Patents

Literature

36 results about "Amantidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

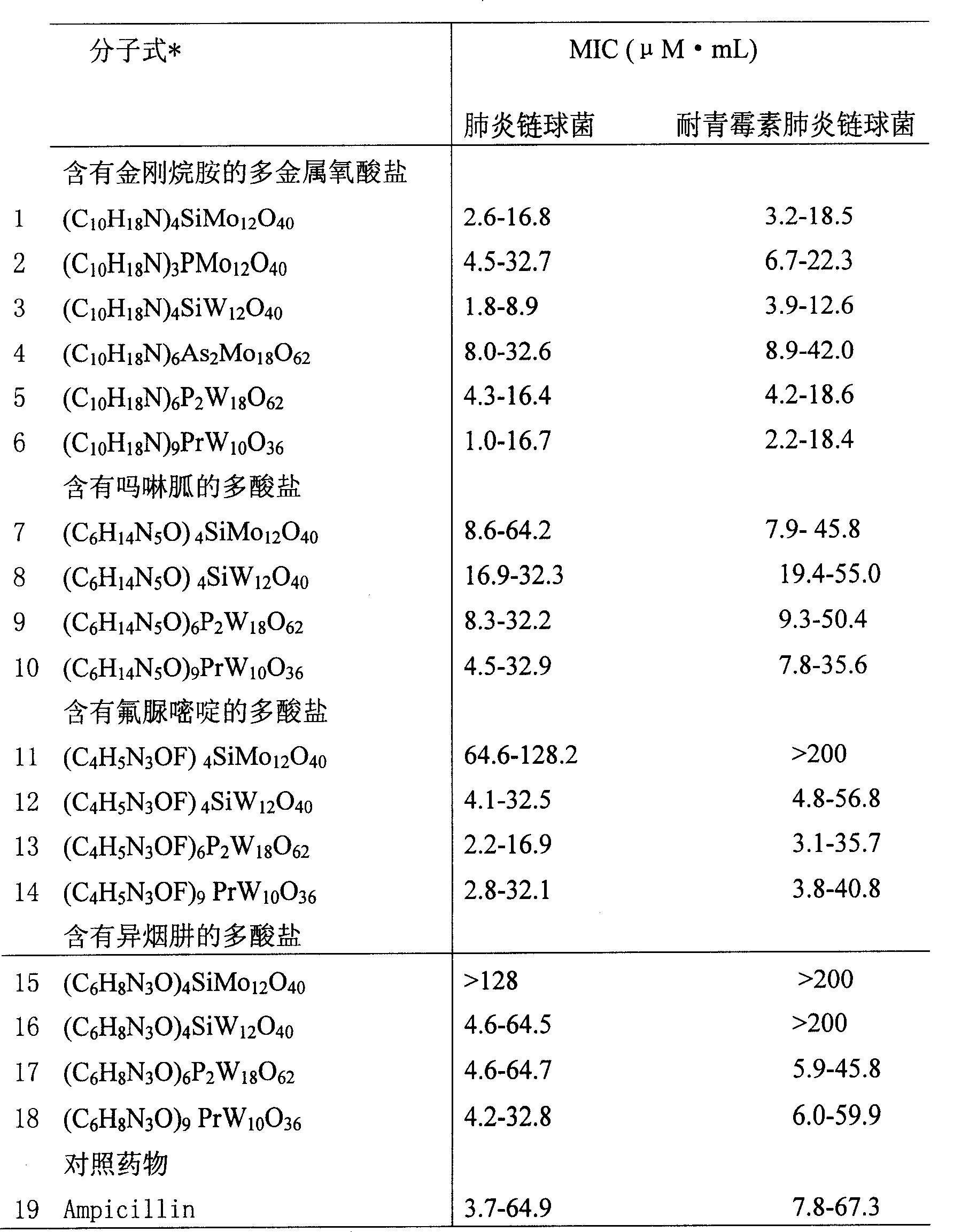

Polyacid compound for resisting penicillin streptococcus pneumoniae (PRSP) and its preparing method

InactiveCN1616466AAntibacterial agentsPhosphorous compound active ingredientsChemical synthesisMoroxydine

The present invention belongs to the field of chemically synthesized medicine and its preparation process. The medicine of the present invention is synthesized with amantadine, moroxydine, 5-Fu (5-Fc), isoniazid and other clinical medicine and polyoxometallate, and through self-assembling. The said polyoxometallate includes heteropoly acid salts of Keggin type with chemical expression XM12O40n-, Dowson type X2M18O62n- and of chemical expression LnW10O36n-. The combined use of said medicines and polyoxometallate has obvious curative effect on intractable streptococcus pneumoniae infection.

Owner:NORTHEAST NORMAL UNIVERSITY

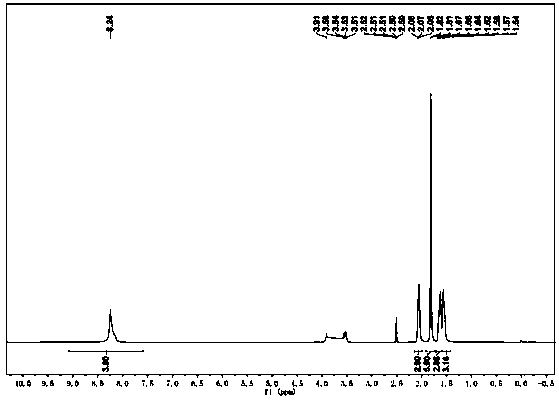

Process for preparing amantadine hydrochloride with high yield

InactiveCN105348111AReduce harmEnvironment-friendlyOrganic compound preparationCarboxylic acid amides preparationAmmoniaPhase-transfer catalyst

The invention discloses a process for preparing amantadine hydrochloride with high yield. The process comprises the steps of (1) preparing 1-acetamidoadamantane; and (2) preparing amantadine hydrochloride. By using the process, amantadine hydrochloride is prepared in one reaction kettle, so that the operation step is simplified; in addition, the reaction effect is promoted due to the adoption of a phase-transfer catalyst, the conversion rate and yield of the reaction can be increased due to the adoption of a solvent system selected after screening, and the cost, energy consumption and environment pollution are reduced.

Owner:天津民祥生物医药股份有限公司

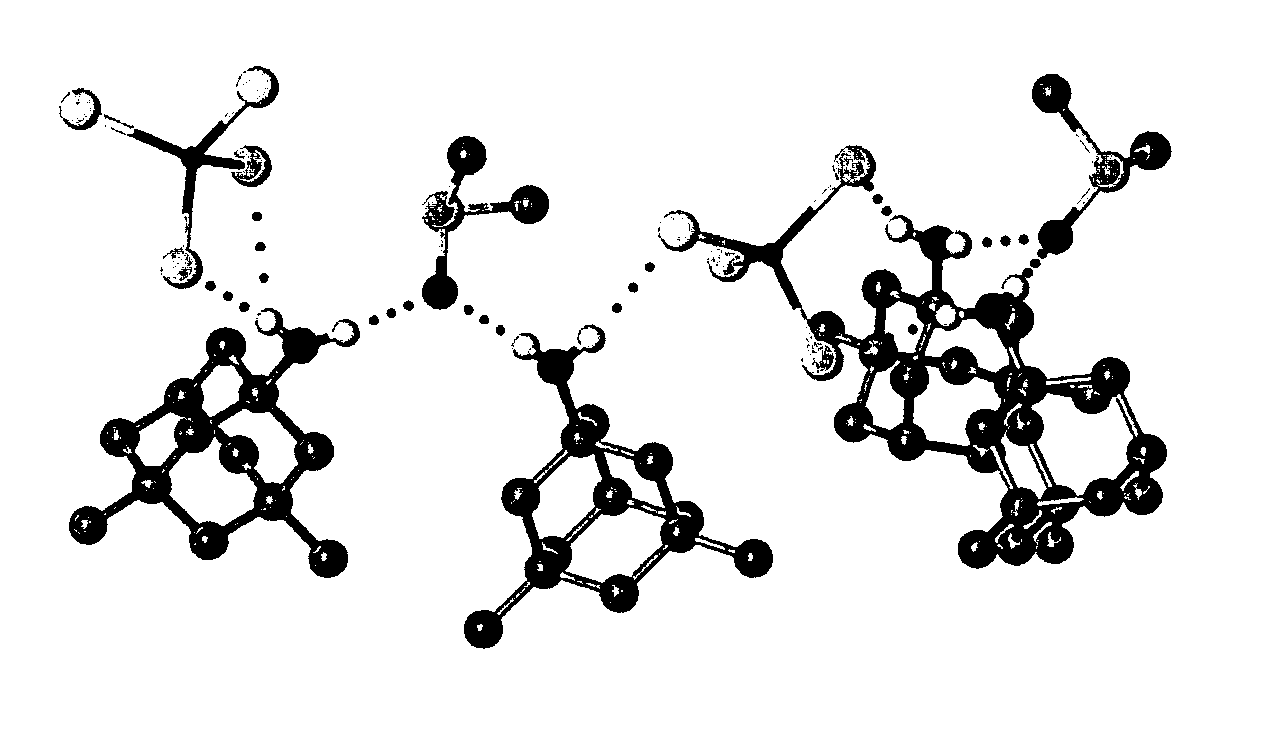

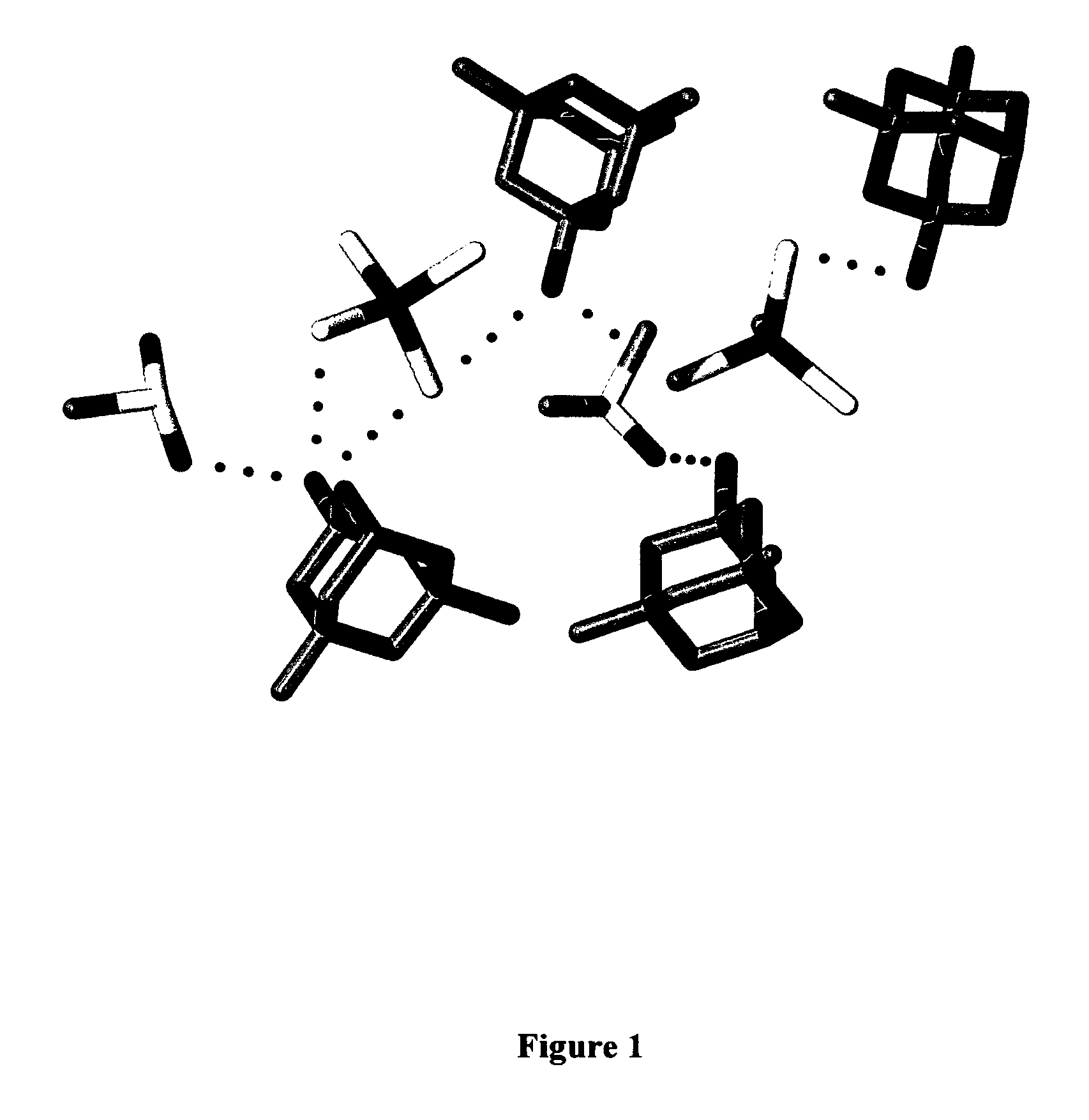

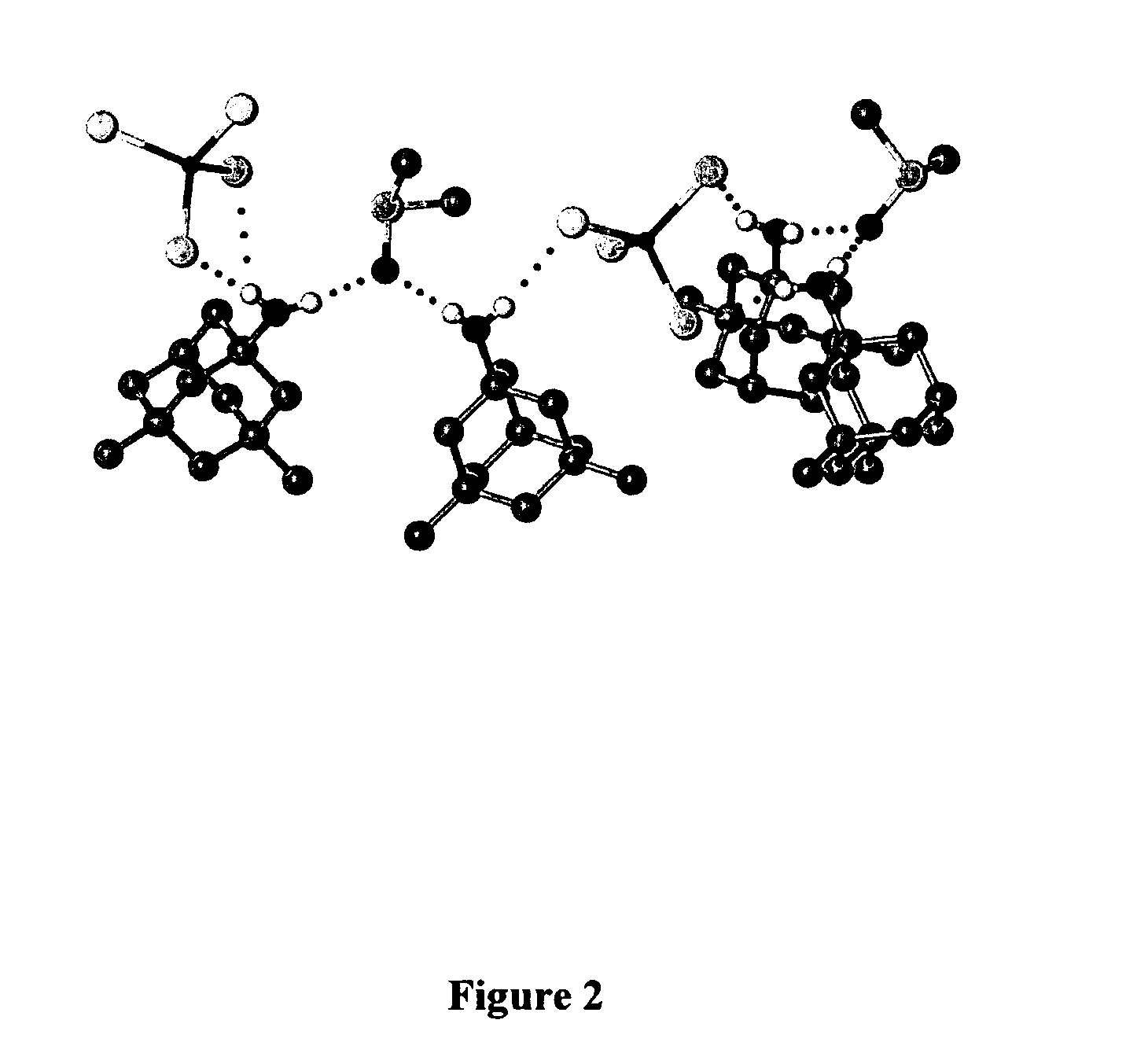

Adamantanamines and neramexane salts of thiomolybdic and thiotungstic acids

ActiveUS7893289B2Efficient removalReduce in quantityBiocideNervous disorderIntestinal tract diseasesDisease cause

This invention concerns adamantanamines (e.g. memantine, amantadine, and rimantadine) and neramexane salts of thiomolybdic and thiotungstic acids, including their preparation and pharmaceutical compositions, as dual acting drugs. These salts are used to treat or potentially arrest the neurodegenerative pathophysiology, clinical signs and symptoms of dementia of the Alzheimer's type, Parkinson's, Huntington's, AIDS-related dementia and Schizophrenia and its cognitive deficits. Additional uses of these derivatives include antiviral activity. The novel compositions of the present invention appear particularly useful in enhancing the therapeutic benefits of copper-sequestering tetrathiomolybdates in treating elevated copper-induced toxicities in neurologically presenting Wilson's disease, and in treating diseases of the inflammatory etiology and abnormal copper biochemistry, such as tumor angiogenesis, liver cirrhosis, hepatitis, pulmonary fibrosis and other fibrotic diseases, cardiovascular disease, cerebral ischemia, renal anemia, rheumatoid arthritis, diabetes, obesity, gastrointestinal disorders, and eye diseases such as glaucoma, proliferative diabetic retinopathy, and age related macular degeneration. These compounds have excellent stability and aqueous solubility for good oral bioavailability.

Owner:SSV THERAPEUTICS

Synthetic method of amantadine hydrochloride

InactiveCN111087308AThe synthesis process is simpleImprove conversion rateOrganic compound preparationCarboxylic acid amides preparationOrganic synthesisPharmaceutical Substances

The invention relates to organic synthesis, in particular to a synthetic method of amantadine hydrochloride. The technical route mainly adopted by the method is as follows: adamantane and acetonitrileare subjected to a Ritter reaction in an acid medium, and a pure amantadine hydrochloride product is obtained through hydrolysis and purification. Compared with the prior art, by adopting a special process and components, amantadine hydrochloride with high yield is prepared, can be used for preparing medicines, has the effects of treating and preventing viral infection, and has important clinicalvalue and market value; the mutual synergistic effect of various components is utilized, the amantadine hydrochloride synthesis process is effectively improved, the amantadine hydrochloride synthesisprocess is green and environmentally friendly, solvents can be recycled, waste gas is remarkably reduced, the problem of environmental pollution in the amantadine hydrochloride synthesis process of atraditional process is effectively solved, the wastewater amount is greatly smaller than that of a previous technical route, and the amantadine hydrochloride synthesis process has good industrial application potential.

Owner:广东仁康达材料科技有限公司

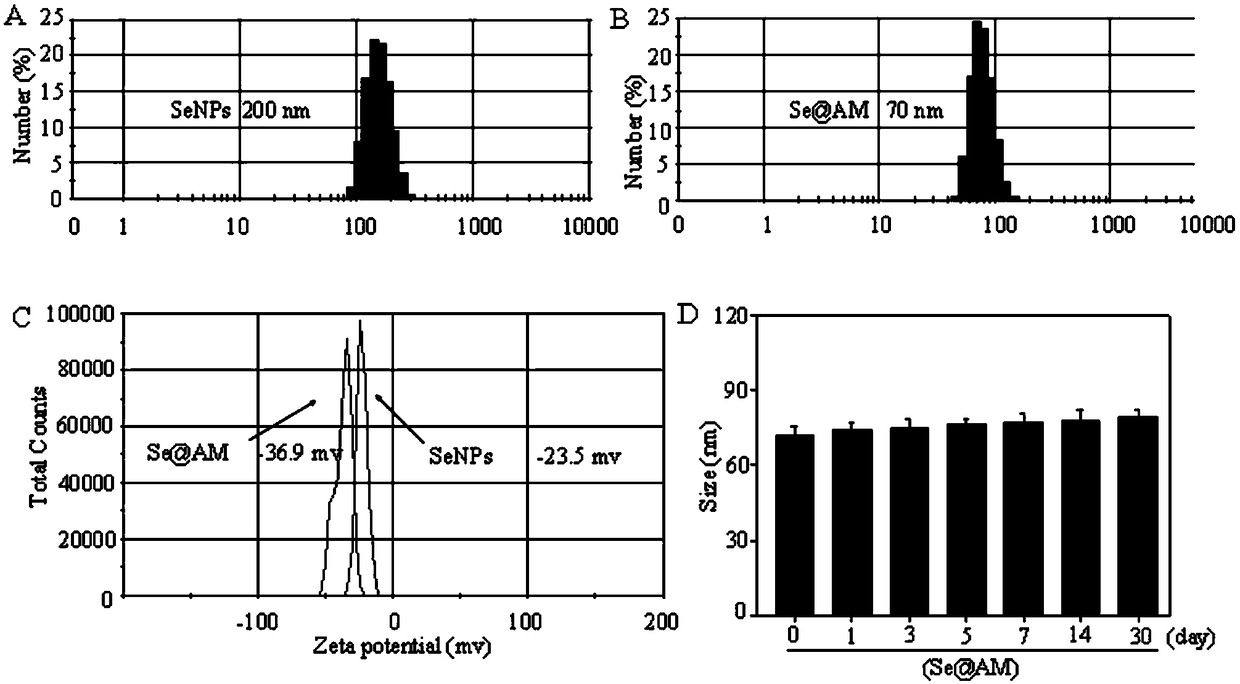

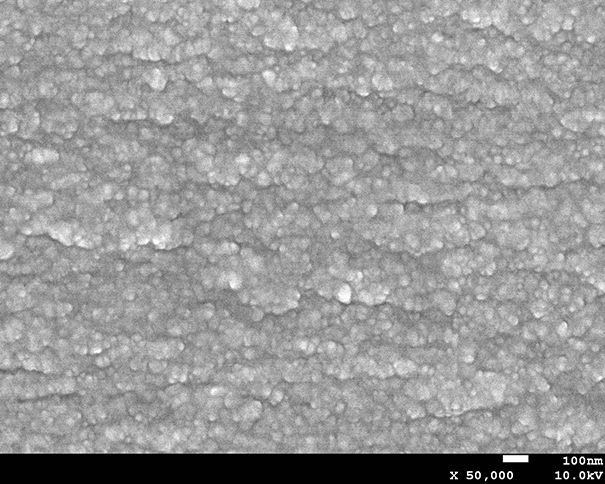

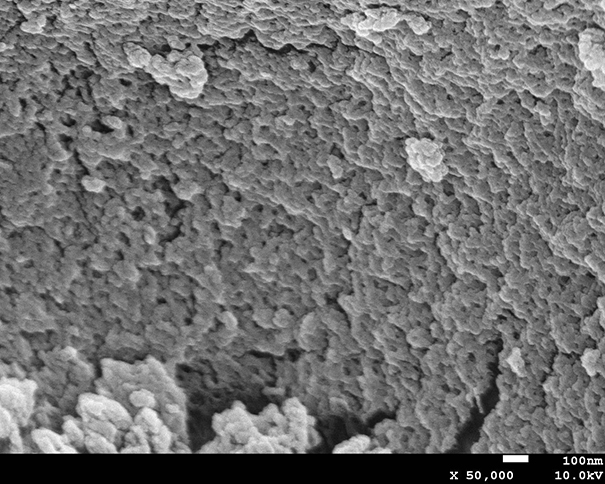

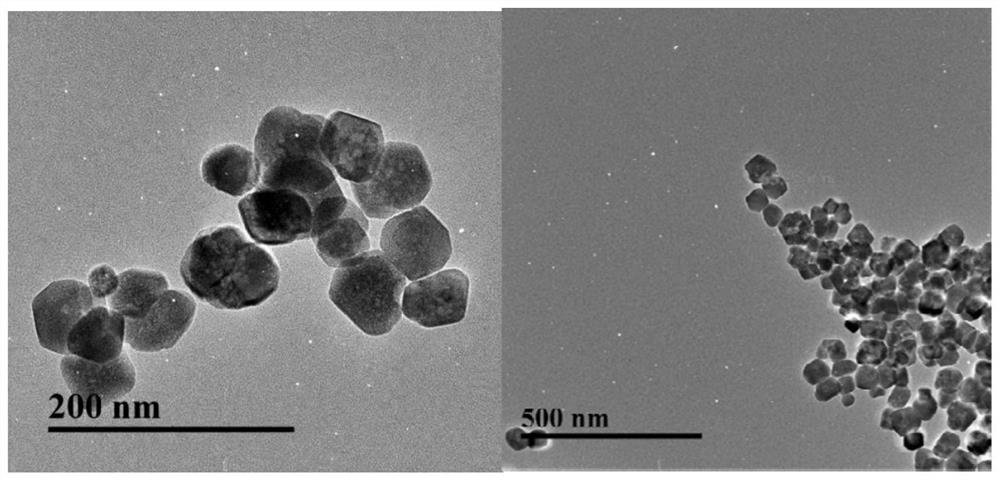

Preparation method and application of nano-selenium-amantadine compound nano-drug carrier

InactiveCN108653742AInhibits neuraminidase activityStrong antiviral activityAntiviralsPharmaceutical non-active ingredientsAmantidineDrug carrier

The invention discloses a preparation method of a nano-selenium-amantadine compound nano-drug carrier, and further discloses application of the nano-selenium-amantadine compound nano-drug carrier in inhibiting of the H1N1 influenza virus. The preparation method comprises the following steps that (1) an antioxidant solvent is taken to be added into a sodium selenite solution drop by drop, deionizedwater is added, and thus a nano-selenium initial solution is obtained; (2) magnetic stirring is conducted for two hours, a purified nano-selenium solution is obtained through dialysis; (3) the nano-selenium solution is taken, an amantadine solution is added into the nano-selenium solution, and thus a nano-selenium-amantadine initial solution is obtained; and (4) magnetic stirring is conducted forone hour, the reacting solution is dialyzed, centrifuged for 10 min at the speed of 10000 rpm and washed through deionized water for three times, and the nano-selenium-amantadine compound nano-drug carrier is obtained after a sample is frozen and dried. According to the preparation method, nano-selenium-carried amantadine drug carrying system which is dispersed uniformly and stably can be obtained. The drug carrier has the good antiviral effect, and nano-selenium-carried amantadine can co-inhibit replication of the H1N1 influenza virus.

Owner:GUANGZHOU WOMEN AND CHILDRENS MEDICAL CENTER

Method for preparing compound paracetamol and amantadine hydrochloride pills

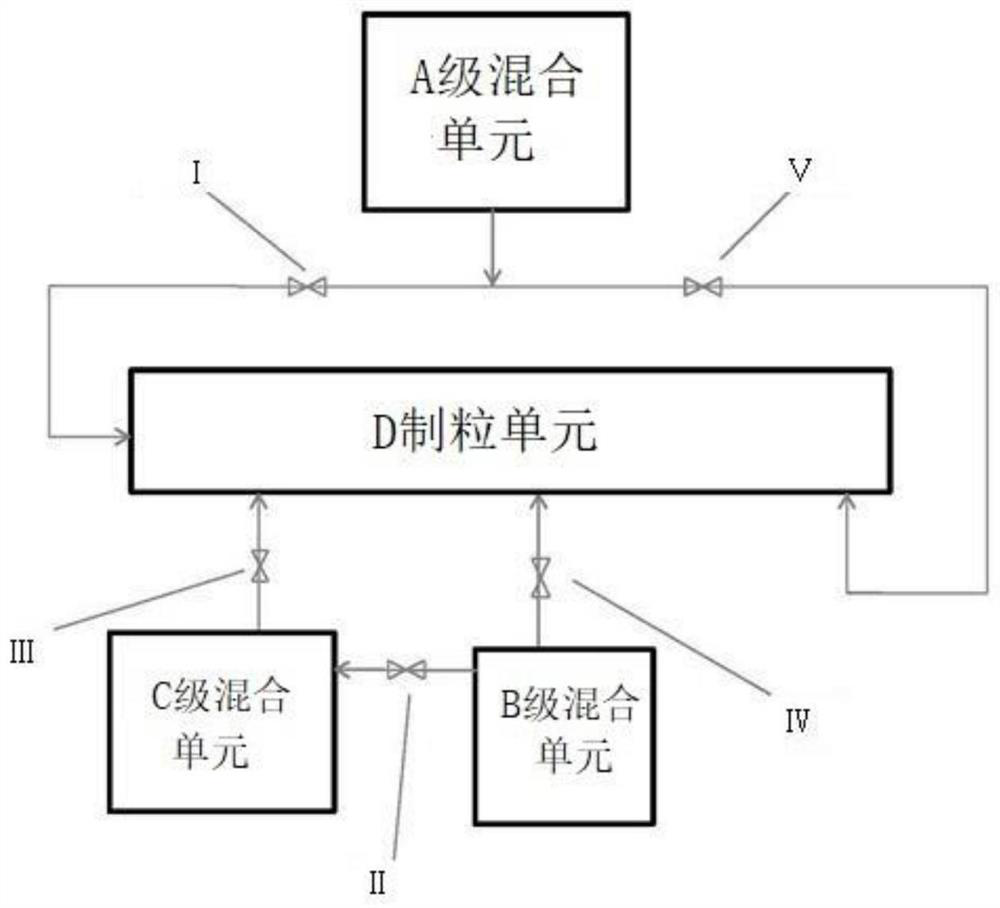

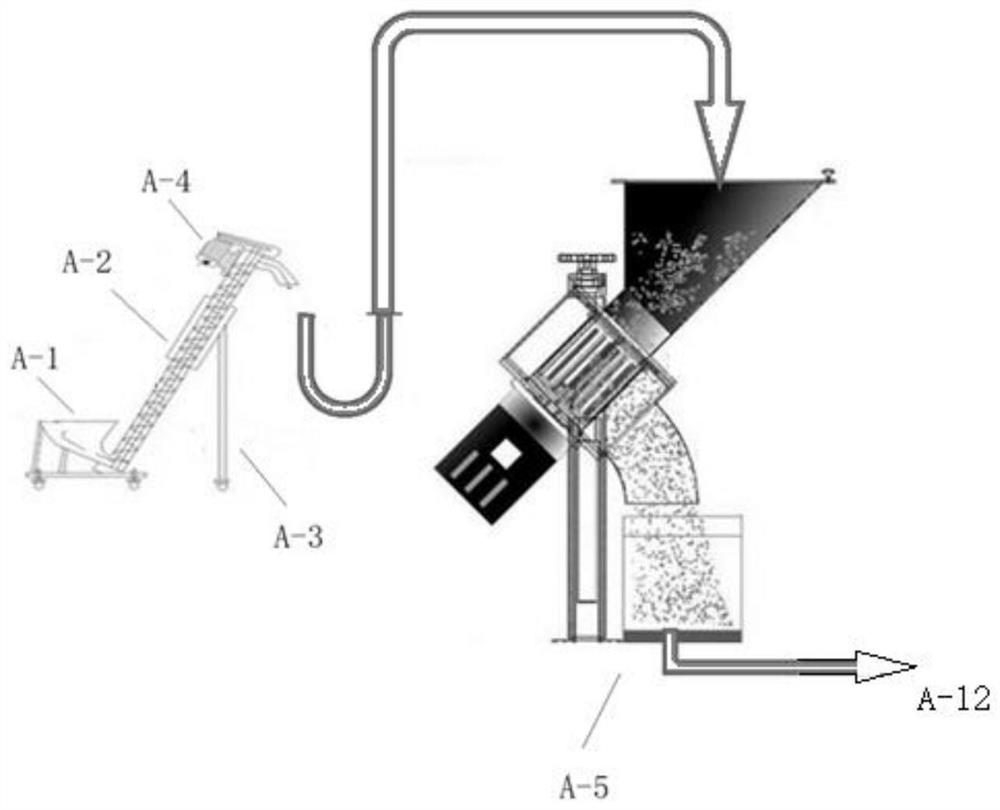

PendingCN113274366AOvercome the disadvantages of uneven distribution of componentsOvercome the disadvantages of uneven distribution of components in the mixing step existing in the production of the prior artNervous disorderAntipyreticAmantidineChlorobenzene

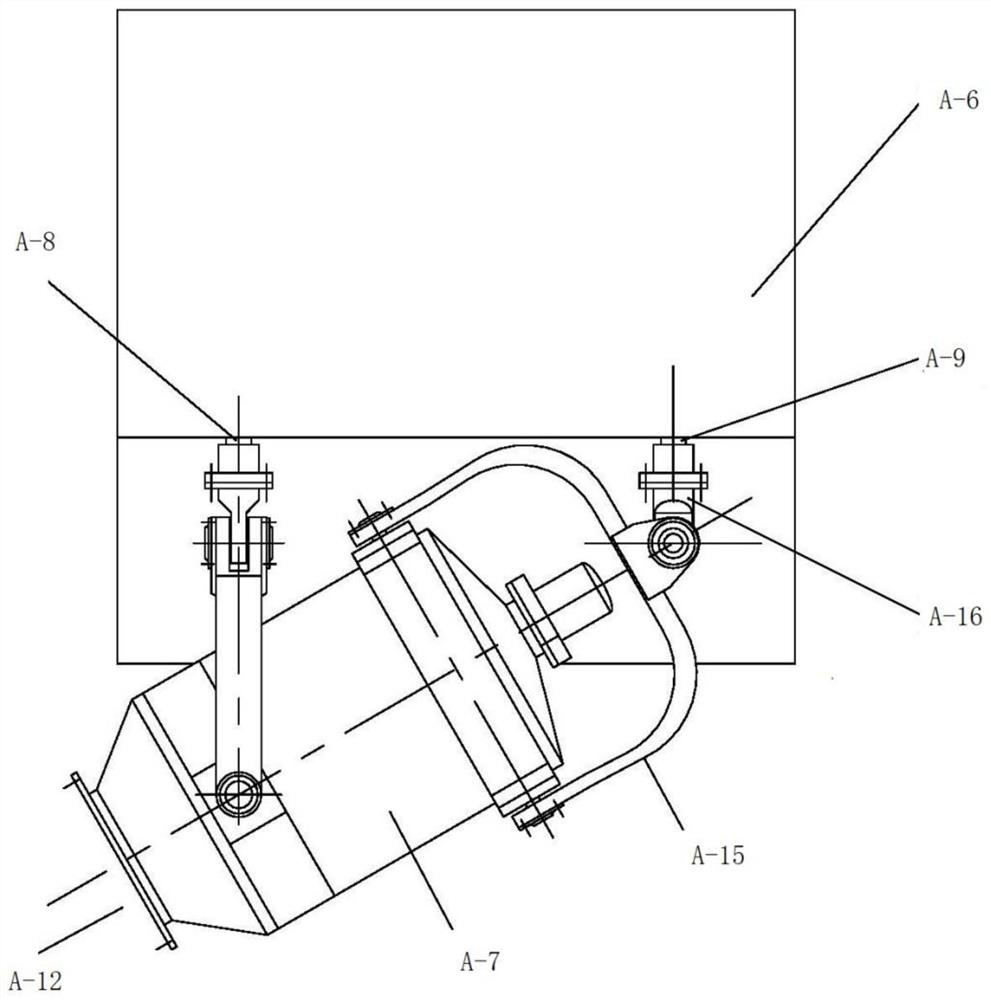

The invention provides a method for preparing compound paracetamol and amantadine hydrochloride pills. The compound paracetamol and amantadine hydrochloride pills are prepared from chlorpheniramine maleate, calculus bovis factitius, caffeine, amantadine hydrochloride, paracetamol and dextrin in parts by mass. The compound paracetamol and amantadine hydrochloride pills comprise core pills, a spraying layer and an outer layer which are prepared in sequence. The process comprises the following steps: respectively connecting the outlet side of an A-grade mixing unit with a feeding hole and a third coating section of a granulation unit D through a tee joint with a valve. According to the technical scheme provided by the invention, the defects that the mixing units are uneven in mixing and the components are not uniformly distributed in a standby state in the preparation process are overcome, unified coordination management among various production steps is lacked, and the production efficiency is greatly improved.

Owner:浙江亚峰药厂有限公司

ICCB-containing compound preparation and preparation method thereof

The invention provides an ICCB-containing (in-vitro-cultured calculus boris) compound preparation which comprises the following components in parts by weight: 0.5 to 2 parts of ICCB, 20 to 30 parts of acetaminophen, 8 to 15 parts of amantadine hydrochloride, 0.1 to 0.4 parts of chlorpheniramine maleate, 1.0 to 2.5 parts of caffeine, and the appropriate amount of sucrose and food flavors auxiliary materials. By using the ICCB compound preparation instead of artificial bezoar, the side reactions in which vomit and jaundice symptoms are caused by over high free bilirubin contained in artificial boris can be reduced; medicament ingredients can be effectively dispersed with an equivalent increment method to mix and grind, thereby reducing side effects caused due to uneven contents of chlorpheniramine maleate, chlorpheniramine maleate and amantadine hydrochloride.

Owner:汤明昌 +1

Compound paracetamol and amantadine hydrochloride composition and preparation method thereof

InactiveCN107320494ALessen liver damageAlgae medical ingredientsUnknown materialsCaffeineAlkyl amine

The invention relates to a compound paracetamol and amantadine hydrochloride composition, which comprises, by weight, 200-300 parts of paracetamol, 80-120 parts of amantadine hydrochloride, 12-18 parts of caffeine, 8-12 parts of artificial bezoar, 1-3 parts of chlorpheniramine maleate, and 200-400 parts of seaweed polysaccharide. According to the present invention, the component ratio is adjusted on the basis of the pharmaceutical components of the conventional paracetamol and amantadine hydrochloride composition, and the specific proportion of the seaweed polysaccharide is added, such that the obtained composition can provide good protection effect on the immune liver injury caused by acetaminophen, and can reduce the degree of liver injury caused by paracetamol.

Owner:HARBIN ZHENBAO PHARMA +1

Treatment method of waste acid in amantadine production

InactiveCN111847491ASolve processing problemsRealize the purpose of resource utilizationWater contaminantsTreatment involving filtrationAmantidineSocial benefits

The invention belongs to the technical field of waste liquid treatment and resource utilization, and provides a treatment method for waste acid produced by amantadine production. The method comprisesthe following steps: mixing amantadine production waste acid with magnesium oxide for reaction to obtain magnesium sulfate heptahydrate, wherein the amantadine production waste acid is specifically waste sulfuric acid. According to the method provided by the invention, amantadine is used for producing waste acid to prepare magnesium sulfate heptahydrate, so that the waste acid is converted into valuable resources, the waste acid treatment cost is reduced, and the purpose of resource utilization is achieved. The treatment method disclosed by the invention is energy-saving, safe and reliable, solves the problem of difficulty in treatment of waste acid produced by amantadine production, maximizes the intrinsic value, has higher economic benefit and social benefit, can recycle the mother liquor, and is green and environment-friendly in treatment process.

Owner:SHANDONG HOLLY PHARM CO LTD

A method for determining the content of 11 kinds of illegally added drugs in Chinese veterinary medicine powder

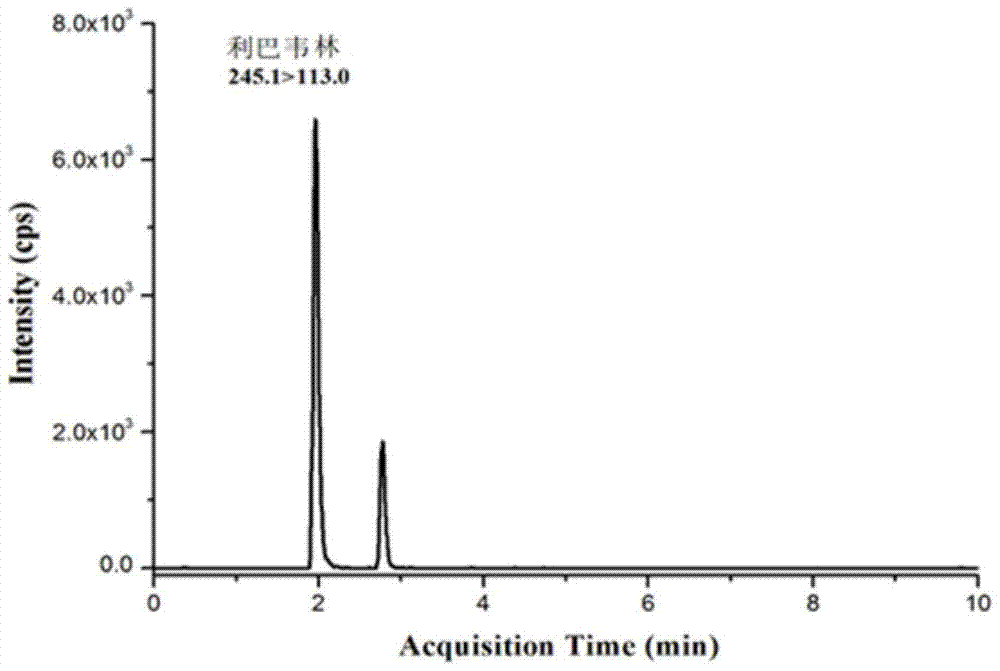

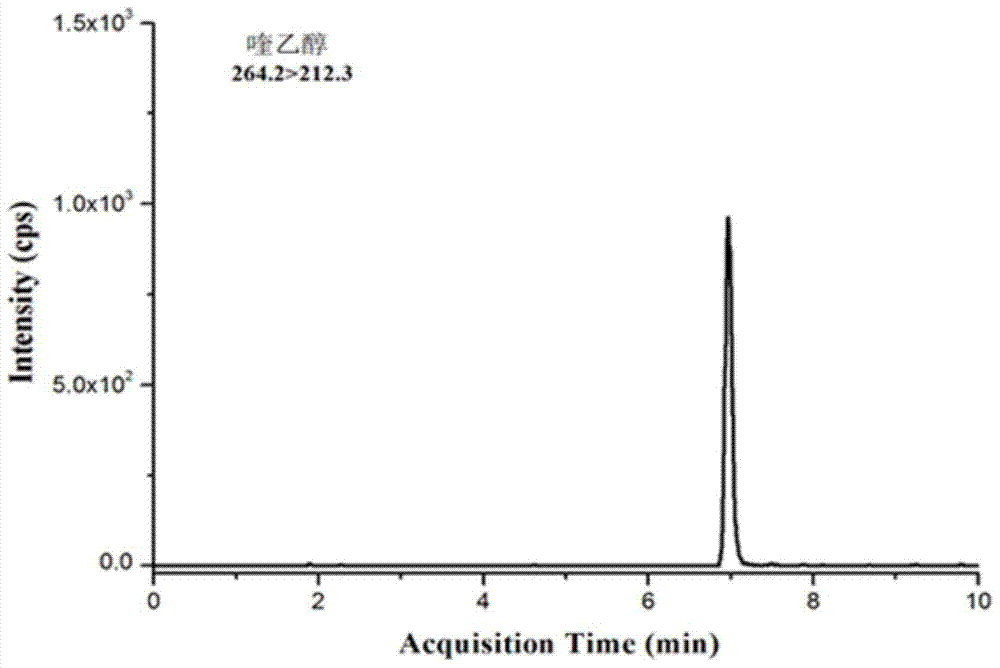

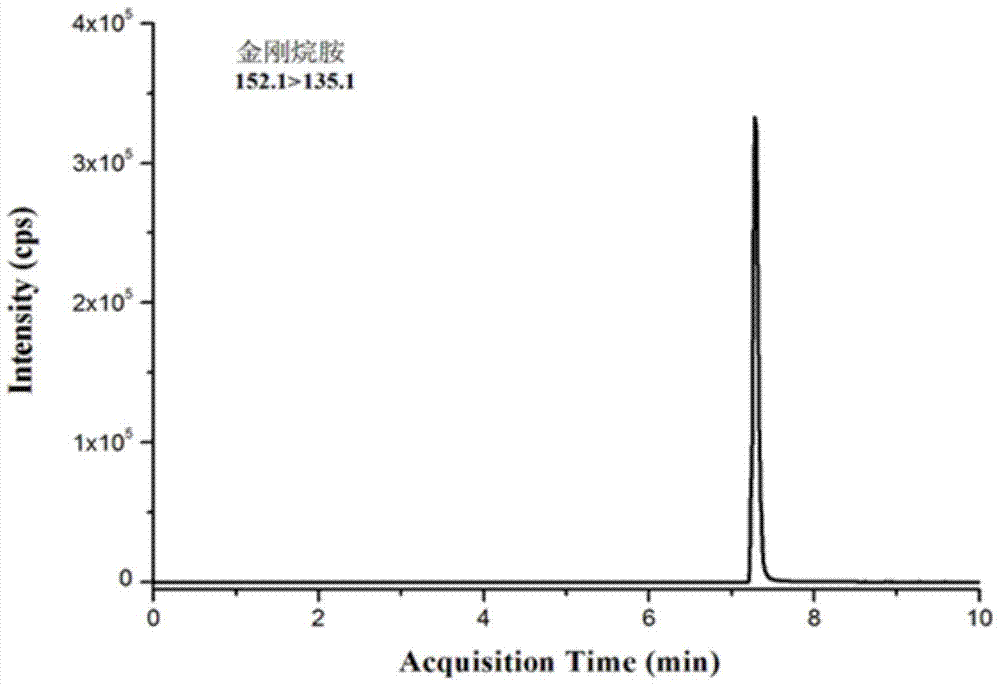

ActiveCN105203654BThe pre-processing process is simpleHigh recovery rateComponent separationNitrofuralFuran

The invention discloses a method for measuring content of 11 illegally added medicaments in veterinary drug powder. The method comprises the following steps of (1) pre-treating veterinary drug powder to be measured by adopting an organic solvent ultrasonic extraction method, wherein an organic solvent is methanol-water, and a volume ratio of methanol to water is (0.9-1.1):(0.9-1.1); (2) detecting olaquindox, ribavirin, amantadine, rimantadine, dexamethasone, chloramphenicol, diethylstilbestrol, furaltodone, nitrofurantoin, nitrofural and furazolidone in extract by adopting liquid chromatography-tandem mass spectrometry. According to the method, a sample can be simply pre-treated by adopting methanol / water (50+50) as an extraction reagent for ultrasonic extraction, and can be loaded on a machine for detection after passing through a filter membrane, and a recovery rate is high; the method is lower in detection limit, a detection limit of the olaquindox, ribavirin, amantadine, rimantadine, dexamethasone, chloramphenicol, furaltodone and furazolidone is 50mu g / kg, and a detection limit of the nitrofurantoin, nitrofural and diethylstilbestrol is 100mu g / kg.

Owner:SHANDONG ANALYSIS & TEST CENT

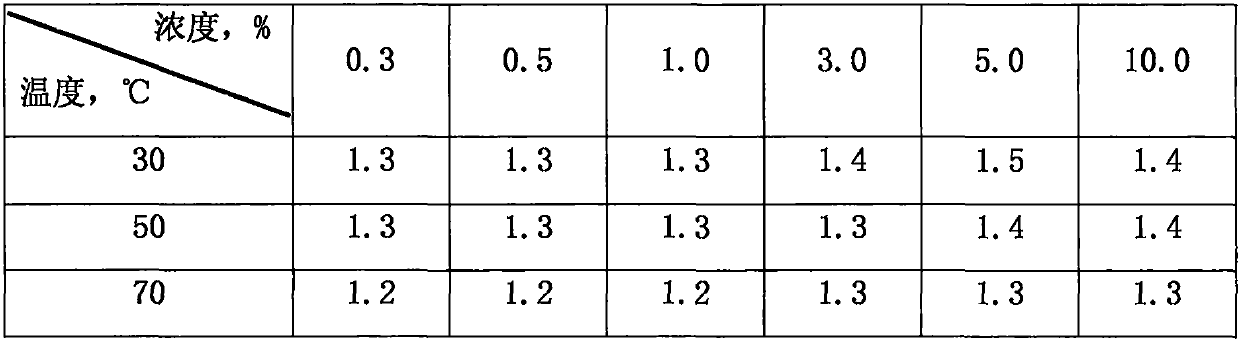

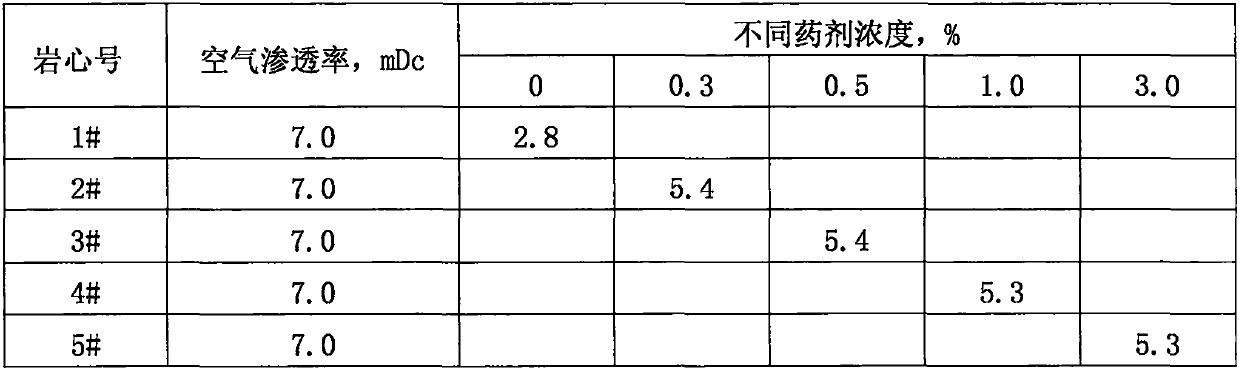

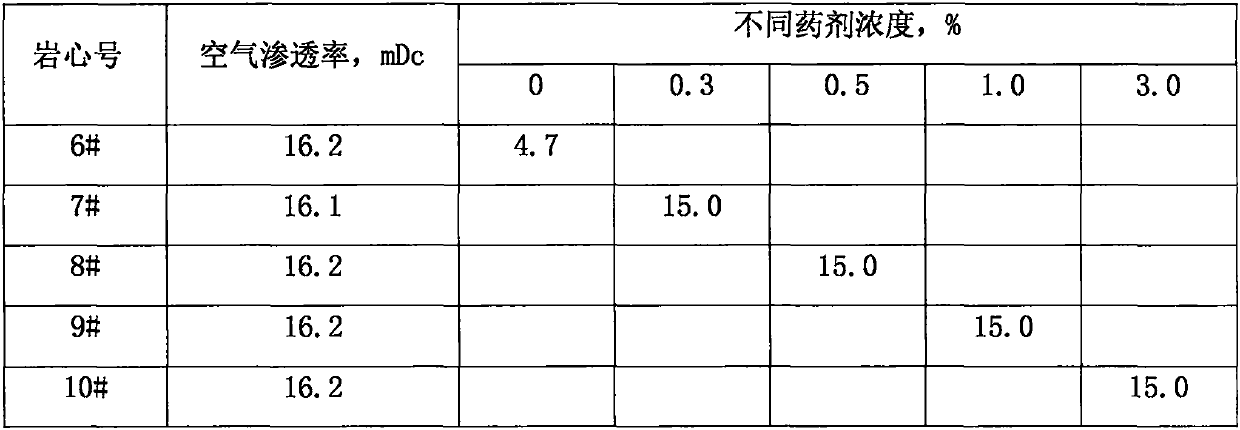

Preparation Method of New Low Permeability Reservoir Water Lock Release Agent

ActiveCN110746310ALow viscosityImprove permeabilityAmino preparation from aminesDrilling compositionAmantidinePtru catalyst

The invention relates to a preparation method of new low permeability reservoir water lock release agent, which uses 2,4-difluorobenzyl chloride and amantadine as main raw materials. Ethanol is used as solvent and reaction medium, potassium hydroxide is used as catalyst, and 2,4-difluorobenzyl chloride and amantadine are reacted in a ratio of 3: 1 to quaternize the amino group of amantadine to prepare a water-soluble molecule with certain monodisperse properties. The molecular aqueous solution has low viscosity and strong permeability, has excellent water locking unlocking ability for low permeability water locking cores, and has reliable preparation process, thus providing a new preparation method for ultra-low permeability reservoir water locking unlocking agent.

Owner:QINGDAO UNIV

Polyacid compound for resisting penicillin streptococcus pneumoniae (PRSP) and preparing method thereof

InactiveCN100460405CAntibacterial agentsPhosphorous compound active ingredientsChemical synthesisMoroxydine

The present invention belongs to the field of chemically synthesized medicine and its preparation process. The medicine of the present invention is synthesized with amantadine, moroxydine, 5-Fu (5-Fc), isoniazid and other clinical medicine and polyoxometallate, and through self-assembling. The said polyoxometallate includes heteropoly acid salts of Keggin type with chemical expression XM12O40n-, Dowson type X2M18O62n- and of chemical expression LnW10O36n-. The combined use of said medicines and polyoxometallate has obvious curative effect on intractable streptococcus pneumoniae infection.

Owner:NORTHEAST NORMAL UNIVERSITY

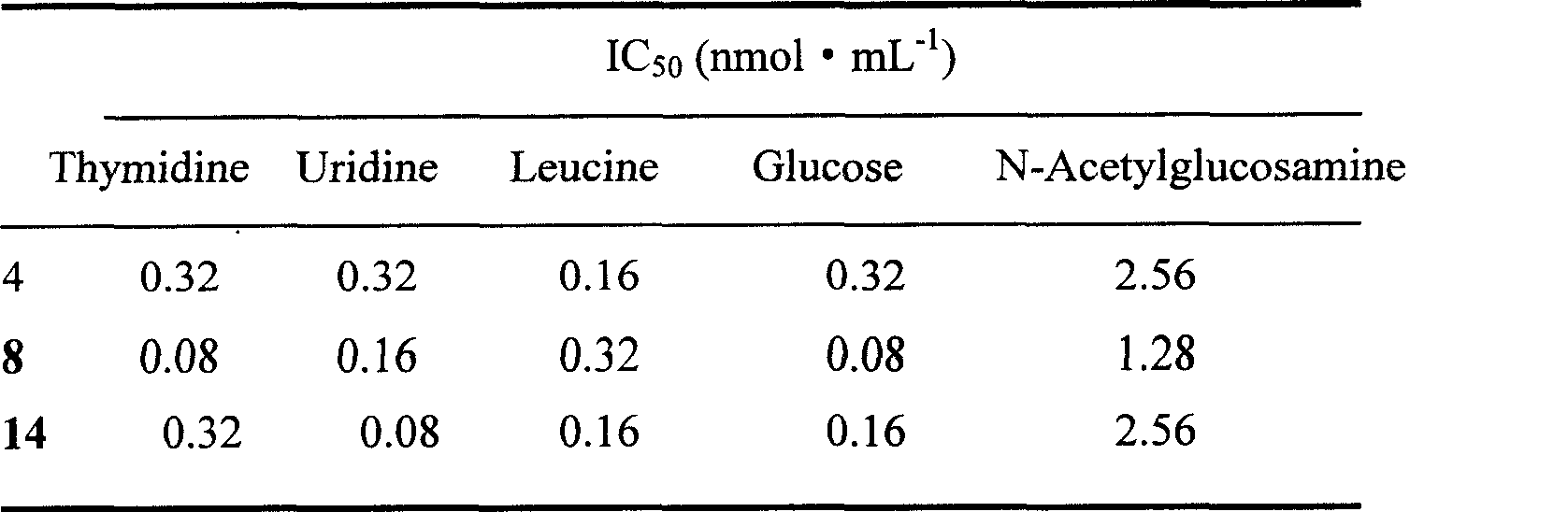

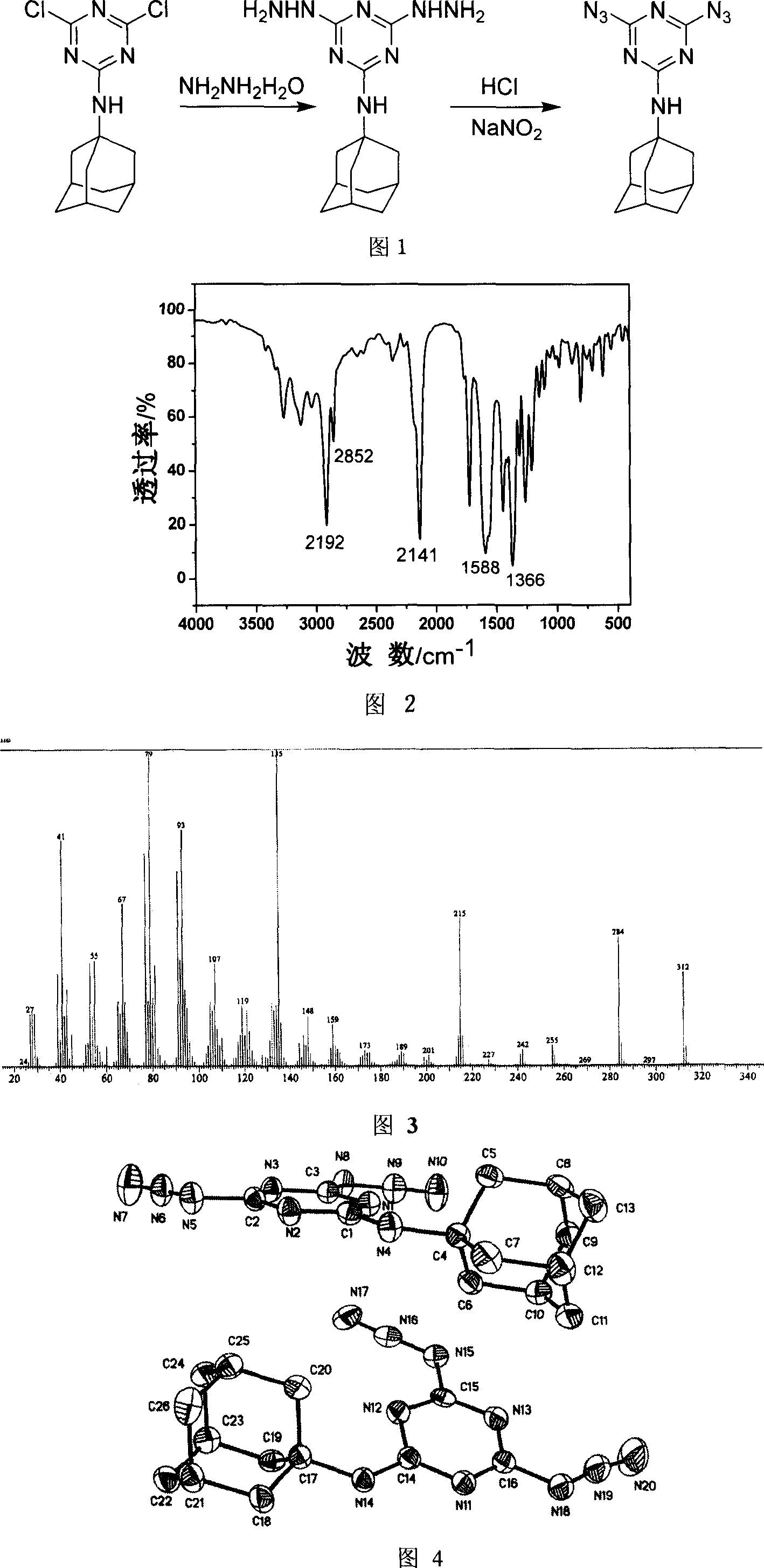

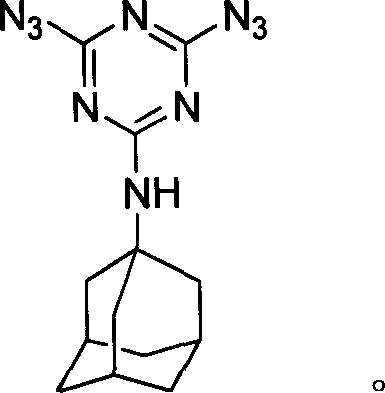

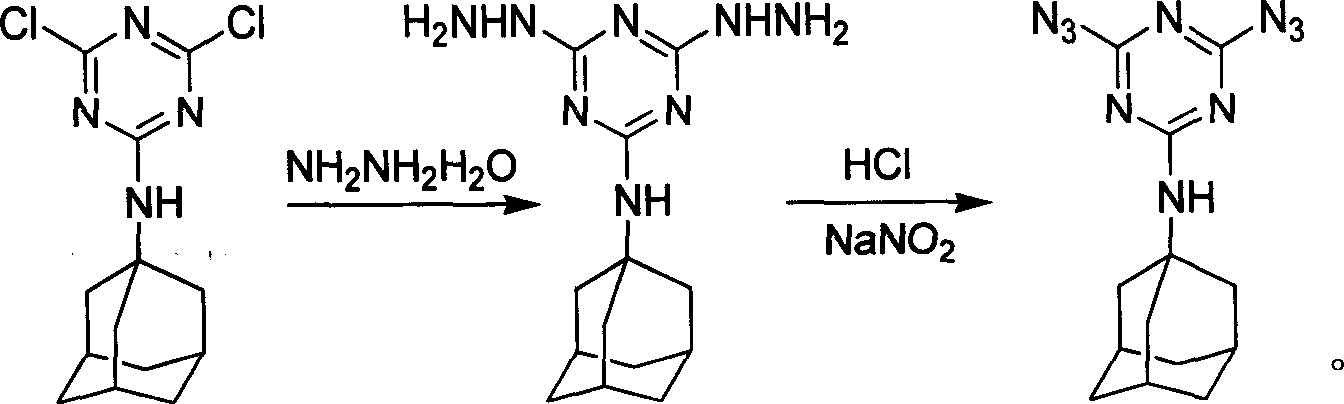

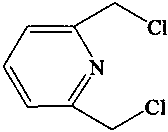

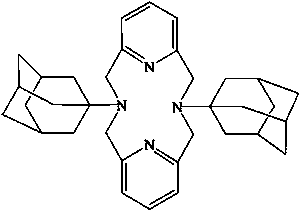

Compound of containing nitrine triazine symmetrel and synthetic method

InactiveCN101003519AOvercome the disadvantage of low sensitivityReduce sensitivityOrganic chemistryHydrazine compoundHigh energy

This invention relates to a method for synthesizing compounds containing azidotriazine amantadine, whose molecular formulae are shown in formulae I and II. The method comprises: reacting dichlorotriazine amantadine and hydrazine hydrate in a mixture of water and organic solvent by nycleophilic substitution, reacting with sodium nitrite in HCl solution to oxidize hydrazine into azide, extracting the product with ethyl acetate for three times, spin-evaporating to concentrate and obtain white product, dissolving in ethyl acetate, and slowly volatilizing to obtain single crystal of the product. The introduction of amantadine into the synthesized compounds has stable thermodynamic properties, and can release stress energy during thermal decomposition to form intramolecular hydrogen bonds, thus lowering sensitivity and improve thermal stability. The new compounds can be used in high-energy insensitive dynamites, low-signal propellants, gas generators, smoke powder and firecrackers. The method has such advantages as simple process, easy purification, no need for nitrogen protection, and no pollution.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

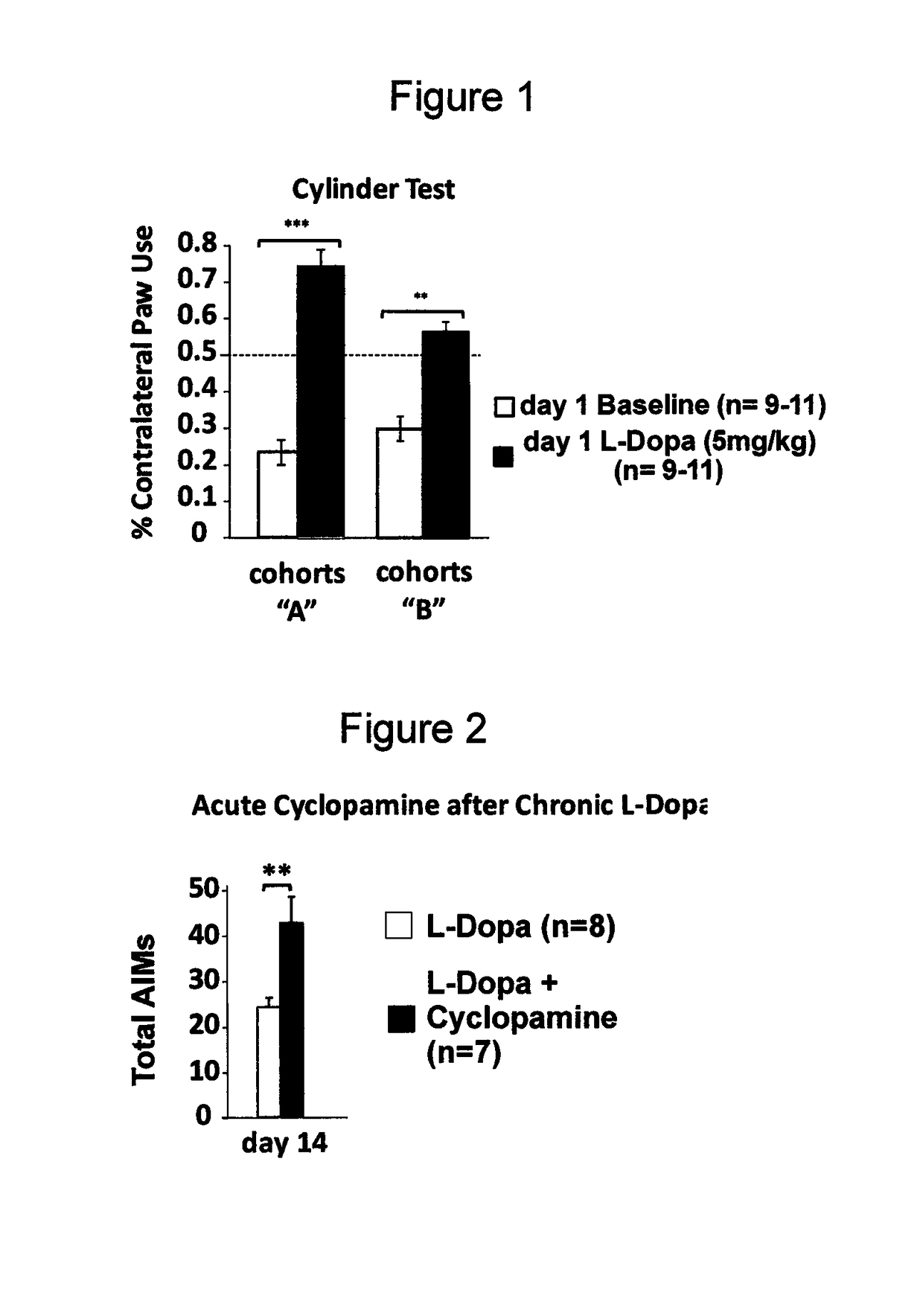

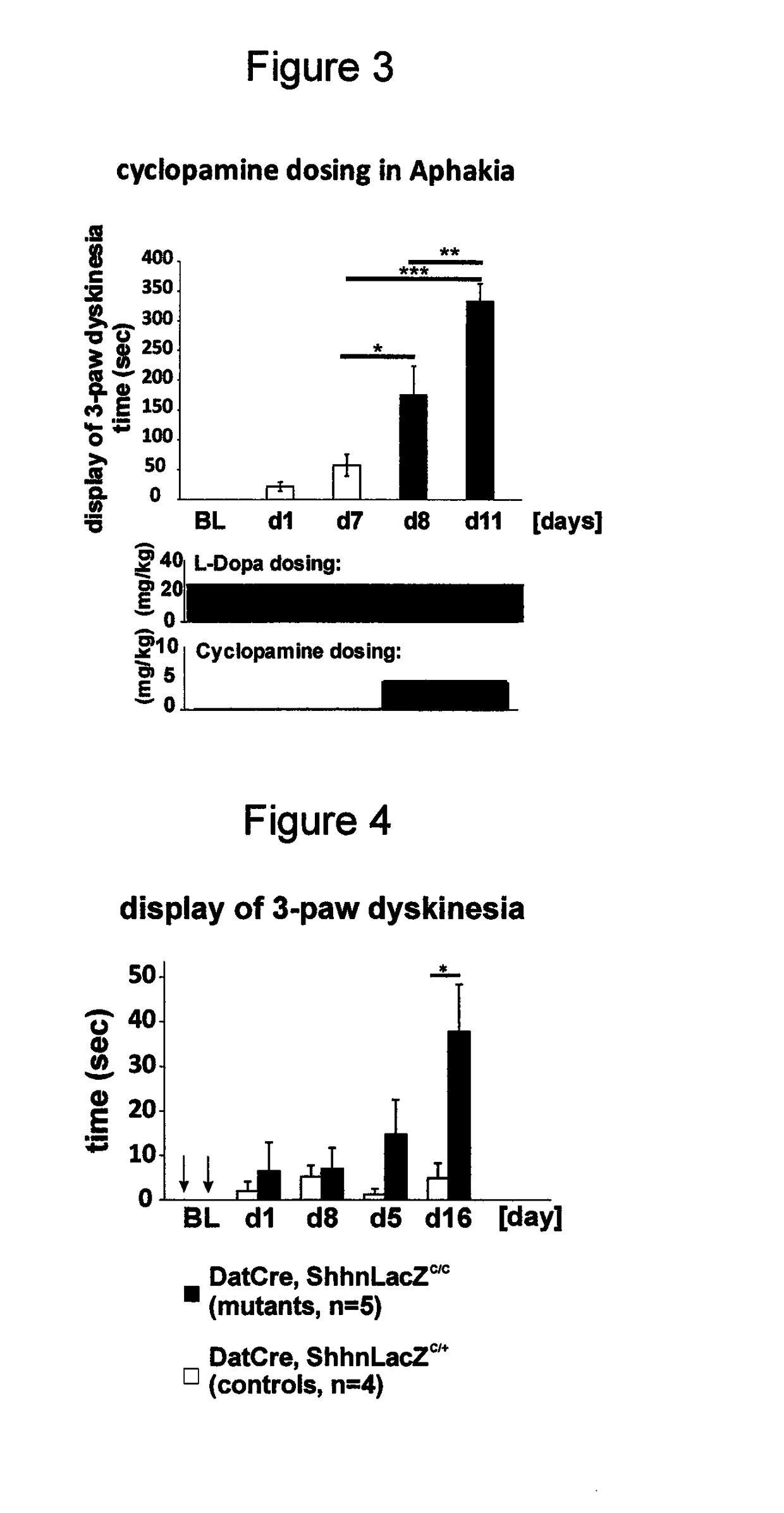

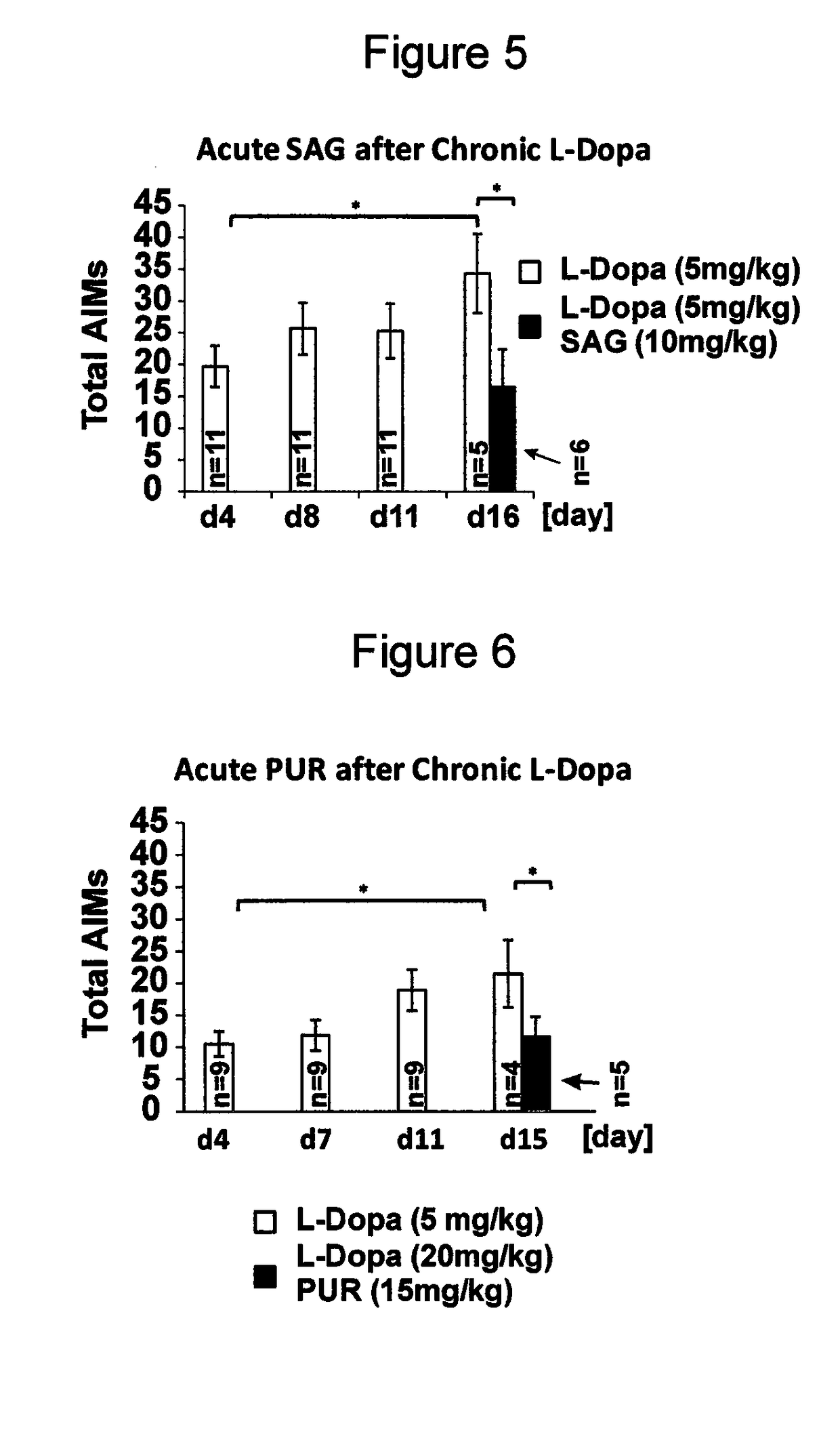

Method for avoiding or inhibition of dyskinesia

Certain neurological disorders are treated with dopamine agonists (e.g. L-Dopa) but these treatments unintentionally cause Levodopa-induced dyskinesias (LIDs) or tardive dyskinesia. An improved treatment is described that treats the patient with both a dopamine agonist and a Smoothened (Smo) agonist or with a dopamine agonist and combination of a Smoothened (Smo) agonist together with Amantadine.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

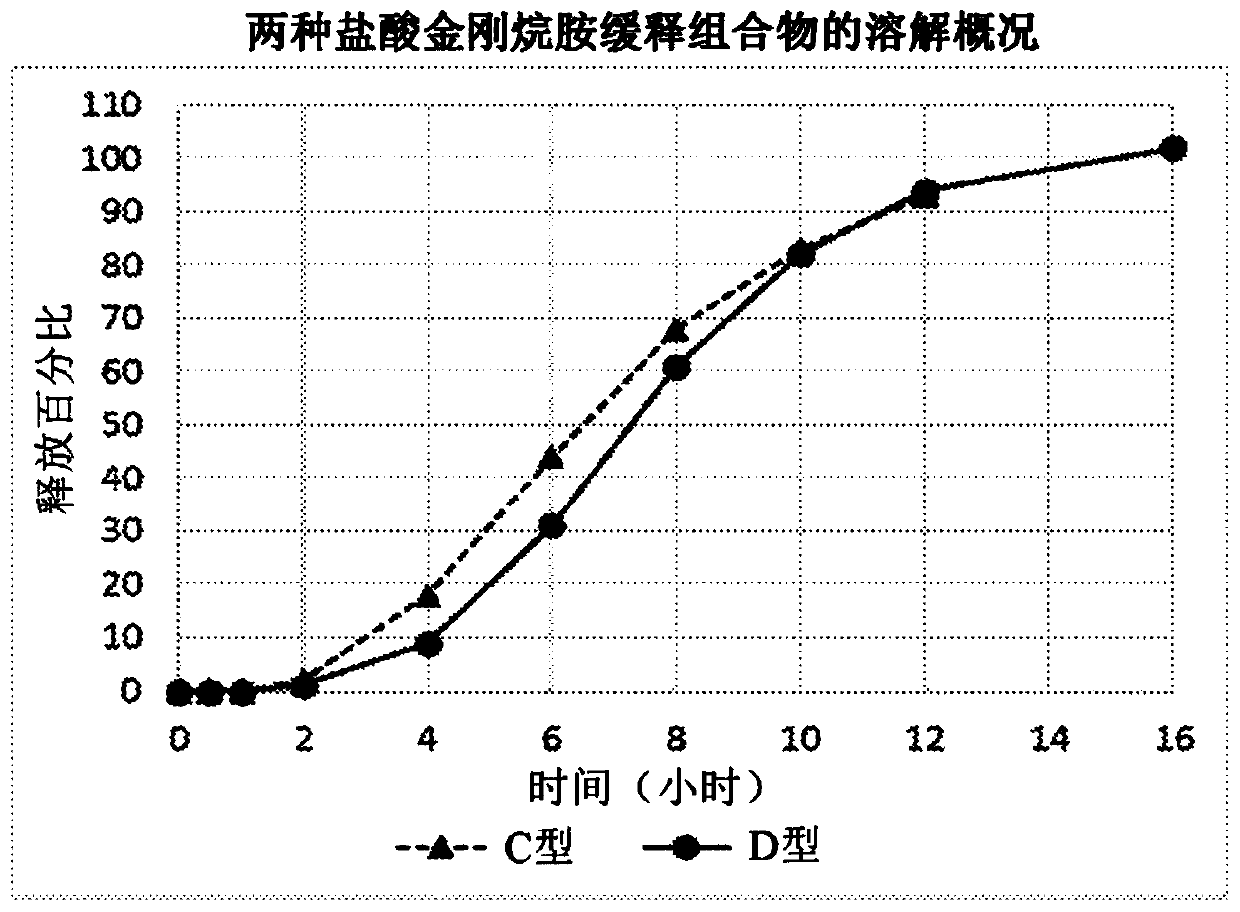

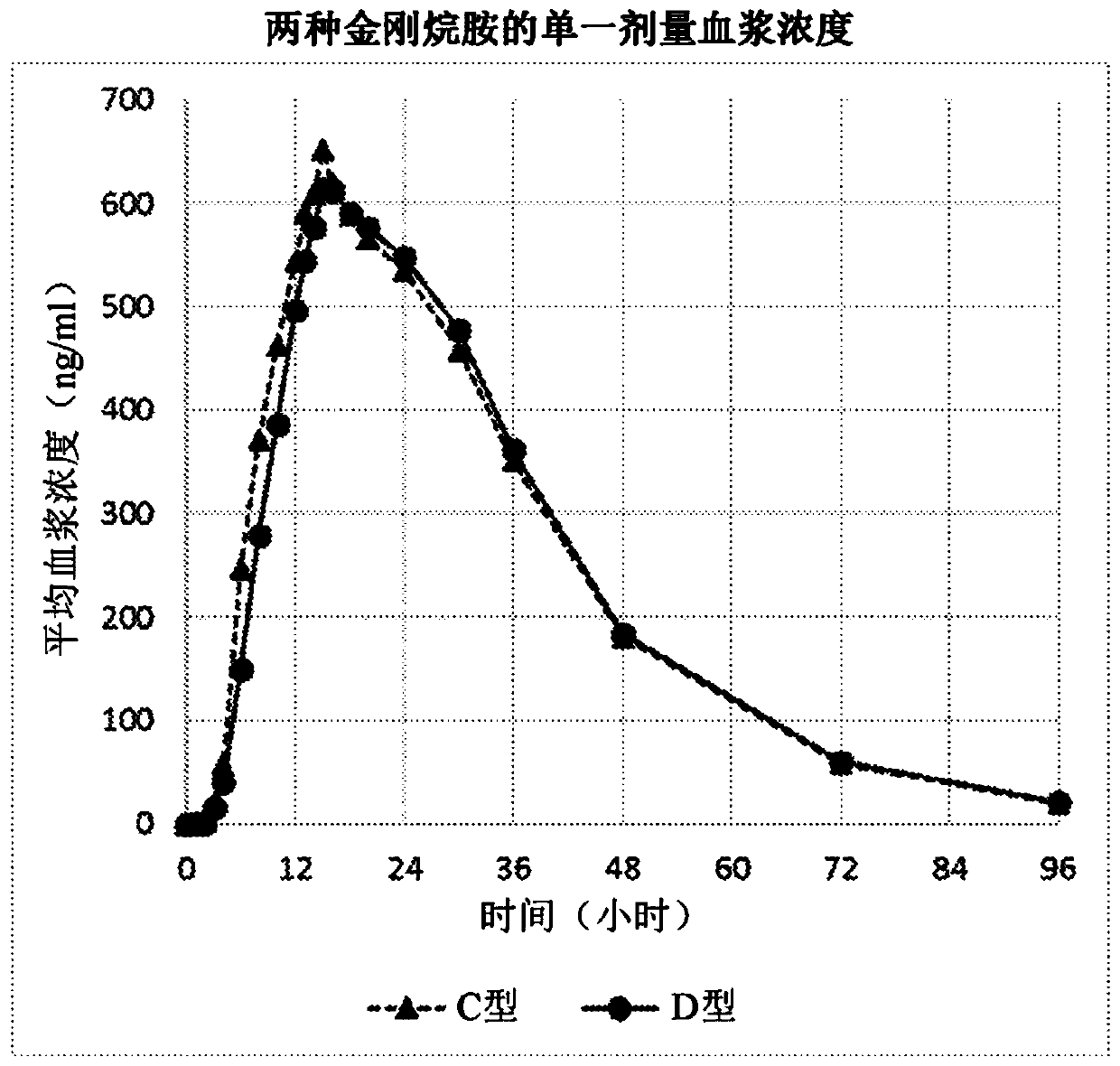

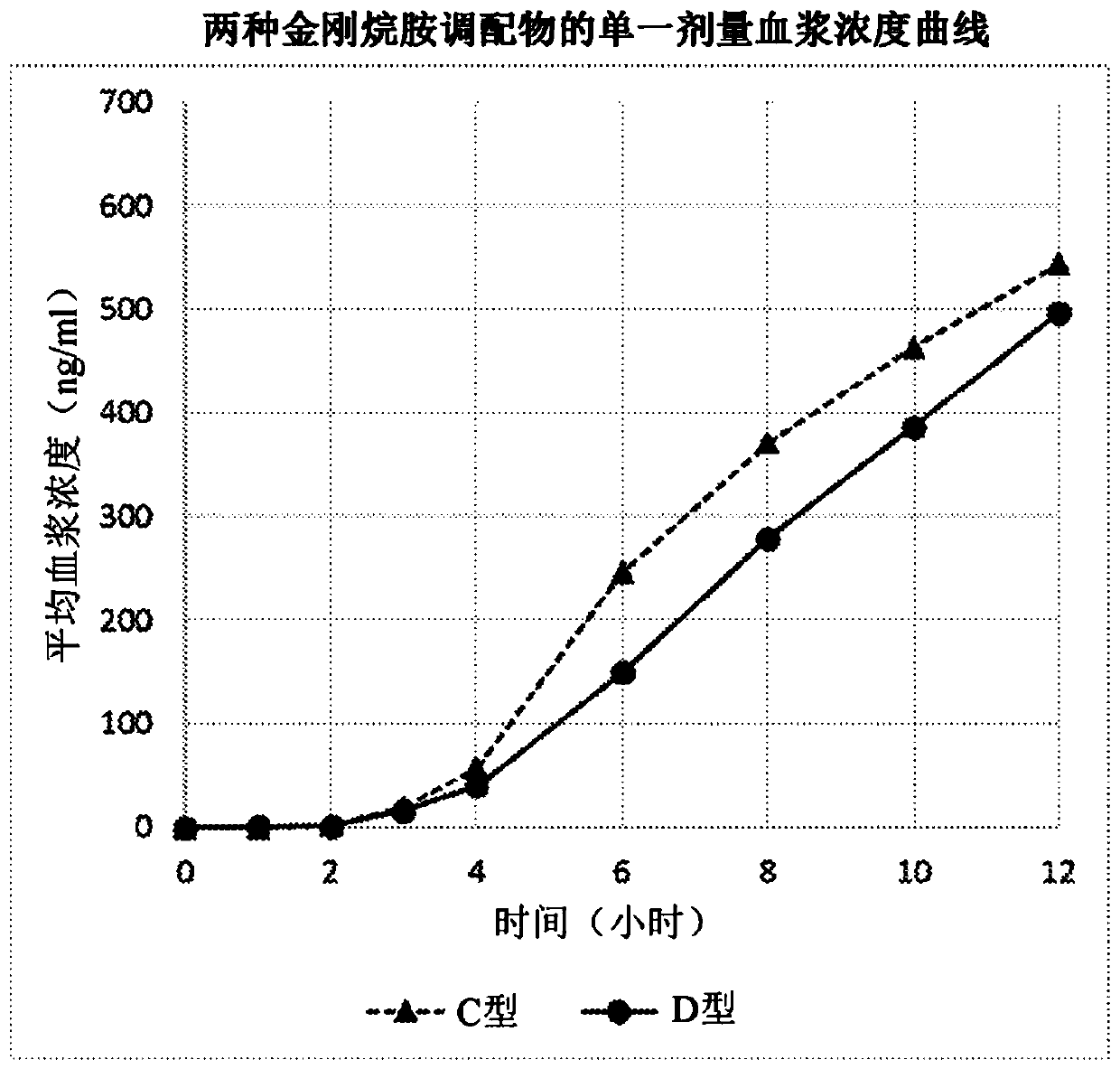

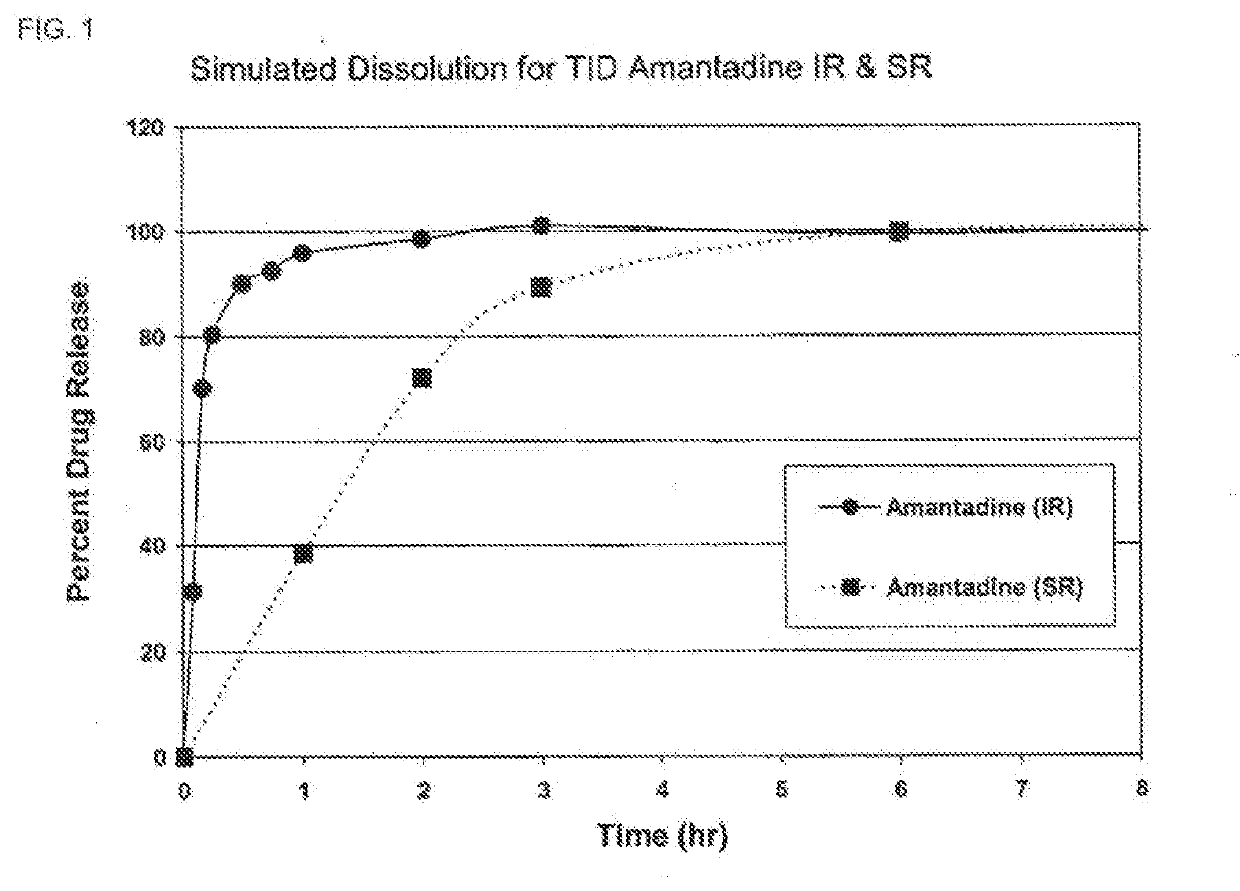

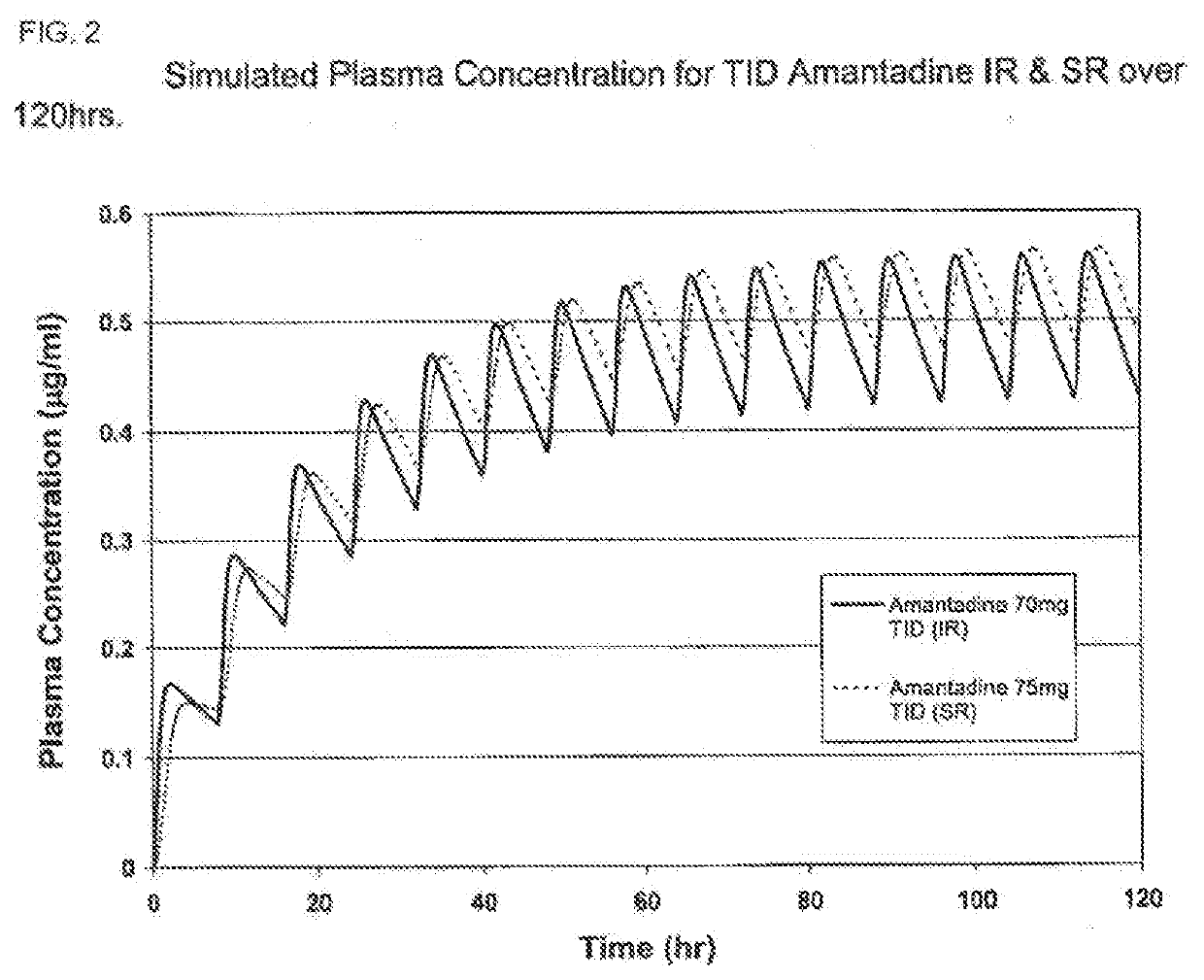

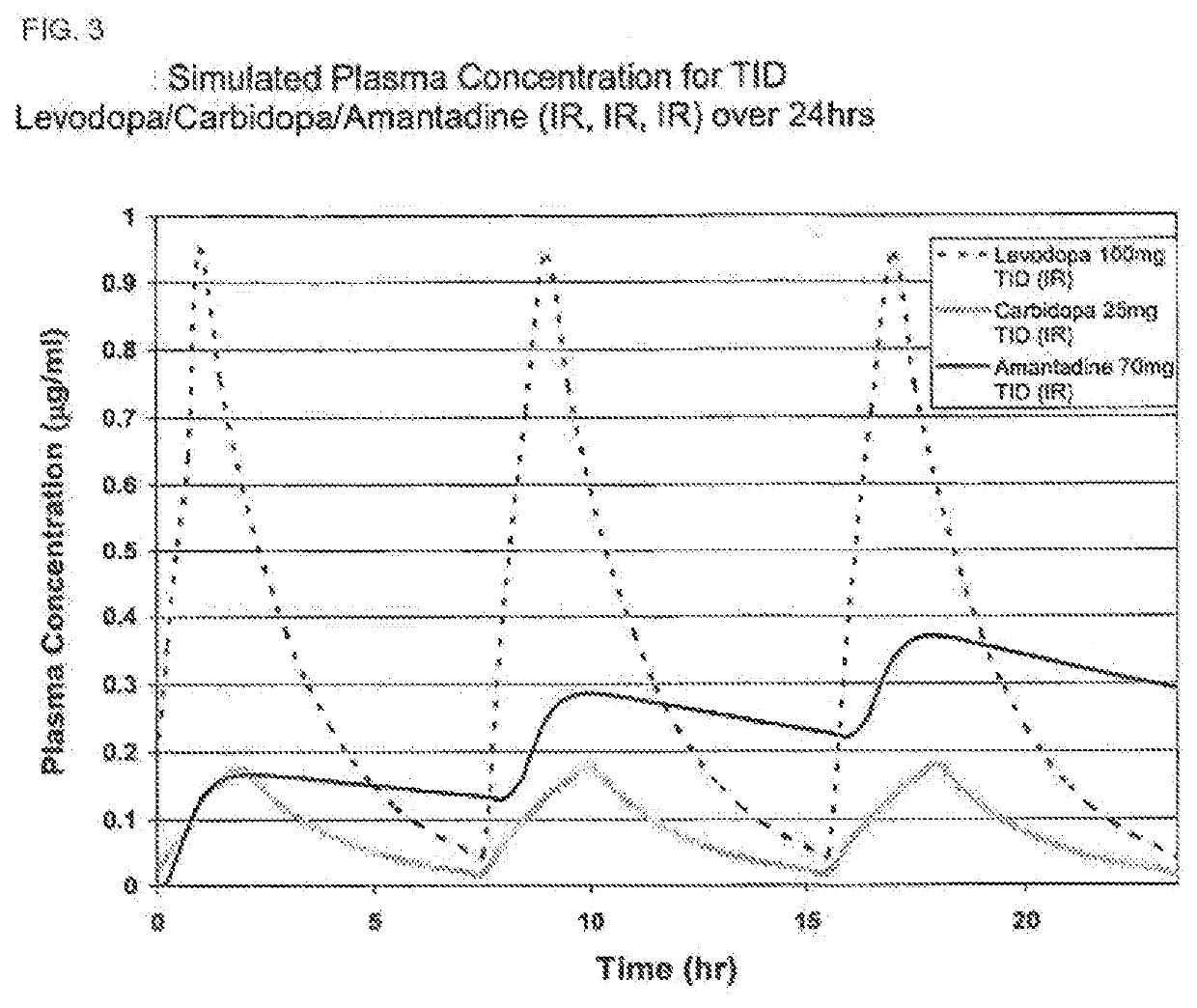

Amantadine compositions, preparations thereof, and methods of use

Provided herein are oral pharmaceutical compositions comprising amantadine, or a pharmaceutically acceptable salt thereof, and a pharmaceutically acceptable excipient, and which have a low level of organic solvent. Provided are also methods of orally administrating a composition comprising amantadine, or a pharmaceutically acceptable salt thereof, to a subject, which has reduced gastrointestinal side effects or sleep disturbances. Further provided are extended release oral compositions comprising amantadine, or a pharmaceutically acceptable salt thereof, that are suitable for once daily administration.

Owner:ADAMAS PHARMA LLC

Composition and method for treating neurological disease

PendingUS20220211641A1Maintain and enhance efficacyEffective compositionNervous disorderGranular deliveryAmantidineDisease

Disclosed are compositions comprising amantadine, or a pharmaceutically acceptable salt thereof, and one or more excipients, wherein at least one of the excipients modifies release of amantadine. Methods of administering the same are also provided.

Owner:ADAMAS PHARMA LLC

CdS quantum dot-complex composite material preparation method and application

InactiveCN108842175AComposite homogeneousShorten the timeOrganic chemistryElectrolytic inorganic material coatingQuantum dotAmantadine

The invention discloses a CdS quantum dot-complex composite material preparation method and application, and belongs to the technical field of nanometer materials, metal organic complexes and electrochemical detection. The method comprises the specific steps that a chemical sensor is prepared based on CdS quantum dot-complex composite material CdS@Cu(II)-ADM / Cu for detecting oestrone, particularly, 1, an amantadine ligand ADM-BP is prepared, and 2, an electrochemical sensor for amantadine complex composite materials Cu(II)-ADM / Cu and CdS quantum dot-complex composite materials CdS@Cu(II)-ADM / Cu is prepared through an electrochemical deposition method. Since Cu(II)-ADM / Cu has the large specific area, more active sites and excellent adsorption performance, the prepared electrochemical sensorhas the advantages of being high in oestrone detection sensitivity, low in detection limit, high in stability, easy to operate and the like.

Owner:SHANDONG JIAOTONG UNIV

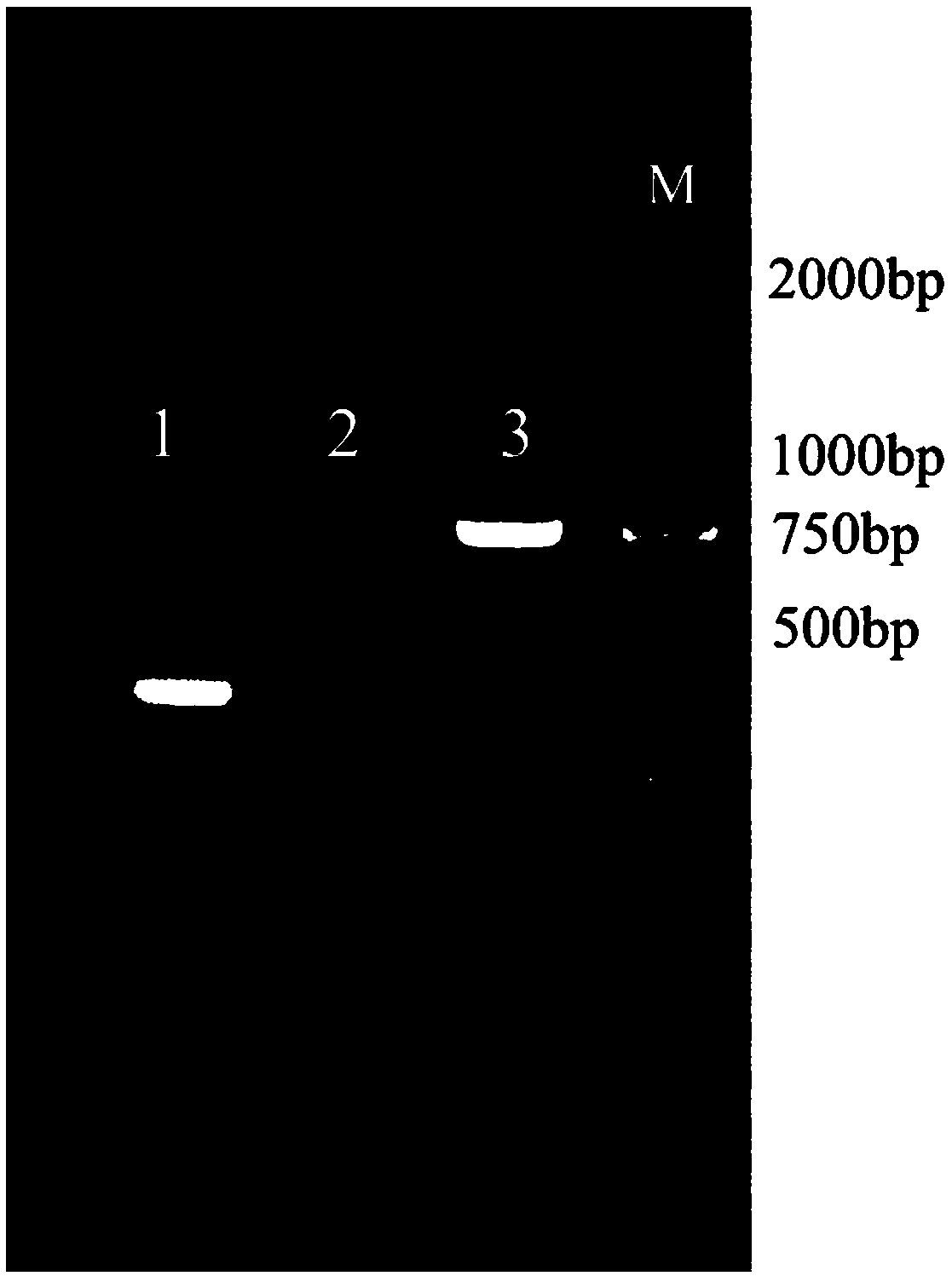

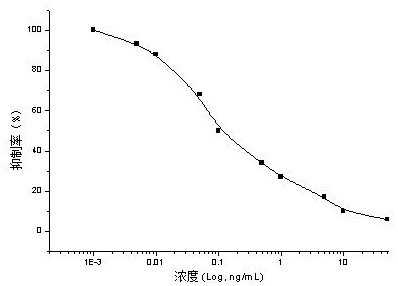

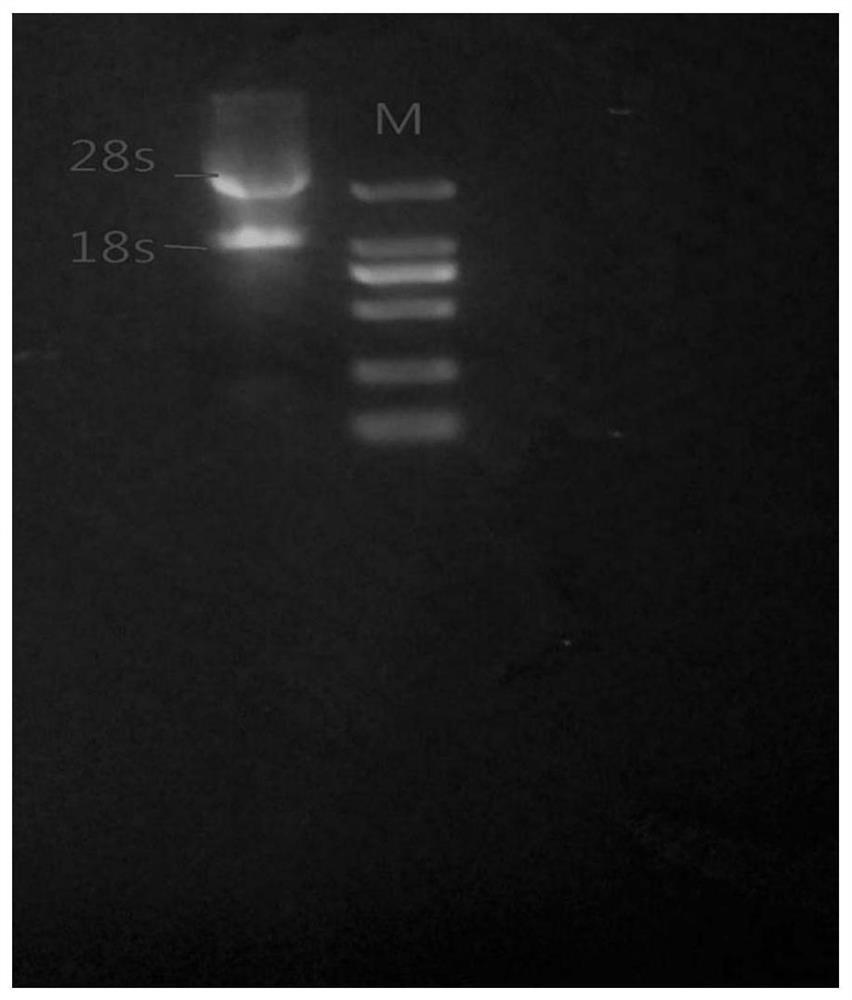

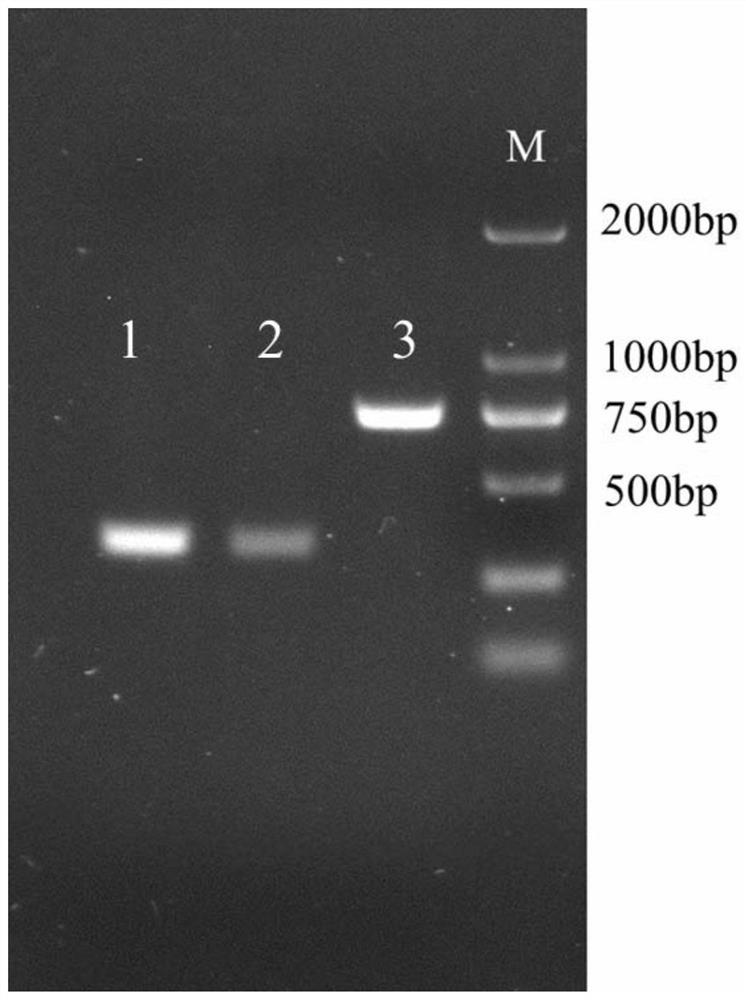

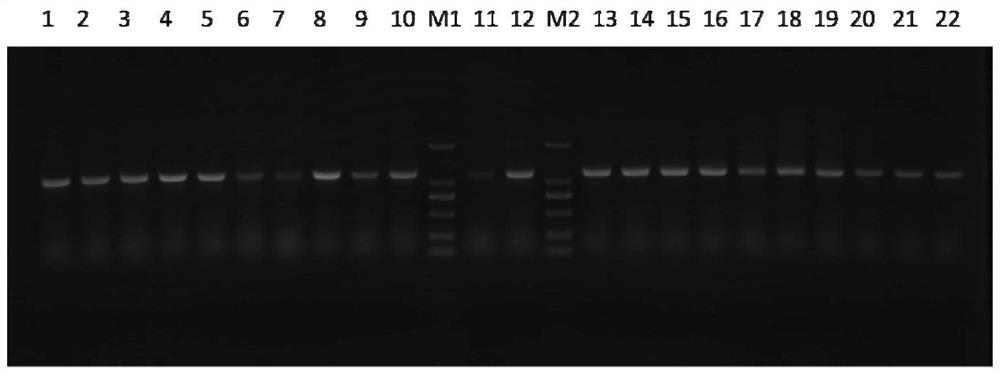

Anti-amantadine (Anti-AMD) single-chain antibody scFv, and preparation method and application thereof

The invention discloses an anti-amantadine AMD single-chain antibody, and a preparation method and application thereof. According to the invention, a heavy-chain variable region gene and a light-chainvariable region gene of the antibody can be obtained from a hybridoma cell strain 3F2 of a monoclonal antibody secreting amantadine (AMD) through a genetic engineering mean; and after the two genes are recombined, a prokaryotic expression plasmid vector is constructed, and escherichia coli is transformed to express scFv antibody active fragments capable of specifically recognizing the AMD. Experiments prove that the recombinant single-chain antibody scFv prepared by the method has specific recognition and binding activity withamantadine. Residual detection of amantadine can be realized through utilization of recognition and binding activity of the recombinant single-chain antibody on amantadine, and the constructed transformation vector plasmid is easy for storage and mass-produce.

Owner:CHINA AGRI UNIV

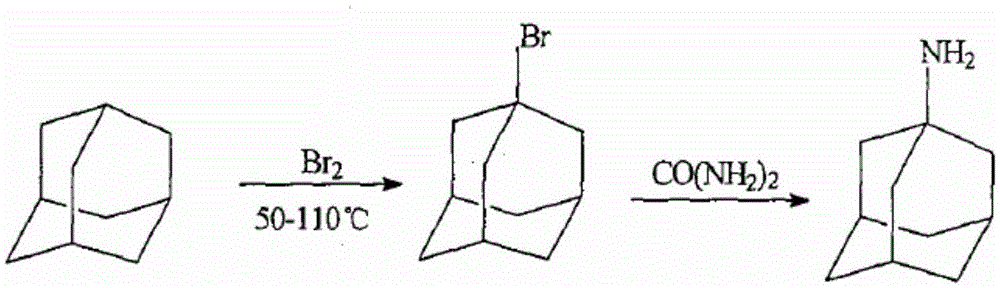

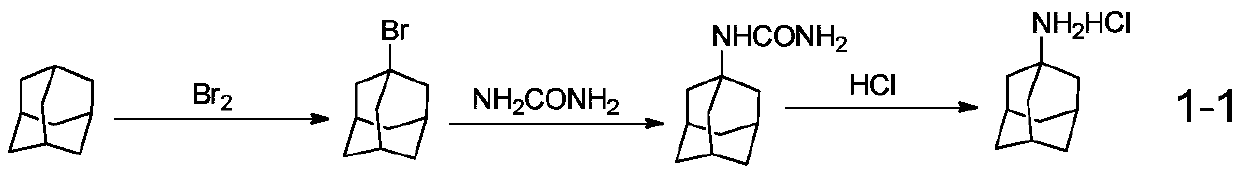

Method for preparing amantadine

ActiveUS20220251023A1Reduce manufacturing costSmall amountAmino compound purification/separationOrganic compound preparationAmantidinePtru catalyst

A method for preparing amantadine includes chlorinating adamantane with chlorine gas in a solvent in the presence of a Lewis acid catalyst to obtain a reaction liquid, and then removing the solvent and residues containing the catalyst in the reaction liquid, to obtain a chlorinated product. The chlorinated product is mixed with urea to a mixture, and the mixture is subjected to an amination reaction, to obtain amantadine. The results of examples show that the purity of the prepared amantadine could reach 99.5% or more.

Owner:SHANDONG HOLLY PHARM CO LTD

A specific molecularly imprinted polymer of amantadine and rimantadine, a chemiluminescence kit, a detection method and application thereof

ActiveCN109001188BQuick checkSensitive detectionComponent separationChemiluminescene/bioluminescenceAmantidineBiochemistry

The invention discloses a specific molecularly imprinted polymer capable of recognizing amantadine and rimantadine, a chemiluminescent reagent kit using it as a recognition element, a detection method and an application. The molecularly imprinted polymer uses adamantane as a pseudomolecular template, and the synthesized specific molecularly imprinted polymer can simultaneously recognize amantadine and rimantadine. The chemiluminescence kit prepared based on the molecularly imprinted polymer can perform multi-residue detection of amantadine and rimantadine in meat tissue, and can be used repeatedly, thereby improving detection sensitivity, shortening detection time, and reducing detection cost.

Owner:HEBEI AGRICULTURAL UNIV.

Traditional Chinese and western medicine pharmaceutical composition for inhibiting novel coronavirus

PendingCN114272360AInhibit neuraminidaseInterference functionPeptide/protein ingredientsAntiviralsAmantidineWestern medicine

The invention relates to a traditional Chinese and western medicine pharmaceutical composition for inhibiting novel coronavirus, belonging to an antiviral traditional Chinese and western medicine pharmaceutical composition. The pharmaceutical composition comprises beta-podophyllopodophyllin, forsythin, ritonavir, amantadine and the like, has an inhibition effect on the activity of topoisomerase, can interfere the functions of nucleoprotein bodies, inhibit influenza virus neuraminidase and prevent RNA (Ribonucleic Acid) viruses from penetrating host cells, and has an inhibition effect on novel coronavirus COVID-19.

Owner:梅鑫

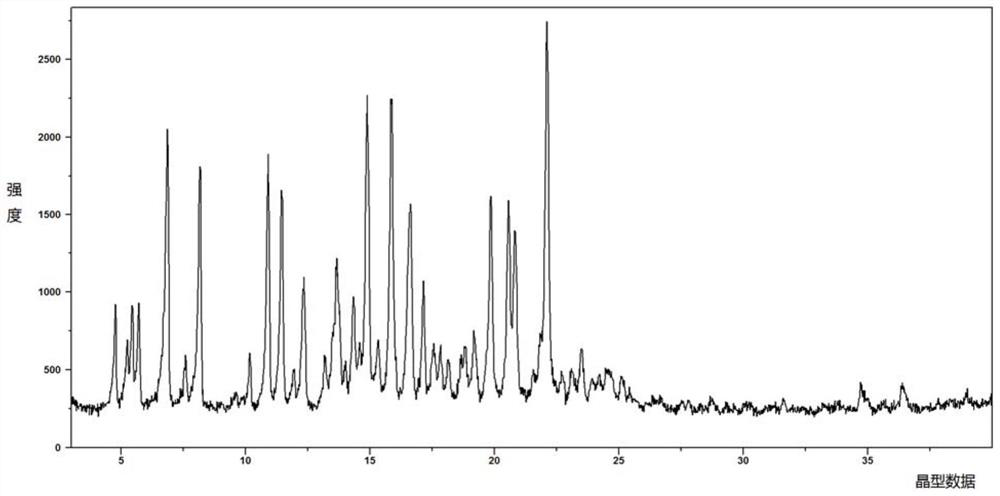

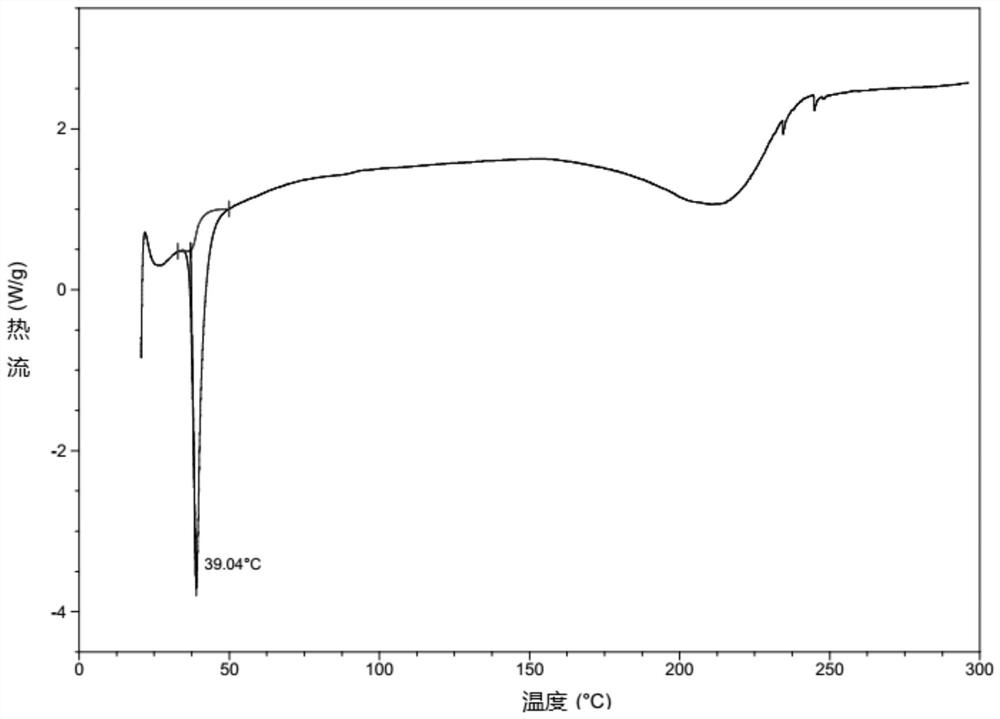

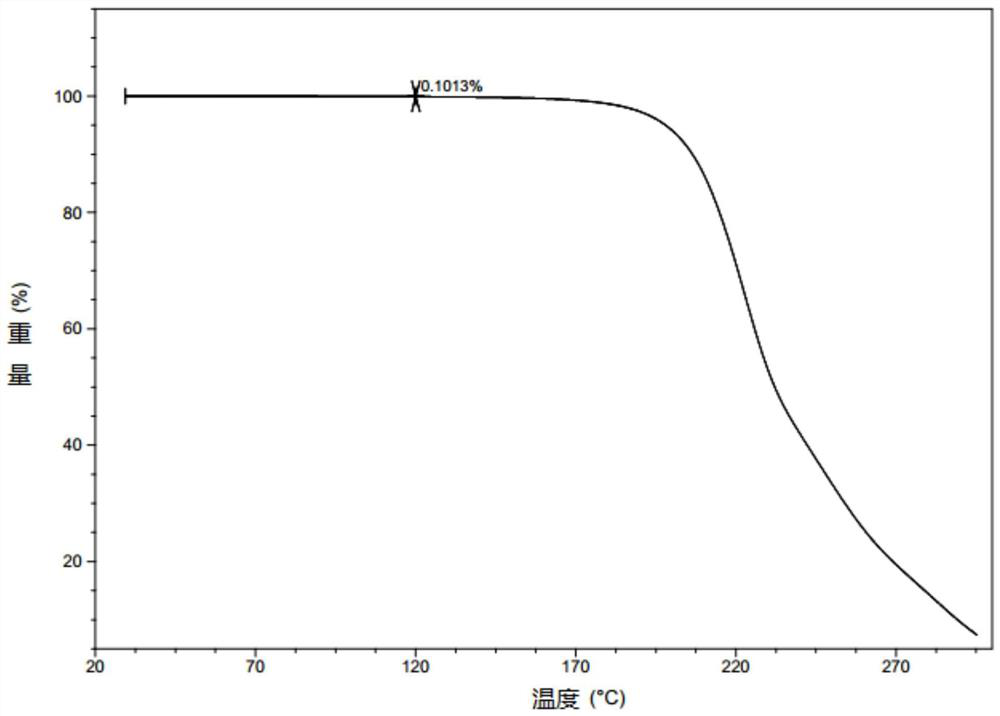

Crystal form of amantadine compound, and preparation method thereof

InactiveCN111662216ANervous disorderCarbamic acid derivatives preparationAmantidinePharmaceutical drug

The invention relates to a crystal form of an amantadine compound, and a preparation method of the crystal form, and belongs to the field of medicinal chemistry. The crystal form disclosed by the invention has good properties in the aspects of stability, solubility, dissolution, pharmacology and the like, and can be used for preparing pharmaceutical preparation production.

Owner:SUNSHINE LAKE PHARM CO LTD

Preparation method of high-purity amantadine hydrochloride

PendingCN111960951AReduce generationImprove product qualityAmino compound purification/separationAmantidineAmantadine HCl

The invention discloses a preparation method of high-purity amantadine hydrochloride. The method comprises the following steps: extraction: extracting the reacted material in the amantadine hydrochloride production process with extraction oil, and standing for layering; washing with water, layering, transferring into a washing kettle, and removing acid and impurities; crystallizing, transferring into a crystallization kettle, crystallizing, and drying the extract oil by a centrifuge to obtain a crude product; washing, separating the crude product by a centrifuge, drying the extract oil to obtain a crude product, putting the crude product into a washing kettle, adding a detergent, stirring and washing; and separating, separating the material from water by using a full-automatic self-discharging centrifuge to obtain a refined product, putting the refined product into a double-cone drying machine, drying, and packaging to obtain a finished product. In actual use, discharged wastewater isreduced, the water yield is low after the process is improved, the wastewater can be recycled in production, zero emission is achieved, and the purity of amantadine hydrochloride is improved to 99.96%from 99.15%; the maximum single impurity content is reduced from 0.26% to 0.03%; amantadine hydrochloride meets the requirements of most samples and reagents, and the recovery rate of amantadine hydrochloride is 89.5%.

Owner:中涛新材料有限公司

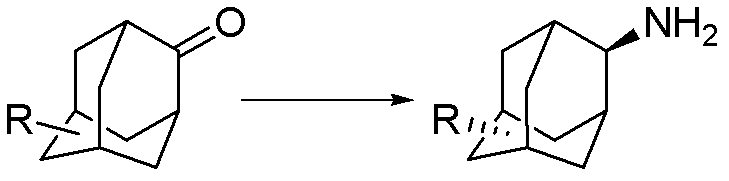

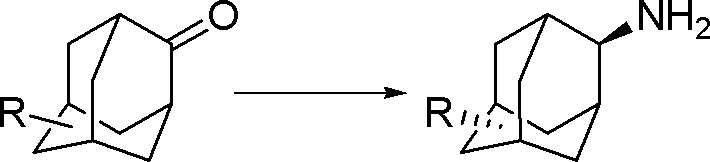

Synthesis method for trans-form amantadine compound

ActiveCN102503754AReduce dosageHigh purityOrganic compound preparationAmino-carboxyl compound preparationSynthesis methodsStructural formula

The invention relates to a synthesis method for a trans-form amantadine compound, which includes the steps of utilizing commercialize raw materials on the market or an easily prepared amantadine compound as initial materials, and carrying out reductive amination reaction between the initial raw materials and liquid ammonia under the action of a reductive agent and a catalyst, so that 100% of the trans-form amantadine compound (chemical structural formula in original text) (wherein R refers to -H, -COOH, -OH, -SO2NH2 and Cl) is obtained. The method has the advantages that raw materials are easy to obtain, both reaction purity and yield are high, loss of the trans-form amantadine compound is decreased by salifying for final treatment, production cost is reduced, and the method is applicable to large-scale production and provides a novel thinking for preparing the trans-form amantadine compound.

Owner:ASYMCHEM LAB TIANJIN +4

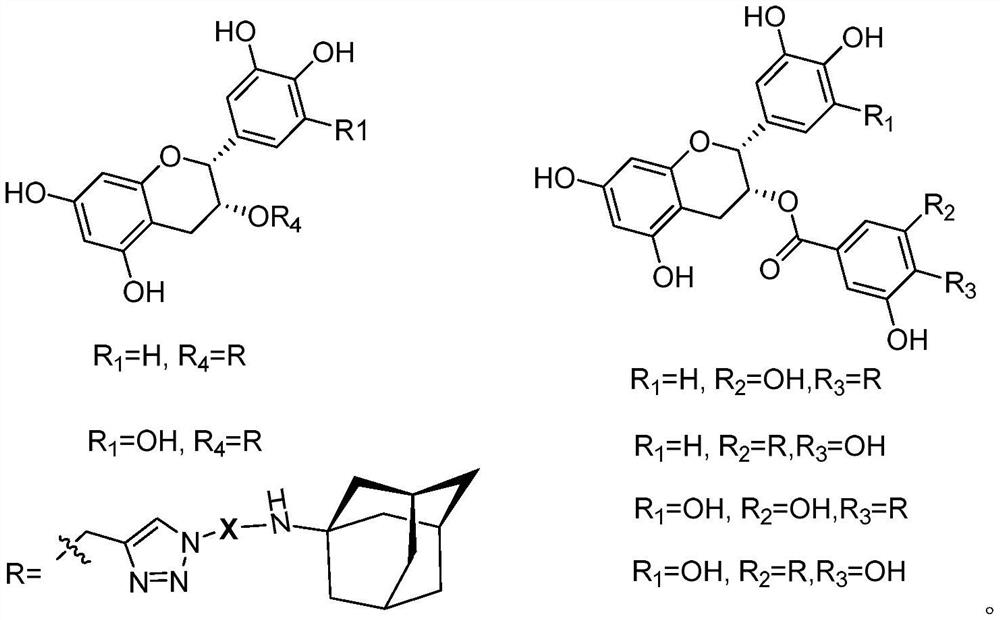

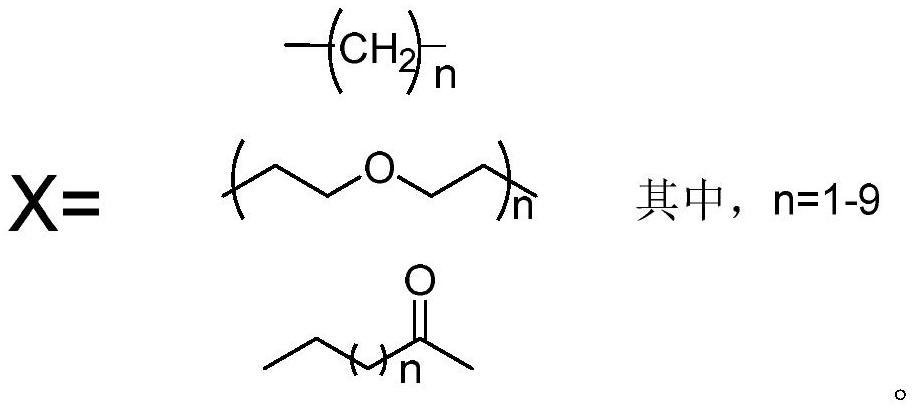

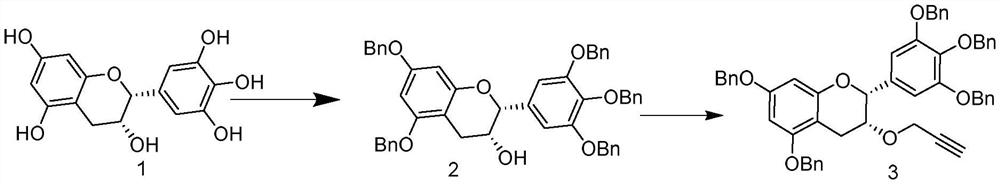

Catechin-amantadine conjugate and its preparation method and application

ActiveCN111606897BImprove bioavailabilityNovel structureOrganic chemistryAntiviralsAmantidinePtru catalyst

The invention discloses a catechin-amantadine conjugate and its preparation method and application. The derivative structure: the preparation method is: selective protection of catechin; under alkaline conditions, synthesizing the protected catechin terminal alkyne body; synthesis of amantadine azide intermediate; click reaction between terminal alkyne precursor and azidoadamantane precursor to synthesize catechin-adamantane conjugate; deprotection synthesis of catechin-amantadine under hydrogenation catalyst couples. The synthetic catechin-amantadine conjugate has novel structure, simple synthesis route, no noble metal catalyst, and the synthesized catechin amantadine has good anti-influenza activity.

Owner:GUIZHOU TEA RES INST

Anti-amantadine amd single-chain antibody scfv and its preparation method and application

The invention discloses an anti-amantadine AMD single-chain antibody and its preparation and application. The present invention can obtain the heavy chain and light chain variable region genes of the antibody from the hybridoma cell line 3F2 secreting the monoclonal antibody of amantadine AMD through genetic engineering, and construct the prokaryotic expression plasmid by recombining the two genes The carrier is transformed into Escherichia coli to express the scFv antibody active fragment that can specifically recognize AMD. It is proved by experiments that the recombinant single-chain antibody scFv prepared by the present invention has specific recognition and binding activity with amantadine AMD. The amantadine residue detection can be realized by using the recognition and binding activity of the recombinant single-chain antibody of the present invention to amantadine, and the constructed transformation vector plasmid is easy to preserve and mass-produce.

Owner:CHINA AGRI UNIV

A kind of method of multiphase duplex continuous production and preparation of vildagliptin

ActiveCN112939837BReduced stirring requirementsReduce post-processing stepsOrganic chemistryOrganic layerVildagliptin

The invention discloses a method for preparing vildagliptin by multiphase duplex continuous production. In the acid chloride solution, the reaction is carried out, the reaction solution is not treated, a dehydrating agent is added, quenched, the pH value is adjusted to neutrality, the organic layer is layered and added dropwise to the amantadine alcohol solution, the temperature is controlled and kept warm, concentrated, pulped, and filtered. , washing the filter cake, and drying to obtain vildagliptin. In the present invention, 2,6-lutidine is also used as a solvent as an acid binding agent, and the addition of amantadine is carried out under homogeneous conditions without generating solids, and the reaction solution is directly used to carry out the next step reaction. The stirring requirement is low; while the post-processing steps are reduced, the energy consumption is reduced and the yield is improved; the commercial production can be more realized; the time is shortened, the post-processing is simple, and the operating conditions are simple.

Owner:CHINA MEHECO SANYANG PHARMA CO LTD

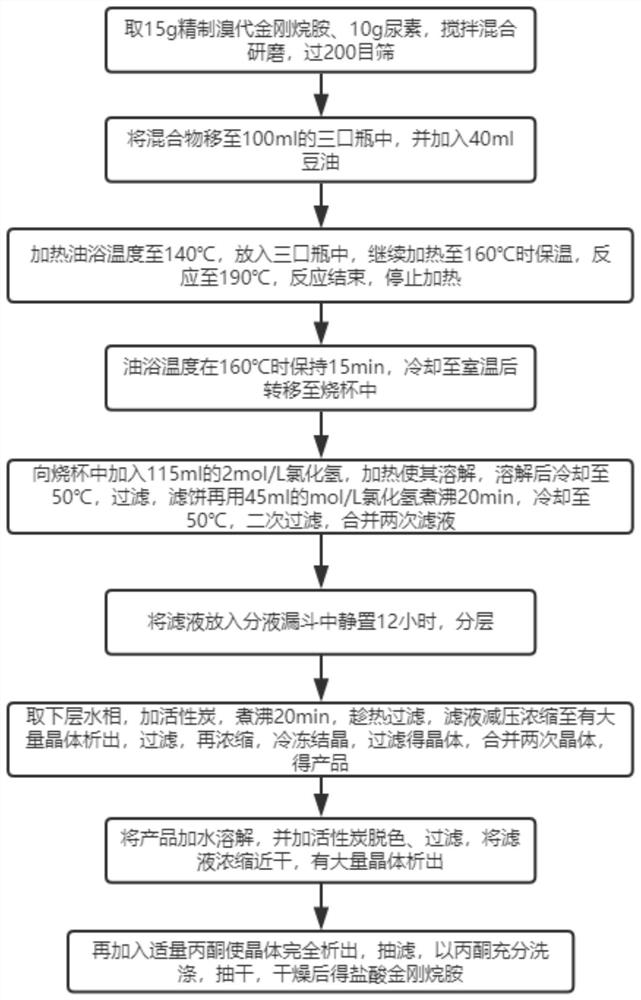

Amantadine hydrochloride impurity removal method

PendingCN112479899AThe synthesis process is simpleImprove pollutionAmino compound purification/separationAmino preparation from aminesChemical synthesisAmantidine

The invention discloses an amantadine hydrochloride impurity removal method, and relates to the technical field of chemical synthesis. The problem that waste gas and waste water are generated by usingfuming sulfuric acid is solved. The preparation method specifically comprises the following steps: taking 15g of refined bromo-amantadine and 10g of urea, stirring, mixing and grinding, and sieving with a 200-mesh sieve; transferring the mixture into a 100ml three-necked bottle, and adding 40ml of soybean oil; heating the oil bath to 140 DEG C, putting the oil bath into a three-neck bottle, continuously heating to 160 DEG C, keeping the temperature, reacting to 190 DEG C, and stopping heating after the reaction is finished. Brominated amantadine and urea are used as raw materials, soybean oilis used as a solvent, the reaction temperature is controlled to be 160 DEG C, the synthesis process of amantadine hydrochloride is improved, an impurity-removed pure amantadine hydrochloride productis obtained through hydrolysis, decoloration and purification, generation of waste gas is effectively reduced, and the problem of environmental pollution in the amantadine hydrochloride synthesis process is solved; compared with the prior art, wastewater is greatly reduced.

Owner:天津民祥药业有限公司

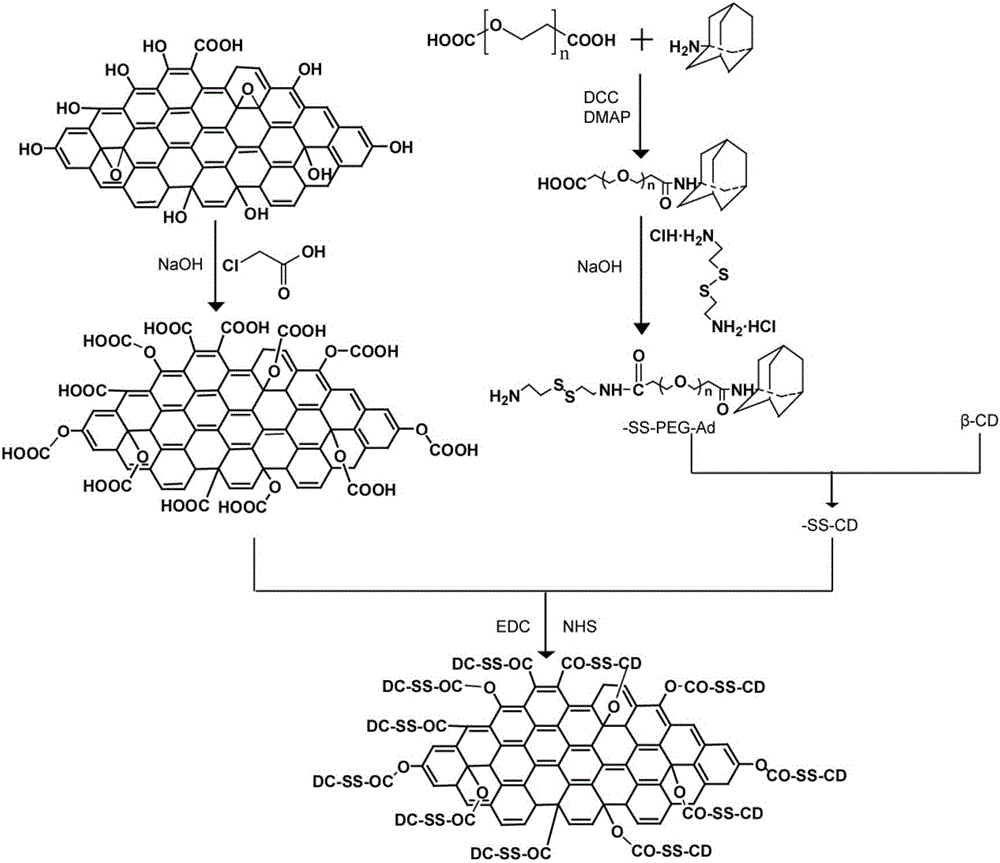

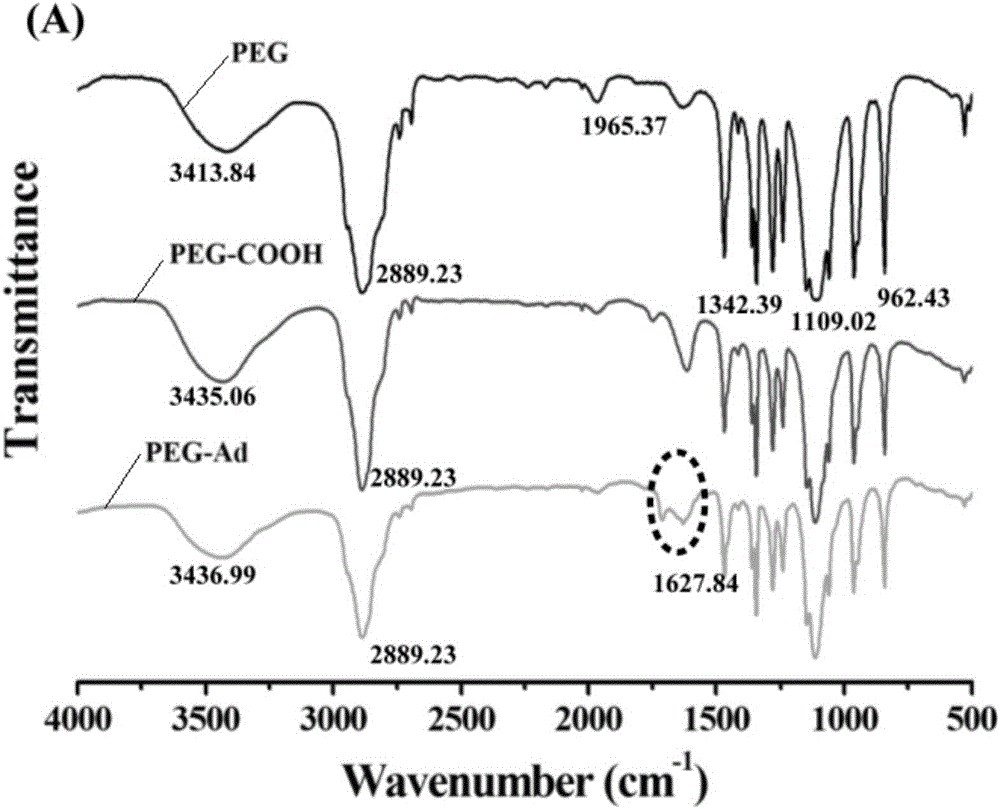

A kind of graphene oxide intelligent drug carrier that can be sensitively shed by supramolecules and its preparation method and application

InactiveCN105688226BDetermining stabilityFunction intelligent releaseOrganic active ingredientsPharmaceutical non-active ingredientsCyclodextrinDrug release

A supramolecular sensitive exfoliated graphene oxide smart drug carrier and its preparation method and application. Dissolve carboxylated amantadine in methylene chloride, then add EDC and NHS, and stir to obtain a solution; dissolve cystamine in In dichloromethane, add it to the solution to obtain amantadine containing disulfide bonds. Dissolve EDC in water, then add it to the GO‑COOH suspension. After sonication, add NH2‑SS‑PEG‑Ad and stir. After dialysis, amantadine-modified graphene oxide containing disulfide bonds was obtained; NGO‑SS‑Ad and cyclodextrin suspension were mixed and shaken to obtain cyclodextrin-modified graphene oxide. The supramolecular functionalized graphene oxide core-shell nano drug carrier synthesized by the present invention carries hydrophobic drugs containing large π conjugated structures through π-π interactions and hydrophobic interactions, and the disulfide bonds can be rapidly cleavable in the intratumor cell environment. , to realize the functions of supramolecular shedding and intelligent drug release.

Owner:NORTHWEST UNIV(CN)

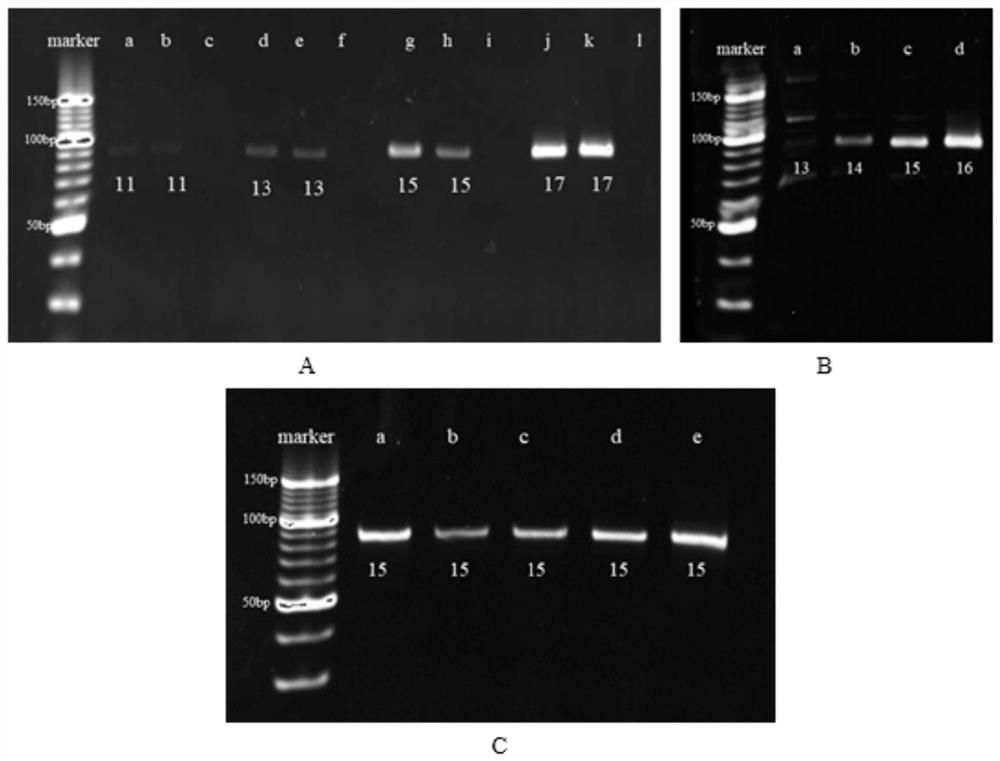

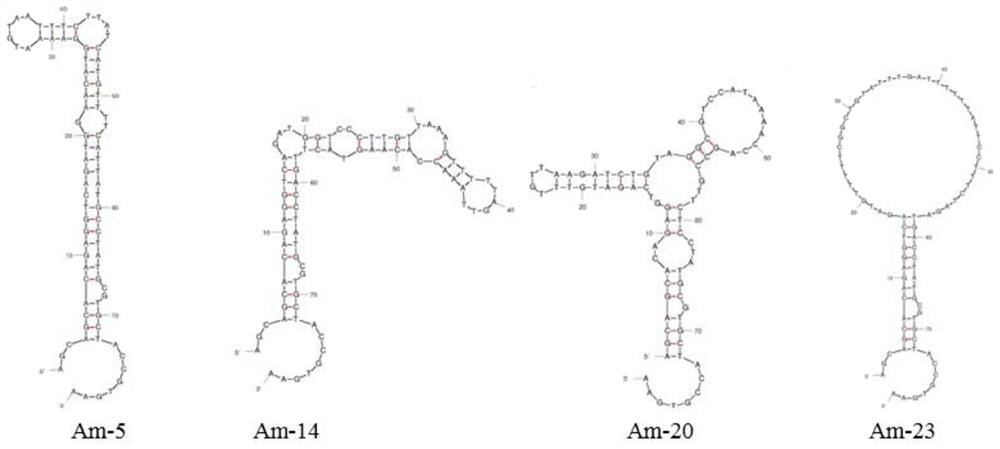

Aptamer for specific recognition of amantadine and its application

ActiveCN112961859BHigh sensitivityStrong specificityBiological testingDNA preparationAptamerAmantidine

The invention discloses an aptamer specifically recognizing amantadine and its application. The nucleotide sequence of the aptamer specifically recognizing amantadine of the present invention is shown in SEQ ID NO.1. The present invention utilizes the systematic evolution technology of library immobilized exponentially enriched ligands, takes amantadine as the target, screens and obtains an aptamer sequence with high affinity and strong specificity for amantadine, and the screened aptamer sequence The ligand sequence is highly sensitive, easy to prepare and easy to modify, and will be applied to the rapid detection of amantadine veterinary drug residues in food.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com