Patents

Literature

130results about How to "Meet the environmental conditions of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified polyvinyl chloride cable sheath material with low-temperature impact resistance

InactiveCN103524949AImprove performanceImprove mechanical propertiesInsulated cablesInsulated conductorsLow-density polyethylenePolyester

The invention relates to a cable material, specifically to a modified polyvinyl chloride cable sheath material with low-temperature impact resistance. The material comprises the following raw materials by weight: 23 to 26 parts of SG-3 polyvinyl chloride, 14 to 18 parts of isotactic polypropylene, 20 to 23 parts of EVA, 4 to 5 parts of low density polyethylene, 2 to 3 parts of zinc oxide, 6 to 8 parts of montmorillonite powder, 12 to 14 parts of meerschaum powder, 4 to 6 parts of diatomite, 1 to 2 parts of sodium carbonate, 15 to 18 parts of poly(propyleneglycol sebacate), 1 to 2 parts of di-n-octyltin bis(isooctyl mercaptoacetate), 3 to 5 parts of zinc oxide, 23 to 25 parts of carbon black 220, 1.2 to 1.5 parts of ethylene bisstearamide, 13 to 16 parts of tributyl citrate and 14 to 16 parts of an auxiliary agent. According to the invention, the advantages of the raw materials like SG-3 polyvinyl chloride, isotactic polypropylene and EVA are combined together, the prepared material has the advantages of flexibility, wear resistance, resistance to high temperature ageing, low-temperature impact resistance, resistance to chemical attack, safety and reliability in utilization, wide applicability to preparation of a variety of cable sheath insulating materials and wide market demands and prospects.

Owner:李小芬

Oil-proof flame-retardant modified polyvinyl chloride cable sheathing material

ActiveCN103540064AHigh strengthImprove performanceInsulated cablesInsulated conductorsParaffin waxPolyvinyl chloride

The invention relates to a cable material, and particularly relates to an oil-proof flame-retardant modified polyvinyl chloride cable sheathing material. The material comprises the following raw materials in parts by weight: 35-38 parts of SG-2 polyvinyl chloride, 12-14 parts of light calcium carbonate, 2-3 parts of stearic acid, 7-9 parts of titanium dioxide, 23-26 parts of chlorinated polyethylene, 12-14 parts of isotactic polypropylene, 6-9 parts of acrylonitrile butadiene styrene (ABS) high-glue powder, 7-9 parts of ethylene vinyl acetate (EVA), 14-18 parts of nano celestite powder, 1-2 parts of triethanolamine, 23-24 parts of castor oil, 1-2 parts of bisphenol A, 12-13 parts of semi-refined paraffin wax, and 14-16 parts of assistant. By adopting the insulated material, the advantages of the raw materials such as the SG-2 polyvinyl chloride, the chlorinated polyethylene, the isotactic polypropylene and the like are combined; the prepared material is high in strength, good in weathering resistance, ozone resistance, oil-resistant flame retardancy and chemical stability, safe to use, and wide in market demand prospect, and can be widely applied to fabrication of kinds of cable sheath insulated materials.

Owner:江苏祥云塑料科技有限公司

Modified low-density polyethylene insulating material for household appliance wiring harness

InactiveCN103554790AImprove performanceHigh strengthPlastic/resin/waxes insulatorsLow-density polyethylenePolytetramethylene terephthalate

The invention relates to an insulating material for a wiring harness and specifically relates to a modified low-density polyethylene insulating material for a household appliance wiring harness. The material is prepared from the following raw materials in parts by weight: 12-15 parts of nylon PA (Polyamide) 66, 10-14 parts of polybutylene terephthalate, 34-38 parts of low-density polyethylene, 2-3 parts of an antioxidant 1010, 2-3 parts of calcium laurate, 18-20 parts of glycerin triacetate, 3-4 parts of sodium hexametaphosphate, 15-18 parts of polyvinylidene chloride, 15-20 parts of active calcium carbonate, 4-7 parts of zinc oxide, 12-15 parts of aluminum hydroxide, 13-14 parts of microcrystalline wax, 22-25 parts of fast extruding furnace carbon black N660, 1-2 parts of accelerator Na-22 and 14-16 parts of auxiliaries. The insulating material disclosed by the invention is combined with the advantages of materials such as low-density polyethylene, nylon PA66 and polyvinylidene chloride, so that performances of the conventional low-density polyethylene material are improved, the processing performances and mechanical performances are good; the prepared material is high in strength, waterproof, flame-retardant, low temperature impact-resistant and tearing-resistant, can be extensively used for manufacturing the insulating sheath of the wiring harness at each part of the household appliance, a wiring terminal, a binding material, and the like, and is broad in prospect of market needs.

Owner:合肥得润电子器件有限公司

Modified polyvinyl chloride cable sheath material

InactiveCN103540063AImprove performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideEngineering

The invention relates to a cable material, and particularly relates to a modified polyvinyl chloride cable sheath material. The modified polyvinyl chloride cable sheath material is prepared from the following raw materials in parts by weight: 25-28 parts of polyvinyl chloride, 12-15 parts of calcium carbonate powder, 10-12 parts of EVA (ethylene-vinyl acetate), 4-6 parts of ACR impact modifier, 5-8 parts of tribasic lead sulfate, 3-5 parts of glass fiber, 3-5 parts of calcium chloride, 2-3 parts of cuprous chloride, 5-8 parts of diatom powder, 4-5 parts of bentonite powder, 1-4 parts of silane coupling agent KH550, 3-4 parts of sodium tetraborate, 20-25 parts of tributyl citrate and 14-16 parts of additive. The modified polyvinyl chloride cable sheath material combines the advantages of the raw materials such as polyvinyl chloride and EVA; the properties of a conventional polyvinyl chloride blending material are improved; the prepared material is flexible, firm, dampproof, water-tolerant and long in service life, resists chemical corrosion and low-temperature ageing, can be widely applied to the production of various cable sheath insulating materials and has good mechanical property and wide market requirement prospect.

Owner:佛山市鸣歆化工有限公司

Flexible oil-proof modified polyvinyl chloride (PVC) cable sheath material

InactiveCN103554753AImprove performanceGood mechanical properties and processing propertiesPlastic/resin/waxes insulatorsCarbon blackStearic acid

The invention relates to a cable material, and in particular relates to a flexible oil-proof modified polyvinyl chloride (PVC) cable sheath material. The material is prepared from the following raw materials in parts by weight: 32-35 parts of SG-4PVC, 14-18 parts of EVA (ethylene-vinyl acetate), 14-16 parts of metallocene linear low-density polyethylene, 3-4 parts of beryllium oxide, 11-15 parts of silicon carbide, 4-6 parts of attapulgite, 1-2 parts of accelerator Na-22, 16-19 parts of epoxy linseed oil, 24-28 parts of N660 carbon black, 3-4 parts of zinc oxide, 3-4 parts of stearic acid, 1-2 parts of anti-aging agent 4010, 3-4 parts of asbestos powder, 17-21 parts of tributyl citrate, and 14-16 parts of additive; the advantages of the raw materials such as SG-4PVC, the EVA and the metallocene linear low-density polyethylene are combined through the insulating material, the prepared material is firm and flexible, oil permeation resistant, low temperature embrittling resistant, chemical medicine erosion resistant, and safe and reliable in use, and can be widely used for manufacturing various cable sheath insulating materials, and the market demand prospect is wide.

Owner:LVBAO CABLE GROUP

Polyphenylene sulfide modified nylon material for automobile plastic members

The invention belongs to the field of high-molecular materials, and specifically relates to a polyphenylene sulfide modified nylon material for automobile plastic members. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 610, 20-23 parts of nylon 6, 5-8 parts of potassium chloride, 4-5 parts of melamine, 12-15 parts of mica powder, 2-3 parts of p-toluenesulfonic acid, 23-25 parts of aluminum sulfate, 1-2 parts of zinc stearate, 15-18 parts of polyphenylene sulfide, 7-9 parts of polyetheretherkrtone, 5-9 parts of tributyl citrate and 12-15 parts of an auxiliary agent. The material combines the advantages of the raw materials such as nylon 610, nylon 6, polyphenylene sulfide and the like; and the prepared material is high in strength, resistant to high temperature, flame-retardant, resistant to chemical corrosion, low in friction coefficient, resistant to wear, good in insulating properties and safe and reliable to use, is widely applicable to prepare various automobile plastic members, and is especially applicable to automobile members in environment with a relatively high temperature.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

Nanometer potter's clay modified nylon material for automobile plastic members

InactiveCN103642218AImprove mechanical propertiesModulus improvementAluminium hydroxideDIETHYLENE GLYCOL ADIPATE

The invention relates to the field of high-molecular materials, and specifically relates to a nanometer potter's clay modified nylon material for automobile plastic members. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 6, 10-12 parts of aluminium hydroxide powder, 7-9 parts of calcium carbonate, 3-4 parts of nanometer potter's clay, 3-5 parts of himic anhydride, 8-9 parts of poly(diethylene glycol adipate), 4-6 parts of dilauryl thiodipropionate, 3-4 parts of zinc oxide and 12-15 parts of an auxiliary agent. The raw materials such as nanometer potter's clay and the like are utilized for performing modification processing on nylon 6, the processed material is improved in mechanical properties, modulus, flame retardance, water proofness and the like; and the prepared material is high in thermal deformation temperature, low in friction coefficient, resistant to wear, resistant to oil, resistant to chemical corrosion, firm and durable, is widely applicable to prepare various automobile plastic members, and is especially applicable to prepare plastic members for tail light covers, wipers, radiator water chambers and the like.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

Antistatic waterproof modified nylon 12 material for automobile plastic part

InactiveCN103665841AHigh hardnessExcellent electrical performanceDiethyl terephthalateHydrophobic silica

The invention belongs to the field of high polymer materials, and particularly relates to an antistatic waterproof modified nylon 12 material for an automobile plastic part. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 12, 7-9 parts of diethyl terephthalate, 15-18 parts of high-density polyethylene, 7-9 parts of ultrafine talcum powder, 3-4 parts of diaminodiphenylmethane, 2-3 parts of diammonium hydrogen phosphate, 6-8 parts of borax, 5-8 parts of rutile titanium white, 1-2 parts of hydrophobic silicon dioxide, 1.6-1.8 parts of antioxidant DSTP, 2-3 parts of stearic acid, 4-6 parts of dibutyl phthalate and 12-15 parts of assistant. According to the invention, the modified nylon 12 material combines the advantages of the raw materials such as the nylon 12, the high-density polyethylene and the like, and improves the performance of the traditional nylon 12 material. Besides, the raw materials such as the rutile titanium white, the hydrophobic silicon dioxide and the like are added, so that the prepared material is high in hardness, waterproof, dampproof, favorable in electric property, antistatic, heat-resistant, light-resistant and long in service life, and can be widely used in manufacturing of various automobile plastic parts.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

Modified polyethylene insulating material for wire harness of communication equipment

ActiveCN103554616AImprove performanceHigh strengthPlastic/resin/waxes insulatorsCellulose acetatePolystyrene

The invention relates to an insulating material for a wire harness, and specifically relates to a modified polyethylene insulating material for a wire harness of communication equipment. The material comprises the following raw materials in parts by weight: 24-28 parts of medium density polyethylene, 12-16 parts of metallocene linear low density polyethylene, 5-9 parts of polyphenylene sulfide, 5-6 parts of cellulose acetate, 16-19 parts of polystyrene, 2-3 parts of an antioxidant 1010, 5-6 parts of hydrogenated rosin, 3-4 parts of coumarone, 30-34 parts of tributyl citrate, 1-3 parts of potassium stearate, 5-10 parts of aluminum nitride, 3-4 parts of zinc borate, 12-15 parts of zinc pyrophosphate, 23-26 parts of carbon black N330 and 14-16 parts of an assistant. The insulating material combines the advantages of the raw materials such as medium density polyethylene and polystyrene and enhances the performance of conventional polystyrene blending materials; and the prepared material is high in strength, impact-resistant, good in toughness, good in electric insulation, chemical-corrosion-resistant, ageing-resistant and long in service life, can be widely applied to manufacture of insulating sheathes, terminals, bandage materials and the like of wire harnesses at all parts of the communication equipment, and is wide in market requirement prospect.

Owner:合肥得润电子器件有限公司

Modified polyvinyl chloride cable sheath material capable of resisting ultraviolet radiation aging

InactiveCN105001547AImprove performanceStable in naturePlastic/resin/waxes insulatorsInsulated cables2-mercaptobenzimidazolePolyvinyl chloride

The invention relates to a cable material, specifically to a modified polyvinyl chloride cable sheath material capable of resisting ultraviolet radiation aging. The material comprises the following raw materials by weight: 50 to 60 parts of polyvinyl chloride, 30 to 40 parts of calcium carbonate, 2 to 3 parts of an anti-oxidant 1035, 2 to 3 parts of propylene glycol, 4 to 5 parts of potash feldspar powder, 12 to 14 parts of nanometer titanium dioxide, 1 to 2 parts of copper oxide powder, 1 to 2 parts of calcium lignin sulphonate, 10 to 12 parts of rosin pentaerythritol ester, 23 to 26 parts of tributyl citrate, 1 to 2 parts of 2-mercaptobenzimidazole, 1 to 3 parts of vinyltris(beta-methoxyethoxy)silane, 1 to 2 parts of oleamide, 23 to 25 parts of dolomite, 10 to 12 parts of bauxitic clay and 14 to 16 parts of an auxiliary agent. According to the invention, the cable sheath material improves performance of traditional polyvinyl chloride materials and has improved mechanical properties; nanometer titanium dioxide can assist the material in resisting ultraviolet radiation aging; and the prepared material has heat resistance, stable properties, resistance to weathering and long service life, can be widely applied to preparation of a variety of cable sheath insulating materials and is greatly needed in market.

Owner:ANHUI TELI SCI & TECH

Weatherable toughened modified polyethylene cable sheath material

ActiveCN103589039AImprove performanceImprove rigidityPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethylenePhosphoric acid

The invention relates to a cable material, and specifically relates to a weatherable toughened modified polyethylene cable sheath material. the material comprises the following raw materials in parts by weight: 15-19 parts of SG-2 PVC resin, 23-25 parts of POE, 24-28 parts of low-density polyethylene, 14-18 parts of calcined potter's clay, 1-2 parts of silver nitrate, 3-4 parts of sodium chloride, 2-3 parts of silane coupling agnet KH-550, 1-2 parts of zirconium fluoride, 6-8 parts of nanometer titanium dioxide, 2-3 parts of nanometer titanium phosphate, 8-10 parts of dimethyl isooctyl thioglycolate tin, 1-2 parts of anti-aging agent 4010, 12-15 parts of diatomite powder, 2-3 parts of ammonium polyphosphate, 25-30 parts of tributyl citrate and 14-16 parts of an auxiliary agent. The insulating material combines the advantages of low-density polyethylene, POE, PVC resin and the like, the prepared material is good in rigidity, high in toughness, good in mechanical properties, resistant to environmental aging, resistant to heat, resistant to flame, and safe and reliable to use, is widely applicable to preparation of various cable sheath insulating materials, and has wide market demanding prospect.

Owner:TONGXIANG GUANGSHENG PLASTIC IND CO LTD

Light polyolefin modified nylon material for automobile plastic parts

The invention belongs to the field of high polymer materials and particularly relates to a light polyolefin modified nylon material for automobile plastic parts. The material comprises the following raw materials in weight part: 100 parts of PA1212, 14-18 parts of SEBS, 10-12 parts of ultra low density polyethylene, 4-5 parts of calcium stearate, 1-2 parts of stearic acid, 6-8 parts of polyethylene wax, 6-9 parts of magnesium hydrate, 8-12 parts of chlorosulfonated polyethylene, 3-5 parts of dioctyl phthalate, 1-2 parts of angelica essential oil and 12-15 parts of an accessory ingredient. According to the invention, the advantages of the raw materials including PA1212, SEBS, ultra low density polyethylene, chlorosulfonated polyethylene and the like are combined, so that the excellent processing property and mechanical property are achieved, the prepared material is light in weight, flexible, solid, firm, heat resistant, aging resistant, temperature resistant, excellent in electrical insulation property, safe and reliable, and has the self-lubrication property, can be widely used for fabricating various plastic parts for automobiles, and the added angelica essential oil enables the material to have pleasant aroma.

Owner:余姚市敏永汽车零部件有限公司

Anticorrosive clothing material and protective garment made from anticorrosive clothing material

ActiveCN106835352AGood mechanical strengthGood corrosion resistanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNanometreCarbon nanotube

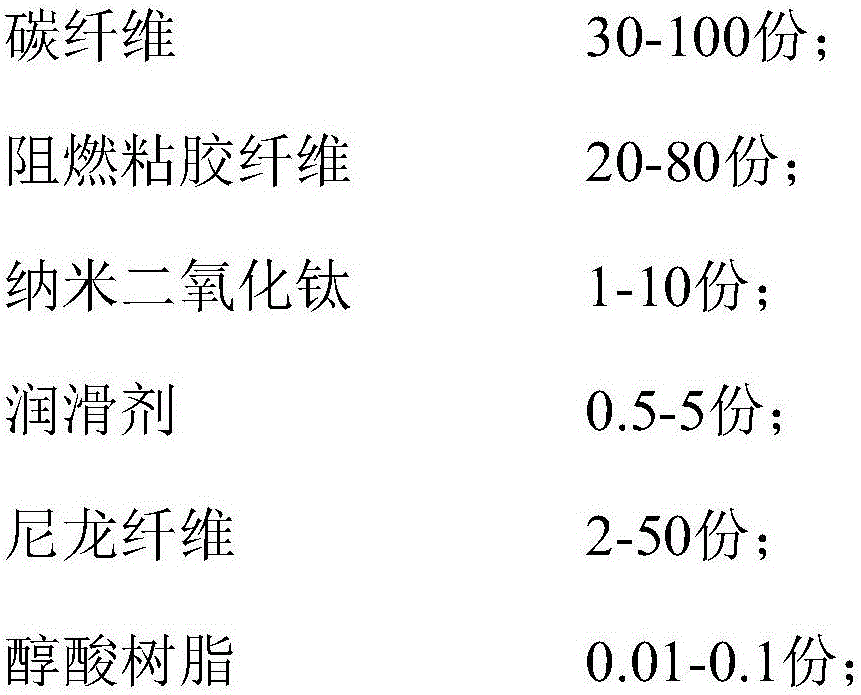

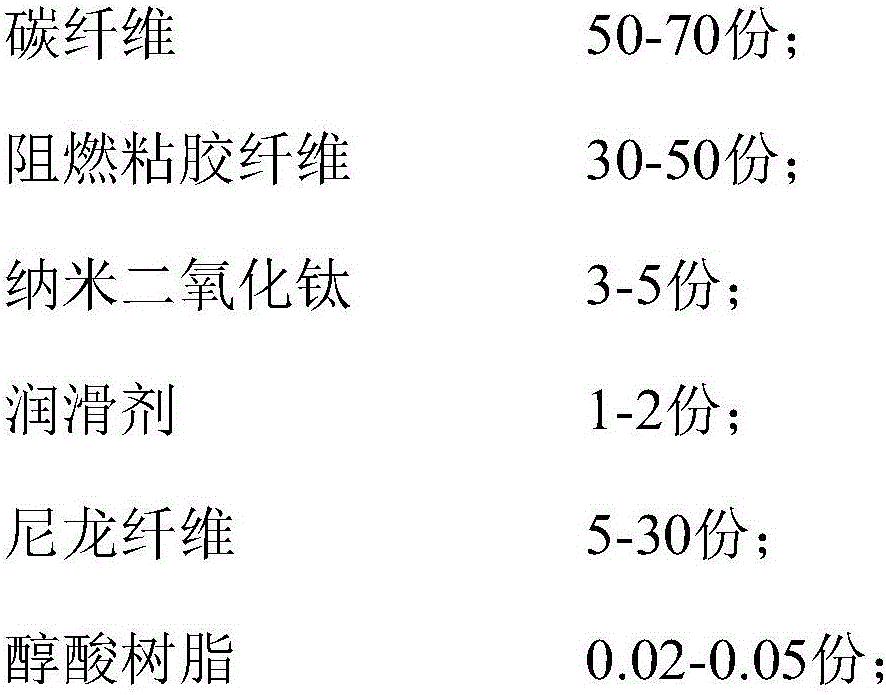

The invention discloses an anticorrosive clothing material and a protective garment made from the anticorrosive clothing material. The clothing material is prepared from the following components in parts by weight: 30 to 100 parts of carbon fiber, 20 to 80 parts of inflaming-retarding viscose glue, 1 to 10 parts of nano titanium dioxide, 0.5 to 5 parts of lubricating agent, 2 to 50 parts of nylon fiber, 0.01 to 0.1 part of alkyd resin, 2 to 15 parts of flexibilizer and 15 to 60 parts of graphene-carbon nano tube pulp, wherein, in the graphene-carbon nano tube pulp, the concentration of a carbon nano tube is 30mg / mL to 50mg / mL, and the concentration of graphene is 2mg / mL to 3mg / mL. The clothing material provided by the invention is light-weight, flexible, anticorrosive and oil-resistant, and is long in service life; a specific service environmental requirement can be met.

Owner:江苏宝美户外用品股份有限公司

Waterproof temperature-resistant modified nylon material for automobile plastic members

The invention belongs to the field of high-molecular materials, and specifically relates to a waterproof temperature-resistant modified nylon material for automobile plastic members. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 12, 12-14 parts of chopped glass fibre, 5-6 parts of octadecanamide, 5-6 parts of ammonium polyphosphate, 12-14 parts of bentonite, 10-20 parts of dimethyl trimethylsilylmethylphosphonate, 30-50 parts of melamine cyanurate, 10-12 parts of antimonony oxide, 23-25 parts of polystyrene, 8-10 parts of montmorillonite, 5-6 parts of ricinoleic acid and 12-15 parts of an auxiliary agent. The material combines the advantages of the raw materials such as nylon 12, polystyrene and the like; and the prepared material is tough, pliable, high in hardness, ling in mass, low in water absorption rate, waterproof, moistureproof, resistant to low-temperature and high-temperature ageing, and safe and reliable to use, and is widely applicable to prepare various automobile plastic members, and is especially applicable to automobile members in environment with relatively high temperature or relatively high humidity.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

High temperature-resistant modified polyethylene moble sheath material

ActiveCN103881210AImprove performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesParaffin waxMicrocrystalline wax

The invention relates to a cable material and specifically relates to a high temperature-resistant modified polyethylene moble sheath material. The material is prepared from the following raw materials in parts by weight: 12-14 parts of polytetrafluoroethylene, 24-28 parts of medium density polyethylene, 15-18 parts of polyvinylidene chloride, 7-9 parts of EVA (Ethylene Vinyl-Acetate copolymer), 1-2 parts of microcrystalline wax, 10-12 parts of nanosilicon dioxide, 4-6 parts of sodium metasilicate, 2-3 parts of glass fiber, 1-2 parts of liquid paraffin, 2-3 parts of styrene, 13-16 parts of trioctyltrimellitate (TOTM), 1-3 parts of aluminate coupling agent DL-411, 20-24 parts of china clay powder, 16-19 parts of tributyl citrate, and 14-16 parts of auxiliaries; the insulating material has all the advantages of the raw materials such as the medium density polyethylene, the polyvinylidene chloride and the polytetrafluoroethylene, and the prepared material is firm and flexible, excellent in mechanical properties, excellent in chemical corrosion resistance, resistant to aging and high temperatures, good in electrical insulating property and long in service life; besides, the material can be widely applied to fabricating various cable sheath insulating materials, and thus is wide in market requirement prospect.

Owner:ANHUI EFARAD ELECTRIC POWER TECH

Anti-ultraviolet modified nylon 66 material for automobile plastic members

The invention belongs to the field of high-molecular materials, and specifically relates to an anti-ultraviolet modified nylon 66 material for automobile plastic members. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 66, 10-12 parts of silicon carbide, 4-6 parts of titanium nitride, 20-24 parts of teflon, 13-16 parts of nanometer potter's clay, 4-5 parts of calcium stearate, 3-4 parts of hexamethylphosphoramide, 3-5 parts of alumina, 2-3 parts of bamboo-charcoal powder, 3-4 parts of stearic acid, 2-3 parts of iron oxide black, 6-9 parts of triolein, 2-3 parts of cross-linking agent TAIC and 12-15 parts of an auxiliary agent. The material combines the advantages of the raw materials such as nylon 66, teflon and the like; the material is subjected to modification processing by utilizing the raw materials such as nanometer potter's clay, silicon carbide and the like, so that the material has good processing performance and mechanical properties; and the prepared material is high in strength, practical, wear-resistant, resistant to high temperature, resistant to thermal ageing, resistant to ultraviolet ageing, flame-retardant, antistatic, safe and reliable, and is widely applicable to prepare various automobile plastic members.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

Modified flexible ozone-resistant polyethylene cable sheath material

InactiveCN103540003AImprove performanceImprove mechanical propertiesInsulated cablesInsulatorsLow-density polyethylenePolyester

The invention relates to a cable material, and in particular relates to a modified flexible ozone-resistant polyethylene cable sheath material. The cable sheath material is prepared from the following raw materials in parts by weight: 28 to 32 parts of low-density polyethylene, 18 to 23 parts of ethylene-vinyl acetate copolymer (EVA), 3 to 5 parts of ACR (Acrylate) impact modifier, 2 to 3 parts of tungsten boride, 4 to 6 parts of aluminum nitride, 1 to 2 parts of ricinoleic acid, 12 to 15 parts of talcum powder, 8 to 12 parts of bentonite powder, 15 to 17 parts of diisononyl phthalate, 15 to 18 parts of propanediol sebacate polyester, 10 to 12 parts of sodium fluosilicate, 4 to 6 parts of barium sulfate, 1 to 2 parts of phenol and 14 to 16 parts of auxiliary agent. The prepared cable sheath material is firm and flexible, and has the performance of aging resistance, ozone resistance, tearing resistance and chemical solvent resistance by combining the advantages of the low-density polyethylene, the ethylene-vinyl acetate copolymer (EVA) and the other raw materials. Thus, the prepared cable sheath material is safe and reliable to use. Therefore, the cable sheath material can be widely used for preparing various cable sheath insulating materials. The cable sheath material provided by the invention has broad market demand prospect.

Owner:LVBAO CABLE GROUP

Toughened low temperature-resisting modified polyphenylene sulfide material applied to automobile plastic part

ActiveCN103937246AHigh heat distortion temperatureImprove performanceLow-density polyethyleneThermal ageing

The invention belongs to the field of high-molecular materials, and particularly relates to a toughened low temperature-resisting modified polyphenylene sulfide material applied to an automobile plastic part. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenylene sulfide, 12-14 parts of ABS (Acrylonitrile Butadiene Styrene) high-rubber powder, 4-6 parts of sodium tungstate, 4-5 parts of magnesium chloride, 2-3 parts of zinc oxide, 1-2 parts of sodium aliphatate, 12-14 parts of polyethylene, 4-5 parts of hydrogenated rosin, 8-12 parts of polyisobutene, 2-3 parts of 3-aminopropyl trimethoxy silane, 2-3 parts of polytetrahydrofuran ether glycol, 4-6 parts of chlorinated paraffin and 12-15 parts of additive. The toughened low temperature-resisting modified polyphenylene sulfide material disclosed by the invention integrates the advantages of the raw materials such as the polyphenylene sulfide 11, the low-density polyethylene and asbestos fibers, so a prepared material is light, wear-resisting, corrosion-resisting, less in possibility of cracking, thermal ageing-resisting, good in color, smooth in hand feeling, beautiful, durable, safe and reliable in use, widely applicable to manufacturing of various plastic parts for automobiles and especially applicable to manufacturing of automobile parts such as tail light covers, automobile roofs and automobile doors.

Owner:安徽省中日农业环保科技有限公司

Heat-conducting voltage-resistant electric insulating material with high breakdown and preparation method thereof

The invention discloses a heat-conducting voltage-resistant electric insulating material with high breakdown and a preparation method thereof. The heat-conducting voltage-resistant electric insulatingmaterial is prepared from the following raw materials in parts by weight: 70-90 parts of epoxy resin, 10-20 parts of polycarbonate, 2-4 parts of graphene, 6-8 parts of polybutylene succinate, 9-13 parts of butyl polymethacrylate, 10-12 parts of white carbon black, 6-8 parts of KH550 silane coupling agent, 10-14 parts of enhanced additive, 25-35 parts of compound rubber, 2-3 parts of vulcanizing agent, 8-10 parts of insulated heat-conducting additive, 2-4 parts of silicon dioxide, 9-11 parts of flame-retardant additive, 7-9 parts of processing aid and 4-8 parts of synergistic aid. The heat-conducting voltage-resistant electric insulating material has the advantages of high heat-conducting coefficient, better mechanical property and compression strength and tensile strength, higher breakdown voltage and excellent insulating property, simultaneously also has certain flame-retardant and antistatic properties; in addition, the preparation method disclosed by the invention has the advantages of lower cost, concise process, easy operation and industrial-production implementation, higher practical value and good application prospect.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Polystyrene electric cable sheath material with characteristics of light weight, water resistance and fire retardation

The present invention relates to an electric cable material, particularly to a polystyrene electric cable sheath material with characteristics of light weight, water resistance and fire retardation, wherein the material comprises the following raw materials by weight: 15-18 parts of a phenol formaldehyde resin, 30-35 parts of polystyrene, 12-15 parts of polyvinyl acetate, 28-33 parts of fluorite powder, 4-5 parts of alumina, 1-2 parts of an antioxidant DSTP, 2-3 parts of propylene glycol, 5-8 parts of silica powder, 6-8 parts of ethylenebis(stearamide), 25-30 parts of epoxy butyl oleate, 10-12 parts of N351 carbon black, 1-2 parts of an anti-aging agent OD, 6-8 parts of dimethyl fumarate, 2-3 parts of triethoxyvinylsilane, 1-2 parts of ammonium dihydrogen phosphate, and 14-16 parts of an auxiliary agent. According to the present invention, the material integrates advantages of the phenol formaldehyde resin, polystyrene, polyvinyl acetate and other raw materials, the processing performance and the mechanical property are improved, and the prepared material has characteristics of light weight, good flexibility, water resistance, damp resistance, high temperature resistance, fire retardation, chemical reagent corrosion resistance, safety, durability and broad market requirement prospect, and can be widely used for production of various types of electric cable sheath insulating materials.

Owner:ANHUI TELI SCI & TECH

Impact resistance modified polyolefin cable sheath material

InactiveCN103642116AGood chemical stabilityExtended service lifePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneElastomer

The invention relates to a cable material, and concretely relates to an impact resistance modified polyolefin cable sheath material, and the material contains the following raw materials by weight: 30-34 parts of ethane-vinyl acetate, 14-17 parts of metallocene linear low density polyethylene, 9-12 parts of poly 1-butylene, 12-15 parts of aluminium hydroxide, 5-7 parts of TPE elastomer, 2-3 parts of zinc stearate, 5-7 parts of melamine resin, 2-3 parts of vinyltriethoxysilane, 1-2 parts of promoter PZ1, 20-25 parts of nanometer silica, 1-2 parts of aluminate coupling agent DL-411, 2-3 parts of methyl diphenylene diisocyanate, 24-30 parts of tributyl citrate, 6-8 parts of alumina and 14-16 parts of auxiliary agent; the insulating material combines advantages of ethane-vinyl acetate copolymer, metallocene linear low density polyethylene and other raw materials, and the prepared material has the advantages of sturdiness and flexibility, anti-impact, ozone age resistance, aging resistance, chemical stability resistance, and can be widely used for making various cable sheath insulating materials with wide market demand prospect.

Owner:ANHUI SIHUI CABLE

Polypropylene modified polyphenyl ether material for automobile plastic parts

InactiveCN103937206AImprove electrical performanceExtended service lifePolypropyleneMechanical property

The invention belongs to the field of the high polymer materials and specifically relates to a polypropylene modified polyphenyl ether material for automobile plastic parts. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenyl ether, 20-24 parts of polypropylene, 1-2 parts of poly dihydropyridine, 5-7 parts of epoxy soybean oil, 5-8 parts of calcium carbonate powder, 12-15 parts of talcum powder, 8-12 parts of bentonite powder, 1-2 parts of antioxidant 168, 1-2 parts of nano-titanium dioxide, 4-6 parts of methyl methacrylate and 12-15 parts of auxiliaries. The polypropylene modified polyphenyl ether material integrates the advantages of the raw materials such as polyphenyl ether and polypropylene, and is modified by using the raw materials such as the bentonite powder and the talcum powder, so that the mechanical properties of the material are improved; the prepared material is firm and flexible, resistant to weather ageing, safe and flame-retardant, and has excellent electrical properties and long service life, and thus can be widely applied to manufacturing of various automobile plastic parts.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Ultraviolet-proof modified nylon 6 material for automobile plastic parts

The invention belongs to the field of high-polymer materials, and particularly relates to an ultraviolet-proof modified nylon 6 material for automobile plastic parts. The material is prepared from the following raw materials in parts by weight: 100 parts of nylon 6, 12-14 parts of aluminum nitrate, 5-8 parts of polyaluminum chloride, 3-4 parts of ferrous sulfate, 3-4 parts of acrylamide, 1-2 parts of oleamide, 16-18 parts of dibutyl phthalate, 2-3 parts of lithium laurate, 1-2 parts of dimethyl bis(isooctylmercaptoacetate) tin, 3-4 parts of bis(octadecyl alcohol ester), and 12-15 parts of auxiliaries. According to the ultraviolet-proof modified nylon 6 material, the nylon 6 is modified by utilizing the raw materials of aluminum nitriate, polyaluminum chloride, ferrous sulfate and the like, and the nylon 6 has excellent processiability and mechanical performance, so that the prepared material is high in hardness, high-temperature-resistant, difficult to age, ultraviolet irradiation-proof, and safe to use, and can be widely used for producing various automobile plastic parts.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

Shell powder modified polyphenyl ether material for auto plastic parts

The invention belongs to the field of a high polymer material, and particularly relates to a shell powder modified polyphenyl ether material for auto plastic parts. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenyl ether, 10-12 parts of shell powder, 3-5 parts of seaweed gel, 12-16 parts of zinc borate, 2-4 parts of basic magnesium carbonate, 1-2 parts of anti-aging agent MB, 1-3 parts of vinyl tri(beta-methoxyethoxy) silane, 1.8-2.5 parts of silane coupling agent KH550, 2-3 parts of feldspar powder, 5-7 parts of itaconate, 3-4 parts of zinc stearate and 12-15 parts of assistant. The polyphenyl ether is modified by using the raw materials such as the shell powder, zinc borate, the feldspar powder and the like, so that the material has good processing performance and mechanical performance, and the prepared material is firm and wearable, high-temperature ageing resistant, environment-friendly and flame retardant, impact resistant, long in service life, safe and reliable, and can be widely applied to fabrication of various auto plastic parts.

Owner:安徽省中日农业环保科技有限公司

Damp-proof flexible modified chlorinated polyethylene cable sheath material

InactiveCN103881250AImprove performanceEasy to processPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneAluminum silicate

The invention relates to a cable material, and particularly relates to a damp-proof flexible modified chlorinated polyethylene cable sheath material. The material comprises the following active ingredients in parts by weight: 23-24 parts of chlorinated polyethylene, 12-14 parts of low-density polyethylene, 14-17 parts of EVA (ethylene / vinyl acetate), 13-14 parts of adipic acid dioctyl ester, 12-13 parts of dioctyl sebacate, 8-10 parts of medical stone powder, 12-14 parts of vermiculite powder, 12-15 parts of aluminum silicate, 10-15 parts of white carbon black, 3-4 parts of hydrogenated cardanol, 1-2 parts of catechol, 4-6 parts of zinc oxide, 2.5-3.5 parts of zinc stearate, 1-2 parts of molybdenum disulfide, and 14-16 parts of auxiliaries. An insulating material combines the advantages of chlorinated polyethylene, low-density polyethylene, EVA and other raw materials, the prepared material is light in weight and flexible, waterproof and damp-proof, tear-proof, chemical reagent-resistant, oil-proof and flame-retardant, can be widely used for producing various cable sheath insulating materials, thus having wide market demand prospects.

Owner:ANHUI EFARAD ELECTRIC POWER TECH

Weather-proof and ozone-proof modified polyethylene cable sheath material

InactiveCN103756117AImprove performanceEasy to processPlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneWear resistant

The invention relates to a cable material, and specifically relates to a weather-proof and ozone-proof modified polyethylene cable sheath material. The material comprises the following raw materials in parts by weight: 40-45 parts of linear low density polyethylene, 14-18 parts of EVA (Ethylene-Vinyl Acetate) resin, 2-3 parts of a silane coupling agent KH-550, 8-10 parts of acrylamide, 2-3 parts of polyvinyl alcohol, 1-2 parts of an accelerant DM, 3-5 parts of zinc oxide, 1-2 parts of phenyltriethoxysilane, 1-2 parts of an accelerant DM, 25-29 parts of carbon black, 1.0-2.0 parts of an accelerant M, 18-22 parts of tributyl citrate, 14-18 parts of bentonite powder and 14-16 parts of an assistant. The insulating material combines the advantages of the raw materials such as linear low density polyethylene and EVA resin, and the prepared material is flexible and wear-resistant, environmental climate aging-resistant, ozone corrosion-resistant, good in chemical stability, dampproof and waterproof and safe and reliable to use, can be widely applied to preparation of various cable sheath insulating materials, and is promising in market requirement.

Owner:ANHUI TELI CABLE

Heat-resisting flame retardant modified polyphenyl ether material for automotive plastic parts

The invention belongs to the field of high molecular materials, and particularly relates to a heat-resisting flame retardant modified polyphenyl ether material for automotive plastic parts. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenyl ether, 12-15 parts of poly(4-methyl-1-pentene), 4-6 parts of stearic acid, 9-12 parts of zinc borate, 6-9 parts of magnesium aluminate, 10-12 parts of antimony trioxide, 1-2 parts of glycerol triacetate, 1-2 parts of sarcandra glabra essential oil, 5-7 parts of dioctyl phthalate, 2-3 parts of tricresyl phosphate, 6-9 parts of pentaerythritol stearate and 12-15 parts of aids. The heat-resisting flame retardant modified polyphenyl ether material combines the advantages of the raw materials such as the polyphenyl ether and the poly(4-methyl-1-pentene); the prepared material has high strength, heat resistance, chemical corrosion resistance, oil resistance and good electrical insulating property, is easy to process and mold, lightweight and safe and reliable to use, can be widely used for manufacturing various automotive plastic parts and is particularly suitable for manufacturing of parts such as automotive oil delivery pipes and brake pipes.

Owner:安徽省中日农业环保科技有限公司

Anti-ageing fire-retarding modified polyolefin elastomer cable sheath material

InactiveCN103756080AImprove performanceFlame retardant safetyInsulated cablesInsulatorsElastomerPolyolefin

The invention relates to a cable material, and particularly relates to an anti-ageing fire-retarding modified polyolefin elastomer cable sheath material. The material is prepared from the following raw materials in parts by weight: 24-28 parts of a polyolefin elastomer, 18-22 parts of polyvinyl chloride, 12-15 parts of diatomite, 8-10 parts of kaolin, 1-2 parts of chloroplatinic acid, 0.1-0.2 part of cerium oxide, 0.2-0.4 part of lanthanum oxide, 2-3 parts of bismuth trioxide, 2-3 parts of dipentaerythritol hexaacrylate, 15-20 parts of tributyl citrate, 8-10 parts of petroleum resin, 15-20 parts of aluminium hydroxide, 1-2 parts of an accelerant TMTD, 3-4 parts of diaminodiphenylmethane and 14-16 parts of an additive. The insulating material is combined with the advantages of the raw materials including the polyolefin elastomer, polyvinyl chloride and the like, so that the prepared material is firm, wear-resisting, high temperature and low temperature ageing-resisting, chemical corrosion-resisting, good in low-temperature toughness, safe in fire retardance, long in service life, widely used for manufacturing various cable sheath insulating materials, and wide in market requirement prospect.

Owner:ANHUI TELI CABLE

Low-cost polyethylene modified polyphenyl ether material for automobile plastic parts

The invention belongs to the field of the high polymer materials and specifically relates to a low-cost polyethylene modified polyphenyl ether material for automobile plastic parts. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenyl ether, 16-19 parts of recycled polyethylene, 2-3 parts of isopropyl tri(dioctyl pyrophosphoric acyloxy) titanate, 2-4 parts of magnesium oxide, 3-5 parts of molybdenum disulfide, 2-4 parts of barium stearate, 1-3 parts of methyltrimethoxysilane, 10-12 parts of kaoline powder, 10-15 parts of polytetrafluoroethylene, 5-7 parts of epoxidized butyl oleate and 12-15 parts of auxiliaries. The low-cost polyethylene modified polyphenyl ether material integrates the advantages of the raw materials such as polyphenyl ether, polyethylene and polytetrafluoroethylene, and thus has excellent processability and mechanical property; the prepared material is firm, flexible, waterproof, moisture-proof, heat aging-resistant, has excellent electrical properties, good chemical stability and self lubricating property, is hard and durable, and can be widely applied to manufacturing of various automobile plastic parts, and furthermore, the production cost is reduced and the waste of resources is avoided.

Owner:JIXI YUANDAO AGRI IND TECH

Temperature-resistant polyvinyl chloride modified polyphenyl ether material for automobile plastic component

The invention belongs to the field of high molecular materials, and in particular relates to a temperature-resistant polyvinyl chloride modified polyphenyl ether material for automobile plastic components. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenyl ether, 10-12 parts of E-12 epoxy resin, 4-7 parts of ammonium dihydrogen phosphate, 1-2 parts of borax, 14-18 parts of calcium carbonate powder, 2-3 parts of diphenylmethane diisocyanate, 6-8 parts of aluminum oxide, 1-3 parts of LK-640 boric acid ester coupling agent, 3-4 parts of polyester silicon oil, 12-16 parts of polyvinyl chloride, 1-2 parts of wood flour, 3-4 parts of stearic acid and 12-15 parts of additives. The material combines the advantages of raw materials such as the polyphenyl ether, the polyvinyl chloride and the E-12 epoxy resin, the property of a conventional polyphenyl ether material is improved, the polyphenyl ether material is good in machining property and mechanical property, the prepared material is high in strength, good in toughness, thermal aging resistant, low-temperature impact resistant, good in chemical stability, flame-retarding, safe and reliable, and can be widely used for manufacturing various automobile plastic components.

Owner:安徽省中日农业环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com