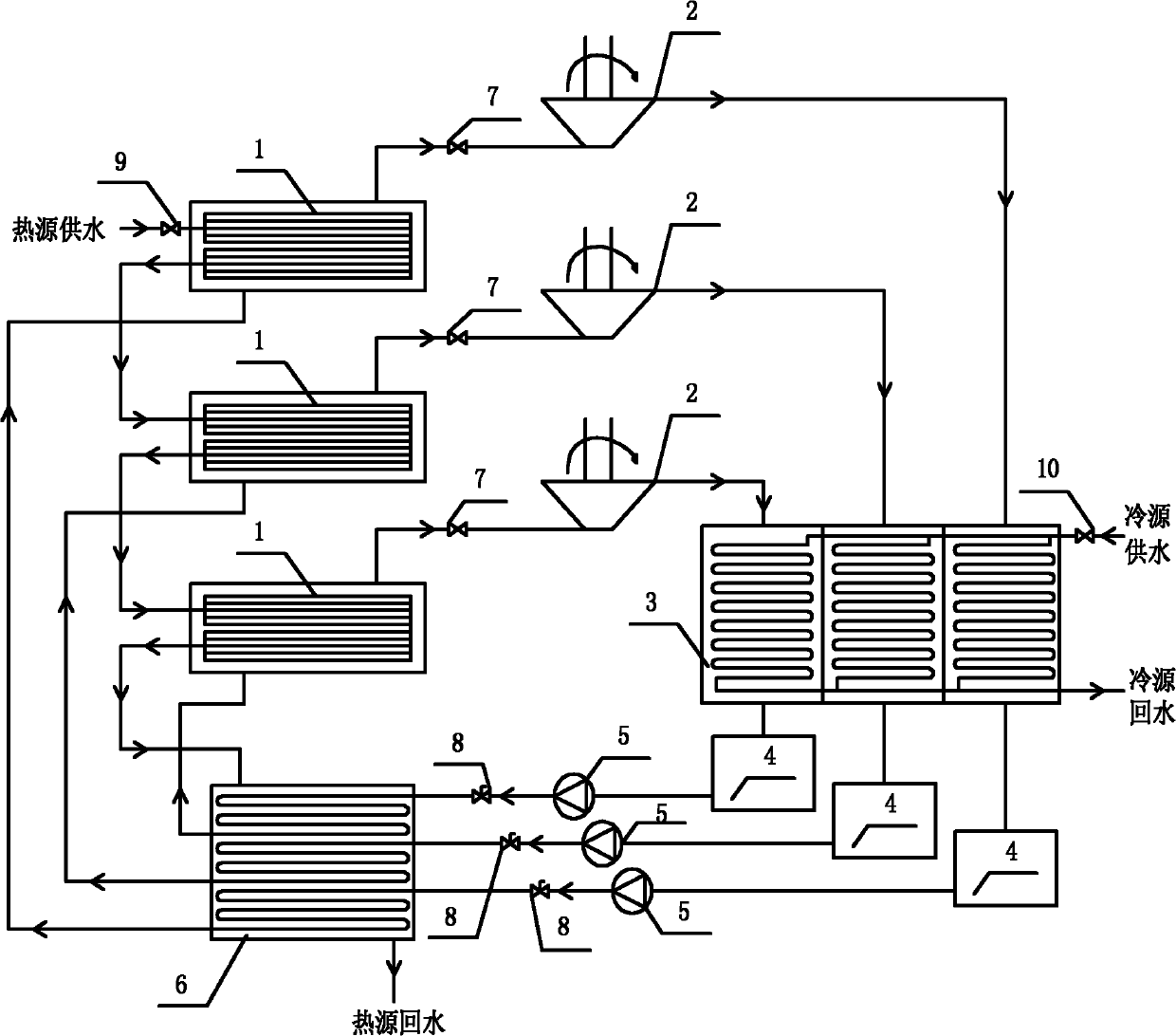

Screw cascade waste heat energy generating device and generating method

InactiveCN101994532AImprove heat transfer coefficientImprove heat transfer effectSteam engine plantsEngineeringCheck valve

The invention discloses a screw cascade waste heat energy generating device and a screw cascade waste heat energy generating method. The device comprises at least one stage of generator sets, and each stage of generator sets comprises a flooded evaporator, a shell and tube preheater, a reservoir, a condenser and a screw expansion machine, wherein a shell pass outlet of the shell and tube preheater is communicated with the tube pass of the flooded evaporator, and a tube pass outlet of the shell and tube preheater is communicated with the shell pass of the flooded evaporator; an opening at the bottom of the reservoir is communicated with a tube pass inlet of the shell and tube preheater through a circulating pipeline on which a working medium circulating pump and a check valve are arranged; the condenser is connected above the reservoir; and a rotating shaft of the screw expansion machine is connected with a rotating shaft of a synchronizing generator, a shell pass outlet of the flooded evaporator is connected with an inlet of the screw expansion machine through a pipeline on which a flow regulating valve is arranged, and an outlet of the screw expansion machine is communicated with the shell pass of the condenser. By using the device and the method, the heat power generation with large temperature drop at low temperature is realized, and the conversion efficiency of low-temperature heat energy is improved.

Owner:TIANJIN UNIV

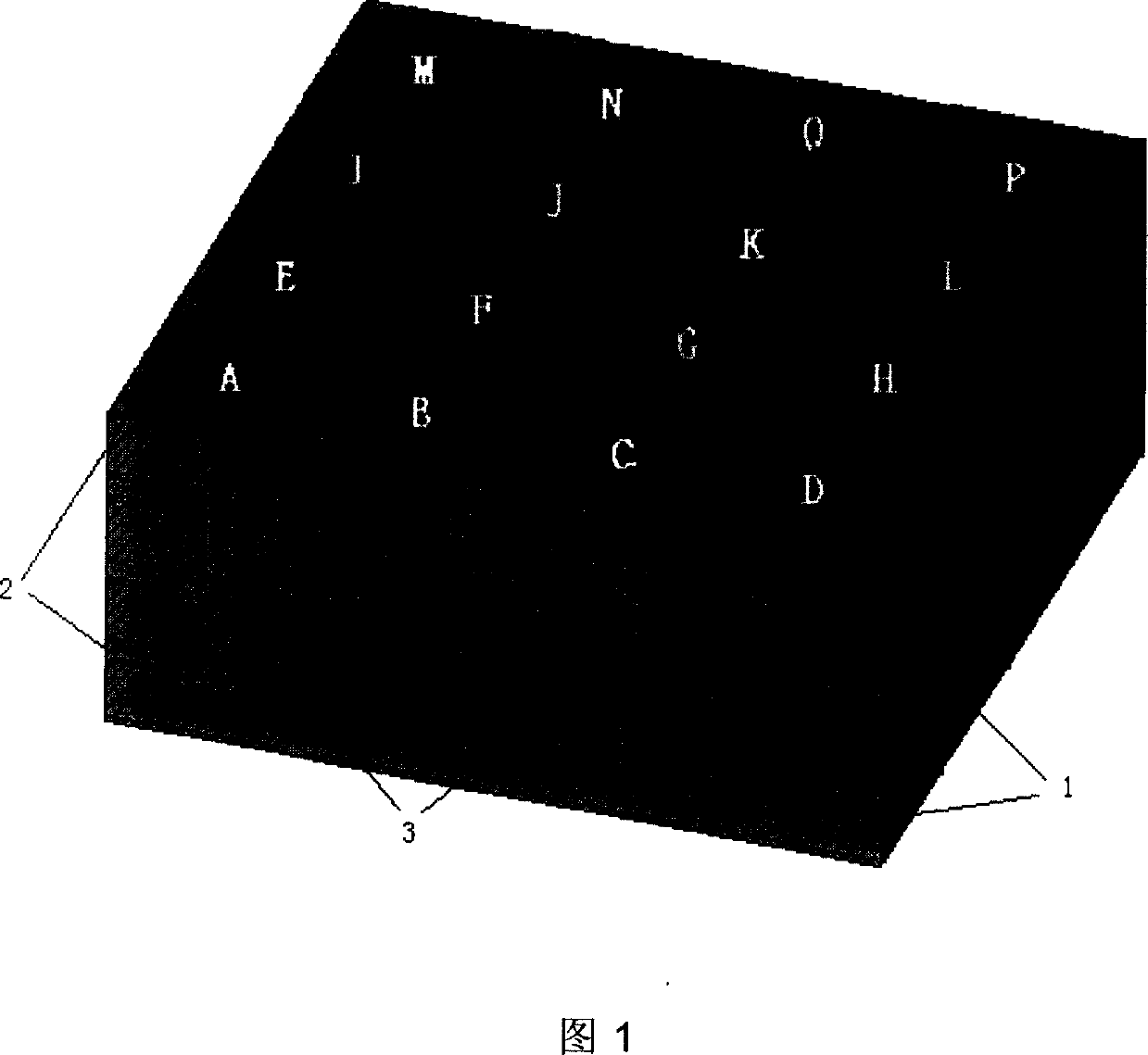

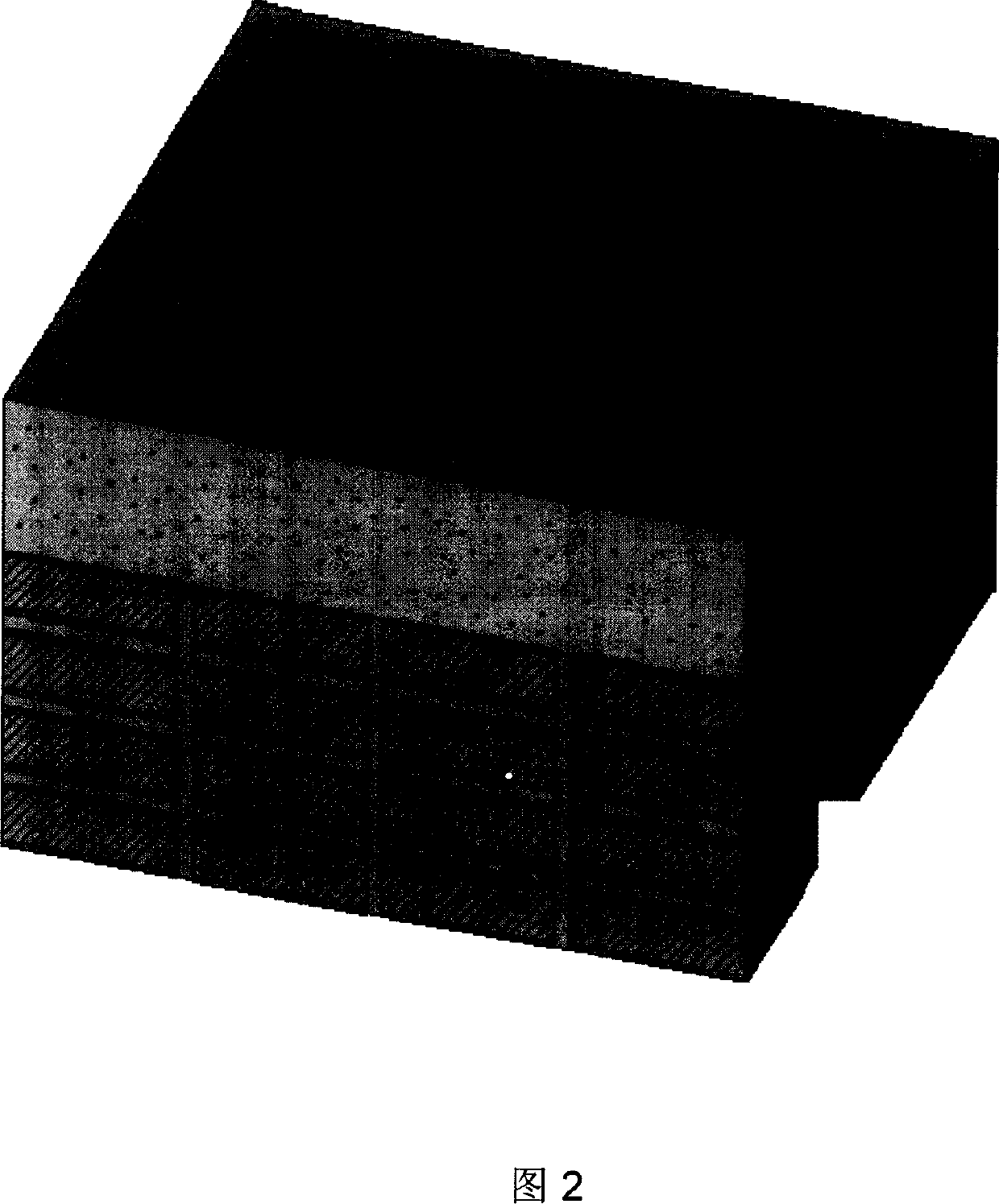

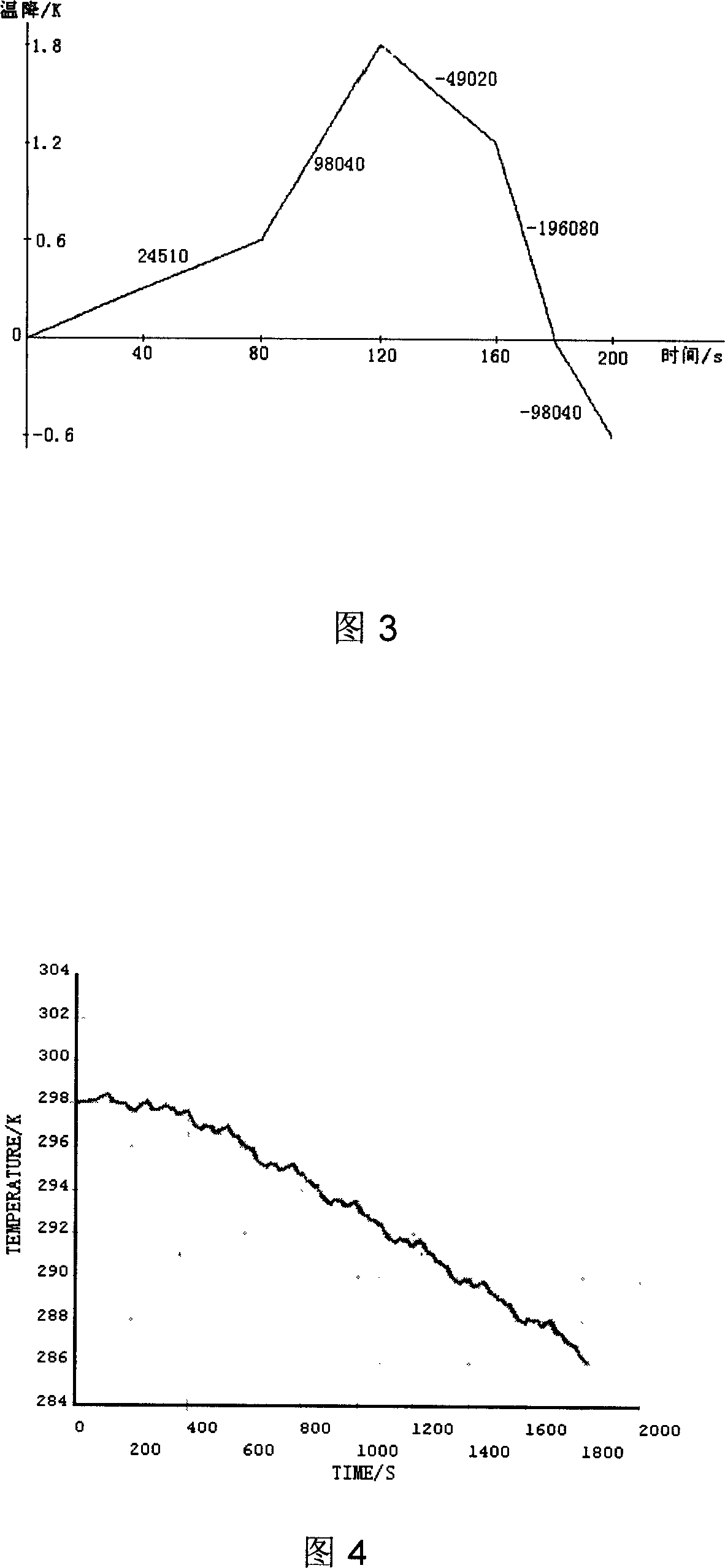

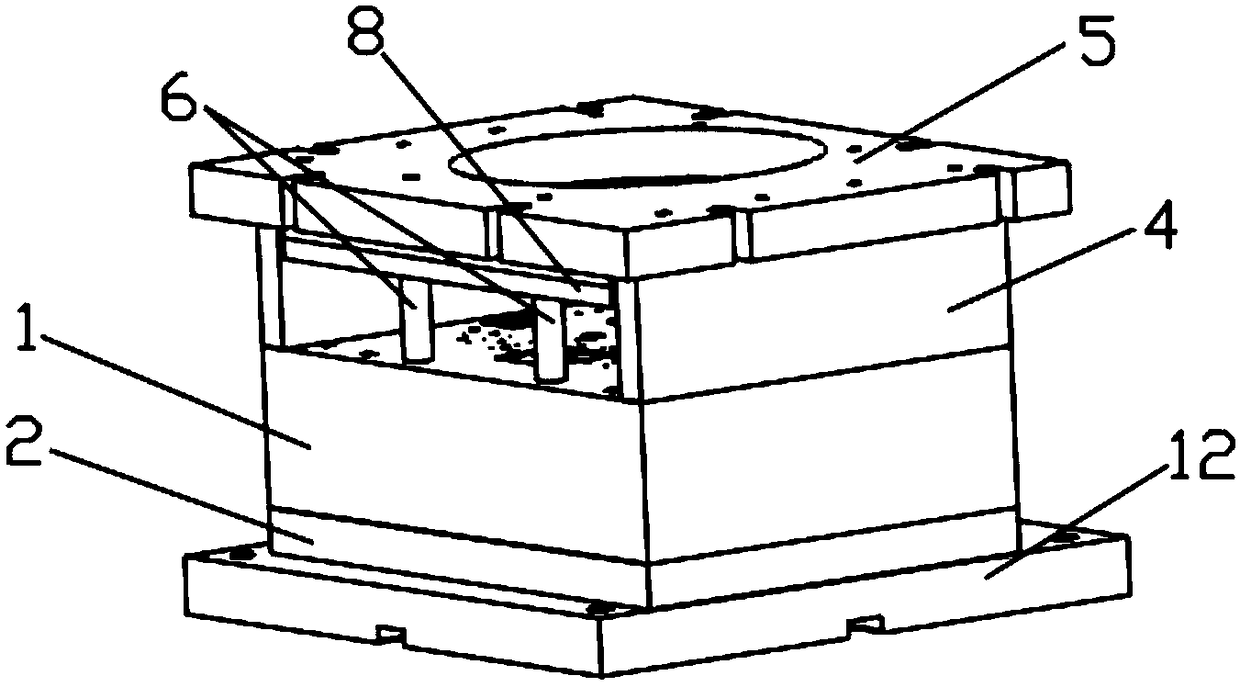

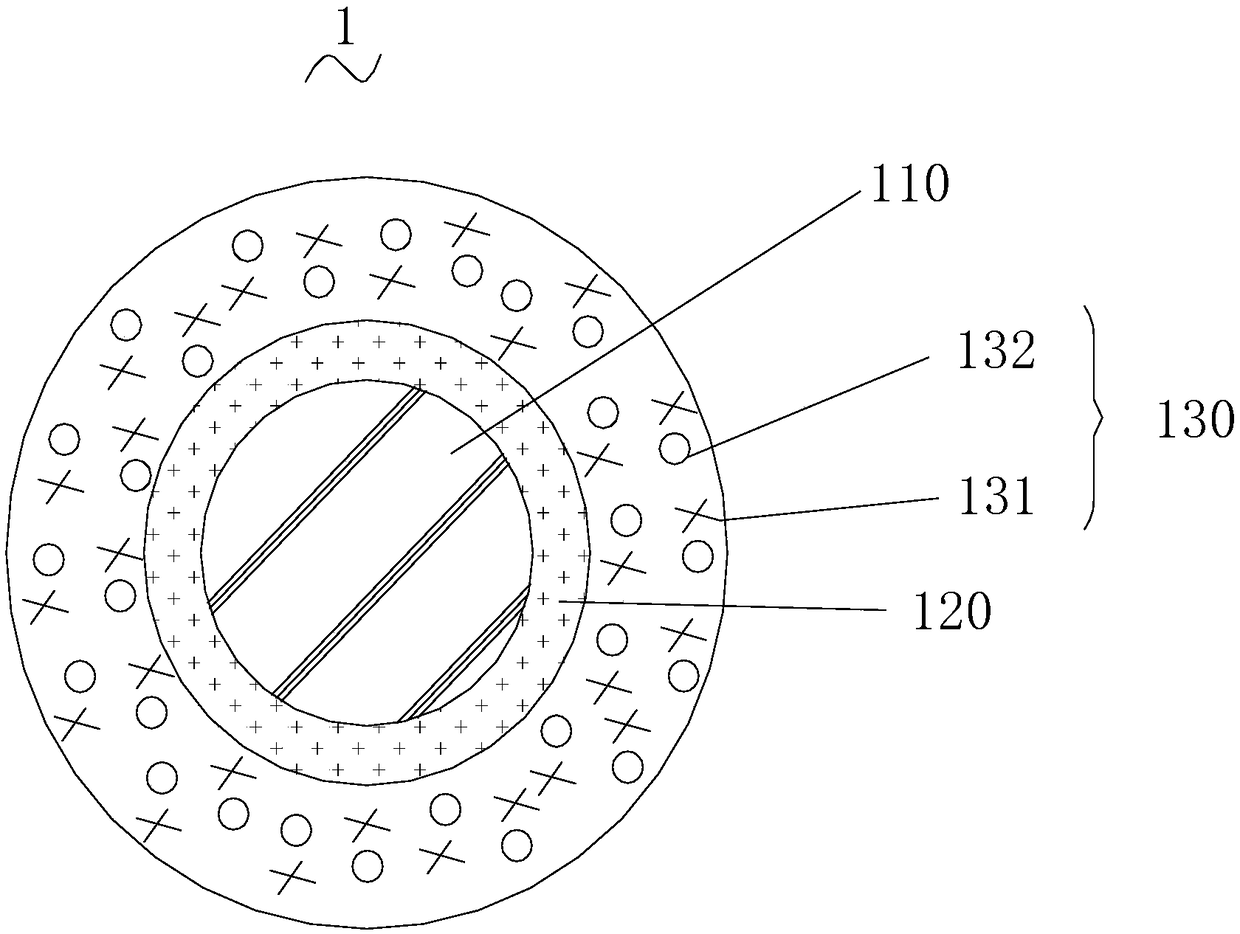

Micro refrigerator and refrigeration method

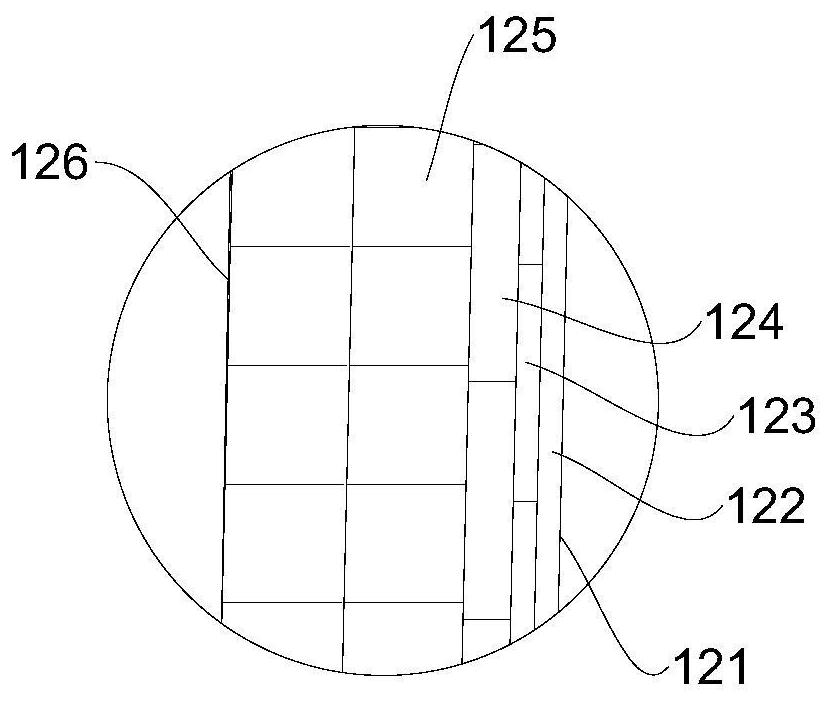

InactiveCN1760605AAchieve large temperature dropGood spatial temperature distribution uniformityEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringRefrigeration

A micro - refrigerator is prepared as applying relaxation ferroelectric material as working media of refrigeration , using n layers of ferroelectric stacks and m x 1 arrays of ferroelectric stacks as sum of n x m x 1 units to form micro ¿C refrigerator . Its refrigerating method includes applying phase transition refrigeration of electric field induction as quickly adding electric field and slowly putting off electric field on each refrigerating sheet (RS), using the same working mode in the same layer or in each interval layer of RS in different line, using specific time sequence and circulation for each layer of RS and operating ferroelectric stack arrays alternatively.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

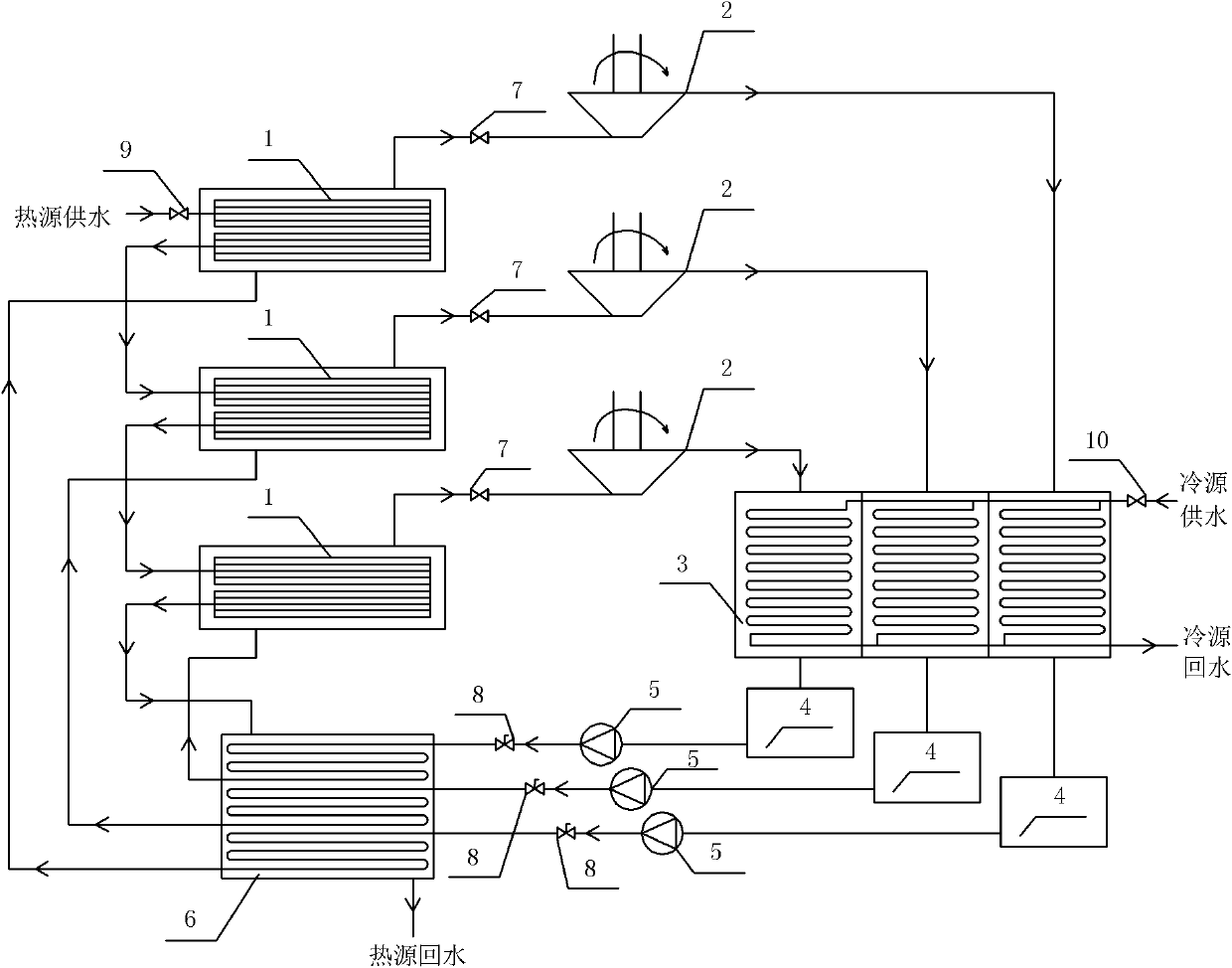

Multi-stage heat pump drying and dehumidifying system with bypass pipeline

ActiveCN107642925AGood dehumidification performanceLower pressure ratioDrying gas arrangementsEfficient regulation technologiesAir volumeEngineering

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidifying system with a bypass pipeline. Thesystem comprises a control unit, a main air channel and a drying chamber which is used for containing to-be-dried materials; an air supply inlet for introducing air and an air exhaust outlet for discharging the air are formed in the drying chamber; the two ends of the main air channel are communicated with the air supply inlet and the air exhaust outlet respectively, and the main air channel is internally provided with a main blower, a dehumidifying chamber, a water baffler and a heating chamber, wherein the dehumidifying chamber, the water baffler and the heating chamber are sequentially arranged in the air flow direction; the multi-stage heat pump drying and dehumidifying system further comprises a multi-stage heat pump unit and the bypass pipeline which is communicated with the dehumidifying chamber, and multi-stage heating and multi-stage humidifying are achieved. Compared with a single-stage heat pump drying system, the pressure ratio of a compressor is reduced, the efficiency ofthe compressor is improved, and the air volume control based on the bypass pipeline effectively adjusts the humidifying performance of the system, so that the system has a wider adjusting range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

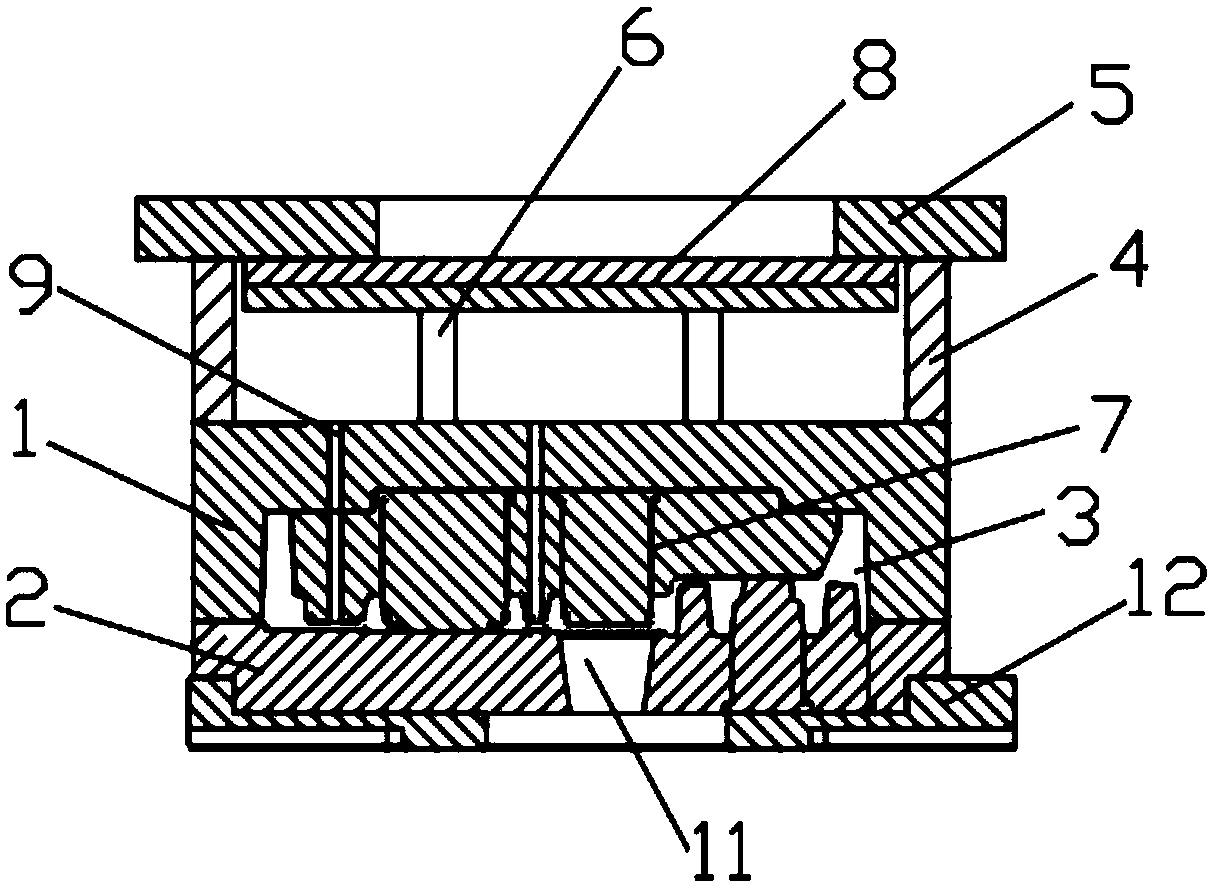

Casting mold and casting process of gearbox body

The invention discloses a casting mold and a casting process of a gearbox body, and relates to the technical field of aluminum alloy casting. The problem that in an existing gearbox body casting process, due to the fact that the wall thickness is large, a transition position is easy to loosen, and even crack can be solved. The casting mold comprises an upper mold, a lower mold and a casting mold cavity formed by cooperating the upper mold and the lower mold, a static insert matched with the shape of the gearbox body is arranged on the inner side of the upper mold, and a runner water inlet is formed in the lower mold; a low-pressure casting process is adopted, the process comprises the following steps of burdening, alloy smelting, alloy solution transferring into low-pressure casting machine, mold preparing, pressure casting, mold opening and alloy taking. By means of the technical scheme, the liquidity of the aluminum alloy solution in the casting mold cavity can be fully improved, theproblems that due to the fact that the wall thickness of the gearbox body is large, looseness and cracking are easy to occur at the transition position are solved, a product qualification rate reaches 95.9% or above, the machining precision of a casting product can be remarkably improved, and subsequent rough machining cost of the casting is reduced.

Owner:四川省犍为恒益铝业有限公司

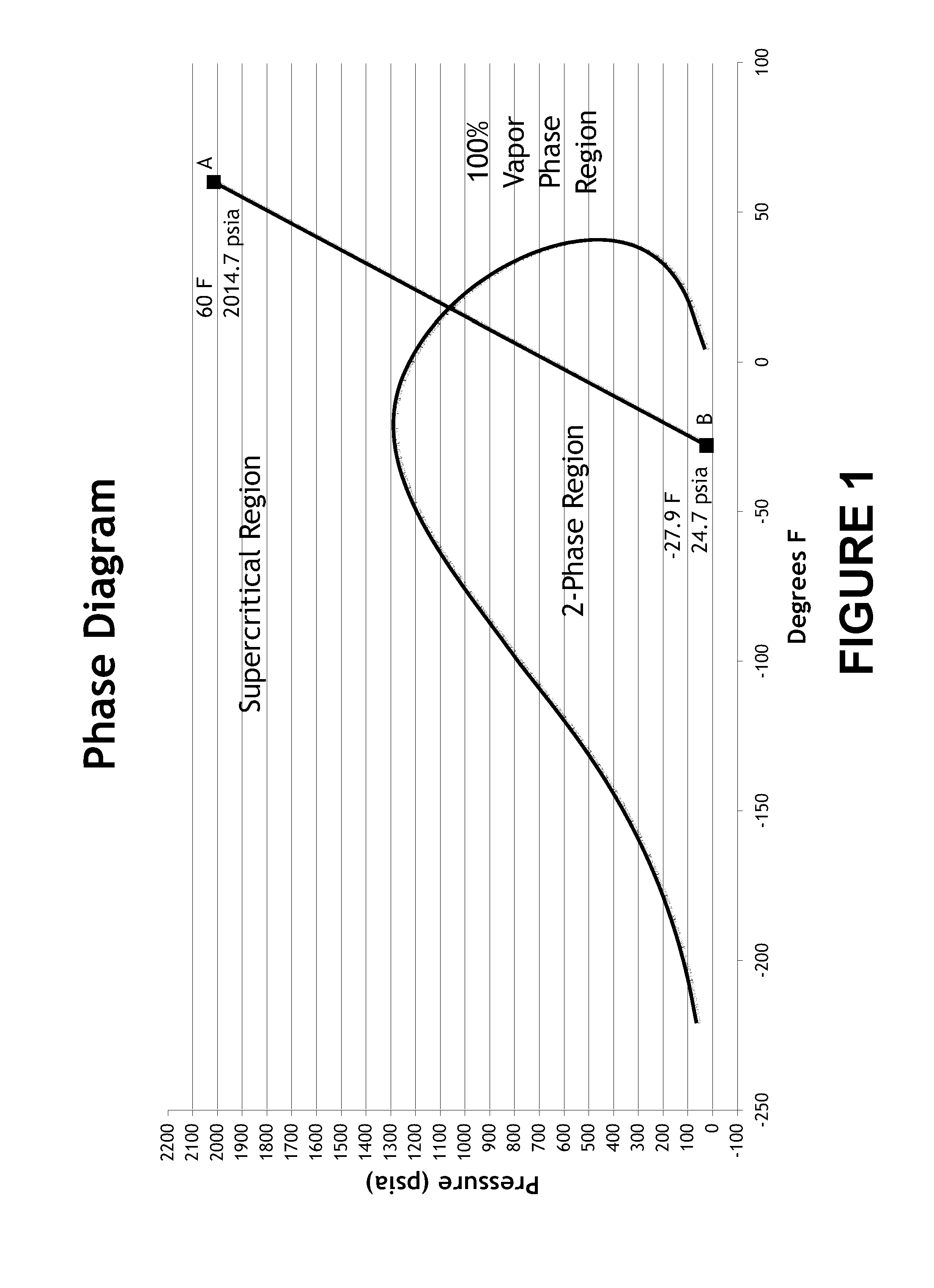

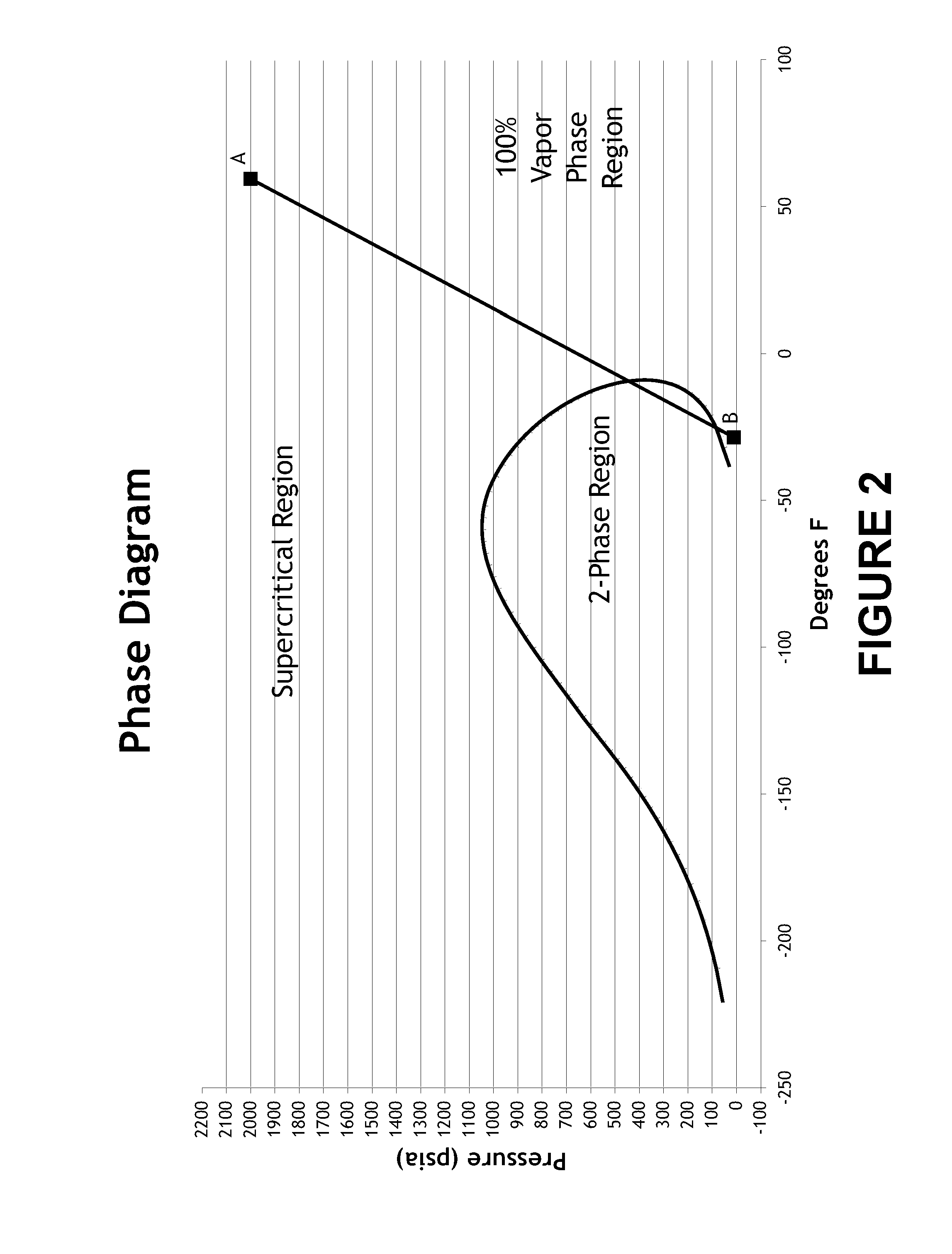

Multi-stage ratio pressure regulator system

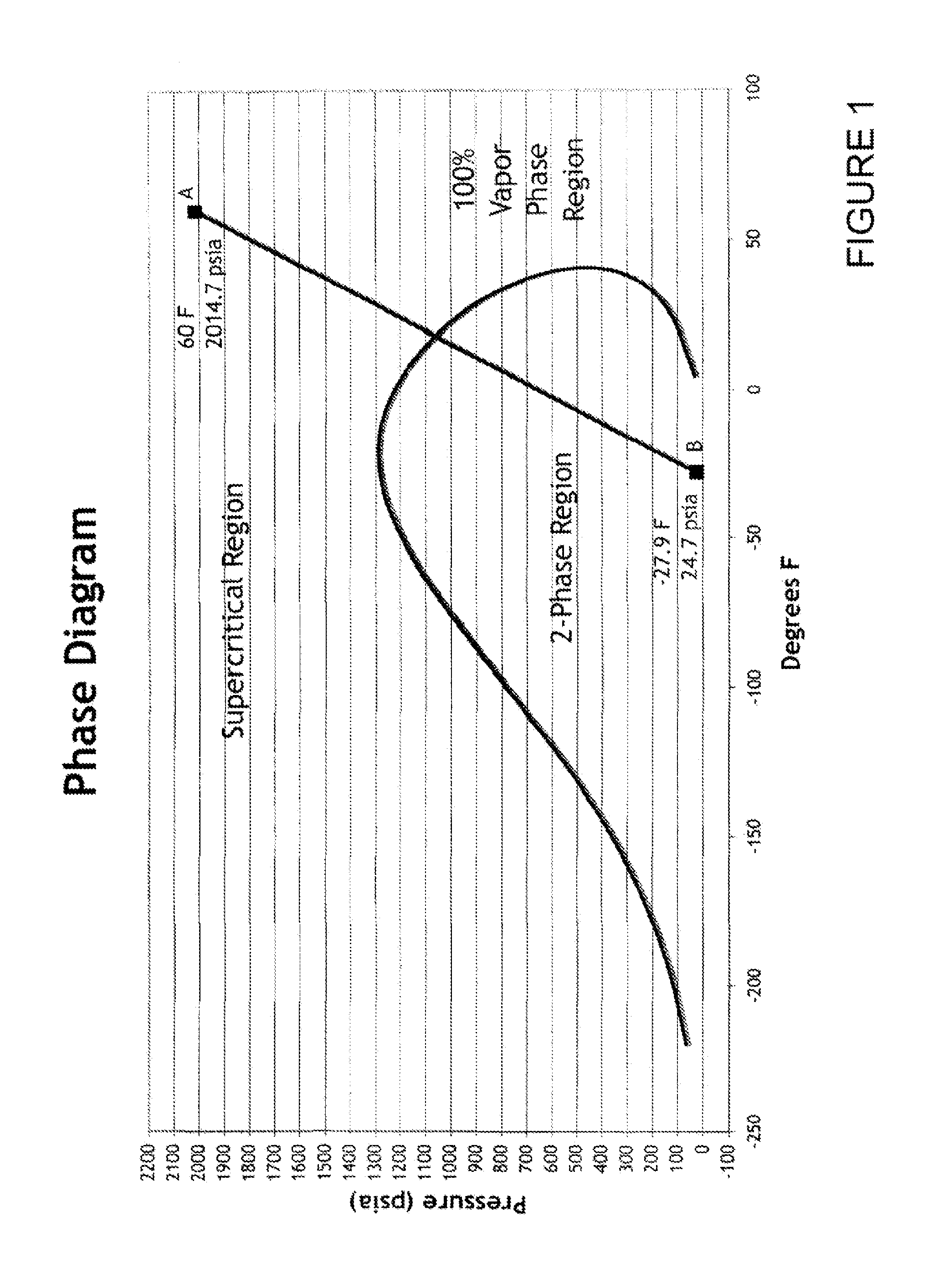

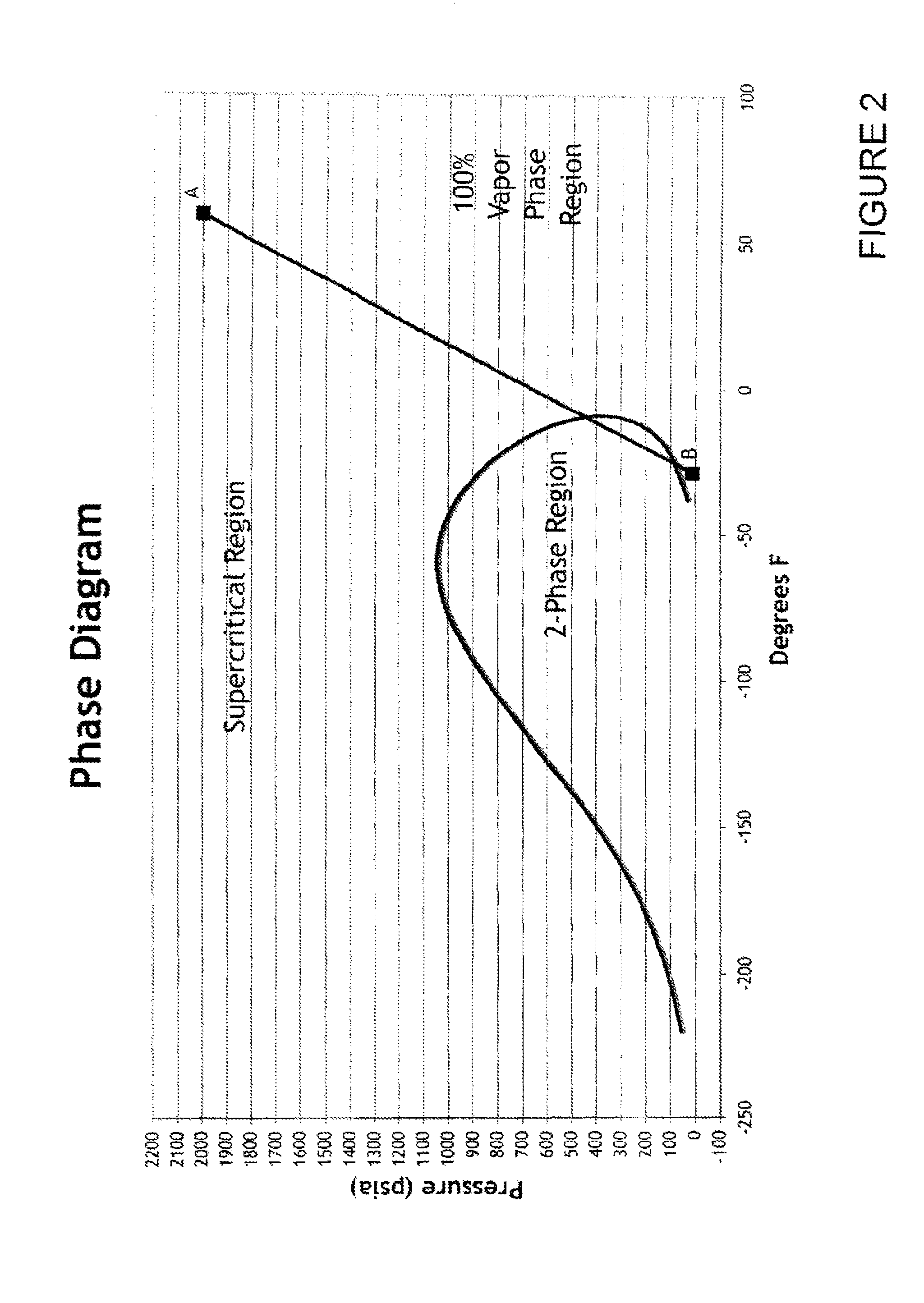

ActiveUS8220479B1Reduce pressureMinimize impactOperating means/releasing devices for valvesPipeline systemsCooling effectEngineering

A multi-stage pressure regulator in which pressure is first reduced by a set ratio in one or more stages followed by an adjustable pressure output stage. The system of the present invention provides for distribution of the Joules-Thomson (JT) cooling effect between multiple stages. The present invention thereby provides a system to control pressure reduction and thus prevent condensation (and associated distortion of a vapor composition sample) of a gas due to J-T cooling effect.

Owner:MAYEAUX HLDG

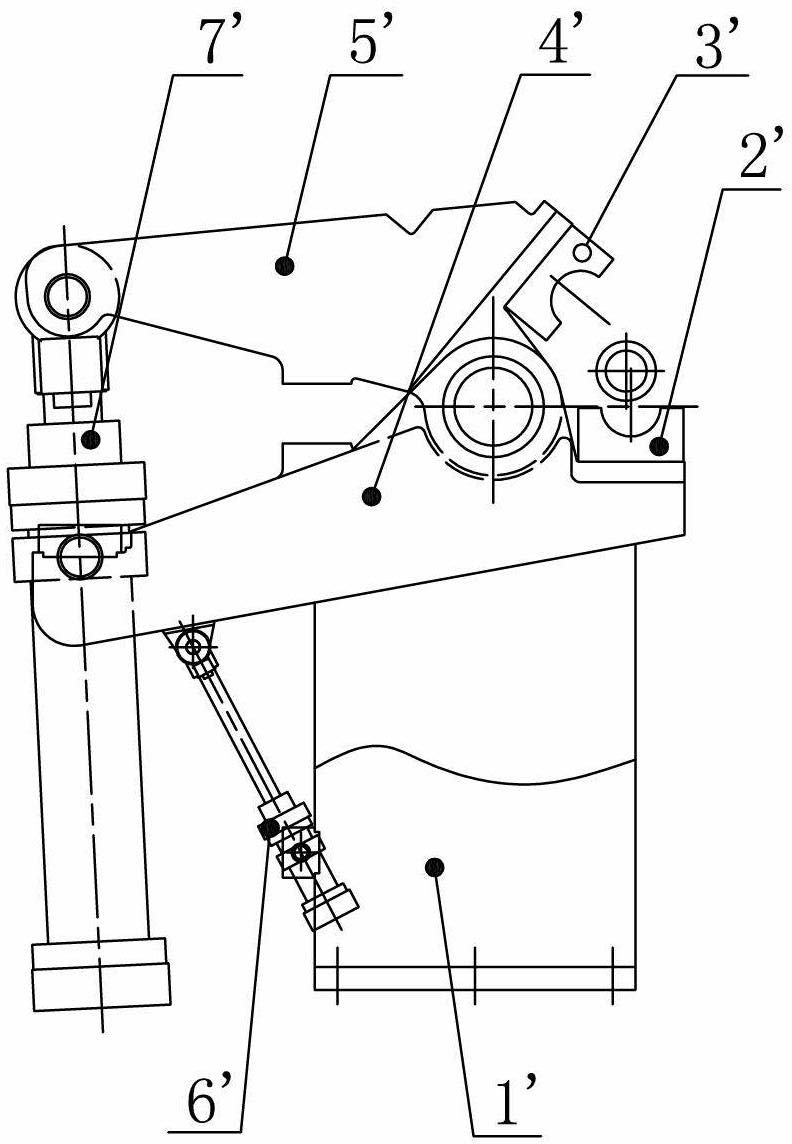

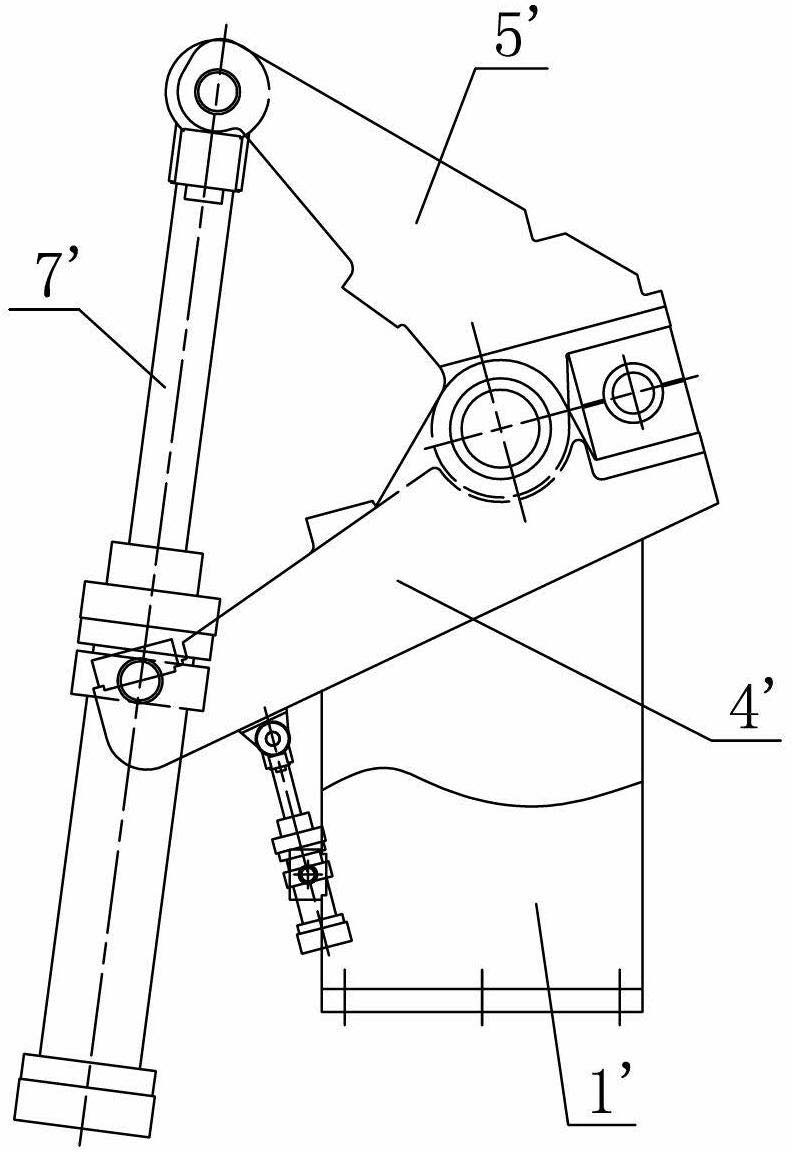

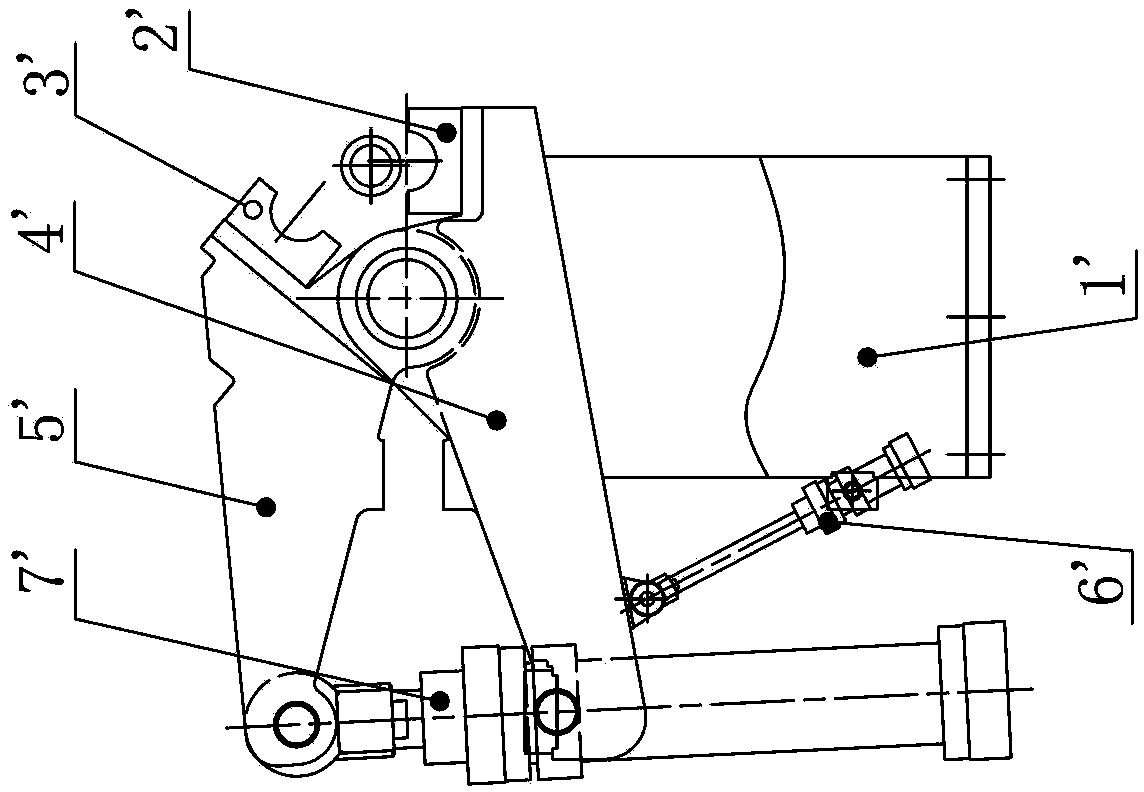

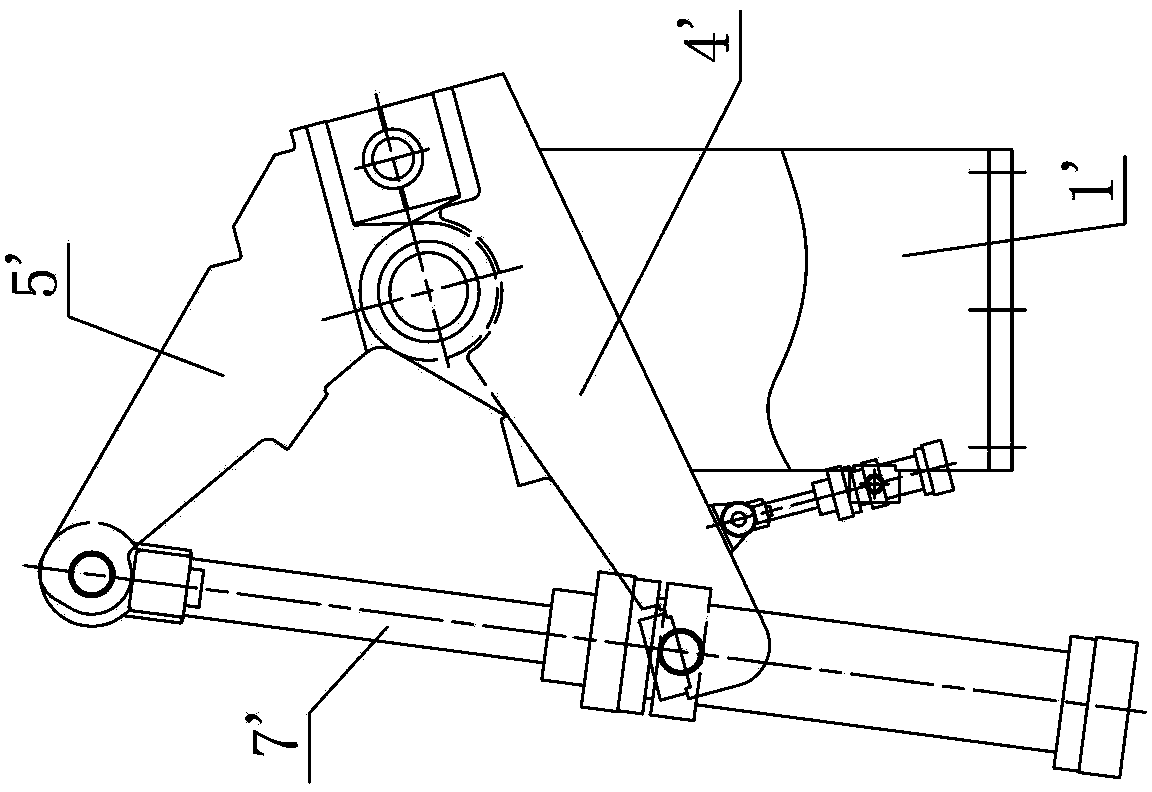

Three-claw opening-shrinking machine synchronized through connecting rods

A three-claw opening-shrinking machine synchronized through connecting rods comprises a supporting seat, a telescopic arm, a first rotating arm, a second rotating arm, a first jaw, a second jaw, a third jaw, a first connecting rod mechanism and a second connecting rod mechanism, wherein the telescopic arm is connected to the supporting seat and can move up and down; the first rotating arm and the second rotating arm are symmetrically positioned on both sides of the telescopic arm respectively; the first rotating arm and the second rotating arm are rotationally connected to the supporting seat through a first pin shaft and a second pin shaft respectively; the first jaw, the second jaw and the third jaw are connected to the first rotating arm, the second rotating arm and the telescopic arm respectively; the first connecting rod mechanism and the second connecting rod mechanism are symmetrically positioned on both sides of the telescopic arm respectively; the top ends of the first connecting rod mechanism and the second connecting rod mechanism are fixed on the first rotating arm and the second rotating arm through the first pin shaft and the second pin shaft respectively, and the lower ends are hinged together; and the lower end of the telescopic arm is connected to the hinged part of the lower ends of the first connecting rod mechanism and the second connecting rod mechanism. Under the action of an acting cylinder and through the first connecting rod mechanism and the second connecting rod mechanism, the first rotating arm and the second rotating arm rotate around the axial lines of the first pin shaft and the second pin shaft, the telescopic arm moves telescopically on the supporting seat, the first jaw, the second jaw and the third jaw are driven by the first rotating arm, the second rotating arm and the telescopic arm to act simultaneously, and the jaws shrink or open.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

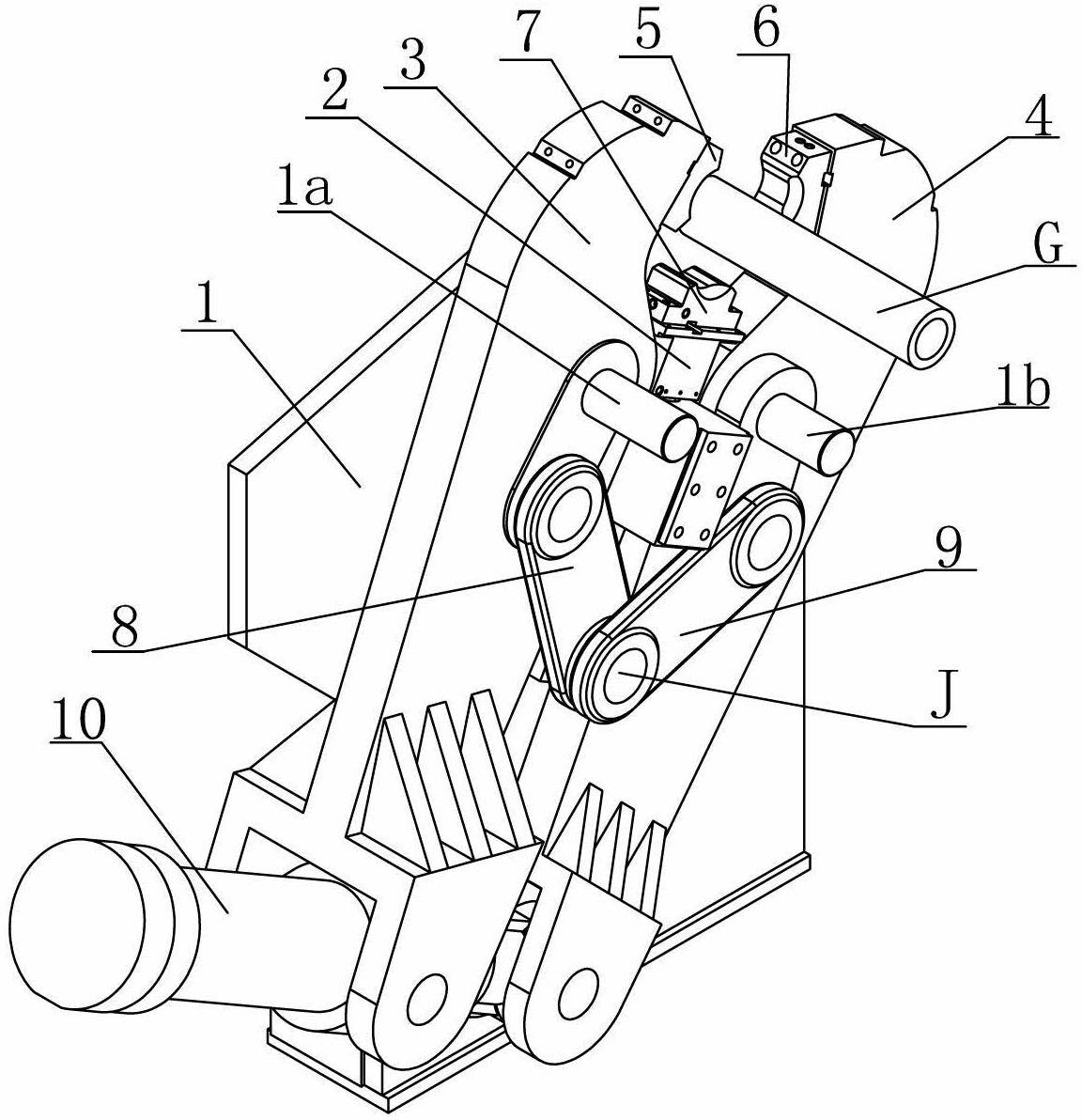

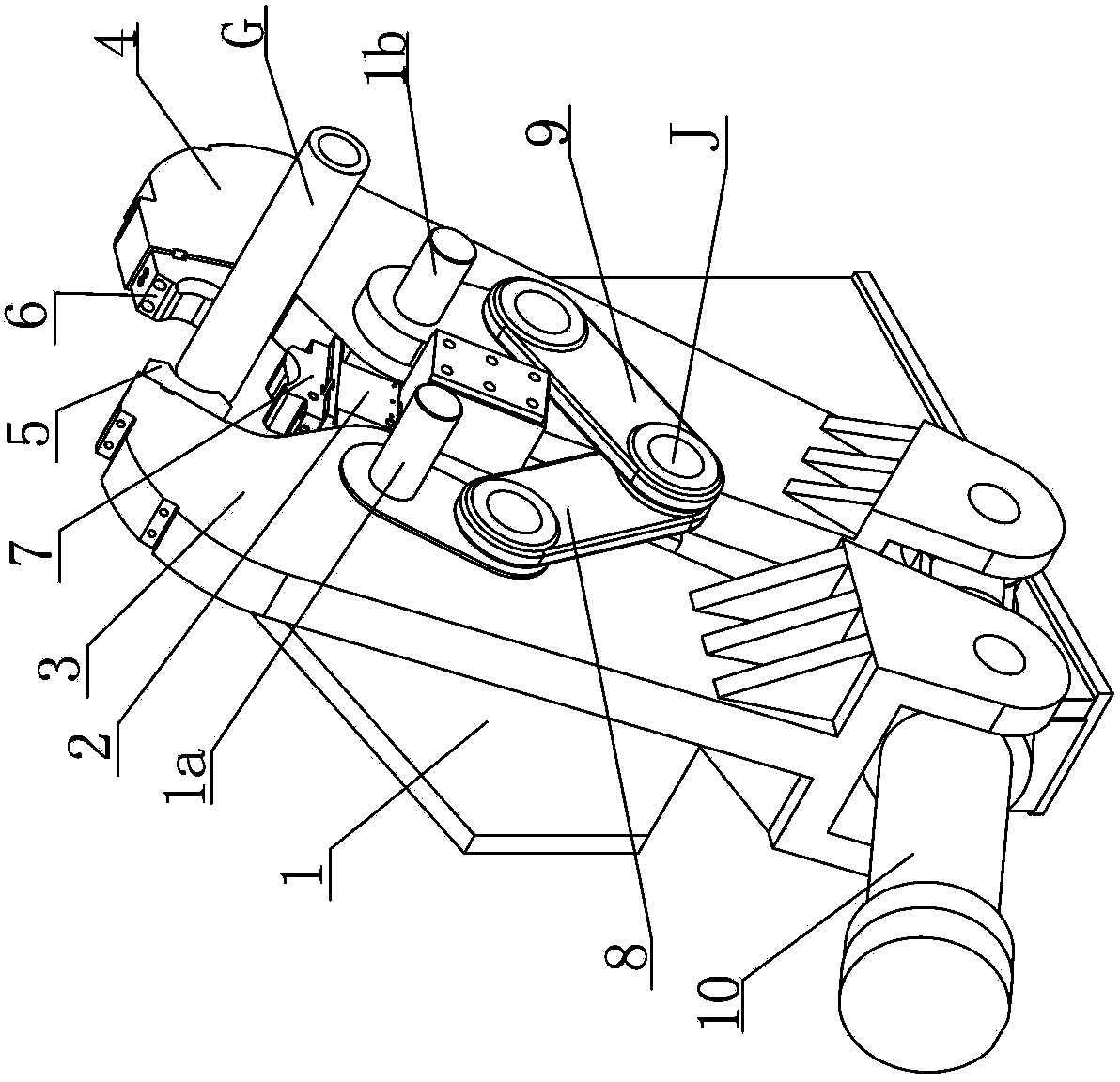

Cold crucible induction melting and die-casting device and method for preparing bulk amorphous material

The invention discloses a cold crucible induction melting and die-casting device. The cold crucible induction melting and die-casting device comprises a vacuum melting chamber, and a water-cooled copper crucible is arranged in the vacuum melting chamber. An induction coil is wound on the outer wall of the water-cooled copper crucible, and a crucible bottom is arranged at the bottom of the water-cooled copper crucible. A push rod is arranged below the crucible bottom, penetrates through the bottom of the vacuum melting chamber through vacuum sealing and is combined with a driving mechanism. A gun barrel is arranged on the water-cooled copper crucible, and a mold chamber is arranged on the gun barrel. The invention further discloses a method for preparing a bulk amorphous material by using the device. The crucible, the gun barrel and the mold chamber are compactly combined without intervals. When the metal bulk amorphous material is prepared, the crucible bottom compulsively presses a metal melting tank into a mold, the liquid metal is short in stroke and small in resistance, so that the temperature drop is small, the flowability is high, the filling property is good, the quality andthe yield of castings are improved, the possibility of local solidification of molten metal in the gun barrel is reduced, the failure rate of blocking in the die casting process is reduced, and the service life of equipment and the production efficiency are improved.

Owner:励德装备技术(宁波)有限公司

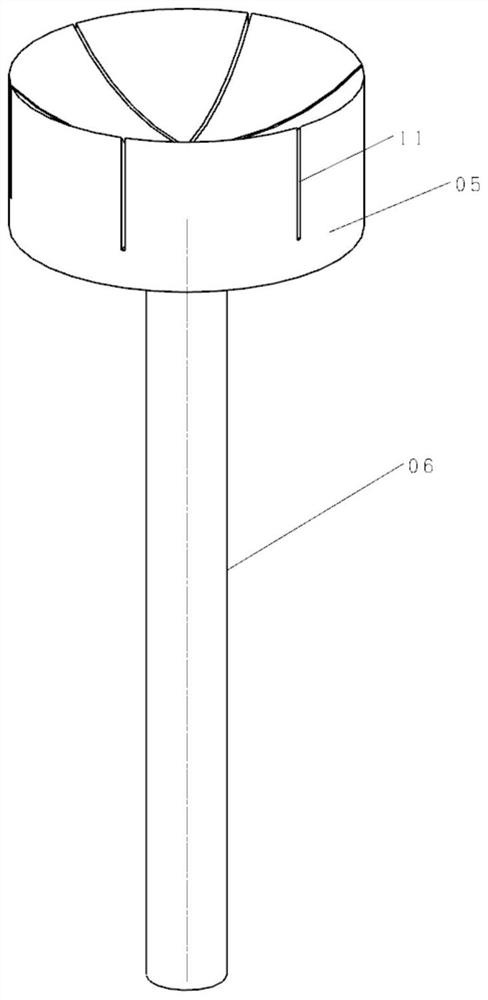

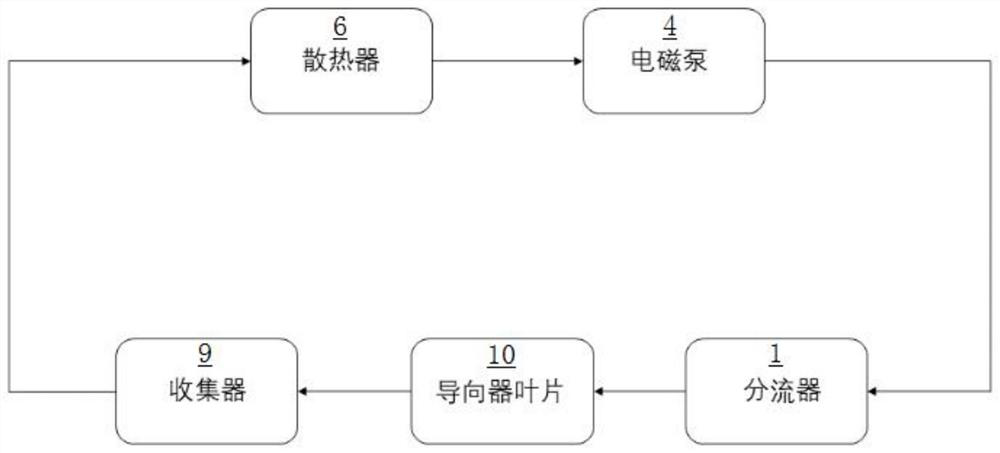

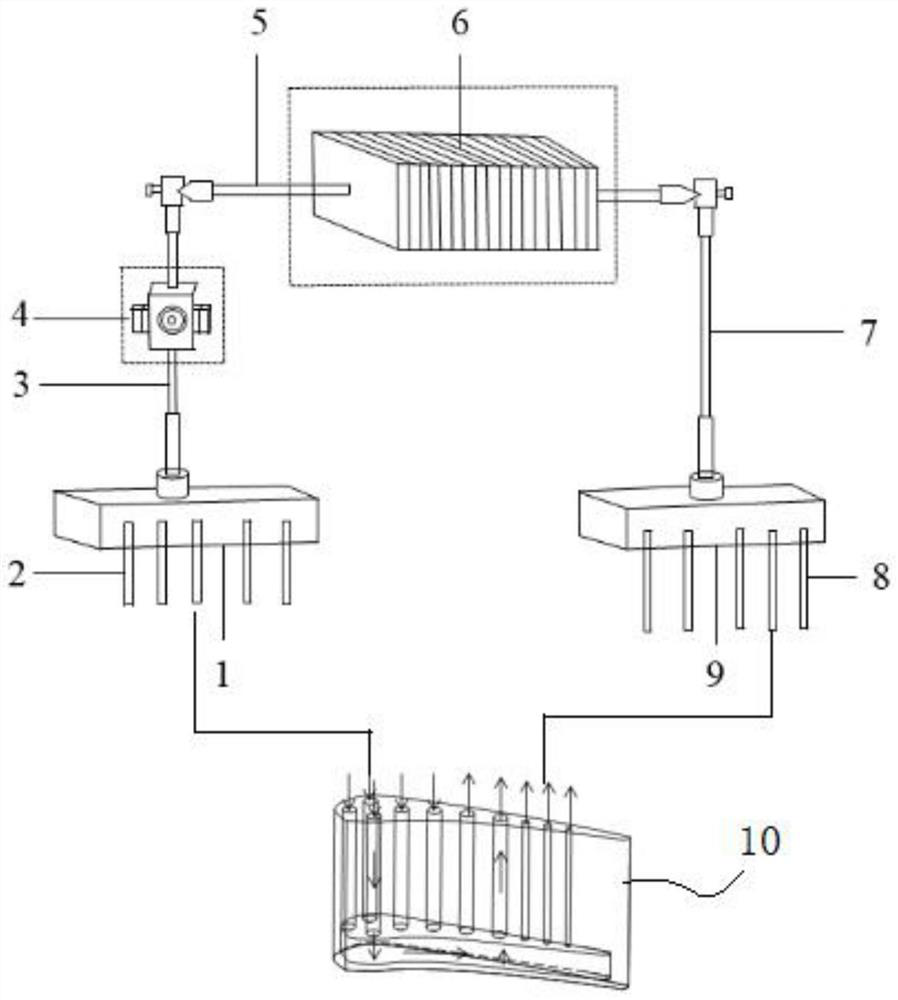

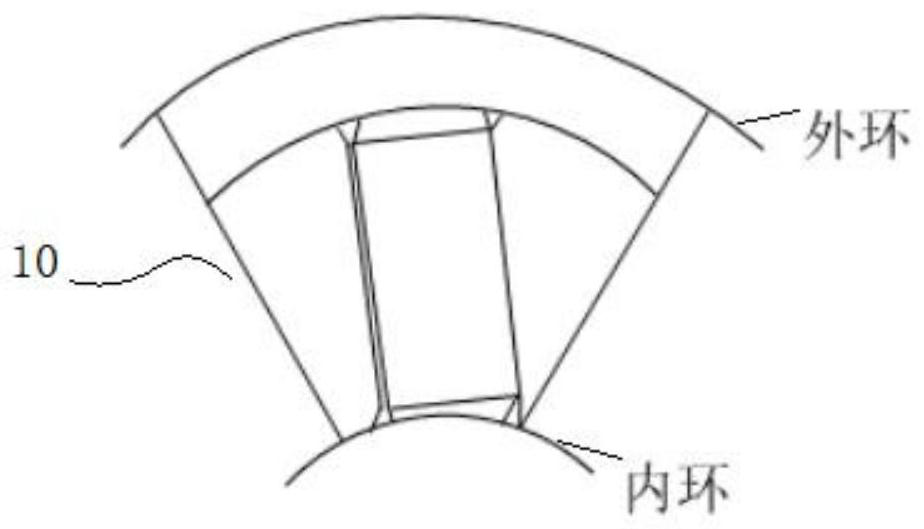

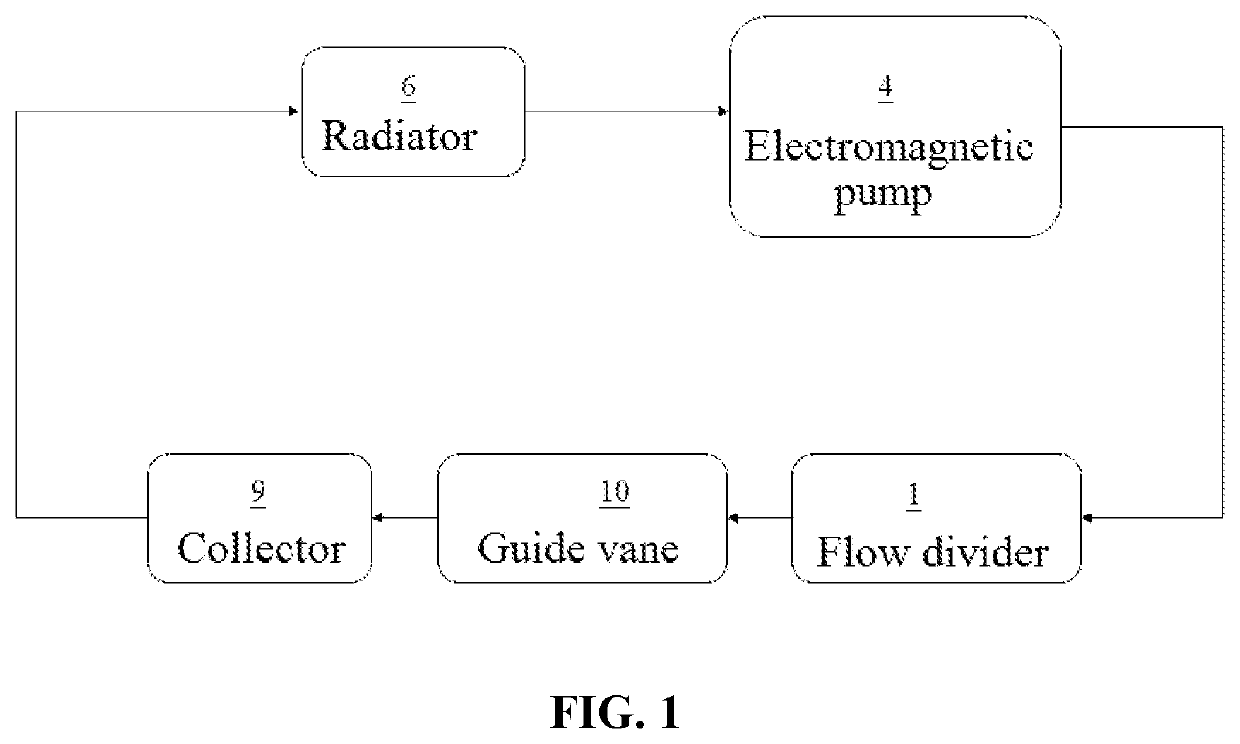

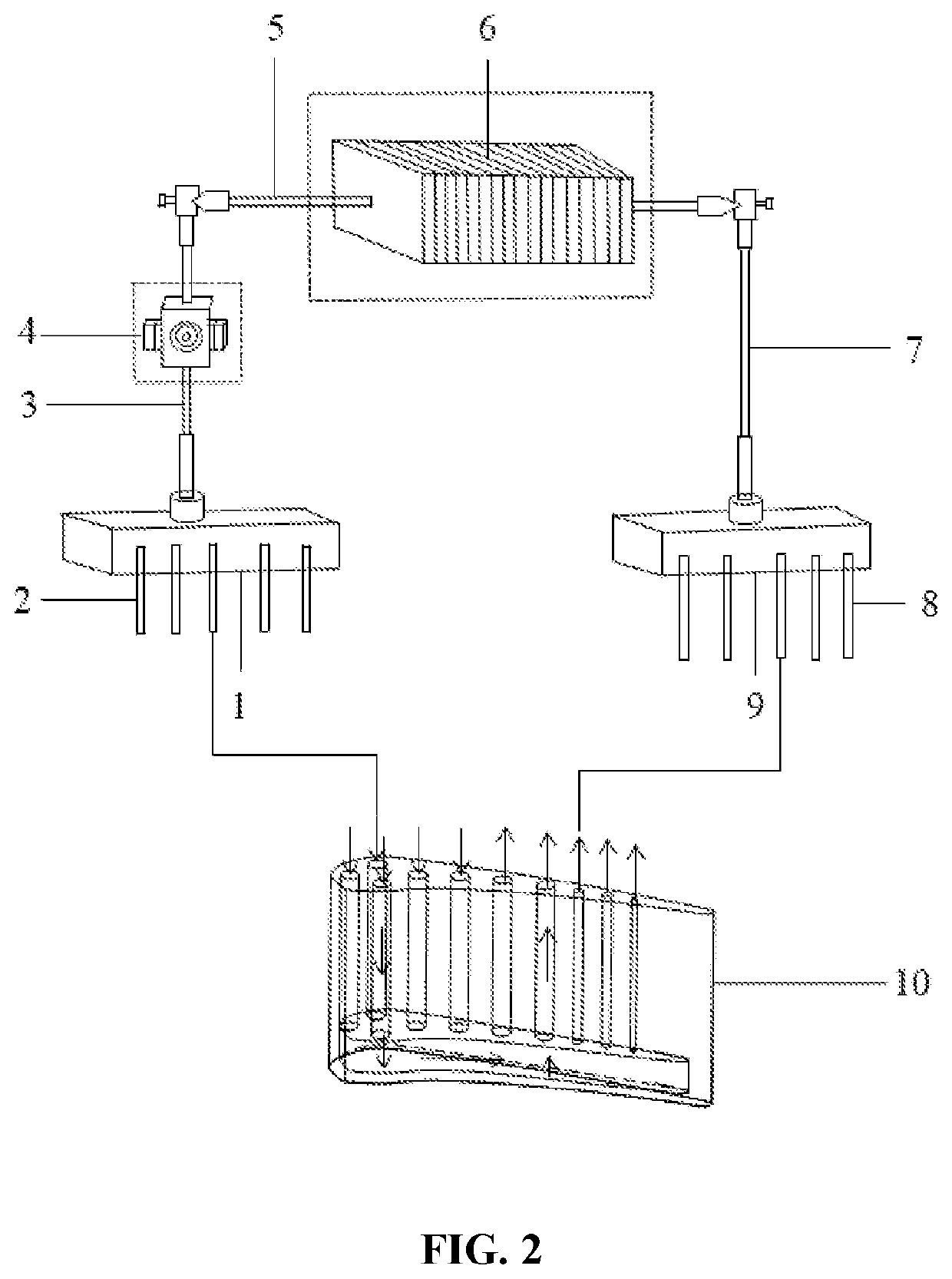

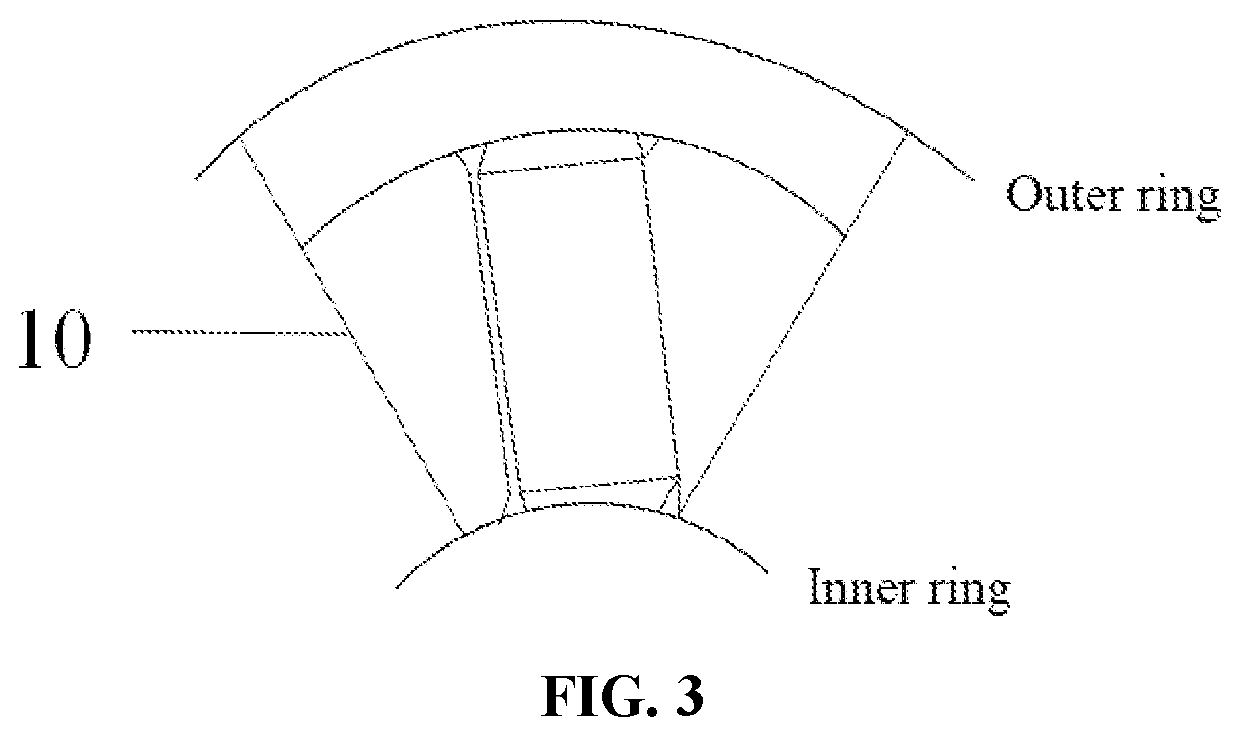

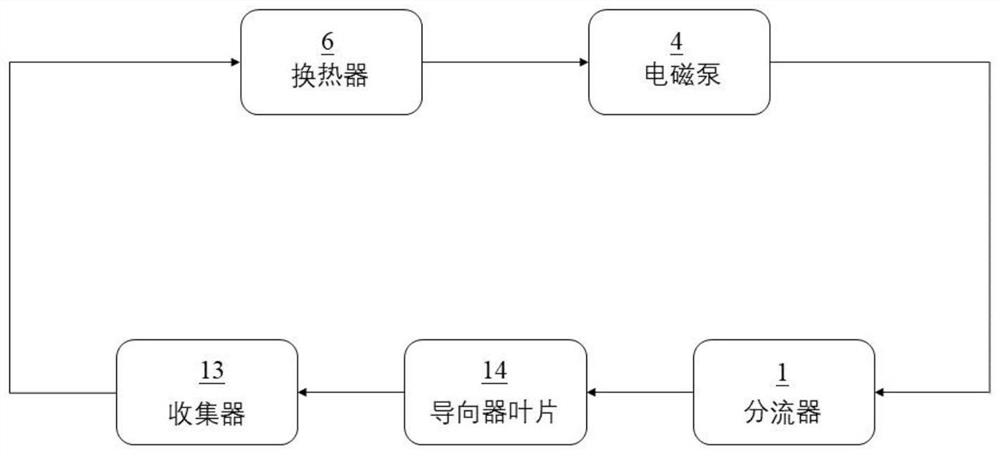

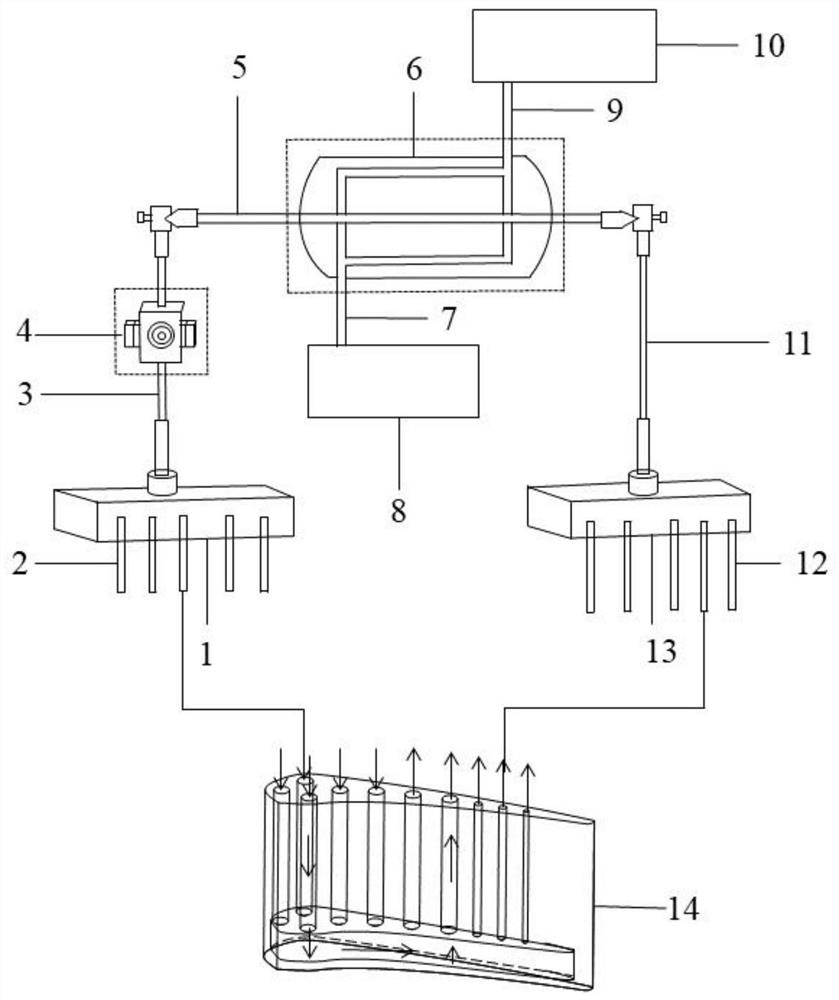

Turbine guider blade cooling device with low-melting-point metal as flowing working medium

ActiveCN112796843AImprove cooling effectLarge temperature dropEngine fuctionsBlade accessoriesGas compressorCooling effect

The invention discloses a turbine guider blade cooling device with low-melting-point metal as a flowing working medium, and relates to guider blade cooling. A plurality of cooling channels and cavities are arranged in a guider blade. The turbine guider blade cooling device with the low-melting-point metal as the flowing working medium comprises a flow divider, a collector, a radiator and an electromagnetic pump, wherein the electromagnetic pump and the guider blade form a closed loop, liquid low-melting-point metal or alloy thereof is driven by the electromagnetic pump to serve as the flowing working medium to circularly flow in the closed loop, and rapid heat dissipation is achieved through the radiator. According to the turbine guider blade cooling device with the low-melting-point metal as the flowing working medium, air cooling is not adopted, cooling air originally led out from a gas compressor is saved, and the propelling power of an aircraft is increased; the cooling effect is far better than that of a gas cooling mode in a traditional process, the heat transfer efficiency is high, and the temperature drop of the guider blade is larger, so that the service life of the guider blade is prolonged; air film holes do not need to be formed in the outer surface of the guider blade, and the strength of the blade is improved; the whole process is cyclically closed, the low-melting-point metal or the alloy thereof is recycled, and the environment is not affected.

Owner:BEIHANG UNIV

A multi-stage heat pump drying and dehumidification system with bypass pipeline

ActiveCN107642925BGuaranteed uptimeMeet drying requirementsMechanical apparatusDrying gas arrangementsAgricultural scienceAir volume

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidification system with a bypass pipeline, comprising: a control unit, a main air duct and a drying room for placing materials to be dried, the drying room An air supply port for introducing gas and an air exhaust port for exhausting gas are provided; the two ends of the main air duct are respectively connected with the air supply port and the air exhaust port, and the main air duct is provided with a main fan and an air exhaust port. A dehumidification chamber, a water baffle, and a heating chamber are arranged in sequence along the airflow direction; it also includes a multi-stage heat pump unit and a bypass pipeline connected with the dehumidification chamber to realize multi-stage heating and multi-stage dehumidification. Compared with the single-stage heat pump drying system, the pressure ratio of the compressor is reduced, and the efficiency of the compressor is improved, and the air volume control based on the bypass pipeline can effectively adjust the dehumidification performance of the system, so that the system has a larger adjustment range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

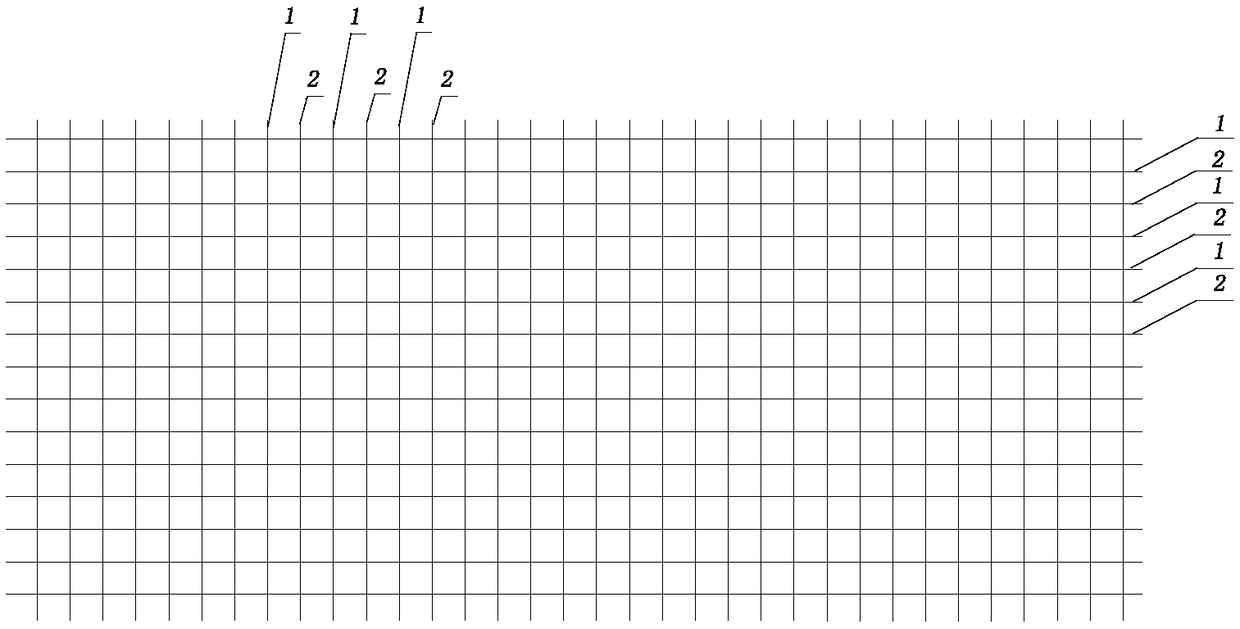

Surface layer fabric having reflecting, radiative-refrigerating and non-ironing functions

InactiveCN108754783AWith passive cooling functionWith non-ironing functionWoven fabricsYarnPolyesterYarn

The invention discloses a surface layer fabric having reflecting, radiative-refrigerating and non-ironing functions. The surface layer fabric comprises radiative-refrigerating yarns and blended yarns,wherein the radiative-refrigerating yarns and the blended yarns are alternatively arranged, and then warp-weft interweaving is performed. The surface layer fabric comprises the radiative-refrigerating yarns and the blended yarns, the radiative-refrigerating yarns and the blended yarns are interwoven in a warp-weft way. The radiative-refrigerating yarns include fibers, metal layers and high polymer material layers. The blended yarns are formed by blending polyester fibers and spandex. The technical scheme aims to make the surface layer fabric have an ultra-strong reflecting function and passive radiative-refrigerating capacity. The surface layer fabric brings cool feeling to a user after the user uses the fabric, and meanwhile has the non-ironing function.

Owner:NINGBO RUILING ADVANCED ENERGY MATERIALS INST CO LTD

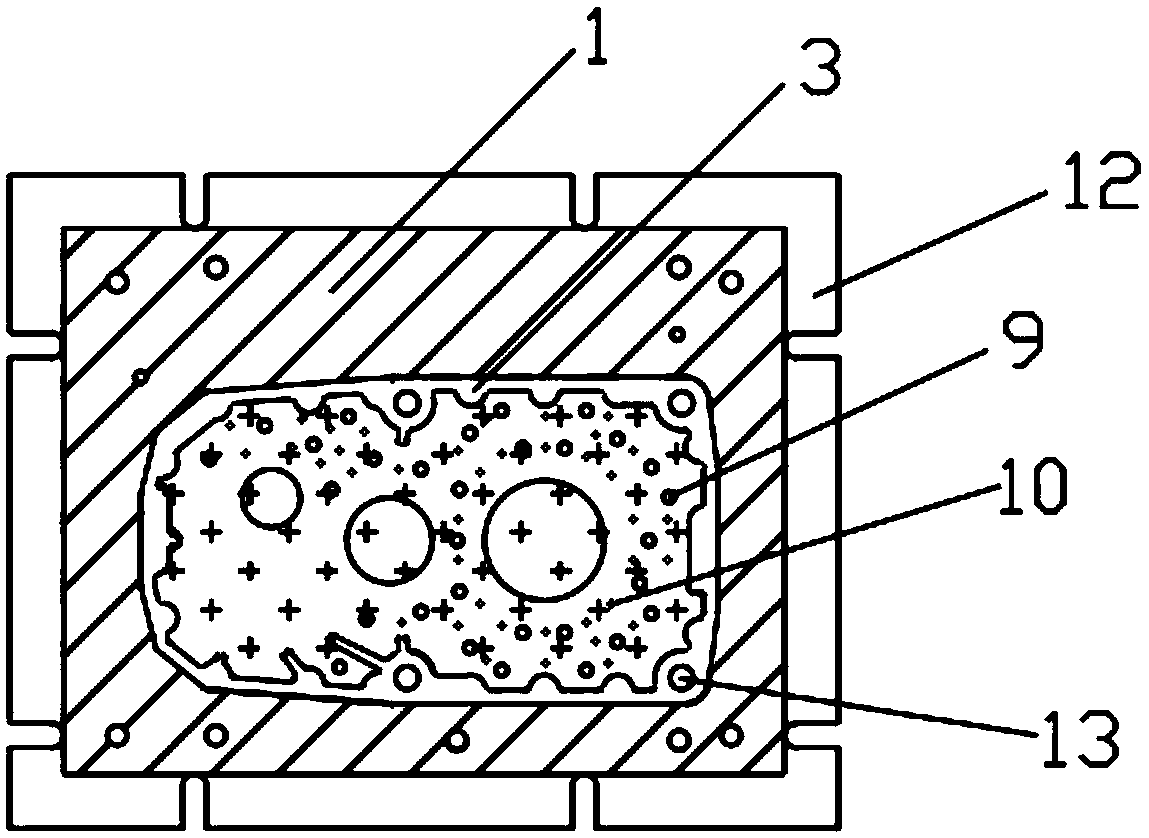

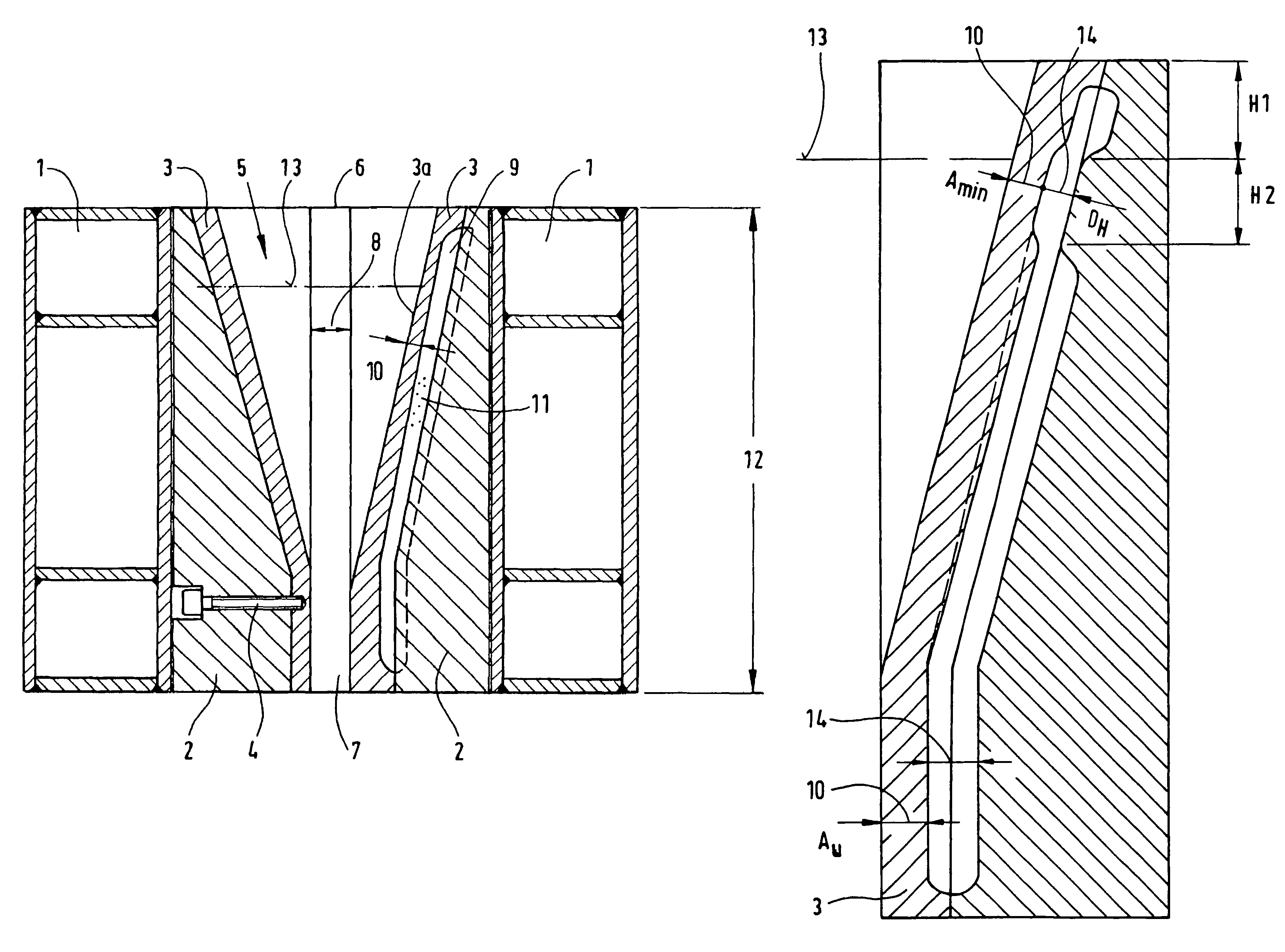

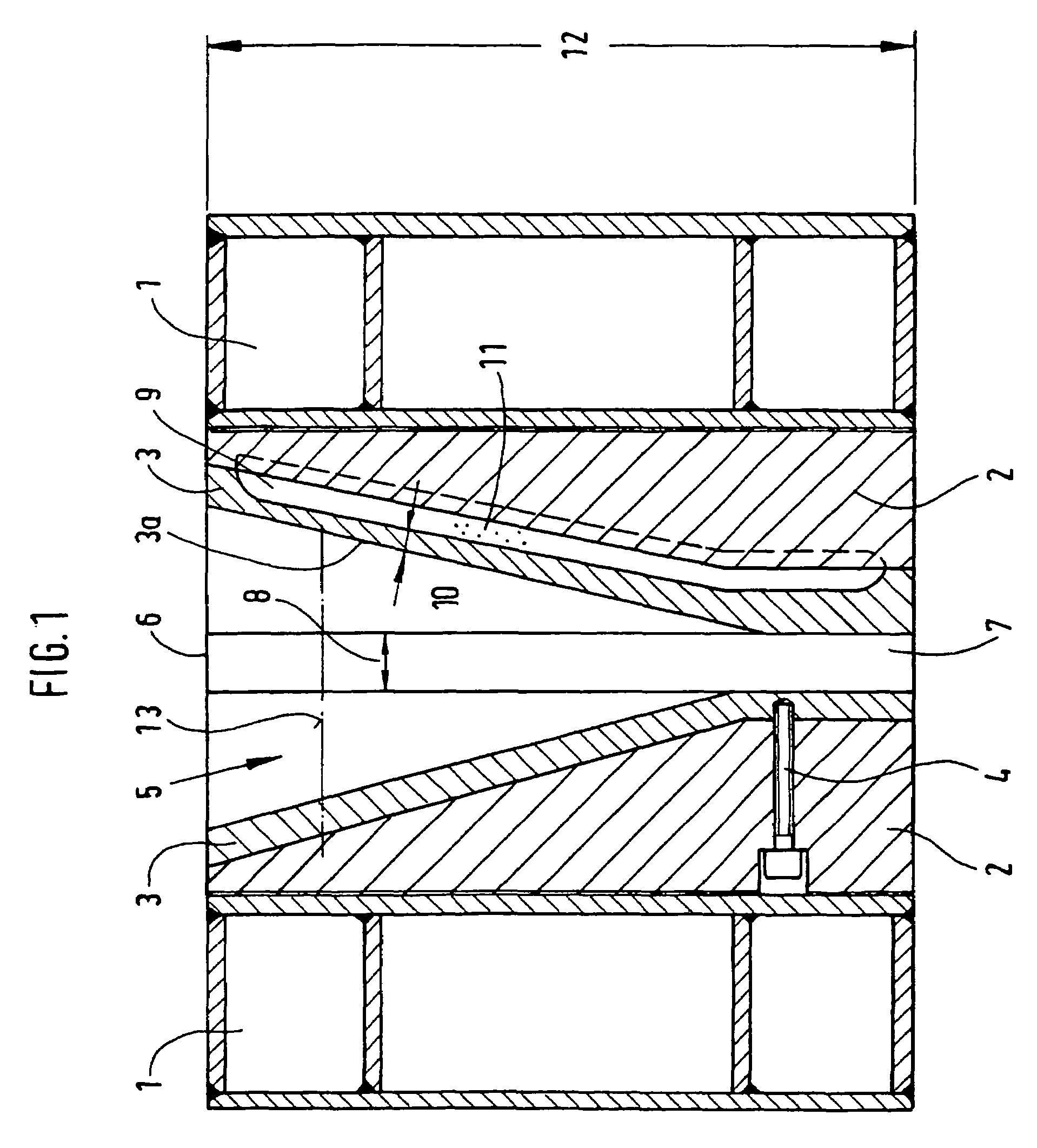

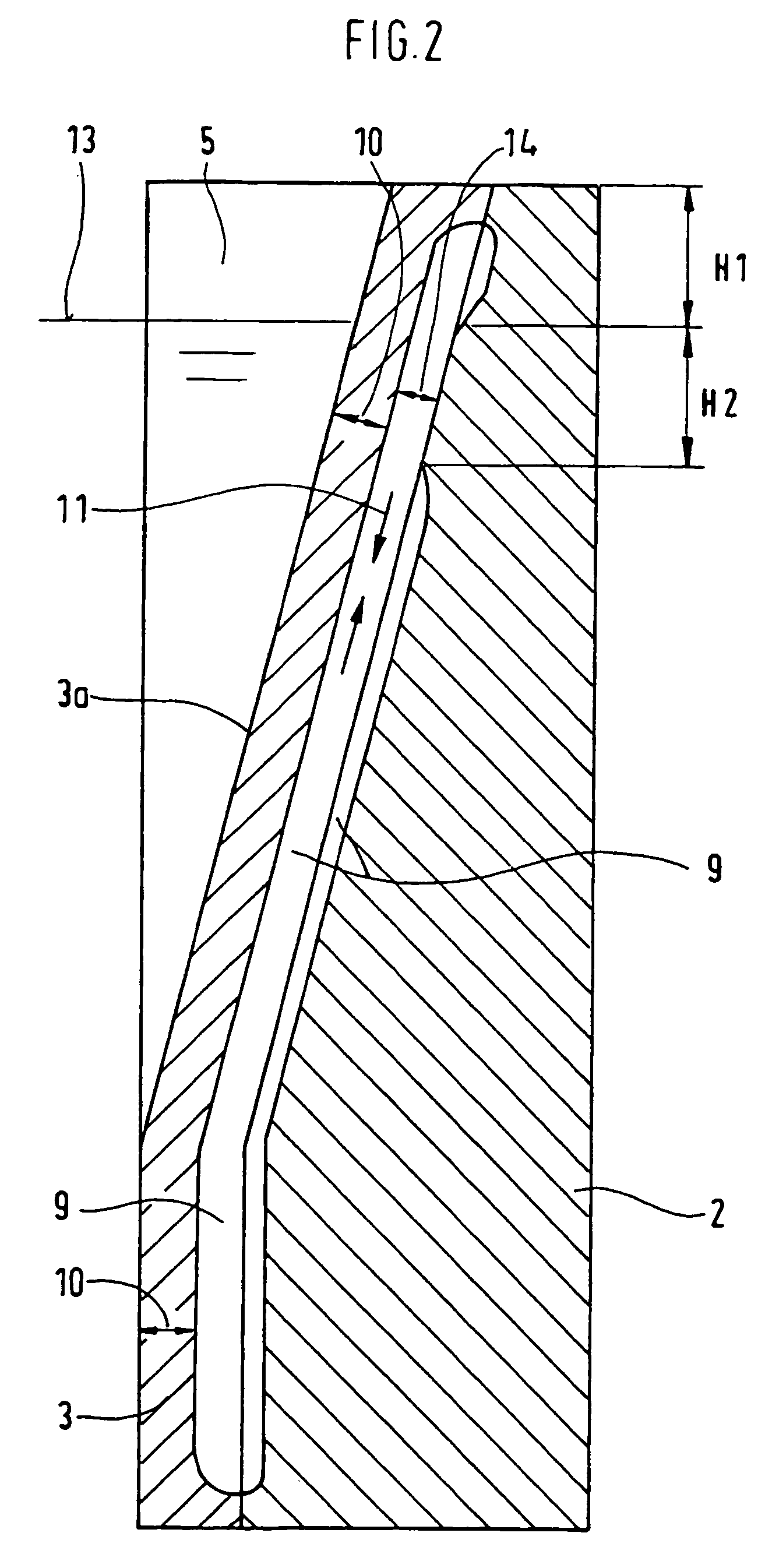

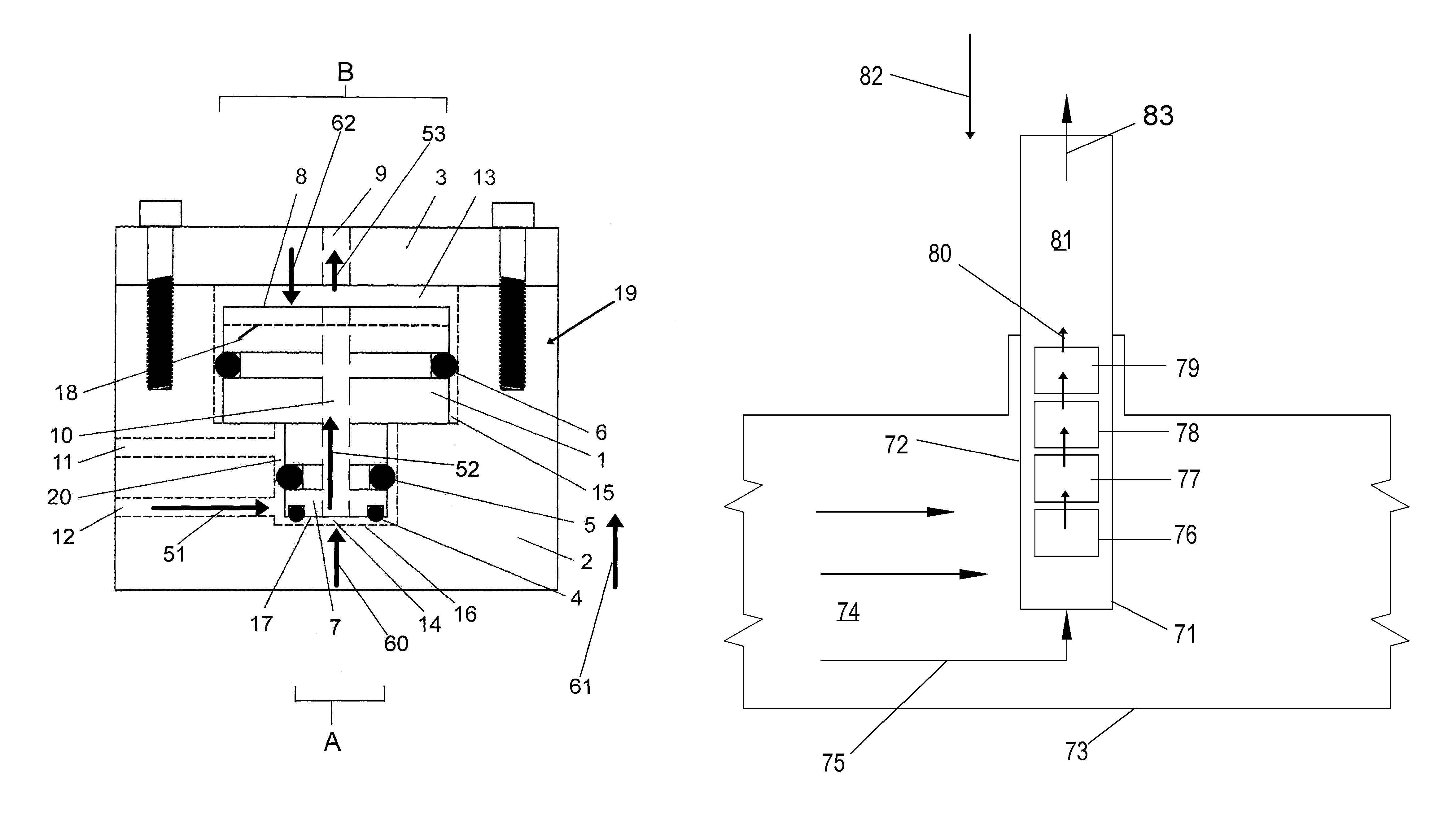

Continuous casting mold for liquid metals, especially for liquid steel

InactiveUS7363958B2Large temperature dropEqual flow rateMelt-holding vesselsLiquid steelWater reservoir

The invention relates to a continuous casting mould for liquid metals, especially for liquid steel, comprising steel charging plates (2) which are surrounded by water reservoirs (1), cassette-type copper plates (3) arranged against the same, end plates (7), if needed, for the thickness and / or the width of the cast billet, and coolant channels (9). The aim of the invention is to take measures to counteract the high temperatures in the meniscus region (13) using appropriate embodiments of the copper plates (3) and / or the steel charging plates (2). To this end, the thickness (10) of the copper plates (3) between the coolant (11) and the hot side (3a) of the copper plates varies along the width (2×L) and / or in terms of the height (12).

Owner:FEHLEMANN GEREON

Micro refrigerator and refrigeration method

InactiveCN100557340CImprove uniformityEasy to control temperatureEnergy efficient heating/coolingMachines using electric/magnetic effectsEngineeringRefrigeration

A micro - refrigerator is prepared as applying relaxation ferroelectric material as working media of refrigeration , using n layers of ferroelectric stacks and m x 1 arrays of ferroelectric stacks as sum of n x m x 1 units to form micro ¿C refrigerator . Its refrigerating method includes applying phase transition refrigeration of electric field induction as quickly adding electric field and slowly putting off electric field on each refrigerating sheet (RS), using the same working mode in the same layer or in each interval layer of RS in different line, using specific time sequence and circulation for each layer of RS and operating ferroelectric stack arrays alternatively.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

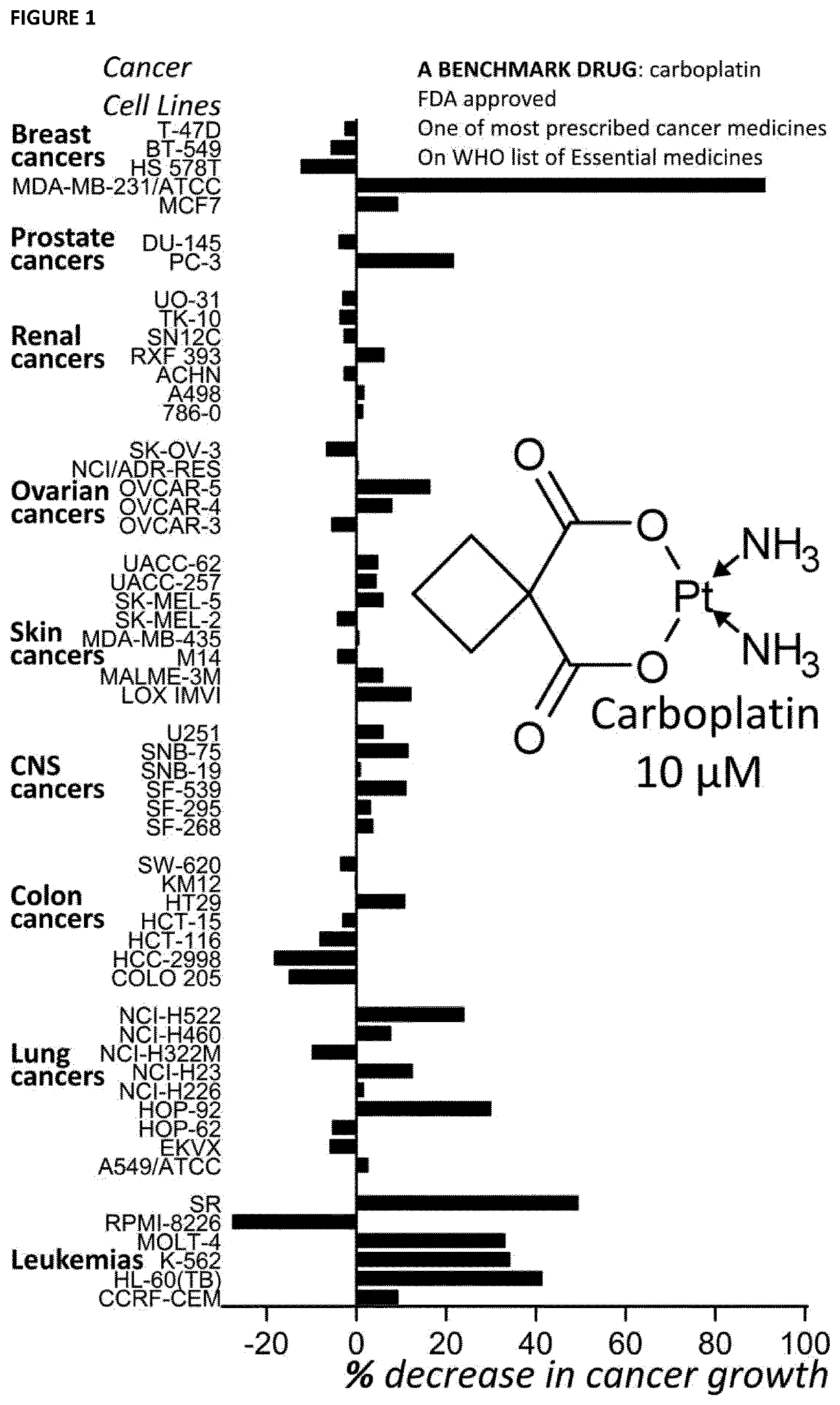

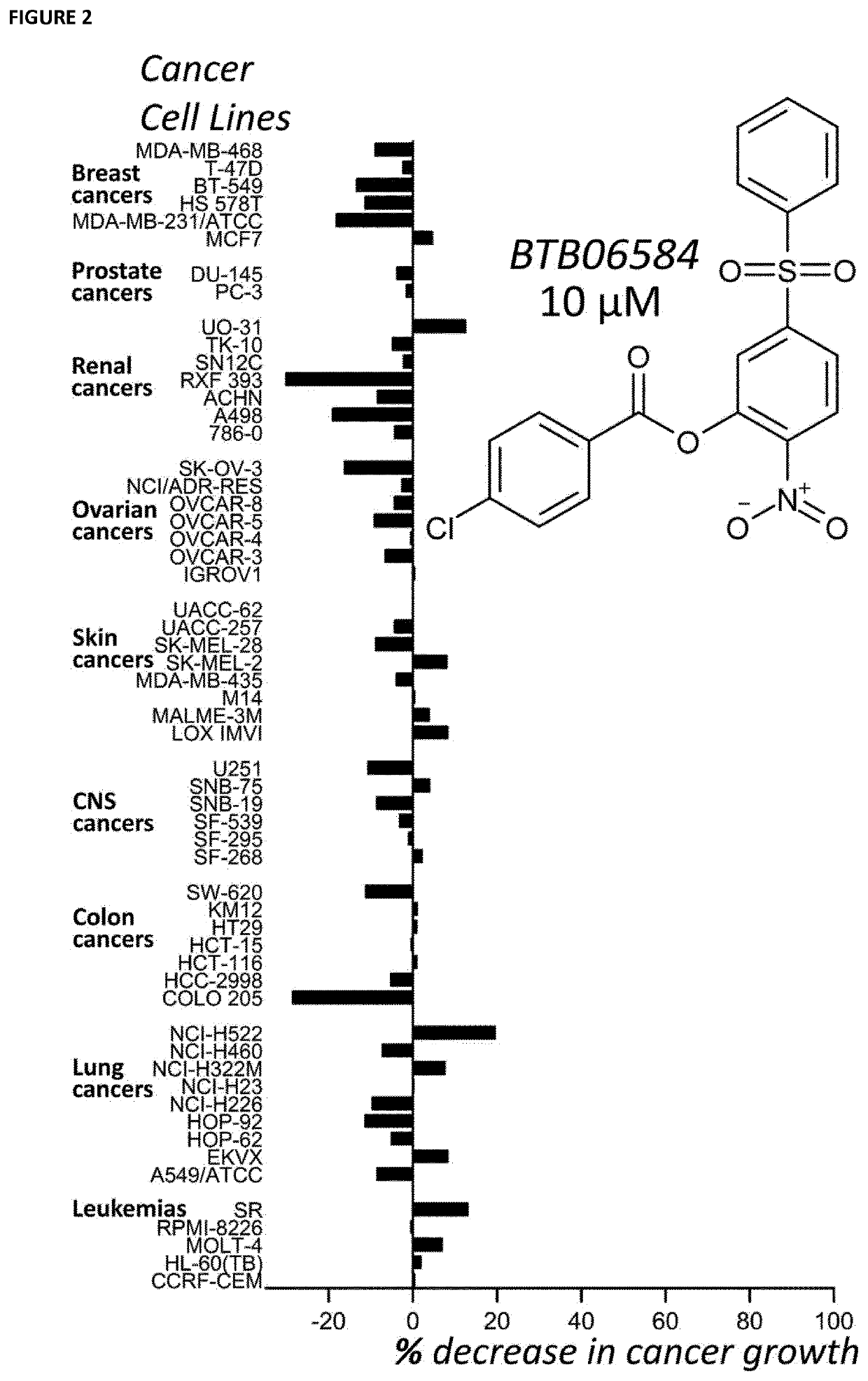

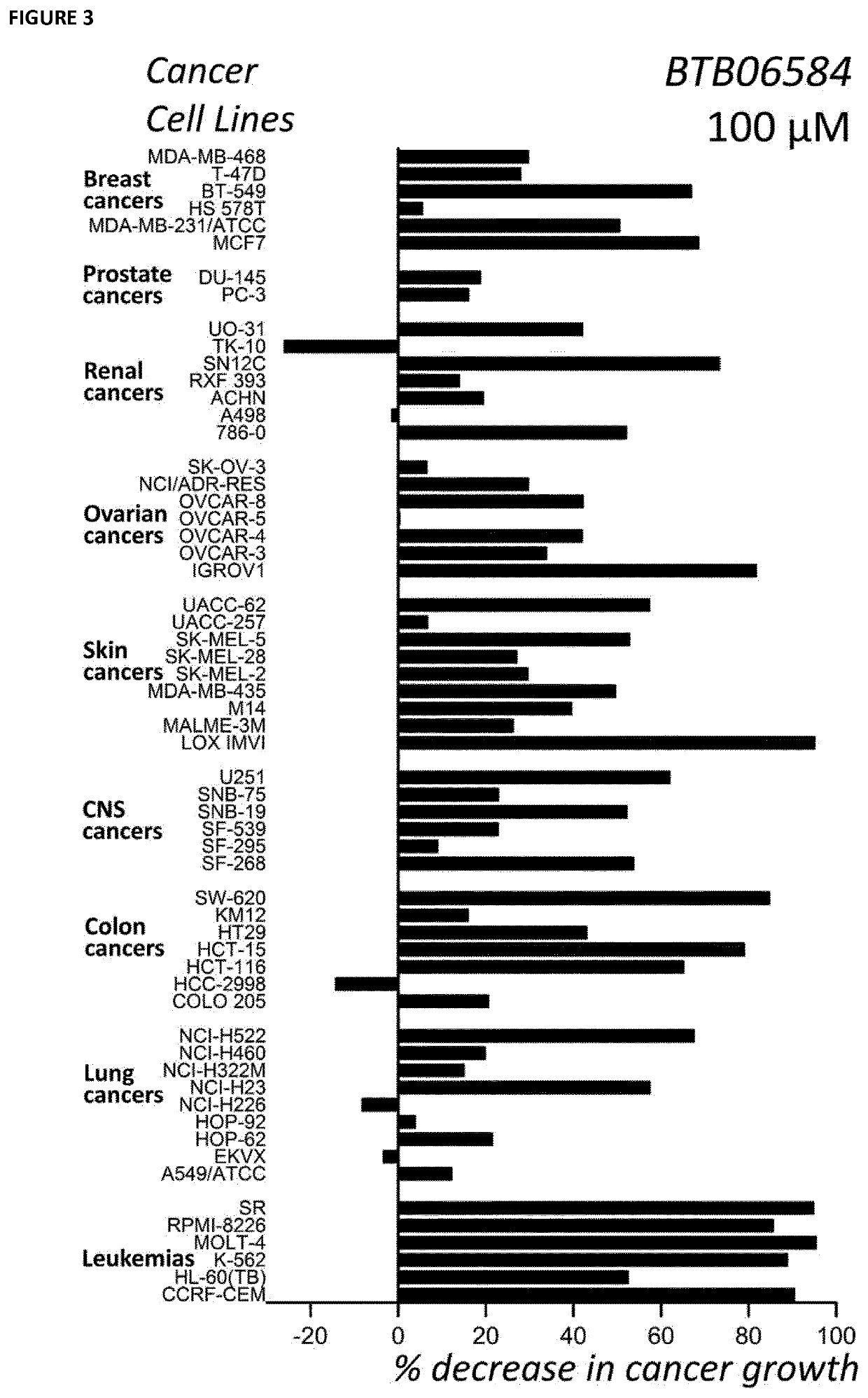

Therapeutic Modulators of the Reverse Mode of ATP Synthase

PendingUS20200306253A1Preventing unwanted pregnancyReduce heatOrganic chemistryAntineoplastic agentsWarburg effectMolecular biology

Compounds of the following formula (I) slow the ATP-hydrolysing mode of ATP synthase and are useful for treating various diseases and disorders including cancer, particularly cancers that utilise the Warburg effect.

Owner:FORREST MICHAEL DAVID

Cooling Device for Turbine Nozzle Guide Vane by Liquid Metal With Low Melting Point

ActiveUS20220228492A1Improve heat exchange efficiencyEfficient heatingEngine fuctionsBlade accessoriesPhysicsFlight vehicle

Disclosed is a cooling device for a turbine nozzle guide vane with a low-melting-point metal as a flowing working media. A plurality of cooling channels and a cavity are arranged in a guide vane. The cooling device includes a flow divider, a collector, a radiator and an electromagnetic pump, the cooling device and the guide vane form a closed loop. Liquid low-melting-point metal or alloy thereof as the flowing working medium is driven by the electromagnetic pump to circularly flow in the closed loop and dissipate rapidly through the radiator. Air cooling is not adopted in the present disclosure, cooling air originally led out from a gas compressor is saved so as to increase the propelling power of an aircraft. Air film holes do not need to be formed in the outer surface of the guide vane so as to improve strength of the guide vane.

Owner:BEIHANG UNIV

Multi-stage ratio pressure regulator system

ActiveUS8616228B1Negates needAvoid condensationVessel mounting detailsOperating means/releasing devices for valvesDecreased pressureCooling effect

A multi-stage pressure regulator system. The system of the present invention provides for distribution of the Joules-Thomson (J-T) cooling effect between multiple stages. In the preferred embodiment of the present invention, the pressure is first reduced by a set ratio in one or more stages followed by an adjustable pressure output stage. The present invention thereby provides a system to control pressure reduction and thus prevent condensation (and associated distortion of a vapor composition sample) of a gas due to J-T cooling effect. The system of the present invention is particularly suitable for use placement (via, for example, a probe) within the source gas supply containment vessel, pipeline or the like, so that pressure reduction occurs at or near isothermal conditions, further lessening the likelihood of J-T condensation.

Owner:MAYEAUX HLDG

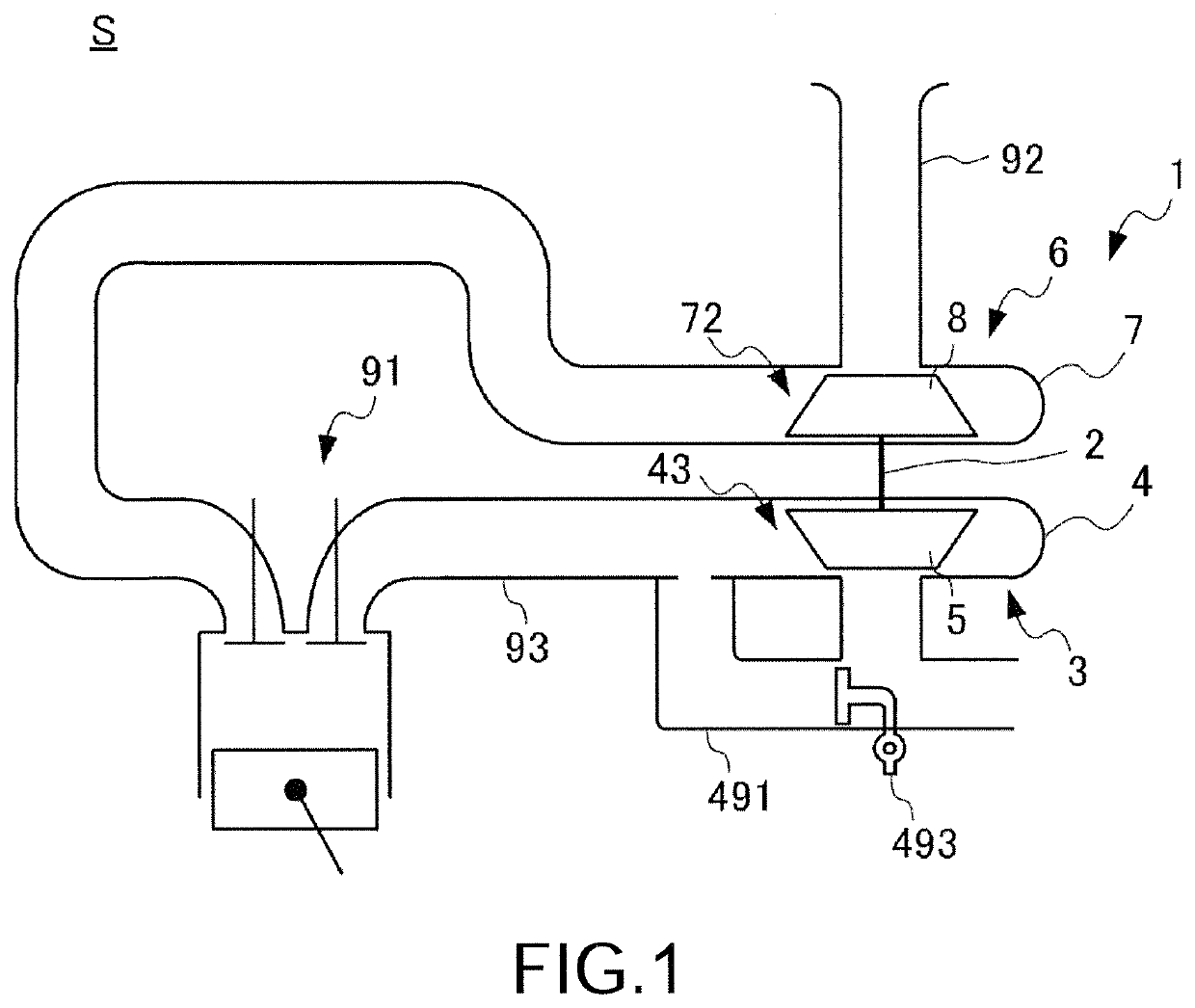

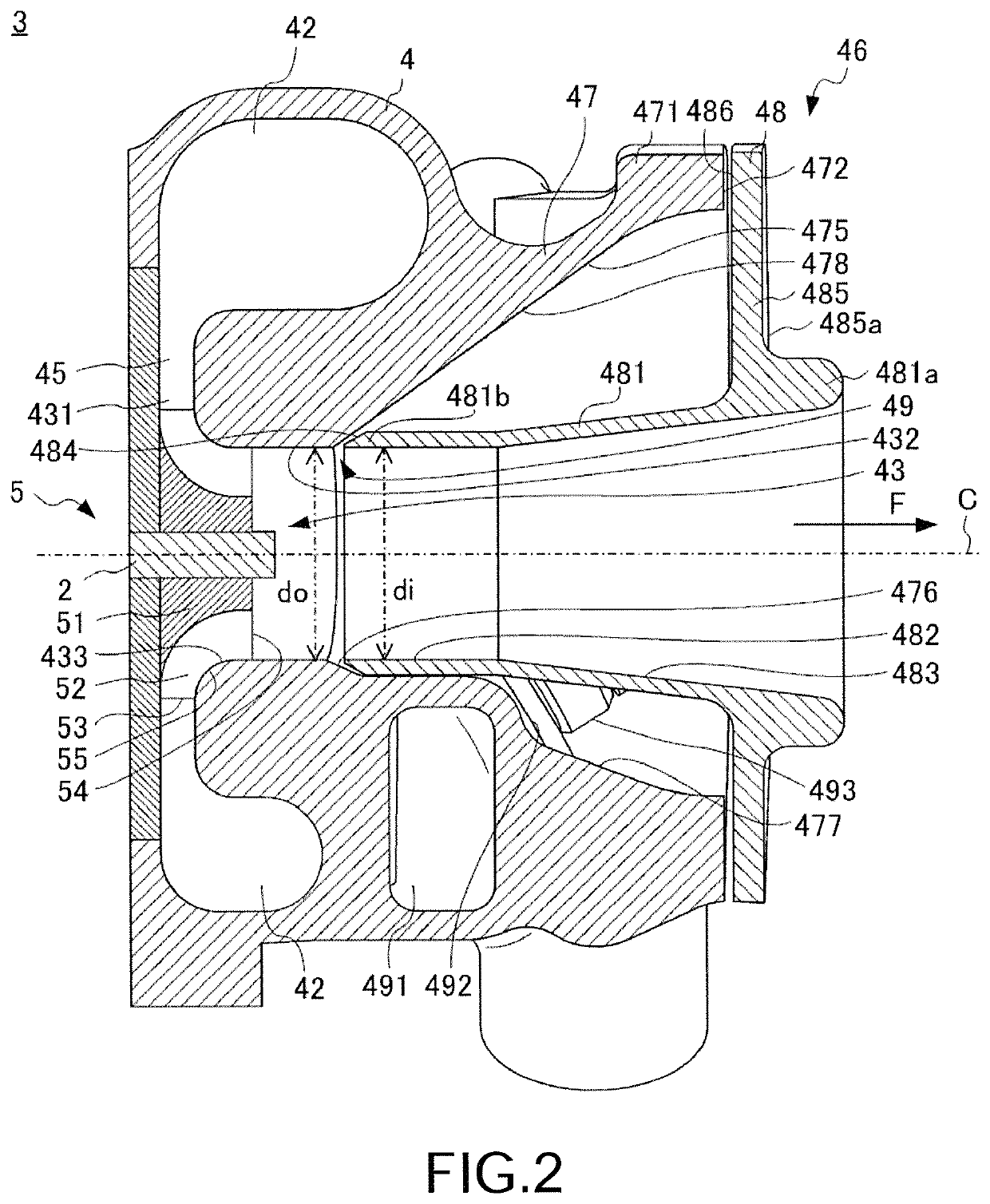

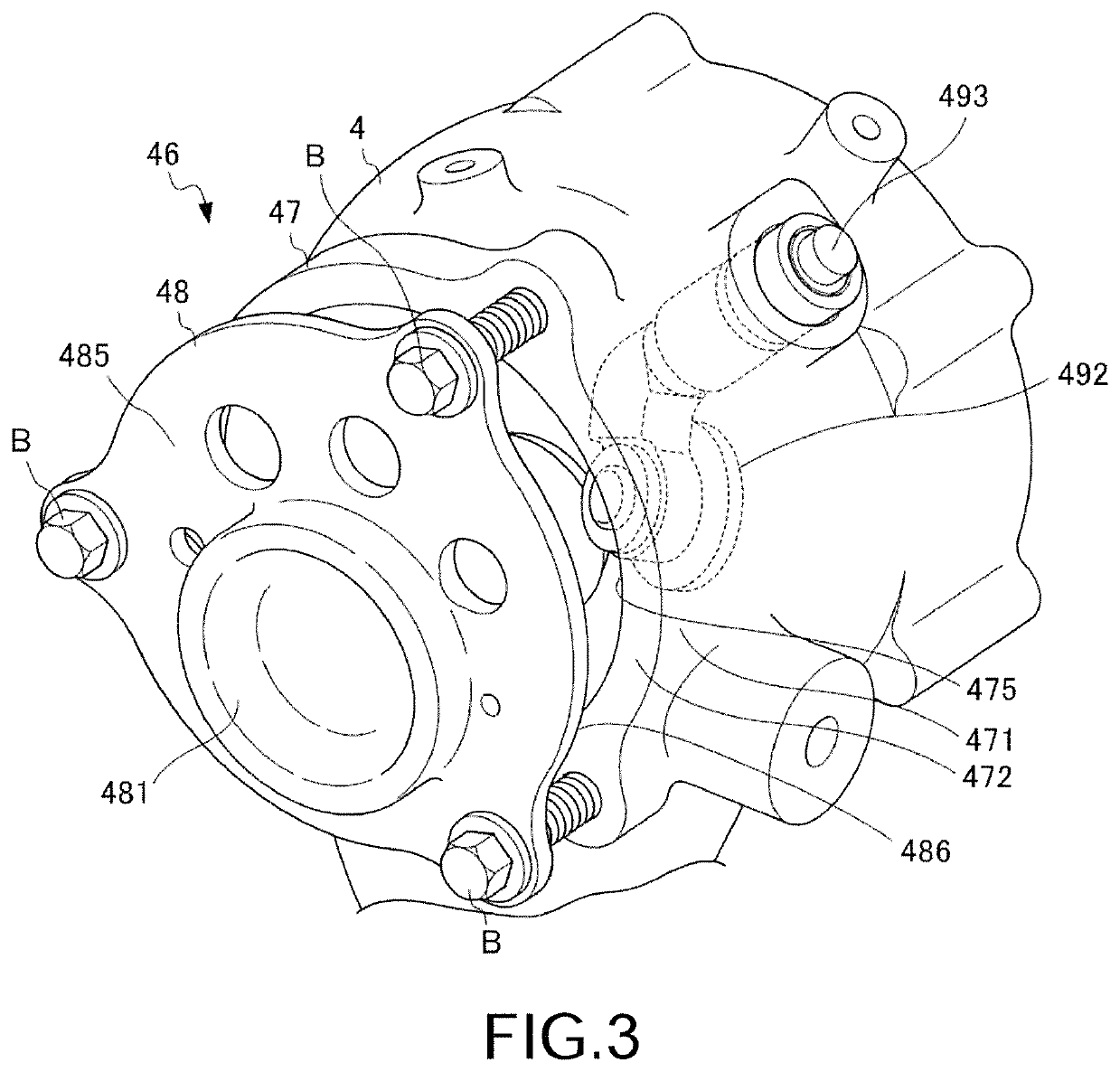

Turbine

ActiveUS10519812B2Release heatIncrease pressureInternal combustion piston enginesBlade accessoriesImpellerTurbine

A turbine (3) includes: a turbine impeller chamber (43) having a tubular outflow portion (432), from which an exhaust gas flows out in an outflow direction (F) substantially parallel to an axis (C) of a turbine impeller (5); a bypass flow passage (491) bypassing the inside of the turbine impeller chamber; an outer duct (47) having an inner peripheral surface (475) that expands in diameter in the outflow direction from the outflow portion; and an inner duct (48) that extends in the outflow direction from the outflow portion. A diffuser flow passage (483) that expands in diameter in the outflow direction is disposed in the inner duct at least in a portion between the outflow portion and a distal end portion (481a). An outlet (492) of the bypass flow passage and a waste gate valve (493) that opens and closes the outlet are disposed on the inner peripheral surface.

Owner:HONDA MOTOR CO LTD

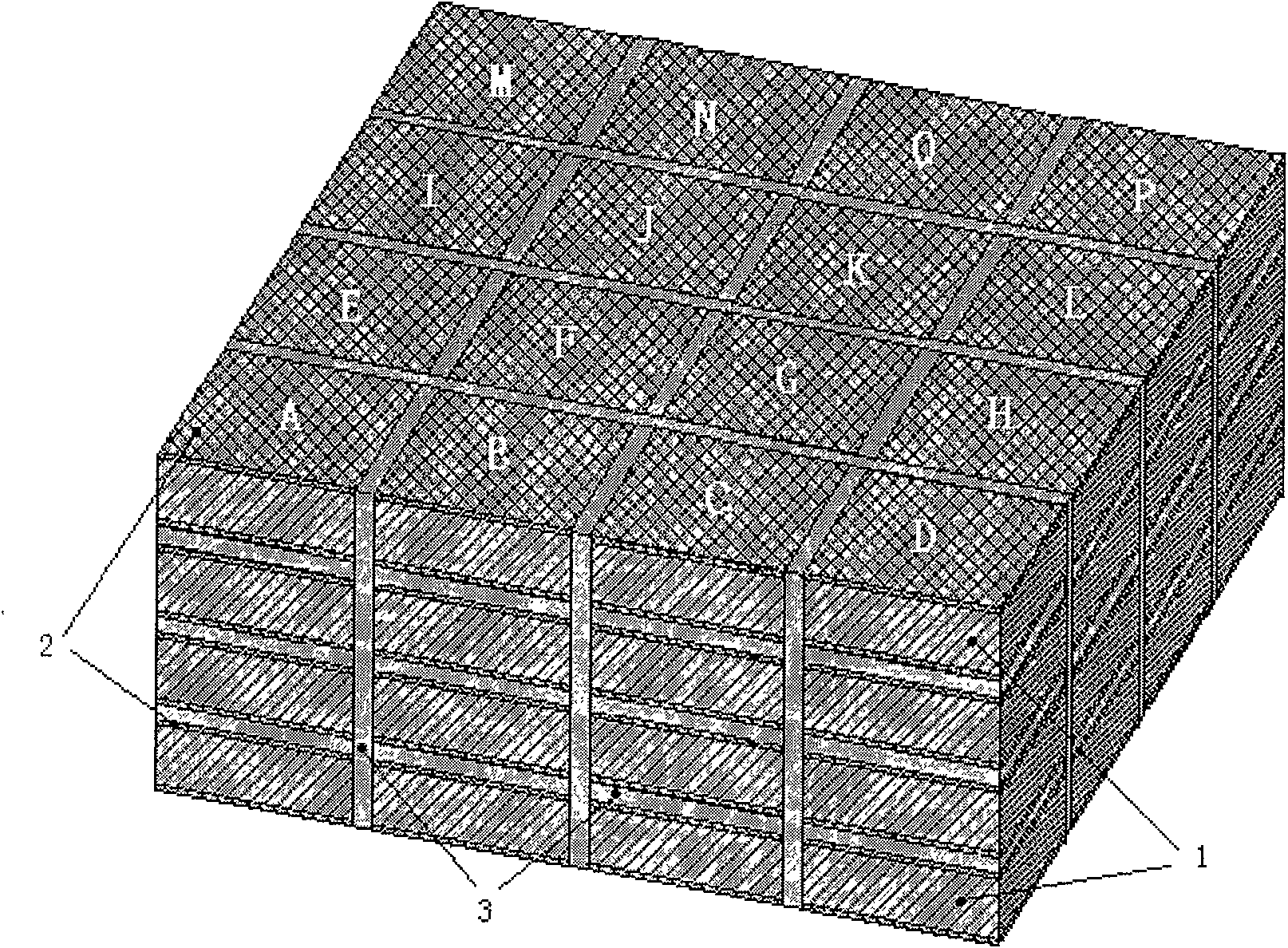

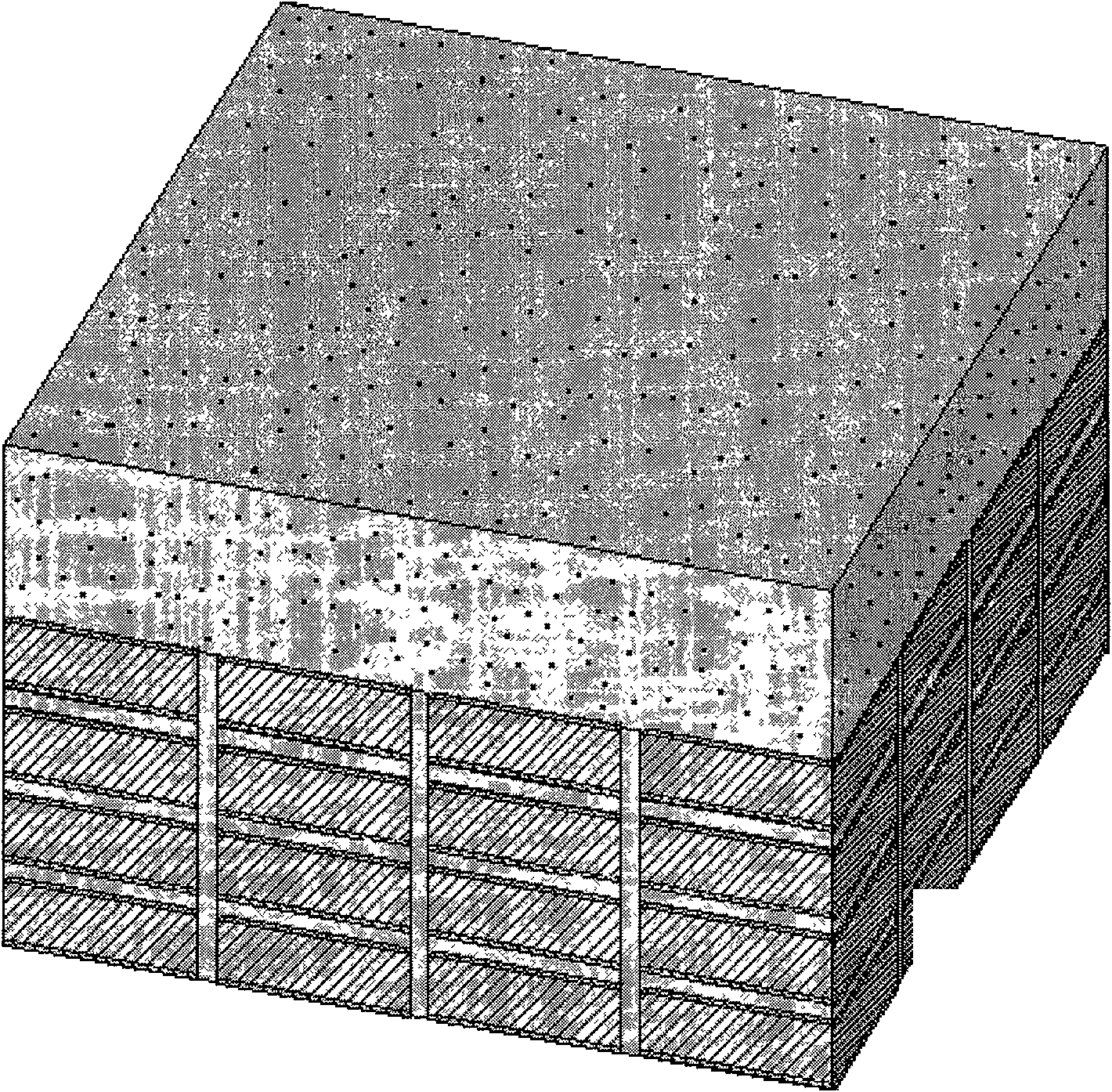

Cyclone cooling method and cooling tower

InactiveCN1200241CImprove heat dissipationImprove cooling efficiencyTrickle coolersCycloneCooling tower

The swirling cooling tower of the invention belongs to the technical field of chemical cooling. The cooling tower of the present invention has no fillers, and it includes layered and stacked dispersion needle wheels 3 or demisting needle wheels 5, and a liquid spray device 4 in the middle. The needle wheels contain radially layered needle seedlings 15. The needle seedlings 15 are rotated to form a swirling flow with a uniform angular velocity. The cooling tower of the present invention increases the specific surface area and distribution uniformity of the liquid droplets through nozzle dispersion, swirl flow dispersion, and the collision and dispersion of the needle seedlings 15 to the droplets, and the swirl flow also increases the centripetal heat transfer speed of the airflow and enhances heat dissipation. effect and heat dissipation intensity, flatten and radialize the heat dissipation process; it is also possible to stack pinwheels and spray layers in layers, and the cross-flow cooling of the tower body 6 can also be divided into multiple layers at a certain height with the help of the air guide plate 7 to enter the air. It not only increases the temperature drop of the cooling tower but also greatly reduces the floor space of the cooling tower. The cooling tower of the present invention adopts the defogging needle wheel 5 to centrifugally remove the fog, which not only fully completes the water removal, but also allows the spray nozzle to have a wide atomization interval.

Owner:高根树

Application of desulfurized injection residues of LF furnace and thermal insulating agent prepared by desulfurization injection residues of LF furnace

ActiveCN103320573AEasy to useRealize comprehensive utilizationRecycling and recovery technologiesProcess efficiency improvementCalcium silicateAlkalinity

The invention discloses an application of desulfurized injection residues of an LF furnace and a thermal insulating agent prepared by the desulfurized injection residues of the LF furnace. The thermal insulating agent comprises the components, in parts by mass: 70-90 parts of the desulfurized injection residues of the LF furnace, 5-20 parts of carbonized rice husks, 5-20 parts of calcium silicate, and a defined amount of a binder. The thermal insulating agent has suitable melting point, good spreading performance and excellent insulation resistance; and the thermal insulating agent has high alkalinity, and thereby having good adsorption of slag inclusions in molten steel.

Owner:BAOSHAN IRON & STEEL CO LTD

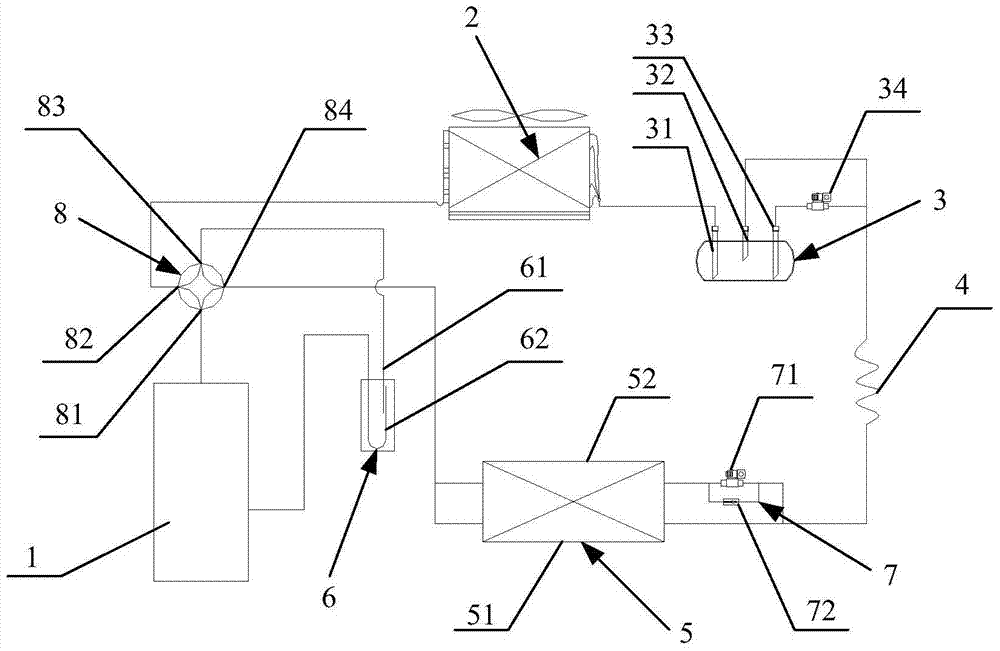

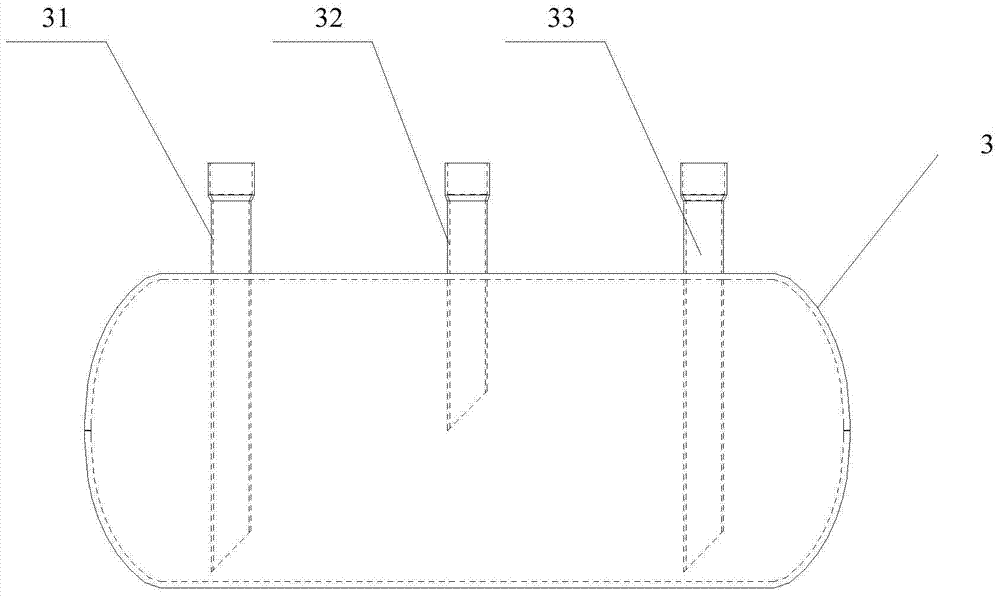

Superposed conjoined evaporation air-cooled compound condenser of air conditioner

ActiveCN102620487BLarge temperature dropImprove cooling energy efficiency ratioCondensate preventionEvaporators/condensersOutfallFan blade

The invention discloses a superposed conjoined evaporation air-cooled compound condenser of an air conditioner, wherein a condenser chamber is provided with an upper and a lower basins, an upper fan and a lower fan are respectively arranged in the upper and the lower basins, wind outlet sides of the fans are all provided with condenser pipe groups with fins, fan blade backspin points of the upper and the lower fans are all lower than a preset water level of the basins, a weeping pipe is arranged above the top spin of the upper fan, an inner diameter of the top of the weeping pipe is expanded into a water collecting cup, the condensed water discharging tube of an evaporator is arranged in the water collecting cup, an overflow tube is arranged in the upper basin, a water inlet is arranged in the preset water level height, a water outlet is arranged at side upward of the top spin of the lower fan blade, a water supply tank is arranged higher than a top cover, and a tank wall is communicated with a water supply tube, the water outlet is arranged in the water collecting cup, an upper part of the water supply tank wall is communicated with a gas inlet tube, a gas inlet is arranged in the preset water level of the lower basin, and the upper and the lower basins are all provided with siphon water discharging tubes. The rotary blades blow the water drops dripped from above and splashed by water inferior on the fins for evaporation and absorption of heat, which obviously reduces the temperature of refrigerating agent and achieves the energy saving purpose.

Owner:ZHEJIANG DONGFENG REFRIGERATION COMPONENTS

Three-claw opening-shrinking machine synchronized through connecting rods

A three-claw opening-shrinking machine synchronized through connecting rods comprises a supporting seat, a telescopic arm, a first rotating arm, a second rotating arm, a first jaw, a second jaw, a third jaw, a first connecting rod mechanism and a second connecting rod mechanism, wherein the telescopic arm is connected to the supporting seat and can move up and down; the first rotating arm and the second rotating arm are symmetrically positioned on both sides of the telescopic arm respectively; the first rotating arm and the second rotating arm are rotationally connected to the supporting seat through a first pin shaft and a second pin shaft respectively; the first jaw, the second jaw and the third jaw are connected to the first rotating arm, the second rotating arm and the telescopic arm respectively; the first connecting rod mechanism and the second connecting rod mechanism are symmetrically positioned on both sides of the telescopic arm respectively; the top ends of the first connecting rod mechanism and the second connecting rod mechanism are fixed on the first rotating arm and the second rotating arm through the first pin shaft and the second pin shaft respectively, and the lower ends are hinged together; and the lower end of the telescopic arm is connected to the hinged part of the lower ends of the first connecting rod mechanism and the second connecting rod mechanism. Under the action of an acting cylinder and through the first connecting rod mechanism and the second connecting rod mechanism, the first rotating arm and the second rotating arm rotate around the axial lines of the first pin shaft and the second pin shaft, the telescopic arm moves telescopically on the supporting seat, the first jaw, the second jaw and the third jaw are driven by the first rotating arm, the second rotating arm and the telescopic arm to act simultaneously, and the jaws shrink or open.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

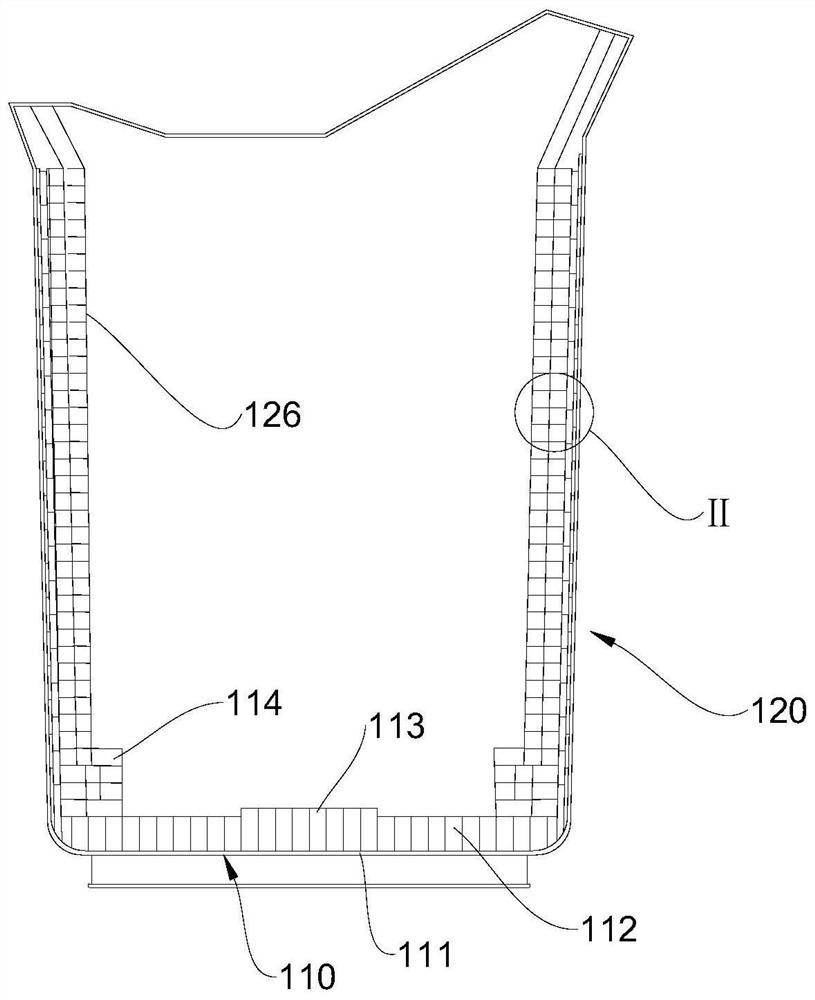

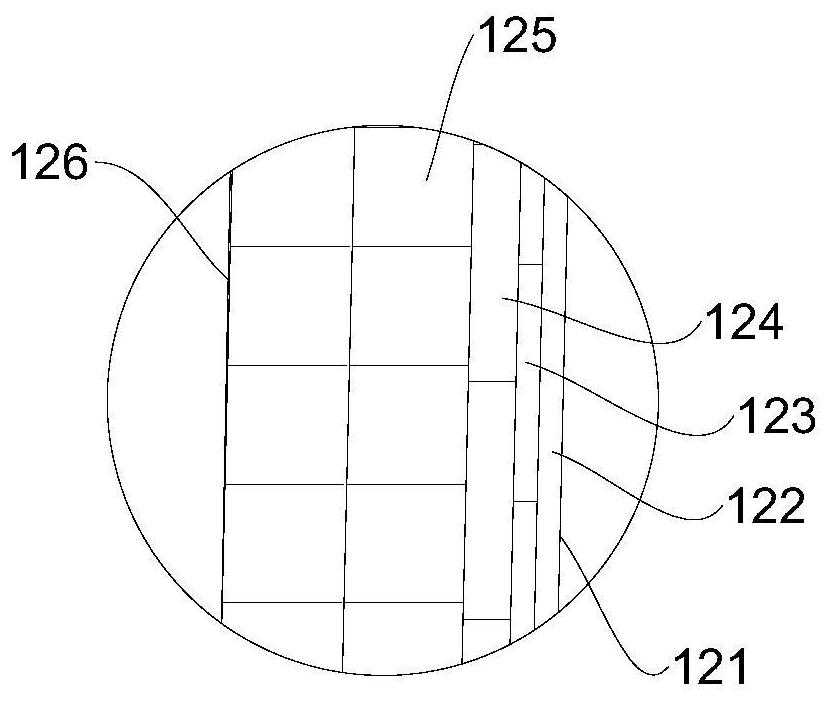

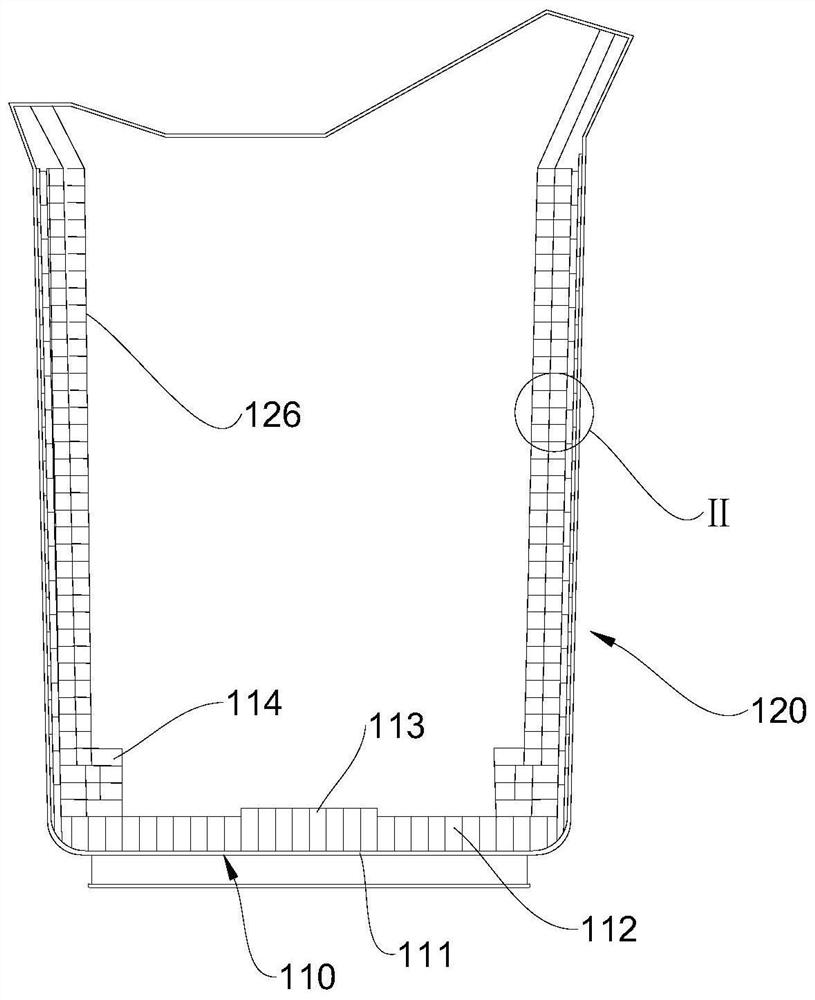

A kind of iron ladle and preparation method thereof

ActiveCN112264610BReduce thicknessReduce quality problemsMelt-holding vesselsInsulation layerThermal insulation

The application provides a molten iron tank and a preparation method thereof, belonging to the technical field of molten iron tanks used in the iron and steel industry. In the ladle, the first working layer includes a layer of working bricks. The first casing and the second casing are integrally formed, and the thickness of the casing is 15-25mm. The insulation layer is a layer of clay bricks, and the thickness of the insulation layer is 30-35mm; the permanent layer includes multiple layers of pyrophyllite bricks and multiple layers of second castable layers stacked from bottom to top, and the gap between two adjacent layers of pyrophyllite bricks Pour a second castable layer, the thickness of the permanent layer is 40-60mm. The nano-reflective layer includes a plurality of nano-reflective plates laid on one layer. The nano-reflective plate includes aluminum foil and nano-silica powder wrapped in the aluminum foil. The thickness of the nano-reflective plate is 4-8mm. The second working layer includes two layers of working bricks from outside to inside. The molten iron tank can maintain the volume of the molten iron tank and increase its strength without increasing the weight, and can avoid excessive temperature drop of the molten iron.

Owner:SGIS SONGSHAN CO LTD

Molten iron tank and manufacturing method thereof

ActiveCN112264610AReduce thicknessReduce quality problemsMelt-holding vesselsPyrophylliteInsulation layer

The invention provides a molten iron tank and a manufacturing method thereof, which belong to the technical field of molten iron tanks for steel industry. In the molten iron tank, a first working layer comprises a working brick layer; a first cladding and a second cladding are integrally formed, and each cladding is 15-25 mm thick; a thermal insulation layer is a clay brick layer, and is 30-35 mmthick; a permanent layer comprises a plurality of pyrophyllite brick layers and a plurality of second casting material layers which are stacked from bottom to top, and one second casting material layer is cast between very two adjacent pyrophyllite brick layers; the permanent layer is 40-60 mm thick; a nano reflection layer comprises a layer of paved nano reflecting plates, wherein each nano reflecting plate comprises an aluminum foil and nano silicon dioxide powder packaged in the aluminum foil, and is 4-8 mm thick; and the second working layer comprises two working brick layers from outsideto inside. In case of not increasing weight, the molten iron tank can keep capacity and improve strength, and temperature drop of molten iron can be prevented from being too great.

Owner:SGIS SONGSHAN CO LTD

Application of desulfurized injection residues of LF furnace and thermal insulating agent prepared by desulfurization injection residues of LF furnace

ActiveCN103320573BEasy to useRealize comprehensive utilizationMetal recyclingProcess efficiency improvementCalcium silicateAlkalinity

The invention discloses an application of desulfurized injection residues of an LF furnace and a thermal insulating agent prepared by the desulfurized injection residues of the LF furnace. The thermal insulating agent comprises the components, in parts by mass: 70-90 parts of the desulfurized injection residues of the LF furnace, 5-20 parts of carbonized rice husks, 5-20 parts of calcium silicate, and a defined amount of a binder. The thermal insulating agent has suitable melting point, good spreading performance and excellent insulation resistance; and the thermal insulating agent has high alkalinity, and thereby having good adsorption of slag inclusions in molten steel.

Owner:BAOSHAN IRON & STEEL CO LTD

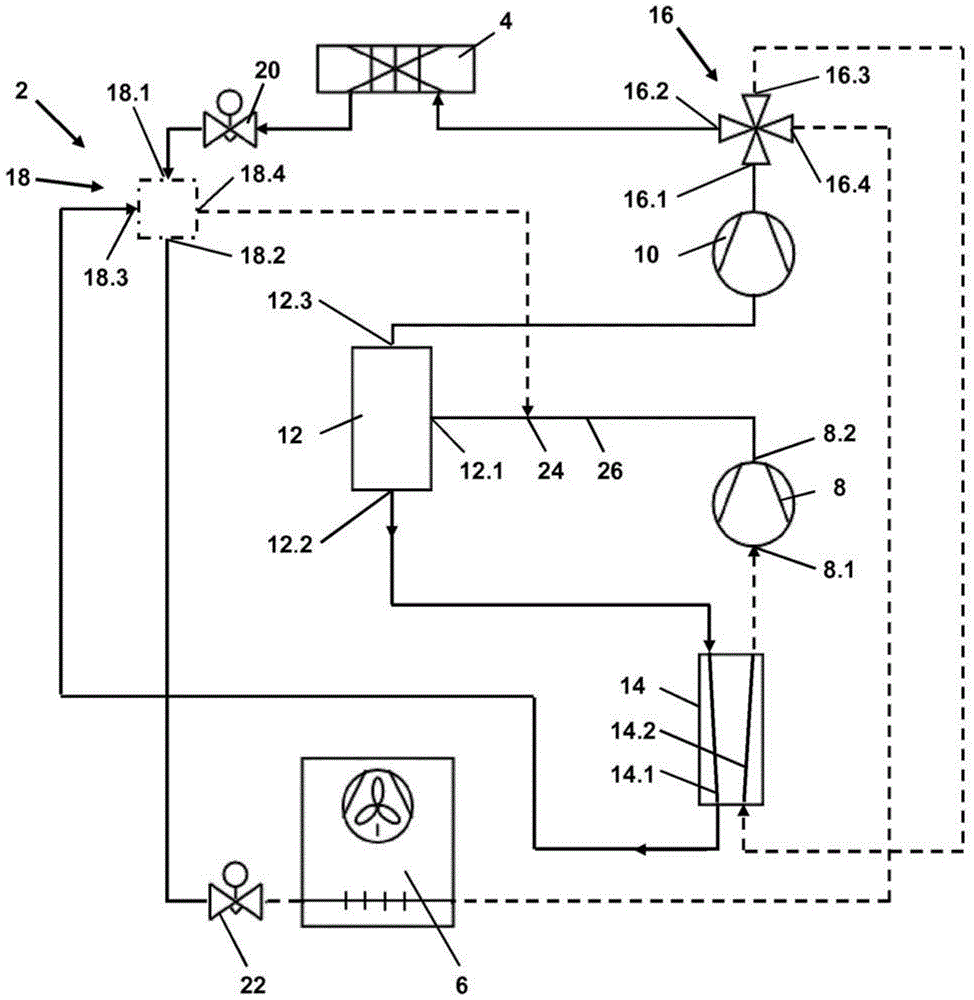

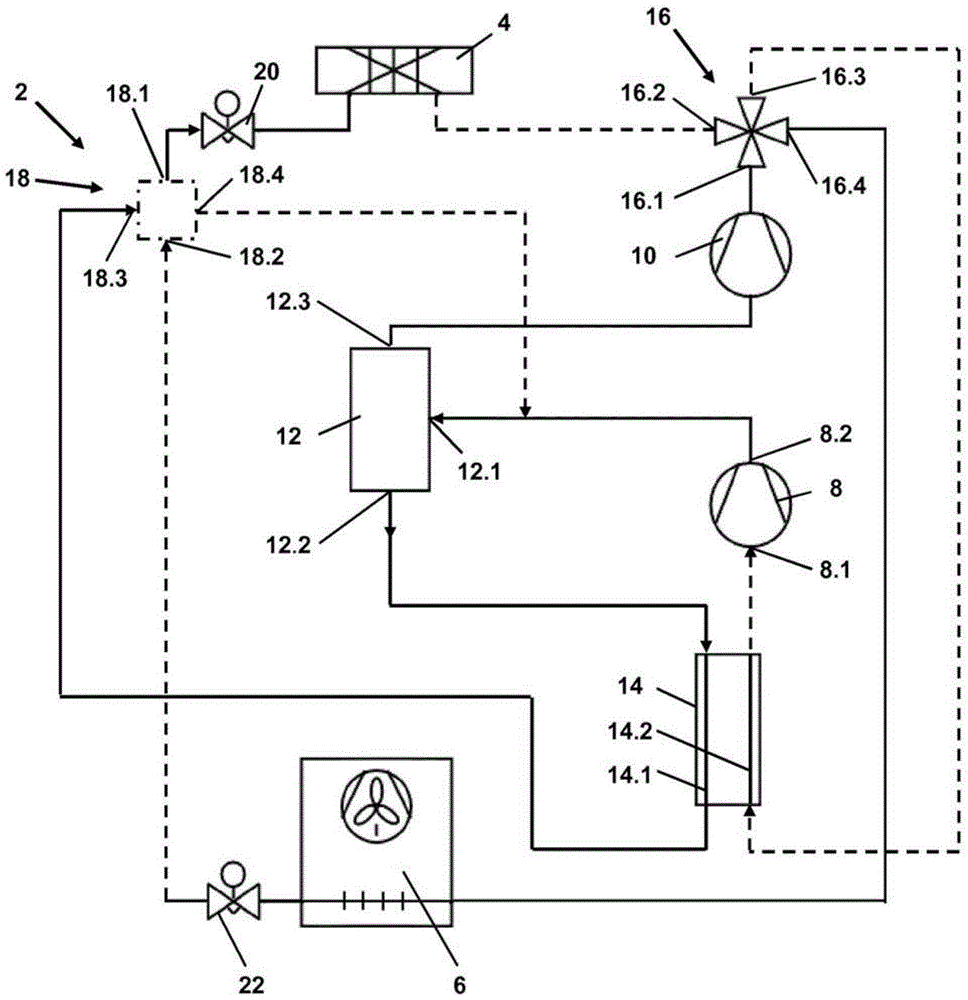

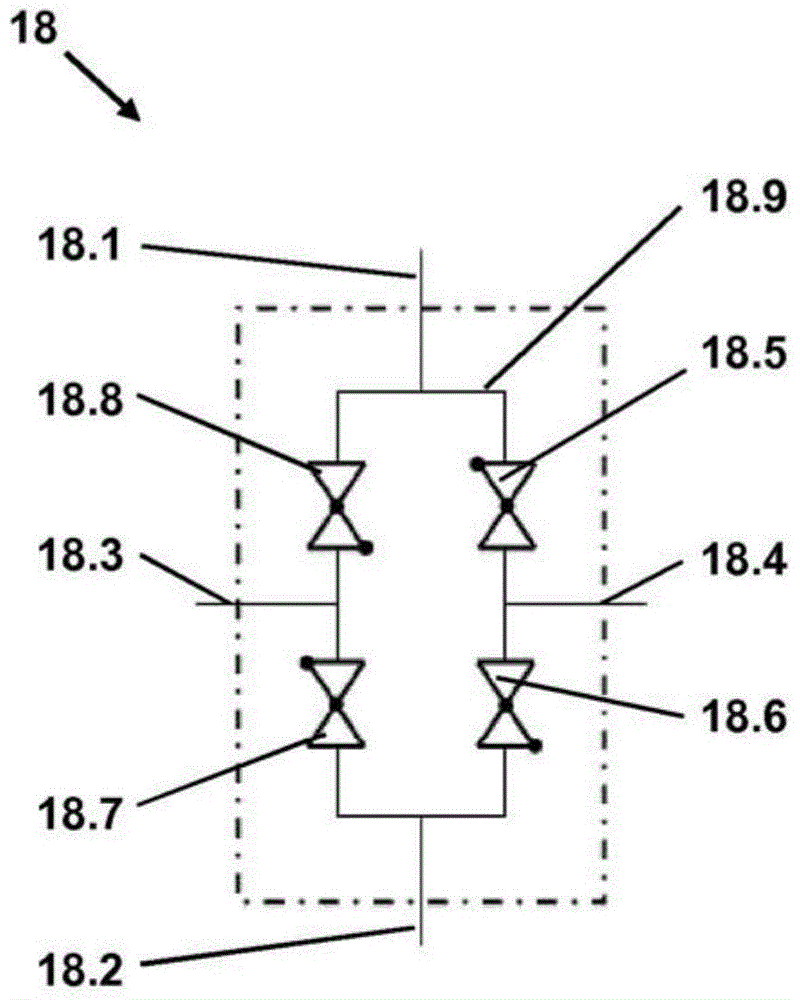

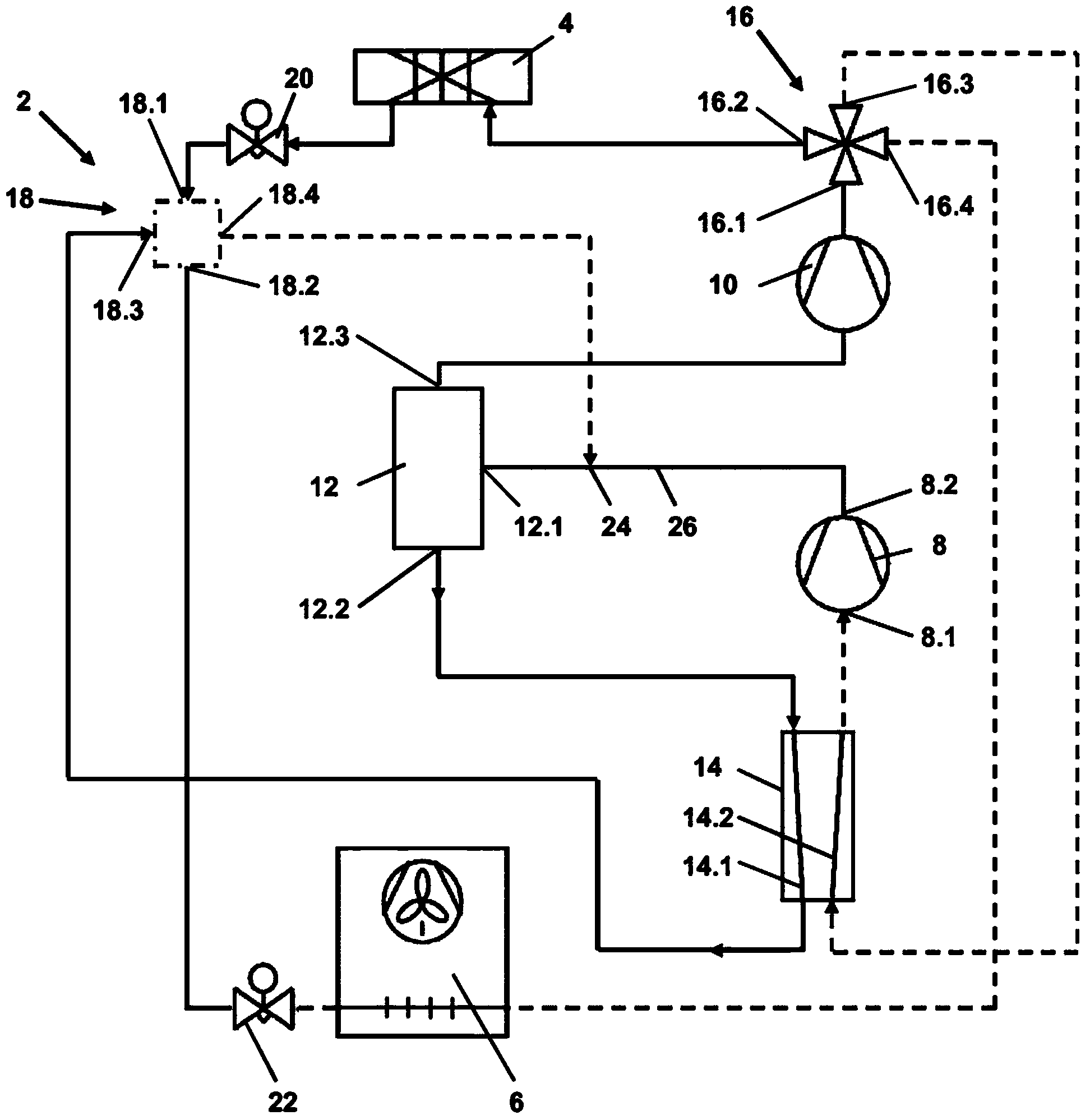

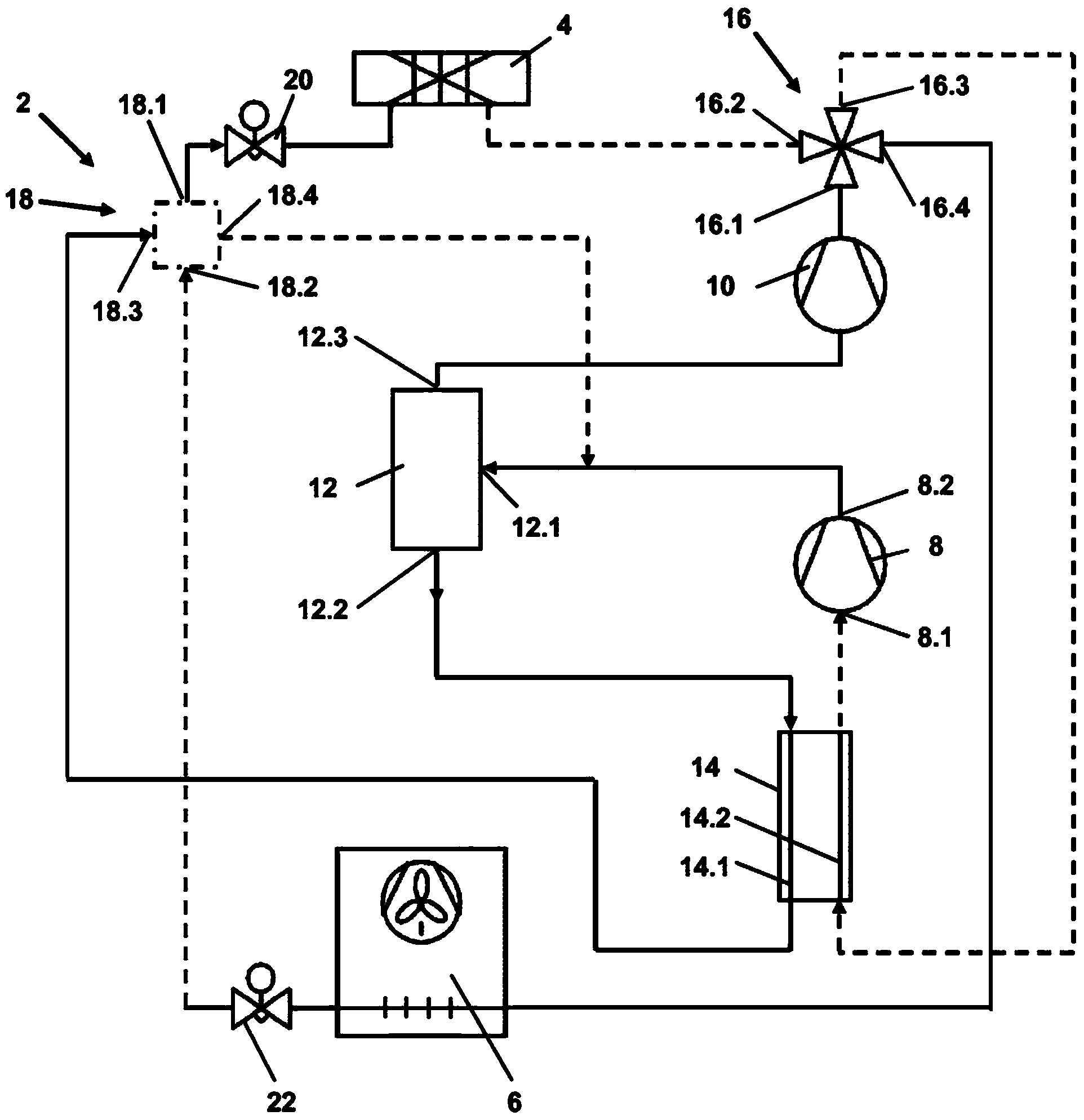

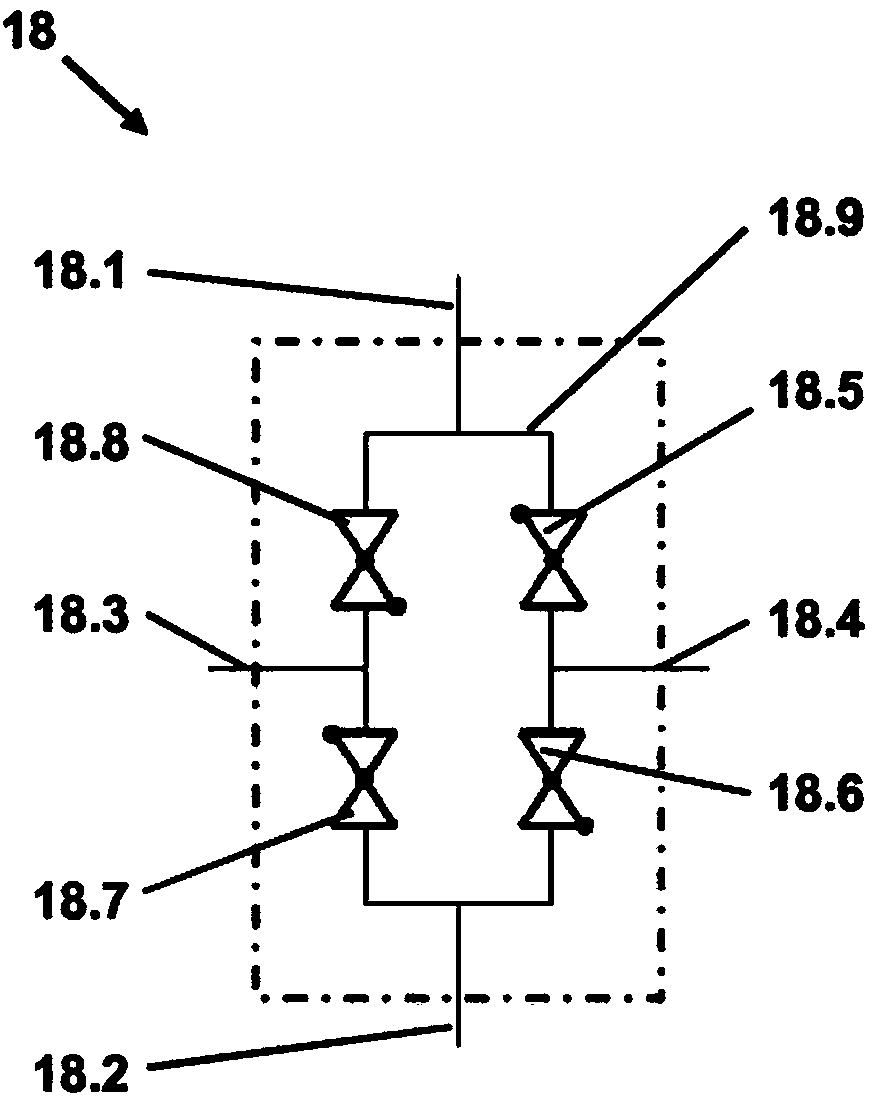

heat pump

InactiveCN104114962BEasy to compressRaise the condensation temperatureCompression machines with non-reversible cycleSuperheatersLiquid mediumProcess engineering

The invention relates to a heat pump (2) switchable between cooling operation and heating operation, having: a first heat exchanger (4), a second heat exchanger (6), two for compressing a medium Compressor stage (8,10), an intermediate pressure bottle (12) used for phase separation of liquid medium connected between compressor stage (6,8) and second compressor stage (10); wherein A switching valve (16) is connected downstream of the second compressor stage (8), by means of which a communication between the second compressor stage (8) and the second heat exchanger (6) can be established during refrigeration operation. A flow connection and a flow connection between the second compressor stage ( 8 ) and the first heat exchanger ( 4 ) can be established during heating operation.

Owner:ROBERT BOSCH GMBH

Heat pump

InactiveCN104114962AReach additional superheatReduce the numberCompression machines with non-reversible cycleSuperheatersEngineeringBottle

The invention relates to a heat pump (2), which can be changed over between cooling mode and heating mode, having a first heat exchanger (4), a second heat exchanger (6), two compressor stages (8, 10) for compressing a medium and a medium pressure bottle (12), inserted between the compressor stages (6, 8) and the second compressor stage (10) for phase separation of the fluid medium. Downstream of the second compressor stage (8), a changeover valve (16) is arranged, by means of which a flow connection between the second compressor stage (8) and the second heat exchanger (6) can be established in cooling mode, and a flow connection between the second compressor stage (8) and the first heat exchanger (4) can be established in heating mode.

Owner:ROBERT BOSCH GMBH

air conditioner

ActiveCN104930593BAvoid frequent power on and offImprove dehumidification effectMechanical apparatusSpace heating and ventilation safety systemsSystem stabilityEngineering

The invention discloses an air conditioner. The air conditioner comprises a compressor, an outdoor heat exchanger and an indoor heat exchanger which are sequentially connected. The indoor heat exchanger comprises a first-layer heat exchanger and a second-layer heat exchanger. The first end of the first-layer heat exchanger and the first end of the second-layer heat exchanger are connected with the compressor. The second end of the first-layer heat exchanger and the second end of the second-layer heat exchanger are connected with the outdoor heat exchanger. The air conditioner further comprises a control part connected with the second-layer heat exchanger. The control part is used for controlling a pipeline of the second-layer heat exchanger to be in a stop state when the air conditioner is in a dehumidification mode. The phenomenon of frequent starting of the compressor is avoided while the dehumidification function of the air conditioner can be improved, and therefore the service life of the compressor is prolonged, and the system stability is improved.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Cooling device for aeroengine turbine guide vane

The application discloses a cooling device for an aeroengine turbine guide blade, and relates to the cooling of the guide blade. In this application, low-melting point metals or their alloys are used as the working medium, and multiple cooling passages and chambers are arranged in the guide blades. The cooling device includes flow dividers, collectors, heat exchangers and electromagnetic pumps, which form a closed loop with the guide blades. loop, the electromagnetic pump drives the working medium to circulate in the closed loop loop, and the heat is quickly dissipated through the heat exchanger. This application can reduce the instability caused by the mixing of cold and hot air; the application has excellent cooling effect and high heat exchange efficiency, which is beneficial to prolong the service life of the guide vane; this application can improve the strength of the guide vane and reduce the processing time. Process cost; this application preheats aviation kerosene in advance to improve its combustion efficiency; the entire process of this application is closed in cycle, low melting point metals or their alloys can be recycled repeatedly, and have no impact on the environment.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com