Patents

Literature

33results about How to "High-power handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

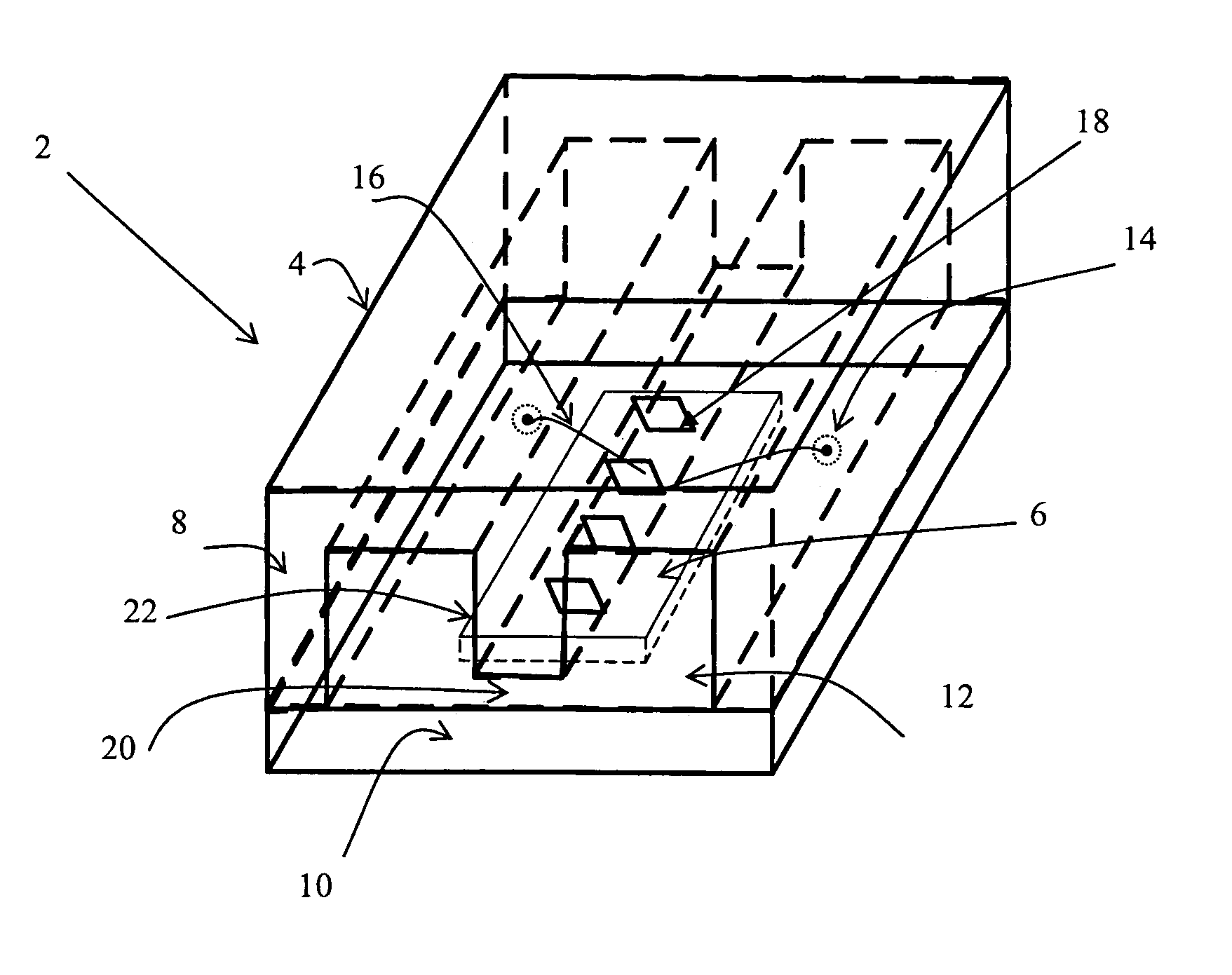

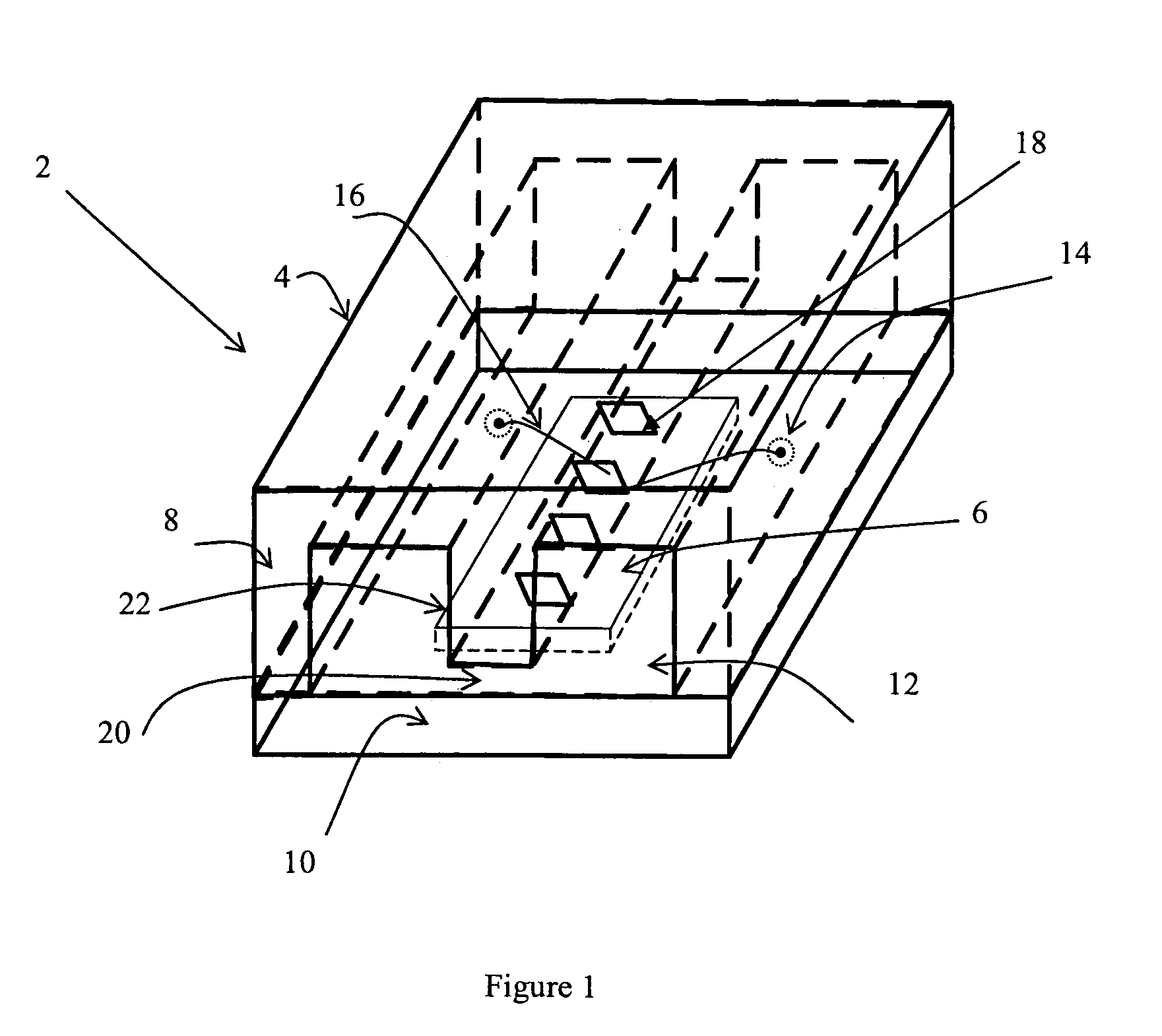

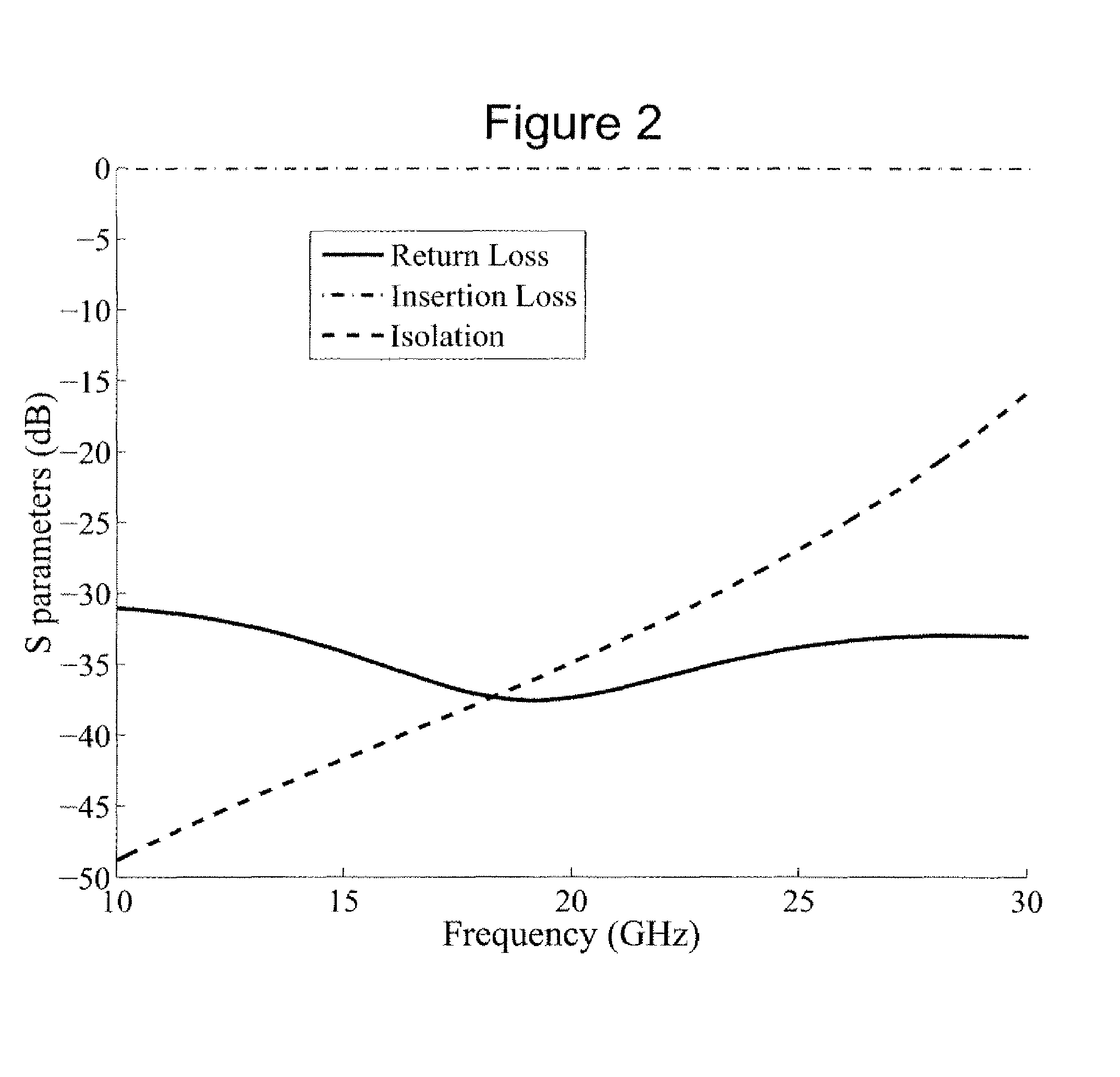

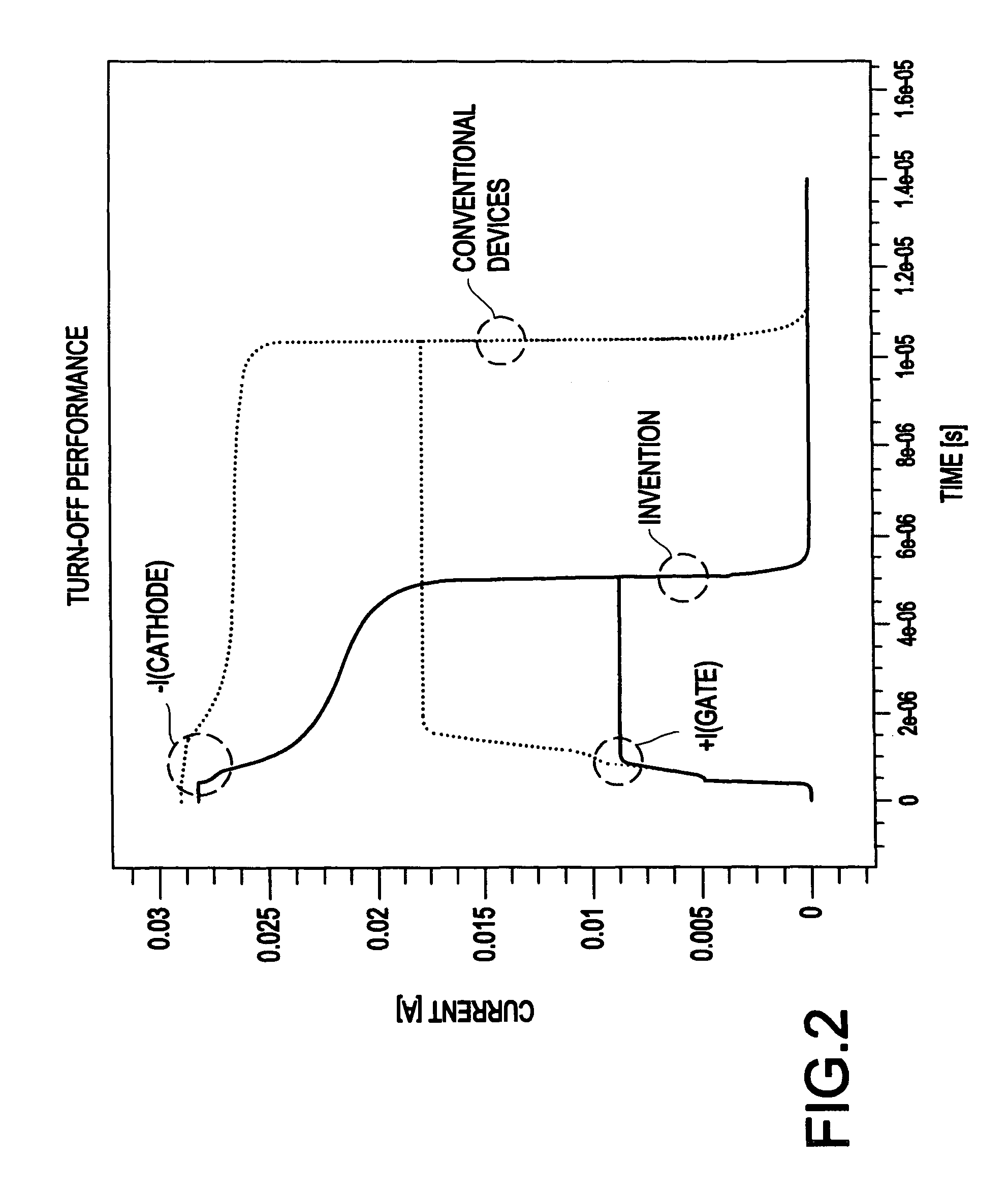

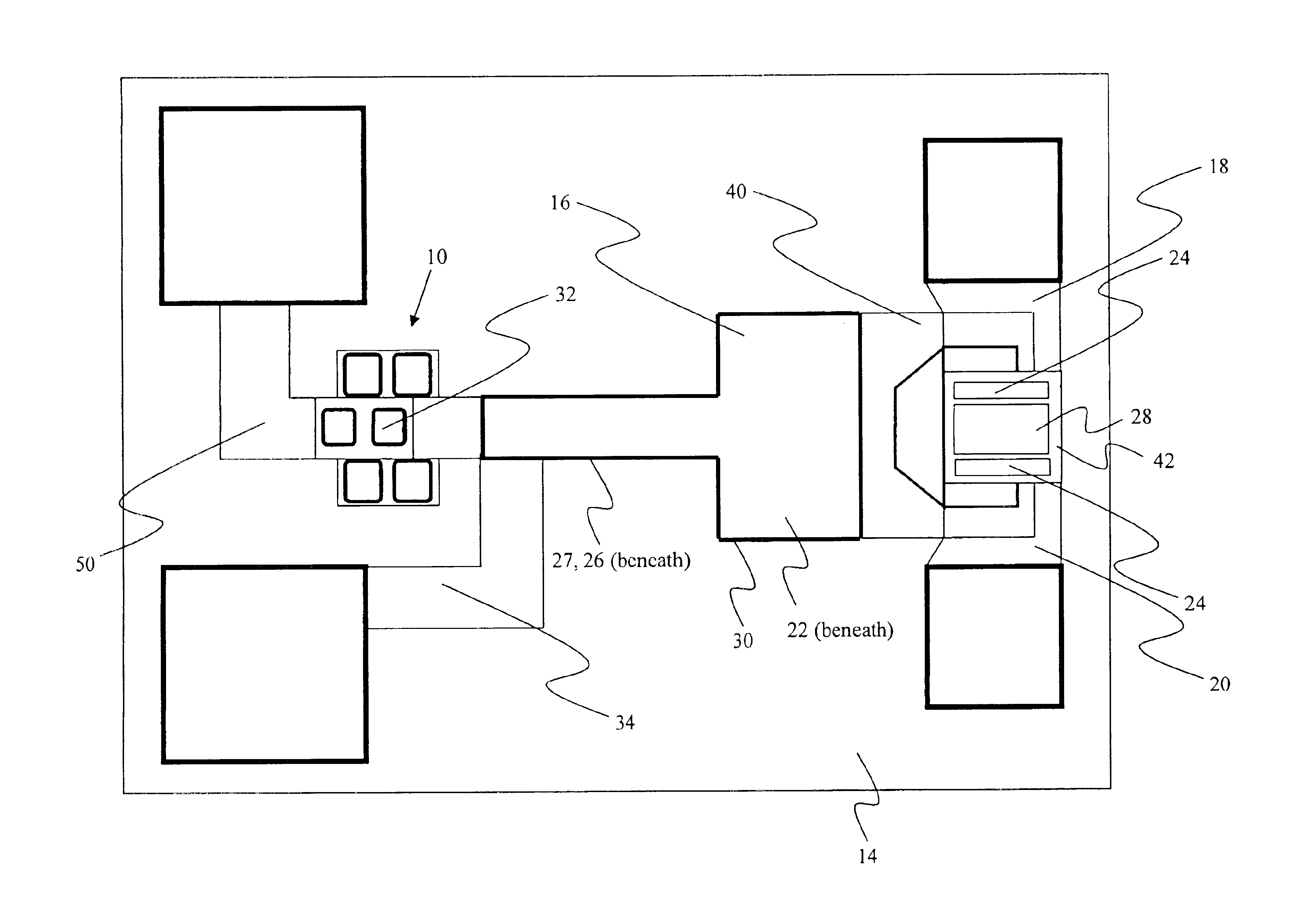

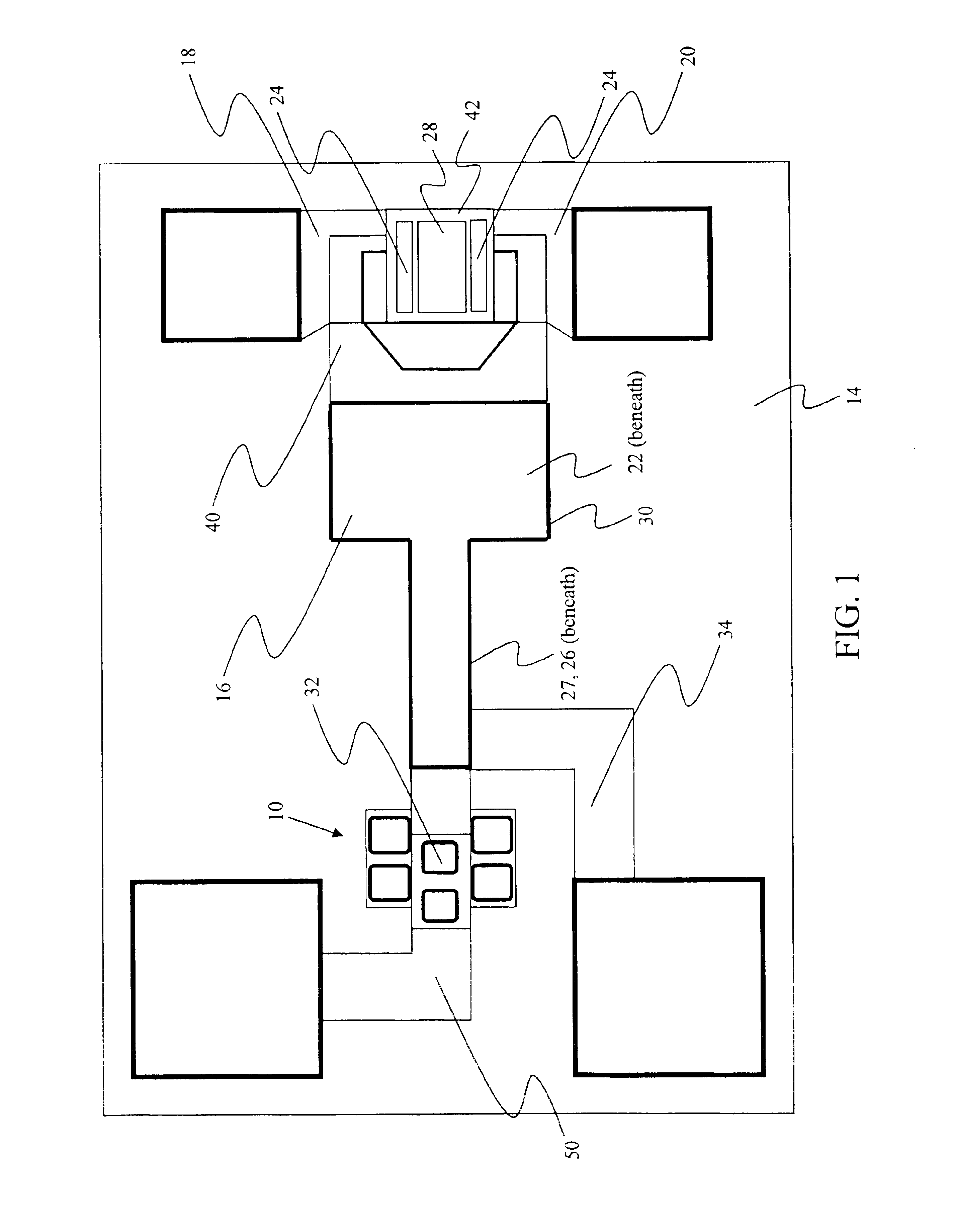

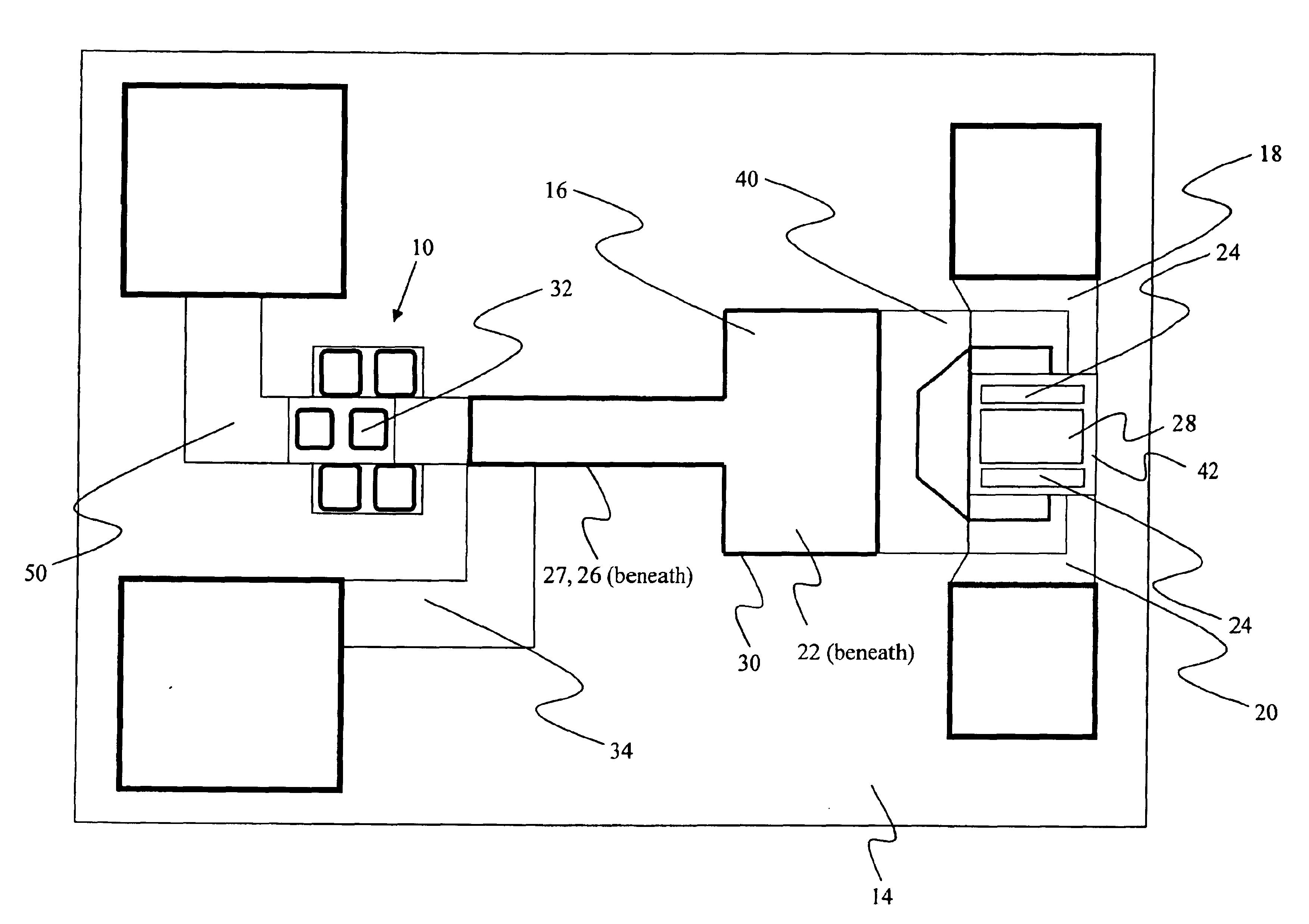

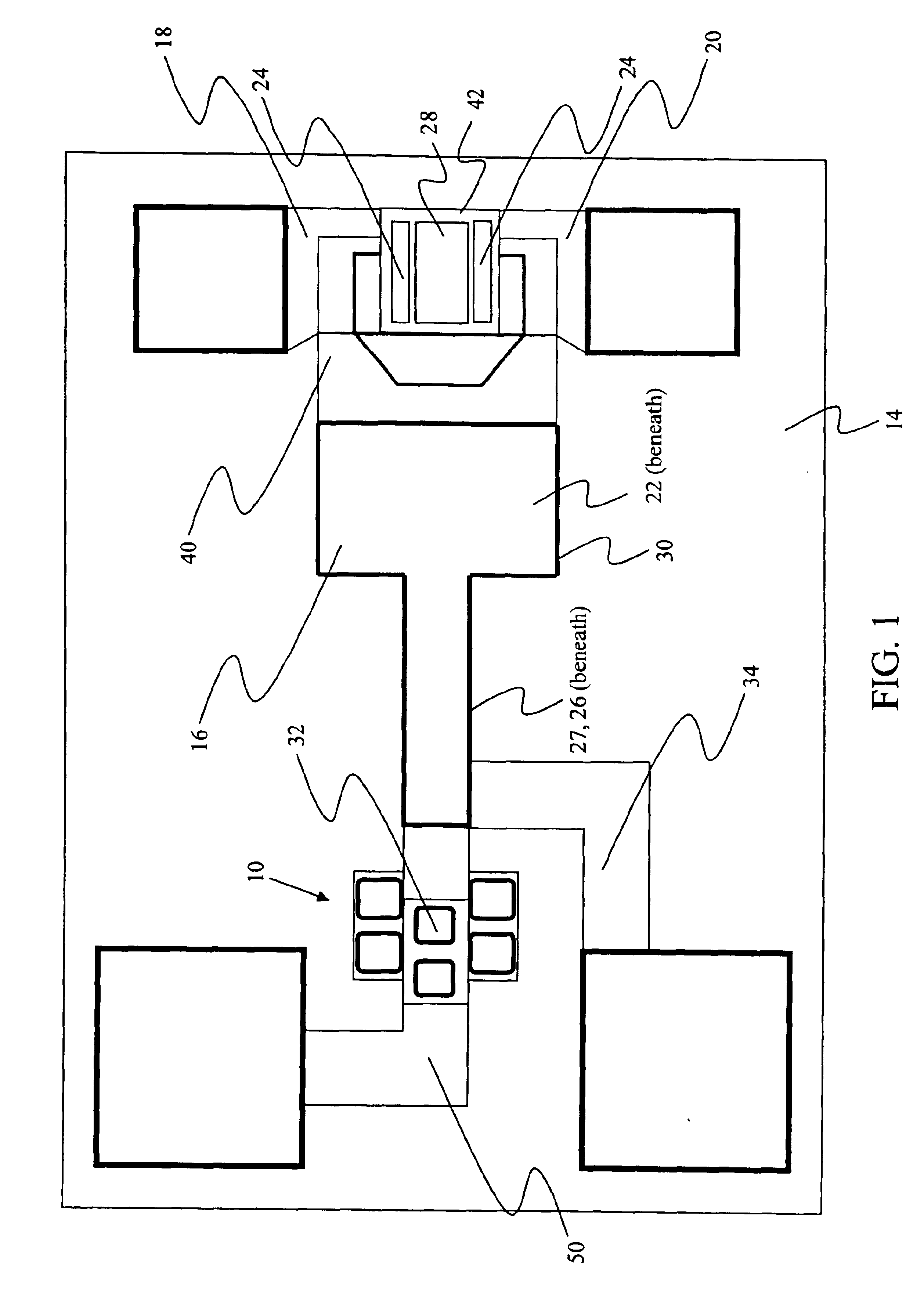

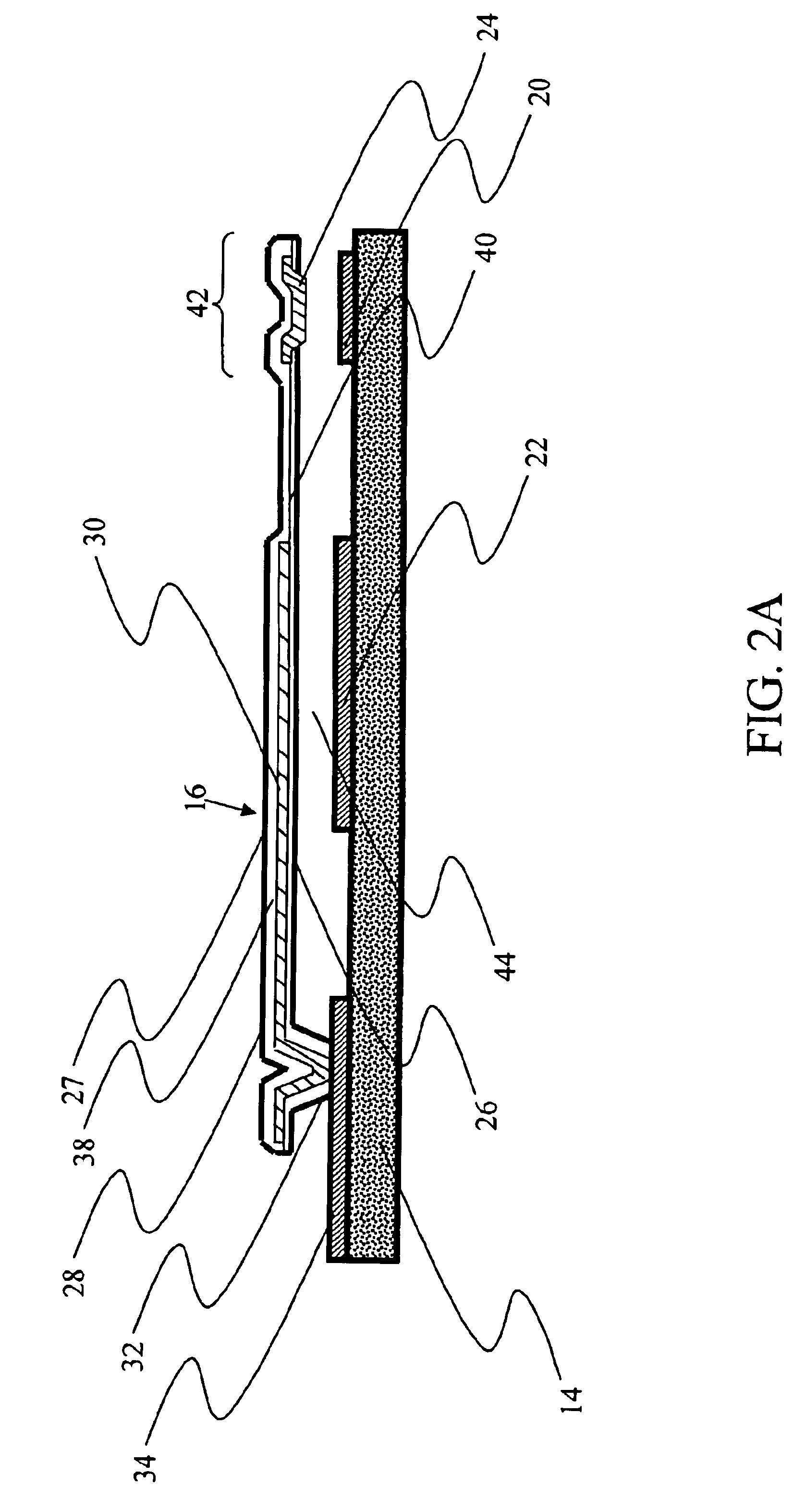

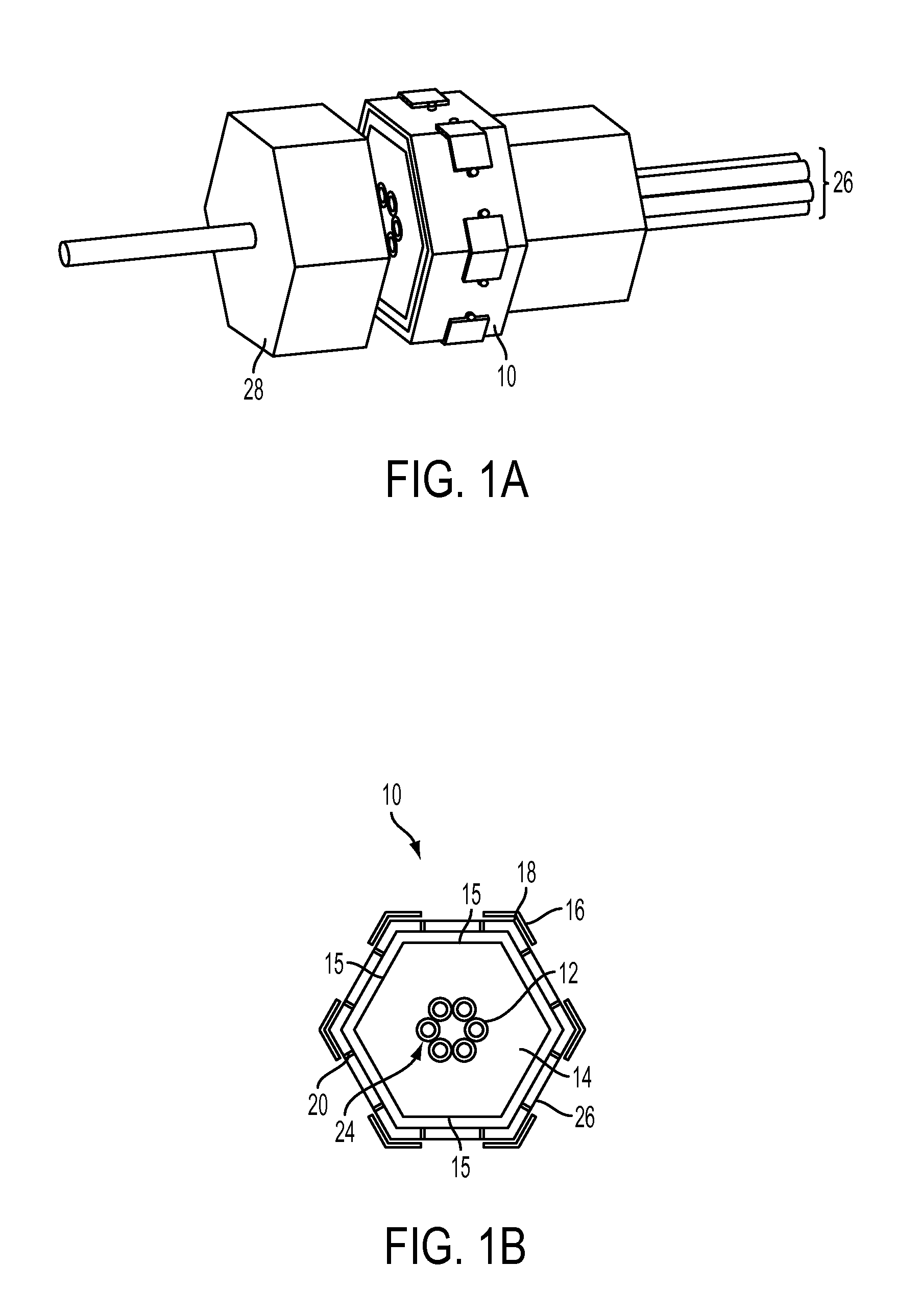

MEMS based RF components and a method of construction thereof

InactiveUS7292125B2Small sizeLight weightCoupling light guidesOptical waveguide light guideWaveguideRf components

A three dimensional waveguide is integrated with a MEMS structure to control a signal in various RF components. The components include switches, variable capacitors, filters and phase shifters. A controller controls movement of the MEMS structure to control a signal within the component. A method of construction and a method of operation of the component are described. The switches have high power handling capability and can be operated at high frequencies. By integrating a three dimensional waveguide with a MEMS structure, the components can be small in size with good operating characteristics.

Owner:MANSOUR RAAFAT R +1

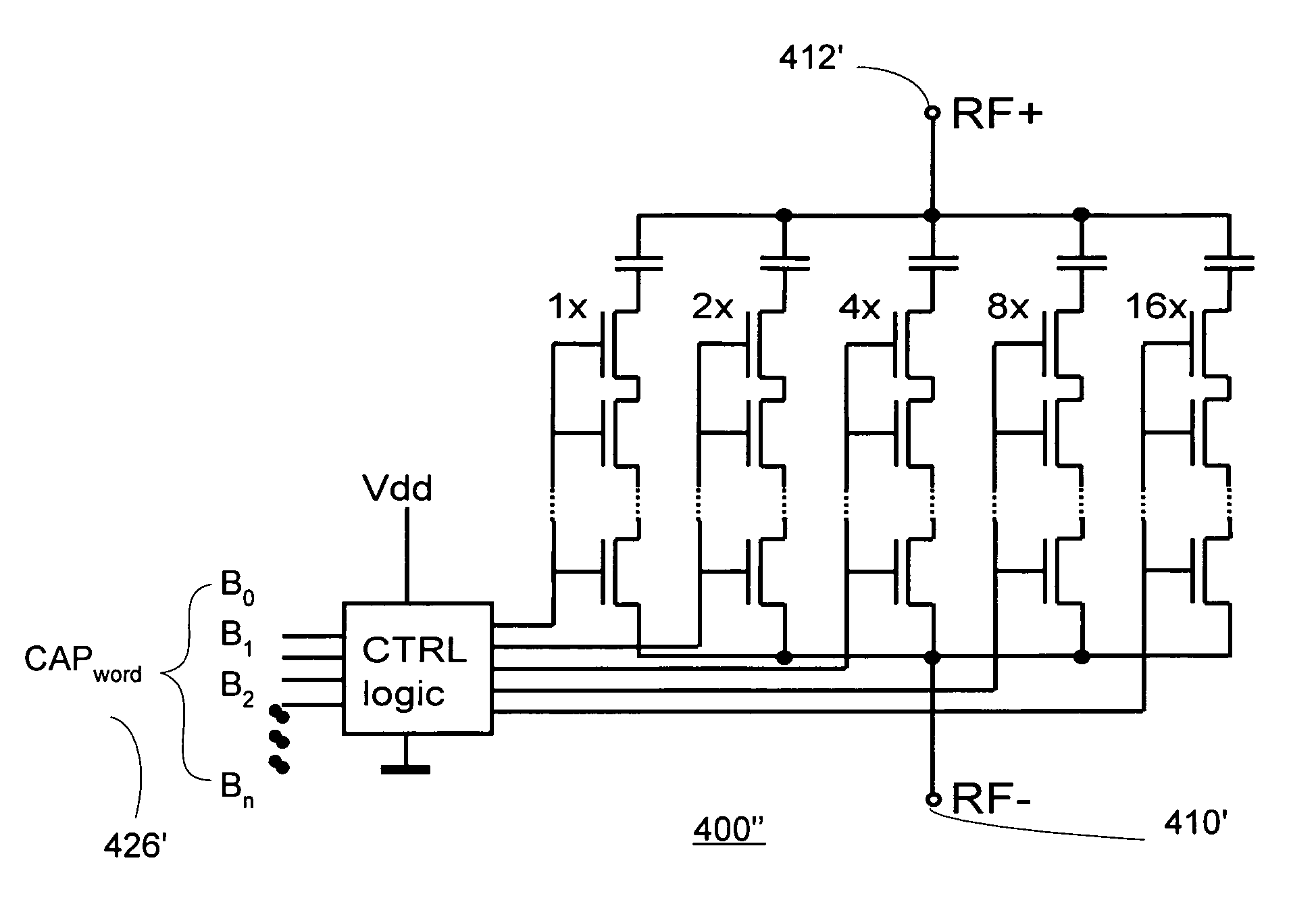

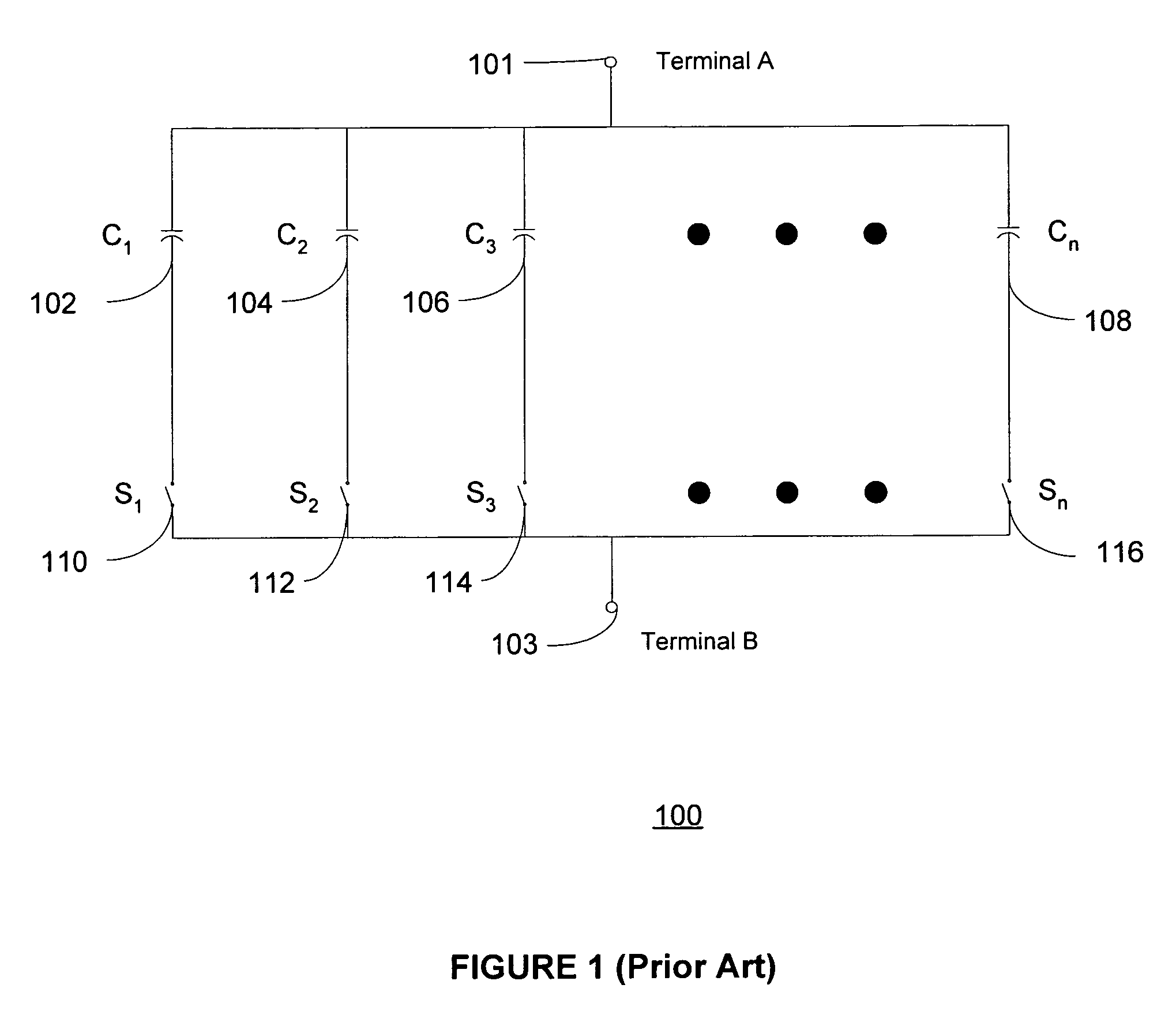

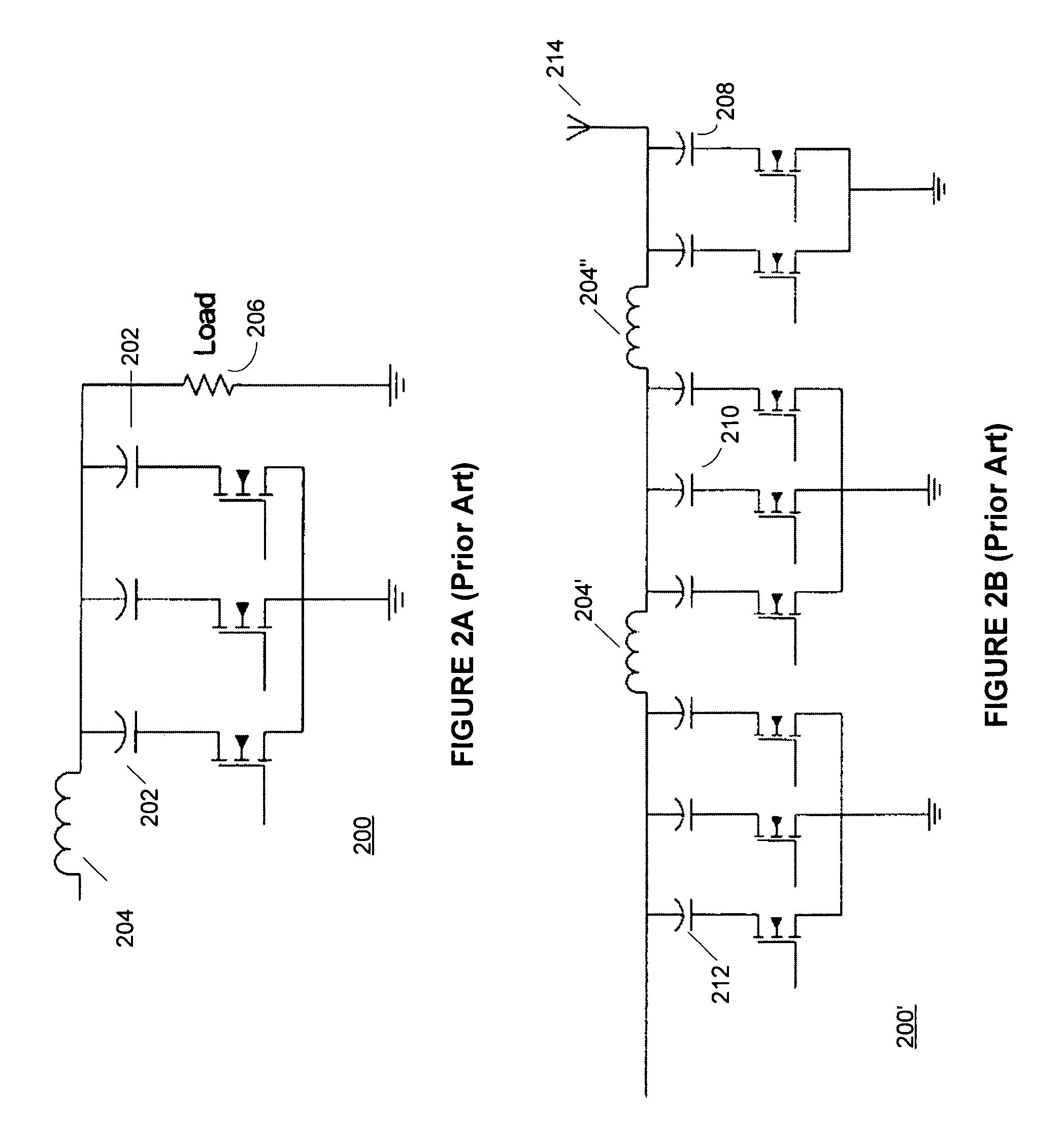

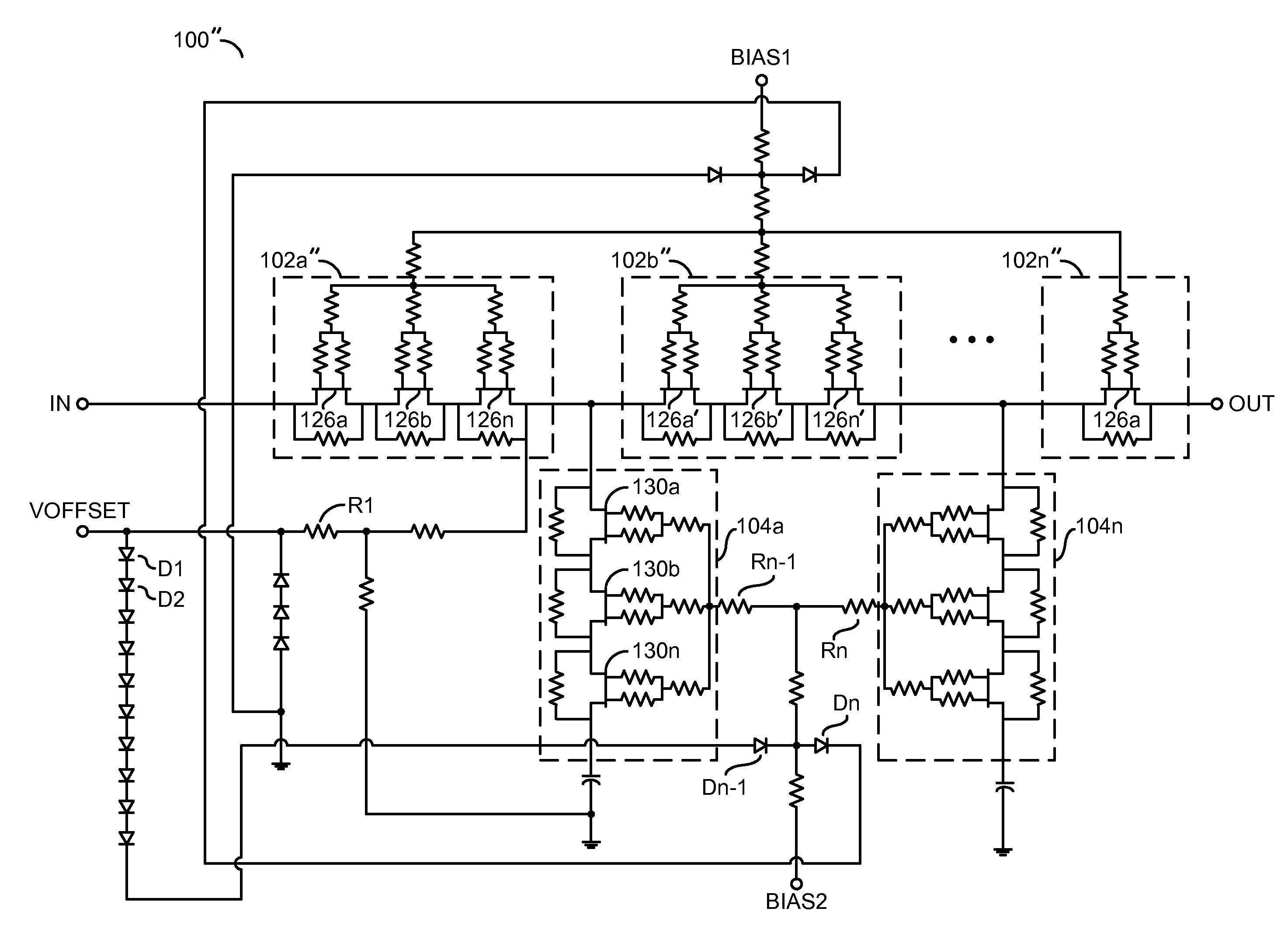

Method and apparatus for use in digitally tuning a capacitor in an integrated circuit device

ActiveUS9024700B2Easy to controlHigh Power Handling CapabilityMultiple-port networksImpedence matching networksCapacitanceLeast significant bit

Owner:PSEMI CORP

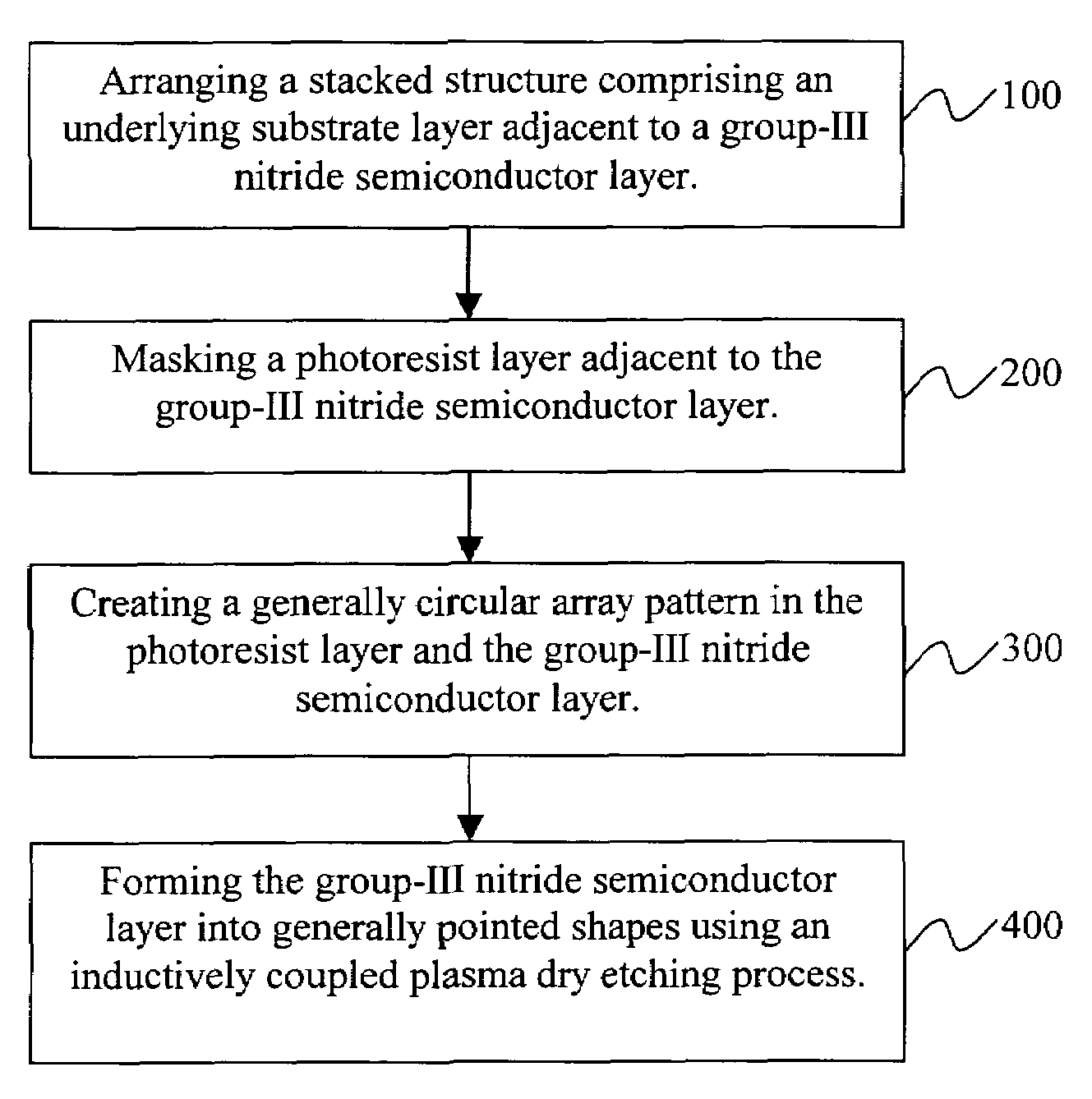

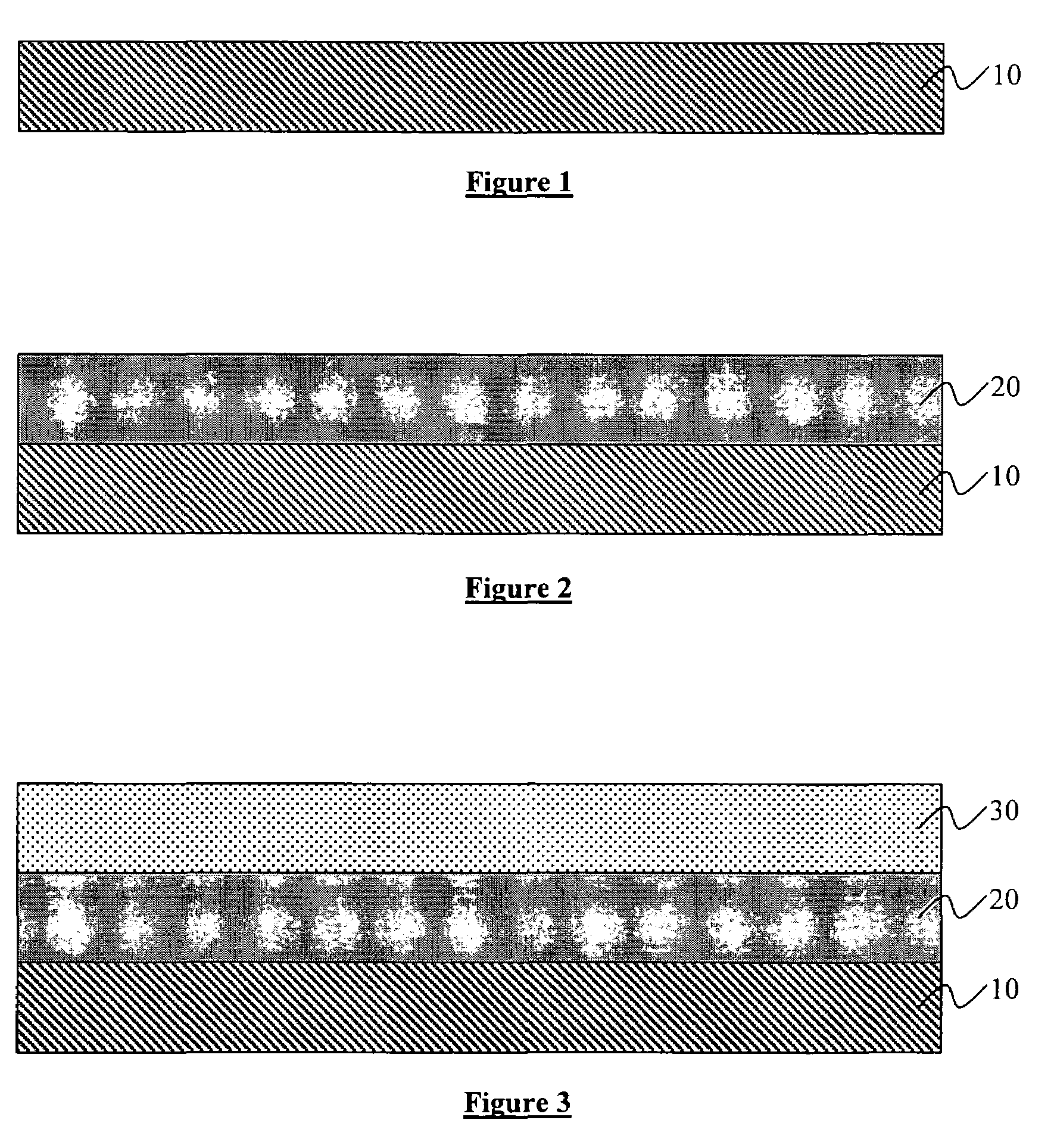

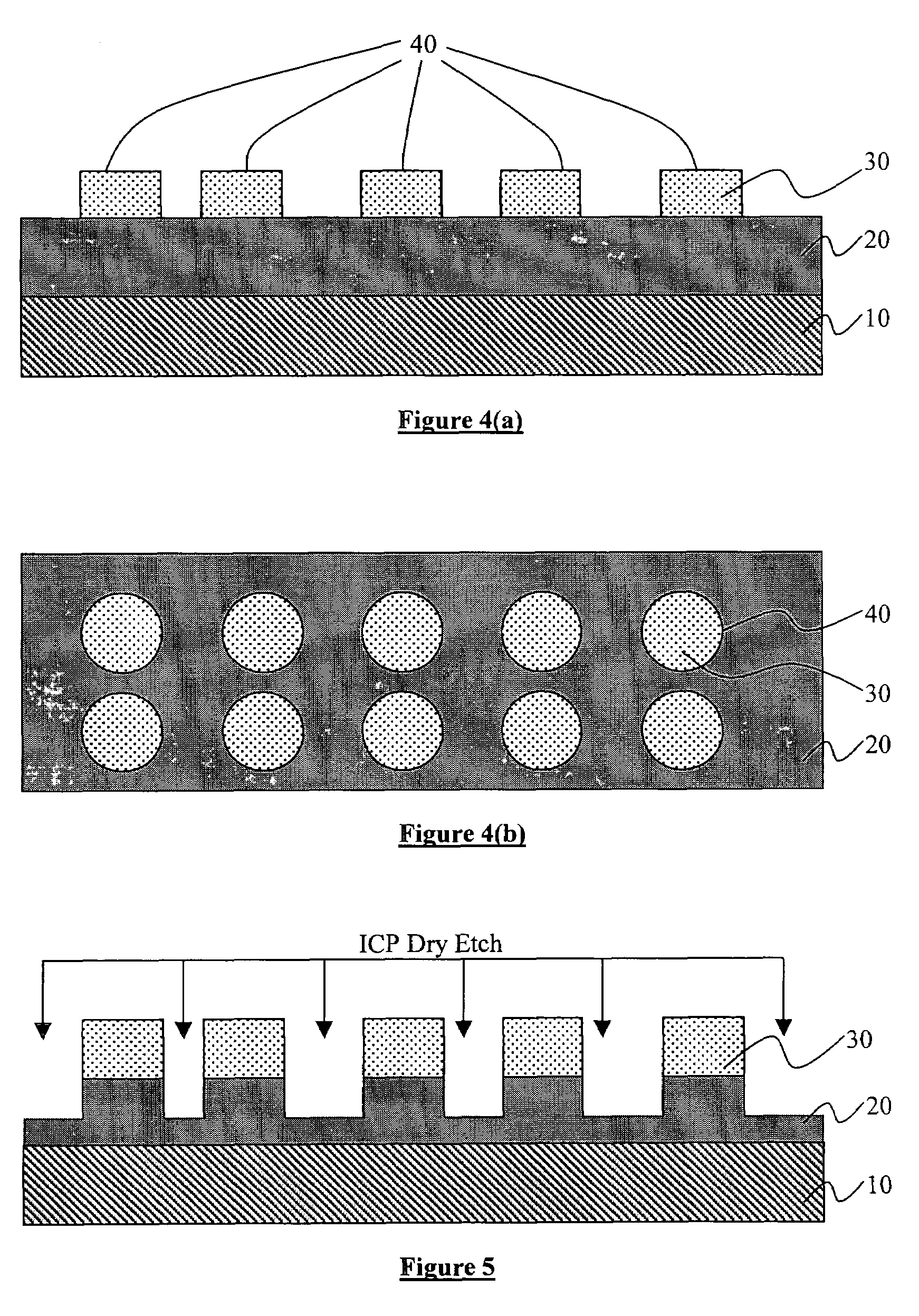

Method of fabricating sub-100 nanometer field emitter tips comprising group III-nitride semiconductors

InactiveUS6960526B1Fast and robust and cost-effective techniqueOpen quicklyElectric discharge tubesSemiconductor/solid-state device manufacturingField emission deviceInductively coupled plasma

A method of producing a field emission device includes laying a group III-nitride semiconductor layer over a substrate, placing a photoresist mask over the group III-nitride semiconductor layer, patterning a generally circular grid in the photoresist mask and the group III-nitride semiconductor layer, and forming the group III-nitride semiconductor layer into generally pointed tips using an inductively coupled plasma dry etching process, wherein the group III-nitride semiconductor layer comprises a group III-nitride semiconductor material having a low positive electron affinity or a even a negative electron affinity, wherein the inductively coupled plasma dry etching process selectively creates an anisotropic deep etch in the group III-nitride semiconductor layer, and wherein the inductively coupled plasma dry etching process creates an isotropic etch in the group III-nitride semiconductor layer. Preferably, the photoresist layer is approximately 1.7 microns in thickness, and the fabricated tips have a radius of curvature of less than 100 nanometers.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

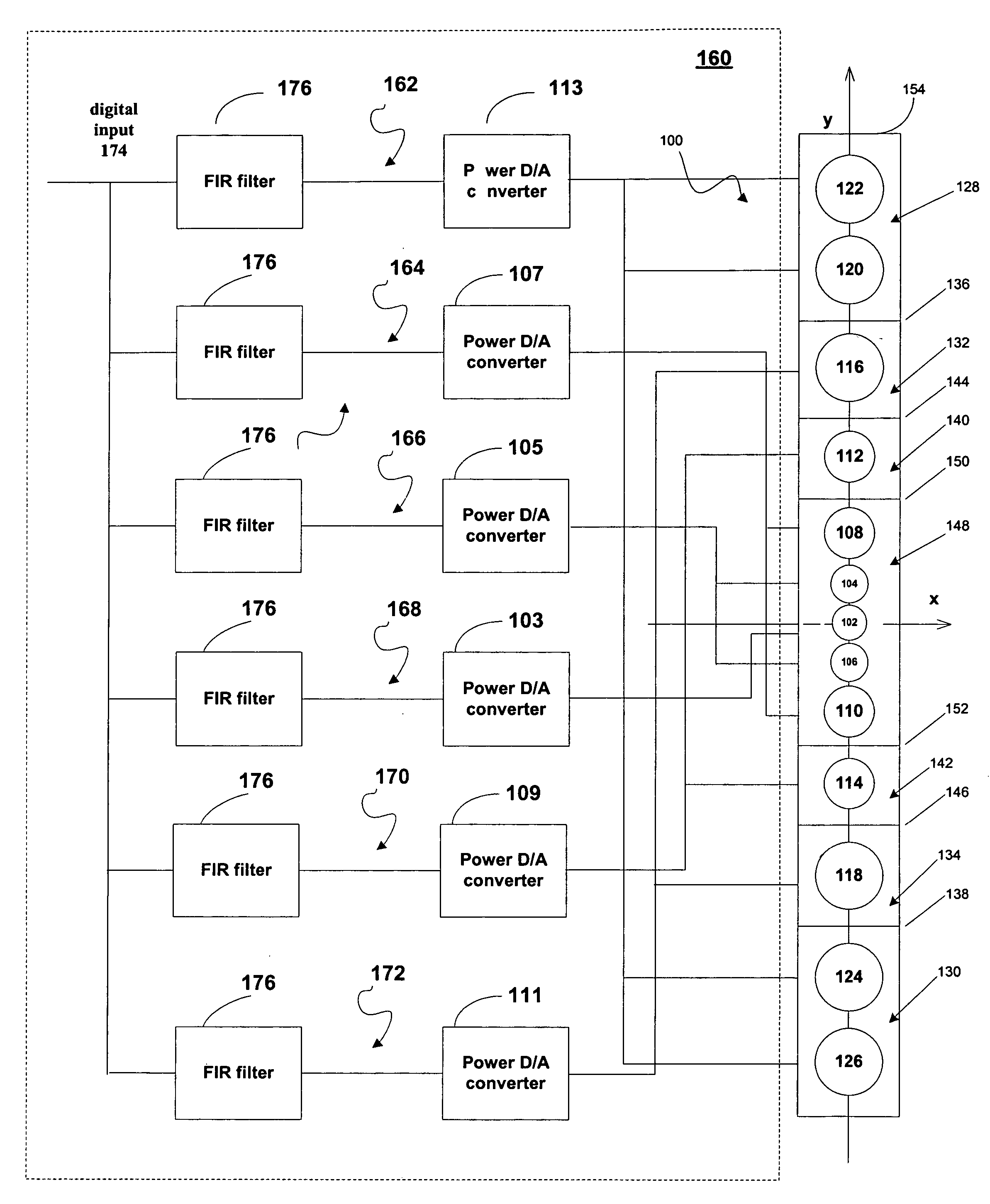

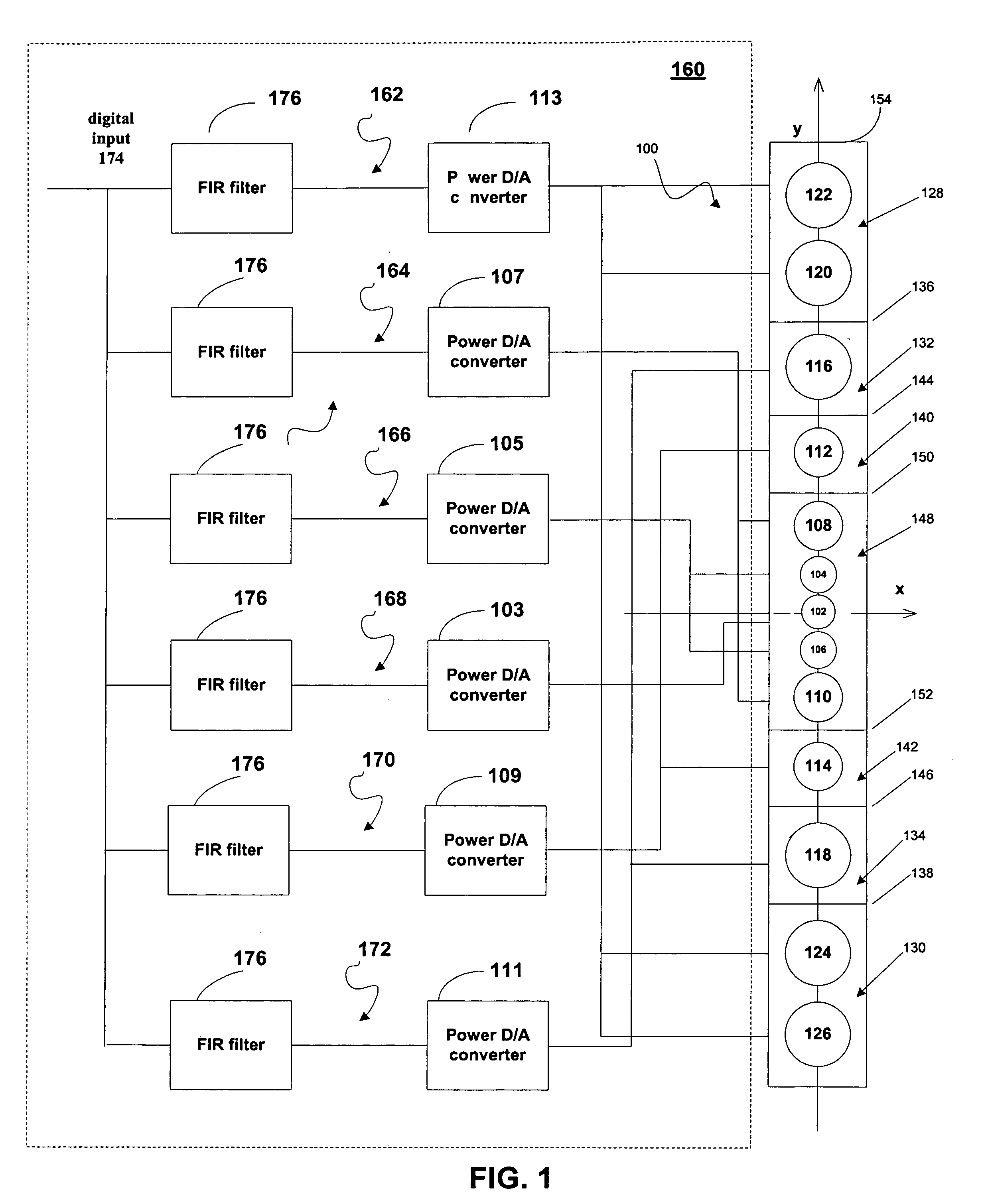

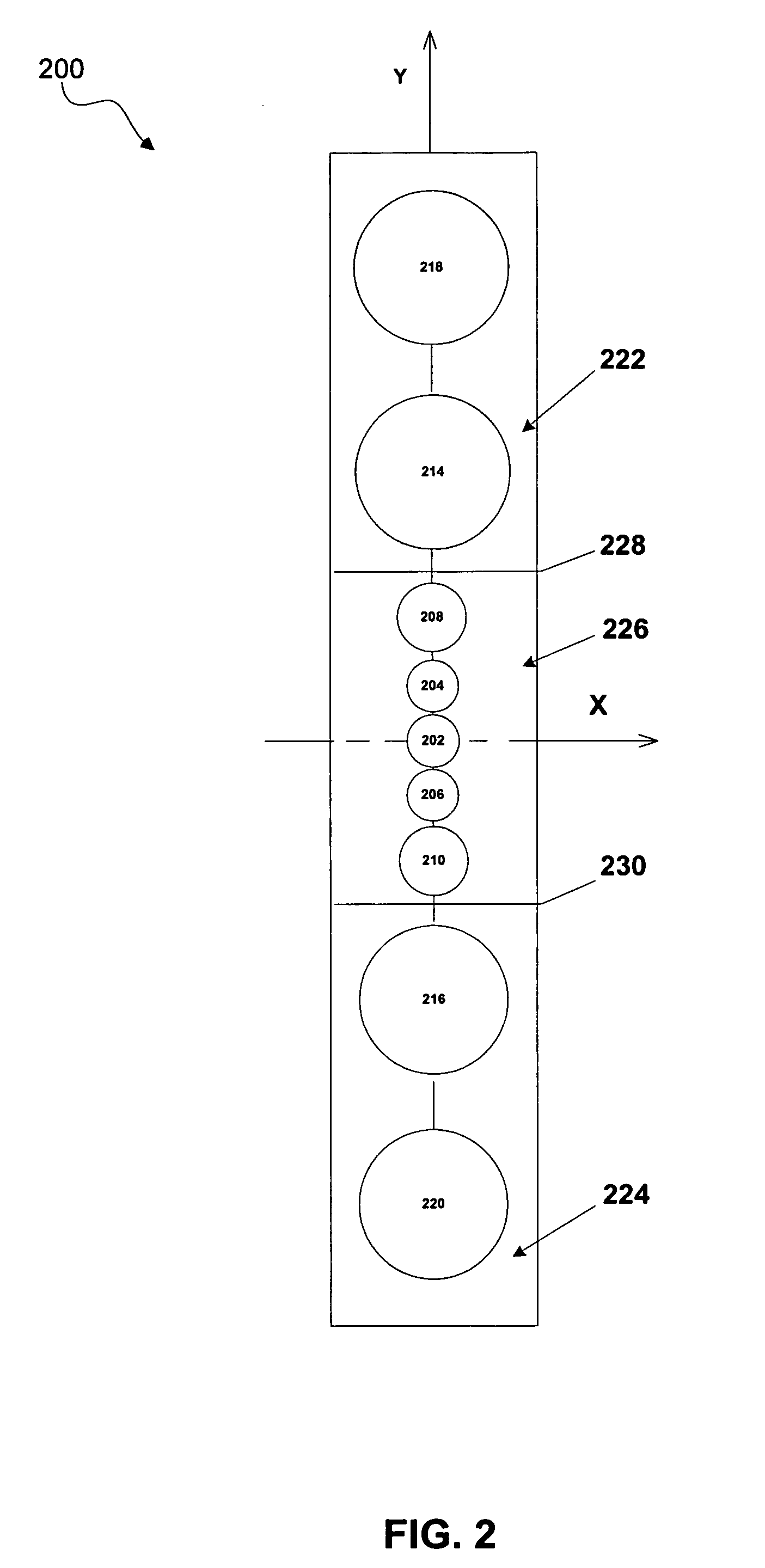

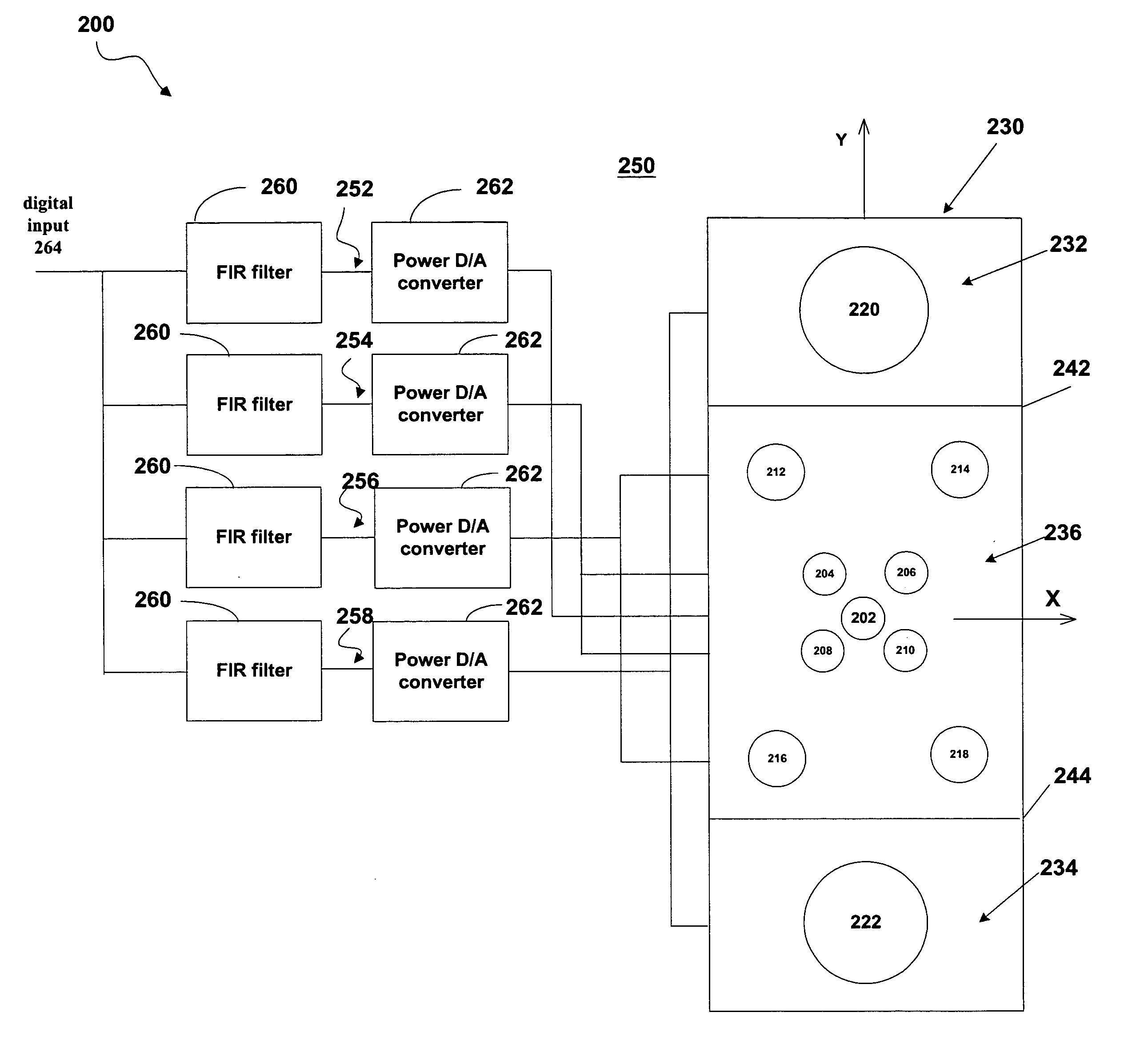

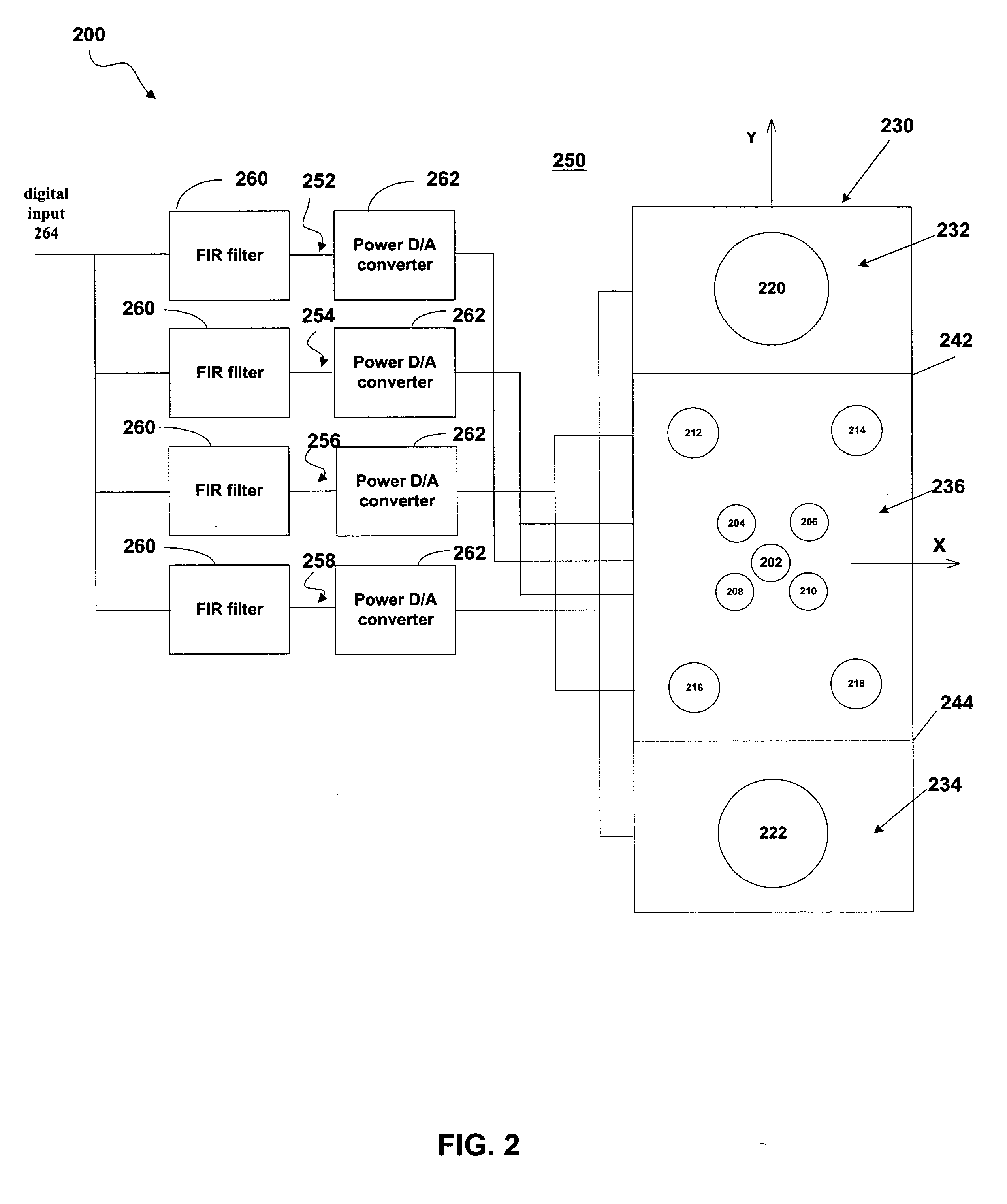

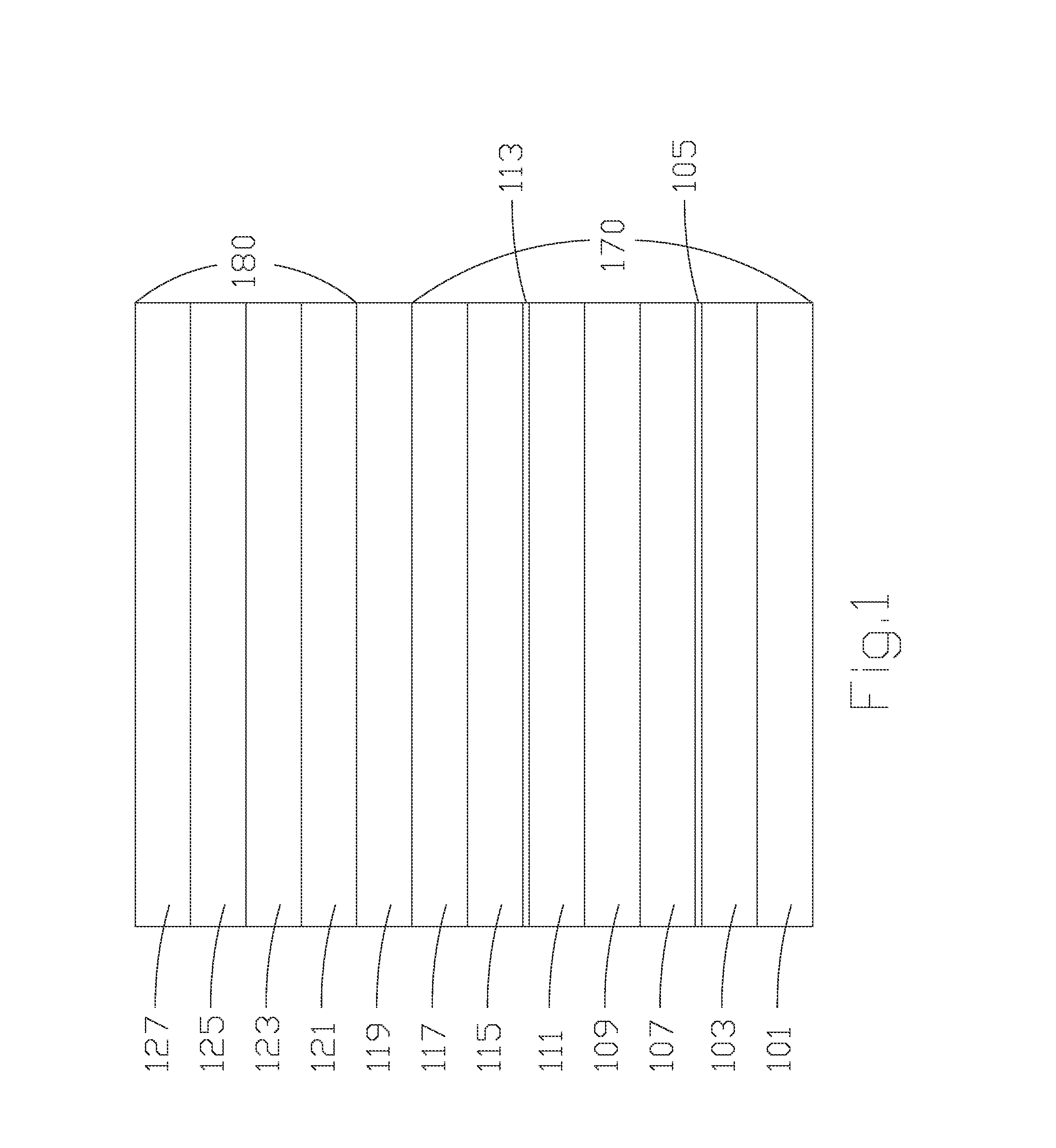

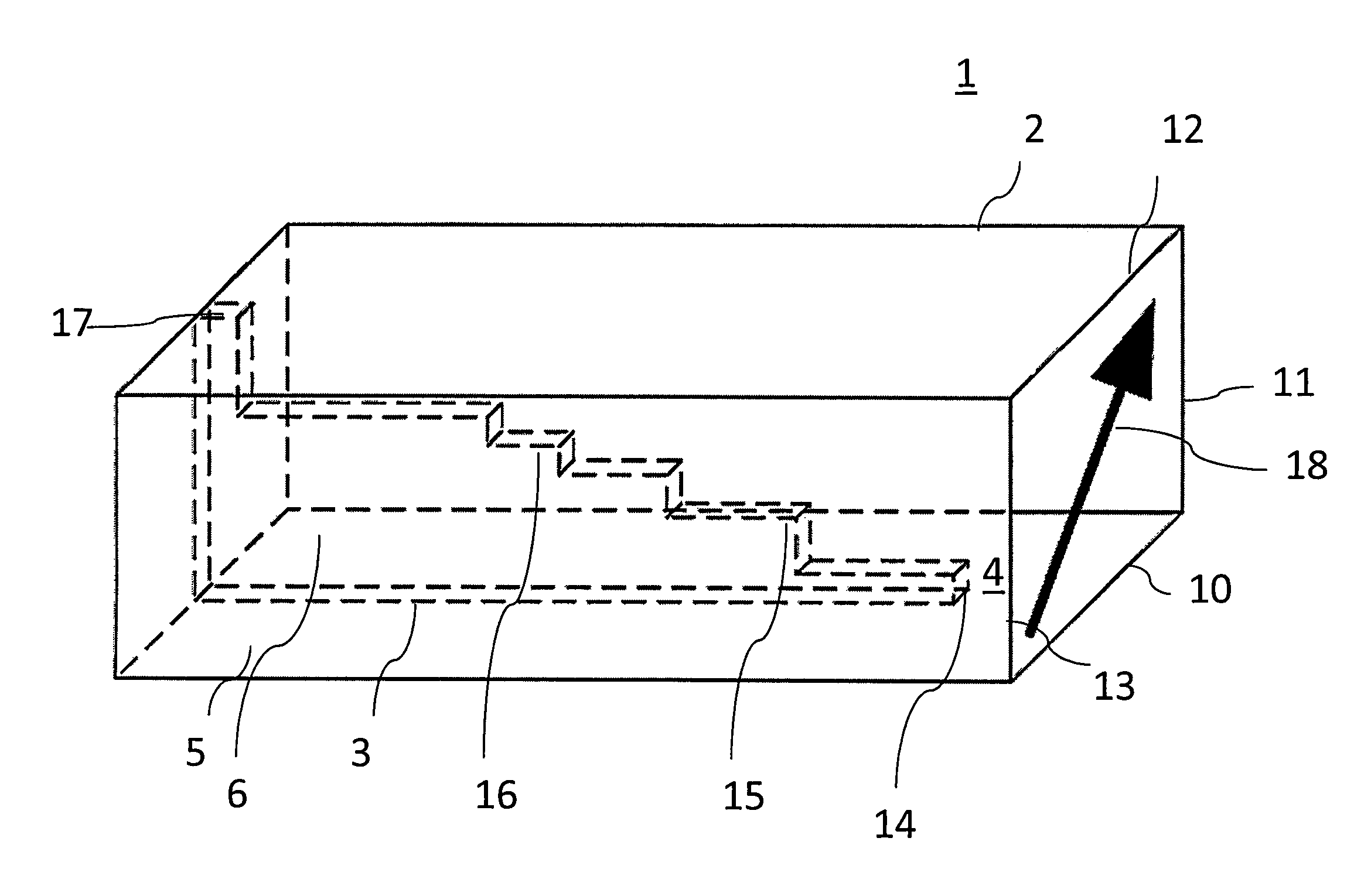

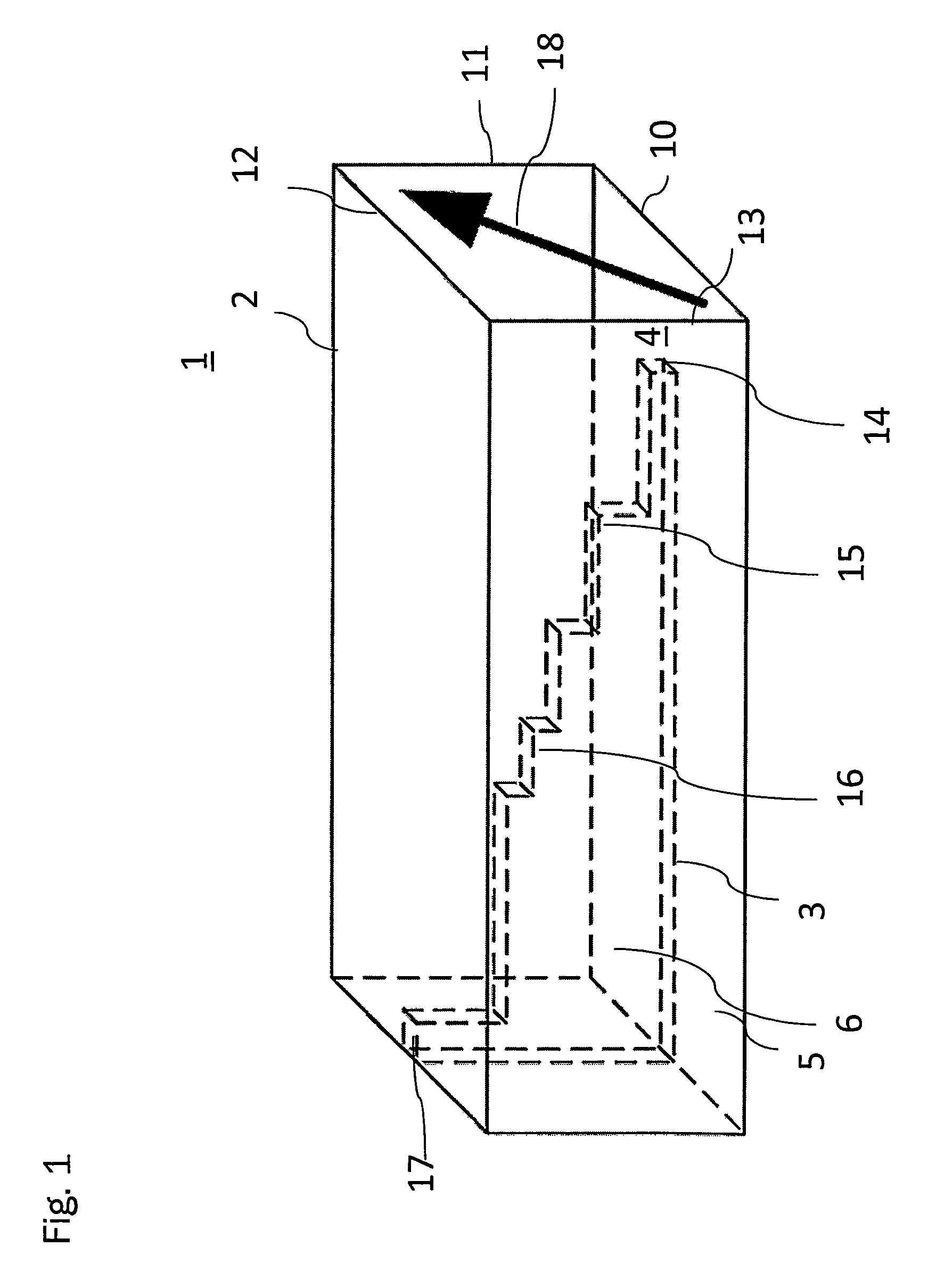

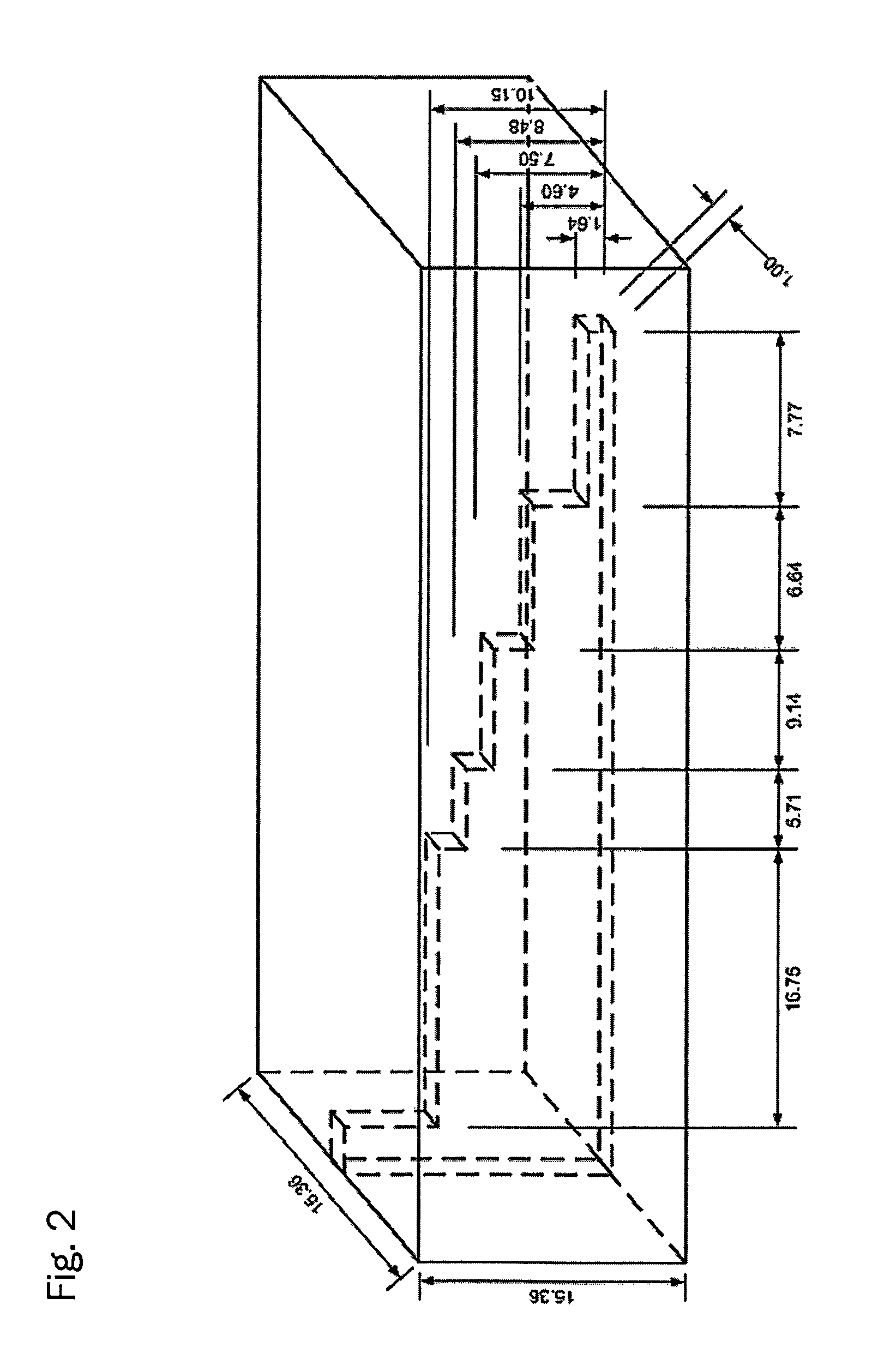

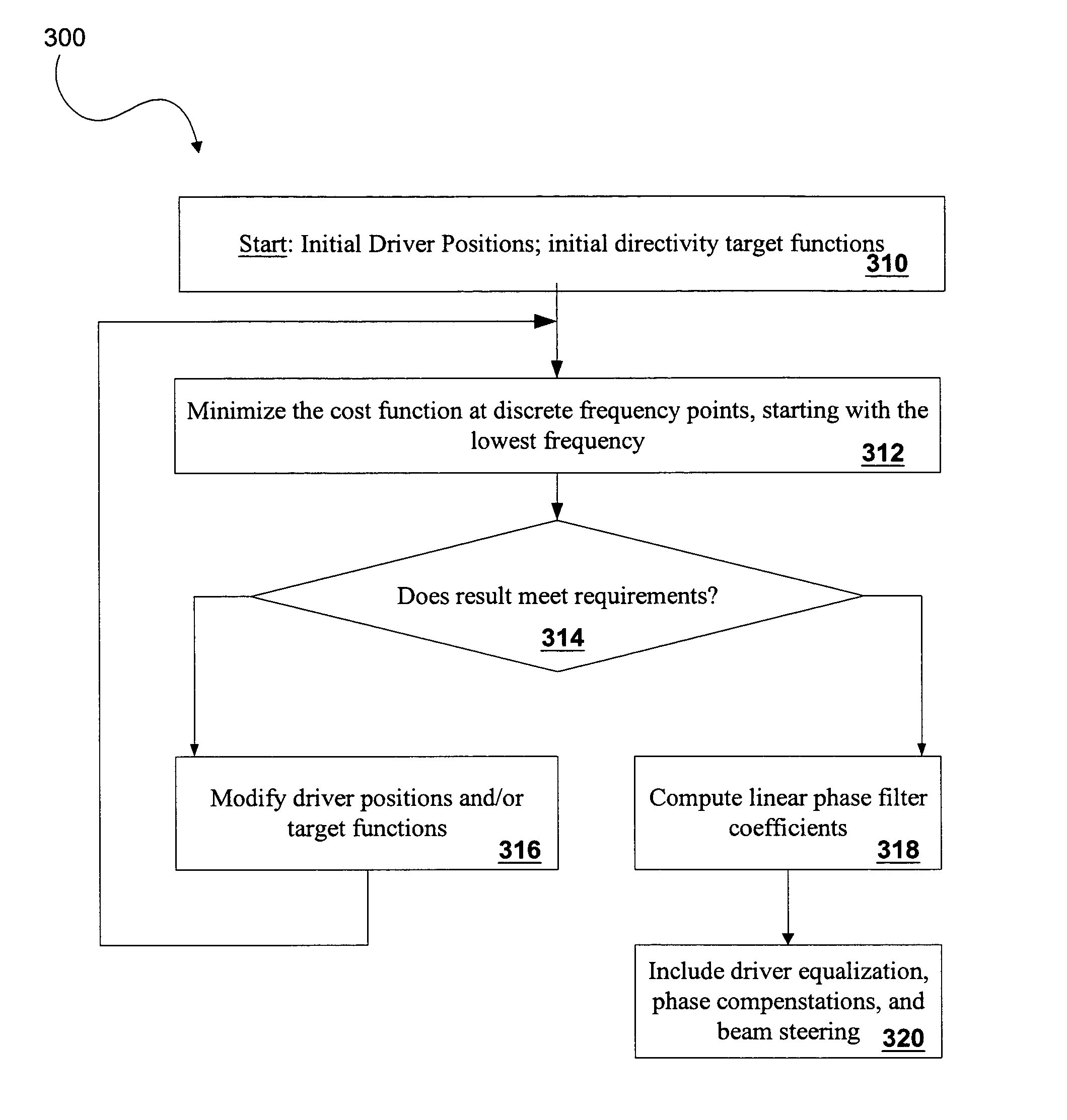

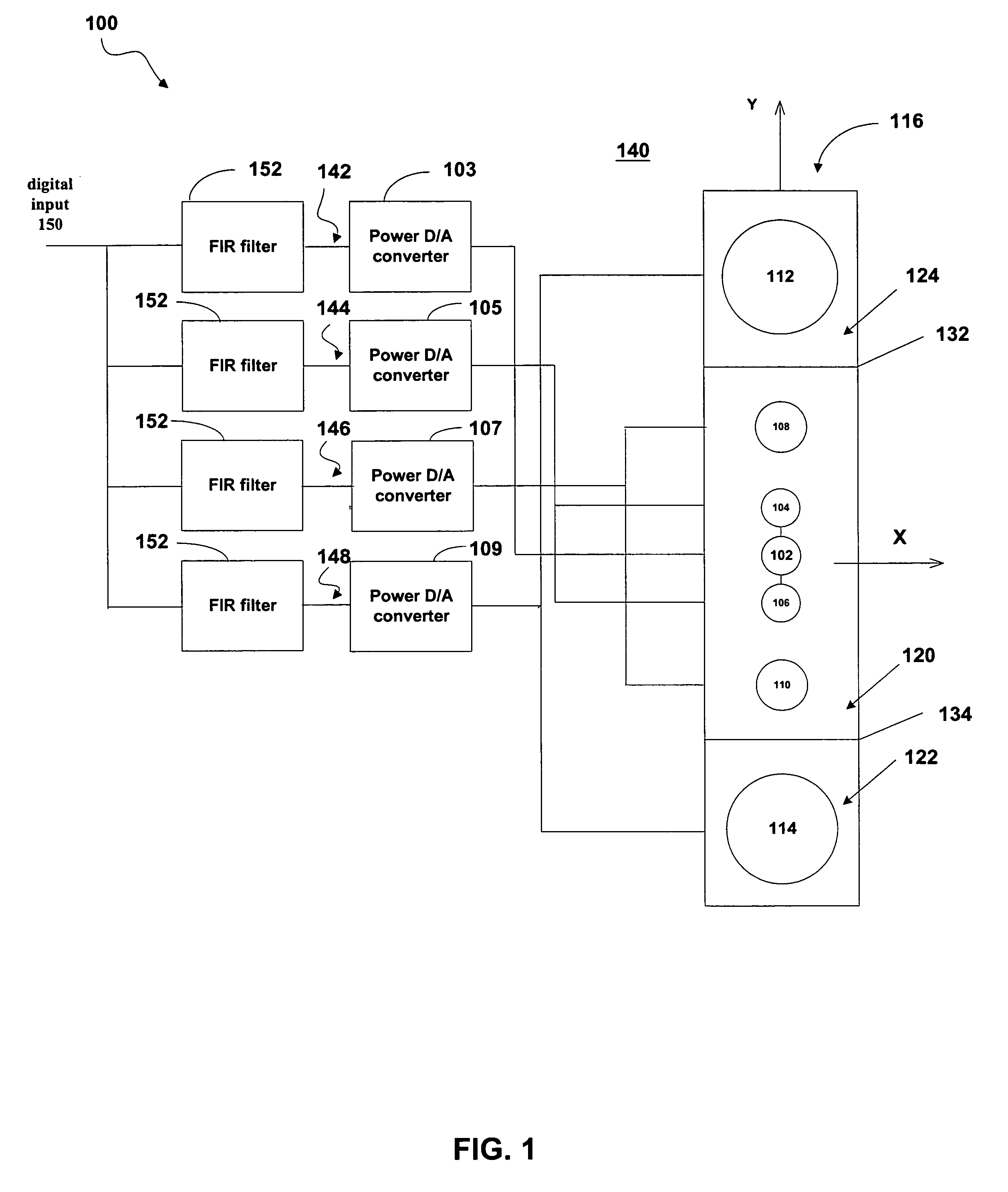

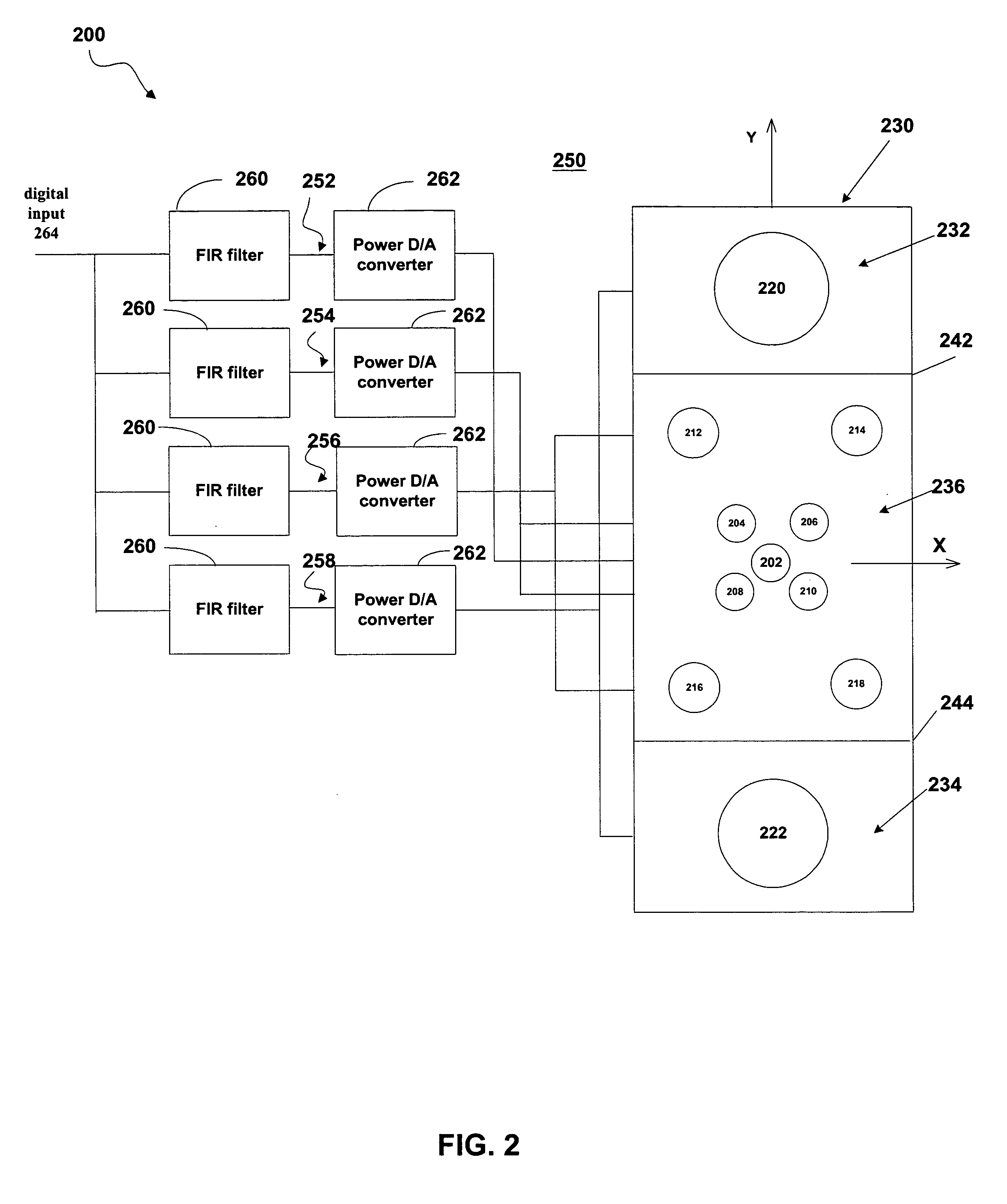

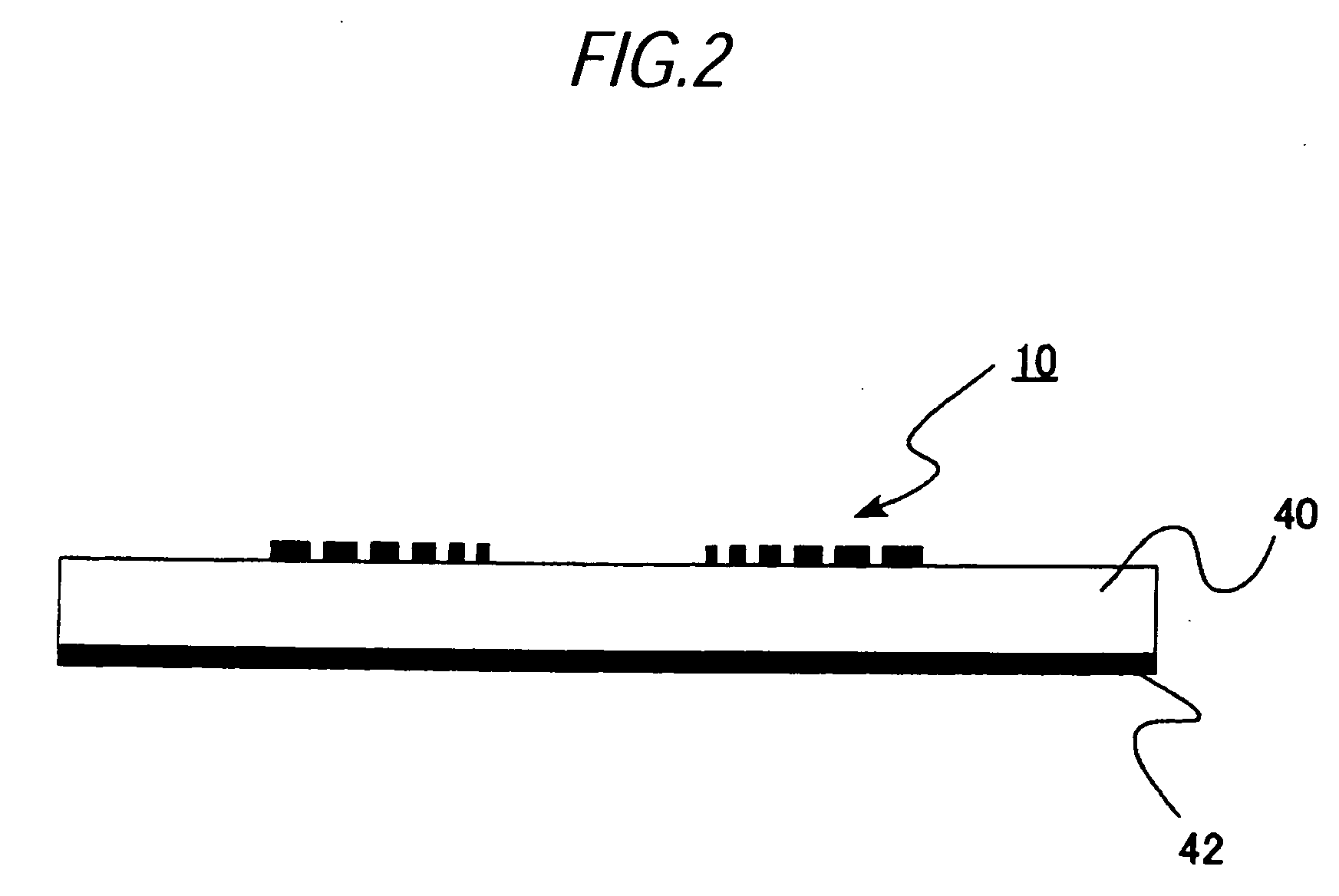

Loudspeaker array system

ActiveUS20050180577A1High-quality soundEasy to controlLoudspeaker signals distributionFrequency/directions obtaining arrangementsDigital signal processingEngineering

The invention is a multi-channel loudspeaker system that provides a compact loudspeaker configuration and filter design methodology that operates in the digital signal processing domain. Further, the loudspeaker system can be designed to include drivers of various physical dimensions and can achieve prescribed constant directivity over a large area in both the vertical and horizontal planes.

Owner:APPLE INC

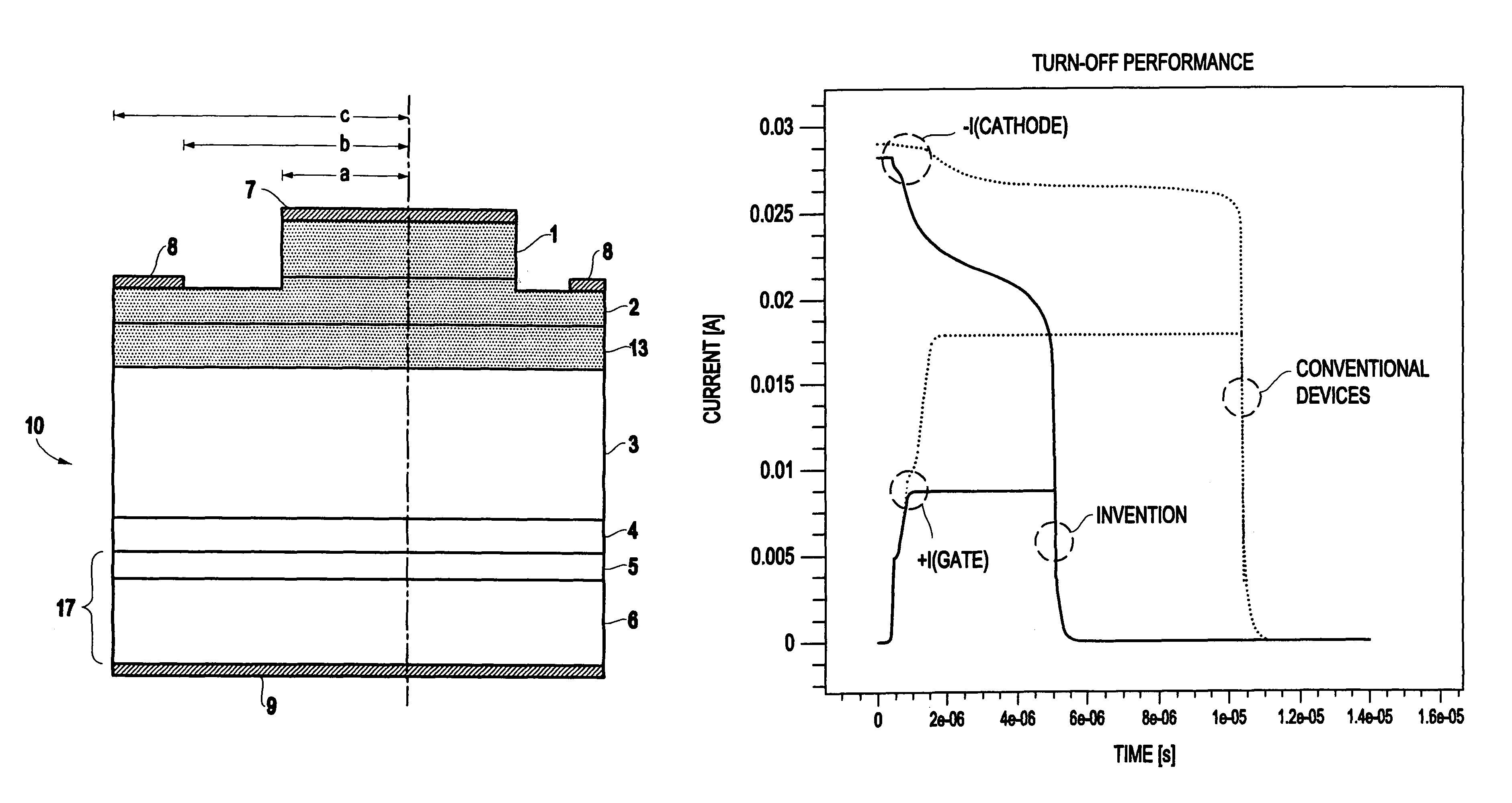

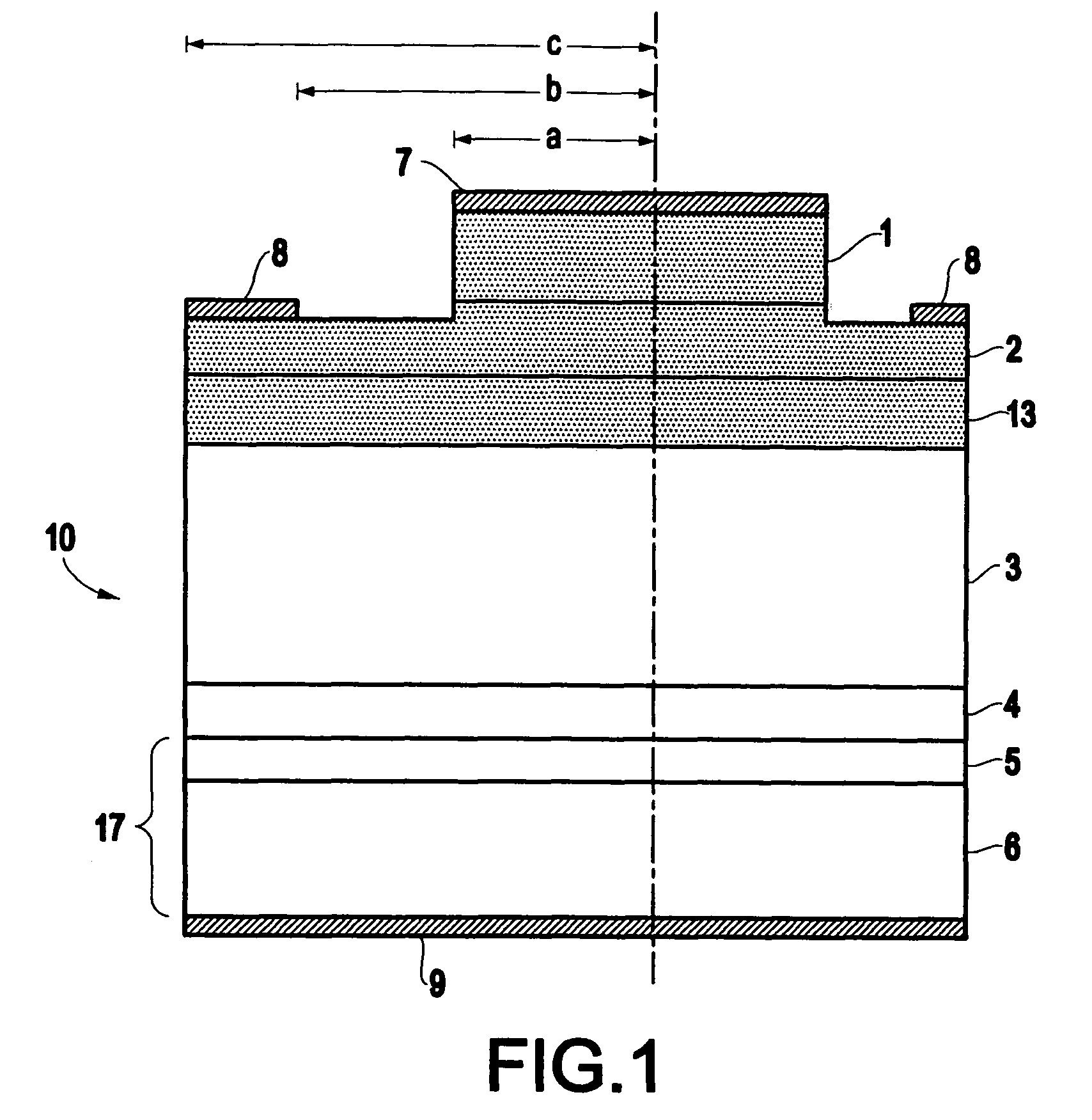

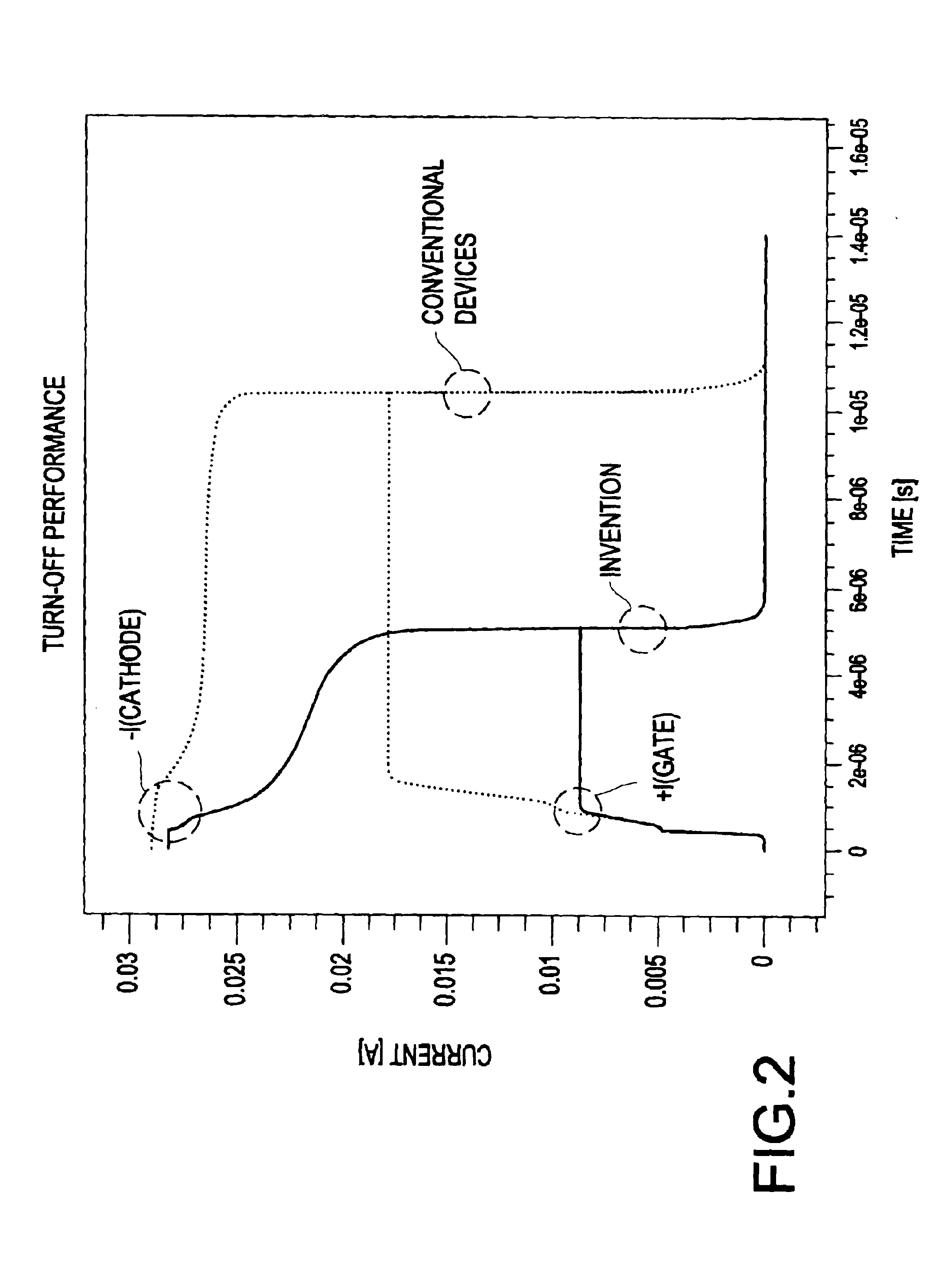

Processing technique to improve the turn-off gain of a silicon carbide gate turn-off thyristor

ActiveUS7851274B1Increased turnLow mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesGate turn-off thyristorNanosecond

A structure and method for a silicon carbide (SiC) gate turn-off (GTO) thyristor device operable to provide an increased turn-off gain comprises a cathode region, a drift region having an upper portion and a lower portion, wherein the drift region overlies the cathode region, a gate region overlying the drift region, an anode region overlying the gate, and at least one ohmic contact positioned on each of the gate region, anode region, and cathode region, wherein the upper portion of the drift region, the gate region, and the anode region have a free carrier lifetime and mobility lower than a comparable SiC GTO thyristor for providing the device with an increased turn-off gain, wherein the free carrier lifetime is approximately 10 nanoseconds. The reduced free carrier lifetime and mobility are affected by altering the growth conditions, such as temperature under which epitaxy occurs.

Owner:ARMY US SEC THE

Torsion spring for electro-mechanical switches and a cantilever-type RF micro-electromechanical switch incorporating the torsion spring

InactiveUS6842097B2Increased durabilityGood electrical contactContact surface shape/structureElectrostatic/electro-adhesion relaysConformal connectionEngineering

A torsion spring for an electro-mechanical switch is presented. The torsion spring comprises a set of tines including at least one tine extending from the free end of the armature of a switch. A terminus portion is rotatably suspended between the tines, and includes a conducting transmission line, at least a portion of which is exposed for electrical contact. The conducting transmission line has a length selected such that the exposed portion of the transmission line forms a circuit between the input and output of the micro-electro-mechanical switch when the micro-electro-mechanical switch is urged into a closed position, with the terminus portion rotating via the tines to form a conformal connection between the exposed portion of the conducting transmission line and the input and output of the switch, thus optimizing the electrical flow therebetween. The switch is also applied to MEMS devices.

Owner:HRL LAB

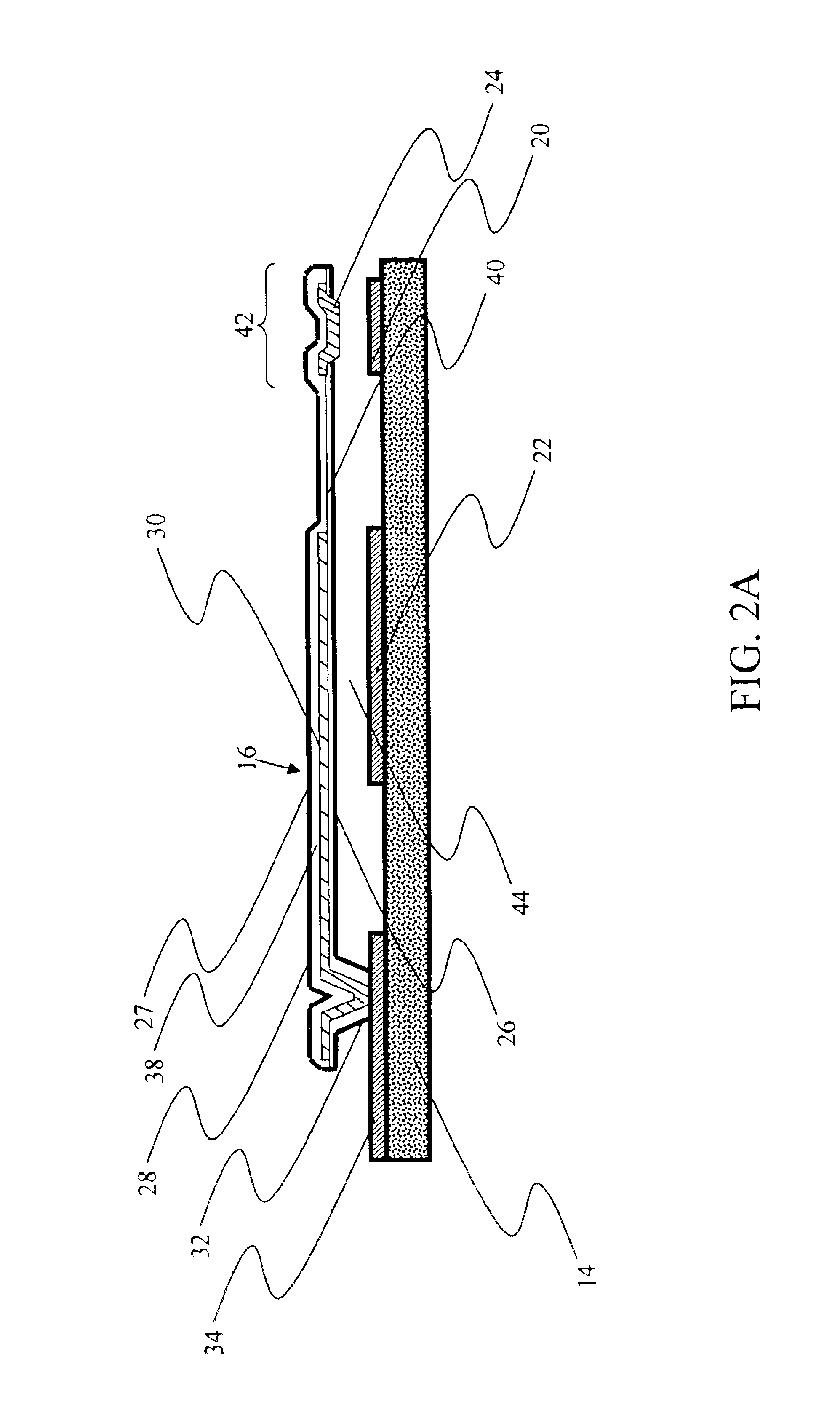

Loudspeaker array system

ActiveUS20050169493A1High-quality soundEasy to controlLoudspeaker signals distributionFrequency/directions obtaining arrangementsPublic address systemDigital signal processing

The invention is a multi-channel loudspeaker system that provides a compact loudspeaker configuration and filter design methodology that operates in the digital signal processing domain. Further, the loudspeaker system can be designed as a multi-way loudspeaker system comprised of a symmetric arrangement of loudspeaker drivers in a two-dimensional plane and can achieve high-quality sound, constant directivity over a large area in both the vertical and horizontal planes and can be used in connection with stereo loudspeaker systems, multi-channel home entertainment systems and public address systems.

Owner:APPLE INC

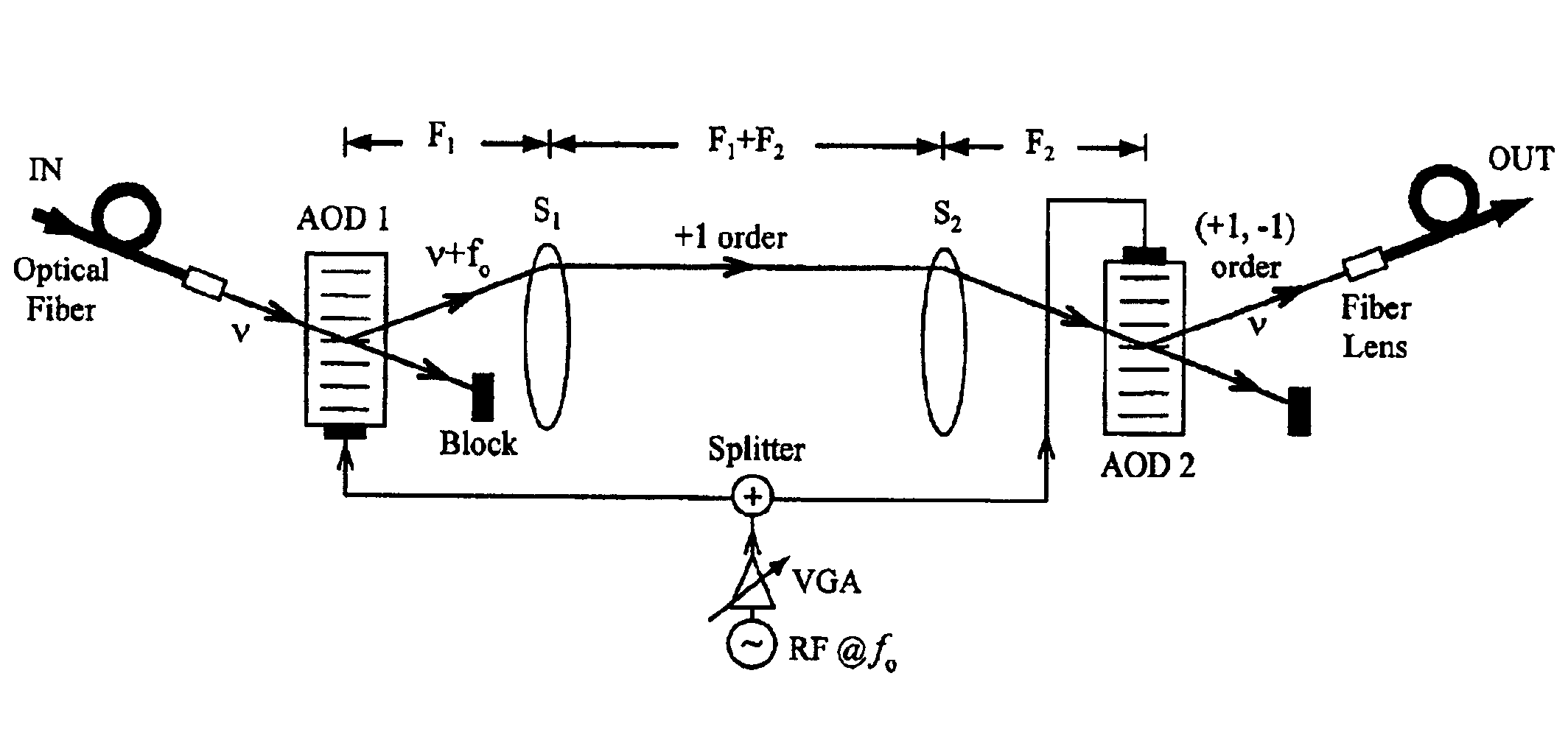

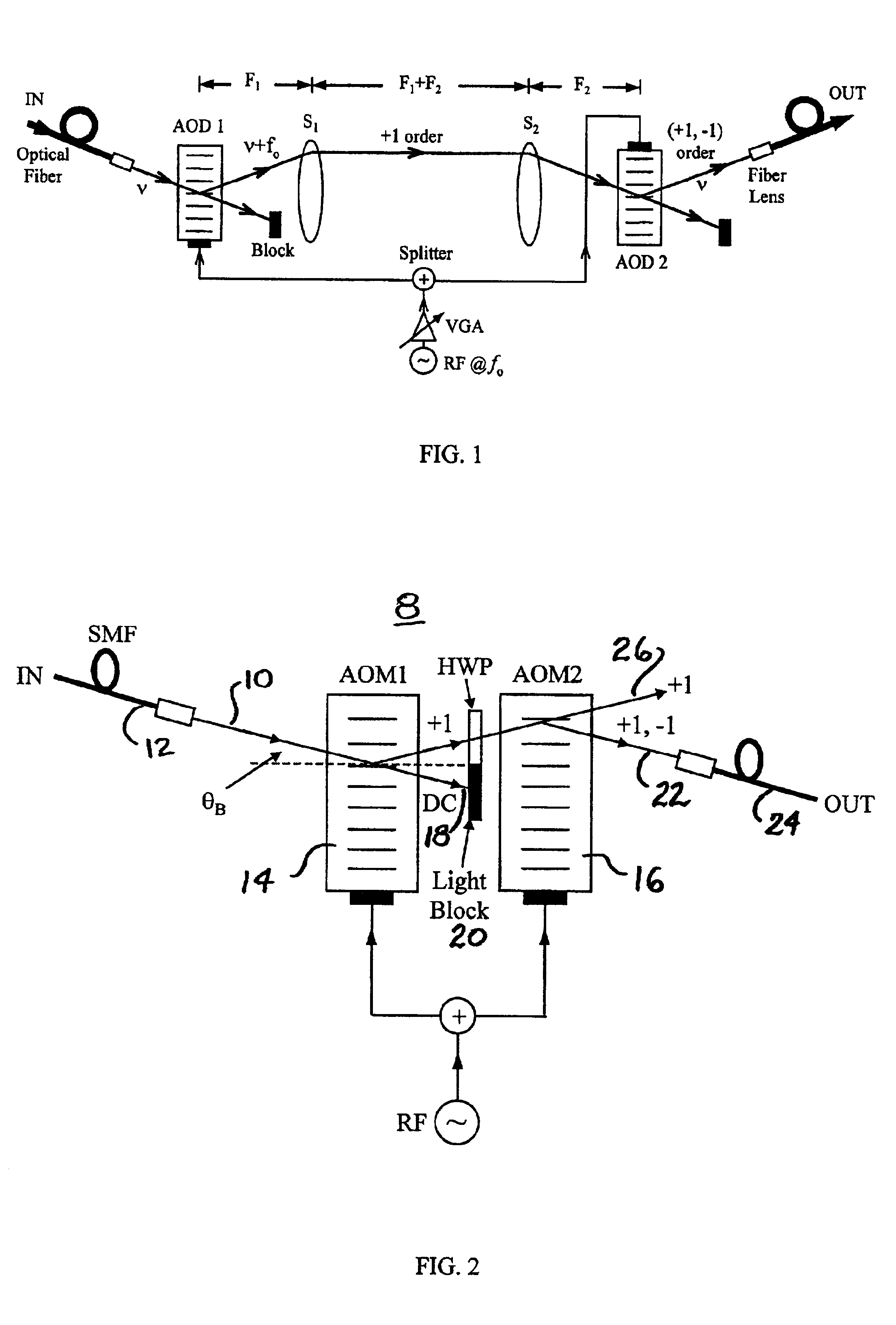

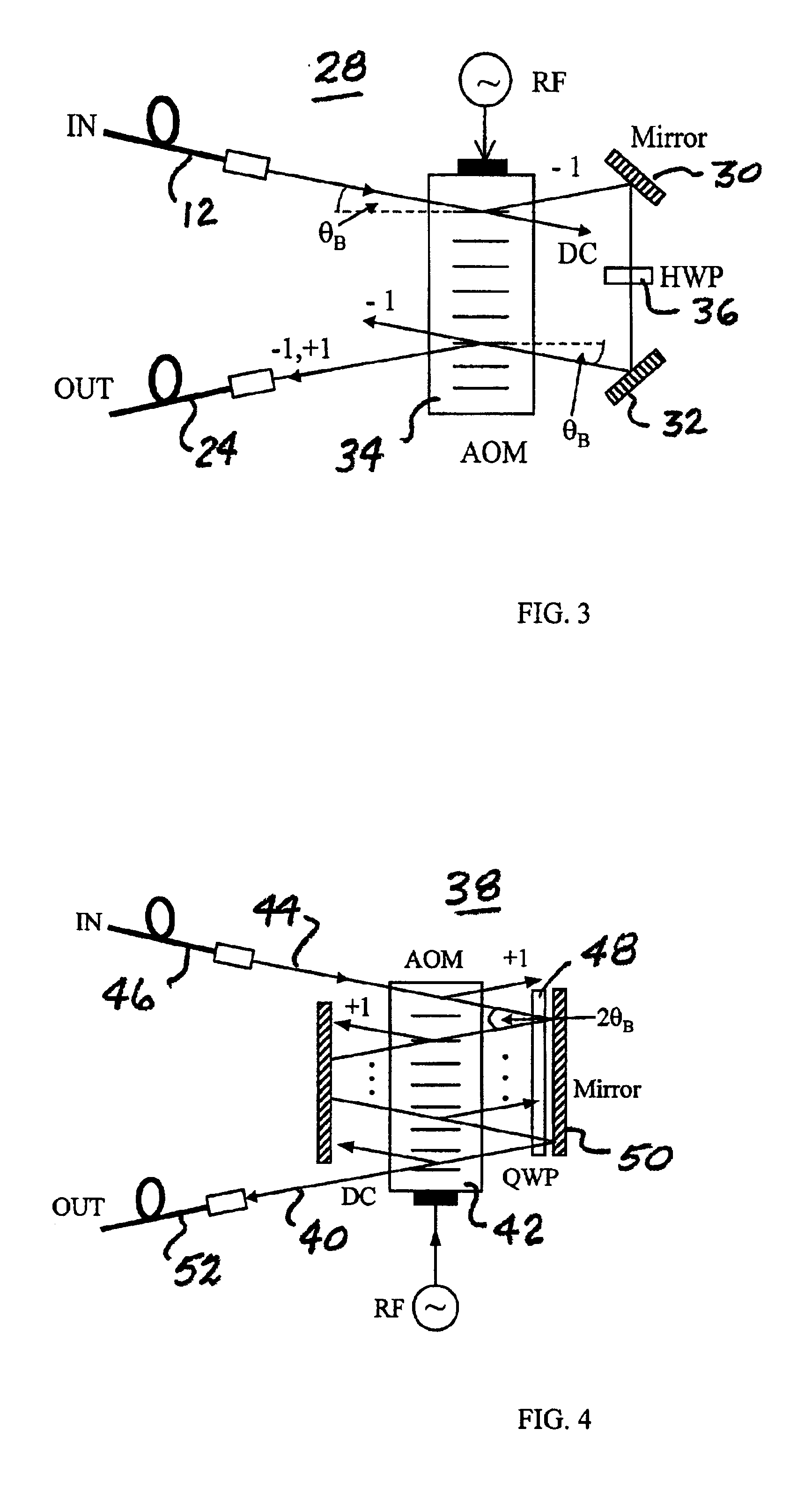

High speed fiber-optic attenuation modules

InactiveUS6885807B2High optical isolationReduce lossWavelength-division multiplex systemsCoupling light guidesAcousto-opticsAutomatic gain control

Unique multi-diffraction structures using electronically controlled Bragg diffraction devices such as acousto-optic (AO) devices to accomplish optical beam attenuation control functions. These variable optical attenuator (VOA) modules can be fully inertialess as they can use electronically programmable sub-microsecond speed AO devices to implement optical gain controls. These VOAs deliver desirable capabilities in one optically reversible unit, making high dynamic range, low loss, high power handling, ultra-fast, high optical isolation, broadband operation, self-aligning robust modules. These VOAs can be made essentially independent of the optical polarization of the incident light by the use of a unique fixed waveplate compensation technique within the VOA configuration that suppresses polarization dependent loss. Broadband gain control operation over several wavelengths can be achieved by controlling the frequency and electrical drive power of the chosen frequencies feeding the acousto-optic devices. Interleaver devices can be cascaded with the acousto-optic modules to improve wavelength selectivity of the overall VOA modules. Alternative embodiments can use electrically programmable Bragg gratings in polymer dispersed liquid crystal and acousto-optic tunable filter devices as Bragg grating devices. Embodiments are proposed using independently controlled Bragg diffractions using multiple drive signals connected to multiple device transducers. Drive signal formats can be digital, analog, or a combination for simultaneously driving the VOA modules. Dual-mode VOA module designs are also described using mirror positioning.

Owner:NUONICS

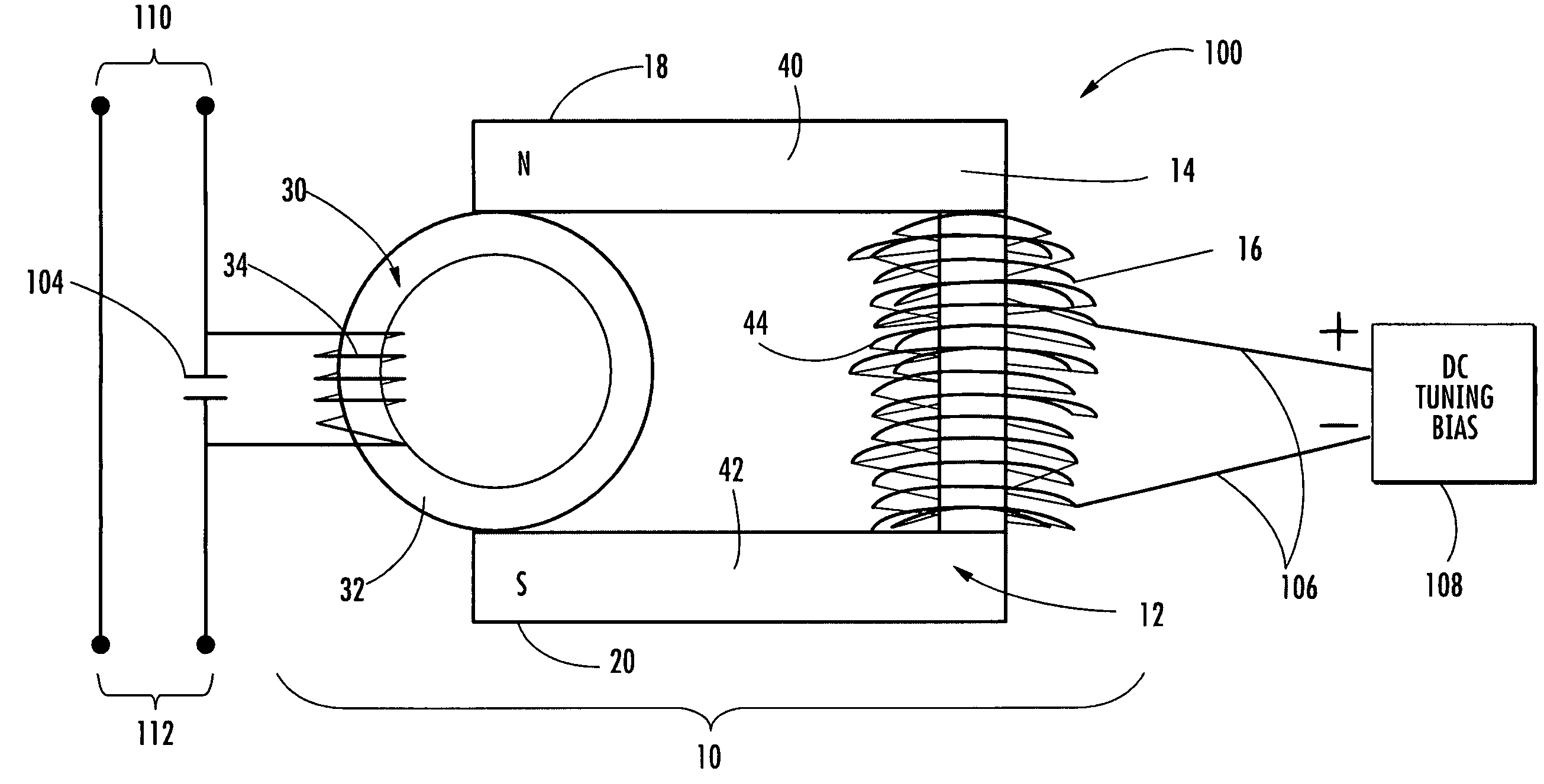

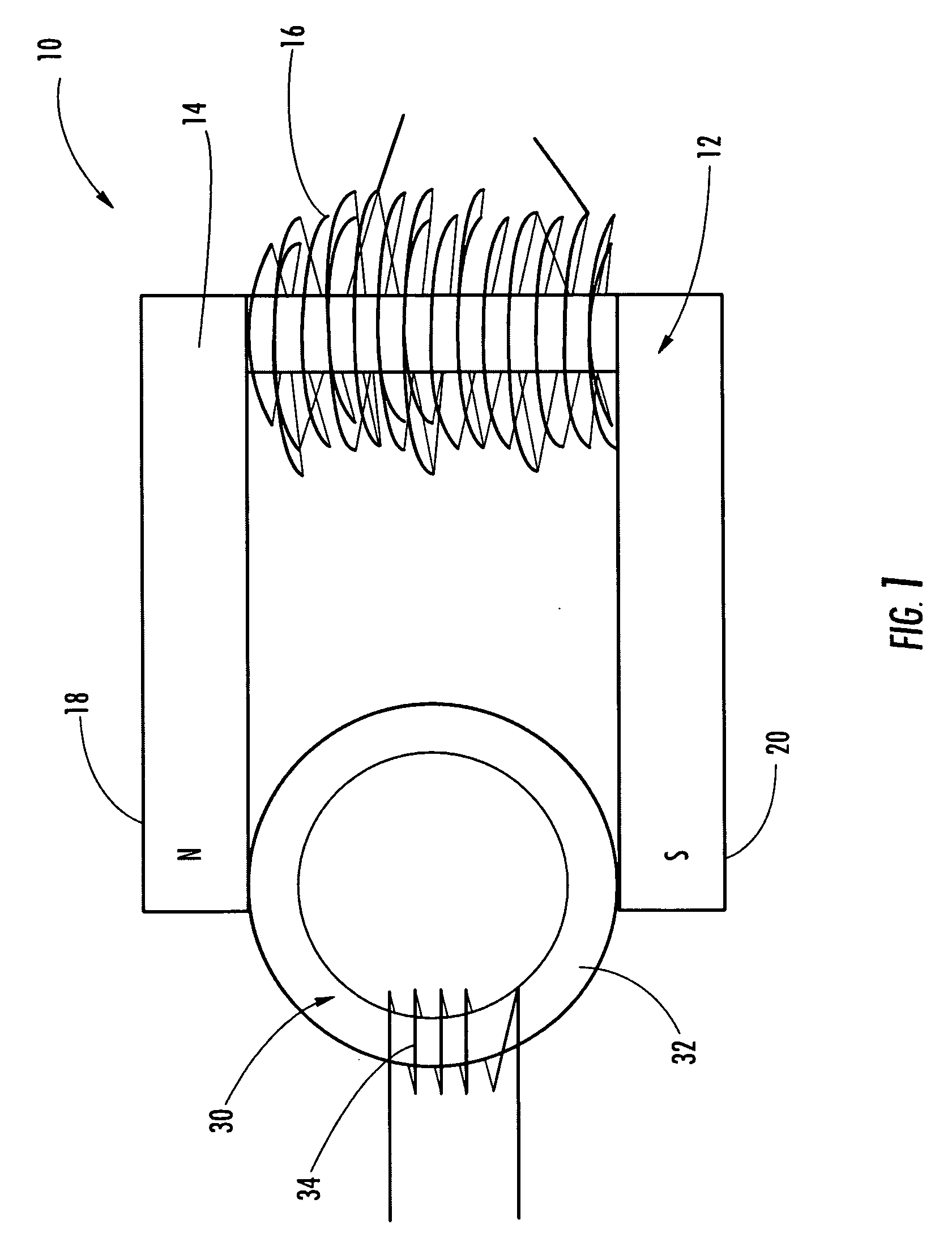

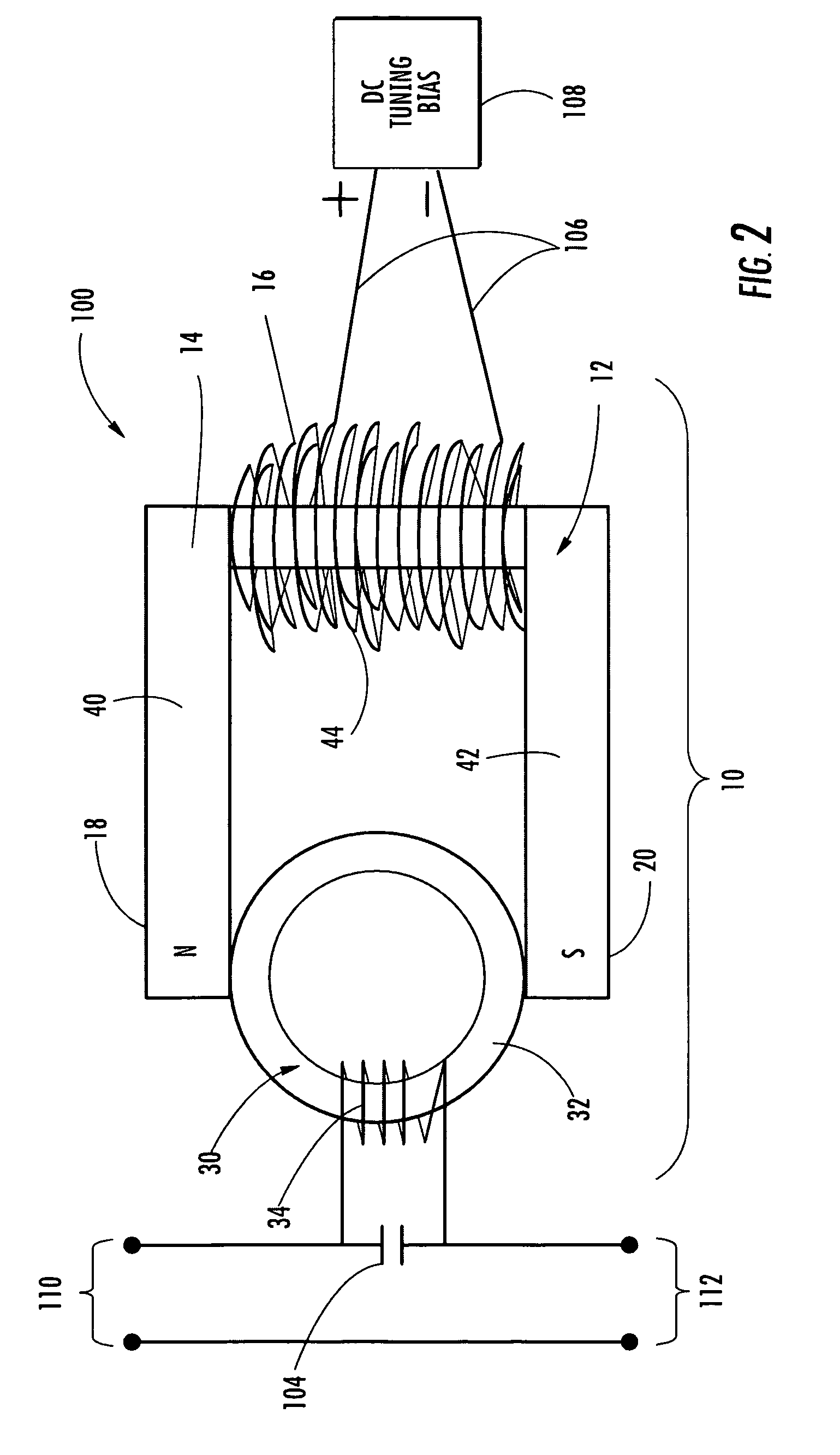

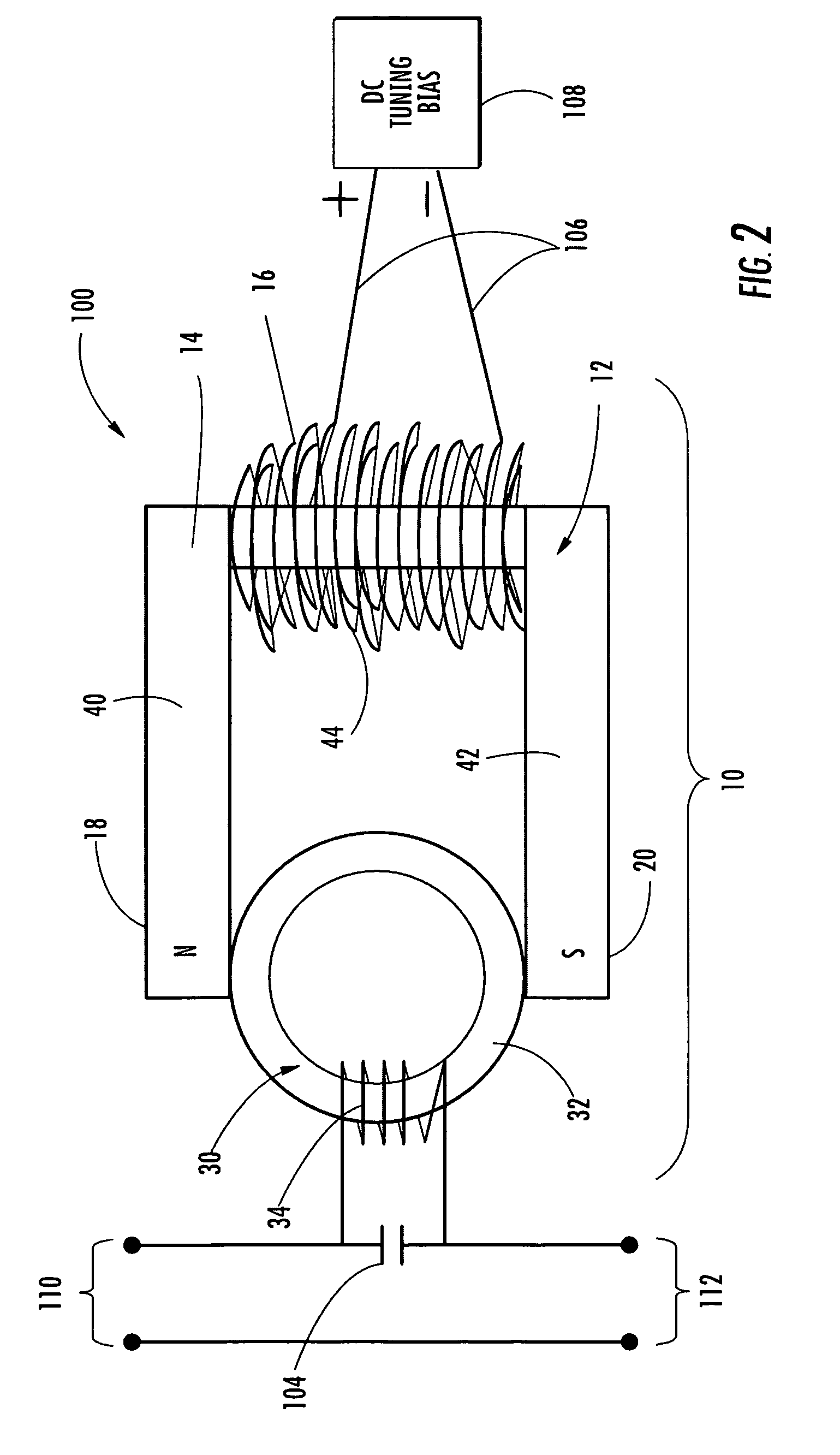

Electronically variable inductor, associated tunable filter and methods

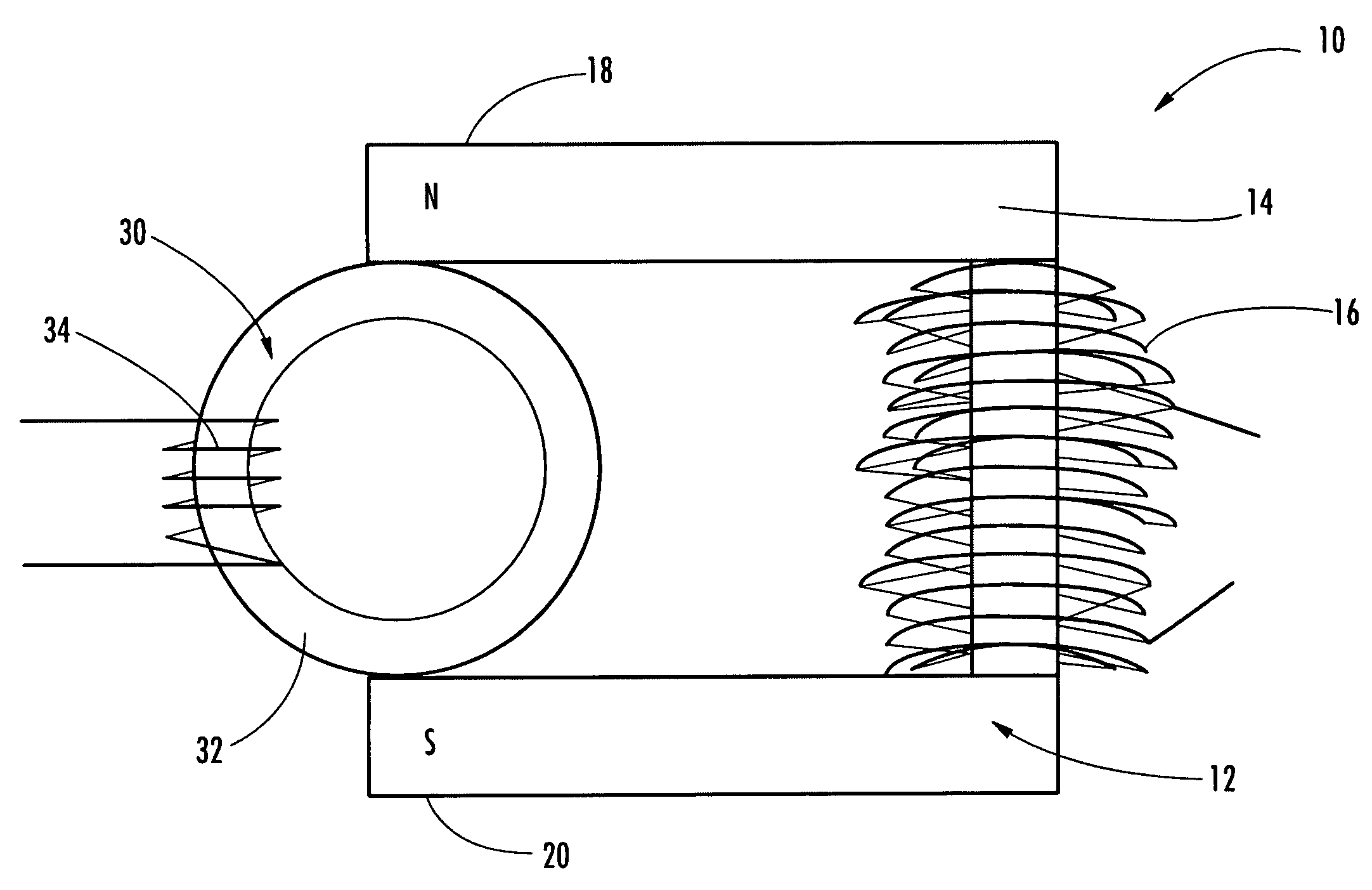

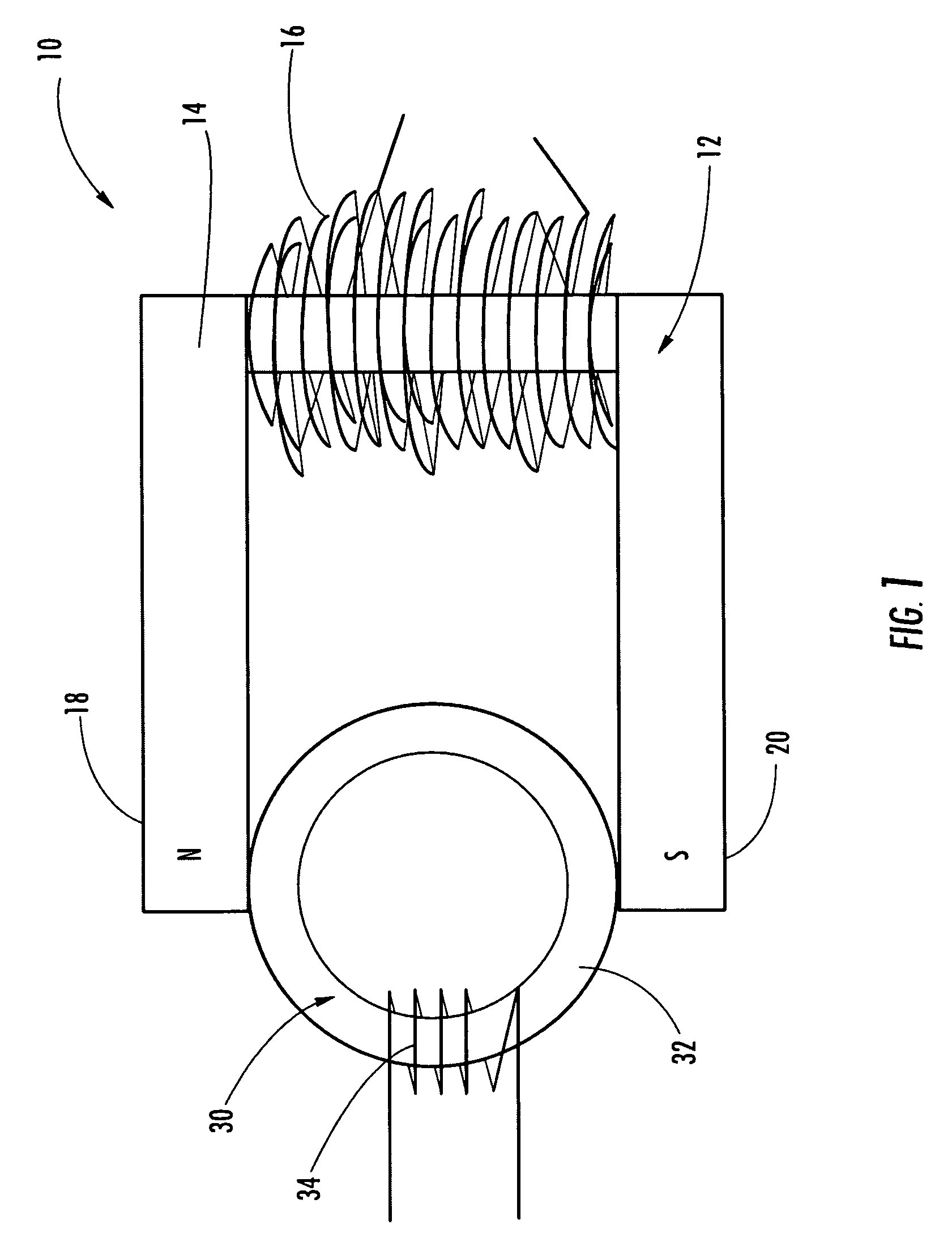

ActiveUS20090174501A1Good precisionIncrease speedMultiple-port networksTransmission control/equlisationMagnetic polesEngineering

The electrically tunable inductive device includes an electromagnet including an electromagnet core and a bias or tuning coil cooperating therewith to define opposing magnetic poles for generating a quiescent magnetic field that may be varied. An inductor is tunable based upon the variable magnetic field and includes an inductor core having a toroidal shape and fixed at a position adjacent the opposing magnetic poles of the electromagnet, and an inductor or signal coil is around at least a portion of the inductor core. The electromagnet core may include a pair of opposing legs and a bight portion therebetween defining a horseshoe shape. The inductor core may be positioned between ends of the opposing legs of the electromagnet core, and the tuning coil may surround the bight portion of the electromagnet core. The electrically tunable inductive device may have the combination of fine precision, high speed and high power handling, useful for tunable RF filters.

Owner:HARRIS CORP

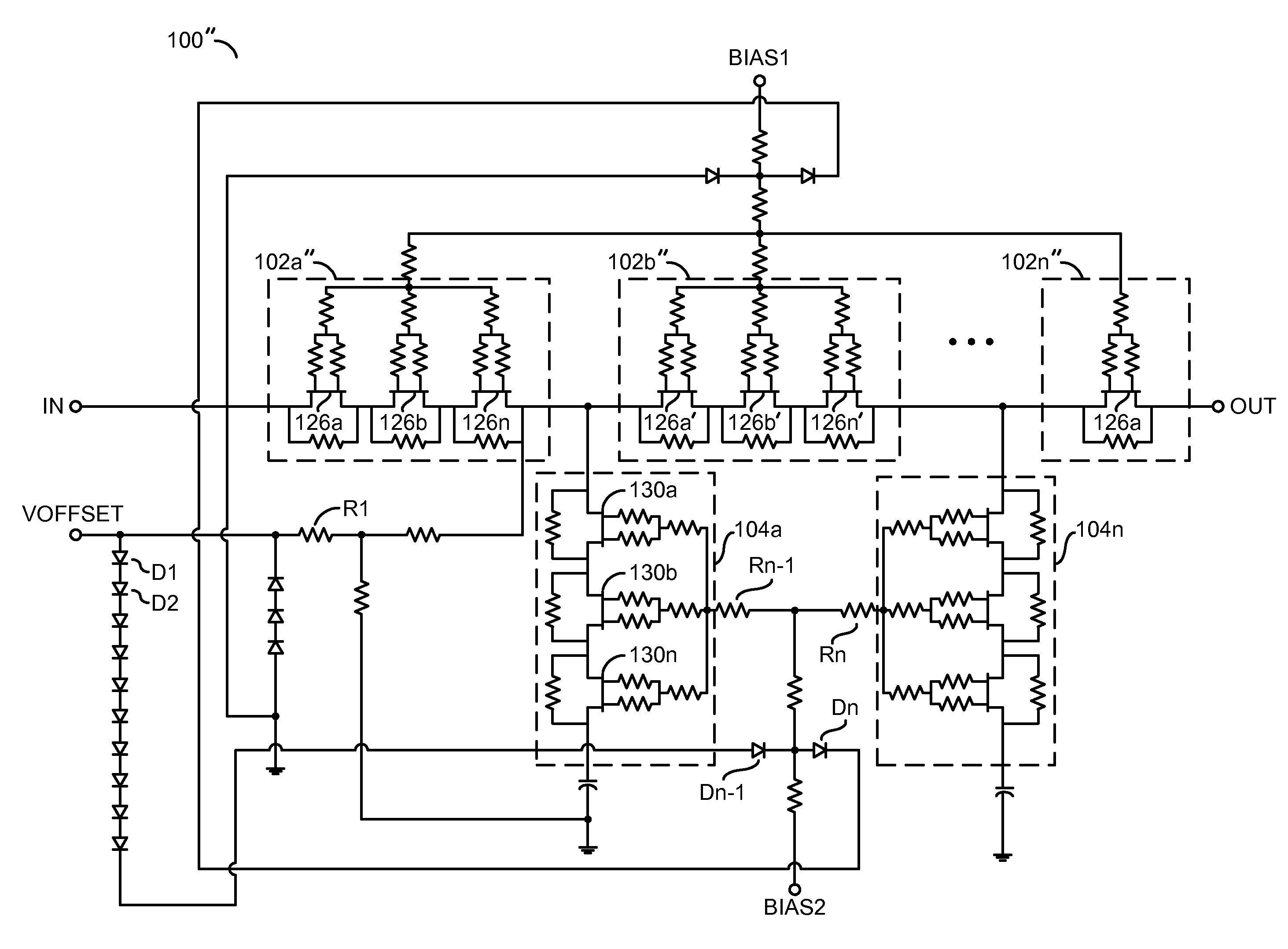

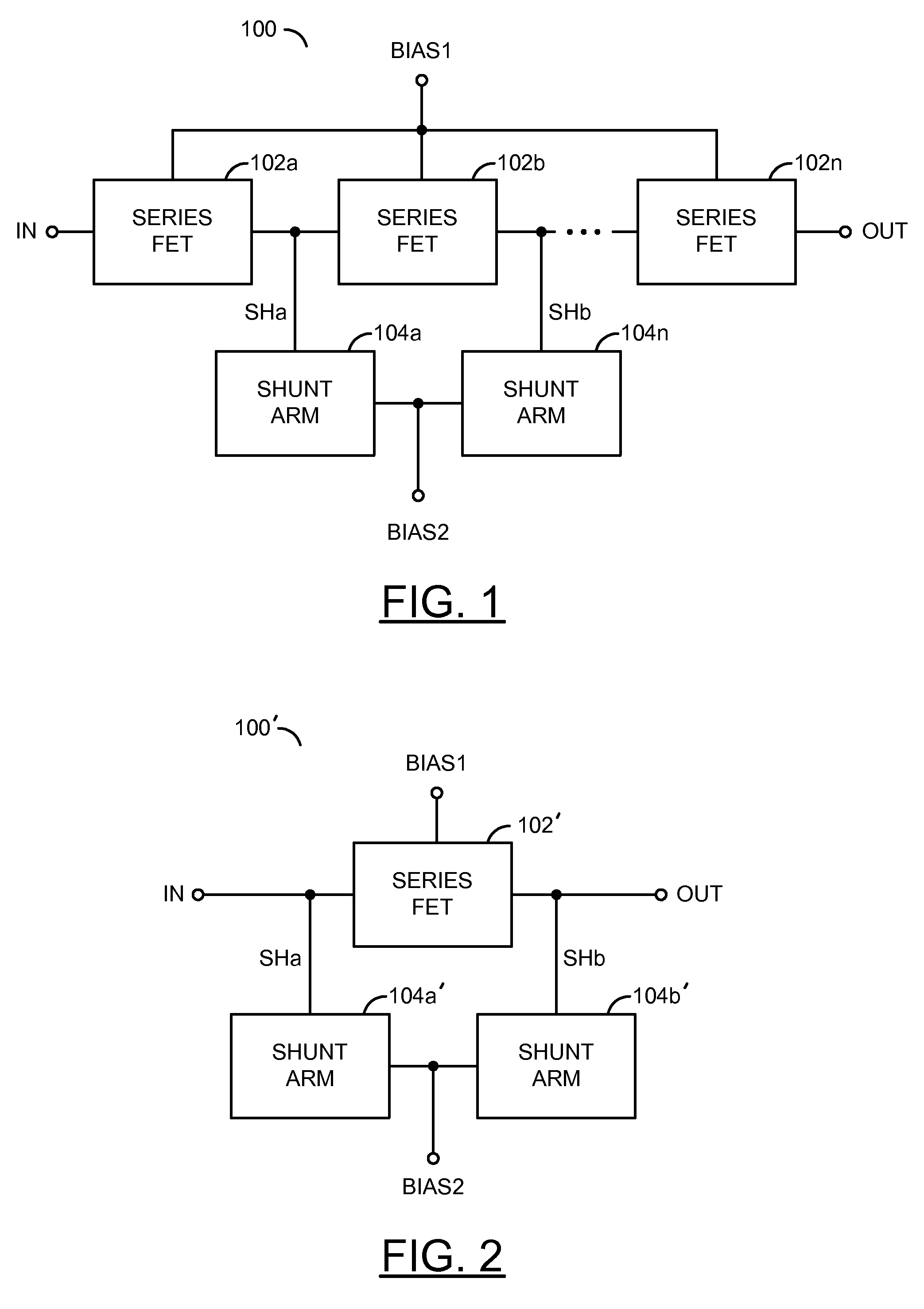

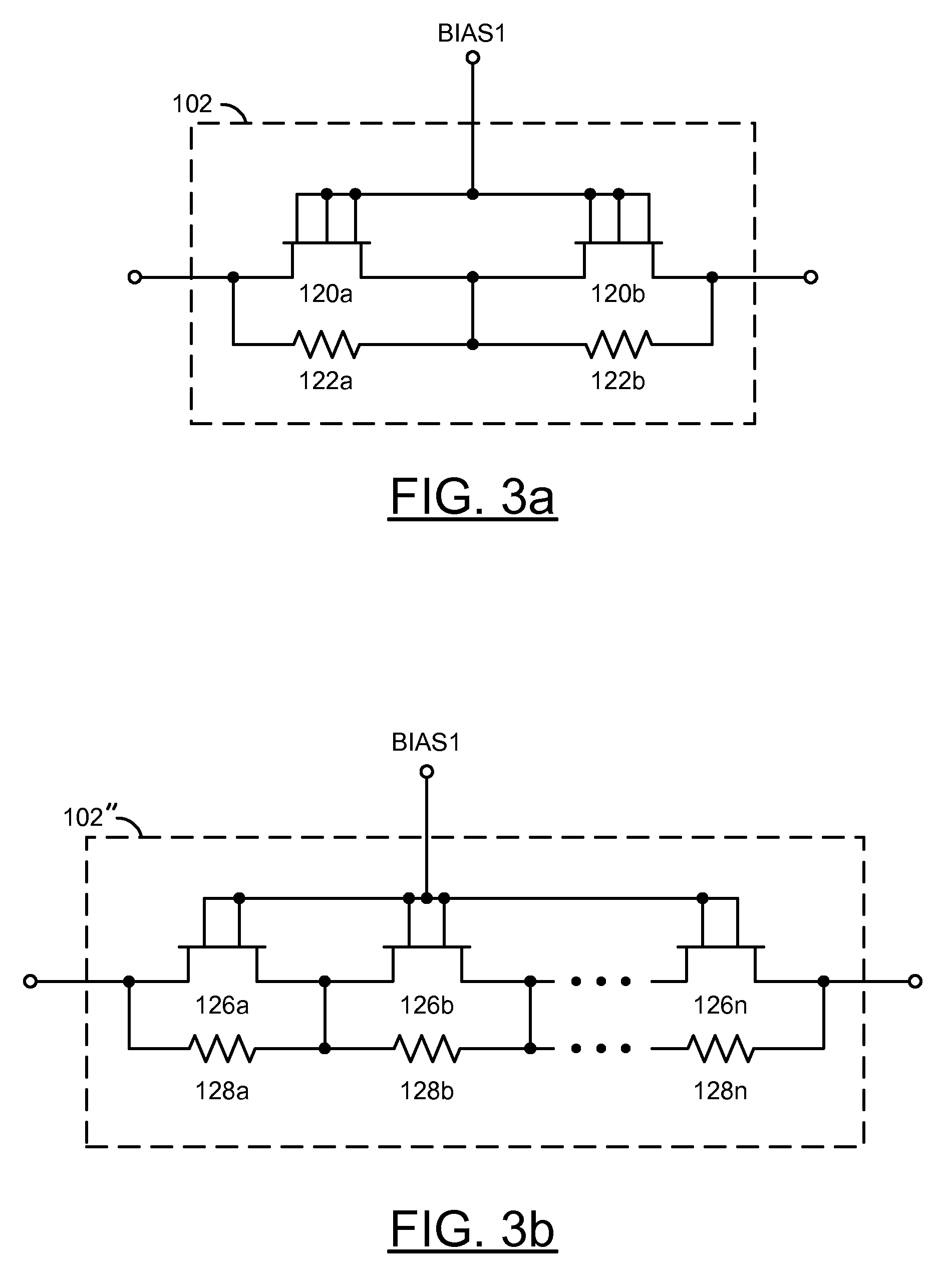

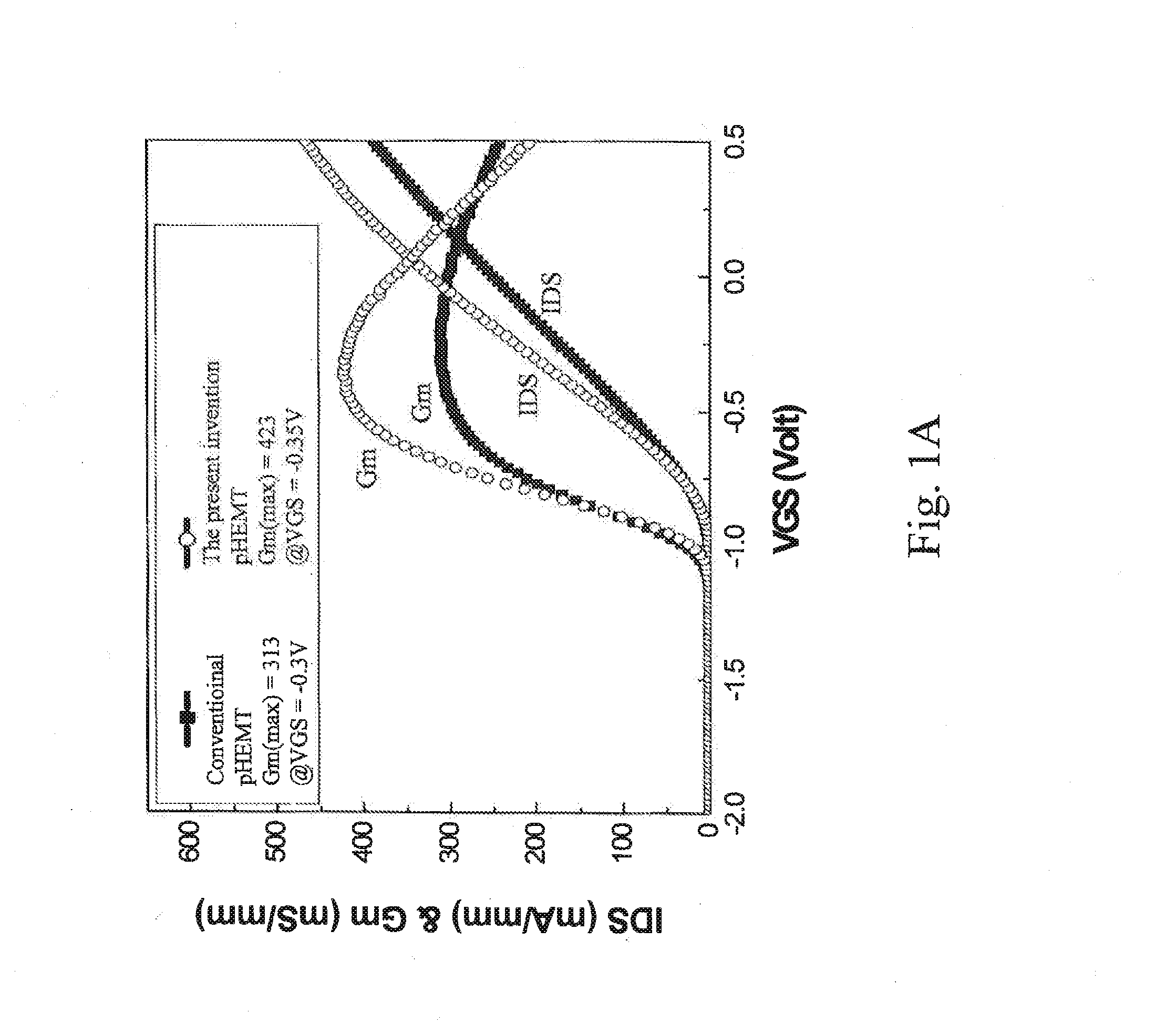

High linear voltage variable attenuator (VVA)

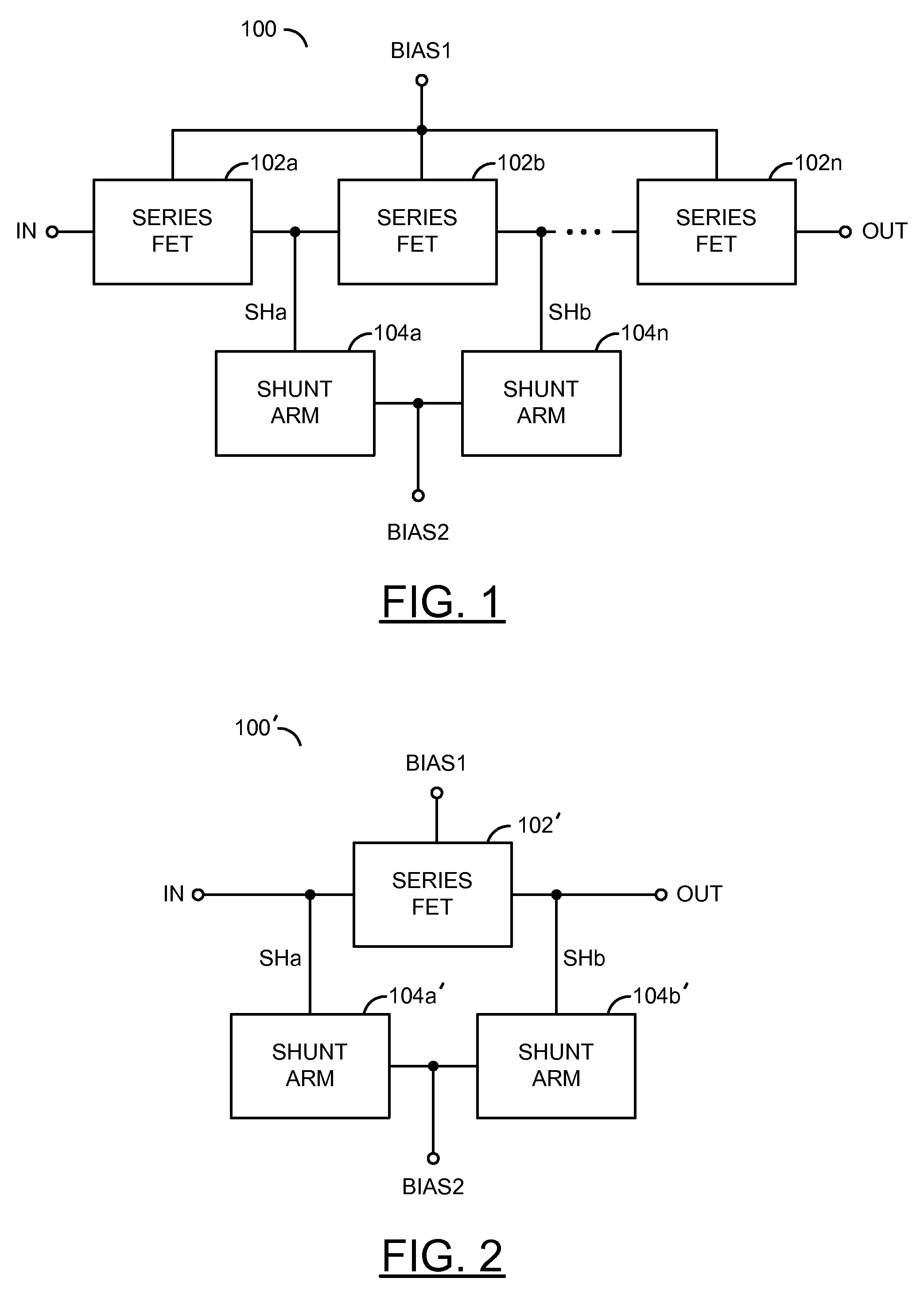

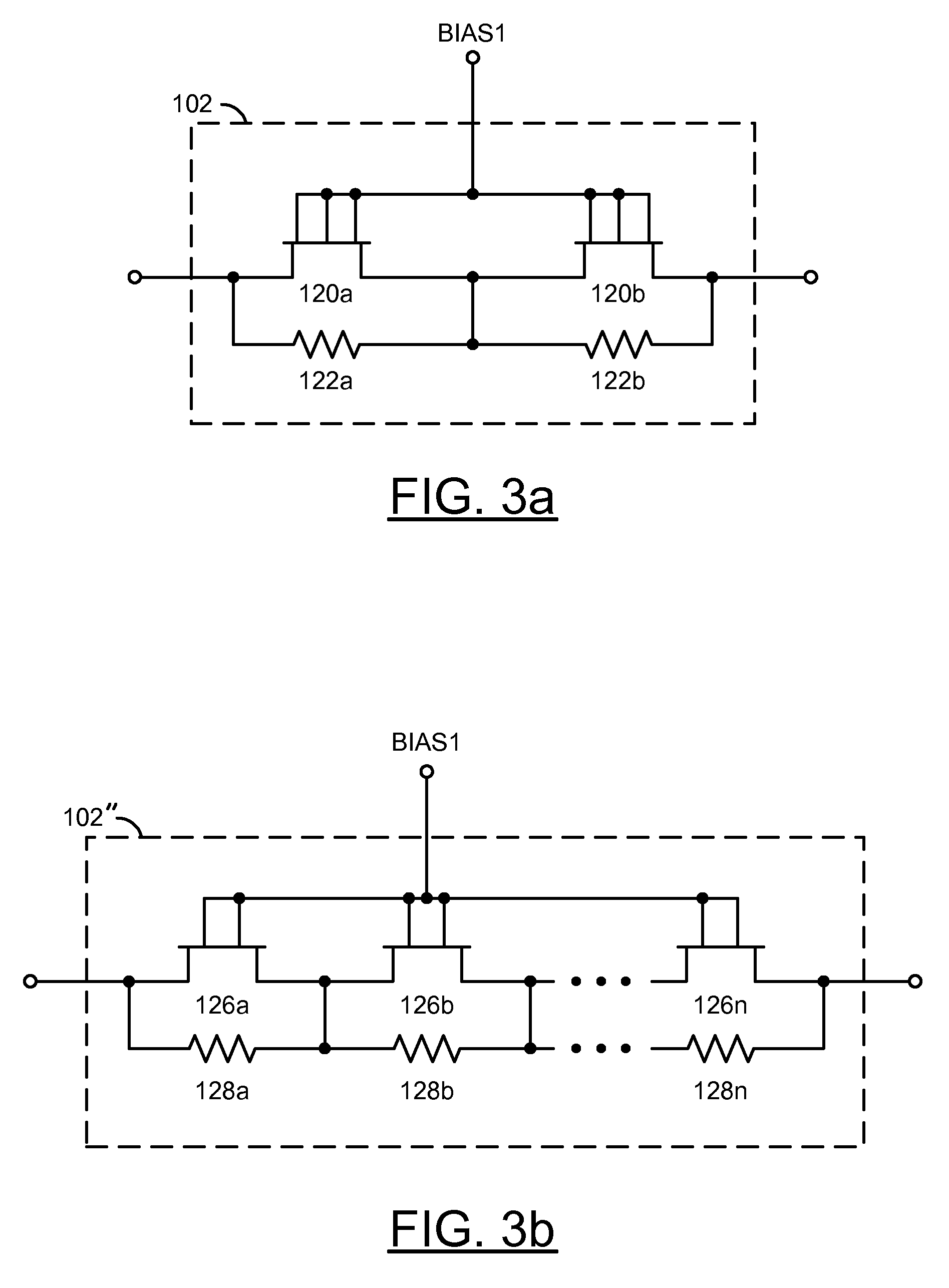

ActiveUS8614597B2High outputHigh power handlingMultiple-port networksPulse automatic controlHemt circuitsControl theory

Owner:MACOM TECH SOLUTIONS HLDG INC

Electronically variable inductor, associated tunable filter and methods

ActiveUS7889026B2Good precisionIncrease speedMultiple-port networksTransmission control/equlisationElectricityMagnetic poles

The electrically tunable inductive device includes an electromagnet including an electromagnet core and a bias or tuning coil cooperating therewith to define opposing magnetic poles for generating a quiescent magnetic field that may be varied. An inductor is tunable based upon the variable magnetic field and includes an inductor core having a toroidal shape and fixed at a position adjacent the opposing magnetic poles of the electromagnet, and an inductor or signal coil is around at least a portion of the inductor core. The electromagnet core may include a pair of opposing legs and a bight portion therebetween defining a horseshoe shape. The inductor core may be positioned between ends of the opposing legs of the electromagnet core, and the tuning coil may surround the bight portion of the electromagnet core. The electrically tunable inductive device may have the combination of fine precision, high speed and high power handling, useful for tunable RF filters.

Owner:HARRIS CORP

High linear voltage variable attenuator (VVA)

ActiveUS20120319755A1Highly linear outputReduce power consumptionPulse automatic controlActive element networkUltrasound attenuationEngineering

An apparatus comprising one or more series transistor network elements and a plurality of shunt circuits. The series transistor network may be configured to generate an output signal in response to (i) an input signal, (ii) a first bias signal, and (iii) a plurality of variable impedances. The plurality of shunt circuits may each be configured to generate a respective one of the variable impedances in response to a second bias signal. The output signal may have an attenuation that is equal to or less than the input power. The amount of the attenuation may be controlled by the first bias signal and the second bias signal. The series transistor elements and the plurality of shunt circuits may be configured as two or more transistors each having two or more gates.

Owner:MACOM TECH SOLUTIONS HLDG INC

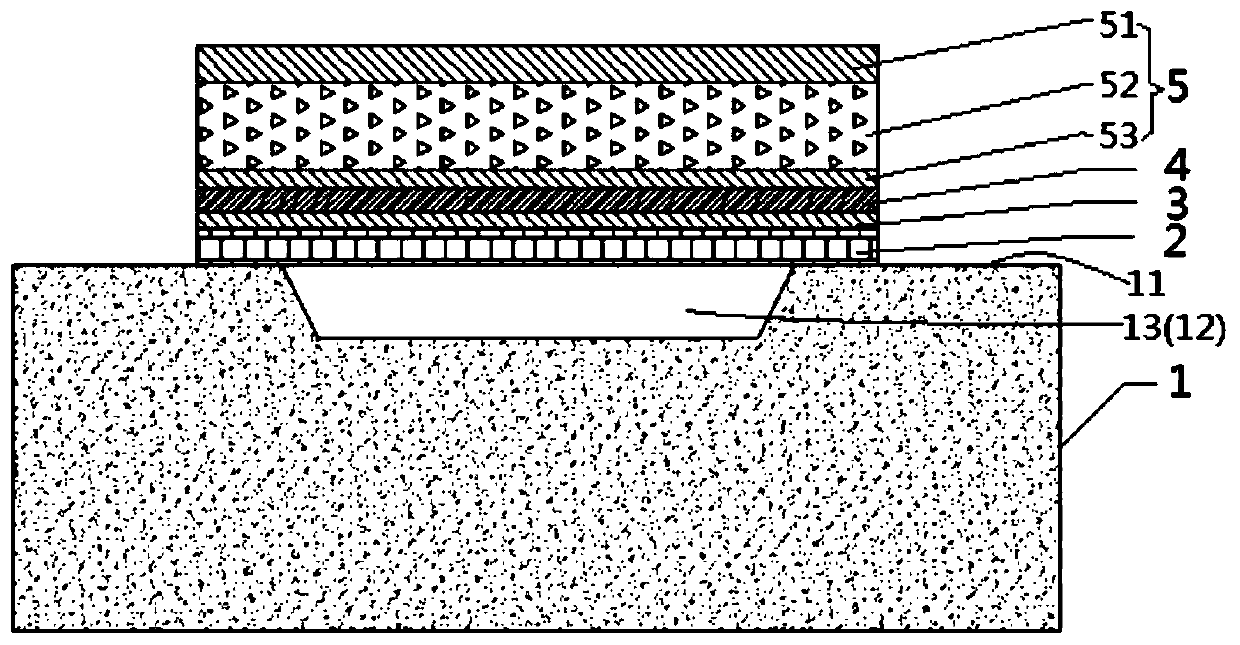

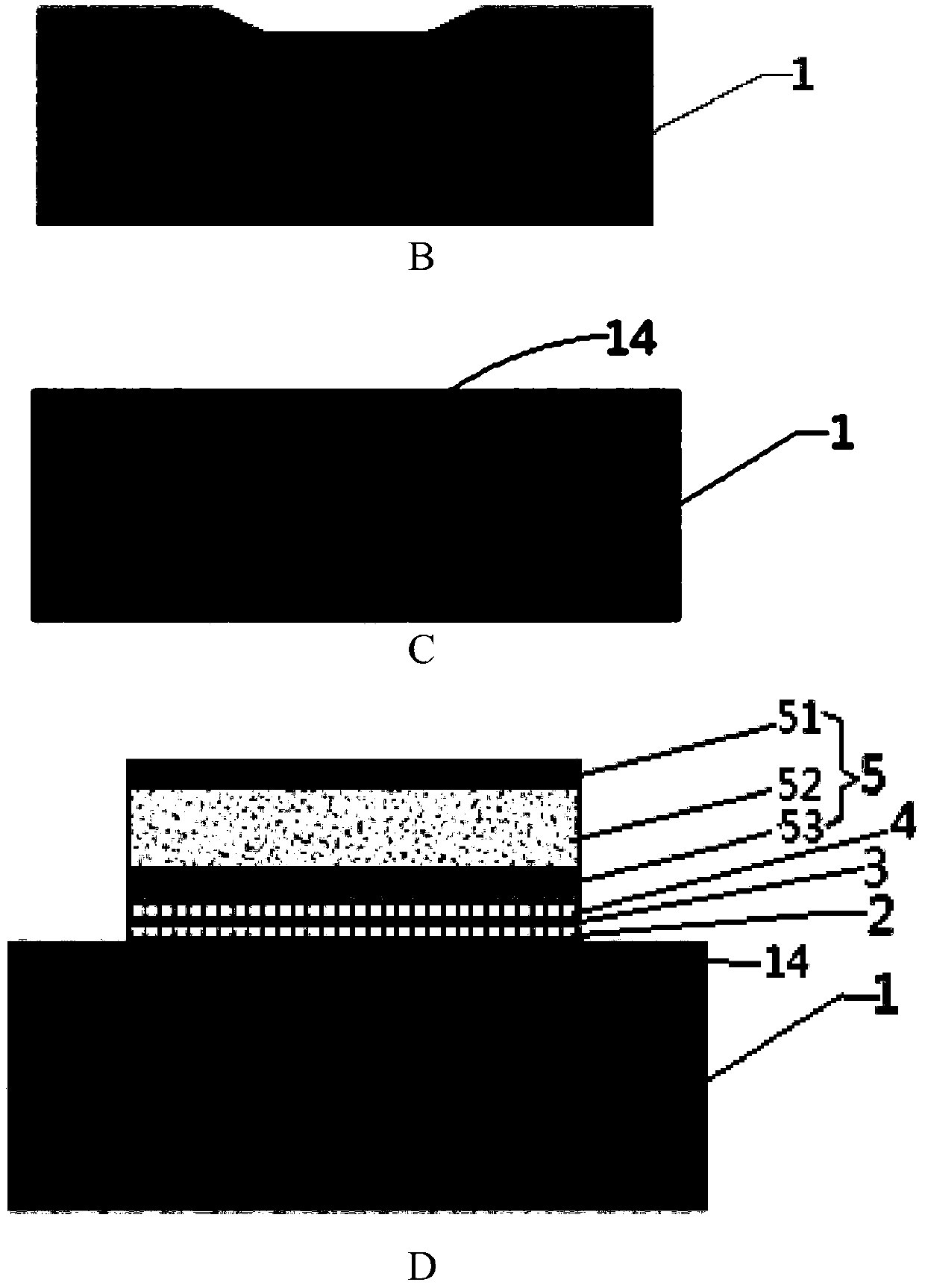

Film bulk acoustic wave resonator and a film bulk acoustic wave filter

PendingCN109756201AWen PiaoxiaoReduce lossImpedence networksThin-film bulk acoustic resonatorElectromechanical coupling coefficient

The invention discloses a film bulk acoustic wave resonator and a film bulk acoustic wave filter. The thin film bulk acoustic wave resonator comprises a silicon substrate, a support layer and a firstbottom electrode layer, a temperature drift layer and a sandwich piezoelectric stack structure, the supporting layer is combined on the surface, provided with the groove, of the substrate in a laminated manner; a closed cavity is defined by the supporting layer and the groove; wherein the first bottom electrode layer is laminated and combined on the surface, deviating from the substrate, of the supporting layer, the temperature drift layer is laminated and combined on the surface, deviating from the supporting layer, of the first bottom electrode, and the sandwich piezoelectric stack structureis laminated on the surface, deviating from the first bottom electrode layer, of the temperature drift layer. The film bulk acoustic wave filter comprises the film bulk acoustic wave resonator. The film bulk acoustic wave filter and the resonator are low in consumption, small in temperature coefficient, low in temperature drift, high in power bearing capacity, high in working frequency, high in electromechanical coupling coefficient, good in compatibility and good in Q value.

Owner:ZHEJIANG HUAYUAN MICRO ELECTRONICS TECH CO LTD +1

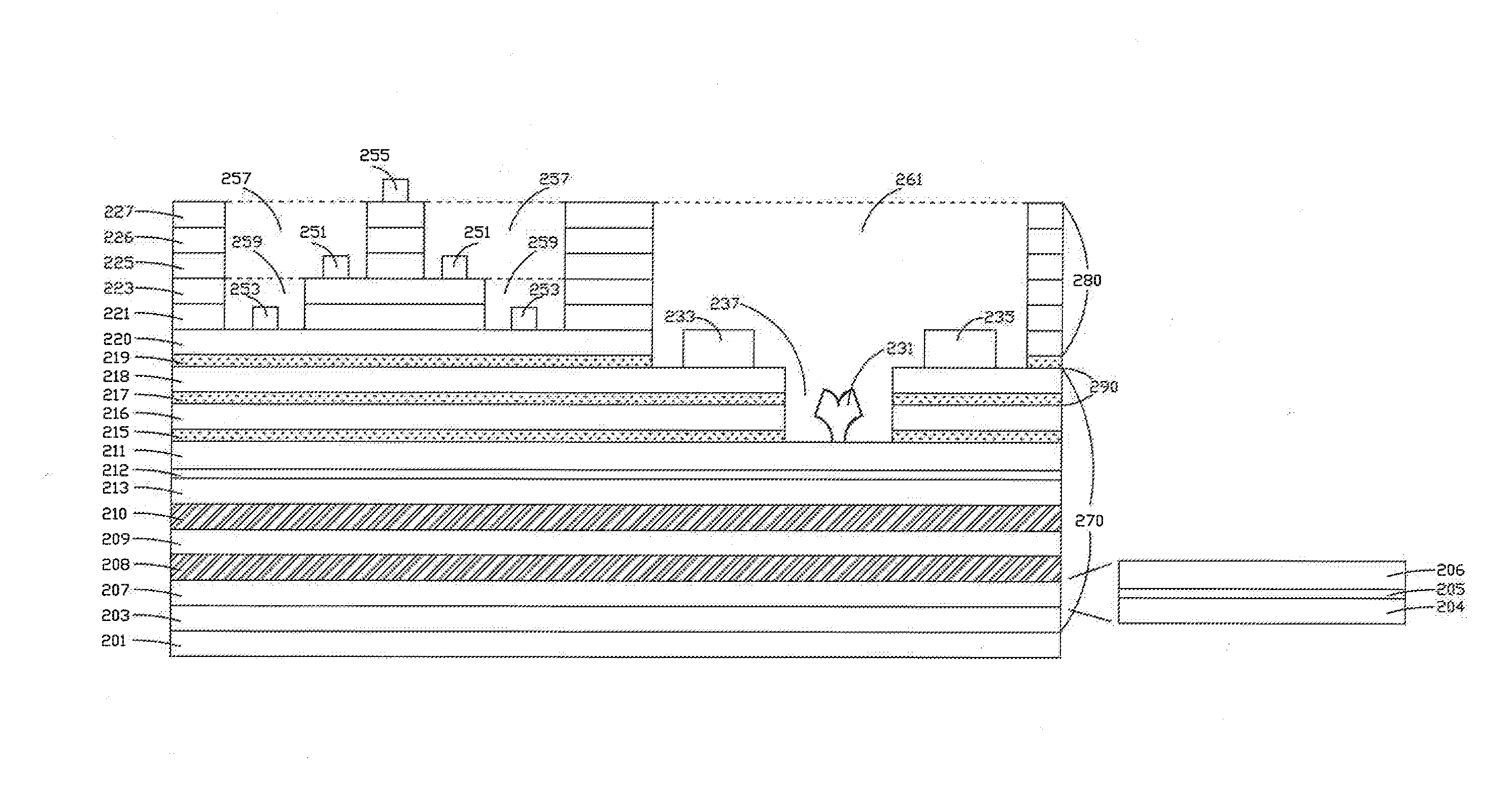

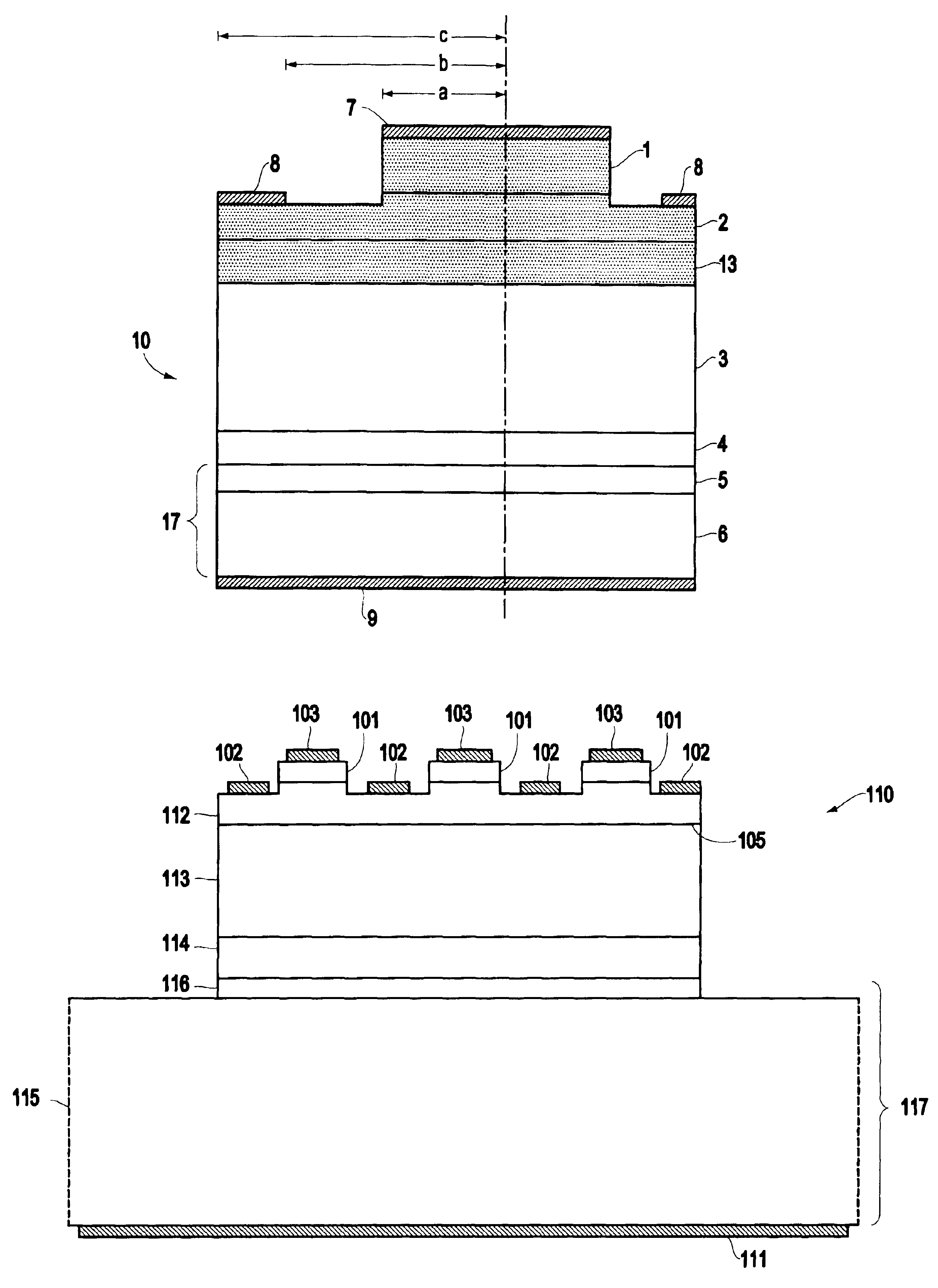

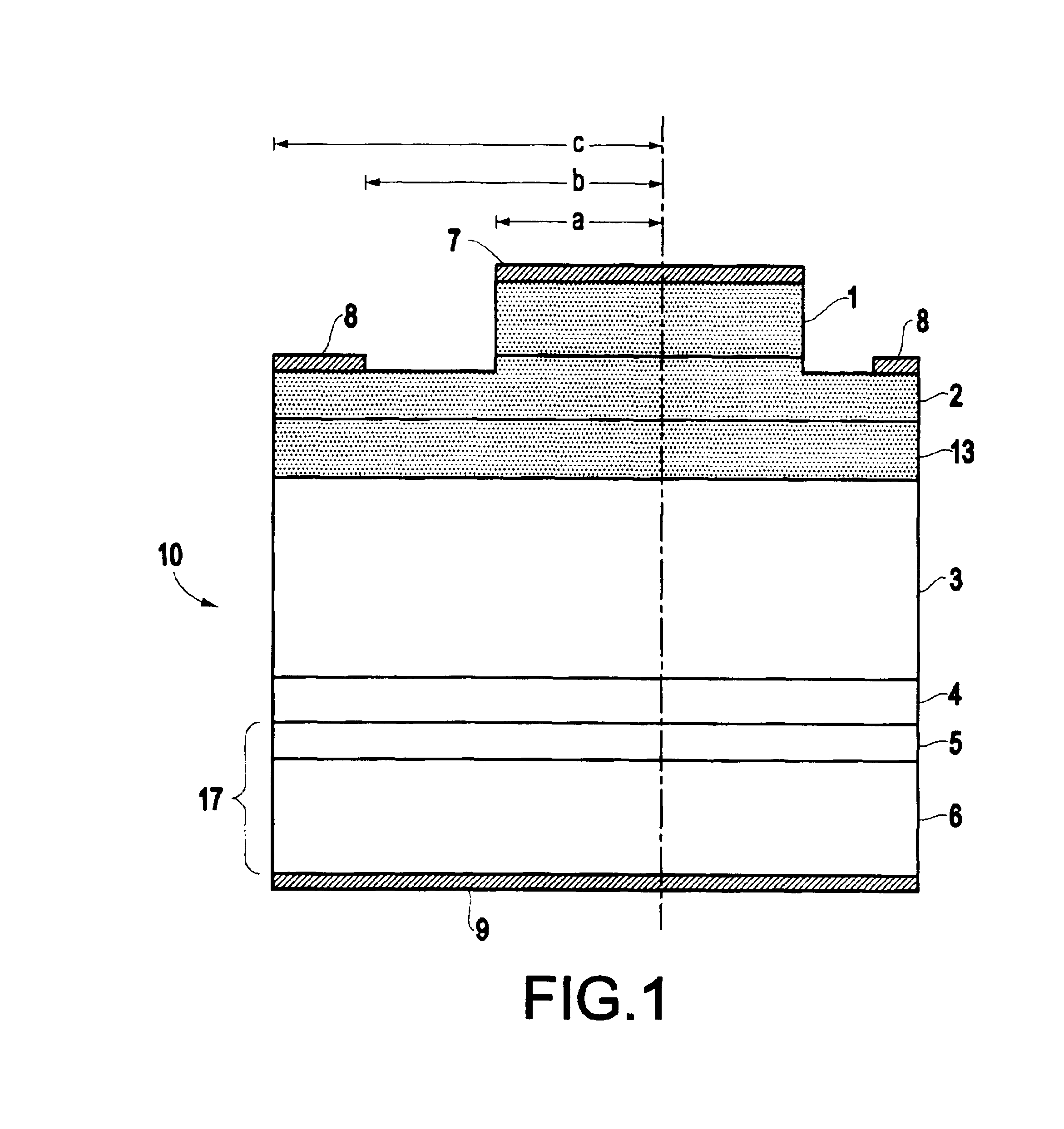

pHEMT and HBT integrated epitaxial structure

InactiveUS20140231876A1High electron mobilityReduce current densityTransistorSolid-state devicesSchottky barrierElectron mobility

An improved pseudomorphic high electron mobility transistor (pHEMT) and heterojunction bipolar transistor (HBT) integrated epitaxial structure, in which the structure comprises a substrate, a pHEMT structure, an etching-stop spacer layer, and an HBT structure. The pHEMT structure comprises a buffer layer, a bottom barrier layer, a first channel spacer layer, a channel layer, a second channel spacer layer, a Schottky spacer layer, a Schottky donor layer, a Schottky barrier layer, an etching-stop layer, and at least one cap layer. By introducing the first channel spacer layer and the second channel spacer layer to reduce the density of the dislocations and to reduce the compressive strain in the pseudomorphic channel layer.

Owner:WIN SEMICON

Processing technique to improve the turn-off gain of a silicon carbide gate turn-off thyristor and an article of manufacture

A structure and method for a silicon carbide (SiC) gate turn-off (GTO) thyristor device operable to provide an increased turn-off gain comprises a cathode region, a drift region having an upper portion and a lower portion, wherein the drift region overlies the cathode region, a gate region overlying the drift region, an anode region overlying the gate, and at least one ohmic contact positioned on each of the gate region, anode region, and cathode region, wherein the upper portion of the drift region, the gate region, and the anode region have a free carrier lifetime and mobility lower than a comparable SiC GTO thyristor for providing the device with an increased turn-off gain, wherein the free carrier lifetime is approximately 10 nanoseconds. The reduced free carrier lifetime and mobility are affected by altering the growth conditions, such as temperature under which epitaxy occurs.

Owner:ARMY US SEC THE

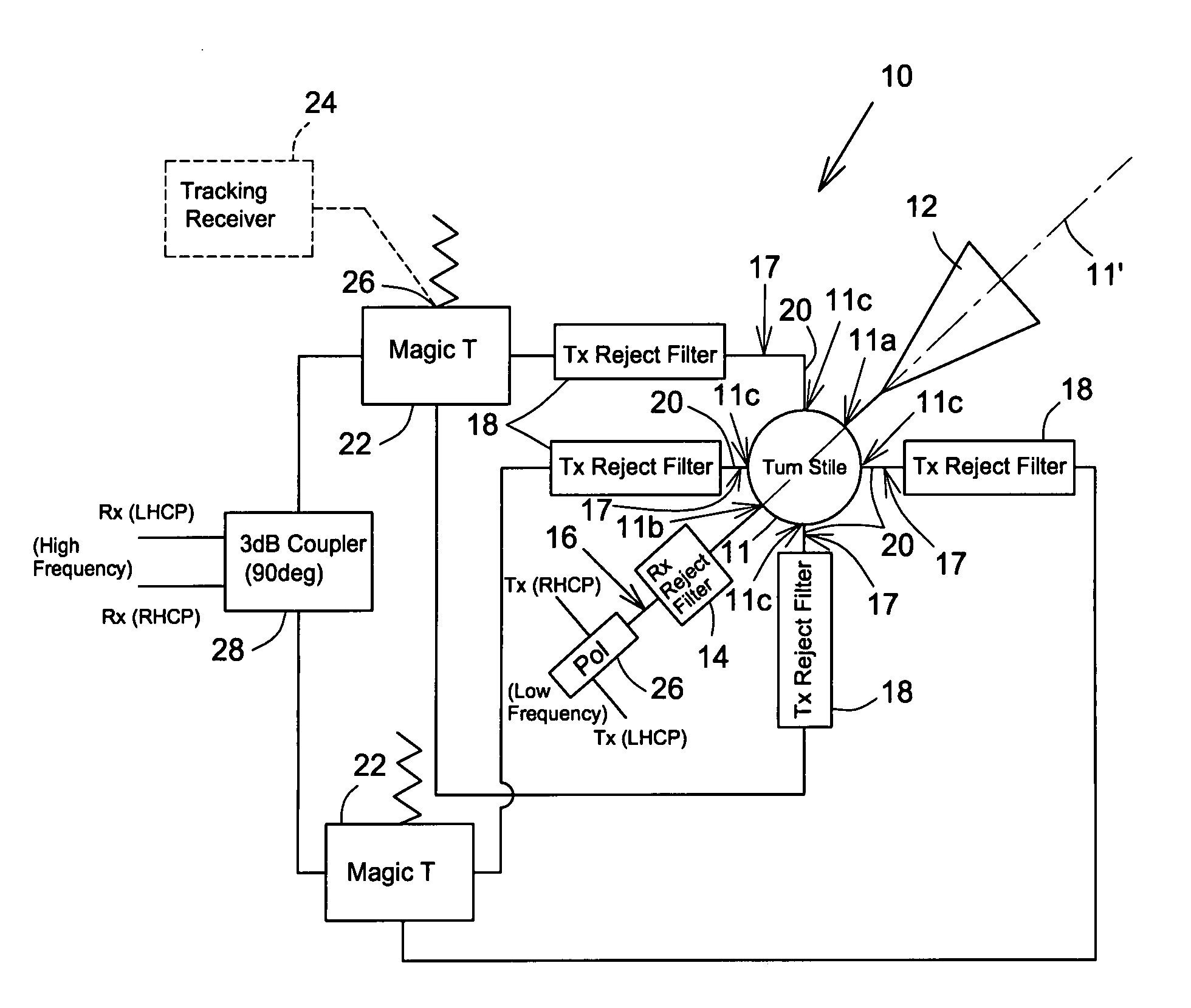

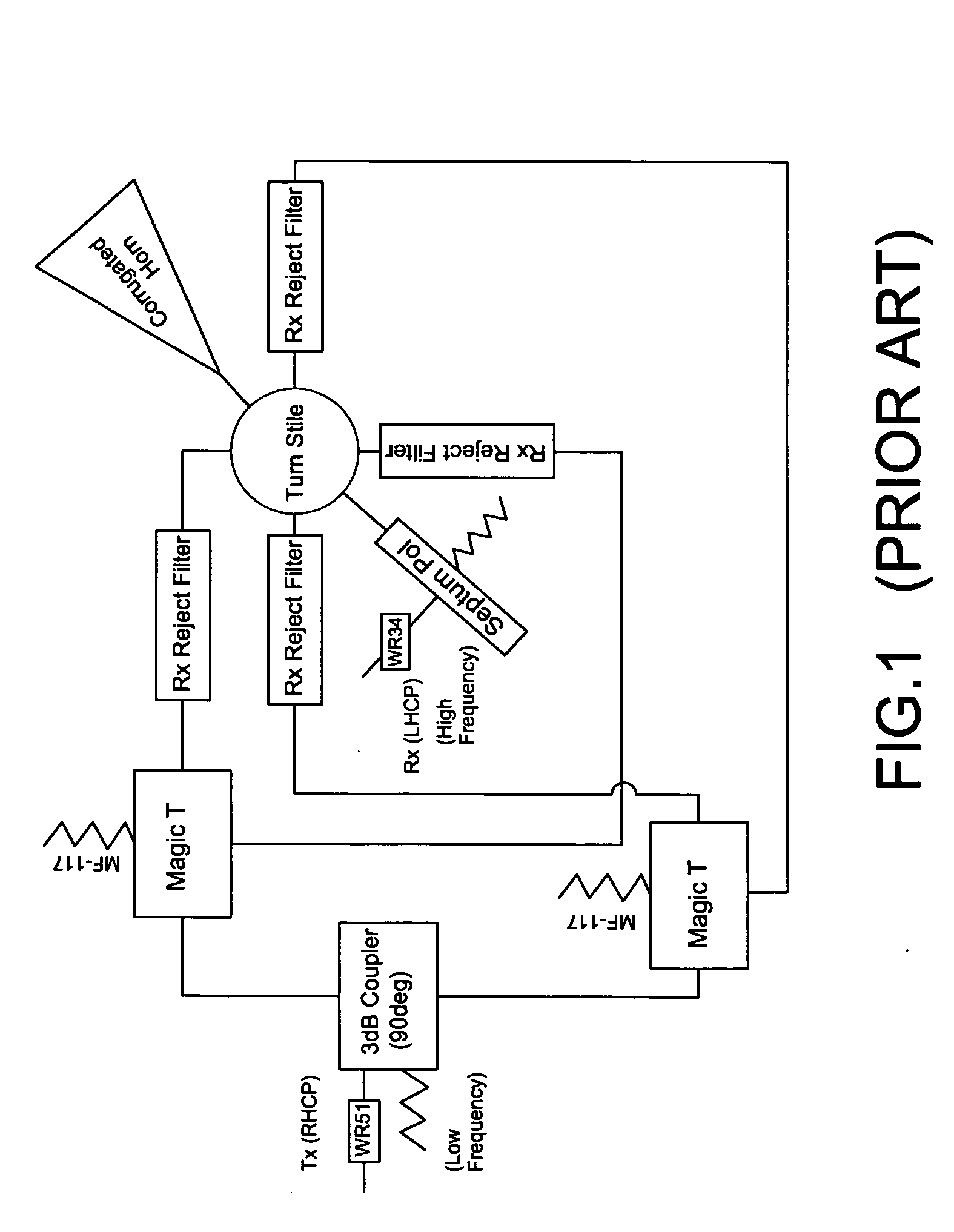

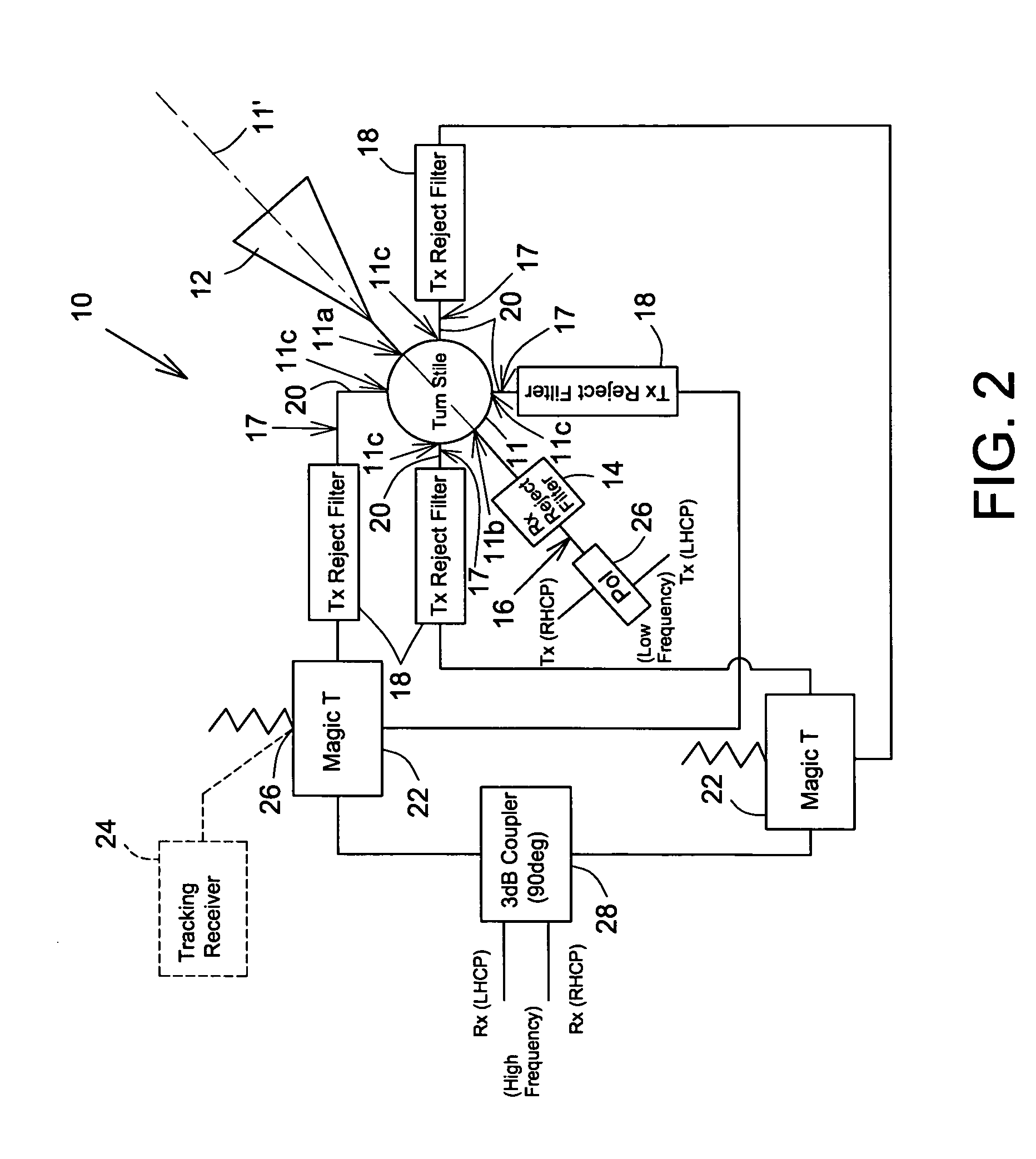

Orthomode junction assembly with associated filters for use in an antenna feed system

InactiveUS20100007432A1Lower insertion lossHigh power handlingMultiple-port networksWaveguide type devicesMagic teeEngineering

A reverse orthomode junction assembly with associated filters for use in an antenna feed system for transmitting a first electromagnetic signal at a first frequency range lower than the second frequency range of a receive second electromagnetic signal. The assembly includes an orthomode junction with an antenna port for connecting to an antenna, an opposed generally coaxial first signal port to transmit the first signal, and a generally perpendicular second signal port, located there between, to receive the second signal. A first signal channel having on-axis second signal reject filters connects to the first port; and a second signal channel having cross-axis first signal reject filters connects to the second port. The use of a magic-tee as a combiner for the receive signal provides tracking capability to the antenna feed system.

Owner:MACDONALD DETTWILER & ASSOC CORP

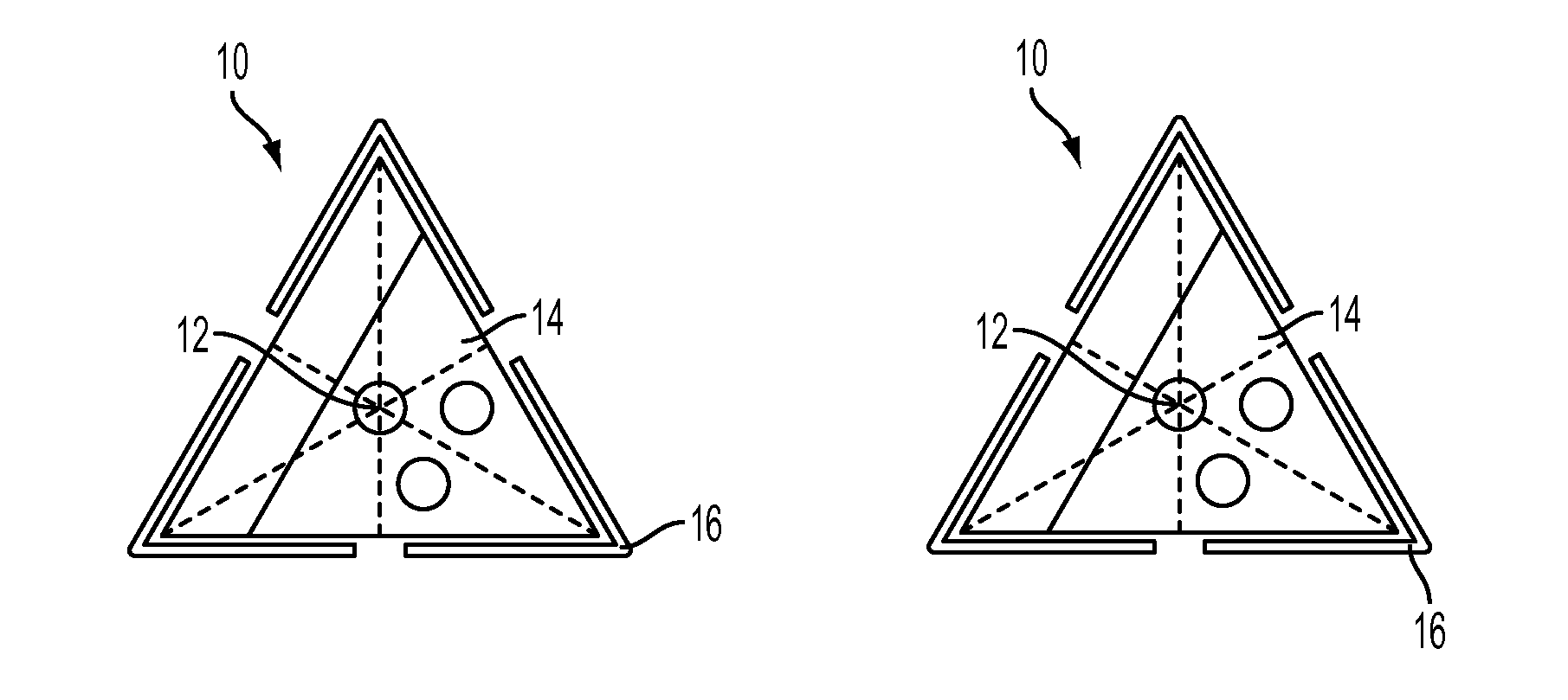

Compact OMT device

ActiveUS9147921B2High power handlingCost efficient to manufactureCoupling devicesAntennasDifferential phaseClassical mechanics

Embodiments are disclosed of an orthomode transducer (OMT) device for splitting a linear orthogonally polarized electromagnetic signal into a plurality of linearly polarized frequency components and vice versa. The device comprises a rectangular or circular guide section having a constant cross-section perpendicular to a lengthwise direction of said guide section and first and second lengthwise opposed open ends, a septum that is successively increased in height; extending from an end of the a waveguide portion towards a second lengthwise open end of the guide section, wherein that the plane of said septum is provided at an angle of 45 degrees relative to the polarization axes of the orthogonal linear polarization modes and said septum induces a differential phase shift of substantially 180 degrees or a multiple thereof between components of the linear polarization modes that are perpendicular to said septum and components that are parallel to said septum.

Owner:EUROPEAN SPACE AGENCY

Loudspeaker array system

InactiveUS8160268B2High-quality soundEasy to controlLoudspeaker signals distributionFrequency/directions obtaining arrangementsPublic address systemDigital signal processing

The invention is a multi-channel loudspeaker system that provides a compact loudspeaker configuration and filter design methodology that operates in the digital signal processing domain. Further, the loudspeaker system can be designed as a multi-way loudspeaker system comprised of a symmetric arrangement of loudspeaker drivers in a two-dimensional plane and can achieve high-quality sound, constant directivity over a large area in both the vertical and horizontal planes and can be used in connection with stereo loudspeaker systems, multi-channel home entertainment systems and public address systems.

Owner:APPLE INC

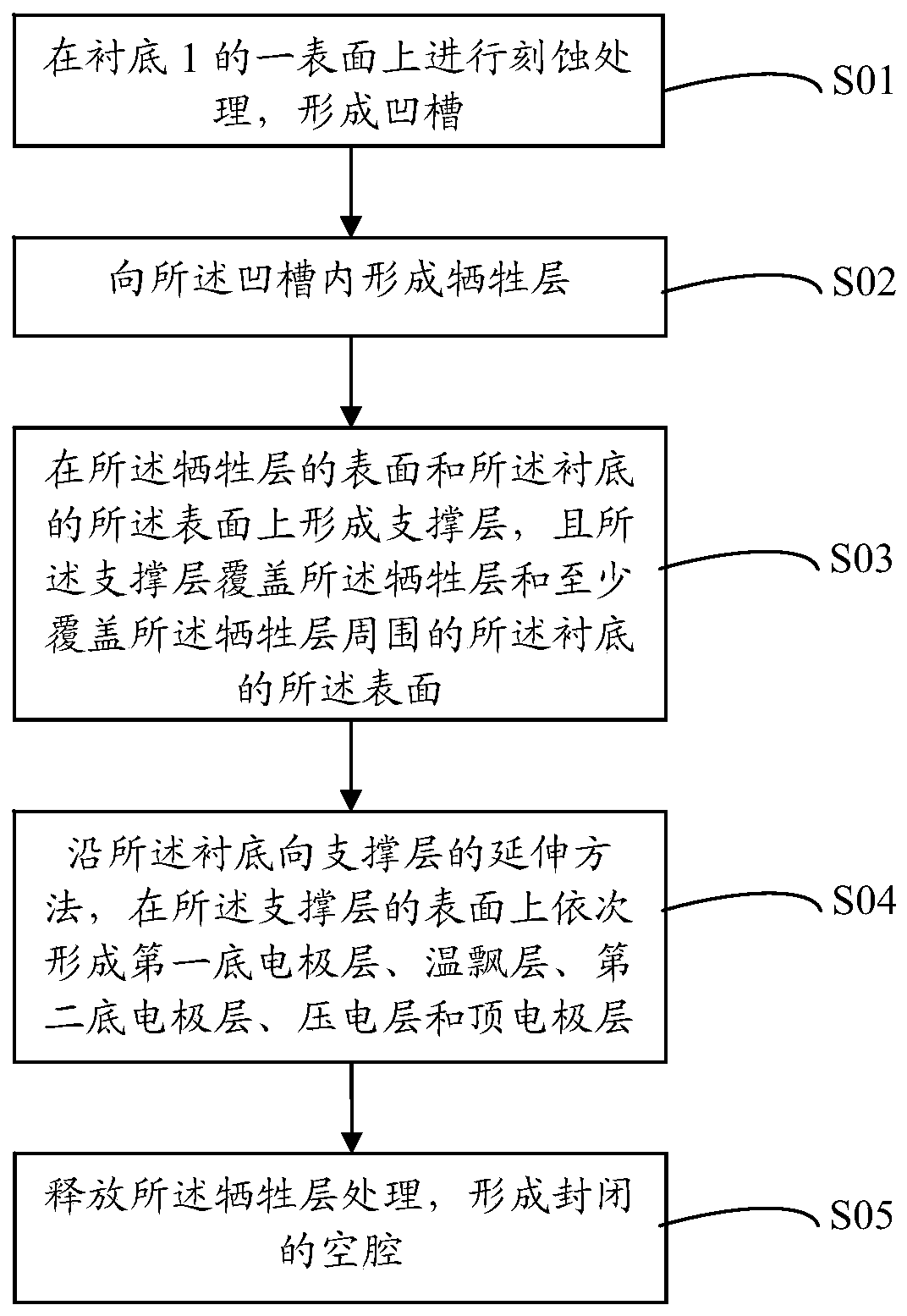

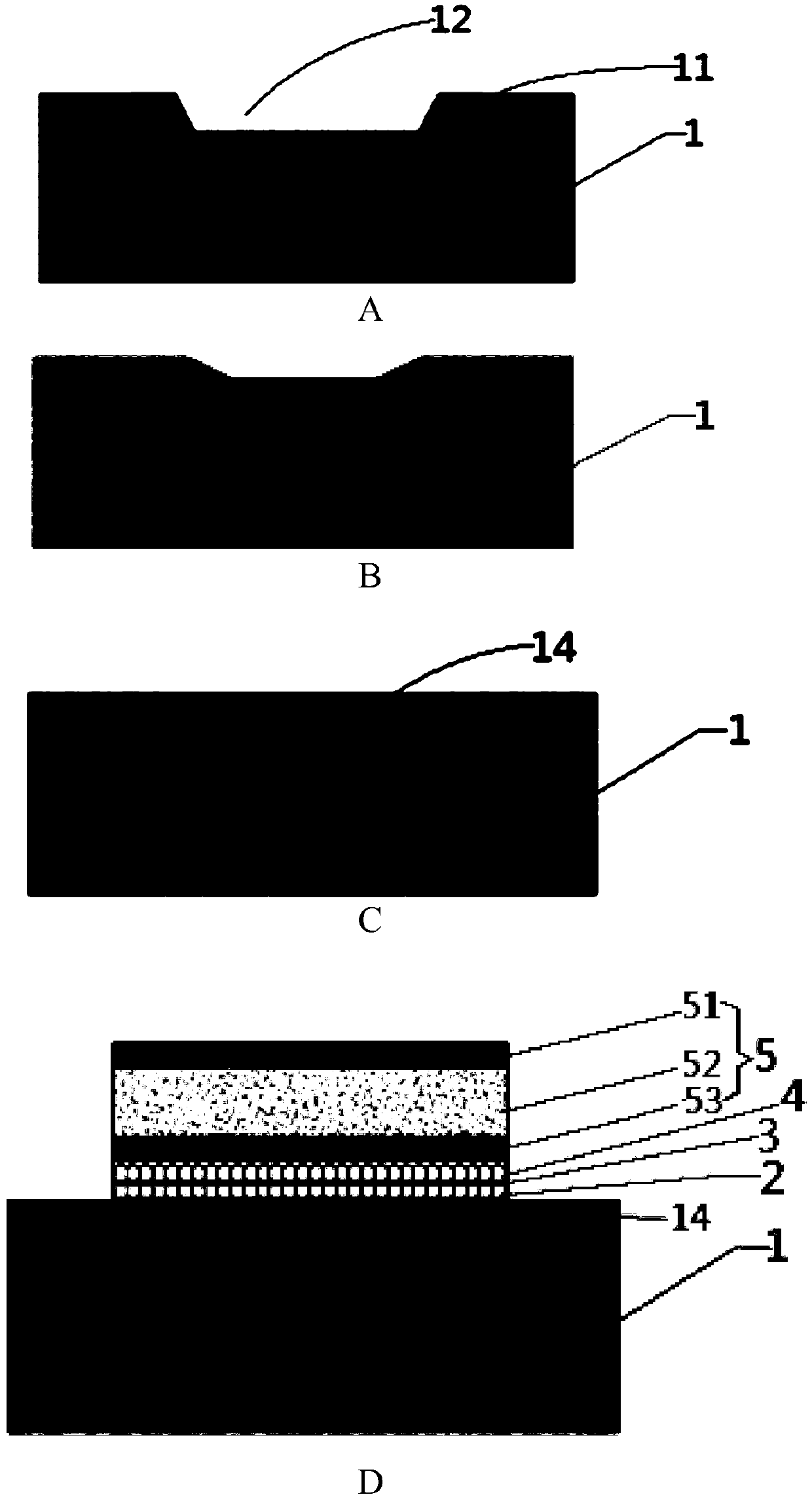

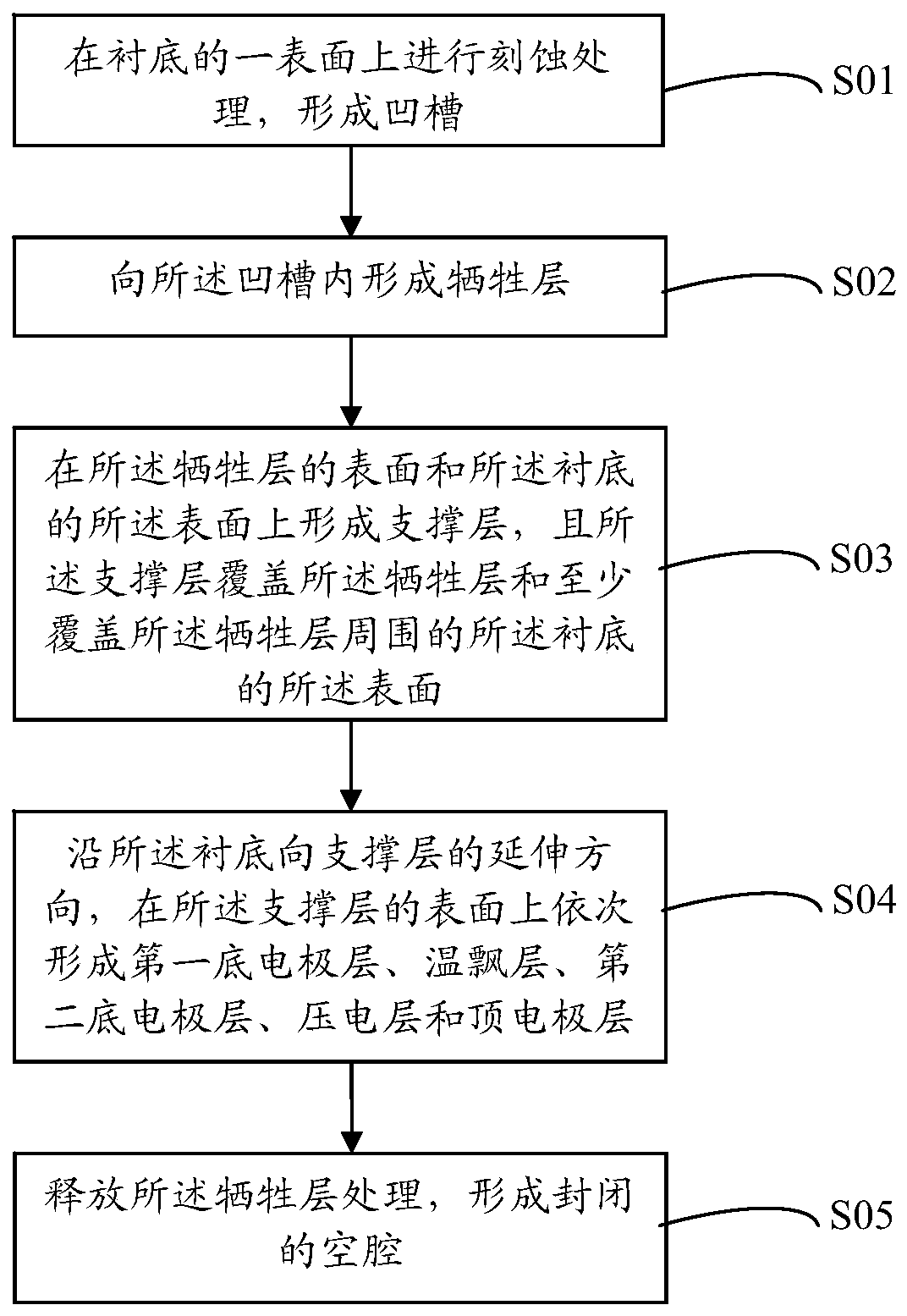

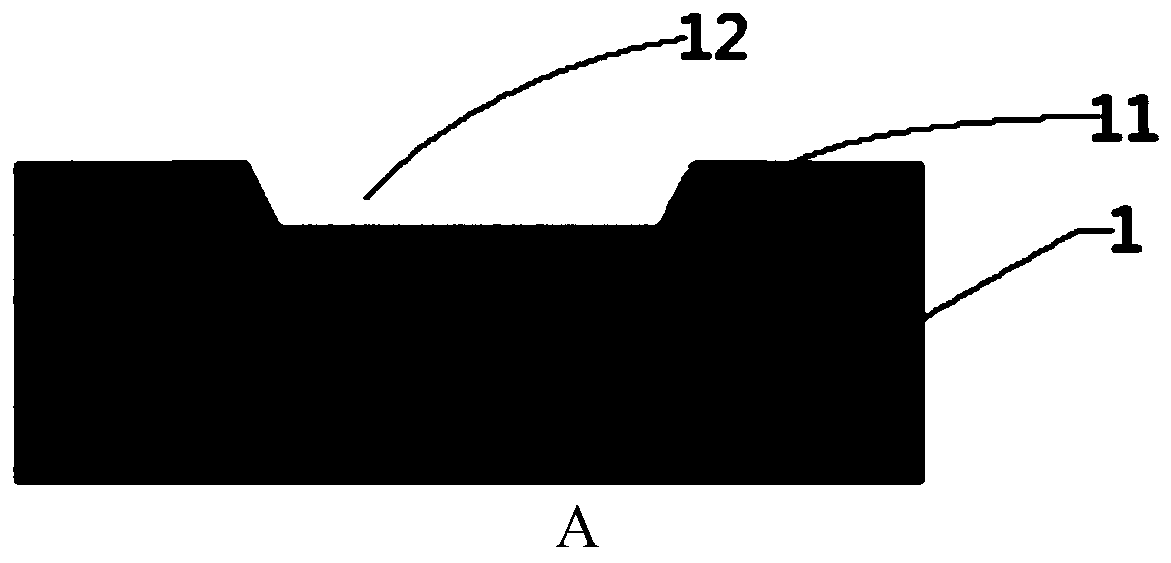

Preparation method of film bulk acoustic resonator and filter

ActiveCN109951171AWen PiaoxiaoReduce lossImpedence networksHigh level techniquesThin-film bulk acoustic resonatorElectromechanical coupling coefficient

The invention discloses a preparation method of a film bulk acoustic resonator and a filter. The preparation method of the film bulk acoustic resonator comprises the following steps: etching one surface of a substrate to form a groove; forming a sacrificial layer in the groove, and forming a supporting layer on the surface of the sacrificial layer and the surface of the substrate; a first bottom electrode layer, a temperature drift layer, a second bottom electrode layer, a piezoelectric layer and a top electrode layer are sequentially formed on the surface of the supporting layer in the extending direction from the substrate to the supporting layer; and releasing the sacrificial layer for processing to form a closed cavity. The preparation method of the filter comprises the step of preparing the film bulk acoustic resonator according to the preparation method of the film bulk acoustic resonator. According to the preparation method of the film bulk acoustic wave resonator, the preparedfilm bulk acoustic wave resonator is low in loss and temperature drift, small in temperature coefficient, high in power bearing capacity, working frequency and electromechanical coupling coefficient and good in compatibility and has a very good Q value.

Owner:ZHEJIANG HUAYUAN MICRO ELECTRONICS TECH CO LTD +1

Torsion spring for electro-mechanical switches and a cantilever-type RF micro-electromechanical switch incorporating the torsion spring

InactiveUS6847277B2Increased durabilityHandle more powerCircuit-breaking switches for excess currentsContact surface shape/structureConformal connectionEngineering

A torsion spring for an electro-mechanical switch is presented. The torsion spring comprises a set of tines including at least one tine extending from the free end of the armature of a switch. A terminus portion is rotatably suspended between the tines, and includes a conducting transmission line, at least a portion of which is exposed for electrical contact. The conducting transmission line has a length selected such that the exposed portion of the transmission line forms a circuit between the input and output of the micro-electro-mechanical switch when the micro-electro-mechanical switch is urged into a closed position, with the terminus portion rotating via the tines to form a conformal connection between the exposed portion of the conducting transmission line and the input and output of the switch, thus optimizing the electrical flow therebetween. The switch is also applied to MEMS devices.

Owner:HRL LAB

Rare-earth doped nickel, cobalt and manganese ternary material wide temperature lithium ion battery and production method thereof

InactiveCN106784787AHigh reversible capacityPromote circulationCell electrodesSecondary cellsNickel saltManganese

The invention provides a rare-earth doped nickel, cobalt and manganese ternary material wide temperature lithium ion battery and a production method thereof. The production method comprises the following step: producing lithium salt, nickel salt, manganese salt, cobalt salt and rare earth nitrate according to a specific ratio through a special process, so as to obtain the rare-earth doped nickel, cobalt and manganese ternary material wide temperature lithium with the anode materials being LiNi0.5Co0.3Mn0.2Bd0.2 compound. A rare earth neodymium element is added into the anode materials nickel, cobalt and manganese of the lithium ion battery, the crystal structures of the anode materials are maintained, and a lattice constant C is only changed. The battery produced through the method has high reversible capacity, high cycle performance and high discharge capability, is wide in applicable temperature range, and can be used at minus 45 DEG C.

Owner:河北绿草地新能源股份有限公司

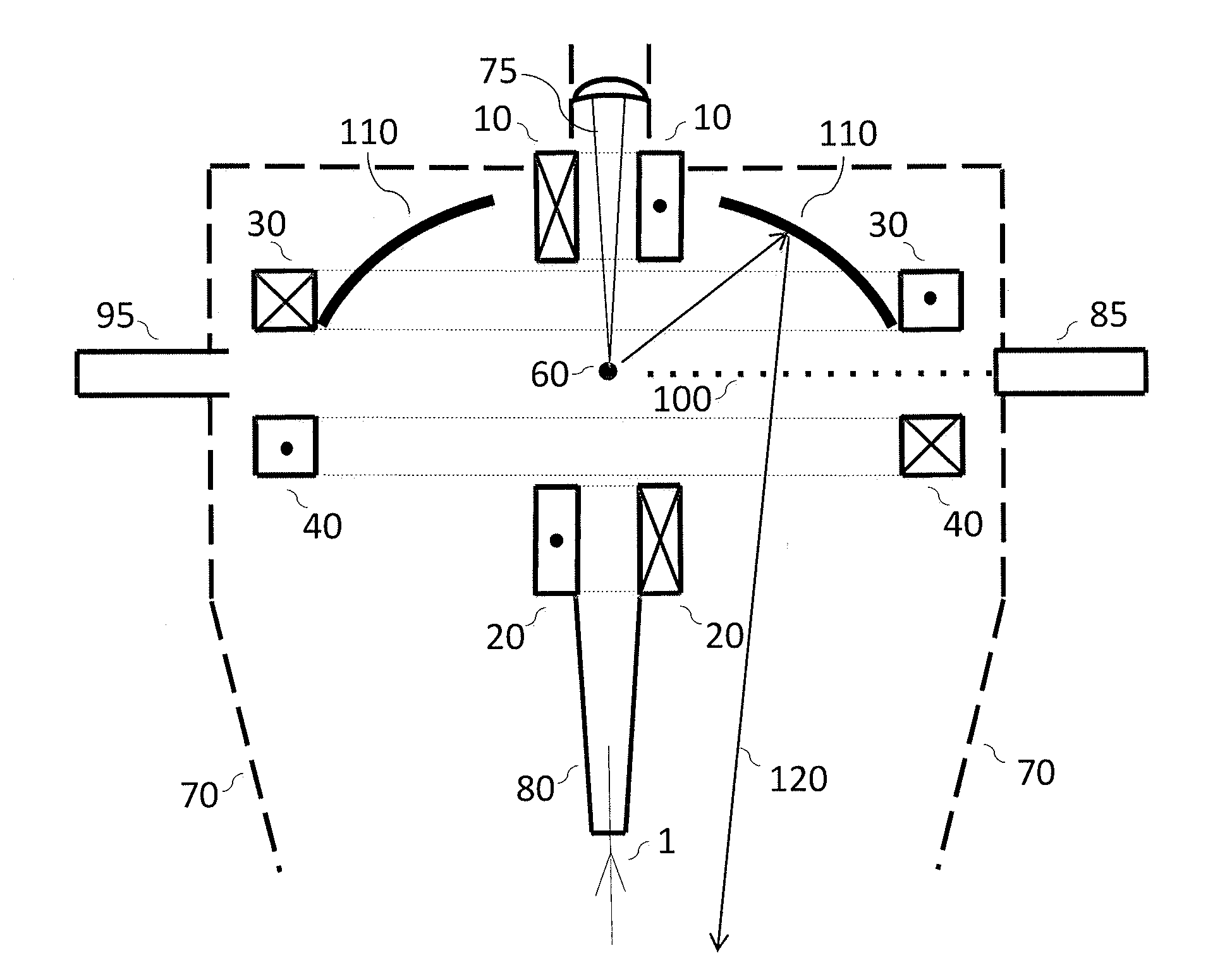

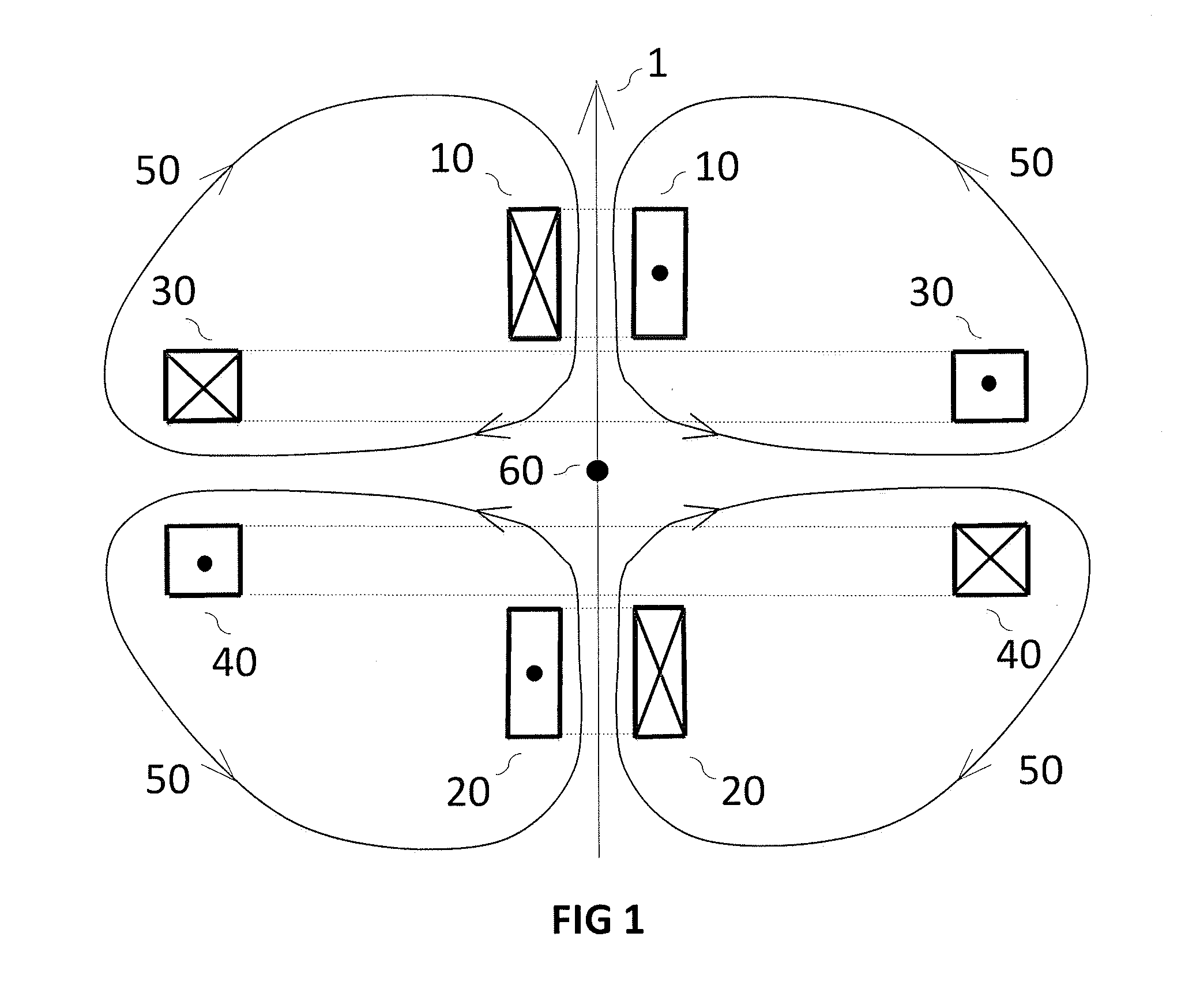

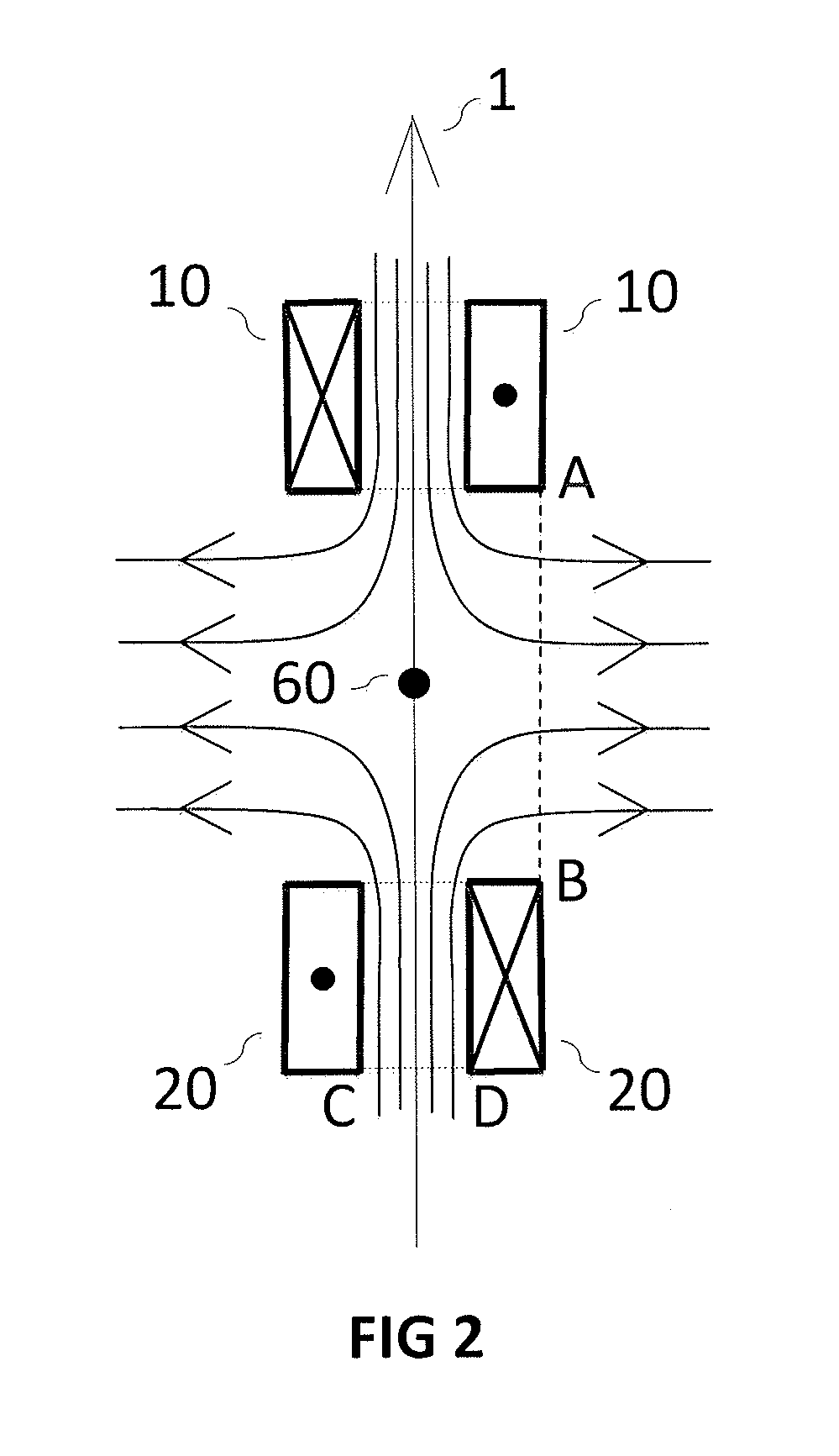

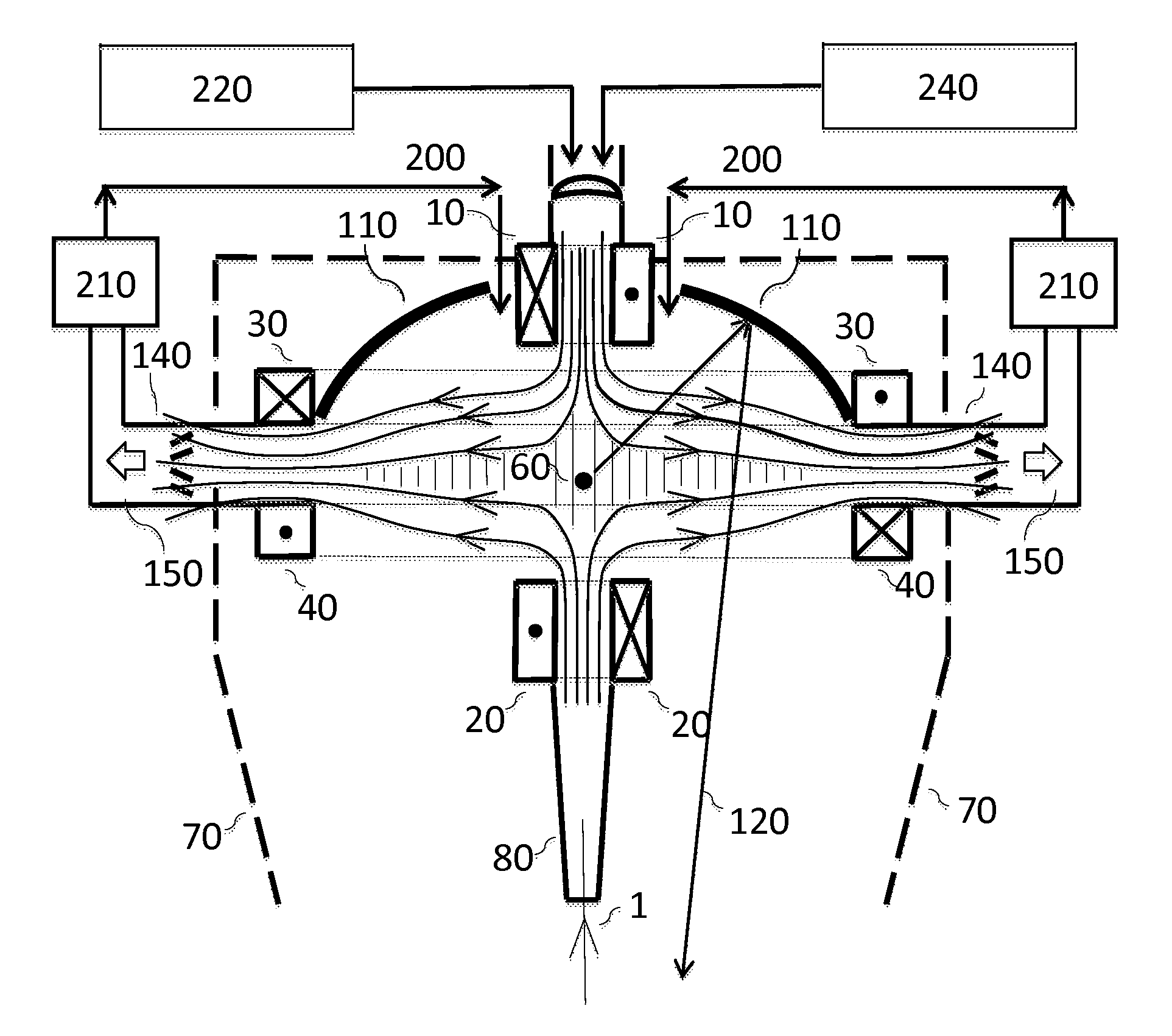

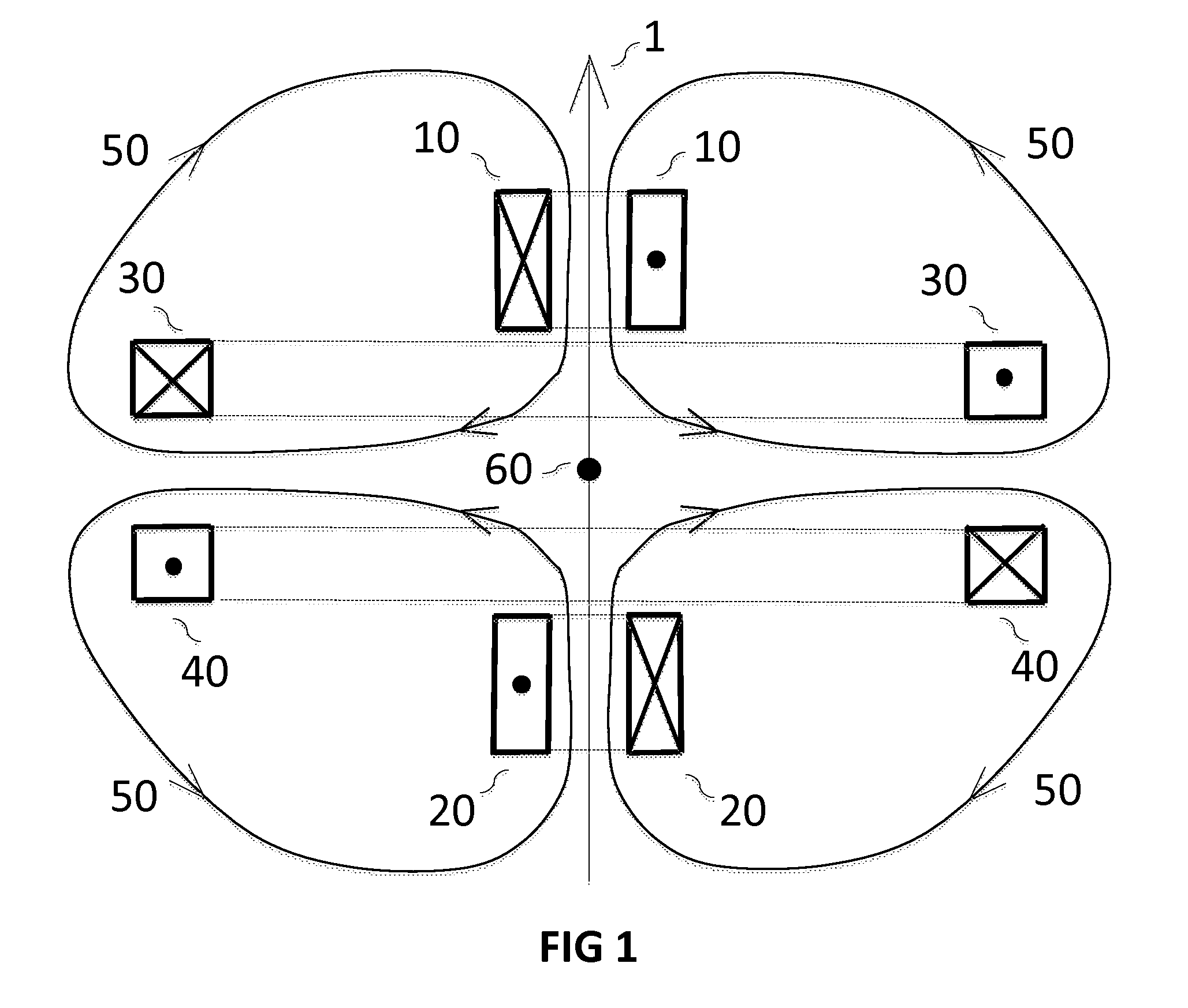

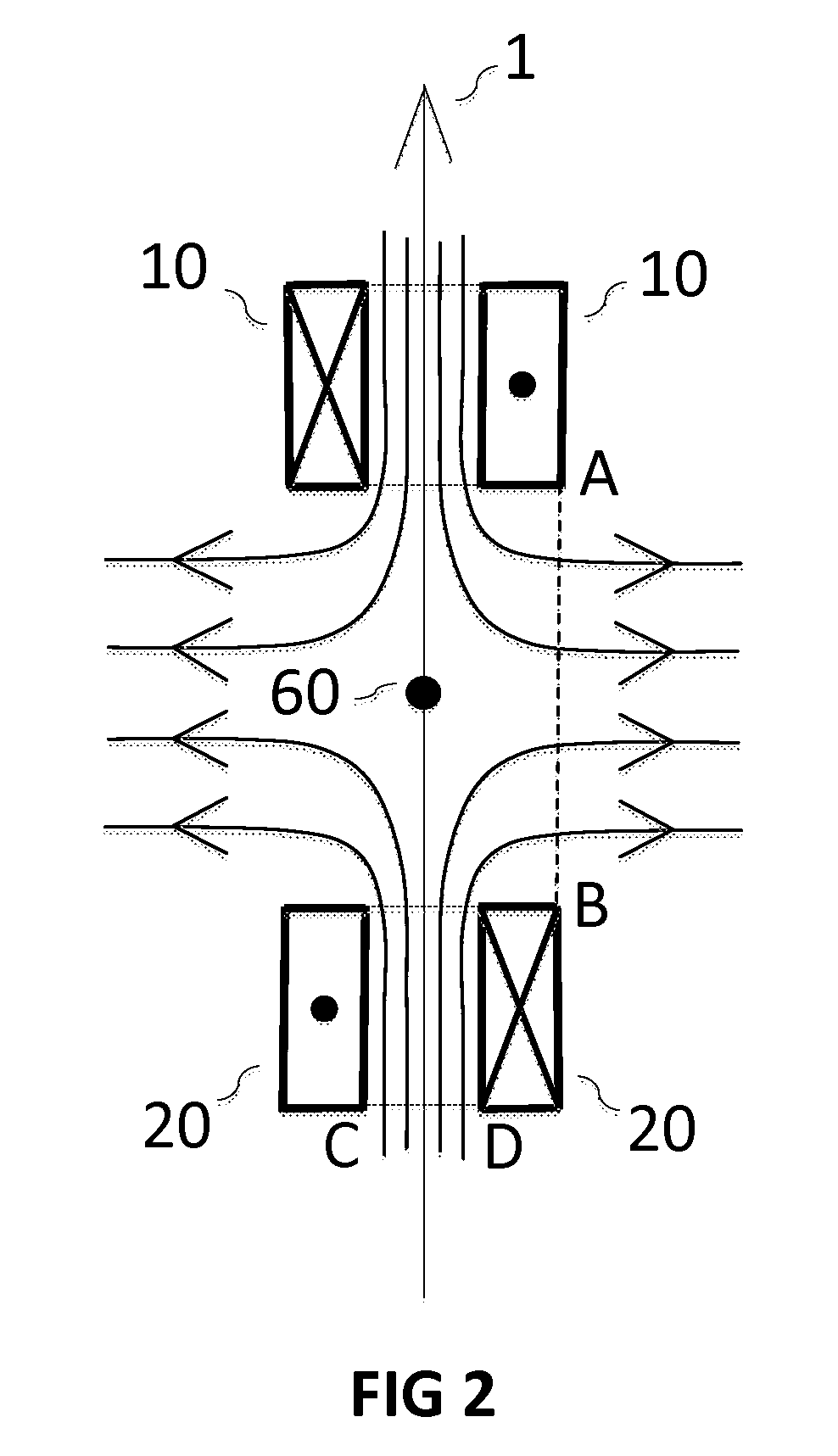

Extreme ultraviolet source with magnetic cusp plasma control

ActiveUS20160007433A1Increase powerHigh power handlingRadiation pyrometryX-ray tube with very high currentRadial motionBeam dump

A laser-produced plasma extreme ultraviolet source has a buffer gas to slow ions down and thermalize them in a low temperature plasma. The plasma is initially trapped in a symmetrical cusp magnetic field configuration with a low magnetic field barrier to radial motion. Plasma overflows in a full range of radial directions and is conducted by radial field lines to a large area annular array of beam dumps.

Owner:PUREX

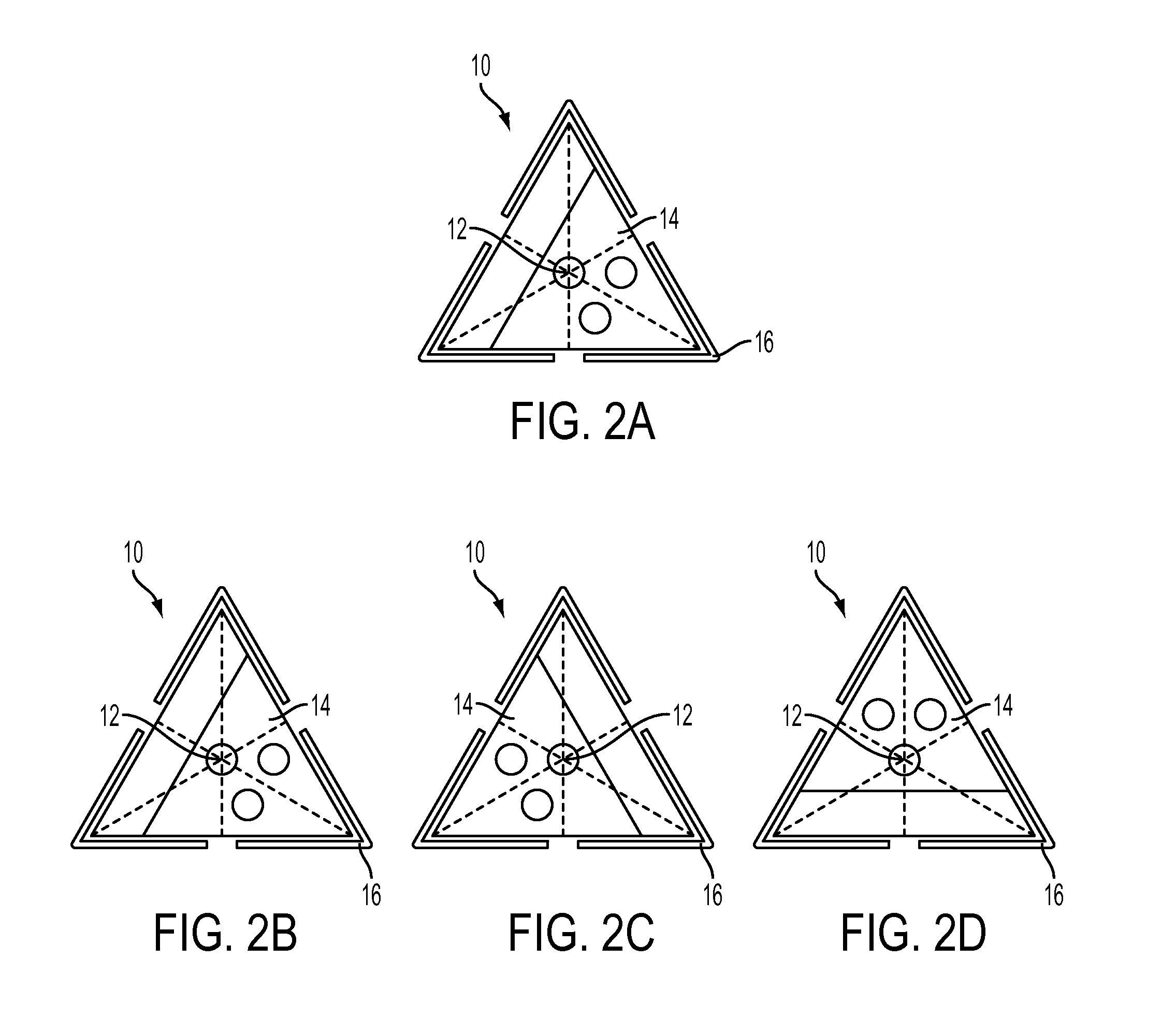

N port fiber optical switch

ActiveUS8929695B1Shorten the switching timeMaintaining mechanical simplicityCoupling light guidesFiberActuator

An N port fiber optical switch includes a movable housing having a perimeter and N corners; a plurality N of optical fibers positioned within the housing and inside the perimeter; and a plurality N of actuators, wherein each actuator is positioned on a corresponding corner such that when selectively activated one or more of the actuators urges the movable housing and the plurality of optical fibers to a selected switch position. The switch provides short switching times and high power handling while allowing for a large number of ports and provides the capability of interfacing with and switching between a variable number of ports.

Owner:UNITED STATES OF AMERICA

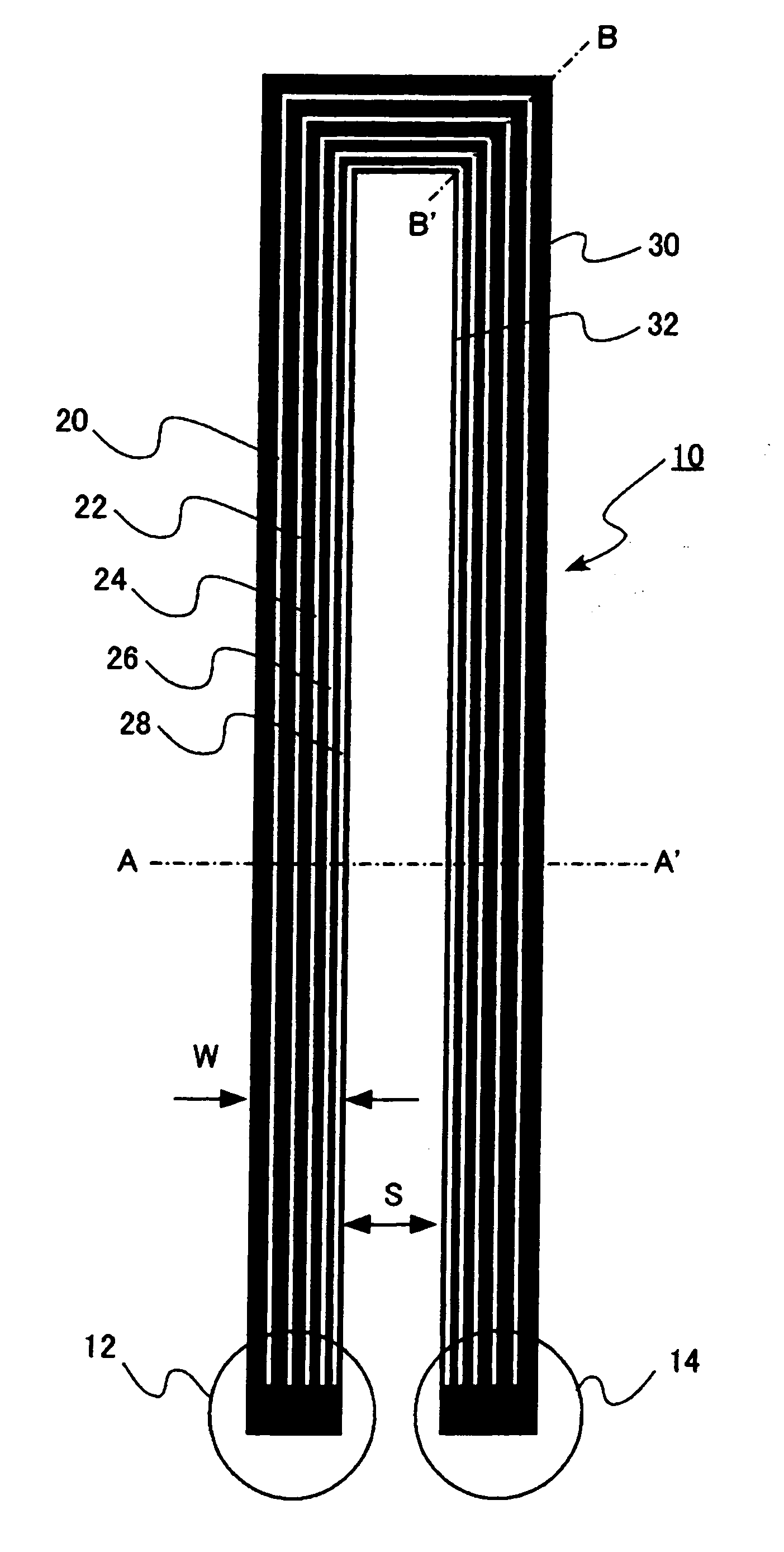

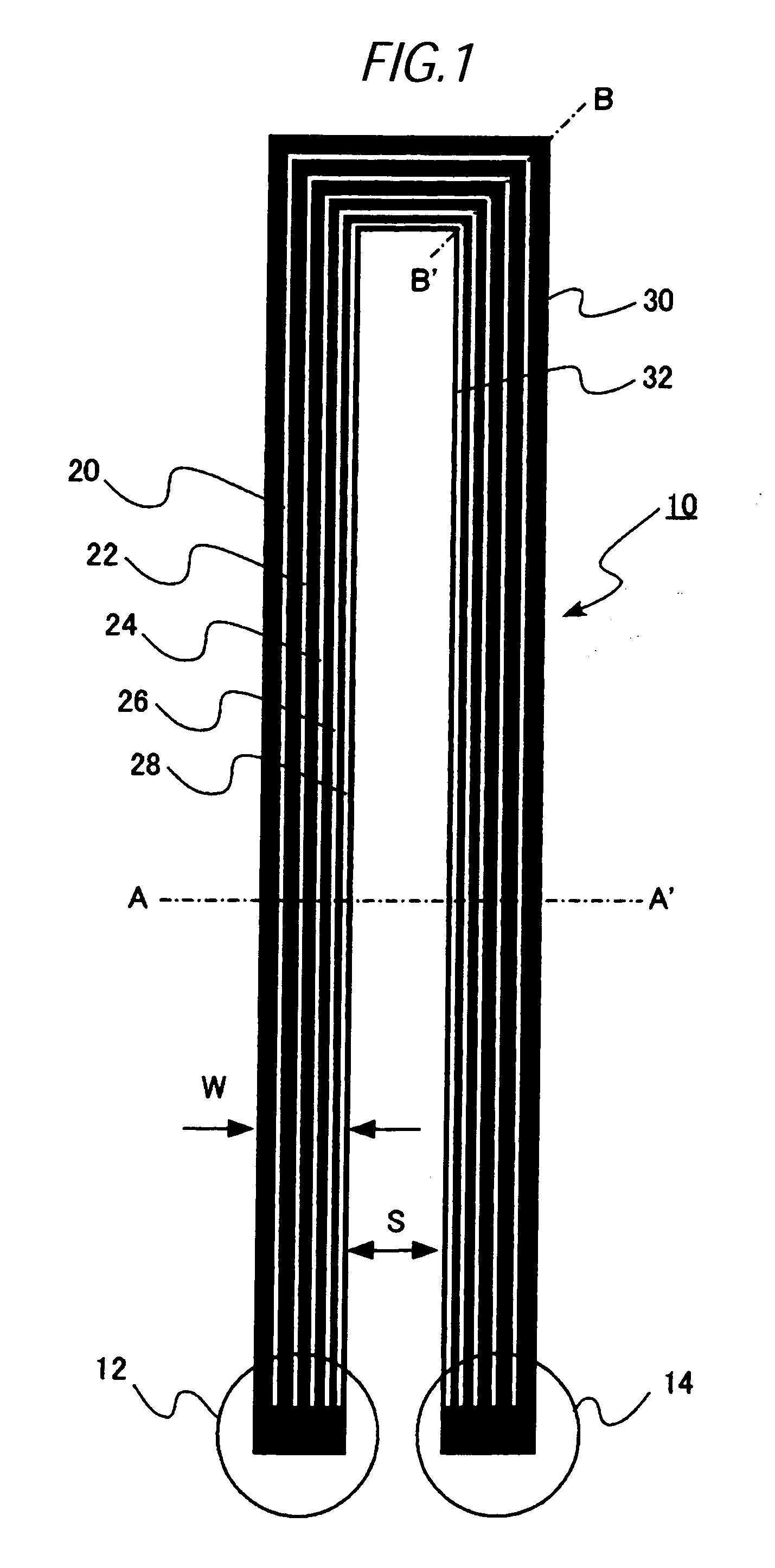

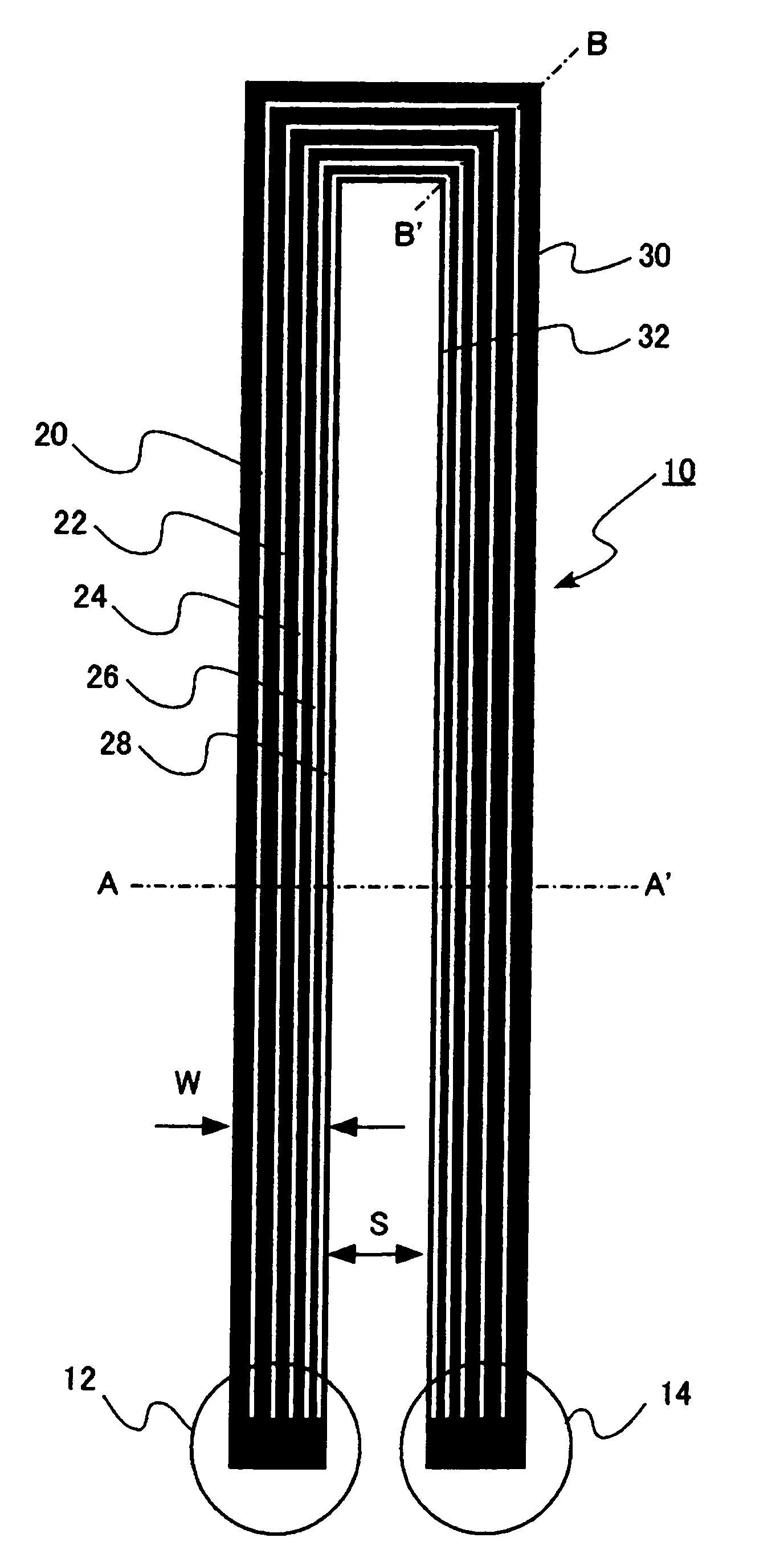

Resonator and filter

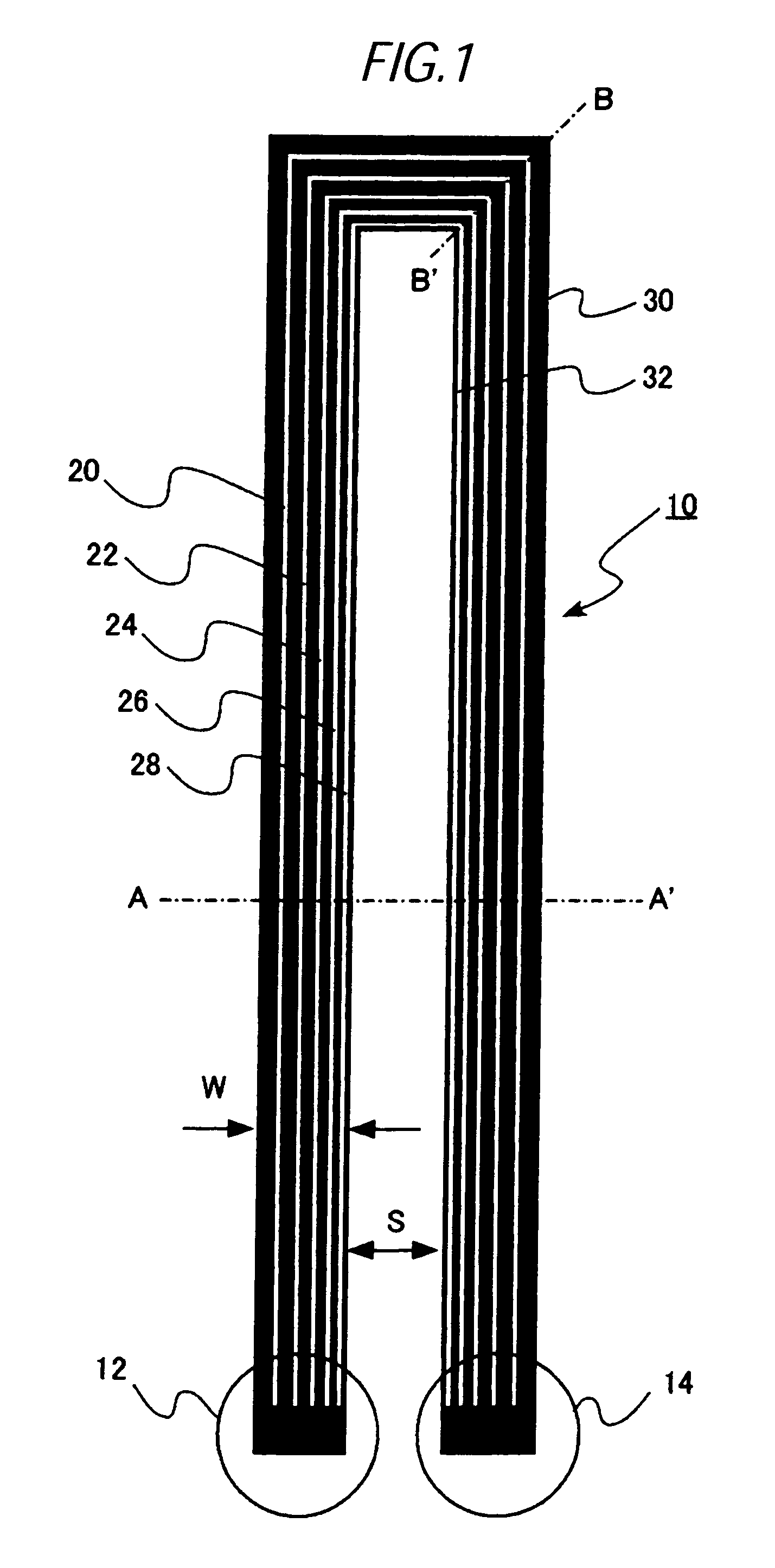

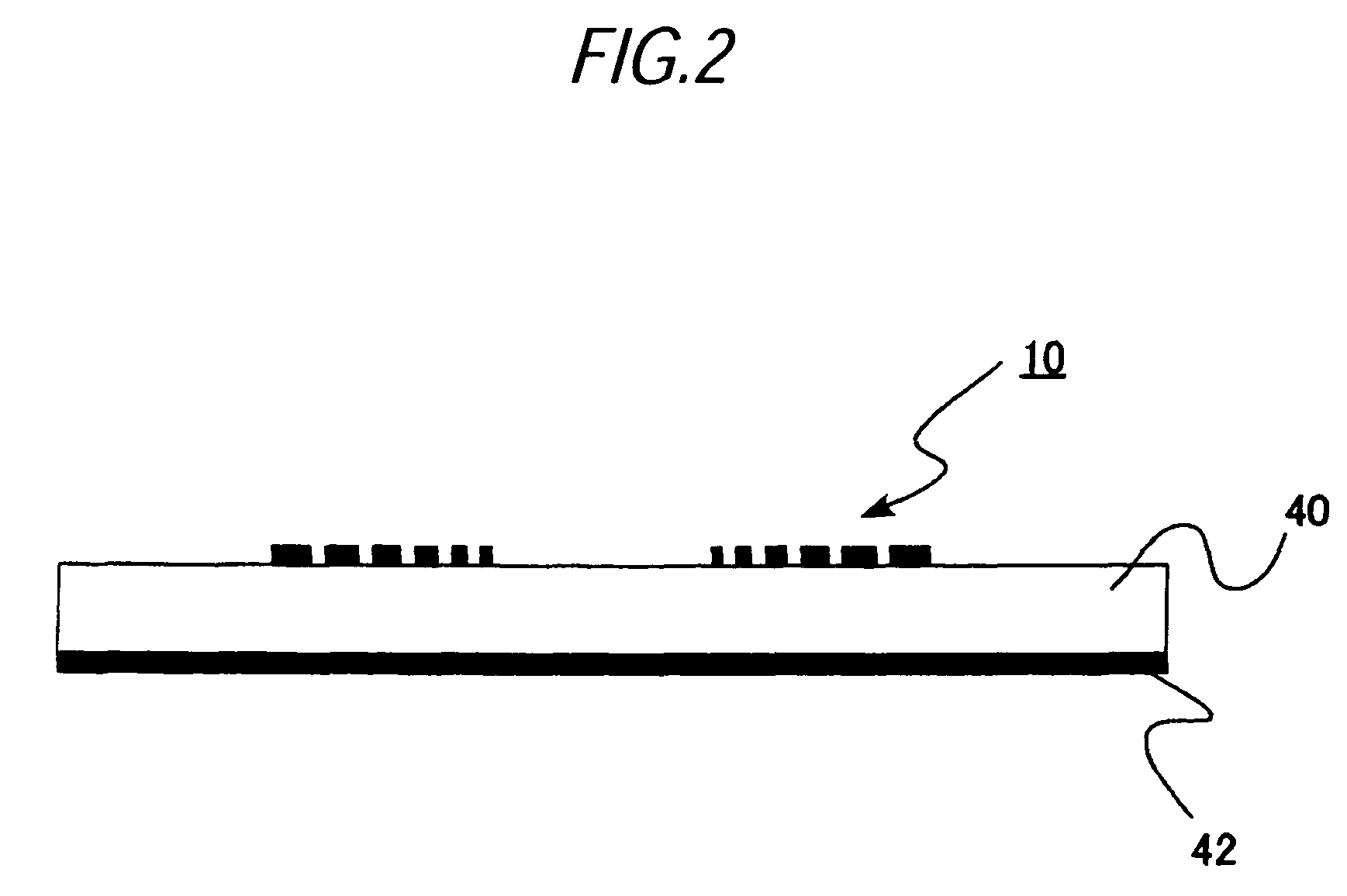

ActiveUS20090146762A1Low loss characteristicHigh-power handlingResonatorsWaveguidesResonatorTransmission line

According to an aspect of the present invention, there is provided a resonator including: a transmission line including a conductor line with a bent portion, wherein the conductor line has a plurality of slits formed therein, the slits being formed in an extending direction of the conductor line to pass through the bent portion, and wherein the slits are formed to have intervals that become narrower from an outer-side toward an inner-side of the bent portion.

Owner:KK TOSHIBA

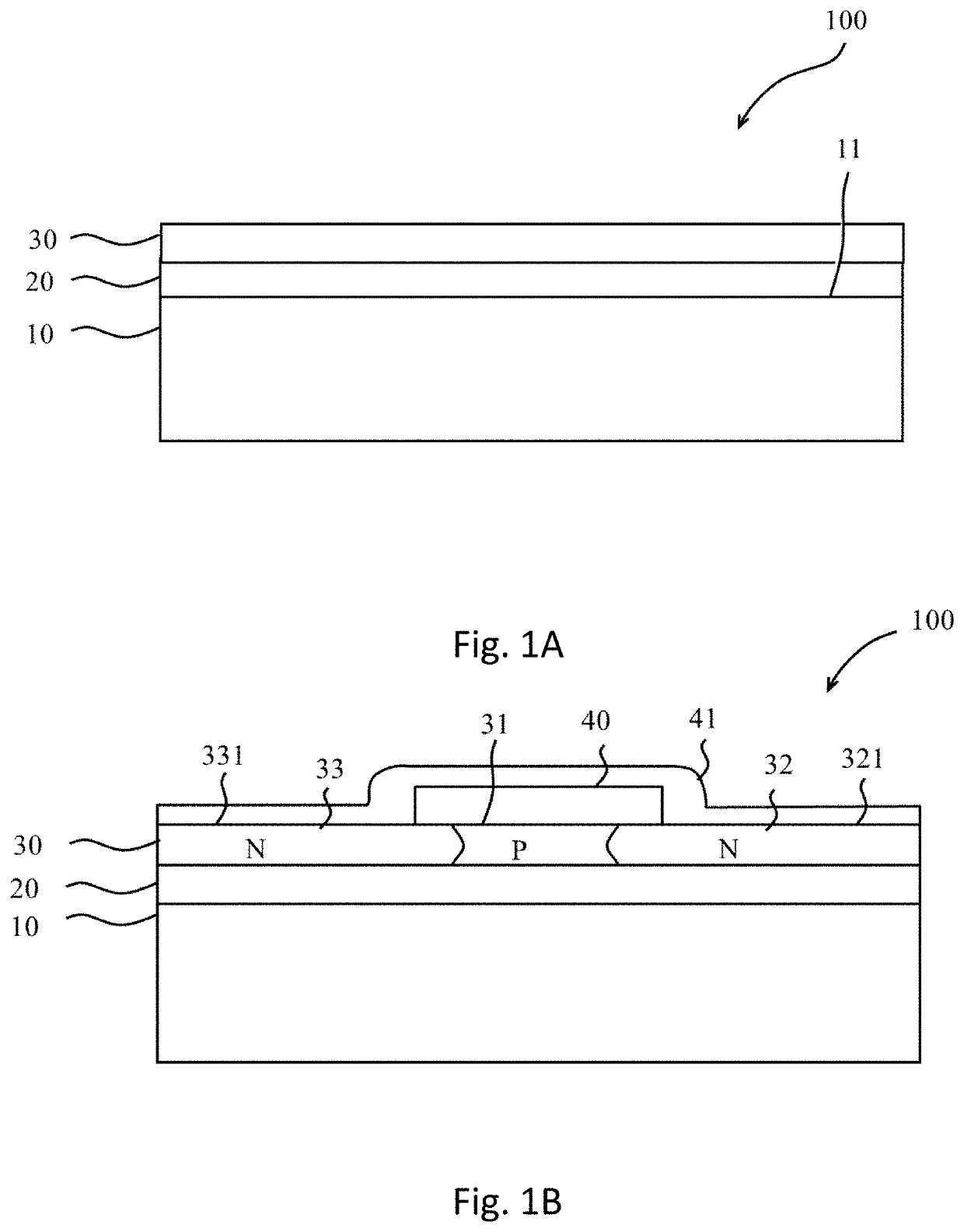

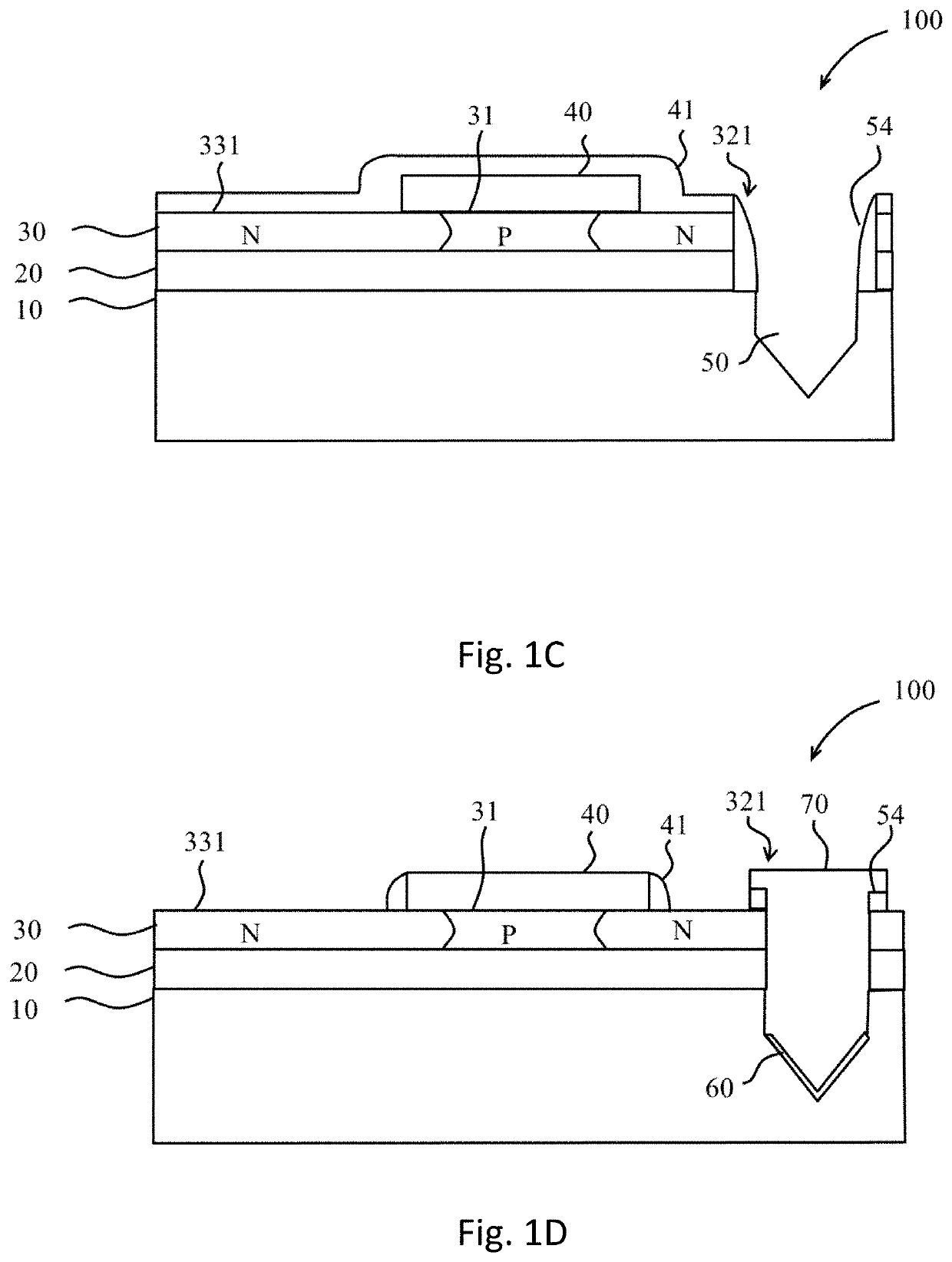

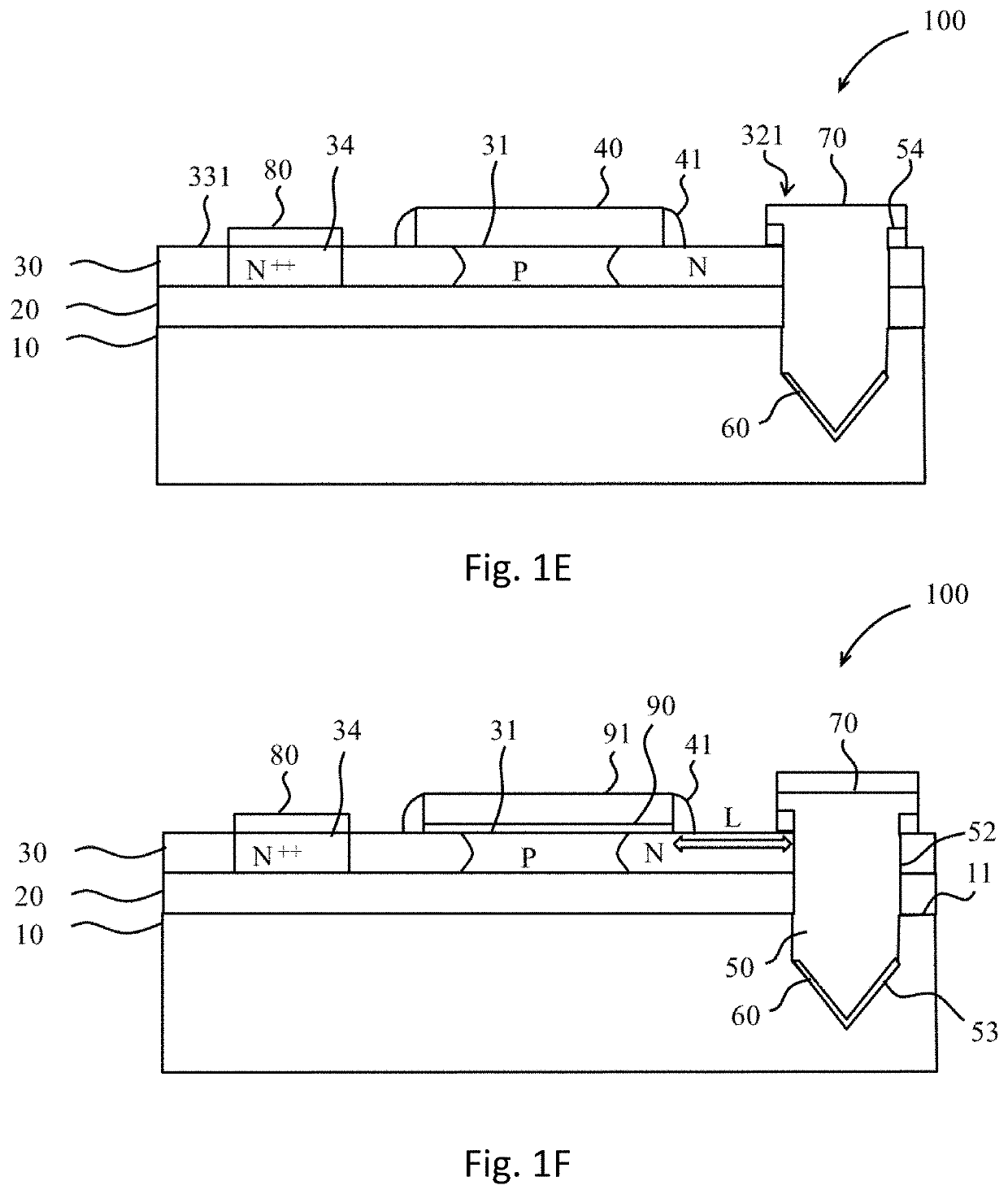

SILICON METAL-OXIDE-SEMICONDUCTOR FIELD EFFECT TRANSISTOR (Si MOSFET) WITH A WIDE-BANDGAP III-V COMPOUND SEMICONDUCTOR GROUP DRAIN AND METHOD FOR FABRICATING THE SAME

ActiveUS20210159338A1Improve epitaxy qualityInsufficient handling capabilityTransistorSemiconductor/solid-state device manufacturingMOSFETPhysical chemistry

A silicon metal-oxide-semiconductor field effect transistor with a wide-bandgap III-V compound semiconductor drain and a method for fabricating the same are disclosed. The method fabricates a hundred nanometer-scale hole in a (100) silicon substrate to expose the (111) facet of the silicon substrate, which favors to use selective area growth to form lattice matched III-V materials with high quality.

Owner:NAT YANG MING CHIAO TUNG UNIV +1

Extreme ultraviolet source with magnetic cusp plasma control

ActiveUS9155178B1Power maximizationIncrease the areaX-ray tube with very high currentX-ray apparatusRadial motionBeam dump

A laser-produced plasma extreme ultraviolet source has a buffer gas to slow ions down and thermalize them in a low temperature plasma. The plasma is initially trapped in a symmetrical cusp magnetic field configuration with a low magnetic field barrier to radial motion. Plasma overflows in a full range of radial directions and is conducted by radial field lines to a large area annular array of beam dumps.

Owner:PUREX

Resonator comprised of a bent conductor line with slits therein and a filter formed therefrom

ActiveUS7983728B2Low loss characteristicHigh-power handlingSuperconductors/hyperconductorsSuperconductor devicesEngineeringResonator

According to an aspect of the present invention, there is provided a resonator including: a transmission line including a conductor line with a bent portion, wherein the conductor line has a plurality of slits formed therein, the slits being formed in an extending direction of the conductor line to pass through the bent portion, and wherein the slits are formed to have intervals that become narrower from an outer-side toward an inner-side of the bent portion.

Owner:KK TOSHIBA

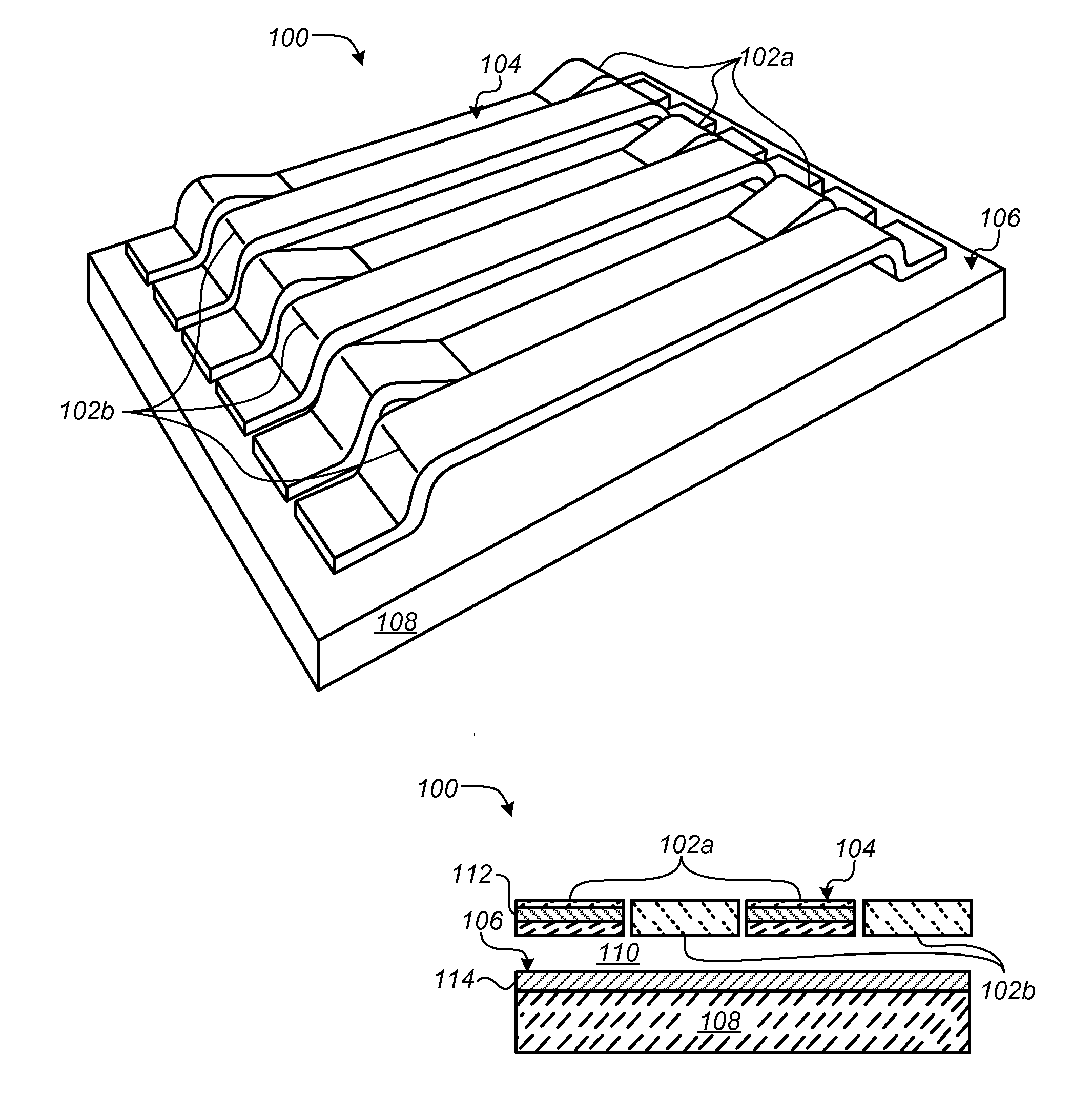

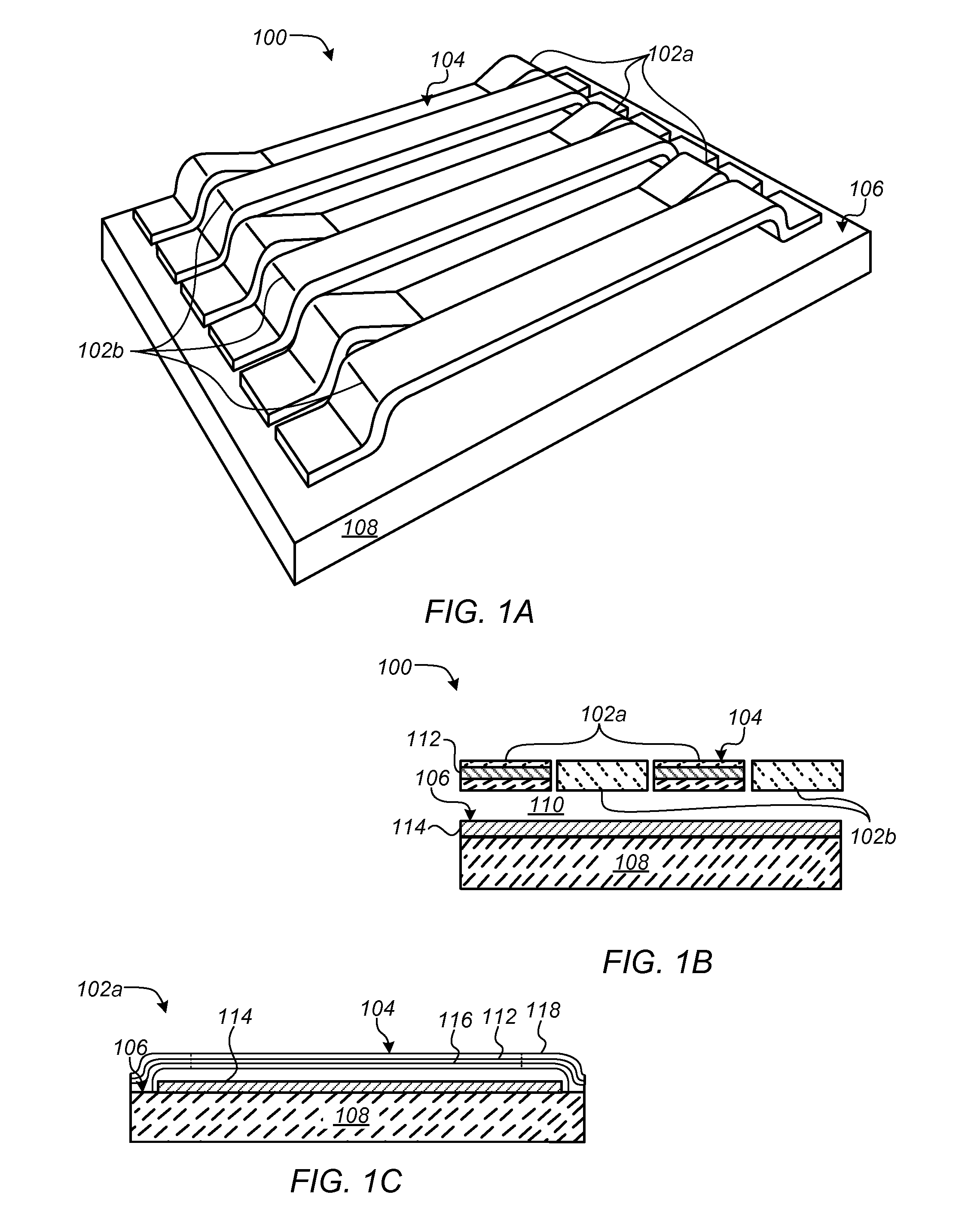

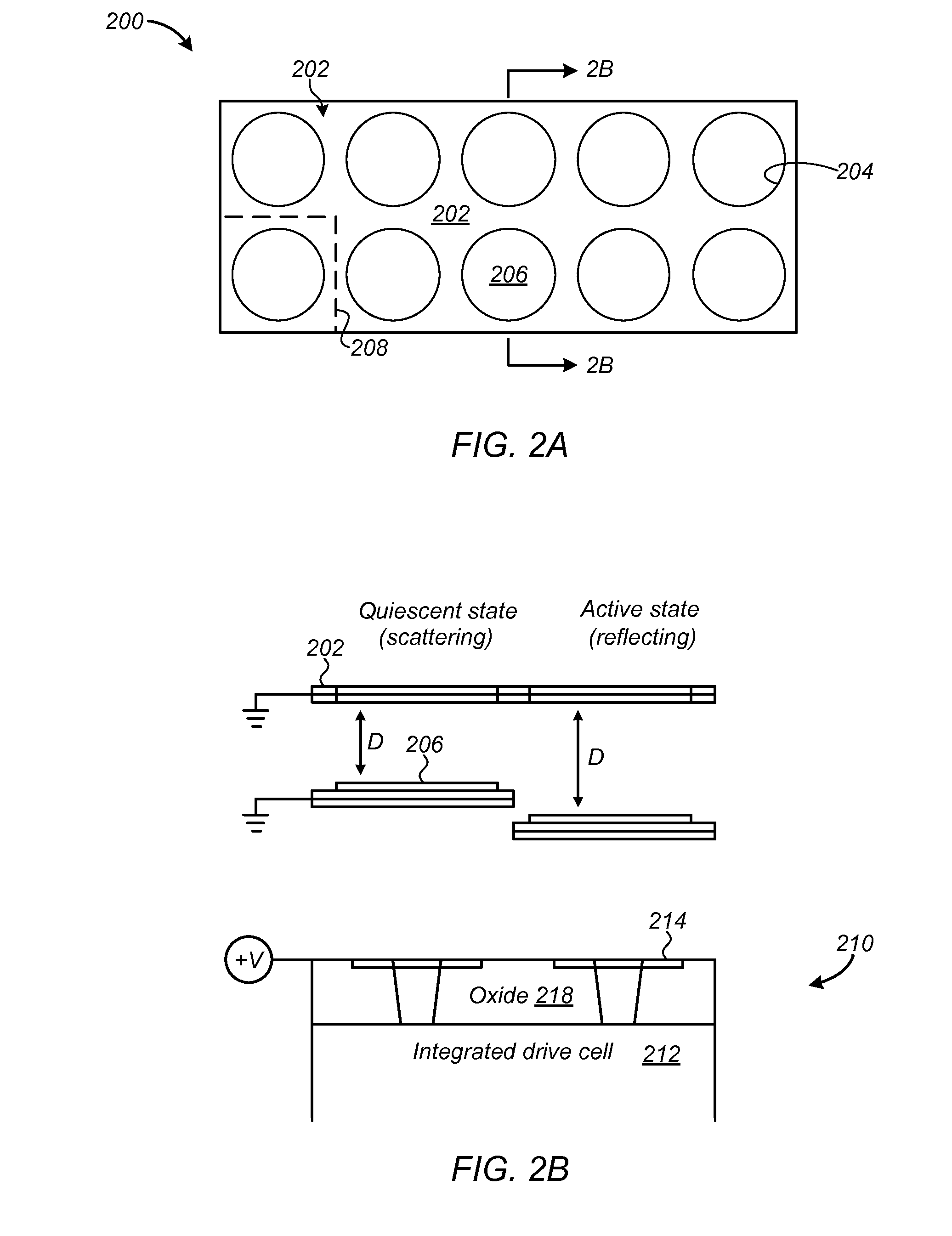

High power handling optical spatial light modulator

InactiveUS20160085067A1High power handlingIncrease powerLaser beam welding apparatusOptical elementsOptical modulatorMaterials processing

Laser-based material processing systems including a Micro-Electromechanical System devices (MEMs) based reflective, optical modulator with dielectric mirrors for high power handling and methods of manufacturing and using the same are described. Generally, the system includes a workpiece support, a laser, a workpiece support, a laser, a MEMs based reflective, optical modulator to modulate a beam generated by the laser; and imaging optics to direct modulated light from the optical modulator onto a workpiece on the workpiece support. The optical modulator includes a number of surfaces with dielectric mirrors formed thereon to modulate the beam generated by the laser. Other embodiments are also described.

Owner:SILICON LIGHT MACHINES CORP

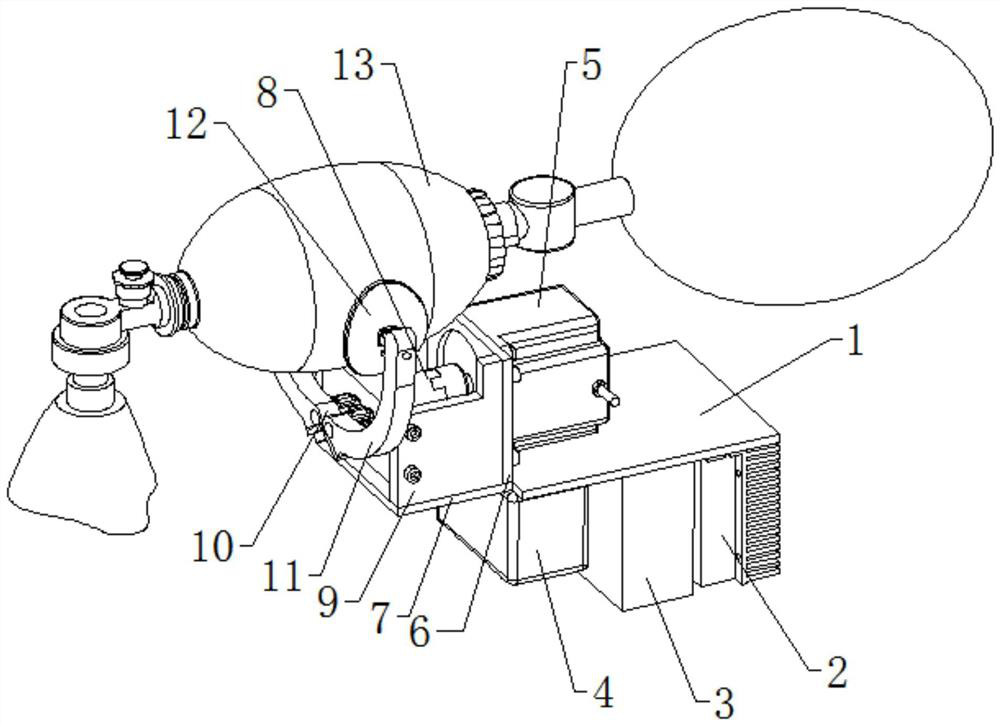

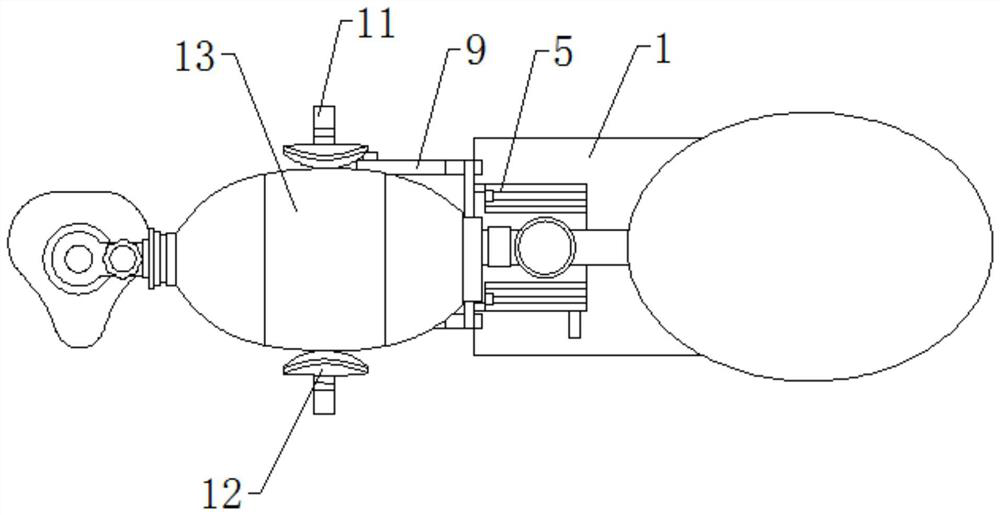

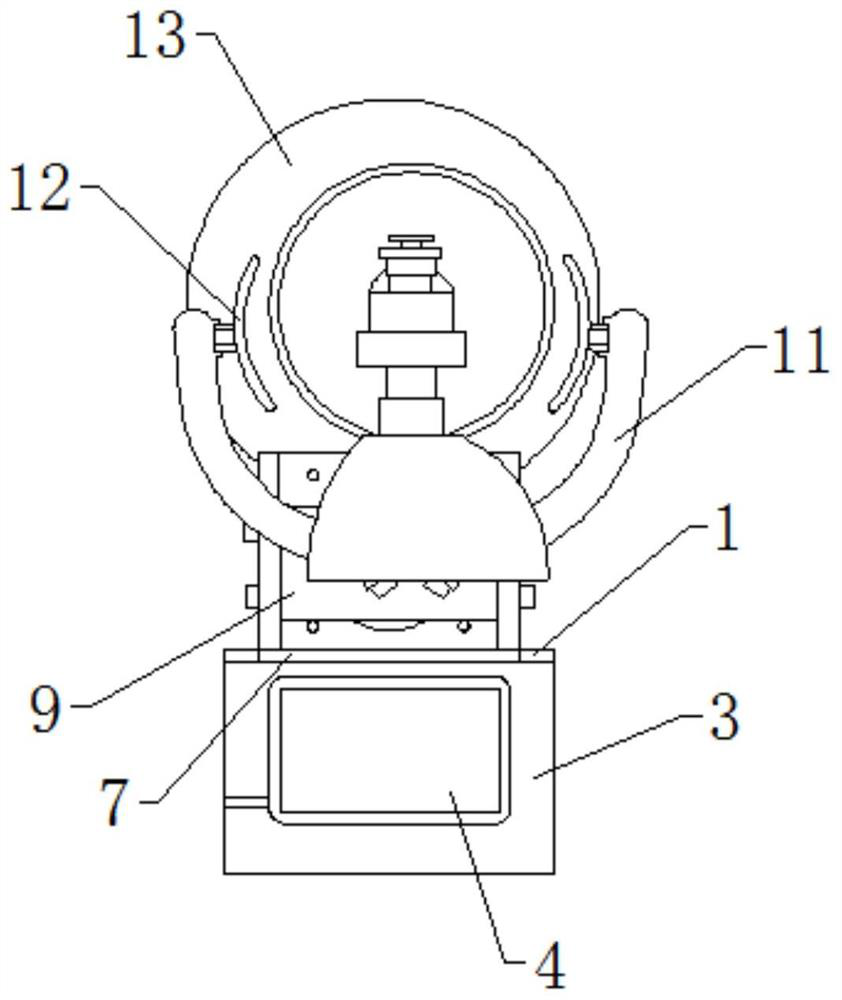

Automatic pressing device of artificial respiration air bag

The invention relates to the technical field of medical treatment auxiliary equipment, in particular to an automatic pressing device of an artificial respiration air bag. The automatic pressing device comprises an installation plate, wherein the right side of the bottom of the installation plate is provided with a driver; on the bottom of the installation plate, the left side of the driver is provided with a controller; on the bottom of the installation plate, the left side of the controller is provided with a lithium battery; the middle of the left side of the base surface of the installation plate is provided with a stepping motor; on the base surface of the installation plate, the left side of the stepping motor is provided with an installation division plate; the end part of the left side of the installation plate is provided with a bottom fixing plate; the middle of the left side of the installation division plate is provided with a coupling; the edge of the base surface of the bottom fixing plate is provided with a side surface fixing plate; the left side of the side surface fixing plate is symmetrically provided with gear shafts; and the left side of each gear shaft is symmetrically provided with swinging arms. The whole equipment can be conveniently carried, is simple in operation, has rich functions, has high stability and practicability and has a certain popularization value.

Owner:李春洁 +1

Production method of rare-earth wide-temperature lithium-ion battery

InactiveCN106532027AHigh reversible capacityPromote circulationFinal product manufactureCell electrodesRare-earth elementYttrium

The invention provides a production method of a rare-earth wide-temperature lithium-ion battery. The production method of the rare-earth wide-temperature lithium-ion battery comprises the steps of preparing a mixed saline solution by using dissoluble metal salts and a rare-earth compound according to a certain mole ratio; and carrying out reaction between the mixed saline solution and a mixed alkaline solution under a certain condition, then mixing with lithium salt powder according to a certain proportion, and roasting the mixture to obtain a cathode material of the rare-earth wide-temperature lithium-ion battery. The rare-earth element is added into the cathode material of the lithium-ion battery to keep the crystal structure of the cathode material, and only the lattice constant C is changed, for example, a rare-earth yttrium element is added into the cathode material lithium manganate to enable yttrium to be doped into the cathode material LiMn2O4, thereby forming a LiY0.02Mn1.98O4 compound. The lithium-ion battery added with the rare-earth element is verified to have relatively high reversible capacity, good cycle performance, strong adaptability to high and low temperatures; and the lithium-ion battery added with the rare-earth element can be used at -45 DEG C after being subjected to technical processing.

Owner:河北绿草地新能源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com