Patents

Literature

34results about How to "Improve nitriding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer material contained ladle bottom argon blowing permeable brick and preparation process thereof

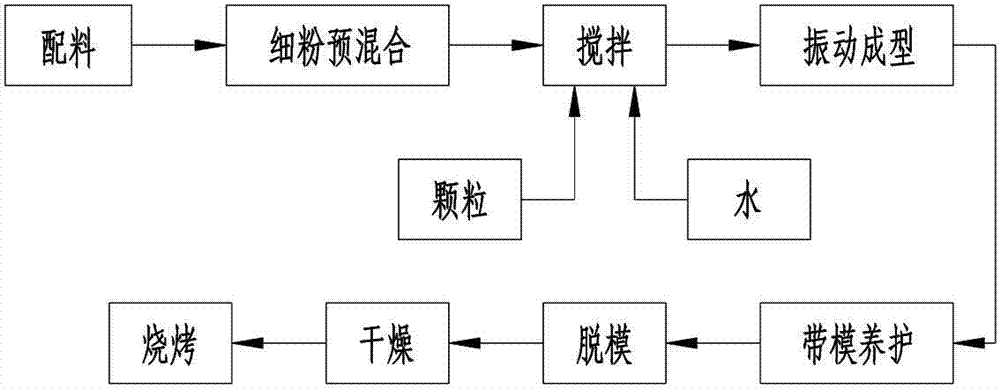

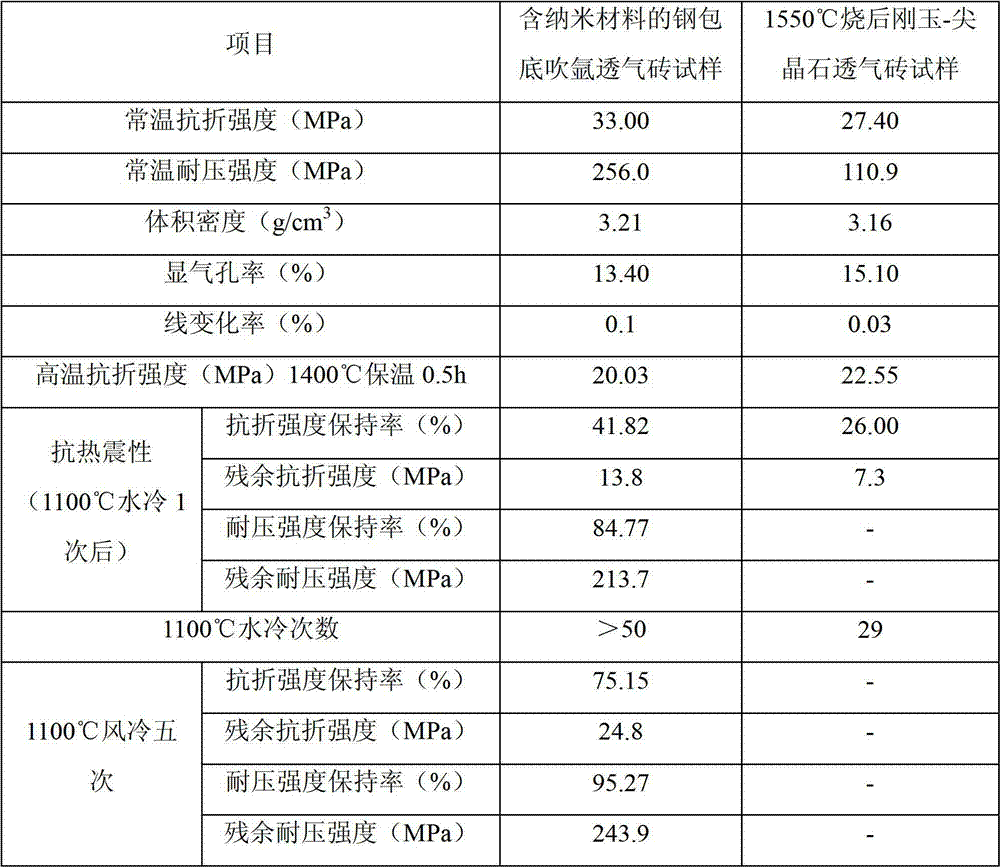

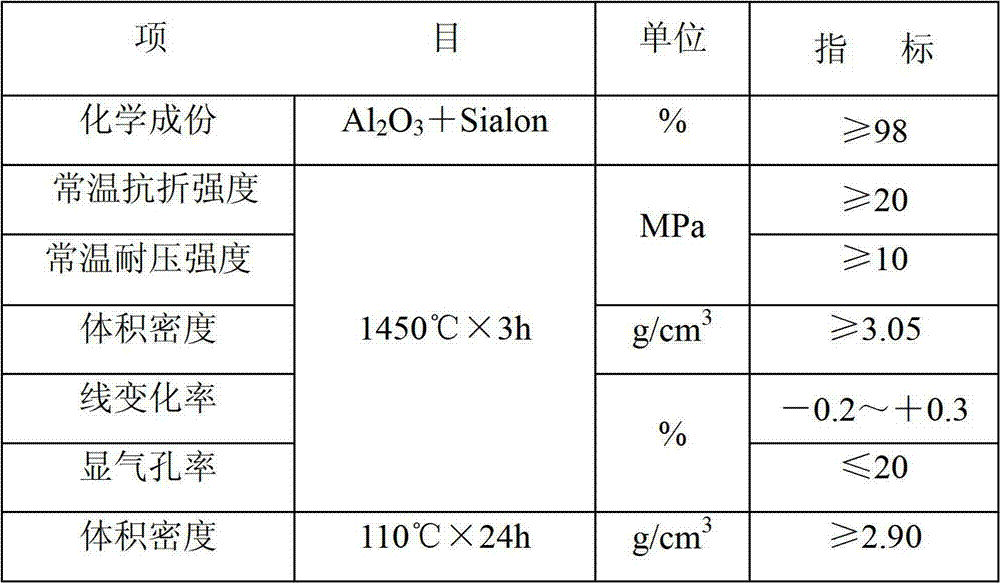

The invention discloses a nanometer material contained ladle bottom argon blowing permeable brick and a preparation process thereof. The permeable brick comprises components of high-purity corundum, spinel, alpha-Al2O3 micro powders, nano calcium carbonate, Si powders, binding agents and antiknock agents. The preparation process of the nanometer material contained ladle bottom argon blowing permeable brick includes the following steps of dosing, fine powder premixing, stirring, vibration forming, curing with molds, demolding, drying and baking. According to the nanometer material contained ladle bottom argon blowing permeable brick and the preparation process thereof, Cr2O3 is not used, and during usage, new pollutants are not generated, so that pollution treatment costs are reduced, and high environmental benefits are achieved; micropores are evenly distributed in the brick, so that cracks are effectively prevented from continuing spreading during usage, the toughness of the permeable brick is improved, the spalling is reduced, the service life of the permeable brick is prolonged, the permeable brick is basically free from bonding slag after usage, cleaning during usage is reduced, and production costs of iron and steel enterprises are reduced.

Owner:成都府天新材料科技有限公司

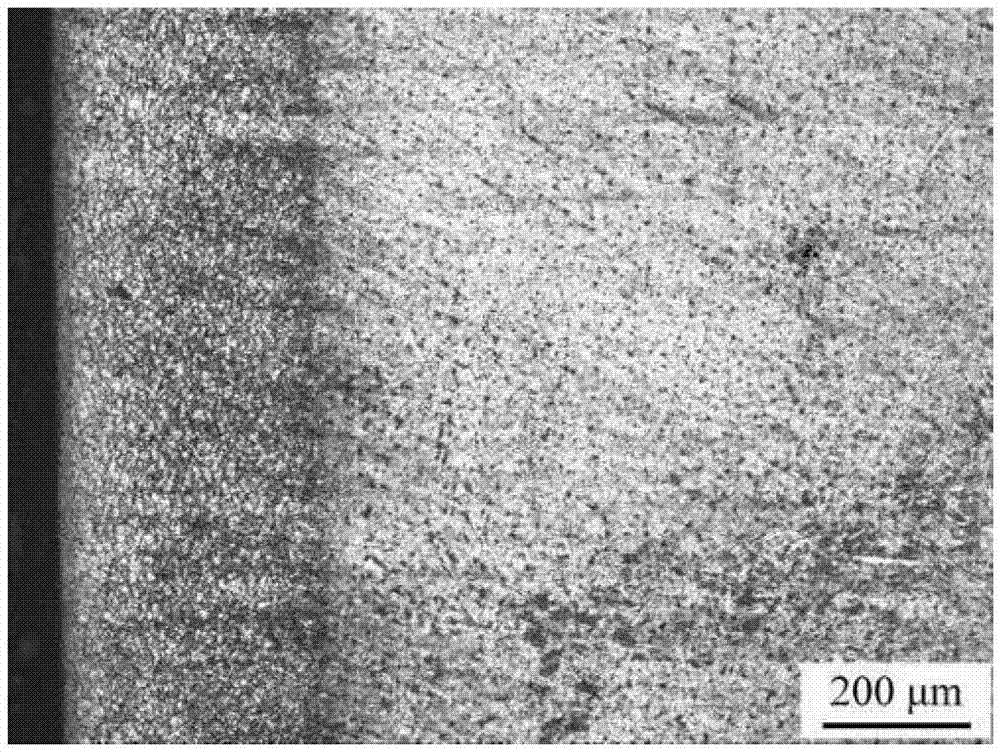

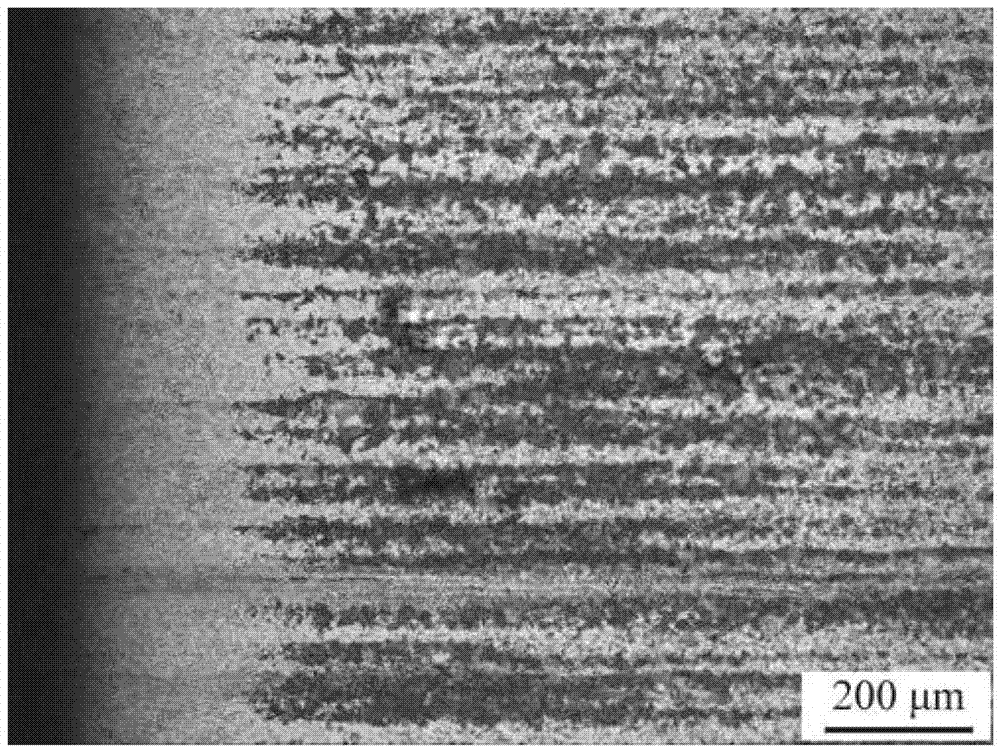

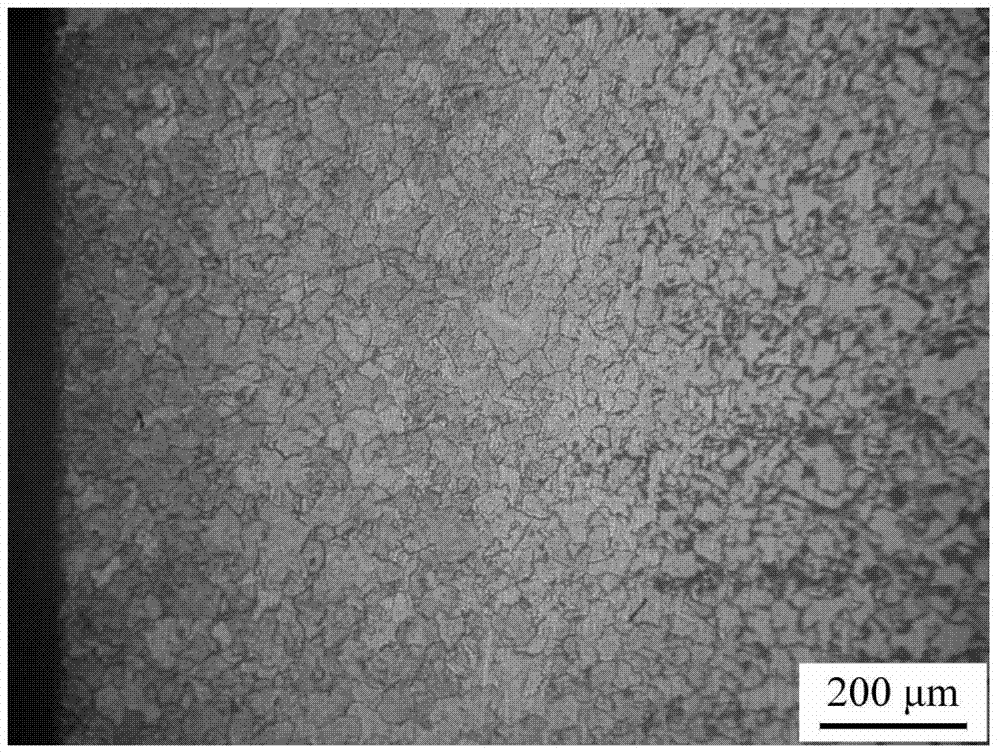

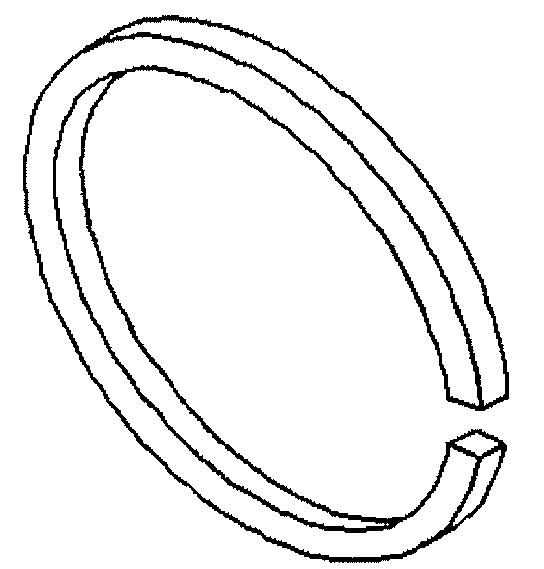

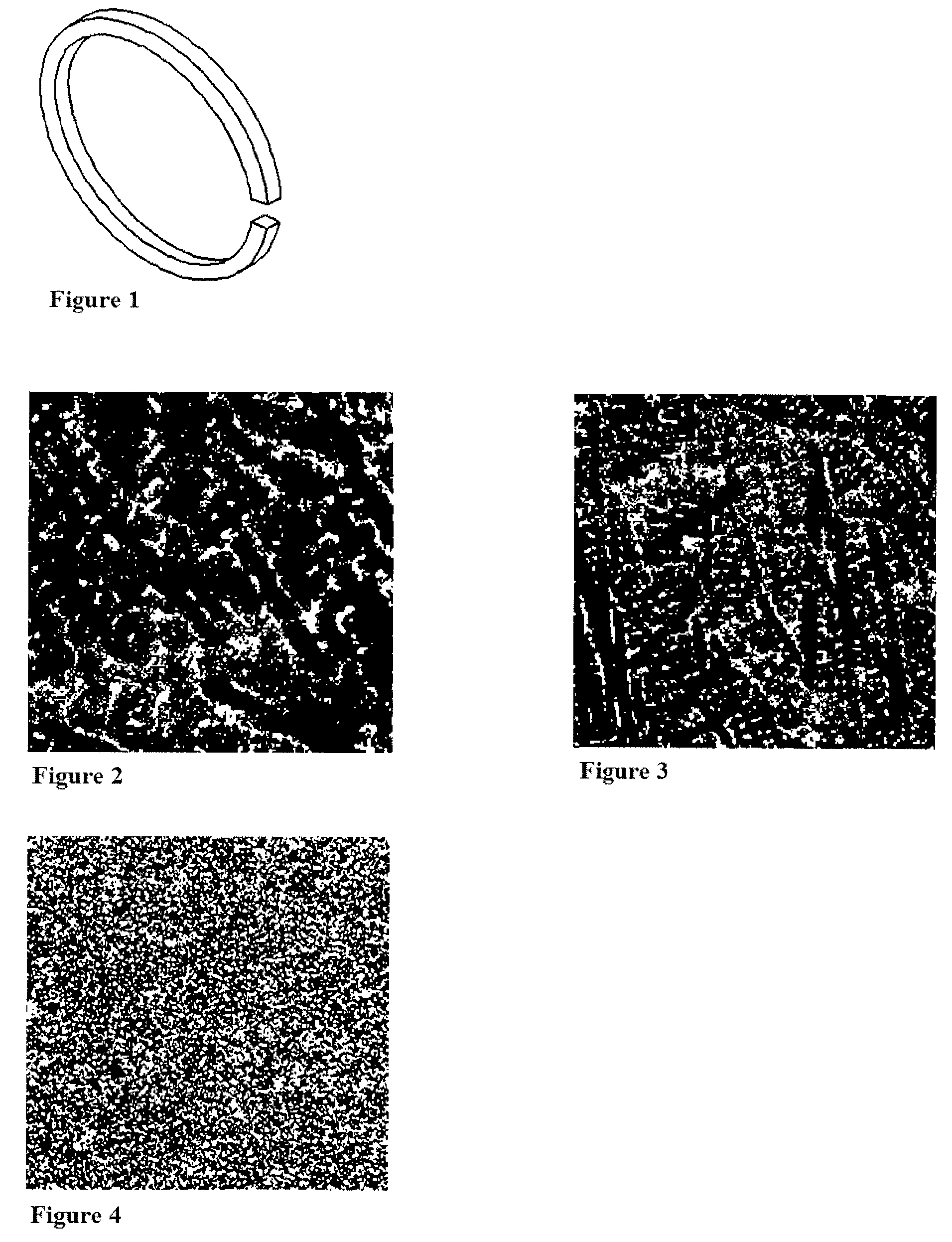

Nitratable steel piston rings and steel cylindrical sleeves, and casting method for the production thereof

InactiveUS20120090462A1Good nitridabilityEasy transitionPiston ringsBraking action transmissionCast ironSteel cylinder

A steel piston ring and a steel cylinder liner are described which comprise as the main body a steel composition which has good nitridability. The steel composition consists of the following elements: 0-0.5 weight % B, 0.5-1.2 weight % C, 4.0-20.0 weight % Cr, 0-2.0 weight % Cu, 45.30-91.25 weight % Fe, 0.1-3.0 weight % Mn, 0.1-3.0 weight % Mo, 0-0.05 weight % Nb, 2.0-12.0 weight % Ni, 0-0.1 weight % P, 0-0.05 weight % Pb, 0-0.05 weight % S, 2.0-10.0 weight % Si, 0-0.05 weight % Sn, 0.05-2.0 weight % V, 0-0.2 weight % Ti and 0-0.5 weight % W. The steel piston ring and the steel cylinder liner can be manufactured in a casting process using the machinery and technology employed for the manufacture of cast iron parts.

Owner:FEDERAL MOGUL BURSCHEID

Method for heat-treating work pieces made of temperature-resistant steels

InactiveUS7108756B2Good strength performanceImprove nitriding effectSolid state diffusion coatingFurnace typesSurface conditionsMachining

A method of producing a workpiece of a heat-resistant steel, such as hot forming tool steel, where the workpiece may be hardened and depassivated after mechanical machining and electrochemical treatment. The hardening including a reduction step, so that no depassivation need be performed by pickling, for example, before nitriding. The result of the hardening treatment is a favorable surface condition for stepwise nitriding.

Owner:ROBERT BOSCH GMBH

Medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method

InactiveCN103160774AImprove adsorption capacityImprove nitriding effectSolid state diffusion coatingDecompositionReaction rate

The invention discloses a medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method. The medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method comprises the following steps of putting a medium and low-carbon alloy constructional steel workpiece into a solid solution nitrogenation furnace which is shown in the patent having a patent name of pressurization high-temperature nitridation device with dual pressure equilibrium structure and having the patent number of 201210530358.6, improving the pressure to 0.1-0.5MPa at a temperature of 500-800 DEG C, feeding NH3 into the solid solution nitrogenation furnace at a flow rate of 0.1-0.5L / min, carrying out gas nitridation treatment at a decomposition rate of 30-80% for 5-20 hours, sequentially feeding NH3 into the solid solution nitrogenation furnace, cooling to a temperature below 150 DEG C, and taking out the workpiece. The medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method can effectively promote adsorption of N atoms on the part surface, improve N activity, an interface reaction rate and a hole and slit nitridation capability, reduce an NH3 decomposition rate, improve nitrogen potential, obviously reduce an NH3 consumption amount in nitridation, greatly improve process effects and realize short-term deep nitridation.

Owner:YANSHAN UNIV

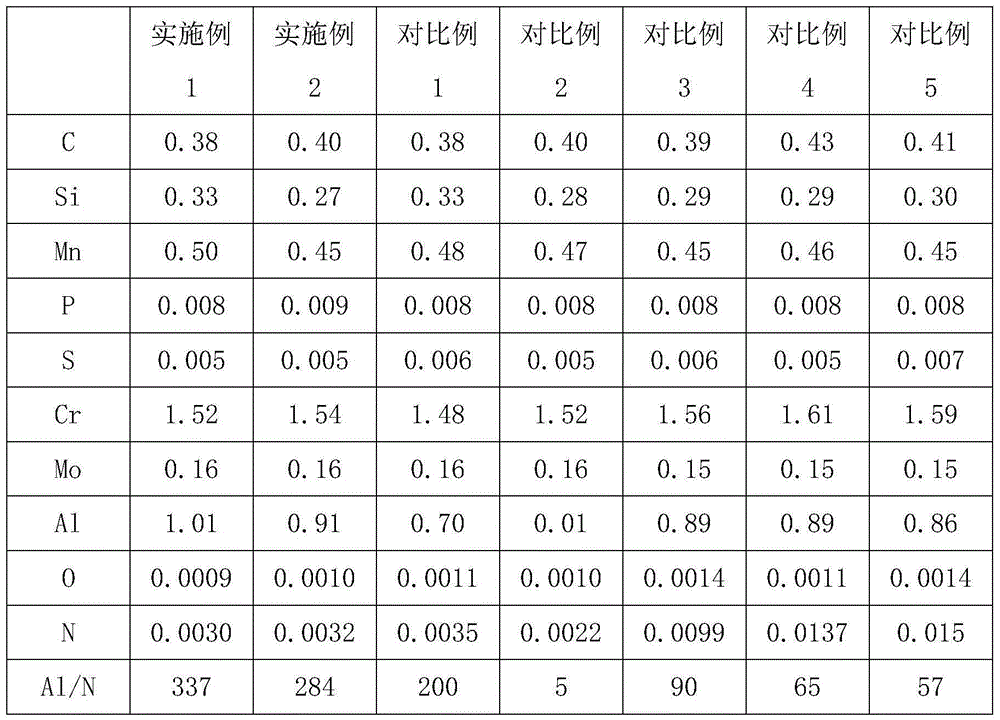

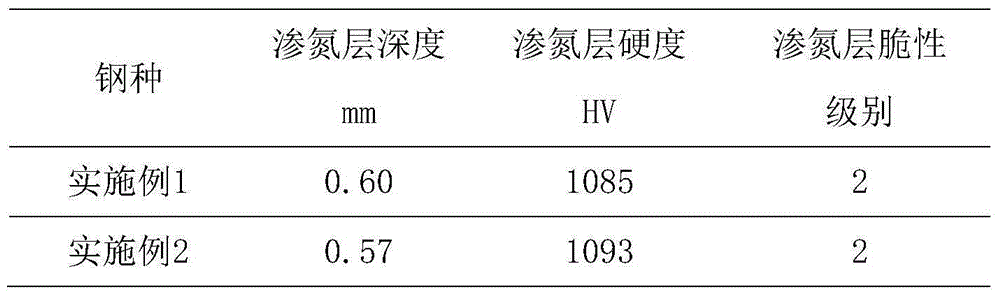

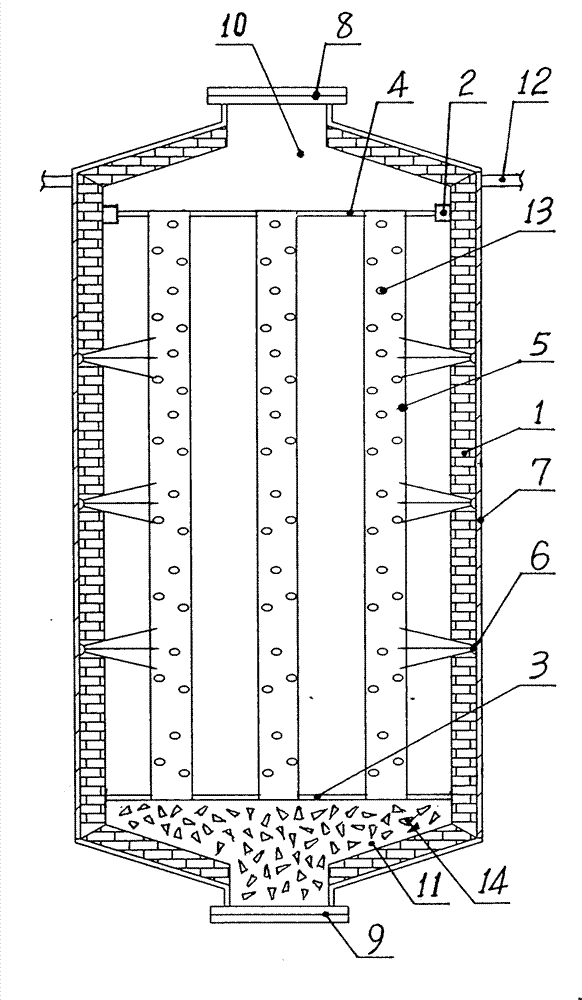

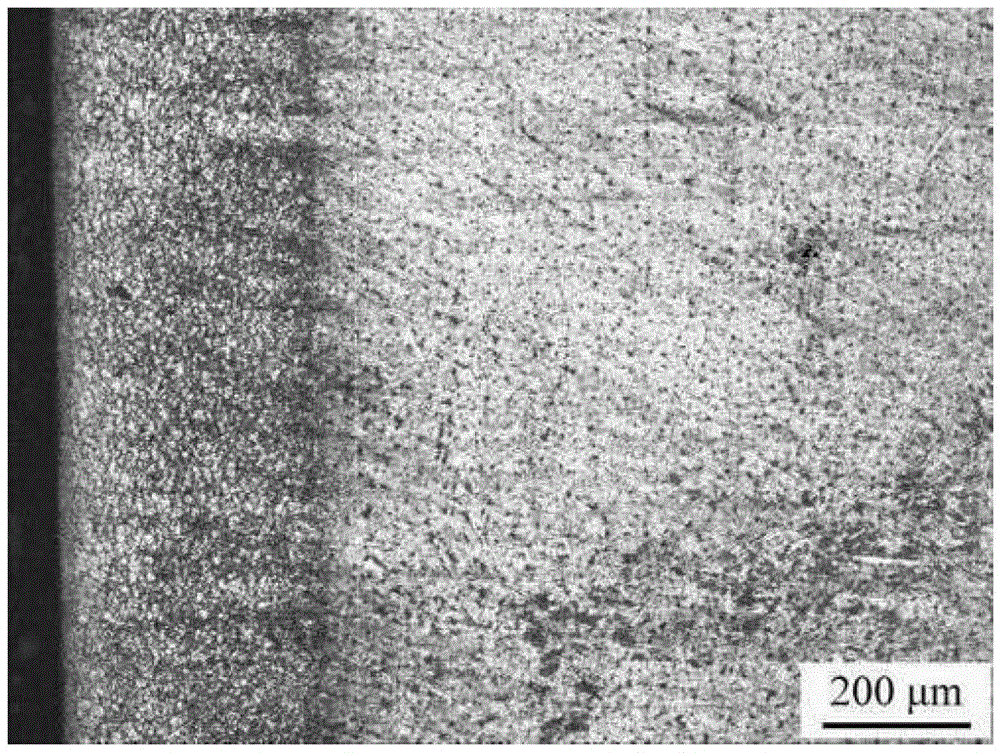

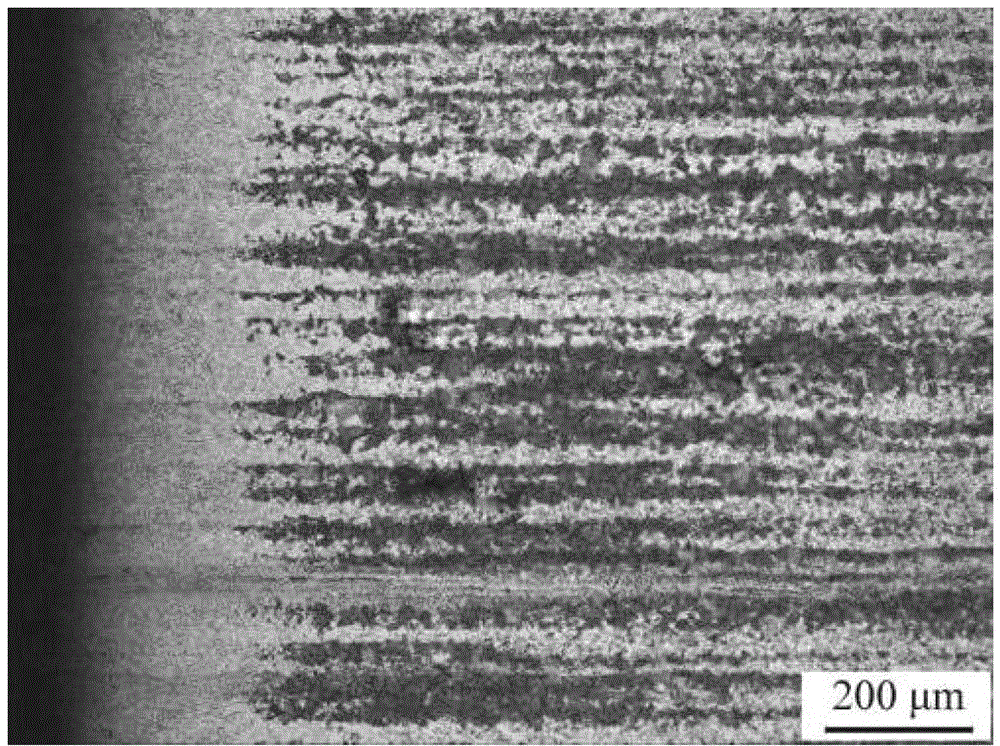

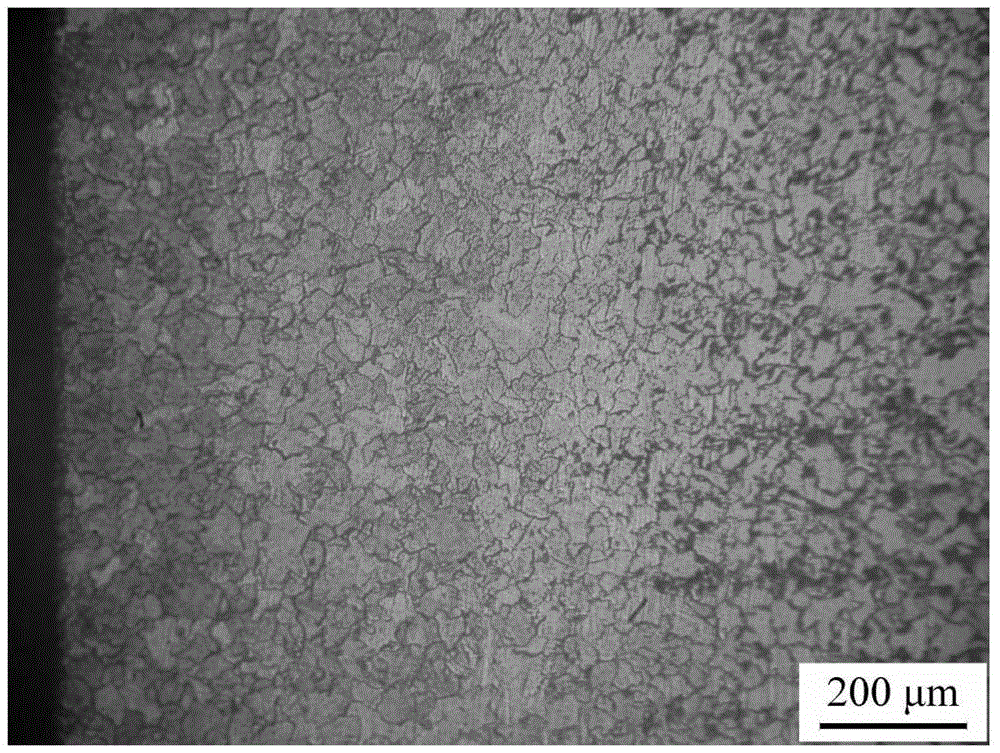

38CrMoAl nitrided steel with nitrided layer low in fragility

The invention discloses 38CrMoAl nitrided steel with a nitrided layer low in fragility and belongs to the technical field of alloy steel. The 38CrMoAl nitrided steel with the nitrided layer low in fragility comprises, by mass, 0.35%-0.42% of carbon, 0.20%-0.45% of silicon, 0.30%-0.60% of manganese, 1.35%-1.65% of chromium, 0.15%-0.25% of molybdenum, 0.70%-1.10% of aluminum, 0%-0.015% of phosphorus, 0%-0.010% of sulphur, 0.001%-0.01% of vanadium, 0.001%-0.01% of niobium, 0.001%-0.01% of titanium, 0.0020%-0.006% of nitrogen, 0.0005%-0.0025% of oxygen and the balance iron and other inevitable impurities. The 38CrMoAl nitrided steel with the nitrided layer low in fragility has the advantages that under the same nitriding process, the fragility of the nitrided layer can be reduced, and production cost and use cost are not increased obviously.

Owner:SHOUGANG CORPORATION

Thermal treatment process for plunger rod (piston rod) of nitrogen gas spring

InactiveCN107058939AImprove wear resistanceImprove corrosion resistanceSolid state diffusion coatingForeign matterCotton cloth

The invention discloses a thermal treatment process for a plunger rod (piston rod) of a nitrogen gas spring. The thermal treatment process comprises the following steps of: selecting 38CrMoAl(GB / T3077-1999) (GB / T3077-19999) high-grade nitriding steel as a base material of the nitrogen gas spring plunger rod (piston rod); cleaning to-be-nitrided workpieces by cleaning liquor to ensure that the surfaces of the workpieces are free of other foreign matters such as scrap iron, greasy dirt and oil paint; performing drying or air-curing, and wiping the surfaces of the workpieces by cotton cloth before charging; uniformly putting the workpieces onto a cathode disc in a glow ion nitriding system, stacking the workpieces layer by layer, ensuring a spacing distance between every two workpieces on the same layer to be greater than 15 mm, ensuring the workpieces in the same furnace to be the same in size to the greatest extent, prolonging heating time while mixed loading is needed if sizes of the workpieces are different, and enabling the workpieces to obtain sufficient heat exchange balance; and setting various process parameters for the glow ion nitriding system, wherein surface hardness of a nitriding layer of the spring plunger rod (piston rod) treated by the glow ion nitriding system is greater than 1000 HV, wear resistance of the plunger rod can be improved, and the service life of the plunger rod of the nitrogen gas spring can be prolonged.

Owner:DONGGUAN XINYUE MOLD

Non-brittle nitridation technique for bearing components

InactiveCN107326322AHigh strengthImprove wear resistanceSolid state diffusion coatingInlet valveHardness

The invention discloses a non-brittle nitridation technique for bearing components. According to the technological process, whether the interior of a nitridation furnace leaks air or not is detected firstly, if the air is not leaked, the inflation stage is executed, and then the temperature in the nitridation furnace is increased to 300-350 DEG C; ammonia gas and mixed liquid of a penetrating agent and ammonium chloride concentrated liquid are led into the nitridation furnace, the leading-in speeds of the ammonia gas and the mixed liquid of the penetrating agent and the ammonium chloride concentrated liquid are controlled, and the interior of the furnace continues to be heated till the temperature is 480-500 DEG C; then the leading-in speeds of the ammonia gas and the mixed liquid of the penetrating agent and the ammonium chloride concentrated liquid are increased, and the temperature of the interior of the furnace is increased to 520-550 DEG C; then the inflation speed of the ammonia gas is decreased, and leading-in of the ammonia gas and the mixed liquid of the penetrating agent and the ammonium chloride concentrated liquid is stopped; gas in the furnace is discharged, the pressure in the furnace is controlled, and the temperature in the furnace is decreased to 100-130 DEG C; and finally an ammonia gas bottle and a nitridation furnace gas inlet valve are closed, vacuumizing is conducted, nitrogen gas is led into the furnace to enable the pressure of the interior of the furnace to be positive, the valve is opened, air in the furnace is replaced, the temperature is decreased, and the components are taken out. According to the non-brittle nitridation technique for the bearing components, the problems that as for an existing nitridation technique, the depth of the effective nitridation layer is small, the surface hardness is low, and deformation is large can be effectively solved.

Owner:JIANGSU FENGDONG HEAT TREATMENT & SURFACE MODIFICATION ENG & TECH RES CO LTD

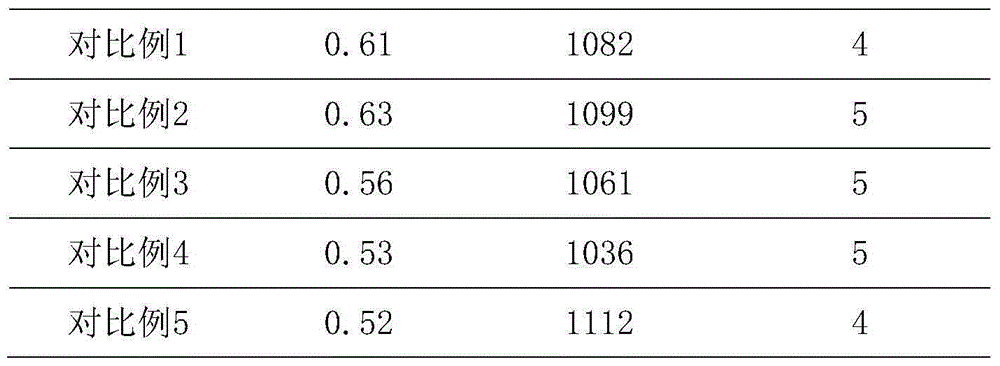

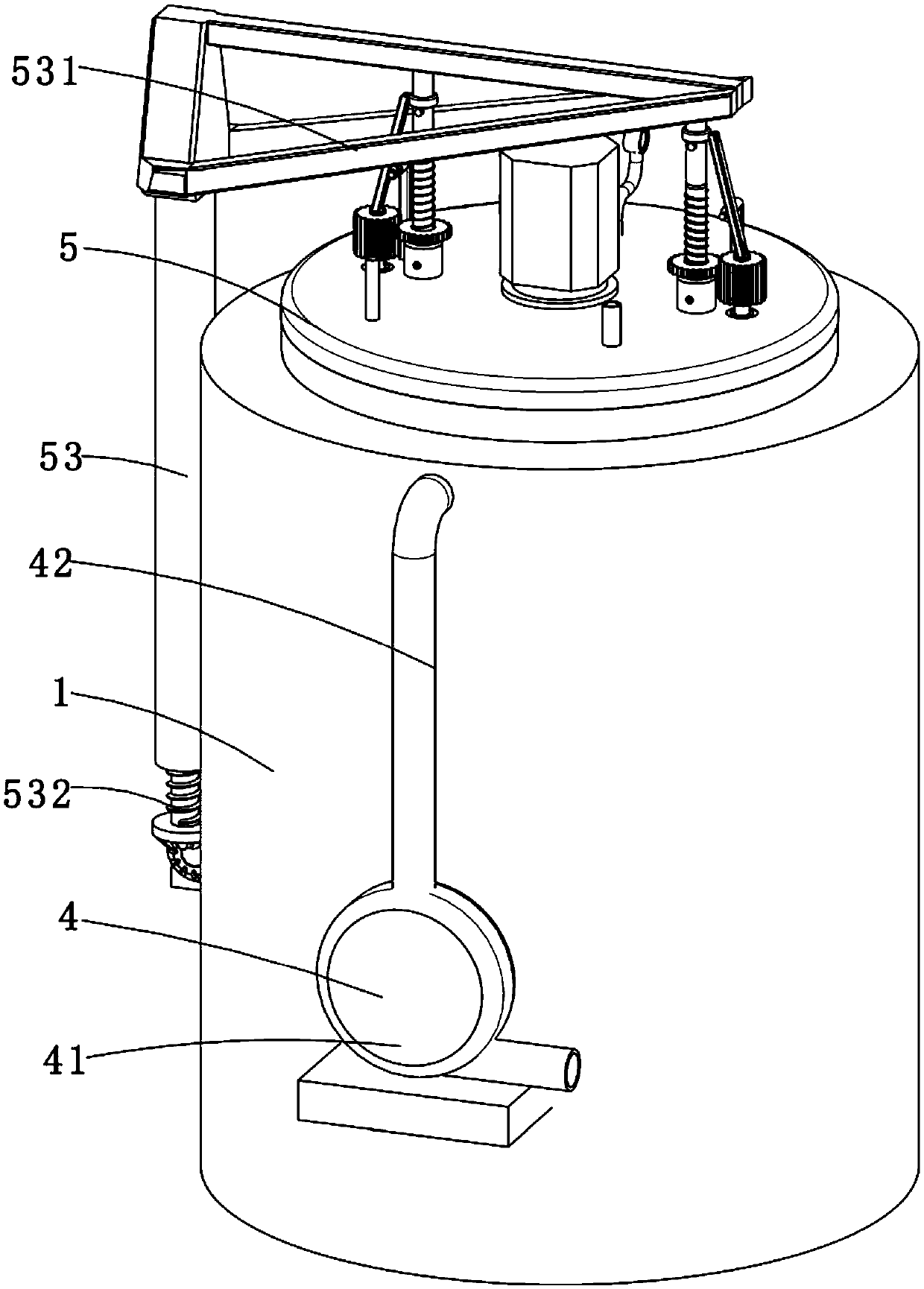

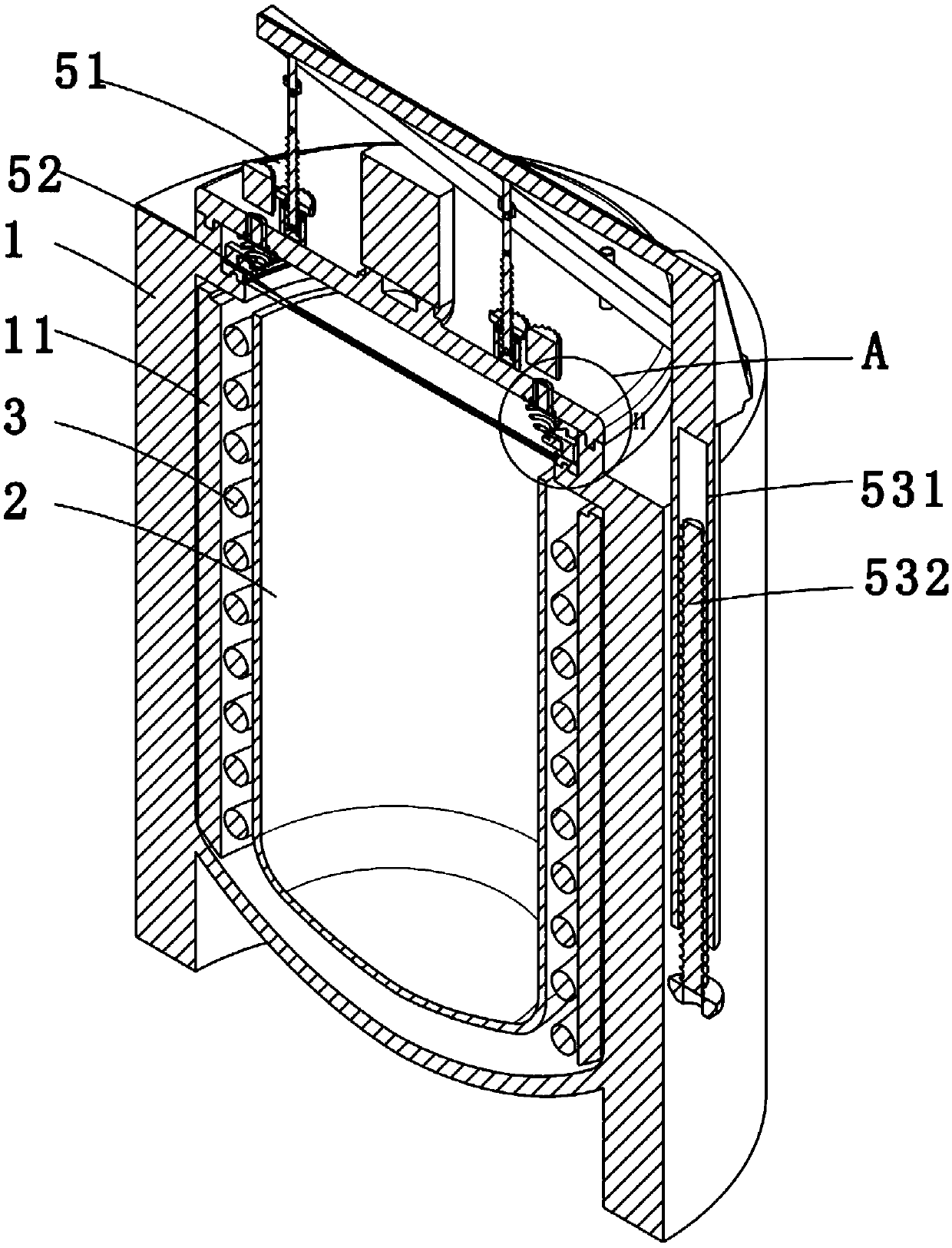

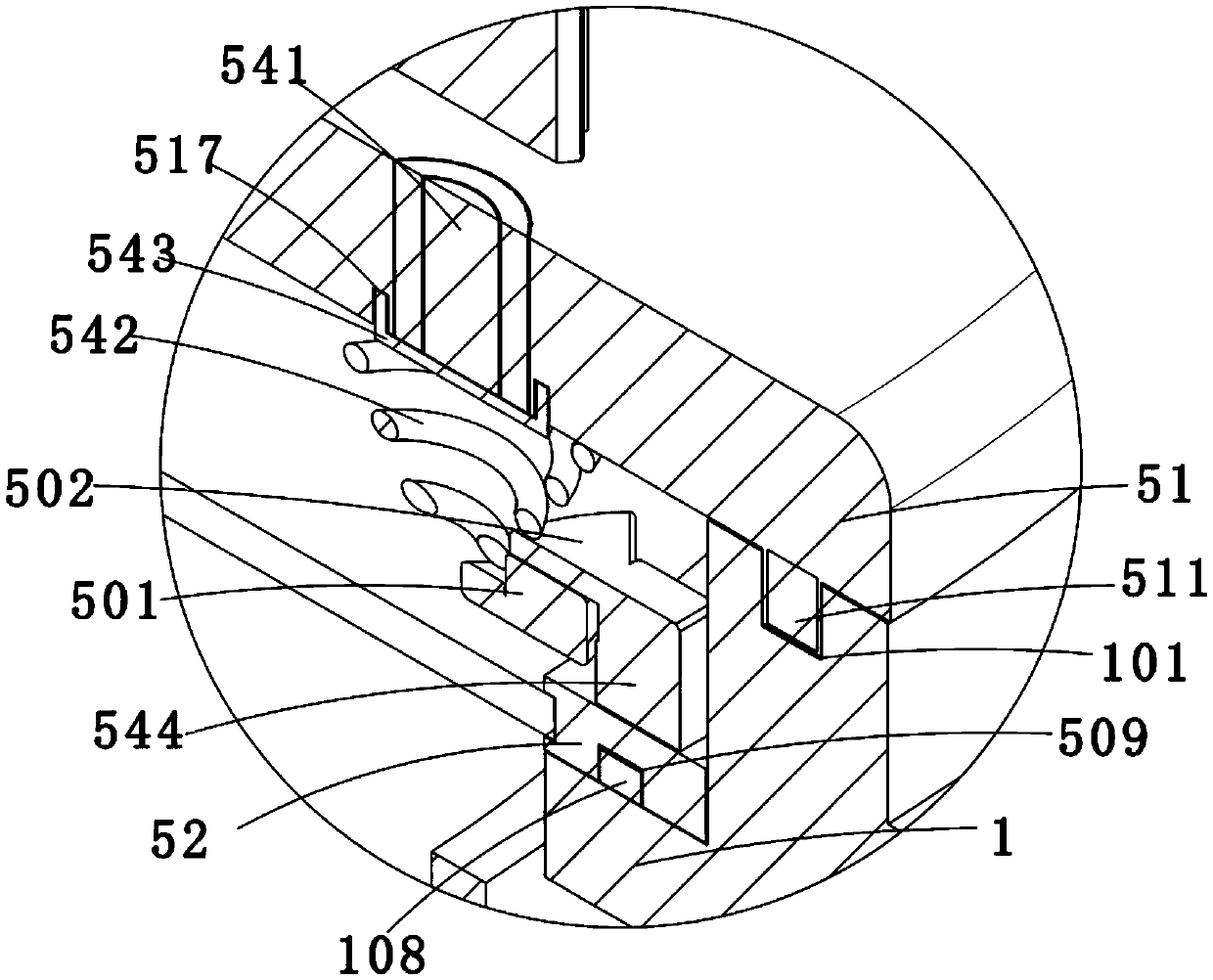

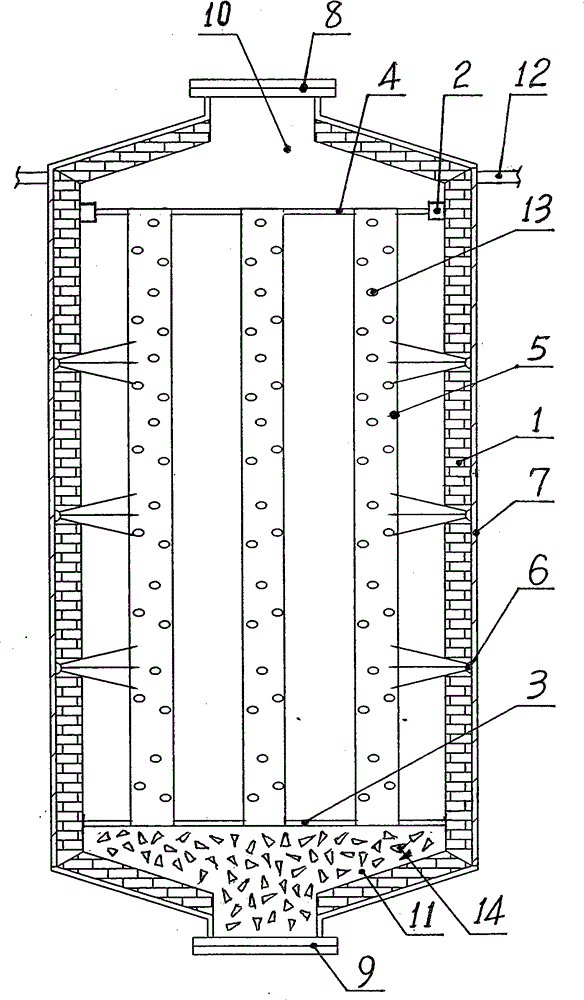

Magnesium smelting technique by microwave heating

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

Metal surface nitriding technology

ActiveCN110230024AImprove efficiencyGuarantee stabilitySolid state diffusion coatingIonMegasonic cleaning

The invention discloses a metal surface nitriding technology. The metal surface nitriding technology involves a to-be-processed metal workpiece, and processing of the workpiece comprises the followingsteps of carrying out immersion cleaning on the workpiece with water containing detergent, carrying out immersion cleaning on the workpiece with water at 100 DEG C after the workpiece is washed withclear water, and placing the oil stain-removed workpiece into a pool for ultrasonic cleaning, wherein the cleaning vibration frequency is 80-160 KHz, the power density is set at 0.6-1.0 W / C, the workpiece is preheated to 300-385 DEG C, and the preheating time period is 6-25 minutes; placing the workpiece in a nitriding furnace containing base salt containing Li ions, raising the temperature of thenitriding furnace to 520-580 DEG C, wherein the nitriding time period is 80-100 minutes; and adding sodium peroxide solid into the base salt, wherein the weight ratio of the solid sodium peroxide tothe base salt is 1 to 2.5-4.5. According to the technology, by adding ultrasonic cleaning, in the process of cleaning the workpiece, a strong cleaning effect on the workpiece can be rapidly realized,so that solid dirt on the surface of the workpiece is separated from the workpiece, and the nitriding effect can be effectively improved in the nitriding process.

Owner:KUNSHAN SUNMIN DRILUBE ELECTRONIC MATERIAL TECHNOLOGY CO LTD

Dental plate surface nitriding technology

The invention discloses a dental plate surface nitriding technology, and relates to the technical field of workpiece nitriding treatment. The technology comprises the steps of 1) preparing before treatment, 2) vacuumizing, 3) heating, 4) reheating, 5) vacuumizing, 6) surface activating, 7) vacuumizing, 8) decomposing through ammonia gas, 9) nitriding, 10) vacuumizing, 11) blackening, and 12) cooling. The technology has the beneficial effects that the fatigue resistance of a workpiece is improved; high pressure stress is generated in a nitriding layer, so that the fatigue limit of the workpieceis high, and the sensitivity of the workpiece is low under the effect of alternating load; and moreover, the fatigue limit of the workpiece subjected to alternating load can be increased by 200%.

Owner:HAIYAN JINGBIN HARDWARE PROD CO LTD

Nitratable steel piston rings and steel cylindrical sleeves, and casting method for the production thereof

InactiveUS8647448B2Good nitridabilityEasy transitionPiston ringsBraking action transmissionCast ironSteel cylinder

A steel piston ring and a steel cylinder liner are described which comprise as the main body a steel composition which has good nitridability. The steel composition consists of the following elements: 0-0.5 weight % B, 0.5-1.2 weight % C, 4.0-20.0 weight % Cr, 0-2.0 weight % Cu, 45.30-91.25 weight % Fe, 0.1-3.0 weight % Mn, 0.1-3.0 weight % Mo, 0-0.05 weight % Nb, 2.0-12.0 weight % Ni, 0-0.1 weight % P, 0-0.05 weight % Pb, 0-0.05 weight % S, 2.0-10.0 weight % Si, 0-0.05 weight % Sn, 0.05-2.0 weight % V, 0-0.2 weight % Ti and 0-0.5 weight % W. The steel piston ring and the steel cylinder liner can be manufactured in a casting process using the machinery and technology employed for the manufacture of cast iron parts.

Owner:FEDERAL MOGUL BURSCHEID

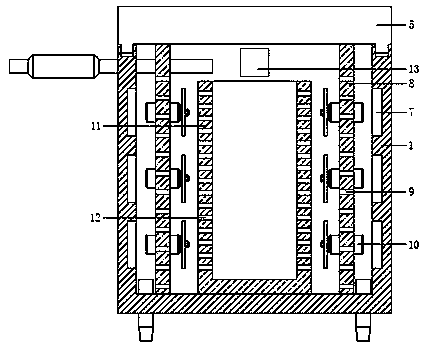

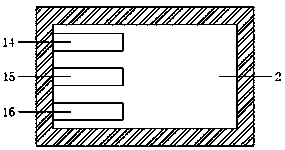

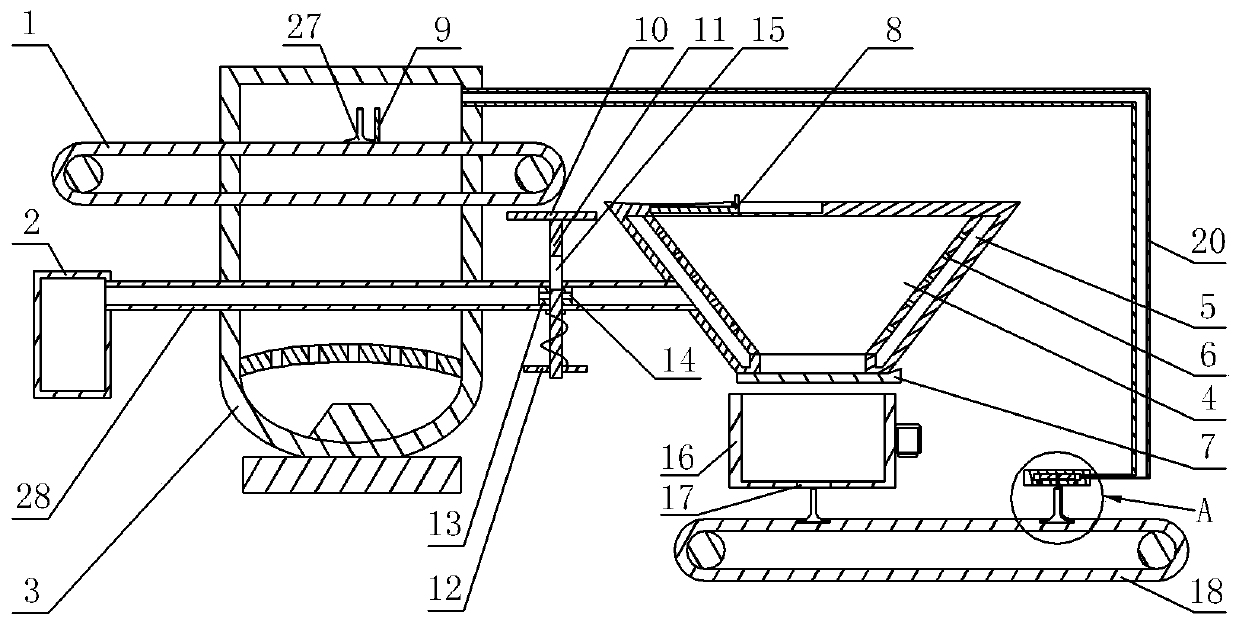

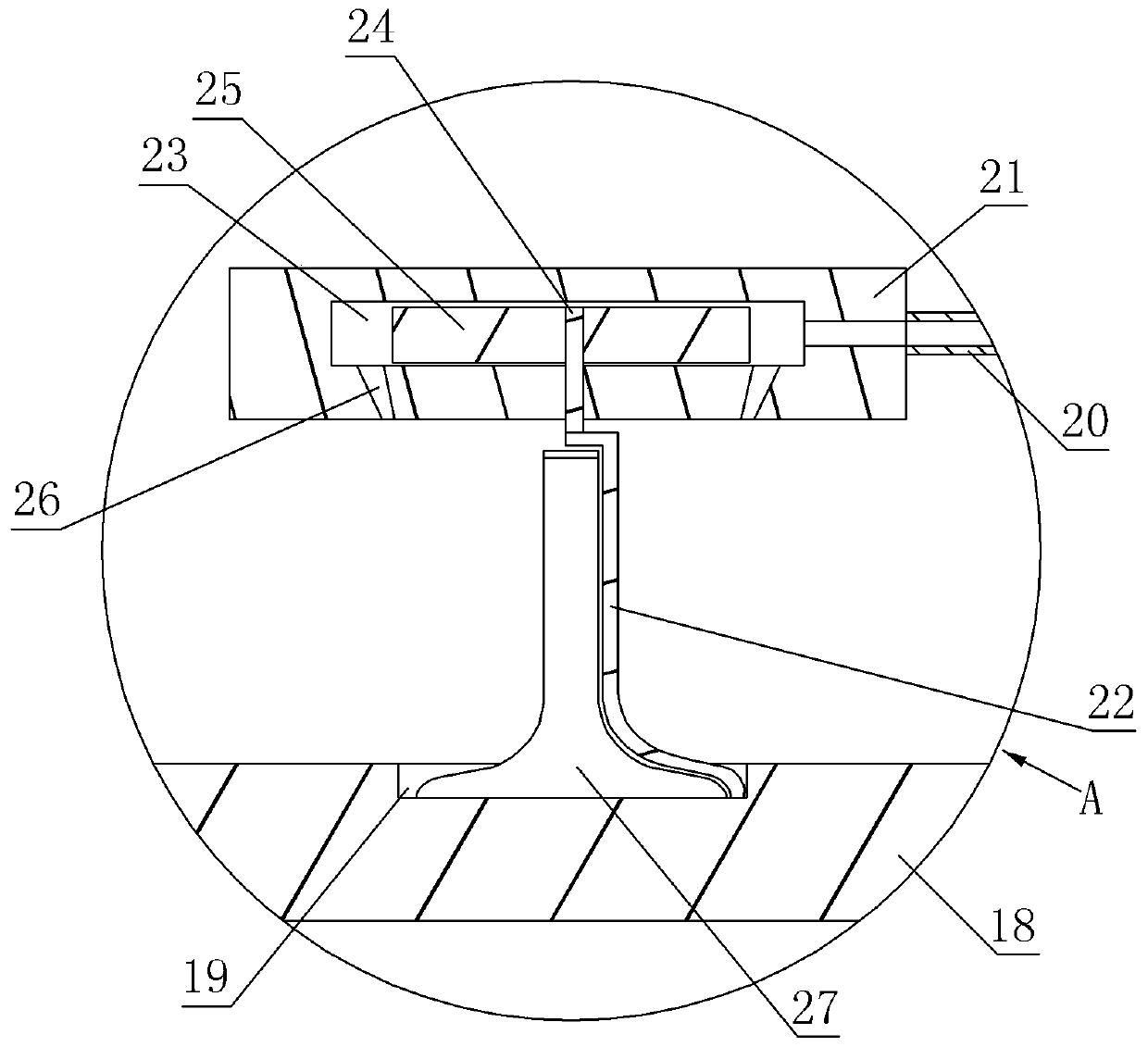

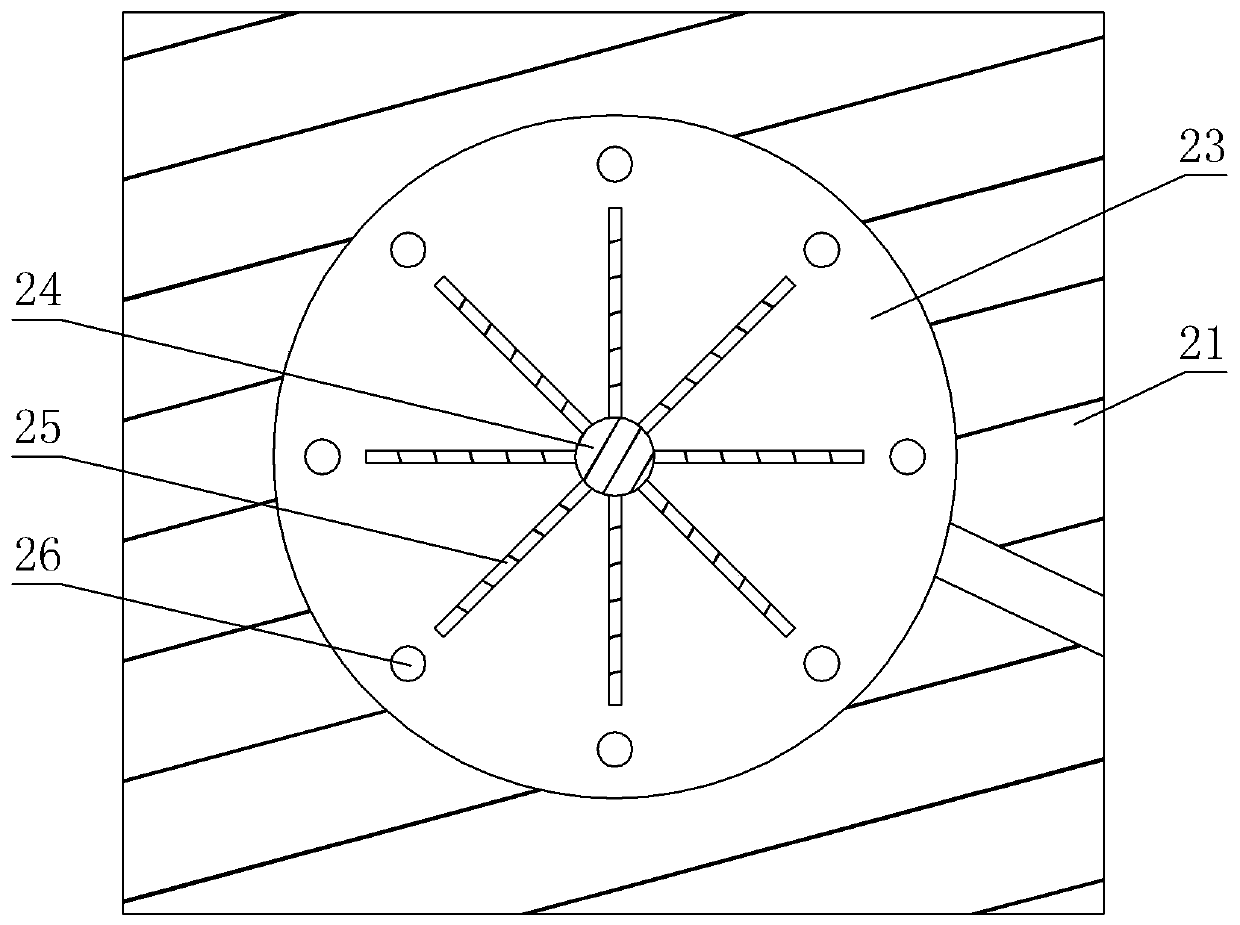

Novel three-section nickel-based screw-grinding waste plastic modification regeneration energy-saving equipment

InactiveCN103978584AFully heated grindingExhausted completelyPlastic recyclingDrive shaftFirst pass yield

Novel three-section nickel-based screw-grinding waste plastic modification regeneration energy-saving equipment relates to the technical field of plastic machinery and is mainly composed of two parts, namely a working part and a base support. The main body of the working part is a heating fusion tube, inside which three sections of grinding mechanisms are arranged. A filament extrusion mechanism is connected to the right end of the heating fusion tube. A cooling device is disposed at the lower end of the filament extrusion mechanism. The base support part mainly comprises a pedestal and an engine and a speed change gear box which are arranged on the pedestal. The engine is connected with the speed change gear box through a transmission shaft. The speed change gear box is connected with the heating fusion tube. The three sections of grinding mechanisms contain a charging barrel and a screw arranged in the charging barrel. Thread of the screw is provided with a trough of 12mm width and 1.5mm depth. A nickel-based ceramic alloy powder is sprayed in the trough. By a three-section twin-exhaust grinding technology, a waste plastic raw material is fully heated and ground. Grinding fineness of waste plastic reaches 40-60 nanometers or molecular state; first pass yield reaches 98%; and energy consumption is saved by more than 46%.

Owner:JIESHOU SHUANGMA MACHINERY CO LTD

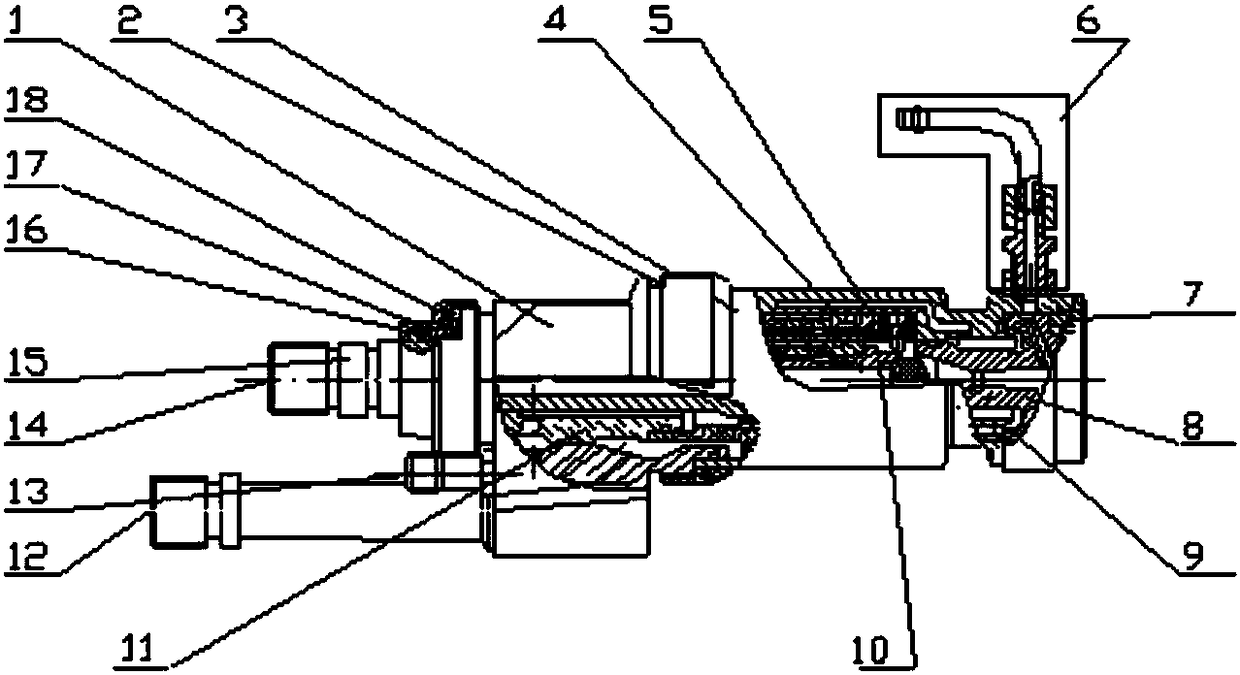

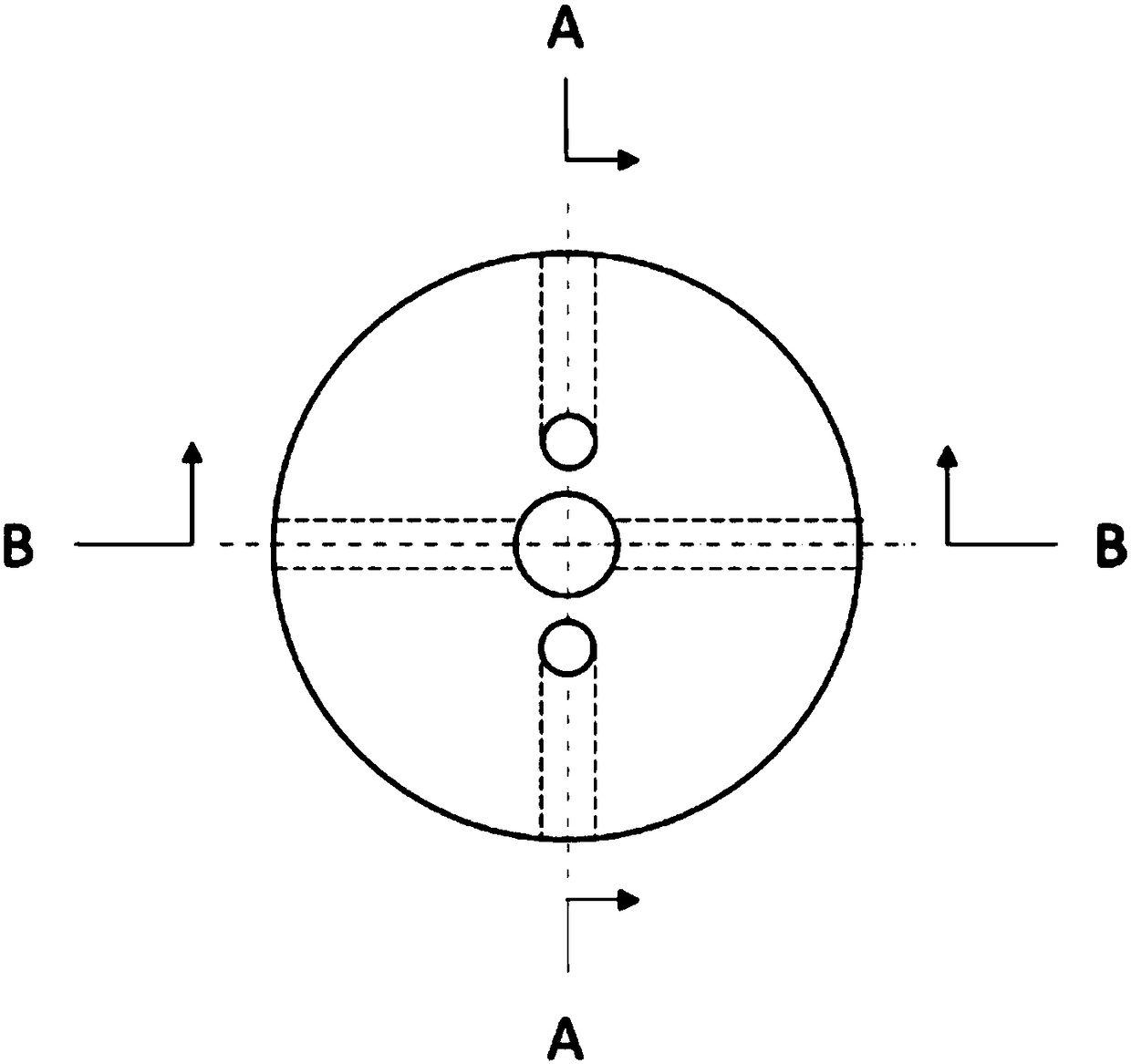

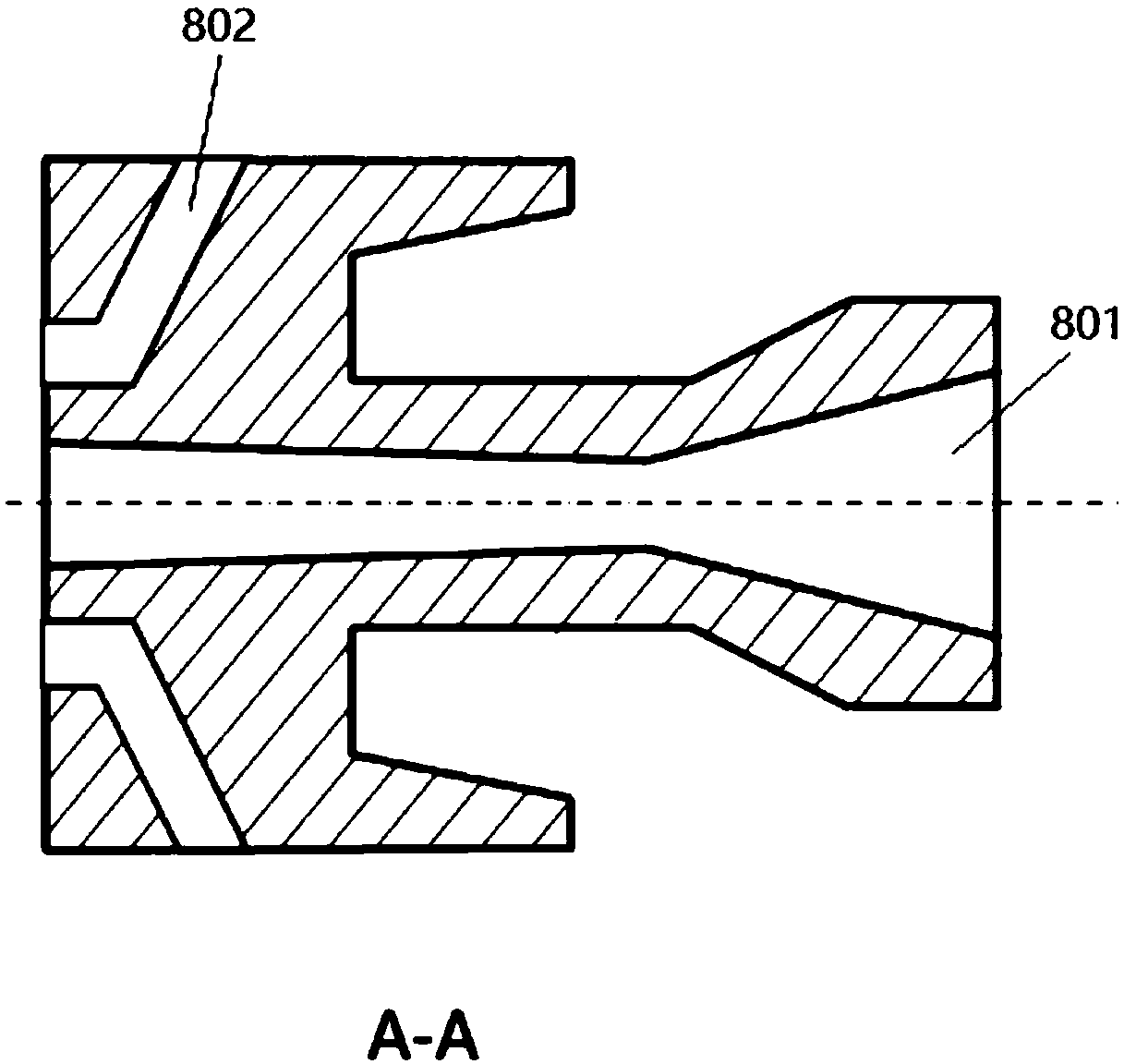

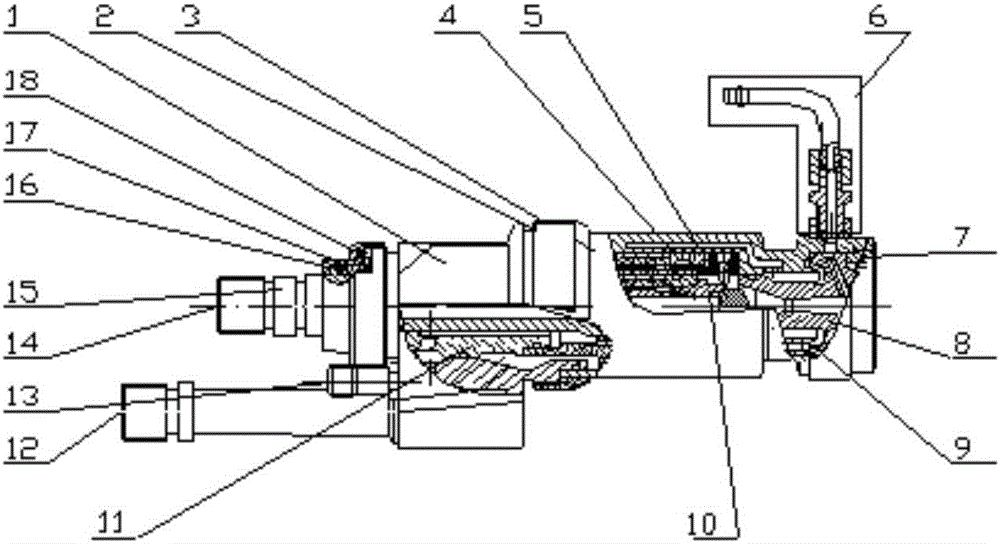

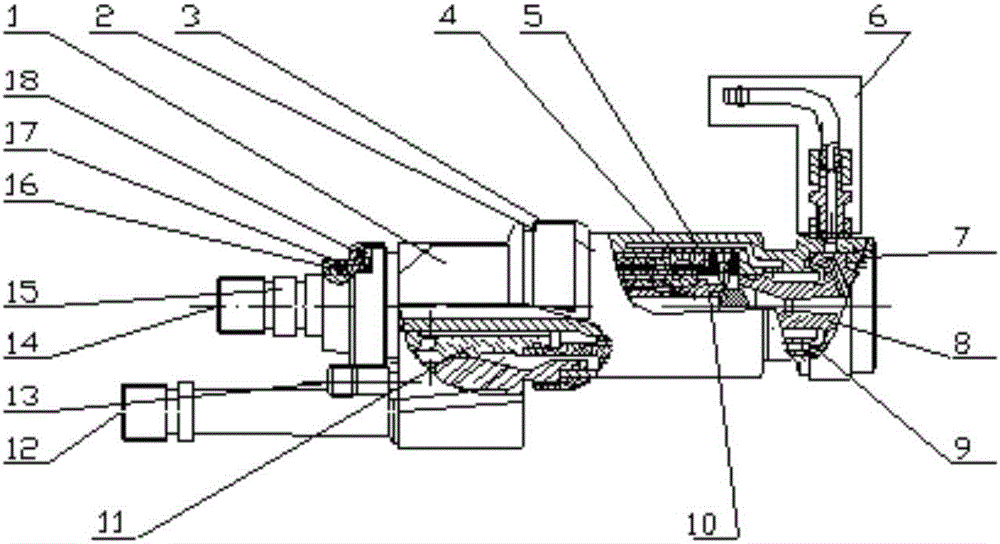

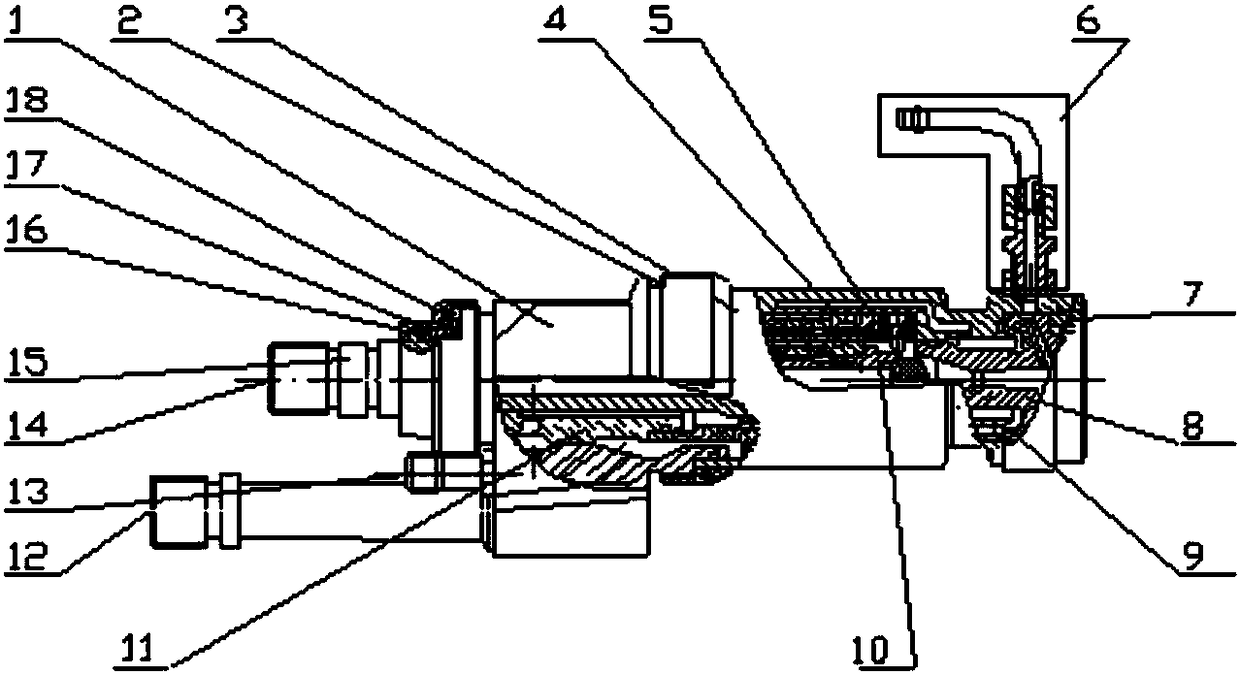

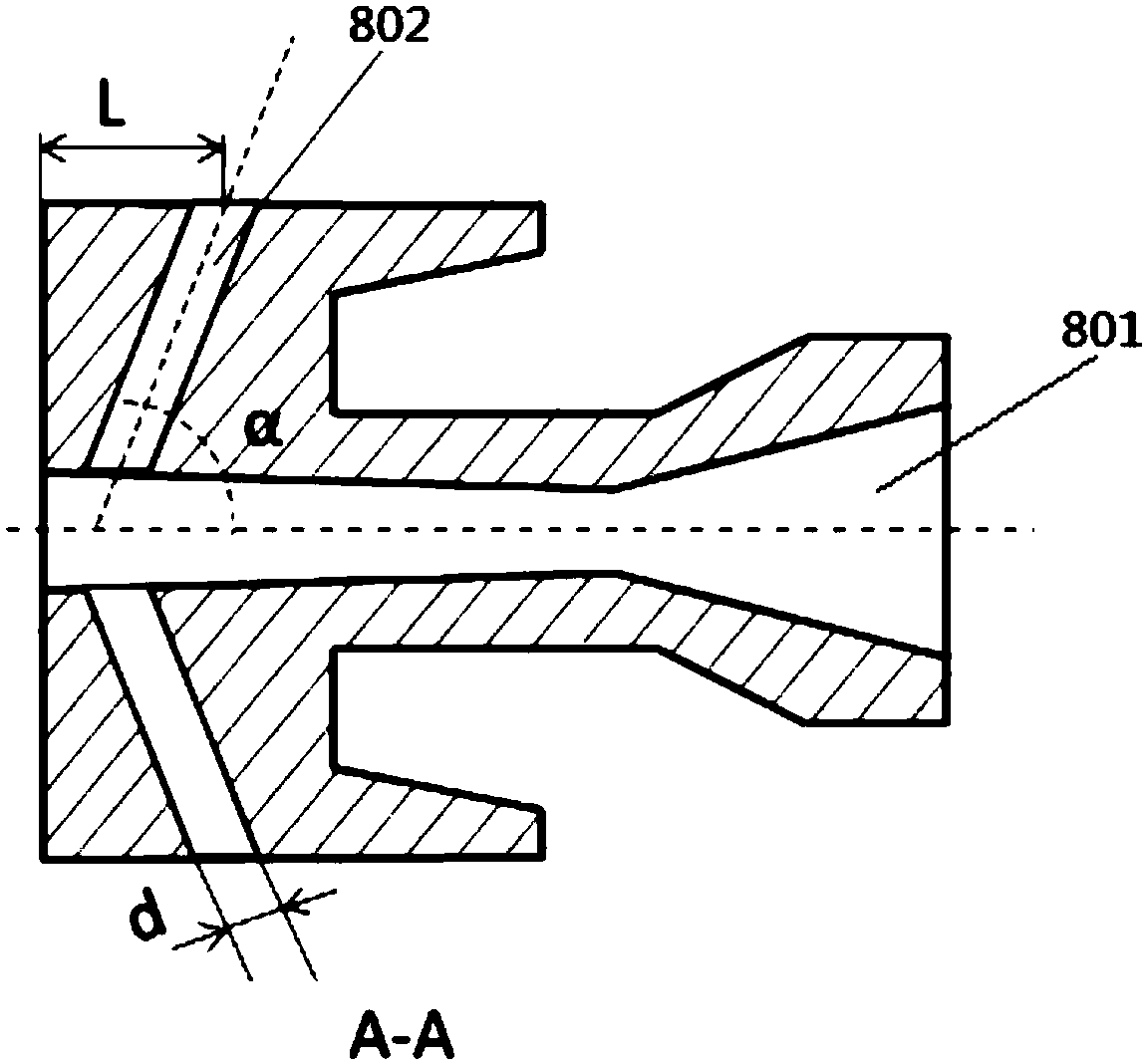

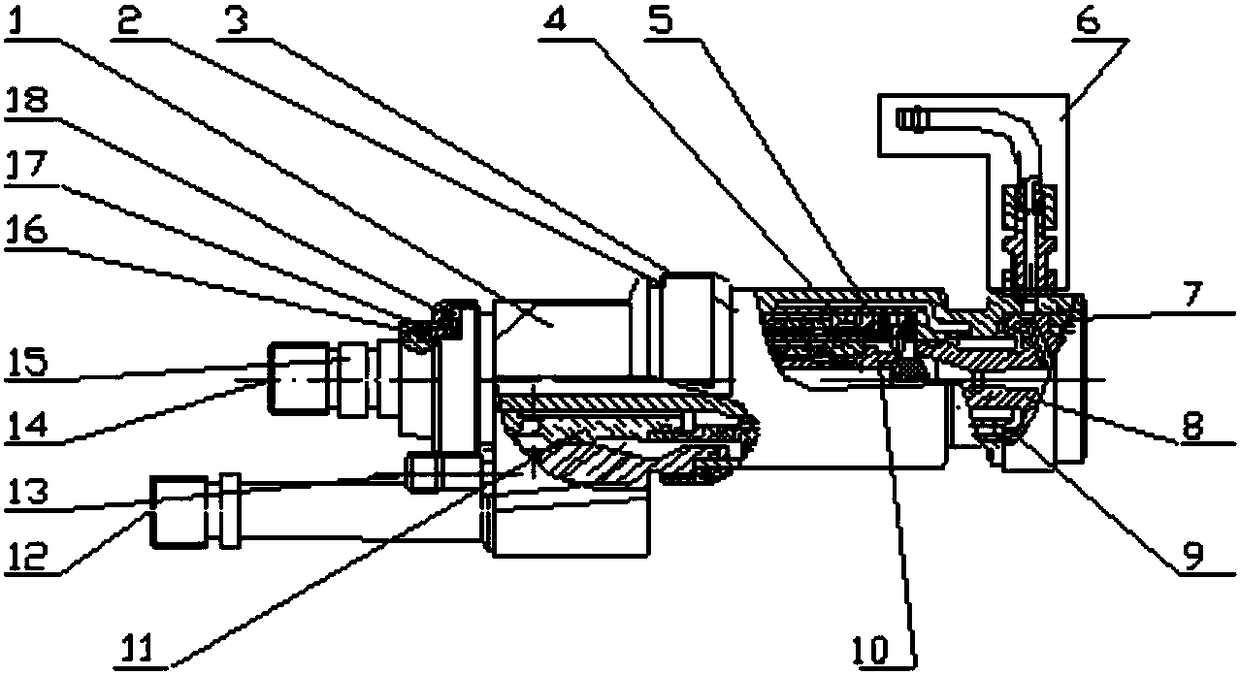

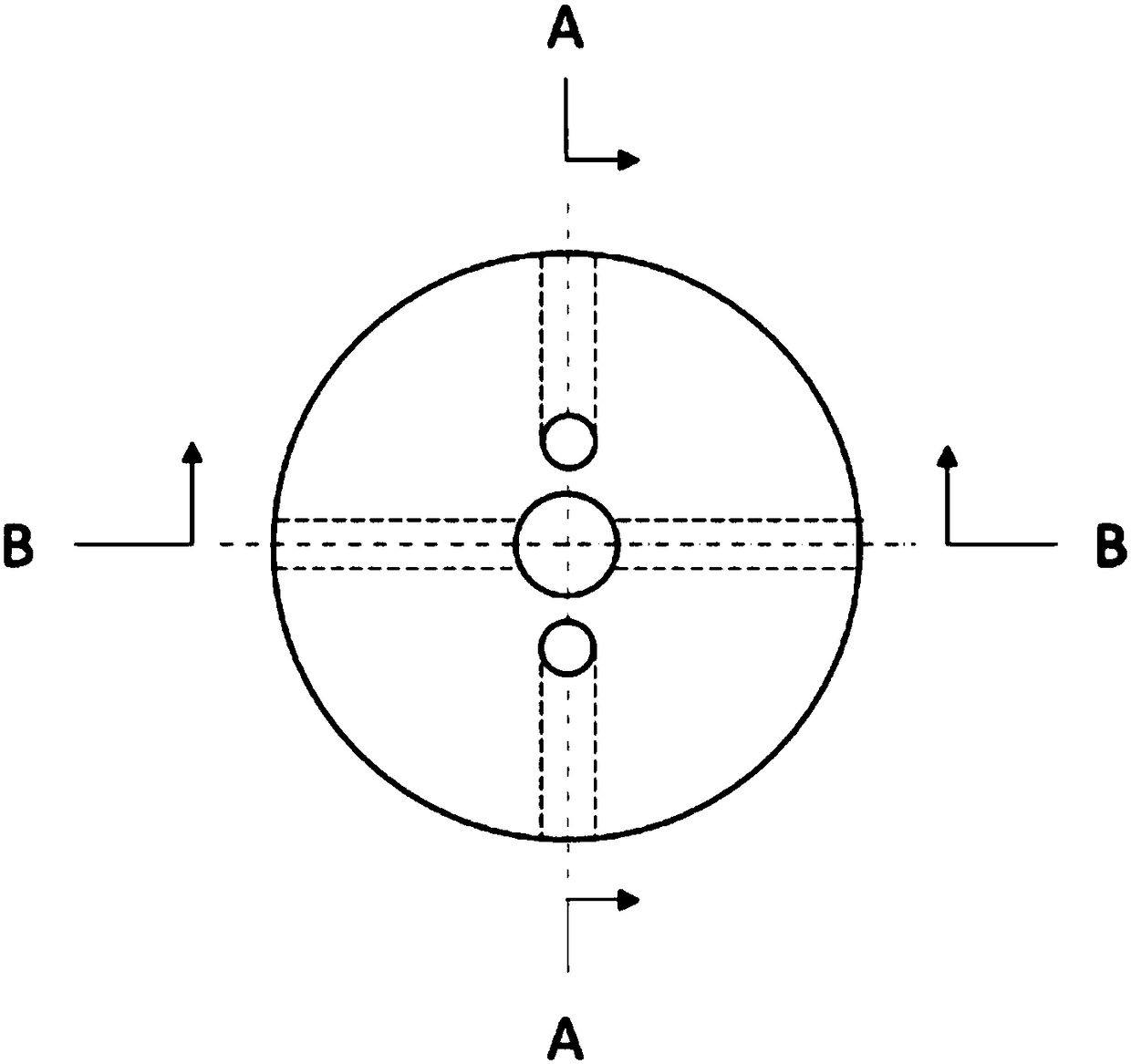

A two-stage protective air hole type atmospheric supersonic plasma spraying device

Owner:ACADEMY OF ARMORED FORCES ENG PLA

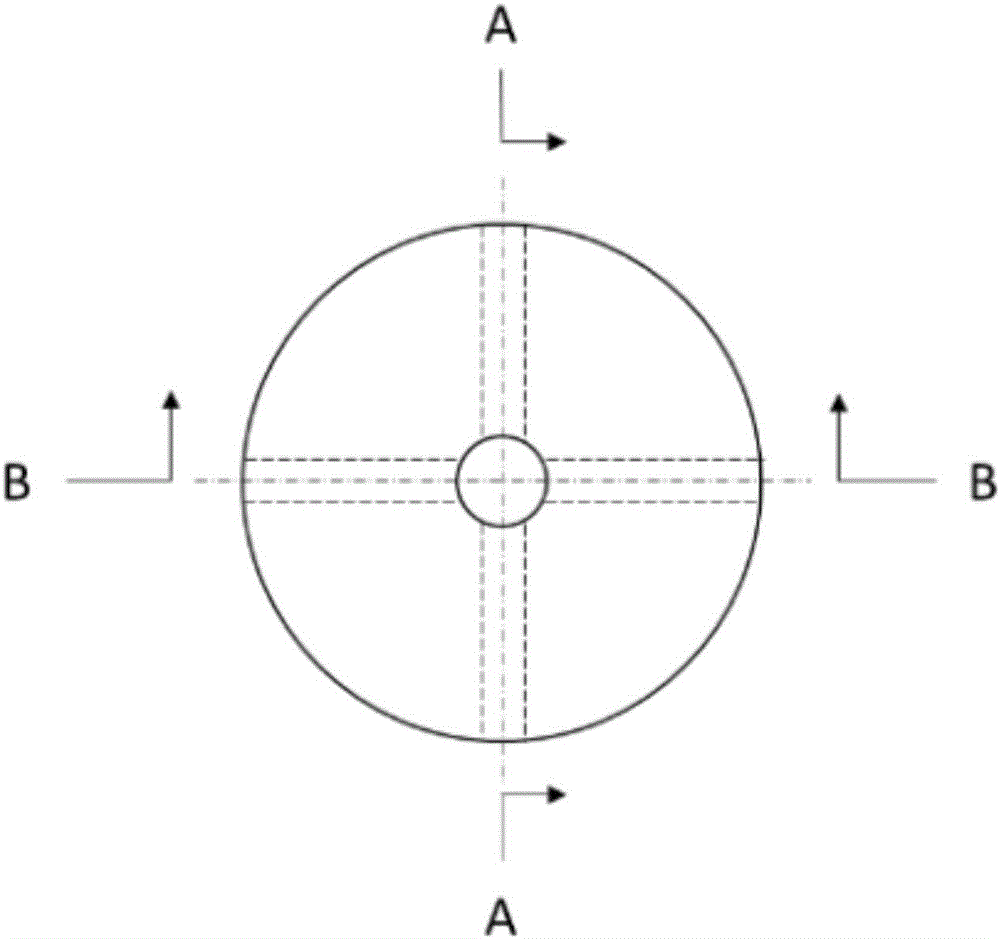

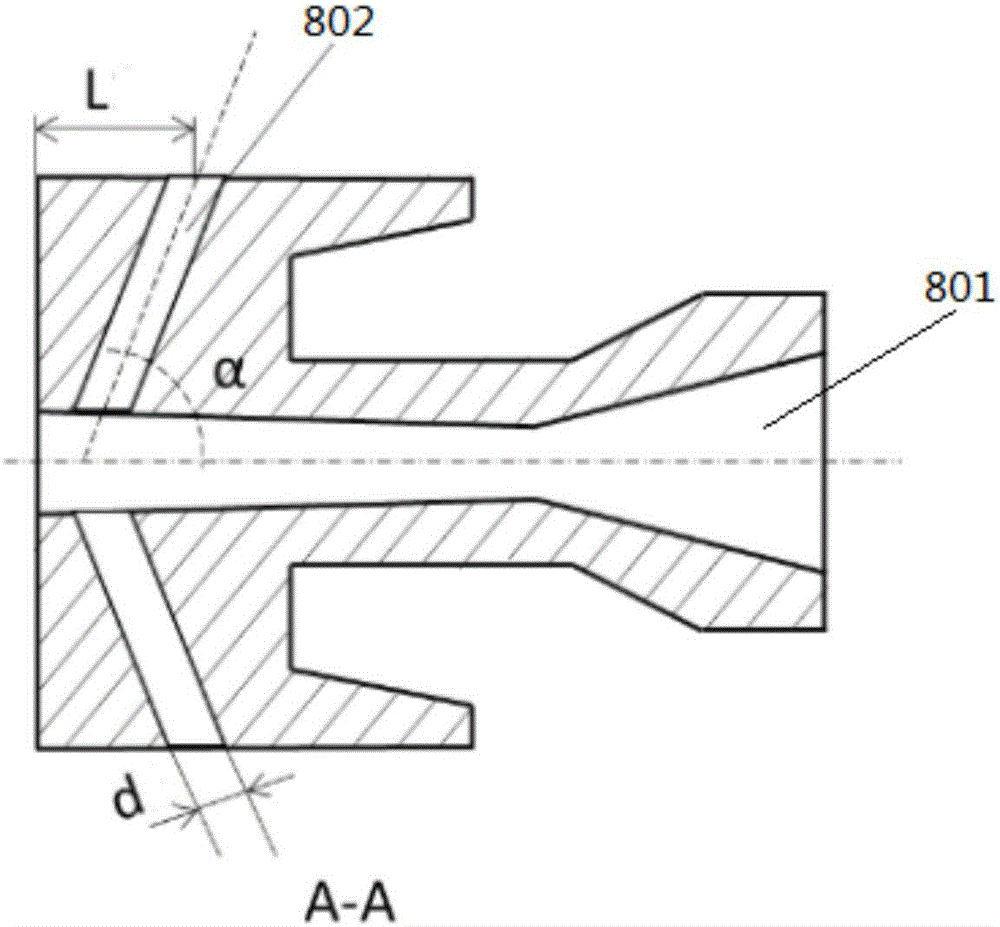

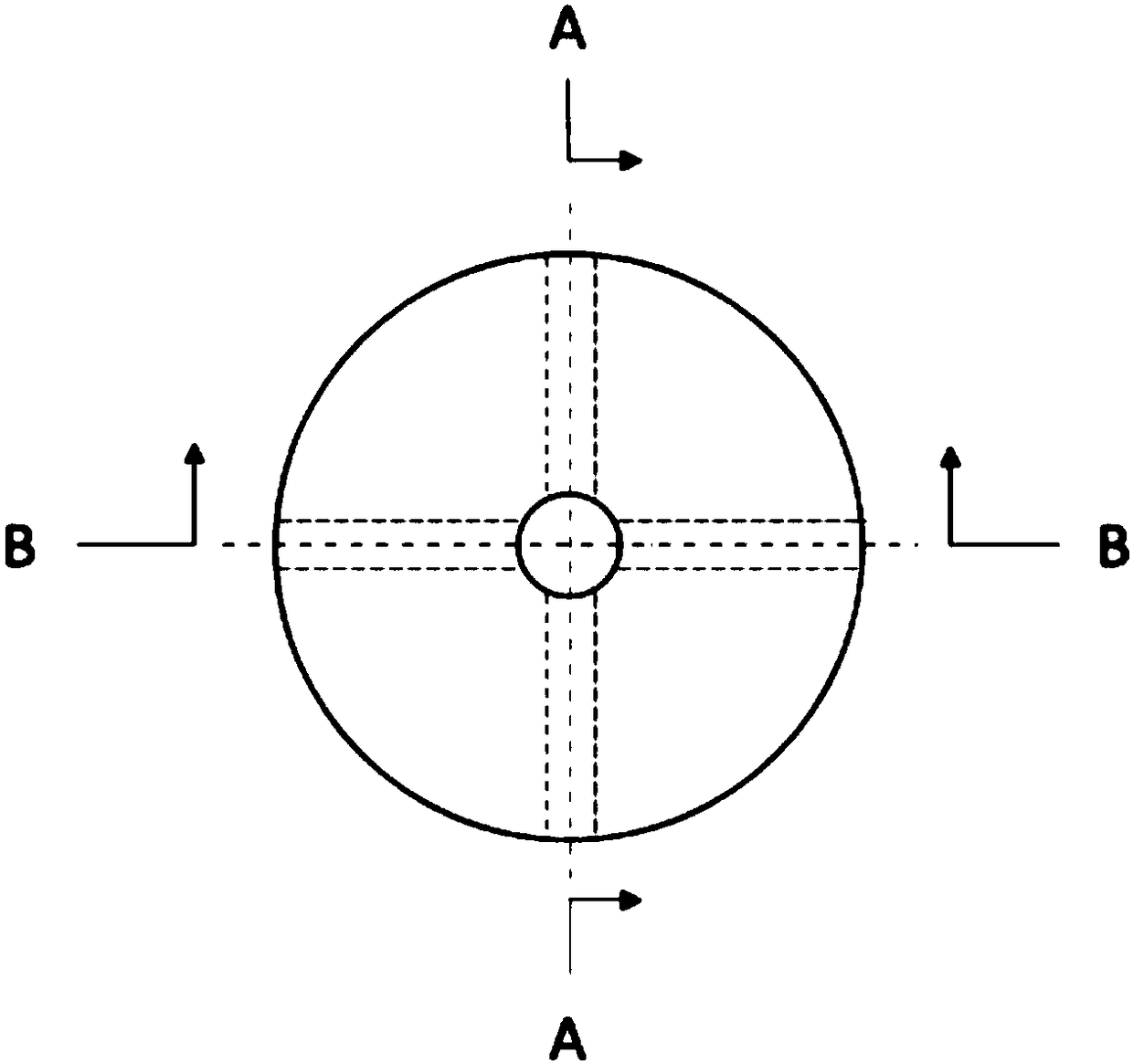

Atmospheric supersonic-speed plasma spraying device capable of forming shielding gas hood

The invention discloses an atmospheric supersonic-speed plasma spraying device capable of forming a shielding gas hood. The atmospheric supersonic-speed plasma spraying device capable of forming the shielding gas hood comprises an anode nozzle, wherein the anode nozzle is in the shape of a rotating body and is provided with a central through hole. The anode nozzle is further provided with a shielding gas hole and a powder feeding hole, wherein the inlet end of the shielding gas hole is arranged on the circumferential surface of the anode nozzle, the outlet end of the shielding gas hole communicates with the central through hole, and an acute angle alpha is formed between the axis of the shielding gas hole and the axis of the central through hole; and the inlet end of the powder feeding hole is arranged on the circumferential surface of the anode nozzle, the outlet end of the power feeding hole communicates with the central through hole, and the axis of the powder feeding hole is perpendicular to the axis of the central through hole. The atmospheric supersonic-speed plasma spraying device capable of forming the shielding gas hood is simple in structure and is not provided with a solid hood, a cold water device does not need to be additionally arranged, and mounting, dismounting and checking are convenient; and sprayed materials are not prone to adhering to a duct of a nozzle, jet flow and the atmospheric environment are isolated to a certain extent by shielding gas, oxidation of sprayed particles in the jet flow can be reduced, the jet flow is cooled to a certain extent, the temperature of the jet flow and the temperature of the sprayed particles are decreased accordingly, and the probability of oxidation of the sprayed particles is lowered.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

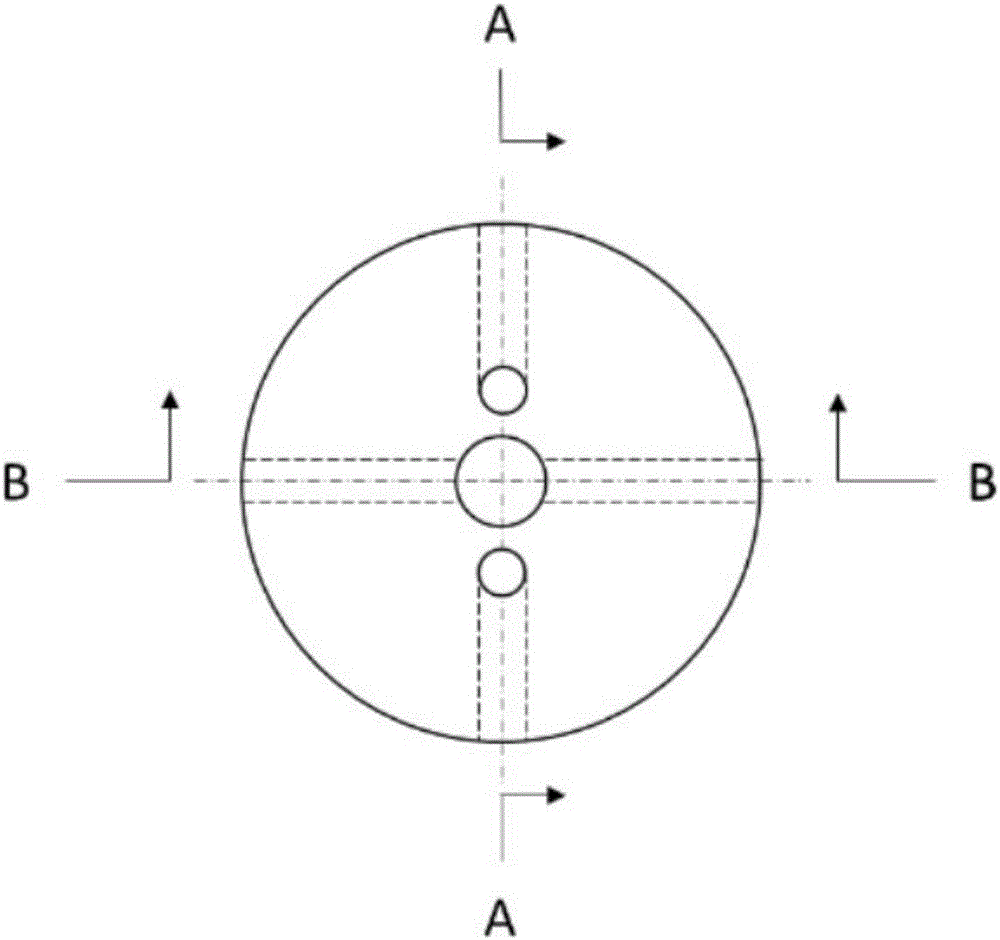

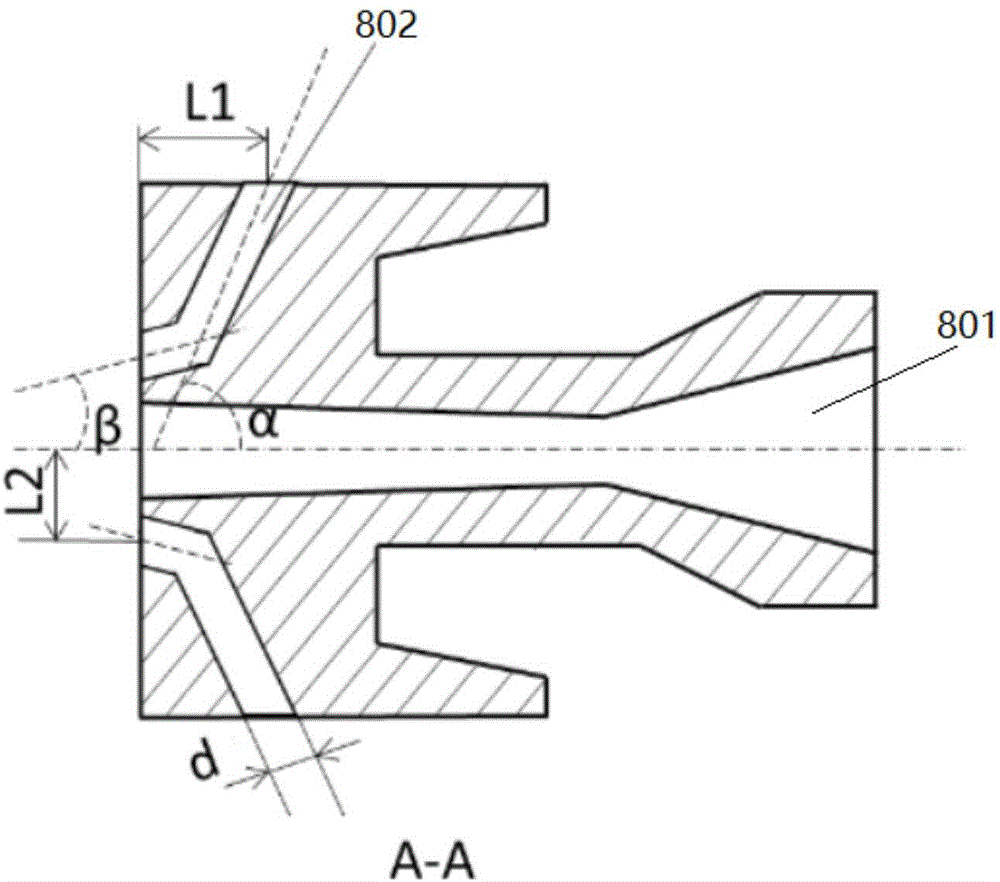

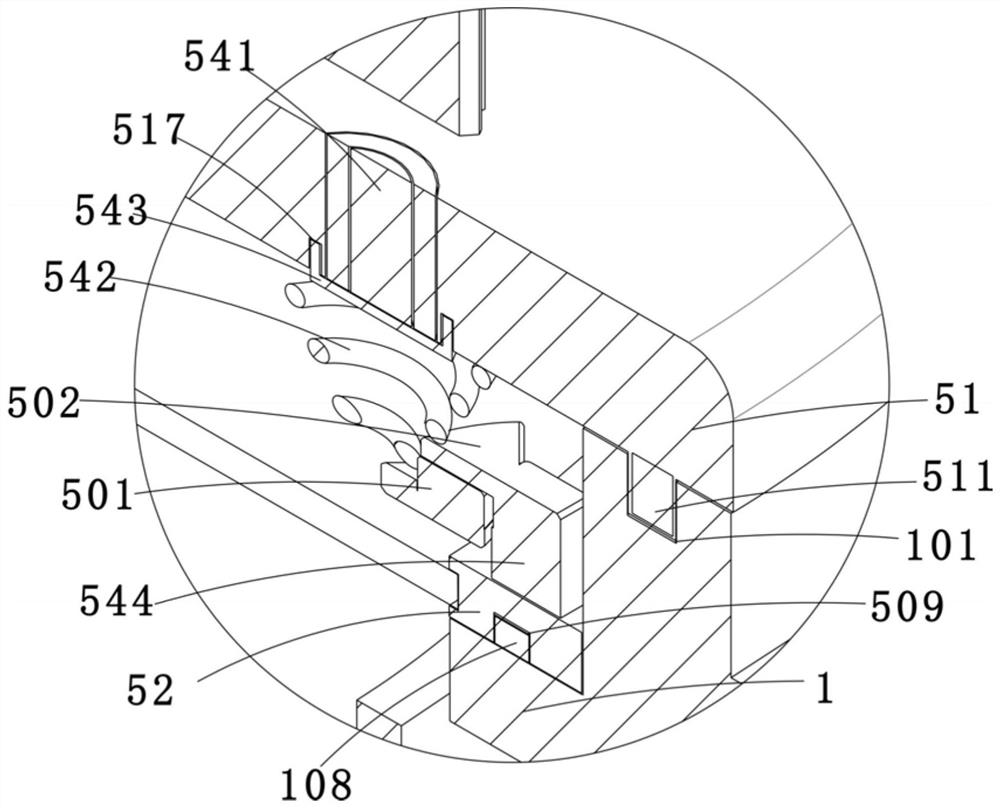

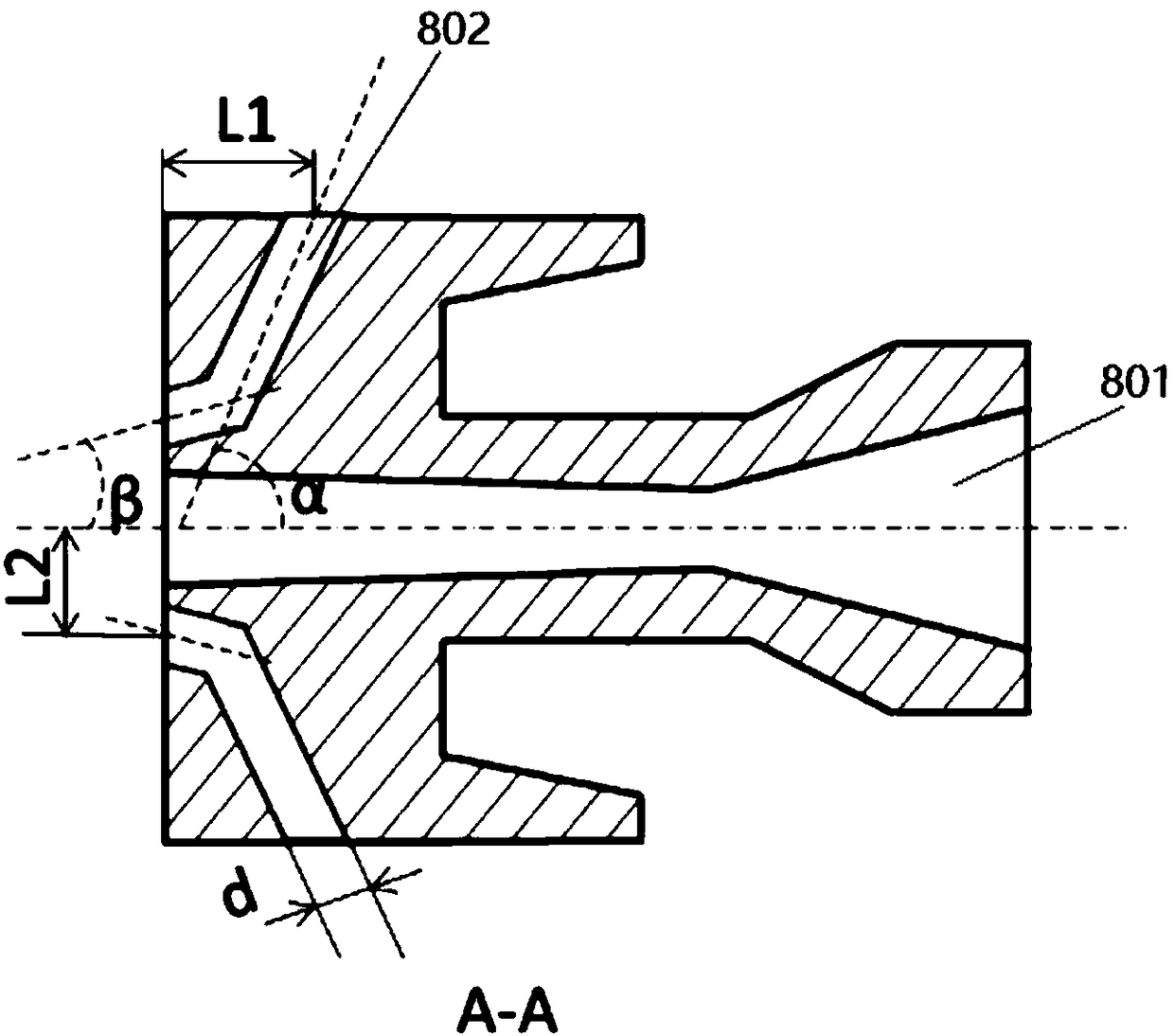

Atmosphere supersonic speed plasma spraying device with two-section type protection air holes

The invention discloses an atmosphere supersonic speed plasma spraying device with two-section type protection air holes. The spraying device comprises an anode nozzle. The front end of the anode nozzle is cylindrical, and a center through hole is formed in the anode nozzle. The anode nozzle is further provided with the protection air holes and powder feeding holes. The inlet ends of the protection air holes are arranged on the circumferential face of the anode nozzle, and the outlet sections of the protection air holes are arranged on the front end face of the anode nozzle. The protection air holes comprise the first section of air holes and the second section of air holes. The axis of the first section of air holes and the axis of the center through hole form an acute angle of alpha, and the axis of the second section of air holes and the axis of the center through hole form an acute angle of beta. The inlet ends of the powder feeding holes are arranged on the circumferential face of the anode nozzle, and the outlet ends of the powder feeding holes communicate with the center through hole. In addition, the axis of the powder feeding holes is perpendicular to the axis of the center through hole. The atmosphere supersonic speed plasma spraying device is simple in structure, a solid cover is omitted, and additional arrangement of a cold water device is needless. Mounting, dismounting and inspection are convenient, the temperature of jet flow and the temperature of spraying particles can be lowered, and oxidization probability of the spraying particles is reduced.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

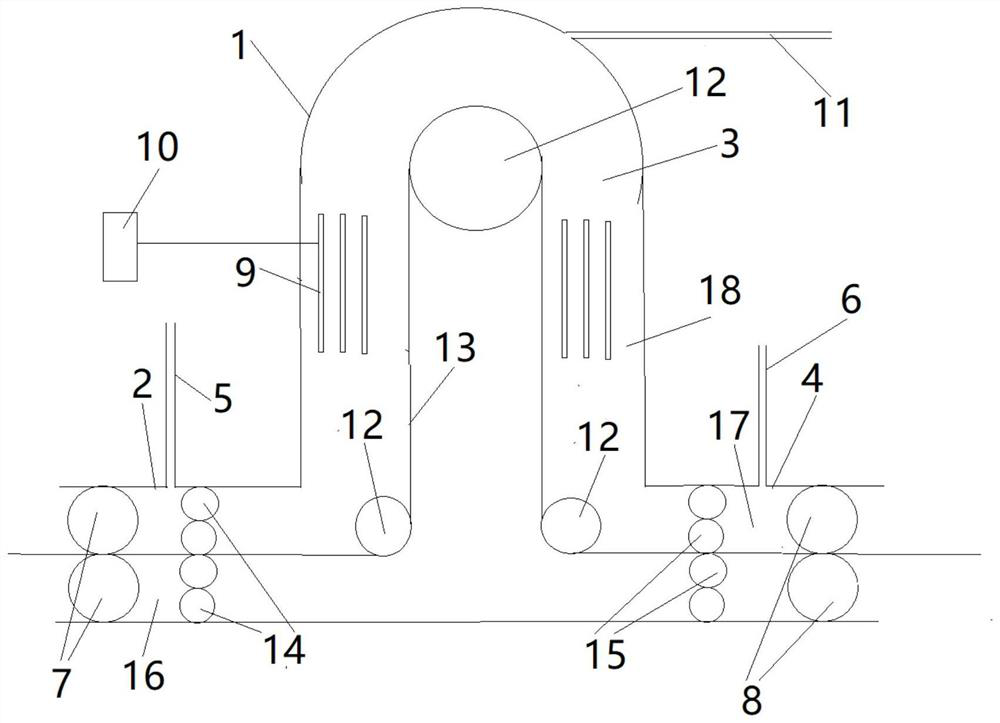

Nitriding device and nitriding method for grain-oriented silicon steel

ActiveCN111304583BFast nitridingImprove processing qualitySolid state diffusion coatingSteel beltAmmonia gas

The invention provides a nitriding method for oriented silicon steel applied in the field of metallurgy technology. The invention also relates to a nitriding device for oriented silicon steel. The nitriding step of the nitriding method of the oriented silicon steel nitriding method is as follows: The roll (7) is energized to make the hydrogen ionization in the cleaning and activation section (2), and the surface of the silicon steel (13) to be treated is cleaned and activated; the silicon steel (13) to be treated enters the nitriding section (3), and the ions 13) Carry out nitriding treatment; the silicon steel (13) to be treated enters the sealing chamber (4), and the rear conductive sealing roller (8) in the sealing chamber (4) is energized to remove the oxide layer on the surface of the silicon steel (13) to be treated, and the nitriding is completed Treatment, the oriented silicon steel nitriding device and nitriding method described in the present invention make the surface of the steel strip clean and active, make the ammonia nitriding process fast and uniform, and the processing quality of the oriented silicon steel is high.

Owner:MAANSHAN IRON & STEEL CO LTD

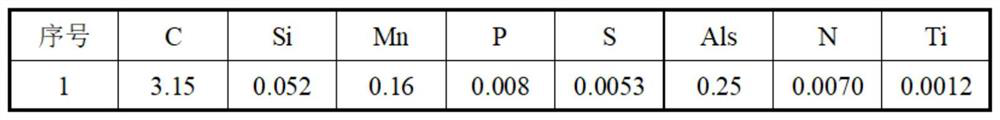

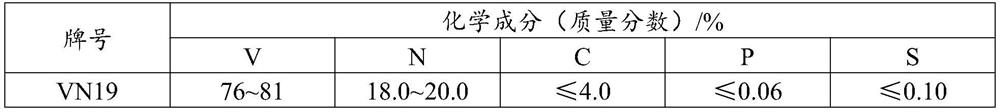

Preparation method of VN19 vanadium-nitrogen alloy and sagger device

ActiveCN113897507AFast preparationEnergy saving preparationSolid state diffusion coatingIron powderCarbonization

The invention relates to the technical field of metallurgy, and provides a preparation method of a VN19 vanadium-nitrogen alloy. According to the preparation method, powdery vanadium oxide, silicon dioxide powder, a carbonaceous reducing agent, iron powder and a binder are mixed and then sequentially subjected to ball pressing, drying, vacuum carbonization reduction and nitridation, and the VN19 vanadium-nitrogen alloy is obtained. The silicon dioxide powder is added into the raw materials, the silicon dioxide powder is reduced, and silicon nitride is generated in the nitriding process, so that the nitrogen content of a product is increased. According to the preparation method, carbonization reduction is carried out under the vacuum condition, nitridation is carried out under the high nitrogen pressure, and the VN19 vanadium-nitrogen alloy can be efficiently and rapidly prepared in an energy-saving mode. Furthermore, the trend of nitrogen gas flow in the nitriding process is optimized, and a weak cooling and strong cooling subsection cooling mode is adopted in the cooling process, so that the nitrogen content of the product is increased, heat energy is fully utilized, and the preparation cost is reduced.

Owner:承德锦科科技股份有限公司 +1

Nitriding equipment for automobile spare parts

InactiveCN110747429AImprove nitriding effectImprove aestheticsSolid state diffusion coatingCold airAir pump

The invention discloses nitriding equipment for automobile spare parts in the technical field of the nitriding equipment. The nitriding equipment comprises an outer shell, wherein a display screen ismounted on the front surface of the outer shell, an air outlet pipeline is inserted into the top of the left side of the outer shell, the right end of the air outlet pipeline penetrates through the outer shell, and the left side of the air outlet pipeline is connected with an air pump. According to the nitriding equipment for the automobile spare parts, an exhaust fan enables nitrogen in the outershell to flow in the outer shell, the automobile spare parts placed in a heating layer can be fully contacted with nitrogen, so that nitrogen atoms can fully penetrate into the automobile spare parts, the nitriding effect of the automobile spare parts is improved, in addition, cold air generated by a thermoelectric refrigeration sheet carries out cooling treatment on the automobile spare parts, so that the automobile spare parts can be cooled in an environment filled with nitrogen, the situation that the automobile spare parts are oxidized after being in contact with the air is avoided, and the attractiveness of the automobile spare parts and the surface quality of the automobile spare parts are improved, and the nitriding quality is improved.

Owner:XUZHOU DINGYUAN MACHINERY

Process for nitriding metal surfaces

ActiveCN110230024BPowerful cleaning effectImprove nitriding effectSolid state diffusion coatingMegasonic cleaningWater immersion

The invention discloses a process for nitriding a metal surface, which includes a metal workpiece to be processed, and the processing of the workpiece includes the following steps: soaking the workpiece with water containing detergent, rinsing with clean water and immersing it in 100°C water Wash the workpiece; place the degreased workpiece in the pool for ultrasonic cleaning, the cleaning vibration frequency is 80-160KHz, and the power density is set at 0.6-1.0W / C; preheat the workpiece to 300-385°C, and the preheating time 6‑25min; place the workpiece in a nitriding furnace with base salt containing Li ions, raise the nitriding furnace to 520‑580°C, and nitriding time is 80‑100min; add sodium peroxide solid to the base salt , and the weight ratio of solid sodium peroxide to the weight ratio of the base salt is 1:2.5-4.5. In the present invention, by adding ultrasonic cleaning, it can quickly realize a strong cleaning effect on the workpiece during the cleaning process of the workpiece, so that the solid dirt on the surface of the workpiece is separated from the workpiece, so that it can effectively clean the workpiece during the nitriding process. Improve the effect of nitriding.

Owner:KUNSHAN SUNMIN DRILUBE ELECTRONIC MATERIAL TECHNOLOGY CO LTD

A kind of preparation method of vn19 vanadium nitrogen alloy and a kind of sagger device

ActiveCN113897507BFast preparationEnergy saving preparationSolid state diffusion coatingIron powderSilicon oxide

The invention relates to the technical field of metallurgy and provides a preparation method of a VN19 vanadium nitrogen alloy. The invention mixes powdery vanadium oxide, silicon dioxide powder, carbonaceous reducing agent, iron powder and binder, and then carries out ball pressing, drying, vacuum carbonization reduction and nitriding in sequence to obtain VN19 vanadium nitrogen alloy. In the present invention, silicon dioxide powder is added to the raw material, and the silicon dioxide powder is reduced to form silicon nitride during the nitriding process, which is beneficial to increase the nitrogen content of the product. The present invention carries out carbonization reduction under vacuum conditions, and carries out nitriding under high nitrogen pressure, and can realize energy-saving, high-efficiency and fast preparation of VN19 vanadium-nitrogen alloy. Furthermore, the present invention optimizes the direction of the nitrogen gas flow during the nitriding process, and adopts weak cooling and strong cooling in the cooling process in sections to increase the nitrogen content of the product, make full use of heat energy, and reduce the production cost.

Owner:承德锦科科技股份有限公司 +1

An Atmospheric Supersonic Plasma Spraying Device Forming a Protective Gas Shield

The invention discloses an atmospheric supersonic plasma spraying device for forming a protective gas hood, which comprises an anode nozzle, which is in the shape of a revolving body and has a central through hole. On the circumferential surface of the anode nozzle, the outlet end communicates with the central through hole, and the axis of the protective air hole forms an acute angle α with the axis of the central through hole; the inlet end of the powder feeding hole is set on the circumferential surface of the anode nozzle, and the outlet end is connected to the axis of the central through hole. The central through hole is communicated, and the axis of the powder feeding hole is perpendicular to the axis of the central through hole. The invention has simple structure, no solid cover, no need to install a cold water device, convenient installation, disassembly and inspection, and the spraying material is not easy to adhere to the nozzle hole. The oxidation of the sprayed particles in the middle, and has a certain cooling effect on the jet, so as to reduce the temperature of the jet and the temperature of the sprayed particles, and reduce the possibility of oxidation of the sprayed particles.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

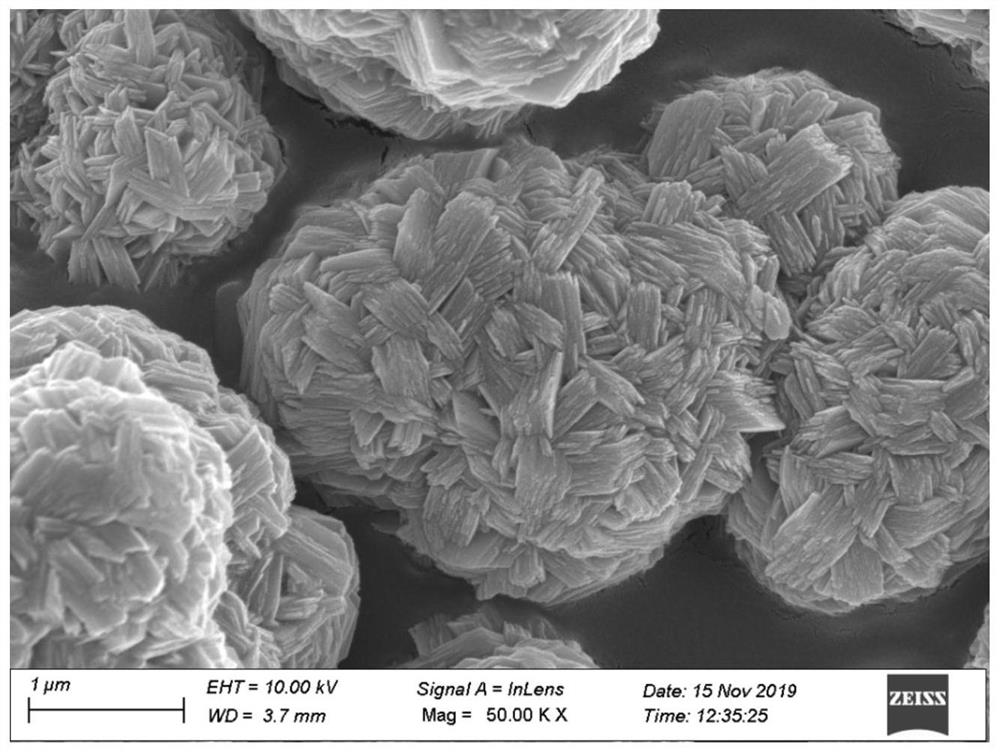

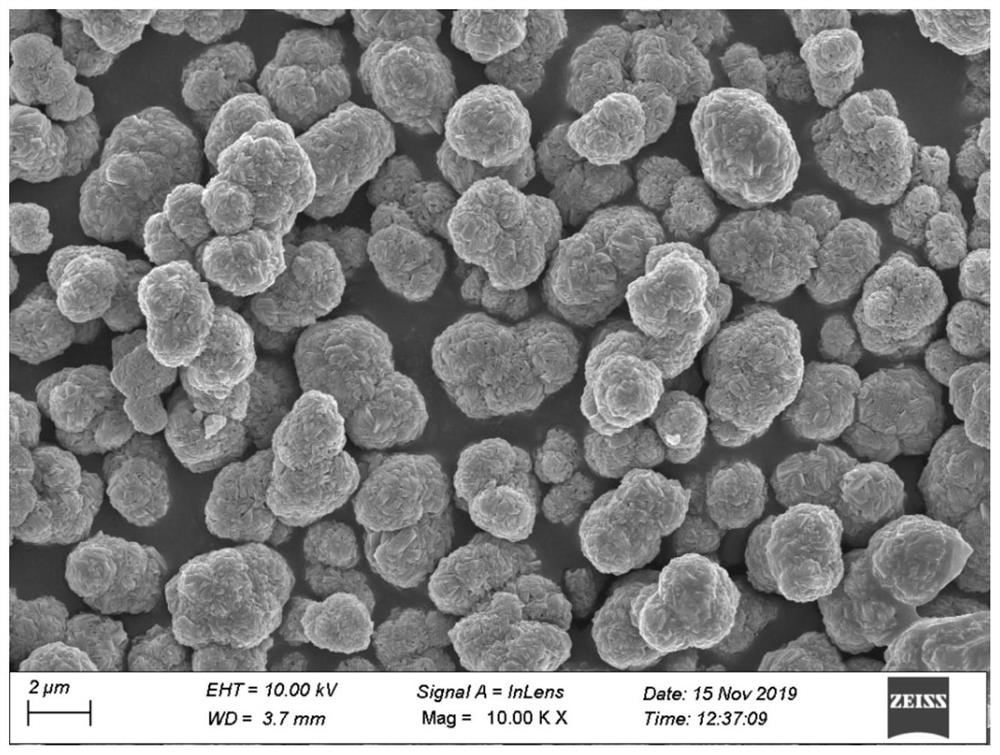

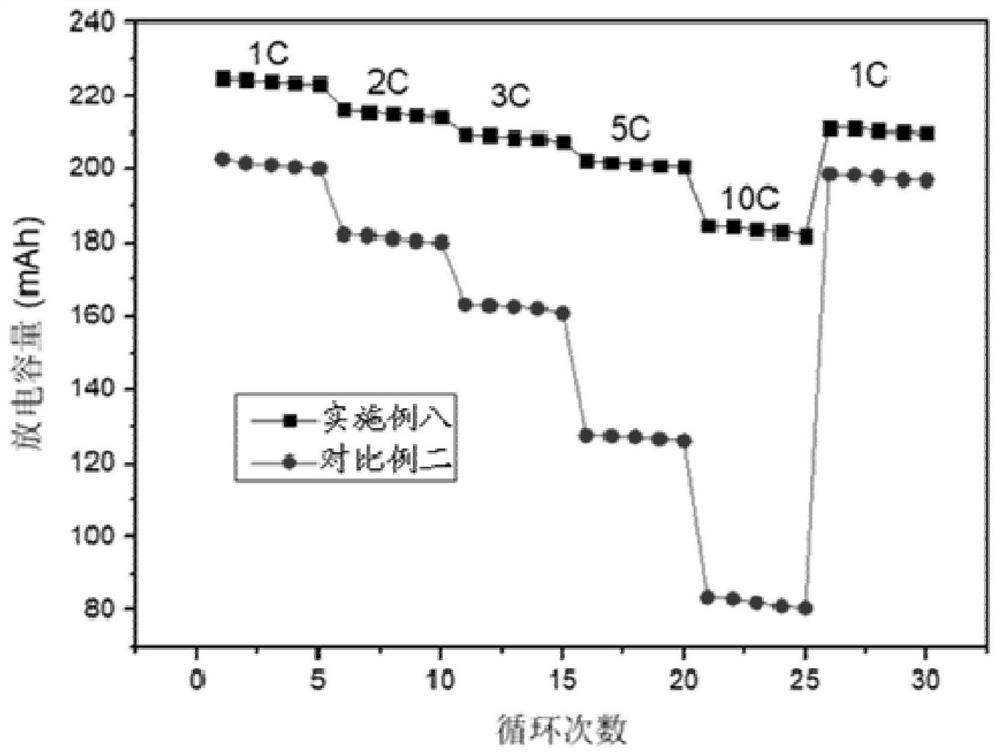

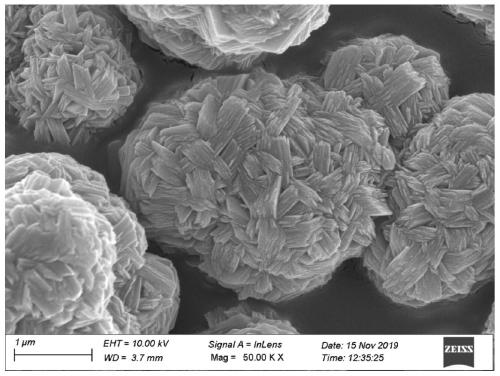

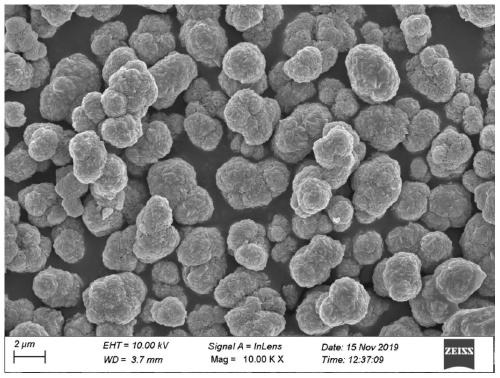

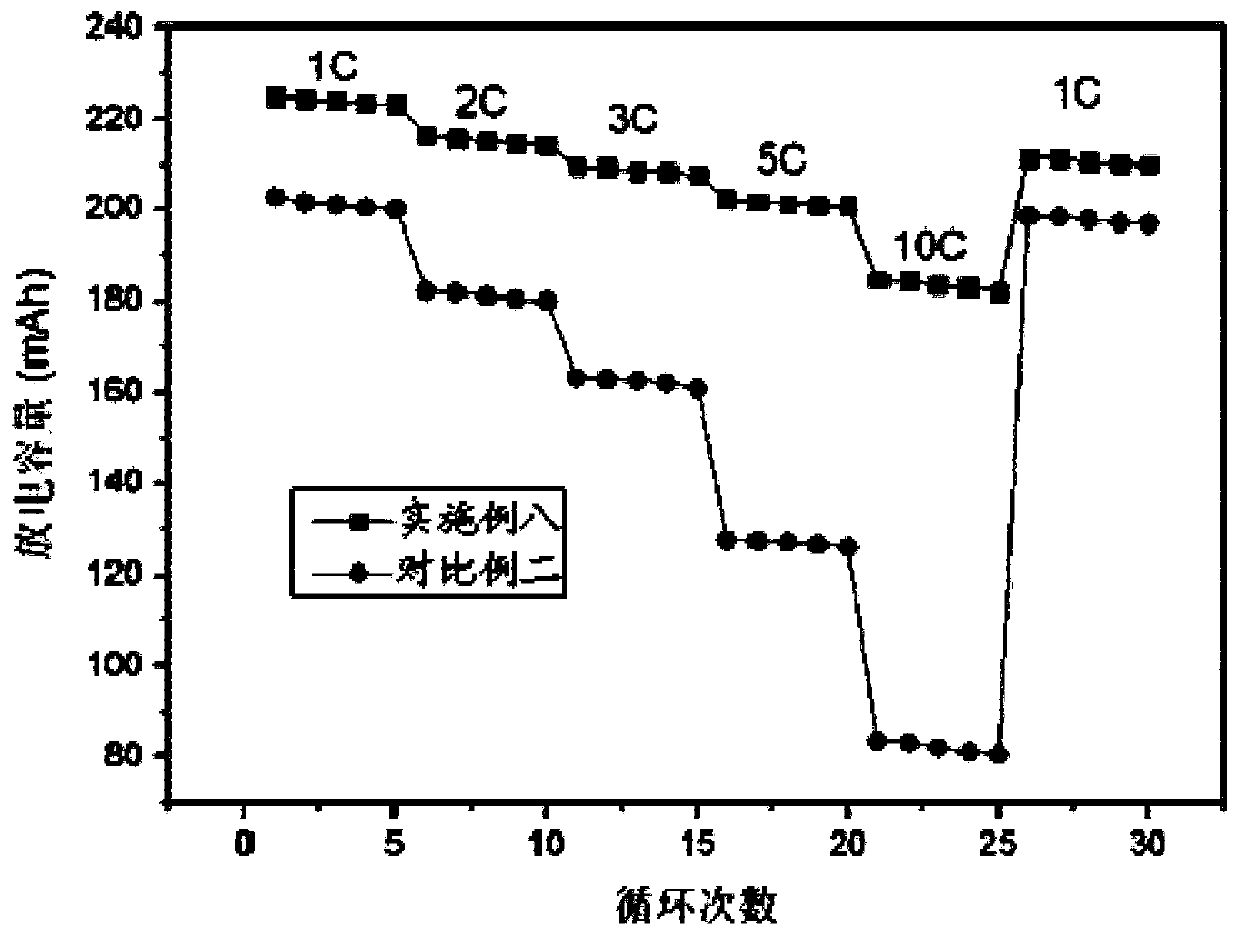

Modified nickel cobalt lithium manganese oxide ternary positive electrode material and its preparation method and application

ActiveCN111430710BImprove capacity playHigh capacity retentionSecondary cellsPositive electrodesElectrolytic agentManganate

The invention provides a modified nickel-cobalt lithium manganate ternary positive electrode material, a preparation method and application thereof. The preparation method of the modified nickel-cobalt lithium manganese oxide ternary positive electrode material includes the following steps: preparing a braided spherical nickel-cobalt lithium manganate ternary material; mixing the nickel-cobalt lithium manganate ternary material powder with rare earth The nitride and lithium nitrogen mixture is subjected to the first ball milling and mixing treatment to obtain the mixture powder; and the mixture powder is subjected to segmental sintering treatment under a nitrogen-oxygen mixed atmosphere. The preparation method of the modified nickel-cobalt lithium manganese oxide ternary positive electrode material uses a mixture of rare earth nitride and lithium nitrogen to coat the ternary material particles, which effectively improves the capacity and cycle retention of the ternary material, and improves the performance of the ternary material. The nitriding effect can better alleviate the mixed lithium and nickel of the material and the excess lithium on the surface of the material; at the same time, the nitride coating layer reduces and prevents the contact between the electrolyte and the active material, reduces irreversible side reactions, and reduces the solid electrolyte membrane (SEI )Formation.

Owner:桂林麦克斯新能源科技有限公司

Atmospheric supersonic plasma spraying device with two-stage protective air holes

The invention discloses an atmosphere supersonic speed plasma spraying device with two-section type protection air holes. The spraying device comprises an anode nozzle. The front end of the anode nozzle is cylindrical, and a center through hole is formed in the anode nozzle. The anode nozzle is further provided with the protection air holes and powder feeding holes. The inlet ends of the protection air holes are arranged on the circumferential face of the anode nozzle, and the outlet sections of the protection air holes are arranged on the front end face of the anode nozzle. The protection air holes comprise the first section of air holes and the second section of air holes. The axis of the first section of air holes and the axis of the center through hole form an acute angle of alpha, and the axis of the second section of air holes and the axis of the center through hole form an acute angle of beta. The inlet ends of the powder feeding holes are arranged on the circumferential face of the anode nozzle, and the outlet ends of the powder feeding holes communicate with the center through hole. In addition, the axis of the powder feeding holes is perpendicular to the axis of the center through hole. The atmosphere supersonic speed plasma spraying device is simple in structure, a solid cover is omitted, and additional arrangement of a cold water device is needless. Mounting, dismounting and inspection are convenient, the temperature of jet flow and the temperature of spraying particles can be lowered, and oxidization probability of the spraying particles is reduced.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

A kind of method for preparing high coercive force samarium iron nitrogen magnet from nitrogen rare earth complex

ActiveCN109036752BImprove nitriding effectIncreased anisotropyInductances/transformers/magnets manufactureMagnetic materialsMagnetocrystalline anisotropyCoordination complex

The invention discloses a method for preparing a samarium ferronitrogen magnet with high coercivity by a nitrogen rare earth complex, belonging to the technical field of magnetic materials. The Sm2Fe17Nx nanocrystalline thin ribbon is immersed in a mixed solution of nitrogen rare earth complex and absolute ethanol, The addition of nitrogen-based rare earth complexes can further enhance the nitriding effect of SmFeN magnets, thus effectively enhancing the magneto-crystalline anisotropy and coercivity of the main phase. The invention has the advantages of simple process, easy operation, low cost, and is favorable for the application of samarium ferronitrogen magnetic powder with high coercivity in more permanent magnetic devices to meet the market demand.

Owner:CHINA JILIANG UNIV

Modified lithium nickel cobalt manganese oxide ternary positive electrode material and preparation method and application thereof

ActiveCN111430710AHigh capacity retentionRelieve excess lithiumSecondary cellsPositive electrodesManganese oxideElectrolyte

The invention provides a modified nickel cobalt lithium manganate ternary positive electrode material as well as a preparation method and application thereof. The preparation method of the modified nickel cobalt lithium manganate ternary cathode material comprises the following steps of preparing a braided spherical nickel cobalt lithium manganate ternary material; carrying out first ball-millingmixing treatment on the nickel cobalt lithium manganate ternary material powder and a rare earth nitride and lithium nitrogen mixture to obtain mixture powder; and carrying out segmented sintering treatment on the mixture powder in a nitrogen-oxygen mixed atmosphere. According to the preparation method of the modified lithium nickel cobalt manganese oxide ternary positive electrode material, the ternary material particles are coated with the rare earth nitride and lithium nitrogen mixture, so that the capacity exertion and the cycle retention rate of the ternary material are effectively improved, the nitridation effect of the ternary material is improved, and the lithium-nickel mixed arrangement of the material and the redundant lithium on the surface of the material are better relieved. Meanwhile, the nitride coating layer reduces and prevents the contact between the electrolyte and the active material, reduces the irreversible side reaction, and reduces the formation of a solid electrolyte membrane (SEI).

Owner:桂林麦克斯新能源科技有限公司

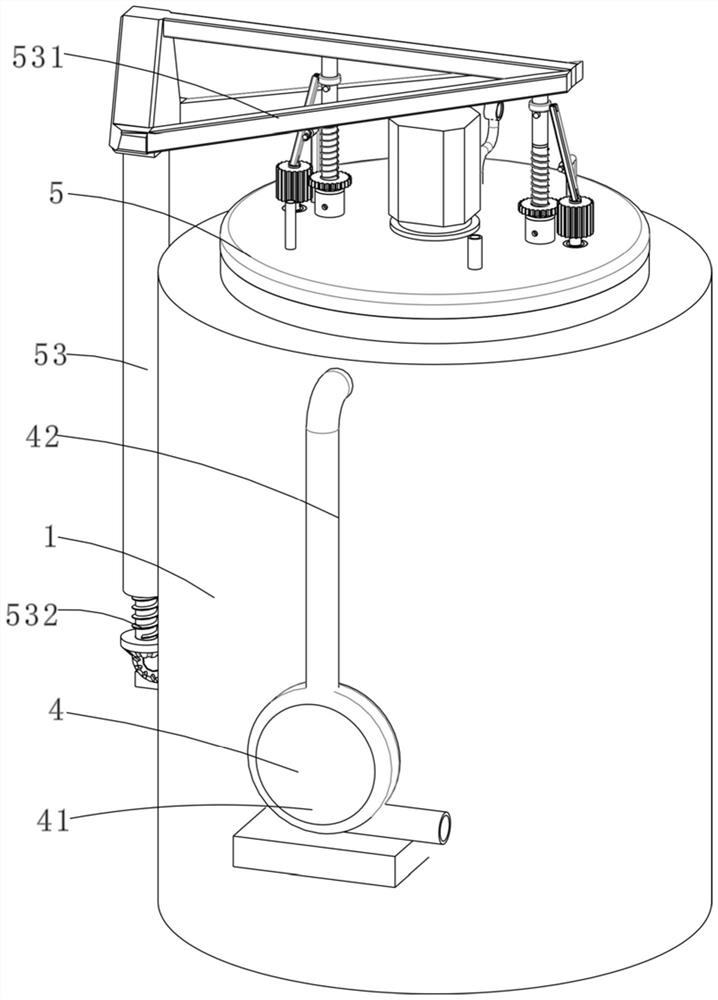

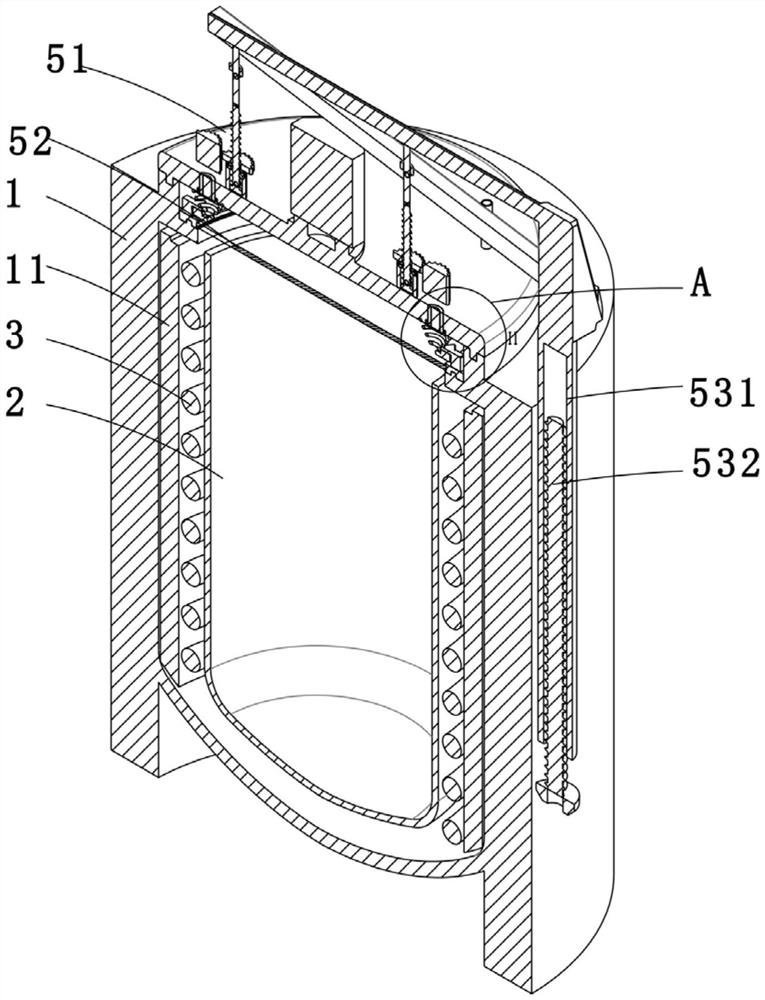

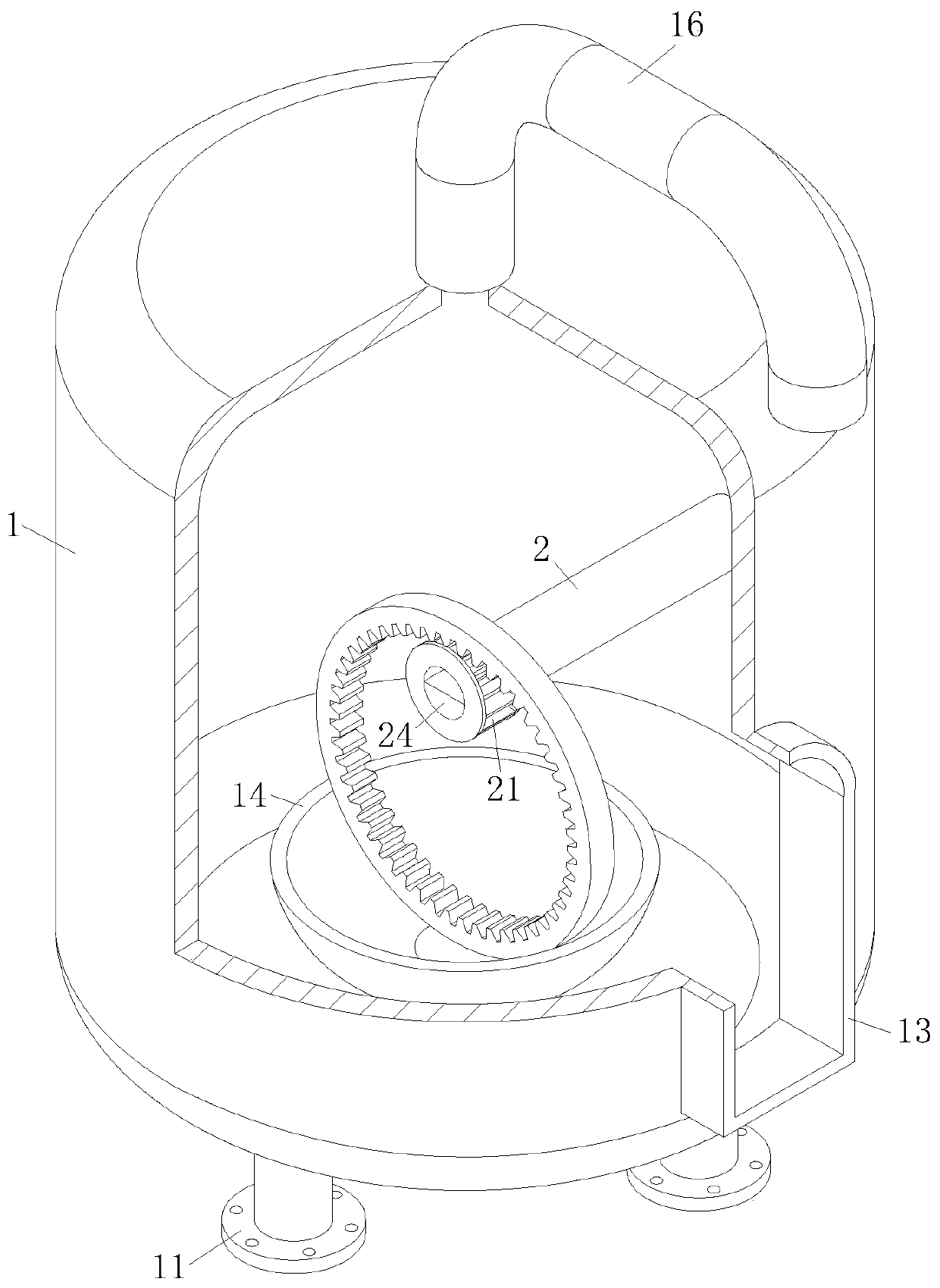

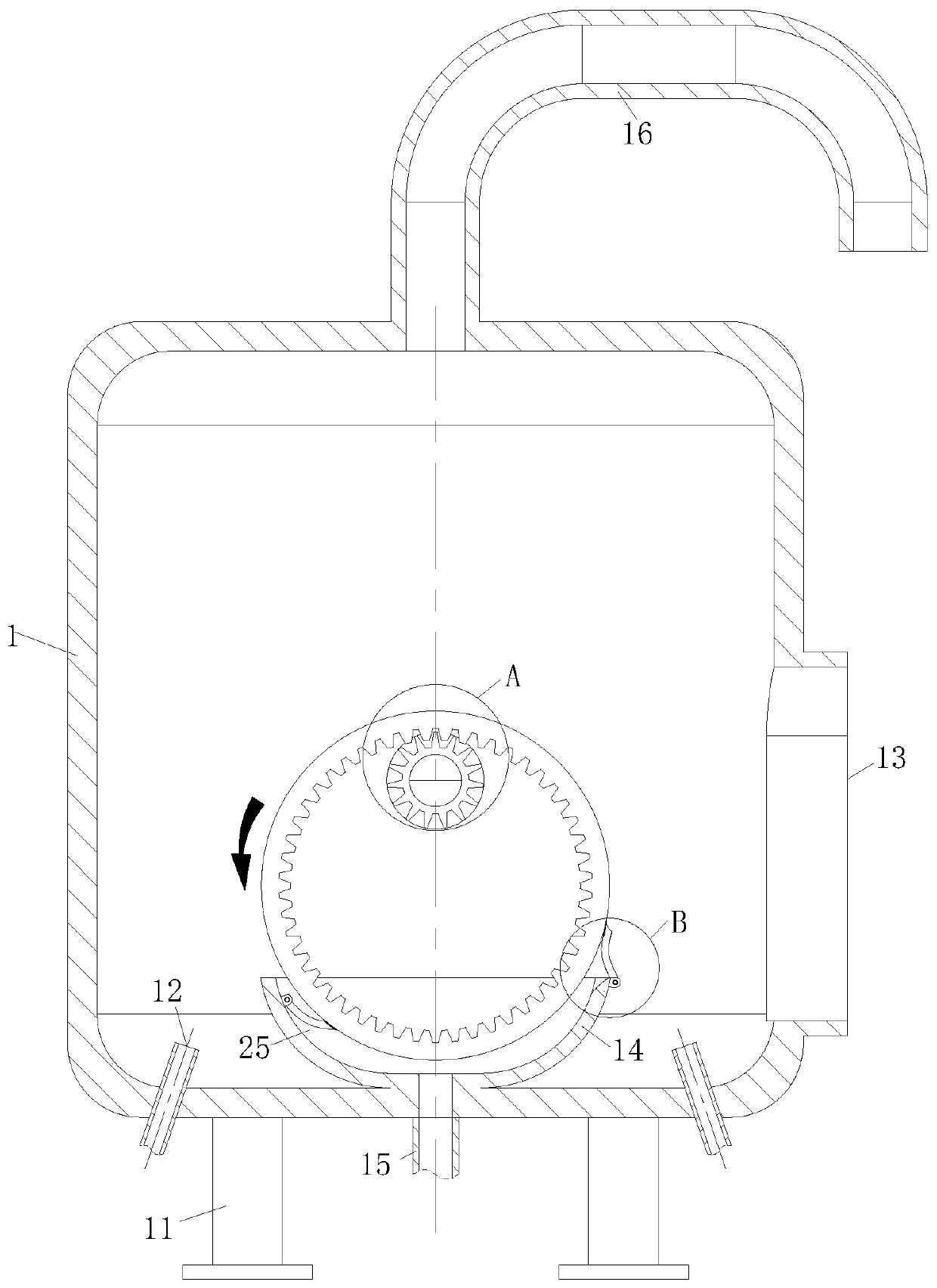

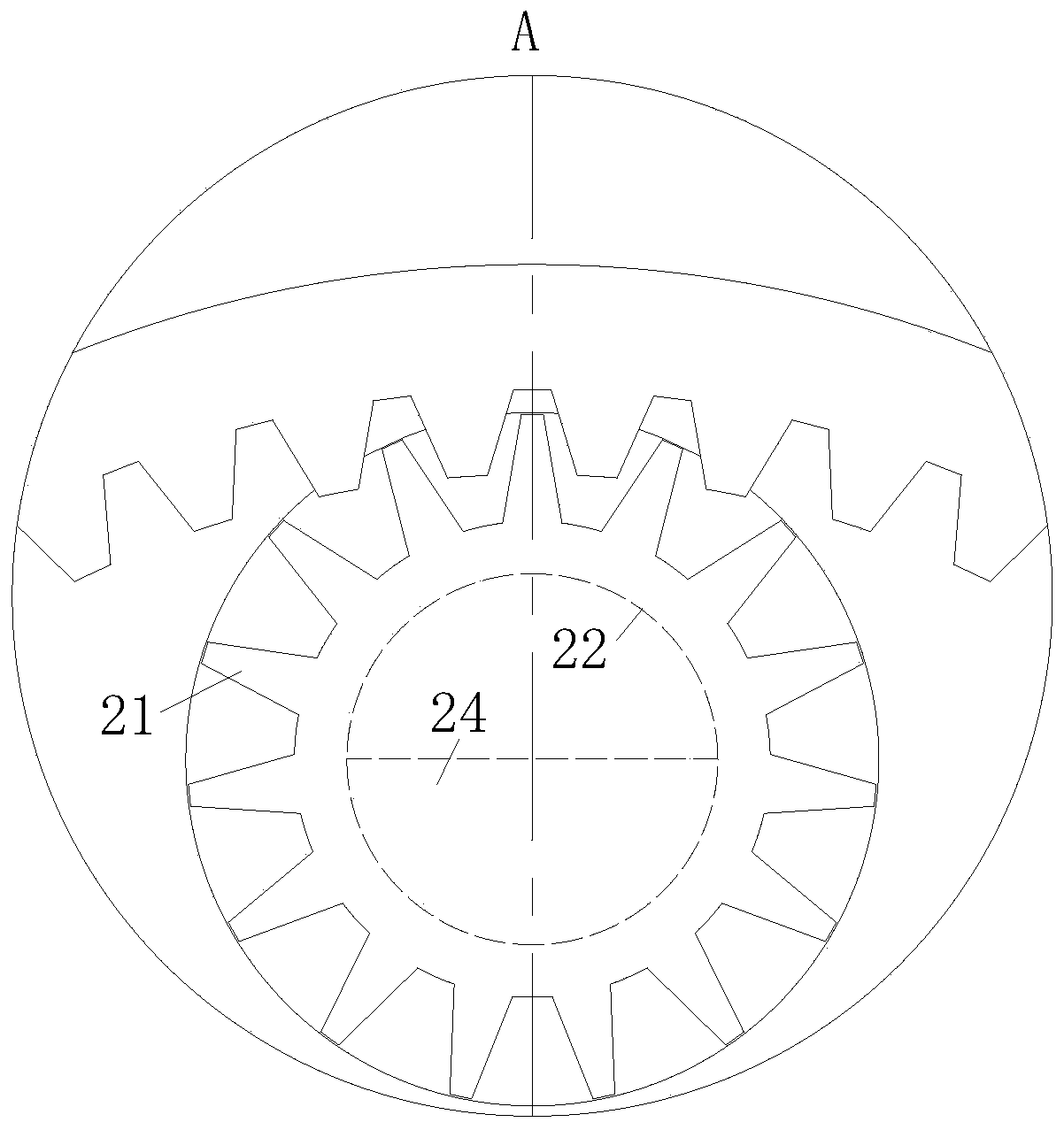

Surface treatment nitridizing furnace

InactiveCN110777325AFast heatingQuality improvementSolid state diffusion coatingThermodynamicsGear drive

The invention belongs to the technical field of part treatment and specifically provides a surface treatment nitridizing furnace. The surface treatment nitridizing furnace comprises a cylindrical furnace body. A set of flame spray pipes are uniformly distributed on the circumference of the bottom of the furnace body. The bottom center of the interior of the furnace body is provided with a nitridizing tank. The nitridizing tank contains a nitridizing agent solution. The bottom of the nitridizing tank is provided with a gas supply pipe communicating with an external nitrogen tank. The middle portion of the furnace body is rotatably connected with a round tube. The round tube is driven to rotate by a motor fixed to the outer wall of the furnace body. The motor is connected with a power supplythrough a controller. The end, close to the middle portion of the furnace body, of the round tube is fixedly connected with a gear. The gear is engaged with a gear ring to be treated. The bottom of the gear ring is soaked in the nitridizing agent solution. According to the surface treatment nitridizing furnace, the gear drives the gear ring to rotate, so that the gear ring is rapidly heated in the furnace body, and the portion, located above the nitridizing agent solution, of the gear ring is rapidly heated and then rotated into the nitridizing agent solution. The temperature rising rate of the gear ring is further increased, and the nitridizing quality and efficiency of the gear ring are improved.

Owner:曹元进

Pressurized gas nitriding method on the surface of medium and low carbon alloy structural steel

InactiveCN103160774BImprove adsorption capacityImprove nitriding effectSolid state diffusion coatingCarbon alloyNitriding

The invention discloses a medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method. The medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method comprises the following steps of putting a medium and low-carbon alloy constructional steel workpiece into a solid solution nitrogenation furnace which is shown in the patent having a patent name of pressurization high-temperature nitridation device with dual pressure equilibrium structure and having the patent number of 201210530358.6, improving the pressure to 0.1-0.5MPa at a temperature of 500-800 DEG C, feeding NH3 into the solid solution nitrogenation furnace at a flow rate of 0.1-0.5L / min, carrying out gas nitridation treatment at a decomposition rate of 30-80% for 5-20 hours, sequentially feeding NH3 into the solid solution nitrogenation furnace, cooling to a temperature below 150 DEG C, and taking out the workpiece. The medium and low-carbon alloy constructional steel surface pressurization gas-nitridation method can effectively promote adsorption of N atoms on the part surface, improve N activity, an interface reaction rate and a hole and slit nitridation capability, reduce an NH3 decomposition rate, improve nitrogen potential, obviously reduce an NH3 consumption amount in nitridation, greatly improve process effects and realize short-term deep nitridation.

Owner:YANSHAN UNIV

Nitriding equipment and process based on high valve stability

ActiveCN109594036BImprove nitriding effectImprove wear resistanceSolid state diffusion coatingProcess engineeringNitrogen gas

Owner:重庆恒蕾工贸有限公司

Nitriding treatment process on the surface of tooth plate

The invention discloses a dental plate surface nitriding technology, and relates to the technical field of workpiece nitriding treatment. The technology comprises the steps of 1) preparing before treatment, 2) vacuumizing, 3) heating, 4) reheating, 5) vacuumizing, 6) surface activating, 7) vacuumizing, 8) decomposing through ammonia gas, 9) nitriding, 10) vacuumizing, 11) blackening, and 12) cooling. The technology has the beneficial effects that the fatigue resistance of a workpiece is improved; high pressure stress is generated in a nitriding layer, so that the fatigue limit of the workpieceis high, and the sensitivity of the workpiece is low under the effect of alternating load; and moreover, the fatigue limit of the workpiece subjected to alternating load can be increased by 200%.

Owner:HAIYAN JINGBIN HARDWARE PROD CO LTD

Microwave Heating Magnesium Smelting Technology

InactiveCN103882247BExploitation of New Technology for Magnesium SmeltingImprovement of Magnesium Refining TechnologyMicrowaveNew energy

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com