Patents

Literature

58 results about "Bacillus acidiceler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bacillus sp. D747 strain, plant disease controlling agents and insect pest controlling agents using the same and control method using the agents

The present invention relates to a novel strain of Bacillus sp. D747 (deposited as FERM BP-8234) and methods for controlling plant diseases and insect pests, comprising administering cultures of Bacillus sp. D747 (including the viable bacteria) or viable bacteria isolated by culturing, on the plant parts such as roots, stems, leaves, seeds, and the like, or in the culture soil.

Owner:KUMIAI CHEM IND CO LTD

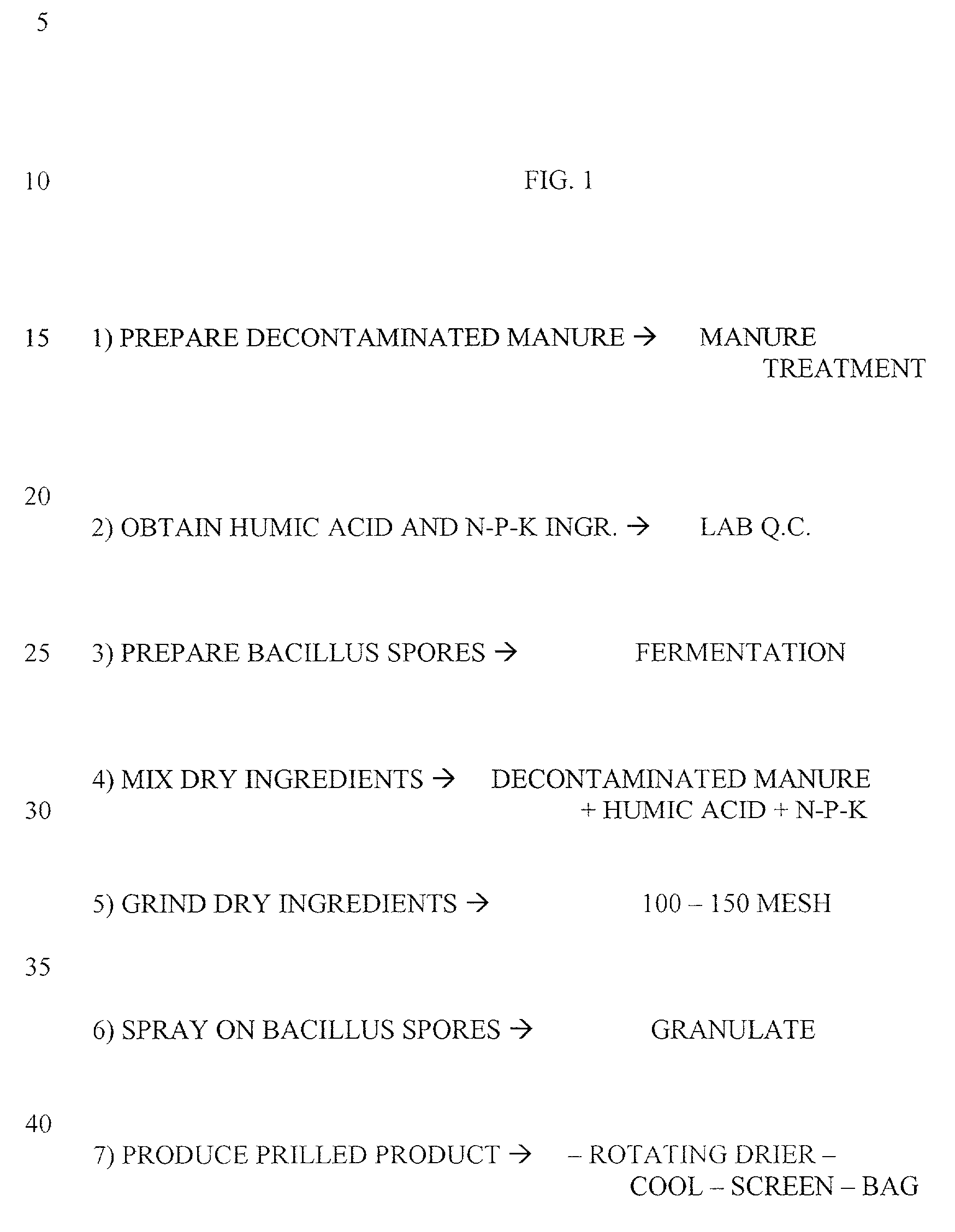

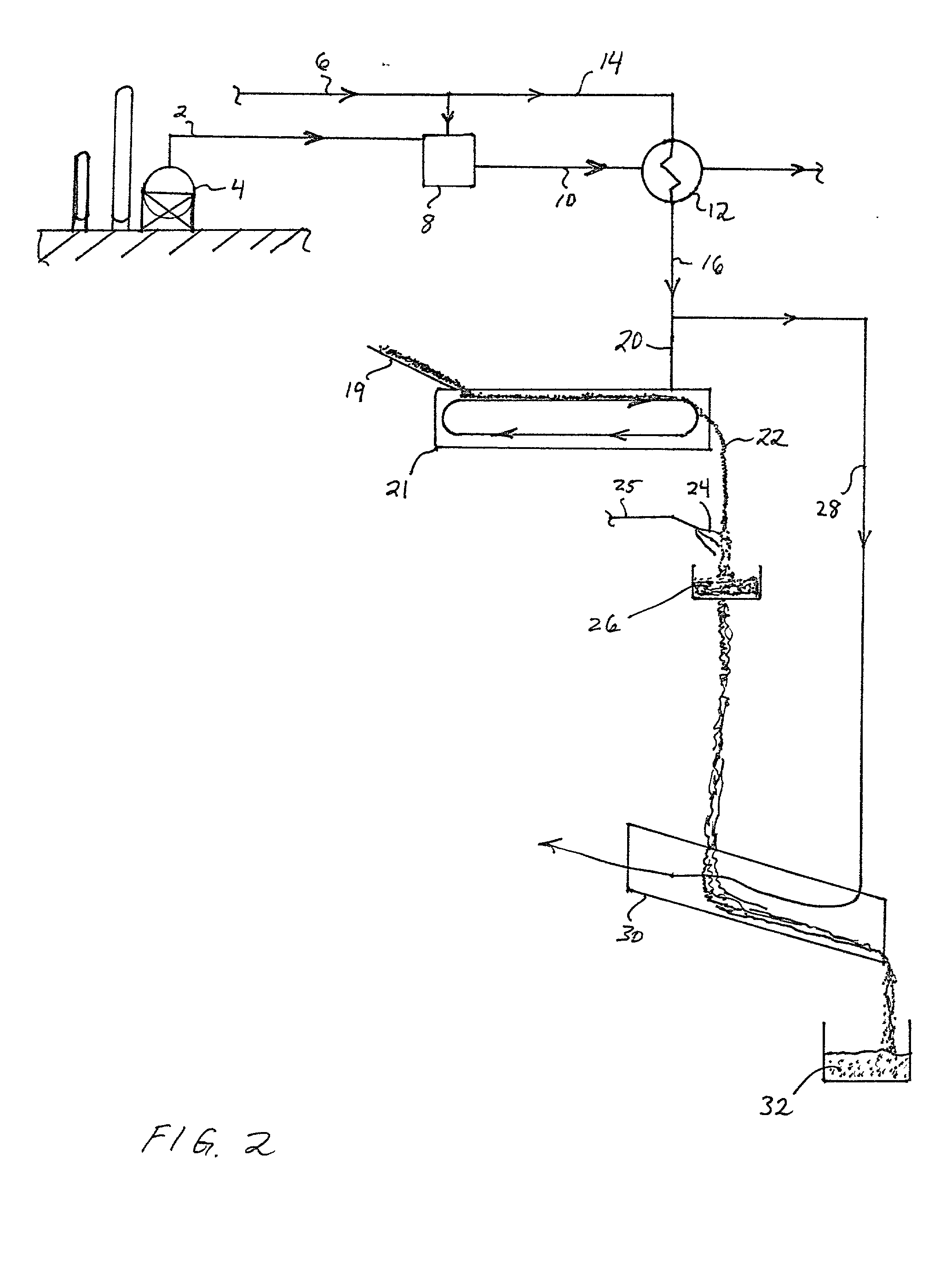

Fertilizer compositions and methods of making and using same

Fertilizer compositions for plant production are described, comprised of decontaminated manure and Bacillus spores, preferably a humic acid derived from lignite and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds. Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened prills or pellets. Processes for production and use are also presented.

Owner:MICROBES

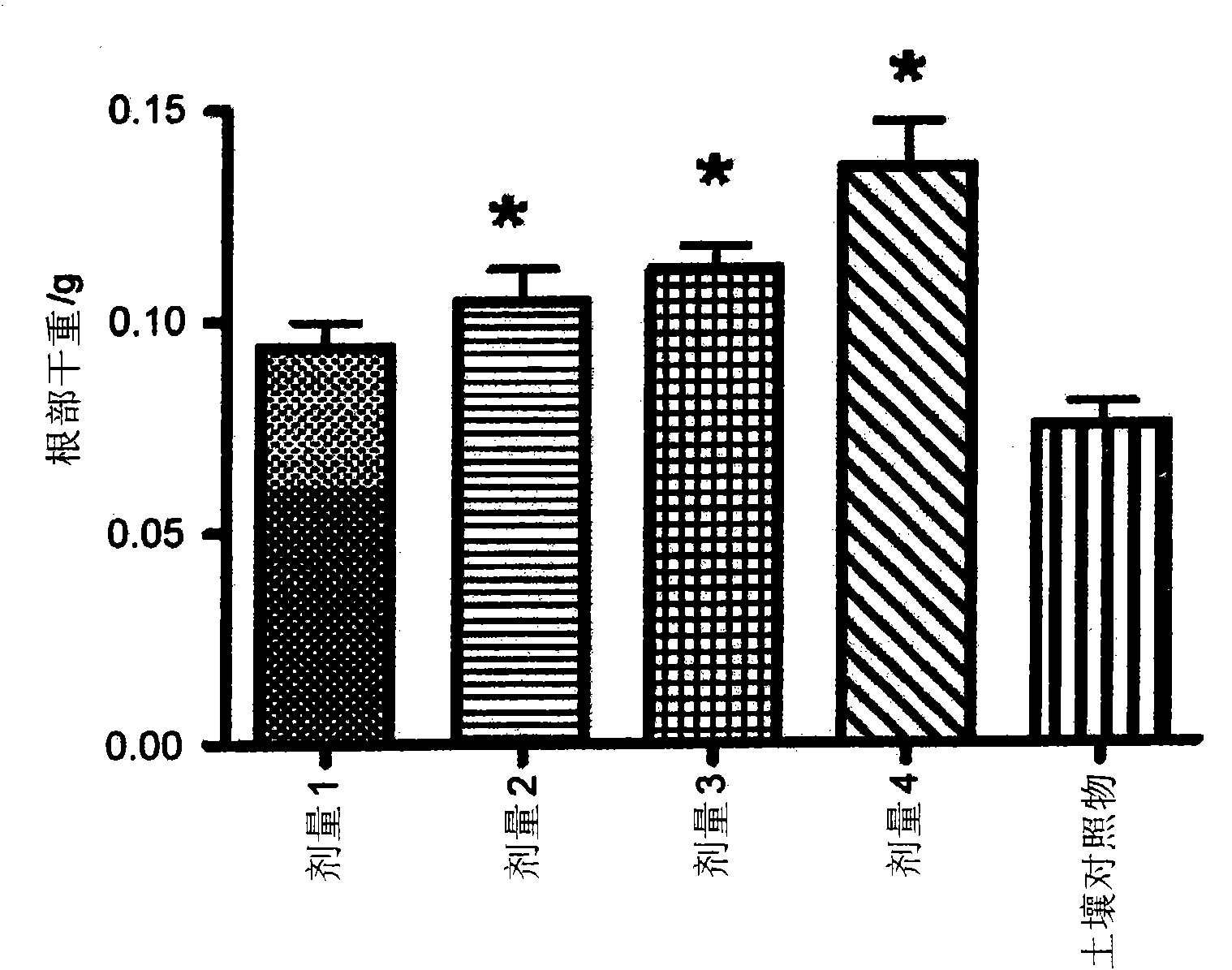

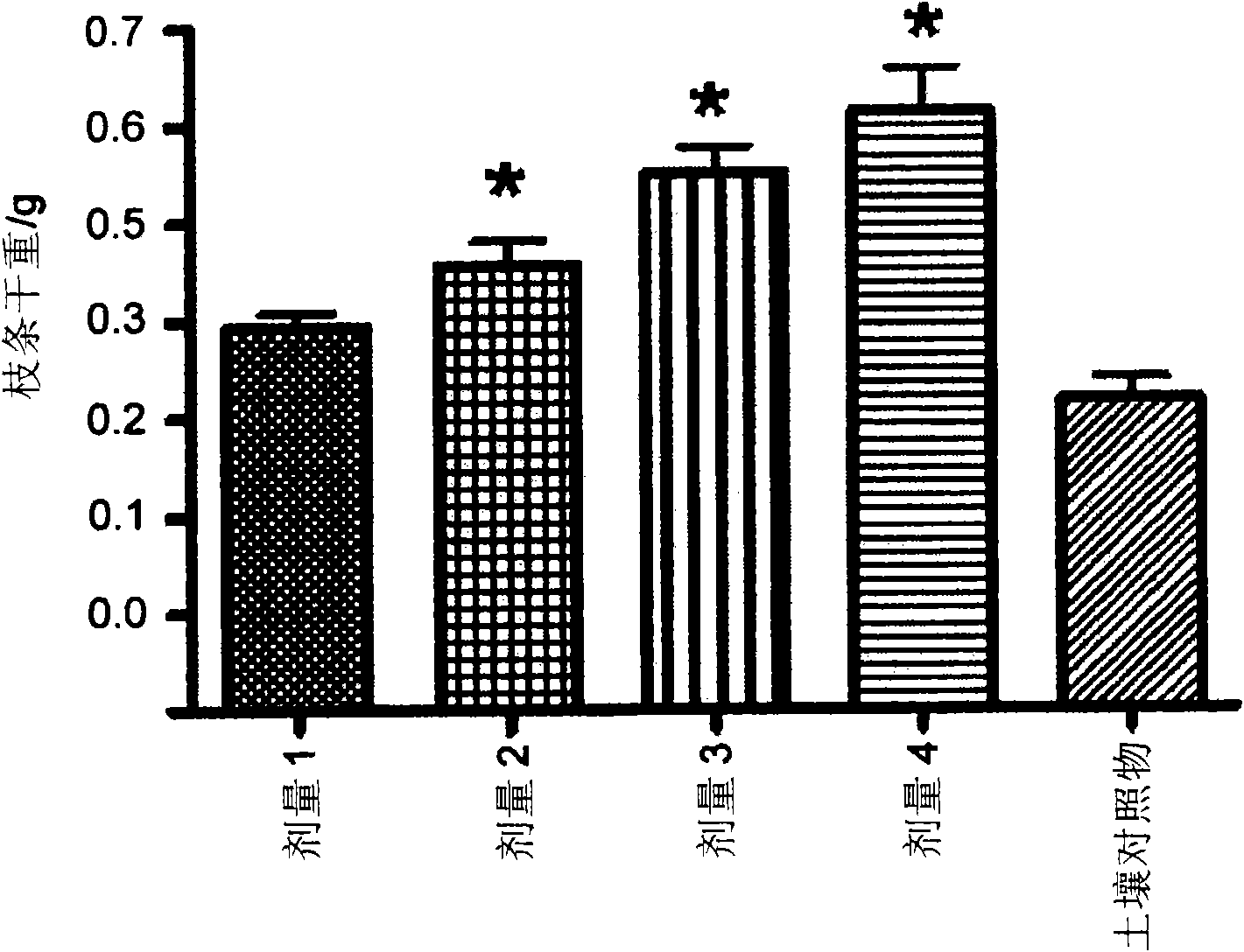

Microbial formulation and method of using the same promote plant growth

A plant growth promoting composition includes beneficial microbes and microbial activators. The beneficial microbes may include Bacillus spp., Azotobacter spp., Trichoderma spp., Saccharomyches spp., or combinations of these, the microtrial activators include enzymes, metabolites, carbohydrate yeast, humic material, staich, amino acids and micornutrients. The plant growth promoting composition may also include organic and inorganic fertilizers.

Owner:ULTRA BIOTECH

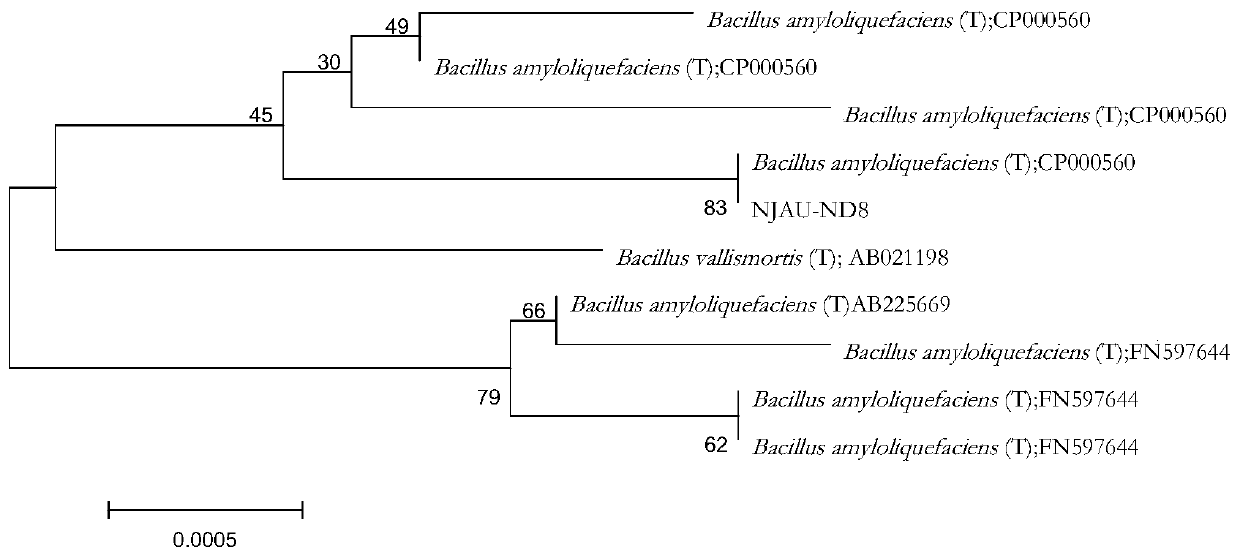

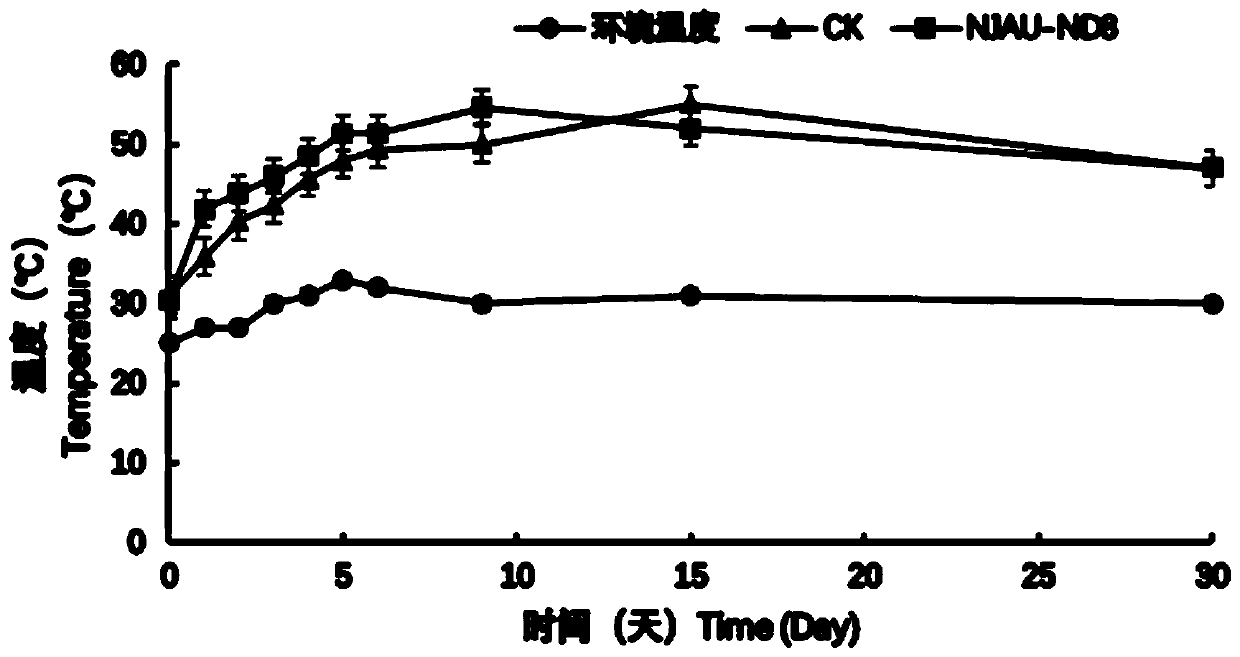

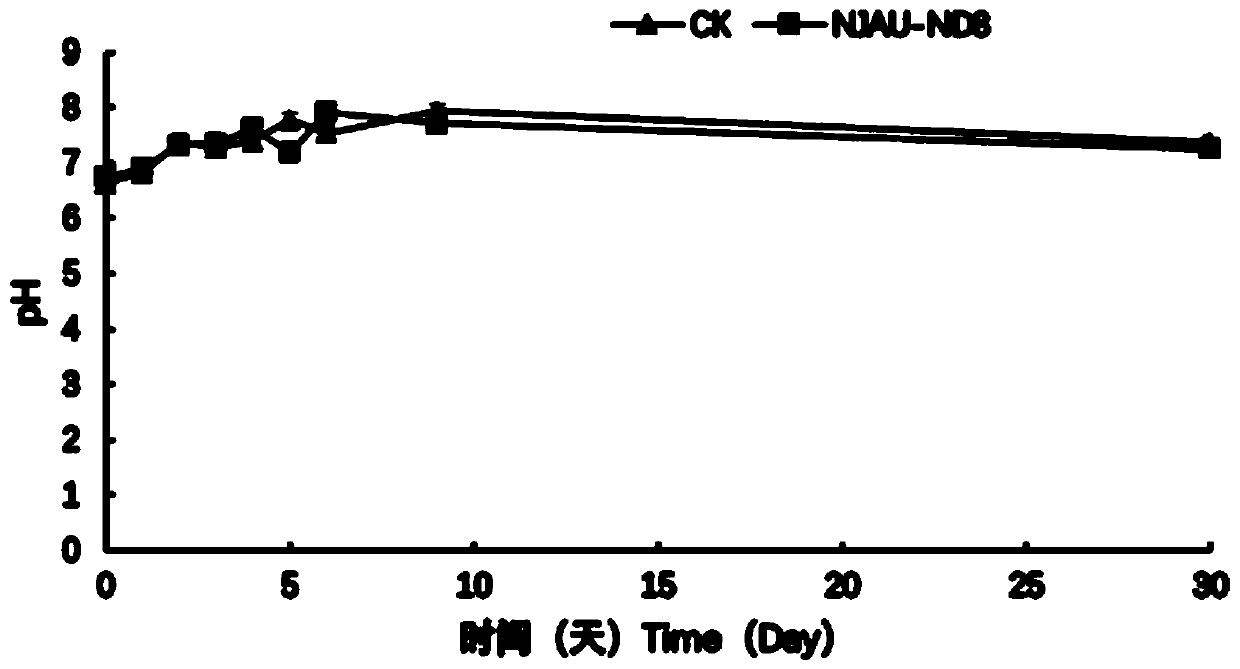

High-temperature-resistant bacillus licheniformis strain NJAU-ND8 for acceleration of compost maturity and application of strain

ActiveCN110066746AFast growth and reproductionHigh-efficiency lignocellulosic enzyme activityBacteriaExcrement fertilisersBacillus licheniformisMicrobiology

The invention provides a high-temperature-resistant bacillus licheniformis strain NJAU-ND8 for acceleration of compost maturity and application of the strain. The preservation number of the bacillus licheniformis strain NJAU-ND8 is CGMCC No.16737, and the strain is applied for acceleration of compost maturity. An application method includes the following steps of uniformly mixing manure of livestock and poultry with auxiliary materials according to a certain C / N rate, then inoculating the liquid strain, adopting a strip-shaped stack fermentation process after strip-shaped stacks are formed, and performing overturning and throwing for fermentation. Compared with a contrast without the strain, the application has the advantages that by adding the strain, temperature raising for the stacks inthe early stage of composting is facilitated, the stacks are pushed to enter a cooling period in advance, thus the increase of a germination index of a compost product is promoted, and the decline ofthe C / N rate of the stacks into a compost maturity range is accelerated.

Owner:NANJING AGRICULTURAL UNIVERSITY

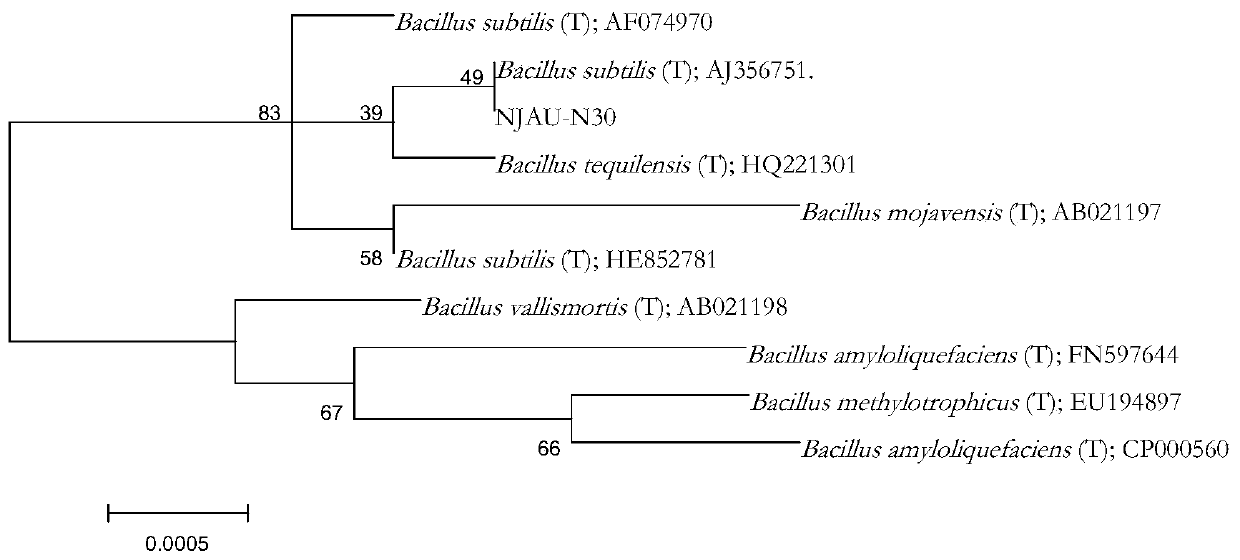

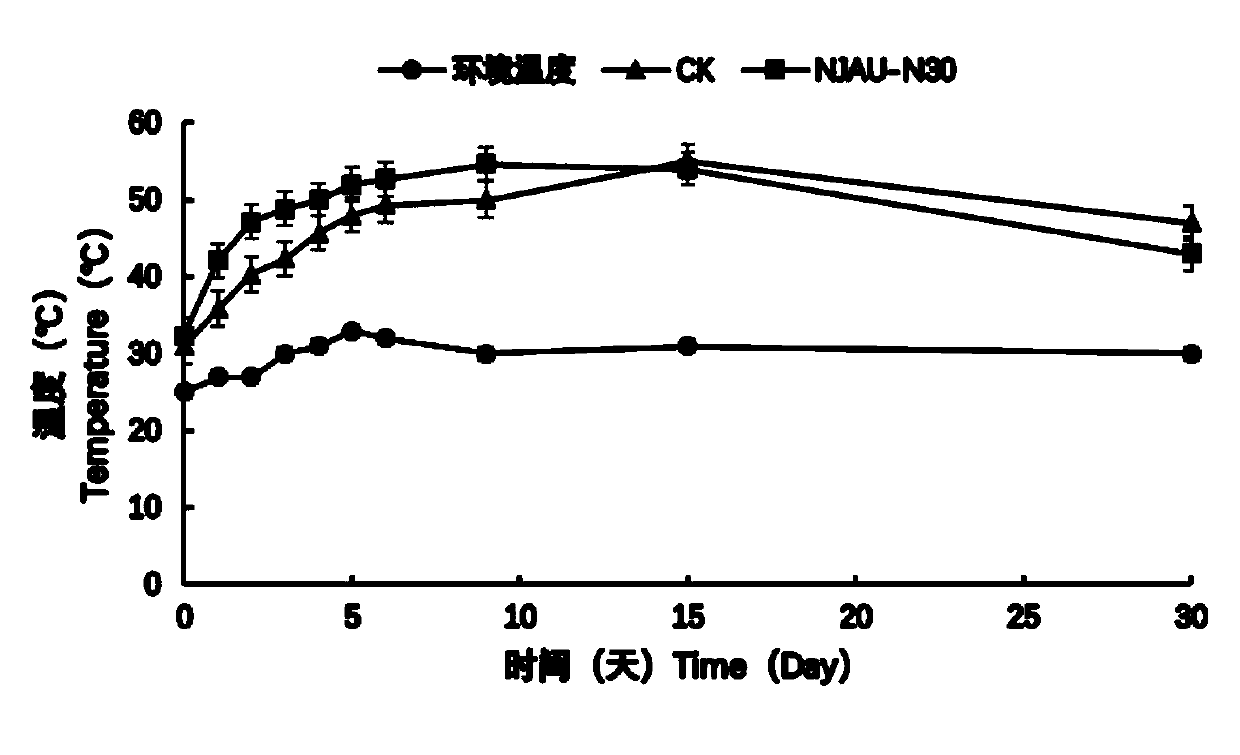

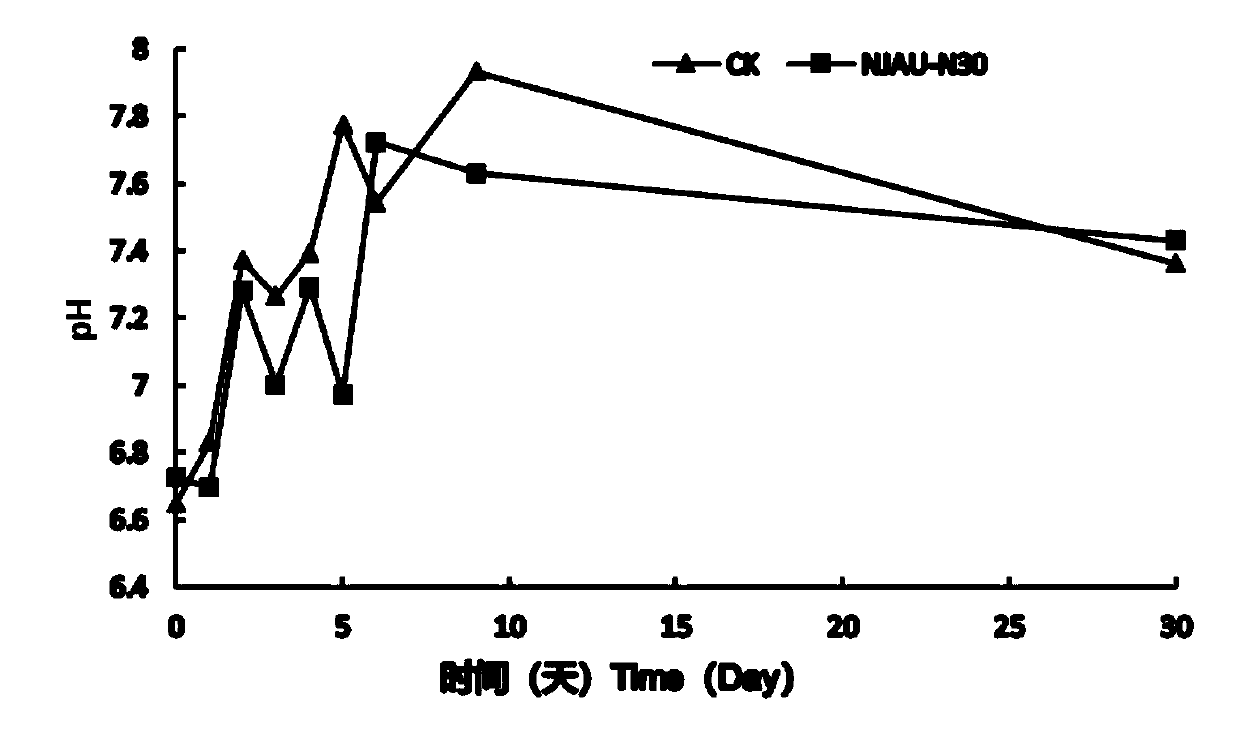

Bacillus high temperature bacteria NJAU-N30 for accelerating composting and decomposition and application thereof

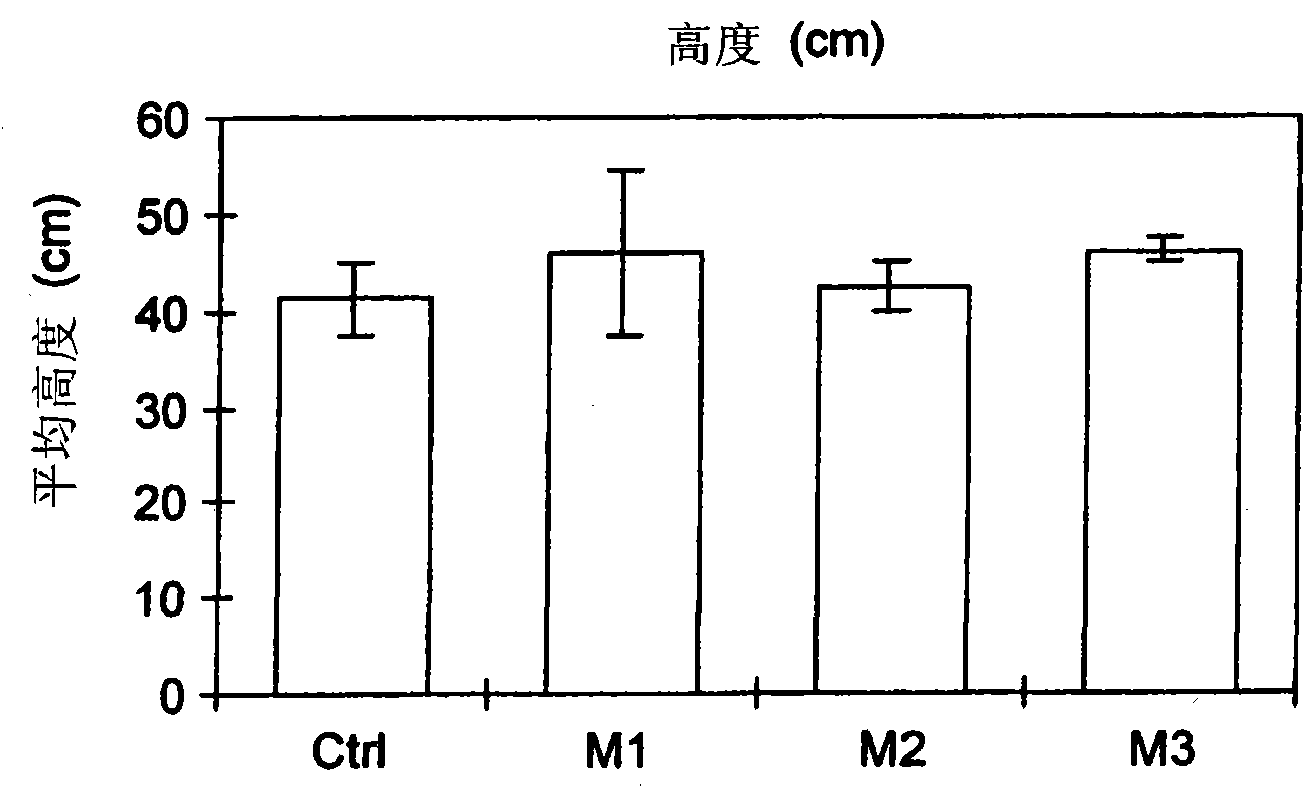

ActiveCN109880771APromote growthIncrease temperatureBacteriaMicroorganism based processesGerminationDecomposition

The invention provides bacillus high temperature bacteria NJAU-N30 for accelerating composting and decomposition and a process for preparing an organic fertilizer by fermentation acceleration throughthe same. A strain has an accession number of CGMCC No. 16736, and the application of the strain is to accelerate composting and fermentation. The process includes the steps of evenly mixing livestockmanure and auxiliary materials according to a certain C / N and then inoculating liquid strains; after forming a stack, adopting a stack type fermentation process, and turning over and fermenting. Compared with a control of no adding of strains, the strain adding effectively promotes the rise in temperature of a stack body at an early stage of composting, the stack body is urged to enter a coolingperiod ahead of time, and the improvement of a compost product germination index and the like is promoted. A prepared organic fertilizer can effectively promote the growth of plants.

Owner:NANJING AGRICULTURAL UNIVERSITY

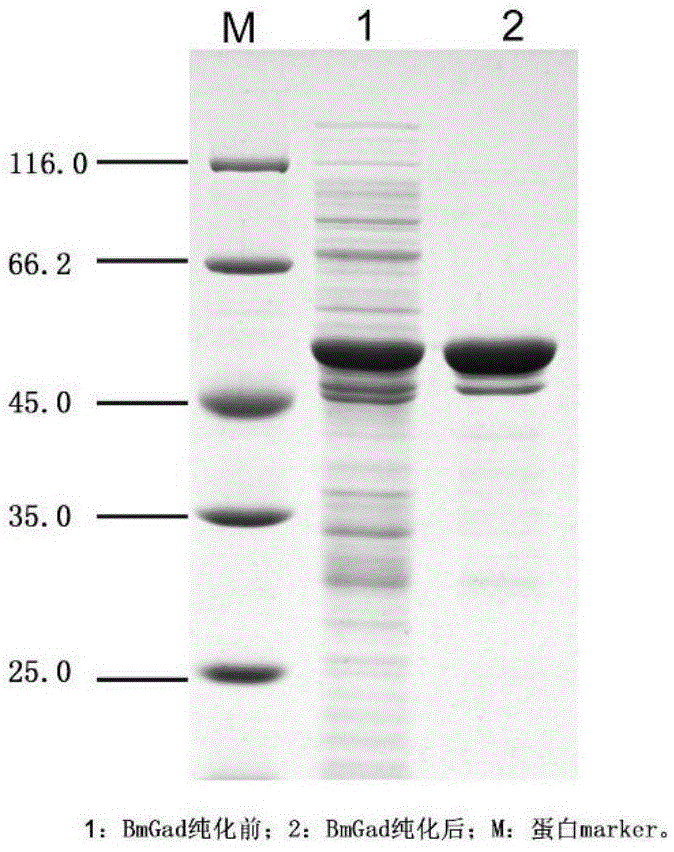

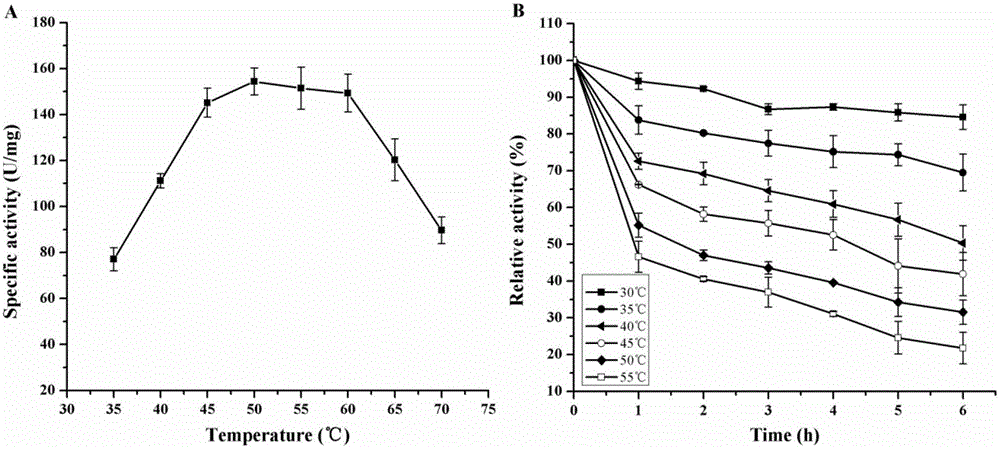

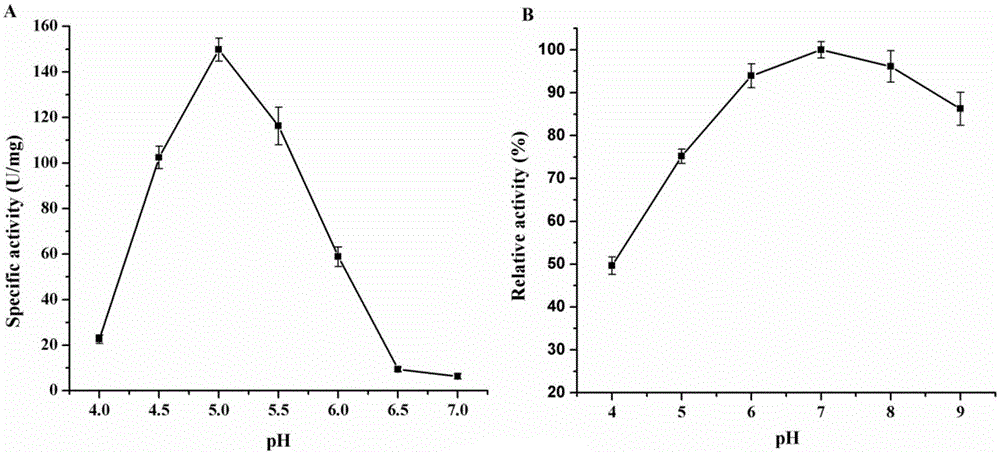

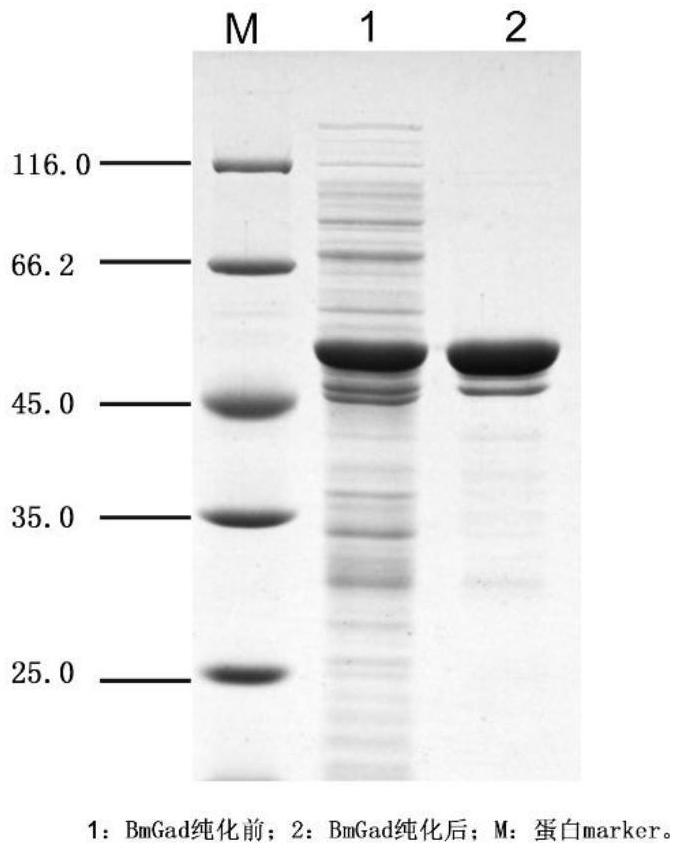

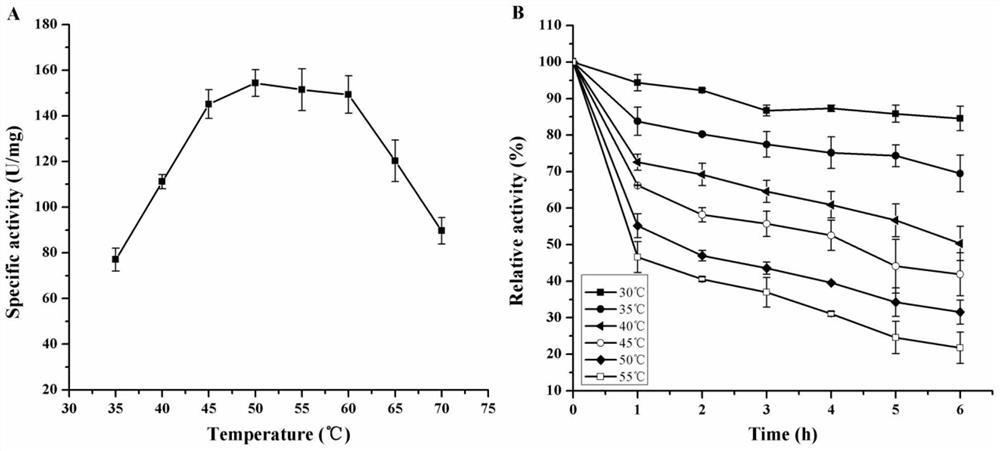

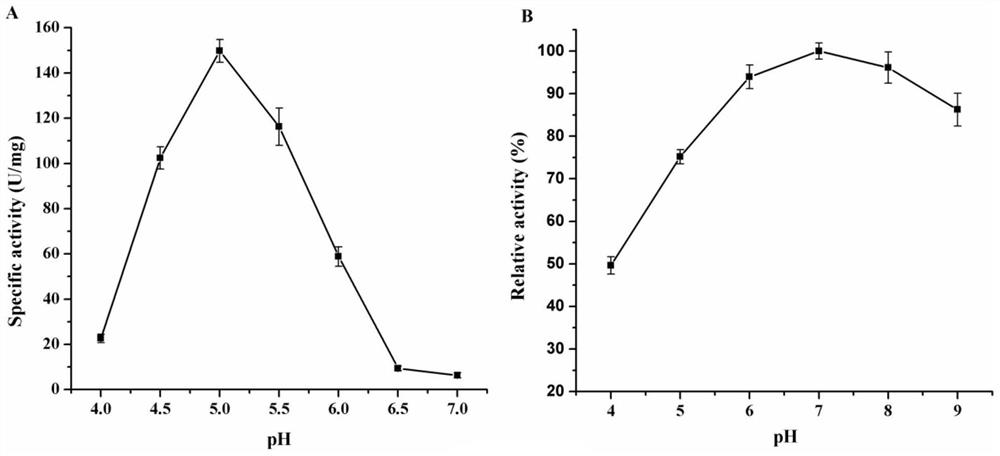

Cloning of novel glutamate decarboxylase gene and application thereof

The invention relates to the cloning of a novel glutamate decarboxylase gene and the application thereof. A glutamate decarboxylase is obtained from bacillus, and then the glutamate decarboxylase is induced to express in escherichia coli. The study on the properties of the glutamate decarboxylase shows that, the glutamate decarboxylase is higher in activity at pH 4.0 to pH 6.0, and the optimum temperature of the glutamate decarboxylase is 45-65 DEG C. The Vmax of the glutamate decarboxylase is 150-200 U / mg, and the Km of the glutamate decarboxylase is 7-9 mmol / L. The recombinant escherichia coli containing the glutamate decarboxylase is subjected to whole-cell transformation, and then 500 g / L L-glutamic acid is added in batches. At 37 DEG C, the recombinant escherichia coli is converted for 12 hours in a sodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution at the pH 7.0, and 347.8 g / L gamma-aminobutyric acid is finally generated. The molar conversion rate is 99.4%. Compared with an existing glutamate decarboxylase, the above novel glutamate decarboxylase is higher in catalytic efficiency and relatively wide in pH range, thus being more suitable for industrial application.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

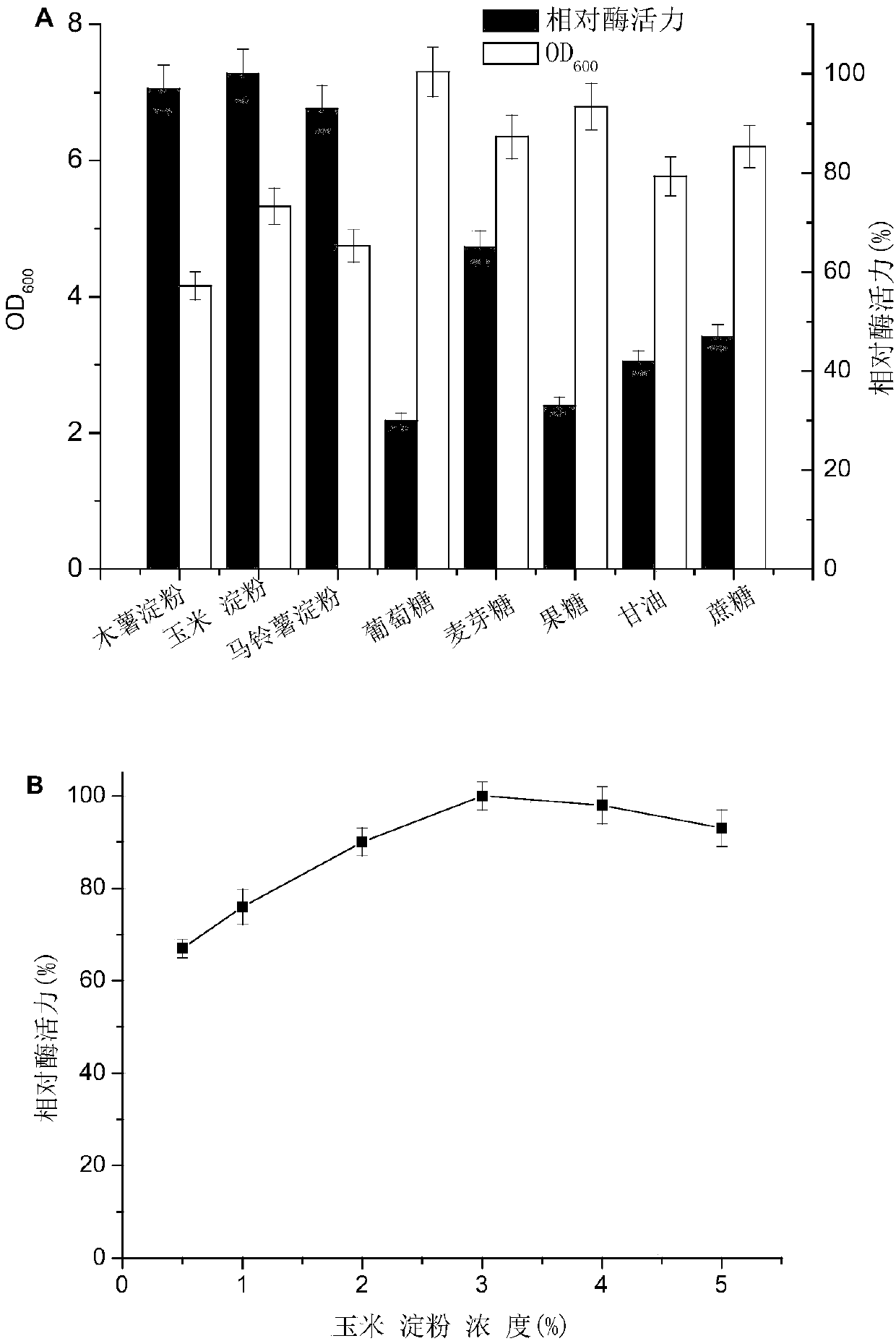

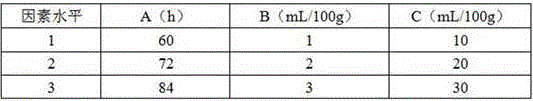

Bacillus addisoni capable of producing neutral raw starch digesting amylase

ActiveCN107760623AStrong ability to hydrolyze raw starchBacteriaMicroorganism based processesMicrobiologyBio engineering

The invention discloses a bacillus addisoni capable of producing neutral raw starch digesting amylase, belonging to the technical field of bioengineering. The wild bacillus strain capable of high-yield raw starch digesting amylase is selected from Guangxi cassava field shallow soil. The strain is preserved in China Center for Type Culture Collection in Wuhan university in Hubei province, with collection Number of being CCTCC M 2017320. The strain is simple and convenient in culturing conditions, short in fermentation period, high in enzyme activity; the produced raw starch digesting amylase isintermediate-temperature neutral enzyme, the most proper temperature and most proper pH distribution are respectively 50 DEG C and 7.0, the raw starch hydrolyzing capability is strong, and the product is mainly maltose. The bacillus addisoni has wide application prospects in the industrial fields of starch sugar, fermentation, food, feed and the like.

Owner:NANJING FORESTRY UNIV

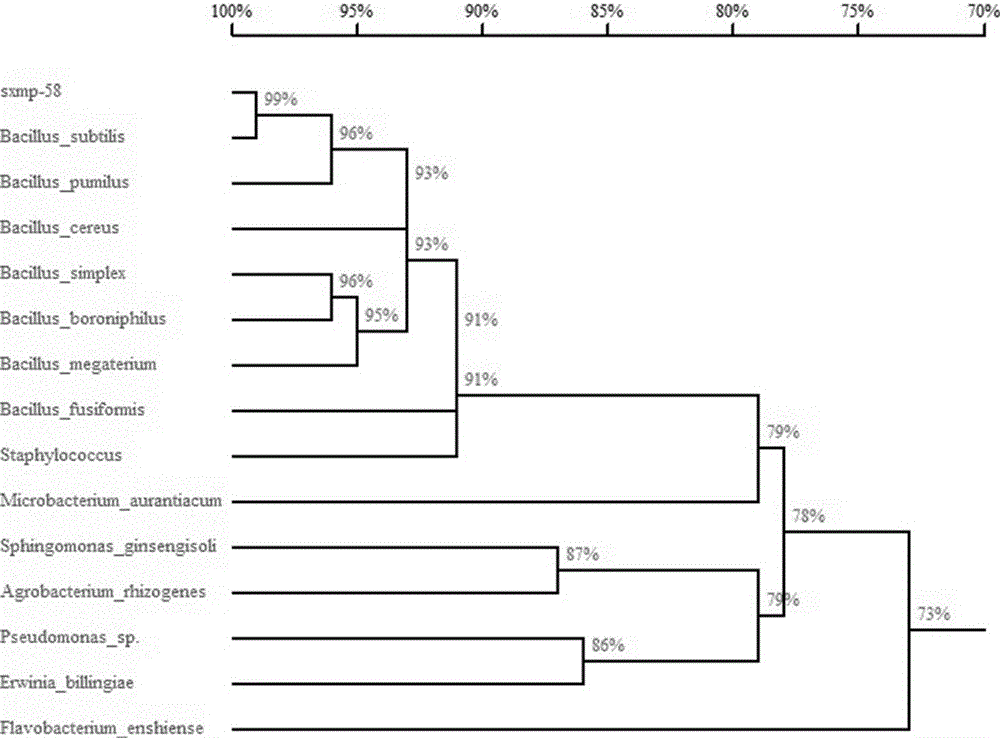

SMXP-58 strain for degrading pectin in tobacco leaves and application of SMXP-58 strain

ActiveCN106434450AReduce pectin contentSimple processTobacco treatmentBacteriaTreatment costsTobacco leaf

The invention belongs to the technical field of cigarette tobacco leaf mellowing, and particularly relates to a bacillus SMXP-58 strain for degrading pectin in tobacco leaves and application of the SMXP-58 strain in tobacco leaf mellowing. The strain is bacillus subtilis SMXP-58 and is preserved in the China Center for Type Culture Collection in Wuhan at present, and the preservation number is CCTCC NO:M 2016083. Due to the fact that the technical scheme for easily and conveniently treating the tobacco leaves through a bacterium agent is designed by screening the specific strain, the bacillus SMXP-58 strain has the technical advantages that the technological processes are simple and convenient to operate, the tobacco leaf treatment cost is low, the tobacco leaf treatment cycle is short, the pectin content in the tobacco leaves can be obviously decreased, and the tobacco leaf quality can be improved, and then the bacillus SMXP-58 strain has a good application and popularization value in the technical field of cigarette manufacturing.

Owner:CHINA TOBACCO HENAN IND +1

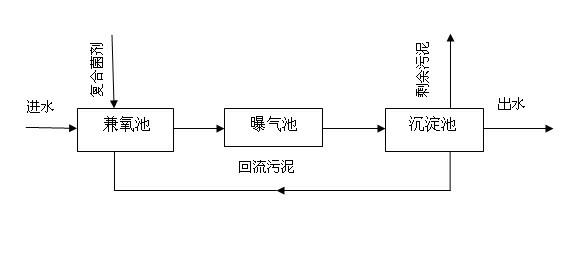

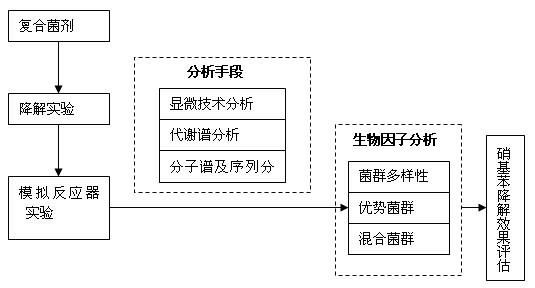

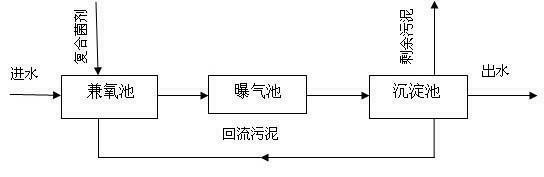

Microbiological degradation method for nitrobenzene industrial wastewater

InactiveCN102515366AImproved shock load capabilityImprove biological activityWater contaminantsSustainable biological treatmentBiotechnologyIndustrial waste water

The invention aims to provide a microbiological degradation method for nitrobenzene industrial wastewater. According to experimental selection, composite bacteria liquid of Pseudomonas, Stenotrophomonas maltophilia, Acinetobacter baumannii, Aquaspirillum, Acidovorax avenae, Alcaligenes faecalis and Bacillus is provided. Domestication culture and three-stage amplification culture are carried out on the composite bacteria liquid so as to obtain a high efficiency composite microbial inoculum suitable for industrial production. When used to treat nitrobenzene wastewater, the microbial inoculum provided in the invention has the advantages of strong biological activity, long survival time, high capability in resisting impact load of influent quality and thorough treatment.

Owner:CHONGQING WENTAI ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH

Solid fermentation and application of bacillus algae dissolving bacteria

InactiveCN102839139ANo biohazardEasy to trainBacteriaMicroorganism based processesBiotechnologyEutrophication

The invention discloses a solid fermentation and application of bacillus algae dissolving bacteria. Bacillus LDrz1 and LDrz2 bacterial strains with algae dissolving bacteria energy and preserved in a laboratory of a company are purified, and then liquid strains are cultured on the aseptic condition of 30-37 DEG C; the liquid strains are inoculated to solid media after sterilization to be in solid fermentation on the condition of 30-37 DEG C; fermentation materials after 36-48 hour solid fermentation are dried on the condition of 60-70 DEG C; algae dissolving bacteria raw powder with the fineness of 50-60 microns are obtained by grinding; and according to requirements, carrier materials are added to prepare single bacteria or compound bacteria algae dissolving bacteria products or modified algae dissolving bacteria products. The products are used in the early period of origination of a eutrophic body of water, algae biomass can be controlled or the algae is prevented from large-scale multiplication in a short period of time, water transparency is quickly improved, recovery of other animals or plants in the water is promoted, ecological balance of the water environment is finally achieved, and the solid fermentation and the application of the bacillus algae dissolving bacteria are an important means of water bloom biological control.

Owner:ANHUI LIANDA BIOLOGICAL ENVIRONMENTAL PROTECTION TECH

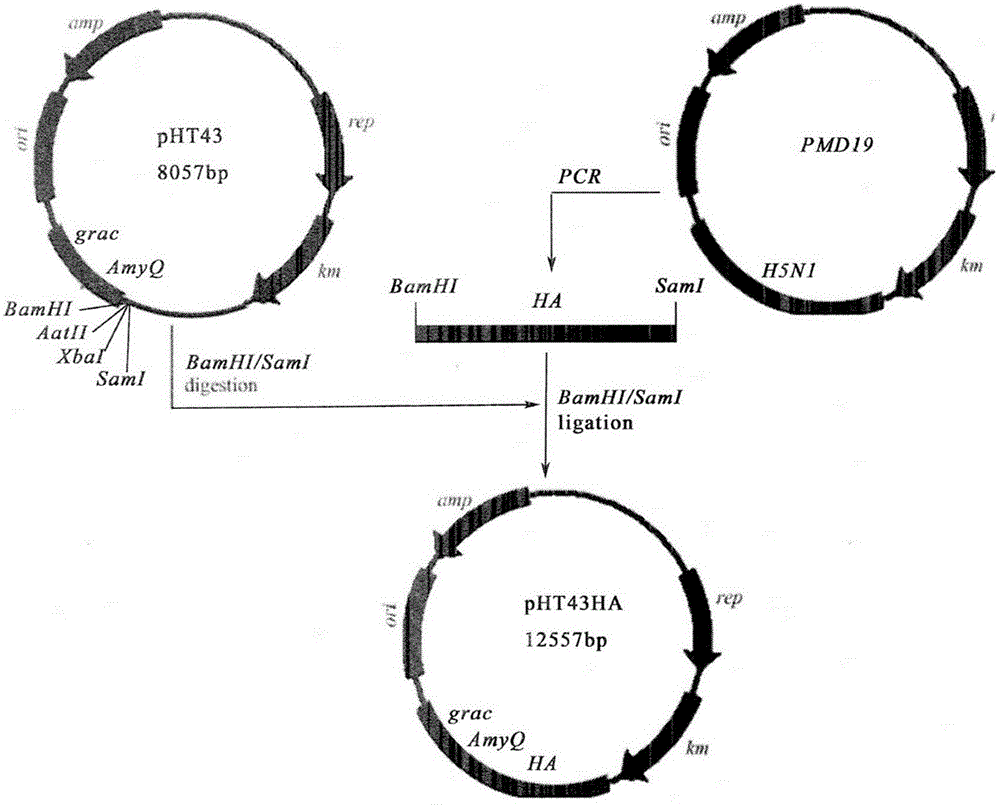

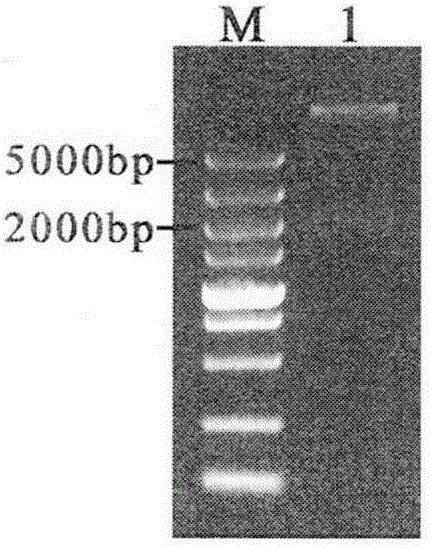

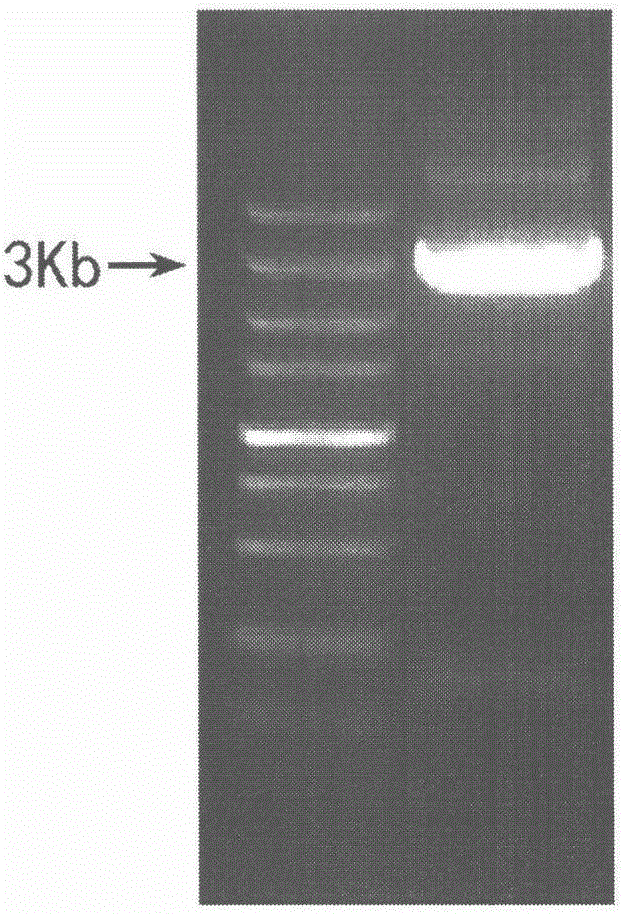

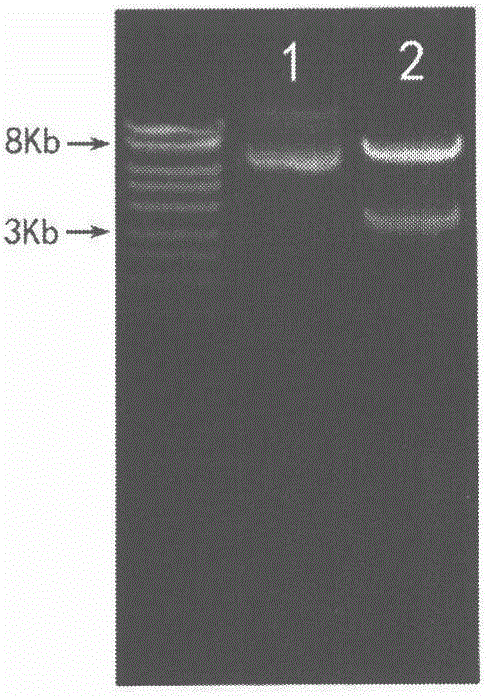

Recombinational bacillus subtilis of expressing highly pathogenic avian influenza H5N1 hemagglutinin HA protein

ActiveCN106434728AImprove developmentBoosts specific immune response levelsSsRNA viruses negative-senseBacteriaHemagglutininWestern blot

The invention relates to recombinational bacillus subtilis(B.S.-HA) of expressing highly pathogenic avian influenza(AIV) HSN1 hemagglutinin HA protein, and belongs to the field of biotechnology genetic engineering. The recombinational bacillus subtilis(B.S.-HA) of expressing the highly pathogenic avian influenza(AIV) HSN1 hemagglutinin HA protein successfully establishes recombinational bacillus subtilis expression plasmid pHT43 of the highly pathogenic avian influenza hemagglutinin HA protein, and successfully conducts elec-transformation of the recombinational bacillus subtilis expression plasmid pHT43 of the highly pathogenic avian influenza hemagglutinin HA protein into bacillus subtilis WB800N bacterial strain (B.S.). As verified by Western-blot, the highly pathogenic avian influenza hemagglutinin HA protein can be successfully expressed in the recombinational bacillus subtilis. Oral immunization can stimulate chicken body of 10-day old chicken to generate an effective AIV specific immune response level. The recombinational bacillus subtilis(B.S.-HA) is hopeful to be developed to genetic engineering oral vaccine in preventing the highly pathogenic avian influenza.

Owner:NANJING AGRICULTURAL UNIVERSITY

Recombinant bacillus subtilis expressing C30 carotenoid

ActiveCN105838731ARelieves Colitis SymptomsBacteriaMicrobiological testing/measurementDendritic cellGenetic engineering

The invention relates to recombinant bacillus subtilis capable of synthesizing carotenoid 4,4'-diaponeurosporene with 30 carbon atoms (C30), and belongs to the biotechnology genetic engineering field. A bacillus subtilis expression plasmid pMK3-crtmn (which is capable of expressing C30 carotenoid synthases Crtm and Crtn in bacillus subtilis) containing C30 carotenoid synthase genes crtm and crtn is successfully constructed, and is successfully electro-transformed into bacillus subtilis WB800. The WB800 strain after transformation turns from the original color of white to yellow. A pigment component extracted from the recombinant WB800 is identified as 4,4'-diaponeurosporene by high performance liquid chromatography (HPLC). 4,4'-diaponeurosporene can stimulate maturation of dendritic cells, and generated cytokines (IL-6, IL-10, IL-12p70 and TNF[alpha]) have the amount increased, and moreover and have stronger ability to stimulate proliferation of T lymphocytes. With oral administration of the bacillus subtilis capable of synthesizing 4,4'-diaponeurosporene, the dextran sulphate sodium (DSS)-induced mice colitis symptoms can be significantly reduced. The bacillus subtilis capable of producing 4,4'-diaponeurosporene is expected to be developed as probiotics for prevention of colitis.

Owner:NANJING AGRICULTURAL UNIVERSITY

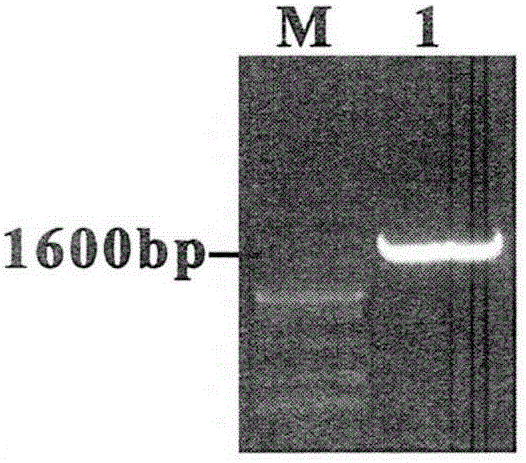

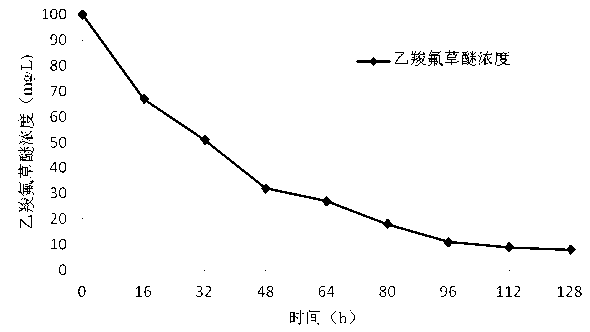

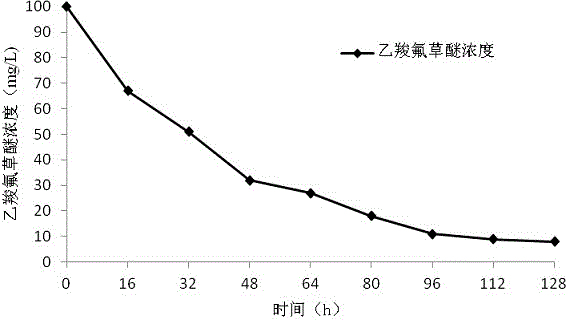

Bacillus subtilis FC12 for degrading fluoroglycofen-ethyl and application thereof

ActiveCN103232965ABroad degradation spectrumResidue reductionBacteriaContaminated soil reclamationBiotechnologyStaining

The invention provides a degrading bactericide for eliminating fluoroglycofen-ethyl residues in wastewater, which belongs to the field of organism high technology. The used bacterial strain is a gram staining reaction negative bacterium FC12 which is identified as bacillus. The main biological property of the gram staining reaction negative bacterium FC12 is G-, the gram staining reaction negative bacterium FC12 is straight rod-shaped, the spore of the gram staining reaction negative bacterium FC12 is elliptical, the peritrichous of the bacillus moves, and the size of the gram staining reaction negative bacterium FC12 is 0.5-2.5*1.2-10 microns; catalase is positive; oxidase is negative; and the gram staining reaction negative bacterium FC12 can be used for hydrolyzing starch and liquefying gelatine. Pesticide residue in water can be reduced by more than 90% by direct application of the degrading bacterium product.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

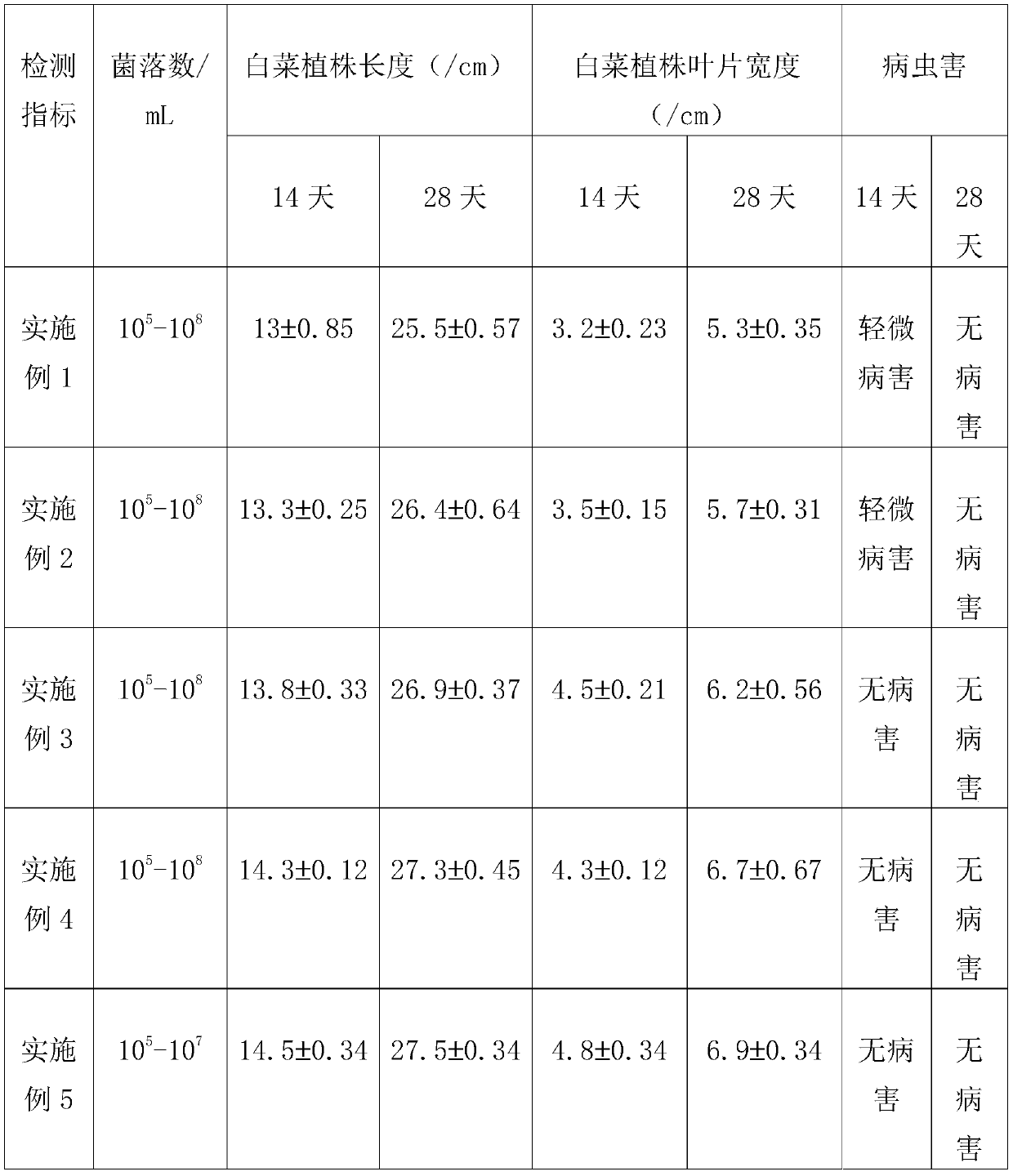

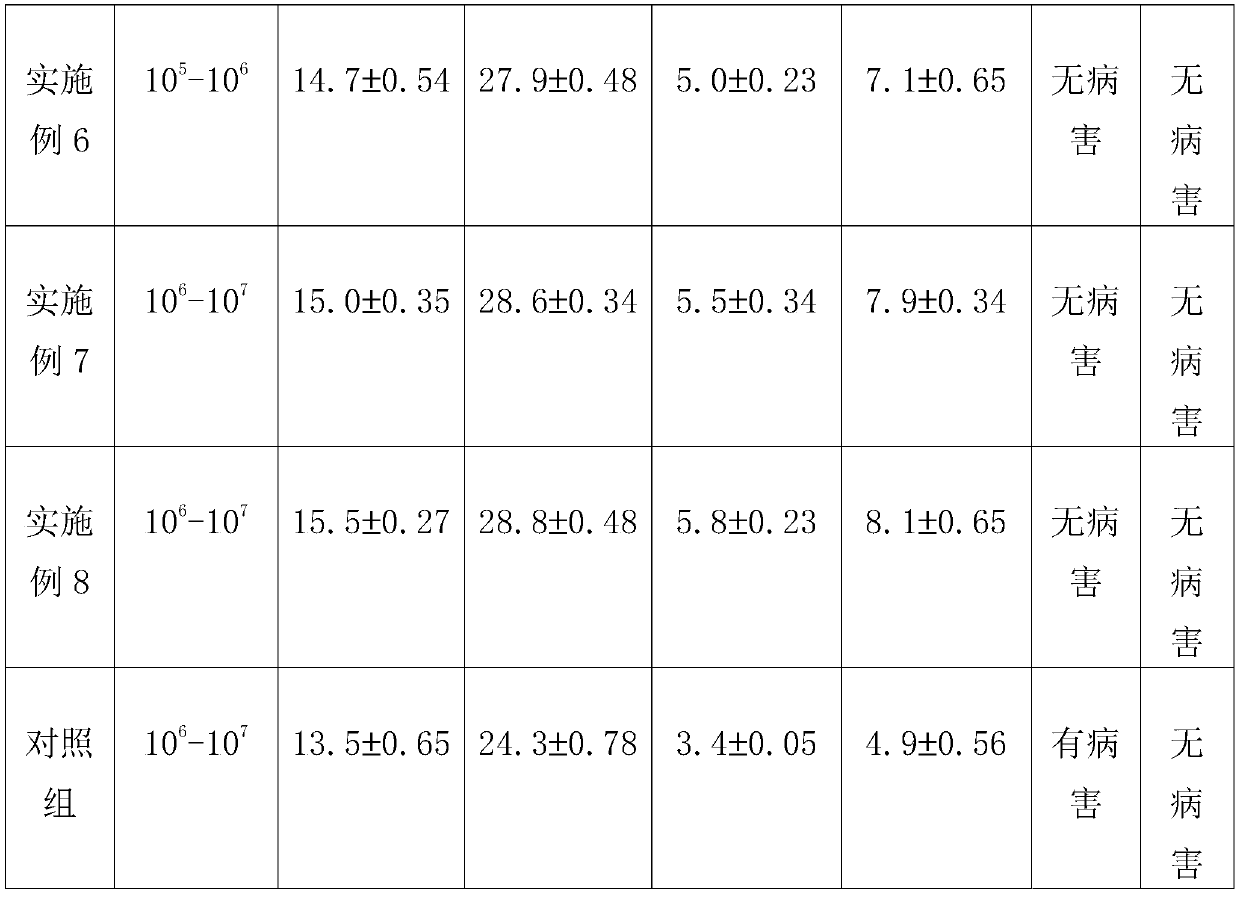

Composite microbiological preparation and preparation method and application thereof

InactiveCN111534468AQuick and easy to manufactureShorten the growth cycleBiocidePlant growth regulatorsBiotechnologyBacillus acidiceler

The invention belongs to the technical fields of a microbiological preparation and a preparation technology and application thereof, and discloses a composite microbiological preparation and a preparation method and application thereof. The composite microbiological preparation is obtained by mixing bacillus subtilis with lactobacillus breris, clostridium thermoaceticum and a culture solution. According to the composite microbiological preparation, activity of biological pesticide and activity of a bio-fertilizer are in mutual relation, and the composite microbiological preparation is used forplants, so that the growth rate can be improved, the growth period of the plants can be efficiently shortened, and the composite microbiological preparation has notable insect resistance. The preparation is simple and convenient in preparation process, small in the quantity of required equipment, and low in labor force. The composite microbiological preparation is a pure biological preparation, is free from toxin, and harmless, and belongs to an environmentally friendly finished product.

Owner:黑龙江土友生物科技有限公司

Nano emulsion for treating anaerobic infections of intestinal tracts of livestocks and preparation method of nano emulsion

InactiveCN102631474AImprove stabilityGood light stabilityAntibacterial agentsHydroxy compound active ingredientsBiotechnologyBacteroides

The invention discloses a nano emulsion for treating anaerobic infections of intestinal tracts of livestocks. The nano emulsion comprises the following raw materials in percent by mass: 0.1-8.0 percent of linaloe oil, 0.1-7.0 percent of carvacrol, 0.01-0.7 percent of metronidazole, 19.0-35.0 percent of surfactant, 0-5.0 percent of cosurfactant and the balance of distilled water, wherein the sum of the mass percent of the raw materials is 100 percent. The nano emulsion has stronger inhibiting and killing functions to most of obligate anaerobes, and is mainly used for treating enteritidis caused by infections of anaerobic bacteria such as bacteroides, clostridium, aerogenesis bacillus, peptococcus, eubacteria and streptococcus faecalis, for the livestocks. The nano emulsion has the advantages of high bioavailability, remarkable antibacterial action and treatment effect, and wide market prospect in the field of veterinary medicines.

Owner:NORTHWEST A & F UNIV

Improvement agent for red mud in-situ soil and application method thereof

PendingCN114015455AAchieve improvementLower pHCalcareous fertilisersAgriculture tools and machinesMicroorganismMicrobial agent

The invention provides an improvement agent for red mud in-situ soil and an application method thereof, the improvement agent comprises a main agent and an auxiliary agent, the main agent comprises inorganic acid waste and organic acid waste; the auxiliary agent comprises an organic fertilizer, an inorganic fertilizer and a microbial agent; the microbial agent comprises halomonas, Nesterensis and bacillus. The application method comprises the following steps: S1, preparing a premix; step S2, preparing a neutralized substance; s3, forming a red mud improvement layer; and S4, activating and diluting the microbial agent, and spraying the microbial agent on the red mud improvement layer. The red mud environment in which plants can normally grow and develop is established, positive evolution of the red mud towards the soil direction is promoted, and thus ecological restoration and ecological reconstruction of the red mud storage yard are achieved, and the problem that the red mud storage yard returns alkali and salt to hinder vegetation growth is solved.

Owner:CHINA NONFERROUS METAL CHANGSHA SURVEY & DESIGN INST CO LTD

Alkaline xyloglucanase

A xyloglucanase having a relative xyloglucanase activity of atleast 50% at pH7 and either no or an insignificant cellulolytic activity is obtainable e.g. from a strain of Bacillus. A xyloglucanase comprising an amino acid sequence as shown in positions 30-261 of SEQ ID NO:2 or homologues may be derived from e.g. Bacillus licheniformis, ATCC 14580, and may be encoded by polynucleotide molecules comprising a nucleotide sequence as shown in SEQ ID NO:1 from nucleotide 88 to nucleotide 783; and a xyloglucanase comprising an amino acid sequence as shown in positions 1-537 of SEQ ID NO:4 or homologues may be derived from e.g. B. agaradhaerens, NCIMB 40482, and may be encoded by polynucleotide molecules comprising a nucleotide sequence as shown in SEQ ID NO:3 from nucleotide 1 to nucleotide 1611. The xyloglucanases are useful e.g. in cleaning compositions and for treatment of cellulosic fibres.

Owner:NOVO NORDISK AS

Production of fucosylated oligosaccharides in bacillus

Disclosed are non-sporulating Bacillus cells for the production of a fucosylated oligosaccharide as well as a method for producing a fucosylated oligosaccharide, wherein said Bacillus cell has been genetically engineered to possess a lactose permease, a GDP-fucose biosynthesis pathway and a fucosyltransferase.

Owner:CHR HANSEN HMO GMBH

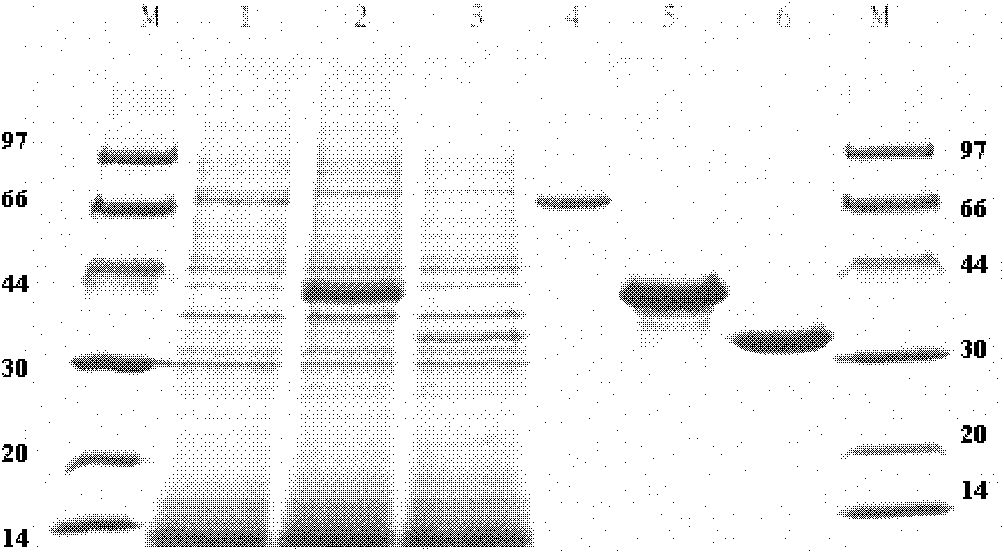

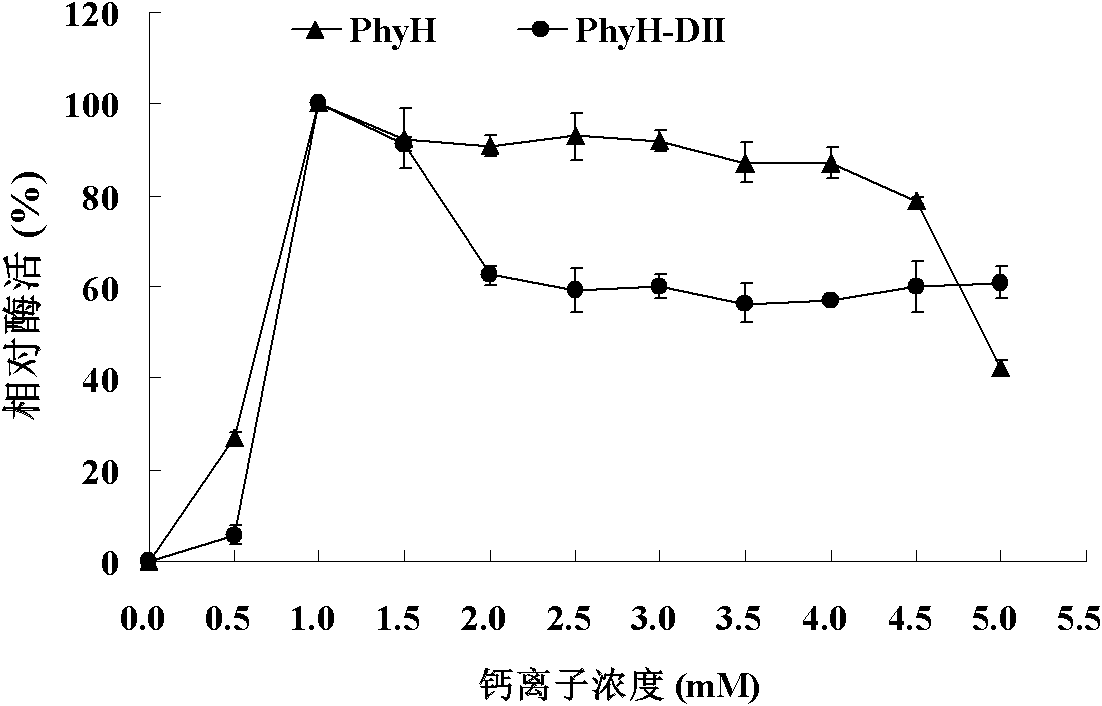

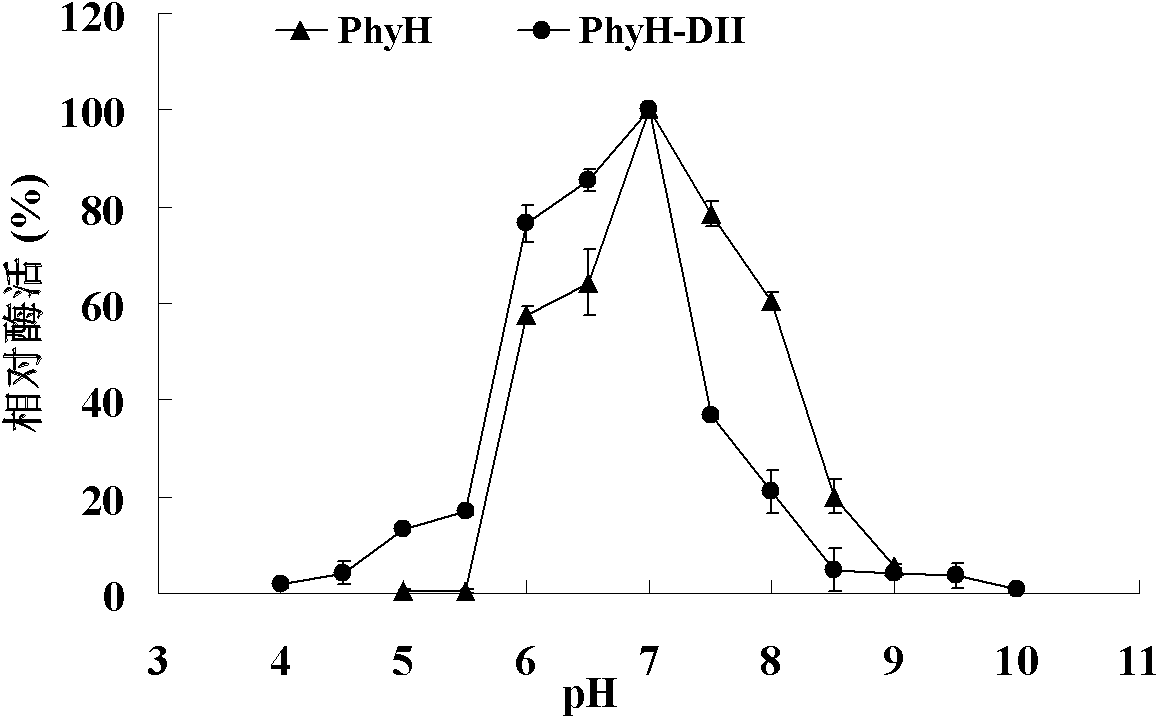

Low-temperature neutral phytase PhyH with double structure domains as well as gene and application thereof

ActiveCN102250853AImprove stabilityHigh catalytic efficiencyBacteriaHydrolasesPhytaseGenetic engineering

The invention relates to the field of genetic engineering, in particular to a low-temperature neutral phytase PhyH with double structure domains as well as a gene and application thereof. The invention provides the neutral phytase PhyH from Bacillus sp.HJB17, and the amino acid sequence of the neutral phytase PhyH is shown as SEQ ID NO.1; and the invention provides a gene PhyH for coding the neutral phytase. The phytase provided by the invention has good pH stability and still keeps higher enzyme activity in the alkaline range; the phytase has higher relative enzyme activity in a low-temperature range; the phytase has double structure domains, an N terminal is an incomplete BPP (Butyl Pivalate Peroxide) phytase structure domain and a C terminal is a complete phytase structure domain. In short, the PhyH obtained by the invention can be used as the low-temperature neutral phytase which can be applied to cultivation of fish; the PhyH-DI structure domain can increase the catalytic efficiency of other phytases and is good for improving the production and the application of the other phytases.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

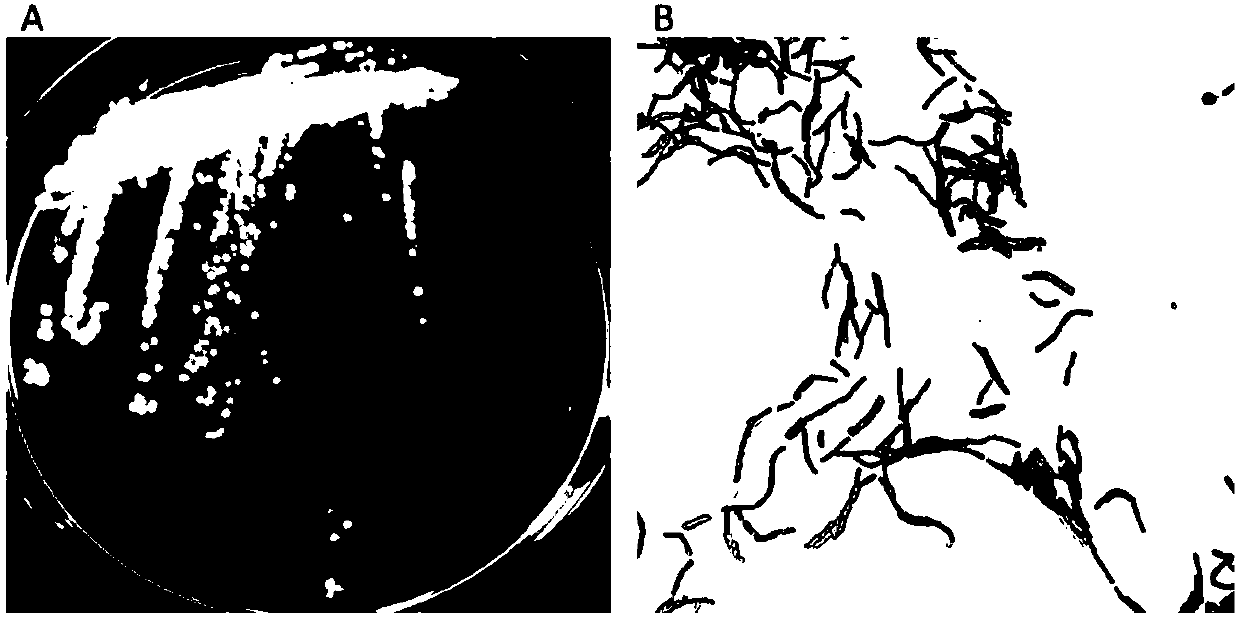

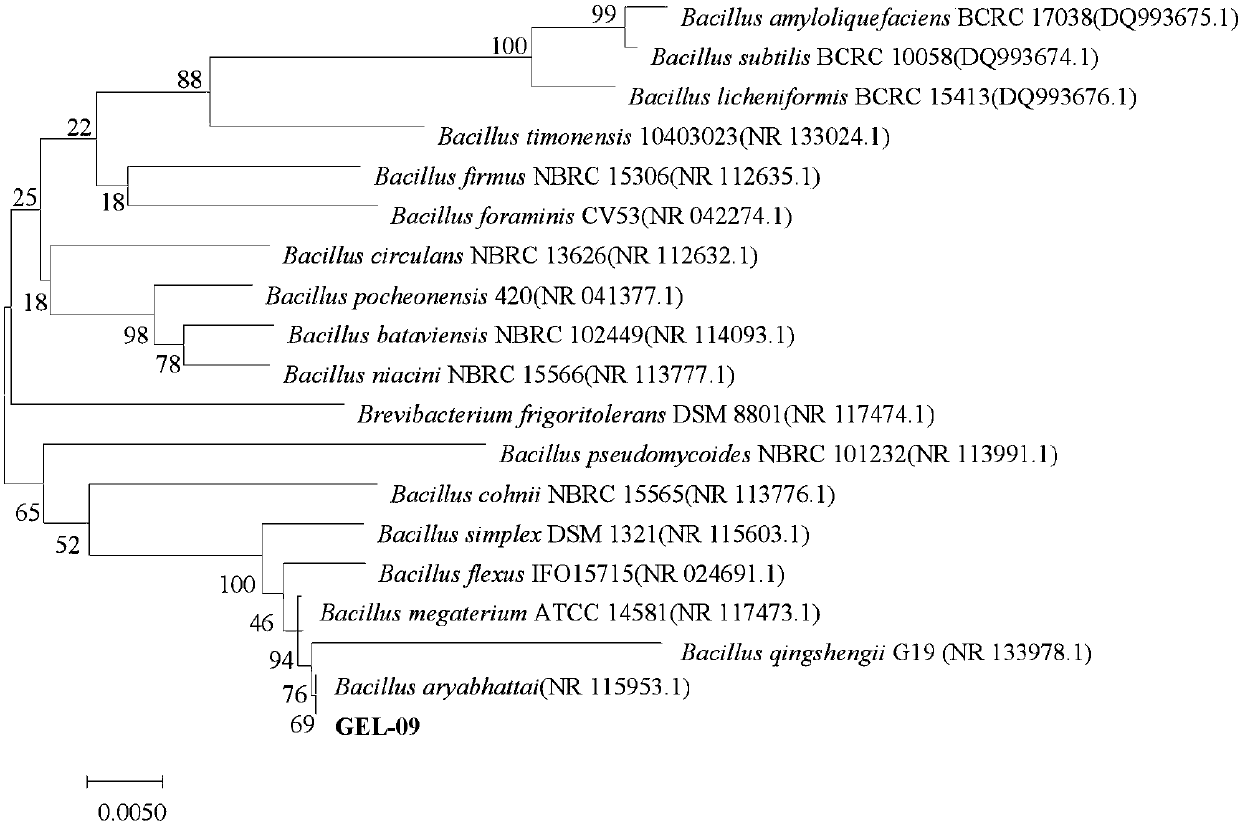

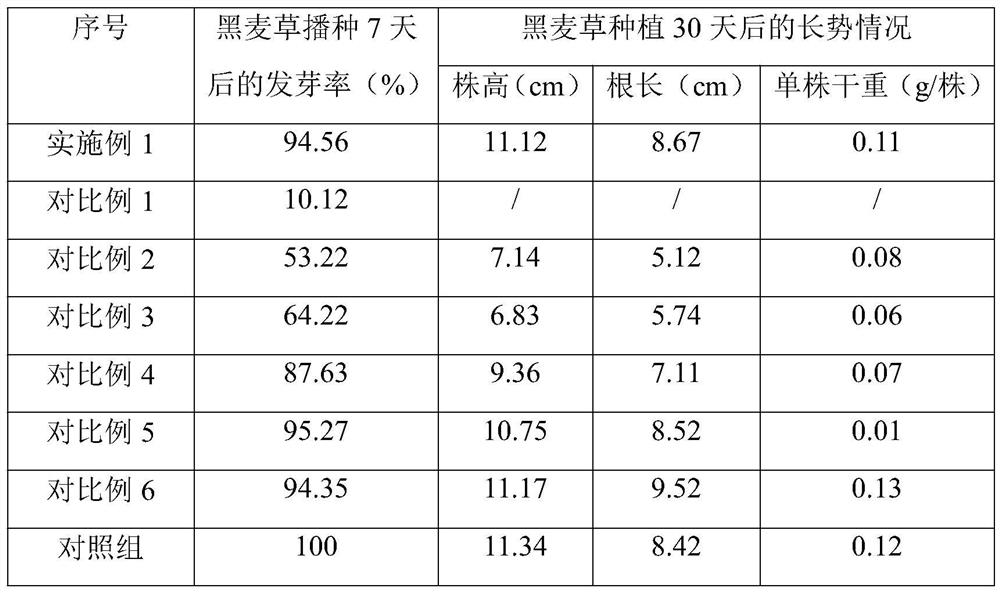

Peanut plant growth promoting bacteria HS3 and application thereof

InactiveCN104630095AHas a dissolving effectIncrease profitBiocidePlant growth regulatorsBiotechnologyMicroorganism

The invention relates to peanut plant growth promoting bacteria HS3 and an application thereof. The peanut plant growth promoting bacteria is peanut plant growth promoting bacteria HS3 and is classified and named as bacillus acidiceler which is collected in General Microorganism Center of China Committee for Culture Collection of Microorganisms with the collection number CGMCC NO.9886 on 31st October, 2014. The peanut plant growth promoting bacteria HS3 and the application have the advantages that the problem that difficultly-soluble potassium-containing silicate is converted into soluble potassium salt can be effectively solved, organophosphorus can be degraded, the utilization rate of fertilizers can be increased, the peanut plant growth promoting bacteria HS3 can be effectively used for planting peanuts, the growth of peanuts can be promoted, the yield can be increased, and the peanut plant growth promoting bacteria HS3 is an important innovation on microorganisms and peanut planting.

Owner:HENAN AGRICULTURAL UNIVERSITY

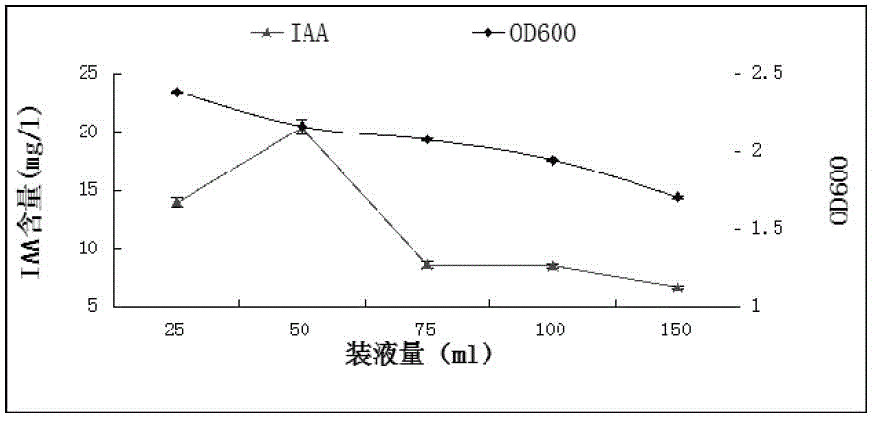

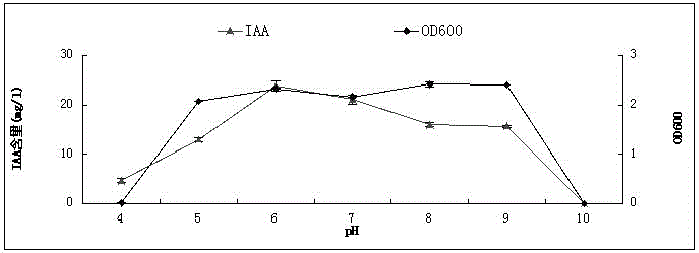

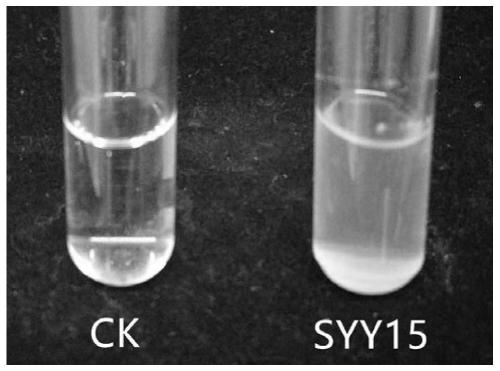

Bacillus acidiceler SYY15 and applications thereof

ActiveCN111154675AImprove stress resistanceObvious anti-stress effectBiocidePlant growth regulatorsEcological environmentDisease resistant

Owner:GENLIDUO BIO TECH CO LTD

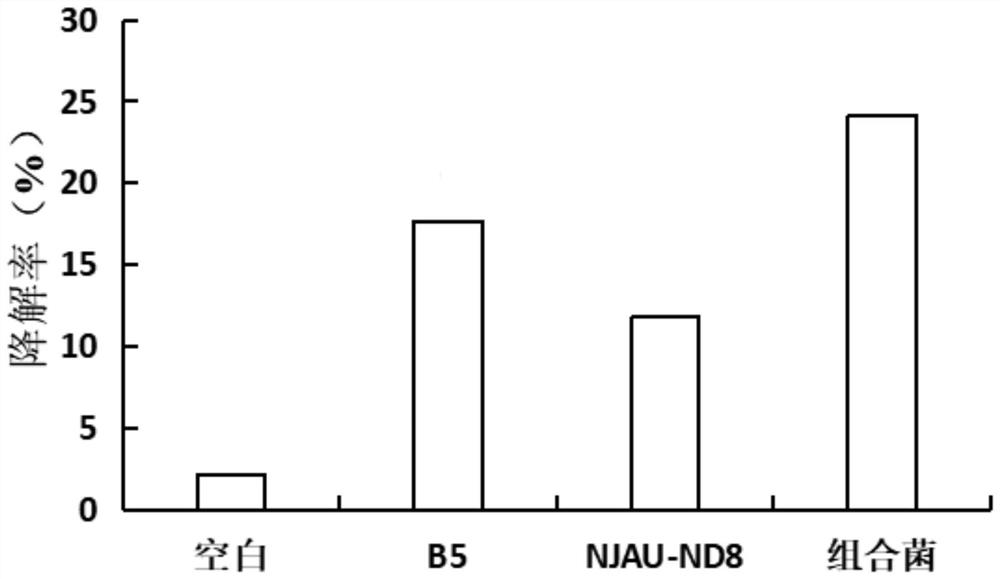

High-temperature-resistant livestock and poultry manure degradation complex microbial inoculant and application thereof

InactiveCN111849804AImprove efficiencyFully degradedBio-organic fraction processingBacteriaBiotechnologyPoultry manure

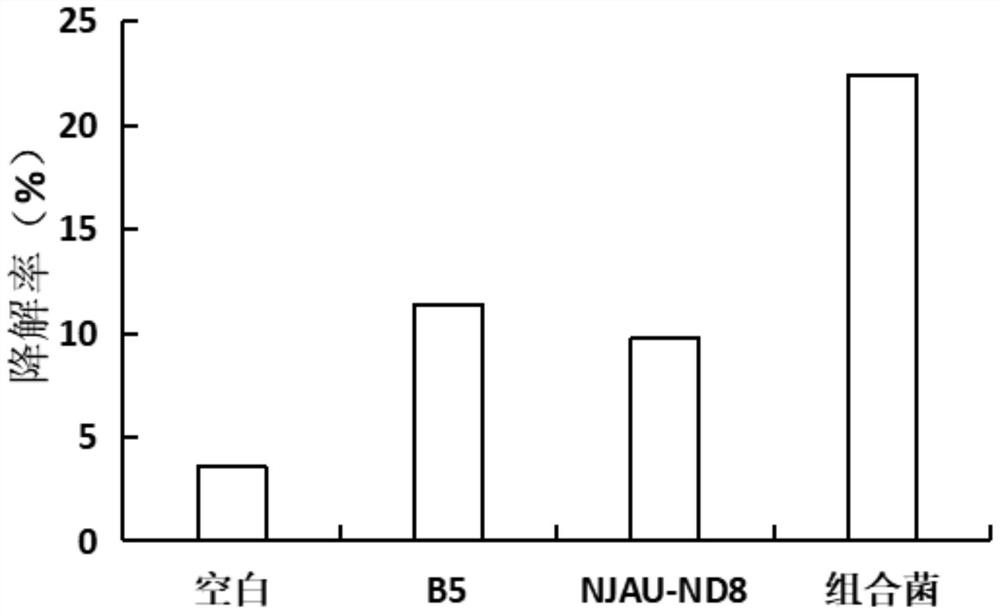

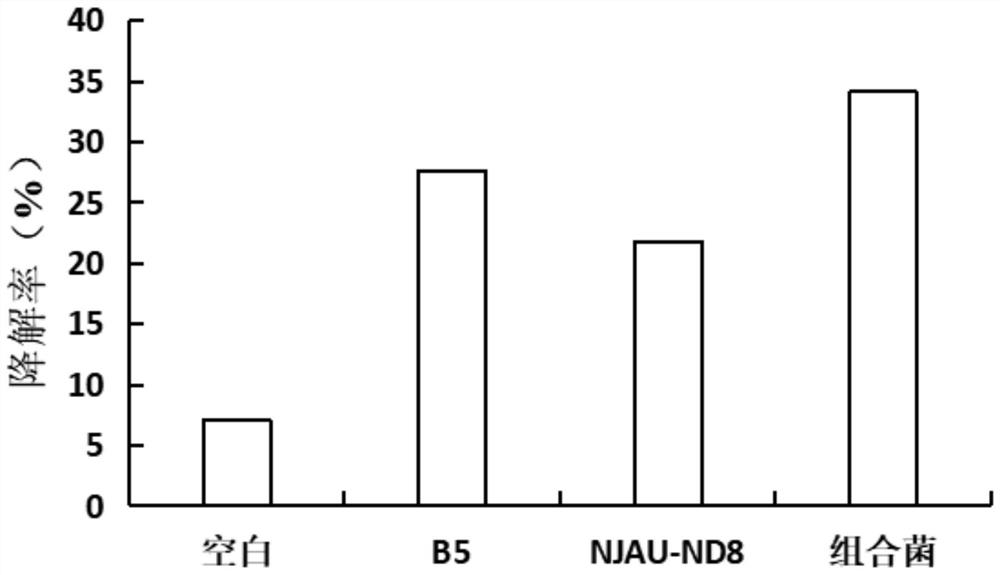

The invention discloses a high-temperature-resistant livestock and poultry manure degradation complex microbial inoculant and application thereof. The invention aims to further improve the compostingeffect of livestock and poultry breeding manure, the complex microbial inoculant containing Bacillus sp. Bacteria NJAU-ND8 and Bacillus stearothermophilus is developed, and the complex microbial inoculant provides the complex microbial resource and the technical support for the livestock and poultry breeding manure. The application of the complex microbial inoculant is to accelerate degradation oflivestock and poultry breeding excrement. When the complex microbial inoculant is used for degrading the chicken manure, the degradation rate of the chicken manure reaches 24.12% after half a month,and the degradation effect is better than that of single bacteria and blank treatment; after the pig manure is degraded for half a month, the degradation rate of the pig manure reaches 22.41 percent and is better than that of single bacteria and blank treatment; after the sheep manure is degraded for half a month, the degradation rate of the sheep manure reaches 34.12 percent and is better than that of single bacteria and blank treatment.

Owner:TAICANG LVFENG BIOLOGICAL ORGANIC FERTILIZER CO LTD

Microbial compound bacteria preparation and preparation method thereof

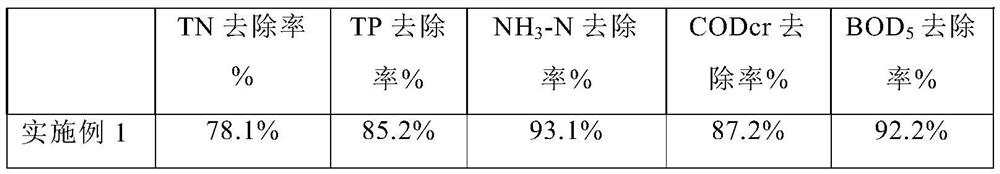

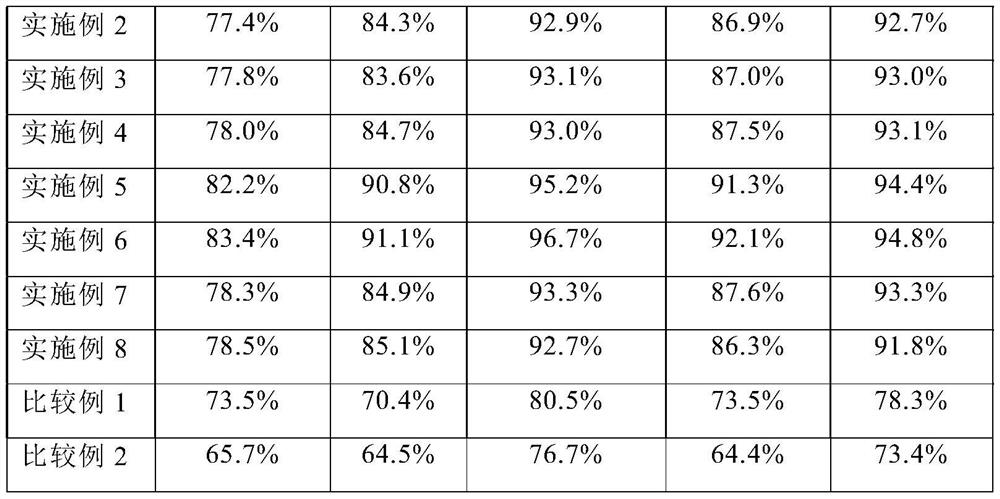

ActiveCN113151010APromote growthPromote reproductionFungiBacteriaGenus NitrosomonasIndustrial waste water

The invention relates to a microbial compound bacterium preparation and a preparation method thereof. The active ingredients of the microbial compound bacteria preparation comprise the following microbial flora of bacillus bacterium, pseudomonas bacterium, lactobacillus bacterium, torulopsis fungus, aspergillus fungus, rhizopus fungus, penicillium fungus, mucor fungus, trichoderma fungus, thiocapsa bacterium, azotobacter bacterium and nitrosmonas bacterium. The microbial compound bacterium preparation disclosed by the invention contains various active bacteria, and through reasonable compatibility of various fungi and bacteria, the microbial compound bacterium preparation exists as a dominant flora in a biological treatment section of sewage treatment, so that the content of pollutant components such as organic pollutants COD, NH3-N, TN and TP and the like in sewage is remarkably reduced, and efficient purification of municipal sewage, domestic garbage leachate wastewater, kitchen and kitchen garbage wastewater, river black and odorous water and industrial wastewater is realized.

Owner:马东兵

Cloning and Application of a Glutamic Acid Decarboxylase Gene

The present invention relates to the cloning and application of a novel glutamic acid decarboxylase gene. The glutamic acid decarboxylase obtained from Bacillus is induced and expressed in Escherichia coli and its properties are studied. It is found that the enzyme has a pH of 4.0 It has higher activity at ~pH6.0, the optimum temperature is between 45℃~60℃, Vmax is 150~200 U / mg, and Km is 7~9 mmol / L. The recombinant Escherichia coli containing the enzyme was transformed into whole cells, and 500 g / L L-glutamic acid was added by fed-batch feeding, at 37°C, in disodium hydrogen phosphate-sodium dihydrogen phosphate buffer, pH 7.0 After 12 h of conversion, 347.8 g / L of γ-aminobutyric acid was finally produced, and the molar conversion rate was 99.4%. Compared with the existing glutamic acid decarboxylase, the novel glutamic acid decarboxylase has higher catalytic efficiency and wider pH range, and is more suitable for industrial application.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

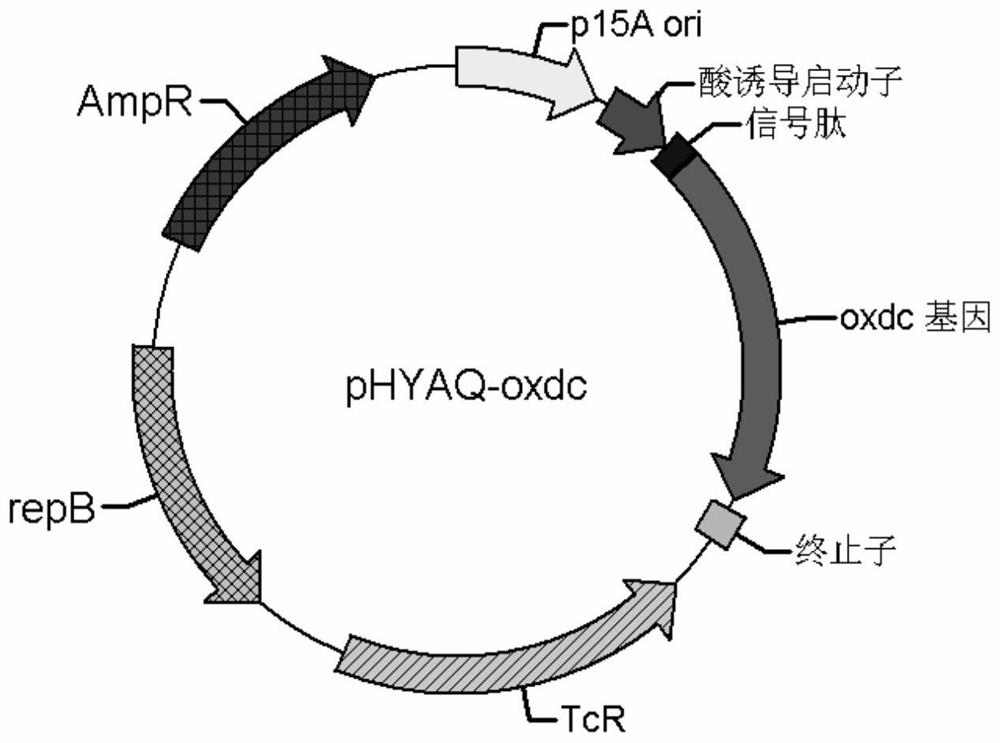

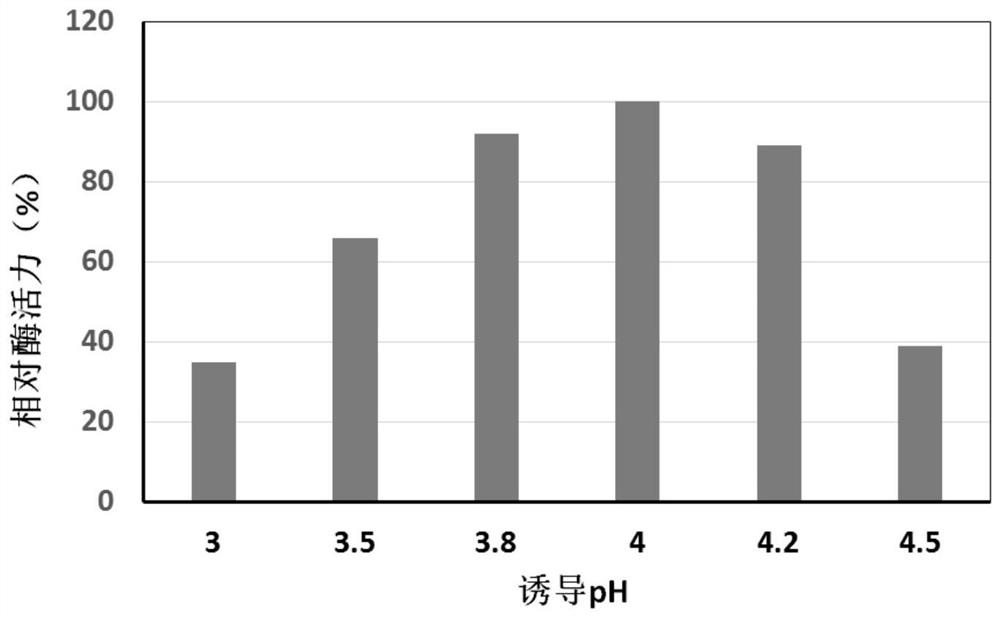

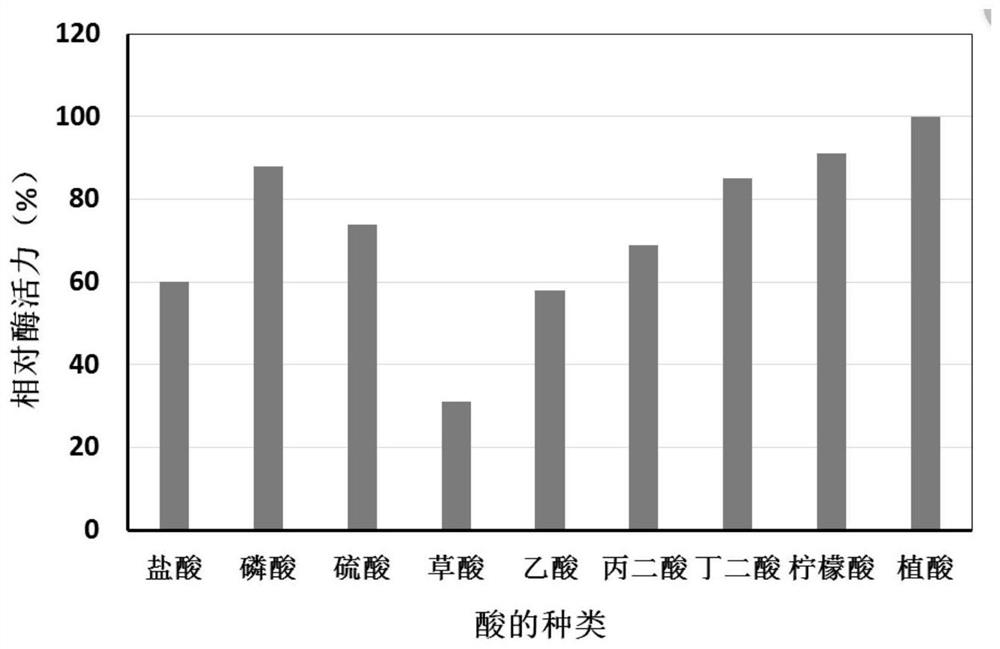

A kind of preparation method and application of oxalate decarboxylase

The invention discloses a preparation method of oxalate decarboxylase. The method comprises the following steps: constructing a recombinant expression plasmid vector comprising Bacillus-containing acid induced promoter, a secretion signal peptide, and a fungus-derived oxalate decarboxylase gene prepared under the control of the secretion signal peptide, transforming bacilli normally growing in a pH value being not more than 4.5 by the vector to prepare oxalate decarboxylase recombinant bacteria; and carrying out culture and acid feeding on the recombinant bacteria in a fermentation medium, inducing the recombinant bacteria, and carrying out simple purification to recover generated extracellular oxalate decarboxylase. The extracellular oxalate decarboxylase prepared through the method is used in diagnosis reagent raw materials, medicinal compositions, healthcare foods or formulated foods with special medical uses. The mutated acid induced promoter is adopted to substitute an original acid induced promoter in the recombinant expression vector, so the transformed bacilli have a high expression level.

Owner:WUHAN KANGFUDE BIOTECH CO LTD

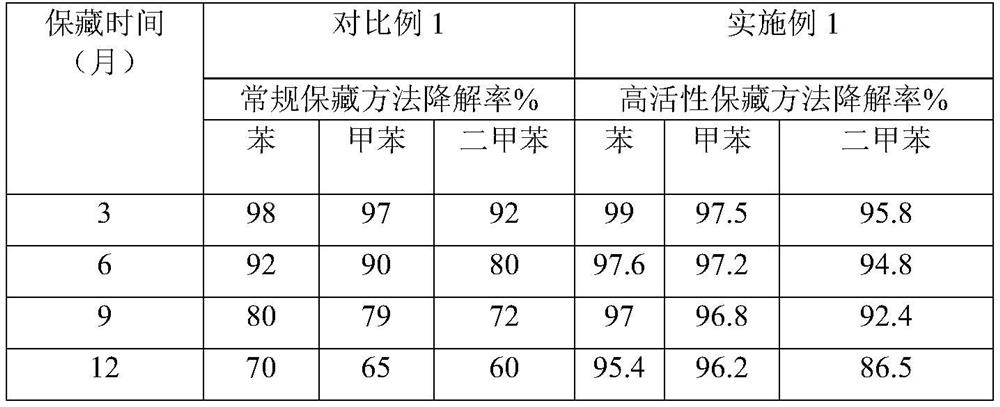

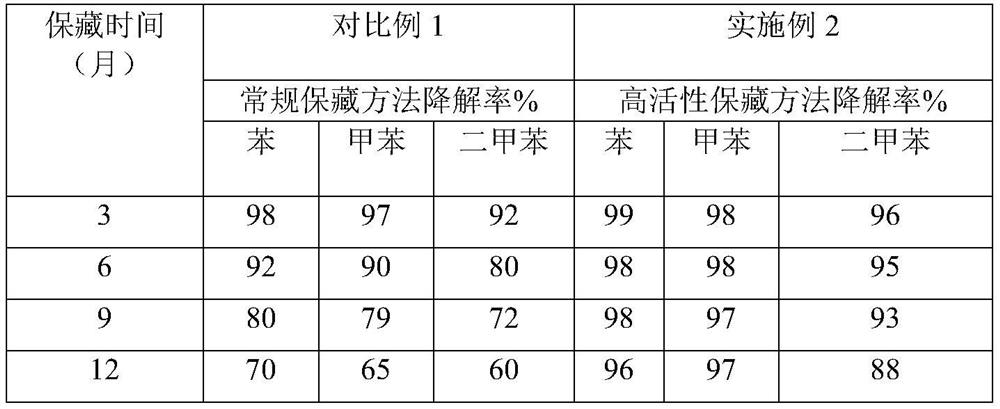

Composite microbial strain for degrading triphenyl waste gas and its preservation and activation method

The invention relates to the technical field of sewage treatment, in particular to a composite microbial strain for degrading "triphenyl" waste gas and a preservation and activation method thereof. The complex microbial species include Bacillus, Pseudomonas, Streptococcus, Rhodococcus and Brevibacterium. The preservation method comprises the following steps: A1, inoculating the compound microbial strains for degrading "triphenyl" waste gas in a sterile enrichment medium at an inoculum amount of 9-11%, and cultivating by shaking to obtain a bacterial liquid; A2, taking the bacterial liquid , protective agent and active stabilizer, mix well and store at -78-82°C. The composite microbial strain of the present invention can efficiently degrade "triphenyl" waste gas, the preservation method is simple and easy to control, and the cost is low, and the activation of the composite microorganism after preservation can maintain a good "triphenyl" degradation ability, which can be benzene series The practical engineering application of waste gas biological treatment can quickly provide microbial strains with high activity to degrade benzene series.

Owner:GUANGDONG ZHONGWEI ENVIRONMENTAL PROTECTION BIOTECH CO LTD

Bacillus subtilis FC12 for degrading fluoroglycofen-ethyl and application thereof

ActiveCN103232965BBroad degradation spectrumResidue reductionBacteriaContaminated soil reclamationBiotechnologyStaining

The invention provides a degrading bactericide for eliminating fluoroglycofen-ethyl residues in wastewater, which belongs to the field of organism high technology. The used bacterial strain is a gram staining reaction negative bacterium FC12 which is identified as bacillus. The main biological property of the gram staining reaction negative bacterium FC12 is G-, the gram staining reaction negative bacterium FC12 is straight rod-shaped, the spore of the gram staining reaction negative bacterium FC12 is elliptical, the peritrichous of the bacillus moves, and the size of the gram staining reaction negative bacterium FC12 is 0.5-2.5*1.2-10 microns; catalase is positive; oxidase is negative; and the gram staining reaction negative bacterium FC12 can be used for hydrolyzing starch and liquefying gelatine. Pesticide residue in water can be reduced by more than 90% by direct application of the degrading bacterium product.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

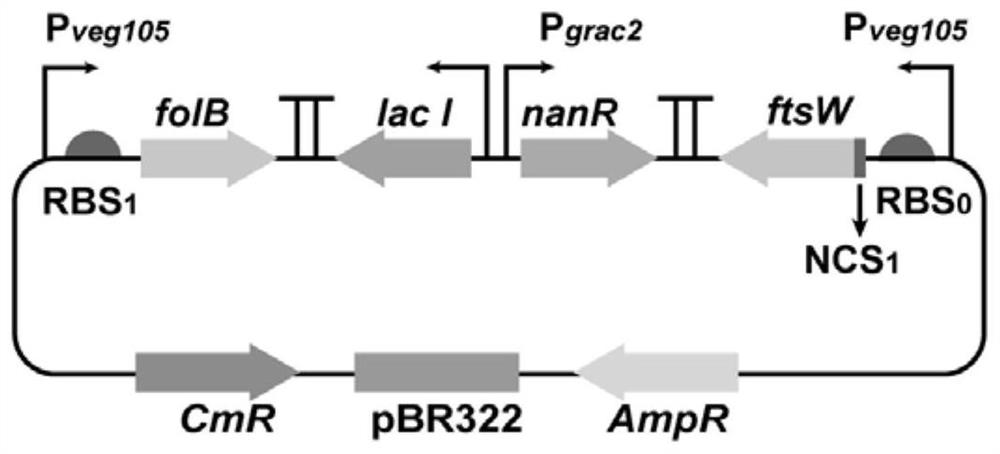

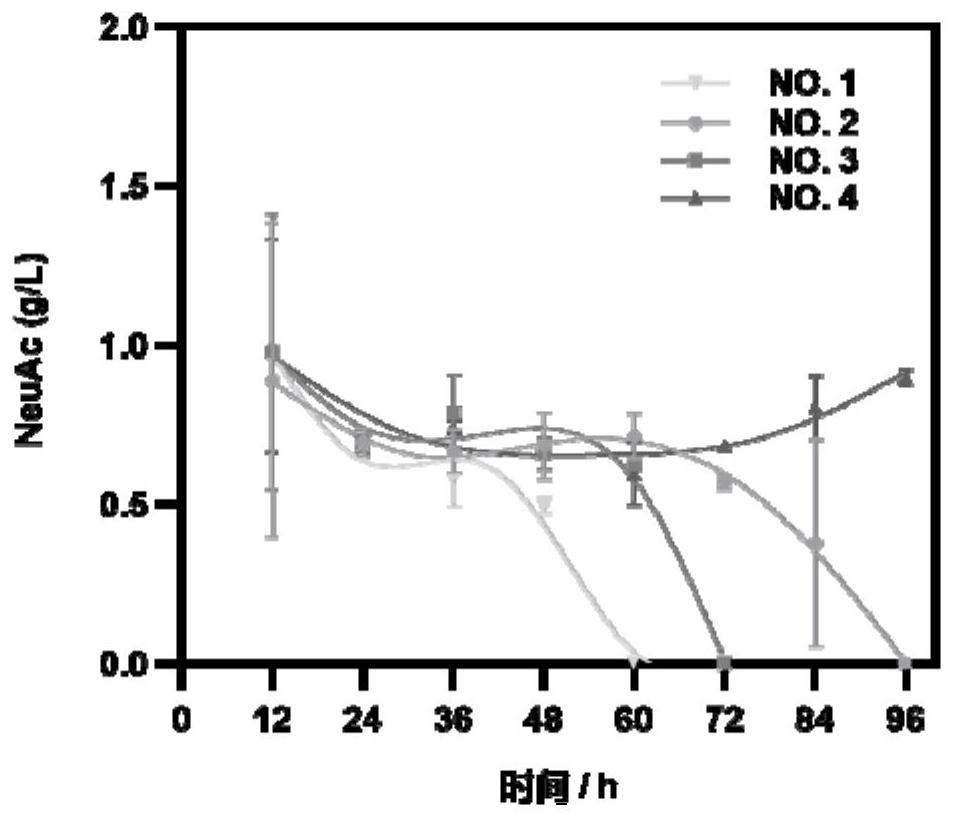

Recombinant bacillus subtilis with improved production stability of N-acetylneuraminic acid

PendingCN112961879AImprove stabilityBacteriaMicroorganism based processesBiotechnologyGenetic engineering

The invention discloses a recombinant bacillus subtilis with improved production stability of N-acetylneuraminic acid, and belongs to the technical field of bacillus subtilis metabolic engineering and genetic engineering. According to the invention, two single-output cell subgroup regulation loops are combined to construct a dual-output subgroup regulation loop capable of improving the stability of the subgroup regulation loop. In the double-output subgroup regulation loop, two sensor promoters Pveg105 are used as output promoters, and the cell subgroup regulation loop can fail only when the two sensor promoters Pveg105 are subjected to genetic mutation at the same time, so that the stability of the subgroup regulation loop is improved. The obtained recombinant bacillus subtilis can maintain NeuAc production all the time in the continuous passage fermentation culture process of 96 hours, and the yield is stabilized at 0.65-0.90 g / L.

Owner:JIANGNAN UNIV

Compound preparation for improving the survival rate of Procambarus clarkii cultured and its application method

ActiveCN110250058BReduce proliferationLarge specific surface areaBacteriaWater treatment compoundsProcambarus clarkiiFlora

The invention discloses a compound preparation for improving the survival rate of Procambarus clarkii cultured and a use method thereof. The preparation mainly includes component A and component B. Among them, component A is 30-50% of Bacillus and 50-70% of aerobic denitrifying bacteria; component B is 10-15% of quorum effect quencher, 10-15% of synergist, and 20-15% of flocculant 30%, surfactant 10‑15%, oxygenator 20‑30%. In this preparation, component B is used first, and component A is used later after expansion. This preparation can improve the oxidation-reduction potential at the bottom of the aquaculture environment, reduce the reproduction of cyanobacteria and Microcystis aeruginosa in the aquaculture water body, and through the synergistic sequential application of component A and component B, based on the quenching of group sensing effect, microbial ecological occupancy, and microbial matrix The principles of competition and inhibition of microbial metabolites reduce harmful bacteria in the bottom environment and harmful algae in the water body, thereby basically eliminating the production of toxic substances such as algae toxins, hydrogen sulfide, ammonia nitrogen, and nitrite, thereby improving the survival rate of Procambarus clarkii. The preparation has the advantages of fast onset of action and strong effect sustainability.

Owner:ZHEJIANG UNIV

Preparation method of portable fish sauce seasoning capsule

PendingCN114190535AStable storageEasy to carryFood preservationFood ingredientsBiotechnologyAnimal science

The invention discloses a preparation method of a portable fish sauce seasoning capsule. The portable fish sauce seasoning capsule comprises components of the portable fish sauce seasoning capsule, and the fish sauce seasoning capsule comprises a capsule shell and content filled in the capsule shell; wherein the capsule shell comprises the following components: 21%-22% of gelatin, 7%-9% of glycerol, 7%-9% of carrageenan, 3%-5% of konjac powder, 3%-5% of locust bean gum, 3%-4% of titanium dioxide powder and the balance of purified water; and the content comprises the following components in percentage by weight: 99.97%-99.99% of fish sauce and 0.01%-0.03% of bacillus subtilis. The bacillus subtilis belongs to aerobic bacteria, enters a dormant state and stops breeding after the oxygen in the capsule is exhausted through mass breeding, so that a stable state is formed, the capsule is convenient to carry and store, can autolyze after being put into hot water condiments, and can also be used for putting granular condiments and counting into a frying pan accurately and conveniently during household cooking; the eating is convenient.

Owner:荣成市百泉水产食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com