Patents

Literature

46results about How to "Realize large-scale industrialized continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

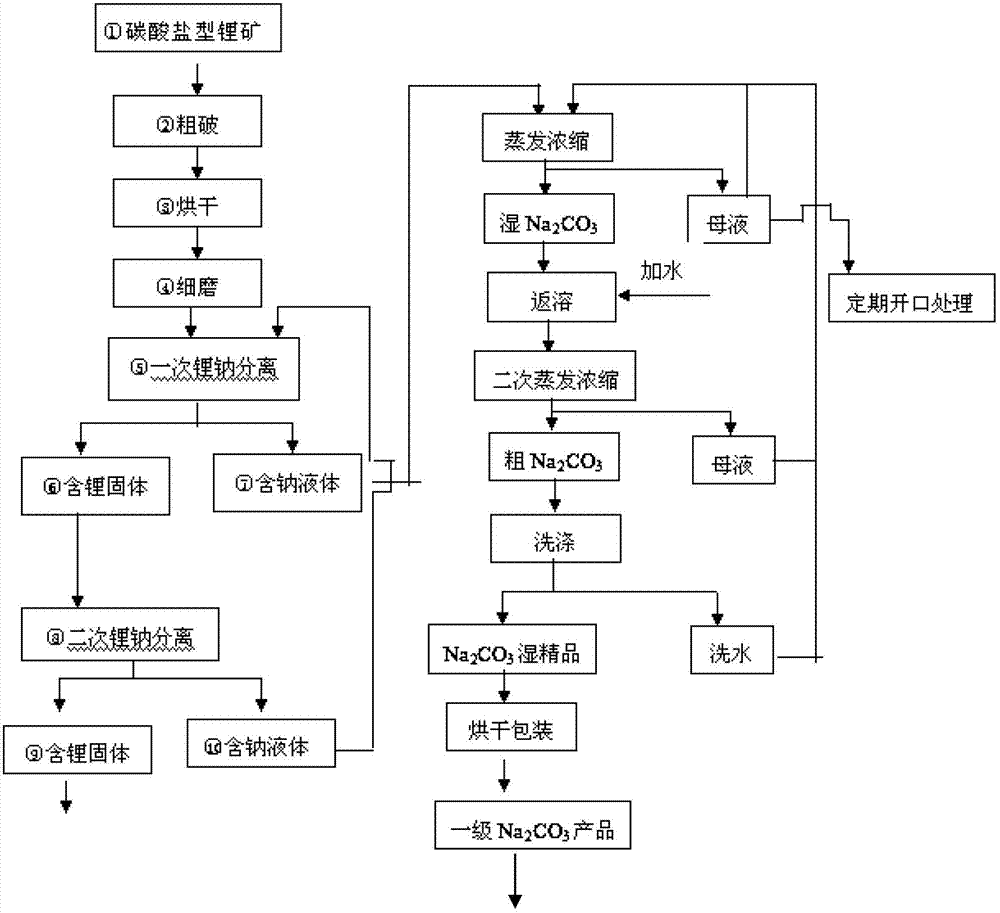

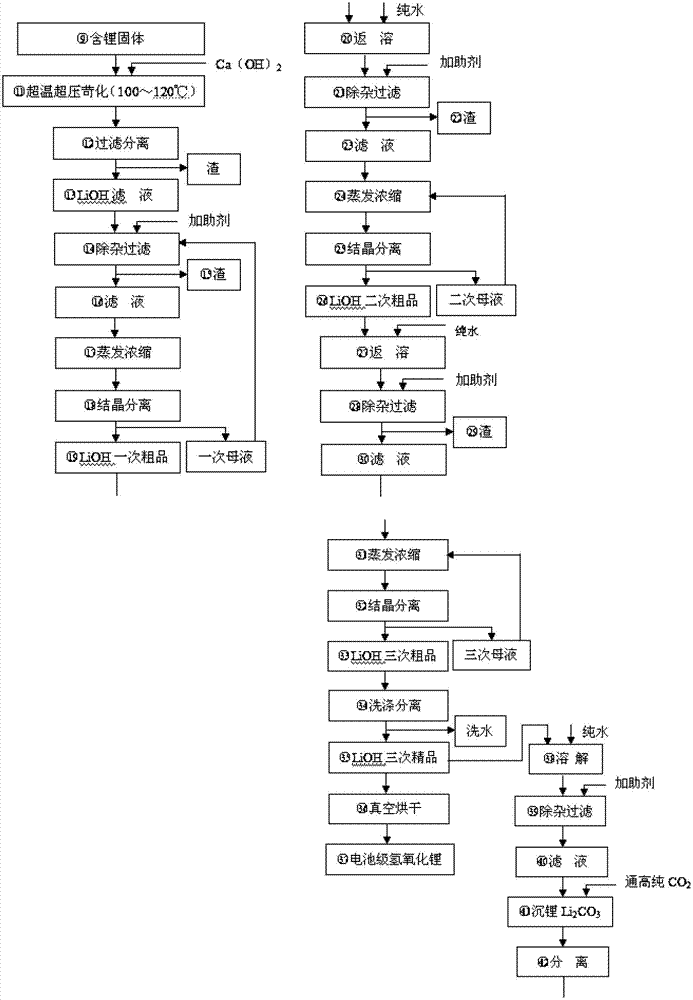

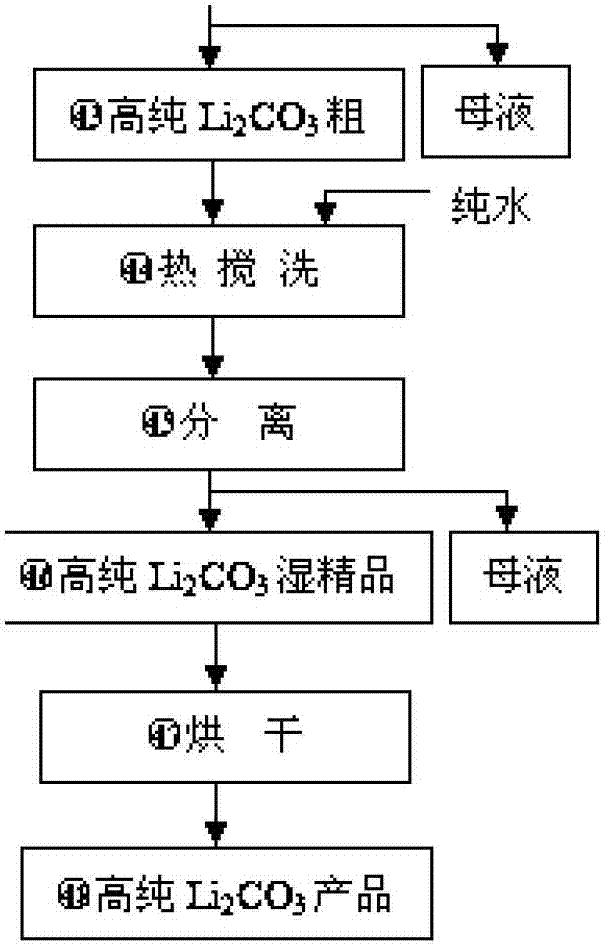

Method for industrially producing industrial, cell-grade or high-purity lithium hydroxide monohydrate

InactiveCN102826576AReduce consumptionReduce pollutionLithium oxides/hydroxidesLithium carbonateWater resources

The invention provides a method for industrially producing an industrial, cell-grade or high-purity lithium hydroxide monohydrate, which comprises the following steps of: (1) grinding; (2) removing impurities by a thermal precipitation method; (3) causticizing; and (4) removing impurities, crystallizing, washing, separating and drying. The invention also provides a method for preparing high-purity lithium carbonate. After causticizing reaction equipment and a reaction method which are provided by the invention are utilized, the feeding amount of the single causticizing production can be greatly improved and the large-scale industrial continuous production of the industrial and cell-grade lithium hydroxide monohydrate and the high-purity lithium carbonate is implemented; the consumption of water resources and energy can be effectively reduced and in the reaction, only a cheap precipitating agent or a cheap complexing agent needs to be used, so that the production cost is reduced; and the reaction is simple and convenient to operate and, the environment pollution is small, the obtained product has high quality and yield, the quality of the obtained product is stable and the product has wide industrial application prospect.

Owner:四川长和华锂科技有限公司

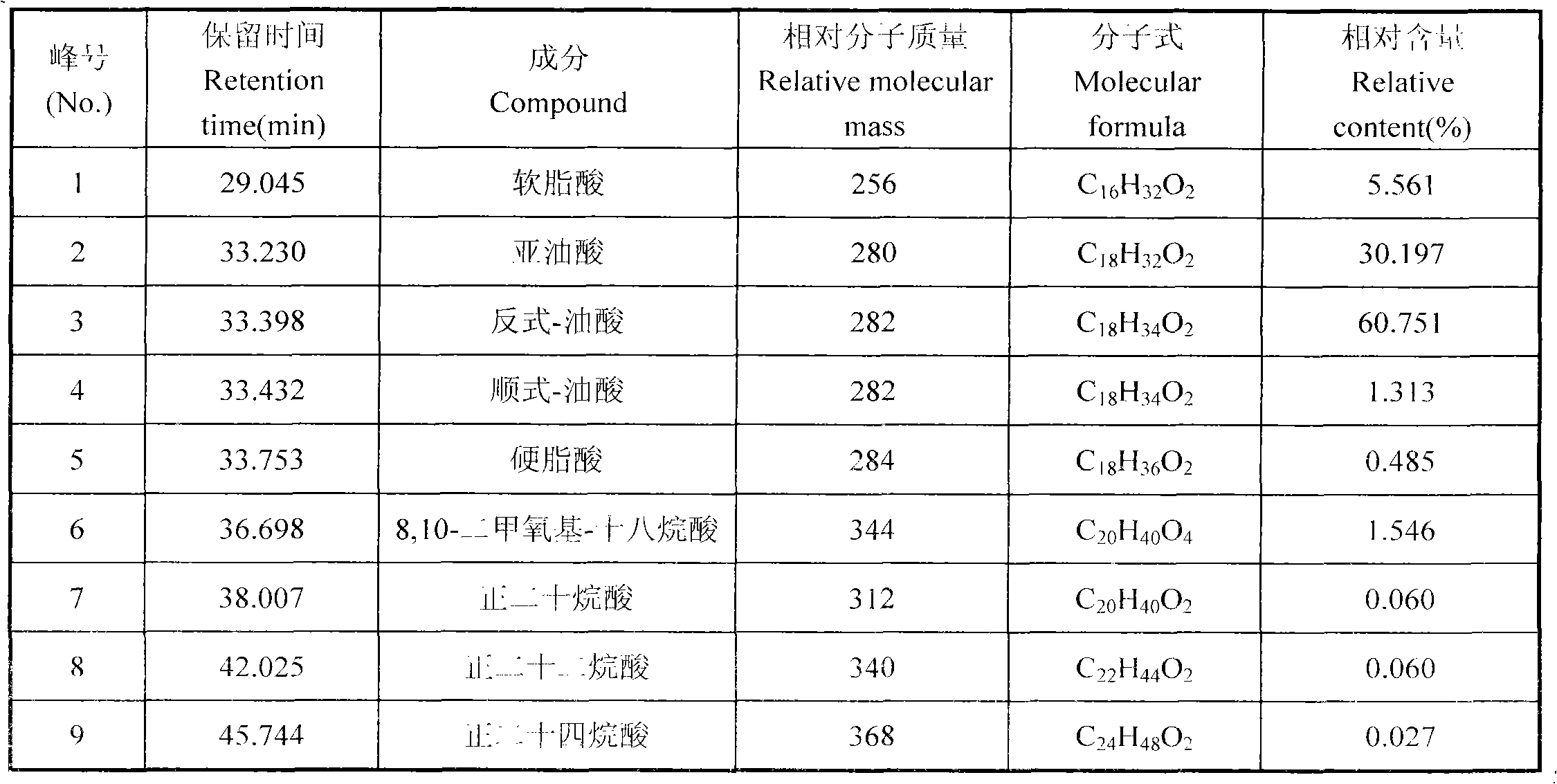

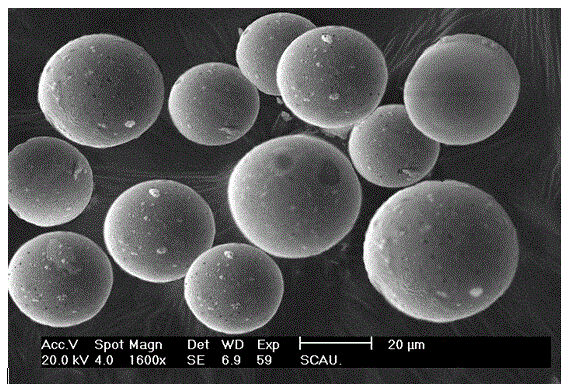

Pressing-low-temperature continuous phase-change castor oil extraction method

InactiveCN103173275AAbundant resourcesReduce manufacturing costFatty-oils/fats productionCastor SeedSulfur hexafluoride

Owner:曹庸

Continuous phase-changed extraction method for orange peel oil

ActiveCN103146486AAbundant resourcesImprove qualityEssential-oils/perfumesFatty-oils/fats productionProduct gasPhase change

The invention provides a continuous phase-changed extraction method for orange peel oil. The method comprises the following steps of: placing dry crushed orange peel raw materials into an extraction kettle; compressing an extraction agent into a liquid under the condition that the pressure and the temperature are always lower than the critical pressure and the critical temperature of the extraction agent; enabling the extraction agent to flow through the extraction kettle at the flow speed of 100-150L / h under the conditions that the extraction temperature ranges from 35 DEG C to 55 DEG C, and the extraction pressure ranges from 0.5Mpa to 2Mpa, and continuously extracting for 50-120min; after the orange peel oil is extracted, enabling the extraction agent to flow into a liberation kettle for liberating at the temperature of 65-75 DEG C and the pressure of 0.1-0.4Mpa; heating and carrying out pressure-reduced phase change on the extraction agent to enable the extraction agent to become a gas, then, immediately condensing the gas to enable the gas to become a liquid, and enabling the liquid to flow through the extraction kettle for extracting the materials again; and circulating many times in such a way. The continuous phase-changed extraction method has the advantages of high supercritical extraction efficiency, no solvent residues in products and high aroma component retention rate; in addition, the extraction pressure and the liberation pressure are lower than the supercritical pressure and temperature; and meanwhile, the continuous phase-changed extraction method has the characteristics of large extraction volume, high mass handling capacity and low production cost of a conventional solvent.

Owner:GREENCREAM BIOTECH +2

Method for extracting sea buckthorn seed oil through subcritical fluid method

InactiveCN102504939AReduce manufacturing costReduce consumptionFatty-oils/fats productionRoom temperatureSolvent

The invention relates to a method for extracting sea buckthorn seed oil through a subcritical fluid method. The method for extracting the sea buckthorn seed oil comprises the following steps: (1), juicing fresh clean sea buckthorn fruit to obtain seeds, drying the seeds in shade under a room temperature, selecting the seeds, smashing the selected seeds, and screening the smashed seeds to obtain a raw sea buckthorn seed material; (2), grinding and drying the raw sea buckthorn seed material; (3), putting the ground dry sea buckthorn seeds and an extracting agent into a subcritical fluid extraction device, so as to obtain an extract; and (4), separating the extract through a pressure reducing and temperature increasing method to obtain an extraction liquid, and standing the extraction liquid under the room temperature to obtain the sea buckthorn seed oil. The method has the advantages that the production cost is effectively reduced; the separation time is shortened; the solvent consumption and the energy consumption in the technological process are reduced; the technological process is simple; the operability is high; the extraction efficiency is high; environmental protection and zero contamination are realized; the security and the repeatability are good; and large-scale industrialized continuous production can be realized.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

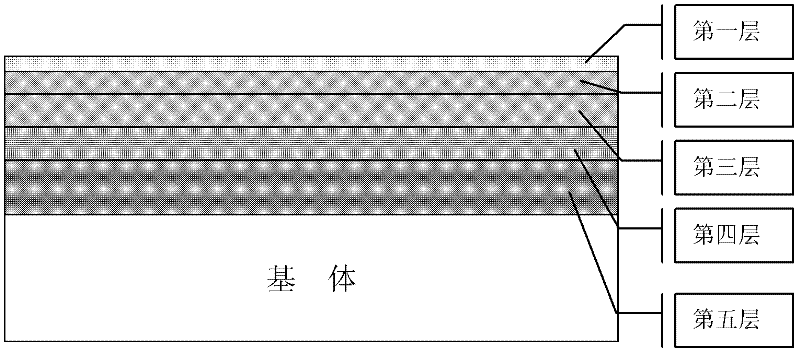

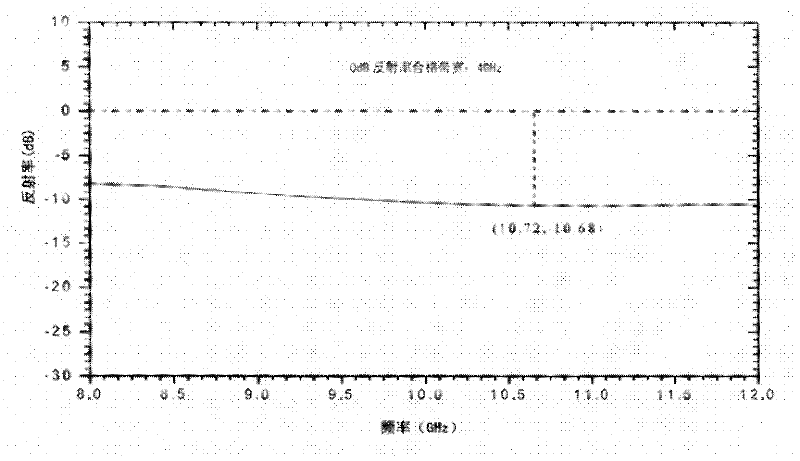

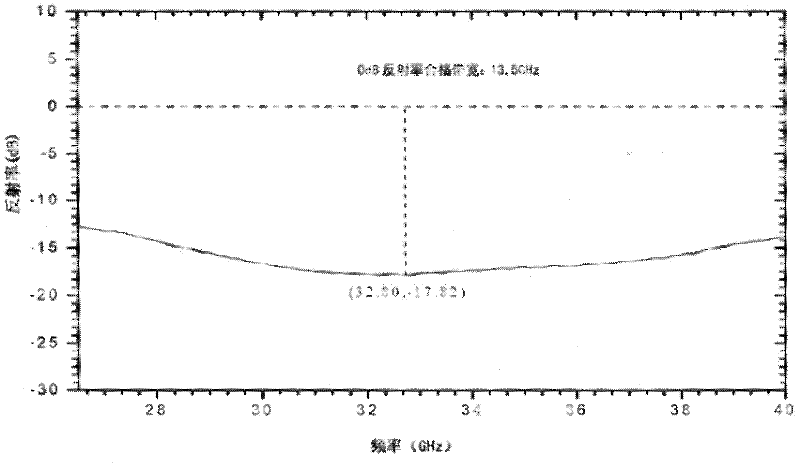

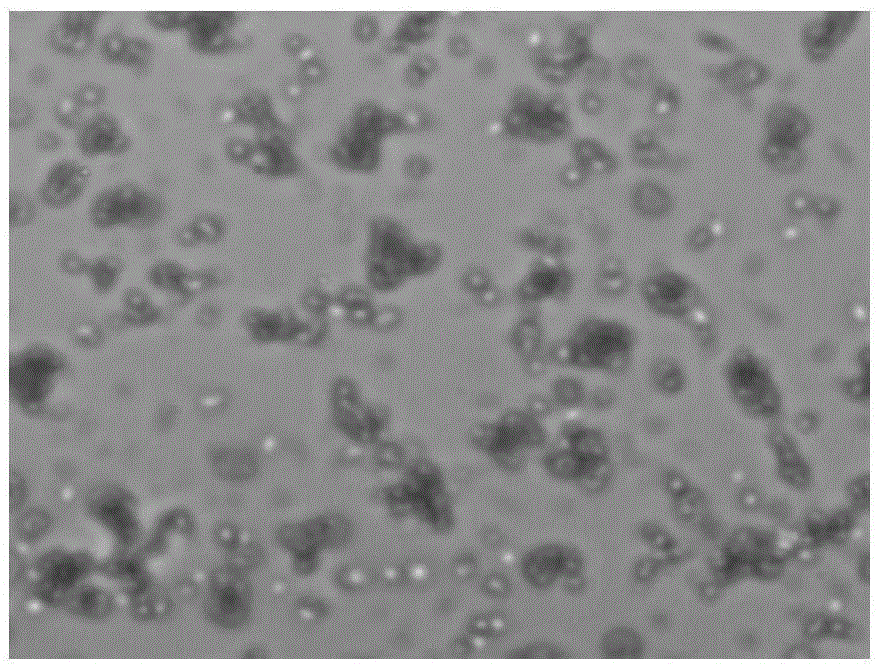

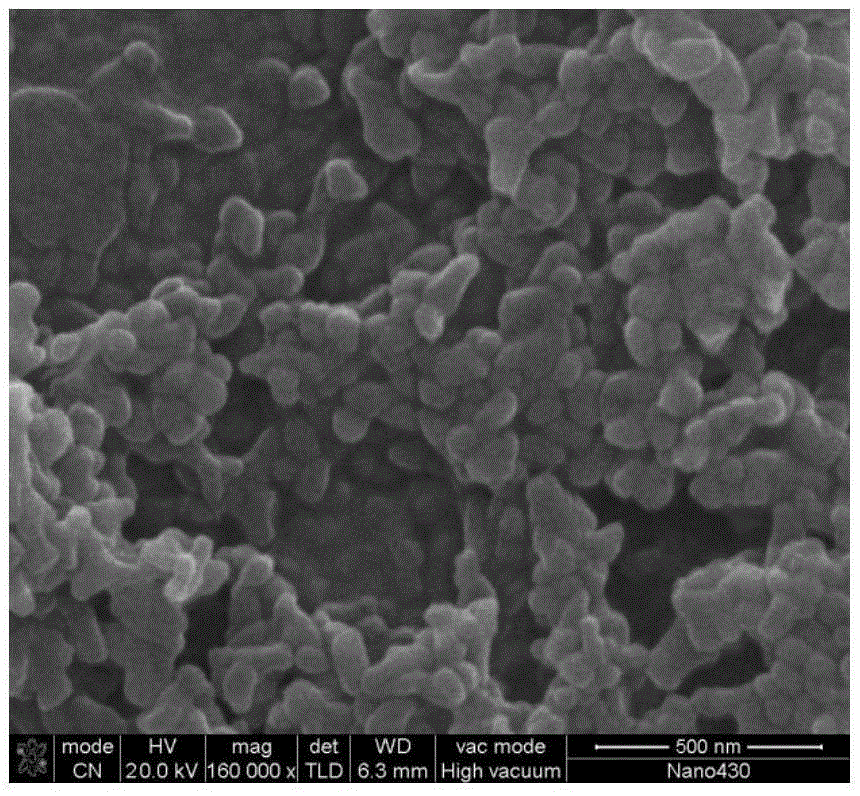

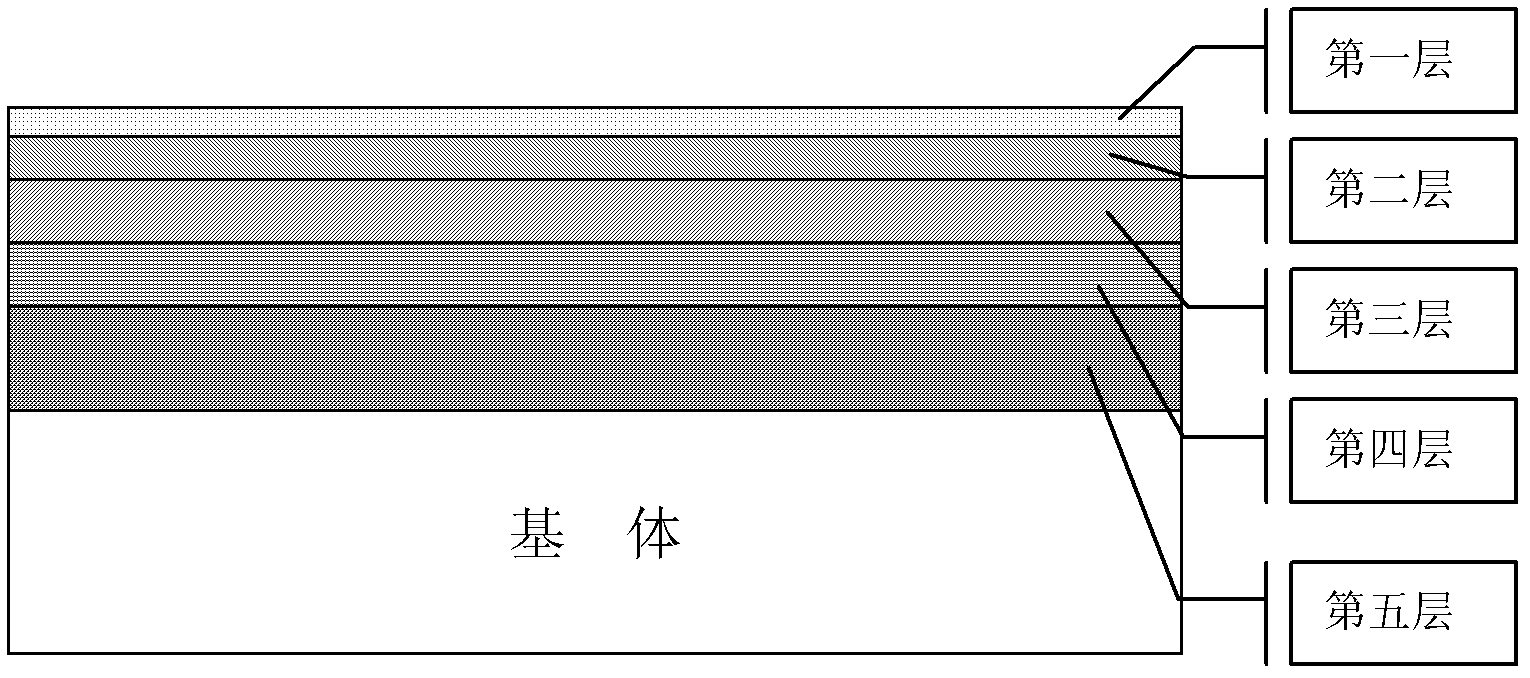

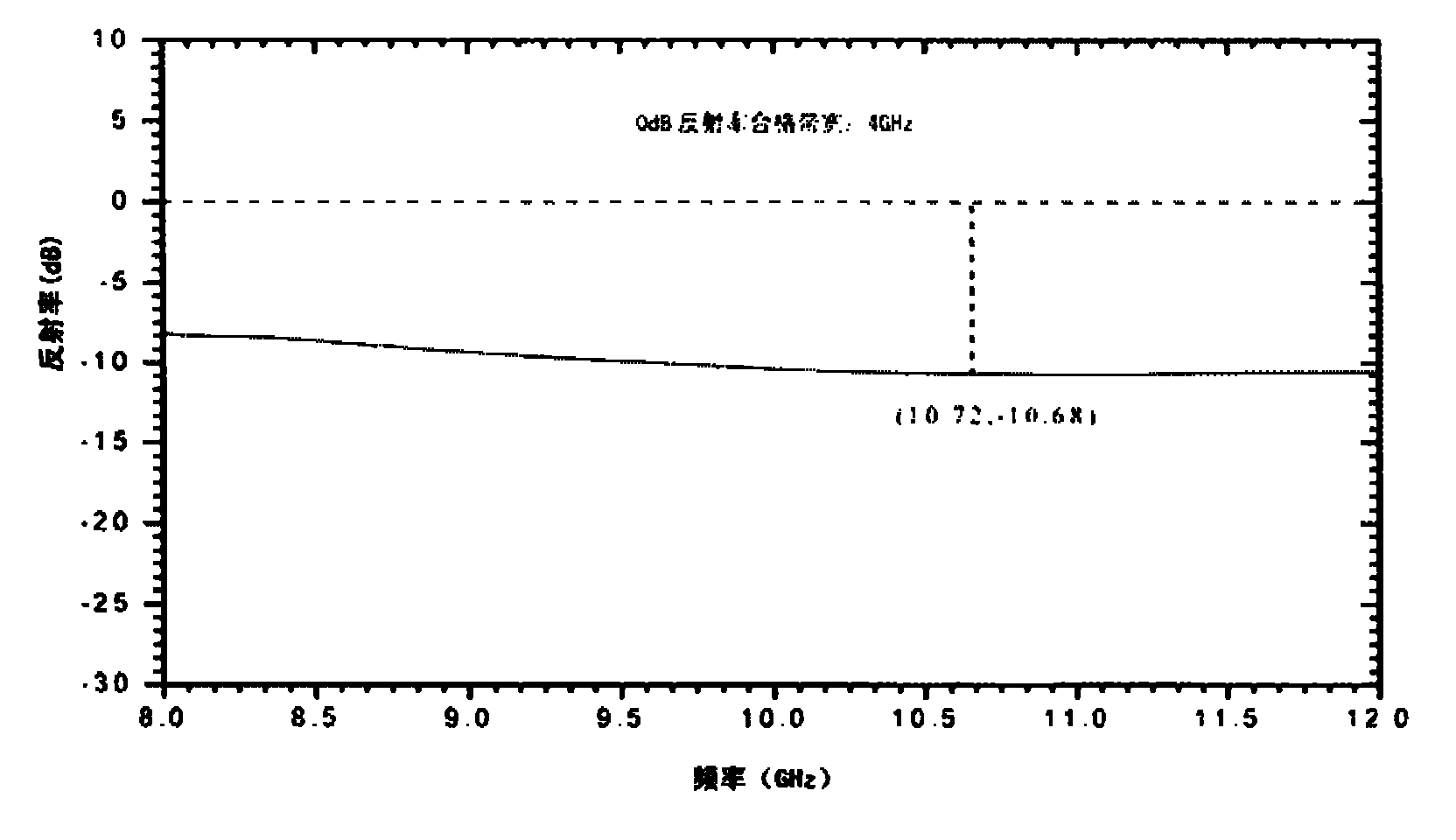

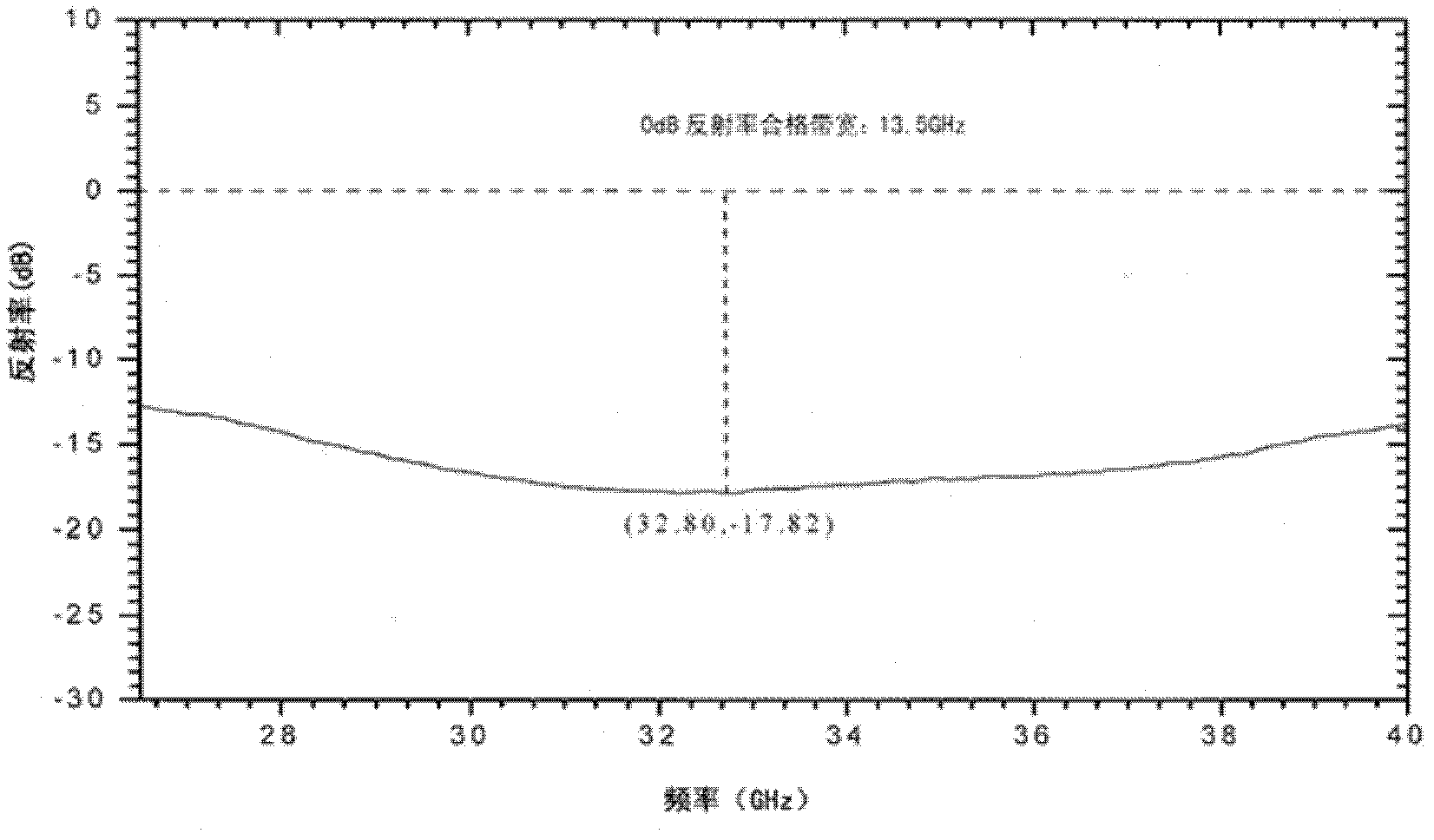

Centimeter wave-millimeter wave compatible absorbing composite material

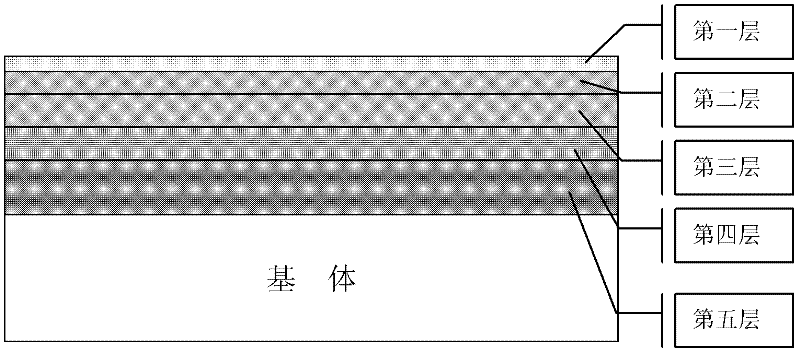

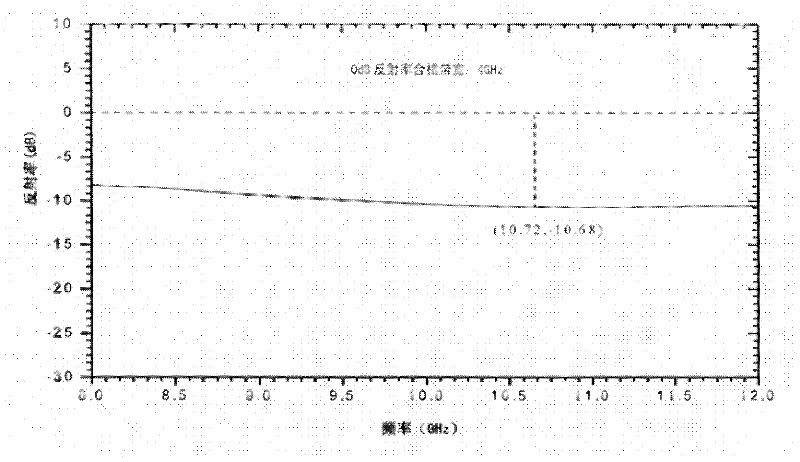

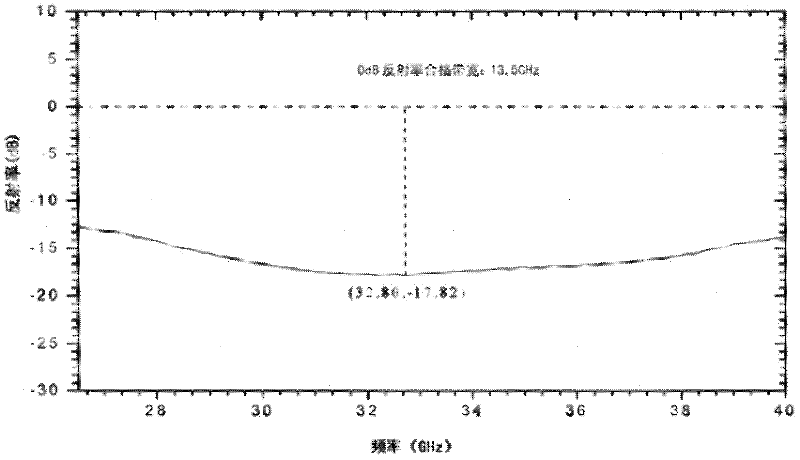

ActiveCN102504659AGood impedance matching effectReduce reflectionPolyurea/polyurethane coatingsRadiation-absorbing paintsPolyurethane adhesiveWave band

The invention discloses a centimeter wave-millimeter wave compatible absorbing composite material. The material has a five-layer structure including a substrate which is an irregular surface made of a random material, a topmost first layer which is composed of a W-shaped hexagonal ferrite absorbent and a acrylic resin adhesive, a second layer which is composed of a carbonyl iron powder absorbent and an epoxy resin adhesive, a third layer which is composed of an Fe85Si1Al6Cr8 nanocrystalline sheet-like absorbent and an epoxy resin adhesive, a fourth layer which is composed of a polycrystallineiron fiber absorbent and an epoxy resin adhesive, and a fifth layer which is composed of a short carbon fiber / carbon black mixed absorbent and a polyurethane adhesive. The material can well solve theproblem of poor centimeter wave-millimeter wave compatible absorbing performance in the prior art, and is a composite wave-absorbing material compatible with electromagnetic waves of centimeter wave-millimeter wave bands.

Owner:HUNAN JINGE NEW MATERIAL

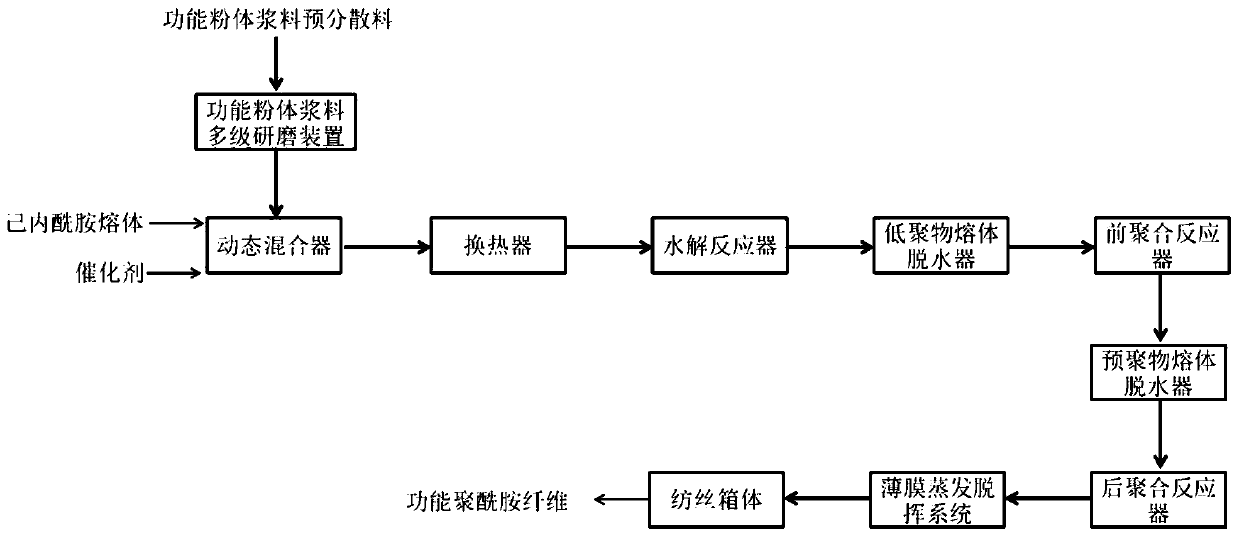

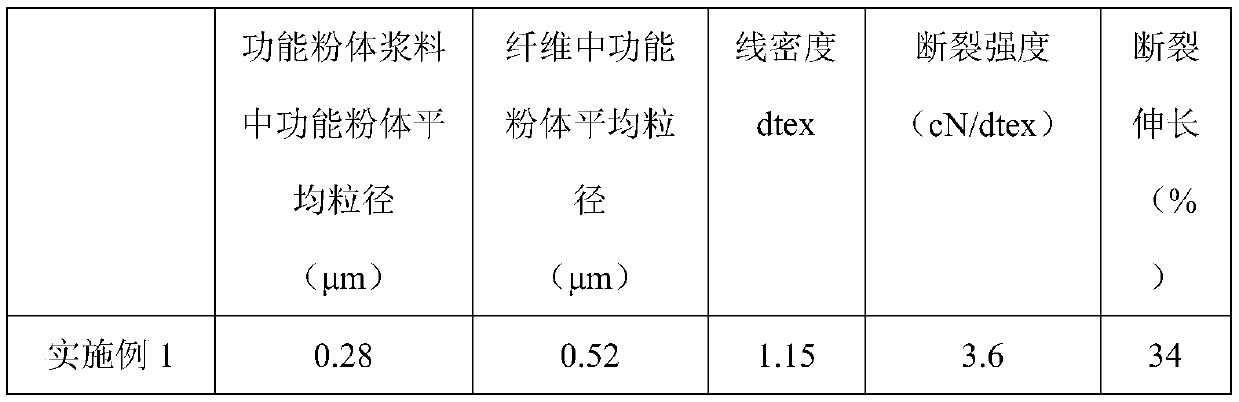

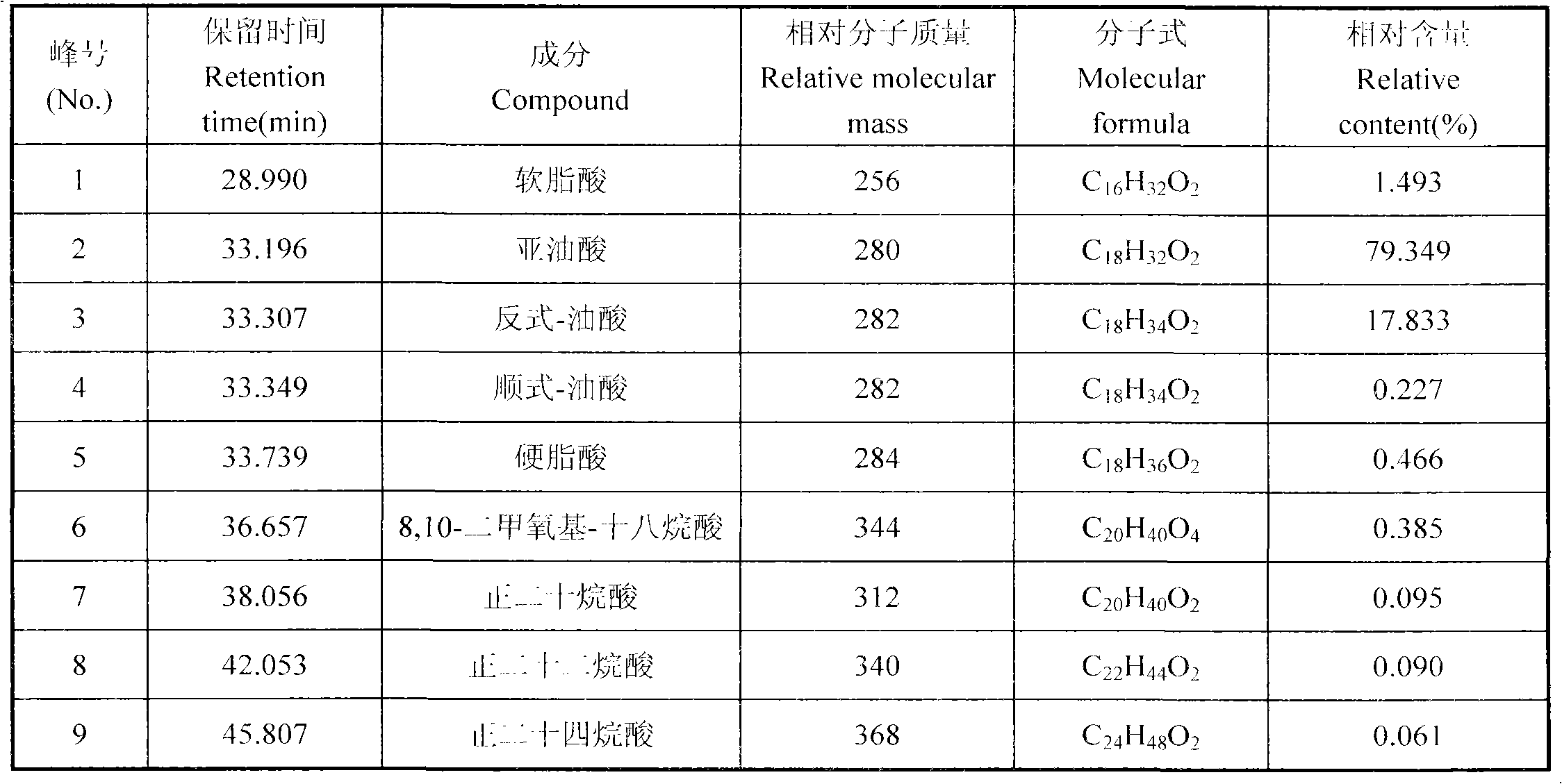

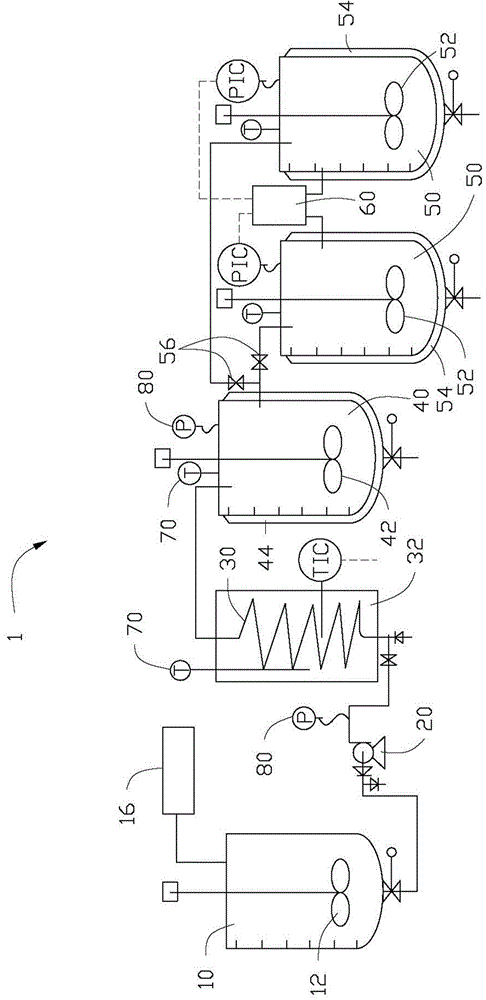

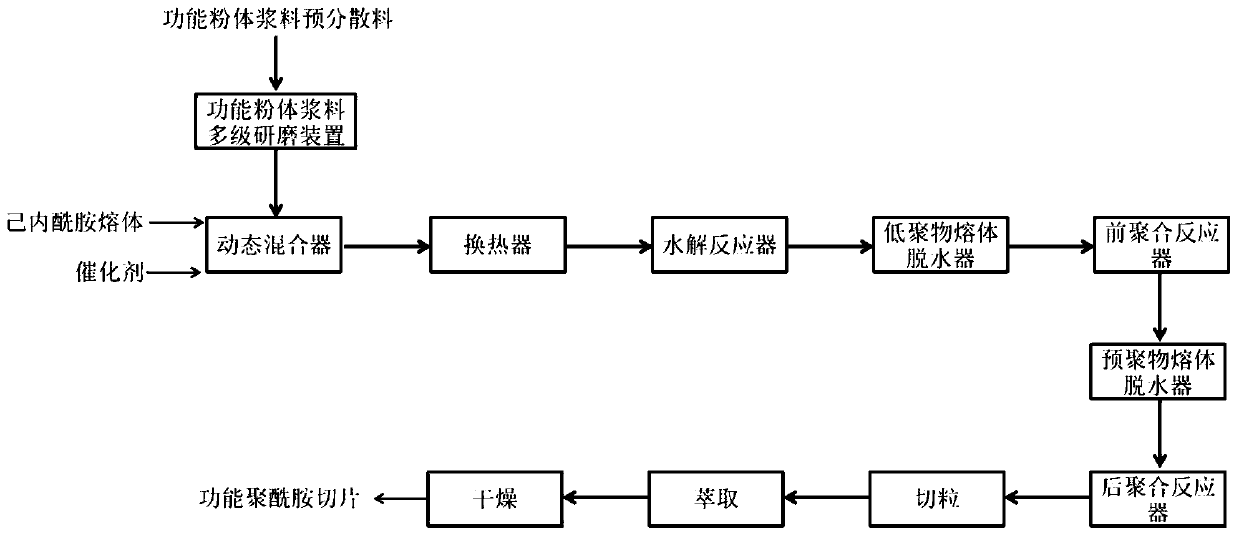

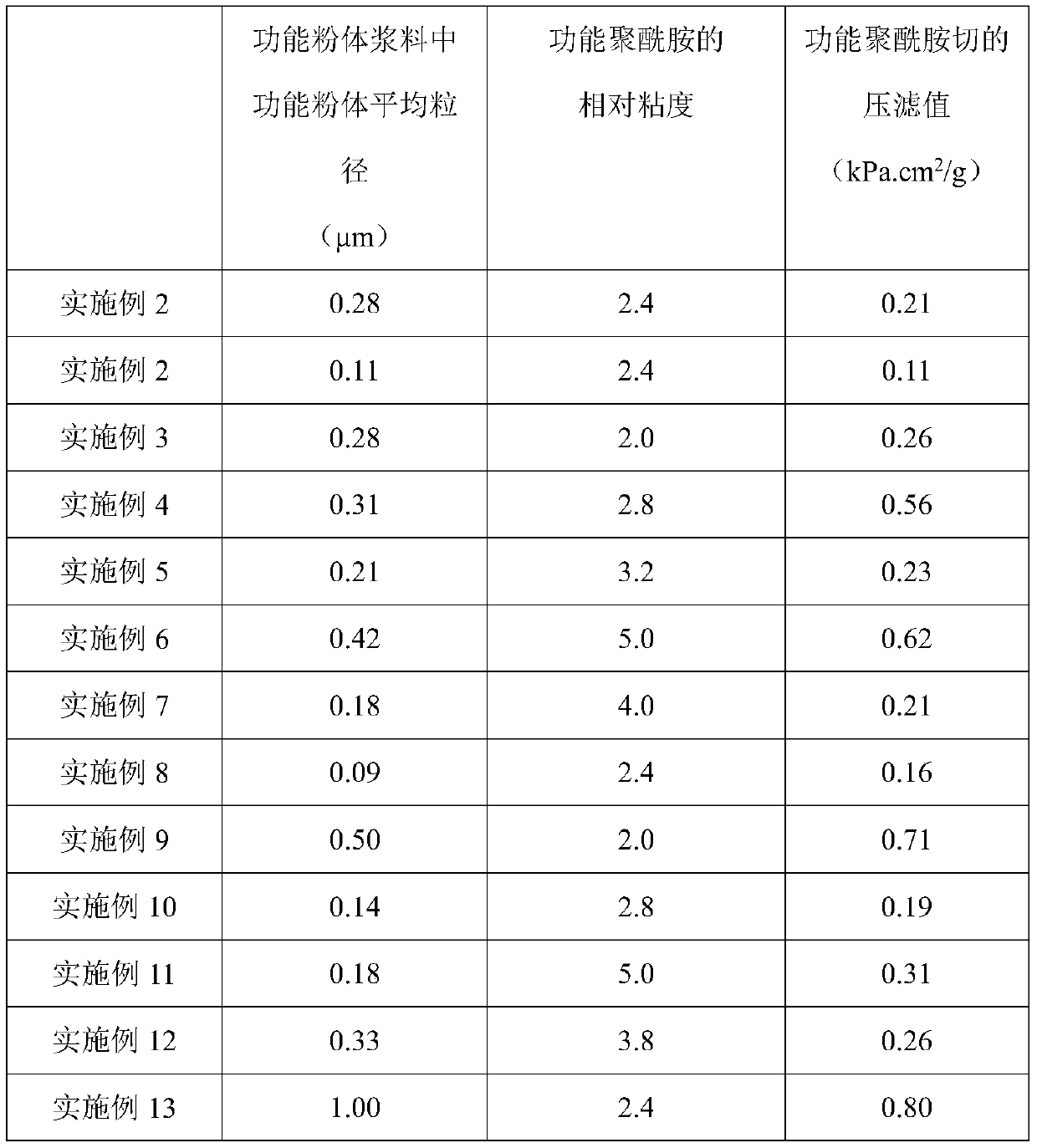

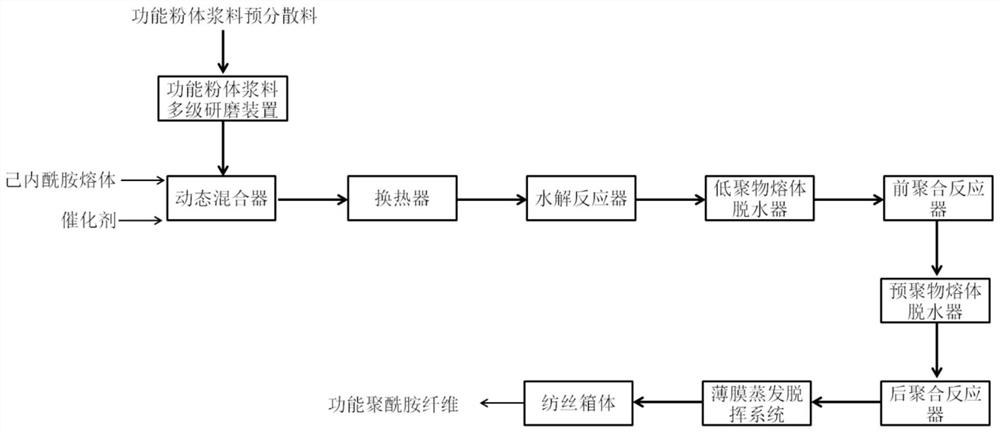

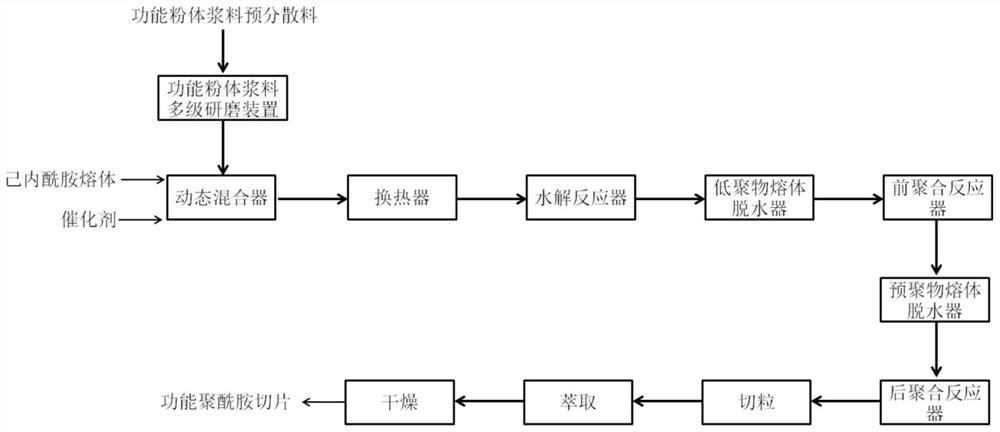

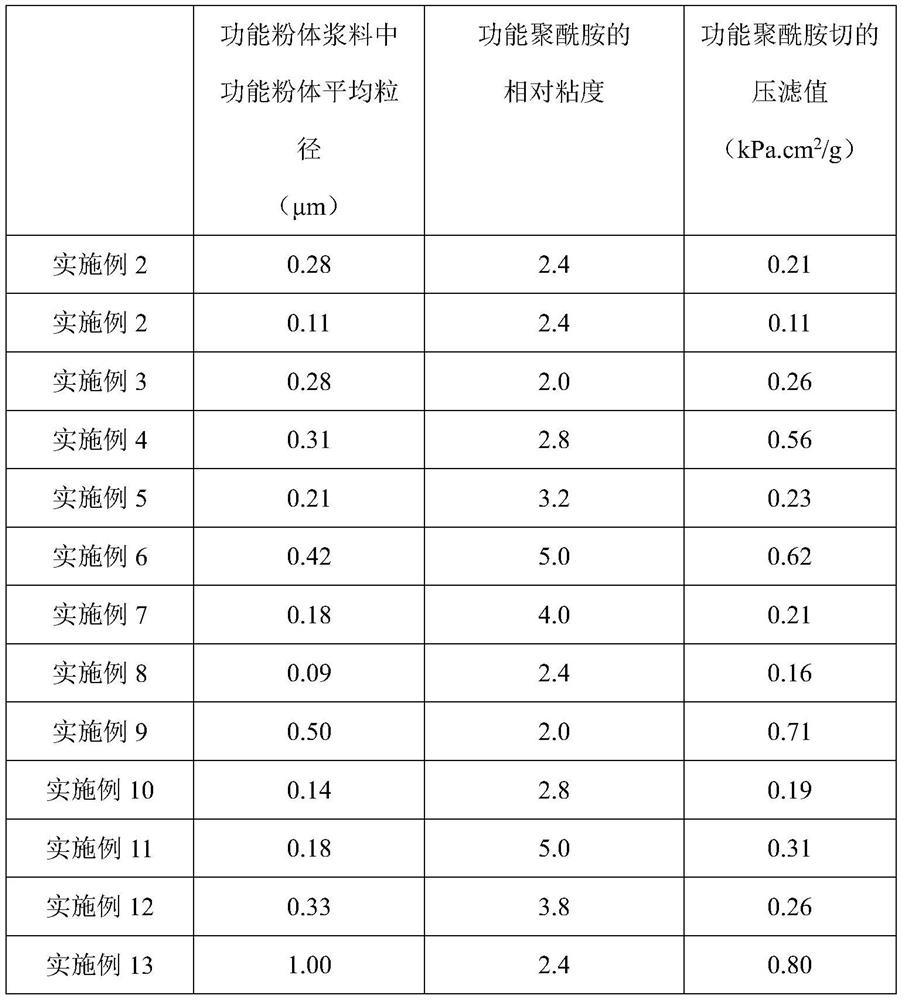

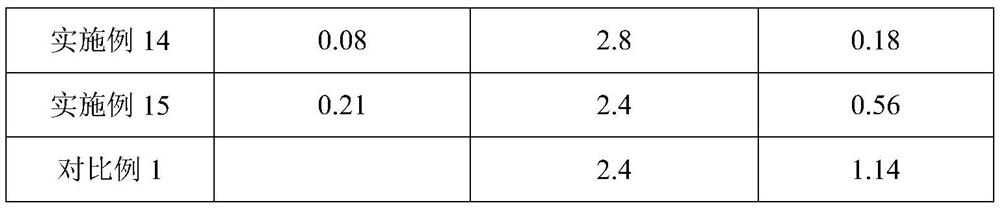

Production method of continuous polymerization melt direct-spinning functional polyarmide fiber, and functional polyarmide fiber

ActiveCN109811423AImprove quality stabilityReduce manufacturing costArtifical filament manufactureMonocomponent polyamides artificial filamentFiberOligomer

The invention discloses a production method of a continuous polymerization melt direct-spinning functional polyarmide fiber, and the functional polyarmide fiber. The production method comprises the steps that a functional powder slurry pre-dispersion material prepared from water, caprolactam and functional powder in a blended mode is continuously delivered to a functional powder slurry multi-stagegrinding device to be ground and dispersed; obtained functional powder slurry is evenly mixed with a caprolactam melt and a catalyst through a dynamic mixer, and after the temperature of a mixture isregulated by a heat exchanger, the mixture enters a hydropysis reactor to be subjected to a ring-opening reaction; after excess water in an obtained functional caprolactam oligomer melt is removed byan oligomer melt dehydrator, the obtained functional caprolactam oligomer melt enters a front polymerization reactor to be subjected to a polyaddition reaction; after residual water in an obtained functional polyarmide prepolymer melt is removed by a prepolymer melt dehydrator, the obtained functional polyarmide prepolymer melt enters a rear polymerization reactor to be subjected to a polycondensation reaction; and after a caprolactam monomer in an obtained functional polyarmide melt is removed by a thin film evaporative devolatilization system, the obtained functional polyarmide melt is directly conveyed to a spinning manifold to be spun, and thus the functional polyarmide fiber is obtained. The functional powder in the functional polyarmide fiber is highly evenly dispersed.

Owner:CHINESE TEXTILE ACAD +1

Preparation method for hemp seed oil microcapsules

InactiveCN104544069AHigh embedding rateHigh oil contentFood shapingFood preparationSucroseEconomic benefits

The invention discloses a preparation method for hemp seed oil microcapsules. The preparation method comprises the following steps: (1) preparation of a wall material solution : taking maltodextrin, modified starch, Arabic gum and saccharose as main wall materials, and mixing the main wall materials and water to prepare the wall material solution; (2) sterilization: sterilizing the wall material solution; (3) emulsification: mixing and emulsifying the sterilized wall material solution and hemp seed oil to obtain an emulsion; (4) drying: spray-drying the emulsion to obtain the hemp seed oil microcapsules. The hemp seed oil microcapsules prepared by the method have the advantages of high oil content, high encapsulation rate, good stability and long quality guarantee period; the method is simple, lower in cost and conductive to practical production and application, and brings better economic benefits.

Owner:INFINITUS (CHINA) CO LTD

Continuous-phase-change tea oil extraction method

InactiveCN103173279AReduce consumptionReduce energy consumptionFatty-oils/fats productionGas phaseProduct gas

The invention provides a continuous-phase-change tea oil extraction method. According to the invention, a dried and crushed tea seed raw material is placed into an extraction kettle of a continuous-phase-change extraction device; under a condition with a pressure constantly lower than an extracting agent critical pressure and a temperature constantly lower than an extracting agent critical temperature, the extracting agent is compressed into a liquid by using a high-pressure pump; the extracting agent flows through the extraction kettle with a certain flow rate, such that tea oil is extracted; the material is delivered into a resolution kettle; heating and pressure reducing are carried out, such that the extracting agent is changed into a gas phase; instant compression is carried out, the extracting agent is changed into liquid, and flows through the extraction kettle, such that the material is extracted again. The steps are repeated several times. The method provided by the invention has the advantaged of high efficiency, no solvent residue in product, and high aroma component retention rate of supercritical extraction and subcritical extraction methods. Extraction pressure and resolution pressure of the method are lower than those of supercritical extraction. The method also has the advantages of large extraction volume, large-amount batch production, low production cost, and the like of conventional solvent extraction methods. Also, the continuous-phase-change extraction method has the advantages that the extraction time is short, instant continuous extraction process can be realized, solvent demand is low, and the solvent can be recovered.

Owner:曹庸

Method for extracting nitraria seed oil from subcritical fluid

InactiveCN102504940AReduce manufacturing costReduce consumptionFatty-oils/fats productionEnvironmental resistanceOperability

The invention relates to a method for extracting nitraria seed oil from subcritical fluid. The method comprises the following steps of: (1) squeezing juice of fresh and clean nitraria fruit, drying the obtained seed at room temperature in the shade and sequentially carrying out sorting, crushing and sieving to obtain nitraria seed raw materials; (2) milling and baking the nitraria seed raw materials to obtain treated nitraria seed; (3) carrying out continuous extraction through putting the treated nitraria seed and extracting agents into an extraction kettle of a subcritical fluid extraction device to obtain extracts; and (4) using a pressure reduction temperature rise method for separating the extracts to obtain extraction liquid and carrying out still standing on the extraction liquid at room temperature to obtain the nitraria seed oil. After the method is adopted, the production cost is effectively reduced, the extraction and separation time is shortened, the solvent consumption and the energy consumption in the technical process are reduced, in addition, the technical flow process is simple, the operability is high, the extraction efficiency is high, the environment is protected, the pollution is avoided, the safety and the repeatability are good, and the large-scale industrial continuous production can be realized.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Continuous lithium iron phosphate preparation device and continuous lithium iron phosphate preparation method

ActiveCN104555975AImprove performanceAvoid backmixingElectrochemical processing of electrodesElectrode thermal treatmentLithium iron phosphateSystem pressure

The invention relates to a continuous lithium iron phosphate preparation device comprising a raw material system, a material conveying system, a pipe-type reaction device, a kettle-type reaction device, a reactions system pressure-adjusting system and a discharge system, wherein the raw material system is used for mixing a raw material solution; the material conveying system is used for continuously conveying the mixed raw material solution to the pipe-type reaction device; the pipe-type reaction device is used for enabling materials to be in plug flow conveying reaction state at the given time, the temperature and the pressure; the kettle-type reaction device is arranged at the back of the pipe-type reaction device and is used for enabling the materials to be in complete mixing flow reaction state at the given time, the temperature and the pressure and enabling the reacted product to be conveyed to the discharge system; and the reaction system pressure-adjusting system is used for adding a volatile solvent component to a reaction system to adjust system pressure so that the pipe-type reaction device and the kettle-type reaction device are maintained at the given pressure condition. The invention also relates to a continuous lithium iron phosphate preparation method.

Owner:江苏合志新能源材料技术有限公司 +1

Continuous phase change-based method for extracting tea polyphenol

InactiveCN104289007AExtraction DynamicsEfficient extractionOrganic chemistrySolid solvent extractionBiotechnologyPhenolic content in tea

The invention discloses a continuous phase change-based method for extracting tea polyphenol. The method comprises the steps of drying tea (including root, stems, leaves, flowers, fruits and the like) under 40-80 DEG C, wherein the content of moisture is controlled to 3-20 percent, crushing to powder of 20-80 meshes to obtain a tea powder material, feeding the tea powder material in an extraction kettle, compressing an extraction agent to a liquid extraction agent under the condition that the pressure and the temperature are lower than the critical pressure and the critical temperature of the extraction agent all the time, then continuously extracting the tea powder material in the extraction kettle for 50-120 minutes under the conditions that the extraction temperature is 50-70 DEG C and the extraction pressure is 0.3-2Mpa, and the liquid extraction agent can flow through the extraction kettle with the flow rate of 80-160L / h so as to obtain tea polyphenol, and enabling the extracted tea polyphenol to flow through a resolving kettle for resolving at 60-75 DEG C resolving temperature and 0.08-0.5Mpa resolving pressure. The method for preparing thw tea polyphenol has the high extraction rate of the tea polypheonl, and is safe, environmentally-friendly, low in cost and suitable for large-scale industrial production; the yield of the tea polyphenol prepared according to the method accounts for 10-35 percent of the yield of dry matters.

Owner:SOUTH CHINA AGRI UNIV

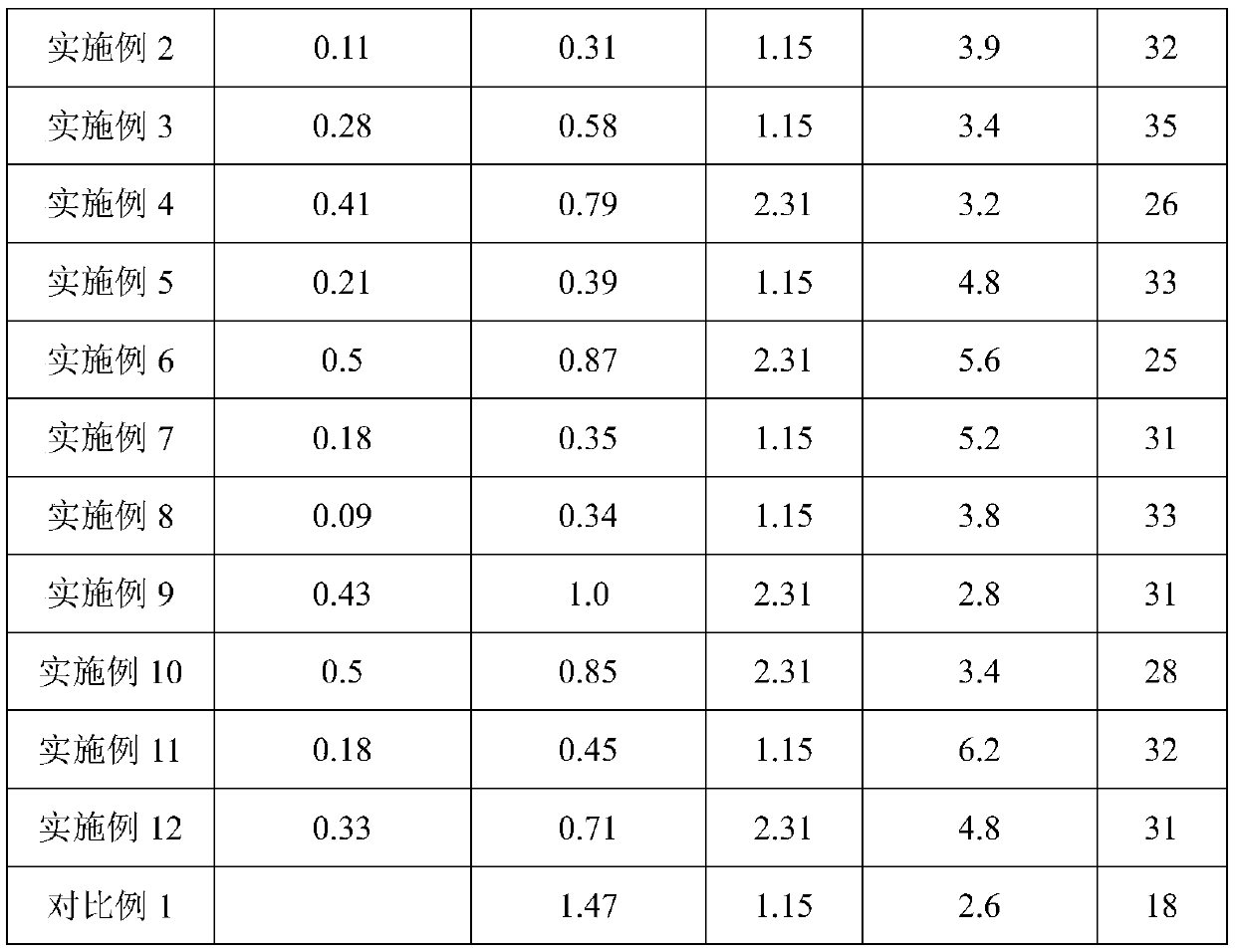

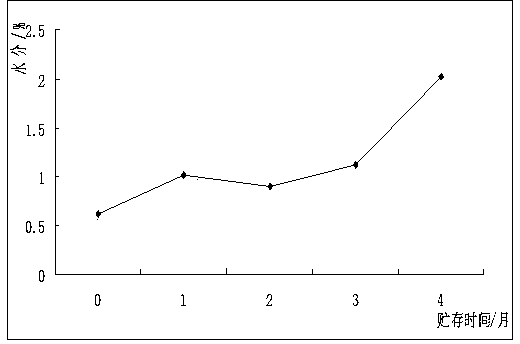

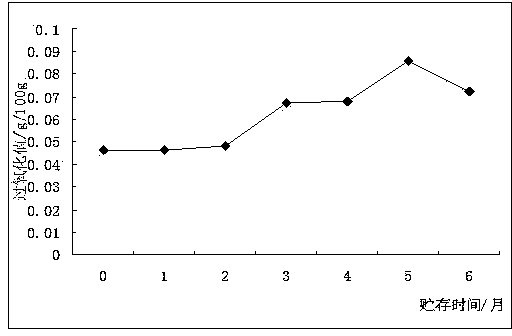

Pomegranate seed oil microcapsule and preparation method thereof

InactiveCN104622921AHigh oil contentReduce surface oil contentMacromolecular non-active ingredientsMicrocapsulesPOMEGRANATE SEED OILHigh pressure

The invention provides a preparation method of a pomegranate seed oil microcapsule. The preparation method of the pomegranate seed oil microcapsule comprises the following steps: (1) preparing a wall material solution, concretely mixing maltodextrin, beta-cyclodextrin, modified starch and Arabic gum, which are taken as raw materials, with water to prepare the wall material solution with the solid matter content of 20-30%; (2) emulsifying, concretely mixing the wall material solution with pomegranate seed oil, stirring until the wall material solution and the pomegranate seed oil are uniformly mixed, and emulsifying to obtain an emulsified liquid; (3) carrying out high pressure homogenizing to homogenize the obtain emulsified liquid; (4) drying, concretely carrying out spray drying on the emulsified liquid by virtue of an atomizer, so that the pomegranate seed oil microcapsule is obtained; and (5) adding an anti-caking agent, concretely adding 0.5-1.5% of the anti-caking agent into the obtained pomegranate seed oil microcapsule, so that the pomegranate seed oil microcapsule finished product is obtained. The invention also provides the pomegranate seed oil microcapsule obtained by adopting the preparation method provided by the invention. The obtained pomegranate seed oil microcapsule has the advantages that oil content is high, surface oil content of the pomegranate seed oil microcapsule is low, namely embedding rate reaches up to more than 97%, a guarantee period is up to 2 years, and peroxidation value and acid value of the pomegranate seed oil microcapsule product are low.

Owner:GUANGZHOU JIAYUAN BIOTECH

Continuous-phase-change soy sauce residue oil extraction method

ActiveCN103173280ALower retention rateHigh retention rateFatty-oils/fats productionSulfur hexafluorideGas phase

The invention provides a continuous-phase-change sauce residue oil extraction method. According to the invention, a dried and crushed sauce residue raw material is placed into an extraction kettle; under a condition with a pressure constantly lower than an extracting agent critical pressure and a temperature constantly lower than an extracting agent critical temperature, the extracting agent is compressed into a liquid; the extracting agent flows through the extraction kettle with a certain flow rate, such that castor oil is extracted; the material is delivered into a resolution kettle; heating and pressure reducing are carried out, such that the extracting agent is changed into a gas phase; instant compression is carried out, the extracting agent is changed into liquid, and flows through the extraction kettle, such that the material is extracted again. The steps are repeated several times. The extracting agent is one of ethanol, propane, butane, high-purity isobutane, R134a, dimethyl ether, liquefied petroleum gas, and sulfur hexafluoride. The method provided by the invention has the advantaged of high efficiency, no solvent residue in product, and high aroma component retention rate of a supercritical extraction method. Extraction pressure and resolution pressure of the method are lower than those of supercritical extraction. The method also has the advantages of large extraction volume, large-amount batch production, low production cost, and the like of a conventional solvent extraction method.

Owner:广东惠尔泰生物科技有限公司

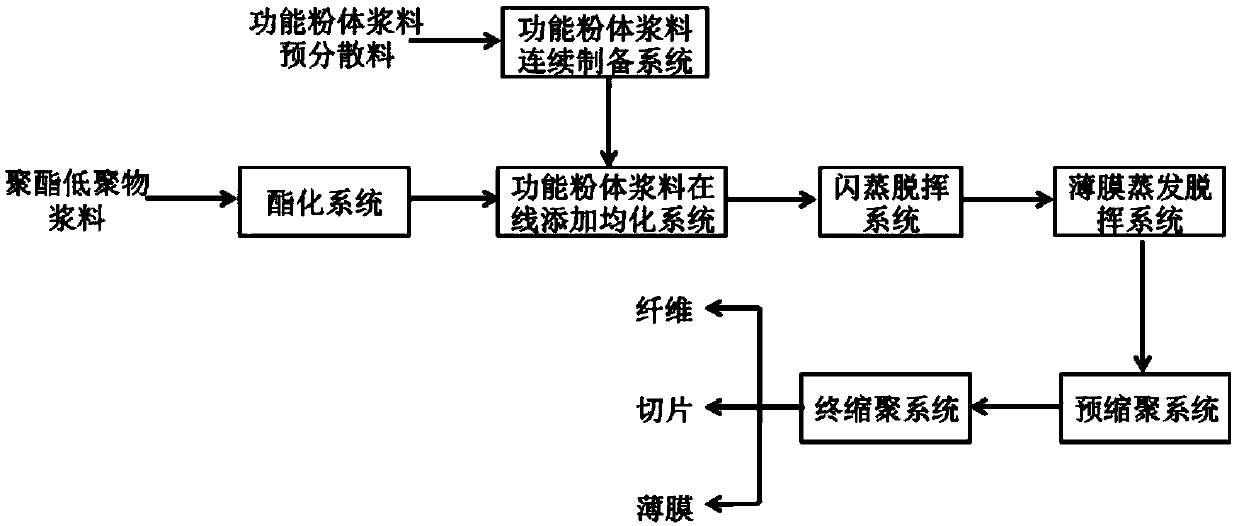

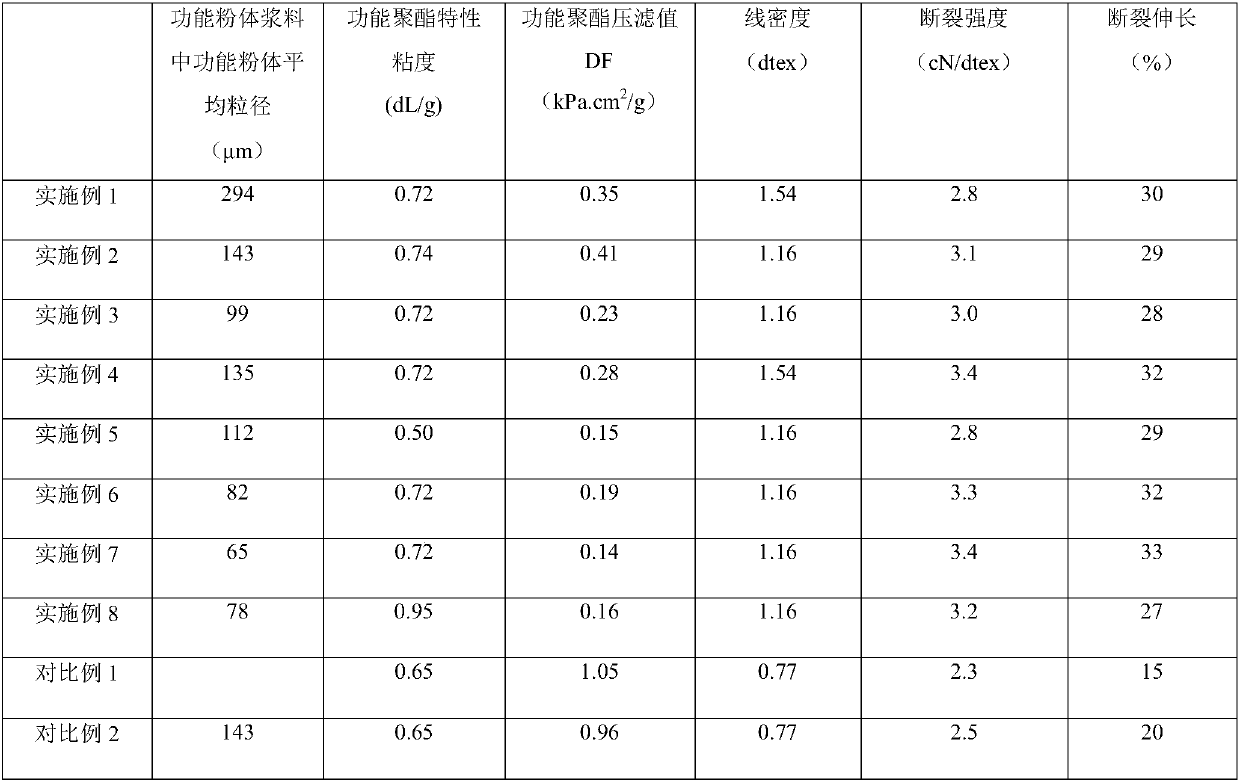

Functional polyester product and preparation method thereof

ActiveCN109679076AGood modification effectAntibacterialPigment addition to spinning solutionMonocomponent polyesters artificial filamentChemistryComposite function

The invention belongs to the field of functional polyester, and particularly discloses a preparation method of functional polyester. The preparation method of the functional polyester comprises the following steps: (1) mixing functional powder with dihydric alcohol, and then grinding the mixture to obtain functional powder slurry; (2) mixing terephthalic acid with dihydric alcohol, and then carrying out esterification reaction on the mixture to prepare a polyester oligomer; (3) mixing the functional powder slurry prepared in step (1) with the polyester oligomer prepared in step (2), depressurizing, and then devolatilizing to obtain a functional polyester oligomer; (4) performing pre-polycondensation reaction and final polycondensation reaction on the functional polyester oligomer obtainedin step (3) to obtain functional polyester; and adding a copolymerization modified monomer slurry in an esterification reaction process, wherein the copolymerization modified monomer slurry is prepared by taking the copolymerization modified monomer as a raw material. By the preparation method disclosed by the invention, high uniform dispersion of the functional powder in the functional polyestercan be realized, and the polyester product further has composite functions of cationic dyeing, disperse dye normal pressure dyeing, antibiosis, hydrophilicity, low melting point, high shrinkage, cotton imitation and the like.

Owner:CHINESE TEXTILE ACAD +1

Preparation technology of centimetre wave-millimeter wave compatible absorbing material

ActiveCN102501492AImproving Impedance Matching PerformanceReduce reflectionSynthetic resin layered productsLaminationFiberEpoxy

The invention relates to a preparation technology of a centimetre wave-millimeter wave compatible absorbing material. The material is of five-layer structure, and a substrate is an irregular surface made of any material; the topmost layer is a first layer, and mainly consists of a W-shaped hexagonal ferrite absorbing agent and an acrylic resin adhesive; a second layer is composed of a carbonyl iron powder absorbing agent and an epoxy resin adhesive, and a third layer is composed of a Fe85Si1Al6Cr8 nanometer crystal thin absorbing agent and an epoxy resin adhesive; a fourth layer is composed of a polycrystal iron fibre absorbing agent and an epoxy resin adhesive; and a fifth layer is composed of a chopped carbon fiber, a sooty mixed absorbing agent and a polyurethane adhesive. A preparation process comprises the following steps: firstly, covering and preparing a bottom fifth-layer medium coating on the substrate; and then successively covering and preparing a fourth-layer medium coating, a third-layer medium coating, a second-layer medium coating and a first-layer medium coating, wherein the coating preparation of each medium coating is as follows: uniformly stirring a coupling agent, a diluting agent and the absorbing agent of each layer, standing, then adding the adhesive of each layer, uniformly stirring to obtain a paint, coating the paint, and curing, thus obtaining the centimetre wave-millimeter wave compatible absorbing material.

Owner:HUNAN JINGE NEW MATERIAL

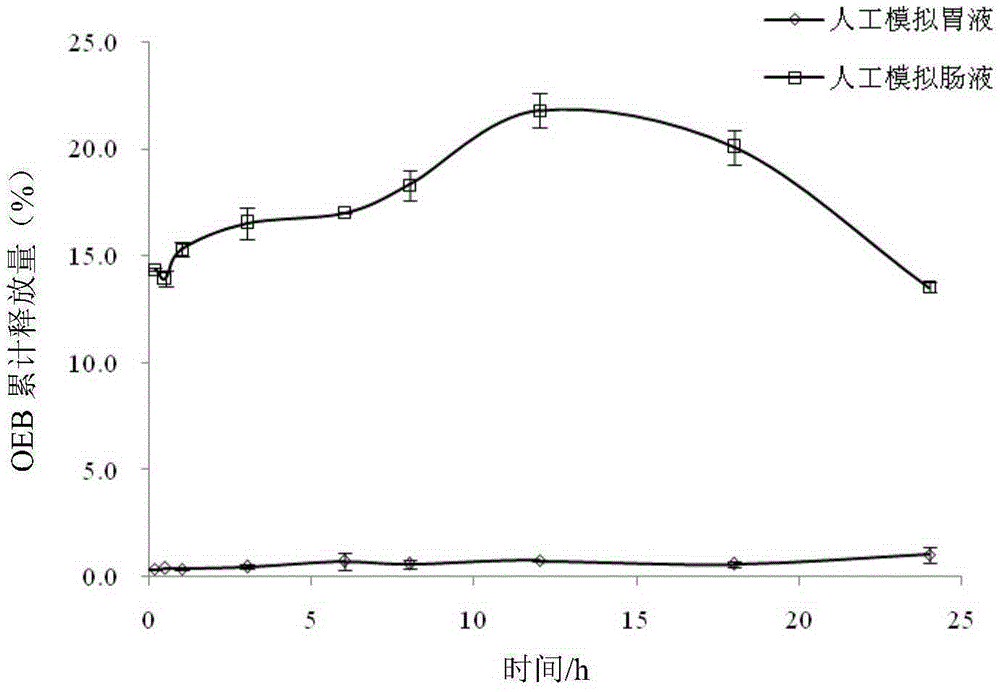

Evening primrose essence B-casein phosphopeptide-chitosan nano particle, preparation method and applications thereof

ActiveCN105381472AHigh encapsulation efficiencyHigh drug loadingOrganic active ingredientsHydrolysed protein ingredientsChemistryCasein

The invention discloses an evening essence B-casein phosphopeptide-chitosan nano particle, a preparation method and applications thereof. The preparation method comprises the following steps: preparing a CPPs solution, a CS solution, and an OEB solution, adding three solutions in a certain sequence, evenly mixing, controlling the mass percentage of CPPs and OEB of the final solution and the total concentration of CPPs, CS, and OEB of the solution, adjusting the pH value of the system to obtain nano spheres; then adding genipin to fix the nano spheres to obtain nano suspension, and subjecting the nano suspension to centrifugation and drying to obtain the evening primrose essence B-casein phosphopeptide-chitosan nano particles. The nano particle has the advantages of adjustable particle size, high embedding rate, pH responding property, green, energy saving, safety, stomach acid resistance, and sustain-released function, and can be widely used in the fields such as pharmacy, food, healthcare product, and the like.

Owner:SOUTH CHINA AGRI UNIV

Method for extracting fructus perillae oil through continuous phase transition

ActiveCN103834467AAbundant resourcesReduce manufacturing costFatty-oils/fats productionSolventContinuous phase transition

The invention provides a method for extracting fructus perillae oil through continuous phase transition, which comprises the steps of putting the dried ground fructus perillae raw material into an extraction kettle; compressing an extraction agent into liquid under the conditions that the extraction temperature is 35-55 DEG C and the extraction pressure is 0.5-2MPa; enabling the liquid to flow through the extraction kettle at a flow speed of 100-150L / h, and continuously extracting for 50-120 minutes; after extracting the fructus perillae oil, enabling the fructus perillae oil to flow into a resolving kettle, wherein the resolving temperature is 65-75 DEG C, and the resolving pressure is 0.1-0.4MPa; heating and reducing pressure of the extraction agent so that the extraction agent phase is changed into gas; performing intermediate compression to change the gas into liquid which flows through the extraction kettle again, and performing secondary extraction on the material; circulating for multiple times. The method provided by the invention has the advantages of efficient supercritical extraction, no solvent residue in product and high retention rate of aroma components; moreover, the extraction pressure and the resolving pressure are lower than the supercritical values, and the method also has the characteristics of large extraction volume of conventional solvent, large batch treatment capacity, low production cost and the like.

Owner:GREENCREAM BIOTECH +2

Functional polyamide and continuous production method thereof

ActiveCN109762162AEase of industrial implementationRealize large-scale industrialized continuous productionPrepolymerPolyamide

The invention discloses functional polyamide and a continuous production method thereof. The method comprises the following steps: continuously conveying a functional powder slurry pre-dispersion prepared from water, caprolactam and functional powder by blending to a functional powder slurry multistage grinding device for grinding and dispersing; uniformly mixing obtained functional powder slurry,caprolactam melt and a catalyst by a dynamic mixer, adjusting the temperature by a heat exchanger, and feeding the mixture into a hydrolysis reactor for ring opening reaction; removing excess water from obtained functional caprolactam oligomer melt by an oligomer melt dehydrator, feeding the melt into a prepolymerization reactor for addition polymerization reaction; removing residual water from obtained functional polyamide prepolymer melt by a prepolymer melt dehydrator, and feeding the melt into a post polymerization reactor for polycondensation reaction; performing granulation, extractionand drying on obtained functional polyamide melt sequentially to obtain functional polyamide chips. Functional powder in functional polyamide continuously produced with the method is highly uniformlydispersed, and functional polyamide is suitable for producing products such as high-quality fibers and films.

Owner:CHINESE TEXTILE ACAD +1

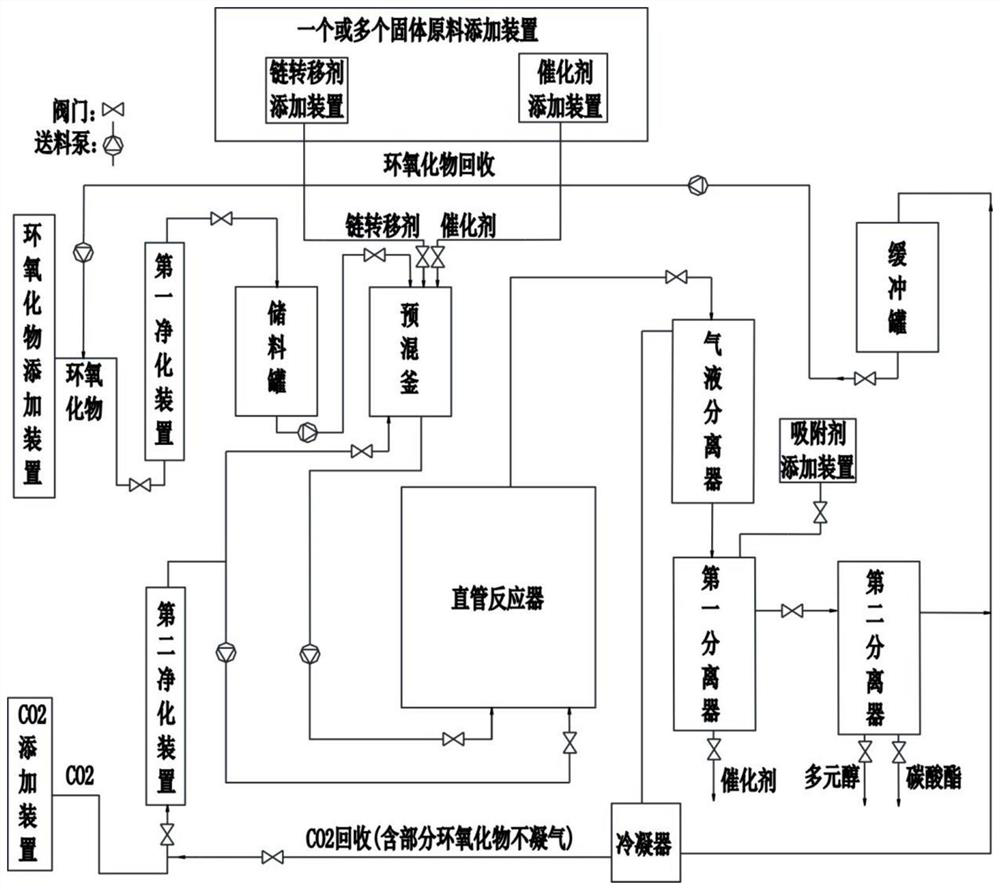

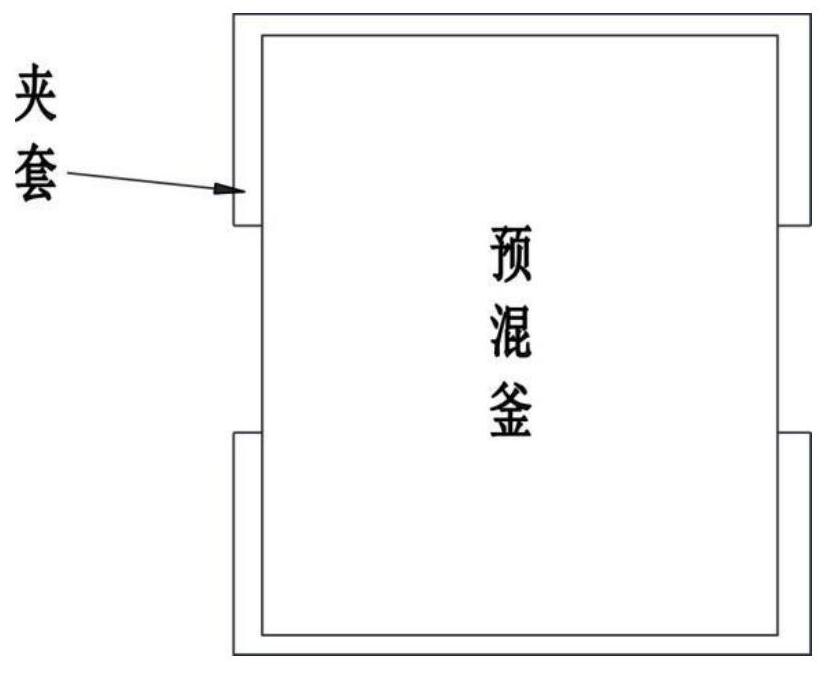

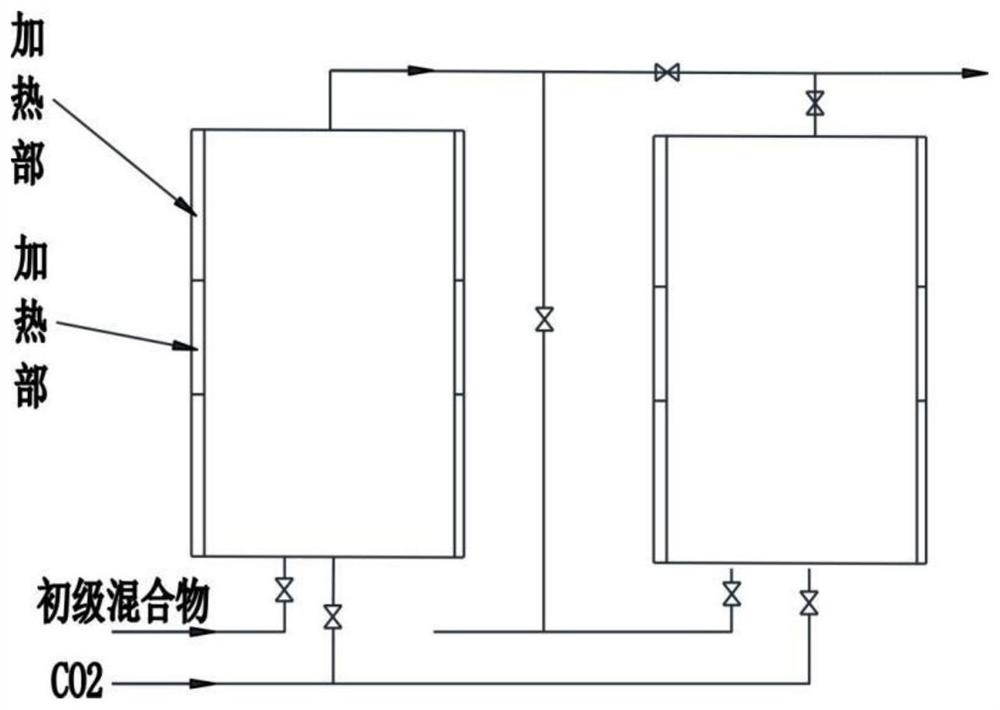

Industrial continuous production equipment for polycarbonate polyether polyol

PendingCN111804218AUniform mass and heat transferAdequate mass and heat transferTransportation and packagingMixer accessoriesPolyolPtru catalyst

Owner:HANGZHOU POLY MATERIAL SCI & TECH CO LTD

Production method of continuous polymerization melt direct spinning functional polyamide fiber and the functional polyamide fiber

ActiveCN109811423BRealize continuous productionRealize large-scale industrialized continuous productionArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSpinning

Disclosed are a production method of continuous polymerization melt direct spinning functional polyamide fiber and the functional polyamide fiber. The method comprises: continuously conveying the functional powder slurry pre-dispersion prepared by water, caprolactam and functional powder to a functional powder slurry multi-stage grinding device for grinding and dispersing; the obtained functional powder slurry is mixed with caprolactam melt and The catalyst is mixed evenly by the dynamic mixer, and the temperature is adjusted by the heat exchanger, and then enters the hydrolysis reactor for ring-opening reaction; the obtained functional caprolactam oligomer melt is removed by the oligomer melt dehydrator, and then enters the pre-polymerization reactor for addition polymerization reaction; the obtained functional polyamide prepolymer melt goes through the prepolymer melt dehydrator to remove residual moisture and then enters the post-polymerization reactor for polycondensation reaction; the obtained functional polyamide melt passes through the thin film evaporation system to remove caprolactam monomer It is directly transported to the spinning box for spinning to obtain functional polyamide fibers. The functional powder in the functional polyamide fiber is highly uniformly dispersed.

Owner:CHINESE TEXTILE ACAD +1

Method for extracting oil from diatom through low-temperature continuous phase transition

InactiveCN106190527AReduce consumptionReduce energy consumptionFatty-oils/fats productionOil and greaseSolvent

The invention belongs to the field of oil extraction, and provides a method for extracting oil from diatom by a low-temperature continuous phase transition technique and by using ethanol as an extraction agent. The method comprises the specific steps of loading diatom dry powder or diatom ooze to an extraction kettle, under the condition that the pressure is lower than the critical pressure of the extraction agent and the temperature is lower than the critical temperature of the extraction agent, enabling the extraction agent namely the ethanol which is compressed into liquid to pass through the extraction kettle at a certain flow rate in a countercurrent manner for extraction, after extraction is completed, enabling the extraction agent namely the ethanol to enter a separation kettle, performing heating and performing decompressing so that the ethanol is turned into gas, and an extract is released. The ethanol gas is compressed into liquid, then the liquid enters the extraction kettle for extraction, and circulation is performed. The method disclosed by the invention has the advantages of being low in extraction and separation pressure and extraction and separation temperature, large in treating capacity, low in cost, and high in extraction rate, and products are free from solvent residues.

Owner:东莞市民益生物科技有限公司

Method for extracting black wolfberry seed oil by virtue of subcritical fluid

InactiveCN105112156AReduce consumptionReduce energy consumptionFatty-oils/fats productionLycium barbarum fruitRoom temperature

The invention discloses a method for extracting black wolfberry seed oil by virtue of subcritical fluid. The method comprises the steps: (1) placing dry black wolfberry seeds and an extracting agent into an extraction kettle of a subcritical fluid extraction apparatus according to a mass-volume ratio of 1:1 to 1: 20, continuously extracting for 1 to 20 times to obtain extract, wherein the extraction time is 10 to 15 minutes per time; (2) separating the extract in the step (1) by utilizing a pressure reduction heating method under the condition that the separation pressure is 0.10 to 1.95 MPa and the separation temperature is 10 to 90 DEG C, to obtain an extraction solution; (3) standing the extraction solution for 10 to 90 minutes under the room temperature, to obtain the black wolfberry seed oil. By adopting the method, not only can the production cost be effectively reduced, the extraction and separation time is shortened, and the consumption of solvent and energy consumption in the process flow can be reduced; moreover, the method is simple in process flow, high in operability, high in extraction efficiency, environment-friendly, pollution-free, good in safety and repeatability and capable of realizing the industrialized continuous mass production.

Owner:QINGHAI TIBET BIOTECH CO LTD

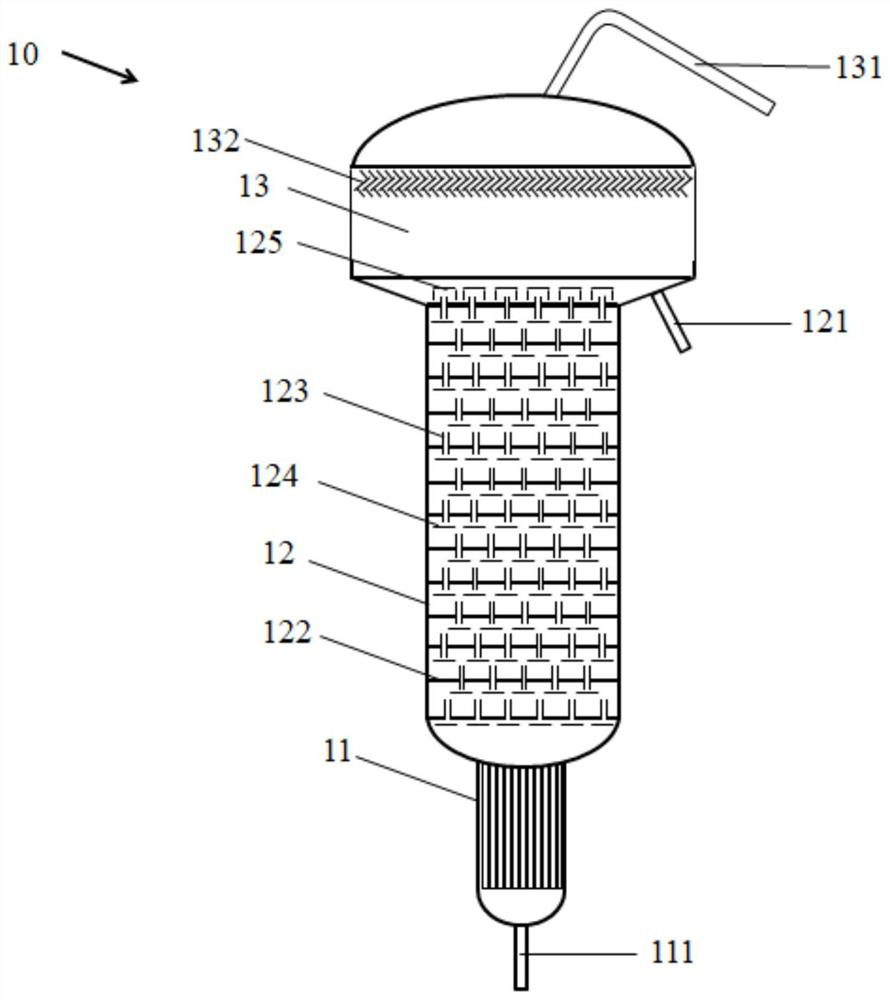

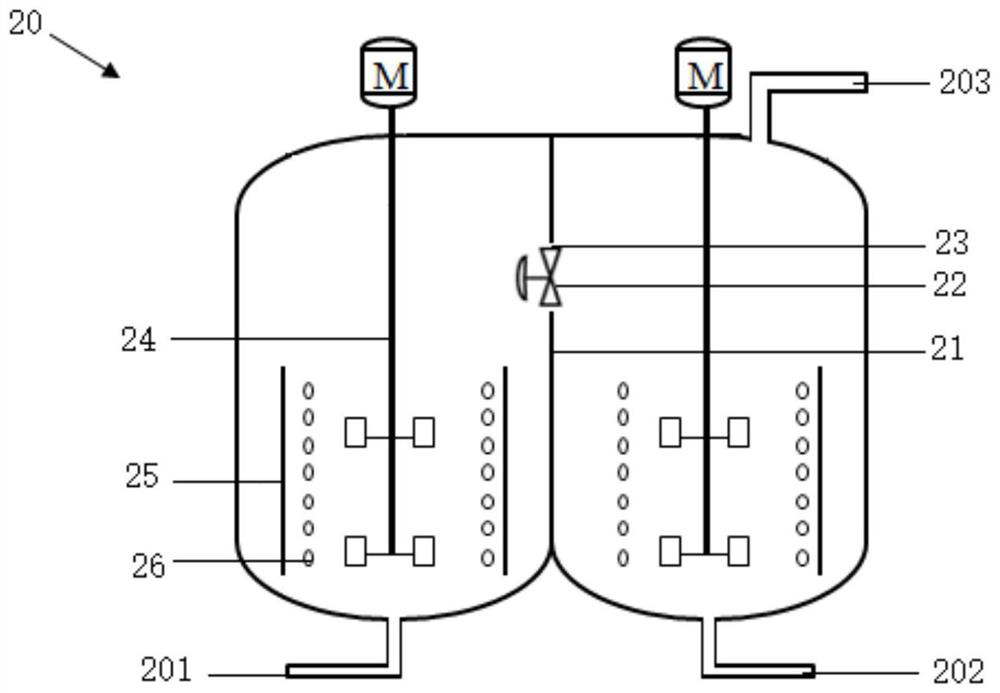

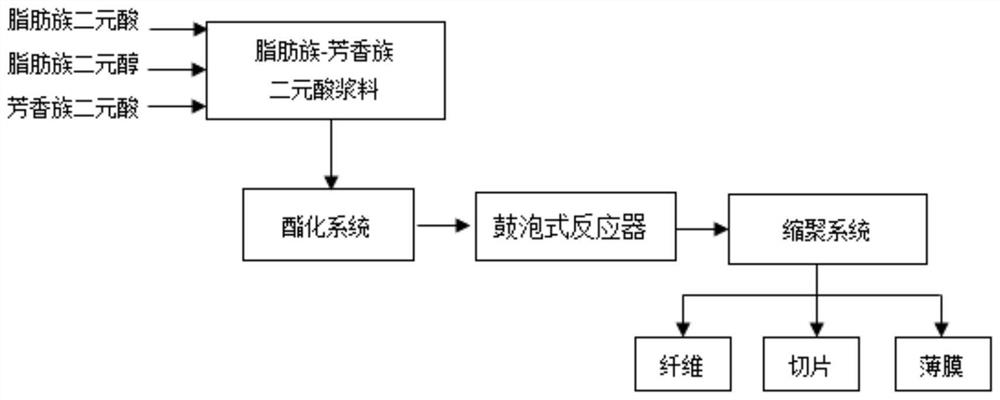

Preparation system and preparation method of biodegradable copolyester and copolyester thereof

ActiveCN112794996AEfficient DepthEfficient melt polycondensationBio-packagingChemical/physical/physico-chemical stationary reactorsPolymer scienceCopolyester

The invention discloses a preparation system and a preparation method of biodegradable copolyester and the copolyester thereof. The preparation system comprises an esterification system and a polycondensation system which are connected in sequence, and a bubbling type reactor is further arranged between the esterification system and the polycondensation system. Materials flowing out of the esterification system are subjected to deep esterification and pre-polycondensation through the bubbling type reactor and then are fed into the polycondensation system. According to the preparation system of the biodegradable copolyester, the simultaneous occurrence of efficient deep esterification and melt polycondensation of aliphatic-aromatic copolyester ester is realized, and the esterification time of aliphatic-aromatic binary acid slurry is greatly shortened; the aliphatic-aromatic copolyester prepolymer meeting the requirements of a subsequent final polycondensation reaction is prepared; the aliphatic-aromatic copolyester continuously produced by using the system has the characteristics of good biodegradability, low terminal carboxyl group content and good hue.

Owner:CHINESE TEXTILE ACAD

Preparation method of purple perilla seed oil microcapsule

ActiveCN103564065BHigh oil contentImprove qualityFood shapingEdible oils/fats production/working-upBiotechnologyEmulsion

The invention provides a preparation method of a purple perilla seed oil microcapsule. The preparation method comprises the following steps: weighing wall materials: 10-15% of saccharose, 55-60% of modified starch and 25-40% of maltodextrin in percent by weight; adding water to prepare wall material aqueous liquor with the content of solids of 33%; after sterilization, adding purple perilla seed oil at 45-50 DEG C in a mass ratio of the wall material and purple perilla seed oil of 1:(1-1.2); preparing an emulsion with the content of solids of 45-50%; and homogenizing, spraying and drying to obtain the purple perilla seed oil microcapsule. The purple perilla seed oil microcapsule prepared by the invention is high in oil content better in quality, still stable in physicochemical property of a product and high in bulk density of the product. The preparation method disclosed by the invention is simple in process flow, strong in operability, low in production cost, free from pollution and good in repeatability, and can realize industrialized continuous production on a large scale.

Owner:GREENCREAM BIOTECH

Method for removing ricin in castor pulp by continuous phase-change extraction

ActiveCN103766598AAddressing a big problem with emergency gapsImprove utilization efficiencyAnimal feeding stuffFatty-oils/fats productionGas phaseRicin

The invention provides a method for removing ricin in castor pulp by continuous phase-change extraction, which comprises the following steps: putting a castor pulp raw material into an extraction kettle, and carrying out continuous extraction at 45-95 DEG C under the extraction pressure of 0.15-0.95 Mpa for 100-250 minutes at the flow rate of 130-210 L / hour; and after extracting the castor pulp, enabling the liquid to flow into a resolution kettle, and resolving at 70-95 DEG C under the pressure of -0.15 to -0.05 Mpa. The extractant is heated under reduced pressure into a gas phase and instantly cooled into a liquid, flows through the extraction kettle, and is subjected to toxin removal; and the cycle is repeated many times. The extractant is 30-100% methanol, ethanol and butanol. The method has the advantages of high toxin removal efficiency, almost no solvent residue and short time, and has the characteristics of high conventional solvent extraction capacity, high batch treatment capacity, low production cost and the like.

Owner:曹庸

A method for continuous phase change extraction of perilla seed oil

ActiveCN103834467BAbundant resourcesReduce manufacturing costFatty-oils/fats productionPerilla oilProduct gas

The invention provides a method for extracting fructus perillae oil through continuous phase transition, which comprises the steps of putting the dried ground fructus perillae raw material into an extraction kettle; compressing an extraction agent into liquid under the conditions that the extraction temperature is 35-55 DEG C and the extraction pressure is 0.5-2MPa; enabling the liquid to flow through the extraction kettle at a flow speed of 100-150L / h, and continuously extracting for 50-120 minutes; after extracting the fructus perillae oil, enabling the fructus perillae oil to flow into a resolving kettle, wherein the resolving temperature is 65-75 DEG C, and the resolving pressure is 0.1-0.4MPa; heating and reducing pressure of the extraction agent so that the extraction agent phase is changed into gas; performing intermediate compression to change the gas into liquid which flows through the extraction kettle again, and performing secondary extraction on the material; circulating for multiple times. The method provided by the invention has the advantages of efficient supercritical extraction, no solvent residue in product and high retention rate of aroma components; moreover, the extraction pressure and the resolving pressure are lower than the supercritical values, and the method also has the characteristics of large extraction volume of conventional solvent, large batch treatment capacity, low production cost and the like.

Owner:GREENCREAM BIOTECH +2

Continuous phase-changed extraction method for orange peel oil

ActiveCN103146486BAbundant resourcesImprove qualityEssential-oils/perfumesFatty-oils/fats productionProduct gasPhase change

The invention provides a continuous phase-changed extraction method for orange peel oil. The method comprises the following steps of: placing dry crushed orange peel raw materials into an extraction kettle; compressing an extraction agent into a liquid under the condition that the pressure and the temperature are always lower than the critical pressure and the critical temperature of the extraction agent; enabling the extraction agent to flow through the extraction kettle at the flow speed of 100-150L / h under the conditions that the extraction temperature ranges from 35 DEG C to 55 DEG C, and the extraction pressure ranges from 0.5MPa to 2MPa, and continuously extracting for 50-120min; after the orange peel oil is extracted, enabling the extraction agent to flow into a liberation kettle for liberating at the temperature of 65-75 DEG C and the pressure of 0.1-0.4MPa; heating and carrying out pressure-reduced phase change on the extraction agent to enable the extraction agent to become a gas, then, immediately condensing the gas to enable the gas to become a liquid, and enabling the liquid to flow through the extraction kettle for extracting the materials again; and circulating many times in such a way. The continuous phase-changed extraction method has the advantages of high supercritical extraction efficiency, no solvent residues in products and high aroma component retention rate; in addition, the extraction pressure and the liberation pressure are lower than the supercritical pressure and temperature; and meanwhile, the continuous phase-changed extraction method has the characteristics of large extraction volume, high mass handling capacity and low production cost of a conventional solvent.

Owner:GREENCREAM BIOTECH +2

A method for continuous phase change extraction to remove ricin in castor meal

ActiveCN103766598BAddressing a big problem with emergency gapsImprove utilization efficiencyAnimal feeding stuffFatty-oils/fats productionGas phaseSolvent

Owner:曹庸

Preparation technology of centimetre wave-millimeter wave compatible absorbing material

ActiveCN102501492BImproving Impedance Matching PerformanceReduce reflectionSynthetic resin layered productsLaminationEpoxyFiber

The invention relates to a preparation technology of a centimetre wave-millimeter wave compatible absorbing material. The material is of five-layer structure, and a substrate is an irregular surface made of any material; the topmost layer is a first layer, and mainly consists of a W-shaped hexagonal ferrite absorbing agent and an acrylic resin adhesive; a second layer is composed of a carbonyl iron powder absorbing agent and an epoxy resin adhesive, and a third layer is composed of a Fe85Si1Al6Cr8 nanometer crystal thin absorbing agent and an epoxy resin adhesive; a fourth layer is composed of a polycrystal iron fibre absorbing agent and an epoxy resin adhesive; and a fifth layer is composed of a chopped carbon fiber, a sooty mixed absorbing agent and a polyurethane adhesive. A preparation process comprises the following steps: firstly, covering and preparing a bottom fifth-layer medium coating on the substrate; and then successively covering and preparing a fourth-layer medium coating, a third-layer medium coating, a second-layer medium coating and a first-layer medium coating, wherein the coating preparation of each medium coating is as follows: uniformly stirring a coupling agent, a diluting agent and the absorbing agent of each layer, standing, then adding the adhesive of each layer, uniformly stirring to obtain a paint, coating the paint, and curing, thus obtaining the centimetre wave-millimeter wave compatible absorbing material.

Owner:HUNAN JINGE NEW MATERIAL

Functional polyamide and its continuous production method

ActiveCN109762162BRealize continuous productionRealize large-scale industrialized continuous productionFiberPolymer science

Disclosed are a functional polyamide and a continuous production method thereof. The method comprises: continuously conveying the functional powder slurry pre-dispersion prepared by water, caprolactam and functional powder to a functional powder slurry multi-stage grinding device for grinding and dispersing; the obtained functional powder slurry is mixed with caprolactam melt and The catalyst is mixed evenly by the dynamic mixer, and the temperature is adjusted by the heat exchanger, and then enters the hydrolysis reactor for ring-opening reaction; the obtained functional caprolactam oligomer melt is removed by the oligomer melt dehydrator and then enters the pre-polymerization reactor for Polyaddition reaction; the obtained functional polyamide prepolymer melt is dehydrated by the prepolymer melt dehydrator and then enters the post-polymerization reactor for polycondensation reaction; the obtained functional polyamide melt is successively pelletized, extracted and dried, A functional polyamide chip is obtained. The functional powder in the functional polyamide continuously produced by the method is highly uniformly dispersed, and is suitable for producing products such as high-quality fibers and films.

Owner:CHINESE TEXTILE ACAD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com