Patents

Literature

38results about How to "Good acid and heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pet foods

InactiveUS20090148560A1Improving pet ' appearanceHigh purityMilk preparationFatty substance preservation using additivesSorghumCompanion animal

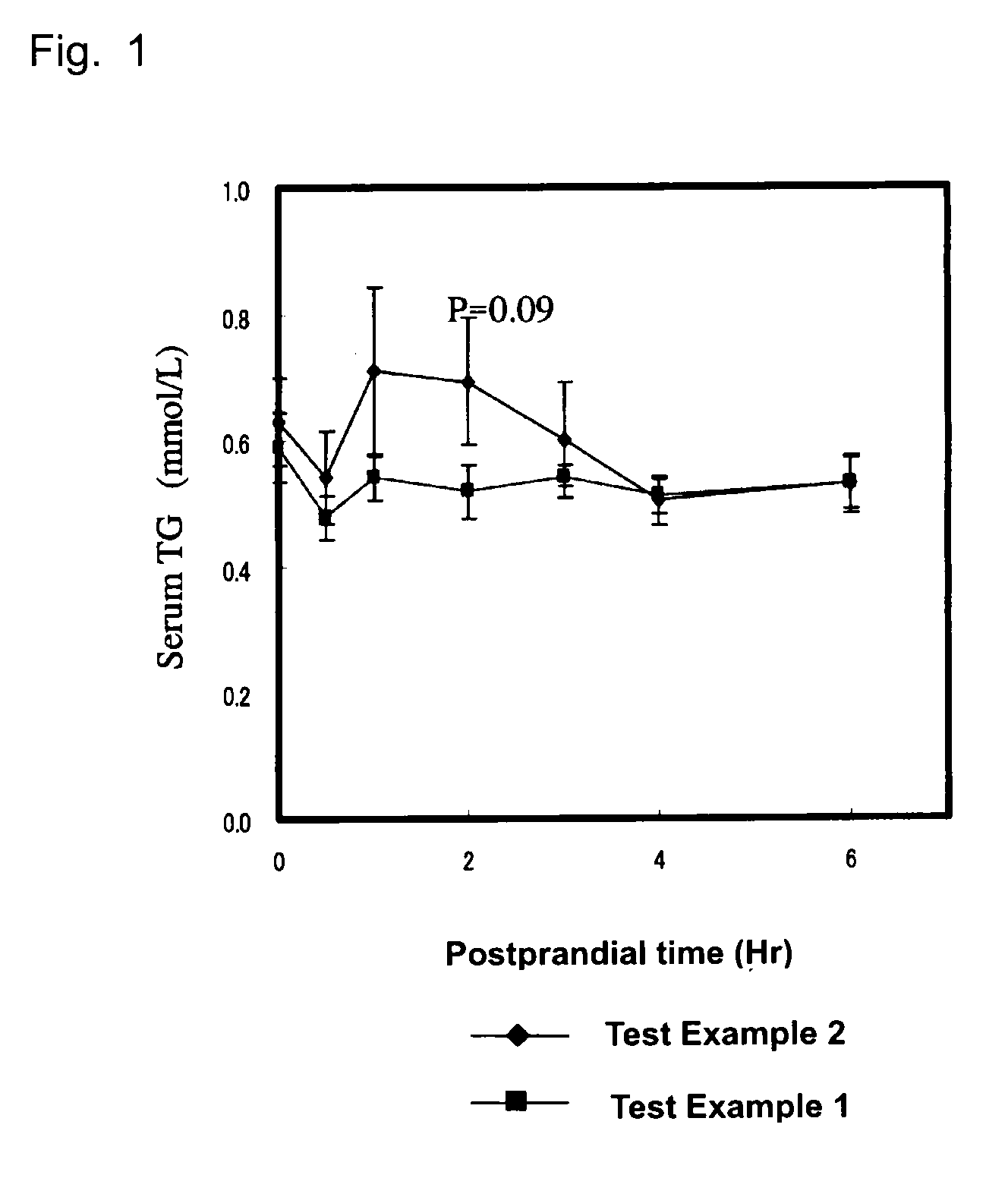

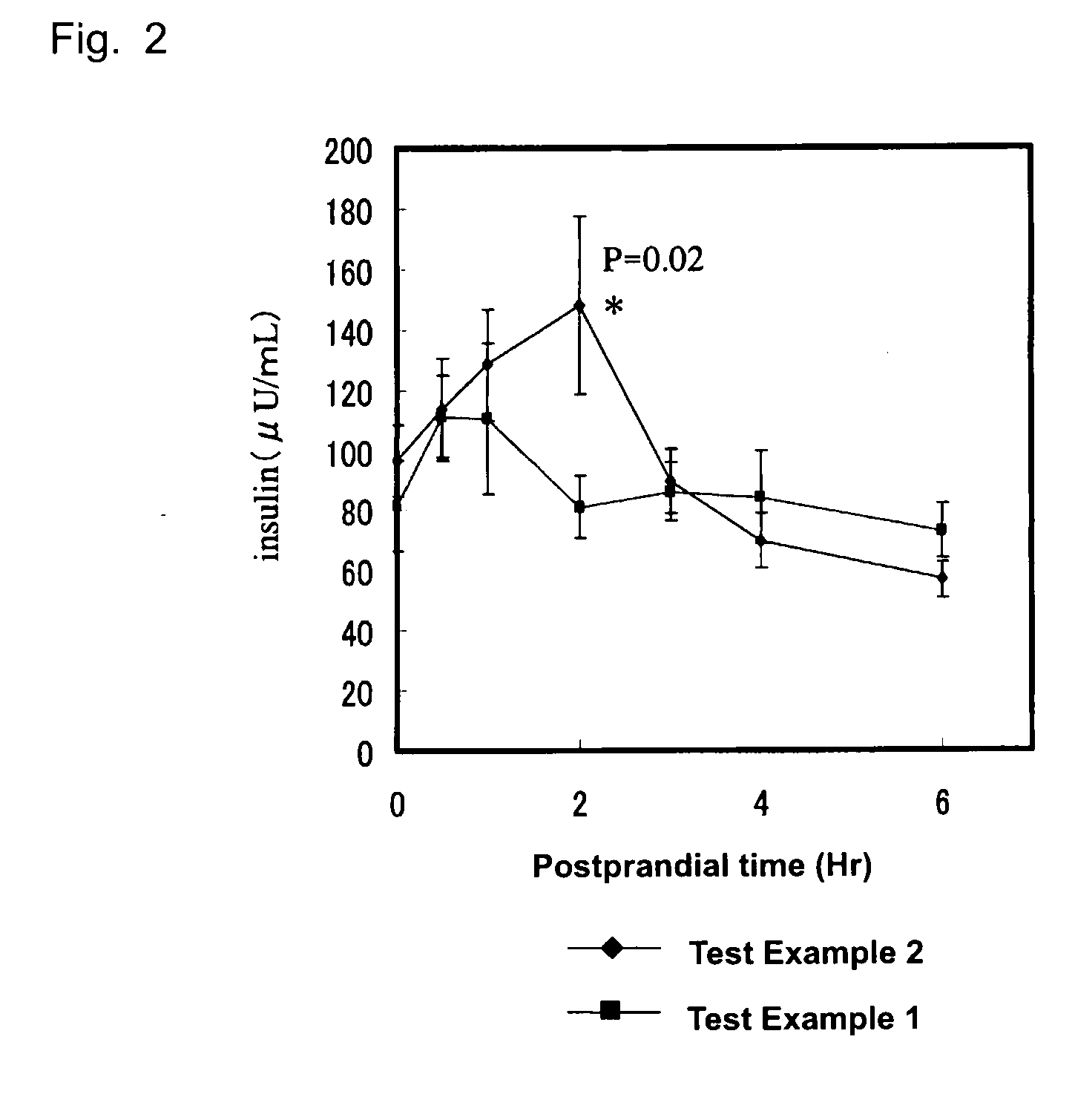

A pet food containing (A) an oil or fat and (B) one or more carbohydrate sources selected from the group consisting of modified starch, barley, sorghum, corn and high-amylose starch, wherein a content of diacylglycerol in the whole oil or fat is 20 wt % or higher.The pet food according to the present invention is excellent in the preventing or controlling effect on obesity, is not reduced in ingestion capacity, and does not affect stool conditions.

Owner:KAO CORP

Method for preparing ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material

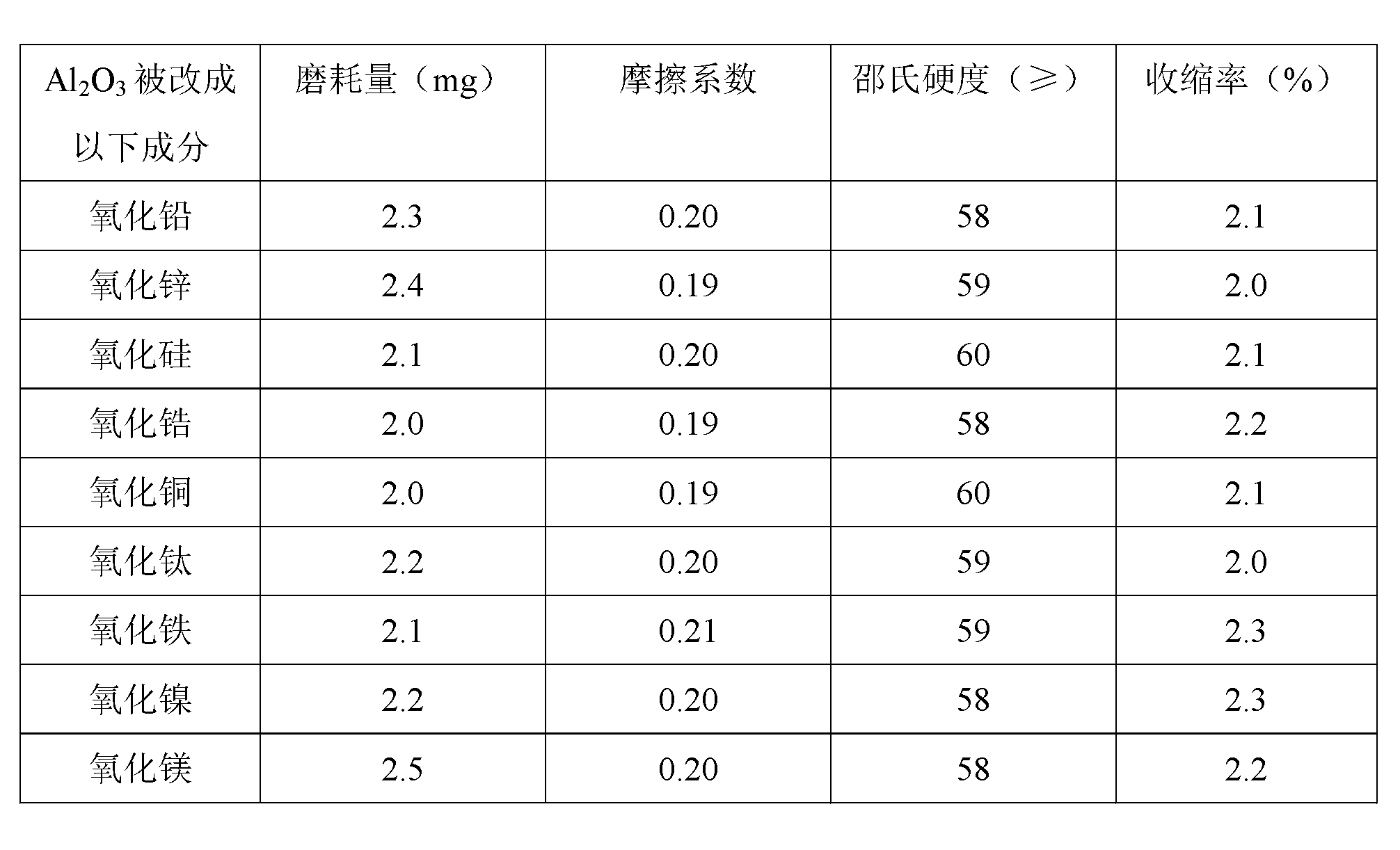

The invention discloses a method for preparing an ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The method comprises the steps of 1) proportioning materials, i.e. mixing polytetrafluoroethylene, ultrafine zeolite powder, a filler I and a filler II according to the ratio; 2) uniformly mixing the mixture proportioned and then carrying out cold press forming under the pressure of 20-40 Mpa; 3) putting the formed object obtained in the step 2) into a high temperature sintering furnace, heating to 330-380 DEG C with the speed of 30-100 DEG C / hour and preserving heat for 0.5-2 hours; and 4) naturally cooling sintering products obtained in the step 3) to the room temperature to obtain the ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material prepared according to the method has excellent performance, the wear resistance of the composite material is improved upon the premise of not remarkably reducing the matrix friction coefficient of PTFE, and the application range of the composite material is wide.

Owner:ZHEJIANG UNIV

Method for preparing solubilized composition containing oil-soluble substance

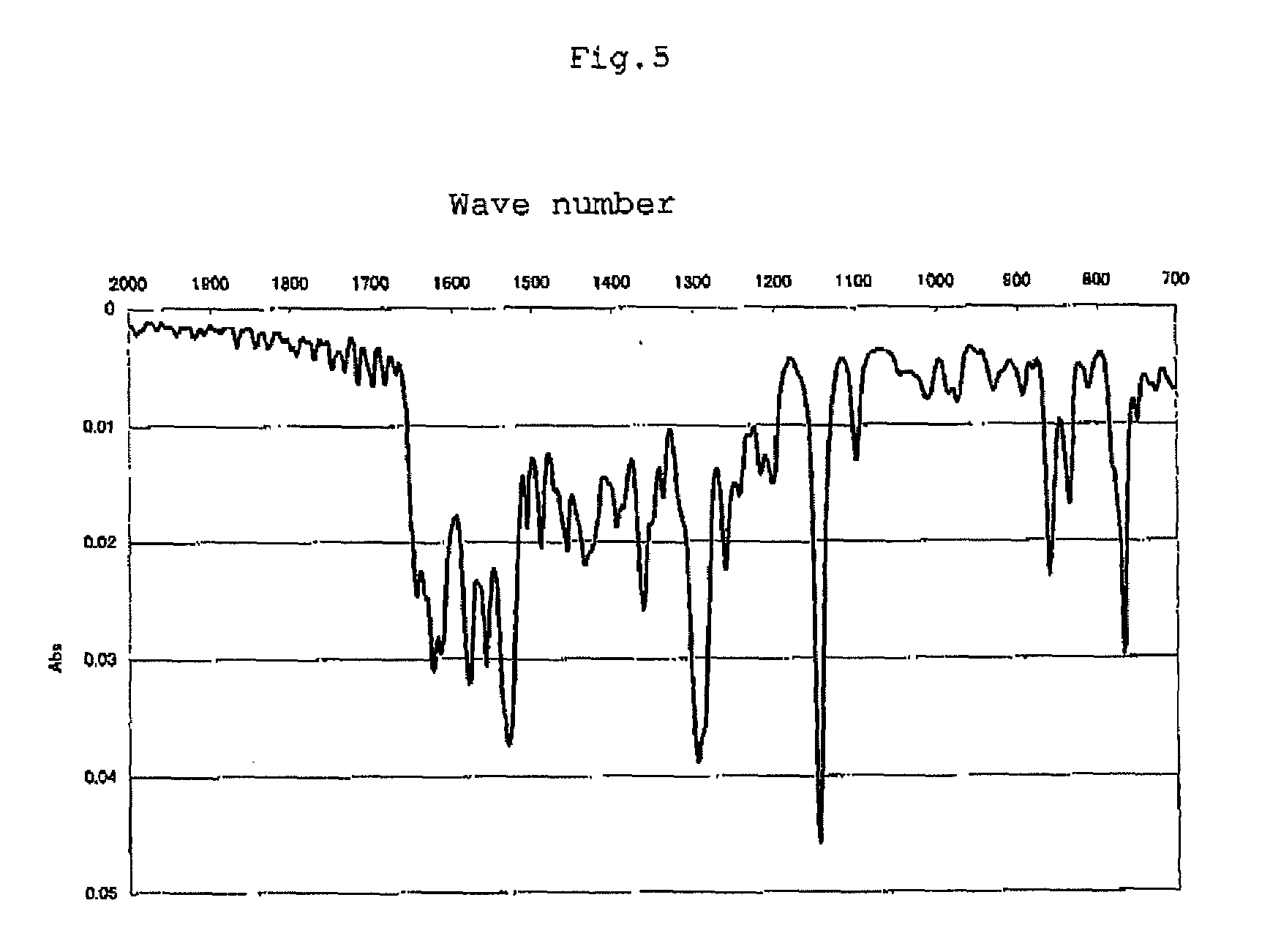

ActiveUS20080070992A1Improve acid resistanceImprove heat resistanceBiocideCosmetic preparationsSucroseEthyl acetate

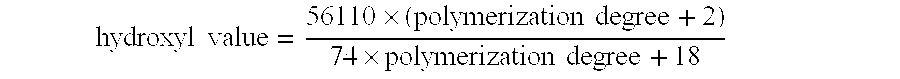

The present invention provides a method for preparing a solubilized composition containing an oil-soluble substance having both acid and heat resistance, including:the step of dissolving an oil-soluble substance and two or three emulsifiers selected from(1) an emulsifier E1 comprising an ester of a fatty acid having an HLB of not less than 10 and not more than 14 carbon atoms with a polyglycerol having a polymerization degree of not less than 3,(2) an emulsifier E2 comprising an ester of a fatty acid having an HLB of not less than 10 and not more than 14 carbon atoms with sucrose, or(3) an emulsifier E3 comprising lecithin in which phosphatidylcholine accounts for not less than 50% and / or lysolecithin in which lysophosphatidylcholine accounts for not less than 50% of a phospholipid content in (a) ethanol or (b) a mixed solvent of ethanol with at least one selected from the group consisting of acetone, hexane, and ethyl acetate to prepare a transparent solution; andthe step of distilling the solvent off from the transparent solution.

Owner:TSUJI SEIYU

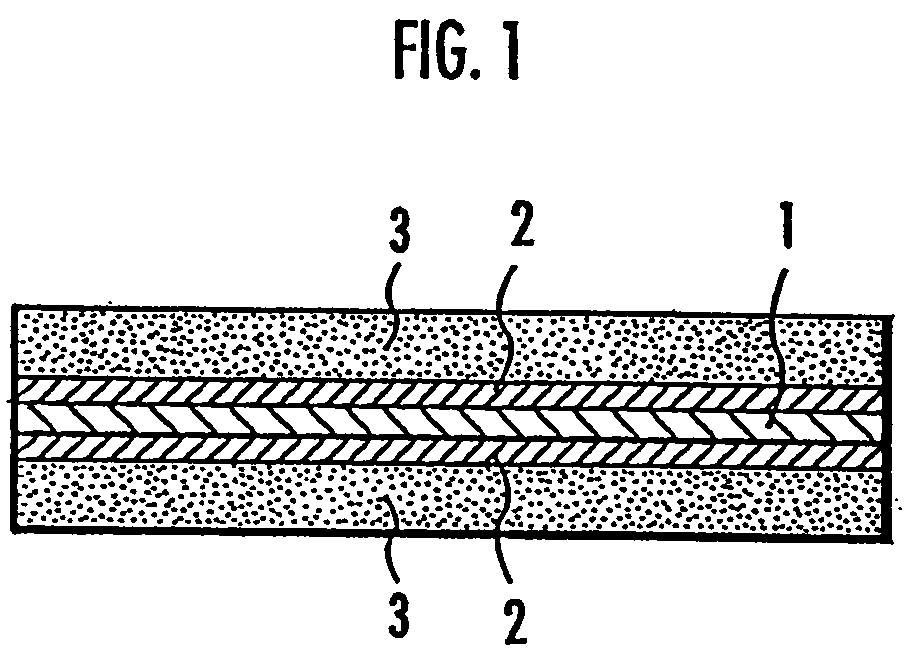

Liquid Crystal Polyester Porous Film

InactiveUS20120164447A1Excellent heat resistance and acid resistanceSufficient acid resistanceLiquid crystal compositionsSemi-permeable membranesPolyesterLiquid crystal

An object of the present invention is to provide a porous membrane having excellent heat resistance and acid resistance. A porous membrane is constituted by a liquid crystal polyester and a polymer other than the liquid crystal polyester. A liquid crystal polyester having a reduced viscosity of 0.40 dL / g or more is used as the liquid crystal polyester. A polymer having a reduced viscosity of 0.40 dL / g or more is used as the polymer other than the liquid crystal polyester. The content of the polymer other than the liquid crystal polyester is adjusted from 10 to 40 parts by mass based on 100 parts by mass of the liquid crystal polyester.

Owner:SUMITOMO CHEM CO LTD

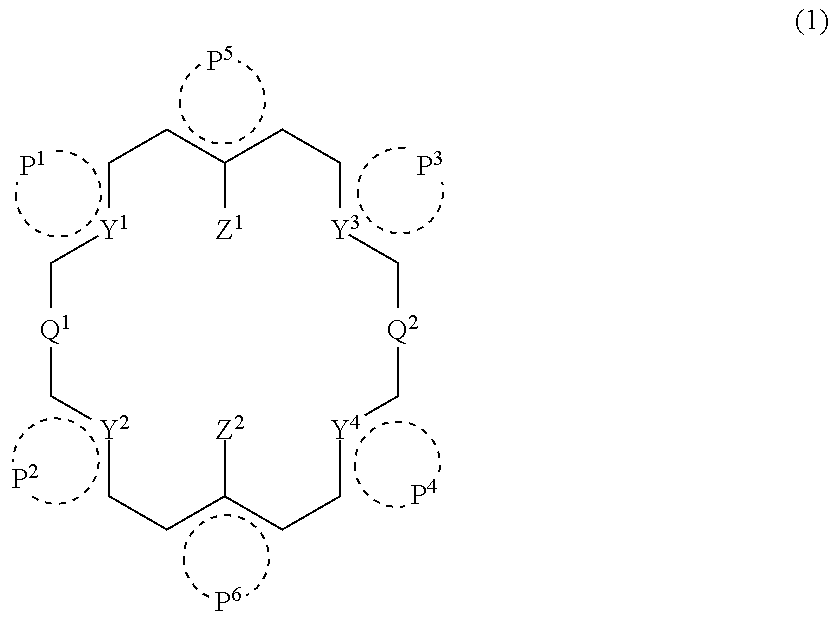

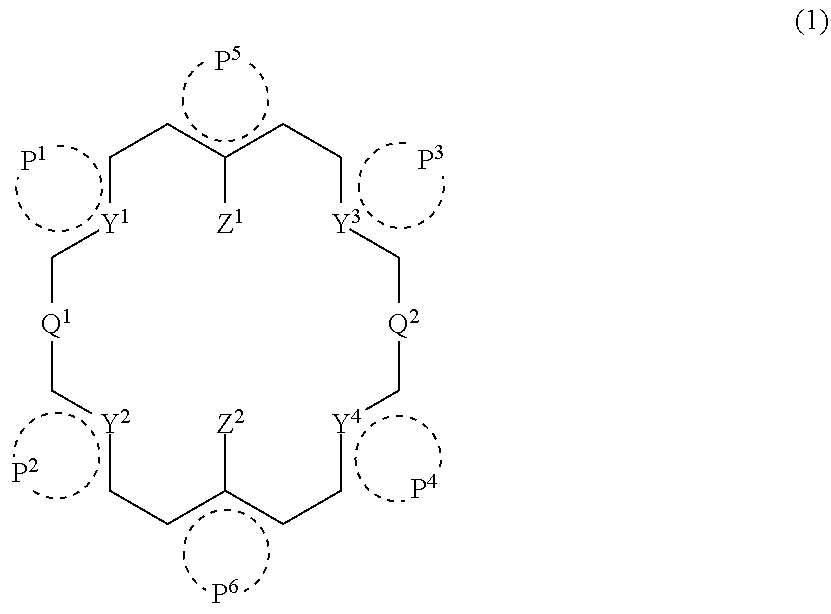

Cyclic compound, its metal complex and modified metal complex

ActiveUS20110015059A1Improve acid resistanceImprove heat resistanceElectrolyte holding meansElectrolytic capacitorsCarbon atomHydrocarbon

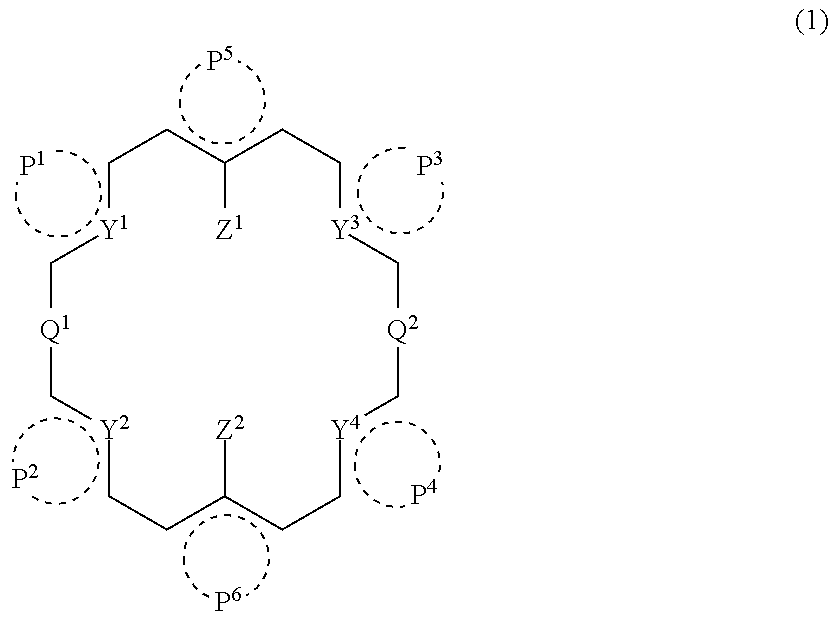

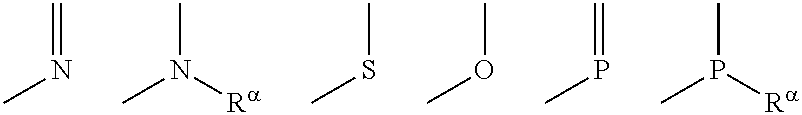

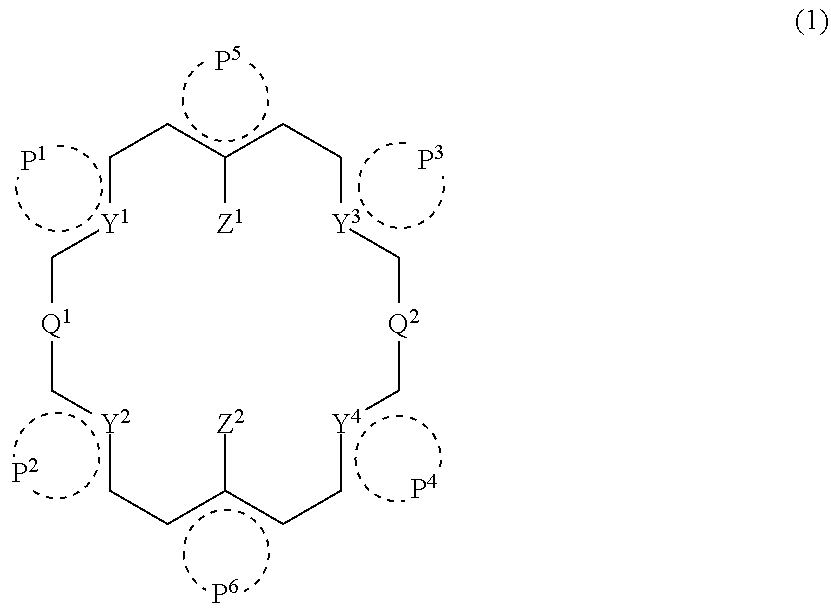

A compound represented by formula (1):wherein Y1 to Y4 each independently represent any one of the following groups:in which Rα represents a hydrogen atom or a monovalent hydrocarbon group; P1 to P4 each independently represent a group of atoms necessary for forming a heterocyclic ring together with each of Y1 to Y4 and the two carbon atoms adjacent to each of Y1 to Y4, respectively; P5 and P6 each independently represent a group of atoms necessary for forming a cyclic skeleton together with the carbon atom to which Z1 bonds or Z2 bonds and the two carbon atoms adjacent to the carbon atom to which Z1 bonds or Z2 bonds; P1 and P2, P2 and P6, P6 and P4, P4 and P3, P3 and P5, and P5 and P1 may further combine with each other to form a ring; Q1 and Q2 each independently represent a connecting group or a direct binding; and Z1 and Z2 each independently represent any one of the following groups;—NRβ2, —ORβ, —SRβ, —PRβ2 in which Rβ represents a hydrogen atom or a monovalent hydrocarbon group, and when plural Rβs are present, these plural Rβs may be the same or different from each other.

Owner:SUMITOMO CHEM CO LTD

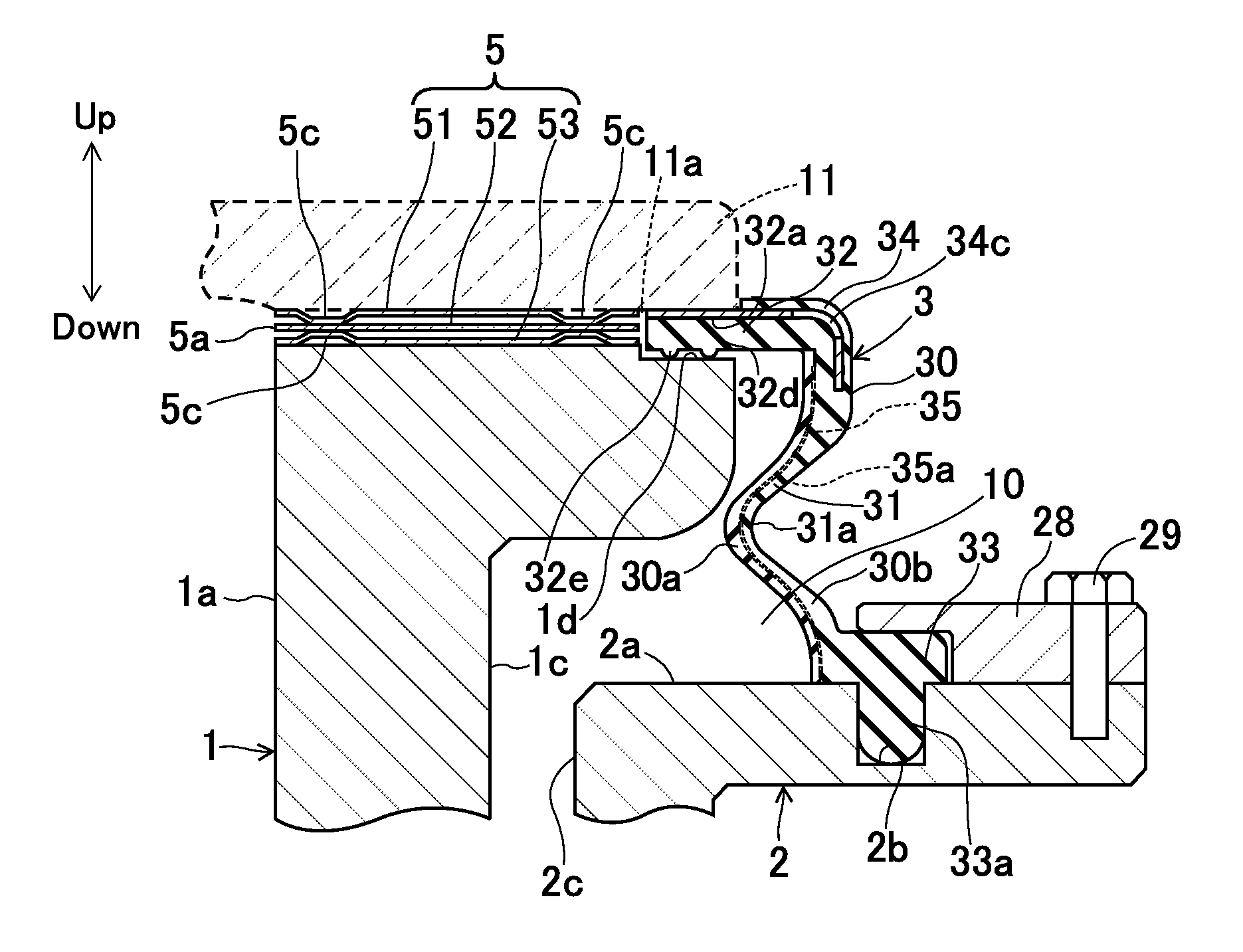

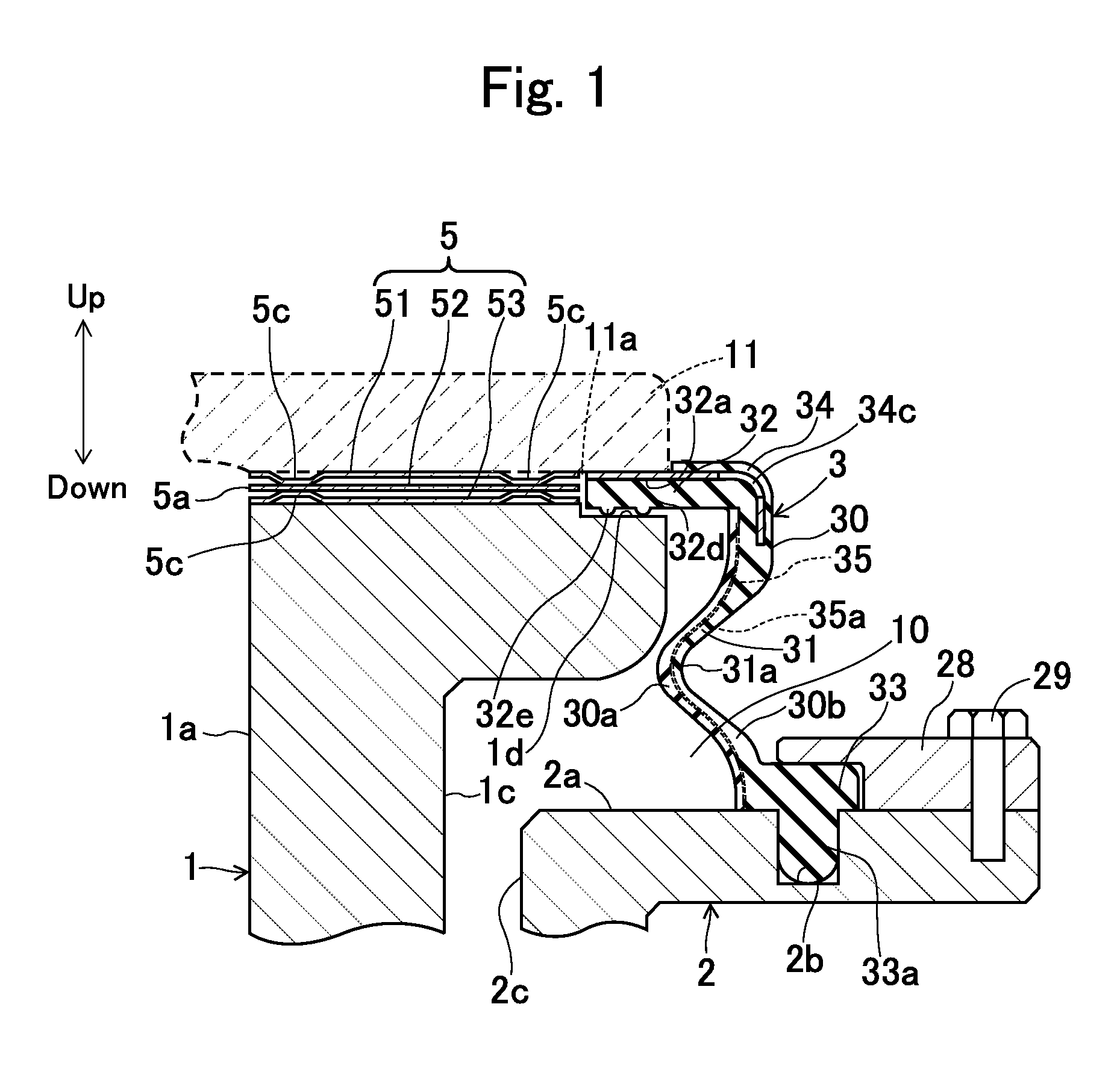

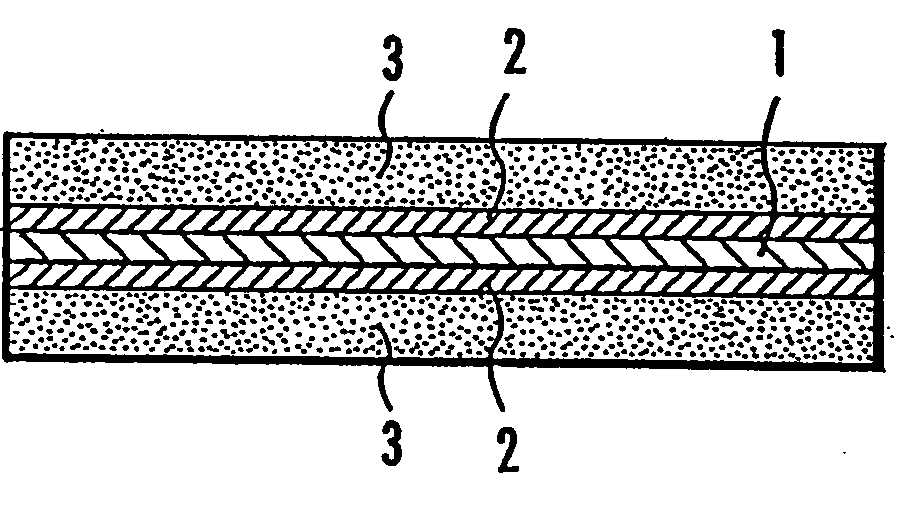

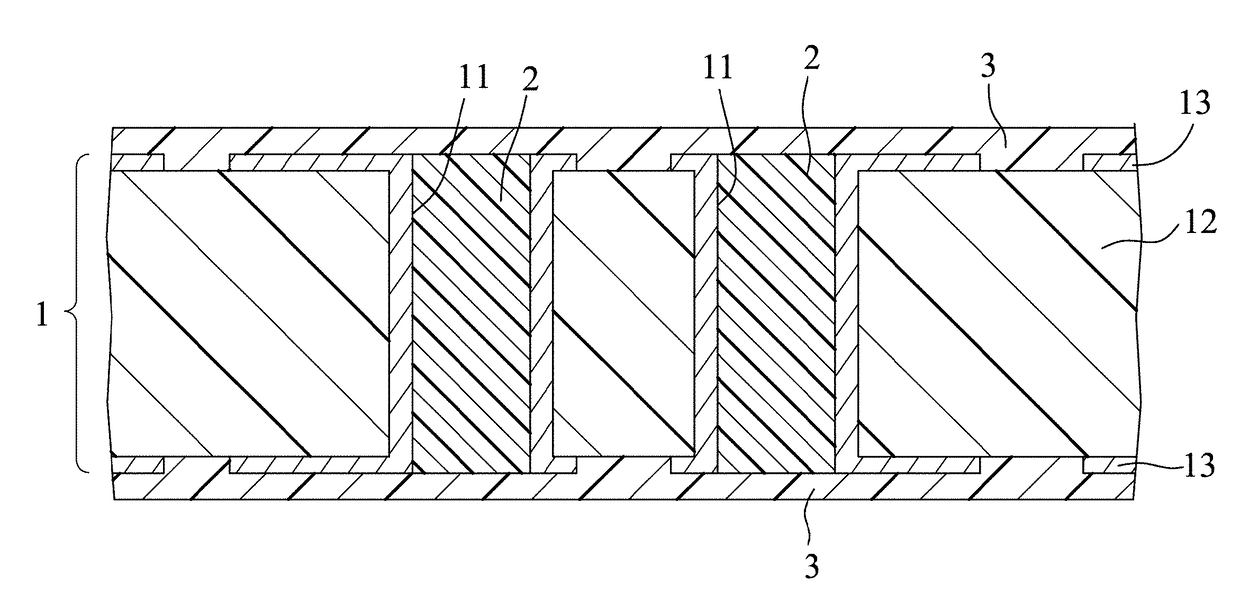

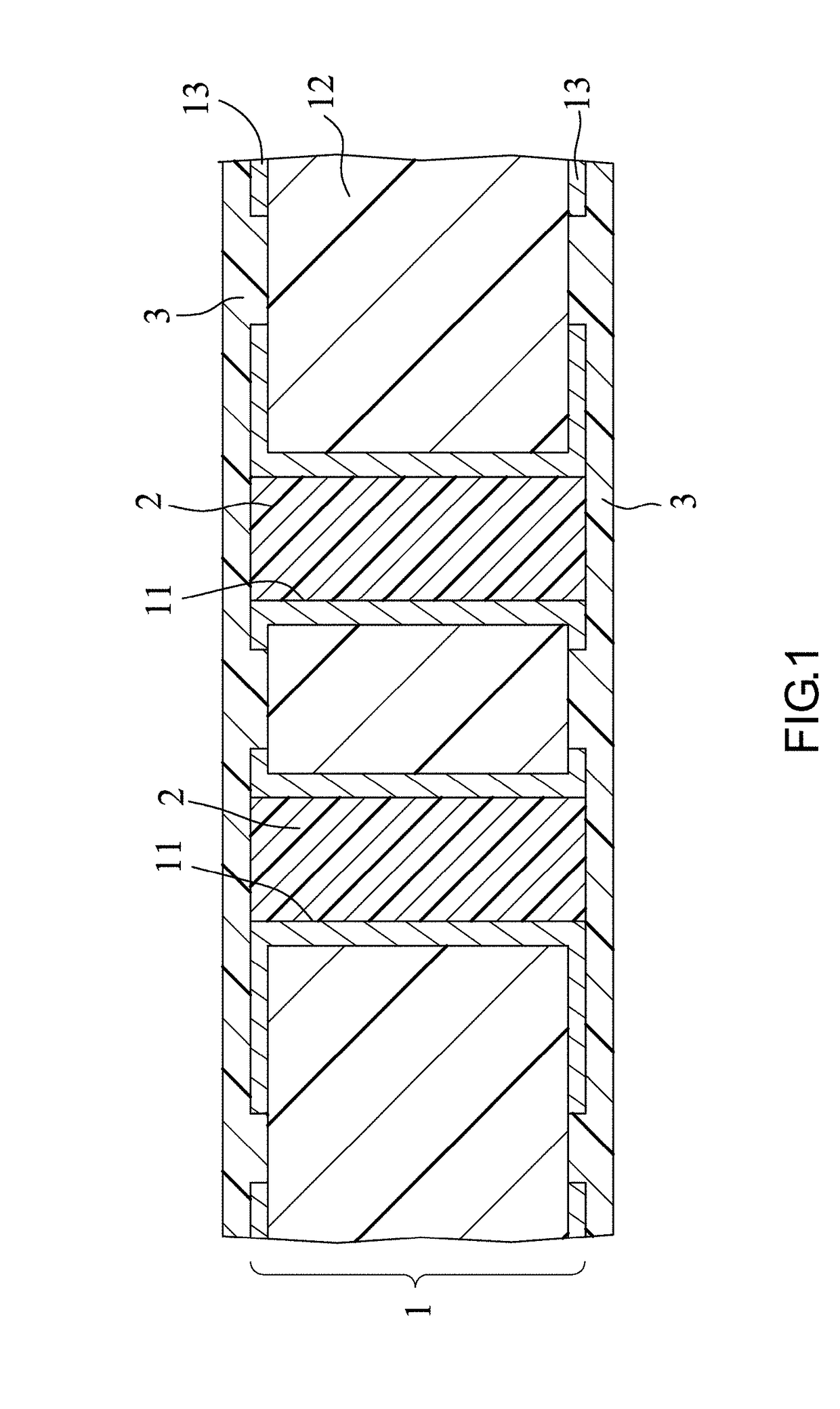

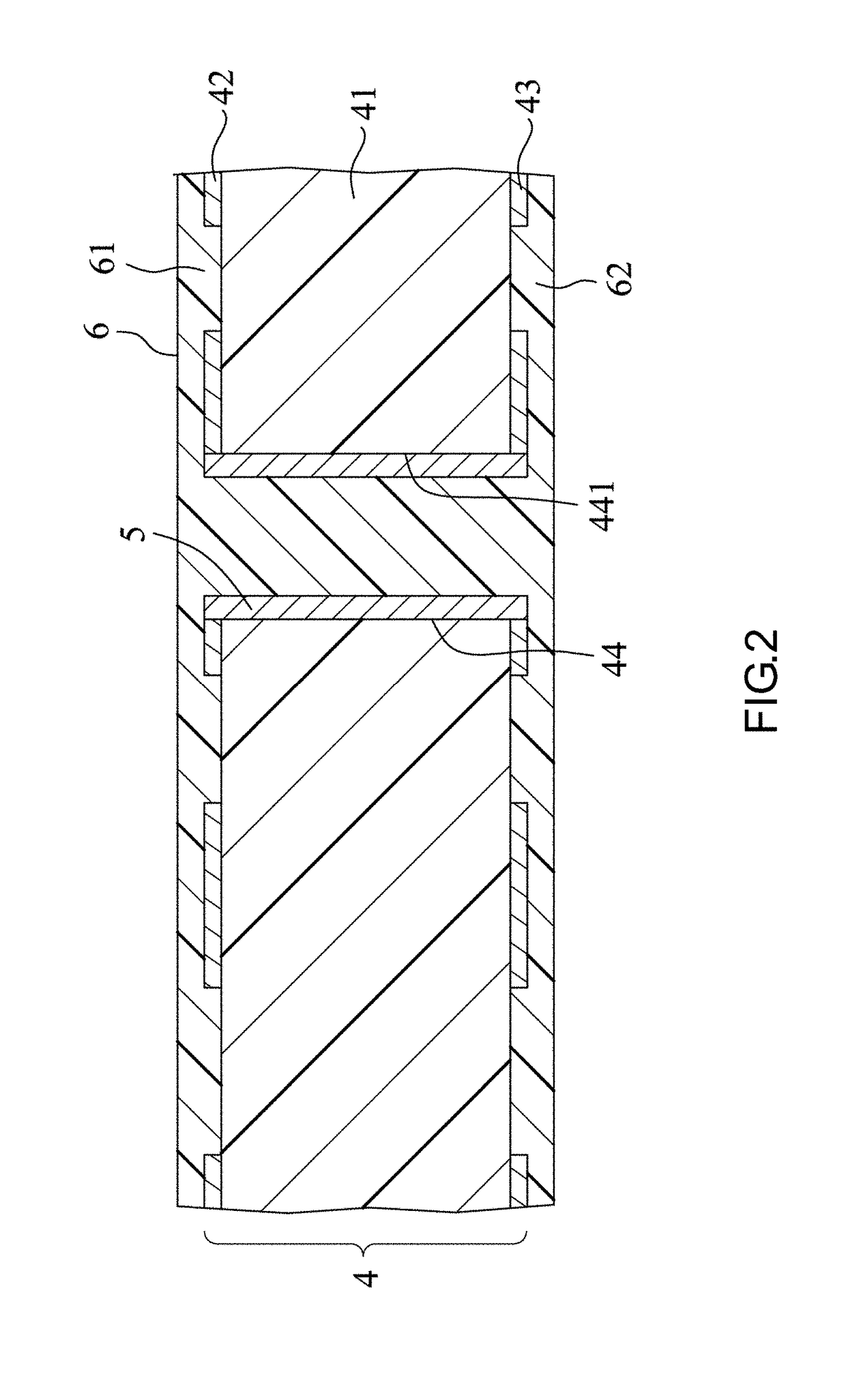

Boot seal for variable compression-rate engine

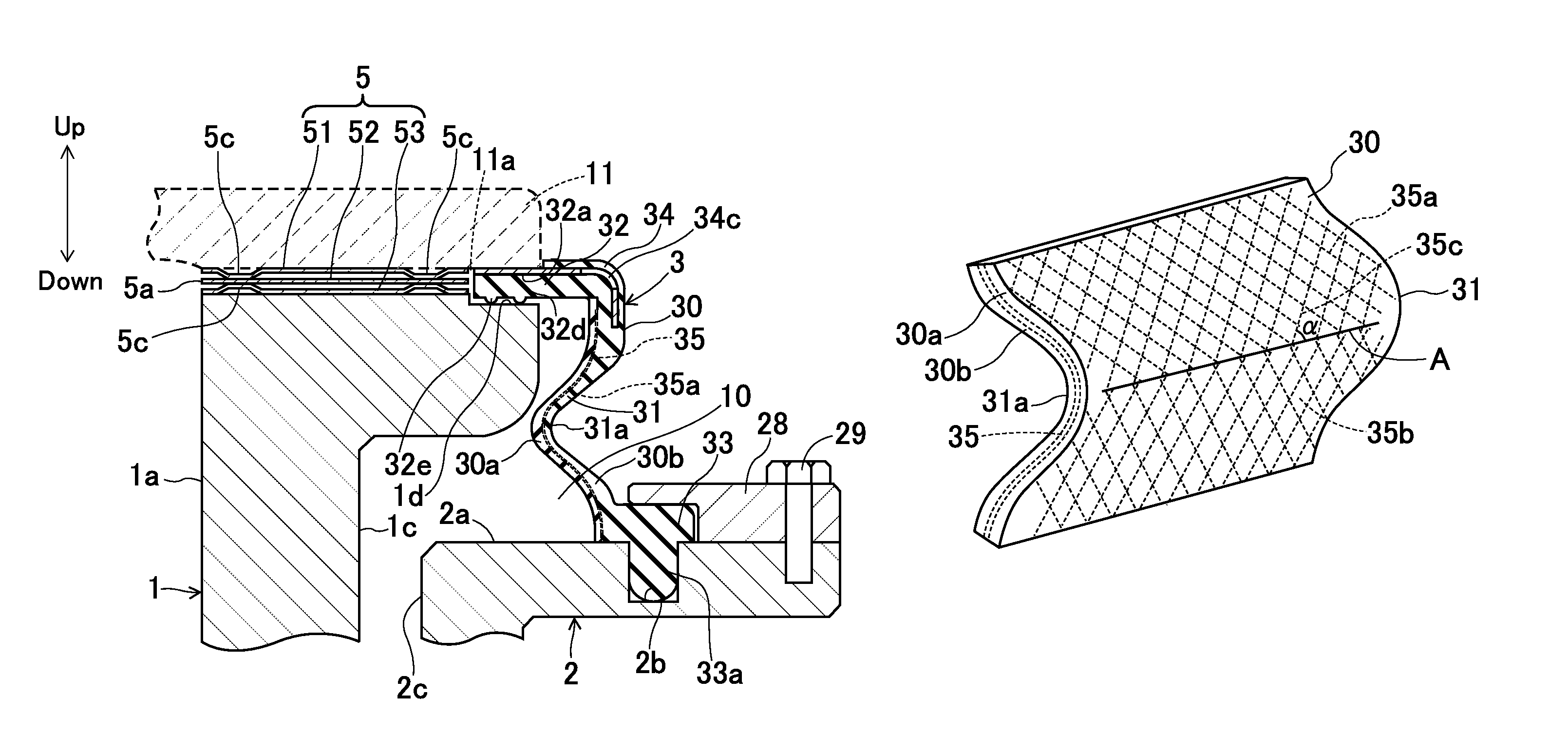

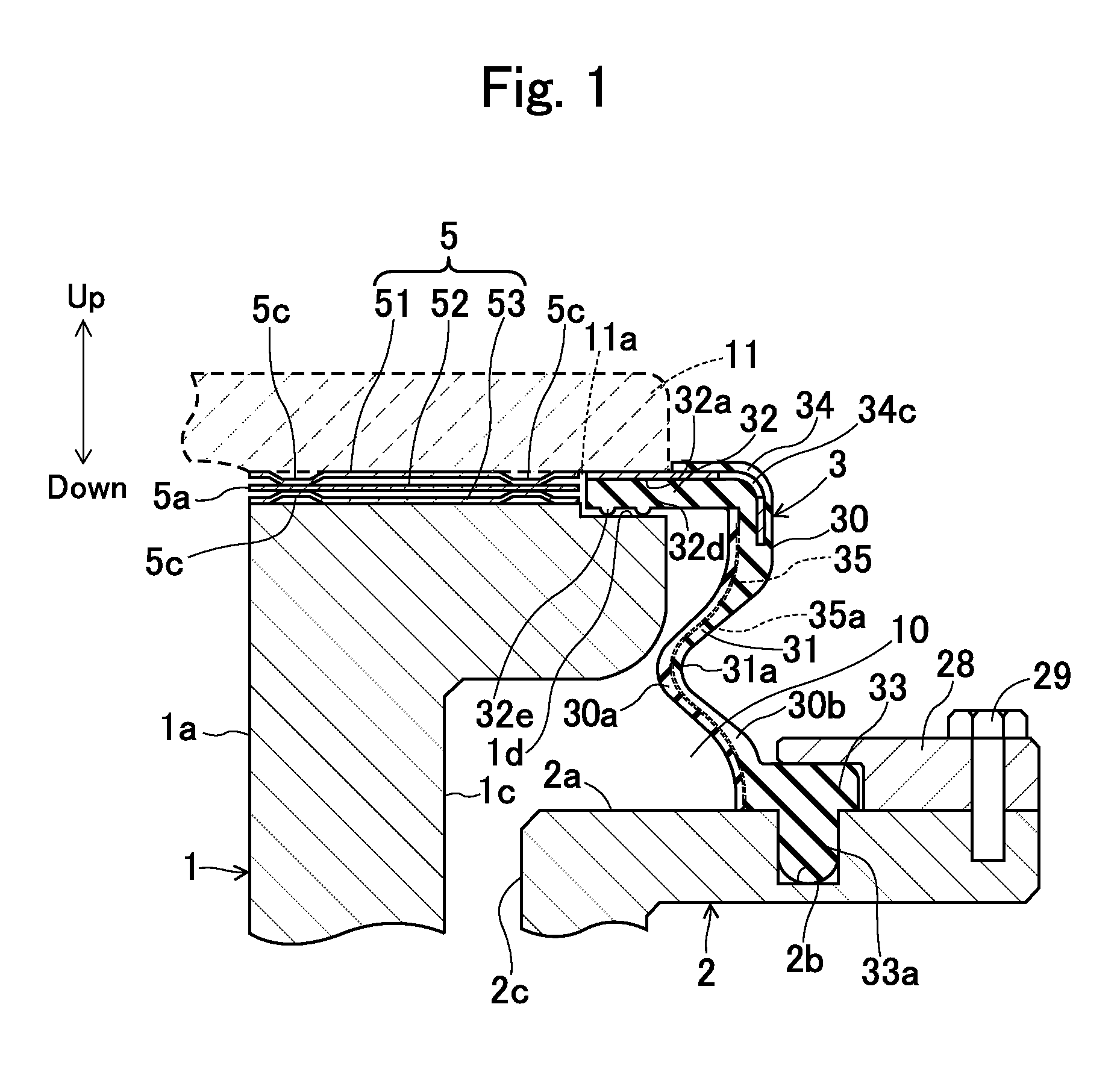

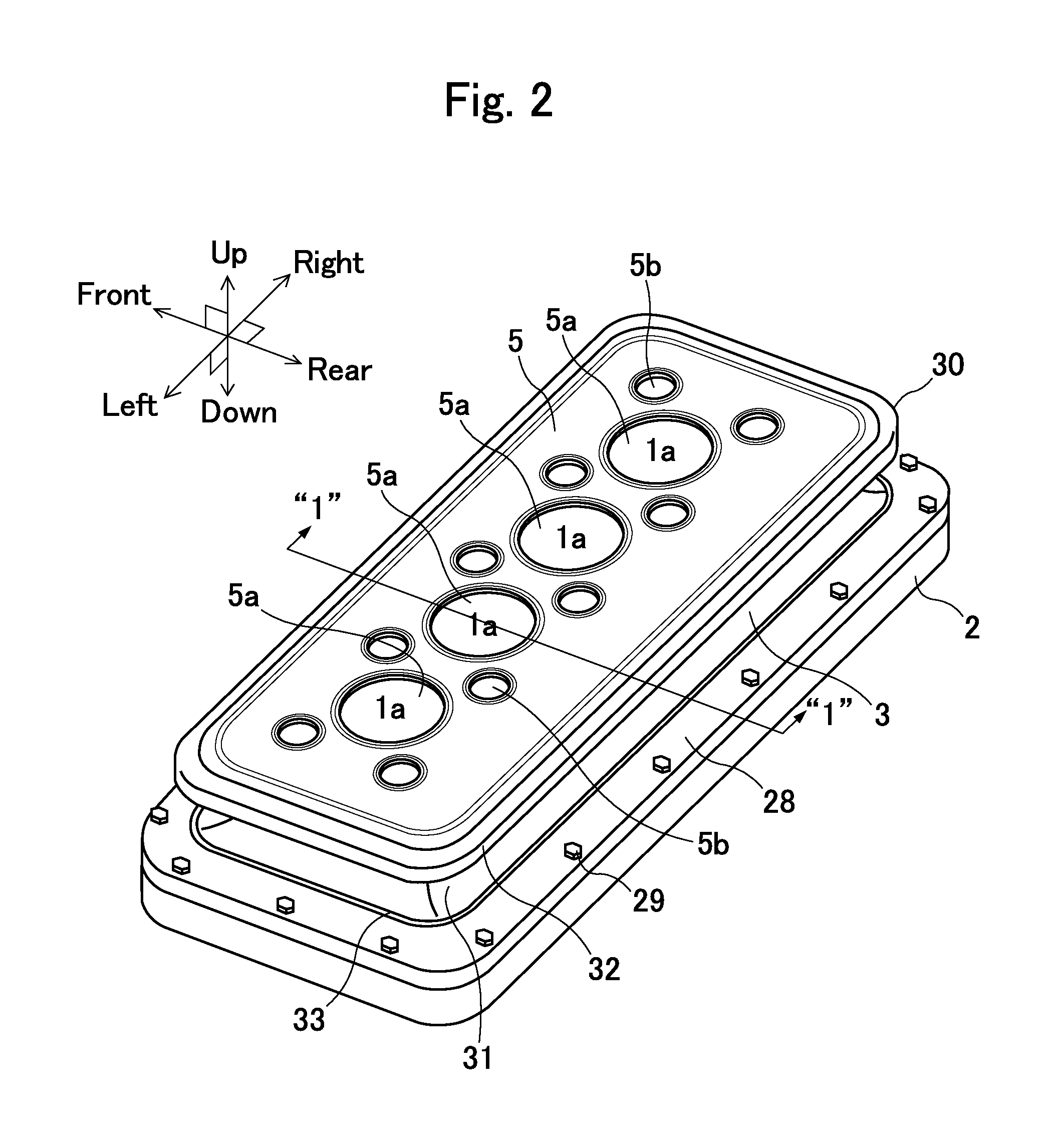

InactiveUS20120248712A1Improve sealingGood acid and heat resistanceSealing arrangements for enginesMachines/enginesEngineeringBellows

A boot seal for variable compression-rate engine includes a boot-seal element, and a reinforcement member. The boot-seal element includes an inner layer, and an outer layer. The inner layer is disposed on the inner face of the boot-seal element, and is composed of a fluorinated rubber. The outer layer is disposed on a more outer side of the boot-seal element than is the inner layer. Moreover, the boot-seal element is formed in a circumferentially developed state so as to have circumferential ends, and is then completed by joining the circumferential ends with each other. Thus, the boot-seal element makes an elastically deformable cylindrical bellows shape having a root that dents inward diametrically. In addition, the reinforcement member is disposed in the root of the cylindrical bellows-shaped boot-seal element at least.

Owner:TOYODA GOSEI CO LTD +1

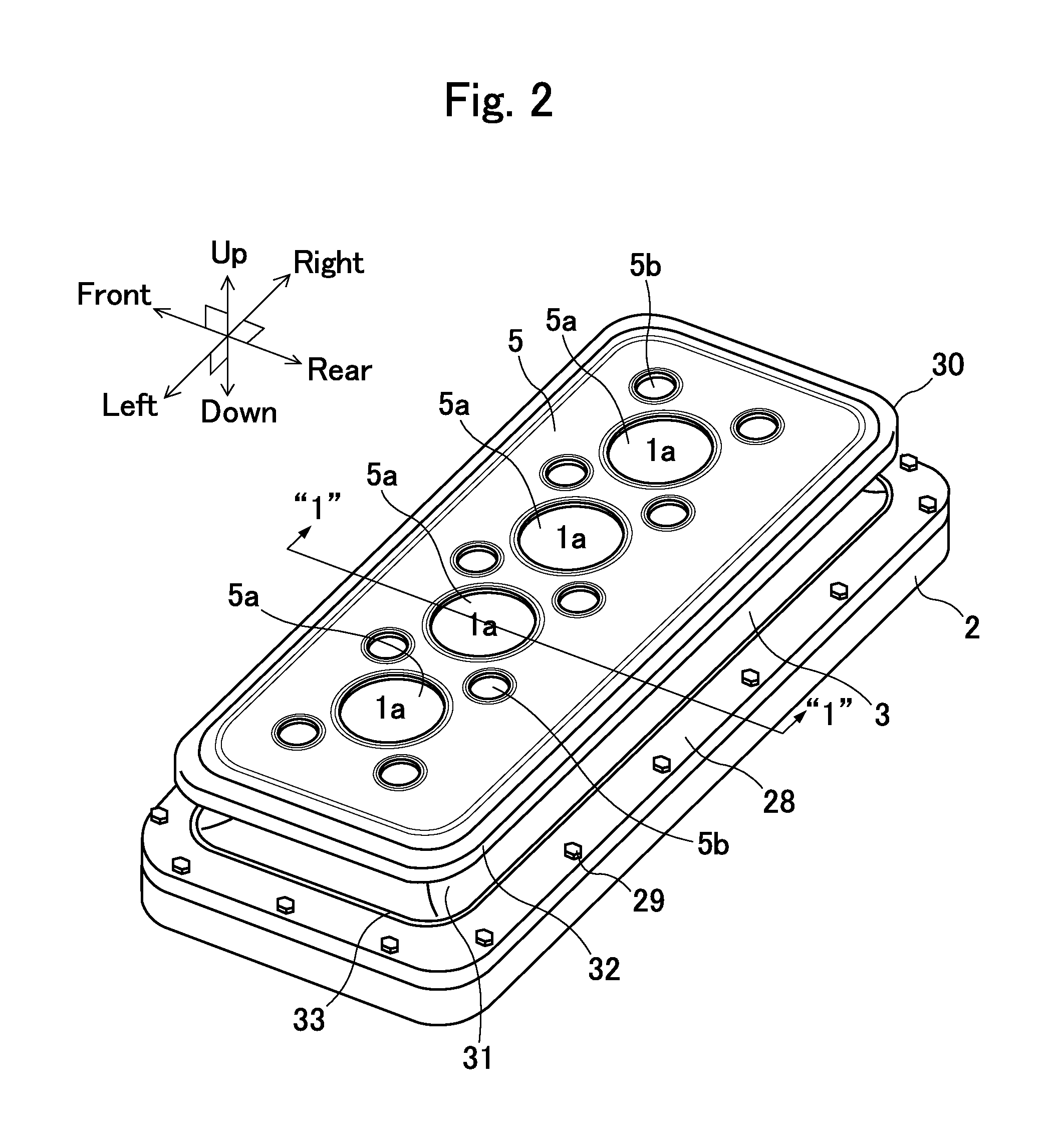

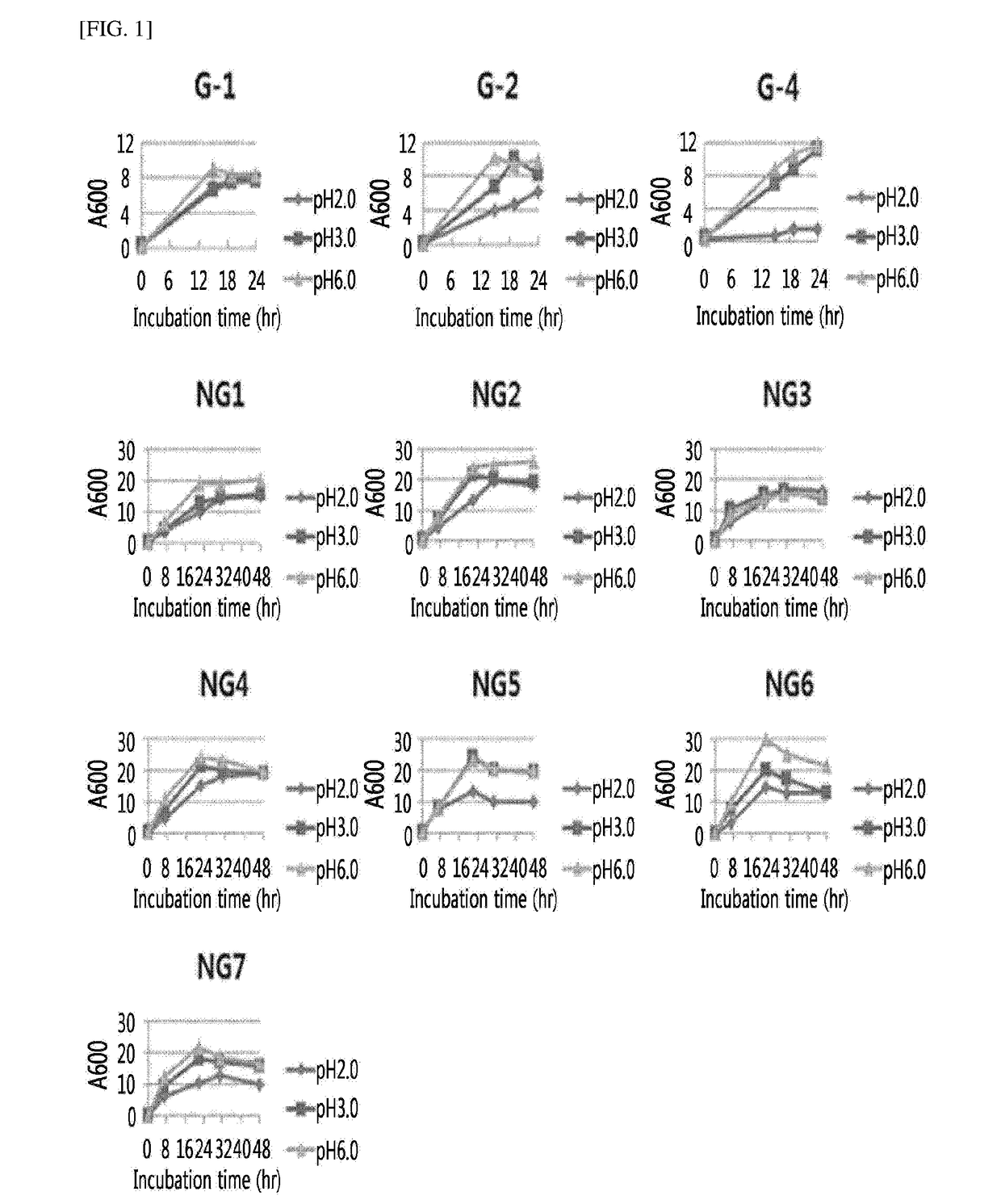

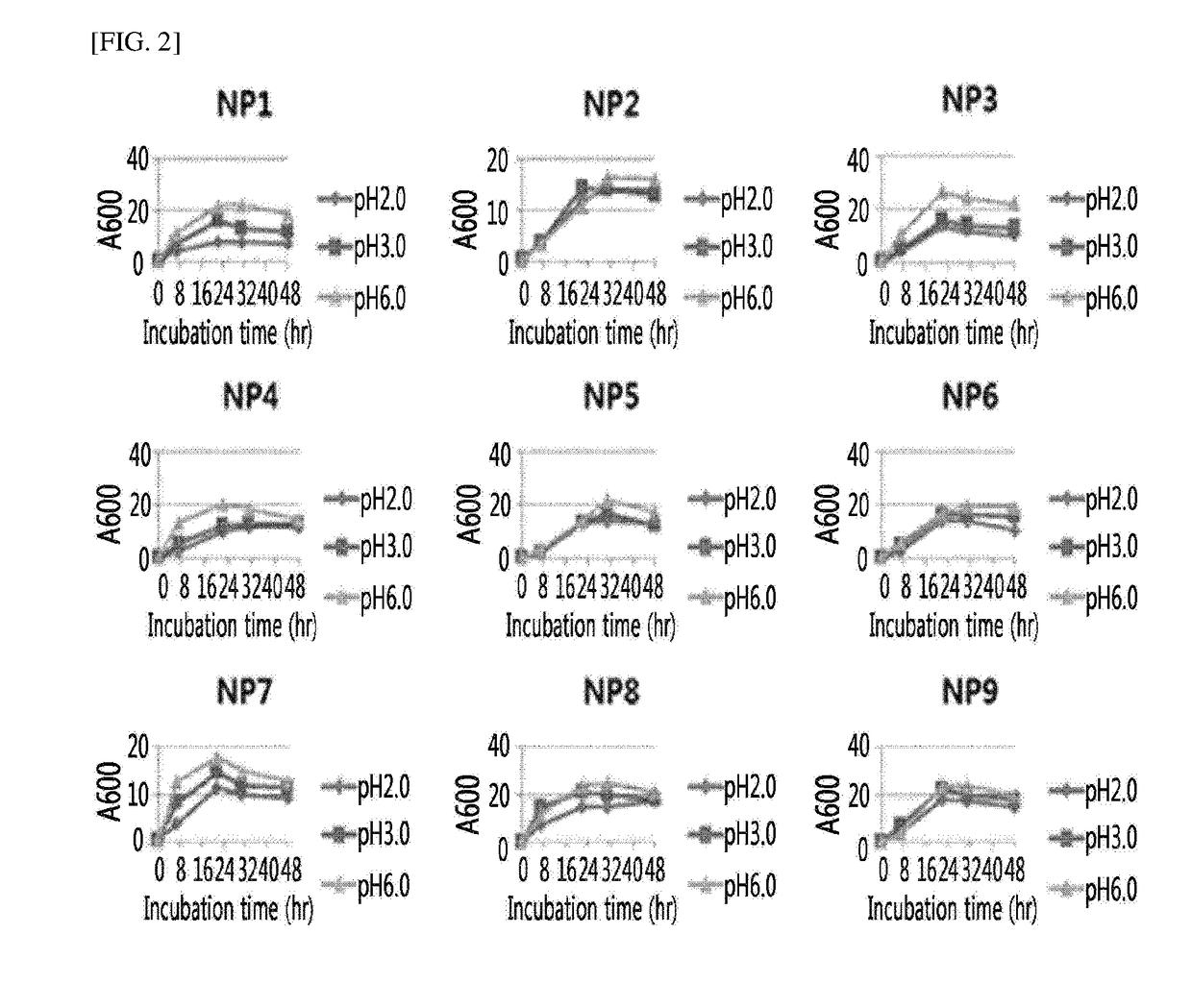

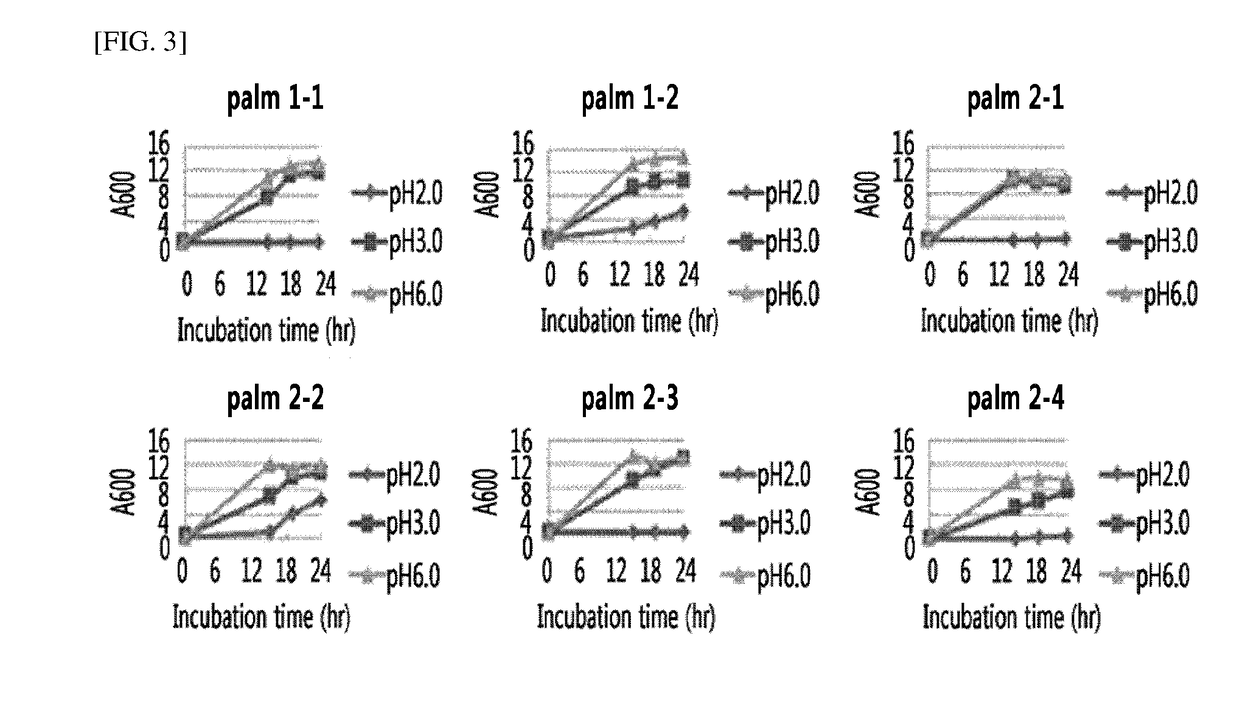

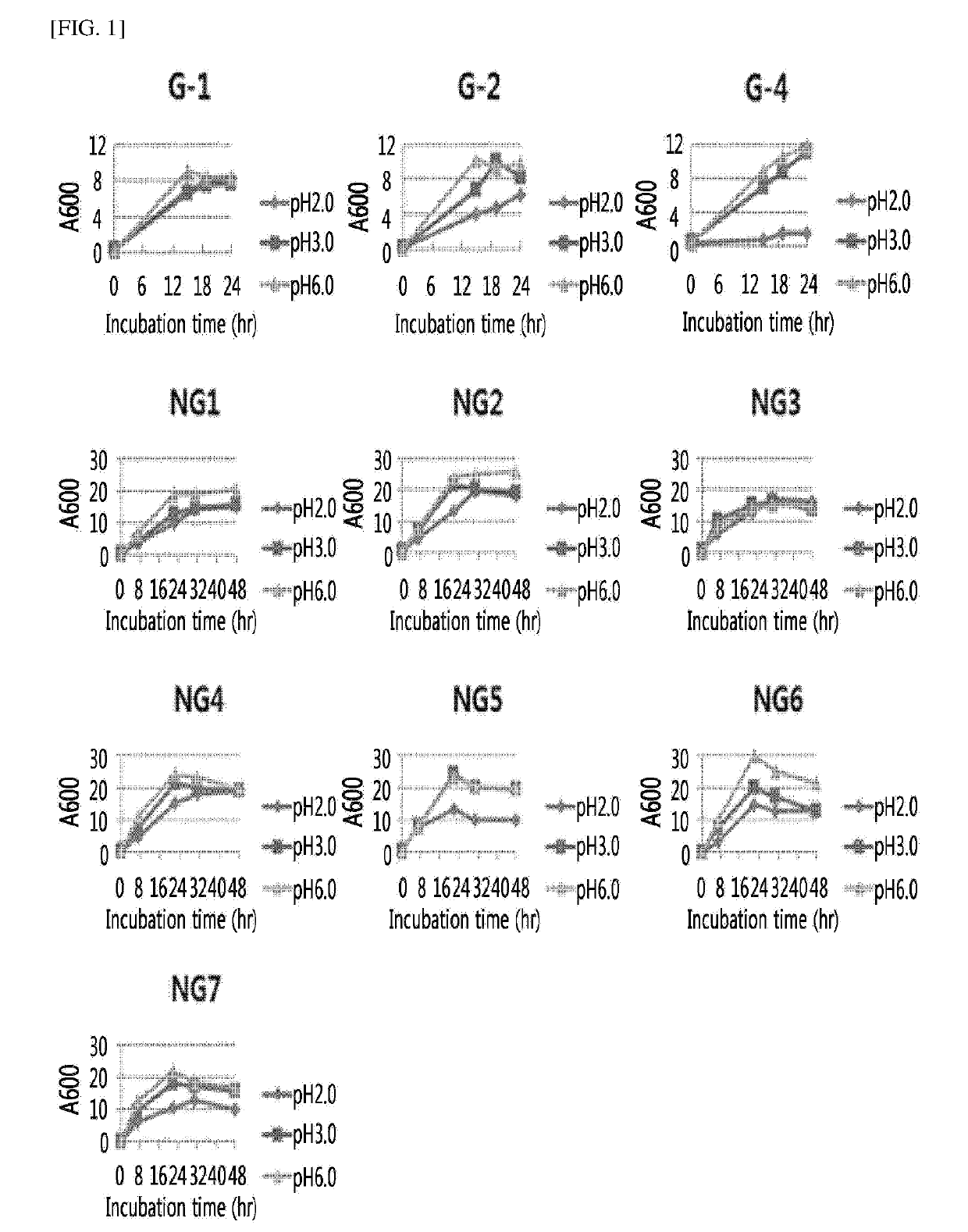

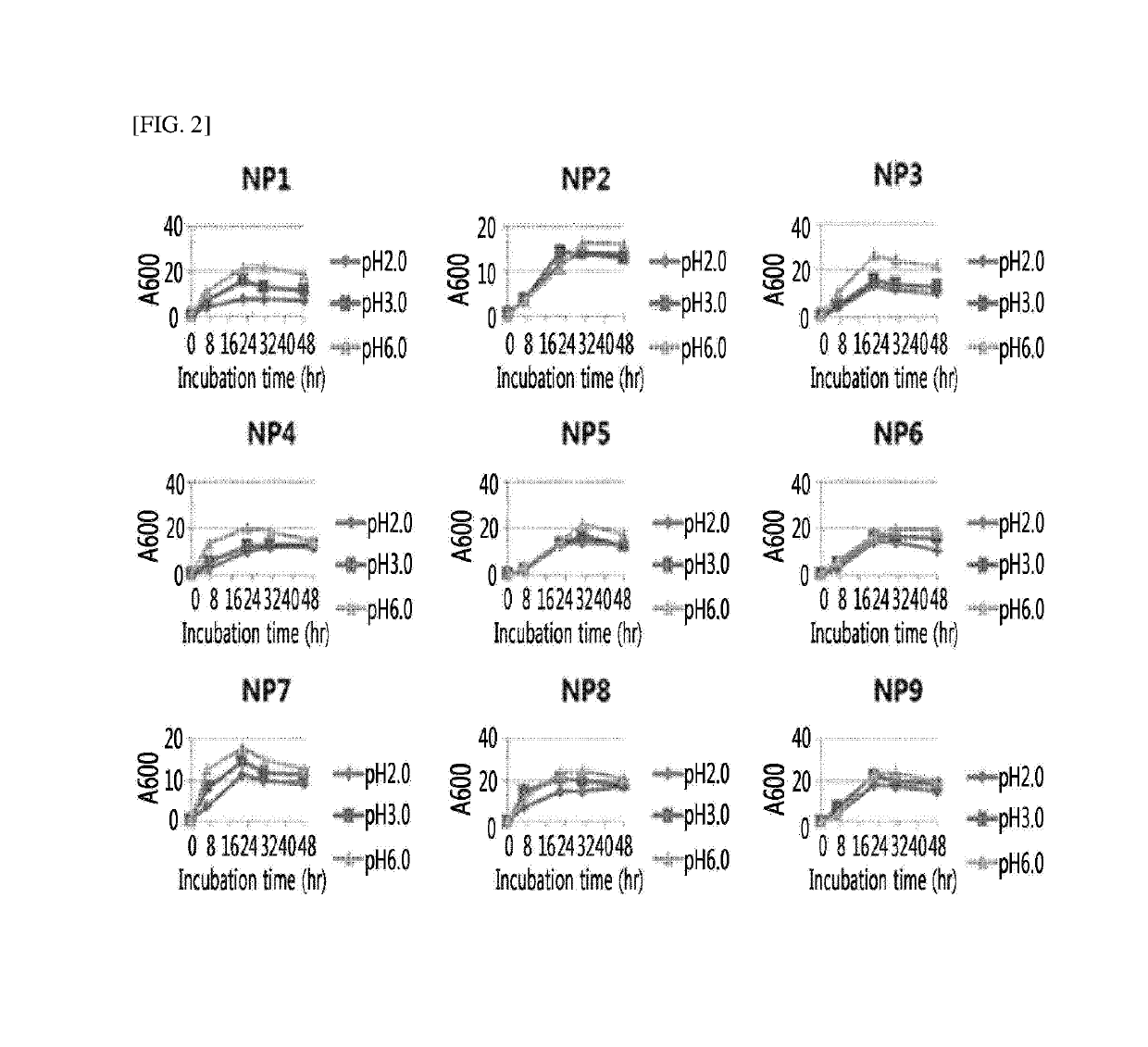

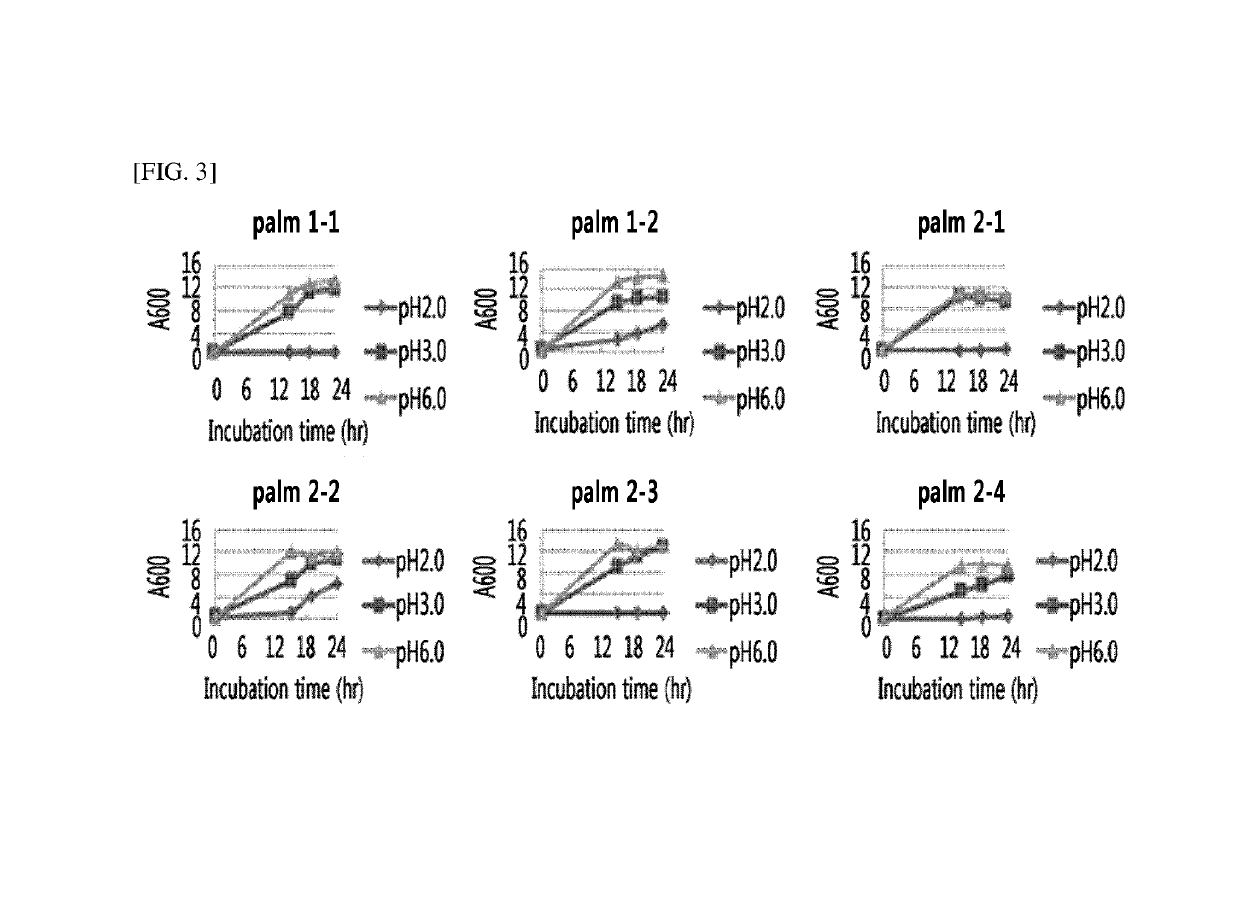

Novel pichia kudriavzevii ng7 microorganism and uses thereof

ActiveUS20170349920A1Improve acid resistanceImprove heat resistanceFungiBiofuelsMicroorganismBiotechnology

The present invention relates to: a novel Pichia kudriavzevii microorganism NG7 showing heat resistance and acid resistance; a composition, for producing organic acid or alcohol, which comprises the microorganism and a culture of the same; and a method, for producing an organic acid or alcohol, which comprises culturing the microorganism.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

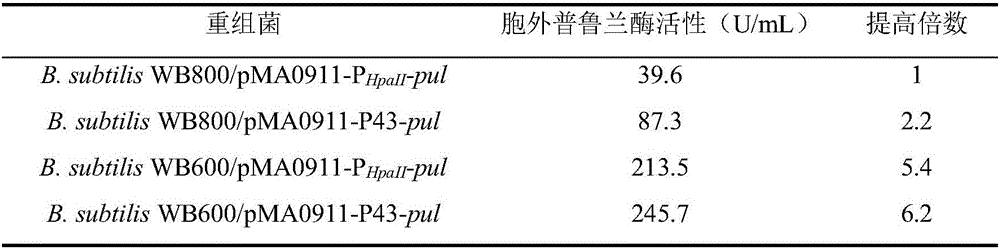

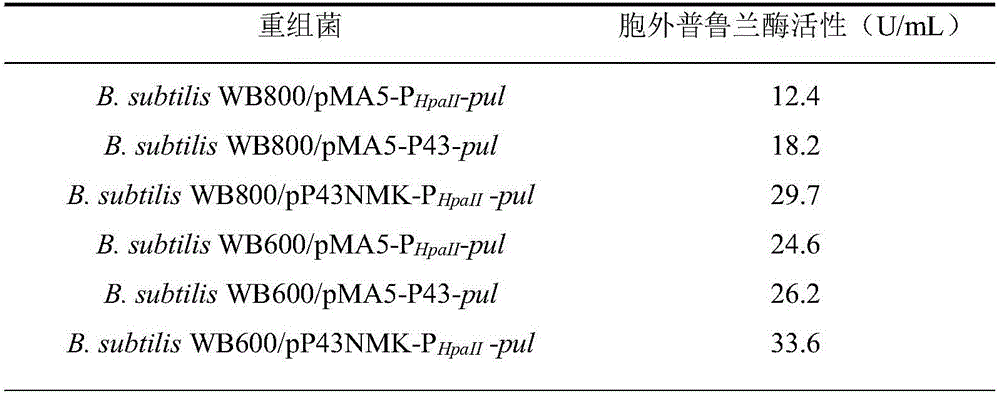

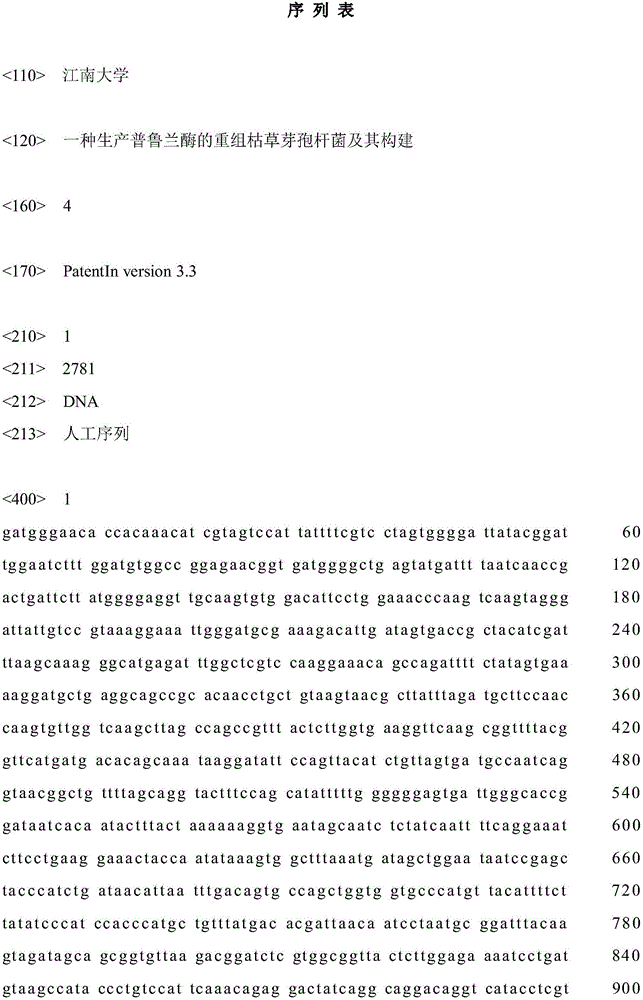

Recombinant bacillus subtilis for producing pullulanase and construction thereof

InactiveCN106190934AResolve dependenciesGood acid and heat resistanceBacteriaMicroorganism based processesShuttle vectorEnzyme Gene

The invention discloses recombinant bacillus subtilis for producing pullulanase and construction thereof, and belongs to the technical field of microbial fermentation production of pullulanase. According to the recombinant bacillus subtilis for producing the pullulanase and the construction thereof, a bacillus naganoensis CCTCC NO:M 2012388 pullulanase gene pul is inserted into a shuttle vector pMA0911, the obtained recombinant plasmid pMA0911-PHpaII-pul is electrically converted into B.subtilis WB800 to construct a recombinant bacterium B.subtilis WB800 / pMA0911-PHpaII-pul, and the extracellular pullulanase activity is 39.6 U / mL. An original promoter PHpaII is replaced with a strong promoter, and the extracellular enzyme activity of recombinant bacterium B.subtilis WB800 / pMA0911-P43-pul is improved to be 87.3 U / mL; the constructed recombinant plasmid pMA0911-PHpaII-pul and the pMA0911-P43-pul are converted into a host bacterium B.subtilis WB600, and the extracellular enzyme activity of the obtained recombinant bacterium B.subtilis WB600 / pMA0911-PHpaII-pul and the extracellular enzyme activity of the obtained recombinant bacterium WB600 / pMA0911-P43-pul are up to 213.5 U / mL and 245.7 U / mL respectively.

Owner:JIANGNAN UNIV

Biologically active substance-containing water-solubilizing preparation and method for producing the same

ActiveUS20130309338A1Improve acid resistanceImprove heat resistanceBiocideDispersion deliveryWater basedAdditive ingredient

An object of the present invention is to provide a water-solubilizing preparation that is obtained by convenient steps without use of a special apparatus such as a high-pressure homogenizer, does not impair the original properties of a water-based material even after being added to the material, has high dispersibility and transparency and excellent heat resistance and acid resistance, and can maintain stability. The water-solubilizing preparation of the present invention is a biologically active substance-containing water-solubilizing preparation comprising 1 to 50% by weight of an oily ingredient (A) containing a biologically active substance and oil, 10 to 98% by weight of a polyglycerin fatty acid ester (B) having an HLB value of 12.5 or larger, and 1 to 40% by weight of a surfactant (C) having an HLB value of 7 to 11.8.

Owner:KANEKA CORP

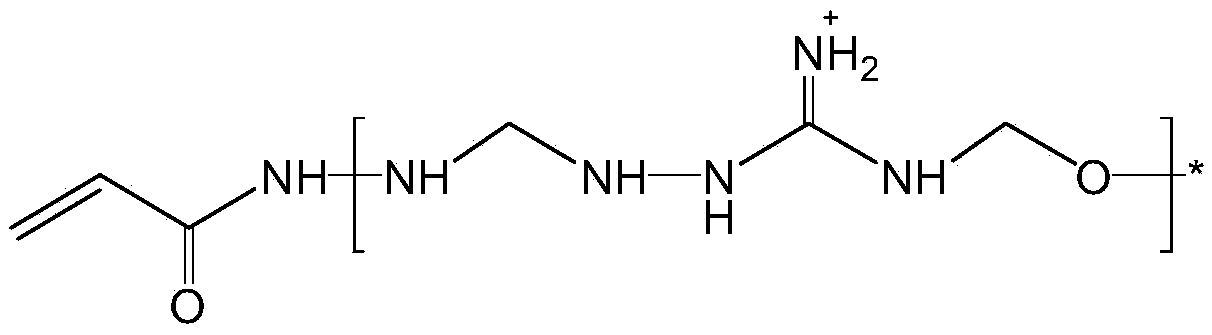

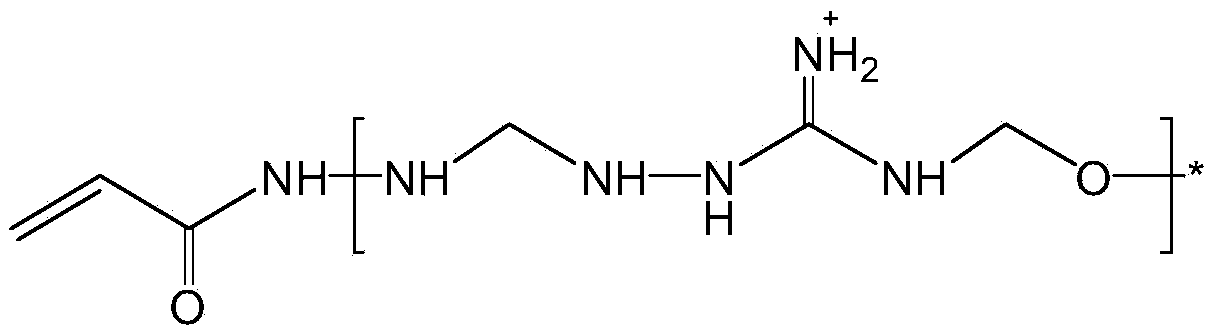

Biological-polysaccharide-based decoloring flocculation agent and preparation method thereof

ActiveCN105366790AGood acid and heat resistanceNo secondary pollutionWater/sewage treatment by flocculation/precipitationDouble bondWater quality

The present invention relates to a biological-polysaccharide-based decoloring flocculation agent and a preparation method thereof, and a large-scale produced non-toxic and degradable biological polysaccharide with the ultra-high molecular weight of 2 to 30 million is used as a basic skeleton for grafting and copolymerizing with a dicyandiamide-formaldehyde cationic polycondensate with a terminal carbon-carbon double bond to prepare the ultra-high molecular weight biological-polysaccharide-based decoloring flocculation agent with both decoloring and flocculation functions. The product is suitable for processing printing and dyeing wastewater large in changes in water quality, has good acid and heat resistant properties, and can make the CODcr removal rate in the water more than 80%, and the decolorization rate more than 93%. Compared with acrylamide and natural high polymer material flocculation agents, the biological-polysaccharide-based decoloring flocculation agent has more extensive market prospects and good social and economic benefits.

Owner:威海汉邦生物环保科技股份有限公司

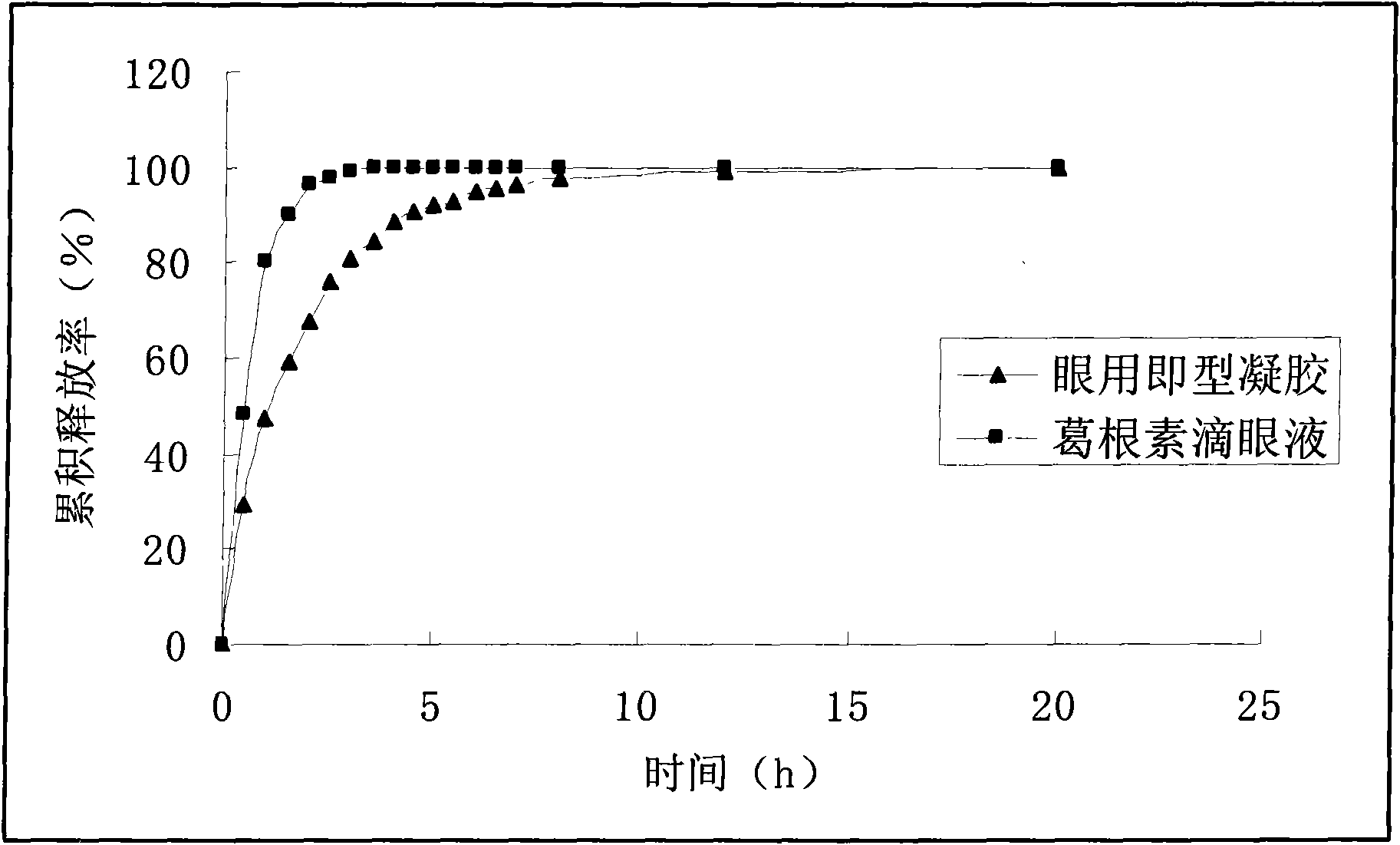

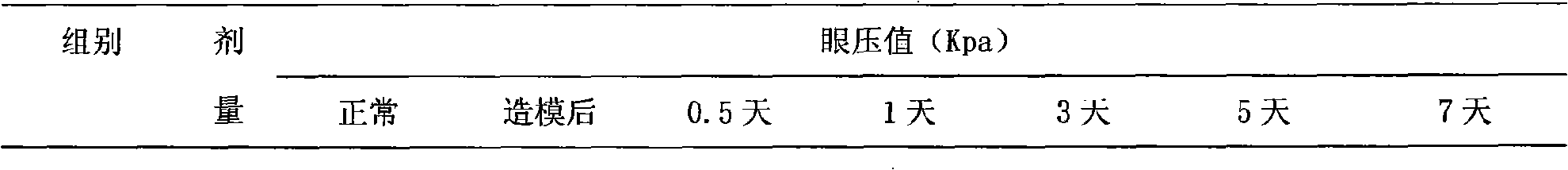

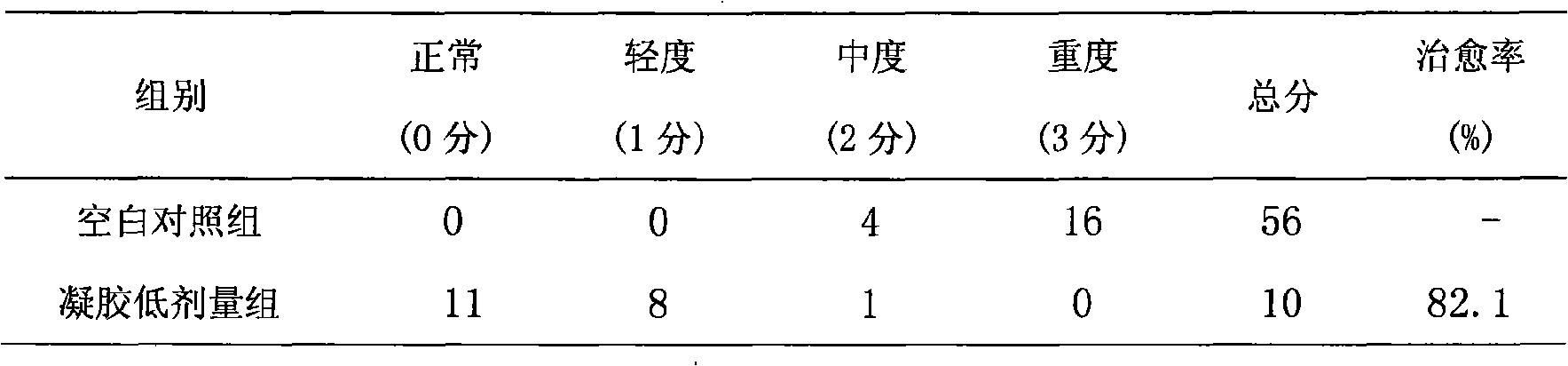

Ready-to-use puerarin ophthalmic gel

InactiveCN101579305AStrong ability to formHigh transparencyOrganic active ingredientsSenses disorderReduced doseRetention time

The invention discloses a ready-to-use puerarin ophthalmic gel preparation belonging to the field of traditional Chinese medicines. The active ingredient of the preparation is puerarin, and the gel base material of the preparation mainly comprises gellan gum accounting for 0.4-0.7 percent of the total weight. The technical scheme overcomes the deficiencies that the prior puerarin ophthalmic preparation has low bioavailability, inconvenient use, short retention time, and the like and has the effects of reducing dose, prolonging the retention time in eyes, having convenient use and accurate dose, and the like.

Owner:BEIJING HERUN INNOVATION PHARMA TECH DEV

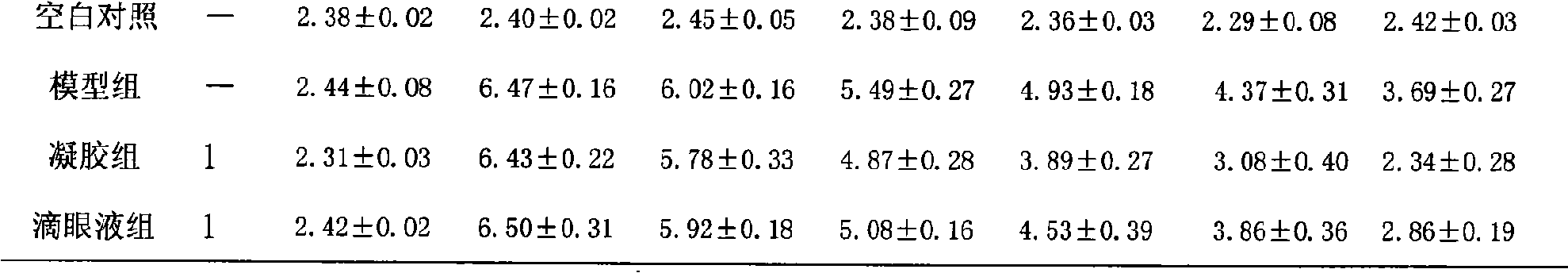

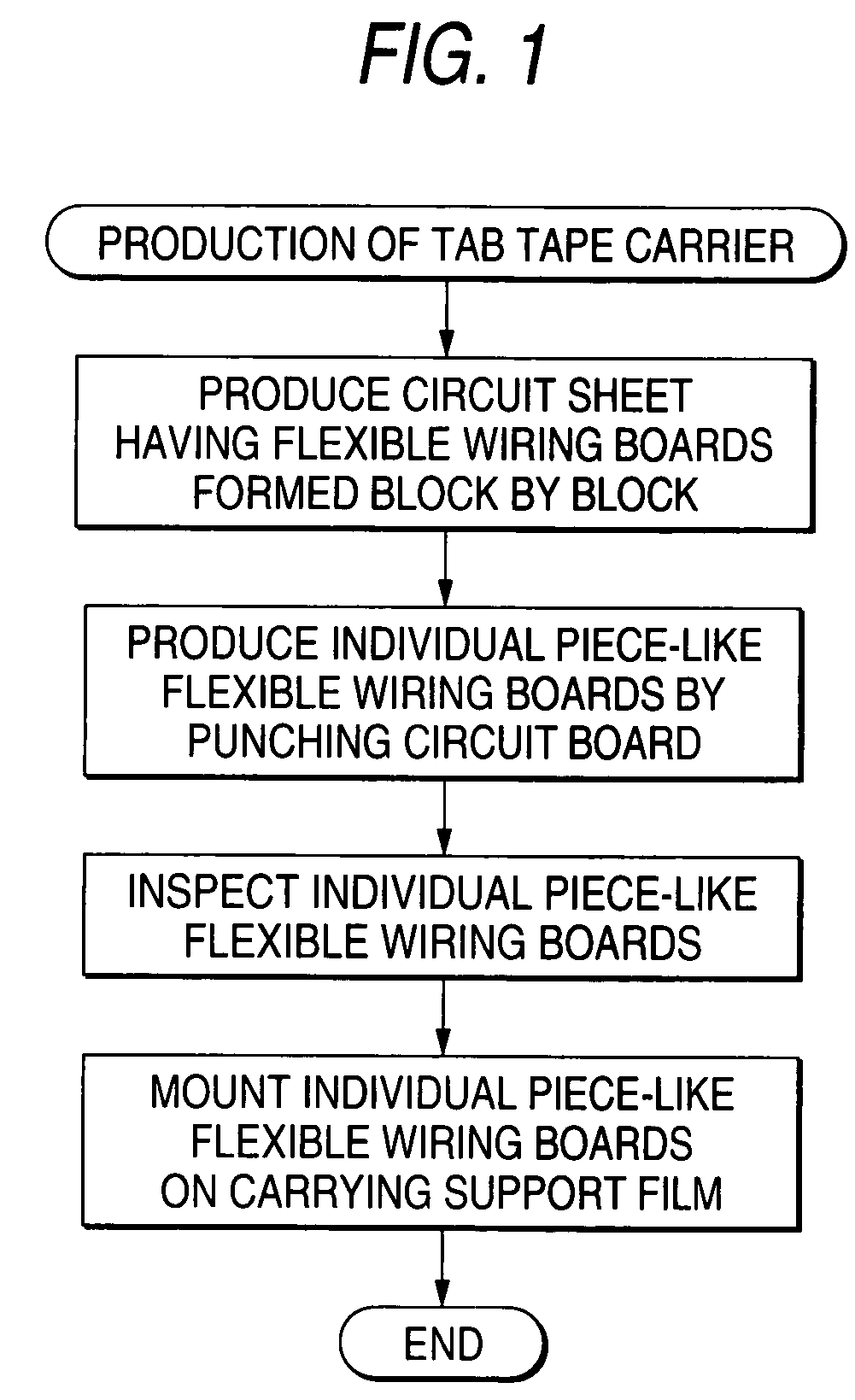

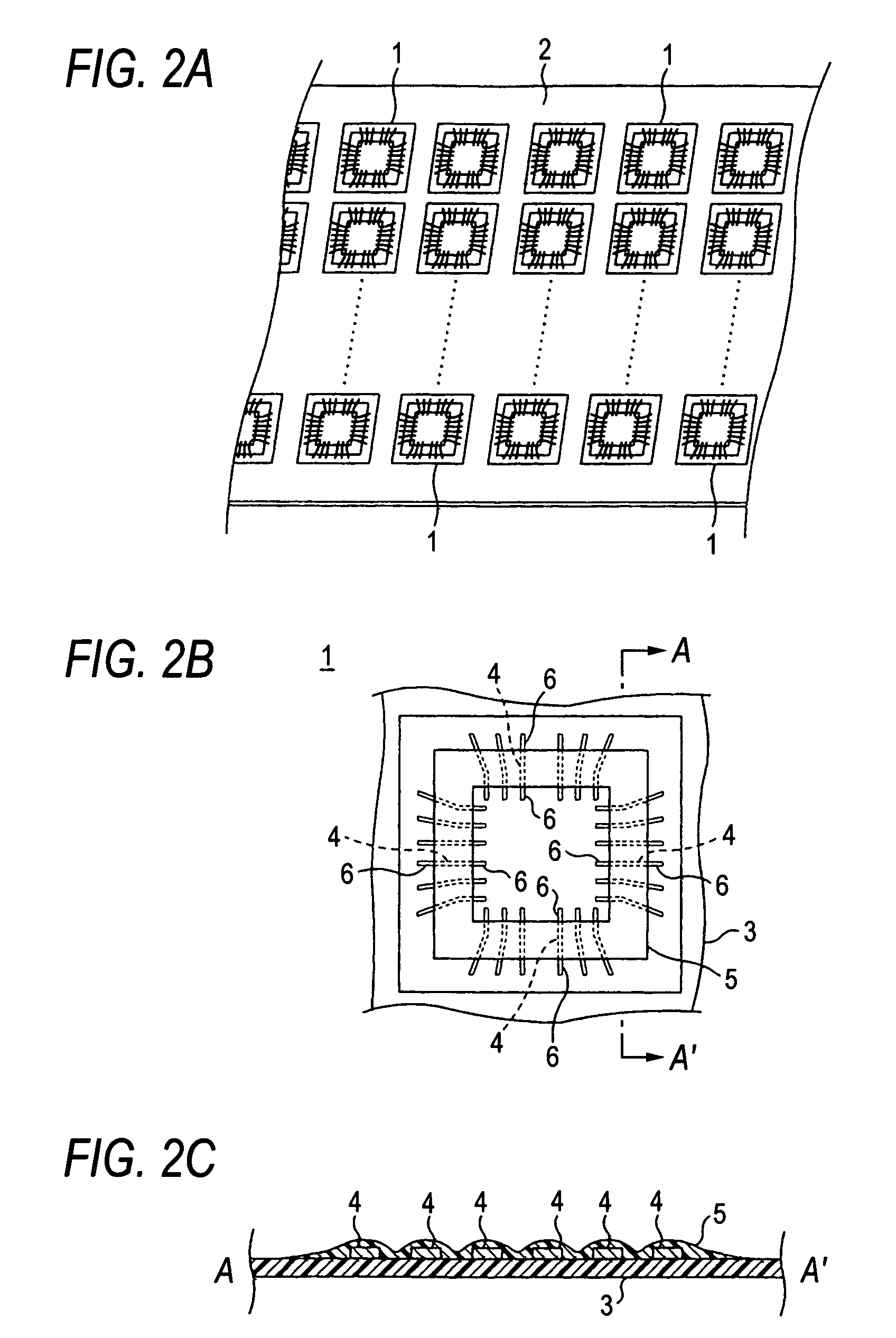

Tape carrier

InactiveUS7439451B2Improve connection reliabilityIncrease productivitySemiconductor/solid-state device detailsPrinted electric component incorporationMagnetic tapeEngineering

Only individual piece-like flexible wiring boards produced separately and judged to be non-defective products in an inspection step in advance are mounted at regular intervals on a carrying support film to thereby obtain a TAB tape carrier. According to this method, the yield on continuous production can be improved while the step of replacing defective flexible wiring boards found by inspection with non-defective flexible wiring boards can be omitted after mounting of the flexible wiring boards. A difference in level between the respective flexible wiring boards can be prevented from being caused by the replacement, so that high connection reliability can be ensured.

Owner:NITTO DENKO CORP

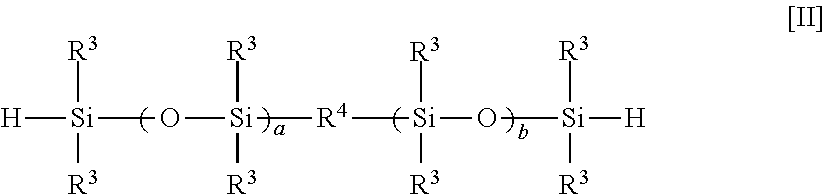

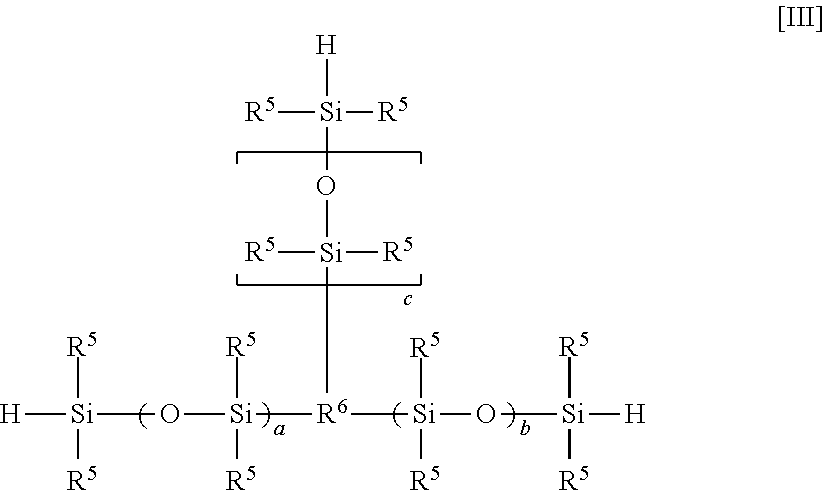

Rubber composition and use thereof

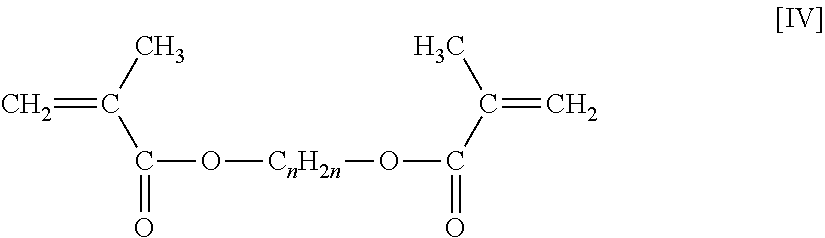

InactiveUS20130030103A1Reduce hardnessReduce reaction forceEngine sealsPlastic/resin/waxes insulatorsMethacrylatePolymer science

Provided is a rubber composition, which has excellent heat resistance, acid resistance, gas permeability resistance, and high-speed moldability, has low hardness and low counterforce, has excellent high-temperature compression set, and does not adhere to the metal of molds, etc. but is self-adhering with respect to organic resins. The rubber composition comprises: a predetermined ethylene / α-olefin / non-conjugated polyene copolymer [A]; a predetermined SiH group-containing compound [B-1] having two SiH groups per molecule and / or a predetermined SiH group-containing compound [B-2] having three SiH groups per molecule; and a predetermined methacrylic acid ester compound [C].

Owner:NOK CORP

Boot seal for variable compression-rate engine

InactiveUS8936248B2Improve sealingGood acid and heat resistanceEngine sealsSealing arrangements for enginesBellows

Owner:TOYODA GOSEI CO LTD +1

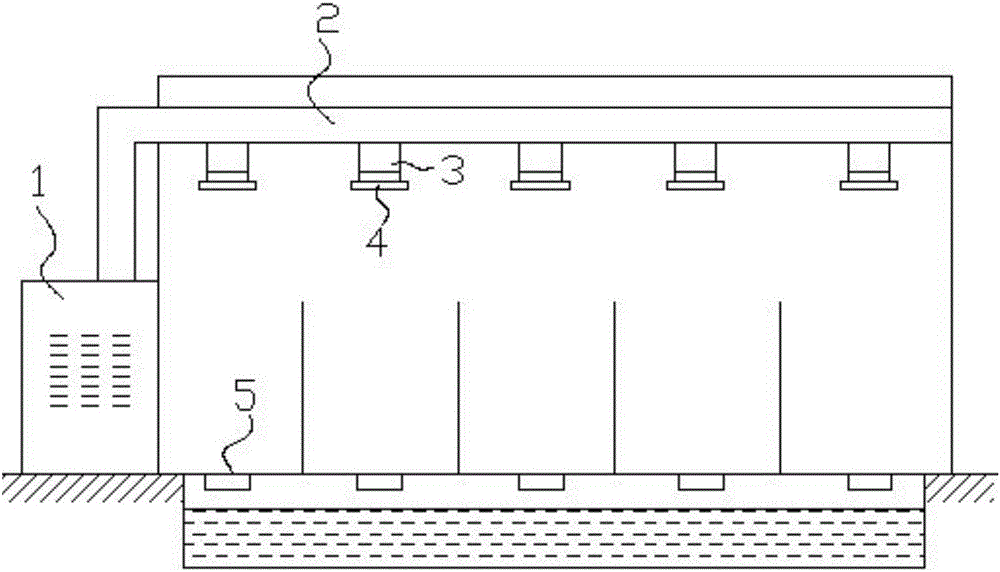

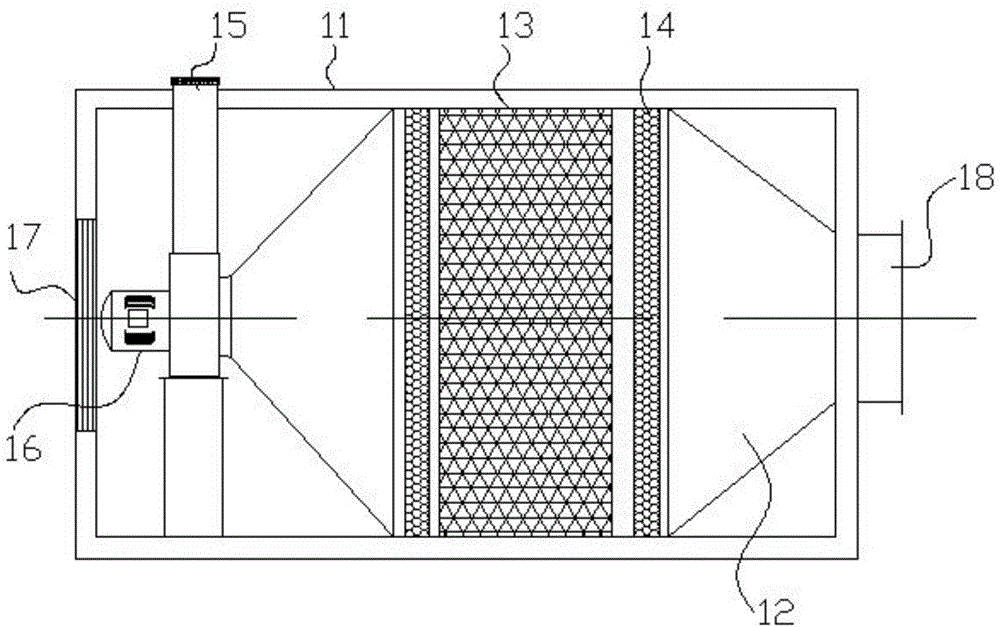

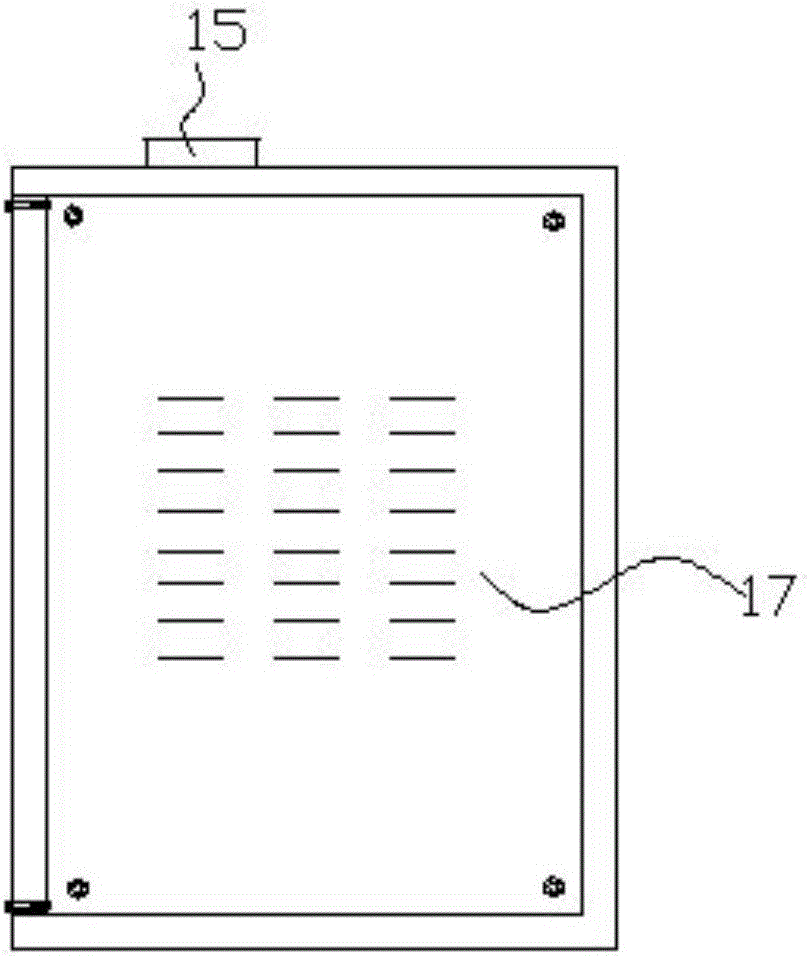

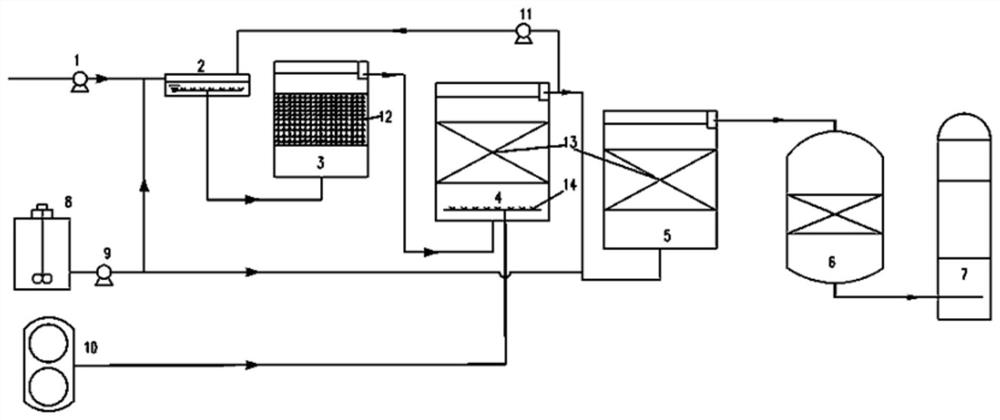

Negative-pressure biofilter equipment used for public toilet deodorization and method for deodorization

InactiveCN106512714ATo achieve the purpose of purifying odorWon't leakGas treatmentDispersed particle separationBiofilterExhaust pipe

The invention discloses negative-pressure biofilter equipment used for public toilet deodorization and a method for deodorization. The deodorization equipment system comprises collecting wind pipes arranged above a public toilet; the collecting wind pipes are connected with a main wind pipe, and the main wind pipe is connected with a negative-pressure biofilter deodorizing box; the negative-pressure biofilter deodorizing box comprises an external box; a biofilter barrel and an exhaust pipe are arranged inside the external box; a ceramic filter element is arranged inside the biofilter barrel; flow equalizing plates are arranged at the two ends of the ceramic filter element; a wind inlet hole is formed in one end of the biofilter barrel, and a centrifugal fan is arranged at the other end of the biofilter barrel; the centrifugal fan is connected with the exhaust pipe; the exhaust pipe is arranged perpendicularly; the lower end of the exhaust pipe is sealed, and the upper end of the exhaust pipe is open; a microorganism deodorizing agent is attached to ceramic filler of the ceramic filter element. The negative-pressure biofilter equipment is simple and stable in structure, low in cost and capable of achieving efficient deodorization. The method for public toilet deodorization comprises the steps that a septic tank is treated with the microorganism deodorization agent, the wall and the floor of the public toilet are treated with a compound deodorization agent, and after odor inside the public toilet is collected, the negative-pressure biofilter deodorization equipment is adopted for treatment. The method is simple, efficient and capable of continuously and automatically achieving deodorization.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

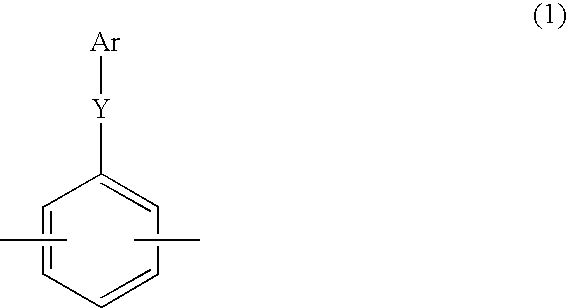

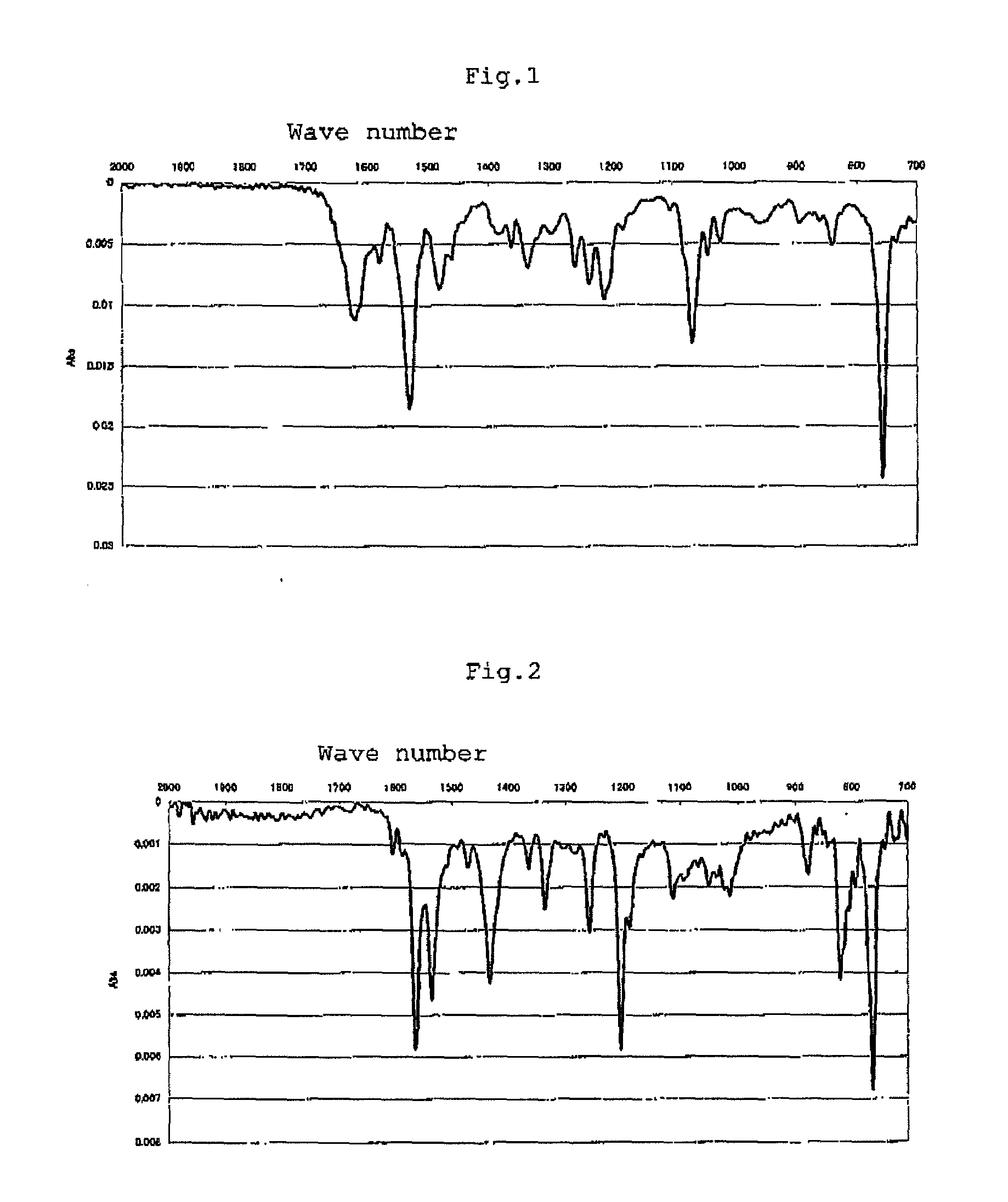

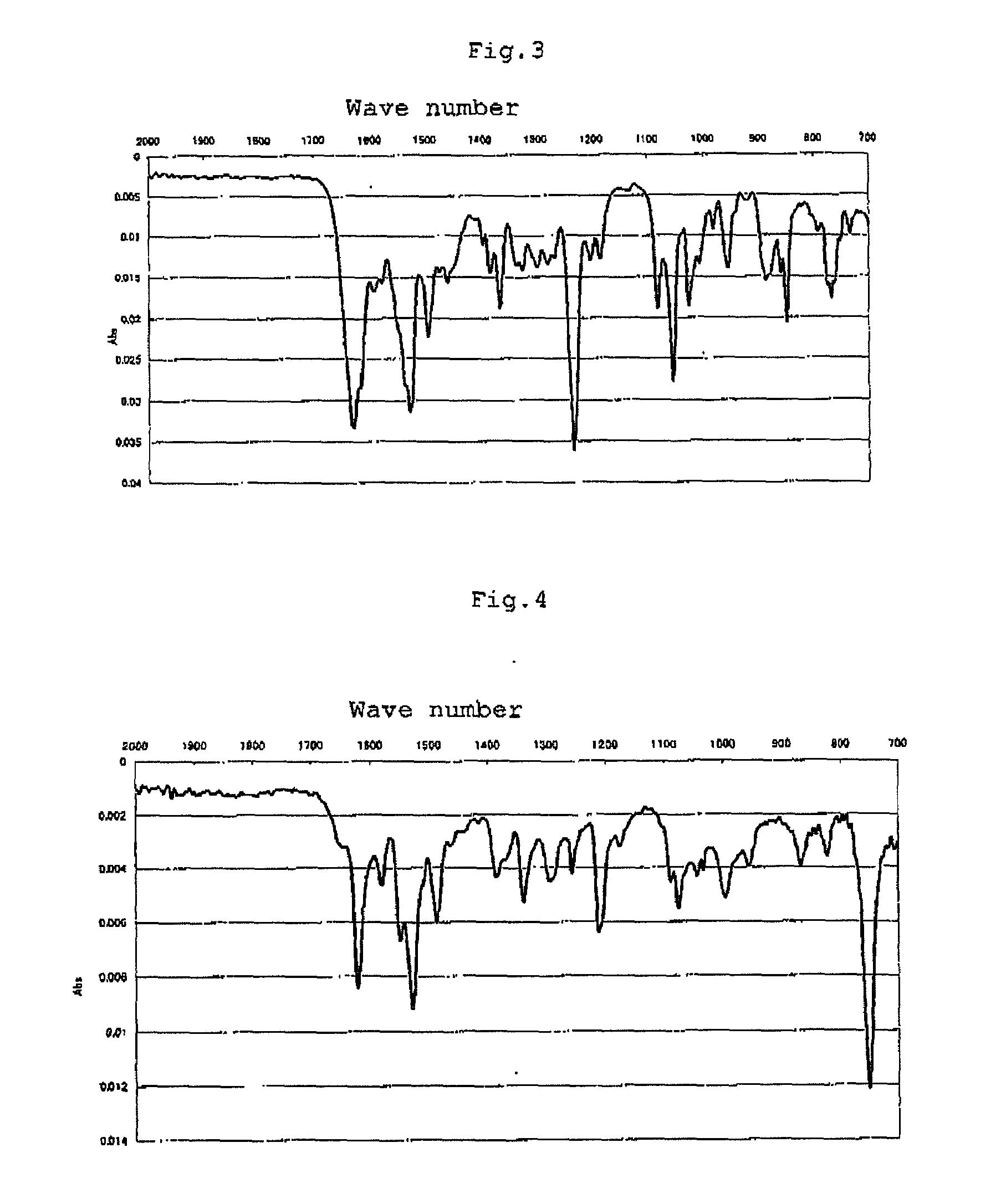

Sulfonated Polymer Comprising Nitrile-Type Hydrophobic Block And Solid Polymer Electrolyte

InactiveUS20080070085A1Strong adhesionImprove power generation effectSolid electrolytesActive material electrodesPolymer electrolytesPolymer science

A membrane-electrode assembly for a solid polymer electrolyte fuel cell having excellent hot water resistance, oxidation resistance and low temperature size stability and exhibiting excellent power generation performance even under low temperature environment. The membrane-electrode assembly is equipped with a polymer electrolyte membrane composed of a sulfonated polyarylene polymer having a recurring unit of the formula (1) and a recurring unit of the formula (2):

Owner:HONDA MOTOR CO LTD

Metal complex, and use thereof

InactiveUS20090318681A1Improve acid resistanceImprove heat resistanceOrganic compound preparationGroup 8/9/10/18 element organic compoundsHeat resistanceRedox

Provided is a metal complex represented by the following formula (A-1) or (B-1) as a metal complex useful for a redox reaction catalyst or some other article that is excellent in heat resistance and acid resistance:

Owner:SUMITOMO CHEM CO LTD

Efficient furan resin for casting as well as preparation method thereof

InactiveCN109175220ALow free formaldehyde contentReduce volatilityFoundry mouldsFoundry coresFuranWater resistant

The invention relates to the technical field of mechanical casting, in particular to efficient furan resin for casting as well as a preparation method thereof. The efficient furan resin for casting can reduce release of formaldehyde and reduce damage to staff; furthermore, when furan resin sand is prepared, various properties of the furan resin sand for casting can be improved; the efficient furanresin for casting is prepared by mixing the following components in parts by weight of 1200 parts of furfuryl alcohol, 650 parts of environmentally-friendly formaldehyde, 300 parts of urea, 100 partsof ammonia water, 4 parts of ammonium chloride, 400 parts of phenol, 100 parts of concentrated hydrochloric acid, 50 parts of a modifier, 20 parts of a filling agent, 10 parts of an anti-ageing agent, 15 parts of a water-resistant agent, 20 parts of a multi-component composite additive, 30 parts of a lubricating agent, 8 parts of a microporous stabilizer and 40 parts of pigment; and the preparation method of the furan resin comprises the following steps of (1) preparing a first intermediate product; (2) cooling the first intermediate product; (3) preparing a second intermediate product; (4) cleaning the second intermediate product; (5) making a condensation polymerization reaction; (6) performing dehydration treatment; (7) performing modification treatment; and (8) performing color adjustment.

Owner:保定永强合成材料有限公司

Photosensitive and via-forming circuit board

ActiveUS20180263122A1Increase flexibilityImprove heat resistanceResist coatingPrinted circuit aspectsEpoxyElectrical conductor

A photosensitive and via-forming circuit board comprising a laminate unit, a conductor unit, and a cover layer unit is provided. The laminate unit includes an insulating layer, a first conductive wiring layer and a second conductive wiring layer formed at two opposite sides of the insulating layer, respectively, and at least one through-hole surface defining a through hole extending from the upper surface of the first conductive wiring layer through the insulating layer to the lower surface of the second conductive wiring layer. The conductor unit is formed on the at least one through-hole surface. The cover layer unit is formed from a photosensitive composition comprising an epoxy group-containing compound and a photosensitive polyimide capable of reacting with the epoxy group of the epoxy group-containing compound, and includes a first cover layer formed on the first conductive wiring layer and extending into and filling the through hole.

Owner:MICROCOSM TECH

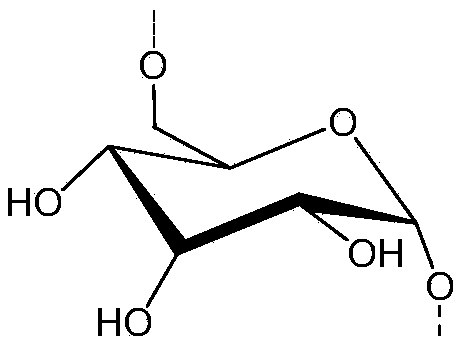

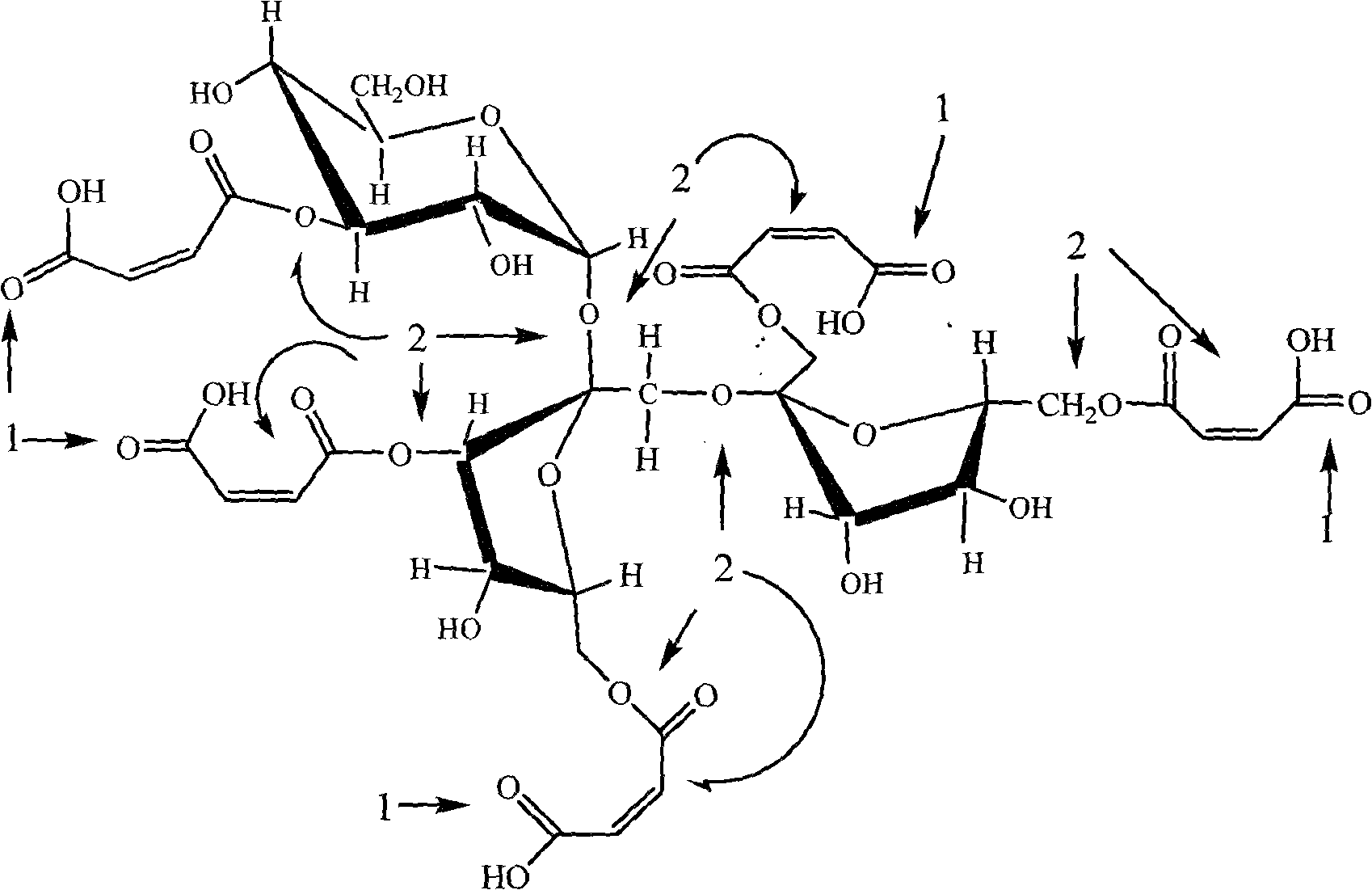

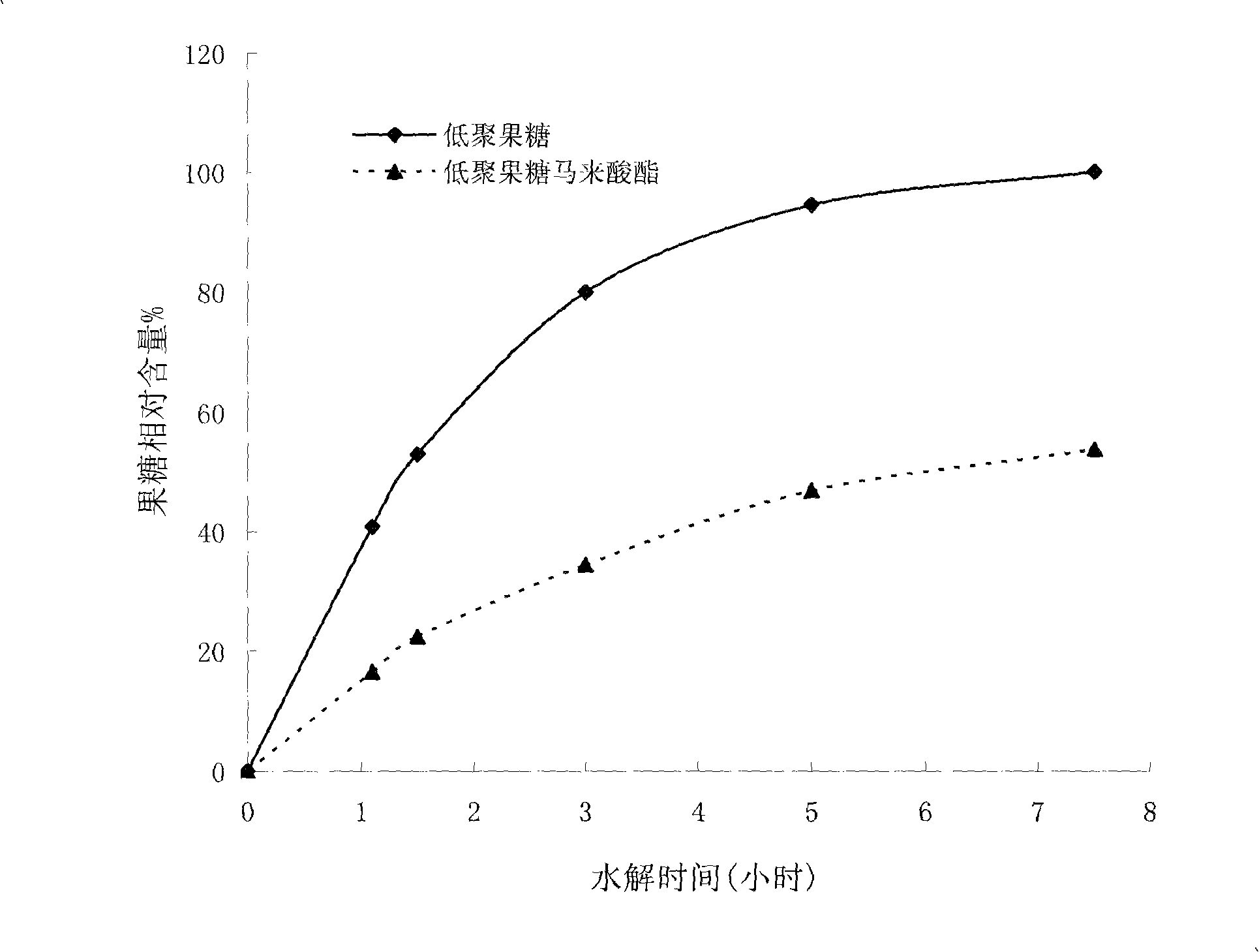

Fructo oligosaccharide maleate and method for preparing the same

ActiveCN101323633AGood acid and heat resistanceLow sweetnessOligosaccharidesFood preparationMaleic anhydrideChemistry

The invention discloses a fructo-oligose maleic acid ester which is formed by the method that maleic anhydride is used for carrying out esterification reaction on fructo-oligose. The steps of the preparation method of the invention is as follows: 1) the maleic anhydride is firstly melted; 2) after the melting, the fructo-oligose is added into the water bath of 80 DEG C to 90 DEG C by a plurality of times with small amount each time, shaken till dissolution; 3) after the complete dissolution of the fructo-oligose, the reaction lasts for about 14 hours to 18 hours in the water bath of 88 DEG C to 92 DEG C; 4) after processes of cooling, washing, purification and vacuum drying, the product obtained is cooled to the room temperature, thus the finished product is generated. The OH group in the molecule of the fructo-oligose has the characteristics of alcoholic hydroxyl group and reacts with the maleic anhydride to carry out the esterification reaction to generate the fructo-oligose maleic acid ester. The fructo-oligose maleic acid ester does not reduce the sweetness and functionality of the ructo-oligose and has better acid resistance and heat resistance compared with the fructo-oligose, and can be better used as a functional food additive to be widely applied to acid food, such as bread, acidophilus milk and the like, or various foods requiring high-temperature processing.

Owner:量子高科(广东)生物有限公司

Cyclic compound, its metal complex and modified metal complex

ActiveUS8546291B2Good acid and heat resistanceElectrolyte holding meansElectrolytic capacitorsHydrogen atomChemical compound

A compound represented by formula (1):wherein Y1 to Y4 each independently represent any one of the following groups:in which Rα represents a hydrogen atom or a monovalent hydrocarbon group; P1 to P4 each independently represent a group of atoms necessary for forming a heterocyclic ring together with each of Y1 to Y4 and the two carbon atoms adjacent to each of Y1 to Y4, respectively; P5 and P6 each independently represent a group of atoms necessary for forming a cyclic skeleton together with the carbon atom to which Z1 bonds or Z2 bonds and the two carbon atoms adjacent to the carbon atom to which Z1 bonds or Z2 bonds; P1 and P2, P2 and P6, P6 and P4, P4 and P3, P3 and P5, and P5 and P1 may further combine with each other to form a ring; Q1 and Q2 each independently represent a connecting group or a direct binding; and Z1 and Z2 each independently represent any one of the following groups;—NRβ2, —ORβ, —SRβ, —PRβ2 in which Rβ represents a hydrogen atom or a monovalent hydrocarbon group, and when plural Rβs are present, these plural Rβs may be the same or different from each other.

Owner:SUMITOMO CHEM CO LTD

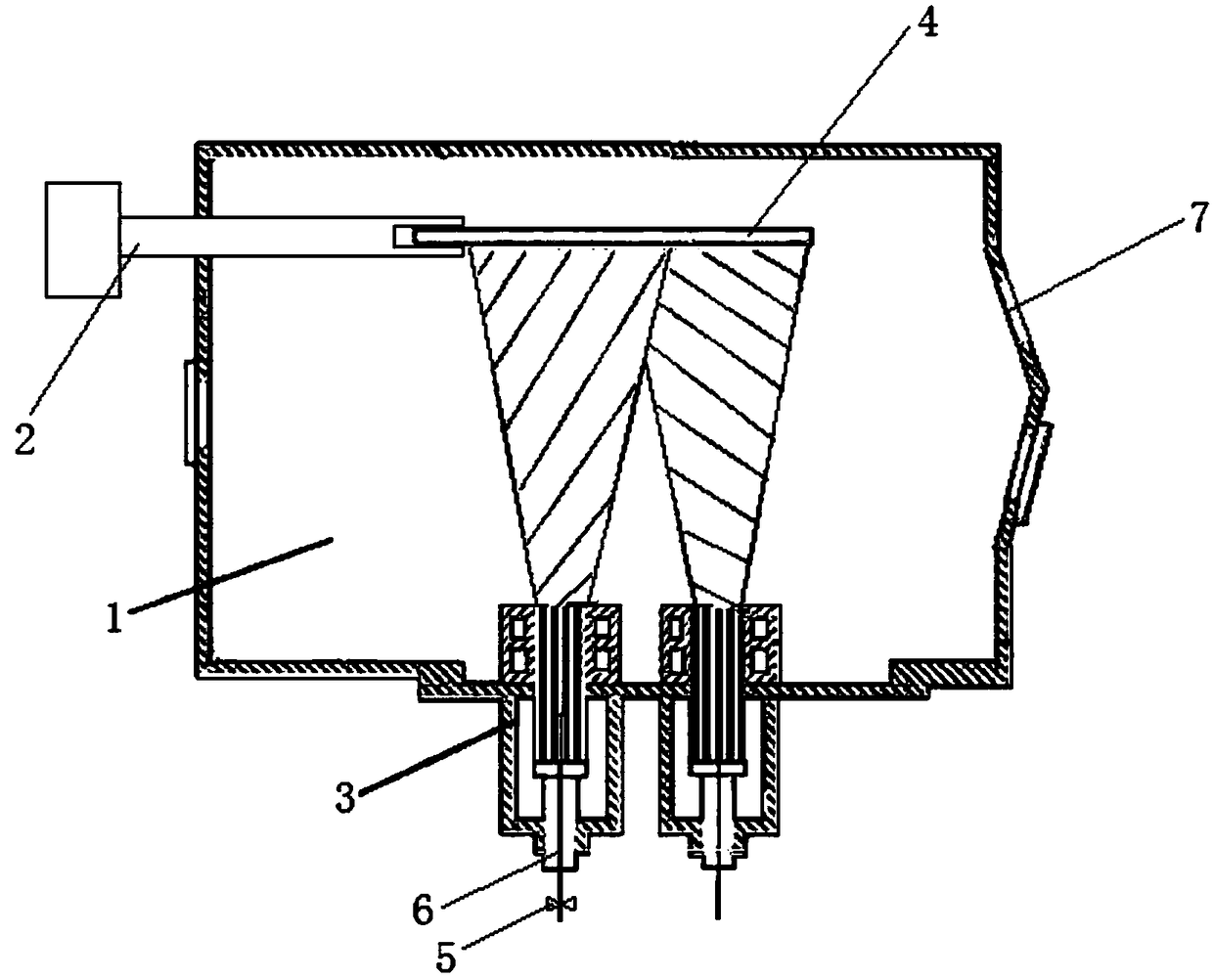

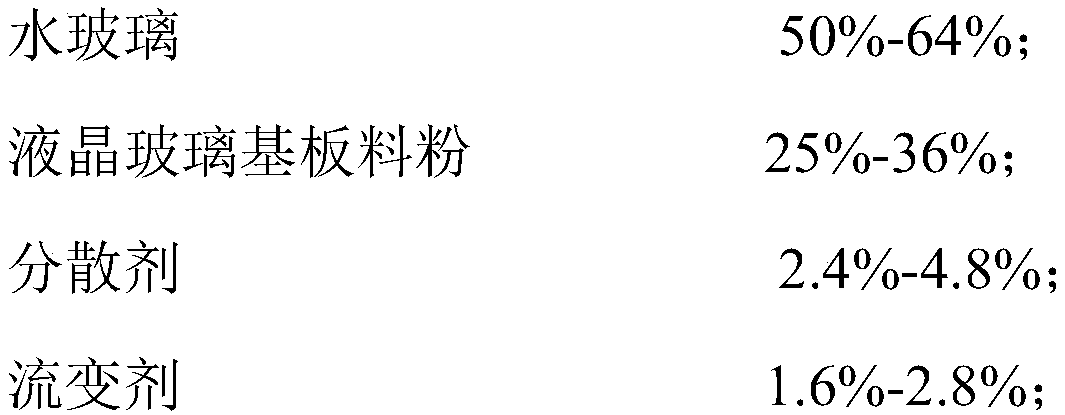

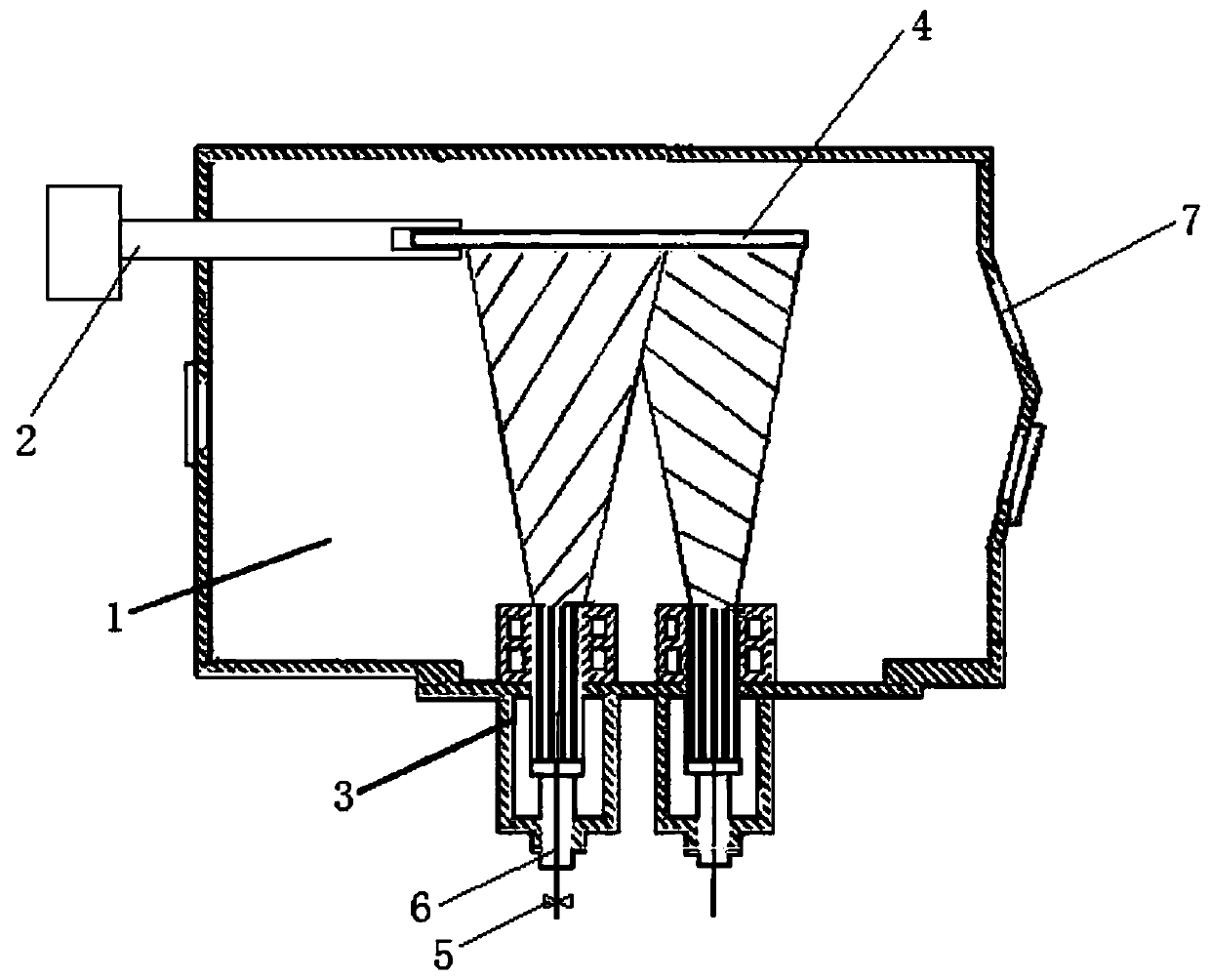

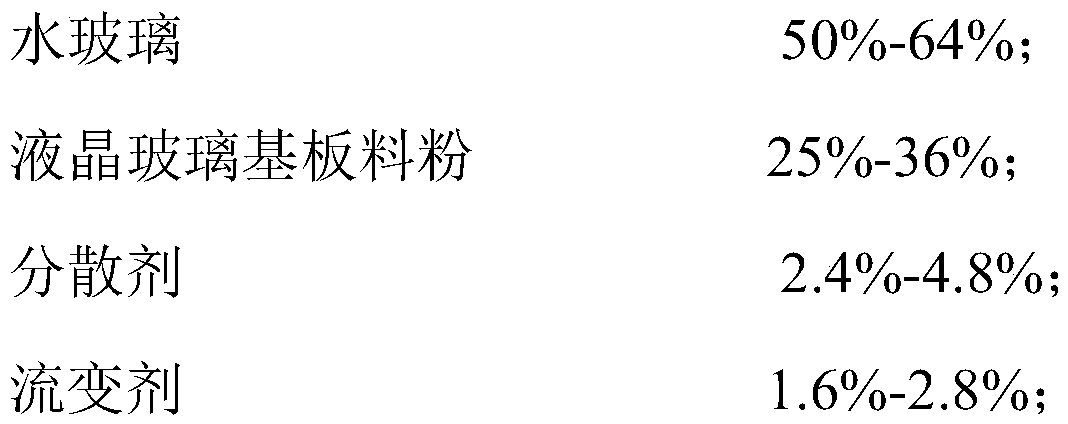

Surface coating slurry of platinum heating wire as well as preparation method and coating device of surface coating slurry

The invention provides surface coating slurry of a platinum heating wire as well as a preparation method and a coating device of the surface coating slurry. The coating slurry comprises 50% to 64% ofwater glass, 25% to 36% of liquid crystal glass substrate powder, 2.4% to 4.8% of a dispersant, 1.6% to 2.8% of a rheological agent and 5% to 15% of a water glass curing agent; the raw materials are mixed, a pH value is adjusted to 10-11, and ball-milling is performed to obtain the surface coating slurry. The coating device comprises a chamber, a rotating mechanism and a crucible, wherein the rotating mechanism is disposed on a side wall of the chamber, fixedly connected with one end of the platinum heating wire and used for driving the platinum heating wire to rotate around the axial direction; the crucible is disposed at the bottom of the chamber, and is opposite to the platinum heating wire and used for holding the surface coating slurry; and a high pressure gas flow tube is inserted into the bottom of the crucible. The surface coating slurry provided by the invention is sprayed by adopting stamping, and the coating has good bonding performance with the platinum heating wire, is noteasy to fall off, and can effectively prevent the platinum heating wire from being oxidized and volatilized at high temperature.

Owner:IRICO DISPLAY DEVICES

Biologically active substance-containing water-solubilizing preparation and method for producing the same

ActiveUS9919017B2Good acid and heat resistanceEasy to spreadBiocideDispersion deliveryWater basedHeat resistance

An object of the present invention is to provide a water-solubilizing preparation that is obtained by convenient steps without use of a special apparatus such as a high-pressure homogenizer, does not impair the original properties of a water-based material even after being added to the material, has high dispersibility and transparency and excellent heat resistance and acid resistance, and can maintain stability. The water-solubilizing preparation of the present invention is a biologically active substance-containing water-solubilizing preparation comprising 1 to 50% by weight of an oily ingredient (A) containing a biologically active substance and oil, 10 to 98% by weight of a polyglycerin fatty acid ester (B) having an HLB value of 12.5 or larger, and 1 to 40% by weight of a surfactant (C) having an HLB value of 7 to 11.8.

Owner:KANEKA CORP

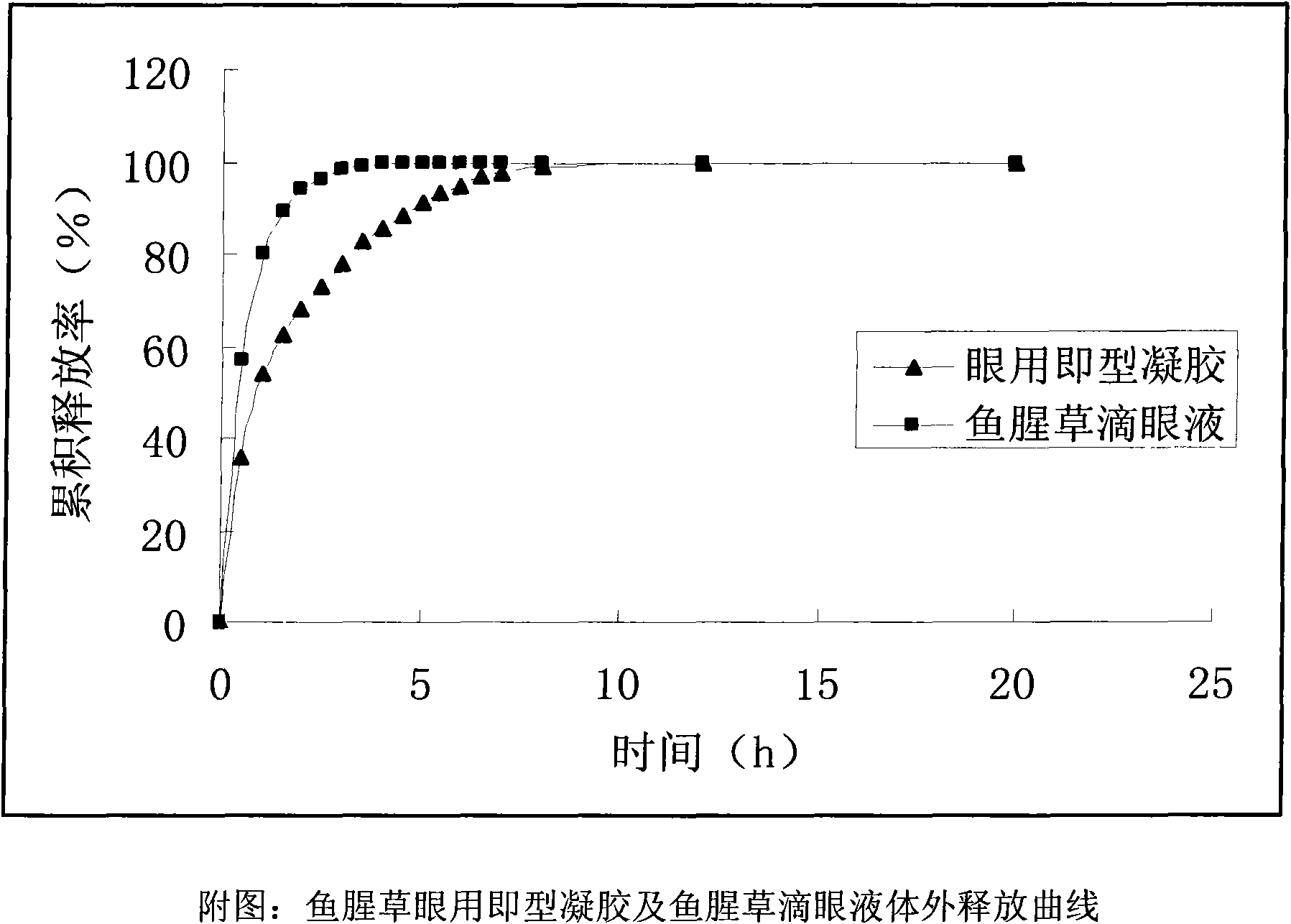

Ready-to-use herba houttuyniae ophthalmic gel

InactiveCN101579431AStrong ability to formHigh transparencySenses disorderPharmaceutical delivery mechanismReduced doseRetention time

The invention discloses a ready-to-use herba houttuyniae ophthalmic gel preparation, belonging to the field of traditional Chinese medicines. The active ingredient of the preparation is from herba houttuyniae and the gel base material of the preparation mainly comprises gellan gum accounting for 0.4-0.7 percent of the total weight. The technical scheme overcomes the deficiencies that the prior herba houttuyniae ophthalmic preparation has low bioavailability, inconvenient use, short retention time, and the like and has the effects of reducing dose, prolonging the retention time in eyes, having convenient use and accurate dose, and the like.

Owner:BEIJING HERUN INNOVATION PHARMA TECH DEV

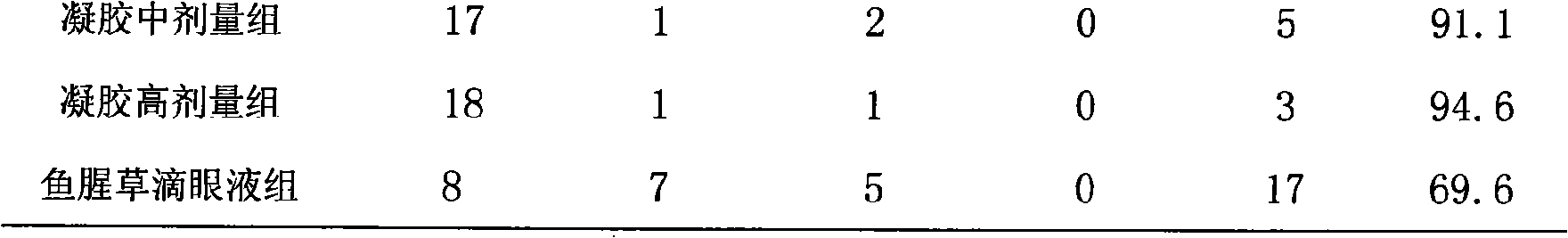

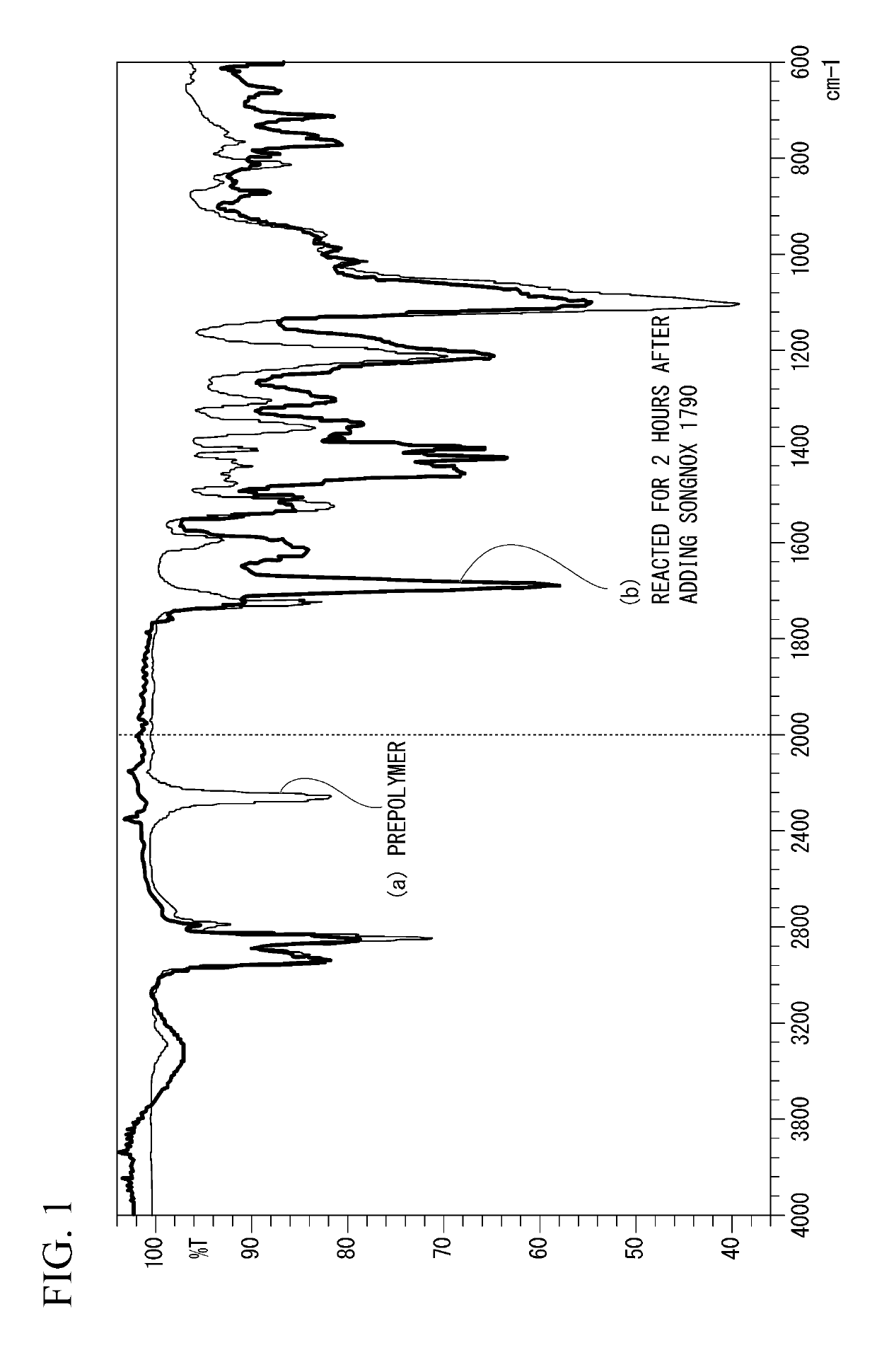

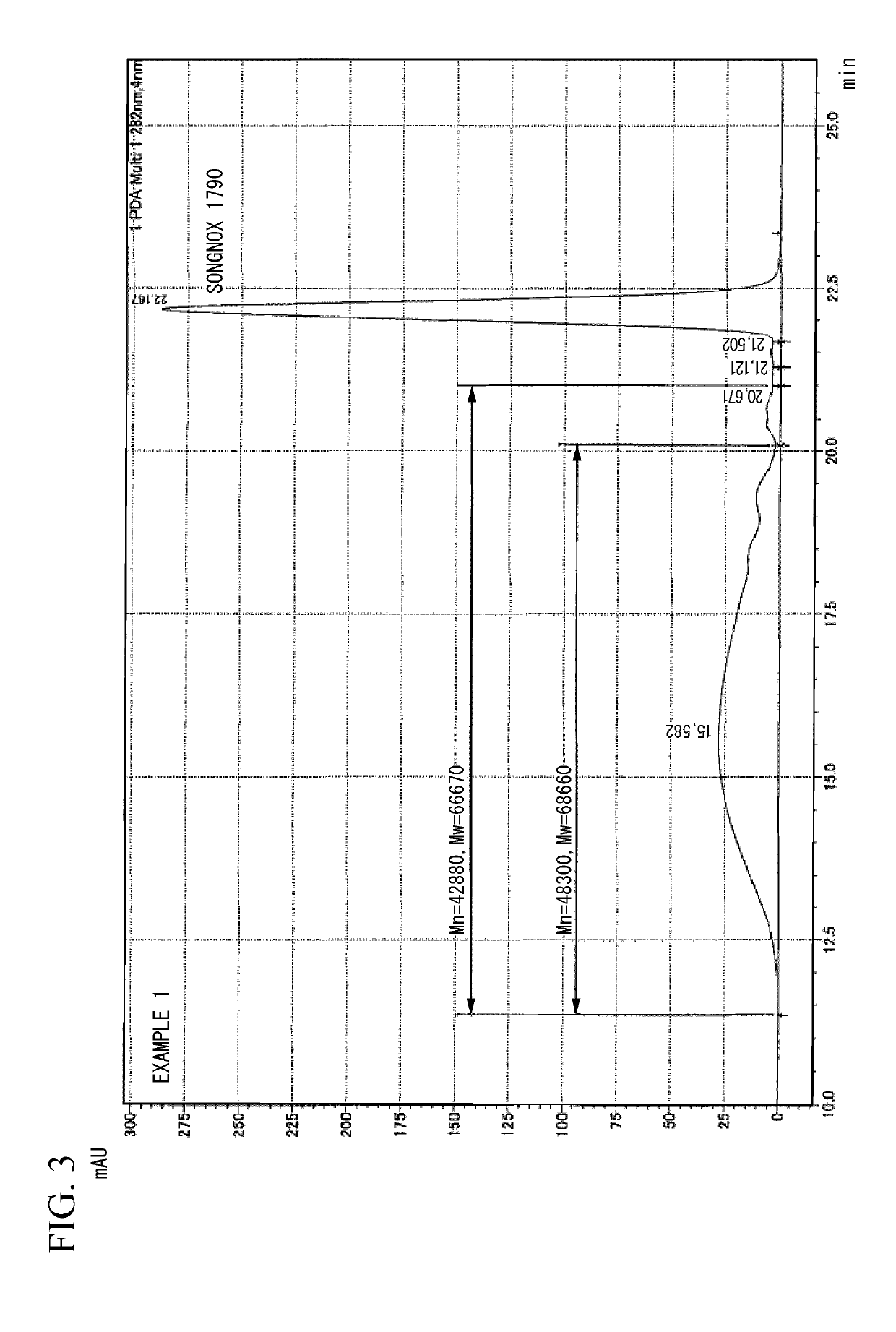

Method for producing antioxidant and method for producing elastic polyurethane fiber

ActiveUS20190249005A1Superior in affinitySuperior in spin stabilityMonocomponent polyurethanes artificial filamentAbsorbent padsDiolFiber

The antioxidant according to the present invention contains a polyurethane compound represented by the following formula (1):(wherein Y1 is a residue of a diol, and plural Y1s may be the same or different, R1 is a residue of an aromatic diisocyanate, and plural R1s may be the same or different, X1 is a residue of a hindered phenol compound having at least k hindered phenolic hydroxyl groups, and plural X1s may be the same or different, m is an integer of 1 or more, n is an integer of 1 or more, and k is an integer of 2 or more).

Owner:SANKO CO LTD

A surface coating slurry for platinum heating wire and its preparation method and coating device

The invention provides surface coating slurry of a platinum heating wire as well as a preparation method and a coating device of the surface coating slurry. The coating slurry comprises 50% to 64% ofwater glass, 25% to 36% of liquid crystal glass substrate powder, 2.4% to 4.8% of a dispersant, 1.6% to 2.8% of a rheological agent and 5% to 15% of a water glass curing agent; the raw materials are mixed, a pH value is adjusted to 10-11, and ball-milling is performed to obtain the surface coating slurry. The coating device comprises a chamber, a rotating mechanism and a crucible, wherein the rotating mechanism is disposed on a side wall of the chamber, fixedly connected with one end of the platinum heating wire and used for driving the platinum heating wire to rotate around the axial direction; the crucible is disposed at the bottom of the chamber, and is opposite to the platinum heating wire and used for holding the surface coating slurry; and a high pressure gas flow tube is inserted into the bottom of the crucible. The surface coating slurry provided by the invention is sprayed by adopting stamping, and the coating has good bonding performance with the platinum heating wire, is noteasy to fall off, and can effectively prevent the platinum heating wire from being oxidized and volatilized at high temperature.

Owner:IRICO DISPLAY DEVICES

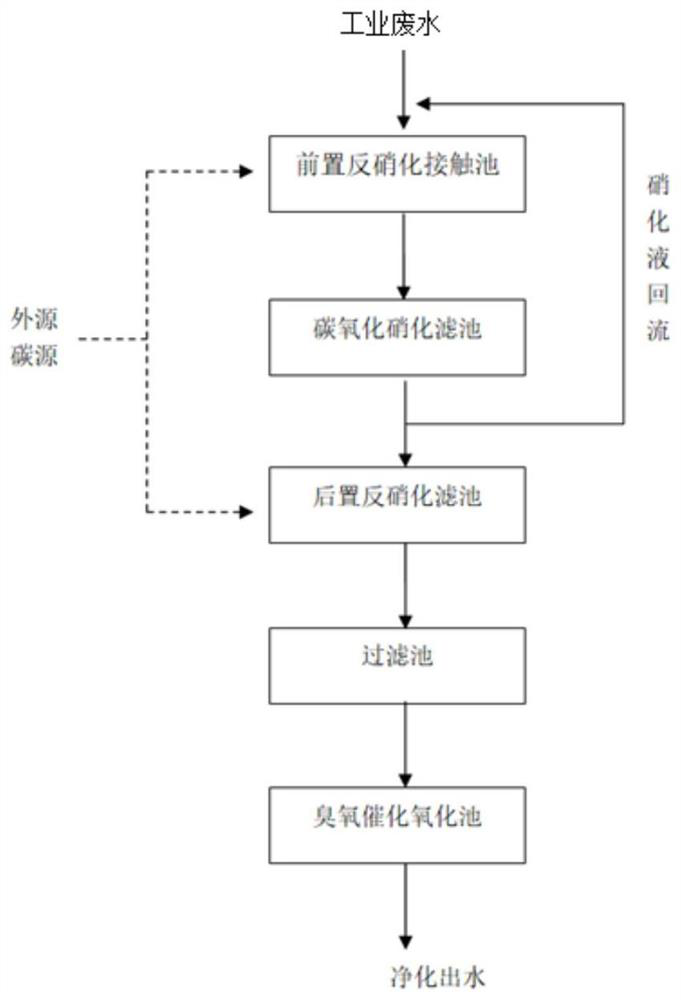

Industrial wastewater advanced total nitrogen removal treatment process and denitrification device thereof

PendingCN112759177AReduce doseIncrease investmentTreatment using aerobic processesWater treatment compoundsIndustrial waste waterTotal nitrogen

The invention relates to an industrial wastewater advanced total nitrogen removal treatment process, which comprises the following steps: 1) industrial wastewater enters a pre-denitrification contact tank after passing through a mixer, water needs to be uniformly distributed in the tank, and meanwhile, a combined filler is arranged in the tank; (2) the wastewater in the step (1) enters a carbon oxidation nitration filter tank, an aeration device is arranged in the carbon oxidation nitration filter tank, and a biological ceramsite filler layer is arranged in the carbon oxidation nitration filter tank; (3) a backflow proportion is selected according to reaction effluent in the step (2), the wastewater flows back to the step (1) and is mixed with industrial wastewater for primary total nitrogen removal, and residual wastewater enters a rear denitrification filter tank; 4) a biological ceramsite filler layer is arranged in the rear denitrification filter tank, and an external carbon source is added; (5) the effluent in the step (4) enters a filter tank; and (6) effluent in the step (5) enters a catalytic ozonation pond, and selective starting is conducted. The invention also relates to a denitrification device for the treatment process, and the problem of deep denitrification in industrial wastewater can be effectively solved.

Owner:BEIJING CAS SHENGTAI ENVIRONMENTAL TECH

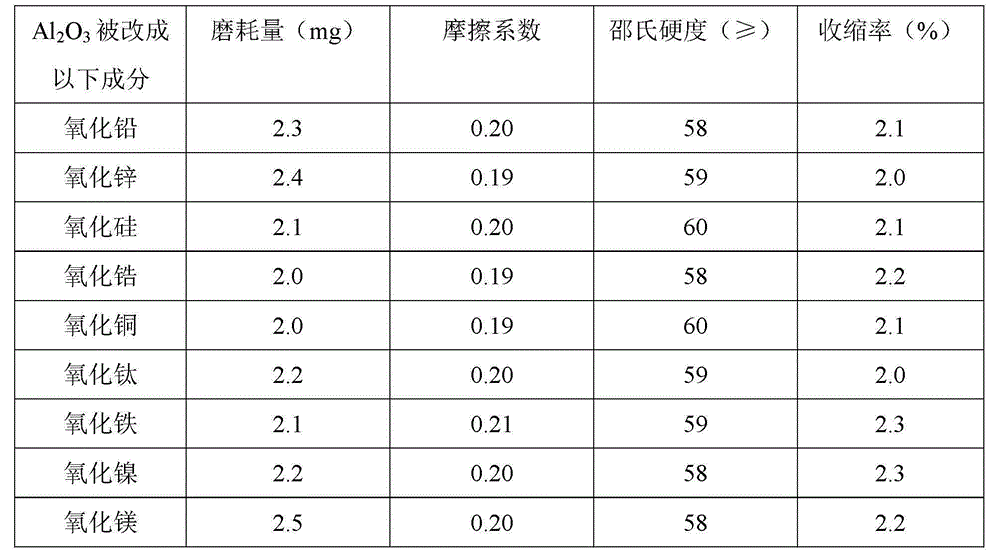

Preparation method of ultrafine zeolite powder filled PTFE composite material

The invention discloses a method for preparing an ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The method comprises the steps of 1) proportioning materials, i.e. mixing polytetrafluoroethylene, ultrafine zeolite powder, a filler I and a filler II according to the ratio; 2) uniformly mixing the mixture proportioned and then carrying out cold press forming under the pressure of 20-40 Mpa; 3) putting the formed object obtained in the step 2) into a high temperature sintering furnace, heating to 330-380 DEG C with the speed of 30-100 DEG C / hour and preserving heat for 0.5-2 hours; and 4) naturally cooling sintering products obtained in the step 3) to the room temperature to obtain the ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material prepared according to the method has excellent performance, the wear resistance of the composite material is improved upon the premise of not remarkably reducing the matrix friction coefficient of PTFE, and the application range of the composite material is wide.

Owner:ZHEJIANG UNIV

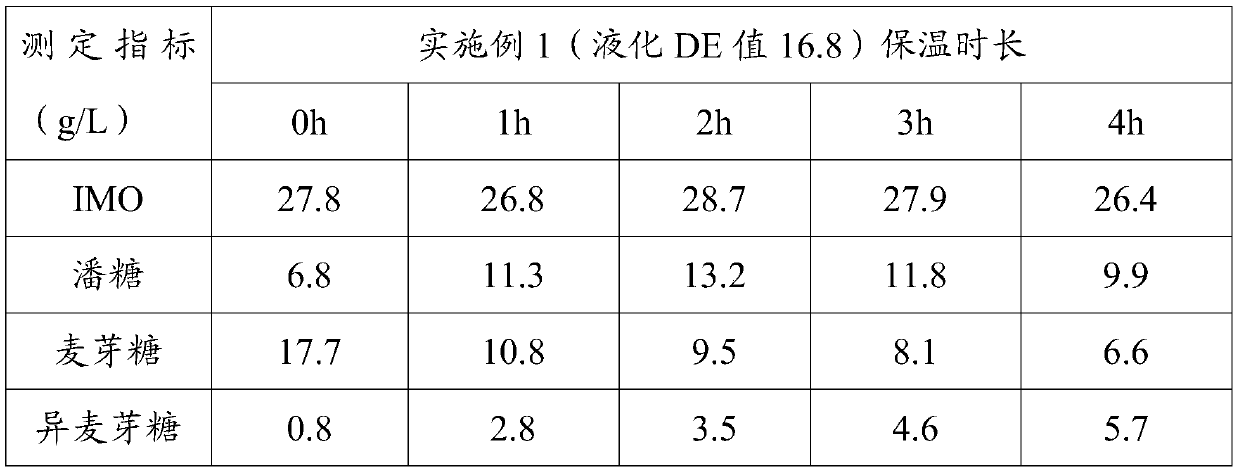

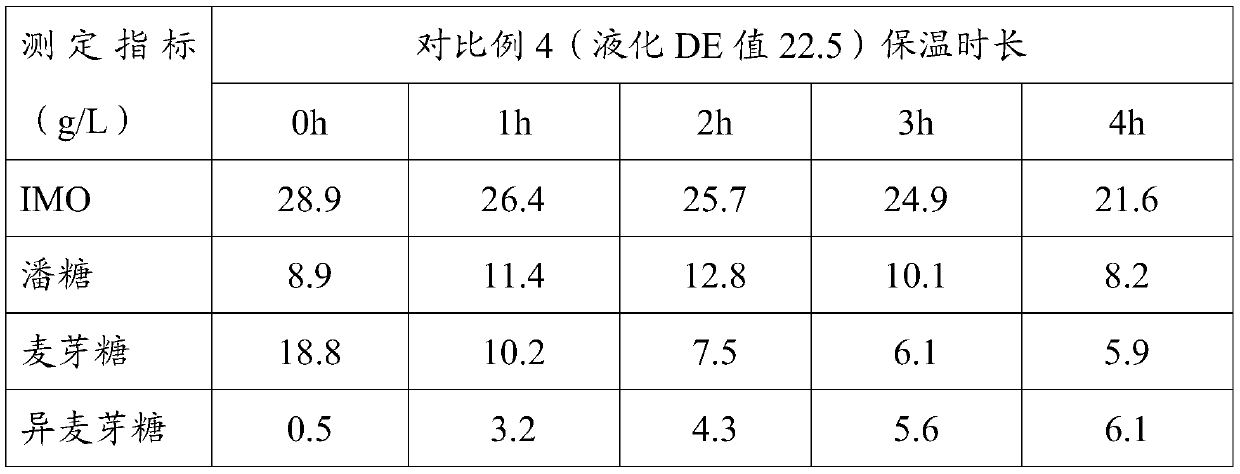

Preparation process of functional tartary buckwheat syrup base material and food prepared thereby

PendingCN111357973AGood moisturizing effectLow sweetnessFood ingredient as taste affecting agentFermentationBiotechnologySugar intake

The invention discloses a preparation process of a functional tartary buckwheat syrup base material. The preparation process comprises the following steps of: S1, cleaning tartary buckwheat, and germinating to obtain tartary buckwheat buds; S2, drying the tartary buckwheat buds, and performing mechanical activation treatment to obtain tartary buckwheat bud powder; S3, adding water into the tartarybuckwheat bud powder to form a first component liquid, precipitating tartary buckwheat protein, and filtering to obtain a second component liquid; S4, gelatinizing, liquefying and saccharifying the second component liquid to obtain tartary buckwheat syrup containing IMO, controlling the liquefaction DE value to be 15-20 percent, and adding citric acid in the gelatinization process; and S5, filtering and sterilizing the tartary buckwheat syrup containing IMO to obtain the functional tartary buckwheat syrup base material. The invention discloses tartary buckwheat food and health food. The functional tartary buckwheat syrup base material is used as a raw material and is prepared according to a conventional method. According to the preparation process, high-content active components and starch easy to enzymatically hydrolyze are obtained by tartary buckwheat germination and activation treatment, and the functional tartary buckwheat syrup base material which can meet the low-sugar intake demand and is eaten by people is obtained by gelatinization, liquefaction and saccharification and glucoside conversion treatment.

Owner:西昌市正中食品有限公司

Pichia kudriavzevii NG7 microorganism and uses thereof

ActiveUS10443078B2Efficient productionGood acid and heat resistanceFungiBiofuelsOrganic acidMicroorganism

The present invention relates to: a novel Pichia kudriavzevii microorganism NG7 showing heat resistance and acid resistance; a composition, for producing organic acid or alcohol, which comprises the microorganism and a culture of the same; and a method, for producing an organic acid or alcohol, which comprises culturing the microorganism.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com