Patents

Literature

47 results about "4-Aminobutyric Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

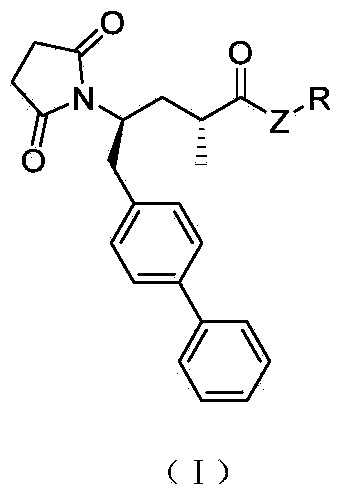

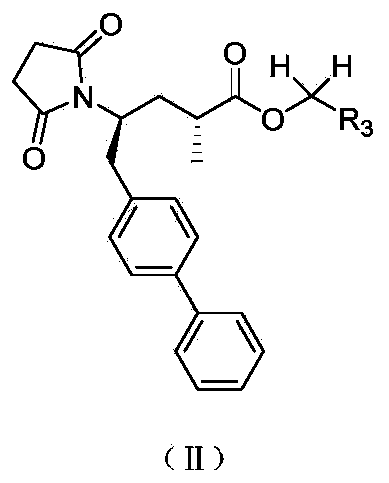

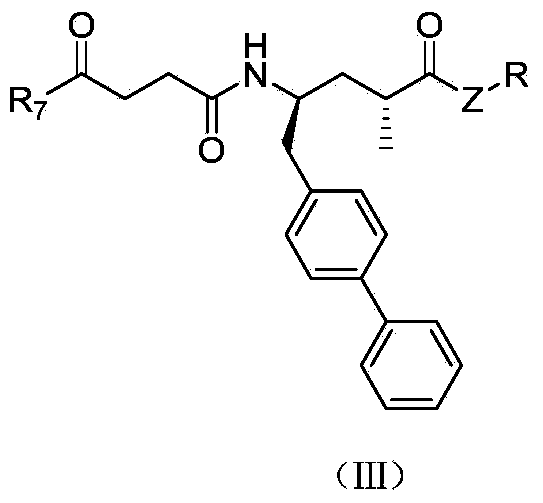

Biaryl-substituted 4-aminobutyric acid derivatives, and preparation method and application thereof

ActiveCN104230865AGood pharmacokinetic activityOrganic active ingredientsSugar derivativesMedicinal chemistryEndopeptidase

The invention relates to biaryl-substituted 4-aminobutyric acid derivatives, and a preparation method and application thereof, particularly biaryl-substituted 4-aminobutyric acid derivatives disclosed as Formula (I), and a preparation method and application thereof, an intermediate of biaryl-substituted 4-aminobutyric acid derivatives prepared by cyclization reaction and a pharmaceutical composition containing the biaryl-substituted 4-aminobutyric acid derivatives. The biaryl-substituted 4-aminobutyric acid derivatives have NEP (neutral endopeptidase) inhibition activity, and can be used as an NEP inhibitor.

Owner:SHANGHAI HANSOH BIOMEDICAL +1

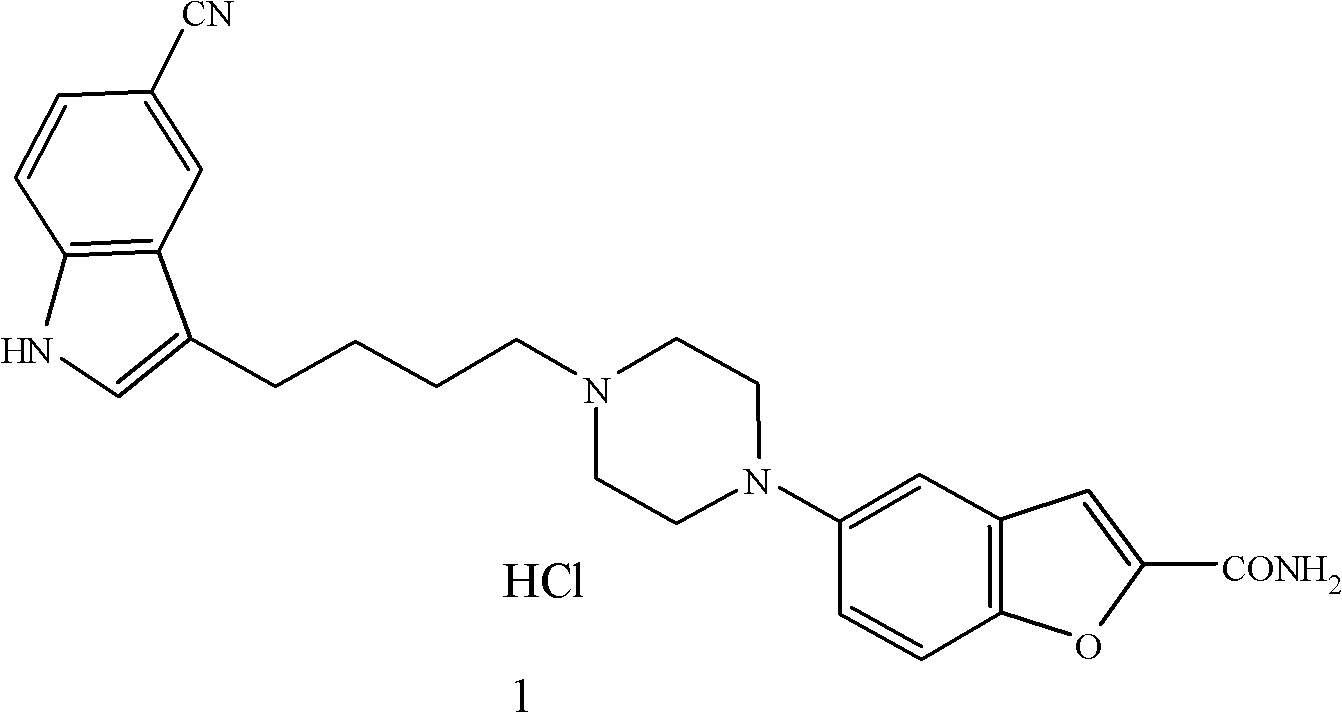

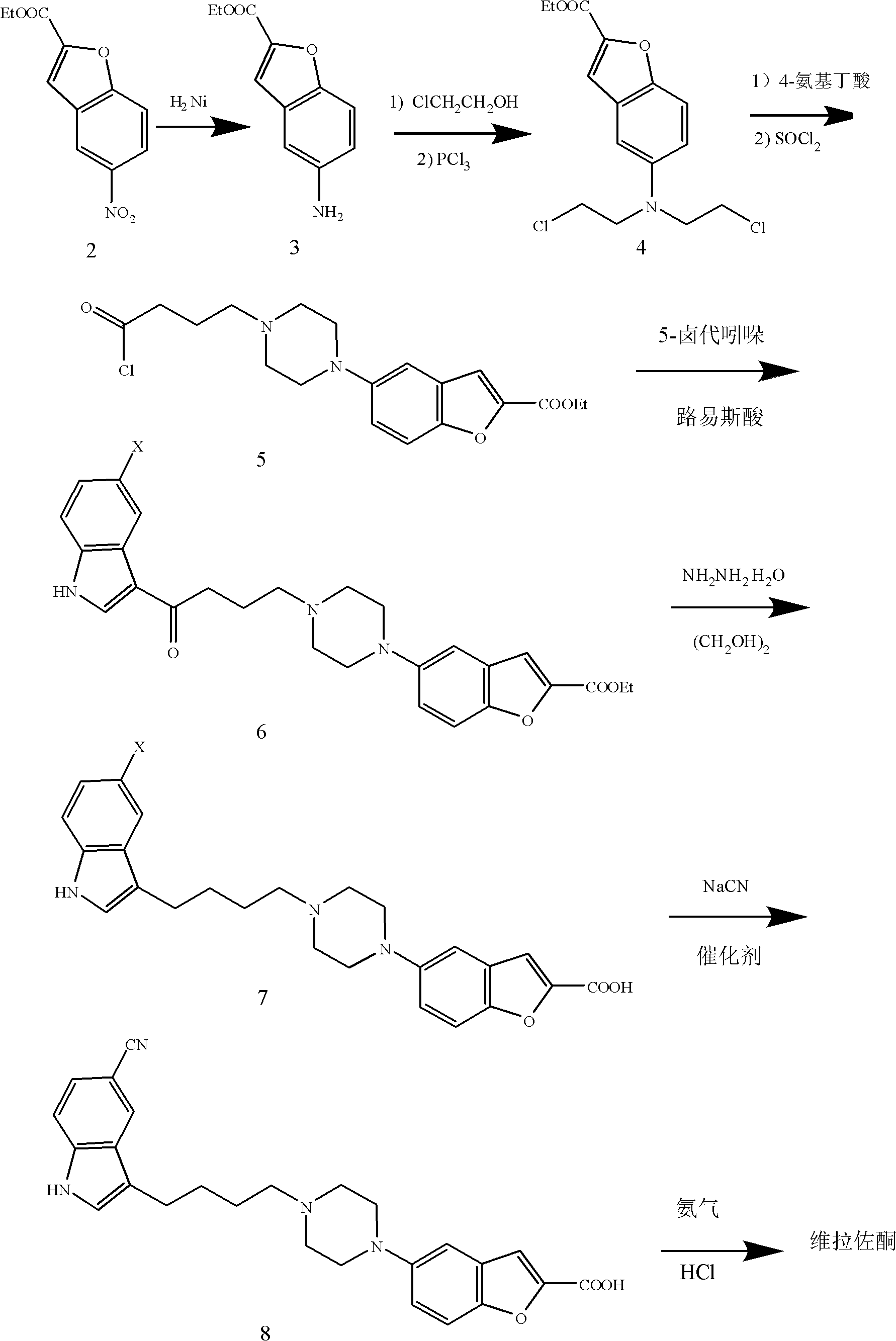

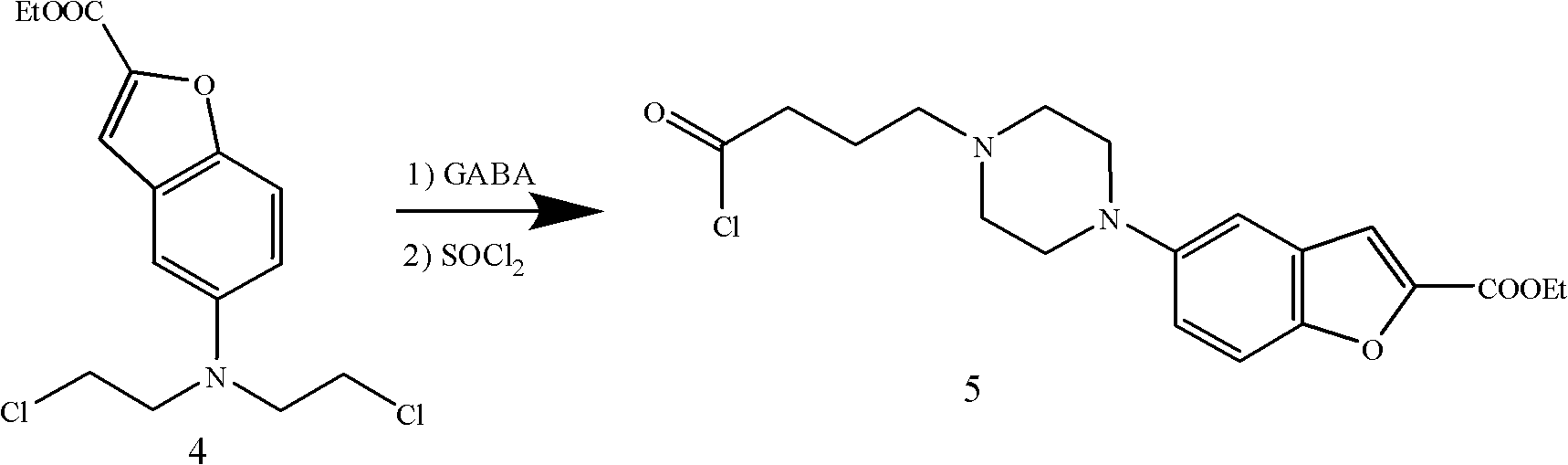

Method for preparing anti-depression medicine vilazodone

InactiveCN102180868AOvercome costsHigh reaction yieldOrganic chemistryCarboxylic acidPhosphorus trichloride

The invention provides a method for preparing an anti-depression medicine vilazodone, which comprises the following steps of: performing nitro reduction on 5-nitrobenzofuran-2-ethyl carboxylate serving as a raw material, conjugating with chlorohydrin, chlorinating by using phosphorus trichloride, cyclizing with 4-aminobutyric acid to generate a piperazine ring, performing acylchlorination, condensing with halogenated indole, performing carbonyl reduction, cyaniding, performing amidation, and the like to obtain the vilazodone. The method overcomes the defects in the prior art, is suitable for industrial production and has high application value, the used raw material is readily available, operating cost is low, and reaction yield is high.

Owner:SCI GENERAL MATERIAL & CHEM

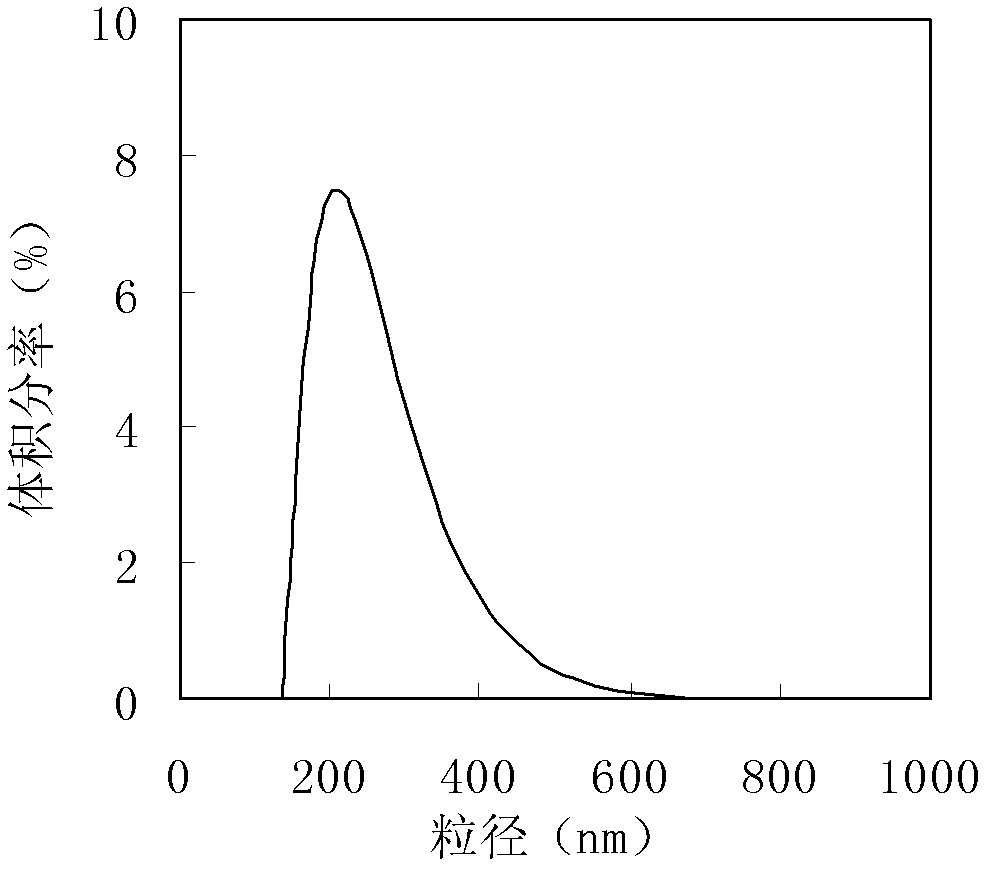

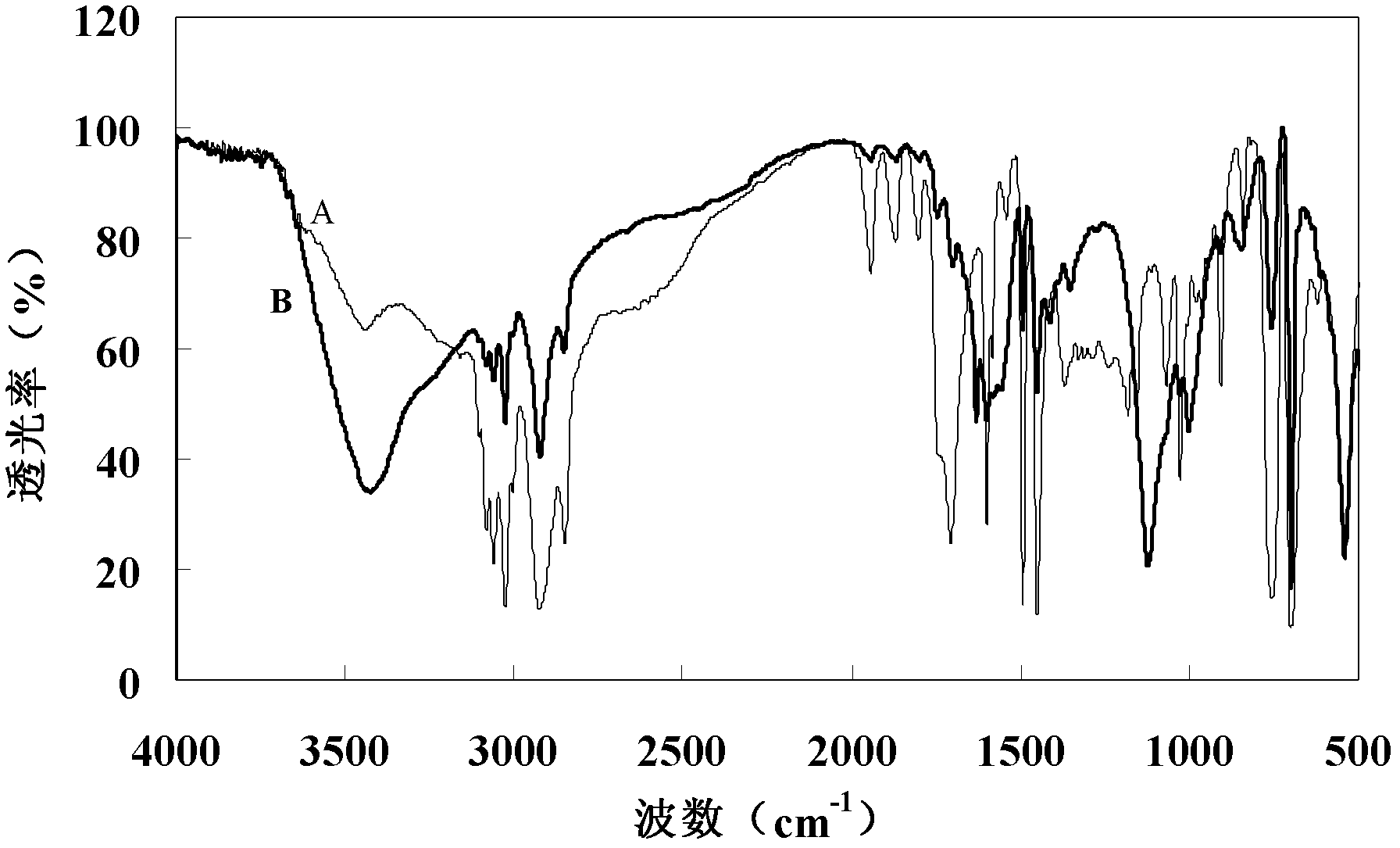

Nanometer carboxylated polystyrene microsphere with spacer arm and preparation method thereof

The invention relates to a nanometer carboxylated polystyrene microsphere with a spacer arm and a preparation method thereof. A nanometer carboxylated polystyrene microsphere A is prepared by taking styrene and acrylic acid as a mixed monomer, taking water as a reaction medium, taking potassium persulfate as an initiator and taking sodium dodecyl sulfate as an emulsifier with an emulsion polymerization method. In the presence of EDC (Ethylidene Dichloride) serving as a coupling agent and Sulfo NHS, 4-aminobutyric acid, 6-amidocaproic acid or 8-aminocaprylic acid is connected to the surface of the microsphere, so that the nanometer carboxylated polystyrene microsphere with the spacer arm is prepared. The spacer arm is introduced into the surface of the nanometer microsphere, so that the steric hindrance of a coupling macromolecule is lowered, the activity and utilization ratio of the macromolecule are increased, and a nonspecific interaction between the macromolecule and the polystyrene microsphere is reduced. Meanwhile, the grain diameter of the microsphere can be adjusted by adjusting the using amount of the emulsifier, the length of the space arm and surface density, so that the nanometer microsphere has a wide application prospect in the fields of immune diagnosis, solid phase extraction and the like when serving as a carrier as well as a template.

Owner:TIANJIN MEDICAL UNIV

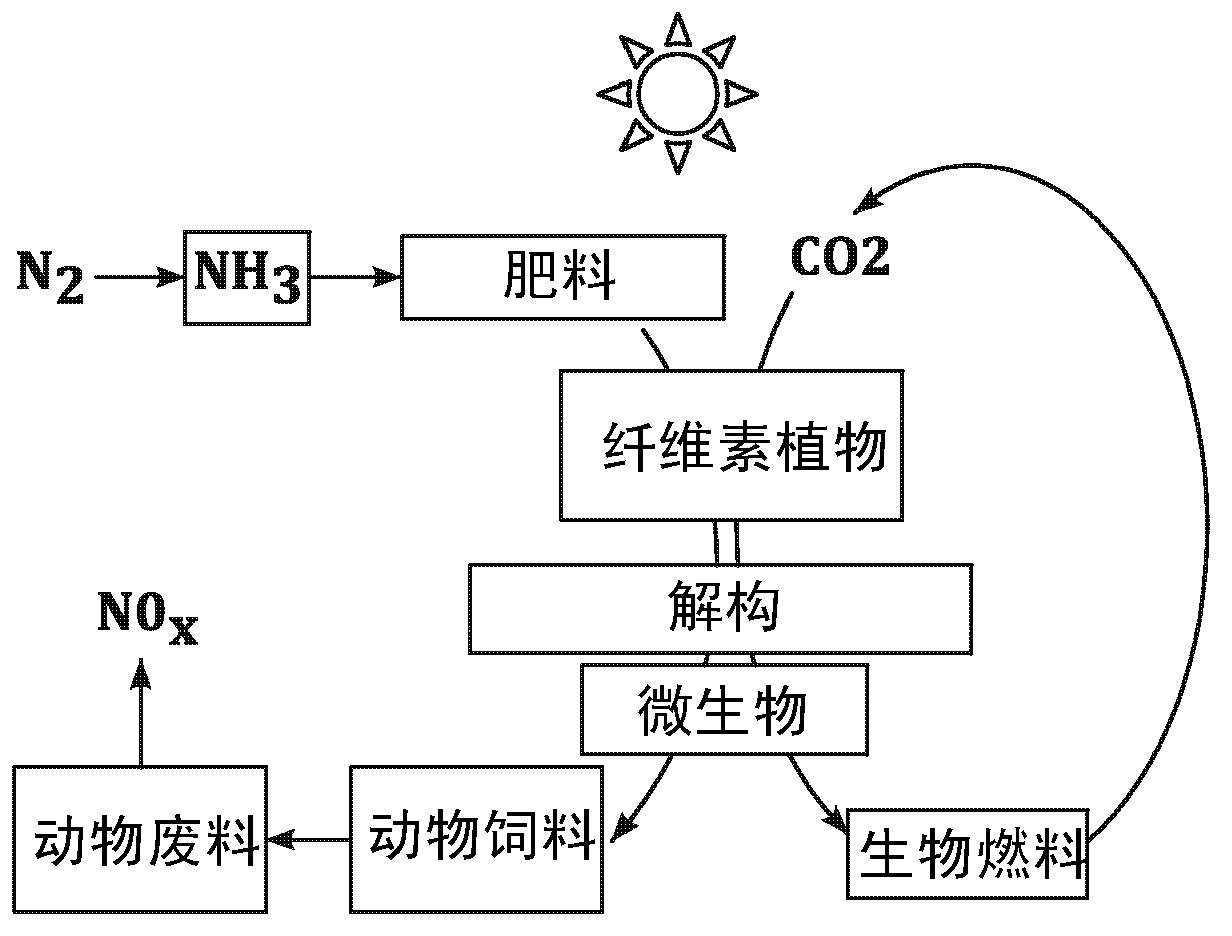

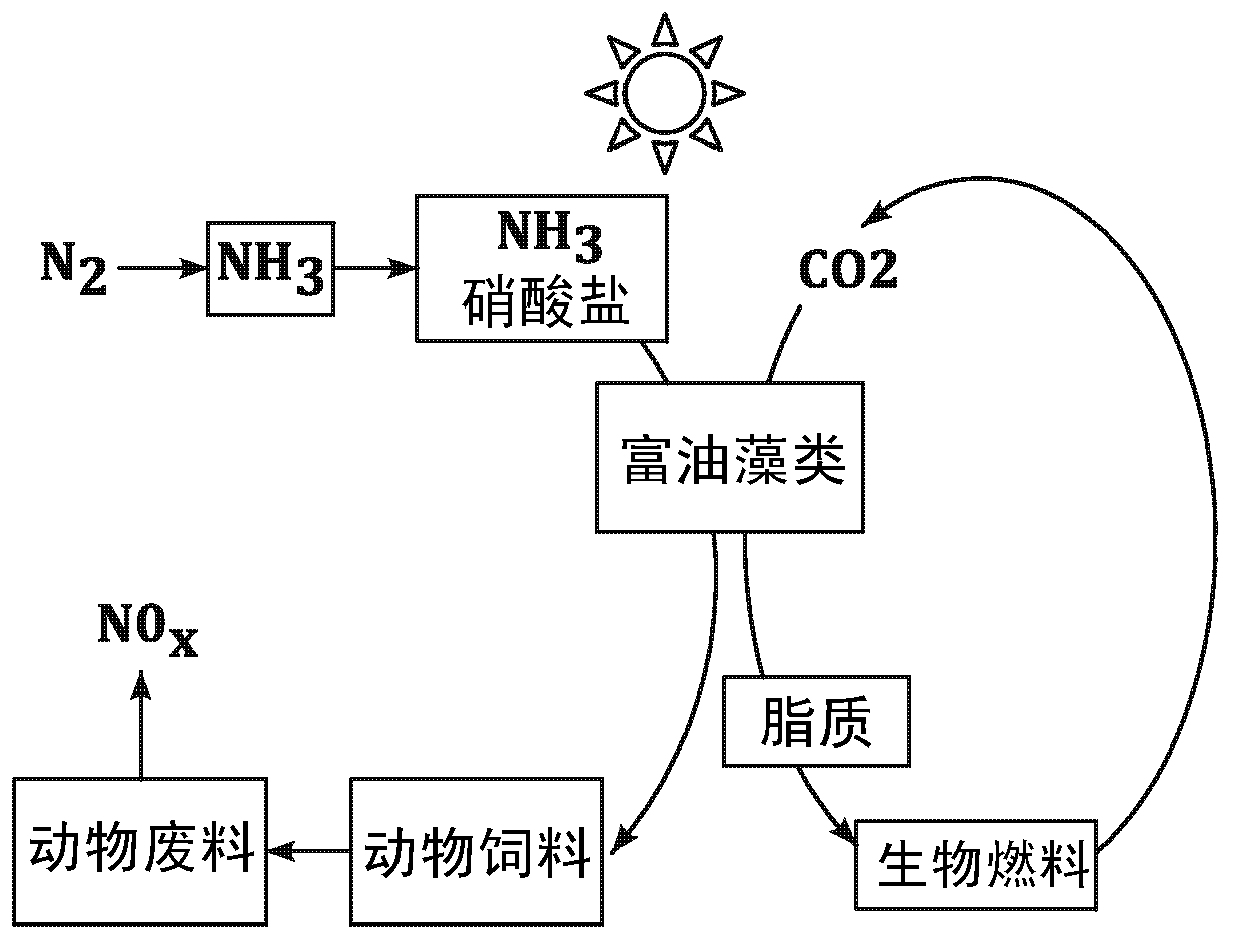

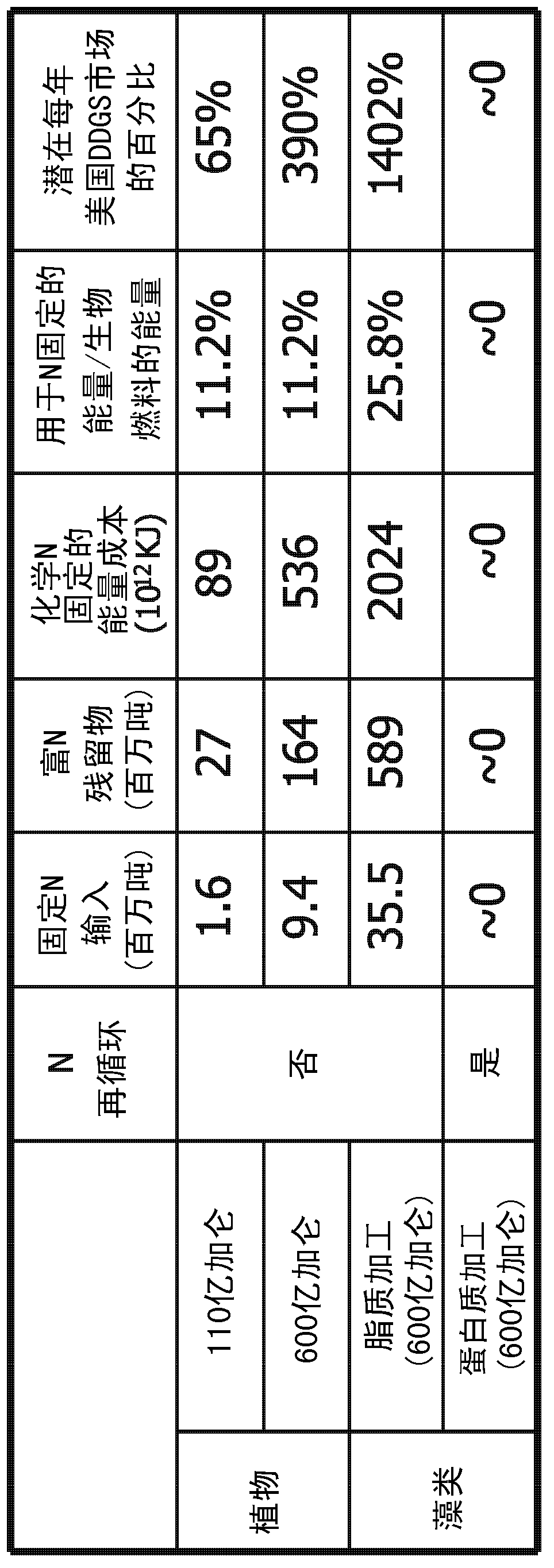

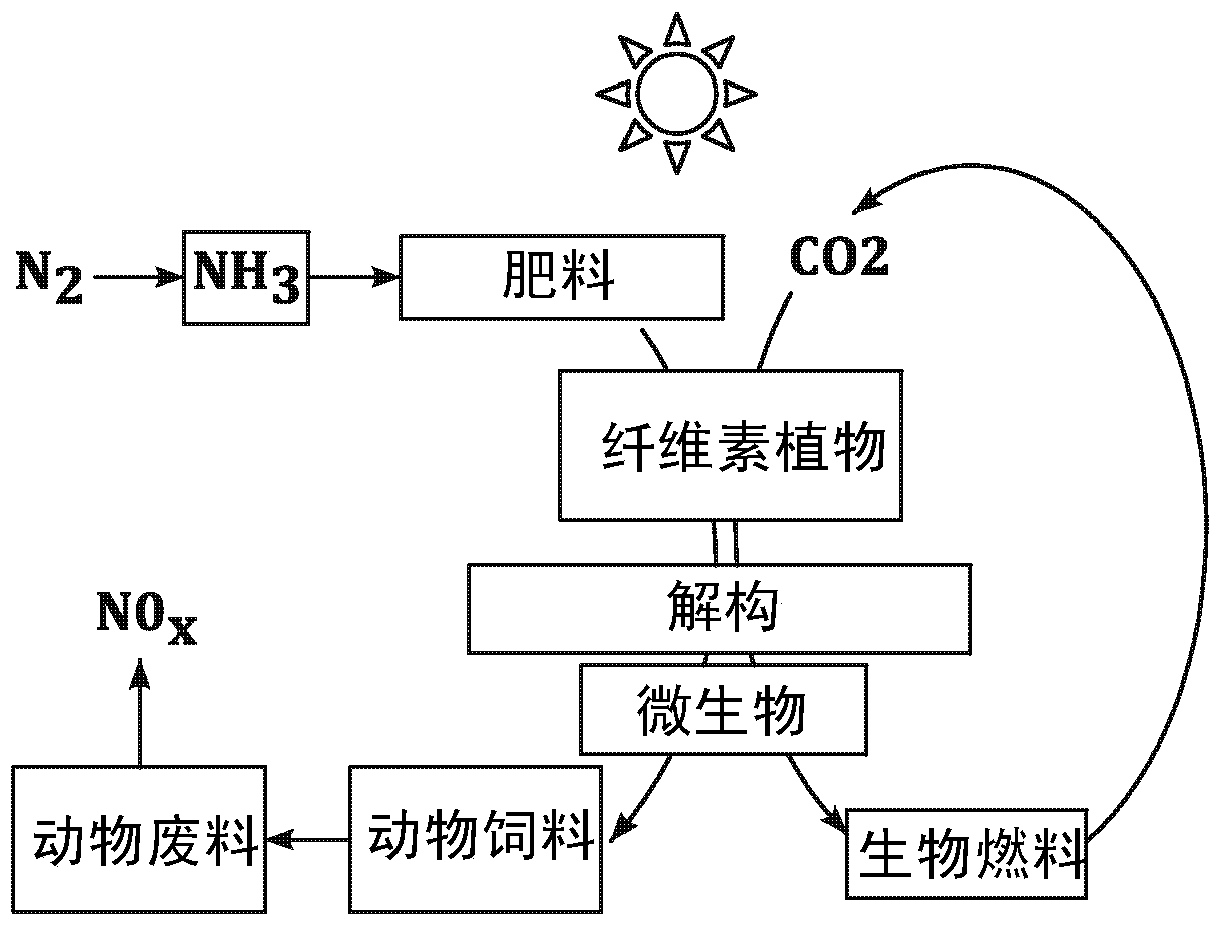

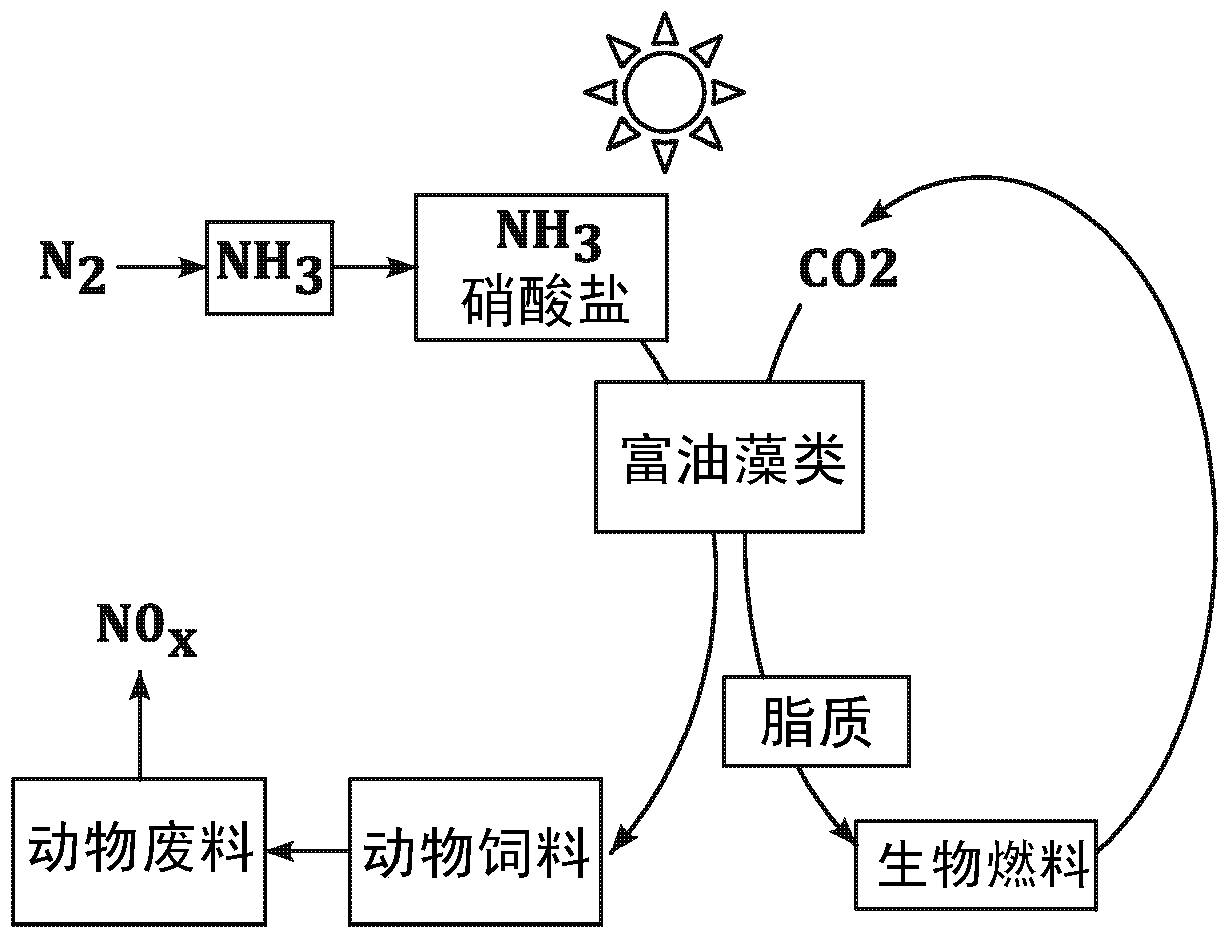

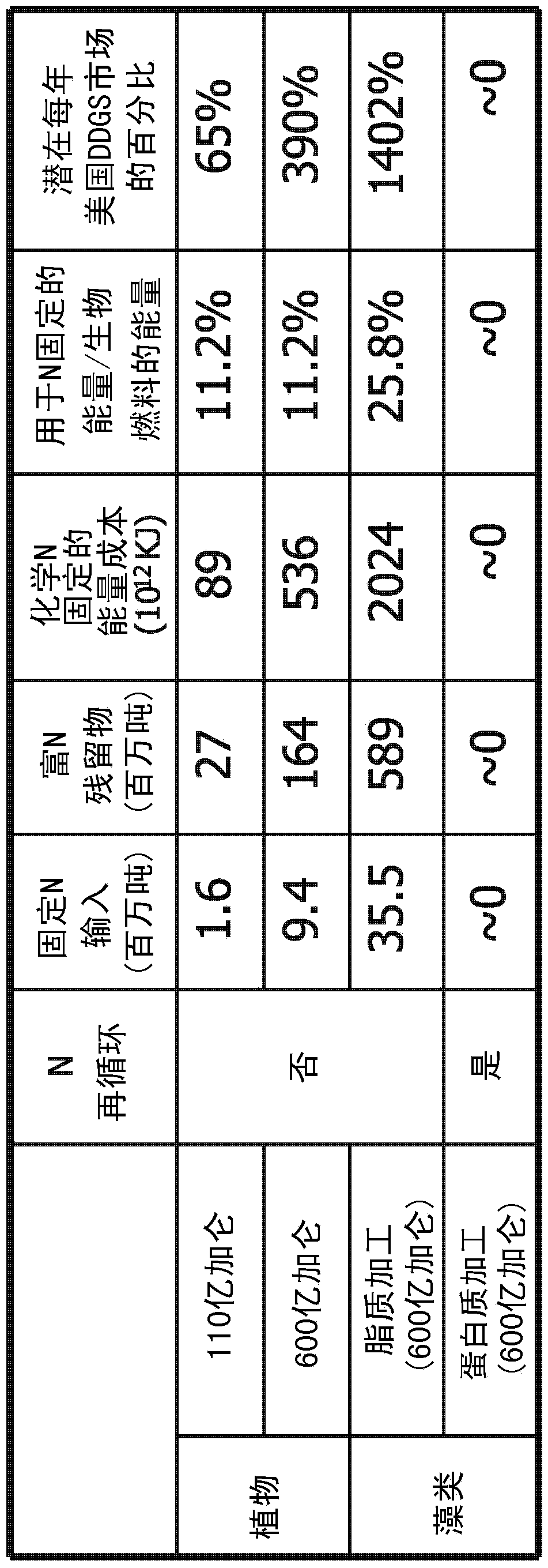

Biofuel and chemical production by recombinant microorganisms via fermentation of proteinacious biomass

Provided herein are metabolically modified microorganisms characterized by having an increased keto-acid flux when compared with the wild-type organism and comprising at least one polynucleotide encoding an enzyme, and causing the production of a greater quantity of a chemical product when compared with the wild-type organism. The recombinant microorganisms are useful for producing a large number of chemical compositions from various nitrogen containing biomass compositions and other carbon sources. More specifically, provided herein are methods of producing alcohols, acetaldehyde, acetate, isobutyraldehyde, isobutyric acid, n- butyraldehyde, n-butyric acid, 2-methyl-l-butyraldehyde, 2-methyl-l -butyric acid, 3- methyl-l-butyraldehyde, 3 -methyl- 1 -butyric acid, ammonia, ammonium, amino acids, 2,3-butanediol, 1,4-butanediol, 2-methyl-l, 4-butanediol, 2-methyl- 1,4-butanediamine, isobutene, itaconate, acetoin, acetone, isobutene, 1,5-diaminopentane, L-lactic acid, D- lactic acid, shikimic acid, mevalonate, polyhydroxybutyrate (PHB), isoprenoids, fatty acids, homoalanine, 4-aminobutyric acid (GABA), succinic acid, malic acid, citric acid, adipic acid, p-hydroxy-cinnamic acid, tetrahydrofuran, 3-methyl-tetrahydrofuran, gamma-butyrolactone, pyrrolidinone, n-methylpyrrolidone, aspartic acid, lysine, cadeverine, 2-ketoadipic acid, and / or S-adenosyl-methionine (SAM), from a suitable nitrogen rich biomass.

Owner:RGT UNIV OF CALIFORNIA

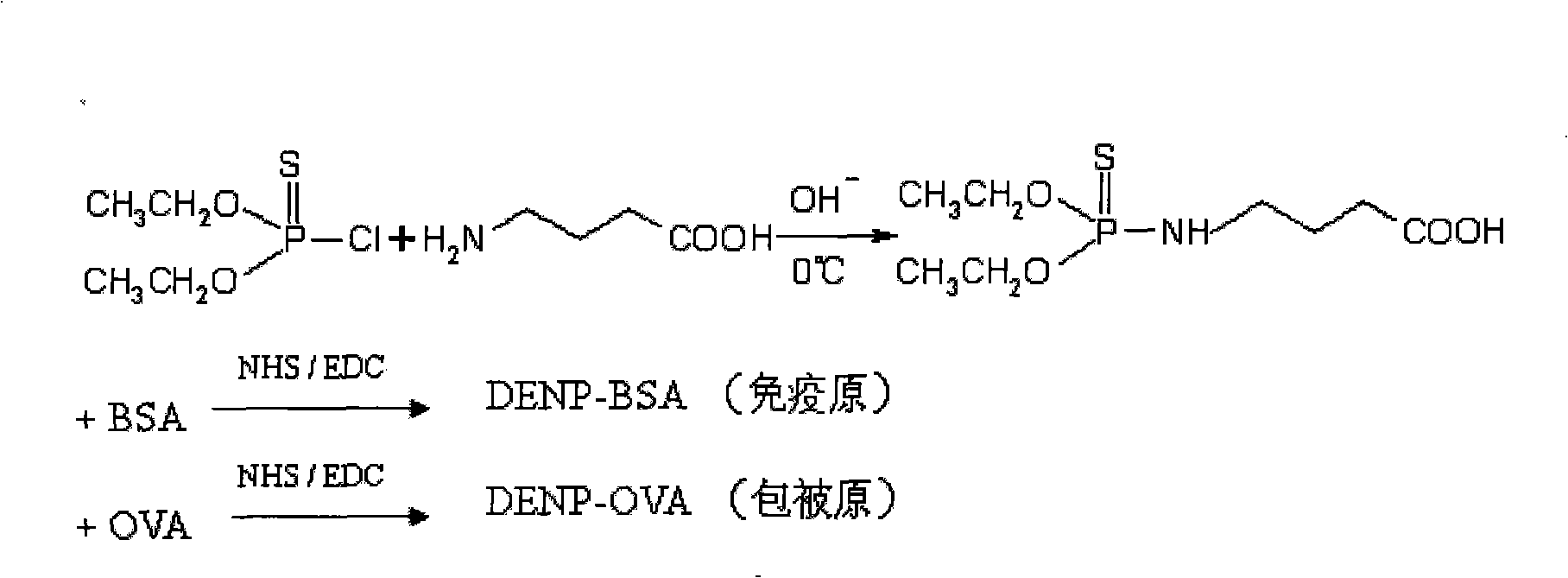

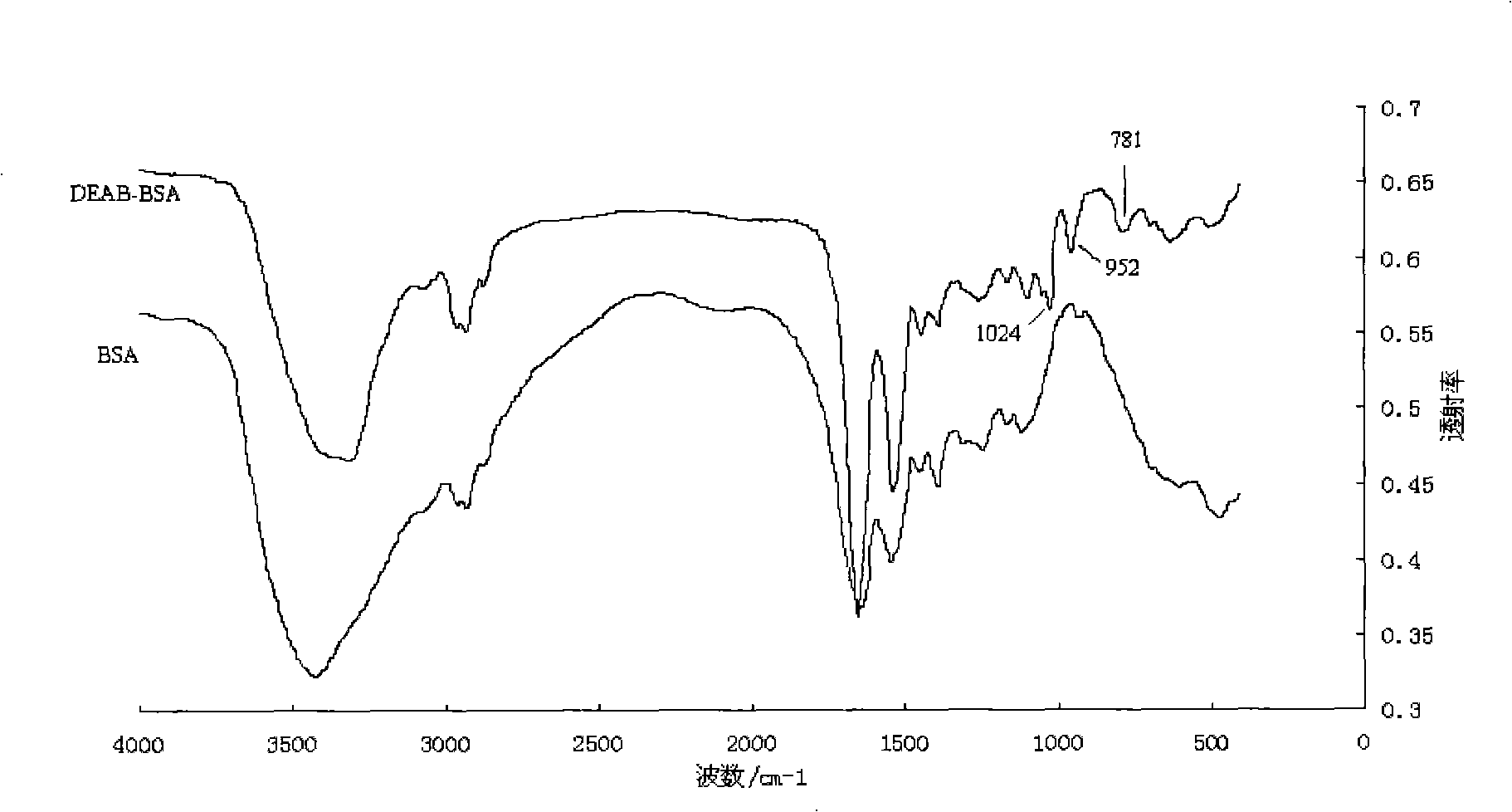

Antibody preparation method capable of detecting multiple organophosphorus pesticide residuals

InactiveCN101343325AFast immunoassaySimple immunoassay techniquePeptide preparation methodsImmunoglobulinsPesticide residueNew Zealand white rabbit

The invention discloses an antibody preparation method through which various organic phosphorus pesticide residues can be detected and the application, which belongs to the technical filed of agriculture. The antibody preparation method adopts the steps that firstly, O,O-diethylthiophosphoryl chloride is used to react with 4-aminobutyric acid to synthesize into general hapten O, O-diethyl-N-(3-carboxy-propyl)-by-sulfur Phosphoramidate DENP which comprises various organic phosphorus pesticide common structures-O, O-diethyl thiosulfate phosphoryl; secondly, the general hapten O, O-diethyl-N-(3-carboxy-propyl)-by-sulfur Phosphoramidate DENP is respectively coupled with bovine serum albumin BSA and chicken ovalbumin OVA by adopting carbodiimide method, to prepare general immunogen DENP-BSA and general coatingen DENP-OVA; and thirdly, multi-clonal antibody is prepared through immunized New Zealand white rabbits, the obtained antibody has obvious specificity to various organic phosphorus pesticides, such as thimet, demeton, disulfoion, omethoate, phoxim and quinalphos and can be used for the immune detection of the organophosphorus pesticides.

Owner:SHANGHAI JIAO TONG UNIV

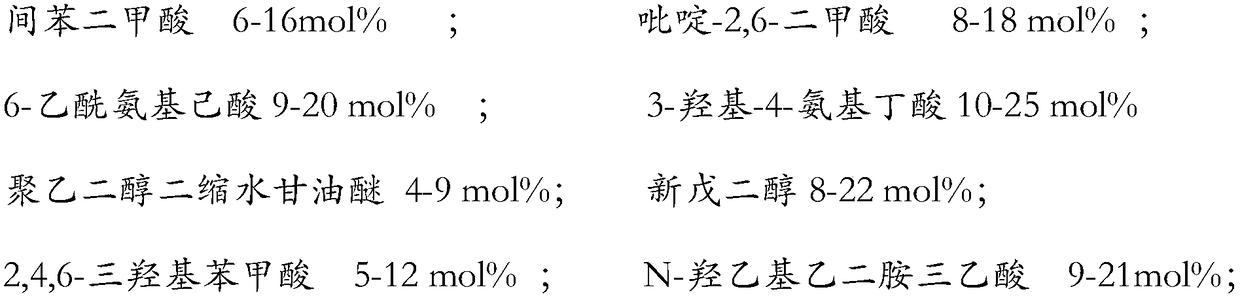

Polyester resin for low-gloss TGIC system powder coating and preparation method and application thereof

InactiveCN109320705AExcellent flatness and smoothnessImprove stabilityPowdery paintsPolyester coatingsEthylenediamineAntioxidant

The invention belongs to the technical field of resin production, and specifically relates to polyester resin for low-gloss TGIC system powder coating, a preparation method of the polyester resin, andapplication of the polyester resin. The polyester resin is mainly prepared from isophthalic acid, pyridine-2,6-dicarboxylic acid, 6-acetylaminocaproic acid, 3-hydroxy-4-aminobutyric acid, polyethylene glycol diglycidyl ether, neopentyl glycol, 2,4,6-trihydroxybenzoic acid, N-hydroxyethyl ethylenediamine tri-acetic acid, an esterification catalyst and an antioxidant. The molecules of the polyesterresin prepared by the method disclosed by the invention simultaneously contain active amino groups, hydroxyl groups and carboxyl groups, difference between the three kinds of base groups and epoxidegroups in TGIC molecules in curing reaction rate can be used for preparing low-gloss powder coating (gloss<20%), and the film coating properties can completely reach various requirements of powder coating.

Owner:周鹤洋

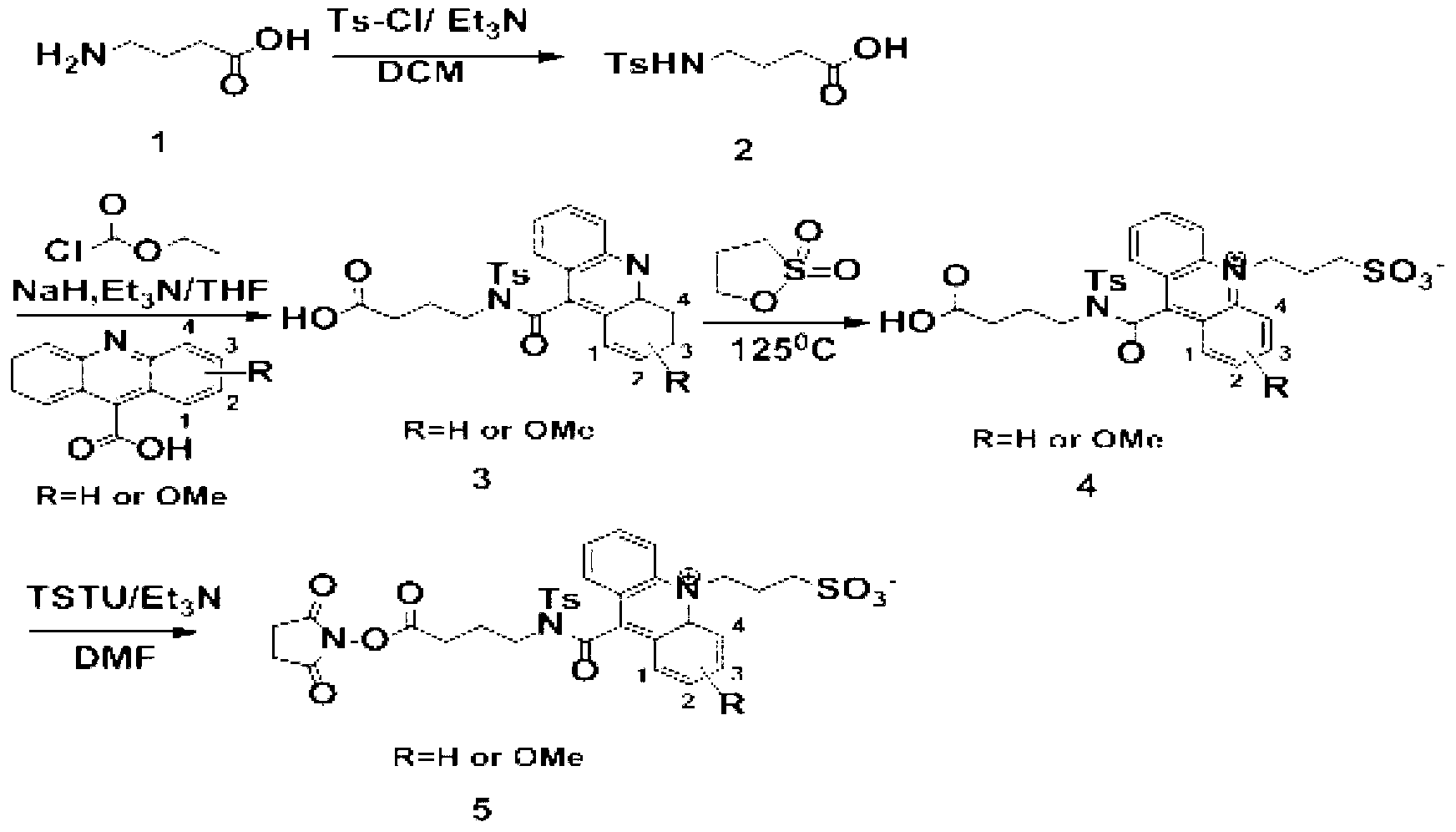

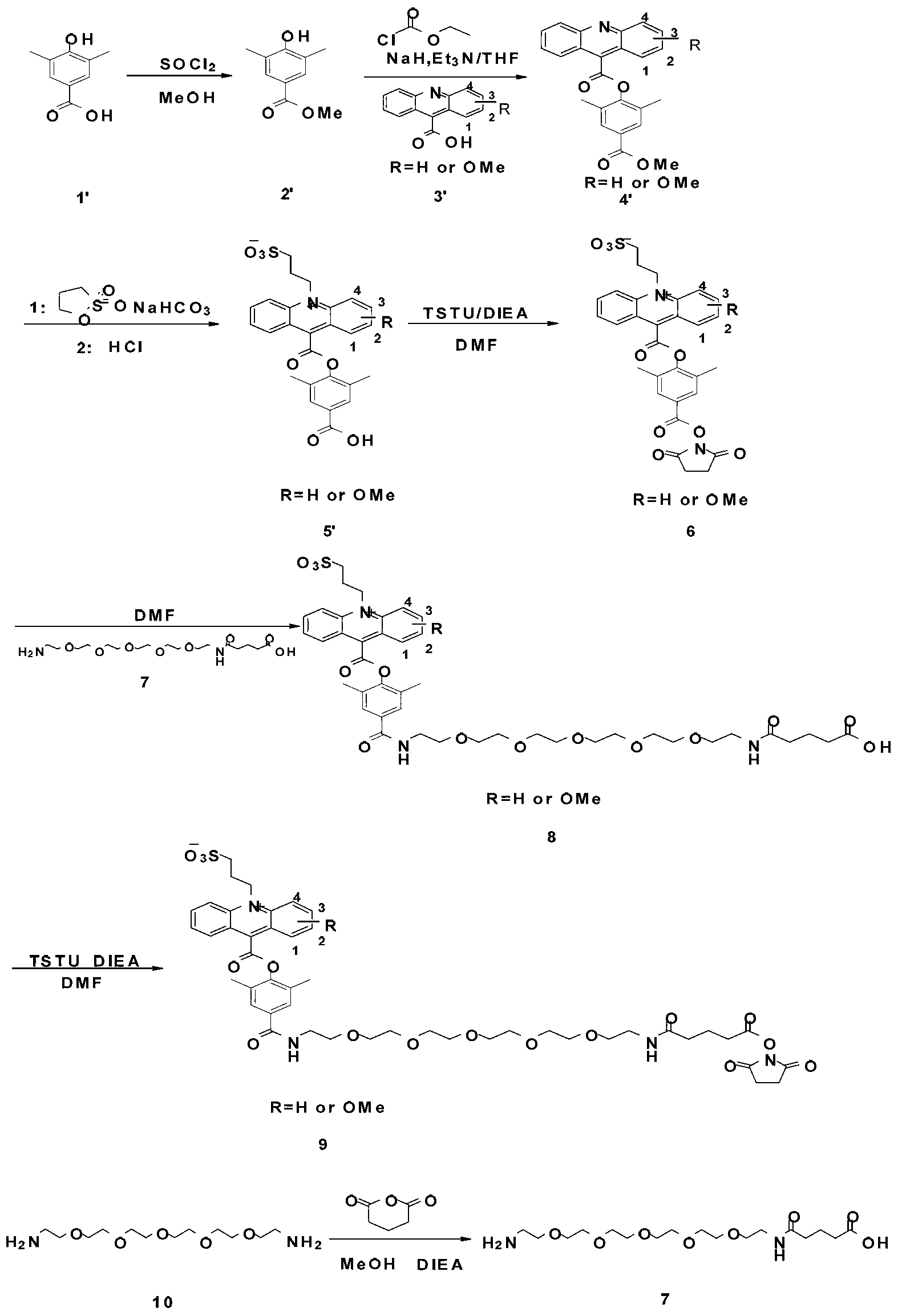

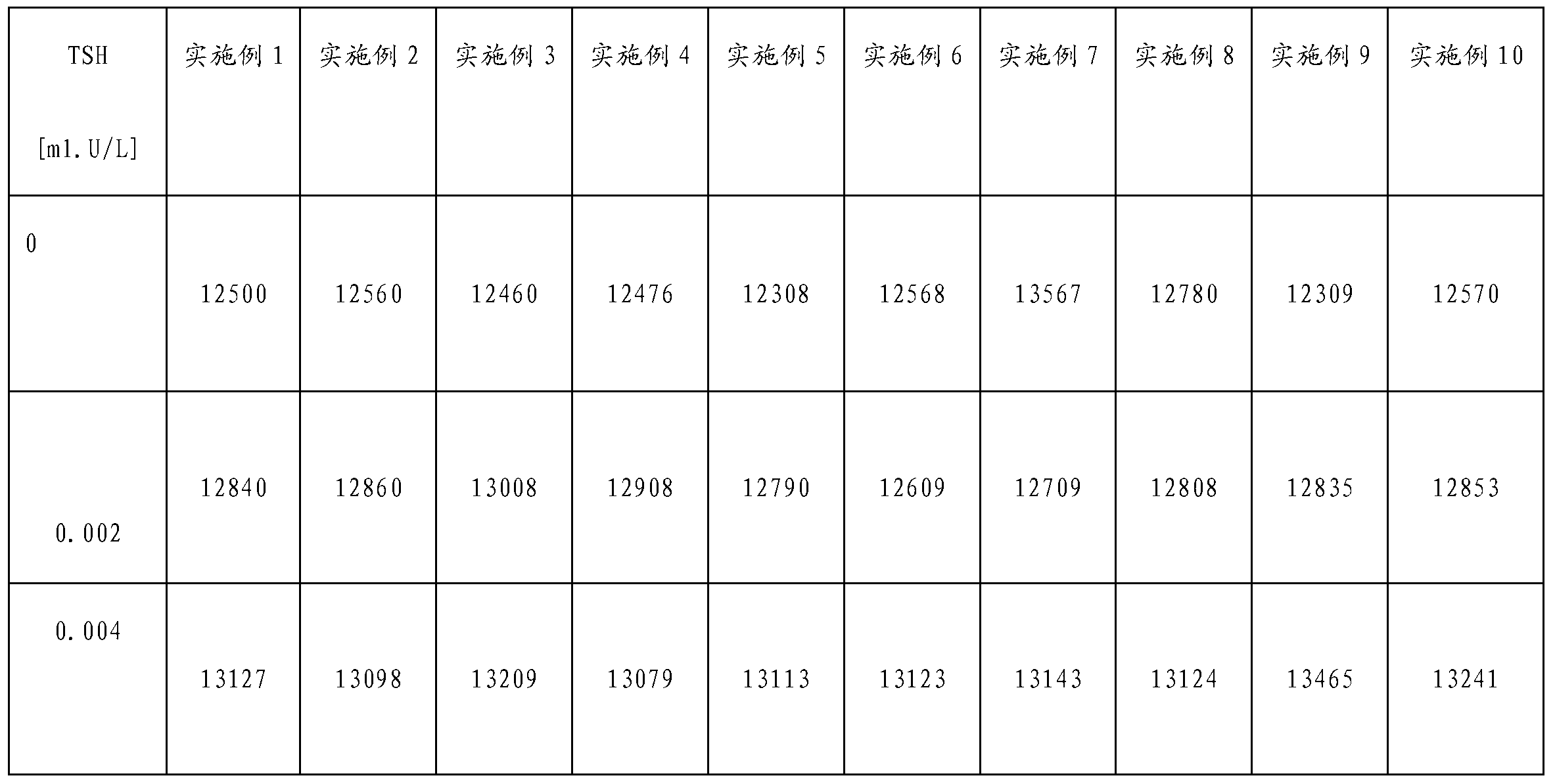

Preparation method for a series of acridine chemiluminescence agents

The invention provides a preparation method for a series of acridine chemiluminescence agents. The preparation method comprises the following steps: 1, dissolving 4-aminobutyric acid in a first solvent, stirring, cooling, sequentially adding triethylamine and p-toluenesulfonyl chloride, and carrying out pressure reduction solvent removing to obtain a product (a compound 2); 2, placing 9-acridinecarboxylic acid in a round bottom flask, adding a second solvent to dissolve the 9-acridinecarboxylic acid, stirring, cooling, sequentially adding a third solvent, carrying out a reaction, filtering the obtained solid, collecting the filtrate to obtain a filtrate A, dissolving the compound 2 with the second solvent, cooling, slowly adding an inorganic alkali in batches, carrying out a reaction, slowly adding the filtrate A to the reaction system in a dropwise manner, heating the reaction system to a room temperature, and carrying out the reaction overnight; and 3, placing a compound 3 in a flask, adding 1,3-propanesultone, stirring, carrying out a heating reaction, cooling to a room temperature, washing, filtering, and collecting the solid to obtain a compound 4 crude product. With the method, characteristics of simple process, green environmental protection, and low cost are provided.

Owner:SHENZHEN MAXCHEMTECH

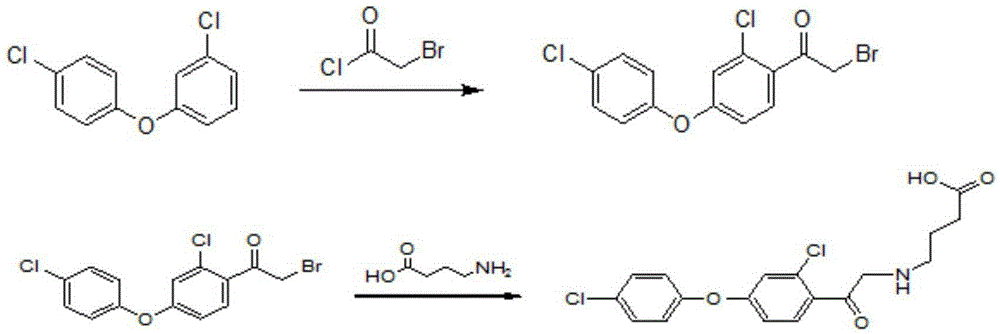

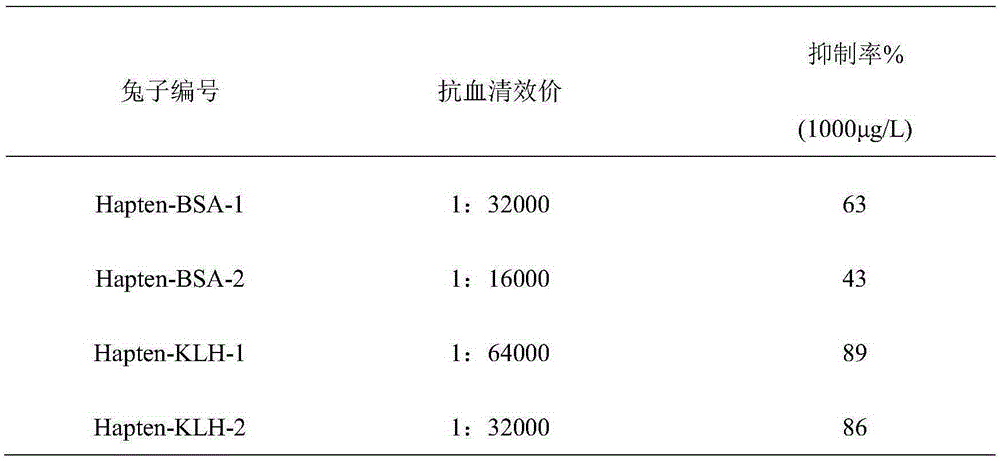

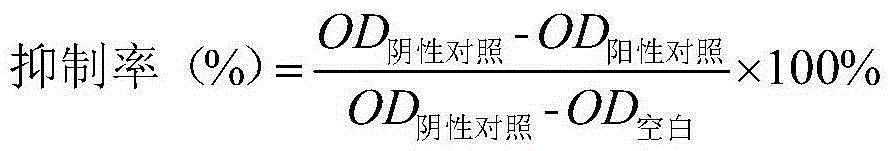

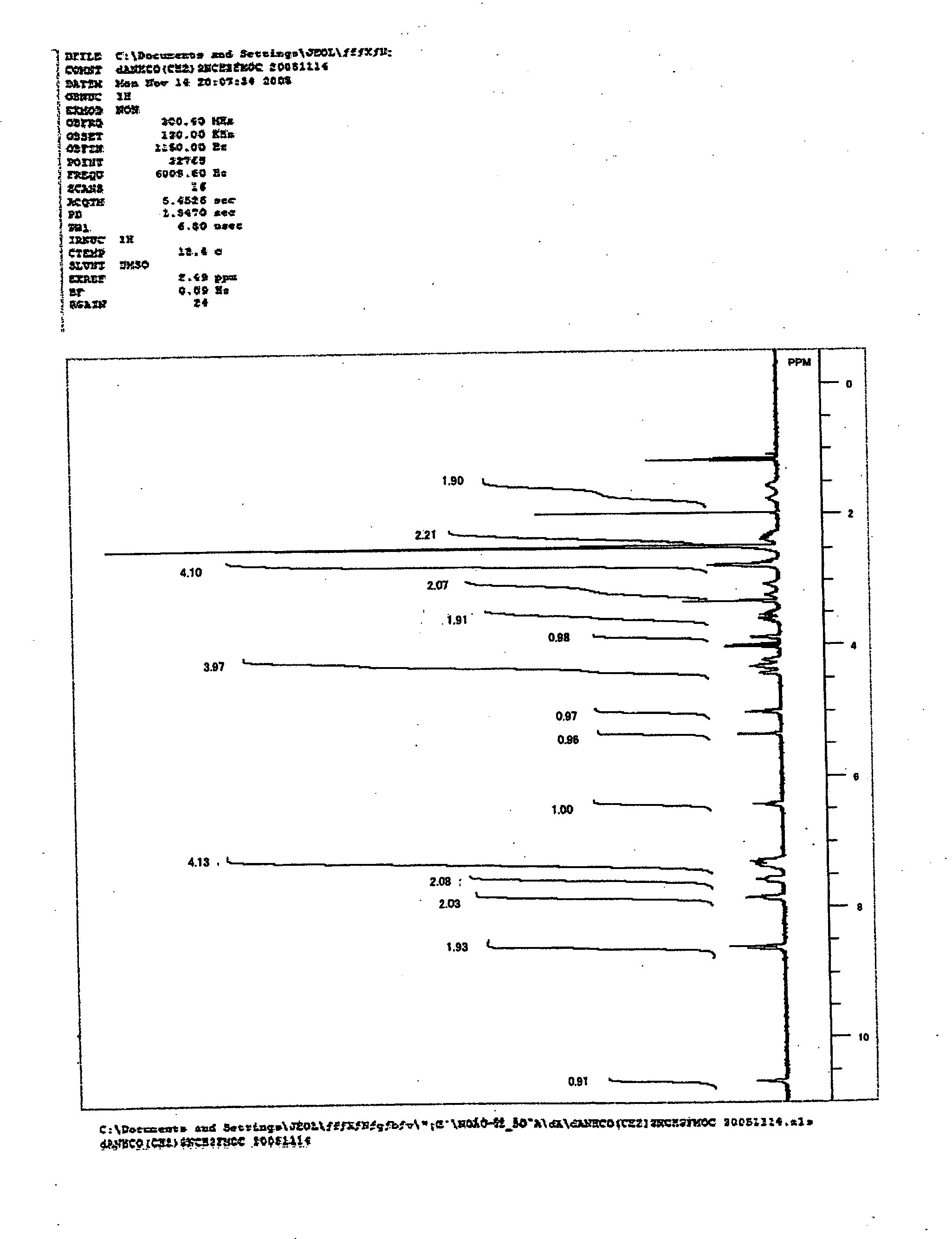

Preparation method for high-specificity difenoconazole polyclonal antibody

ActiveCN105294862AReduce detectionQuick checkPeptide preparation methodsImmunoglobulinsEtherChloride

The invention provides a preparation method for a high-specificity difenoconazole polyclonal antibody, and belongs to the immune analysis technology. The polyclonal antibody is prepared by the steps of combining a difenoconazole hapten with a carrier protein and immunizing animals, wherein the difenoconazole hapten is prepared by carrying out a reaction of 3,4'-dichlorodiphenyl ether and bromoacetyl chloride to obtain an intermediate, and then connecting with 4-aminobutyric acid. The prepared difenoconazole polyclonal antibody has higher specificity, and fills up a blank in a research direction of preparation of the high-specificity difenoconazole polyclonal antibody.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Amidite for nucleic acid synthesis and nucleic acid synthesizing method

To provide an amidite for nucleic acid synthesis, which enables a protective group therein to be removed under moderate conditions and can be practically used, and a nucleic acid synthesizing method using the amidite for nucleic acid synthesis. Specifically, the present invention relates to an amidite for nucleic acid synthesis represented by General Formula (I) below, and a nucleic acid synthesizing method using the amidite for nucleic acid synthesis:where X denotes a base; Y denotes a protective group formed of any one of a 4-aminobutyric acid derivative, an o-aminomethylbenzoic acid derivative, an o-aminophenylacetic acid derivative, an o-aminoethylbenzoic acid derivative, an o-aminomethylphenylacetic acid derivative, an o-aminophenylpropionic acid derivative and a 5-aminovaleric acid derivative; and Q denotes one of a hydrogen atom and a hydroxyl group.

Owner:APTA BIOSCI

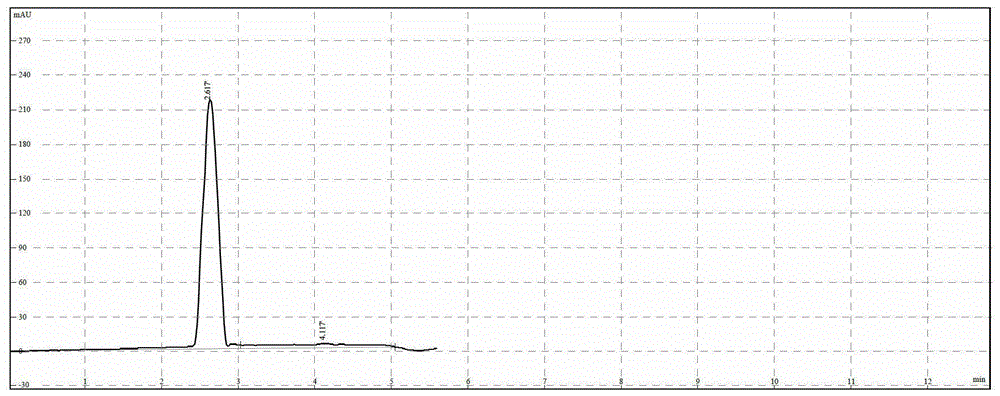

Technology for preparing 3-phenyl-4-aminobutyric acid hydrochloride

ActiveCN103232356AImprove reaction efficiencyImprove hydrogenation efficiencyOrganic compound preparationAmino-carboxyl compound preparationMethyl 4-nitrobutyrateHydrogen atmosphere

The invention provides a technology for preparing 3-phenyl-4-aminobutyric acid hydrochloride. According to the technology, methyl cinanmate and nitromethane are used as oligomers, nitromethane is taken as an oligomer and a solvent, and a series of troubles in treatment caused when a third reagent is introduced as a solvent is avoided; 94.1% 3-phenyl-4-nitryl methyl butyrate can be obtained by a triethylamine and anhydrous MgC12 mixed catalyst, and the reaction efficiency is improved; raney nickel is used as a catalyst for converting the 3-phenyl-4-nitryl methyl butyrate into 3-phenyl valerolactam, the hydrogenation efficiency is improved, and the conversion rate of the 3-phenyl-4-nitryl methyl butyrate reaches 95.7%; and a methanol and dichloromethane mixed solvent serves as a solvent used for recrystallizing 3-phenyl-4-aminobutyric acid hydrochloride; and through recrystallization, the purity of the target product is above 99.0%. The technology has the advantages that reaction conditions are mild and easy to control, hydrogenation is finished in one step, high pressure does not need to be maintained; as long as bubbling is carried out and hydrogen atmosphere is maintained, the good reaction rate and yield can be obtained; and the control is simple and convenient.

Owner:TIANJIN JUDE TECH

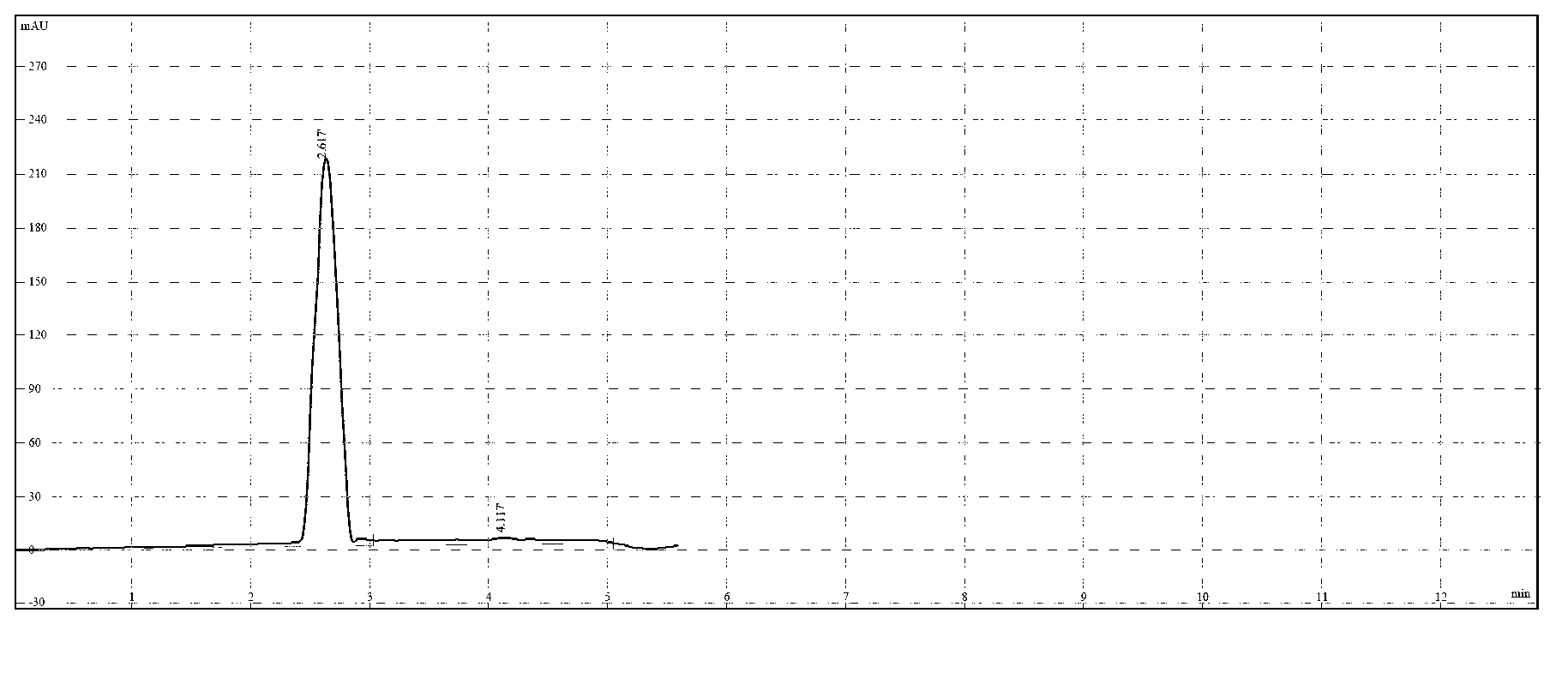

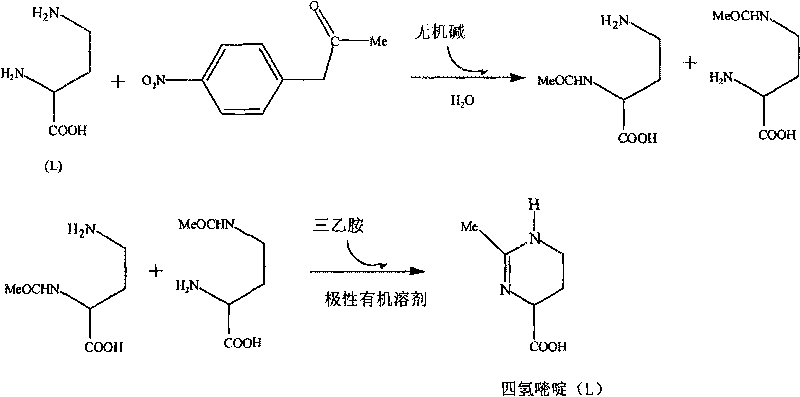

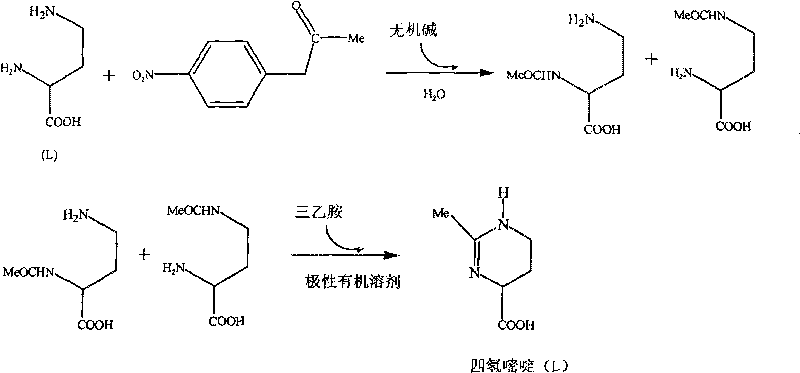

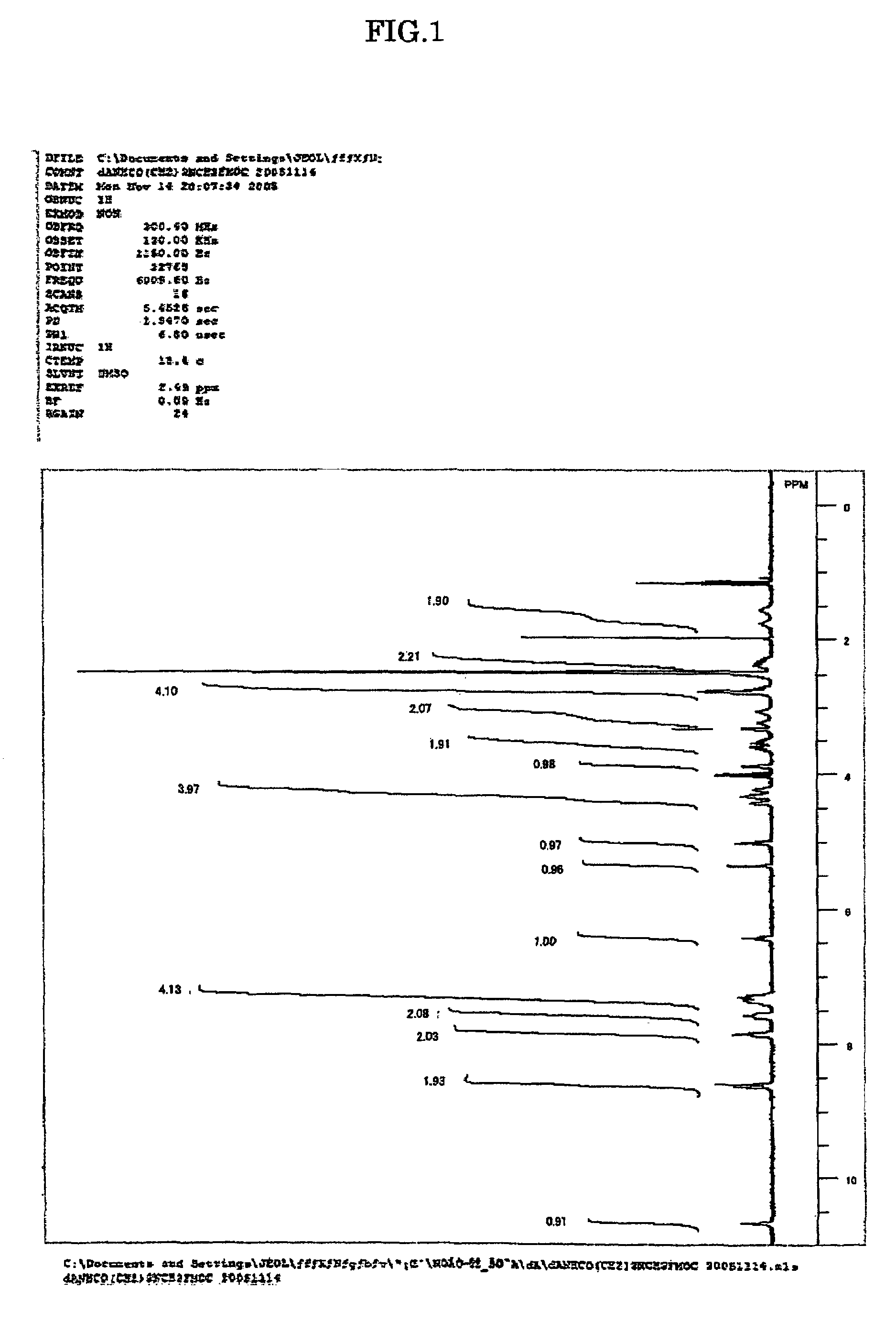

Artificial synthesis method of 1,4,5,6-tetrahydro-2-methyl-4-pyrimidine carboxylic acid

InactiveCN101698662AReduce pollutionThe synthesis process steps are simpleOrganic chemistrySynthesis methodsCarboxylic acid

The invention discloses an artificial synthesis method of 1,4,5,6-tetrahydro-2-methyl-4-pyrimidine carboxylic acid, comprising the following steps: (1) taking 4-nitrophenol acetate and inorganic base, then mixing, adding the mixture into L-2,4-diaminobutyric acid water solution for reaction along with stirring to generate the mixture of 2-acetamido-4-aminobutyric acid and 2-amino-4-acetamido aminobutyric acid, and then extracting with CH2Cl2 to obtain the extractive liquid, drying, reducing pressure for distilling, carrying out vacuum drying to obtain the mixture of 2-acetamido-4-aminobutyric acid and 2-amino-4-acetamido aminobutyric acid; and (2) dissolving the above reaction mixture in polar organic solvent, then adding triethylamine, heating and refluxing, reducing pressure to evaporate the organic solvent, then using column chromatography to purify the mixture to obtain the 1,4,5,6-tetrahydro-2-methyl-4-pyrimidine carboxylic acid. The synthesis process of the invention has simple steps, little environment pollution, and 50%-70% of yield, thus being applicable to industrial production.

Owner:SHANDONG UNIV

Amidite for nucleic acid synthesis and nucleic acid synthesizing method

To provide an amidite for nucleic acid synthesis, which enables a protective group therein to be removed under moderate conditions and can be practically used, and a nucleic acid synthesizing method using the amidite for nucleic acid synthesis. Specifically, the present invention relates to an amidite for nucleic acid synthesis represented by General Formula (I) below, and a nucleic acid synthesizing method using the amidite for nucleic acid synthesis:where X denotes a base; Y denotes a protective group formed of any one of a 4-aminobutyric acid derivative, an o-aminomethylbenzoic acid derivative, an o-aminophenylacetic acid derivative, an o-aminoethylbenzoic acid derivative, an o-aminomethylphenylacetic acid derivative, an o-aminophenylpropionic acid derivative and a 5-aminovaleric acid derivative; and Q denotes one of a hydrogen atom and a hydroxyl group.

Owner:APTA BIOSCI

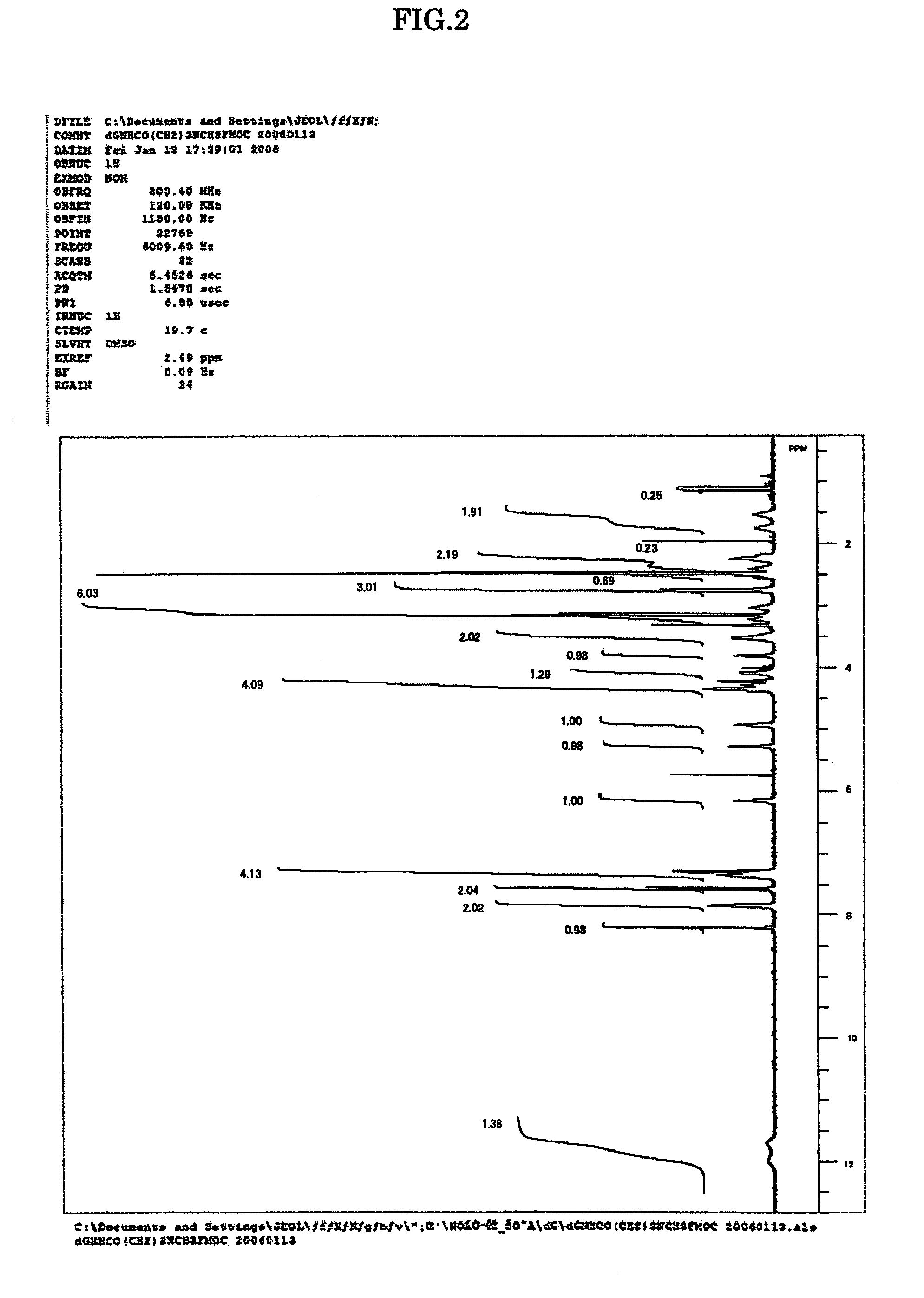

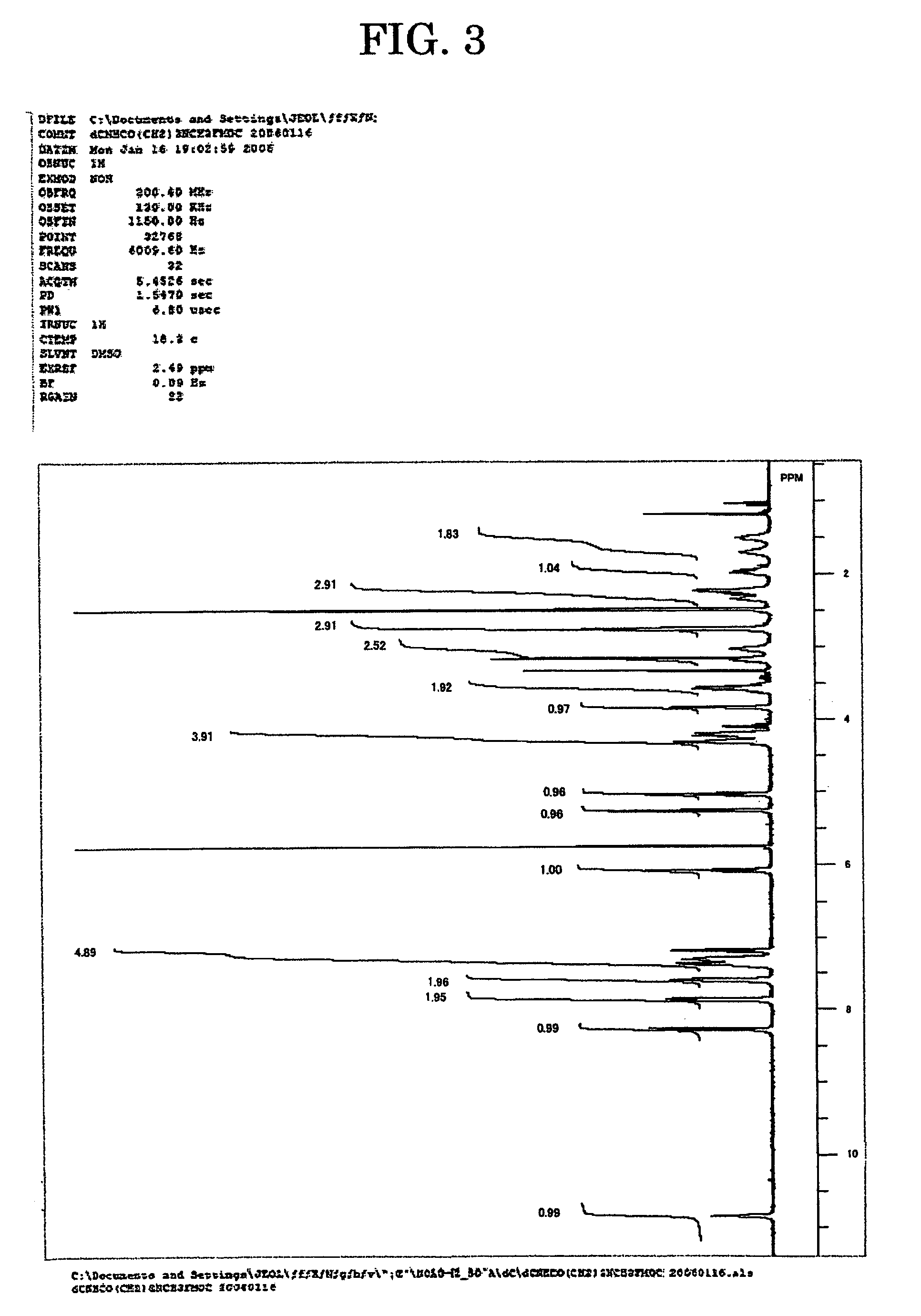

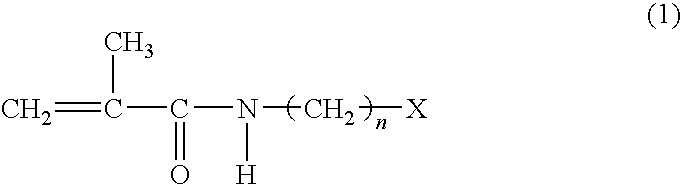

Dental self-etching primer

Bond strength of a composite resin, an adhesive resin cement or the like to dentin or enamel of tooth is remarkably improved by treating the dentin or the enamel with a self-etching primer agent comprising an aqueous solution of a methacrylic acid derivative such as N-methacryloylglycin, N-methacryloyl-3-aminopropionic acid, N-methacryloyl-4-aminobutyric acid, N-methacryloyl-5-aminovaleric acid, N-methacryloyl-6-aminocaproic acid, N-methacryloyl-2-aminomethylphosphonic acid, N-methacryloyl-3-aminoethyl-phosphonic acid and N-methacryloyl-4-aminopropylphosphonic acid.

Owner:NIHON UNIVERSITY

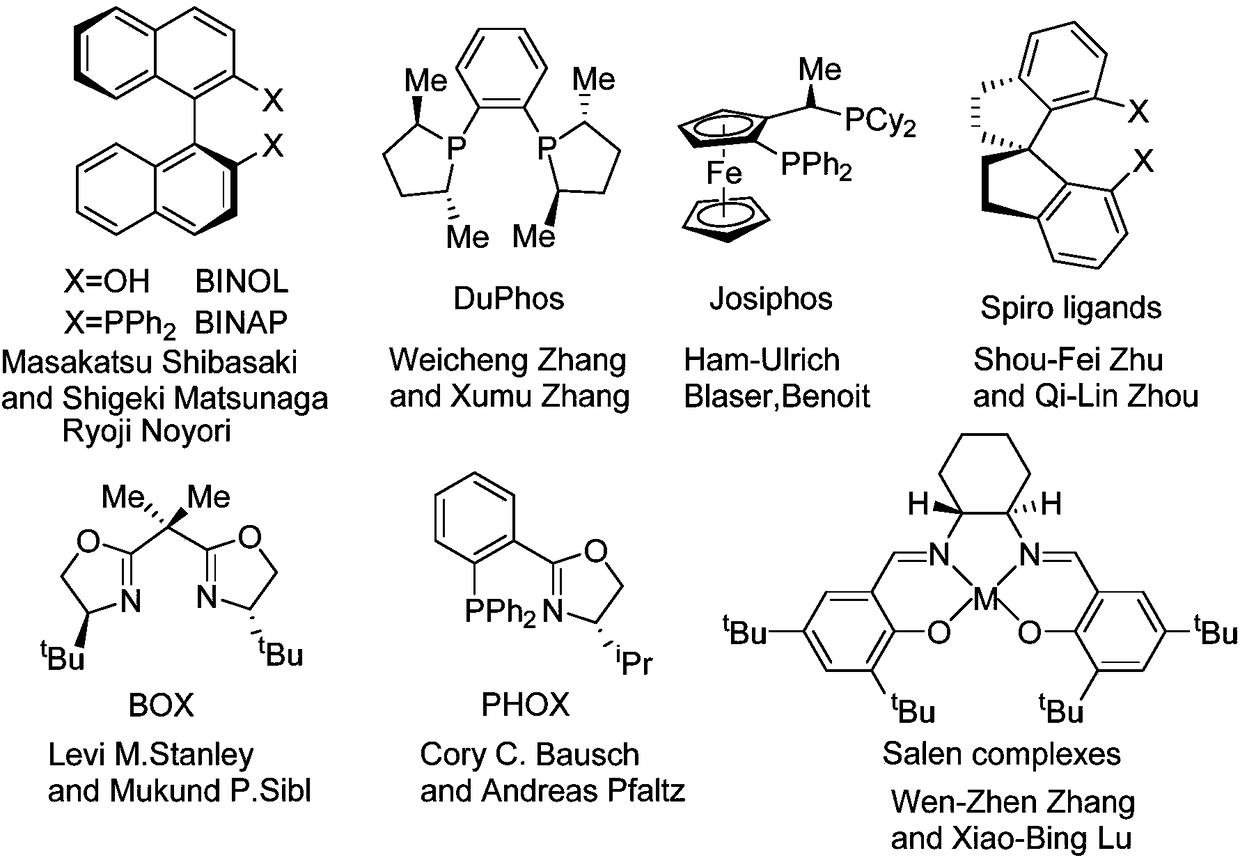

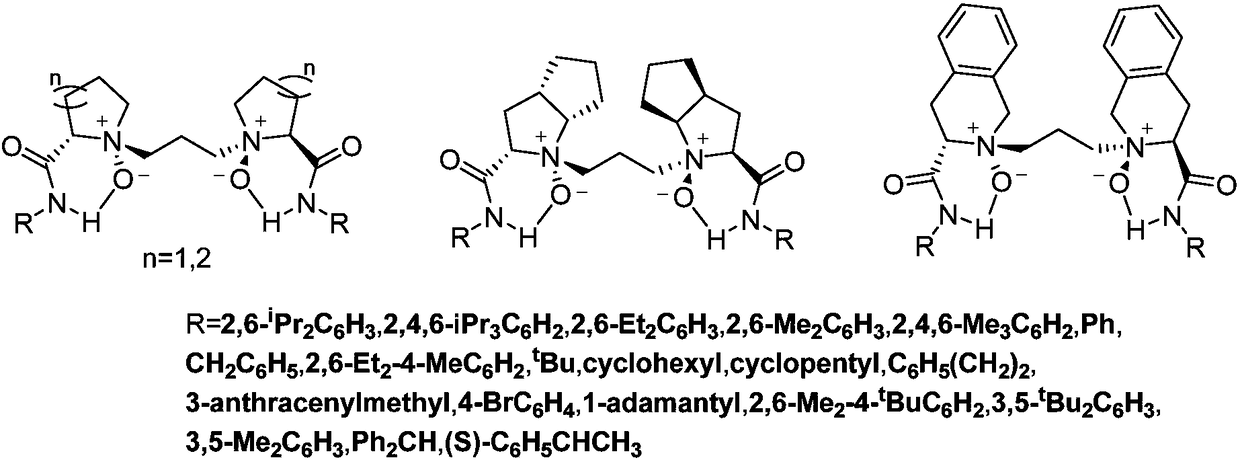

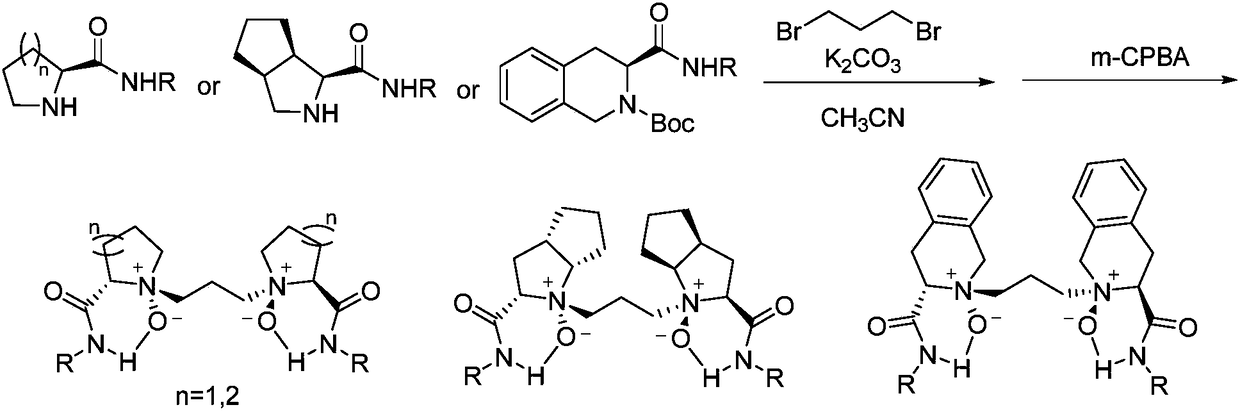

Novel chiral nitrogen oxygen ligands and synthesis method thereof

InactiveCN108084079AThe synthesis method is simpleHigh enantioselectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsCyclobutane

The invention discloses a series of novel chiral nitrogen oxygen ligands and a synthesis method thereof. According to the invention, simple amino acids, amino acid derivatives proline and Leimi acid,4-aminobutyric acid and tetrahydroisoquiline acid are adopted as raw materials, and a series of key processes are adopted, so that 4-carbon, 6-carbon, 7-carbon and 8-carbon novel chiral nitrogen oxygen ligands, 2-A-propane 3-carbon novel chiral nitrogen oxygen ligands, 2,2-di(B)-propane 3-carbon novel chiral nitrogen oxygen ligands, 1,1-dimethyl cyclopropane 3-carbon novel chiral nitrogen oxygen ligands, 1,1-dimethyl cyclobutane 3-carbon novel chiral nitrogen oxygen ligands, 1,1-dimethyl cyclopentane 3-carbon novel chiral nitrogen oxygen ligands and 1,1-dimethyl cyclohexane 3-carbon novel chiral nitrogen oxygen ligands, p-xylene and m-xylene and o-xylene novel chiral nitrogen oxygen ligands, and p-diethylbenzene, m-diethylbenzene and o-diethylbenzene novel chiral nitrogen oxygen ligands, and other novel chiral nitrogen oxygen ligands are finally synthesized. The above novel chiral nitrogen oxygen molecules can realize high enantioselectivity and high reaction activity in a variety of asymmetric reactions, and have great significance in solving reactions which cannot be completed by existing nitrogen oxygen ligands.

Owner:SICHUAN UNIV

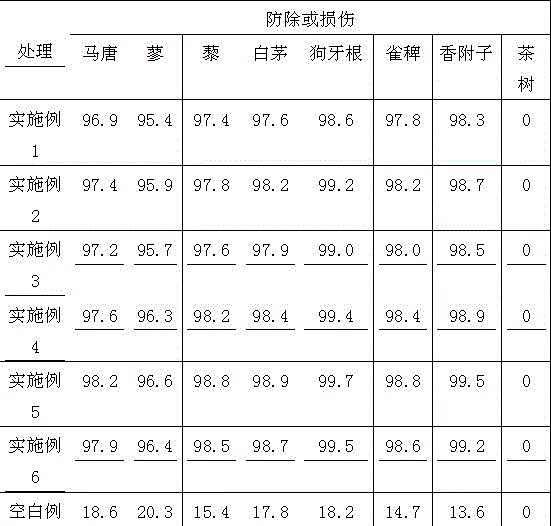

Weed killer for tea garden

InactiveCN105532684AHigh removal typeRemove all typesBiocideAnimal repellantsKetoneChloroacetaldehyde

The invention relates to pesticide, in particular to a weed killer for a tea garden. The weed killer is prepared from alpha-ketoglutaric acid, methoxyacetophenone, chloroacetaldehyde diethyl acetal, 4-aminobutyric acid, 3-methoxy-1,3,5(10)-trien-17-ketone and the like. The weed killer for the tea garden is environmentally friendly, does not damage the environment, and is high in weeding efficiency, complete in weeding varieties and low in cost, the preparation method is simple, more importantly, tea trees are not damaged, much labor force is saved for a fruit farmer, and the weed killer is suitable for being widely applied and popularized in the field of weed killers.

Owner:烟台顺隆化工科技有限公司

Synthetic method of clinic effect of alendronate

ActiveCN101284848AOvercoming the disadvantages of solidification and inability to stirAvoid spontaneous combustion, dangerous problemsGroup 5/15 element organic compoundsSkeletal disorderPhosphorous acidOperability

The invention provides a method for synthesizing alendronic acid. According to the invention, 4-aminobutyric acid, phosphorous acid, phosphorus trichloride or phosphorus pentachloride are reacted in aprotic polar solvent, and then the mixture obtained through the reaction is hydrolyzed and crystallized to obtain the alendronic acid. The method has high safety and reliability, easily separated product, strong operability, high yield and low cost, and is particularly suitable for large-scale production.

Owner:CSPC OUYI PHARM CO LTD

Biofuel and chemical production by recombinant microorganisms through fermentation of proteinaceous biomass

Provided are metabolically improved microorganisms characterized by increased ketoacid flux compared to wild-type organisms and comprising at least one polynucleotide encoding an enzyme which, when expressed, elicits higher amounts of chemical products compared to wild-type organisms generate. The recombinant microorganisms are used to produce a wide variety of chemical compositions from various nitrogen-containing biomass compositions and other carbon sources. More specifically, provided herein are methods for the production of alcohol, acetaldehyde, acetic acid, isobutyraldehyde, isobutyric acid, n-butyraldehyde, n-butyric acid, 2-methyl-1 -butyraldehyde, 2-methyl-1-butyric acid, 3-methyl-1-butyraldehyde, 3-methyl-1-butyric acid, ammonia, ammonium, amino acid, 2,3-butanediol, 1, 4-butanediol, 2-methyl-1,4-butanediol, 2-methyl-1,4-butanediamine, isobutene, itaconate, acetoin, acetone, isobutene, 1,5 -Diaminopentane, L-lactic acid, D-lactic acid, shikimic acid, mevalonic acid, polyhydroxybutyric acid (PHB), isoprenoid, fatty acid, homoalanine, 4-aminobutyric acid (GABA ), succinic acid, malic acid, citric acid, adipic acid, p-hydroxy-cinnamic acid, tetrahydrofuran, 3-methyl-tetrahydrofuran, gamma-butyrolactone, pyrrolidone, n-methylpyrrolidone, aspartic acid, lysine acid, cadaverine, 2-ketoadipate, and S-adenosyl-methionine (SAM).

Owner:RGT UNIV OF CALIFORNIA

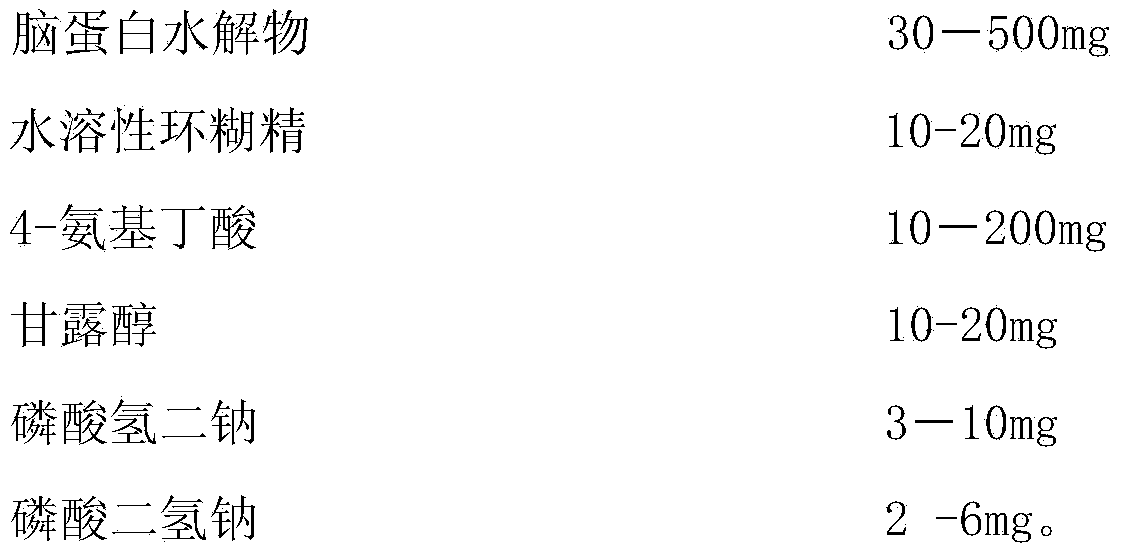

Pharmaceutical composition of cerebrolysin vial for injection

The invention relates to a pharmaceutical composition of cerebrolysin vial for injection. The pharmaceutical composition comprises the main components of cerebrolysin vial and 4-aminobutyric acid.

Owner:GUANGDONG LONGFU MEDICINE CO LTD

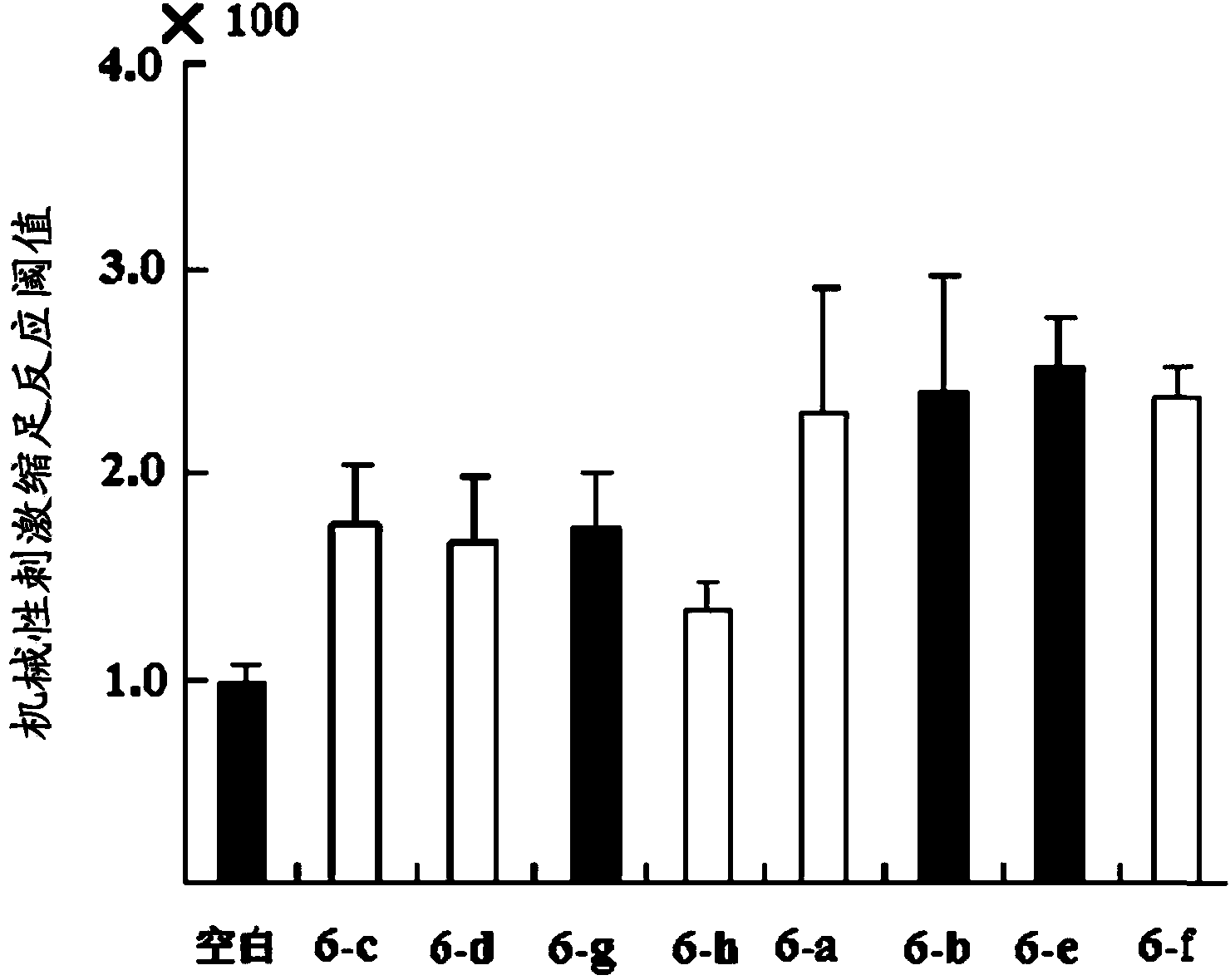

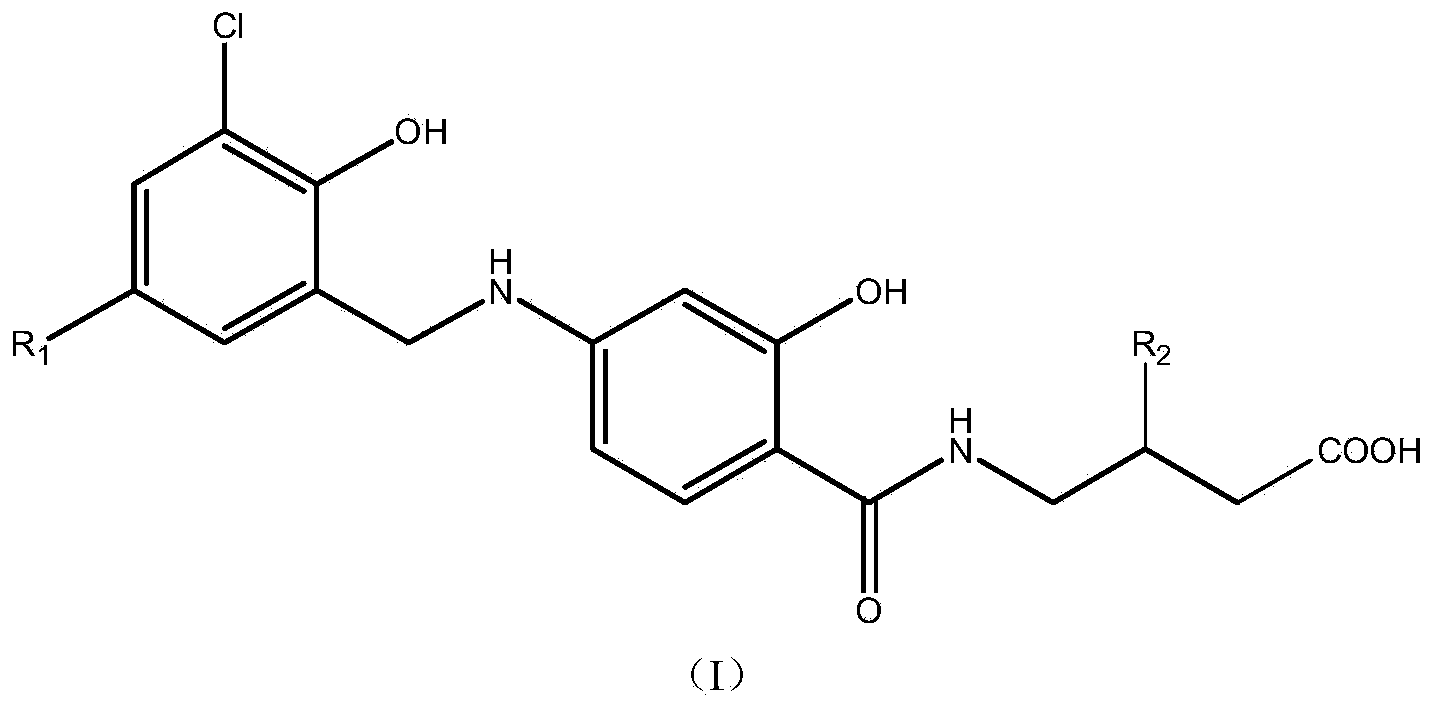

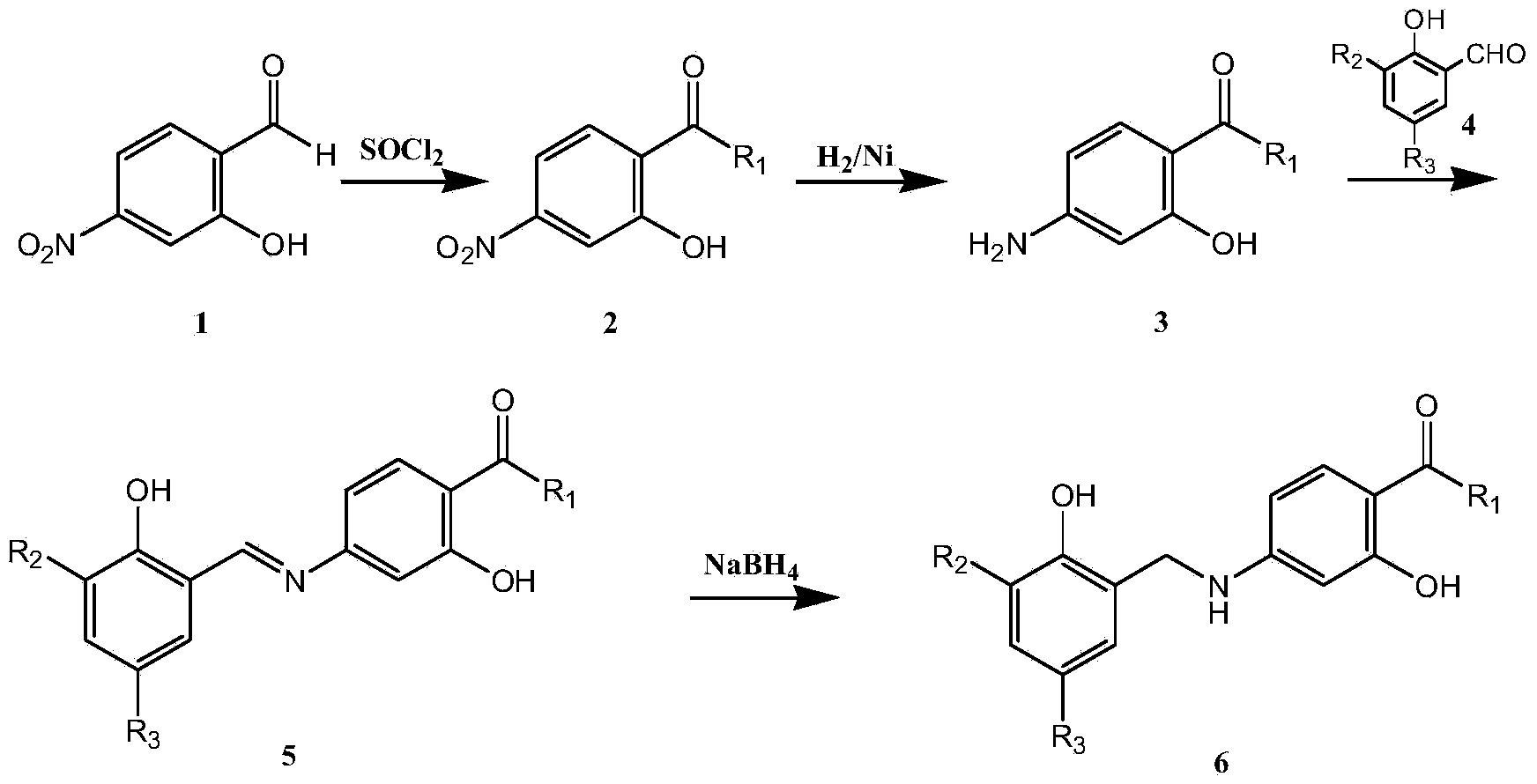

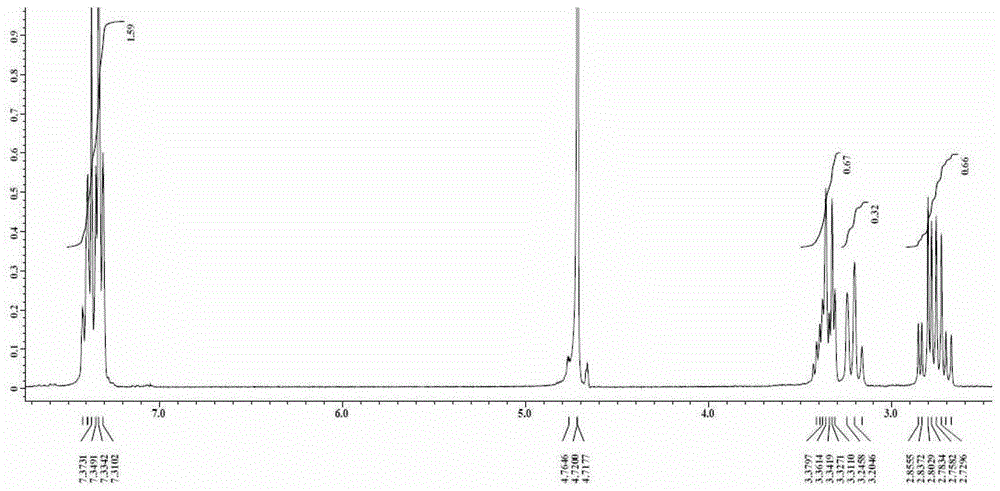

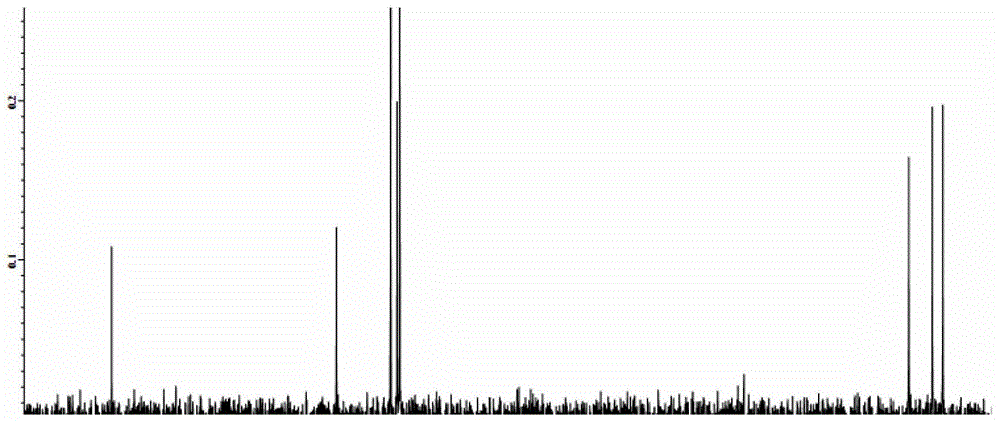

N-benzyl-substituted amide derivatives of amino salicylic acid and 4-aminobutyric acid and drug application of N-benzyl-substituted amide derivatives

InactiveCN104230745AGood analgesic effect for neuropathic painOrganic active ingredientsNervous disorderGabapentinSalicylic acid

The invention relates to N-benzyl-substituted amide derivatives of amino salicylic acid and 4-aminobutyric acid and a drug application of the N-benzyl-substituted amide derivatives. The N-benzyl-substituted amide derivatives have the structures which are in line with the general formula shown in the specification. The drug is a multi-target twin drug of a nNOS-PSD-95 decoupling agent, gabapentin and pregabalin and has better analgesic effect on the neuropathic pain than the single-target drugs such as nNOS-PSD-95 decoupling agent, gabapentin and pregabalin, and the N-benzyl-substituted amide derivatives can be used for preparing drugs for treatment of neuropathic pain diseases.

Owner:NANJING MEDICAL UNIV

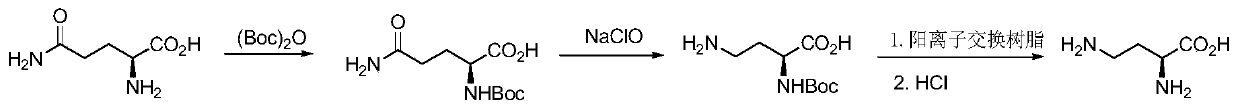

Preparation method of L-2,4-diaminobutyrate hydrochloride

ActiveCN110317143AReduce usageSimple and fast operationCarbamic acid derivatives preparationOrganic compound preparationL-glutamineIndustrial scale

The invention belongs to the technical field of organic chemistry, and discloses a preparation method of L-2,4-diaminobutyrate hydrochloride. The method includes the following steps that S1, L-glutamine is subjected to Boc protection under an alkaline condition to obtain a N-BOC-L-glutamine aqueous solution; S2, a saturated sodium hypochlorite solution is dropwise added into the N-Boc-L-glutamineaqueous solution obtained in the S1 for a degradation reaction, and a L-2-N-Boc-4-aminobutyric acid crude product solution is obtained; S3, the L-2-N-Boc-4-aminobutyric acid crude product solution iscondensed, the pH is adjusted with 2N hydrochloric acid, salt is removed with cation exchange resin, dilute ammonia water is used as an elution agent for elution, the eluent is condensed, concentratedhydrochloric acid is added for adjusting the pH of a concentrated solution, absolute ethyl alcohol is added, and after crystallization, filtering and drying, the L-2,4-diaminobutyrate hydrochloride is obtained. The method has the advantages that the synthetic route is short, operation is simple, three wastes pollution is less, the yield is high and the cost is low, and the method is an ideal scheme for industrial scale-up production.

Owner:CHENGDU BAISHIXING SCI & TECH IND

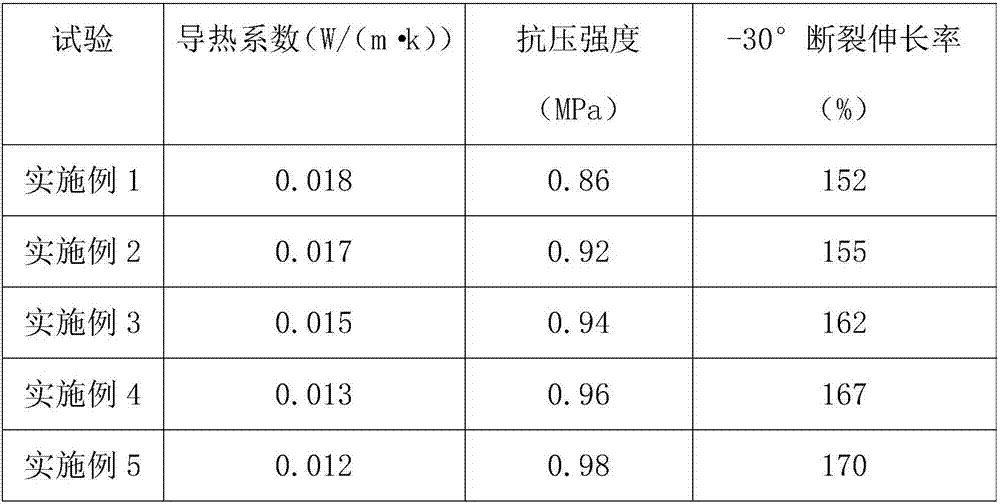

Thermal-insulation and heat-preservation material with cold resistance and preparation method thereof

The invention discloses a thermal-insulation and heat-preservation material with cold resistance and a preparation method thereof. The preparation method comprises the following steps: crushing 8-12 parts of hollow glass microspheres, 40-50 parts of polyphenyl particles, 8-10 parts of clay, and 5-10 parts of quartz sand, and performing mixing uniformly under stirring; adding 10-15 parts of allyl methacrylate, 8-12 parts of cyclopentanol, 10-20 parts of 4-aminobutyric acid, and 5-10 parts of di-n-hexyl azelate, and performing a reaction for 8-12h at a water bath temperature of 60-80 DEG C; adding 5-8 parts of alkyl diphenyl phosphate, 6-9 parts of ethyl pelargonate, 7-10 parts of N,N-dimethylurea, and 4-6 parts of polyacrylamide, and performing stirring at a temperature of 80-100 DEG C to form a foamed mixture; performing vacuum filtration and concentration on the foamed mixture, wherein a sold phase mass content of foamed slurry is controlled to be 8-20%; performing pressing to form a prefabricated body, wherein an amount of compression is controlled to be 20-60%, and a density is controlled to be 0.2-0.4g / cm<3>; and performing drying at a temperature of 160-200 DEG C, performing melting extrusion, and performing granulation.

Owner:浙江中泰绝热材料有限公司

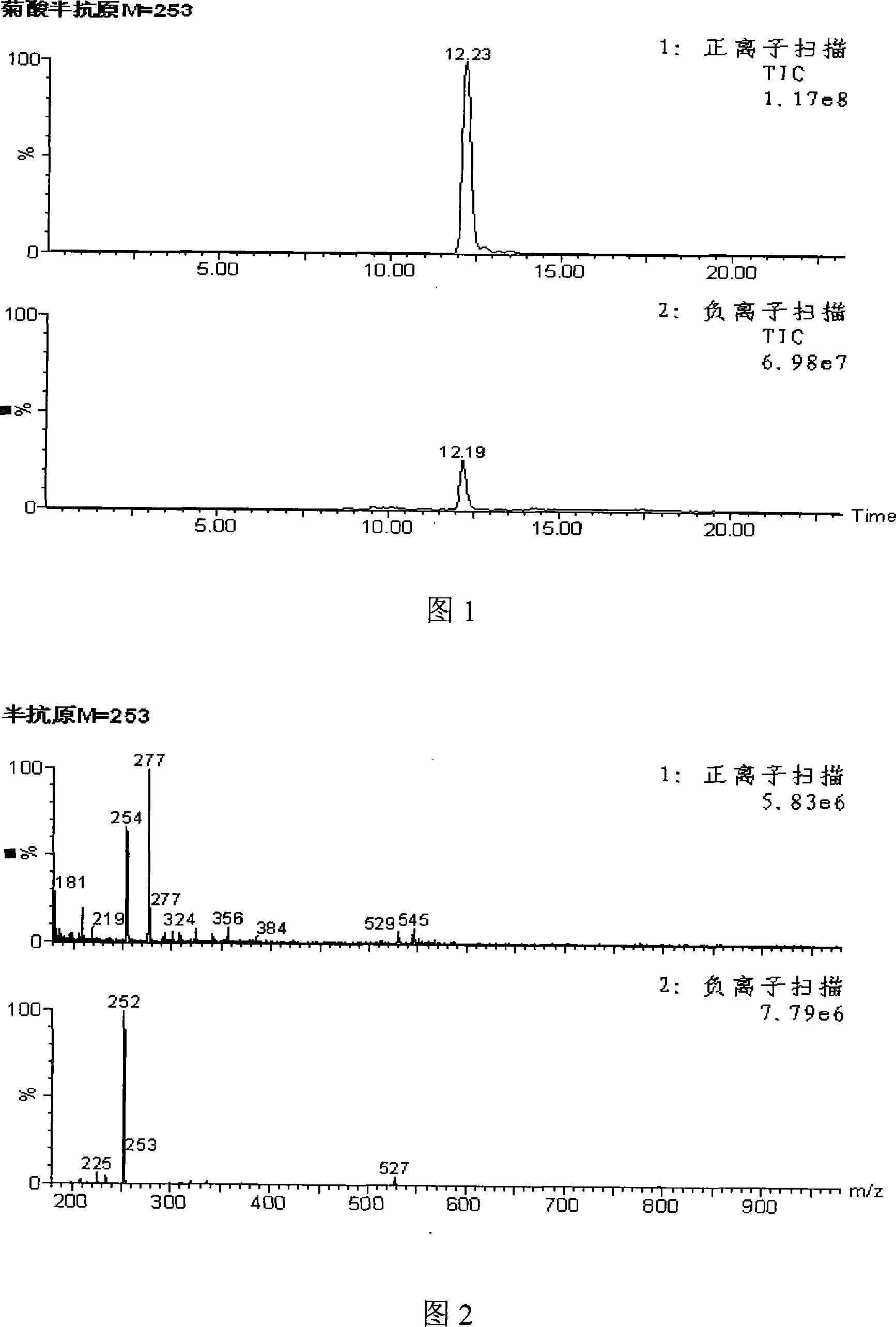

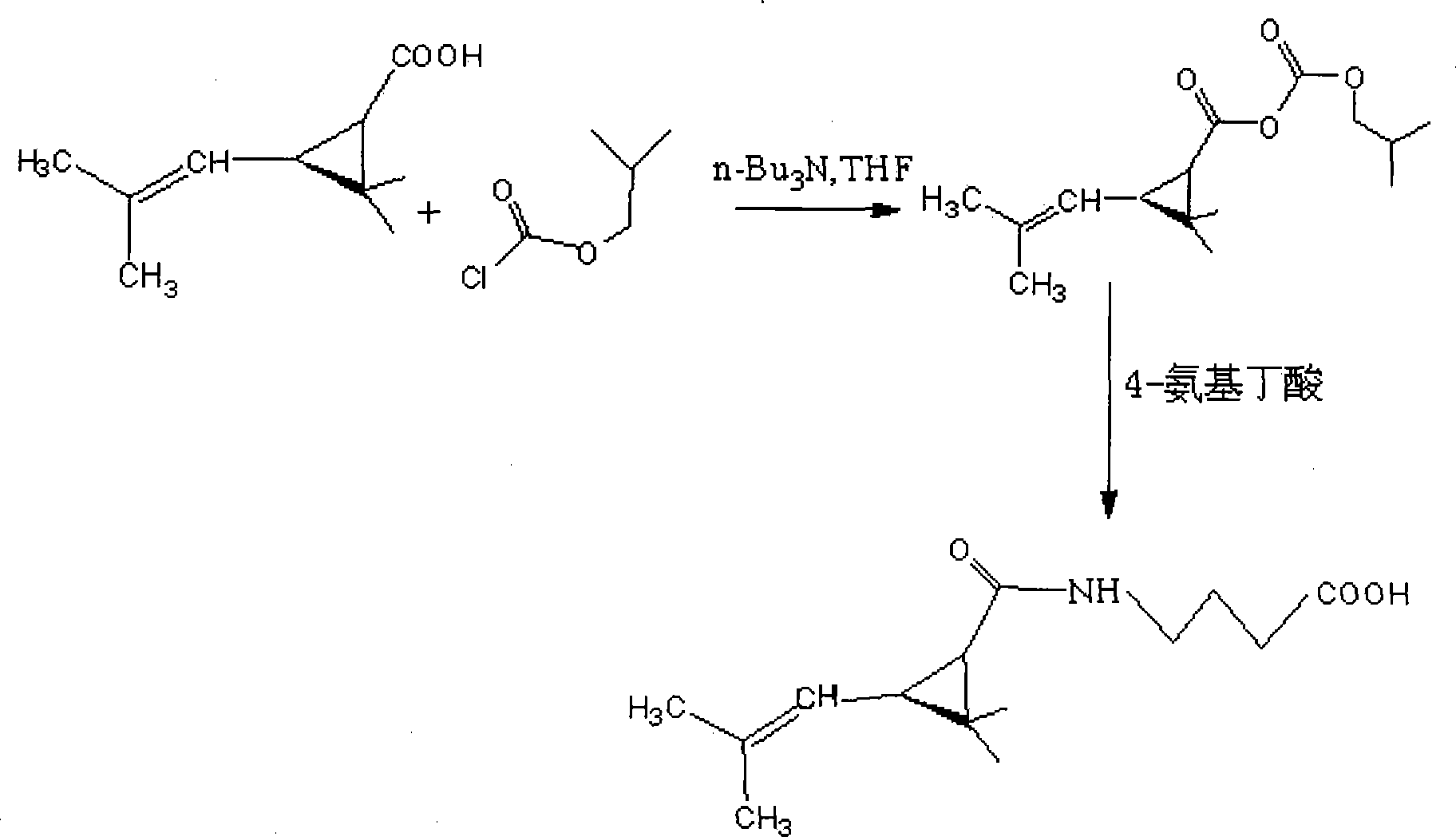

Method for synthesizing 4-reanal condensation chrysanthemic acid hapten

ActiveCN101219965AThe synthesis steps are simpleHigh purityOrganic compound preparationComponent separationSynthesis methodsChrysanthemic acid

Owner:山东美正生物科技有限公司

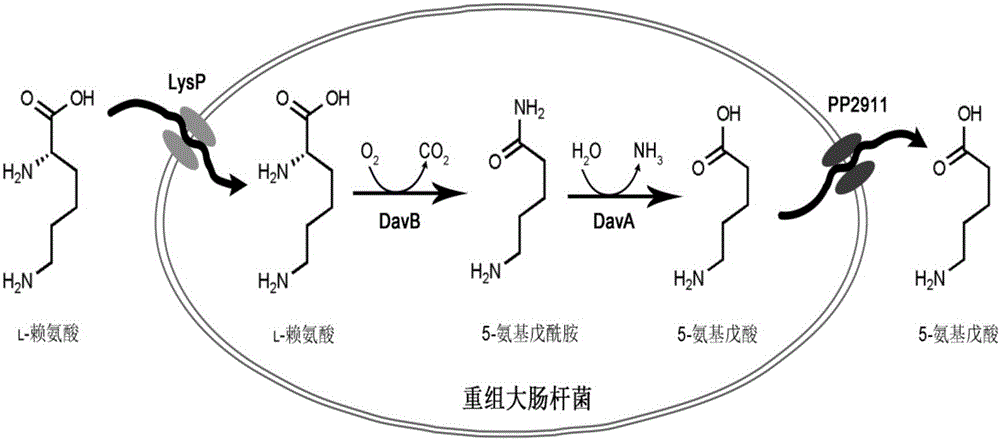

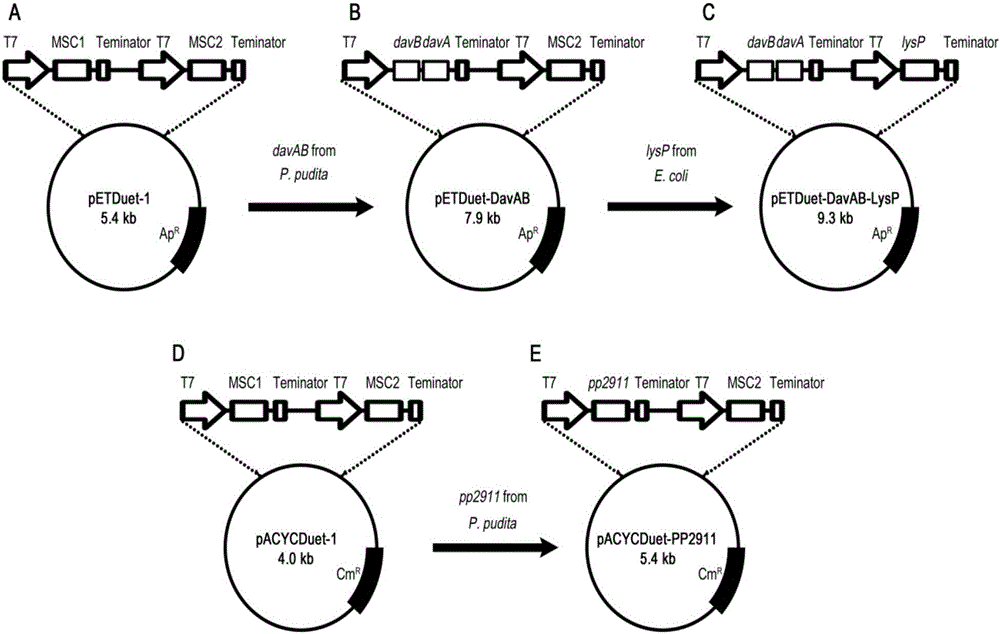

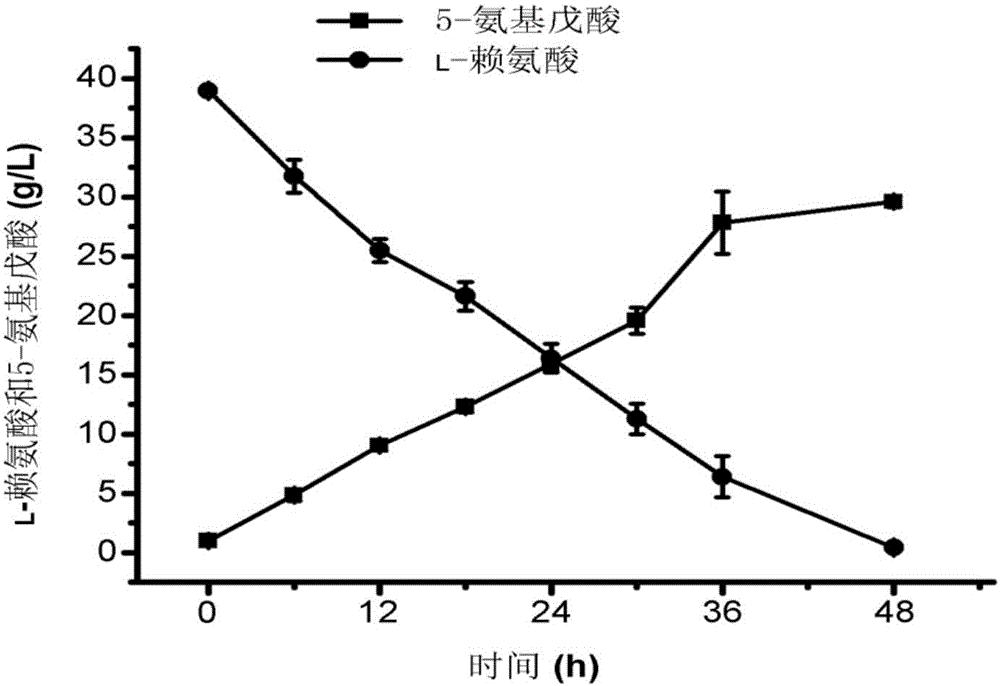

Method for accelerating biological production of 5-aminovaleric acid

ActiveCN106191089ASimple separation and purificationReduce consumptionHydrolasesPeptidesHydrolase GeneAminopentamide

The invention discloses a method for accelerating biological production of 5-aminovaleric acid. Through co-expression of a lysine specific permease gene lysP and a 4-aminobutyric acid transporter gene pp2911 in an engineering bacterium that an L-lysine 2-monooxygenase gene davB and a [delta]-amino valeramide hydrolase gene davA are co-expressed, the speed and the yield of producing the 5-aminovaleric acid by catalyzing L-lysine through the engineering bacterium are improved. In comparison with a recombinant bacterium that either the L-lysine 2-monooxygenase gene davB or the [delta]-amino valeramide hydrolase gene davA is expressed, the method, which achieves the co-expression of the lysine specific permease gene lysP and the 4-aminobutyric acid transporter gene pp2911, can improve the yield of the 5-aminovaleric acid by virtue of the genetically engineered bacterium by 67.3%, and the conversion rate of the 5-aminovaleric acid can reach 0.94mol / mol or above. The method disclosed by the invention has a broad application prospect for the industrial production of the 5-aminovaleric acid.

Owner:SHANDONG UNIV

Foliar spray fertilizer

InactiveCN105461455AQuick clearPromote absorptionOrganic fertilisersLiquid fertilisersDimethylglycinePlant disease

The invention discloses a foliar spray fertilizer, comprising the following material components in parts by weight: 35-70 parts of wood vinegar, 20-40 parts of potassium peroxymonosulfate, 6-20 parts of 4-aminobutyric acid, 8-20 parts of gluconolactone, and 6-15 parts of N-dodecyl-N,N-dimethylglycine. Compared with the prior art, the foliar spray fertilizer disclosed by the invention has the following significant advantages: diseases can be eliminated quickly, and nutrient can be supplied to plants; the fertilizer can be absorbed by the plants quickly, and is strong in effect and high in disease elimination efficiency; and the fertilizer is stable and has a long shelf life.

Owner:XINJI YUAN XIANG GREEN ENERGY TECHOLOGY CO LTD

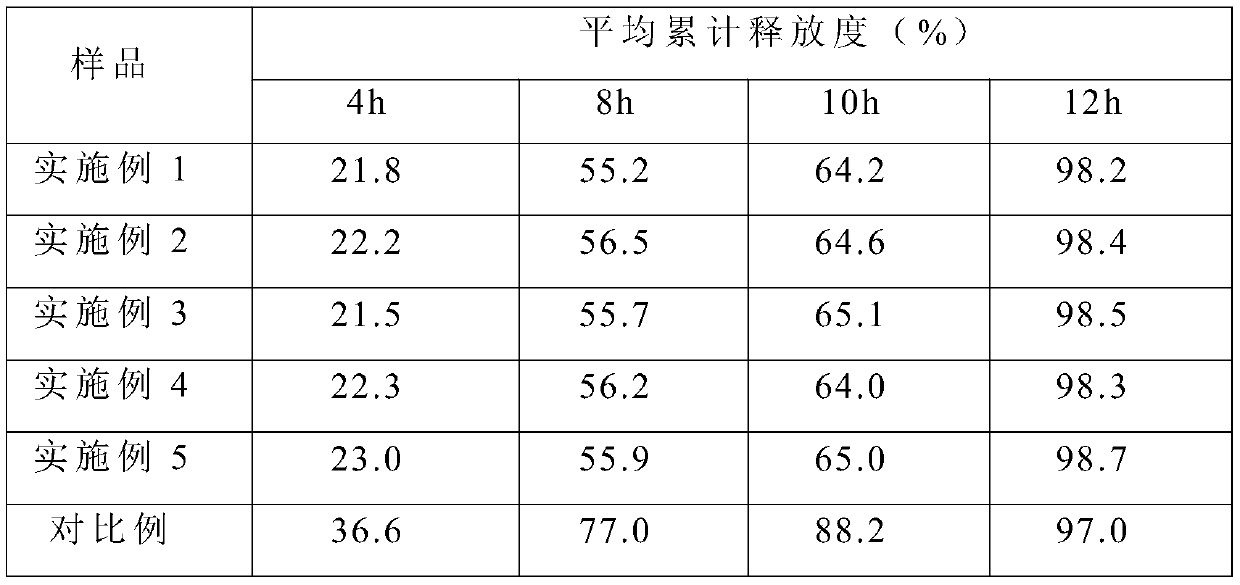

Slow release medical composition for treating anxiety disorders and preparation method of slow release medical composition

InactiveCN109847008ASimple processRaw materials are easy to getOrganic active ingredientsNervous disorderSide effectTherapeutic effect

The invention discloses a slow release medical composition for treating anxiety disorders. The slow release medical composition is characterized by being prepared from the following raw materials in parts by weight: 45-55 parts of tandospirone citrate, 10-15 parts of 4-aminobutyric acid alginic acid co-modified copolymers, 5-10 parts of fillers, 3-5 parts of pore forming agents, 1-3 parts of a lubricant, 3-5 parts of a Chinese herbal medicine extract and 5-10 parts of water, wherein the copolymers are prepared through a co-polymerization reaction on allyl beta-D-glucopyranoside, sweet glucoside and 1-butyl-3-vinylimidazolium chloride through free radicals. The slow release medical composition for treating anxiety disorders disclosed by the invention is good in slow release effects, excellent in the effect of treating the anxiety disorders, high in efficiency, stable in treatment effects, long-lasting to act, convenient in administration, simple in preparation technology, rich in raw material sources, good in medication compliance, small in toxic and side effects and safe to use, and is suitable for clinical use.

Owner:徐维亮

Compound preparation for improving organism functions of astronaut

InactiveCN110384234APrevent Alzheimer'sIncrease vitalityAcidic food ingredientsNatural extract food ingredientsOrganismSoybean Phospholipids

The invention relates to a compound preparation for improving organism functions of an astronaut. The compound preparation is prepared from the following raw materials: soybean phospholipid, phosphatidylserine, 4-aminobutyric acid, a valerian extract, lycium ruthenicum, sea buckthorn powder, oat-beta-glucan, vegetable fat powder and maltodextrin. The provided preparation can improve the organism functions of the astronaut and enables the astronaut to complete the flight task more successfully. In addition, the preparation further has the effects of resisting aging, maintaining beauty and keeping young.

Owner:威海赛瑞航天科技有限公司

Method for increasing content of 4-aminobutyric acid in sporocarp of pleurotus geesteranus

ActiveCN109479619AImprove functionalityGood for healthCultivating equipmentsMushroom cultivationBiotechnologyDry weight

The invention provides a method for increasing the content of 4-aminobutyric acid in sporocarp of pleurotus geesteranus, and belongs to an edible mushroom cultivation technology. The method comprisesthe step of adding vital gluten, L-calcium glutamate and soybean oil in a pleurotus geesteranus cultivation material. The method is simple and convenient, is easy to operate, can be well integrated with an existing pleurotus geesteranus cultivation system, production of the pleurotus geesteranus rich in GABA is realized, the content of GABA in the sporocarp of the pleurotus geesteranus can reach 100-200 mg / kg dry weight, and the method is of great help to improvement of functionality of pleurotus geesteranus products, increasing of added value of products and benefiting of health of consumers.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

A kind of technique for preparing 3-phenyl-4-aminobutyric acid hydrochloride

ActiveCN103232356BImprove reaction efficiencyImprove hydrogenation efficiencyOrganic compound preparationAmino-carboxyl compound preparationMethyl 4-nitrobutyrateHydrogen atmosphere

The invention provides a technology for preparing 3-phenyl-4-aminobutyric acid hydrochloride. According to the technology, methyl cinanmate and nitromethane are used as oligomers, nitromethane is taken as an oligomer and a solvent, and a series of troubles in treatment caused when a third reagent is introduced as a solvent is avoided; 94.1% 3-phenyl-4-nitryl methyl butyrate can be obtained by a triethylamine and anhydrous MgC12 mixed catalyst, and the reaction efficiency is improved; raney nickel is used as a catalyst for converting the 3-phenyl-4-nitryl methyl butyrate into 3-phenyl valerolactam, the hydrogenation efficiency is improved, and the conversion rate of the 3-phenyl-4-nitryl methyl butyrate reaches 95.7%; and a methanol and dichloromethane mixed solvent serves as a solvent used for recrystallizing 3-phenyl-4-aminobutyric acid hydrochloride; and through recrystallization, the purity of the target product is above 99.0%. The technology has the advantages that reaction conditions are mild and easy to control, hydrogenation is finished in one step, high pressure does not need to be maintained; as long as bubbling is carried out and hydrogen atmosphere is maintained, the good reaction rate and yield can be obtained; and the control is simple and convenient.

Owner:TIANJIN JUDE TECH

Inorganic phosphorus (phosphate radical) diagnosis/determination kit and method for determining inorganic phosphorus (phosphate radical) concentration

InactiveCN101620148AFast measurementImprove accuracyMicrobiological testing/measurementColor/spectral properties measurementsPhosphateGlutamate decarboxylase

The invention relates to an inorganic phosphorus (phosphate radical) diagnosis / determination kit using the technology of an enzyme colorimetric method and an ELISA method, a method for determining inorganic phosphorus (phosphate radical) concentration and composition and components of a reagent, and belongs to the technical field of test and determination of medical science, food, and environment. The kit comprises the following main components: buffer solution, coenzyme, adenosine diphosphate, oxaloacetic acid, 4-aminobutyric acid, pyruvate carboxylase, glutamate dehydrogenase, glutamate synthetase and a stabilizer. The method comprises the following steps: mixing a sample and the reagent according to a certain volume ratio to perform a series of enzymic reaction, and then placing reactants under a UV / visible light analyzer to test the ascending speed of absorbance at the position where the dominant wave length is 340nm to determine the inorganic phosphorus (phosphate radical) concentration.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

Inorganic phosphorus (phosphate radical) diagnosis/determination kit and method for determining inorganic phosphorus (phosphate radical) concentration

InactiveCN101620158AFast measurementImprove accuracyMicrobiological testing/measurementColor/spectral properties measurementsPhosphateGlutamate decarboxylase

The invention relates to an inorganic phosphorus (phosphate radical) diagnosis / determination kit using the technology of an enzyme colorimetric method and an ELISA method, a method for determining inorganic phosphorus (phosphate radical) concentration and composition and components of a reagent, and belongs to the technical field of test and determination of medical science, food, and environment. The kit comprises the following main components: buffer solution, coenzyme, oxaloacetic acid, 4-aminobutyric acid, phosphoenolpyruvate carboxykinase, glutamate dehydrogenase, glutamate sythetase and a stabilizer. The method comprises the following steps: mixing a sample and the reagent according to a certain volume ratio to perform a series of enzymic reaction, and then placing reactants under a UV / visible light analyzer to test the descending speed of absorbance at the position where the dominant wave length is 340nm to determine the inorganic phosphorus (phosphate radical) concentration.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com