Patents

Literature

31 results about "Ethyleneimines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymeric chelant and coagulant to treat metal-containing wastewater

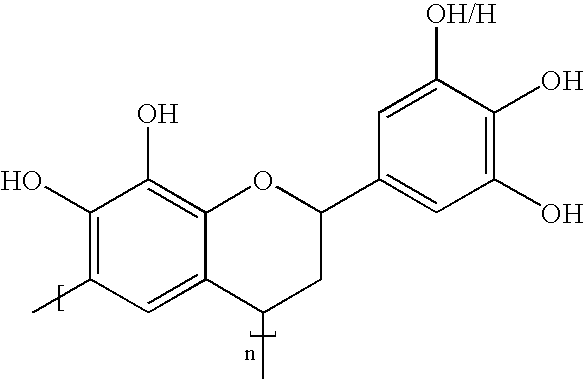

The present invention is directed to the use of a combination of a polymeric chelant and coagulant to treat metal containing wastewater. More particularly, the invention is directed at removing copper from CMP wastewater. The composition includes a combination of (a) a polymeric chelant derived from a polyamine selected from the group consisting of diethylenetriamine (DETA), triethylenetetraamine (TETA), tertraethylenepentaamine (TEPA), poly[vinylamine], and branched or linear poly[ethylenimine] (PEI); and (b) a water soluble or dispersible copolymer of a tannin and a cationic monomer selected from the group consisting of methyl chloride or dimethyl sulfate quaternary salt of dimethyl aminoethyl acrylate, diethylaminoethyl acrylate, dimethylaminoethyl methacrylate, diethylaminoethyl methacrylate, dimethylaminopropyl methacrylamide, dimethylaminopropyl acrylamide, and diallyl dimethyl ammonium chloride.

Owner:GENERAL ELECTRIC CO

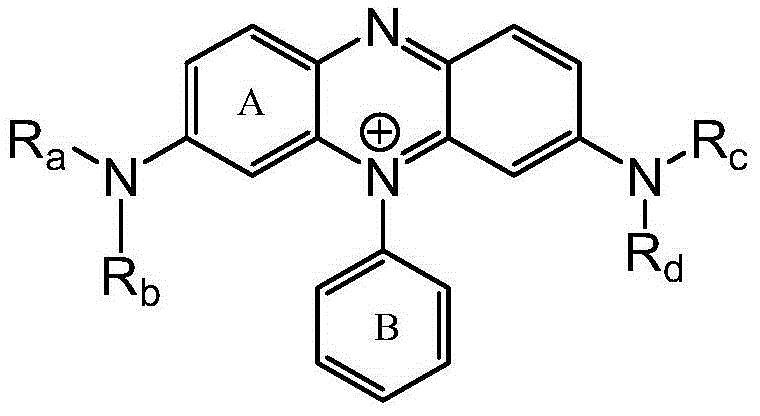

Leuco polymers as bluing agents in laundry care compositions

ActiveUS20180119063A1Organic detergent compounding agentsSurface-active detergent compositionsNitrogenLaundry

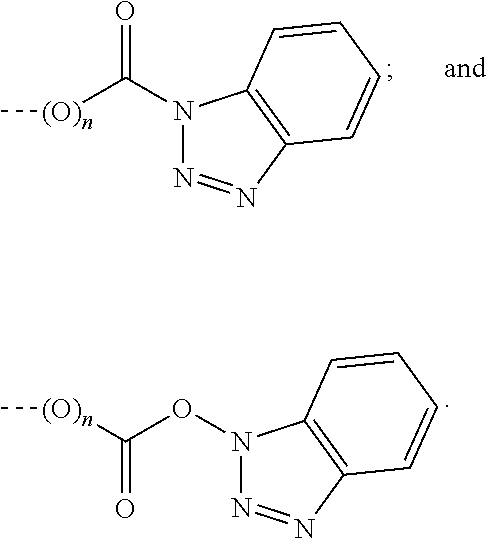

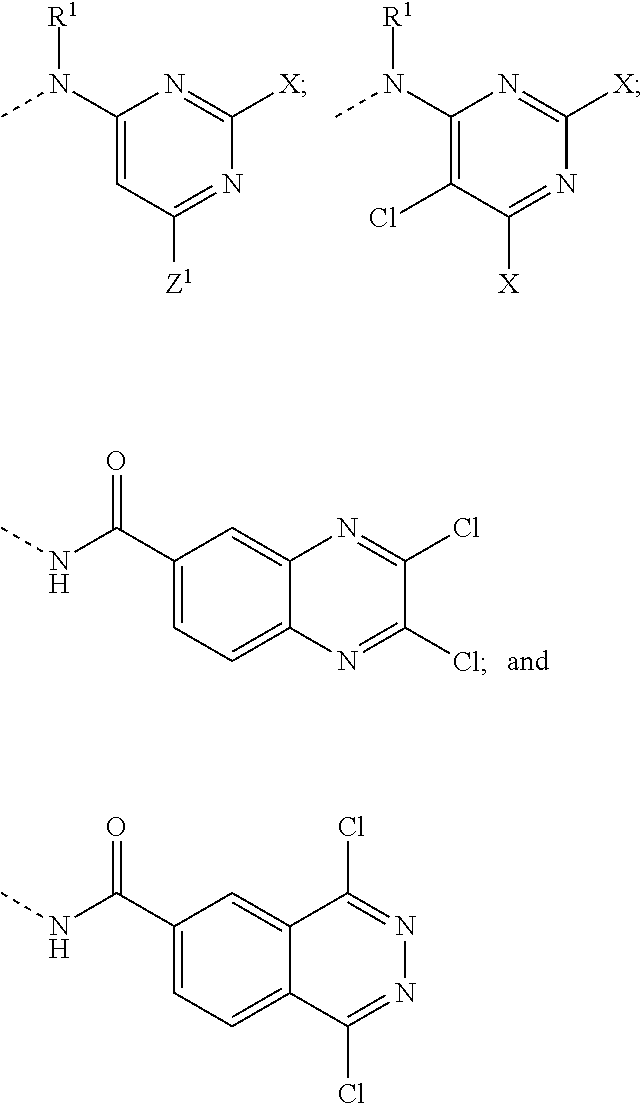

A laundry care composition including (i) from 2 to 70 wt % of a surfactant; and (ii) from 0.0001 to 20.0 wt % of a leuco polymer including an alkoxylated polyethyleneimine covalently bound to a leuco moiety. At least a first portion of nitrogen atoms of the alkoxylated polyethyleneimine have covalently bound thereto a leuco moiety. At least a second portion of nitrogen atoms of the alkoxylated polyethyleneimine have covalently bound thereto a moiety selected from the group consisting of oxyalkylene moieties, polyoxyalkylene moieties, and mixtures thereof; and at least a third portion of nitrogen atoms of the alkoxylated polyethyleneimine have covalently bound thereto a moiety selected from the group consisting of an alkylene chain, an alkylene chain having covalently bound thereto a phenyl or naphthyl group, and mixtures thereof. Methods of making the leuco polymer and methods of treating textiles with such laundry care compositions.

Owner:THE PROCTER & GAMBLE COMPANY

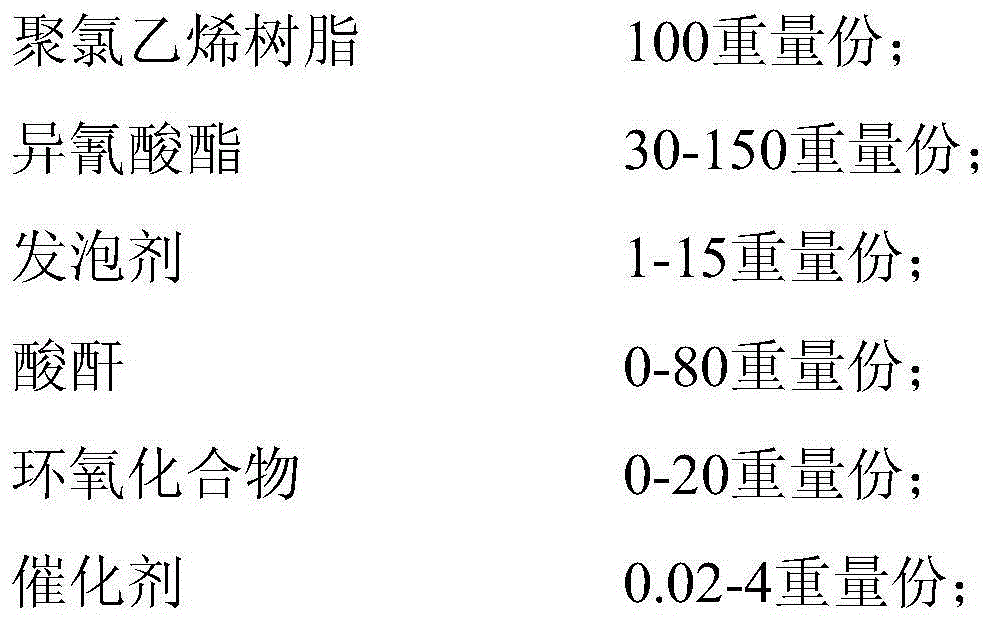

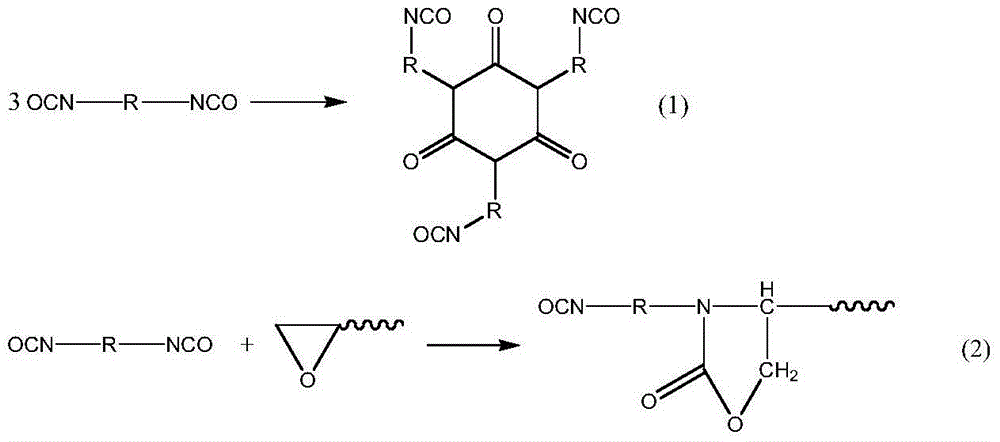

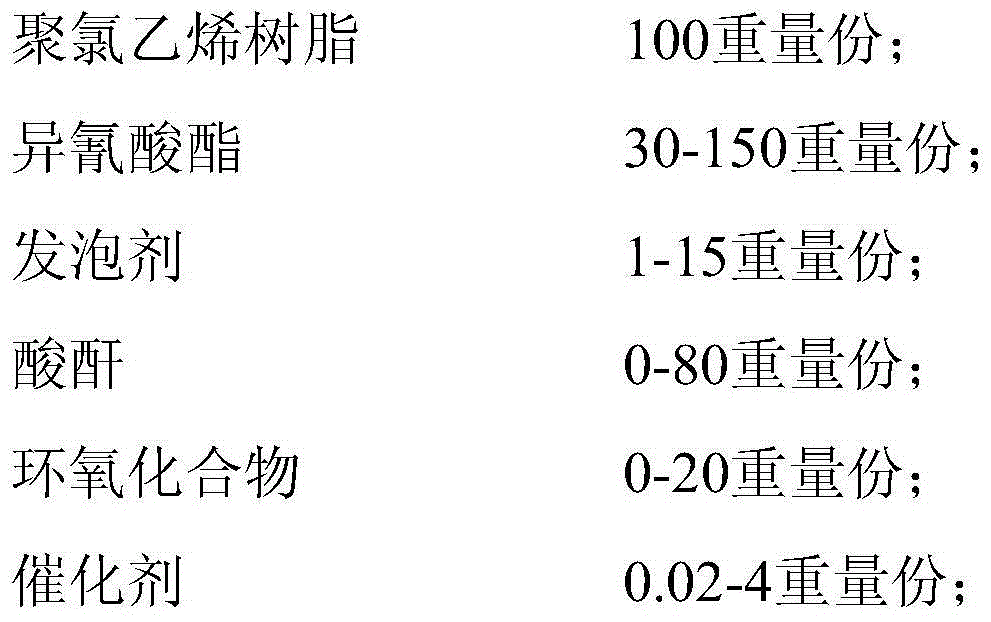

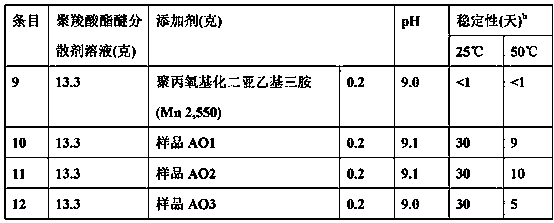

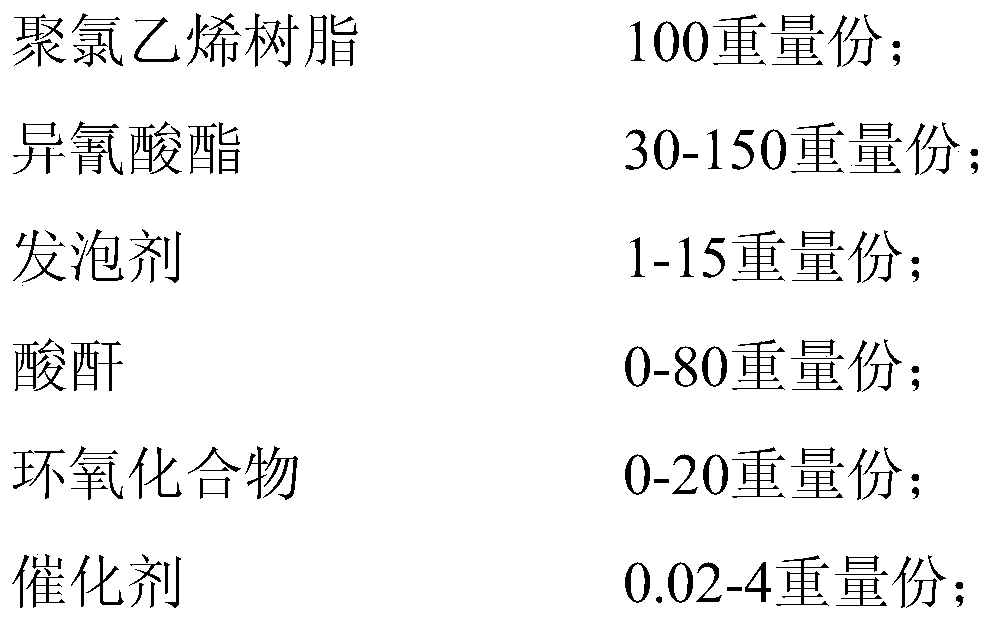

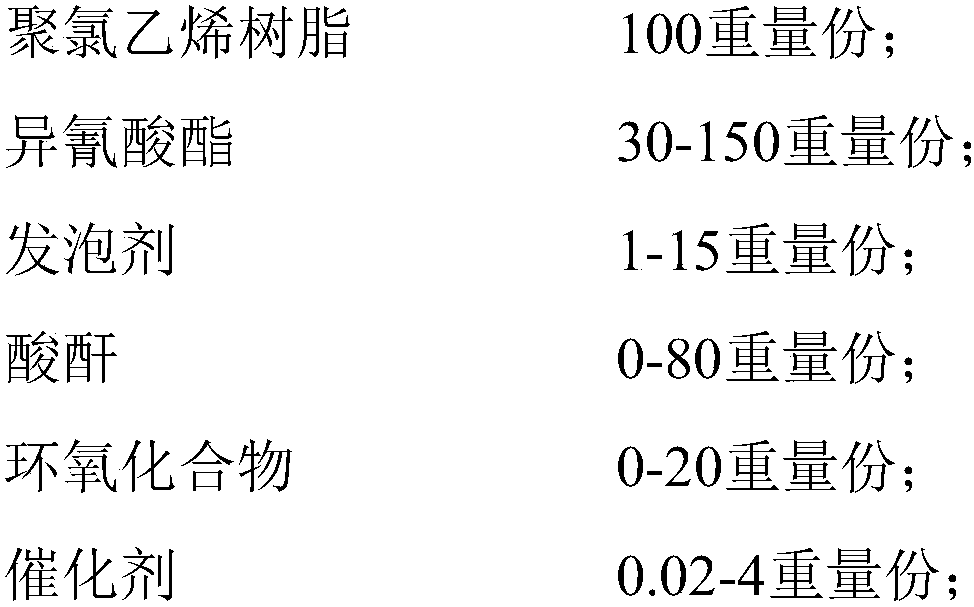

Crosslinking polyvinyl chloride foam and preparation method thereof

The invention discloses crosslinking polyvinyl chloride foam and a preparation method thereof, and belongs to the technical field of foamed materials. The problem of long time consumption of preparation of a crosslinking polyvinyl chloride foamed material in the prior art is solved, so that the quality and heat-resistant performance of the foamed material can be improved. The crosslinking polyvinyl chloride foam comprises the components in parts by weight: 100 parts of PVC resins, 30-150 parts of isocyanate, 1-15 parts of foaming agents, 0-80 parts of anhydride, 0-20 parts of epoxy compounds and 0.02-4 parts of catalysts, wherein the catalyst is one or more of N',N'',N'''-tri(dimethyl aminopropyl) symmetrical hexahydro-triazine, N-(alpha-ethoxyl) dimethylenimine, indole, sodium caprylate, isocaprylic acid, potassium oleate and potassium stearate. The foamed material is high in quality and heat-resistant performance, and high in production efficiency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

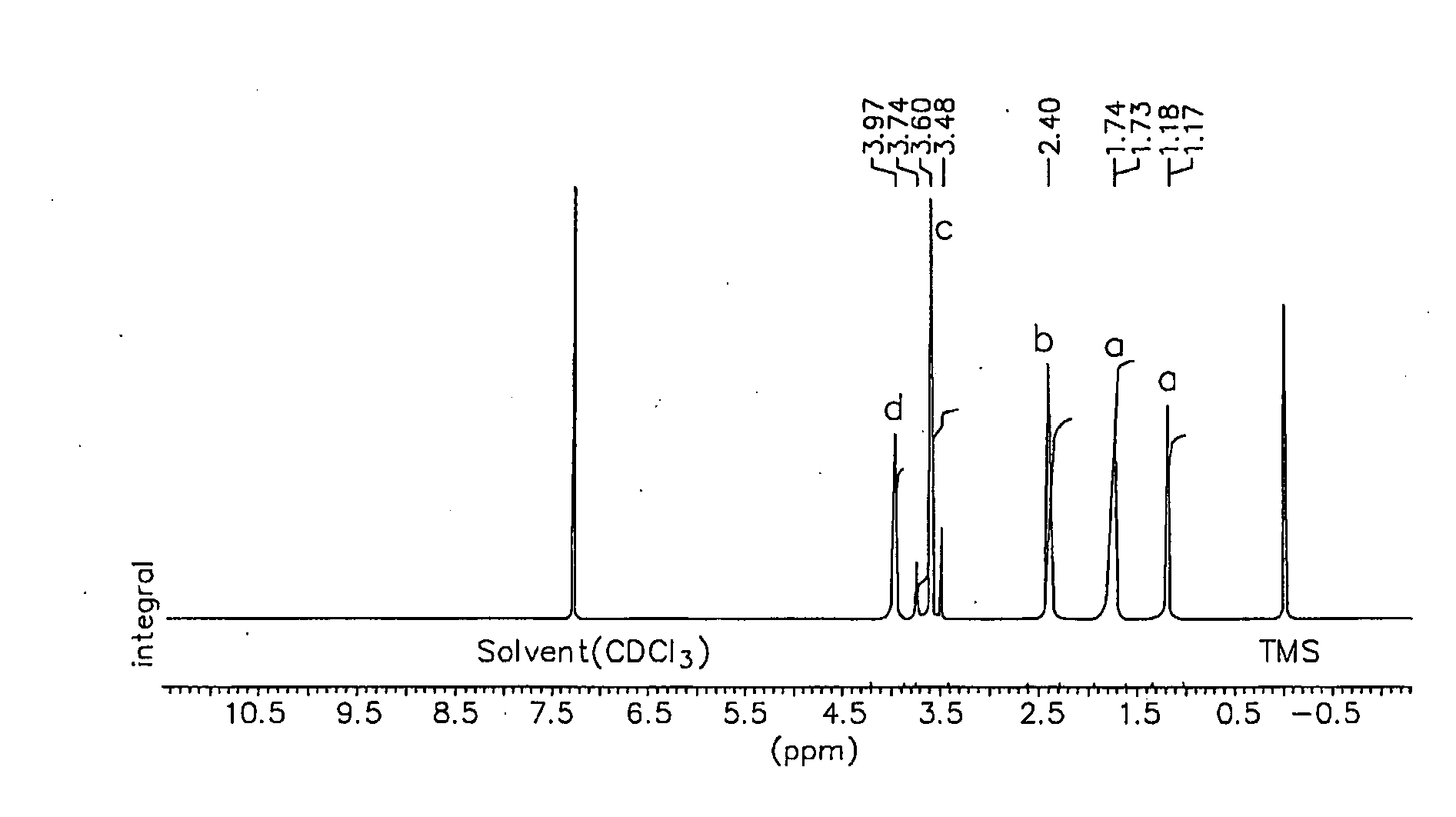

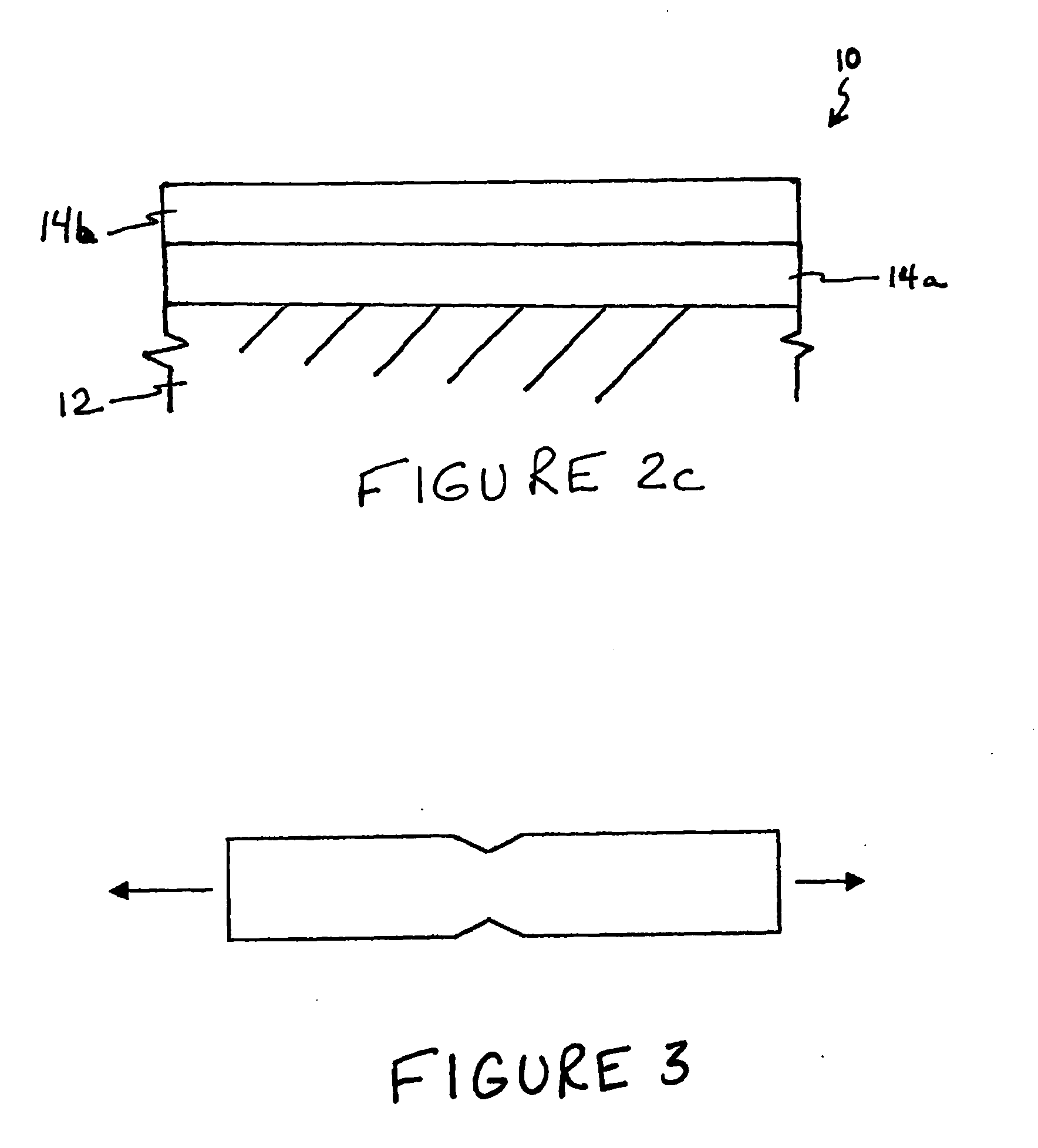

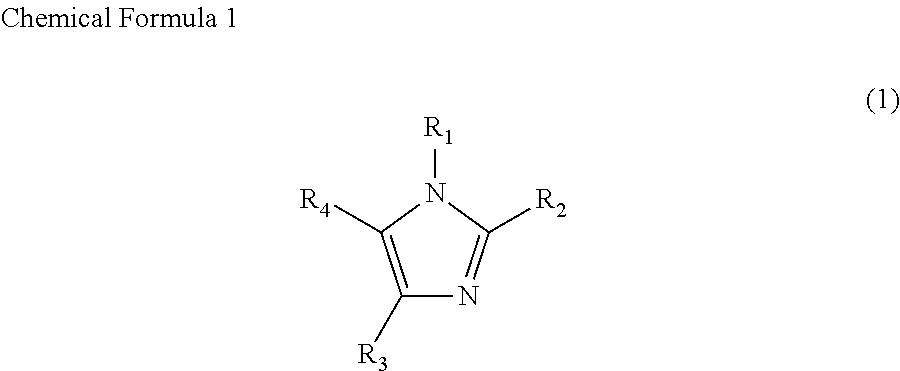

Method of surface modification of polyimide film using ethyleneimines coupling agent, manufacturing method of flexible copper clad laminate and its product thereby

InactiveUS20090023010A1Low costReduce environmental pollutionSilicon organic compoundsPrinted circuit aspectsChip on filmCopper foil

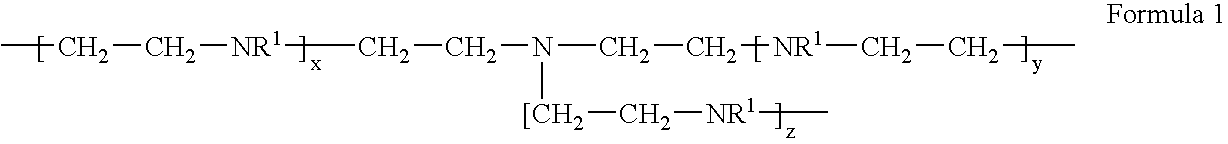

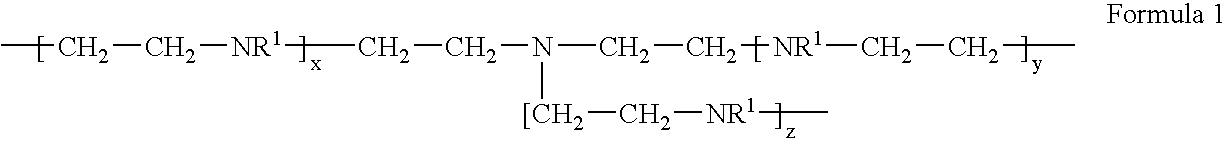

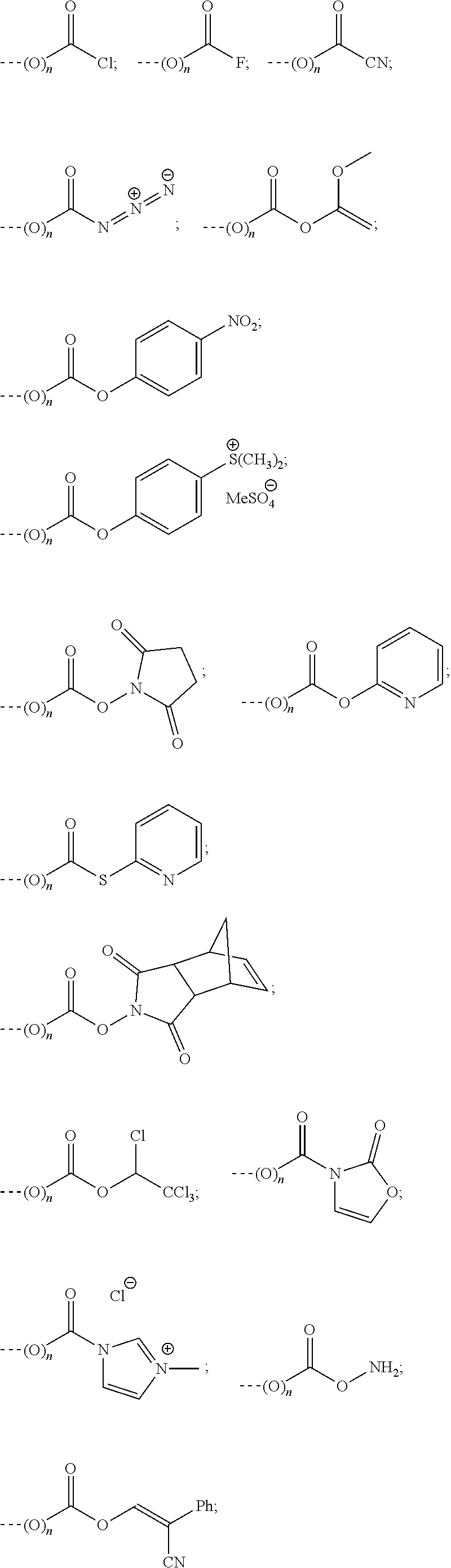

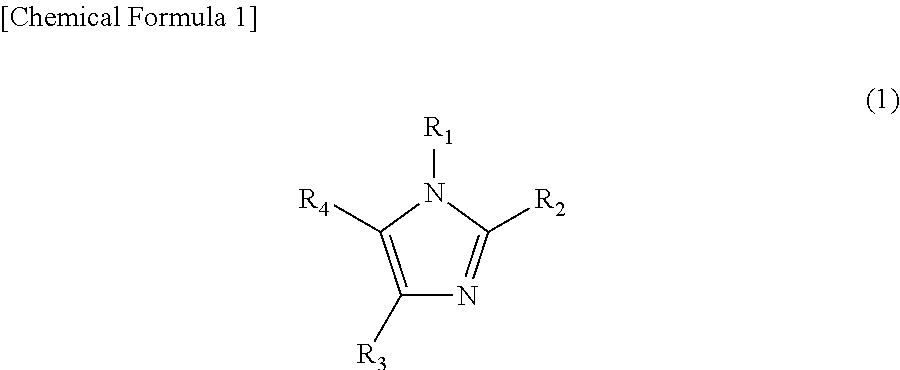

A method of surface modifying a polyimide film, a method of manufacturing a flexible copper clad laminate using the same, and a flexible copper clad laminate (FCCL) having a two-layer structure manufactured thereby. The method of surface modifying a polyimide film is conducted by modifying the surface of a polyimide film through a first plasma treatment, dipping the polyimide film into a solution containing an ethyleneimine-based silane coupling agent prepared by mixing the compound of Formula 1 and the compound of Formula 2 at a molar ratio of with 0.25˜1, and then modifying the surface of the polyimide film through a second plasma treatment. The method of surface modifying a polyimide film is advantageous because it may be substituted for a conventional surface treatment processes using ion beams. Also, the FCCL having a two-layer structure, formed by conducting copper sputtering and electroplating on the surface modified polyimide film, has good adhesive strength between the polyimide film and the copper foil and can maintain such adhesive strength even at high temperatures for a long period of time. Further, it may be usefully applied to electronic parts, such as flexible printed circuit boards, TCP (Tape Carrier Package), COF (Chip On Film), etc.

Owner:KOREA RES INST OF CHEM TECH

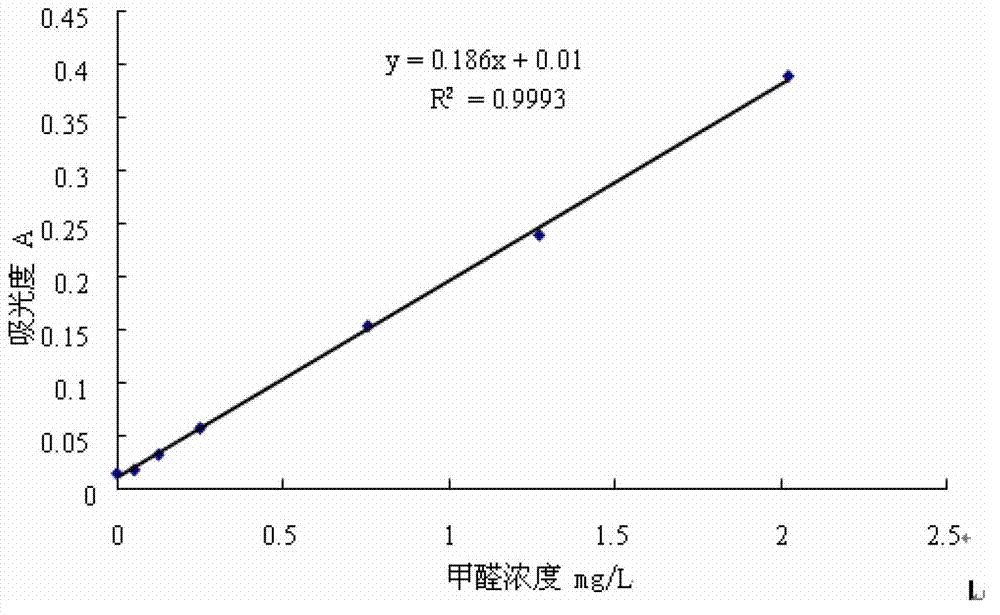

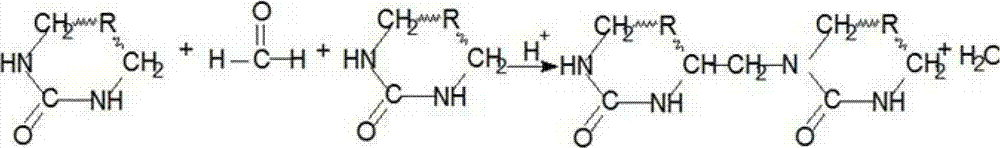

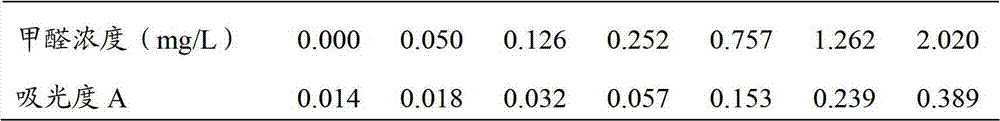

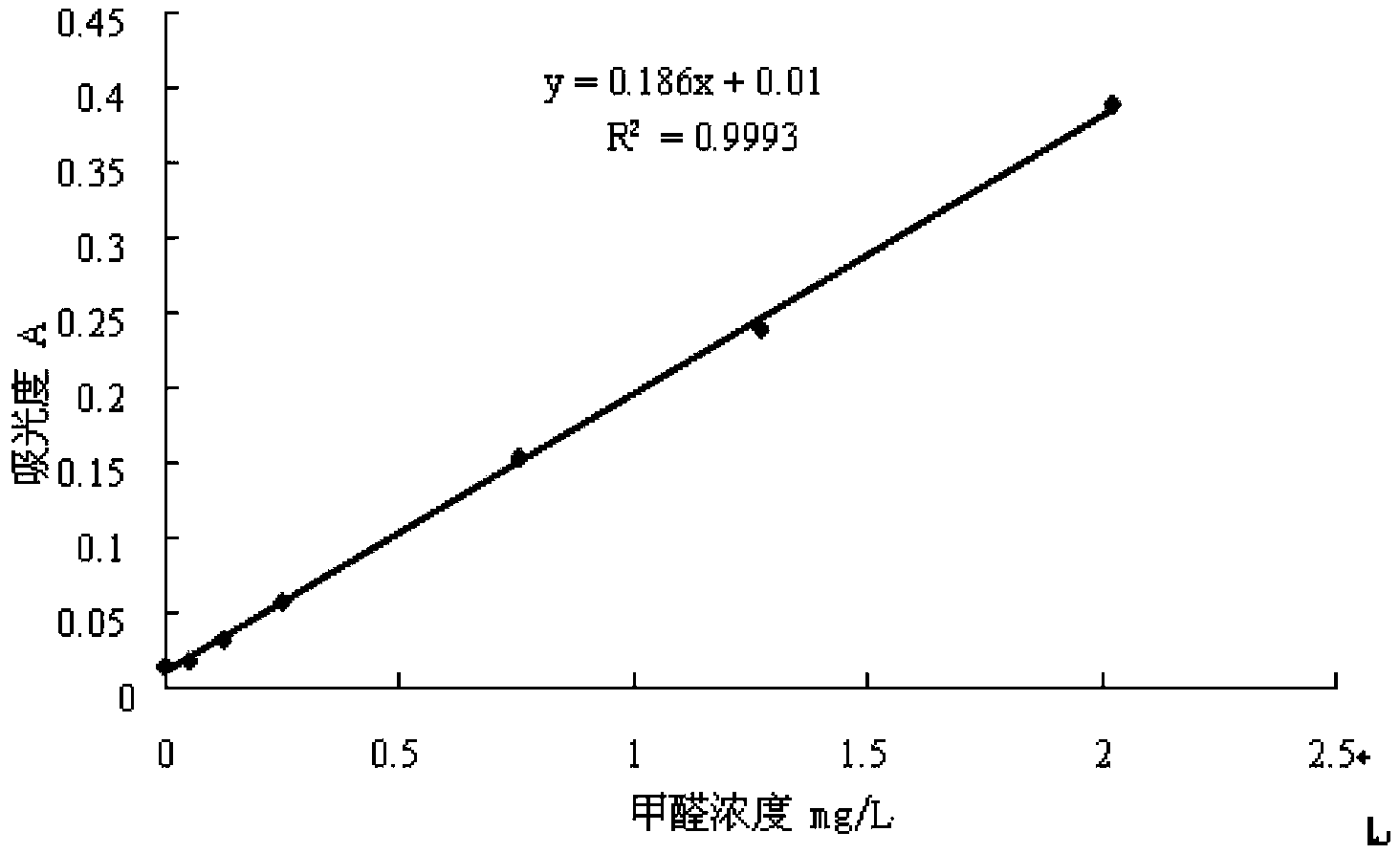

Environmentally friendly water-based paint capable of removing formaldehyde through reacting and preparation method thereof

ActiveCN102827516AInhibition releaseSignificant reaction adsorption capacityCoatingsEnvironmental resistanceWater based

An environmentally friendly water-based paint capable of removing formaldehyde through reacting comprises 1 to 10 weight parts of ethylideneimine ketone, 30 to 45 weight parts of polymer emulsion, 0.5 to 2.0 weight parts of a film forming additive, 0.1 to 0.5 weight parts of an antifoaming agent, 20 to 40 weight parts of filling materials, 15 to 30 weight parts of distilled water and 2 to 5 parts of other additives. The preparation method of the environmentally friendly water-based paint comprises successively adding a wetting agent, a dispersant, parts of the antifoaming agent and the filling materials into the distilled water and then grinding to disperse to get slurry ; preparing a 30 % ethylideneimine ketone solution which is then added into the polymer emulsion; and successively adding the slurry, the film forming additive, the remaining antifoaming agent, a mildew preventor, an antifreeze, a levelling agent and a thickening agent into the polymer emulsion, adjusting a PH value to 8.0 to 9.5, and finally carrying out constant volume operation with the distilled water. The paint can effectively inhibit release of the formaldehyde in water-based paints, and has advantages of low production cost, simple process and suitability for popularizing.

Owner:FUZHOU BIMITER ENVIRONMENT FRIENDLY PROD

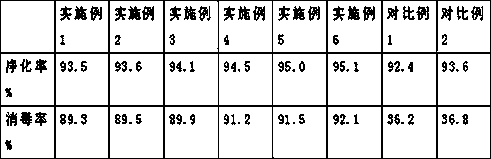

Sewage purification disinfectant and preparation method thereof

ActiveCN104355373ANot affected by hardnessHas purifying and sterilizing effectBiocideDead animal preservationDisinfectantRaw material

Owner:重庆中迪水处理技术有限公司

Primer composition for acrylic adhesive, bonding method and assembly

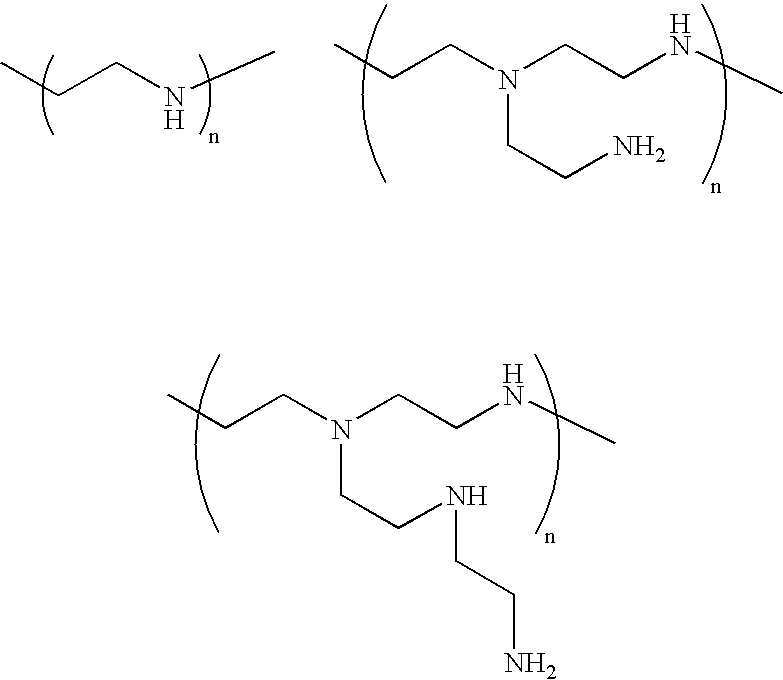

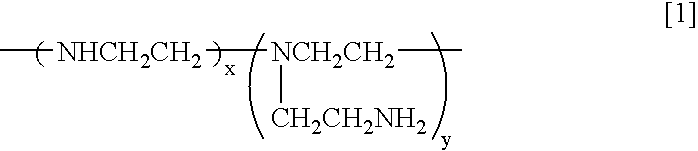

InactiveUS20100119854A1Rapid responseOther chemical processesSynthetic resin layered productsEthyleneimineOligomer

To provide a primer composition for assisting an acrylic adhesive which exhibits a temporarily fixing effect very quickly and which is completely cured quickly at room temperature, while maintaining excellent characteristics of the acrylic adhesive.A primer composition, which comprises a component (A): a basic compound having a primary, secondary or tertiary amine structure, a component (B): a liquid oligomer, and a component (C): a solvent. Preferably, the component (A) is a compound having a main chain of which the skeleton is ethyleneimine, or ethyleneimine having a molecular weight of from 50 to 70,000. Further, a bonding method, which comprises applying the above primer composition on a surface of an object to be bonded by dot coating, and bonding the object to another object to be bonded by means of the acrylic adhesive.

Owner:DENKA CO LTD

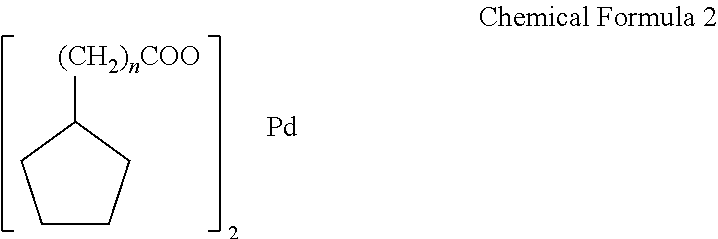

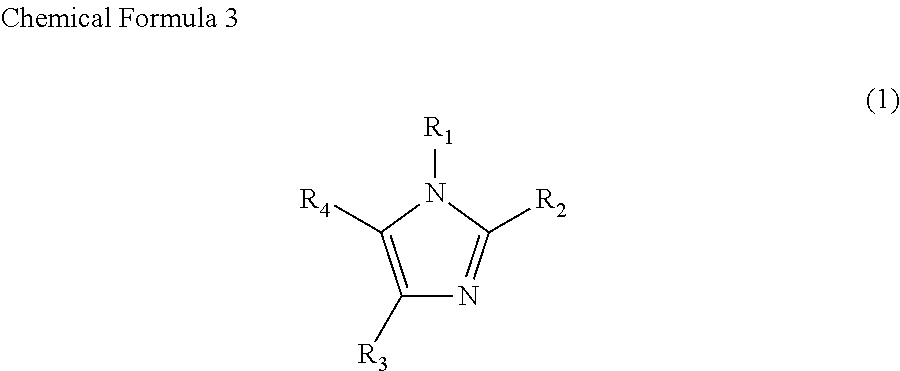

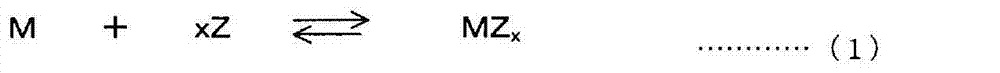

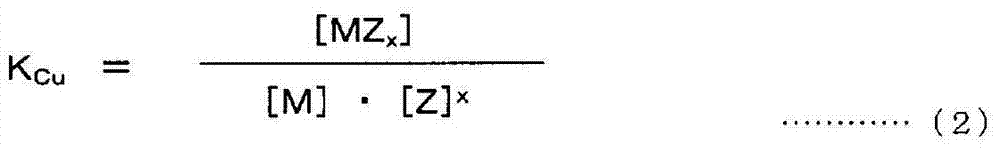

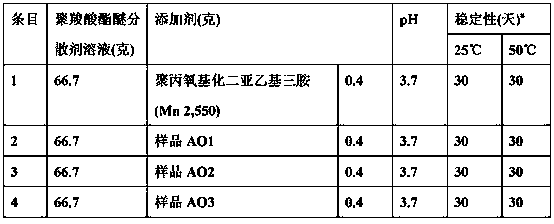

Electroless plating pretreatment agent, electroless plating method using same, and electroless plated object

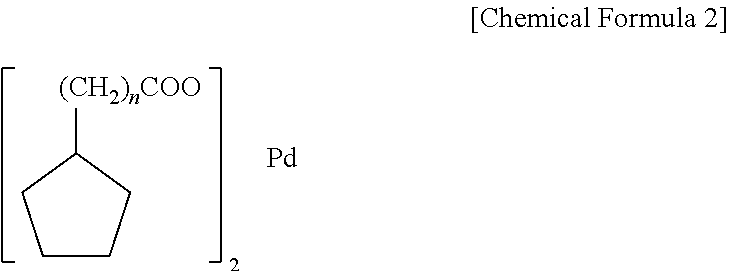

ActiveUS20120192758A1High bonding strengthActivation treatmentPretreated surfacesAnti-corrosive paintsElectroless platingEthyleneimines

It is an object of the present invention to provide an electroless plating pretreatment agent that can retain stably Pd(II) over a long period of time in an organic solvent, an electroless plating method using the same that is capable of forming an electroless plated film having excellent adhesion, and an electroless plated object. The object is achieved by an electroless plating pretreatment agent comprising an organic palladium compound and a coordination compound having a functional group with a metal-capturing capability dissolved in an organic solvent, the coordination compound being selected from the group consisting of the imidazole analogs, polyethyleneamines, ethyleneimines and polyethyleneimines.

Owner:JX NIPPON MINING& METALS CORP

Compostable reinforced paper, method of making same

A composite material includes at least one layer of fibrous material; and at least one biodegradable polymer layer composed of at least one biodegradable polymer, at least one biodegradable copolymer or both at least one biodegradable polymer and at least one biodegradable copolymer. The biodegradable polymer and biodegradable copolymer are each composed of a polymer block selected from the group consisting of poly(alkylene glycol), poly(alkylene oxide), poly(ethylene imine), polyalkylene, polyvinyl, polyvinylether, poly(vinylacetate), polyvinylpyrrolidine, polyester, polylactide, polyglycolide, polycaprolactone, poly(hydroxyalkanoate), poly(meth)acrylates, poly(acrylic acid) and salts thereof, polyether, polyurethane, poly(methacrylic acid) and salts thereof, polyacrylamide, polyepoxide, polyol, polysaccharide, and latex.

Owner:C J MULTI TECH ENTERPRISES

Multiple sewage processing material

InactiveCN104944503AImprove adsorption capacityEasy to handleOther chemical processesWater/sewage treatment by sorptionFerric hydroxideCellulose

The invention relates to a multiple sewage processing material, which comprises the following raw materials by weight: 3-10 parts of polyvinyl ester, 5-7 parts of heavy liquid paraffin, 3-5 parts of attapulgite, 3.2-6 parts of maleic anhydride grafted polypropylene, 4-9 parts of sodium sulfate, 2.5 parts of 8 parts of active carbon, 1-5 parts of sodium benzenesulfonate, 4-8 parts of cobalt oxide, 12-18 parts of alumina, 1.5-7 parts of sodium dodecanesulphonate, 6-11 parts of montmorillonite, 6-14 parts of carboxymethyl methyl cellulose, 1-5 parts of ferric hydroxide, 1.2-3 parts of anatase titanium dioxide, 6-13 parts of polyethyleneimine and 6-10 parts of aluminum sulfate. The multiple sewage processing material has good processing effect, can better absorb particles, and can reduce the metal ion in sewage with little usage amount.

Owner:青岛千帆高新技术有限公司

Method of surface modification of polyimide film using ethyleneimines coupling agent, manufacturing method of flexible copper clad laminate and its product thereby

InactiveUS8419918B2Low costReduce environmental pollutionSilicon organic compoundsPrinted circuit aspectsChip on filmCopper foil

A method of surface modifying a polyimide film, a method of manufacturing a flexible copper clad laminate using the same, and a flexible copper clad laminate (FCCL) having a two-layer structure manufactured thereby. The method of surface modifying a polyimide film is conducted by modifying the surface of a polyimide film through a first plasma treatment, dipping the polyimide film into a solution containing an ethyleneimine-based silane coupling agent prepared by mixing the compound of Formula 1 and the compound of Formula 2 at a molar ratio of with 0.25˜1, and then modifying the surface of the polyimide film through a second plasma treatment. The method of surface modifying a polyimide film is advantageous because it may be substituted for a conventional surface treatment processes using ion beams. Also, the FCCL having a two-layer structure, formed by conducting copper sputtering and electroplating on the surface modified polyimide film, has good adhesive strength between the polyimide film and the copper foil and can maintain such adhesive strength even at high temperatures for a long period of time. Further, it may be usefully applied to electronic parts, such as flexible printed circuit boards, TCP (Tape Carrier Package), COF (Chip On Film), etc.

Owner:KOREA RES INST OF CHEM TECH

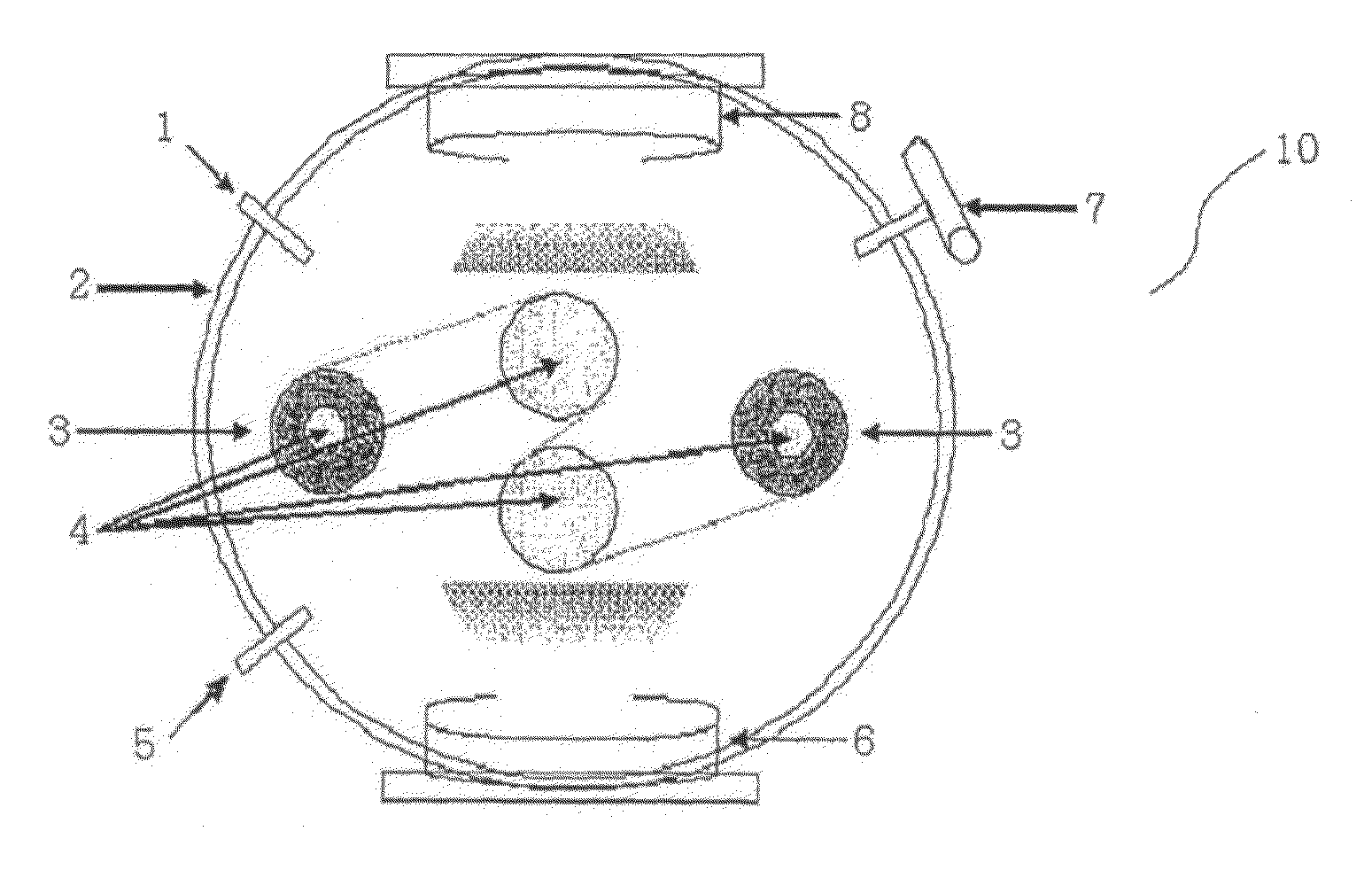

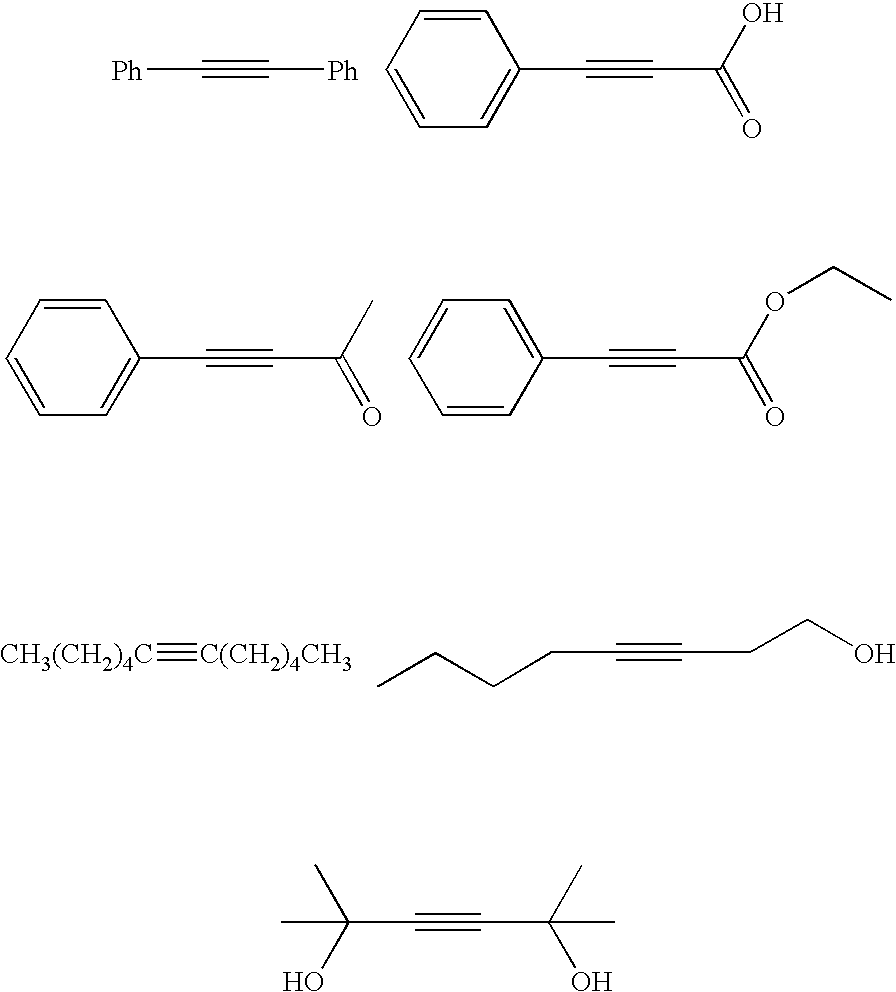

Novel Catalyst

InactiveUS20080269425A1Easy to usePreparation by hydrogenationHydrocarbon by hydrogenationHydrogenCombined use

The present invention is directed to provide a catalyst for reduction, which is capable of reducing even mono-substituted alkynes to alkenes and does not require the coexistence (combined use) of a toxic compound, and a method for reduction from alkynes to alkenes using the catalyst; and relates to a palladium-supported polyethyleneimine compound obtained by contacting a polyethyleneimine, a palladium compound and hydrogen gas in an oxygen-free state, a method for producing the above palladium-supported polethyleneimine compound, a catalyst for reduction comprising the above palladium-supported polyethyleneimine compound, and a method for reducing from alkynes to alkenes characterized by contacting an alkyne and hydrogen in the presence of a palladium-supported polyethyleneimine compound, which is obtained by reacting a polyethyleneimine, a palladium compound and hydrogen gas in an oxygen-tree state.

Owner:WAKO PURE CHEMICAL INDUSTRIES

Coating agent for recording layer protection and recording medium coated therewith

InactiveCN1956851AHigh recording mediumImprove water resistanceLiquid surface applicatorsInksPolyvinyl alcoholPolyamide

The invention provides a coating agent for recording layer protection, characterized by comprising a carboxy-modified polyvinyl alcohol (A), a polyamide-polyamine epihalohydrin (B), and polyethyleneimine (C). Preferably, it is characterized in that the carboxy-modified polyvinyl alcohol (A) has a degree of saponification of 90 to 99.5 mol%. The coating agent for recording layer protection is highly effective in imparting water resistance to a recording medium. Also provided is a recording medium having high water resistance, characterized by being obtained by applying the coating agent for recording layer protection to a recording layer.

Owner:SEIKO PMC CORP

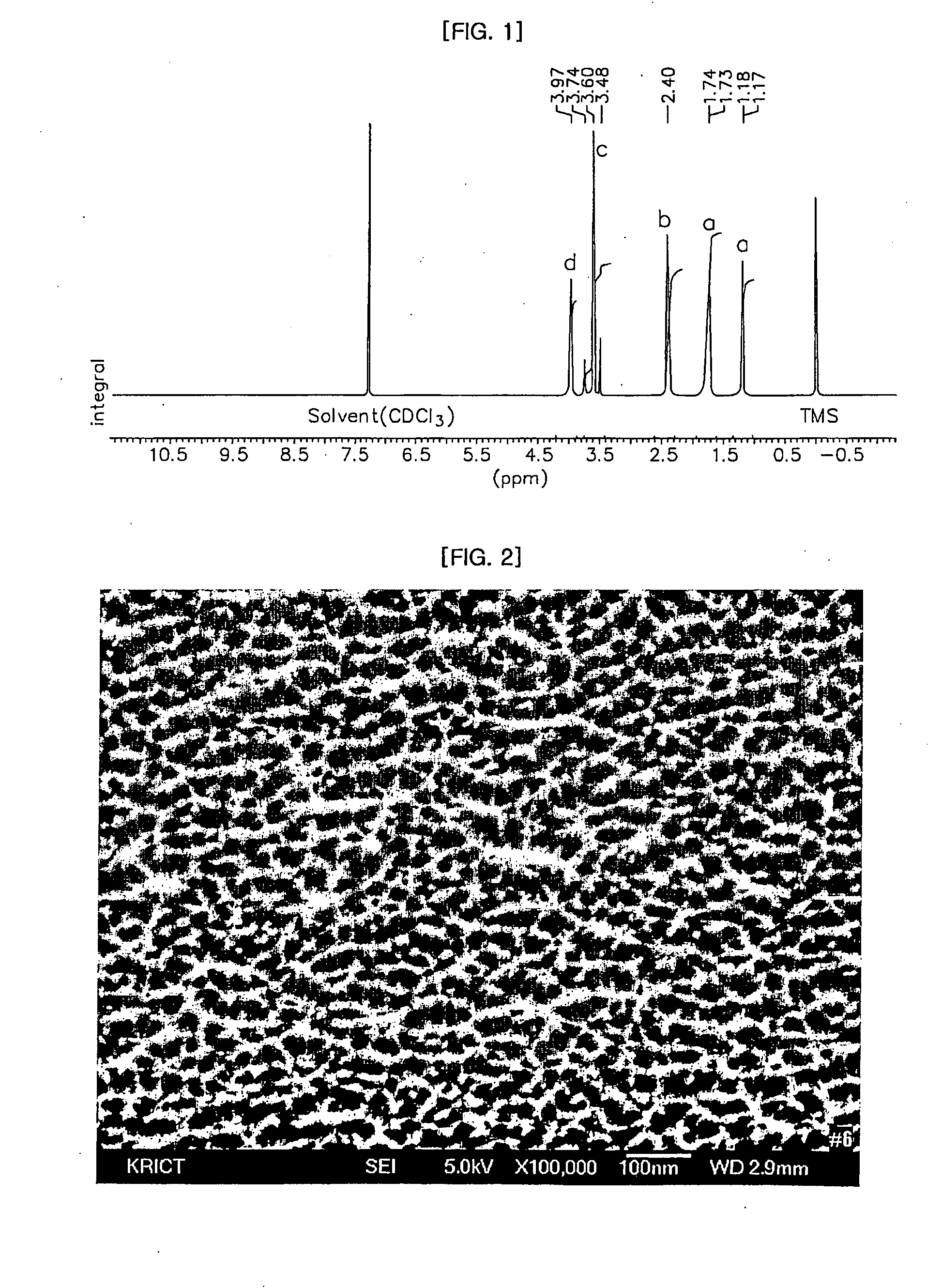

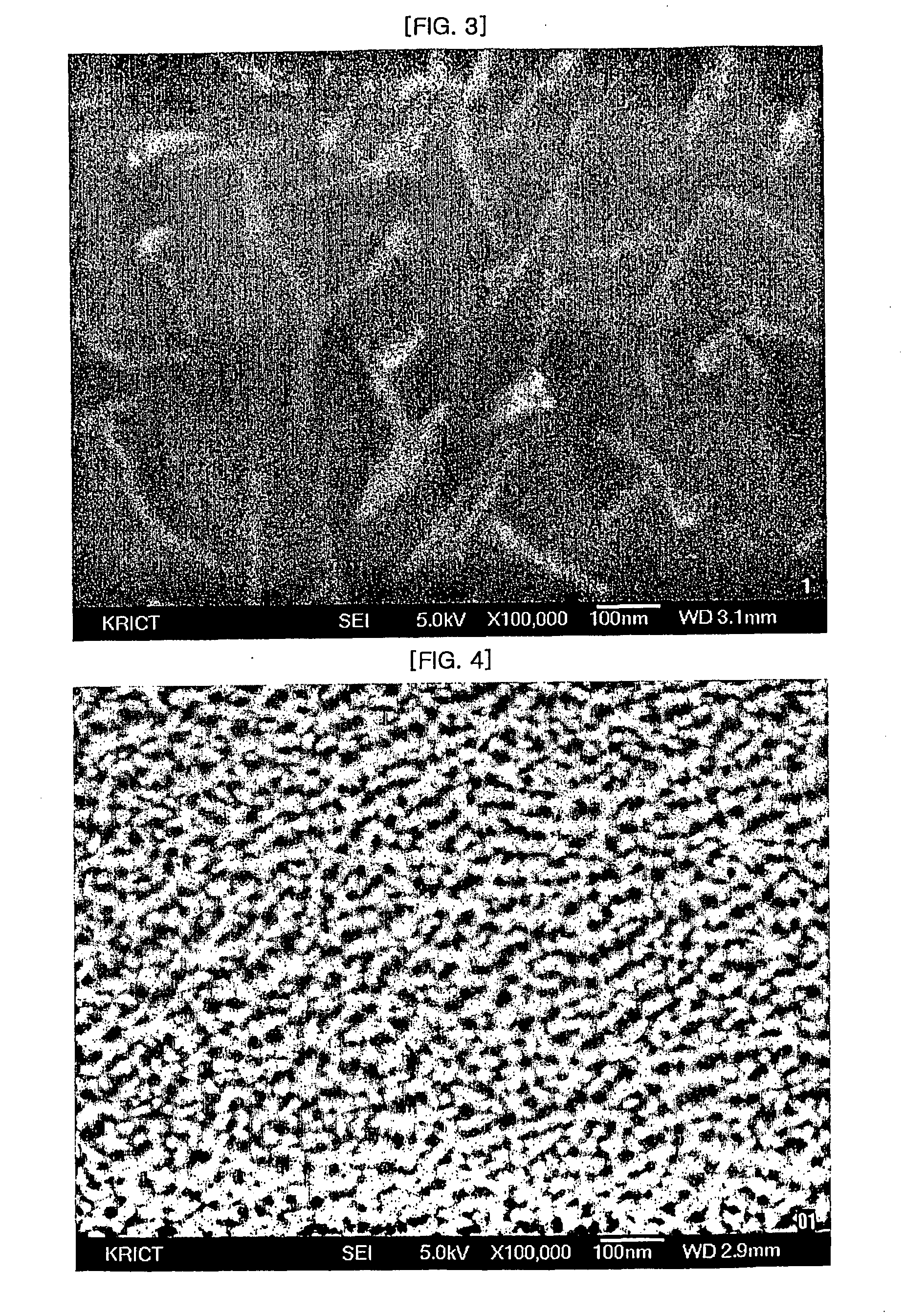

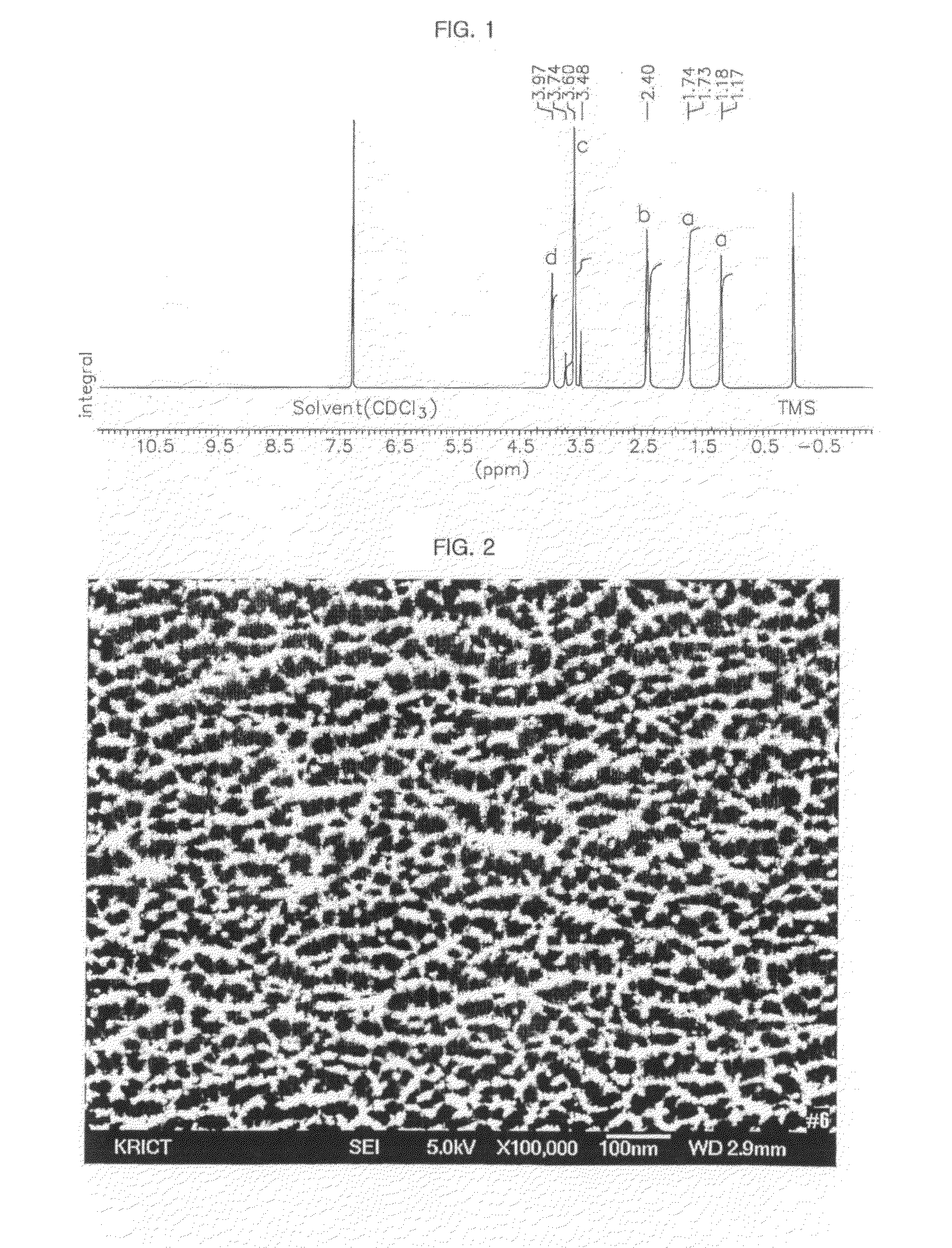

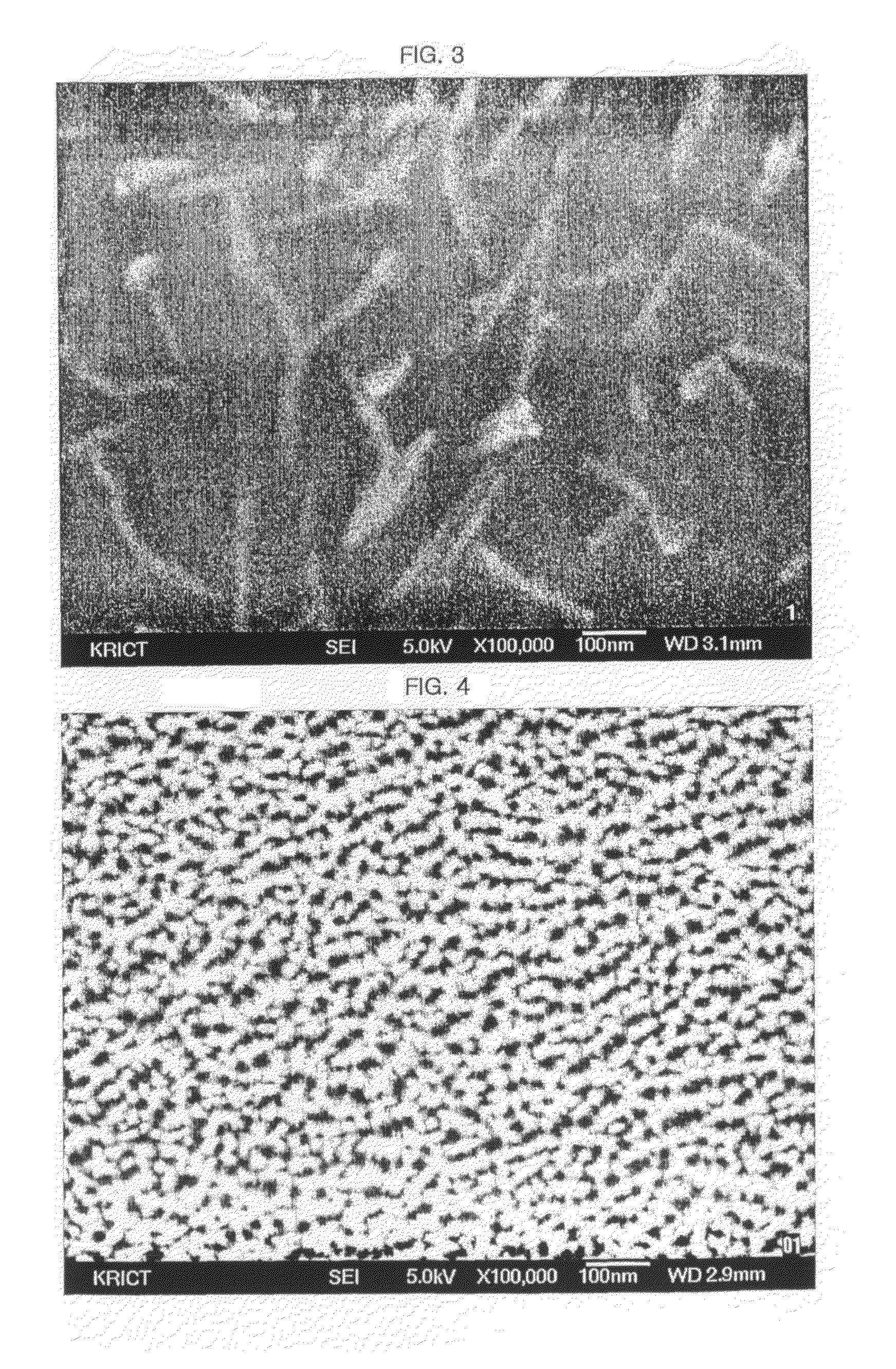

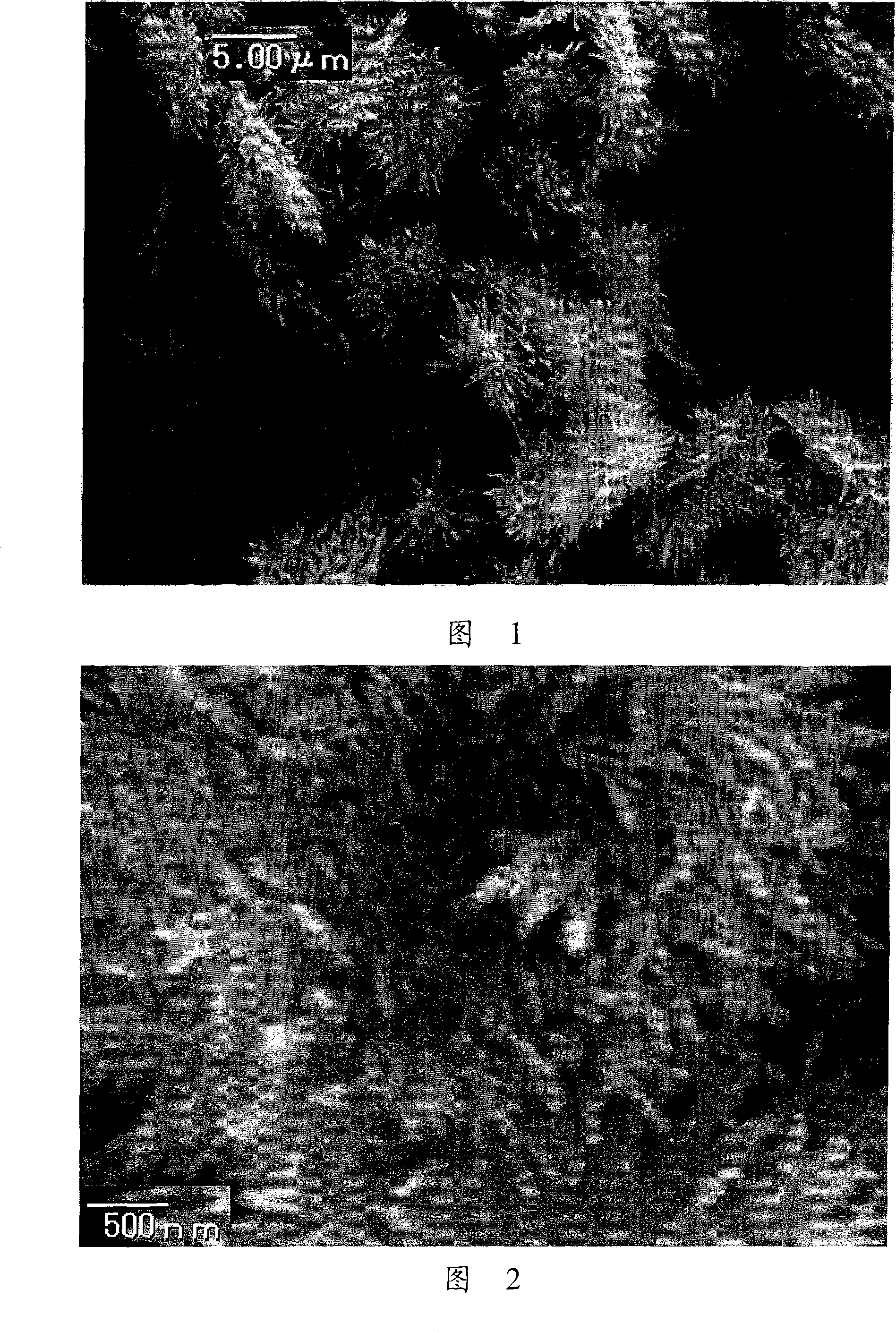

Organic and inorganic composite nanofiber, organic and inorganic composite structure and methods for producing the same

ActiveCN1922275AIncrease surface areaExcellent molecular selectivityMaterial nanotechnologyFiberComposite nanofibers

Disclosed is an organic-inorganic composite nanofiber composed of a crystalline polymer filament made of a polymer having a linear polyethyleneimine skeleton and a silica covering the crystalline polymer filament. Also disclosed are a structure composed of such an organic-inorganic composite nanofiber, and a method for producing the same.

Owner:KAWAMURA INST OF CHEM RES +1

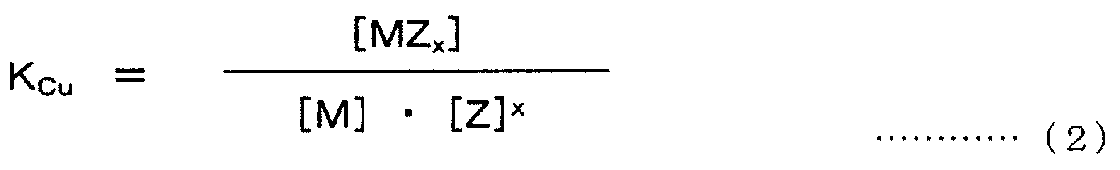

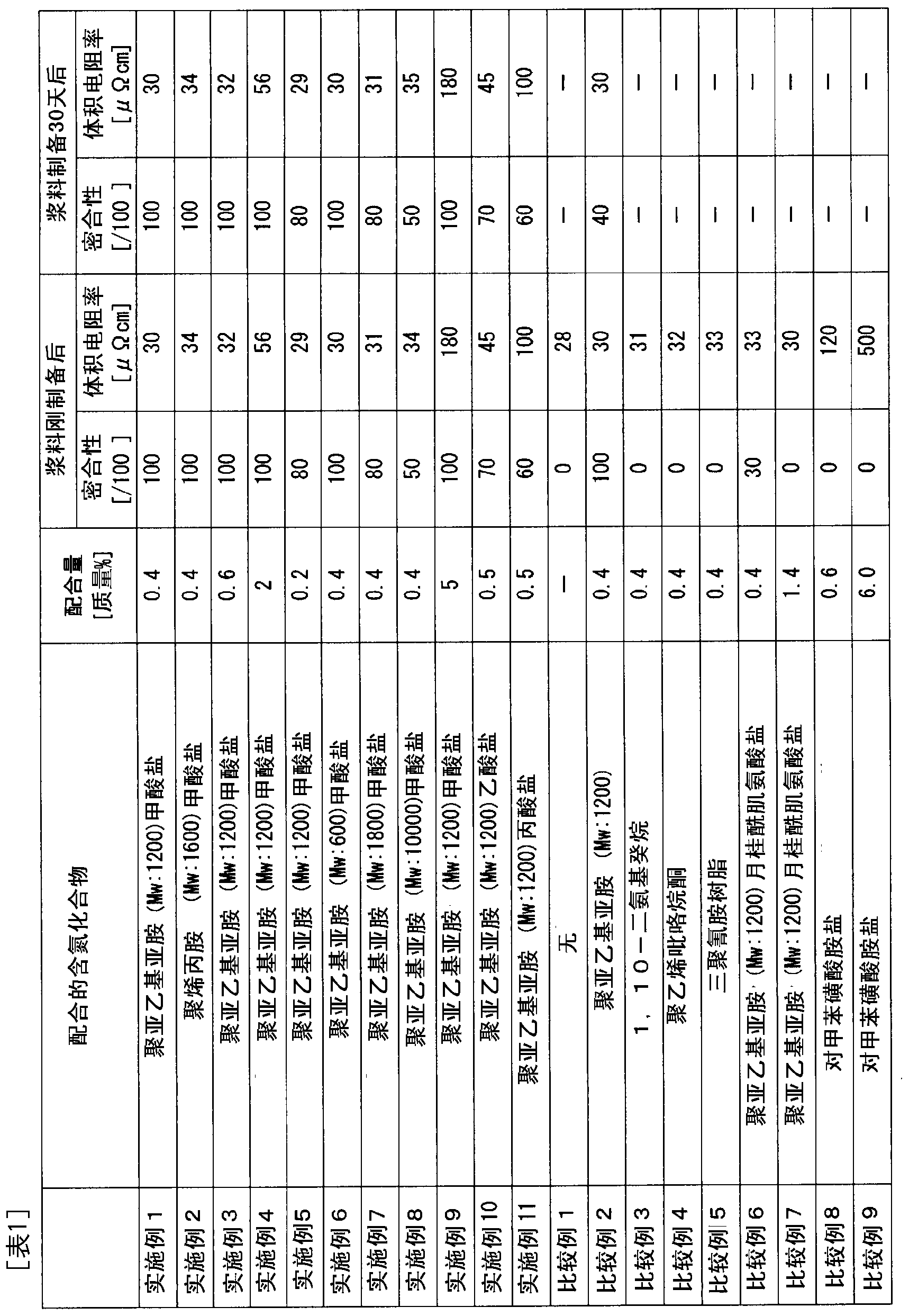

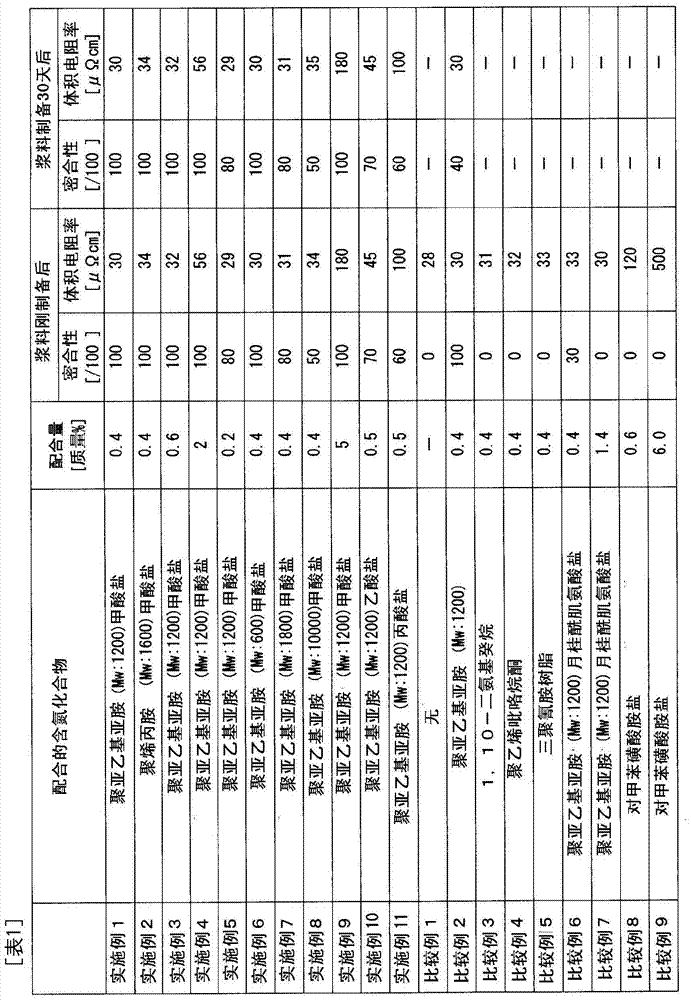

Conductive paste and base with conductive film

ActiveCN103210452AExcellent adhesionImprove conductivityConductive materialNon-conductive material with dispersed conductive materialCarboxylic saltCarboxylic acid

Provided is a conductive paste which exhibits good adhesion by merely being applied over an ITO film directly without the formation of a base layer and being cured thereon and is capable of forming a conductive film that has high conductivity. This conductive paste contains (A) copper particles having an average particle diameter from 10 nm to 20 [mu]m, (B) a carboxylic acid salt of a polymer compound that has at least one primary amino group in each molecule (provided that the carboxylic acid has 10 or less carbon atoms including the carbon atoms of the carbonyl group) and (C) a resin that has an acidic functional group that is reactive with the primary amino group. Specifically, the polymer compound that has primary amino group(s) is preferably a polyethylene imine or a polyallyl amine. In addition, the carboxylic acid salt thereof is preferably a formic acid salt.

Owner:UNKNOWN +1

Disinfectant capable of clearing away methanal

InactiveCN104855439AQuick clearImprove securityBiocideDispersed particle separationDisinfectantAlkylbenzenes

The invention discloses a disinfectant capable of clearing away methanal. The disinfectant is formed by the following raw materials in parts by weight: 15-20 parts of aluminum sulfate, 3-5 parts of Polyethyleneimine, 4-7 parts of sodium silicate, 6-8 parts of fructus forsythiae, 4-9 parts of garden burnet, 26-36 parts of activated carbon, 7-9 parts of kieselguhr, 12-18 parts of nanometer zirconia, 4-6 parts of sodium alkyl benzene sulfonate, 3-7 parts of methanoic acid, 7-9 parts of sodium chloride, 6-12 parts of sodium carbonate and 7-9 parts of sodium tripolyphosphate. The disinfectant capable of clearing away methanal has the advantages that the physical effect of the activated carbon is used for deodorizing, thus having no influence on human bodies, the methanal and bacteria can be quickly removed, and the safety is good.

Owner:青岛千帆高新技术有限公司

Anti-aging filament used for woven bags

InactiveCN107629291AEasy accessMaintain mechanical propertiesFibre typesLow-density polyethyleneCross-link

The invention provides an anti-aging filament used for woven bags. The anti-aging filament used for woven bags comprises, by mass, 75 to 105 parts of low density polyethylene resin, 15 to 21 parts ofpolyester imide resin, 5 to 7 parts of an inorganic filling material, 3 to 5 parts of polyethyleneimine, 3 to 5 parts of a repairing ingredient, and 2 to 4 parts of an auxiliary agent; the repairing ingredient comprises mineral oil, a repairing activator, and nanocarbon; the auxiliary agent comprises an ultraviolet ray absorber, a lubricant, a coupling agent, a stabilizing agent, a cross-linking agent, and an anti-oxidant. The composition and the ratio of the anti-aging filament are unique; a preparation method is simple and rapid; excellent aging resistance is ensured, and excellent repairingfunction is achieved at the same time; obvious effect in maintaining mechanical properties of woven bags and aging resistance is achieved; the raw materials are cheap and easily available; and the anti-aging filament is suitable for popularization in small and medium-sized enterprises.

Owner:盐城华和再生物资有限公司

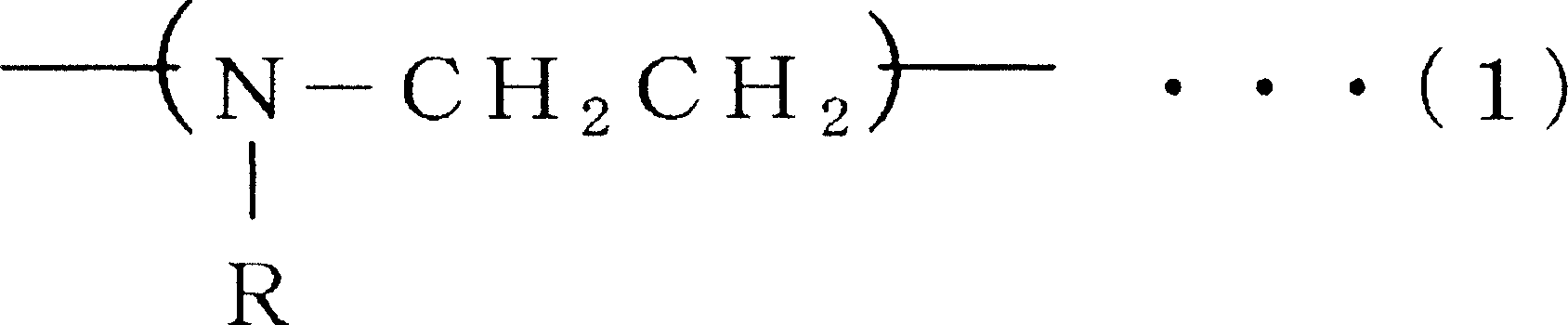

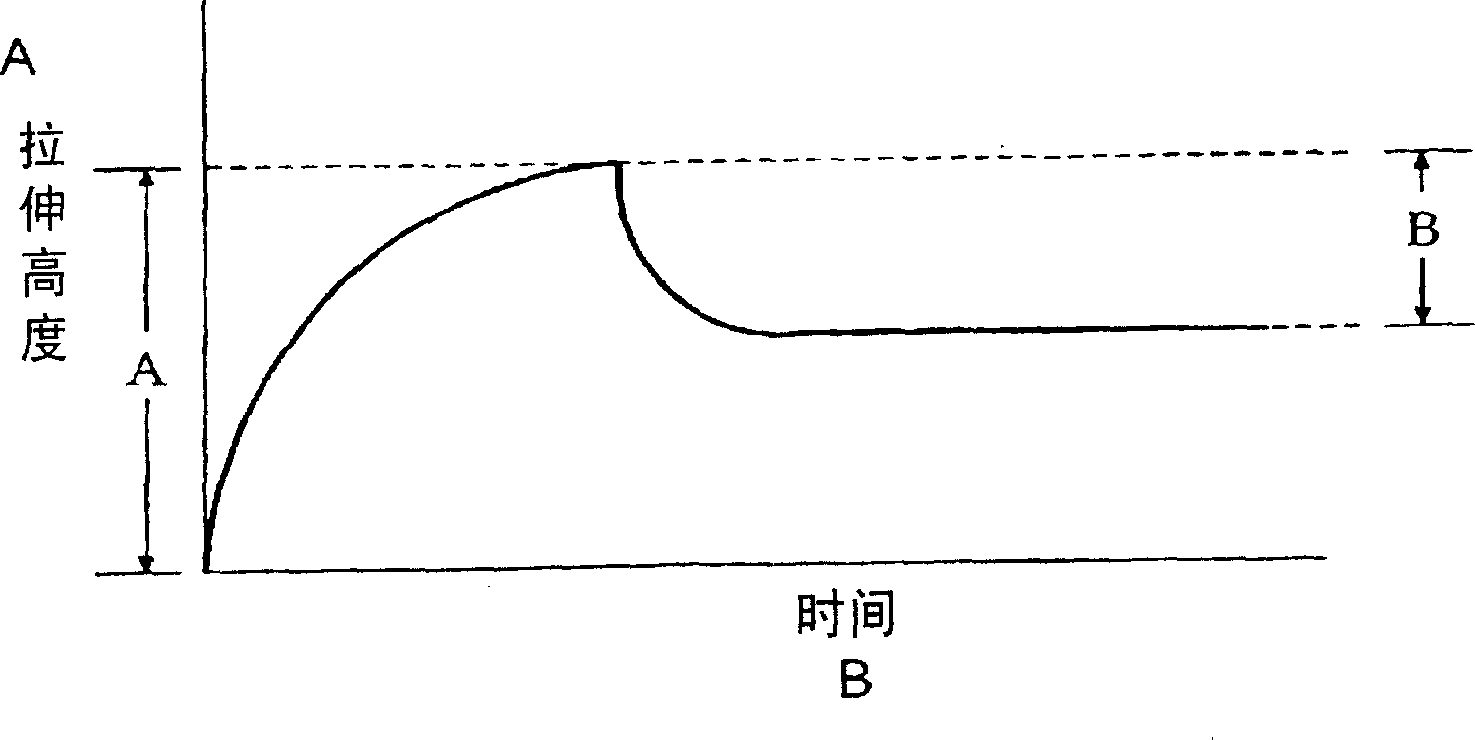

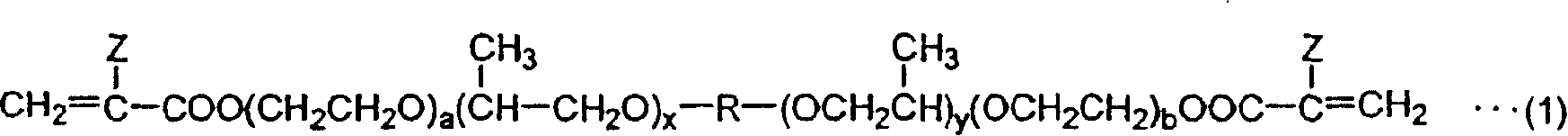

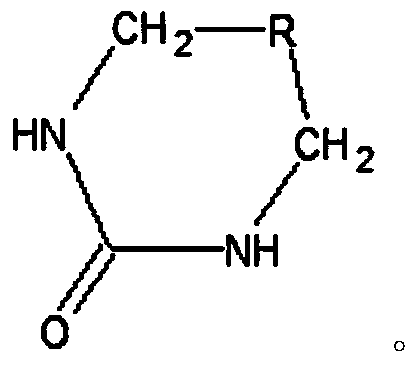

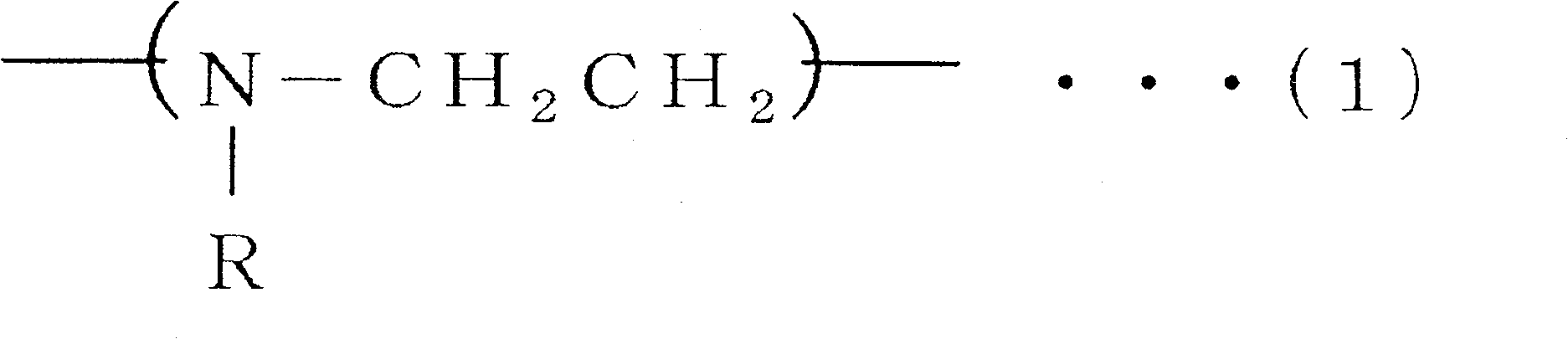

Fiber-treating liquid, modified fiber cloth, and process for producing the same

ActiveCN1906353AGuaranteed softnessImprove water absorptionFibre treatmentWoven fabricsFiberPolymer science

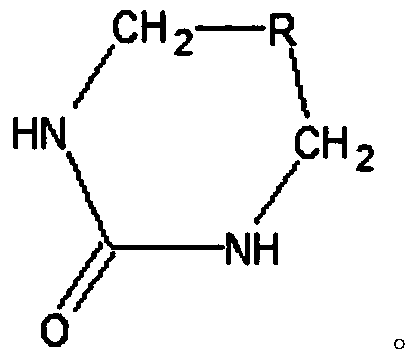

The present invention provided a fiber-treating liquid, modified fiber cloth, and process for producing the same. A modified fiber fabric obtainable by polymerizing a component (X) which is a water-soluble eggshell membrane powder, a component (A) which is a bifunctional monomer represented by the following formula (1), a component (B) which is a monomer containing any one of a hydroxyl group, carboxyl group, amino group, sulfonic acid group, and phosphoric acid group, and a component (C) which is a monomer containing at least one aziridine group, or a water-soluble polymer containing a polycarbodiimide group, polyethyleneimine group, or oxazoline group, on a fiber fabric, wherein R represents any one of and -C n H 2n - (n is an integer of 1 to 6) ; Z is a hydrogen atom or a methyl group;a and b are integers where 'a+b' is 0 to 50; x and y are integers where 'x+y' is 0 to 30; and 'a+b+x+y' is 10 or more.

Owner:日迸昌株式会社

Nano-mud material moisturizing coating

InactiveCN111548691AIncrease usage intensityImprove the quality of useCoatingsMethacrylate methylSlurry

The invention discloses a nano-mud material moisturizing coating, which is prepared by the following steps: mixing ethyleneimine ketone and vinyl acetate-butyl acrylate copolymer emulsion to obtain anemulsion mixture, adding acrylic acid and methyl methacrylate into the emulsion mixture, and performing high-speed stirring and mixing to obtain a moisturizing coating; neutralizing the moisturizingcoating, adding an auxiliary agent, and carrying out high-speed mixing to obtain a composite moisturizing coating, wherein the pH value of the obtained mixture is 7.5-10; grinding silica, cinnabar, tourmaline, negative ion powder, aluminum oxide, ferric oxide and calcium oxide at a high speed through a ball mill to obtain composite powder, and mixing the obtained composite powder with distilled water to obtain composite slurry; and calcining the composite slurry in a calcining furnace at the temperature of 950-1100 DEG C. The nano-mud material moisturizing coating has good hardness while the moisturizing sealing performance is guaranteed in the nano-mud material moisturizing coating, the use texture of the nano-mud material moisturizing coating can be further improved, and the nano-mud material moisturizing coating can be used in multiple directions of industry, buildings and the like.

Owner:潮州市泥香陶瓷新材料有限公司

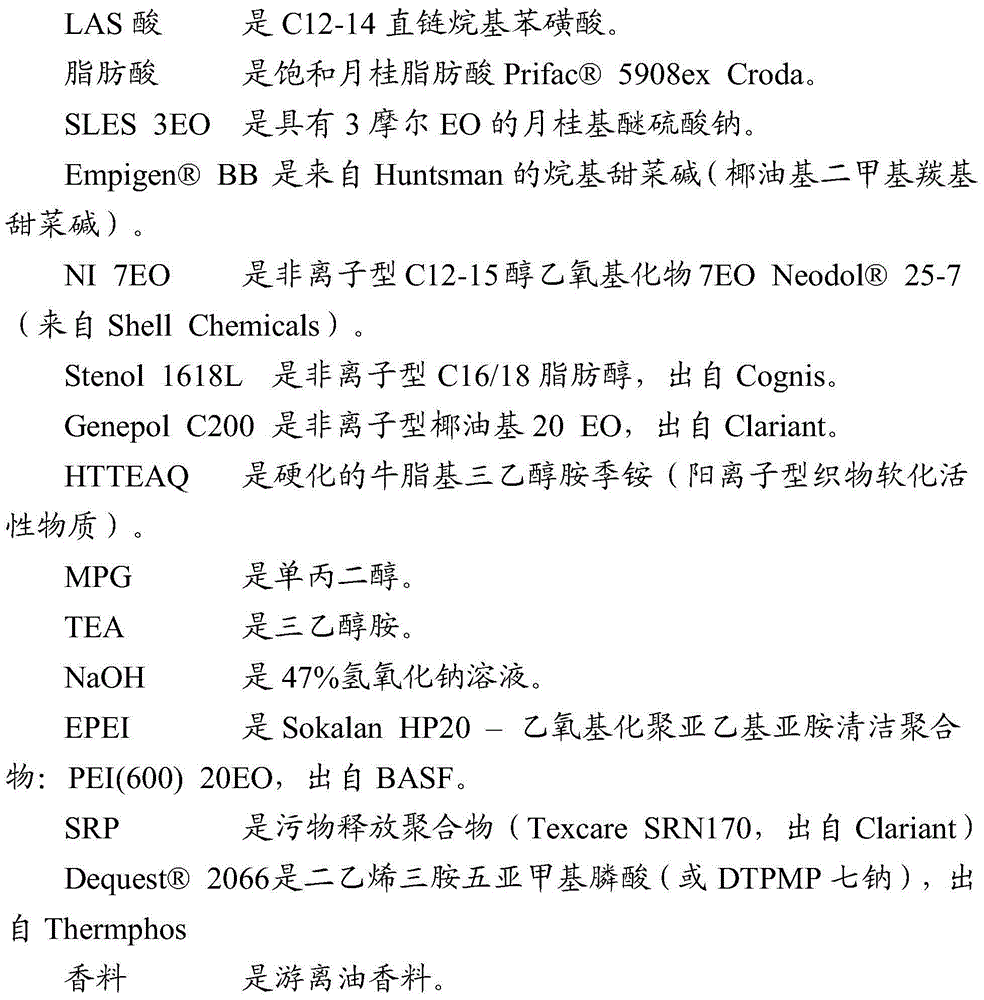

Method of laundering fabric

ActiveCN103459577BLower levelReduce lossesOrganic detergent compounding agentsDetergent mixture composition preparationPolyesterCellulase

A method of washing fabrics on which cationic fabric softening actives have been deposited and dried, said method comprising the step of contacting said fabrics with an aqueous wash liquor having the following composition: a) 15 to 600 ppm non-soap surfactant , b) at least 50 ppm ethoxylated polyethyleneimine, c) at least 25 ppm polyester soil releasing polymer, the total level of polymer (b+c) being at least 20 wt. of the level of non-soap surfactant (a) %, d) 0.1 to 100 ppm of an enzyme selected from protease, amylase, cellulase, e) optional lipase.

Owner:UNILEVER IP HLDG BV

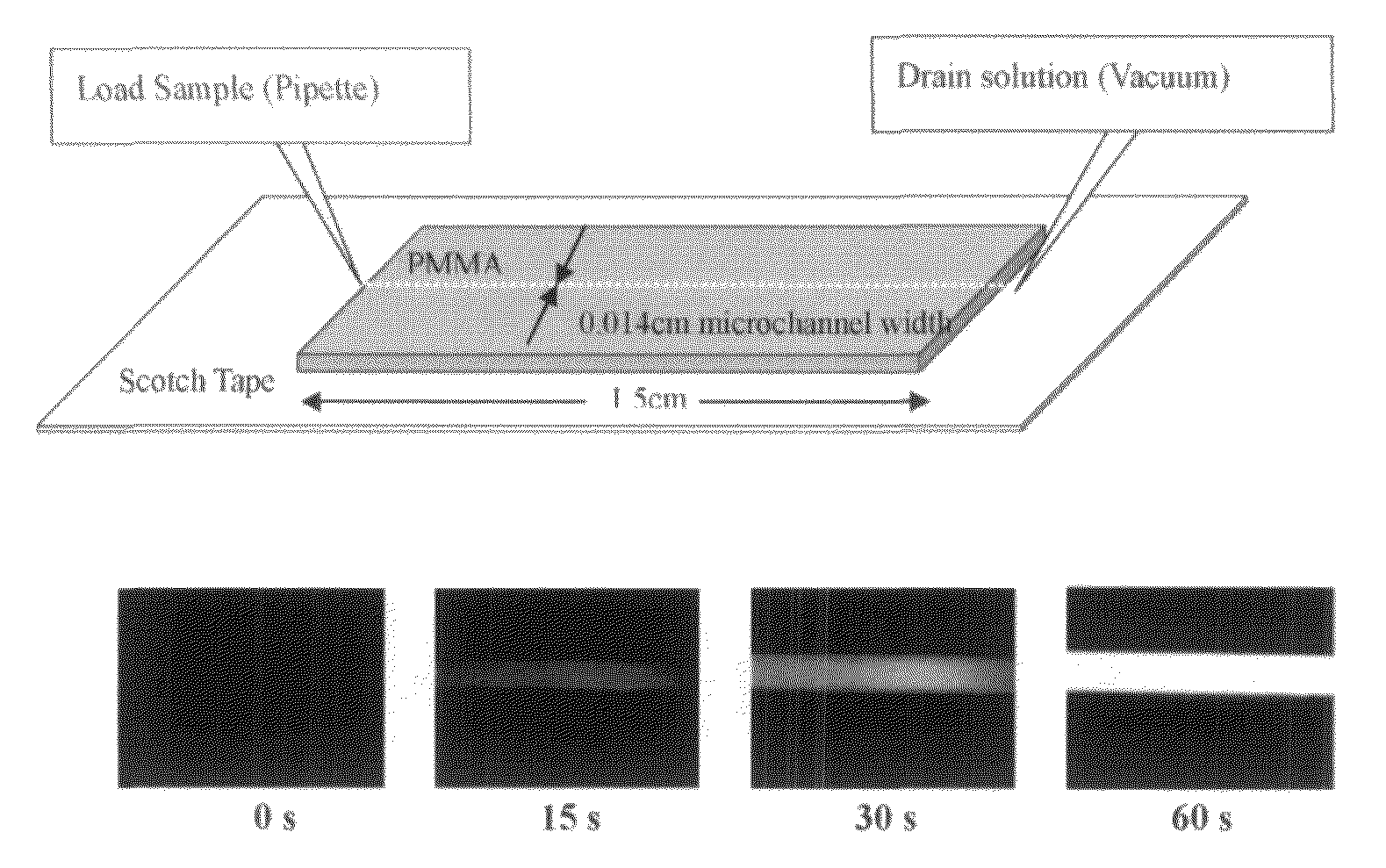

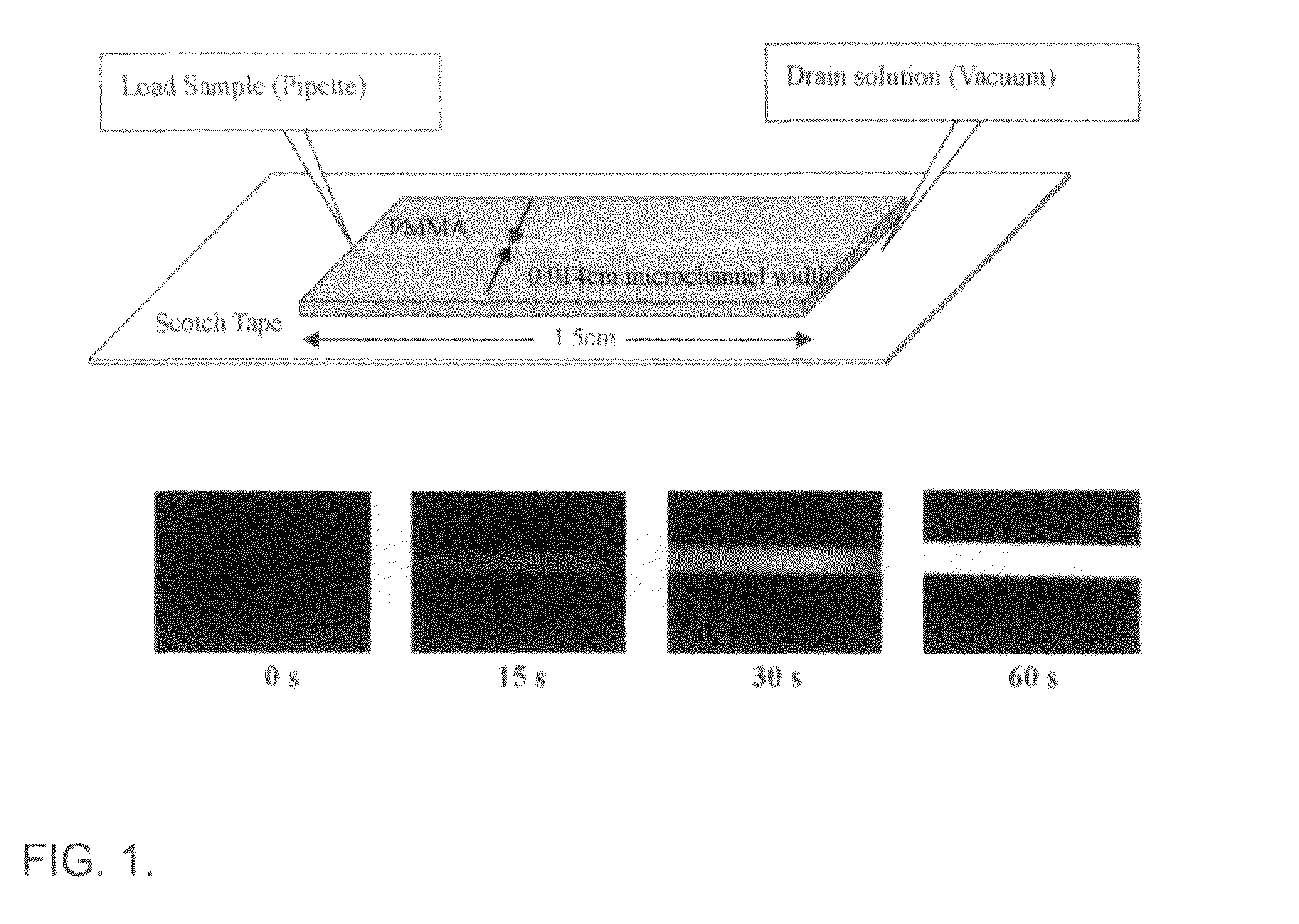

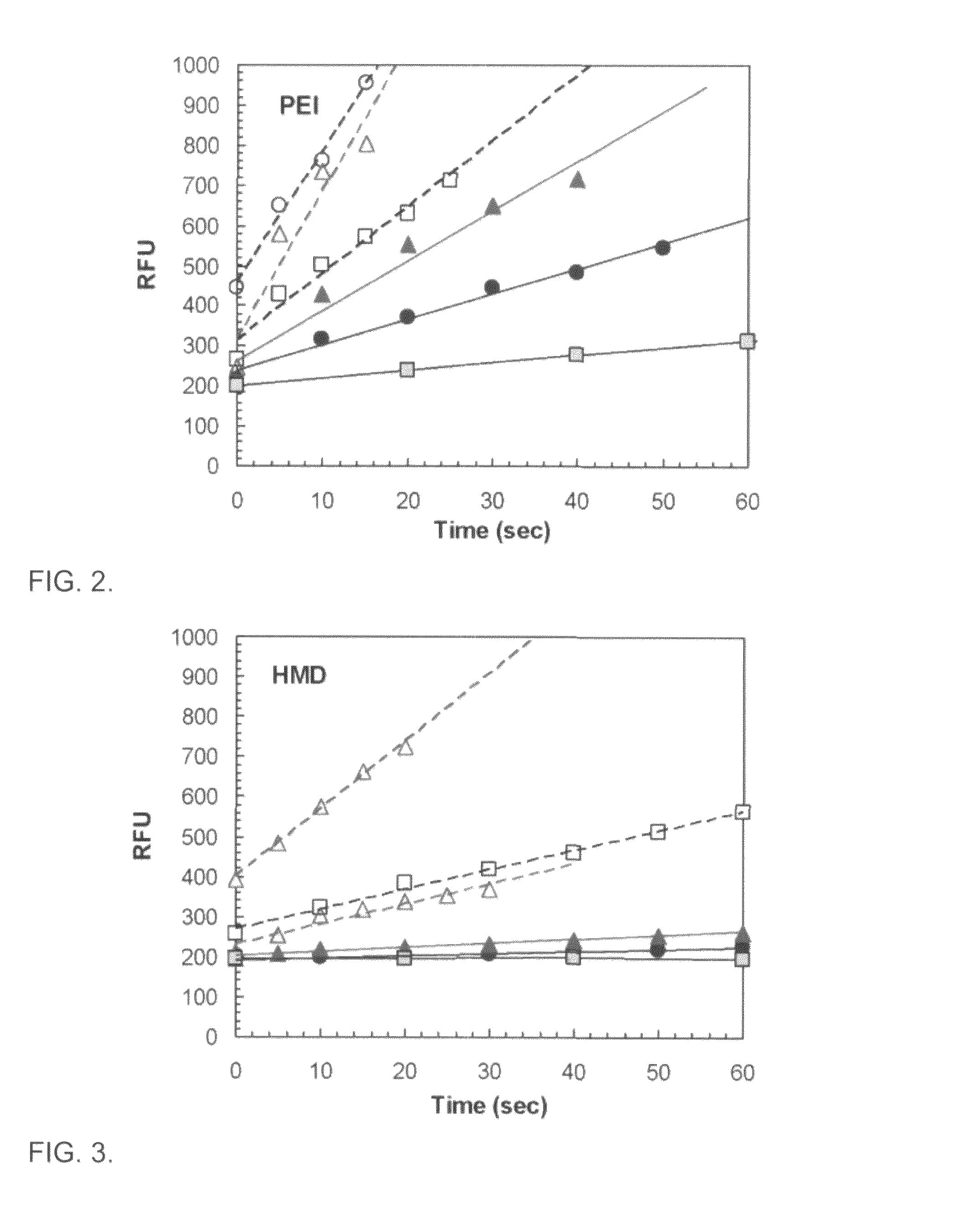

Aminated materials for assays

ActiveUS8652564B2Improve performanceDead plant preservationPreparing sample for investigationPolymeric surfacePolymer chemistry

Owner:THE OHIO STATE UNIV RES FOUND

Electroless plating pretreatment agent, electroless plating method using same, and electroless plated object

ActiveUS8814997B2High bonding strengthActivation treatmentPretreated surfacesAnti-corrosive paintsEthyleneimineOrganic solvent

Owner:JX NIPPON MINING & METALS CORP

Environmentally friendly water-based paint capable of removing formaldehyde through reacting and preparation method thereof

ActiveCN102827516BInhibition releaseSignificant reaction adsorption capacityCoatingsEnvironmental resistanceWater based

An environmentally friendly water-based paint capable of removing formaldehyde through reacting comprises 1 to 10 weight parts of ethylideneimine ketone, 30 to 45 weight parts of polymer emulsion, 0.5 to 2.0 weight parts of a film forming additive, 0.1 to 0.5 weight parts of an antifoaming agent, 20 to 40 weight parts of filling materials, 15 to 30 weight parts of distilled water and 2 to 5 parts of other additives. The preparation method of the environmentally friendly water-based paint comprises successively adding a wetting agent, a dispersant, parts of the antifoaming agent and the filling materials into the distilled water and then grinding to disperse to get slurry ; preparing a 30 % ethylideneimine ketone solution which is then added into the polymer emulsion; and successively adding the slurry, the film forming additive, the remaining antifoaming agent, a mildew preventor, an antifreeze, a levelling agent and a thickening agent into the polymer emulsion, adjusting a PH value to 8.0 to 9.5, and finally carrying out constant volume operation with the distilled water. The paint can effectively inhibit release of the formaldehyde in water-based paints, and has advantages of low production cost, simple process and suitability for popularizing.

Owner:FUZHOU BIMITER ENVIRONMENT FRIENDLY PROD

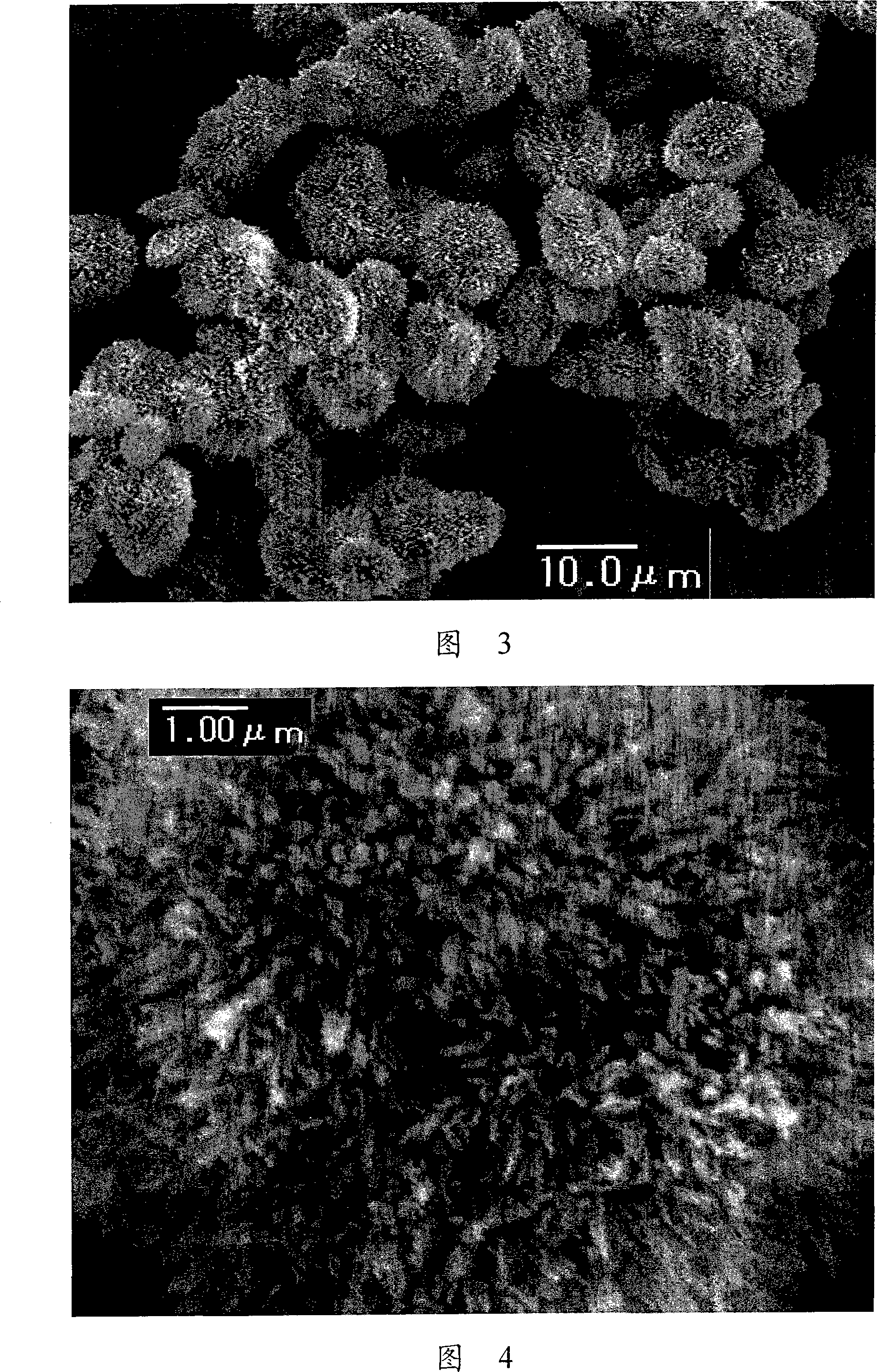

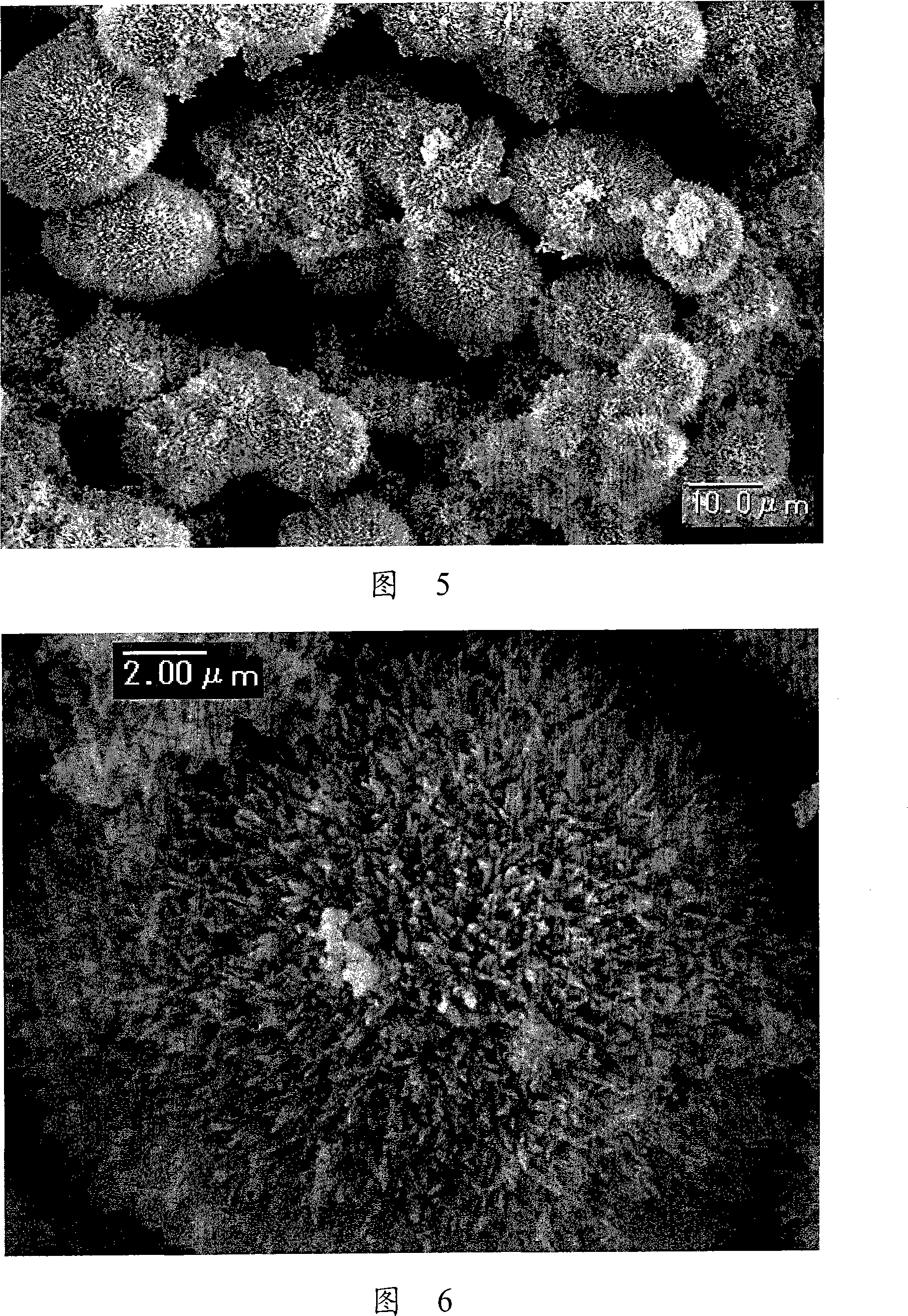

Minute particle with needlelike surface and its manufacturing method

InactiveCN101203550AImprove concentrationImprove reducibilityThin material handlingSilicon dioxideNanotechnology

The present invention provides organic-inorganic composite particles containing metal complexes, which have multiple needle-like structures on the surface and contain metal complexes; and a simple manufacturing method of the particles. This can be achieved by inducing a metal complex composed of a polymer having a linear polyethyleneimine skeleton and a metal ion to induce composite particles with a fine needle-like surface containing the metal complex inside the silica. Needle-shaped surface particles with multiple nanoscale needle-like structures on the surface of the particles. The needle-like structure of the resulting needle-shaped surface particles and the spatial structure of the particles can be controlled by changing the metal ion species and the metal complex support medium.

Owner:KAWAMURA INST OF CHEM RES +1

Conductive paste and base with conductive film

ActiveCN103210452BExcellent adhesionImprove conductivityConductive materialNon-conductive material with dispersed conductive materialConductive pasteCarboxylic salt

Provided is a conductive paste which exhibits good adhesion by merely being applied over an ITO film directly without the formation of a base layer and being cured thereon and is capable of forming a conductive film that has high conductivity. This conductive paste contains (A) copper particles having an average particle diameter from 10 nm to 20 µm, (B) a carboxylic acid salt of a polymer compound that has at least one primary amino group in each molecule (provided that the carboxylic acid has 10 or less carbon atoms including the carbon atoms of the carbonyl group) and (C) a resin that has an acidic functional group that is reactive with the primary amino group. Specifically, the polymer compound that has primary amino group(s) is preferably a polyethylene imine or a polyallyl amine. In addition, the carboxylic acid salt thereof is preferably a formic acid salt.

Owner:UNKNOWN +1

Polyalkoxylated polyamine oxide defoaming compositions

ActiveCN107835795AReduce pinhole effectHigh barrier propertiesSolid waste managementCoatingsAdhesiveSealant

The present invention provides a composition and method for controlling air voids in aqueous systems such as paints, coatings, sealants, adhesives, mastics, cements, mortar, masonry, or concrete, which comprises the reaction product of an oxidizing agent and a compound comprising at least one polyalkoxylated polyalkylene polyamine, at least one polyalkyoxylated polyethyleneimine, or a mixture thereof.

Owner:GCP APPL TECH INC

Cross-linked polyvinyl chloride foam and its preparation method

The invention discloses crosslinking polyvinyl chloride foam and a preparation method thereof, and belongs to the technical field of foamed materials. The problem of long time consumption of preparation of a crosslinking polyvinyl chloride foamed material in the prior art is solved, so that the quality and heat-resistant performance of the foamed material can be improved. The crosslinking polyvinyl chloride foam comprises the components in parts by weight: 100 parts of PVC resins, 30-150 parts of isocyanate, 1-15 parts of foaming agents, 0-80 parts of anhydride, 0-20 parts of epoxy compounds and 0.02-4 parts of catalysts, wherein the catalyst is one or more of N',N'',N'''-tri(dimethyl aminopropyl) symmetrical hexahydro-triazine, N-(alpha-ethoxyl) dimethylenimine, indole, sodium caprylate, isocaprylic acid, potassium oleate and potassium stearate. The foamed material is high in quality and heat-resistant performance, and high in production efficiency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

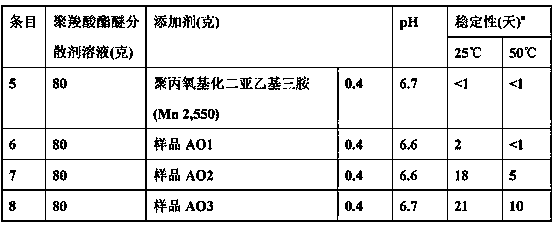

Compositions comprising ethoxylated/propoxylated polyalkyleneamine polymers as soil dispersing agents

InactiveCN1086732CImprove combination dirt dispersing propertiesNon-ionic surface-active compoundsOrganic detergent compounding agentsEthyleneimineEthoxylation

Cleaning and soil dispersing compositions comprising ethoxylated / propoxylated polyalkyleneamine polymers are provided. Thus, detergent compositions which comprise ethoxylated / propoxylated polyalkyleneamine polymers, such as poly(ethyleneimine) with a degree of ethoxylation of 1.0, provide soil dispersing performance in the wash liquor and whitening and / or cleaning benefits to fabrics, hard-surfaces, or dishware.

Owner:THE PROCTER & GAMBLE COMPANY

Coating agent for recording layer protection and recording medium coated therewith

InactiveCN100515792CHigh recording mediumImprove water resistanceLiquid surface applicatorsInksPolyvinyl alcoholPolyamide

A coating agent for recording layer protection, characterized by comprising a carboxy-modified polyvinyl alcohol (A), a polyamide-polyamine epihalohydrin (B), and polyethyleneimine (C). Preferably, it is characterized in that the carboxy-modified polyvinyl alcohol (A) has a degree of saponification of 90 to 99.5 mol%. The coating agent for recording layer protection is highly effective in imparting water resistance to a recording medium. Also provided is a recording medium having high water resistance, characterized by being obtained by applying the coating agent for recording layer protection to a recording layer.

Owner:SEIKO PMC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com