Patents

Literature

30 results about "3-Hydroxyhexanoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl (R)-3-hydroxyhexanoate is the (R)-enantiomer of ethyl 3-hydroxyhexanoate. It is an enantiomer of an ethyl (S)-3-hydroxyhexanoate . Ontology Summary from ChEBI

Polyhydroxyalkanoate biopolymer compositions

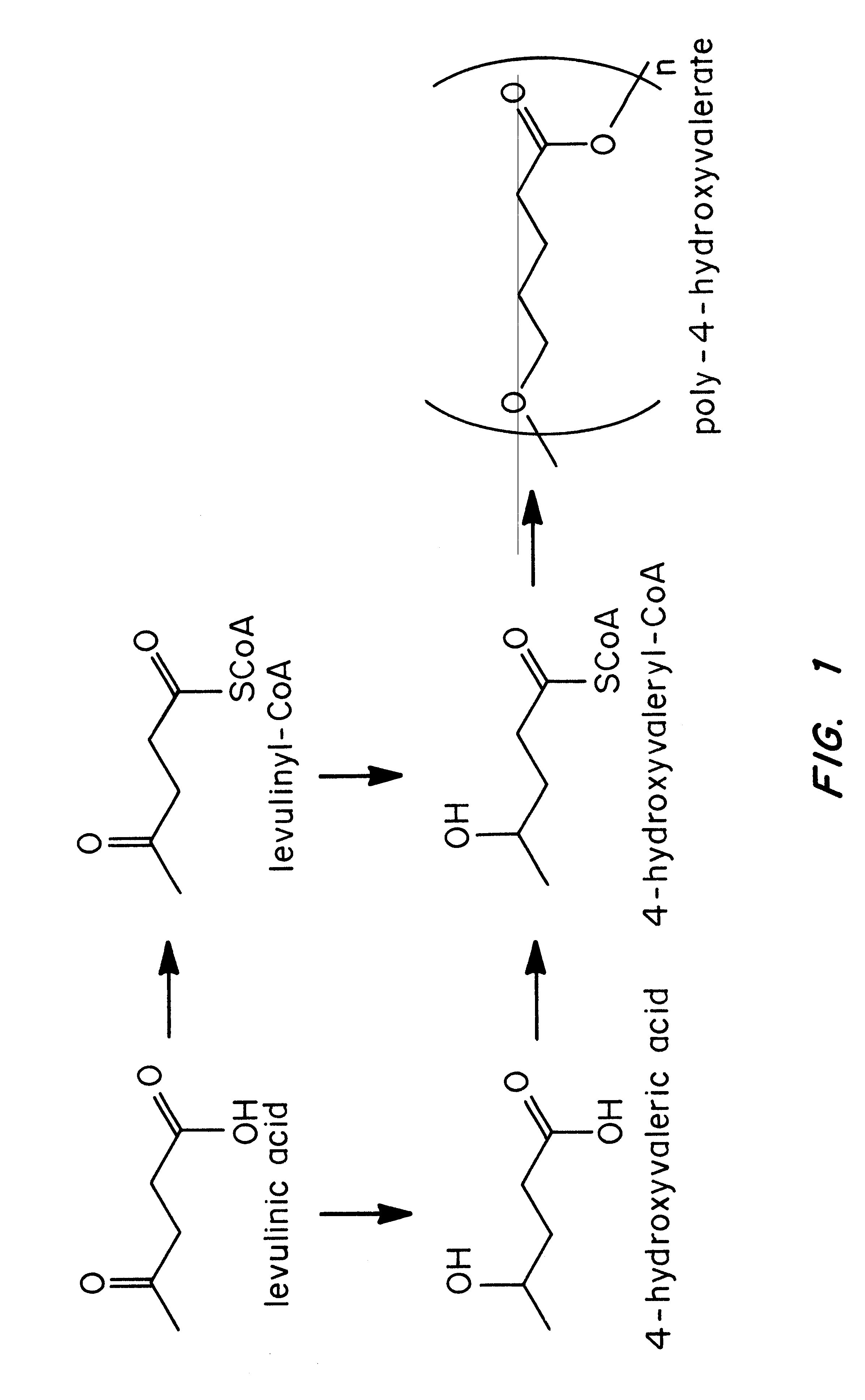

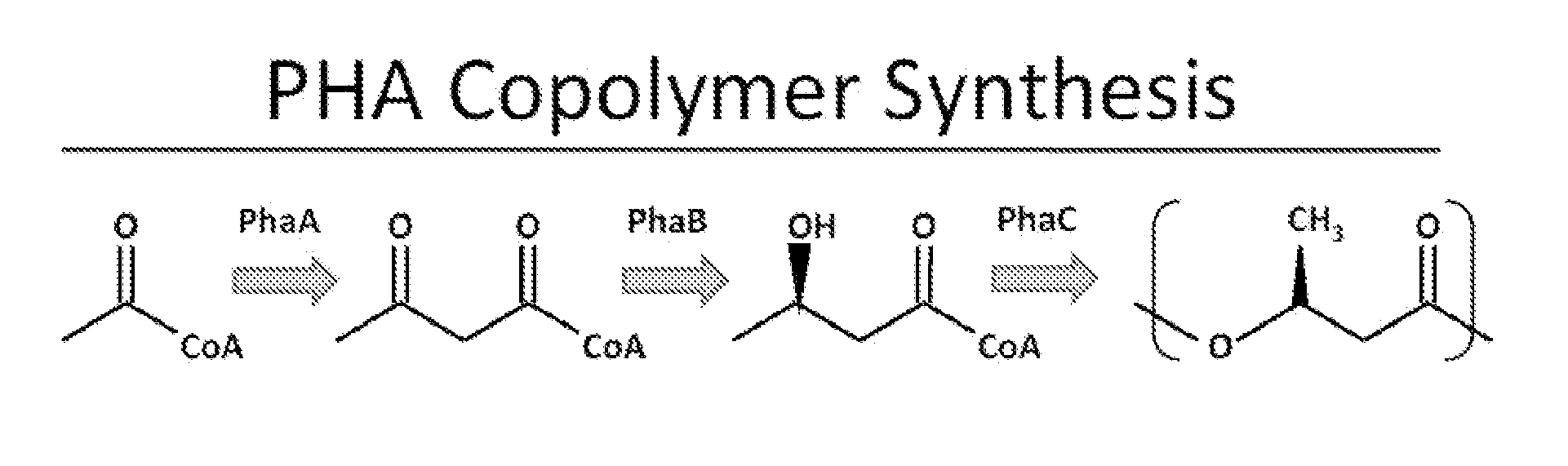

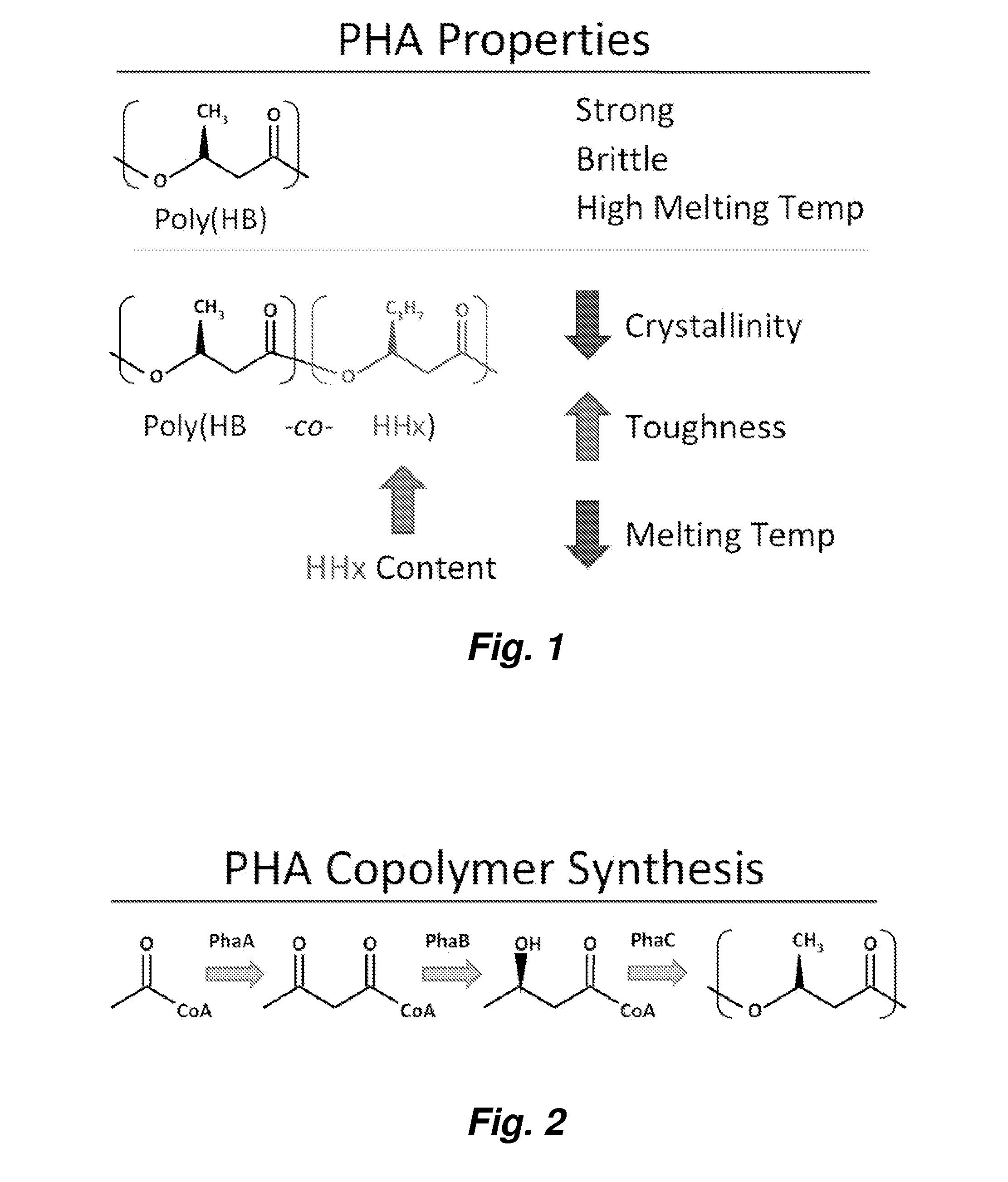

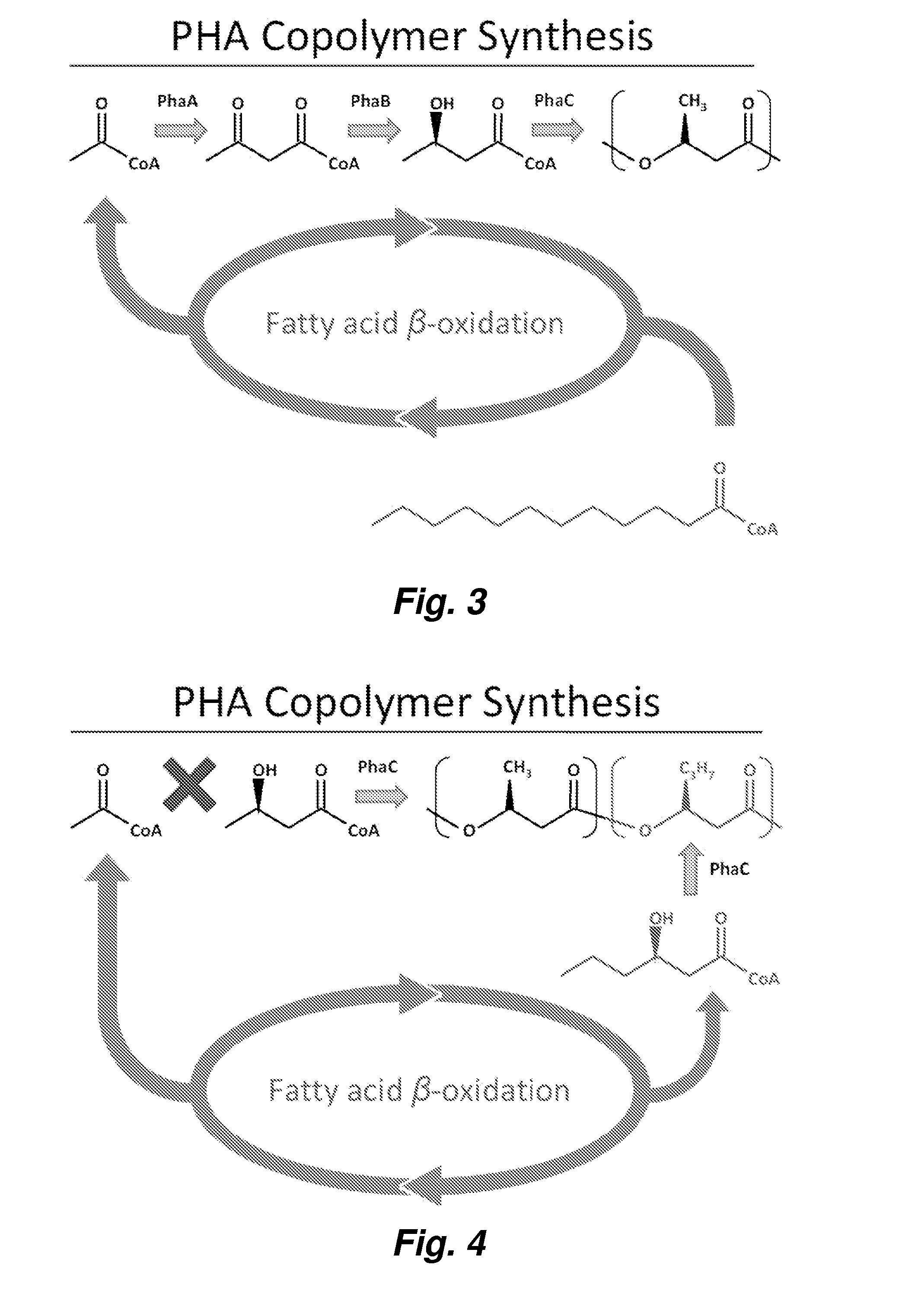

Several novel PHA polymer compositions produced using biological systems include monomers such as 3-hydroxybutyrate, 3-hydroxypropionate, 2-hydroxybutyrate, 3-hydroxyvalerate, 4-hydroxybutyrate, 4-hydroxyvalerate and 5-hydroxyvalerate. These PHA compositions can readily be extended to incorporate additional monomers including, for example, 3-hydroxyhexanoate, 4-hydroxyhexanoate, 6-hydroxyhexanoate or other longer chain 3-hydroxyacids containing seven or more carbons. This can be accomplished by taking natural PHA producers and mutating through chemical or transposon mutagenesis to delete or inactivate genes encoding undesirable activities. Alternatively, the strains can be genetically engineered to express only those enzymes required for the production of the desired polymer composition. Methods for genetically engineering PHA producing microbes are widely known in the art (Huisman and Madison, 1998, Microbiology and Molecular Biology Reviews, 63: 21-53). These polymers have a variety of uses in medical, industrial and other commercial areas.

Owner:METABOLIX

Fibers, nonwoven fabrics, and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate

InactiveUS6013590AProtect and promote and control plant growthHigh elongationBaby linensAdhesivesPolymer scienceBiodegradable copolymers

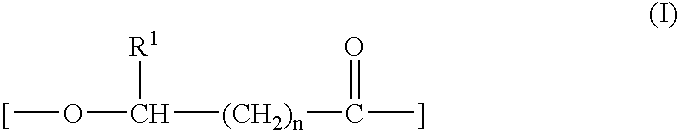

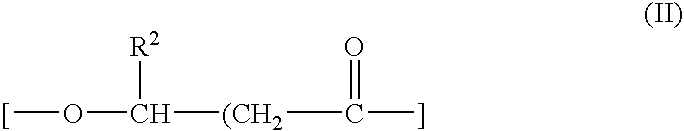

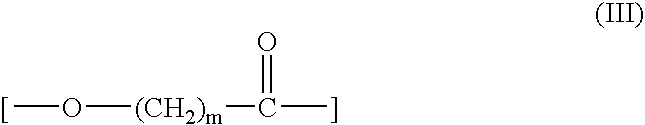

The present invention relates to fibers, and nonwovens comprising said fibers, comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid previous topsheet, a biodegradable liquid impervious backsheet comprising the above fibers and / or nonwovens, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

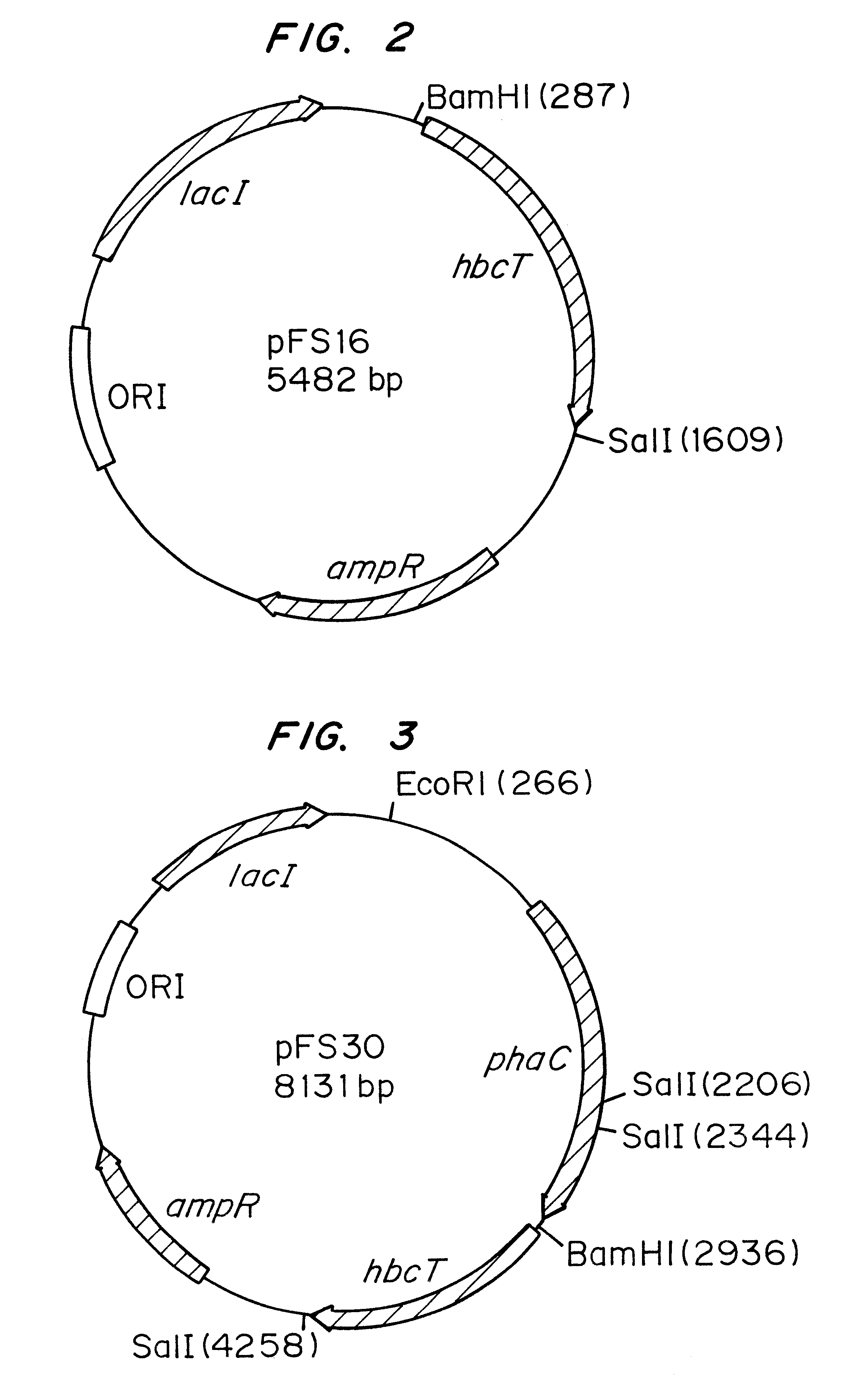

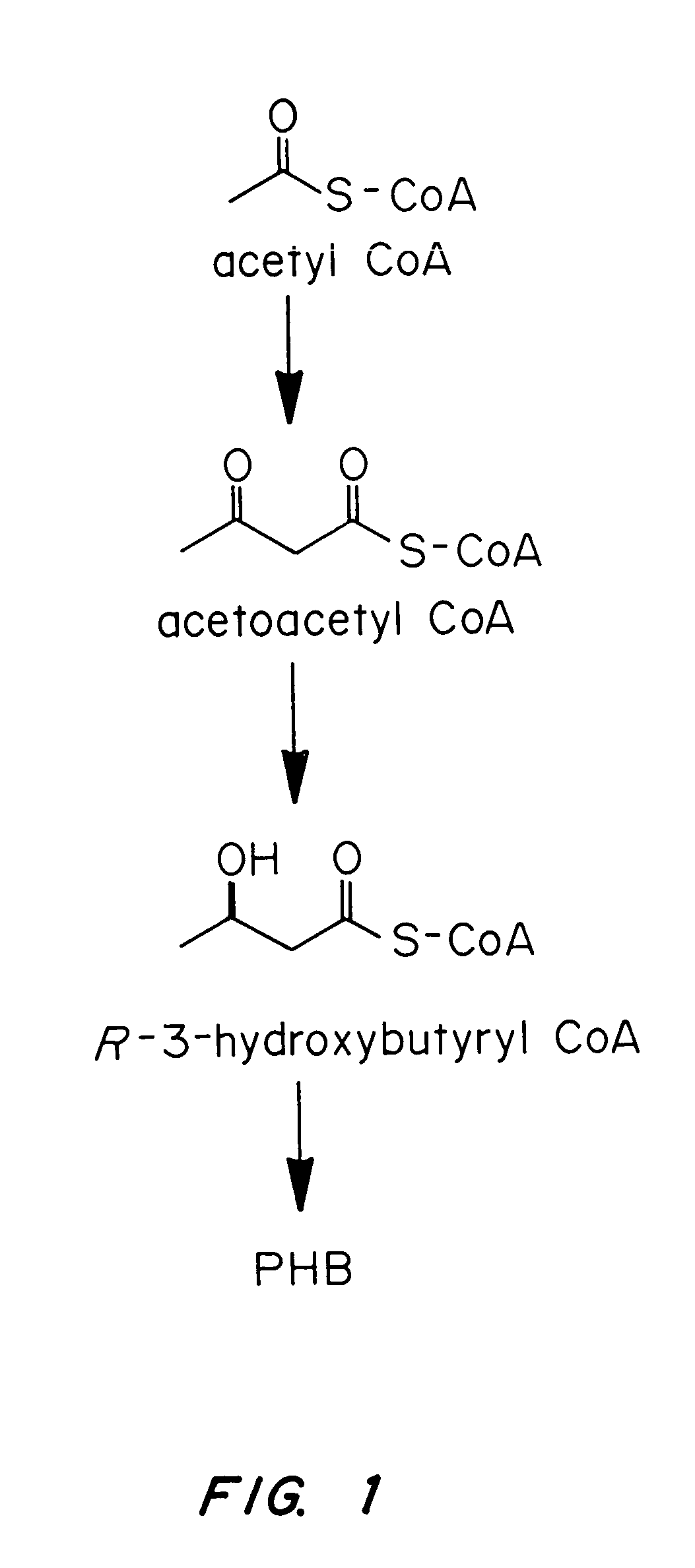

Transgenic systems for the manufacture of poly (3-hydroxy-butyrate-co-3-hydroxyhexanoate)

InactiveUS7455999B2Efficient PHA synthesisHigh expressionBacteriaMicroorganism based processesBacteroidesBiosynthetic genes

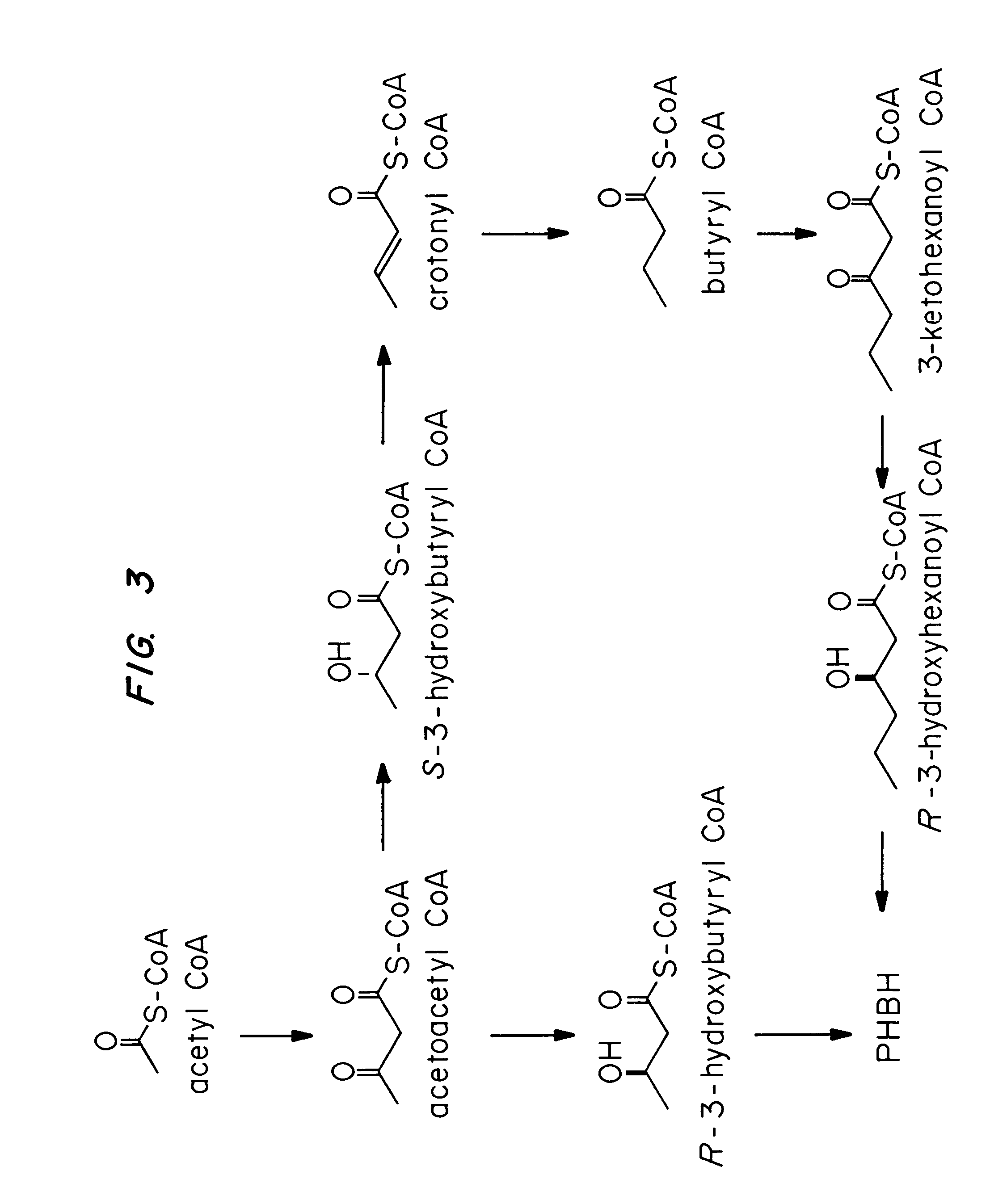

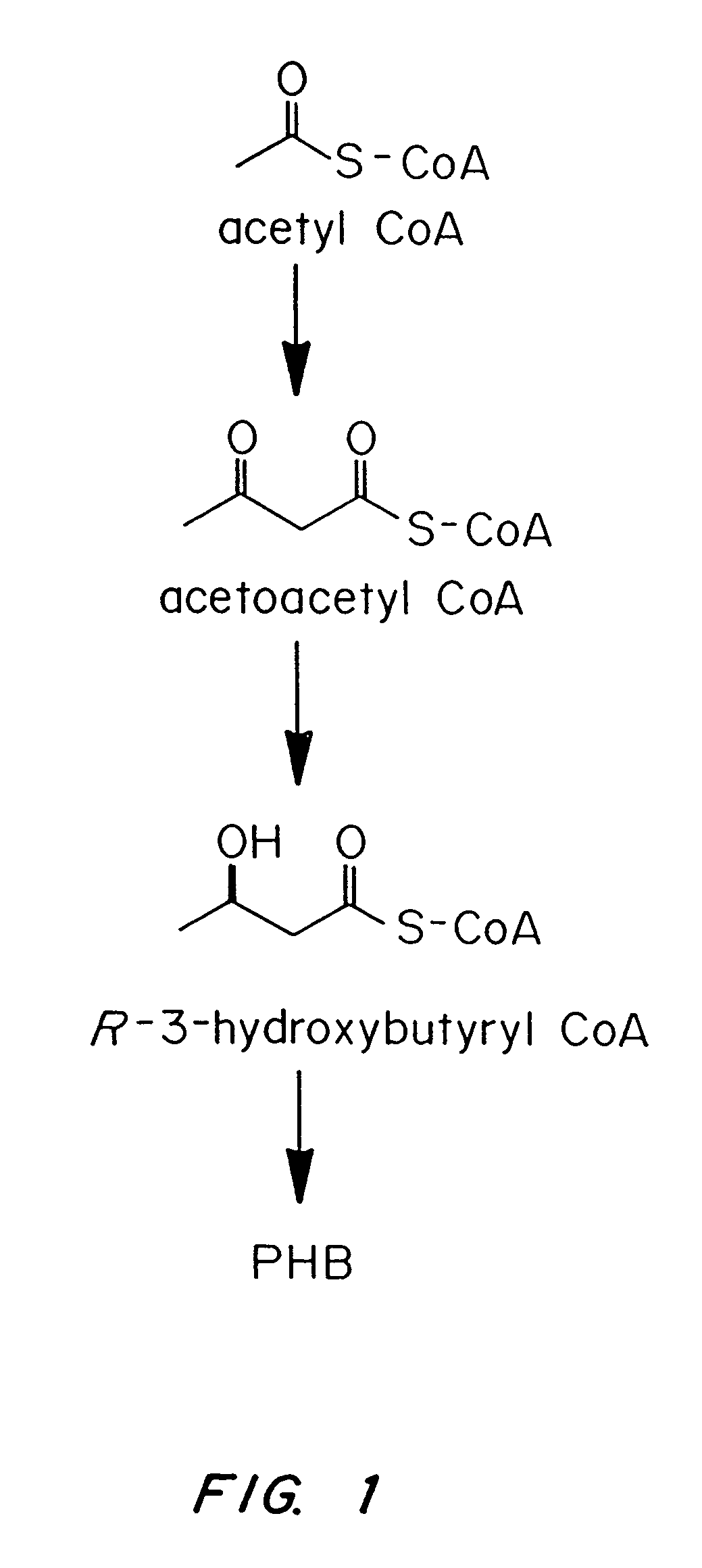

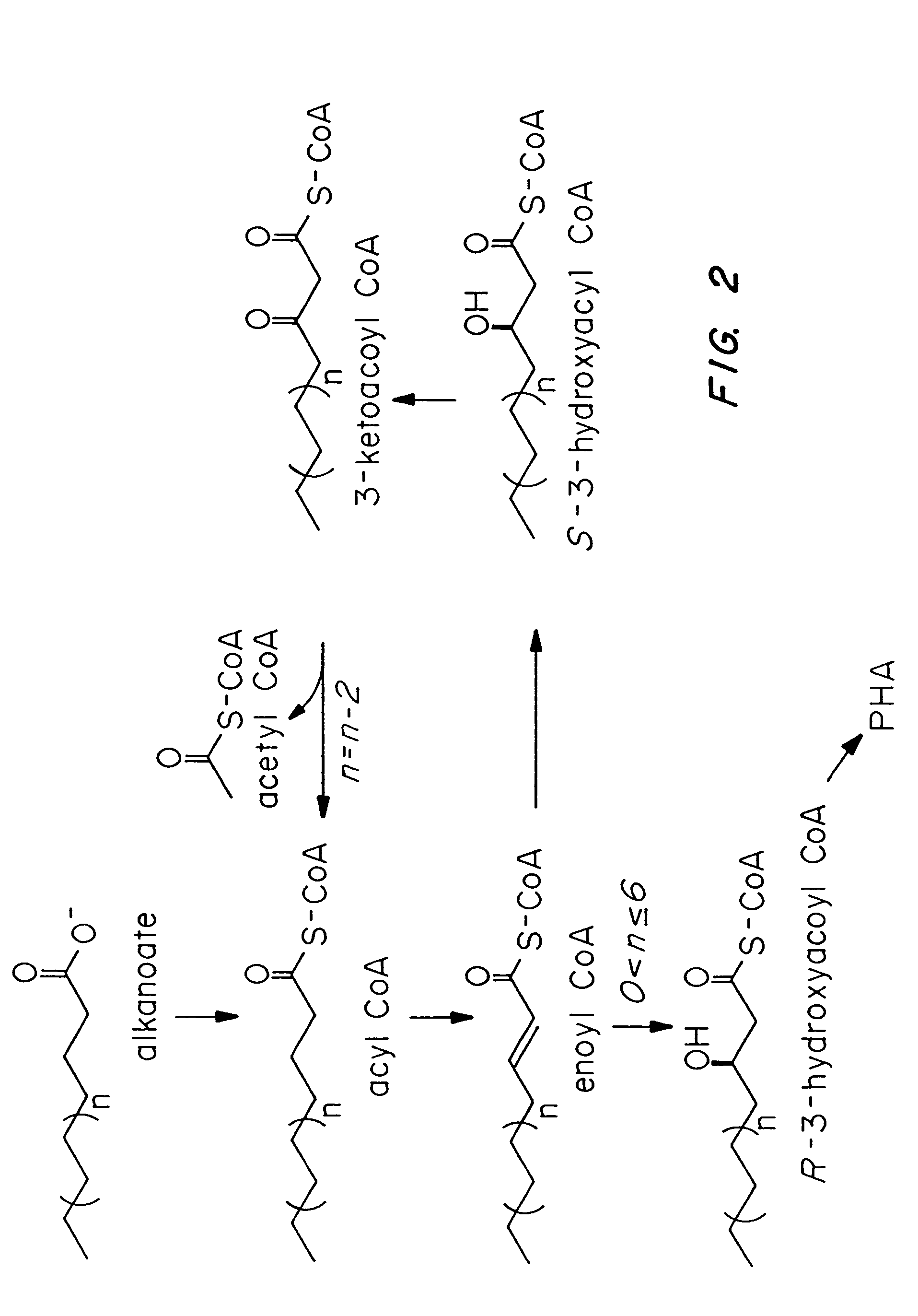

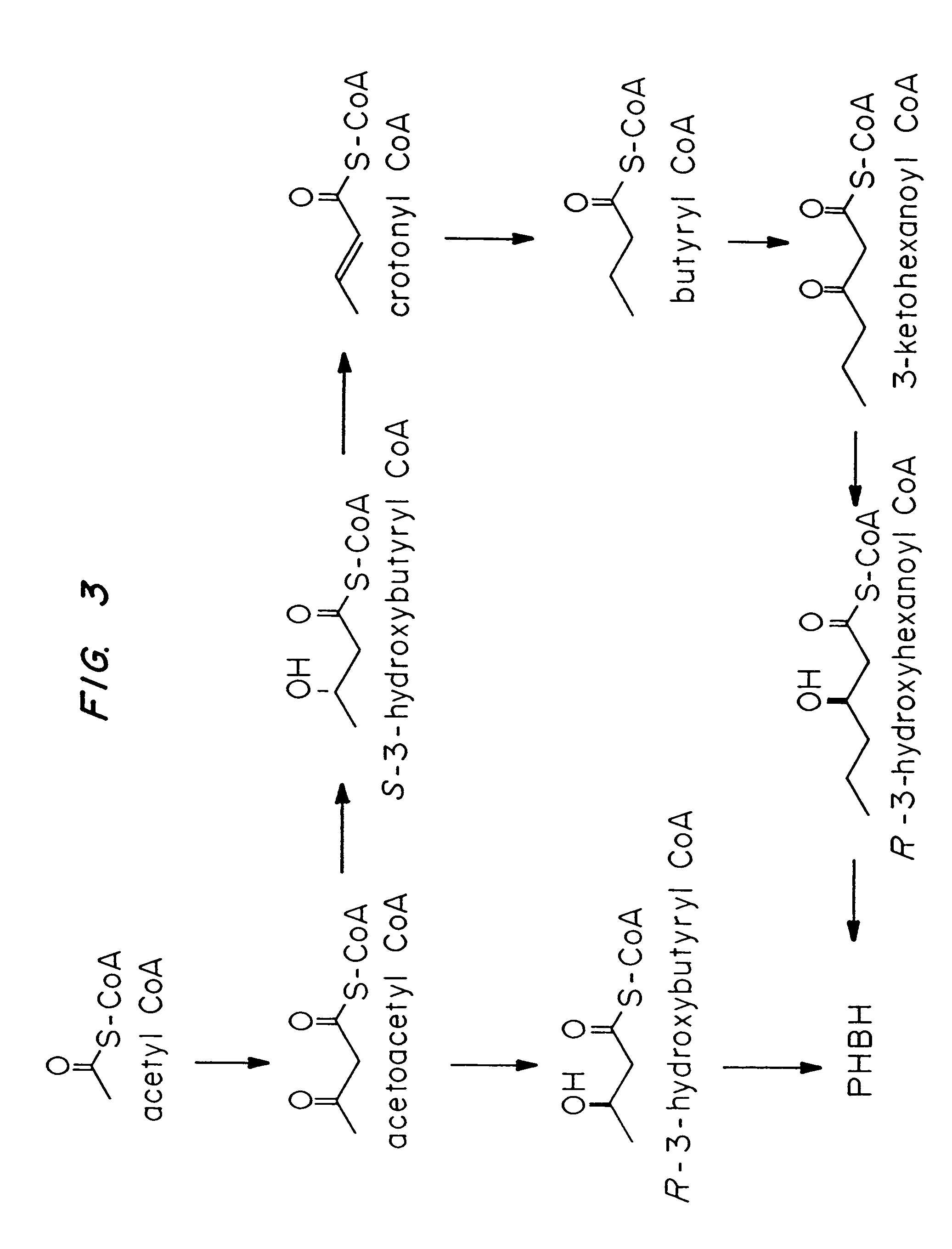

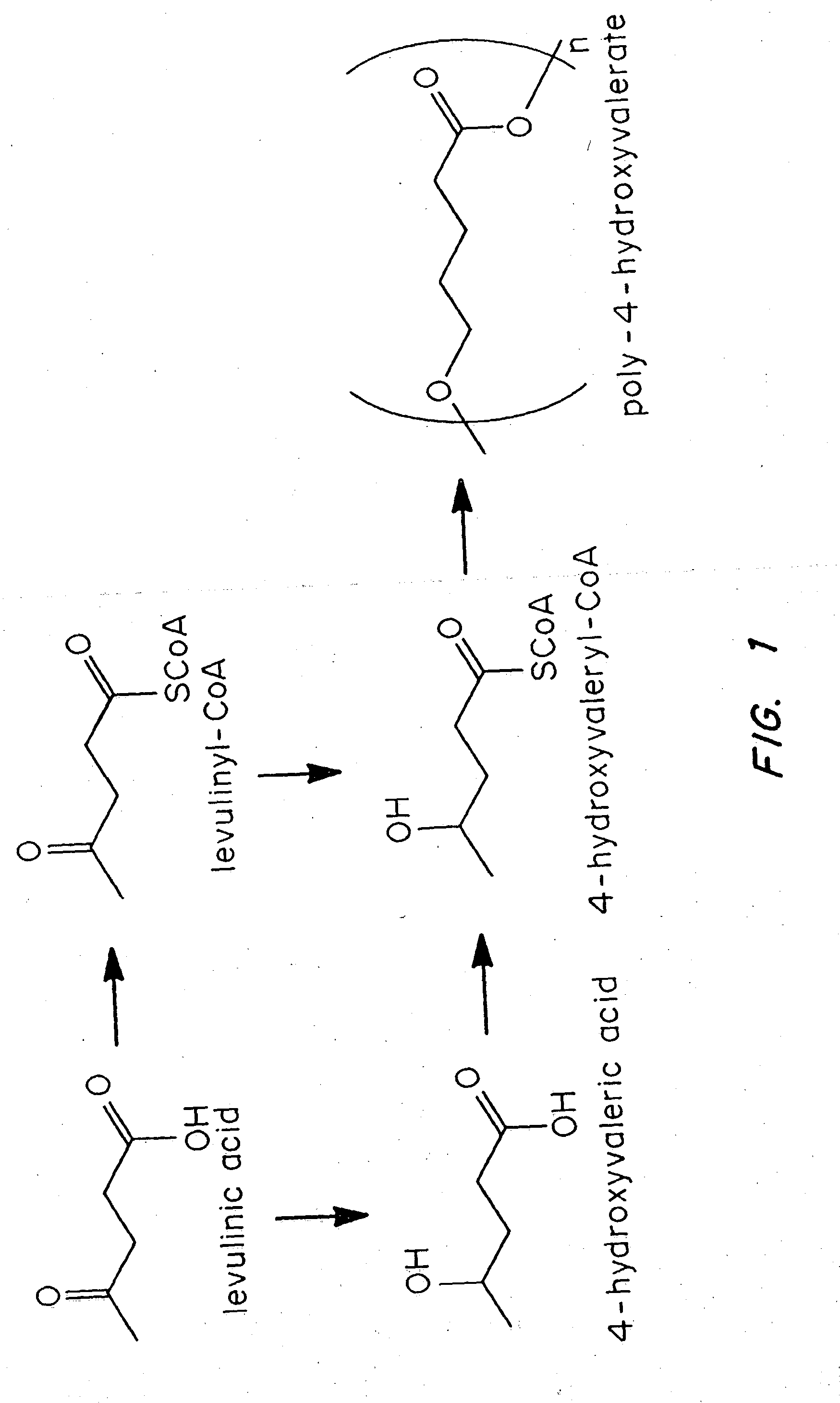

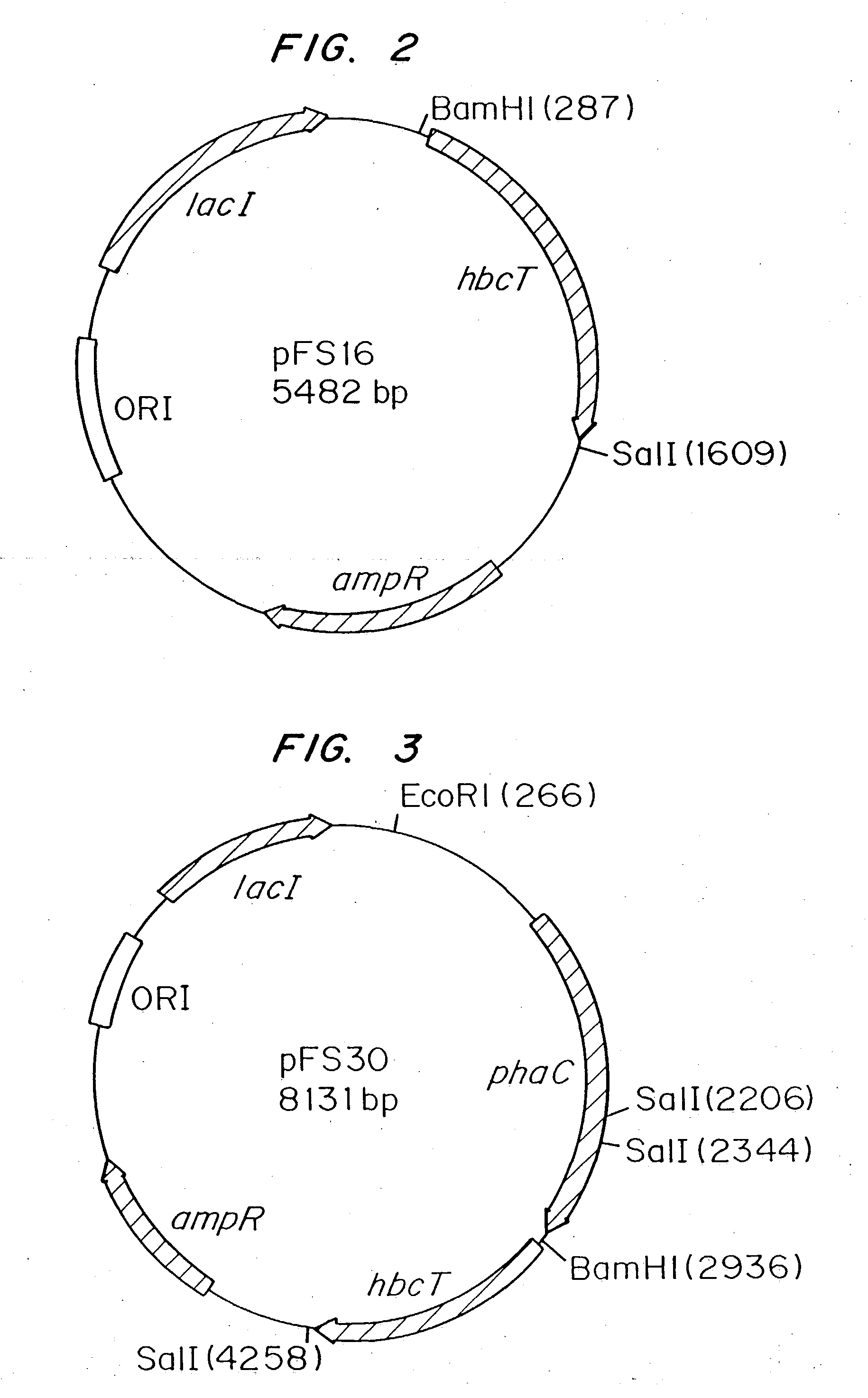

Methods for engineering transgenic organisms that synthesize polyhydroxyalkanoates (PHAs) containing 3-hydroxyhexanoate as comonomer have been developed. These processes are based on genetically engineered bacteria such as Escherichia coli or in plant crops as production systems which include PHA biosynthetic genes from PHA producers. In a preferred embodiment of the method, additional genes are introduced in wild type or transgenic polyhydroxybutyrate (PHB) producers, thereby creating new strains that synthesize 3HH monomers which are incorporated into PHAs. The 3HH monomer preferably is derived in microbial systems using butanol or butyrate as feedstocks, which are precursors of 3-hydroxyhexanoyl-CoA. Pathways for in vivo production of butyrol-CoA specifically encompassing butyryl-CoA dehydrogenase activity are provided.

Owner:METABOLIX

Transgenic systems for the manufacture of poly(2-hydroxy-butyrate-co-3-hydroxyhexanoate)

InactiveUS7504556B2ProductionHigh speedBacteriaMicroorganism based processesEscherichia coliBacteroides

Owner:CJ CHEILJEDANG CORP

Fibers, nonwoven fabrics and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate

InactiveUS6143947AProtect and promote and control plant growthHigh elongationEngine sealsBaby linensPolymer scienceBiodegradable copolymers

The present invention relates to fibers, and nonwovens comprising said fibers, comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above fibers and / or nonwovens, and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

Films and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate comonomer units

InactiveUS6027787AEasily processed into filmPromote degradationSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to a film comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above film, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Elastomer composition, method for producing the same, and eraser using the same

An elastomer composition is provided which contains a matrix of poly-(3-hydroxybutyrate-co-3-hydroxyhexanoate) produced from microorganisms and crosslinked natural rubber particles dispersed like islands in the matrix. An eraser using the elastomer composition is also provided. The present invention is capable of providing an elastomer composition and eraser using the same, which can be recycled, are friendly to the environment, and corresponds to the recycling society, without relying on fossil resources.

Owner:SEED CO LTD

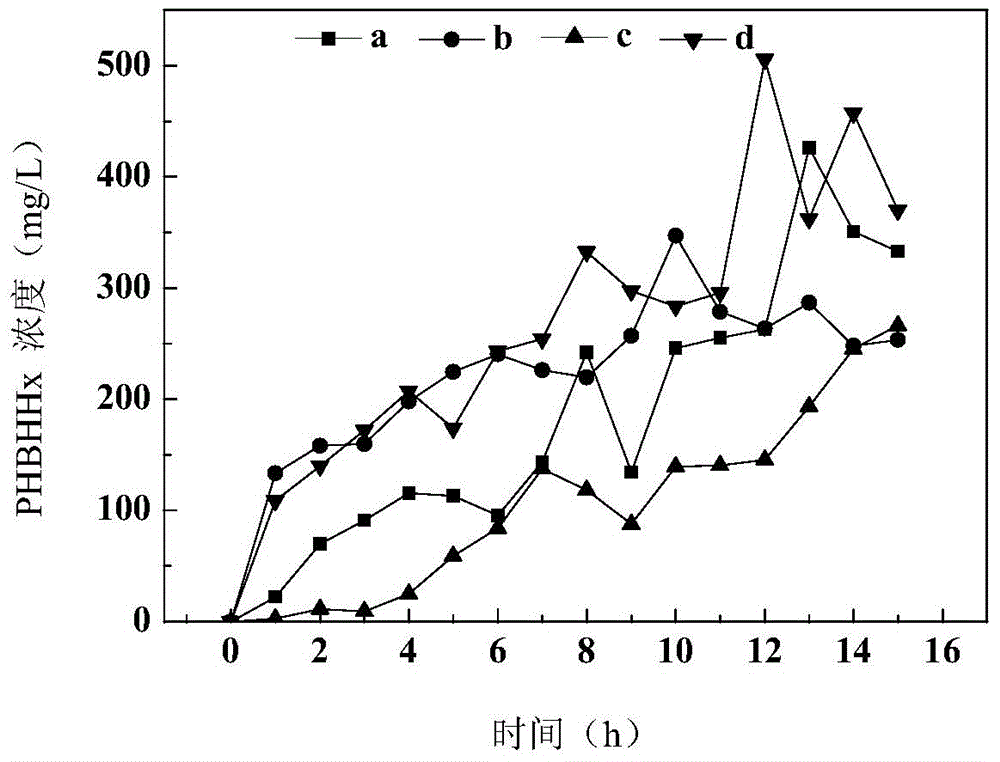

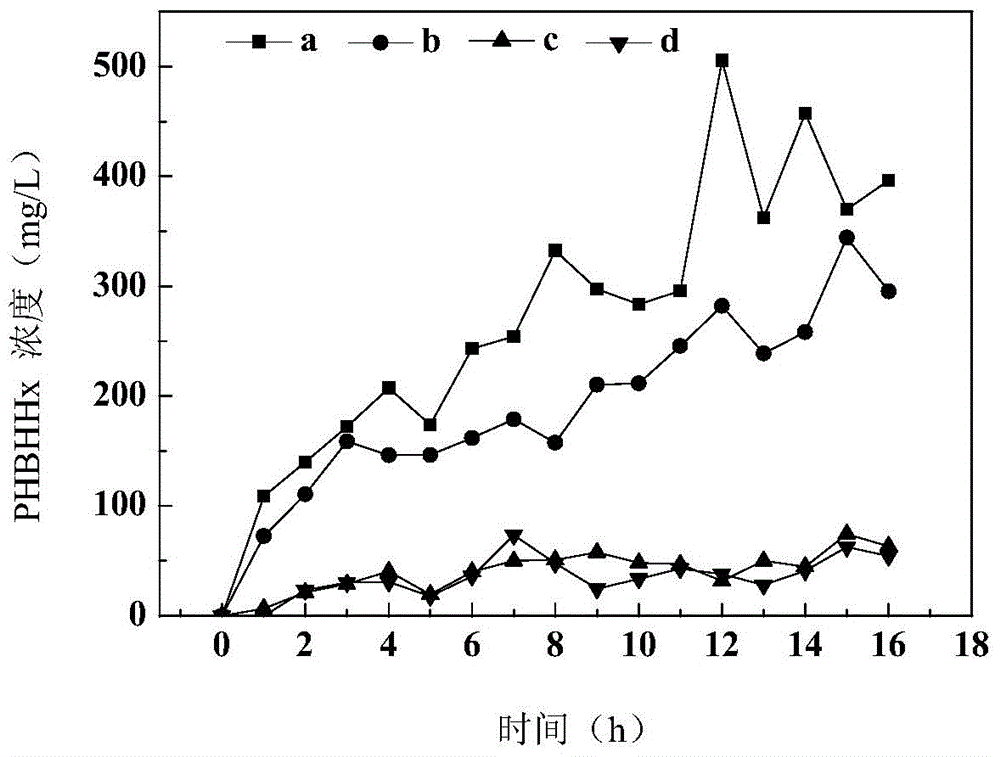

Method for producing medium-chain-length polyhydroxyalkanoates by virtue of excess activated sludge

The invention discloses a method for producing medium-chain-length polyhydroxyalkanoates by virtue of excess activated sludge, and relates to polyhydroxyalkanoates. The method comprises the following steps: using sodium laurate as a unique substrate carbon source for domesticating original sludge, and synthesising poly-3-hydroxybutyrate-co-3-hydroxyhexanoate by virtue of the stably-domesticated activated sludge, wherein 1.5g / L sodium laurate is uniformly poured for three times while being used as the unique substrate, and the highest concentration of cumulative PHBHHx of the sludge is 505.5mg / L under a continuous aeration condition and in case of nitrogen deficiency and phosphorus deficiency; the PHBHHx are synthesised by virtue of activated sludge mixed micro-organisms for the first time, and an infrared absorption spectrum and thermogravimetric analysis proves that PHBHHx samples have chemical structures and physical properties similar to those of PHBHHx standard substances synthesised from pure strains. The method is simple in equipment, easy to operate, free from a sterile working condition and rich in excess sludge source, and therefore has a great application prospect in the aspect of producing plastic products needed in the industry and the agriculture.

Owner:XIAMEN UNIV

Polyhydroxyalkanoate biopolymer compositions

Several novel PHA polymer compositions produced using biological systems include monomers such as 3-hydroxybutyrate, 3-hydroxypropionate, 2-hydroxybutyrate, 3-hydroxyvalerate, 4-hydroxybutyrate, 4-hydroxyvalerate and 5-hydroxyvalerate. These PHA compositions can readily be extended to incorporate additional monomers including, for example, 3-hydroxyhexanoate, 4-hydroxyhexanoate, 6-hydroxyhexanoate or other longer chain 3-hydroxyacids containing seven or more carbons. This can be accomplished by taking natural PHA producers and mutating through chemical or transposon mutagenesis to delete or inactivate genes encoding undesirable activities. Alternatively, the strains can be genetically engineered to express only those enzymes required for the production of the desired polymer composition. Methods for genetically engineering PHA producing microbes are widely known in the art (Huisman and Madison, 1998, Microbiology and Molecular Biology Reviews, 63: 21-53). These polymers have a variety of uses in medical, industrial and other commercial areas.

Owner:CJ CHEILJEDANG CORP

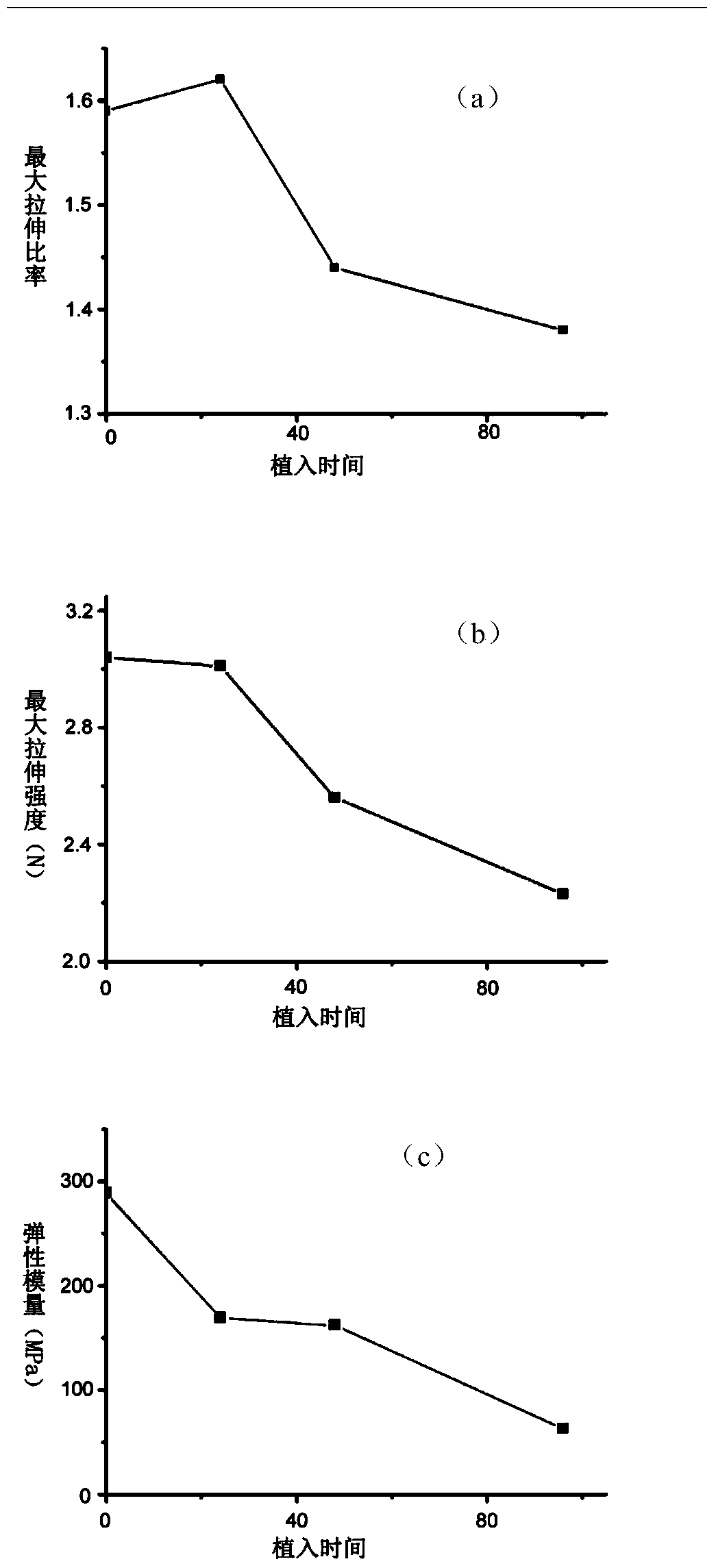

Absorbable suture containing PHBHHx/PLA (poly-3-hydroxybutyrate-co-3-hydroxyhexanoate/polylactic acid)

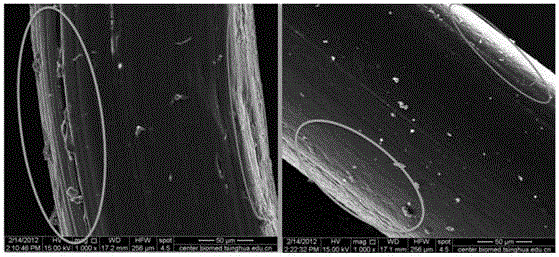

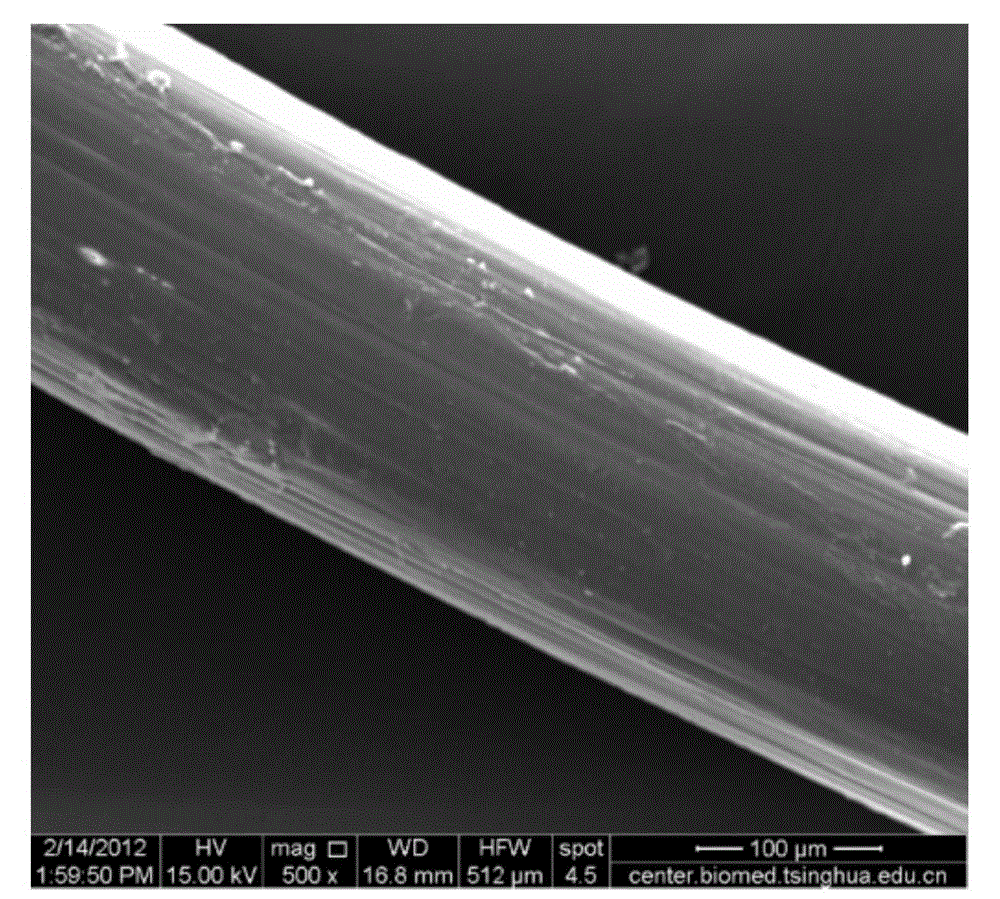

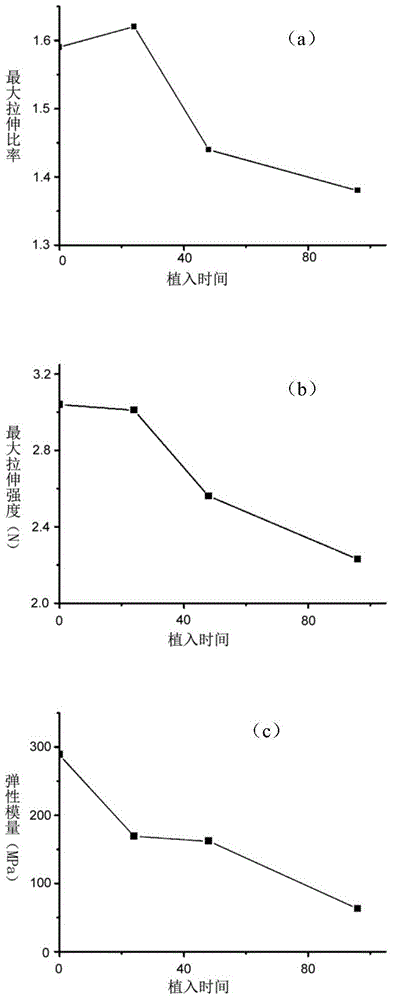

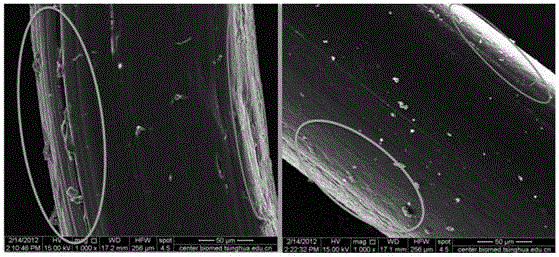

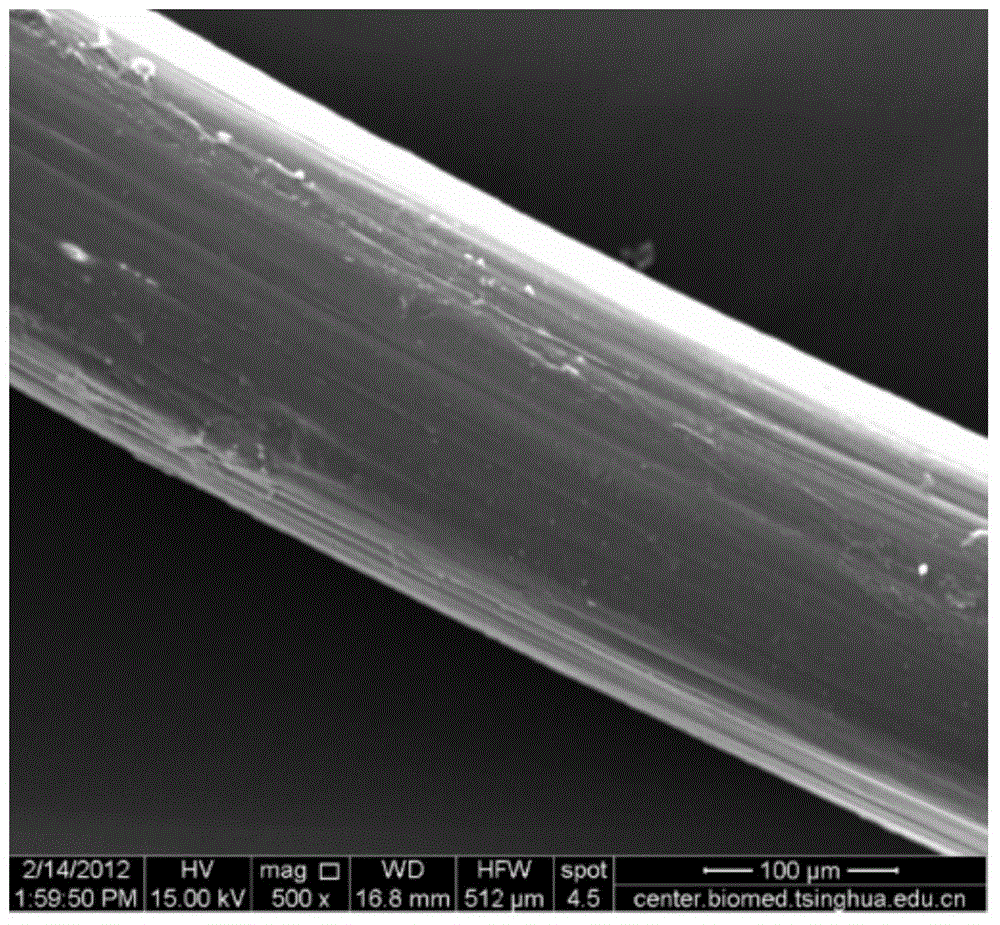

InactiveCN105063789AHigh mechanical strengthEasy to holdSuture equipmentsMonocomponent copolyesters artificial filamentFiberBiocompatibility Testing

The invention discloses an absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate) (PHBV (Polyhydroxylbutyrate Valerate) or PHBHHx (poly (3-hydroxybutyrate-co-3-hydroxyhexanoate))). The invention specifically discloses a PHBHHx monofilament fiber, a PHBHHx / PLA (Poly Lactic Acid) monofilament fiber and a PHBV / PLA bunched fiber and preparation methods thereof. Blending with the PLA is performed, so that a spinning process is simple, complementary material performance is achieved, and the PHBHHx and the PHBV fibers are good in handfeel. Compared with the conventional material, the absorbable suture has the advantage of higher biocompatibility in the field of nerve and vascular repair due to the use of the PHA material. Moreover, the PHA is high in mechanical strength and slow in degradation speed, so that the PHA is excellent in application effect on the suture repair of cartilages and bone tissues. On the aspect of novel minimally invasive surgical repair, the PHBHHx and the PHBV contain nontoxic and non-irritant degradation products with high compatibility, so that surgical scars can be effectively reduced, and the absorbable suture has an application prospect in esthetic restoration.

Owner:TSINGHUA UNIV

Aqueous Dispersion Of Biodegradable Polyester and Process For Preparing The Same

ActiveUS20060258833A1Maintain strengthWell formedDyeing processPolyester coatingsFiberPolymer science

An aqueous dispersion of a biodegradable polyester, which comprises a copolymer of 3-hydroxybutylate and 3-hydroxyhexanoate having a weight average molecular weight of 50,000 to 3,000,000 and a flexural modulus of 100 to 1500 MPa, wherein the copolymer has an average particle diameter of 0.1 to 50 μm in the aqueous dispersion. The aqueous dispersion of a biodegradable polyester is excellent in film forming characteristics and can provide a resin coating film which is soft, exhibits good elongation and is proof to bending, when it is applied to a coating material, an adhesive agent, fiber texturing, sheet or film processing, paper conversion or the like.

Owner:KANEKA CORP

Methods for producing polyhydroxyalkanoate copolymer with high medium chain length monomer content

Owner:MASSACHUSETTS INST OF TECH

Elastomer composition, method for producing the same, and eraser using the same

An elastomer composition is provided which contains a matrix of poly-(3-hydroxybutyrate-co-3-hydroxyhexanoate) produced from microorganisms and crosslinked natural rubber particles dispersed like islands in the matrix. An eraser using the elastomer composition is also provided.The present invention is capable of providing an elastomer composition and an eraser using the same, which can be recycled, are friendly to the environment, and corresponds to the recycling society, without relying on fossil resources.

Owner:VIEWDLE INC

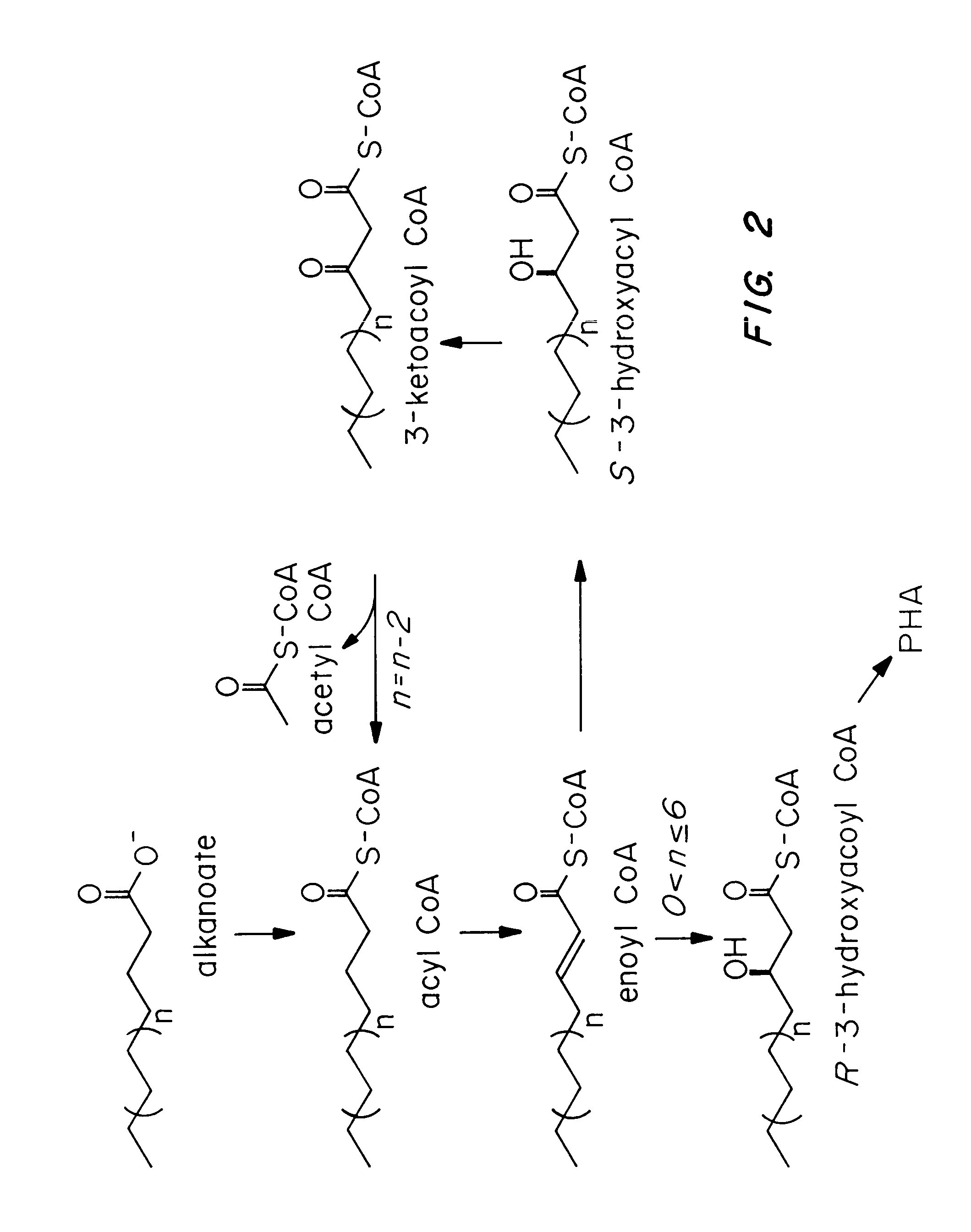

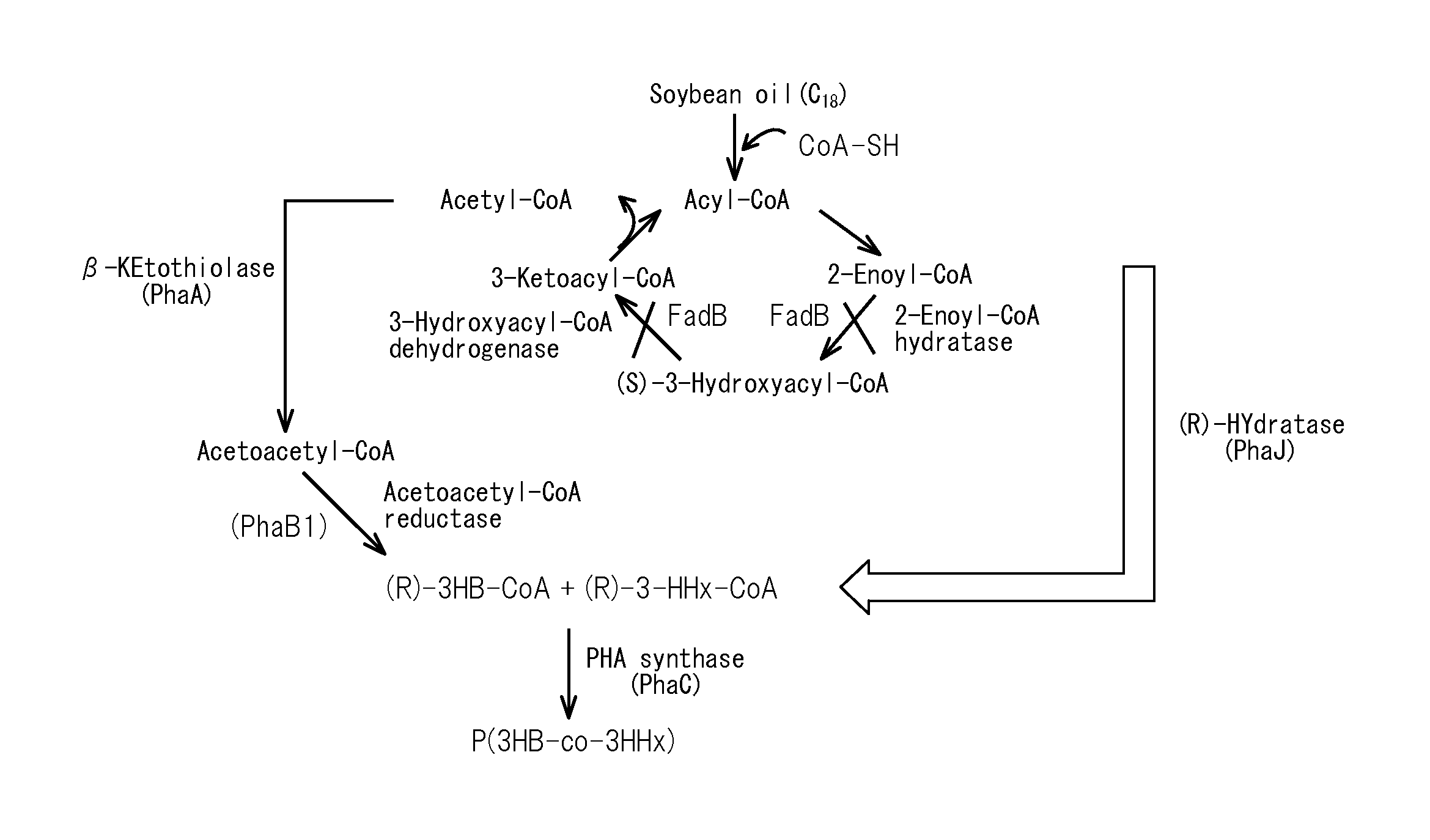

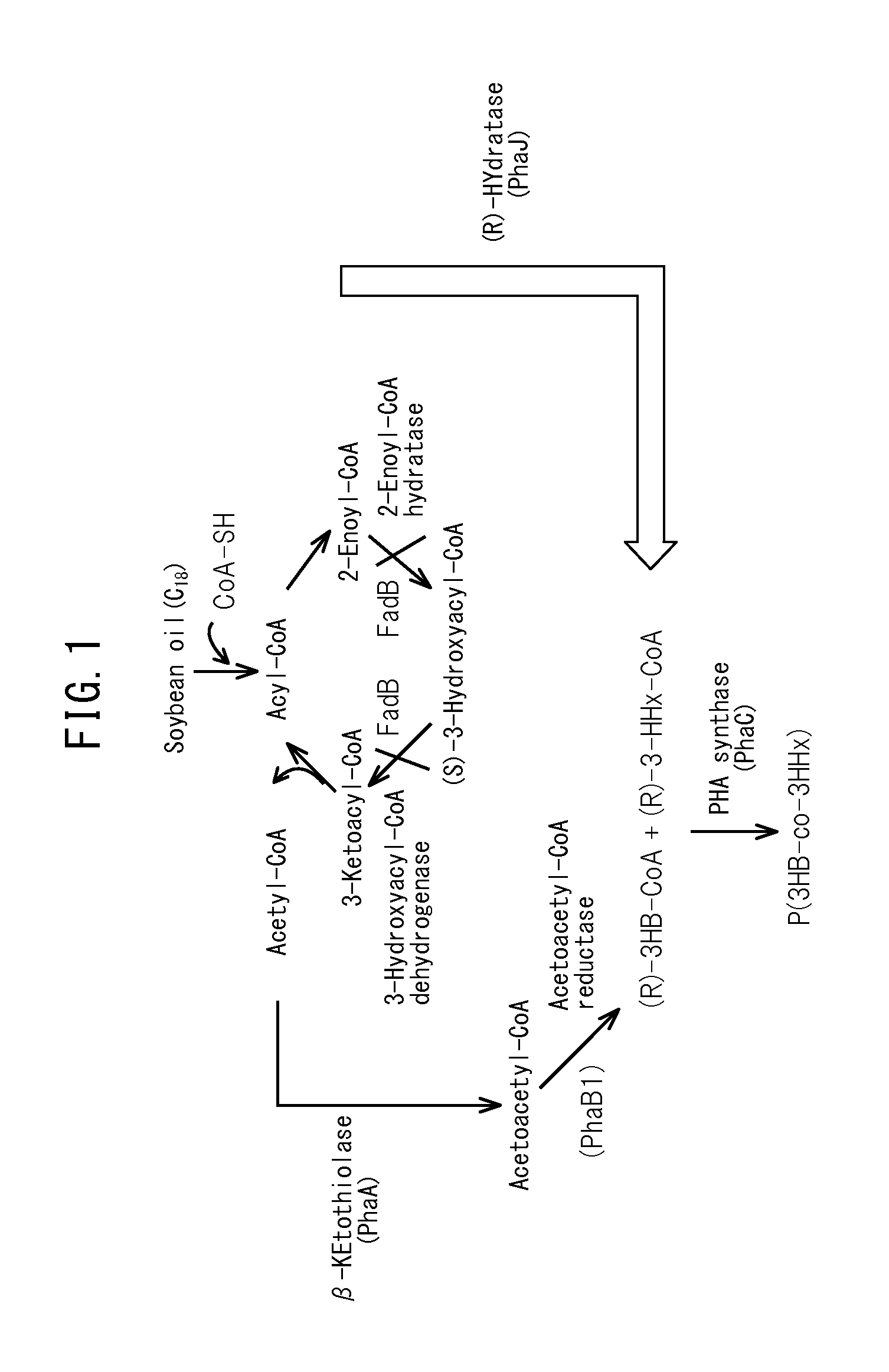

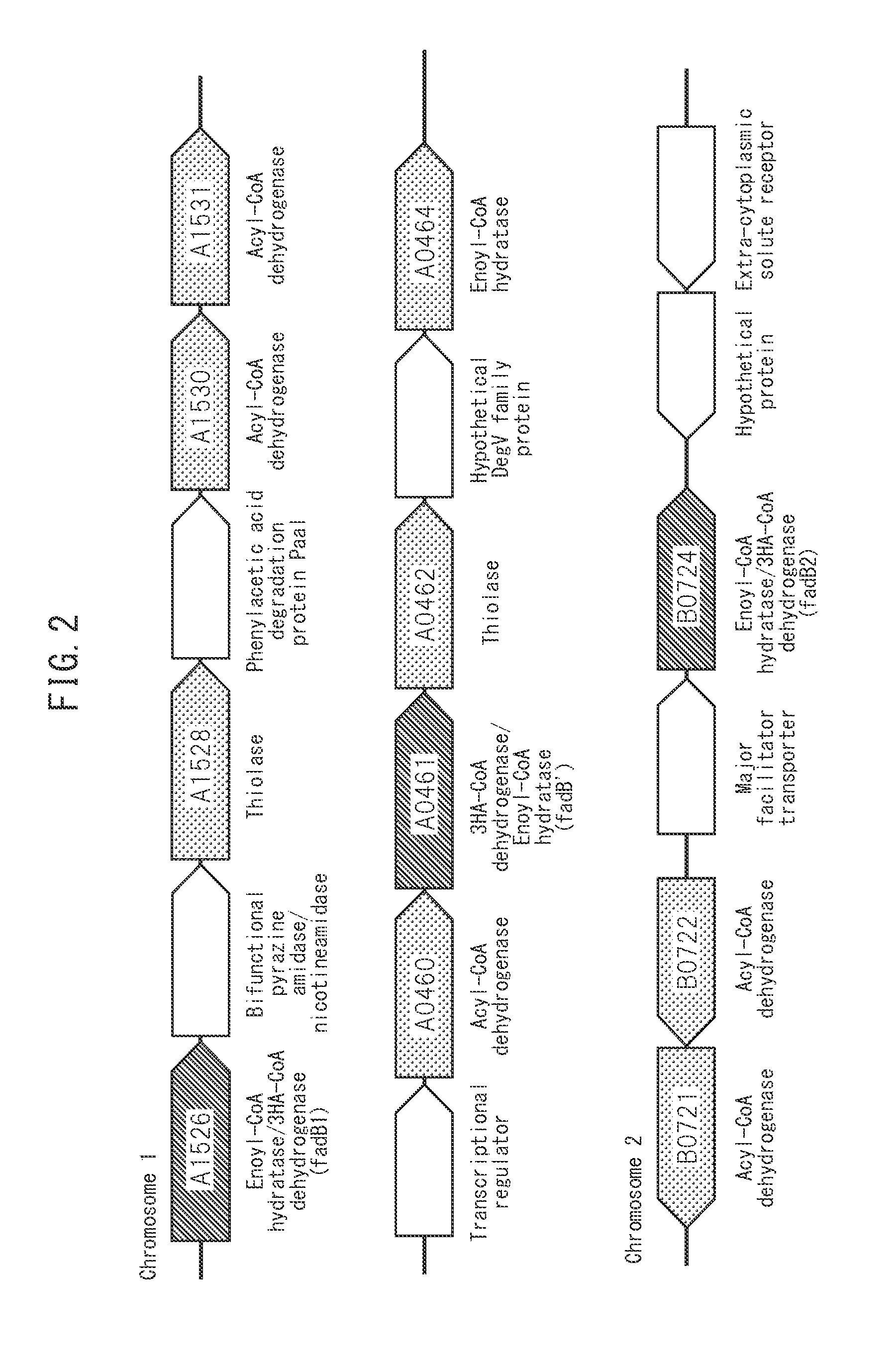

PROCESS FOR PRODUCTION OF POLYHYDROXYALKANOIC ACID USING GENETICALLY MODIFIED MICROORGANISM HAVING ENOYL-CoA HYDRATASE GENE INTRODUCED THEREIN

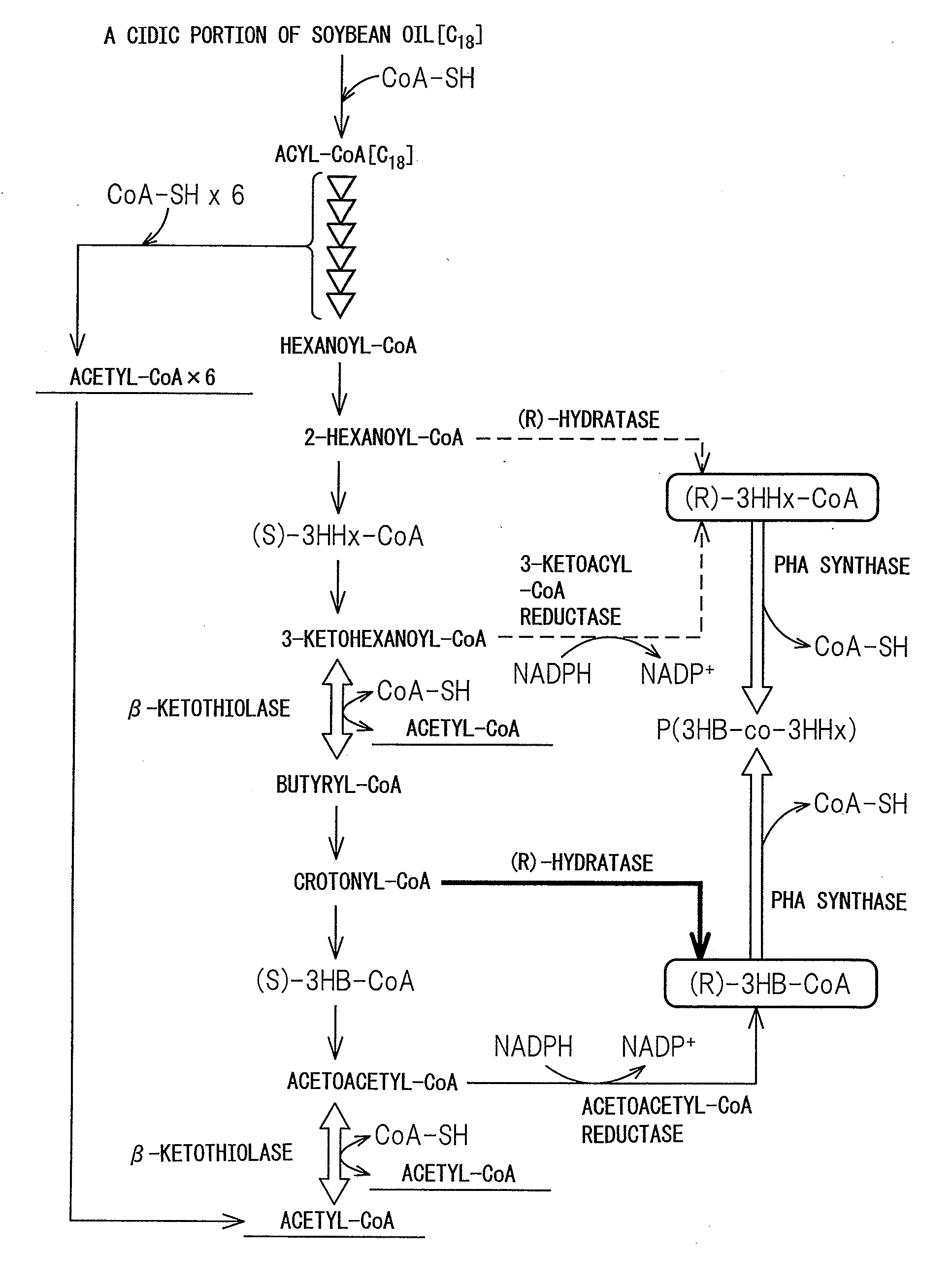

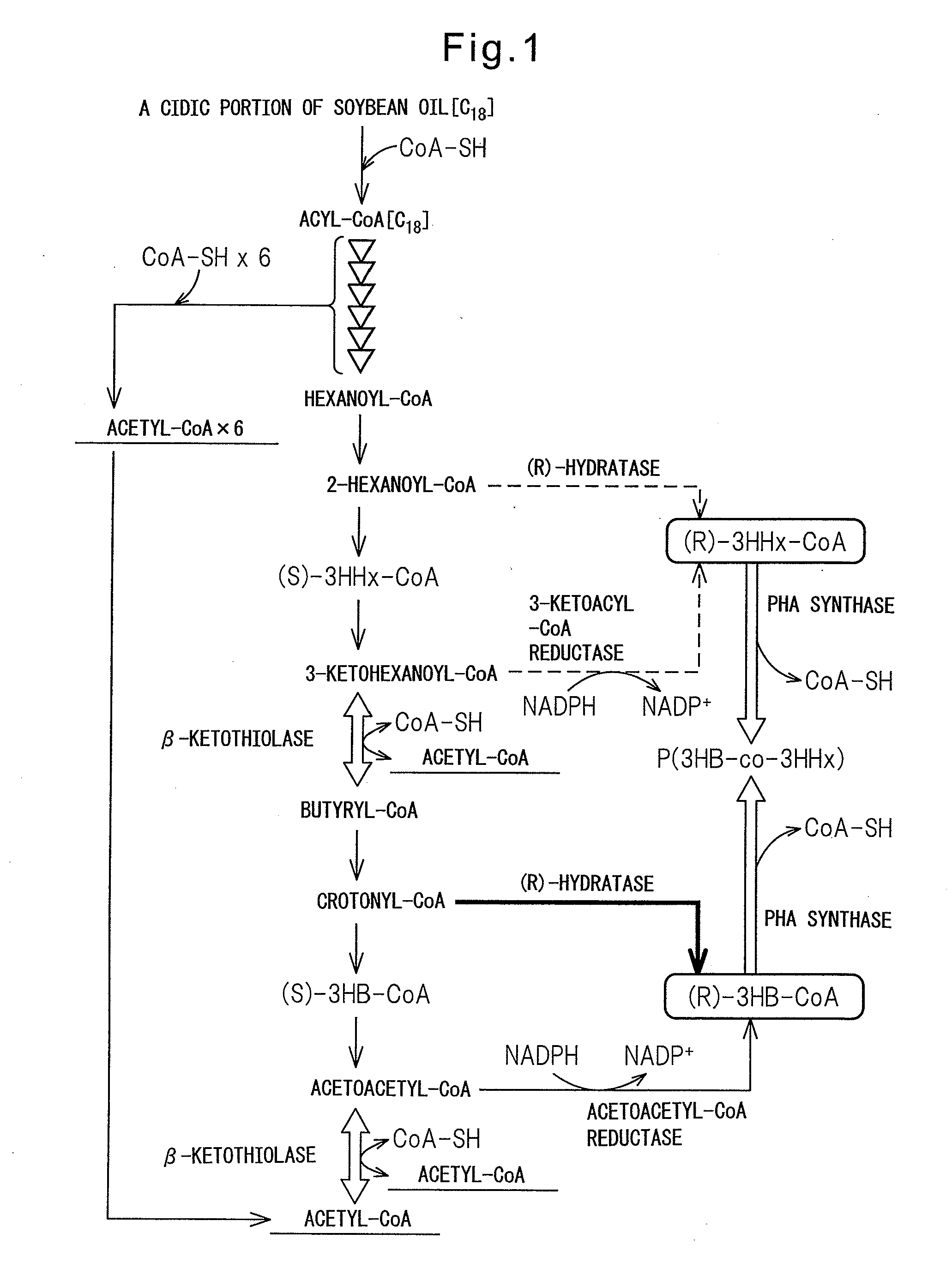

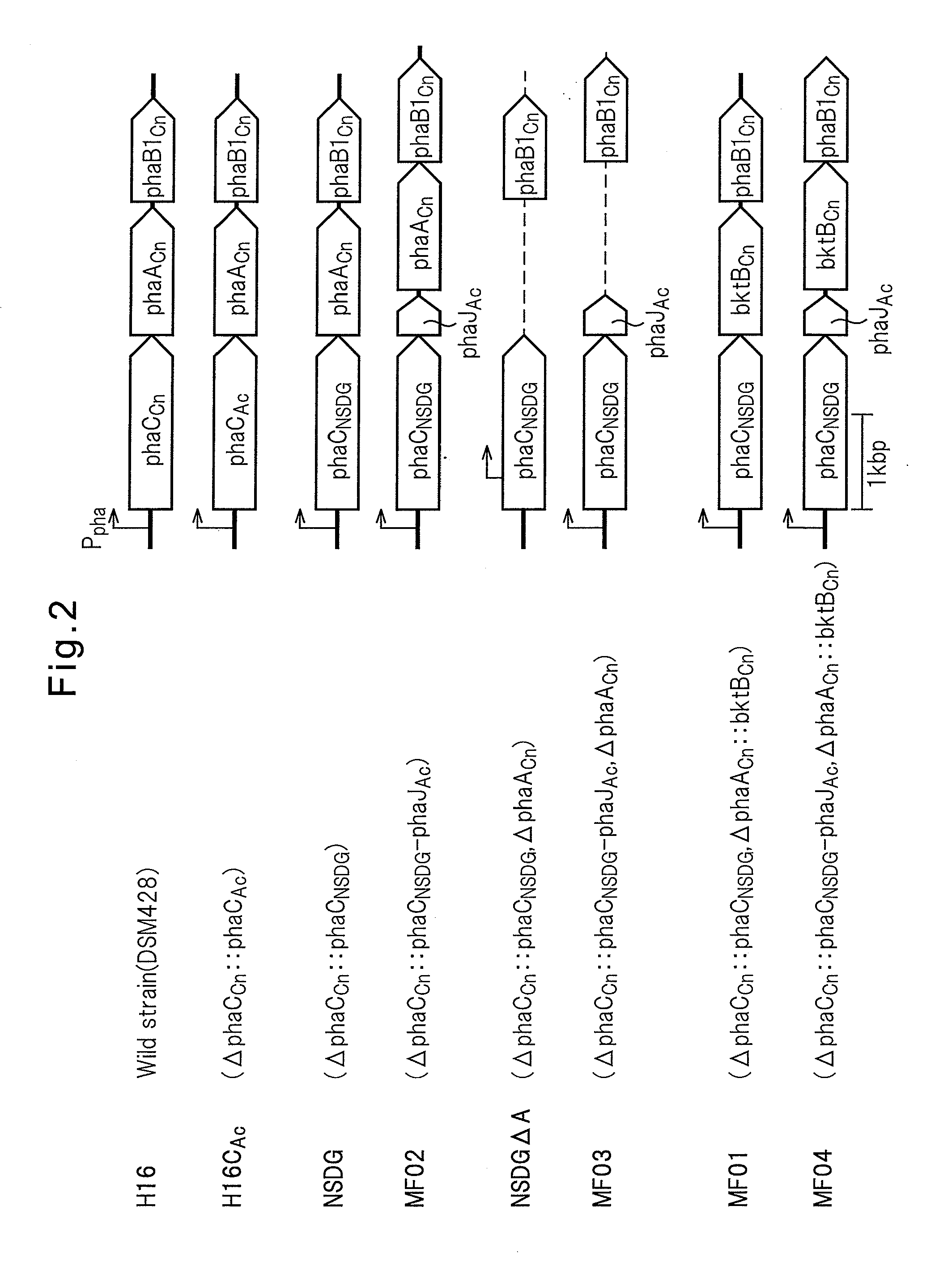

InactiveUS20130071892A1High 3HHx fractionImprove growth performanceFermentationCarbon-oxygen lyasesBiotechnologyVegetable oil

The present invention intends to produce poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) [P(3HB-co-3HHx)] with a high 3-hydroxyhexanoic acid fraction using a vegetable oil as a basic raw material. In accordance with the present invention, there is provided a method of producing a microorganism that produces poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) with a high 3-hydroxyhexanoic acid fraction using a vegetable oil as a basic raw material, by introducing a gene encoding R-hydratase that converts a fatty acid β-oxidation system intermediate to a monomer, (R)-3-hydroxyacyl-CoA [R-3HA-CoA], into a recombinant Cupriavidus necator strain that was conferred an ability of producing P(3HB-co-3HHx).

Owner:TOKYO INST OF TECH

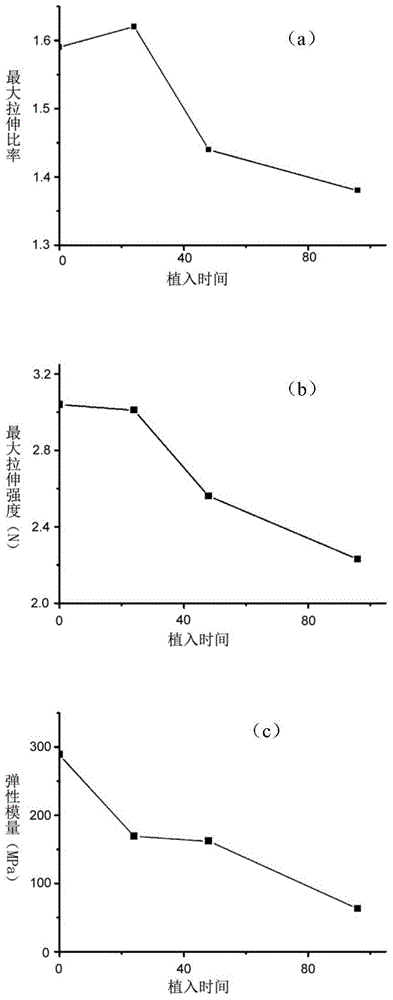

Absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate)

InactiveCN103628174AWith mechanical compatibilityIncrease elasticitySuture equipmentsMonocomponent copolyesters artificial filamentFiberBiocompatibility Testing

The invention discloses an absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate) (PHBV (Polyhydroxylbutyrate Valerate) or PHBHHx (poly (3-hydroxybutyrate-co-3-hydroxyhexanoate))). The invention specifically discloses a PHBHHx monofilament fiber, a PHBHHx / PLA (Poly Lactic Acid) monofilament fiber and a PHBV / PLA bunched fiber and preparation methods thereof. Blending with the PLA is performed, so that a spinning process is simple, complementary material performance is achieved, and the PHBHHx and the PHBV fibers are good in handfeel. Compared with the conventional material, the absorbable suture has the advantage of higher biocompatibility in the field of nerve and vascular repair due to the use of the PHA material. Moreover, the PHA is high in mechanical strength and slow in degradation speed, so that the PHA is excellent in application effect on the suture repair of cartilages and bone tissues. On the aspect of novel minimally invasive surgical repair, the PHBHHx and the PHBV contain nontoxic and non-irritant degradation products with high compatibility, so that surgical scars can be effectively reduced, and the absorbable suture has an application prospect in esthetic restoration.

Owner:TSINGHUA UNIV

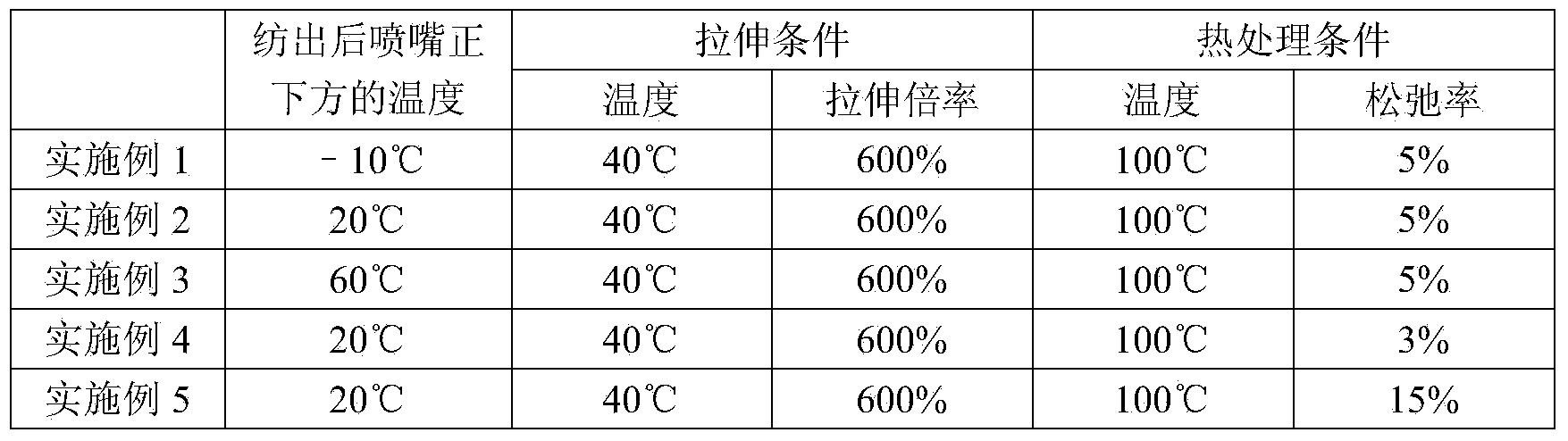

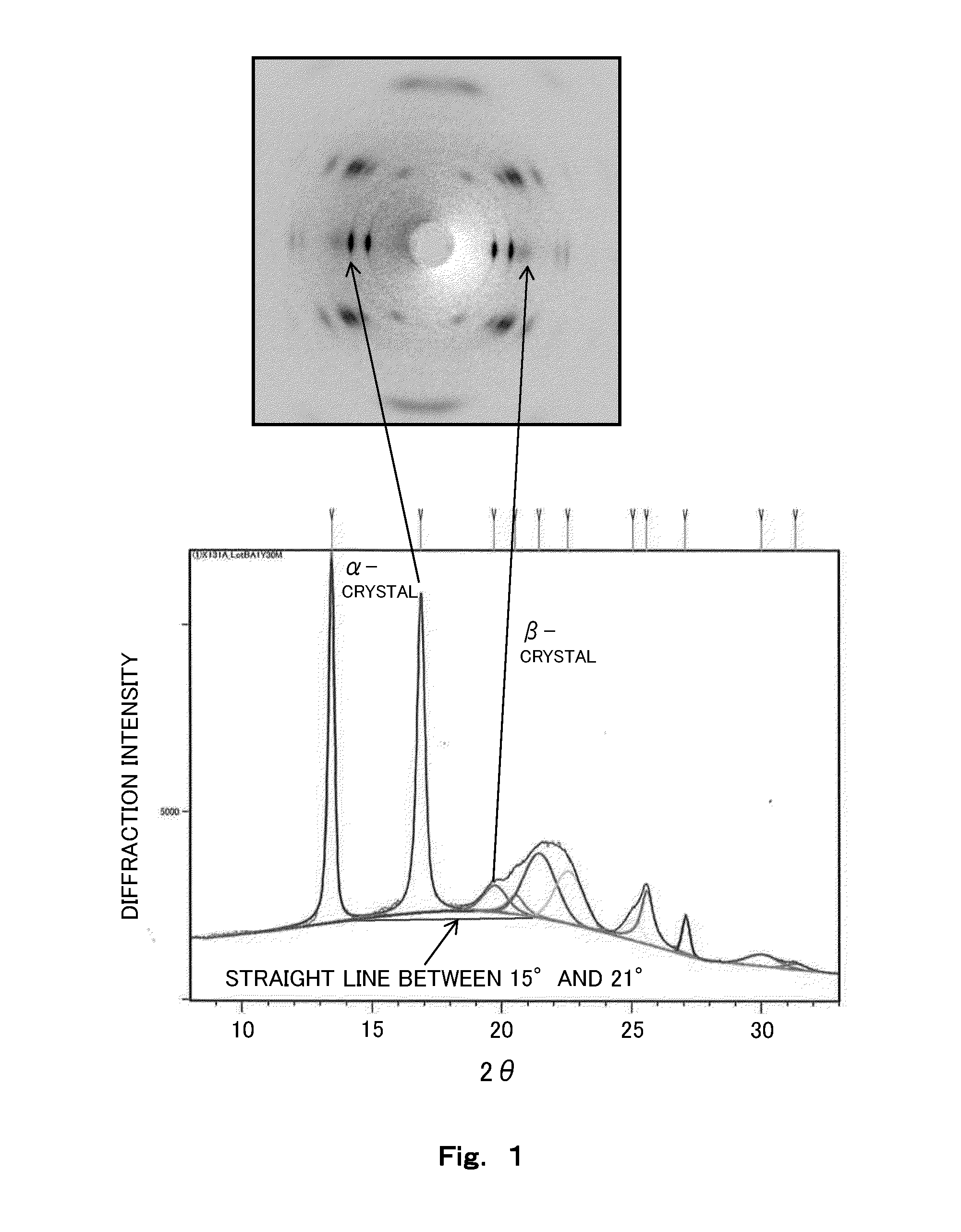

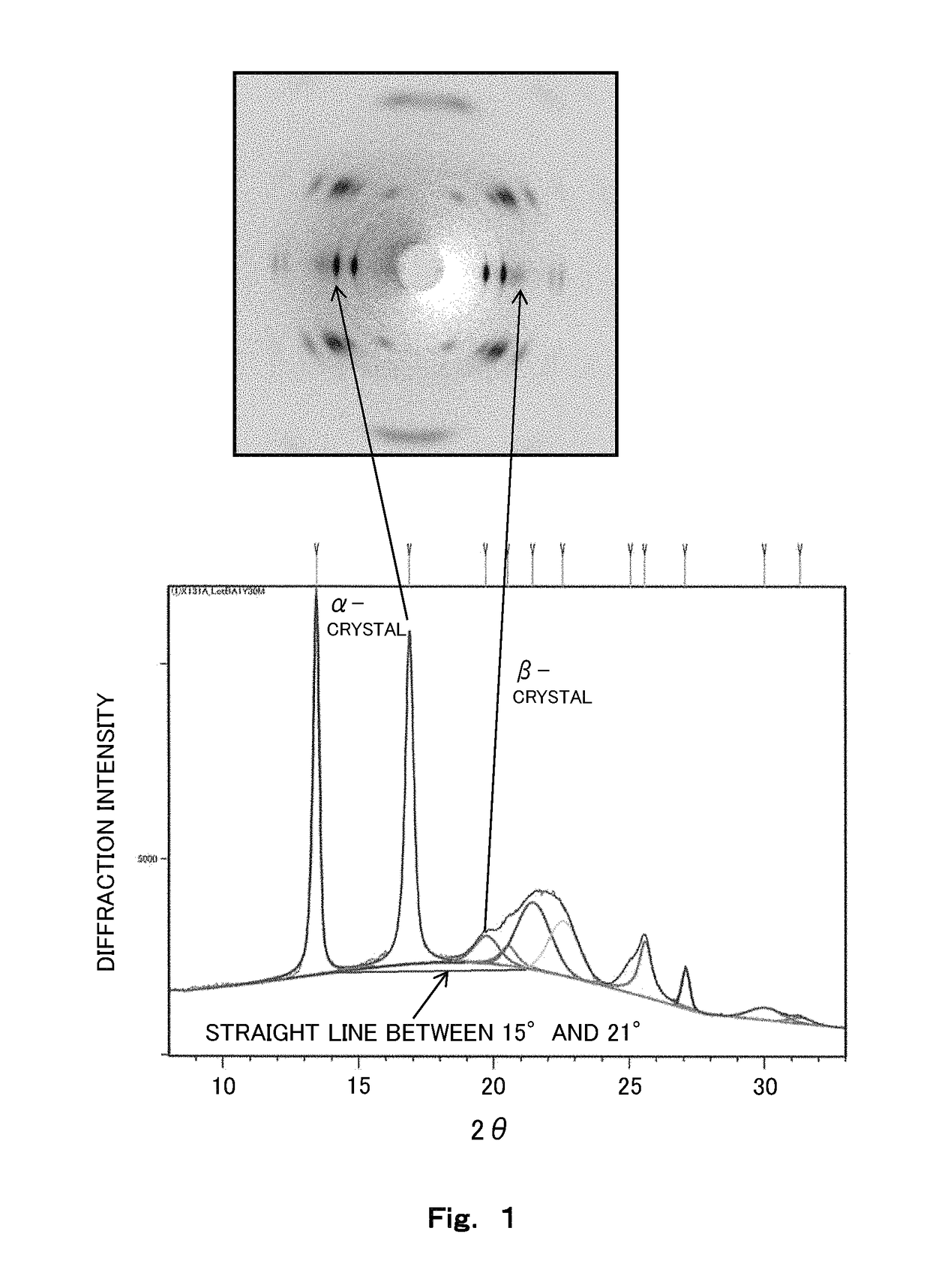

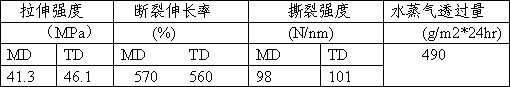

Biodegradable polyester fiber having excellent thermal stability and strength, and method for producing same

InactiveCN103443339ADimensional stabilityHigh fiber strengthMonocomponent copolyesters artificial filamentMelt spinning methodsVitrificationThermal stability

Owner:THE UNIV OF TOKYO +1

PHBV/PLA absorbable suture

InactiveCN105063790AHigh mechanical strengthEasy to holdSuture equipmentsMonocomponent copolyesters artificial filamentFiberAbsorbable suture

The invention discloses an absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate) (PHBV (Polyhydroxylbutyrate Valerate) or PHBHHx (poly (3-hydroxybutyrate-co-3-hydroxyhexanoate))). The invention specifically discloses a PHBHHx monofilament fiber, a PHBHHx / PLA (Poly Lactic Acid) monofilament fiber and a PHBV / PLA bunched fiber and preparation methods thereof. Blending with the PLA is performed, so that a spinning process is simple, complementary material performance is achieved, and the PHBHHx and the PHBV fibers are good in handfeel. Compared with the conventional material, the absorbable suture has the advantage of higher biocompatibility in the field of nerve and vascular repair due to the use of the PHA material. Moreover, the PHA is high in mechanical strength and slow in degradation speed, so that the PHA is excellent in application effect on the suture repair of cartilages and bone tissues. On the aspect of novel minimally invasive surgical repair, the PHBHHx and the PHBV contain nontoxic and non-irritant degradation products with high compatibility, so that surgical scars can be effectively reduced, and the absorbable suture has an application prospect in esthetic restoration.

Owner:TSINGHUA UNIV

Biodegradable polyester fiber having excellent thermal stability and strength, and method for producing same

InactiveUS20140088288A1High fiber strengthImprove thermal stabilityMonocomponent copolyesters artificial filamentMelt spinning methodsGlass transitionBiodegradable polyester

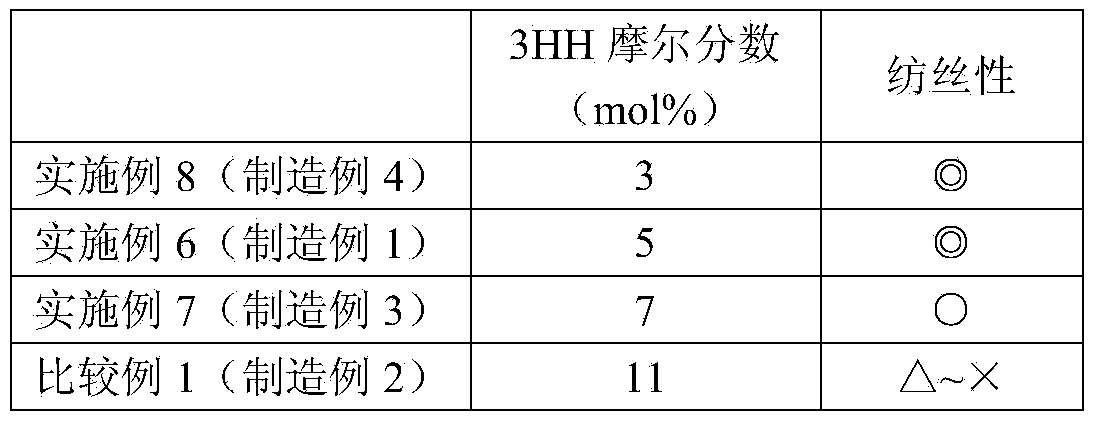

The present invention aims to provide biodegradable polyester fibers excellent in thermal stability and fiber strength. Another aim is to provide a method for producing biodegradable polyester fibers excellent in mechanical properties, particularly in thermal stability. The present invention relates to biodegradable polyester fibers comprising a poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) that has a 3HH molar fraction of 2 to 9 mol %. The present invention also relates to a method for producing the biodegradable polyester fibers, comprising a fiber forming step of melt-extruding a poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) to form fibers at a temperature higher than or equal to the glass transition temperature of the poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) but not higher than 70° C.

Owner:THE UNIV OF TOKYO +1

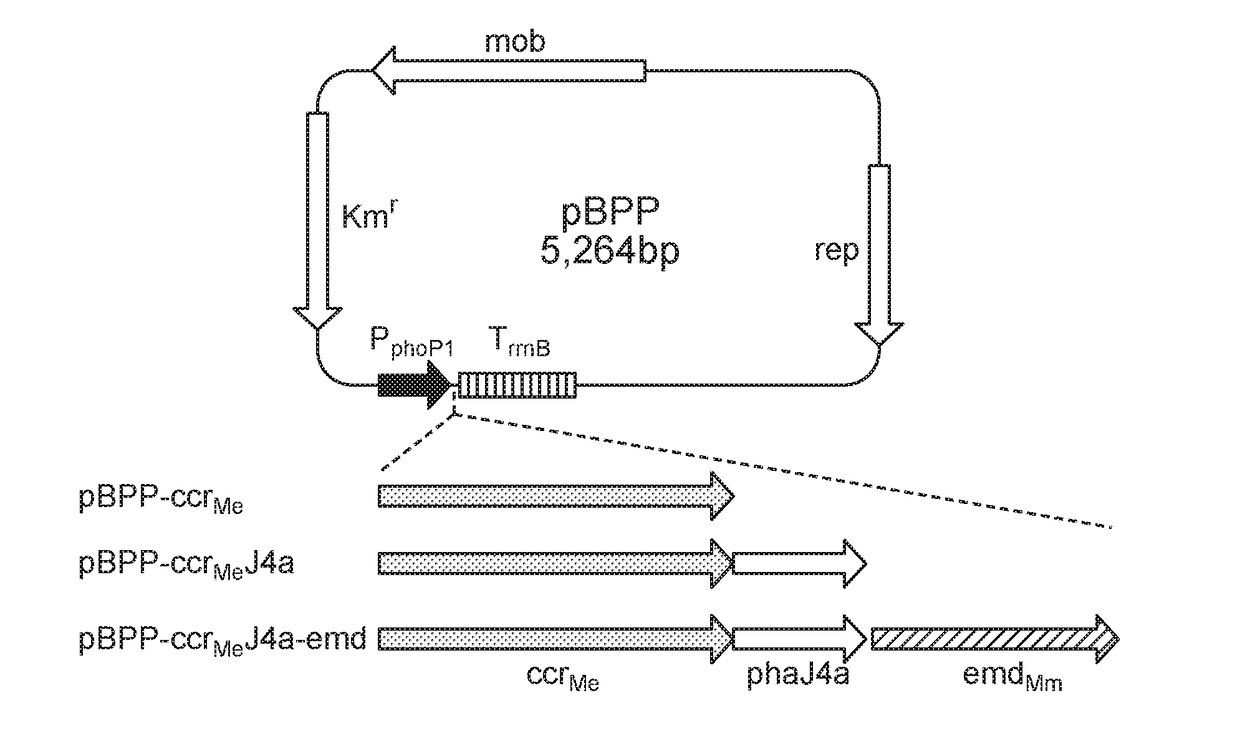

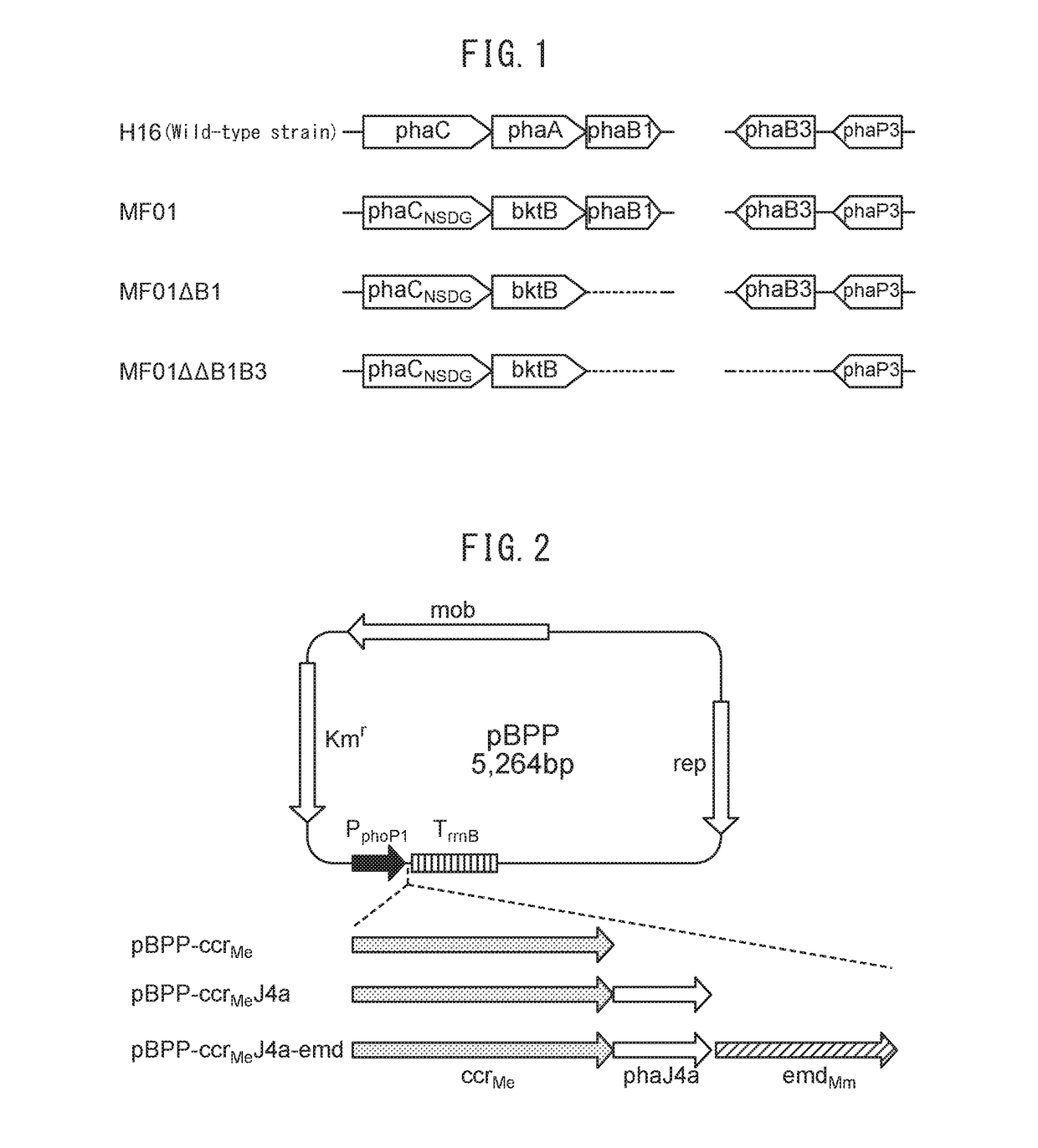

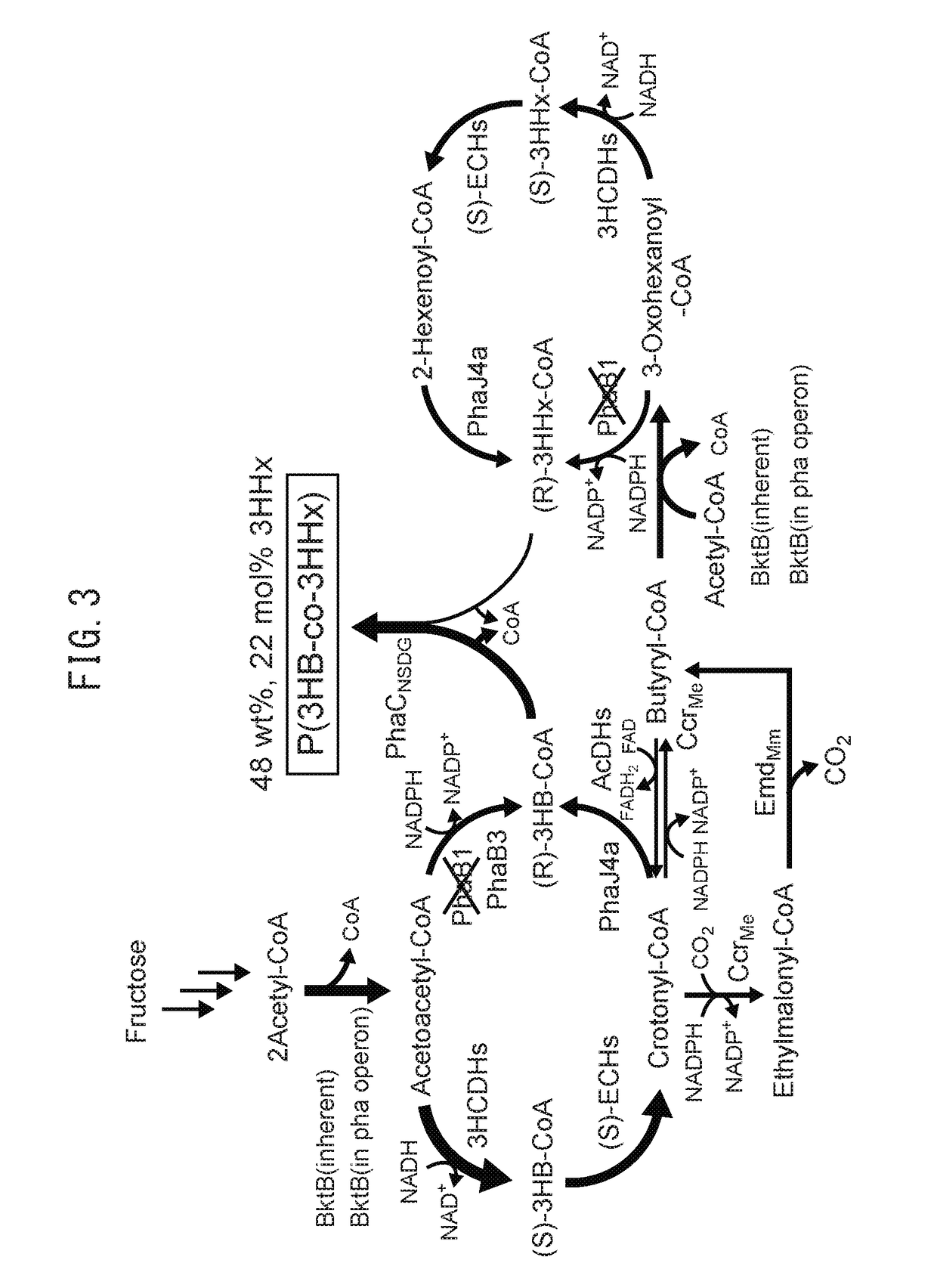

Method for producing polyhydroxyalkanoate copolymer from saccharide raw material

ActiveUS20170218411A1Increase productionEnhancing the fraction of 3HHxOxidoreductasesFermentationGlycerolCopolymer

The purpose of the present invention is to provide a method for enhancing the production quantity of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (P(3HB-co-3HH)) having a high fraction of 3-hydroxyhexanoate (3HH) using a saccharide or glycerol as a starting material. The present invention provides: a method for producing a P(3HB-co-3HH) copolymer including performing transformation by homologous recombination of a crotonyl-CoA reductase gene in a chromosome of a recombinant strain of Cupriavidus necator endowed with the ability to produce P(3HB-co-3HH), or performing transformation by introducing an autonomous replication vector in which the crotonyl-CoA reductase gene is incorporated in the aforementioned strain, and cultivating the transformant in a medium containing a saccharide or glycerol as a carbon source; and a method for enhancing the production quantity of the copolymer and / or the fraction of 3HHx in the copolymer.

Owner:TOKYO INST OF TECH +1

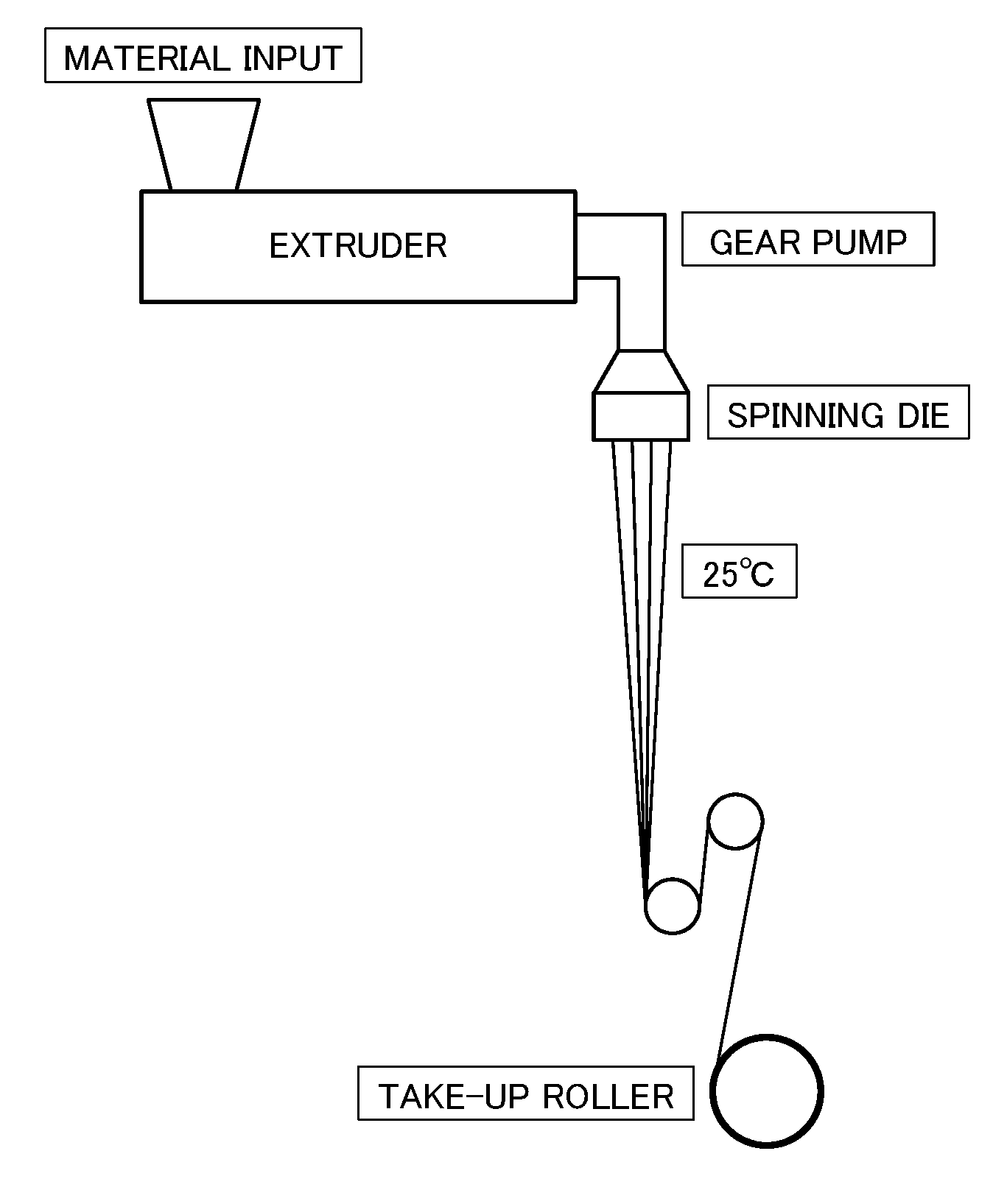

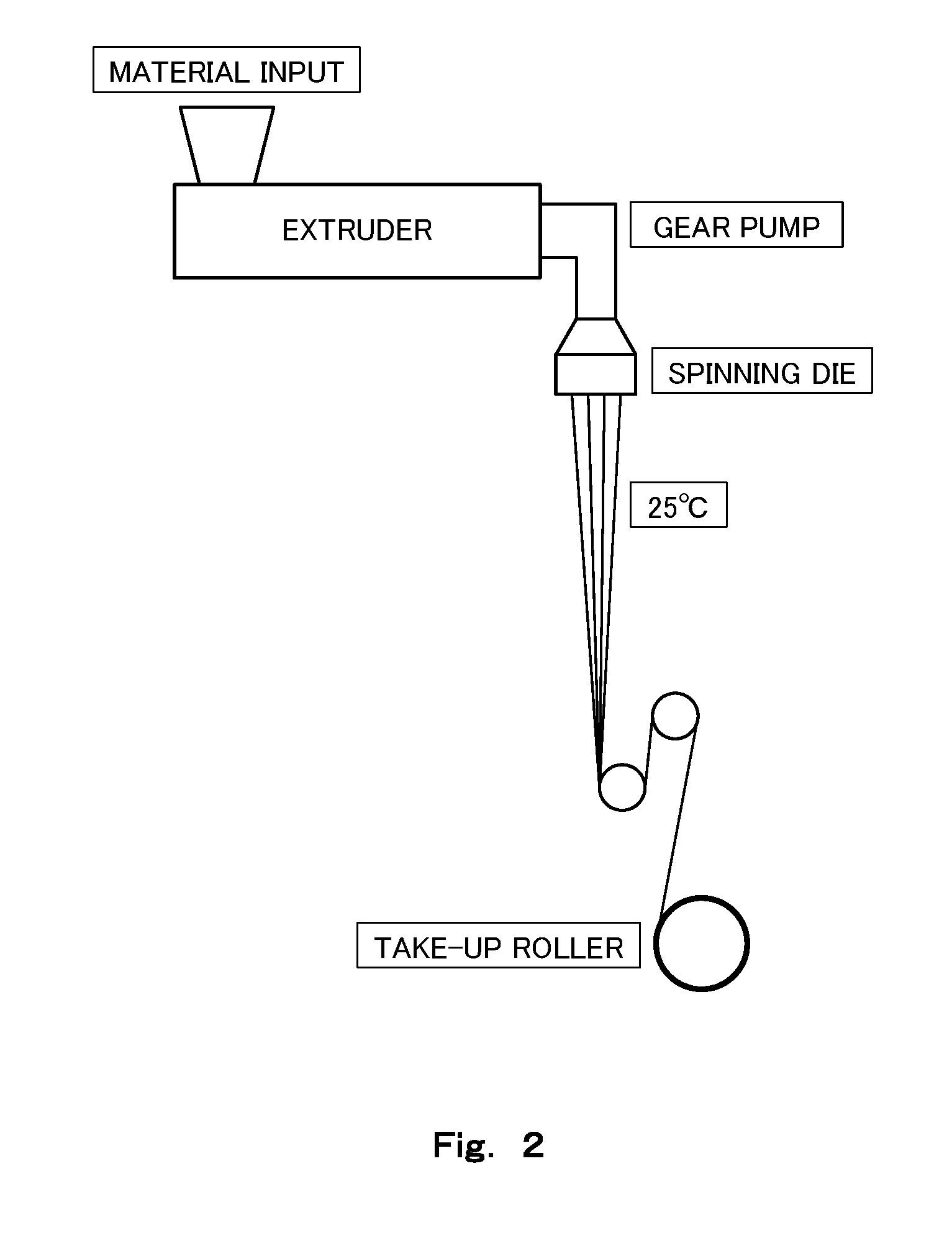

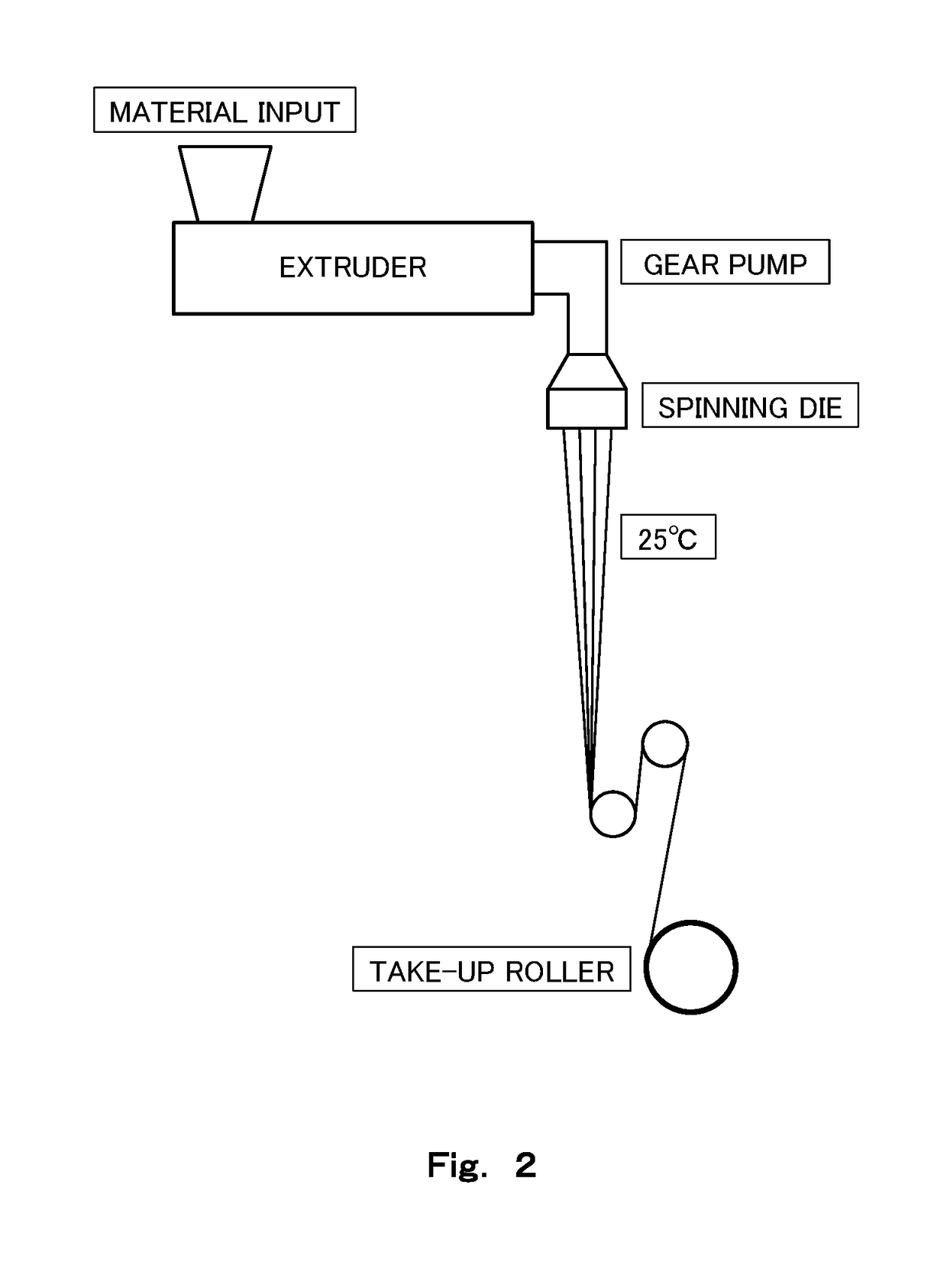

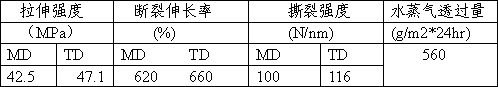

Polyester fiber

ActiveUS20160230313A1Increase productivityImprove spinnabilityMonocomponent copolyesters artificial filamentDomestic articlesProduction rateFiber

An object of the present invention is to improve spinnability, productivity, and tensile strength of a polyester fiber containing poly(3-hydroxybutyrate-co-3-hydroxyhexanoate).By spinning the polyester resin containing the poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) at a high spinning velocity, the spinnability, productivity, and tensile strength of the polyester fiber can be improved.

Owner:TOKYO INST OF TECH +1

Preparation method of polymer oil-absorbing paper

The invention discloses a preparation method of polymer oil-absorbing paper. The preparation method comprises steps as follows: step (1), an organic phase of a polylactic acid and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate mixed solution is prepared; step (2), ammonium bicarbonate is dissolved in water, and an aqueous phase is prepared; step (3), natural fibers are added to the aqueous phase, the length of the natural fibers is 30-50 mu m, the organic phase is divided into 4-7 parts and is added to the aqueous phase part by part, homogenization processing is performed after addition of every part of the organic phase, an emulsion is obtained, a volume ratio of total volume of the organic phase to the aqueous phase is (6-8):1, and a mass ratio of the natural fibers to the organic phase is (0.03-0.05): 1; step (4), the emulsion is left to stand at the normal temperature for 1-2 h, then the temperature is reduced from the normal temperature to 5 DEG C, and the emulsion is left to stand continuously at the temperature of 5 DEG C for 1h; step (5), the emulsion is subjected to freeze drying at the temperature of subzero 10 DEG C-subzero 15 DEG C for 3-4 h. The oil-absorbing paper prepared with the method has good oil absorbing capacity.

Owner:李冬琼

Production method for copolymer polyhydroxyalkanoate using genetically modified strain of fatty acid ß-oxidation pathway

InactiveUS20160040197A1Improve proliferative abilityImprove abilitiesOxidoreductasesFermentationVegetable oilFatty acid

An object of the present invention is to provide a method for producing poly(3-hydroxybutyrate-co-3-hydroxyhexanoate (P(3HB-co-3HHx)) having a high 3-hydroxyhexanoate fraction using a vegetable oil as a basic raw material. According to the present invention, a method is provided for producing P(3HB-co-3HHx) having a high 3-HHx fraction using a vegetable oil as a basic raw material by disrupting and so forth at least one gene encoding 2-enoyl-CoA hydratase or at least one gene encoding 3-hydroxyacyl-CoA dehydrogenase on a chromosome of a recombinant Cupriavidus necator strain imparted with the ability to produce P(3HB-co-3HHx).

Owner:TOKYO INST OF TECH +1

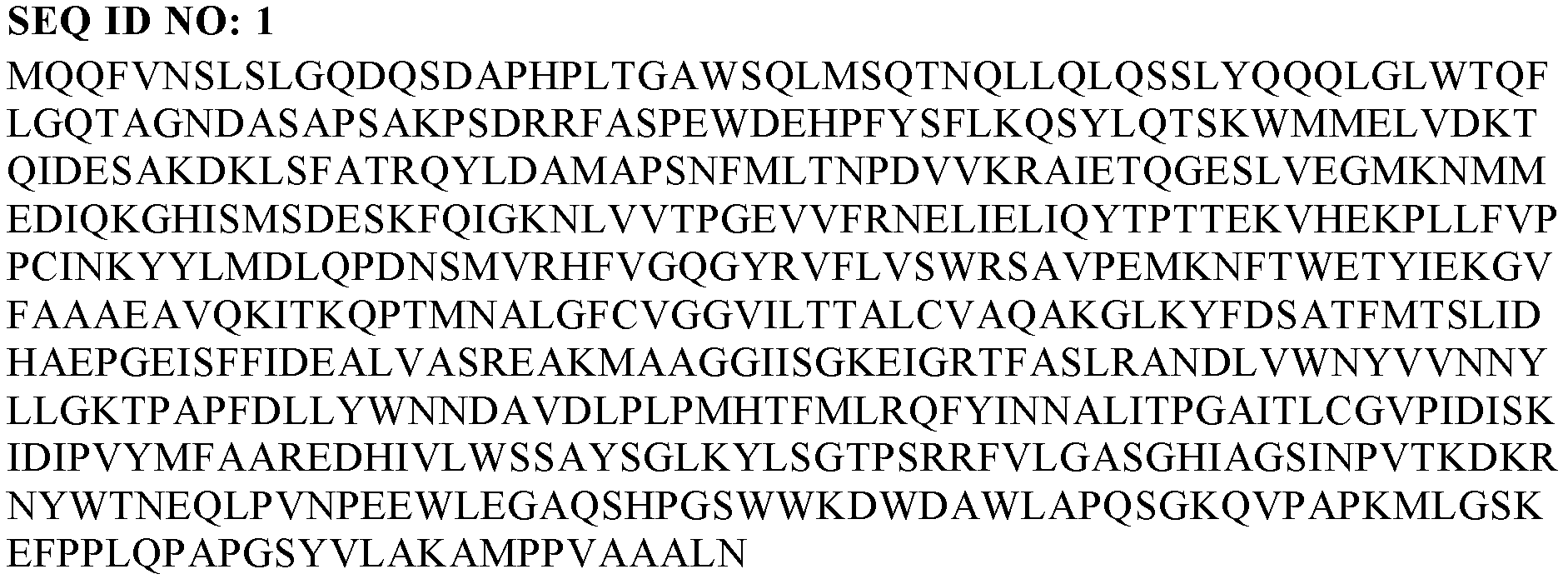

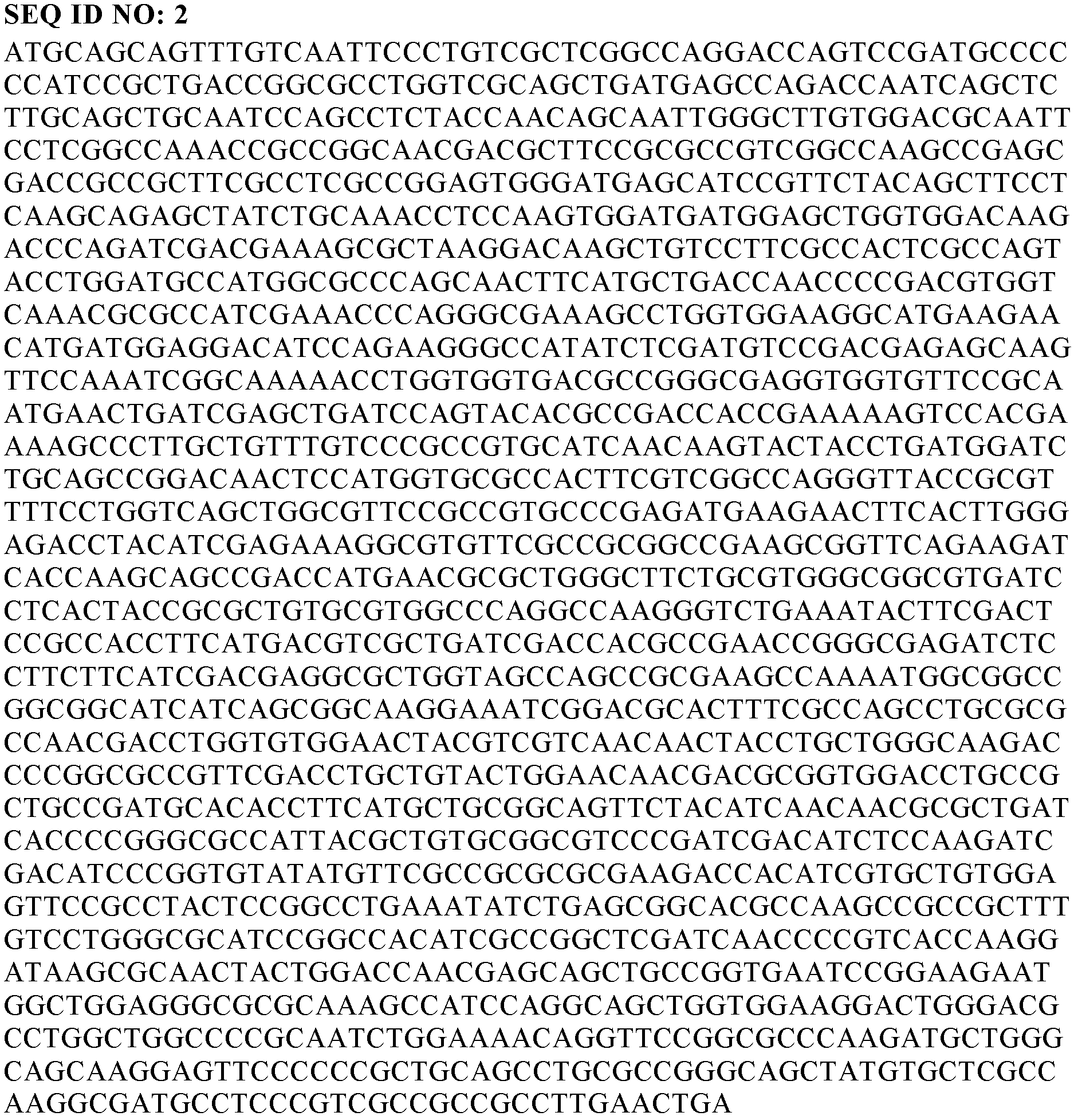

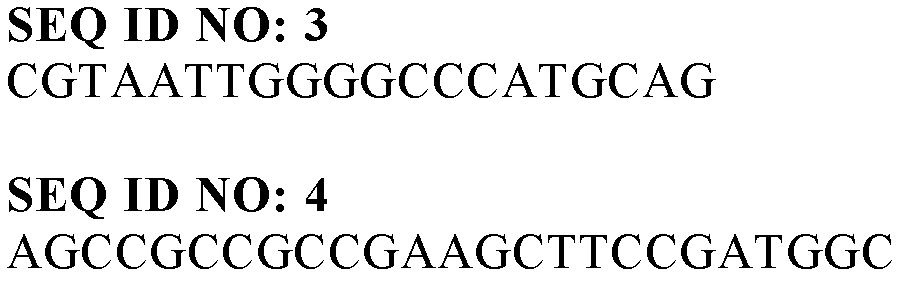

Gene encoding polymer synthase and a process for producing polymer

InactiveCN102459601AAchieve the purpose of the inventionEnzymesFermentationHydroxybutyric acidChromobacterium sp.

Polyhydroxyalkanoate (PHA) synthase gene (SEQ ID NO:2) isolated from fresh water Chromobacterium sp. USM2, its amino acid sequence (SEQ ID NO: 1) and its use to produce polymers incorporating C3 to C7 monomer units, including poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) random copolymer P(3HB-co-3HHx), poly(3- hydroxybutyrate-co-3-hydroxycalerate) random copolymer P(3HB-co-3HV) and P(3HB-co-3HV-co-3HHx) terpolymer. Production of polymer by expression of SEQ ID NO:2 in recombinant hosts including microorganisms such as Cupriavidus or Pseudomonas.

Owner:UNIVERSITI SAINS MALAYSIA

Polyester fiber

ActiveUS9732443B2Increase productivityImprove spinnabilityMonocomponent copolyesters artificial filamentDomestic articlesFiberPolyester resin

An object of the present invention is to improve spinnability, productivity, and tensile strength of a polyester fiber containing poly(3-hydroxybutyrate-co-3-hydroxyhexanoate).By spinning the polyester resin containing the poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) at a high spinning velocity, the spinnability, productivity, and tensile strength of the polyester fiber can be improved.

Owner:TOKYO INST OF TECH +1

High-barrier biodegradable mulching film and preparation method thereof

InactiveCN109370036AImprove barrier propertiesPromote degradationClimate change adaptationPlant protective coveringsCross-linkLinear low-density polyethylene

The invention discloses a high-barrier biodegradable mulching film and a preparation method thereof. The high-barrier biodegradable mulching film is composed of the following components in parts by weight: 20-50 parts of propylene polycarbonate, 30-60 parts of linear low density polyethylene, 2-3 parts of 2,4-dihydroxy benzophenone, 2-2.5 parts of bitetradecyl alcohol esters, 20-57 parts of poly-3-polyhydroxybutyrate-co-3-hydroxyhexanoate, 15-55 parts of polybutylene terephthalate, 13-32 parts of poly(butylene succinate), 3-10 parts of glycidyl acrylate grafted polyethylene, 0.5-1.5 parts of ahindered amine light stabilizer, 0.2-1.5 parts of dimethyl tin isooctyl dithioacetate, 10-30 parts of a filler and 0.2-1 part of a cross-linking agent. The high-barrier biodegradable mulching film disclosed by the invention has excellent barrier property and biodegradable property.

Owner:苏州福慧材料科技有限公司

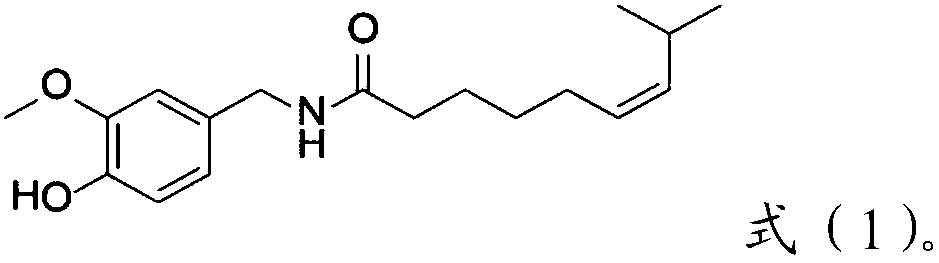

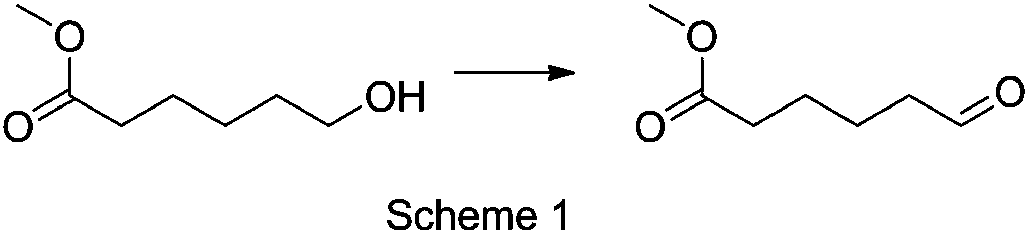

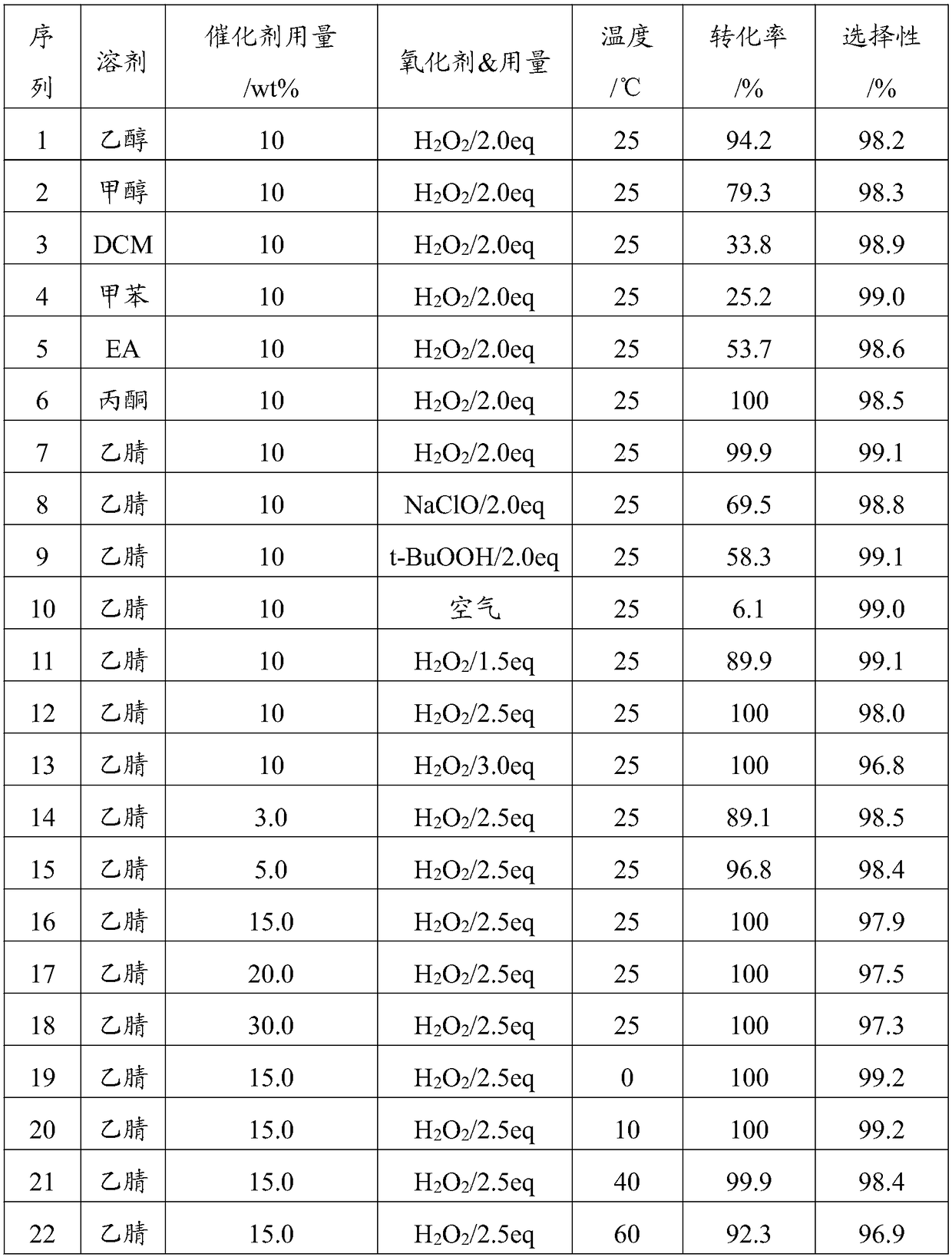

Method for preparing medicine intermediate for treating osteoarthritis

ActiveCN108516938AEfficient CatalysisOvercome the defects of producing heavy metal wastewaterOrganic compound preparationCarboxylic acid esters preparationApatiteIon exchange

The invention belongs to the technical field of chemical research and development, and particularly relates to a method for preparing a medicine intermediate for treating osteoarthritis. According toa preparing method for a zinc-salt-modified-hydroxyapatite ceric-ammonium-nitrate-loading catalyst, the catalyst is obtained after zinc-salt-modified hydroxyapatite and ceric ammonium nitrate are subjected to ion exchange in an ethanol water solution; the zinc-salt-modified hydroxyapatite is prepared under the alkaline condition with the chemical precipitation method, wherein Ca(NO3)2.4H2O and diammonium hydrogen phosphate serve as raw materials, and Zn(NO3)2.6H2O serves as a modifying agent; the catalyst prepared with the method can catalyze 6-methyl 3-hydroxyhexanoate to prepare medicine cis-capsaicine intermediate 6-carbonyl methyl caproate for treating osteoarthritis. The catalyzing technology is high in yield and environmentally friendly.

Owner:深圳市资福药业有限公司

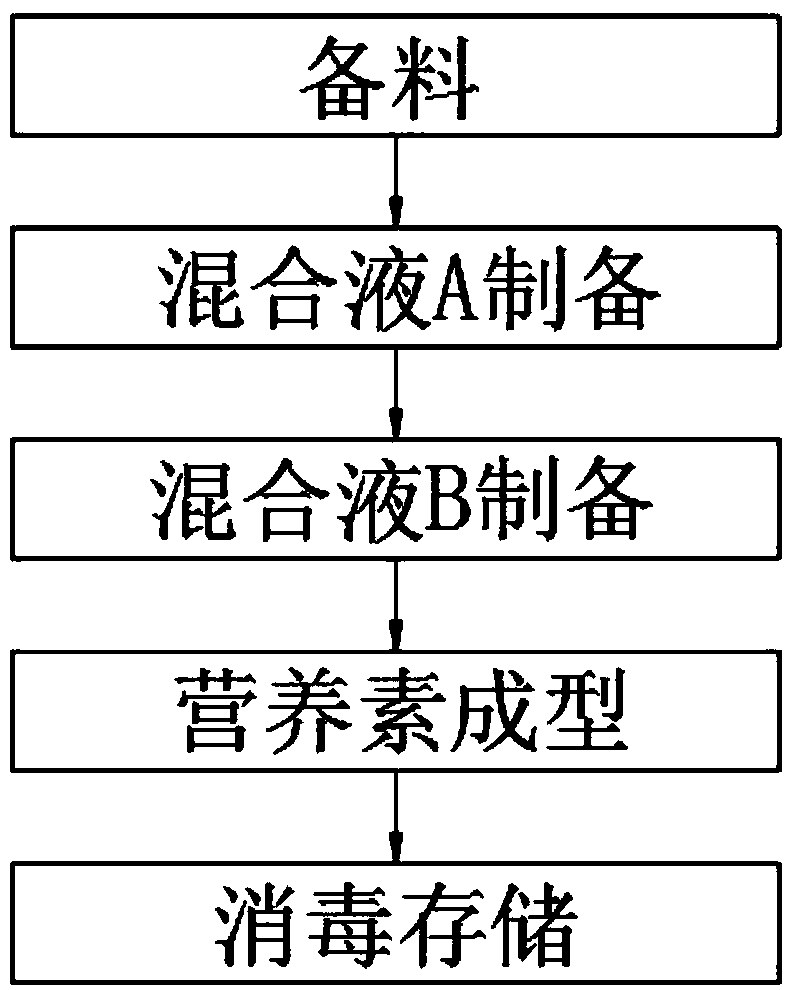

Nutrient contributing to fusion of prosthesis and human tissue in augmentation rhinoplasty

InactiveCN108187150APromote healingImprove healing efficiencySurgeryBiocompatibility TestingSeaweed extract

The invention discloses a nutrient contributing to fusion of prosthesis and human tissue in augmentation rhinoplasty. The nutrient is prepared from raw materials in parts by weight as follows: collagen peptide, liquid xanthan gum, agar, albumin, keratin, diguanosine tetraphosphate, hyaluronic acid, hexapeptide, chitosan, glucosamine hydrochloride, sea cucumber extract, seaweed extract, methylprednisolone, antilymphocyte globulin, magnesium stearate, antibiotics, PhaP-PGD fusion protein, poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) and heparinoid. The preparation process of the nutrient comprises steps as follows: material preparation, preparation of a mixed solution A, preparation of a mixed solution B, nutrient forming, disinfection and storage. With addition of the sea cucumber extractand the seaweed extract, wound healing can be promoted effectively, and wound heating efficiency is increased; with addition of PhaP-PGD fusion protein and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate), cell identifiability and biocompatibility of a material are improved, and success rate of a surgery is effectively increased.

Owner:티안지우안

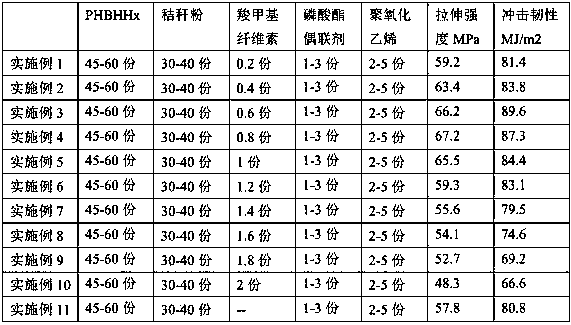

Poly(3-hydroxybutyrate-3-hydroxyhexanoate) carboxymethyl cellulose straw powder composite full biodegradable material

The invention provides a poly(3-hydroxybutyrate-3-hydroxyhexanoate)-carboxymethyl cellulose-straw powder composite full biodegradable material. The material is prepared by the following steps: mixingpoly(3-hydroxybutyrate-3-hydroxyhexanoate) (PHBHHx) and straw powder, adding a certain amount of carboxymethyl cellulose, phosphate coupling agent and polyoxyethylene, putting all the materials into athree-dimensional mixing machine for mixing, transferring the mixture into a mould, and putting the mould onto a plate vulcanizing machine for compression molding, so as to obtain a composite material. Compared with a poly(3-hydroxybutyrate-3-hydroxyhexanoate) product, a product prepared from the poly(3-hydroxybutyrate-3-hydroxyhexanoate)-plant fiber composite material has great advantages that the hydrophilicity of the material is improved, the mixing efficiency of the composite material is increased, and the processing property of the composite material can be obviously improved; the mechanical property and the mechanical property of the prepared product are greatly improved; the prepared composite material is high in tensile strength and strong in impact toughness, therefore, the composite material is a full degradable material with good environmental protection value and economic value.

Owner:中科众创(重庆)秸秆产业研究院有限公司

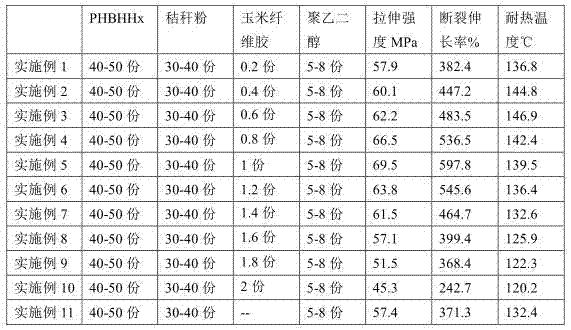

Poly-(3-hydroxybutyrate-3-hydroxyhexanoate)corn fiber glue plant fiber fully-degraded composite material

InactiveCN107987499AImprove mechanical propertiesImprove brittlenessPolyethylene glycolMixed materials

The invention provides a poly-(3-hydroxybutyrate-3-hydroxyhexanoate)corn fiber glue plant fiber fully-degraded composite material which is prepared by the following steps: mixing poly-(3-hydroxybutyrate-3-hydroxyhexanoate)(PHBHHx) with straw powder, and adding a certain amount of corn fiber glue and polyethylene glycol; putting all materials in a three-dimensional mixing machine so as to be mixed;transferring the mixture into a mold; and putting the mold on a plate vulcanizing machine so as to be subjected to compression molding, thereby obtaining the composite material. Compared with a PHBHHx product, a product prepared from the PHBHHx plant fiber composite material has great advantages that the hydrophilicity is improved, the material mixing difficulty is greatly reduced, the adhesion property of the mixed material is enhanced, the dynamical strength and the mechanical strength of the product are obviously improved, and the tensile strength and the elongation at break are enhanced;the product prepared from the composite material provided by the invention has high toughness and high heat resisting temperature; no coupling agent is added, so that the composite material is safe and nontoxic, and the cost of the fully-degraded material is greatly lowered; and the composite material has good environmental protection value and economic value.

Owner:中科众创(重庆)秸秆产业研究院有限公司

Poly(3-hydroxybutyrate-3-hydroxyhexanoate)Arabic gum straw powder composite biodegradable material

A poly(3-hydroxybutyrate-3-hydroxyhexanoate) gum arabic straw powder composite biodegradable material, which is made of poly(3-hydroxybutyrate-3-hydroxyhexanoate) (PHBHHx) Mix it with straw powder, add a certain amount of gum arabic, lignin, and polyethylene oxide, put all the materials in a three-dimensional mixer and mix them, then move the mixture into a mold, place it on a flat vulcanizer, and mold it to form a composite material . The products made by poly(3-hydroxybutyrate-3-hydroxyhexanoate) plant fiber composite materials of the present invention have much better properties than poly(3-hydroxybutyrate-3-hydroxyhexanoate) products Big advantages: mainly include improving the hydrophilicity of the material, increasing the mixing efficiency of the composite material, and significantly improving the processing performance of the composite material; the products made by the present invention have high tensile strength and greatly improved mechanical properties; The prepared composite material has high heat-resistant temperature, greatly reduces the cost of fully degradable materials, and has good environmental protection value and economic value.

Owner:中科众创(重庆)秸秆产业研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com