Patents

Literature

184 results about "Iron(II) sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) sulfate (British English: iron(II) sulphate) or ferrous sulfate denotes a range of salts with the formula FeSO₄·xH₂O. These compounds exist most commonly as the heptahydrate (x = 7) but are known for several values of x. The hydrated form is used medically to treat iron deficiency, and also for industrial applications. Known since ancient times as copperas and as green vitriol (vitriol is an archaic name for sulfate), the blue-green heptahydrate (hydrate with 7 molecules of water) is the most common form of this material. All the iron(II) sulfates dissolve in water to give the same aquo complex [Fe(H₂O)₆]²⁺, which has octahedral molecular geometry and is paramagnetic. The name copperas dates from times when the copper(II) sulfate was known as blue copperas, and perhaps in analogy, iron(II) and zinc sulfate were known respectively as green and white copperas.

Aqueous culture method of anoectochilus

InactiveCN102100171AAbsorb evenlyAdequately meet nutritional needsCultivating equipmentsSoilless cultivationBiotechnologyCalcium nitrate tetrahydrate

The invention relates to an aqueous culture method of anoectochilus. In the method, anoectochilus germchits are cleaned and sterilized, transplanted in a culture dish and cultured in a culture groove filled with an aqueous culture solution; each 10L of aqueous culture solution contains the following components: 650 to 800mg of calcium nitrate tetrahydrate, 50 to 60mg of ammonium nitrate, 280 to 350mg of potassium nitrate, 100 to 130mg of potassium dihydrogen phosphate, 350 to 380mg of magnesium sulfate, 0.5 to 0.8mg of potassium iodide, 2 to 5mg of manganese sulfate, 0.2 to 0.3mg of sodium molybdate, 0.1 to 0.2mg of cobalt chloride, 2 to 4mg of boric acid, 0.5 to 1mg of zinc sulfate, 0.3 to 0.5mg of copper sulfate and 3 to 5ml of iron salt solution, wherein the iron salt solution is prepared by mixing water, green vitriol and ethylenediamine tetraacetic acid disodium. The method has the advantages of lowering production cost, simplifying production process, improving the growth of anoectochilus plants and improving the survival rate of anoectochilus plants.

Owner:福建永安天奇健金线莲生态实业有限公司

Compound microbiological oxygenate for removing ammonia nitrogen in aquatic water and preparation method of compound microbiological oxygenate

ActiveCN104671433AImprove solubilityQuick breakdownWater contaminantsBiological water/sewage treatmentDiseaseWater quality

The invention belongs to the technical field of aquiculture and discloses a compound microbiological oxygenate for removing ammonia nitrogen in aquatic water and a preparation method of the compound microbiological oxygenate. The oxygenate is prepared from the following raw material components in parts by weight: 15-25 parts of zeolite powder, 10-15 parts of chlorite, 10-15 parts of citric acid, 15-20 parts of a powdery bacillus subtilis, photosynthetic bacterium and EM bacterium mixture, 5-15 parts of a proteolytic enzyme, 5-15 parts of silicate, 20-25 parts of sodium percarbonate, 5-10 parts of quicklime, 1-4 parts of ferrous sulfate, 3-5 parts of dextrin, 3-5 parts of starch slurry and 15-20 parts of a protective agent. The oxygenate disclosed by the invention is suitable for sterilizing, oxygenating and preventing and treating diseases in aquiculture and can be used for improving the water quality, reducing the ammonia nitrogen content in a water area, improving the water level transparency, improving the substrate and purifying water.

Owner:SOUTH CHINA UNIV OF TECH

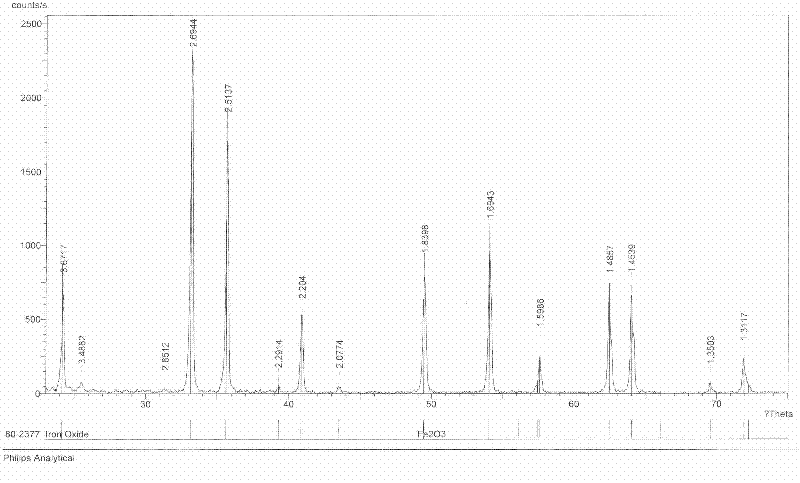

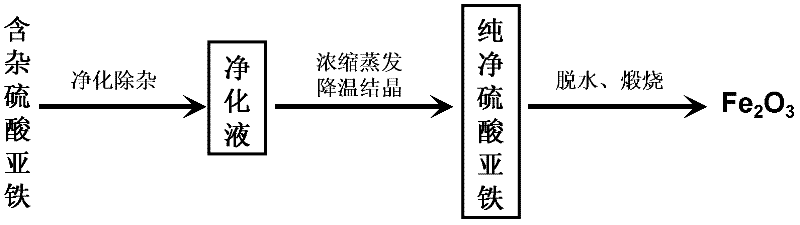

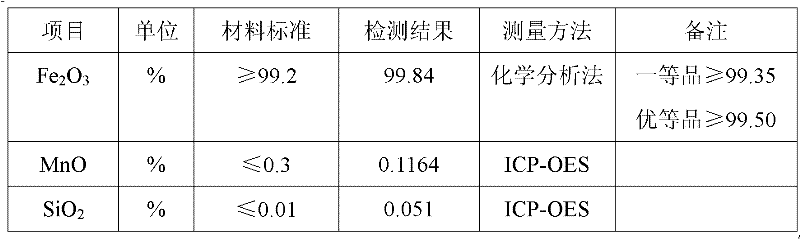

Method for producing iron oxide red by using ferrous sulfate as titanium dioxide byproduct

The invention discloses a method for producing oxide red by using ferrous sulfate as a titanium dioxide byproduct. The method comprises the following process steps of: firstly, dissolving the ferrous sulfate as the titanium dioxide byproduct with water of which the temperature is 50-80DEG C at normal pressure to form an aqueous solution; then adding ammonia water into the aqueous solution; adjusting the pH value of the aqueous solution to 2.2-4.0; adding soluble fluoride into the aqueous solution; reacting at the temperature of 50-80DEG C and normal pressure for 20-60 minutes by stirring; and after the reaction time reaches, separating a precipitation to obtain a purified liquid, wherein the addition mount of the soluble fluoride is 0.3-10 percent of the mass of the ferrous sulfate as the titanium dioxide byproduct; secondly, condensing and crystallizing the purified liquid obtained in the first step to obtain a pure ferrous sulfate crystal; and thirdly, dehydrating the pure ferrous sulfate crystal obtained in the second step at the temperature of 200-350DEG C and normal pressure for 20-60 minutes and calcining the reacted product at the temperature of 800-900DEG C and normal pressure for 1-4h to obtain the iron oxide red.

Owner:SICHUAN UNIV

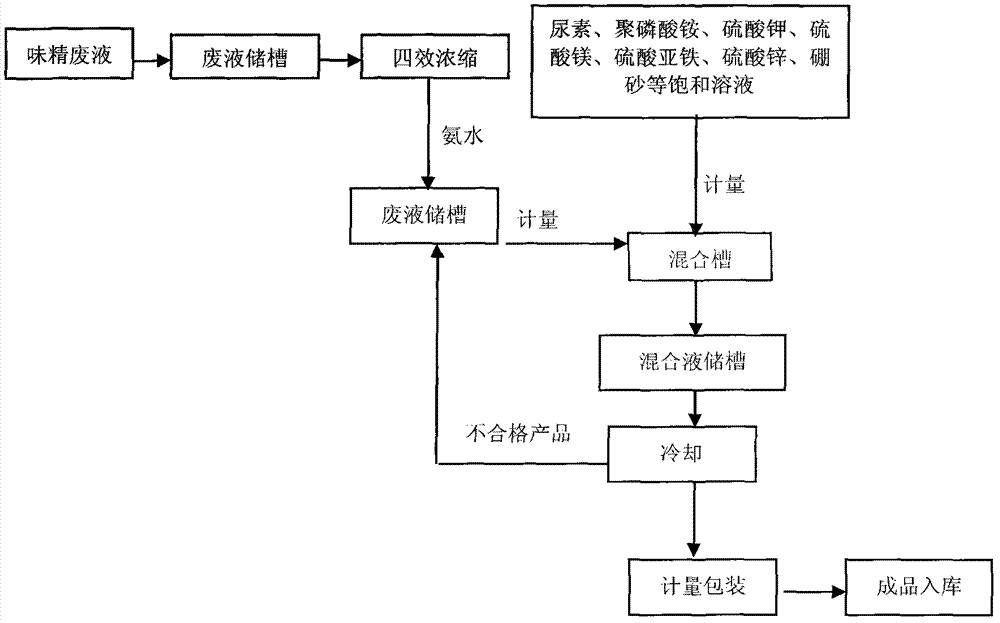

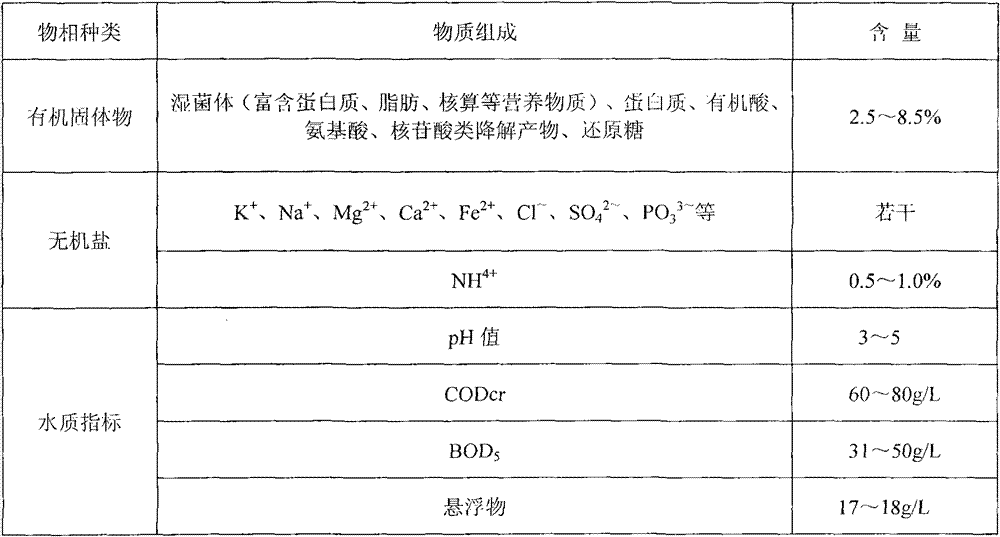

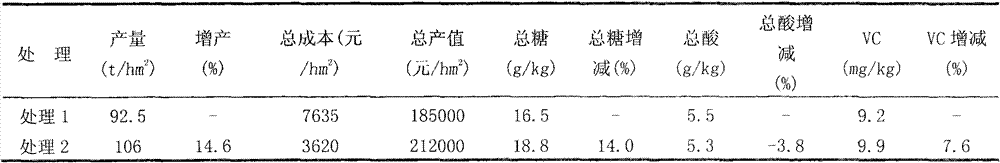

Method for preparing full nutritional high nitrogen type liquid flush fertilizer by monosodium glutamate waste liquid and product

InactiveCN103086754AImprove chelation abilityAbsorption synchronizationClimate change adaptationBioloigcal waste fertilisersLiquid wasteMonosodium glutamate

The invention discloses a method for preparing a full nutritional high nitrogen type liquid flush fertilizer by monosodium glutamate waste liquid and a product, and belongs to the technical field of production of liquid flush fertilizers. The preparation process comprises the following steps of: 1, performing quadruple effect concentration for monosodium glutamate waste liquid; 2, adding ammonia water in a certain proportion to the concentrated liquor, and adjusting pH value through neutralization reaction; 3, mixing the mixed liquid, urea, potassium sulphate, and ammonium polyphosphate saturated liquid in volume percentage of 50-60%, 15%, 15% and 10%; and 4, adding magnesium sulfate, zinc sulfate, ferrous sulfate and borax saturated liquid in volume percentage of 1-2% in the mixed liquid for chelation reaction. According to the invention, three nitrogen adding processes are performed, and the full nutritional high nitrogen type (25% of N) fertilizer is prepared through chelation reaction of amino acids in the monosodium glutamate waste liquid and ammonium polyphosphate and trace elements added. According to the invention, the deficiency that precipitates are produced by phosphate radicals and medium trace elements and the liquid flush fertilizer in low in nitrogen is overcome, so that the process is simple and the cost is low. Field trail results of greenhouse vegetable show that the yield-increasing effect is remarkable and the quality of vegetables is remarkably improved.

Owner:周涛 +2

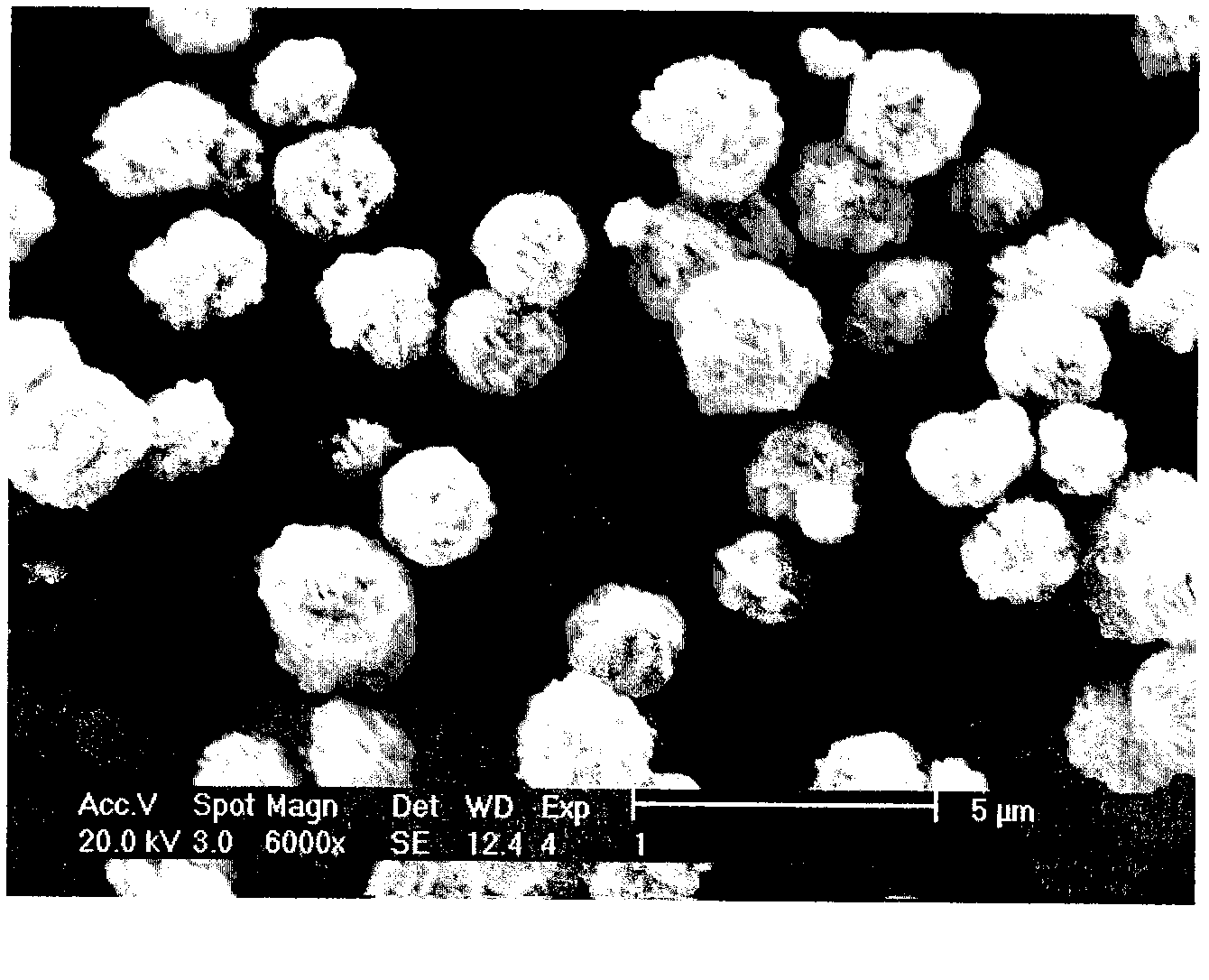

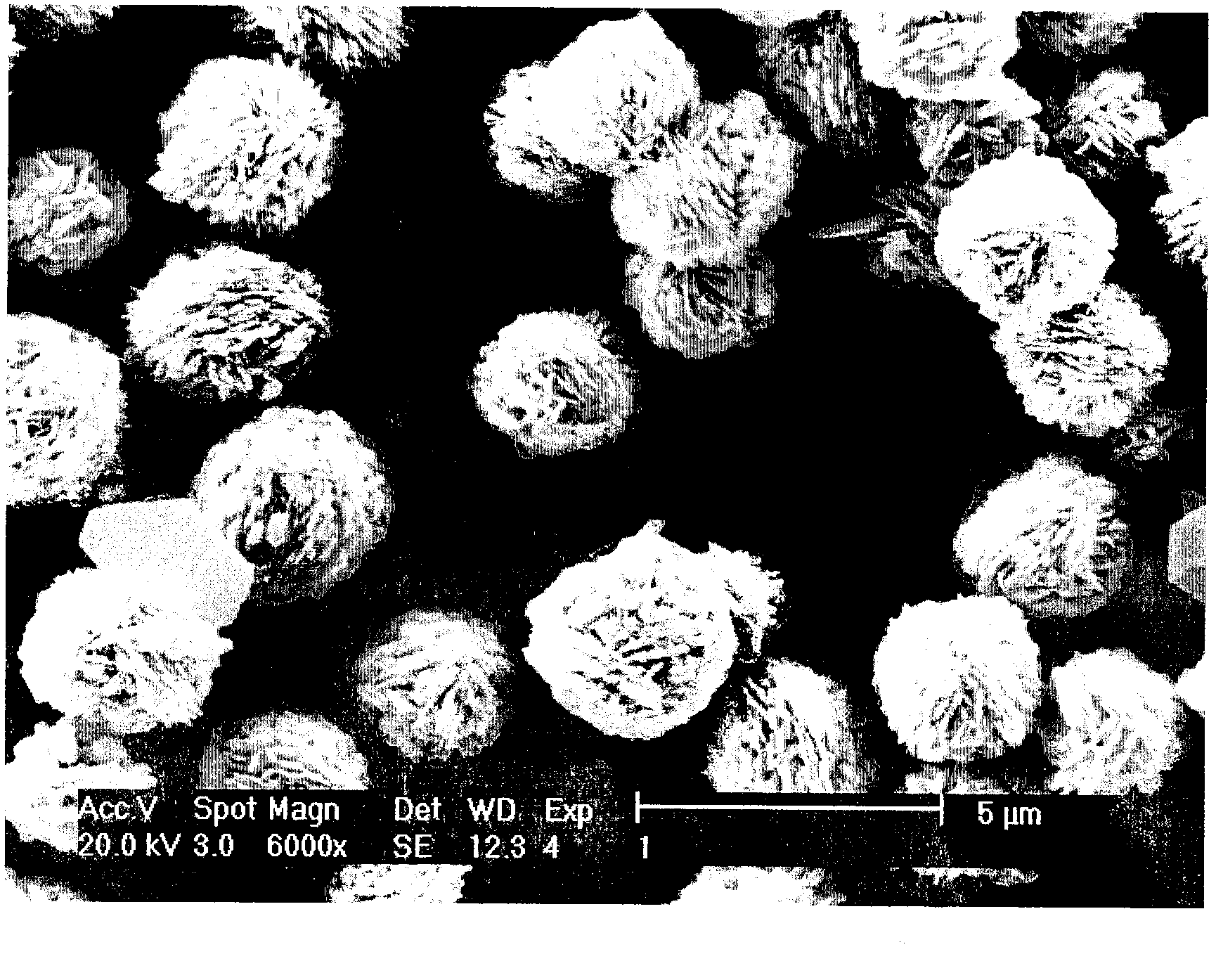

Flower-like spherical silver powder preparing method

InactiveCN103273082ANo pollution in the processSimple processSpherical shapedAcid anhydride formation

The invention discloses a flower-like spherical silver powder preparing method which includes steps that: (1) 1-50g / L silver nitrate solutions and 1-200g / L ferrous sulfate reductant solutions are prepared; (2) complexing agents are added into the silver nitrate solutions and the silver nitrate solutions with the complexing agents are evenly mixed, wherein the complexing agents are binary and n-nary (n>2) organic acids, organic acid anhydrides or organic acid salts, the ratio of carboxyl group concentration and silver ion concentration of the mixed silver nitrate solutions is 0.1:1-1:1, and the silver nitrate solutions and the ferrous sulfate reductant solutions are cooled to be at 0-20 DEG C; (3) reductants are added into the silver nitrate solutions and are continuously stirred until the color of the solutions does not change any more; and (4) deionized water is used for washing for several times after centrifugal separation or natural setting, absolute ethyl alcohol is used for washing for several times, and then the silver nitrate solutions are dried in vacuum on the condition of 0-80 DEG C to obtain flower-like spherical silver powder. The flower-like spherical silver powder obtained in the flower-like spherical silver powder preparing method has good sphericity degree and has a rough surface and narrow particle size distribution, and the number of pieces of the flower-like silver powder can be freely adjusted.

Owner:昆山西微美晶电子新材料科技有限公司

Multifunctional transpiration inhibitor

InactiveCN101798244AReduce harmEnsure normal breathingBiocidePlant growth regulatorsSodium acetateCellulose

The invention discloses a multifunctional transpiration inhibitor which comprises the following ingredients in percentage by weight: 35-55 percent of cellulose ether, 9-26 percent of biochemical fulvic acid powder, 1-9 percent of organic rare earth, 1-5 percent of sodium hexametaphosphate, 5-20 percent of chelating trace elements, 0-3.5 percent of polyacrylamide and 0-2 percent of Alpha-sodium acetate; wherein the organic rare earth is rare earth prepared from the chelation reaction by adopting a chelating agent; the chelating trace elements are generated by adding ionized water and the chelating agent into the combination of copper sulfate, zinc sulfate, ferrous sulfate and manganese sulfate for performing the chelation reaction; and the cellulose ether is series products of water-soluble cellulose ethers. The multifunctional transpiration inhibitor has the functions of inhibiting transpiration, resisting drought and wind, strengthening nutrition, and the like, can improve the survival ratio, the preservation ratio and the survival state of plants, further enhance the capacities of resisting stress, diseases, draught, cold and the like of the plants and achieves the aims of resisting draught and saving water, ensuring seedlings to survive as well as increasing both production and income.

Owner:北京中科环发生物技术研究院

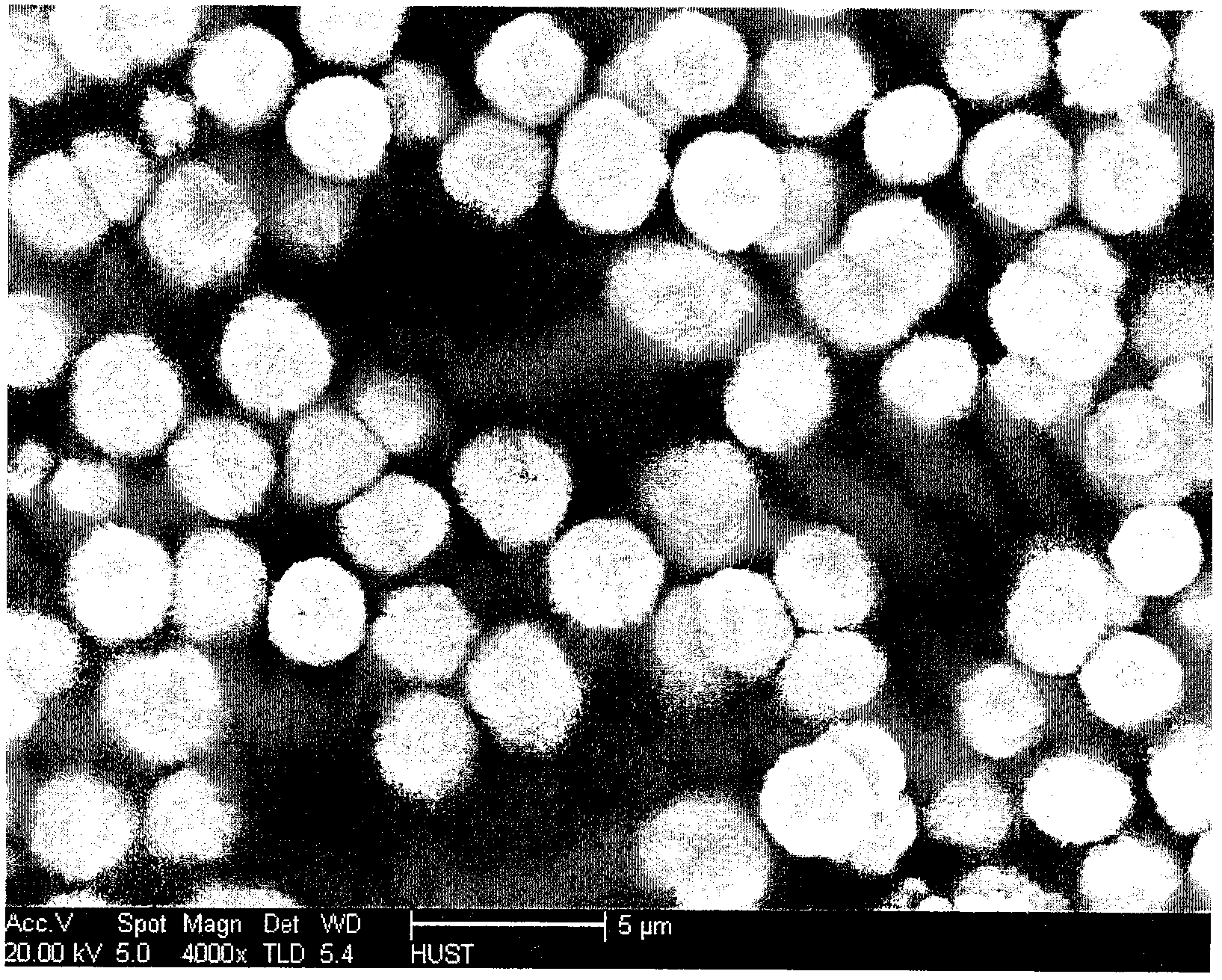

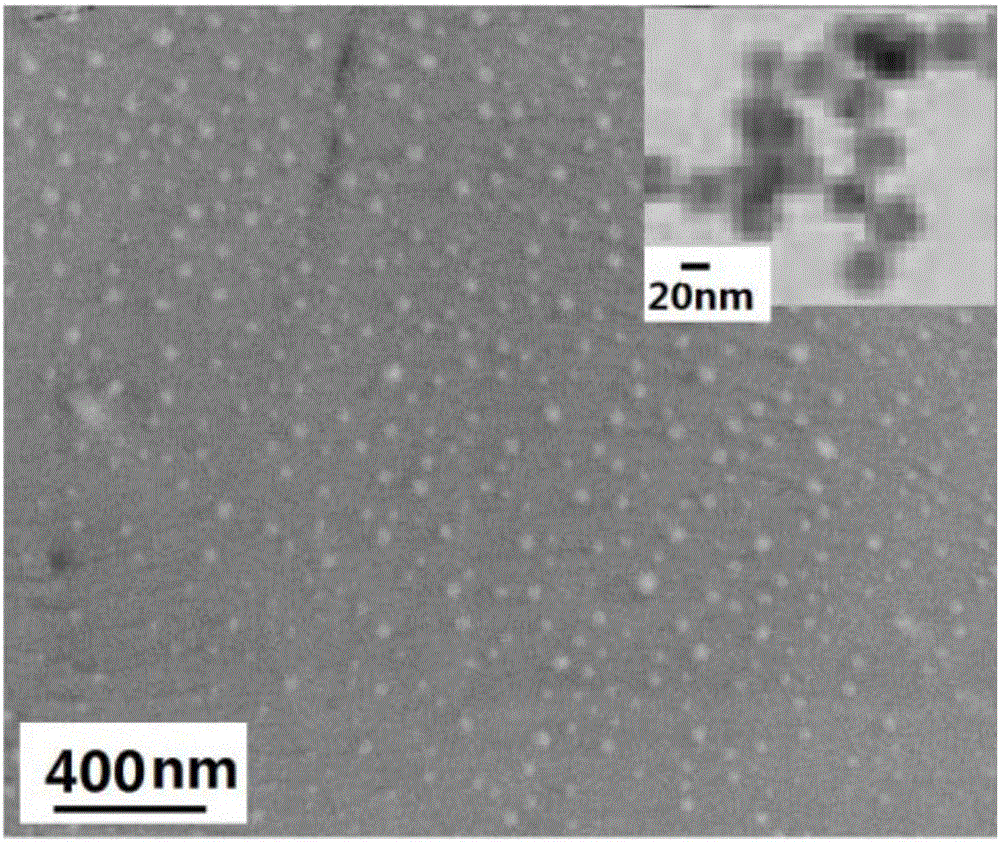

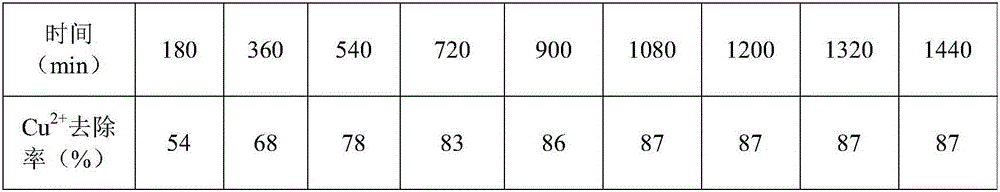

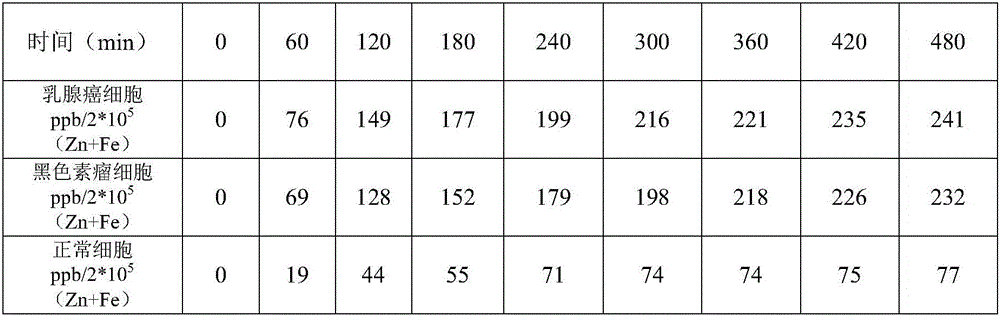

Prussian blue analog nanoparticles, and preparation method and application thereof

ActiveCN106727432AThe preparation process is uniform and stableMild responseHeavy metal active ingredientsPharmaceutical non-active ingredientsIron saltsCancer cell

The invention discloses Prussian blue analog nanoparticles. The nanoparticles are formed by using Prussian blue analog nanoparticles as the core and coating organic high-polymer surface protectants polyvinylpyrrolidone / chitosan and hyaluronic acid on the nanoparticle surface. The preparation method of the Prussian blue analog nanoparticles comprises the following steps: S1. preparing a mixed solution containing a zinc salt, ferrous sulfate, an iron salt and an organic high-polymer surface protectant; S2. stirring at room temperature for 30 minutes to 2 hours, putting the solution into a dialysis bag filled with distilled water, and dialyzing for two days; and S3. taking out the solid matter, and collecting the solid product by freeze-drying. The Prussian blue analog nanoparticles are used in cancer targeted therapy. The Zn-FePB NPH drug is very safe. The copper element in cancer cells can be replaced to achieve the goal of starving the cancer cells. PVP (or chitosan) doping is carried out on the basis of the high targeting action of the hyaluronic acid to better regulate the size of the nanoparticles.

Owner:SHANGHAI LINKCHEM TECH CO LTD

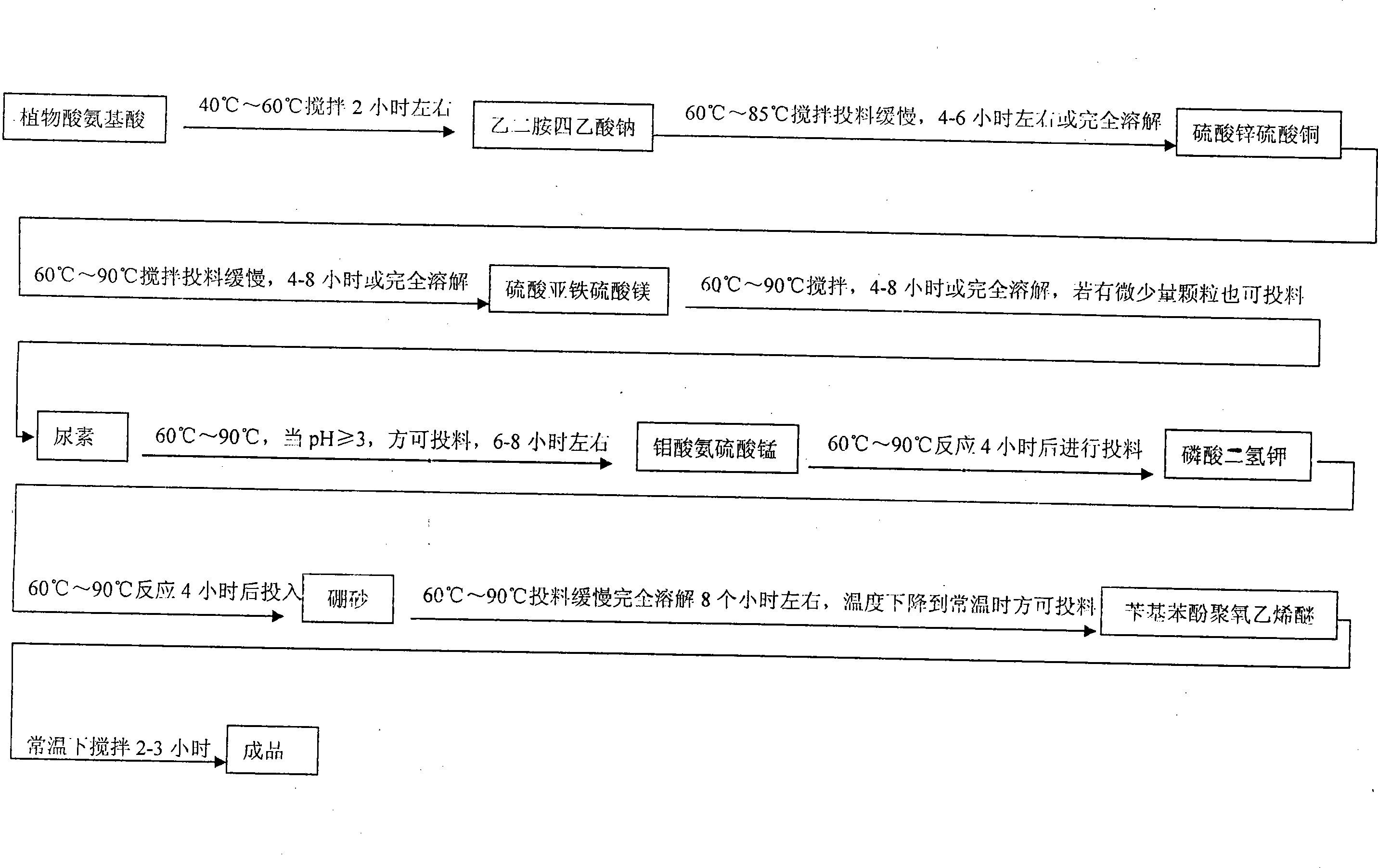

Organic acid inorganic salt complex agent for crop and preparation method thereof

InactiveCN101182270ASolve fertilizer and pesticide problemsGood harvest guaranteeBiocideMagnesium fertilisersPhosphateManganese

The invention relates to an organic acid and inorganic salt complex agent and a preparation method thereof, which effectively solves the problem of fertilizer used for the crop to ensure the high yield and harvest. The complex agent is made by compounding the following components of plant acid, complex amino acid, sodium ethylenediamine tetraacetate or citric acid, zinc sulfate, bluestone, ferrous sulfate, bitter salt, urea element, ammonium molybdate, manganese sulfate, potassium dihydrogen phosphate, borax and benzylphenol polyoxyethylene ether. The preparation method is that firstly the plant acid and the complex amino acid are mixed uniformly; then the sodium ethylenediamine tetraacetate is added to be dissolved completely; the zinc sulfate and the bluestone are added to be dissolved completely; the ferrous sulfate and the manganese sulfate are added to be dissolved, and the urea is added to be mixed uniformly; then the ammonium molybdate and the manganese sulfate are added to react; the potassium dihydrogen phosphate is added after the reaction to react; the borax is added after the reaction for completely dissolving, and then the benzylphenol polyoxyethylene ether is added to be mixed uniformly. The product can fertilize the farmland, as well as can prevent and cure the plant diseases and insect pests, has wide purposes and is a great creation of the agricultural fertilizer.

Owner:李海涛

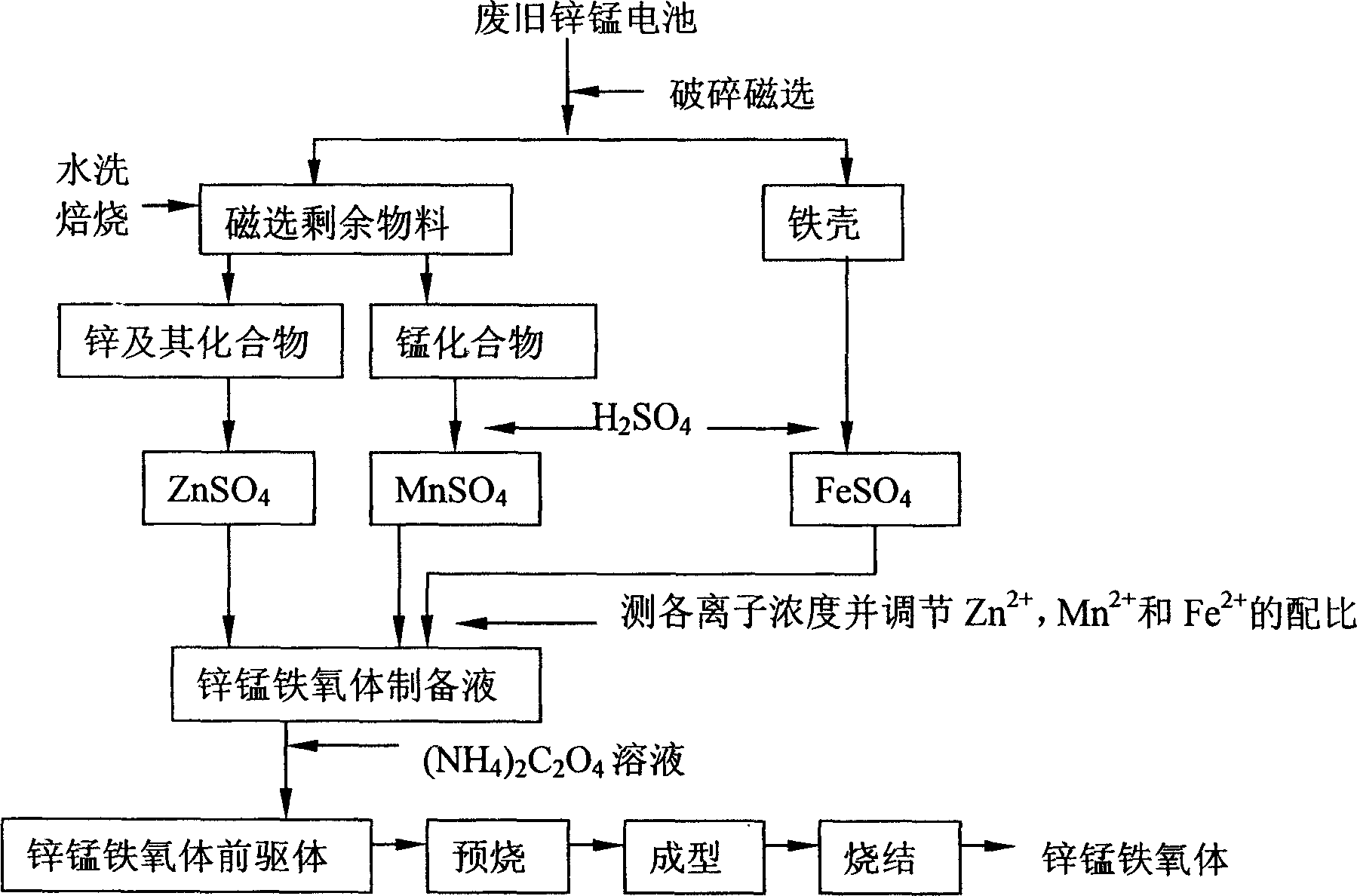

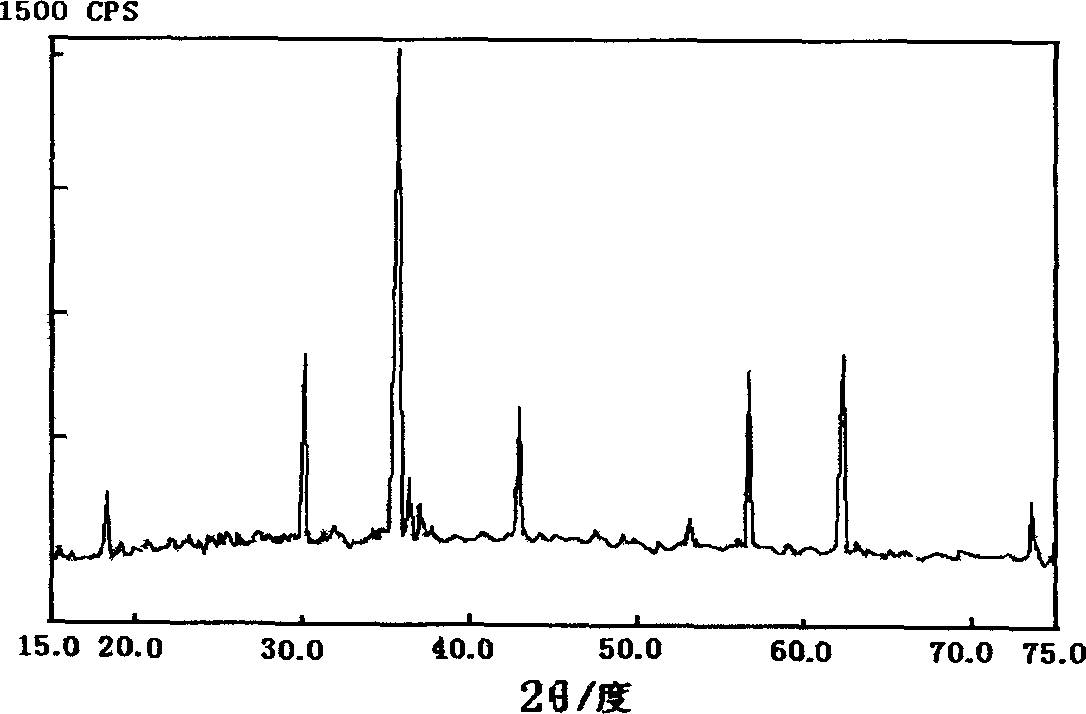

Method of prepn of ferrite from waste zinc-magnesium battery

InactiveCN1601661AAvoid pollutionRealize recyclingSolid waste disposalReclaiming serviceable partsManganesePhysical chemistry

The method includes following steps: (1) crashing zinc-manganese cells, solving coarsely separated iron-zinc-manganese so as to obtain solution of reaction predecessor: ferrous sulfate, zinc sulfate and manganese sulfate; (2) preparing predecessor of ferrite by reaction between mixed predecessors according to proportion and ammonium oxalate; (3) baking predecessor of ferrite in high temperature so as to obtain product of ferrite. The method carries out innoxiousness treatment and changes matter in cells to resources. Features are simple, economical and practical.

Owner:SOUTH CHINA NORMAL UNIVERSITY

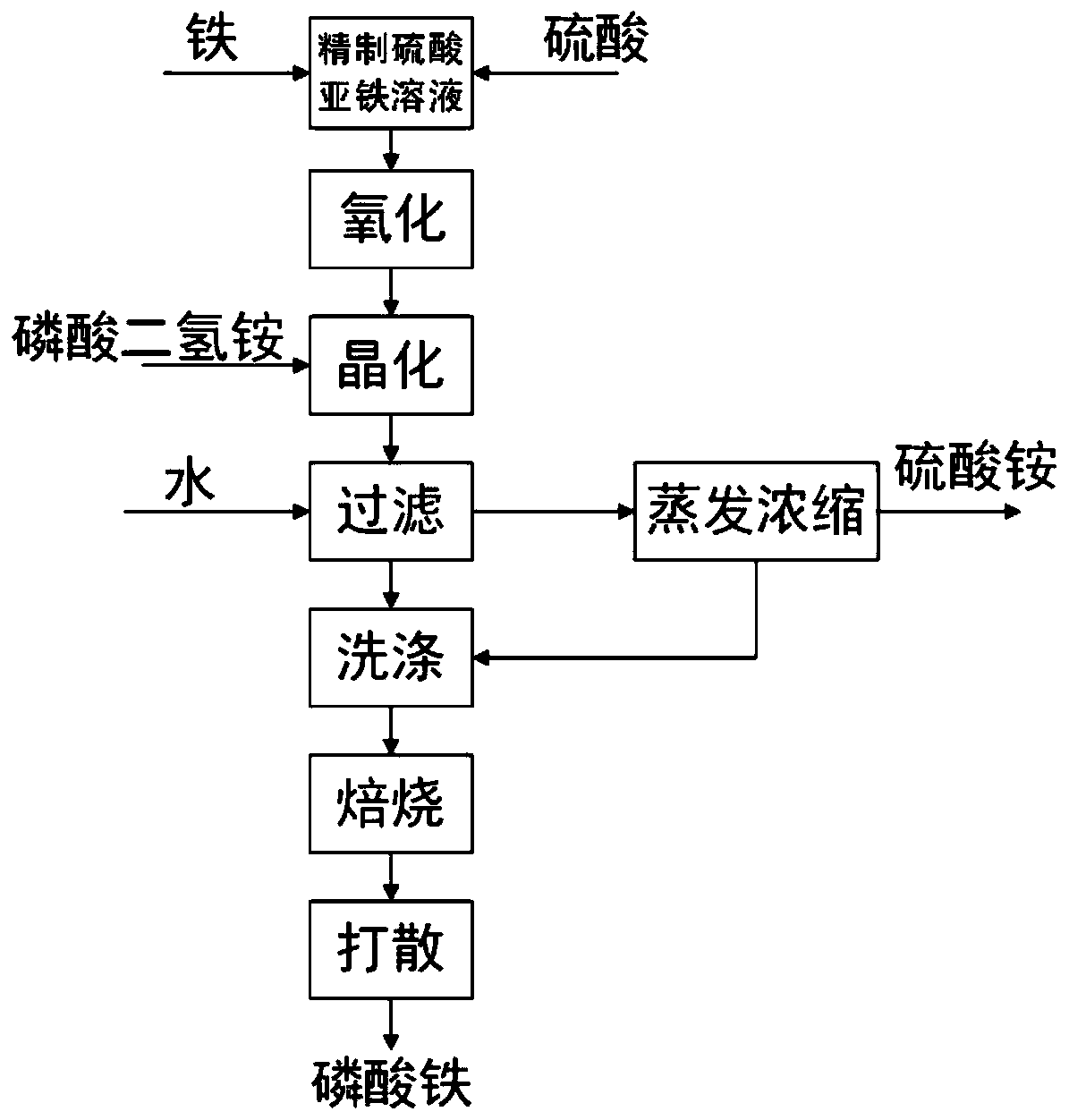

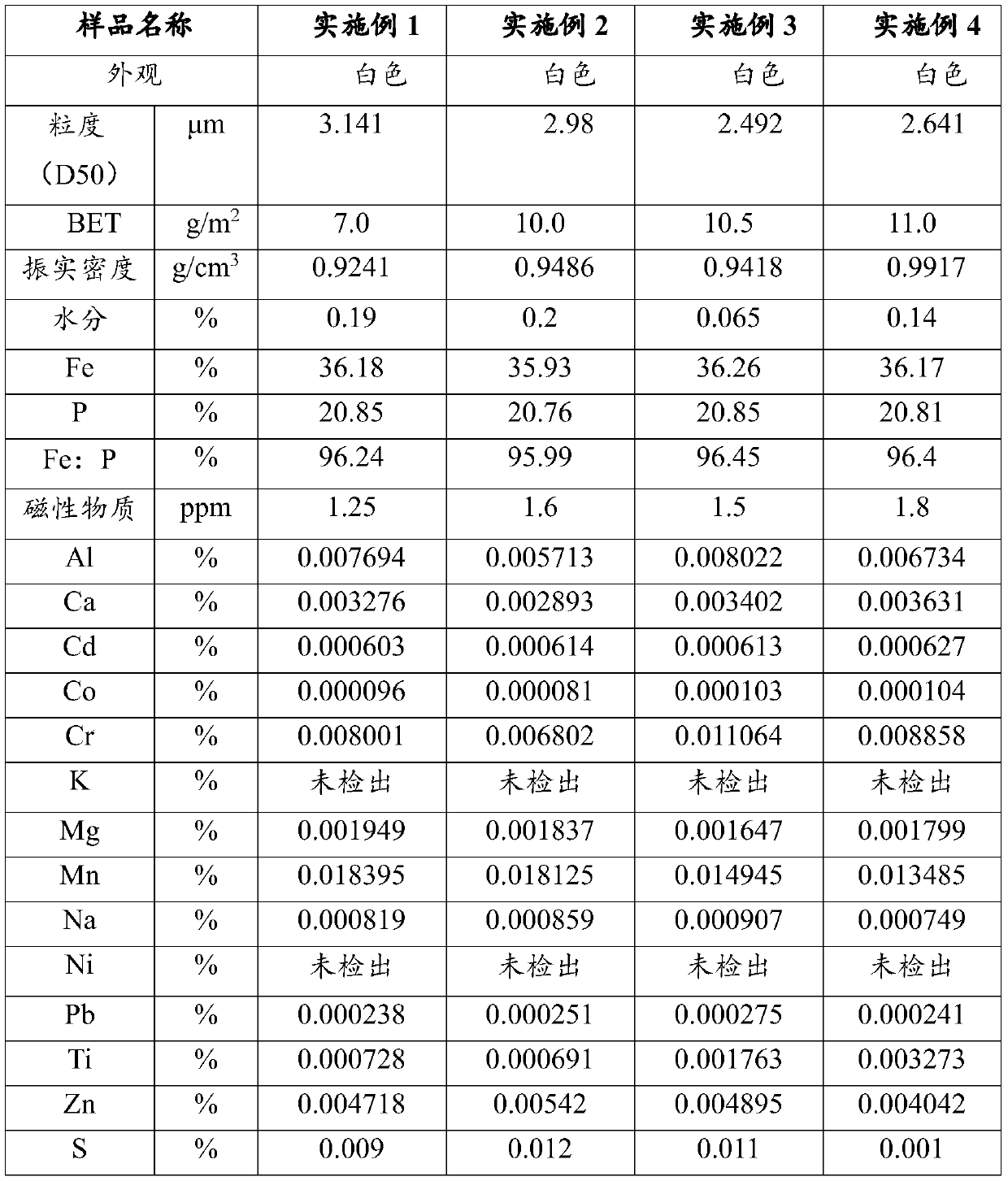

Preparation method of battery-grade anhydrous iron phosphate

ActiveCN110482514AEliminate microscopic component differencesImprove performancePhosphorus compoundsPhosphate ionPhosphoric acid

The invention belongs to the technical field of battery material preparation, and particularly discloses a preparation method of battery-grade anhydrous iron phosphate. The method includes preparing aferrous solution by adopting cold-rolled iron plate leftover materials and / or beneficiation reduced iron powder as an iron source, or preparing a ferrous solution by adopting by-product ferrous sulfate of sulfuric acid method titanium dioxide production; then removing impurities by using a flocculating agent; then oxidizing ferrous ions into ferric ions; mixing the ferric ions with a solution containing phosphate ions; adding a dispersing agent; carrying out crystallization reaction to obtain iron phosphate crystals; subjecting the iron phosphate crystals to drying and roasting to obtain thebattery-grade anhydrous iron phosphate. According to the preparation method, low-cost cold-rolled iron plate leftover materials, beneficiation reduced iron powder or byproduct ferrous sulfate in a sulfuric acid method titanium dioxide production process is used as an iron source for preparation; the flocculating agent is adopted for impurity removal, and then crystallization is performed to prepare the battery-grade anhydrous iron phosphate. The method has the advantages of low raw material cost, high product purity and high tap density, is of a spherical structure, and can be used as a precursor of lithium iron phosphate with high tap density.

Owner:安徽丰原锂电能源有限公司 +1

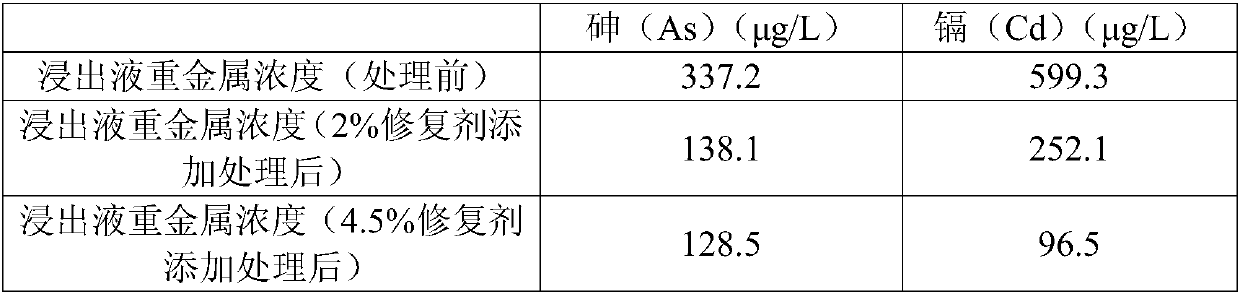

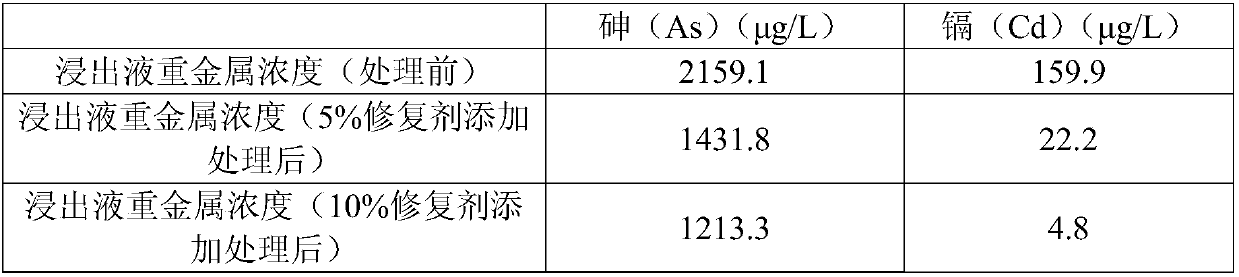

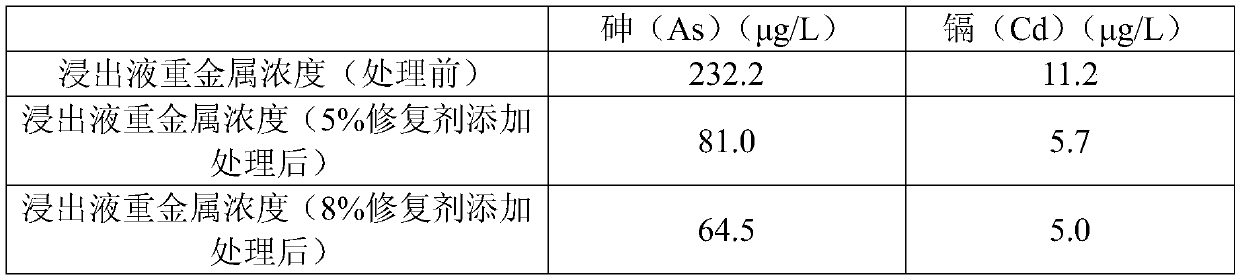

Cadmium-arsenic composite polluted soil remediation agent

PendingCN109575926AReduced ability to migrateReduce ecological and environmental risksOrganic fertilisersSoil conditioning compositionsEcological environmentIon exchange

The invention discloses a cadmium-arsenic composite polluted soil remediation agent, which comprises the following raw materials in parts by weight: 0-10 parts of hematite; 20-30 parts of ferrous sulfate; 10 parts of manganese dioxide; 15-20 parts of fly ash; 10-15 parts of quicklime; 10-15 parts of sepiolite; 10-15 parts of calcium dihydrogen phosphate; and 0-10 parts of wollastonite. The remediation agent enables cadmium and arsenic heavy metals to form stable chemical forms through oxidation reduction, adsorption, ion exchange, precipitation or coprecipitation and the like to reduce the migration and diffusion capability of the cadmium and arsenic heavy metals in the environment, so that the ecological environment risk of the cadmium and arsenic heavy metals is reduced; and the remediation agent has the advantages of high remediation efficiency for cadmium-arsenic composite polluted soil, short remediation period, low remediation cost, easily available raw material components and simple application method, so that the agent is one of the few remediation agents in the industry that simultaneously act on yin and yang heavy metal ions.

Owner:HUAZHONG AGRI UNIV

Large-scale sympodial bamboo callus induction and plant regeneration high efficiency culture medium and culture method thereof

InactiveCN101849504AAccelerated differentiationAccelerated rootingPlant tissue cultureHorticulture methodsPhosphateThiamine hcl

The invention relates to a culture medium suitable for a large-scale sympodial bamboo including sinocalamus affinis and Mianzhu and a culture method, in particular to a large-scale sympodial bamboo callus induction and plant regeneration high efficiency culture medium and a culture method thereof. The culture medium comprises an MS (Murashige and Skoog) culture medium and a callus induction and plant regeneration high efficiency culture medium and is characterized in that the MS culture medium is prepared from the following raw materials: (a) macroelements: potassium nitrate, ammonium nitrate, potassium dihydrogen phosphate, magnesium sulfate and calcium chloride; (b) microelements: potassium iodide, boric acid, manganese sulfate, zinc sulfate, sodium molybdate, copper sulfate and cobalt chloride; (c) organic components: inosite, glycine, aneurin hydrochloride, puridoxinehydrochloride and niacin; and (d), ferric salts: disodiumedetate and ferrous sulfate.

Owner:胡尚连

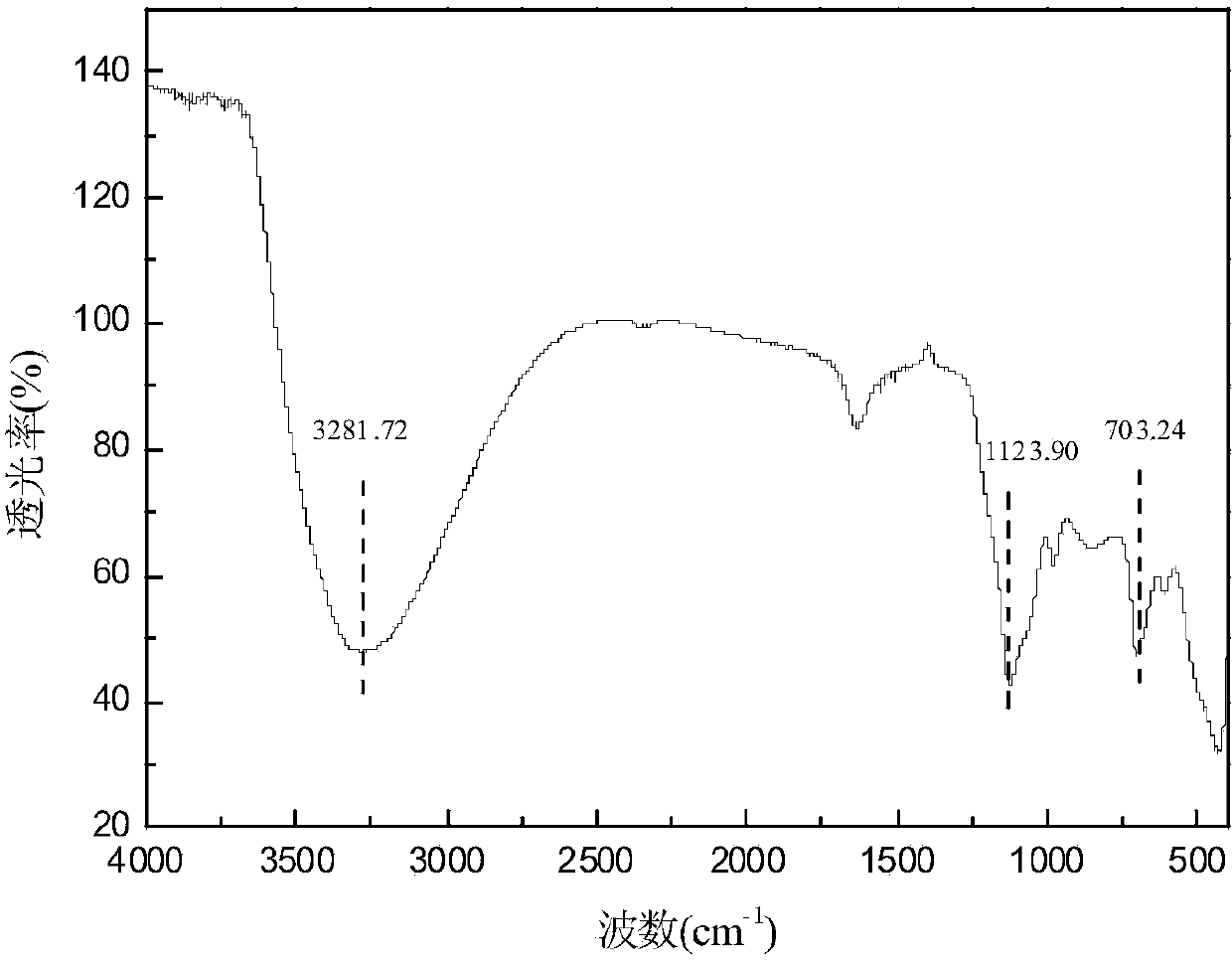

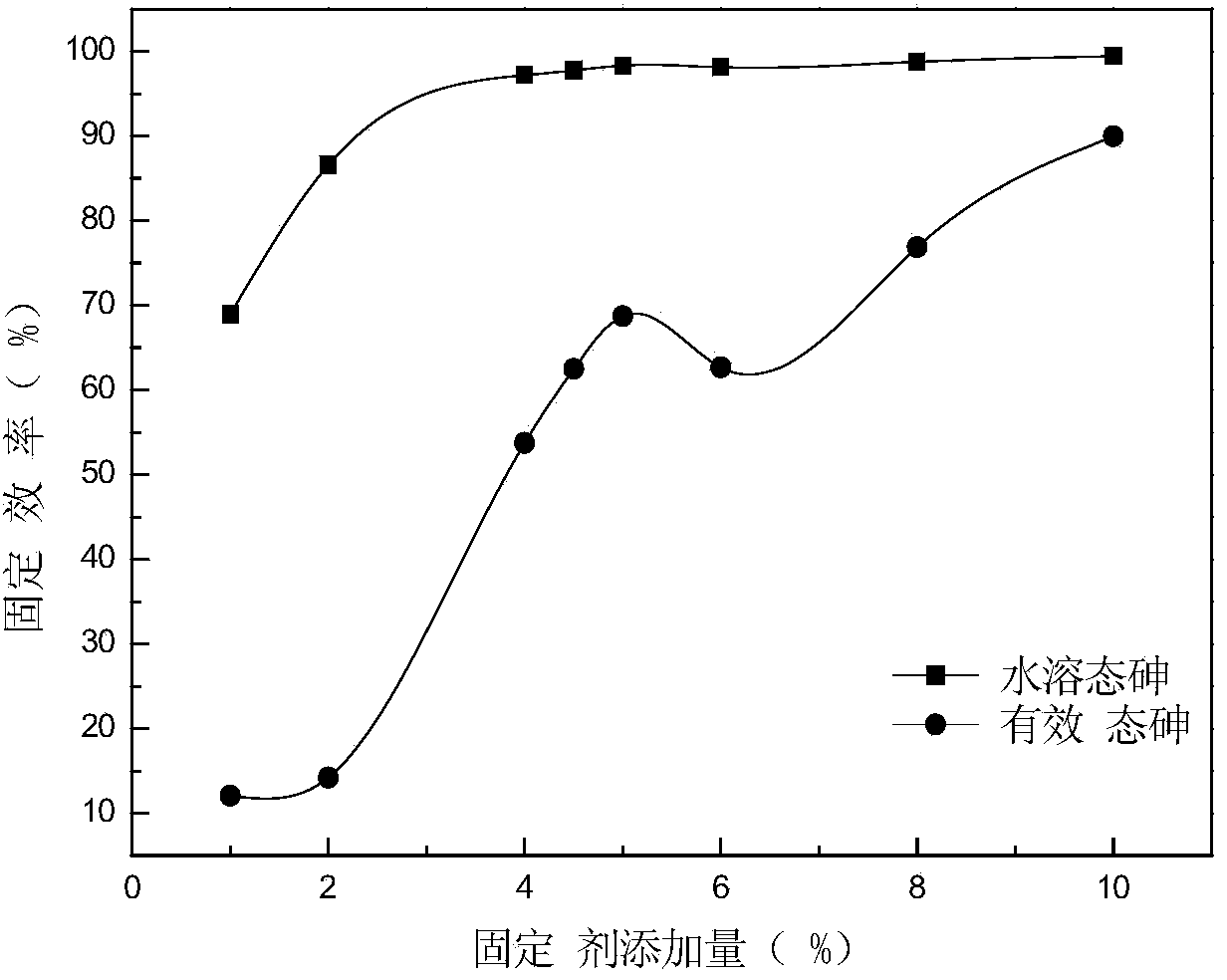

Fixing agent for repairing arsenic-polluted soil, and preparation and application method thereof

InactiveCN103740372AEasy to operateWide variety of sourcesAgriculture tools and machinesContaminated soil reclamationGrowth plantWater soluble

The invention discloses a fixing agent for repairing arsenic-polluted soil, and preparation and an application method thereof. The preparation of a chemical fixing agent comprises the following steps: 1) preparing a solution by using ferrous sulfate as a raw material, slowly adding an oxidant to the solution while stirring, collecting sediments after reacting for a period of time; 2) adding a sodium hydroxide solution to the collected sediments; filtering after reacting for 6-24 hours; and baking residues at 40-70 DEG C, grinding and sieving by a 100-mesh sieve, so as to obtain the chemical fixing agent. After the chemical fixing agent is added to the arsenic-polluted soil, the fixed rates of water-soluble arsenic and effective-state arsenic respectively reach 99.5% and 72.81%; the pH value of the soil does not need to be adjusted when the chemical fixing agent is in use, the physicochemical property of the soil is not destroyed, and the repaired soil is still applicable to plant growth.

Owner:CENT SOUTH UNIV

Repairing agent and repairing method of saline alkali land for planting cotton

InactiveCN106242883APromote growthImprove the growing environmentCalcareous fertilisersOrganic fertilisersMicrobial agentPotassium

The present invention discloses a repairing agent of a saline alkali land for planting cotton. The components in the formula of the repairing agent comprise, by weight, 28-44 parts of desulfuration gypsum, 20-35 parts of a microbial agent, 5-11 parts of polyacrylate potassium, 25-45 parts of silica, 16-32 parts of sodium-based bentonite, 3-7 parts of sulfur, 8-19 parts of soluble humic acid, 4-12 parts of ferrous ammonium sulfate, and 8-17 parts of amino acid powder. According to the present invention, with the added soluble humic acid, the added ferrous ammonium sulfate and the added amino acid powder, the soil can be further improved, the growth environment of the cotton can be improved, the salt rejection rate of the soil can be increased, and the growth of the cotton can be promoted; and the rich raw materials are used to replace the single raw material in the traditional repairing agent, such that the repairing time of the saline alkali land can be substantially shortened, and the repairing agent and the repairing method can be widely promoted and used.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Dedicated chemical fertilizer for grape and preparation method thereof

InactiveCN107285861AMeet nutrient needsReduce pollutionBio-organic fraction processingMagnesium fertilisersInsect pestPlant disease

The invention discloses dedicated chemical fertilizer for grape. The dedicated chemical fertilizer is prepared from the following components in parts by weight: 25 to 30 parts of nitrogen fertilizer, 10 to 15 parts of phosphate fertilizer, 20 to 25 parts of potash fertilizer, 8 to 10 parts of magnesium sulfate, 20 to 30 parts of straw, 8 to 10 parts of sugar beet pulp, 5 to 10 parts of boron-magnesia fertilizer, 3 to 5 parts of zinc sulfate, 1 to 3 parts of chelate zinc, 3 to 5 parts of copper amino acid chelate, 3 to 5 parts of ammonium ferrous sulfate, 3 to 5 parts of humic acid, 3 to 5 parts of manganous sulfate, 3 to 5 parts of ammonium molybdate, 3 to 5 parts of amino acid, 1 to 3 parts of cnidium lactone and the like. The invention belongs to the technical field of agricultural fertilizer, and particularly provides the dedicated chemical fertilizer for the grape, which is comprehensive and balanced in nutrient, high in pertinence, and capable of effectively improving the structure of soil, increasing the yield of the grape, preventing and controlling plant diseases and insect pests and improving freezing resistance of grape plants, and a preparation method of the dedicated chemical fertilizer.

Owner:徐州沃尔地农业科技有限公司

Sulfuric acid and fine iron powder co-production method using iron vitriol

InactiveCN102344123AEffective temperature regulationOvercome the phenomenon of cakingSulfur compoundsResource utilizationSlurry

A sulfuric acid and fine iron powder co-production method using iron vitriol. A raw material of iron vitriol which is a by-product from a sulfuric acid process for producing a titanium pigment is heated by steam and dehydrated into monohydrate ferrous sulfate slurry; the slurry is injected a pyrites fluidizing roaster; monohydrate ferrous sulfate is decomposed into sulfur dioxide gas and ferric oxide or ferriferrous oxide under high temperature; the sulfur dioxide gas is used in sulfuric acid production, and the ferric oxide or ferriferrous oxide is high-quality fine iron powder. The technology of the invention is simple and convenient for operation; a temperature of the roaster and an addition of the monohydrate ferrous sulfate can be effectively adjusted to overcome an abuse of caking pyrite and solve a utilization problem of iron vitriol, a by-product from a sulfuric acid process for producing a titanium pigment, so as to efficiently increase resource utilization efficiency and reduce environmental pollution; therefore, the method is suitable for industrialized production.

Owner:HUNAN HENGGUANG TECH

Treatment method of arsenic-containing wastewater

InactiveCN107162273AShort processEasy to operateWater contaminantsTreatment involving filtrationPrecipitationFERRIC IRON

The invention discloses a treatment method of arsenic-containing wastewater. The method comprises the following steps: adding ferrous sulfate heptahydrate to the arsenic-containing wastewater at a pH value of 5-6 according to a mass ratio of iron to arsenic of 14-25, adding hydrogen peroxide as an assistant according to a mass ratio of hydrogen peroxide to arsenic of 10-30 in order to oxidize the arsenic in the wastewater into to pentavalent arsenic and oxidize ferrous iron in ferrous sulfate into ferric iron, and reacting the ferric iron with the arsenic to produce a high-stability ferric arsenate precipitate; and adding an alkali to adjust the pH value to 7-9, reacting the remaining ferric iron with calcium hydroxide to produce iron hydroxide, allowing the iron hydroxide and the iron arsenate to undergo adsorption co-precipitation in order to achieve arsenic solidification, carrying out solid-liquid separation, and discharging standard meeting wastewater. Compared with traditional pretreatment and deep arsenic removal two-stage treatment technologies, the method which realizes standard meeting discharge through one-shot arsenic-containing wastewater treatment has the advantages of short flow, proceeding under normal conditions, cheap and easily available reagents, low cost, small investment, and convenience in promotion and application.

Owner:CHENZHOU YANGTAO CHEM

Method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red

InactiveCN102674480AReduce consumptionNo emissionsFerric oxidesIron sulfatesSludgeAmmonium Hydrogen Carbonate

The invention discloses a method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red and relates to a technological method for chemical extraction and separation. The method is an organic solvent effect crystallization process for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red, consists of four technical processes and realizes the chemical goal of extracting and separating iron and preparing ferrous sulfate and iron oxide red. The four technical processes are respectively as follows: 1) a diluted sulfuric acid leaching process of industrial waste iron sludge; 2) an iron crystallization and separation process under the effect of monobasic alcohol serving as organic solvent; 3) an iron oxide red preparation process through reaction between ferrous sulfate solution and ammonium hydrogen carbonate and oxidizing roasting of sediment; and 4) an ammonium sulfate preparation process through evaporative crystallization of sedimentation solution. The method is suitable for extracting and separating iron element from all kinds of iron-containing minerals and industrial waste residues, valuable components are comprehensively utilized and the environmental pollution and the resource wastage are reduced.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

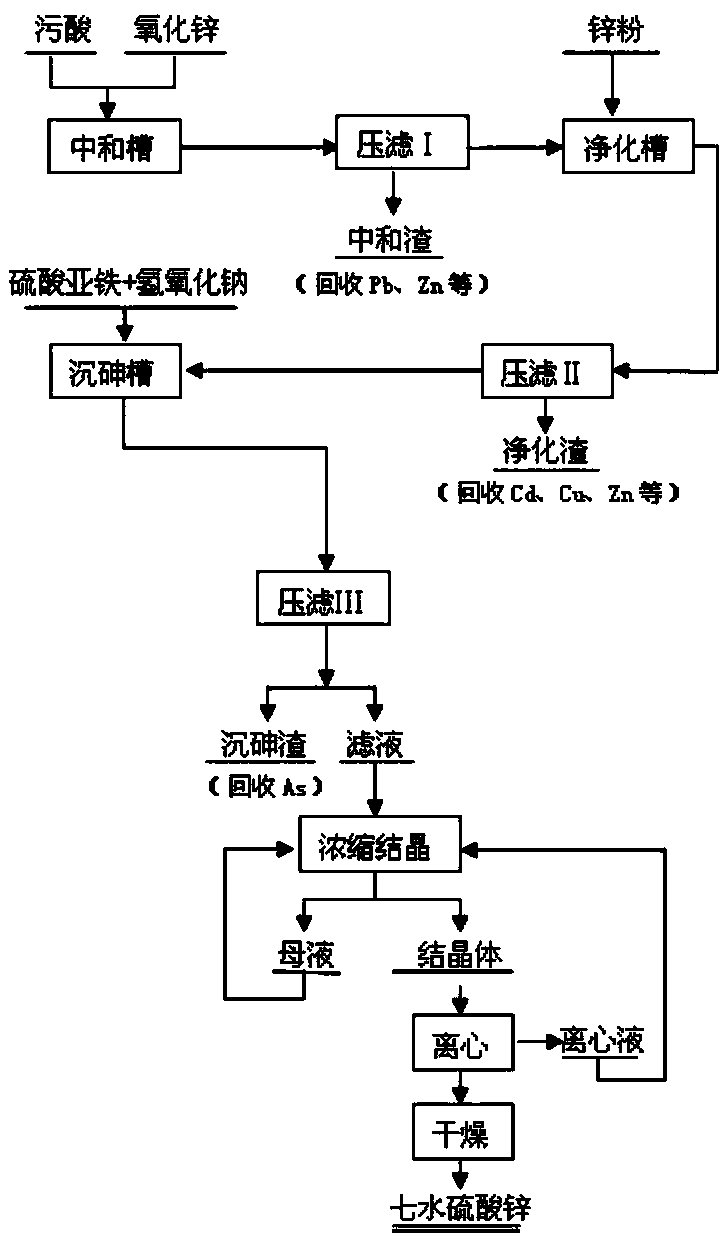

Green utilization method of waste acid

ActiveCN103588240ALow costImprove adsorption capacityZinc sulatesChemical industryZINC SULFATE HEPTAHYDRATE

The invention discloses a green utilization method of a waste acid, and belongs to the fields of the metallurgy and the chemical industry. The method comprises the following steps: adding zinc oxide powder to neutralize sulfuric acid in the waste acid and generate zinc sulfate; adding zinc powder to replace heavy metal ions comprising lead ions, cadmium ions, copper ions and the like in the waste acid to enrich most heavy metals in the waste acid; adding ferrous sulfate to precipitate arsenic, and utilizing the strong adsorption and flocculation capability characteristics of hydroxide of iron to further remove a small amount of harmful heavy metal ions comprising lead ions, cadmium ions, copper ions and the like residual in the waste acid; and carrying out concentrating crystallization, centrifugation and drying of an arsenic-precipitated filtrate to obtain zinc sulfate heptahydrate. The method has the advantages of short process flow, reduction of the waste acid treatment cost of traditional methods, economic benefit and good application prospect.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Yeast iron-rich premix and preparation method thereof

InactiveCN102726609AHigh content of live bacteriaAchieve recyclingAnimal feeding stuffNitrogen sourceMicroecology

The invention provides a yeast iron-rich premix and a preparation method thereof. The raw materials of the premix comprise saccharomyces cerevisiae, ferrous sulfate and fermentation auxiliary materials. The fermentation auxiliary materials comprise malt wort, a carbon source, and a nitrogen source. The invention provides a preparation method of the premix. The method comprises the steps that: (1)the fermentation auxiliary materials are weighed according to a certain proportion, and are mixed, such that a mixture is obtained; (2) saccharomyces cerevisiae and 1 / 2 of the total amount of ferroussulfate are added to the mixture; an obtained mixture is cultivated for 18-24h under a temperature of 35-37 DEG C; the rest of the ferrous sulfate is added to the mixture, and the mixture is cultivated for 24-48h under a constant temperature of 36-37 DEG C; when it is detected that an organic iron content in the product reaches 30-35mg / g, cultivation is stopped, such that the yeast iron-rich premix is obtained. The strain contained in the premix provided by the invention is strictly selected and bred according to the law of microecology. The quality of the strain is excellent, and viable cellcontent is high. The iron-rich yeast premix is prepared by using waste saccharomyces cerevisiae, such that resource recycling is realized.

Owner:TIANJIN DAYS NONGDA BIOTECH DEV LIMITED

Iron mineral inhibitor and production method thereof

ActiveCN106824550AImprove acceleration performanceHigh selectivityFlotationSodium acetateSodium chloroacetate

The invention discloses a production method of an iron mineral inhibitor. The production method comprises the following steps: step I, enabling a mixture of following components in parts by weight to react for 1 to 4 hours at 60 to 90 DEC to obtain an additive (1): 100 parts of corn starch, cassava starch or wheat starch, 0.5 to 4.0 parts of sodium ethoxide or sodium hydroxide and 5 to 15 parts of sodium chloroacetate; step II, enabling a mixture of following components in parts by weight to react for 3 to 6 hours at 50 to 80 DEG C to obtain an additive (2): 100 parts of the additive (1) obtained in the step I, 5 to 15 parts of ethylene oxide, and 0.2 to 1.0 part of sodium carbonate or sodium acetate; and step III, enabling a mixture of the following components in parts by weight to react for 1 to 3 hours at 30 to 60 DEG C to obtain an inhibitor finished product: 100 parts of the additive (2) obtained in the step II, 1 to 12 parts of sodium periodate or hydrogen peroxide, and 0.2 to 1.0 part of ferrous sulfate or cupric sulfate.

Owner:天津天宝翔科技有限公司

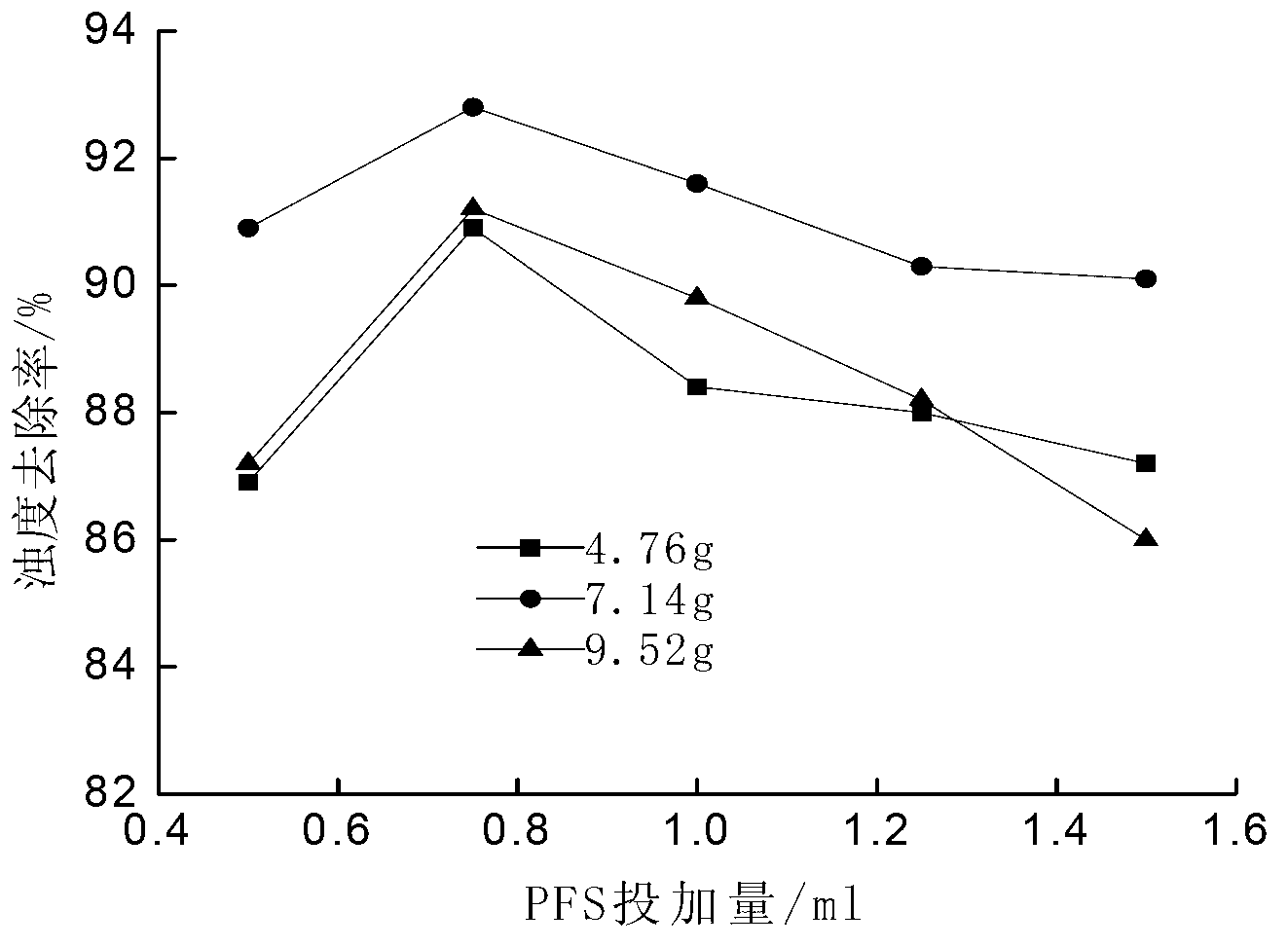

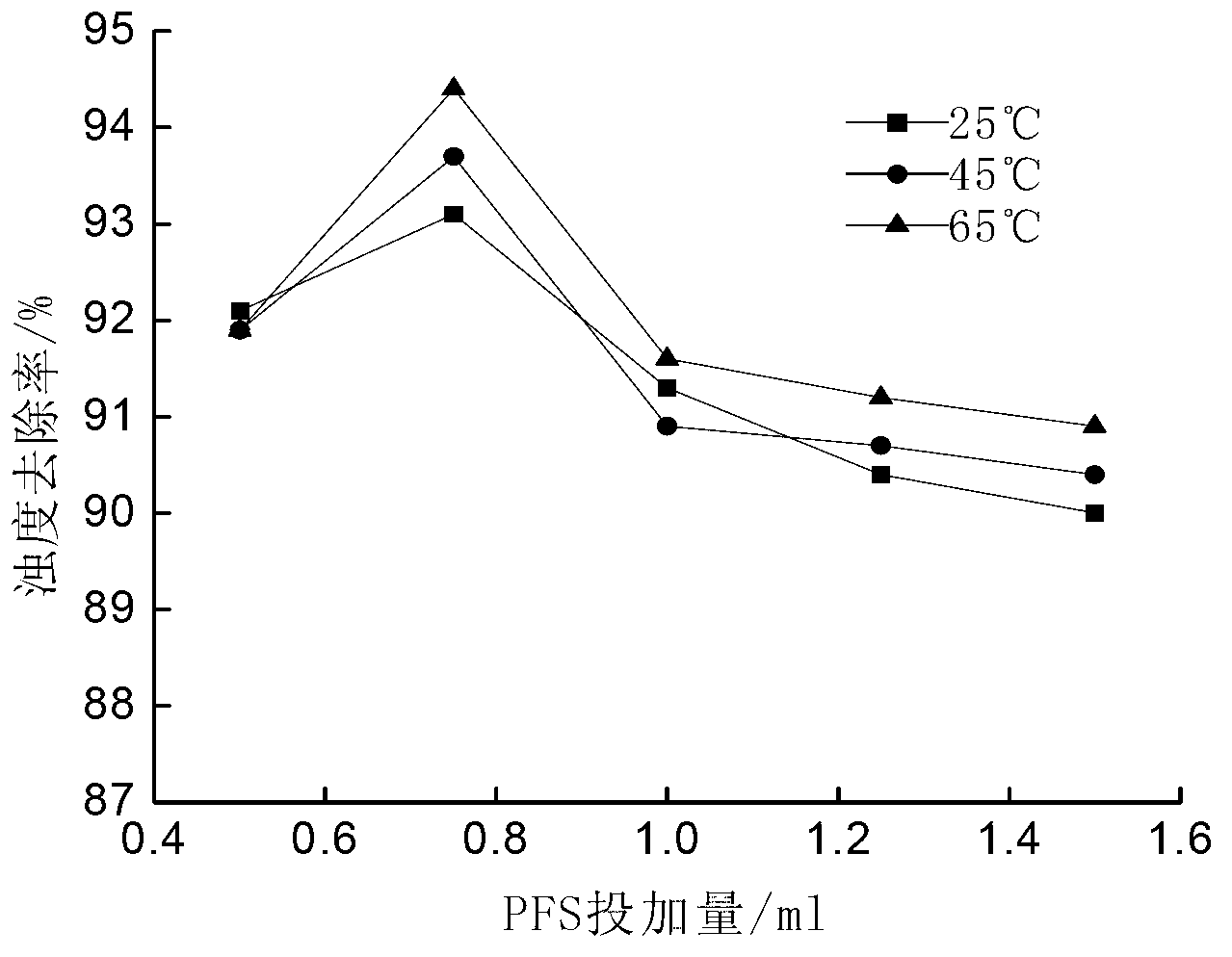

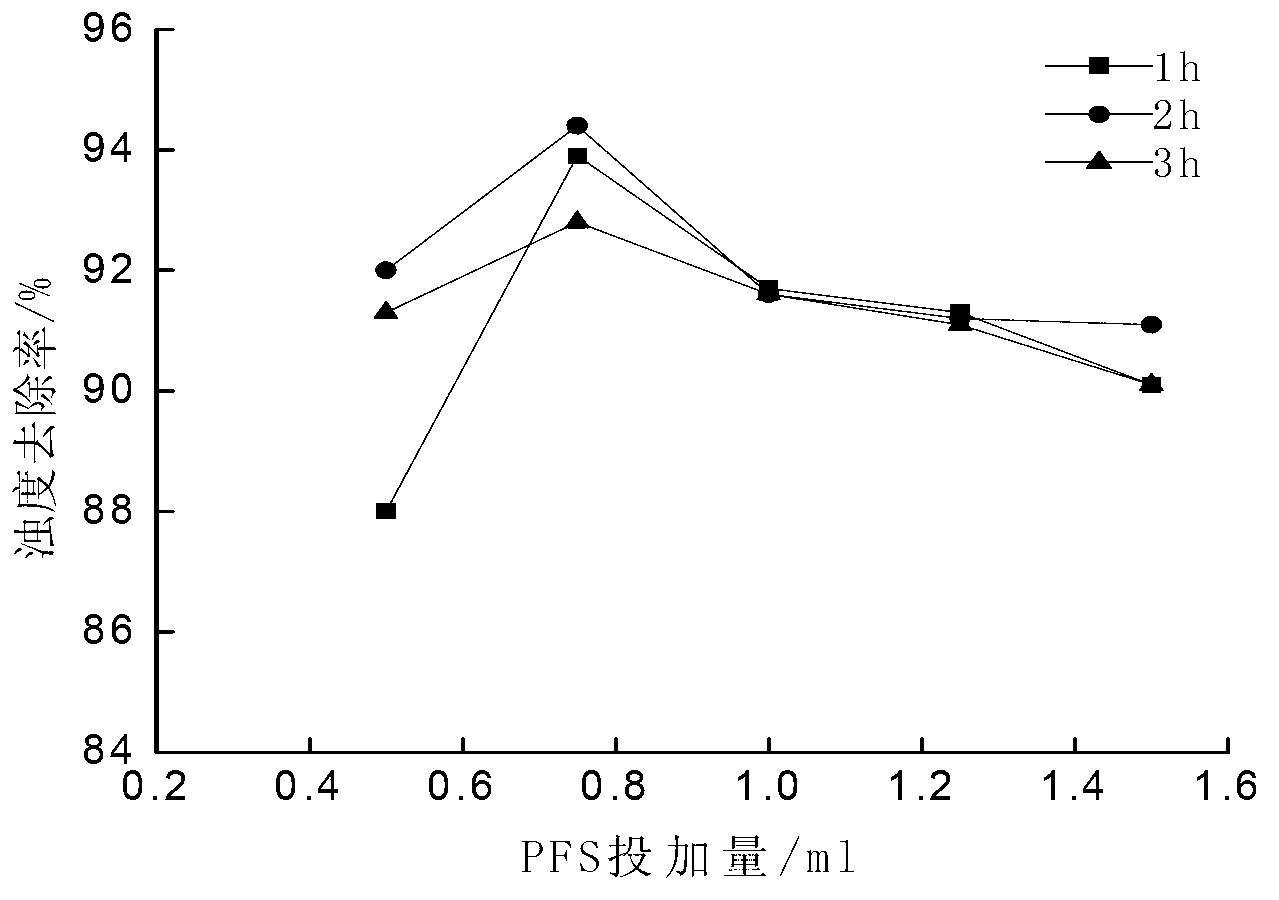

Preparation method of polyferric sulfate (PFS)

InactiveCN103241779AImprove the coagulation effectHigh turbidity removal rateIron sulfatesWater/sewage treatment by flocculation/precipitationWater bathsPersulfate

The invention relates to a preparation method of polyferric sulfate (PFS). The method comprises the following steps of dissolving a certain amount of bivalent ferric salt into water; adjusting the pH value through sulfuric acid, and heating and stirring in a water bath; adding a certain amount of persulfate serving as an oxidant to oxidize Fe<2+> in solution; and performing hydrolytic polymerization to obtain PFS. A novel method is provided for the preparation of PFS. The method disclosed by the invention has a simple process; a prepared PFS coagulant has a good coagulation effect and high turbidity removal rate of up to 94.6 percent; moreover, various indexes of the prepared PFS coagulant are consistent with the requirement of PFS serving as a GB14591-2006 water treatment agent; furthermore, the using amount of ferrous sulfate required to be added in the method is small, the adding speed of sodium persulfate serving as an oxidant is easy to control, and ferrous iron is fully oxidized; and moreover, the method has the advantages of simple operating process, no corrosion, wide pH application range, low cost, high performance and a very good market prospect.

Owner:XIAN UNIV OF SCI & TECH

Technology for preparing iron hydroxide with high specific surface area and cooperatively producing ammonium sulfate

ActiveCN106185988ALarge specific surface areaImprove adsorption capacityIron oxides/hydroxidesWaste water treatment from plant processingDistillationDiammonium carbonate

The invention provides a technology for preparing iron hydroxide with a high specific surface area and cooperatively producing ammonium sulfate. The technology includes mixing and kneading solid ferrous sulfate, solid ammonium carbonate and / or solid ammonium bicarbonate which are used as raw materials, adding water into the raw materials in mixing and kneading procedures to form slurry and controlling a pH (potential of hydrogen) value of the slurry so that the pH value of the slurry is 6.5-7 in the mixing and kneading procedures and is 7-8 when the raw materials are completely mixed and kneaded; separating solid from liquid in the slurry, respectively collecting solid phases and liquid phases and drying the liquid phases by means of distillation to obtain the ammonium sulfate; preparing serous fluid from the solid phases by the aid of water, adding hydrogen peroxide into the serous fluid to carry out oxidation reaction to obtain products and filtering the products after the reaction is completely carried out to obtain filter cake which is the iron hydroxide. The technology has the advantages that green rust which is an intermediate product is oxidized by the aid of the hydrogen peroxide, and accordingly a final product is assuredly the amorphous iron hydroxide; the iron hydroxide prepared by the aid of the technology has the large specific surface area, is high in oxidation capacity and accordingly can be widely applied to the field of gas purification and sewage treatment.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for treating pyridine wastewater

ActiveCN105923828AMeet emission requirementsWater/sewage treatment by irradiationWater treatment compoundsCobalt saltNational standard

The invention discloses a method for treating pyridine wastewater. The method comprises the following steps: step 1, adjusting the pH of the wastewater to 5-10, adding heavy metallic salt to react, forming an insoluble complex and filtering to obtain treatment liquid; step 2, regulating the pH of the treatment liquid to be acidic and performing Fenton oxidation. The heavy metallic salt is at least one of soluble iron salt, soluble copper salt, soluble cobalt salt and soluble manganese salt. When the mass of the wastewater is taken as a reference, the adding quantity of the heavy metallic salt is 0.5-10 percent. In the step 2, when the mass of the treatment liquid is taken as a reference, 0-2 percent of ferrous sulfate and 0.5-10 percent of hydrogen peroxide are added into the treatment liquid to perform the Fenton oxidation, and the mass percentage of the hydrogen peroxide is 30 percent. According to the method for treating the pyridine wastewater, disclosed by the invention, the removal rate of pyridine substances reaches 95 percent or higher, and the final effluent water meets national standard emission requirements.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

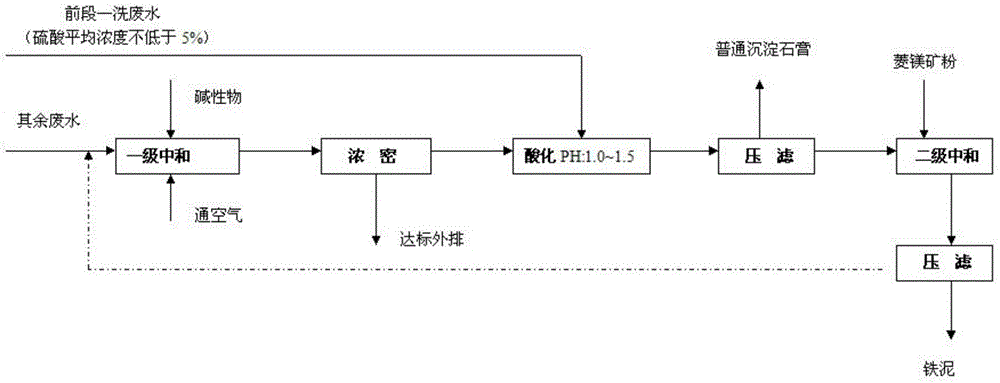

Method for treating titanium dioxide wastewater through sulfuric acid process

ActiveCN104086027AThere will be no problem of polluting the environmentMultistage water/sewage treatmentSludgeSesquioxide

The invention relates to a method for treating titanium dioxide wastewater through a sulfuric acid process. The method comprises the steps of feeding front-section primarily washed wastewater with sulfuric acid concentration being not less than 5% in the metatitanic acid primary washing section into an acidizing tank, homogenizing others, then neutralizing by using carbide slag or lime and introducing air for oxidizing, precipitating, discharging supernate out, feeding thick slurry into the acidizing tank, stirring and separating solid from liquid so as to obtain common precipitated gypsum, feeding the mixed solution of ferric sulfate and ferrous sulfate into a neutralizing pool, neutralizing by using magnesite powder, separating solid from liquid to obtain iron sludge containing ferric sulfate and iron sesquioxide. The method does not generate titanium gypsum, the problem that the stacked titanium gypsum occupies lots of land and pollutes the environment since titanium gypsum is difficult to us is solved, the content of Fe in dry residue of the iron sludge is more than 55%, and Fe can be recycled to be used as raw material of ironmaking.

Owner:TONGLING CHEM IND GRP

Mineral matter element added liquid condition milk for baby

ActiveCN101218941AInsignificant effect on natureImprove absorption rateMilk preparationFood preparationManganeseCALCIUM LACTOBIONATE

The invention relates to milk and a method for preparing the milk, in particular to baby liquid state milk added with mineral elements, which belongs to the technical field of milk products. The baby liquid state milk comprises protein, fat, sugar, vitamin, mineral elements and water. The mineral elements comprise Mg, Fe, Zn, Cu, Ca, I, and Mn; wherein, the Mg can be provided by the combination of one or a plurality of Mg preparations among magnesium sulfate, magnesium chloride and magnesium citrate; the Fe can be provided by the combination of one or a plurality of Fe preparations among gluconic acid ferrous iron, green copperas, ferrous lactate, ironic citrate and ferric pyrophosphate; the Zn can be provided by the combination of one or a plurality of Zn preparations among zinc sulfate, zinc gluconate, zinc lactate and zinc butter; the Cu can be provided by bluestone; the Ca can be provided by the combination of one or a plurality of Ca preparations among milk calcium, calcium citrate, calcium phosphate, calcium chloride, calcium carbonate and calcium lactate; the I can be provided by potassium iodide; and the Mn can be provided by manganese sulfate. The invention has the advantages that the selected combination is suitable for the liquid state milk.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

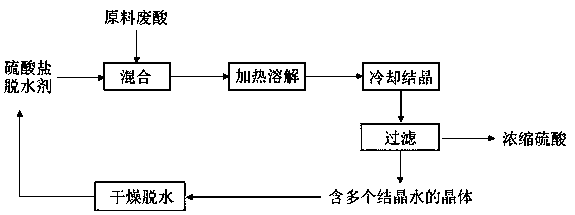

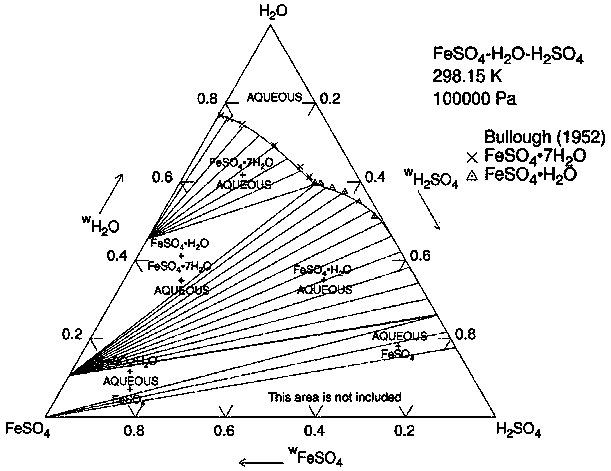

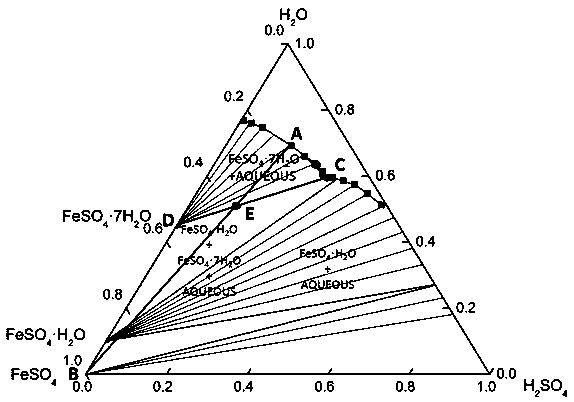

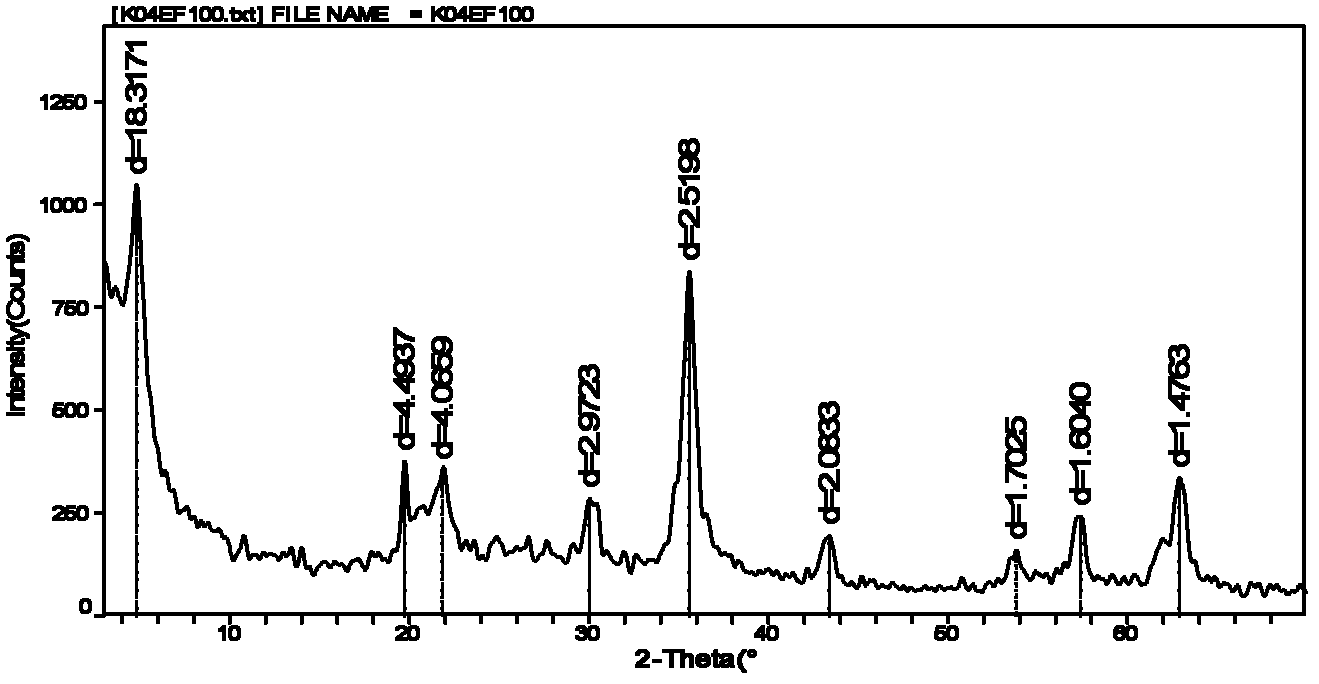

Process for concentrating titanium white waste acid through generation of crystalline hydrate by utilizing phase equilibrium principle

InactiveCN109368604AAvoid introducingAvoid it happening againSulfur-trioxide/sulfuric-acidResource utilizationCopper sulfate

The invention provides a process for concentrating titanium white waste acid through generation of crystalline hydrate by utilizing the phase equilibrium principle. According to the process, ferrous sulfate, copper sulfate or other sulfate capable of forming crystalline hydrates are added into titanium white waste acid, the phase equilibrium process is controlled by utilizing the equilibrium relationship among sulfuric acid, water and sulfate, moisture is brought out by generating sulfate hydrates containing different crystal water and crystallizing and separating the sulfate hydrate from diluted sulfuric acid, and the diluted sulfuric acid can be concentrated; and the separated ferrous sulfate and other crystalline hydrates can be recycled after being dried to remove crystal water; different concentration degrees can be realized by controlling the mode of generated crystalline hydrate and can be adjusted according to requirement, and a concentrated sulfuric acid product having an acidconcentration of higher than 60 percent can be obtained; and anhydrous ferrous sulfate and other sulfates capable of forming crystalline hydrate can be utilized as raw materials, and the raw materials have wide sources. The process is simple, has low operation temperature, small equipment investment and weak corrosion, moisture of waste acid is not needed to be directly evaporated, energy consumption is low, and resource utilization of titanium white waste acid can be realized.

Owner:SICHUAN UNIV

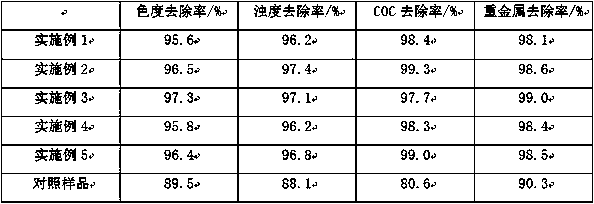

Enzyme imitation type water treatment agent for degrading polycycic/heterocyclic aromatic hydrocarbon, and preparation method for enzyme imitation type water treatment agent

InactiveCN102350300AEfficient catalytic reactionImprove removal efficiencyOther chemical processesAlkali metal oxides/hydroxidesEnvironmental resistanceSodium Bentonite

The invention relates to an enzyme imitation type water treatment agent for degrading polycycic / heterocyclic aromatic hydrocarbon, and a preparation method for the enzyme imitation type water treatment agent. The technical scheme comprises the following steps of: uniformly mixing bentonite and deionized water in a mass ratio of 1:(30-60), standing, and taking an intermediate layer to obtain purified bentonite; mixing the purified bentonite and NaCl in a mass ratio of 1:(1-2.5), and stirring for 30 to 60 minutes to obtain sodium-activated bentonite; adding 1.5 to 5.0 weight percent of sodium-activated bentonite slurry into an aluminum crosslinker until the volume ratio of the sodium-activated bentonite slurry to the aluminum crosslinker is (4-7):1 to obtain aluminum pillared bentonite; andmixing aluminum pillared bentonite, deionized water, and hexadecyltrimethylammonium bromide in a mass ratio of 1:(40-100):(0.1-0.4), adding ferrous sulfate and ferric trichloride until the molar ratio of Fe<2+> to Fe<3+> is 1:(1.5-3), introducing nitrogen, stirring at the temperature of between 60 and 80 DEG C for 10 and 15 minutes, and adjusting pH to be 9 to 12 to obtain the enzyme imitation type water treatment agent for degrading polycycic / heterocyclic aromatic hydrocarbon. The enzyme imitation type water treatment agent has the advantages of high removal efficiency, low cost and environment-friendliness, and can be recycled.

Owner:WUHAN UNIV OF SCI & TECH

Printing and dyeing wastewater flocculating agent and preparation method thereof

InactiveCN108502943AImprove purification effectReduce dosageWaste water treatment from quariesFatty/oily/floating substances removal devicesSodium BentoniteDyeing wastewater

The invention relates to the technical field of sewage treatment and in particular relates to a printing and dyeing wastewater flocculating agent and a preparation method thereof. The flocculating agent is prepared from the following components in parts by weight: 20 to 30 parts of butyl xanthate, 50 to 60 parts of melamine, 25 to 35 parts of ferrous sulfate, 20 to 25 parts of bentonite, 15 to 20parts of dimethyl diallyl ammonium chloride, 10 to 15 parts of starch aluminium octenylsuccinate, 12 to 18 parts of polyvinylpyrrolidone, 10 to 16 parts of itaconic acid copolymer, 10 to 20 parts of zeolite, 5 to 10 parts of calcium hydroxide, 8 to 10 parts of fungicide and 100 to 150 parts of de-ionized water. The preparation method comprises the following steps: firstly, modifying the melamine;then mixing the melamine with other raw materials to prepare the printing and dyeing wastewater flocculating agent. The flocculating agent provided by the invention can be used for effectively removing pollutants in a dyestuff and has the advantages of good flocculating effect, rapid sedimentation speed and small dosage.

Owner:NANNING XIAYANG CHEM TECH CO LTD

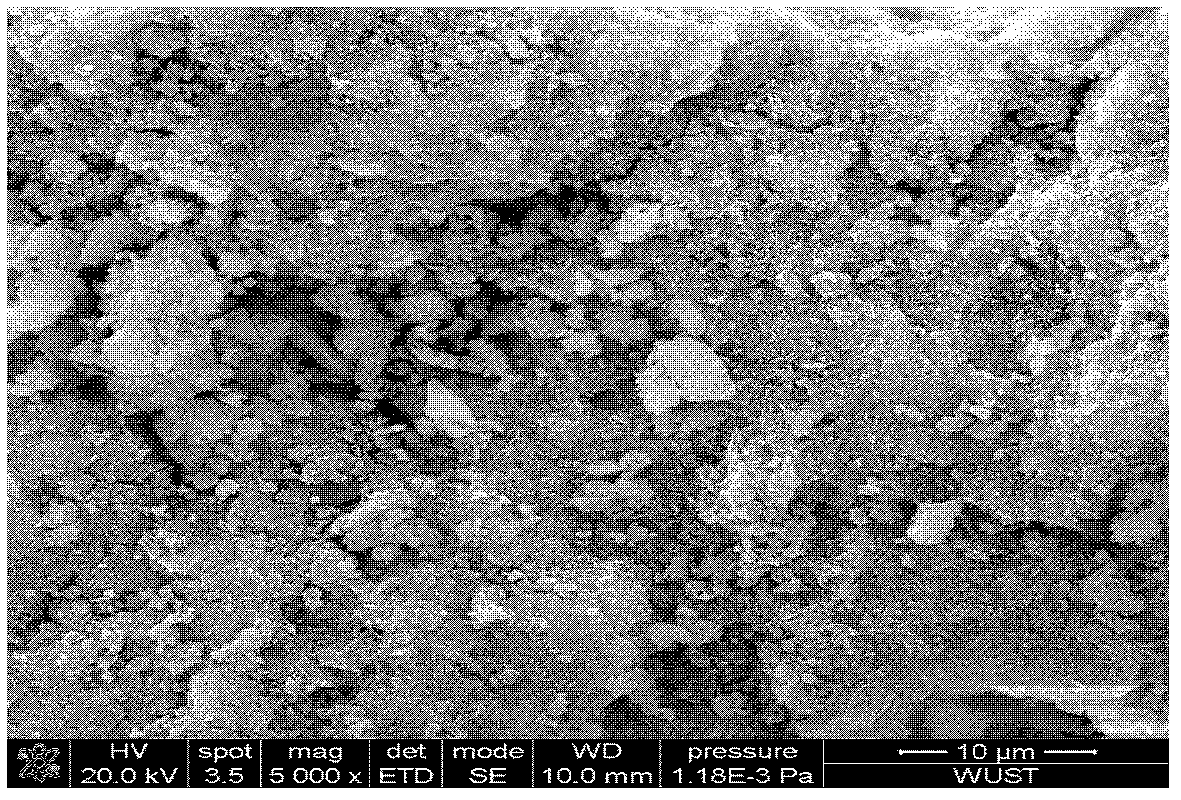

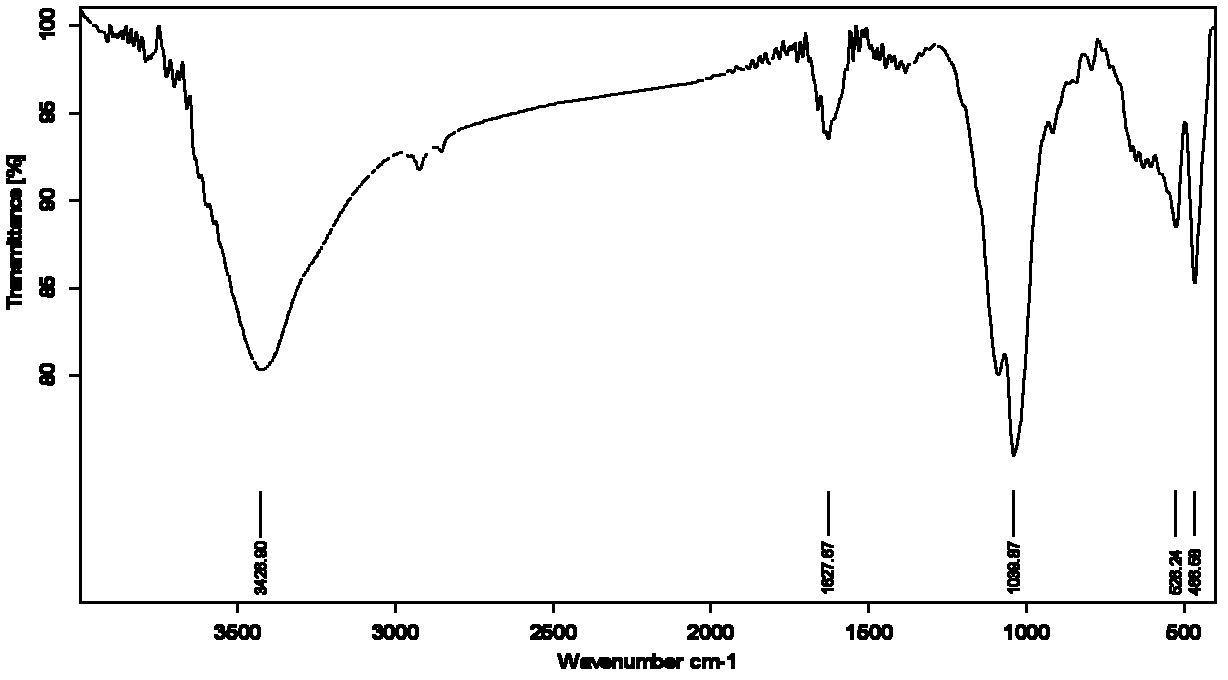

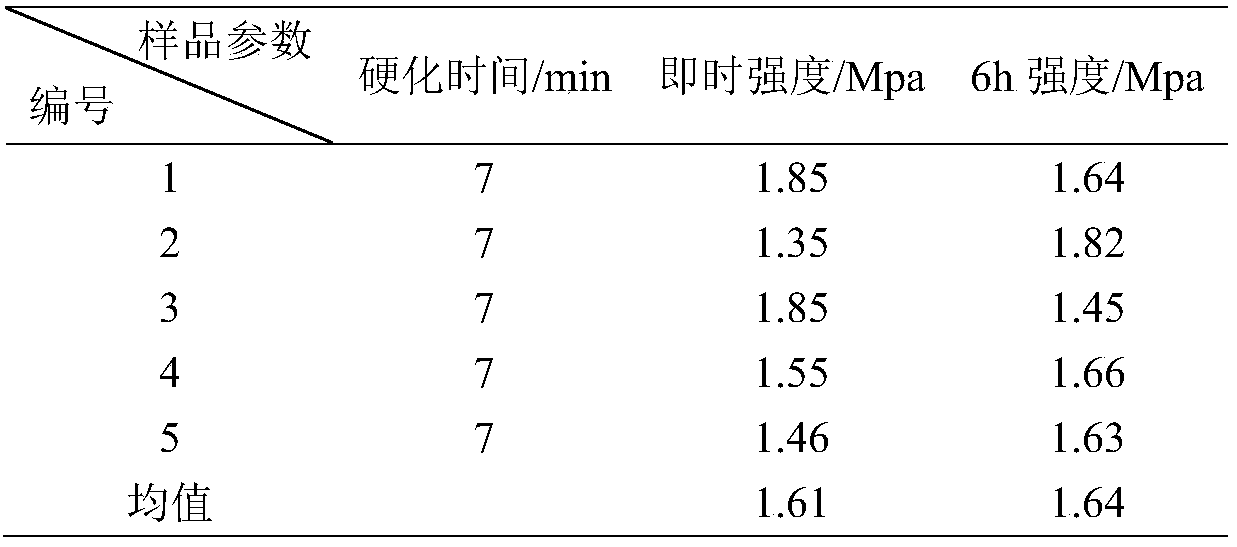

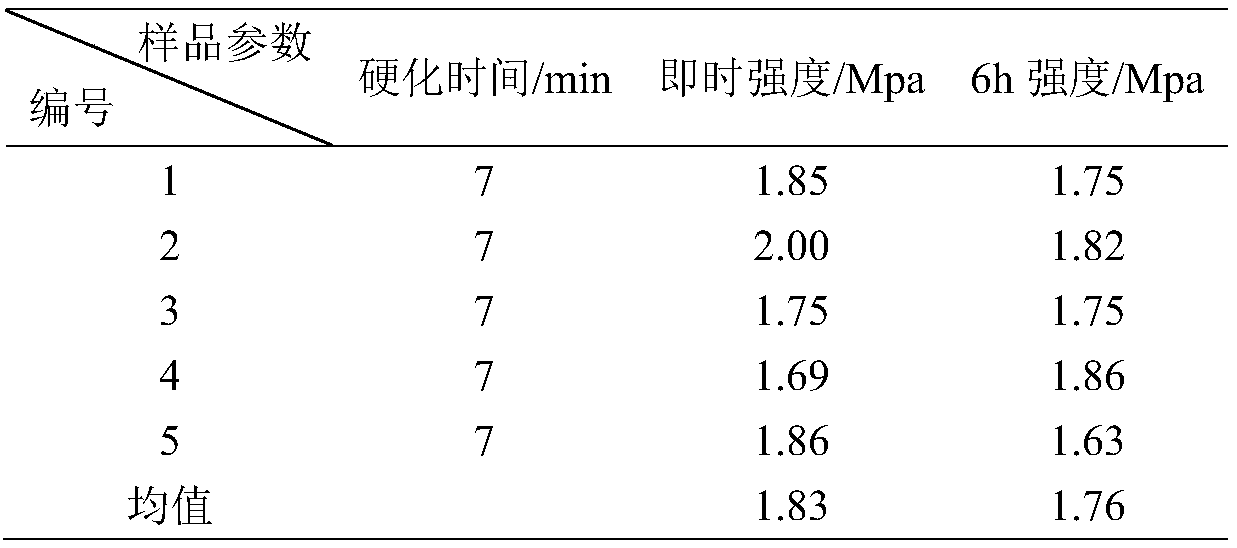

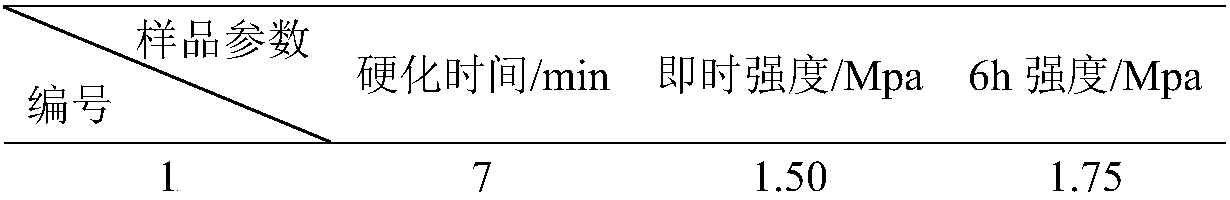

Ferrous sulfate modified phosphate binder and preparation method thereof

ActiveCN108907069AImprove mechanical propertiesImprove moisture resistanceFoundry mouldsFoundry coresSilicic acidAluminium hydroxide

The invention discloses a ferrous sulfate modified phosphate binder and a preparation method thereof. The ferrous sulfate modified phosphate binder is prepared from raw materials as follows: 53.74%-53.81% of phosphoric acid for industrial use, 10.81%-10.83% of aluminium hydroxide powder, 1.908%-1.910% of boric acid, 0.318% of silicic acid, 1.272%-1.274% of magnesium oxide, 0.02%-0.159% of ferroussulfate and 31.8%-31.84% of water. The preparation method comprises following steps: the raw materials are added in specific sequence, and with addition of ferrous sulfate, a macromolecular compound with constitution water can be formed in a reaction process, so that the finally prepared phosphate binder has higher stability and higher moisture absorption performance. A test indicates that a sandmold prepared from the binder has higher instant strength and constant-humidity room (RH40%) 6h strength, the maximum instant strength can reach 1.86 MPa, and the maximum constant-humidity room (RH40%) 6h strength can reach 1.76 MPa.

Owner:HUBEI UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com