Patents

Literature

37 results about "D-Aspartic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

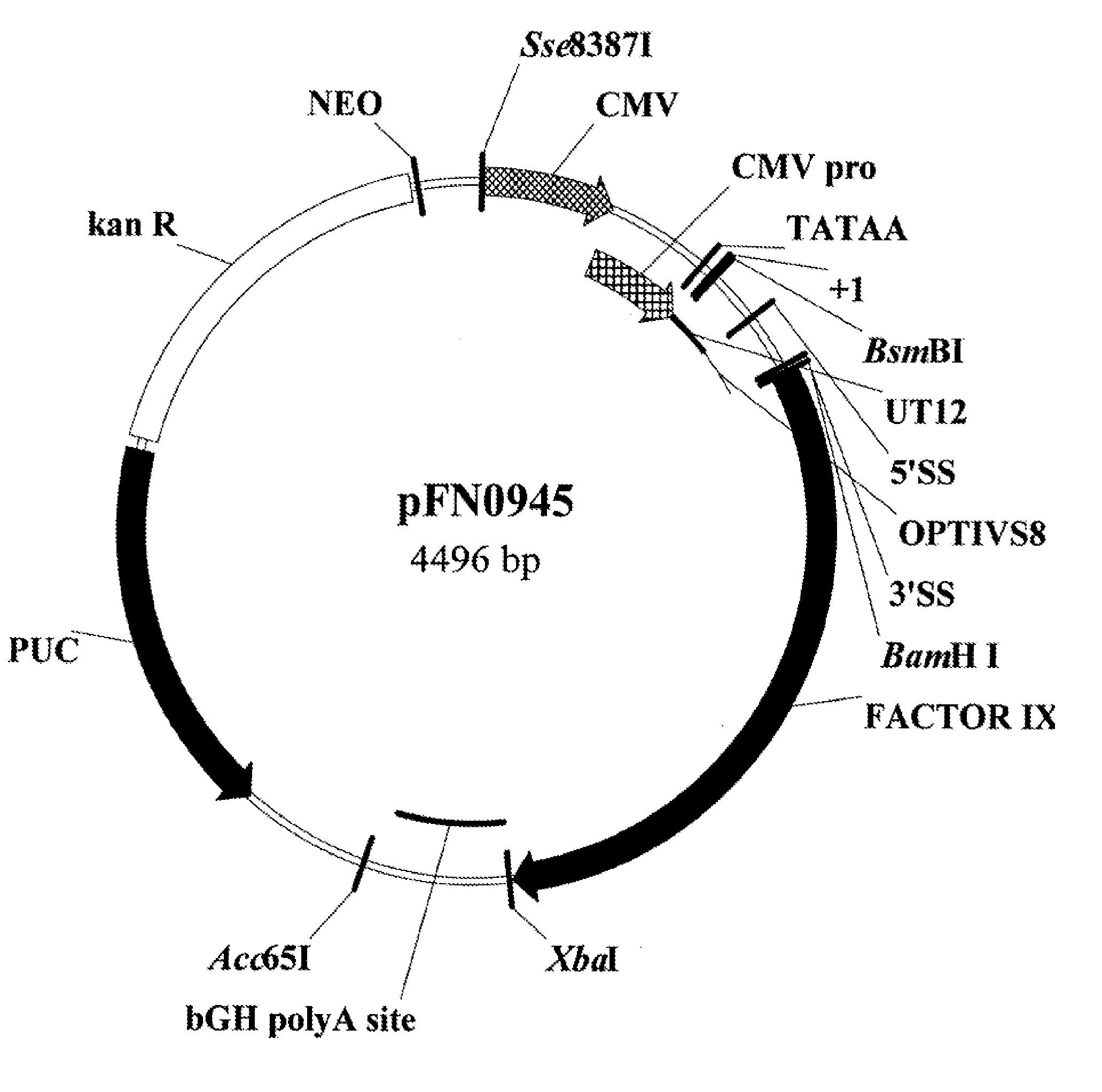

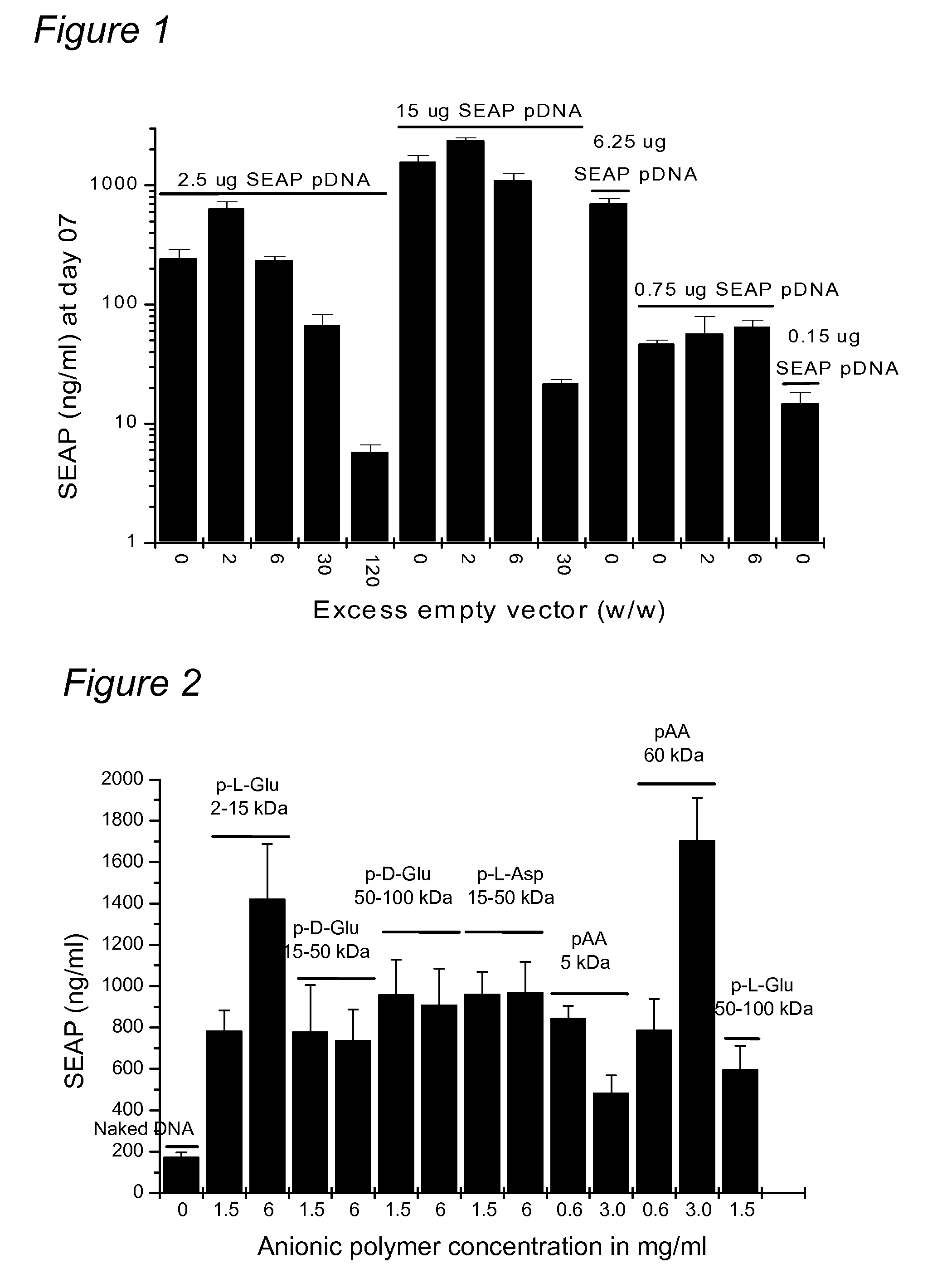

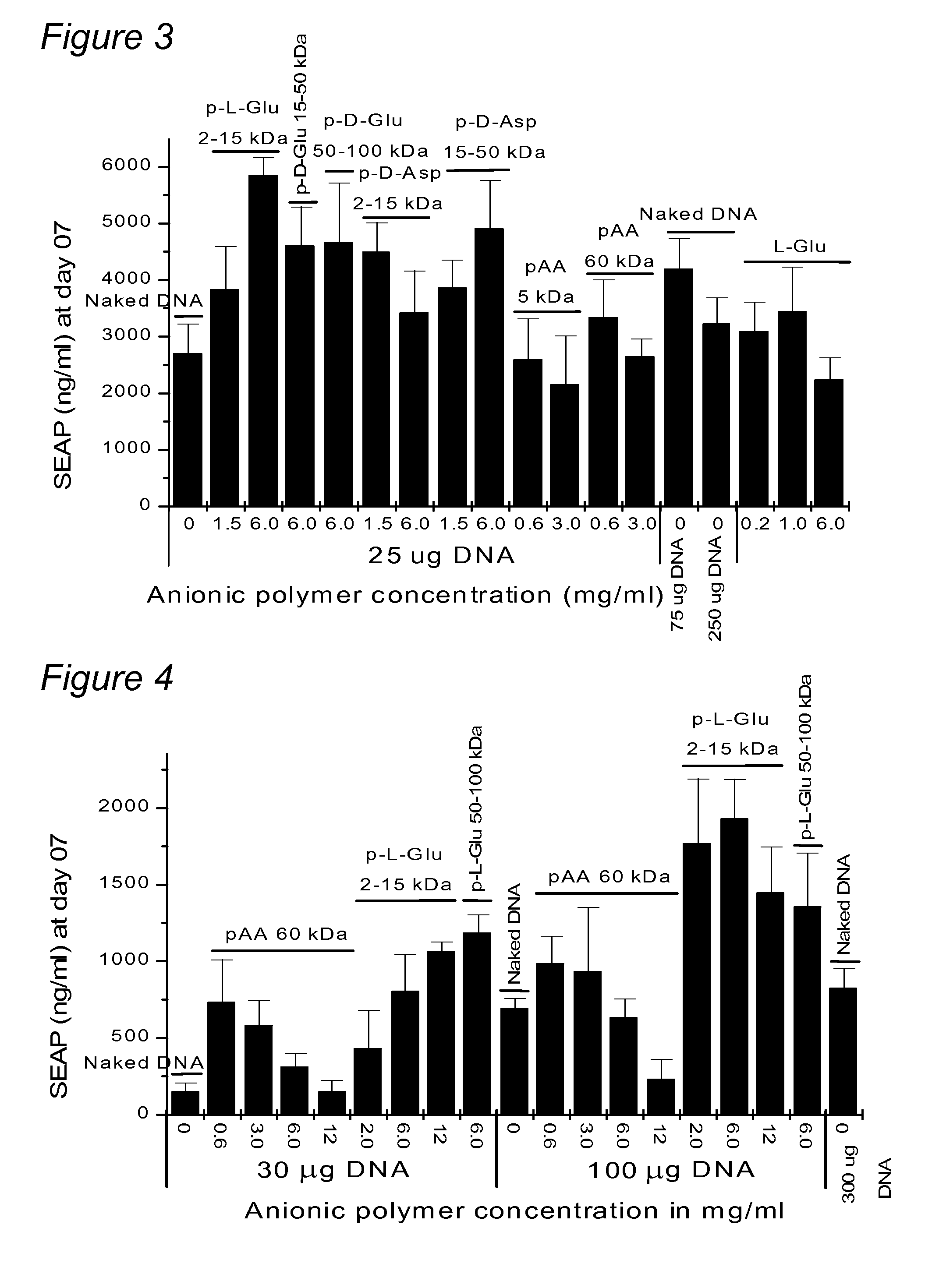

Nucleic Acid Formulations for Gene Delivery and Methods of Use

InactiveUS20070213287A1Improve topical bioavailabilityHigh expressionOrganic active ingredientsPeptide/protein ingredientsGene deliveryD-glutamic acid

A nucleic acid formulation for use in gene delivery comprising a nucleic acid and an anionic polymer is disclosed. Examples of the anionic polymer includes anionic amino acid polymer or poly-amino acid (such as poly-L-glutamic acid, poly-D-glutamic acid, poly-L-aspartic acid, poly-D-aspartic acid), poly-acrylic acid, polynucleotides, poly galacturonic acid, and poly vinyl sulfate.

Owner:INOVIO PHARMA

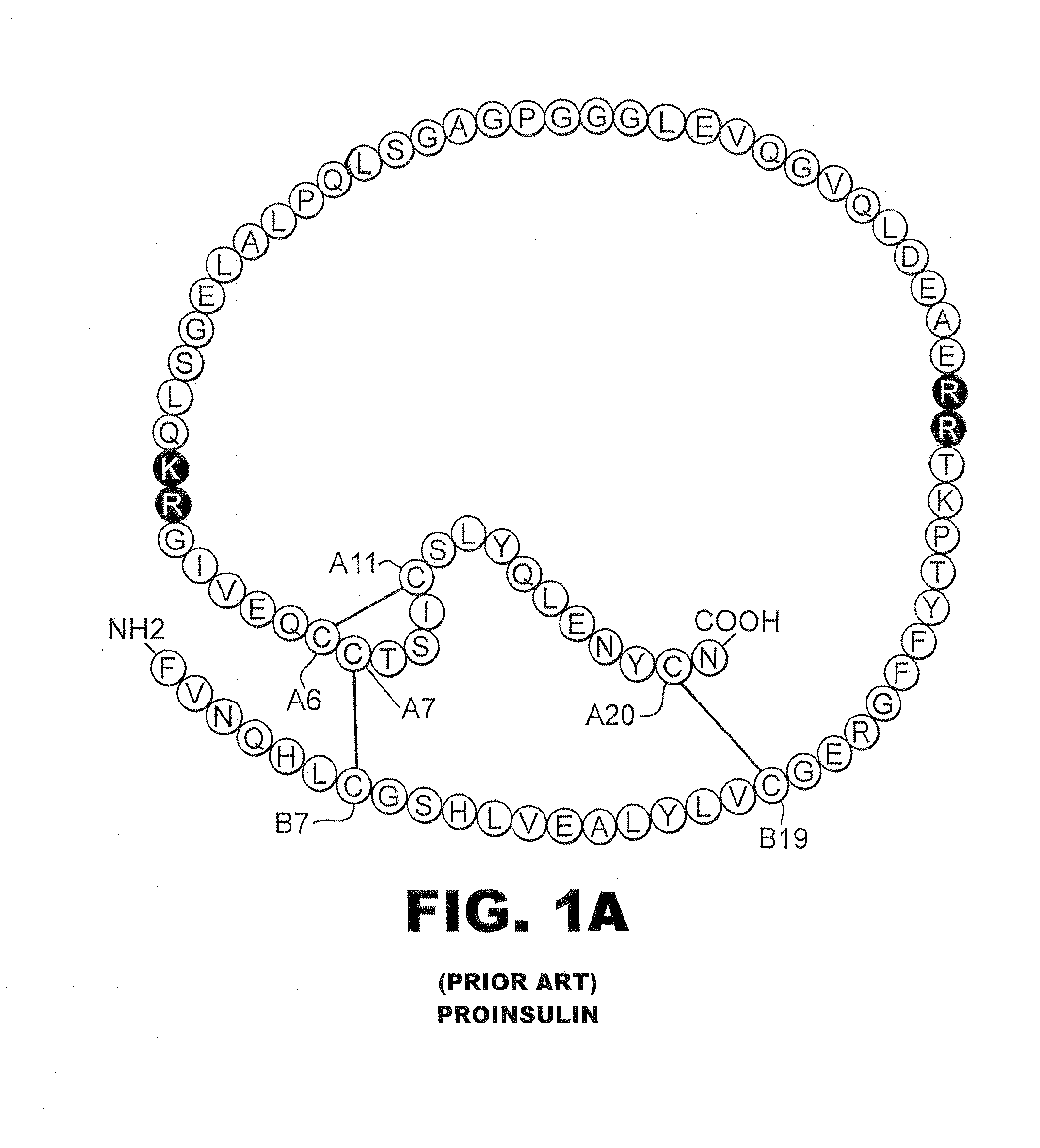

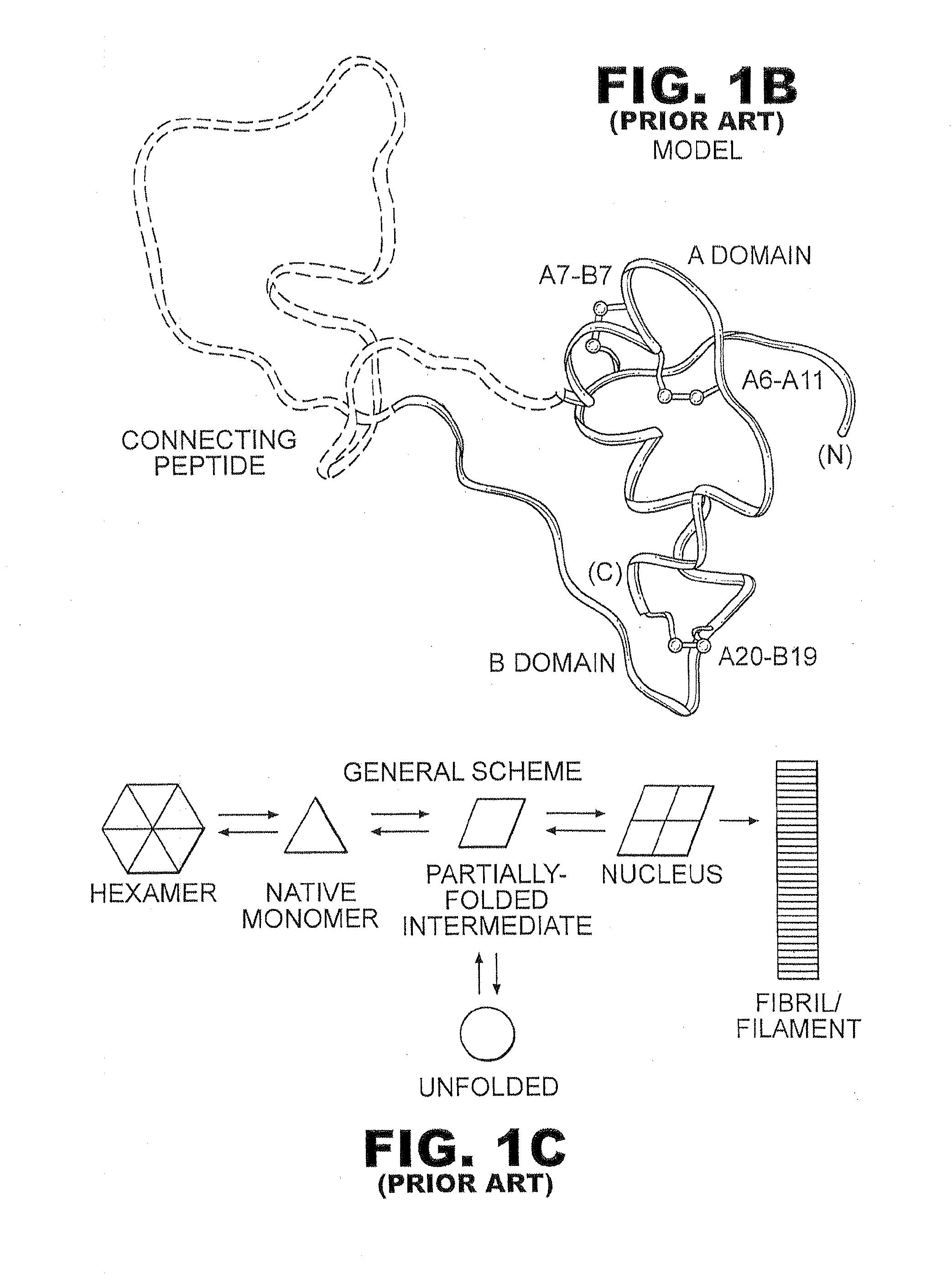

Insulin analogues of enhanced receptor-binding specificity

InactiveUS20120184488A1Good physical propertiesPeptide/protein ingredientsMetabolism disorderInsulin A ChainArginine

A method of treating a patient includes administering a physiologically effective amount of an insulin analogue or a physiologically acceptable salt thereof to the patient. The insulin analogue or physiologically acceptable salt thereof contains an insulin A-chain sequence modified at positions selected from the group consisting of A0, A1, A4, A8, and A21. The insulin analogue may exhibit decreased affinity for the IGF receptor in comparison to wild type insulin of the same species and at least 20% of the affinity of wild-type insulin for the insulin receptor of the same species. Position A0 may be arginine. Position A1 may be D-alanine, D-aspartic acid, or D-leucine. Position A8 may be histidine, lysine, or arginine. Optionally, an insulin B-chain analogue sequence comprises a histidine at position B1. A nucleic acid may encode such an insulin polypeptide.

Owner:CASE WESTERN RESERVE UNIV

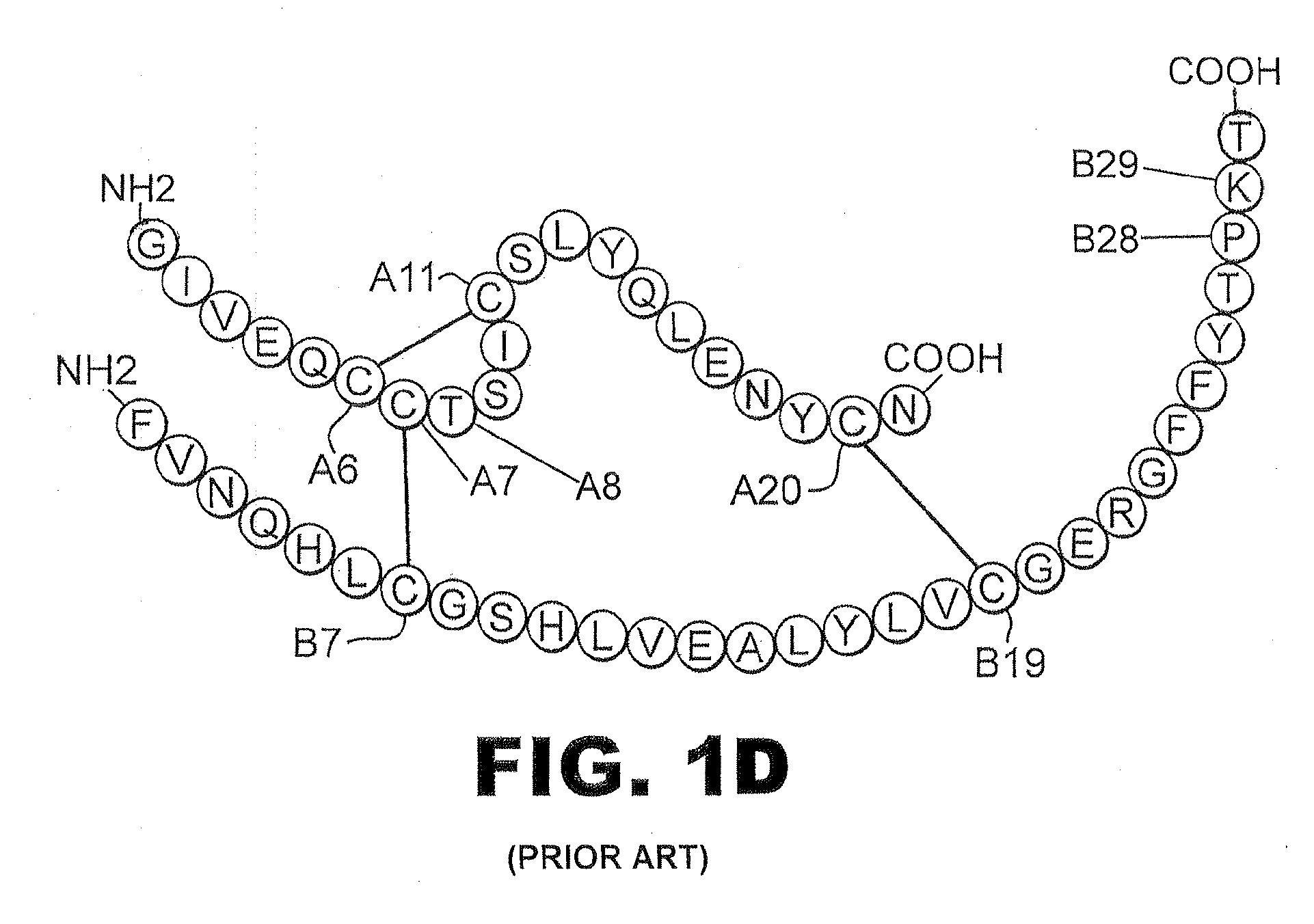

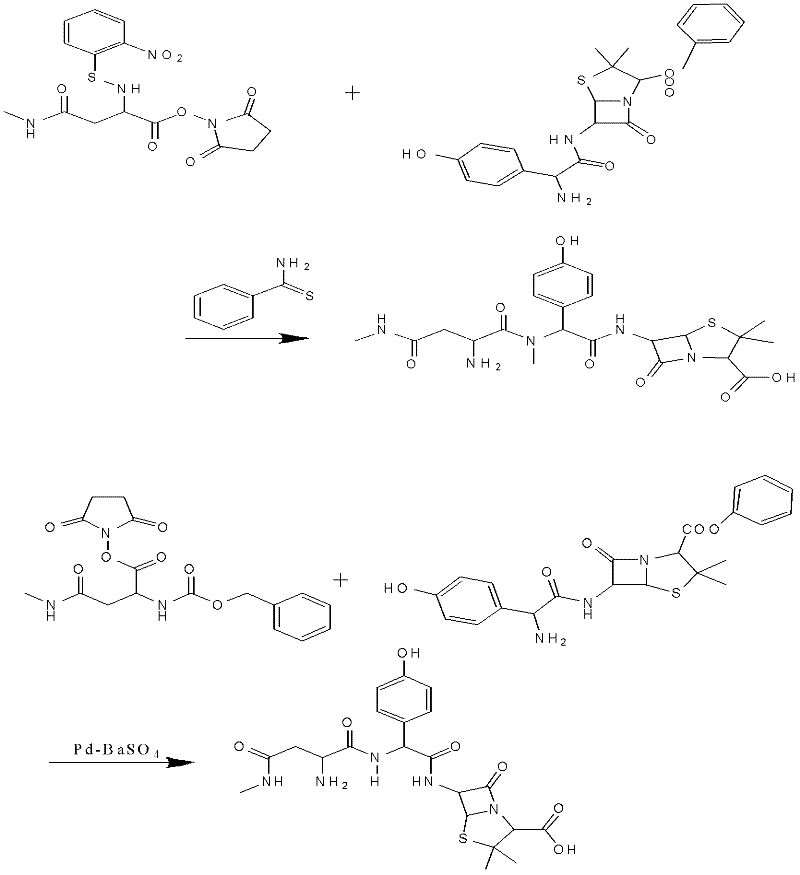

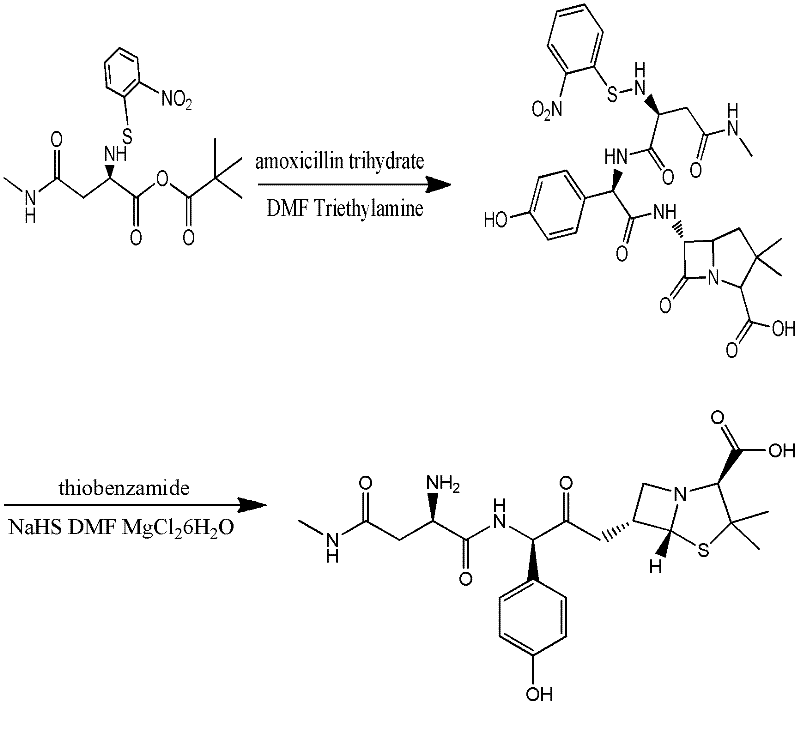

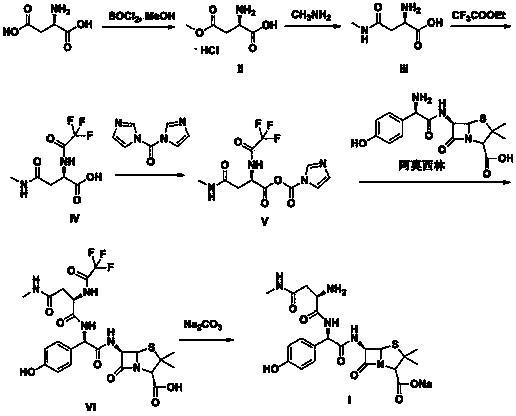

Preparation method for Aspoxicillin

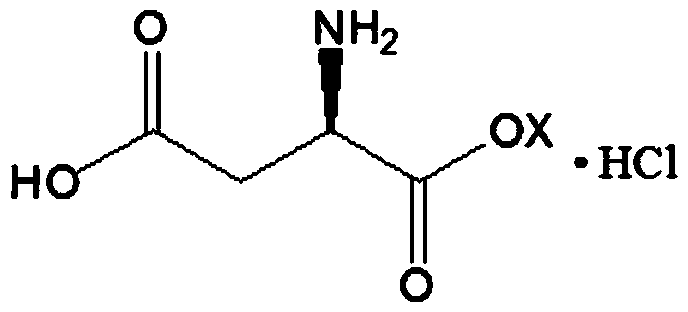

The invention discloses a preparation method for Aspoxicillin. D-aspartic acid is added into a mixture liquid of sulfuryl chloride and carbinol under a low temperature of zero to prepare D-aspartic acid methyl ester hydrochloride; the obtained D-aspartic acid methyl ester hydrochloride and triethylamine are reacted in ethanol to obtain D-aspartic acid methyl ester educt; the D-aspartic acid methyl ester educt and methylamine aqueous liquid with a concentration of 40 percent are reacted in a room temperature to prepare aspartic formamide; the aspartic formamide, ethyl acetoacetate and potassium hydroxide are reacted in isopropanol to prepare diene salt (D-2-amino-3N-methylamino oxo-propionic acid diene formamide); the diene salt and pivaloyl chloride are reacted in acetone under the catalysis of pyridine to obtain active anhydride; then the active anhydride is condensed and further protected by deacidification to obtain a target product-crude product of Aspoxicillin. The preparation method for Aspoxicillin has the advantages of cheap and easily-obtained reagent, lower toxicity and lower environment pressure, stable and simple technological operation and high yield.

Owner:SOUTHWEST JIAOTONG UNIV

Synthesis and preparation process of RGD cyclopeptide

ActiveCN103588863AReasonable workmanshipEasy to operatePeptide preparation methodsCyclic peptidesSide chainTrityl chloride

The invention discloses a synthesis and preparation process of an RGD cyclopeptide in the field of solid-phase polypeptide synthesis. A new method comprises the steps as follows: a 2-chlorine trityl chloride resin is selected and taken as a carrier; D aspartic acid amino acid with a special protection group of a first side-chain carboxyl is grafted firstly; then a linear peptide of an RGD sequence peptide is grafted on the resin; after the last amino acid is grafted, the protection group FMOC of the amino group is not required to be removed by using piperidine, a special catalyst is added, and the side-chain carboxyl protection group of the first D aspartic acid is removed from the resin directly; then piperidine is added, and the amino protection group FMOC of the terminal amino acid is removed; then a condensing agent is directly added to the resin, the carboxyl and the amino group which are exposed at the head end and the tail end of the linear peptide are subjected to dehydration synthesis, so that the cyclopeptide is formed in an amido bond manner; and finally, the cyclopeptide is cut down from the resin directly by using a cutting liquid. The synthesis and preparation process of the RGD cyclopeptide has the advantages as follows: the process is advanced, the operation is simple, the product yield is high, the synthetic efficiency is improved, and the like.

Owner:苏州强耀生物科技有限公司

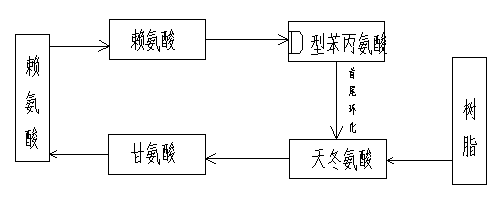

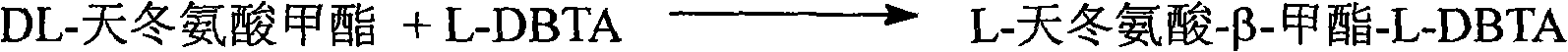

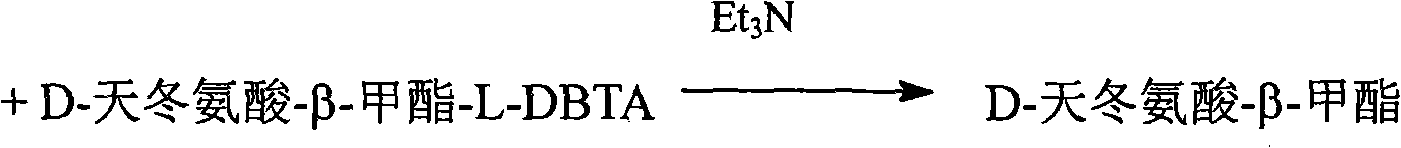

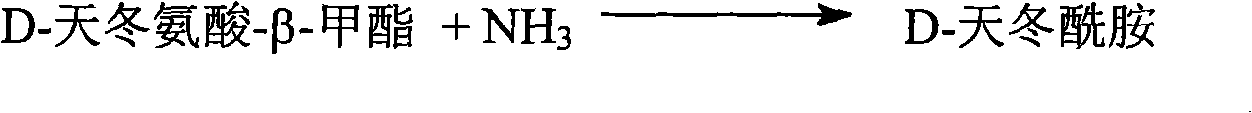

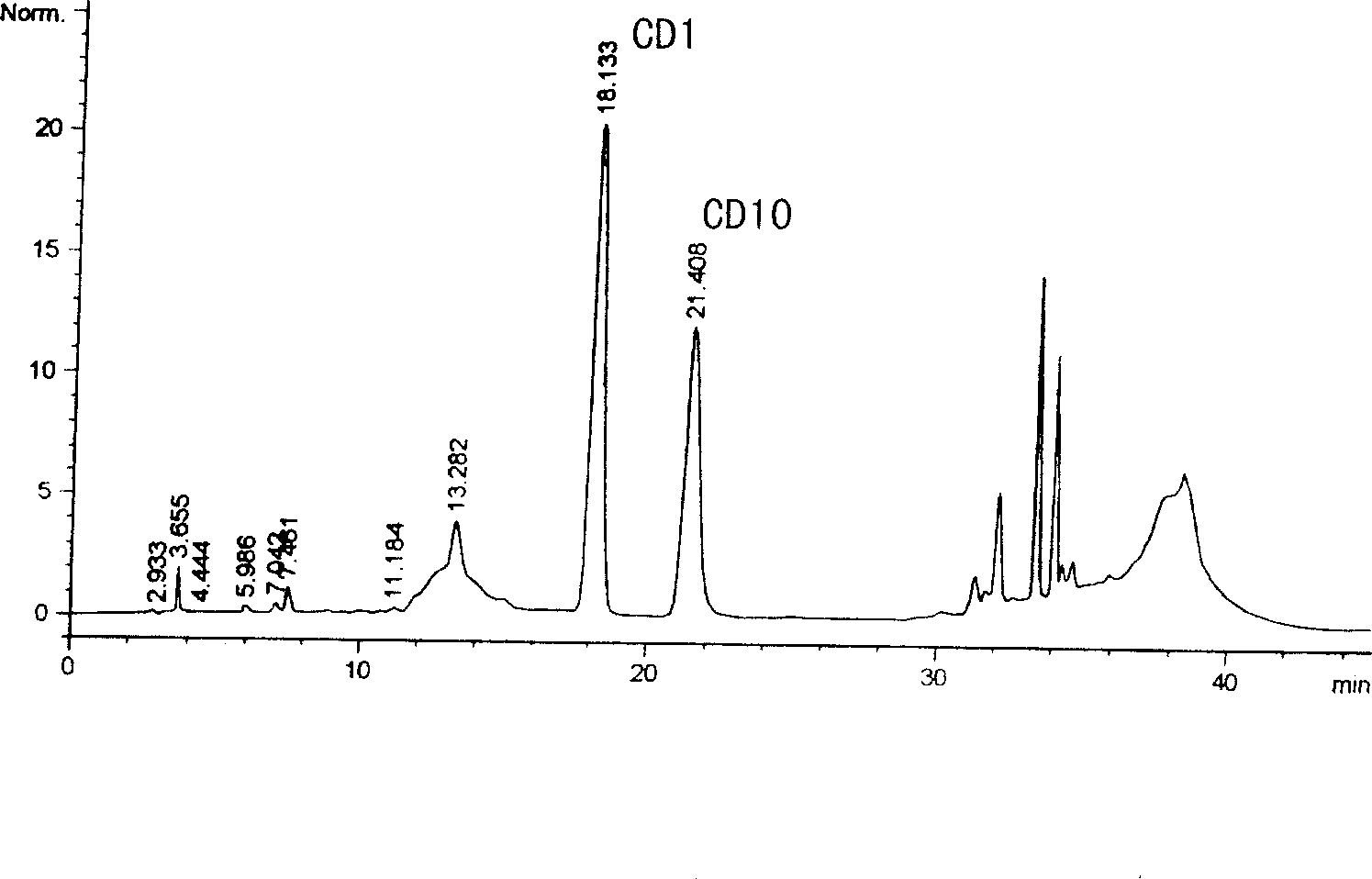

Method for preparing D-asparagine and D-homoserine

InactiveCN101333175AReduce pollutionReduce manufacturing costOrganic compound preparationCarboxylic acid amides optical isomer preparationSolventReducing agent

A preparation method for D-asparagine and D-homoserine comprises the following steps: a, DL-aspartic acid methyl ester is taken as raw material, L-DBTA as resolving agent, water as solvent to carry through resolution reaction for 0.5-5 hours at 40-95 DEG C so as to get D-aspartic acid methyl ester-L-DBTA salt; b, the D-aspartic acid methyl ester-L-DBTA salt is stirred and hydrolyzed for 2-4 hours at room temperature in the presence of alkali to get D-aspartate-beta-methyl ester; c, the D-aspartate-beta-methyl ester is ammonolyzed in a solvent with ammonia gas, ammonia or liquid ammonia to get the D-asparagine; d, the D-aspartate-beta-methyl ester is deoxidized with reductant for 1-10 hours at 0-80 DEG C, neutralized with acid and then concentrated and processed through hydrogen or sodium cation exchange resin to get the D-homoserine. The invention provides a technology which uses cheap DL-aspartate to prepare D-asparagine and D-homoserine through esterification, resolving, ammonolysis, deoxidizing and other processes, thereby laying a solid foundation for the industrial production of two important D-type amino acids.

Owner:SOUTHEAST UNIV

Parenteral and topical compositions for pain

InactiveUS20180000804A1Inorganic non-active ingredientsAnaestheticsAdrenergic receptor agonistsN-methyl-D-aspartate Receptor Antagonists

This invention provides compositions, kits containing compositions, and methods for their use in treating subjects with pain. Instant compositions comprise two or more long acting aminoamide local anesthetics, at least one NSAID, at least one corticosteroid, at least one alpha-2 (α2) adrenergic receptor agonist, at least one N-methyl-D aspartate receptor antagonist, and optionally, epinephrine. Instant compositions are useful for infiltration anesthesia, field block anesthesia, regional anesthesia, peripheral nerve block, plexus anesthesia, epidural (or extradural) anesthesia, spinal anesthesia, local anesthesia, and transincision catheter anesthesia. The instant compositions have one or more superior properties of analgesia, duration of analgesia, safety, narcotic sparing, and motor sparing properties.

Owner:BERKHEIMER DAVID

Corydalis decumbens extract, and its preparing method and use

The present invention discloses a Chinese medicinal material Jilong corydalis extract, its preparation method and application. Said extract contains protopine and L-tetrahydropalmatine, their summation is not less than 50% (W / W), in which the protopine content is 24%-50% (W / W), and the L-tetrahydropalmatine content is 26%-50% (W / W). The pharmological tests show that it can be used as N-methyl-D asparaginic acid acceptor antagonist and acetylcholine esterase inhibibor. Besides, said invention also provides the application of said extract in the preparation of medicine for preventing and curing the hypomnesis due to vascular dementia and senile dementia.

Owner:SHANGHAI HUATUO MEDICAL SCI CO LTD

D-aspartic acid supplement

ActiveUS8202908B1Increase volumeIncreasing testosterone levelBiocideOrganic active ingredientsInsulin-like growth factorGrowth hormone

The physical condition of adult male humans of all ages is improved by administering an effective amount of a D-aspartic acid compound. The administration of this compound increases their levels of testosterone, growth hormone, and / or insulin-like growth factor.

Owner:THERMOLIFE INT

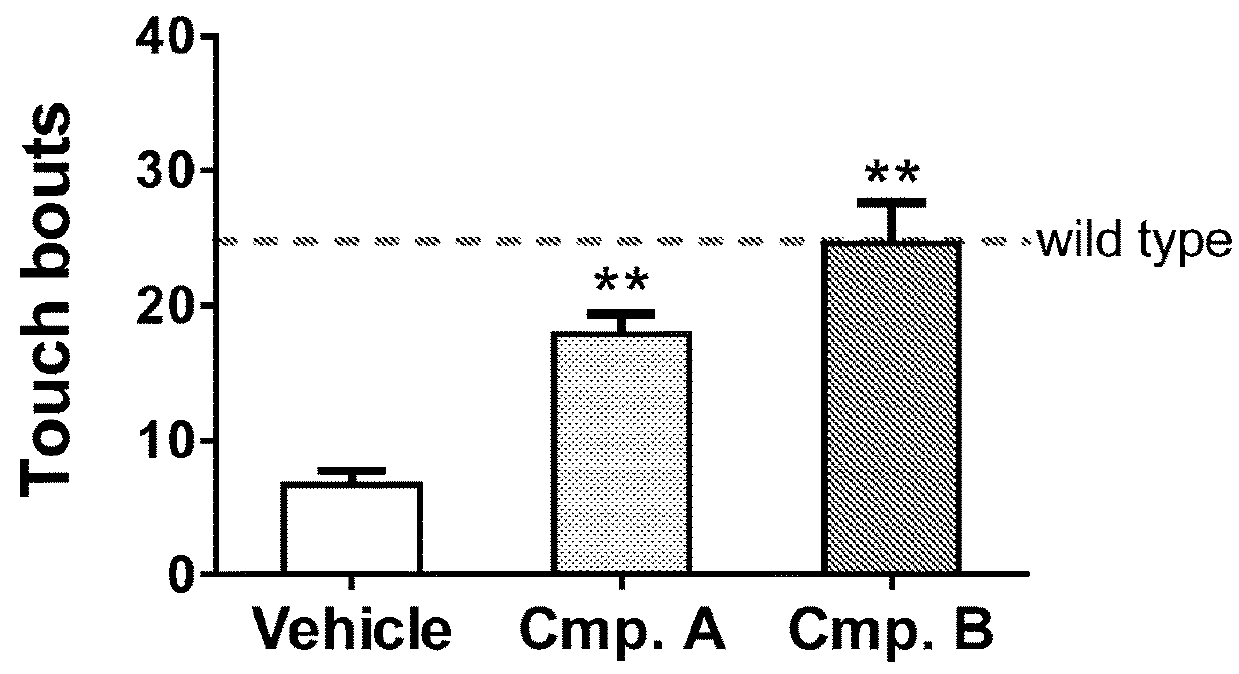

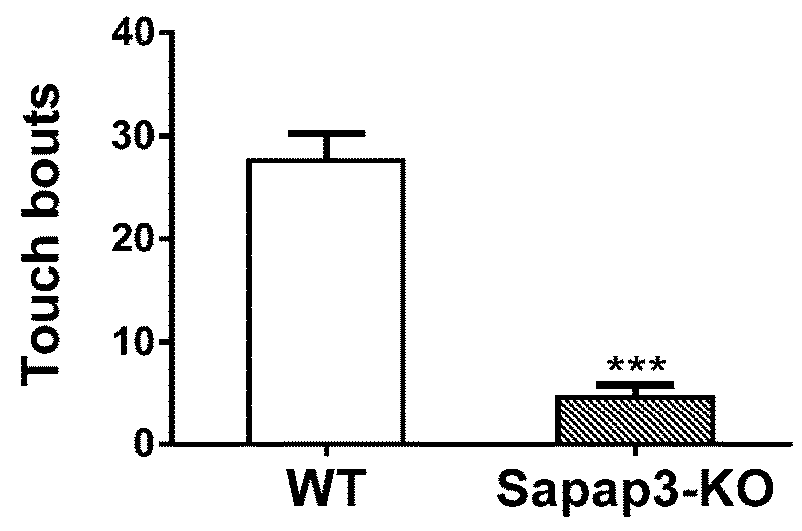

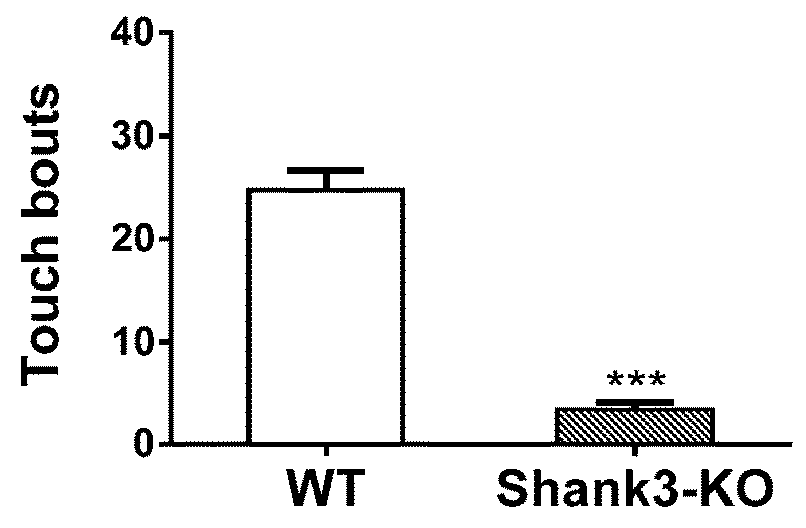

Treatment of anxiety disorders and autism spectrum disorders

InactiveUS20180271869A1Alleviate associated behavioral abnormalityEffective treatmentOrganic active ingredientsNervous disorderGeneralized anxiety disorderRecurrent anxiety

Disclosed are methods for treating autism spectrum disorders and / or anxiety disorders by administering certain NR2B subunit-selective NMDA (N methyl-D aspartate) antagonists. Anxiety disorders include agoraphobia (with or without panic disorder), generalized anxiety disorder (GAD), social anxiety disorder (SAD), panic disorder (PD), post-traumatic stress disorder (PTSD) and obsessive-compulsive disorder (OCD).

Owner:RUGEN HLDG CAYMAN

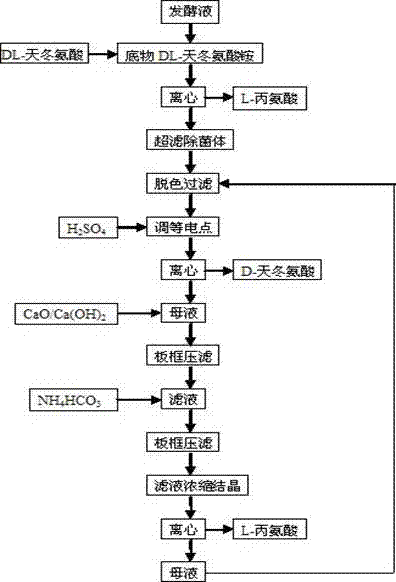

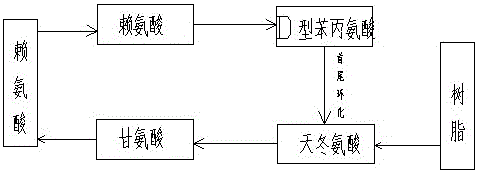

Production technology of D-aspartic acid and L-alanine

InactiveCN102443612AIncrease concentrationIncrease productivityOrganic compound preparationAmino-carboxyl compound preparationHigh concentrationL-Aspartate

The invention relates to a production technology of D-aspartic acid and L-alanine. With DL-aspartic acid ammonium as a substrate, the technology utilizes a fermentation liquid rich in L-aspartic acid-beta-decarboxylase to conduct a conversion reaction so as to produce D-aspartic acid and L-alanine. During the reaction process, fed-batch of DL-aspartic acid is performed continuously to control the pH value of the reaction system, and the substrate concentration can also be doubled, so that finally the concentration of D-aspartic acid in the system can reach 50%. For the generated mother liquid, the technology makes the following treatments: first recovering the L-alanine precipitated from crystallization through centrifugation, then using H2SO4 to adjust isoelectric points so as to separate out D-aspartic acid crystals, then utilizing calcium salt precipitation method to extract L-alanine dissolved in the mother liquid, collecting the mother liquid for circulation of isoelectric points and calcium salt precipitation combined extraction. By means of fed-batch of the substrate, the technology of the invention can produce D-aspartic acid and L-alanine of high concentration, has acid and base consumption reduced by half during production, and has the advantages of simple extraction process, high yield, as well as substantially reduced cost.

Owner:ANHUI HUAHENG BIOTECH

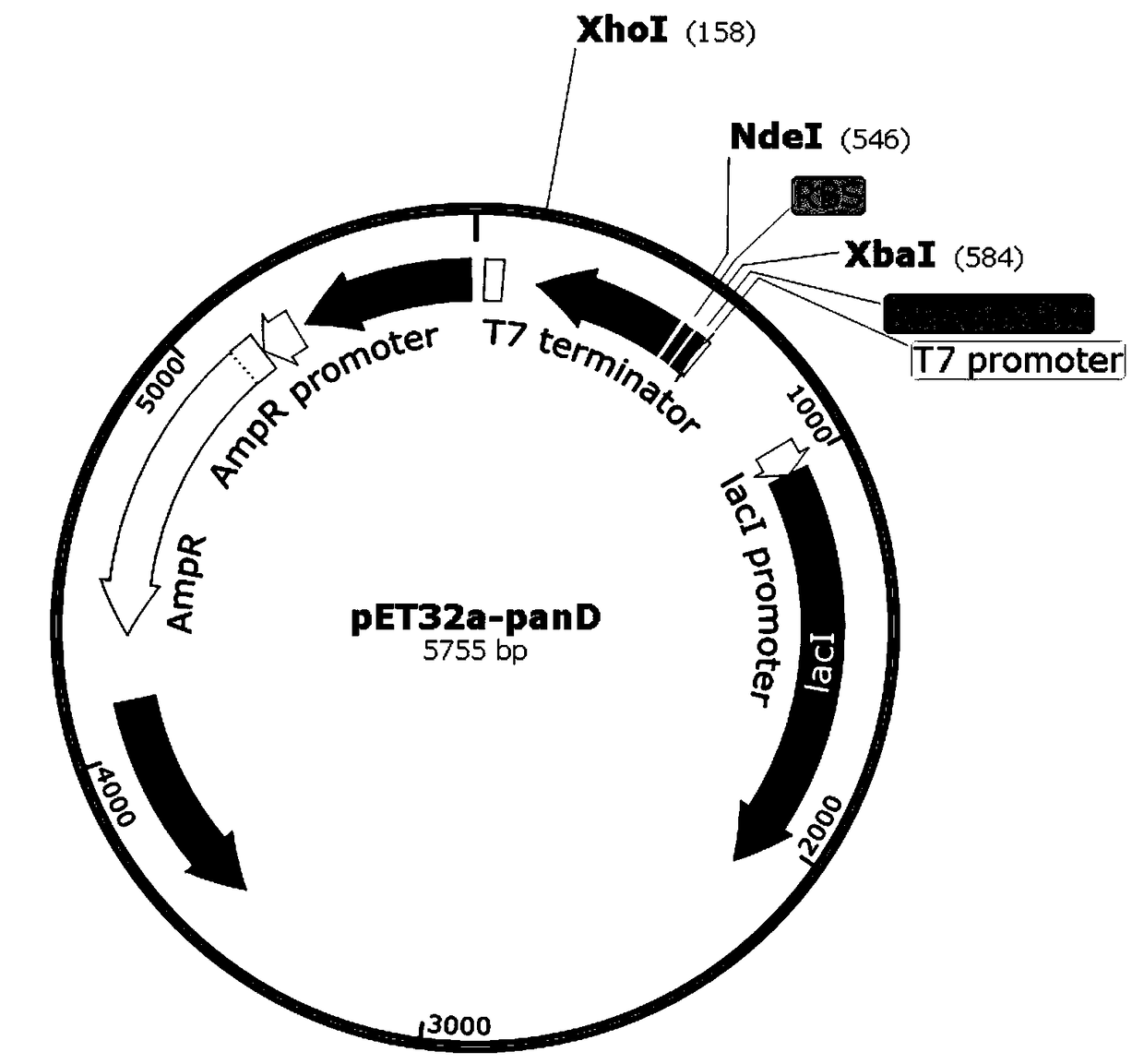

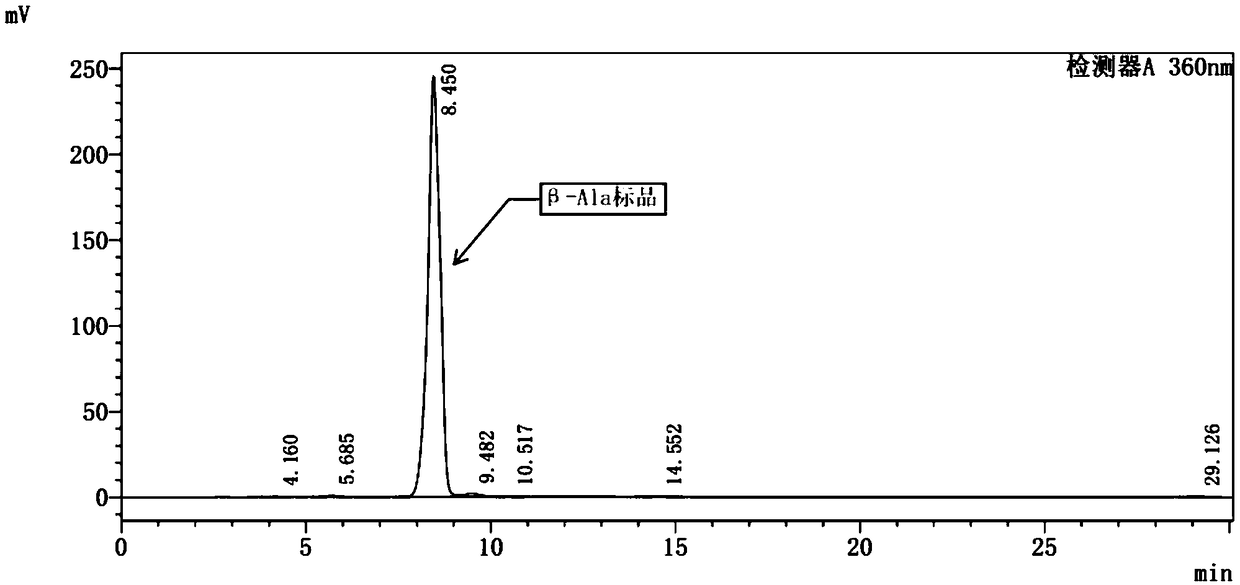

Method for producing beta-alanine and D-aspartic acid through conversion with biological enzyme method

InactiveCN108841883AEasy to operateEasy to controlBacteriaMicroorganism based processesEscherichia coliAspartate decarboxylase

The invention belongs to the technical field of enzyme catalysis, particularly relates to a method for producing beta-alanine and D-aspartic acid through conversion with a biological enzyme method, and aims to solve the problem that existing methods for synthetizing the beta-alanine and the D-aspartic acid with the biological enzyme method are not suitable for industrialization due to the fact that the existing methods are too low in yield or solid substrates are required to be manually and uninterruptedly added in biological conversion processes. According to the technical scheme, the methodcomprises steps as follows: [1] engineered Escherichia coli for overexpression of L-aspartate decarboxylase is obtained through high-density fermentation; [2] biological conversion is performed by theaid of the engineered Escherichia coli by using DL-aspartic acid as a substrate, a DL-sodium aspartate solution is fed for substrate addition during conversion, meanwhile, the pH of the conversion system is controlled through feeding of a DL-aspartate hydrochloride solution, and the beta-alanine and the D-aspartic acid are obtained. The beta-alanine can be synthetized separately by replacing thesubstrate with L-aspartic acid. The method is applicable to synthesis of the beta-alanine and D-aspartic acid.

Owner:SICHUAN TONGSHENG BIOTECH

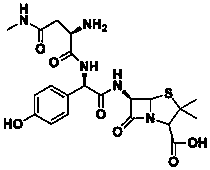

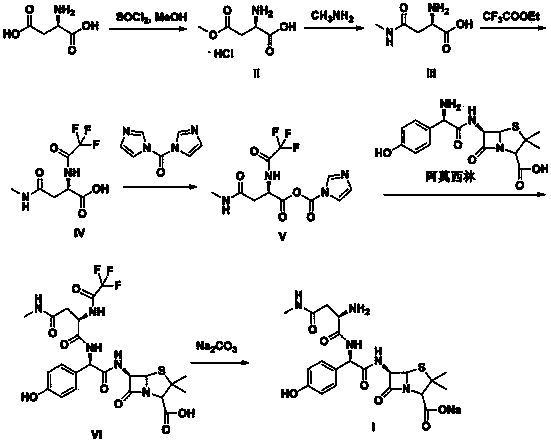

Convenient method for preparing aspoxicillin sodium

ActiveCN103992337ARelieve pressureImprove responseOrganic chemistryBulk chemical productionCarbonyldiimidazoleSodium salt

The invention discloses a convenient method for preparing aspoxicillin sodium. The method comprises the steps of adding D-aspartic acid into a mixed solution of thionyl chloride and methanol, reacting to prepare D-aspartic acid methyl ester hydrochloride, reacting the D-aspartic acid methyl ester hydrochloride with an aqueous solution of methylamine to obtain aspartic formamide, protecting the first amino on the aspartic formamide by using trifluoroacetyl, then reacting the aspartic formamide with carbonyldimidazole to form an active mixed acid anhydride, condensing the active mixed acid anhydride with an amoxicillin triethylamine salt, finally removing the protective ground and forming a sodium salt under the alkali condition to obtain a crude aspoxicillin product of the target product, and refining the crude product to obtain the high-purity aspoxicillin sodium finished product. The method has the advantages that the reagents are cheap, readily available and low in toxicity and environmental pressure, the process operation is compact and stable, the purity of the product is high and the like.

Owner:NANJING YOUKE BIOLOGICAL MEDICAL RES +2

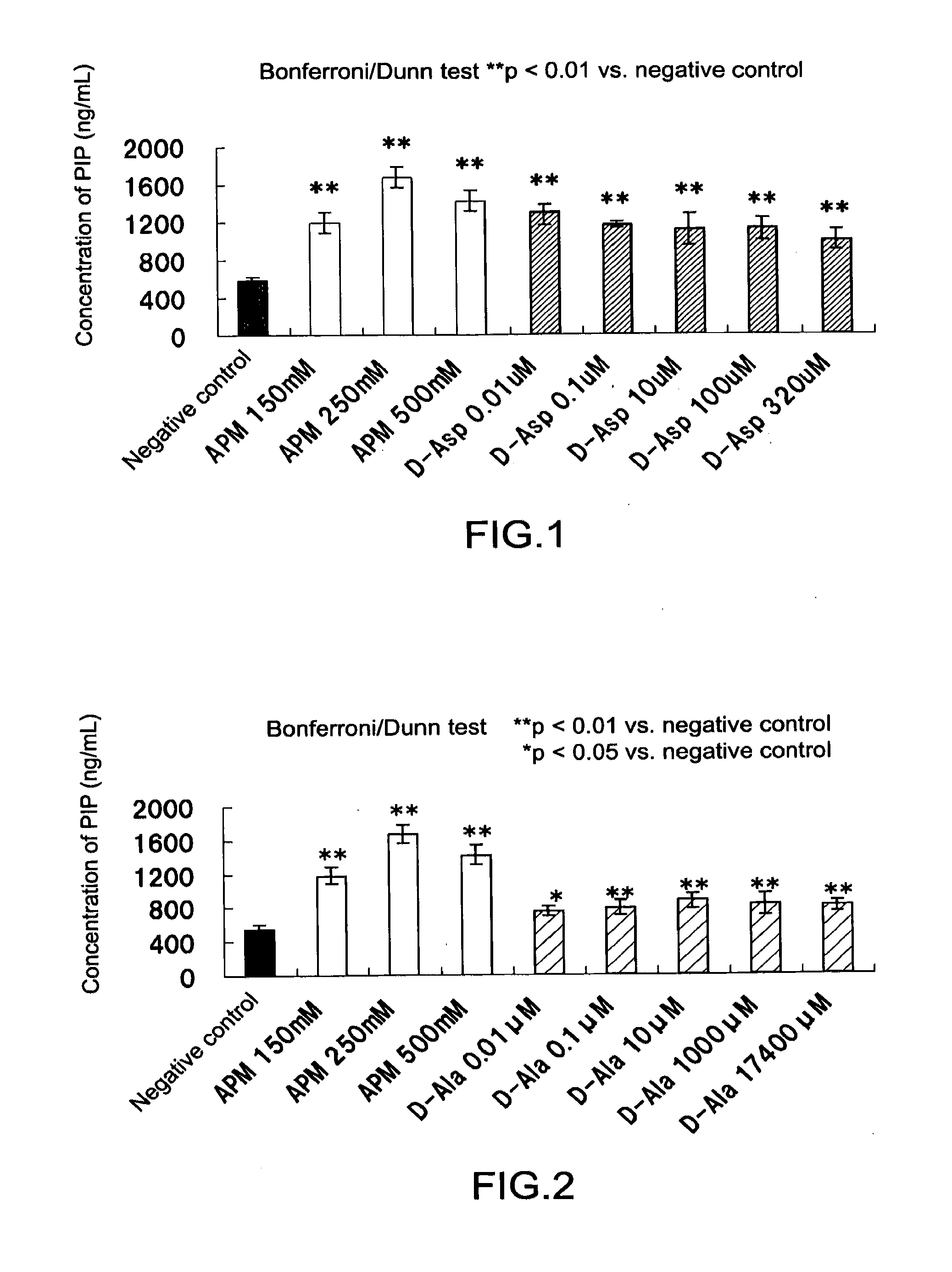

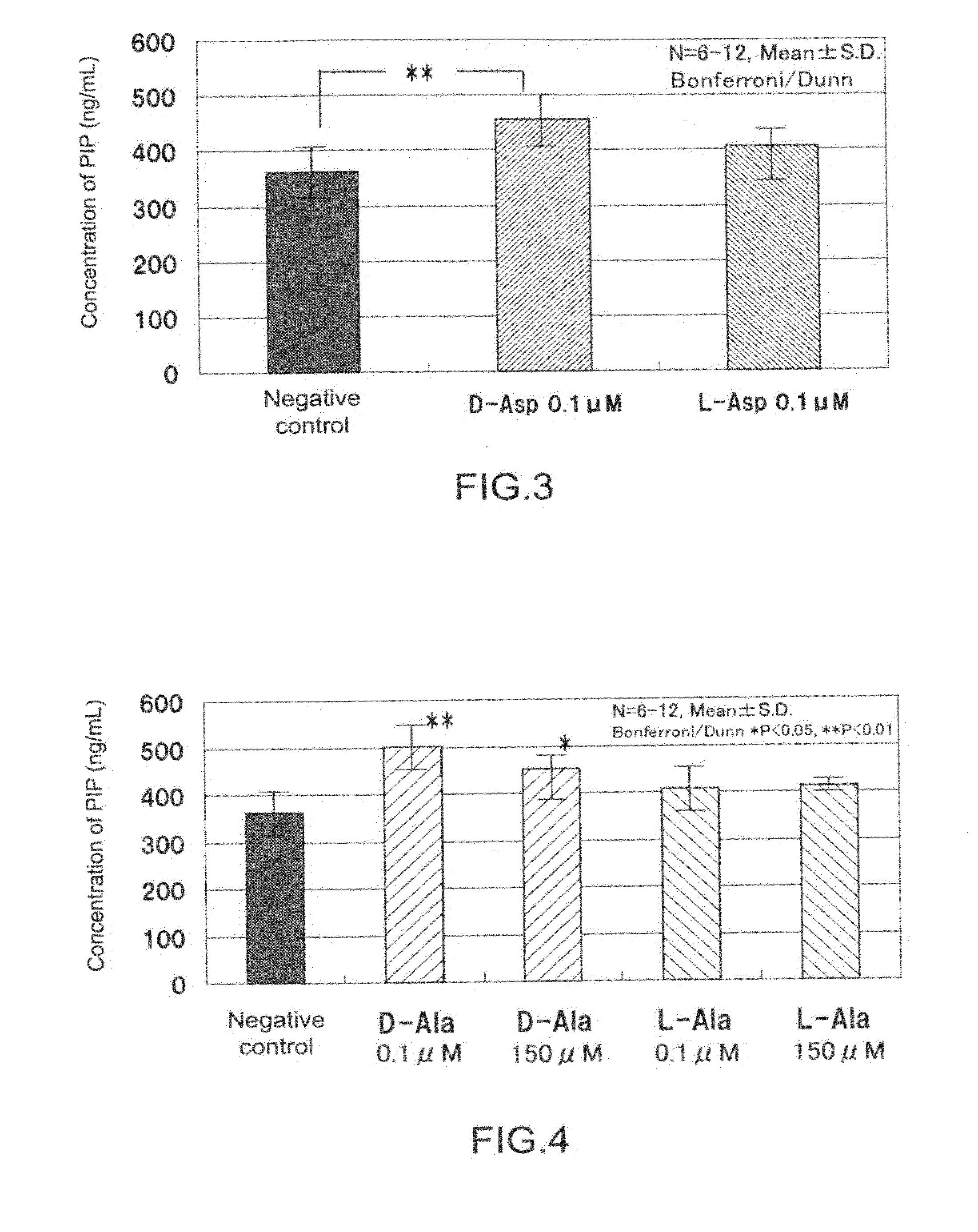

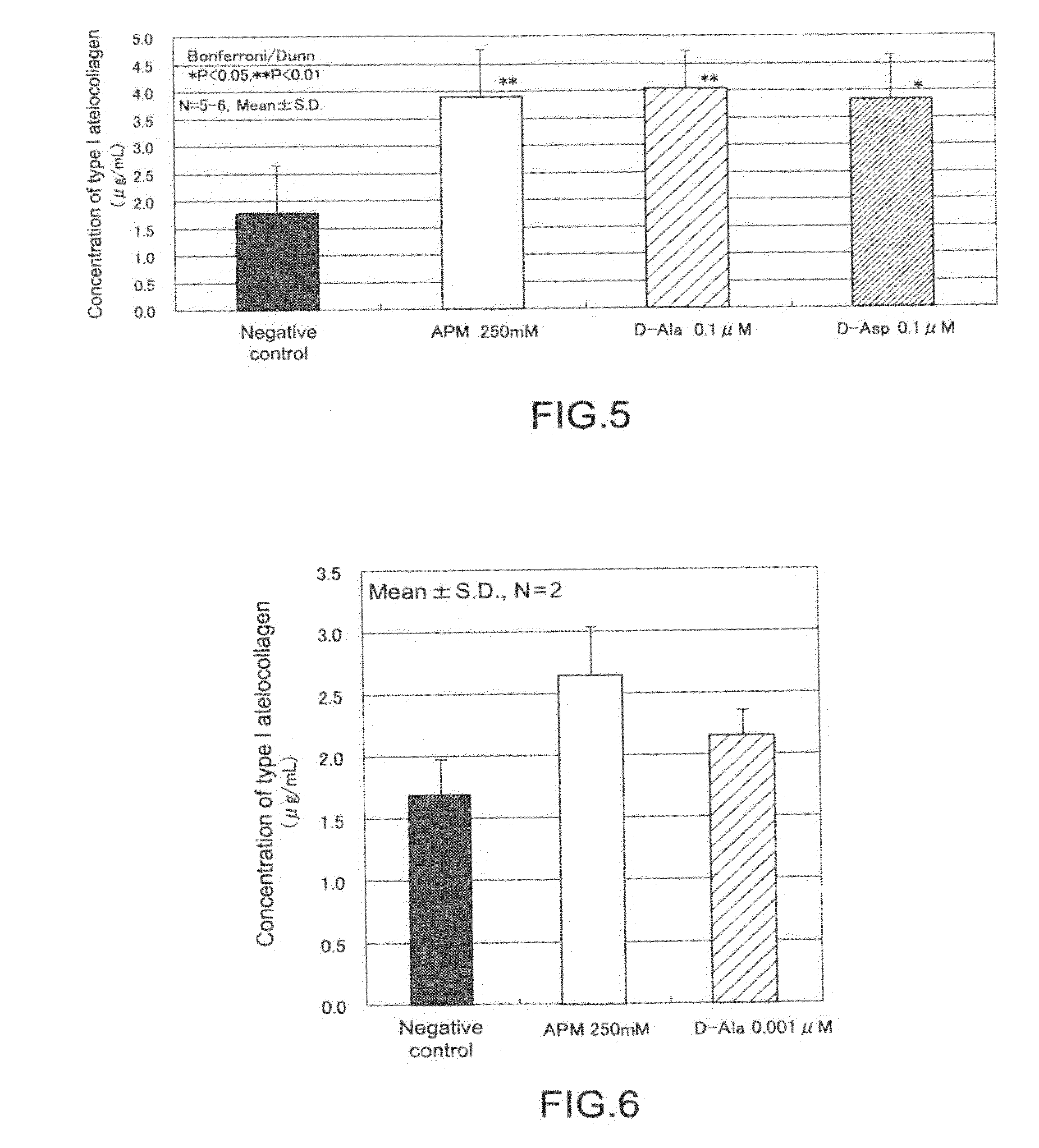

Composition for promoting collagen production

ActiveUS20120184619A1Low costPromotes collagen productionCosmetic preparationsBiocideWrinkle skinType I Procollagen

Disclosed is a novel composition which has an effect on promoting production of collagen. The composition has high photostability and is free from side effects such as those of retinoids. Specifically disclosed is a composition for promoting collagen production which contains one or more compounds selected from the group consisting of D-aspartic acid, D-alanine, derivatives and / or salts thereof. The composition may be used for the purpose of suppressing and / or improving skin a condition. The skin condition may include but is not limited to photoaging and / or wrinkles. The composition may be used for an external preparation for the skin or food. The composition may be a composition for promoting type I collagen production.

Owner:SHISEIDO CO LTD

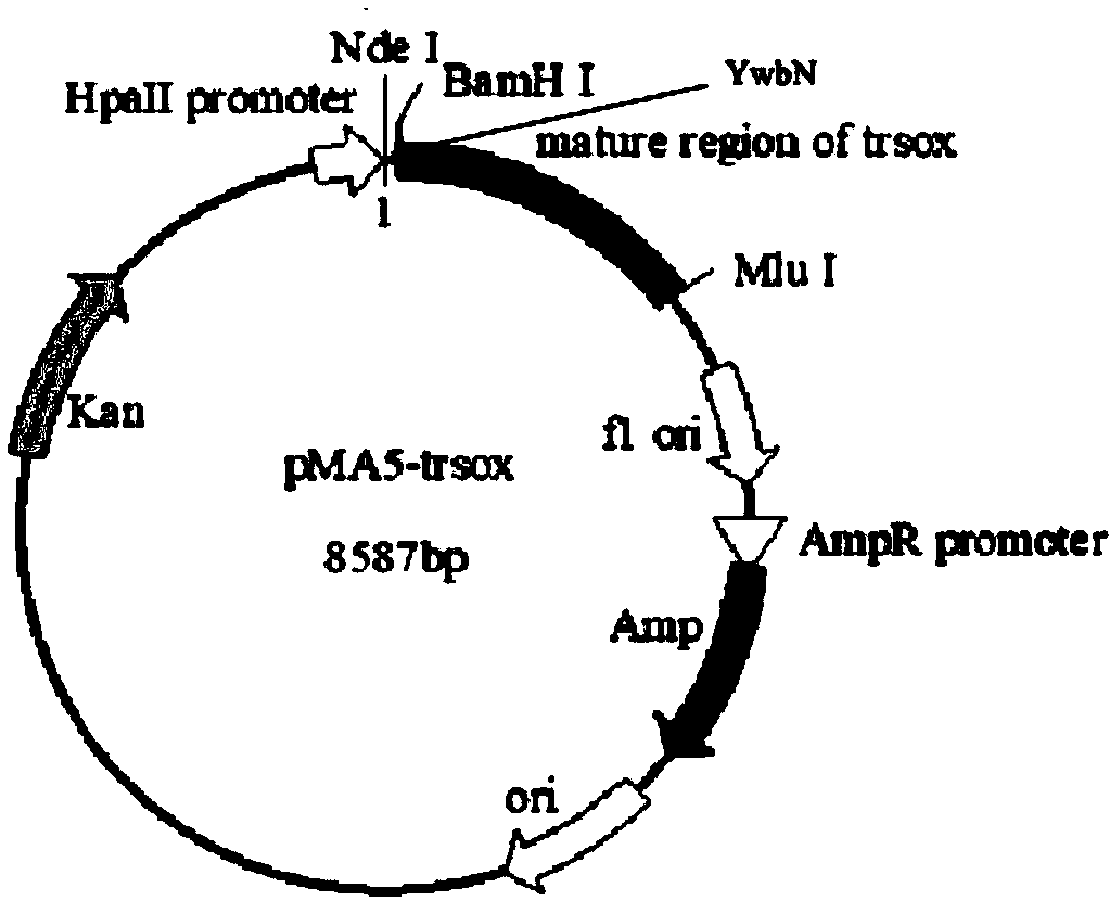

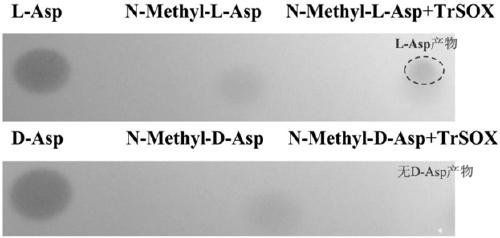

Method for enzymatic resolution of N-methyl-D-aspartic acid

ActiveCN109628519AStrong chiral selectivityQuick split preparationFermentationChiral selectivityMethyl group

The invention discloses a method for enzymatic resolution of N-methyl-D-aspartic acid. The method comprises the following steps that 1, thermomicrobiumroseum sarcosine oxidase genes are constructed into pMA5-YwbN-trsox plasmids and transformed into Bacillus subtilis WB600 cells for secretory expression; 2, Bacillus subtilis WB600 cells transfected with the pMA5-YwbN-trsox gene plasmids are fermented, supernatant of the obtained culture solution is mixed with an N-methyl-DL-aspartic acid solution for chiral selective biocatalysis of N-methyl-L-aspartic acid; 3, an isoelectric point crystallization method is used for separation, and N-methyl-D aspartic acid is obtained.

Owner:JIANGNAN UNIV

Preparation method for agent capable of promoting growth gene expression of pigs

InactiveCN106916076ANo pollution in the processPromote growthOrganic compound preparationAmino-carboxyl compound preparationLean meatMethyl group

The invention discloses a preparation method for an agent capable of promoting growth gene expression of pigs. The invention relates to synthesis of amino acid derivatives, specifically to a preparation method for a growth-gene-expression promoting agent N-methyl-D-aspartic acid, i.e., a derivative of D-aspartic acid. The preparation method comprises the following steps: with D-aspartic acid as a raw material, reacting D-aspartic acid with methanol and thionyl chloride so as to produce dimethyl-D-aspartate hydrochloride; then subjecting dimethyl-D-aspartate hydrochloride and 40% formaldehyde to hydroxymethylation under an alkaline condition so as to produce N-hydroxymethyl-D-aspartic acid; and then carrying out hydrogenation at normal temperature and normal pressure under the action of a Pd / C catalyst so as to obtain N-methyl-D-aspartic acid. The preparation method is simple; the prepared N-methyl-D-aspartic acid is stable in quality; no environmental pollution is produced during preparation; and the prepared N-methyl-D-aspartic acid can promote the growth of livestock and poultry, improves the utilization rate of feeds, the carcass quality of pigs and the rate of lean meat, and is convenient for promotion and application.

Owner:CHANGSHA POWERLIFE BIOTECH

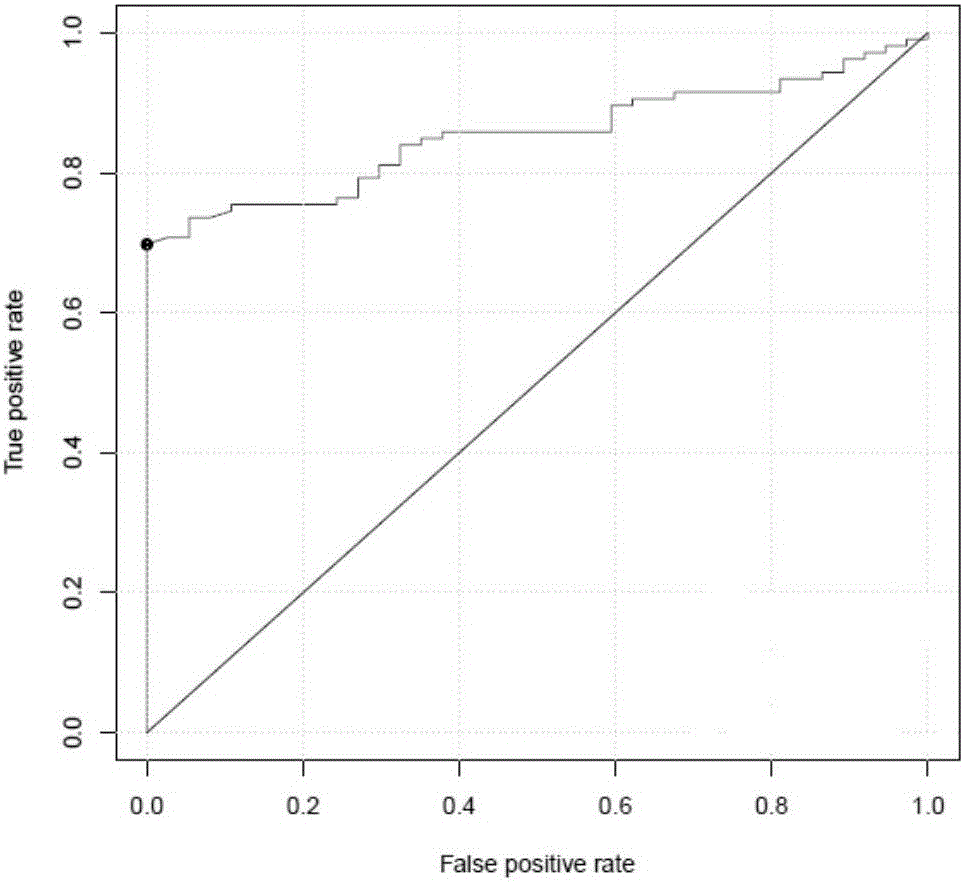

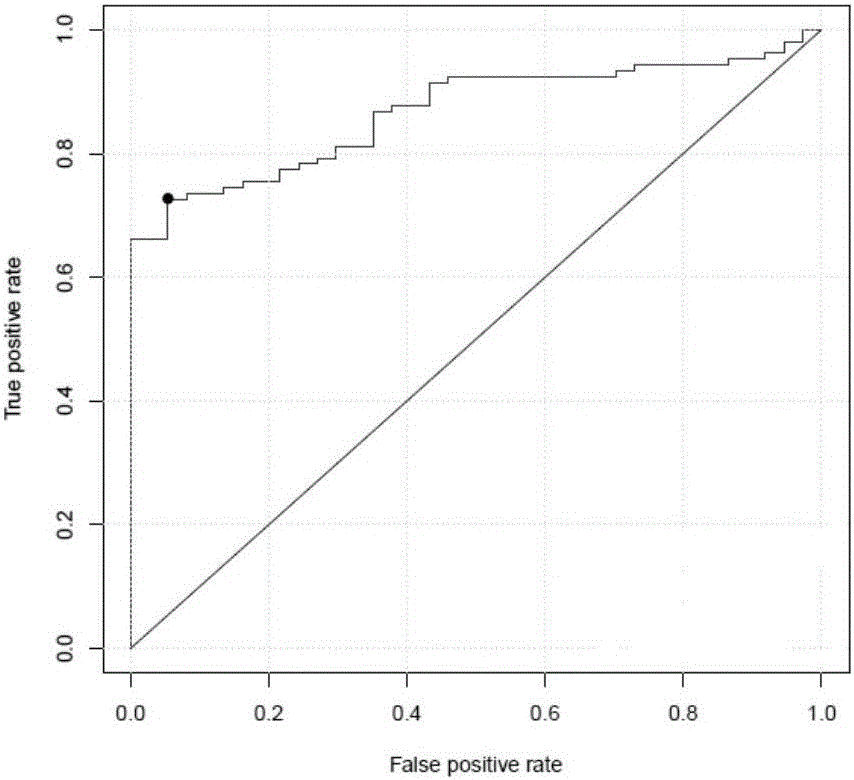

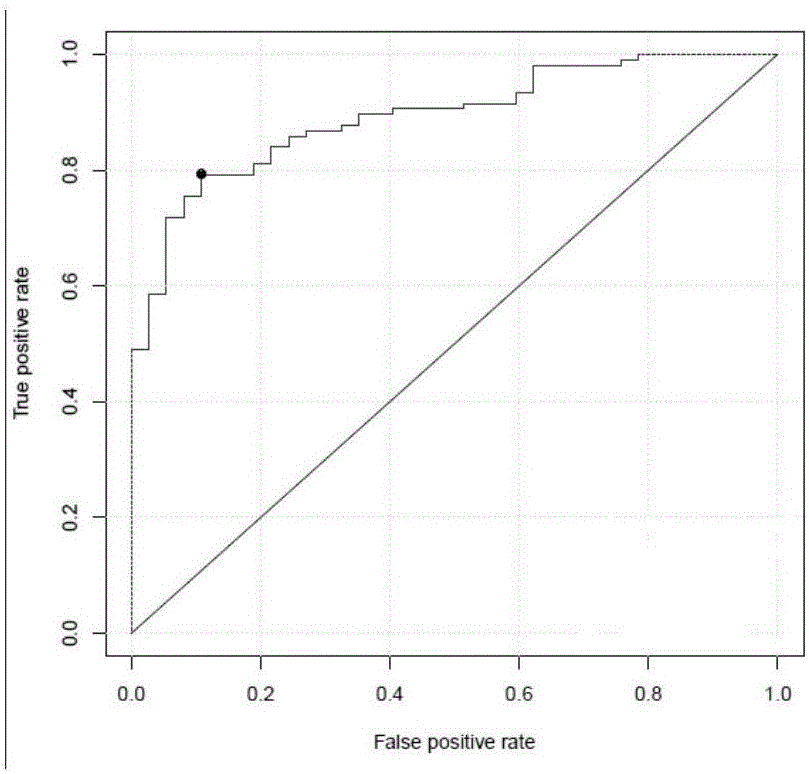

Primary liver cancer accompanying bile duct cancer embolus biomarker and application thereof

The invention provides a marker used for distinguishing primary liver cancer accompanying bile duct cancer emboli from bile duct system diseases. The sensitivity and specificity obtained when five indexes, namely 5,6-dihydrouracil, D-aspartic acid, stearic acid, docosanoic acid and tetracosanoic acid, are combined are effective and reach 99.06% and 0 respectively compared with those obtained in single-index diagnosis.

Owner:上海百趣生物医学科技有限公司

Composite biological preservative and preparation method thereof

InactiveCN107212236AWide range of antibacterialGood antibacterial effectClimate change adaptationFood preservationEscherichia coliVitamin B12

The invention discloses a composite biological preservative and a preparation method thereof. The composite biological preservative is prepared from N-benzyloxycarbonyl-D-aspartic acid, nisin, L-polylysine, vitamin B12, chromium nicotinate, sodium glycine fumarate, Oleum Ocimi gratissimi, powder of Lycoperdon, powder of Smilax glabra, powder of Nardostachyos roots and rhizomes, silica powder, organic acid, borneol, disodium ethylene diamine tetraacetate and distilled water. The composite biological preservative provided by the invention has a wide bacteriostatic scope, exerts good bacteriostatic effect on Gram-negative bacteria, saccharomycetes, Escherichia coli and Staphylococcus aureus, and is low in dependence on the pH value and temperature of environment and wide in an application scope.

Owner:苏州凌科特新材料有限公司

Environment friendly quenching agent used for abrasion-resistant alloy machining and preparation method thereof

The invention discloses an environment friendly quenching agent used for abrasion-resistant alloy machining. The environment friendly quenching agent used for abrasion-resistant alloy machining is composed of the following raw materials including, by weight, 5-13 parts of ethyl alcohol, 2-7 parts of acetic acid ester, 0.5-1.4 parts of stearic acid, 7-10 parts of sodium sulfate, 2-4 parts of potassium hydroxide, 15-26 parts of sweet potato starch, 3-8 parts of 6-acetyl oxygen methyl-2,2-dimethyl-1,2-dioxolame-tert-butyl acetate, 5-10 parts of D-aspartic acid, 10-17 parts of palm oil and 8-12 parts of polyethylene glycol. The stearic acid, the sweet potato starch and the palm oil are dissolved in ethyl alcohol firstly, and a mixed solution is obtained; then the mixed solution is added with water and transferred into a reaction still; after the reaction is finished, temperature reduction is conducted, the acetic acid ester and the 6-acetyl oxygen methyl-2,2-dimethyl-1,2-dioxolame-tert-butyl acetate are added, and still standing is conducted after stirring; then centrifugation is conducted, and a liquid supernatant is taken after centrifugation; and the sodium sulfate, the potassium hydroxide, the D-aspartic acid and the polyethylene glycol are added, temperature rising, thermal insulation, temperature reduction and mouth sealing through paraffin oil are conducted after even stirring, and the environment friendly quenching agent is obtained. The prepared environment friendly quenching agent used for abrasion-resistant alloy machining can greatly improve abrasive resistance of alloys.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

Synthesis and preparation process of rgd cyclic peptide

ActiveCN103588863BReasonable workmanshipEasy to operatePeptide preparation methodsCyclic peptidesCyclic peptideAmino acid side chain

Owner:苏州强耀生物科技有限公司

Parenteral and topical compositions for pain

InactiveUS10143685B2Powder deliveryInorganic non-active ingredientsAdrenergic receptor agonistsSpinal anesthetic

Owner:BERKHEIMER DAVID

D-aspartic Acid Pro-nutrients with Improved Solubility Characteristics

InactiveUS20120270943A1Increase profitEasy to useBiocideOrganic active ingredientsNasal sprayEthyl ester

D-aspartic acid is prepared as its hydrochloride salt or as the hydrochloride salt of its diethyl ester, thereby providing soluble forms of D-aspartic acid that are readily taken up by a human body via its digestive tract. The D-aspartic acid is administered as pills, capsules, powdered drink mixes, beverages, confectionaries, syrups, chewable tablets, nasal sprays, or injectable formulations.

Owner:KIM KYUNG SUK +1

Quenching agent for abrasion-resistant alloy processing

The invention discloses a quenching agent for abrasion-resistant alloy processing. The quenching agent for abrasion-resistant alloy processing comprises, by weight, 5-13 parts of polyether, 2-7 parts of laurate, 0.5-1.4 parts of stearic acid, 7-10 parts of sodium benzoate, 2-4 parts of potassium chloride, 15-26 parts of corn starch, 3-8 parts of 6-acetyl oxygen methyl-2,2-dimethyl-1,3- dioxolame-tert-butyl acetate, 5-10 parts of D-aspartic acid, 10-17 parts of palm oil, and 8-12 parts of polyethylene glycol. Firstly, the stearic acid, the corn starch and the palm oil are dissolved in the polyether, so that mixed liquor is obtained; secondly, water is added, the mixed liquor is transferred into a reaction kettle, after the reaction is completed, the temperature is decreased, the laurate and the 6-acetyl oxygen methyl-2,2-dimethyl-1,3- dioxolame-tert-butyl acetate are added, and standing is conducted after stirring; thirdly, centrifugation is conducted, supernate is obtained after centrifugation, the sodium benzoate, the potassium chloride, the D-aspartic acid and the polyethylene glycol are added, the temperature is increased, maintained and then decreased after even stirring, sealing is conducted through paraffin oil, and then the quenching agent is obtained. The prepared quenching agent can greatly improve the abrasion resistance of alloy.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

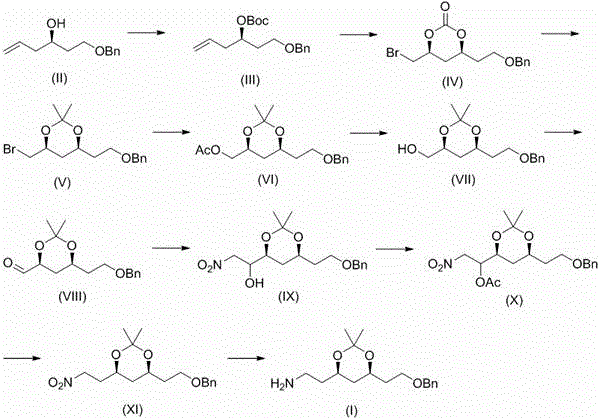

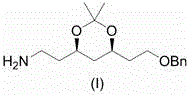

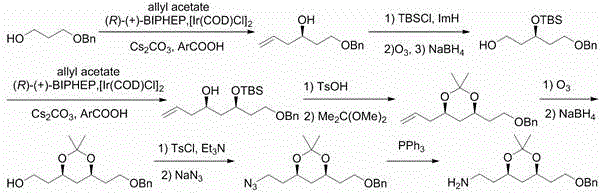

Preparation method of atorvastatin measuring chain intermediate

ActiveCN106496182ARaw materials are easy to getMild reaction conditionsOrganic chemistryTert-Butyloxycarbonyl protecting groupNitromethane

The invention belongs to the technical field of organic chemistry and concretely relates to a preparation method of an atorvastatin measuring chain intermediate 2-((4R, 6S))-6-(2-(benzyloxy)ethyl)-2, 2-dimethyl-1, 3-dioxane-4-yl)ethylamine (I). The preparation method comprises that, through tert-butoxycarbonylation, intramolecular bromination cyclization, acetonide protection, acetylation, hydrolysis and oxidation, an aldehyde is prepared from (R)-1-benzyloxy-hex-5-en-3-ol (II) prepared from D-aspartic acid by tert-butoxycarbonylation, and through a Henry reaction, acetylation and reduction, the desired compound 2-((4R, 6S))-6-(2-(benzyloxy)ethyl)-2, 2-dimethyl-1, 3-dioxane-4-yl)ethylamine (I) is prepared from the aldehyde and nitromethane. The preparation method utilizes easily available raw materials, is carried out under mild reaction conditions, can be simply operated and is convenient to use in industrial production.

Owner:FUDAN UNIV

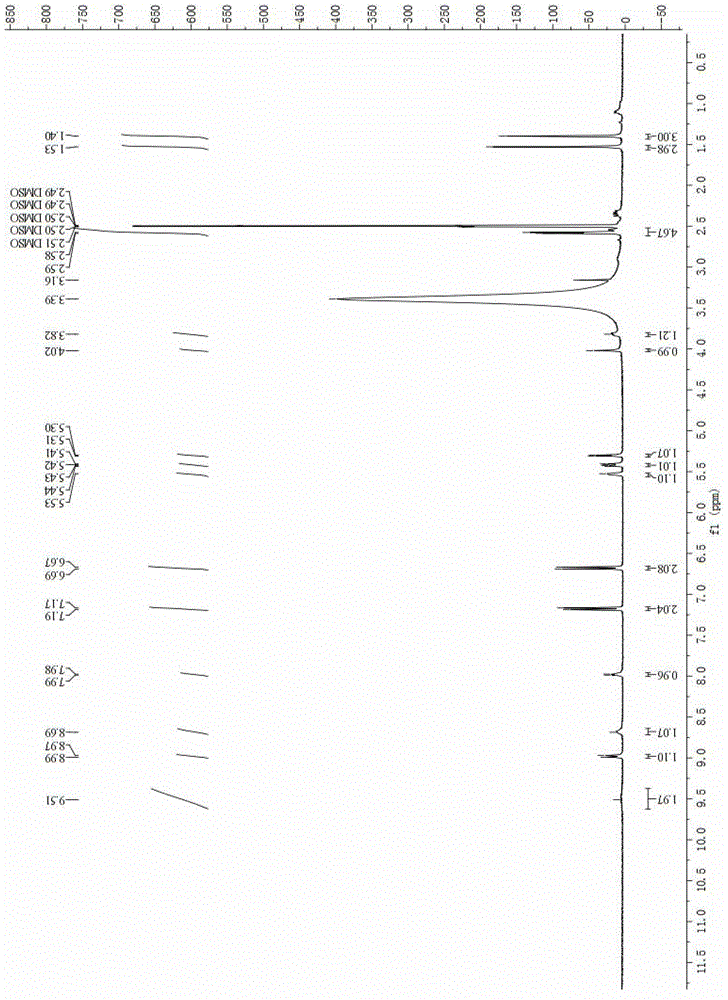

D-aspartic acid derivative and preparation method thereof

The invention relates to the technical field of pharmacy, in particular to a preparation method of a D-aspartic acid derivative. The derivative is formed by a reaction of D-aspartic acid and liquid monohydric alcohol or organic acid. The reaction condition is simple, scale production is easy to achieve, the reaction time can be shortened significantly, the conversion rate can be 96% or above, there are few impurities in the reaction products, and the purity can reach 95% or above.

Owner:JING JING PHARMA

A kind of preparation method of apoxicillin trihydrate

The present invention discloses an aspoxicillin trihydrate preparation method, which comprises: 1, carrying out a reaction of D-aspartic acid and BTC in methanol, and adding a solvent after completing the reaction to precipitate aspartic acid-beta-methyl ester hydrochloride; 2, carrying out a reaction of the aspartic acid-beta-methyl ester hydrochloride and a methylamine solution to produce D-aspartic acid-beta-formamide, adding a solvent in a dropwise manner after completing the reaction to precipitate the D-aspartic acid-beta-formamide crude product, and carrying out recrystallization and drying on the D-aspartic acid-beta-formamide crude product to obtain the D-aspartic acid-beta-formamide; 3, carrying out a reaction of the D-aspartic acid-beta-formamide and BTC in a solvent to produce D-aspartic acid-N-cyclic anhydride, and adding a solvent after completing the reaction to precipitate the D-aspartic acid-N-cyclic anhydride; and 4, carrying out a reaction of the D-aspartic acid-N-cyclic anhydride and amoxicillin in a solvent of acetonitrile and a sodium hydroxide aqueous solution to remove one molecule of carbon dioxide to prepare an aspoxicillin crude product, and carrying out decoloration, recrystallization, filtration and drying on the aspoxicillin crude product to obtain the aspoxicillin trihydrate.

Owner:ZHEJIANG APELOA TOSPO PHARMA +1

Blood sample analysis method and system, for determining diabetes

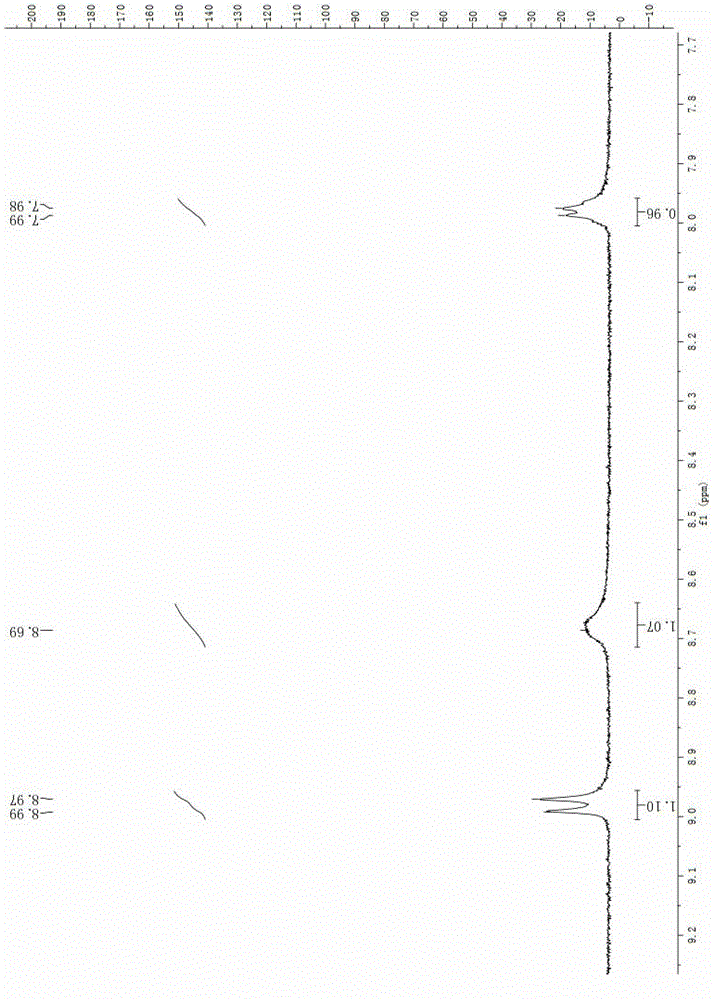

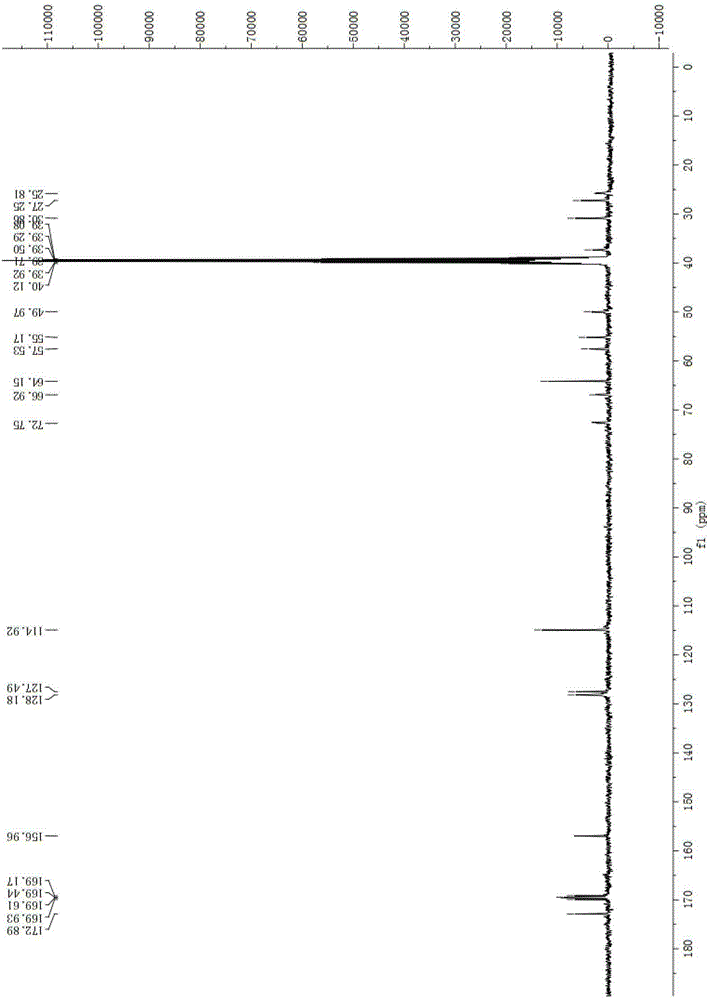

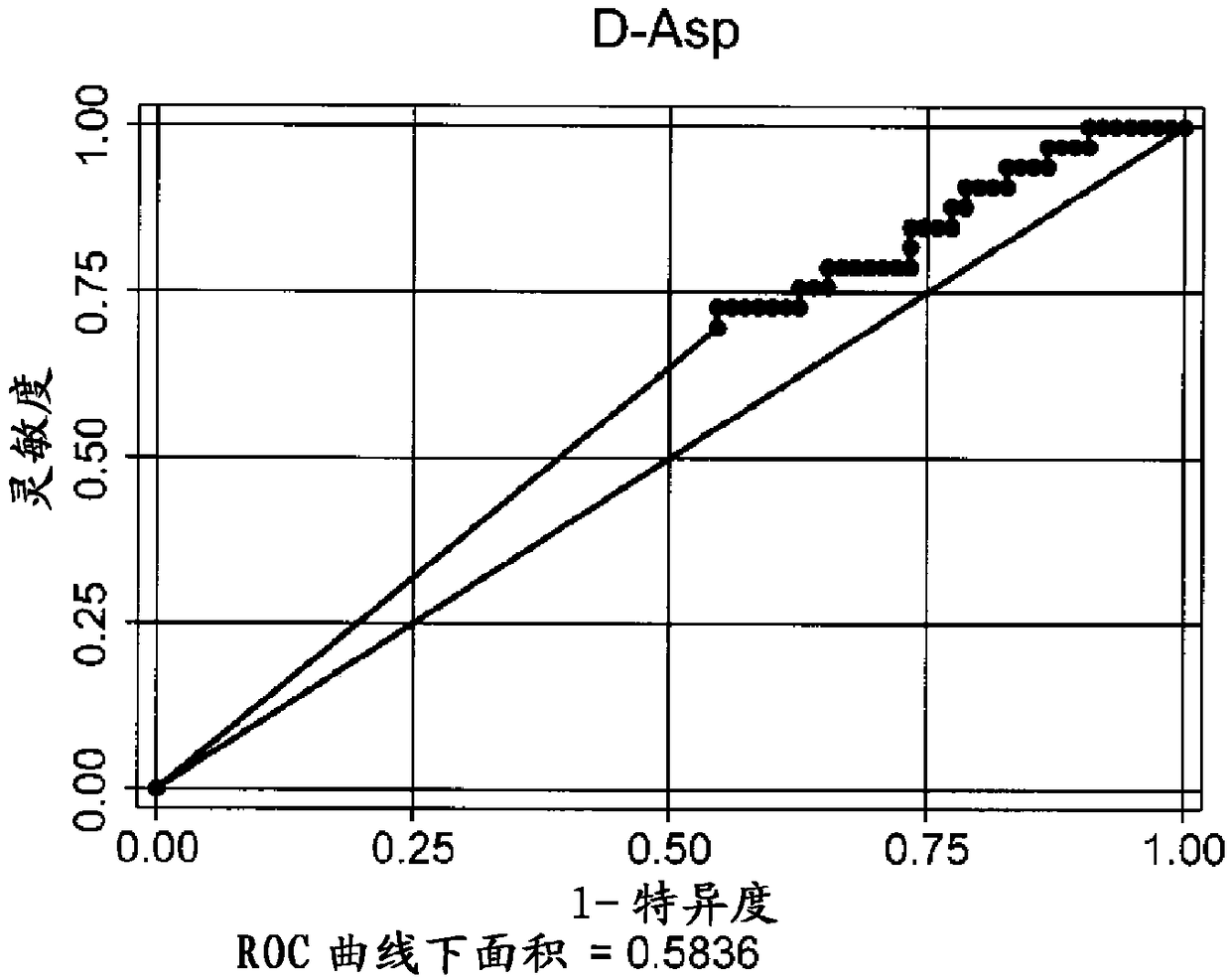

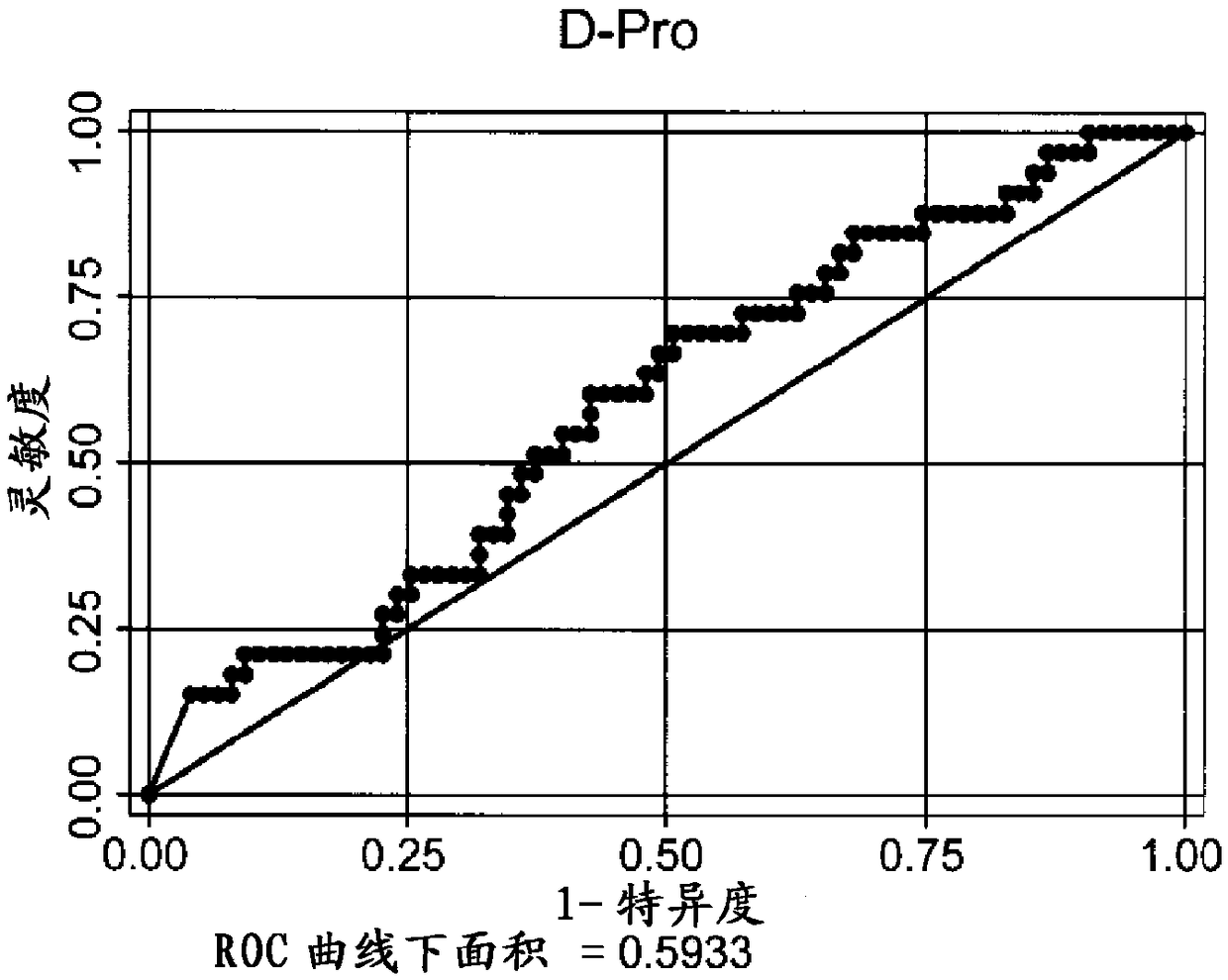

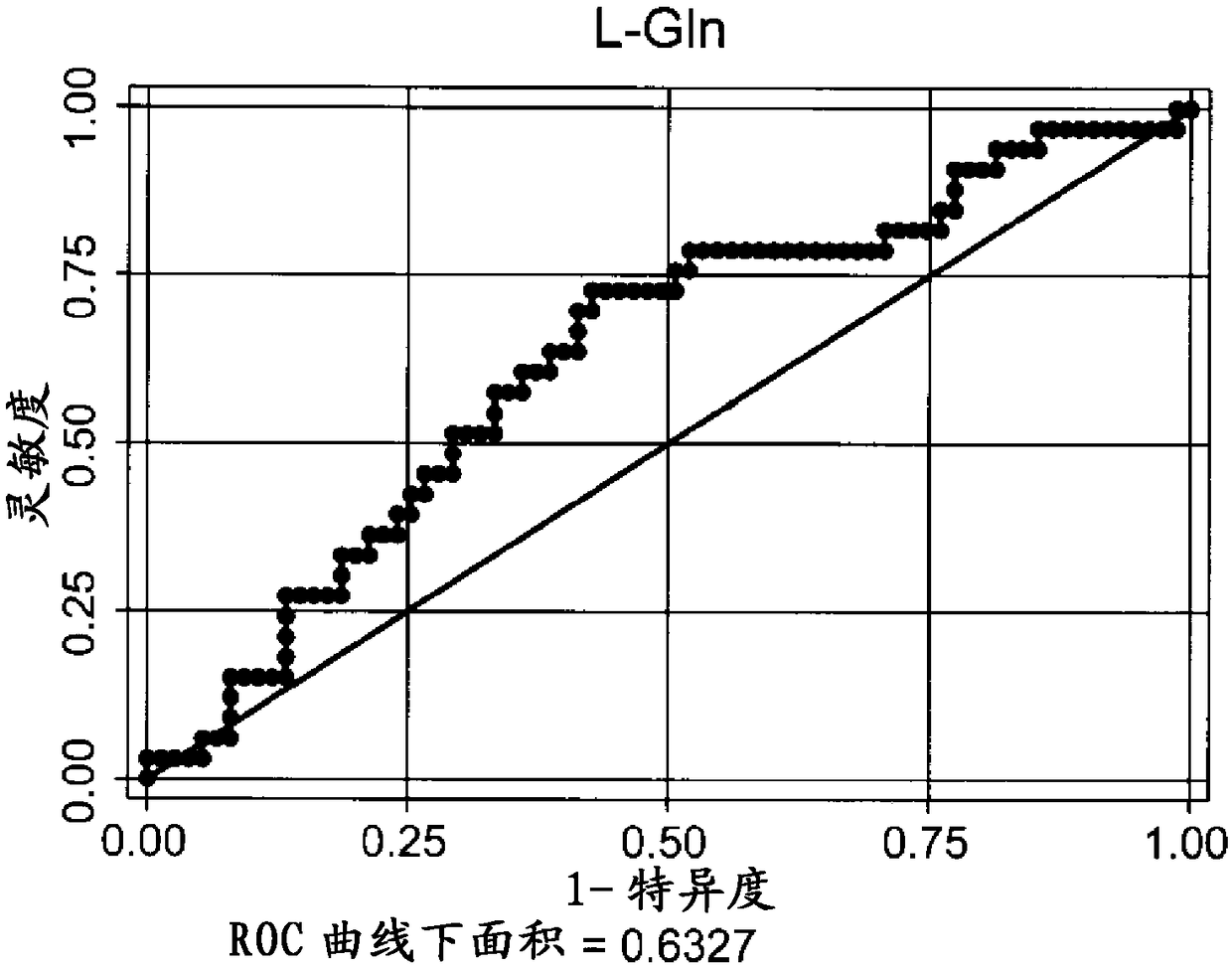

The purpose of the present invention is to provide: a blood sample analysis method for determining diabetes complications in subjects with kidney damage on the basis of D- and L-amino acid content, from a blood sample; a method for examining diabetes complications; and a sample analysis system that outputs pathological information about diabetes complications. The purpose of this invention is achieved by using at least one amino acid selected from the group consisting of D-aspartic acid, D-proline, L-glutamine, and L-isoleucine, in order to determine diabetes complications.

Owner:OSAKA UNIV +1

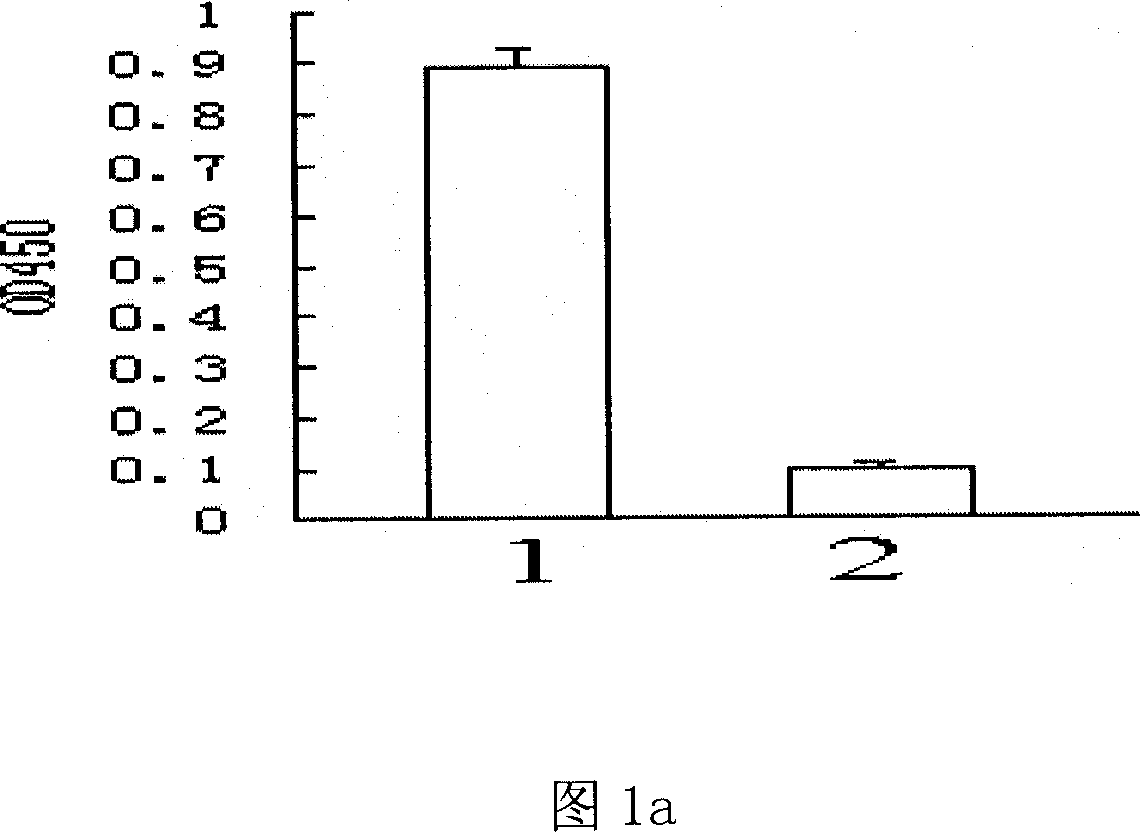

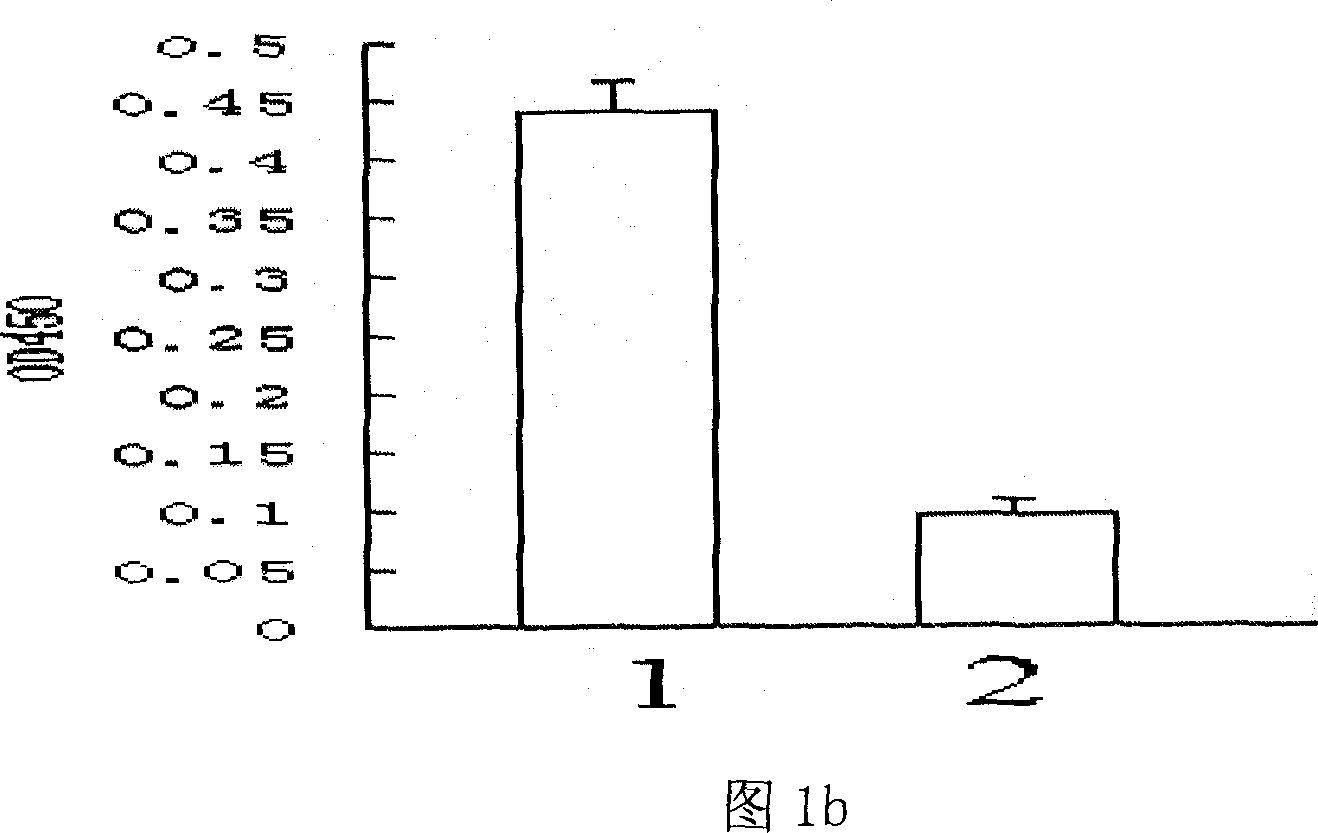

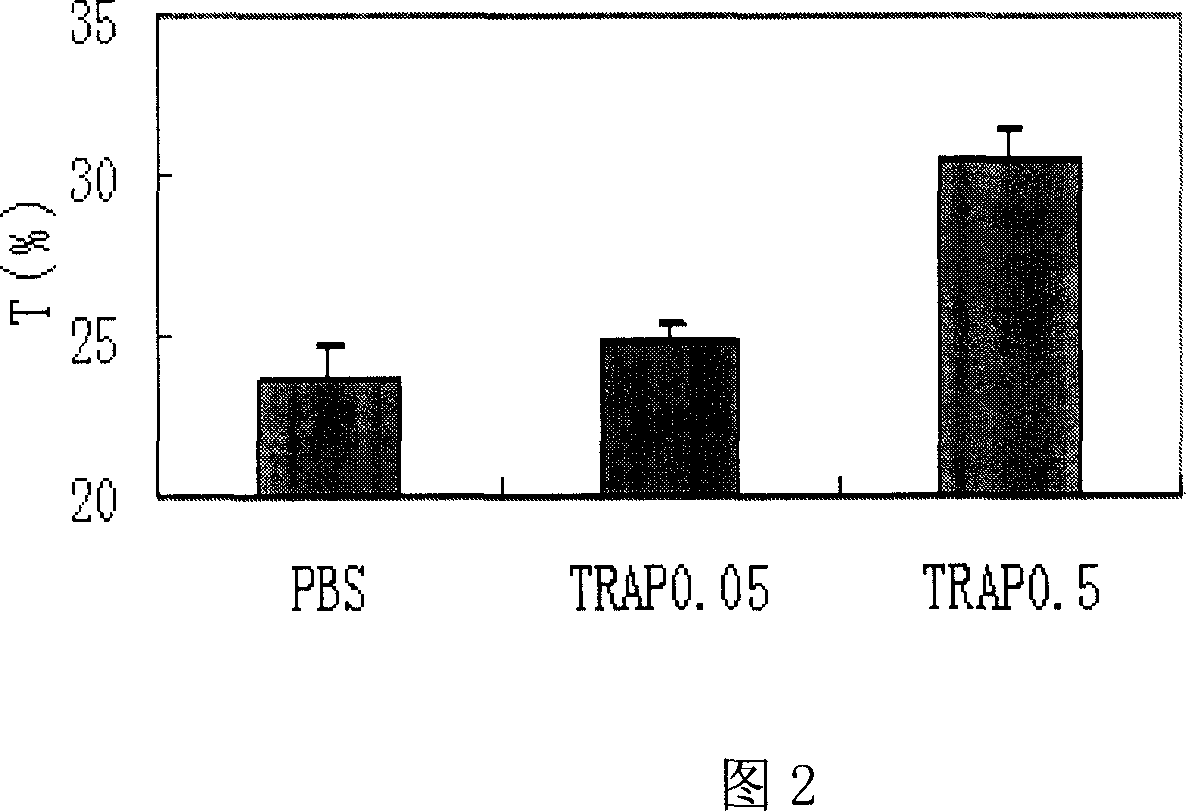

Protein and small molecule polypeptide for increasing lysozyme bacteriolysis activity and its use

InactiveCN1944458AEnhance bacteriolytic activityAntibacterial agentsPeptide/protein ingredientsAspartic acid residueThreonine

The present invention is TRAP protein capable of combining with lysozyme mutually and promoting the activity of lysozyme and its homologous small molecular polypeptides. The polypeptides possess amino acids with the general expression of S / T-Y / W-F-E / D-X-X-L-Y-P / A-X-X-X, where S represents serine residue, T threonine, Y asparatic acid residue, W tryptophane residue, F phenylalanine residue, E glutamic acid residue, D aspartic acid residue, L leucine residue, P proline residue, A alanine residue, X any natural L-amino acid residue or D-isomer. The TRAP protein and the polypeptides of the present invention may be applied in medicine and microbe fermentation fields for enhancing the bacteriolysis activity of lysozyme.

Owner:INST OF BASIC MEDICAL SCI ACAD OF MILITARY MEDICAL SCI OF PLA

Quenching agent used for machining abrasion-resistant alloy and preparing method thereof

The invention discloses a quenching agent used for machining an abrasion-resistant alloy and a preparing method thereof. The quenching agent used for machining the abrasion-resistant alloy is composed of, by weight, 5-13 parts of polyvinyl alcohol, 2-7 parts of polyglycol laurate, 0.5-1.4 part of stearic acid, 7-10 parts of sodium sulfite, 2-4 parts of potassium trichlorine, 15-26 parts of corn starch, 3-8 parts of 6-acetyl oxygen methyl-2,2-dimethyl-1,3-dioxolame-tert-butyl acetate, 5-10 parts of D-aspartic acid, 10-17 parts of palm oil and 8-12 parts of polyethylene glycol; at first, stearic acid, corn starch and the palm oil are dissolved into polyvinyl alcohol to obtain mixed liquor, then water is added, the mixed liquor is transferred into a reaction kettle, after the reaction is finished, polyglycol laurate and 6-acetyl oxygen methyl-2,2-dimethyl-1,3-dioxolame-tert-butyl acetate are added in a cooling manner, and after stirring is carried out, the mixture stands; and then centrifuging is carried out, after centrifuging is carried out, supernatant liquor is taken, sodium sulfite, potassium trichlorine, D-aspartic acid and polyethylene glycol are added, after the mixture is stirred uniformly, temperature rising, temperature preserving and cooling are carried out, and sealing is carried out through paraffin oil, so that the quenching agent is obtained. The prepared quenching agent can improve abrasion resistance of the alloy greatly.

Owner:HENAN BALING ELECTRONICS TECH CO LTD

Traditional Chinese medicine preparation for preventing chronic hepatitis B YMDD (tyrosine, methionine, d-aspartic acid, d-aspartic acid) mutation

The invention discloses a traditional Chinese medicine preparation for preventing chronic hepatitis B YMDD (tyrosine, methionine, d-aspartic acid, d-aspartic acid) mutation. According to traditional Chinese medicine, the etiology and pathogenesis of chronic hepatitis B are complicated, a patient is infected with damp-heat epidemic toxin, so that damp toxin accumulation, qi-stagnation and blood stasis and insufficient anti-pathogenic energy are caused and can cause the chronic hepatitis B. Traditional Chinese medicines comprising herb of sword brake, Chinese knotweed, roots of common sesbania, frangrant ainsliaea herb, all-grass of straightstalk alpine meadowrue, roots of puberulous glochidion herb, multibract raspberry roots, herb of rupestrine dragonhead, roots or leaves of redback christmashush, roots of canna indica and rabdosia serra are selected and decocted to decoction with water. Clinical tests show that the curative effect is remarkable.

Owner:王新

Preparation for repairing and activating skin and preparation method of preparation

InactiveCN110522679AProtected from ultraviolet raysProtects against oxygen free radicalsCosmetic preparationsToilet preparationsVitamin CGlycerol

The invention discloses a preparation for repairing and activating skin and a preparation method of the preparation. The preparation is prepared from the following raw materials in percentage by weight: 40% of living spring water, 20% of an oil phase, 10% of cinnamic acid, 3% of zinc dioxide, 0.2% of triple lipidosome, 0.3% of an active moisturizing component, 0.5% of mucoprotein, 6% of glucolipid-protein, 5% of decavitamin E, 5% of glycerin, 3% of vitamin C, 3% of vitamin B2, 3% of D-aspartic acid and 1% of collagen. The preparation and the preparation method thereof have the beneficial effects that the collagen necessary for a human body is adopted, the preparation can directly participate in skin metabolism and is easy to absorb by the human body, cell activity is stimulated, the skin is protected against being damaged by ultraviolet rays and oxygen free radicals, and effective oxidation resistance is achieved.

Owner:青岛华澳现代医疗美容有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com