Patents

Literature

33results about How to "Good steric repulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

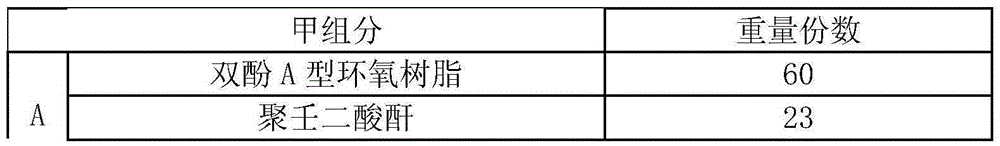

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Special coating for acrylic finishes, and making method thereof

ActiveCN103992720AImprove adhesionGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

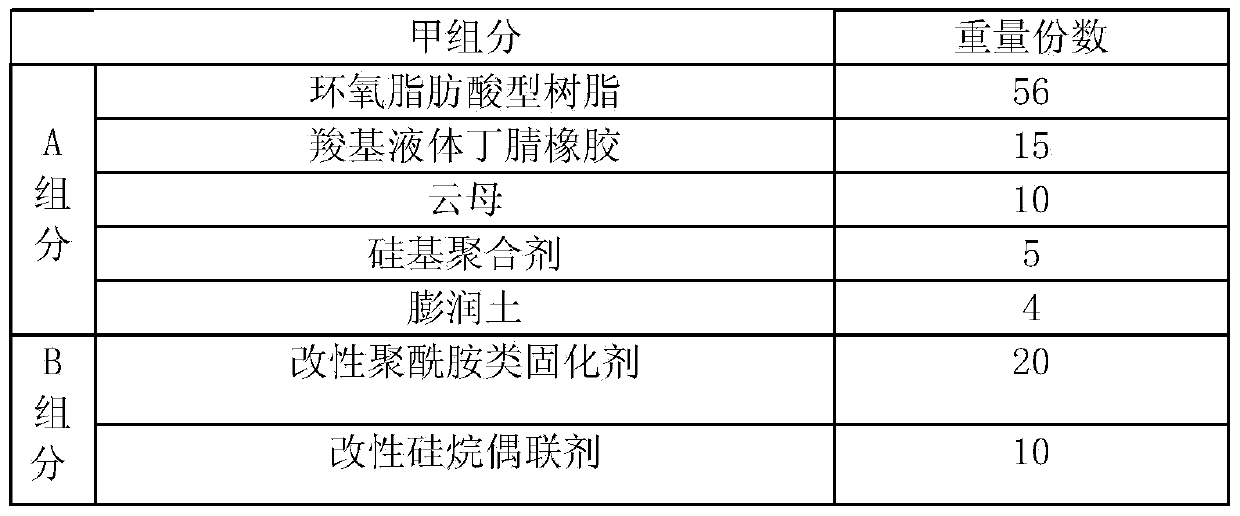

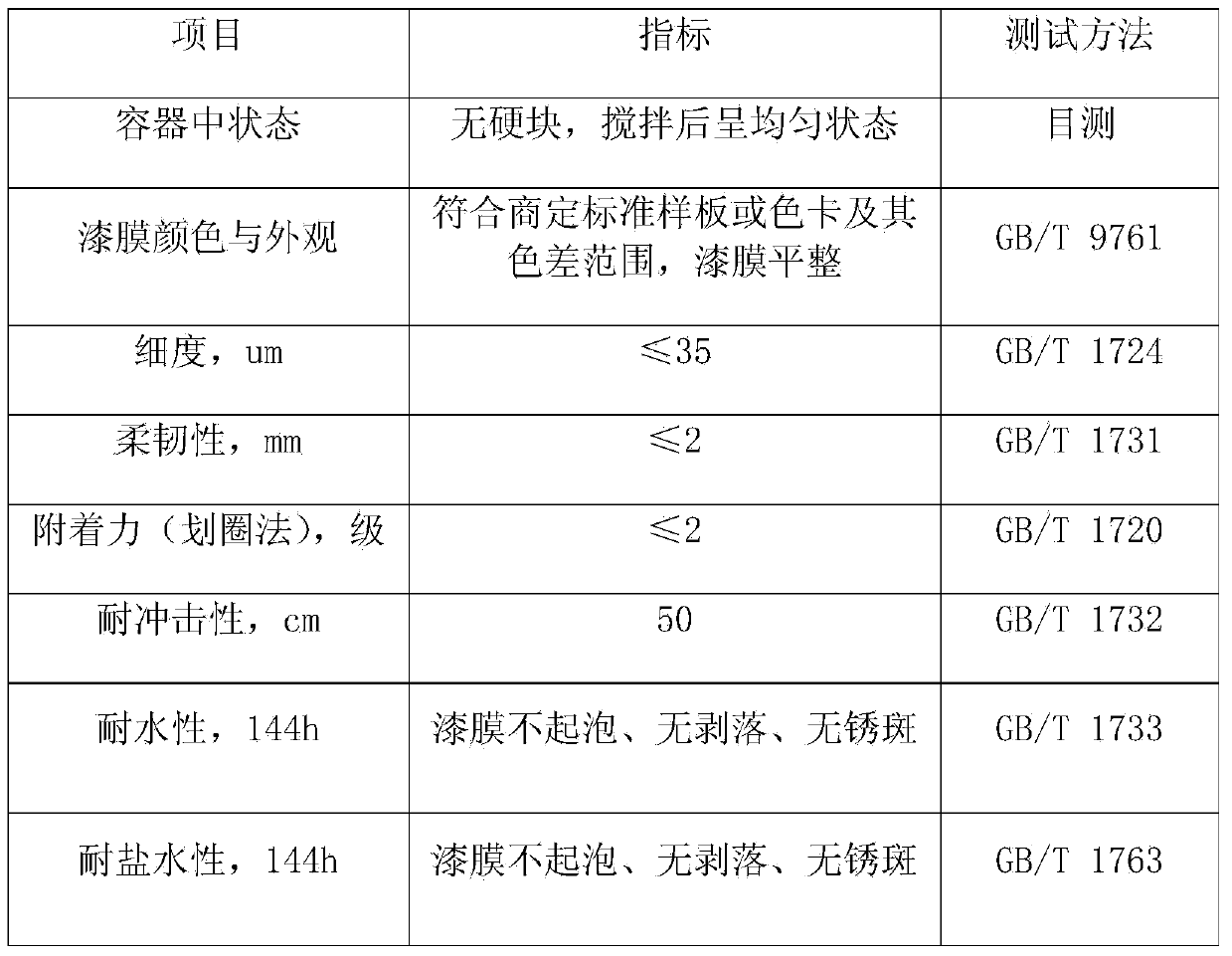

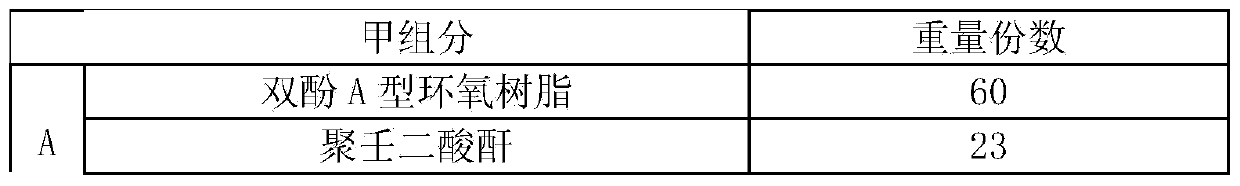

The invention discloses a special coating for acrylic finishes, and a making method thereof. The special coat comprises a component I and a component II having a same amount with the component II, the component I is formed by a component A and a component B, the component A in the component I comprises modified epoxy resin, a flexibilizer, mica, an assistant and an anti-settling agent, the component B in the component comprises a curing agent and a coupling agent; and the component II comprises polyurethane modified acrylic resin, rutile titanium dioxide, a film forming assistant, purified water, an antifoaming agent, a dispersant, a flash rust inhibitor and a thickening agent. The special coating is obtained by preparing the component I, preparing the component II and compounding the component I with the component II. The coating has the advantages of strong adhesion, unlikely shedding, good impermeability, good corrosion resistance, strong weatherability, unlikely saponification and fast drying, and has a very good protection effect at a low temperature.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Household socket and flame-retardant treatment process thereof

InactiveCN107868577AHigh affinityPrevent flocculationFireproof paintsContact member cases/bases manufactureEpoxyEmulsion

The invention discloses a household socket. The household socket comprises a socket box, wherein an insertion surface butted with a plug is arranged on the socket box; a cover body is also arranged onthe socket box; a protection layer is arranged on the inner wall of the cover body. The protection layer is prepared from the following components in parts by mass: 20-30 parts of organosilicone modified epoxy resin, 10-15 parts of a polyvinyl acetate emulsion, 0-15 parts of a plasticizer, 2-4 parts of a flame retardant, 5-8 parts of diatomite, 1-3 parts of pigments and fillers, 5-7 parts of a silane coupling agent, 4-6 parts of a curing agent, 0.5-1 part of a flame-retardant synergist, 0.1-0.5 part of an antioxidant and 0.2-0.4 part of composite rare earth. The flame-retardant treatment process is simple and is easy to operate; the treated socket has extremely high flame resistance; the service life of the socket is prolonged; and the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

High-temperature-resistant coating containing hydantoin epoxy resin and preparation method of high-temperature-resistant coating

InactiveCN104673092ALow viscosityImprove insulation performanceAnti-corrosive paintsEpoxy resin coatingsChemistrySilicone resin

The invention discloses a high-temperature-resistant coating containing hydantoin epoxy resin. The coating comprises a component I and a component II, wherein the component I is blended by a component A and a component B, the component A comprises ingredients as follows: the hydantoin epoxy resin, filler, a dispersing agent, an auxiliary, a coalescing agent, a thickening agent and a defoaming agent, and the component B comprises ingredients as follows: grafted organic silicon resin, a thixotropic agent, a matting agent, antimonous oxide, an auxiliary and a mildew preventive; the component II comprises components as follows: a curing agent, a coupling agent and a solvent. The invention further designs a preparation method of the high-temperature-resistant coating containing the hydantoin epoxy resin. The preparation method is simple to operate and low in cost, and the prepared coating has excellent high temperature resistance and high adhesive force, and is non-poisonous and pollution-free.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Anticorrosive high-speed gear case and preparation method thereof

InactiveCN106497187AHigh affinityPrevent flocculationFireproof paintsAnti-corrosive paintsEpoxyFire retardant

The invention discloses an anticorrosive high-speed gear case and a preparation method thereof. The surface of the high-speed gear case is coated with a layer of an anticorrosive coating which is prepared by compounding a component A and a component B according to a ratio of 2: 1. The component A comprises, by mass, 22 to 26 parts of organosilicon-modified epoxy resin, 25 to 28 parts of pigment, 10 to 13 parts of a filling material, 9 to 13 parts of a plasticizer, 4 to 8 parts of a dispersing agent, 20 to 23 parts of itaconic acid, 19 to 25 parts of a film-forming aid, 9 to 14 parts of an antifoaming agent and 11 to 14 parts of active carbon. The component B comprises, by mass, 18 to 24 parts of polyphenyl ether resin powder, 13 to 16 parts of styrene butadiene rubber, 13 to 18 parts of toluene, 6 to 10 parts of a plasticizer, 8 to 11 parts of a leveling agent, 11 to 14 parts of silica, 9 to 15 parts of a coupling agent, 2 to 4 parts of an auxiliary material, 45 to 49 parts of water and 9 to 15 parts of a fire retardant. The anticorrosive high-speed gear case is reduced in a rejection rate and production cost and improves work efficiency.

Owner:南京创贝高速传动机械有限公司

Easy-to-clean wear-resistant resin material

InactiveCN109266037AHigh affinityPrevent flocculationSynthetic resin layered productsWater-setting substance layered productEpoxyWear resistant

The invention discloses an easy-to-clean wear-resistant resin material. The easy-to-clean wear-resistant resin material comprises a base layer, a resin layer and an easy-to-clean wear-resistant surface layer which are sequentially arranged from right bottom to top, wherein the base layer is prepared from the following components in parts by mass: 13 to 19 parts of white cement, 11 to 18 parts of concrete, 2 to 7 parts of asphalt and 5 to 9 parts of lime soil; the resin layer is prepared from the following components in parts by mass: 13 to 18 parts of waterborne polymer emulsion, 10 to 16 parts of polyaryl ether sulfone ketone modified resin, 3 to 8 parts of silicon carbide micropowder, 1 to 3 parts of graphite fluoride, 14 to 19 parts of modified epoxy resin, 13 to 17 parts of a curing agent, 3 to 7 parts of a coupling agent and 15 to 19 parts of an assistant; the easy-to-clean wear-resistant surface layer is prepared from the following components in parts by mass: 3 to 10 parts of tinting pigment, 13 to 19 parts of D9050 modified aromatic aliphatic amine epoxy resin, 14 to 19 parts of the curing agent, 3 to 8 parts of C5 hydrogenated petroleum resin, 11 to 17 parts of an ionic liquid flame inhibitor, 5 to 8 parts of a crystal form modifier, 1 to 4 parts of a delustering agent, 15 to 18 parts of a defoaming agent and 4 to 9 parts of a surface layer assistant.

Owner:江苏天泽教育咨询有限公司

Heat insulation mvr equipment and preparation method thereof

The invention discloses heat insulation mvr equipment and a preparation method thereof. A heat insulation protection layer coats the outside of the mvr equipment. The heat insulation protection layer is prepared from the following ingredients: 32 to 36 parts of ATO powder, 27 to 33 parts of alcohol soluble acrylate resin, 9 to 13 parts of ethyl alcohol, 12 to 16 parts of dispersants, 8 to 13 parts of flatting agents, 5 to 7 parts of thickening agents, 9 to 13 parts of ultraviolet absorbents, 3 to 6 parts of sodium tetraborate, 4 to 8 parts of potassium acid phthalate, 11 to 16 parts of antifoaming agents, 2 to 5 parts of mixed phosphate, 13 to 16 parts of butadiene styrene rubber, 11 to 14 parts of silicon dioxide, 9 to 15 parts of fire retardants, 3 to 6 parts of auxiliary materials, 18 to 24 parts of polyphenyl ether resin powder and 44 to 48 parts of water. The heat insulation mvr equipment and the preparation method of the heat insulation mvr equipment have the advantages that the rejection rate and the production cost are reduced; in addition, the work efficiency is improved.

Owner:南京创贝高速传动机械有限公司

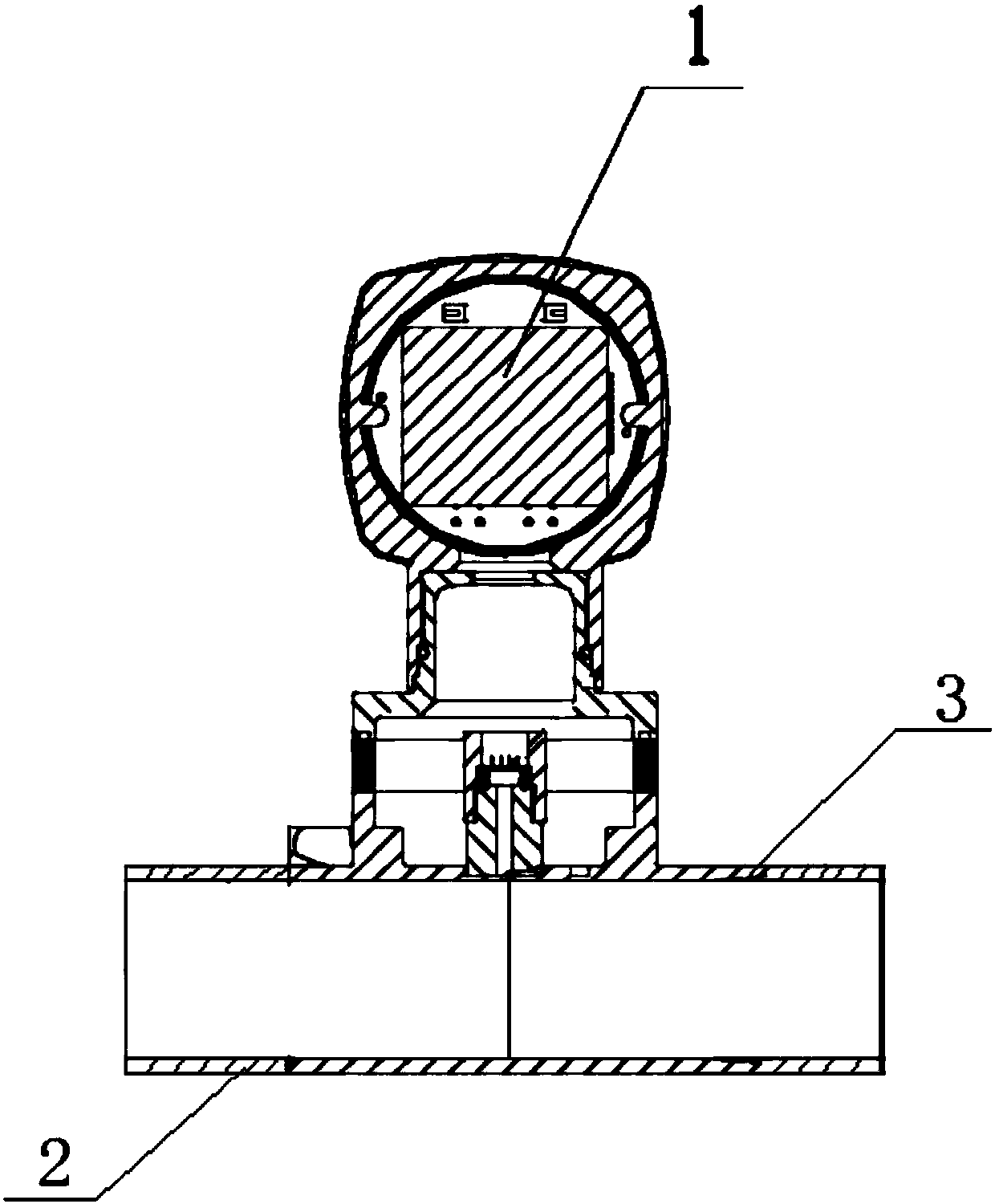

Flowmeter provided with protective cover

InactiveCN107796445AWon't splashImprove rain resistanceFireproof paintsVolume/mass flow measurementEngineering

Owner:博维恩冷冻科技(苏州)有限公司

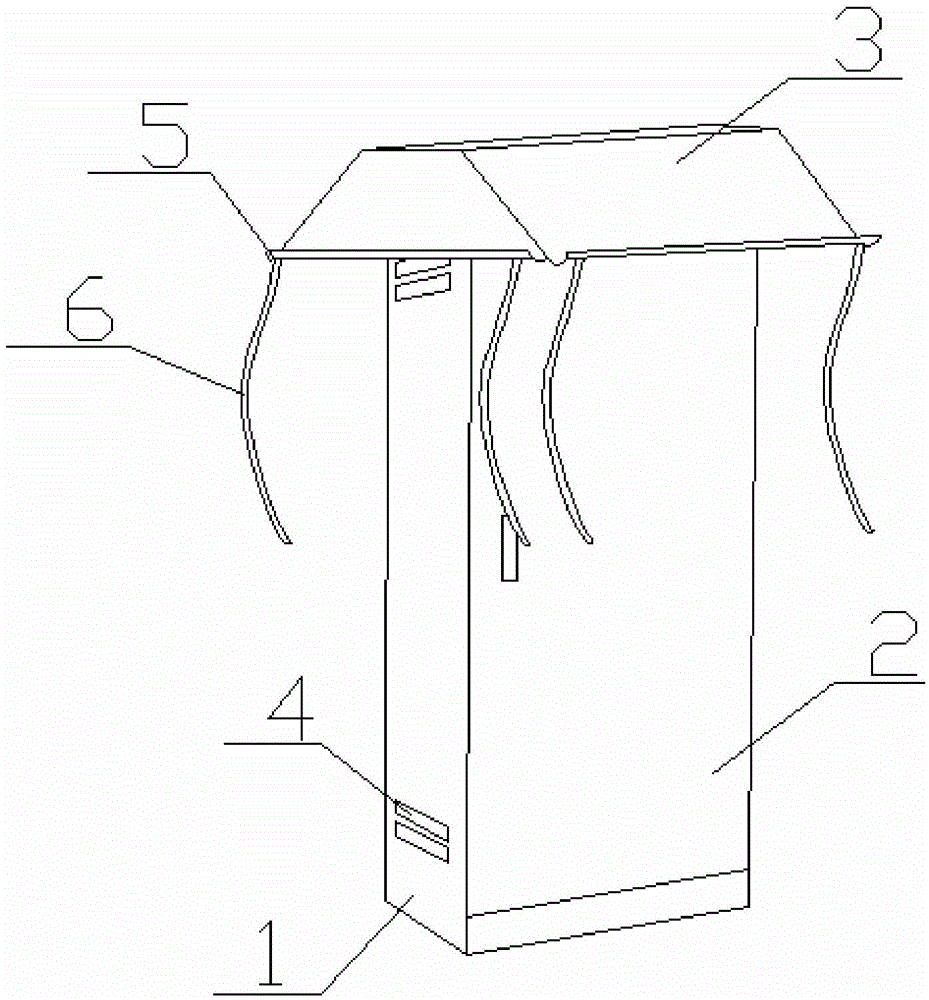

Outdoor high temperature-resisting power distribution box

InactiveCN104868377AAvoid enteringImprove applicabilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringProtection layer

The invention discloses an outdoor high temperature-resisting power distribution box, which comprises a box body, and a box door connected onto the box body. The upper end of the box body is also provided with a rainproof cover; two sides of the box body are provided with vent holes; a protection layer is arranged outside the box body; a heat insulation board is arranged inside the box body; the rainproof cover comprises a rainproof cover body and a water guide groove arranged at the edge of the rainproof cover body, the rainproof cover body has a hollow ladder-shaped structure, the rainproof cover body is fixed above the box body, the water guide groove is arranged at the edge of the rainproof cover body, round holes are arranged at four corners of the rainproof cover body on the water guide groove, and hoses are arranged in the round holes; and the protection layer is a layer of high temperature-resisting coating material coating the surface of the box body. The outdoor high temperature-resisting power distribution box has the advantages that the structure is simple, high temperature can be resisted, waterproof performance and dustproof performance are good, the service life of the power distribution box is prolonged, normal operation of the power distribution box can be ensured, and the working efficiency is improved.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

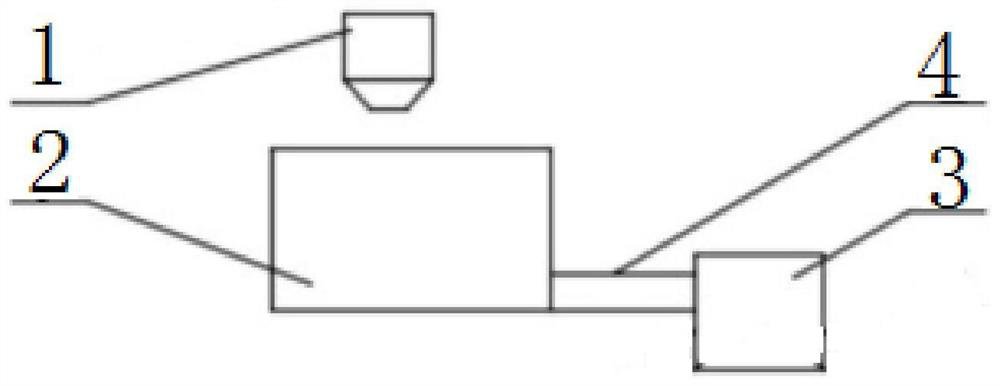

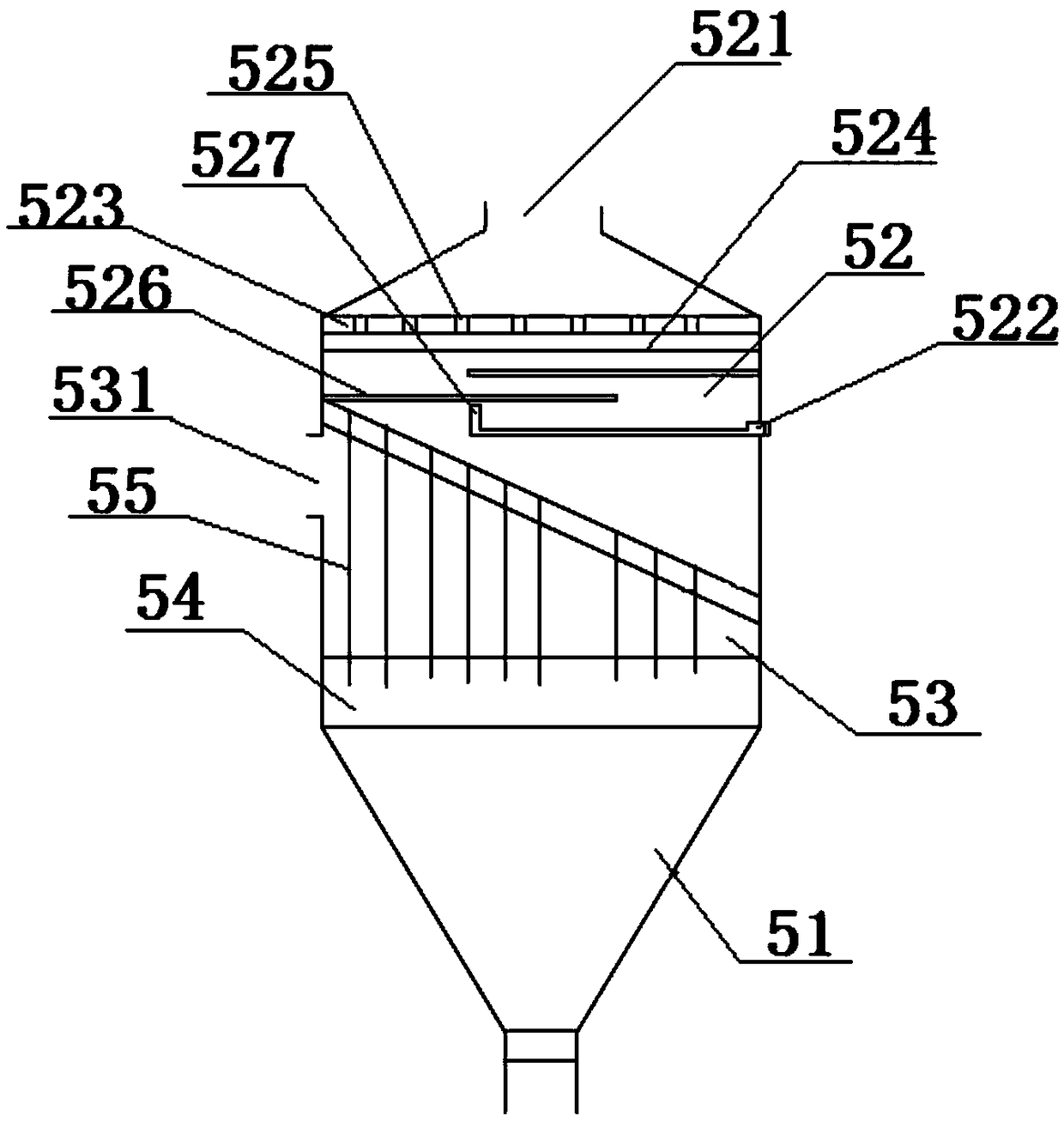

Full-automatic slag sample preparation system

PendingCN112304672AGuaranteed uptimeReduce labor intensityWithdrawing sample devicesPreparing sample for investigationSlagStructural engineering

The invention discloses a full-automatic slag sample preparation system, and the system comprises an automatic sampling machine, a crusher, a division machine and a conveying belt; the crusher is arranged at the lower end of the sampling machine, the division machine is arranged on one side of the crusher, the conveying belt is arranged between the crusher and the division machine, and the automatic sampling machine samples slag regularly; the crusher crushes the slag output by the automatic sampler, and the crushed slag is conveyed to the division machine through the conveying belt; a filterscreen is arranged at an outlet of the crusher; a plurality of material distributing grooves are formed in the division machine, material distributing bags are correspondingly arranged at the bottom ends of the material distributing partition grooves, and outlets of the material distributing bags correspond to the material receivers respectively. Protective layers are arranged on the inner surfaces and the outer surfaces of the crusher and the splitting machine and formed by spraying and drying protective paint. According to the system, the slag is continuously sampled according to the actualoperation condition of the boiler, the accuracy of the slag is effectively improved, the labor intensity is reduced, and the cost is reduced.

Owner:江苏南冶智能装备研究院有限公司

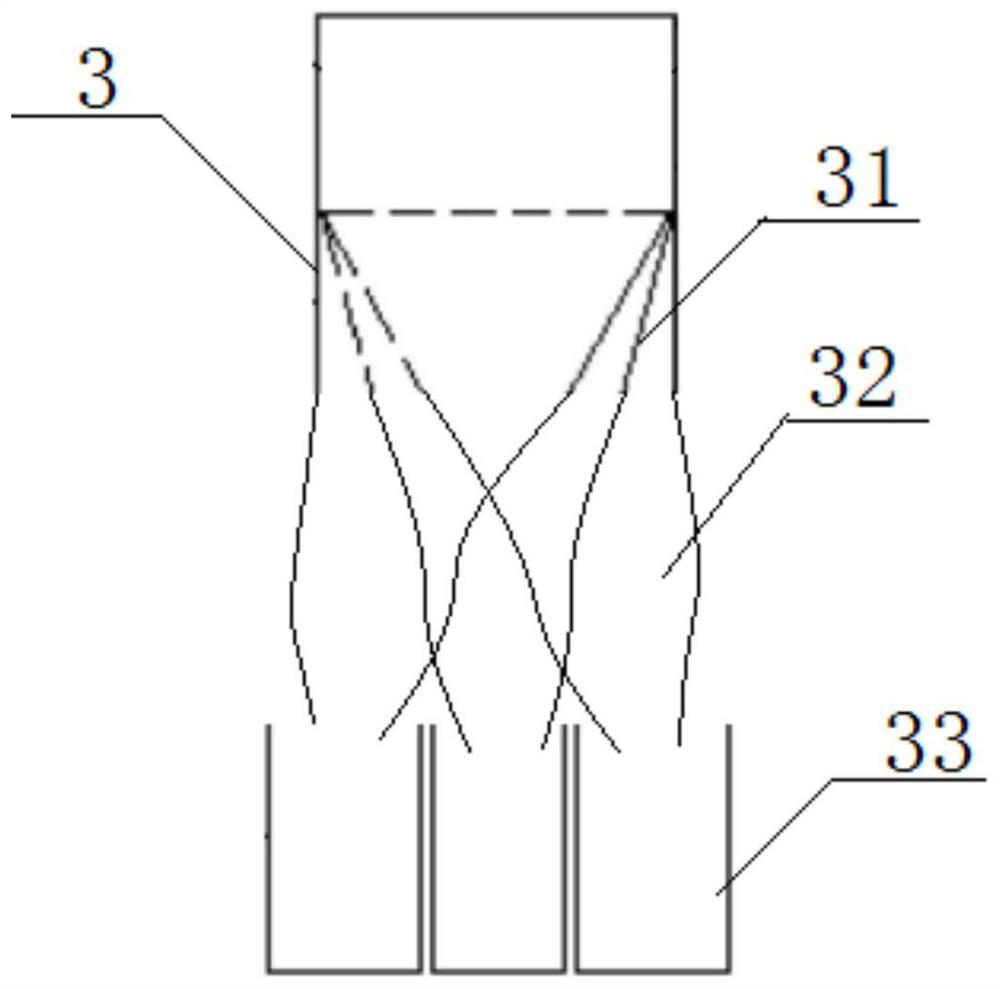

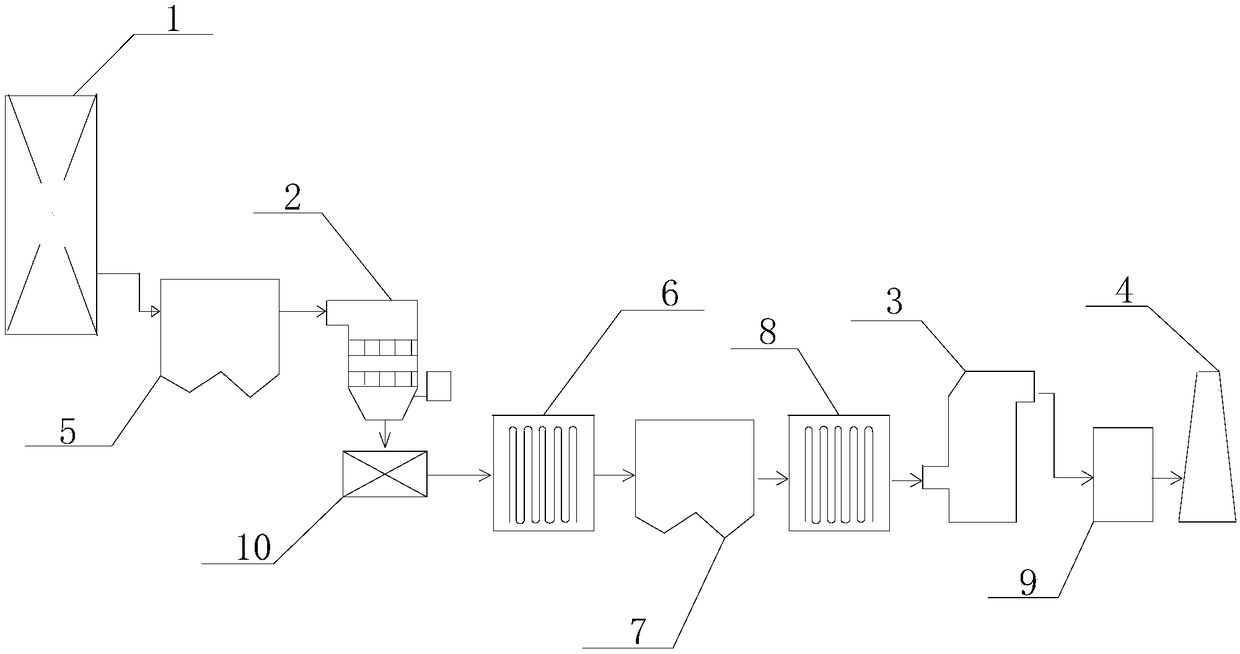

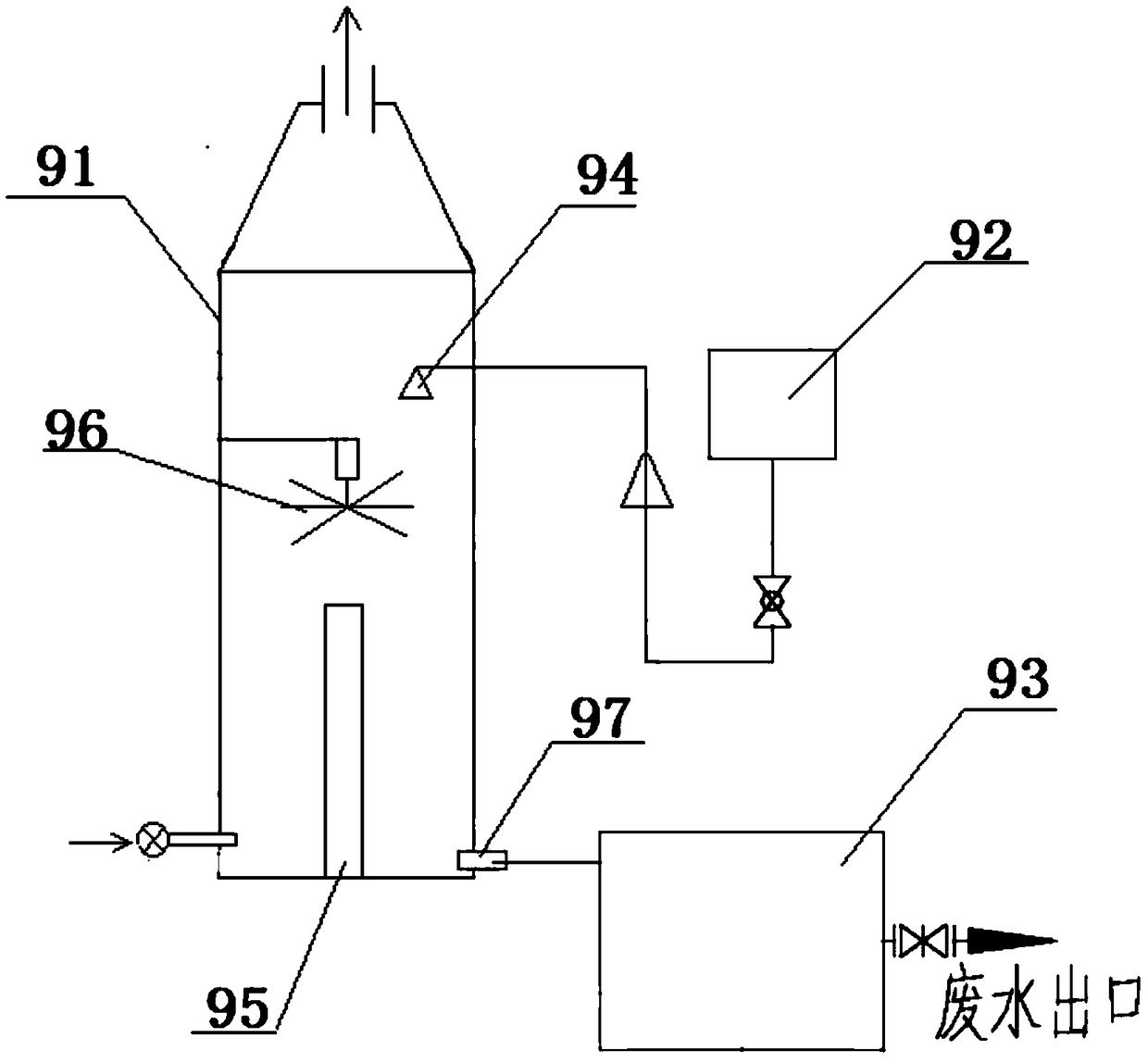

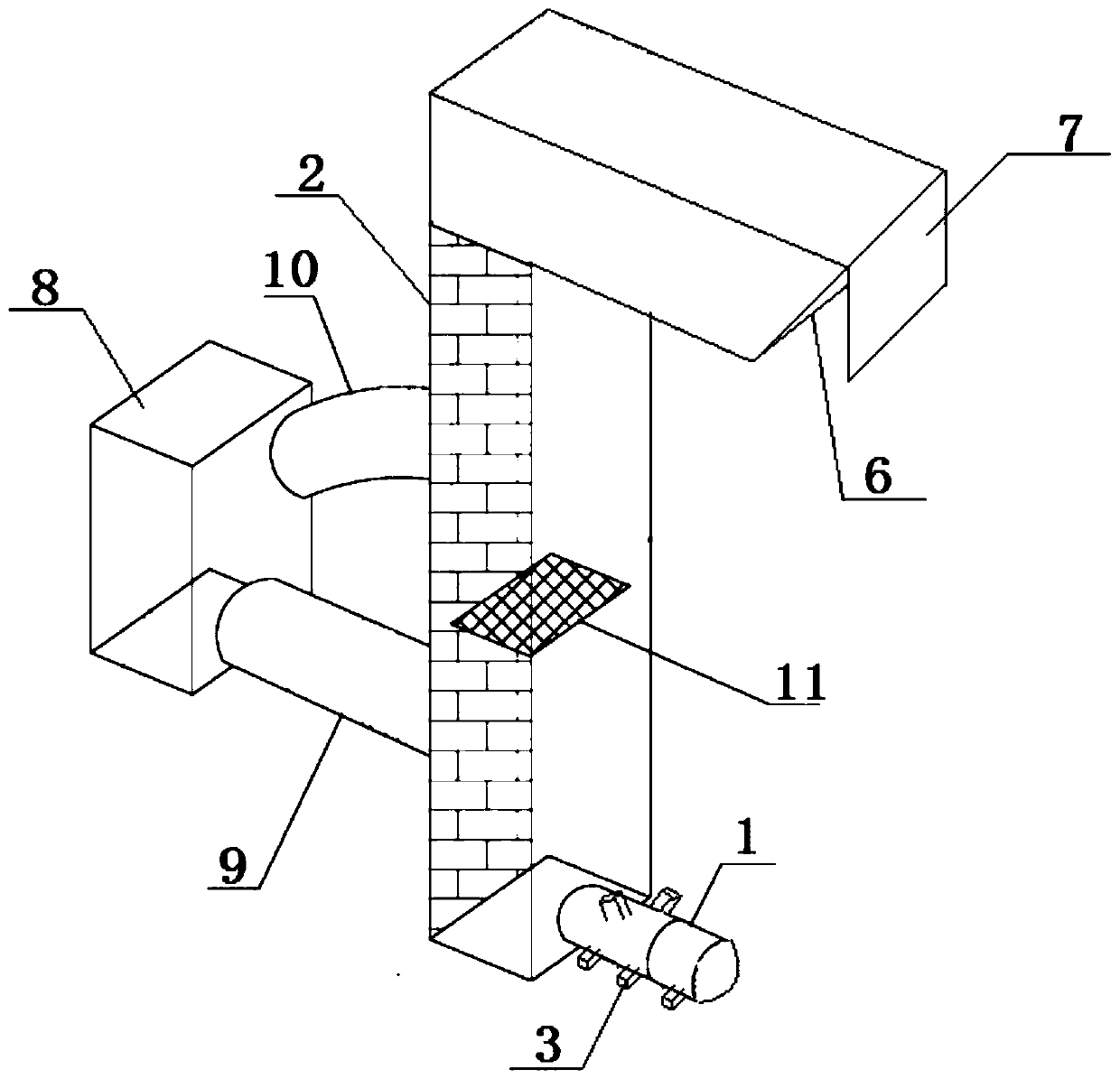

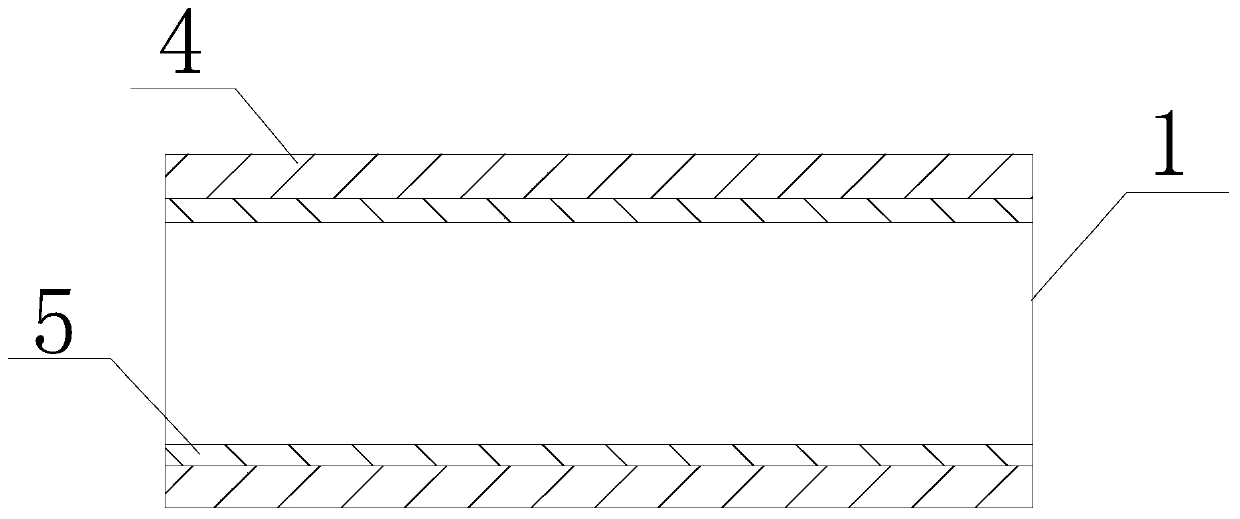

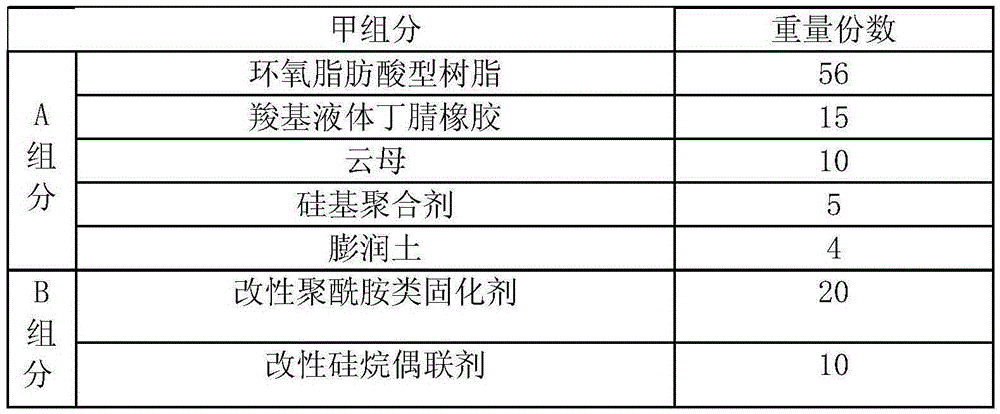

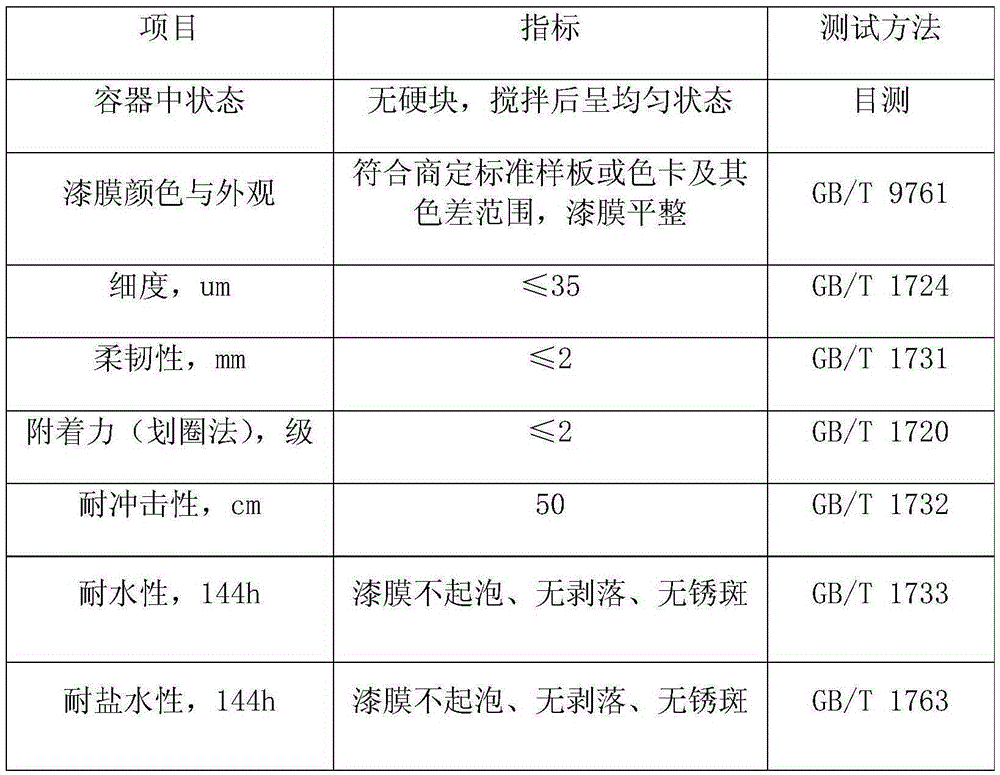

Device with energy conservation and emission reduction effects and simultaneous desulfurization and denitrification effects on flue gas and special coating for device

PendingCN109364668AImprove interchangeabilityReduce weightCombination devicesGas treatmentAir preheaterFlue gas

The invention discloses a device with the energy conservation and emission reduction effects and the simultaneous desulfurization and denitrification effects on flue gas. The device comprises a boiler, a denitrification device body, a desulfurization device body and a chimney, the output end of the boiler is connected to the input end of the denitrification device body through a first dust remover, the output end of the denitrification device body is connected with an air preheater, the output end of the air preheater is connected with a first heat exchanger, the output end of the first heat exchanger is connected to the input end of a second dust remover, the output end of the second dust remover is connected to a second heat exchanger through a fan, the output end of the second heat exchanger is connected with the desulfurization device body, the output end of the desulfurization device is connected with an alkali liquor absorption device, and the output end of the alkali liquor absorption device is connected to the chimney. The device has the advantages of being simple and compact in structure, obvious in effect, good in energy conservation and emission reduction effects and denitrification and desulfurization effects and low in cost. The invention further discloses a coating of the device. The coating of the device is further designed and has good chemical reagent resistance, and the service life of the device is prolonged.

Owner:YIXING HAINA ENVIRONMENTAL ENG

Corrosion-resistant air cooler and reinforcing process thereof

InactiveCN107988559AImprove atomic activityHigh strengthAnti-corrosive paintsPolyurea/polyurethane coatingsRare-earth elementEngineering

The invention discloses a corrosion-resistant air cooler. The corrosion-resistant air cooler is characterized in that the corrosion-resistant air cooler comprises an air cooler shell, a draught fan, arefrigerant circulation system and a control module. The draught fan and the refrigerant circulation system are arranged in the air cooler shell. The control module is used for controlling the draught fan and the refrigerant circulation system. The air cooler shell comprises, by mass percentage, 8-10% of Al, 1-3% of Mn, 0.18-0.3% of C, 0.05-0.1% of Cr, 0.01-0.05% of Nb, 0.01-0.03% of Cu, 2-5% ofSr, 0.0002-0.005% of Nb, 0.005-0.008% of N, 0.0002-0.005% of S, 0.5-0.8% of Zn, 1.5-1.8% of Si, 3-5% of Ca, 0.5-0.8% of Ti, 0.3-0.5% of Ni, 0.002-0.004% of B, 0.1-0.4% of V, 0.5-0.8% of a rare earth element and the balance Fe. The invention further designs a reinforcing process of the corrosion-resistant air cooler. The air cooler is simple and compact in structure and good in corrosion resistingeffect; the service life of the air cooler is prolonged; and the cost is lowered.

Owner:博维恩冷冻科技(苏州)有限公司

Heat pump with sound insulating effect

InactiveCN107987669AGood heat resistanceExtended service lifeFireproof paintsAnti-corrosive paintsEngineeringHeat pump

The invention discloses a heat pump with a sound insulating effect. The heat pump with the sound insulating effect comprises a heat pump machine set box body, a heat exchanger and a fan; the heat exchanger is arranged in the heat pump machine set box body; the fan is arranged on one side of the heat exchanger; a sound insulating layer is arranged on the surface of the heat pump machine set box body. The heat pump with the sound insulating effect disclosed by the invention is simple and compact, and has a good sound insulating effect.

Owner:博维恩冷冻科技(苏州)有限公司

Preparation method of corrosion resistant filter core for air inflow of efficient combustion gas turbine

InactiveCN107540131AReduce ion concentrationInhibition of killingMultistage water/sewage treatmentActivated carbonGlass fiber

The invention discloses a preparation method of a corrosion resistant filter core for air inflow of an efficient combustion gas turbine. The filter core consists of a core shell and a core body arranged in the core shell, a fiberglass filter layer, an activated carbon layer, an ion resin layer and a composite filter layer are successively arranged inside the core body from top to bottom, the composite filter layer is formed by recombining a first filter layer and a second filter layer, and the preparation method comprises the following technological process: preparation of the first filter layer-preparation of the second filter layer-recombination; the preparation method is simple and easy to perform, the prepared filter core has a compact structure, the filter effect is good, and the service life is long.

Owner:江苏华强新能源科技有限公司

Vehicle engine cover and treatment process thereof

InactiveCN108018468AHigh affinityPrevent flocculationAnti-corrosive paintsSuperstructure subunitsRare earthImpurity

The invention discloses a vehicle engine cover. The vehicle engine cover comprises an engine cover body, an embedded piece and a mounting piece; and the engine cover body comprises the following components in percentage by mass: 0.2-0.4% of C, 0.3-0.5% of Mg, 0.1-0.2% of Mn, 3-5% of Si, 0.003-0.005% of P, S not more than 0.0025%, 0.1-0.3% of Mo, 0.02-0.04% of Ni, 3-5% of Cr, 0.1-0.3% of V, 0.05-0.06% of Ca, 0.01-0.04% of Cu, 0.001-0.002% of B, 0.1-0.3% of rare earth, and the balance of aluminum and inevitable impurities. The invention further designs a treatment process of the vehicle engine cover; the treatment process is simple and feasible; and the treated engine cover is long in service life and low in cost.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

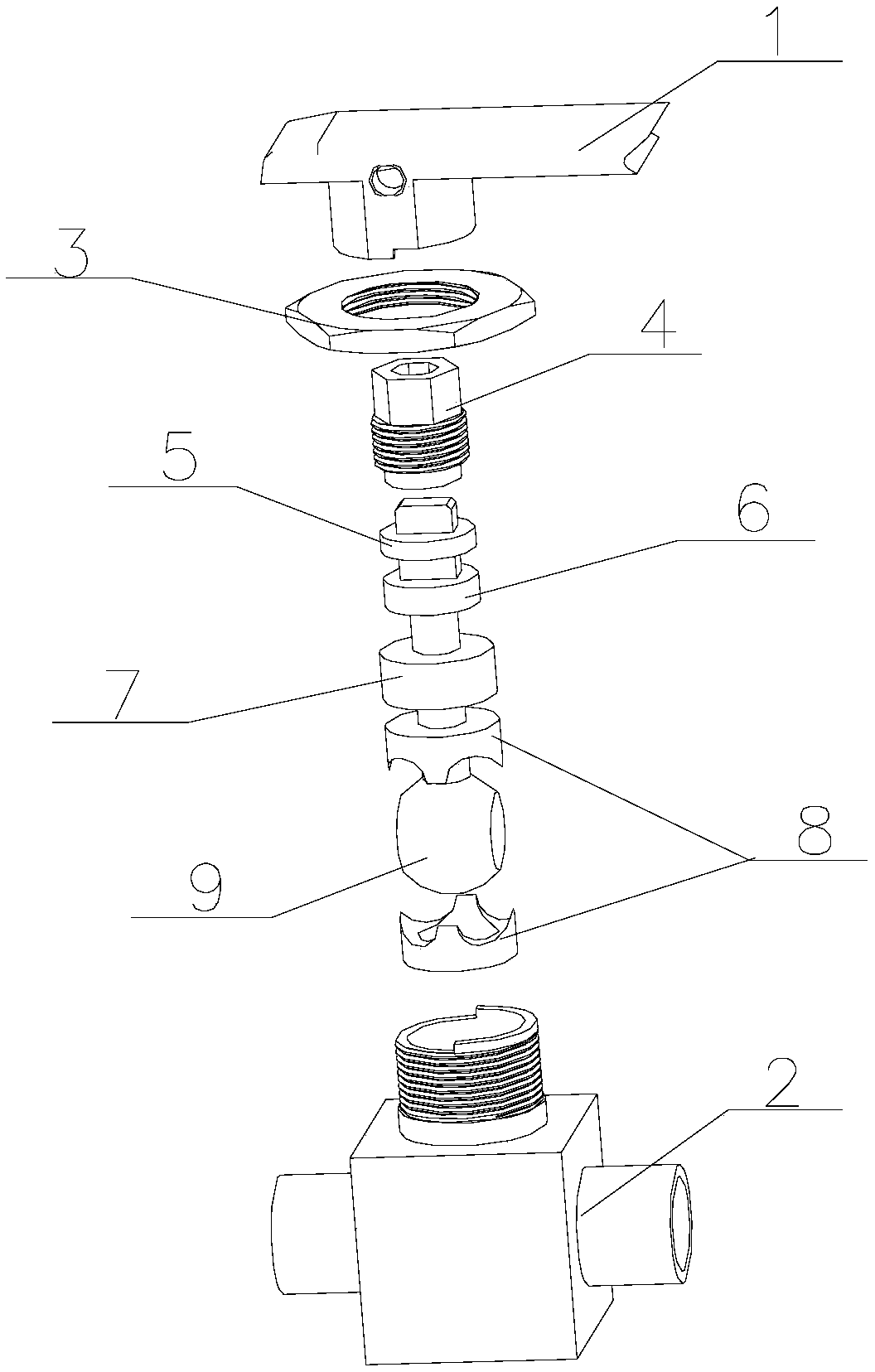

Wear-resisting high-temperature-resistant integrated type power station instrument ball valve

InactiveCN109111828AInhibition formationImprove stabilityFireproof paintsAnti-corrosive paintsElastomerRare-earth element

The invention discloses a wear-resisting high-temperature-resistant integrated type power station instrument ball valve which comprises a handle and a valve body, wherein the handle is connected witha locking nut, the locking nut is connected with a pressure pad, the pressure pad is connected with a lining, the lining is connected with a press cover, the press cover is connected with a lining disk through a lining ring, filler and a connection rod ball is arranged between the press cover and the lining disk, the lining disk is connected with the valve body, and a protection layer is further arranged on the valve body; the protection layer is prepared from the following ingredients in mass fraction: black silicon carbide, fine grain aluminum oxide, organosilicone modified epoxy resin, methylphenyl silicone resin, polyolefin elastomer, glass fiber, modified vermiculite powder, a flame retardant, a synergistic flame retardant, a dispersing agent, filler, a thickening agent, an antioxidant and rare earth elements. The instrument valve disclosed by the invention has the advantages of simple structure, good wear resistance and high temperature resistance, prolonged service life and reduced cost.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

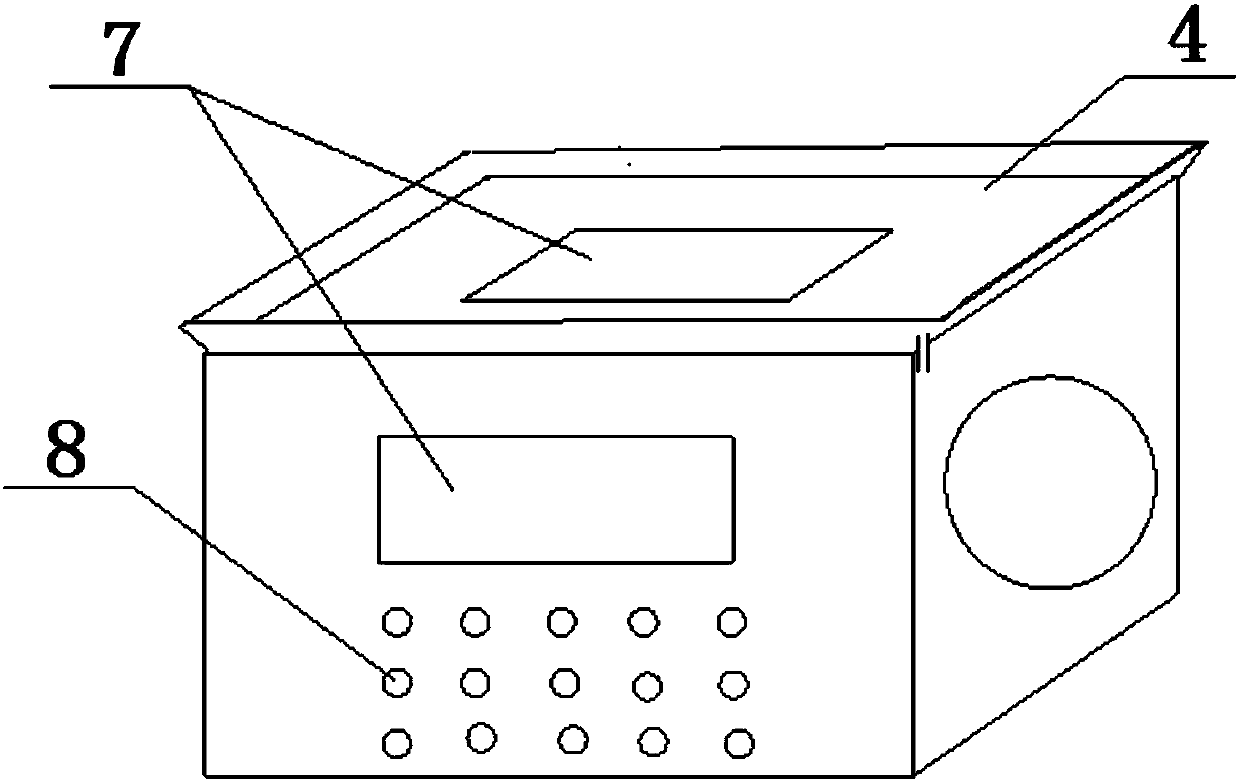

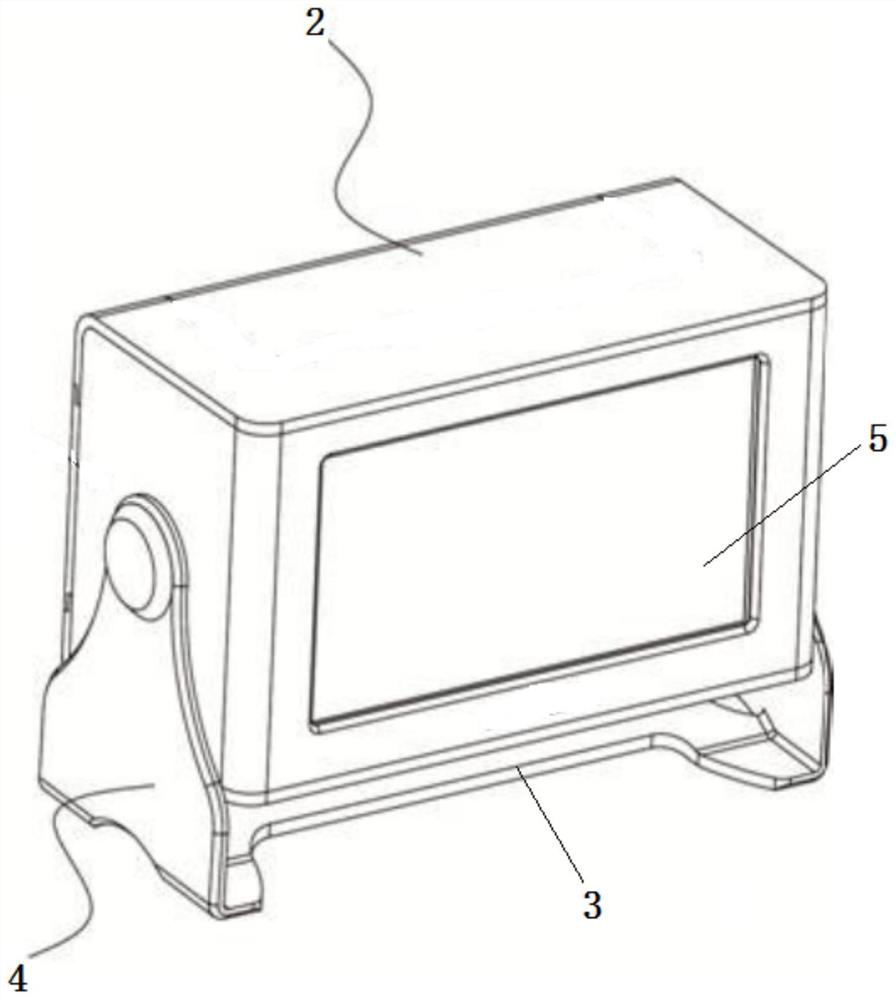

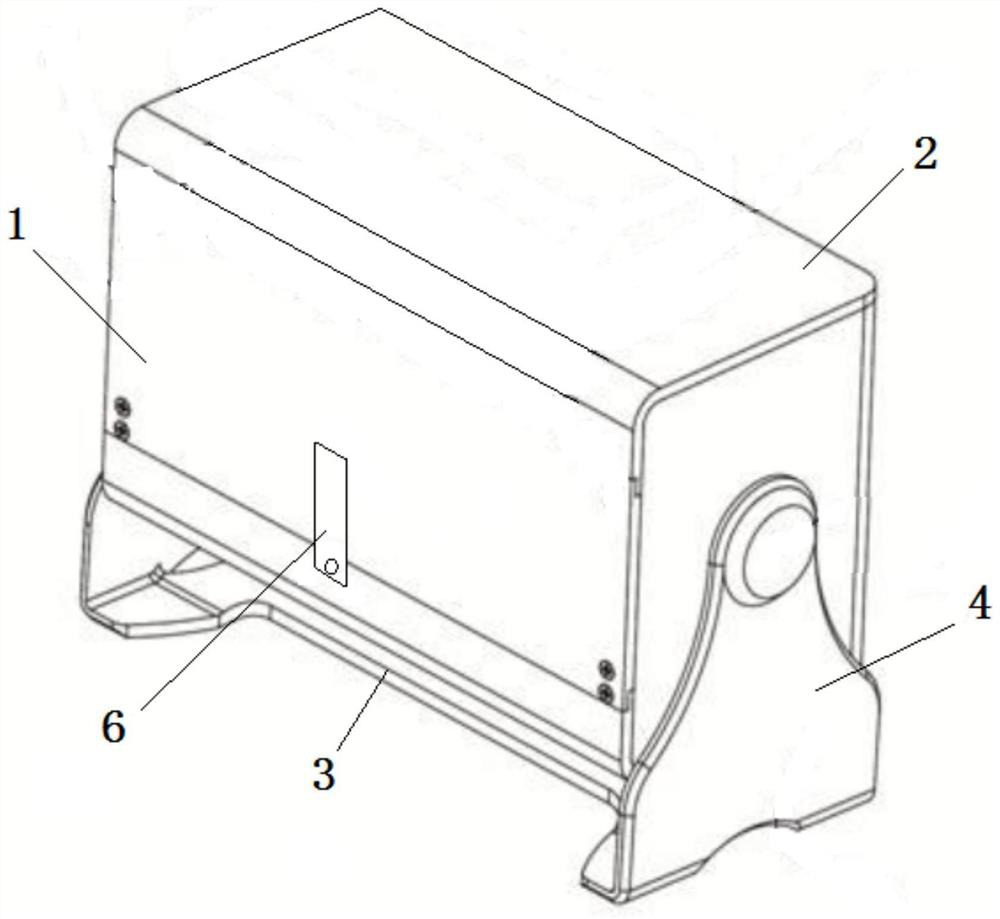

Weather resistance detection instrument

InactiveCN112251104AEasy to placeEasy to install and disassembleFireproof paintsAnti-corrosive paintsWeather resistanceStructural engineering

The invention discloses a weather resistance detection instrument. The weather resistance detection instrument comprises an instrument main body and a support; the support is arranged at the bottom end of the instrument main body; and a protective layer is arranged on the surface of the instrument main body. The support comprises an installation groove, a support bottom plate and connecting arms;the two sides of the support bottom plate are symmetrically provided with the connecting arms; and the two connecting arms are arranged on the two sides of the installation groove; the instrument mainbody is arranged in the installation groove; a transparent observation window is arranged on one side of the installation groove; the other side of the installation groove is of an opening structure;a fixing block is arranged at the lower end of the opening structure of the installation groove. The weather resistance detection instrument is simple in structure, adjustable, good in adaptability and good in weather resistance, and the service life of the weather resistance detection instrument is prolonged.

Owner:南京鹏安智慧科技有限公司

Anti-corrosion boiler blast blower

InactiveCN107903772AHigh affinityPrevent flocculationFireproof paintsAnti-corrosive paintsEpoxyAgricultural engineering

The invention discloses an anti-corrosion boiler blast blower, which comprises a wind box, wherein a main shaft is arranged in the wind box; an impeller is arranged on the main shaft; a motor is arranged outside the wind box; an anti-corrosion layer is arranged outside the wind box, and is prepared from the following ingredients in parts by mass: 15 to 20 parts of water-borne epoxy resin emulsion,10 to 20 parts of bisphenol F epoxy resin, 1 to 3 parts of nanometer titanium dioxide, 5 to 7 parts of dispersing agents, 1 to 3 parts of surfactants, 3 to 5 parts of foaming agents, 1 to 3 parts ofthickening agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of pigment and filler, 3 to 5 parts of silicon micro powder, 1 to 3 parts of modified magnesium hydrate, 20 to 30 parts of solvents and 0.1 to 0.3 part of composite rare earth. The anti-corrosion boiler blast blower has the advantages that the anti-corrosion performance is good; the service life is prolonged; the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Anticorrosive chlorinated rubber coating and production process for same

InactiveCN109054513AIncrease wettabilityImprove adhesionFireproof paintsRubber derivative coatingsEpoxyPolymer science

The invention discloses an anticorrosive chlorinated rubber coating, which is prepared from the following components: chloroprene rubber, chlorinated rubber, a refractory material, a dispersant, dimethylbenzene, fluorocarbon resin, organic silicone modified epoxy resin, Songxiashui, baryta powder, vermiculite powder, a surfactant, a binder, a plasticizer, micaceous iron oxide and composite rare earth. The invention also discloses a production process for the anticorrosive chlorinated rubber coating. The production process is simple and easy, the produced anticorrosive material is high in anticorrosive performance and protection performance, the service life of the anticorrosive material is prolonged, and the cost is reduced.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

A groove-type cable bridge and an anticorrosion process thereof

InactiveCN108988237AImprove stabilityAvoid generatingFireproof paintsElectrical apparatusEngineeringImpurity

The invention discloses a groove-type cable bridge, comprising a groove frame and a shield arranged on the groove frame, wherein the groove frame comprises the following components in percentage by mass: C: 0.15-0.19%, Cr:1.0-3.0%, Si:2-4%, Al:0.5-0.9%, Ti:0.2-0.5%, Cu:0.05-0.08%, B:0.05-0.08%, Sb:0.1-0.3%, Mo:0.2-0.35%, Zr:0.03-0.05%, Zn:0.5-0.8%, Nb:0.05-0.07%, Mn:0.45-0.48%, S:0.003-0.005%, P:0.005-0.007%, V: 0.01-0.03%, rare element: 0.15-0.18%, the rest is Fe and inevitable impurities; the invention also designs an anticorrosion process of the groove cable bridge, which has good anticorrosion performance and long service life.

Owner:江苏大印电子科技有限公司

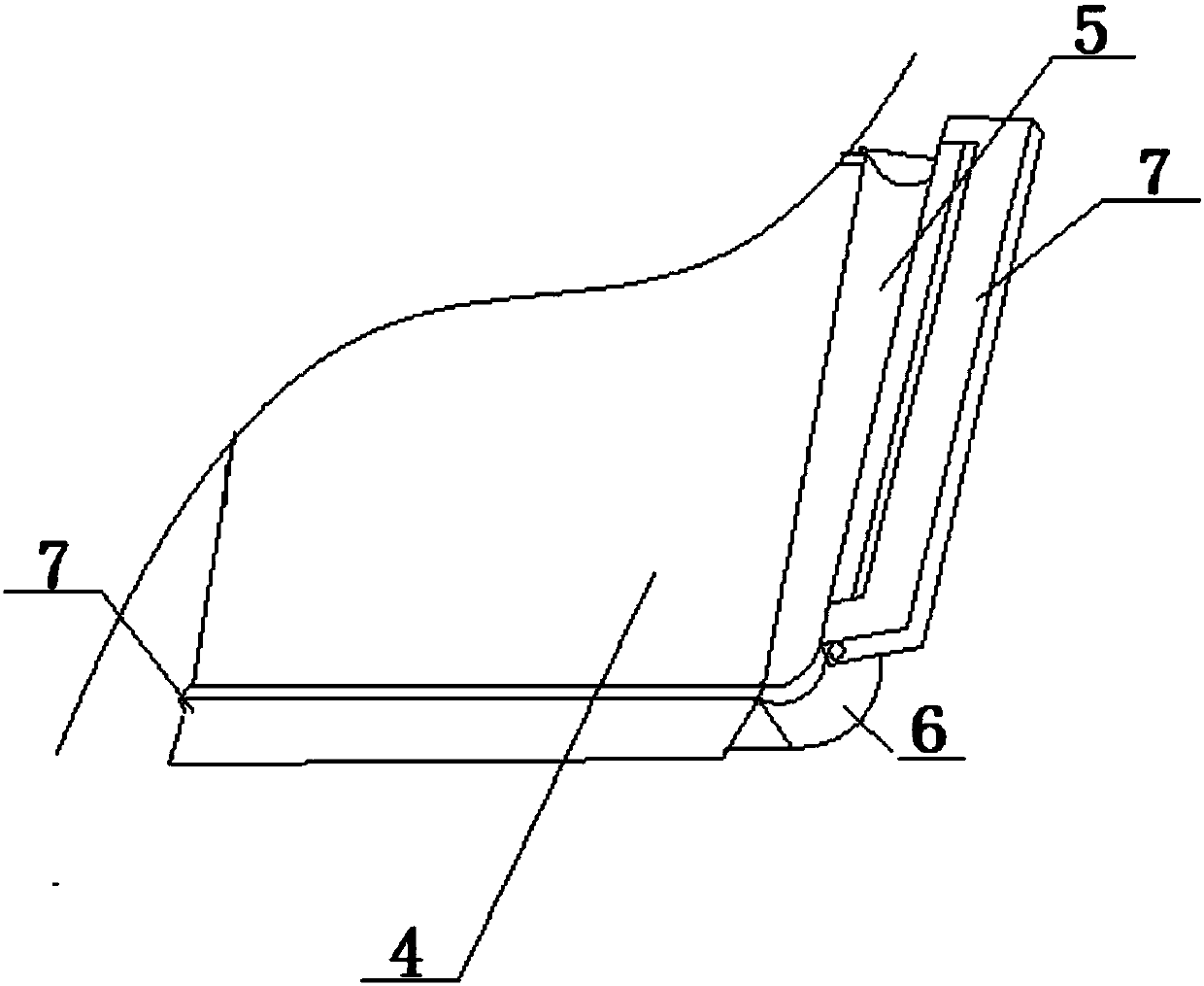

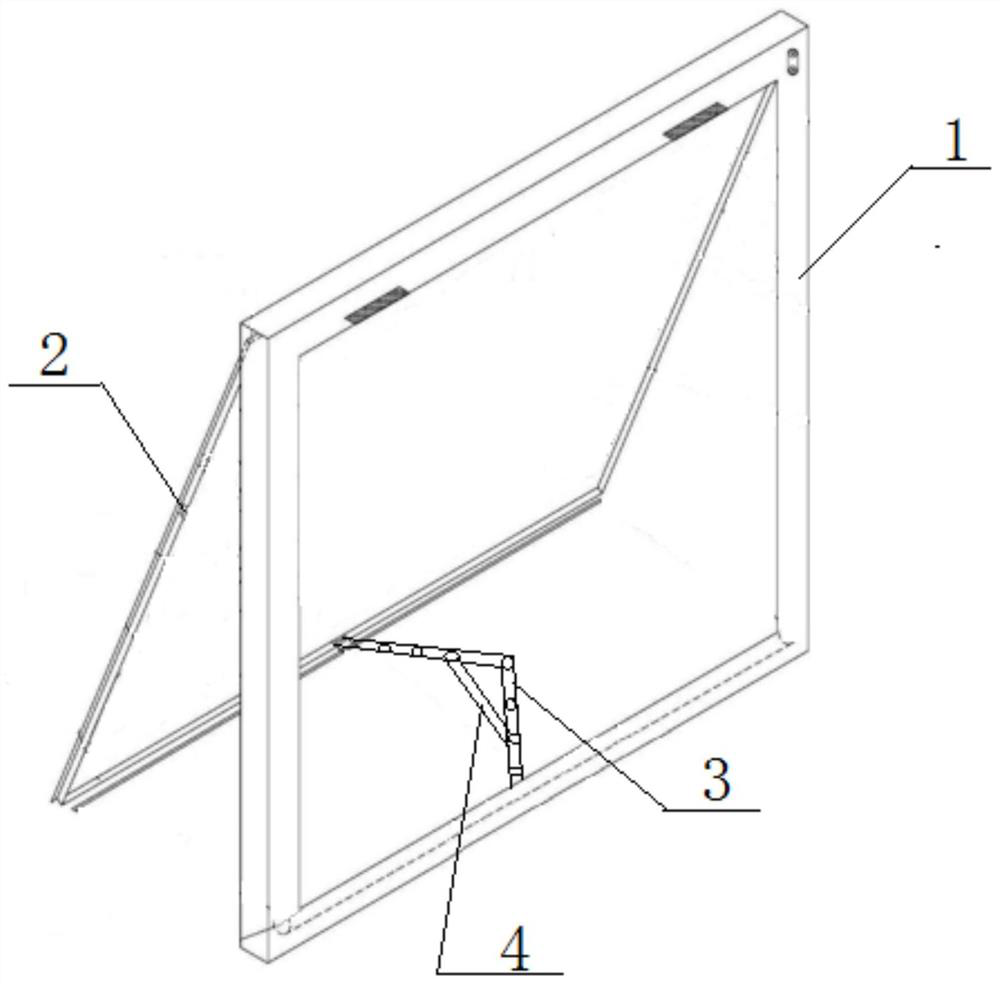

Photovoltaic power generation window with high wear resistance

PendingCN112260381AEasy to installBeautiful and transparentBatteries circuit arrangementsPretreated surfacesWeather resistanceStructural engineering

The invention discloses a photovoltaic power generation window with high wear resistance. The photovoltaic power generation window comprises a window frame, a window body, a solar photovoltaic panel,a control circuit board, a storage battery, an inverter, a load wiring port and a support rod, wherein the window frame is coated with a wear-resistant layer; the window body is composed of the solarphotovoltaic panel and hollow glass; one end of the window body is rotationally connected to the window frame, the control circuit board, the storage battery and the inverter are arranged in the window frame, and the load wiring port is formed in the inner side surface of the window frame; and the support rod comprises two independent supporting rods which are movably connected and a fixing rod, fixing holes are formed in the independent supporting rods respectively, fixing columns are arranged at the two ends of the fixing rod, the fixing rod is arranged between the two independent supportingrods, one end of each supporting rod is arranged on the window frame, and the other end of each supporting rod is arranged on the window body. The power generation window is simple in structure, highin adaptability, high in abrasion resistance, long in service life and low in cost.

Owner:JIANGSU DONGZHAO CONSTR IND INNOVATION & DEV RES INST CO LTD

A kind of composite epoxy anticorrosion coating and preparation method thereof

ActiveCN104231857BHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses a composite epoxy anticorrosion coating and a preparation method thereof. The composite epoxy anticorrosion coating is composed of two components A and B according to the ratio of A:B=2:1. Group A includes the following components: organosilicon Modified epoxy resin, pigment, filler, plasticizer, dispersant, film-forming aid and defoamer; component B includes the following components: polyphenylene ether resin powder, styrene-butadiene rubber, toluene, plasticizer, Coupling agent, auxiliary material and flame retardant; Prepare by mixing components A and B separately, and then spray B on A to form a composite epoxy anti-corrosion coating. The composite epoxy anti-corrosion coating is made of two-component composite with excellent resistance High temperature and wear resistance, it also has good adhesion and low shrinkage, and has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents. At the same time, the composite epoxy anti-corrosion coating The composite epoxy anticorrosion paint has excellent flexibility and paint construction performance, and the preparation method of the composite epoxy anticorrosion paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

High-performance combustion gas turbine gas-exhaust system

InactiveCN110307049AReduce weightImprove thermal stabilityFireproof paintsChemical industryCombustionProcess engineering

The invention discloses a high-performance combustion gas turbine gas-exhaust system. The high-performance combustion gas turbine gas-exhaust system comprises a gas exhaust barrel, a gas exhaust towerand a heat storage device, wherein one end of the gas exhaust barrel is connected to a gas exhaust hole of a combustion gas turbine, and the other end of the gas exhaust barrel is connected to the gas exhaust tower; the heat storage device is further connected on the gas exhaust tower; the gas exhaust barrel is of a cylindrical steel plate structure with a big end and a small end; a plurality ofbumps are arranged on the outer wall of the gas exhaust barrel; a heat dissipation layer and an isolating layer are arranged on the inner wall of the gas exhaust barrel; the top end of the gas exhausttower is outwards extended to form a gas exhaust tower opening; a plurality of rainproof baffle plates are arranged on the gas exhaust tower opening from top to bottom; and the heat storage device comprises a heat storage box as well as a gas inlet tube and a gas outlet tube which are connected to the heat storage box, an electric louver valve is arranged in the gas exhaust tower, and the position, on the gas exhaust tower, of the electric louver valve is positioned between the gas inlet tube and the gas outlet tube. The high-performance combustion gas turbine gas-exhaust system is simple instructure, is high in safety, can recycle heat energy to certain extent, can reduce energy loss, and improves energy utilization efficiency.

Owner:江苏华强新能源科技有限公司

A special coating for acrylic topcoat and preparation method thereof

ActiveCN103992720BImprove adhesionGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a special coating for acrylic finishes, and a making method thereof. The special coat comprises a component I and a component II having a same amount with the component II, the component I is formed by a component A and a component B, the component A in the component I comprises modified epoxy resin, a flexibilizer, mica, an assistant and an anti-settling agent, the component B in the component comprises a curing agent and a coupling agent; and the component II comprises polyurethane modified acrylic resin, rutile titanium dioxide, a film forming assistant, purified water, an antifoaming agent, a dispersant, a flash rust inhibitor and a thickening agent. The special coating is obtained by preparing the component I, preparing the component II and compounding the component I with the component II. The coating has the advantages of strong adhesion, unlikely shedding, good impermeability, good corrosion resistance, strong weatherability, unlikely saponification and fast drying, and has a very good protection effect at a low temperature.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Gas-fired wall-hung boiler and reinforcing process thereof

InactiveCN108019919AHigh affinityPrevent flocculationPolyurea/polyurethane coatingsWater heatersRare-earth elementZinc borate

The invention discloses a gas-fired wall-hung boiler which comprises a boiler body, a smoke discharging pipe and a temperature sensor, wherein one end of the smoke discharging pipe is arranged on theboiler body in a room; the other end of the smoke discharging pipe extends out of the room; the temperature sensor is arranged on the smoke discharging pipe which extends out of the room; and a flame-retardant layer is arranged on the inner surface of the boiler body, and comprises the following components in parts by mass: 15-20 parts of bromine carbon polyurethane resin, 10-15 parts of zinc borate modified phenolic resin, 2-4 parts of a filler; 0.5-1 part of an antioxidant T501, 0.05-0.1 part of a heat stabilizer, 1-3 parts of aluminum hydroxide, 1-3 parts of magnesium hydroxide, 2-4 parts of a flame retardant, 1-3 parts of a synergistic flame retardant, 1-3 parts of modified vermiculite powder, 4-7 parts of silicon oil, 3-5 parts of a catalyst, 1-3 parts of an anti-aging agent KY and 0.1-0.2 part of a rare earth element. The invention further discloses a reinforcing process of the gas-fired wall-hung boiler. The reinforcing process is simple and feasible. The reinforced gas-fired wall-hung boiler is better in abrasion-resistant property and flame-retardant property, longer in service life and lower in cost.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Wear-resistant treatment technology of double-air outlet air cooler

InactiveCN108059901AHigh affinityPrevent flocculationMetallic material coating processesEpoxy resin coatingsWear resistantEngineering

The invention discloses a wear-resistant treatment technology of a double-air outlet air cooler. The wear-resistant treatment technology comprises the following steps: (1), slightly roughening the surface of the double-air outlet air cooler by using fine sandpaper; (2), putting the shell of the double-air outlet air cooler into a sodium hydroxide tank for degreasing cleaning, then rinsing by usingclear water, then performing blow drying, putting into pickling equipment for pickling rust removal, then rinsing by using clear water, and then performing blow drying; (3), phosphorizing the double-air outlet air cooler by using a phosphorizing solution at the phosphatization temperature of 30-40 DEG C, and then performing blow drying; (4), spraying the surface of the treated double-air outlet air cooler with wear-resistant coating to form a wear-resistant layer. The air cooler is simple and compact and has a good wear-resistant effect; the service life of the air cooler is prolonged, and the cost of the air cooler is reduced.

Owner:博维恩冷冻科技(苏州)有限公司

Refrigeration equipment with low noise

InactiveCN107868374AImprove heat resistanceImprove adhesionLighting and heating apparatusDomestic refrigeratorsIsolation effectLow noise

The invention discloses refrigeration equipment with low noise. The refrigeration equipment comprises a casing, a refrigeration chamber and a door body, wherein the refrigeration chamber is arranged in the casing; the door body is movably connected onto the casing; the refrigeration chamber is closed in the casing through the door body; a sound isolation layer is also arranged on the outer surfaceof the casing; the sound isolation layer comprises a base layer, a sound isolation layer and a waterproof layer; the sound isolation layer is arranged on the upper and lower surfaces of the base layer; a waterproof layer is respectively arranged on each sound isolation layer. The refrigeration equipment provided by the invention is simple and compact; a good sound isolation effect is achieved; the noise pollution is reduced.

Owner:博维恩冷冻科技(苏州)有限公司

Corrosion resistant heat exchanger and strengthening technology thereof

InactiveCN108103364AImprove the extrusion effectGrain refinementAnti-corrosive paintsEpoxy resin coatingsRare-earth elementCorrosion resistant

The invention discloses a corrosion resistant heat exchanger comprising a shell and a heat exchange pipe arranged in the shell. The shell comprises, by mass, 0.1%-0.3% of C, 0.5%-0.8% of Mn, 0.5%-0.7%of Ni, 2%-4% of Cr, 0.4%-0.6% of Nb, 0.1%-0.3% of Si, 0.2%-0.5% of Fe, 1.5%-2.0% of Mg, no more than 0.2% of Cu, no more than 0.015% of s, no more than 0.025% of p, 0.3%-0.5% of Mo, 0.3%-0.5% of Ti,0.02%-0.03% of B, 0.0018%-0.0022% of v, 0.1%-0.3% of composite rare earth, 0.2%-0.4% of rare earth elements and the balance Al. The invention provides the corrosion resistant heat exchanger and a strengthening technology thereof; and the strengthening technology is simple and practicable, and the strengthened heat exchanger is high in corrosion resistance.

Owner:博维恩冷冻科技(苏州)有限公司

A high-temperature wear-resistant coating at a high temperature of 800 degrees and its preparation method

The invention discloses a high temperature wear-resistant coating at a high temperature of 800 degrees and a preparation method thereof. : black silicon carbide, fine-grained alumina, dispersant, zinc oxide, modified epoxy resin, matting agent and auxiliary materials; component B in component A includes the following components: silicone modified epoxy resin, filler, Antimony trioxide, film-forming aid and thickener; B component is curing agent and coupling agent, mix A and B components in A, and then use B component to cure A component to obtain 800 degrees High-temperature wear-resistant coating at high temperature, the high-temperature wear-resistant coating is made of two-component composite. It has excellent high temperature resistance and wear resistance, and also has good hardness, high thermal stability, ductility and machinability Excellent properties such as durability; the present invention also designs a method for preparing the high-temperature wear-resistant coating, the preparation method is simple and the cost is low.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com