Patents

Literature

45 results about "4-methoxybenzophenone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

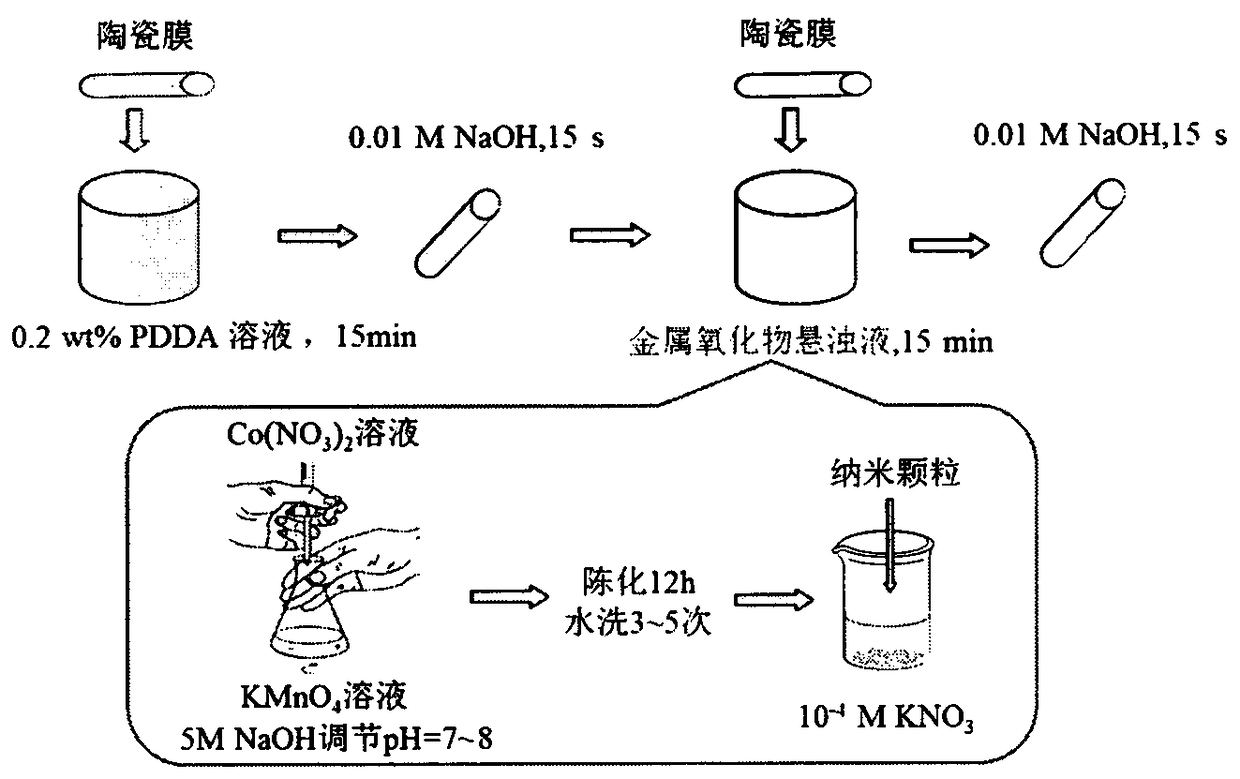

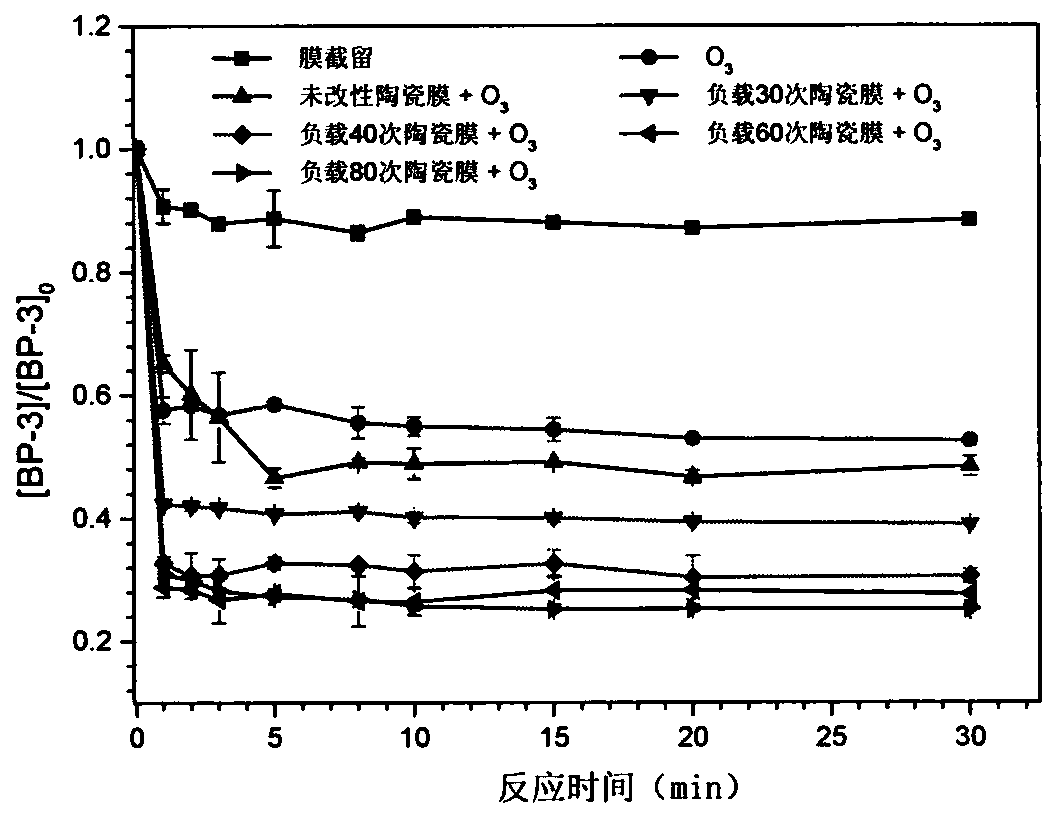

Novel manganese-cobalt complex oxide nanoparticle modified ceramic membrane, and assembly and application method thereof in water treatment

ActiveCN105800735AAchieve separationAvoid formingWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by oxidationNatural organic matterDecomposition

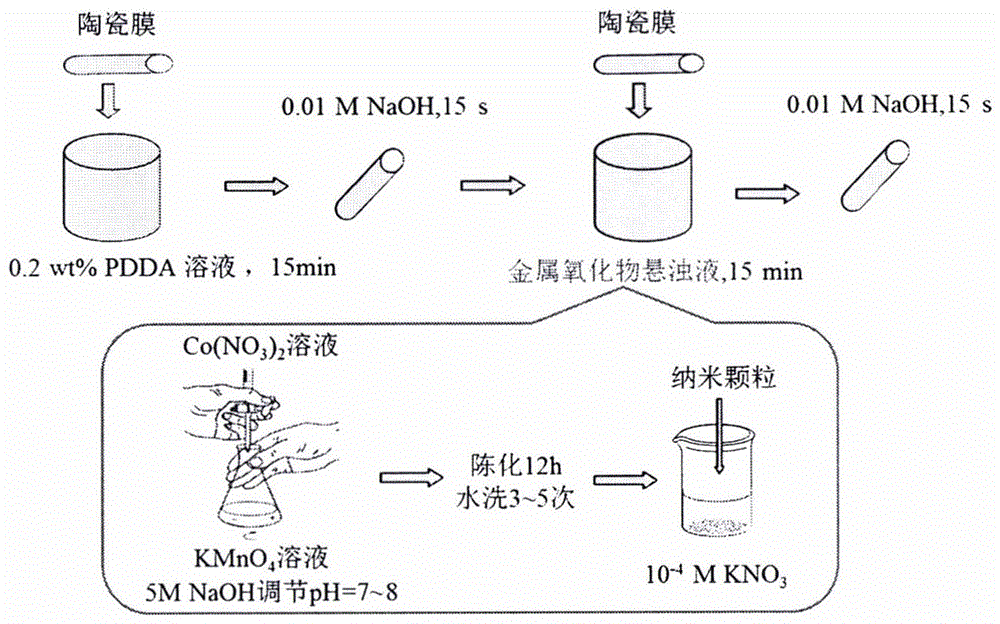

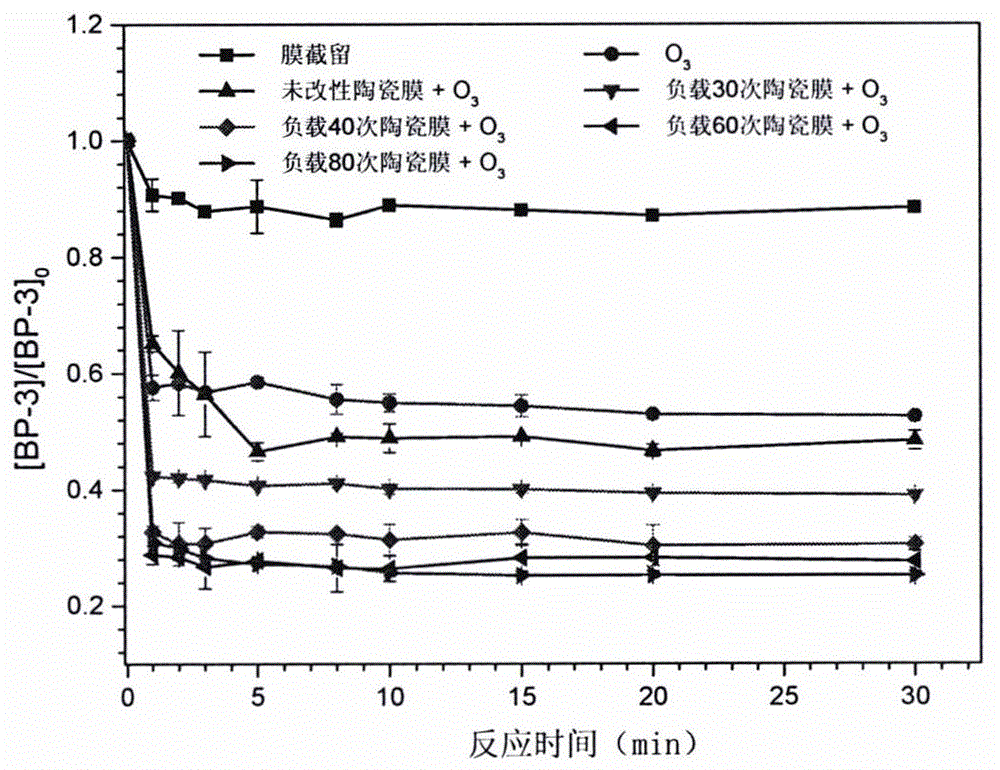

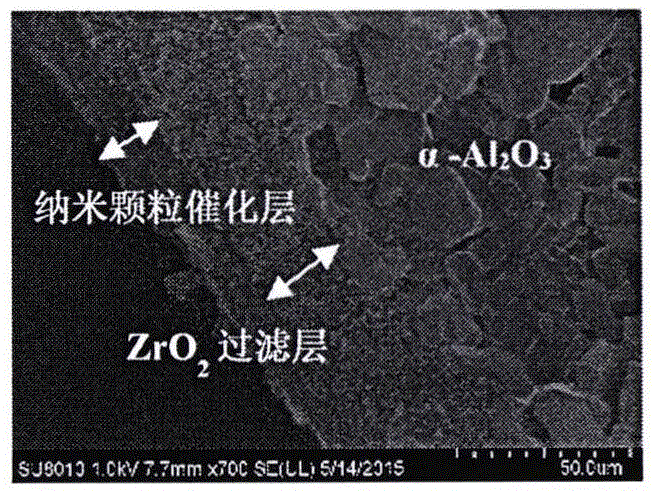

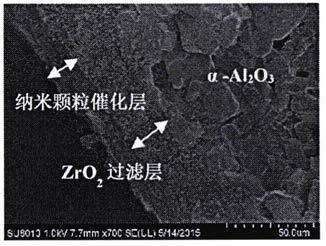

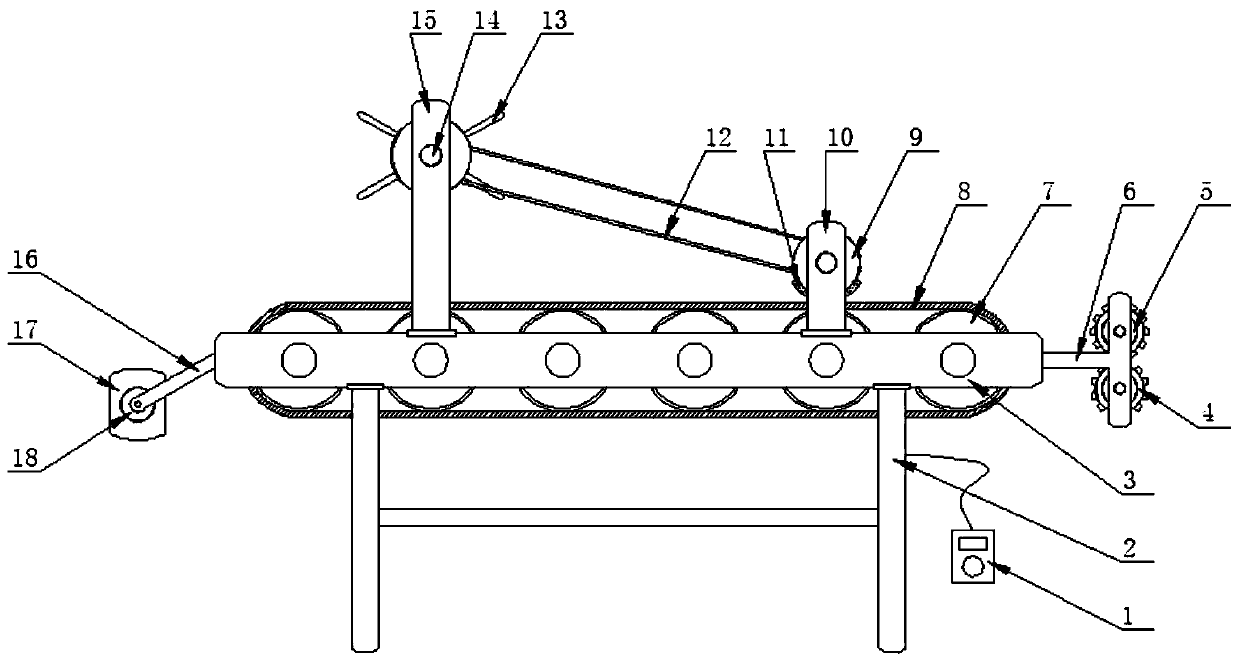

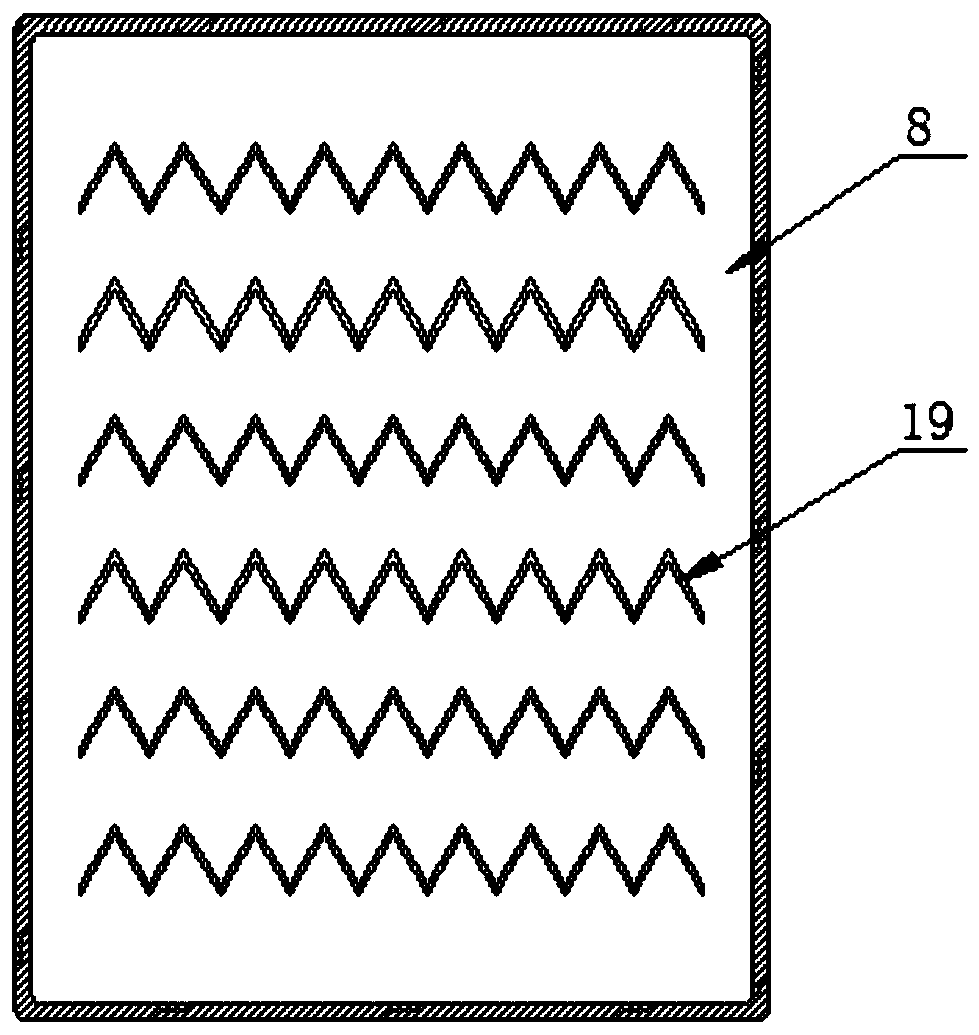

The invention relates to an advanced water treatment technique for pollution removal through heterogeneous catalytic ozonation. Directed at the disadvantage that a conventional powdery catalyst is unfavorable for realizing separation and inactivation in a water phase, an assembly method for a novel manganese-cobalt complex oxide nanoparticle catalyst-loaded ceramic membrane is provided. The assembly method aims to combine heterogeneous ozonation with a ceramic membrane filtration technique, and utilizes a ceramic membrane structure and active components (MnO2 and Co3O4) on a catalytic layer to catalyze ozone so as to generate -OH with high oxidation capacity, wherein organic compounds can realize reinforced removal of pharmaceutical and personal care products (PPCPs) like 2-hydroxyl-4-methoxybenzophenone in water through direct reaction with molecular ozone or reaction with -OH generated by ozone decomposition; meanwhile, ozone can react with humic acid and natural organic matters (NOMs) in the water, so the formation of membrane pollution is effectively controlled. The manganese-cobalt complex oxide nanoparticles are loaded on the surface of the ceramic membrane, so separation of the catalyst from the water is realized, and a novel method for cleaning and repeated use of the catalyst is provided.

Owner:BEIJING FORESTRY UNIVERSITY

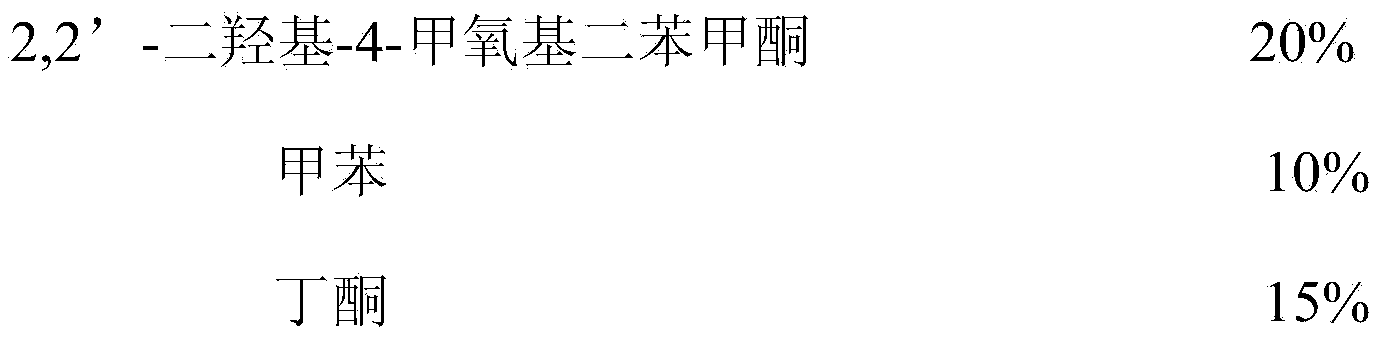

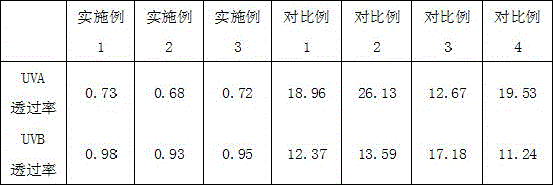

Total ultraviolet-proof automobile film and manufacturing method thereof

ActiveCN103725218AAvoid harmAnti-explosion effectFilm/foil adhesivesSynthetic resin layered productsComposite filmPolyethylene terephthalate

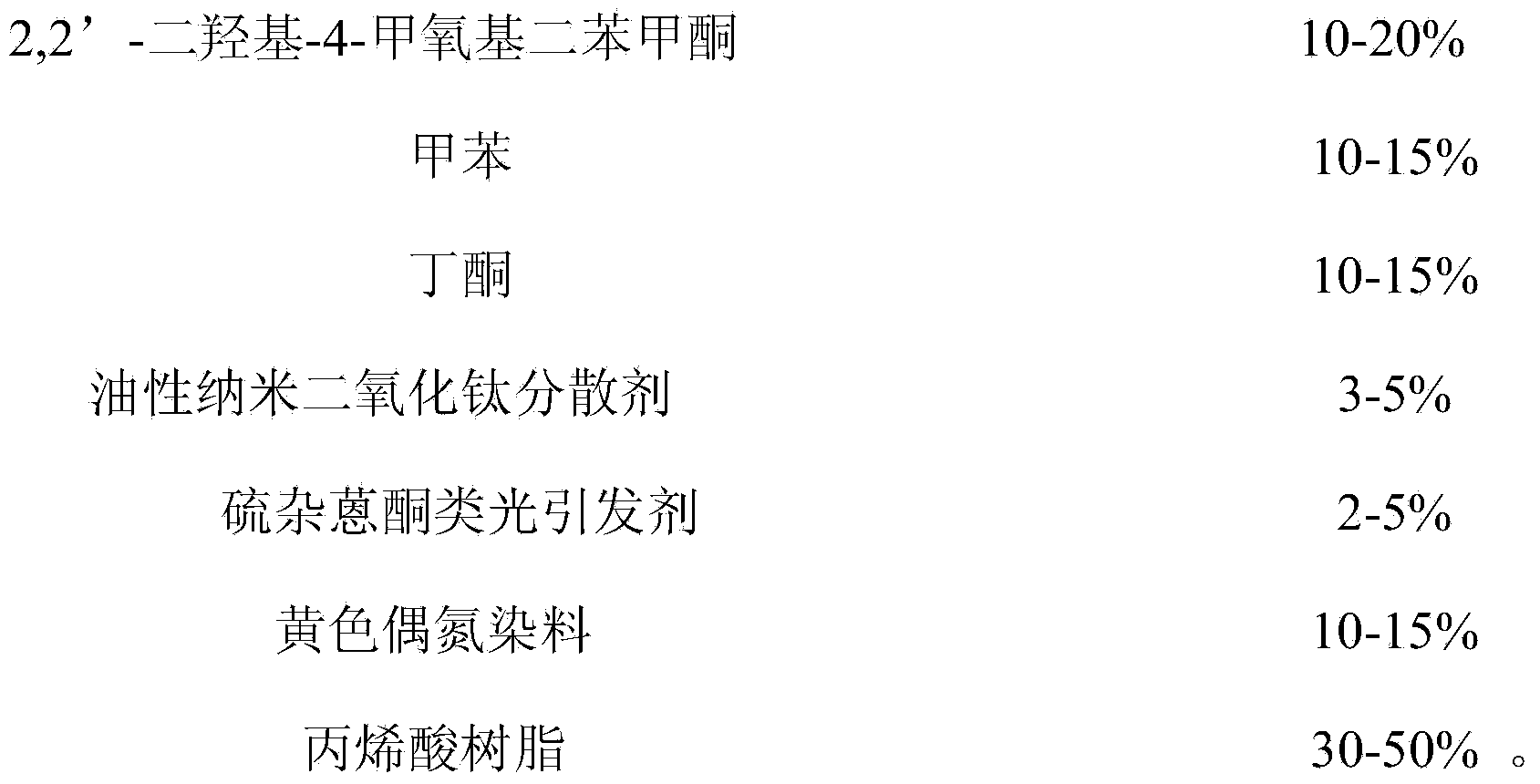

The invention provides a total ultraviolet-proof automobile film, comprising a PET (Polyethylene Terephthalate) composite film, a PET protective film and a PET coating film arranged between the PET composite film and the PET protective film; the side of the PET coating film in contact with the PET composite film is coated with a uv400 total ultraviolet-proof slurry; the side of the PET coating film in contact with the PET protective film is coated with an adhesive; the uv400 total ultraviolet-proof slurry is composed of 2,2'-dihydroxyl-4-methoxybenzophenone, methylbenzene, butanone, an oil-based nano titanium dioxide dispersant, a thioxanthone photoinitiator, a yellow azo dye and acrylic resin. The invention also provides a manufacturing method of the automobile film; the manufactured automobile film is capable of completely stopping ultraviolet rays and preventing the ultraviolet rays from hurting the human body, and also long in service life, good in clarity, and further capable of achieving certain anti-explosion effect on the automobile glass.

Owner:ZHEJIANG SHICHUANG OPTICAL FILM MFG

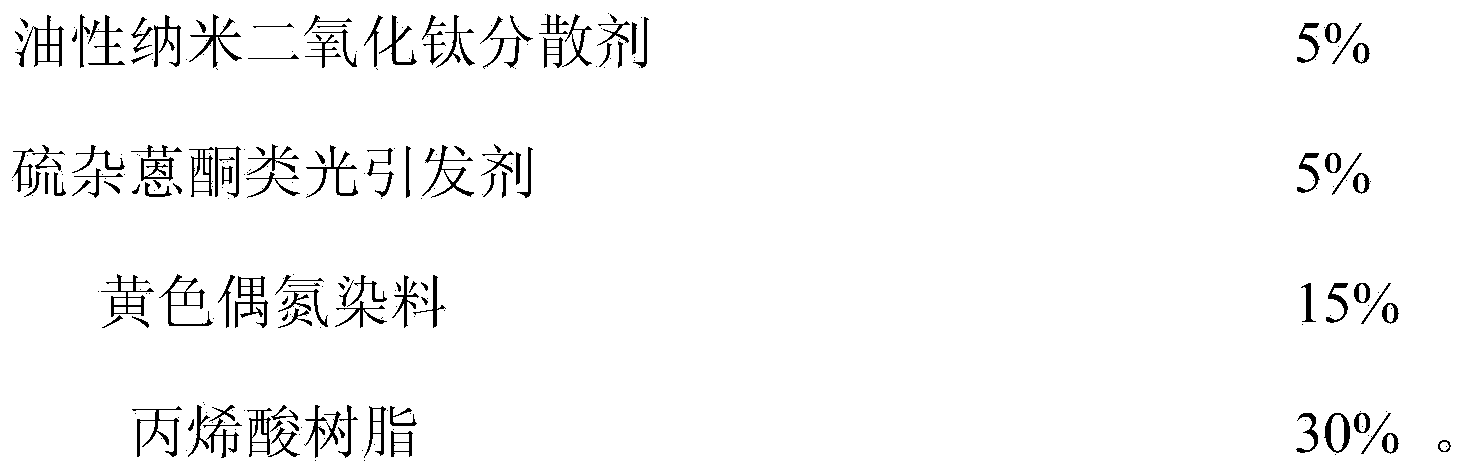

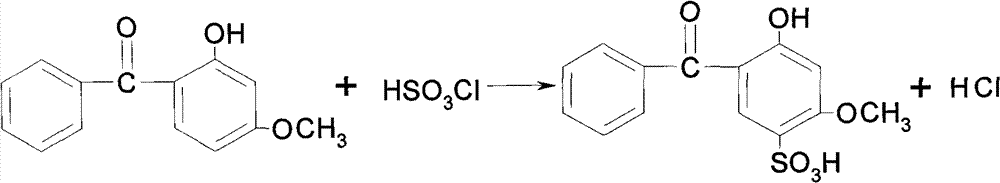

Method for producing 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid

ActiveCN101624357AResidue reductionOvercoming toxicityCosmetic preparationsOrganic compound preparationMethyl carbonateUltraviolet

The invention provides a method for producing benzophenone ultraviolet absorbent 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid (BP-4). The invention uses a BP-3 refined product and chlorsulfonic acid to synthesize and prepare the BP-4 in methyl carbonate, and is characterized in that the method comprises the following steps: adding BP-3 refined product, chlorsulfonic acid, methyl carbonate andwater according to a production ratio into a crude product reaction kettle, controlling the temperature to be 23-38 DEG C, keeping temperature and reacting for 18-20 hours to obtain a BP-4 crude product; dissolving the BP-4 crude product in the mixed solvent of the methyl carbonate and a latent solvent, recrystallizing, separating solid phase from liquid phase to obtain the solid phase BP-4 refined product; refining and drying the BP-4 refined product to obtain a finished product. The invention reduces the harmful solvent residue of the product, decreases production cost, and has notable economic benefit and environmental benefit. The product yield reaches 92% and the product purity is increased to 99.5% from 99%.

Owner:宜都市华阳化工有限责任公司

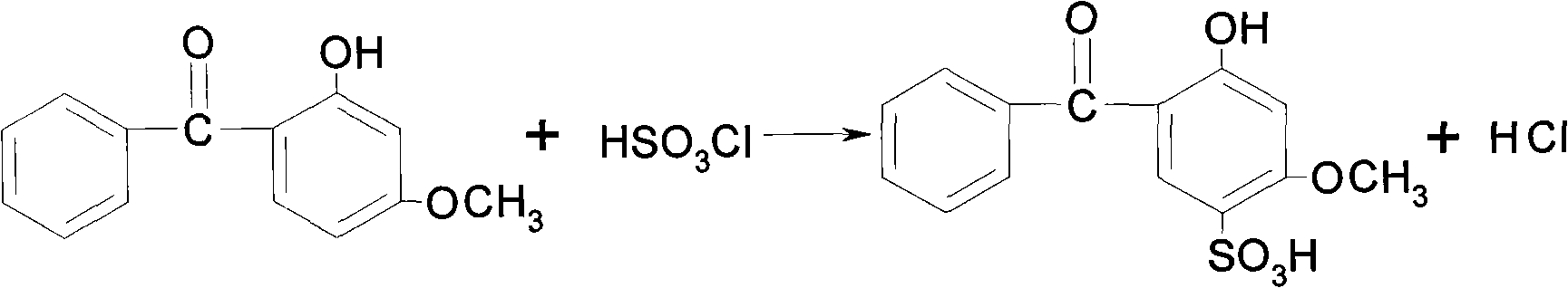

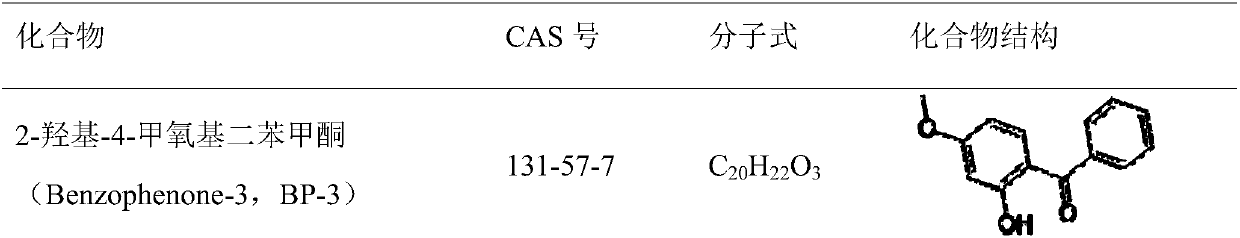

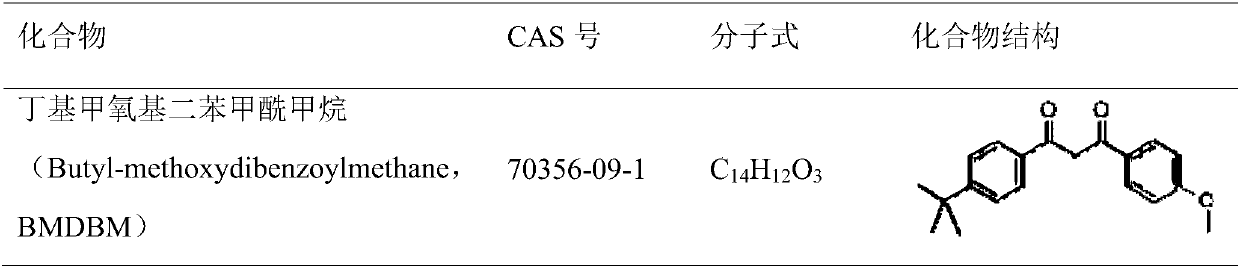

Determination method of 2‑hydroxy‑4‑methoxybenzophenone and butylmethoxydibenzoylmethane in soil

The invention provides a method for detecting 2-hydroxyl-4-methoxybenzophenone and butyl methoxydibenzoylmethane. According to the method provided by the invention, a quick and efficient extraction method with a high recovery rate is established by using an accelerated solvent extraction technology, then detection is performed by using a high-performance liquid chromatography-mass chromatography, and quantification is performed by using an internal standard method, so that the 2-hydroxyl-4-methoxybenzophenone and butyl methoxydibenzoylmethane in soil are effectively analyzed and detected. The average recovery rates of the 2-hydroxyl-4-methoxybenzophenone and the butyl methoxydibenzoylmethane are 95.1-93.3% and 92.7-93.2%, the detection limit is less than 1.0ng / g, the quantification limit is less than 2.0ng / g, and the method is high in recovery rate, high in sensitivity and good in repeatability and can be used for detecting 2-hydroxyl-4-methoxybenzophenone and butyl methoxydibenzoylmethane in soil.

Owner:中科检测技术服务(广州)股份有限公司

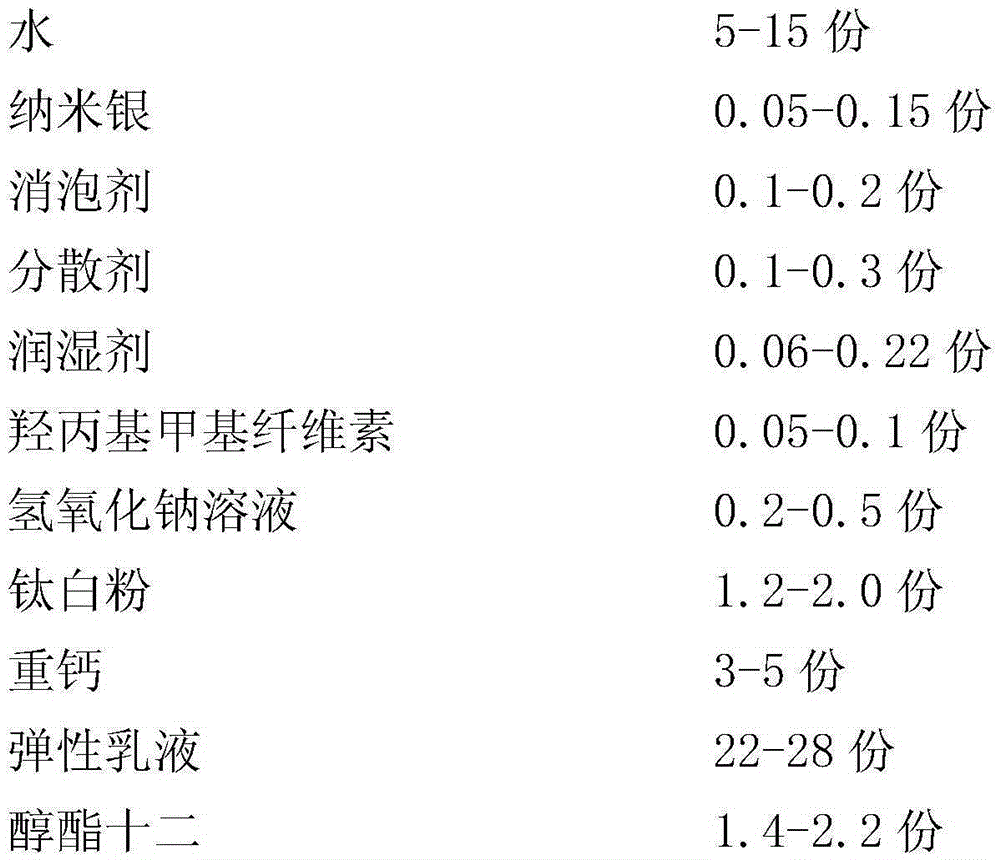

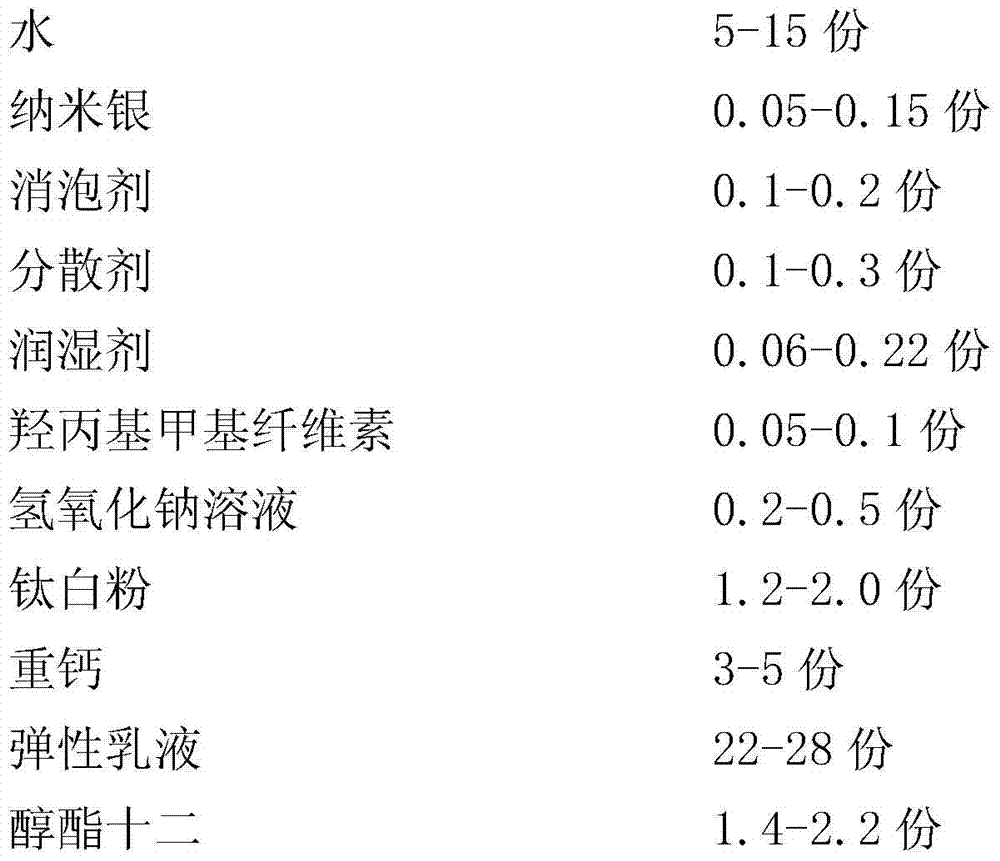

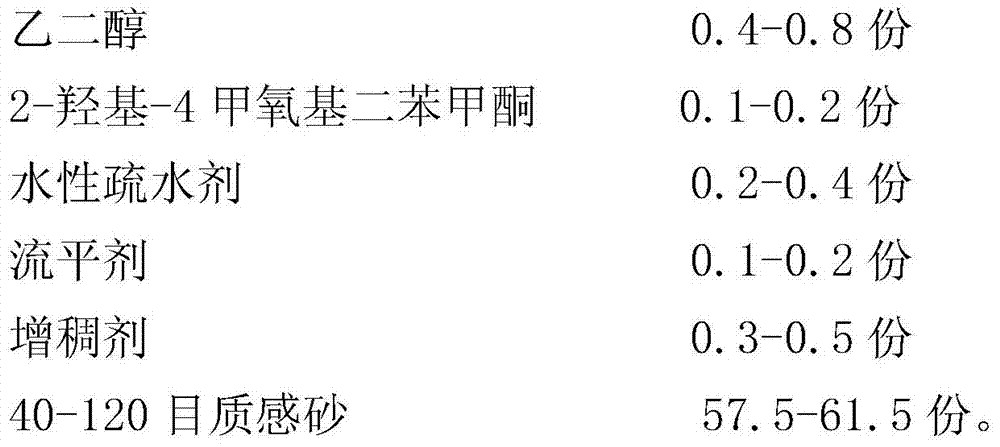

Elastic texture paint and preparation method thereof

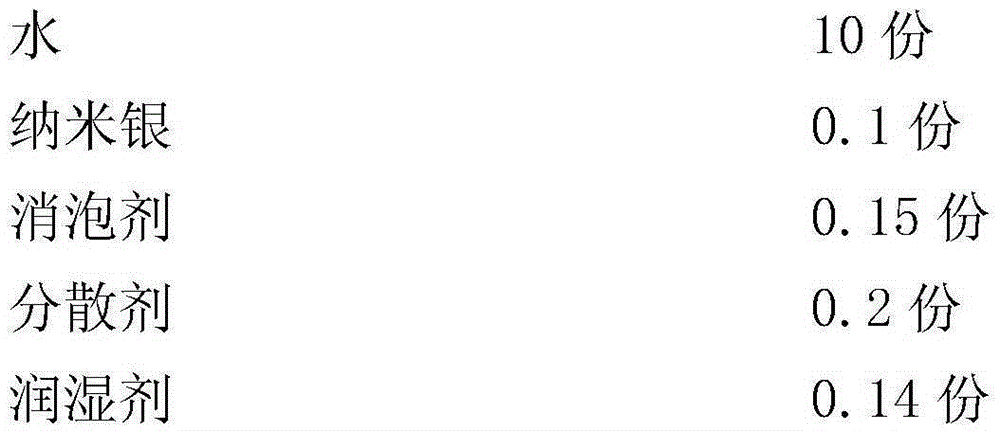

The invention relates to elastic texture paint. The elastic texture paint is prepared from water, nano silver, a dofoaming agent, a dispersing agent, a wetting agent, hydroxy propyl methyl cellulose, a sodium hydroxide solution, titanium dioxide, coarse whiting, elastic emulsion, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, ethylene glycol, 2-hydroxy-4-methoxy diphenyl ketone, a water-based hydrophobic agent, a flatting agent, a thickening agent and (40-120)-mesh texture sand. The elastic texture paint has a compact elastic film and is high in coating rate, excellent in dirt resistance, weather resistance and water resistance and remarkable in crazing resistance and tenacity, wall cracks can be effectively warped and connected, and a building is protected better.

Owner:SKSHU PAINT

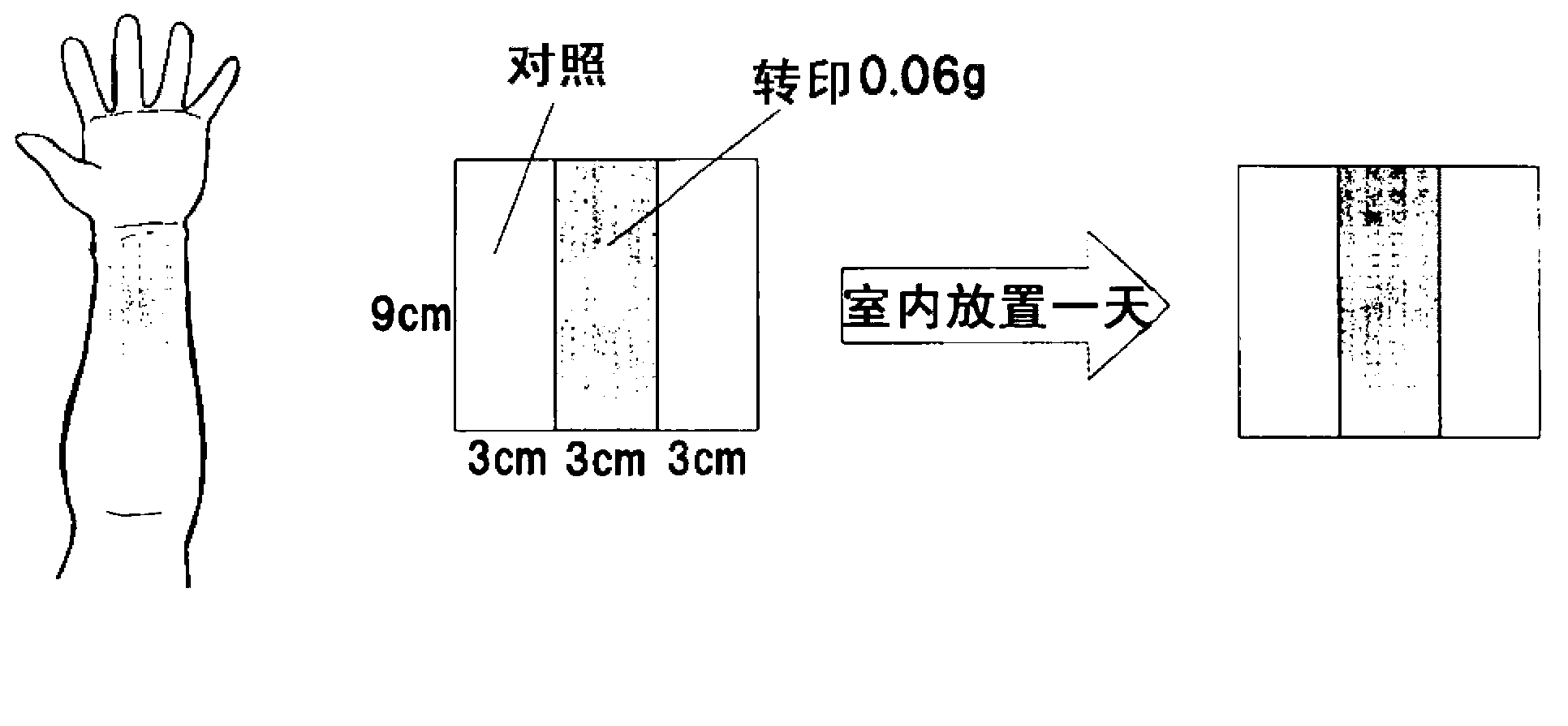

Sun-screen and skin-whitening fabric

InactiveCN105755817AStrong antibacterial and sunscreen effectCool textureBiochemical fibre treatmentGrip property fibresFiberSalicylic acid

The invention relates to sun-screen and skin-whitening fabric. The fabric is formed by blending and weaving raw materials in parts by weight as follows: 40-80 parts of bamboo fibers, 40-80 parts of long stapled cotton fibers, 10-30 parts of pearl fibers, 10-30 parts of linen fibers, 10-20 parts of aloe fibers, 10-20 parts of mica fibers and 5-20 parts of milk protein fibers, and the fabric is formed after treatment with an anti-bacterial and sun-screen finishing liquid, wherein the anti-bacterial and sun-screen finishing liquid contains 5-10 parts of chitosan, 5-10 parts of tea polyphenol, 0.5-3 parts of 2-hydroxyl-4-methoxybenzophenone, 0.5-3 parts of salicylic acid phenyl ester, 0.5-2 parts of sodium tripolyphosphate, 5-8 parts of trimethyltetradecylammonium chloride, 5-10 parts of polyethylene glycol, 5-10 parts of polyhexamethylene biguanidine, 5-15 parts of nano titanium dioxide, 3-8 parts of N-dodecyl glucosyl lauramide and 5-10 parts of waterborne polyurethane. The fabric has high antibacterial and sun-screen effects, has a skin-whitening and skin-care effect and cool texture and is anti-pilling, breathable, good in moisture absorption, soft, comfortable, wear-resisting and very suitable for being used for making clothes such as underwear, outerwear, shirts, T-shirts and the like.

Owner:卢洁

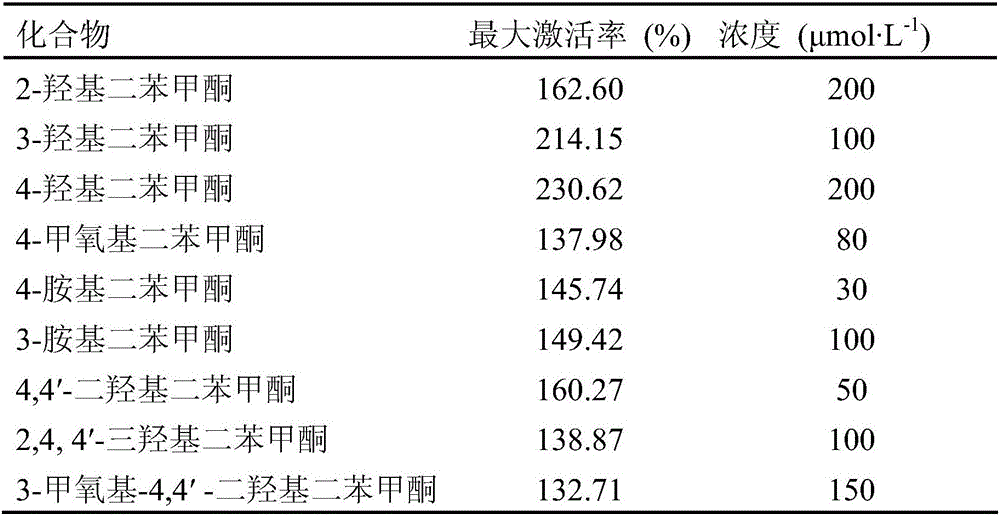

Benzophenone derivatives serving as tyrosinase activating agents and applications thereof

ActiveCN106420680AGood activation rateEfficient activationCosmetic preparationsHair cosmetics2-hydroxybenzophenoneFood chemistry

The invention belongs to the technical field of cosmetics, medicines and food chemistry, and discloses benzophenone derivatives serving as tyrosinase activating agents and applications thereof. The benzophenone derivatives serve as the tyrosinase activating agents and are one or more than one of 2-hydroxybenzophenone, 3-hydroxybenzophenone, 4-hydroxybenzophenone, 4-methoxybenzophenone, 4-aminobenzophenone, 3-aminobenzophenone, 4, 4'-dihydroxy benaophenonel, 2, 4, 4'-trihydroxybenzophenone or 3-methoxyl-4, 4'-dihydroxy benaophenonel. The compounds disclosed by the invention have intense tyrosinase activation activity and obvious application prospect in medicines (such as treatment of leucoderma) and cosmetics (such as hair-blacking liquid shampoo).

Owner:GUANGDONG IND TECHN COLLEGE

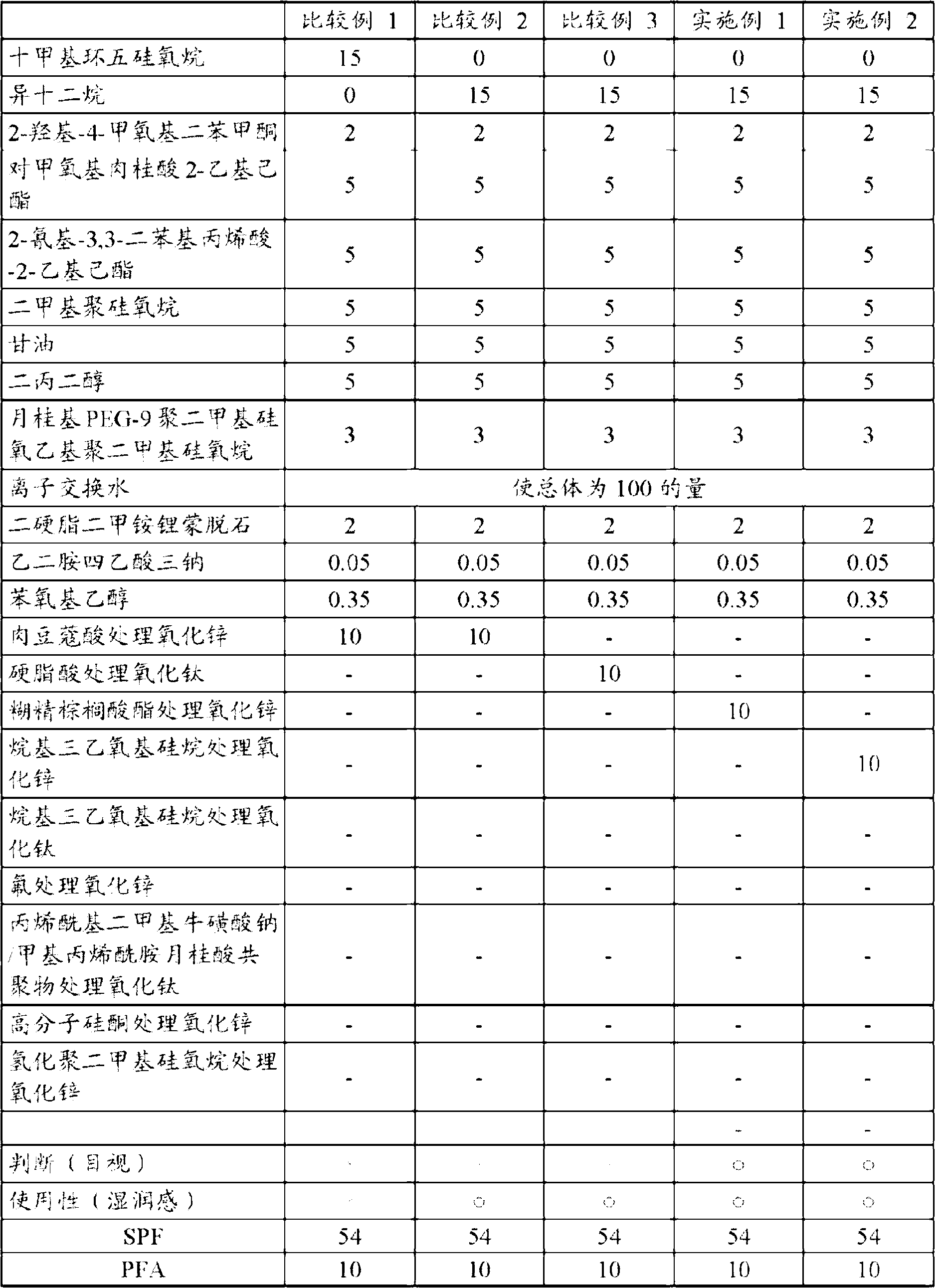

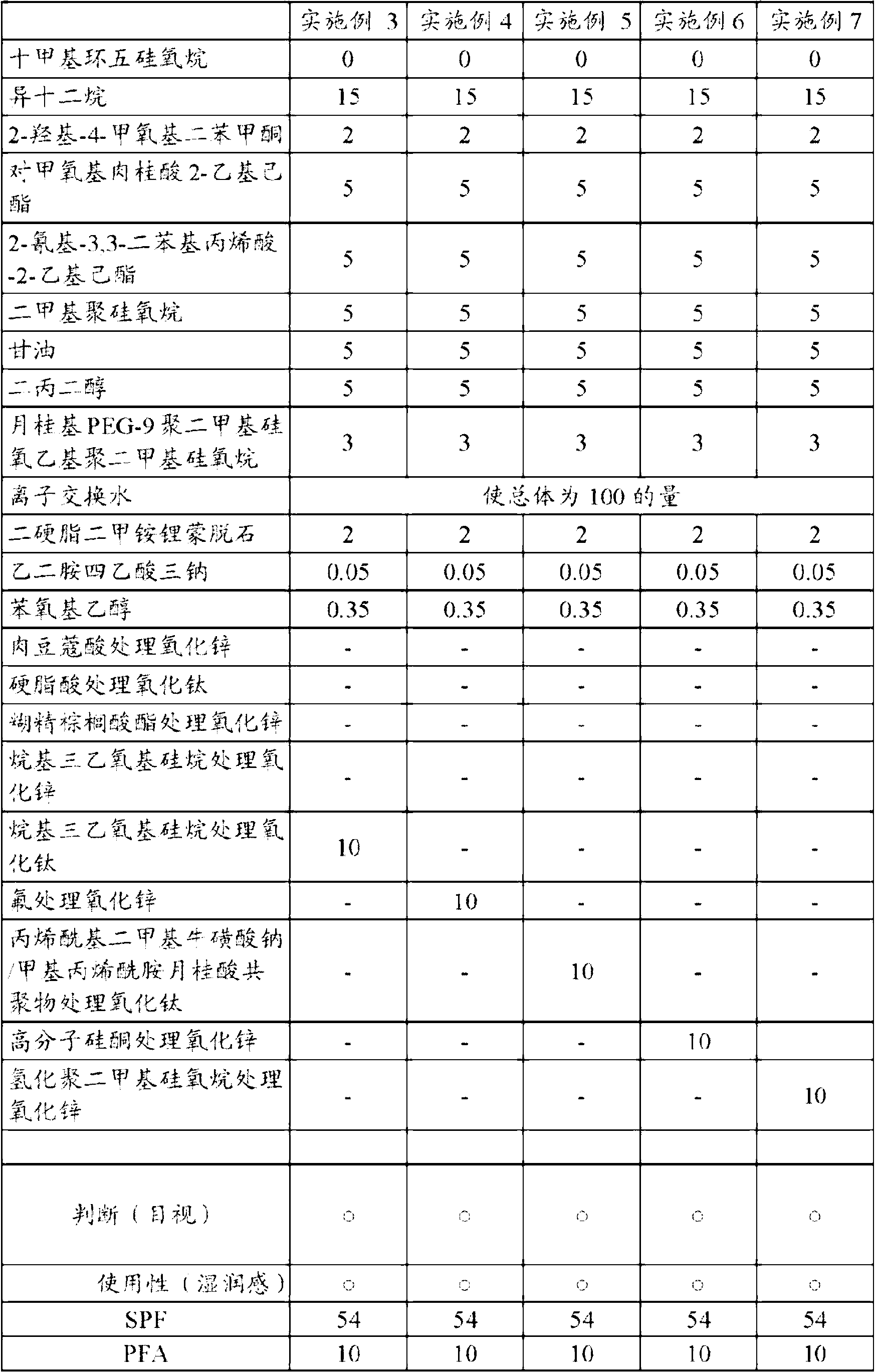

Sunscreen cosmetic

InactiveCN102869337APromote absorptionNo secondary adhesion (contamination) problemCosmetic preparationsToilet preparationsUltravioletDiethylamino hydroxybenzoyl hexyl benzoate

Disclosed is a sunscreen cosmetic that does not contain diethylamino hydroxybenzoyl hexyl benzoate, absorbs a wide range of wavelengths of ultraviolet rays across the UVA and UVB regions, and also does not cause staining (dyeing) through secondary adhesion to clothing. The sunscreen cosmetic is characterized by containing: 2-hydrdoxy-4-methoxybenzophenone, 2-ethylhexyl p-methoxycinnamate, octocrylene, a volatile hydrocarbon oil, and zinc oxide and / or titanium oxide that has undergone hydrophobizing treatment other than with a fatty acid.

Owner:SHISEIDO CO LTD

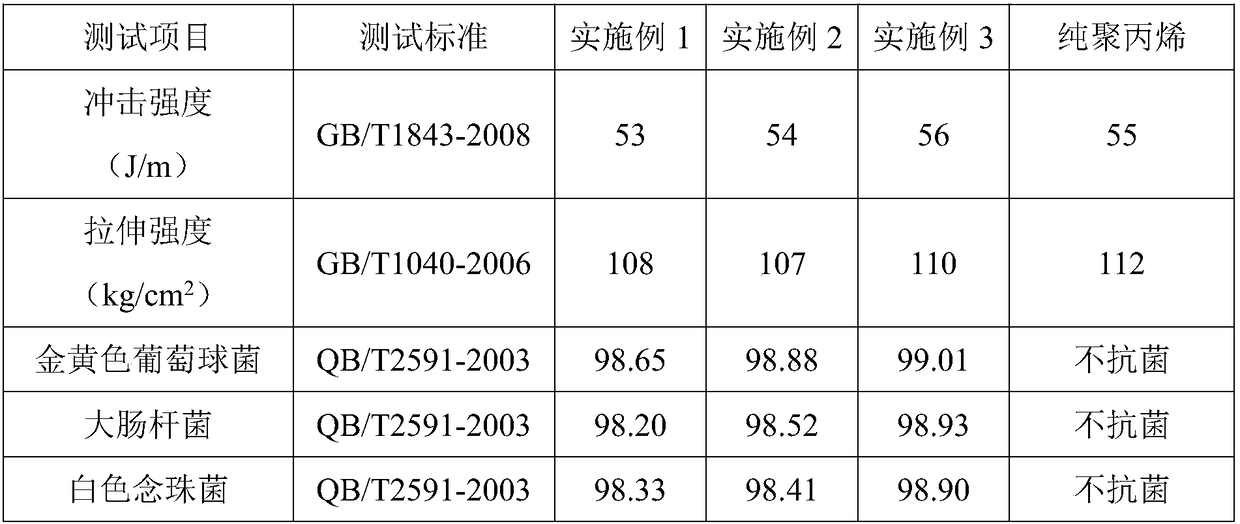

PETG (Polyethylene Terephthalate Glycol) modified copolyester

InactiveCN109232869AMaintain chemical balanceReduce surface tensionPolyethylene terephthalate glycolTemperature resistance

The invention discloses a PETG (Polyethylene Terephthalate Glycol) modified copolyester. The PETG modified copolyester comprises the following components in parts by weight: 65-85 parts of terephthalic acid, 15-20 parts of ethylene glycol, 18-25 parts of neopentyl glycol, 10-15 parts of aminopropyl methyl diethoxysilane, 5-7 parts of trialkylphosphate, 20-25 parts of trimellitic anhydride, 12-18 parts of 1,1-cyclopropyl dicarboxylic acid, 8-13 parts of decabromodiphenyl ethane, 10-15 parts of 2-acetoxyl-4-methoxybenzophenone, 5-12 parts of 3,5-dichlorobenzene sulfonamide, 6-10 parts of manganese dioxide, 1-2 parts of a stabilizer, 2-3 parts of an antioxidant and 2-3 parts of a compatilizer. The preparation method comprises the following steps: mixing, performing microwave heating, and carrying out an esterification reaction in mixed gas so as to obtain an oligomer; charging the oligomer to carry out a condensation polymerization reaction so as to obtain a copolymer; and finally, charging the copolymer and regulating the pH value, and stirring, thereby obtaining the final copolyester. The copolyester is modified by utilizing the esterification and condensation polymerization processes, the characteristics of the original PETG copolyester are changed, and the prepared copolyester has high strength, high temperature resistance, lubricating and anti-adhesion properties and wide application range.

Owner:腾龙特种树脂(厦门)有限公司

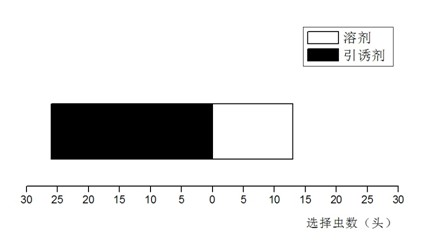

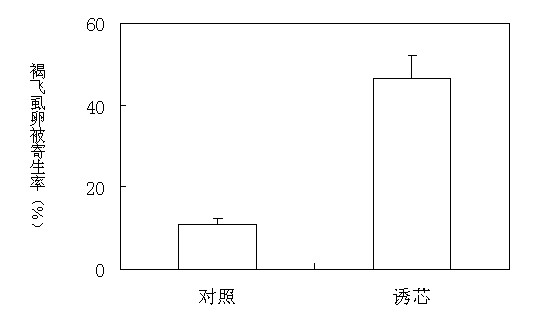

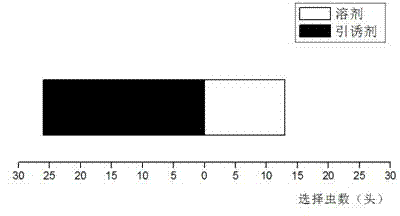

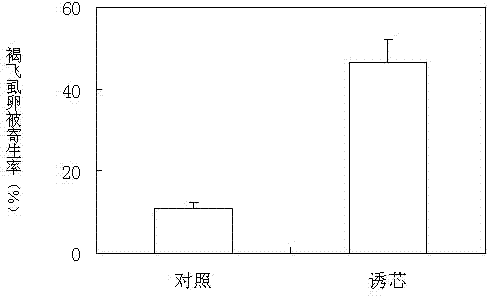

Natural enemy attractant for controlling population quantity of rice planthoppers

The invention discloses a natural enemy attractant for controlling the population quantity of rice planthoppers. The natural enemy attractant comprises the following components: linalool, cis-3-hexenoicaldehyde, cis-acetate-3-hexenyl ester, liquid paraffin, 2,6-di-tert-butyl-p-cresol, 2-hydroxyl-4-methoxybenzophenone at a weight ratio of (0.01-0.10): (0.01-0.10): (0.01-0.10): (0.2-2): (0.01-0.1):(0.01-0.1). The natural enemy attractant disclosed by the invention attracts the female adults of anagrus nilaparvatae which is an important natural enemy of rice planthoppers in an egg stage, thus reducing the population quantity of rice planthoppers and reducing harm to the rice plants. The attractant is low in cost, high in efficiency, friendly to environment, safe to people and livestock and the like. The attractant for anagrus nilaparvatae which is the natural enemy of rice planthoppers has a broad industrial prospect, and due to the simple preparation method, is particularly suitable for the harmless production of rice, and has high economic, social and ecological benefits.

Owner:ZHEJIANG UNIV

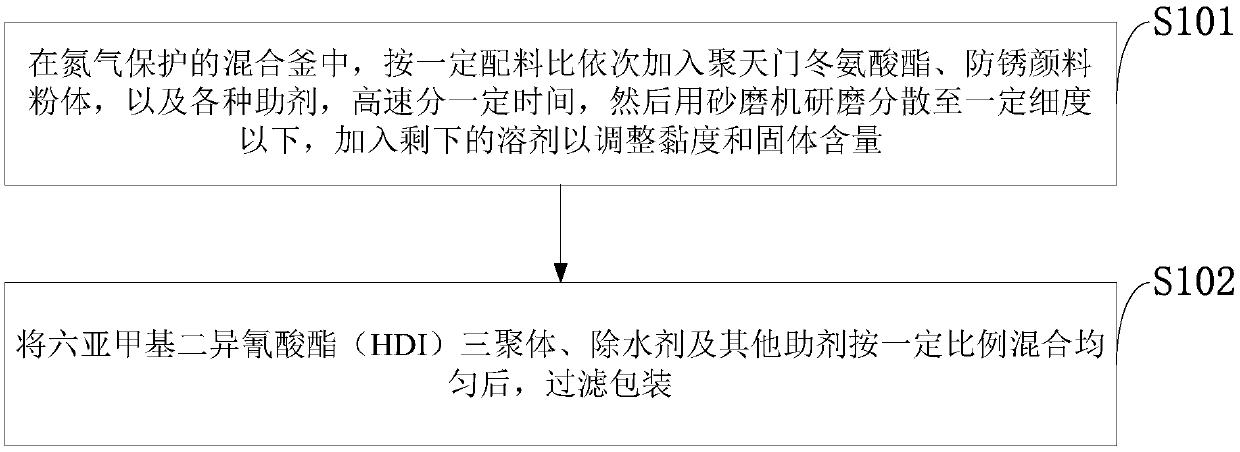

Heavy-duty waterproof coating, preparation method thereof, special building, ship and car

InactiveCN107805449AGood weather resistanceImprove heat resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSodium BentoniteSalt spray test

The invention belongs to the technical field of heavy-duty waterproof coating and discloses heavy-duty waterproof coating, a preparation method thereof, a ship and a car. The heavy-duty waterproof coating comprises Bayer polyaspartic acid resin, Bayer polyaspartic acid resin, hexamethylene diisocyanate, a titanate coupling agent, titanium dioxide, magnet powder, doped polyaniline, 2-hydroxyl-4-methoxybenzophenone and HY-708Y organic bentonite. The heavy-duty waterproof coating has the advantages that the neutral salt spray test time of the heavy-duty waterproof coating is not smaller than 3000hours or the copper acetate salt spray acceleration test time of the heavy-duty waterproof coating is not smaller than 300 hours; the adhesive force of the heavy-duty waterproof coating is not smaller than 15MPa or 10MPa; the toughness of the heavy-duty waterproof coating is not larger than 1mm; the impact resistance of the heavy-duty waterproof coating is not smaller than 80kg*cm; the VOC of theheavy-duty waterproof coating is not larger than 320g / L; the 0.1mol / LH2SO4 solution corrosion resistance of the heavy-duty waterproof coating is not smaller than 720 hours; the 0.1mol / L NaOH solutioncorrosion resistance of the heavy-duty waterproof coating is not smaller than 1000 hours.

Owner:四川正大新材料科技有限公司

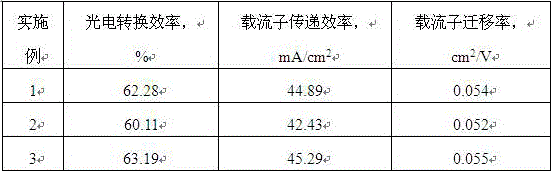

Novel environment-friendly broad-spectrum solar cell material

InactiveCN106356459AReduce total usageEfficient use ofFinal product manufactureSolid-state devicesCharge carrier mobilityThiadiazoles

The invention discloses a novel environment-friendly broad-spectrum solar cell material, made from Beta-methoxythiophene, 2-amino-5-thiol-1,3,4-thiadiazole, trimethylolpropane, an epoxysilane coupling agent, maleic acid grafted compatibilizer, acrylic bridging agent, palladium catalyst, graphite, carbon black, silicon carbide, aluminum nitride, silicon nitride, aluminum trioxide, silicon dioxide, montmorillonite, carbon fiber, ceramic fiber, carboxyl methyl cellulose, dibasic lead phosphite, an acrylate regulator, epoxypropoxypropyltrimethoxysilane, 701 powder, aluminum polychloride, ethylene propylene rubber, bis(2,2,6,6-tetramethyl-4-piperidine) sebacate, dibasic lead stearate, 2-hydroxyl-4-methoxybenzophenone, and ammonium polyphosphate. The solar cell material of the invention is efficient in using energy of sunlight, including ultraviolet and infrared bands, photoelectric conversion efficiency is improved, carrier transmission efficiency is improved, and carrier migration rate is increased.

Owner:广西南宁荣威德新能源科技有限公司

Sunscreen skin-moistening lotion

The invention provides a sunscreen skin-moistening lotion which comprises, by mass, 5-30 parts of 2, 2'-dihydroxy-4-methoxybenzophenone, 3-10 parts of 3-(4-methylbenzal) camphor, 2-20 parts of zinc oxide, 2-8 parts of stearic acid, 1-5 parts of essence, 40-80 parts of water, 5-10 parts of tea polyphenol, 4-10 parts of zinc metallothionein and 10-30 parts of vaseline. The sunscreen skin-moistening lotion can nourish and whiten skin and delay skin aging and is simple in preparation method, low in cost and suitable for general use.

Owner:李尧

Exterior wall coating

InactiveCN107011754AImprove wear resistanceImprove thermal stabilityCoatingsHexamethylphosphoramideSlag

The invention discloses an exterior wall coating. The exterior wall coating is prepared from the following raw materials: wollastonite, diatomite, fine coal slag, glycol, an emulsion, hexamethylphosphoramide, 2-hydroxyl-4-methoxybenzophenone, a film forming aid, pigment and deionized water. The fine coal slag, wollastonite and diatomite exert synergistic effect, so the wear resistance of the exterior wall coating is improved; glycol is added to prevent generation of orange skin after usage of the coating; and hexamethylphosphoramide can improve weatherability and cold resistance besides functioning as a light stabilizing agent. The exterior wall coating provided by the invention has good weatherability, anti-ultraviolet performance and high weatherability and heat stability and is not prone to generation of orange skin.

Owner:广西烽盛科技有限公司

Mirror surface special-purposed resin composition and preparation method thereof

The invention relates to a mirror surface special-purposed resin composition and a preparation method thereof. According to the mass, the mirror surface special-purposed resin composition comprises the following raw materials: 65-68 parts of acrylic resin, 15-18 parts of silicon carbide fiber, 3-5 parts of dimethyl silicone oil, 1-5 parts of trimethyl citrate, and 0.3-0.8 parts of 2-hydroxyl-4-methoxybenzophenone. According to the invention, traditional acrylic resin is modified, and is reasonably complexed with other raw materials and auxiliary agents. The obtained resin composition has excellent wear resistance. When the resin composition is used as a mirror surface for a long time, the mirror surface can maintain clear with no scratch.

Owner:WUJIANG DEZUO DAILY CHEM PROD

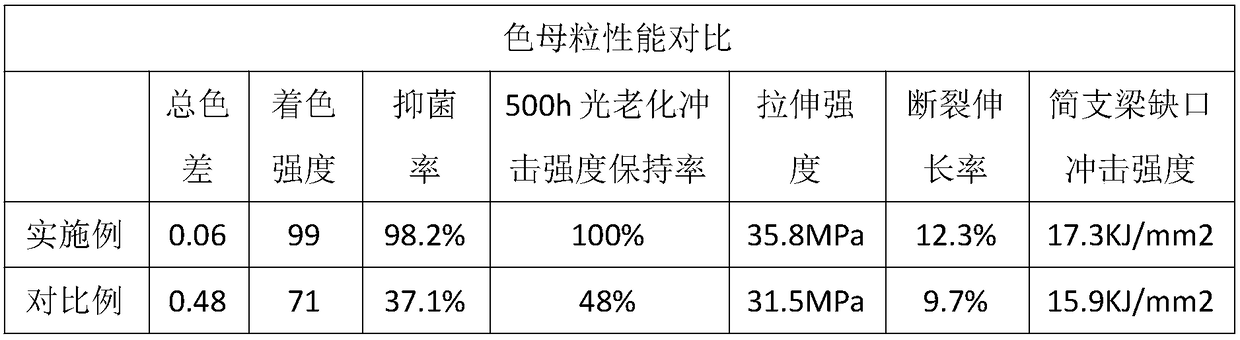

Anti-aging polyethylene color masterbatch and preparation method thereof

The invention discloses anti-aging polyethylene color masterbatch. The anti-aging polyethylene color masterbatch is prepared from, by weight, 60-90 parts of polyethylene, 20-30 parts of inorganic pigments, 2-3 parts of a composite dispersion agent, 2-3 parts of an ultraviolet absorber, 20-30 parts of bamboo charcoal fibers, 1-2 parts of a phenol antioxidant 1010 and 1-2 parts of filler. The polyethylene color masterbatch is low in cost, safe and environmentally friendly and contains bamboo charcoal fibers, the antibacterial rate reaches 90% or above, and low ultraviolet transmittance is realized; by adoption of phenyl salicylate and 2-hydroxyl-4-methoxybenzophenone as the ultraviolet absorber, high resin compatibility and wide absorption wavelength range are realized, and effects of a stabilizing agent and a plasticizer are achieved. In application to coloring of polyethylene products, the anti-aging polyethylene color masterbatch has advantages of high aging resistance, uniformity incoloring, freeness of discoloration, high antibacterial rate, low consumption, freeness of influences on mechanical performances of the products and the like, and the service life of the polyethylenematerial is greatly prolonged.

Owner:合肥卡洛塑业科技有限公司

Natural enemy attractant for controlling population quantity of rice planthoppers

The invention discloses a natural enemy attractant for controlling the population quantity of rice planthoppers. The natural enemy attractant comprises the following components: linalool, cis-3-hexenoicaldehyde, cis-acetate-3-hexenyl ester, liquid paraffin, 2,6-di-tert-butyl-p-cresol, 2-hydroxyl-4-methoxybenzophenone at a weight ratio of (0.01-0.10): (0.01-0.10): (0.01-0.10): (0.2-2): (0.01-0.1):(0.01-0.1). The natural enemy attractant disclosed by the invention attracts the female adults of anagrus nilaparvatae which is an important natural enemy of rice planthoppers in an egg stage, thus reducing the population quantity of rice planthoppers and reducing harm to the rice plants. The attractant is low in cost, high in efficiency, friendly to environment, safe to people and livestock and the like. The attractant for anagrus nilaparvatae which is the natural enemy of rice planthoppers has a broad industrial prospect, and due to the simple preparation method, is particularly suitable for the harmless production of rice, and has high economic, social and ecological benefits.

Owner:ZHEJIANG UNIV

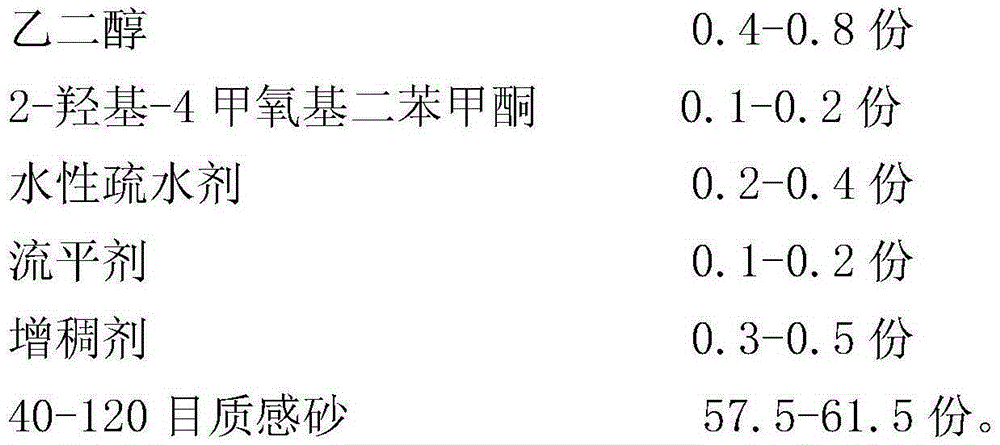

A kind of elastic texture coating and preparation method thereof

The invention relates to an elastic texture coating, which is prepared from the following components: water, nano silver, defoamer, dispersant, wetting agent, hydroxypropyl methylcellulose, sodium hydroxide solution, titanium dioxide, heavy Calcium, elastic emulsion, alcohol ester dodeca, ethylene glycol, 2-hydroxy-4 methoxybenzophenone, water-based hydrophobic agent, leveling agent, thickener, 40-120 mesh texture sand. The invention has a dense elastic coating film, high spreading rate, excellent stain resistance, weather resistance and water resistance, as well as excellent crack resistance and flexibility, which can effectively warp the cracks of the wall and better protect the building things.

Owner:SKSHU PAINT

Powerful acrylate adhesive

InactiveCN103497692AGood weather resistanceImprove toughnessNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveWear resistantAdhesive

The invention discloses a powerful acrylate adhesive. The powerful acrylate adhesive comprises acrylate, a waterproof agent, an anticorrosive agent, a toughening agent, a wear-resistant agent and a weather-resistant agent, wherein the waterproof agent is sodium methyl silicate; the anticorrosive agent is mercaptobenzothiazole; the toughening agent is carboxylated nitrile rubber; the weather-resistant agent is polyurethane plastic; the weather-resistant agent is 2-hydroxyl-4-methoxybenzophenone. The powerful acrylate adhesive product is prepared from the acrylate and various additives; the prepared adhesive is good in weather resistance, waterproof, anticorrosive, good in toughness, good in wear resistance, stable in performance, and good in flow speed.

Owner:SUZHOU HUAZHOU TAPE

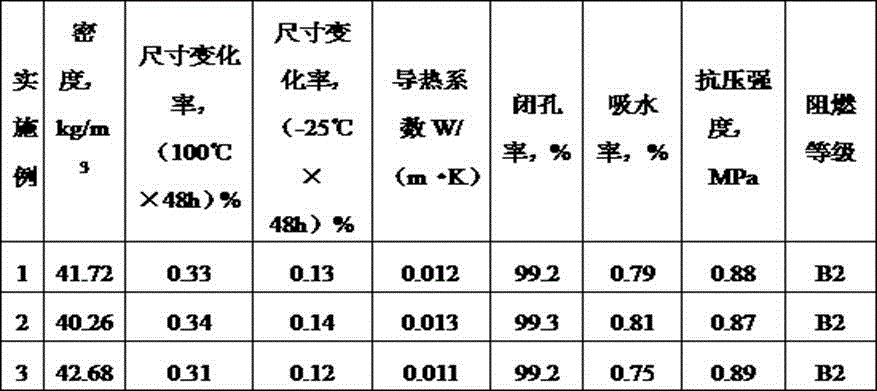

Novel solar environmentally-friendly thermal insulation material

InactiveCN106433093AHigh compressive strengthImprove flame retardant performancePolybutyleneAtmospheric ozone

The invention discloses a novel solar environmentally-friendly thermal insulation material. The material is prepared from polyurethane, polyether, polybutylene glycol, vinyl resin, white latex, fly ash, talc, calcium carbonate powder, montmorillonoid powder, silicone oil, silicon carbide fiber, glass fiber, polypropylene fiber, hydroxypropyl methyl cellulose, maleic anhydride-grafted compatilizer, an acrylic acid bridging agent, a dispersing agent NC, stannous octoate, azodicarbonamide, an acrylic ester foaming control agent, silicone amide, an epoxy resin binder, dioctyl adipate, liquid polybutadiene rubber, polyaluminum cloride, p-hydroxybenzenesulfonic acid, styrene, a fatty acid stabilizer, an antioxidant 1010, decabromodiphenyl ethane, ammonium octamolybdate and 2-hydroxyl-4-methoxybenzophenone. The prepared novel solar environmentally-friendly thermal insulation material has no deformation phenomenon at high temperature and low temperature; in addition, the compressive strength is high, the flame retardant efficiency is good, an atmospheric ozone layer is not destroyed, and the novel solar environmentally-friendly thermal insulation material is excellent in property.

Owner:广西南宁荣威德新能源科技有限公司

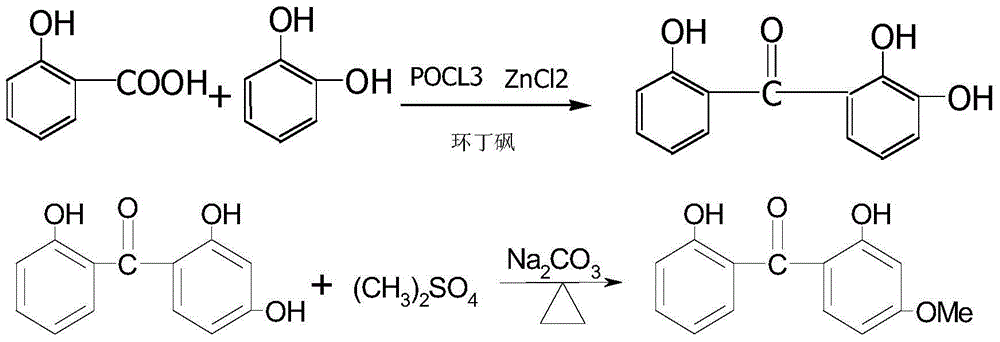

Preparation method of 2,2'-dihydroxy-4-methoxybenzophenone

ActiveCN104945234AImprove the efficiency of industrial productionHigh yieldOrganic compound preparationCarbonyl compound preparationSalicylic acidMethylation

A preparation method of 2,2'-dihydroxy-4-methoxybenzophenone comprises the following steps: synthesizing 2,2'4-trihydroxybenzophenone from salicylic acid and resorcinol, and carrying out a methylation reaction on 2,2'4-trihydroxybenzophenone and dimethyl sulfate to prepare 2,2'-dihydroxy-4-methoxybenzophenone. The method has the advantages of high purification efficiency, good separation effect of byproducts, high product purity reaching 99.5%, and realization of industrial production requirements of the above product.

Owner:宜都市华阳化工有限责任公司

Chlorinated polyvinyl chloride sheath for 30kV power cable

InactiveCN107189244AImprove bindingHigh bonding strengthPlastic/resin/waxes insulatorsPolyethylene glycolChlorinated paraffins

The invention discloses a chlorinated polyvinyl chloride sheath for a 30kV power cable. The chlorinated polyvinyl chloride sheath is prepared from the following raw materials in parts by weight: 40 to 50 parts of nitrile silicone rubber, 90 to 110 parts of chlorinated polyvinyl chloride, 2 to 4 parts of barium stearate, 1 to 2 parts of dioctyl sebacate, 1 to 2 parts of epoxidized soybean oil, 2 to 4 parts of chlorinated paraffin, 2 to 4 parts of polyethylene glycol, 50 to 70 parts of a filling material, 6 to 12 parts of a flexibilizer, 1 to 2 parts of maleic anhydride and 1 to 2 parts of 2-hydroxyl-4-methoxybenzophenone. The chlorinated polyvinyl chloride sheath for the 30kV power cable is extremely high in deformation resistance and tear resistance and relatively excellent in mechanical property and can bear most charges, effectively enhance the toughness and avoid the phenomenon of brittle failure.

Owner:JINYUAN ELECTRIC GRP

Uvioresistant color masterbatches for polypropylene and preparation process of uvioresistant color masterbatches

The invention discloses uvioresistant color masterbatches for polypropylene. The uvioresistant color masterbatches for polypropylene is prepared from the following raw materials in parts by weight: 60-85 parts of polypropylene, 10-15 parts of an ethylene-vinyl acetate copolymer, 7-11 parts of polyolefin elastomer, 3-5 parts of a stryenemaleic anhydride copolymer, 1.5-3 parts of zinc stearate, 1.7-2.5 parts of calcium stearate, 12-18 parts of pigment, 0.35-0.85 part of 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-benzotriazole chloride, 0.2-0.4 part of 2-hydroxyl-4-methoxybenzophenone, 0.2-0.6 partof 2-hydroxyl-4-n-octyloxybenzophenone, 1.5-2.5 parts of silver nitrate, 3.5-6 parts of bis (2,4-di-tert-butyl-phenyl) propionic acid] pentaetythritol diphosphite and 4-7 parts of 2,5 dimethyl-2,5 di-tert-butyl hexane peroxide. The uvioresistant color masterbatches for the polypropylene are good in uvioresistant effect; and the uvioresistant color masterbatches for the polypropylene and a coloredproduct are good in mechanical property, and the comprehensive using performance is good; and the antibacterial property, oxidation resistance, thermal stability and the like are good.

Owner:海宁彩源新材料科技有限公司

Resin material resistant to light, heat, corrosion and aging for gardening ornaments

The invention relates to the technical field of organic materials, in particular to a resin material resistant to light, heat, corrosion and aging for gardening ornaments. The resin material comprisesthe following components: polycarbonate, ABS resin, modified mineral fiber, nano titanium dioxide, talc, pigment, dydecyl thiopropionate, butylated hydroxytoluene, a light stabilizer, a coupling agent, a light diffusing agent and a plasticizer; wherein, the modified mineral fiber is the fiber obtained through the acidification, softening and surface modification treatment of a mixture of brucitefiber and wollastonite fiber; the light stabilizer is 2-hydroxy-4 methoxybenzophenone or 2-hydroxy-4 n-octyloxybenzophenone; through the use of various additives, the resin material is capable of improving the anti-aging properties of the resin material under the action of various outdoor oxidation factors, and prolonging the service life of the gardening ornaments prepared with the resin material.

Owner:合肥谦尧建筑装饰工程有限公司

UV-resistant anti-crack modified plastic and production method thereof

The invention discloses a type of UV-resistant anti-crack modified plastic. The UV-resistant anti-crack modified plastic comprises, by weight, 50 parts to 60 parts of polyethylene, 30 parts to 40 parts of EVA resin, 5 parts to 8 parts of nanometer tin antimony oxide, 1 part to 3 parts of nanometer titanium dioxide, 2 parts to 4 parts of China hemp fiber powder, 1.1 parts to 2.3 parts of zinc stearate, 1 part to 2 parts of nanometer organic montmorillonite, 0.2 part to 0.4 part of antimony oxide, 0.1 part to 0.3 part of 2-Dihydroxy-4-methoxybenzophenone, 0.5 part to 1.2 parts of polydimethylsiloxane, and the appropriate amount of absolute ethyl alcohol. The produced plastic is resistant to UV light and cracking, is remarkably improved in tensile strength and impact strength, and is improved to some extent in chemical resistance and heat resistance; when the plastic is deeply processed to form film which is used for vegetable greenhouses, the plastic has the advantages of being high in low temperature resistance, obvious in heat insulation, self-cleaning, antibacterial, high in light transmittance and the like.

Owner:WUHU ZHONGLI PARTS

Oil stain-resistant thin film and preparation method thereof

InactiveCN108822688AImprove hydrophobicity and oleophobicityGood light transmissionAntifouling/underwater paintsPaints with biocidesPolyethylene terephthalate glycolAntioxidant

The invention discloses an oil stain-resistant thin film. The oil stain-resistant thin film is prepared from the following raw materials in parts by weight: 60 to 80 parts of bisphenol A type epoxy resin, 20 to 30 parts of polyacrylate, 5 to 10 parts of o-cresol formaldehyde epoxy resin, 5 to 10 parts of polyethylene terephthalate, 3 to 5 parts of zinc oxide, 2 to 4 parts of polyaluminum iron silicate, 1 to 2 parts of 2-hydroxyl-4-methoxybenzophenone, 1 to 2 parts of 2-(2'-hydroxyl-5'-tert octyl phenyl)benzotriazole, 6 to 10 parts of organic solvent, 2 to 4 parts of flatting agent, 1 to 3 parts of curing agent, 0.5 to 1.5 parts of photoinitiator and 0.5 to 1 part of antioxidant. The invention also discloses a preparation method of the oil stain-resistant thin film. Under the common matching action of all raw materials, the oil stain-resistant thin film prepared by the invention is strong in anti-ultraviolet capacity, and the damage of ultraviolet rays to eyes can be reduced.

Owner:李金磊

Method for producing 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid

ActiveCN101624357BResidue reductionSolve the problem of residual toxic solventsCosmetic preparationsOrganic compound preparationChlorosulfuric acidMethyl carbonate

The invention provides a method for producing benzophenone ultraviolet absorbent 2-hydroxyl-4-methoxybenzophenone-5-sulfonic acid (BP-4). The invention uses a BP-3 refined product and chlorsulfonic acid to synthesize and prepare the BP-4 in methyl carbonate, and is characterized in that the method comprises the following steps: adding BP-3 refined product, chlorsulfonic acid, methyl carbonate andwater according to a production ratio into a crude product reaction kettle, controlling the temperature to be 23-38 DEG C, keeping temperature and reacting for 18-20 hours to obtain a BP-4 crude product; dissolving the BP-4 crude product in the mixed solvent of the methyl carbonate and a latent solvent, recrystallizing, separating solid phase from liquid phase to obtain the solid phase BP-4 refined product; refining and drying the BP-4 refined product to obtain a finished product. The invention reduces the harmful solvent residue of the product, decreases production cost, and has notable economic benefit and environmental benefit. The product yield reaches 92% and the product purity is increased to 99.5% from 99%.

Owner:宜都市华阳化工有限责任公司

A water treatment method based on manganese-cobalt composite oxide nanoparticles modified ceramic membrane

ActiveCN105800735BAchieve separationAvoid formingWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by oxidationNatural organic matterDecomposition

The invention relates to an advanced water treatment technique for pollution removal through heterogeneous catalytic ozonation. Directed at the disadvantage that a conventional powdery catalyst is unfavorable for realizing separation and inactivation in a water phase, an assembly method for a novel manganese-cobalt complex oxide nanoparticle catalyst-loaded ceramic membrane is provided. The assembly method aims to combine heterogeneous ozonation with a ceramic membrane filtration technique, and utilizes a ceramic membrane structure and active components (MnO2 and Co3O4) on a catalytic layer to catalyze ozone so as to generate -OH with high oxidation capacity, wherein organic compounds can realize reinforced removal of pharmaceutical and personal care products (PPCPs) like 2-hydroxyl-4-methoxybenzophenone in water through direct reaction with molecular ozone or reaction with -OH generated by ozone decomposition; meanwhile, ozone can react with humic acid and natural organic matters (NOMs) in the water, so the formation of membrane pollution is effectively controlled. The manganese-cobalt complex oxide nanoparticles are loaded on the surface of the ceramic membrane, so separation of the catalyst from the water is realized, and a novel method for cleaning and repeated use of the catalyst is provided.

Owner:BEIJING FORESTRY UNIVERSITY

Ultravioresistant polyurethane plastic racetrack and preparation method thereof

The invention discloses an ultravioresistant polyurethane plastic racetrack, which is characterized in that the plastic racetrack is prepared from the following raw materials: paraformaldehyde, dimethylethanolamine, methylbenzene, colophony, phenol, hydrogen peroxide, formic acid, phosphoric acid, trimethylolpropane, gamma-glycidoxypropyltrimethoxysilane, nano cerium oxide, acetone, bisphenol A glycerol dimethacrylate, methanol, propylene glycol monomethyl ether, dioctyl phthalate, tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 2,2'-dihydroxy-4-methoxybenzophenone, polypropylene glycol, diphenylmethane diiso-cyanate, 8-10% of NaOH solution and deionized water. The polyurethane plastic racetrack prepared according to the invention has excellent properties of good elasticity, wear resistance, skid resistance, attractive color, clean site and easiness for maintenance and management, and is not influenced by weather and like conditions.

Owner:安徽潜源教学设备有限公司

Preparing method used for food vacuum freshness retaining compression bag

ActiveCN110271224ASync outImprove processing qualityBag making operationsPaper-makingZno nanoparticlesMaterials science

The invention discloses a preparing method used for a food vacuum freshness retaining compression bag. The food vacuum freshness retaining compression bag is composed of an aluminum foil bottom layer and polyethylene coating. The aluminum foil bottom layer is composed, by weight percent, 45% of aluminum powder, 25% of polyethylene resin, 15% of nanopowder, 10% of glycerin monostearate, 3% of paroline and 2% of bamboo charcoal particles; the nanopowder is formed through blending of nanosilicon dioxide powder, nanometer titania powder and nano-zinc oxide powder according to the weight percent of 3:1:1; through combination of the ultraviolet shielding effect of the nanopowder in the aluminum foil bottom layer and ultraviolet absorbing effect of 2-hydroxide radical-4-methoxybenzophenone in the polyethylene coating, the food vacuum freshness retaining compression bag can be sufficiently protected, and the conditions that under long-term light irradiation, color is prone to changing, embrittlement is prone to happening, the packaging food goes bad, and the use effect is greatly affected are avoided.

Owner:YUYAO HUAYIN PACKING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com