Patents

Literature

45 results about "P-Dihydroxybenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

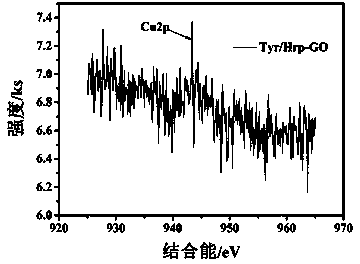

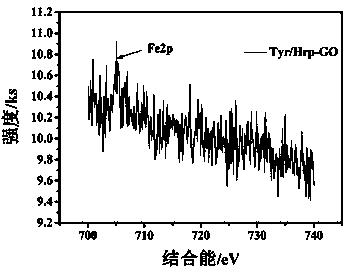

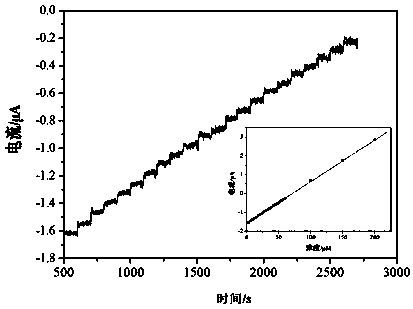

Preparation method and application of co-immobilized enzyme electrode used for detecting p-dihydroxybenzene and o-dihydroxybenzene

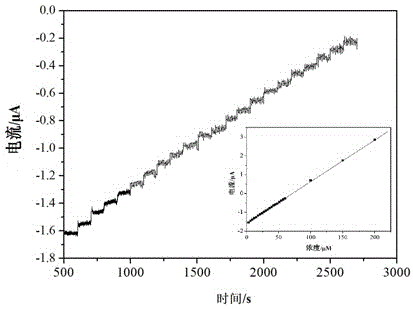

InactiveCN104007156ALow detection limitQuick checkMaterial analysis by electric/magnetic meansPeroxidaseEnzyme electrode

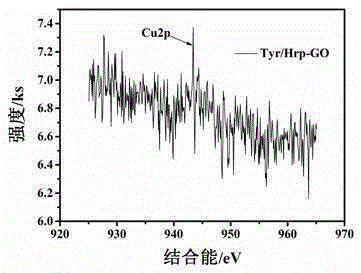

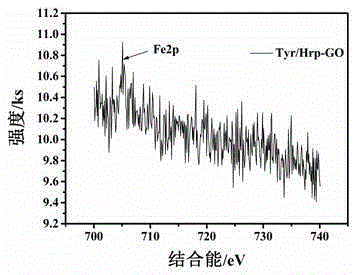

The invention provides a preparation method and an application of a co-immobilized enzyme electrode which is used for detecting p-dihydroxybenzene and o-dihydroxybenzene. The preparation method comprises steps of: immobilizing tyrosinase and peroxidase on oxidized grephene to obtain a co-immobilized enzyme liquid and smearing dropwisely the co-immobilized enzyme liquid and a chitosan solution successively on a surface of a glassy carbon electrode to obtain the co-immobilized enzyme electrode which is used for detecting p-dihydroxybenzene and o-dihydroxybenzene. The electrode is low in cost, is easy and convenient to operate, is quick and sensitive, is low in detection limit, is good in selectivity and can be used for detecting microscale p-dihydroxybenzene and o-dihydroxybenzene in environment.

Owner:HOHAI UNIV

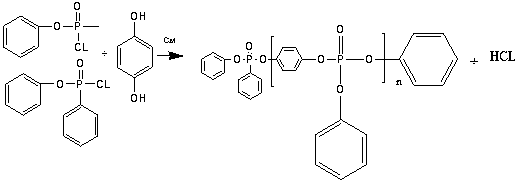

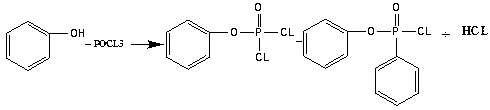

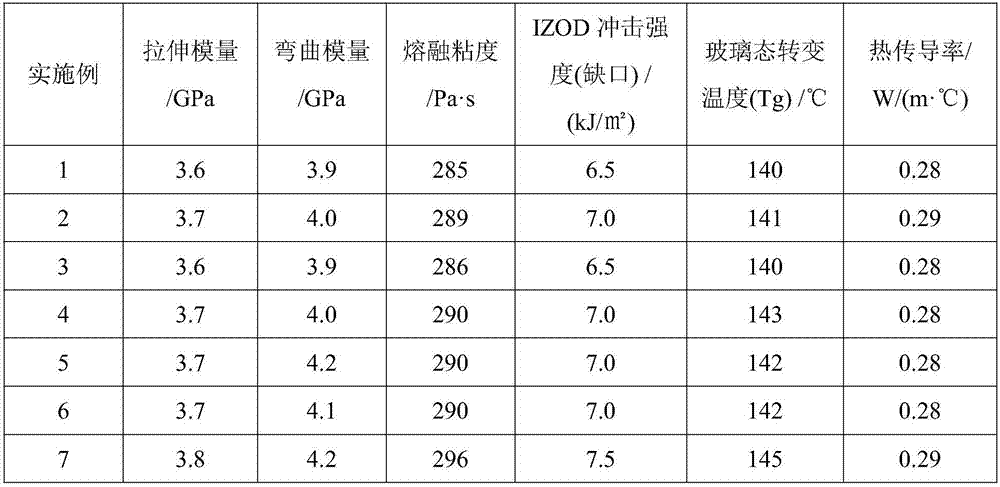

Preparation method of low-triphenyl phosphate engineering plastic halogen-free flame retardant

ActiveCN107629086AReduce contentReduce the temperatureGroup 5/15 element organic compoundsEnvironmental resistanceEngineering plastic

The invention belongs to the technical field of applied engineering plastics, and in particular, relates to a preparation method of a low-triphenyl phosphate engineering plastic halogen-free flame retardant. The method comprises the steps: under the action of a Lewis catalyst, carrying out a reaction of phenol with phosphorus oxychloride, reducing the pressure and distilling out excess phosphorusoxychloride, to obtain a mixture intermediate; carrying out a condensation reaction of the mixture intermediate and p-dihydroxybenzene, carrying out a reaction of the mixed intermediate with a properamount of p-dihydroxybenzene firstly, after a part of p-dihydroxybenzene is completely reacted, carrying out high vacuum dehydrochlorination, then adding triethylamine and the remaining p-dihydroxybenzene at relatively low temperature, and carrying out a reaction, wherein increase of the content of triphenyl phosphate is greatly reduced, toxicity to human bodies is reduced, and at the same time, the purity and the yield of the product are improved; and the preparation method has the advantages of simple process operation, short production cycle, economy and environmental protection, can satisfy the requirements of industrial scale production, and is suitable for industrialized popularization and application.

Owner:ZHEJIANG WANSHENG

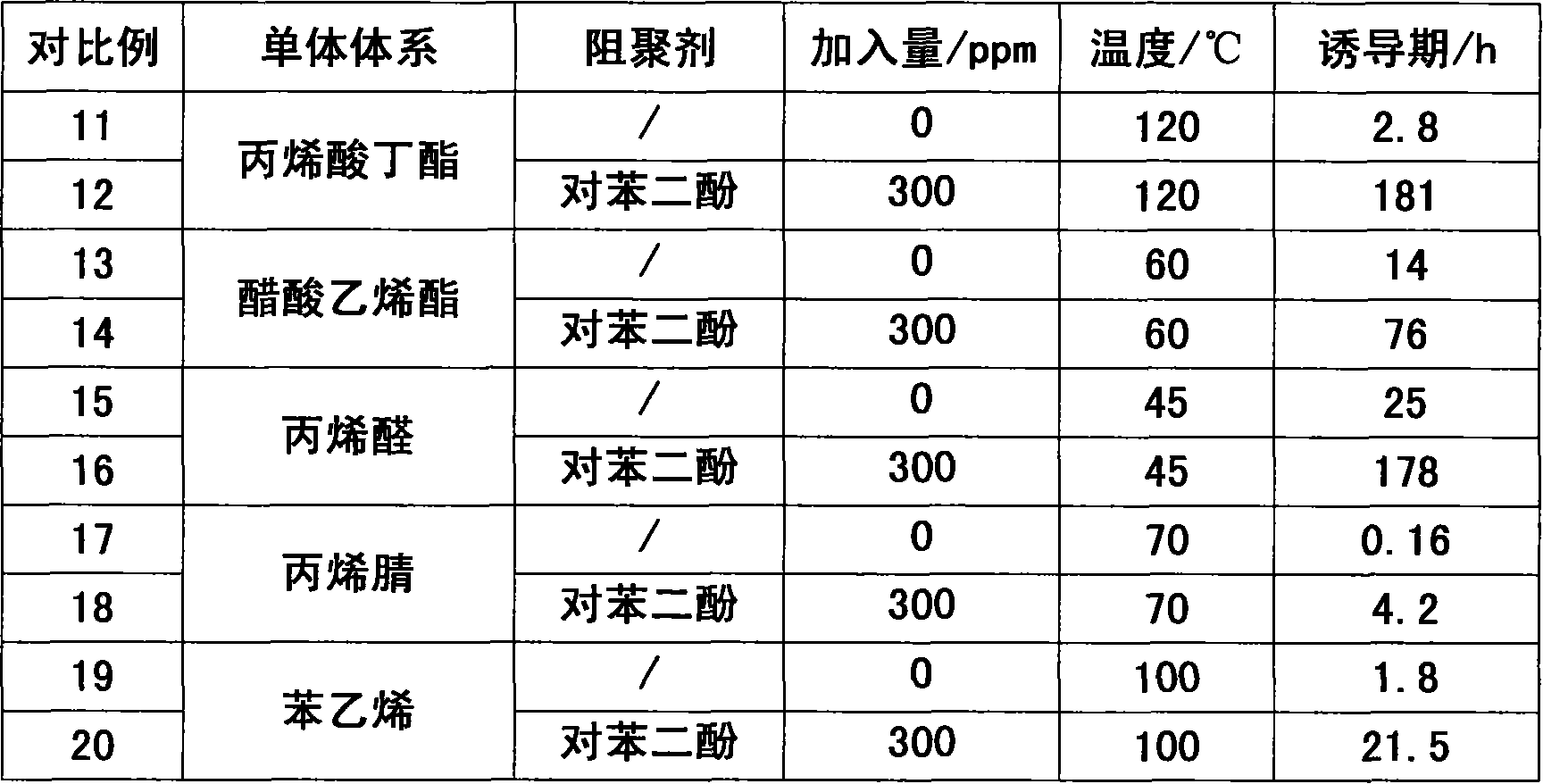

Reutilizing method for phenol coke tar waste slag

ActiveCN101240169AReduce consumptionSimple recycling processOrganic compounds purification/separation/stabilisationChemical inhibitorsSlagTar

The invention relates to a method for using phenol tar obtained from the process of producing o-dihydroxybenzene / p-dihydroxybenzene by phenol hydroxylation as an inhibitor of unsaturated compound monomer, specifically, adopting tar dregs signally or mixing it with one or several of copper salt compounds, nitroxy free radical compounds, phenol and amine compounds as the inhibitor of unsaturated compound monomer, wherein the adding amount of the inhibitor is 50 to 5000ppm to the unsaturated compound unit by mass. With reuse of tar dregs, dregs in dihydroxybenzene production is processed, saving energy and reducing environmental pollution. In addition, compared with other inhibitor systems adopted in various unsaturated compound monomers in industry, the invention has better inhibition effect and lower cost.

Owner:SHANGHAI HUAYI NEW MATERIAL

Preparation method of polyether ether ketone terpolymer

The invention provides a preparation method of polyether ether ketone terpolymer. The polyether ether ketone terpolymer, which is prepared by taking 4,4'-difluorobenzophenone, p-dihydroxybenzene and 4,4'-biphenol as raw materials, taking diphenyl sulfone as a solvent and taking a mixture of sodium bicarbonate and potassium bicarbonate as a salt-forming agent, has high heat stability, high mechanical property and high processability. The p-dihydroxybenzene and the 4,4'-biphenol serve as a phenol monomer mixture, the steric hindrance of the polyether ether ketone polymer is increased and the temperature resistance of the product is improved; in addition, the 4,4'-biphenol is not liable to oxidation compared with the p-dihydroxybenzene, and the stability of the phenol monomer can be improved due to addition of the 4,4'-biphenol.

Owner:YIBIN TIANYUAN GRP CO LTD

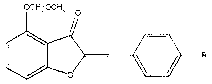

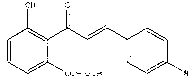

Preparation method of 4-hydroxy aurone compound

The invention relates to a synthesis method of a hydroxy aurone compound, and particularly relates to a preparation method of a 4-hydroxy aurone compound. The preparation method is as below: reacting raw materials comprising 2',6'-dihydroxy acetophenone and a benzaldehyde derivative; first protecting 2',6'-dihydroxy acetophenone with one hydroxy; then conducting condensation and cyclization on the 2',6'-dihydroxy acetophenoneand benzaldehyde derivative; and conducting deprotection to obtain the 4-hydroxy aurone compound. The 4-hydroxy aurone compound has a structural formula as below; and R represents any substituent group. Compared with the existing method, the preparation method provided by the invention has advantages of low price of raw materials, high yield, short reaction time, simple and mild reaction conditions, and simple operation, etc.

Owner:UNIV OF JINAN

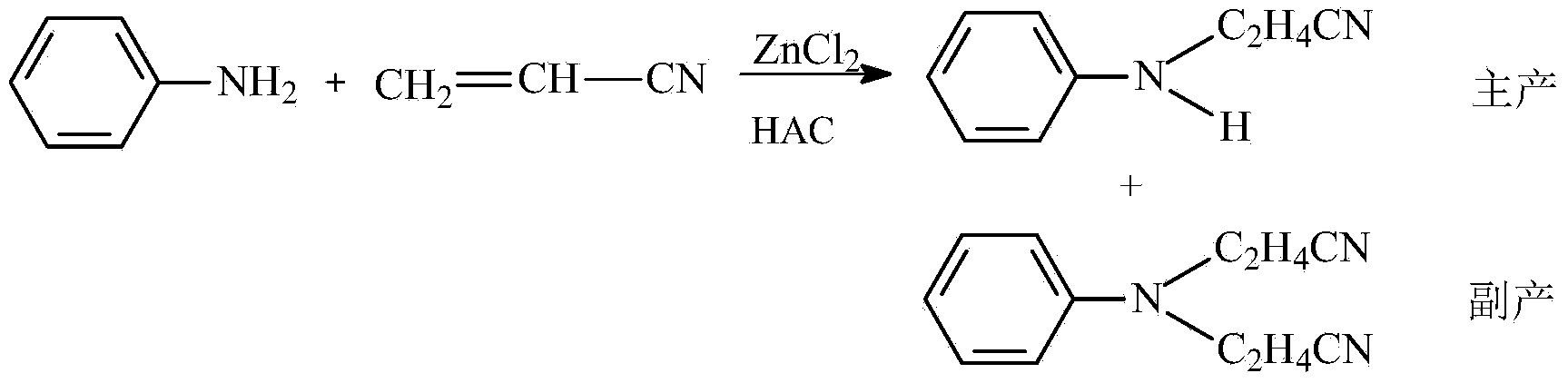

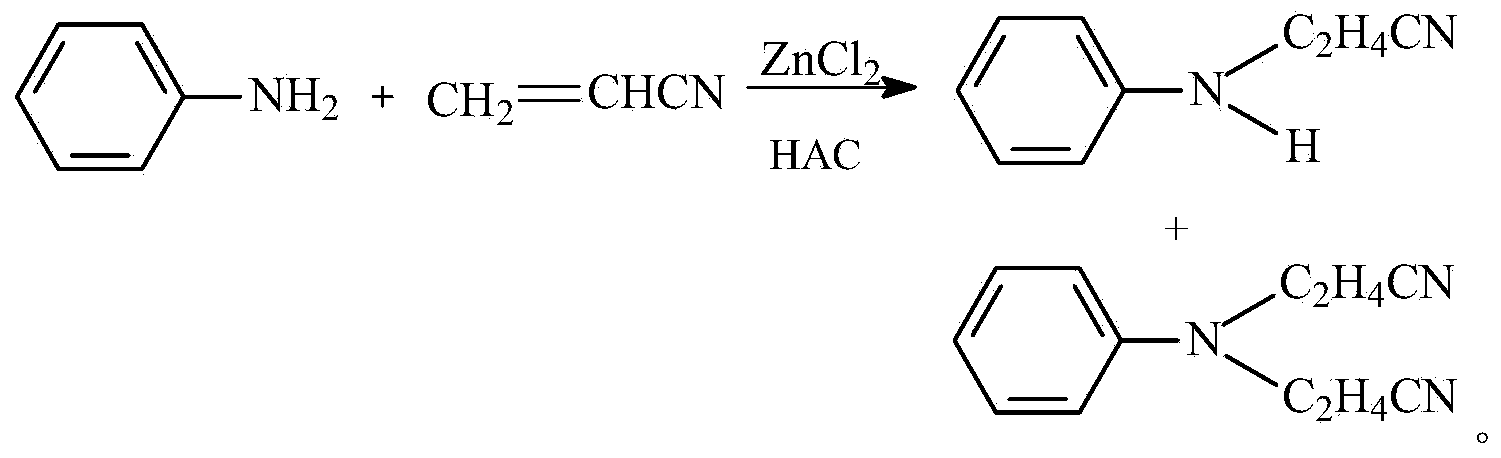

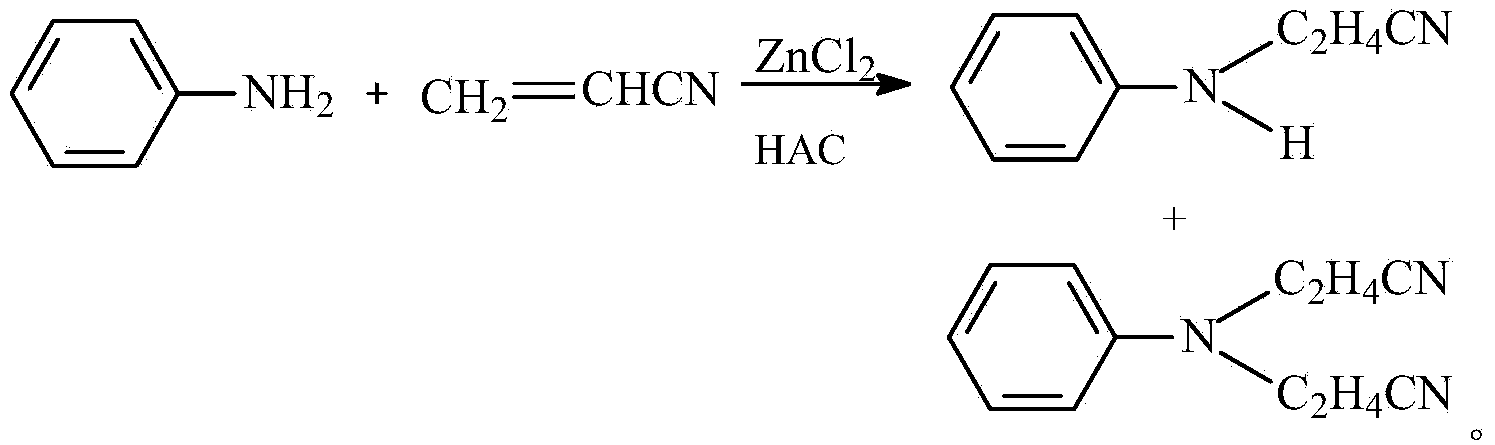

Method for producing N-cyanoethylaniline and N,N-dicyanoethylaniline by adopting one-step cleaning process

ActiveCN104003905AReduce processing costsReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationAcetic acidDistillation

The invention relates to the field of chemical engineering and in particular relates to a method for producing N-cyanoethylaniline and N,N-dicyanoethylaniline by adopting a one-step cleaning process. The method comprises the following steps: adding aniline, acetic acid, zinc chloride, acrylonitrile, water and a small quantity of p-dihydroxybenzene into a reaction kettle in sequence; slowly heating while starting a re-distillation condenser, and keeping re-distillation for 10 hours after the re-distillation temperature meets the requirement; keeping standing for 1-2 hours, barreling a lowest-layer water phase for analyzing and metering, and feeding an upper-layer organic phase into a middle tank to take part in next reaction; preserving heat of the middle tank to be not less than 60 DEG C, rectifying the product by using a continuous rectifying tower to obtain light components from a first outlet, and returning the light components to a reaction system to obtain N-cyanoethylaniline from a second outlet and obtain N,N-dicyanoethylaniline from a third outlet, wherein the light components are mainly HAC, H2O and acrylonitrile; and incinerating rectified residues to obtain zinc chloride powder which continues to be used as a catalyst. The novel process is simple to control, clean, environment-friendly, low in consumption and safe.

Owner:浙江汇翔新材料科技股份有限公司

Purification method for longifolene

InactiveCN104193579AMild reaction conditionsSimple processChemical modification purification/separationAcetic acidPurification methods

The invention discloses a purification method for longifolene, belonging to the technical field of deep processing of turpentine. The purification method comprises the following steps of placing longifolene to be treated, water, acetic acid, p-dihydroxybenzene and p-toluenesulfonic acid into a reaction kettle under a stirring condition, heating to 40-60 DEG C, continuing to stir, stopping stirring after 6-10 hours, standing for separating a material layer, and then, distilling after washing the obtained material. The purification method has the advantages of mild reaction conditions, simplicity and convenience in process and flow, few utilization equipment and low cost.

Owner:WUZHOU PINE CHEM

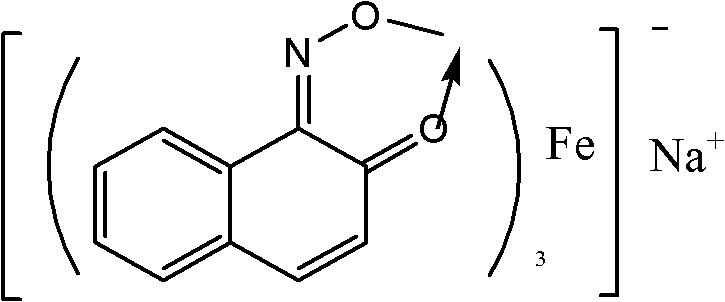

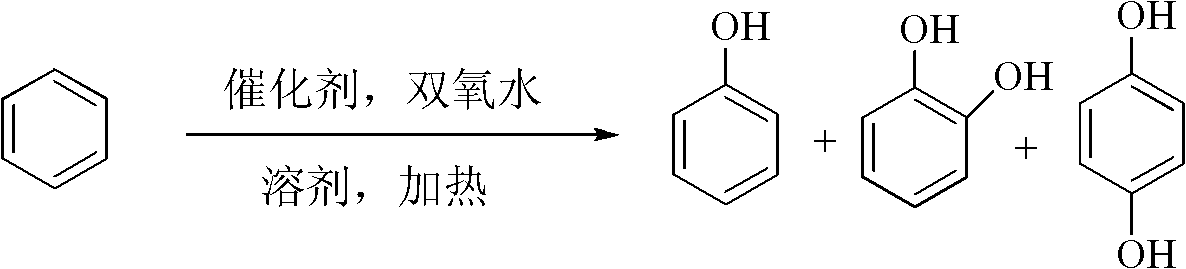

Method for preparing phenol and dihydroxybenzene by catalytic hydroxylation of benzene

InactiveCN102627530AHigh yieldTake advantage ofOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention discloses a method for preparing phenol and dihydroxybenzene by catalytic hydroxylation of benzene. The method comprises that benzene undergoes a one-step hydroxylation reaction in the presence of acetonitrile as a solvent, H2O2 as a hydroxylation reagent and pigment green B as a catalyst to be converted into phenol, o-dihydroxybenzene and p-dihydroxybenzene, wherein a mass ratio of H2O2 to benzene is (3 to 8): 1; a mass ratio of acetonitrile to benzene is (15 to 30): 1; a mass ratio of the catalyst to benzene is (0.05 to 0.1): 1; catalytic hydroxylation time is in a range of 4 to 7 hours; and a catalytic hydroxylation temperature is in a range of 40 to 70 DEG C. The method adopts the pigment green B as a catalyst and provides a novel catalysis system for synthesizing phenol, o-dihydroxybenzene and p-dihydroxybenzene by pigment green B catalysis of benzene. The method overcomes the defects that the traditional technology has a lot of reaction steps, produces serious pollution and has a low atom utilization rate. Catalytic hydroxylation is carried out under mild conditions so that discharge of three wastes is reduced; the catalyst can be separated out easily; and a phenol yield is high. Therefore, the method is an environmentally-friendly green synthesis technology of phenols.

Owner:TIANJIN UNIV

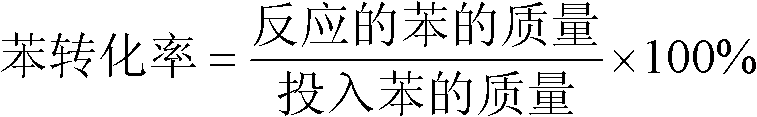

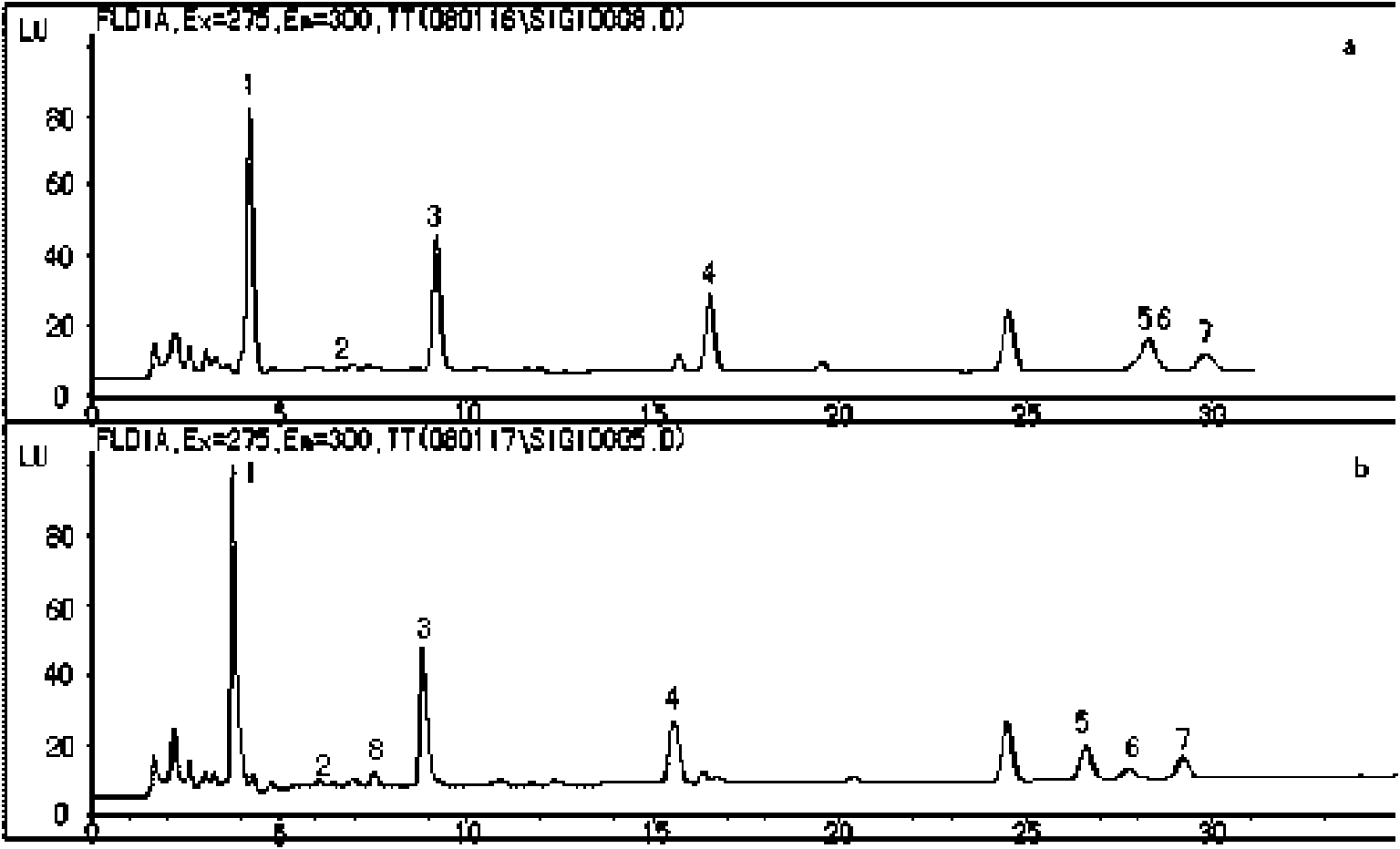

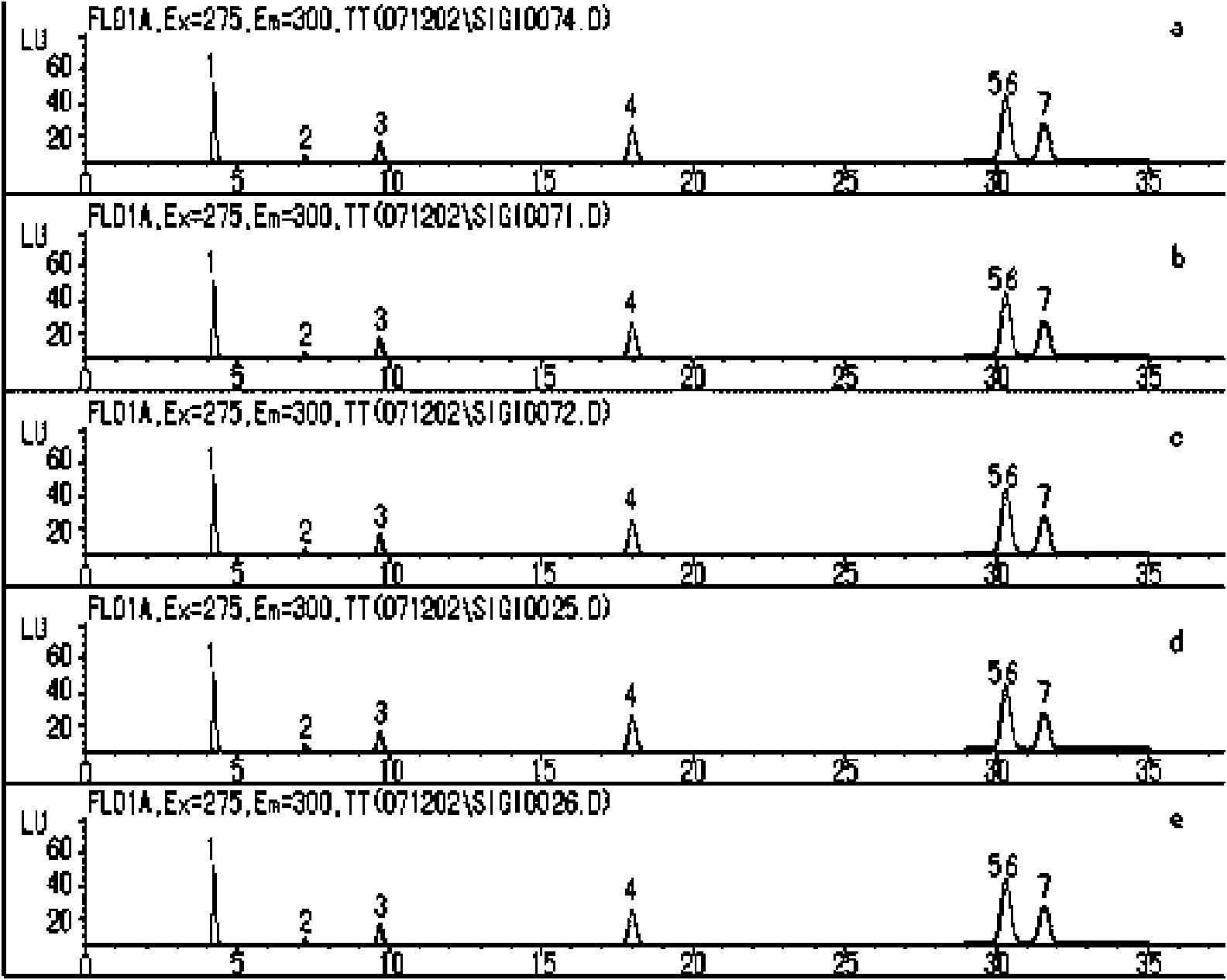

Method for separating and detecting harmful phenols in main stream smoke of cigarettes

ActiveCN101592638AEasy to separateAvoid scrappingComponent separationWithdrawing sample devicesM-CresolBeta-Cyclodextrins

The invention provides a method for separating and detecting harmful phenols in main stream smoke of cigarettes to overcome the drawback of the prior art that a high efficiency liquid chromatography can only measure the mixed content of m-cresol and p-cresol when used to detect the harmful phenols in the main stream smoke of the cigarettes by adding a certain amount of beta-cyclodextrin in a flowing phase of the high efficiency liquid chromatography. Thus, while successfully separating and detecting isomers of the m-cresol and the p-cresol, the method avoids influencing the separation and measurement of the content of o-dihydroxybenzene, m-dihydroxybenzene, p-dihydroxybenzene, phenol and o-cresol. The method is expected to be applied to daily detection of harmful phenol substances of cigarette products.

Owner:CHINA TOBACCO GUIZHOU IND +1

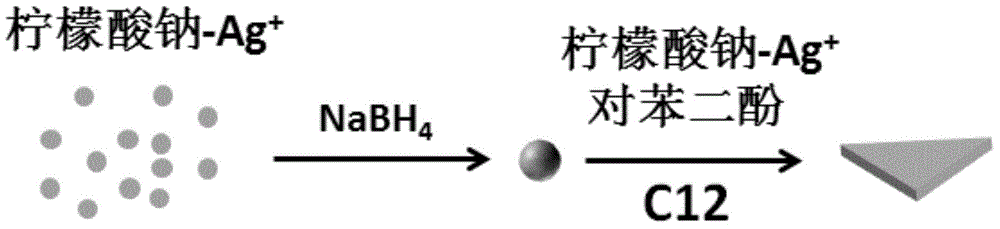

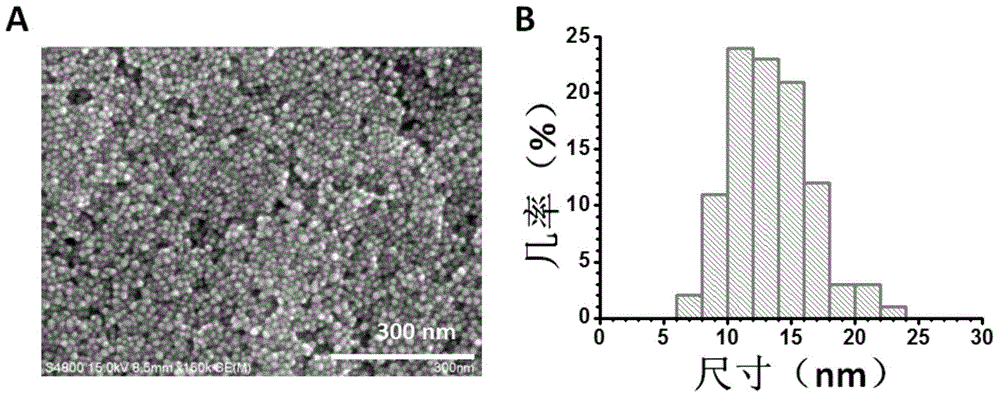

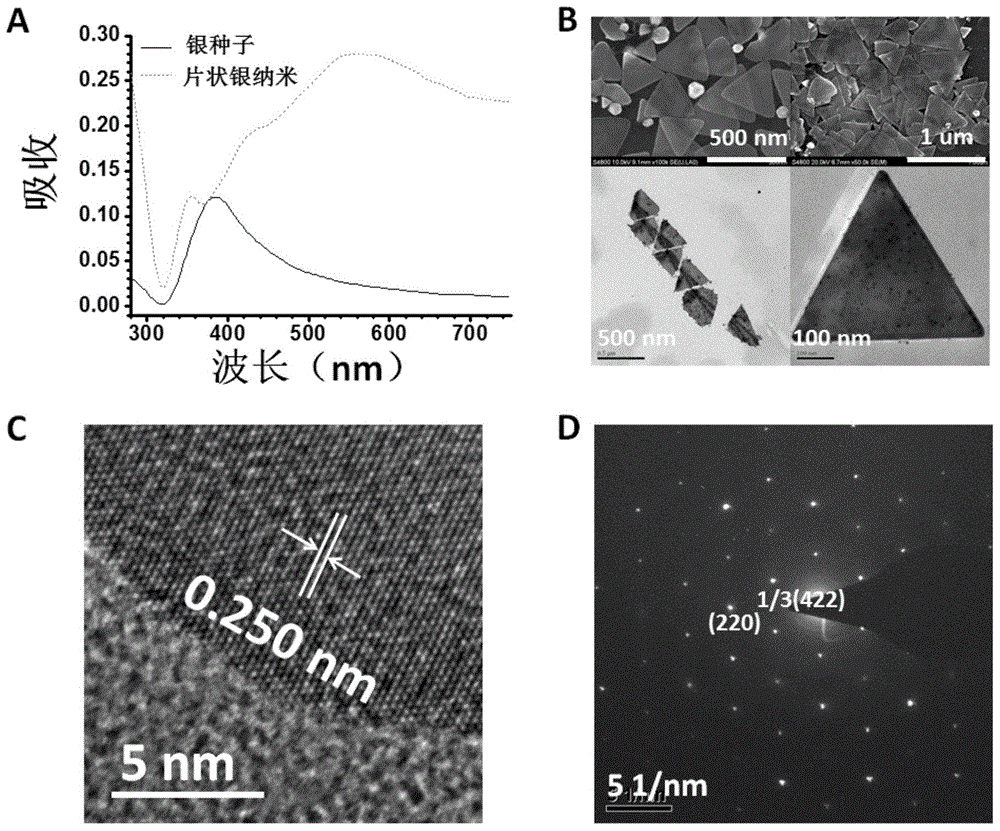

Preparation method for flaky silver nanometer materials

ActiveCN105149613AGood biocompatibilityReduce usageNanotechnologyDNA SolutionsBiocompatibility Testing

The invention discloses a preparation method for flaky silver nanometer materials. The method includes the following steps that firstly, at the existence of sodium citrate, a sodium borohydride solution prepared through ice water is used for reducing silver nitrate so that a silver seed solution is formed; secondly, a p-dihydroxybenzene solution, a sodium citrate buffer solution, the silver seed solution, a DNA solution, water and a silver nitrate solution are measured and taken according to the volume ratio of 3-5:3-5:1-3:1-3:27-30:9-12; and thirdly, after the p-dihydroxybenzene solution, the sodium citrate buffer solution, the silver seed solution, the DNA solution and the water are fully mixed, the silver nitrate solution is added, the mixture is kept away from light and grows for 12-14 h at the temperature of 20-24 DEG C, and then the flaky silver nanometer materials can be obtained. Compared with a traditional method, the preparation method is good in biocompatibility and high in universality, and a new platform is provided for application of the flaky silver nanometer materials in biological analysis and biomedicine.

Owner:XIAMEN UNIV

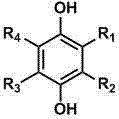

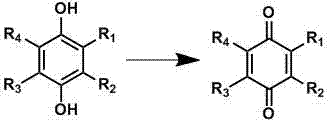

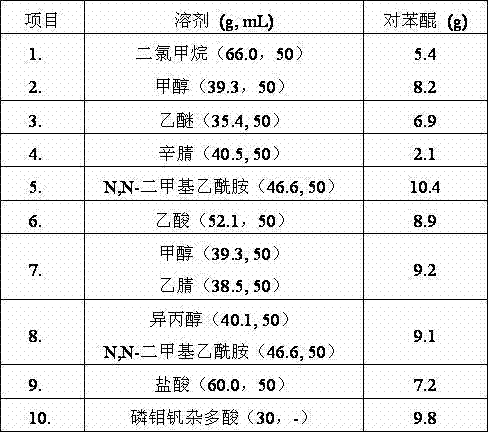

High-efficiency preparation method of p-benzoquinone compounds

The invention relates to a high-efficiency preparation method of p-benzoquinone compounds. According to the high-efficiency preparation method, a p-dihydroxybenzene compound is taken as a raw material, and the p-benzoquinone compounds are prepared in the presence of an alkali / alkali-earth metal catalyst. Advantages are that: 1) the high-efficiency preparation method is simple, and amplification of operation processes and industrialized production can be realized easily; 2) a plurality of the p-benzoquinone compounds can be synthesized, and the high-efficiency preparation method is an universal method used for preparing the p-benzoquinone compounds.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

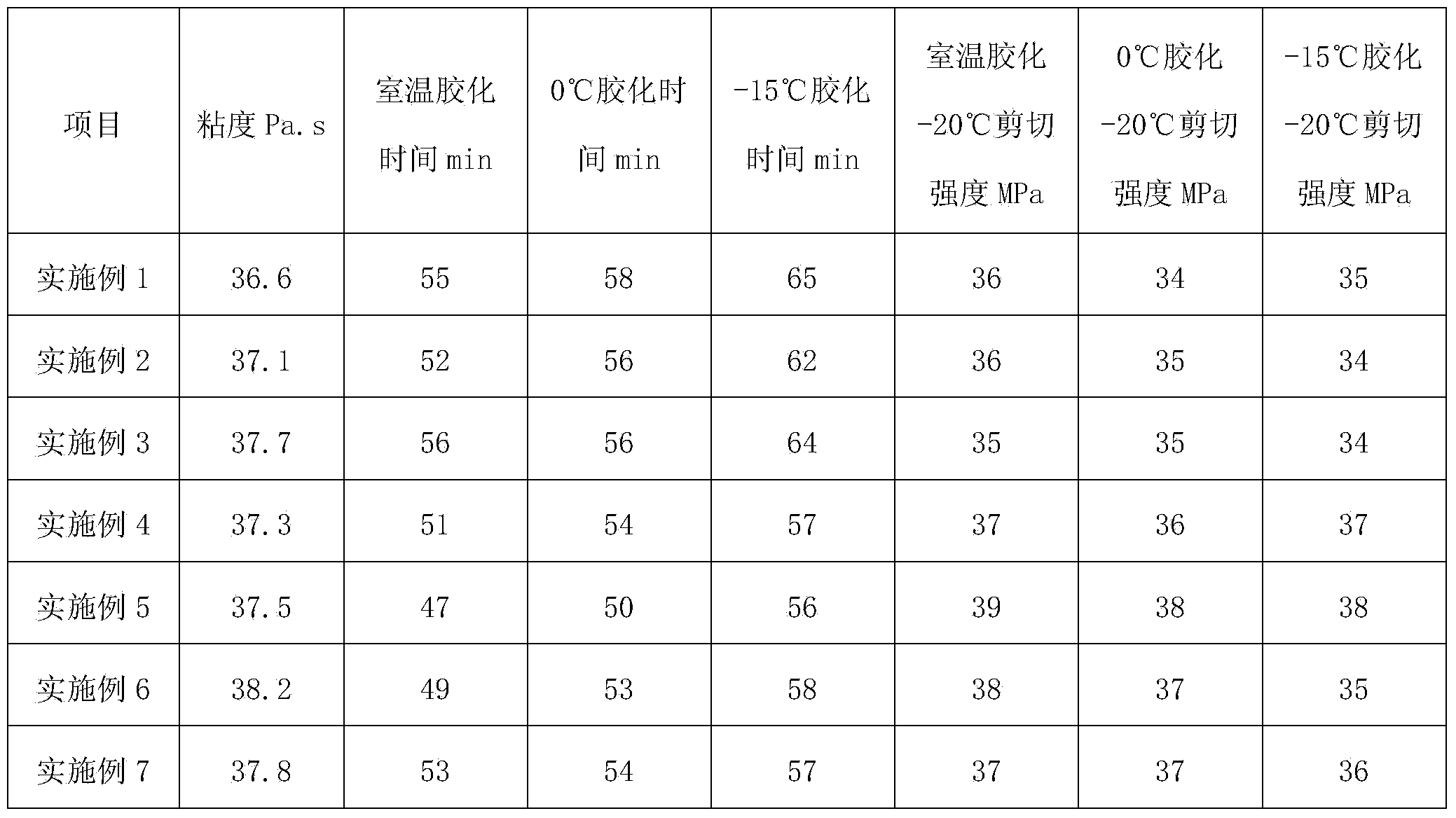

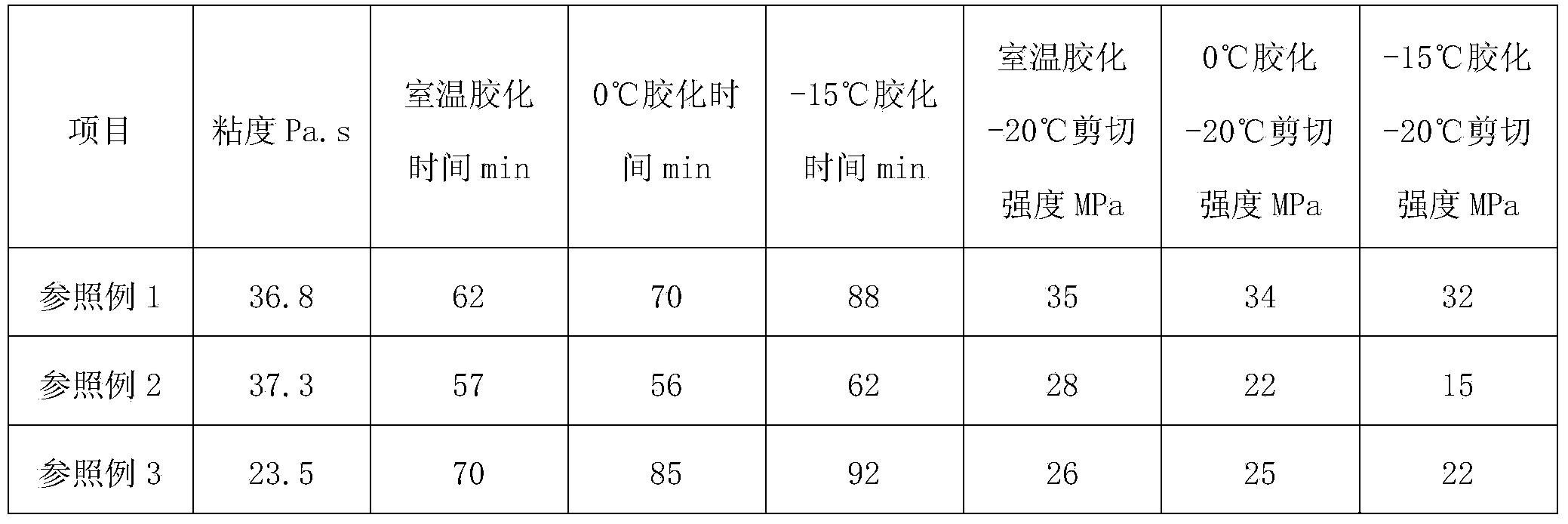

Low-temperature metal adhesive and preparation method thereof

ActiveCN104031565AImprove performanceNormal function of adhesiveNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEthylenediamineEpoxy

The invention discloses a low-temperature metal adhesive and a preparation method thereof. The adhesive comprises the following components in parts by weight: 45-60 parts of 2-ethyl cyanoacrylate, 35-45 parts of tetrahydrofuran polyether epoxy resin, 5-10 parts of ethylene carbonate, 8-15 parts of cyanoethyl ethylenediamine, 10-20 parts of aluminum oxide powder, 0.5-1 part of p-dihydroxybenzene, 1-5 parts of zinc oxide, 2-8 parts of titanium tetrachloride and 5-10 parts of polyvinyl butyral. The preparation method comprises the steps of adding 2-ethyl cyanoacrylate, tetrahydrofuran polyether epoxy resin, ethylene carbonate and polyvinyl butyral into a reaction kettle, and performing reaction for 40-60 minutes at 60-70 DEG C; then adding the other components into the mixture obtained in the above reaction, and reacting for 1-3 hours at 50-60 DEG C under the pressure of 0.02-0.06 MPa. The low-temperature metal adhesive disclosed by the invention can keep good adhesion performance at a low temperature and has stable performances at the same time.

Owner:上海汉司实业有限公司

Modified montmorillonite catalyst, preparation and application thereof

ActiveCN104248947ASimple preparation processImprove stabilityOrganic chemistryPhysical/chemical process catalystsAlkyl transferBenzene

The invention relates to a modified montmorillonite catalyst, a preparation method and an application thereof. The preparation method of the modified montmorillonite catalyst comprises the following steps: selecting montmorillonite with average particle size of 1-50mum and roasting for 2-8 hours at 200-600 DEG C; adding an inorganic acid solution with mass concentration of 5-40% in the roasted and activated montmorillonite, wherein the solid-liquid mass ratio of montmorillonite to the acid solution is 1: 5-30, reacting for 2-8 hours under temperature of 60-110 DEG C to obtain a montmorillonite slurry; filtering the montmorillonite slurry, washing by deionized water under 30-60 DEG C, and then drying the washed and filtered montmorillonite at 60-120 DEG C. The catalyst has the advantages of simple preparation technology, wide raw material source, good stability and high yield. The catalyst is used for performing an alkylation synthesis to obtain a compound by taking p-dihydroxybenzene, organic acidity and benzene as raw materials, and the alkylation catalysis performance is good.

Owner:PETROCHINA CO LTD

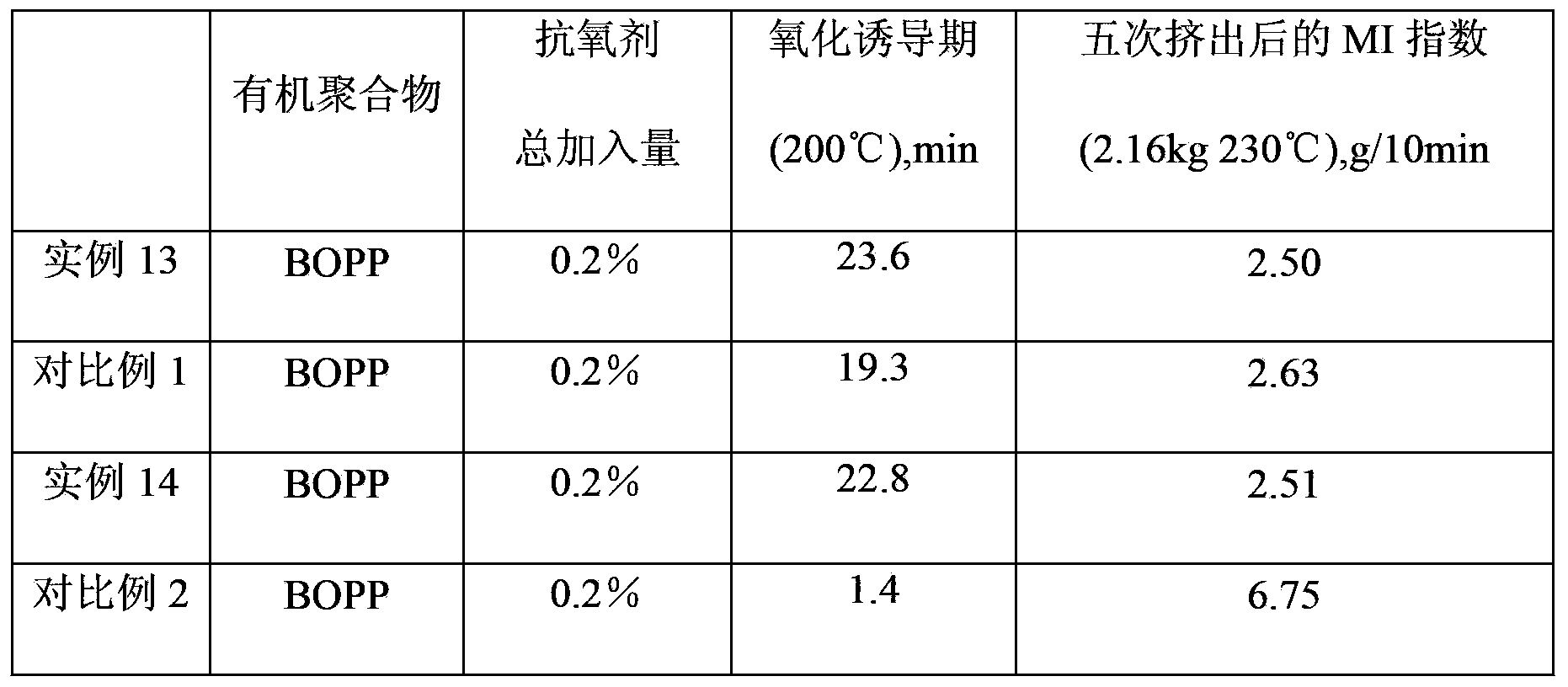

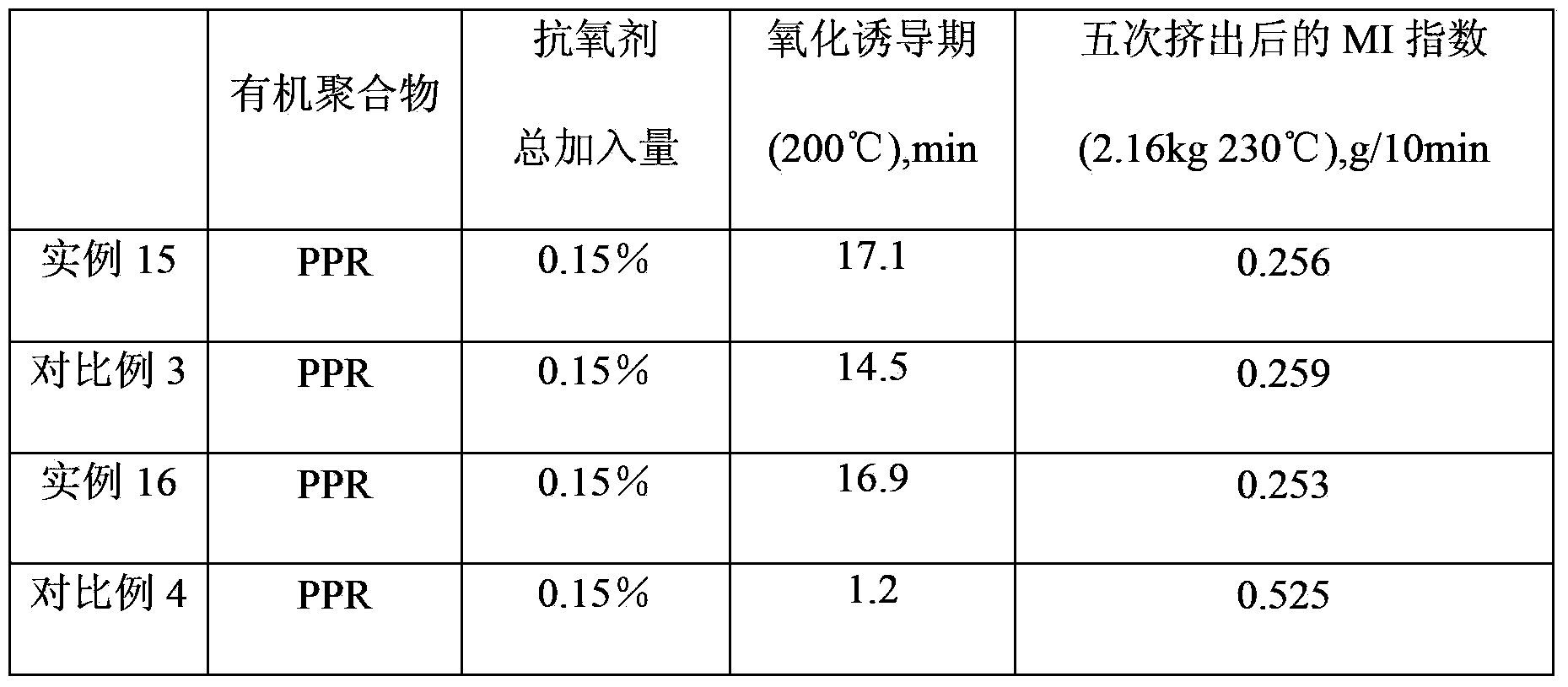

Antioxidant plastic color masterbatch and preparation method thereof

The invention discloses antioxidant plastic color masterbatch. The antioxidant plastic color masterbatch is prepared from, by weight, 16-20 parts of titanium dioxide, 10-15 parts of carbon black, 25-30 parts of iron oxide red, 12-14 parts of iron oxide yellow, 7-9 parts of phthalocyanine blue, 6-10 parts of phthalocyanine green, 13-18 parts of polyester fibers, 15-20 parts of sodium stearate, 6-10 parts of N,N-ethylene bis-stearamide, 14-18 parts of microcrystalline wax, 22-26 parts of oxidized polyethylene wax, 7-9 parts of activated carbon nanoparticles, 4-8 parts of butyl hydroxy anisd, 22-28 parts of butylated hydroxytoluene, 10-15 parts of diphenylamine, 20-25 parts of p-phenylenediamine, 6-8 parts of dodecyl mercaptan, 18-22 parts of p-dihydroxybenzene, 20-25 parts of thio-bis-phenol and 36-40 parts of polyvinyl chloride. The antioxidant plastic color masterbatch is good in coloring effect, has an antioxidant effect, cannot fade and is long in storage time.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Method for preparing soft magnetic manganese-zinc-iron composite material by using manganese-containing waste liquid and zinc mud produced in the production of hydroquinone

ActiveCN104086168BSolve the pollution of the environmentRealize high value utilizationInorganic material magnetismSesquioxideSludge

The invention discloses a method for preparing a soft magnetic manganese-zinc-iron composite material by using manganese-containing waste liquor and zinc sludge produced during production of p-dihydroxybenzene. The method comprises the following steps: adding the zinc sludge into the manganese-containing waste liquor, leaching under stirring, filtering, adding a flocculating agent into filtrate to remove silicon and aluminum impurities, adding ammonium bicarbonate into purified liquid containing manganese and zinc for co-precipitating, and washing to obtain co-precipitated powder; calcining the co-precipitated powder for decomposing, and washing by using organic acid to obtain a manganese-zinc composite material; and adding iron sesquioxide or a mixture of iron sesquioxide and at least one of manganous-manganic oxide and zinc oxide into the manganese-zinc composite material, and pre-burning to obtain the soft magnetic manganese-zinc-iron composite material. By taking the manganese-containing waste liquor and the zinc sludge produced during production of p-dihydroxybenzene as raw materials, the problem of environmental pollution is solved, high-value utilization of waste is fully realized, and a manufactured magnetic device is free from crystal spots, is non-crispy, and has high shearing resistance as well as fully-qualified physicochemical indexes and electromagnetic performance.

Owner:CHONGQING SHANGJIA ELECTRONIC CO LTD

Concrete water reducer and preparation method thereof

The invention discloses a concrete water reducer and a preparation method thereof. The water reducer is synthesized by using raw materials including vegetable oil, acrylic acid, methoxy polyethylene glycol, an initiator, p-toluene sulphonic acid, concentrated sulphuric acid, p-dihydroxybenzene and an emulsifying agent through esterification, wherein the synthesis method is mainly realized through the steps of stirring, mixing, controlling the temperature to carry out esterification reaction, regulating the pH value and the like. The preparation method is simple in process flow and easy to operate; meanwhile, the water reducer provided by the invention is small in mixing amount, high in water reducing rate, low in cost and environment-friendly.

Owner:大连市铭源全科技开发有限公司

Medicinal adhesive and preparation method thereof

ActiveCN104368030ALess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideAdhesive

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

Waterproof and anti-cracking ceramic tile seam filling adhesive

InactiveCN106833463AImprove adhesionCompact structureNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseSodium Bentonite

The invention discloses a waterproof and anti-cracking ceramic tile seam filling adhesive. The waterproof and anti-cracking ceramic tile seam filling adhesive is prepared from the following raw materials in parts by weight: 70 to 90 parts of bisphenol A epoxy resin, 10 to 20 parts of a curing agent, 5 to 12 parts of antimony oxide, 1 to 9 parts of organic bentonite, 2 to 6 parts of kaolin, 2 to 8 parts of a toughening agent, 3 to 5 parts of an accelerant, 2 to 10 parts of p-dihydroxybenzene, 2 to 10 parts of nano wollastonite powder, 2 to 8 parts of cellulose nitrate and 3 to 10 parts of ethanol. The product provided by the invention has a good bonding performance and is tightly combined with material bodies on different base surfaces in a tile seam; meanwhile, the product is used for enabling an inner structure of a material to be more dense in a condensation period and can effectively prevent external water from permeating into a matrix from the tile seam, so that the stability and waterproof performance of a decorative system are improved.

Owner:吴中区穹窿山天仲高分子材料技术研究所

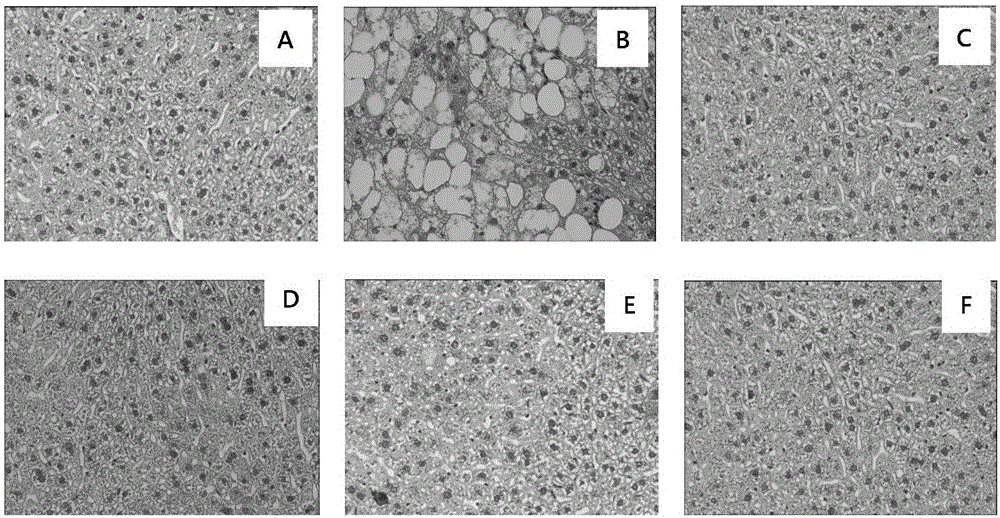

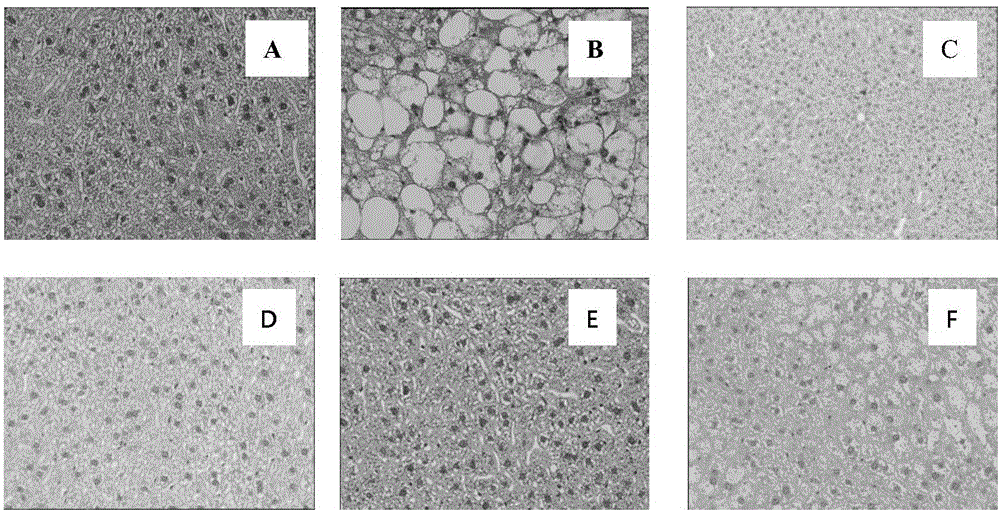

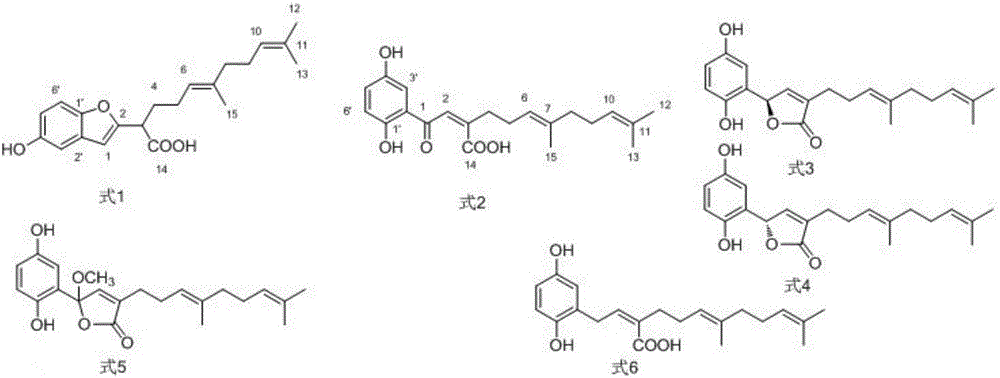

Application of p-dihydroxybenzene farnesyl compounds

ActiveCN107519160APrevent proliferationMetabolism disorderDigestive systemHMG-CoA reductaseSide effect

Owner:HANGZHOU BIO SINCERITY PHARMA TECH CO LTD

Method for preparing carrier resin for high-temperature-resistant molding process coloring materials

InactiveCN109575258AAccurate control of heating ratePrecise control of cooling rateAlcoholLiquid state

The invention discloses a method for preparing carrier resin for high-temperature-resistant molding process coloring materials. The method includes steps of 1, uniformly mixing and stirring, by weight, 70-100 parts of dihydric alcohol, 60-100 parts of polyacid and 15-25 parts of diacid anhydride with one another to obtain first mixtures in nitrogen atmosphere, gradually heating the first mixturesuntil the temperatures of the first mixtures reach 195-235 DEG C, carrying out condensation reaction, preserving heat after reaction systems become uniform and transparent, and continuing to carry outreaction; 2, cooling products obtained at the step 1 until the temperatures of the products reach 175-185 DEG C, adding 7-8 parts of p-dihydroxybenzene into the products, uniformly stirring the p-dihydroxybenzene and the products to obtain second mixtures, then cooling the second mixtures until the temperatures of the second mixtures are lower than 45 DEG C, and filtering the second mixtures to obtain the carrier resin. The method for preparing the carrier resin for the high-temperature-resistant molding process coloring materials has the advantages that the dihydric alcohol, the polyacid anddiacid are mixed with one another to obtain the first mixtures in the nitrogen atmosphere, the first mixtures are heated until the temperatures of the first mixtures reach 195-235 DEG C, the condensation reaction is carried out, the heating rates can be accurately controlled, accordingly, products only contain few small molecules and are in excellent liquid states, and the high-temperature resistance of the products can be improved.

Owner:镇江利德尔复合材料有限公司

Preparation method and application of co-immobilized enzyme electrode for detecting hydroquinone and catechol

InactiveCN104007156BLow detection limitQuick checkMaterial analysis by electric/magnetic meansEnzyme electrodeHydroquinone Compound

The invention provides a preparation method and an application of a co-immobilized enzyme electrode which is used for detecting p-dihydroxybenzene and o-dihydroxybenzene. The preparation method comprises steps of: immobilizing tyrosinase and peroxidase on oxidized grephene to obtain a co-immobilized enzyme liquid and smearing dropwisely the co-immobilized enzyme liquid and a chitosan solution successively on a surface of a glassy carbon electrode to obtain the co-immobilized enzyme electrode which is used for detecting p-dihydroxybenzene and o-dihydroxybenzene. The electrode is low in cost, is easy and convenient to operate, is quick and sensitive, is low in detection limit, is good in selectivity and can be used for detecting microscale p-dihydroxybenzene and o-dihydroxybenzene in environment.

Owner:HOHAI UNIV

A kind of medical adhesive and preparation method thereof

ActiveCN104368030BLess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideDIETHYL SEBACATE

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

Transformer framework

The invention discloses a transformer framework. The transformer framework comprises a plastic main body, and the plastic main body comprises the following components in parts by weight: 1-2 parts of solid coumarone, 8.4 parts of polycarbonate resin, 0.3 part of nanoscale aluminium hydroxide, 1.2 parts of p-dihydroxybenzene diglycidyl ether, 2.1 parts of alkylbenzenesulfonate, 1.3 parts of hydroxyl silicone oil and 1.4 parts of vinyl trimethoxy silane. The transformer framework disclosed by the invention has flame retardant property and high impact strength, tensile strength and bending strength.

Owner:常熟市白茆通讯配件厂

Photocuring powder coating

InactiveCN104861832AAvoid stickinessHigh glass transition temperaturePowdery paintsPolyester coatingsChemical reactionUltraviolet lights

The invention discloses a photocuring powder coating and belongs to the field of coatings, in particular to the field of photocuring powder coatings. The photocuring powder coating comprises a film forming substance, a photocatalyst, filler and an auxiliary, wherein the film forming substance comprises matrix resin and curing resin, the matrix resin is prepared through chemical reaction synthesis of raw materials of p-phthalic anhydride, pentanediol, diethylene glycol, maleic anhydride, o-dimethoxybenzene, p-dihydroxybenzene and paraphthaloyl chloride, the matrix resin and the curing resin are mixed to form the film forming substance, the photocatalyst, the filler and the auxiliary are added to the film forming substance, and the photocuring powder coating is obtained. The photocuring powder coating can be cured under ultraviolet light and is convenient to prepare and environment-friendly.

Owner:CHENGDU NASHUO TECH

Mechanochemical synthesis method of 1,4-bis(4-nitrophenoxy)benzene

ActiveCN110256255AAtom economy is highHigh yieldOrganic chemistryOrganic compound preparationChemical reactionSynthesis methods

The invention relates to a mechanochemical synthesis method of 1,4-bis(4-nitrophenoxy)benzene. The mechanochemical synthesis method is a natural synthesis method which includes that p-dihydroxybenzene and p-nitryl benzene halide are synthesized to form the 1,4-bis(4-nitrophenoxy)benzene by catalysis of metal salt and promotion of mechanical force. The mechanochemical synthesis method specifically includes: adding the p-dihydroxybenzene and the p-nitryl benzene halide into a ball-milling tank, adding a catalyst, alkali silica gel and a milling ball to perform mechanical and chemical reactions, after the reaction is over, transferring a reaction mixture by an organic solvent, filtering out undissolved matters, concentrating a filter liquid, and recrystallizing the concentrated filter liquid to obtain the yellow and green crystal product 1,4-bis(4-nitrophenoxy)benzene. The mechanochemical synthesis method of the 1,4-bis(4-nitrophenoxy)benzene has the advantages of simplicity in operation, short reaction time, high atom economy, high product yield, high product purity which is higher than 99% and applicability to industrial use.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of powder coating containing calcium carbonate

InactiveCN104861833AAvoid stickinessHigh glass transition temperaturePowdery paintsPolyester coatingsMethacrylateMechanical property

The invention discloses a preparation method of a powder coating containing calcium carbonate and belongs to the field of coatings, in particular to the field of powder coatings. The powder coating containing calcium carbonate comprises a film forming substance, filler and an auxiliary, wherein the film forming substance comprises matrix resin and curing resin; the matrix resin is prepared through synthesis of p-phthalate anhydride, pentanediol, diethylene glycol, maleic anhydride, o-dimethoxybenzene, p-dihydroxybenzene and paraphthaloyl chloride; the curing resin is a mixture of one or two of styrene and benzene methacrylate with ethanolamine, and the film forming substance is formed by the matrix resin and the curing resin; calcium carbonate and the auxiliary are added to the film forming substance, and the powder coating containing the calcium carbonate can be prepared. The photocuring powder coating is convenient to prepare and environment-friendly, can be cured at lower temperature and has excellent mechanical performance.

Owner:CHENGDU NASHUO TECH

Method for synthesizing arbutin by catalyzing through immobilized biological complex enzyme

InactiveCN105925644ANo pollution in the processEasy to operateFermentationOn/in inorganic carrierArbutinUrsolic acid

The invention discloses a method for synthesizing arbutin by catalyzing through an immobilized biological complex enzyme and belongs to the field of biological catalysis. The method takes white jade snails as raw materials; an extracting enzyme solution and nano attapulgites are compounded to prepare the immobilized biological complex enzyme; the immobilized biological complex enzyme is used for catalyzing a synthetic reaction of p-dihydroxybenzene and glucose to finally obtain the arbutin. The method is simple in process; the white jade snails are used as the raw materials so that the production cost is saved; in an operation process, no toxic reagent is used; ursolic acid is synthesized by utilizing the immobilized biological complex enzyme; reaction conditions are moderate, a production period is shortened and the yield of the arbutin is improved, so that the large-scale production of the arbutin becomes possible.

Owner:郭舒洋

High-temperature-resistant rice transplanter plastic shell material and preparation method thereof

InactiveCN105802072AIncrease the strength of hydrogen bondsReduce entanglementEthylenediaminePhosphate

The invention discloses a high-temperature-resistant rice transplanter plastic shell material. The high-temperature-resistant rice transplanter plastic shell material is prepared from, by weight, 6-10 parts of bisphenol A phosphate, 0.7-2 parts of barium naphthenate, 3-4 parts of carbon nano tubes, 40-50 parts of sulfoxide chloride, 3-5 parts of N,N-dimethyl formamide, 100-120 parts of ethylenediamine, 16-20 parts of melamine, 36-40 parts of 35-37% formalin, 170-200 parts of polyvinyl chloride, 20-30 parts of 75-80 wt% sulfuric acid, 30-40 parts of 95-98 wt% nitric acid, 6-8 parts of caprylic / capric triglyceride, 0.4-1 part of tertiary butyl p-dihydroxybenzene, 26-30 parts of stalactite powder, 5-7 parts of calcium fluoride, 3-4 parts of magnesium fluoride and 2-3 parts of terpilenol. Bisphenol A phosphate, barium naphthenate and the like are added into a plastic shell, heat resistance can be effectively improved, it is achieved that the plastic shell material is in a work environment under high-temperature solarization for a long time, and the service life is prolonged.

Owner:ANHUI TONGCHANG MACHINERY

Automobile part adhesive

InactiveCN104152062AGood adhesivenessHigh bonding strengthOrganic non-macromolecular adhesiveBenzoyl peroxideAdhesive

The invention discloses an automobile part adhesive, which comprises the following components in parts by weight: 400 to 800 parts of urethane acrylate, 100 to 120 parts of dibenzoyl, 40 to 60 parts of N-vinyl pyrrolidone, 20 to 28 parts of methyl methacrylate, 20 to 30 parts of 1,6-hexanediol diacrylate, 12 to 24 parts of styrene, 20 to 30 parts of benzoyl peroxide, 3 to 6 parts of p-dihydroxybenzene, 4 to 8 parts of acrylonitrile, and 12 to 48 parts of talcum powder. The provided automobile part adhesive has a good adhesive effect, and high adhesive strength, is fast to dry, and lasts for a long time.

Owner:王新民

Insulating anti-aging coating for unit-type looped network cabinet and preparation method of insulating anti-aging coating

InactiveCN106147583AImprove insulation performanceGood anti-aging performancePolyurea/polyurethane coatingsEthyl fumarateTungsten disulfide

The invention discloses an insulating anti-aging coating for a unit-type looped network cabinet and a preparation method of the insulating anti-aging coating. The method comprises the steps that 1, polyether diols, diisocyanate, expanded vermiculite, zinc borate, 4-amino-1,2,4-triazole, silica sol, ethyl acetate and tungsten disulfide are subjected to a contact reaction under the vacuumizing condition to prepare a first component; 2, ethylene-vinyl acetate emulsion, polyether triols, inorganic salt whiskers, lead naphthenate, p-dihydroxybenzene, kieselguhr, aluminum oxide fibers and alkyl sulfonic acid alcohol ether are subjected to a contact reaction in the presence of ultraviolet rays to prepare a second component; 3, the first component and the second component are mixed, then bone glue, urea, asphalt and silicon dioxide are added, ultrasonic oscillation is conducted, and then the insulating anti-aging coating is prepared. The insulating anti-aging coating prepared through the method has the excellent insulativity and aging resistance, and therefore the insulating anti-aging coating is suitable for the unit-type looped network cabinet; meanwhile, the preparation method has the advantages that the process is simple, the raw materials are easy to obtain, and mass production is convenient to achieve.

Owner:ANHUI ROBUTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com