Patents

Literature

41results about How to "Efficient refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

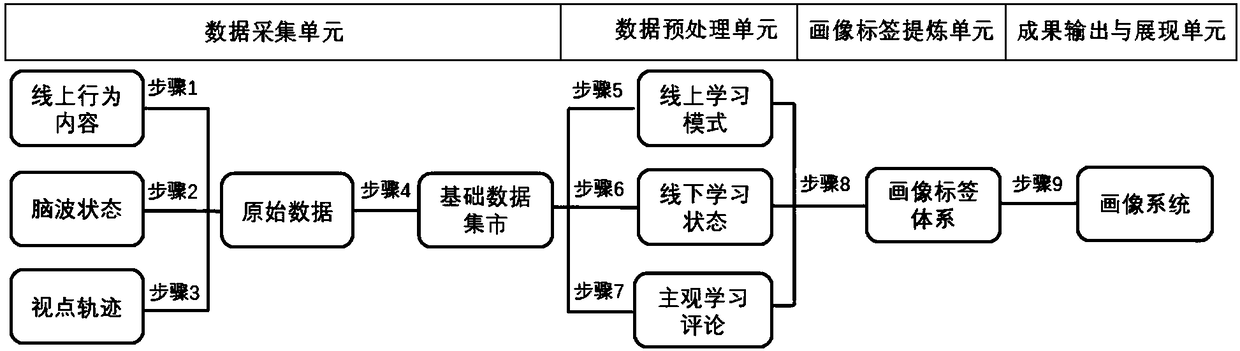

Student comprehensive portrait label management system for online teaching based on deep learning

PendingCN108492224AEfficient summarization and efficient refinementEfficient inductionData processing applicationsSpecial data processing applicationsImage identificationData acquisition unit

The invention discloses a student comprehensive portrait label management system for online teaching based on deep learning, and the system comprises a data acquisition unit, a data preprocessing unit, an image label refining unit, and a result output and presentation unit. The system employs the point burying technology, the brain wave acquisition technology, the viewpoint tracking technology, the image recognition technology, the text mining technology and a deep learning algorithm for the learning contents, behaviors, physical sings and result data of students, and carries out the integration, checking and cleaning of the data collected and obtained from a plurality of data sources. The important dimension information is screened out of the basic data, and a representative portrait label is extracted, and a top-to-bottom integrated label system is formed. The portrait label result is displayed and used in a visualized manner through a proper logic. The system achieves the scientificevaluation of the hierarchical capability of student groups and individuals, achieves the scientific evaluation and presentation of the hierarchical capability of student groups and individuals in asystematic manner, and effectively guides the optimization and improvement of a student training scheme and a teaching content plan.

Owner:SHANGHAI OPEN UNIVERSITY

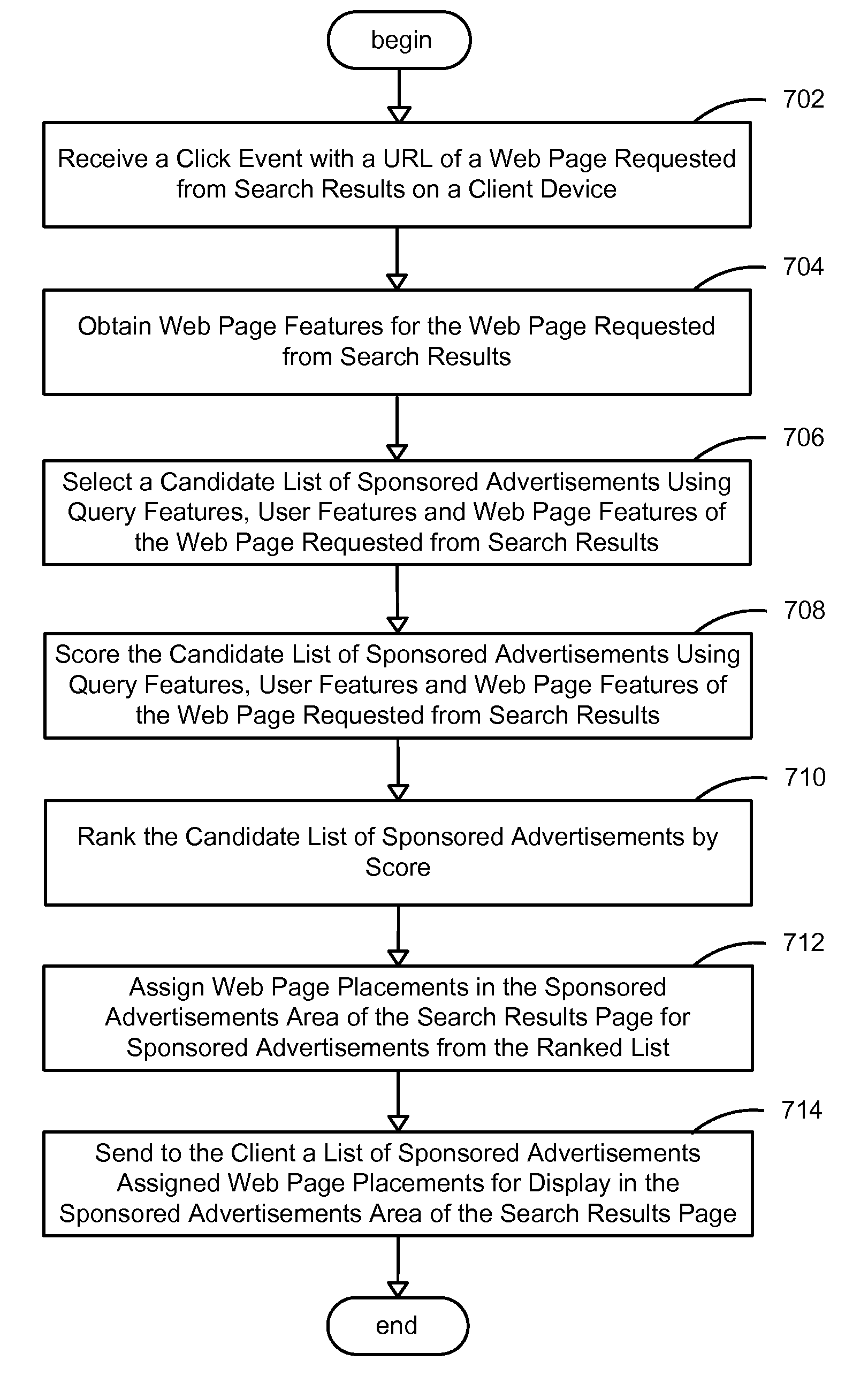

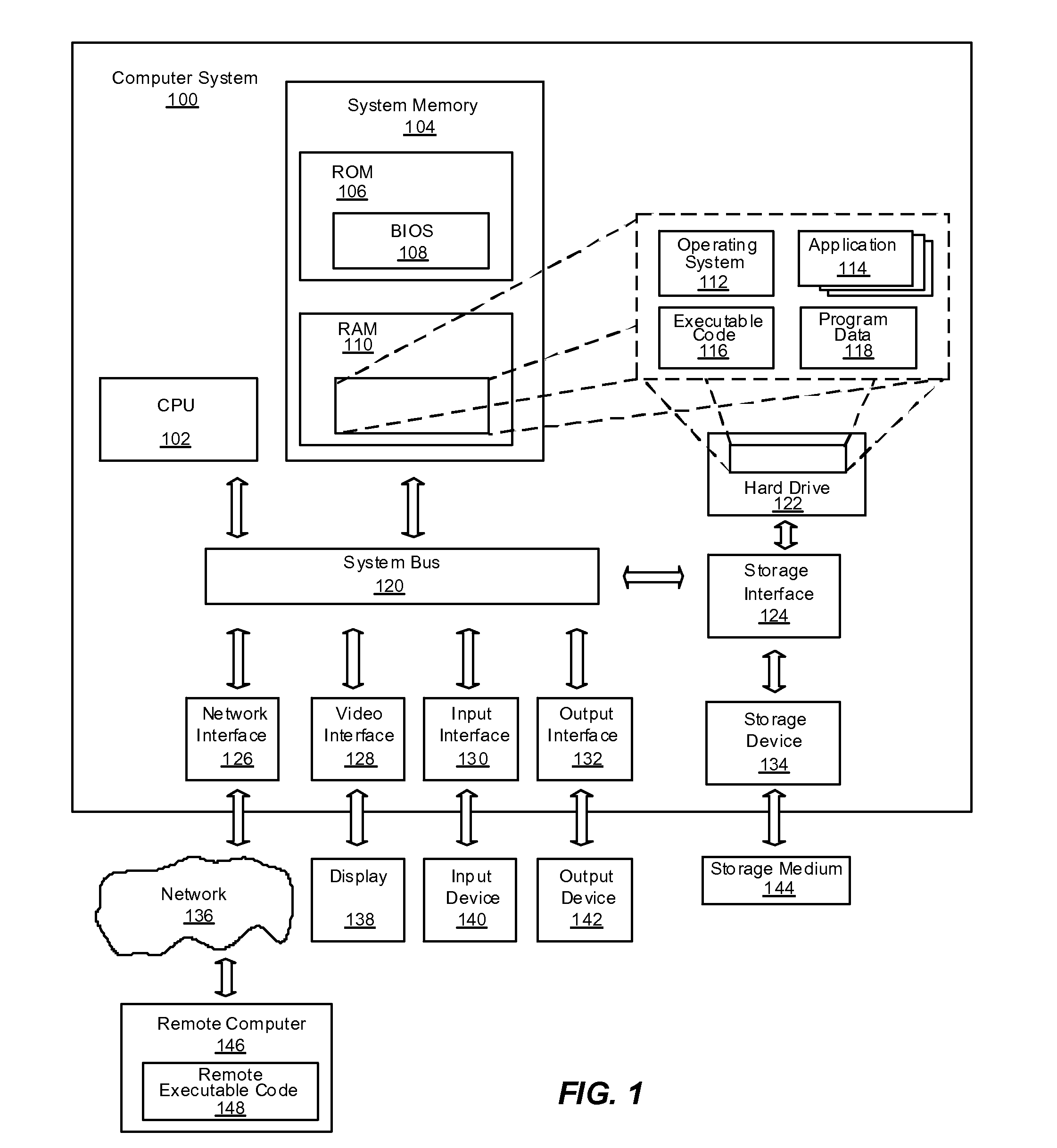

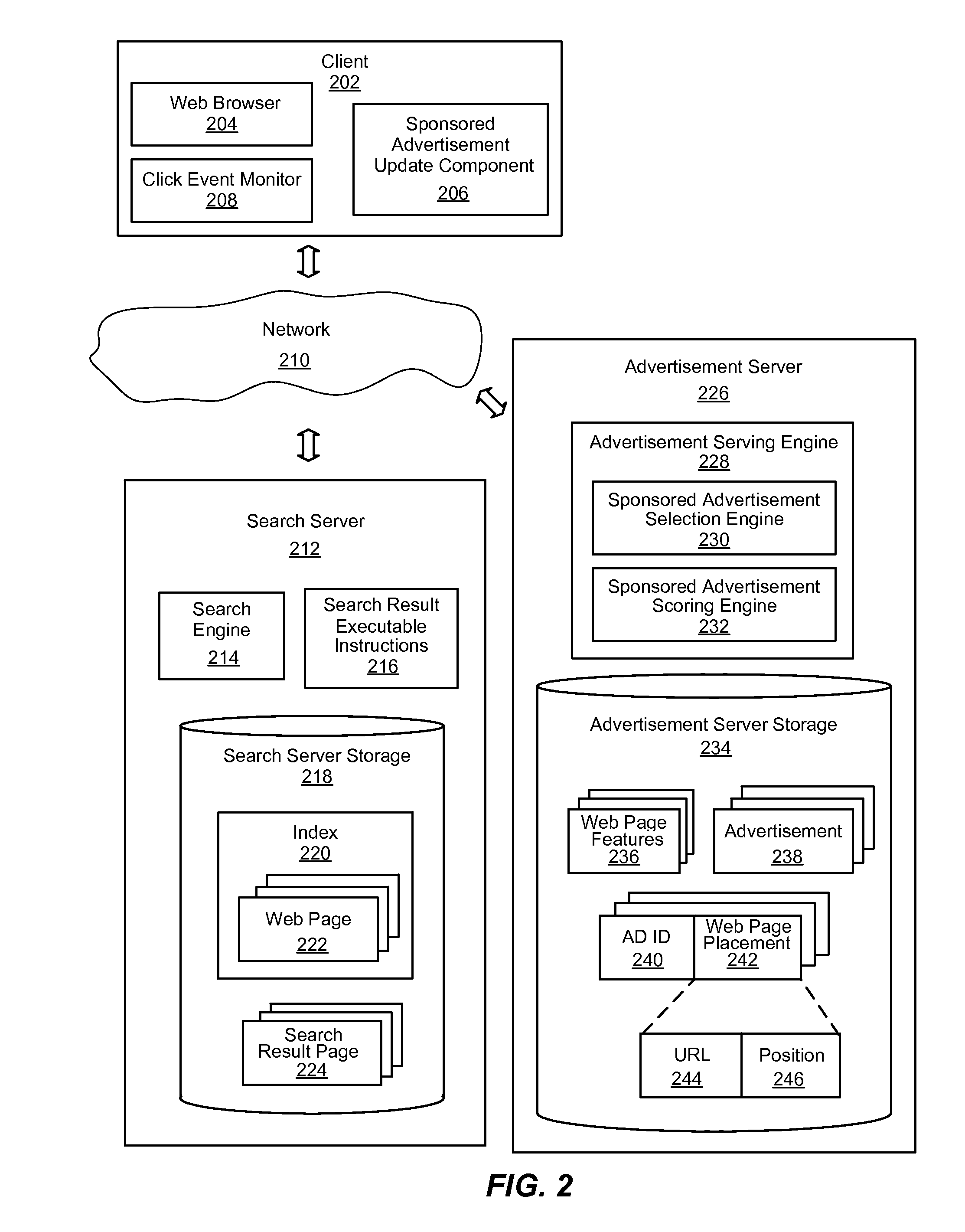

System and method for updating search advertisements during search results navigation

InactiveUS20110071898A1Efficient refiningMore personalized search advertisementsCommerceSpecial data processing applicationsSearch advertisingClient-side

An improved system and method for updating search advertisements during search results navigation is provided. A search server may return search results from a search query with executable instructions that monitor events selecting a web page in the search results. When a web page may be selected in the search results on the client, a request that includes an address of a web page selected from the search results may be sent from the client to an advertiser server to update sponsored advertisements displayed in a sponsored advertisement area of the search results web page. The advertisement server may select an update of sponsored advertisements using query features, user features and web page features of the web page selected from the search results web page. The update may be sent to the client for display in the sponsored advertisement area of the search results web page.

Owner:YAHOO INC

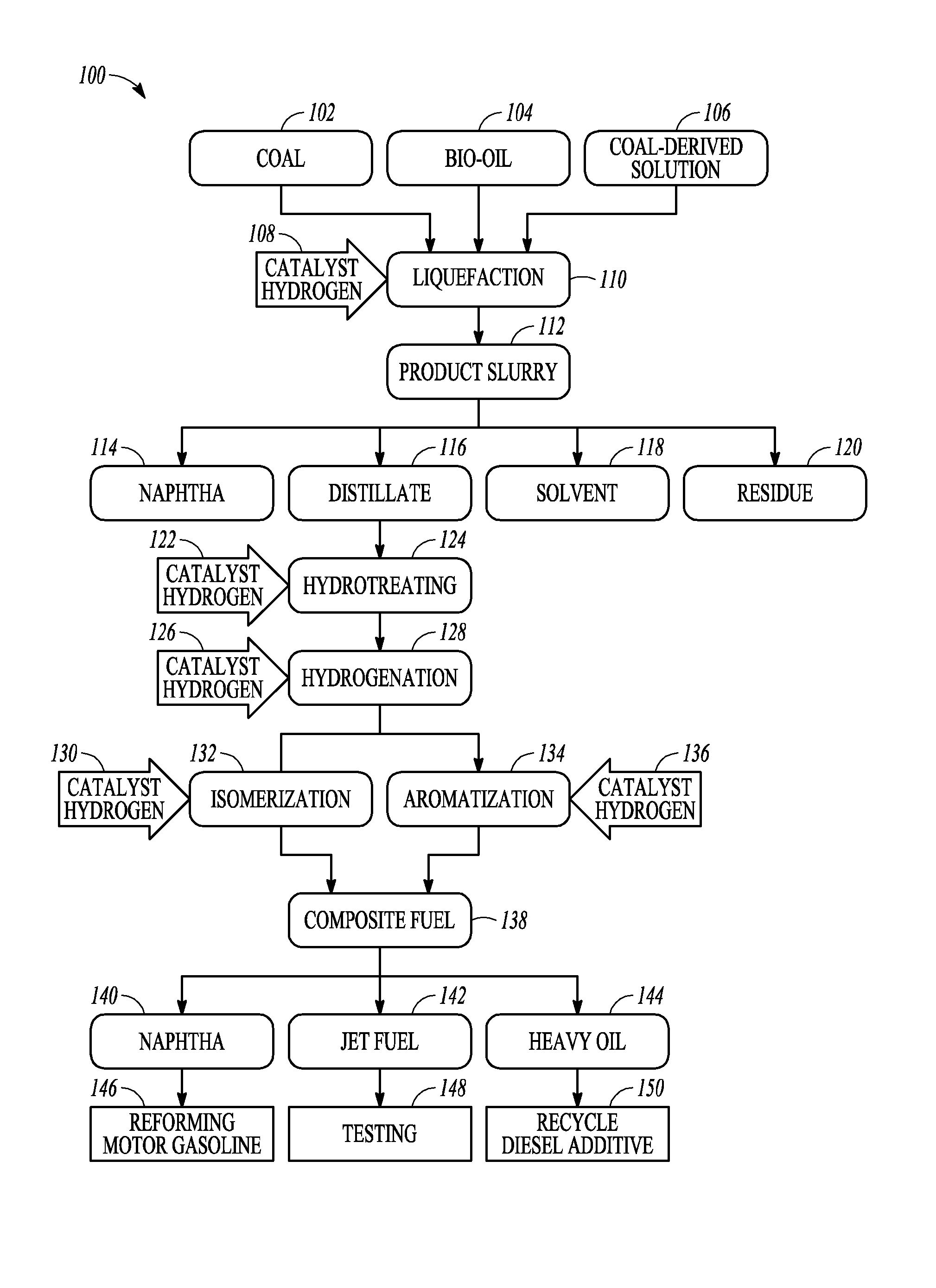

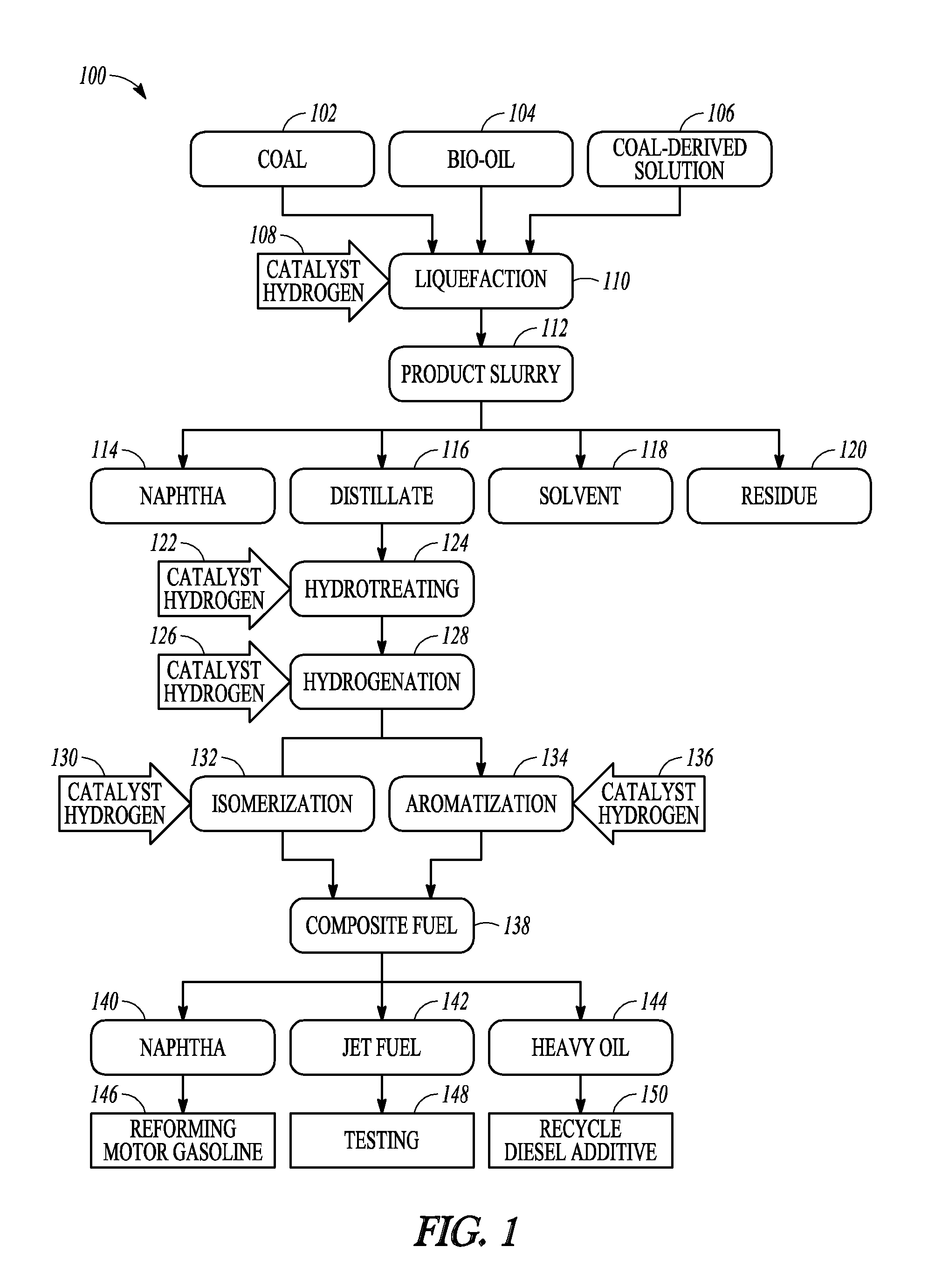

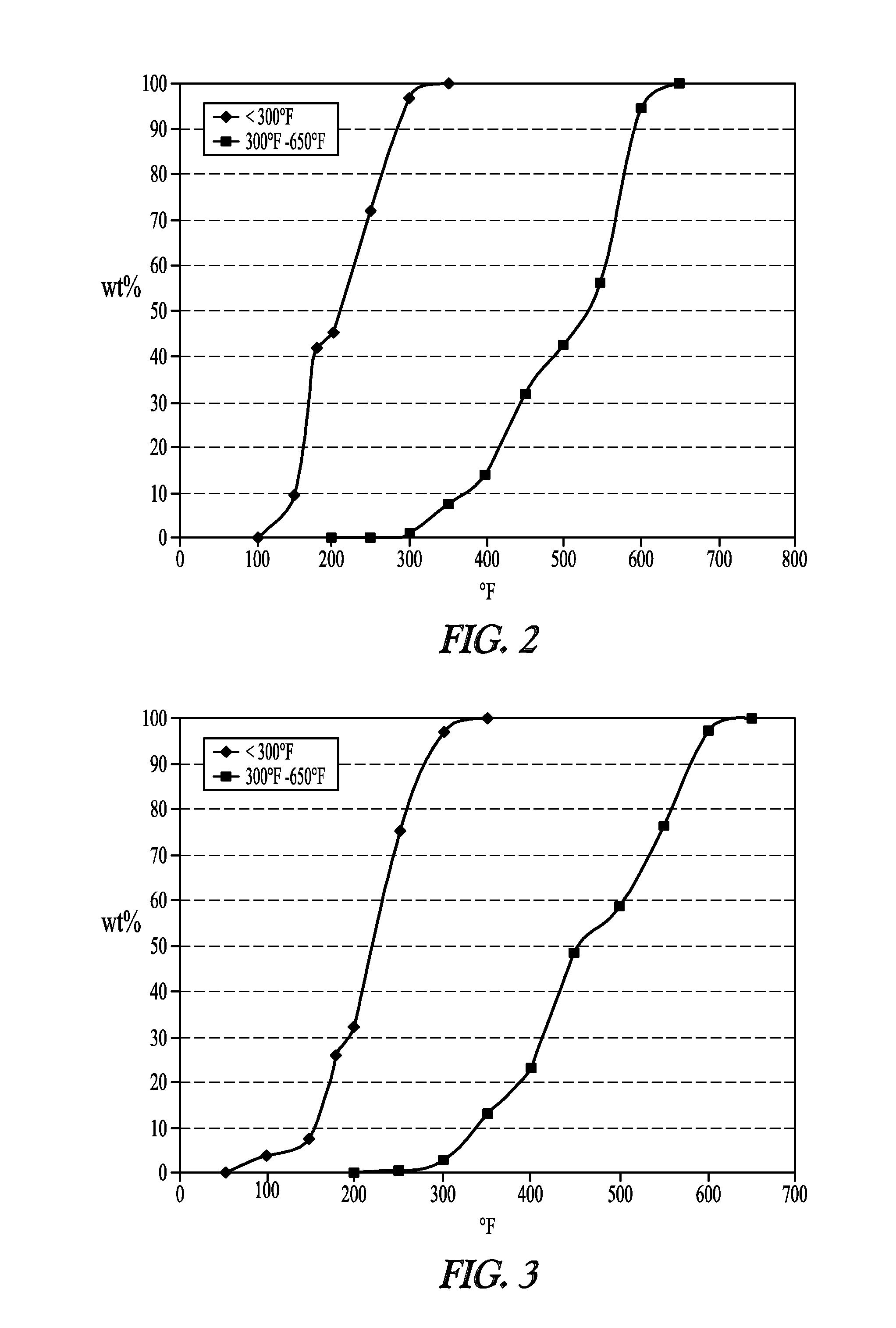

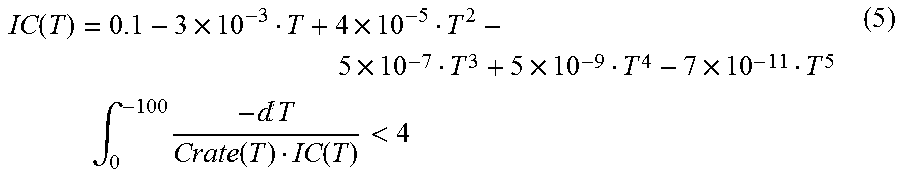

Liquefaction of carbonaceous material and biomass to produce a synthetic fuel

InactiveUS20130338411A1Less overall consumptionLess materialLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionSlurryPetroleum

The present invention relates to production of fuels from carbonaceous material and biomass. In some examples, the carbonaceous material is nonpetroleum fossil fuel or petroleum residuals. Various embodiments of the present invention provide a method of liquefaction of carbonaceous material and biomass. The method includes providing or obtaining a feed mixture, the mixture including carbonaceous material and biomass. The method also includes subjecting the feed mixture to liquefaction, to provide a product slurry. Various embodiments of the present invention provide a method of fuel production from carbonaceous material and biomass. The method includes separating the product slurry from the liquefaction, to give a conversion component. The method also includes processing the conversion component, to give a fuel.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

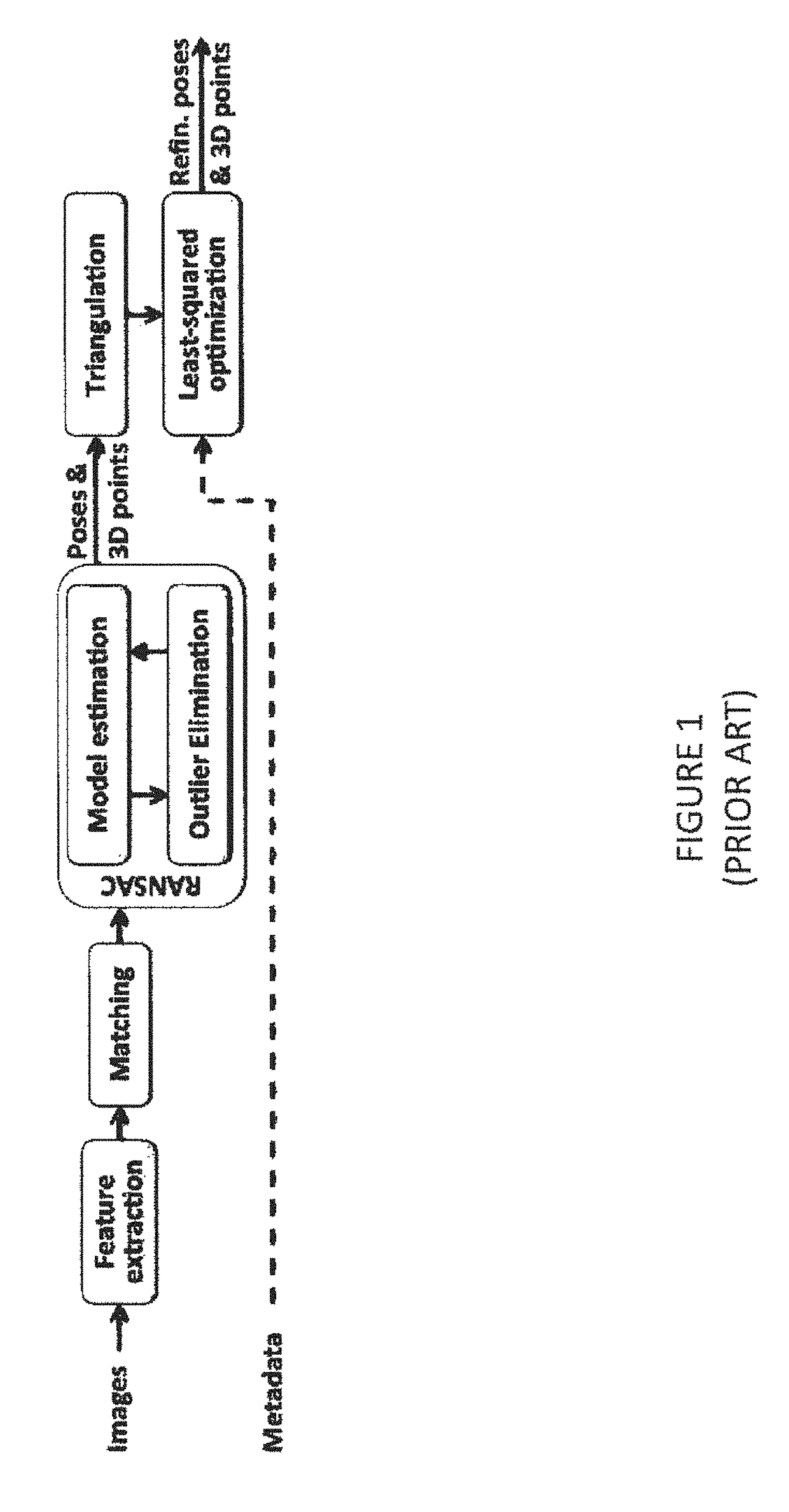

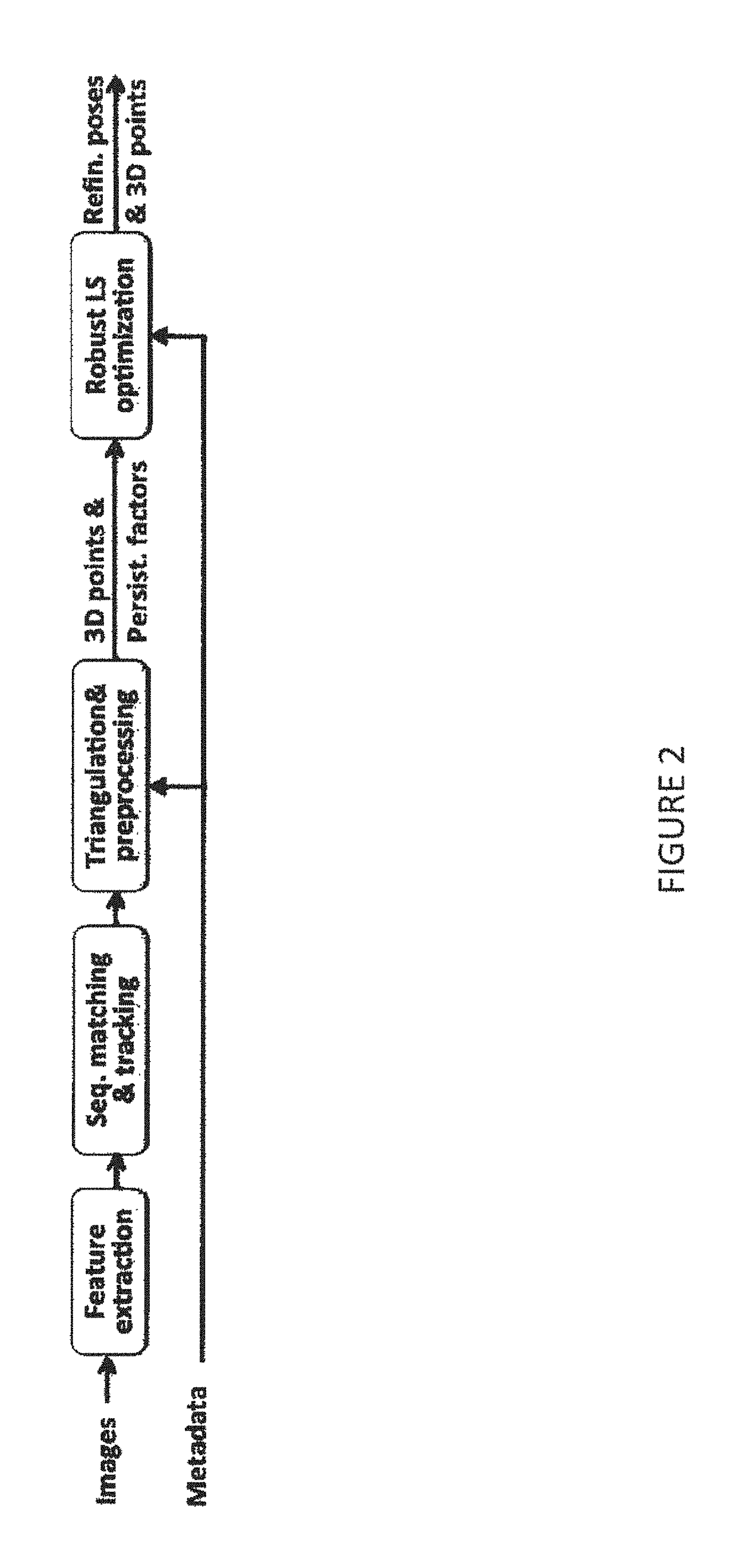

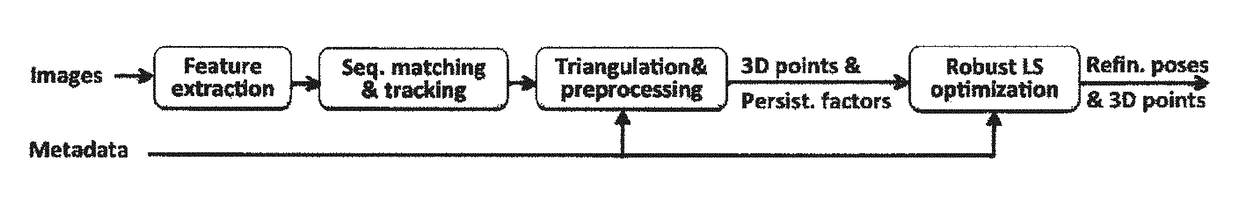

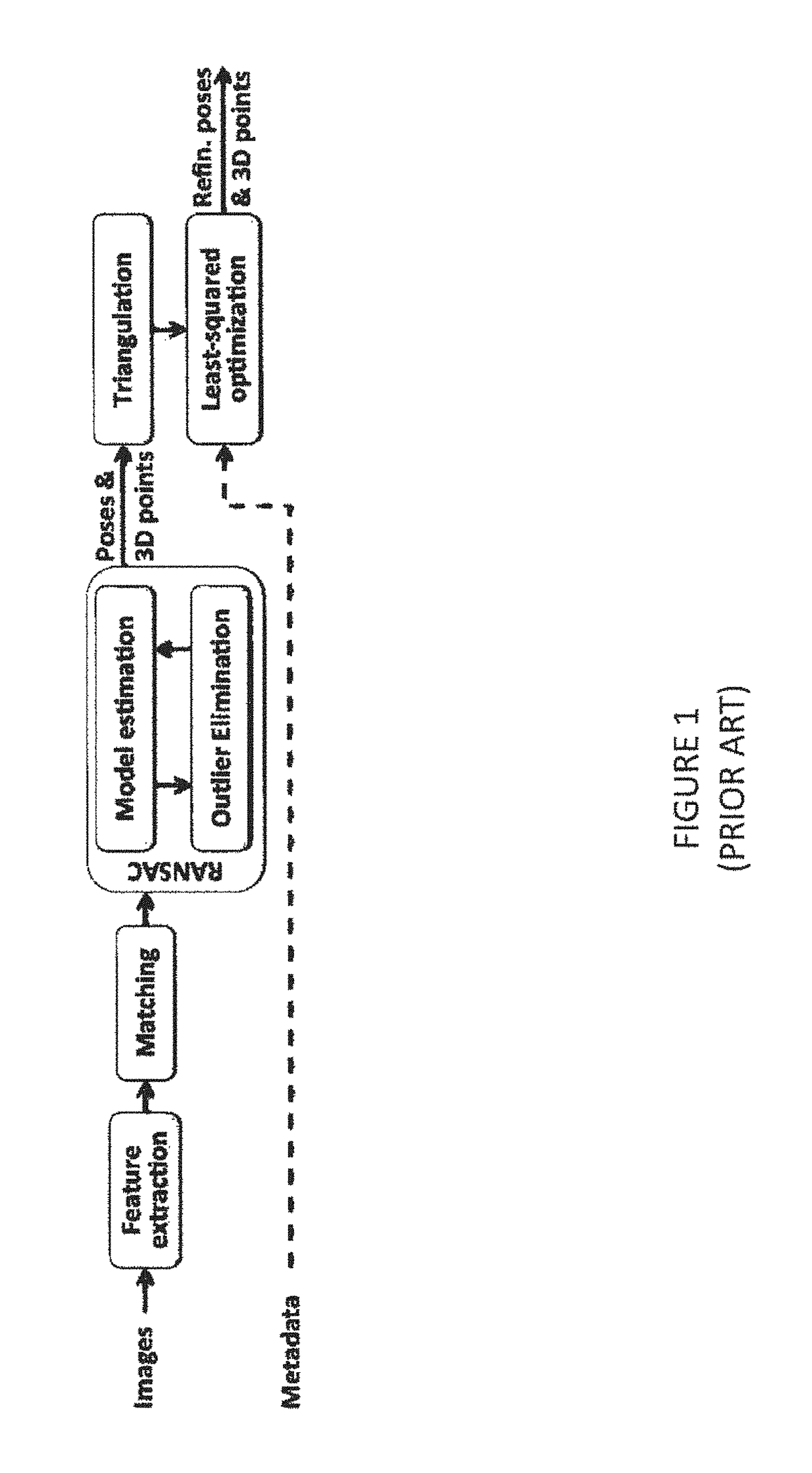

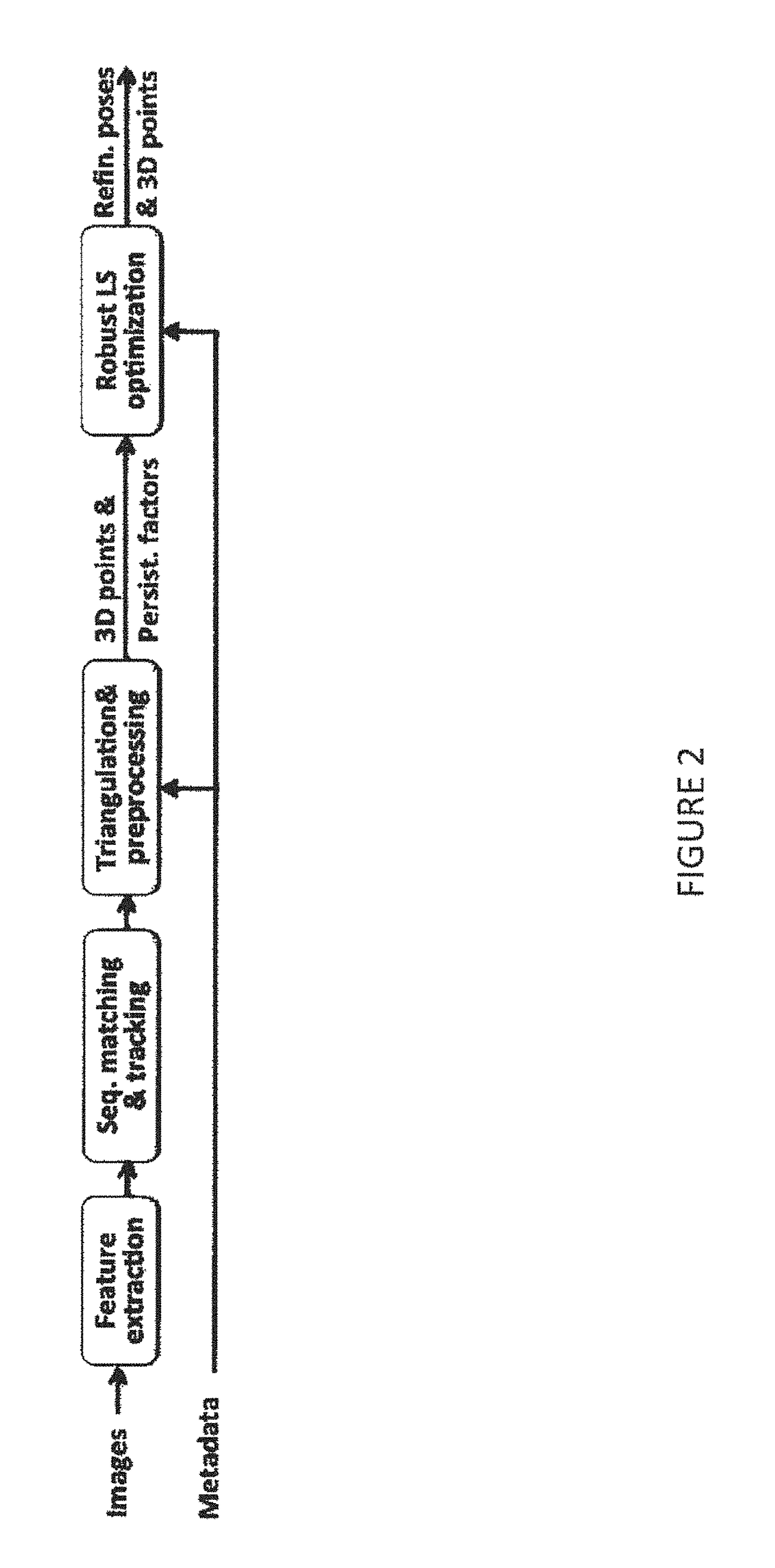

Method for fast camera pose refinement for wide area motion imagery

ActiveUS20170186164A1Not be eliminateReduce impactImage enhancementTelevision system detailsWide areaEssential matrix

The present invention provides a method for fast, robust and efficient BA pipeline (SfM) for wide area motion imagery (WAMI). The invention can, without applying direct outliers filtering (e.g. RANSAC) or re-estimation of the camera parameters (e.g. essential matrix estimation) efficiently refine noisy camera parameters in very short amounts of time. The method is highly robust owing to its adaptivity with the persistency factor of each track. The present invention highly suitable for sequential aerial imagery, particularly for WAMI, where camera parameters are available from onboard sensors.

Owner:THE DEPT OF THE AIR FORCE +1

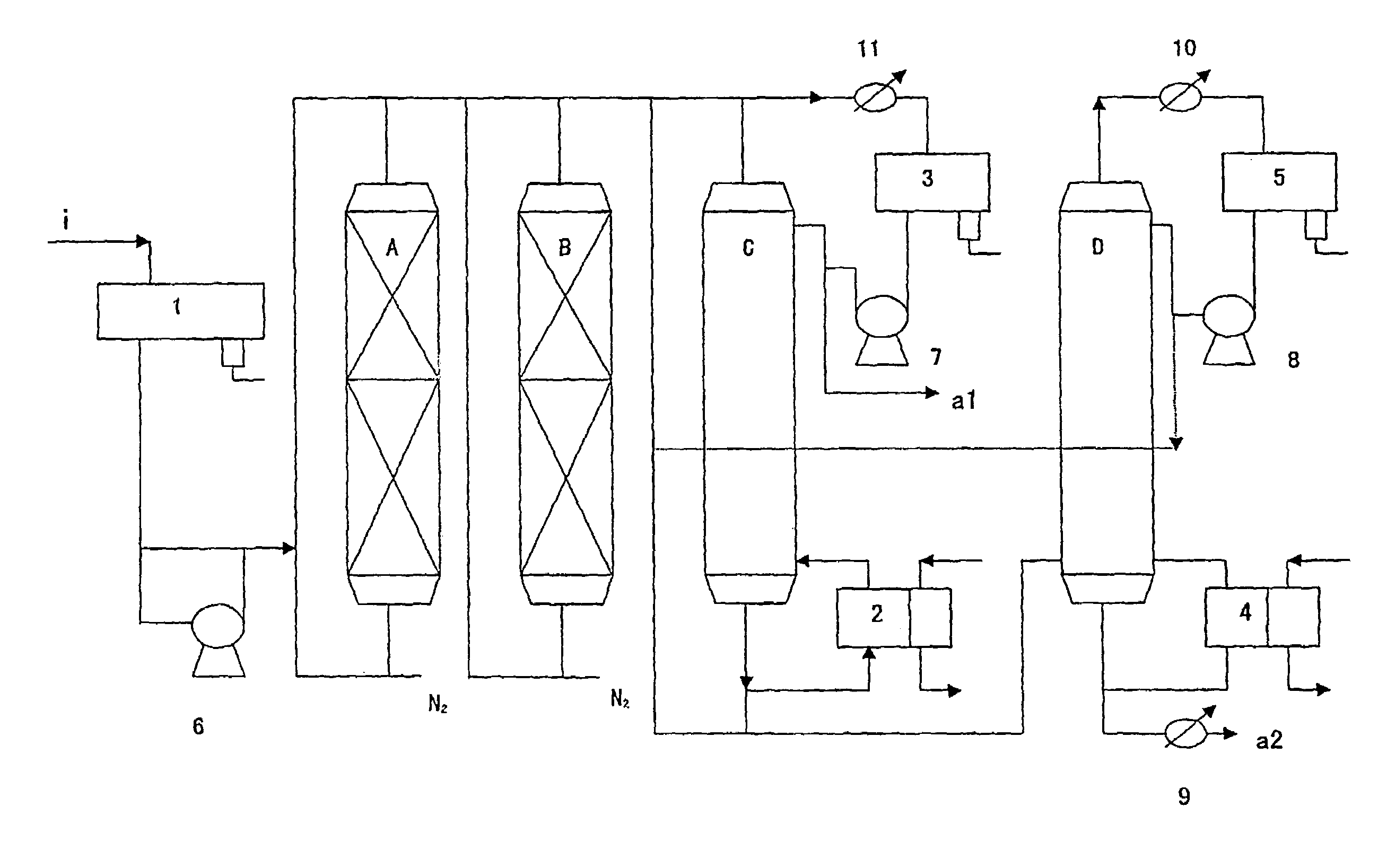

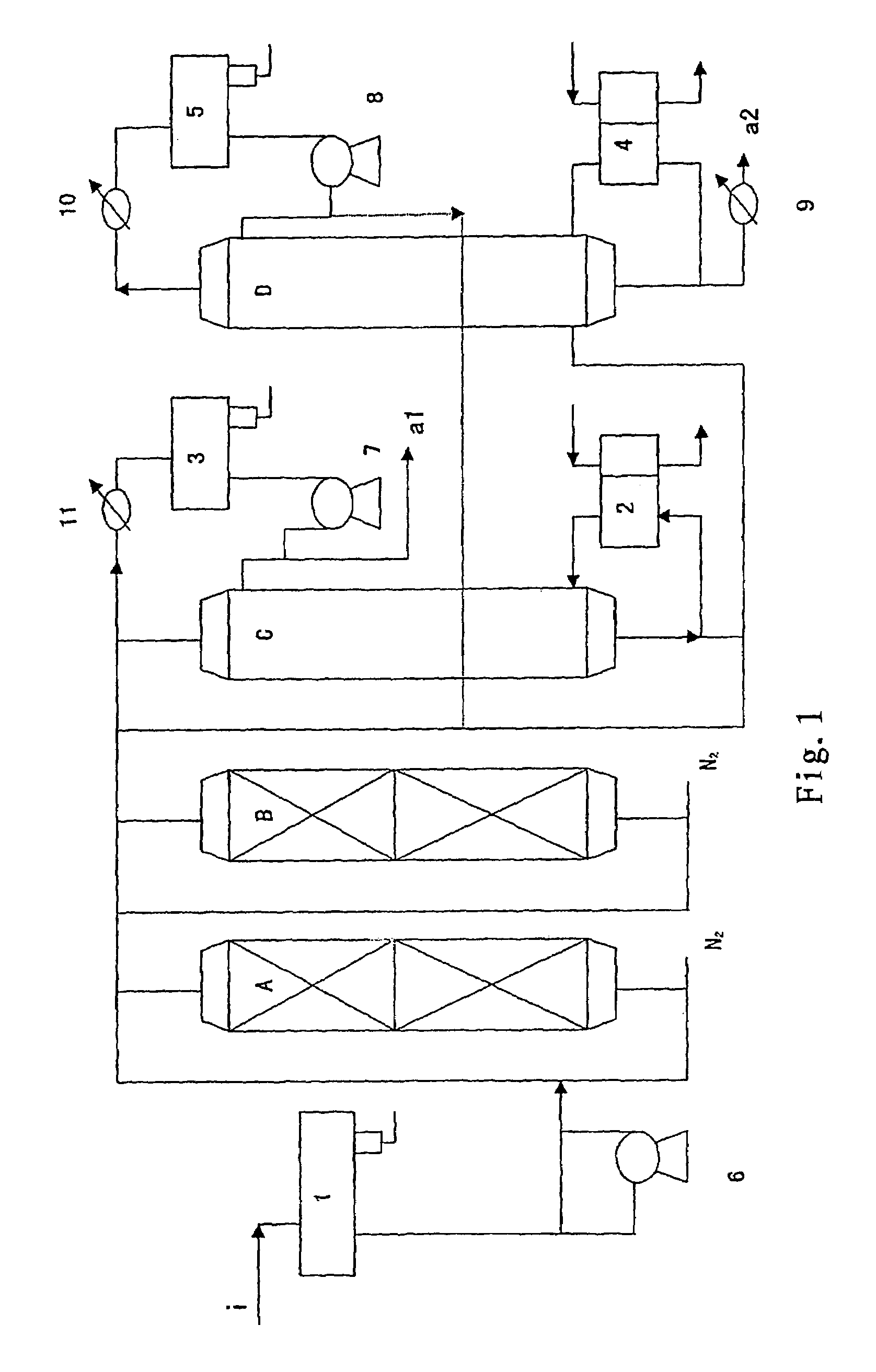

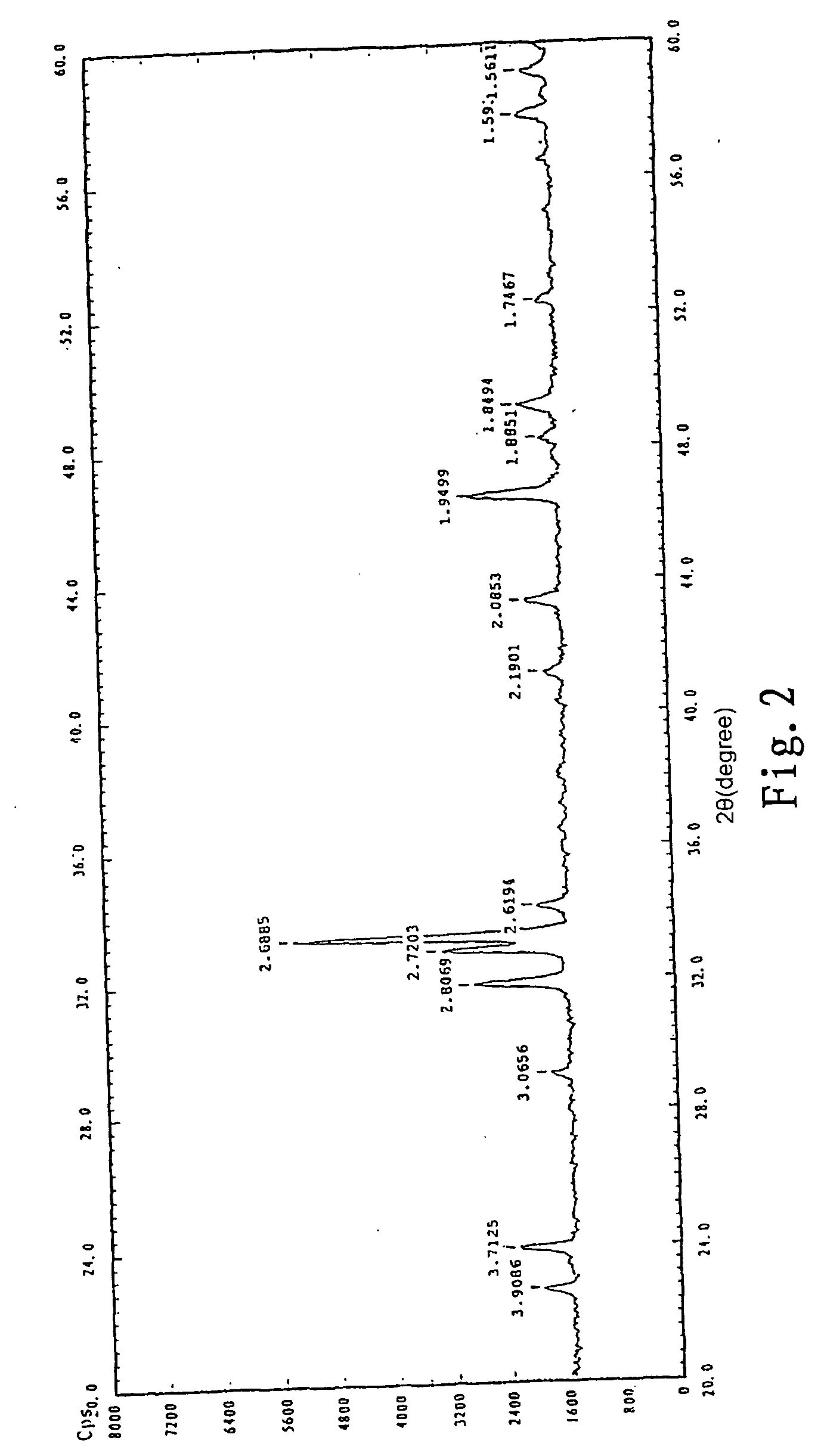

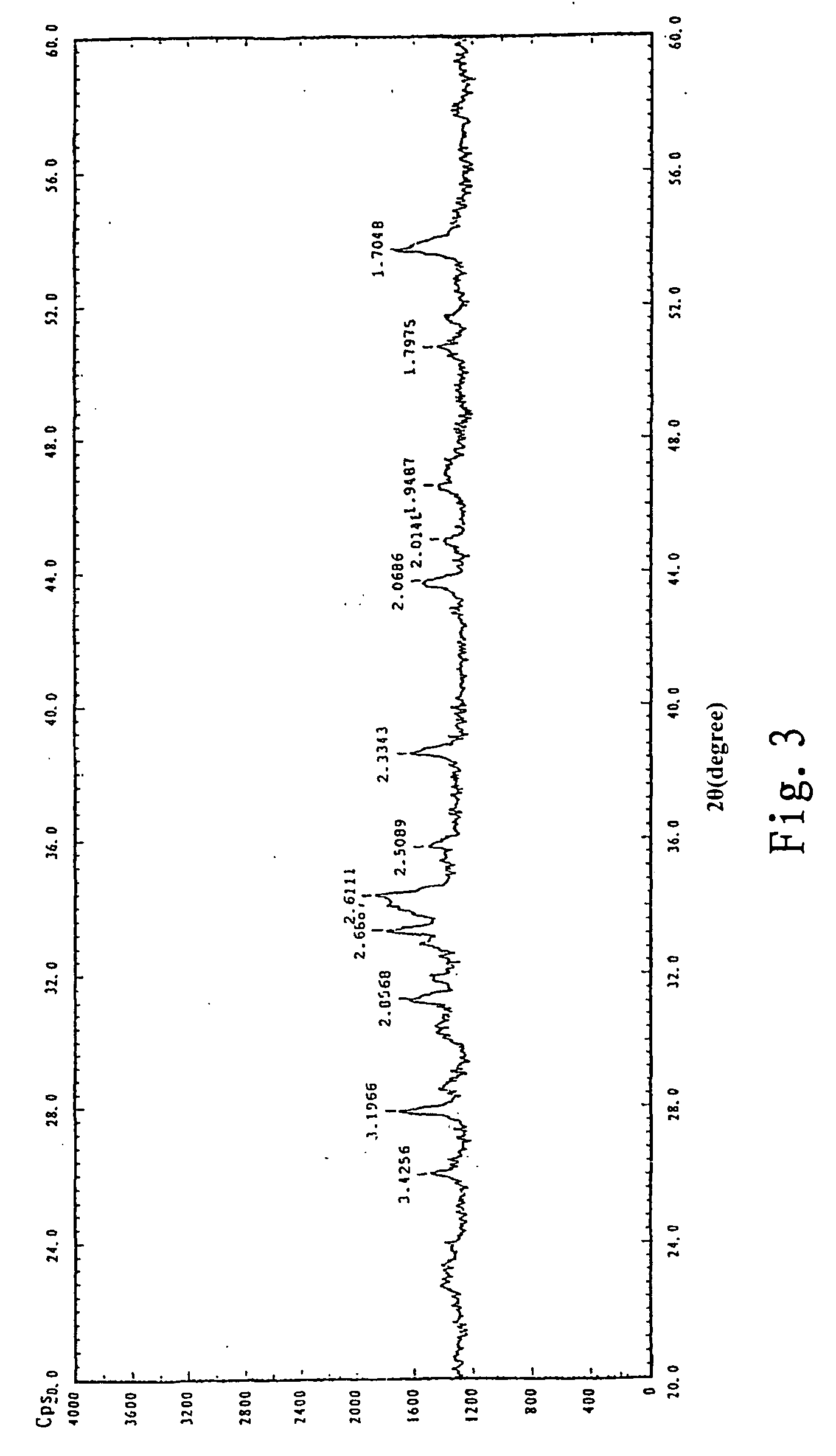

Process for refining liquefied petroleum gas in a commercial scale

ActiveUS7342145B2Efficient refiningImprove overall utilizationGaseous fuelsRefining with metal oxidesThiolAlcohol

The present invention relates to a novel process for refining the liquefied petroleum gas (LPG) in a commercial scale. The process comprises: sequentially performing fine desulfurization and mercaptan conversion of the LPG after alcohol amine treatment through desulfurizer and catalyst set in fixed bed reactor in the absence of alkali, wherein, during the fine desulfurization, the resultants of reaction between hydrogen sulfide in the LPG and Fe—Ca oxides or their hydrates adhered on the desulfurizer, and during the mercaptan conversion, the mercaptan in the LPG reacts with the residual trace amount of air in the LPG under the action of the catalyst to produce the disulfides; letting the formed disulfides along with the LPG flow out of the fixed bed reactor; rectifying the LPG after the mercaptan conversion to obtain the refined LPG products, with further rectification to obtain the valuable disulfide products. The present process has advantages of high efficiency, no alkali discharge, being a simplified process over the prior method using alkali treatment and making no environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

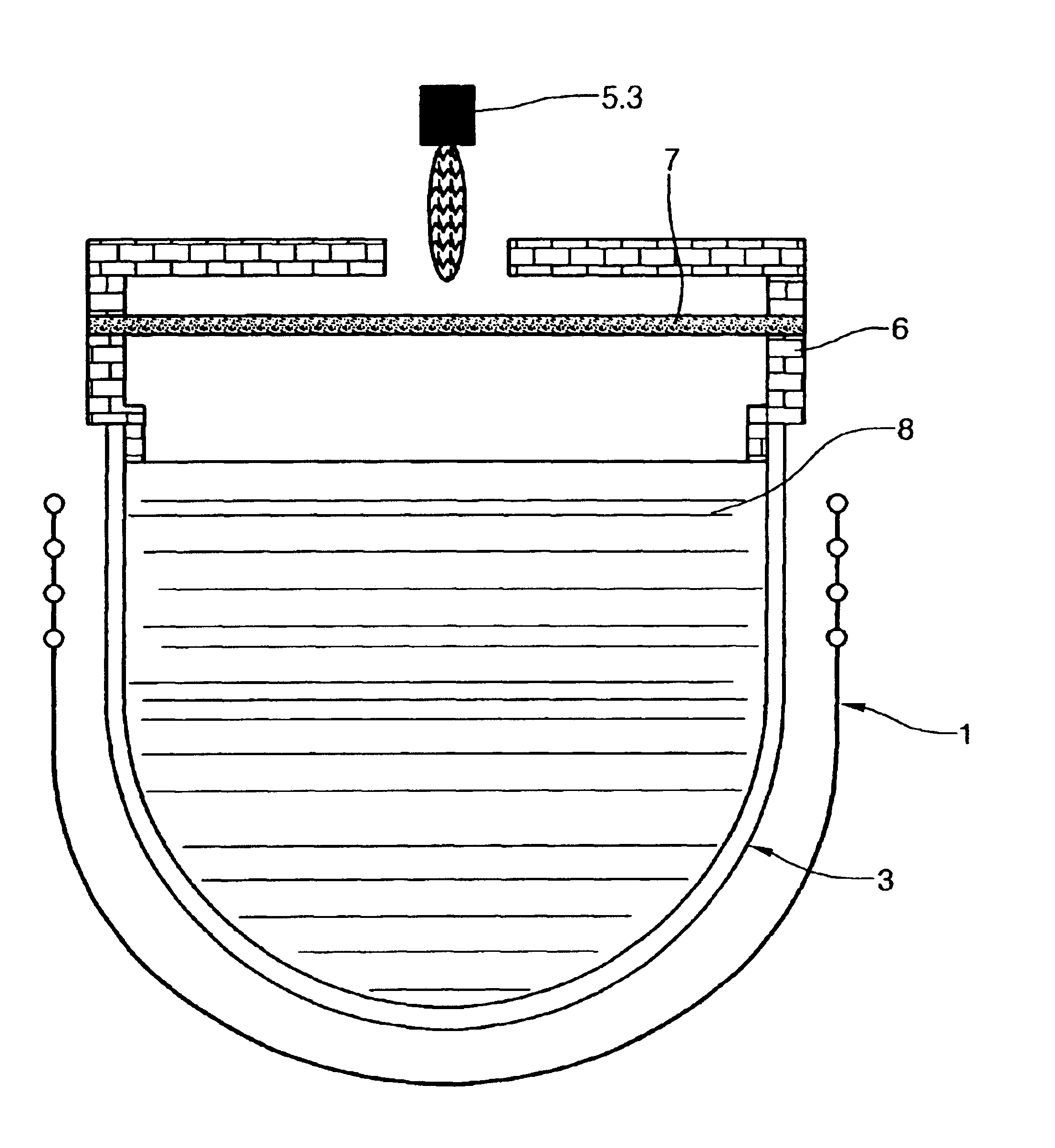

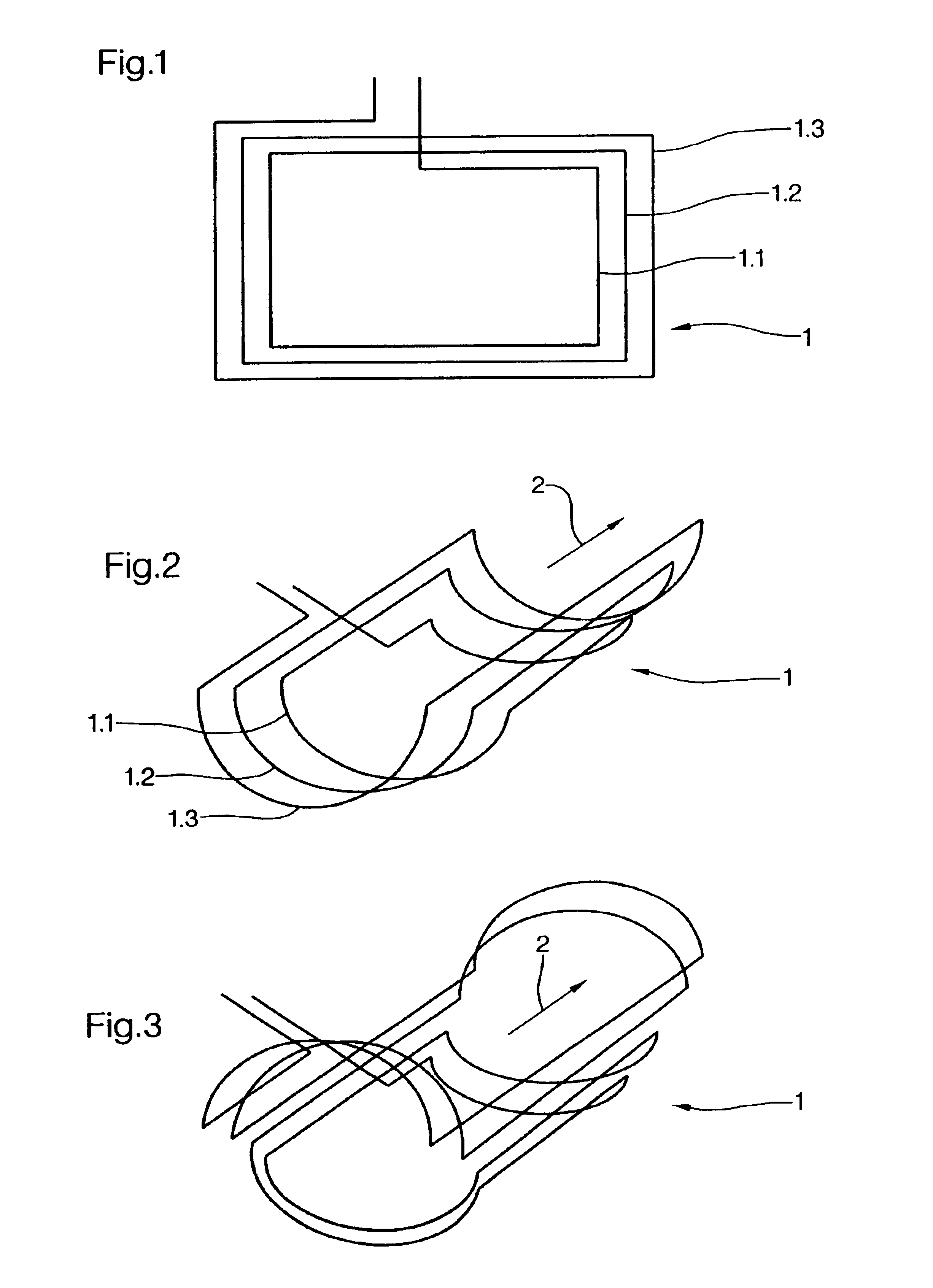

Method for melting or refining glasses or glass ceramics

InactiveUS6848275B1Efficient refiningFurnaces without endless coreCoil arrangementsGlass-ceramicMetal

This invention relates to a device for melting or refining glass or glass ceramics. According to the invention, such a device is provided with the following characteristics: a channel which is arranged in an essentially horizontal manner and which is provided with an inlet and an outlet for the glass melt; and an HF coil for coupling HF energy into the melt is allocated to the channel. The channel is made of a plurality of metal pipes in a similar way to a skull pot. Said pipes can be connected to a cooling medium.

Owner:SCHOTT AG

Cold-rolled steel sheet and process for manufacturing same

ActiveUS20150037610A1Excellent stretch-flangeabilityStretch flangeabilityFurnace typesHeat treatment process controlNiobiumChromium

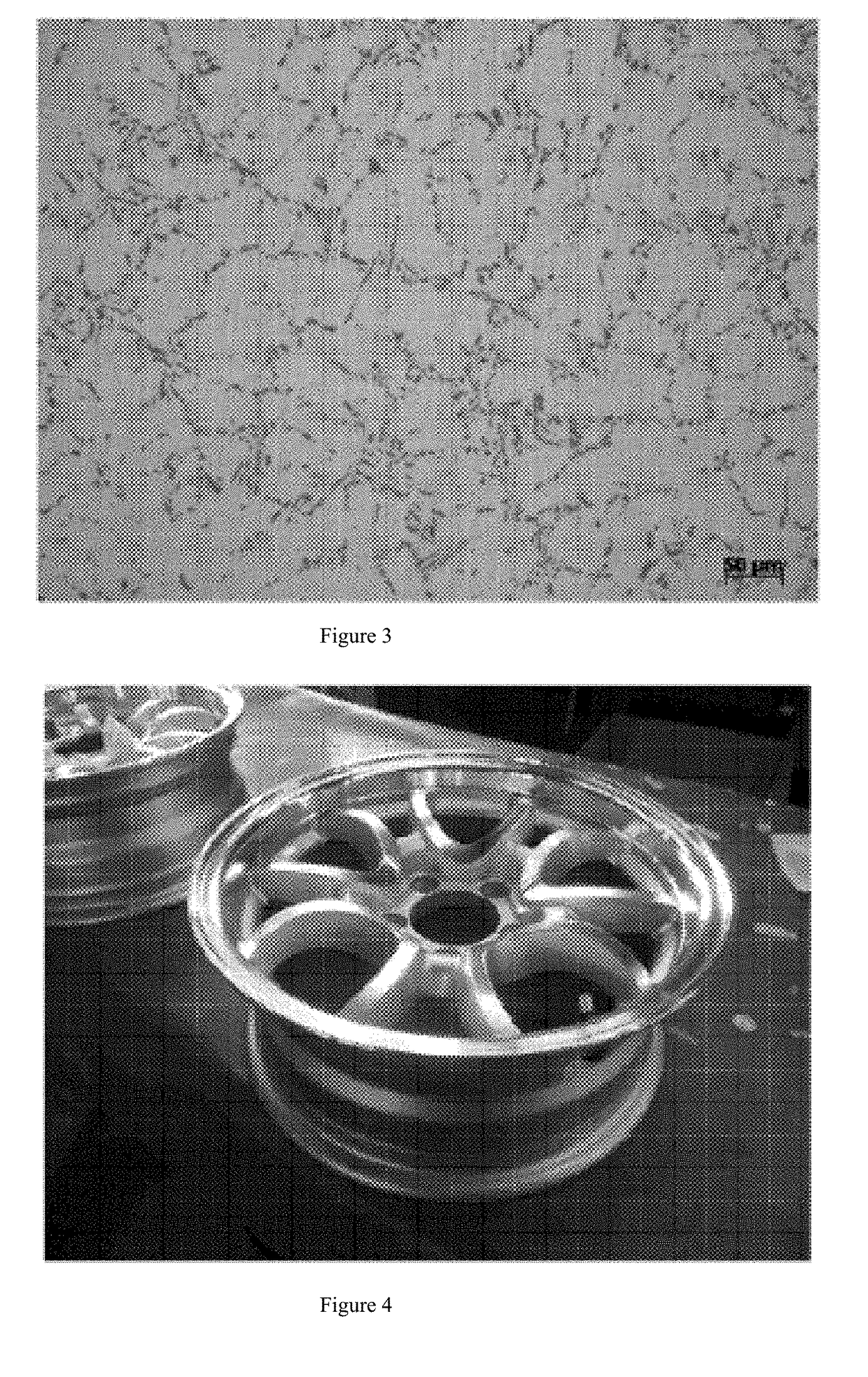

A high-strength cold-rolled steel sheet includes a composition having controlled amounts of carbon, silicon, manganese, phosphorous, sulfur, titanium, niobium, sol. Aluminum, chromium, molybdenum, vanadium, boron, calcium, REM, and iron. A microstructure thereof has a main phase of ferrite of at least 40 area %, and a second phase of a low-temperature transformation phase consisting either or both of martensite and bainite, which comprises at least 10 area % in total and retained austenite (γ) at least comprising 3 area %. An average grain diameter of ferrite has a tilt angle of at least 15° is at most 5.0 mm, an average grain diameter of the low-temperature transformation-produced phase is at most 2.0 mm, an average grain diameter of lump-like retained γ having an aspect ratio of less than 5 is at most 1.5 mm, and an area fraction of the lump-like retained γ relative to the retained γ is at least 50%.

Owner:NIPPON STEEL CORP

1500 mpa-grade steel with high product of strength and elongation for vehicles and manufacturing methods therefor

ActiveUS20190271064A1High strengthHigh strength and elongationFurnace typesHeat treatment furnacesAusteniteUltimate tensile strength

Owner:BAOSHAN IRON & STEEL CO LTD

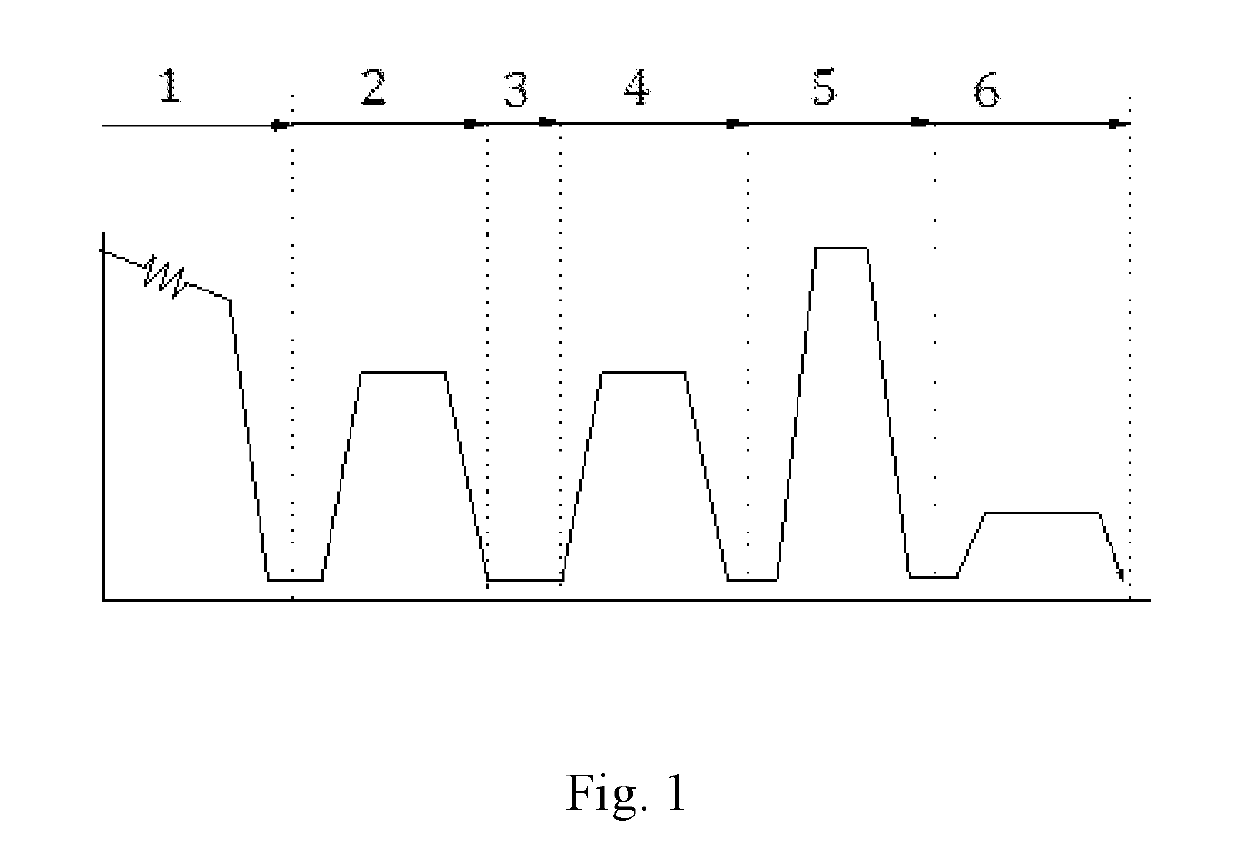

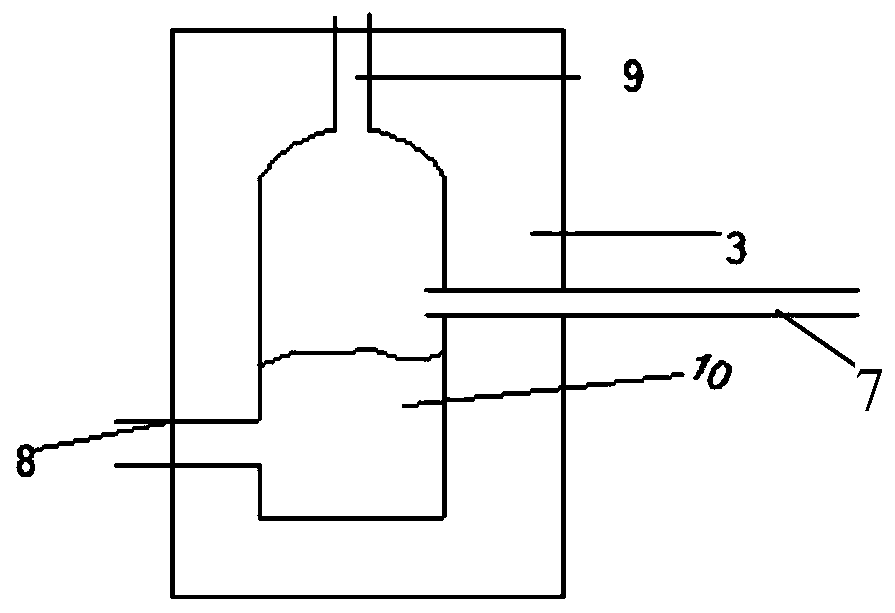

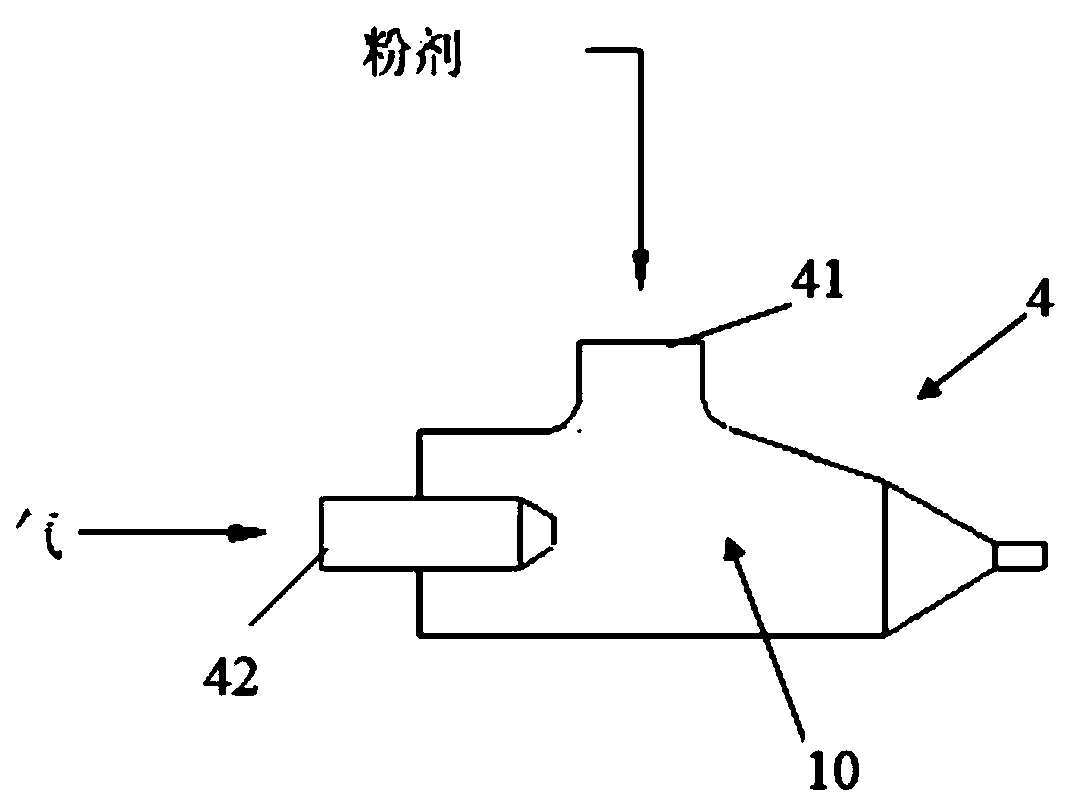

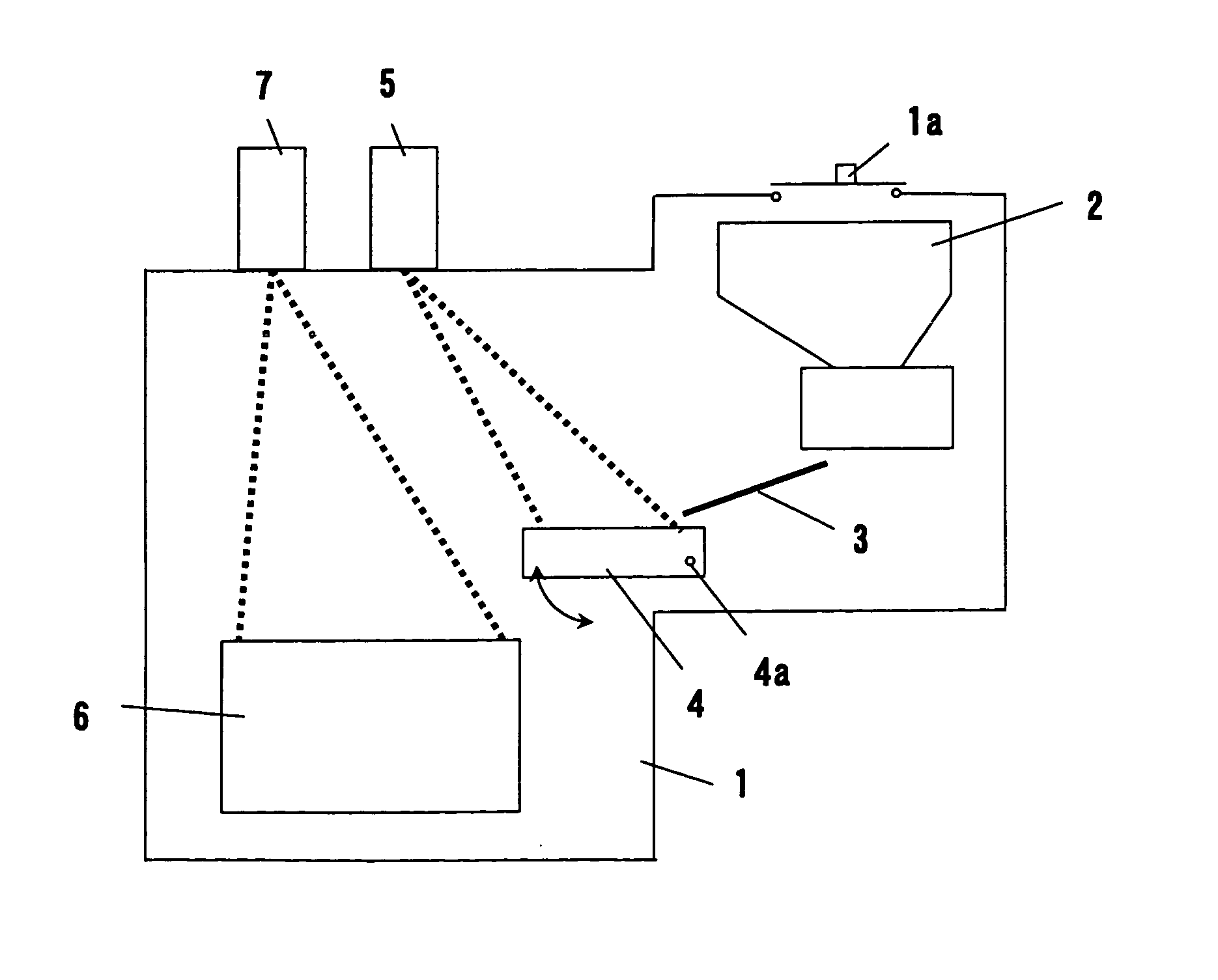

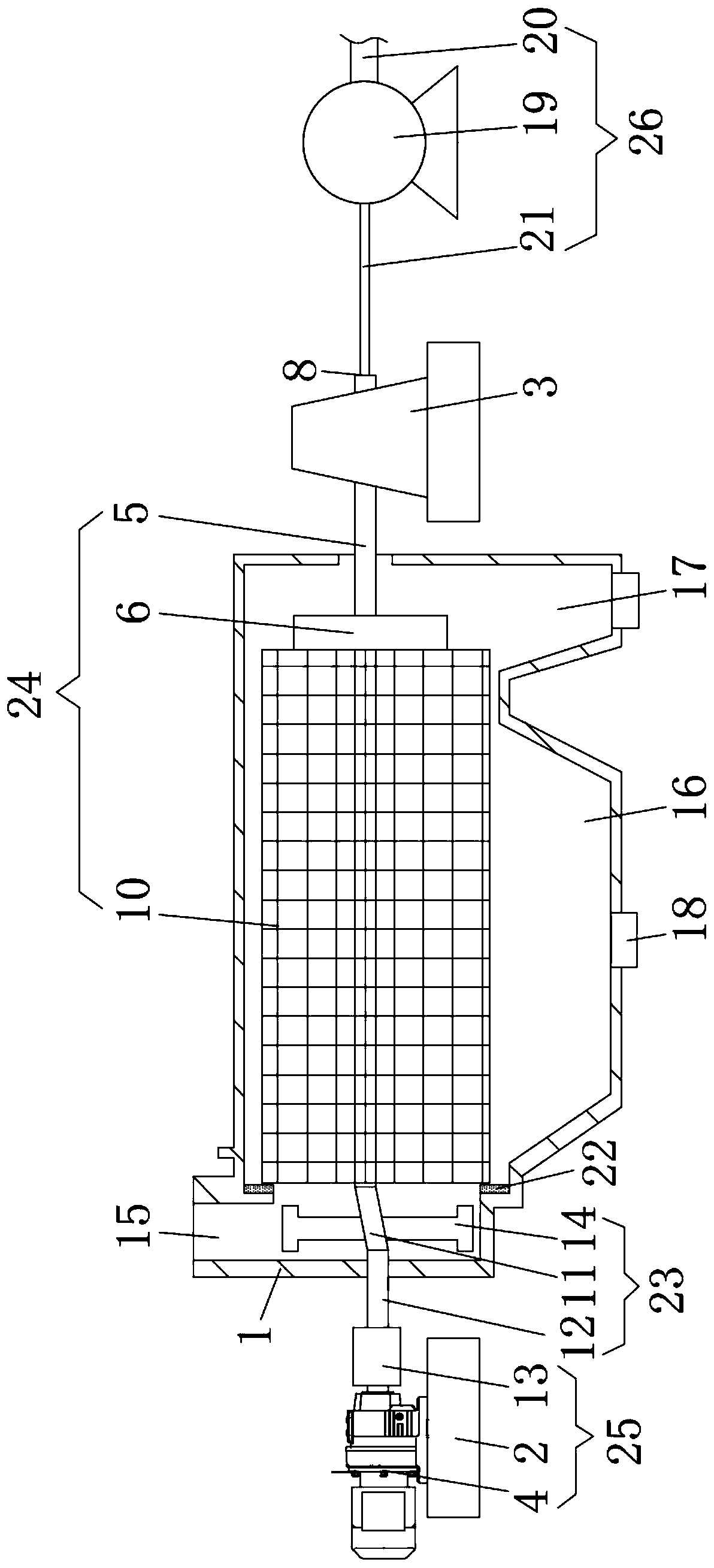

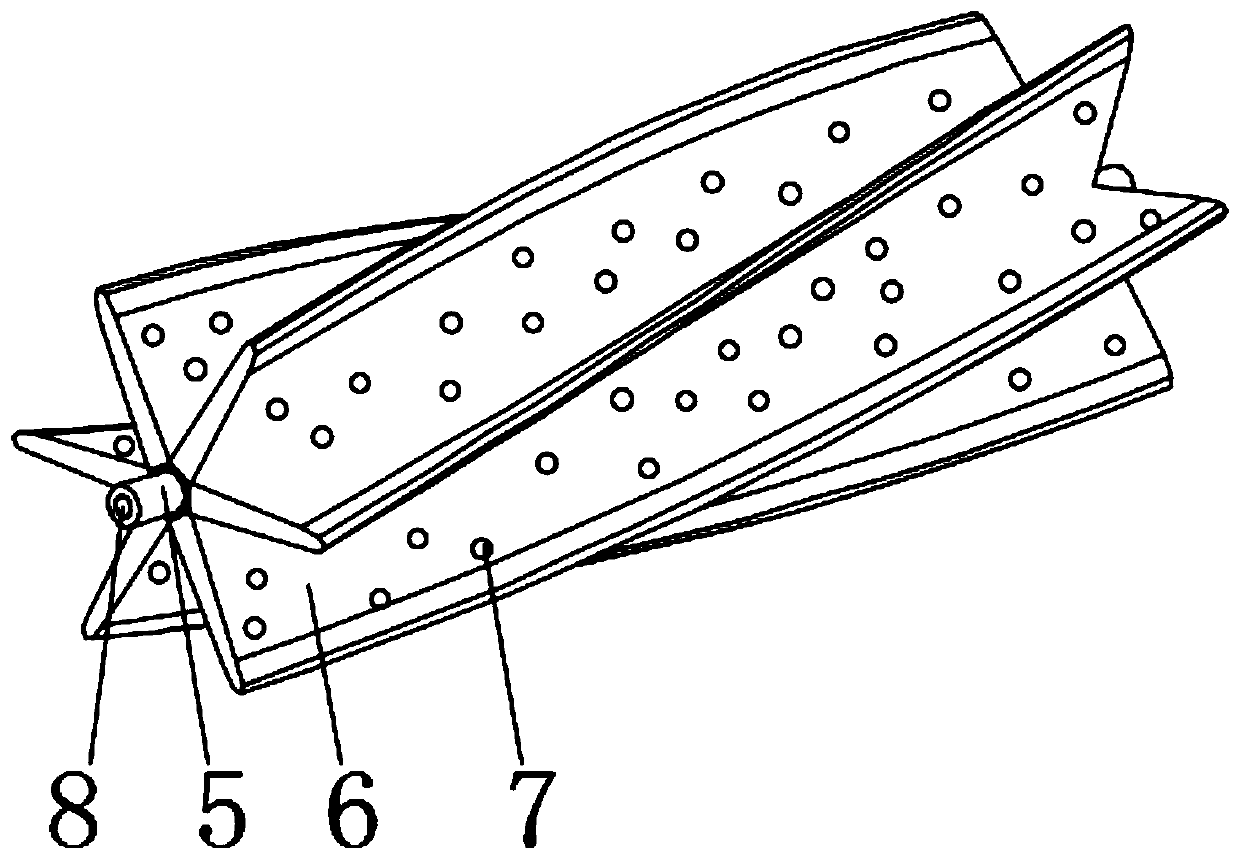

Converter tapping injection refining desulfurization method and device

The invention provides a converter tapping injection refining desulfurization method and device. In the converter tapping process, with Ar (or N2) as powder spraying carrier gas, a spraying gun injects powdery desulfurization agents to molten steel streams in the tapping process, so that the powdery desulfurization agents are fed in a ladle with the molten steel streams; and the full mixing is realized under the effect of bottom blowing argon stirring of the ladle, so that the contact specific surface area of the powdery desulfurization agents and molten steel is increased, the inter-phase mass transfer speed and the molten steel desulfurization reaction speed are accelerated, the effective utilization efficiency of the powdery desulfurization agents is improved, the desulfurization refining production takt is accelerated, and the continuous stable efficient refining is realized. The defects in a traditional desulfurization process can be overcome; and the quick and efficient smeltingcan be realized. The powdery desulfurization agents can be replaced by carbon powder, desulfurization powder agents, desulfurization powder agents or alloy powder agents; and the multifunctional refining can be realized. The device and the method are not only suitable for molten steel desulfurization refining processes, but also suitable for other refining processes.

Owner:NORTHEASTERN UNIV

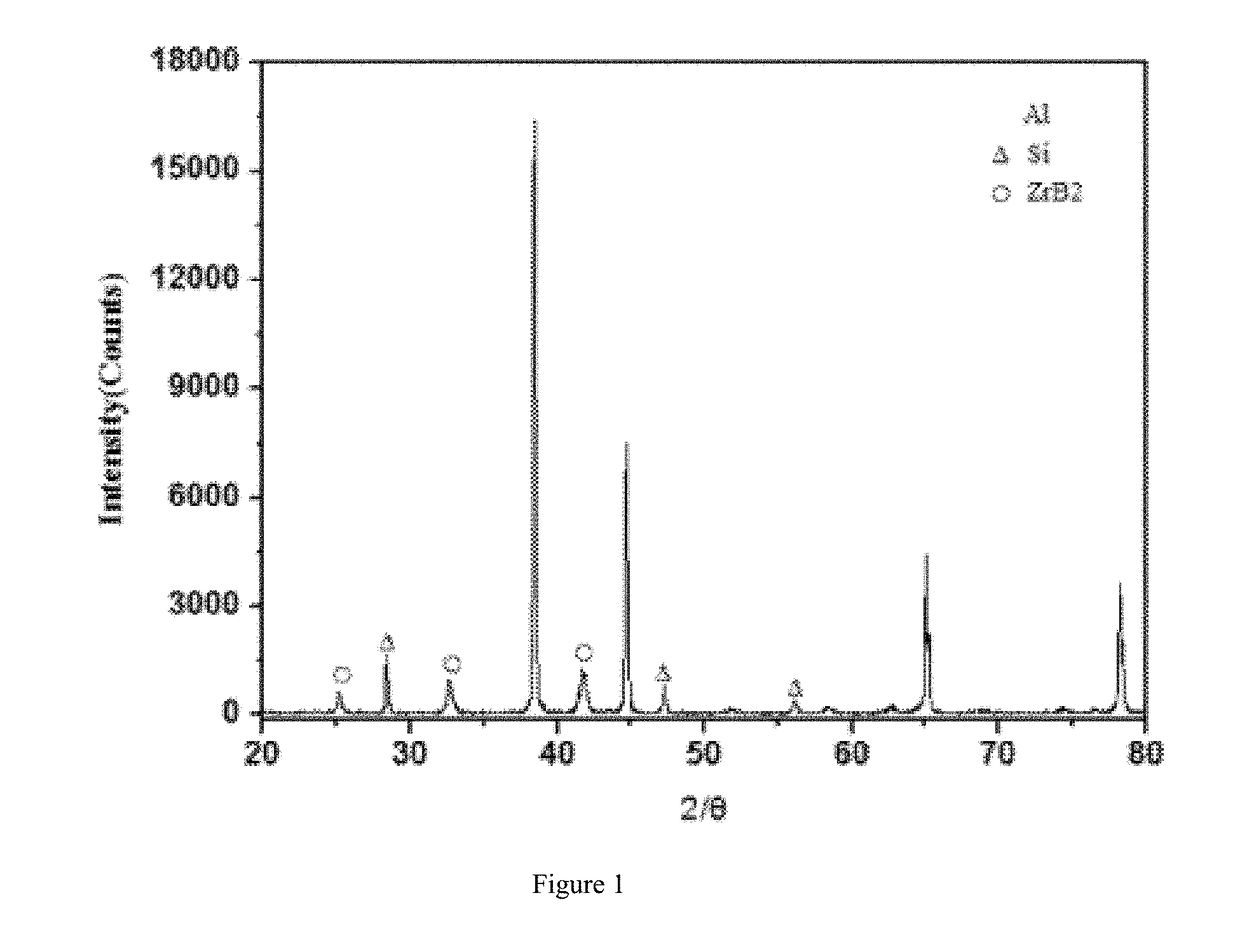

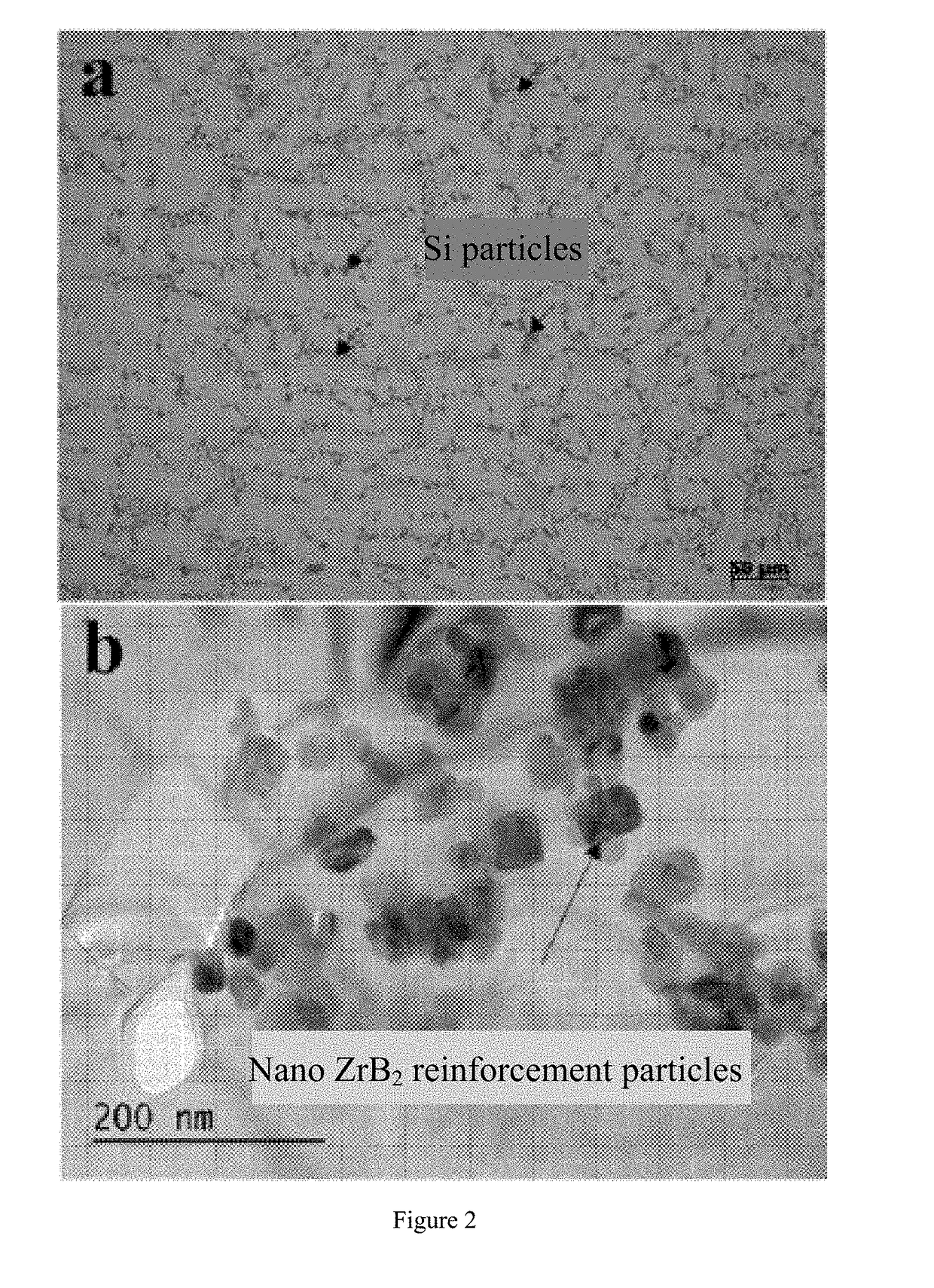

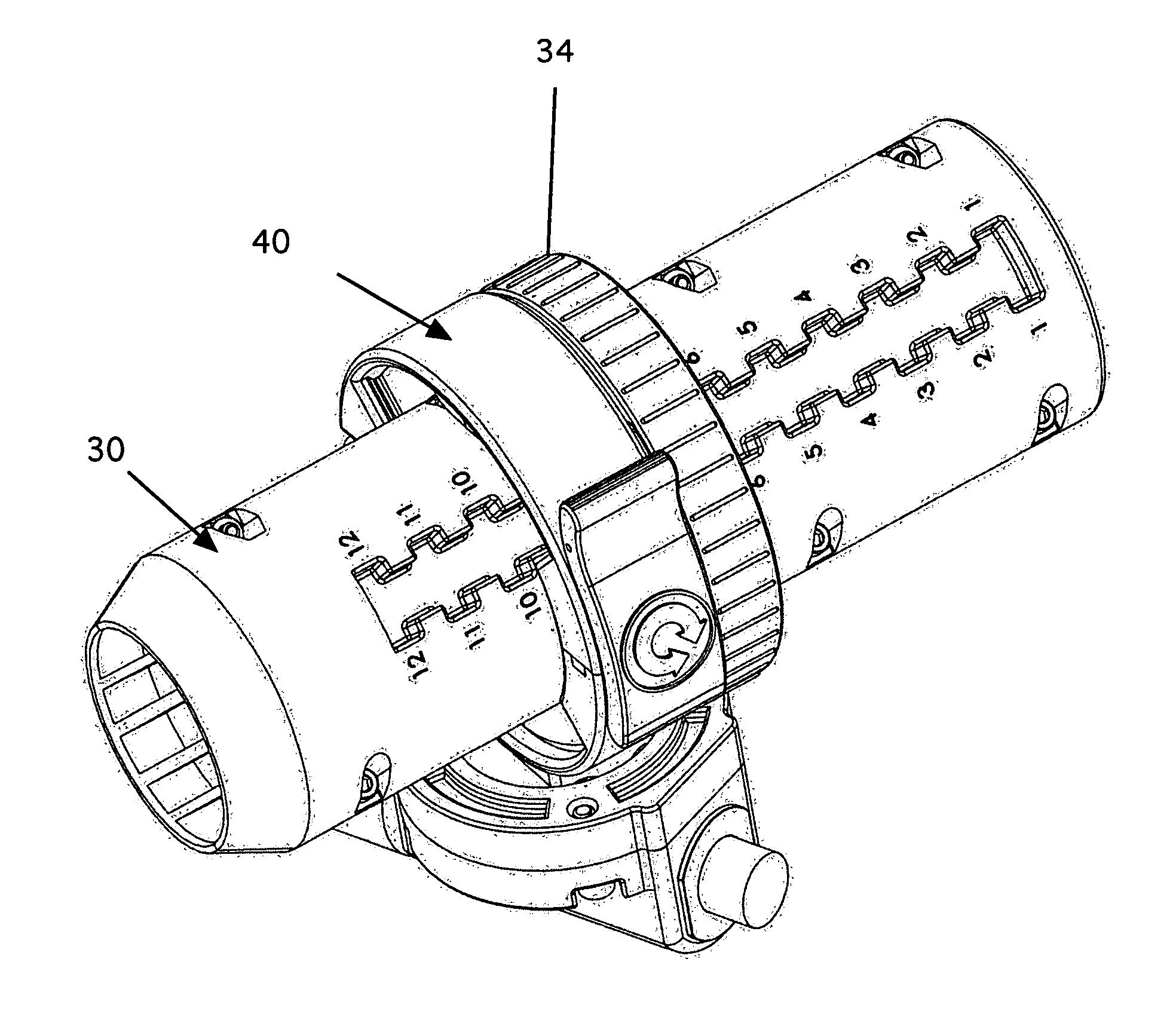

Anti-fatigue in-situ aluminum-based composite material for heavy-load hubs and preparation method therefor

ActiveUS20190010580A1High strengthHigh modulusMaterial nanotechnologyHubsRare-earth elementAdditive ingredient

Provided are an anti-fatigue in-situ aluminium-based nanocomposite material for heavy-load automobile hubs and a preparation method therefor. By means of the fine adjustment of components and a forming process, in situ nano-compositing, micro-alloying and rapid compression moulding techniques are combined. That is, after the addition of elements Zr and B, an in-situ reaction occurs to form a nano ZrB2 ceramic reinforcement which is distributed in aluminium crystals and crystal boundaries and bonded to a metallurgical interface kept firm with the matrix. Moreover, with rare earth elements Er and Y and element Zr as addition ingredients and after the increase in the contents of Cr and Mn, a structure having fine aluminium crystal grains with a large number of micro-alloyed nano precipitated particles contained in the grains, fine and round eutectic silicon grains and a fine Mg2Si phase mainly dispersed inside the grains is obtained in the process of the rapid compression moulding and thermal treatment of the hubs; and thus, the tensile strength, the yield strength and the fatigue strength of an alloy are effectively improved.

Owner:JIANGSU UNIV +1

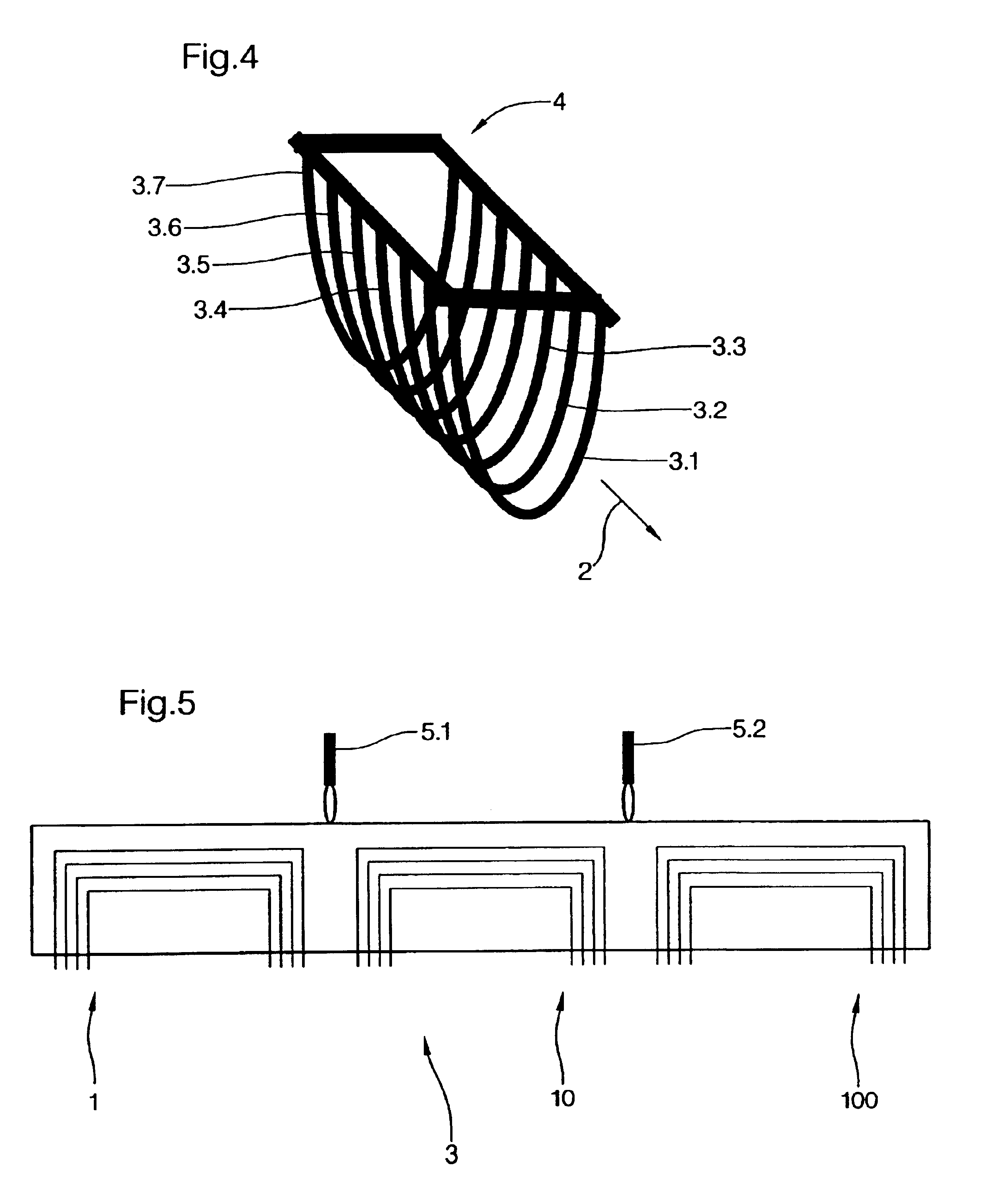

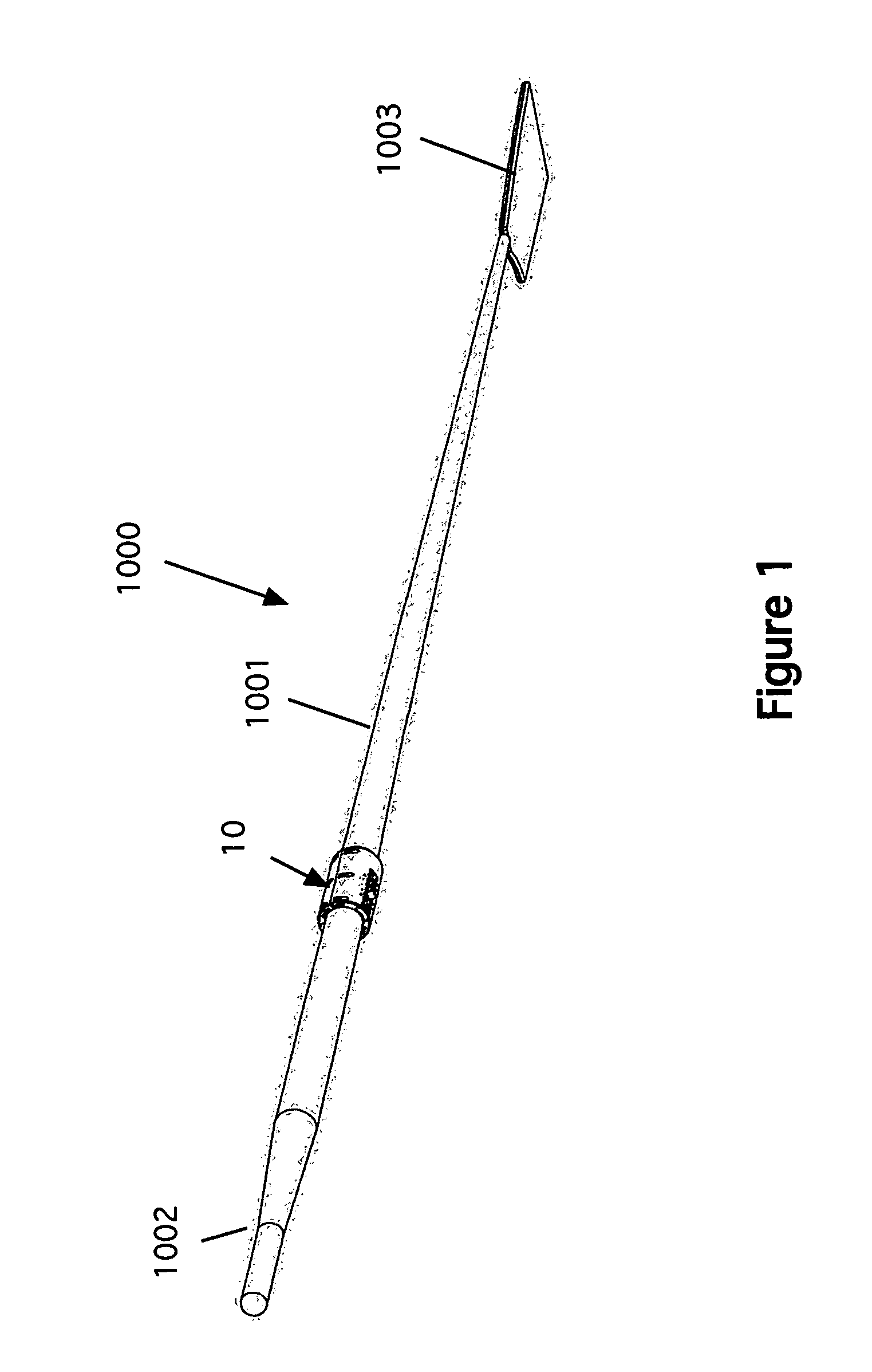

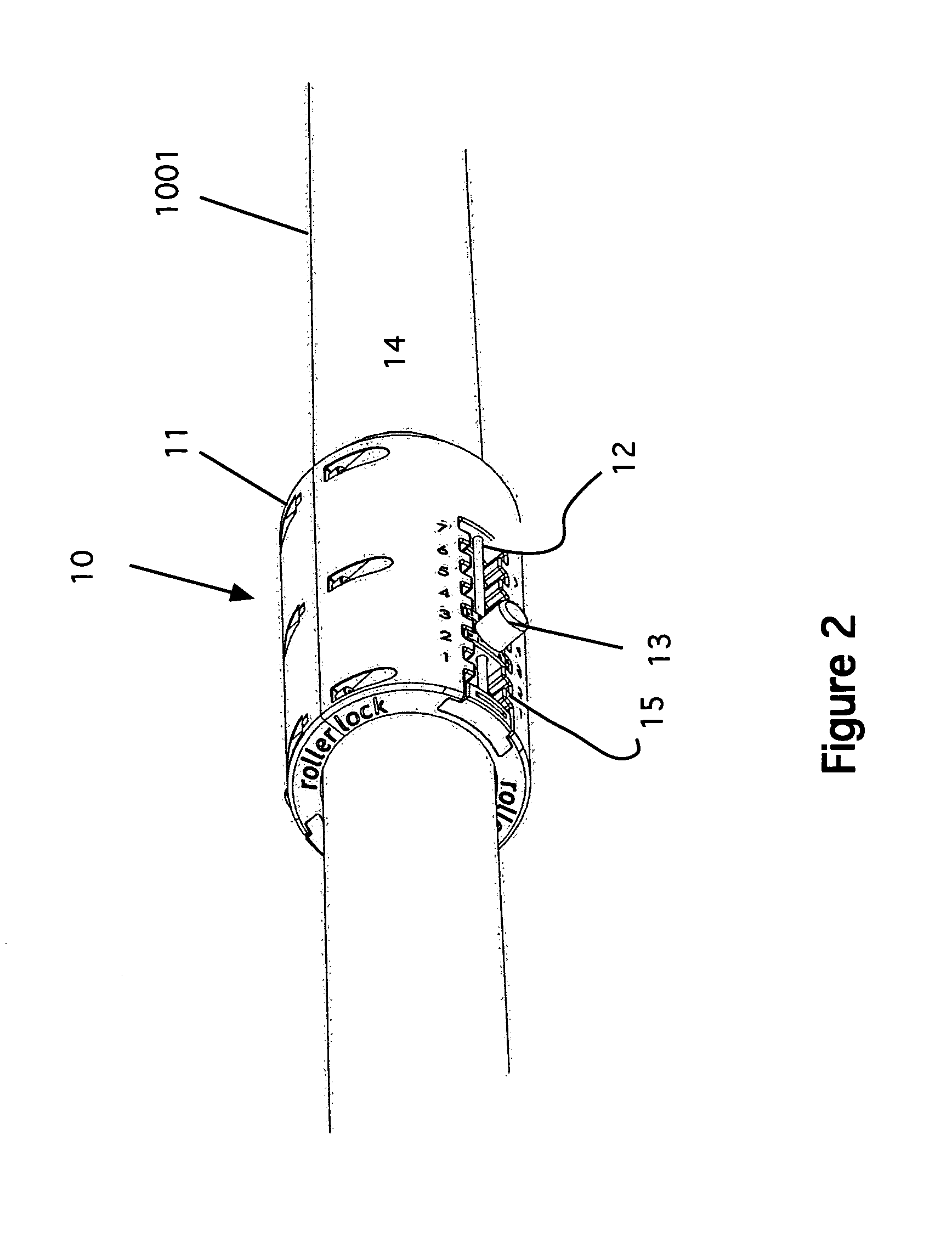

Oarlock system

InactiveUS9394044B1Improves rowing geometryEliminates free-playMuscle power acting propulsive elementsEngineeringRisk stroke

The invention is made up of three major components, a sleeve that is mounted on an oar shaft; a dock, which is mounted to the shell's riggers; and a pair of oar retainers that clamp around the sleeve and pivotally mount to the dock. The sleeve is locked into the oar retainers via a latch. The sleeve has a movable block that has a cam, which engages grooves in the oar retainers. The sleeve and can rotate around its axis, which allows the oar to be feathered. The oar retainers hold the sleeve and allow it to rotate and pivot during the rowing stroke. The dock attaches the oar retainer to the shell or outrigger. Its purpose is twofold: first, it provides a stable vertical platform on which the oar retainers can pivot up and down; second, it swivels left and right.

Owner:FLEXOARS CORP

Method for fast camera pose refinement for wide area motion imagery

ActiveUS9959625B2Reduce impactEfficient refiningImage enhancementImage analysisAviationEssential matrix

The present invention provides a method for fast, robust and efficient BA pipeline (SfM) for wide area motion imagery (WAMI). The invention can, without applying direct outliers filtering (e.g. RANSAC) or re-estimation of the camera parameters (e.g. essential matrix estimation) efficiently refine noisy camera parameters in very short amounts of time. The method is highly robust owing to its adaptivity with the persistency factor of each track. The present invention highly suitable for sequential aerial imagery, particularly for WAMI, where camera parameters are available from onboard sensors.

Owner:THE DEPT OF THE AIR FORCE +1

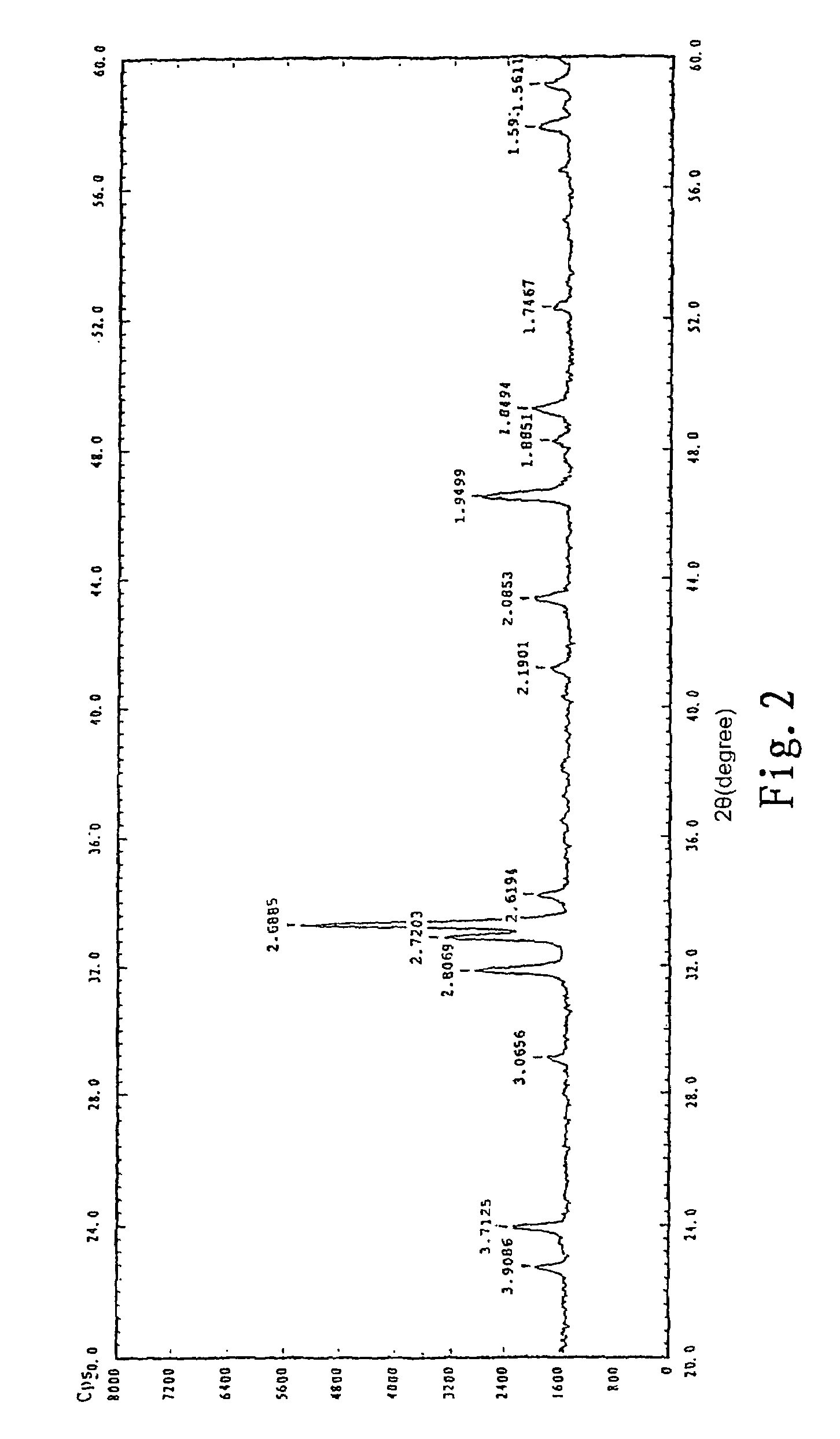

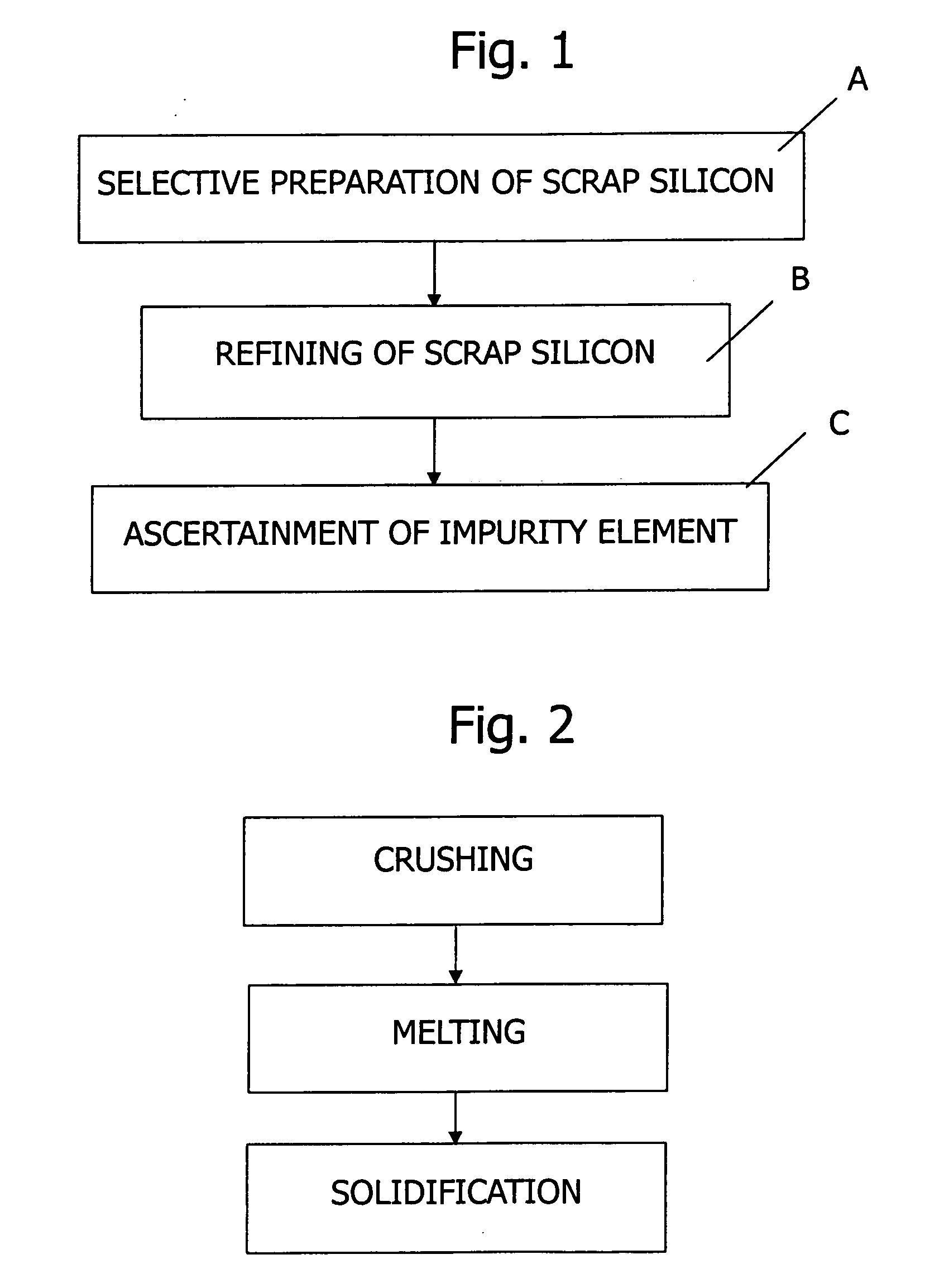

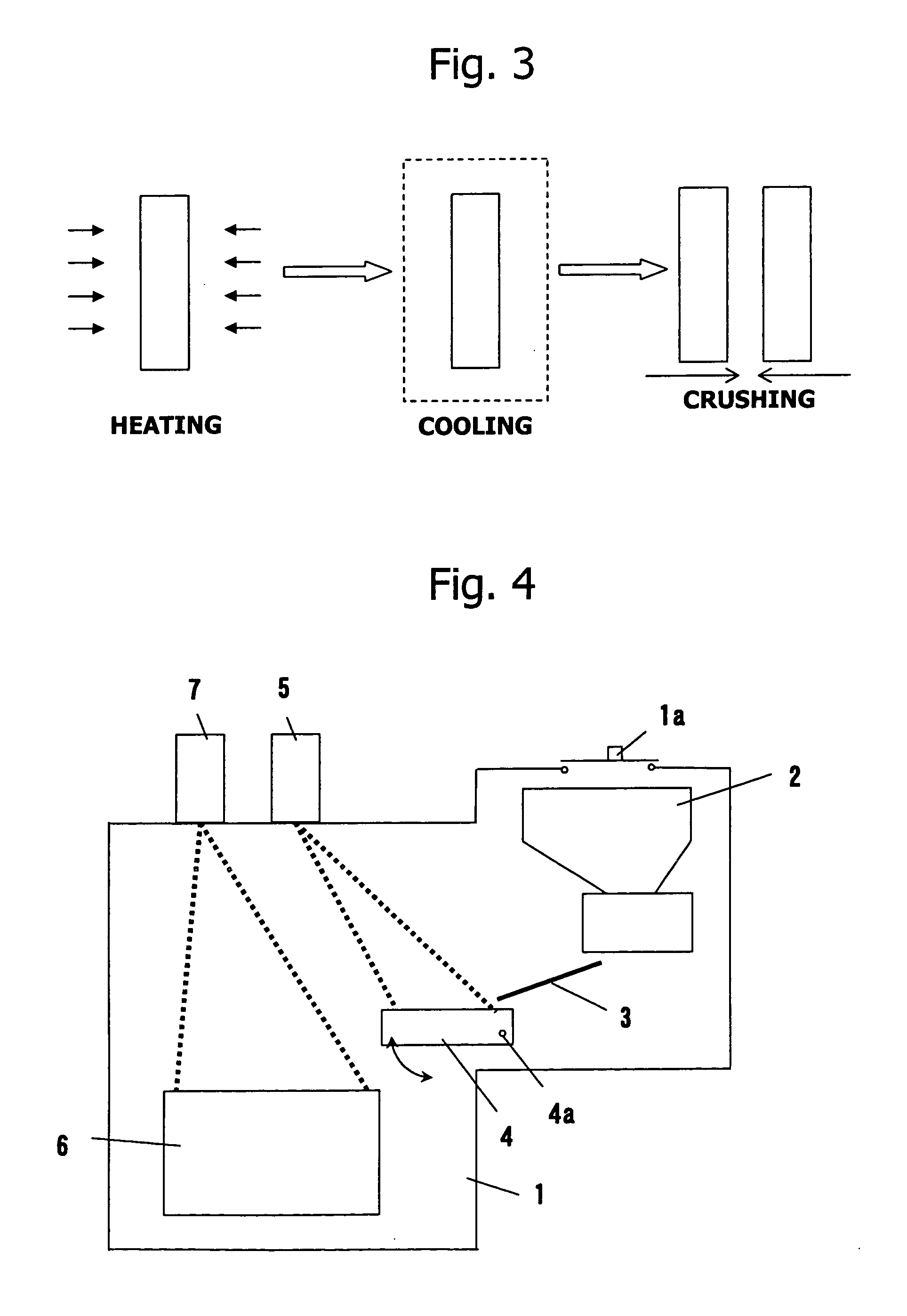

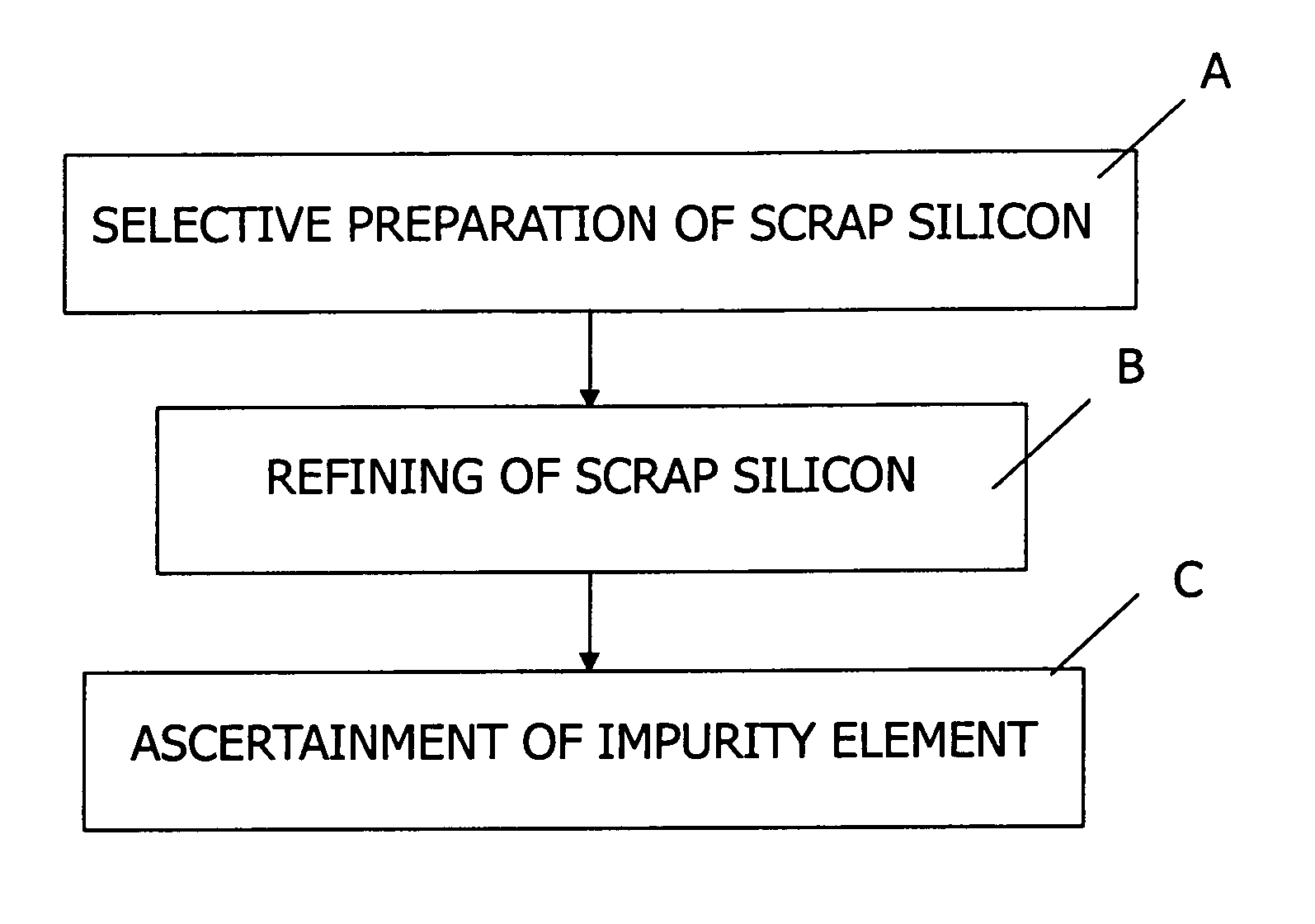

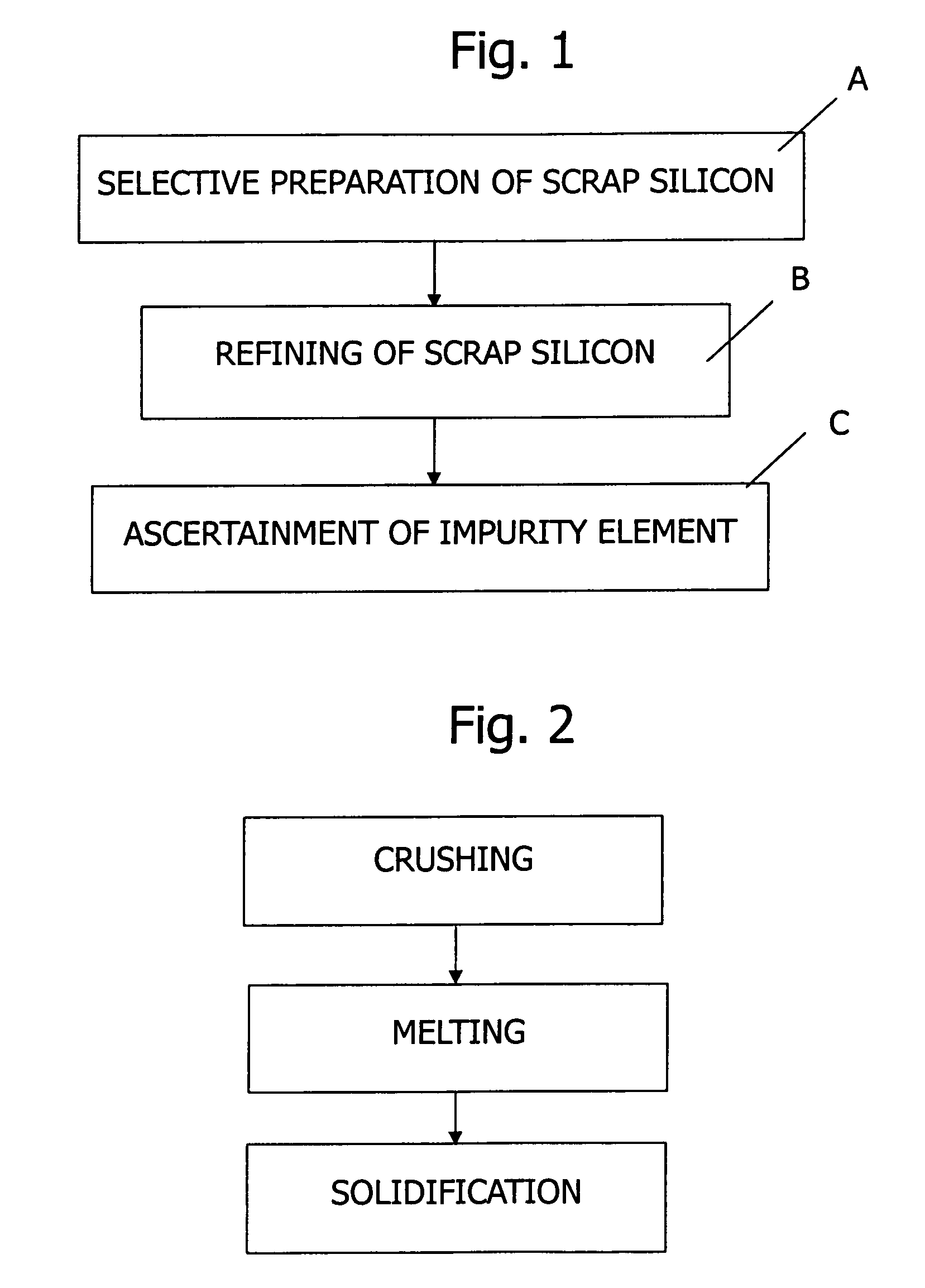

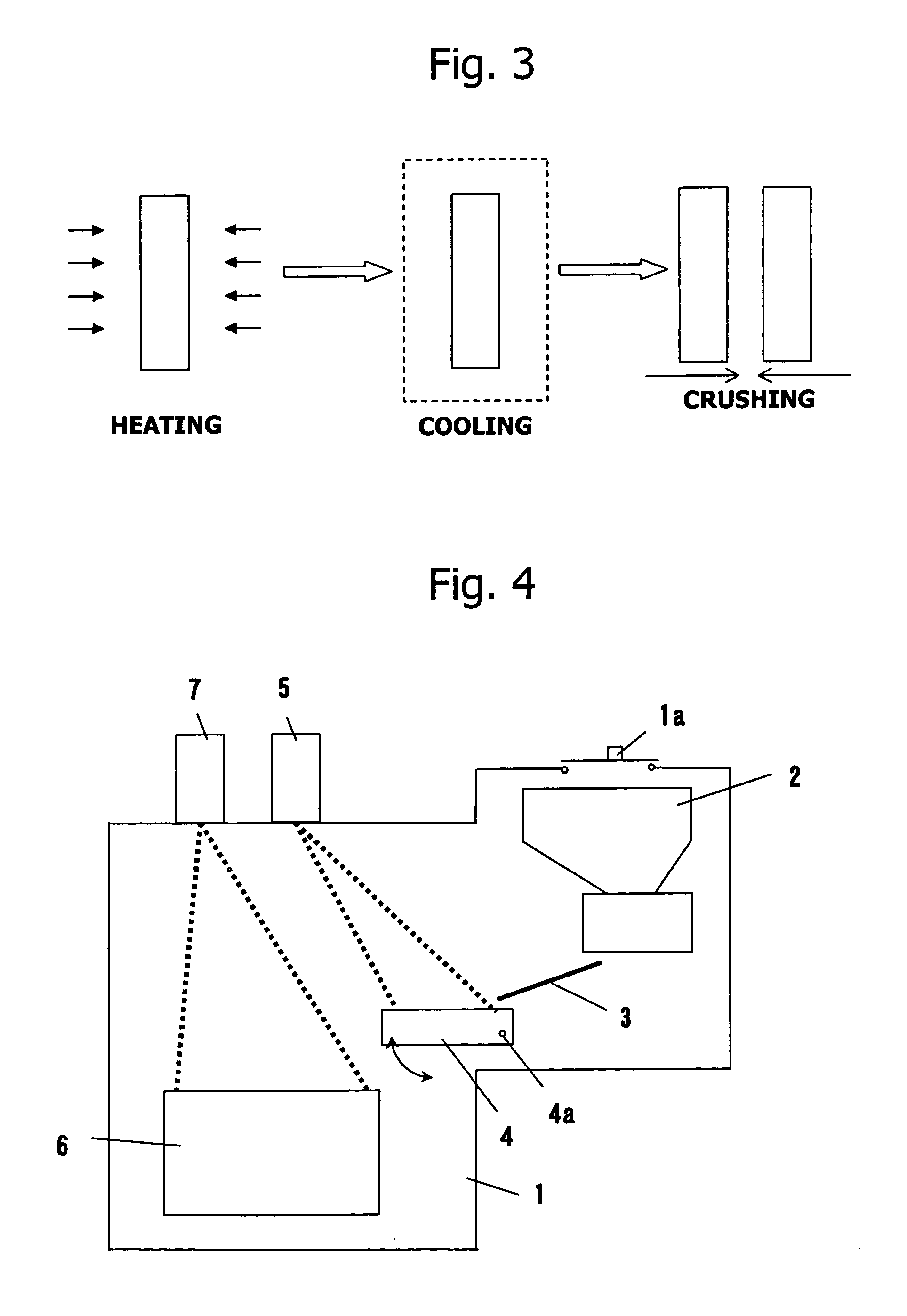

Method of refining scrap silicon using an electron beam

A method of refining scrap silicon using an electron beam includes a step of selectively preparing lumps of n-type scrap silicon containing a specific impurity element as a dopant, a step of crushing the prepared lumps of scrap silicon, a step of placing the crushed silicon into a vacuum vessel, a step of irradiating the crushed silicon which was placed into the vacuum vessel with an electron beam to melt it and vaporize at least a portion of the impurity element, and a step of solidifying the resulting silicon.

Owner:IIS MATERIALS CORP

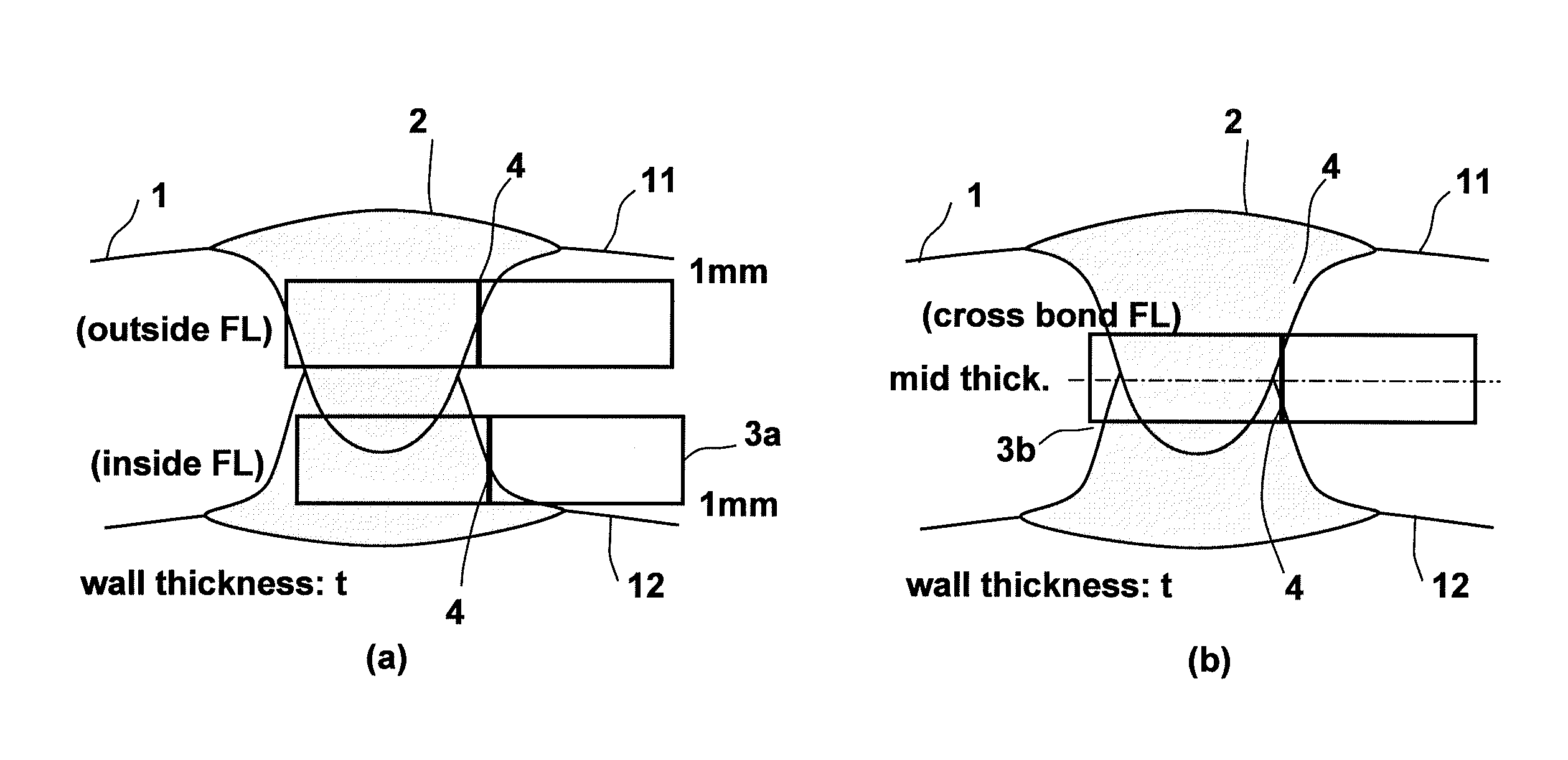

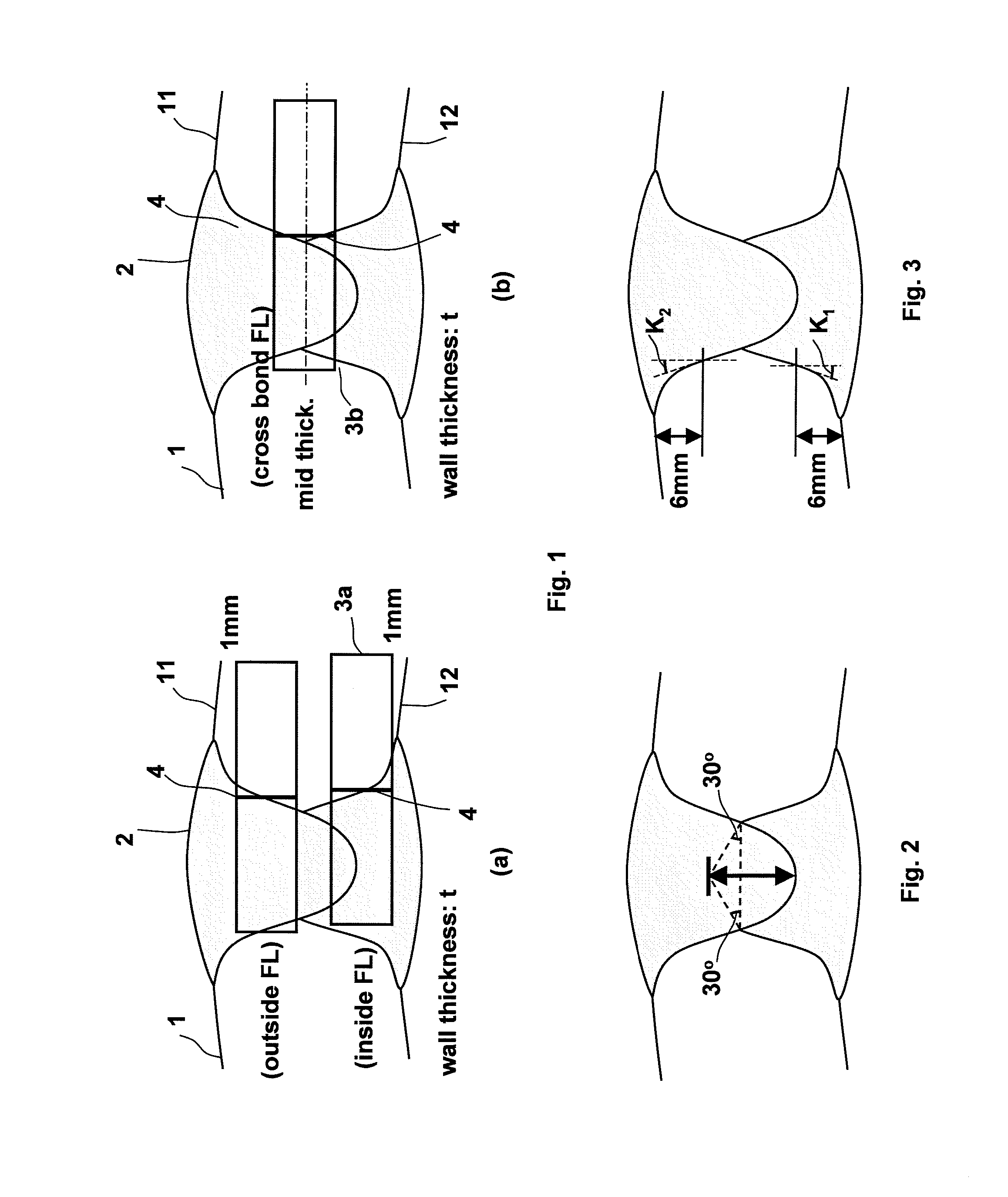

Welded steel pipe with excellent welded heat-affected zone toughness and process for producing same

InactiveUS20140227549A1Improve productivityLow costArc welding apparatusFurnace typesButt weldingAustenite grain

A welded steel pipe with excellent welded heat-affected zone toughness includes a butt weld formed by prior welding either an inner surface or an outer surface with a single layer for each of the inner and outer surfaces, wherein in the metallographic structure of a welded heat-affected zone, the martensite-austenite constituent (MA) area fraction is 4% or less, the average prior-austenite grain size is 400 μm or less, and the following items are taken into account: the average prior-austenite grain size of a welded heat-affected zone formed by prior welding, the average prior-austenite grain size of a welded heat-affected zone formed by subsequent welding, the bead width determined at a position 5 mm apart from the tip of a weld bead formed by subsequent welding, the fusion line tilt angle of a weld bead of prior welding, and the fusion line tilt angle of a weld bead of subsequent welding.

Owner:JFE STEEL CORP

Process for manufacturing cold-rolled steel sheet

InactiveUS20170121788A1Improve ductilityHigh strengthFurnace typesThin material handlingMetallurgyImpurity

A hot-rolled steel sheet having a composition comprising, in mass %, C: 0.06 to 0.3%, Si: 0.4 to 2.5%, Mn: 0.6 to 3.5%, P: at most 0.1%, S: at most 0.05%, Ti: 0 to 0.08%, Nb: 0 to 0.04%, a total content of Ti and Nb: 0 to 0.10%, sol.Al: 0 to 2.0%, Cr: 0 to 1%, Mo: 0 to 0.3%, V: 0 to 0.3%, B: 0 to 0.005%, Ca: 0 to 0.003%, REM: 0 to 0.003%, the remainder Fe and impurities, is cold rolled, then heated at an average heating rate of at least 15° C. / sec so that a proportion of an unrecrystallization of a region not transformed to austenite at a time of reaching (Ac1 point+10° C.) is at least 30 area %, and then held for 30 seconds at temperature of at least (0.9×Ac1 point+0.1×Ac3 point) and at most (Ac3 point+100° C.).

Owner:NIPPON STEEL CORP

Method for producing borosilicate glasses

InactiveUS7490486B2Glass quality being affectedReduce solubilityGlass furnace apparatusAlkaline earth metalSulfate

The process of producing a refined borosilicate glass includes preparing a glass batch with a composition in wt. % on the basis of oxide content of SiO2, 65-82; Al2O3, 2-8; B2O3, 5-13; MgO+CaO+SrO +BaO+ZnO, 0-7; ZrO2, 0-2; and Li2O+Na2O+K2O, 3-10; adding 0.05 wt. % to 0.6 wt. % of sulfate(s) expressed as SO3 to the glass batch as the refining agent; melting the glass batch including the refining agent to form melted glass; and then hot-shaping the borosilicate glass. The refining agent may also include from 0.01 wt. % to 0.6 wt. % of F− or from 0.015 wt. % to 0.6 wt. of Cl−. The sulfate is preferably an alkali metal and / or alkaline earth metal sulfate or sulfates.

Owner:SCHOTT AG

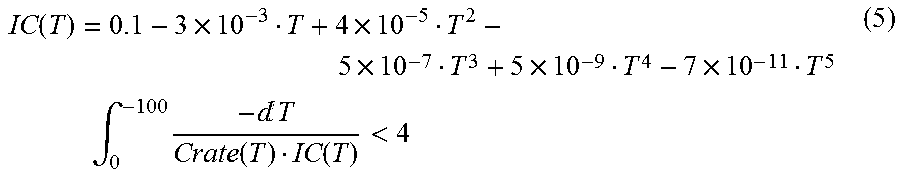

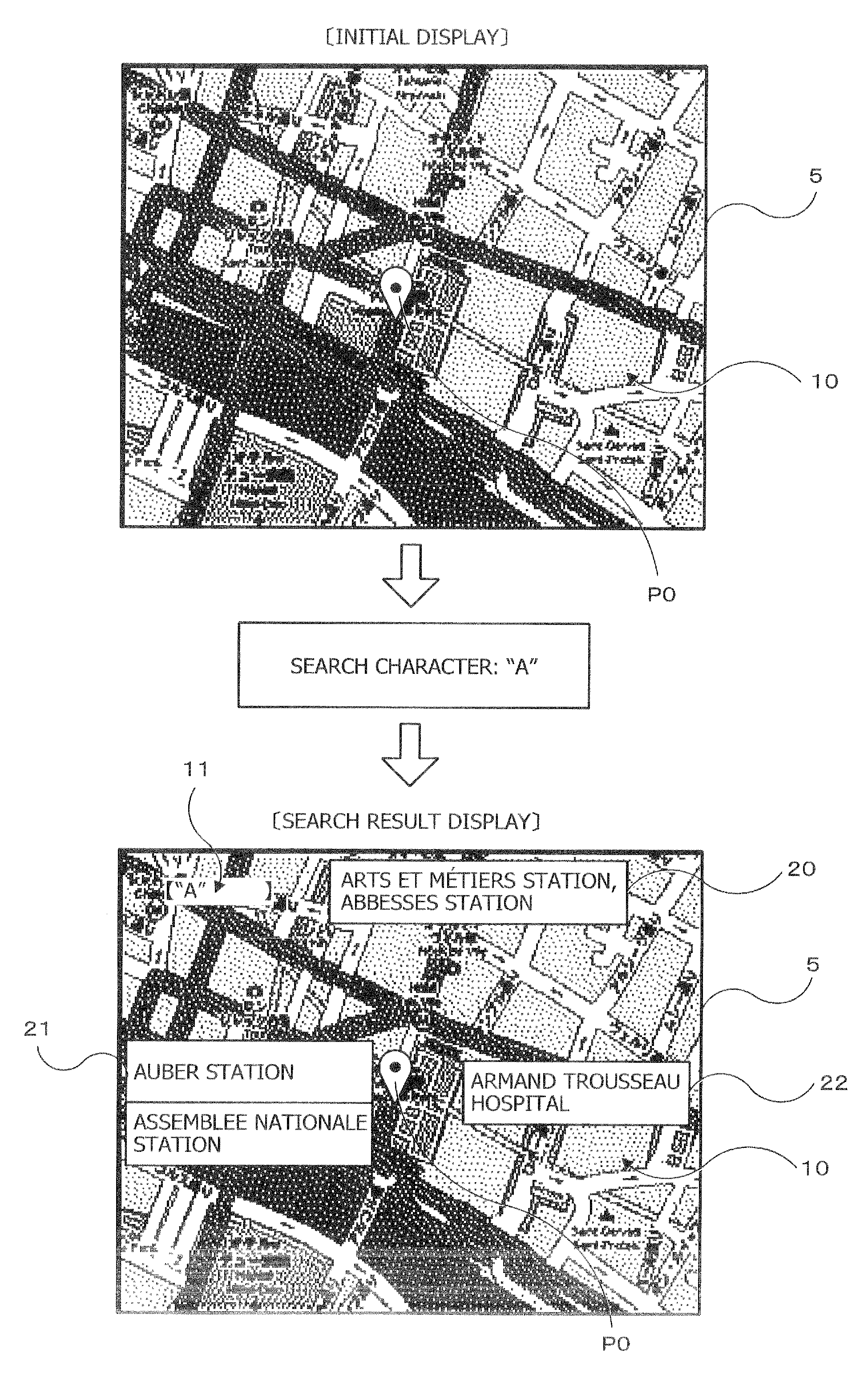

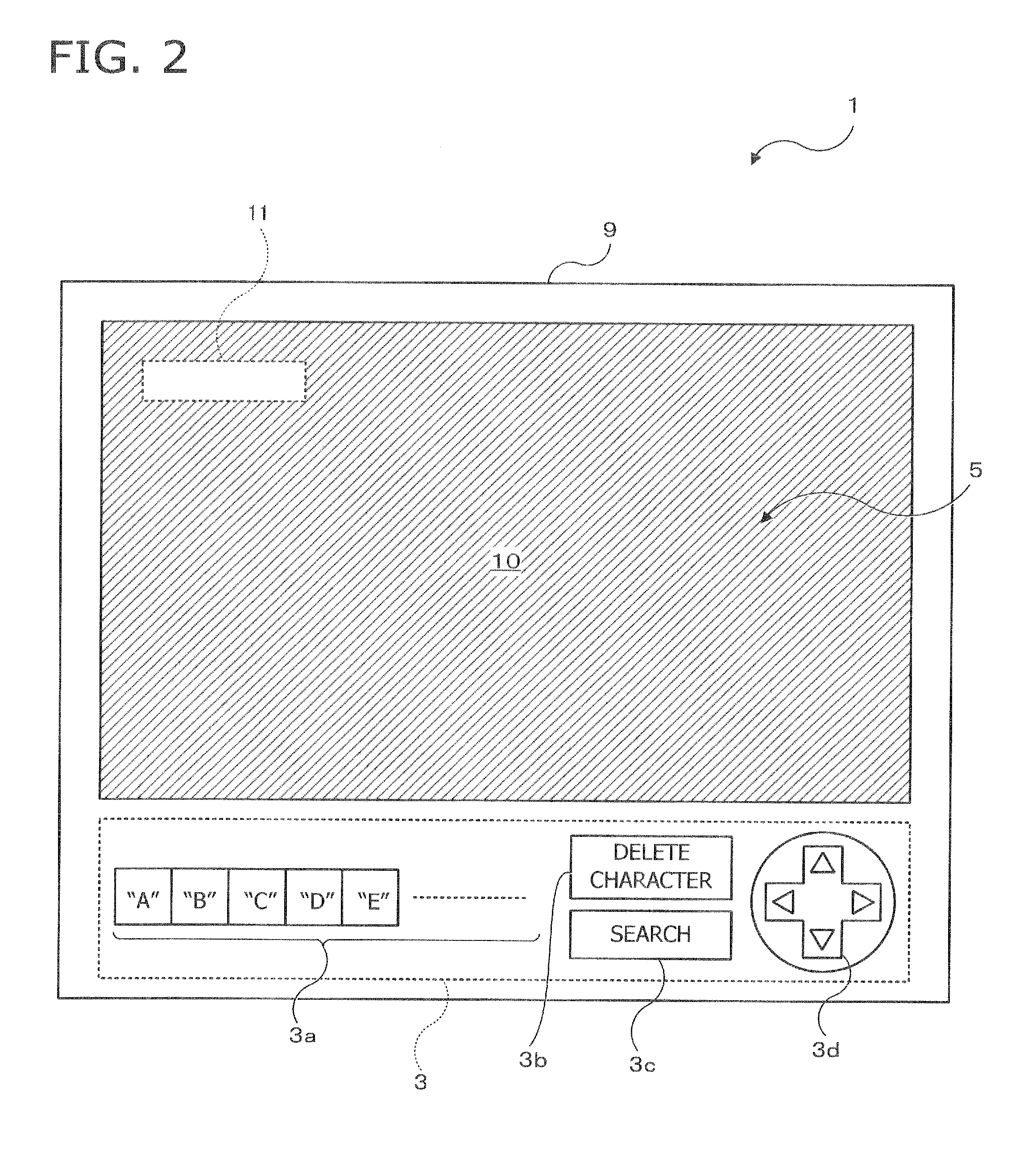

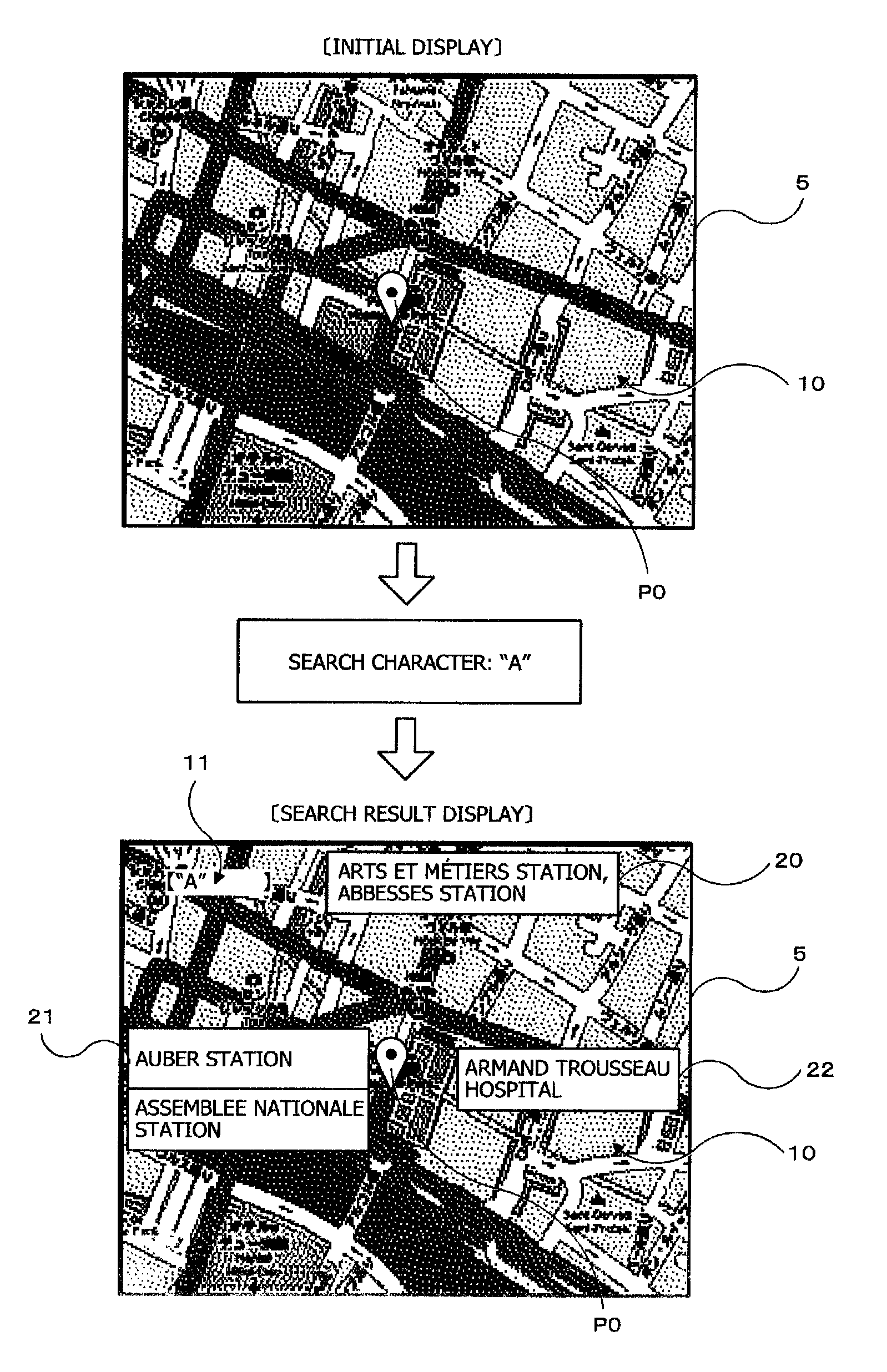

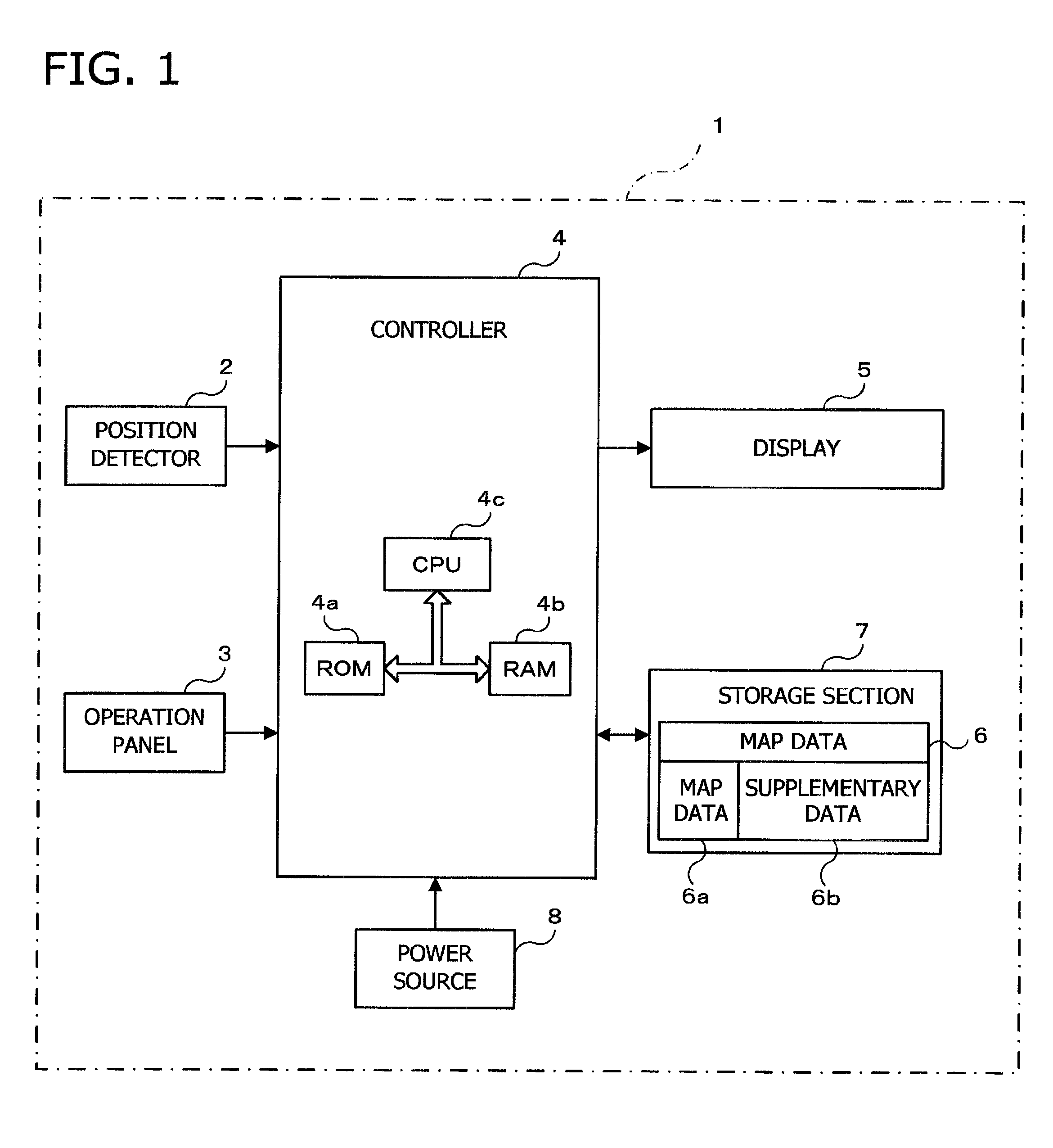

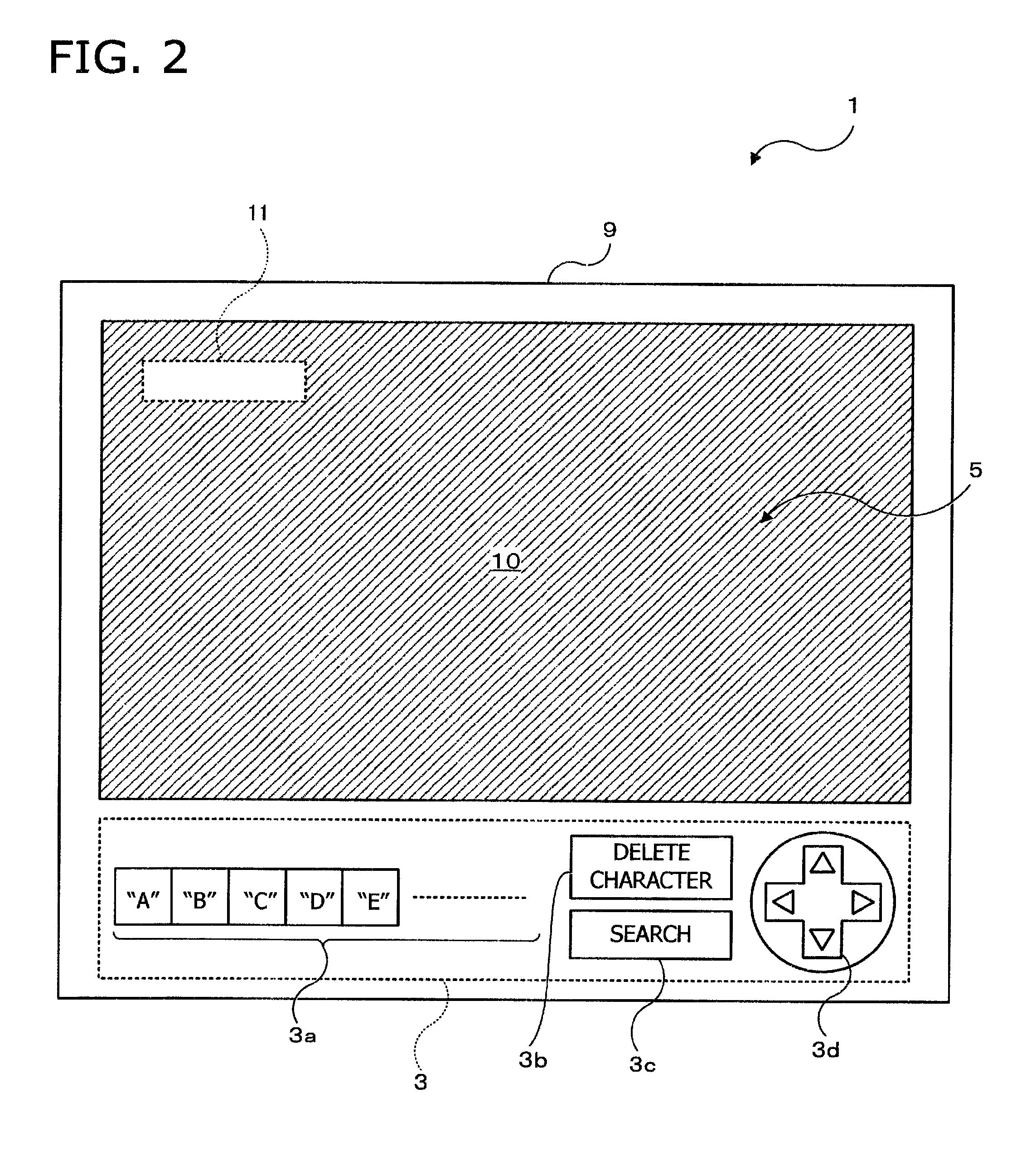

Map display control apparatus, map display control method and computer readable medium

ActiveUS20110234634A1Efficient refiningQuick displayGeometric image transformationCathode-ray tube indicatorsLine searchComputer science

There is provided a map display control apparatus. The apparatus includes: an accepting section configured to accept a search character; a search section configured to search for a landmark on a map, a name of the landmark at least partly matching the search character; a position adjusting section configured to adjust a display position of the map such that the searched landmark appears in the map; a search refining section configured to perform a new search for the landmark and refine the landmark whenever a new character is added to the search character; and a position movement section configured to move the display position of the map, depending on the number of the refined landmark or a position of the refined landmark.

Owner:CASIO COMPUTER CO LTD

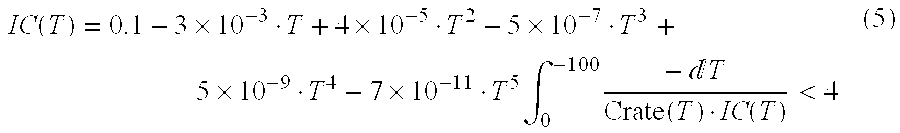

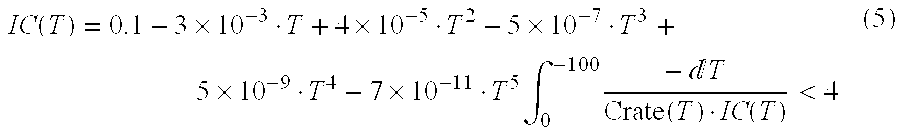

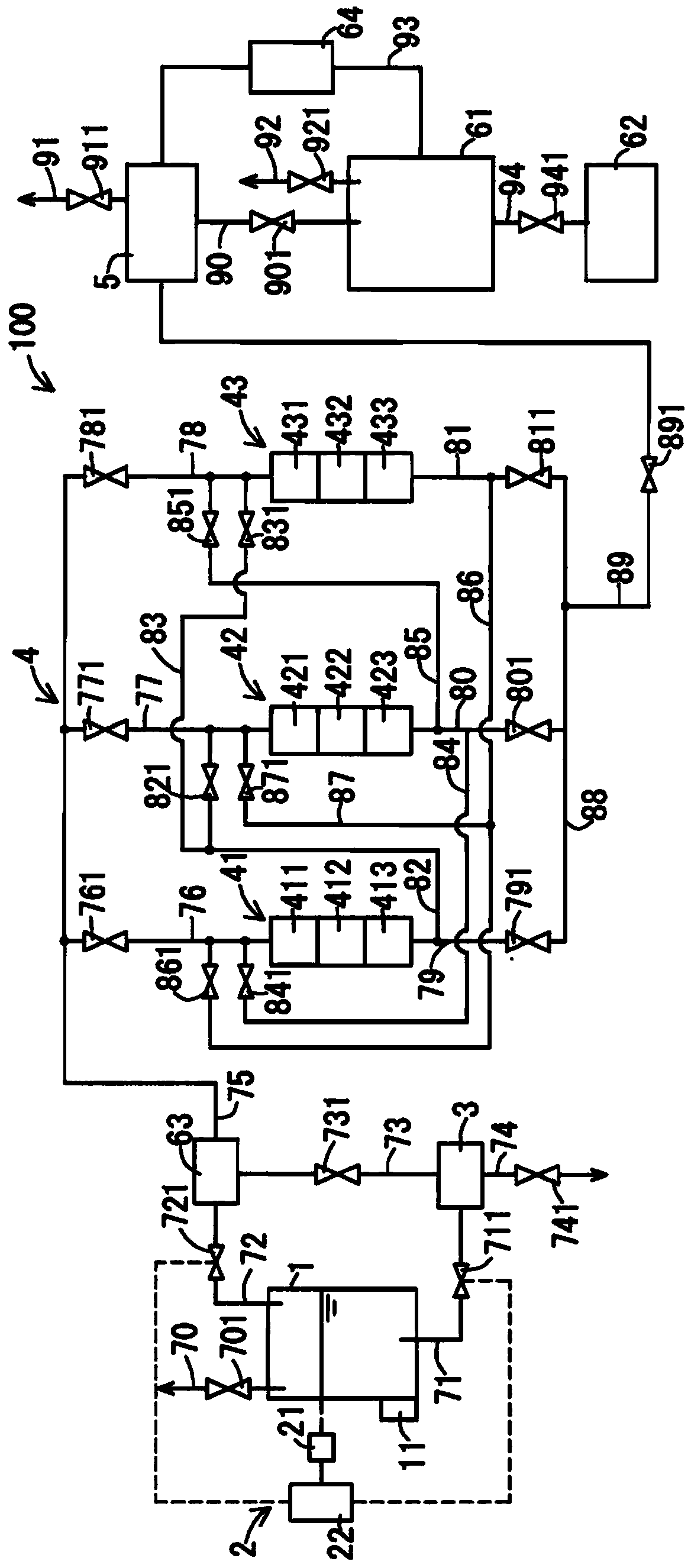

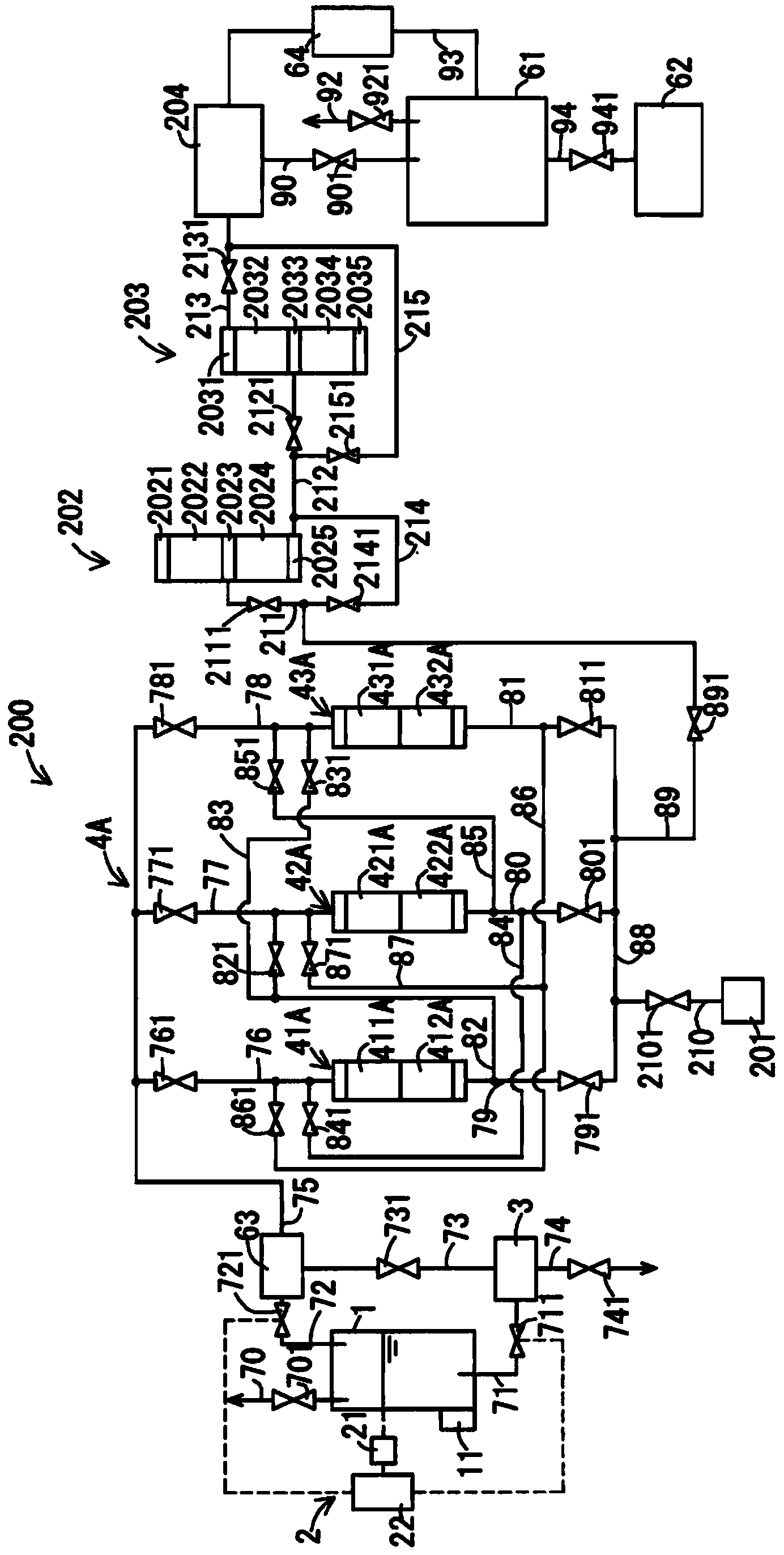

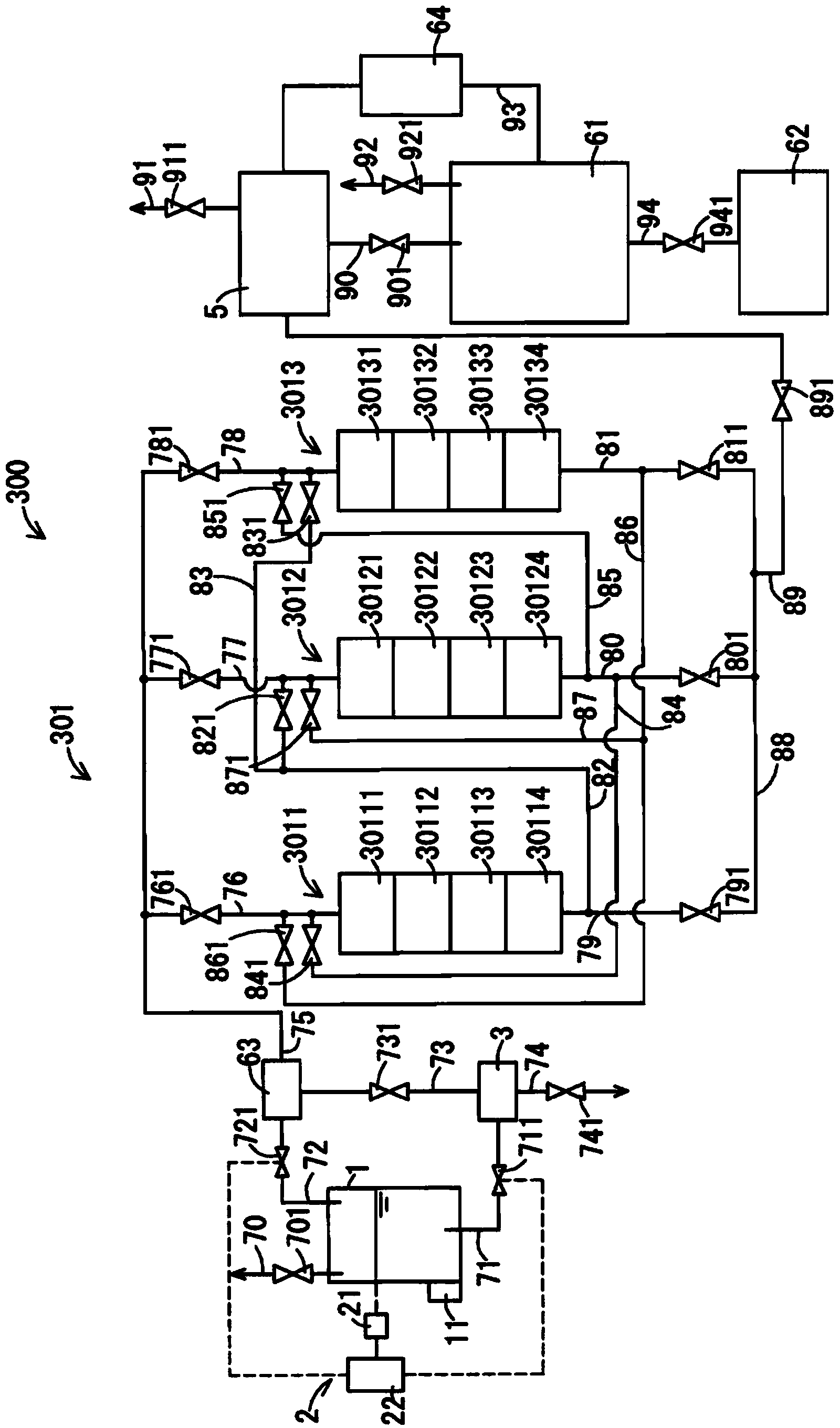

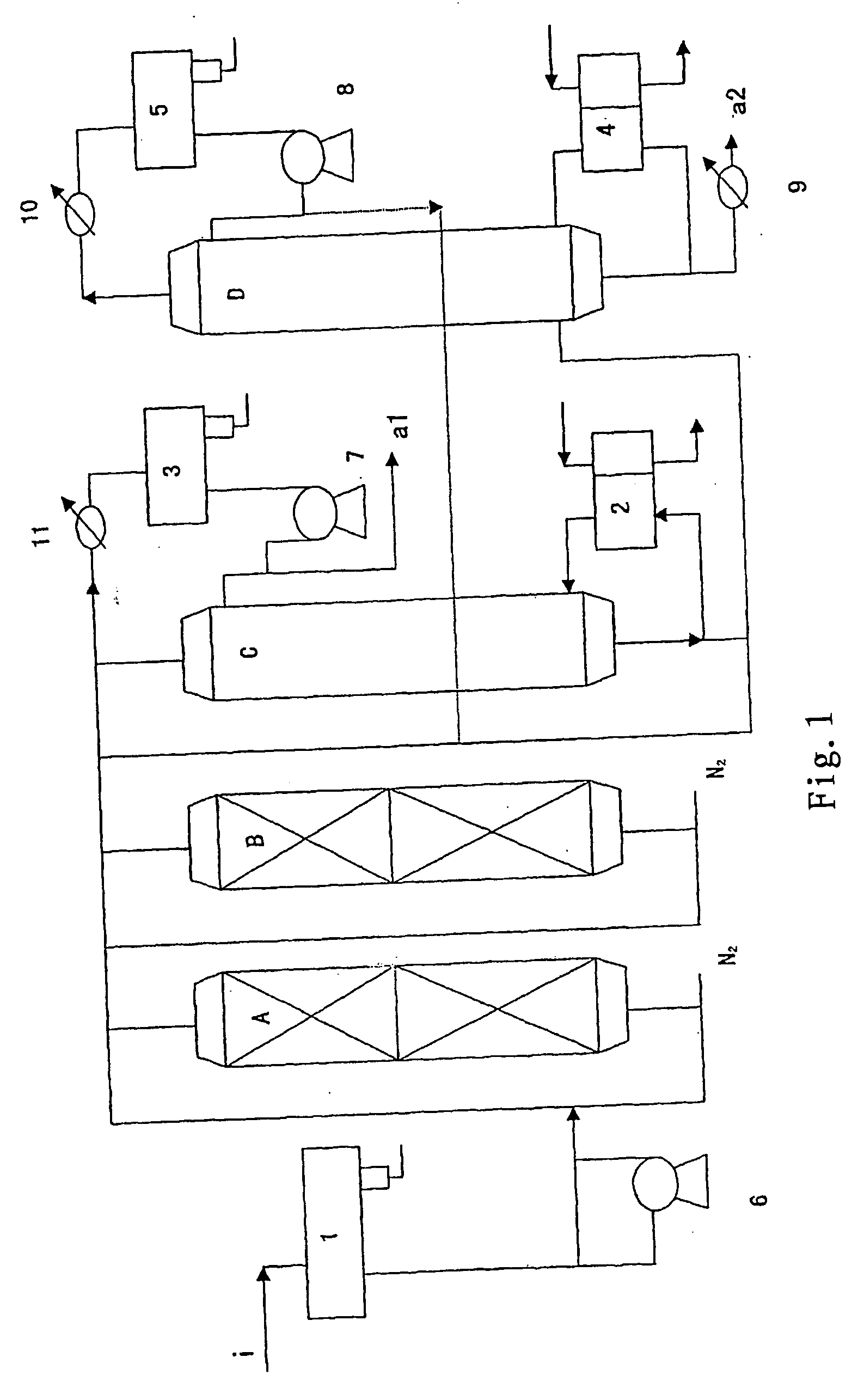

Ammonia purification system

InactiveCN103619756ACurb energy consumptionConcentration deviation preventionGas treatmentChemical industryChemistrySorbent

Provided is an ammonia purification system which can prevent large variations in purity of the final refined ammonia. In this ammonia purification system (100), a control unit (2) controls a raw material storage tank (1) such that if, in the raw material storage tank (1), the volume ratio of the liquid phase to the total volume of the internal space is greater than or equal to a preset threshold value, then crude ammonia is delivered from the liquid phase, and if said volume ratio is less than said threshold value, then the crude ammonia is delivered from the gas phase. Further, an adsorption unit (4) delivers either the gaseous crude ammonia taken from the gas phase of the raw material storage tank (1), or the gaseous ammonia obtained by adsorbing with an adsorbent and removing impurities contained in the gaseous ammonia delivered from a vaporizer (3).

Owner:SUMITOMO SEIKA CHEM CO LTD

Process for commercial-scale refining liquefied petroleum gas

ActiveUS20050038309A1Simple procedureLow costGaseous fuelsRefining with metal oxidesFixed bedPollution

The present invention relates to a novel process for refining the liquefied petroleum gas (LPG) in a commercial scale. The process comprises: sequentially performing fine desulfurization and mercaptan conversion of the LPG after alcohol amine treatment through desulfurizer and catalyst set in fixed bed reactor in the absence of alkali, wherein, during the fine desulfurization, the resultants of reaction between hydrogen sulfide in the LPG and Fe—Ca oxides or their hydrates adhered on the desulfurizer, and during the mercaptan conversion, the mercaptan in the LPG reacts with the residual trace amount of air in the LPG under the action of the catalyst to produce the disulfides; letting the formed disulfides along with the LPG flow out of the fixed bed reactor; rectifying the LPG after the mercaptan conversion to obtain the refined LPG products, with further rectification to obtain the valuable disulfide products. The present process has advantages of high efficiency, no alkali discharge, being a simplified process over the prior method using alkali treatment and making no environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

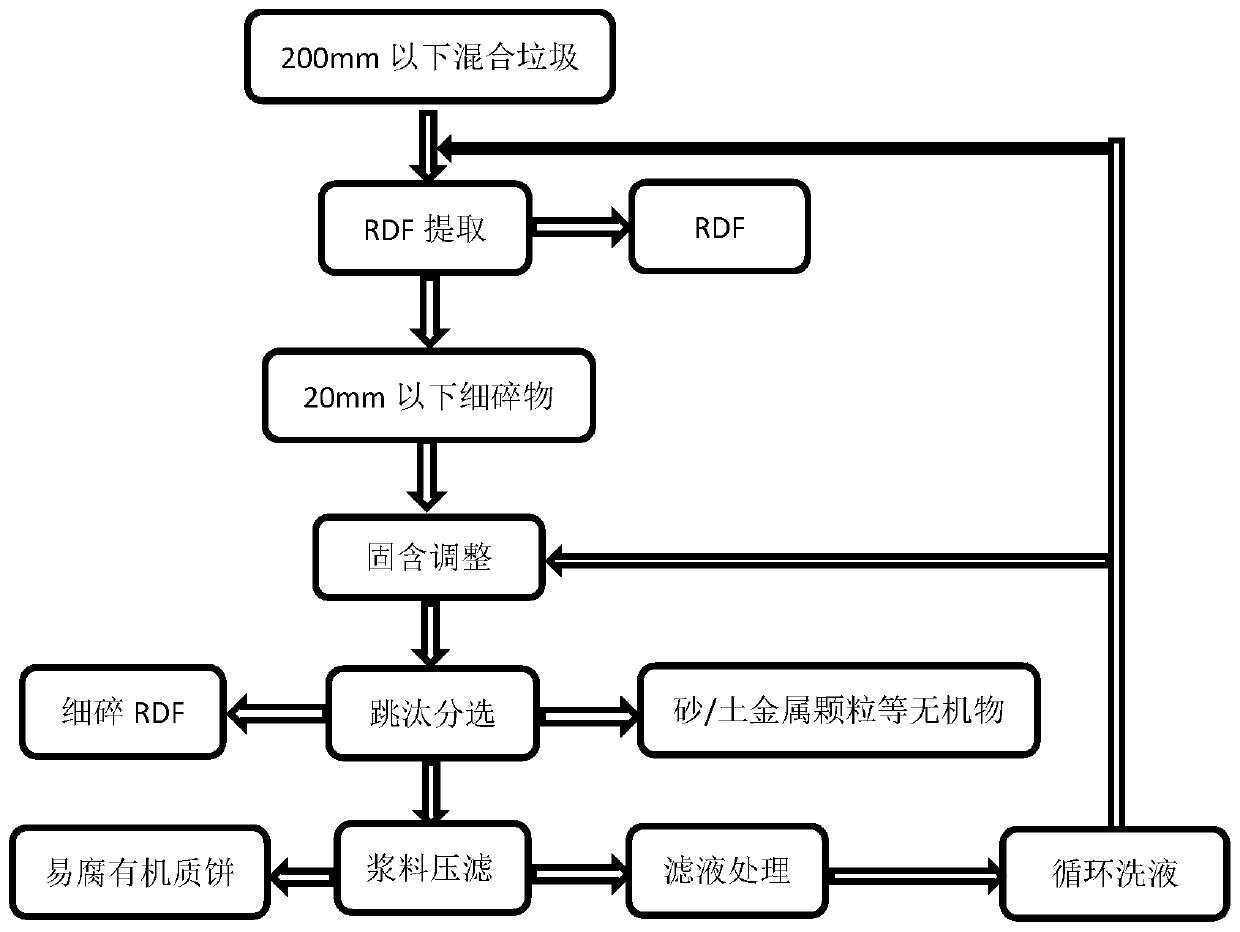

Extraction and refining process of perishable organic matters in garbage

InactiveCN110576027AEfficient fine classification and sortingImplement extractionSolid waste disposalTransportation and packagingParticulatesResource utilization

The invention discloses an extraction and refining process of perishable organic matters in garbage. The process comprises the steps that mixed garbage with the particle size of 200mm or below is impacted and crushed, RDF is separated from the fine crushed mixed garbage by utilizing the characteristic of the RDF as a soft material, then perishable organic matters containing fine crushed slurry isobtained, jugging separation is carried out after RDF washing water and circulating process water are added to adjust the solid content of the slurry, inorganic particulate matters, sediment and residual fine crushed RDF in the slurry are separated, finally the perishable organic matters containing fine crushed slurry is filter pressed into an organic matter filter cake, the moisture content of the filter cake is controlled to be in the optimal range of aerobic fermentation of the organic matter filter cake, then the aerobic fermentation treatment is carried out on the organic matter filter cake, and filtrate is recycled and not discharged after the treatment. According to the extraction and refining process of the perishable organic matters in the garbage, the perishable organic matters are separated from the soft RDF by utilizing the characteristics of low strength and easy impact and crushing of the perishable organic matters, perishable organic matters with high purity, small particles, stable moisture and controllable pollutants are obtained through refining, and channels are opened for resource utilization of the perishable organic matters in the garbage.

Owner:中原环资科技有限公司

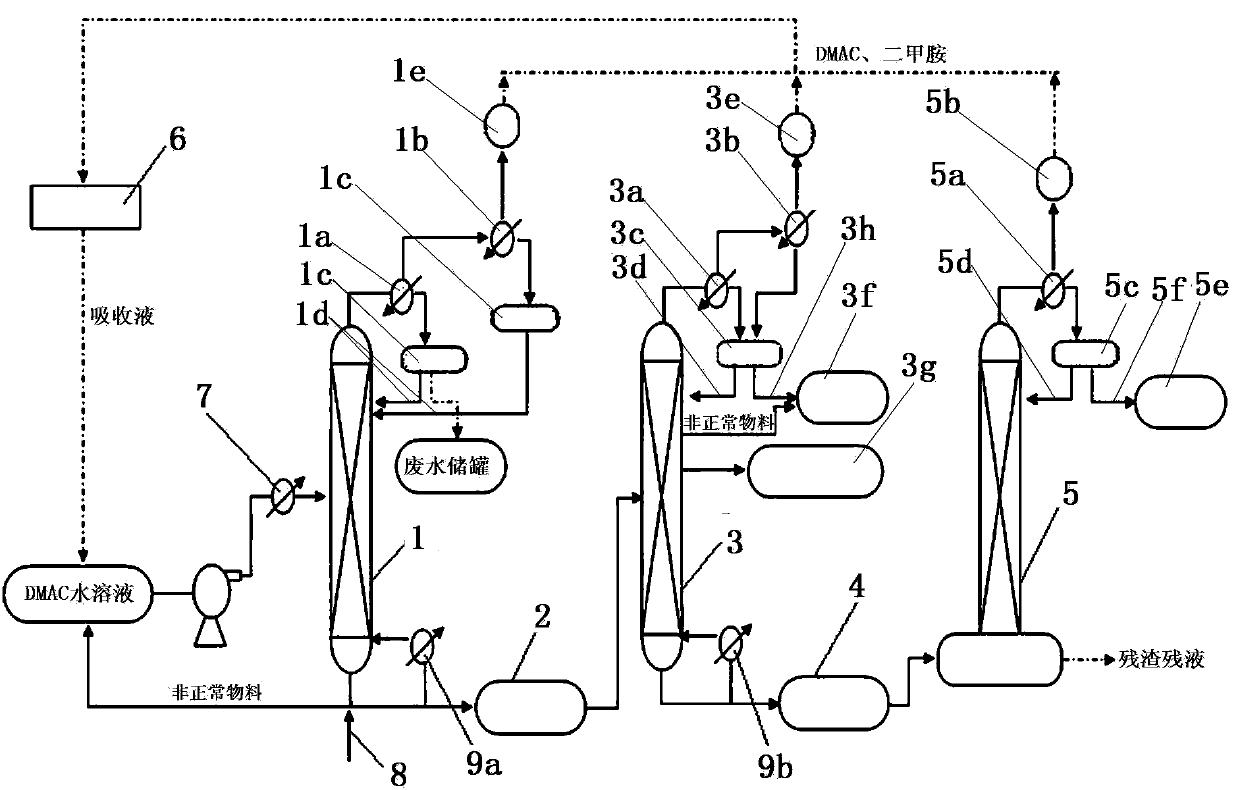

Physical index optimizing system for recycling DMAC (dimethylacetamide)

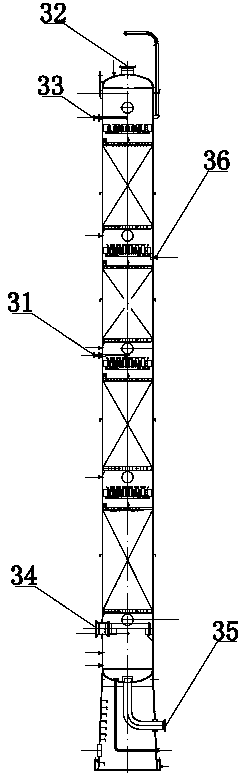

ActiveCN104043260AGood yieldAchieve recyclabilityCarboxylic acid amide separation/purificationFractional distillationDistillationPulp and paper industry

The invention relates to a physical index optimizing system for recycling DMAC (dimethylacetamide), which belongs to the technical field of spandex production. The physical index optimizing system for recycling DMAC comprises a dehydrating tower, a coarse solvent tank, a refining tower, a distillation still supplying tank and a recovery tower, wherein the dehydrating tower is connected with a feed pipe, the bottom of the dehydrating tower is communicated to the middle of the refining tower through the coarse solvent tank, and the bottom of the refining tower is communicated with the bottom of the recovery tower through the distillation still supplying tank; a preheater is connected to the middle of the dehydrating tower, and a No.1 condenser and a No.1 chiller are connected to the top of the dehydrating tower; a No.2 condenser and a No.2 chiller are connected to the top of the refining tower; a No.3 condenser is arranged on the top of the recovery tower, a No.3 condensate receiving tank is arranged on the No.3 condenser, and a No.3 vacuum pump is arranged on the top of the No.3 condenser. By adopting the physical index optimizing system to recycle DMAC in the process of spandex production, normal operation of a DMAC distillation system is guaranteed, and the yield and physical indexes of the recycled DMAC are greatly increased.

Owner:ZHEJIANG KAIPUTE SPANDEX

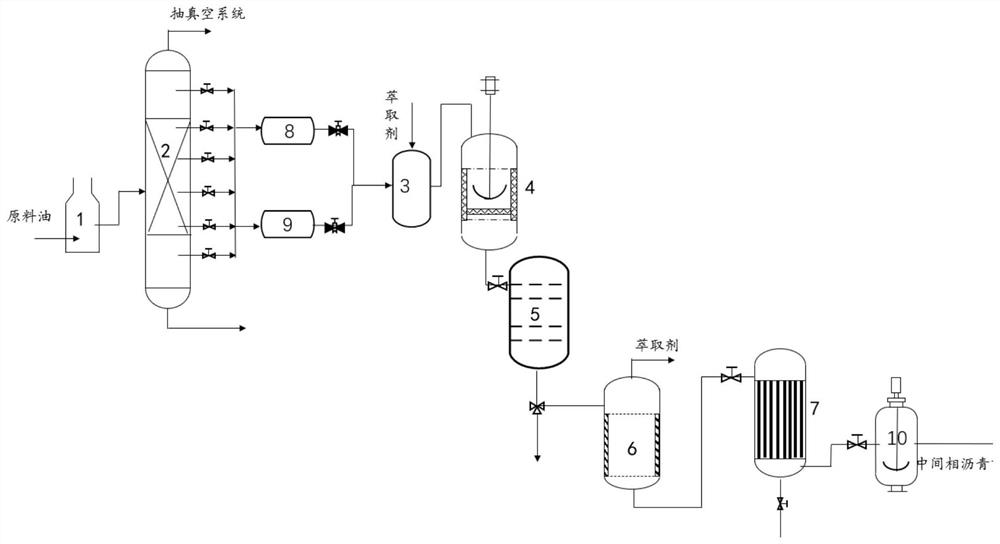

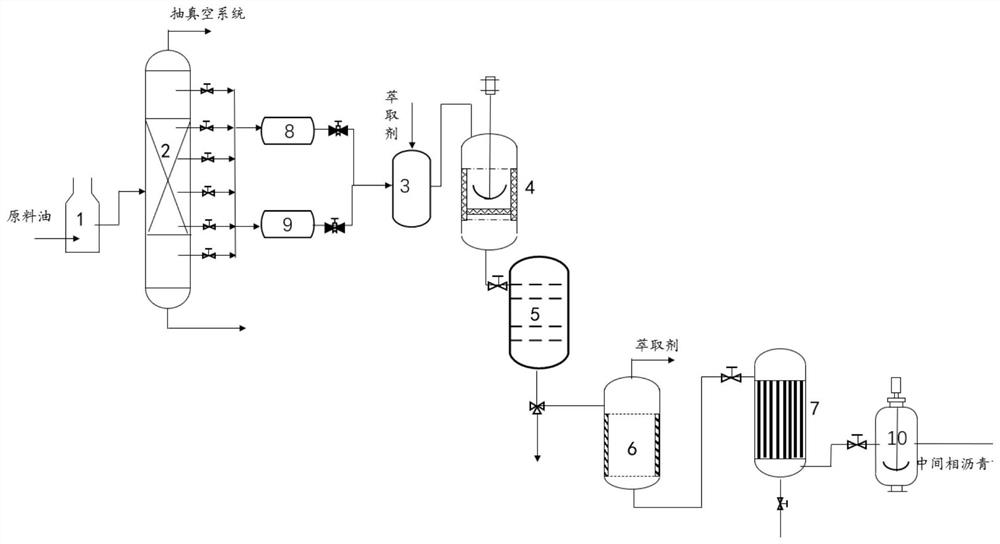

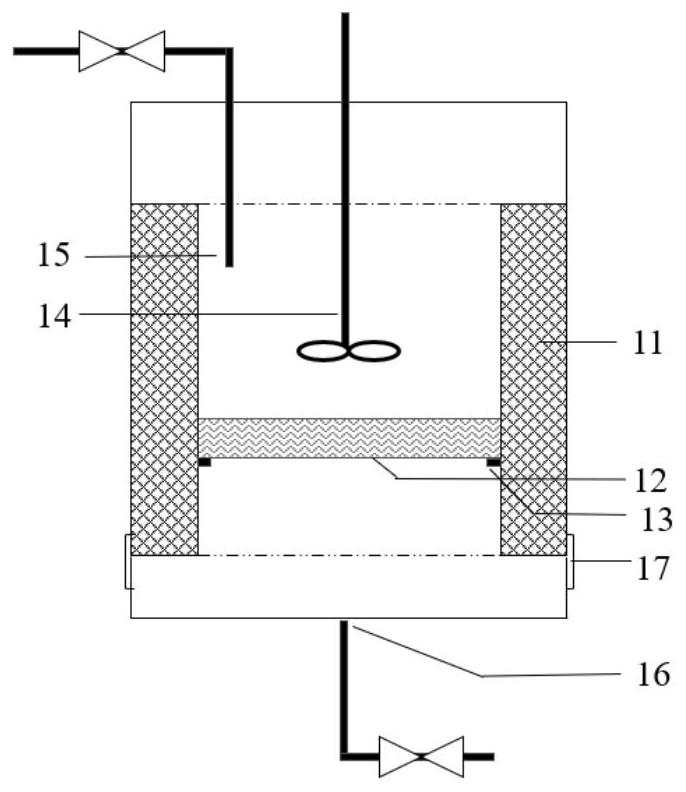

Continuous process for preparing mesophase pitch from refined raw oil

ActiveCN112812802APromote dissolution penetrationLow viscosityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiltrationCarbonization

The invention provides a continuous process for preparing mesophase pitch from refined raw oil, which comprises the following steps: by taking one or more of aromatic hydrocarbon-rich heavy oil, catalytic slurry oil, coal tar or ethylene tar as a raw material, decompressing to obtain a heavy fraction section of which the temperature is greater than 300 DEG C, and sequentially passing through an ultrasonic-assisted filtration de-ashing coupling enhanced extraction unit, a sedimentation unit and a solvent-oil separation unit, integrating a liquid-solid adsorption separation unit to obtain refined raw oil which is single in structural composition, narrow in molecular weight distribution and low in content of heteroatoms and solid impurities, and introducing the refined raw oil into a co-carbonization unit to be subjected to co-carbonization reaction with naphthenic base vacuum three-line and four-line distillate oil to obtain the mesophase pitch with the softening point being 220-310 DEG C, the mesophase content being larger than 92% and good spinnability. According to the method, high value-added utilization of the heavy distillate oil is realized through a highly integrated process, the operable space is large, the universality is high, and an important foundation is laid for preparing a high-performance petroleum-based carbon material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Map display control apparatus, map display control method and computer readable medium

ActiveUS8723892B2Efficient refiningQuick displayInstruments for road network navigationRoad vehicles traffic controlComputer graphics (images)Landmark

A map display control apparatus includes: an accepting section configured to accept a search character; a search section configured to search for a landmark on a map, wherein a name of the landmark at least partly matches the search character; a position adjusting section configured to adjust a display position of the map such that the searched landmark search results appear in the map; a search refining section configured to perform a new search for the landmark and refine the landmark search results whenever a new character is added to the search character; and a position movement section configured to move the display position of the map, depending on a number of the refined landmark search results or a position of the refined landmark search results.

Owner:CASIO COMPUTER CO LTD

Edible oil with less cooking fume

The edible oil with less cooking fume is prepared with edible containing monobasic unsaturated fatty acid over 70% and through efficient refining at 230 deg.c and 10 mmHg vacuum. The edible oil has fume amount less than 60 ppm produced when heated.

Owner:WEI CHUAN FOODS CORP

Cold-rolled steel sheet and process for manufacturing same

A high-strength cold-rolled steel sheet having excellent ductility and stretch flangeability includes: a chemical composition consisting, in mass %, C: 0.06 to 0.3, Si: 0.6 to 2.5%, Mn: 0.6 to 3.5%, P: at most 0.1%, S: at most 0.05%, Ti: 0 to 0.08%, Nb: 0 to 0.04%, total of Ti and Nb: 0 to 0.10%, sol.Al: 0 to 2.0%, Cr: 0 to 1%, Mo: 0 to 0.3%, V: 0 to 0.3%, B: 0 to 0.005%, Ca: 0 to 0.003%, REM: 0 to 0.003% and the remainder of Fe and impurities; a microstructure having a main phase including at least 40 area % in total of martensite and / or bainite; and a texture in which proportion of an average X-ray intensity in an {100}<011> to {211}<011> orientations relative to an average X-ray intensity of a random structure not having a texture is less than 6.

Owner:NIPPON STEEL CORP

Method of refining scrap silicon using an electron beam

InactiveUS7632329B2Easy to disassembleEfficient preparationElectric furnaceSilicon compoundsDopantImpurity

A method of refining scrap silicon using an electron beam includes a step of selectively preparing lumps of n-type scrap silicon containing a specific impurity element as a dopant, a step of crushing the prepared lumps of scrap silicon, a step of placing the crushed silicon into a vacuum vessel, a step of irradiating the crushed silicon which was placed into the vacuum vessel with an electron beam to melt it and vaporize at least a portion of the impurity element, and a step of solidifying the resulting silicon.

Owner:IIS MATERIALS CORP

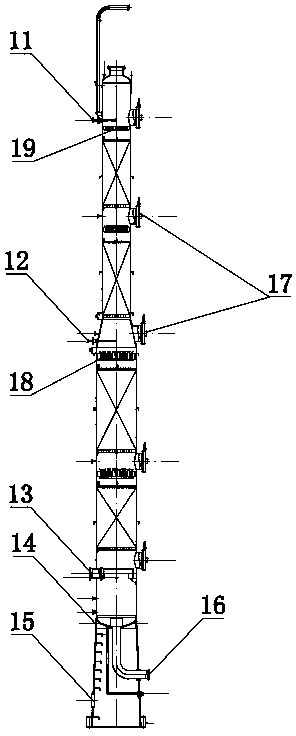

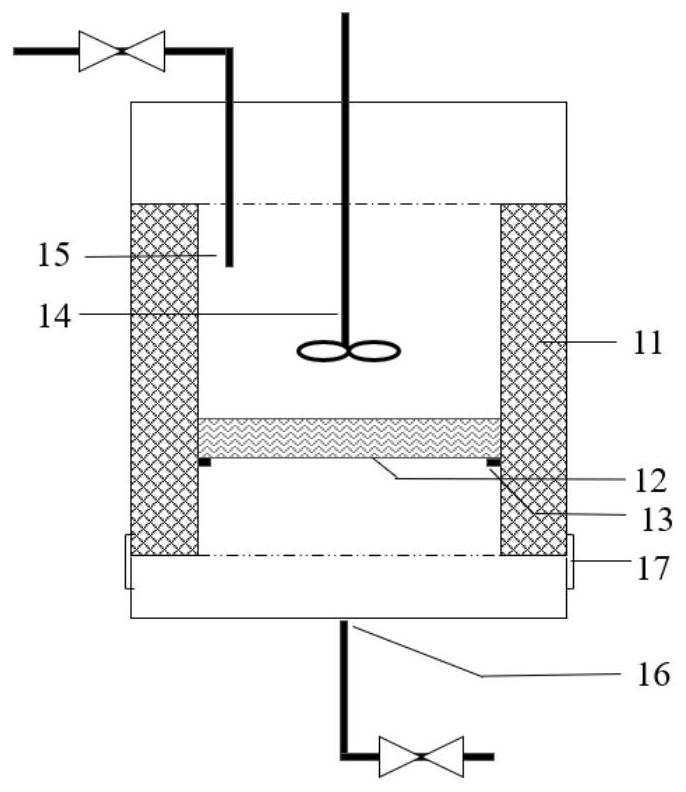

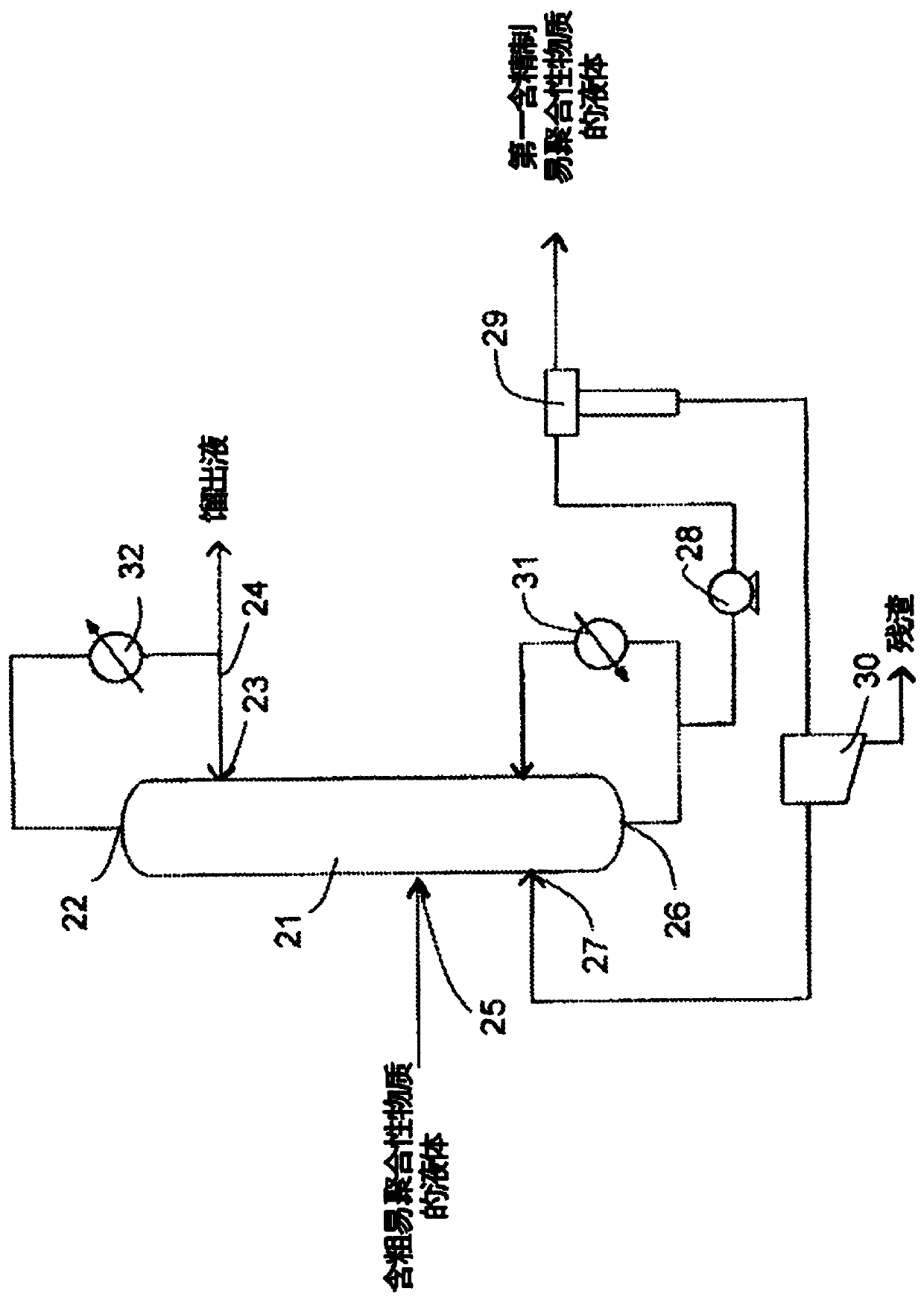

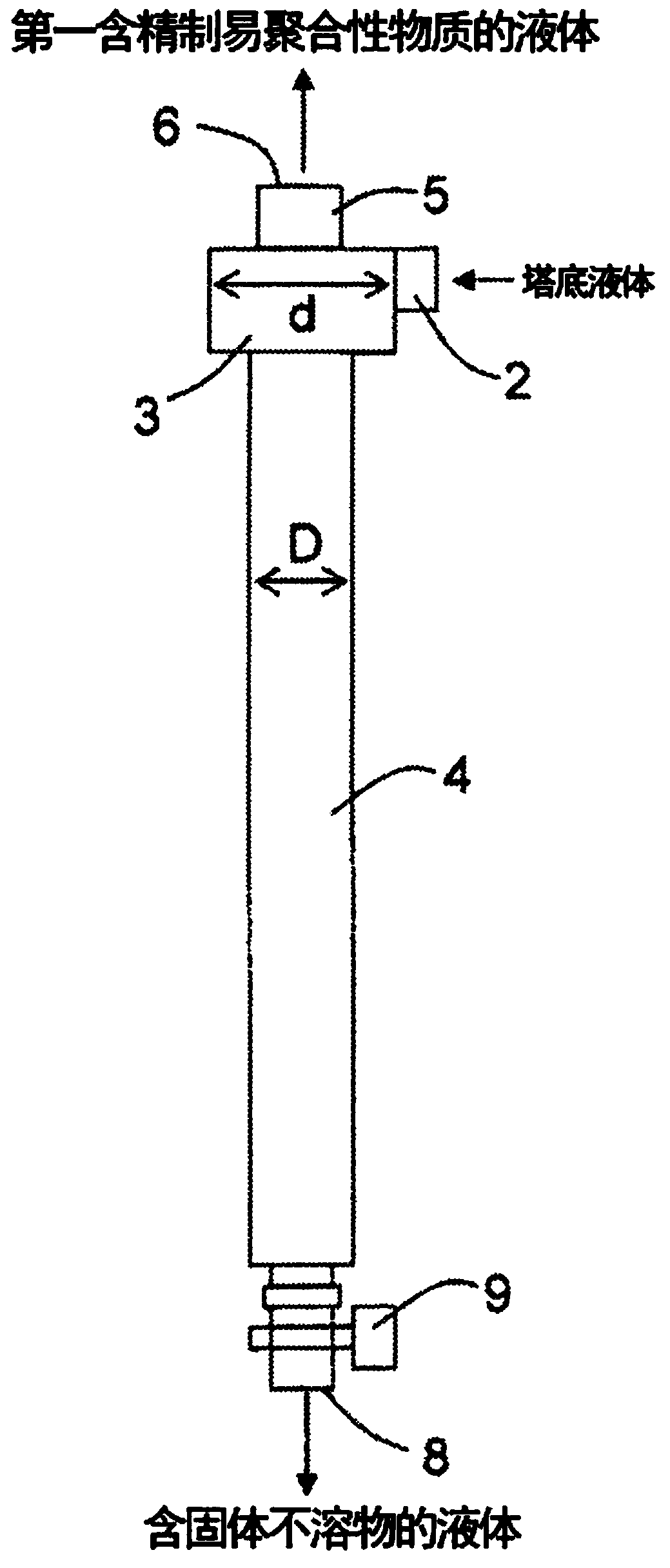

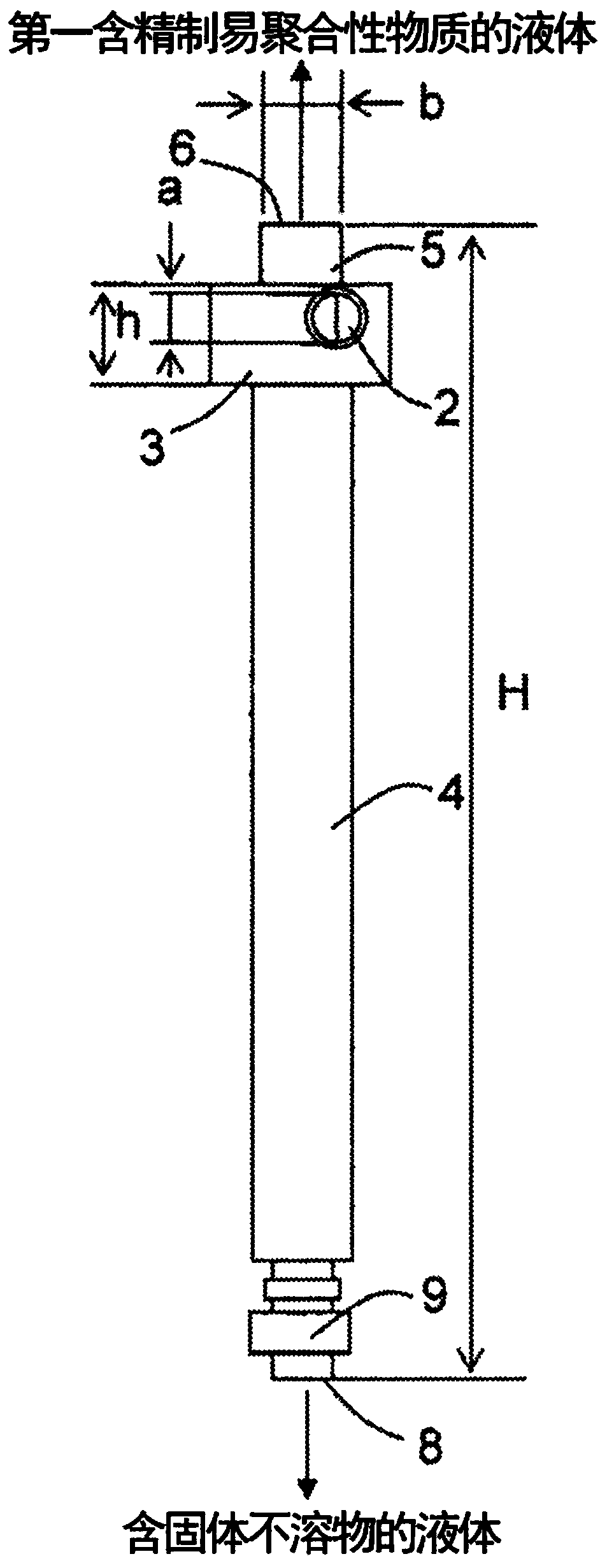

Purification method of easily polymerizable substances

ActiveCN107001229BEfficient refiningReduce lossesVortex flow apparatusVapor condensationDistillationTower

The invention provides a method for reducing the number of times of cleaning the wire mesh, etc., improving the complexity of the operation, and efficiently refining the easily polymerizable substance. The method for purifying an easily polymerizable substance according to the present invention is characterized in that the method includes introducing a liquid containing a crude easily polymerizable substance into a distillation column, and introducing a bottom liquid recovered from a recovery part of the distillation column into a wet cyclone. In the container, and separate into the first separation process of the liquid containing the first refined polymerizable substance and the liquid containing the solid insoluble matter.

Owner:NIPPON SHOKUBAI CO LTD

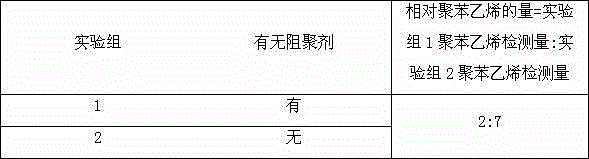

Refining method of styrene

ActiveCN103265398BLow costEffectively refinedHydrocarbonsChemical modification purification/separationAnti ageingPetroleum

Owner:NANTONG HONGTU RUBBER & PLASTIC

A continuous process for preparing mesophase pitch from refined raw material oil

ActiveCN112812802BPromote dissolution penetrationLow viscosityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiltrationCarbonization

The invention provides a continuous process for preparing mesophase pitch from refined raw material oil, using one or more of aromatic-rich heavy oil, catalytic oil slurry, coal tar or ethylene tar as raw material, and depressurizing to obtain heavy In the distillate section, through ultrasonic-assisted filtration deashing coupling enhanced extraction unit, sedimentation unit, agent-oil separation unit, and integrated liquid-solid adsorption separation unit, a refined product with a single structure, narrow molecular weight distribution, and low heteroatom and solid impurity content is obtained. The raw material oil is introduced into the co-carbonization unit, and undergoes co-carbonization reaction with naphthenic vacuum third-line and fourth-line distillates to obtain mesophase pitch with a softening point of 220-310°C, a mesophase content of >92%, and good spinnability. The invention realizes high value-added utilization of heavy distillate oil through a highly integrated process, has large operable space and high universality, and lays an important foundation for preparing high-performance petroleum-based carbon materials.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

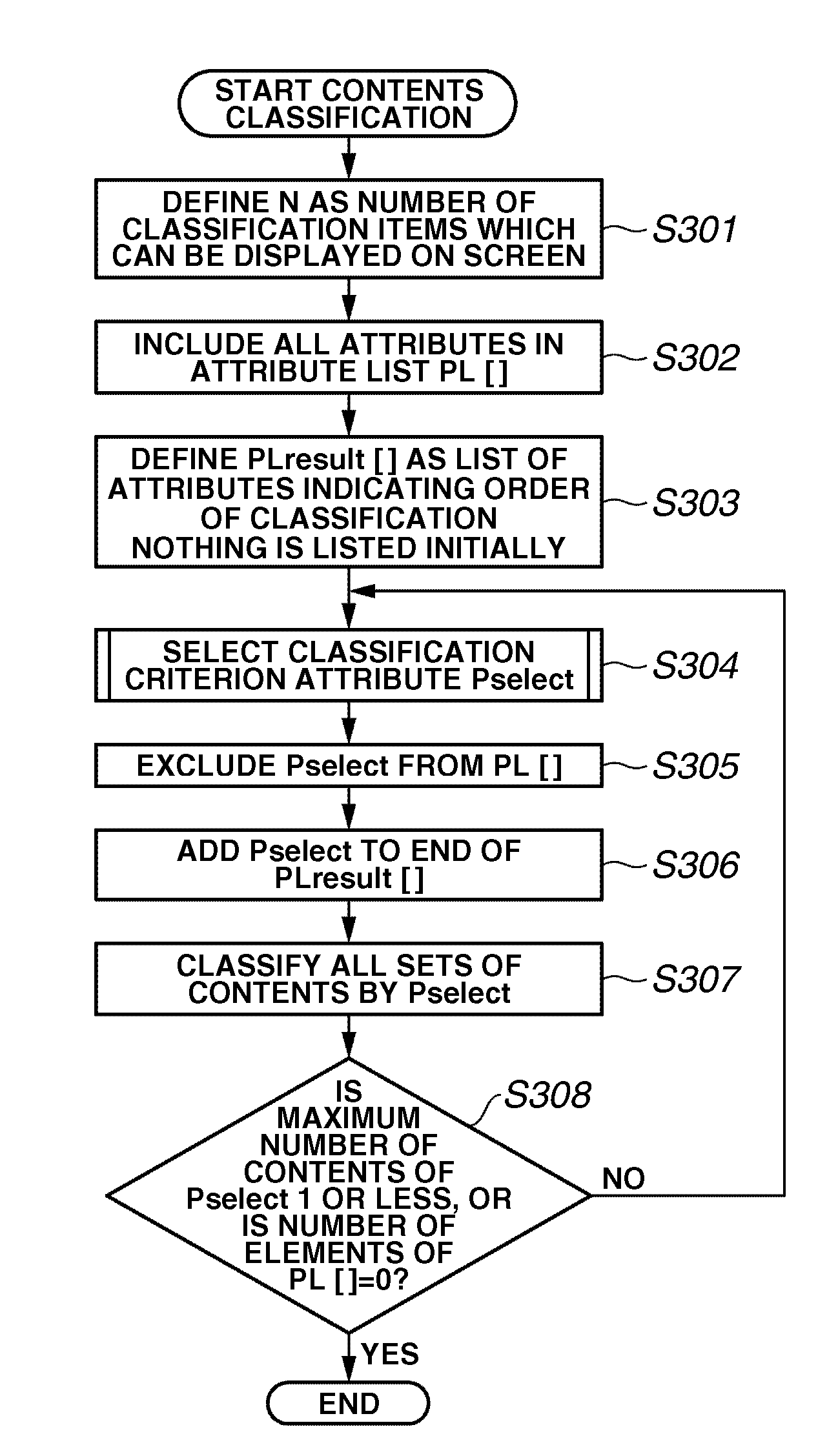

Information processing apparatus, information processing method, and storage medium

InactiveUS7730100B2Increase contentRefine a search efficientlyWeb data indexingDigital data processing detailsInformation processingData mining

An information processing apparatus for searching for a desired content from a storage unit storing a plurality of contents to which a plurality of attributes is set classifies stored contents by each of the attributes. The information processing apparatus then counts the number of registered contents classified by each of the attributes and determines an attribute as a criterion for classifying contents.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com