Patents

Literature

49results about How to "Filter out high frequency noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

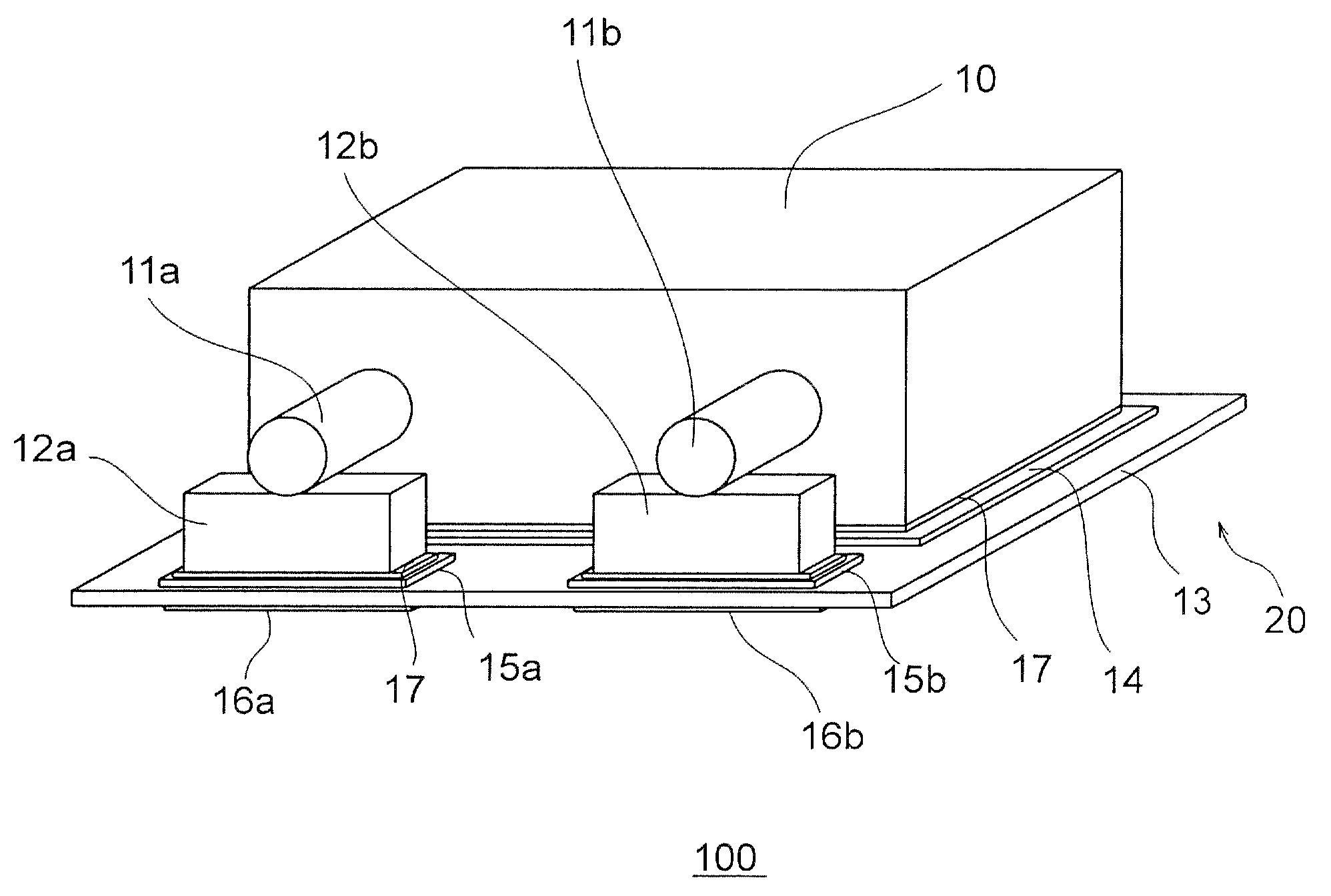

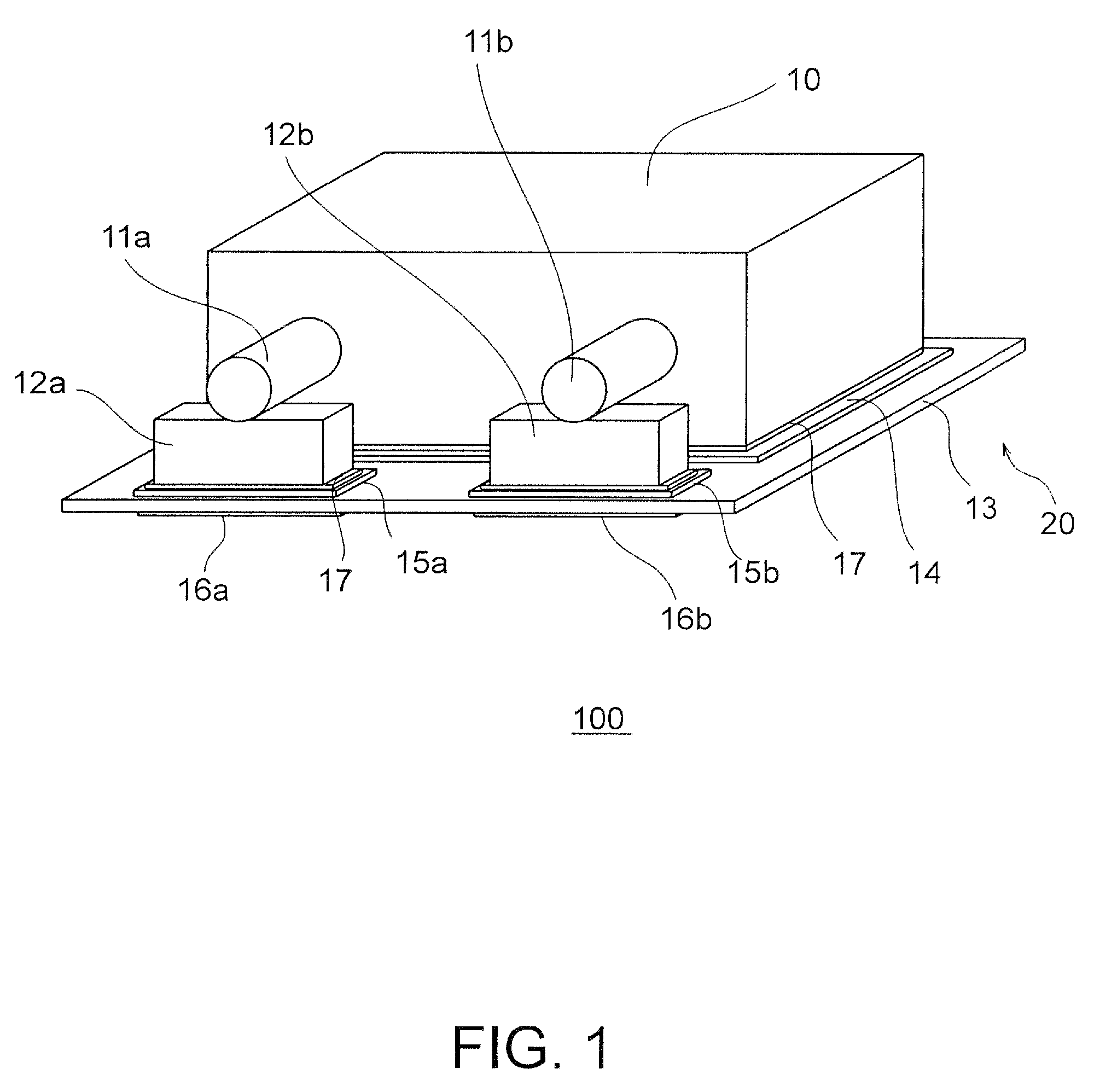

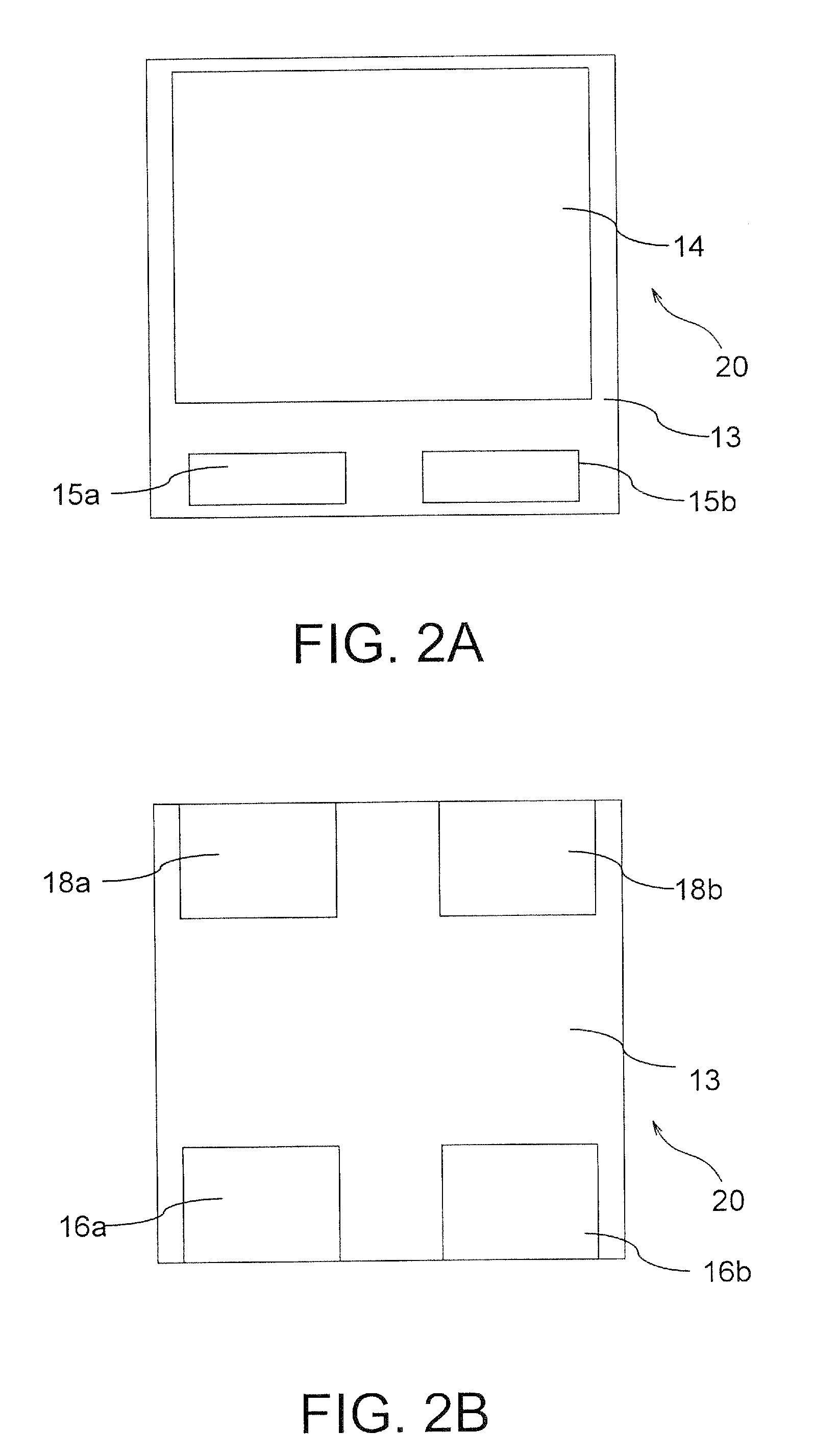

Multiterminal solid electrolytic capacitor

InactiveUS20090103243A1Improve filtering effectReduce transmission lossSolid electrolytic capacitorsFixed capacitor terminalsPath lengthElectrolysis

A multiterminal solid electrolytic capacitor includes a capacitor element including a porous sintered body which includes a plurality of anode leads projecting from a surface of the porous sintered body and which is made from a valve metal powder, a dielectric oxide coating disposed on the porous sintered body, and a cathode including a solid electrolyte layer disposed on the dielectric oxide coating. The multiterminal solid electrolytic capacitor further includes a substrate which carries the capacitor element, which includes a plurality of anode-mounting terminals and a cathode-mounting terminal, and which is covered with resin. The anode leads are portions of a valve metal pattern which extends in the porous sintered body and which bends at a plurality of locations so as to have a desired path length.

Owner:TOKIN CORP

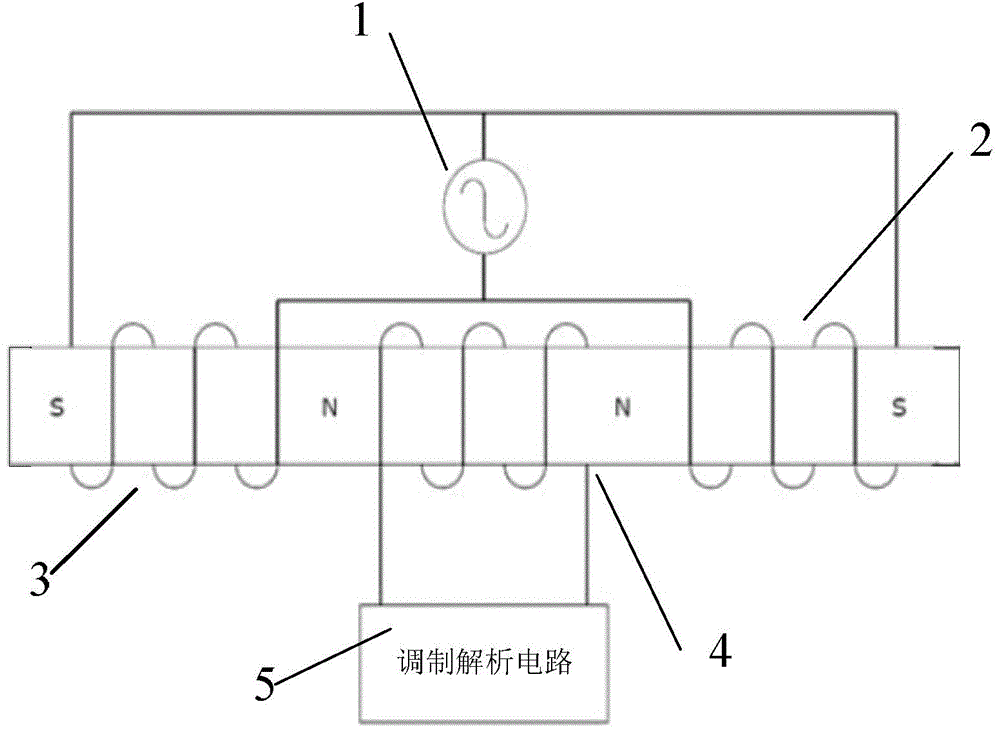

Oil abrasive particle detecting sensor and design method thereof

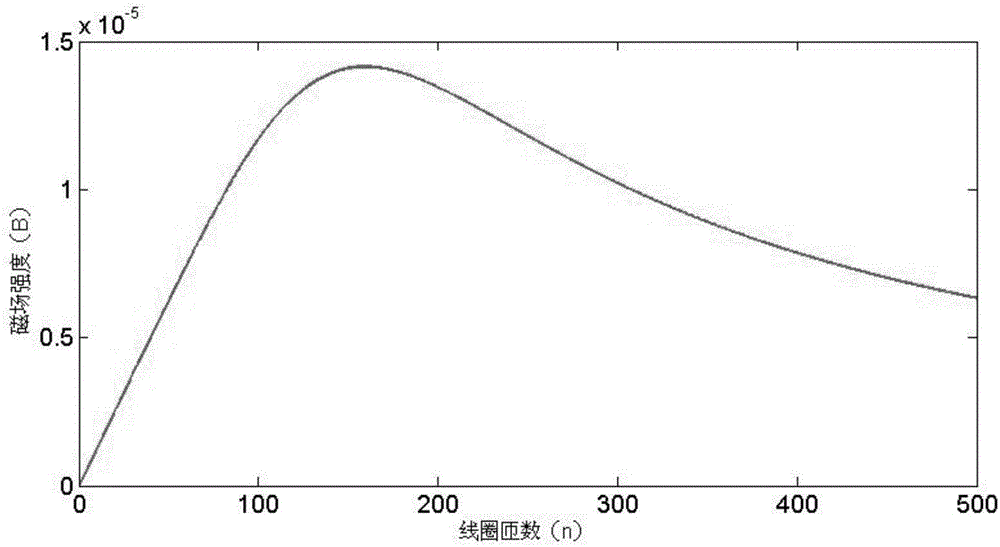

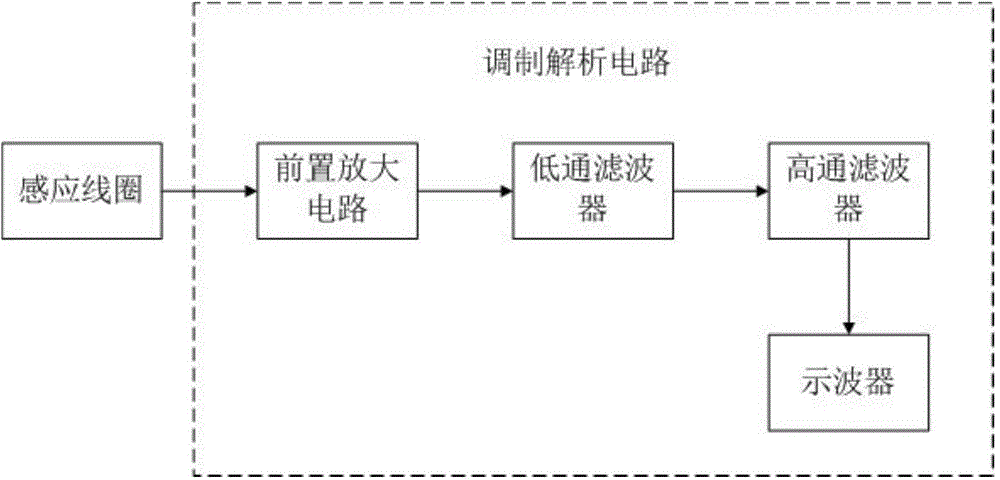

ActiveCN104697905AMaximum voltage value of signal to be modulatedSimple methodParticle size analysisComputational physicsUltimate tensile strength

The invention relates to an oil abrasive particle detecting sensor and a design method thereof. The design method comprises, after a sensor framework is determined, calculating the relation curve between magnetic field intensity B and number of coil turns n by formula, take the n, which corresponds to the maximum value of the B, as the number of turns of an induction coil and two exciting coils. According to the oil abrasive particle detecting sensor, the number of coils of every coil is determined according to the design method; the output end of the induction coil is connected with a modulation and demodulation circuit, which is sequentially connected with a pre-amplification circuit, a low-pass filter, a high-pass filter and an oscilloscope. For signal output components, the oil abrasive particle detecting sensor provides the modulation and demodulation circuit comprising the pre-amplification circuit, the low-pass filter and the high-pass filter. The design method of the oil abrasive particle detecting sensor helps design the number of turns of the induction coil, which can maximize signal output amplitude, and under the dimension of the mass-produced sensor framework, the induction coil can be conveniently mounted on various oil-lubricated engines. The oil abrasive particle detecting sensor can accurately obtain abrasive particle associated information and be applied to measuring metal abrasive particles only with a diameter of 500 mu m.

Owner:GUILIN UNIV OF ELECTRONIC TECH

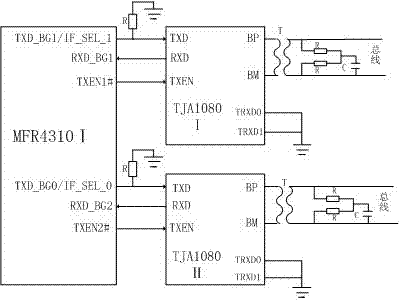

Four-channel FlexRay bus communication module

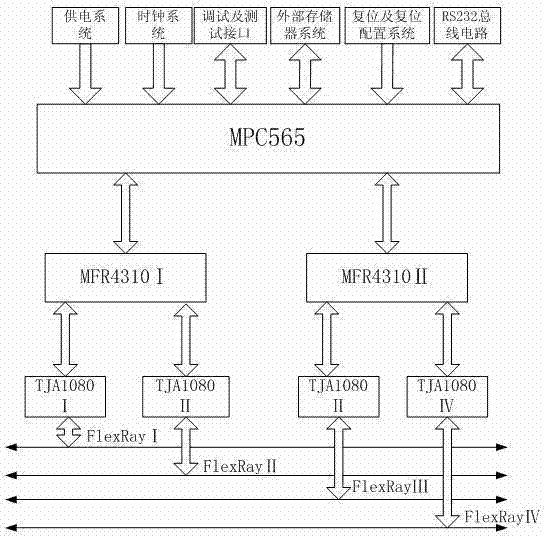

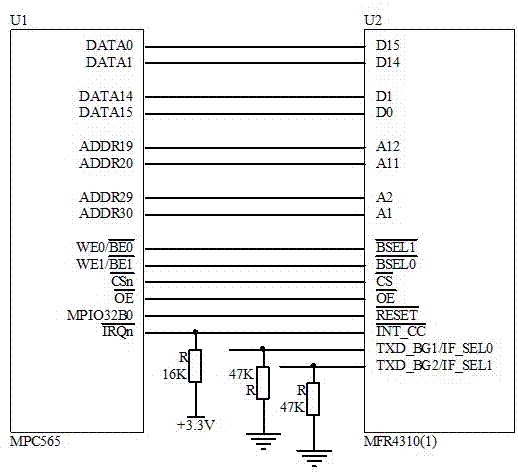

ActiveCN103034609AExpand the scope of applicationImprove stabilityElectric digital data processingBus interfaceIntegrated circuit

The invention discloses a four-channel FlexRay bus communication module which comprises a FlexRay bus interface circuit, a microprocessor, as well as a debugging and testing interface circuit, a power supply circuit, a clock circuit, a reset circuit and an LED (Light-Emitting Diode) circuit which are respectively connected with the microprocessor, wherein the FlexRay bus interface circuit is divided into four branches, comprises a bus transceiver connected with a FlexRay bus and a communication controller for connecting the microprocessor with the bus transceiver, and is used for receiving external data information by virtue of the bus transceiver and transmitting the data information to the microprocessor by the action of the communication controller; and after being processed by the microprocessor, the data is transmitted to external equipment by virtue of the FlexRay bus interface circuit. According to the four-channel FlexRay bus communication module, the microprocessor MPC565 is adopted in the communication module, the four-channel FlexRay bus output capability is realized, and the FlexRay application range is expanded.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

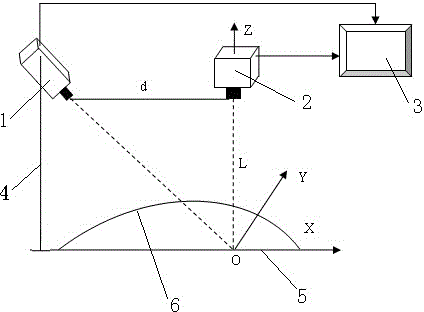

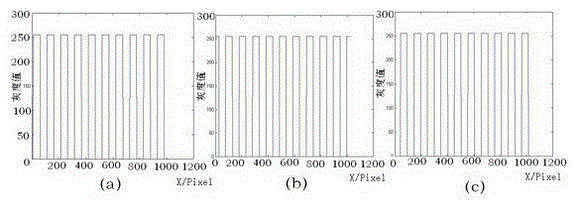

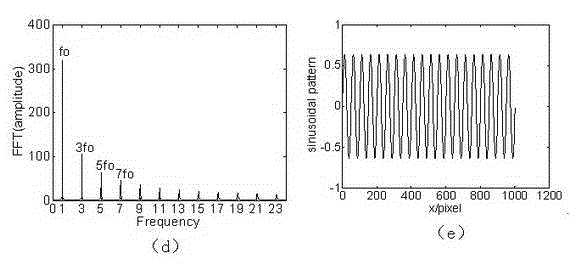

Out-of-focus projection three-dimensional measurement method of color binary fringes

InactiveCN103983208AIncreased projection speedImprove the speed of 3D measurementUsing optical meansProjection systemThree dimensional measurement

The invention discloses an out-of-focus projection three-dimensional measurement method of color binary fringes. The method involves three key parts including the color binary fringe coding principle, an out-of-focus projection system and the three-dimensional measurement principle. The out-of-focus projection three-dimensional measurement method of color binary fringes has the advantages that first, according to a traditional color sine fringe projection method, the color sine fringe gray level of projection of a traditional method projector is distributed between 0 and 255, the projection speed is limited within 120 frames / s, and the measurement speed is restricted; according to the method, because the projection color binary fringes only have the two gray levels of 0 and 255, the projection speed of a projector is greatly increased, and thus three-dimensional measurement speed is greatly increased; second, the three-step phase shift method is adopted, three-dimensional measurement can be achieved with only one set of color binary fringes, and the method has high three-dimensional measurement speed; third, the method has very high practical value in high-speed and high-precision three-dimensional measurement.

Owner:NANCHANG HANGKONG UNIVERSITY

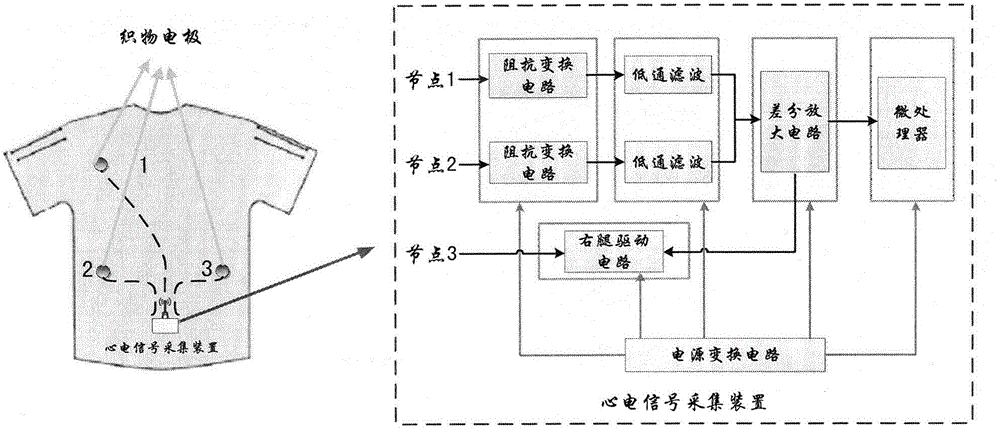

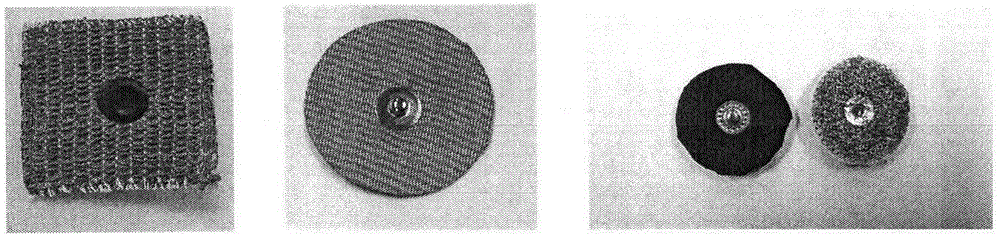

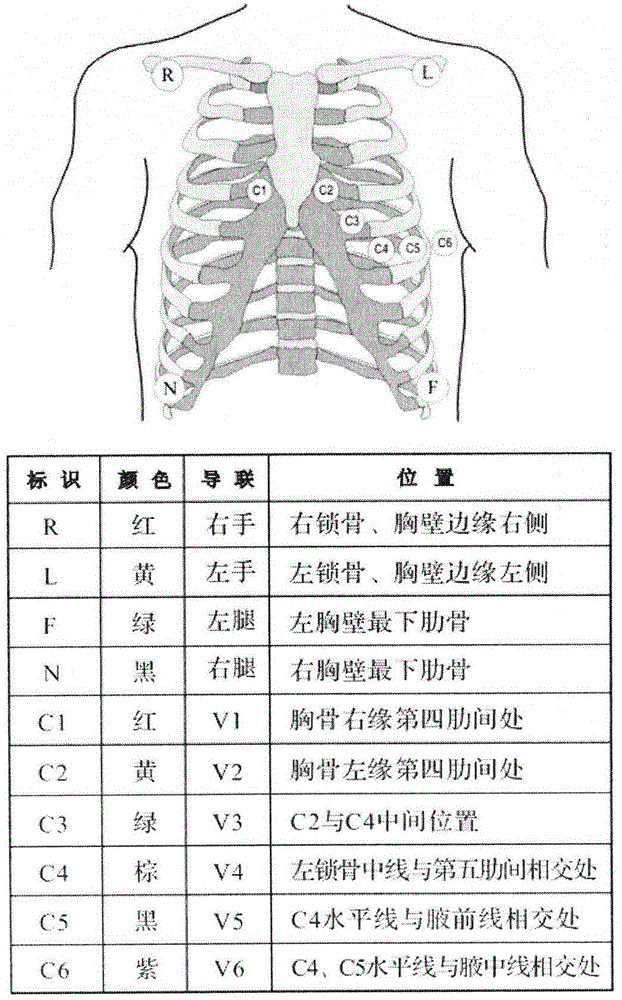

Wearable electro-cardio signal collection device based on fabric electrode

InactiveCN106606359ARealize transmissionEnables continuous monitoringDiagnostic recording/measuringSensorsEcg signalData set

The invention discloses a wearable electro-cardio signal collection device based on a fabric electrode. The device can carry out complete collection of electro-cardio signals of a human body aiming at the fabric electrode which is a novel flexible electrode. The device is characterized in that input impedance conversion of the fabric electrode could be achieved by an impedance conversion circuit, so the problem about high input impedance of the fabric electrode could be solved; common mode rejection and differential amplification are completed by a low-pass filtering circuit and a differential circuit; and finally, AD sampling and data set package transmission could be achieved. In comparison with a traditional electro-cardio collection circuit, the device disclosed by the invention is characterized in that the impedance conversion circuit is added at the fabric electrode part; power is supplied by a single power source; and an operational amplifier with a high signal to noise ratio and high input impedance is selected. In this way, the puzzle that signals are incomplete when the traditional electro-cardio collection circuits are used to extract the electro-cardio signals of the human body with application of the fabric electrode could be solved. The device is characterized by good performance, the small size and low power consumption. The device can be widely applied to wearable electro-cardio signal collection based on the fabric electrode; and comfort and convenience of use are enhanced.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

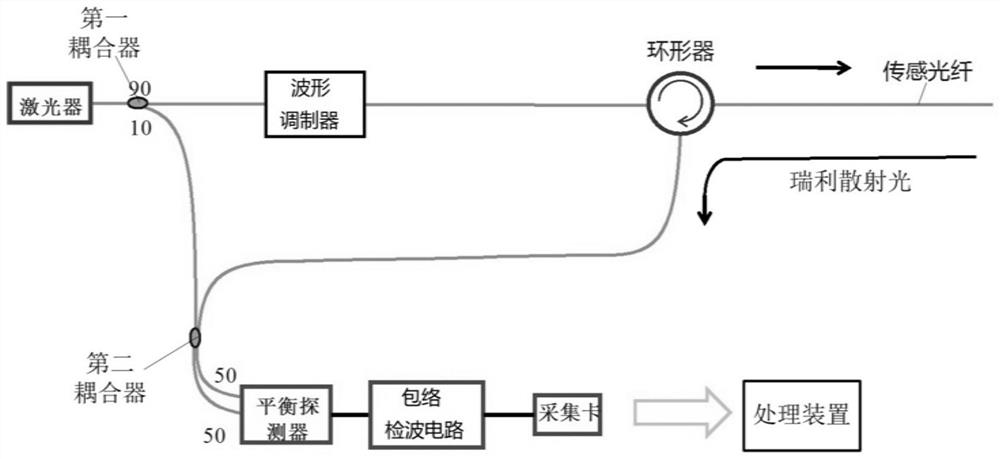

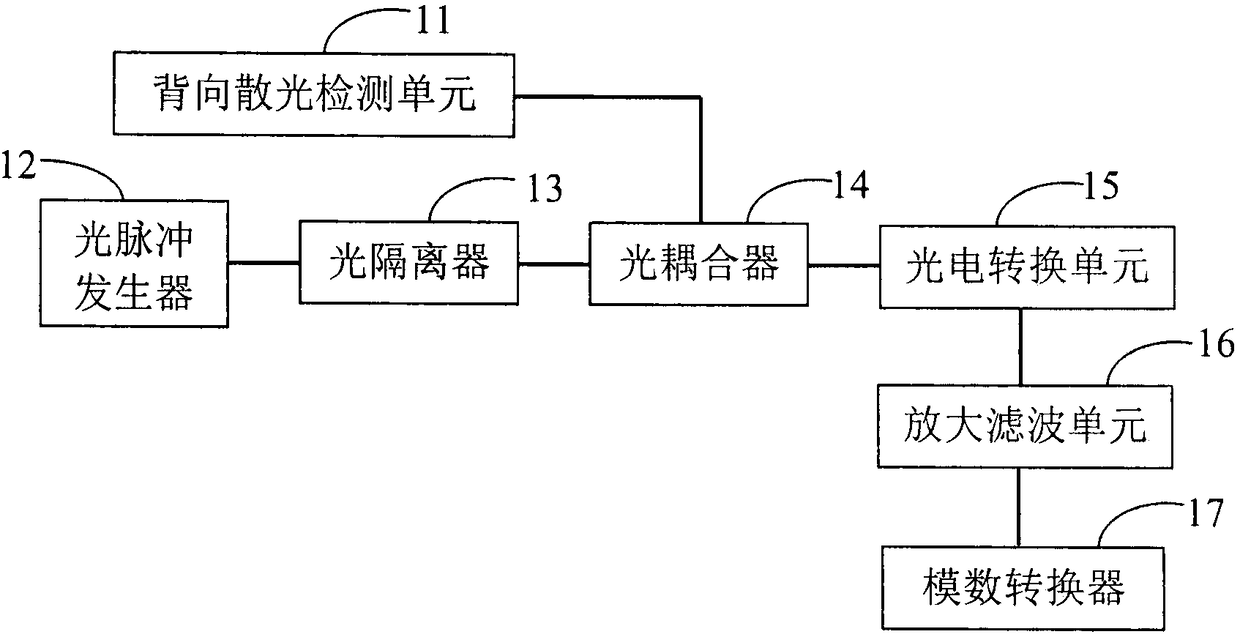

Optical fiber distributed vibration sensing system based on envelope detection circuit

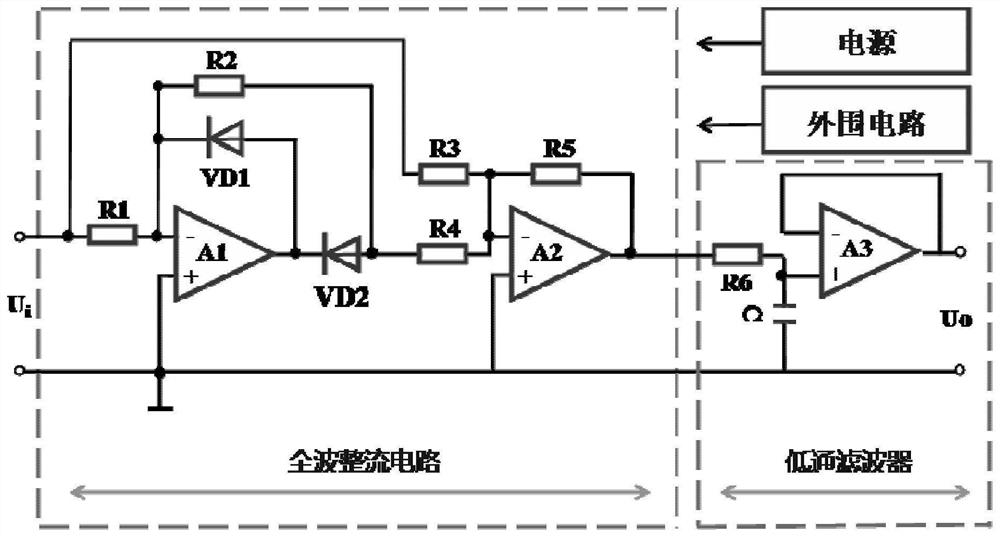

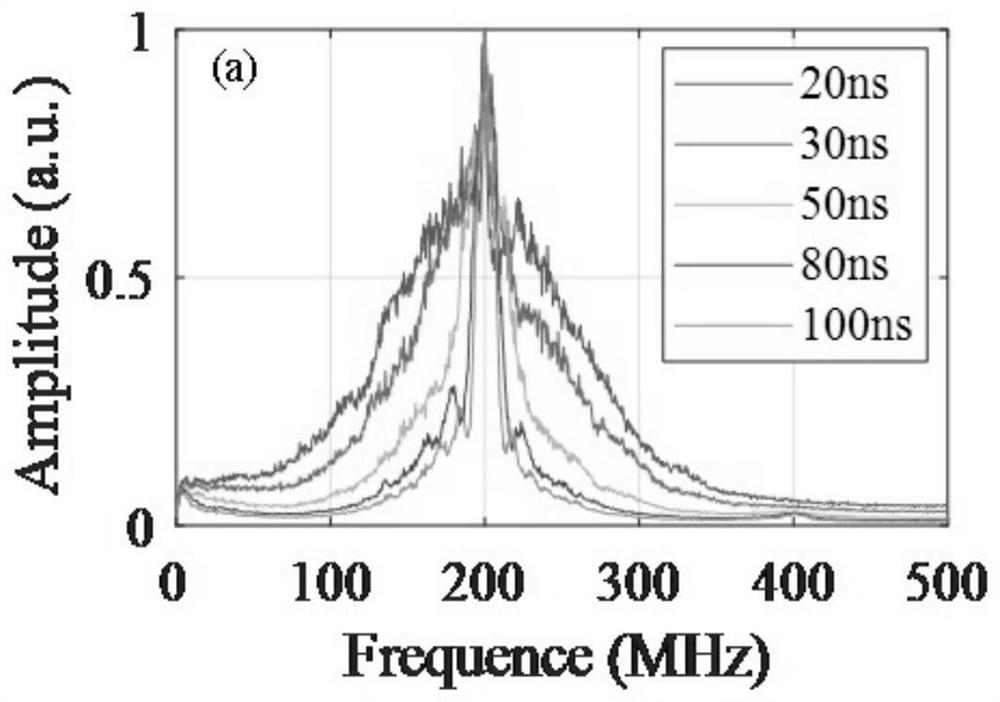

InactiveCN111609918AWide detection rangeReduce digitsSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansScattered lightFrequency domain

The invention provides an optical fiber distributed vibration sensing system based on an envelope detection circuit. The system modulates a divided first path of direct current laser into pulsed lightand sends the pulsed light to a sensing optical fiber; the sensing optical fiber carries out vibration detection based on pulsed light to generate Rayleigh scattering light transmitted backwards, then the second path of direct current laser and the Rayleigh scattering light are coupled to generate two paths of scattering light interference signals with the phase difference of 180 degrees; coherent detection is carried out on the two paths of scattering light interference signals; common-mode components are filtered out, and beat frequency electric signals are obtained. After passing through an envelope detection circuit consisting of full-wave rectification and low-pass filtering, the beat frequency electric signals are moved to a baseband from a carrier in a frequency domain, so that therequirement of the system on the sampling rate of an acquisition card is reduced; the envelope of the beat frequency electric signals is obtained in the time domain; digital demodulation in coherentdetection is avoided, and the burden of a processing device is reduced. The full-wave rectification circuit and coherent detection are combined, and the sensing distance is increased while the high signal-to-noise ratio of coherent detection is ensured.

Owner:CHONGQING UNIV

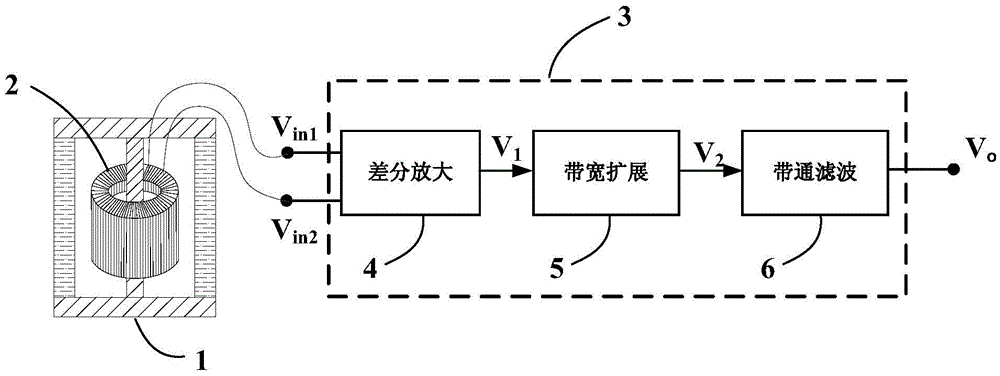

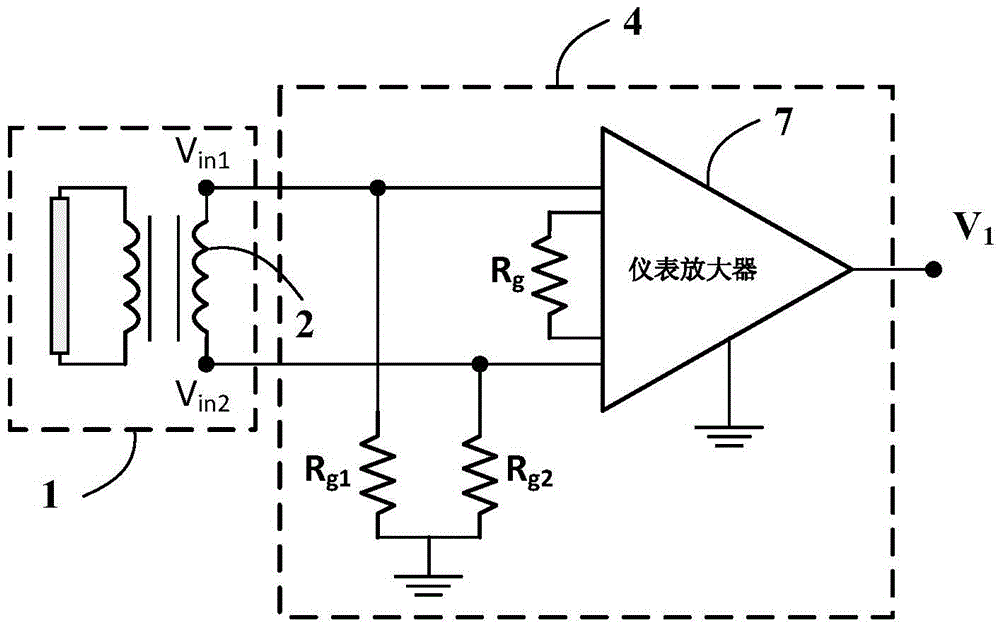

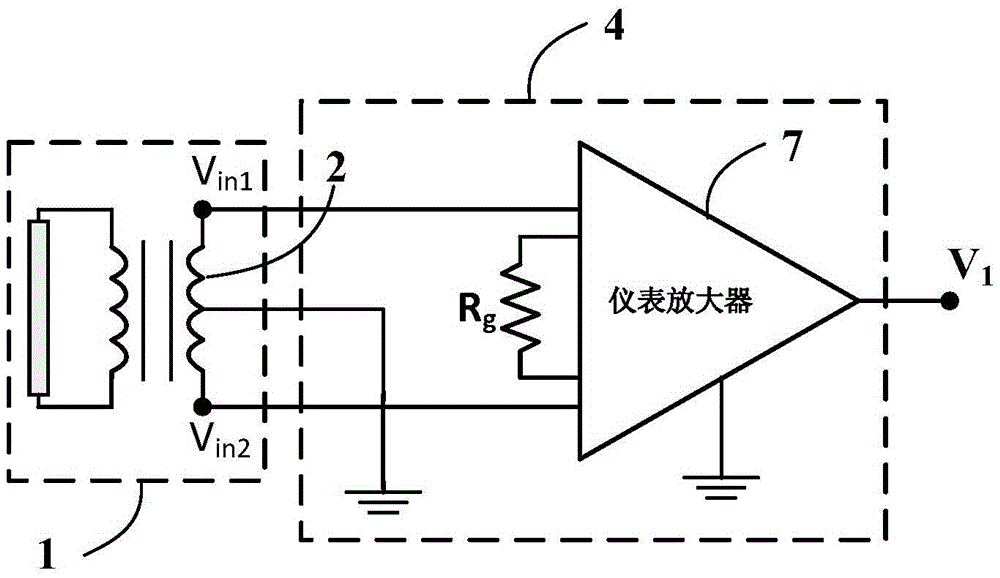

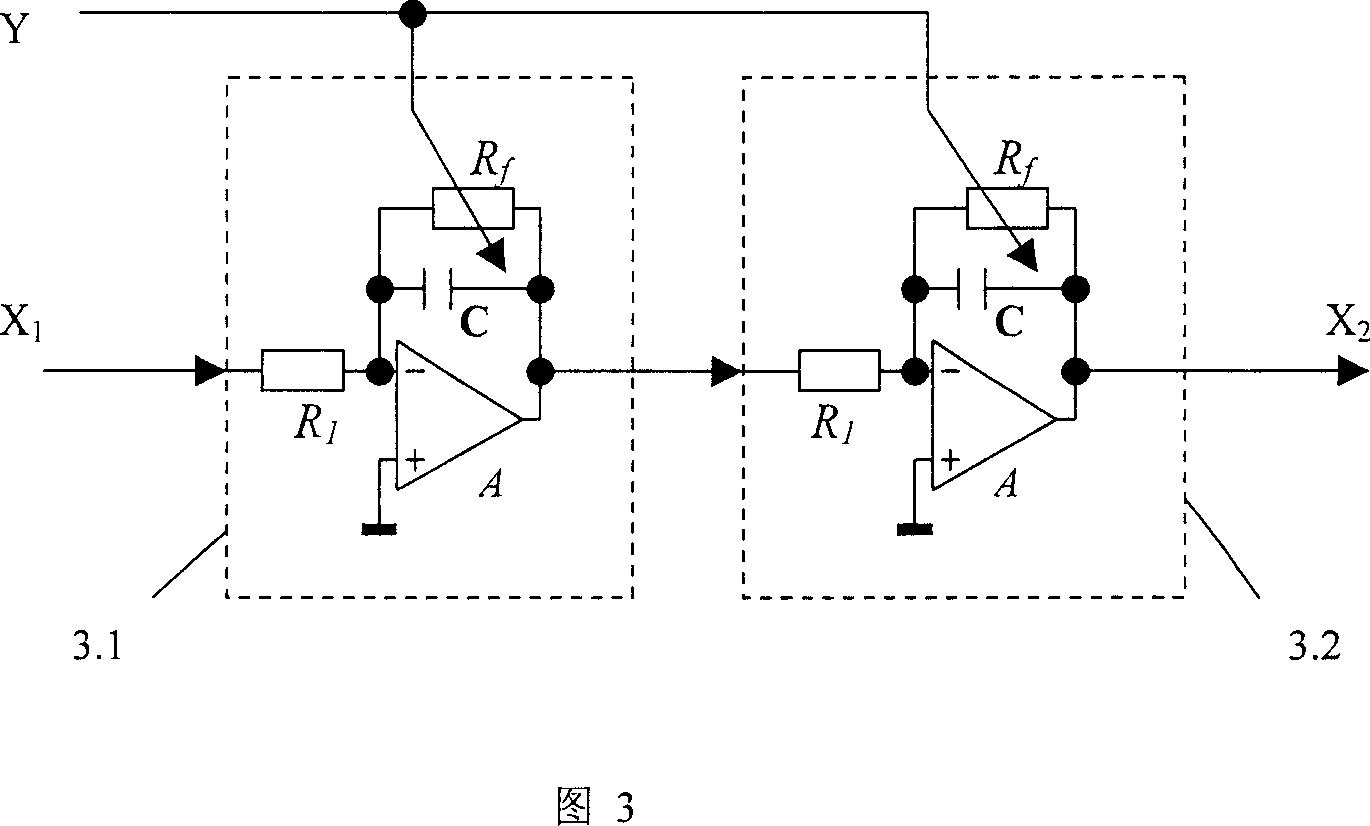

Detection device for MHD angular-rate sensor

ActiveCN105486882AImprove scalabilityWorking bandwidthTesting/calibration of speed/acceleration/shock measurement devicesDevices using electric/magnetic meansNoise levelAngular rate sensor

The invention relates to a detection circuit for a magnet-hydro-dynamics (MHD) angular-rate sensor. The detection circuit is formed by function modules: a differential amplification module, a bandwidth expansion module and a band-pass filtering module and the like, and can control noise level of the sensor effectively, improve weak signal detection capability and expand work bandwidth. Besides, the detection circuit can achieve the effect of suppressing zero position bias and zero position temperature drift of the sensor under the condition of not adding a special zero position bias adjusting module and a zero position temperature drift compensation module.

Owner:BEIJING RES INST OF TELEMETRY +1

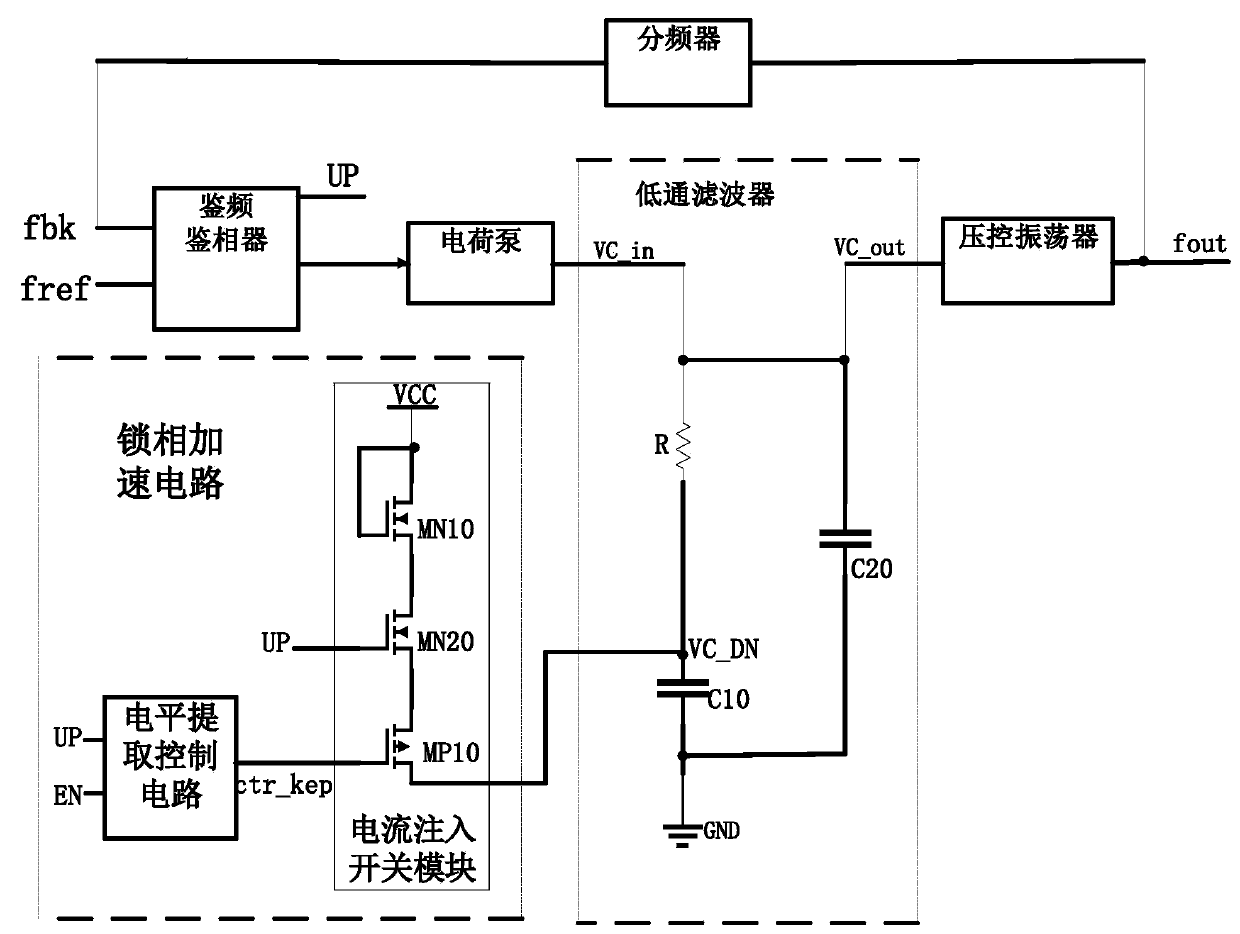

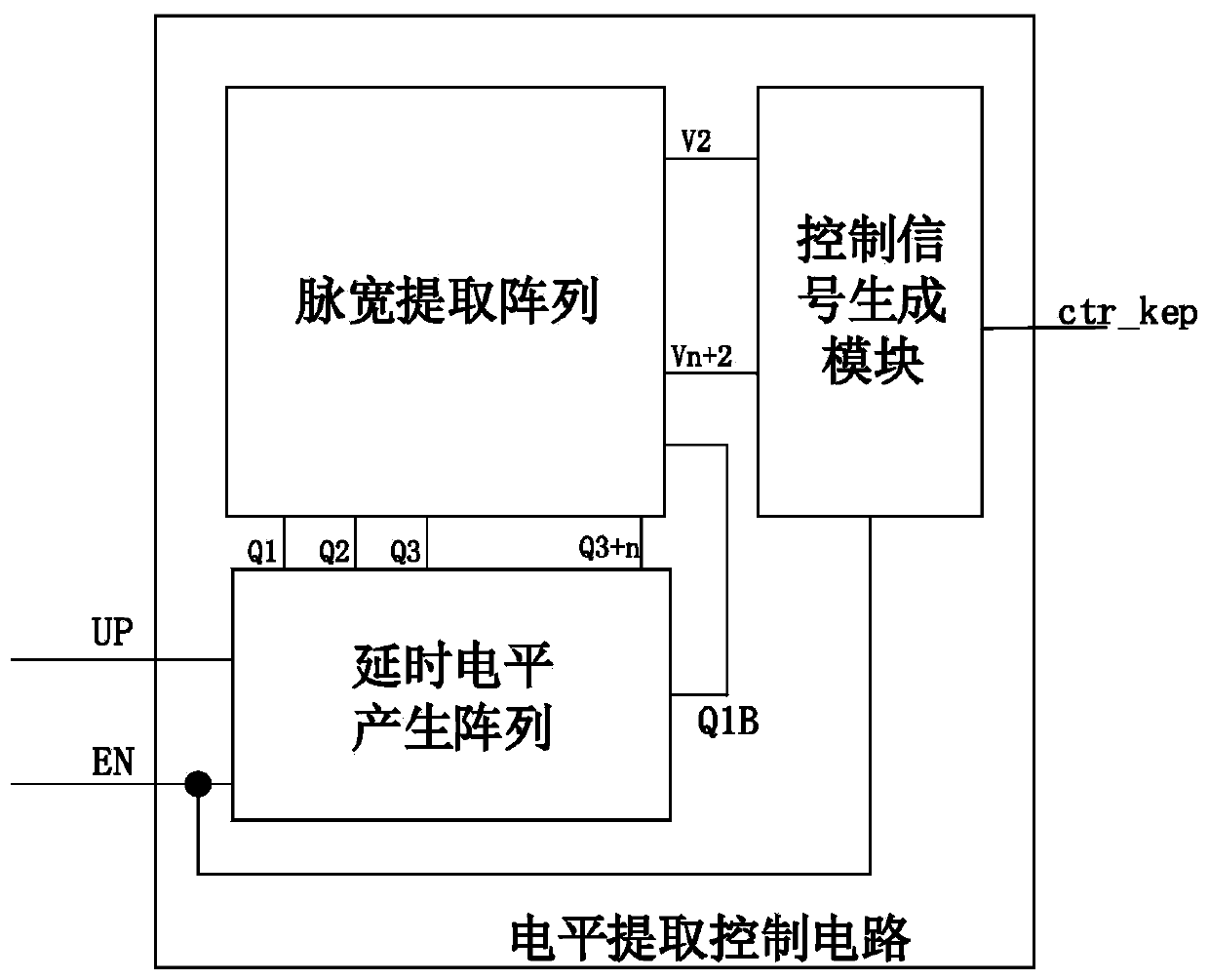

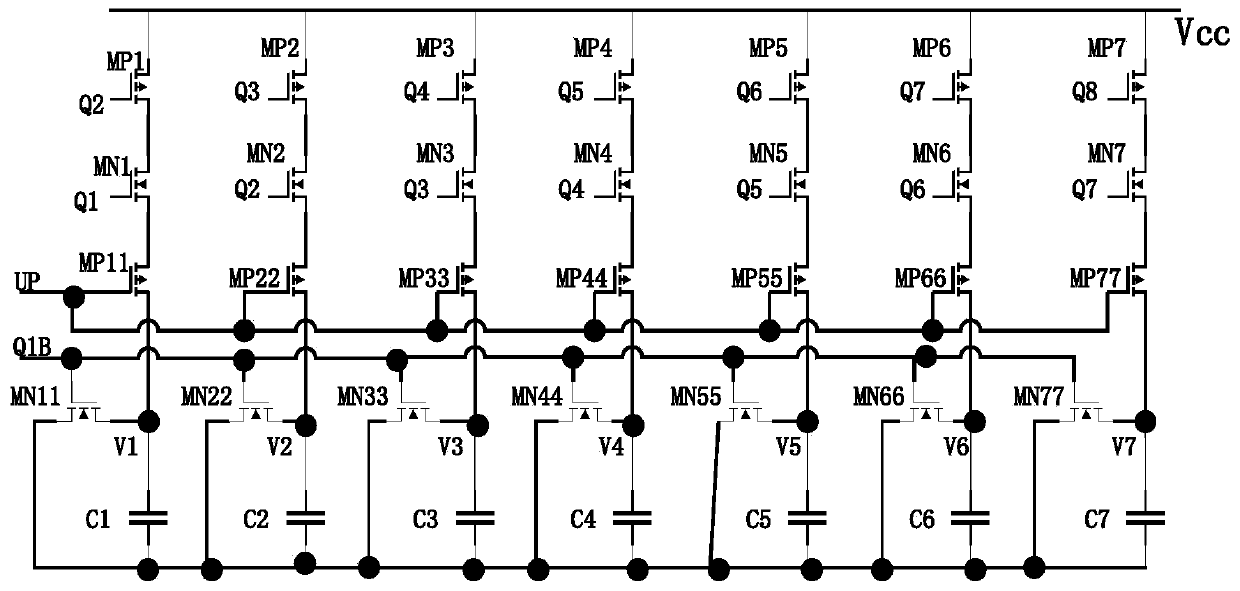

Phase-locked acceleration circuit based on level width extraction and phase-locked loop system

PendingCN110635803AIncrease the oscillation frequencyShorten lock timePulse automatic controlPulse manipulationCharge injectionControl signal

Owner:AMICRO SEMICON CORP

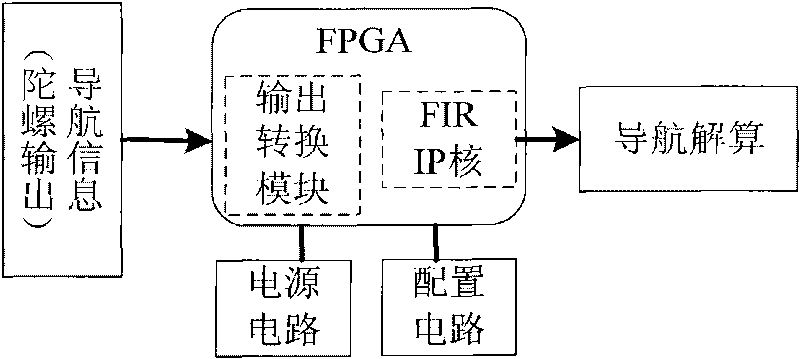

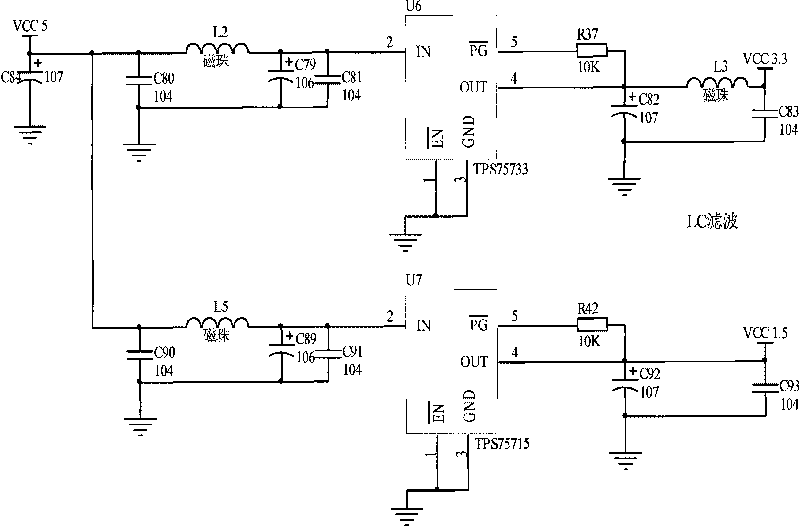

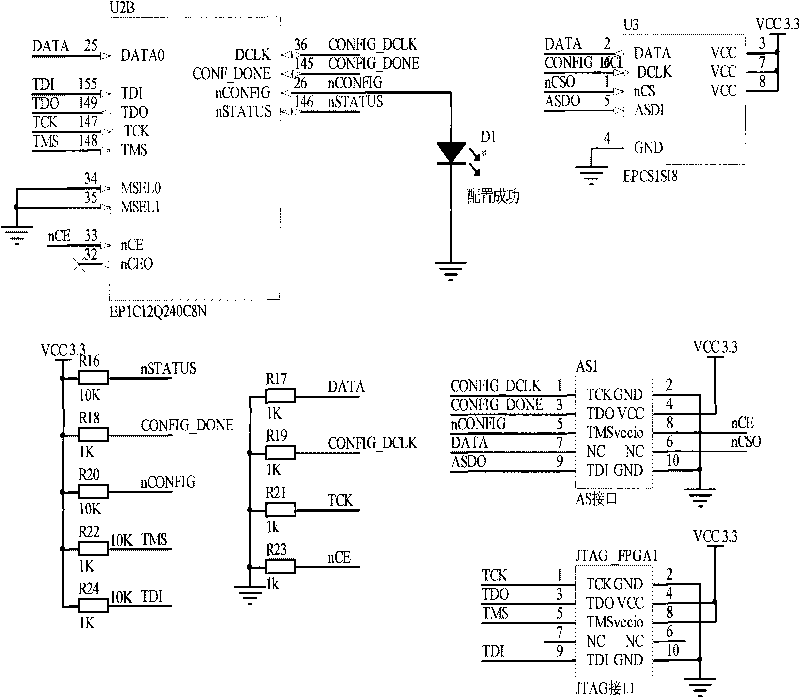

Laser gyroscope strapdown inertia navigation system output conversion device based on reusable IP core

InactiveCN101718558ASimplify complexityFilter out high frequency noiseNavigation by speed/acceleration measurementsGyroscopeSystem configuration

The invention relates to a laser gyroscope strapdown inertia navigation system output conversion device based on a reusable IP core. Navigation information output by a laser gyroscope is input into a field programmable gate array (FGPA), information output by the FGPA is input into a navigation resolving module for resolution, wherein the FGPA consists of an output conversion module and an FIR IP core filtering module and is configured by a configuration circuit, and a power supply circuit supplies power for the FGPA. The device greatly simplifies the complexity and improves the flexibility of the configuration.

Owner:HARBIN ENG UNIV

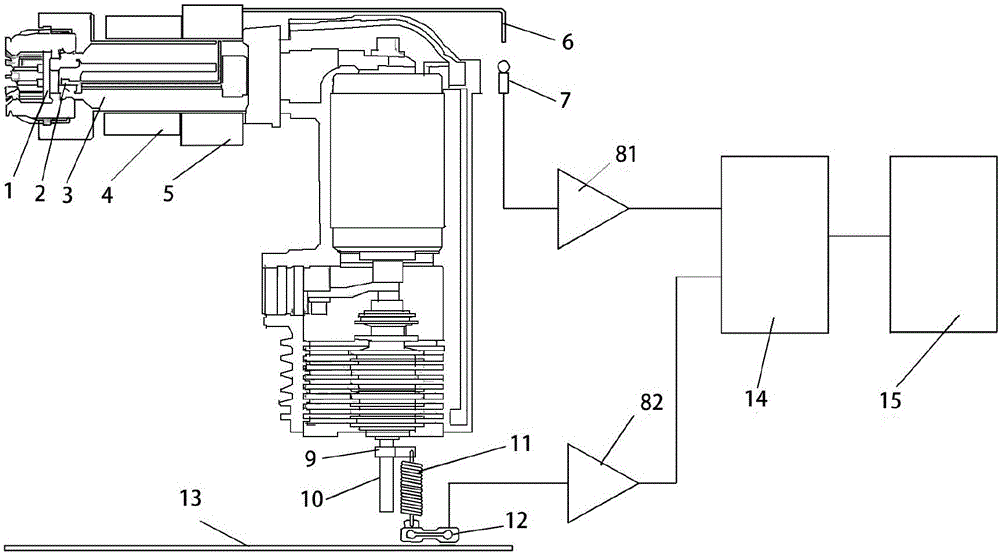

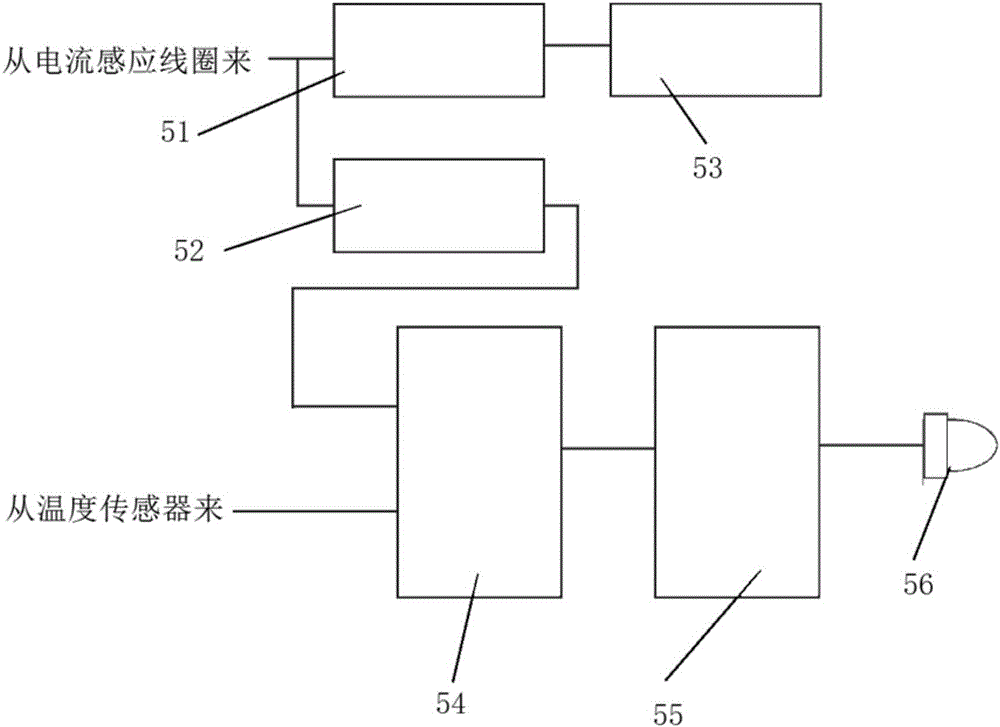

Device and method for online monitoring comprehensive characteristics of high-voltage circuit breaker

InactiveCN105974307ASimple structureSolve the installationMachine part testingCircuit interrupters testingAudio power amplifierLow voltage

The invention discloses a device and method for online monitoring the comprehensive characteristics of a high-voltage circuit breaker. A tulip contact is installed on a conductive rod. A temperature sensor is installed on the tulip contact. The output end of the temperature sensor is connected with a high-voltage side circuit processing unit. A current induction coil is arranged on the periphery of the conductive rod in a sleeving mode. The output end of the current induction coil is connected with the high-voltage side circuit processing unit. The high-voltage side circuit processing unit is connected with a photoelectric sensor through an optical fiber. The output end of the photoelectric sensor is connected with a first front end signal amplifier. A spring fixing base is installed on an insulating pull rod. One end of a spring body is installed on the spring fixing base, and the other end of the spring body is installed on a force sensor. The force sensor is installed on a base. The output of the force sensor is connected with a second front end signal amplifier. The output end of the first front end signal amplifier and the output end of the second front end signal amplifier are both connected with a low-voltage side circuit processing unit. The output end of the low-voltage side circuit processing unit is connected with a main control unit. By means of the device, the problem of how to online monitor the comprehensive characteristics when the circuit breaker actually runs can be solved.

Owner:XIAMEN UNIV OF TECH

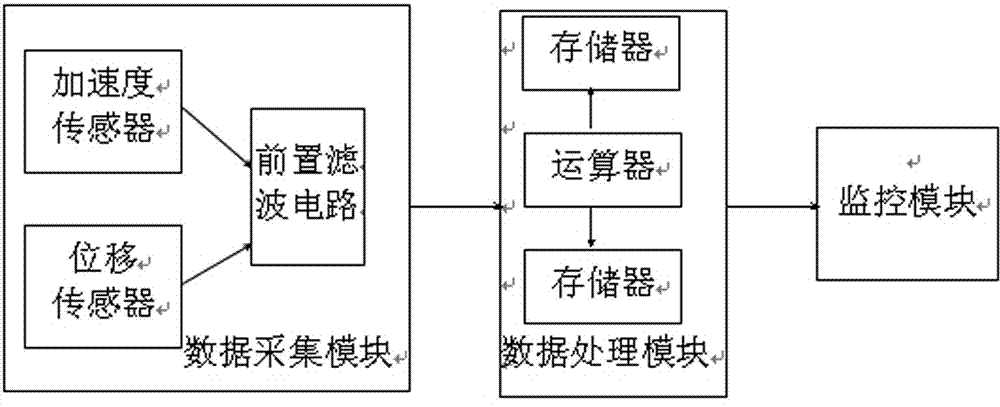

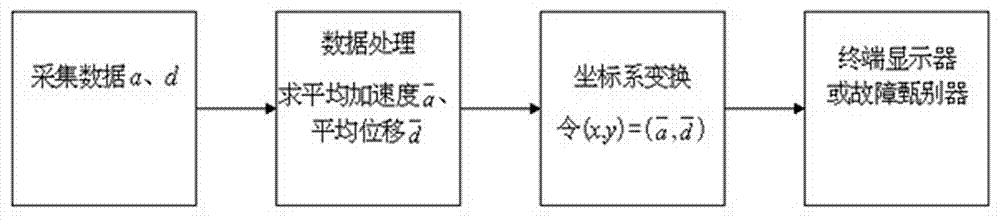

Train operation state monitoring system based on data projection mode conversion

InactiveCN103759955AImprove securityImprove comfortRailway vehicle testingProgramme total factory controlStructure of Management InformationData acquisition module

The invention discloses a train operation state monitoring system based on data projection mode conversion. The train operation state monitoring system comprises a data collecting module, a data processing module and a monitoring module. The data collecting module comprises a sensor for collecting data and a pre-filtering circuit. The data processing module comprises an arithmetic unit used for data calculation and a storage device used for data storage. The arithmetic unit processes the data according to the mode that multiple characteristic data are projected at the same time. The sensor transmits the collected data filtered by the pre-filtering circuit to the arithmetic unit, and the arithmetic unit processes the characteristic data in the mode of one-data-point projection and then transmits the data to the storage device and meanwhile transmits the data to the monitoring module. The train operation state monitoring system is simple in structure and data processing algorithm, free of calculation which is complex, large in time and resource consumption and expenditure and capable of meeting the requirements for real-time performance, instantaneity and timeliness of monitoring performed on safety and comfort of train operation.

Owner:SOUTHWEST JIAOTONG UNIV

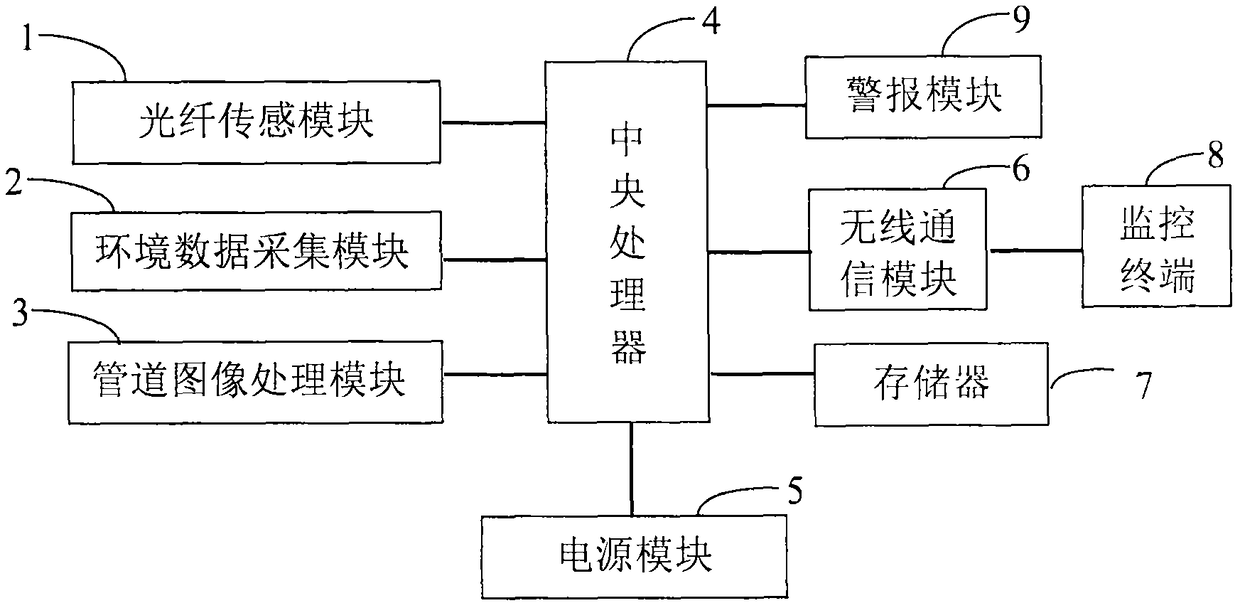

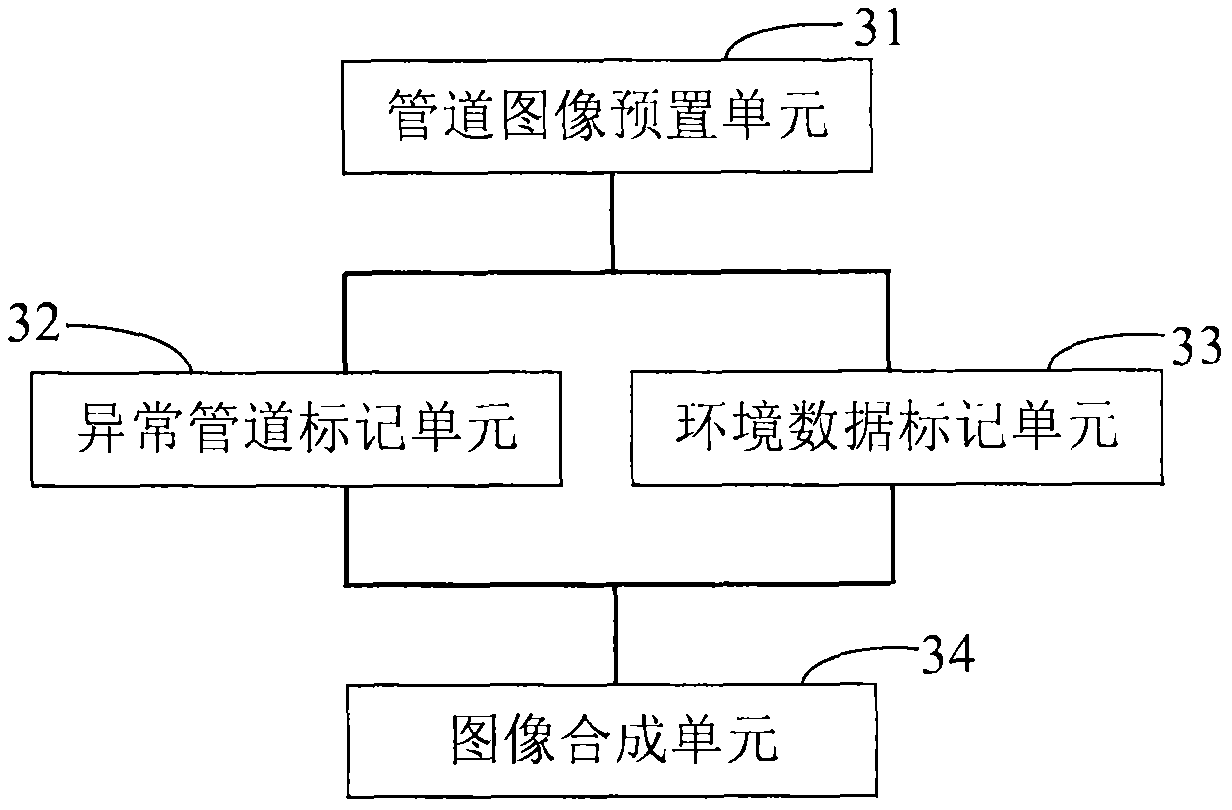

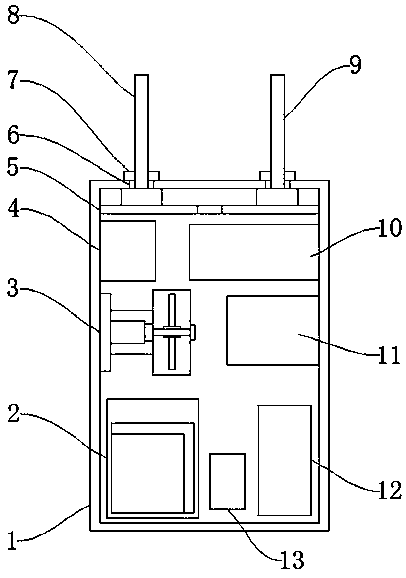

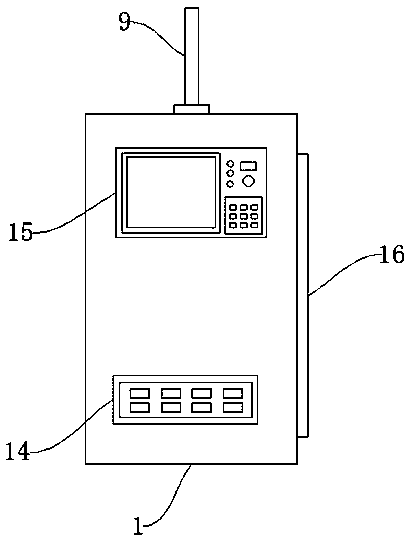

Safety protection early warning system for buried natural gas pipeline

PendingCN108426173ARealize online monitoring and safety warningAchieve securityPipeline systemsEngineeringNatural gas

The invention discloses a safety protection early warning system for a buried natural gas pipeline. The system comprises a central processing unit, an optical fiber sensing module, an environmental data acquisition module, a pipeline image processing module, a memory, a warning module, a power supply module, a wireless communication module and a monitoring terminal. According to the safety protection early warning system, the running state of the pipeline is detected in real time through the optical fiber sensing module; the environmental data around the pipeline is acquired through the environmental data acquisition module; when the leakage and sudden shock of natural gas occur, the optical fiber sensing module can be used for detecting the abnormal information of the pipeline and the position where the abnormal position of the pipeline is located; the abnormal point of the pipeline and the environmental data are marked on a pipeline image through the pipeline image processing module;meanwhile, the system is used for sending warning information and marked pipeline image information to the monitoring terminal, and thus, the on-line monitoring and safety early warning function of the pipeline are realized.

Owner:QINZHOU UNIV

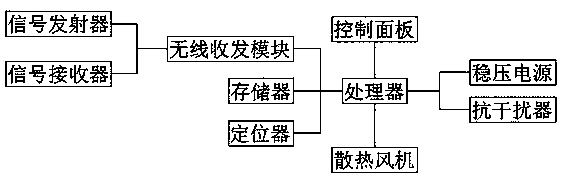

IoT-based anti-interference electronic communication device

InactiveCN109951996AEasy to useFlexible operationMagnetic/electric field screeningNon-rotating vibration suppressionElectronic communicationSoftware engineering

The invention discloses an IoT-based anti-interference electronic communication device comprising a casing, a positioner, a signal receiver and an anti-interference device, wherein the casing is provided therein with a processor; a heat dissipation fan is installed above the processor; a mounting plate is mounted above the positioned; the top of the casing is provided with a through hole; a fixingring is mounted on the upper end of the casing; a signal transmitter is mounted on the upper end of the mounting plate; and a stabilized voltage supply is disposed under the anti-interference device;a binding post is disposed outside the casing; a control panel is disposed above the binding post; and the casing is provided with an access door. The IoT-based anti-interference electronic communication device has the advantages of 1, convenient use, flexible operation, stable power supply, convenient detection and maintenance, and good practicability; 2, reinforcing the signal transmitter and the signal receiver to prevent loosening and falling off; 3, being resistant to interference, dissipating heat inside the device and extending the service life of the device.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

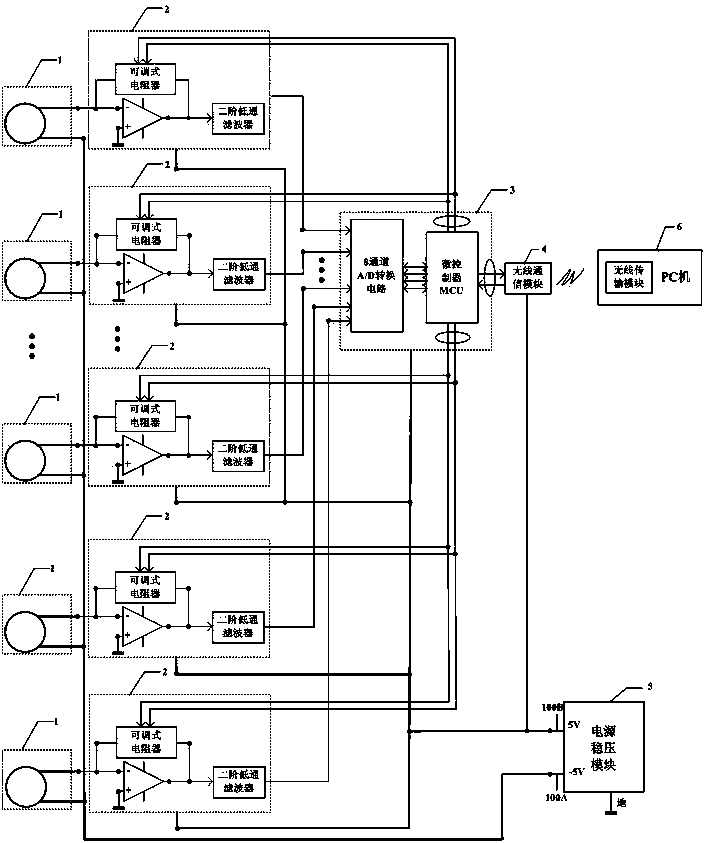

Measurement range automatic adjustable traditional Chinese medical massage manipulation mechanical information obtaining system

InactiveCN103549965AHigh measurement accuracyWide measurement rangeMuscle exercising devicesMicrocontrollerResistor

The invention relates to a measurement range automatic adjustable traditional Chinese medical massage manipulation mechanical information obtaining system. The system comprises two gloves. A plurality of film pressure sensors are stuck on fingertip portions and palm portions of two glove bodies, the output ends of the film pressure sensors are connected with the input ends of signal conditioning modules, and the input and output ends of the signal conditioning module are connected with the input and output ends of a signal acquisition and processing module which communicates with a personal computer (PC) through a wireless communication module. According to the system, the amplitude of the application force during palm or finger massage is measured in real time through the film pressure sensors, so that the measuring accuracy is high; the change of resistances of adjustable resistors is controlled through a microcontroller unit (MCU), magnification factors of amplifiers are adjusted automatically according to the amplitude of the application force during massage, automatic magnification and reduction of the measurement range are achieved, the measurement range is wide, and the measurement accuracy is improved; a wireless transmission and PC receiving display mode is used, so that the amplitude and the variation trend of the massage force are represented accurately, visually and quantitatively.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

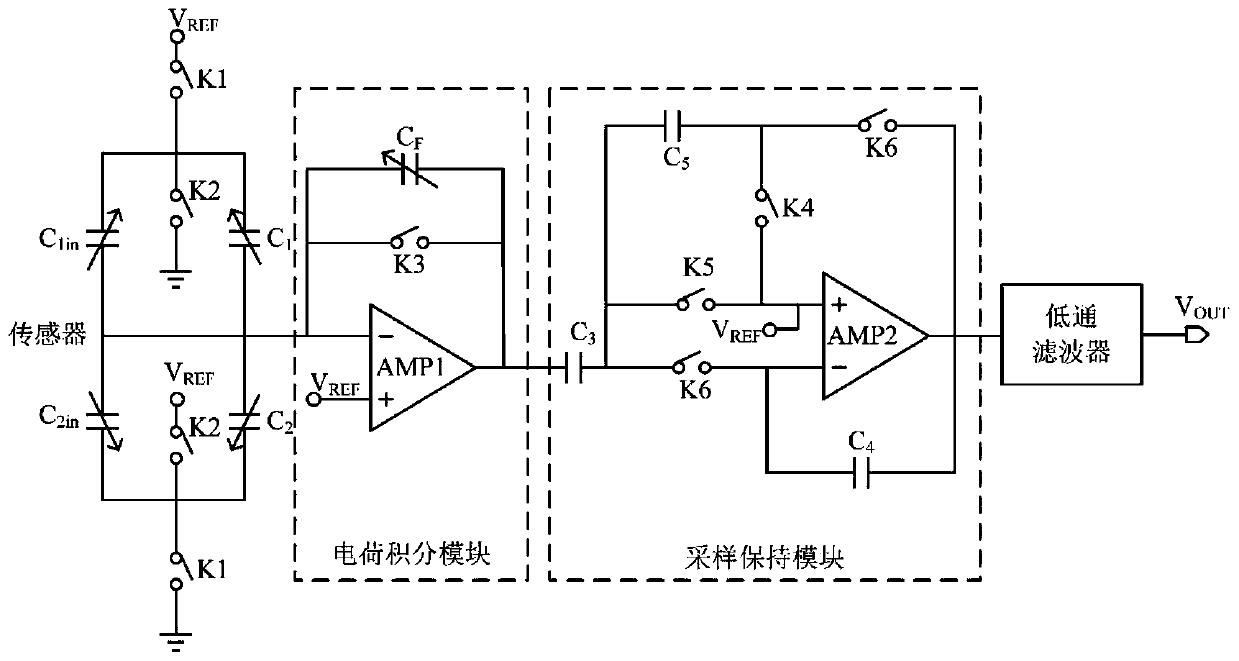

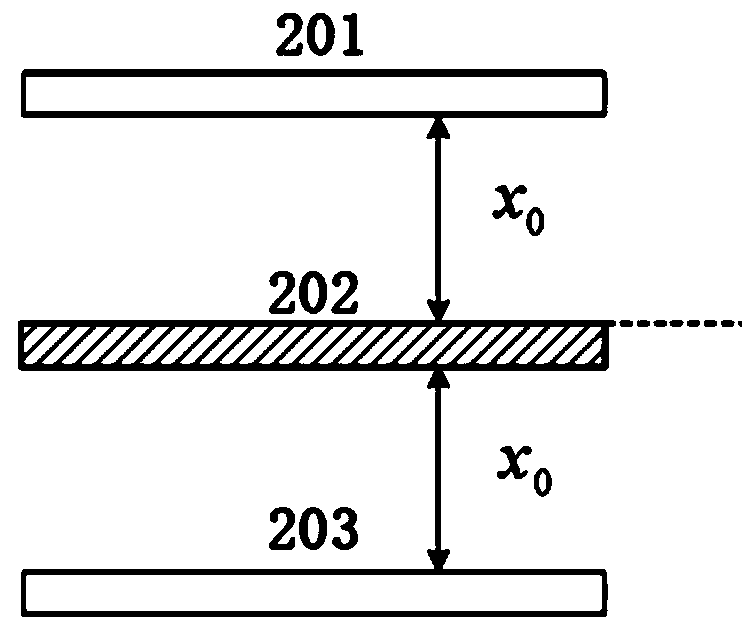

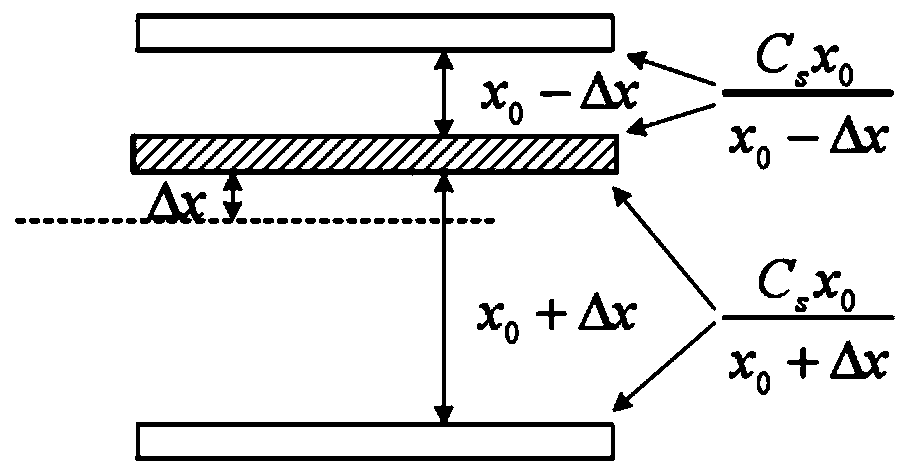

Capacitor voltage conversion device

PendingCN111404551AEliminate the effects ofAdjustable voltage rangeAnalogue/digital conversionElectric signal transmission systemsCapacitanceCapacitor voltage

The invention provides a capacitor voltage conversion device, and the device comprises: a charge integration module which comprises a first operational amplifier, a feedback capacitor, and a third switch; a sample hold module which comprises a third capacitor, a fourth capacitor, a fifth capacitor, a second operational amplifier and a plurality of switches, wherein one end of the fifth capacitor is connected with the other end of the third capacitor, the other end of the fifth capacitor is connected with the output end and the in-phase input end of the second operational amplifier through twoswitches, the fourth capacitor is in bridge connection with the output end and the reverse input end of the second operational amplifier, and the in-phase input end of the second operational amplifieris also connected with a reference voltage input end; and at least one adjustable capacitance compensation module, wherein each adjustable capacitance compensation module comprises a plurality of capacitor branches connected in parallel, and each capacitor branch comprises a compensation capacitor and an adjusting switch; wherein one or more of a detection capacitor and a feedback capacitor of the detection sensor are adjustable capacitance compensation modules.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

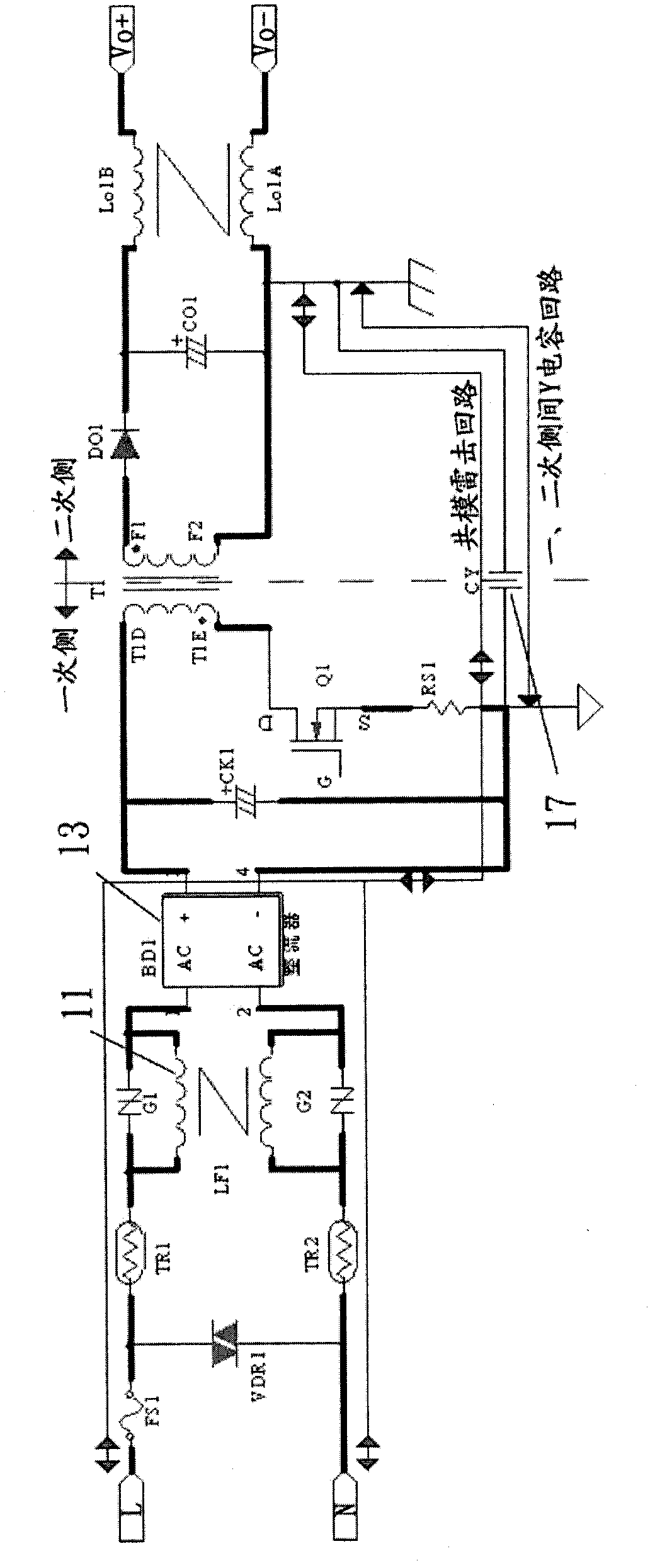

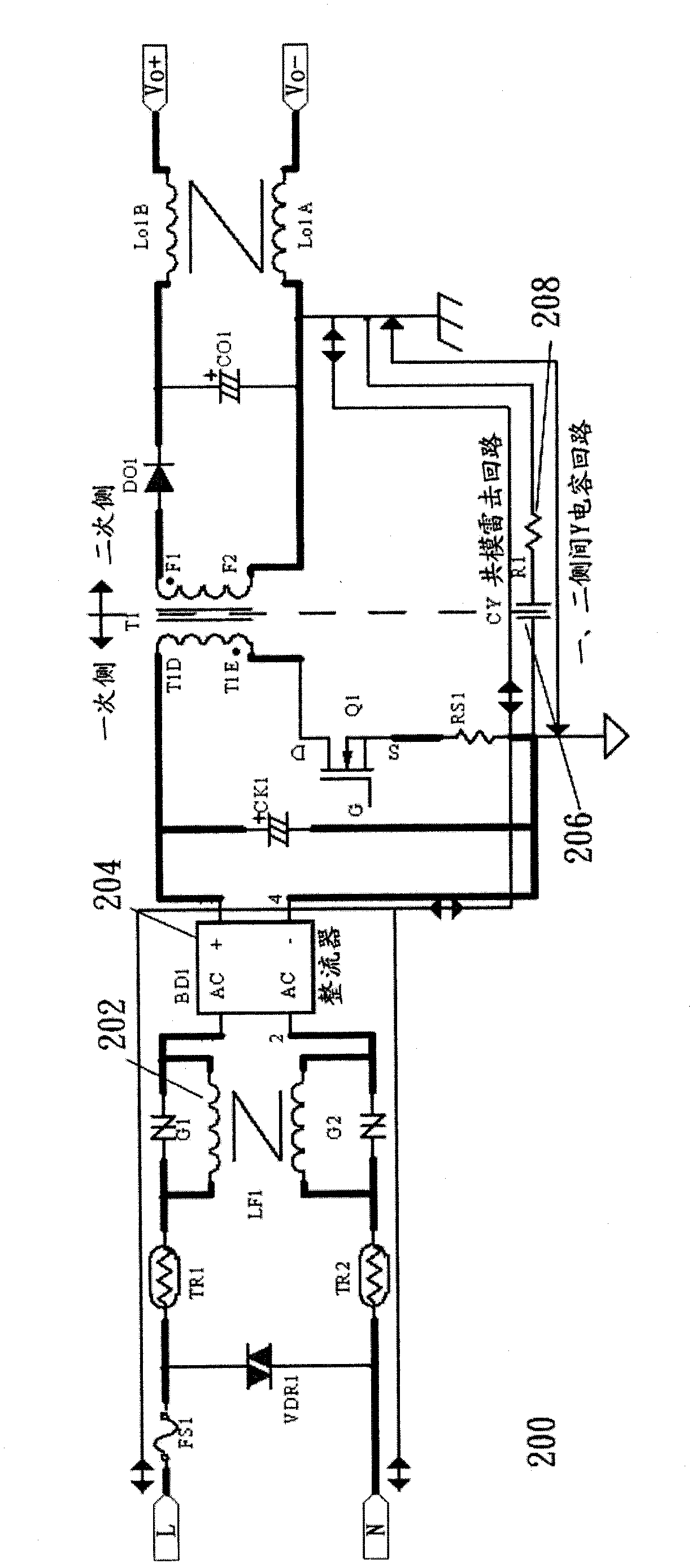

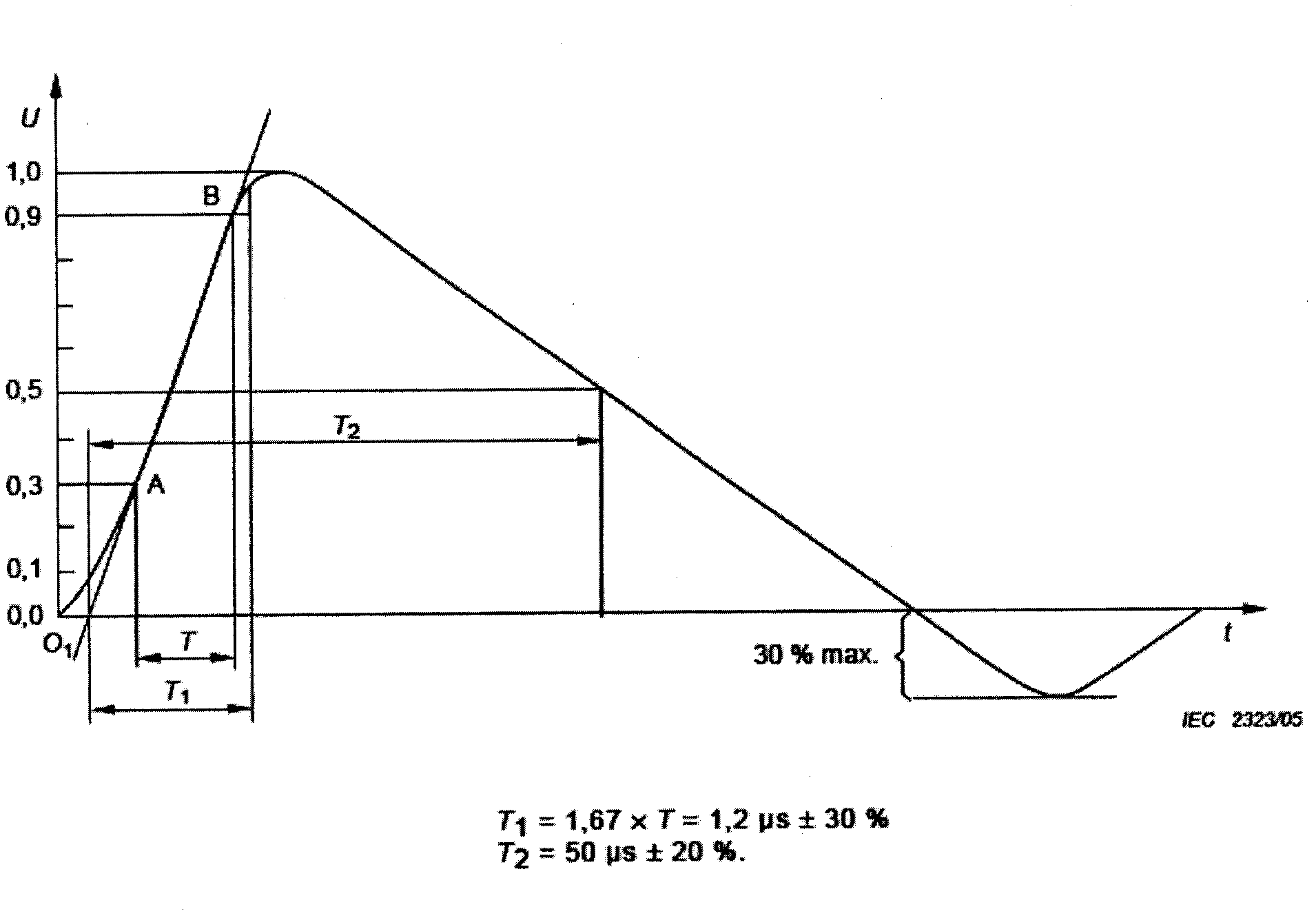

Common mode thunderstrike killer circuit of power supply

InactiveCN102931824AEMI suppressionFilter out high frequency noisePower conversion systemsCapacitanceThermistor

A common mode thunderstrike killer circuit of a power supply comprises: a filter, the filter can be one or two difference mode inductors, or can be a common mode inductor of a conjugate iron core, so high frequency noises are filtered; a rectifier, and the rectifier can be full wave rectification or half wave rectification of any mode; an isolation transformer; a Y capacitance used for suppressing electromagnetic interference; and common mode strike killing member being impedance member, the common mode strike killing member can be constant value resistance, variable resistance, or thermistor, the common mode strike killing member is connected in series with the Y capacitance, and two ends of the common mode strike killing member connected in series with the Y capacitance are respectively connected with a primary side ground wire and a secondary side ground wire of the isolation transformer.

Owner:ASIAN POWER DEVICES

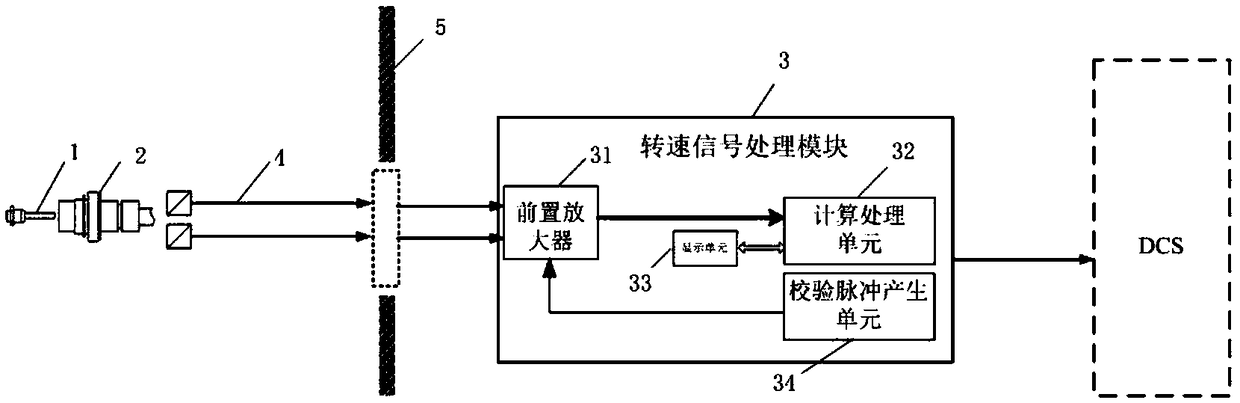

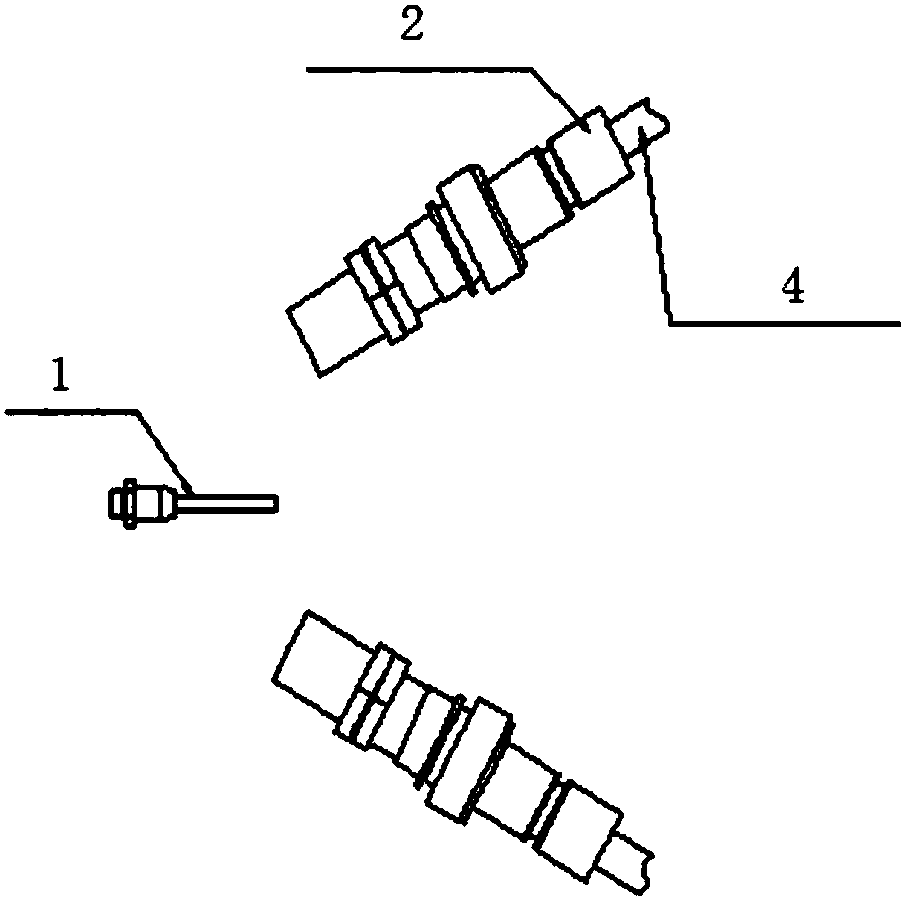

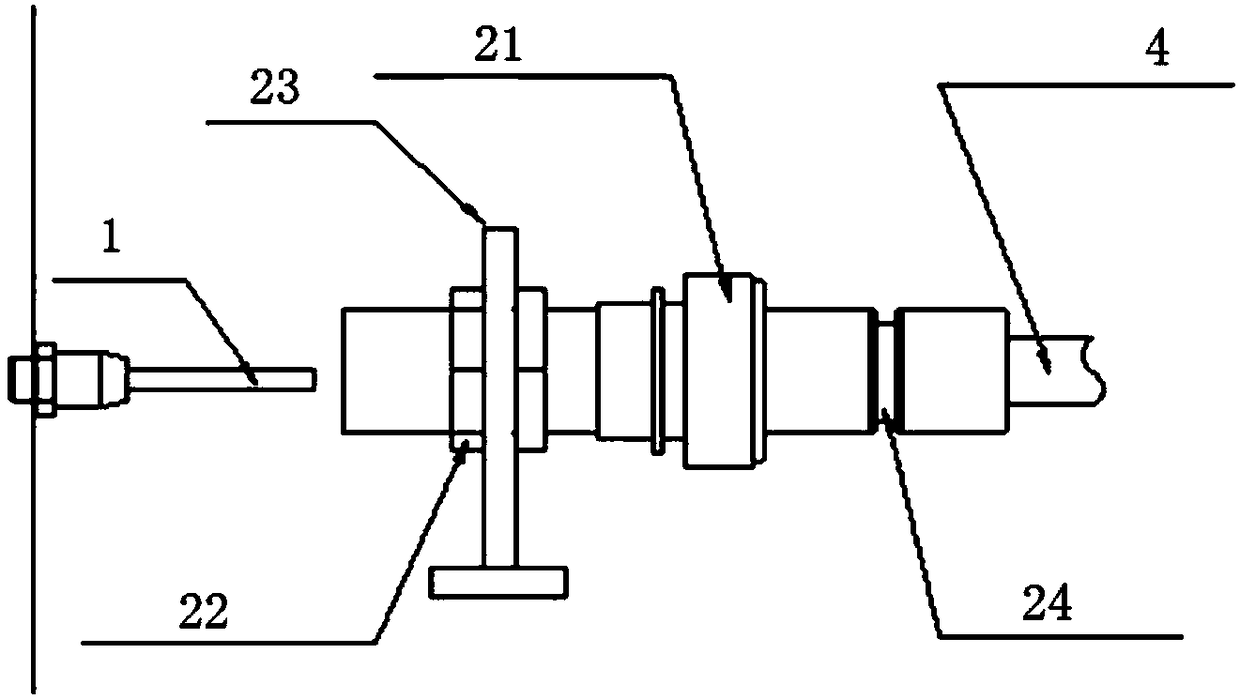

Nuclear power station main pump rotating speed measurement system and method

InactiveCN108107230AAvoid failureAvoid collision riskLinear/angular speed measurementCoaxial cableNuclear engineering

A nuclear power station main pump rotating speed measurement system disclosed by the present invention comprises a target arranged on a main pump and used for following the main pump to rotate; a sensor assembly fixedly arranged on a support in a rotation plane of the target, enabling the target to have a gap with the sensor assembly when the target rotates and enabling the projection not to havethe intersection and used for generating a pulse signal when meeting the target every time; and a rotating speed signal processing module connected with the sensor assembly via three coaxial cables and used for processing the pulse signals and obtaining the rotating speed of the main pump. The present invention also discloses a nuclear power station main pump rotating speed measurement method. According to the present invention, the rotating speed of the main pump can be measured accurately and reliably under a harsh electromagnetic interference environment of a nuclear power station and on the long-distance transmission condition.

Owner:中广核工程有限公司 +1

Analog interface digital control servo amplifier

InactiveCN106483894ARich extension interfaceSimplify the commissioning processProgramme controlComputer controlControl mannerCurrent sensor

A novel analog interface digital control servo amplifier of the invention comprises a digital interface (1), an analog interface (2), a communication circuit (3), a conditioning circuit (4), a current sensor (5), a potentiometer (6), a DSP controller (7), an isolation circuit (8), a pre-driver circuit (9), and a power output circuit (10), wherein the DSP controller (7), the isolation circuit (8), the pre-driver circuit (9) and the power output circuit (10) are connected in series. The technical scheme of the invention is designed based on the fact that the servo control signals of small and medium-sized guided missiles are mainly analog control signals and the advantages in digital circuit control. Compared with a traditional control mode in which an analog circuit is built with an integrated operational amplifier circuit chip, the analog interface digital control servo amplifier has higher adaptability and good performance.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

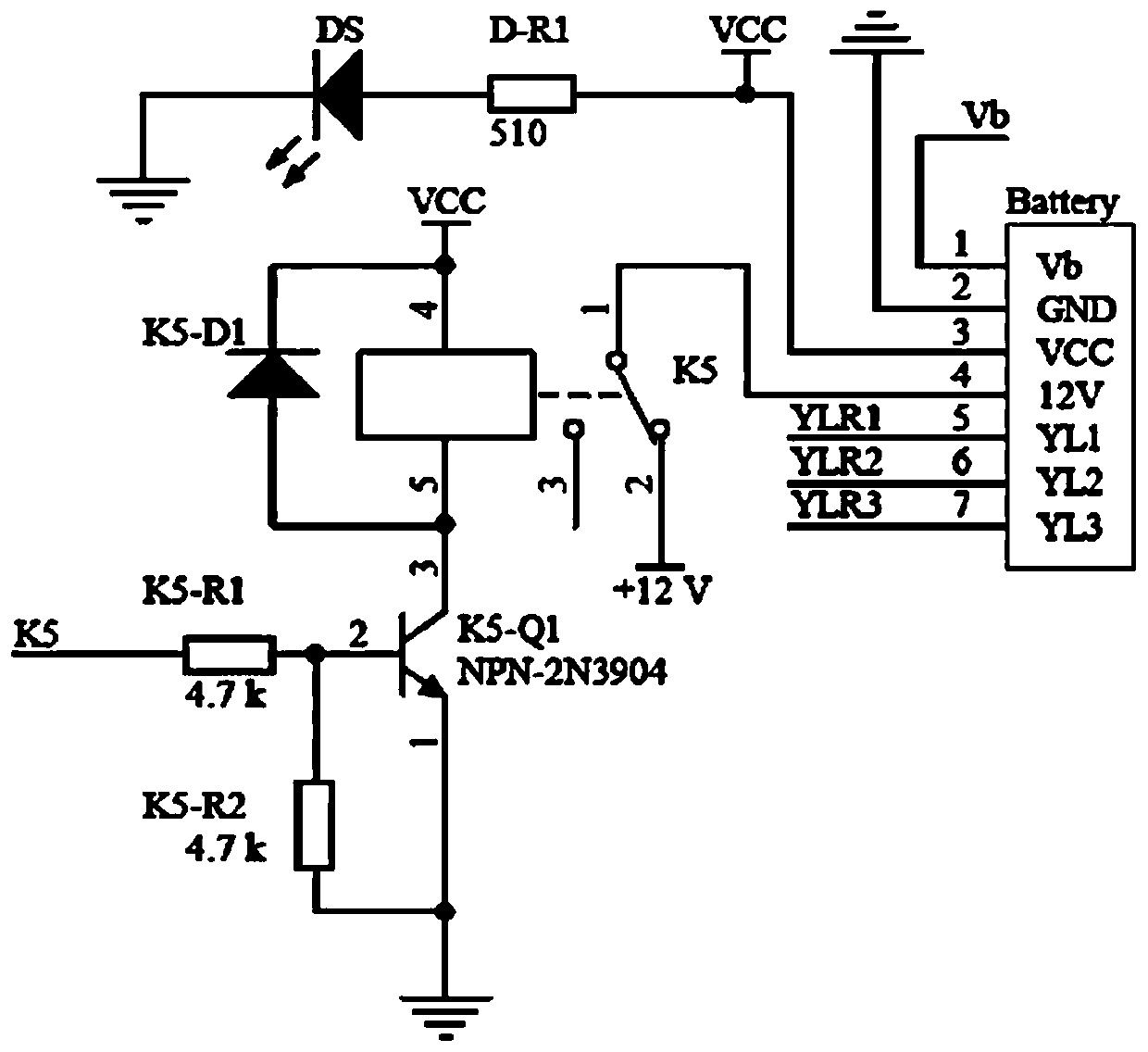

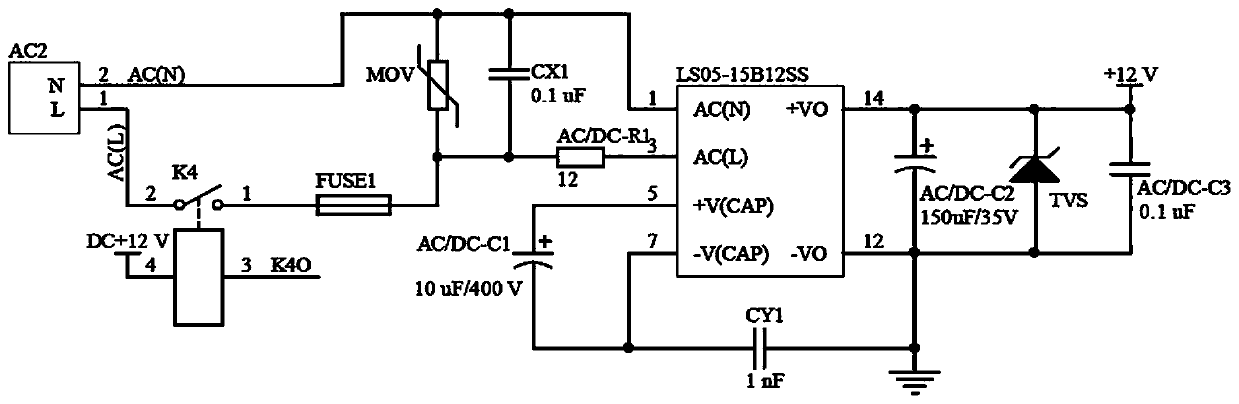

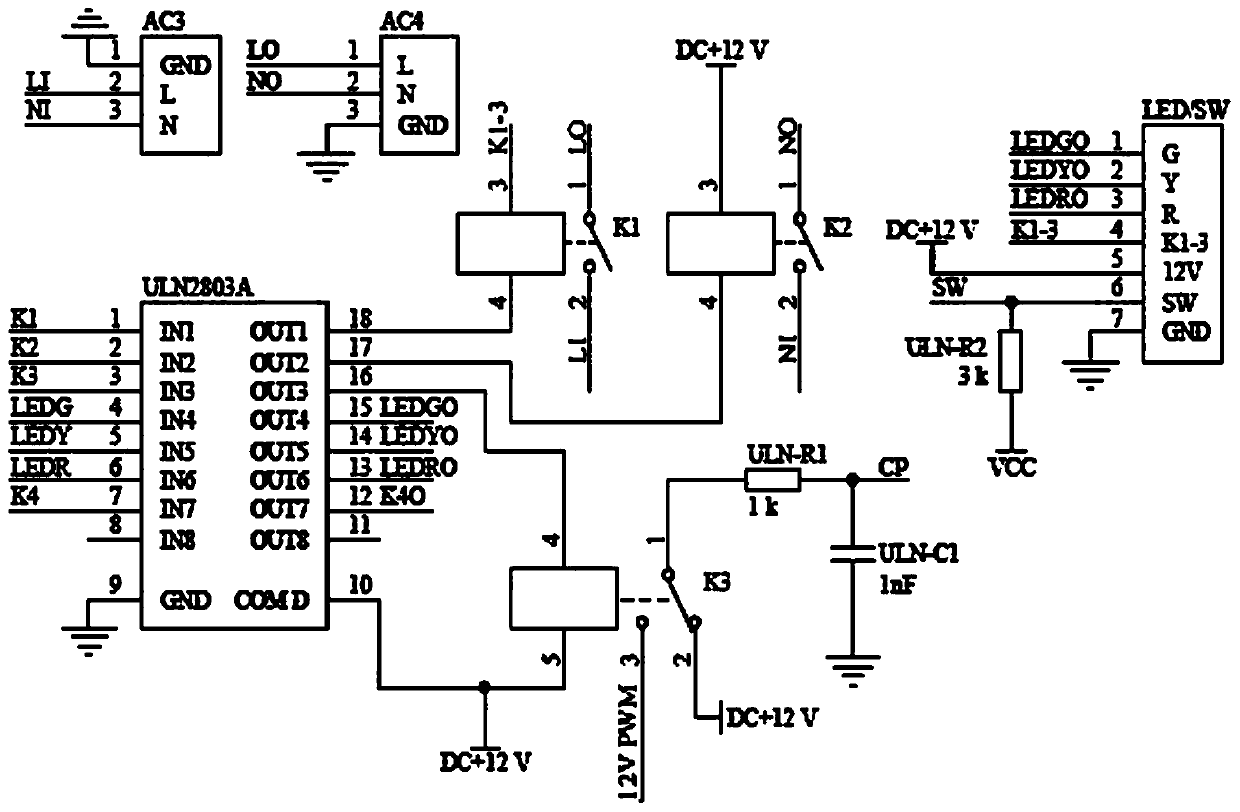

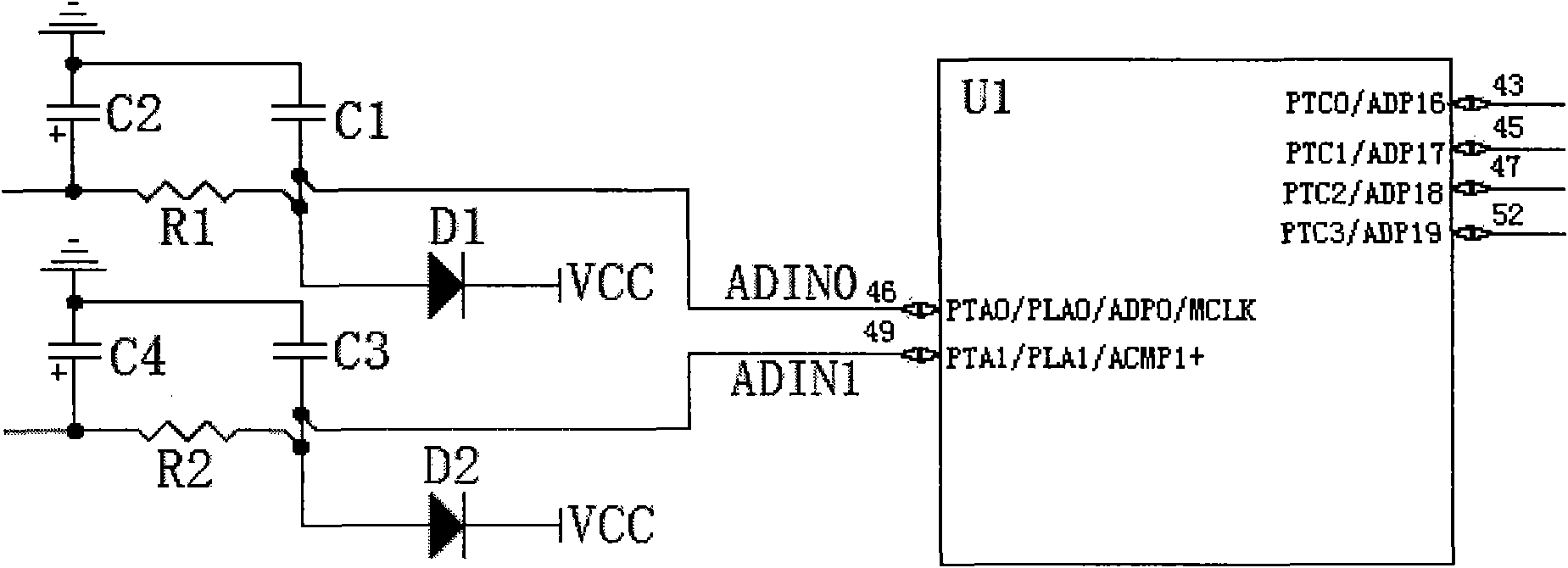

Control system of solar AC charging piles based on HCS08 single-chip microcomputer

ActiveCN109866647ASolve fever problemImprove safety and reliability performanceCharging stationsElectric vehicle charging technologyControl systemLow voltage

The invention discloses a control system of solar AC charging piles based on an HCS08 single-chip microcomputer. The control system uses the HCS08 single-chip microcomputer produced by Freescale as acontroller, and mainly consists of a power supply module, a drive module, a control guiding module, a communication module and a voltage and current detection module. The control system can make corresponding protection and alarm actions according to various conditions occurring in the charging process of electric vehicles. A low-voltage system adopts a two-circuit power supply mode, so that the control system can be powered not only by a power grid but also by a solar panel and a storage battery; and the power supply mode of the low-voltage system can be automatically switched according to the voltage of the storage battery. The AC charging piles in the standby state display the standby state by indicator lights instead of an LCD screen, thereby further reducing the standby power consumption of the AC charging piles. The control system optimizes PWM output and a detection circuit, and effectively reduces the communication error between the AC charging piles and vehicle-mounted chargers.

Owner:JIANGSU UNIV

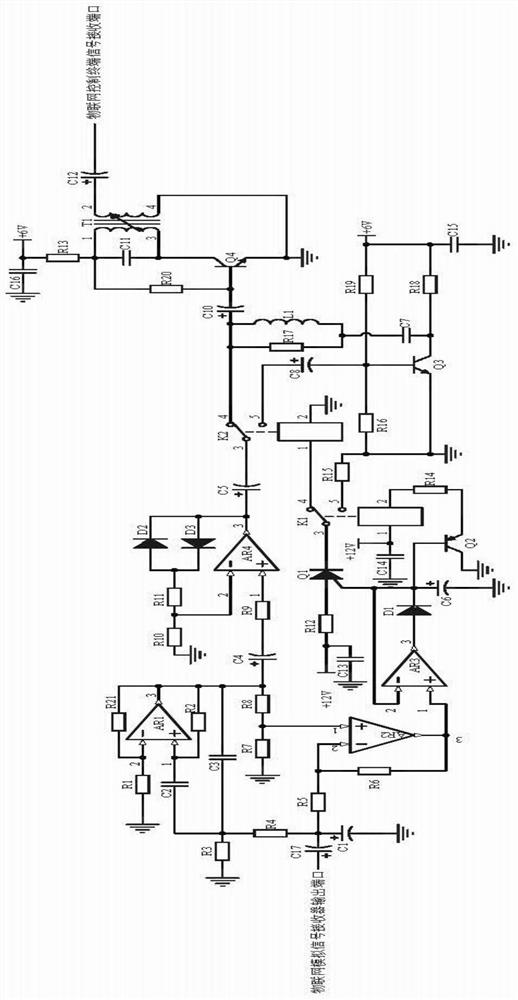

Internet-of-Things signal transmission noise reduction system

InactiveCN112003579AImprove vibrationAccurate resonant frequencyMultiple-port networksElectronic switchingBandpass filteringSilicon-controlled rectifier

The invention discloses an Internet-of-Things signal transmission noise reduction system. The circuit comprises a band-pass filter circuit, a phase detection compensation circuit, an amplitude stabilization circuit and a frequency selection output circuit. Band-pass filtering is carried out on the received analog signal; the amplitude stabilization circuit utilizes the characteristic that the sumof parallel dynamic resistances of a diode D2 and a diode D3 changes along with the current of a feedback loop to adjust the amplification factor of the amplitude stabilization circuit, signal amplitudes are stabilized, the phase detection compensation circuit adopts operational amplifiers AR2 and AR3 to detect signal phase differences before and after band-pass filtering and takes amplitudes of the signal phase differences; the conduction states of the silicon controlled rectifier Q1 and the triode Q2 are controlled; the frequency selection output circuit utilizes parallel resonance of the adjustable transformer T1 and the capacitor C11 to achieve signal frequency selection, noise reduction processing is carried out on analog signals of the Internet of Things, and meanwhile the problem ofsignal distortion caused by nonlinear phase shift of an analog filter is solved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +1

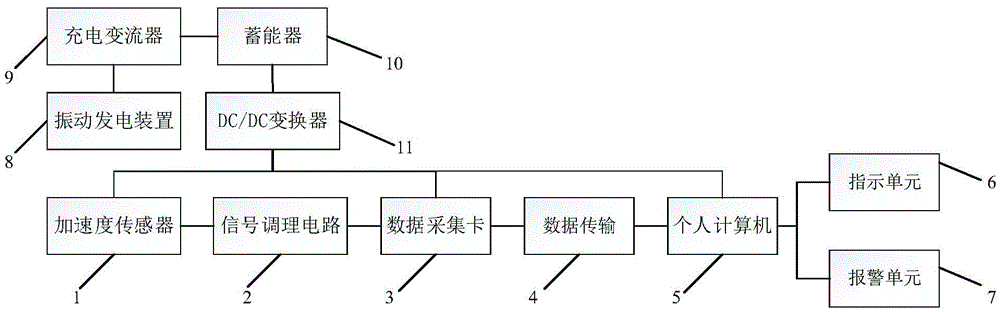

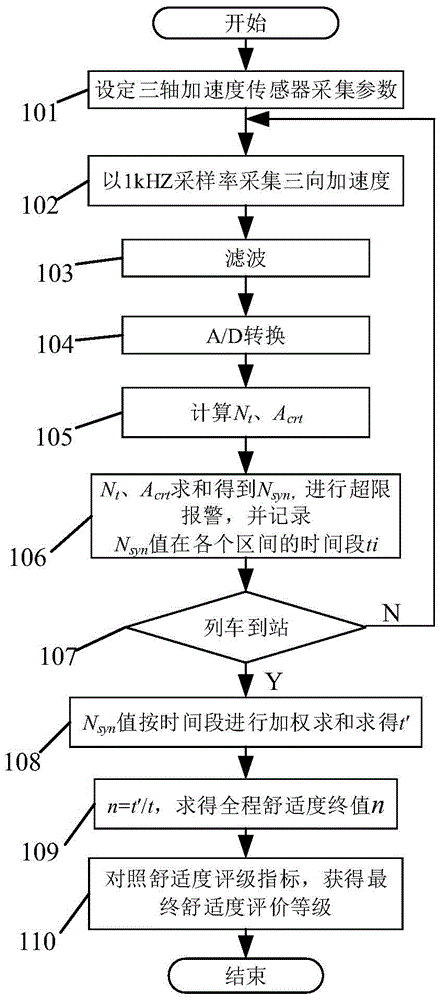

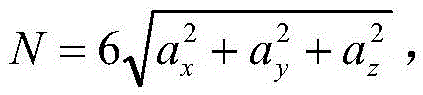

Self-powered urban rail train operation comfort level detecting device based on LabVIEW

InactiveCN105486522AFilter out high frequency noiseRealize digital processingRailway vehicle testingReal-time dataLabview software

The invention relates to a self-powered urban rail train operation comfort level detecting device based on LabVIEW. The self-powered urban rail train operation comfort level detecting device comprises the components of an accelerator sensor (1), a data acquisition unit, a self-powered power supply unit, a data transmission unit (4), a personal computer (5) and an indicating unit (6); wherein the acceleration sensor (1), the data acquisition unit, the self-powered power supply unit and the data transmission unit are mounted in a train compartment; and the personal computer (5) and the indicating unit (6) are mounted in a cab. LabVIEW software is installed on the personal computer (5). The self-powered power supply unit is connected with the acceleration sensor (1), the data acquisition unit and the personal computer (5). The data acquisition unit is connected with the acceleration sensor (1) and the data transmission unit (4). The data transmission unit (4) is connected with the personal computer (5) and the indicating unit (6). Compared with the prior art, the self-powered urban rail train operation comfort level detecting device has advantages of self-powering capability, convenient use, real-time data recording, scientific and reliable detecting result, etc.

Owner:SHANGHAI UNIV OF ENG SCI

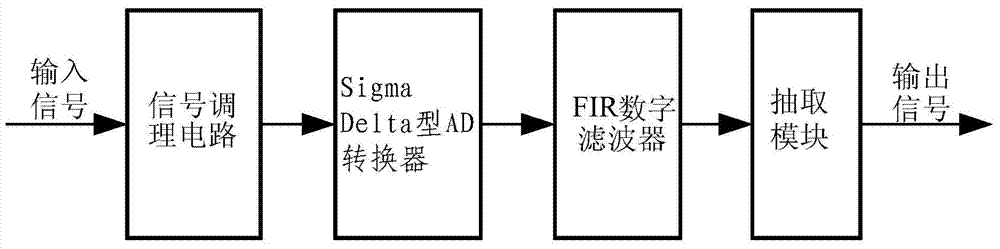

High-precision measuring system and method for mechanical environment parameter of aircraft

InactiveCN104729540AFilter out high frequency noiseHigh measurement accuracyAnalogue-digital convertersSpecial purpose recording/indication apparatusNoise shapingOversampling

The invention discloses a high-precision measuring system and method for the mechanical environment parameter of an aircraft in order to achieve high-precision measuring of the mechanical environment parameter of the aircraft. The method includes the steps that input signals are conditioned first, a Sigma Delta type AD converter is selected to be used for conducting oversampling and noise shaping on the conditioned signals, high-frequency noise can be filtered out by FIR digital filtering, at last, the data output rate requirement is guaranteed through an extracting technology, and high-precision measuring of the mechanical environment parameter of the aircraft is achieved.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

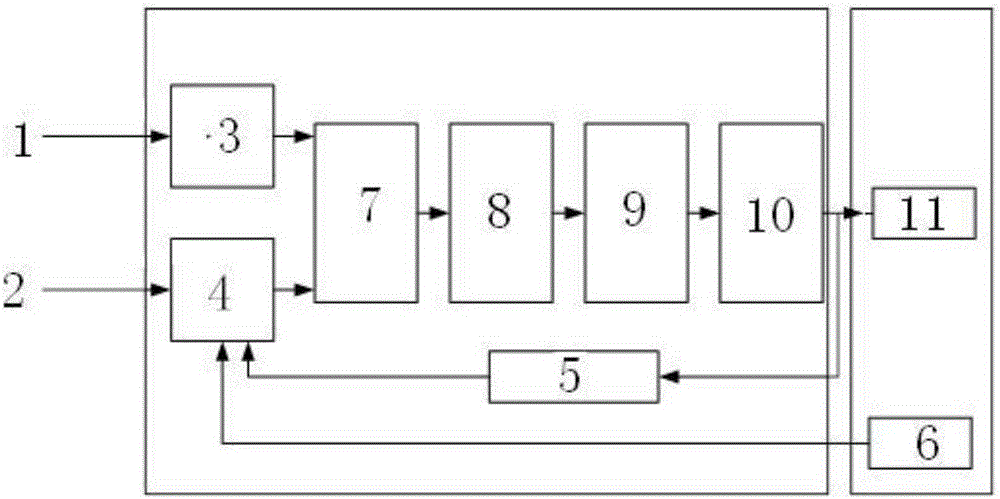

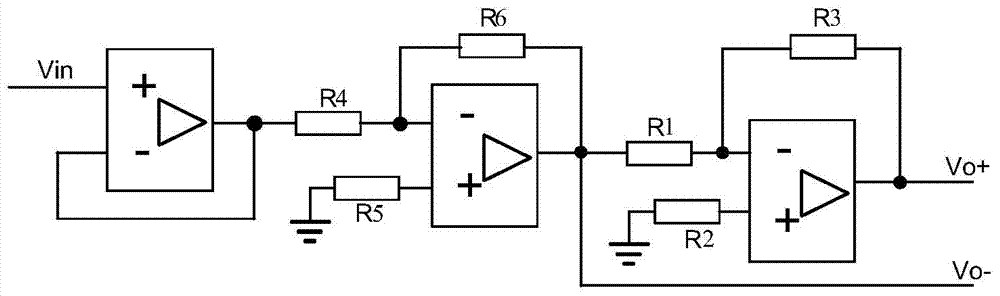

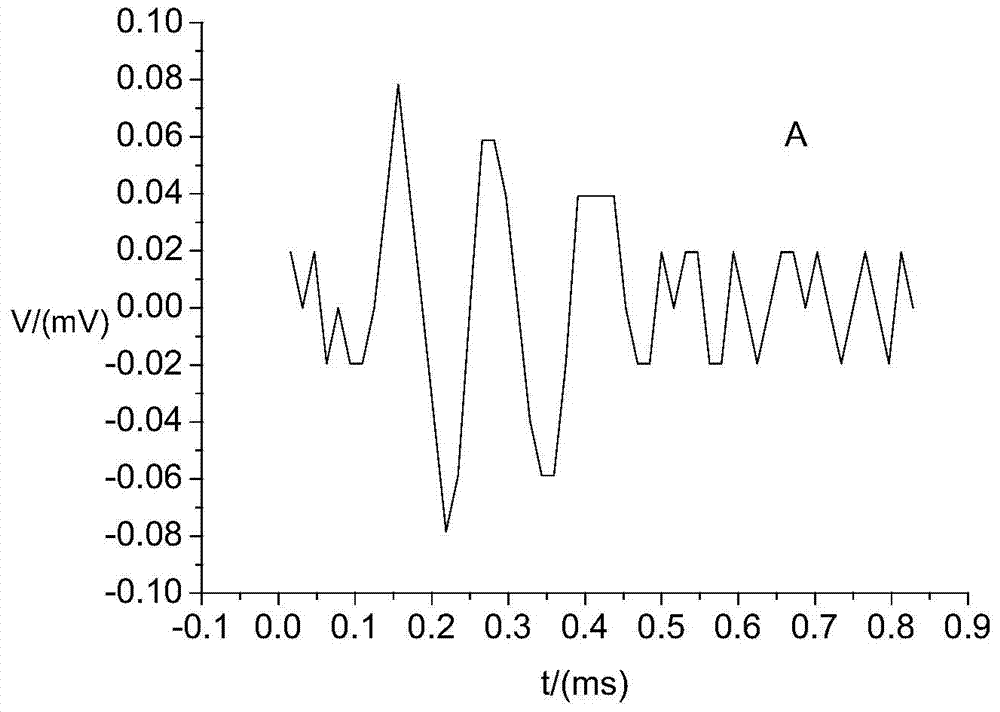

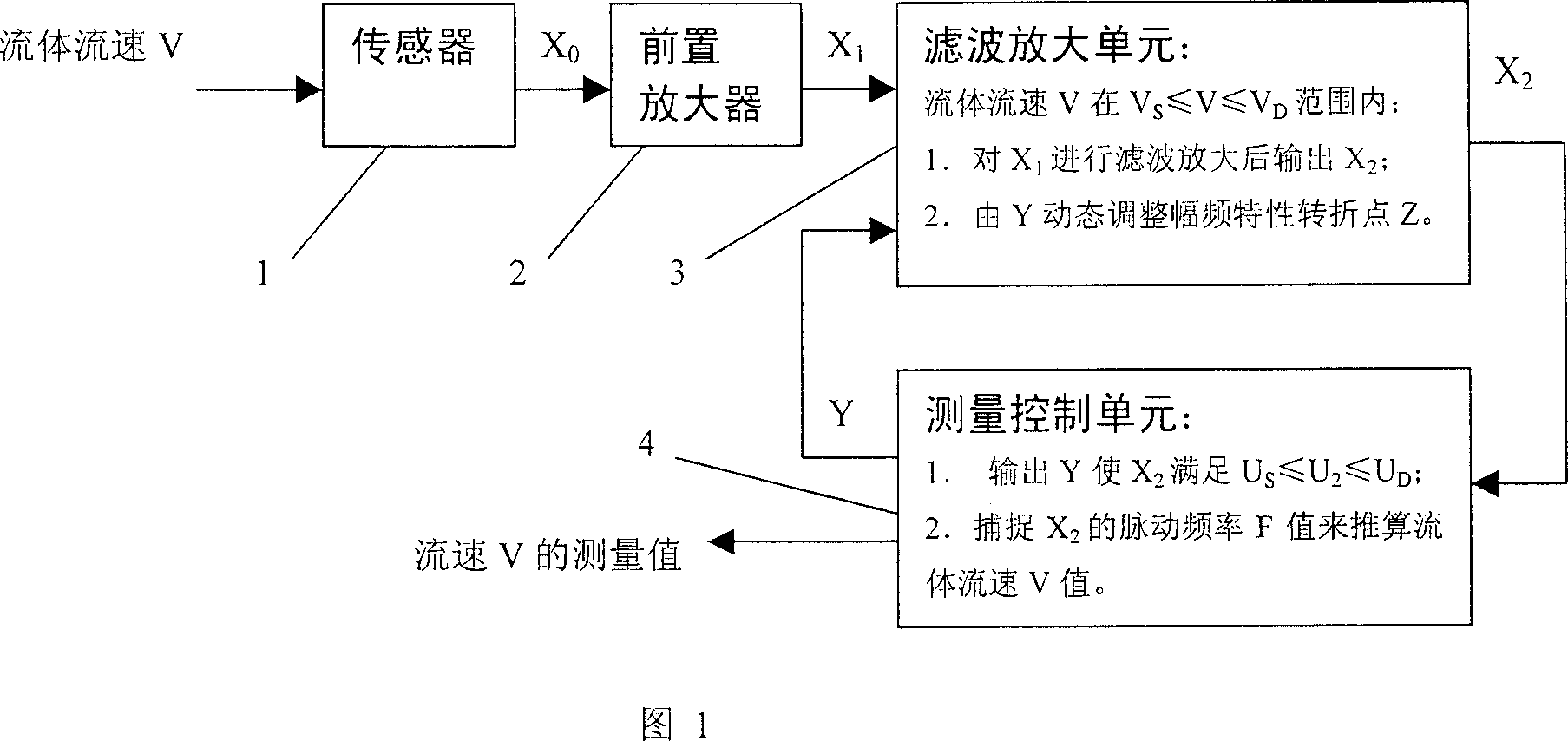

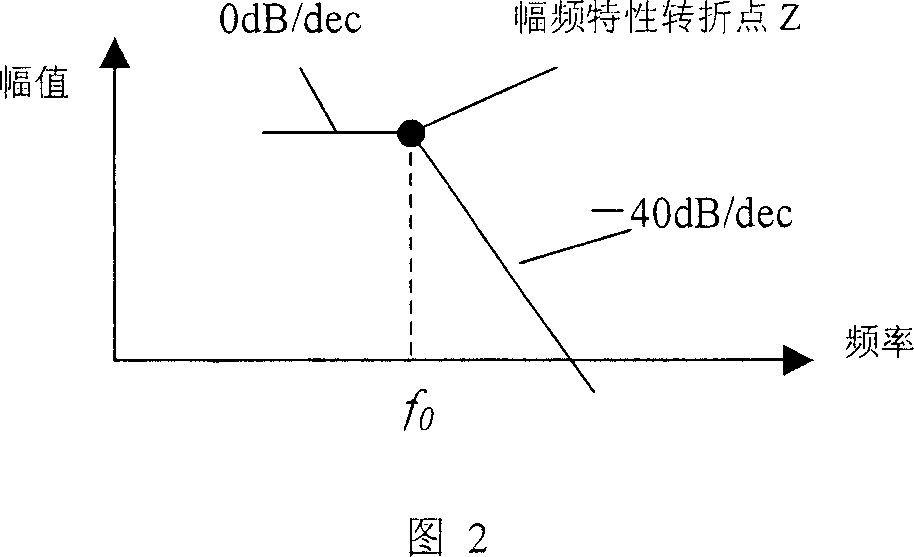

Signal processing method and system of vortex street flowmeter

InactiveCN1928506AAccurate captureReduce power consumptionVolume/mass flow by dynamic fluid flow effectAudio power amplifierLow-pass filter

The related signal processing method with vortex shedding flowmeter dynamic adjusts the amplitude-frequency characteristics break over point Z of filter amplifier to control the dynamic range of signal pulse amplitude and eliminate high-frequency interference noise and inhibit low-frequency swing noise. This invention can work well on 4-20mA low-consumption two-wire system.

Owner:李斌

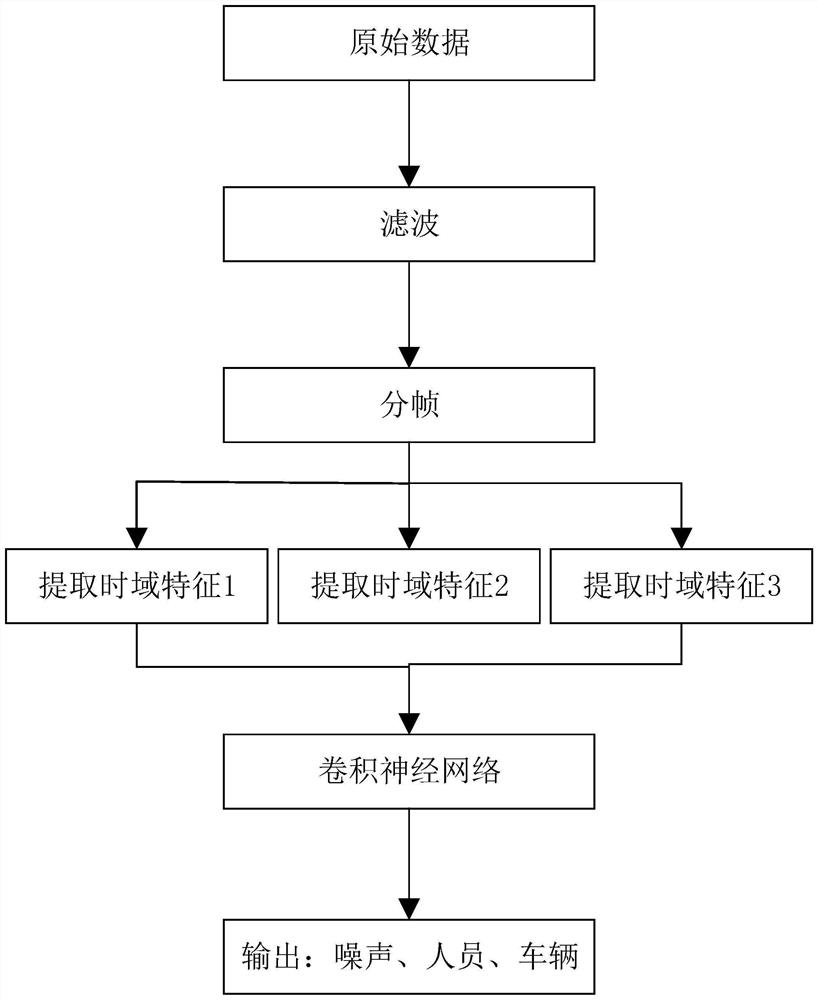

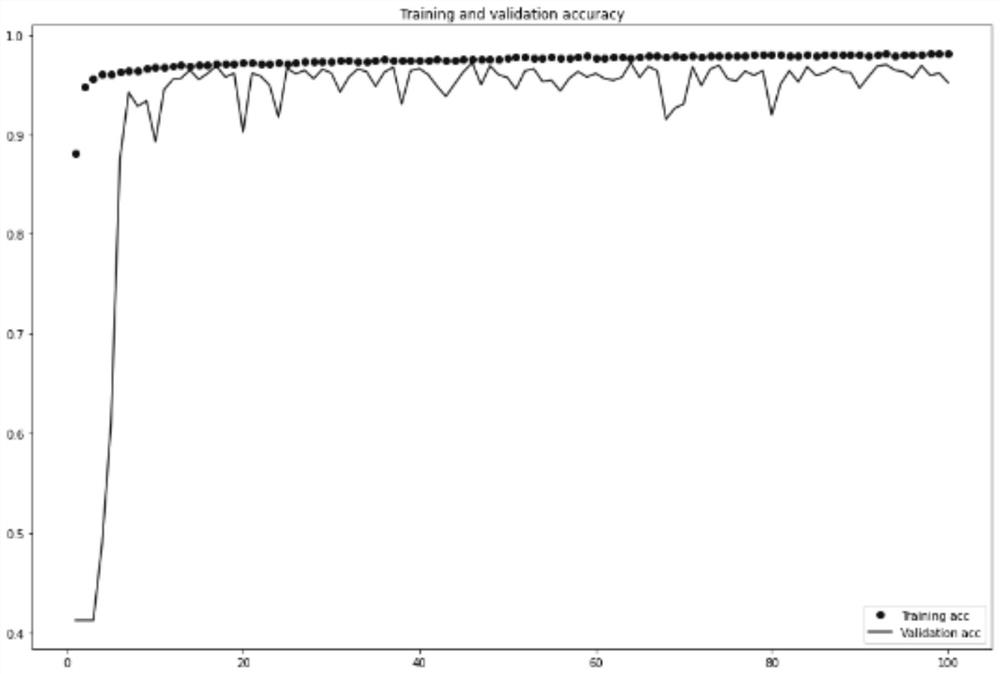

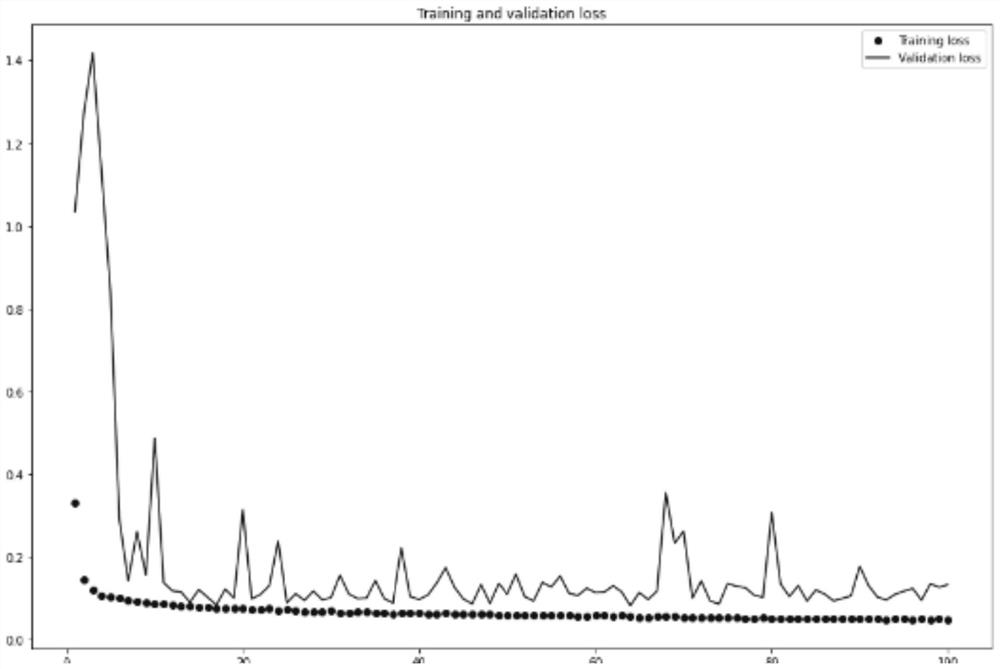

Multi-category target recognition method and system for unattended sensor system

PendingCN113283331ALess input dataUniversalCharacter and pattern recognitionNeural architecturesTime domainFeature extraction

The invention discloses a multi-category target recognition method and system for an unattended sensor system. The method comprises the following steps: S1, data preprocessing: framing original data collected by unattended sensor equipment; s2, signal feature extraction: extracting multiple segments of independent time domain features of the framed data at the same time; s3, convolutional neural network model training: taking the multiple segments of independent time domain features obtained in the step S2 as training samples, inputting the training samples into a convolutional neural network for training, and establishing a convolutional neural network model; and S4, signal recognition: recognizing the signal through the convolutional neural network model established in the step S3 to obtain an recognition result. The invention has the advantages of being easy and convenient to operate, small in calculation amount, high in recognition rate, capable of being applied to an embedded system and the like.

Owner:长沙融创智胜电子科技有限公司

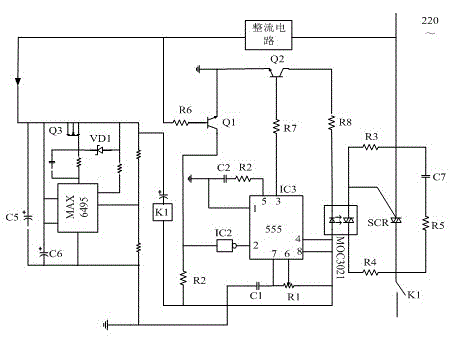

Zero-crossing protection circuit for switching power supply

InactiveCN105071348AImprove work efficiencyFilter out high frequency noiseEmergency protective circuit arrangementsSilicon-controlled rectifierDIAC

The invention discloses a zero-crossing protection circuit for a switching power supply, and includes a zero sequence detection module, a delay control module and a bidirectional silicon controlled rectifier connected on an alternating current loop. The zero sequence detection module includes a rectification circuit, a first triode and a phase inverter, an input end of the rectification circuit is connected on the alternating current loop, an output end is connected on a base electrode of the first triode, an emitting electrode of the first triode is connected on an input end of the phase inverter, the delay control module includes a 555 timing chip, an output end of the 555 timing chip is connected on a base electrode of a second triode, the first triode and the second triode form an independent electrical signal loop, a photoelectric coupler is connected in series between the first triode and the second triode, and an output end of the photoelectric coupler is connected on a control electrode of the bidirectional silicon controlled rectifier. The zero-crossing protection circuit for the switching power supply has the beneficial effect that a phenomenon that originally alternating current is directly connected and an electrical element is subjected to impact of alternating current instantaneous current can be prevented.

Owner:重庆市志益鑫电子科技有限公司

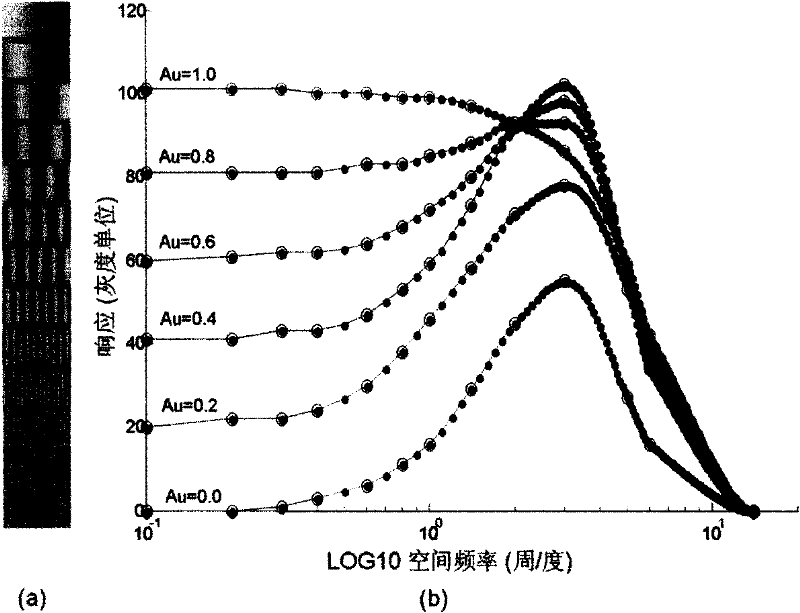

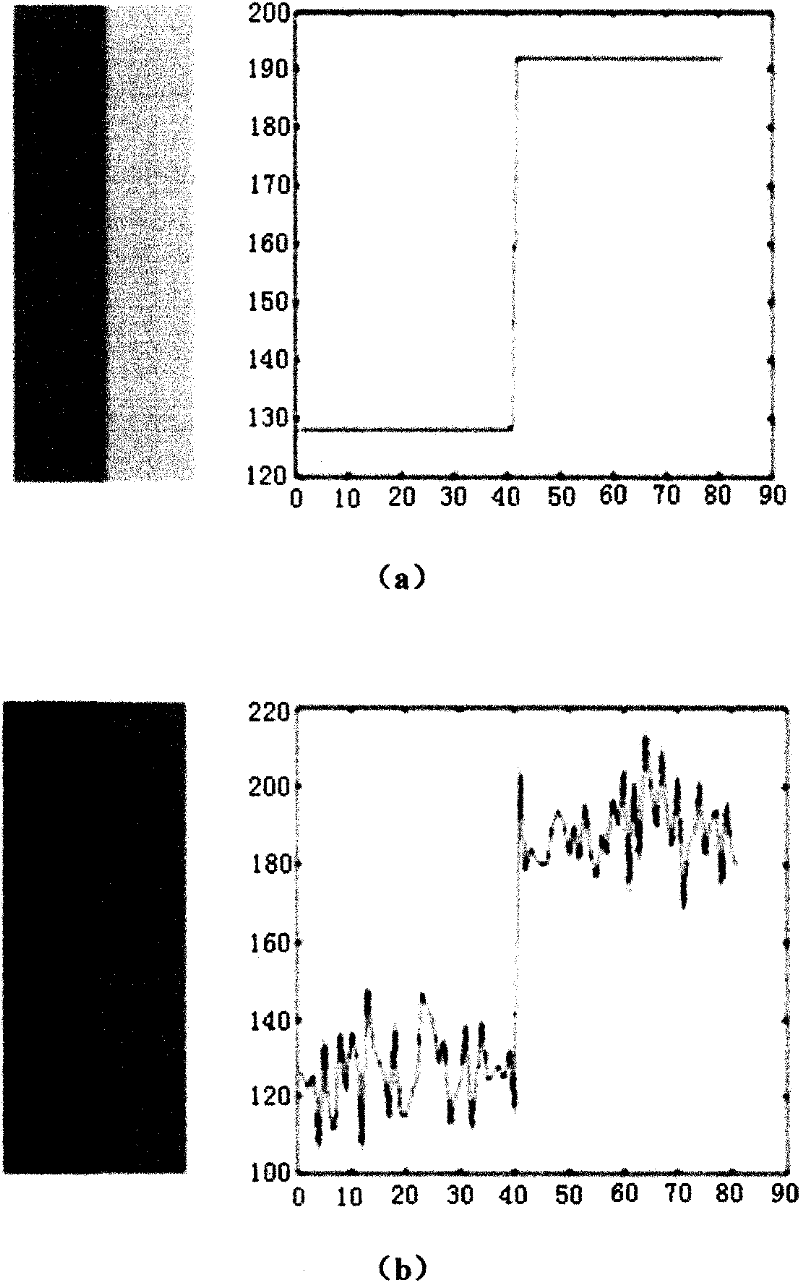

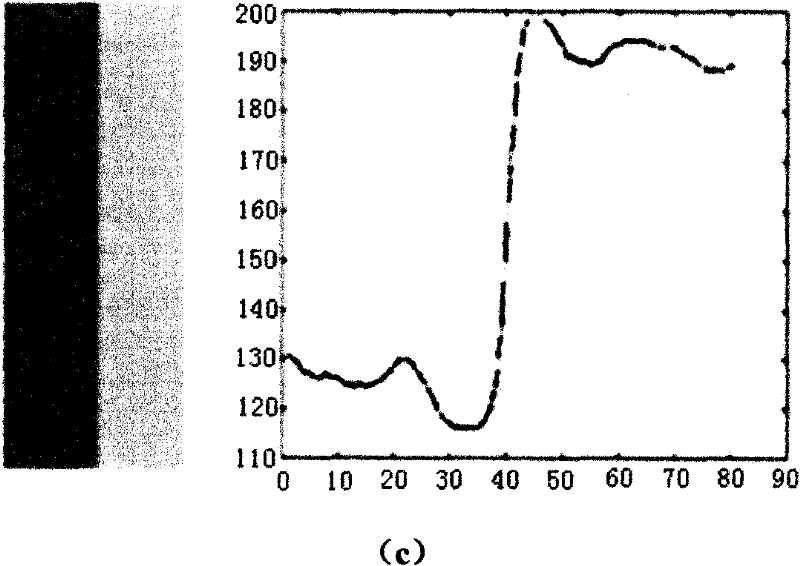

Image denoising method based on visual non-classical receptive field model

InactiveCN101930592BFilter out high frequency noiseKeep detailsImage enhancementBiological neural network modelsPattern recognitionImage denoising

The invention discloses an image denoising method based on a visual non-classical receptive field model, belonging to the technical field of image processing, and relating to an image denoising method. Based on the newest optic nerve electrophysiology research result, the invention simulates the retina visual mechanism of human eyes, builds a visual non-classical receptive field model and realizes the image denoising processing. The invention not only can remove common noise in the image processing process and has the function of strengthening image edge details. Mass biology experiment result stimulation and practical image denoising experiments prove the accuracy and the effectiveness of the invention.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

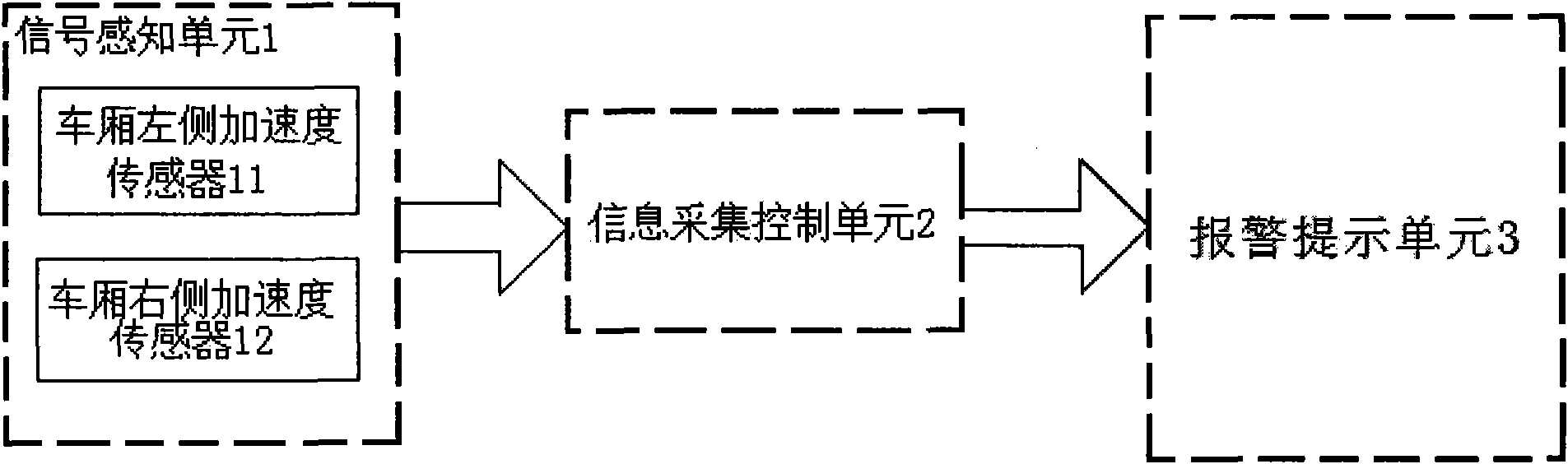

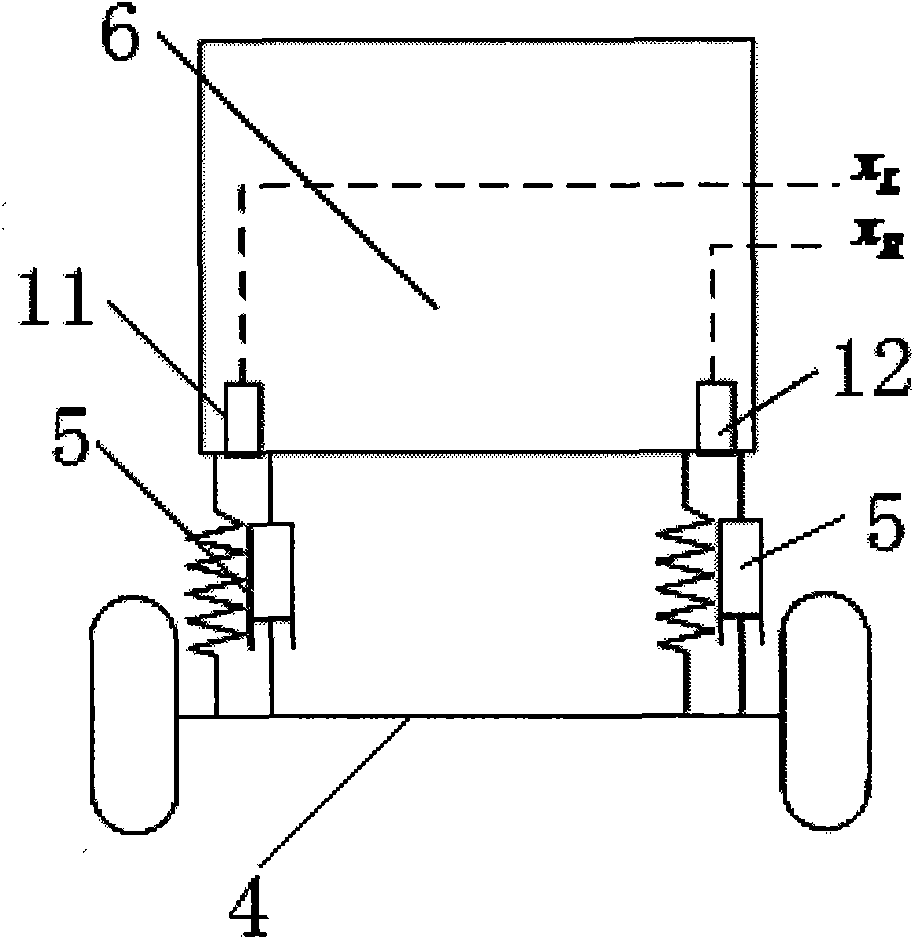

Method and warning system for unbalanced loading dynamic detection for truck

InactiveCN101614754AEasy to installImprove reliabilityProgramme controlComputer controlMicrocontrollerSimulation

The invention relates to a method and a warning system for unbalanced loading dynamic detection for a truck. The method comprises the following steps that: 1) the warning system for unbalanced loading dynamic detection for the truck is set, and the warning system comprises a signal sensing unit comprising a left acceleration sensor and a right acceleration sensor, an information acquisition control unit comprising a singlechip, and a warning prompt unit; the singlechip comprises two A / D conversion circuits and an unbalanced loading dynamic detection module; and an unbalanced loading warning threshold value and an unbalanced loading warning range are preset in the unbalanced loading dynamic detection module; 2) the left acceleration sensor and the right acceleration sensor acquire left and right acceleration signals of the truck; 3) the unbalanced loading dynamic detection module calculates the unbalanced loading coefficient of the truck; 4) the unbalanced loading dynamic detection module sends out corresponding warning signals to the warning prompt unit according to the calculated difference of the unbalanced loading coefficient of the truck and the preset unbalanced loading warning threshold value and by combining the preset unbalanced loading warning range; and 5) after the unbalanced loading dynamic detection module finishes unbalanced loading warning, the method returns to the step 2). The method and the warning system have high reliability and wide application, and can actively, accurately and timely provide unbalanced loading warning information of the truck during the transportation of the truck.

Owner:TSINGHUA UNIV

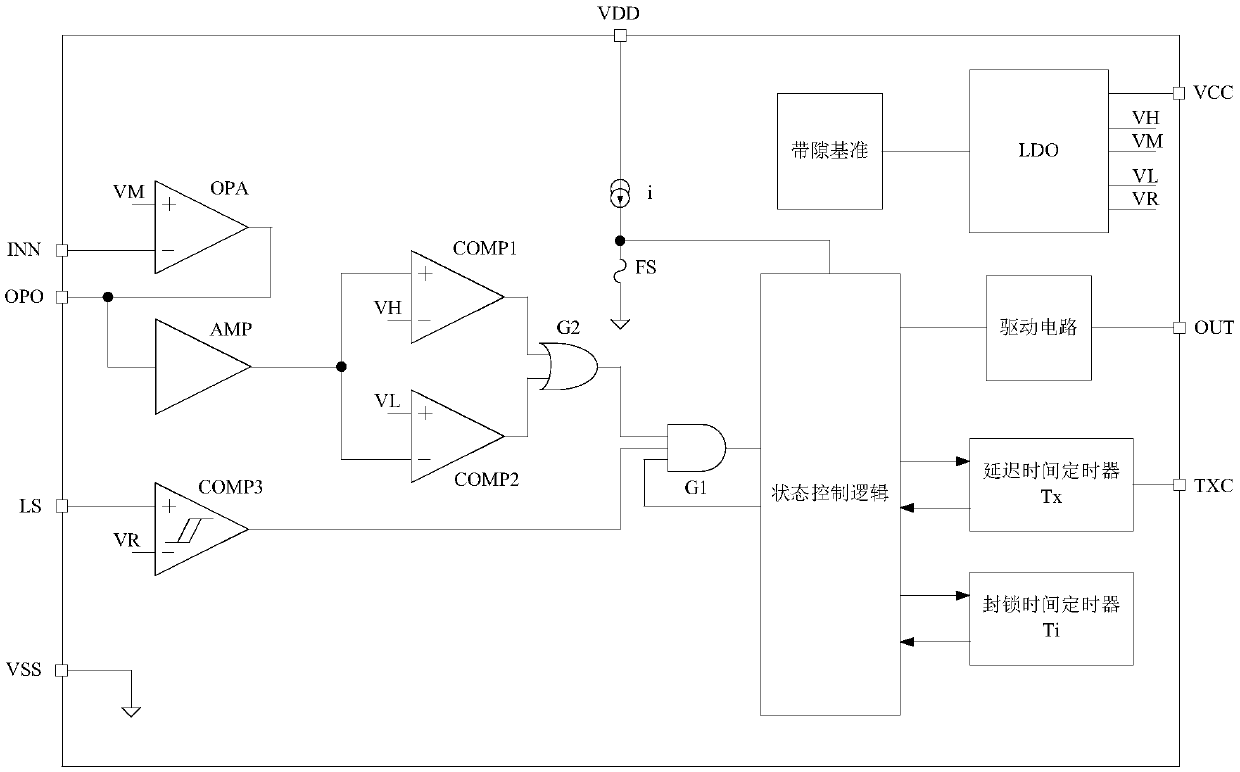

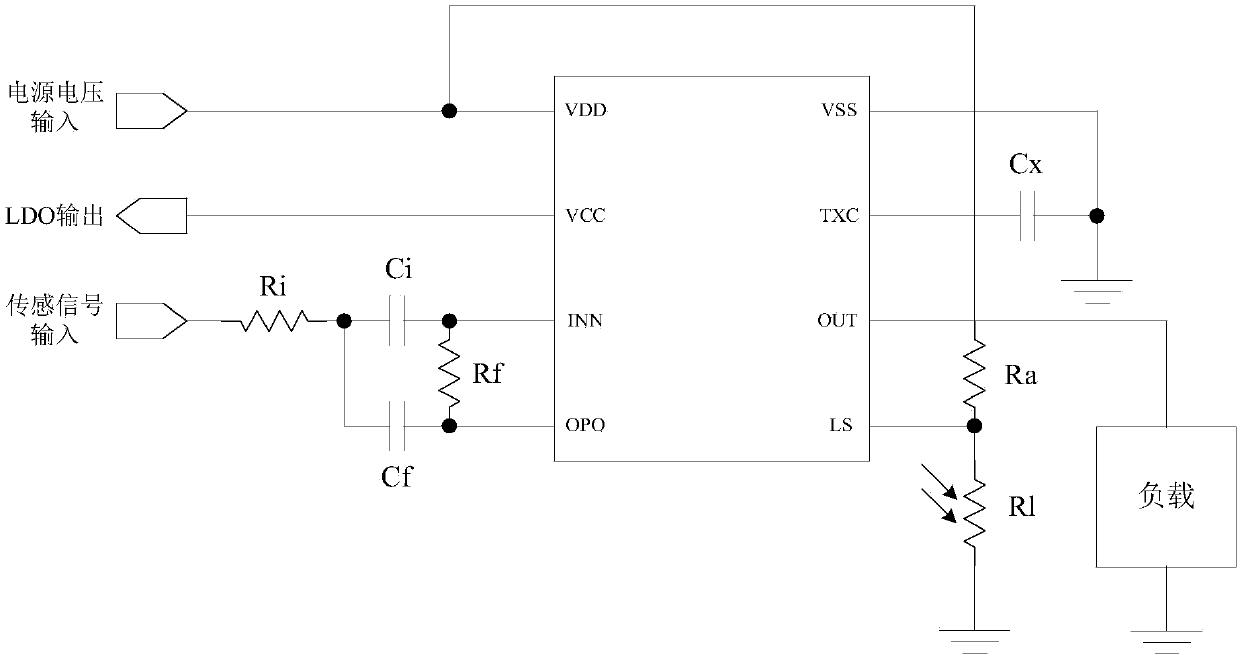

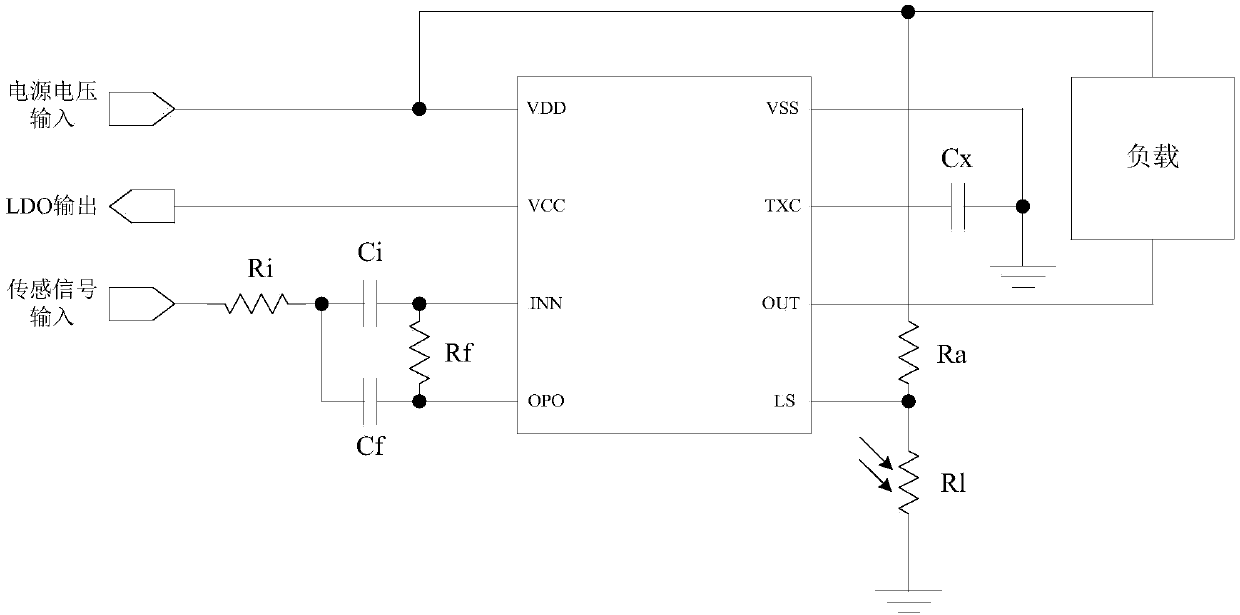

Detection of low-frequency signal processing chip and low-frequency signal processing circuit

ActiveCN108681361AEffectively filter out low-frequency fluctuationsAvoid false triggersElectric variable regulationLinear regulatorSignal processing circuits

The invention relates to detection of low-frequency signal processing chip and low-frequency signal processing circuit. The detection of low-frequency signal processing chip comprises a VDD pin, a VCCpin, an OUT pin, a TXC pin, a VSS pin, an LS pin, an OPO pin and an INN pin; the VCC pin is electrically connected with the band-gap reference circuit through a low-dropout linear regulator LDO circuit; the INN pin is connected with the negative electrode of an operational amplifier OPA, the OPO pin is connected with the output end of the operational amplifier OPA, a fixed gain amplifier AMP is connected between the OPO pin and the output end of the operational amplifier OPA, the output of the fixed gain amplifier AMP is connected to the positive electrode of a comparator COMP1 and the negative electrode of a comparator COMP2. The chip integration level is high, the peripheral circuit is simple, the peripheral components are small, the miniaturization is convenient, the system is low in cost, the anti-interference capability is strong, the error is not triggered, and the installation and debugging are convenient.

Owner:QX MICRO DEVICES

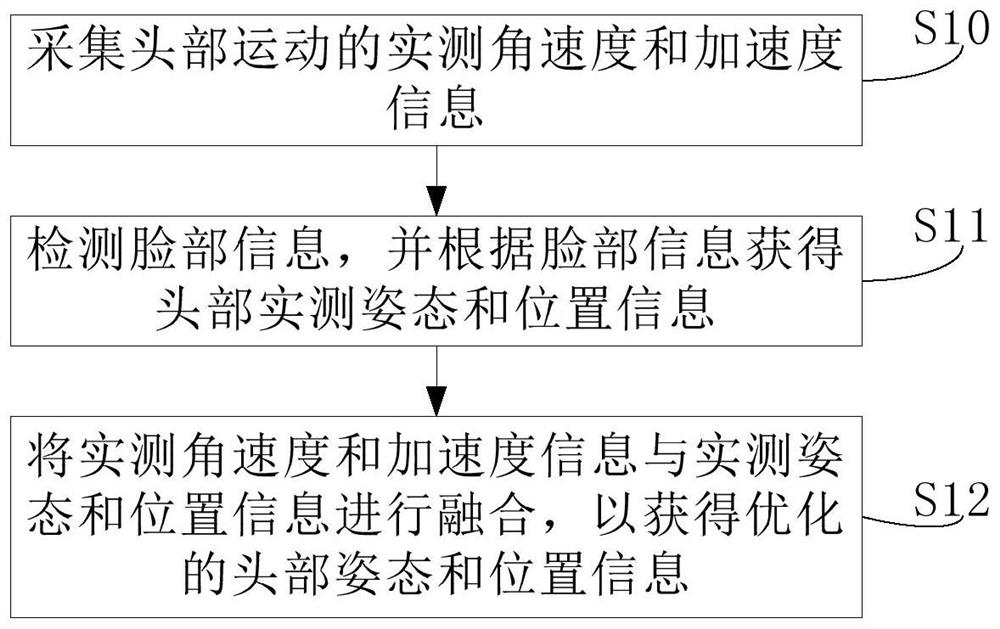

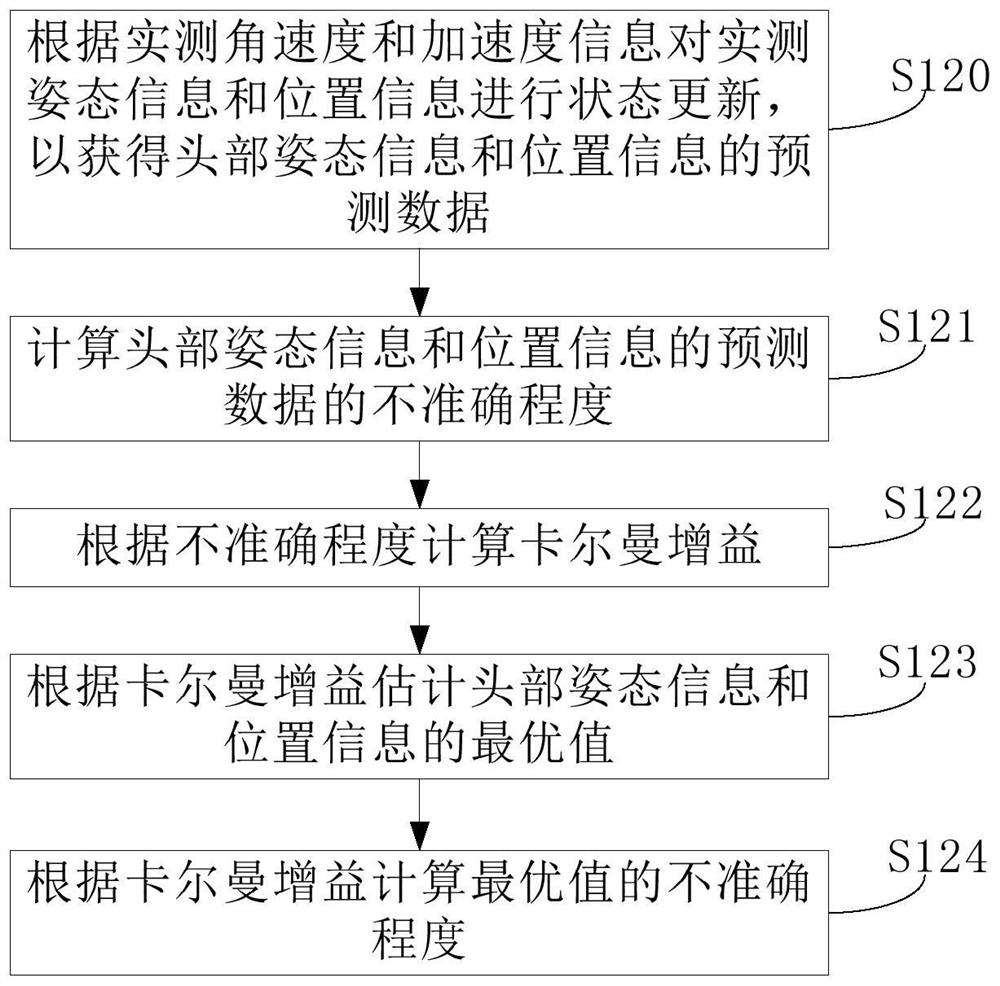

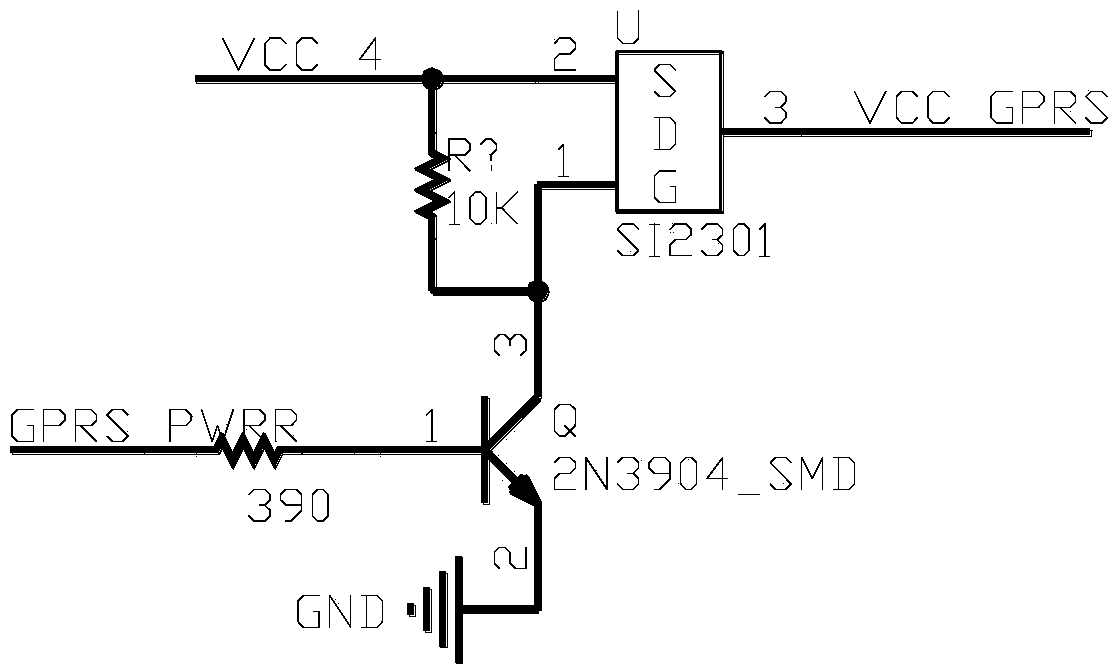

A head motion tracking method and system

PendingCN111723624AOptimize head pose and position informationImprove accuracyCharacter and pattern recognitionPhysicsHead movements

The invention provides a head movement tracking method and system. The method comprises the following steps: acquiring actually measured angular velocity and acceleration information of head movement;detecting face information, and obtaining actually measured posture and position information of the head according to the face information; and fusing the actually measured angular velocity and acceleration information of the head with the actually measured attitude and position information to obtain optimized head attitude and position information. According to the method, auxiliary correction of actually-measured attitude and position information by actually-measured angular velocity and acceleration information can be realized; therefore, optimized head posture and position information areobtained; compared with the actual measurement attitude and position information of the head, the optimized attitude and position information can obtain a higher frame rate, and inherent high-frequency noise of the actual measurement attitude and position information is filtered out, so that the phenomena of scene lag, jumping and the like of head motion tracking are avoided, and the accuracy andstability of head motion tracking are improved.

Owner:BOE TECH GRP CO LTD +1

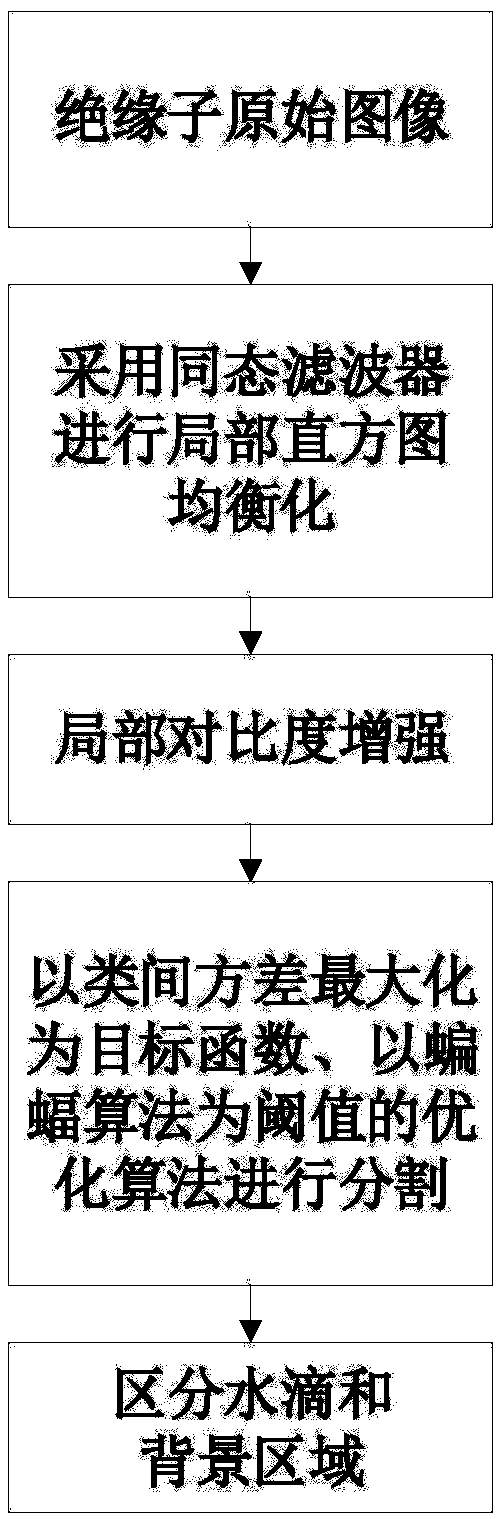

An insulator hydrophobic image segmentation device and method

PendingCN109285171AFilter out high frequency noiseAvoid lossImage enhancementImage analysisHead shakingBat algorithm

An insulator hydrophobic image segmentation device and method includes such step as equalizing local histogram of hydrophobic image by homomorphic filter; then the local contrast of the hydrophobic image is enhanced. Finally, the target region and background region of the hydrophobic image are used as the objective function to maximize the variance between classes, and the bat algorithm is used asthe threshold optimization algorithm for the adaptive threshold selection of the hydrophobic image segmentation, to achieve the hydrophobic image segmentation of insulators; an insulator hydrophobicimage segmentation device comprises a single chip microcomputer module, a head shaking steering engine, a head nodding steering engine, a DC water pump, an nRF24L01 wireless module and a power management module. The technical method and the device of the invention can better distinguish the background area and the water droplet area of the insulator, and provide a good basis for the classificationof the hydrophobic grade of the insulator.

Owner:STATE GRID GASU ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com