Patents

Literature

54 results about "Laminaria japonica extract" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of skin care compositions comprising laminariacea extract for treatment of skin aging signs

InactiveUS20120195923A1Extend your lifeImprove propertiesBiocideCosmetic preparationsCellular AgingSeaweed extract

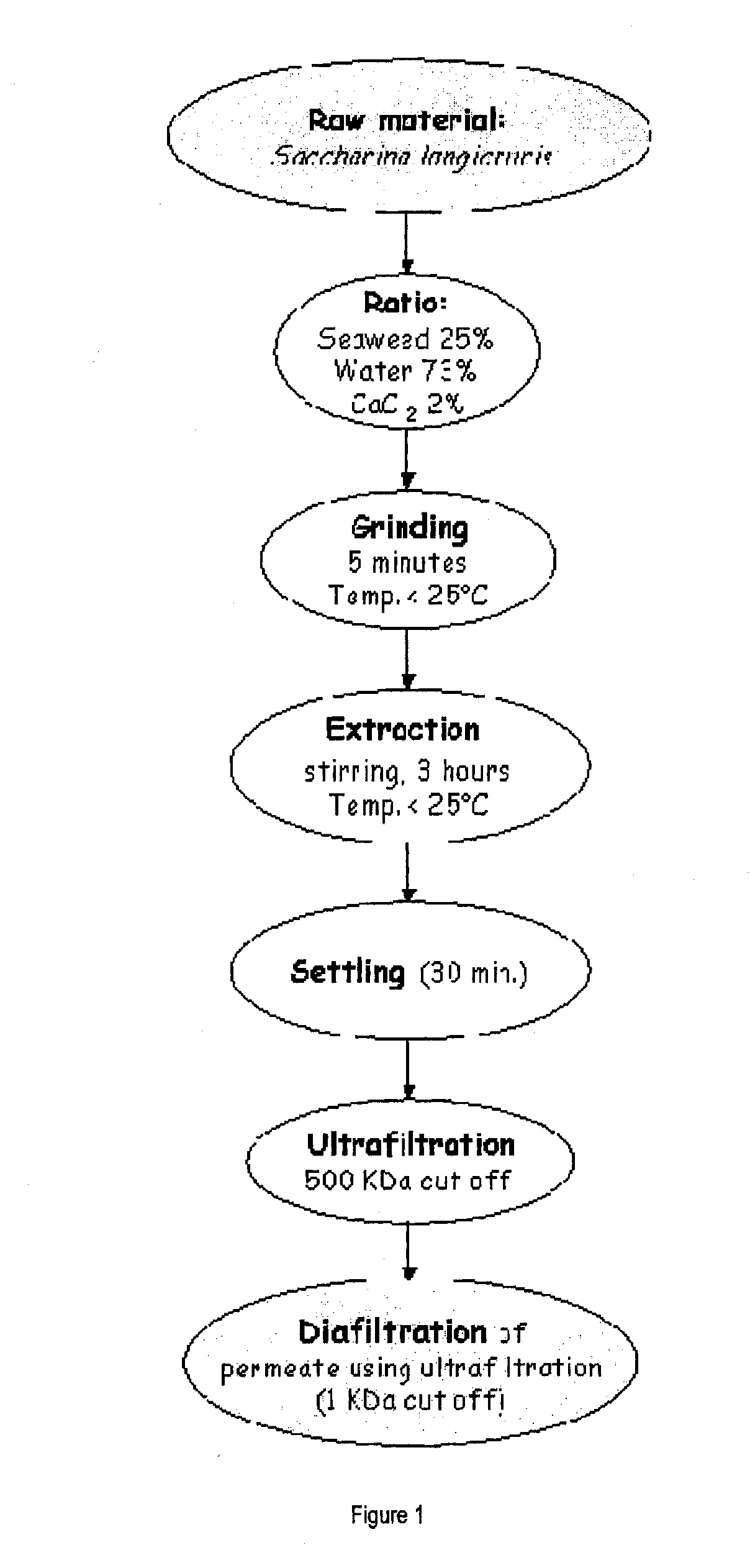

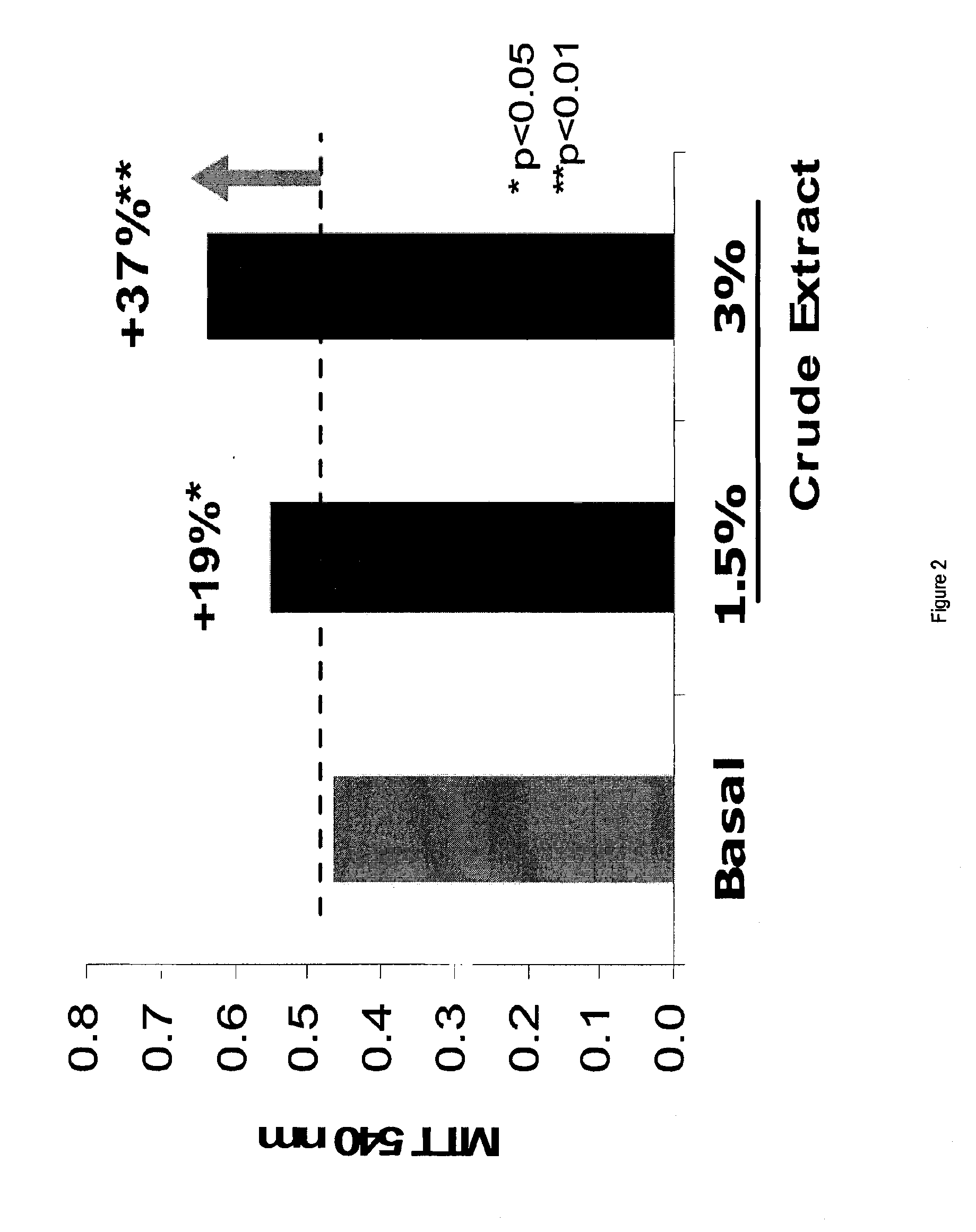

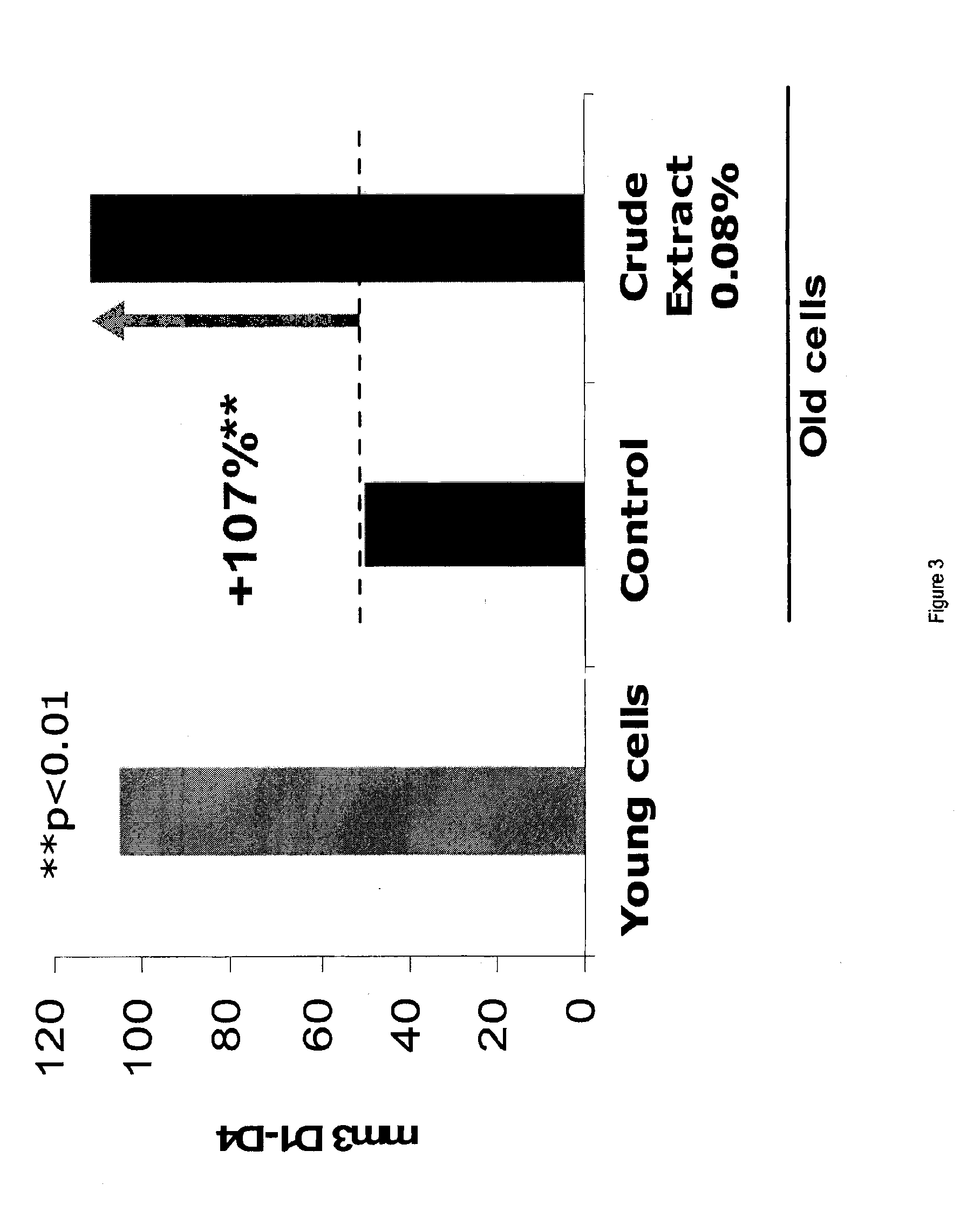

This invention is directed to a skin care composition comprising a laminriacea (brown seaweed) extract and the use of said composition in the treatment of skin aging signs Specifically, it was discovered that a crude extract of the laminariacea Saccharina Longicruris has a strong potential for anti-senescence and anti-cellular aging effect and is efficient to restore the contraction of the collagen network of aged cell lattices to the level of contraction of young cells.

Owner:UNIV LAVAL

Solid beverage having assisted blood glucose lowering function, and preparation method thereof

InactiveCN106983052AFunction increaseRepair functionNatural extract food ingredientsFood ingredient functionsBiotechnologyTrehalose

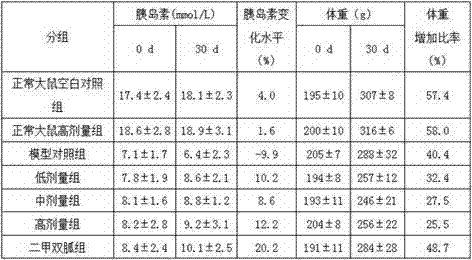

The invention relates to a solid beverage having an assisted blood glucose lowering function, and a preparation method thereof, wherein the main function components are three or more than three materials selected from kelp or a kelp extract, potassium alginate (low molecular weight potassium alginate), common yam rhizome or a common yam rhizome extract, Chinese wolfberry or a Chinese wolfberry extract, radix puerariae or a radix puerariae extract, mulberry leaf or a mulberry leaf extract, a polygonatum odoratum extract, a bitter gourd extract, the leaf of cyclocarya paliurus and corn stigma, the auxiliary materials comprise one or more than one materials selected from inulin, resistant dextrin, bean powder, tea powder, pumpkin powder, soybean protein powder, barley leaf powder, oat fiber powder, konjac powder and citrus fiber powder, and the flavoring agent is one or a plurality of materials selected from stevioside, xylitol, fructo oligosaccharide, isomaltitol, sucralose, trehalose, matcha powder, and fruit and vegetable powder. The preparation method comprises: 1, crushing, and screening; 2, weighing; 3, carrying out mixing stirring, or carrying out stirring mixing and granulation; and 4, packaging. The solid beverage of the present invention has advantages of significant blood glucose lowering effect, good safety, and no side effect.

Owner:DALIAN YAWEITE BIOTECH

Health-care food for assisting blood glucose decreasing and preparation method of granule and capsule thereof

InactiveCN106666312AGood effectImprove securityNatural extract food ingredientsFood ingredient functionsSide effectMomordica

The invention discloses health-care food for assisting blood glucose decreasing. The main functional components of the health-care food are three or more than three types of the following raw materials: kelp or kelp extract, potassium alginate (low molecular weight potassium alginate), rhizoma dioscoreae or rhizoma dioscoreae extract, lycium Chinense miller or lycium Chinense miller extract, radix puerariae or radix puerariae extract, folium mori or folium mori extract, rhizoma polygonati odorati extract, momordica charantia extract, cyclocarya paliurus leaf, corn stigma, rhizoma polygonati, radix astragali seu hedysari, radix notoginseng or radix notoginseng extract, rhodiola rosea or rhodiola rosea extract, inulin and citrus fiber powder. A preparation method of the health-care food for assisting the blood glucose decreasing comprises the following steps of 1, crushing and screening; 2, weighing; 3, mixing and stirring. The health-care food for assisting the blood glucose decreasing has the advantages that the effect of assisting blood glucose decreasing is obvious, the safety is good, any side effect is avoided, and complications and side effects caused by long-time administration of western blood glucose decreasing medicines are avoided; the administration is convenient, and the carrying is easy; the action mechanism is clear, the economic and practical effects are realized, and the application range is wide.

Owner:DALIAN YAWEITE BIOTECH

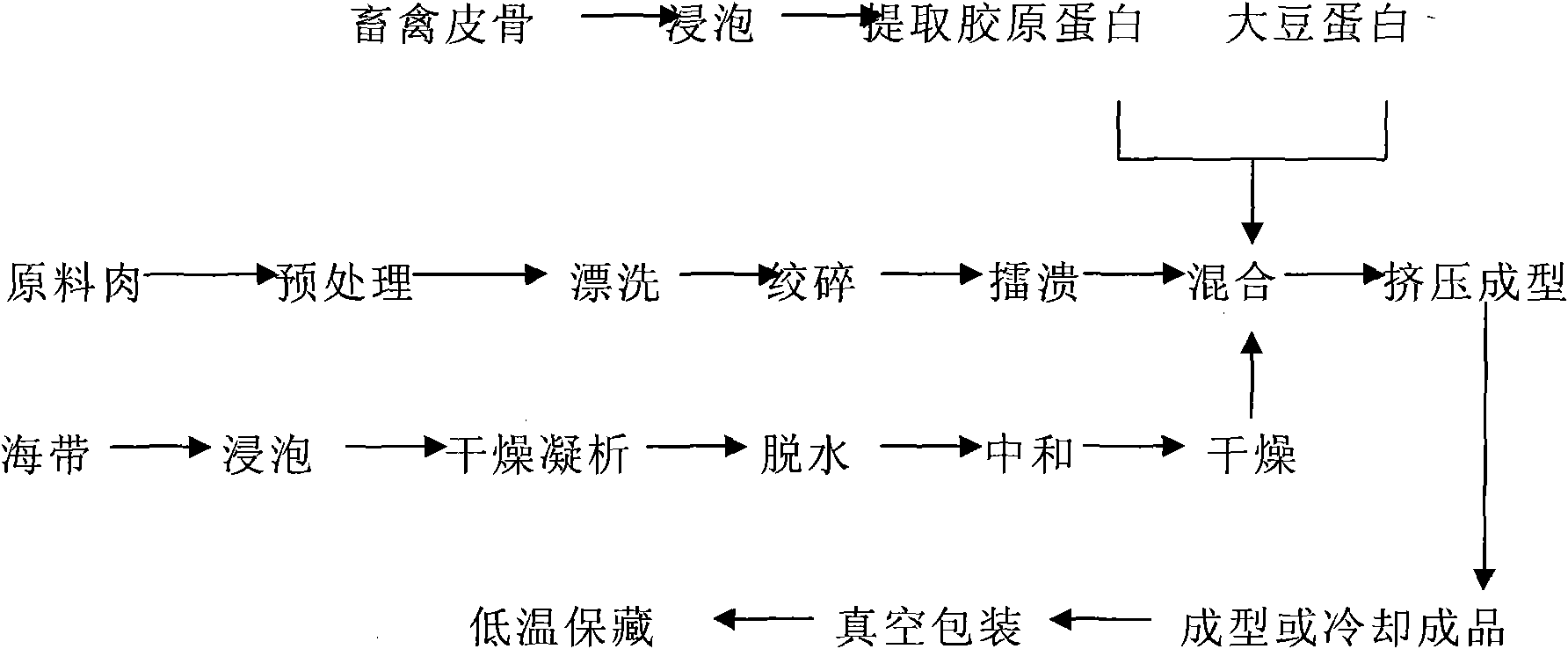

Extrusion production technique for meat simulated fibers

The invention relates to an extrusion production technique for meat simulated fibers, and belongs to the technical field of food science. A low-value meat raw material is used as a main raw material. The technique comprises the following steps of: adding auxiliary materials such as soy protein, animal dermal bone collagen, transglutaminase serving as meat protein coagulation additive, kelp glue serving as kelp extract and the like, performing recombination and cross-linking on multiple proteins and macromolecular polysaccharides by adopting double-screw extrusion technology (the rotational speed of screws is 280 to 450 revolutions per minute, the pressure of a micropore template is 1.7 to 6.0MPa at the temperature of between 150 and 200 DEG C, and the temperature of a cylinder is 170 DEG C), forming meat silk simulated fibers by extrusion, forming cross-linking reaction among meat protein molecules and in molecules, and reshaping micropore formed fibers to obtain recombinant meat food with good color, fragrance, taste and shape. The meat product produced by using the silk muscle simulated fibers produced by the technique is pure natural green food, does not contain chemical substances or preservatives, has the mouthfeel of real meat silks and the specific flavor of meat, has special fragrance and color at the same time, and can be absorbed more easily. Moreover, the added auxiliary materials such as collagen, kelp glue and the like form protein and polysaccharide polymers, so the nutritional components of the product are increased, the quality and structure properties of the product are greatly improved, the water holding property is improved, the problems such as gel cracking and the like are effectively avoided, the quality guarantee period of the product is prolonged, and the social benefit and the economic benefit of the product are increased.

Owner:TIANJIN UNIV OF SCI & TECH

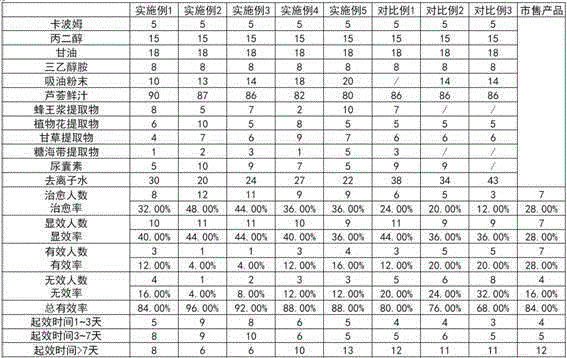

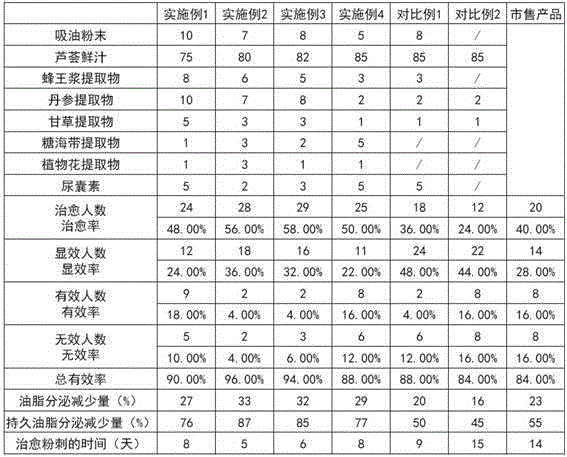

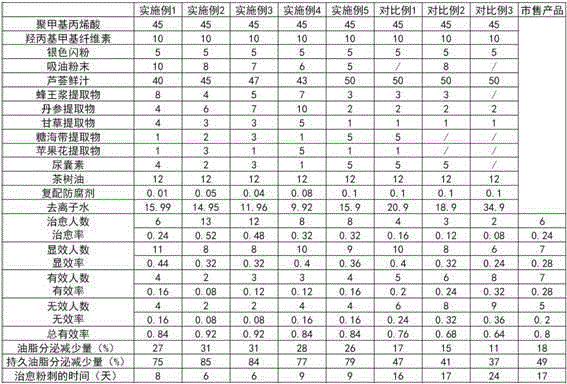

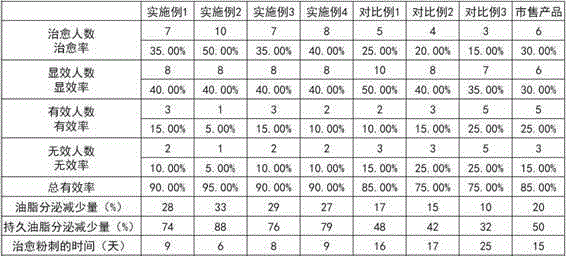

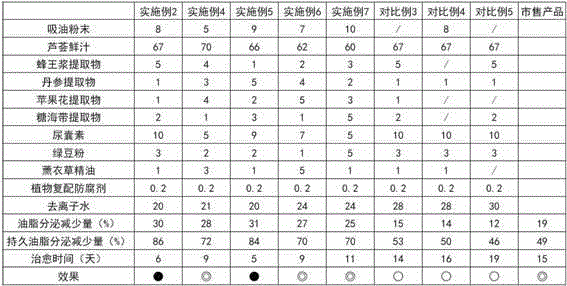

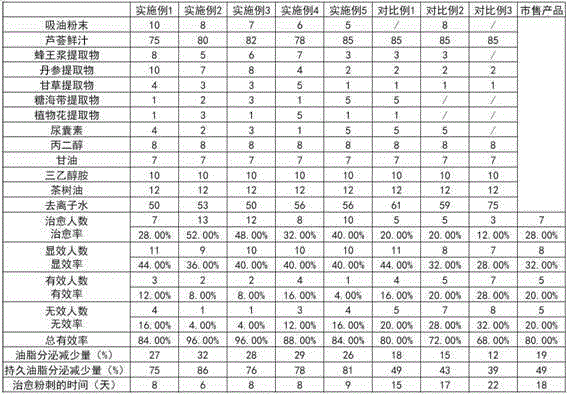

Acne-removing aloe vera gel

InactiveCN105168094AGood acneGood scar removalCosmetic preparationsToilet preparationsSugarSebum secretion

The invention discloses acne-removing aloe vera gel. The acne-removing aloe vera gel, 200 parts in total, is prepared from, by weight, 10-20 parts of sebum absorbing powder, 80-90 parts of fresh aloe vera juice, 2-10 parts of bee milk extract, 5-10 parts of plant flower extract, 4-10 parts of radix glycyrrhizae extract, 1-5 parts of sugar kelp extract, 5-10 parts of allantoin, 2-6 parts of carbomer, 10-15 parts of propylene glycol, 15-20 parts of glycerinum, 5-15 parts of triethanolamine and the balance deionized water. The acne-removing aloe vera gel can reduce sebum secretion and absorb skin sebum, has good effects on removing acnes, removing scars and promoting skin regeneration, and is remarkable in effect.

Owner:吴颖斯

Acne removal composition and acne removal skin-care product

InactiveCN105106100AQuick killBalance secretionCosmetic preparationsToilet preparationsGLYCYRRHIZA EXTRACTChinese licorice

The invention discloses acne removal composition. The acne removal composition comprises components in parts by weight as follows: 5-10 parts of oil-absorption powder, 75-85 parts of fresh aloe juice, 3-8 parts of royal jelly extract, 2-10 parts of danshen root extract, 1-5 parts of liquorice extract, 1-5 parts of laminaria saccharina extract, 1-5 parts of plant flower extract and 1-5 parts of allantoin. The invention further discloses a skin-care product using the acne removal composition. The acne removal composition can reduce secretion of grease, absorb skin grease, has good effects of acne removal, scar removal and promotion of skin recovery, can be used for preventing and treating acnes, has remarkable effect and takes effect quickly, and no acne marks are left after acnes are healed.

Owner:吴颖斯

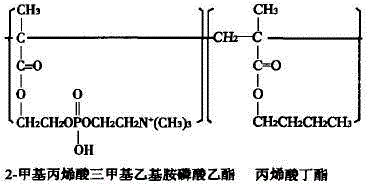

Cationic nano emulsion with anti-allergic effect and preparation method of cationic nano emulsion

ActiveCN104784074ANo toxicityImprove permeabilityCosmetic preparationsAntipyreticSkin sensitizationGlycerol

The invention relates to cationic nano emulsion with an anti-allergic effect. The cationic nano emulsion is characterized by comprising the following components in percentage by mass: 10-30% of a plant anti-allergic compound, 3-30% of glycerin, 5-30% of caprylic / capric triglyceride, 0.1-3% of cholesterol, 2-25% of glycolipid, 0.1-2% of polyquaternary ammonium salt-51, 0.05-0.3% of methylparaben and the balance of water, wherein the plant anti-allergic compound comprises the following components in percentage by mass: 15-30% of olive leaf extract, 5-10% of gorgonian extract, 10-20% of laminaria saccharina extract, 3-5% of piper methysticum extract and the balance of octyldodecanol; the average particle size of nanoparticles is 100-600 nm. The cationic nano emulsion has the benefit of capability of comprehensively and efficiently resisting a skin allergy symptom, is nontoxic to skin, penetrates the skin easily and can quickly achieve the anti-allergic effect.

Owner:PROYA COSMETICS

Hydrogel microcapsule for oil control and acne removal

InactiveCN105125470AOverall light weightEasy to carryCosmetic preparationsToilet preparationsSalvia miltiorrhizaPlant roots

The invention discloses a hydrogel microcapsule for oil control and acne removal. The hydrogel microcapsule is composed of a capsule wall and a capsule core. The capsule core is prepared from, by weight, 5-10 parts of oil absorbing powder, 40-50 parts of fresh aloe vera juice, 3-8 parts of bee milk extracts, 2-10 parts of salvia miltiorrhiza extracts, 1-5 parts of licorice extracts, 1-5 parts of sugar kelp extracts, 1-5 parts of apple blossom extracts, 1-5 parts of allantoin, 5-10 parts of tea tree oil, 0.01-0.1 part of compound corrosion remover and the balance deionized water, and the total weight of the capsule core is supplemented to 100 parts. The compound corrosion remover is prepared from, by weight, 1-20 parts of plant root extracts, 1-20 parts of plant flower extracts, 10-20 parts of plant leaf extracts and 1-10 parts of plant peel extracts. By means of the hydrogel microcapsule for oil control and acne removal, oil secretion can be lowered, skin grease is absorbed, good acne removal, scar removal and skin repairing promotion effects are achieved, the hydrogel microcapsule can be used for preventing and treating whelks, the effect is obvious, the fast effect is achieved, and no trace is left after healing.

Owner:吴颖斯

Acne-removing bamboo charcoal mask

InactiveCN105168093AGood acneGood scar removalCosmetic preparationsToilet preparationsAllantoinSugar

The invention discloses an acne-removing bamboo charcoal mask. The acne-removing bamboo charcoal mask is prepared from, by weight, 15-25 parts of nanometer modified bamboo charcoal powder, 20-35 parts of acne-removing active ingredients, 5-10 parts of tea soup, 1-3 parts of EDTA-2Na and the balance deionized water, wherein acne-removing active ingredients are prepared from, by weight, 5-10 parts of sebum absorbing powder, 75-85 parts of fresh aloe vera juice, 3-8 parts of bee milk extract, 2-10 parts of salviae miltiorrhizae extract, 1-5 parts of radix glycyrrhizae extract, 1-5 parts of sugar kelp extract, 1-5 parts of plant flower extract and 1-5 parts of allantoin. The acne-removing bamboo charcoal mask can reduce sebum secretion and absorb skin sebum, has good effects on removing acnes, removing scars and promoting skin regeneration, and is remarkable in effect.

Owner:吴颖斯

Oil-controlling acne-removing wet tissue possessing plant compound antiseptic

InactiveCN105267117AHas the function of deperspiration and moisture absorptionIt has the following beneficial effects: the wet wipe not only has the function of removing sweat and absorbing moistureCosmetic preparationsToilet preparationsSalvia miltiorrhizaAntiseptic solutions

A disclosed oil-controlling acne-removing wet tissue possessing a plant compound antiseptic is composed of the following compositions in parts by weight: 5-10 parts of an oil-absorbing powder, 60-70 parts of aloe fresh juice, 1-5 parts of royal extractive, 1-5 parts of salvia miltiorrhiza extractive, 1-5 parts of apple flower extractive, 1-5 parts of sugar-dipped seatangle extractive, 5-10 parts of allantoin, 1-5 parts of mung bean powder, 1-5 parts of lavender essential oil, 0.1-0.3 part of a plant compound antiseptic, and 20-25 parts of deionized water. The oil-controlling acne-removing wet tissue possessing the plant compound antiseptic is capable of reducing grease secretion and absorbing skin oil, possesses good effects of removing acnes, removing scars and promoting skin restoration, is obvious in effect, is simple and practicable, and is applicable to neutral and oily skins. Also, the added plant compound antiseptic is capable of effectively inhibiting growth of bacteria, fungi and other microbes in skin-care products and prolonging the usage period of skin-care products, and possesses the advantages of being nontoxic and stimulation-free, not causing skin allergy, and the like.

Owner:吴颖斯

Skin care composition with moisturizing, wrinkle removing and elasticity regaining functions and cosmetic

InactiveCN106902030AIncrease elasticityStay hydratedCosmetic preparationsToilet preparationsWrinkle skinHuman skin

The invention belongs to the technical field of daily chemical products, and particularly relates to a skin care composition with moisturizing, wrinkle removing and elasticity regaining functions. The skin care composition comprises, by weight, 1-4 parts of ceramide, 1-4 parts of alternative monad fermentation product extracts, 1-4 parts of kelp extracts, 0.5-3 parts of hydrolyzed collagen, 0.5-3 parts of magnolia officinalis bark extracts and 0.05-0.2 part of dipotassium glycyrrhizinate. The invention further provides a cosmetic containing the skin care composition, the weight ratio of the skin care composition to the cosmetic is 4%-18%, the cosmetic can be directly acted onto the surface of human skins, so that the moisturizing, wrinkle removing and elasticity regaining functions are achieved, the appearance and the internal quality of the cosmetic can keep long-term stabilization, and the cosmetic is convenient to use.

Owner:国东启

Aquatic feed vegetable adhesive and preparation method thereof

InactiveCN104543629AEasy to get materialsSimple extraction processFood processingClimate change adaptationBiotechnologyAnimal science

The invention discloses an aquatic feed vegetable adhesive and a preparation method thereof. The aquatic feed vegetable adhesive is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of a kelp extract, 2-4 parts of a dried tangerine peel extract, 1-3 parts of a compound Chinese herbal medicine, 2-4 parts of alpha-starch and 5-8 parts of bentonite. The adhesive has the characteristics of simple process, low cost and appropriate adhesiveness, and can increase nutritional ingredients of in a bait material, improve the palatability of a feed, promote in vivo nutrition metabolism and improve the anti-stress capability of fishes.

Owner:JIANGXI INST OF AQUATIC SCI

Composition with function for promoting lead-expelling and method for preparing the same

InactiveCN101461881APromote lead discharge functionAntinoxious agentsPill deliveryBiotechnologyPharmaceutical Aids

The invention discloses a composition with the function of promoting lead discharging and a preparation method thereof. The composition comprises: taking a mung bean extract, a seatangle extract, a china root extract and a medlar extract as raw materials which are mixed in appropriate proportion; adding pharmaceutically acceptable auxiliary materials, and preparing the preparation types including troche, capsule, granule and oral liquid.

Owner:BEIJING INCREASEPHARM CORP LTD

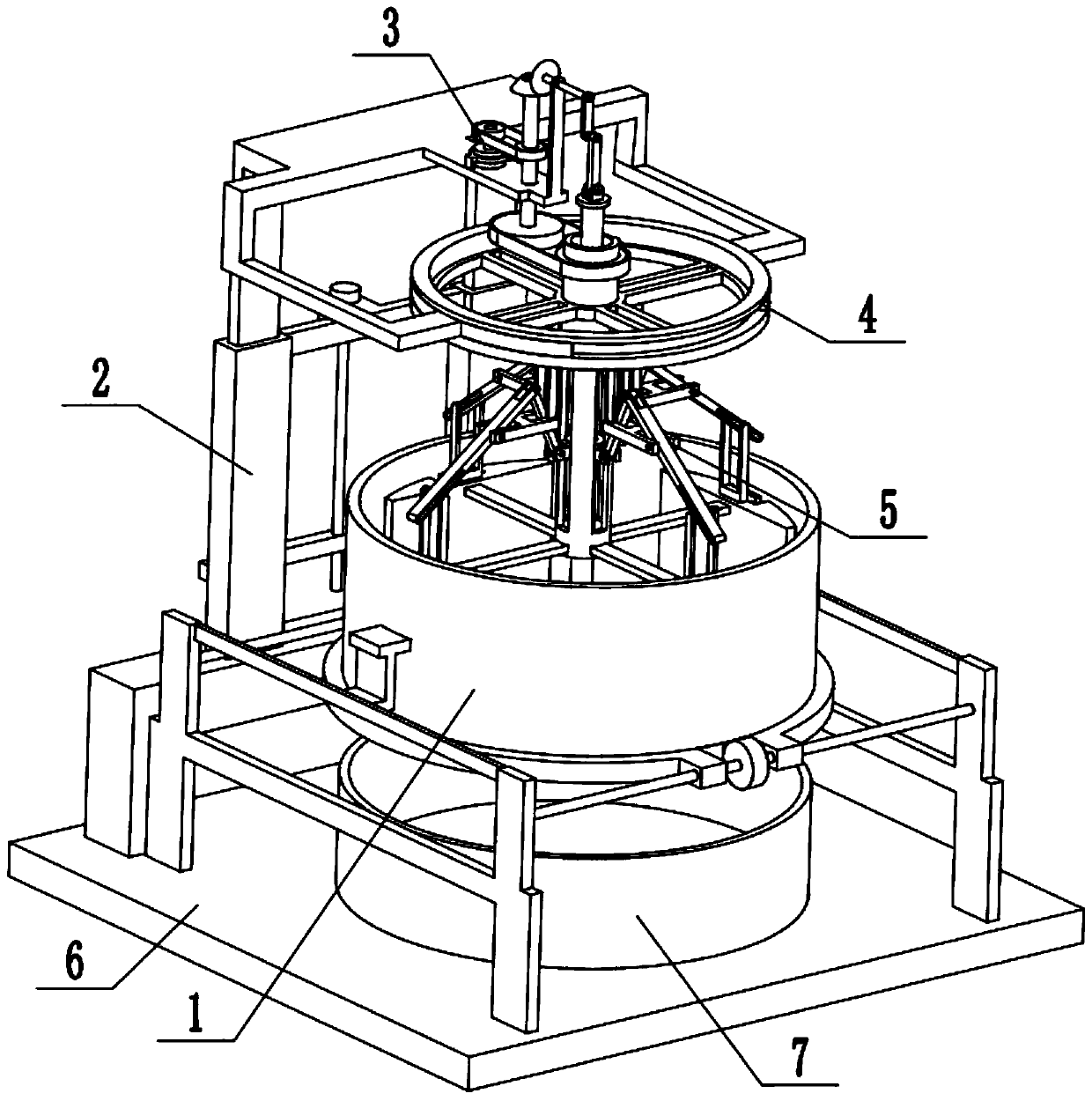

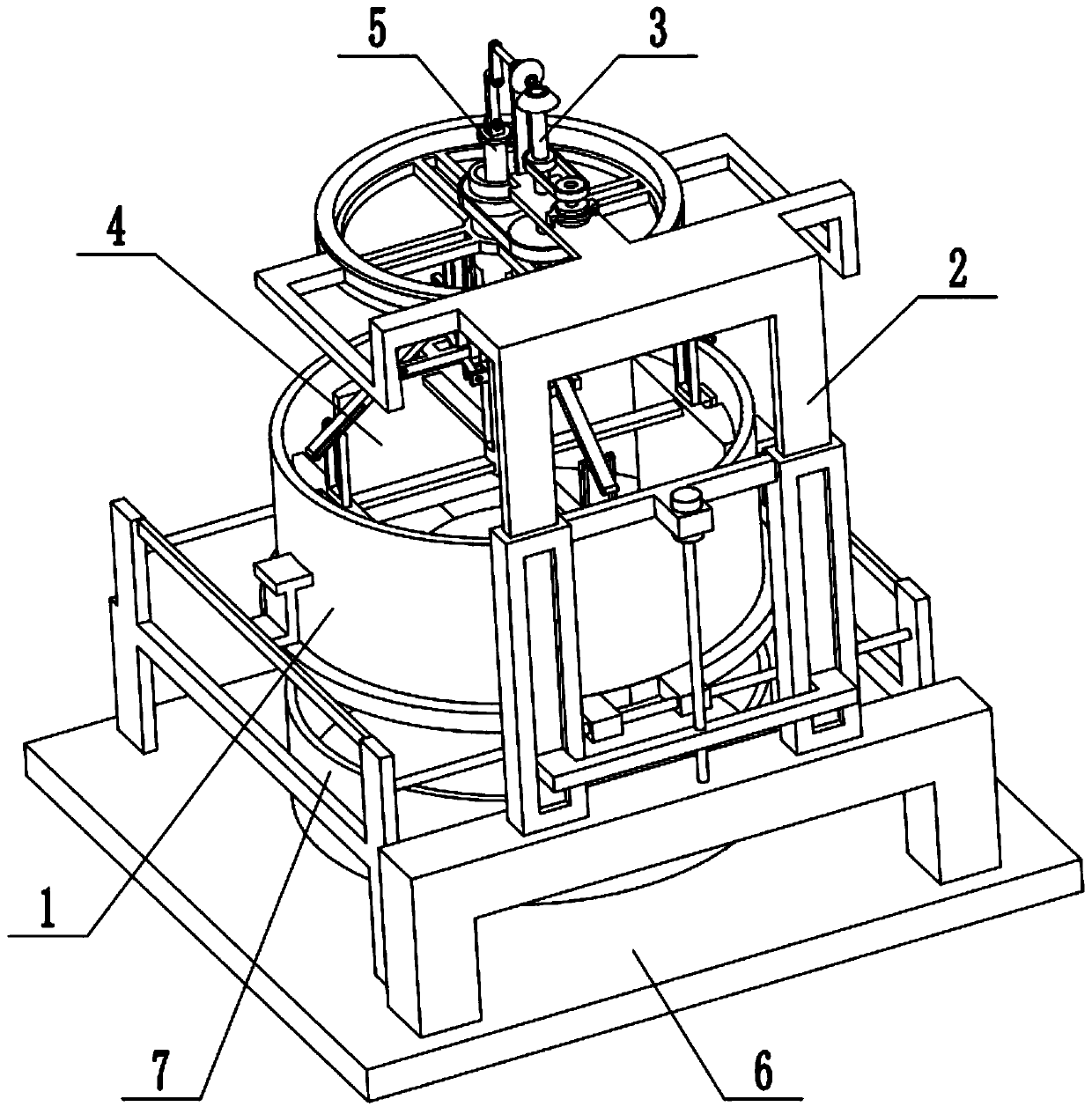

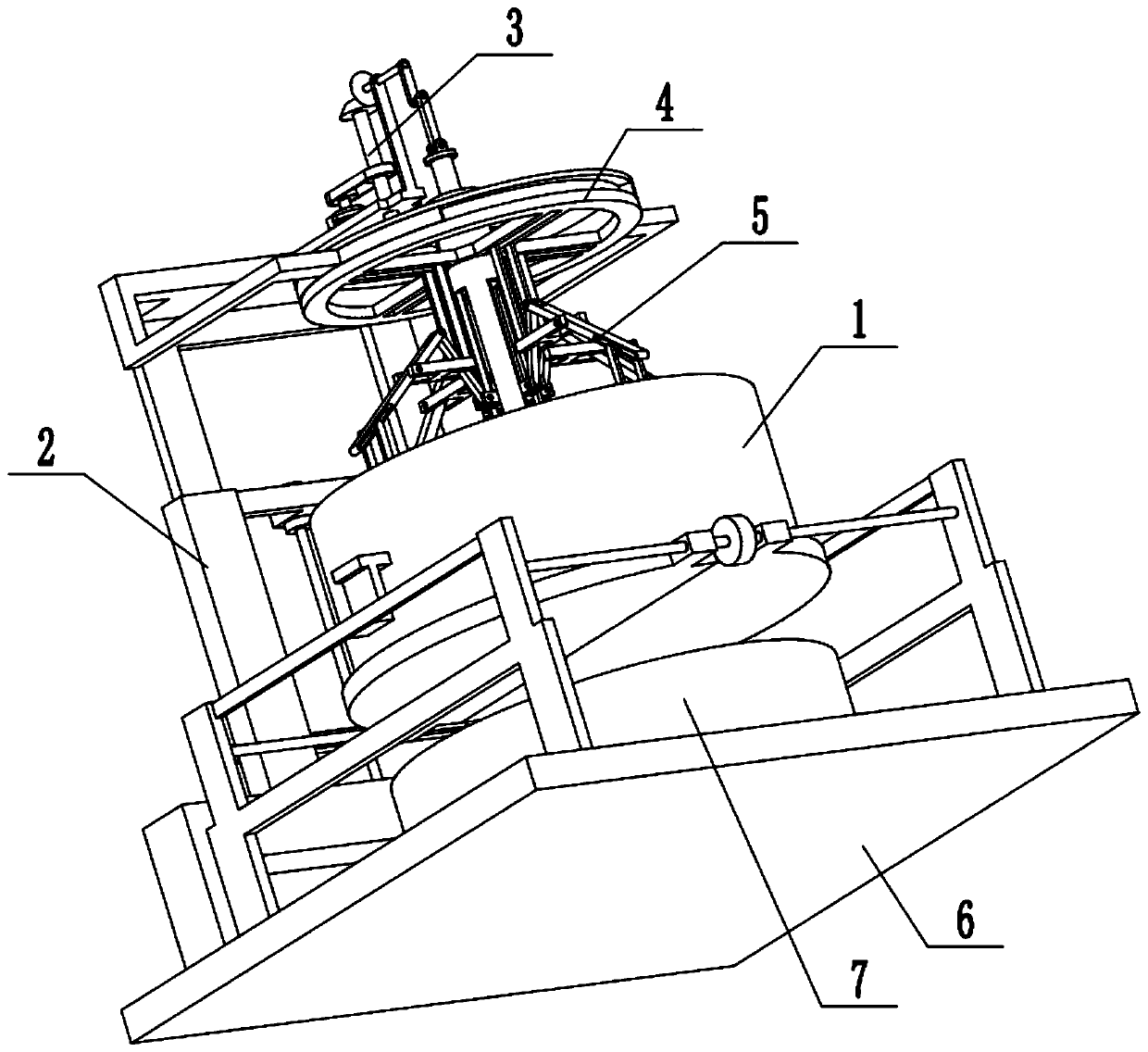

Anti-dandruff shampoo and preparation system and processing method thereof

ActiveCN110815906ABeat the juice fullyCosmetic preparationsHair cosmeticsPolymer scienceCoconut diethanolamide

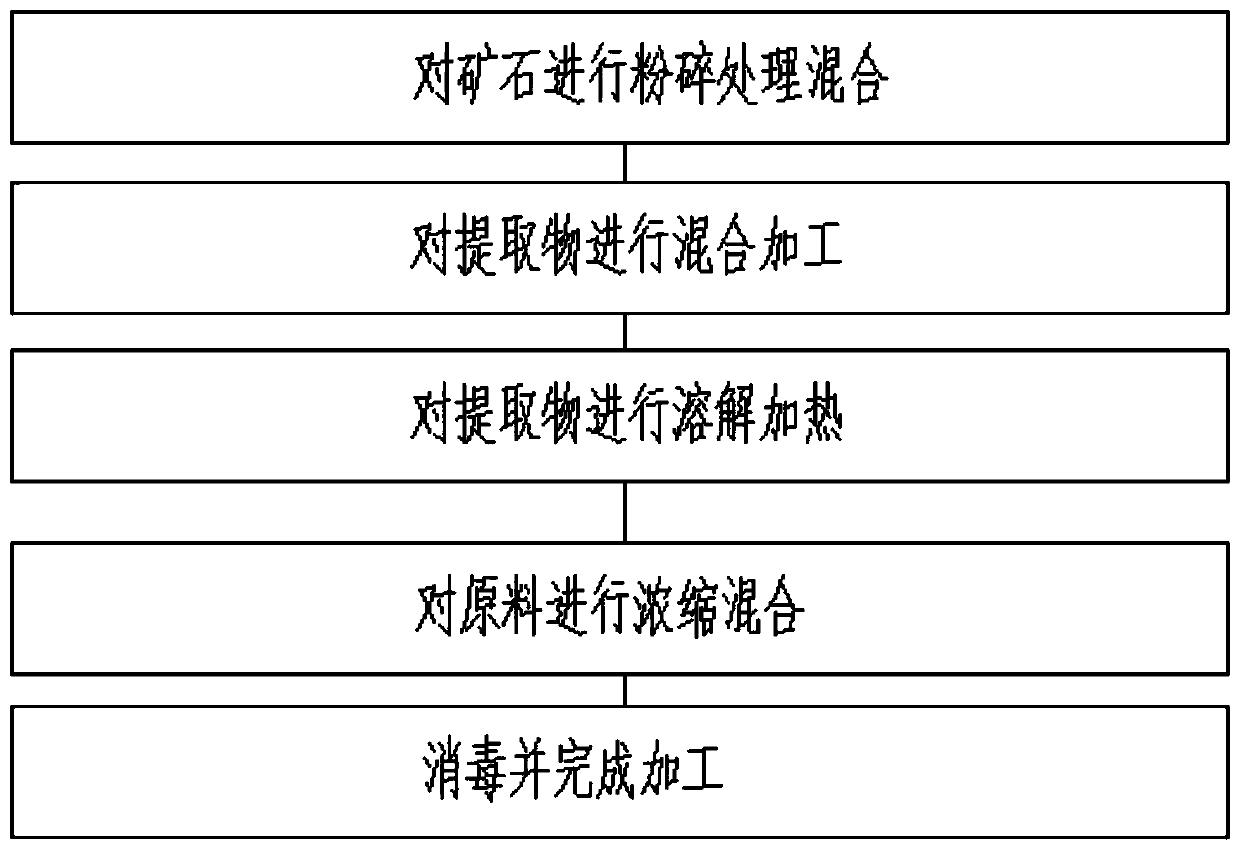

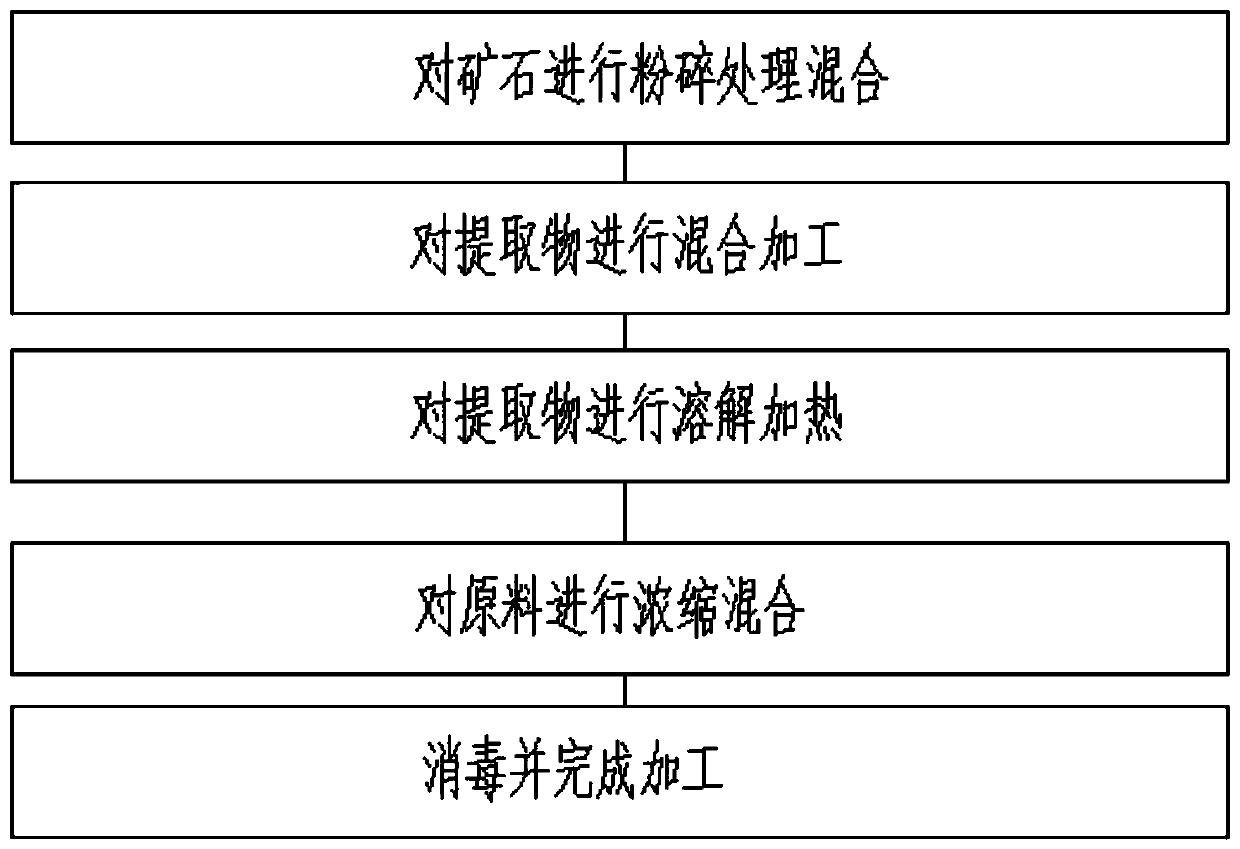

The invention discloses anti-dandruff shampoo and a preparation system and processing method thereof. The shampoo comprises the components of 10 parts of coix seed extract, 2 parts of camellia extract, 5 parts of cinnamon extract, 3 parts of ginseng extract, 1 part of red peony root extract, 2.5 parts of coconut diethanolamide, 0.5 part of astragalus extract, 0.5 part of kelp extract, 10 parts ofglycerin, 8 parts of conditioners, 0.1 part of essence, 0.1 part of preservative and 25 parts of deionized water. The processing method comprises the steps that 1, raw materials obtained after soakingare put into a material extrusion barrel assembly; 2, the raw materials in the material extrusion barrel assembly are hit by a round pressing disc, and meanwhile four extrusion plates constantly pushand gather pressed-scattered raw materials to be below the round pressing disc; 3, the four rotating extrusion plates push all the raw materials to be below the round pressing disc to be hit; 4, a material rotary extrusion mechanism and an extrusion driving mechanism move upwards; and 5, the raw materials in a material collection box and other components are stirred so as to be mixed evenly.

Owner:佛山市百分之秀化妆品有限公司

Method for treating sea-tangle through microbial fermentation

InactiveCN104692881ASolve the real problemOrganic fertilisersFertilizer mixturesBiotechnologyMicroorganism

The invention relates to a method for treating sea-tangle through microbial fermentation. The treating method adopts microbial degradation technology to shorten degradation time of sea-tangle, thereby realizing energy-saving and environment-friendly treatment of sea-tangle. The invention also relates to screening and domestication of a microbial strain used for degrading sea-tangle and post-utilization of a sea-tangle degradation liquid which is used for producing a variety of sea-tangle alga fertilizers and a variety of sea-tangle extracts.

Owner:QINGDAO GENYUAN BIOLOGICAL TECH GRP

Acne-removing repairing liquid

InactiveCN105250194AContinuous oil controlSustained anti-acne effectAntibacterial agentsCosmetic preparationsSalvia miltiorrhizaSkin repair

The invention discloses acne-removing repairing liquid. The acne-removing repairing liquid is prepared from, by weight, 5 parts to 10 parts of oil absorption powder, 75 parts to 85 parts of fresh aloe juice, 3 parts to 8 parts of bee milk extract, 2 parts to 10 parts of salvia miltiorrhiza extract, 1 part to 5 parts of liquorice extract, 1 part to 5 parts of laminaria saccharina extract, 1 part to 5 parts of plant flower extract, 1 part to 5 parts of allantoin, 5 parts to 10 parts of propylene glycol, 5 parts to 10 parts of glycerin, 6 parts to 12 parts of triethanolamine, 10 parts to 15 parts of tea tree oil and the balance deionized water, wherein the sum of the weight parts is 200. By means of the acne-removing repairing liquid, grease secretion can be reduced, skin grease can be absorbed, and the good effects of acne removing, scar removing and skin repairing promoting are achieved; the acne-removing repairing liquid can be used for preventing and treating whelks and is obvious in effect, high in acting speed and free of scars after curing.

Owner:吴颖斯

Alkaline plant salt with function of relieving cardiovascular and cerebrovascular diseases and preparation method thereof

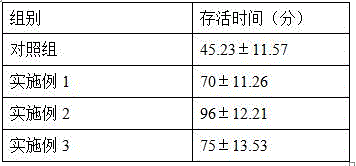

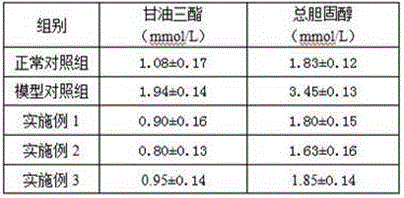

InactiveCN105770557AProlong hypoxic survival timeImprove blood supplyOrganic active ingredientsAlgae medical ingredientsBiotechnologyDisease

The invention provides alkaline plant salt with the function of relieving cardiovascular and cerebrovascular diseases. The alkaline plant salt is prepared from suaeda salsa plant salt, salvia miltiorrhiza extracts, pomegranate extracts, kelp extracts, chlorella powder, dried jasmine products, mint extract, epimedium extract, wheat dietary fiber powder, lentinan and salidroside. The invention further provides a preparation method of the alkaline plant salt. The alkaline plant salt can prolong survival time of hypoxia and improve heart blood supply capacity. The alkaline plant salt can improve arrhythmia and reduce the occurrence rate of ventricular tachycardia (VT) and the occurrence rate of ventricular fibrillation (VF); the occurrence time of ventricular premature (VP) is prolonged; the sinus rhythm recovery rate is increased. The alkaline plant salt can improve myocardial ischemia, reduce the content of lactate dehydrogenase (LDH) and malondialdehyde (MDA) in serum and increase the content of superoxide dismutase (SOD).

Owner:王胜

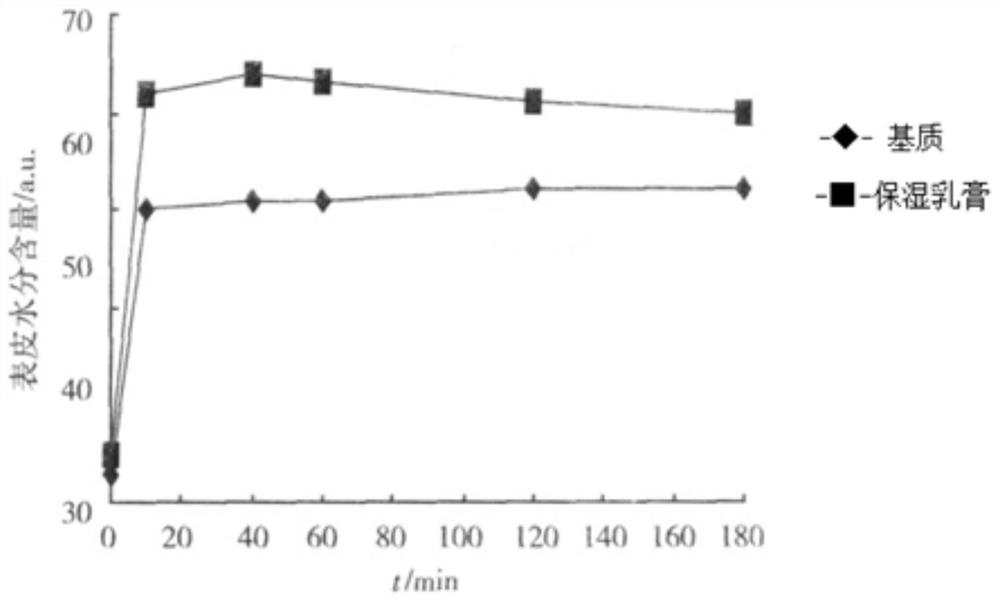

A kind of skin care product for skin moisturizing and barrier repair and preparation method thereof

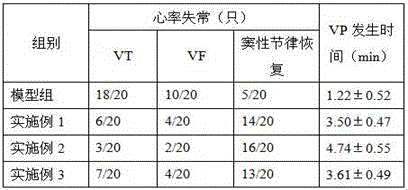

ActiveCN108721154BIncrease moisture contentReduce churnCosmetic preparationsToilet preparationsContinuous useNutrition

The invention discloses a skin care product for skin moisturizing and barrier repairing. The skin care product contains the following components by mass: 0.15%-0.25% of marine fish skin collagen oligopeptide, 0.8%-1.2% of a kelp extract, and 0.04%-0.06% of low molecular weight sodium hyaluronate. The invention also discloses a preparation method of the skin care product. Tests prove that the skincare product provided by the invention has very ideal moisturizing and nutrition repairing effects, after continuous use, the facial skin sensitivity, erythema and other symptoms of subjects are obviously improved, the damaged skin barrier can be quickly and effectively repaired, and the moisture content of the skin is obviously increased. All the raw materials adopted by the skin care product provided by the invention are all natural extracts or conventional skin care product additives, the adding amounts of all the components also meet the conventional requirements of skin care product production, therefore the skin care product is safe and reliable after long-term use.

Owner:SHANGHAI DERMATOLOGY HOSPITAL

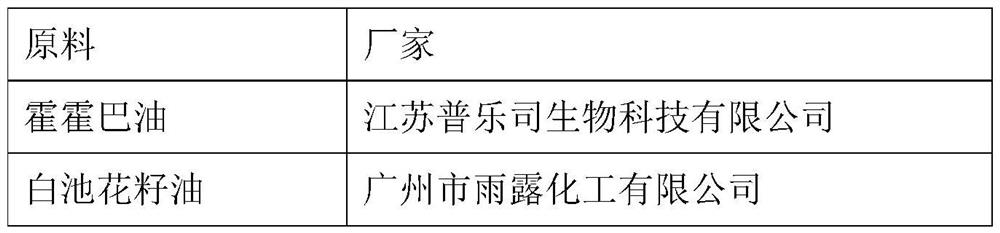

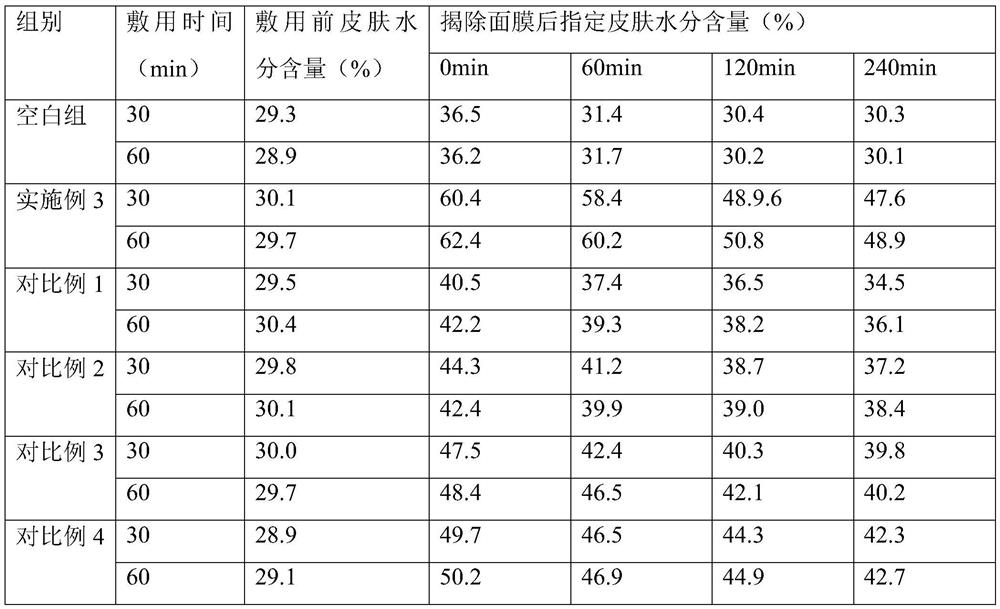

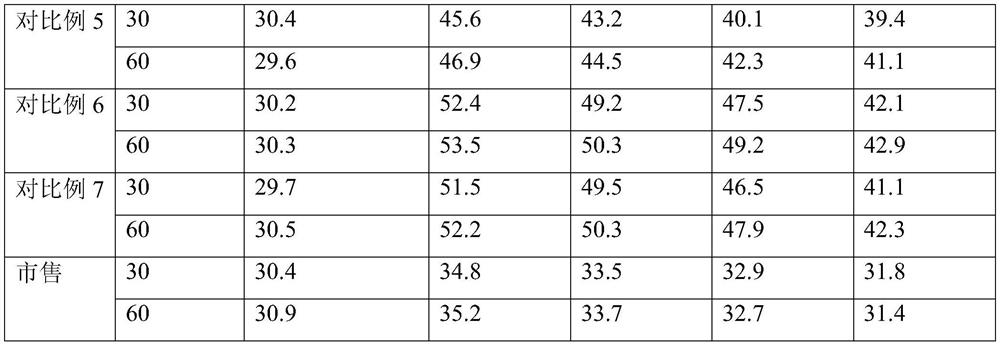

Moisturizing emulsion and preparation method thereof

PendingCN113384502AImprove securityImprove stabilityCosmetic preparationsToilet preparationsBiotechnologyFennel extract

The invention discloses a moisturizing emulsion and a preparation method thereof. The emulsion is prepared from multiple components including jojoba oil, Limnanthes Alba seed oil, trehalose, panthenol, astaxanthin, resveratrol, laminaria digitata extracts, tranexamic acid, grape seed extracts, chlorella extracts, matricaria recutita extracts, crithmum maritimum extracts, ectoin, acetyl hexapeptide-8, allantoin, bisabolol, dipotassium glycyrrhizinate, sweet orange peel extracts and the like. While the effects of deeply retaining water, moisturizing, nourishing and repairing the skin and the like are achieved, a self-protection barrier can be established for the skin, and various irritations of the external environment can be isolated. In addition, the moisturizing emulsion disclosed by the invention has high safety and stability, the preparation technology is simple, conditions are controllable, and the moisturizing emulsion can be popularized and applied on a large scale.

Owner:上海蕾俪生物科技有限公司

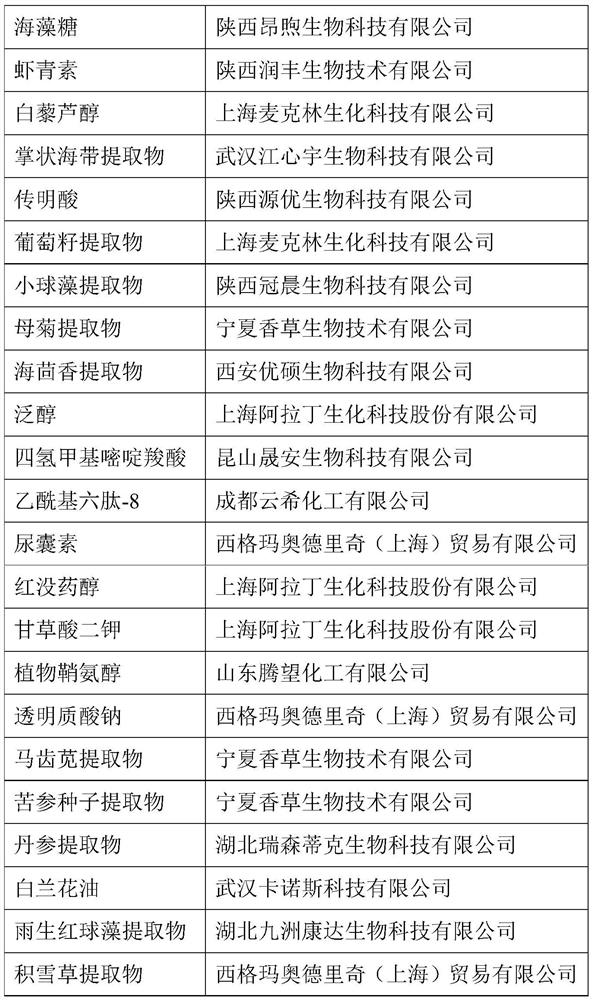

Marine bioactive composition and pharmaceutical preparation

InactiveCN106668077AStrong targetingGood curative effectBacteria material medical ingredientsAlgae medical ingredientsSide effectOyster

The invention provides a marine bioactive composition and a pharmaceutical preparation. The marine bioactive composition is prepared from the following components in parts by weight: 10 to 30 parts of oyster extract, 2 to 6 parts of kelp extract, 4 to 8 parts of seaweed extract, 5 to 10 parts of gloiopeltis furcata extract, 10 to 16 parts of hippocampus enzymolysis extract, 10 to 16 parts of sea cucumber extract, 4 to 8 parts of marine sponge extract, 2 to 6 parts of shark extract, and 15 to 25 parts of marine actinomycete fermentation liquor. The pharmaceutical preparation is a capsule, granules, an oral solution, a pill or medicinal granules prepared through mixing the composition, a pharmaceutical carrier and an additive. The composition has high pertinency, a good curative effect, little toxic or side effect, and a good antitumous effect.

Owner:SHANDONG TIANWANG PHARMA TECH

Anti-depression nutritional electuary and preparation method thereof

InactiveCN111869807ASimple manufacturing methodImprove production efficiencyNervous disorderInanimate material medical ingredientsBiotechnologyNutritive values

The invention discloses an anti-depression nutritional electuary. The anti-depression nutritional electuary is characterized by comprising the following components in parts by weight: 10-20 parts of plant polysaccharide, 5-10 parts of animal polysaccharide, 15-25 parts of hyperbranched polyamino acids, 2-5 parts of vegetable oil, 2-4 parts of folium isatidis extracts, 4-9 parts of anti-depressionChinese herbal medicine extracts, 0.1-0.6 part of vitamin B complex, 0.2-0.6 part of vitamin C, 0.5-1.2 parts of vitamin E, 1-3 parts of kelp extracts, 0.003-0.008 part of selenium lactate and 1-2 parts of food emulsifiers. The invention also provides a preparation method of the anti-depression nutritional electuary. The anti-depression nutritional electuary disclosed by the invention is balancedin nutrition, high in nutritional value, remarkable in mental pressure relieving and anti-depression effects, good in taste and good in patient taking compliance.

Owner:张伟

Haiyangzhishui cream and preparation method thereof

InactiveCN105796470AStrong sense of waterRefreshing and lightCosmetic preparationsToilet preparationsBiotechnologySkin repair

The embodiment of the invention discloses a Haiyangzhishui cream. The Haiyangzhishui cream comprises, by mass, 16-25% of a humectant, 2-3% of an emollient, 6-10% of a skin conditioning agent, 0.3-0.5% of an antiseptic, 0.2-0.5% of a desensitizer, 0.5-1.0% of a high-molecular polymer, and the balance of a solvent. The humectant comprises seawater, Laminaria digitata extract and trehalose; the emollient is squalane; the skin conditioning agent is hydrolyzed elastin and alga extract; the antiseptic is sea salt; the desensitizer is dipotassium glycyrrhizinate; and the high-molecular polymer is ammonium acryloyldimethyl taurate. The embodiment of the invention also discloses a preparation method of the Haiyangzhishui cream. The preparation method comprises the steps of emulsifying, mixing, cooling and stirring. The Haiyangzhishui cream prepared through the method integrates respective characteristics of toner, lotion, cream and mask, can instantly becomes a liquid, and has water supplementing, damaged skin repairing and skin resistibility and ageing resistance enhancing ability.

Owner:GUANGZHOU GELIN COSMETICS CO LTD

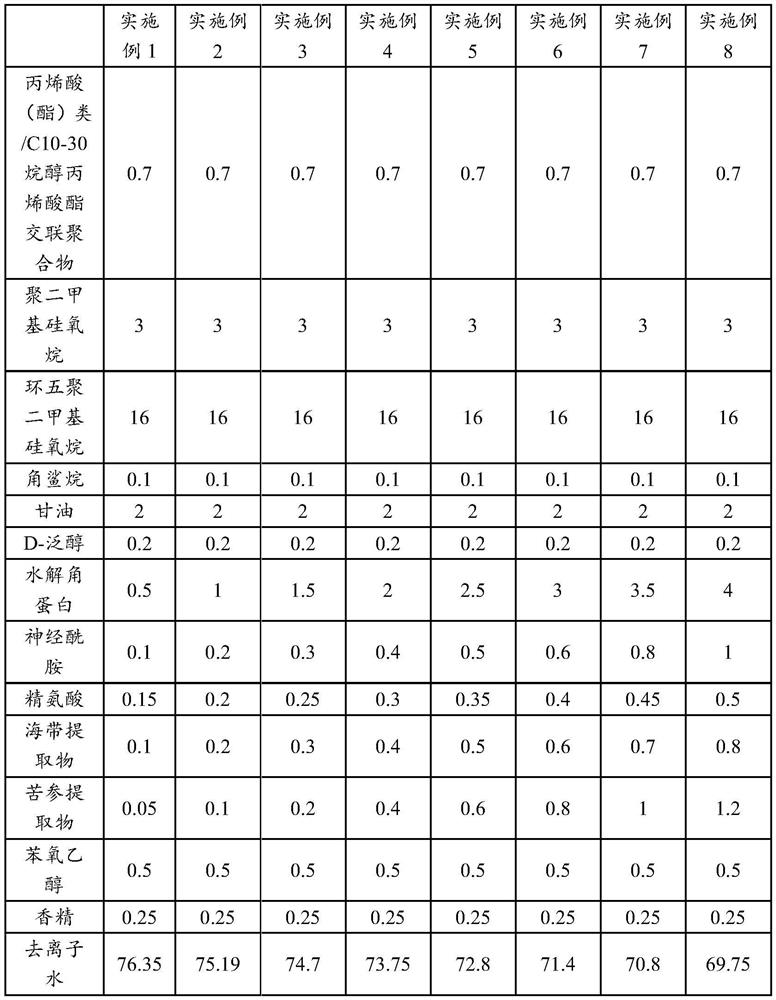

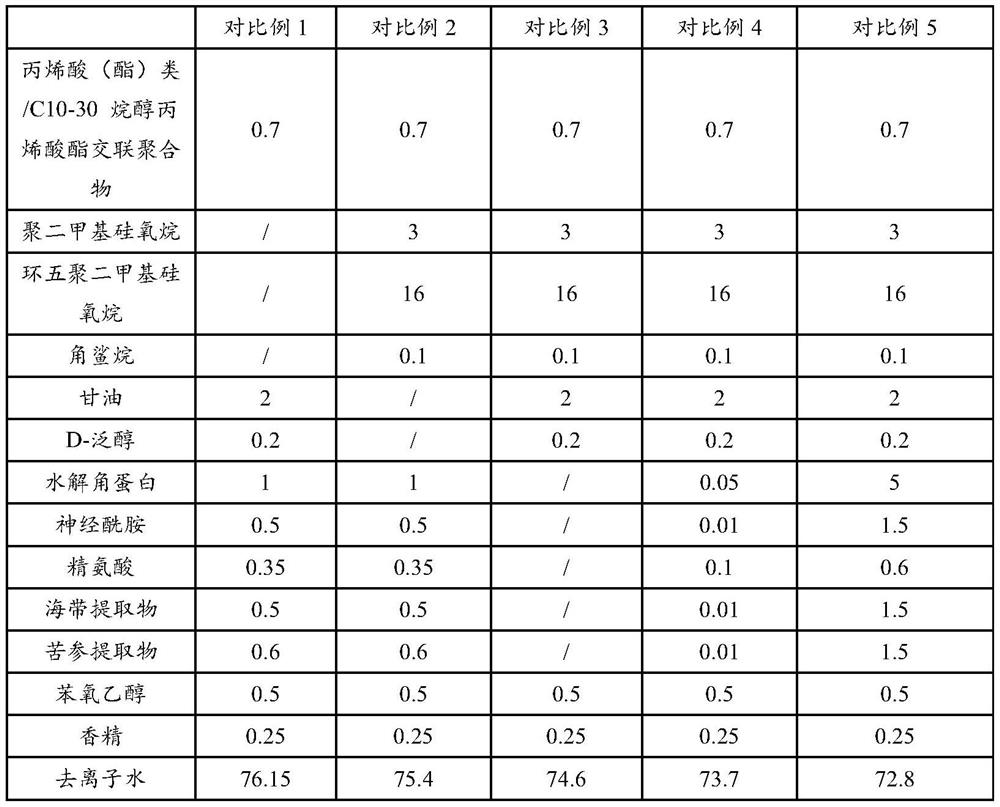

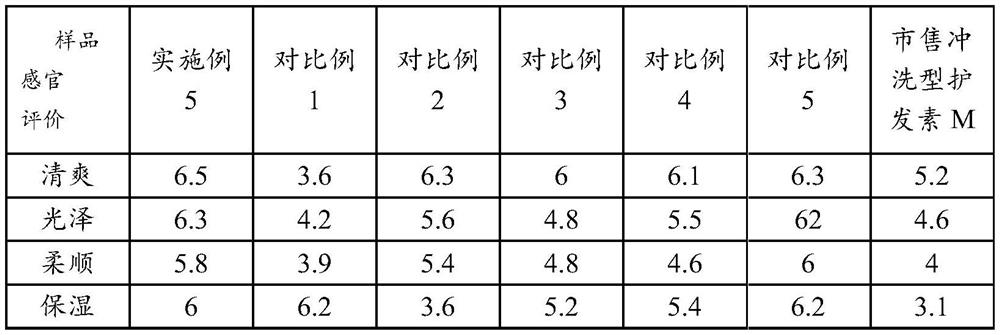

Haircare nutritional composition, wash-free haircare product, preparation method therefor and application of wash-free haircare product

PendingCN113143790AImprove health statusRepair damageCosmetic preparationsHair cosmeticsBiotechnologyArginine

The invention relates to a haircare nutritional composition, a wash-free haircare product, a preparation method therefor and application of the wash-free haircare product. The haircare nutritional composition is prepared from the following ingredients: 0.01-10 parts of hydrolyzed keratin, 0.01-5 parts of ceramide, 0.05-5 parts of amino acid and 0.01-3 parts of natural plant extract, wherein the natural plant extract comprises a kelp extract and a flavescent sophora root extract, and the amino acid is arginine. According to the haircare nutritional composition, all the ingredients are in synergism so as to provide nutrients for hair, and problems of the hair such as dryness, tangle, yellowing, forking and easily breaking are effectively improved so as to recover a state of health of the hair. According to the wash-free haircare product, the added hydrolyzed keratin and amino acid are important components of the hair, the natural plant extract, a humectant and the like are high-water-replenishing moisture-preserving ingredients, and the ingredients are in synergism, so that nutrients and moisture of the hair lost due to scalding, dyeing, blowing, drawing and sunning can be rapidly supplemented, injury to hair cuticles is repaired, and the problems of the hair such as dryness, tangle, yellowing, forking and easily breaking are effectively improved so as to recover the state of health of the hair.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

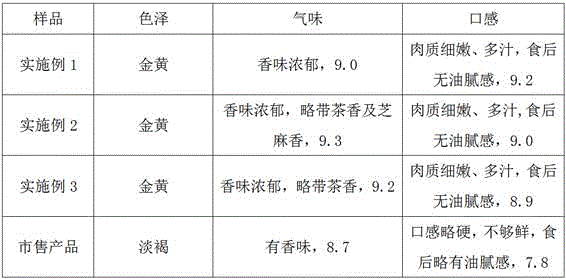

A kind of low-cholesterol steak and preparation method thereof

The invention discloses a low-cholesterol steak and a preparation method thereof. The low-cholesterol steak is prepared by thawing frozen beef raw materials, filling and rolling, marinating and mixing powder, filling bags for quick freezing, and slicing and packaging. In the present invention, various ingredients such as hawthorn juice and kelp extract are used to marinate the beef, and the obtained steak can be eaten after frying or microwave heating, and it is tender and juicy, easy to digest, and the cholesterol in the body will not increase after eating. It is also edible for people with poor gastrointestinal digestion function and high cholesterol; and the method of the invention has a high degree of standardization and is suitable for industrialized production of black pepper steak and filet mignon.

Owner:FUJIAN JUYUAN FOOD CO LTD

Melanin inhibiting cosmetic additive, preparation method and whitening cosmetic

InactiveCN112545927AEnhance anti-inflammatoryGood moisturizing effectCosmetic preparationsToilet preparationsBiotechnologyAllergy

The invention provides a melanin inhibiting cosmetic additive, a preparation method and a whitening cosmetic. The melanin inhibiting cosmetic additive is prepared from the following raw materials in parts by weight: 15-30 parts of a pogostemon auricularius extract, 10-20 parts of a phaeodactylum tricornutum extract, 5-12 parts of a nostoc commune extract, 2-5 parts of a euglena extract and 1-5 parts of a kelp extract. The melanin inhibiting cosmetic additive can prolong the moisturizing and water-locking effects of cosmetics by 5-7 hours, inhibit the formation of melanin, slow down the deposition of the melanin and improve the whitening effect, also has good effects of removing freckles, resisting allergy, resisting oxidation, resisting ultraviolet rays and the like, and has a wide application prospect.

Owner:上海典实医疗科技有限公司

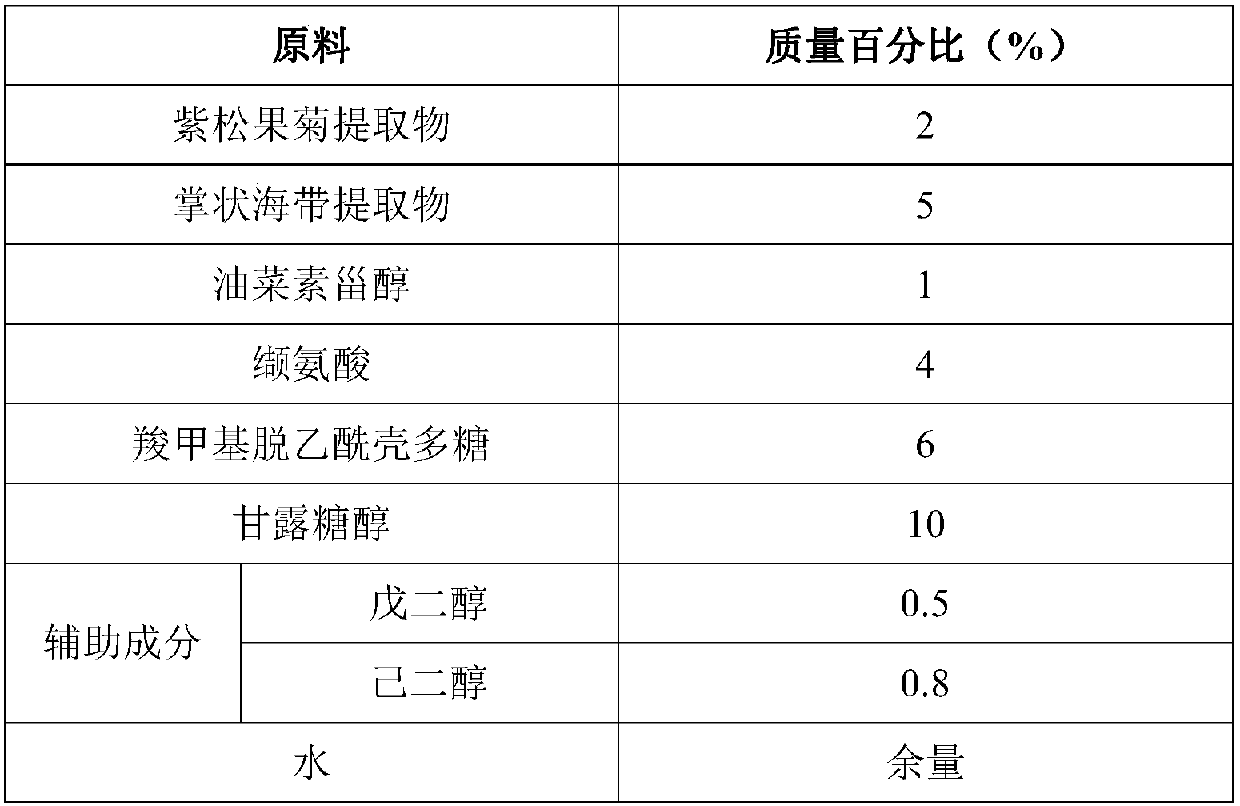

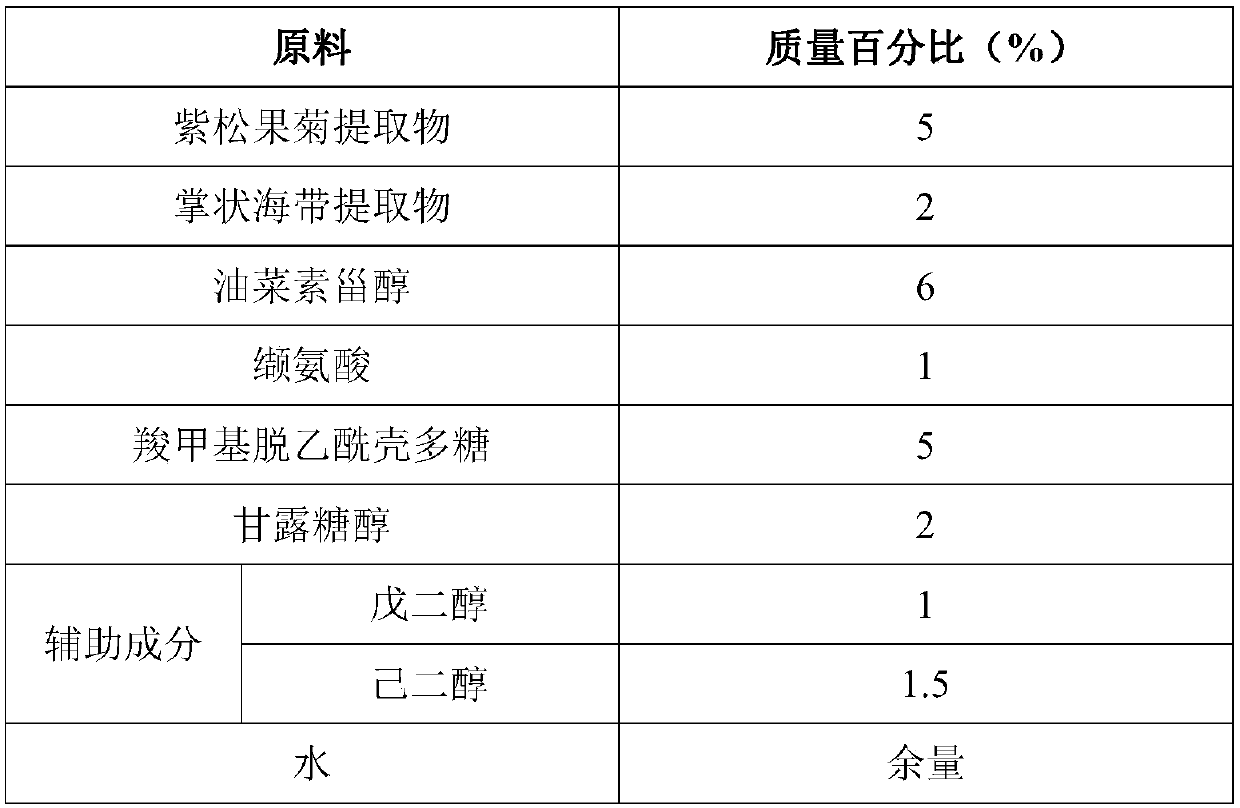

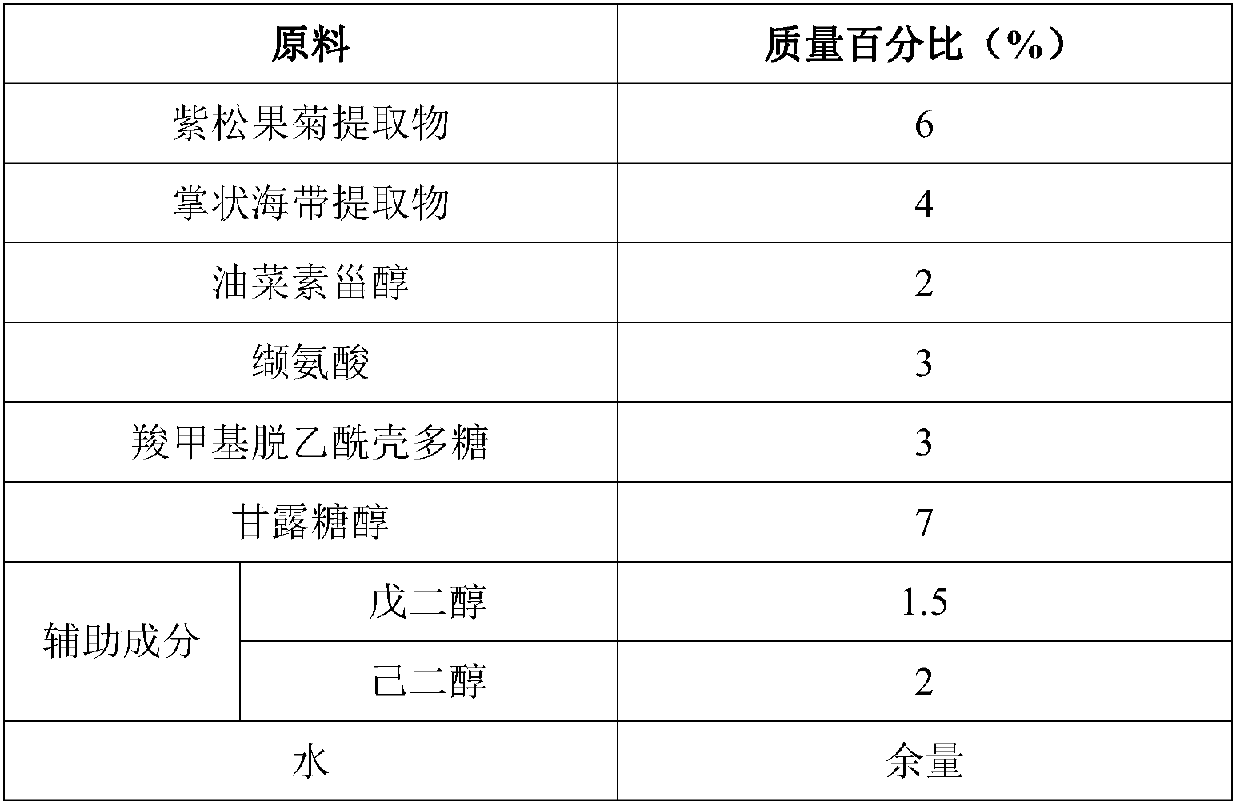

Scalp-care compound and application thereof

InactiveCN109674672AImprove protectionPrevent and Reduce EczemaCosmetic preparationsHair cosmeticsMetaboliteAdditive ingredient

The invention discloses a scalp-care compound and an application thereof. The scalp-care compound is composed of purple coneflower extract, laminaria digitata extract, brassinosteroid, valine, carboxymethyl deacetylchitosan, mannite, auxiliary ingredients and water. The scalp-care compound disclosed by the invention is mild and is capable of supplementing nutrients required by scalp, effectively protecting tender scalp skin of infant and assisting in cleaning scalp metabolite, preventing and reducing infant scalp eczema and inflammation, relieving and eliminating cradle cap symptom; the scalp-care compound fully conforms to various indexes of Cosmetics Safety Technical Specification (2015 version) issued by China; the scalp-care compound contains no toxic or harmful ingredient and is freefrom potential hazard.

Owner:GUANGZHOU BAOYAN BIOTECH

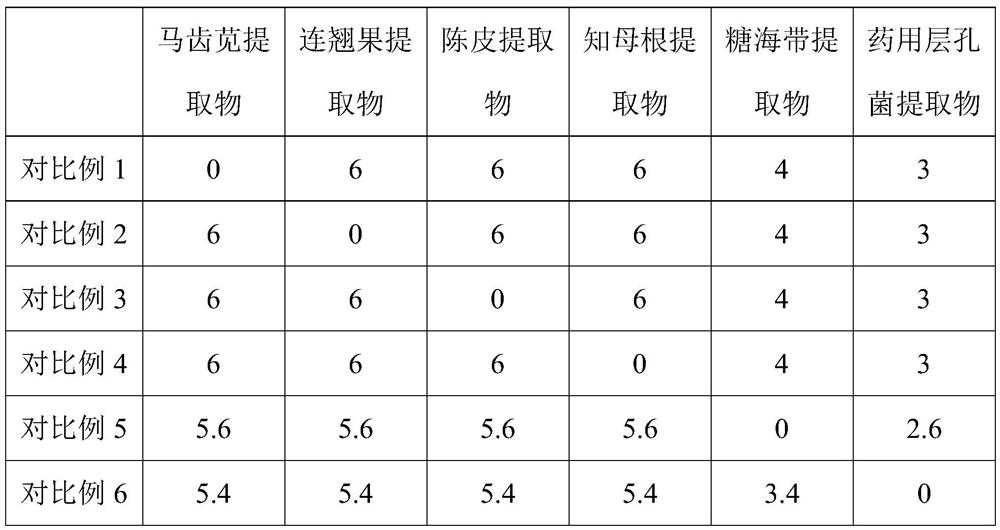

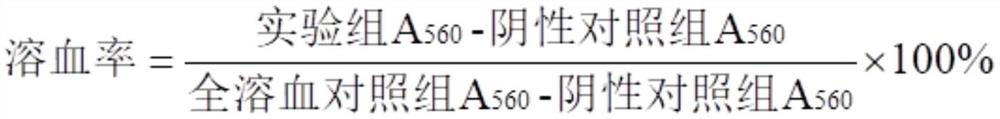

Pure natural plant oil-control astringent composition, essence and preparation method of essence

ActiveCN111643425AEliminate the danger of clogged poresReduce secretionCosmetic preparationsToilet preparationsBiotechnologyPurslane extract

The invention provides a pure natural plant oil-control astringent composition, essence and a preparation method of the essence. The pure natural plant oil-control astringent composition comprises herba portulacae extract, fructus forsythiae extract, pericarpium citri reticulatae extract, rhizoma anemarrhenae root extract, laminaria saccharina extract and fomes officinalis extract. The essence isprepared from the following raw materials: pure natural plant oil-control astringent composition, a humectant, a skin conditioner, a thickener and water. All the components in the pure natural plant oil-control astringent composition cooperate with one another and have a synergistic interaction effect, so that oil control and pore astringing are integrated, thick pores are astringed while oil control is performed, the problem of excessive grease secretion is radically reduced, and the problem of greasy skin is fundamentally solved; and by three major ways of inhibiting 5[alpha]-reductase, regulating sebum flow and rapidly converging pores, the effect of reducing grease secretion from the source is achieved.

Owner:广州极男化妆品有限公司

Freckle-removal moisturizing cream

InactiveCN104971023AWith whitening and freckle removalWrinkle freeCosmetic preparationsToilet preparationsBiotechnologySodium lactate

A freckle-removal moisturizing cream is prepared from the following raw materials in parts by weight: 6-9 parts of fish bone meal, 5-7 parts of kelp extract, 4-8 parts of vitamin C, 3-6 parts of aluminium silicate, 5-7 parts of turtle active peptide, 3-8 parts of plant amino acid, 4-7 parts of soybean symbiont extract, 2-5 parts of xanthan gum, 0.2-0.5 part of salvia miltiorrhiza extract, 5-10 parts of milk, 4-6 parts of disodium lauroamphodipropionate, 7-12 parts of sodium lactate, 6-10 parts of disodium stearoamphodiacetate, 8-16 parts of linseed oil, 8-17 parts of lily, 0.2-0.4 part of methylparaben, and 3-6 parts of licorice extract. The freckle-removal moisturizing cream has the benefits as follows: the freckle-removal moisturizing cream has the effects of whitening the skin, removing freckles and wrinkles, and tendering the skin, enables the skin to be glossy and elastic, nourishes the skin, and delays senescence.

Owner:QINGDAO YUXING INTELLIGENT TECH DEV CO LTD

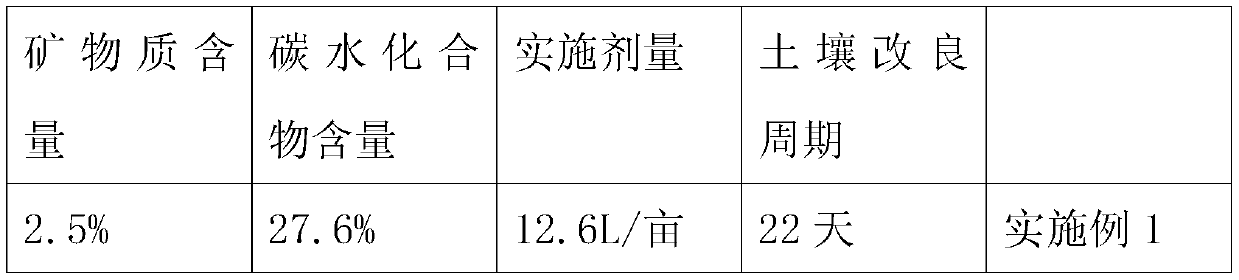

Mineral multifunctional fruit and vegetable soil conditioner and preparation method thereof

InactiveCN111171834AEfficient replacementHigh content of mineral elementsAgriculture tools and machinesOrganic fertilisersEngineeringPolyacrylamide

The invention discloses a mineral multifunctional fruit and vegetable soil conditioner, which comprises the following components in parts by weight: 2-4 parts of weathered coal, 3-8 parts of lime, 4-7parts of gypsum, 3.5-6 parts of vermiculite, 3-8 parts of a keratophyta extract, 0.3 to 1 part of kelp extract, 0.7 to 1.5 parts of tomato extract, 0.9 to 3.2 parts of blue algae extract, 0.6 to 2.3parts of laver extract, 1.2-1.5 parts of lignin, 1-4 parts of resin adhesive, 1.2-4.3 parts of urea, 0.8-1.8 parts of polyacrylamide, 0.6-1.5 parts of formaldehyde, 4-8 parts of fruit residues, 0.4-0.9 part of mineral powder, 2-4 parts of citric acid, 4.5-5.5 parts of sodium dodecyl benzene sulfonate, 1.7-3 parts of ferric chloride and 1.1-3 parts of manganese chloride. Extracts of multiple algaeare mixed, multiple beneficial microorganisms can survive, meanwhile, multiple ores are mixed, the mineral element content of the product is increased, the structure of soil can be effectively replaced, the regeneration capacity is high, the overall processing method is simple, and the method is worthy of popularization.

Owner:华仲动芯新材料(盱眙)有限公司

Feed capable of improving quality of eggs

The invention relates to animal feed and particularly relates to feed capable of improving quality of eggs. The feed is prepared from the following components in percentage by mass: 50-100 parts of barley, 50-100 parts of sorghum, 50-100 parts of soybean cake, 50-100 parts of maize, 50-100 parts of peanut cake, 100-120 parts of rice, 60-80 parts of rape seed cake, 50-60 parts of watermelon peel, 50-60 parts of sweet potato powder, 45-50 parts of martianus dermestoides meal, 25-30 parts of dried konjac, 10-15 parts of calcium hydrophosphate, 8-10 parts of folium artemisiae argyi, 12-15 parts of fructus crataegi, 3-5 parts of vitamin premix, 2-5 parts of radix astragali, 4-6 parts of fermented glutinous rice, 9-12 parts of rhizoma atractylodis, 20-25 parts of jujube dates, 8-10 parts of laminaria japonica extract, 18-22 parts of grape seeds, 1-2 parts of salt, 4-5 parts of phagostimulant and 1-3 parts of herba lysimachiae powder. The eggs of laying hens fed by the chicken feed are bright in color, rich in nutrient, smooth in eggshell and large in yolk.

Owner:QINGDAO BEIDOUXINGYUN COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com