Patents

Literature

82 results about "Wahlenbergia marginata" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wahlenbergia marginata (Thunb.) A. DC. – southern rockbell Subordinate Taxa. This plant has no children Legal Status. Wetland Status. Interpreting Wetland Status. Related Links. More Accounts and Images; ARS Germplasm Resources Information Network (WAMA) Integrated Taxonomic Information System (WAGR) ...

Feed for promoting growth and development of broilers and preparation method thereof

InactiveCN104431535AIncrease contentRegulated contentFood processingAnimal feeding stuffDiseaseWater Chestnuts

The invention discloses feed for promoting growth and development of broilers and a preparation method thereof. The feed is prepared from the following raw materials in parts by weight: 170-180 parts of dried sweet potato, 30-40 parts of corncob, 12-14 parts of dried distillers grain, 8-12 parts of red clover, 6-8 parts of egg-shell meal, 7-9 parts of sunflower meal, 10-15 parts of sargassum thunbergii, 5-7 parts of coconut shell flour, 4-5 parts of garlic powder, 15-20 parts of field-snail-meat, 20-30 parts of setosa immature stems, 16-18 parts of banana skin, 10-14 parts of ulva, 9-11 parts of kelp, 5-7 parts of chrysanthemum nankingense, 15-17 parts of water chestnut stems, 12-15 parts of coffee leaves, 2-3 parts of salt, 8-10 parts of Poria cocos, 7-9 parts of lycium barbarum, 3-5 parts of rhizoma curculiginis, 2-4 parts of isatis root, 1-3 parts of wahlenbergia marginata, 6-8 parts of fructus amomi, 0.5-0.7 part of choline chloride, 3-5 parts of medical stone powder and 7-9 parts of nutrition additives. The feed disclosed by the invention has the effects of regulating the metabolism of body cells, increasing the appetite of broilers, increasing the feed intake, improving the digestive absorption capacity and promoting growth and development, the weight of the broilers can be effectively increased, and the growth cycle of the broilers is shortened. Moreover, diseases of the broilers can be reduced, and the death rate of the broilers is reduced.

Owner:叶红

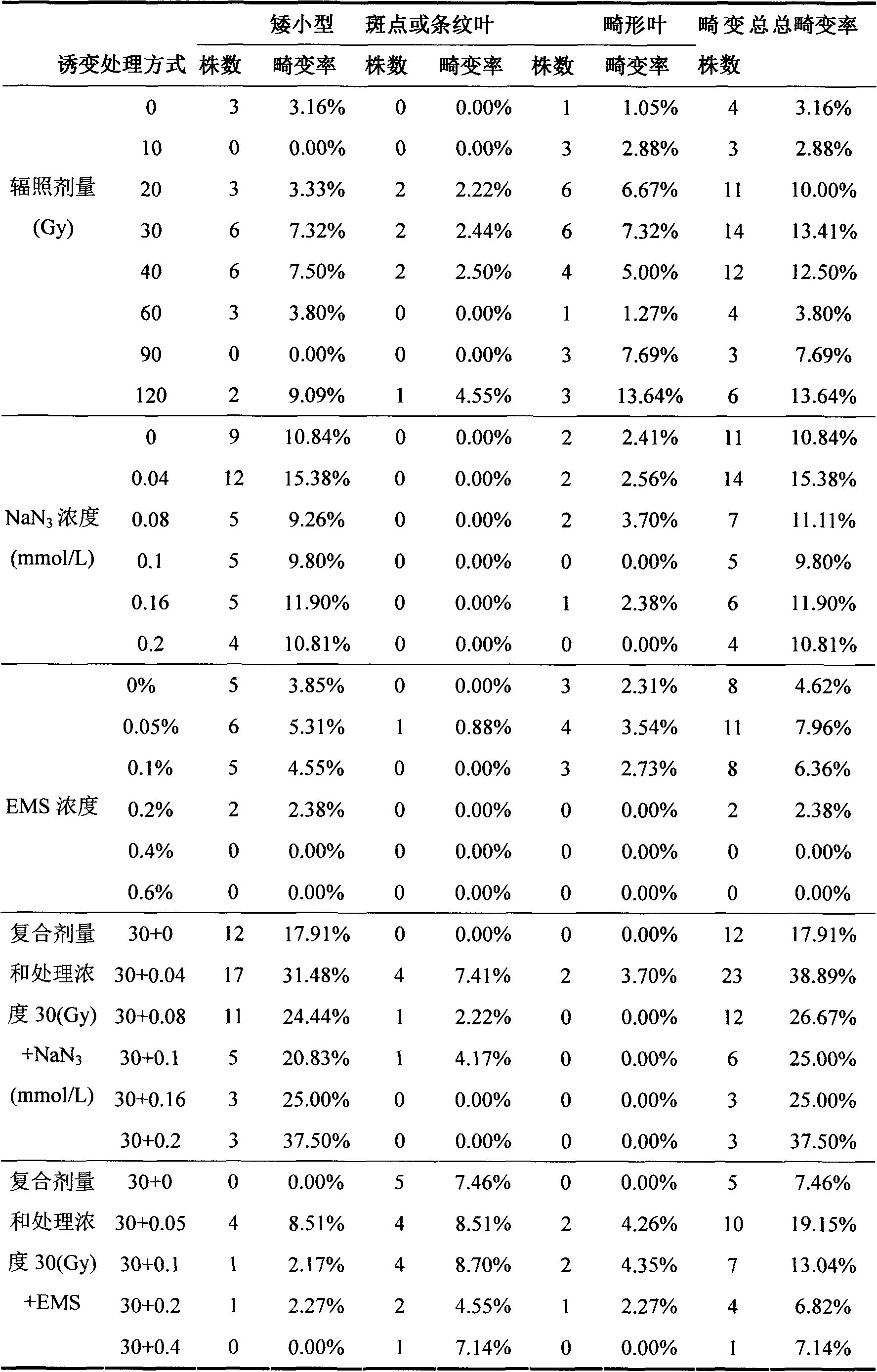

Seed breeding method of moso bamboo by physical and chemical composite mutagenesis

InactiveCN102696478AHigh mutation rateVariations in traitsPlant genotype modificationEthylmethane SulfonateWarm water

The invention discloses a seed breeding method of moso bamboo by physical and chemical composite mutagenesis. The seed breeding method comprises the following five steps of: (1) collection of the moso bamboo seeds, wherein the purity of the seeds is more than or equal to 90%, the thousand seed weight is more than or equal to 28g, the moisture content is 10%-14%, and after being sealed, the seeds are stored for later use at the temperature of 4 DEG C; (2) irradiation ray selection of caesium Gamma rays with the atomic weight being 137 as an irradiation source, and selection of two types of mutagen treating liquid; (3) preparation of the two types of mutagen treating liquid; (4) physical and chemical composite mutagenesis treatment, wherein the radiation dose rate is 1Gy / min, the radiation dose is 30Gy, the seeds are soaked for tens of hours with warm water, after water-absorbing paper absorbs the surface water of the seeds completely, the seeds are soaked and mutagenized for eight hours by using a sodium azide solution (NaN3) or ethylmethane sulfonate (EMS) solution with the concentration of 0.04mmol / L, and after being taken, the seeds are cleaned repeatedly for 2 hours by using clean water to obtain the moso bamboo seeds treated by composite mutagenesis; and (5) germination test of the seeds, verification of mutagenic effect and determination of mutagenesis dose. The seed breeding method disclosed by the method has the advantages that the mutants in mutagenesis are more in quantity, the character mutation is diversified, and the selection range of excellent characters needed in seed breeding is large.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Edible bamboo charcoal paste and its production method

InactiveCN101120790ADetailed disinfection processAntinoxious agentsFood preparationCarbonizationProduct base

The present invention relates to an edible bamboo charcoal and the manufacturing method which is made through three stages and seven steps. The first stage: the selection of raw bamboo should be monitored. The stage involves two steps: firstly, the soil of bamboo original existing areas should be detected and controlled, in particular to the content of heavy metal which can not be over a certain standard; secondly, the raw bamboo must be one-year-life south bamboo, and the parts of bamboo shoot and root which is lower than 500mm should be removed, and the outer of bamboo and bamboo reed must be sampled and tested to make the raw materials enter into kiln to meet the standard. The second stage: carbonization and steam reactivation which contains four steps: first, the fresh bamboo with moisture content of 30-40 percent encased into stainless run kiln and steamed with smoke to dehydrate for 3-6 days; second, the dehydrated fresh bamboo is distilled and carbonized; third, the temperatureof the kiln is increased to 500-800 centigrade, and the edible bamboo is refined and sprayed with water to reactivate, and the time is about 1 hour; four, materials are reclaimed after the kiln is closed 2 days. The third stage: aseptic product processing, which is the last step, and contains the procedures of bamboo charcoal crushing, thinning and sterilizing and aseptic packaging. When edible bamboo charcoal produced by aseptic special equipment reaches to 1000-1500 meshes, encapsulation and sampling inspection for a record should be made. The edible bamboo charcoal produced by the method, the content of heavy metal is much lower than national hygienic standard. The finished edible bamboo charcoal can be eaten directly after being manufactured into capsule, and also can be added into the rice or wheat flour finished product based on various ratios, which can make the excellent characteristics of activated bamboo charcoal melt into various foods.

Owner:陈文照

Green tea flour and preparation method thereof

InactiveCN104126754ADelicate tasteUnique flavorNatural extract food ingredientsFood ingredient functionsWater ChestnutsWahlenbergia marginata

The invention discloses a green tea flour and a preparation method thereof, and is characterized in that the green tea flour is prepared from the following raw materials in parts by weight: 500-510 parts of wheat, 10-12 parts of wheat germs, 25-30 parts of green tea leaves, 30-32 parts of red dates, 18-20 parts of banana paste, 2-3 parts of honey, 5-6 parts of yogurt, 17-19 parts of water chestnut, 15-17 parts of capsella bursa-pastoris, 5-6 parts of ichthyocolla, 3-4 parts of small shrimps, 3-4 parts of pickled Chinese cabbage, 0.8-1 part of cistanche deserticola, 1-1.2 parts of cordyceps sinensis, 0.9-1 part of poria cocos, 1.2-1.4 parts of radix astragali, 0.8-1 part of flos notoginseng, 1.1-1.2 parts of viola arcuata, 0.7-1 part of wahlenbergia marginata, and 11-12 parts of a nutrition additive. The flour is fine and smooth in mouthfeel, unique in flavor, reasonable and scientific in formula, and rich in nutrition; tea polyphenol contained in the added green tea leaves has quite strong oxidation resistance and physiological activity, and can clear away free radicals in human bodies; and with collocation of the added various Chinese herbal medicines, the flour can reach the effect of delaying senescence.

Owner:凤阳县小岗村粮油食品发展有限公司

Traditional Chinese medicine liquid shampoo for alleviating hair loss caused by chemotherapy and preparation method thereof

InactiveCN103893063AAddress and Control Hair Loss SymptomsCosmetic preparationsHair cosmeticsAlysicarpus vaginalisCissus pteroclada

The invention discloses a traditional Chinese medicine liquid shampoo for alleviating hair loss caused by chemotherapy and a preparation method thereof. The traditional Chinese medicine liquid shampoo comprises an ordinary shampoo, a traditional Chinese medicine extracting solution and auxiliary materials, wherein the traditional Chinese medicine extracting solution comprises the following components by weight: 60 g of white mulberry root-bark, 20 g of polygonum multiflorum, 40 g of wahlenbergia marginata, 55 g of medlar, 50 g of herba violae, 60 g of brooklet anemone root, 10 g of pubescent holly root, 20 g of radix gaultheriae, 20 g of cissus pteroclada, 30 g of tinomiscium, 20 g of alysicarpus vaginalis, 25 g of delavay ampelopsis root, 15 g of ficus lyrata, 20 g of impetiens loulanensis hook.f and 10 g of codonacanthus pauciflorus. The traditional Chinese medicine liquid shampoo disclosed by the invention is capable of specially alleviating hair loss caused by chemotherapy and solving and controlling hair loss syndromes in the field of personal daily care.

Owner:HOSPITAL ATTACHED TO QINGDAO UNIV

Brown rice lipid-lowering flour and preparation method thereof

InactiveCN104126757ADelicate tasteUnique flavorNatural extract food ingredientsFood ingredient functionsCholesterol bindingLactarius

The invention discloses an brown rice lipid-lowering flour and a preparation method thereof, and is characterized in that the brown rice lipid-lowering flour is prepared from the following raw materials in parts by weight: 500-520 parts of wheat, 10-12 parts of wheat germs, 50-55 parts of brown rice, 7-8 parts of sesame seeds, 5-6 parts of chickpea, 7-8 parts of apricot kernel, 10-11 parts of breadcrumbs, 8-9 parts of lemon, 10-11 parts of watermelon, 5-6 parts of brassica oleracea, 6-7 parts of maltose, 20-22 parts of crab meat, 4-5 parts of milky tea, 2-3 parts of folium mori, 1-2 parts of gynostemma pentaphylla, 2-2.4 parts of momordica grosvenori swingle, 1-1.2 parts of fructus hippophae, 0.9-1.3 parts of lotus leaves, 0.8-1 part of herb of lygodium japonicum, 1.2-1.4 parts of wahlenbergia marginata, 0.8-1 part of lactic acid bacteria, and 10-12 parts of a nutritional additive. The flour is fine and smooth in mouthfeel, unique in flavor, and reasonable and scientific in formula; dietary fibers contained in the added brown rice can be combined with cholesterol in bile, so as to promote discharge of cholesterol; with collocation of the added folium mori, gynostemma pentaphyllum, momordica grosvenori swingle and other Chinese herbal medicines, the flour can reach a blood lipid-lowering effect, and is suitable for patients with hyperlipidemia to eat.

Owner:凤阳县小岗村粮油食品发展有限公司

Traditional Chinese medicinal composition for treating deficiency of lung Qi and preparation method thereof

The invention discloses a traditional Chinese medicinal composition for treating deficiency of lung Qi and a preparation method thereof. The traditional Chinese medicinal composition comprises the following raw materials: root of large flower morina, wahlenbergia marginata, mangnolia, radix semiaquilegiae, radix campanumoeae, grape, radix stemonae, Indian kalimeris herb, olive, buckwheat, taro leaf, andrographis laxiflora (Bl.) lindau, delavey greenleaf elaeagnus leaf, liquorice and peanut shell, and is prepared by the following steps: preprocessing the raw materials, carrying out ethanol centrifugal extraction and vapor extraction, removing impurities and settling the obtained liquid, and producing the liquid to the corresponding form of the medicine according to requirements of technologies and auxiliaries for the various form on pharmacy. The medicine can clear away heat and toxic materials, benefit lung and spleen, tonify qi and deficiency, moisten lung to arrest cough, supplement qi and blood, and strengthen bones and muscles, and can achieve significant effects on cough due to deficiency syndrome of the lung, spontaneous perspiration, cough, asthma and the like.

Owner:张绍坤

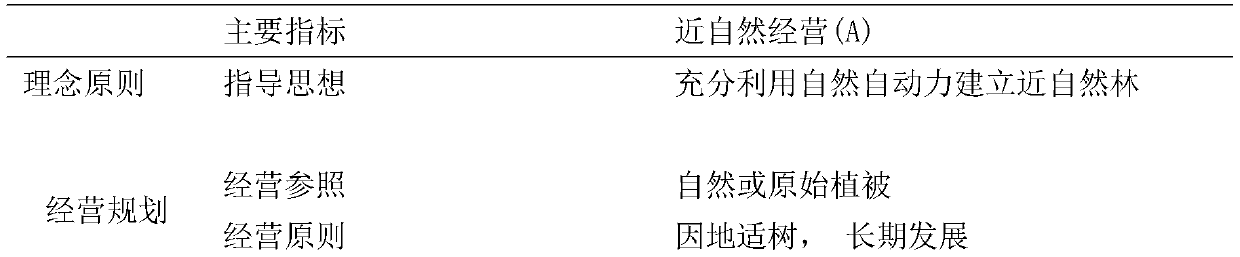

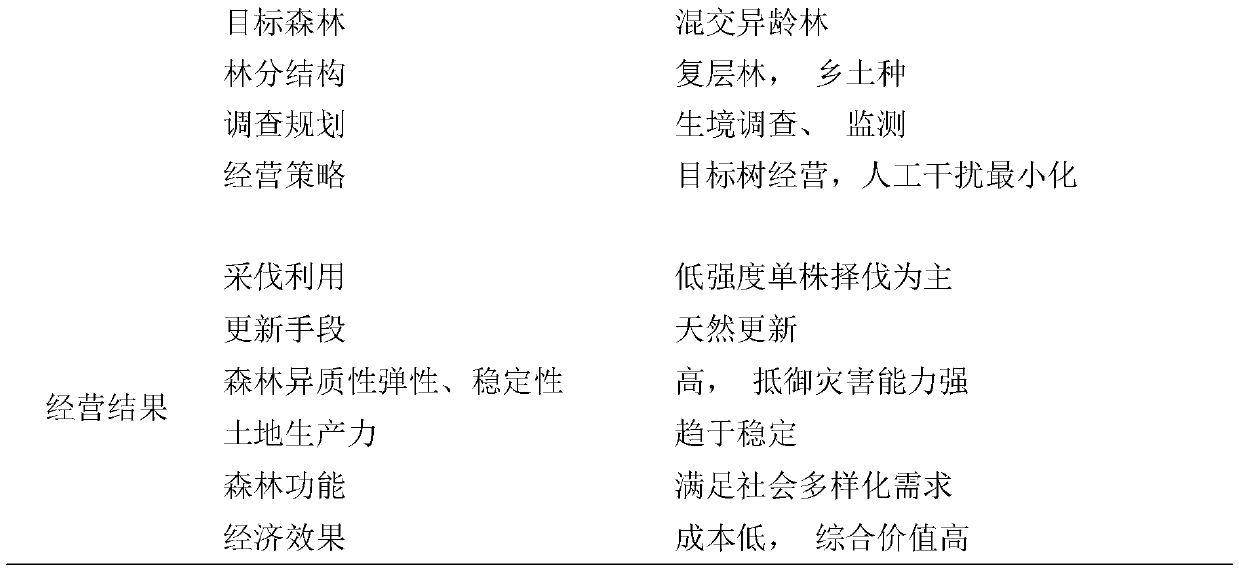

Close-to-nature cultivation method for patch mosaic mixing of degraded phyllostachys pubescens forest

InactiveCN109757286AMaintain ecological functionMaximum average growthCultivating equipmentsForestryEntropy weight methodInsect pest

The invention relates to a close-to-nature cultivation method for the patch mosaic mixing of a degraded phyllostachys pubescens forest. The close-to-nature cultivation method comprises the following steps: 1) establishing division of site conditions of a phyllostachys pubescens forest land; 2) choosing a proper land and proper trees; 3) performing forest health assessment by using a combination weighting method combining an analytic hierarchy process with an entropy weight method; and 4) cultivating the close-to-nature phyllostachys pubescens forest. Local tree species are used as the main managerial object to keep the fertility of the forest land, the irresistible disasters such as forest decline in the early period, explosive plant diseases and insect pests and the like are guaranteed not to occur; a target forest form is determined by referring to site environments, indicative plants, forest succession stages, and potential native vegetation, management measures for stand structureare designed and regulated; the ecological and economic consequences of various management measures are analyzed as much as possible, the designed system is guaranteed to be optimal; and the growth and health states of the forest are periodically monitored and evaluated.

Owner:国家林业和草原局竹子研究开发中心

Dendrobium lily honey for clearing heat and disinfecting and preparation method therefor

InactiveCN104824505ARetain efficacyHas heat-clearing and disinfecting effectFood preparationWahlenbergia marginataMonochoria

The present invention discloses a dendrobium lily honey for clearing heat and disinfecting and a preparation method therefor. The dendrobium lily honey is prepared from the following raw materials in parts by weight: 130-138 parts of jujube honey, 10-15 parts of dendrobium powder, 8-10 parts of lilies, 3-4 parts of radix codonopsis, 2-3 parts of longspur epimedium, 4-5 parts of Chinese wolfberry, 2-3 parts of prepared rehmannia roots, 2-3 parts of Chinese scholartree flowers, 1-2 parts of clustered knotweed herbs, 2-3 parts of mottled bamboo roots, 4-7 parts of nutrient additives, 1-2 parts of bamboo fungus juice, 3-5 parts of coconut shreds, 10-15 parts of leaf mustard, 1.5-2 parts of sanguis draconis, 1.5-2.5 parts of corium elephatis, 1.5-2 parts of sheathed monochoria herbs, 0.5-1.5 parts of dried orange peel, 1-1.5 parts of wahlenbergia marginata and 2-3 parts of artemisia absinthium. For the nutrient health-care honey disclosed by the present invention, various traditional Chinese medicine materials such as the artemisia absinthium, the wahlenbergia marginata and the sanguis draconis are added to the honey by using a micro powder technology, so that the health-care honey can stop bleeding and promote tissue regeneration and is beneficial for people to eat; and further, the dendrobium powder and the lilies are added to the honey, so that the honey not only reserves original efficacies but also has efficacies of clearing heat and disinfecting.

Owner:ANHUI FENGXIAN BEE IND

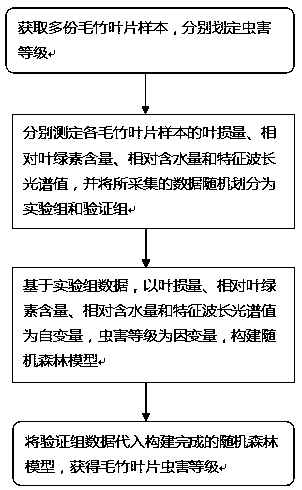

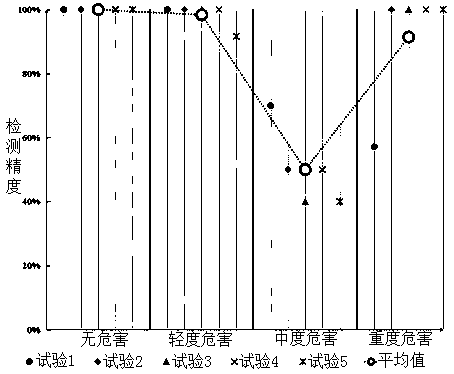

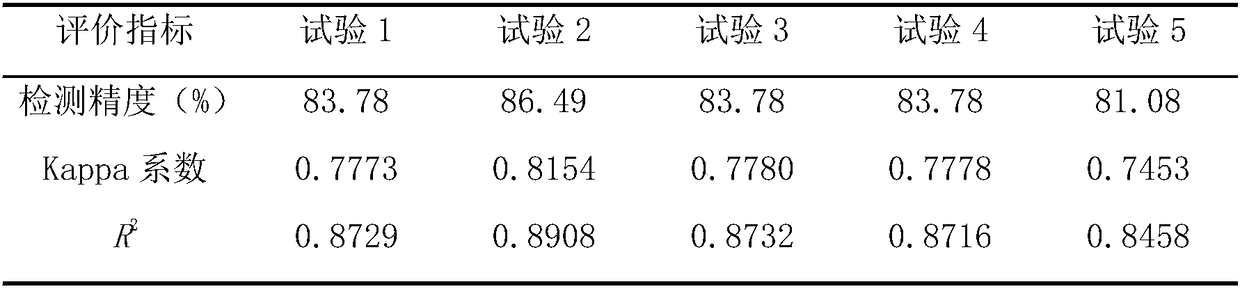

Method for detecting harm of Pantana phyllostachysae Chao by coupling multiple representations of leaves

ActiveCN108596254AImprove detection efficiencyImprove accuracyCharacter and pattern recognitionWahlenbergia marginataLength wave

The invention puts forward a method for detecting harm of Pantana phyllostachysae Chao by coupling multiple representations of leaves, comprising: a step 1 of defining pest harm grades of Phyllostachys pubescent leaves according to a <forestry pest occurrence and disaster standard> in combination with an expert consultation method; a step 2 of respectively measuring an LL (Leaf Loss), an RCC (Relative Chlorophyll Content), an RWC (Relative Water Content) and a characteristic wavelength spectral value of a plurality of Phyllostachys pubescent leaves; a step 3 of building a random forest model by using the LL, the RCC, the RWC and the characteristic wavelength spectral value of the Phyllostachys pubescent leaf as independent variables and using the pest harm grade as a dependent variable; and a step 4 of acquiring the LL, the RCC, the RWC and the characteristic wavelength spectral value of a Phyllostachys pubescent leaf outside the measuring range, plugging the acquired values into the random forest model to obtain the corresponding pest harm grade of the Phyllostachys pubescent leaf. The method of the invention has the advantages of high detection efficiency, high accuracy, and capacity for quickly, easily and accurately discriminating the harm grade of the Pantana phyllostachysae Chao of the Phyllostachys pubescent leaf.

Owner:FUZHOU UNIV

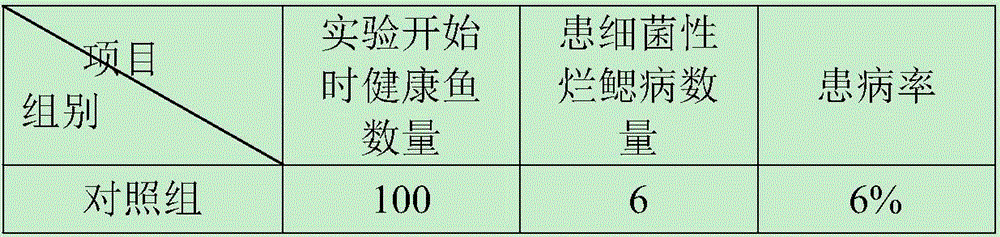

Chinese herb feed additive for preventing bacterial gill-rot disease of fancy carps and preparation method thereof

InactiveCN105194231ABoost taste budsImprove immunityAntibacterial agentsAnthropod material medical ingredientsDiseaseTorilis japonica

The invention relates to a Chinese herb feed additive for preventing a bacterial gill-rot disease of fancy carps and a preparation method thereof. The Chinese herb feed additive for preventing the bacterial gill-rot disease of the fancy carps is prepared from, by mass, 23-34 parts of onion juice, 20-28 parts of dandelion, 18-25 parts of wahlenbergia marginata, 18-25 parts of calamus, 17-25 parts of Chinese pulsatilla roots, 16-22 parts of folium artemisiae argyi, 16-22 parts of cortex mori, 12-19 parts of torilis japonica, 6-13 parts of Pu-erh ripe tea, 15-24 parts of serrate rabdosia herbs, 9-14 parts of semen oroxyli, 6-13 parts of herba violae, 8-13 parts of calyx seu fructus physalis, 6-11 parts of mint oil, 18-29 parts of dried earthworm powder, 6-12 parts of fish oil and the like. The feed additive has the good preventing effect on the bacterial gill-rot disease of the fancy carps.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

Health tea drink and preparation method thereof

The invention relates to a health tea drink and a preparation method thereof. The health tea drink is prepared from the following crude drugs: cyperus malaccensis, leontopodium alpinum, white chinaure herb, folium hibisci mutabilis, common nightblooming cereus, Japanese ligusticum leaves, crossostephium chinense, hoya lancilimba, fagopyrum dibotrys, herba achyranthis asperae, symplocos sumunlia, herba ardisiae japonicae, oroxylum indicum, Japanese inula herb, bambusa sinospinosa, concretio silicea bambusae, helicteres isora, lindernia ruellioides, wahlenbergia marginata, radix liriopes, rhizoma polygonati, folium ilicis cornutae, white granulated sugar, xylosic alcohol and citric acid. The health tea drink prepared by adopting the preparation method provided by the invention has the efficacies of removing heat to cool blood, promoting blood circulation to remove blood stasis, reducing phlegm, soothing the liver, and tonifying qi and yin, and further has the advantages of obvious clinical effect, little toxic and side effect, low recurrence rate and high simplicity and feasibility in preparation process.

Owner:宁波好口味食品有限公司

Spleen invigorating and phlegm reducing linden nutritional honey and preparation method thereof

InactiveCN104304872AChange the tasteEasy to prepareNatural extract food ingredientsFood ingredient functionsAbsinthiumShrimp

The present invention discloses spleen invigorating and phlegm reducing linden nutritional honey comprising the following raw materials by weight: 130-138 parts of linden honey, 4-7parts of nutrition additive, 2-4 parts of cowpea, 2-3 parts of dried small shrimp, 1-2 parts of dictyophora juice, 3-4 parts of apple pulp residue, 3-5 parts of coconut shred, 2-4 parts of chicken powder, 10-15 parts of shepherd's purse, 5-7 parts of grapefruit, 4-6 parts of jelly, 1-2 parts of mashed garlic, 15-20 parts of dilute tomato Juice, 1.5-2 parts of dragon's blood, 1.8-2.3 parts of elephant skin, 1.3-2 parts of sheathed monochoria herb, 0.5-1.4 parts of dried orange peel, 0.8-1.2 parts of wahlenbergia marginata and 2-3 parts of wormwood; the wormwood, the wahlenbergia marginata, the dragon's blood and other traditional chinese medicinal materials are added into the honey through micro powder technology, the spleen invigorating and phlegm reducing linden nutritional honey not only can clear away heat, detoxify, stop bleeding and promote tissue regeneration, is simple in production method and easy to carry, changes the Chinese herbal medicine taste, and is beneficial to people taking.

Owner:汤兴华

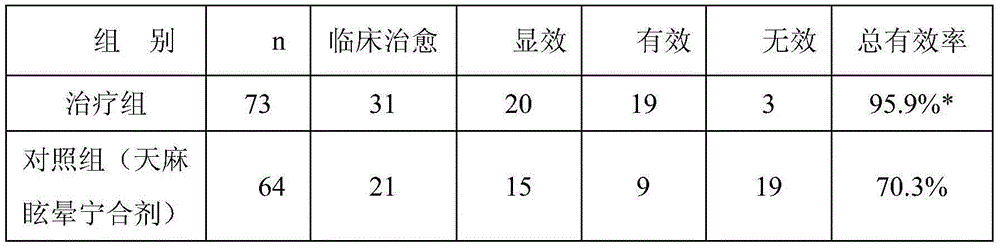

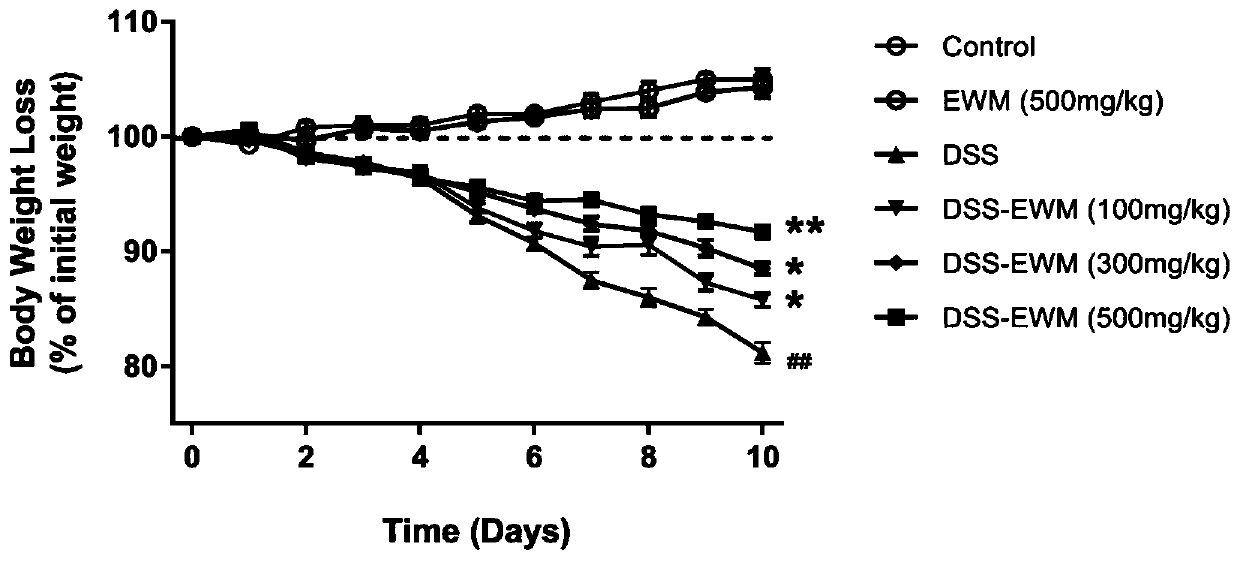

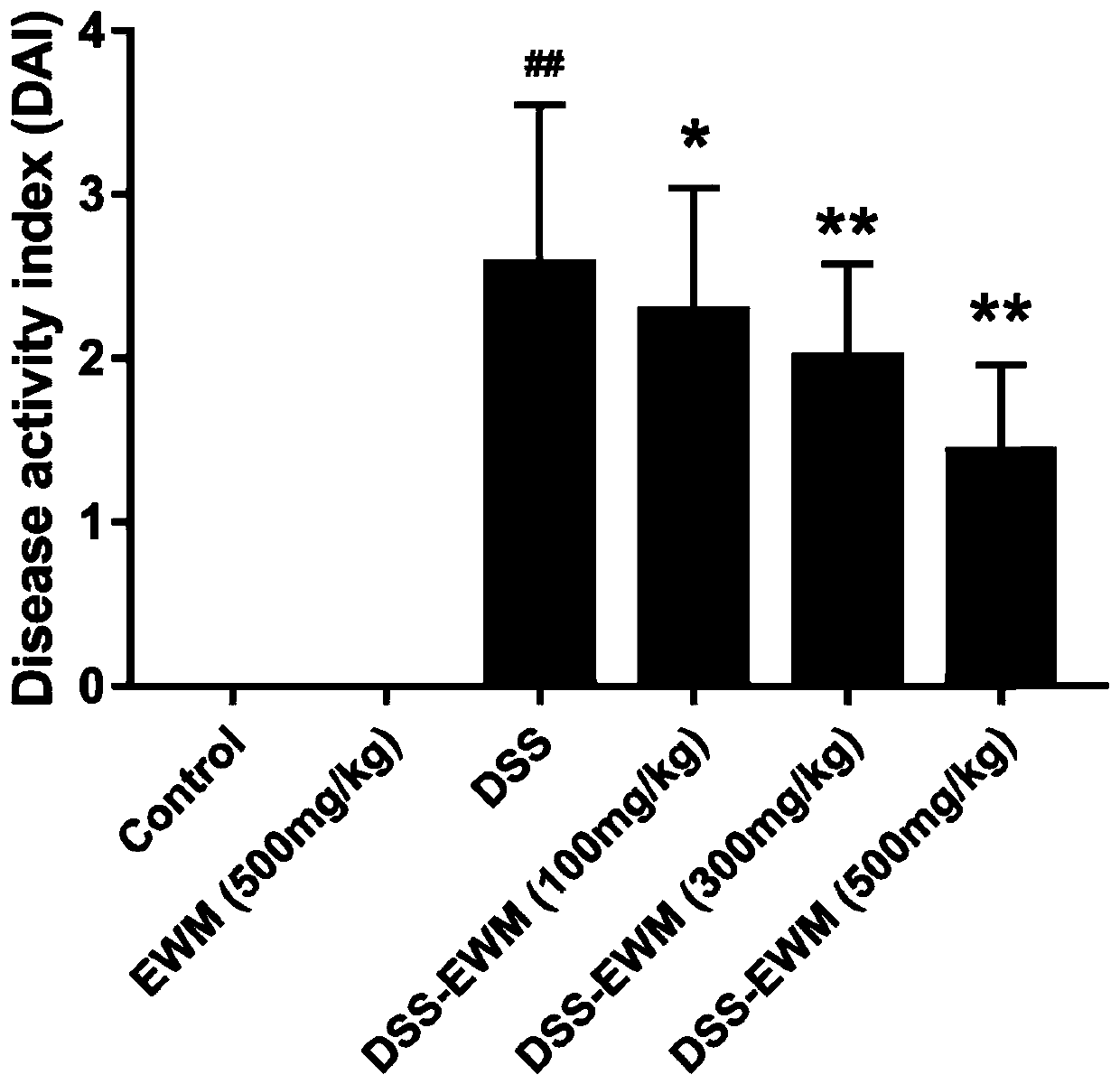

Application of wahlenbergia marginata extract to preparation of medicines for treatment or prevention of inflammatory bowel diseases

InactiveCN110433188ALower levelReduced activityDigestive systemPlant ingredientsWahlenbergiaActive component

The invention relates to the field of medicines, in particular to an application of a wahlenbergia bmarginata extract to preparation of medicines for treatment or prevention of inflammatory bowel diseases. Natural plant, namely wahlenbergia marginata, is used as the raw material, and through a soxhlet method, an effective active component namely a wahlenbergia marginata extract in the wahlenbergiamarginata can be extracted and can be used for preventing and treating application to the inflammatory bowel diseases. The wahlenbergia marginata plant extract can be used as a safe and effective treatment drug for inflammatory bowel diseases.

Owner:CHILDRENS HOSPITAL OF CHONGQING MEDICAL UNIV

Traditional Chinese medicine composition for treating qi deficiency caused fluid keeping failure symptom type purpura

InactiveCN104547713AImprove clinical symptomsClinical symptoms improvedHeavy metal active ingredientsAluminium/calcium/magnesium active ingredientsWahlenbergia marginataYin deficiency

The invention discloses a traditional Chinese medicine composition for treating qi deficiency caused fluid keeping failure symptom type purpura. The traditional Chinese medicine composition is characterized by consisting of pterygopleurum neurophyllum, meconopsis horridula, wild clausena lansium, Chinese Starjasmine stems, herba swertiae davidi, chalk, polygala fallax, myriopteron extensum, hyacinth bean flower, tofieldia divergens, ficus comate roots, corallodiscus cordatulus, red halloysite, ginkgo roots, wahlenbergia marginata, hedge glorybind flower roots, satyrium henryi, salvia scapiformis, panax japonicas leaves, eria graminifolia, prickly pear fruit, pennisetum, dryopteris crassirhizoma and liquorice in a certain ratio. The traditional Chinese medicine composition can be used for treating yin deficiency caused fire excess symptom type purpura, and is good in treatment effect and high in curative effect, and the disease does not relapse after being healed.

Owner:柏伟伟

Arrowroot reed rhizome honey capable of reducing blood pressure and blood lipid and preparation method of arrowroot reed rhizome honey

InactiveCN104855765ARetain efficacyHas the effect of lowering blood pressure and fatNatural extract food ingredientsFood ingredient functionsShrimpAbsinthium

The invention discloses arrowroot reed rhizome honey capable of reducing blood pressure and blood lipid and a preparation method of the arrowroot reed rhizome honey. The arrowroot reed rhizome honey is prepared from the following raw materials in parts by weight: 130-138 parts of honeysuckle honey, 10-15 parts of arrowroot, 8-10 parts of reed rhizomes, 4-7 parts of nutrient additives, 2-4 parts of cress rhizomes, 2-3 parts of dried small shrimps, 1-2 parts of bamboo fungus juice, 3-5 parts of desiccated coconuts, 10-15 parts of leaf mustard, 5-7 parts of grapefruit, 1-2 parts of mashed garlic, 10-15 parts of thin tomato juice, 1.5-2 parts of dragon's blood, 1.5-2.5 parts of elephant hide, 1.5-2 parts of sheathed monochoria herb, 0.5-1.5 parts of dried orange peel, 1-1.5 parts of wahlenbergia marginata and 2-3 parts of artemisia absinthium. The arrowroot reed rhizome honey disclosed by the invention is the nutrient health-care honey, and through a micro powder technique, various traditional Chinese medicine materials of the artemisia absinthium, the wahlenbergia marginata, the dragon's blood and the like are added to the honey, so that the arrowroot reed rhizome honey can clear heat, remove toxicity, stop bleeding and promote tissue regeneration, and is convenient for people to take; besides, the arrowroot and the reed rhizomes are added to the honey, so that the honey reserves original efficacies, and besides, the honey has the effects of reducing the blood pressure and reducing the blood lipid.

Owner:ANHUI FENGXIAN BEE IND

Traditional Chinese medicine composition for treating spontaneous perspiration disease and preparation method thereof

ActiveCN103040906AEnhance yang and qiEnhance the effect of solid surface antiperspirantDrug compositionsPlant ingredientsPseudostellariaPerspiration

The invention relates to traditional Chinese medicine composition for treating spontaneous perspiration disease and a preparation method thereof. The traditional Chinese medicine composition is prepared from the following raw traditional Chinese medicine in parts by weight: 20-80 parts of radix pseudostellariae and 20-80 parts of Wahlenbergia marginata. The invention further provides a preferable preparation method of the traditional Chinese medicine composition for treating the spontaneous perspiration disease. The traditional marketed medicine for treating the spontaneous perspiration disease is basically a medicine for treating a sweating disease and has defects that the curative effect is slow, the secretion of regular sweat glands is also sealed when the spontaneous perspiration disease is treated, the certain side effect exist; therefore, under the guidance of traditional Chinese medical theory, a medicine for treating the spontaneous perspiration disease with good effect, convenience in administration, good compliance and good safety is provided by utilizing reasonable compositions and combining with a modern preparation process; and the source of the raw materials is wide, the preparation process is simple, the cost is low and the preparation process is easy to be realized.

Owner:FUJIAN MINDONG REJUVENATION PHARMA

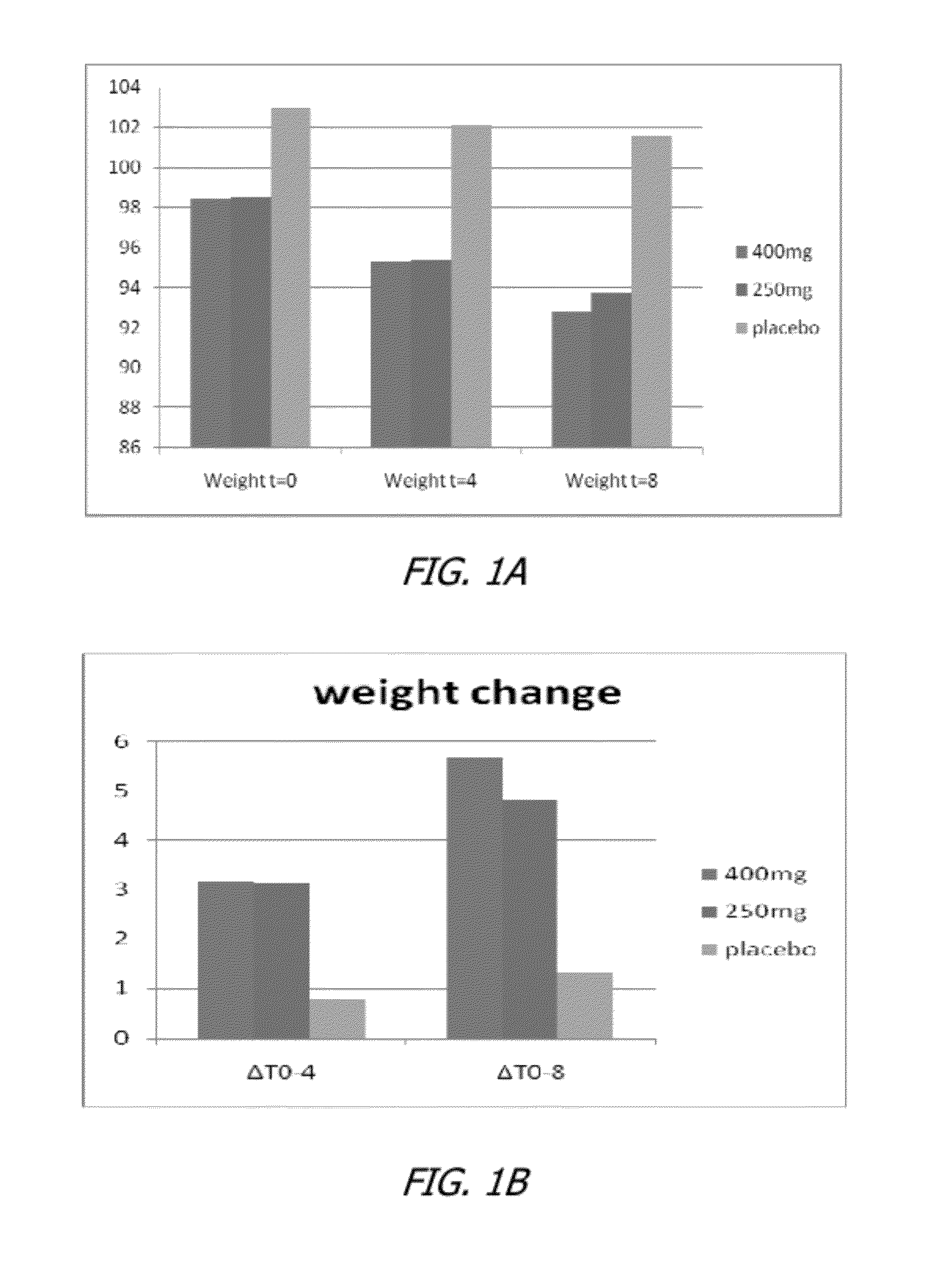

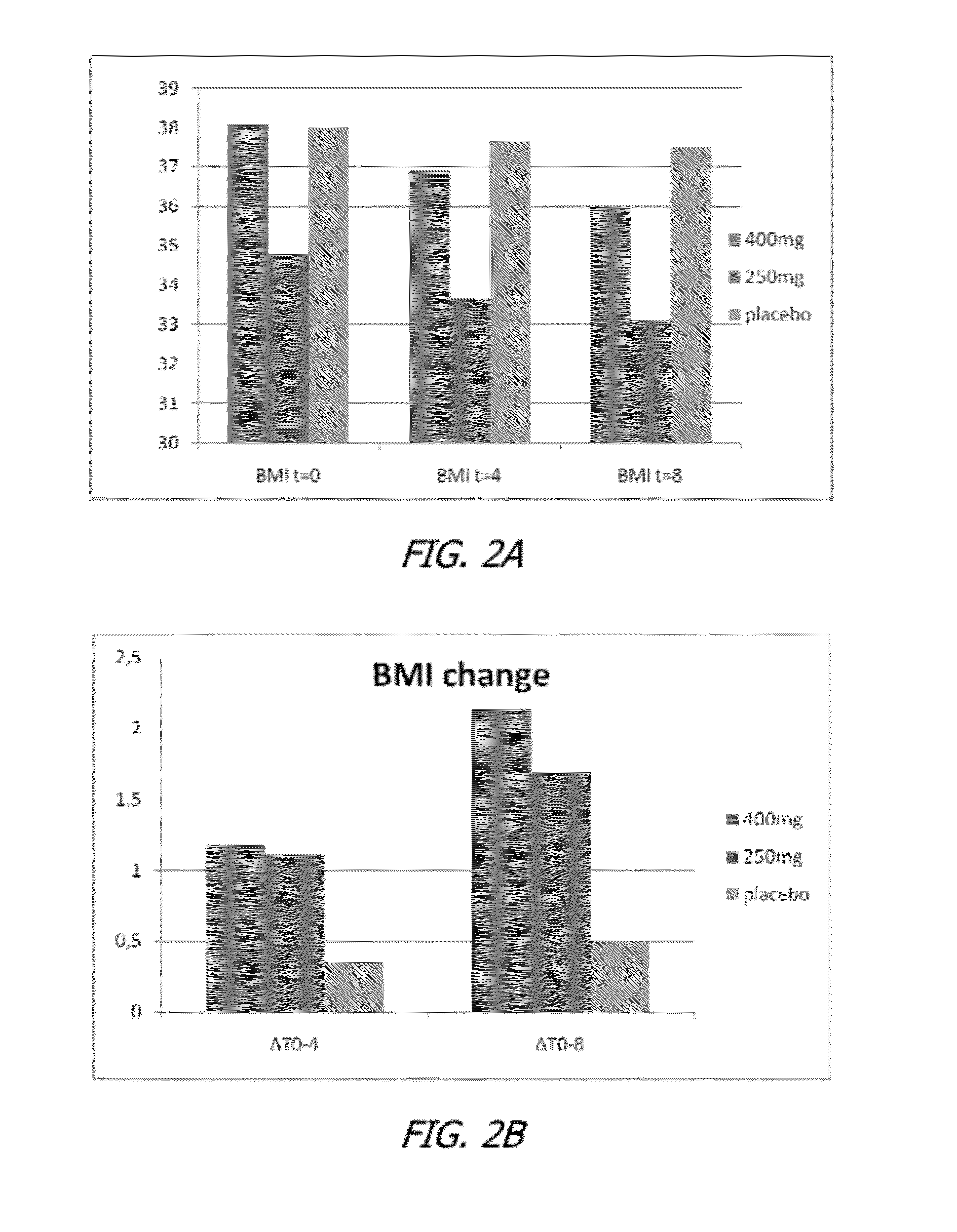

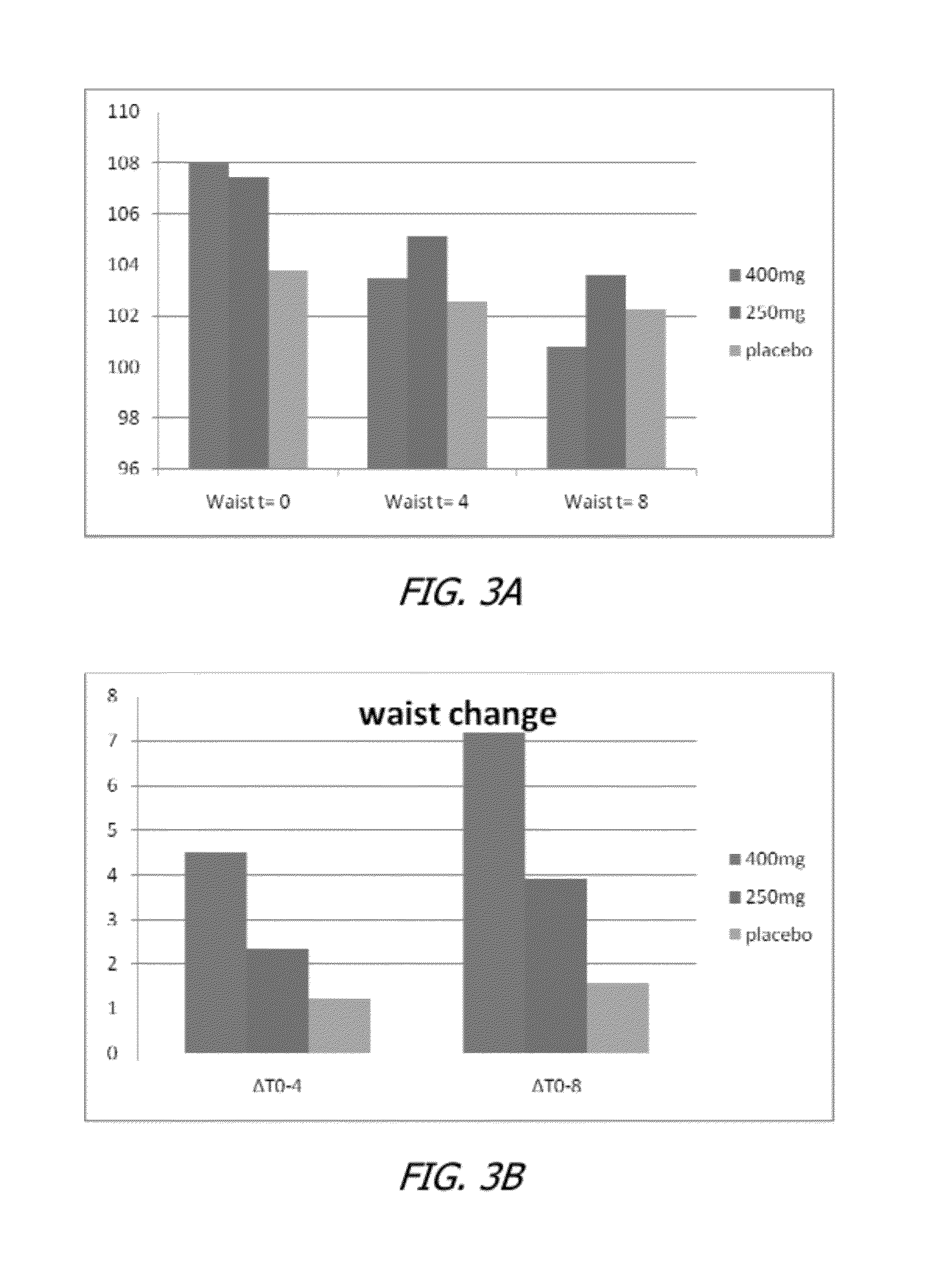

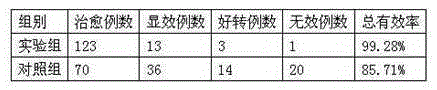

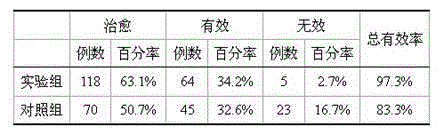

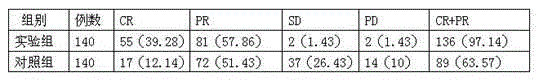

Effects of Dichrostachys glomerata DG, Hypodaphnis zenkeri HZ, and Xylopia aethiopica XA on various cardiovascular risk factors and metabolic syndrome

ActiveUS8241682B2Reduce weightReducing weigh in the mammalBiocideMetabolism disorderMammalHypodaphnis

Methods of improving a variety of health related factors including, but not limited to weight, cholesterol levels, triglyceride levels and HDL levels, is provided. In one embodiment, a method of reducing LDL cholesterol levels of a mammal in need thereof is provided, the method comprises administering a composition containing an effective amount of Dichrostachys glomerata, to a mammal, whereby the administering of the composition to the mammal is effective in reducing LDL cholesterol levels in the mammal.

Owner:GATEWAY HEALTH ALLIANCES

Preparing method of muntingia calabura flavor aglaia odorata cake

The invention discloses a preparing method of a muntingia calabura flavor aglaia odorata cake. Muntingia calabura and aglaia odorata are used as raw materials, and radix puerariae and radix wahlenbergia marginata are added to prepare the muntingia calabura flavor aglaia odorata cake. Nutritive value of muntingia calabura and aglaia odorata is fully used, by means of compatibility of traditional Chinese medicine, the synergistic effect is achieved, and the cake has the effects of promoting appetite, dispelling melancholy and alleviating depression. Fruit wine yeast primary fermentation is carried out on muntingia calabura, a mellow smell is added to the cake, and the prepared finished product is fragrant, sweet, tasty, rich in nutrition and easy to store, has strong fragrance and a remarkable healthcare function and can obviously improve discomfort of people groups with dyspepsia and stomach and abdomen distension after being eaten for a long time. The cake is simple in preparing process, easy to obtain, wide in market prospect and capable of being produced in batches.

Owner:王芳

Chinese medicinal herb for treating cancer

InactiveCN101085163AGrowth inhibitionInhibition of killingInorganic active ingredientsMammal material medical ingredientsOral medicationWahlenbergia marginata

The invention discloses a medicament for treating cancer which is an oral administration decoction extracted from the following constituents (by weight ratio): hairy holly root 6-12 parts, Catharanthus roseus 8-16 parts, barbat skullcap 7-14 parts, Tuyaoqi 20-48 parts, Bianmagen 8-16 parts, chloris virgata swartz 10-30 parts, tabasheer 20-40 parts, cogongrass rhizome 35-65 parts, Wahlenbergia marginata 8-16 parts, Paris polyphylla 10-20 parts, and oldenlandia 35-65 parts and water 800-2000 parts.

Owner:李联奎

Traditional Chinese medicine composition and preparation method thereof

InactiveCN106334140ASignificant effectAnthropod material medical ingredientsPteridophyta/filicophyta medical ingredientsCurative effectParis verticillata

The invention belongs to the technical field of traditional Chinese medicines, and in particular relates to a traditional Chinese medicine composition and a preparation method thereof. The traditional Chinese medicine composition comprises the following traditional Chinese medicine raw materials in parts by weight: 10 to 55 parts of snakeskin, 10 to 45 parts of rhizoma smilacis glabrae, 15 to 45 parts of black nightshade, 10 to 55 parts of wahlenbergia marginata, 5 to 50 parts of paris verticillata, 5 to 45 parts of walnuts, 10 to 45 parts of selfheal, 10 to 120 parts of astragalus membranaceus and 5 to 50 parts of coniferopsida. The traditional Chinese medicine composition provided by the invention has a good curative effect on various tumors and various cancers.

Owner:赵国林

Medical film with antisepsis and anti-inflammation effects and preparation process thereof

InactiveCN105396171AHas antibacterial and anti-inflammatory effectsGood antibacterial and anti-inflammatory effectOrganic active ingredientsMacromolecular non-active ingredientsGlycerolCarpesium divaricatum

The invention discloses a medical film with antisepsis and anti-inflammation effects and a preparation process thereof. The medical film is mainly prepared from, by weight, 65-78 parts of collagen, 10-15 parts of sodium alga acid, 4-8 parts of wahlenbergia marginata, 3-6 parts of lotus leaves, 4-10 parts of tartary buckwheat heads, 6-10 parts of Lindernia crustacea (L.)F. Muell, 5-9 parts of carpesium divaricatum, 6-12 parts of milkvetch roots, 3-8 parts of Lysimachia lobelioides Wall., 5-9 parts of eriocaulon buergerianum, 7-11 parts of the root of common peony, 4-8 parts of Anoectochilus roxburghii (Wall) Lindc, a proper amount of glycerinum, a proper amount of laurocapram, a proper amount of Tween 80 and a proper amount of calcium chloride solution with the mass fraction of 2%.

Owner:耿文真

Method for preparing lophatherum gracile bamboo acid mixed solution for skin liquor for treating athlete's foot

The invention relates to a method for preparing a lophatherum gracile bamboo acid mixed solution for skin liquor for treating athlete's foot. The method is characterized by comprising the following steps of: mixing lophatherum gracile acid liquor and moso bamboo acid liquor, which are extracted from lophatherum gracile and moso bamboo respectively, in a volume ratio of 1:1-3 to obtain a first mixed solution; mashing garlic, mixing the mashed garlic and the first mixed solution, and standing at normal temperature and in a dark place for more than 2 months, wherein the standing solution has three liquid layers: an upper layer, a middle layer and a lower layer; separating and extracting the middle water layer to obtain a second mixed solution; decocting more than one type of dried Chinese herbal medicament, which contains one or both of gleditschia horrida and gentian and has the bactericidal action with water, adding the extracting solution of the decocting solution into the second mixed solution and stirring, and standing the mixed solution at normal temperature and in a dark place for more than one month; adding deodorant solution into the standing solution, and filtering the standing solution after the deodorization effect is achieved. In addition, if more than one of pine oil, extracting solution of cinnamon, perilla herb oil and citric acid is added into the second mixed solution, the same effect can also be achieved.

Owner:浅川君子

Traditional Chinese medicine prescription for prevention and treatment of arrhythmia and preparation method thereof

InactiveCN105056071AFormulation ScienceEasy to prepareCardiovascular disorderPlant ingredientsAngelica Sinensis RootValerian Root

The invention discloses a traditional Chinese medicine prescription for prevention and treatment of arrhythmia. The traditional Chinese medicine prescription mainly comprises, by mass, 8-13 parts of notopterygium roots, 10-14 parts of fortune windmillpalm wood, 7-12 parts of anthriscus sylvestris, 9-14 parts of acorus tatarinowii, 6-13 parts of sophora fruits, 8-14 parts of alpinia katsumadai, 7-13 parts of farges fir cones, 10-18 parts of angelica sinensis, 6-14 parts of star-flower lysimachia, 8-12 parts of henry clematis roots, 6-9 parts of valerian roots, 9-15 parts of taibai-gense, 8-16 parts of oxalis corymbosa, 9-13 parts of polygala tenuifolia and 10-15 parts of wahlenbergia marginata. The prescription is formed through many years of clinical practice summary, has the effects of calming the nerves by nourishing the heart and nourishing qi to invigorate the spleen, and is remarkable in treatment effect.

Owner:霍同颜

Hard lump-resolving agent for treating gastric cancer and preparation method

InactiveCN104800457AEasy to takeEasy to carryAntineoplastic agentsMolluscs material medical ingredientsWater ChestnutsActinidia

The invention discloses a hard lump-resolving agent for treating gastric cancer and a preparation method. The hard lump-resolving agent is prepared by taking the following raw materials by weight part: 13 to 20 parts of cinnamon, 11 to 15 parts of flos caryophylli, 12 to 18 parts of corydalis tuber, 9 to 13 parts of patrinia heterophylla, 7 to 12 parts of cactuses, 9 to 14 parts of flos mume, 12 to 19 parts of codonopsis pilosula, 6 to 13 parts of cephalotaxus fortunei, 9 to 11 parts of water chestnut, 10 to 13 parts of Chinese actinidia roots, 12 to 17 parts of wahlenbergia marginata, 7 to 12 parts of rhizoma cimicifugae, 8 to 14 parts of lindernia crustacean, 7 to 11 parts of common tetragonia herbs, 9 to 15 parts of kelp, 6 to 14 parts of rhizoma pinellinae praeparata, 9 to 12 parts of fructus aurantii, 10 to 13 parts of ligusticum wallichii and 6 to 9 parts of concha arcae. The hard lump-resolving agent is free from risk, operative complications, pain of sequela, wound and side effect of chemoradiotherapy; the cancer is difficult to transfer and relapse; pure natural Chinese herbal medicines are taken as the main raw materials, so that the hard lump-resolving agent is environment-friendly and safe; the effects in counteracting toxic substances and strengthening the body resistance are both achieved; the capability of the whole body to prevent and resist against cancer can be improved by regulating the viscera channel physiological function; the anticancer immunity of a patient can be enhanced; the living quality and the survival rate are increased.

Owner:王小华

Traditional Chinese medicine prescription for treating pulmonary interstitial fibrosis and preparation method thereof

InactiveCN104645004AActivation of autoimmune activityRestore respiratory functionAntipyreticAnalgesicsFritillaria cirrhosaRHODIOLA ROSEA ROOT

The invention belongs to the technical field of traditional Chinese medicine and particularly relates to a traditional Chinese medicine prescription for treating the pulmonary interstitial fibrosis. The traditional Chinese medicine is prepared from the following traditional Chinese medicine raw materials in parts by weight: 15-20 parts of cordyceps sinensis, 5-10 parts of rhodiola rosea, 5-10 parts of gynostemma pentaphylla, 3-5 parts of wahlenbergia marginata, 3-5 parts of peperomia blanda, 3-8 parts of greenish lily flower, 3-8 parts of ophiopogon root, 3-5 parts of rhizoma panacis majoris, 3-8 parts of radix asteris, 3-5 parts of fritillaria cirrhosa, 3-5 parts of radices primulae, 3-5 parts of walking spleenwort, 1-3 parts of toasted ephedra, 3-5 parts of patrinia, 1-3 parts of dysosma versipellis, 1-3 parts of chrysanthemum morofolium ramat, 3-5 parts of folium agaves america nae, 3-5 parts of erigeron breviscapus, 3-5 parts of rabdosia japonica, 1-3 parts of livistona chinensis, and 1-3 parts of stigma croci. By virtue of the conditioning of the traditional Chinese medicines, the autoimmune activity of the lung cell can be activated, the fibrosis can be controlled and the respiratory function can be recovered; the preparation method is simple and convenient and easy to implement.

Owner:QINGDAO CENT HOSPITAL

Chinese herbal medicine preparation for treating bacterial gill-rot disease of cryprinus carpiod and preparation method of Chinese herbal medicine preparation

InactiveCN105168802ANo floating head phenomenonGood healing effectAntibacterial agentsAnthropod material medical ingredientsDiseaseAcorus calamus

The invention relates to a Chinese herbal medicine preparation for treating a bacterial gill-rot disease of cryprinus carpiod, and further relates to a preparation method of the Chinese herbal medicine preparation for treating the bacterial gill-rot disease of the cryprinus carpiod. The Chinese herbal medicine preparation for treating the bacterial gill-rot disease of the cryprinus carpiod provided by the invention is prepared from the following components in parts by weight: 23-34 parts of onion juice, 20-28 parts of dandelion, 18-25 parts of wahlenbergia marginata, 18-25 parts of acorus calamus, 17-25 parts of pulsatilla chinensis regel, 16-22 parts of folium artemisiae argyi, 16-22 parts of cortex mori radicis, 12-19 parts of Xiaoqiecao, 6-13 parts of cooked puerh, 15-24 parts of serrate rabdosia herb, 15-21 parts of shepherd's purse, 13-20 parts of folium isatidis, 11-18 parts of purslane, 12-18 parts of Chinese gall, 11-16 parts of Indian kalimeris herb, 8-18 parts of common cephalanoplos herb, 9-17 parts of creeping oxalis and the like. The Chinese herbal medicine preparation provided by the invention is high in recovery rate on the bacterial gill-rot disease of the cryprinus carpiod.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

Preparation method of Wahlenbergia marginata root or herb healthcare lozenge

InactiveCN107212396AHas the function of clearing away heatWith phlegm and coughFood ingredient functionsFreeze-dryingWahlenbergia marginata

The invention discloses a preparation method of a Wahlenbergia marginata root or herb healthcare lozenge. The Wahlenbergia marginata root or herb healthcare lozengeis mainly prepared from Wahlenbergia marginata root or herb through the steps of pretreatment, enzyme treatment, homogenization, freeze-drying, mixing, softening granulation, tabletting, drying, and shaping drying. The Wahlenbergia marginata root or herb healthcare lozenge made through the method has the advantages of portability, convenience in eating and richness in nutrients, can be directly eaten, also can be drunk after being dissolved in drinking water, can be preserved for a long term without deterioration, and also has the exterior syndrome relieving, heat clearing, phlegm reducing and cough relieving effects of the Wahlenbergia marginata root or herb.

Owner:芜湖市三山区绿色食品产业协会

Pharmaceutical composition for treating bronchopneumonia

InactiveCN105343833ADefinite curative effectSignificant effectFungi medical ingredientsPteridophyta/filicophyta medical ingredientsSide effectWahlenbergia marginata

The invention relates to a pharmaceutical composition for treating bronchopneumonia. The pharmaceutical composition is composed of the following traditional Chinese medicine raw materials according to a weight ratio: 3-7 parts of winged laggera herb, 3-5 parts of old radish root, 2-5 parts of flower of aglaia odorata, 5-8 parts of whole herb of amethystea caerulea, 5-10 parts of whole herb of andrographis laxiflora, 3-7 parts of root of artemisia dracunculus, 3-7 parts of whole herb of lysimachia microcarpa, 2-8 parts of rhizome of mioga ginger, 3-5 parts of capitulum of picris hieracioides, 3-5 parts of whole herb of salvia substolonifera, 5-12 parts of involute spikemoss herb, 5-10 parts of cryptoporus volvatus, 3-8 parts of whole herb of juncellus serotinus, 3-7 parts of cudweed herb, 3-5 parts of ludwigia hyssopifo-lia (G.Don)Exekk, 2-7 parts of whole herb and flower of lotus corniculatus, 3-7 parts of roots and rhizomes of primula sieboldii, 5-15 parts of Indian rorippa herb and 5-15 parts of roots or whole herb of wahlenbergia marginata. The pharmaceutical composition has the efficacies of clearing heat, ventilating the lung, clearing away phlegm, relieving asthma, relieving cough, reducing sputum, invigorating qi and strengthening spleen, has a definite and remarkable curative effect for treating bronchopneumonia, is high in effective rate and safe, has no toxic or side effects and is low in possibility of relapse.

Owner:郑__路

Preparation method and quality control method of Yulan Jiangtang capsule extract

InactiveCN108619361AGood product qualityControl product qualityMetabolism disorderComponent separationHerba Scutellariae BarbataeRelative density

The invention relates to a preparation method and quality control method of Yulan Jiangtang capsule extract. The preparation method comprises the following steps: taking radix scutellariae, folium mori, fructus arctii, radix wahlenbergiae marginatae, herba scutellariae barbatae, disporopsis longifolia root and semen celosiae; crushing part of the folium mori into fine powder; adding water into theresidual folium mori and the residual six medicines and decocting for two times; combining decoction and filtering; concentrating filtrate to obtain extract with the relative density of 1.17 to 1.20(at 80 DEG C), so as to obtain a product. According to the method provided by the invention, effective components can be sufficiently kept; the invention further discloses the quality control method of the Yulan Jiangtang capsule extract, and the quality of the product can be controlled better.

Owner:贵州健兴药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com