Patents

Literature

54results about How to "Promote sustainable development of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete inner curing agent and preparing method thereof

The invention relates to an internal concrete curing compound and manufacturing method thereof. The ingredients include de-ionized water, non-metallic minerals, sodium hydroxide, acrylic acid and / or derivative monomer, water-soluble initiators of free radical polymerization, water-soluble cross-linker of free radical polymerization and addictive. The preparing method for the internal curing compound of solution-type concrete is characterized in that the following procedures are applied: 1) preparation of raw materials; 2) mixing of de-ionized water, sodium hydroxide, acrylic acid and / or derivative monomer; 3) the mixed solution is added and mixed with and in order of cross-linker, initiator, non-metallic minerals, epoxy ethane, rust retardant agent; the internal concrete curing compound can be obtained following a homogeneous mixing and heating with recycled hot air. The invention can save curing water, reduce manpower / material input, minimize addictive cost, effectively control water evaporation, reduce the cost for late concrete curing and enhance the comprehensive performance of concrete addictives, which proves to be environment friendly with respect to environmental impact.

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

Water retaining slow-release / controled fertilizer, and preparation method

InactiveCN101050147AIncrease profitReduce churnFertiliser formsFertilizer mixturesChemical synthesisControlled release

This invention relates to a method for preparing water-retaining sustained / controlled-release fertilizer, which comprises: nonmetal minerals, water-soluble ethylene-based unsaturated monomer, water-soluble free radical polymerization initiator, crosslinker, fertilizer, and excipient. The method comprises physical mixing, chemical synthesis and coating. The obtained fertilizer has sustained / controlled release, water retaining, and soil improving functions. The fertilizer has such advantages as high fertilizer utility, low cost of water-retaining agent, convenient application, and no pollution.

Owner:ZHUHAI GUOJIA NEW MATERIAL

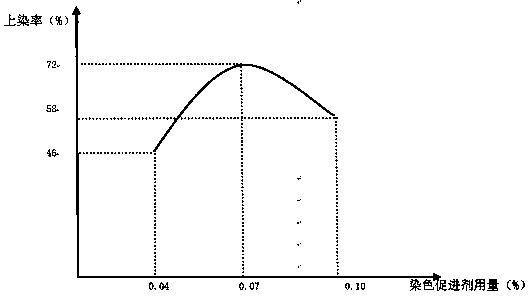

Method for improving dyeing rate of flax blended fiber fabric

PendingCN110804885AImprove surface affinityFacilitates adsorption and diffusionDyeing processFlax fiberDyeing

The invention relates to the technical field of dyeing and environmental protection, and discloses a method for improving the dyeing rate of a flax blended fiber fabric. Through the study of a fiber structure and a dyeing principle, the problems that in an existing process, flax blended fibers are adopted to process a fabric, the dyeing efficiency is low, dyeing is uneven and the cost is over highare solved, and the method comprises the steps of preparation of a dyeing accelerant, pretreatment before dyeing of the flax blended fiber fabric, dyeing process and air drying and washing. The prepared dyeing accelerant has a nano-scale titanium dioxide coating shell structure. The surface affinity of the flax fibers can be remarkably improved, and dye molecules can rapidly penetrate into the fibers. Diffusion and adsorption of the dye on the surface of a fiber fabric are promoted, and the dyeing is facilitated; the dyeing rate of the flax blended fiber fabric can be improved, and the dyed product is uniform in color and high in firmness; the application range of the flax fibers in the textile field is expanded; and by the process, the defects in the dyeing process of an existing flax blended fiber fabric can be overcome well.

Owner:界首市苏澳纺织科技有限公司

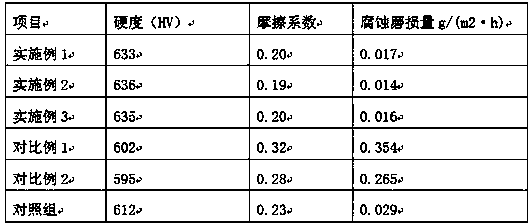

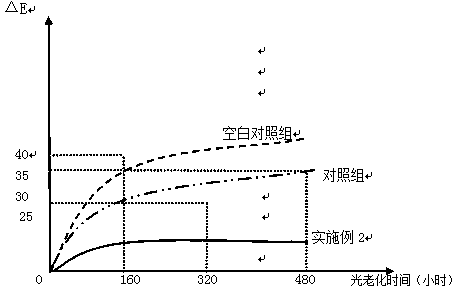

Powder coating for improving wear resistance and wear reduction of surface of aluminum profile

InactiveCN111763461AImprove heat resistanceShort curing timeFireproof paintsLiquid surface applicatorsWeather resistanceCorrosive substance

The invention relates to a powder coating for improving wear resistance and wear reduction of the surface of an aluminum profile. According to the invention, modified epoxy resin prepared by introducing polyfunctional groups into epoxy resin improves heat resistance and corrosion resistance and shortens curing time; melt extrusion is performed in order to further make up the defects of insufficient adhesive force and no wear resistance; an anti-scratching agent is added, so binding force to the aluminum profile is strong, and protective performance cannot be gradually reduced along with the prolonging of the service time of the coating. The powder coating prepared by the invention is applied to the surface of the aluminum profile, and has good associativity; and when the surface of the aluminum profile is coated with the powder coating, the powder coating shows excellent adhesion capability, has high mechanical strength, good weather resistance, chemical resistance, scratch resistanceand scuff resistance, cannot be damaged and lose efficacy, presents very strong wear resistance and reduction performance and high chemical corrosion resistance, plays an excellent protection role invarious complex environments, can bear erosive wear of gas, solid and liquid, has excellent outdoor stability, and prolongs the service life of the aluminum profile.

Owner:ANHUI SHUNBANG FINE CHEM

Preparation method of high-specific-capacity lithium battery cathode material

ActiveCN112447961ARichly intertwinedIncrease the areaMaterial nanotechnologyPositive electrodesCarbon compositesElectrical battery

The invention relates to the technical field of lithium battery cathode material preparation, discloses a preparation method of a high-specific-capacity lithium battery cathode material, and solves the problems that a sulfur-containing composite material cannot meet the requirement of rapid charging and discharging, a large amount of auxiliary conductive agent needs to be added, the sulfur-containing composite material is easily dissolved in electrolyte during discharging and the service life of a battery is influenced, the performance of the sulfur-containing composite material in the lithiumbattery is remarkably improved, the performance of the positive electrode material can be effectively improved, the performance of the prepared positive electrode material is comprehensively improved, and the circularity is enhanced. According to the invention, the conductivity of the sulfur-carbon composite positive electrode material is improved, the specific capacity is high, the effective value reaches 1240-1300mAh / g, the sulfur-carbon composite positive electrode material can also show excellent cycle performance at room temperature, the properties of quick charge and discharge, long discharge time, light weight and the like of a lithium battery are further improved, the requirements of modern electronic equipment industry are met, the use amount of a conductive agent is reduced, andcost is reduced.

Owner:安徽嘉誉伟丰机电科技股份有限公司

Method for improving performance of alloy cast iron for automobile mold

The invention relates to the technical field of new material processing and discloses a method for improving the performance of alloy cast iron for an automobile mold. Through the research on the alloy cast iron mold steel structure and material service performance, the low fatigue resistance of the alloy cast iron is solved from internal factors. The comprehensive performance of the mold materialis improved. After the alloy cast iron is smelted into molten iron and poured into a ladle in which the modified silica ceramic powder is placed in advanced, spheroidizing and inoculating are performed. After the reaction is completed, the slag removal purification is performed, and then the pouring forming is performed. In the preparation process of the modified silica ceramic powder, europium oxide and zirconium acetate are used as raw materials, and a rod-shaped nano europium oxide / zirconium oxide composite material is prepared through the reaction; and the nanostructure can prevent intercrystal grain from aggregating and growing and prevent the crack propagation, the good adhesion is shown, and the fatigue of the alloy structure is improved by forming an oxide mass point on the surface of an alloy, so that the prepared mold material has excellent thermal fatigue resistance.

Owner:MAANSHAN SANCHUAN MACHINERY MFG CO LTD

Polyester type high-temperature-resistant powder coating

InactiveCN111793417AImprove thermal stabilityImprove bindingFireproof paintsPowdery paintsSocial benefitsEconomic benefits

The invention relates to a polyester type high-temperature-resistant powder coating. According to the invention, the preparation formula of the traditional polyester resin and the synthesis conditionsof reaction temperature, reaction time, additive addition and the like in the preparation process are changed; the physical and chemical properties of the prepared modified polyester resin are completely different from those of conventional polyester resin, the acid value of the prepared modified polyester resin is 69-79 mgKOH / g, the viscosity is 32-37 P / DEG C, the glass-transition temperature and decomposition temperature are increased, and the prepared modified polyester resin has good stability and heat resistance. The prepared powder coating is good in storage stability, not prone to agglomeration, beneficial to electrostatic spraying construction, good in film mechanical property and high in coating performance, the problem that a polyester resin system is poor in thermal stability is effectively solved, the mechanical property of a coating film is improved, and the effects of remarkably improving heat resistance, enhancing and toughening are achieved. The method is suitable forbatch production, the production cost of enterprises is greatly reduced, more economic benefits and social benefits are brought, and the method has very wide application prospects.

Owner:ANHUI SHUNBANG FINE CHEM

Method for improving corrosion resistance of surface of power distribution cabinet

InactiveCN110499087AHigh thermal and chemical stabilityPrevent liquid phase transferAnti-corrosive paintsEpoxy resin coatingsElectrochemical responseOrganic structure

The invention relates to the technical field of novel material processing, and discloses a method for improving the corrosion resistance of the surface of a power distribution cabinet. According to the method provided by the invention, the principle of electrochemical corrosion and the change law of the physical and chemical properties of a corrosive scale layer are studied, in the preparation process of a protective coating, a layered polymetallic material is prepared by using lanthanum oxide as a raw material and an atom with a special electronic structure as a center and utilizing magnesiumions and metaaluminate radicals, the layered polymetallic material is subjected to organic structural modification to form a composite system, the composite system is added into an epoxy resin coating, the obtained anticorrosive coating coats the power distribution cabinet, so that the thermal stability and chemical stability of the metal material are improved, the free energy is a positive value, liquid phase transmission is prevented, and progress of corrosion is inhibited; and in the mass transfer process, resistance is set in an adsorption, charge transfer and electrochemical reaction tolimit an electrode reaction in the electrochemical reaction, so that electrochemical corrosion is effectively inhibited, the power distribution cabinet has excellent corrosion resistance in harsh working environments, and the safety and service life of the power distribution cabinet are improved.

Owner:刘宁

Method for preparing zinc oxide from material recovered from zinc-containing anticorrosive paint waste

InactiveCN110878391ASolve the dosageSolve process problemsProcess efficiency improvementPregnant leach solutionHigh energy

The invention relates to the technical field of novel material processing, and discloses a method for preparing zinc oxide from a material recovered from zinc-containing anticorrosive paint waste. Through pretreatment of the zinc-containing anticorrosive paint waste, the influence of hydrolysis of organic matter in paint on leaching extraction separation purification in a next step is reduced, theleaching rate is improved, the separation difficulty is reduced, the leaching time is shortened, the leaching temperature is reduced, and the acidity of a leaching solution can be selected at a lowerlevel range; in the extraction process, an extraction reagent and control conditions are selected to achieve high-efficiency low-energy consumption extraction results, finally the zinc oxide is prepared through recovery, the recovery rate is increased by 15-20%, the impurity content is less than 0.001%, and the purity reaches a class-I standard; and the method can significantly improve the quality of the zinc oxide prepared through recovery, reduce energy consumption and save costs, the recovery rate reaches 94% or more, the problems of a complex process, high energy consumption, a low yieldand low quality of current raw ore zinc pyrometallurgy can be solved, and the economic and social benefits are significantly improved.

Owner:安徽泰龙锌业有限责任公司

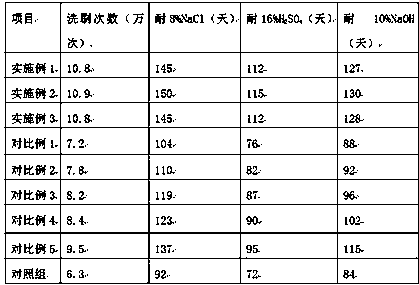

Long-acting flame-retardant treatment method suitable for wicker artware

ActiveCN111113605ADimensional Stability EffectStrong loss resistanceWood treatment detailsReed/straw treatmentThermodynamicsHigh humidity

The invention relates to the technical field of wicker artware development, and discloses a long-acting flame-retardant treatment method suitable for wicker artware. According to the method, a prepared flame-retardant material is allowed to infiltrate into a wicker material by adopting a normal-pressure heating impregnation treatment method; in the treatment process, adverse effects on the dimensional stability of the wicker material are avoided; the flame-retardant material has hydrophobicity, can shield the influence of moisture, can stably exist in the wicker material even under the conditions of high humidity and strong light irradiation, does not fade away flame-retardant effect, and is high in loss resistance and remarkable in flame-retardant effect; and the flame-retardant materialis economical and environment-friendly, is very stable in physical and chemical properties, large in specific heat capacity and capable of insulating heat and oxygen, can generate a free radical inhibitor when being heated, interrupts conditions for forming a combustion reaction, and expands the application range of wicker artware in other fields.

Owner:阜南佳利工艺品股份有限公司

Processing method of wicker artware raw materials

ActiveCN111185984AImprove antistatic performanceImprove corrosion resistanceWood treatment detailsReed/straw treatmentEmulsionMaterials processing

The invention relates to the technical field of wicker artware research, and discloses a processing method of wicker artware raw materials. According to the method, a protective coating material is prepared from prepared protective particles and a polyurethane emulsion, wicker artware raw materials are brushed with the protective coating material to form a protective film, and wicker artware is further prepared. According to the invention, with the treatment method, the physical and mechanical properties of wicker artware raw materials are improved, wherein when the water content is 4-5%, thecompressive strength reaches 93-96 MPa, and the wicker artware raw materials are not prone to cracking and deforming; the treatment method is easy to construct and short in curing and drying time, thetreatment reagent can be recycled, and the treated wicker has good antistatic and corrosion-resistant properties; and the method can well solve the problem that the processing and using properties ofweaving materials in the field of wicker artware cannot be effectively improved.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

Concrete inner curing agent and preparing method thereof

Owner:GUOJIA NEW MATERIAL HUBEI ENVIRONMENTAL PROT GEL IND PARK CO LTD

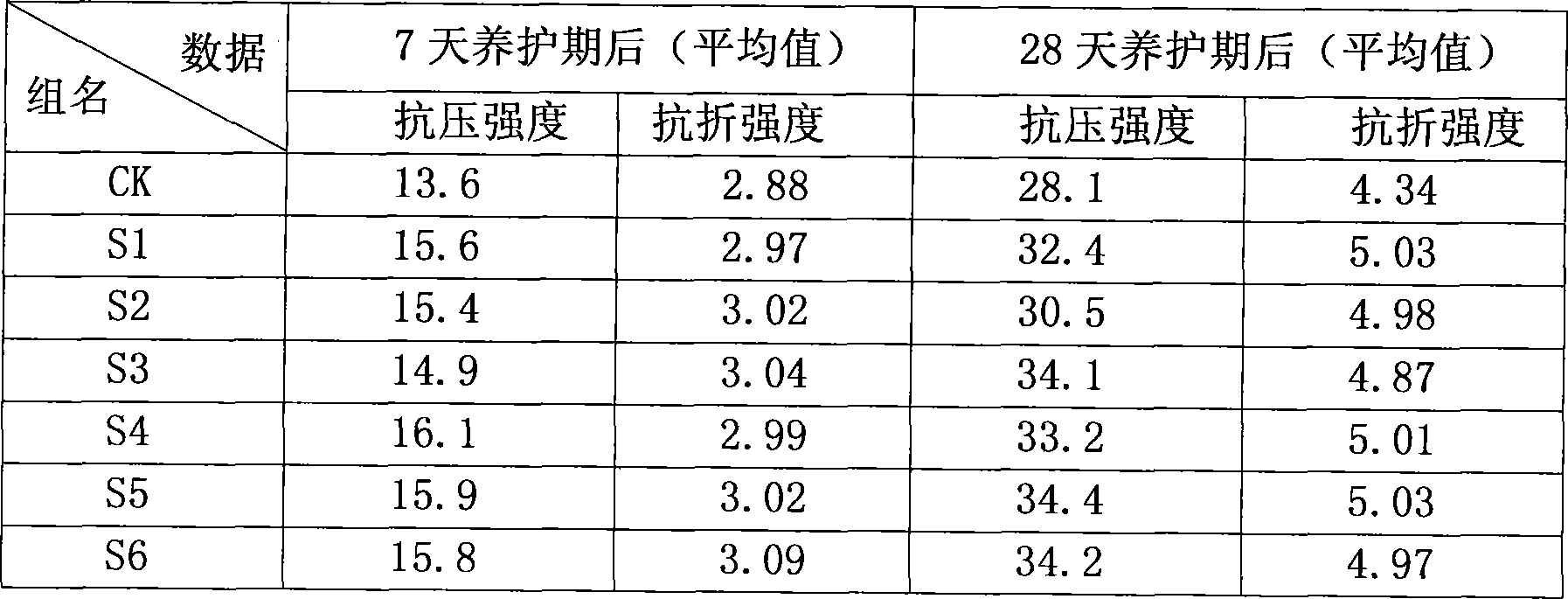

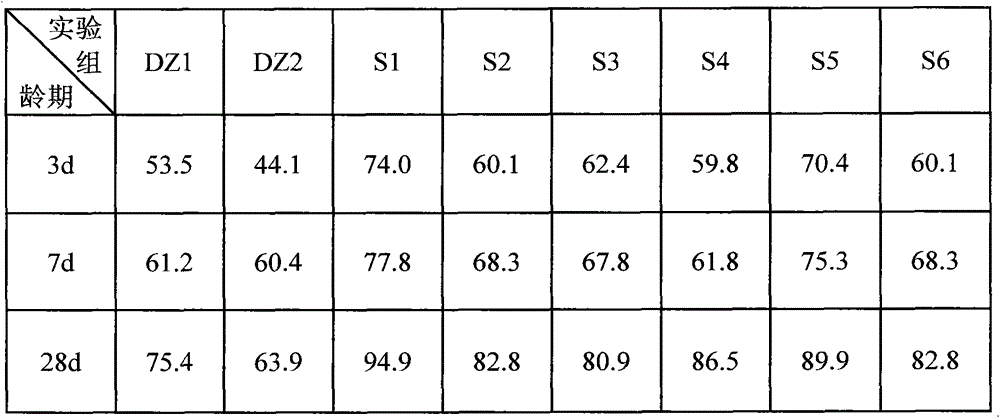

Method for improving utilization efficiency of gypsum in sulphoaluminate cement

InactiveCN111470789ASuppression of compressive strength shrinkage defectsImprove performanceCompressive resistancePhysical chemistry

The invention relates to the technical field of preparation of novel building materials, and discloses a method for improving the utilization efficiency of gypsum in sulphoaluminate cement. The methodincludes pre-treating Gypsum to improve the activation performance of the gypsum; applying same for respectively preparing sulphoaluminate cement clinker and adding pretreated gypsum into the sulphoaluminate cement clinker in a post-mixing manner, thus improving the gel strength and reducing the water demand, promoting sulphoaluminate cement clinker firing, and reducing combustion temperature andcarbon dioxide yield; according to the invention, the zinc-containing multi-metal nano powder is utilized to improve the hydration activity of the calcium sulphoaluminate mineral, a large amount of post-doped gypsum is not needed, and the prepared sulphoaluminate cement has the strength 12-17% higher than that of the sulphoaluminate cement added by 2 times of the amount of gypsum. The invention solves the problems of high gypsum consumption and poor accumulation effect in the preparation of sulphoaluminate cement, further enhances the resistance, durability, cracking resistance and other properties of the sulphoaluminate cement, and effectively inhibits the defect of later compressive strength shrinkage of the sulphoaluminate cement.

Owner:肥西县创玺建材科技有限公司

Antibacterial and odor-removing treatment method of cicada pupa protein fiber textile

InactiveCN110924146AShort processing timeGood effectBiochemical fibre treatmentAnimal fibresChemistryAnti bacterial

The invention relates to the technical field of textile industry development, and discloses an antibacterial and odor-removing treatment method of a cicada pupa protein fiber textile. The cicada pupaprotein fiber textile is subjected to oscillation cleaning in a treatment liquid containing an antibacterial porous adsorption material, the treatment time is short, and the effect is remarkable; according to the prepared antibacterial porous adsorption material, the specific surface area is large, well-developed pore structure and strong adsorption capacity causes no damage to cicada pupa proteinfibers, the surface gloss and mechanical strength of the cicada pupa protein fiber are kept, and the physical and chemical property is very stable; and the cicada pupa protein fiber textile has excellent antibacterial adsorption property, can remove peculiar smell, prevent discoloration, adsorb and remove harmful substances, the cicada pupa protein fiber textile becomes softer and has fine hand feeling, the application range of the cicada pupa protein fiber in the textile field is expanded, the process can well solve the technical dilemma that the existing cicada pupa protein fiber is easy tohydrolyze and the processing treatment performance is poor, and the protein fiber loss rate is less than 0.01%.

Owner:安徽省锦元纺织品科技有限公司

Surface coating for automobile aluminum profile part

InactiveCN112063286AImprove film toughnessHigh tensile strengthAnti-corrosive paintsPolyurea/polyurethane coatingsCorrosion resistantEmulsion

The invention relates to a surface coating for an automobile aluminum profile part, which takes an environment-friendly waterborne polyurethane emulsion as a basic raw material, and a prepared modified protective agent is added into the coating, so that the film-forming toughness can be improved, the tensile strength is obviously improved, and the binding force of intermolecular bonds is obviouslyenhanced; therefore, the anti-aging performance is correspondingly enhanced; the defects of insufficient adhesive force and no wear resistance of the water-based paint can also be overcome; and the added modified protective agent can obviously enhance the corrosion resistance and wear resistance after curing and film formation, thereby preventing the permeation and diffusion of the water and corrosive medium. The prepared coating has very high chemical stability, corrosion resistance and non-mobility, the corrosion resistance of the surface of the aluminum profile is improved, the prepared water-based paint is different from common solvent type paint, the binding force to the aluminum profile is high, the protective performance cannot be gradually reduced along with prolonging of the service life of the coating, and very wide application prospects are achieved.

Owner:MAANSHAN SANCHUAN MACHINERY MFG CO LTD

Method for reducing preparation cost of sulphoaluminate cement

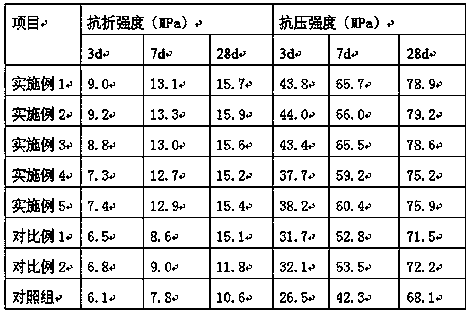

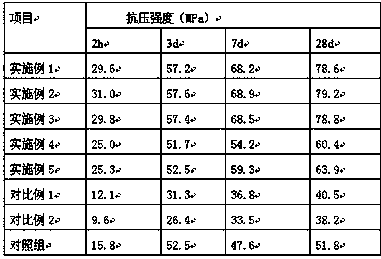

InactiveCN111499233AReduce manufacturing costImprove microstructureCement productionAluminateCompressive resistance

The invention relates to the technical field of preparation of novel building materials, and discloses a method for reducing the preparation cost of sulphoaluminate cement. The method performs modification of fly ash, and the obtained modified fly ash is used as a bauxite substitute for preparing sulphoaluminate cement clinker; rare earth is used for activating hydration activity of mineral substances in the coal ash so as to provide early hydration strength for cement, and the stability of later activity is maintained; the method has a fast hydration speed, stimulates activity, exerts later strength, improves the microstructure of the sulphoaluminate cement slurry, inhibits the later strength from collapsing, is very beneficial to the performance development of sulphoaluminate cement, andreduces the production cost of cement. The prepared sulphoaluminate cement has the 3-day compressive strength of 56 MPa or above and the 28-day compressive strength of 78 MPa or above, fly ash is effectively utilized, and the cost is reduced.

Owner:肥西县创玺建材科技有限公司

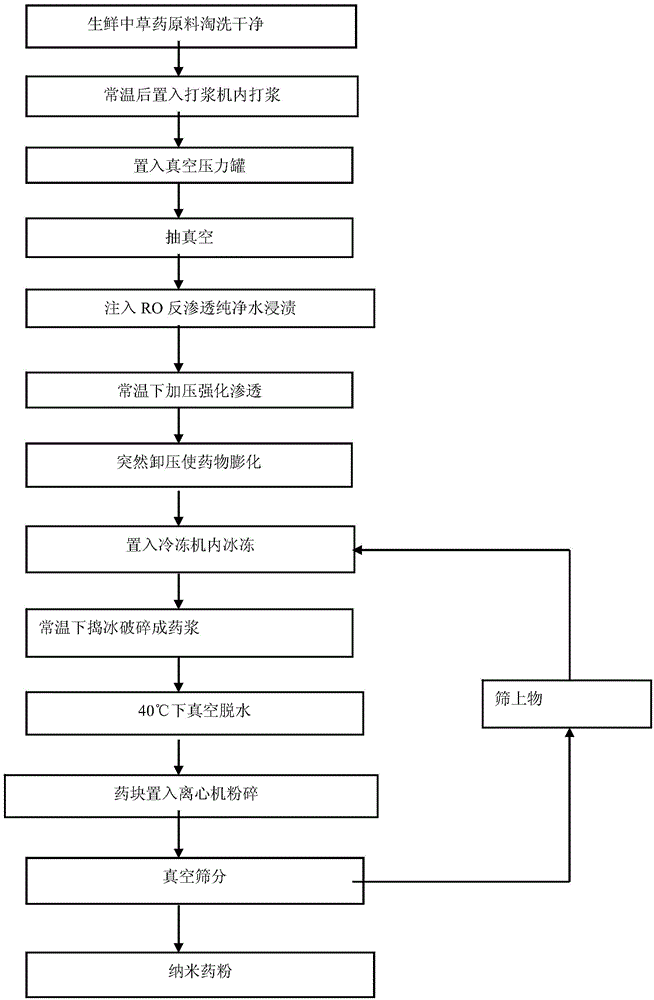

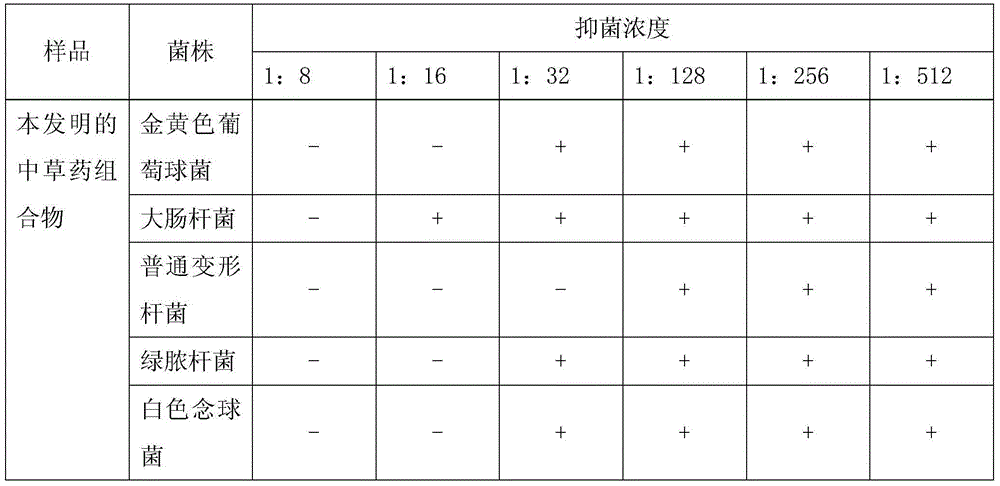

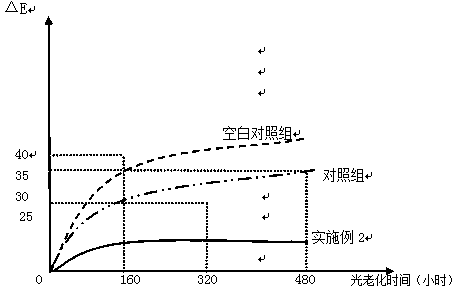

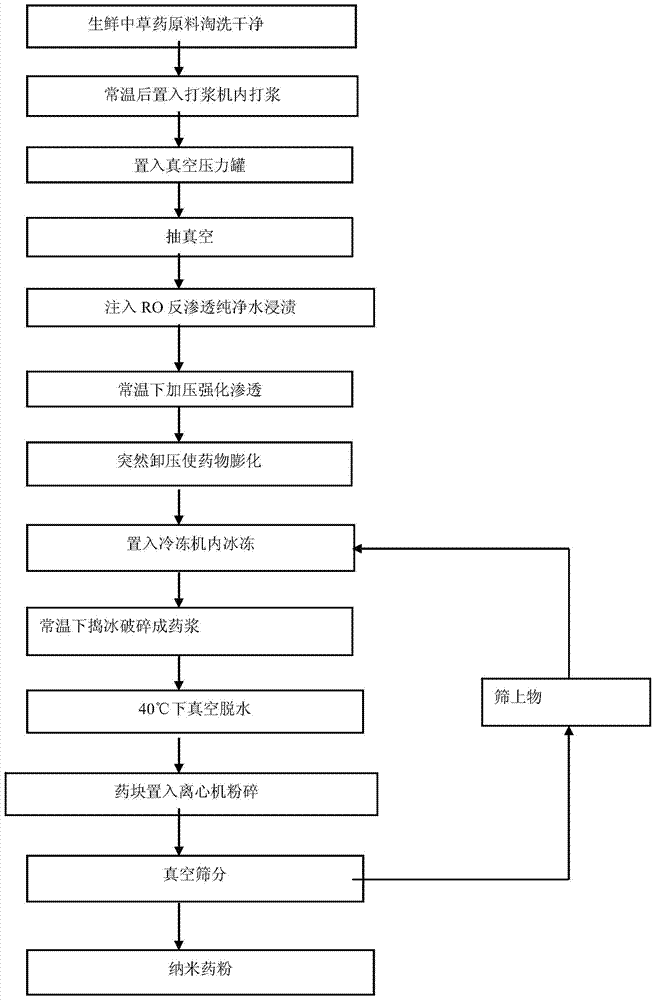

Primitively ecological nano processing method for Chinese herbal medicines

InactiveCN104083698AGuaranteed efficacyAvoid lostAntibacterial agentsPowder deliveryReverse osmosisSlurry

The invention discloses a primitively ecological nano processing method for Chinese herbal medicines. The method comprises the following process steps: washing raw and fresh Chinese herbal medicines, smashing the Chinese herbal medicines into slurry at normal temperature, adding the obtained slurry in a vacuum pressure tank and vacuumizing, impregnating at normal temperature in vacuum by using reverse osmosis (RO) purified water, pressurizing to enhance osmosis at normal temperature, suddenly relieving the pressure so that the medicines are bulked, freezing in a refrigerator, smashing ice and breaking to form slurry at normal temperature, performing vacuum dehydration at the temperature of 40 DEG C, and performing vacuum screening to obtain dried nano powder. The method has the advantages of energy conservation, low carbon, primitive ecology as well as capacities of keeping the drug effects of original medicines as much as possible, fully exerting the effects of drug resources and improving sustainable development of the drug resources.

Owner:广西仁普医院投资管理有限责任公司 +4

Method for prolonging service life of oil extraction pump for oil field

PendingCN111394760AHigh thermodynamic stabilityNot prone to electrochemical corrosionJewelleryOil fieldElectroplating

The invention relates to the technical field of performance research of pumps, and discloses a method for prolonging the service life of an oil extraction pump for an oil field. Prepared electroplating liquid is electro-deposited onto a pump body to-be-plated piece of the oil extraction pump through an electroplating method to form a dense electroplated coating with the thickness being 17.0-19.0 microns, immersion and flushing of corrosive media can be borne for a long term, and excellent chemical resistance and corrosion resistance are achieved; meanwhile, the prepared coating is hard, the surface friction coefficient is low, scaling is inhibited, and the defect that an existing protection coating cannot solve the problem of stress cracking corrosion caused by the corrosive media of the oil field is overcome; and the binding performance of the coating and a pump body can further be enhanced while the corrosion resistance of the coating is improved, defects such as blistering and falling are avoided, and high actual application value is achieved.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

Processing method for improving pilling resistance of wool fabric

InactiveCN111270517AReduce coefficient of frictionKeep the glossGrip property fibresAbrasion resistant fibresProcess engineeringWool fibre

The invention relates to the technical field of textile industry development, and discloses a processing method for improving pilling resistance of a wool fabric. An anti-pilling finishing agent is prepared by a polymerization reaction; after finishing the wool fabric, a uniform breathable coating layer can be formed on the surface of a wool fiber, the relative breaking strength and the relative breaking elongation are improved to a certain extent, the wet mechanical performance is improved, the electrostatic phenomenon is significantly improved, both the static friction coefficient and the dynamic friction coefficient of the wool are substantially reduced, a fiber scale layer can be effectively fixed, and the stability of wool keratin is improved, so that the hair shaft can resist the erosion of external machinery, chemicals, etc., the wool gloss, the hand feeling and the comfort are maintained, the anti-pilling performance of the wool fabric is improved, and the wool fabric can be subjected to machine wash; and the process can well solve the problem of large fiber damages caused by the fact that the existing anti-pilling method destroys and removes the fiber scale layer by usingchemical reagents.

Owner:阜南华翔羊毛衫有限公司

Method for recycling and preparing high-quality zinc oxide from zinc wastes

ActiveCN110723747AIncrease surface areaHigh recovery rateMaterial nanotechnologyAluminium silicatesProcess engineeringWaste material

The invention relates to the technical field of new material processing, and discloses a method for recycling and preparing high-quality zinc oxide from zinc wastes. Zinc waste components and the separation and recovery principle are researched, so the problems of poor quality and low recovery rate of existing recycled zinc products are solved from internal factors; and the zinc wastes are dissolved through an alkali liquor, a magnetic adsorption material is added into the obtained dissolving solution, and filtration is performed to prepare zinc oxide. The method can remarkably improve the quality of the recycled zinc oxide, reduce energy consumption and save the cost; and the energy consumption of 1 ton of yield in the regenerated zinc oxide production process is only 14-15% of the energyconsumption of primary zinc preparation, so the problems of complexity and high energy consumption of an existing pyrogenic zinc smelting technology and the problems of waste residue treatment difficulty increase, low yield and low quality, caused by loss of a large amount of the zinc element in extraction residues due to difficult increase of the extraction rate of acid process zinc smelting, are solved, and economic benefits and social benefits are remarkably improved.

Owner:安徽泰龙锌业有限责任公司

A kind of concrete internal curing agent, its preparation method and application method

The invention discloses a concrete internal curing agent. The concrete internal curing agent is super absorbent resin which has intelligent water absorption and water release functions and stably exists in concrete for a long term. The concrete internal curing agent comprises deionized water, sodium hydroxide, acrylic acid, a water-soluble initiator, a water-soluble crosslinking agent and natural grafted skeleton kaolin which is calcined kaolin. The concrete internal curing agent disclosed by the invention is environmentallyenvironment-friendly, high-efficiency and convenient to use; the addition amount of the concrete internal curing agent is small; raw materials for preparation are low in cost; and by adopting the concrete internal curing agent, the water consumption of fresh mixed concrete can be obviously reduced, the concrete property is improved, and the service life of the concrete is prolonged.

Owner:SHENZHEN UNIV

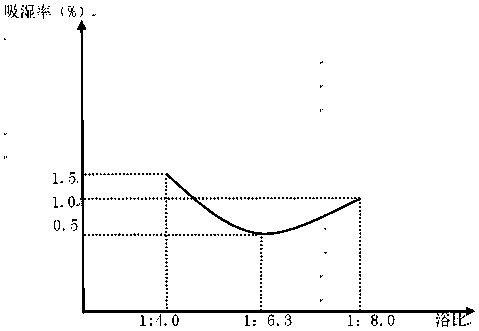

Method for improving durability of fast-growing wood furniture

ActiveCN111136742AReduce drying shrinkageLow swelling ratePressure impregnationWood impregnation detailsPulp and paper industryIndustrial engineering

The invention relates to the technical field of furniture material performance research, and discloses a method for improving the durability of fast-growing wood furniture. The method comprises the following steps: preparing a fast-growing wood dipping treatment solution from a prepared silane modified polyether emulsion and a silica sol, then carrying out a hydrothermal pressure impregnation reaction so as to obtain modified fast-growing wood which is excellent in aging resistance and mechanical strength, and carrying out further processing so as to prepare wooden furniture. According to thetreatment method, the fast-growing wood has excellent properties of wear resistance, compression resistance, corrosion resistance, water resistance, aging resistance, stable physical and chemical properties and the like, can be widely applied to production of various furniture, and has excellent processing performance; and the method can well solve the problems that the fast-growing wood in the furniture field is common in processing and using performances and has a plurality of defects in processing and application, improves the strength performance of a fast-growing wood material, achieves good effect in a plurality of aspects, relieves the supply and demand contradiction of the wood, and realizes highly-efficient utilization of the fast-growing wood.

Owner:FUNAN COUNTY TIANYI CRAFTS

Original ecological nano-processing method of Chinese herbal medicine

InactiveCN104083698BGuaranteed efficacyAvoid lostAntibacterial agentsPowder deliveryReverse osmosisSlurry

Owner:广西仁普医院投资管理有限责任公司 +4

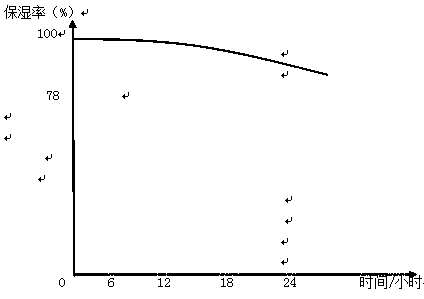

Water-retention moisturizing night cream suitable for dry skin type

PendingCN111388373AStrong water-locking and moisturizing abilityCurb churnCosmetic preparationsAntipyreticBiotechnologySkin barrier function

The invention relates to the technical field of skin care product research, and discloses a water-retention moisturizing night cream suitable for a dry skin type. A prepared plant additive with a water-retention moisturizing effect is added into a base formula according to the mass percentage of 1.4-1.6% to be mixed to prepare a mixed cream, wherein the plant additive is prepared from pea extractand chenopodium quinoa extract, thereby achieving strong water retention and moisturizing capability, and also playing an anti-inflammatory and detumescence effect; and in addition, the night cream isvery stable in physical and chemical properties, has excellent water retention performance, inhibits moisture loss in the skin, repairs water shortage and damage to the skin state, enables skin to besmooth and flexible, can maintain the integrity of the facial skin structure, plays a good skin barrier function, and prevents excessive loss of moisture and electrolyte.

Owner:蚌埠天泽家用化学品有限公司

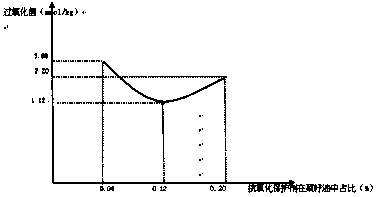

Method for reducing deterioration speed of rapeseed oil in frying process

InactiveCN110699177ASolve the problem of rapid deteriorationSolve the problem of generating hazardous substancesFatty substance preservation using additivesFatty-oils/fats productionFood materialProcess engineering

The invention relates to the technical field of agricultural and sideline product processing, and discloses a method for reducing the deterioration speed of rapeseed oil in a frying process. Accordingto the invention, the physical and chemical properties and the cooking taste of oil frying are studied, so that the problem that the rapeseed oil is oxidized and deteriorated to generate harmful substances in the high-temperature frying process is solved, the thermal oxidation, thermal polymerization, thermal decomposition and oxidation reactions are prevented under the frying high-temperature condition, the taste of the erucic acid in the rapeseed oil can be covered by adding the prepared anti-oxidation protection agent, the taste of the dish is not affected, the generation of the fragrancein the cooking can be promoted, and the food material processing is facilitated; the method comprises: preparing low-fat rapeseed oil by adopting a low-temperature squeezing method, adding a preparedanti-oxidation protection agent, and finally blending; and the process can well solve the disadvantage of high-temperature intolerance and easy deterioration of the existing rapeseed oil, is not addedwith harmful substances in the treatment process, has characteristics of no impurity residue, simple technology and low cost, and improves the utilization rate of the rapeseed oil in the frying process.

Owner:安徽省含山县油脂有限公司

Method for improving wear resistance of motor running bearing

Relating to the technical field of new material processing, the invention discloses a method for improving the wear resistance of a motor running bearing. By studying the performance of a superfine nano material, a prepared lubricating oil additive is added into base lubricating oil to lubricate a motor running bearing, thus greatly improving the lubricating properties of the lubricating oil, reducing the friction coefficient, and playing a pressure-resistant and antifriction role, even under the conditions of high load and high rotating speed, the bearing anti-wear capability of a rotating shaft can be permanently guaranteed. The lubricating oil additive material can reinforce the lubricating properties of base oil, reduce the roughness of a contact surface, has good dispersity in lubricating oil and small dosage, can effectively fill micro pits, scratches and the like on a friction contact surface in a motor running process, repair a damaged friction surface and reduce wear, and evenunder an oil shortage state, the material also can form an excellent surface lubricating protection film, thus broadening the use occasion of the material.

Owner:安徽实友电力金具有限公司

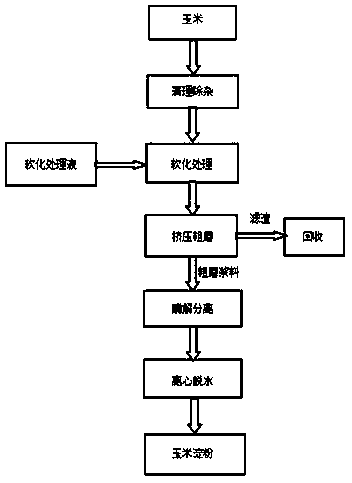

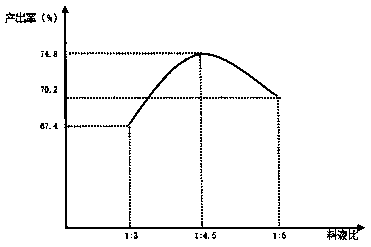

Processing process for increasing yield of corn starch

The invention relates to the technical field of agricultural and sideline product processing. The invention discloses a processing process for increasing the yield of corn starch. Through researchinga starch structure and an enzymolysis separation principle, the problems in the prior art that starch purity is not high due to incomplete fiber separation caused by excessive grinding, and the problem of a low powder yield caused by starch residues in slag due to too light grinding are solved. The method comprises the steps of cleaning and impurity removal, softening treatment, extrusion and coarse grinding, enzymolysis separation, and dehydration and air drying. Corn subjected to softening treatment has a loose cell tissue structure; the better the cell wall separation effect is, the more thorough various substances are released, enzymolysis is facilitated, the corn pulping rate and the starch conversion rate can be increased, starch components are kept to a great extent, and corn starchobtained is high in purity. The process can solve the disadvantages in the existing corn starch processing extraction process, improves the corn comprehensive utilization rate, reduces the cost, andincreases the yield of the corn starch.

Owner:安徽金玉米农业科技开发有限公司

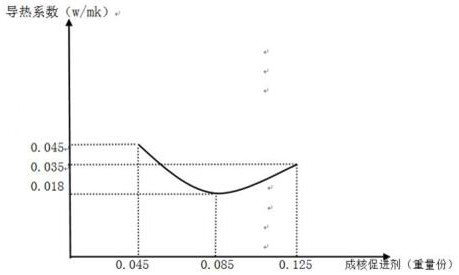

A kind of anti-compression and anti-deformation thermal insulation material for furniture production

The invention relates to the technical field of furniture material performance research, and discloses a pressure-resistant and deformation-resistant thermal insulation material for furniture production, which uses acrylonitrile and methacrylic acid as monomers, adds a prepared nucleation accelerator, and performs pre-polymerization to obtain a pre-polymerized material. The polymer is further foamed at high temperature to obtain the compression-resistant and anti-deformation thermal insulation material; the thermal conductivity of the prepared thermal insulation material is 0.018-0.020w / mk, the thermal conductivity will not increase due to moisture absorption, and the aging resistance and mechanical strength are excellent. The thermal insulation material has excellent properties such as light weight, insulation, shock resistance, compression resistance, corrosion resistance, water resistance, aging resistance, and stable chemical properties. It can be widely used in the insulation core layer of furniture and has excellent forming properties. It solves the dilemma of general thermal insulation performance of thermal insulation materials in the furniture field and many shortcomings in processing and application. In addition to improving the thermal insulation performance of materials, it has also achieved good results in other aspects.

Owner:ANHUI CHANGFA IND

Preparation method of heating material for heating self-heating food

InactiveCN110845999ASolve the problem of less heat production and uneven heatEvenly heatedHeat-exchange elementsSelf-heating food packagingIron oxide

The invention relates to the technical field of processing of new materials and discloses a preparation method of a heating material for heating self-heating food. According to the invention, based onstudies on the principles of heat conduction, heat convection and heat transfer, the prepared magnetic porous-structure heating material is used as a heat source for self-heating of food, and good heat conduction effect is obtained; non-magnetic components are magnetized in virtue of magnetocaloric effect under the action of the magnetic force of nanometer iron oxide, so heat is further generatedto heat food; and the heating material does not generate harmful and dangerous gas in the use process, is high in heat release efficiency, can be repeatedly used after demagnetization, and is not affected in use effect. With the preparation method in the invention, the heating efficiency of the heating material for food can be remarkably improved, and heat production is stable; the heat release amount of the prepared heating material per unit mass reaches 1700-1800 kcal / kg; the prepared heating material is resistant to storage, light in weight, high in heat production efficiency, uniform in food heating, friendly to environment, and safe and convenient to used; and overturning is not needed in the using process of the heating material, so the taste and convenience of self-heating food areimproved.

Owner:安徽省三车节能科技有限公司

Method for improving production efficiency of vat dark blue BO

InactiveCN110791115ASolve the disadvantages of dyeingLow costAnthracene dyesExhaust fumesProcess engineering

The invention relates to the technical field of new material processing, and discloses a method for improving the production efficiency of vat dark blue BO. The process steps are integrated and optimized; the problem of low raw material utilization rate in vat dark blue BO production is solved from the aspect of reducing consumables; waste gas and waste liquid generated in the production process are repeatedly recycled; in the production process of the vat dark blue BO, three sets of synthesis methods of triethylene glycol, primary mother liquor and secondary mother liquor are carried out at the same time; the process conditions of the steps are tightly controlled, the reaction rate is accelerated, the loss is reduced, and the reaction time can be prevented from being too long; the dye hascharacteristics of crystallization and precipitation, peroxidation can be avoided, the prepared vat dye has excellent comprehensive performance, the process can well solve the disadvantages of a conventional anthrone vat dye during dyeing, and the comprehensive utilization rate of the processing raw material is improved so as to reduce the cost and improve the recycling performance of the recovered raw material.

Owner:安徽融创化工科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com