Patents

Literature

35 results about "High pressure liquid chromatography procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low volatile isocyanate monomer containing polyurethane prepolymer and adhesive system

InactiveUS20060079661A1Lower potential for exposurePolyureas/polyurethane adhesivesAdhesiveHigh pressure

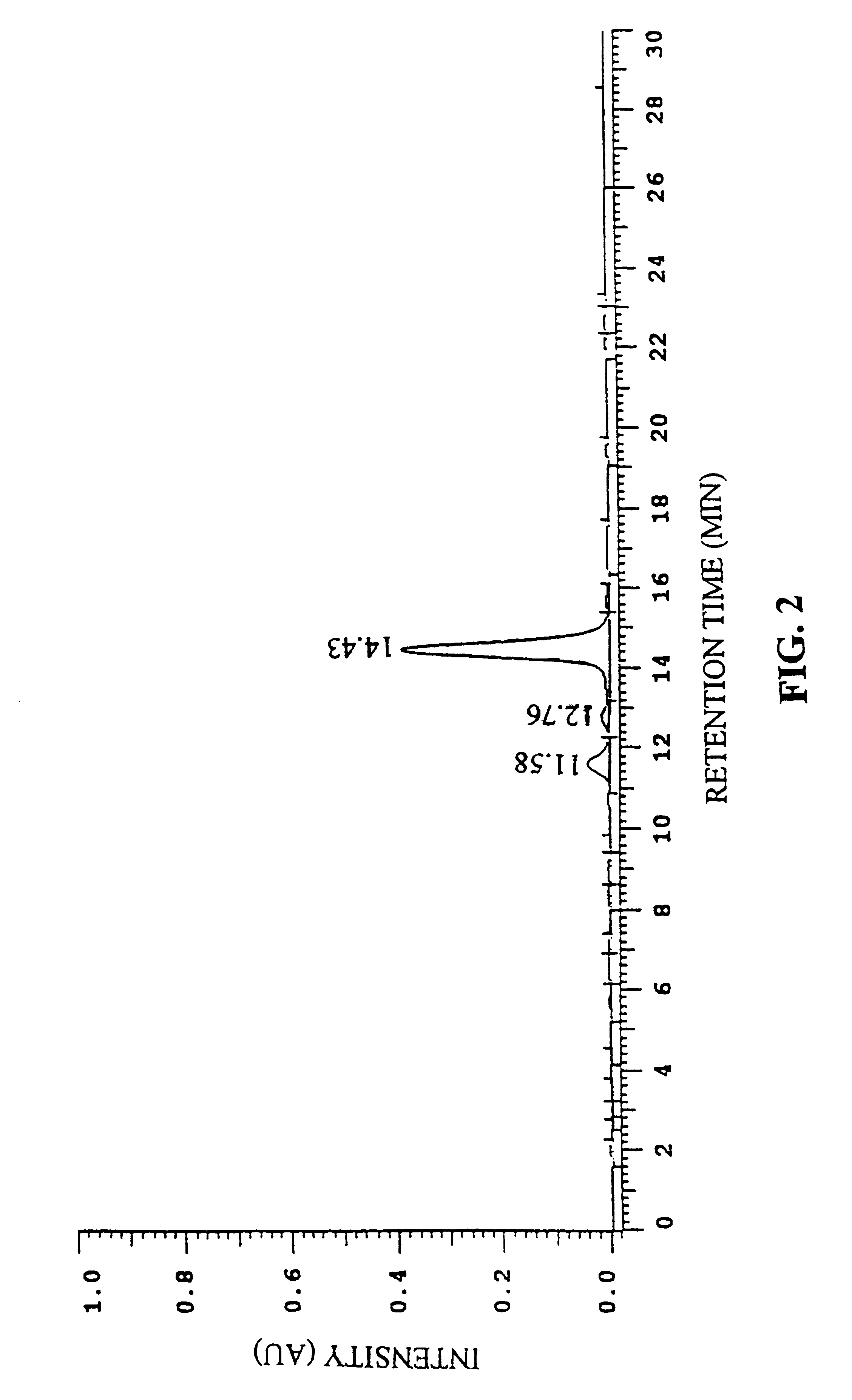

In one aspect the invention is a composition comprising a prepolymer which is the reaction product of di(isocyanatophenyl)methane or a polymeric di(isocyanatophenyl)methane having an isocyanato functionality of about 2.1 to about 3.0 with a mixture of one or more diols and one or more triols wherein the ratio of isocyanate equivalents to hydroxyl equivalents in the reaction mixtures used to prepare the prepolymer is from about 1.2 to about 1.8 and the ratio of diol to triol where the diisocyanate is a di(isocyanatophenyl)methane in the reaction mixture is from about 5:1 to about 1:1. and where the isocyanate is a polymeric di(isocyanatophenyl)methane is from about 8:1 to about 4:1; wherein the prepolymer could further react with an isocyanate reactive monofunctional compound. The prepolymer herein has an isocyanate content of about 0.5 to about 1.5 percent by weight, a free isocyanate monomer content of about 1.0 percent by weight or less as measured by high pressure liquid chromatography. These prepolymers can be used in many applications including adhesive, sound dampening sealer and coating and especially in making adhesives or adhesive systems with a low content of monomeric isocyanate to bond together similar or dissimilar substrates such as metal, glass, ceramics, plastic and painted steel panel.

Owner:DOW GLOBAL TECH LLC

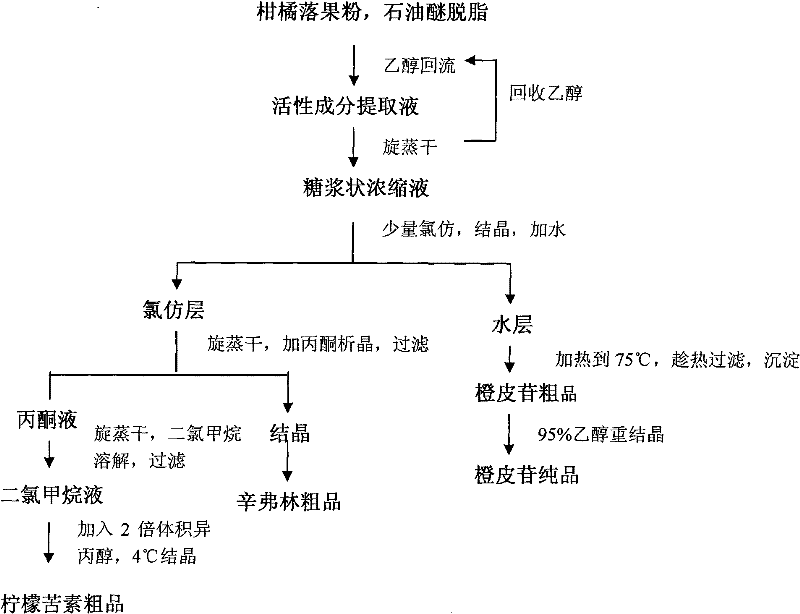

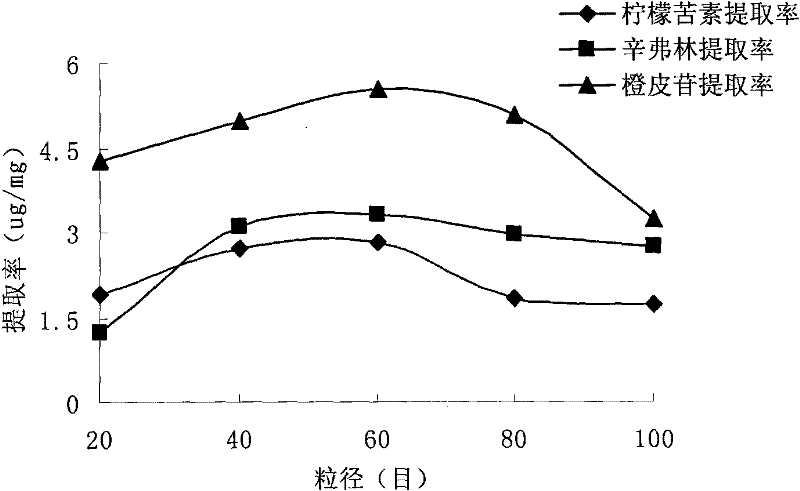

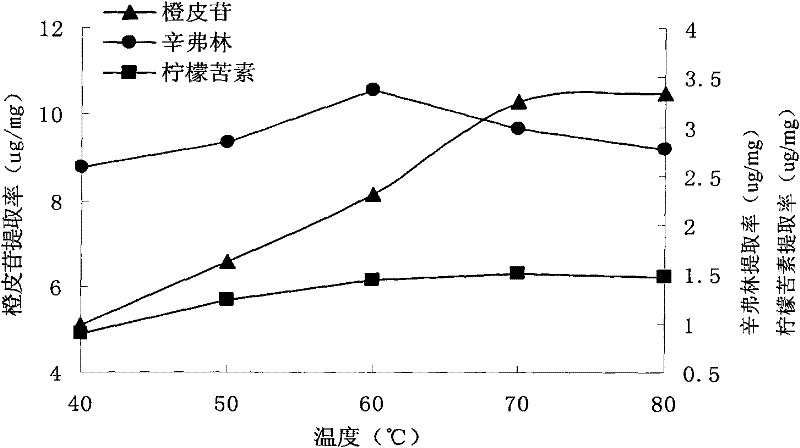

Method for extracting natural activated products from orange drops

InactiveCN102442916AImprove use valueSugar derivativesOrganic compound preparationLimonoidFiltration

The invention belongs to the technical field of natural product extraction from oranges, and specifically relates to a method for continuously extracting natural activated products such as synephrine, hesperidin and limonin from physiological orange drops. The method comprises the following steps: using orange drops which are dried and crushed into 20-100 meshes as raw materials, adding 50-90% ethanol according to a weight / volume ratio of (1:10)-(1:50), extracting under reflux at 40-80 DEG C for 1-3 hours, filtering, recovering ethanol from the filtrate, and obtaining a concentrated solution for later use; adding a small number of chloroform crystals into the concentrated solution, adding water for layering, directly heating the water layer to 75 DEG C, filtering, adding 0.1mol / L hydrochloric acid to regulate the pH value to 3-4, and precipitating to obtain a hesperidin crude product; carrying out spin drying on the obtained chloroform layer solution, adding a right number of acetone crystals, and carrying out vacuum drying to obtain a synephrine crude product; and carrying out spin drying on the acetone solution after the crystal filtration, adding dichloromethane for dissolution, filtering, adding isopropanol into the solution according to a volume ratio of 1:2, and crystallizing to obtain a limonin crude product. Qualitative and quantitative analysis are carried out on the three resulting activated products through high-pressure liquid chromatography, and the result shows that the hesperidin has the highest purity (91.41%).

Owner:HUAZHONG AGRI UNIV +1

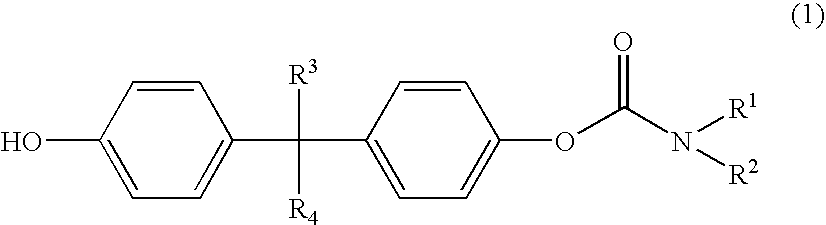

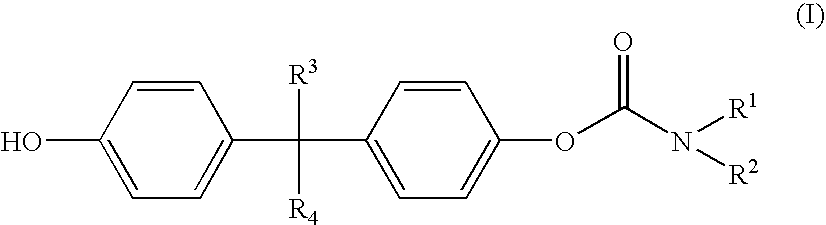

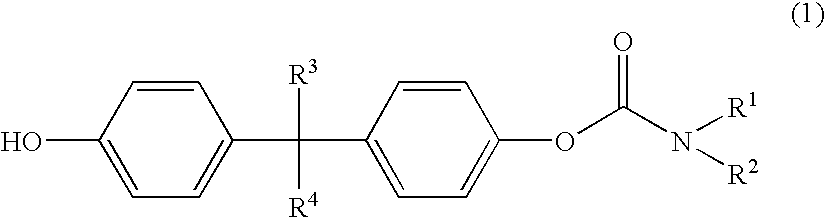

Polycarbonates with good wettability

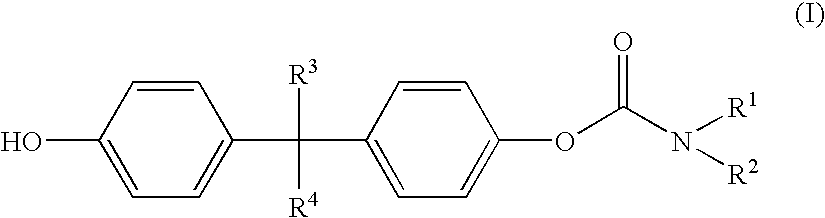

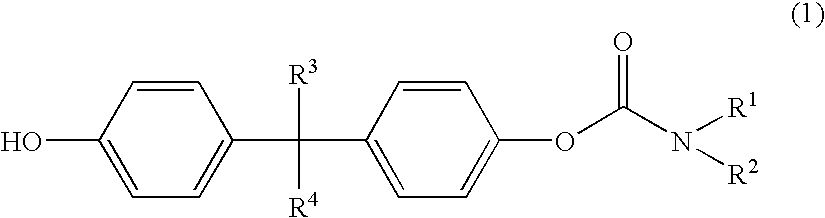

ActiveUS20060135735A1Record information storageThin material handlingCarbamateHigh pressure liquid chromatography procedure

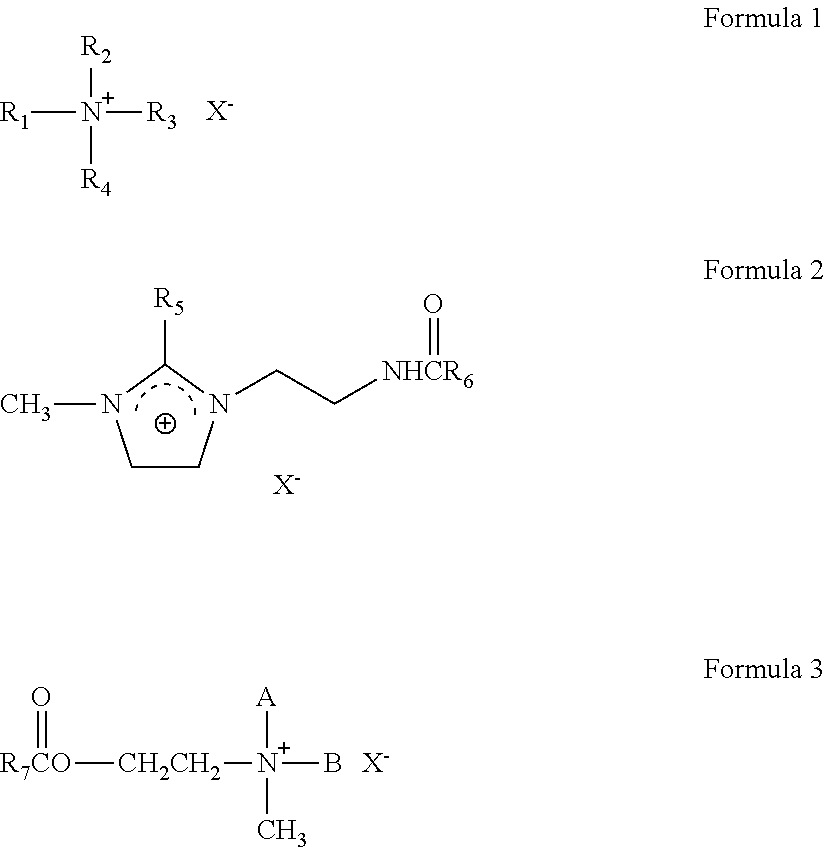

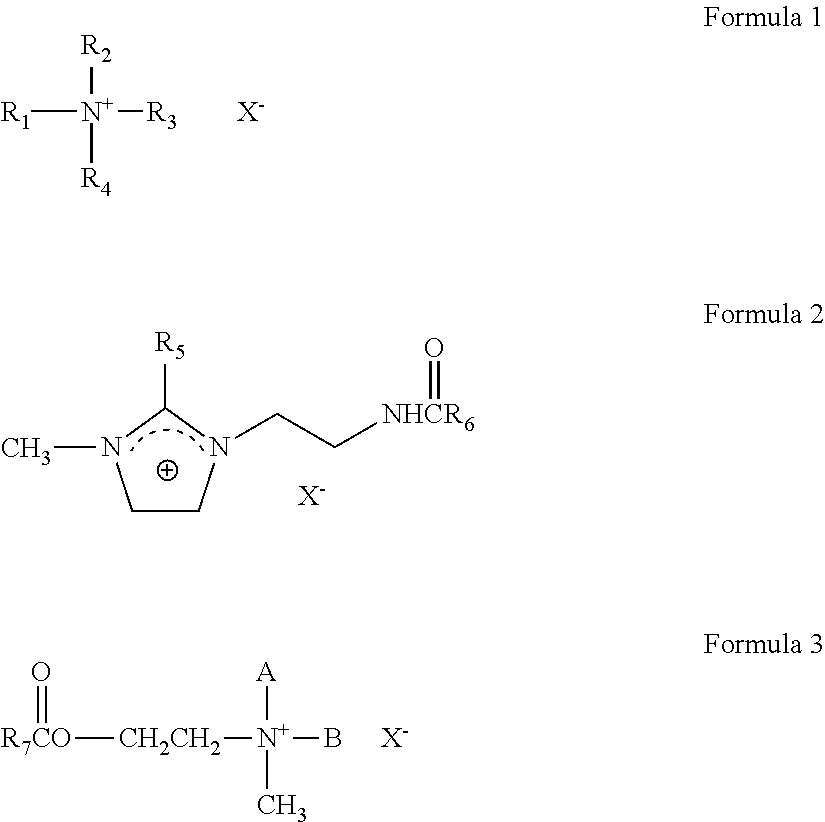

A polycarbonate resin that after alkaline hydrolysis with sodium hydroxide contain an amount of 0.01 to 150 ppm of carbamate compounds according to formula (1) wherein R1 and R2 independently of one another denote hydrogen or C1-C12-alkyl, or together denote C4-C12-alkylidene, and R3 and R4 independently of one another denote hydrogen, C1-C12-alkyl or phenyl, or together with the carbon atom to which they are bonded form cyclohexyl or trimethylcyclohexyl, said amount measured after alkaline hydrolysis with sodium hydroxide by high pressure liquid chromatography.

Owner:COVESTRO DEUTSCHLAND AG

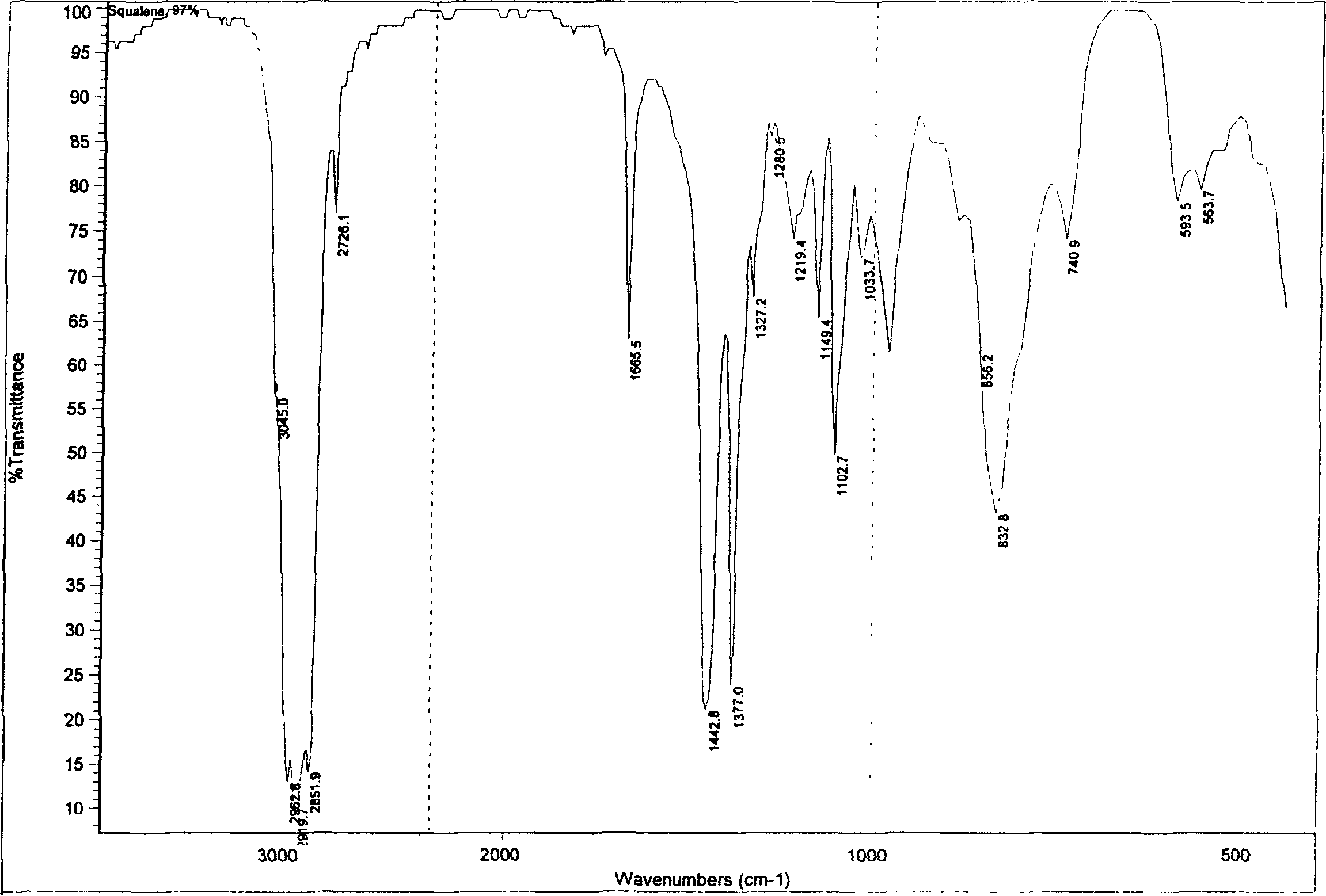

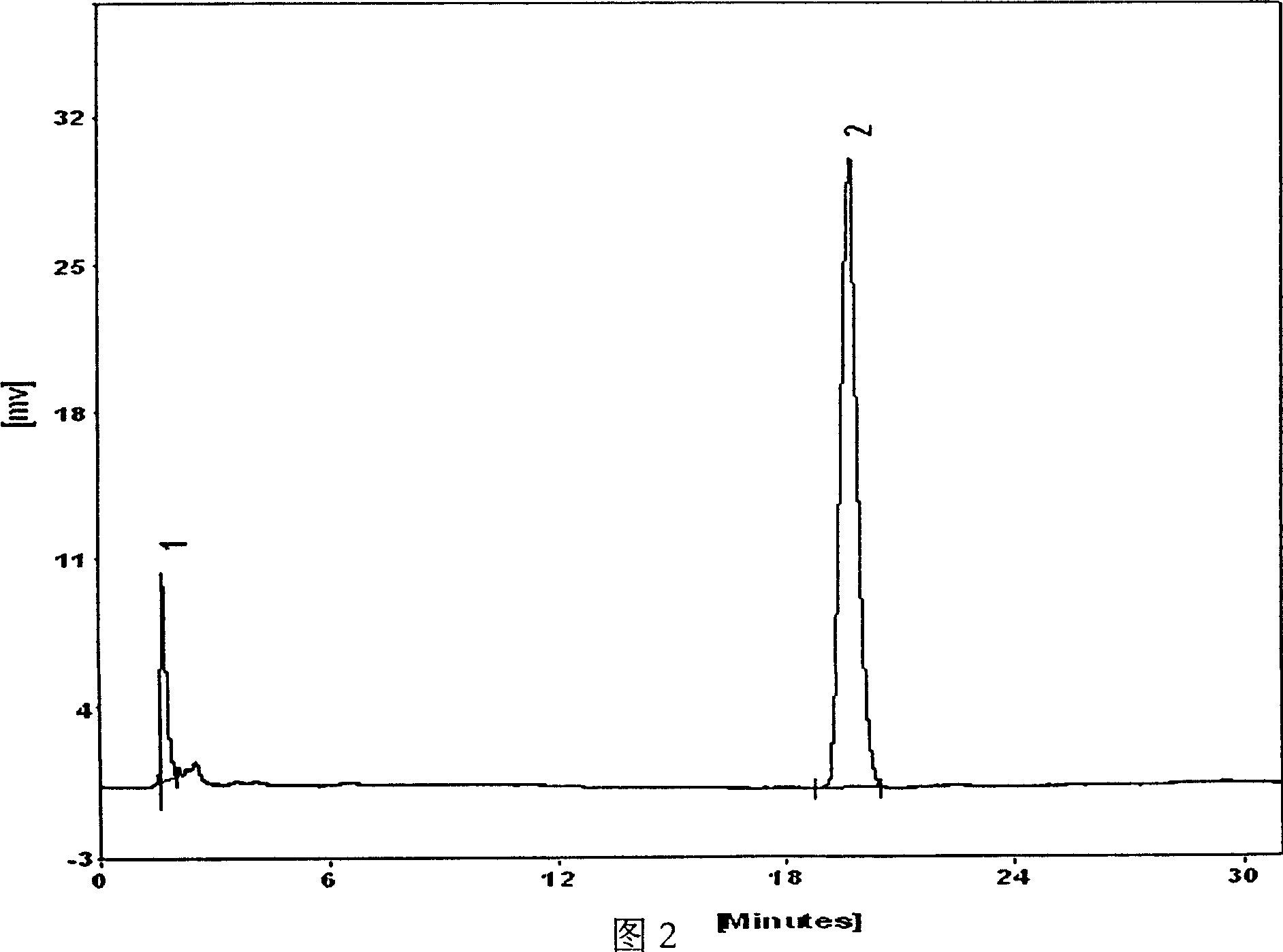

Plant squalene and its preparation method

The invention relates to a method for preparing momordica grosvenori squalene, which comprises the following step: breaking kernels or seeds of the momordica grosvenoris, leaching the liposolubility substance by organic solvent, then removing the organic solvent in the liposolubility substance to get the crude momordica grosvenori squalene, getting raw momordica grosvenori squalene through a silica gel chromatography column and eluting by organic solvent, collecting the achromatic color part of the eluent, removing the organic solvent using vacuum distillation process to get the momordica grosvenori squalene super quality. The content of squalene is more than 40 % in the crude production and more than 95 % in the exquisite production. The production has the special perfume and can substitute completely squalene abstracted from the liver of abyssal sea sharks.

Owner:桂林中族中药股份有限公司

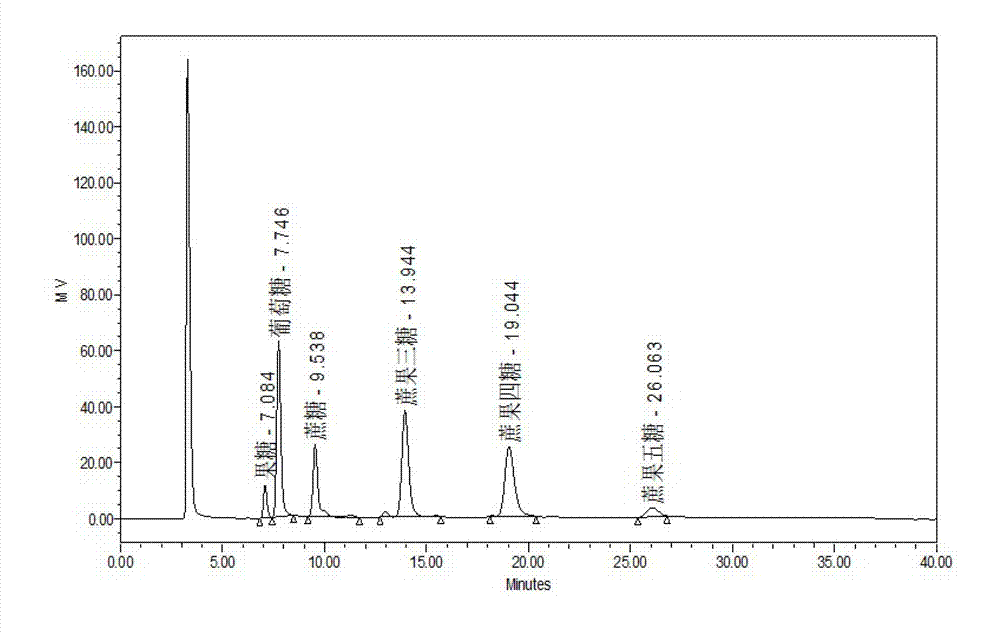

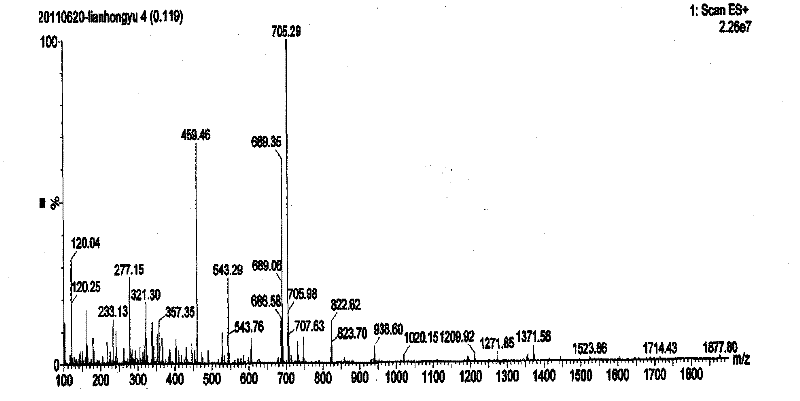

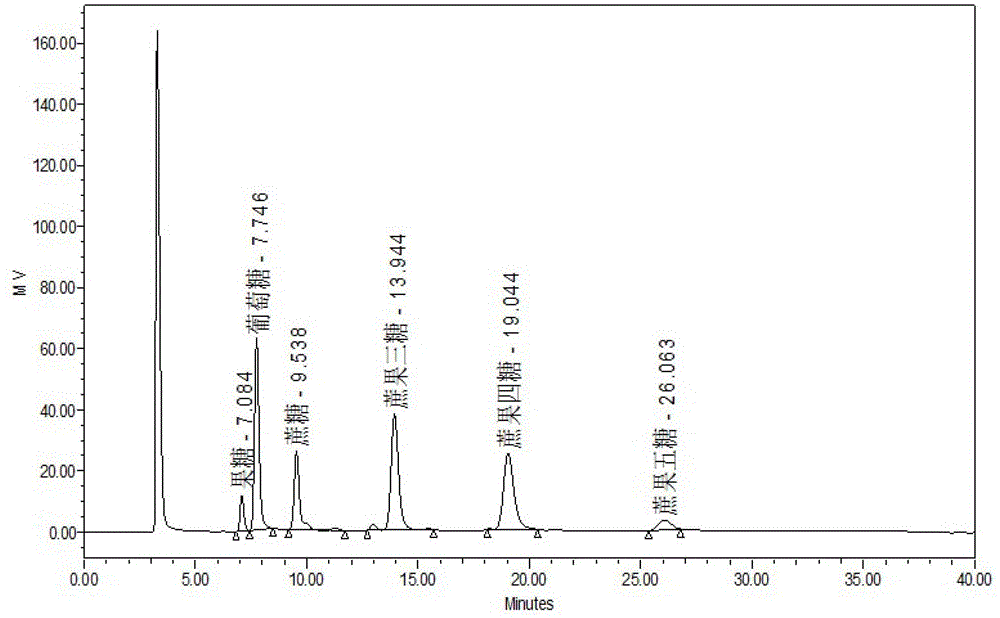

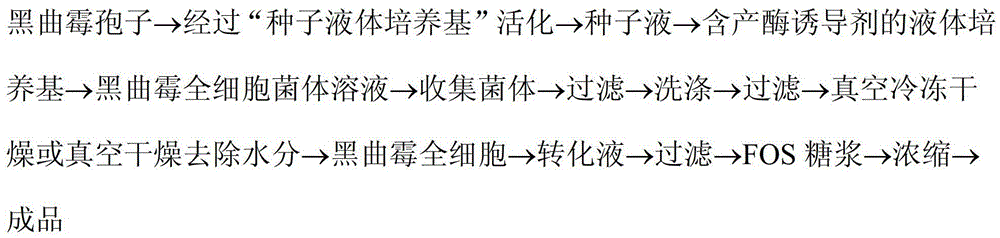

Aspergillus niger and method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger

ActiveCN103045489AEasy to prepareSimplify investmentFungiMicroorganism based processesTransformation efficiencyHigh pressure

The invention discloses aspergillus niger and a method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger. The aspergillus niger FOS-0620 is an aerobe, has black spores and milk-white hyphae, and is collected in China General Microbiological Culture Collection Centre (CGMCC for short) on September 28, 2012. The method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger comprises the following steps of: (1) preparing aspergillus niger whole-cells by virtue of the aspergillus niger FOS-0620 according to claim 1; and (2) catalytically producing fructo-oligosaccharide by virtue of the aspergillus niger whole-cells. The product obtained by the method disclosed by the invention is detected that the content (occupying total solids) of the fructo-oligosaccharide is not less than 50% via high-pressure liquid chromatography; and the method disclosed by the invention is simple in process, convenient to operate, high in enzymatic activity, high in conversion efficiency, and important in industrial value.

Owner:SOUTH CHINA UNIV OF TECH

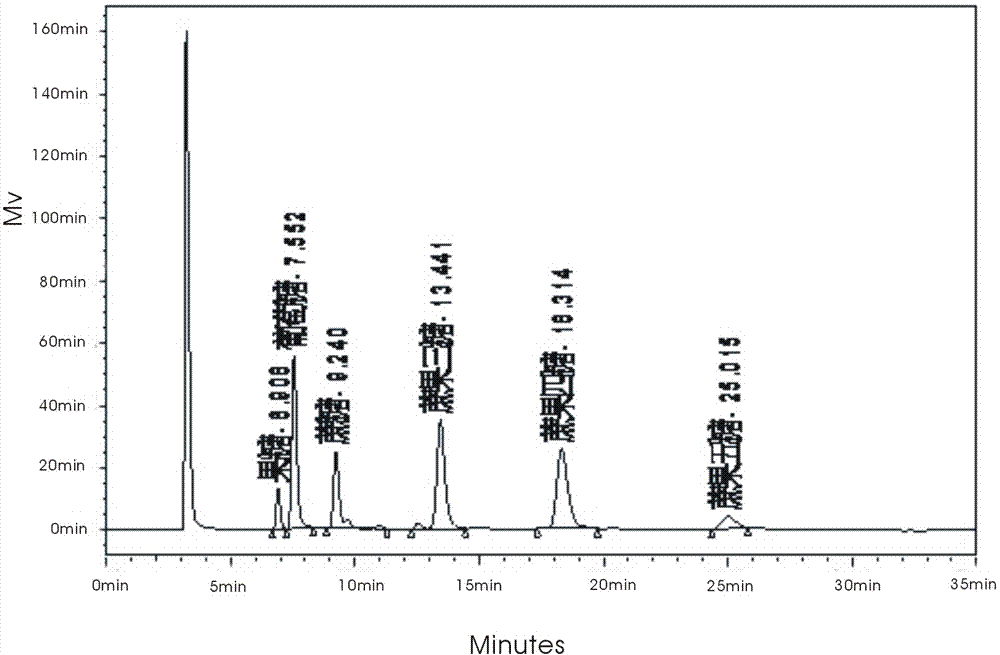

High-pressure liquid chromatography of diode array detector for detecting tripolycyanamide in food

InactiveCN101713767AHarm reductionReduce pollutionComponent separationPreparing sample for investigationHigh pressureZinc Acetate Dihydrate

The invention relates to a high-pressure liquid chromatography of a diode array detector for detecting tripolycyanamide in foods, which is characterized by comprising the following steps of: sampling and then extracting tripolycyanamide by 0.2-0.3% trichloroacetic acid; precipitating protein in extracting liquid by a precipitating agent; centrifugally separating supernatant in the extracting liquid, purifying and filtering; setting the method of a liquid chromatography instrument of the diode array detector to recognize the tripolycyanamide and a hydrolysis product; preparing a standard curve to obtain a regression equation of an analyzing method; detecting the tripolycyanamide by a liquid chromatograph and calculating the tripolycyanamide content. The 0.2-0.3% trichloroacetic acid extracting liquid has good extracting effect and less detecting interference; the protein is precipitated by zinc acetate and potassium ferrocyanide, the precipitation efficiency is high, and the pollution is less; the tripolycyanamide and the hydrolysis product can be detected, the result is more accurate, the used instrument and reagent are cheap and are easy for popularization, and the liquid chromatography is suitable for the detection of a plurality of samples.

Owner:郝文

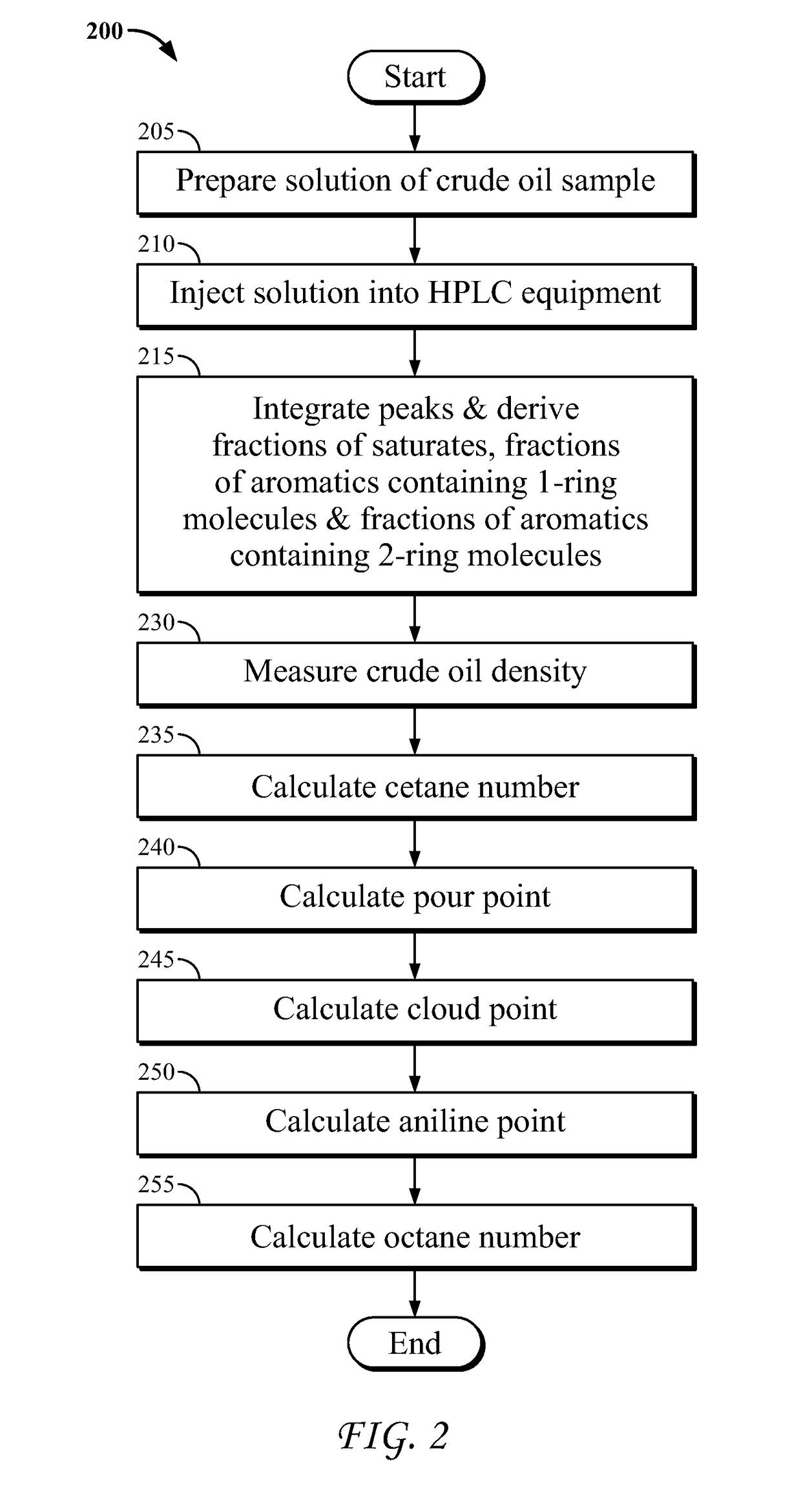

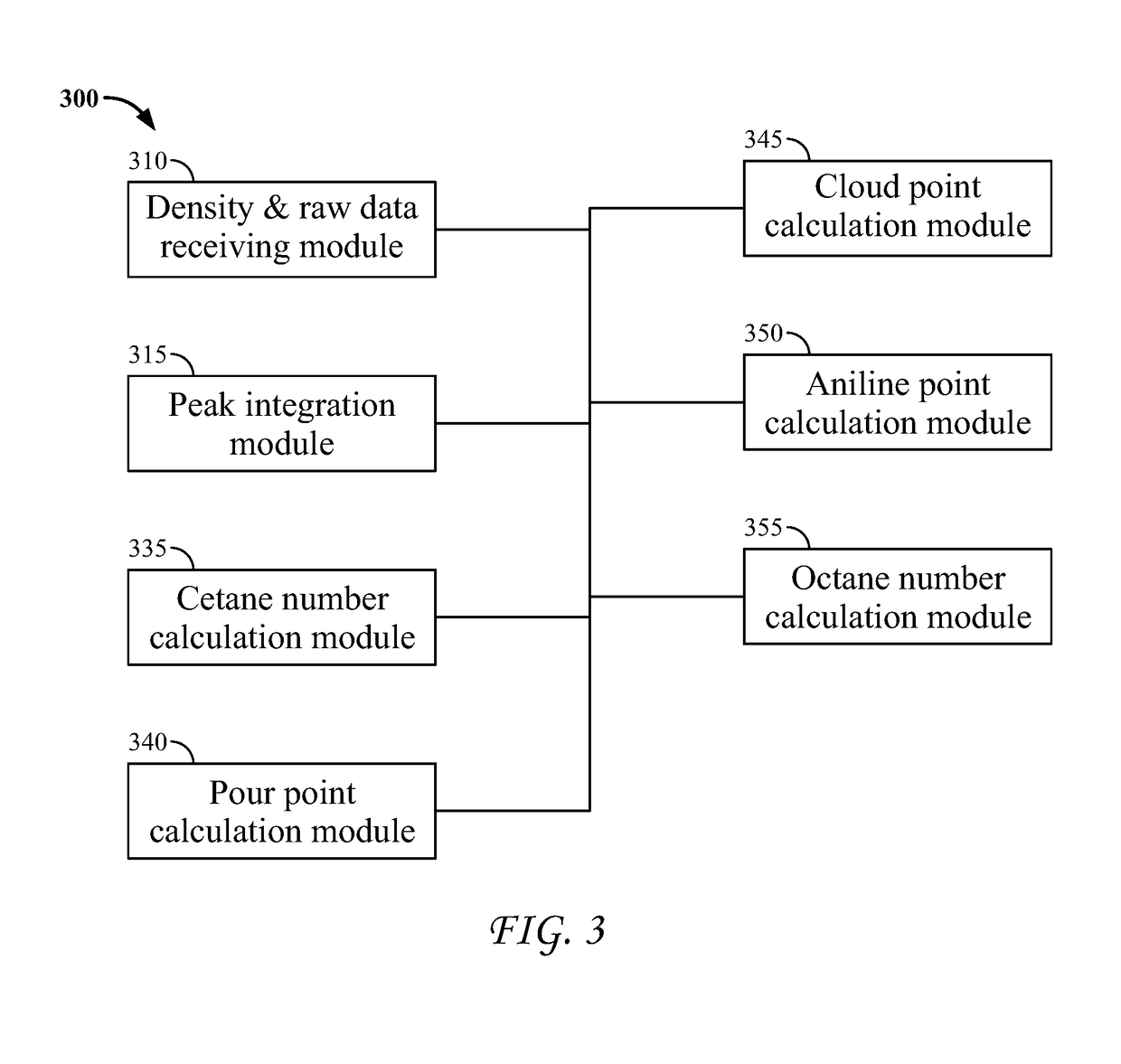

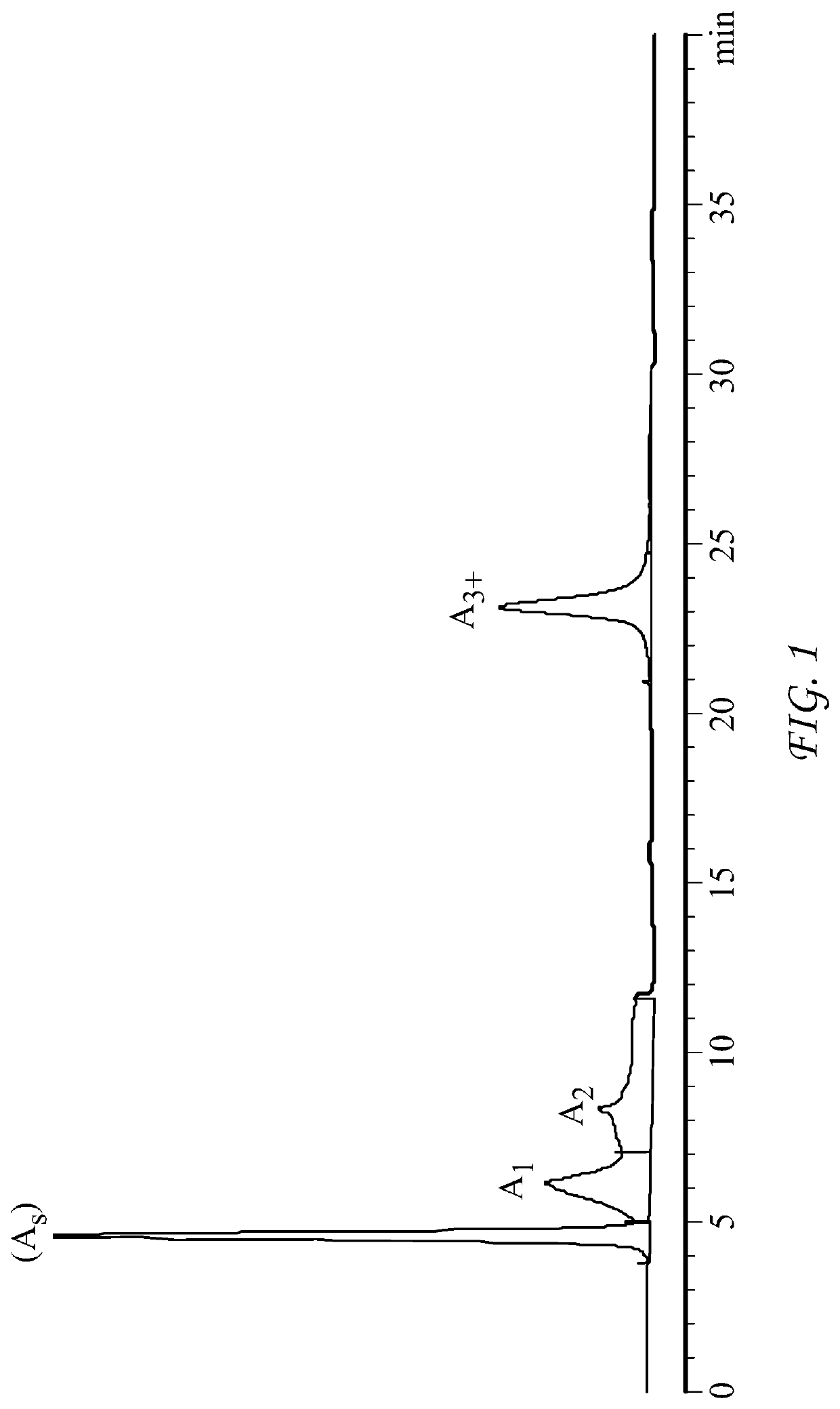

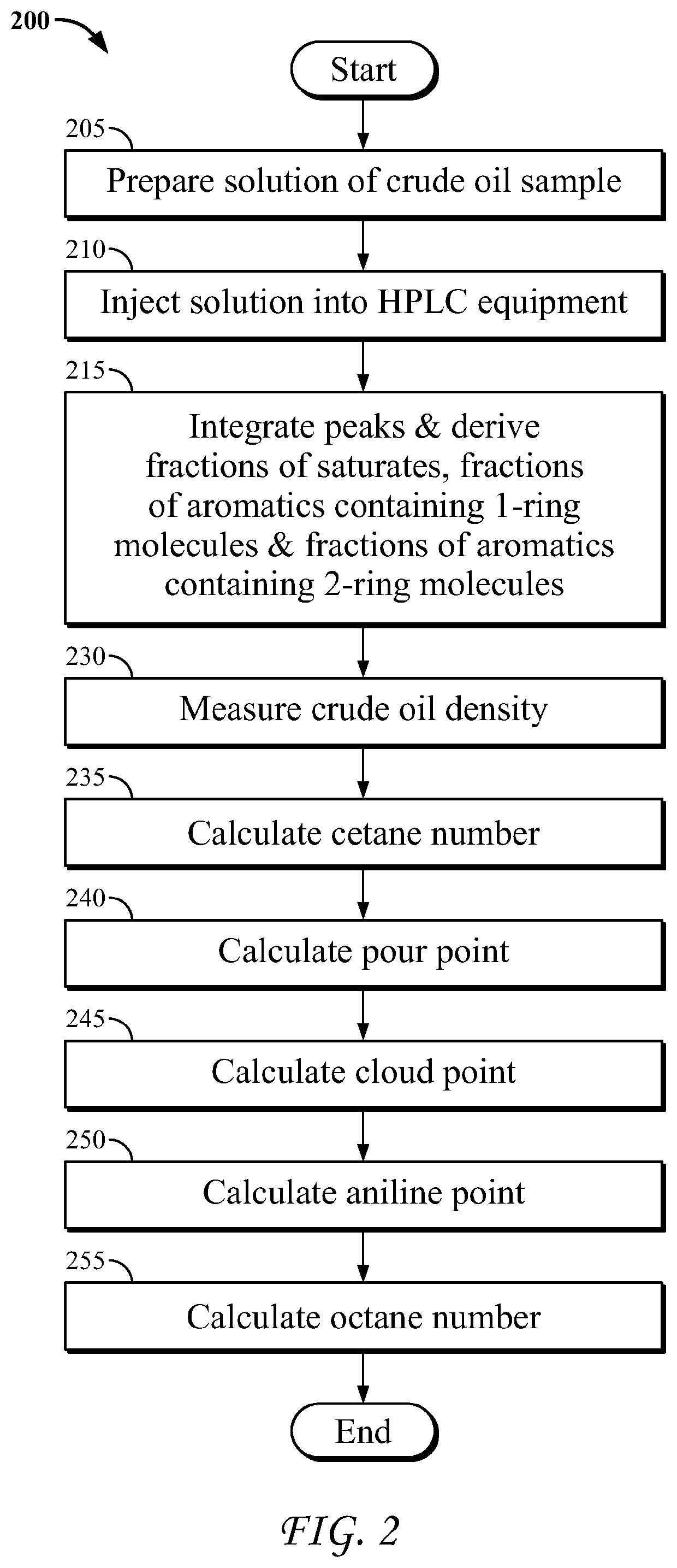

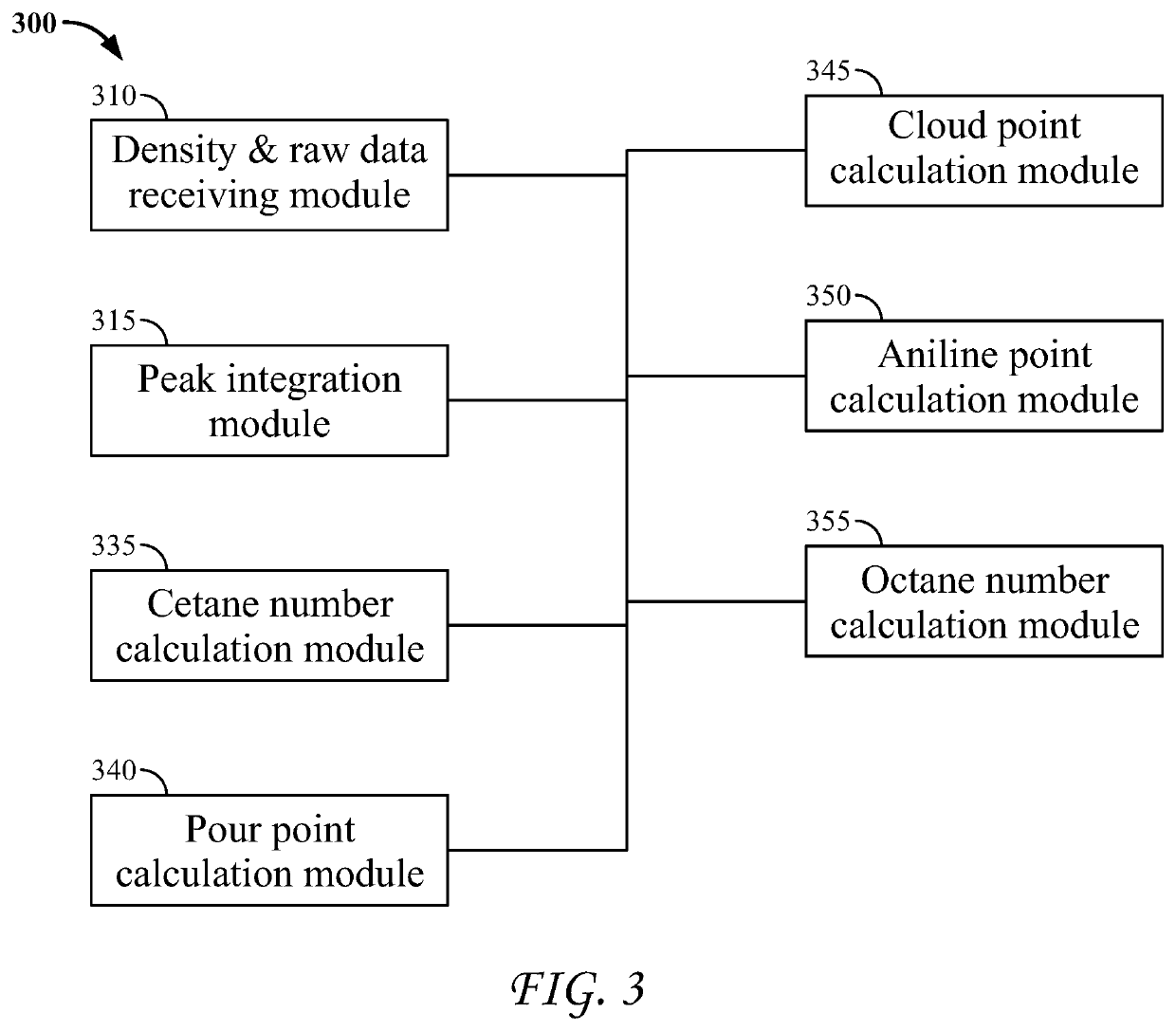

Characterization of crude oil by high pressure liquid chromatography

ActiveUS20170363603A1Provide informationImprove oil qualityComponent separationMaterial testing goodsAniline pointHigh pressure liquid chromatography procedure

A system and a method are provided for calculating one or more indicative properties, e.g., one or more of the cetane number, octane number, pour point, cloud point and aniline point of oil fractions, from the density and high pressure liquid chromatography (HPLC) data of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

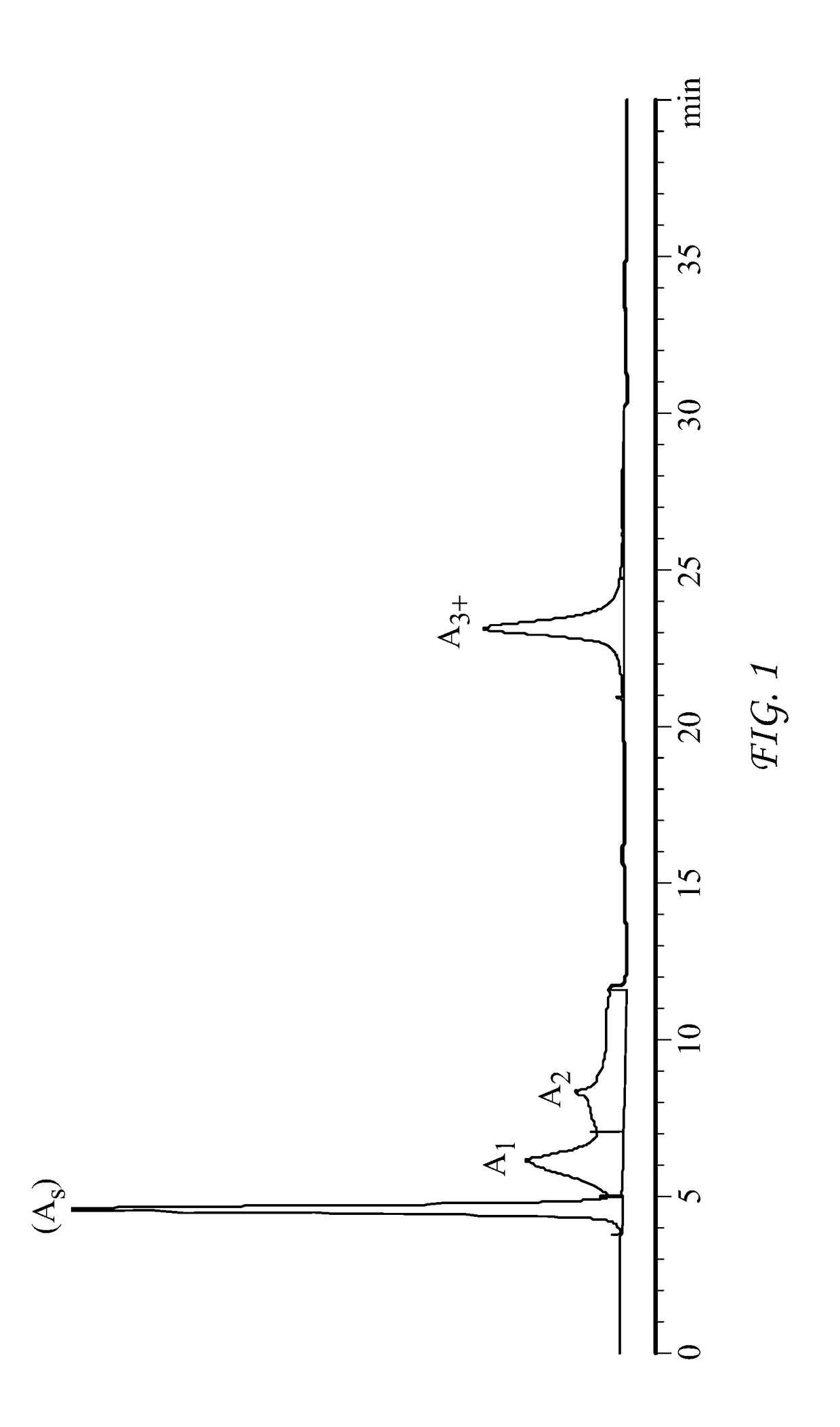

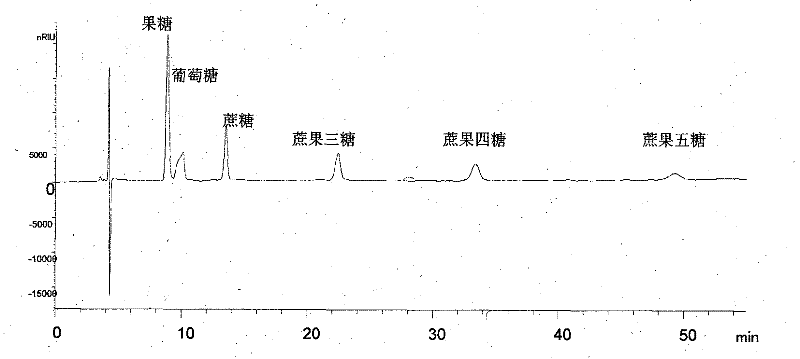

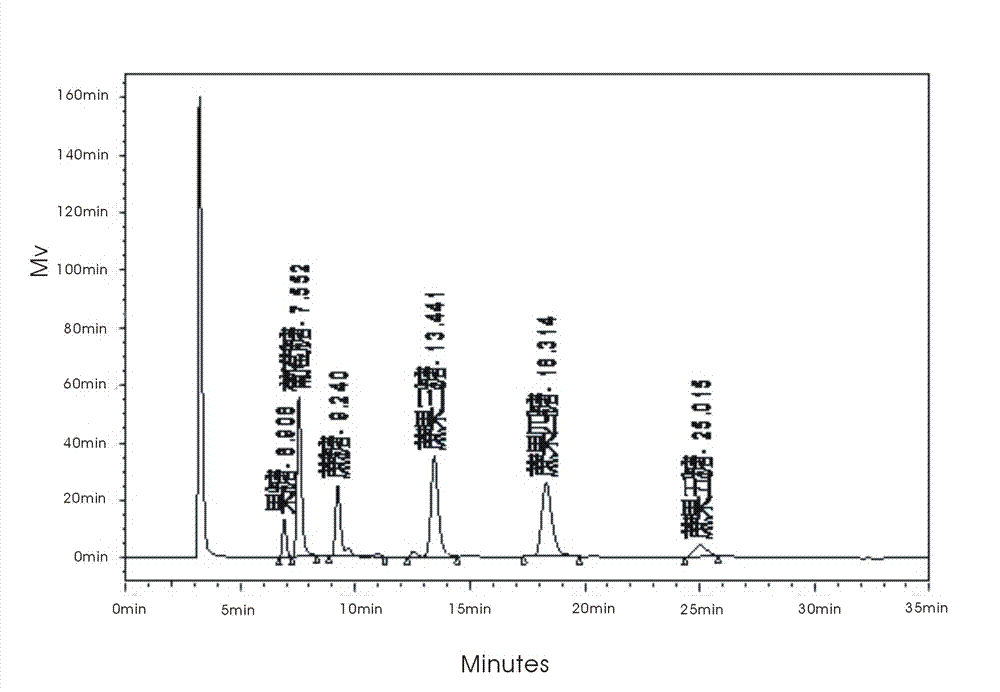

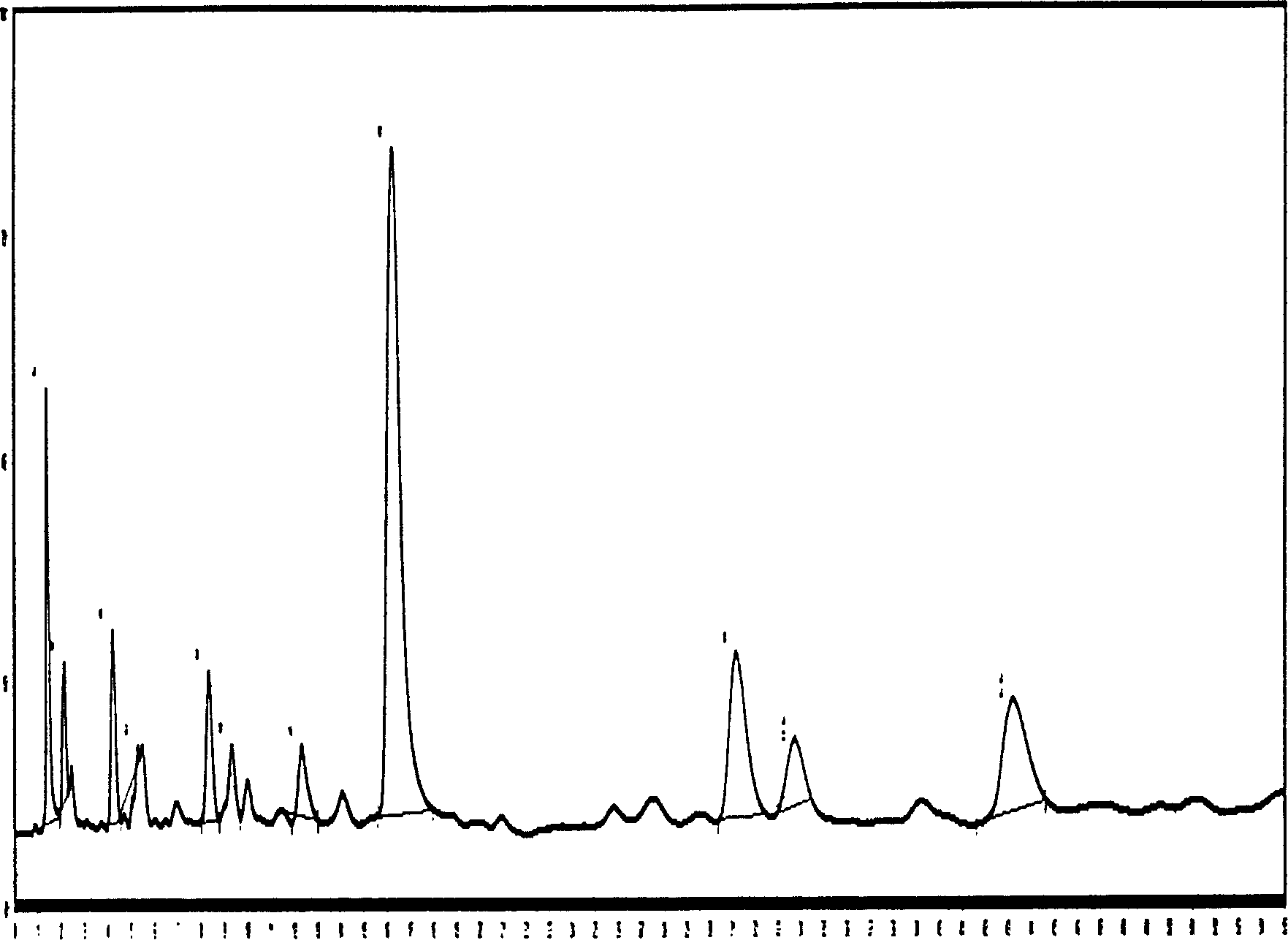

Method for preparing kestose and nystose through yacon

InactiveCN102408457ASimple extraction methodSugar derivativesOligosaccharidesSucroseColumn temperature

The invention discloses a method for preparing kestose and nystose through yacon. Method of water extraction by alcohol sedimentation is adopted and supernate thereof is taken, concentrated, frozen and dried to obtain faint yellow yacon oligosaccharide. The yacon oligosaccharide is analyzed through high pressure liquid chromatography with a chromatography condition as follows: a chromatographic column is APS-2HYPERSIL, a column temperature is 30 DEG C, a moving phase is acetonitrile-water (75 to 25, V / V), a flow velocity is 0.8ml / min, a sample size is 20 Mul and a differential detector is arranged. The yacon oligosaccharide comprises fructose, glucose, saccharose, kestose, nystose and 1F-Fructofuranosyl nystose with contents respectively as 38,30 percent, 16.44 percent, 14.58 percent, 12.29 percent, 12.17 percent and 6.2 percent. Silicagel column chromatography is implemented on a prepared oligosaccharide sample; glacial acetic acid, chloroform, absolute ethyl alcohol and water with a proportion of 3 to 11 to 11 to 1 are used as an eluant for elution; the eluant is collected in sequence and then is concentrated, frozen and dried to obtain the kestose and nystose. The purity of the kestose and nystose prepared through high pressure liquid chromatography can be more than 90 percent.

Owner:TIANJIN UNIV OF SCI & TECH

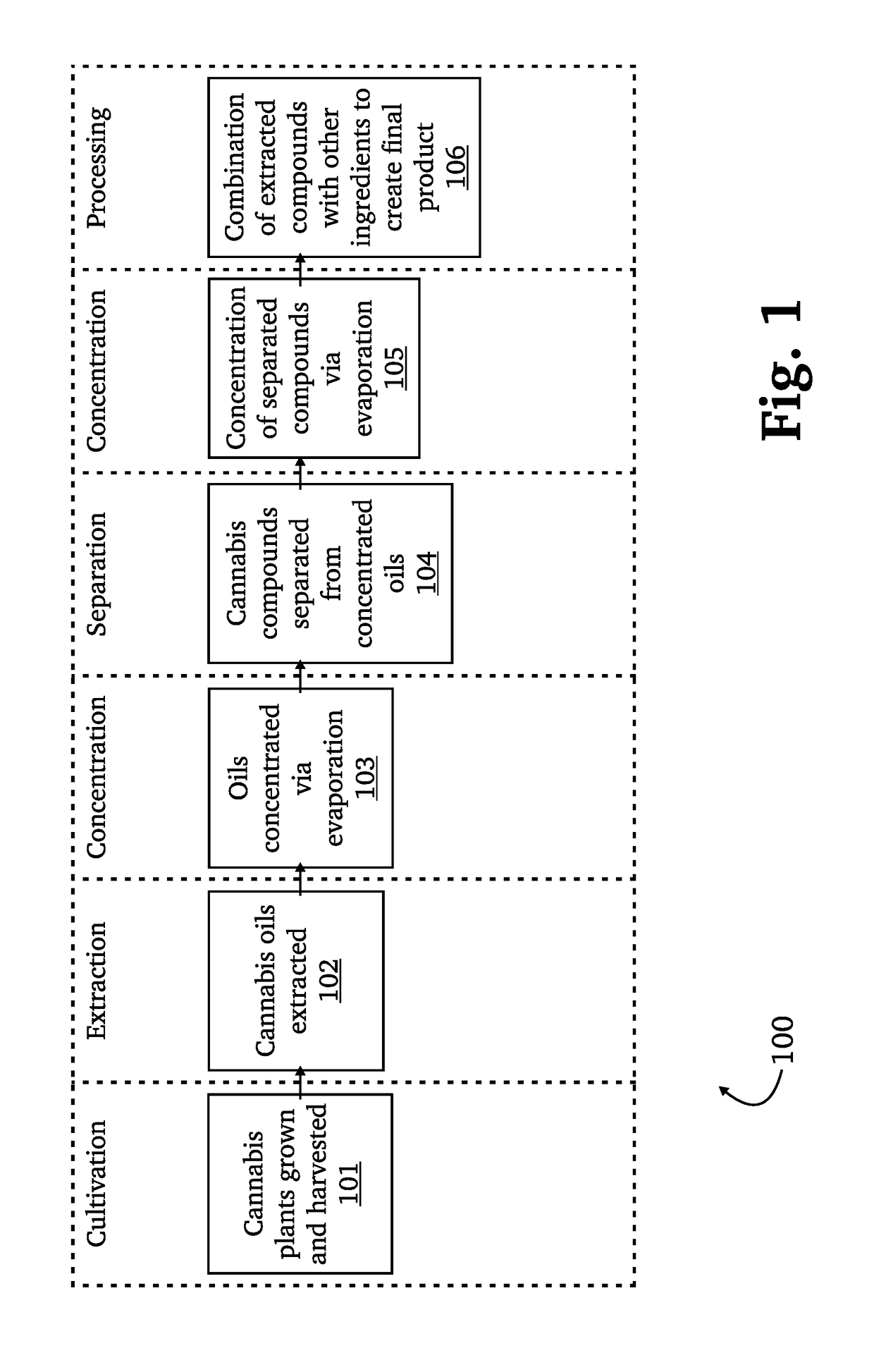

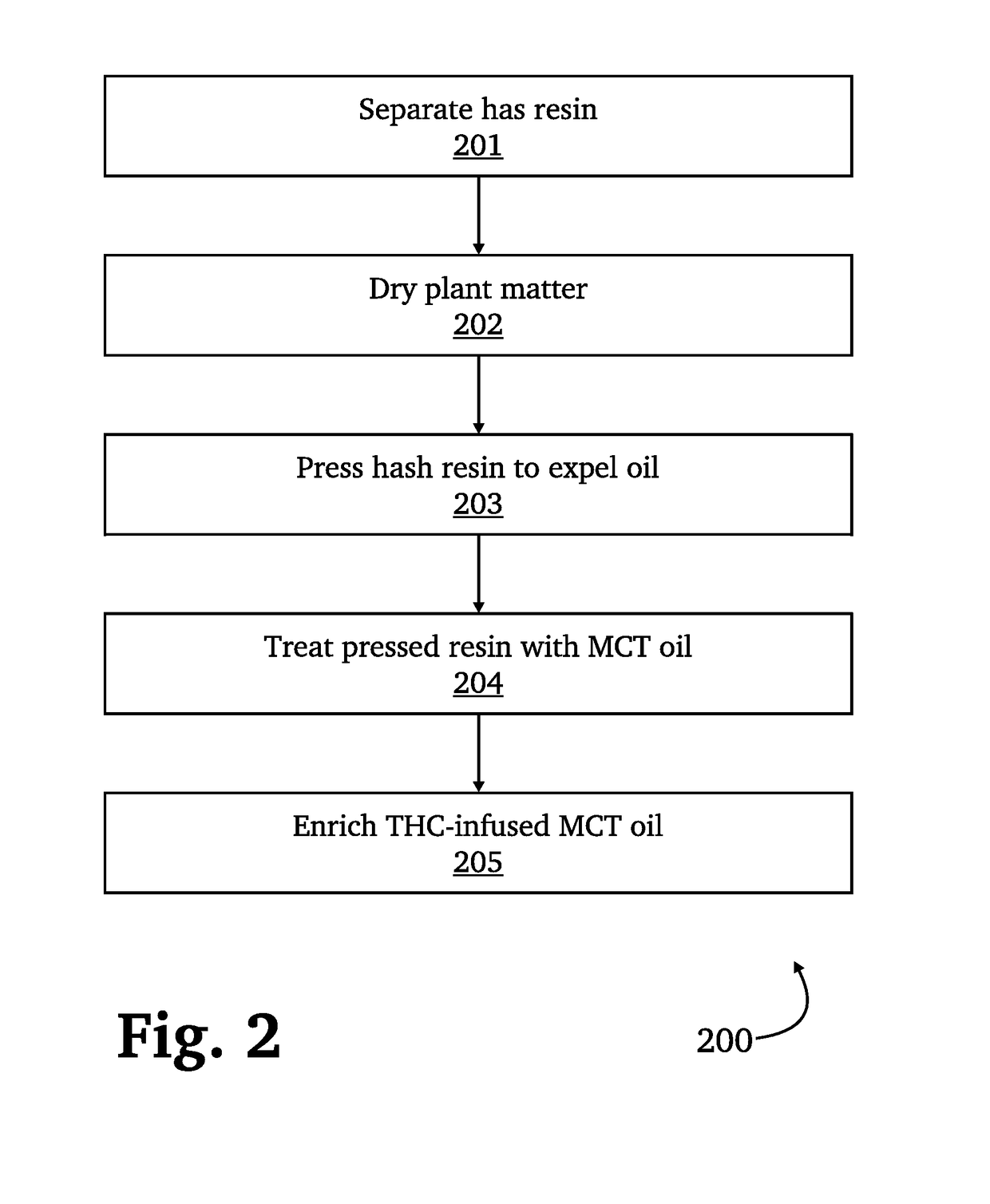

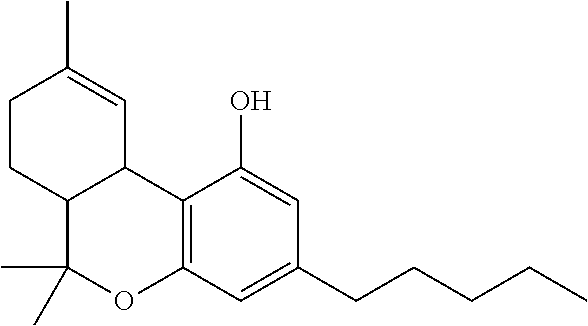

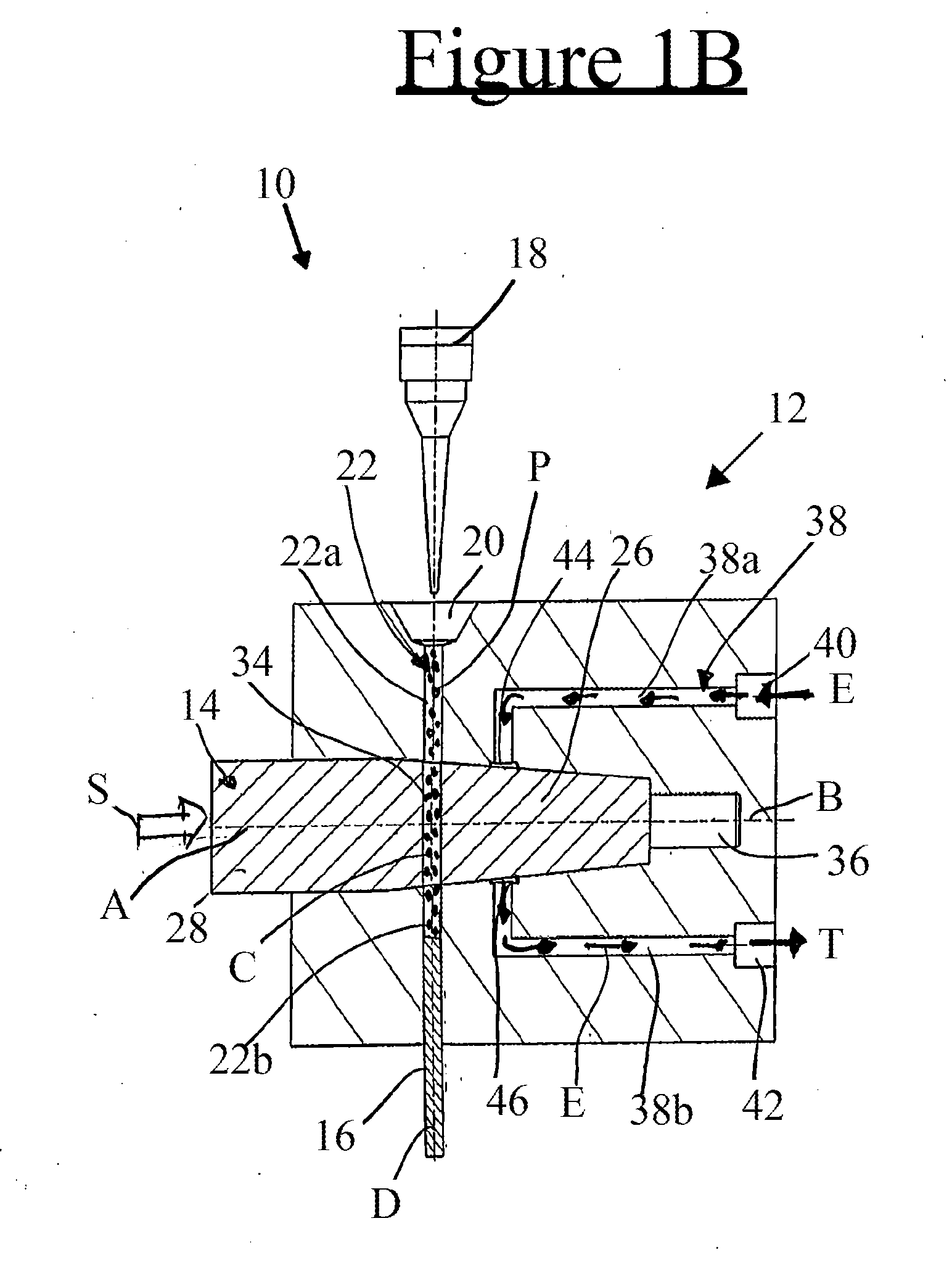

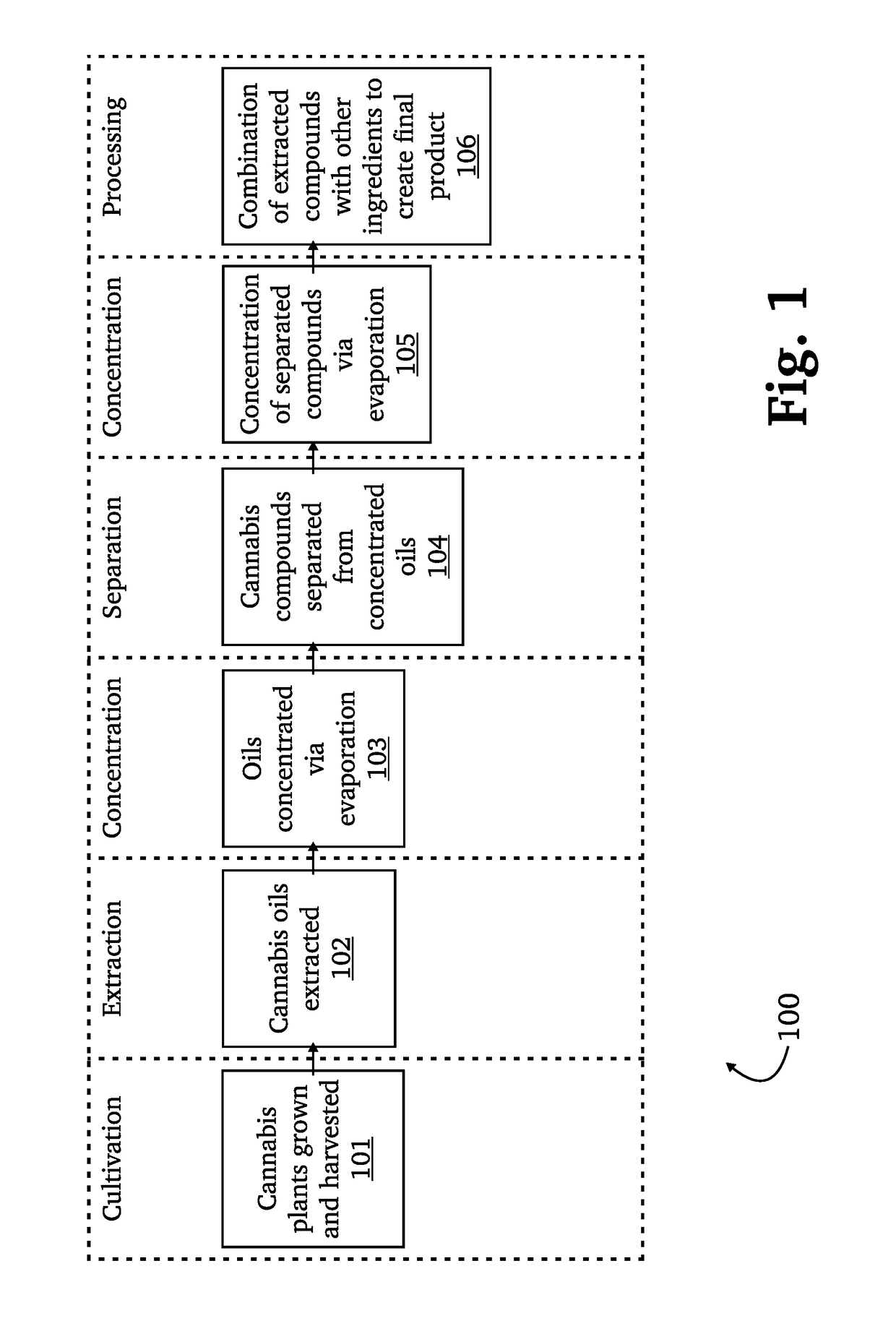

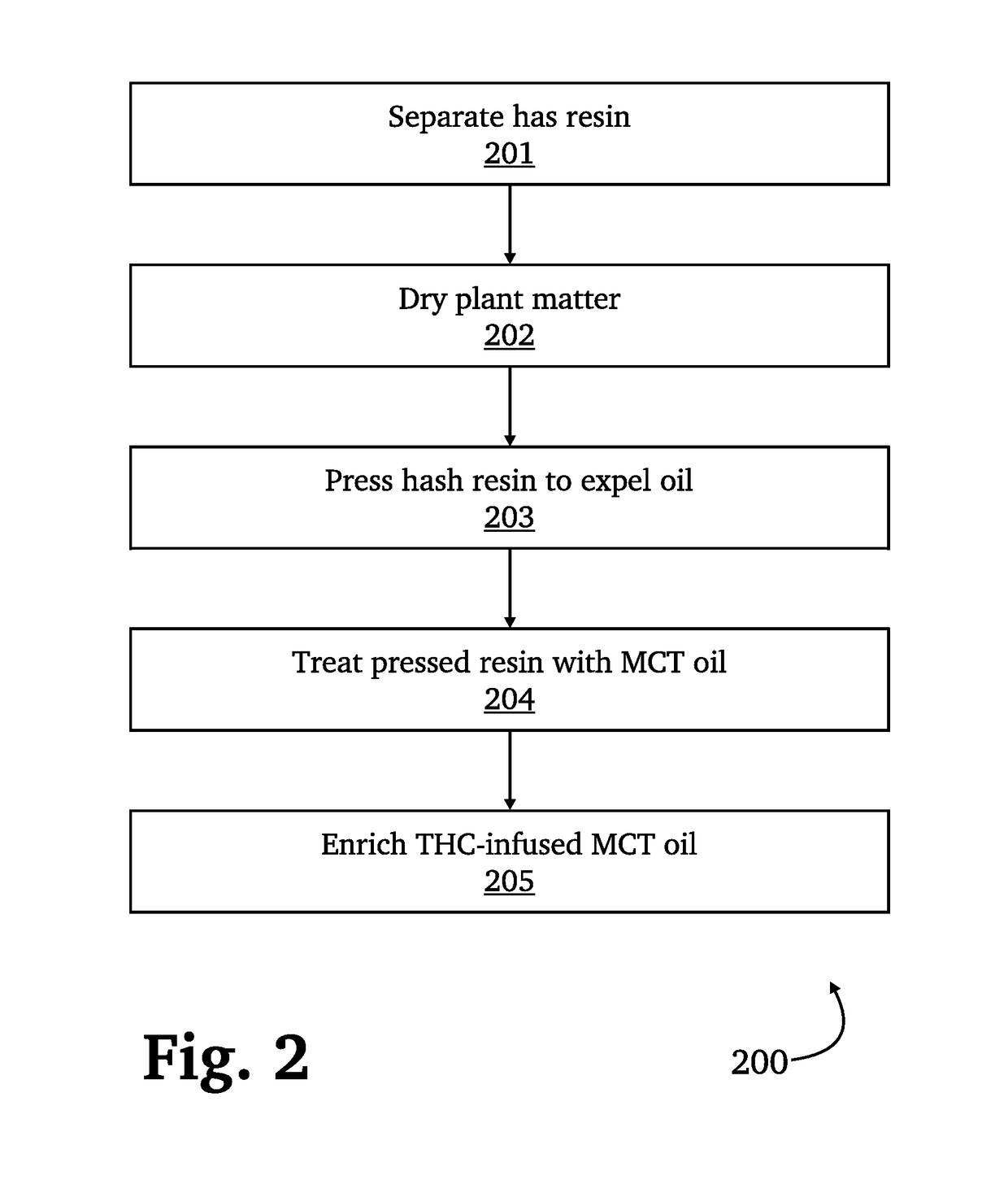

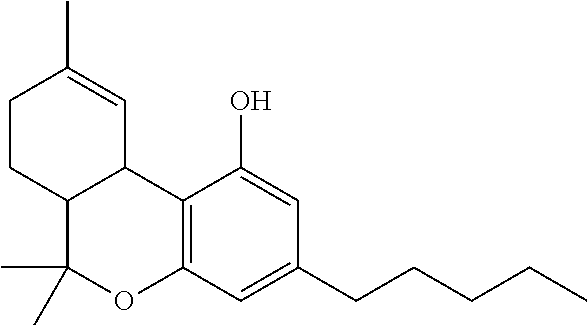

Cannabis-based therapeutic product for treatment of chronic pain

InactiveUS20180344663A1Improve breathabilityReduce chronic painHydroxy compound active ingredientsOintment deliveryCannabisChronic pain

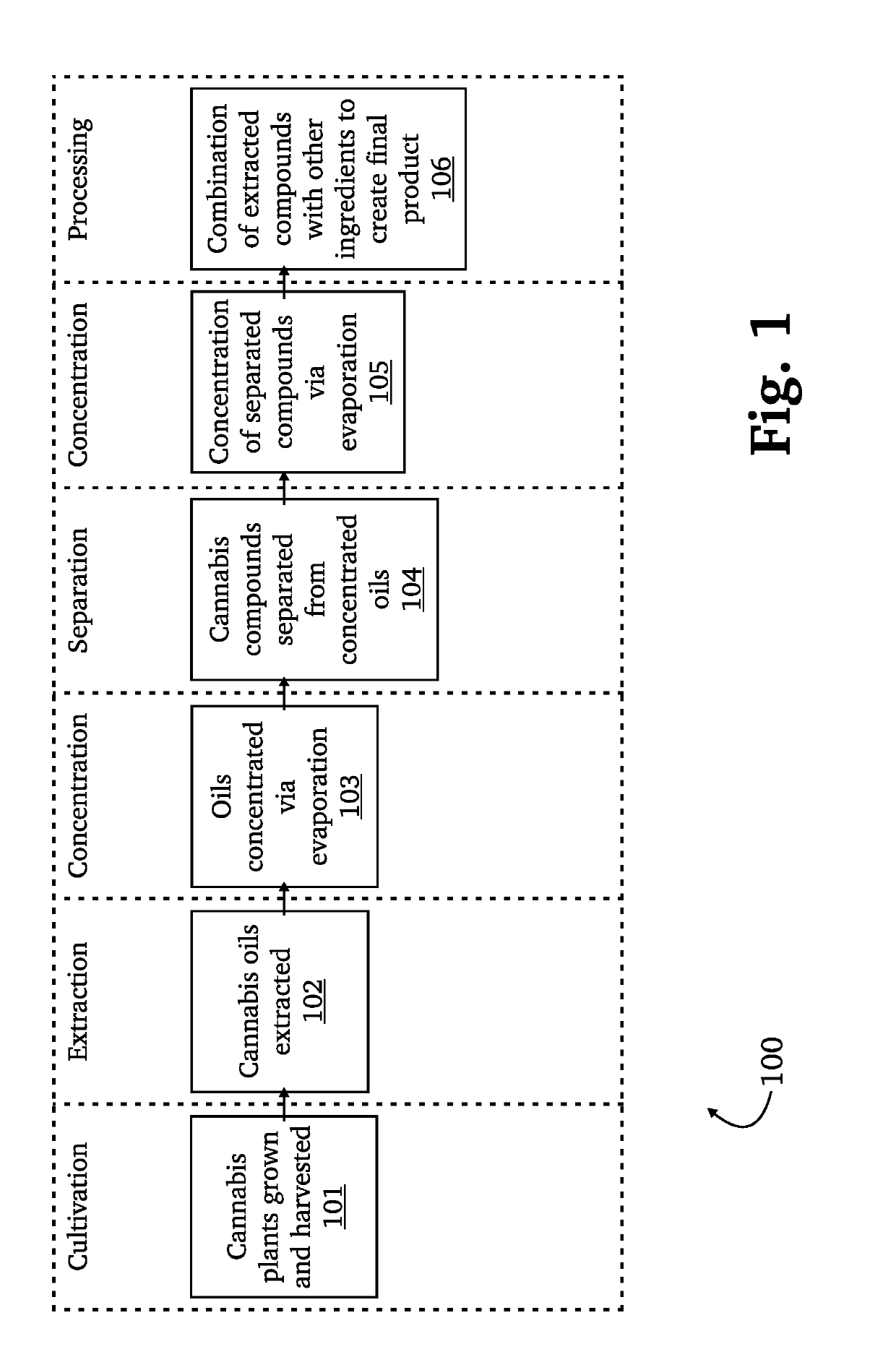

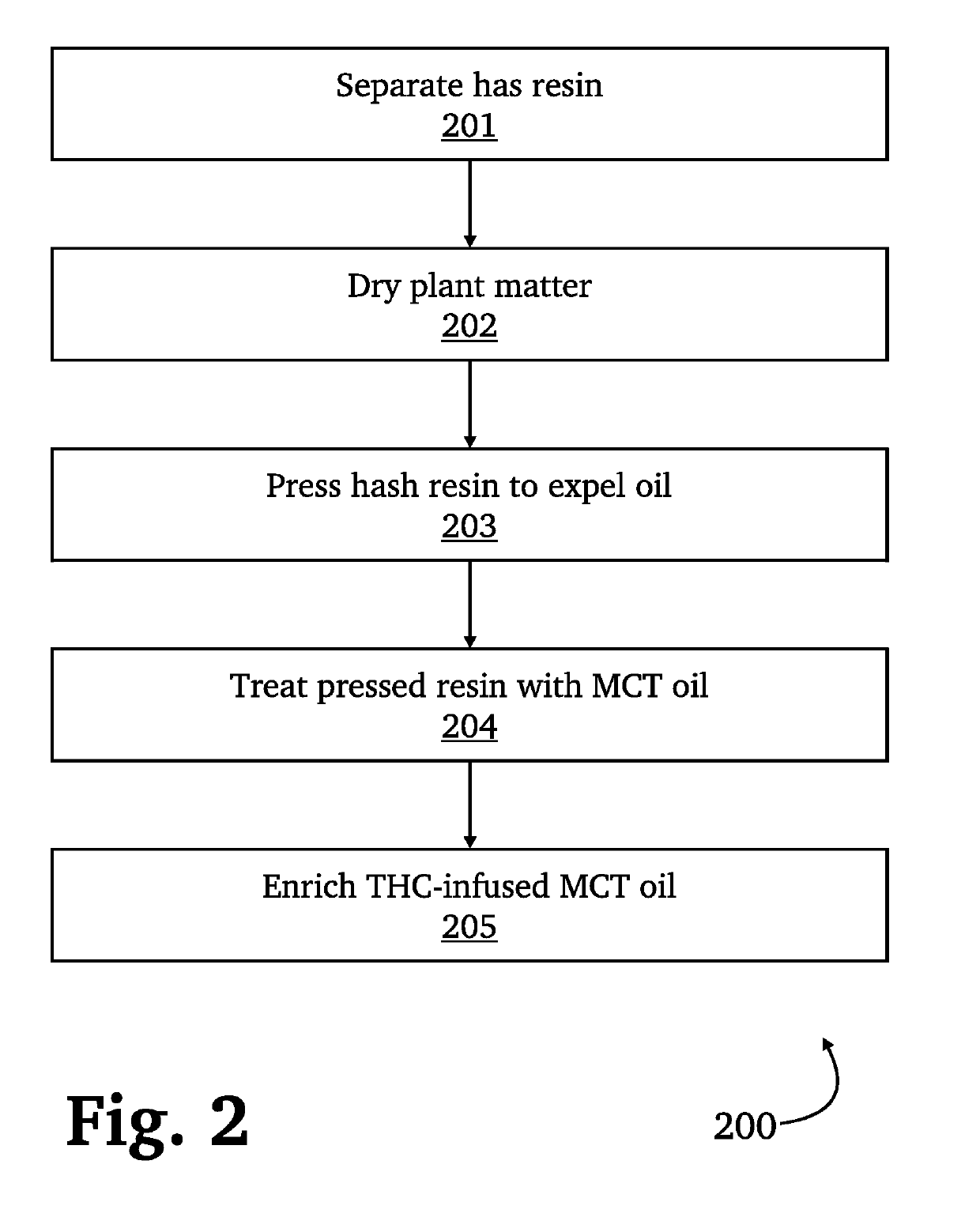

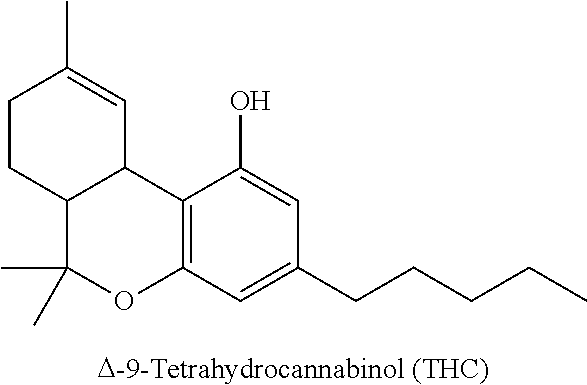

A cannabis based therapeutic product for treatment of chronic pain produced by separating hash resin from plant material of the cannabis plant, pressing the hash resin to expel oil, leaving spent hash resin, extracting further cannabinoids from the spent hash resin using MCT oil, separating the cannabis compounds from the oils using high pressure liquid chromatography, flash chromatography, or similar techniques, and processing selected cannabis compound formulations into a pill, tablet, liquid, or other form suitable for administration as a therapeutic product for treatment of chronic pain, optionally with the further step of enriching the product with a formulation comprising at least 1% by weight purified -myrcene, prior to processing into a final product.

Owner:CMG PARTNERS INC

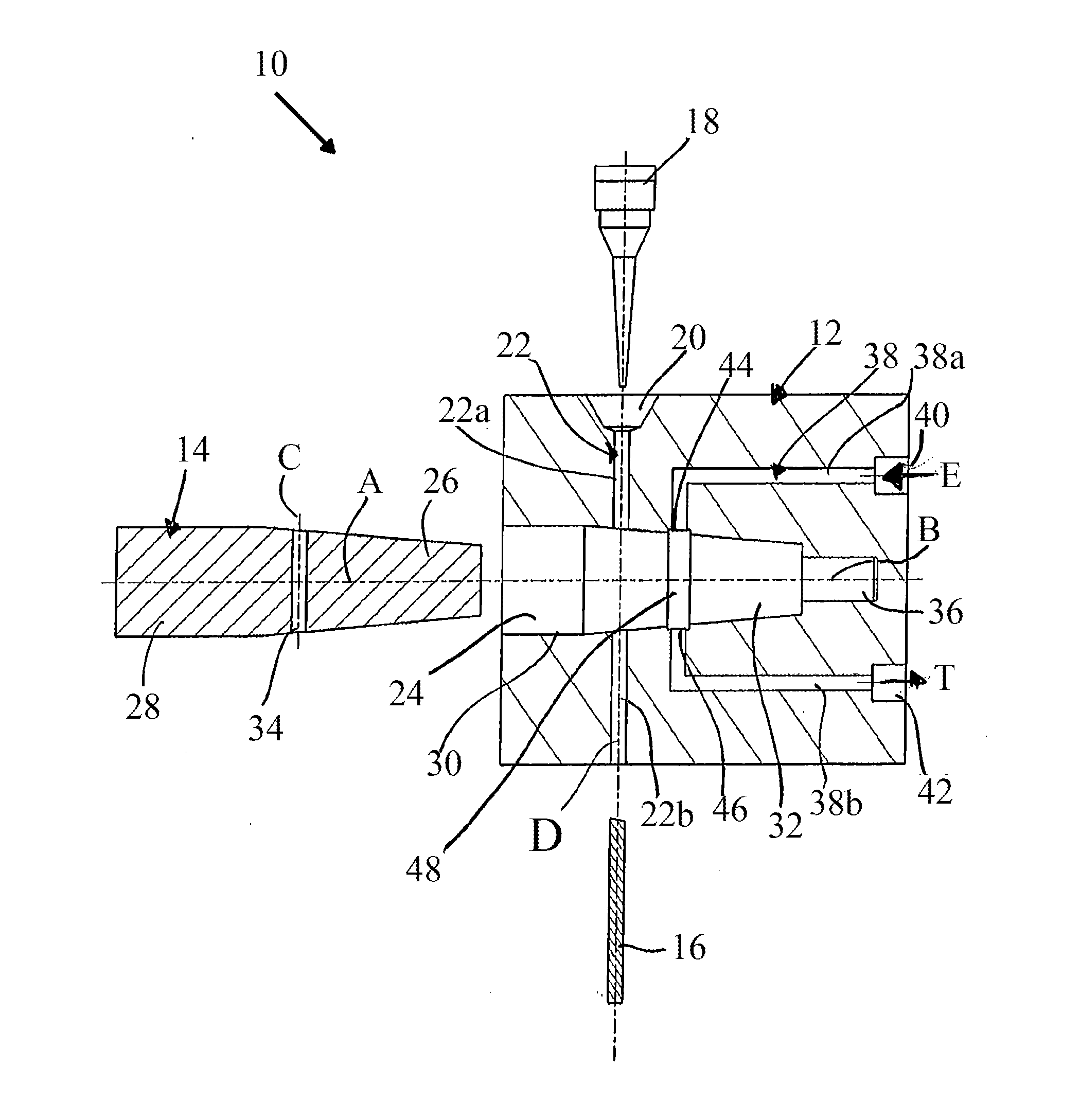

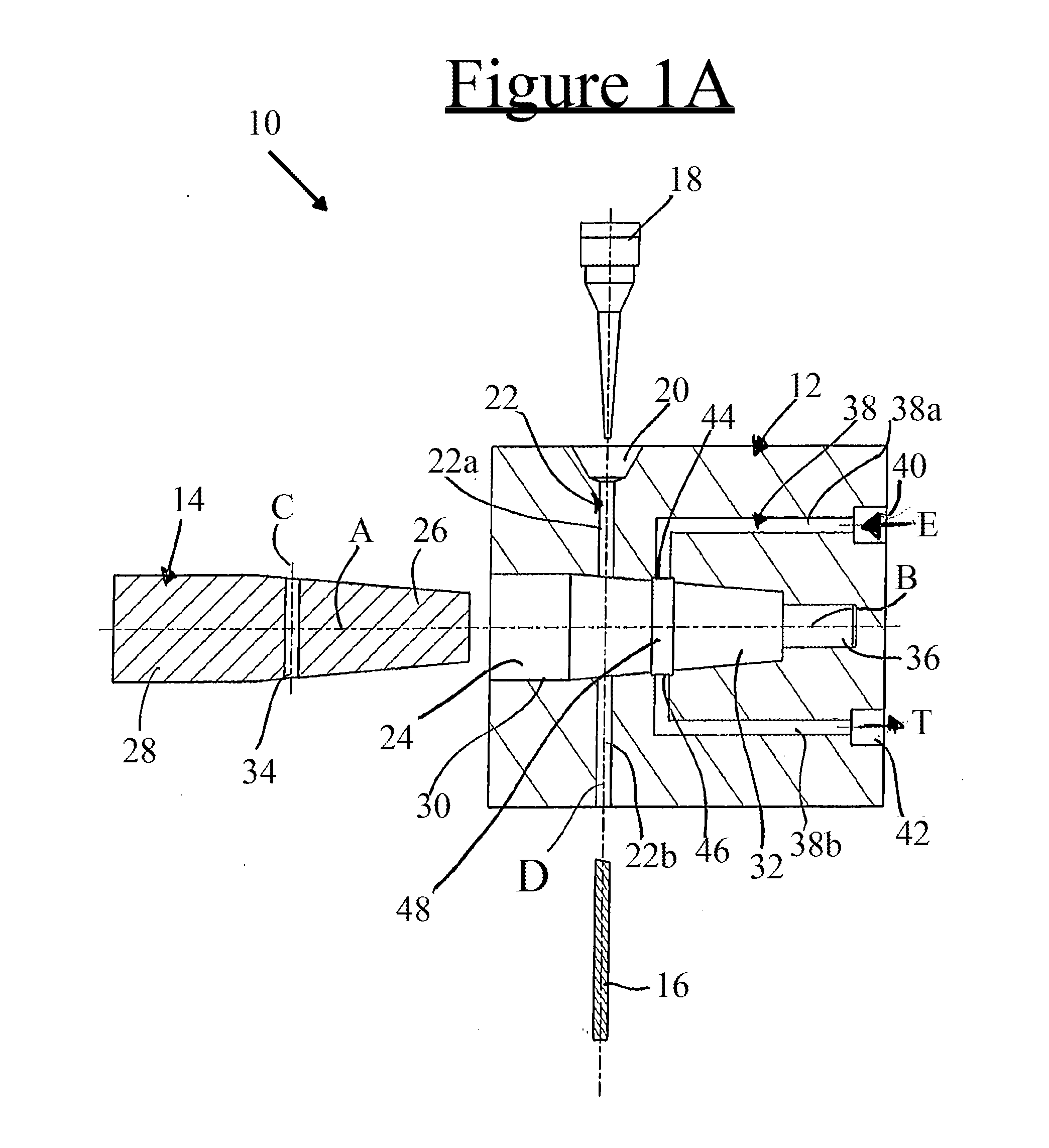

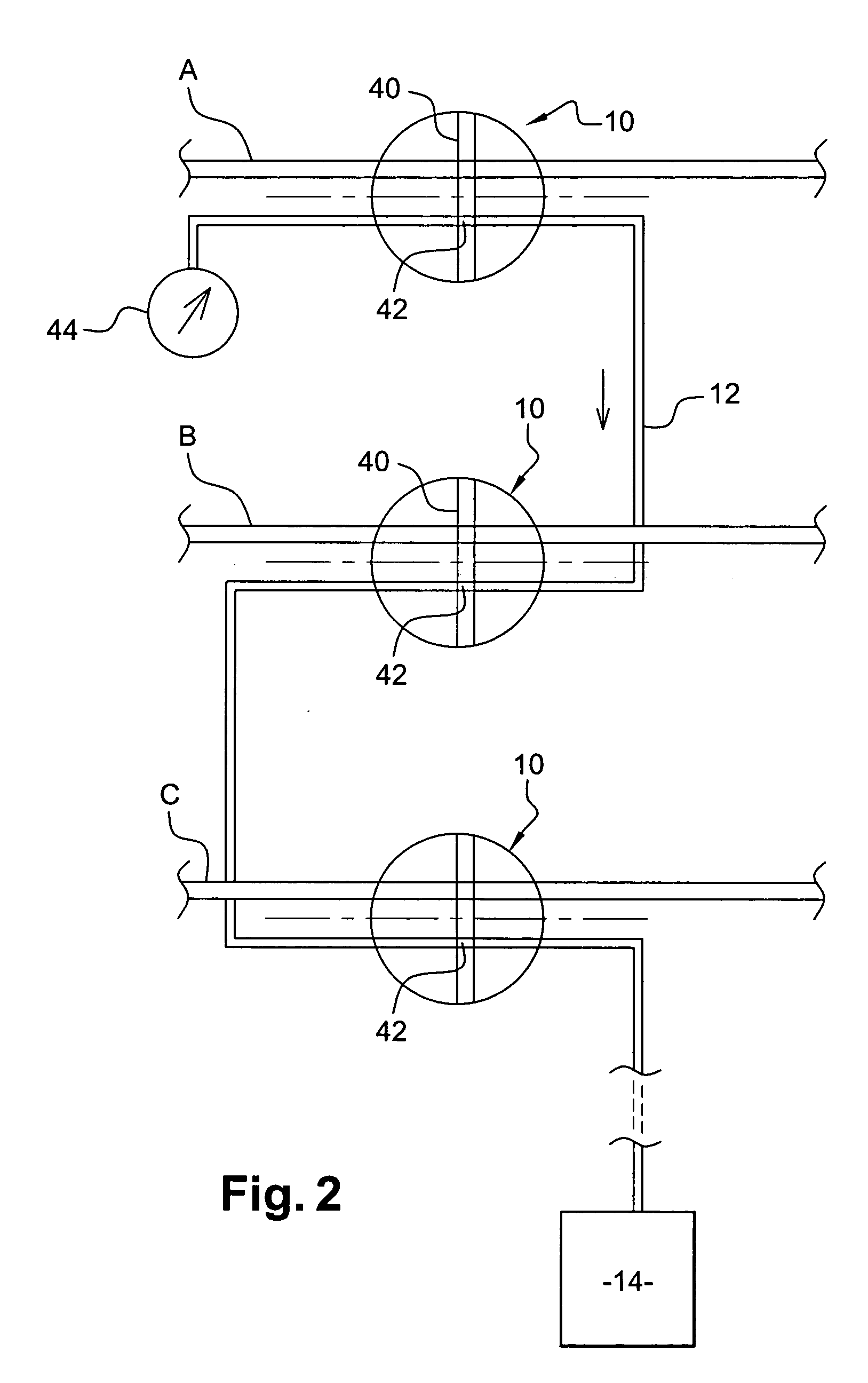

Sample dispenser for an analytical device

ActiveUS20160077062A1Simple designEliminate the effects ofSamplingComponent separationHigh pressure liquid chromatography procedureEngineering

A sample dispenser for an analysis device, in particular for an analysis device working according to the principle of liquid chromatography, in particular high pressure liquid chromatography, or gas chromatography, comprising a sample intake for receiving a sample to be analyzed, an inlet through which an eluent can be supplied, an outlet, and an injection valve arrangement, which can be switched at least from an intake position to an injection position, wherein, at least in the intake position and in the injection position, the inlet is in fluid connection with the outlet to deliver the eluent—if applicable, having the sample added thereto—at least partly to the outlet, wherein, in the intake position, the sample intake is separated from the eluent in a fluid-tight manner, and wherein, in the injection position, the sample in the sample intake can combine with the eluent, wherein the sample dispenser is configured as a disposable component.

Owner:HAMILTON BONADUZ AG

Low volatile isocyanate monomer containing polyurethane prepolymer and adhesive system

InactiveUS20080041522A1Lower potential for exposurePolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolymer scienceFluid phase

In one aspect the invention is a composition comprising a prepolymer which is the reaction product of di(isocyanatophenyl) methane or a polymeric di(isocyanatophenyl) methane having an isocyanato functionality of about 2.1 to about 3.0 with a mixture of one or more diols and one or more triols wherein the ratio of isocyanate equivalents to hydroxyl equivalents in the reaction mixtures used to prepare the prepolymer is from about 1.2 to about 1.8 and the ratio of diol to triol where the diisocyanate is a di(isocyanatophenyl) methane in the reaction mixture is from about 5:1 to about 1:1. and where the isocyanate is a polymeric di(isocyanatophenyl) methane is from about 8:1 to about 4:1; wherein the prepolymer could further react with an isocyanate reactive monofunctional compound. The prepolymer herein has an isocyanate content of about 0.5 to about 1.5 percent by weight, a free isocyanate monomer content of about 1.0 percent by weight or less as measured by high pressure liquid chromatography. These prepolymers can be used in many applications including adhesive, sound dampening sealer and coating and especially in making adhesives or adhesive systems with a low content of monomeric isocyanate to bond together similar or dissimilar substrates such as metal, glass, ceramics, plastic and painted steel panel.

Owner:DOW GLOBAL TECH LLC

Cannabis-based therapeutic product for treatment of chronic pain

InactiveUS10206888B2Improve breathabilityMitigate at least one medical issueHydroxy compound active ingredientsOintment deliveryCannabisChronic pain

Owner:CMG PARTNERS INC

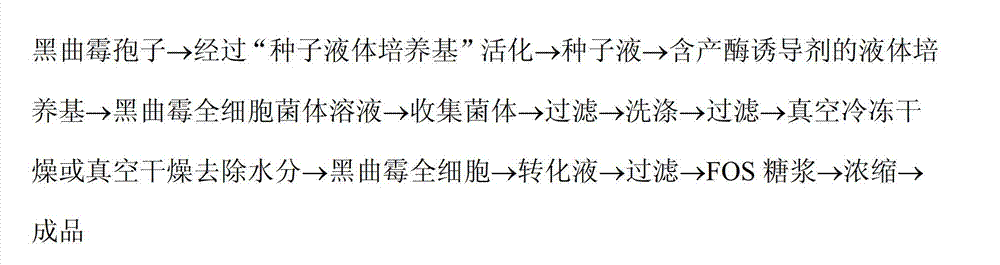

Method for catalytic production of fructo-oligosaccharides by aspergillus oryzae whole cells

ActiveCN103194506AEasy to prepareSimplify investmentMicroorganism based processesFermentationFreeze-dryingFiltration

The invention discloses a method for catalytic production of fructo-oligosaccharides by aspergillus oryzae whole cells. The method comprises the following steps of 1, whole-cell catalyst preparation comprising inoculating a seed medium with aspergillus oryzae spores, preparing a seed solution under a certain condition, inoculating a liquid fermentation enzyme-production medium for producing an enzyme inducer with the seed solution, preparing a whole-cell aspergillus oryzae solution under a certain condition, collecting aspergillus oryzae, filtering the aspergillus oryzae by a filter cloth of 200 to 400 meshes, and carrying out washing, re-filtration and vacuum freeze drying to obtain aspergillus oryzae whole cells, and 2, aspergillus oryzae whole cell-based fructo-oligosaccharide catalytic production comprising carrying out conversion under a certain conditions and carrying out filtration and vacuum concentration of the obtained fructo-oligosaccharide liquid to obtain fructo-oligosaccharide syrup. A high pressure liquid chromatography test on the fructo-oligosaccharide product proves that the solids comprise greater than or equal to 50% of total oligosaccharides. The method has simple processes, is convenient for operation, and has high enzyme activity, high conversion efficiency and an important industrial value.

Owner:广东比克生物科技有限公司

Novel process for preparing eptifibatide by purification

InactiveCN101372506AReduce processing difficultyEase of industrial scale productionPeptide preparation methodsUv detectorIon exchange

The invention relates to a new technique for purifying and preparing eptifibatide. At present, the eptifibatide is separated, purified and produced by adopting opposite phase high pressure liquid chromatography. However, mass production is not easy to realize, and the equipment are expensive. Separation and purification are carried out by the method by applying two solvent systems which are not dissolved in each other and make epicyclic motion at high speed in a chromatographic column tube; the processing steps comprises: a. synthetic crude product of the eptifibatide is dissolved by solvent; b. the dissolved crude product of the eptifibatide is separated and purified by high-speed centrifugation separation chromatography (FCPC), and is tested by a uv detector from the distance of 230nm, so that target peak is collected by subsection; c. the collected cut fraction is tested by HPLC, wherein, the cut fraction with the purity higher than 98% is bended to be treated by the next step, and the cut fraction with the purity lower than 98% is recycled and purified again; d. ion exchange is carried out on the cut fraction with qualified purity to remove trifluoroacetic acid (TFA), and then the cut fraction is transformed into acetic acid eptifibatide. The new technique has no irreversible adsorption and the advantages of no loss of sample, no pollution, high speed and high efficiency, and is suitable for mass production.

Owner:HYBIO PHARMA

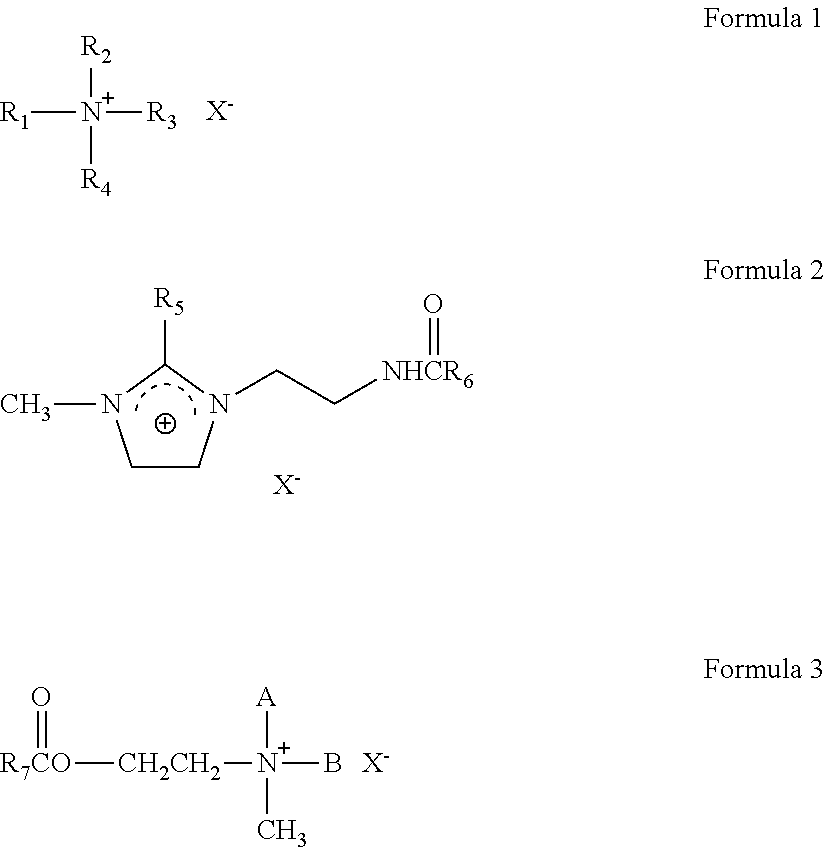

Polycarbonates with good wettability

The present invention provides a polycarbonate resin produced by the continuous interfacial process characterized in that after alkaline hydrolysis with sodium hydroxide, the polycarbonate resin contains an amount of 0.01 to 150 ppm of carbamate compounds according to formula (1)said amount measured by high pressure liquid chromatography, wherein R1 and R2 independently of one another denote hydrogen or C1-C12-alkyl, or together denote C4-C12-alkylidene, and R3 and R4 independently of one another denote hydrogen. C1-C12-alkyl or phenyl, or together with the carbon atom to which they are bonded form cyclohexyl or trimethylcyclohexyl, the process comprising phosgene reacting with at least one bisphenol at 8 to 17% molar excess of phosgene relative to the bisphenol.

Owner:COVESTRO DEUTSCHLAND AG

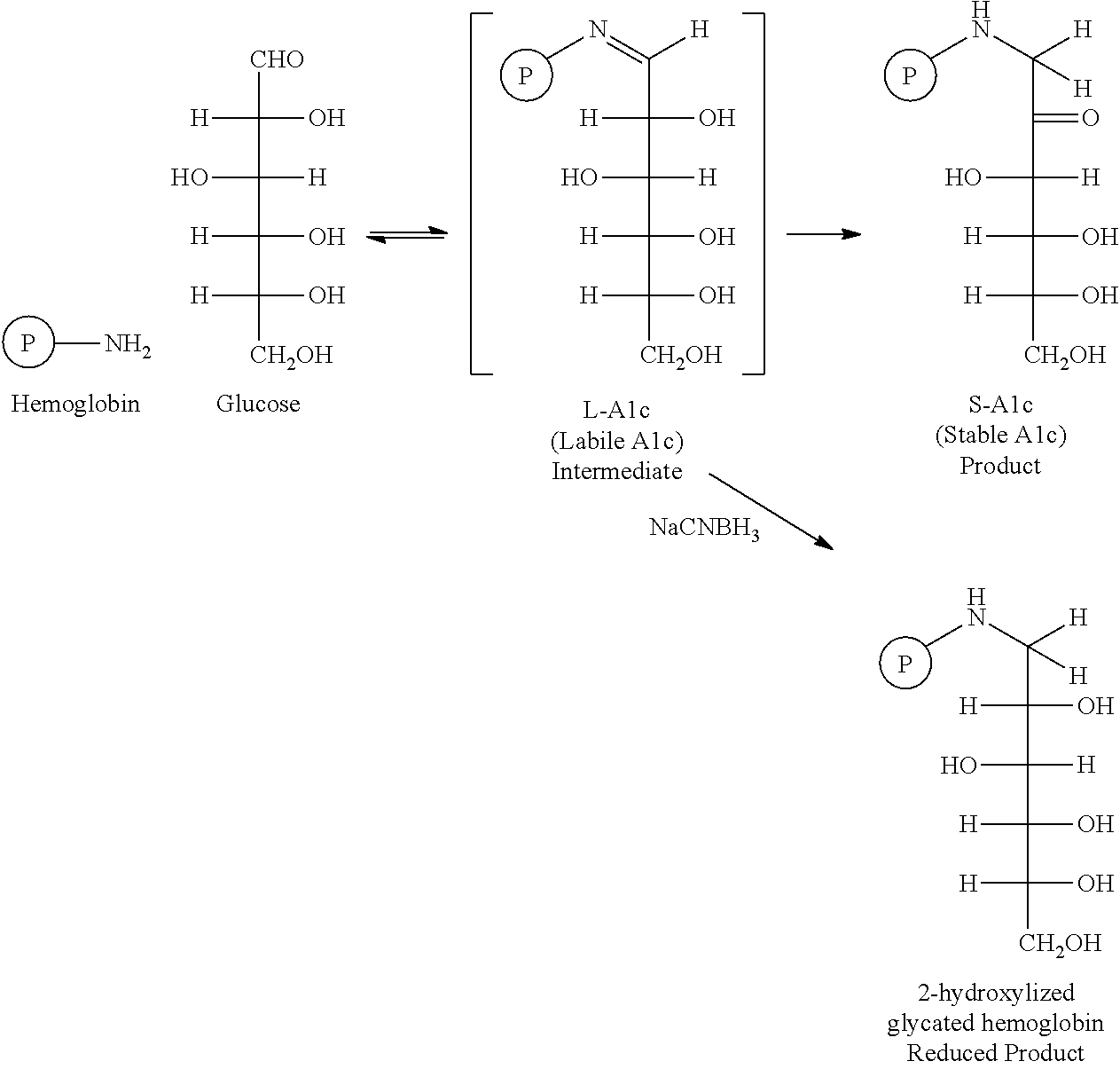

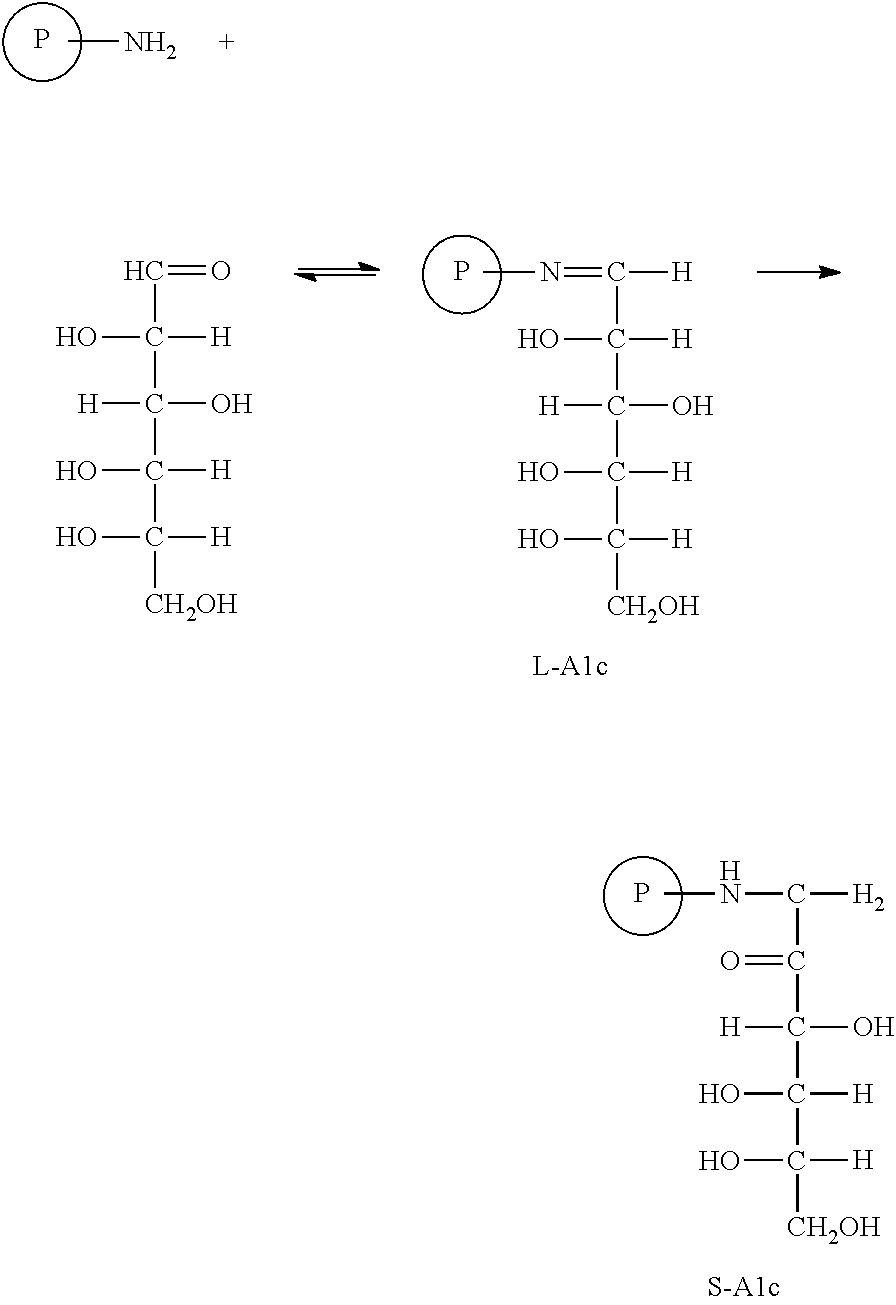

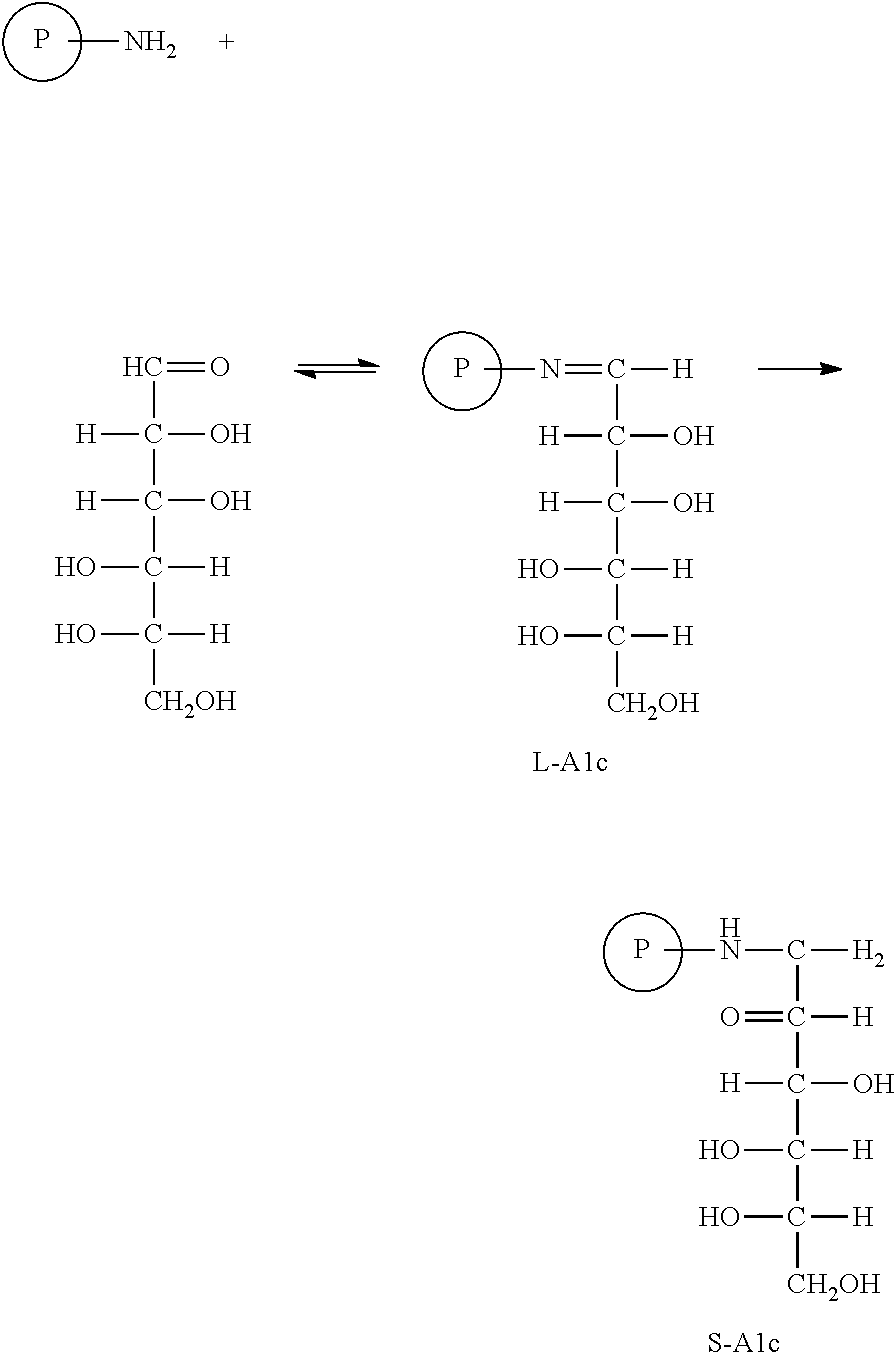

Cis di-ahl modified controls for glycated hemoglobin S-A1c derived from healthy blood cells

ActiveUS8551784B2Improve accuracyGood precisionMicrobiological testing/measurementCulture processHigh pressure liquid chromatography procedureHEMOGLOBIN I

The invention is composition comprising red blood cells in an aqueous suspension medium and one or more cis di-ahls; wherein more than 6 percent by weight of the hemoglobin in the red blood cells is S-Alc glycated hemoglobin. In another embodiment, the invention is a method comprising contacting red blood cells in a suspension medium having a concentration of S-Alc glycated hemoglobin of greater than 6 percent by weight of the hemoglobin in the red blood cells with a sufficient amount of one or more cis di-ahls such that the concentration of S-Alc glycated hemoglobin in resulting composition as measured by high pressure liquid chromatography, immunoassay and boronate affinity methods is consistent.

Owner:STRECK LLC

Plant squalene and its preparation method

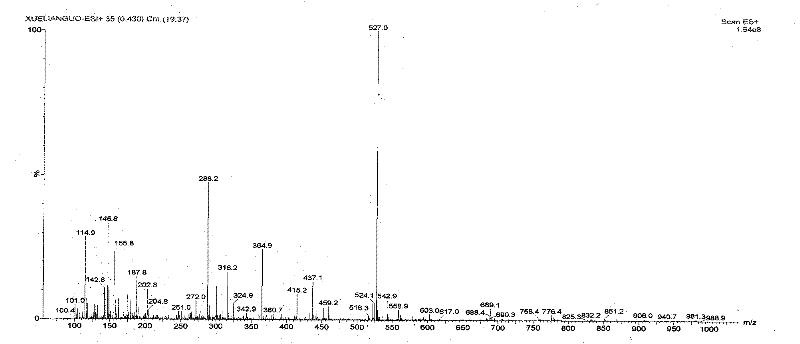

The invention crushes the kernels or seeds of Luo Han Guo, extracts fat-soluble substances with an organic solvent, removes the organic solvent in the fat-soluble substances, and obtains the crude product of Luo Han Guo squalene. Then pass the crude product of Luo Han Guo squalene through a silica gel chromatography column, elute with an organic solvent, collect the colorless part of the eluate, and remove the organic solvent by vacuum distillation to obtain the fine product of Luo Han Guo squalene. The squalene content in the crude product is more than 40%, and the squalene content in the fine product is more than 95%. The signals are consistent with the squalene standard sample spectrum after determination by high-pressure liquid chromatography, infrared spectroscopy, and nuclear magnetic resonance. , and the product has the unique fragrance of squalene, which can completely replace squalene, which can only be extracted from the liver of deep-sea sharks. Luo Han Guo squalene boutique can be used as a squalene standard sample. The development and utilization of Luo Han Guo squalene has huge social and economic benefits.

Owner:桂林中族中药股份有限公司

Characterization of crude oil by high pressure liquid chromatography

ActiveUS10571452B2Provide informationImprove oil qualityComponent separationMaterial testing goodsAniline pointFluid phase

A system and a method are provided for calculating one or more indicative properties, e.g., one or more of the cetane number, octane number, pour point, cloud point and aniline point of oil fractions, from the density and high pressure liquid chromatography (HPLC) data of a sample of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Aspergillus niger and method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger

ActiveCN103045489BEasy to prepareSimplify investmentFungiMicroorganism based processesSporeMicroorganism

The invention discloses aspergillus niger and a method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger. The aspergillus niger FOS-0620 is an aerobe, has black spores and milk-white hyphae, and is collected in China General Microbiological Culture Collection Centre (CGMCC for short) on September 28, 2012. The method for catalytically producing fructo-oligosaccharide by virtue of whole-cells of aspergillus niger comprises the following steps of: (1) preparing aspergillus niger whole-cells by virtue of the aspergillus niger FOS-0620 according to claim 1; and (2) catalytically producing fructo-oligosaccharide by virtue of the aspergillus niger whole-cells. The product obtained by the method disclosed by the invention is detected that the content (occupying total solids) of the fructo-oligosaccharide is not less than 50% via high-pressure liquid chromatography; and the method disclosed by the invention is simple in process, convenient to operate, high in enzymatic activity, high in conversion efficiency, and important in industrial value.

Owner:SOUTH CHINA UNIV OF TECH

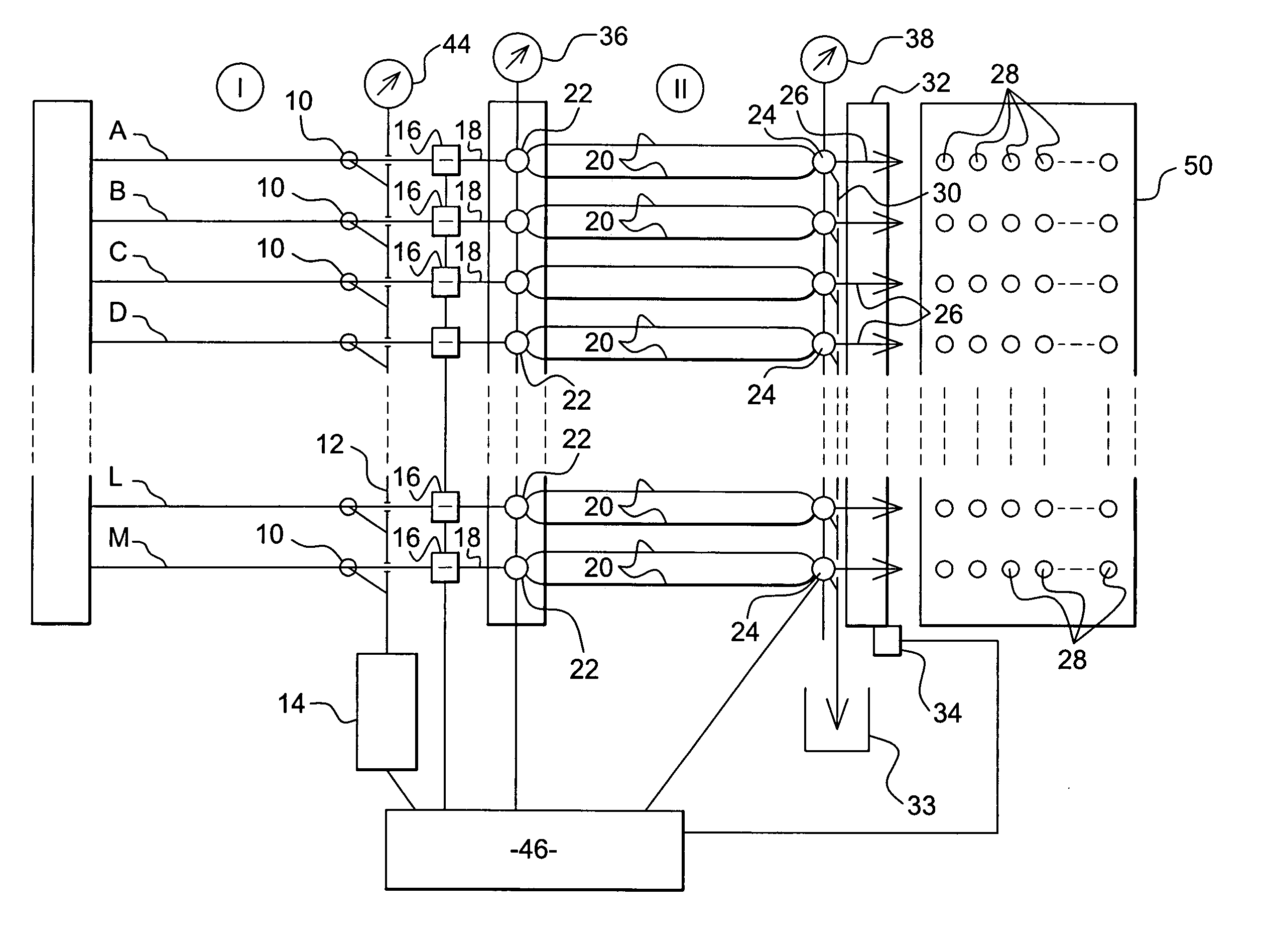

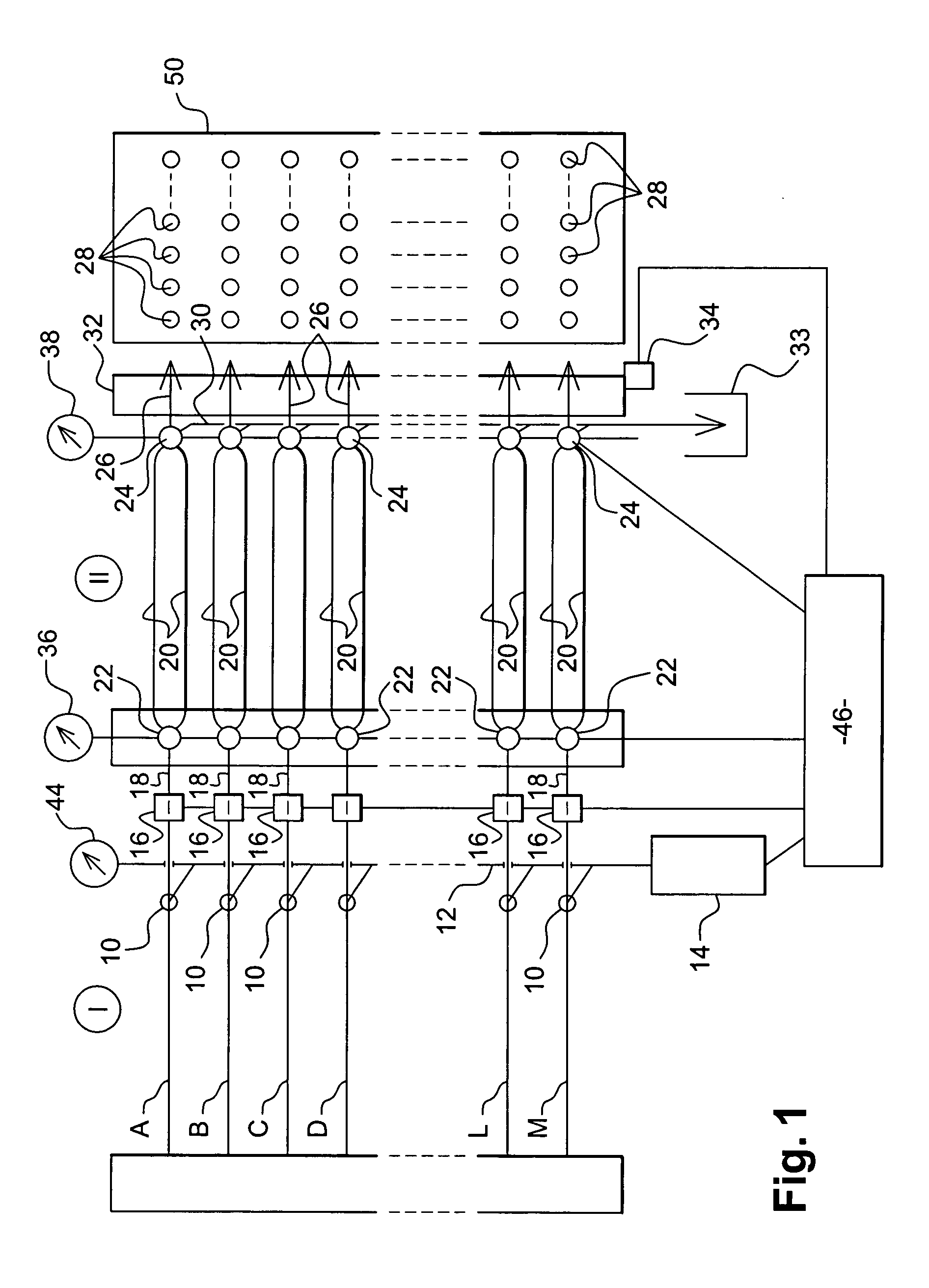

Installation for separating components in a plurality of parallel channels

InactiveUS20050224402A1Simple and effective and inexpensiveEnough timeIon-exchange process apparatusSamplingHigh pressure liquid chromatography procedureEngineering

An installation for separating components, in particular by high-pressure liquid chromatography along a plurality of channels in parallel, the outlets from the channels being connected via controlled selective connection means to the inlets of parallel temporary storage means whose outlets are connected via controlled selective connection means to ducts for depositing in collector means or in disposal means.

Owner:BIONISIS SA

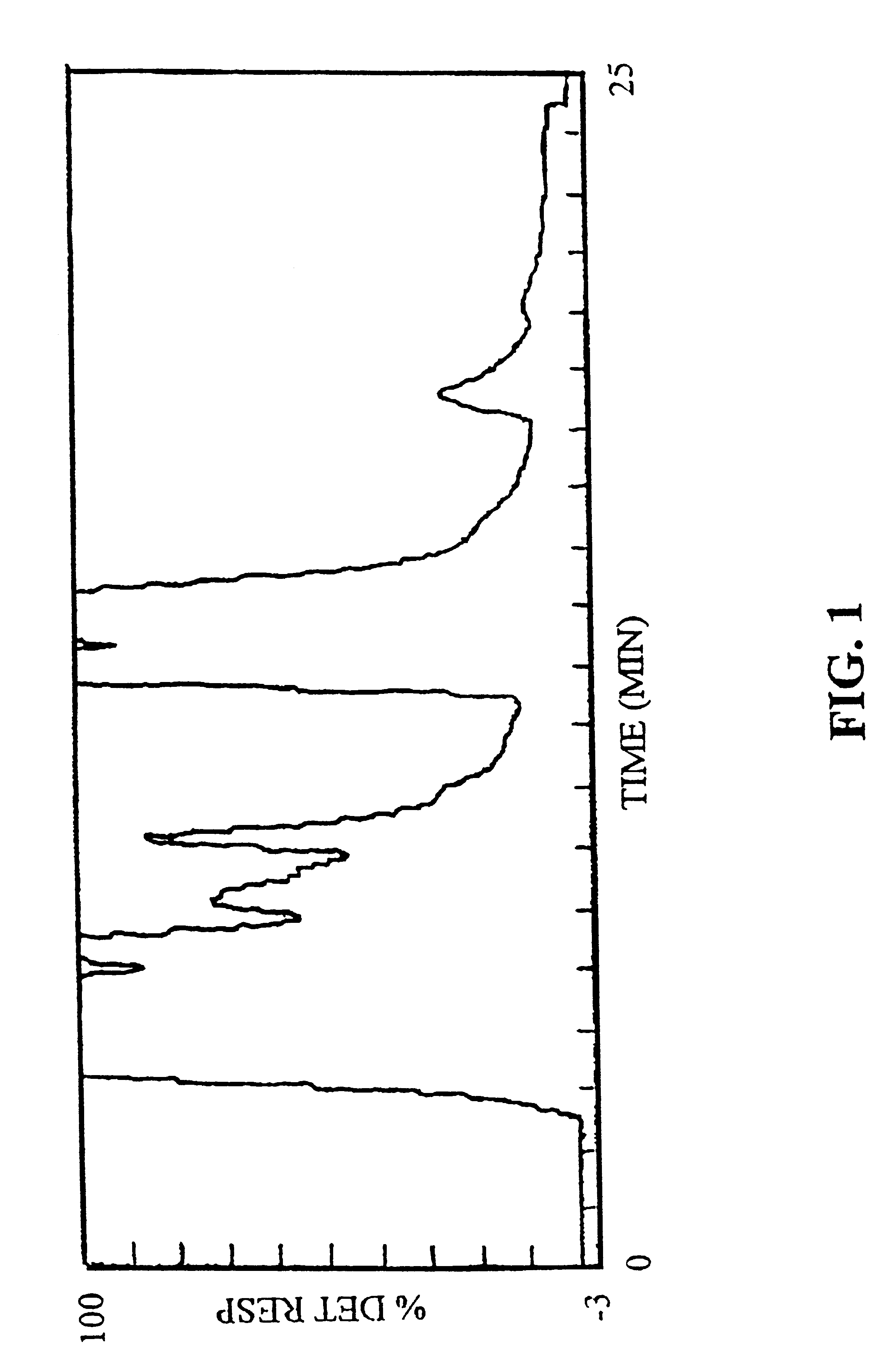

Method for detection of adenosine and metabolites thereof

This invention relates is a label-free, enzyme-free, aptamer-free method for simultaneously measuring adenosine, and its intracellular metabolites, e.g., AMP, ADP and ATP, using high pressure liquid chromatography coupled to electrochemical detector (HPLC-ECD).

Owner:ST JUDE CHILDRENS RES HOSPITAL INC

Cannabis-based therapeutic product for treatment of chronic pain

InactiveUS20190224142A1Substantial therapeutic benefitImprove breathabilityHydroxy compound active ingredientsCrystallization separationChronic painHigh pressure liquid chromatography procedure

A cannabis-based therapeutic product for treatment of chronic pain produced by separating hash resin from plant material of the cannabis plant, pressing the hash resin to expel oil, leaving spent hash resin, extracting further cannabinoids from the spent hash resin using MCT oil, separating the cannabis compounds from the oils using high pressure liquid chromatography, flash chromatography, or similar techniques, and processing selected cannabis compound formulations into a form suitable for administration as a therapeutic product for treatment of chronic pain. The therapeutic product has at least 28% w / w cannabinol (CBD), and at least 2% w / w β-myrcene.

Owner:CMG PARTNERS INC

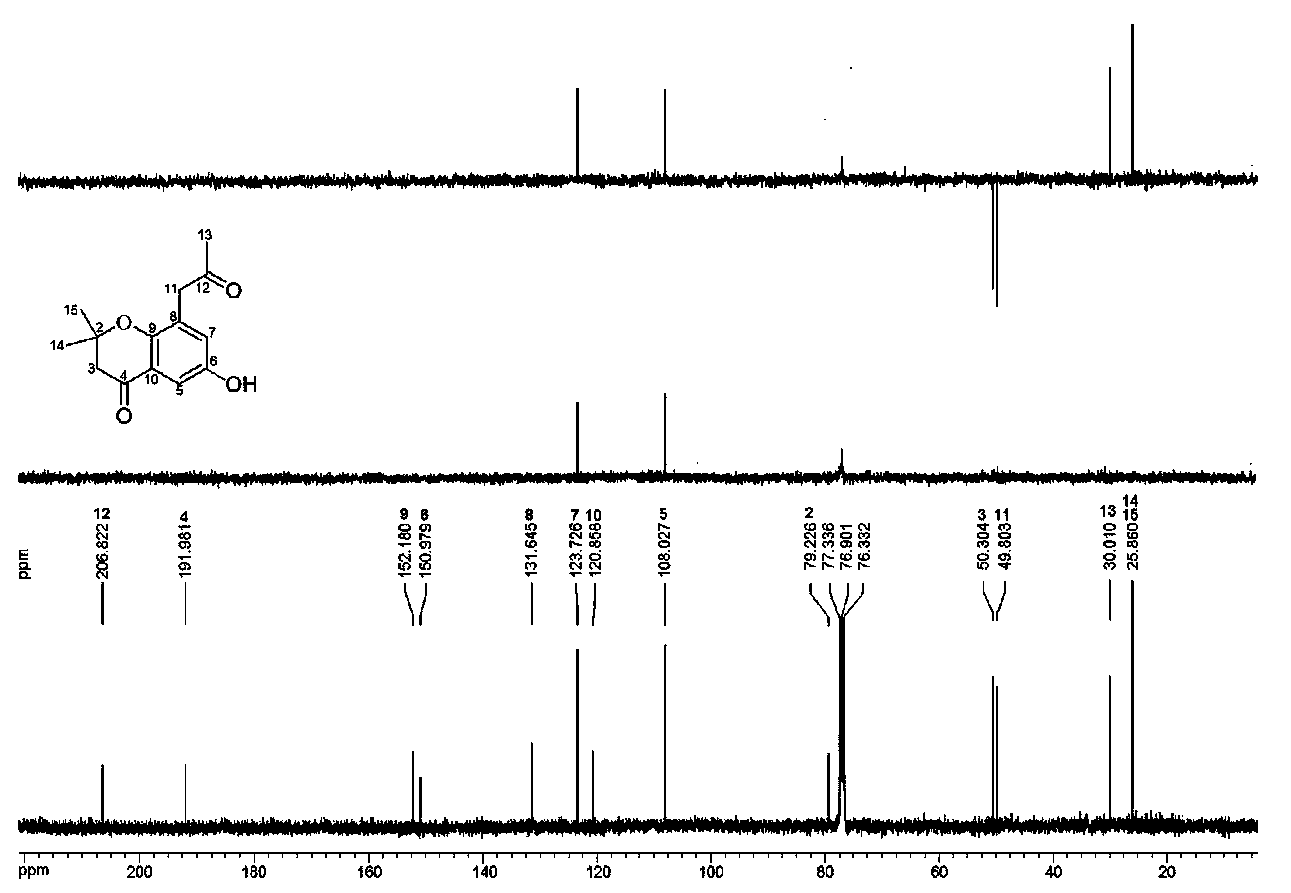

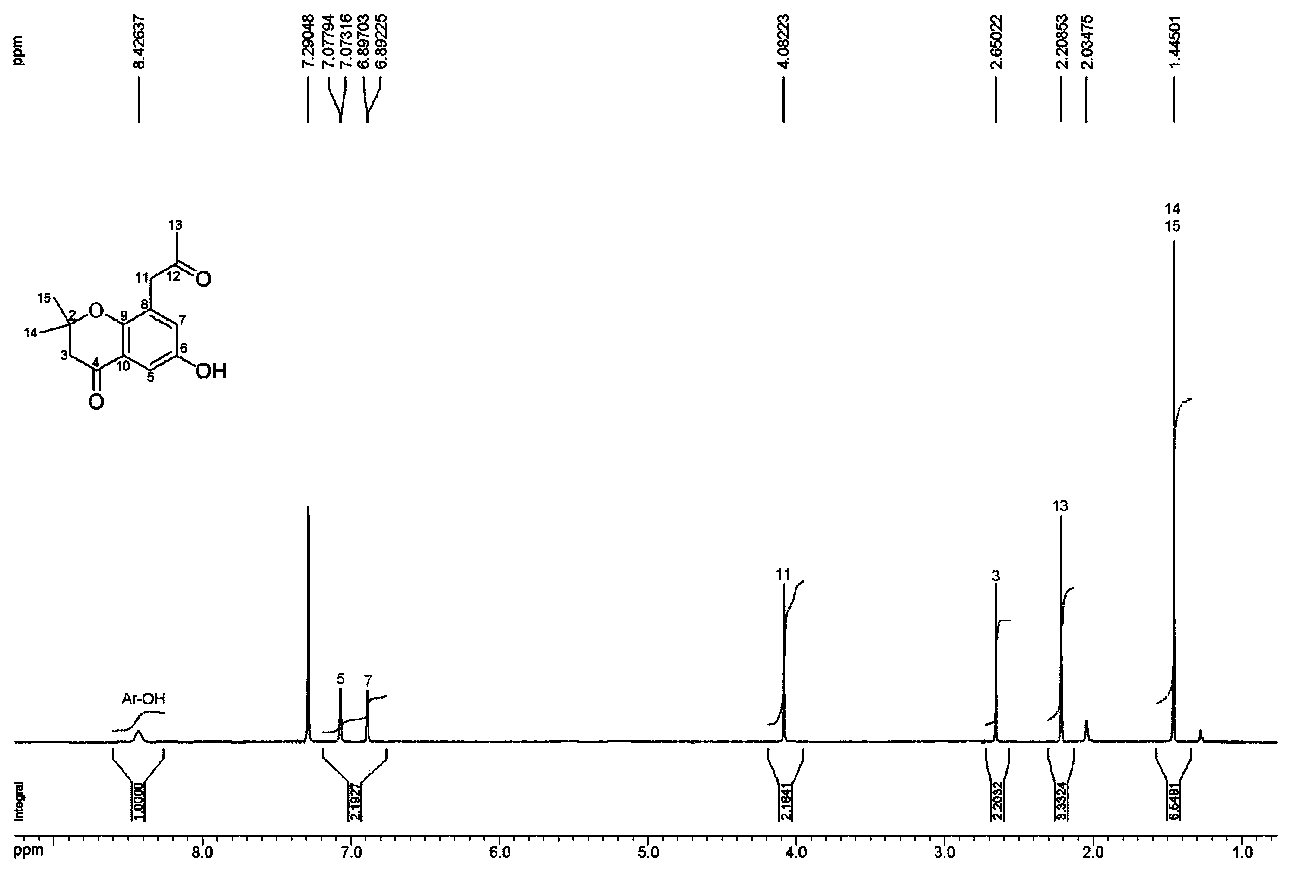

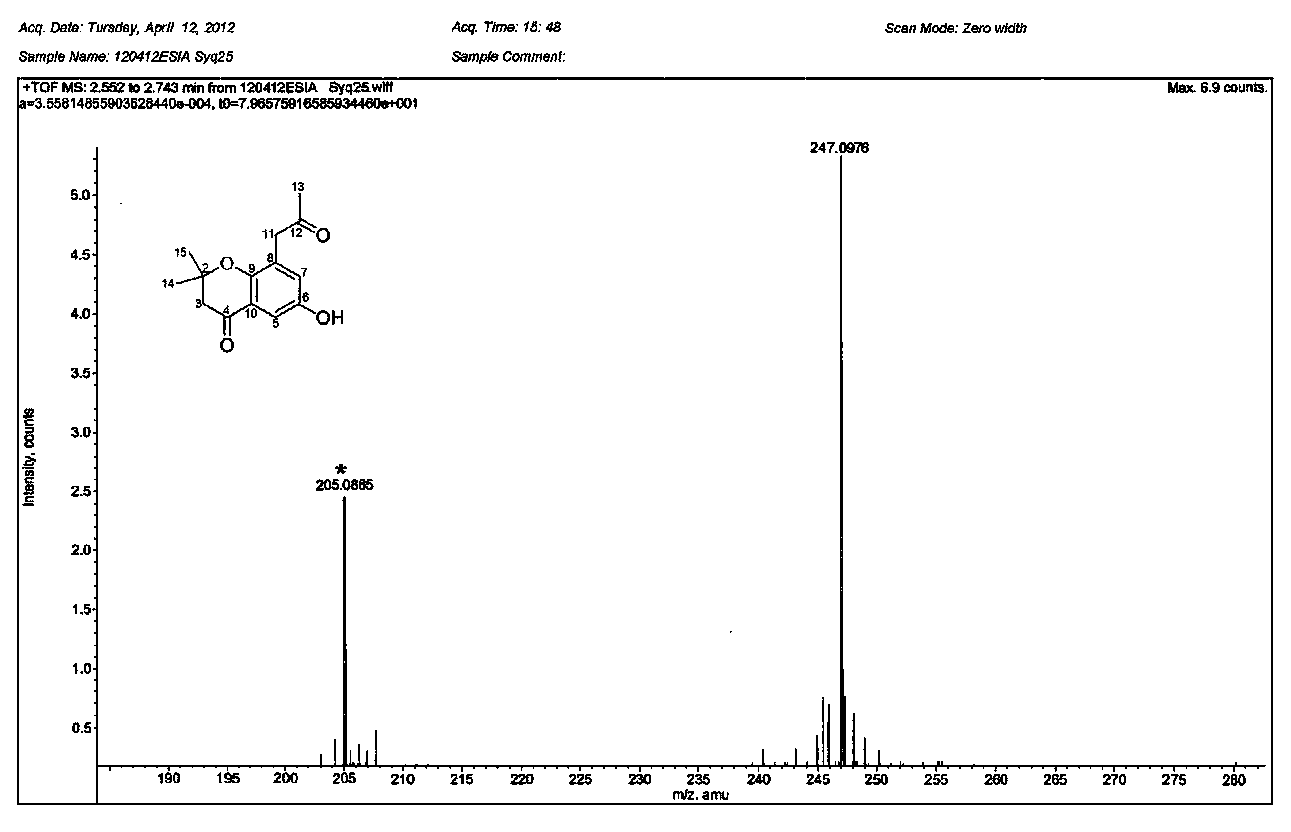

Chromanone compound, and preparation method and application thereof

The invention discloses a chromanone compound, and a preparation method and application thereof. The chromanone compound is Tobchromanone A and is separated from aromatic tobacco; the molecular formula is C14H16O4; and the structure is shown in the specification. The preparation method of the chromanone compound comprises the following steps: crushing an aromatic tobacco sample, performing ultrasonic extraction with 95% ethanol for 3-5 times, merging the extracting solutions, and concentrating under reduced pressure to obtain an extract; and performing primary separation on the extract through silica gel column chromatography, and then performing further separation through high pressure liquid chromatography to obtain the required compound, namely the Tobchromanone A. The compound has a better cytotoxic effect on human neuroblastoma cells (SHSY5Y) with the IC50 value up to 2.8 mu M, and indicates a medium cytotoxic effect on other measured cell strains.

Owner:YUNNAN MINZU UNIV

Composition for textile softener having low temperature activity and textile softener sheet comprising the same

ActiveUS20120309668A1Efficient use ofEasy to useCationic surface-active compoundsDetergent materialsHigh pressure liquid chromatography procedureVapor phase chromatography

Disclosed is a composition for textile softener containing a cationic surfactant, the ratio of which C7-C21 alkyl substituents analyzed by HLPC (high pressure liquid chromatography) or GC (gas chromatography) is 0.6 or more, as an effective ingredient, a sheet for textile softener including the same, and method of softening a textile using the sheet. Since the composition for textile softener has excellent dissolving and dispersing effect even in low temperature water, the sheet containing this composition is used at a rinse time during washing procedures to represent excellent anti-static effect and textile softening effect to textiles and clothes.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

Method for catalytic production of fructo-oligosaccharides by aspergillus oryzae whole cells

ActiveCN103194506BEasy to prepareSimplify investmentMicroorganism based processesFermentationSporeFreeze-drying

The invention discloses a method for catalytic production of fructo-oligosaccharides by aspergillus oryzae whole cells. The method comprises the following steps of 1, whole-cell catalyst preparation comprising inoculating a seed medium with aspergillus oryzae spores, preparing a seed solution under a certain condition, inoculating a liquid fermentation enzyme-production medium for producing an enzyme inducer with the seed solution, preparing a whole-cell aspergillus oryzae solution under a certain condition, collecting aspergillus oryzae, filtering the aspergillus oryzae by a filter cloth of 200 to 400 meshes, and carrying out washing, re-filtration and vacuum freeze drying to obtain aspergillus oryzae whole cells, and 2, aspergillus oryzae whole cell-based fructo-oligosaccharide catalytic production comprising carrying out conversion under a certain conditions and carrying out filtration and vacuum concentration of the obtained fructo-oligosaccharide liquid to obtain fructo-oligosaccharide syrup. A high pressure liquid chromatography test on the fructo-oligosaccharide product proves that the solids comprise greater than or equal to 50% of total oligosaccharides. The method has simple processes, is convenient for operation, and has high enzyme activity, high conversion efficiency and an important industrial value.

Owner:广东比克生物科技有限公司

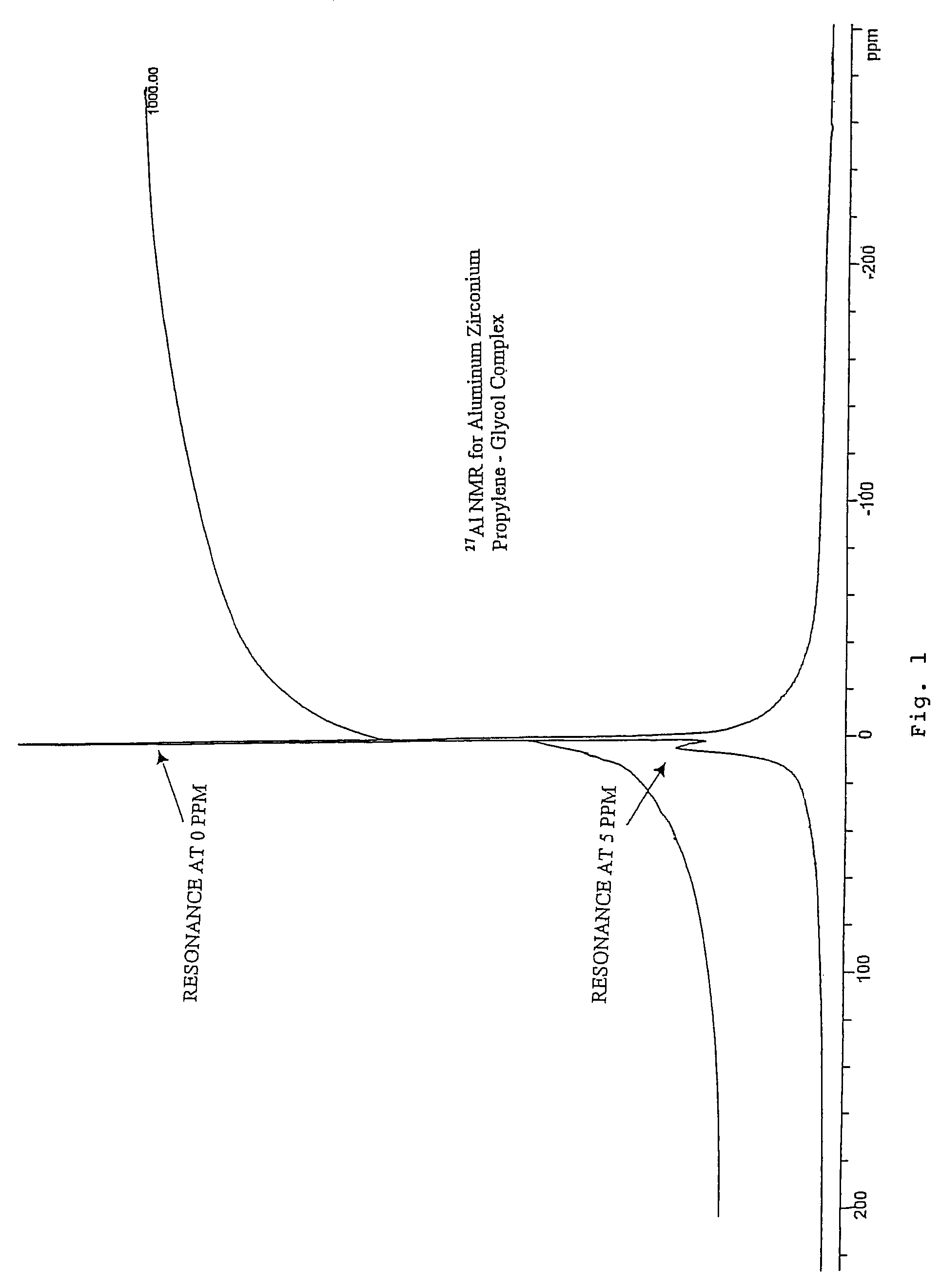

Amino acid free stable aluminum/zirconium antiperspirant solution

InactiveUS7144571B2Improve efficacyHigh proportionCosmetic preparationsToilet preparationsAlcoholPolyol

An amino acid free stable aluminum zirconium polyhydric alcohol aqueous solution having a high anhydrous antiperspirant solid concentration and a high percentage of low molecular weight aluminum species, i.e., containing 60% or more of band IV peak area based on high pressure liquid chromatography, is prepared by adding a zirconium salt to an aqueous polyhydric alcohol solution of a basic aluminum chloride.

Owner:SUMMIT RES LAB +1

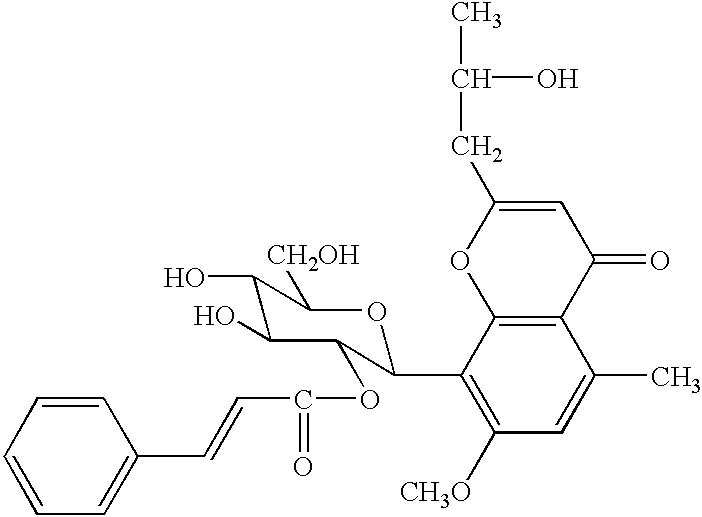

Purification of cinnamoyl-C-glycoside chromone

The present invention provides a process for purifying the cinnamoyl-C-glycoside, <DEL-S DATE="20020625" ID="DEL-S-00001" / >8-C-beta-D-[2-O-(E)-cinnamoyl]glycopyranosyl-2- [(R)-2-hydroxy]propyl-7-methoxy-5-methyl-chromone.<DEL-E ID="DEL-S-00001" / > <INS-S DATE="20020625" ID="INS-S-00001" / >8-C-beta-D-[2'-O- (E)-cinnamoyl]glycopyranosyl-2-[(S) -2-hydroxy]propyl-7-methoxy-5-methylchromone, <INS-E ID="INS-S-00001" / >referred to herein as the "540 compound." In one embodiment of the present invention the 540 compound is purified by extraction from a decolorizing agent with an organic solvent. The extracted product can be purified by high pressure liquid chromatography. In a second embodiment crude 540 compound, which has not been treated with a decolorizing agent, is purified by passage over neutral alumina or sephadex.

Owner:UNIGEN

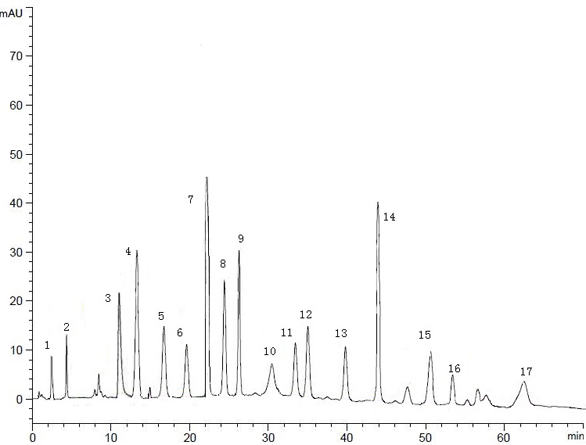

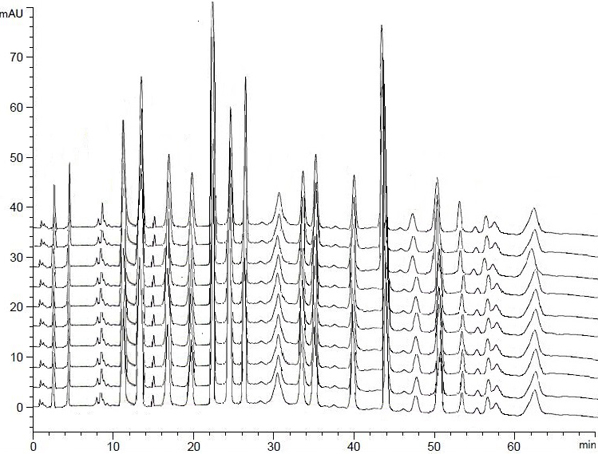

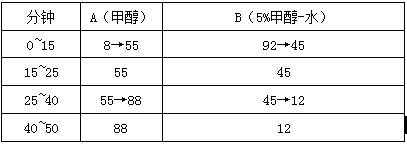

A kind of fingerprint detection method of white ginseng bacteria

ActiveCN110542731BFully reflect the quality informationEasy to identifyComponent separationBiotechnologyFluid phase

The invention discloses a fingerprint detection method of white ginseng fungus, which uses high-pressure liquid chromatography to measure the fingerprint with reference to a schizophyllin reference substance. The invention establishes the HPLC characteristic fingerprint of the white ginseng fungus, overcomes the singleness and one-sidedness of the existing quality standards, and can fully reflect the quality information of the white ginseng fungus, thereby achieving the purpose of more comprehensive and effective quality control of the white ginseng fungus. The white ginseng bacteria fingerprint spectrum obtained by the method of the invention has many peaks, good peak shape, easy identification, high similarity, accuracy and reliability.

Owner:湖南宇山玉月农业科技有限公司

Novel process for preparing eptifibatide by purification

InactiveCN101372506BReduce processing difficultyEase of industrial scale productionPeptide preparation methodsIon exchangeUv detector

The invention relates to a new technique for purifying and preparing eptifibatide. At present, the eptifibatide is separated, purified and produced by adopting opposite phase high pressure liquid chromatography. However, mass production is not easy to realize, and the equipment are expensive. Separation and purification are carried out by the method by applying two solvent systems which are not dissolved in each other and make epicyclic motion at high speed in a chromatographic column tube; the processing steps comprises: a. synthetic crude product of the eptifibatide is dissolved by solvent;b. the dissolved crude product of the eptifibatide is separated and purified by high-speed centrifugation separation chromatography (FCPC), and is tested by a uv detector from the distance of 230nm, so that target peak is collected by subsection; c. the collected cut fraction is tested by HPLC, wherein, the cut fraction with the purity higher than 98% is bended to be treated by the next step, andthe cut fraction with the purity lower than 98% is recycled and purified again; d. ion exchange is carried out on the cut fraction with qualified purity to remove trifluoroacetic acid (TFA), and thenthe cut fraction is transformed into acetic acid eptifibatide. The new technique has no irreversible adsorption and the advantages of no loss of sample, no pollution, high speed and high efficiency, and is suitable for mass production.

Owner:HYBIO PHARMA

Composition for textile softener having low temperature activity and textile softener sheet comprising the same

ActiveUS8420589B2Efficient use ofEasy to useCationic surface-active compoundsDetergent compounding agentsHigh pressure liquid chromatography procedureHigh pressure

Disclosed is a composition for textile softener containing a cationic surfactant, the ratio of which C7-C21 alkyl substituents analyzed by HLPC (high pressure liquid chromatography) or GC (gas chromatography) is 0.6 or more, as an effective ingredient, a sheet for textile softener including the same, and method of softening a textile using the sheet. Since the composition for textile softener has excellent dissolving and dispersing effect even in low temperature water, the sheet containing this composition is used at a rinse time during washing procedures to represent excellent anti-static effect and textile softening effect to textiles and clothes.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com