Patents

Literature

36 results about "Ethyl p-Aminobenzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine

ActiveCN101481330AReduce consumptionLower the condensation reaction temperatureOrganic chemistryN-MethylanilineEthyl aminobenzoate

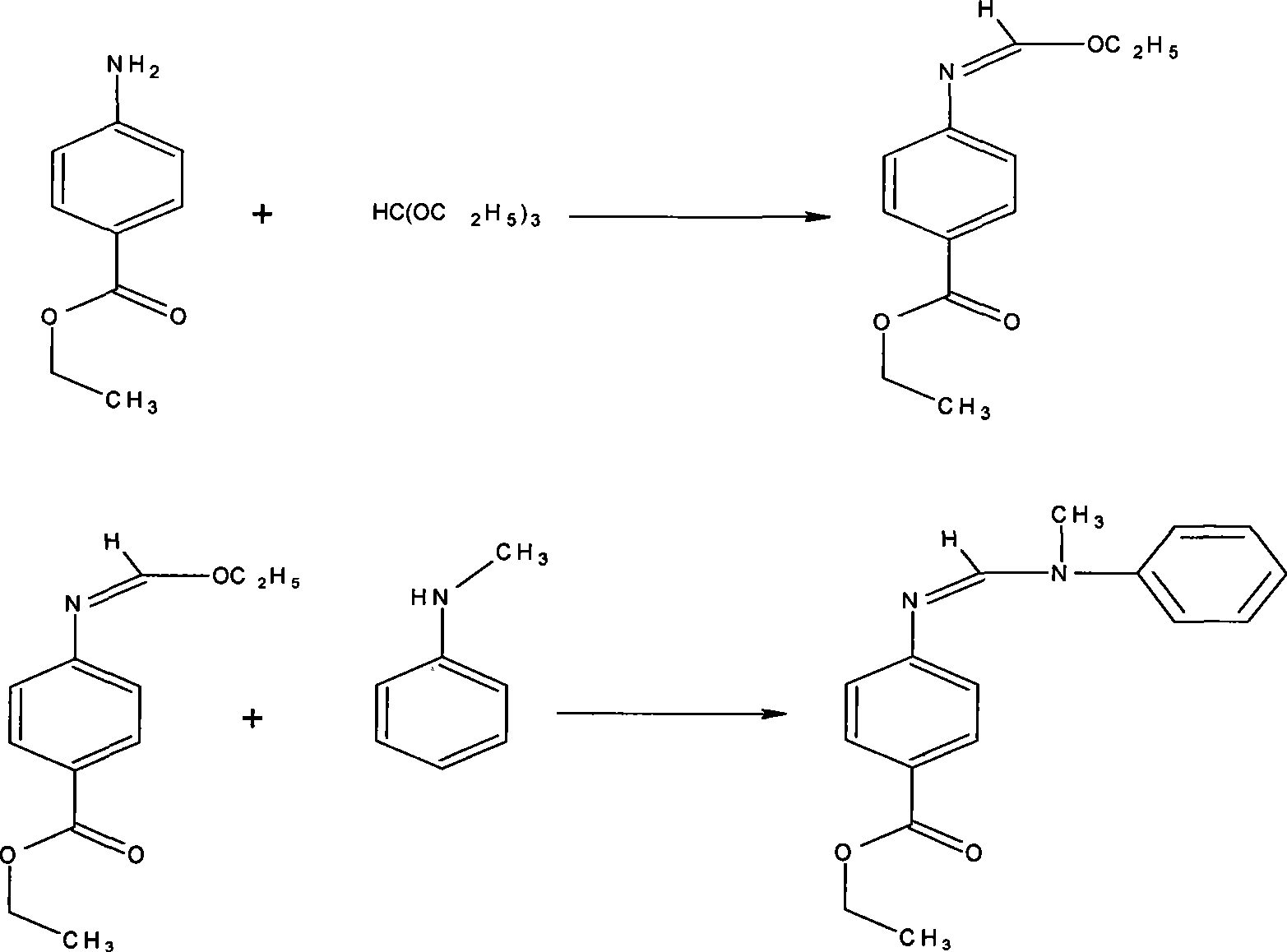

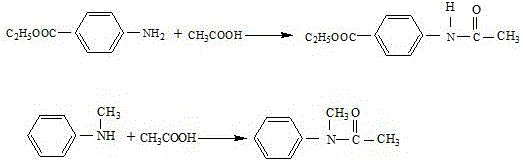

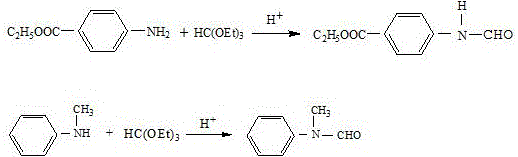

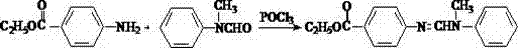

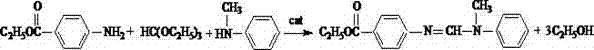

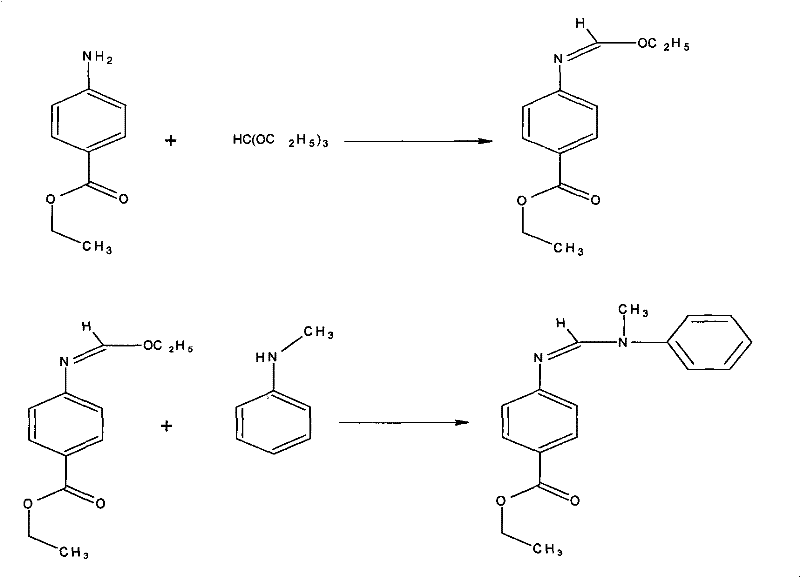

The invention relates to the technical field of fine chemistry industry, in particular to a method for preparing N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenylformamidine, comprising the following two condensation reaction processes: in the first condensation reaction process, parathesin is mixed with trialkyl ortho-formate according to the mass ratio of 1:1-1:10 for the condensation reaction at the temperature of 100-200 DEG C and reduced pressure distilling is carried out to obtain intermediate; in the second condensation reaction process, the condensation reaction is carried out on the intermediate generated in the first condensation reaction process and N-methylaniline according to the mass ratio of 1:1-1:5 at the temperature of 100-200 DEG C and simple reduced pressure distilling is carried out on reaction liquid to obtain the N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenylformamidine. The method solves the problem of difficulty in large-scale industrial production in the prior art.

Owner:CHANGZHOU SUNLIGHT PHARMA

Method for preparing N-(4-ethyoxylcarbonylphenyl)-N'-methyl-N'-phenyl carbonamidine

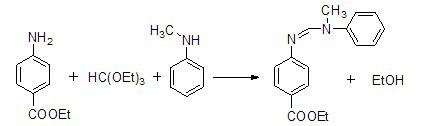

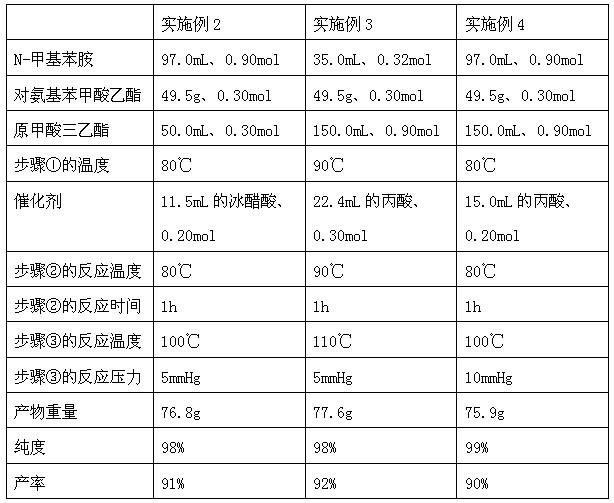

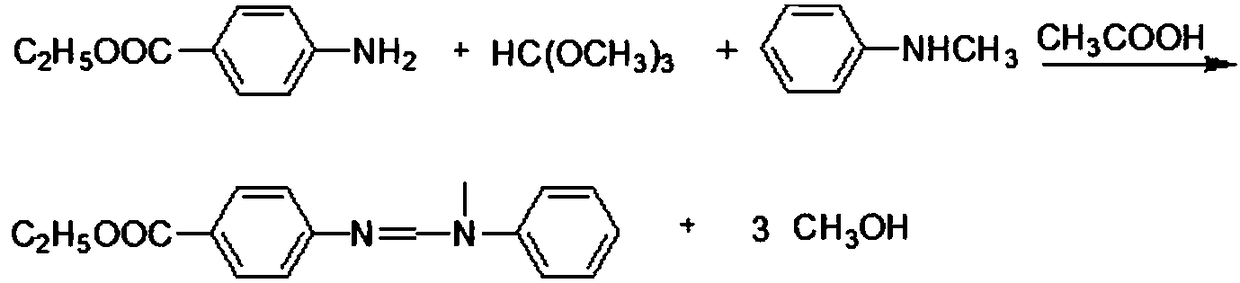

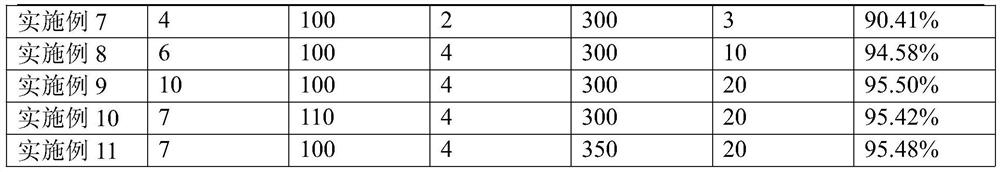

The invention discloses a method for preparing N-(4-ethyoxylcarbonylphenyl)-N'-methyl-N'-phenyl carbonamidine. The method comprises the following steps of: (1) adding N-methylaniline, ethyl p-aminobenzoate and triethyl orthoformate into a reaction device, stirring and heating up to 80-90 DEG C; (2) adding propionic acid or glacial acetic acid used as a catalyst into the reaction device, meanwhile, evaporating out generated alcohol, and reacting for 1-3 hours at a temperature of 80-90 DEG C; (3) heating up to 100-110 DEG C, meanwhile, reducing the pressure to 1-20mmHg, continuously reacting until no alcohol is evaporated out; and (4) after the reaction ends, reducing the pressure and distilling to obtain the N-(4-ethyoxylcarbonylphenyl)-N'-methyl-N'-phenyl carbonamidine. The method has the advantages of simple process, moderate condition and high productivity and is suitable for large-scale industrial production.

Owner:大连新阳光材料科技有限公司 +1

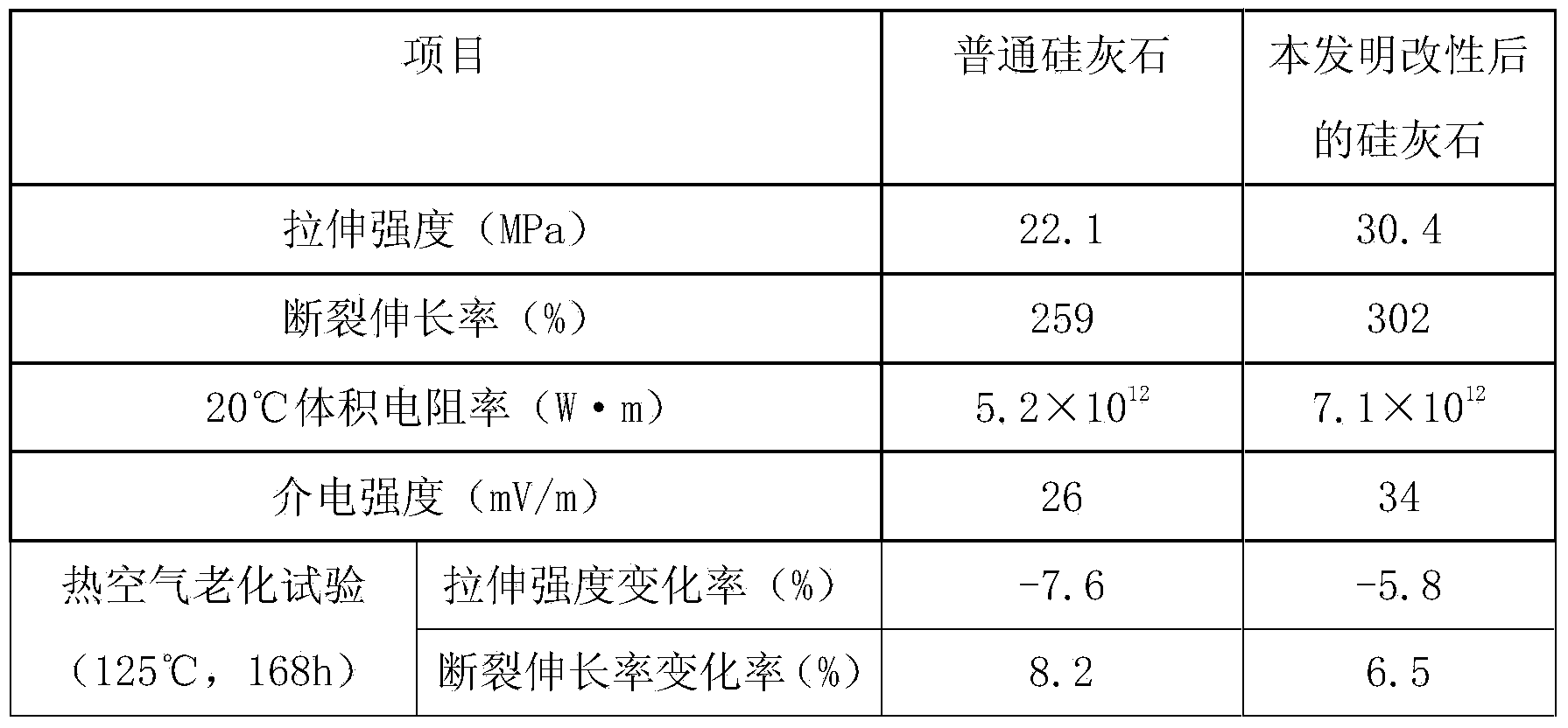

Modified wollastonite for polyvinyl chloride (PVC) cable sheath material capable of resisting 105 DEG C and preparation method of modified wollastonite

InactiveCN104212089AGood compatibilityHigh tensile strengthPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSperm oilPolyvinyl chloride

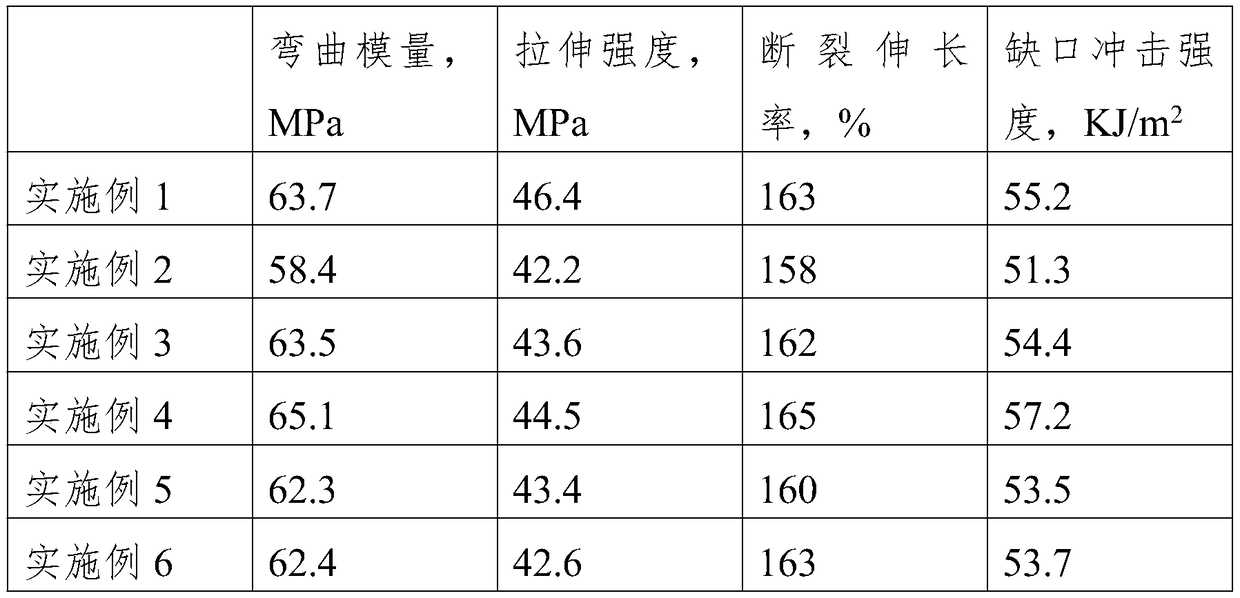

The invention discloses modified wollastonite for a polyvinyl chloride (PVC) cable sheath material capable of resisting 105 DEG C and a preparation method of the modified wollastonite. The modified wollastonite is prepared from the following raw materials in parts by weight: 40 to 60 parts of wollastonite, 10 to 15 parts of polycaprolactone, 5 to 10 parts of aluminum dihydrogen tripolyphosphate, 3 to 6 parts of sperm oil, 1 to 2 parts of sorbitan oleate, 2 to 3 parts of polydiphenylsiloxane, 3 to 5 parts of zinc stannate, 5 to 10 parts of natural zeolite powder, 4 to 7 parts of nano tungsten carbide, 2 to 4 parts of dibromo triphenyl antimony, 1 to 2 parts of dibutyltin dilaurate, 5 to 10 parts of epoxy silkworm chrysalis butyl oleate, 2 to 4 parts of bisphenol A polyoxyethylene ether, 1.5 to 2.5 parts of ethyl p-aminobenzoate and 3.5 to 4.5 parts of auxiliaries. The modified wollastonite has good compatibility with a PVC base material, so that the filling performance of the modified wollastonite in PVC resin is improved so as to enhance a reinforcing effect. Thus, the tensile strength, the electric insulativity, the heat resistance and the like of the PVC cable material are obviously improved. As a result, the modified wollastonite has a wide application prospect.

Owner:安徽吉安特种线缆制造有限公司

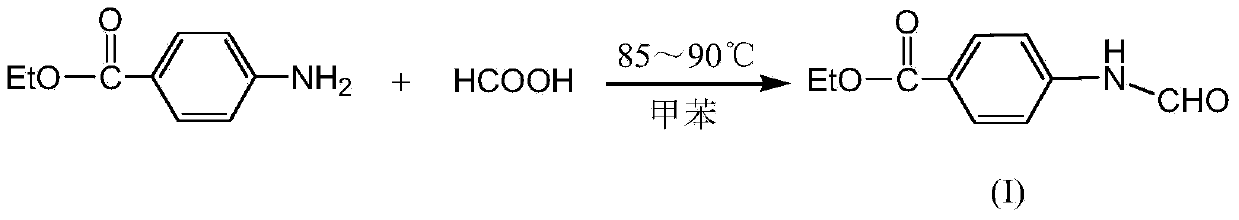

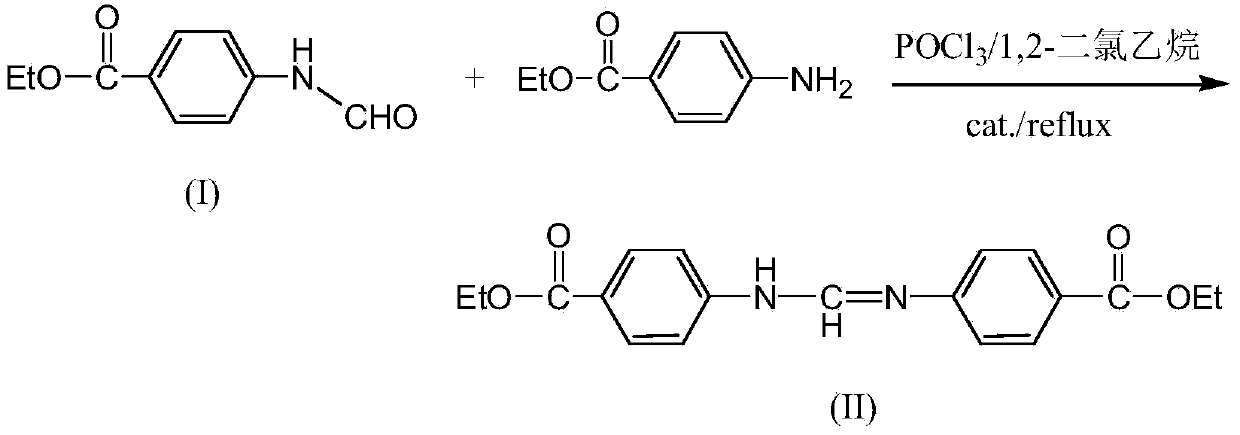

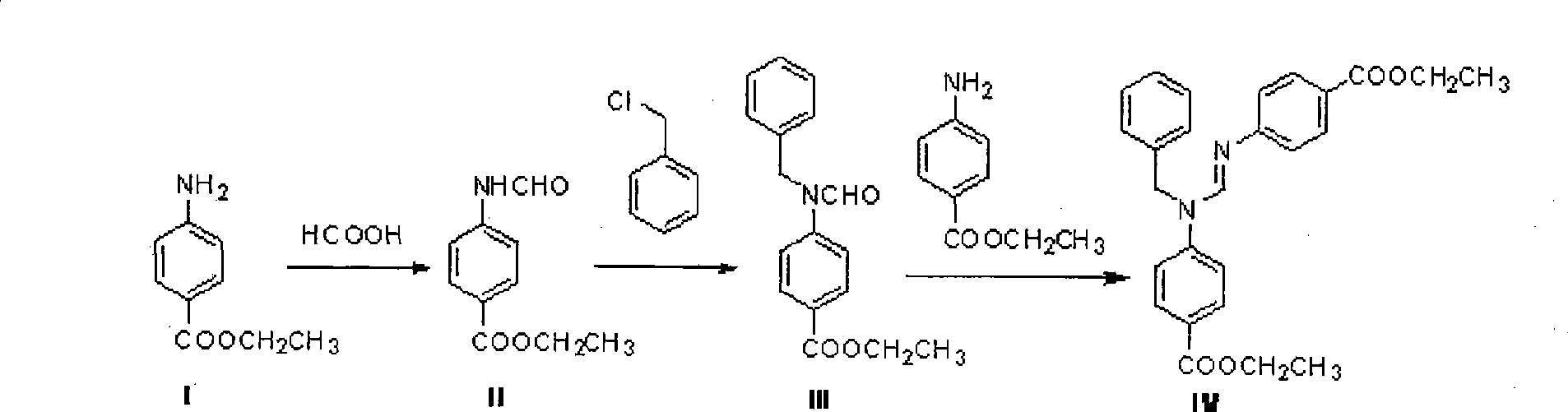

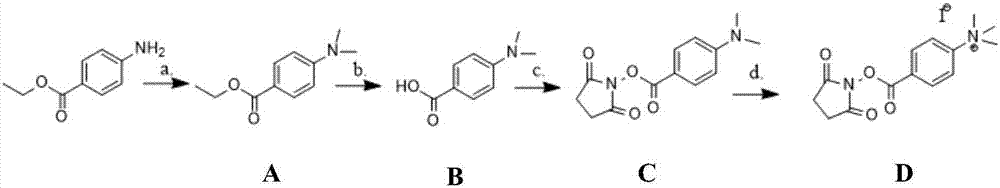

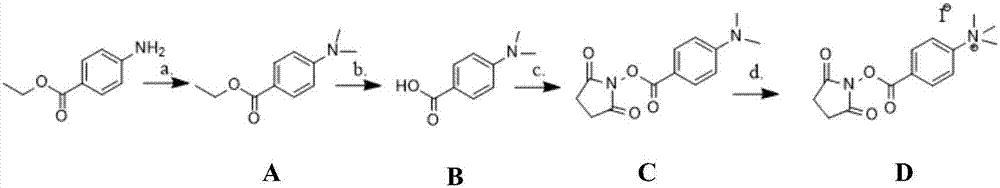

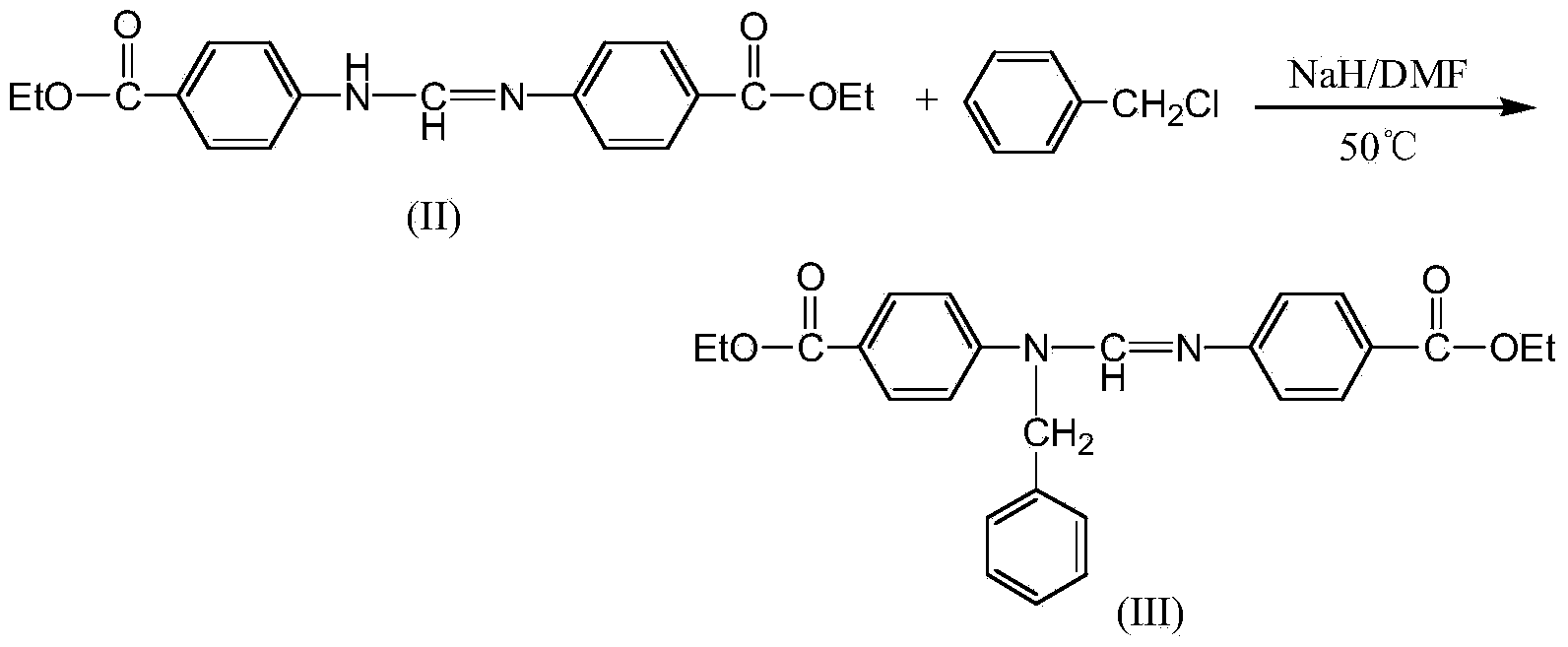

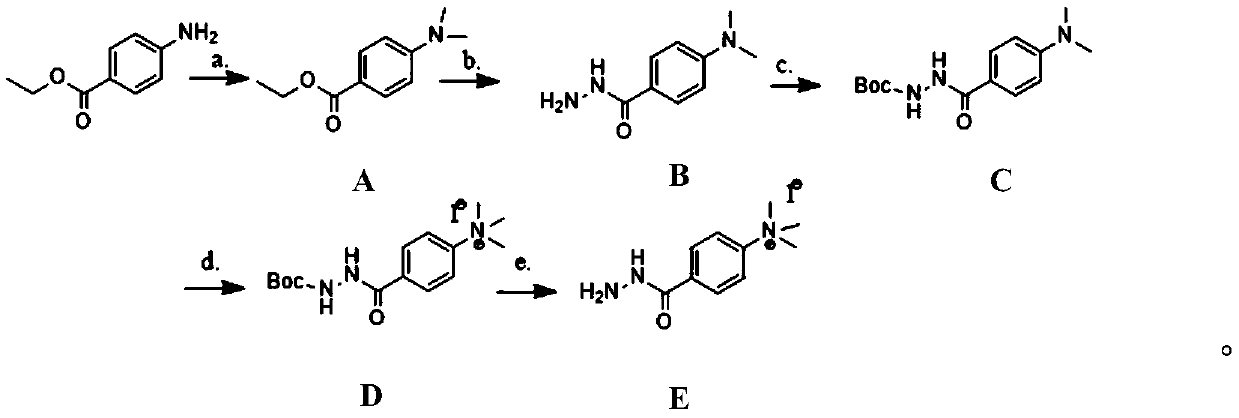

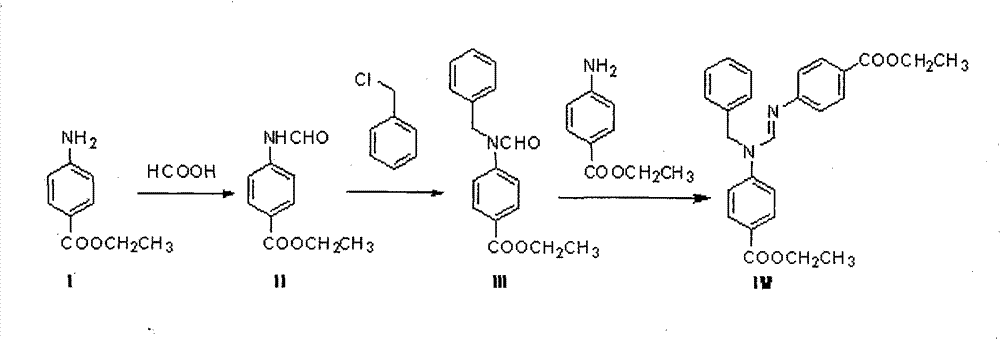

N, N'-di (4-ethyoxyl carbonyl phenyl)-N'-benzyl formamidine preparation method

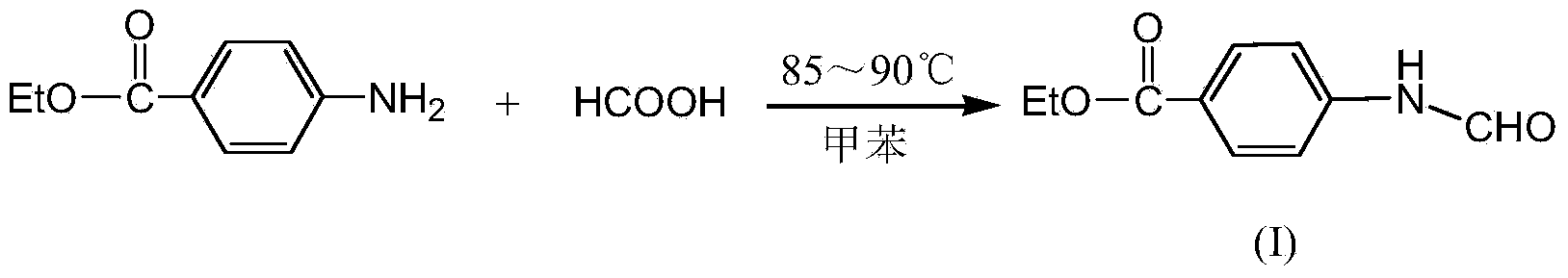

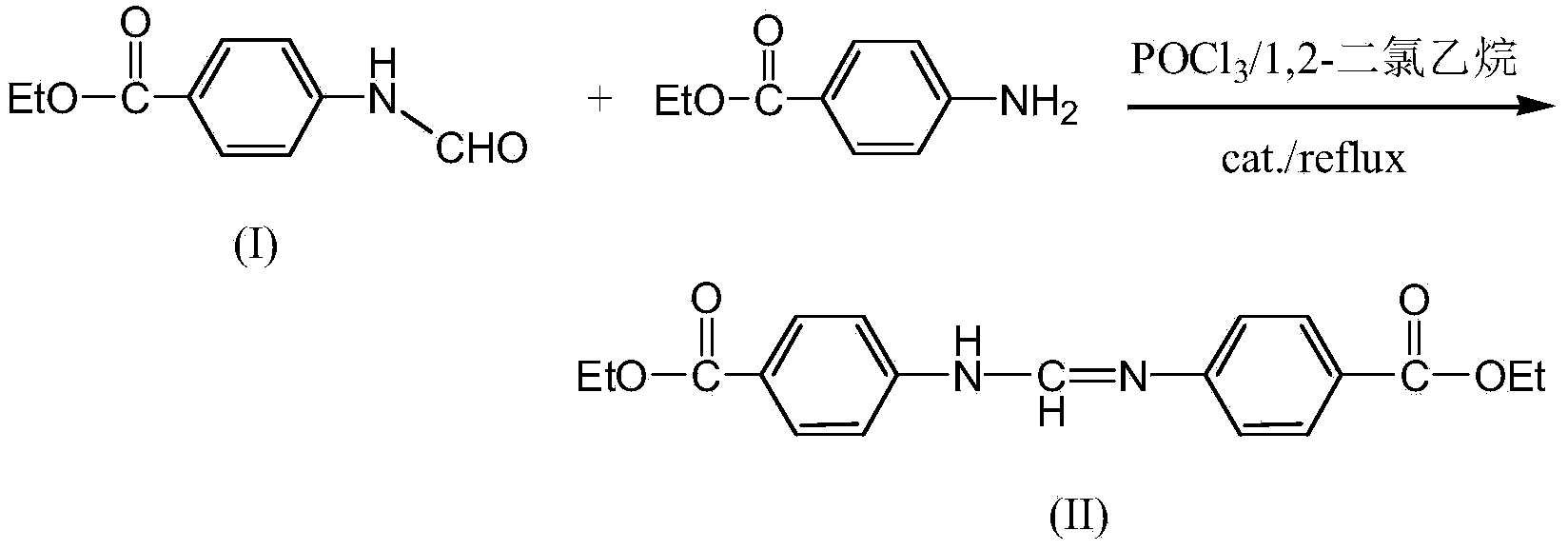

InactiveCN103420873AShort reaction timeHigh yieldImino compound preparationBenzoic acidFormylation reaction

The invention discloses an N, N'-(4-ethyoxyl carbonyl phenyl)-N'-benzyl formamidine preparation method, and belongs to the technical field of benzyl formamidine compound preparation, wherein N, N'-(4-ethyoxyl carbonyl phenyl)-N'-benzyl formamidine is mainly used for an ultraviolet light absorber. According to the N, N'-(4-ethyoxyl carbonyl phenyl)-N'-benzyl formamidine preparation method, ethyl p-aminobenzoate is used as the raw material, and the ethyl p-aminobenzoate is subjected to a synthetic route including formylation, condensation and N-alkylation to prepare the N, N'-(4-ethyoxyl carbonyl phenyl)-N'-benzyl formamidine product. The N, N'-(4-ethyoxyl carbonyl phenyl)-N'-benzyl formamidine preparation method has the remarkable advantages that the time for the overall reaction process is shortened, the total yield is increased, the cost is reduced because filtrate in an aftertreatment process of the formylation reaction and the condensation reaction can be recycled and reused, the yield of final products can be stabilized between 65% and 70%, and the preparation method is beneficial to industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Environment-friendly preparation process of N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine intermediate

ActiveCN105315168AReduce pollutionImprove the yield of esterification reactionOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidPhenyl group

The invention discloses an environment-friendly preparation process of an N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine intermediate. The process comprises the steps of making p-nitrobenzoic acid and ethyl alcohol be subjected to an esterification reaction under the catalysis of concentrated sulphuric acid, conducting aftertreatment and catalytic hydrogenation on materials generated after the esterification reaction, and obtaining ethyl p-aminobenzoate; an aftertreatment procedure comprises the steps of removing ethyl alcohol in the materials generated after the esterification reaction through evaporation, then leaving remaining materials standing still for layering, and conducting neutralization treatment on materials on the lower layer. According to the environment-friendly preparation process, the concentrated sulfuric acid is separated out before neutralization treatment is conducted on the materials obtained after the esterification reaction, a great amount of high salinity waste water cannot be generated, environment pollution is reduced, and the yield of the esterification reaction can be raised.

Owner:CHANGZHOU YONGHE FINE CHEM

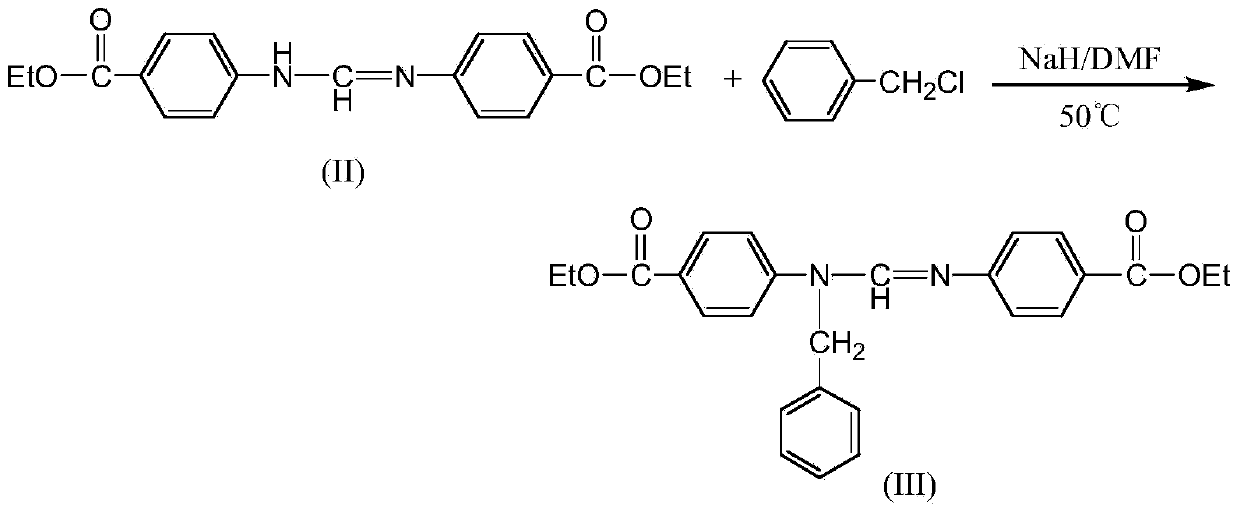

N,N'-bis(4-ethoxy carbonyl phenyl)-N'-benzyl formamidine

ActiveCN101481331AHigh yieldEasy to separate and purifyOrganic chemistryOrganic compound preparationFormylation reactionFiltration

The invention relates to the technical field of fine chemistry industry, in particular to a method for preparing N, N'-di(4-ethoxycarbonylphenyl)-N'-phenylformamidine. Parathesin and benzyl chloride are taken as raw materials. The method comprises a formylation reaction process, an N alkylation reaction process and a condensation reaction process; wherein, in the N alkylation reaction process, 4-formamido ethyl benzoate generated in the formylation reaction process is added into dipolar aprotic solvent, and then inorganic weak base and the benzyl chloride are added, the temperature rises and is preserved and the reaction lasts for 20-25 hours; then the temperature is lowered to the room temperature and suction filtration and washing are carried out on the separated pale yellow solid to obtain pale yellow intermediate; the intermediate and the parathesin are added into halogenated hydrocarbon and then dehydrant is added; after heatingup and reflux for 15-17 hours, the temperature is cooled to the room temperature; NaOH aqueous solution is added to steam out the halogenated hydrocarbon under normal pressure and then separate out offwhite solid; suction filtration, washing by water and drying are carried out on the solid and the white solid of N, N'-di(4-ethoxycarbonylphenyl)-N'-phenylformamidine is obtained by recrystallization and cooling the solid to the room temperature afterwashing.

Owner:CHANGZHOU SUNLIGHT PHARMA +1

Environment-friendly preparation process of N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine

ActiveCN105315176AHigh yieldReduce pollutionOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidPhenyl group

The invention discloses an environment-friendly preparation process of N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine. The process comprises the steps of firstly, making p-nitrobenzoic acid be subjected to an esterification reaction and catalytic hydrogenation, obtaining ethyl p-aminobenzoate, then making ethyl p-aminobenzoate be subjected to two steps of condensation reactions, and obtaining N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine, wherein ethanol adopted in the esterification reaction is recycled and processed ethanol, and the recycled and processed ethanol is obtained by collecting, recycling and processing ethanol generated in the condensation reactions. According to the process, the ethanol generated in the condensation reactions are recycled and processed and then applied to the esterification reaction, production cost is lowered, environmental pollution is reduced, the process is an environment-friendly preparation process, and in particular, compared with absolute ethyl alcohol on the market, the ethanol recycled and processed through the process hardly has influence on the esterification effect.

Owner:CHANGZHOU YONGHE FINE CHEM

Synthetic method of ethyl p-aminobenzoate

InactiveCN102311356AQuick responseHigh yieldOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidEthyl aminobenzoate

The invention discloses a synthetic method of ethyl p-aminobenzoate, comprising the following steps: using alcohol to dissolve para amino benzoic acid, preparing a para amino benzoic acid solution with the mass fraction of 5-30 %, adding thionyl chloride dropwisely in the para amino benzoic acid solution at the temperature of 0-50 DEG C for esterification reaction for 4-10 hours, after adding dropwisely, heating until reflux; after the reaction ends, cooling the reaction materials, after the solid substance is dissolved out, carrying out filtering, using water to dissolve the solid substance, adding weak base to neutralize the pH to 7-8, after the solid substance is dissolved out, carrying out filtering again, and then washing and drying to obtain the product of ethyl p-aminobenzoate. The method adopts para amino benzoic acid as raw material, uses thionyl chloride as desiccant for esterification reaction to prepare ethyl p-aminobenzoate, the advantages of rapid reaction speed, high yield, and high product purity are achieved, and the method has a good application prospect in industry.

Owner:HAINING CHONGSHUN CHEM

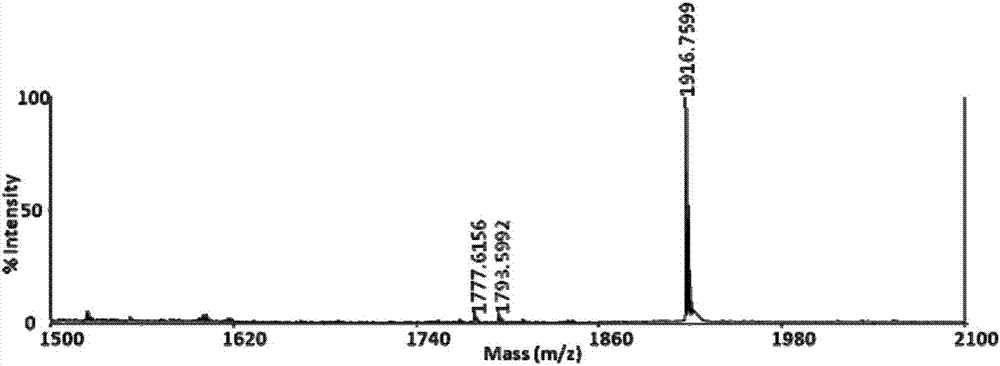

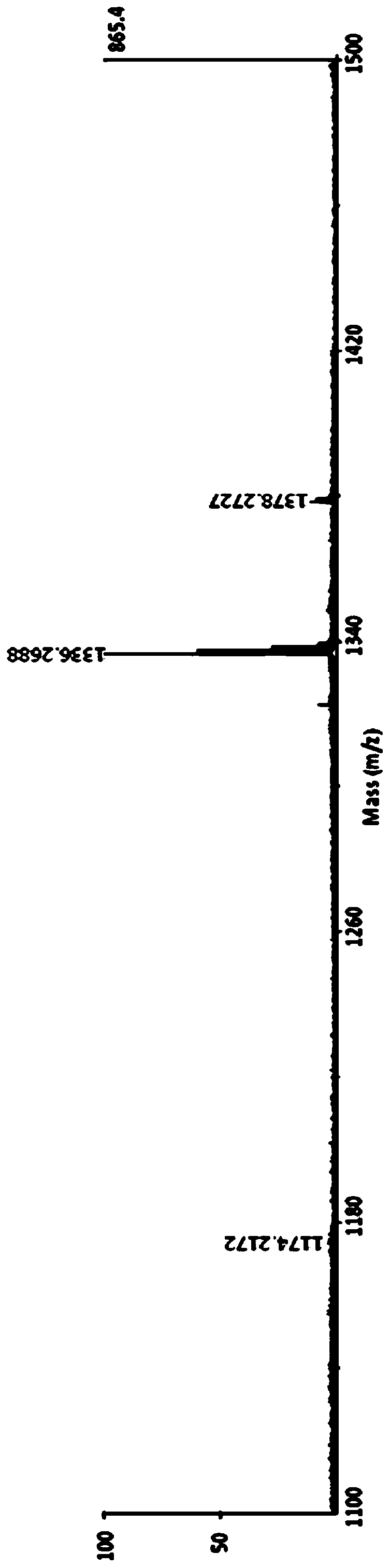

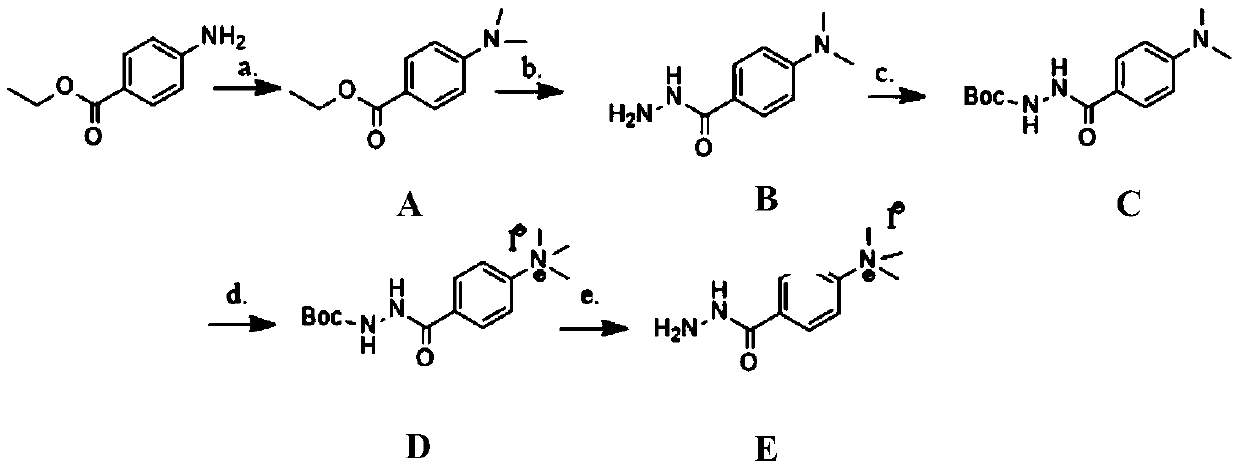

Preparation method of amboryl ester type sugar marker with permanent charges and application

InactiveCN107400078AMild reaction conditionsHigh detection sensitivityOrganic chemistryComponent separationOrganic synthesisHigh-performance liquid chromatography

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

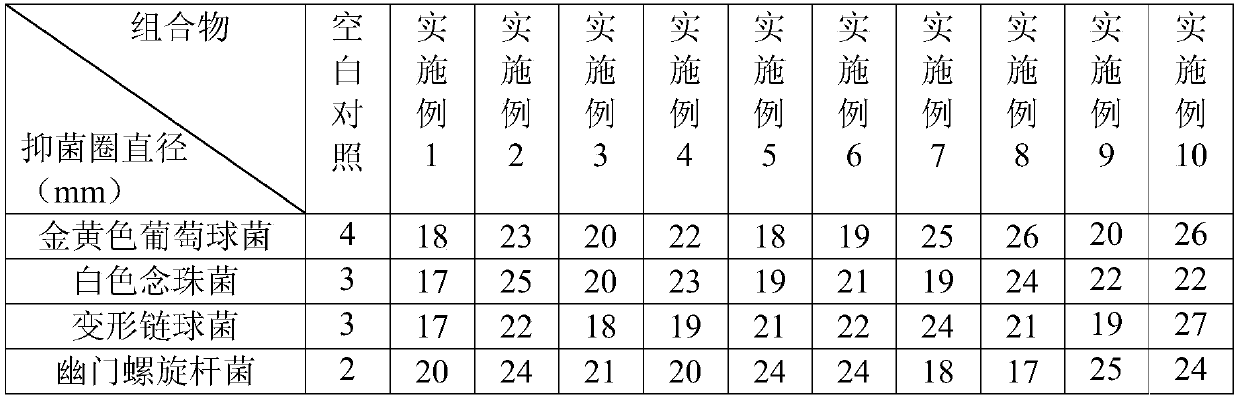

Antibacterial fabric and preparation method thereof

InactiveCN107938102AEfficient removalEfficient and complete removalWeft knittingWarp knittingHydrogen SulfateAnimal fiber

The invention provides antibacterial fabric and a preparation method thereof. The antibacterial fabric comprises, by weight, raw materials of 3-10 parts of animal fibers, 2-8 parts of polyethylene fibers, 4-16 parts of ethyl p-aminobenzoate, 5-7 parts of potassium hydrogen sulfate, 8-10 parts of terylene, 11-15 parts of PET resin, 12-18 parts of cotton fibers, 7-16 parts of bamboo charcoal fibers,11-19 parts of polystyrene resin, 11-21 parts of dioctyl sebacate, 15-20 parts of polyimide and 7-15 parts of bamboo pulp fibers. Bacteria, fungi and mould on the fabric are efficiently and completely removed, the fabric is kept clean, regeneration and propagation of the bacteria can be prevented, and antibacterial performance can be improved.

Owner:JIANGSU GIRMES SPECIAL TEXTILES

Preparation method of N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenylformamidine

PendingCN110437105ALow costHigh purityOrganic chemistryTrifluoromethanesulfonic anhydrideUltraviolet lights

The invention discloses a preparation method of an ultraviolet light absorber UV-1. The ultraviolet light absorber UV-1 is prepared by condensation of ethyl p-aminobenzoate and N-methylformanilide inthe presence of thionyl chloride or trifluoromethanesulfonic anhydride. The condensation reaction comprises the following steps: performing a reaction at room temperature for 12-24 hours, heating thereactants to 45-60 DEG C, and performing a reaction for 5-10 hours. The molar ratio of the ethyl p-aminobenzoate to the N-methylformanilide is (1:0.5)-(1:1.5). The molar ratio of thionyl chloride or trifluoromethanesulfonic anhydride to N-methylformamide is 1:1-10:1. According to the method, trimethyl orthoformate / triethyl orthoformate can be prevented from being used as a main raw material, so that the cost for preparing the UV-1 is greatly reduced; thionyl chloride / trifluoromethanesulfonic anhydride is used as a reaction reagent of ethyl p-aminobenzoate and N-methylformyl aniline, so that the method is not only environment-friendly, but also can obtain higher reaction yield and product purity.

Owner:CHANGZHOU YONGHE FINE CHEM

Preparation method of N,(4-ethyoxyl carbonyl phenyl)-N'-methyl-N'-phenyl formamidine

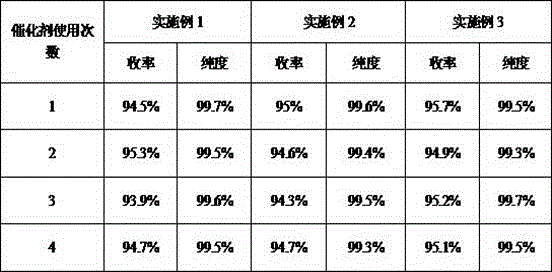

ActiveCN106431990ASimple processEasy to operateOrganic chemistryChemical recyclingMethylanilineBenzoic acid

The invention discloses a preparation method of N,(4-ethyoxyl carbonyl phenyl)-N'-methyl-N'-phenyl formamidine. According to the method, ethyl p-aminobenzoate, orthoformic acid trialkyl ester and N-methylaniline are adopted as original raw materials, activated aluminum oxide is adopted as a catalyst, and N,(4-ethyoxyl carbonyl phenyl)-N'-methyl-N'-phenyl formamidine is prepared through a one-step reaction. The method is simple in process, convenient to operate, free of contamination and high in product purity, and the adopted catalyst aluminum oxide can be recycled.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

Preparation method of N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzyl formamidine

ActiveCN103709073BHigh reaction yieldSuitable for industrial productionOrganic chemistryAlkyl transferEthyl aminobenzoate

The invention discloses a preparation method of N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzyl formamidine. The preparation method comprises the steps of carrying out condensation reaction on ethyl p-aminobenzoate and trialkyl ortho-formate to obtain N,N'-bis (4-ethoxycarbonylphenyl) formamidine; reacting benzyl chloride with the N,N'-bis (4-ethoxycarbonylphenyl) formamidine through N-alkylation reaction to obtain the N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzyl formamidine, wherein the molar ratio of the ethyl p-aminobenzoate and the trialkyl ortho-formate is 1:0.3-1:0.7. According to the preparation method, two 4-ethoxycarbonylphenyls are grafted once, and only two reaction steps are required to obtain the N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzyl formamidine, therefore, the synthetic route is greatly shortened, the total reaction yield can be up to more than 60%, and the preparation method is particularly suitable for industrial production.

Owner:CHANGZHOU YONGHE FINE CHEM

N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenyl formamidine preparation method

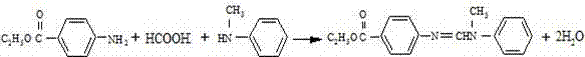

InactiveCN107235859ASimple processEasy to operateOrganic chemistryN-MethylanilineEthyl aminobenzoate

The invention discloses an N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenyl formamidine preparation method. According to the method, ethyl p-aminobenzoate, N-methylaniline and formic acid serve as starting raw materials to prepare N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenyl formamidine through one-step reaction. The method is simple in process and convenient to operate; a byproduct only comprises water, so that safety, environmental friendliness and freeness of pollution are realized.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

Synthesis technology of N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenyl amidine

ActiveCN108640857AReduce dosageGood removal effectOrganic chemistryChemical synthesisReaction temperature

The invention discloses a synthesis technology of N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenyl amidine, and belongs to the technical field of chemical synthesis. The synthesis technology is one-step,that is, ethyl p-aminobenzoate, trialkyl orthoformate and N-methylaniline are added simultaneously, and N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenyl amidine is synthesized from petroleum ether as a solvent and glacial acetic acid as a catalyst by one step. Besides, a water separator is arranged on a reaction vessel and pre-filled with frozen liquid. The solvent can be recycled after refining, no toxic solvent is needed for post-treatment, the byproduct methanol can be discharged from the reaction system in time, and the yield is increased. The whole technological process has low reaction temperature and short reaction time, and the synthesis technology has the advantages of low energy consumption, low cost, low pollution and high yield.

Owner:YANTAI XINXIU CHEM TECH CO LTD

High compatibility modifier for plastic processing

The invention provides a high compatibility modifier for plastic processing. The high compatibility modifier for plastic processing comprises, by weight parts, 5-15 parts of nano calcium carbonate, 5-10 parts of chlorinated polyethylene, 5-10 parts of silicone acrylic emulsion, 2-5 parts of dimethicone copolyol, 0.5-2 parts of grafted polyether polyol, 3-10 parts of polyethylene glycol, 0-1 part of ethyl p-aminobenzoate, 0-1 part of heat stabilizer, 0-1 part of coupling agent and 0-0.5 part of surfactant. Through the reasonable raw material ratio, the made modifier has excellent dispersibilityand compatibility for plastic processing and improves plastic product quality stability. In addition, the high compatibility modifier also has excellent weather resistance, UV resistance and toughness, the comprehensive quality is obviously improved, the practical benefit is improved, and the high compatibility modifier is worth promoting.

Owner:NANJING CONCORD FERTILIZER CHEM

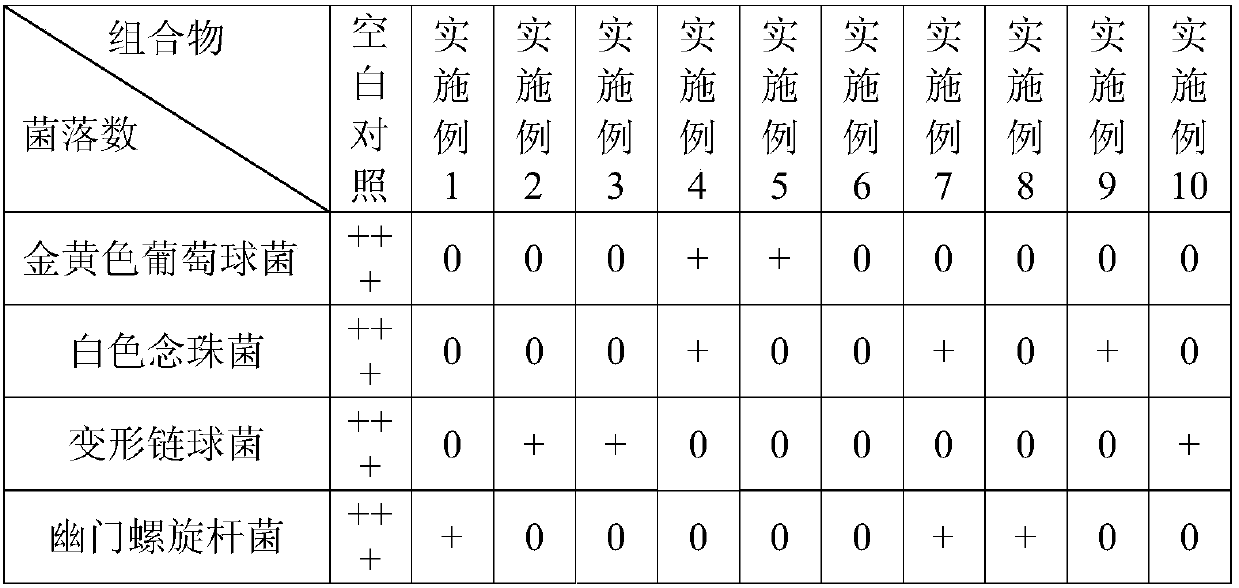

Povidone iodine compound, preparation method and application thereof

ActiveCN109512683AImprove antibacterial propertiesObvious analgesic effectAntibacterial agentsCosmetic preparationsDiseaseOral disease

The invention provides a povidone iodine compound which comprises the following components in parts by weight: 10-25 parts of povidone iodine powder, 1-10 parts of polyoxyethyl nonyl phenyl ether, 50-100 parts of polyhydric alcohols, 0.1-0.5 part of zinc oxide, 0.1-2.1 parts of flavoring agent, 0.1-1 part of acetoglycine ethylenediamine and 0.4-1.8 parts of ethyl p-aminobenzoate, wherein the flavoring agent includes one or two of storax oil and star anise oil. An oral care product prepared from the povidone iodine compound provided by the invention has excellent anti-microbial, pain-relievingand bleeding-stopping effects, little irritation to oral mucosa and functions of preventing and treating oral diseases.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

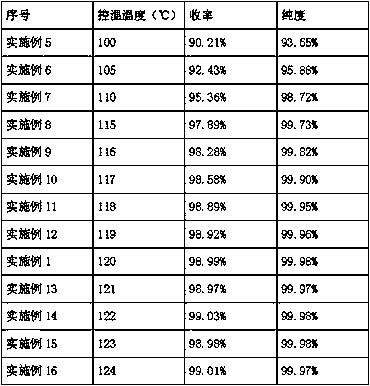

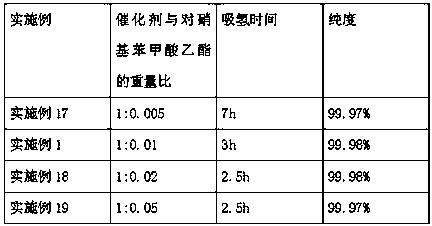

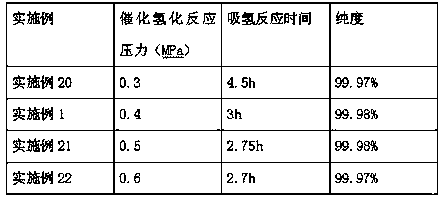

Process for preparing benzocaine through solvent-free hydrogenation

ActiveCN110590585AReduce volatilityEmission reductionOrganic compound preparationAmino-carboxyl compound preparationHydrogenEthyl aminobenzoate

The invention relates to a process for preparing benzocaine (ethyl p-aminobenzoate) through solvent-free hydrogenation, and belongs to the field of chemical engineering. The process comprises: (1) heating ethyl p-nitrobenzoate for more than 1 h at a temperature of more than 100 DEG C; (2) adding a catalyst and the ethyl p-nitrobenzoate treated in the step (1); and (3) in the absence of a solvent,introducing hydrogen until the reaction does not absorb hydrogen, and carrying out post-treatment to obtain the product.

Owner:浙江优创材料科技股份有限公司

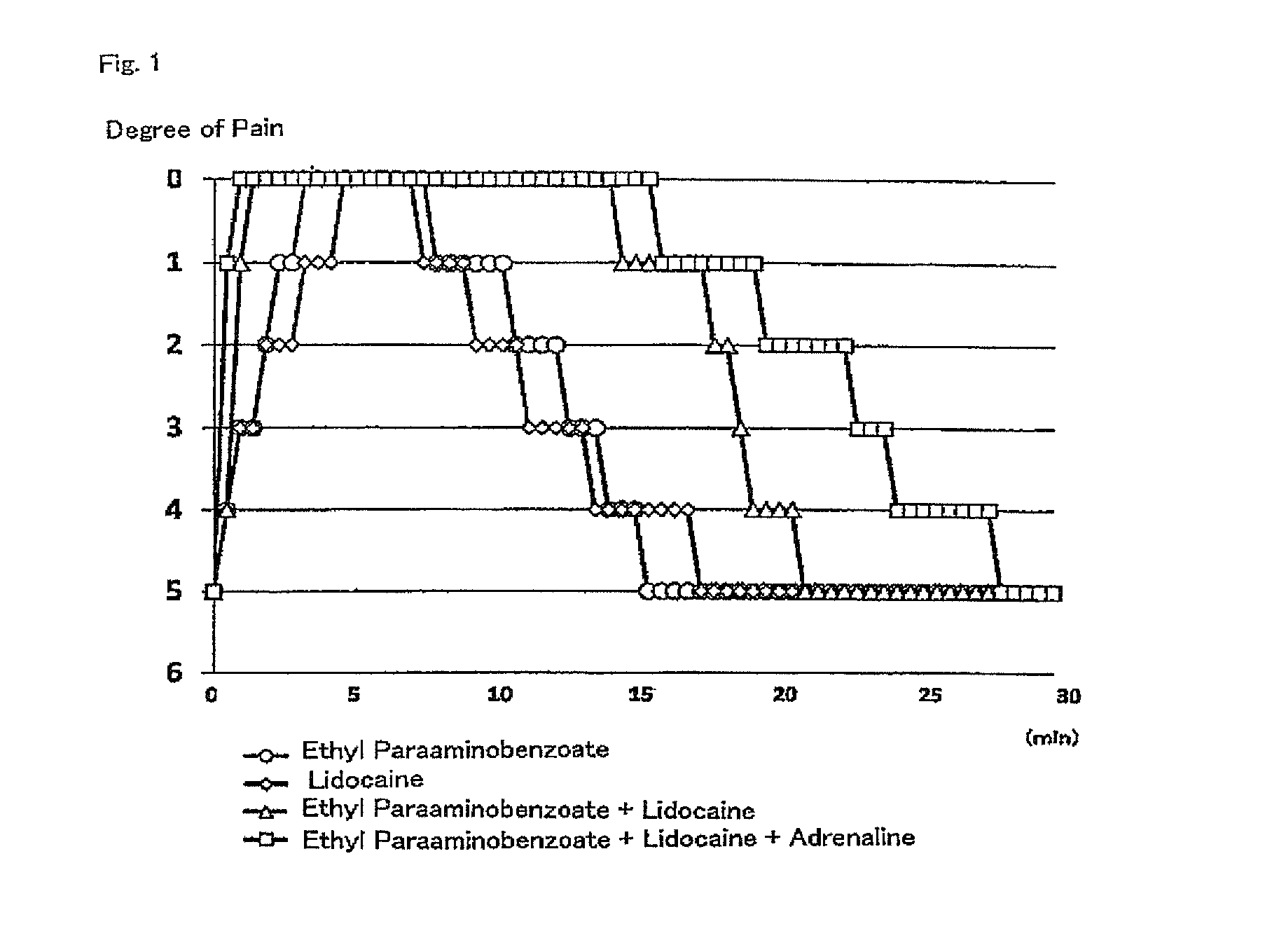

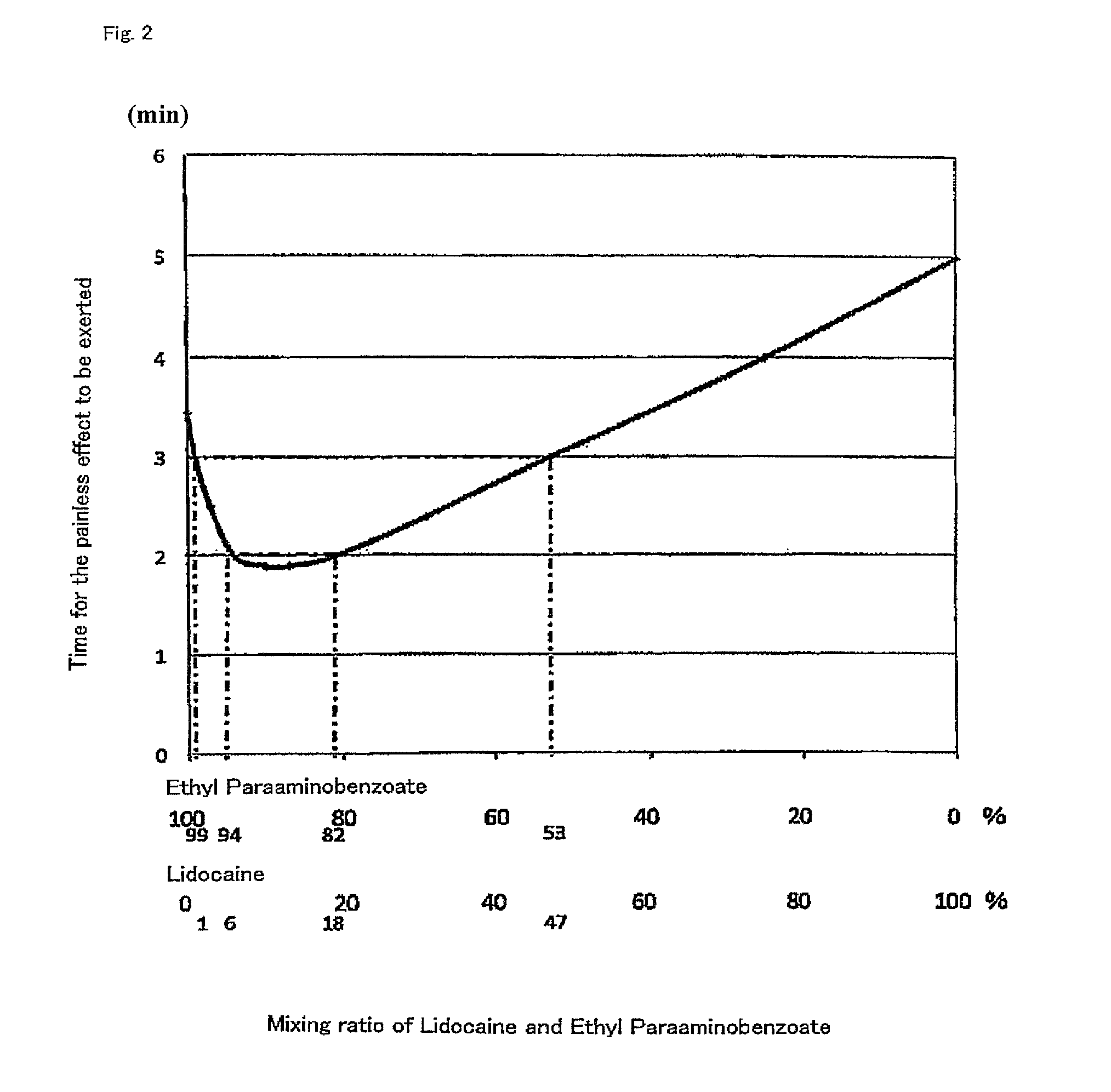

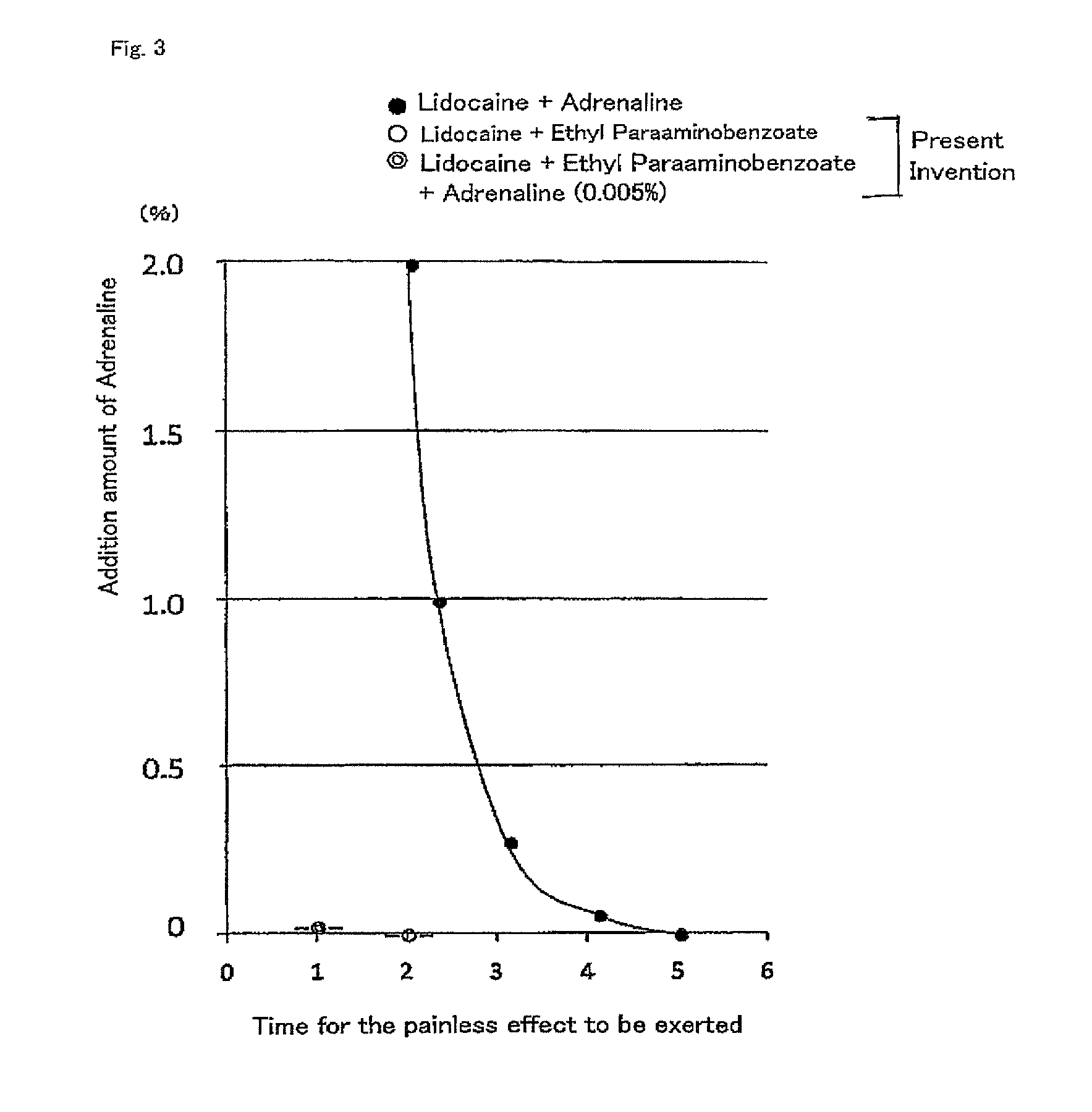

Surface Anesthetic Agent

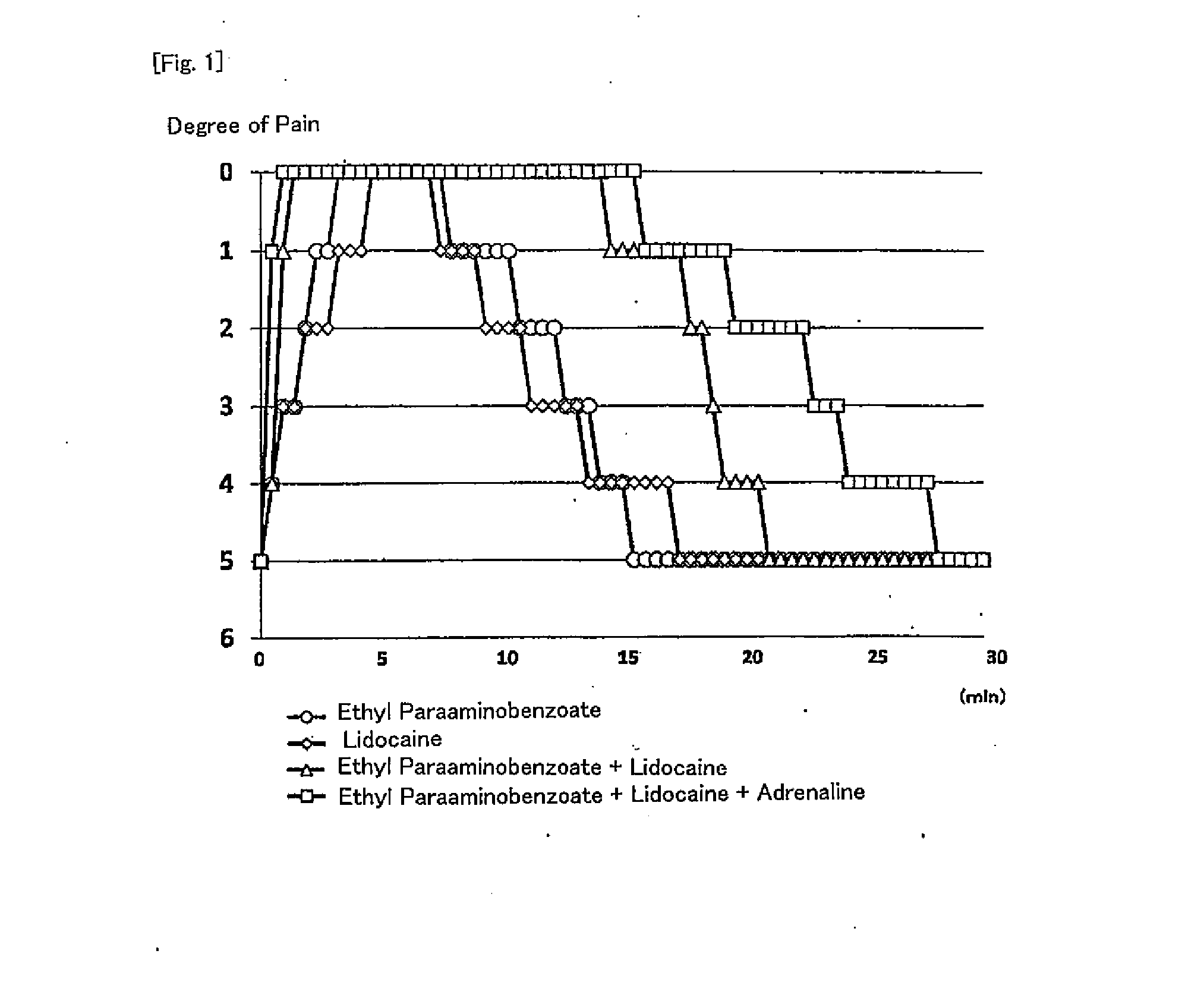

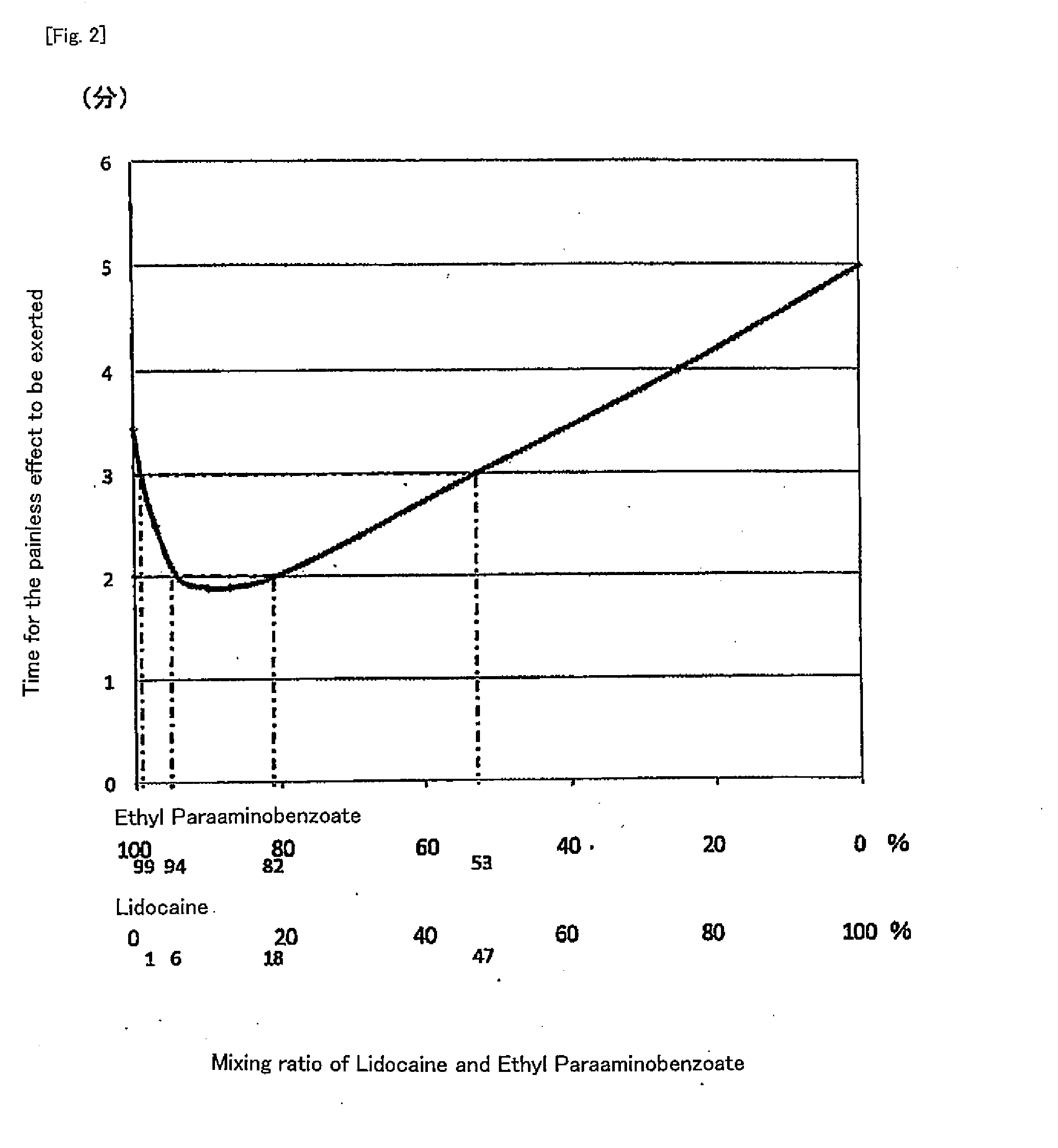

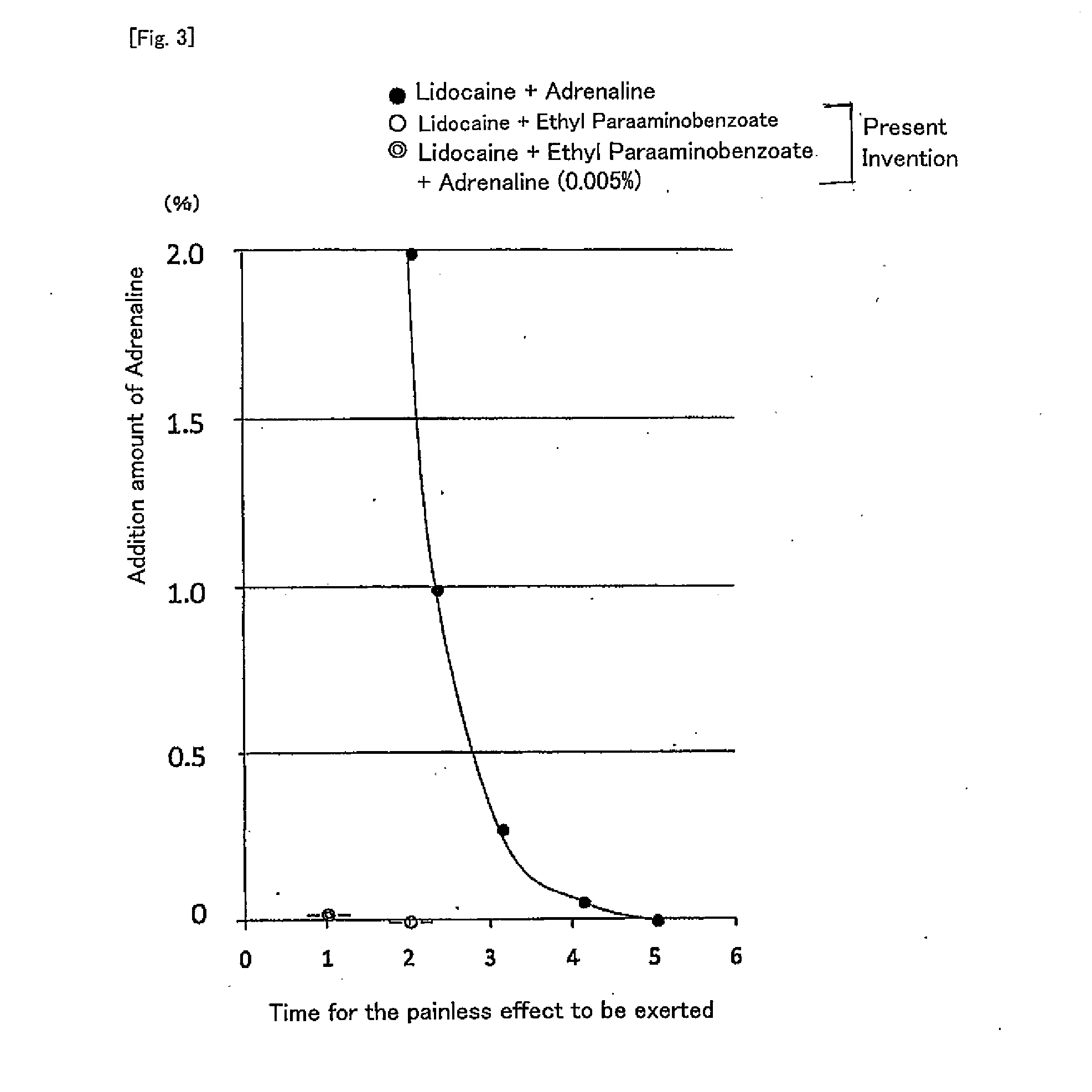

Provided is an anesthetic agent which can exhibit an anesthetic effect rapidly when adhered on mucosal membranes, the skin or the like by means of application or the like in local anesthesia, particularly surface anesthesia. Prepared are: a fast-acting surface anesthetic agent containing lidocaine and ethyl paraaminobenzoate at a specific ratio; and a super fast-acting surface anesthetic agent containing lidocaine, ethyl paraaminobenzoate and adrenaline at a specific ratio.

Owner:YAMAGUCHI UNIV

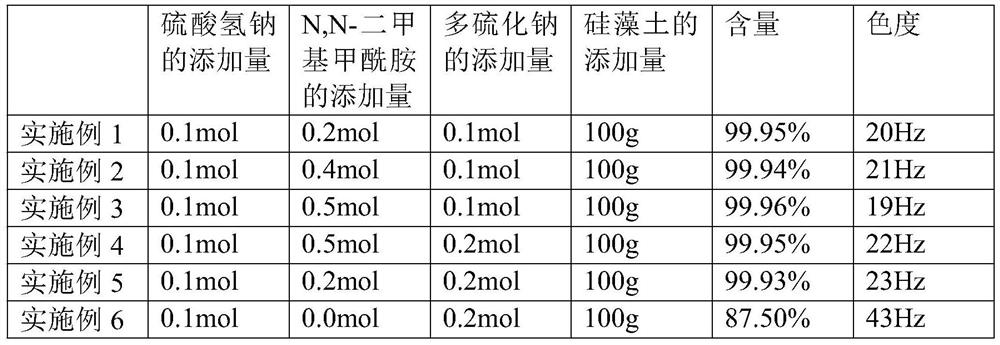

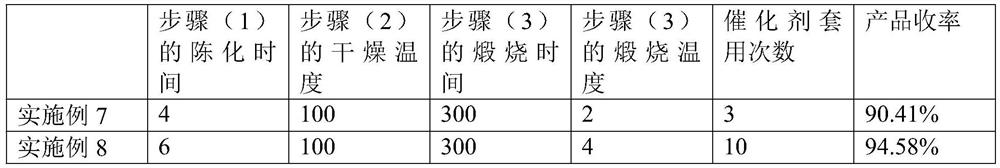

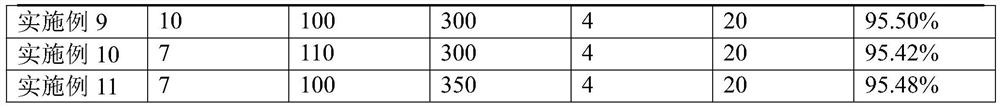

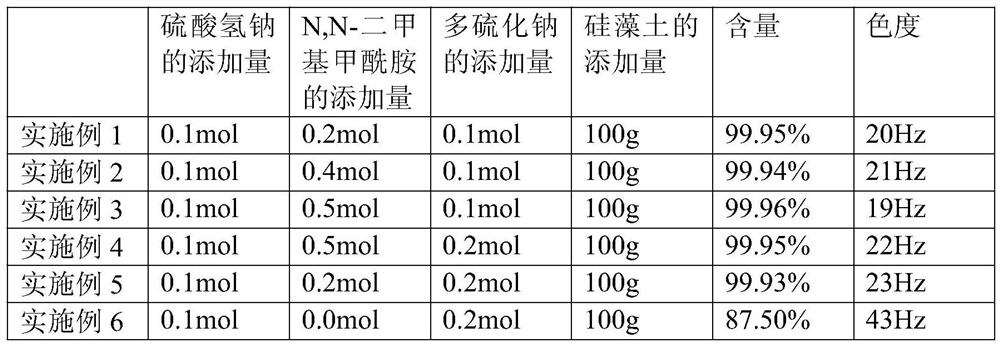

Preparation method of ethyl p-aminobenzoate

ActiveCN111732521ASimple processImprove product qualityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPtru catalyst

The invention relates to the technical field of fine chemical engineering, in particular to a preparation method of ethyl p-aminobenzoate. The invention relates to a preparation method of ethyl p-aminobenzoate, which is characterized by comprising the following steps: (1) adding p-nitrobenzoic acid, ethanol and a composite catalyst into a reaction kettle; (2) carrying out a reaction for 6-8 h under a reflux condition to obtain ethyl p-aminobenzoate, an intermediate p-aminobenzoic acid and p-nitrobenzoic acid which is not completely reacted; and (3) carrying out post-treatment to obtain the ethyl p-aminobenzoate finished product. The composite catalyst is composed of sulfate, an inorganic reducing agent, a diatomite and an amine accelerator.

Owner:浙江优创材料科技股份有限公司

A kind of preparation method of ethyl p-aminobenzoate

ActiveCN111732521BSimple ingredientsSimple processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPtru catalyst

The invention relates to the technical field of fine chemicals, in particular to a preparation method of ethyl p-aminobenzoate. A kind of preparation method of p-aminobenzoic acid ethyl ester of the present invention is characterized in that, comprises the following steps: (1) p-nitrobenzoic acid, ethanol, composite catalyst are dropped into reactor; (2) react 6- 8h, obtain ethyl p-aminobenzoate, intermediate p-aminobenzoic acid, and unreacted complete p-nitrobenzoic acid; (3) aftertreatment, obtain the finished product of p-aminobenzoic acid ethyl ester; the composite catalyst consists of sulfate , Inorganic reducing agent, diatomaceous earth, amine accelerator composition.

Owner:浙江优创材料科技股份有限公司

Preparation of N-(4-ethoxy carbonyl phenyl)-N'-methyl-N'-phenyl formamidine

ActiveCN101481330BReduce consumptionLower the condensation reaction temperatureOrganic chemistryN-MethylanilineEthyl aminobenzoate

Owner:CHANGZHOU SUNLIGHT PHARMA

Preparation method of n,n'-bis(4-ethoxycarbonylphenyl)-n'-benzylformamidine

InactiveCN103420873BShort reaction timeHigh yieldImino compound preparationAlkyl transferFormylation reaction

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Green preparation process of n-(4-ethoxycarbonylphenyl)-n'-methyl-n'-phenylformamidine intermediates

ActiveCN105315168BReduce pollutionImprove the yield of esterification reactionOrganic compound preparationAmino-carboxyl compound preparationAlcoholP-nitrobenzoic acid

Owner:CHANGZHOU YONGHE FINE CHEM

Surface anesthetic agent

Owner:YAMAGUCHI UNIV

Method for preparing N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzylformamidine from waste residues for preparing UV-1

The invention discloses a method for preparing N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzylformamidine from waste residues for preparing UV-1. According to the method, after reaction treatment or separation treatment is carried out on the NE waste residues generated by production of N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-benzylformamidine, the product and benzyl chloride are subjected to N-alkylation reaction, and N,N'-bis (4-ethoxycarbonylphenyl)-N'-benzylformamidine is obtained. The reaction treatment includes the steps that the NE waste residues are dissolved in a polar aprotic solvent, activated carbon treatment is carried out, then ethyl p-aminobenzoate is added for condensation reaction, and finally, the product and benzyl chloride are subjected to the N-alkylation reaction. The separation treatment includes the steps that the NE waste residues are dissolved in a methylbenzene solvent, after NE is separated, the product is dissolved in the polar aprotic solvent, and after activated carbon treatment, the product and benzyl chloride are subjected to N-alkylation reaction. By means of the reaction method, more NEPA can be obtained, and by means of the separation method, NEPA higher in purity can be obtained.

Owner:CHANGZHOU YONGHE FINE CHEM

Burn and scald ointment and preparation method thereof

InactiveCN106606510ARelieve painImprove medication complianceOrganic active ingredientsAntipyreticSodium sulfateSulfadiazine Silver

The invention discloses a burn and scald ointment and a preparation method thereof. The burn and scald ointment is prepared from the following components in parts by weight: 20 parts of sulfadiazine silver, 10 parts of sulfadiazine zinc, 10 parts of ethyl p-aminobenzoate with D90 less than or equal to 50 microns, 90 parts of hexadecanol, 60 parts of liquid paraffin, 140 parts of albolene, 10 parts of lauryl sodium sulfate, 1.5 parts of ethylparaben, 50 parts of glycerin, 9 parts of laurocapram, and 599.5 parts of purified water. According to the burn and scald ointment and the preparation method thereof, micronized ethyl p-aminobenzoate (D90 is less than or equal to 50 microns) is adopted, and a weight ratio of sulfadiazine silver, sulfadiazine zinc and ethyl p-aminobenzoate is controlled to be 2 : 1 : 1, so that ethyl p-aminobenzoate can be in close contact with a wound for quickly taking a pain-relieving effect, the pain of the wound surface of a patient is relieved, and the medication compliance of the patient is improved.

Owner:CHANGZHOU SUNLIGHT PHARMA

Preparation method and application of permanently charged hydrazine sugar markers

ActiveCN107501123BHigh sensitivityHigh resolutionComponent separationOrganic compound preparationBenzoic acidOrganic synthesis

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

N,N'-bis(4-ethoxy carbonyl phenyl)-N'-benzyl formamidine

ActiveCN101481331BHigh yieldEasy to separate and purifyOrganic chemistryOrganic compound preparationBenzoic acidHalohydrocarbon

The invention relates to the technical field of fine chemistry industry, in particular to a method for preparing N, N'-di(4-ethoxycarbonylphenyl)-N'-phenylformamidine. Parathesin and benzyl chloride are taken as raw materials. The method comprises a formylation reaction process, an N alkylation reaction process and a condensation reaction process; wherein, in the N alkylation reaction process, 4-formamido ethyl benzoate generated in the formylation reaction process is added into dipolar aprotic solvent, and then inorganic weak base and the benzyl chloride are added, the temperature rises and is preserved and the reaction lasts for 20-25 hours; then the temperature is lowered to the room temperature and suction filtration and washing are carried out on the separated pale yellow solid to obtain pale yellow intermediate; the intermediate and the parathesin are added into halogenated hydrocarbon and then dehydrant is added; after heatingup and reflux for 15-17 hours, the temperature is cooled to the room temperature; NaOH aqueous solution is added to steam out the halogenated hydrocarbon under normal pressure and then separate out offwhite solid; suction filtration, washing by water and drying are carried out on the solid and the white solid of N, N'-di(4-ethoxycarbonylphenyl)-N'-phenylformamidine is obtained by recrystallization and cooling the solid to the room temperature after washing.

Owner:CHANGZHOU SUNLIGHT PHARMA +1

Anti-fatigue PVC tubular material and preparation method thereof

The invention discloses an anti-fatigue PVC tubular material and a preparation method thereof. The anti-fatigue PVC tubular material is prepared from the following raw materials in parts by weight: 50-70 parts of SG-2 type PVC, 15-25 parts of polyformaldehyde, 4-8 parts of barium fluoride, 3-6 parts of polyamide wax micropowder, 4-8 parts of propolis, 6-12 parts of basic magnesium carbonate, 4.5-6.5 parts of low molecular weight polybutadiene, 17-23 parts of acrylonitrile / EPDM / styrol copolymer, 8-12 parts of dihexyl adipate, 10-15 parts of activated clay, 2-3 parts of p-tert-butyl zinc benzoate, 1-2 parts of calcium naphthenate, 10-15 parts of epoxy acetyl methyl ricinoleate, 1.5-2.5 parts of ethyl p-aminobenzoate, 1-2 parts of 3-(3, 5-ditertiary butyl-4-hydroxy phenyl) methyl propionate and 3-5 parts of addition agent. The PVC tubular material prepared by the invention is excellent in fatigue performance, high in fatigue strength and tensile strength, good in environment resistance and organic solvent resistance, excellent in size stability without crack after being used for a long time, long in service life and wide in application prospect.

Owner:ANHUI JIUZISHAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com