Patents

Literature

36results about How to "Applicable method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

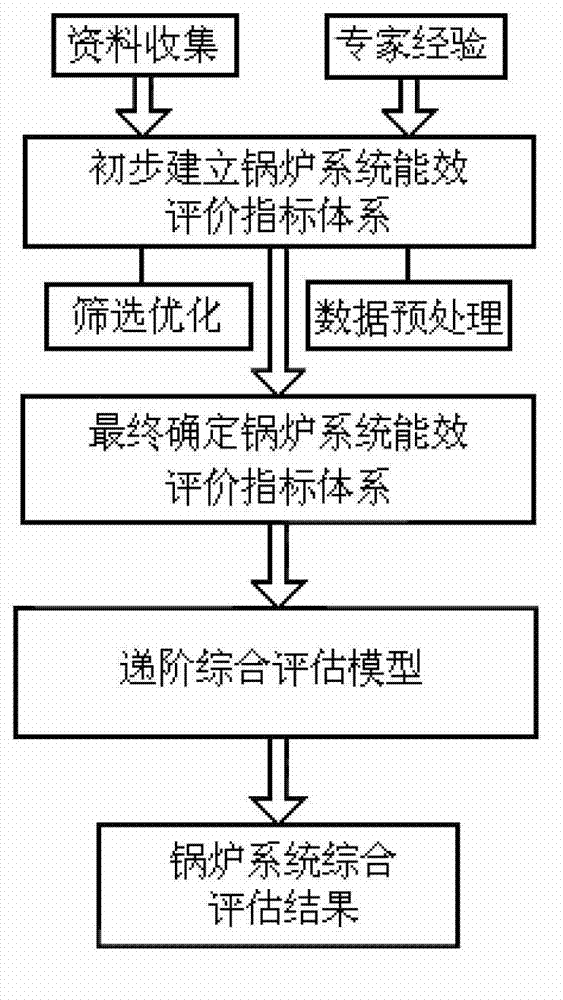

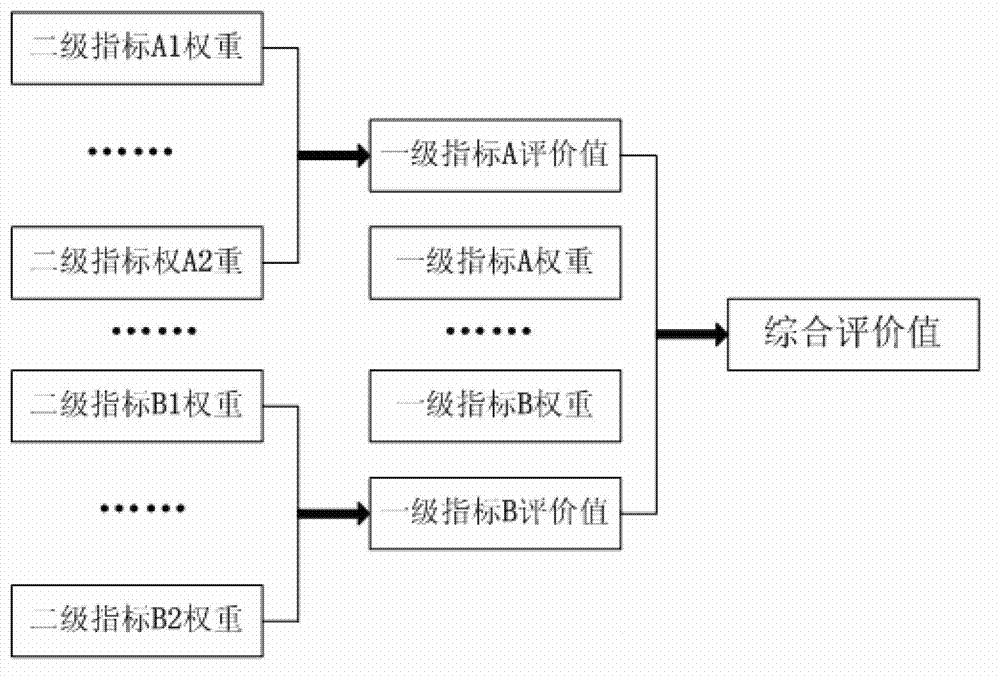

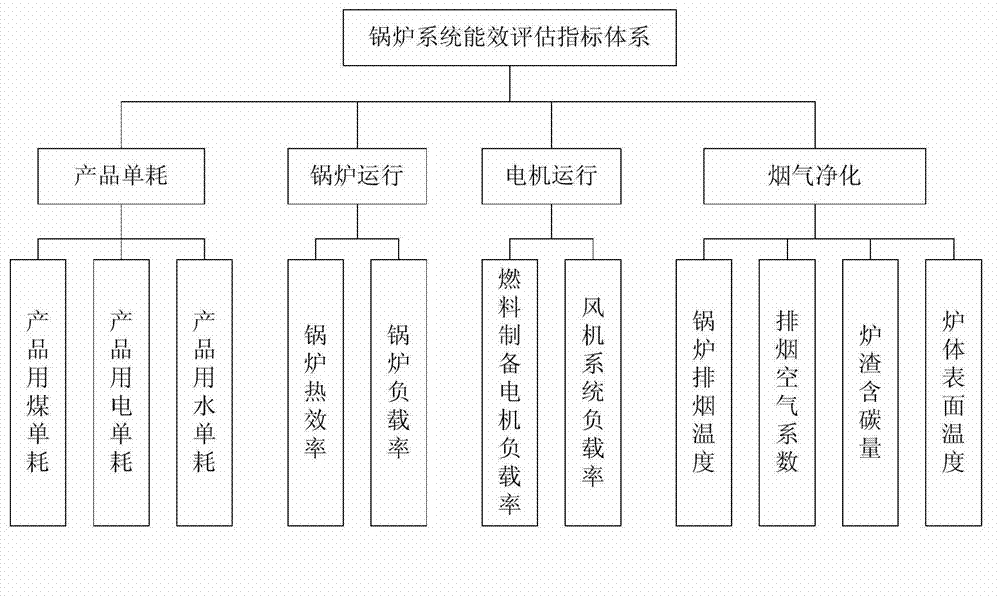

Energy efficiency assessment model and method for boiler system

InactiveCN102968561AGuide economic operationAchieve the ultimate goal of energy saving and emission reductionSpecial data processing applicationsSubjective dataMathematical model

The invention relates to an energy efficiency assessment model and an energy efficiency assessment method for a boiler system. The method comprises the following specific steps of: (1) collecting basic data of the boiler system; (2) inspecting economic running of a boiler, and putting forward an economic running employee evaluation form of the boiler; and (3) performing energy efficiency assessment on the boiler system: initially establishing an energy efficiency index system of the boiler system; performing data preprocessing on the initially-established energy efficiency index system, wherein data preprocessing comprises type uniformization of an evaluation index, non-dimensional normalization and optimal filtration; computing the value of a secondary index in the energy efficiency index system; computing weights of a primary index and the secondary index by applying a hierarchical comprehensive evaluation model, and completing objective assessment of the primary index based on G1 group judgment and subjective assessment of the secondary index based on an entropy method; and completing determination of the comprehensive weight of the hierarchical comprehensive evaluation model by adopting organic combination of expert experience and subjective data, establishing a mathematical model of comprehensive energy efficiency evaluation of the boiler system, and quantifying the evaluation result of the boiler system.

Owner:国网电力科学研究院武汉能效测评有限公司 +2

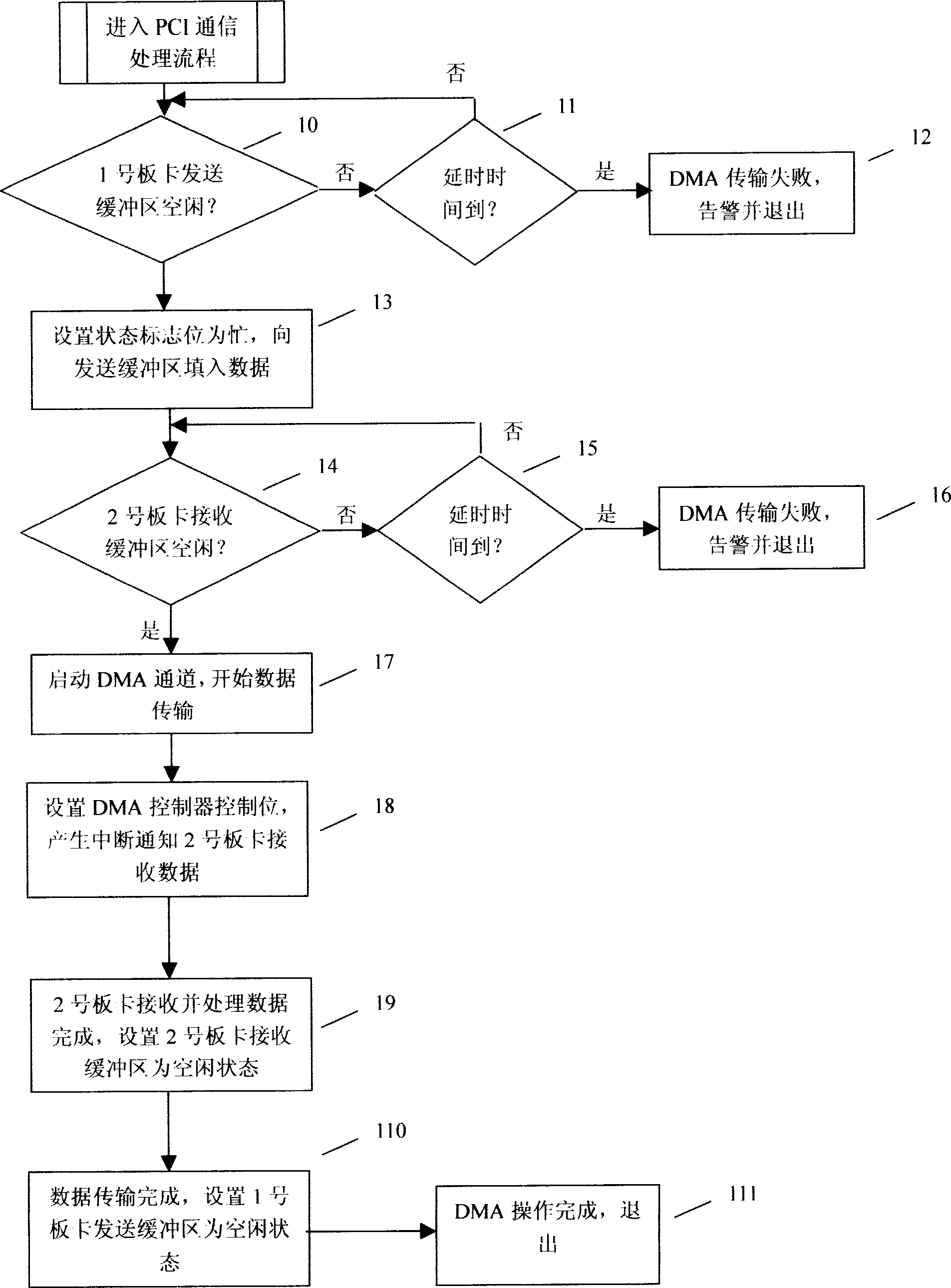

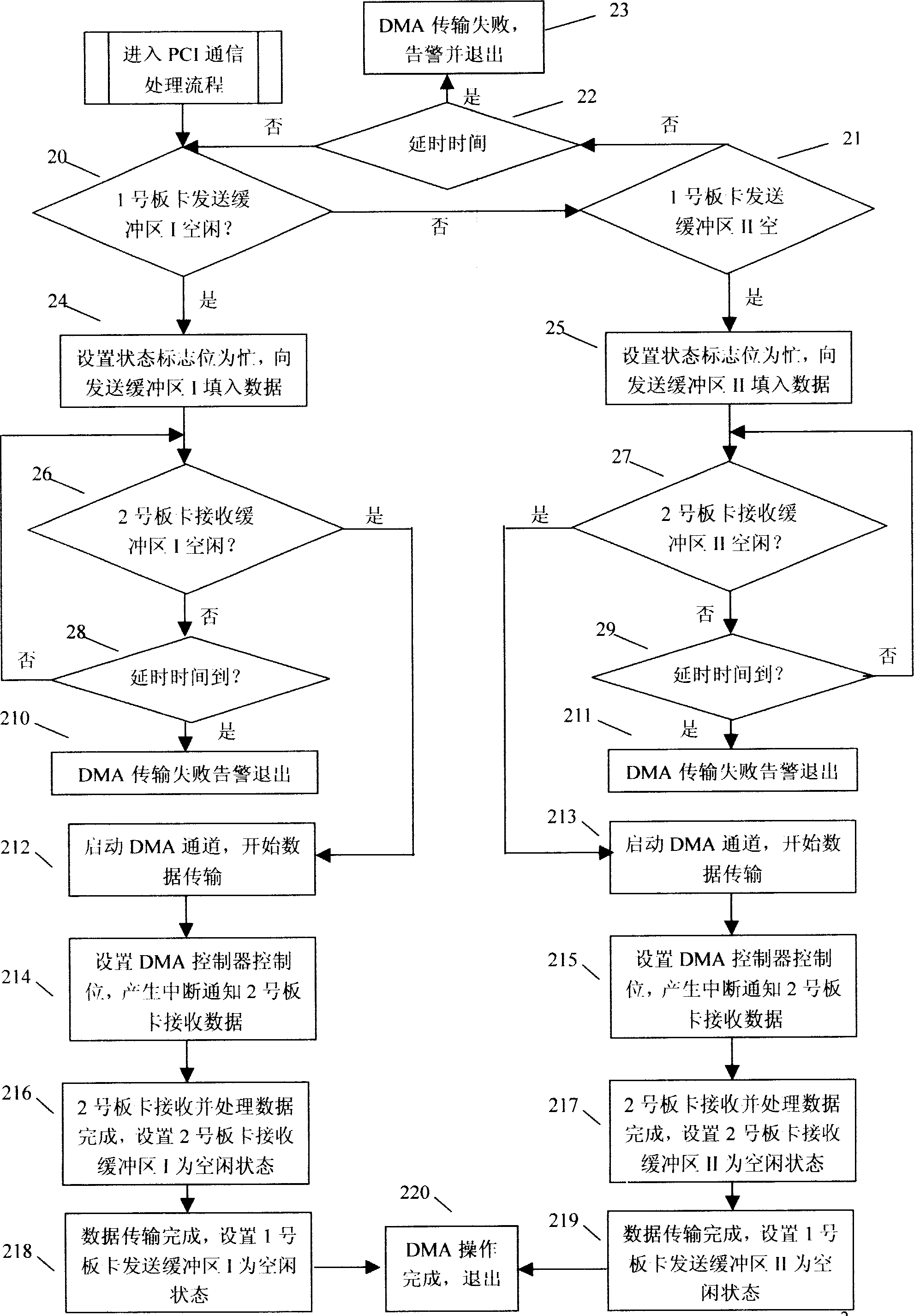

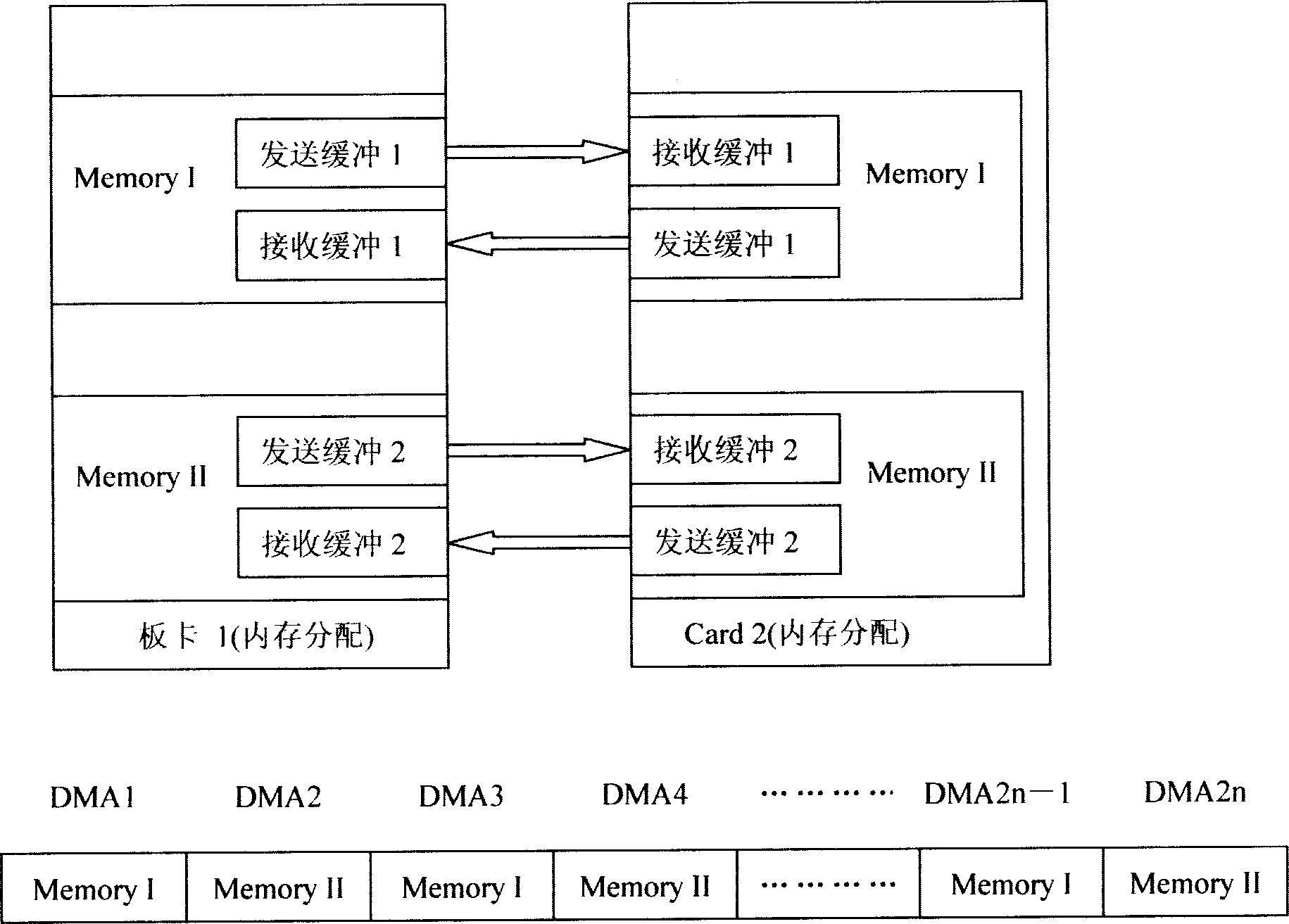

Method for improving PCI communication credibility and efficiency

InactiveCN1908925AProblems preventing reentrancyFix missing errorsElectric digital data processingDependabilityData error

The related method to improve reliability and efficiency for PCI communication comprises: arranging processor and memory on every board, assigning two or three independent areas with same structure on memory as DMA data buffer; alternative operating the two or three areas every with a state flag bit. This invention can prevent data error operation, and improves reliability and efficiency for communication.

Owner:WUHAN HONGXU INFORMATION TECH

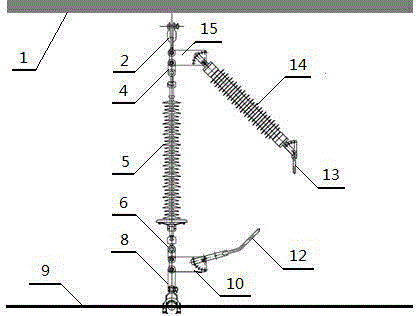

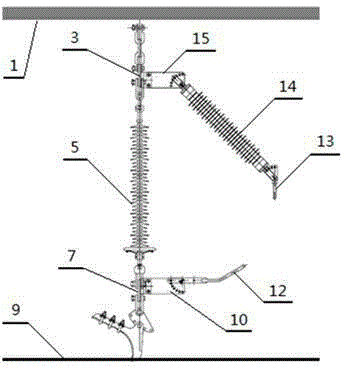

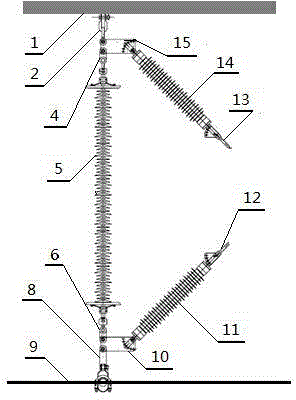

Alternating current electric transmission line lightning flashover restriction method and device

InactiveCN104600567AImprove reliabilityImprove application levelSpark gap detailsInstallation of lighting conductorsBreakdown strengthCombustion

The invention relates to an alternating current electric transmission line lightning flashover restriction method and device. The method includes the steps of current steering, voltage limiting and arc blowing-out. The current steering includes the steps of providing a current discharge channel for power frequency short-circuit current through a parallel gap, wherein the parallel gap is mounted on both ends of an insulator, the breakdown strength of the parallel gap is lower than that of the insulator, and lightning current flows through the parallel gap rather than passing through the insulator when the parallel gap is broken down by lightning. The voltage limiting includes the steps of connecting a non-linear energy absorbing assembly in series with the parallel gap and limiting over-voltage at both ends of the insulator to prevent the insulator from being damaged by lightning flashover, wherein the non-linear energy absorbing assembly is used for absorbing lightning current energy on the basis of current steering. The arc blowing-out includes the steps of treating continuous combustion caused by arc produced in the parallel gap when the power frequency short-circuit current continues to flow through the parallel gap after lightning current passes to prevent tripping of a circuit breaker. The alternating current electric transmission line lightning flashover restriction device is composed of the parallel gap, electrodes, the non-linear energy absorbing assembly and a special-shaped connecting unit which are assembled and connected with one another and is simple in structure, light in weight and small in size.

Owner:STATE GRID CORP OF CHINA +2

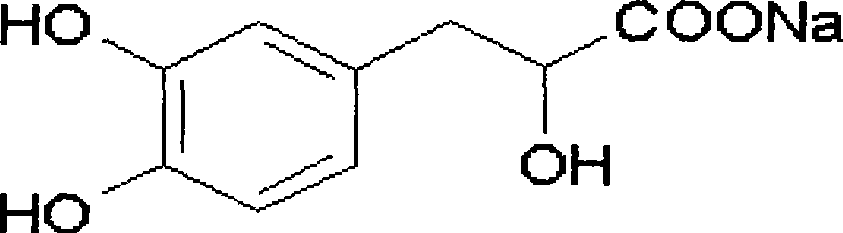

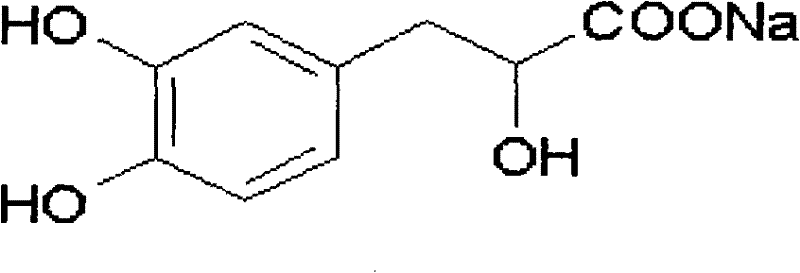

Method for preparing high-purity salvianic acid A sodium

InactiveCN101445451AEconomical and energy-savingGood effectCarboxylic acid salt preparationCarboxylic compound separation/purificationChemistryEthyl acetate

The invention relates to a method for preparing high-purity salvianic acid A sodium. The method comprises the following steps: micronization of radix salviae miltiorrhizae, sopping extraction of ethyl acetate, sopping extraction of dregs, adsorption of extracting solution by AB-8 resin, elution, eluent concentration to adjust the pH value to 7-8, heating for 30 min at high temperature of 110-130 DEG C, filtering, adjusting the pH value to 1-3 for the filter liquor, standing, precipitation, filtering, adsorption of filter liquor under the AB-8 resin acidic condition, pure water elution, adjusting the pH value to 7-8 for the eluent, concentration, drying, obtaining salvianic acid A sodium solid and methanol recrystallization to obtain the high-purity salvianic acid A sodium.

Owner:HEFEI ZIJIN PHARMA TECHNOLOGICAL

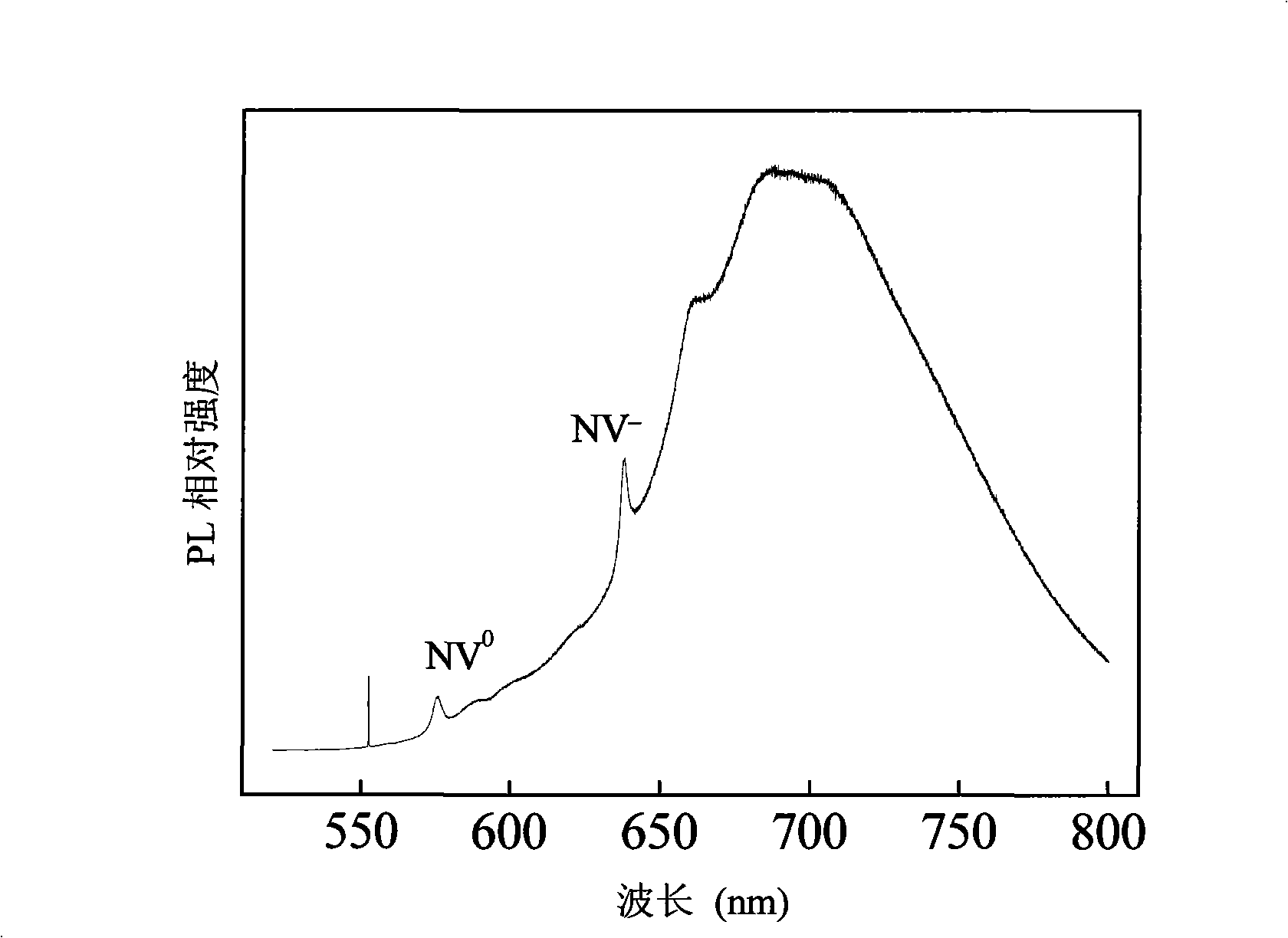

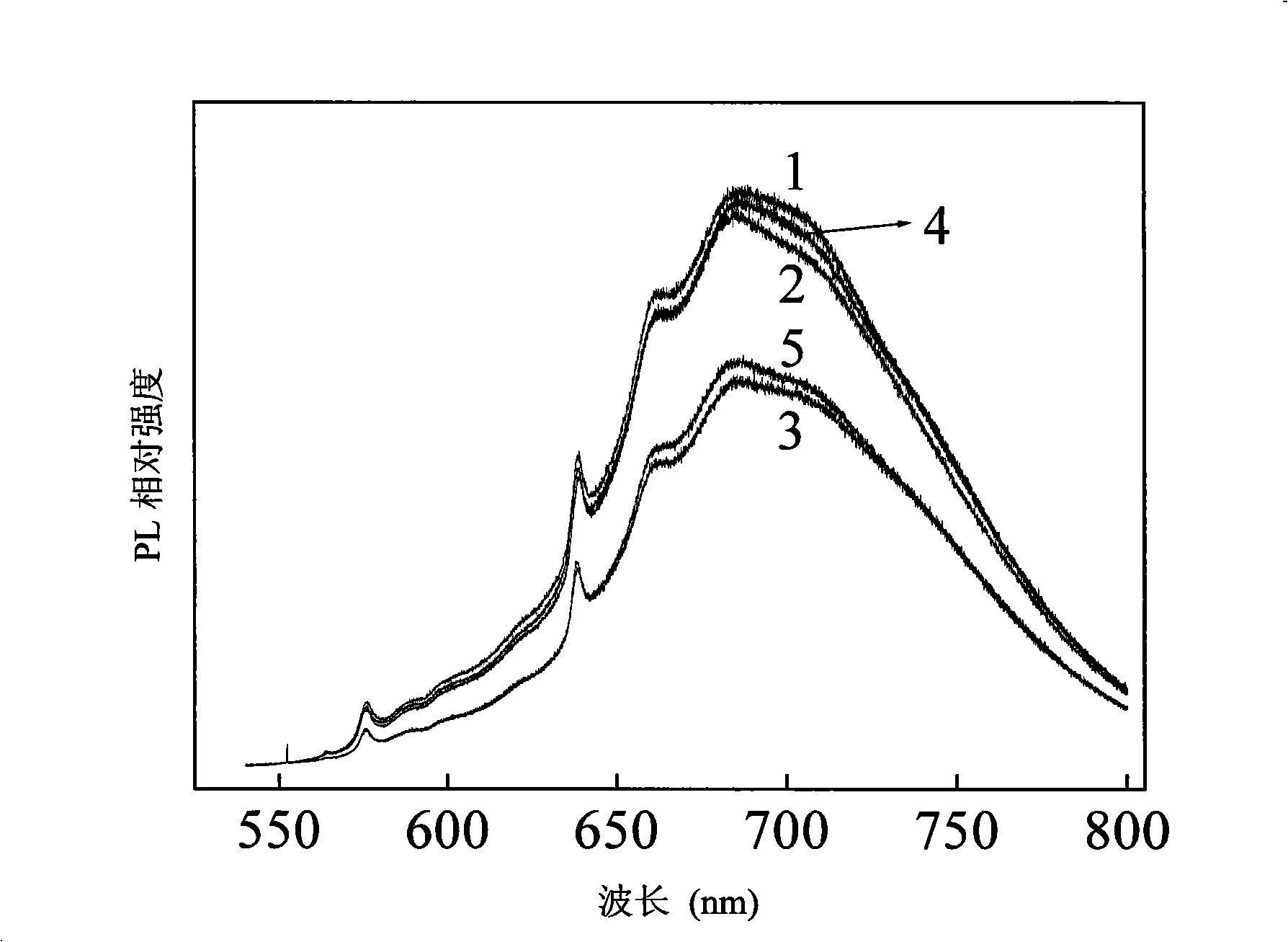

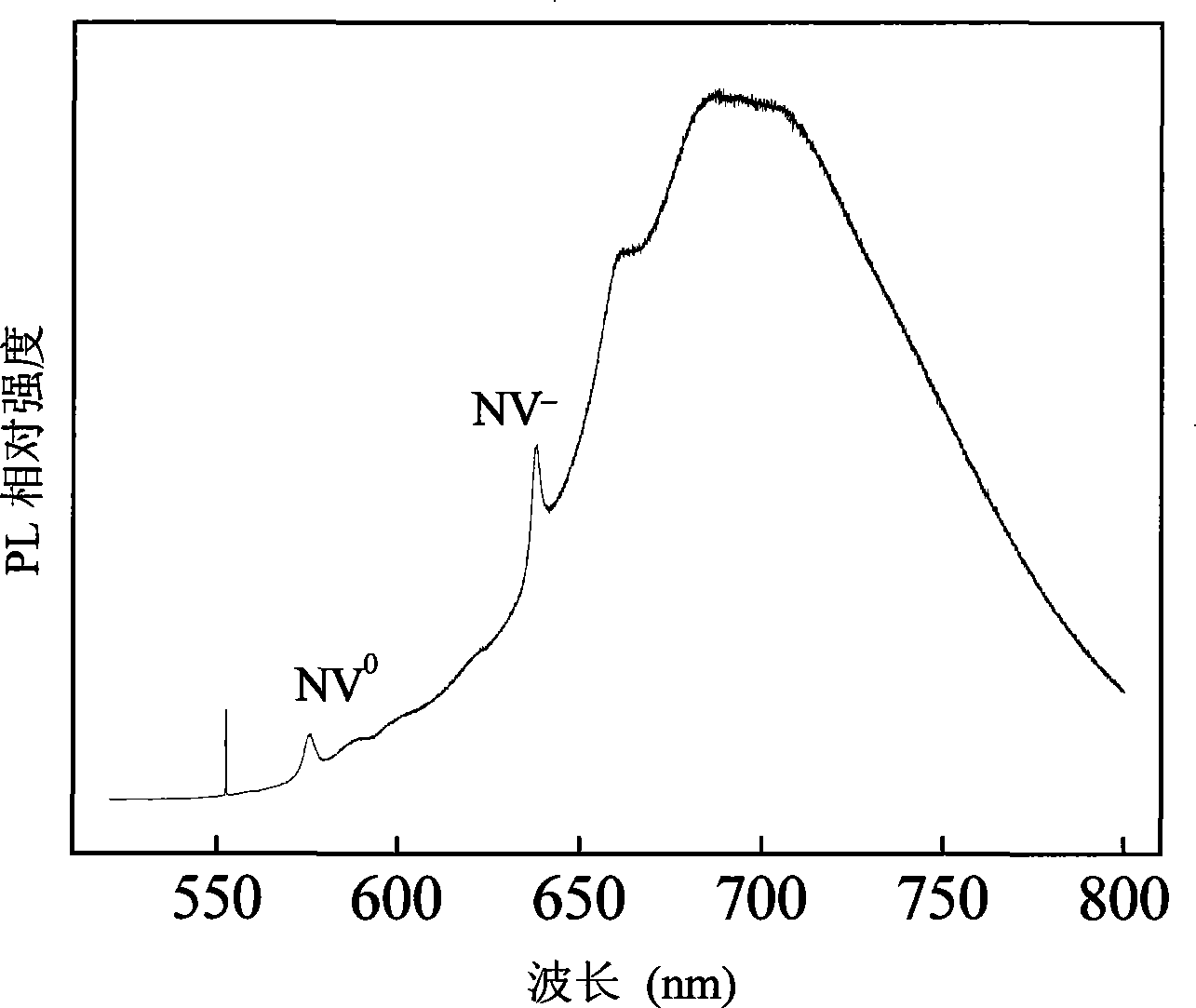

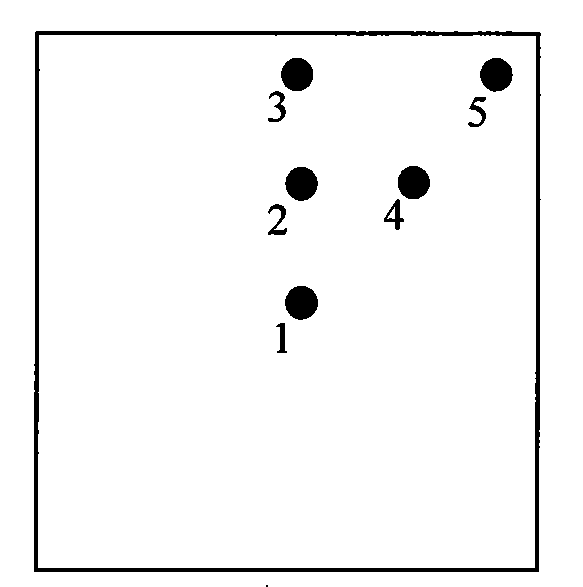

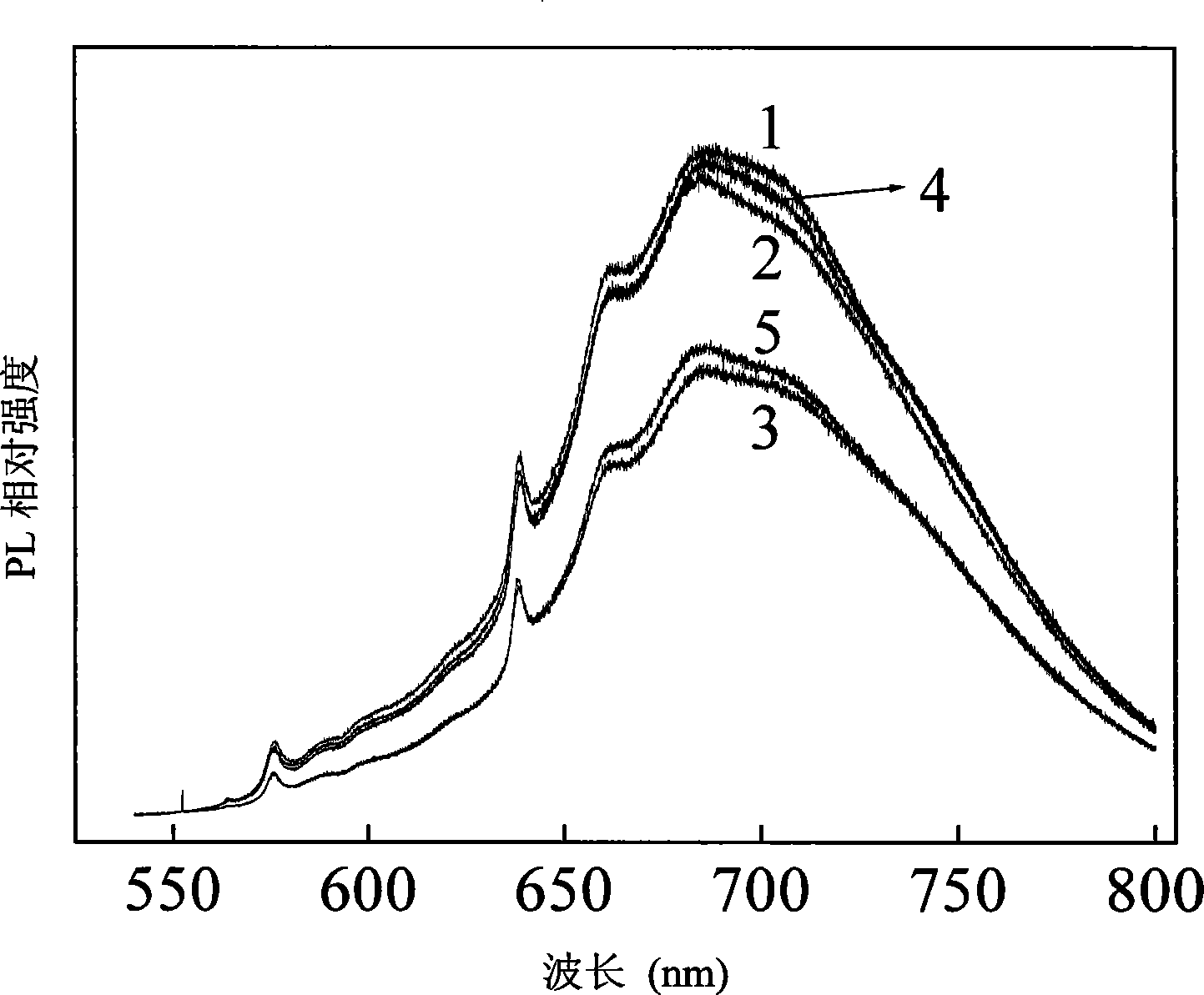

Process for discriminating high growth rate chemical vapour deposition diamond single crystal

InactiveCN101311339ACause damageSolve the puzzle of impactPolycrystalline material growthFrom chemically reactive gasesPhotoluminescenceSingle crystal

The invention discloses a method for identifying high-speed growing chemical vapor deposition diamond single crystal, belonging to the technology field of diamond material. By testing the photoluminescence fluorescence spectrum on the growing surface of the CVD diamond single crystal got by taking the methane, hydrogen and nitrogen as the reactive gas on different positions along the side of the growing direction, the diamond single crystal with regular change of spectra strength is nitrating high-speed chemical vapor deposition diamond single crystal. Therefore, the CVD diamond single crystal can be separated from other diamond single crystals according to the changes of the strength of the photoluminescence fluorescence peak related to the nitrogen content. The method of the invention is simple, suitable and rapid, which can not damage the growing CVD single crystal diamond.

Owner:JILIN UNIV

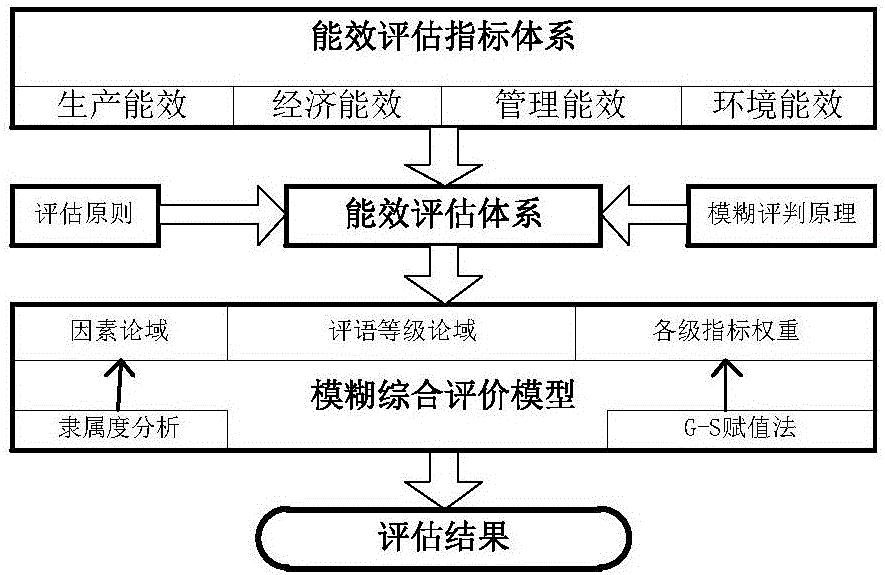

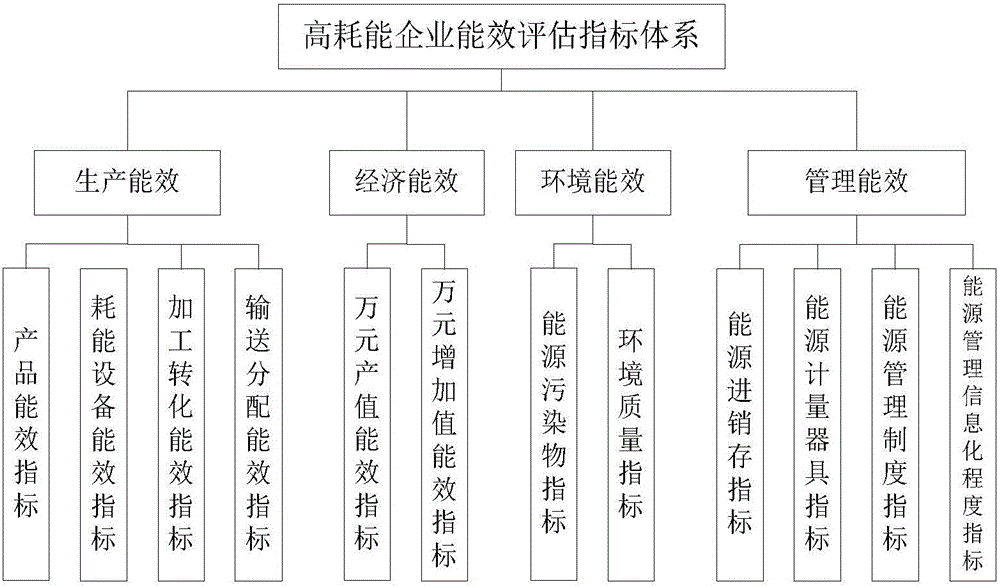

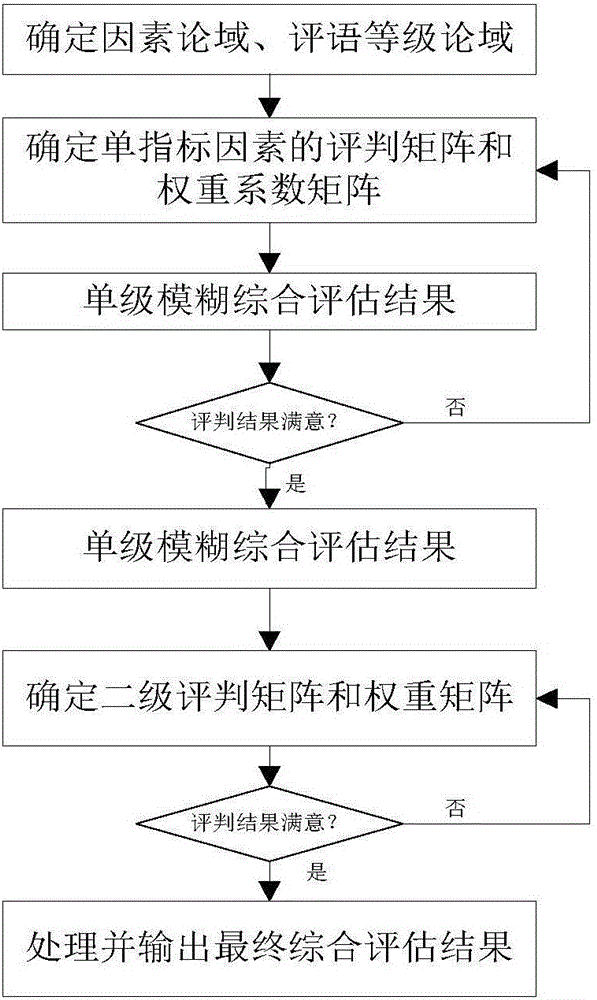

Energy efficiency assessment method for high-energy-consumption enterprises

InactiveCN106127388AGuaranteed accuracyIndicate energy saving potentialEnergy industryTechnology managementAssessment methodsIndex system

The present invention relates to an energy efficiency evaluation method for high energy-consuming enterprises, comprising the following steps: S1) collecting data and establishing an energy efficiency evaluation index system, which includes a plurality of first-level indicators, and each first-level indicator includes a plurality of second-level indicators. Each second-level index is normalized; S2) Based on the energy efficiency evaluation index system, determine the factor domain and comment level domain of the first-level index and the second-level index in turn, and determine the weight set of the first-level index and the second-level index , obtain a comprehensive evaluation matrix, and establish a mathematical model of multi-level fuzzy comprehensive evaluation; S3) use the mathematical model of multi-level fuzzy comprehensive evaluation to complete the energy efficiency evaluation of high energy-consuming enterprises, and analyze the results. The present invention retains all the information of evaluation indicators at all levels, and through multi-level evaluation and subjective and objective comprehensive weighting, it effectively overcomes the industry limitations of a single evaluation method and the subjective randomness of traditional fuzzy comprehensive evaluation, and the calculation method is scientific, Fast, high reliability, strong engineering practicality and application promotion value.

Owner:国网电力科学研究院武汉能效测评有限公司 +3

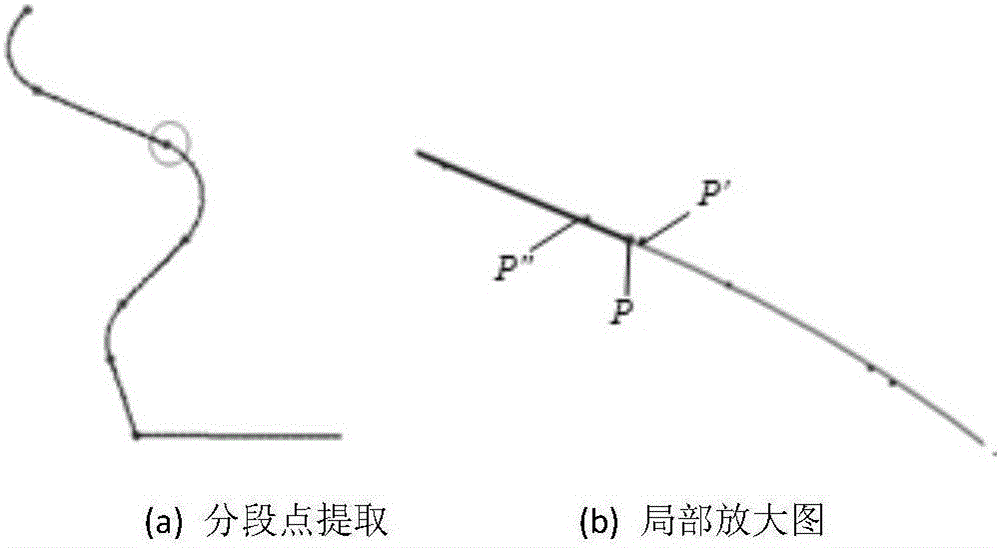

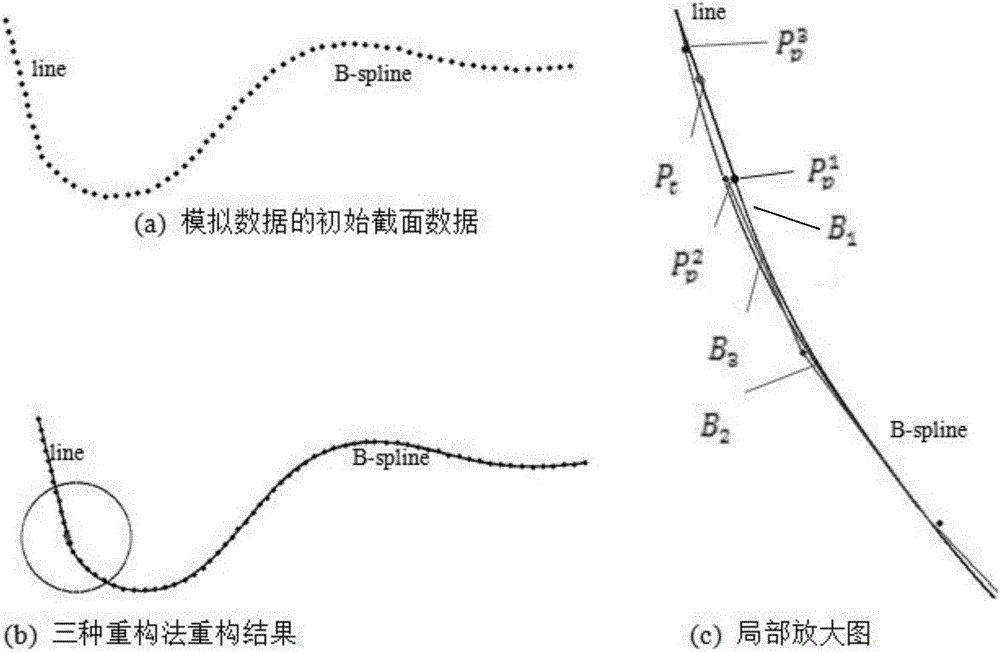

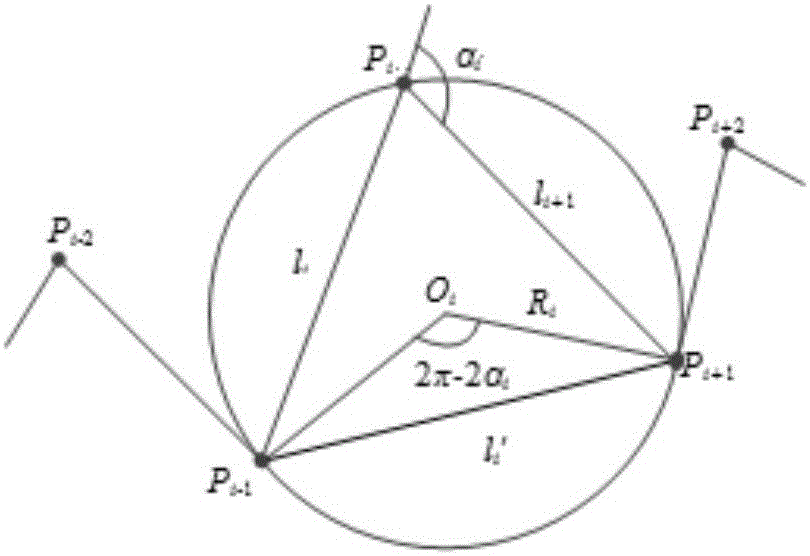

Cross section curve reconstruction method for three-dimensional model reconstruction

The invention discloses a cross section curve reconstruction method for three-dimensional model reconstruction, which comprises the steps of carrying out segmentation on data points according to curvature information of discrete data, determining corresponding characteristics, and determining an area in which an ideal segmentation point is located; referring to the density of data sampling, determining a reasonable grid division spacing, and carrying out gridding on a target area; firstly fitting a straight line as for each node of the current grid, then fitting a B spline curve based on boundary constraint conditions, and calculating the total error of all data points to the curve and the number of control vertexes of the B spline curve; comprehensively analyzing the two groups of calculated data, and determining a current optimal segmentation point; outputting the optimal segmentation point if the density of the current grid node satisfies the precision; and otherwise, reducing the target area by taking the current optimal segmentation point as a center, reducing the spacing, dividing the grid, and reconstructing a cross section curve according to the current optimal segmentation point.

Owner:SHANGHAI UNIV OF ENG SCI

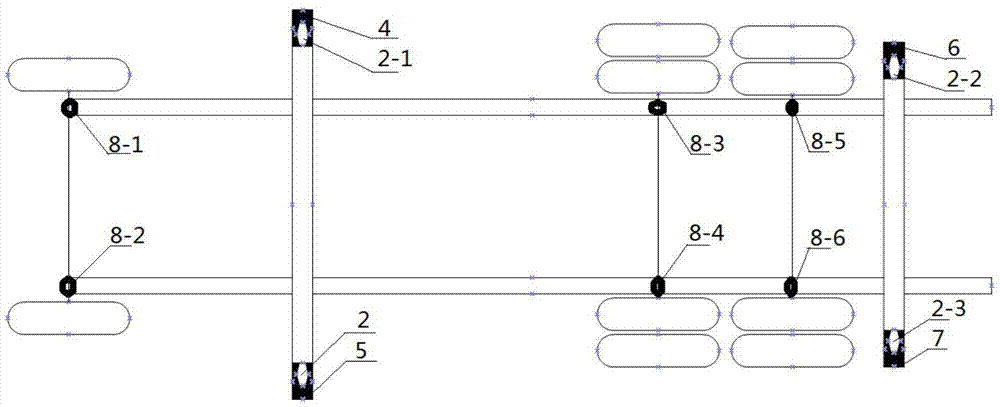

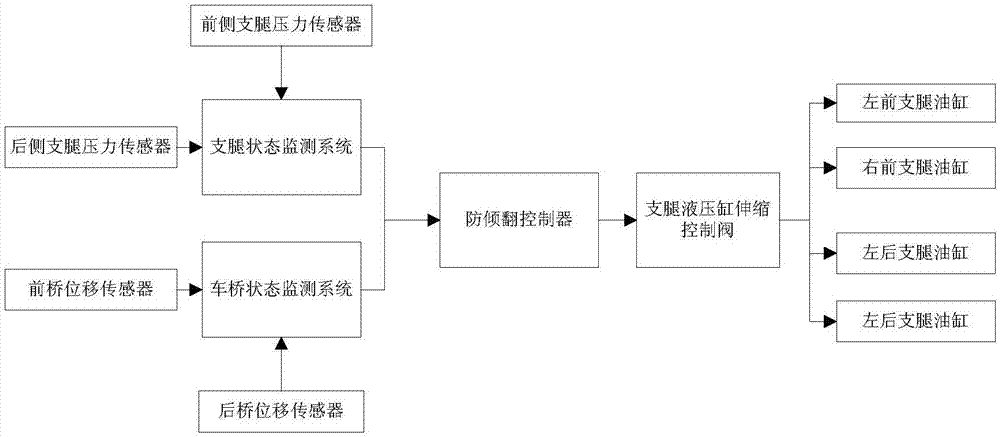

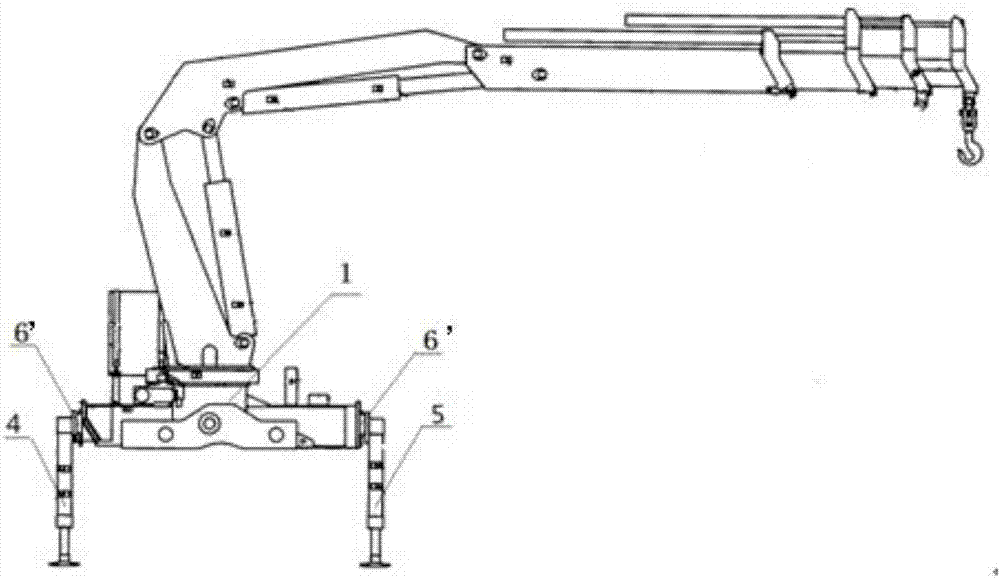

Anti-rollover system and method for lorry-mounted crane

ActiveCN107572433AImprove reliabilityRealize the purpose of active anti-rolloverCranesCondition monitoringEngineering

The invention belongs to the field of engineering machinery, and particularly relates to an anti-rollover system and method for a lorry-mounted crane. The anti-rollover system comprises a support legstate monitoring system, an axle state monitoring system, an anti-rollover controller and a support leg hydraulic cylinder telescopic control valve, and is characterized in that pressure information detected by front side support leg pressure sensors and rear side support leg pressure sensors is transmitted to the support leg state monitoring system; displacement information detected by front axledisplacement sensors and rear axle displacement sensors is transmitted to the axle state monitoring system; the support leg state monitoring system and the axle state monitoring system separately transmit the pressure information and the displacement information to the anti-rollover controller; and the anti-rollover controller performs data treatment and drives the support leg hydraulic cylindertelescopic control valve to drive oil cylinders corresponding to different vertical support legs, so that stress states of the different vertical support legs and lorry posture are adjusted. By adopting the anti-rollover system and method, initiative anti-rollover of the lorry-mounted crane can be realized automatically and safely.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

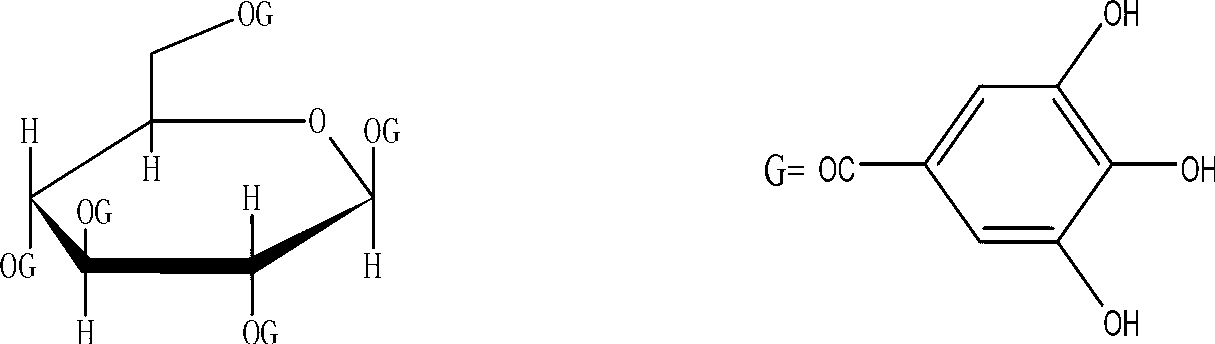

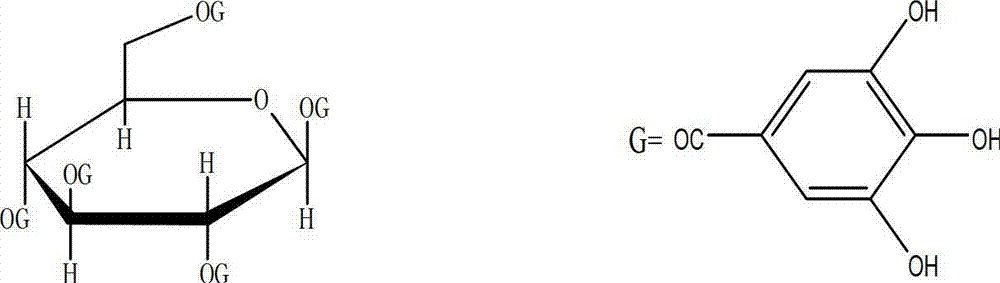

Preparation method of 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product

InactiveCN101863935ASimple stepsStrong specificitySugar derivativesSugar derivatives preparationMethanol waterAlcohol

The invention relates to a preparation method of a 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product. The method comprises the following steps of: pulverizing a rhizoma bletillae medicinal material into coarse powder, extracting in alcohol and recovering the alcohol; adding water to an obtained concentrated solution to dilute and enriching through a macroporous adsorption resincolumn; hydrolyzing and adsorbing in alcohol, and recovering the alcohol to obtain a concentrated solution; adding silica gel to the concentrated solution and uniformly mixing; drying to form powder and eluting by using chloroform and methanol to obtain a crude 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate product; carrying out gel column chromatography to obtain a fine 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate product; and then carrying out preparative reverse silica gel column chromatography and methanol-water elution to obtain the 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product. Detected by using a high efficiency liquid chromatography method, the content of the 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate can reach higher than 98 percent. The method has lower cost, simple step and strong specificity.

Owner:BEIJING UNIV OF TECH

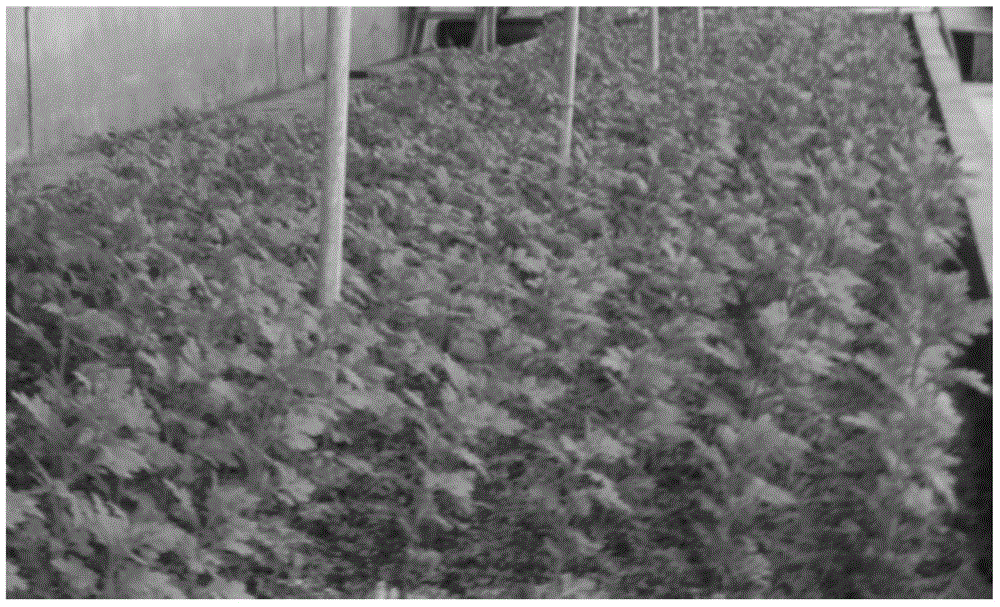

Factory-like rapid propagation method for test-tube seedlings of dendranthema morifolium

InactiveCN103651141AApplicable methodSave landCultivating equipmentsPlant tissue cultureField cropShoot

The invention discloses a factory-like rapid propagation method for test-tube seedlings of dendranthema morifolium. The method comprises the following steps: by taking a flower bud of dendranthema morifolium as an explant, inducing dedifferentiation and redifferentiation; obtaining the test-tube seedlings through a tissue culture technique; carrying out transitional planting in a vermiculite matrix or a matrix with a ratio of peat to vermiculite to perlite being 33% to 33% to 33% to obtain a shoot with 3-5 leaves and height of 15-20cm after about 30 days; and transplanting to a land for growing field crops, thus harvesting in the current year. By adopting the technical scheme, the seedlings are fully originated from a same plant which accords with inheritable character, so that virus accumulation is reduced, the period is short and the effect is achieved fast. Genuine medicinal material dendranthema morifolium is convenient to store and quick to popularize as a conventional resource, and the method is an effective method suitable for factory-like production of the test-tube seedlings.

Owner:INST OF GARDENING ANHUI ACADEMY OF AGRI SCI

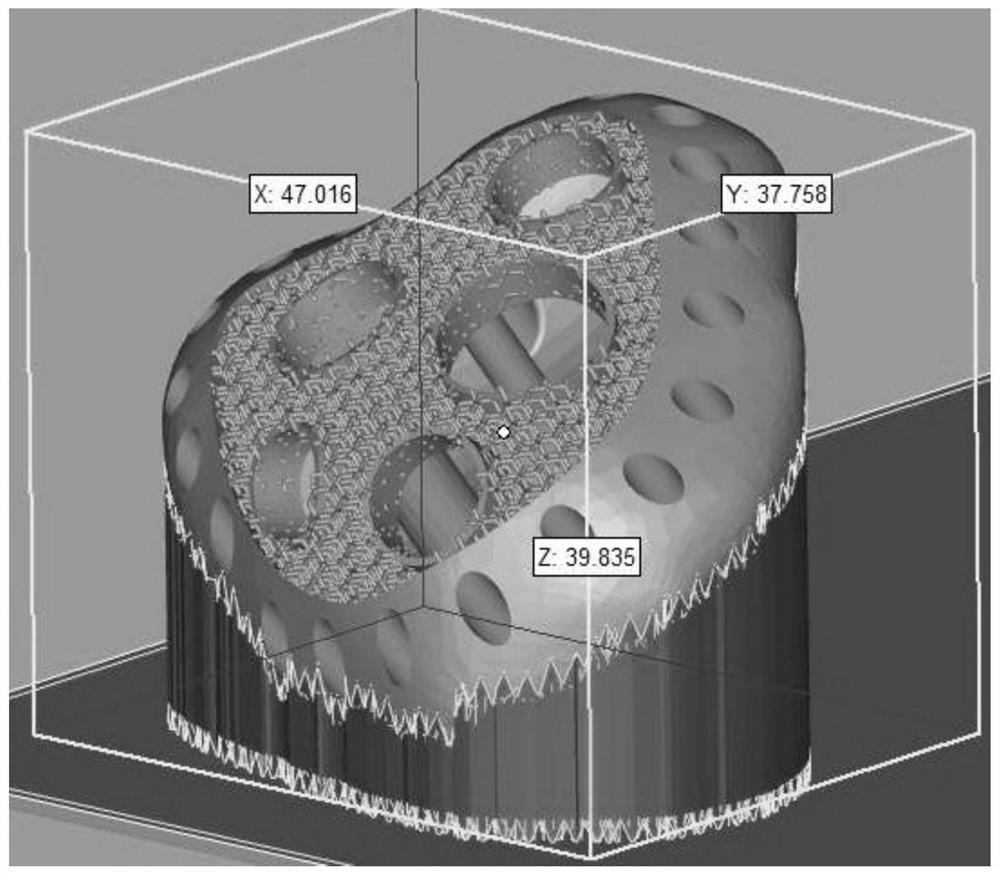

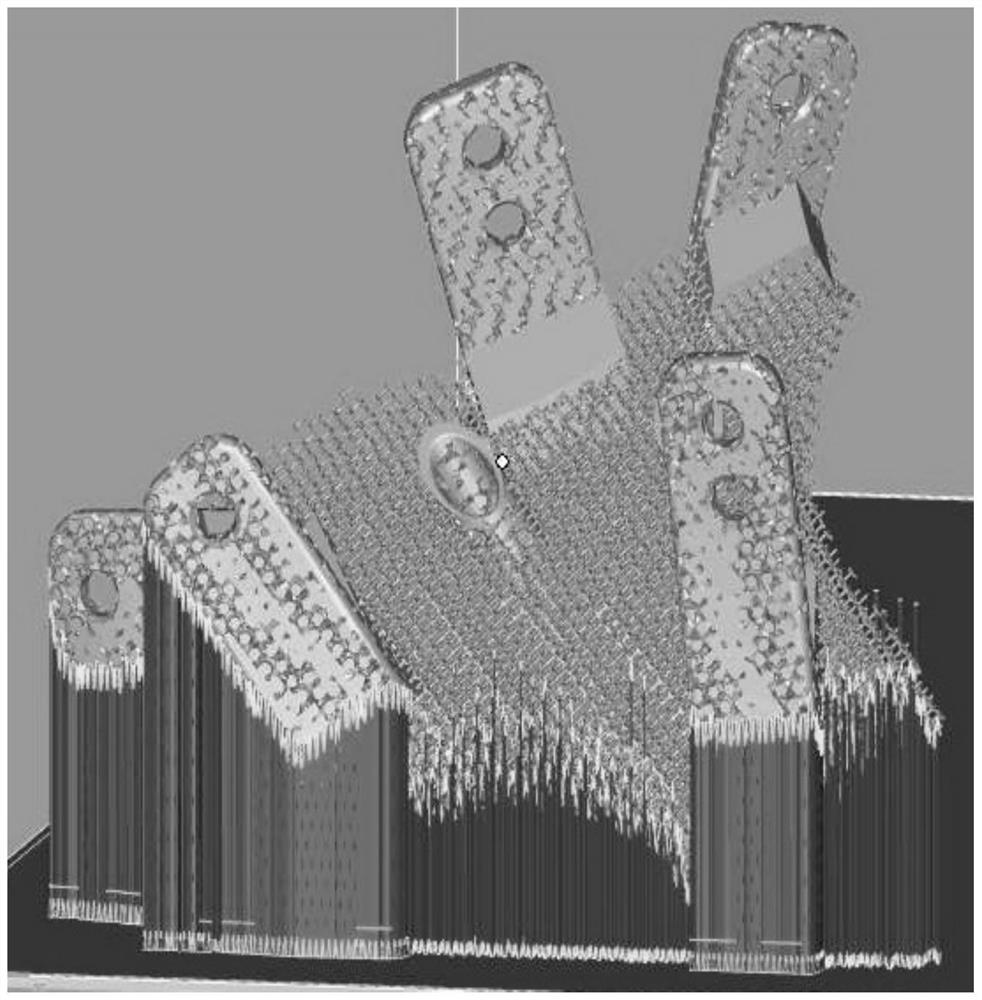

Manufacturing method of medical bionic trabeculae structure multihole tantalum bone implant prosthesis through laser additive manufacturing-high-temperature vacuum sintering

ActiveCN110742711AAvoid pollutionReduce oxygen contentBone implantJoint implantsPorous tantalumBone implant

The invention discloses a manufacturing method of a medical bionic trabeculae structure multihole tantalum bone implant prosthesis through laser additive manufacturing-high-temperature vacuum sintering. The method comprises the following steps of establishing a bone defect prosthesis three-dimensional graph by using CT scanning data, performing transformation design on the bone defect prosthesis graph into a bionic trabeculae multihole shape of which the air porosity is 60-85%; designing a support, wherein the support sufficiently forms firm connection between a basal plate and a printed transplant prosthesis, and after printing is performed, the printed transplant prosthesis is easy to taken off from the printing basal plate by a manual method; and reducing the oxygen content of the transplant prosthesis and relieving stress by using an ultrahigh temperature vacuum sintering heat treatment method so as to obtain a qualified human body transplant prosthesis. The method can prevent pollution of wire cutting on the multihole tantalum transplant prosthesis, the oxygen content of the multihole tantalum transplant prosthesis is reduced, through a conventional technology, connection in series is performed, so that the manufacturing method of the medical bionic trabeculae structure multihole tantalum bone implant prosthesis through laser additive manufacturing-high-temperature vacuumsintering is formed, and the method is a complete technology manufacturing method.

Owner:湖南华翔医疗科技有限公司

Preparation method of 1,2,3,4,6-pentagalloylglucose reference substances

InactiveCN103012510ASimple stepsStrong specificityEsterified saccharide compoundsSugar derivativesReflux extractionChromatographic separation

The invention discloses a preparation method of 1,2,3,4,6-pentagalloylglucose reference substances, belonging to the technical field of extraction and purification of traditional Chinese medicine and natural product reference substances. The method comprises the following steps of: crushing white peony root herbs, carrying out reflux extraction and concentration on the crushed white peony root herbs, adding water into the obtained object to dilute, carrying out macroporous adsorptive resin enrichment and desorption on the diluted object two times, and carrying out gel column chromatographic separation on the obtained product so as to obtain a 1,2,3,4,6-pentagalloylglucose reference substance; and through carrying out detection by using a high-performance liquid chromatography, the content can reach more than 98%. The method is lower in cost, simple in steps and strong in specificity.

Owner:BEIJING UNIV OF TECH

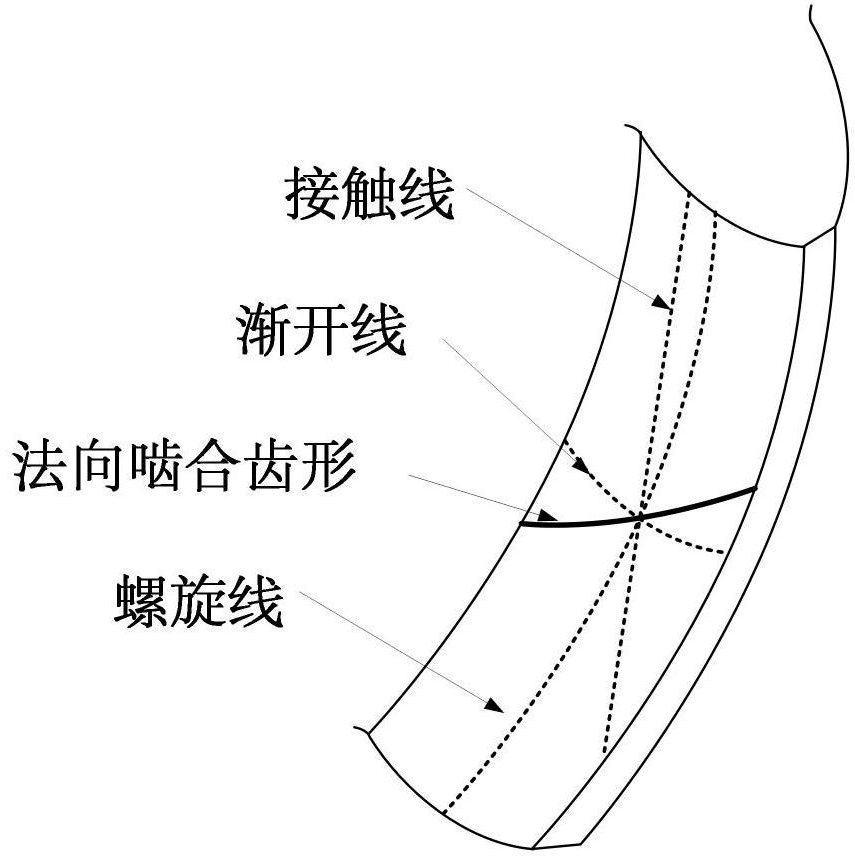

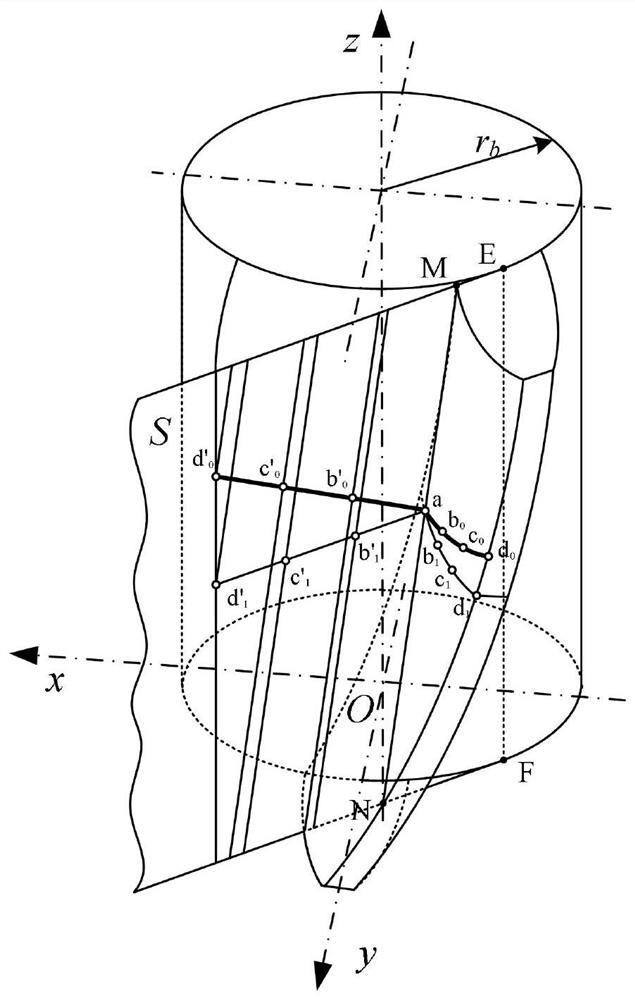

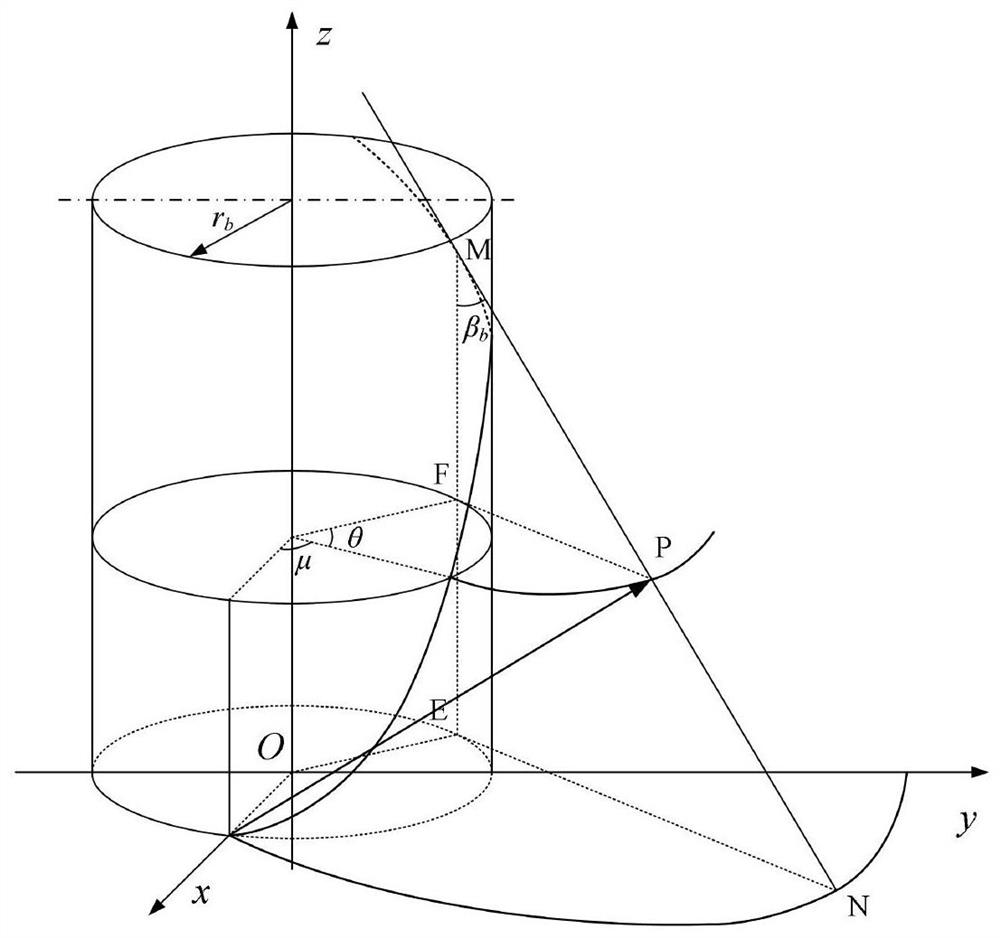

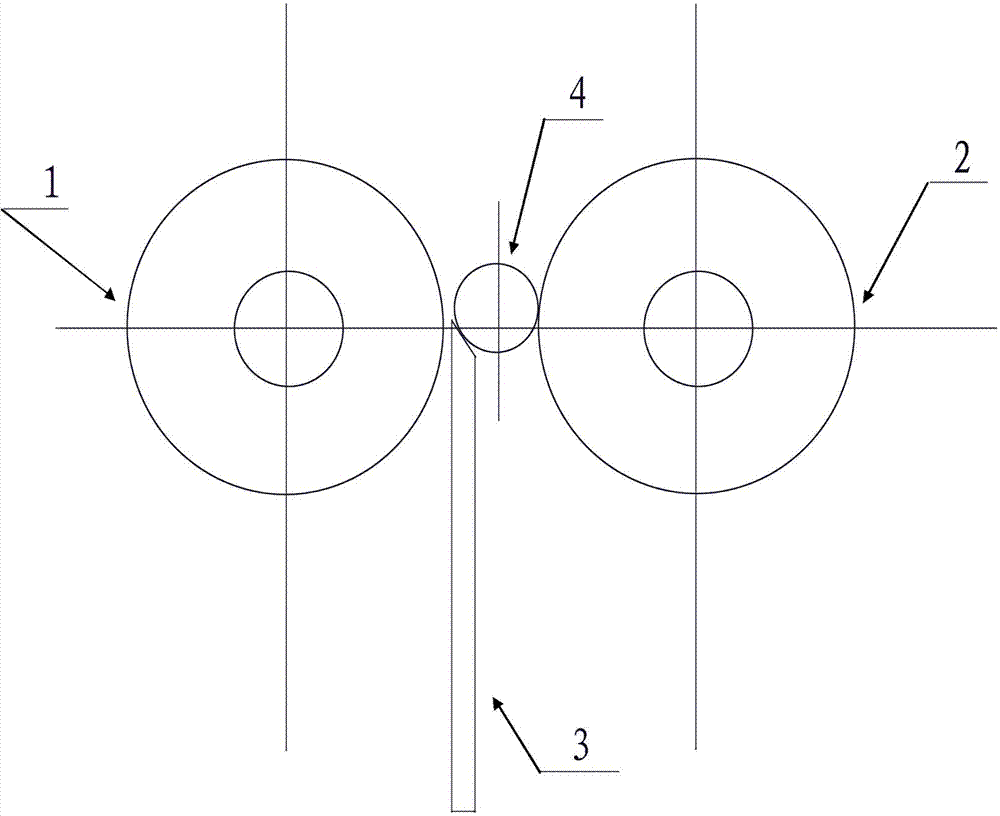

Method for measuring normal meshing tooth profile of involute spiral cylindrical gear

ActiveCN112798270AImproved susceptibility to measured gear sizeHigh measurement accuracyMachine part testingMechanical measuring arrangementsHobbingGear wheel

The invention discloses a method for measuring the normal meshing tooth profile of an involute spiral cylindrical gear, which is used for measuring the normal meshing tooth profile on the tooth surface of a measured gear, and a cross-axis involute spiral cylindrical gear is driven to move through the normal meshing tooth profile. The actual movement working conditions of the transmission quality and the working stability of the gear reflected by the normal meshing tooth profile are measured; in gear hobbing, gear shaving and worm grinding wheel grinding generating method machining, movement of a tool and a gear is achieved based on the normal meshing tooth shape, and control over the normal meshing tooth shape has the unique advantage on control over the gear machining quality. Measurement is achieved through a gear measurement center, four-axis linkage measurement is adopted, and the situation that the measurement precision is prone to being affected by the size of a measured gear is effectively improved. Radial and axial motions are respectively limited to realize simplified measurement of normal meshing tooth profiles and measurement of involutes by a meshing method. The method is suitable for measuring the involute of the straight toothed cylindrical gear, and the normal meshing tooth form on the tooth surface of the gear coincides with the involute, so that the method is also suitable for measuring the involute of the straight toothed spur gear.

Owner:BEIJING UNIV OF TECH

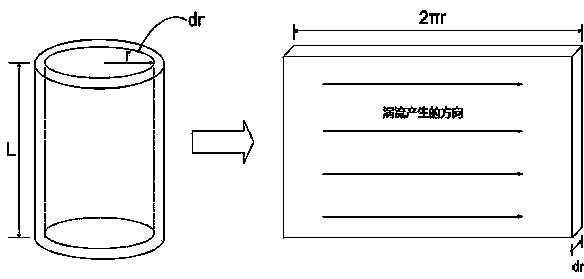

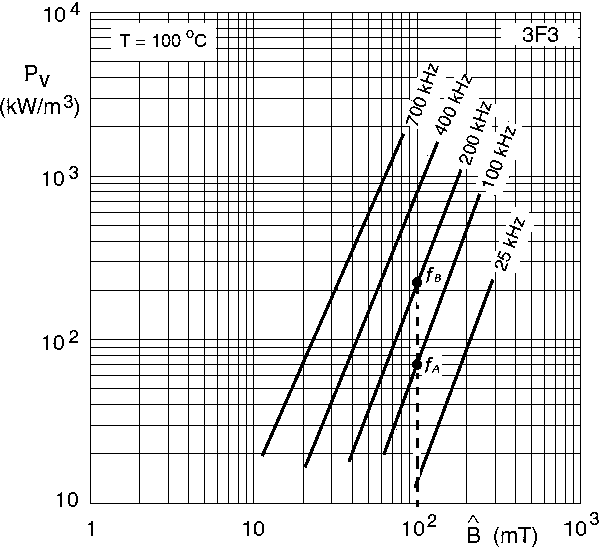

Method for calculating losses of magnetic cores with different sectional areas

ActiveCN103745124AAvoid undetermined coefficientsSimple methodSpecial data processing applicationsEddy currentMagnetic flux

Owner:NANJING UNIV OF POSTS & TELECOMM

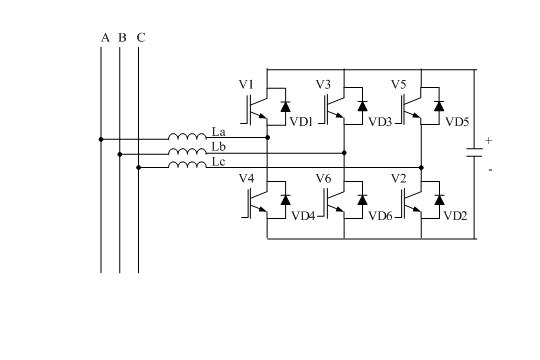

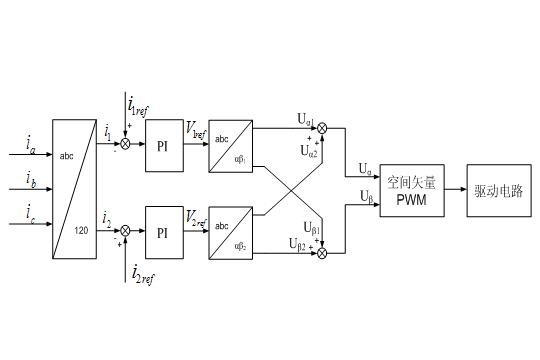

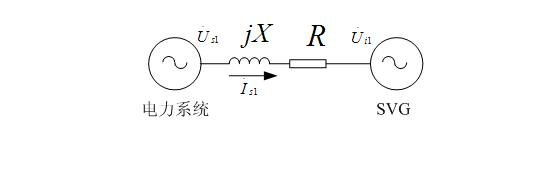

Static reactive power compensation control method based on sequence component method

InactiveCN102684206AMethod scienceReasonable methodReactive power adjustment/elimination/compensationReactive power compensationPower compensationDriver circuit

The invention relates to a static reactive power compensation control method based on a sequence component method. The static reactive power compensation control method is characterized by comprising the following steps of: converting a, b and c three-phase current to sequence current; performing positive-sequence voltage space vector conversion, negative-sequence voltage space vector conversion and positive-negative-sequence space vector synthesis on the current to obtain positive-sequence and negative-sequence compensating current through a symmetrical component method according to the three-phase current to be compensated; transferring positive-sequence voltage and negative-sequence voltage to be under an (alpha, beta) coordinate system; laminating the values of positive-sequence components and negative-sequence components under the (alpha, beta) coordinate system; performing SVPWM (Space Vector Pulse Width Modulation) control through a DSP (Digital Signal Processor) to generate a series of PWM (Pulse-Width Modulation) signals; and driving an IGBT (Insulated Gate Bipolar Translator) module through a driving circuit to generate the necessary compensation current so as to realize asymmetric static reactive power compensation. The static reactive power compensation control method has the advantages of being scientific, reasonable and applicative, being capable of performing reactive power compensation on a static reactive power compensator of a distribution system, having a good compensation effect, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY +2

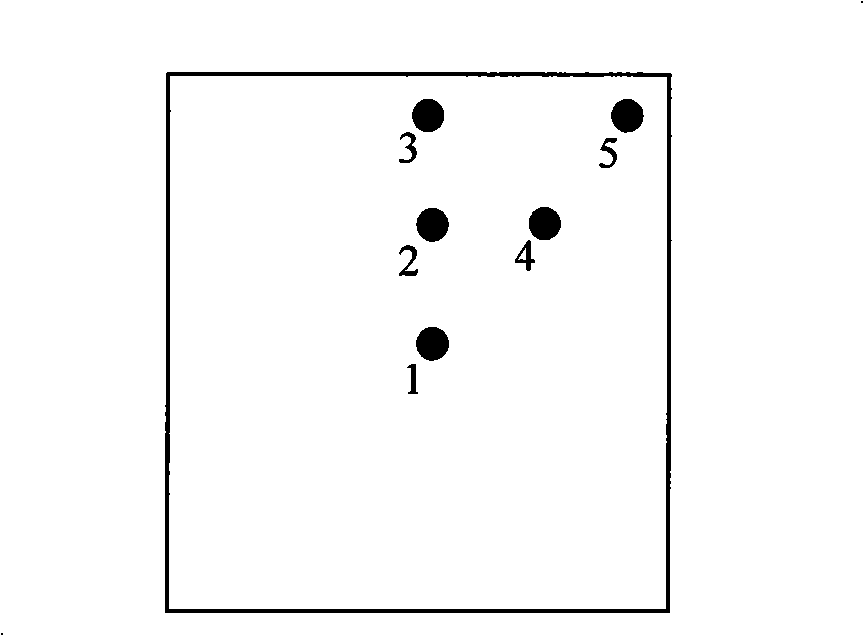

Method for monitoring movement of dam body of five-level tailings pond

InactiveCN102878966AMeet the needs of displacement observationThe principle is simpleMeasurement devicesObservation pointMonitoring methods

A method for monitoring movement of a dam body of a five-level tailings pond is characterized by comprising the following contents of: (1) arrangement of a working base point and a movement observation point; (2) a measurement method; (3) office computation; and (4) achievement data. By the technical scheme, angle measuring accuracy and distance measuring accuracy of the method meet technical requirements of a four-level network, and requirements on observation of the movement of the dam body of the five-level tailings pond can be met basically. The method has the advantages that the tailings pond can be monitored by using a simple measuring method, the principle is simple, the method is suitable and easy to operate, and investment cost is low.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

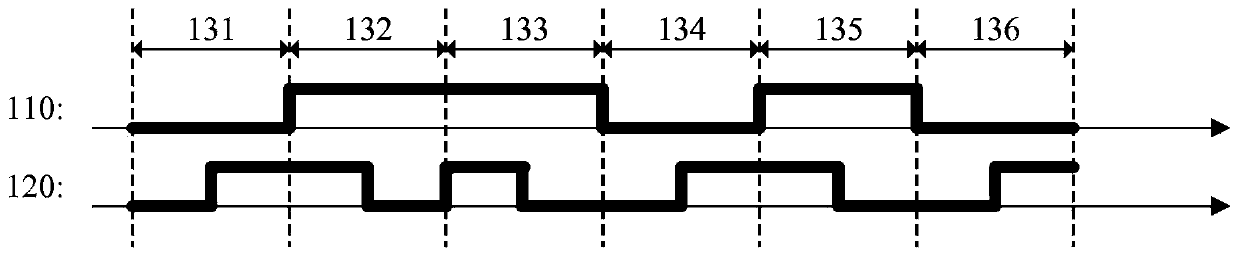

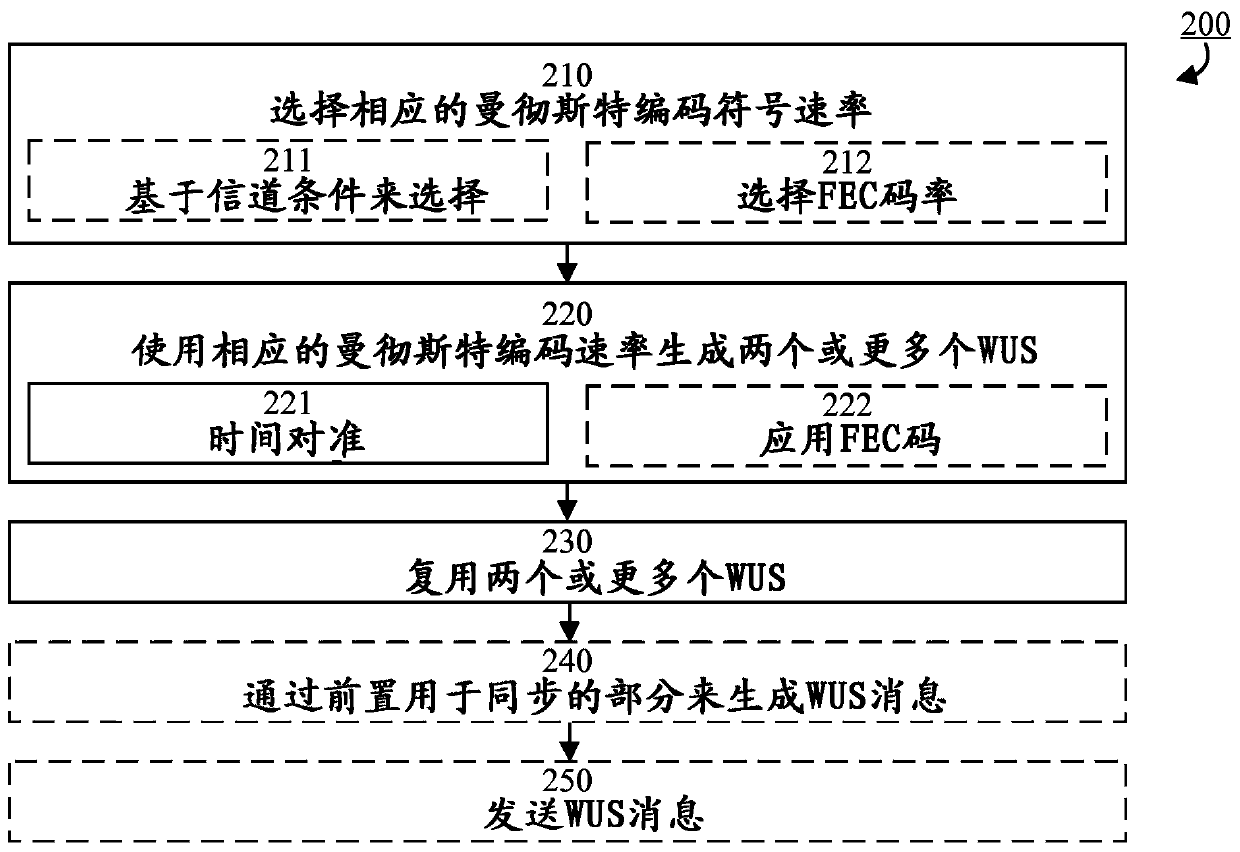

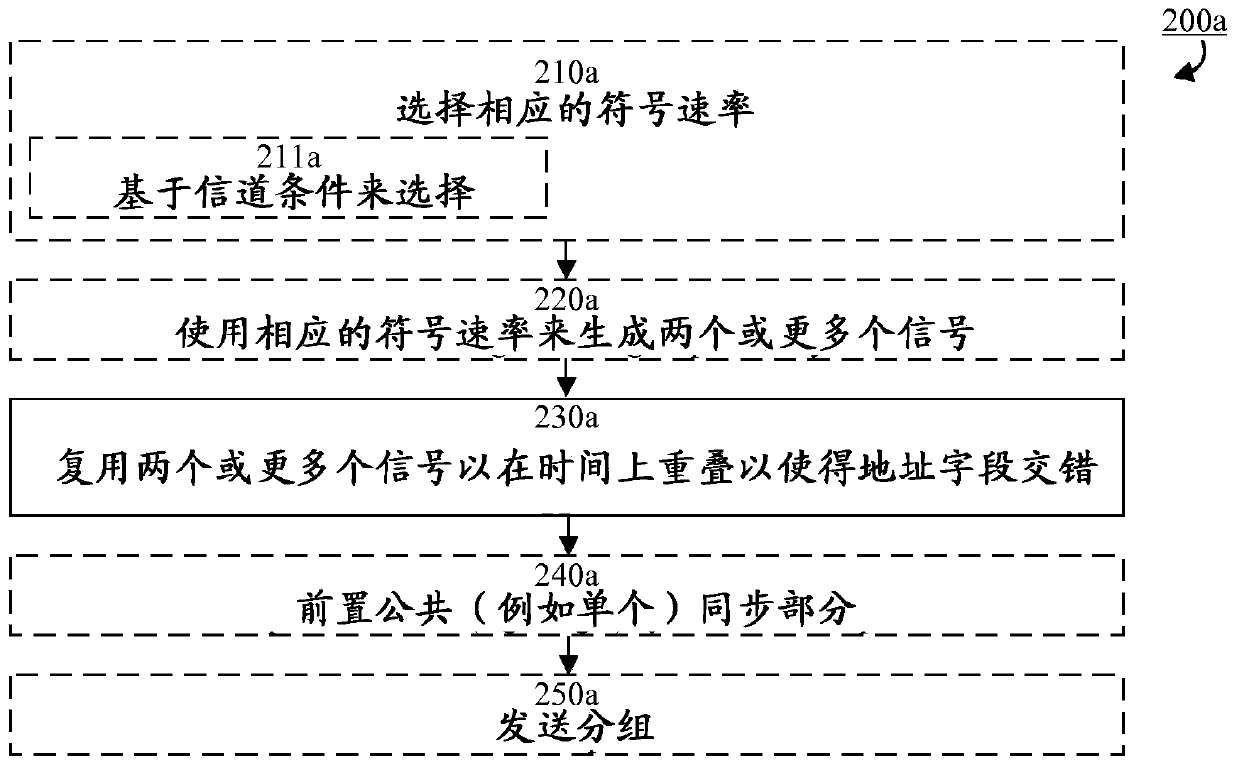

Wake-up signal transmission

ActiveCN111052807AEffective use of capacityLess complicated to implementPower managementSynchronisation arrangementManchester codeSignal generator

A method of a network node is disclosed. The method is for concurrently transmitting two or more wake-up signals (WUS) using an signal generator applying an signal generator symbol rate, wherein eachWUS is for reception by a wake-up receiver (WUR) of a respective wireless communication device. The method comprises selecting a respective Manchester coding symbol rate for each of the two or more WUS, wherein all of the selected respective Manchester coding symbol rates are different from each other, and all Manchester codes having the selected respective Manchester coding symbol rates are orthogonal to each other. The method also comprises generating each of the two or more WUS using the signal generator and application of a Manchester code of the selected respective Manchester coding symbol rate, and multiplexing the two or more WUS for transmission in a WUS message. A corresponding arrangement, a network node and a computer program product are also disclosed, as well as counterparts for a wireless communication device.

Owner:TELEFON AB LM ERICSSON (PUBL)

Method for machining oil seal shaft

ActiveCN102275101BMeet sealing requirementsSimple methodRevolution surface grinding machinesMachineMachining

The invention discloses a method for machining an oil seal shaft. In the method, the conventional centerless grinding machine is retrofitted; a grinding wheel of the centerless grinding machine is required to meet the following requirements that: the roughtness Ra is 0.2 to 0.4 and Rz is less than 4; texture directions produced by grinding are required to be parallel with one another and verticalto the central line of the shaft; the grinding wheel is required to be abrasion-proof; the thickness of the grinding wheel is equal to the axial length of an oil seal slot of the shaft; a guide wheelis arranged on one side of the grinding wheel; the axial lines of the grinding wheel and the guide wheel are parallel with each other; a distance between the grinding wheel and the guide wheel is equal to a difference between the diameter of a workpiece and the depth of the oil seal slot; the axle of the guide wheel is connected with the output shaft of a motor; a vertical supporting plate is arranged between the grinding wheel and the guide wheel; the workpiece with a horizontal axial line is arranged on the top face of the supporting plate; and a rotating roller parallel to the axial line of the workpiece is arranged above the position of the workpiece. A machining method for statically grinding comprises the following steps of: positioning the workpiece through the grinding wheel, the guide wheel, the supporting plate and the rotating roller; and starting the motor and injecting grinding solution into a part to be ground for grinding. The roughness and the texture directions of theoil seal slot machined by using the method can completely meet the technical requirements of the oil seal shaft.

Owner:DALIAN DEMAISHI PRECISION TECH CO LTD

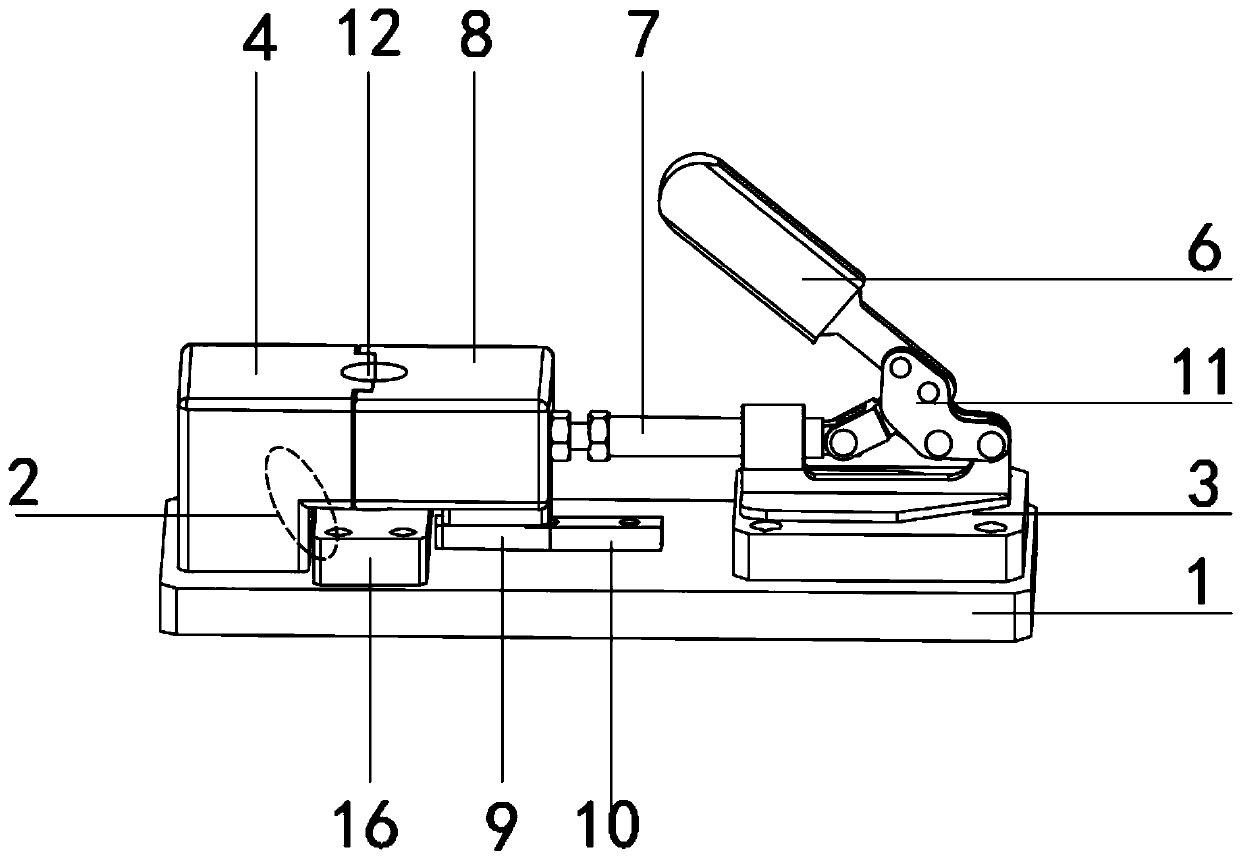

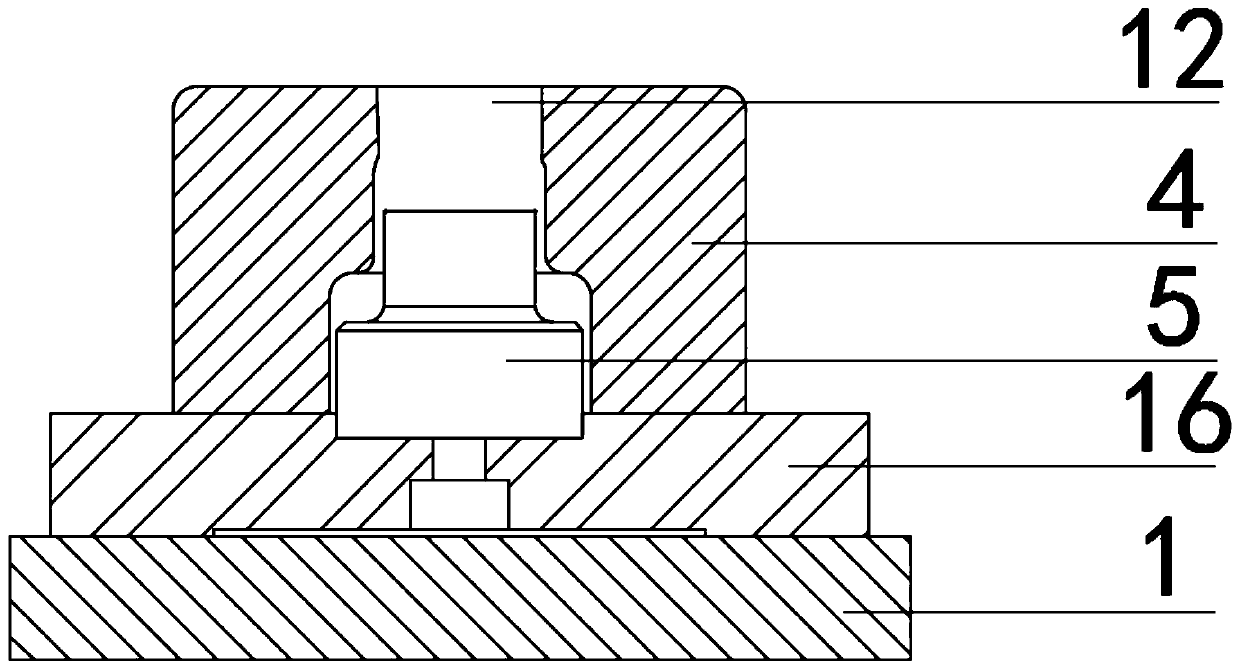

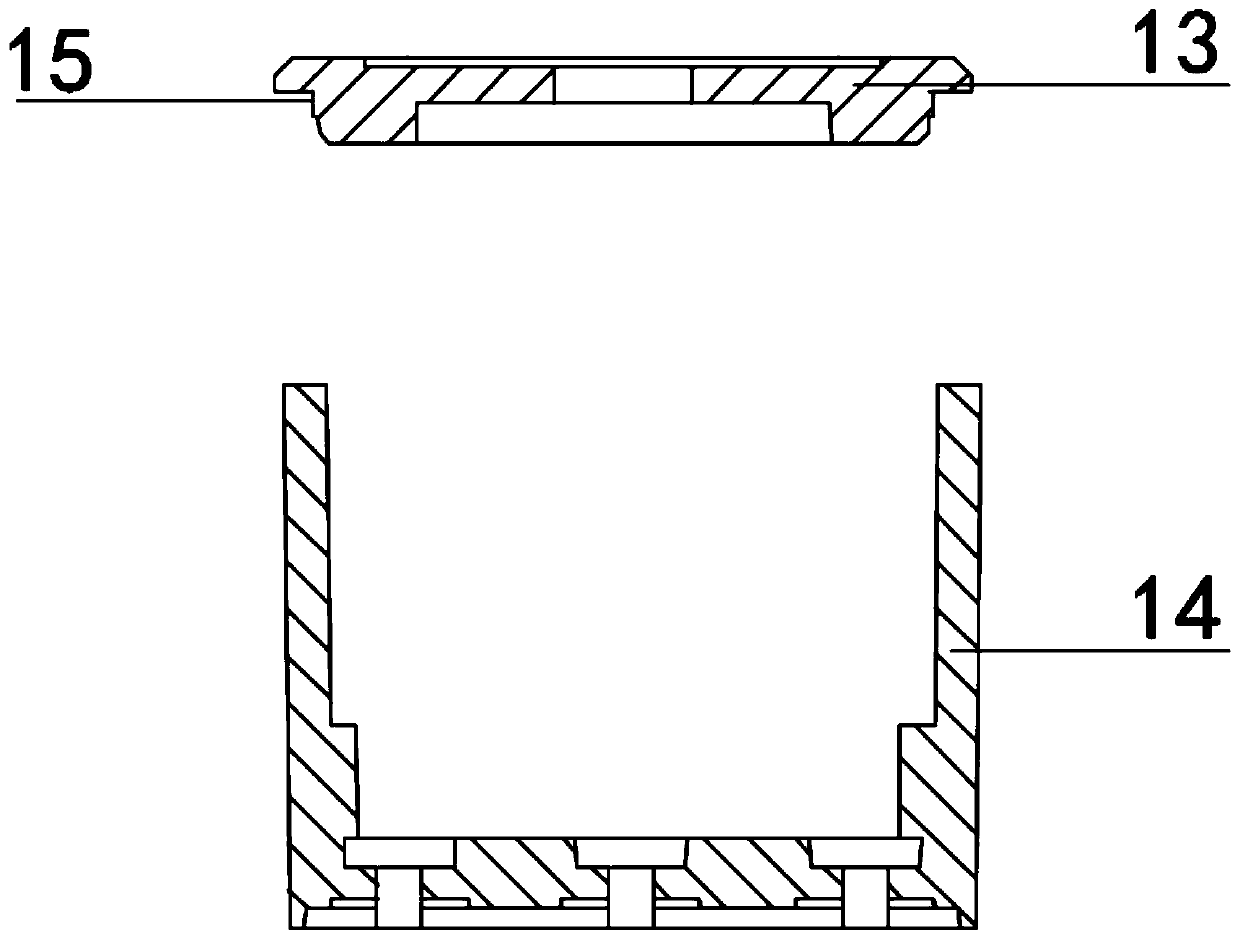

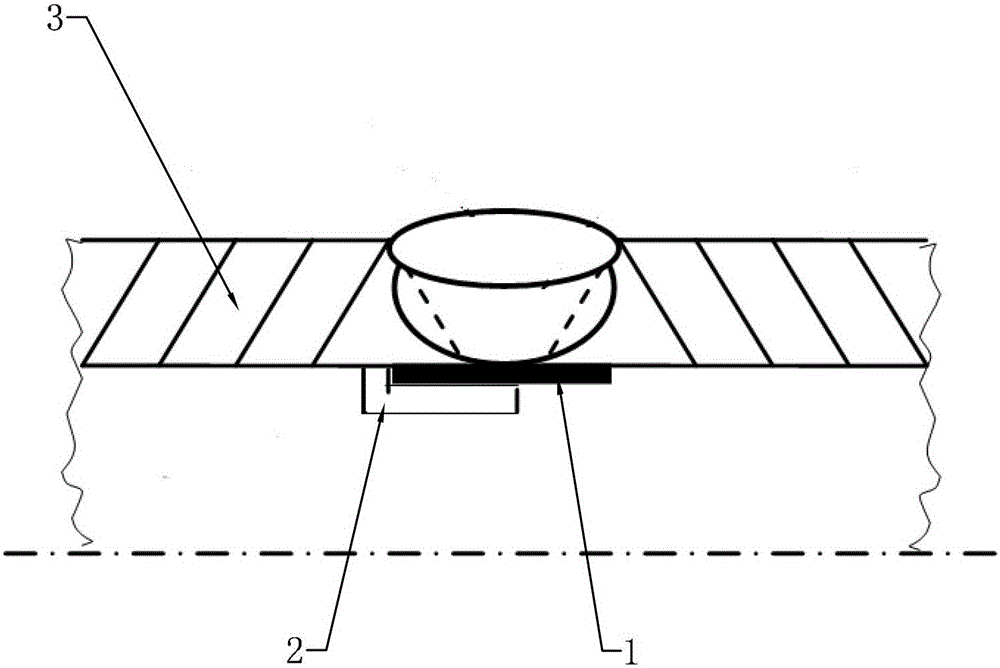

Electrochemical gas sensor ultrasonic welding tool and method

InactiveCN111230384ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesElectrochemical gas sensorUltrasonic welding

The invention provides an electrochemical gas sensor ultrasonic welding tool. The electrochemical gas sensor ultrasonic welding tool comprises a base plate. A containing mechanism for containing an electrochemical gas sensor lower shell is arranged at one end of the length direction of the base plate, and a pressing mechanism cooperating with the containing mechanism to press the electrochemical gas sensor lower shell on the containing mechanism is arranged at the end, away from the containing mechanism, of the base plate. The tool is simple in structure and convenient to operate, the weldingquality and the consistency can be improved, and the situation of pseudo soldering or material overflowing is avoided. The invention further provides an electrochemical gas sensor ultrasonic welding method.

Owner:南京艾伊科技有限公司

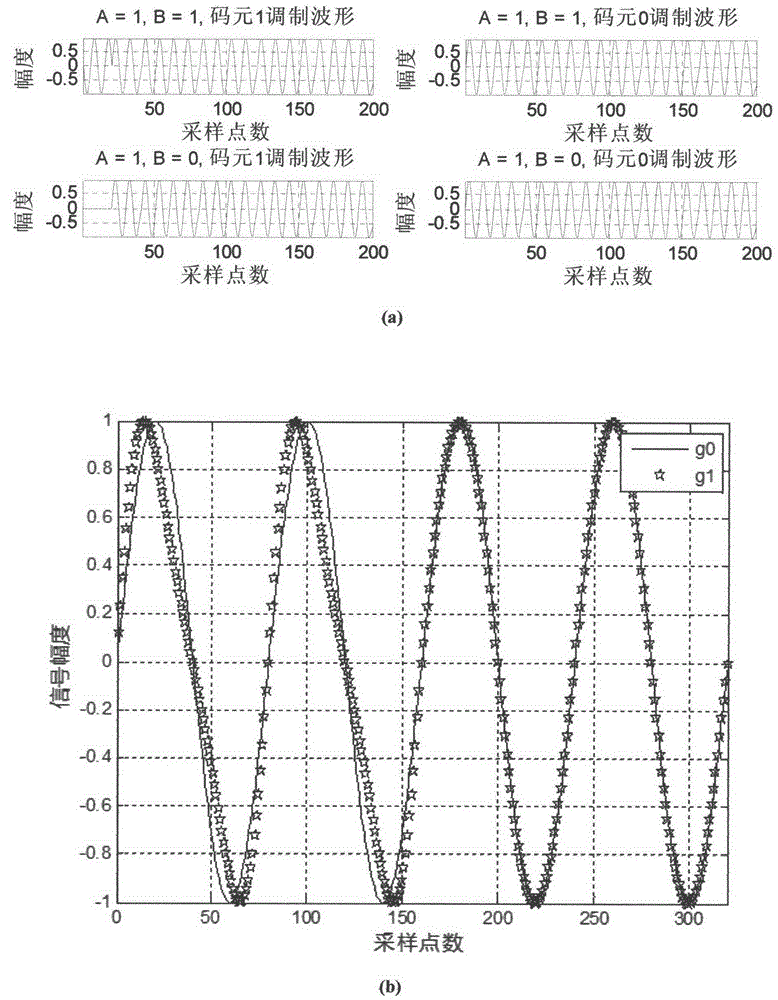

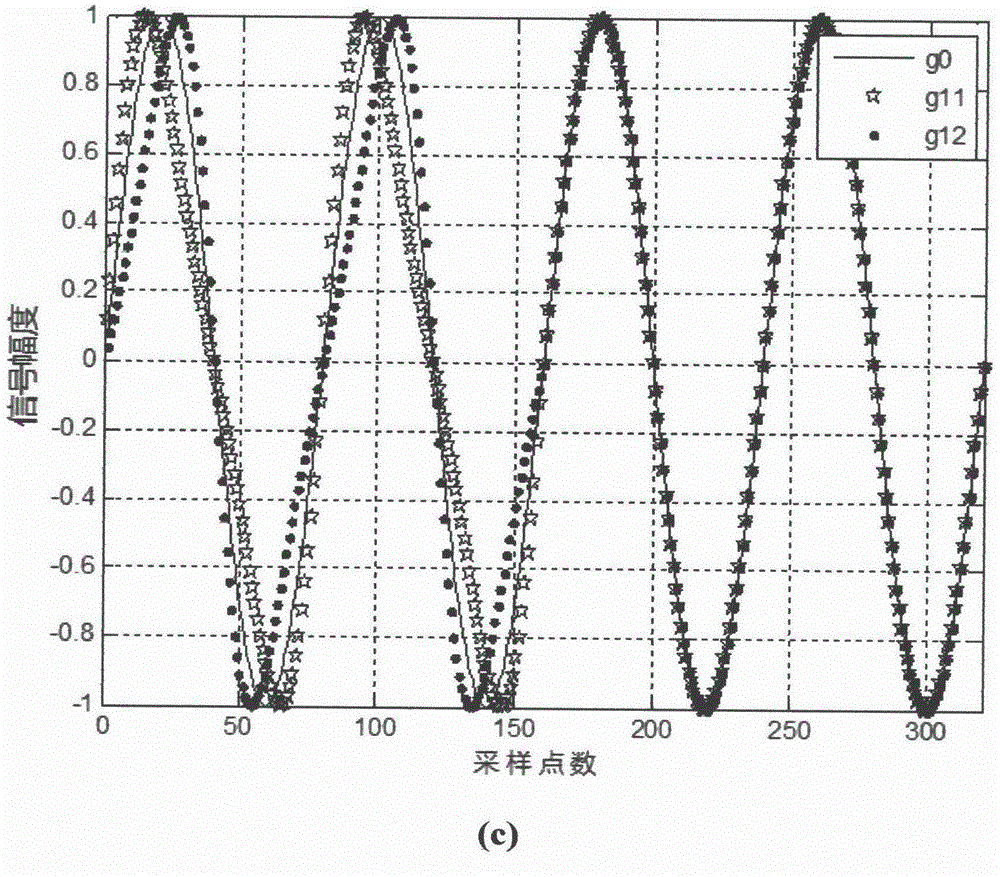

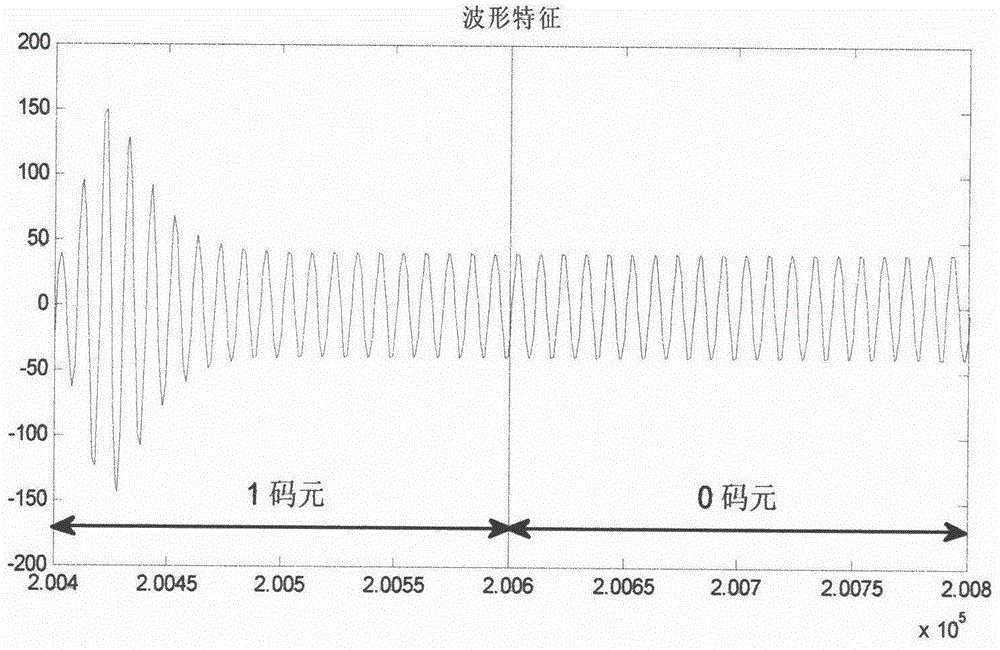

Method for eliminating initial oscillation of shock filter response of absk signal

ActiveCN102857453BEliminate initial oscillationsImprove transmission efficiencyEnergy efficient ICTModulated-carrier systemsPacket communicationTransient state

Owner:苏州东奇信息科技股份有限公司

A manufacturing method of laser additive manufacturing-high temperature vacuum sintering porous tantalum bone implant prosthesis with bone-imitation trabecular structure

ActiveCN110742711BAvoid pollutionReduce oxygen contentBone implantJoint implantsPorous tantalumBone implant

The invention discloses a manufacturing method of a porous tantalum bone implanted prosthesis with a medical imitation trabecular structure manufactured by laser additive manufacturing. The method includes the following steps: using CT scanning data to establish a three-dimensional figure of the bone defect prosthesis, using software to convert the figure of the bone defect prosthesis into a porous shape with a porosity of 60-85% and imitating bone trabecula; designing a support, which is sufficient to form a base plate and The printed implants are firmly connected, and it is easy to manually remove the printed implants from the printed substrate after printing; then the ultra-high temperature vacuum sintering heat treatment method is used to reduce the Oxygen content and stress relief to obtain qualified human implant prostheses. The invention avoids the pollution of the porous tantalum implant prosthesis by wire cutting, reduces the oxygen content of the porous tantalum implant prosthesis, and connects conventional processes in series to form a unique laser additive manufacturing-high temperature vacuum sintering The manufacturing method of medical porous tantalum implanted bone prosthesis with imitation trabecular structure is a complete process manufacturing method.

Owner:湖南华翔医疗科技有限公司

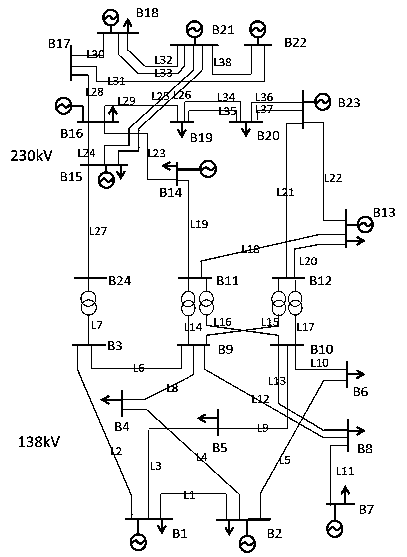

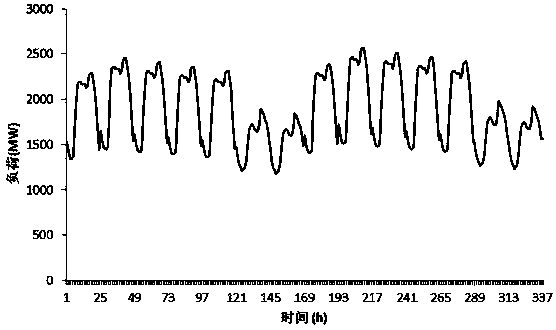

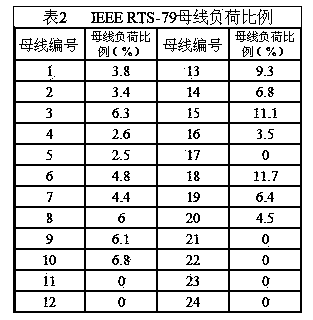

Electric power system risk assessment common cause failure sampling method

ActiveCN103544659ASimple methodApplicable methodData processing applicationsCorrelation coefficientElectric power system

The invention discloses an electric power system risk assessment common cause failure sampling method. The method comprises the steps that a plurality of elements where common cause failures occur during electric power system risk assessment are given, the random number representing the failure state of each element independently is obtained through sampling respectively at first, then a dependency sampling matrix is built, and the random numbers representing the failure states of the elements respectively and obtained through sampling are converted into the random numbers representing the failure states and considering the common cause failure dependency sampling according to the dependency sampling matrix. Further more, the converted random numbers are compared with the failure probabilities of the elements, and finally the failure states of the common cause failure elements are determined through one sampling process. The electric power system risk assessment common cause failure sampling method uses a correlation coefficient matrix to carry out conversion on sampling values, changes independent sampling into dependency sampling, and achieves the sampling of electric power system risk assessment common cause failures. The electric power system risk assessment common cause failure sampling method is simple and suitable, can achieve common cause sampling accurately and is applied to the sampling of electric power system risk assessment common cause failures.

Owner:STATE GRID CORP OF CHINA +1

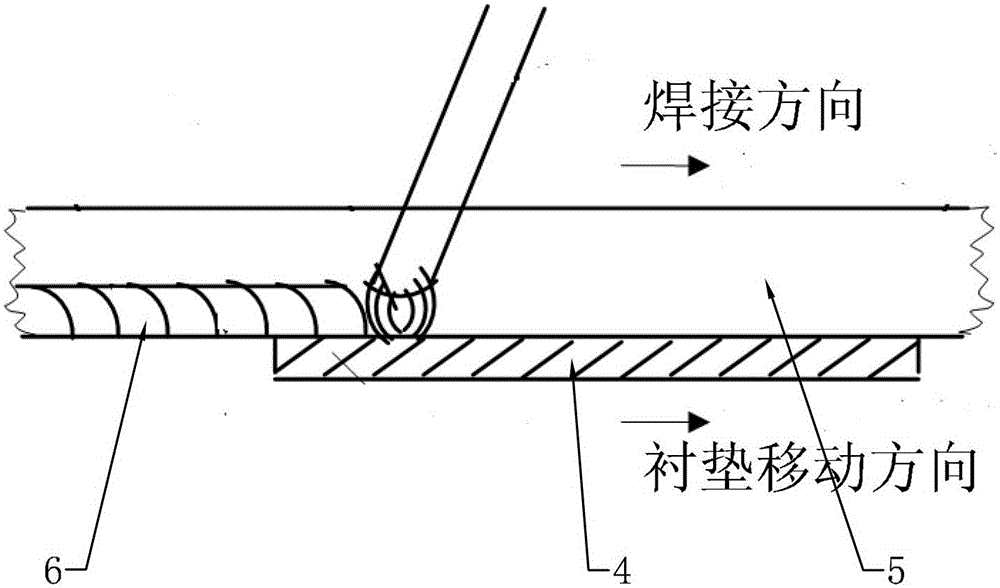

A kind of repair method of aluminum and aluminum alloy welding seam

ActiveCN102848057BAvoid softeningReduce intensityArc welding apparatusWelding/soldering/cutting articlesMetallic materialsDissolution

The invention relates to a technique for reworking a welding seam of an aluminum and aluminum alloy apparatus or pipeline. The method for reworking a welding seam of aluminum and aluminum alloy comprises the following steps: 1) determining the position of a welding defect at the welding seam of a weldment, and forming a penetrating opening in the position of the defect, wherein the opening is provided with a groove, and the clearance of the groove is less than or equal to 8 millimeters; 2) mounting a fixed or movable temporary pad at the opening on the inner wall of the weldment, and ensuring that the pad is tightly attached to the inner wall of the weldment, wherein the pad is made of a nonmetal or metal material of which the melting point is higher than that of the aluminum or aluminum alloy weldment, the pad can not burn in the welding process, and the pad and the aluminum or aluminum alloy can not be subjected to mutual dissolution in the welding process; 3) performing root pass welding in an argon tungsten-arc welding manner; and 4) performing filling pass and capping pass welding in an argon tungsten-arc welding manner. The method can effectively solve the problem on welding reworking of aluminum or aluminum alloy, raise the reworking qualification rate and reduce the reworking frequency.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

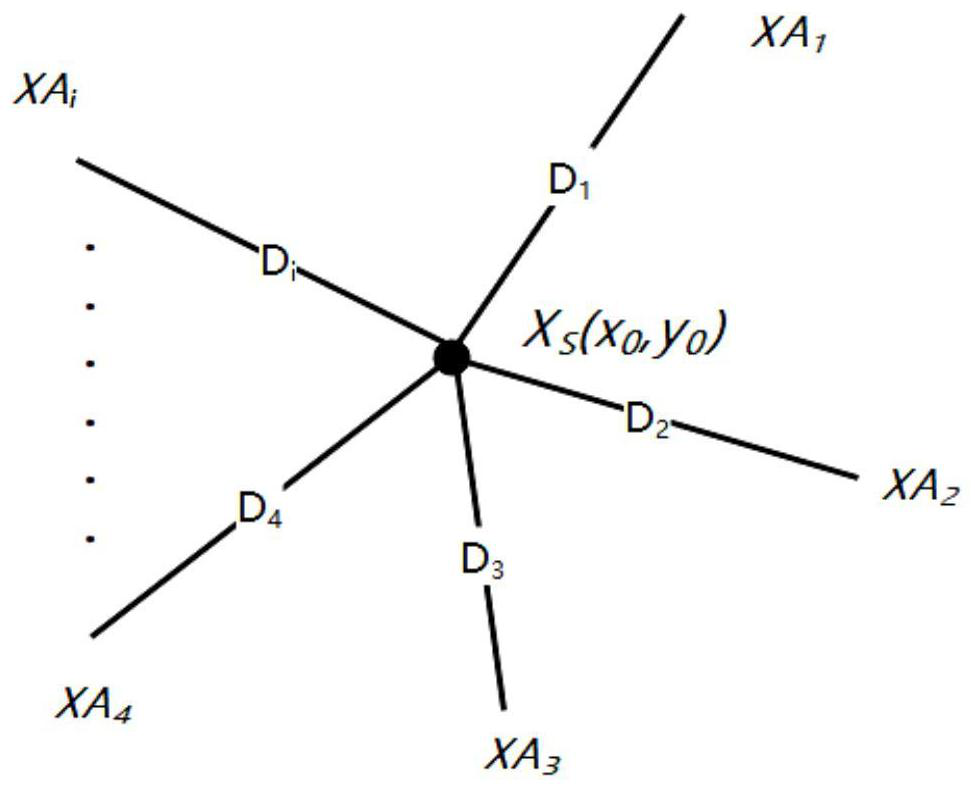

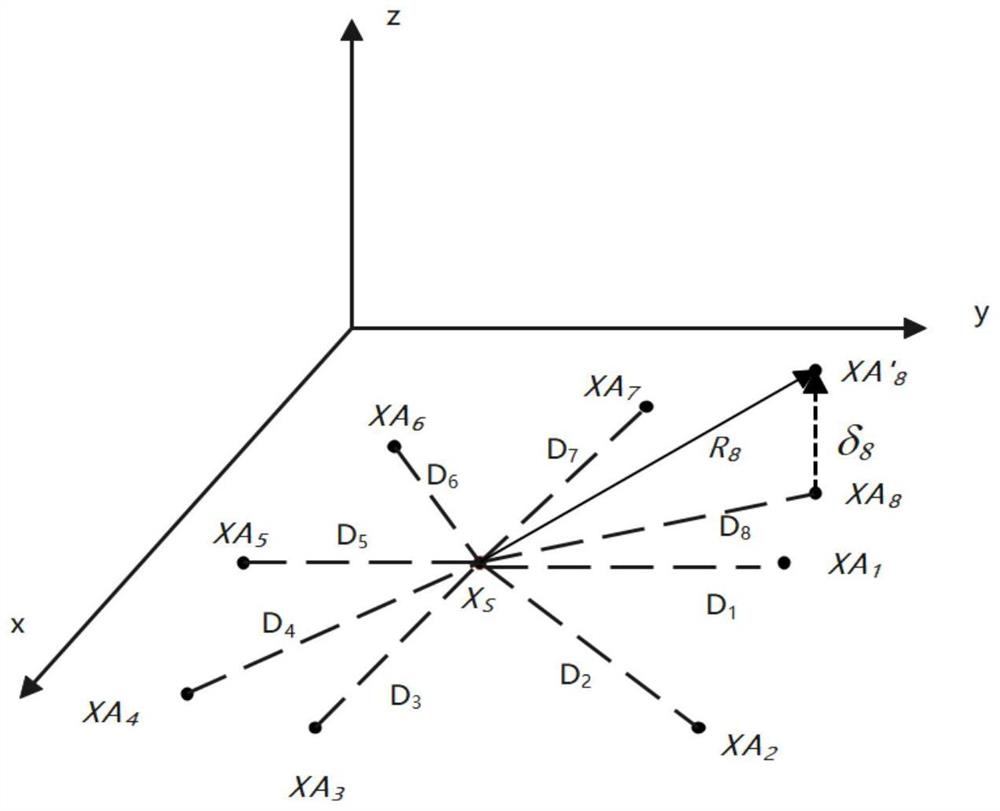

Non-line-of-sight identification and positioning method by using anchor point high-dimensional space coordinate information

PendingCN113804181ARealization of non-line-of-sight recognitionHigh positioning accuracyNavigation instrumentsSpatial positioningThree-dimensional space

The invention provides a non-line-of-sight identification and positioning method by using anchor point high-dimensional space coordinate information. The method comprises the following steps of in an N-dimensional space multilateral measurement method positioning model, expanding N-dimensional coordinates of the anchor point into N + 1-dimensional coordinates, solving the N + 1-dimensional coordinates, and measuring an error of non-line-of-sight measurement by using the N + 1-dimensional coordinates; and carrying out the non-line-of-sight identification and positioning by using the high-dimensional space coordinate information of the anchor point, and optimizing the positioning result of the to-be-positioned point. The method is suitable for two-dimensional space positioning, three-dimensional space positioning and even N-dimensional space positioning.

Owner:JILIN UNIV

The Method for Rapid Propagation of Bo Chrysanthemum Plantlets in Industrialized Test Tubes

InactiveCN103651141BApplicable methodSave landCultivating equipmentsPlant tissue cultureField cropShoot

The invention discloses a factory-like rapid propagation method for test-tube seedlings of dendranthema morifolium. The method comprises the following steps: by taking a flower bud of dendranthema morifolium as an explant, inducing dedifferentiation and redifferentiation; obtaining the test-tube seedlings through a tissue culture technique; carrying out transitional planting in a vermiculite matrix or a matrix with a ratio of peat to vermiculite to perlite being 33% to 33% to 33% to obtain a shoot with 3-5 leaves and height of 15-20cm after about 30 days; and transplanting to a land for growing field crops, thus harvesting in the current year. By adopting the technical scheme, the seedlings are fully originated from a same plant which accords with inheritable character, so that virus accumulation is reduced, the period is short and the effect is achieved fast. Genuine medicinal material dendranthema morifolium is convenient to store and quick to popularize as a conventional resource, and the method is an effective method suitable for factory-like production of the test-tube seedlings.

Owner:INST OF GARDENING ANHUI ACADEMY OF AGRI SCI

Process for discriminating high growth rate chemical vapour deposition diamond single crystal

InactiveCN101311339BCause damageSolve the puzzle of impactPolycrystalline material growthFrom chemically reactive gasesPhotoluminescenceSingle crystal

Owner:JILIN UNIV

Preparation method of 1,2,3,4,6-pentagalloylglucose reference substances

InactiveCN103012510BSimple stepsStrong specificityEsterified saccharide compoundsSugar derivativesReflux extractionChromatographic separation

The invention discloses a preparation method of 1,2,3,4,6-pentagalloylglucose reference substances, belonging to the technical field of extraction and purification of traditional Chinese medicine and natural product reference substances. The method comprises the following steps of: crushing white peony root herbs, carrying out reflux extraction and concentration on the crushed white peony root herbs, adding water into the obtained object to dilute, carrying out macroporous adsorptive resin enrichment and desorption on the diluted object two times, and carrying out gel column chromatographic separation on the obtained product so as to obtain a 1,2,3,4,6-pentagalloylglucose reference substance; and through carrying out detection by using a high-performance liquid chromatography, the content can reach more than 98%. The method is lower in cost, simple in steps and strong in specificity.

Owner:BEIJING UNIV OF TECH

A kind of mycotoxin adsorbent for livestock and poultry

ActiveCN103585961BStable physical and chemical propertiesExcellent immune stimulatorOther chemical processesAnimal feeding stuffMycotoxinOrganism

The invention discloses a novel mycotoxin adsorbent for livestock and poultry and a preparation method of the novel mycotoxin adsorbent. The novel mycotoxin adsorbent comprises the following components in parts by weight: 2 parts of effective contents and 8 parts of aluminosilicate mineral, wherein the effective contents consist of the following components in percentage by mass: 30-40% of mannan oligosaccharide, 50-65% of ascorbic acid, 4-9% of bacillus and 0.2-1% of cobalt sulfate. The invention further discloses a preparation method of the mycotoxin adsorbent. In the preparation method, the mycotoxin adsorbent is prepared through steps such as three-dimensional mixing. The mycotoxin absorbent can fully absorb mycotoxins in a feed to prevent the feed from mildewing in the production and storage processes, and meanwhile can improve the gastrointestinal functions of the livestock and the poultry to enhance the organism immunity to improve the organism health of the livestock and poultry.

Owner:中鲨动物保健品(厦门)有限公司

A kind of preparation method of high-purity danshensu sodium

InactiveCN101445451BPromote dissolutionEasy extractionCarboxylic acid salt preparationCarboxylic compound separation/purificationSalvia miltiorrhizaAcetic acid

The invention relates to a preparation method of high-purity salvia miltiorrhiza, which comprises superfine grinding of salvia miltiorrhiza medicinal material, soaking and extracting in ethyl acetate, soaking and extracting medicinal dregs in water, absorbing the extract by AB-8 resin, eluting and eluting After the solution is concentrated, adjust the pH to 7-8, heat at 110°C-130°C for 30 minutes, filter, adjust the pH of the filtrate to 1-3, let stand, precipitate, filter, the filtrate is adsorbed by AB-8 resin under acidic conditions, and eluted with pure water , the eluate was adjusted to a pH value of 7-8, concentrated and dried to obtain a solid Danshensu sodium, which was recrystallized from methanol to obtain a high-purity Danshensu sodium.

Owner:HEFEI ZIJIN PHARMA TECHNOLOGICAL

Preparation method of 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product

InactiveCN101863935BSimple stepsStrong specificitySugar derivativesSugar derivatives preparationMethanol waterAlcohol

The invention relates to a preparation method of a 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product. The method comprises the following steps of: pulverizing a rhizoma bletillae medicinal material into coarse powder, extracting in alcohol and recovering the alcohol; adding water to an obtained concentrated solution to dilute and enriching through a macroporous adsorption resincolumn; hydrolyzing and adsorbing in alcohol, and recovering the alcohol to obtain a concentrated solution; adding silica gel to the concentrated solution and uniformly mixing; drying to form powder and eluting by using chloroform and methanol to obtain a crude 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate product; carrying out gel column chromatography to obtain a fine 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate product; and then carrying out preparative reverse silica gel column chromatography and methanol-water elution to obtain the 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product. Detected by using a high efficiency liquid chromatography method, the content of the 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate can reach higher than 98 percent. The method has lower cost, simple step and strong specificity.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product Preparation method of 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product](https://images-eureka.patsnap.com/patent_img/d5788754-2923-46da-9d43-2f1cccb9d65b/BSA00000165662100011.PNG)

![Preparation method of 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product Preparation method of 1,4-di-[4-(glucosyloxy) benzyl]-2-isobutyl malate comparison product](https://images-eureka.patsnap.com/patent_img/b39bd776-aa02-4bf8-9601-7ff08c217c4a/BSA00000165662100011.PNG)